Patents

Literature

831 results about "Diamond thin film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for synthesizing solids such as diamond and products produced thereby

InactiveUS6342195B1Enhanced interactionIncreasing amount of possibleUltra-high pressure processesDiamondHydrogenBoron nitride

The present invention relates generally to methods for the synthesis of various solids such as diamonds, diamonds films, boron nitride and other similar materials. This invention specifically relates to utilizing novel sources of reaction species (e.g., in the case of diamond formation, novel sources of carbon and / or hydrogen and / or seeds) for the manufacture of various materials and the use of such materials for various commercial purposes.

Owner:PENN STATE RES FOUND

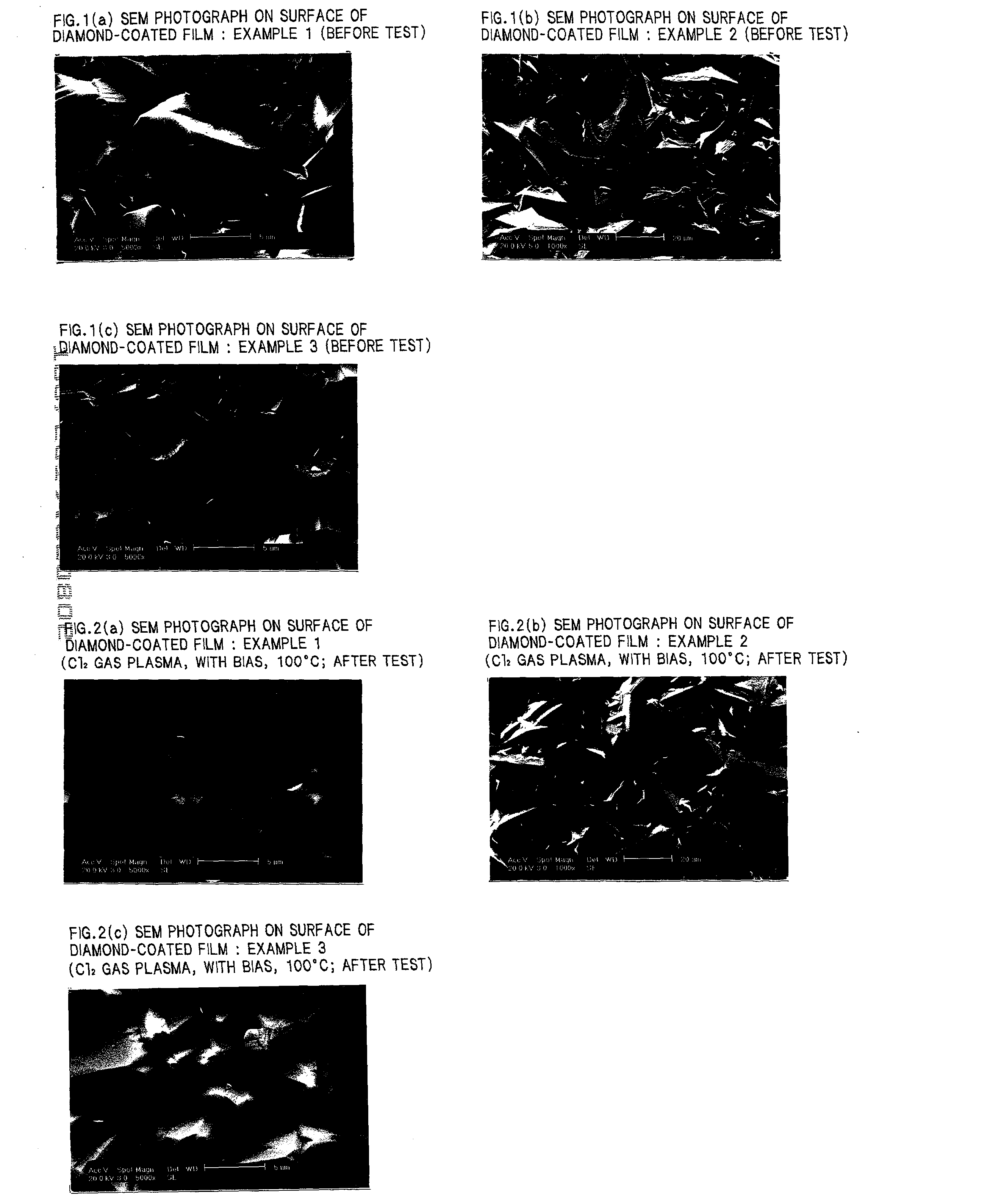

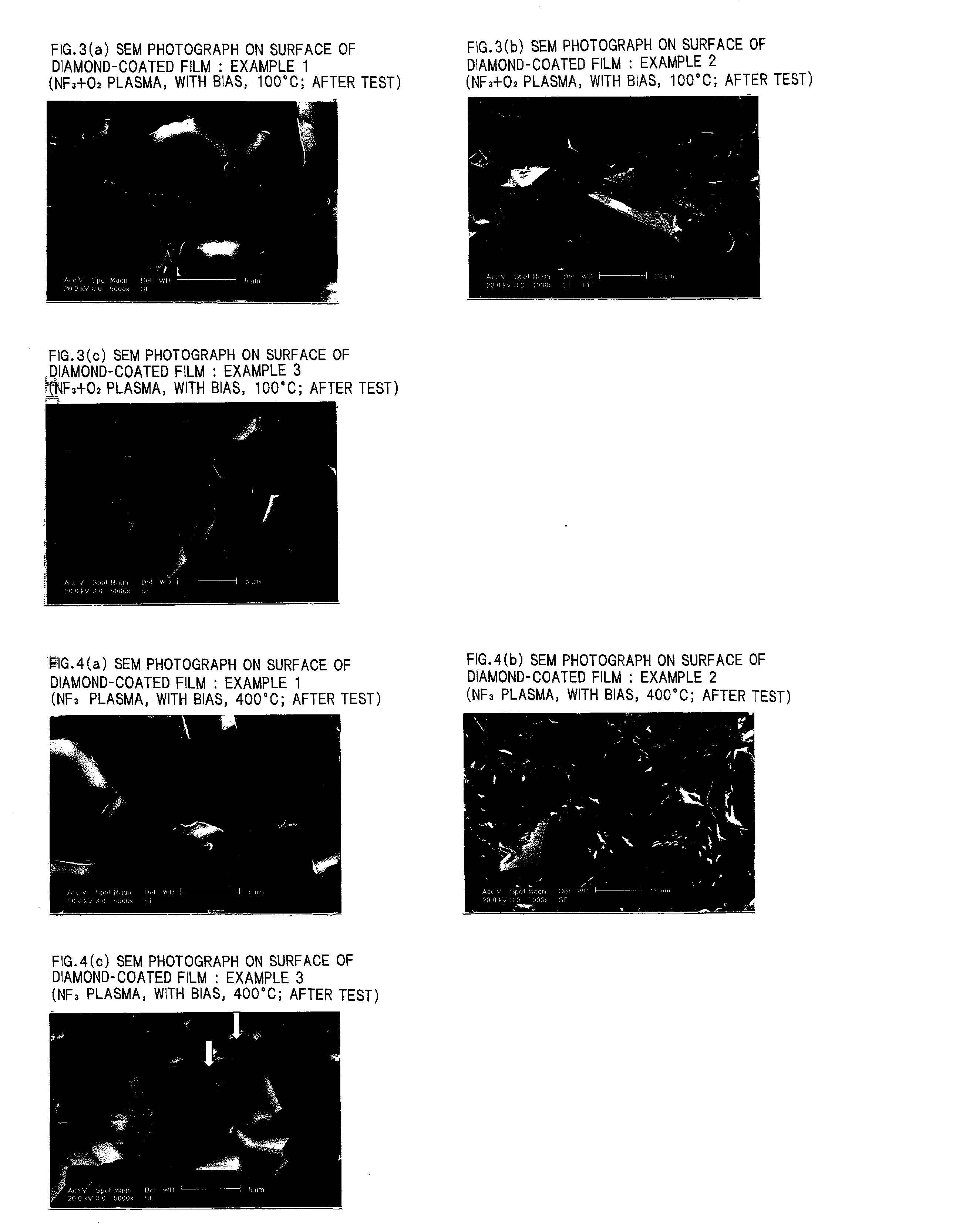

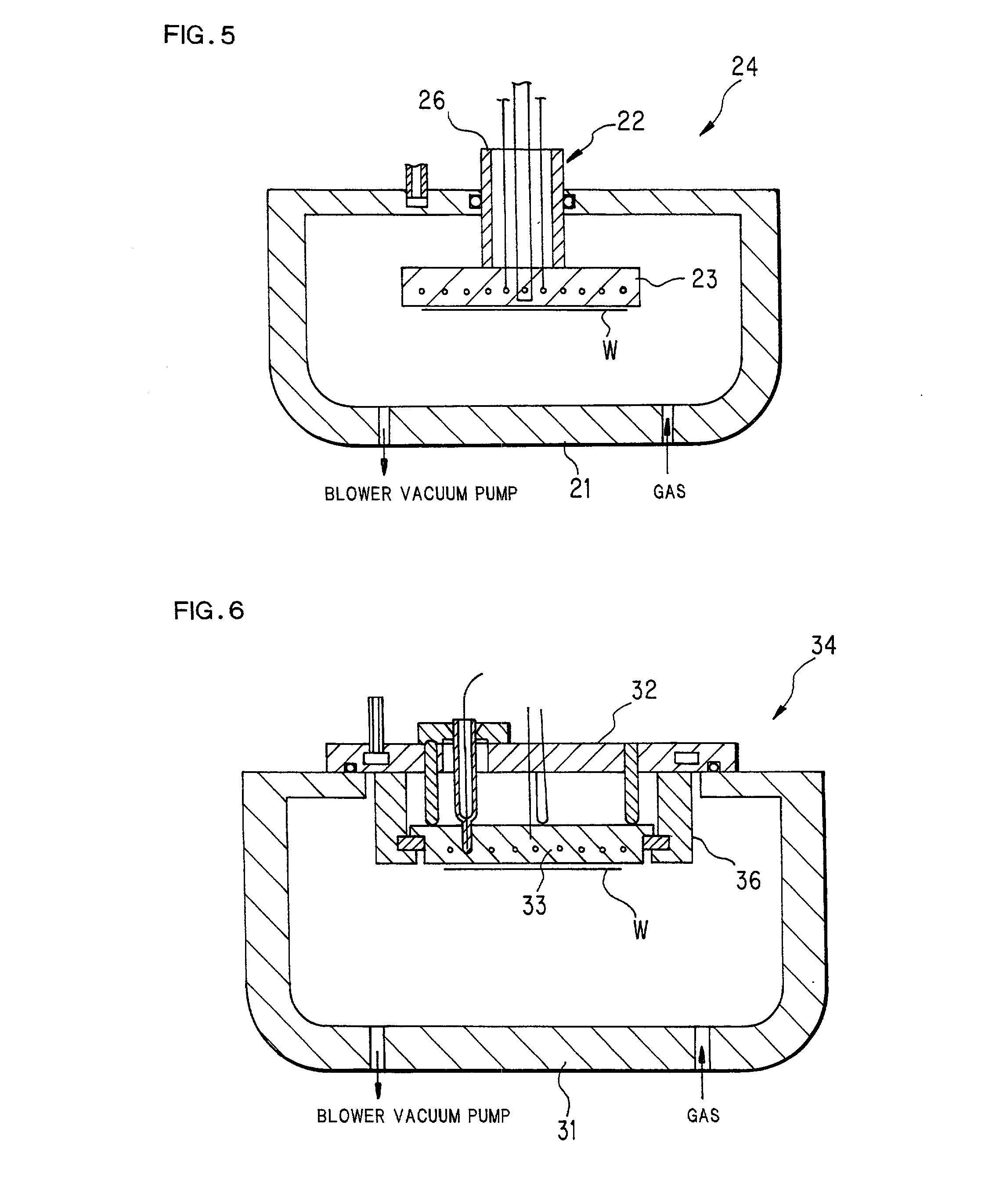

Diamond-coated member

InactiveUS20030064225A1Polycrystalline material growthElectric discharge tubesSusceptorAdhesion strength

A diamond-coated member includes a basal material such as aluminum nitride, and a diamond thin film coating at least one part of a surface of the basal material, being adhered thereto, and has corrosion-erosion resistance. Adhesion strength between the thin film and the basal material is 15 MPa or more. Or, in diamond thin film, degree of orientation of diamond {220} plane present in faces parallel to the basal material is expressed by following formula: [Im220 / (Im220+Im111)] / [Ip220 / (Ip220+Ip111)]<1. The diamond-coated corrosion-erosion resistant member has excellent corrosion-erosion resistance, and is used mainly for a semiconductor producing apparatus; being preferably applied as a member inside a reaction chamber where a substrate, represented by silicon wafer, is exposed to plasma, corrosion gas or the like, inclusive of rings, a chamber inner lining, a gas shower plate, nozzles, a susceptor, an electrostatic chuck, a heater, or the like.

Owner:NGK INSULATORS LTD

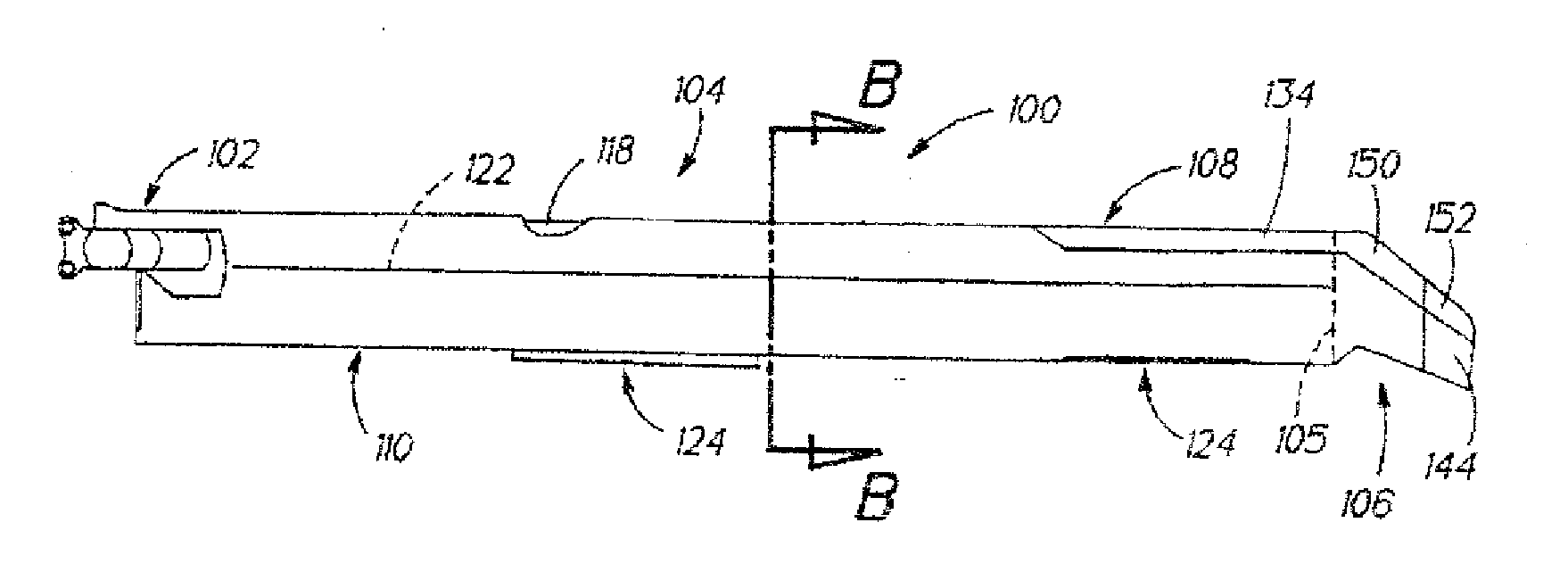

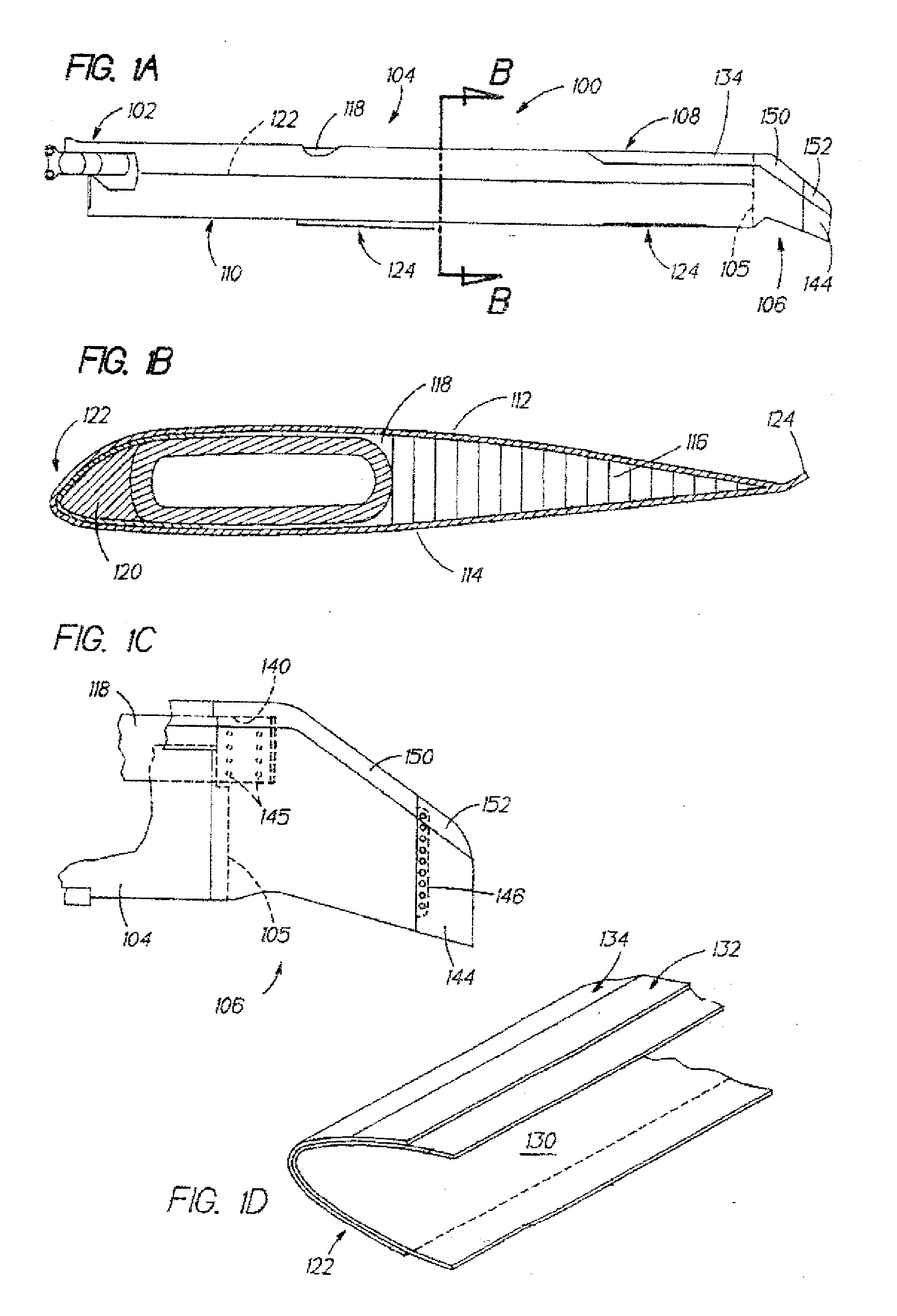

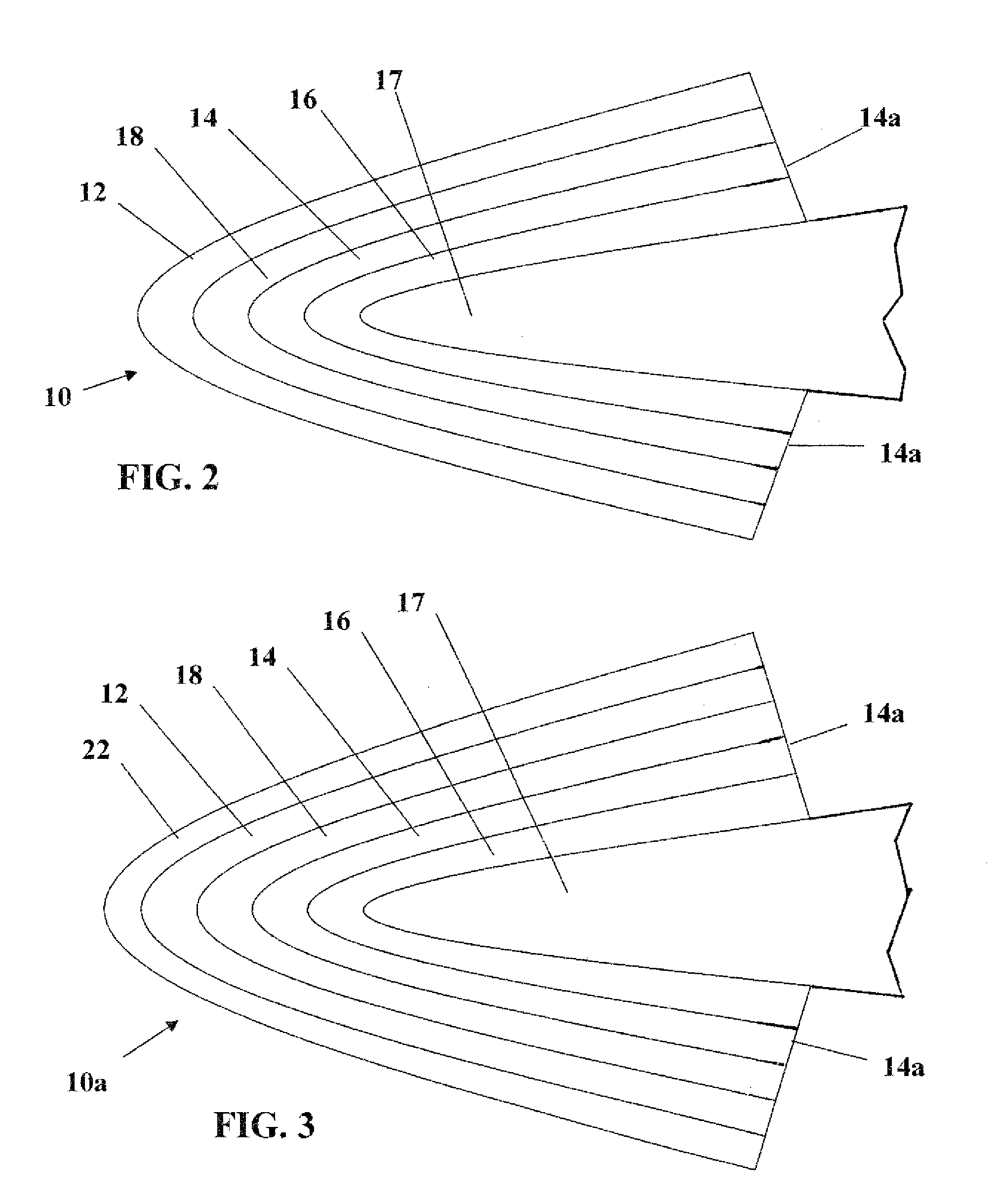

Protector for a leading edge of an airfoil

InactiveUS20100008788A1Reduce resistanceAvoid serious impactBlade accessoriesEfficient propulsion technologiesLeading edgeParticulates

A protector for the leading edge of a rotor blade to provide enhanced erosion protection thereof. In an embodiment, the protector includes an energy absorption member attached to the rotor blade by a first adhesive bond layer and an erosion resistant member attached to the energy absorption member by a second adhesive bond layer. The erosion resistant member is operative to protect the leading edge of the rotor blade from erosion due to impacts from particulate matter, such as sand and rain. The energy absorption member is operative to absorb and disburse energy from impacts to the erosion protection member so that forces from the impacts are diminished or not transferred to the rotor blade. In another embodiment, the erosion resistant member is coated with a diamond film. As the diamond film is harder than sand, excellent resistance to wear from particulate matter and impacts rain is obtained. Other advantages provided by use of the diamond film include: 1) an ultra-smooth surface that reduces drag on the rotor blade whereby flight performance may be improved, and 2) by being ultra-smooth and chemically inert de-icing equipment may not be needed.

Owner:UNITED PROTECTIVE TECH

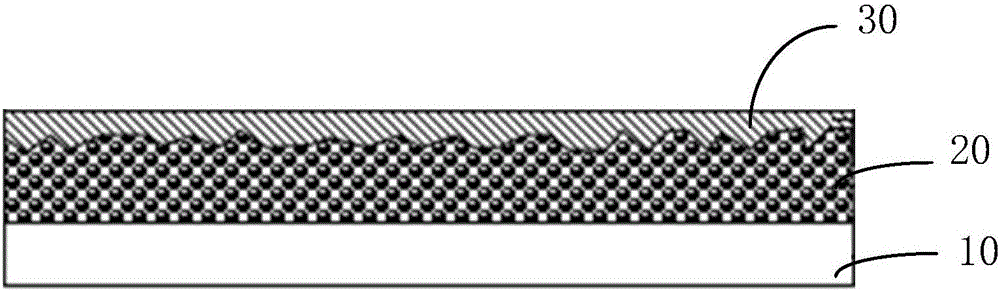

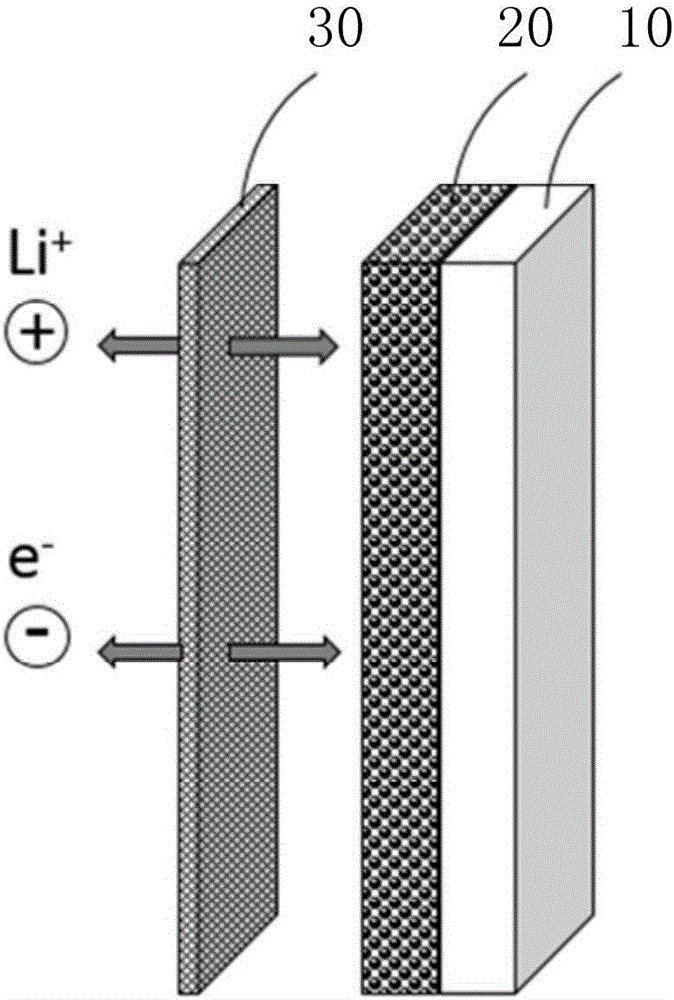

Lithium ion battery negative electrode comprising diamond-like thin film layer, preparation method for negative electrode, and lithium ion battery

InactiveCN106684387AImprove conductivityHigh mechanical strengthCell electrodesSecondary cellsElectrical batteryElectrochemistry

The invention provides a lithium ion battery negative electrode comprising a diamond-like thin film layer. The negative electrode comprises a conductive current collector, a negative electrode active material layer arranged on the conductive current collector and a diamond-like thin film layer deposited on the surface of the negative electrode active material layer; and the diamond-like thin film layer comprises doped elements, wherein the doped elements comprises one or more of Si, B, N, P, Al, Be, Mg, Ti, Cr, W, Fe, Zr, Pt, Mo, Co, Ni and Sb. According to the lithium ion battery negative electrode, the diamond-like thin film layer is deposited on the surface of the negative electrode active material layer, and the diamond-like thin film layer has excellent electrochemical inertness and conductivity and high mechanical strength, so that occurrence of an unstable SEI layer on the surface of the negative electrode active material is avoided, and the cycling stability of the electrode is greatly improved. The invention also provides a preparation method for the lithium ion battery negative electrode, and the lithium ion battery.

Owner:SHENZHEN INST OF ADVANCED TECH

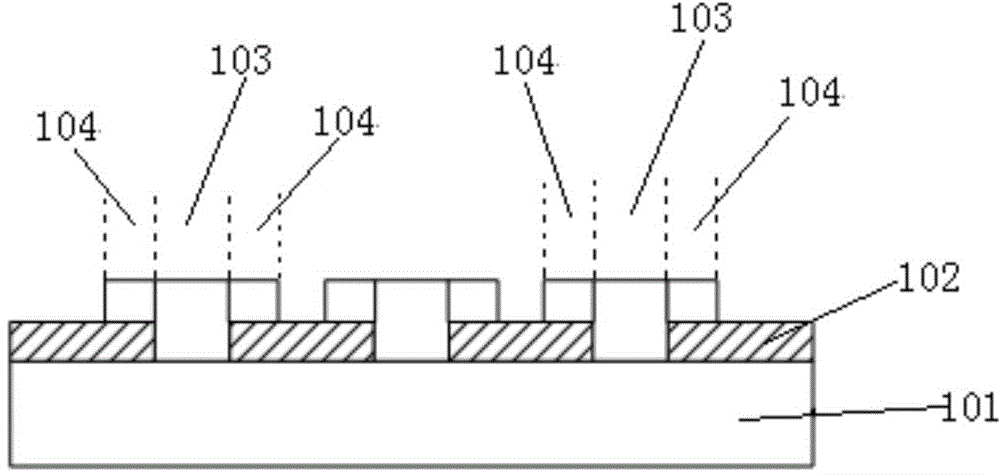

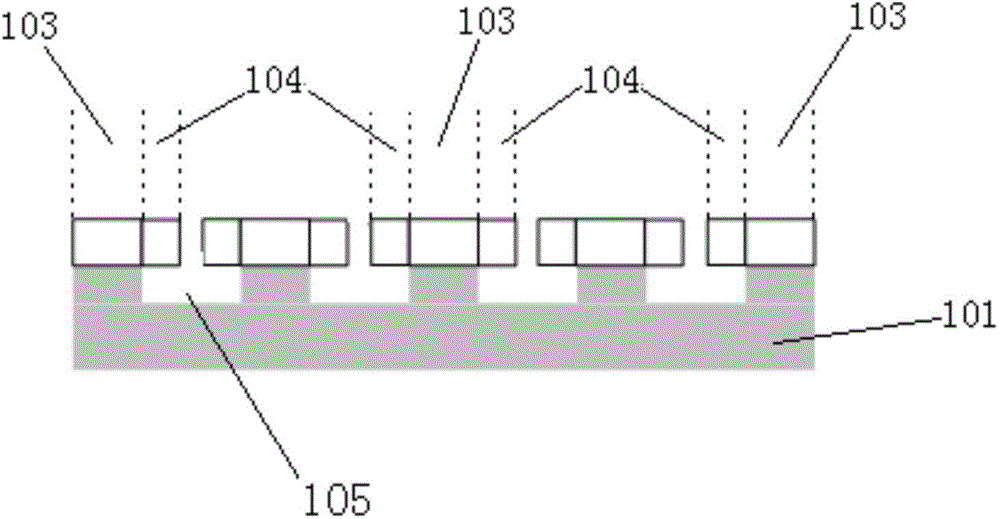

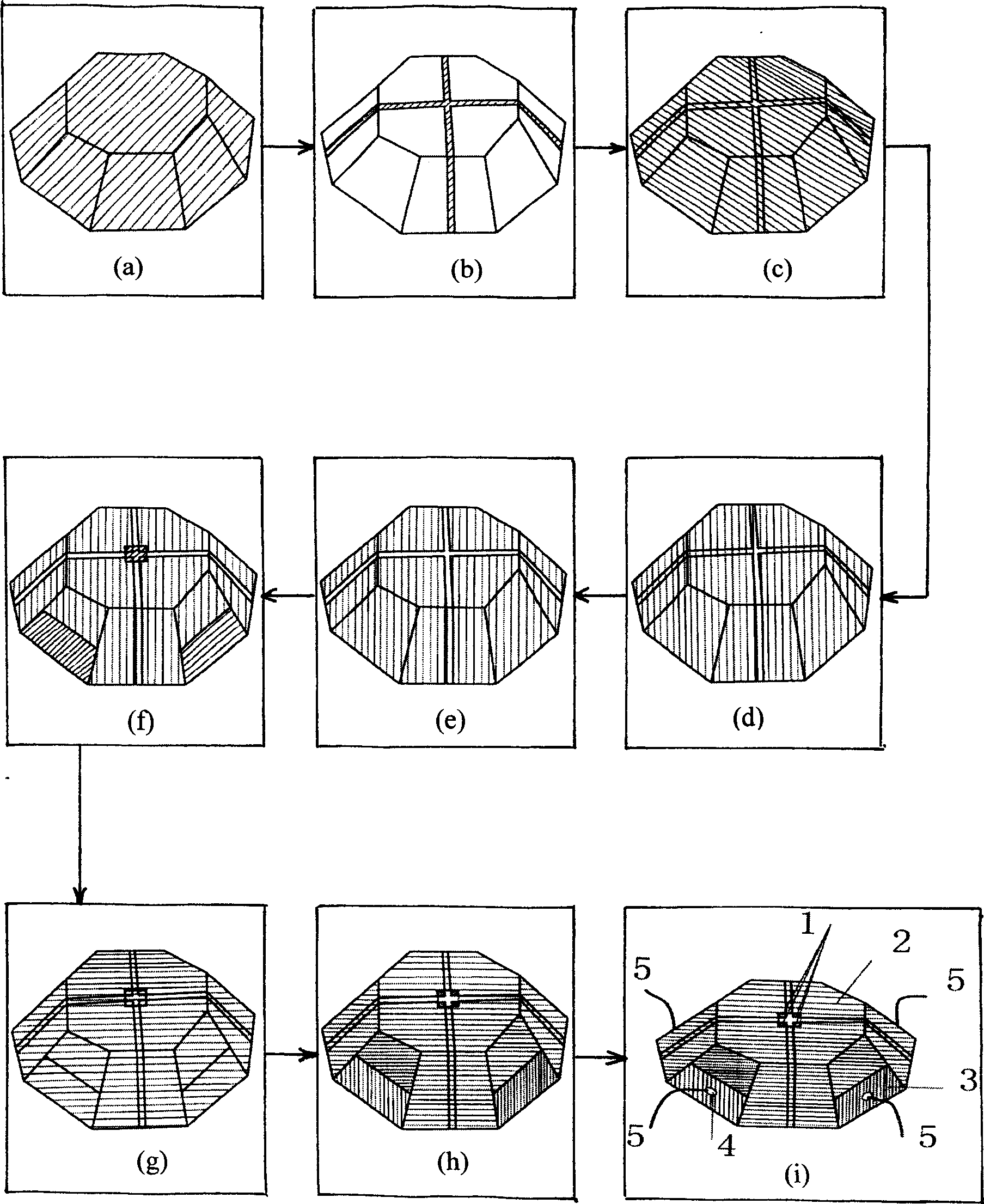

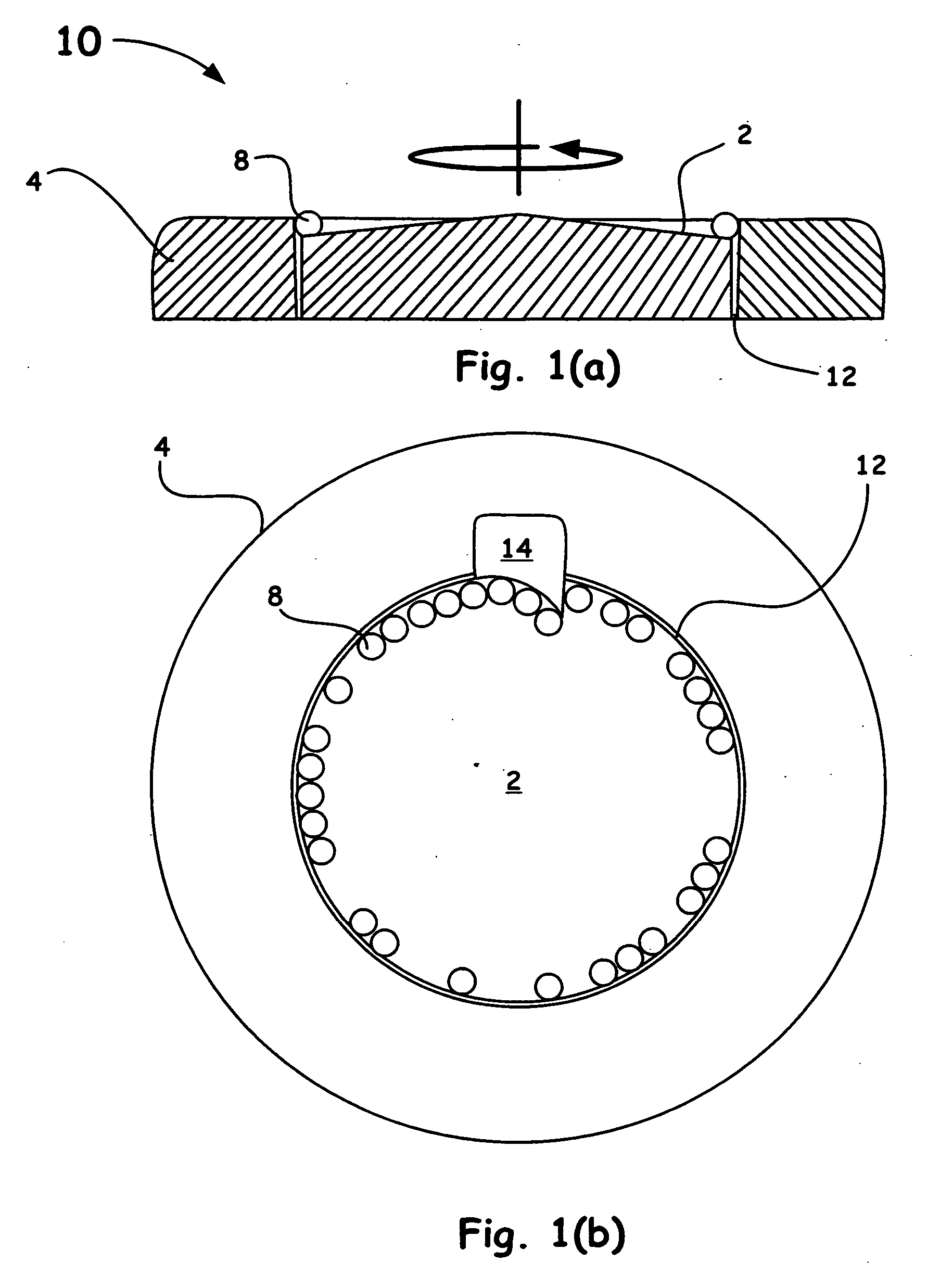

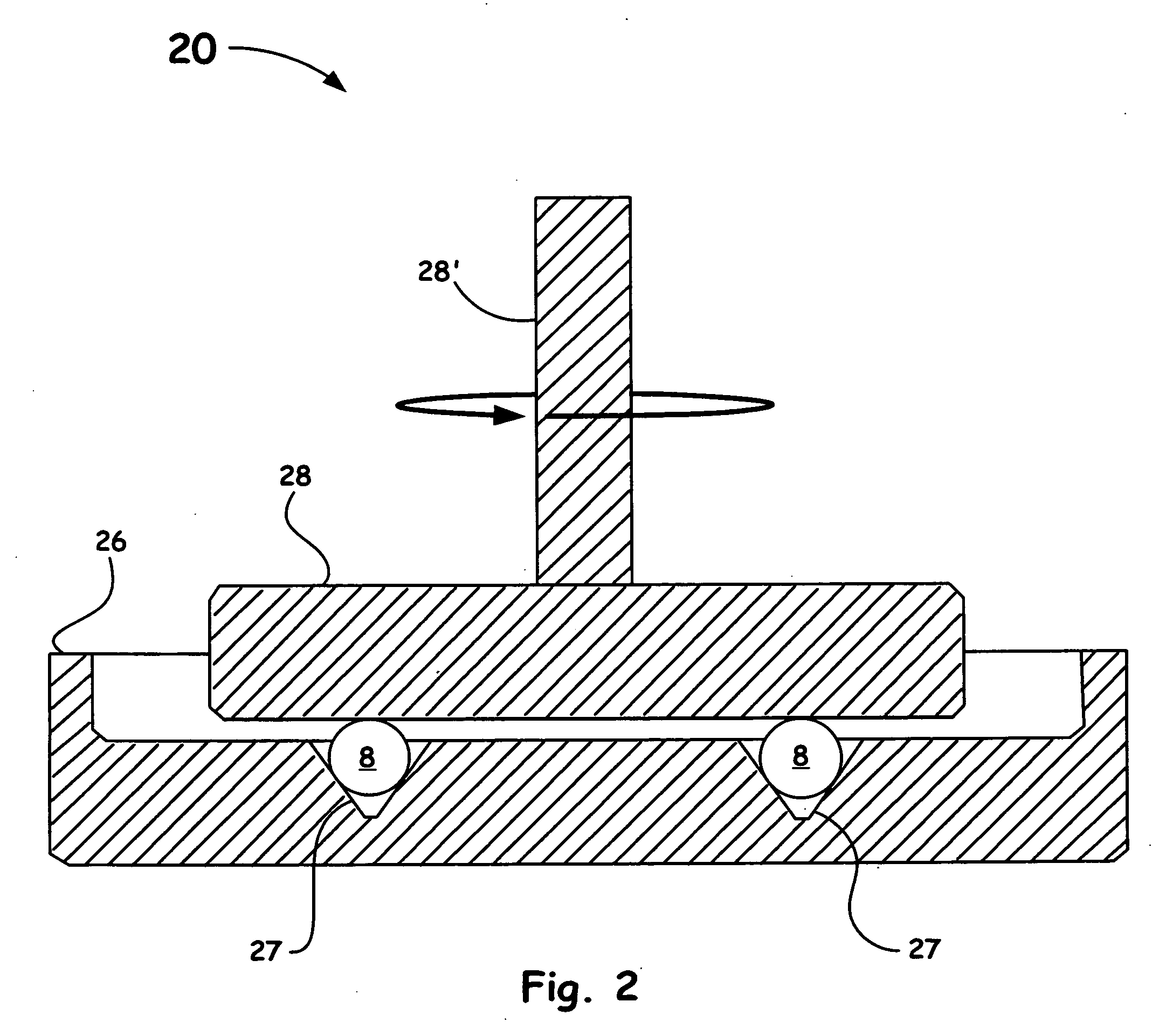

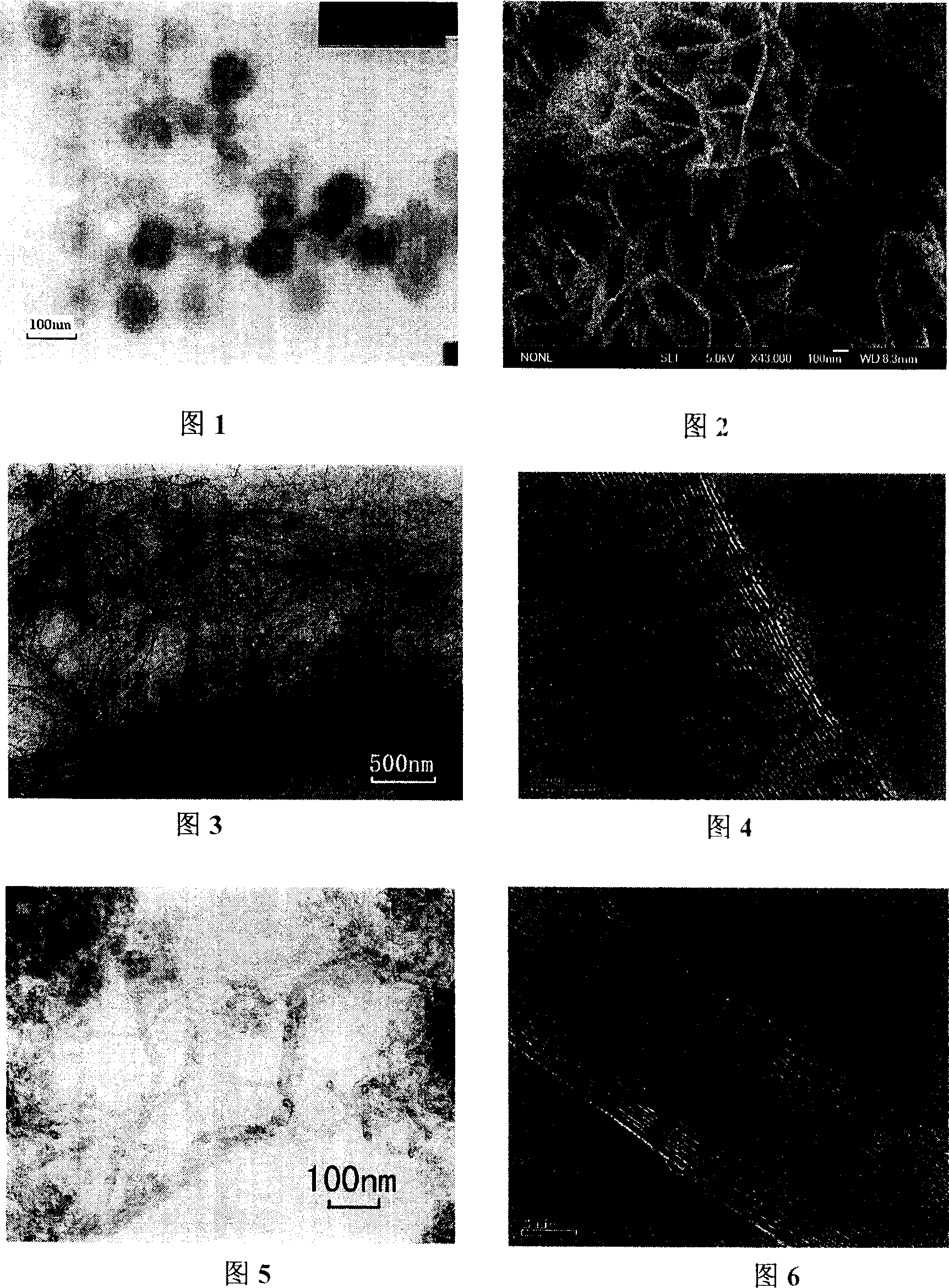

Homogeneous epitaxial lateral growth method for diamond

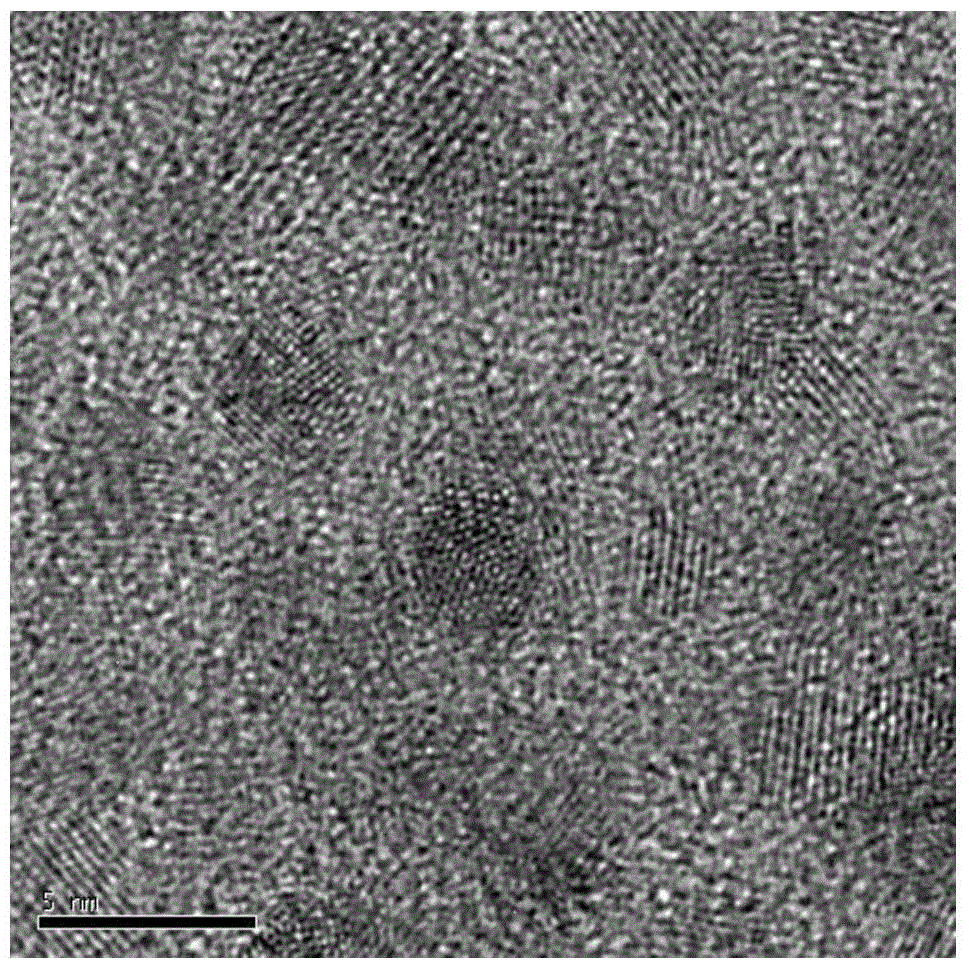

InactiveCN104651928AReduce dislocation densityQuality improvementPolycrystalline material growthFrom chemically reactive gasesMicro structureSingle crystal

The invention discloses a homogeneous epitaxial lateral growth method for diamond. The method comprises the following steps: 1, depositing a mask layer on the bottom surface of a monocrystal diamond substrate; 2, patterning the surface, deposited with the mask layer, of the substrate, thus forming the substrate with a patterned surface, wherein the patterned surface of the substrate is divided into a homogeneous epitaxial growth area and a lateral growth area; and 3, carrying out homogeneous epitaxial diamond growth in the homogeneous epitaxial growth area, and carrying out lateral diamond growth in the lateral growth area. By combining with the lateral growth method, an existing homogeneous epitaxial growth technique of monocrystal diamond is improved; a monocrystal diamond film which is low in dislocation density, high in quality and smooth in surface can effectively grow; the difficulty in epitaxial growth of the monocrystal diamond film for an electronic device is reduced; the film quality is improved; and meanwhile, the technique can be applied to control over the growth structure of the monocrystal diamond film, so as to obtain a monocrystal diamond micro-structure required by MEMS and the like.

Owner:王宏兴

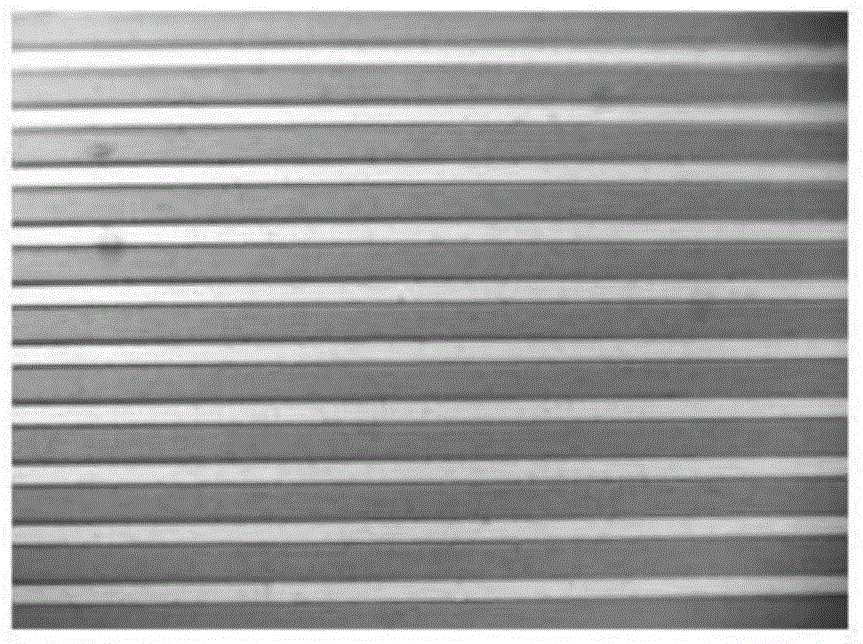

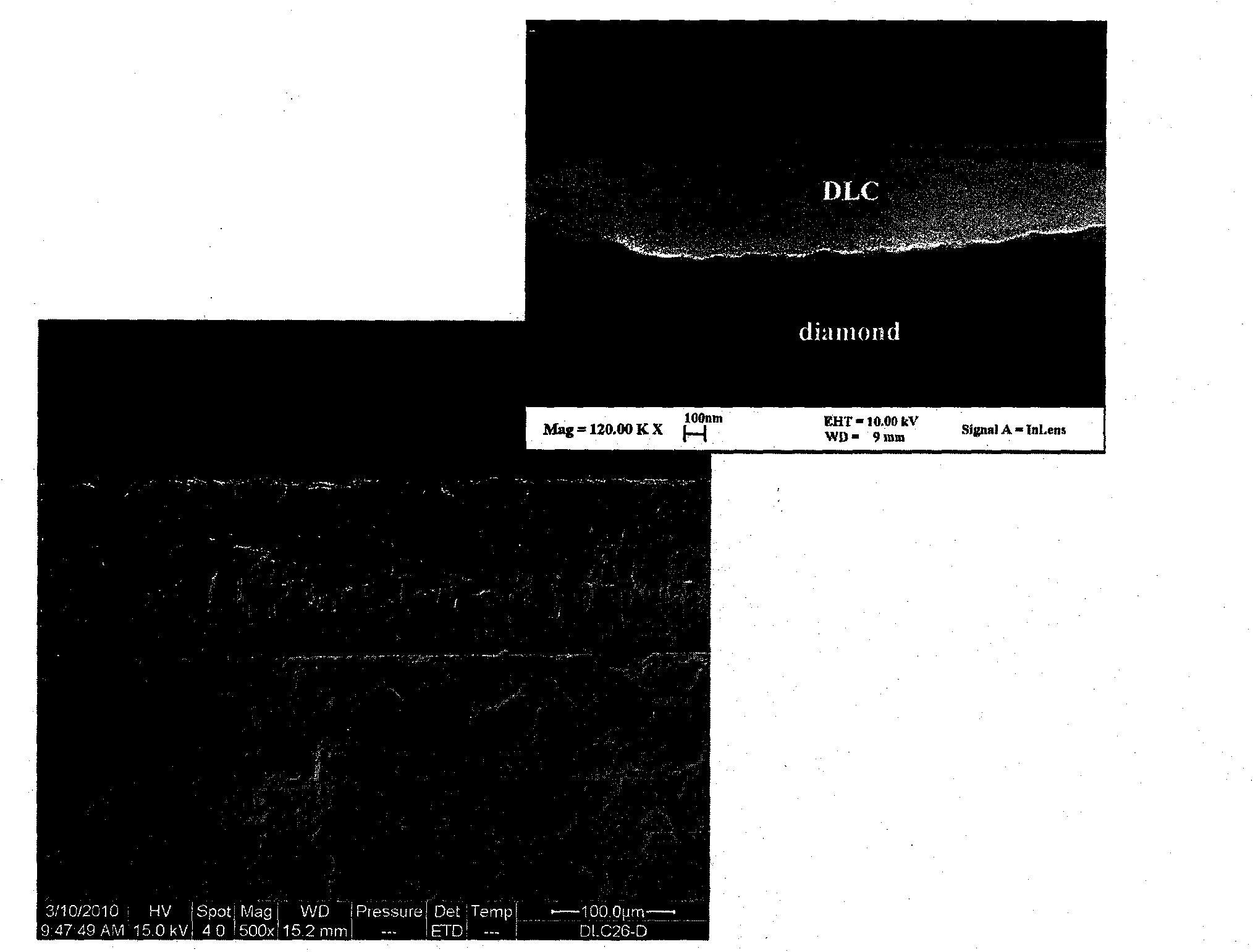

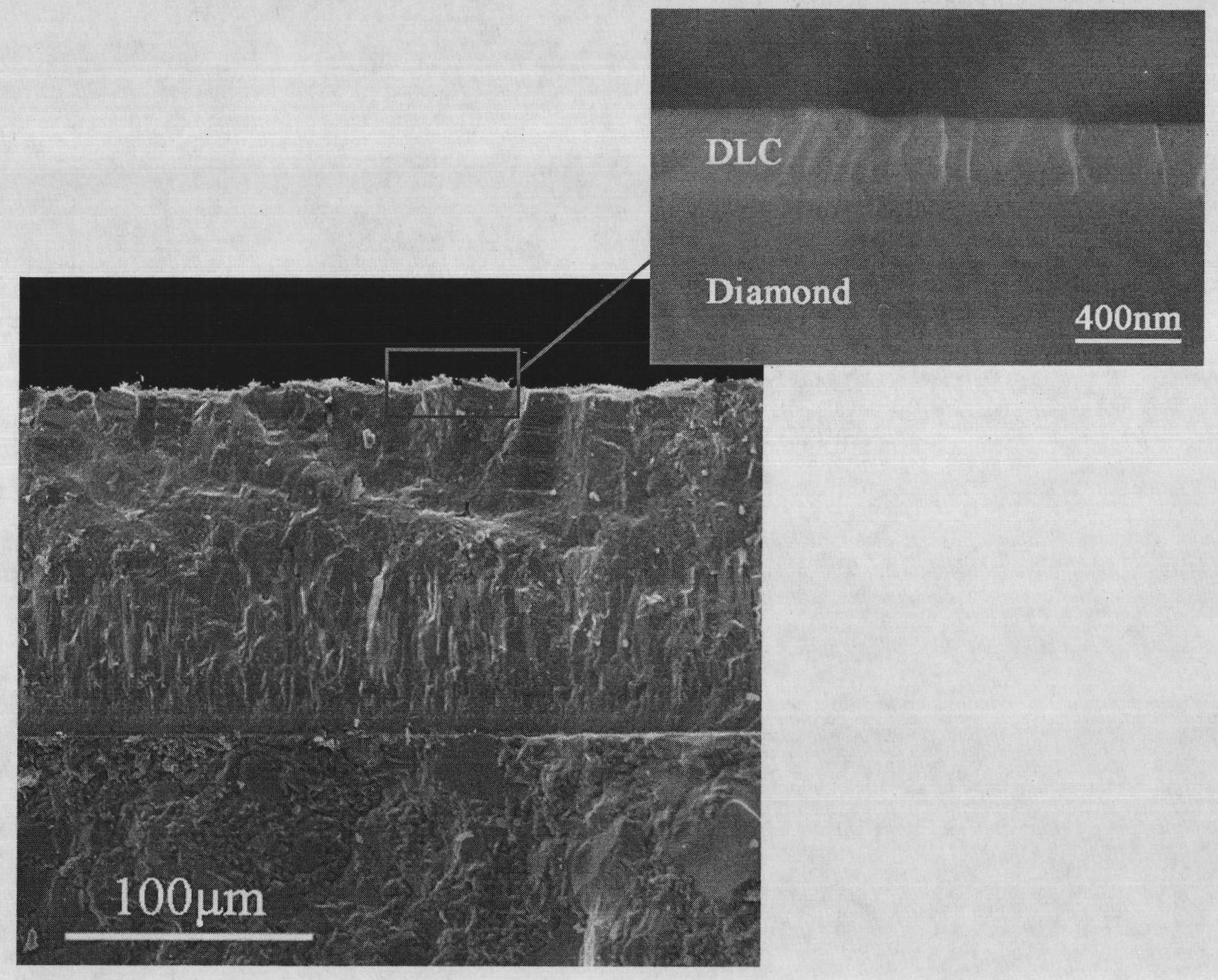

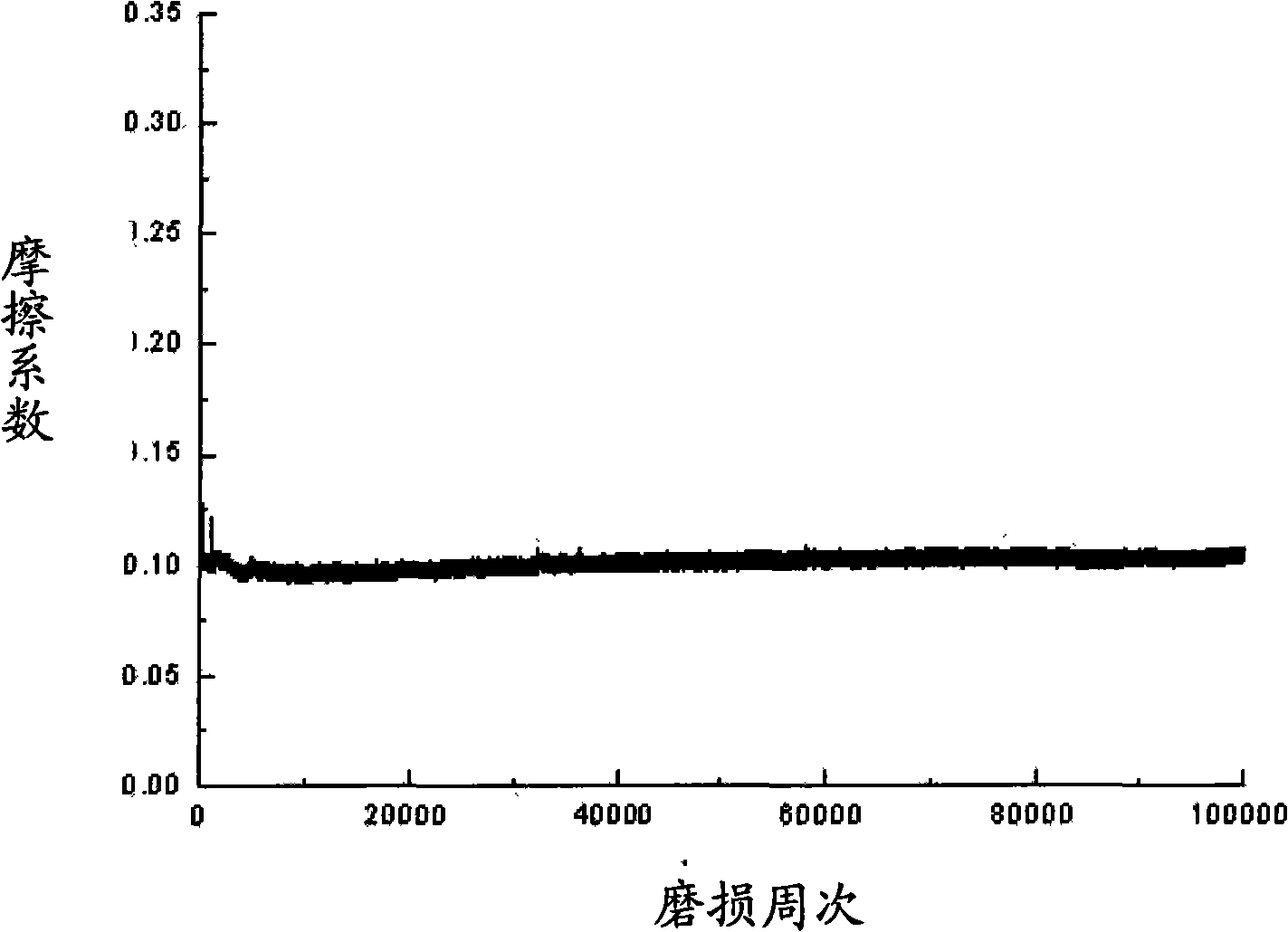

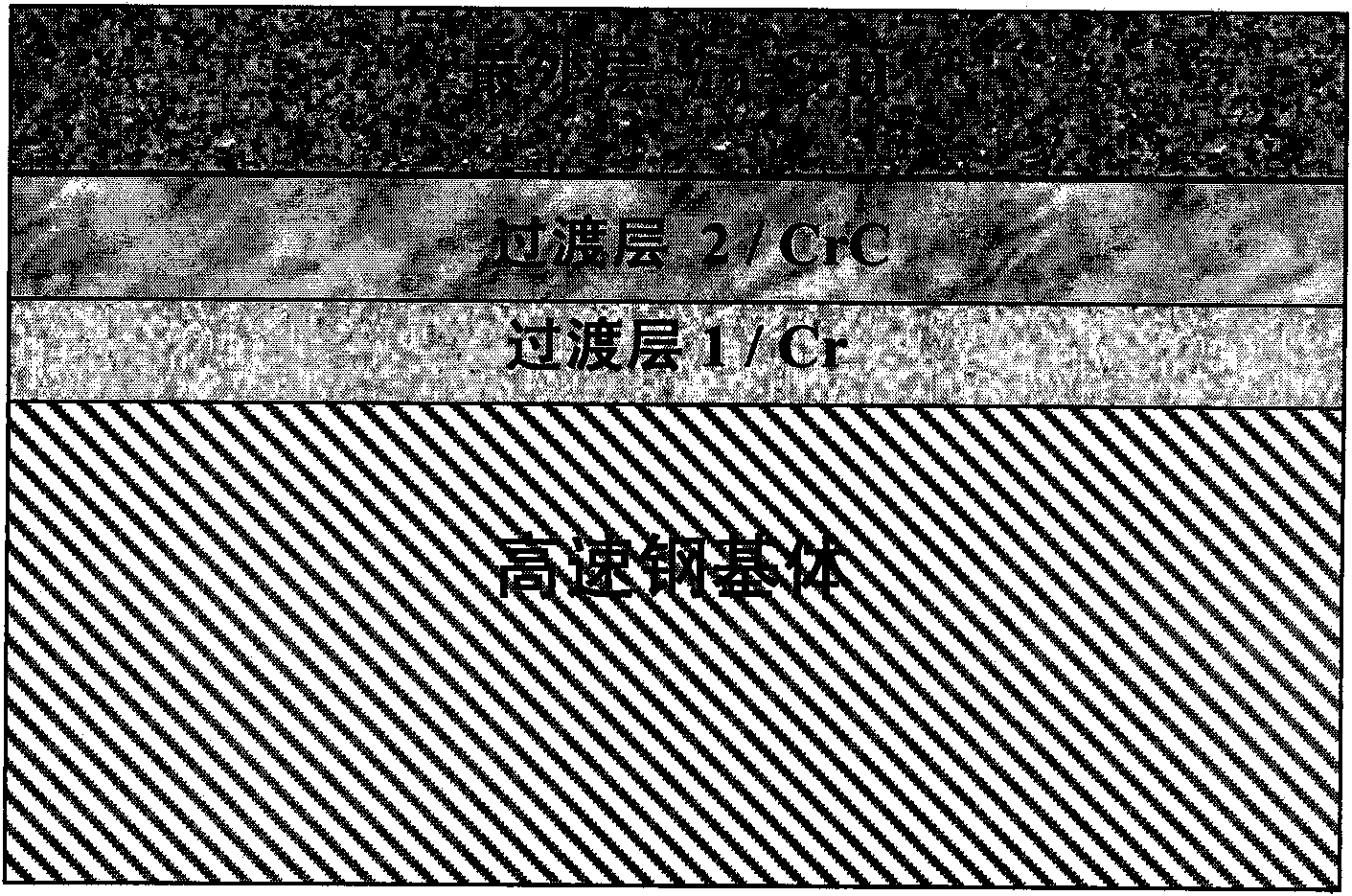

Super-hard self-lubricating diamond/diamond-like composite laminated coating material and preparation method thereof

ActiveCN101818332AThe process steps are simplePrecise and controllable synthesis conditionsChemical vapor deposition coatingPolymer scienceMagnetic filtration

The invention relates to a tool coating material and a preparation method thereof, and belongs to the technical field of material preparation and application. The material is a diamond / diamond-like composite laminated coating material with super-hard self-lubricating property. The method for preparing the diamond / diamond-like composite laminated coating material is characterized by comprising the following steps of: firstly, pretreating a matrix by using mixed solution of acid and alkali respectively; secondly, synthesizing diamond with ultrahigh hardness and good crystalline form on the matrix, which serves as the main body of the composite coating, by adopting hot filament chemical vapor deposition; and finally, depositing a high-hardness diamond-like thin film on the main body of the diamond, which serves as a self-lubricating surface layer, by using magnetic filtration cathodic vacuum arc. In order to improve the binding force between the diamond thin film and the matrix and between the diamond-like thin film and the diamond thin film, a transition layer is coated between adjacent layers respectively. The method has the advantages of simple process, precise and controllable synthesis conditions, high film-forming quality, high product yield, low cost, and the like. The obtained diamond / diamond-like composite laminated coating material has ultrahigh hardness, extremely low friction factor and extremely low wear rate, shows excellent self-lubricating friction and wear resistance, and has significance for application of tools or molds under rigorous service conditions.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +2

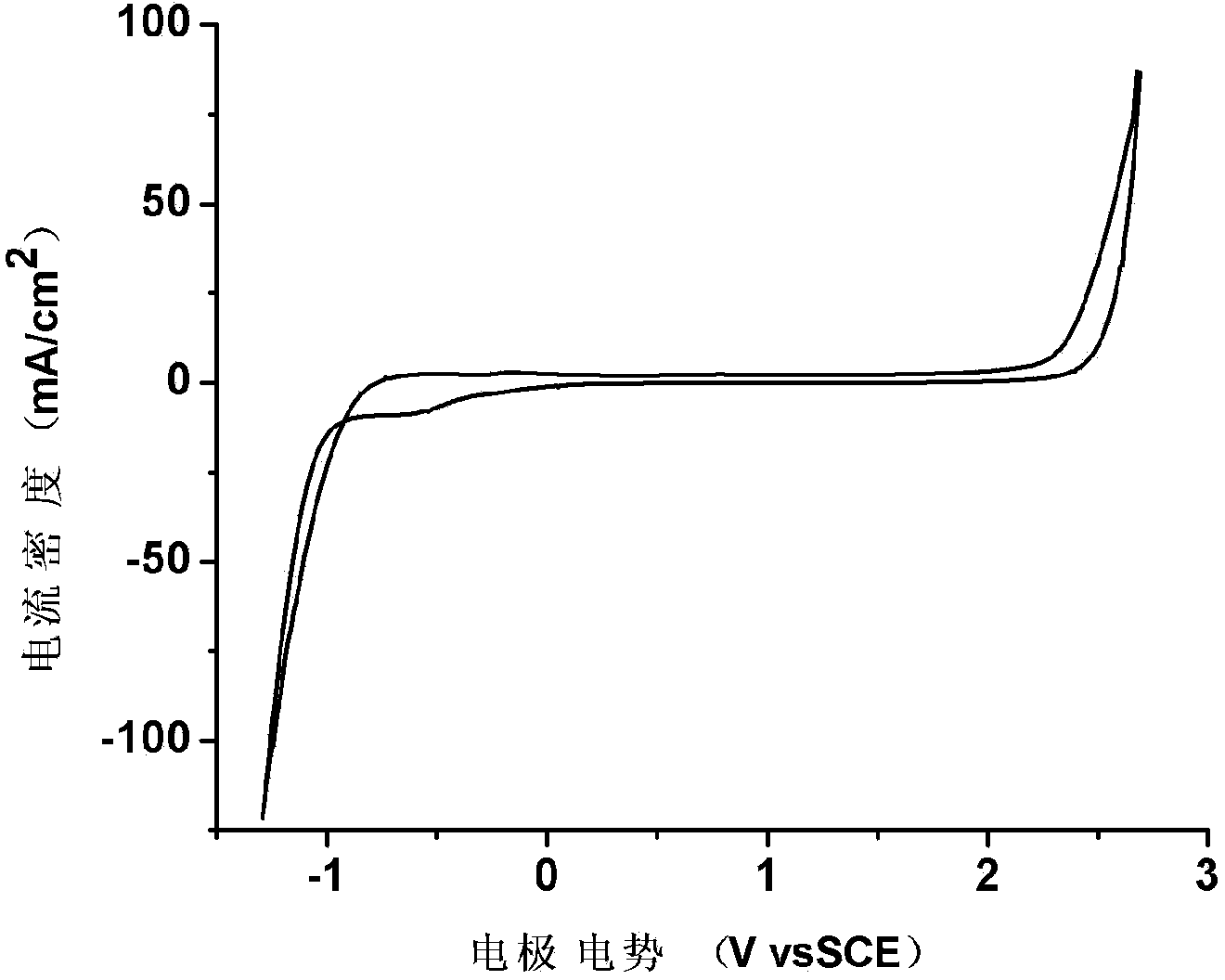

Preparation method of boron-doped diamond film electrode taking porous titanium as matrix

InactiveCN103643219AIncrease growth rateImprove stabilityChemical vapor deposition coatingGas phaseChemical vapor deposition

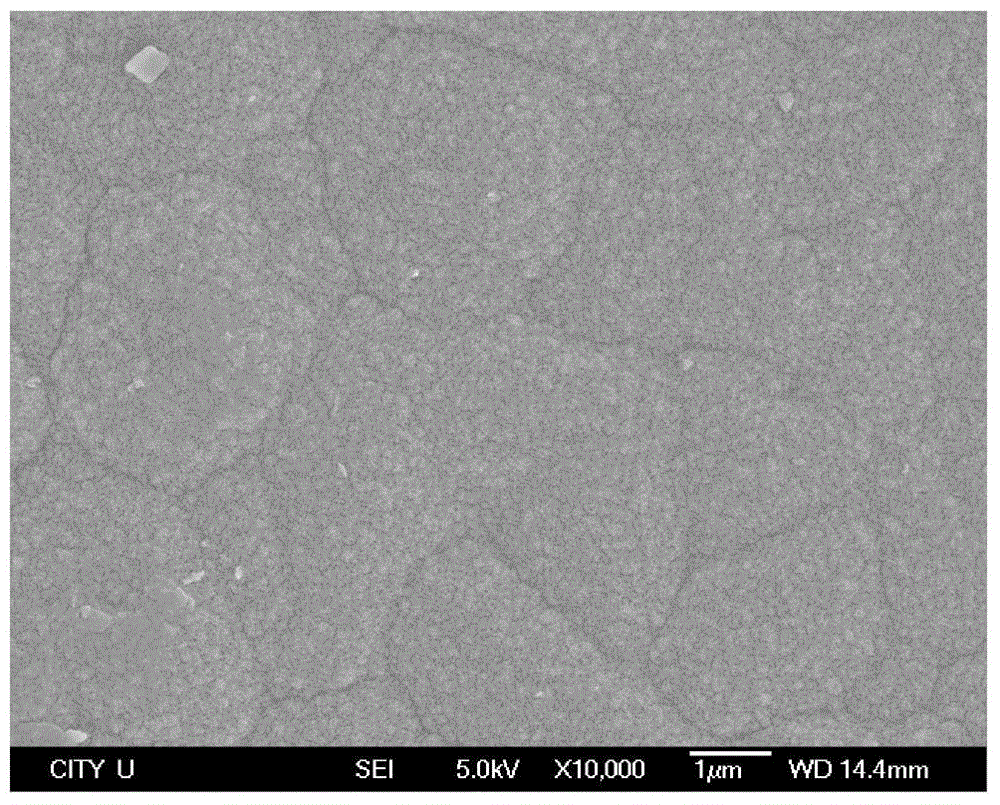

The invention discloses a preparation method of a boron-doped diamond (BDD) film electrode taking porous titanium as a matrix. The preparation method is characterized in that the titanium matrix is a porous titanium material with the porosity of 20-50%, hot filament chemical vapor deposition equipment is adopted, and a porous titanium base BDD electrode is prepared through chemical vapor deposition by using a second-order boron concentration control mode. By adopting the method, the generation capacity of TiC is controlled by adjusting boron source concentrations of different stages during chemical vapor deposition, namely the formation of TiC is inhibited by using high boron doping at the initial stage to improve the bonding force between a base and a film, and the boron source concentration is reduced in the later period of reaction to perform low boron doping. The porous titanium base BDD electrode prepared by the method disclosed by the invention is uniform and compact in diamond grain, and the porous titanium matrix is completely covered by a diamond film, so that the electrode has good stability and a relatively wide potential window.

Owner:JILIN UNIV

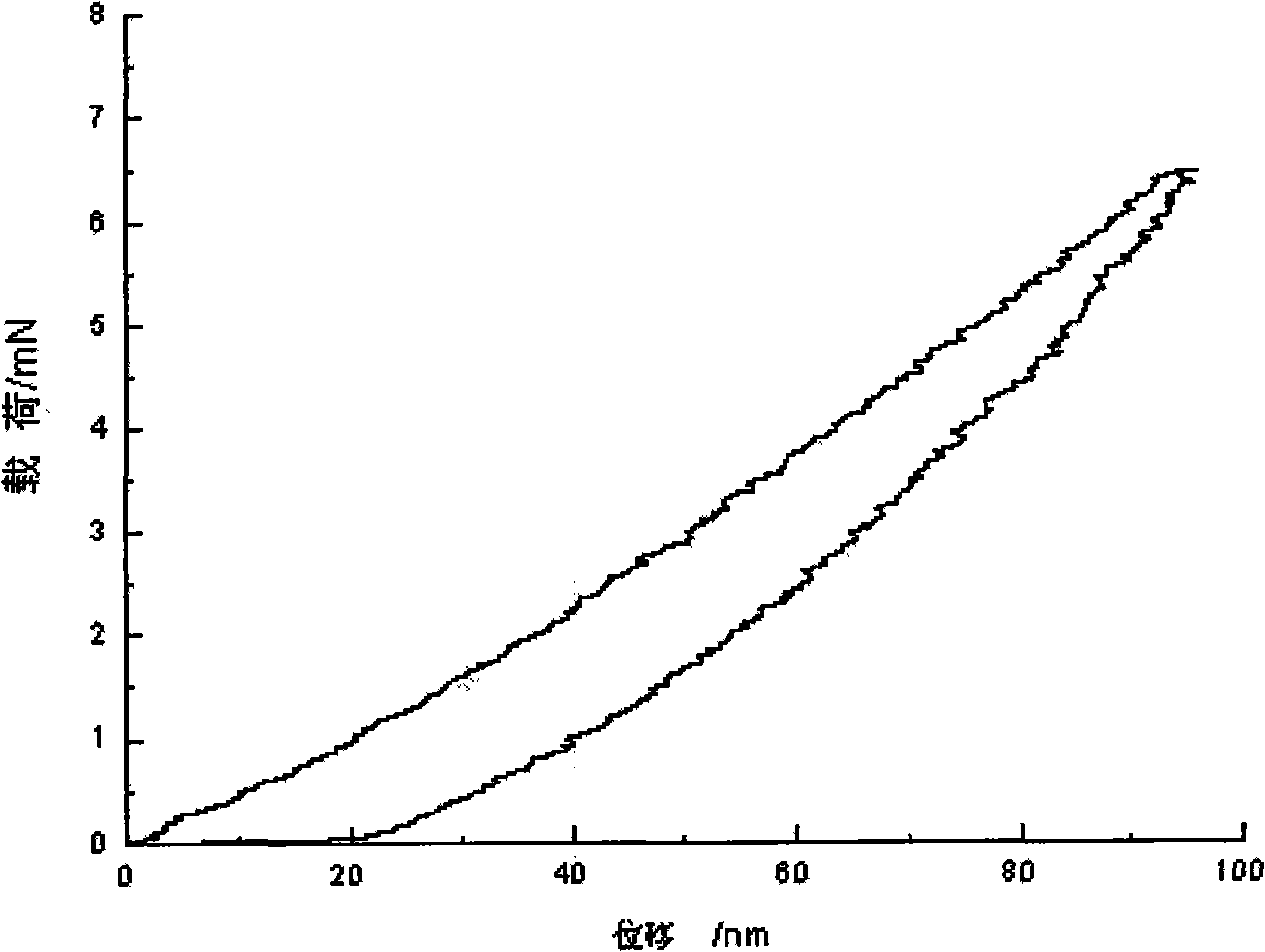

Preparation of high-hardness diamond-like multi-layer film

InactiveCN101298656AIncreasing the thicknessReduce hardnessVacuum evaporation coatingSputtering coatingVacuum chamberVacuum arc

The invention discloses a preparation method of a multilayer diamond-like film with high hardness, which comprises the following steps: a substrate is sputter cleaned, the diamond-like film is deposited by a depositing method with magnetic filtering and cathode vacuum arc, and the depositing method comprises steps of closing a vacuum chamber, vacuumizing the vacuum chamber to the pressure of 10<-3> Pa, turning on a pot lead cathode arc source, exerting negative bias voltage from minus 50 V to minus 200 V on the substrate and simultaneously and periodically letting in argon of 99.99 percent; furthermore, a control period lasts for 120 to 600 seconds, the time for letting in the argon is 10 to 50 percent of the control period, and the argon pressure in the vacuum chamber during argon inletting is 0.01 to 0.1 Pa; time for shutting off the argon is 90 to 50 percent of the control period, and the vacuum degree of the vacuum chamber at the time is 10<-4> to 10<-3> Pa; the number of the control periods is 3 to 50. The preparation method of the multilayer diamond-like film with high hardness has simple technique, low cost, produced films with strong bonding force, high hardness, large thickness, small stress and excellent mechanical and tribology performance; as well as wide application space in the industrial application field.

Owner:SOUTHWEST JIAOTONG UNIV

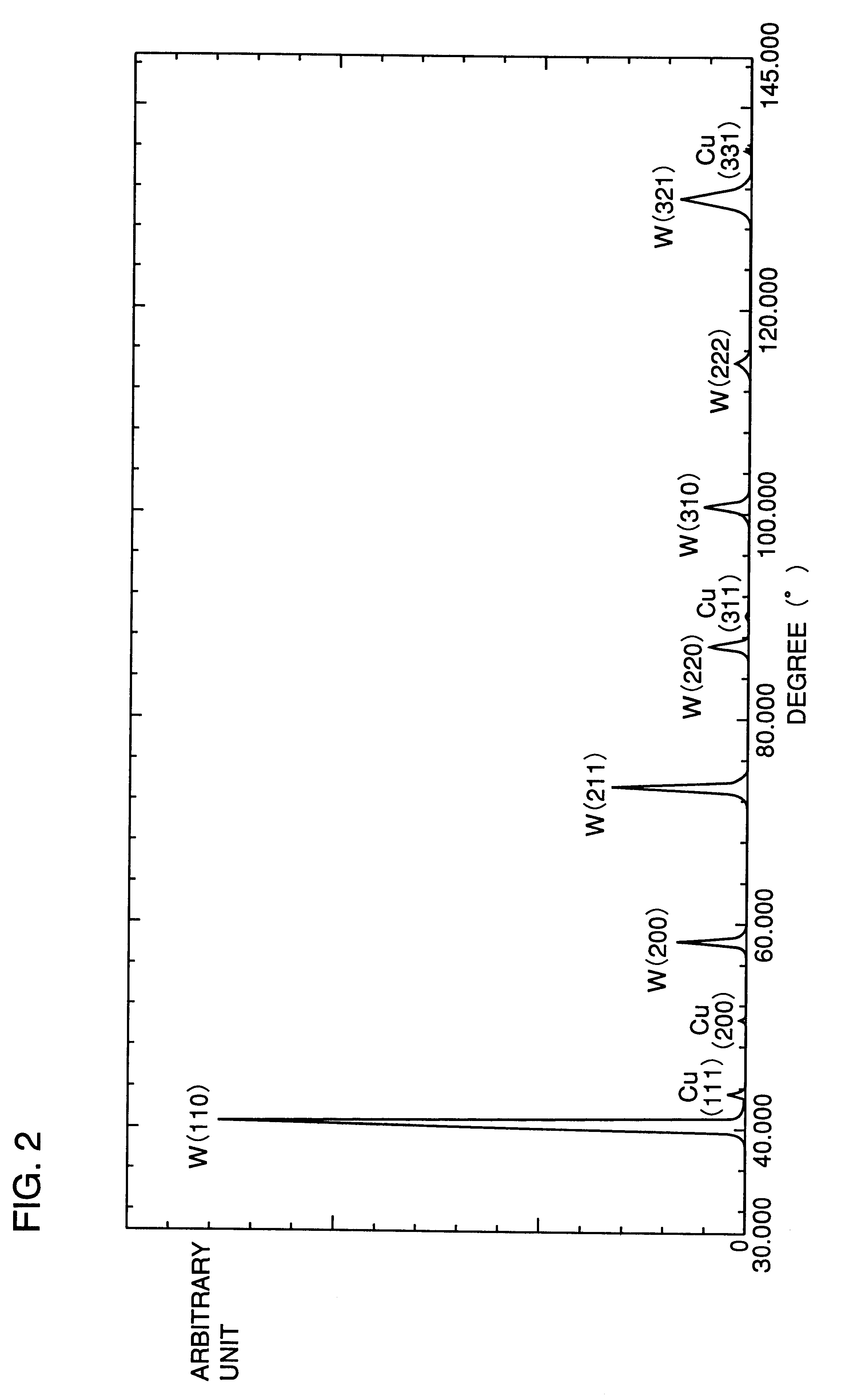

Heatsink and fabrication method thereof

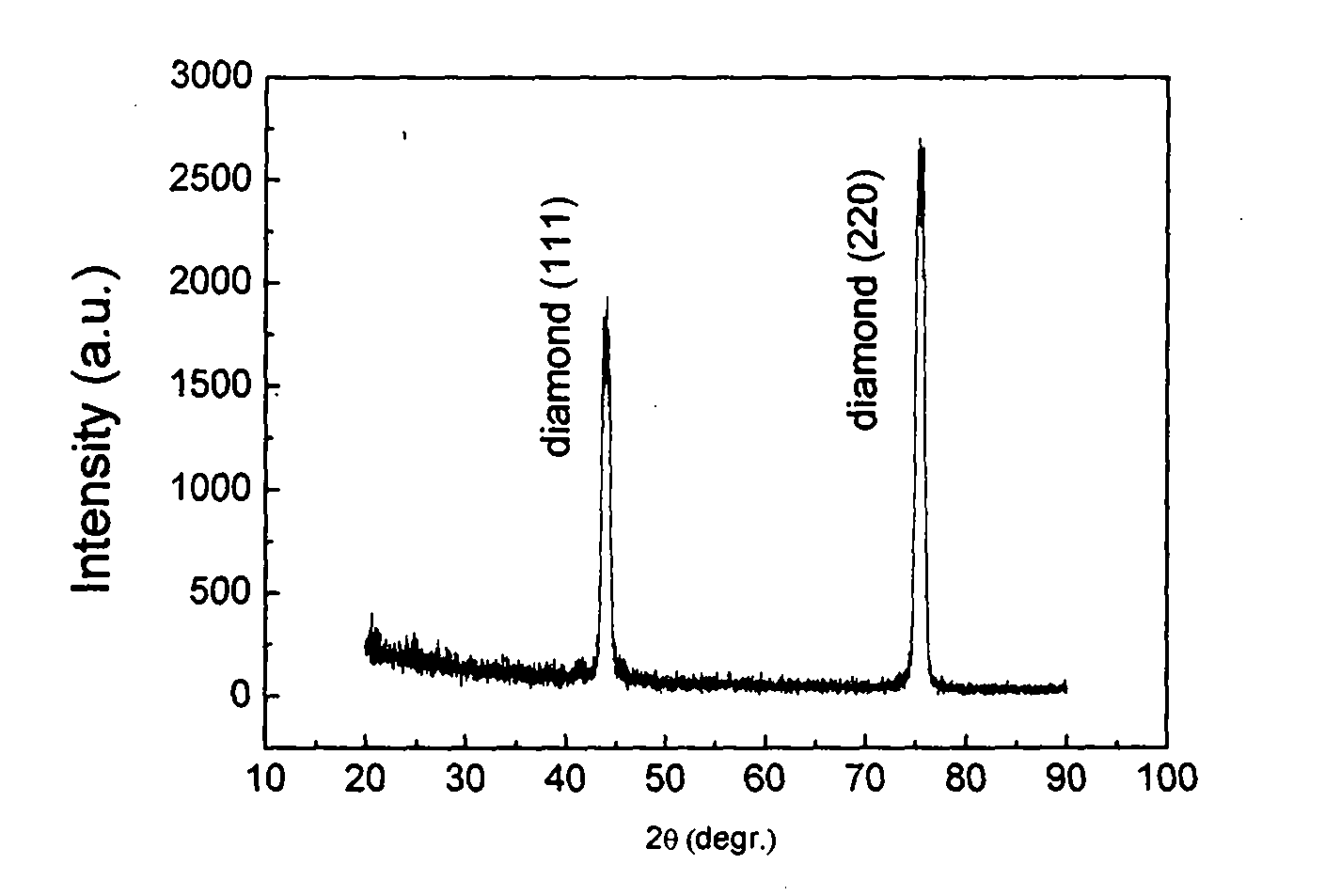

InactiveUS6361857B1High densityAdherenceSemiconductor/solid-state device detailsSolid-state devicesX-rayOptoelectronics

A thin diamond film layer is formed on a substrate with good adherence. A heatsink includes a substrate of a sintered compact including Cu and W, and a thin diamond film layer formed on the surface of the substrate. The Cu content in the substrate is at least 5% by weight. In an X-ray diffraction chart obtained by irradiating the thin diamond film layer with an X-ray, the diffraction peak intensity of the (110) plane of W is at least 100 times the diffraction peak intensity of the (200) plane of Cu.

Method for preparing diamond-like composite coating on surface of magnesium alloy

InactiveCN101665941AImprove carrying capacityImprove wear resistanceVacuum evaporation coatingSurface reaction electrolytic coatingPlasma electrolytic oxidationMicro arc oxidation

The invention relates to a method for a titanium doped diamond-like composite coating with good abrasion proof and self lubricating properties on the surface of magnesium alloy. The method comprises the following steps that: firstly, a ceramic transition layer, which has a porous structure and is high in bonding strength and hardness, is formed on the surface of magnesium alloy by the micro arc oxidation treatment process; secondly, a titanium doped diamond-like film surface layer with solid lubricating property is deposited by the magnetic control sputtering method; and finally the micro arcoxidation / diamond-like composite coating is obtained on the surface of magnesium alloy. The coating can be used in oil-free lubrication fields such as magnesium alloy parts of an automobile, aviation / aerospace and the like, and the application range of the coating on moving parts is widened.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

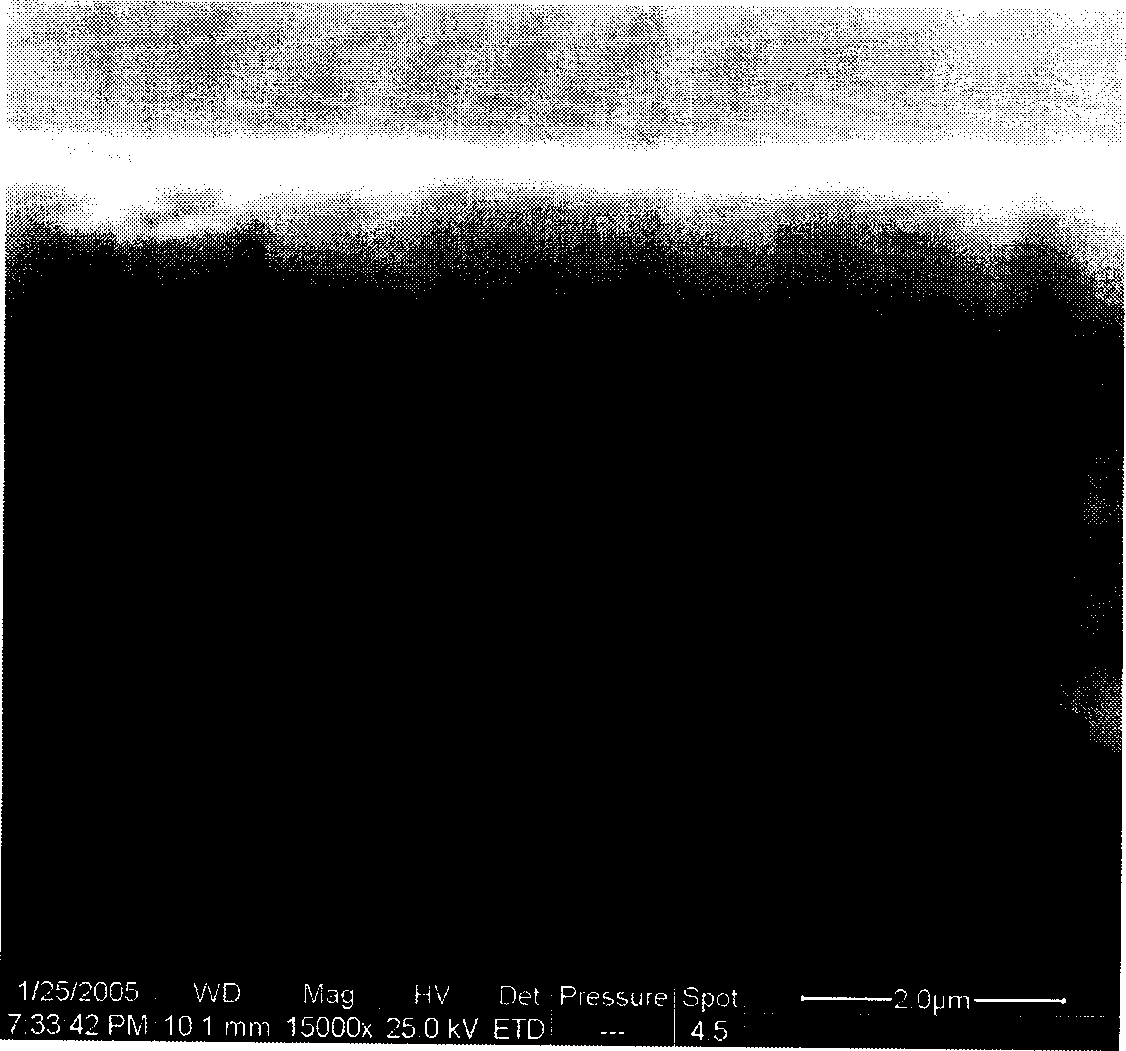

Diamond film coated tool and process for producing the same

ActiveUS20060216515A1High densityImprove adhesionThread cutting toolsPretreated surfacesMicrometerSurface roughness

The invention provides a diamond coated tool having an excellent cutting performance, wear resistance, adhesion resistance and work surface roughness in combination and a method of producing such a tool. A diamond coated tool comprising a substrate and a diamond coating formed on the surface of the substrate, wherein said substrate is made of a cemented carbide or a cermet, diamond grains constituting a growth surface of said diamond coating has an average grain size of about 1.5 micrometers or below, said diamond coating has a thickness ranging from about 0.1 micrometer to 20 micrometers, and said diamond coating has an average surface roughness Ra ranging from about 0.01 micrometer to 0.2 micrometer. Such a diamond coated tool can be obtained by carburizing the substrate consisting of a cemented carbide or a cermet, and growing up a diamond coating thereon.

Owner:SUMITOMO ELECTRIC IND LTD

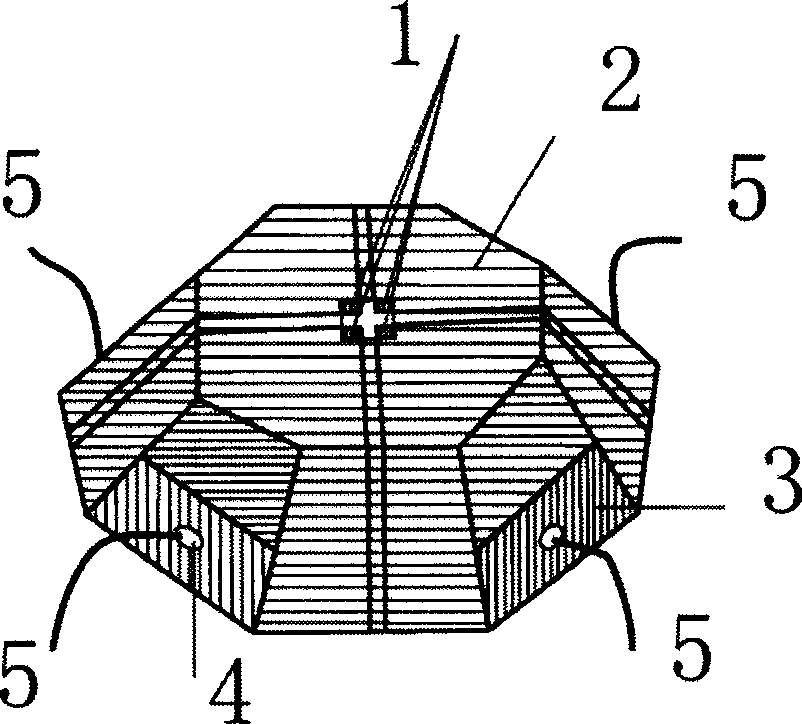

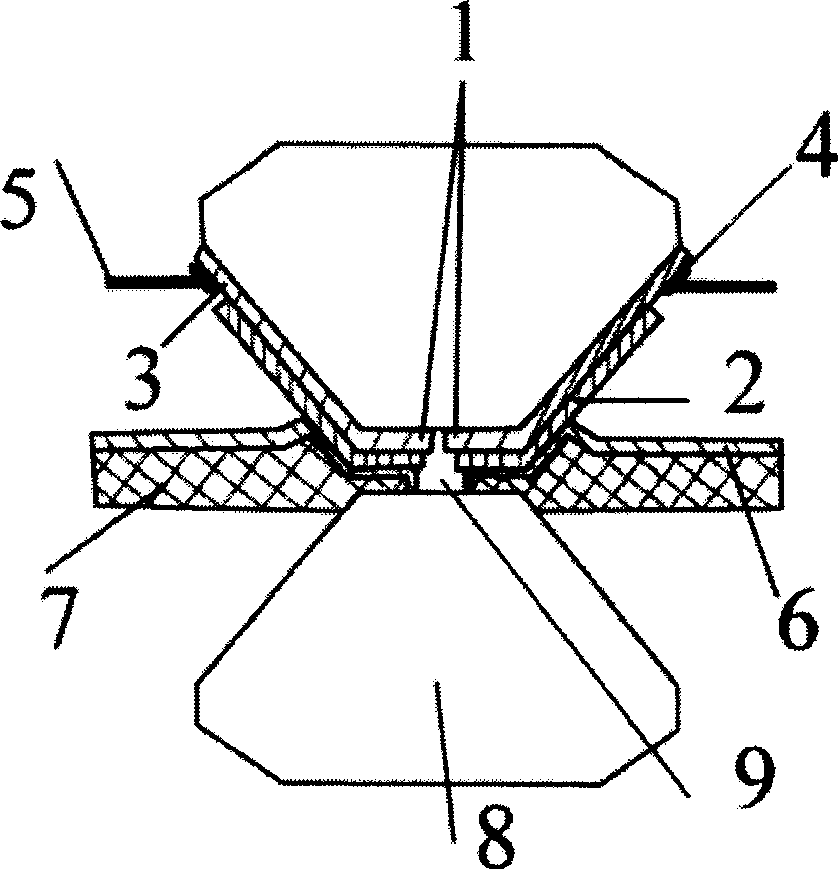

Electrode for in-situ electrical measurement for diamond anvil cell and method for producing the same

InactiveCN101509947ANo breakage problemGood chemical stabilityMaterial analysis by electric/magnetic meansElectrical testingBoronDiamond thin film

The invention discloses an in-situ electrical measuring electrode that is used in diamond-pair anvil cells and a manufacturing method thereof, and belongs to the technical field of high-temperature and high-voltage devices. Four electrodes (1) are deposited on the surface of a diamond anvil cell (8) and distribute from an anvil surface to a lateral surface of the diamond anvil cell (8); the electrodes (1) are diamond films doped with boron; a diamond insulating layer (2) covers the anvil surface and the lateral surface of the diamond anvil cell (8) as well as the electrodes (1) thereof; the electrodes (1) are exposed at one end of the anvil surface, the exposed position lies inside a sample cavity (9), and the electrodes (1) are exposed at one end of the lateral surface and connected with an electrode lead (5). A diamond film microcircuit and the diamond insulating layer are simultaneously integrated onto the surface of the diamond anvil cell by utilizing the film deposition technique, the nanometer seeding technique, the masking technique and the photolithographic method. The manufacturing method of the in-situ electrical measuring electrode prevents the electrode from being destroyed by transverse shearing force and overcomes the electrode corrosion by samples under the high-voltage condition, thus widening the research field of electrical in-situ measurement under high voltage.

Owner:JILIN UNIV

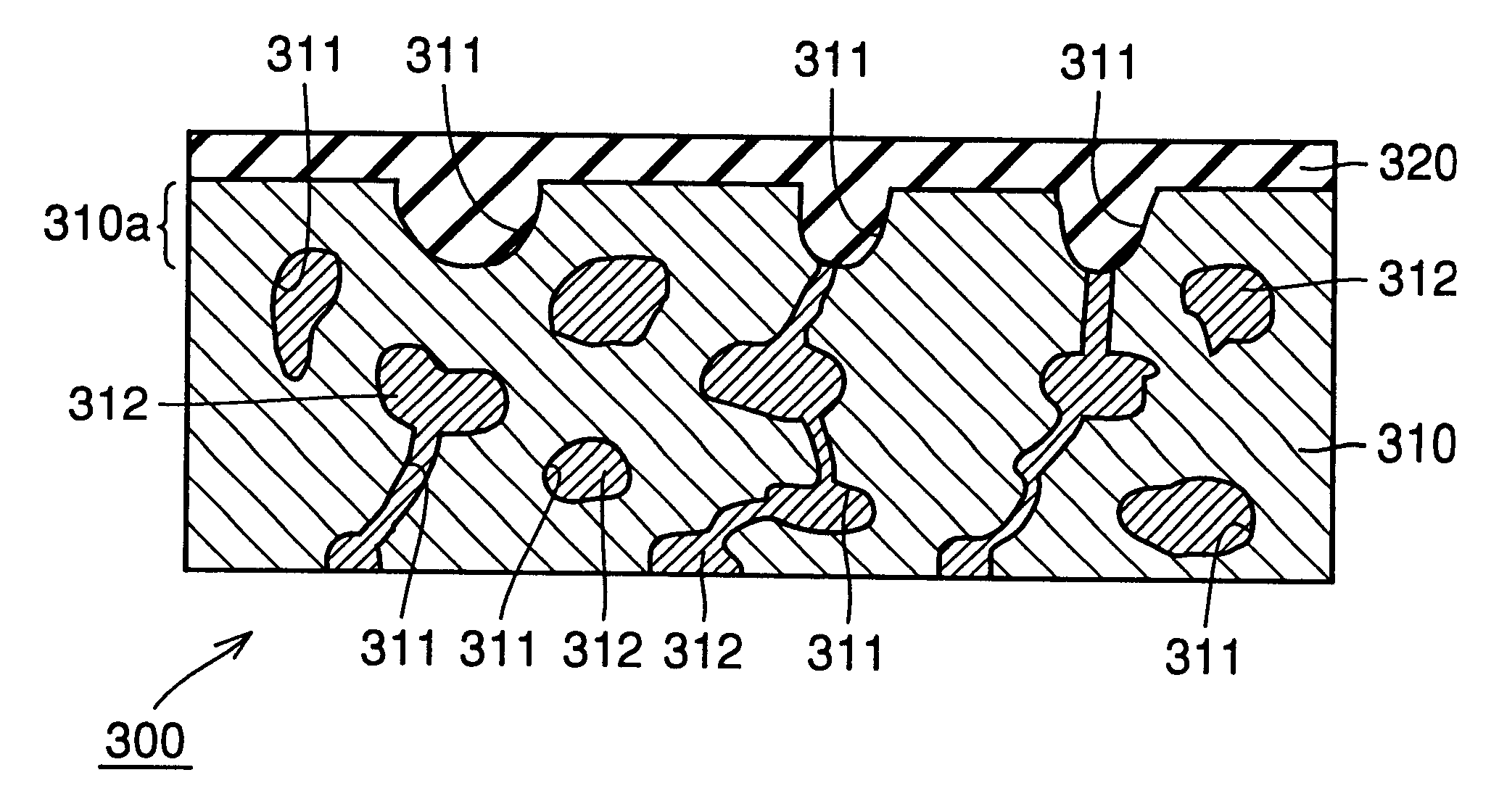

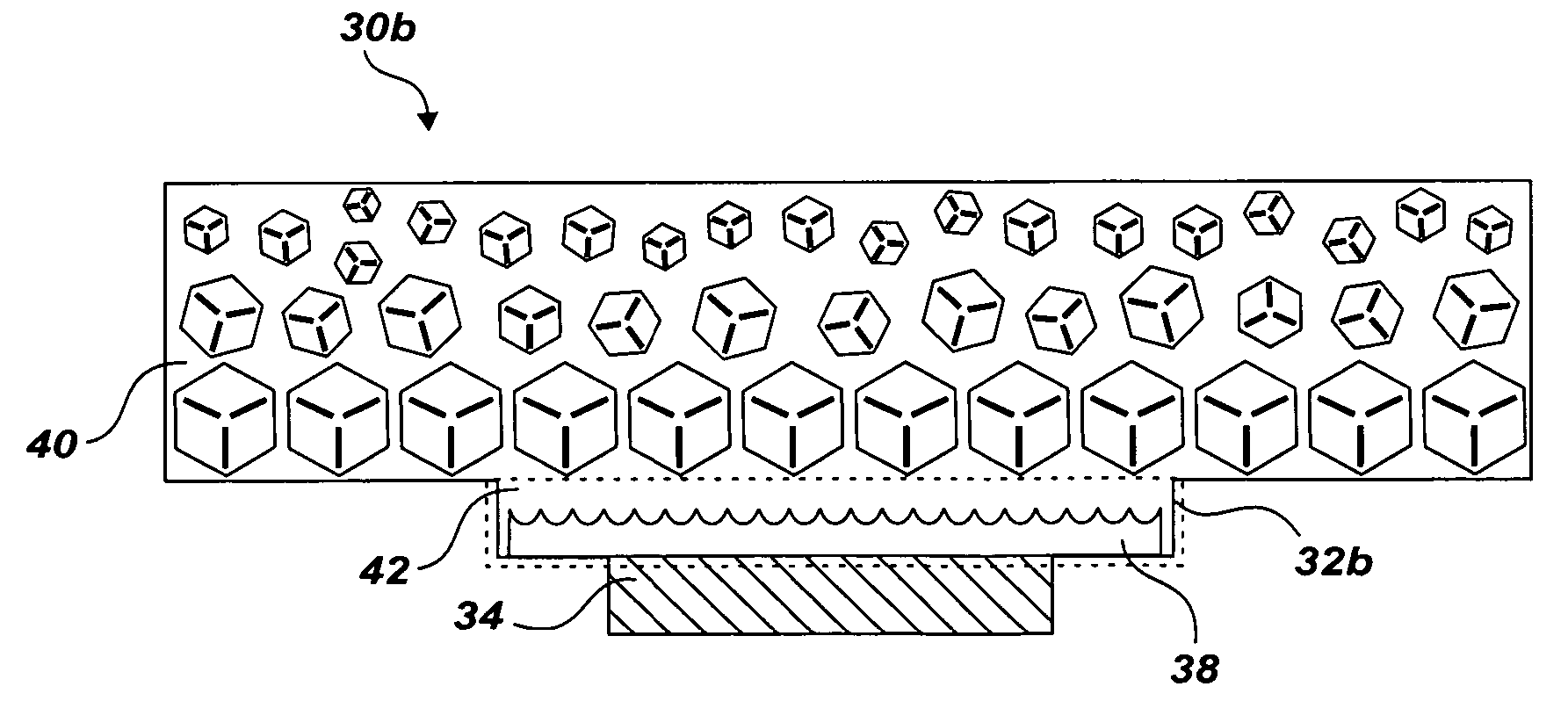

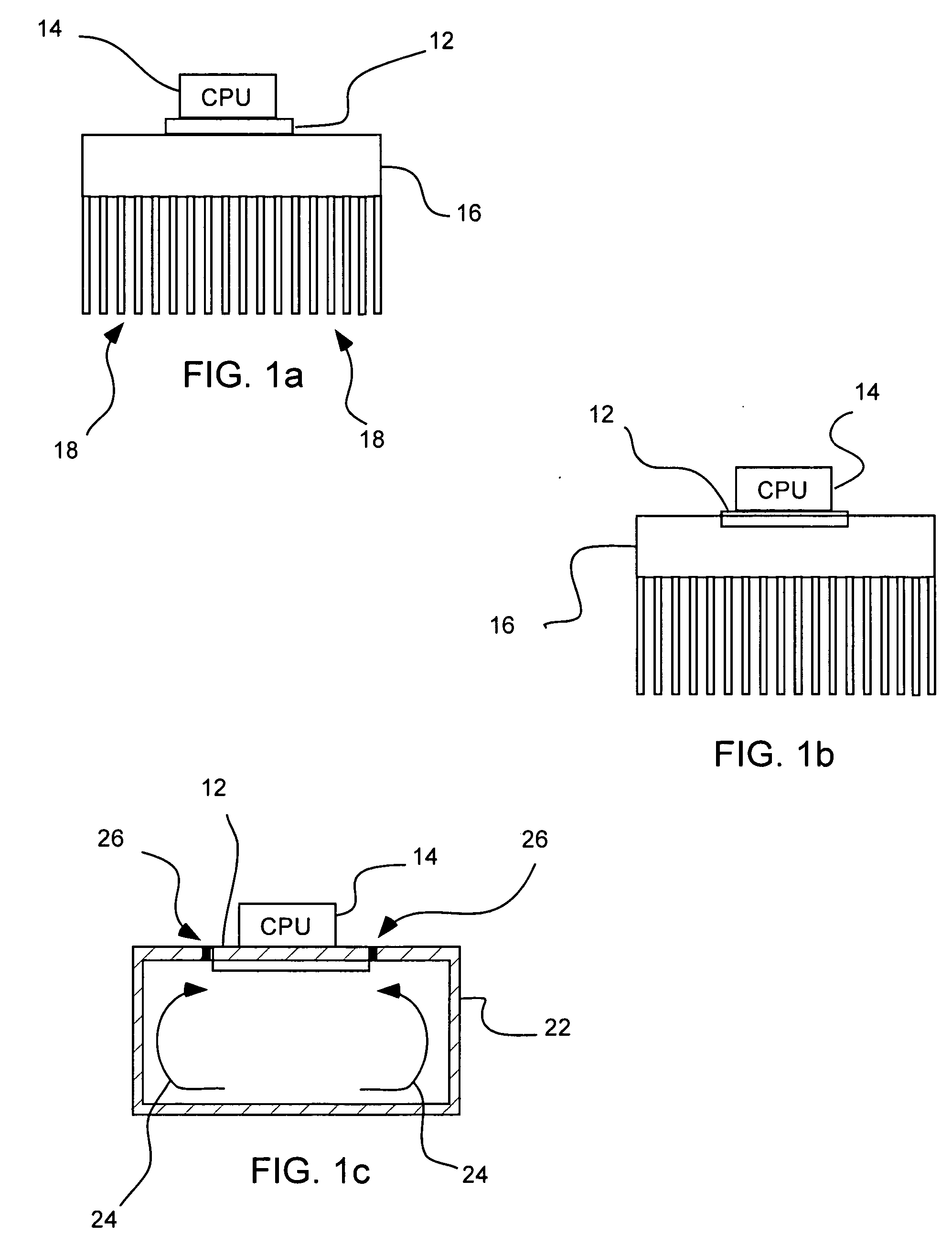

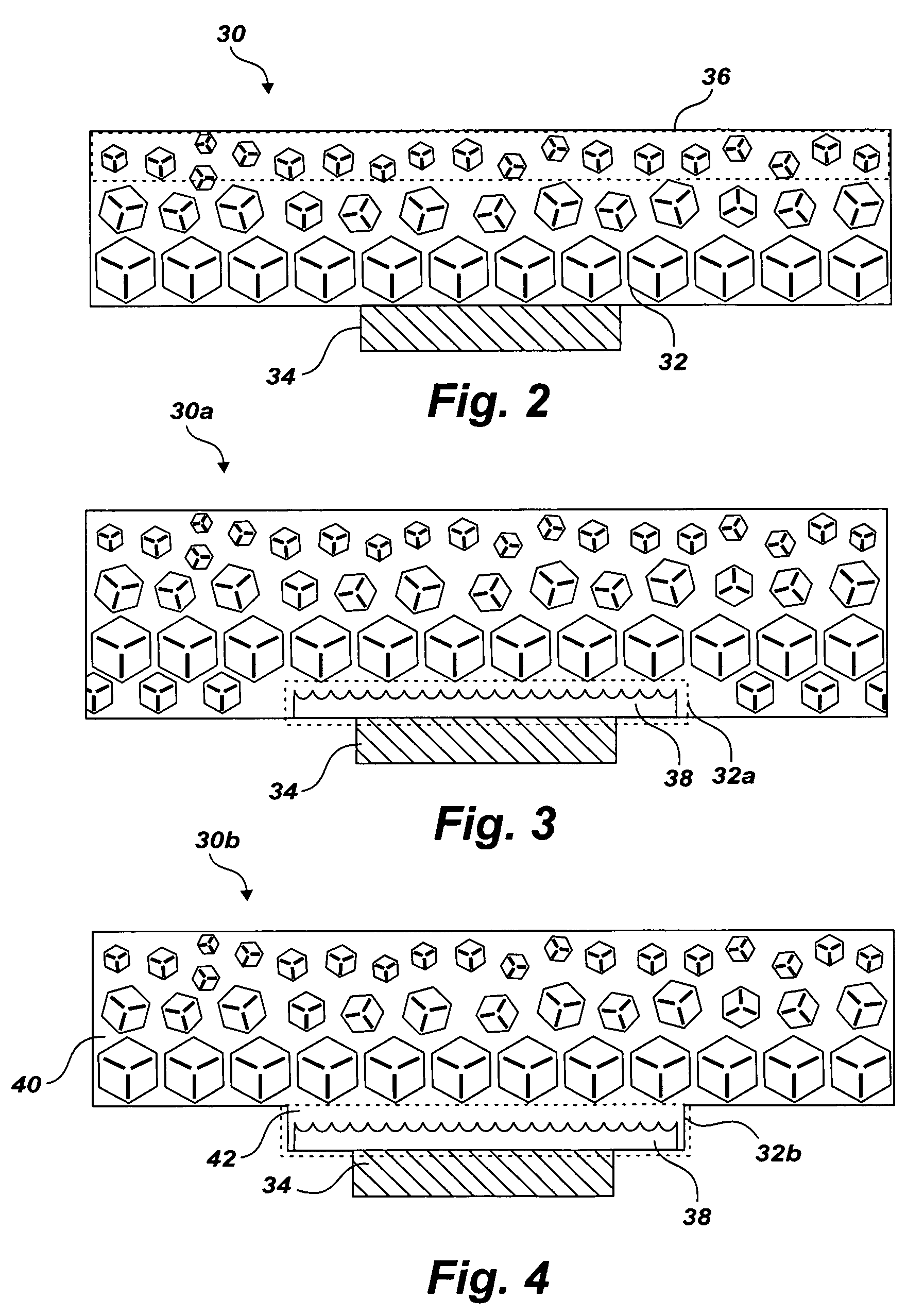

Diamond composite heat spreader having thermal conductivity gradients and associated methods

InactiveUS20050250250A1Easy to controlImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesParticulatesDiamond thin film

A diamond composite heat spreader having a variable thermal conductivity gradient can improve control of heat transfer based on a specific application. A diamond-containing region of the heat spreader can contain diamond particles such that the diamond concentration and / or the diamond particle size a varied to produce a desired thermal conductivity gradient. Regions proximate to a heat source can have a higher thermal conductivity than regions further away from the heat source. Thin diamond films can also be used in conjunction with the particulate diamond in order to provide a region of maximum thermal conductivity adjacent a heat source. By providing a variable thermal conductivity gradient, more expensive materials such as diamond film and larger diamond particles can be selectively used in regions closer to a heat source, while allowing for cheaper smaller diamond particles and materials to be used farther away from the heat source where thermal conductivity can be lower without sacrificing overall performance.

Owner:RITEDIA CORPORATION

Fabrication of diamond shells

ActiveUS20070104399A1Good chemical stabilityAbsorb large mechanical stressPaper/cardboard articlesTransportation and packagingInfraredInfra-red color

A novel method for fabricating diamond shells is introduced. The fabrication of such shells is a multi-step process, which involves diamond chemical vapor deposition on predetermined mandrels followed by polishing, microfabrication of holes, and removal of the mandrel by an etch process. The resultant shells of the present invention can be configured with a surface roughness at the nanometer level (e.g., on the order of down to about 10 nm RMS) on a mm length scale, and exhibit excellent hardness / strength, and good transparency in the both the infra-red and visible. Specifically, a novel process is disclosed herein, which allows coating of spherical substrates with optical-quality diamond films or nanocrystalline diamond films.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

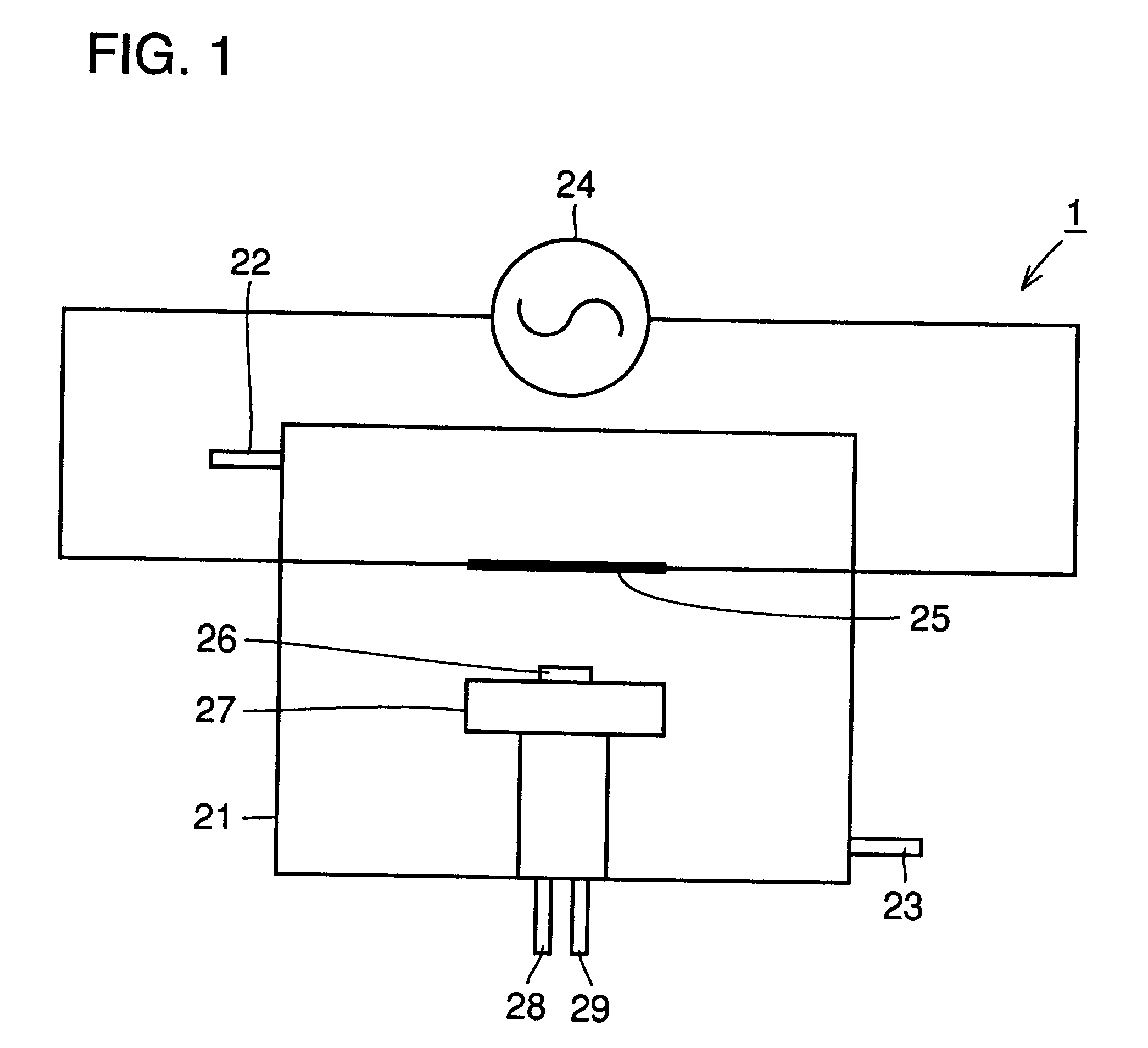

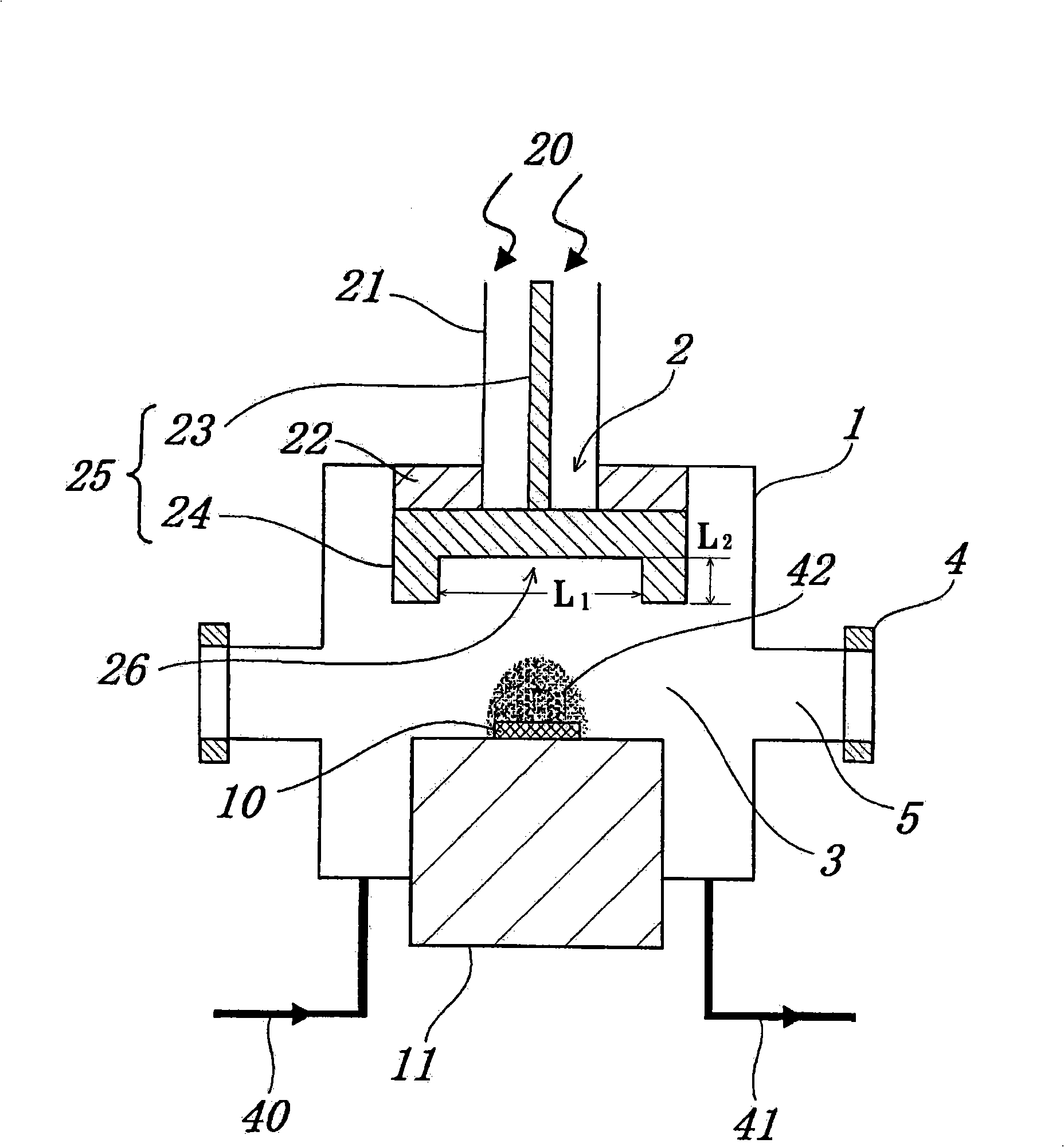

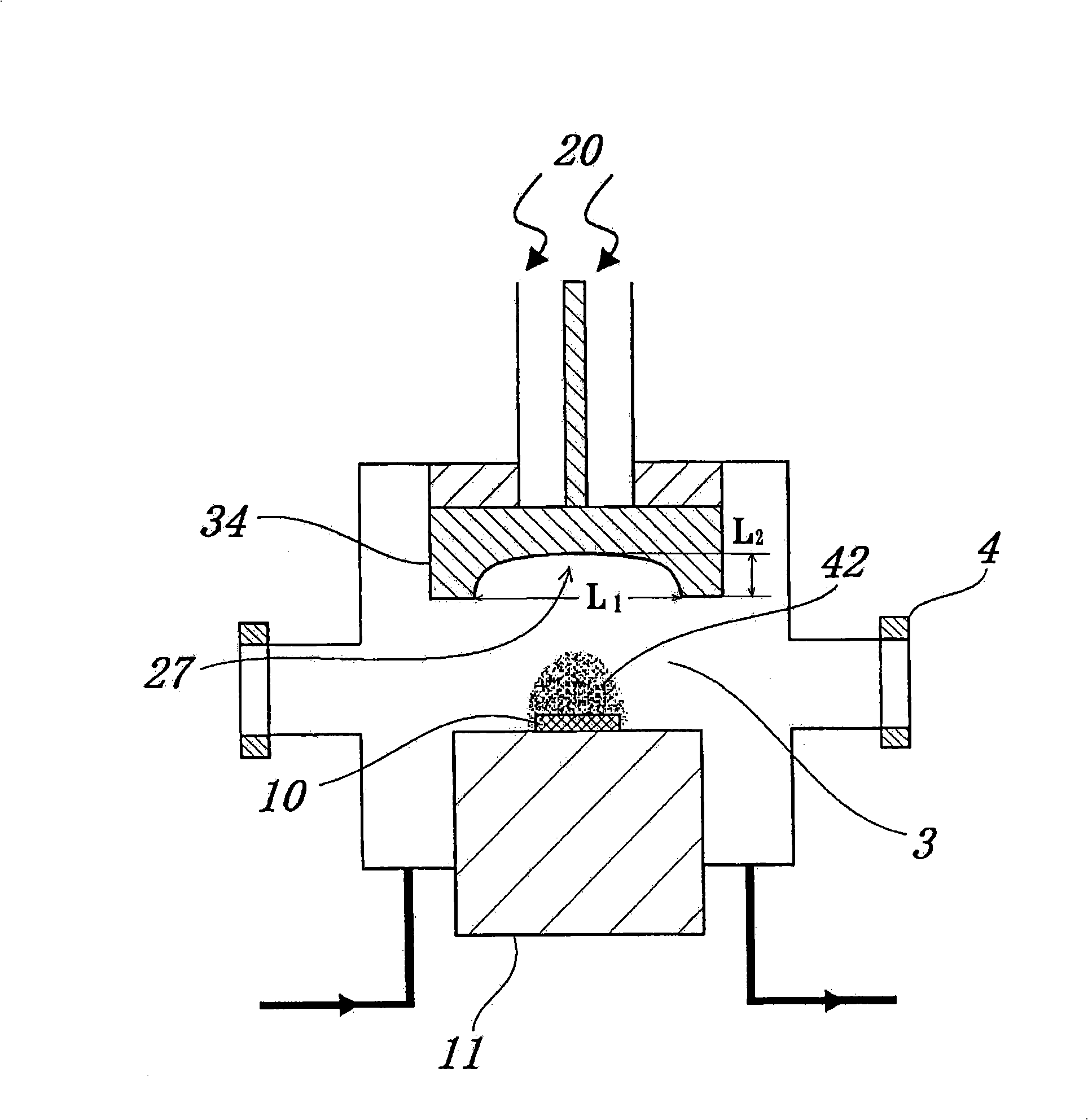

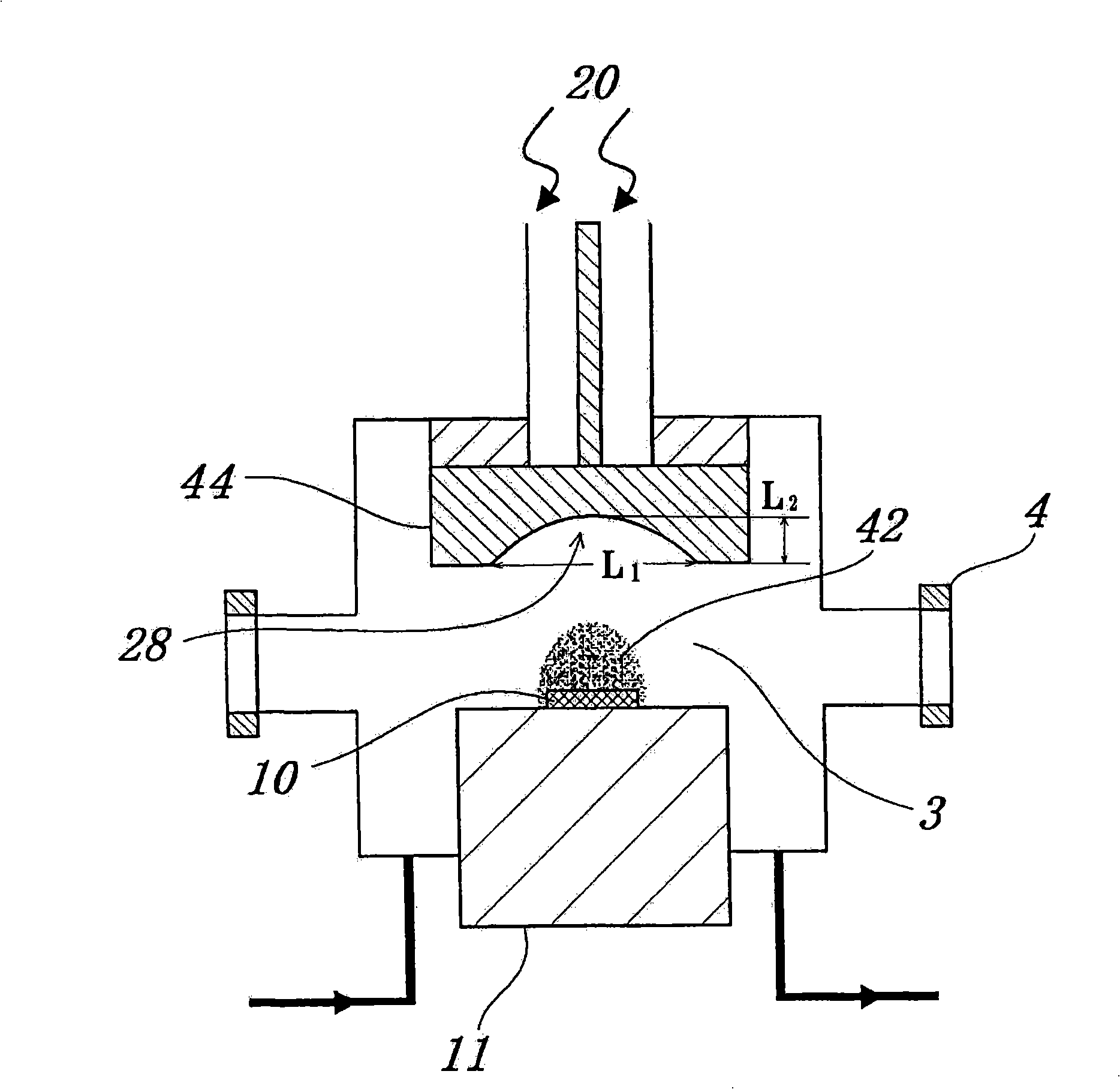

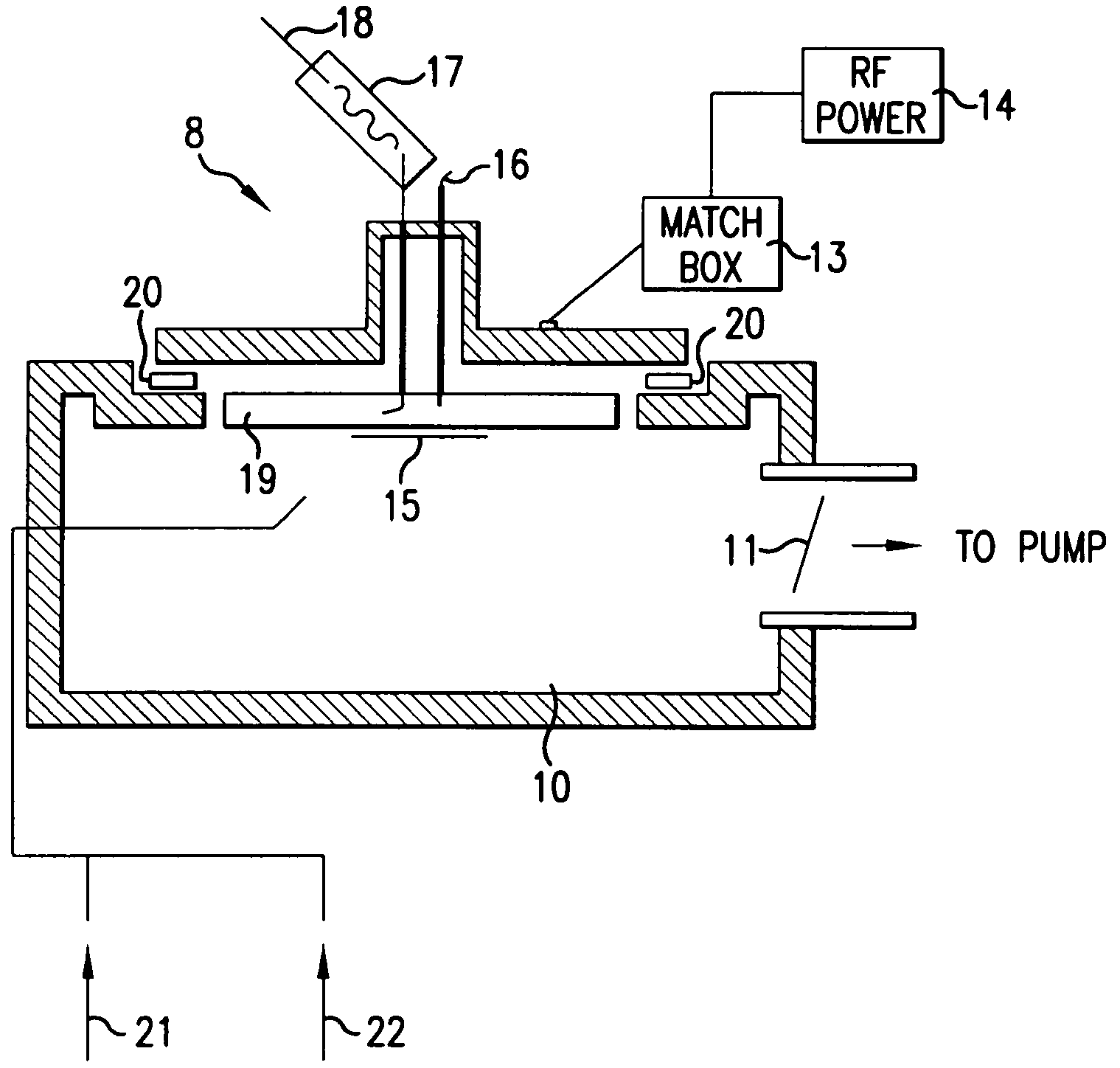

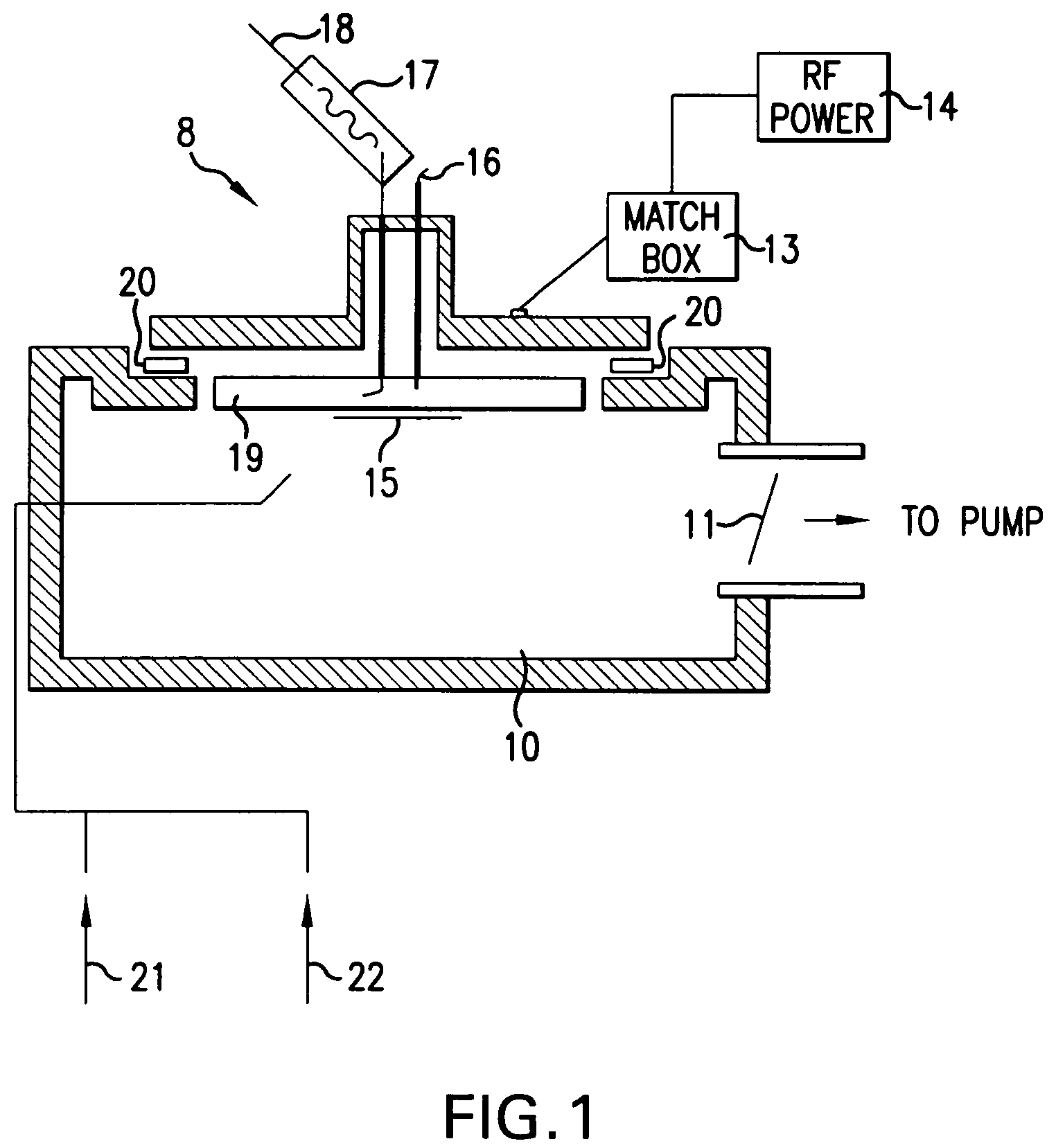

Microwave plasma CVD system

InactiveCN101410549AEasy and stable generationPolycrystalline material growthElectric discharge tubesMicrowaveWaveguide

Owner:SUMITOMO ELECTRIC IND LTD

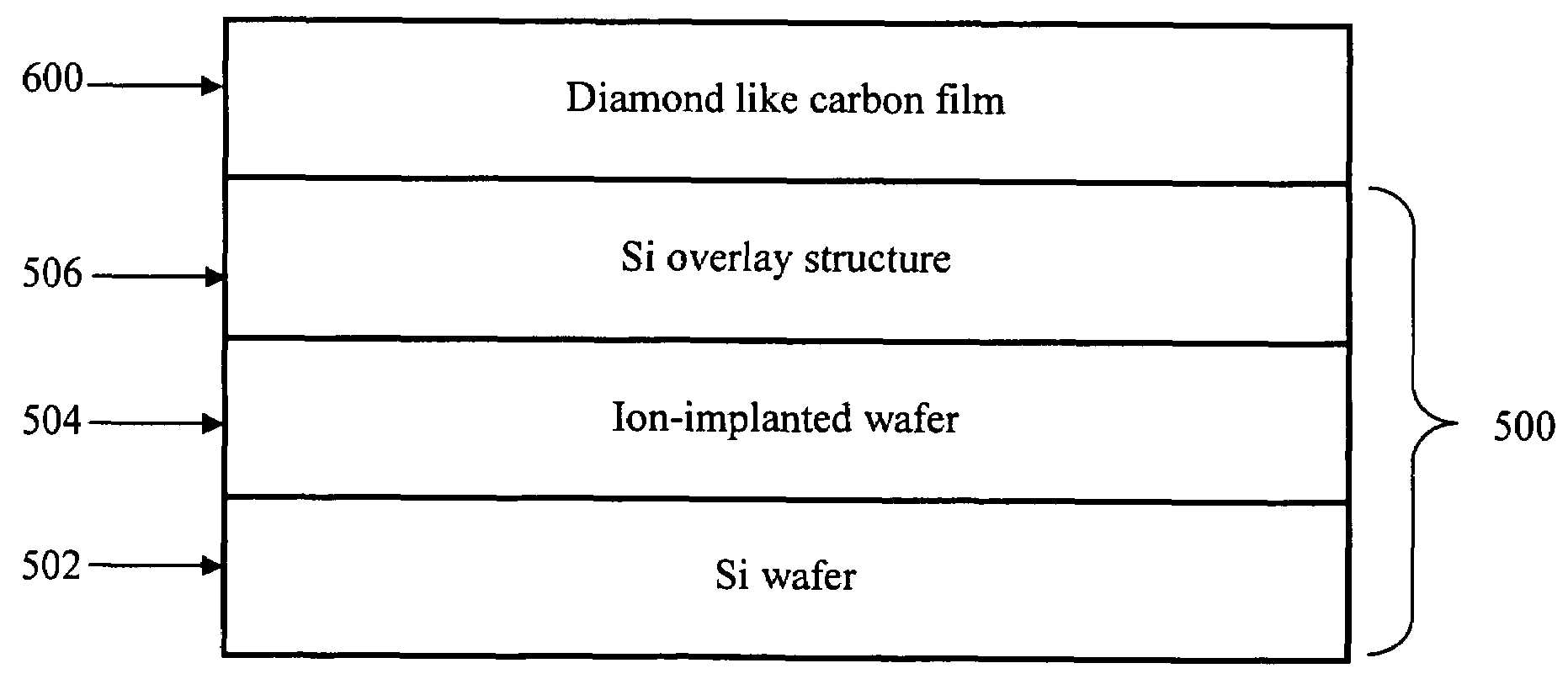

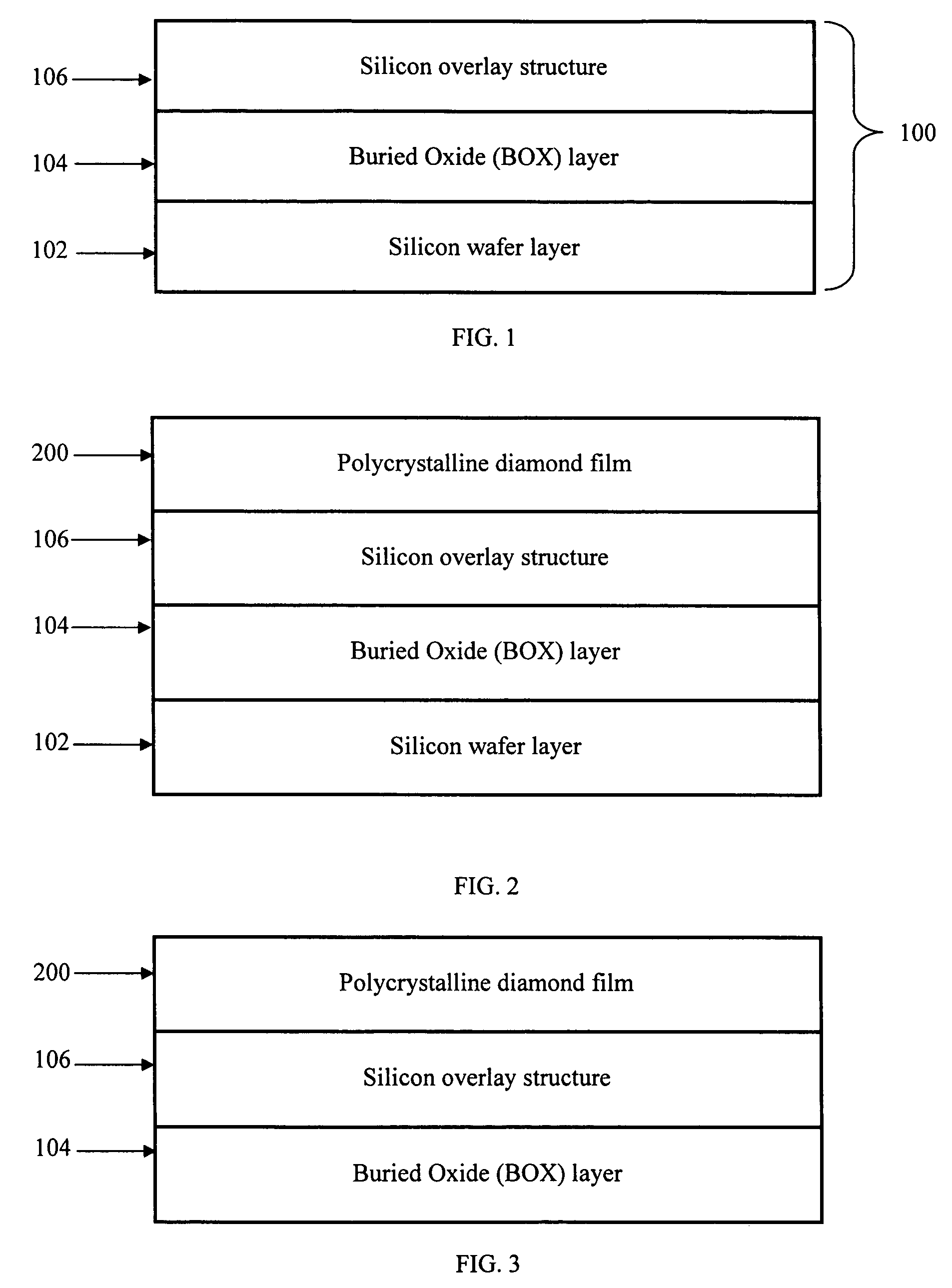

Thermal management substrate

InactiveUS7695564B1Improve wafer flatnessHigh surface finishFrom gel statePolycrystalline material growthDiamond-like carbonWafering

The present invention is directed to a method for fabricating a thermal management substrate having a Silicon (Si) layer on a polycrystalline diamond film, or on a diamond-like-carbon (DLC) film. The method comprises acts of fabricating a separation by implantation of oxygen (SIMOX) wafer; depositing a polycrystalline diamond film onto the SIMOX wafer; and removing various layers of the SIMOX wafer to leave a Si overlay layer that is epitaxially fused with the polycrystalline diamond film. In the case of the DLC film, the method comprises acts of ion-implanting a Si wafer; depositing an amorphous DLC film onto the Si wafer; and removing various layers of the Si wafer to leave a Si overlay structure epitaxially fused with the DLC film.

Owner:HRL LAB

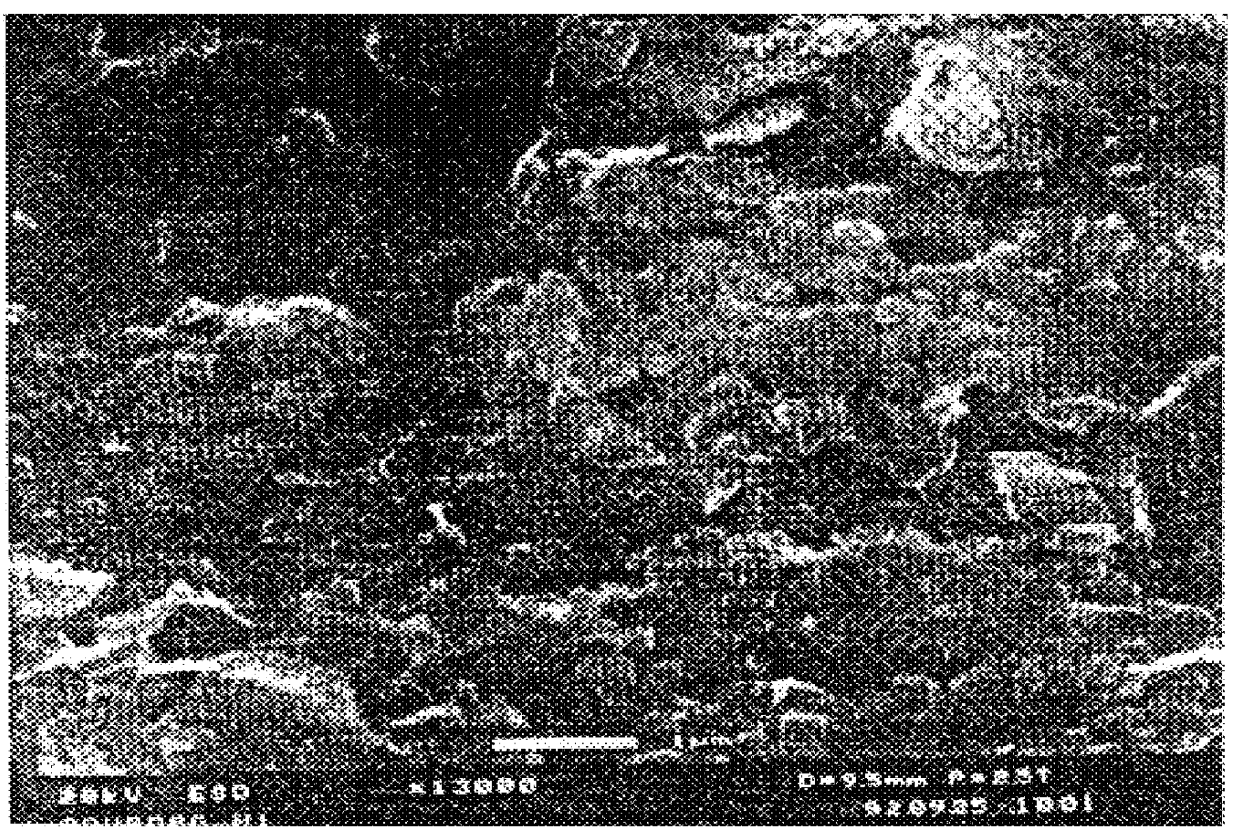

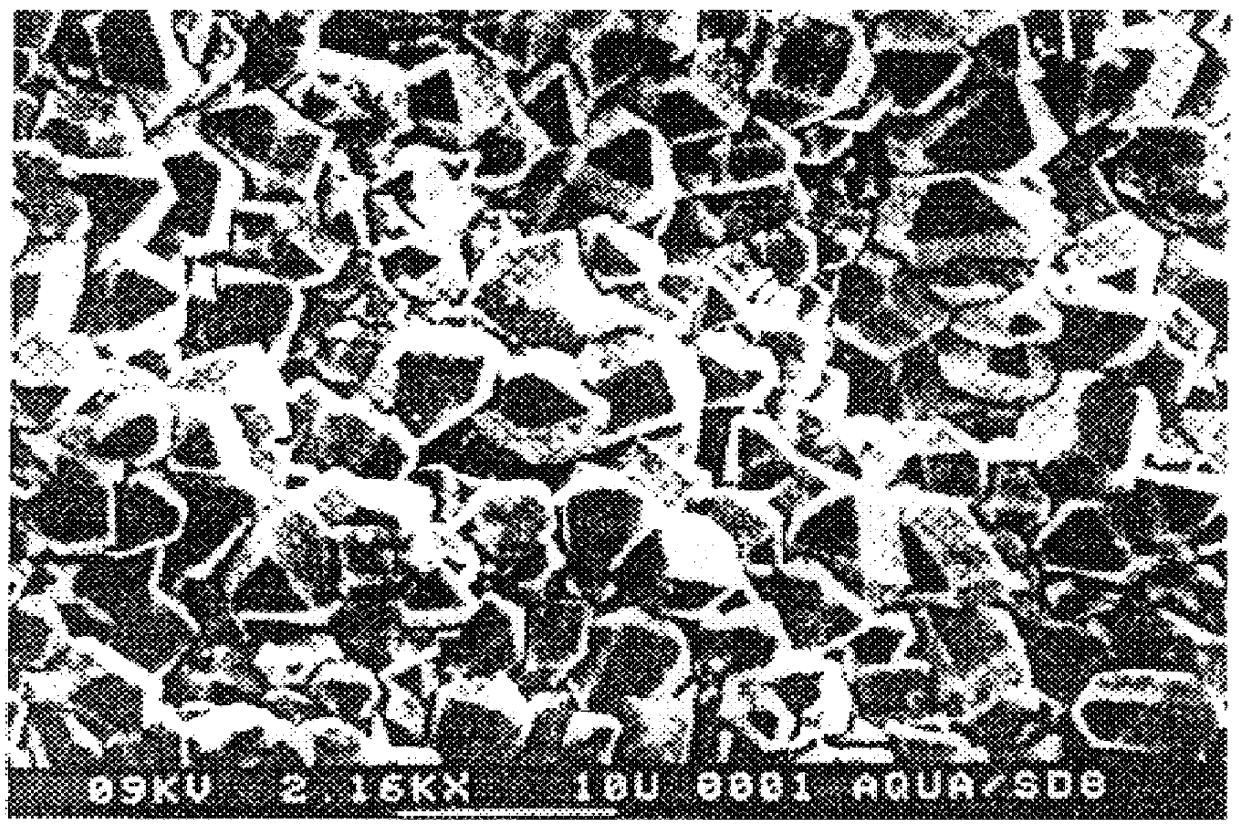

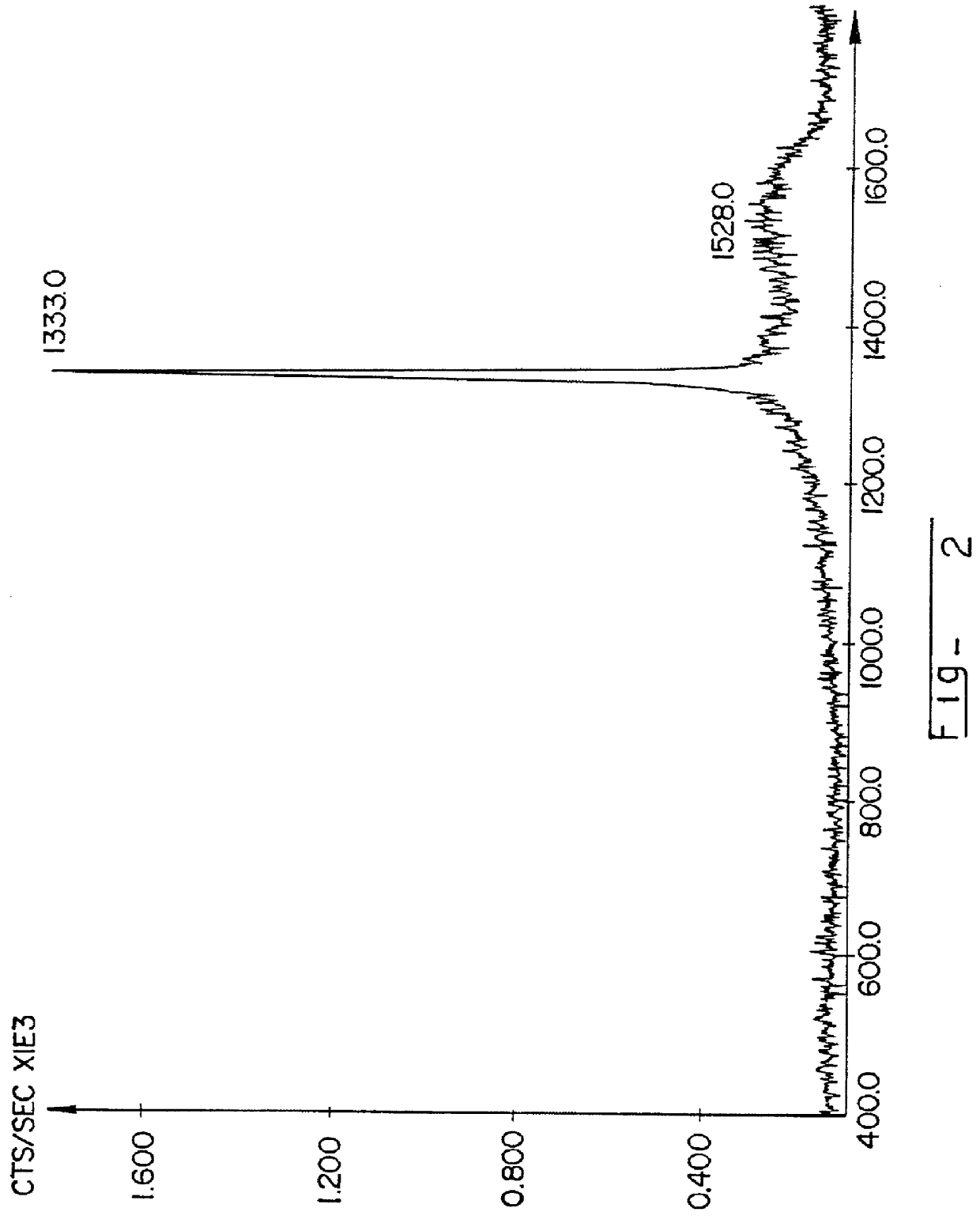

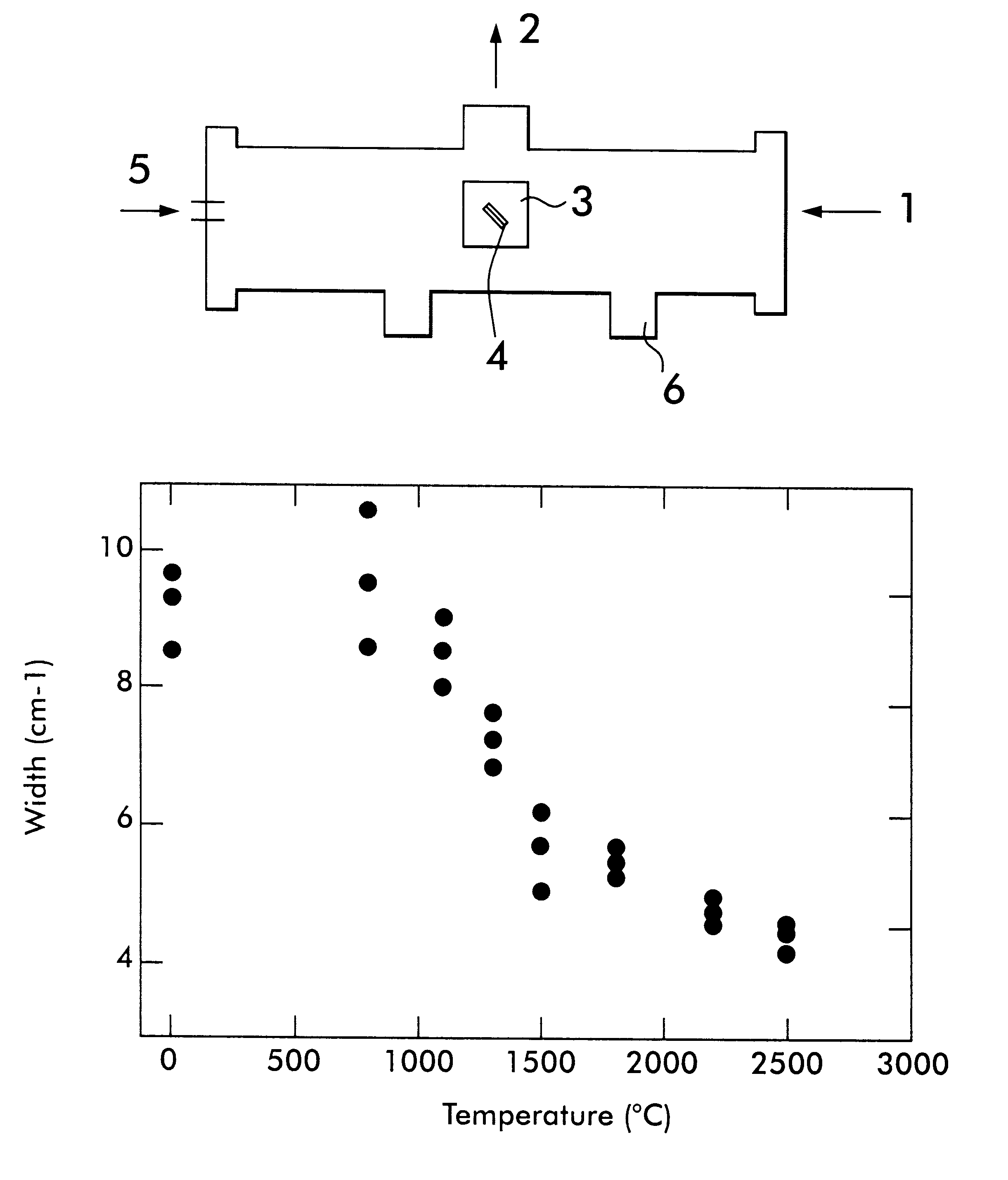

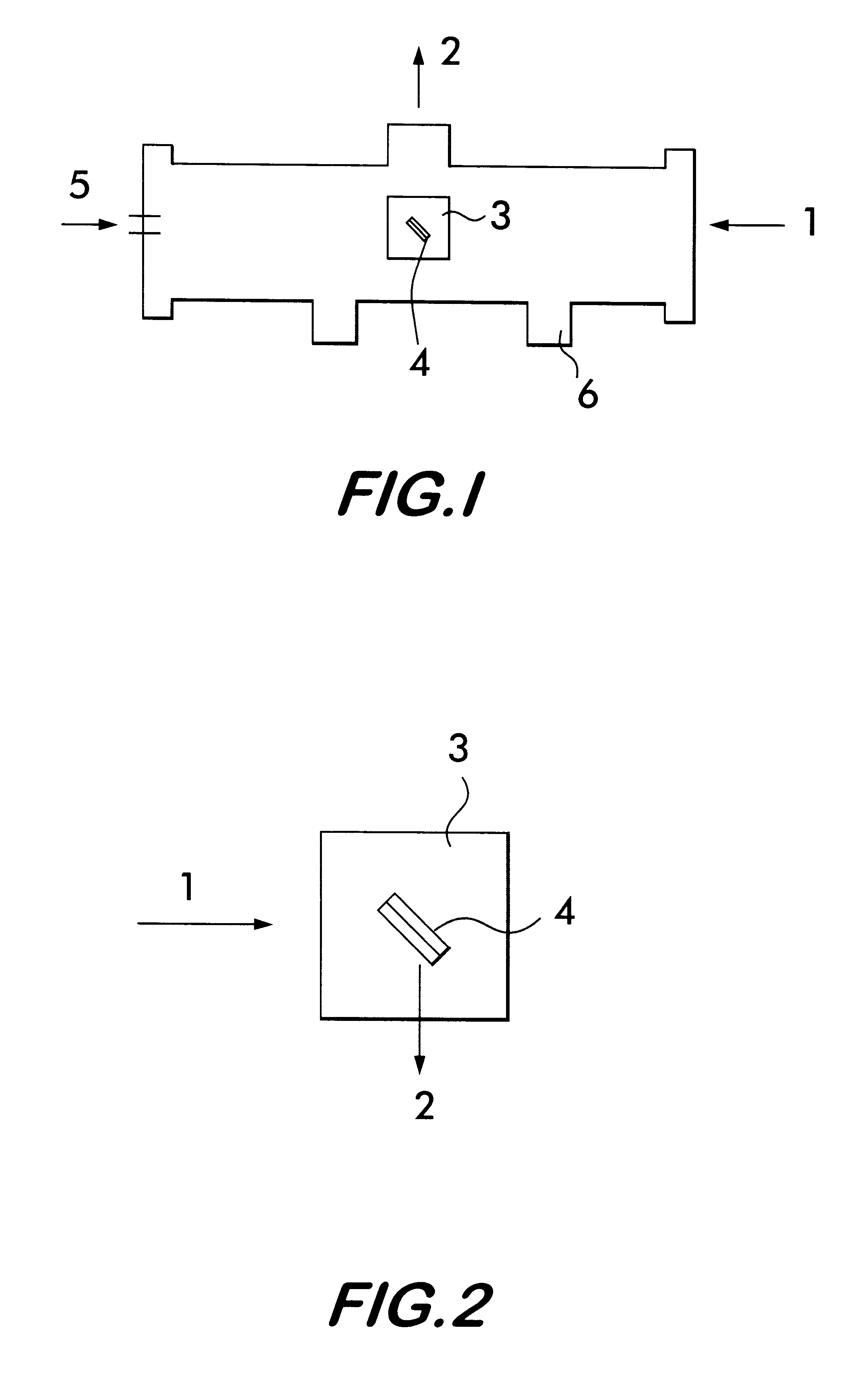

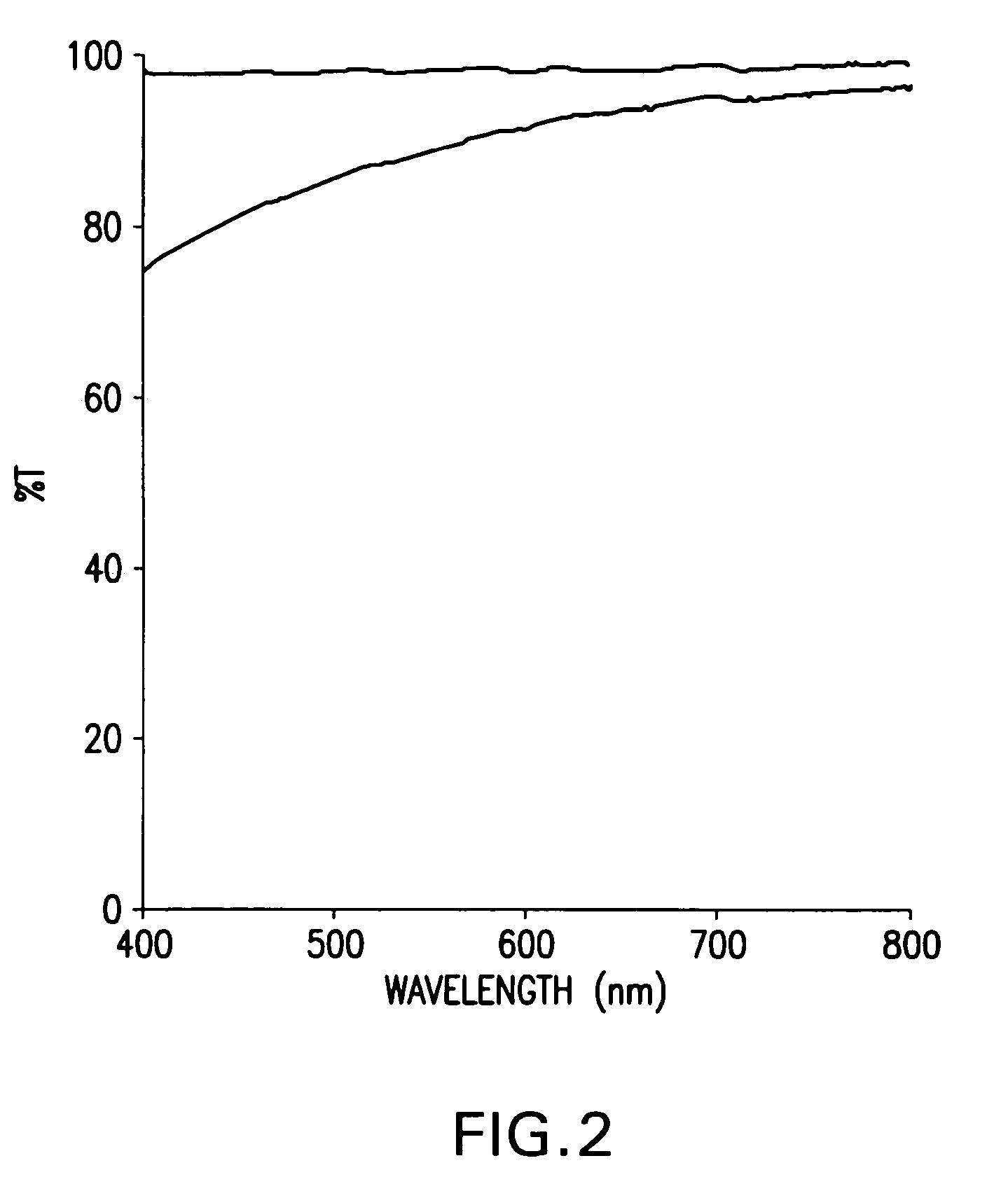

Diamond thin film or the like, method for forming and modifying the thin film, and method for processing the thin film

An improved gas phase synthesized diamond, CBN, BCN, or CN thin film having a modified region in which strain, defects, color and the like are reduced and / or eliminated. The thin film can be formed on a substrate or be a free-standing thin film from which the substrate has been removed. The thin film can be stably and reproducibly modified to have an oriented polycrystal structure or a single crystal structure. The thin film is modified by being subjected to and heated by microwave irradiation in a controlled atmosphere. The thin film has a modified region in which a line width of the diamond spectrum evaluated by Raman spectroscopy of 0.1 microns or greater is substantially constant along a film thickness direction of the thin film, and the line width of the modified region is 85% or less of a maximum line width of the residual portion of the film thickness.

Owner:APPLIED DIAMOND

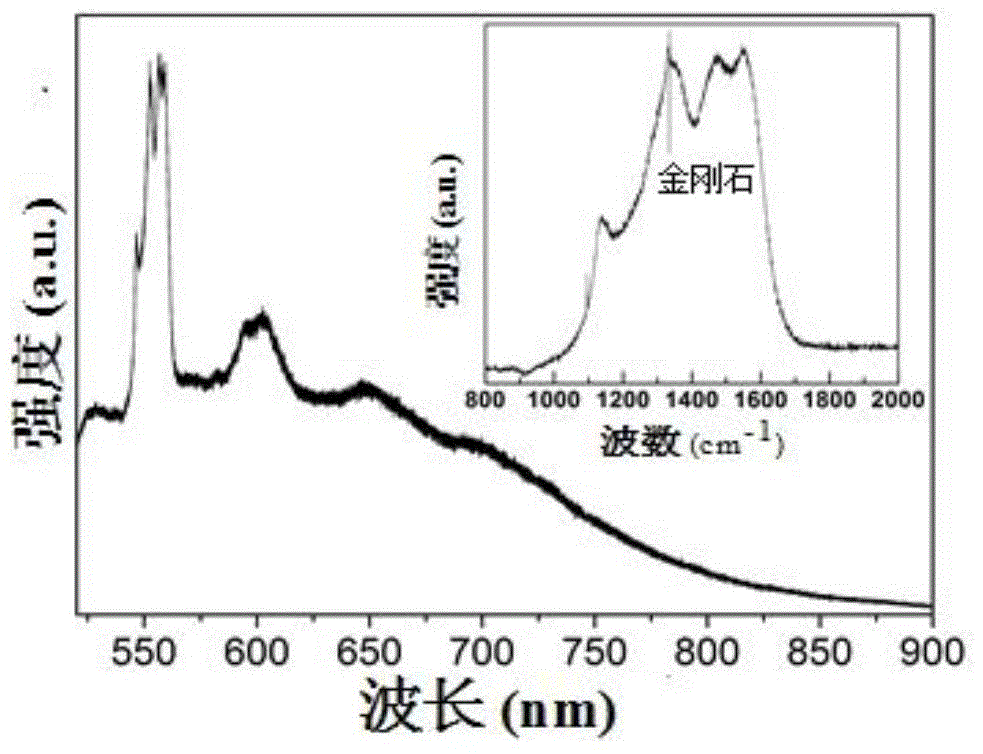

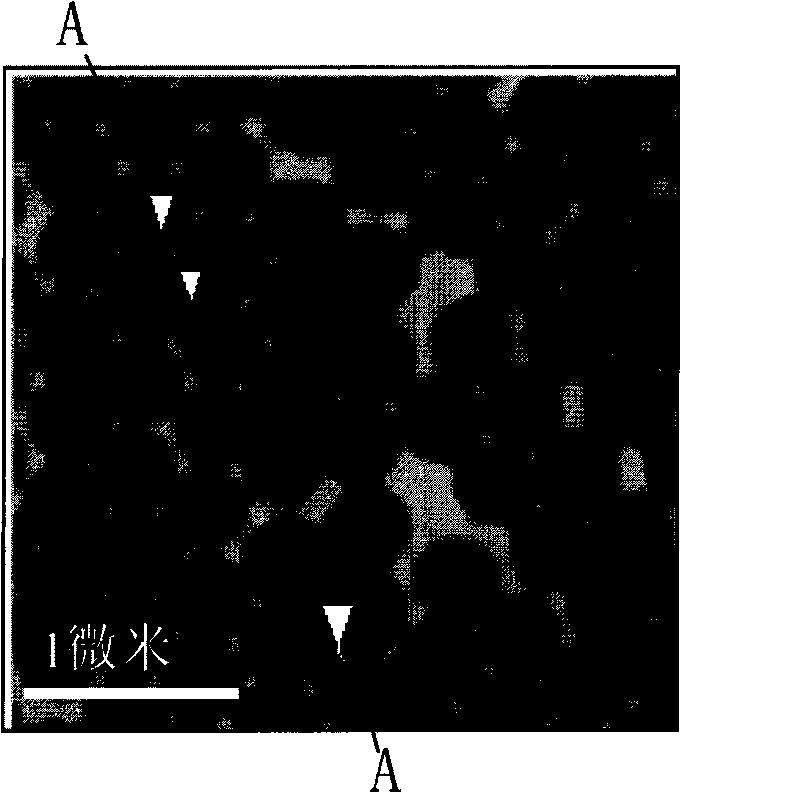

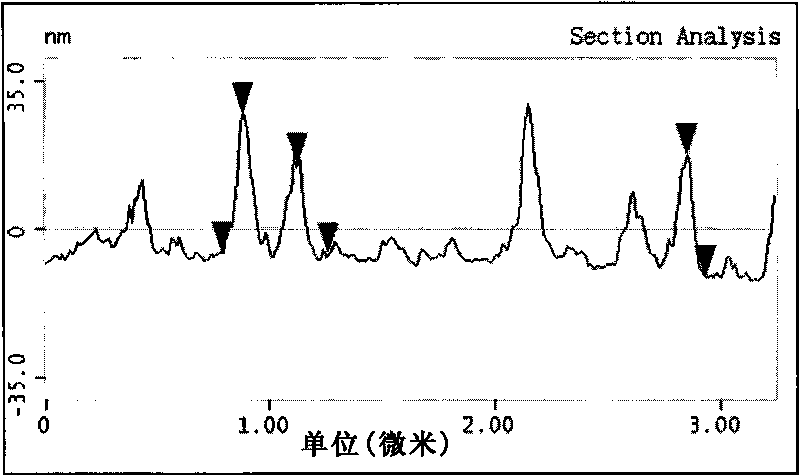

Nano-diamond film with Si-V luminescence and preparation method thereof

ActiveCN104060237AWith Si-V light emitting performanceSi-V has strong luminous performanceMaterial nanotechnologyChemical vapor deposition coatingGas phaseDisplay device

The invention provides a nano-diamond film with Si-V luminescence and a preparation method thereof. The nano-diamond film is prepared on a single crystal silicon substrate by use of a hot filament chemical vapor deposition method; heat preservation is performed on the film for 5-150 minutes in air at a temperature ranging from 500 to 700 DEG C, and then the nano-diamond film with Si-V luminescence is obtained. The nano-diamond film prepared has relatively high Si-V luminescence intensity which has very important scientific significance and engineering value for the application of the nano-diamond film in the fields such as single photon sources, quantum information processing, photoelectric devices, biomarkers, semiconductor devices and field emission displays.

Owner:ZHEJIANG UNIV OF TECH

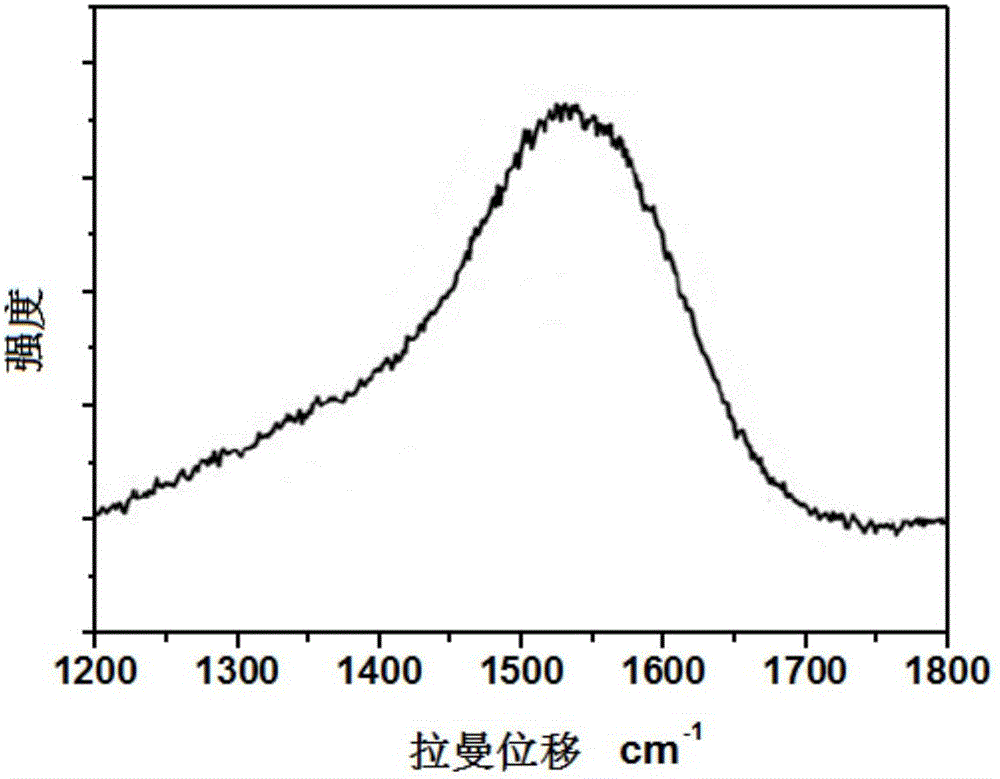

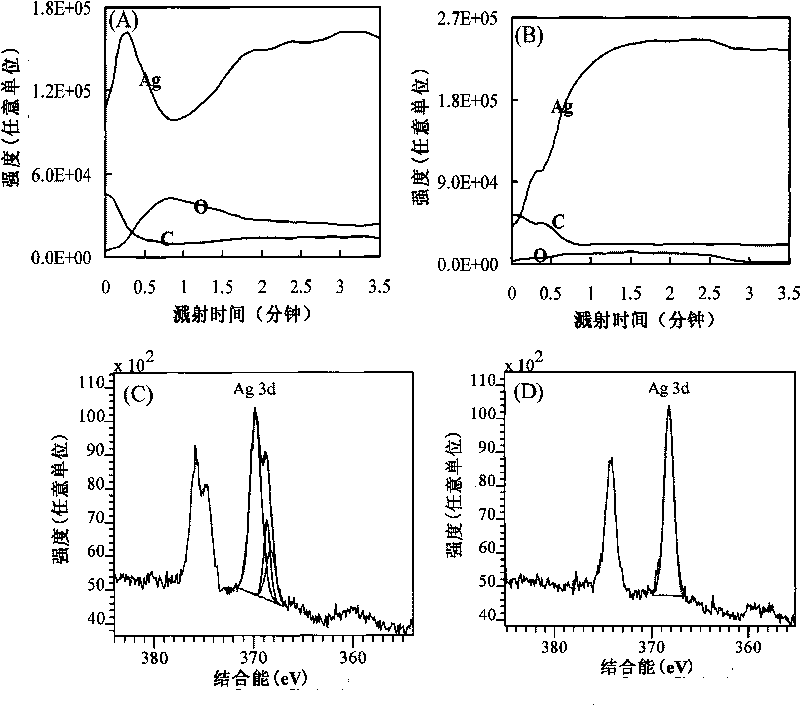

Surface-enhanced Raman substrate based on diamond-like carbon film modified metal nano structure and preparation method thereof

InactiveCN101726480AEnhanced Raman effectGood biocompatibilityRaman scatteringDiamond-like carbonNanostructure

The invention discloses a surface-enhanced Raman substrate based on a diamond-like carbon film modified metal nano structure and a preparation method thereof. The surface-enhanced Raman substrate consists of a substrate in a metal nano structure and a diamond-like carbon film deposited on the substrate in a metal nano structure. In the invention, when nano metal Ag is used as the substrate material and after the diamond-like carbon film is deposited, the nano material metal Ag can not be oxidized, thereby enhancing the chemical stability of the nano structure substrate which takes Ag as the material, and enhancing the Raman effect of the substrate; the preparation method for the surface-enhanced Raman substrate based on the diamond-like carbon film modified metal nano structure, which is provided by the invention, has mature super-thin ta-C film technology and low cost, thereby being capable of realizing industrialized production.

Owner:NANJING UNIV

Preparation method of textured diamond-like carbon composite film for water lubrication

ActiveCN101748370AImprove stabilityImprove anti-friction and anti-wear propertiesVacuum evaporation coatingSputtering coatingDiamond-like carbonComposite film

The invention discloses a preparation method of a textured diamond-like carbon composite film for water lubrication. In the invention, by adopting a laser surface micro-processing technology, a microtexture appearance molding can be obtained on the surface of a workpiece, and a film can be obtained on the surface of the workpiece by plating a titanium transition layer and doping a diamond-like carbon film of titanium after the workpiece is plasma-cleaned by a magnetic control sputtering deposition technology. The film greatly enhances the stability and the antifriction and abrasion resistance performance of the conventional diamond-like carbon film under the condition of water lubrication with the friction coefficient reduction reaching up to 40 percent and the abrasion resistance enhanced by 1-3 times. The invention is suitable for surface protection and strengthening of a transmission friction pair of a mechanical sealing ring, a thrust bearing and other machines under the water-consuming environment, and the service life is prolonged.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

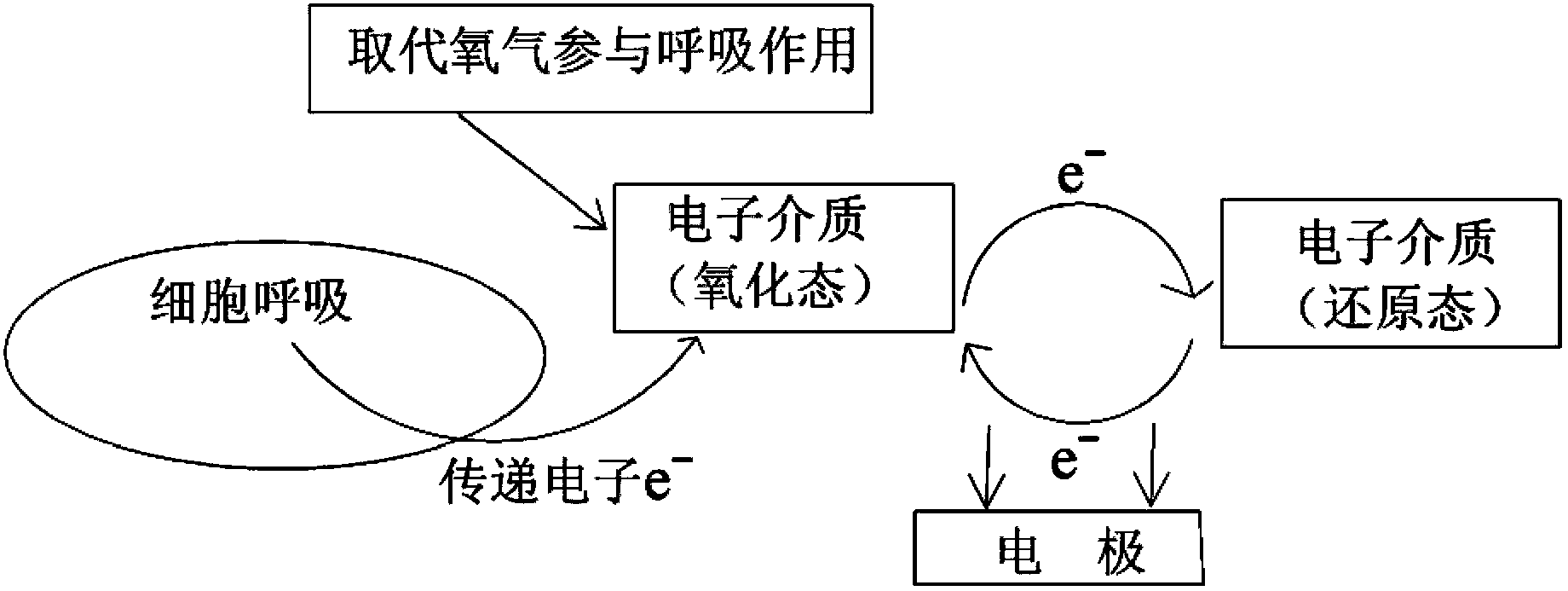

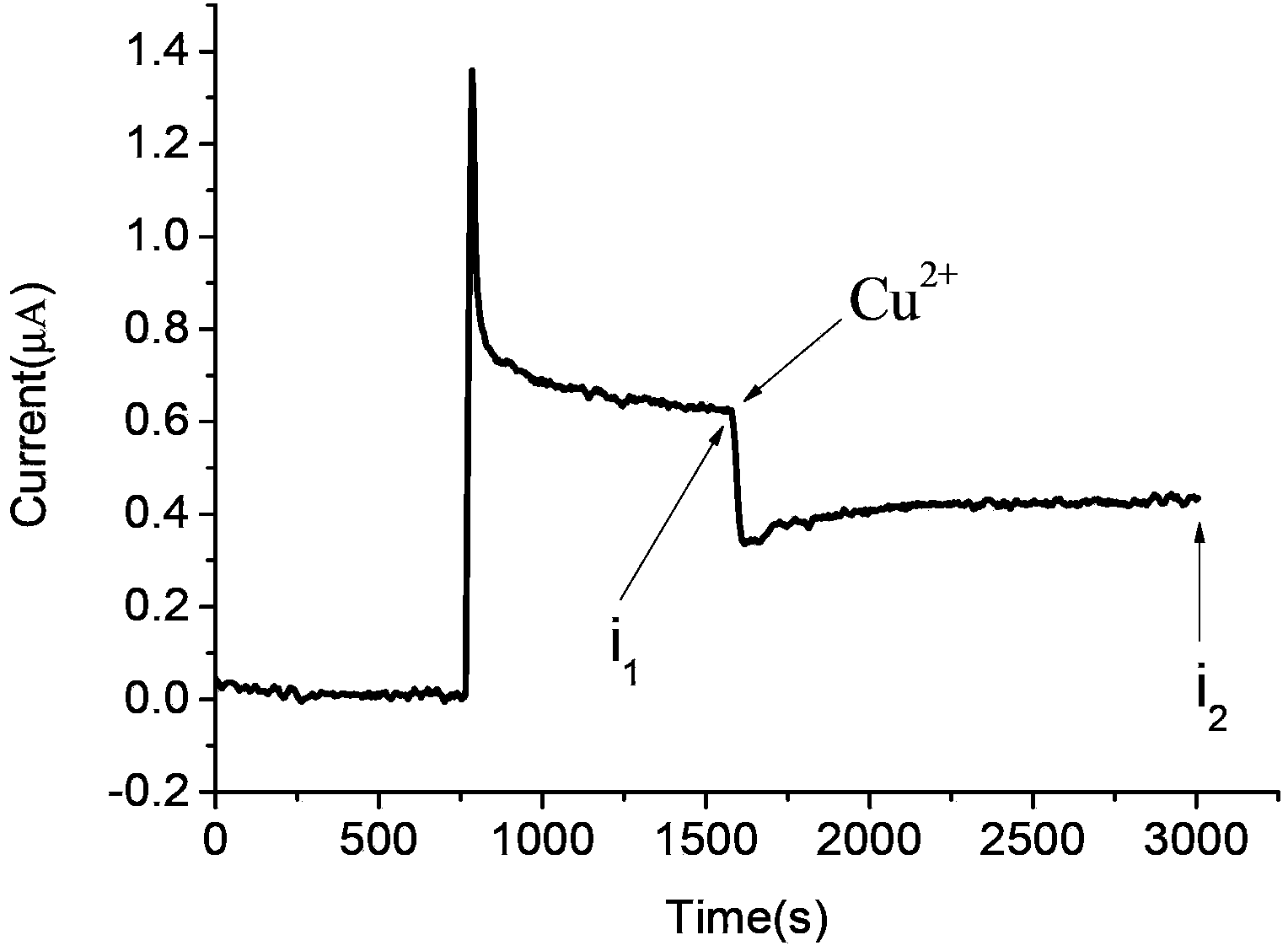

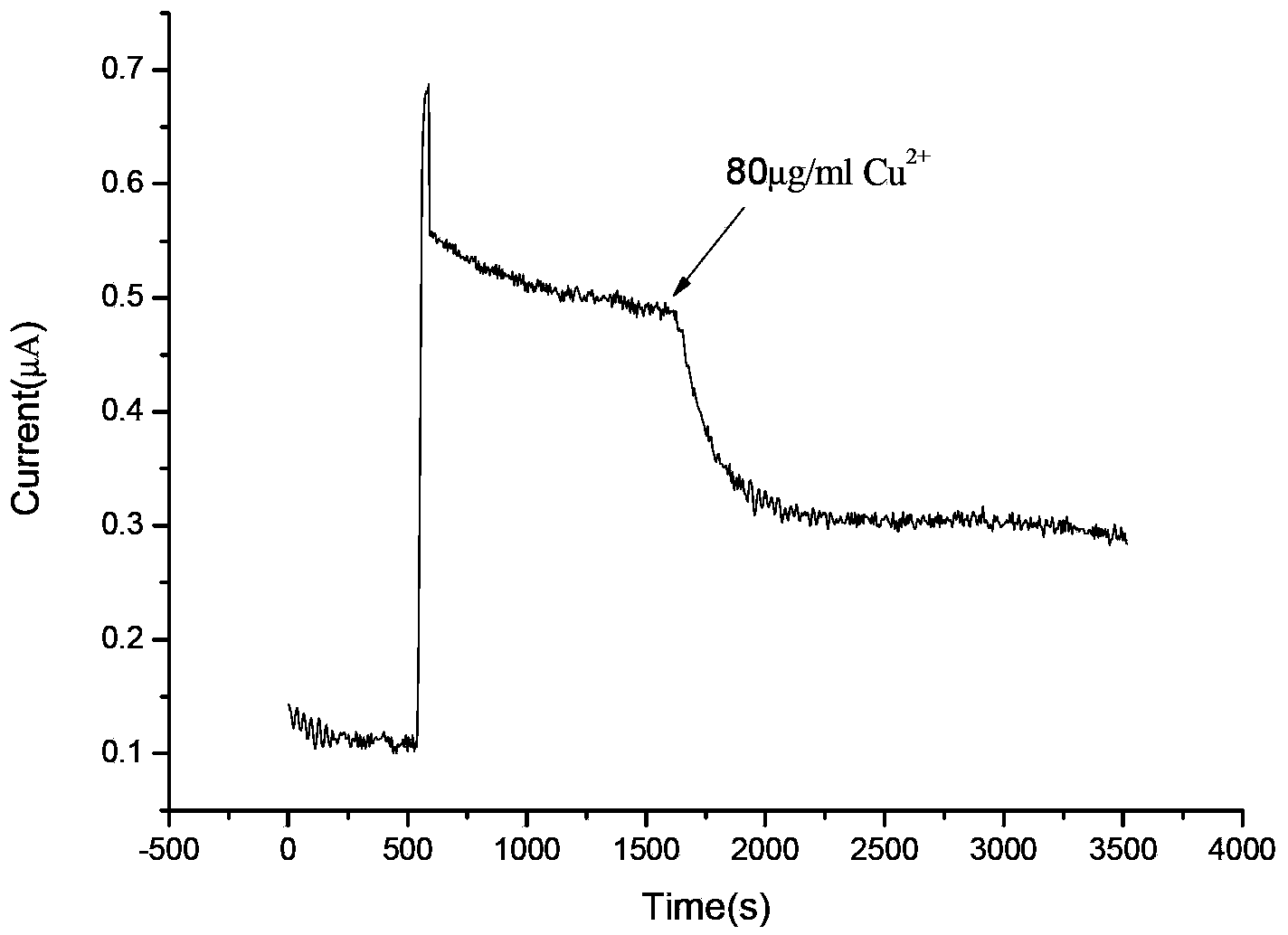

Electrochemical sensor used for instantly monitoring and detecting water biotoxicity, and apparatus thereof

ActiveCN103512938AHigh analytical sensitivityLow costMaterial electrochemical variablesElectrochemical gas sensorAssay sensitivity

The invention discloses an electrochemical sensor used for instantly monitoring and detecting the water biotoxicity. The electrochemical sensor comprises a work electrode, a counter electrode, a reference electrode and a electrolytic cell; the work electrode is a polymer fixed microbial electrode, and the polymer fixed microbial electrode comprises an electrode and a polymer and bacteria mixed layer coated outside the electrode; and the material of the above polymer is gelatin or chitosan, the above bacteria comprise Escherichia coli and / or yeast, and the electrode is a glassy carbon electrode, a gold electrode, a platinum electrode or a boron-doped diamond film electrode. The invention also discloses an apparatus of the electrochemical sensor used for instantly monitoring and detecting the water biotoxicity. The electrochemical sensor can instantly monitor the water biotoxicity change and detect the water biotoxicity value, can realize instant, online and continuous detection, and has the characteristics of high analysis sensitivity, low cost, simple operation, portability and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

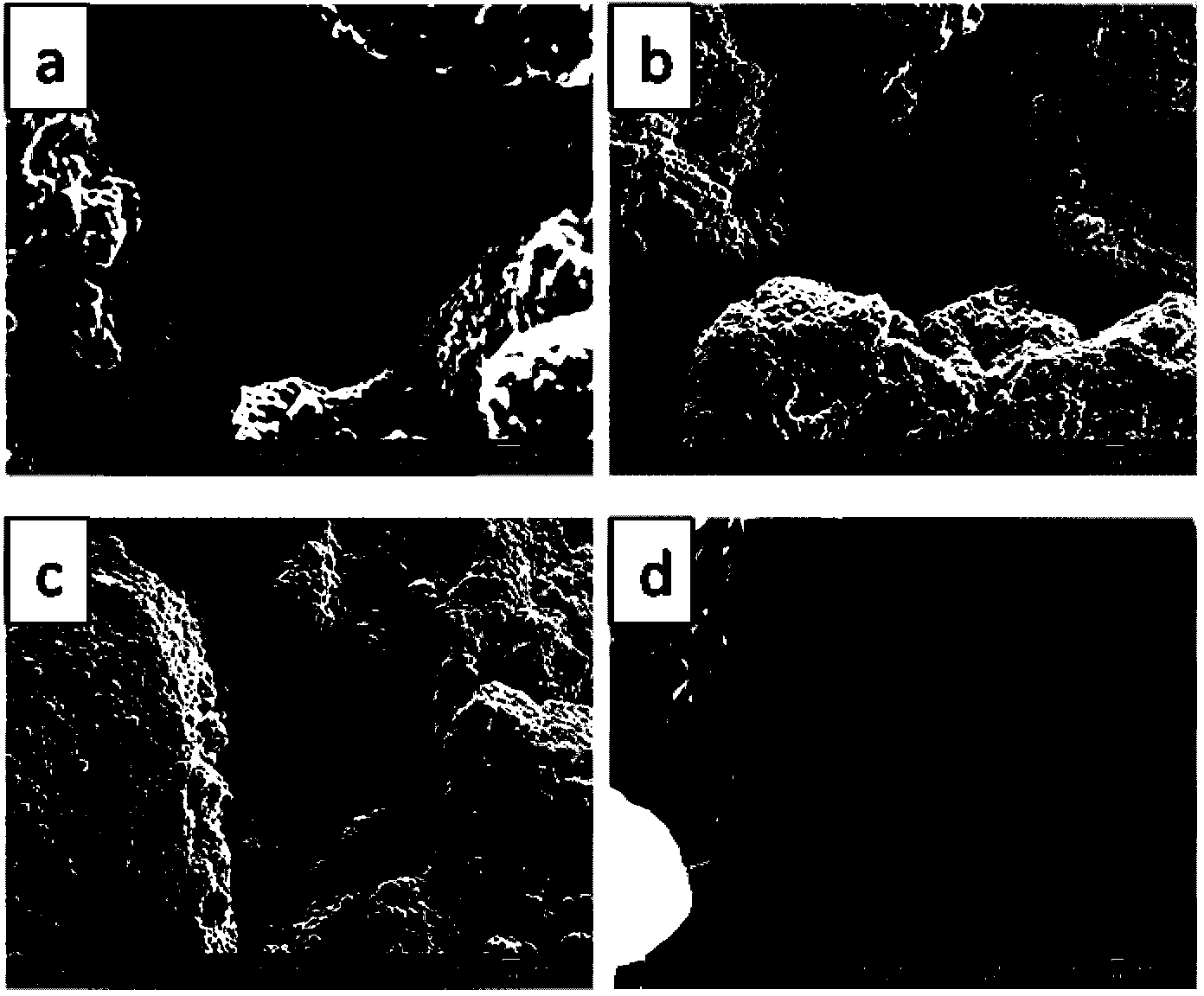

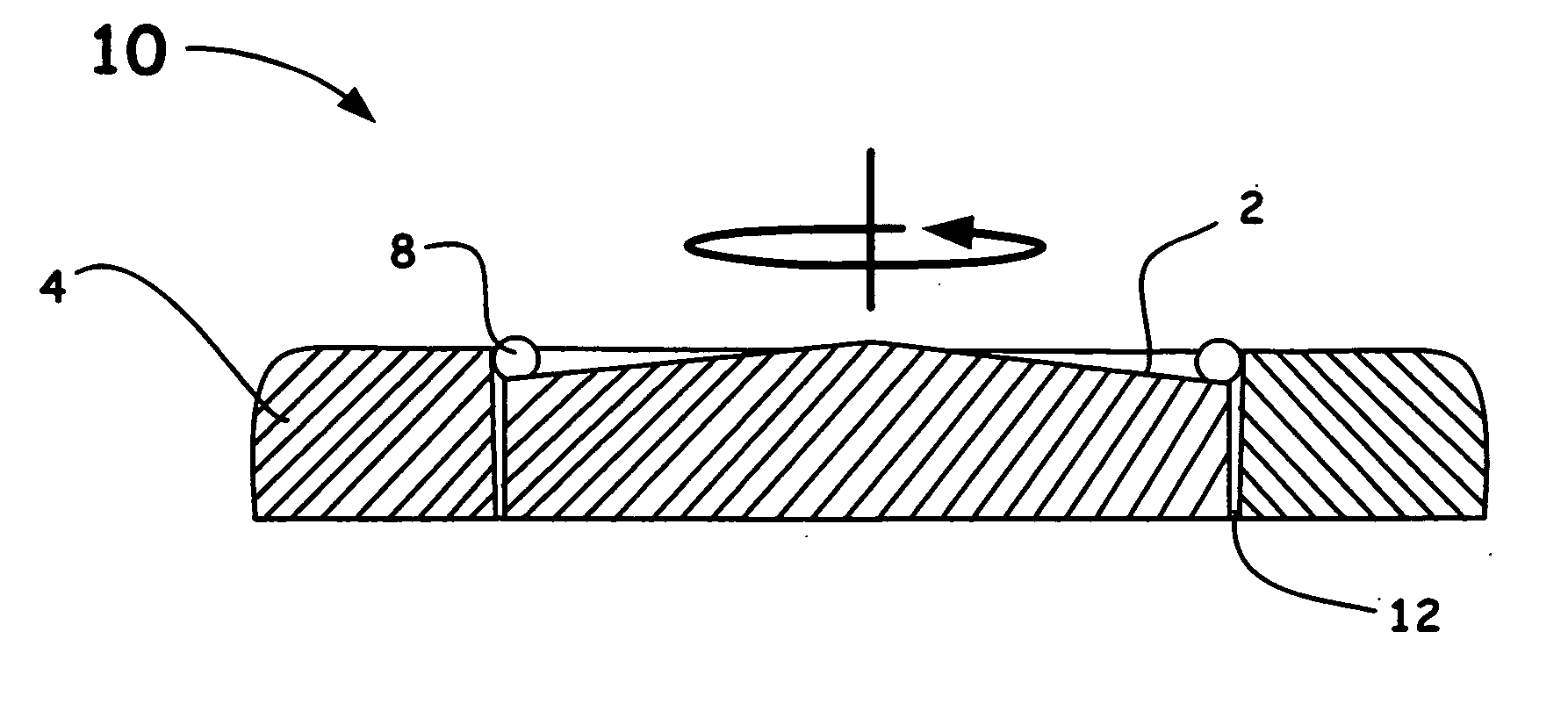

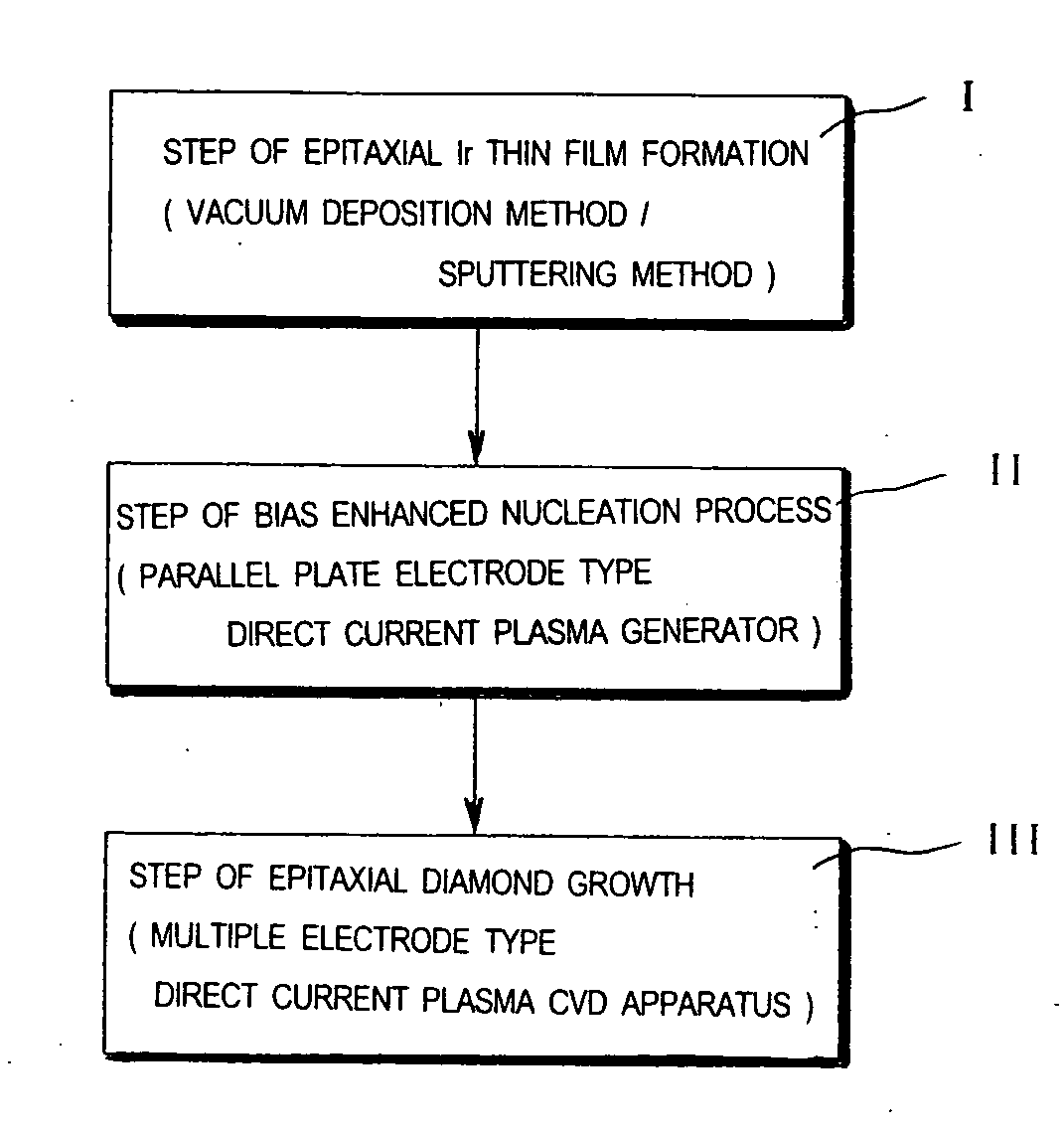

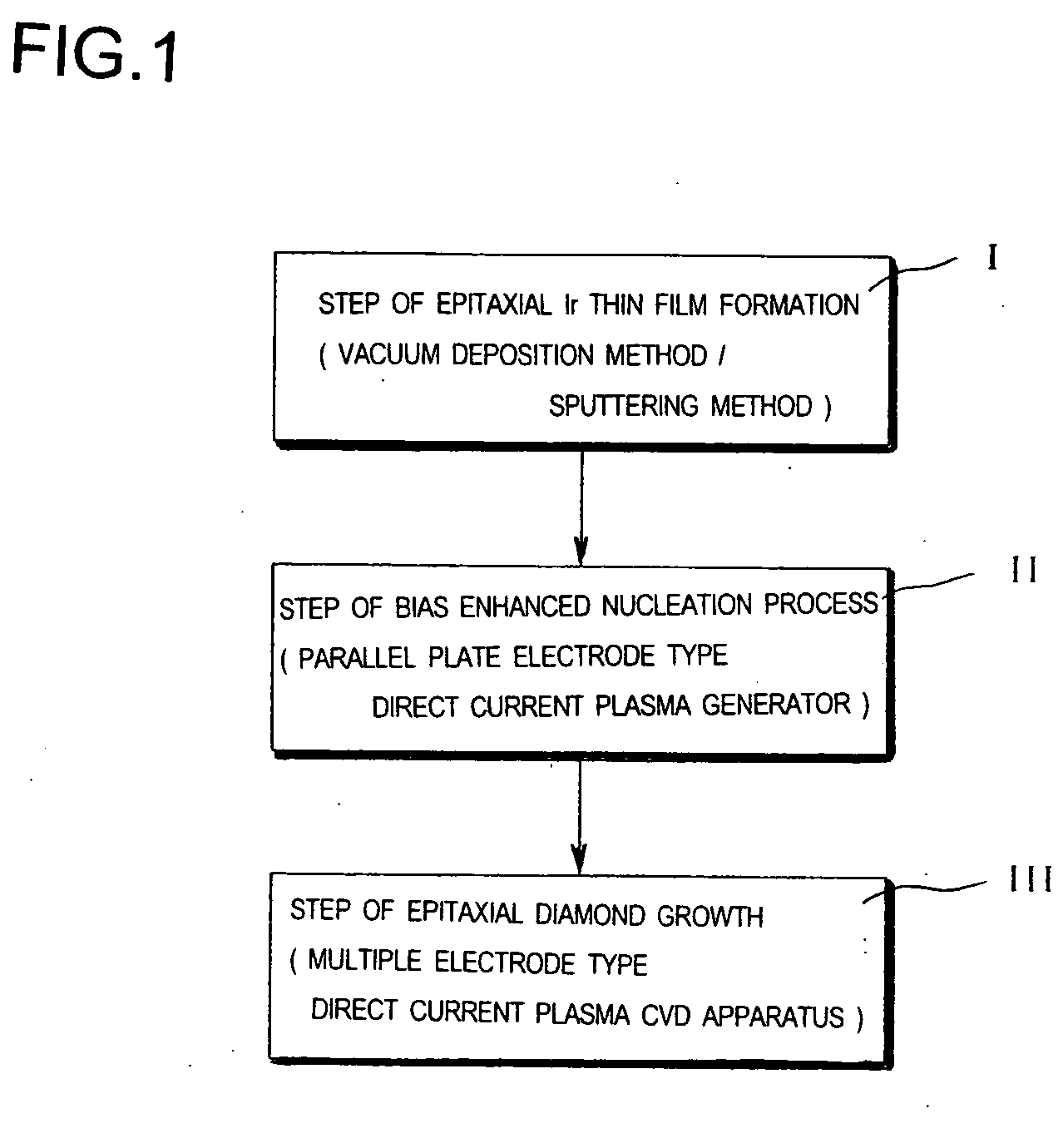

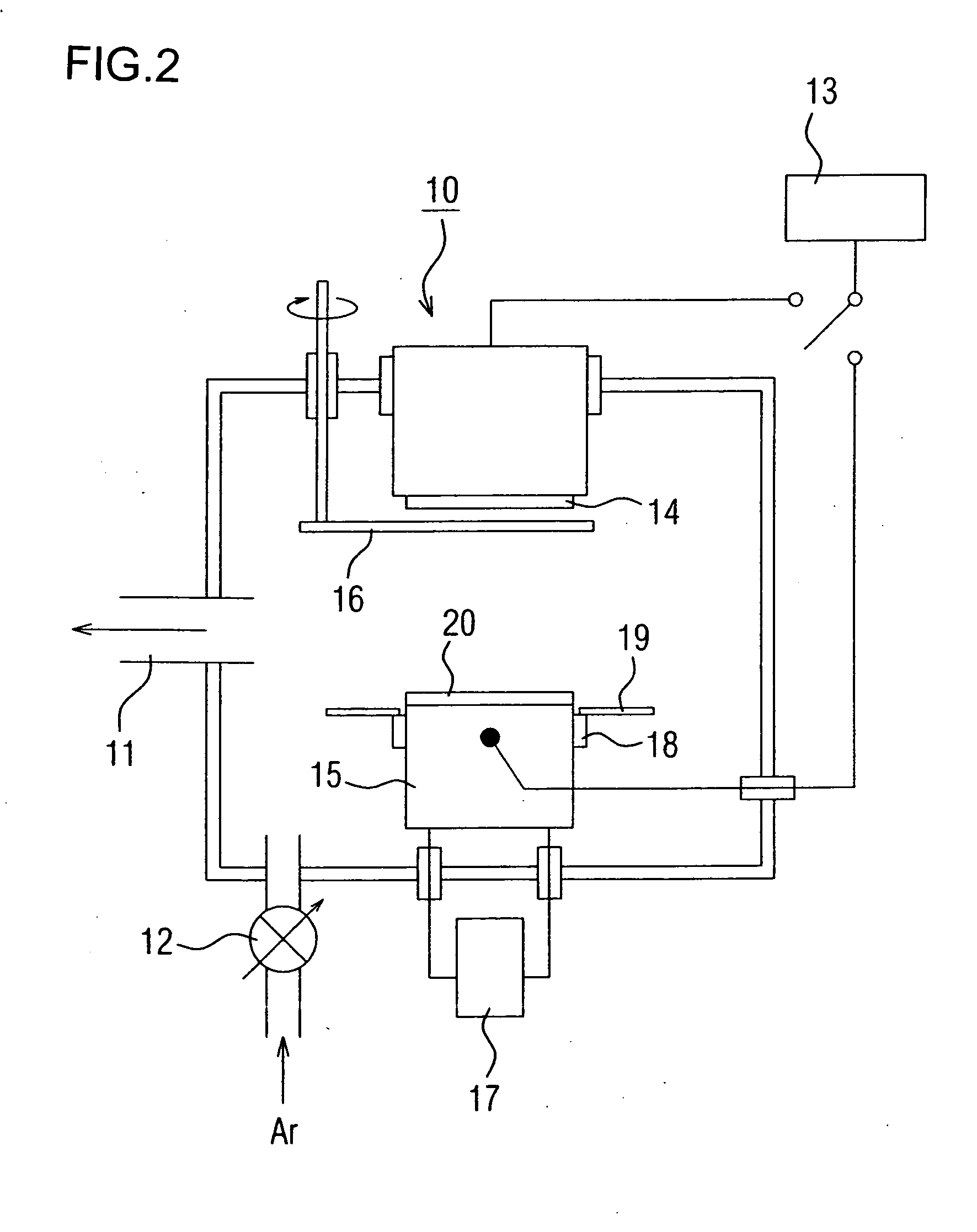

Base Substrate for Epitaxial Diamond Film, Method for Producing the Base Substrate for Epitaxial Diamond Film, Epitaxial Diamond Film produced With the Base Substrate for Epitaxial Diamond Film, and Method for Producing the Epitaxial Diamond Film

ActiveUS20090176114A1Easy to produceUniformly and highly densely generatingFrom gel stateFrom solid stateIridiumGeneration process

The present invention provides a base substrate for epitaxial diamond film capable of epitaxially growing a large area of high quality diamond, having a diameter of 1 inch (2.5 cm) or more, on an iridium base by using the CVD method, a method for producing the base substrate for epitaxial diamond film, an epitaxial diamond film produced with the base substrate for epitaxial diamond film and a method for producing the epitaxial diamond film. An iridium (Ir) film is formed by epitaxial growth on a single crystal magnesium oxide (MgO) substrate or a single crystal sapphire (α-Al2O3) substrate by means of a vacuum deposition method or a sputtering method, and a bias nucleus generation process of forming epitaxial diamond nuclei is applied to the surface of the iridium (Ir) base formed as a film by exposing an ion-containing direct current plasma to the surface of the iridium (Ir) base formed as a film.

Owner:SAWABE ATSUHITO

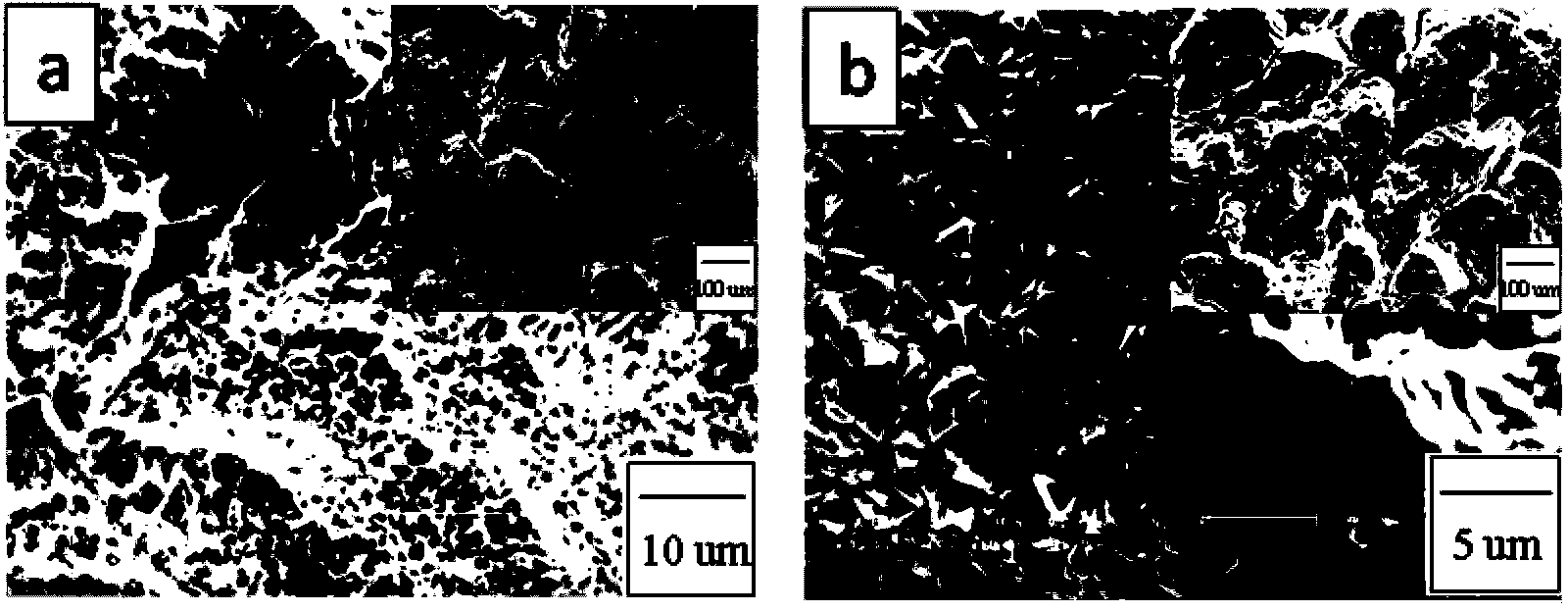

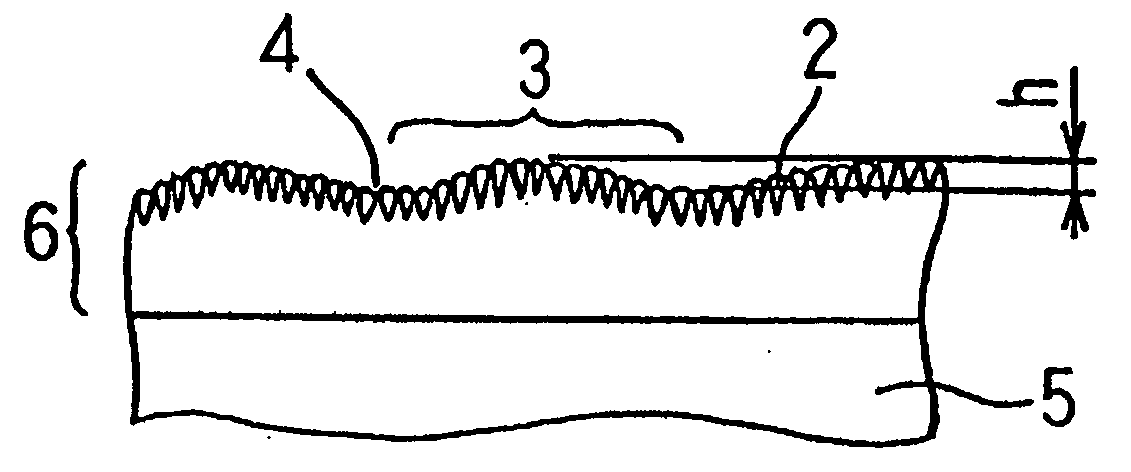

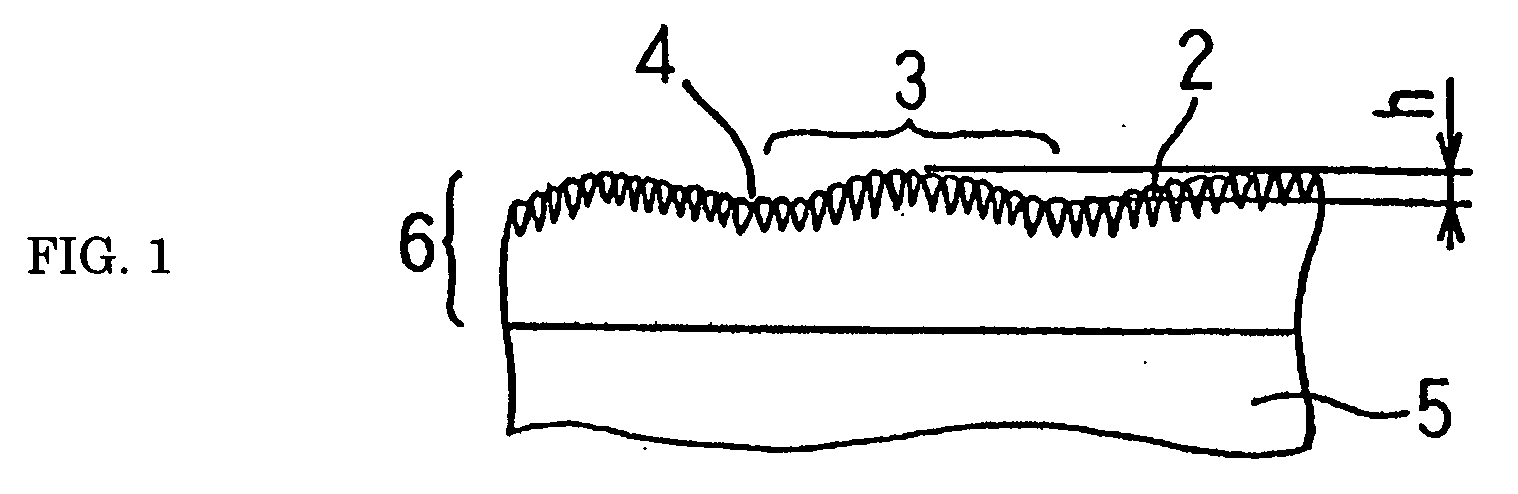

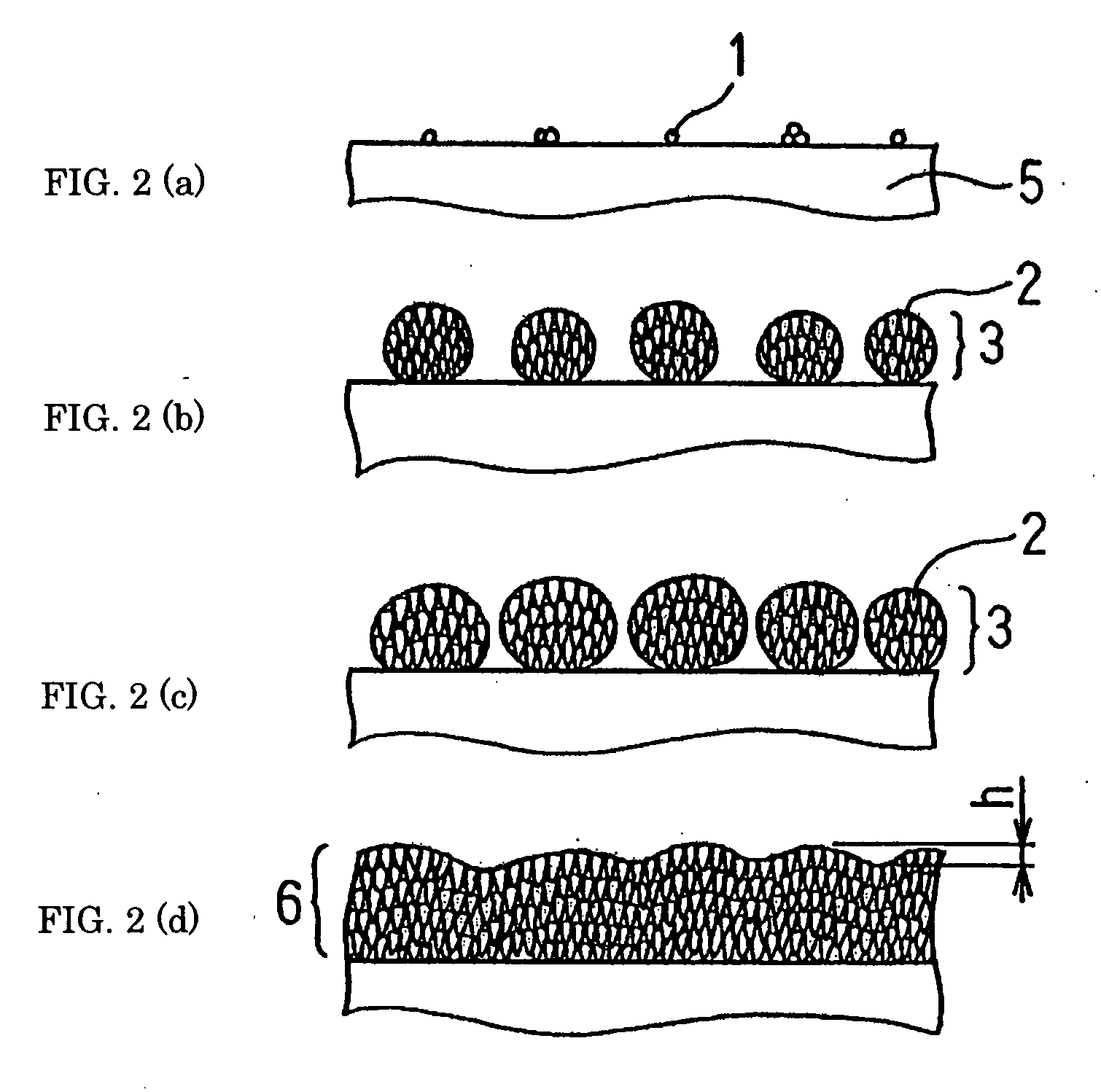

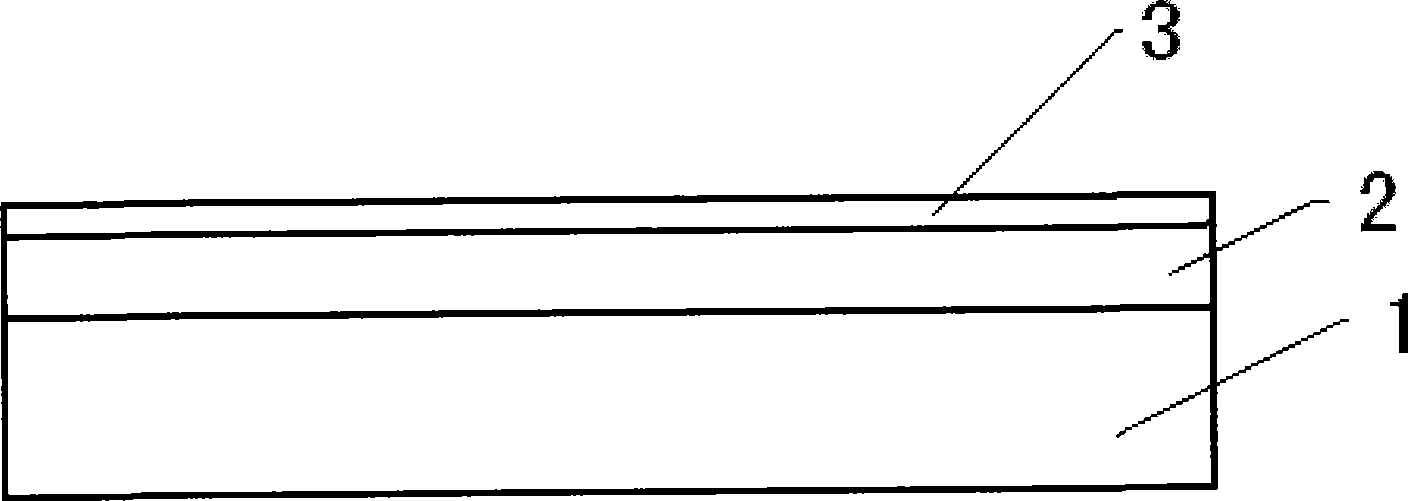

CVD diamond layer overlapped diamond composite sheet for drilling and its production method

InactiveCN101476445AExtended service lifeImprove temperature resistanceDrill bitsChemical vapor deposition coatingGas phaseChemical vapor deposition

The invention relates to a diamond compact for drilling to cover a CVD diamond coating and a preparing method thereof. The novel diamond compact is prepared from a new material by depositing a layer of diamond film on the surface of the prior diamond compact through chemical vapor deposition methods. The preparing method is disclosed as figure 1, a CVD diamond film 3 with the thickness of between 0. 01 and 2 mm is deposited and covered on the PCD surface 2 of a PDC sheet. The method for preparing the diamond compact adopts the vapor deposition methods of a microwave plasma method, a direct current glow-discharged plasma method, a plasma injection method, a heat wire method, an arc discharge method, a multiple laser beam assistance decomposition method, and the like. Carbon-containing gas or carbon-containing liquid is decomposed, and a CVD diamond film with the thickness of bwteen 0.01 and 2mm is deposited on the PCD surface which is treated. The obtained new material greatly improves the temperature resistance and the wearability of the prior diamond compact, thereby the service life of a drill bit made of the new material is prolonged greatly. The diamond compact can be widely used in drilling industry, construction industry and machining operation industry.

Owner:陈继锋

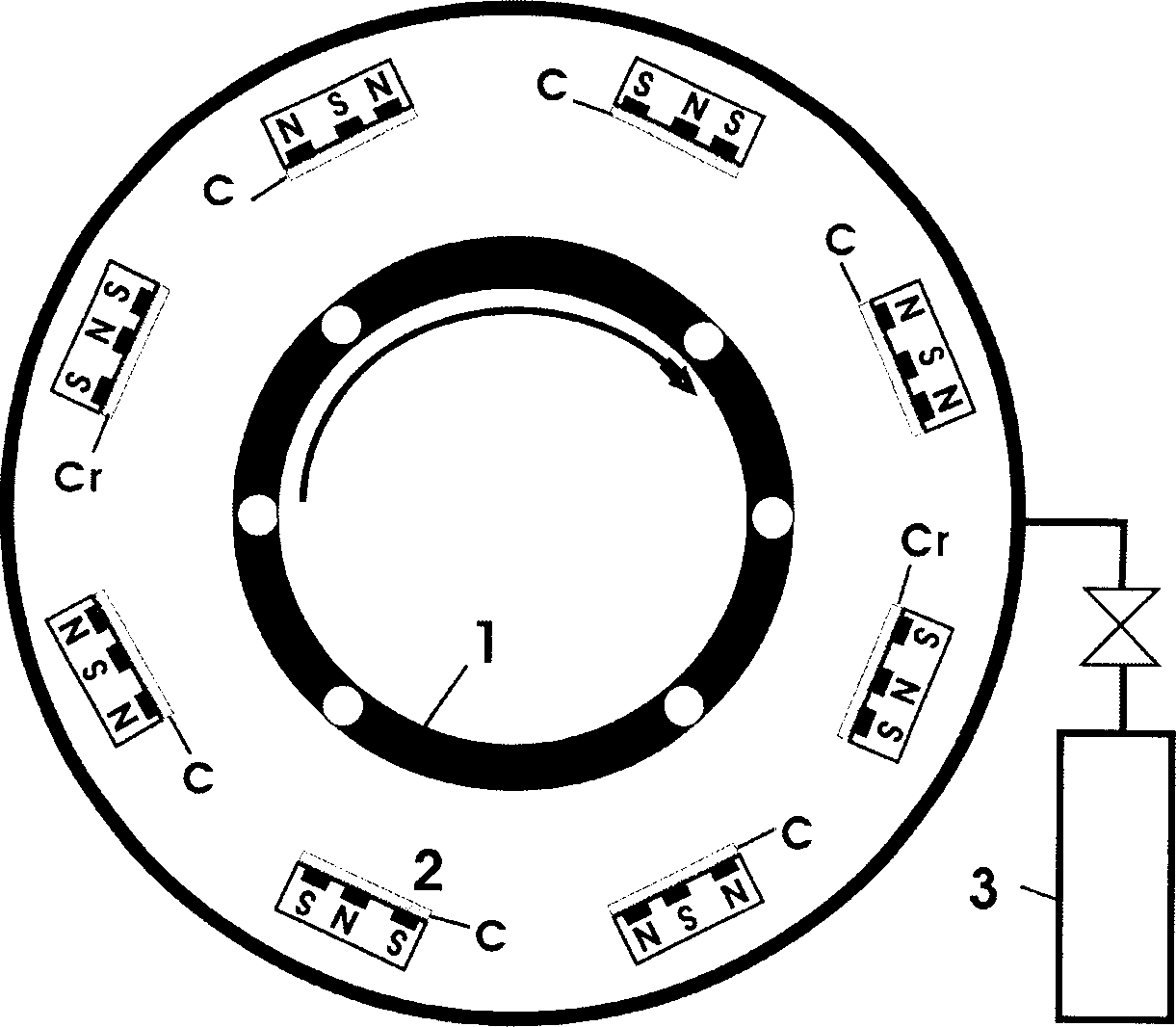

Diamond film containing chronium and its preparing method

InactiveCN1743503AImprove bindingEliminate internal stressVacuum evaporation coatingSputtering coatingIntermediate frequencyPulsed DC

This invention discloses a diamond film containing Cr and its preparation method. Said film is a H-free film containing Cr deposited in gas phase on a matrix surface having the alternative condensed multi-layer gradient structure of Cr, CrNx, CryCz, Cr, CrNx, CryCz layers orderly from inside to outside along the vertical direction of the matrix surface, the film thickness is not less than 2 mum, which has a fine film / matrix binding force and good wearability. The preparation method includes utilizing the magnet control sputtering system to coat, the magnet control targets are a pair of unbalanced magnet controlled Cr targets and 1-4 pairs of un-balanced magnet controlled C targets, the supply of which is 20-250KHz IF AC supply, a pulse matrix negative bias voltage is applied on the armed coating matrix by single-level pulse DC supply, the sputtering gas is Ar.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +1

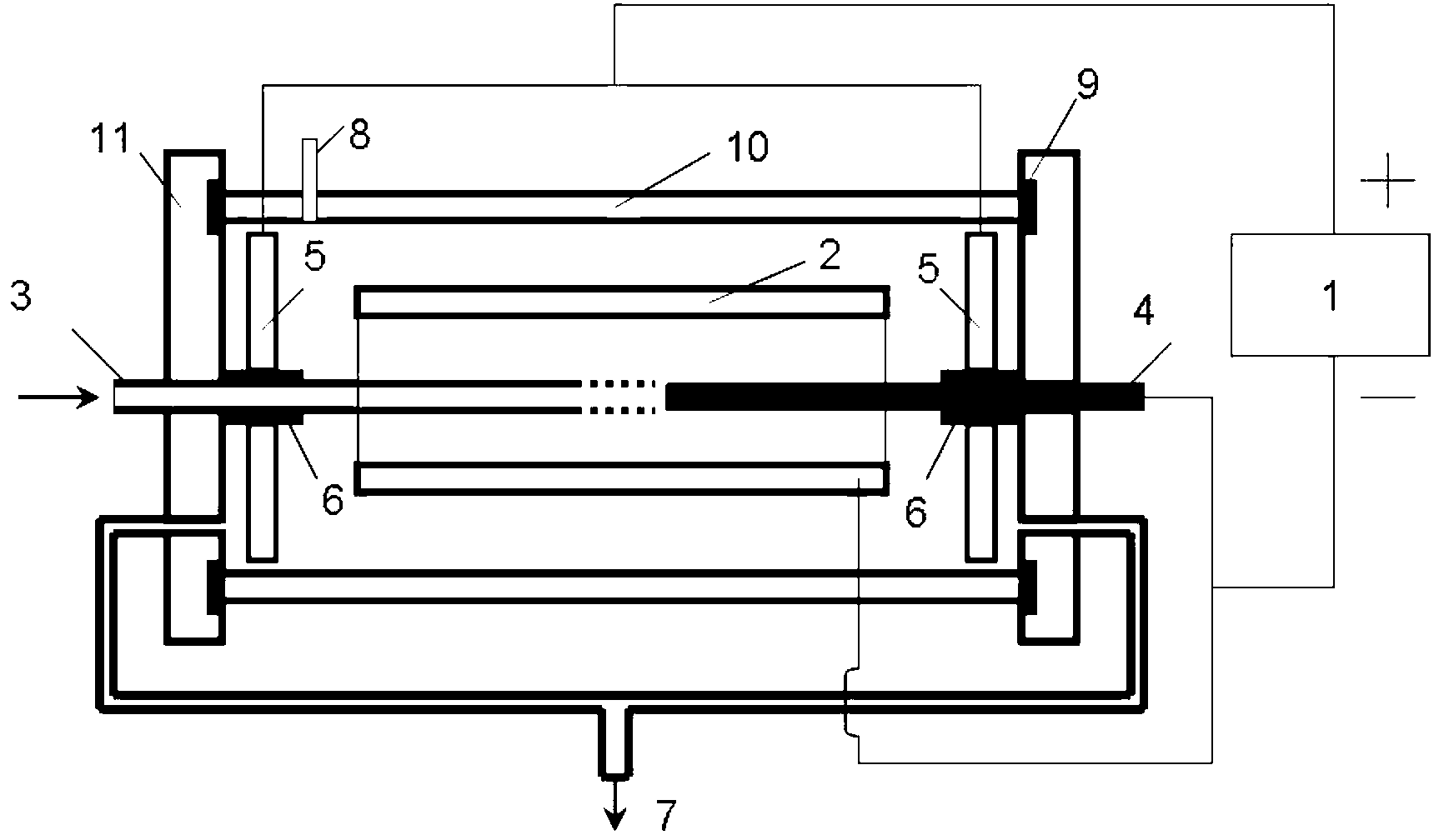

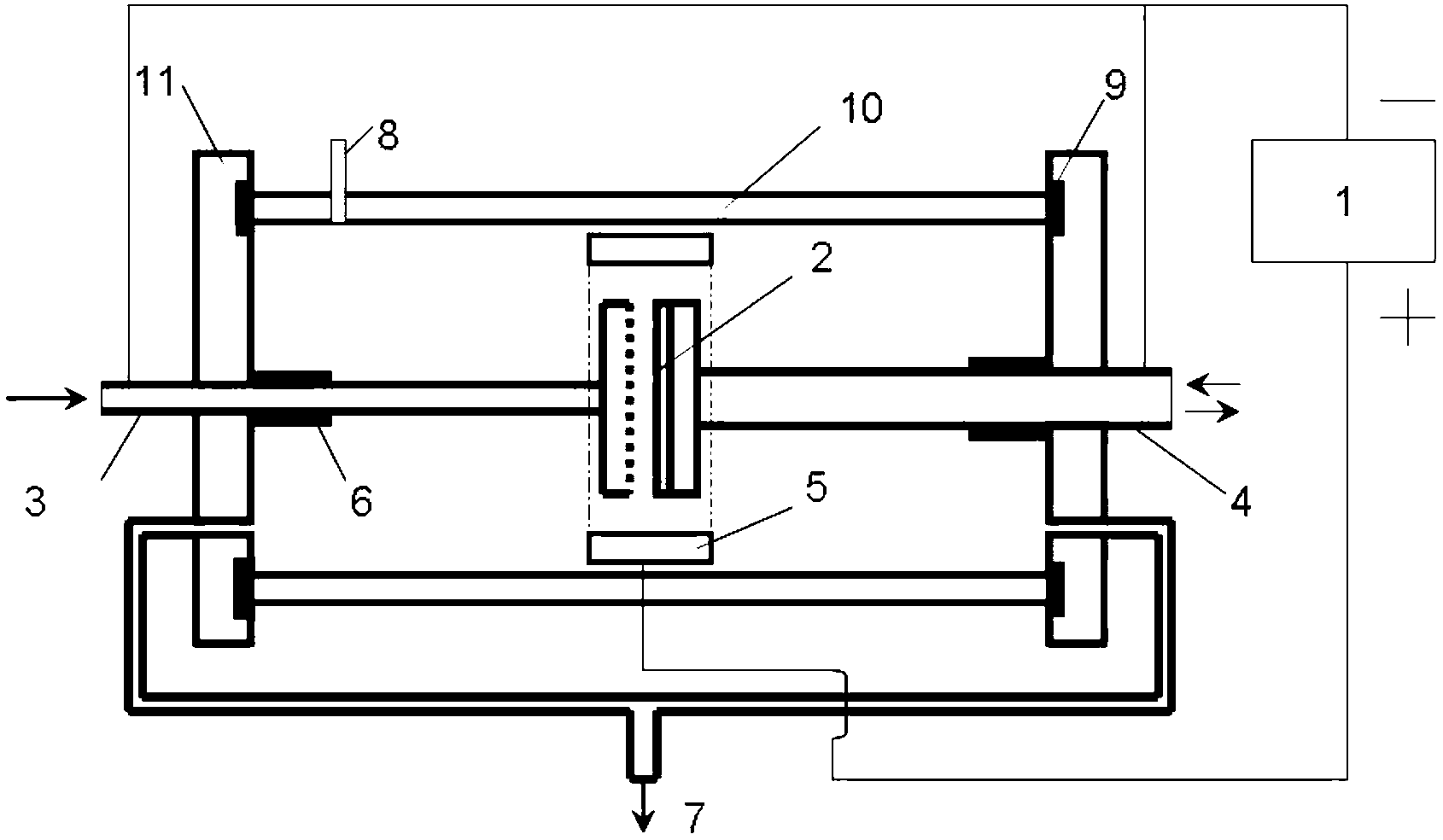

Metal inner surface modification device and method

InactiveCN103320772AAchieve chemical permeationImprove surface modification efficiencySolid state diffusion coatingChemical vapor deposition coatingDiamond-like carbonNitrogen gas

The invention discloses a metal inner surface modification device and method and belongs to the technical field of plasma surface modification. The method is characterized by comprising the following steps: generating plasmas on a metal inner surface by utilizing the principle of hollow-cathode discharge, and nitriding or depositing diamond like carbon, so as to improve the hardness, the wear resistance and the corrosion resistance of the metal inner surface; by taking a treated piece as a cathode, arranging the cathode inside, adjusting the distance and the vacuum degree between a workpiece and the cathode to reach the discharge condition, arranging an anode at the periphery of a cathode cavity, and adding a direct current pulse power supply between the anode and the cathode, wherein reaction gas is nitrogen or ammonia gas and carrier gas is argon gas during the nitriding, and the reaction gas is methane or acetylene and the carrier gas is argon gas in the process of depositing a hard carbon film. The method has the effects and advantages of simple process, low cost and high efficiency and is particularly suitable for treating the metal inner surface and pipe fittings of large draw ratios.

Owner:DALIAN UNIV OF TECH

Cathode gas film microarc discharging method for preparing carbon nanometer material in solution

The invention discloses a carbon nanometer material preparing method through micro-arc discharging of cathode gas film in the solution, which comprises the following steps: adopting acid, alkaline and salt solution as basic electrolyte; applying DC through area rate of cathode and anode; discharging gas film arc on the cathode; adopting high-purity graphite as cathode and carbon source or adopting high purity graphite with doped catalyst as cathode, carbon source and catalyst; or Fe or Co or Ni or their alloy as cathode; adding soluble organics in the basic electrolyte as carbon source; obtaining ocimene, carbon nanometer ball, carbon nanometer flower, carbon nanometer fiber and carbon nanometer pipe; forming diamond film on the cathode surface.

Owner:UNIV OF SCI & TECH BEIJING

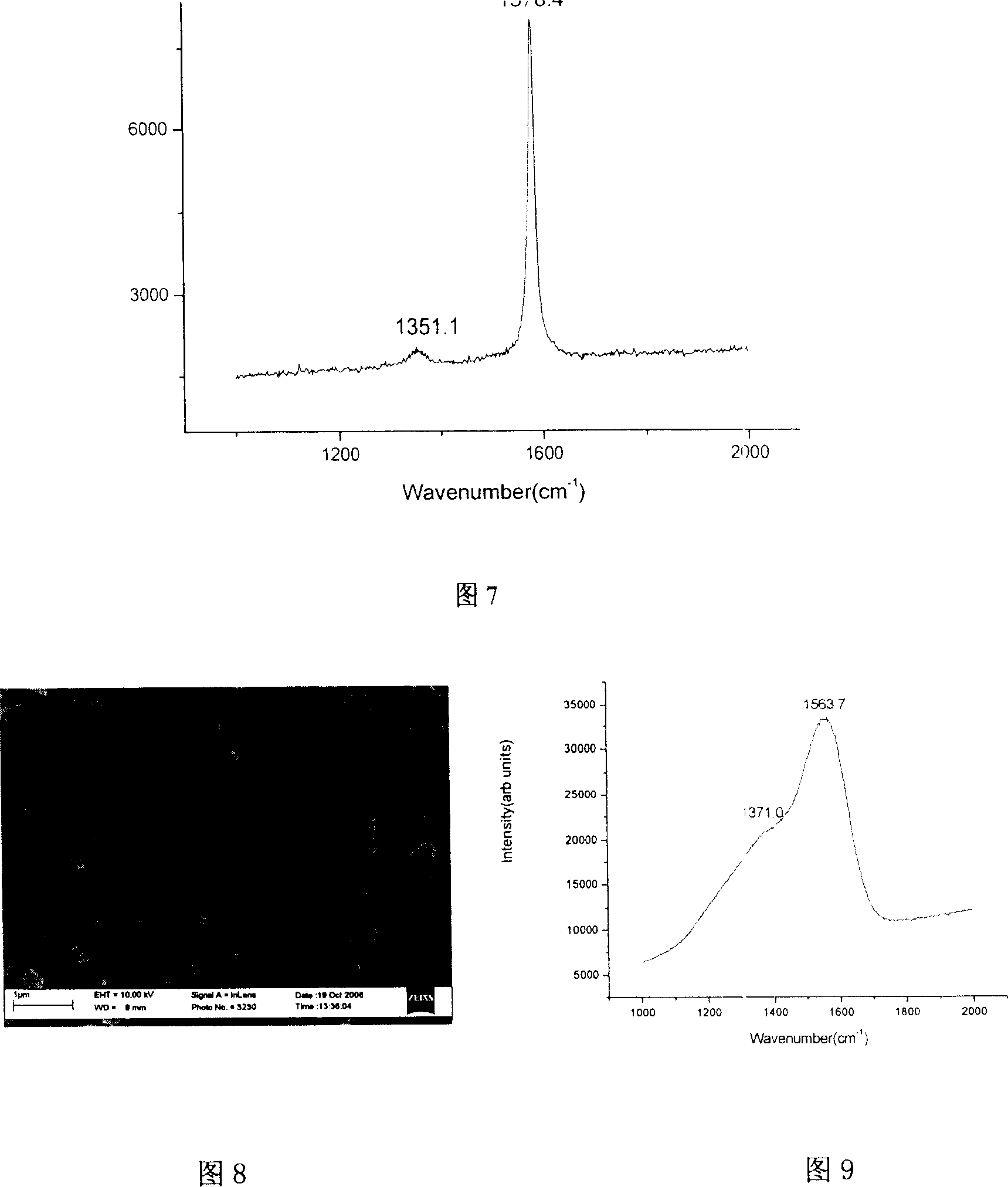

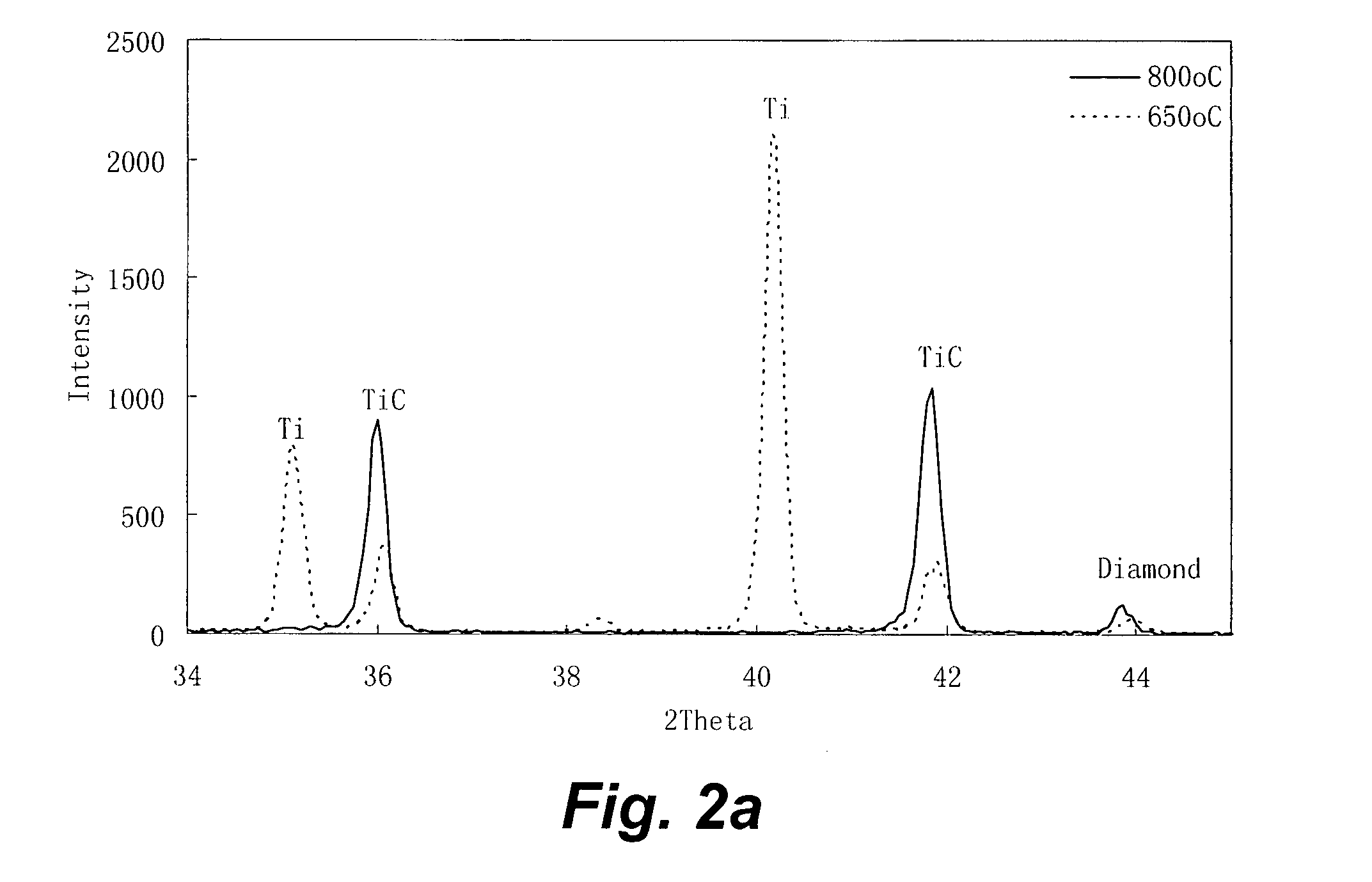

Method for making a highly stable diamond film on a subtrate

InactiveUS20080070049A1Increase substrate temperatureMultiple component coatingsWater/sewage treatmentCarbideTitanium

A method of depositing a stable diamond film on a metal substrate includes pretreating a surface of the substrate and depositing a diamond film on the substrate by way of a multi-stage chemical vapor deposition, in which each subsequent stage is performed at progressively higher temperature. The deposited diamond may be doped with boron. The substrate may be titanium, a titanium alloy, iron, an iron alloy, or any other valve metal. The diamond deposition may be a high temperature chemical vapor deposition. The first deposition stage may optionally create a carbide of diamond and substrate, and an optional mixture of diamond and amorphous carbon may be deposited to bond this carbide layer to a subsequently applied layer. The resulting product may be used as an electrode, as a tooth or blade in a cutting tool, or may have many other uses.

Owner:THE HONG KONG UNIV OF SCI & TECH

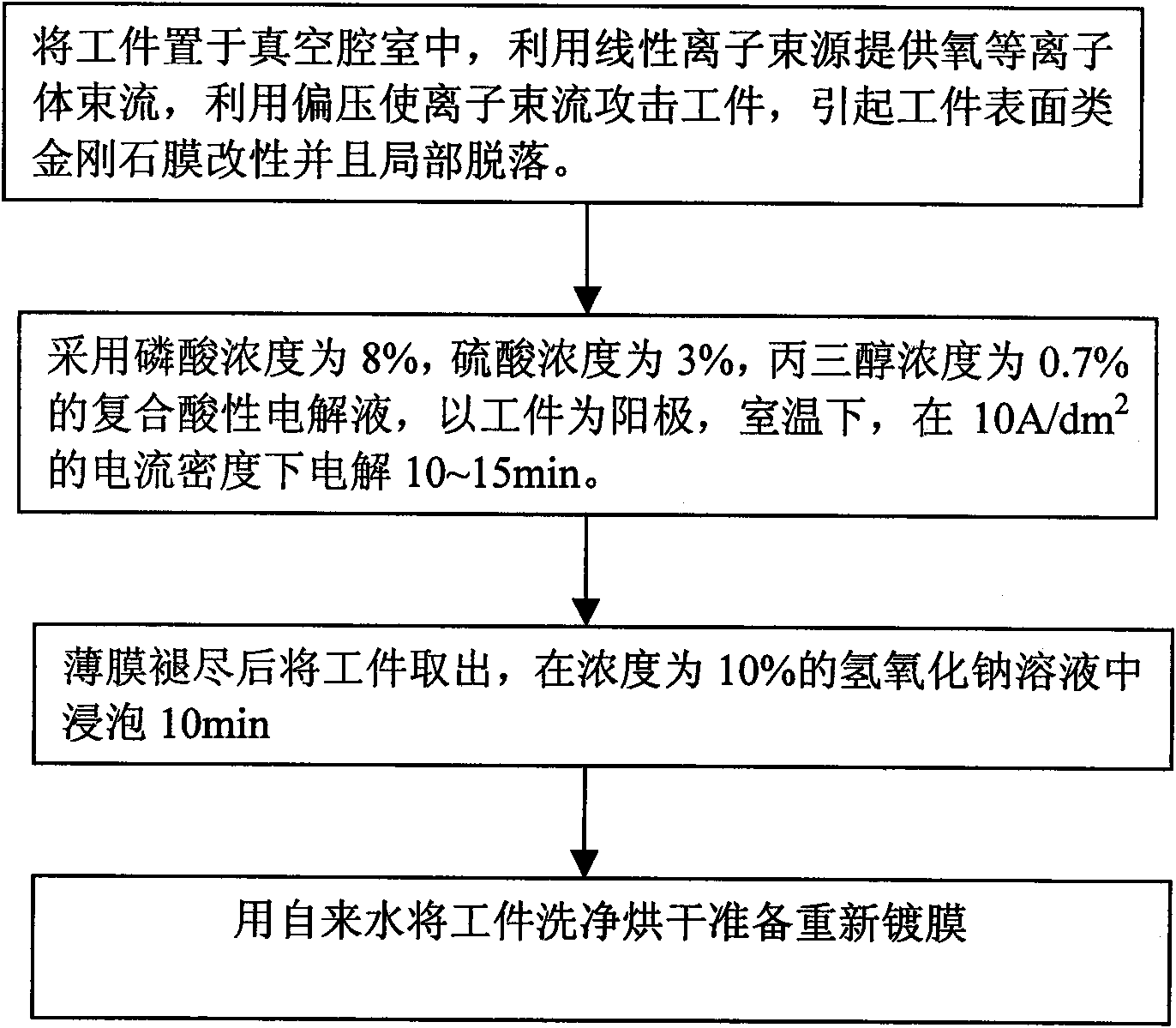

Method for removing diamond-like carbon film on steel surface

The invention provides a method for removing a diamond-like carbon film on a steel surface. The method comprises the step of adopting an iron and steel workpiece as an anode to electrolyze in acid electrolyte formed by mixing phosphoric acid, sulfuric acid, glycerine and deionized water till the diamond-like carbon film is completely removed. The method can rapidly remove the diamond-like carbon film on the steel surface, does not generate destructive corrosion on the surface of a matrix and less changes the size and the shape of the workpiece; and the the workpiece can be re-plated with film and used after the film is removed.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

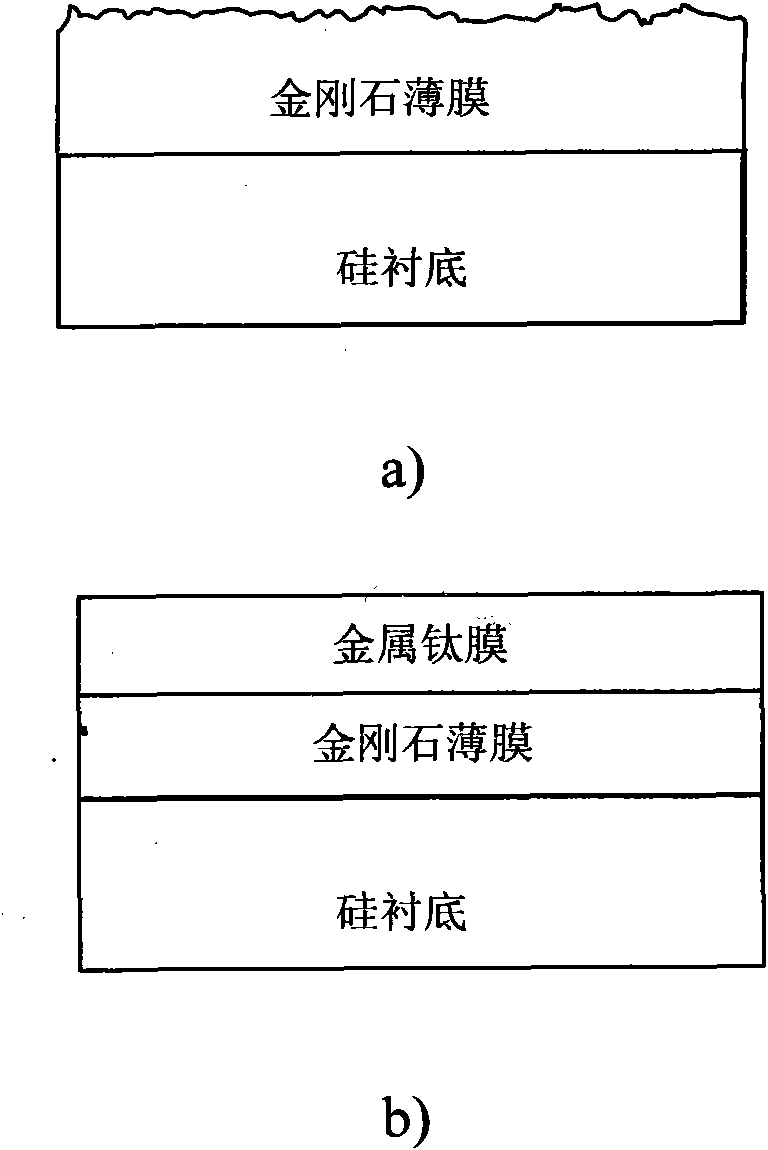

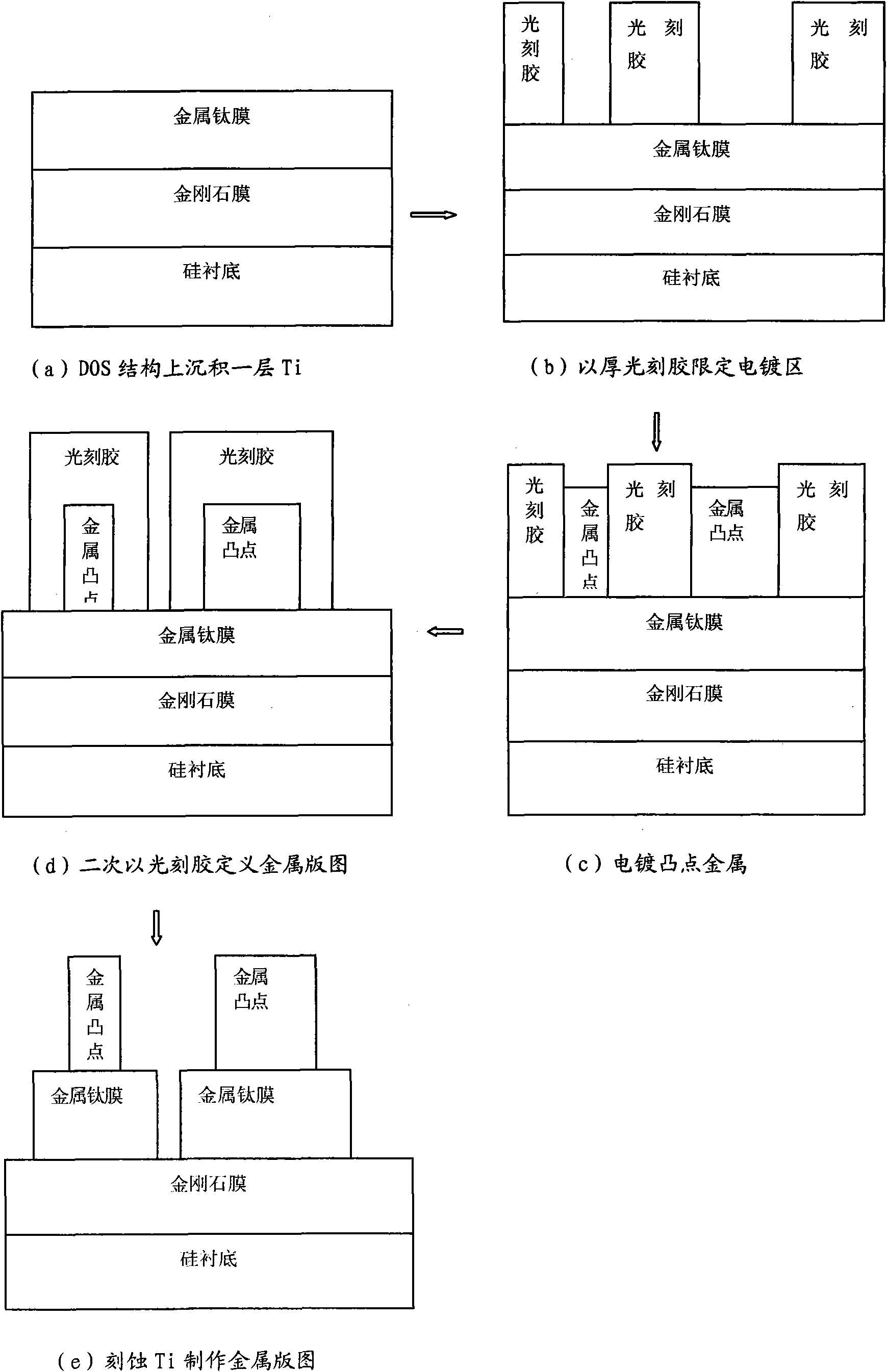

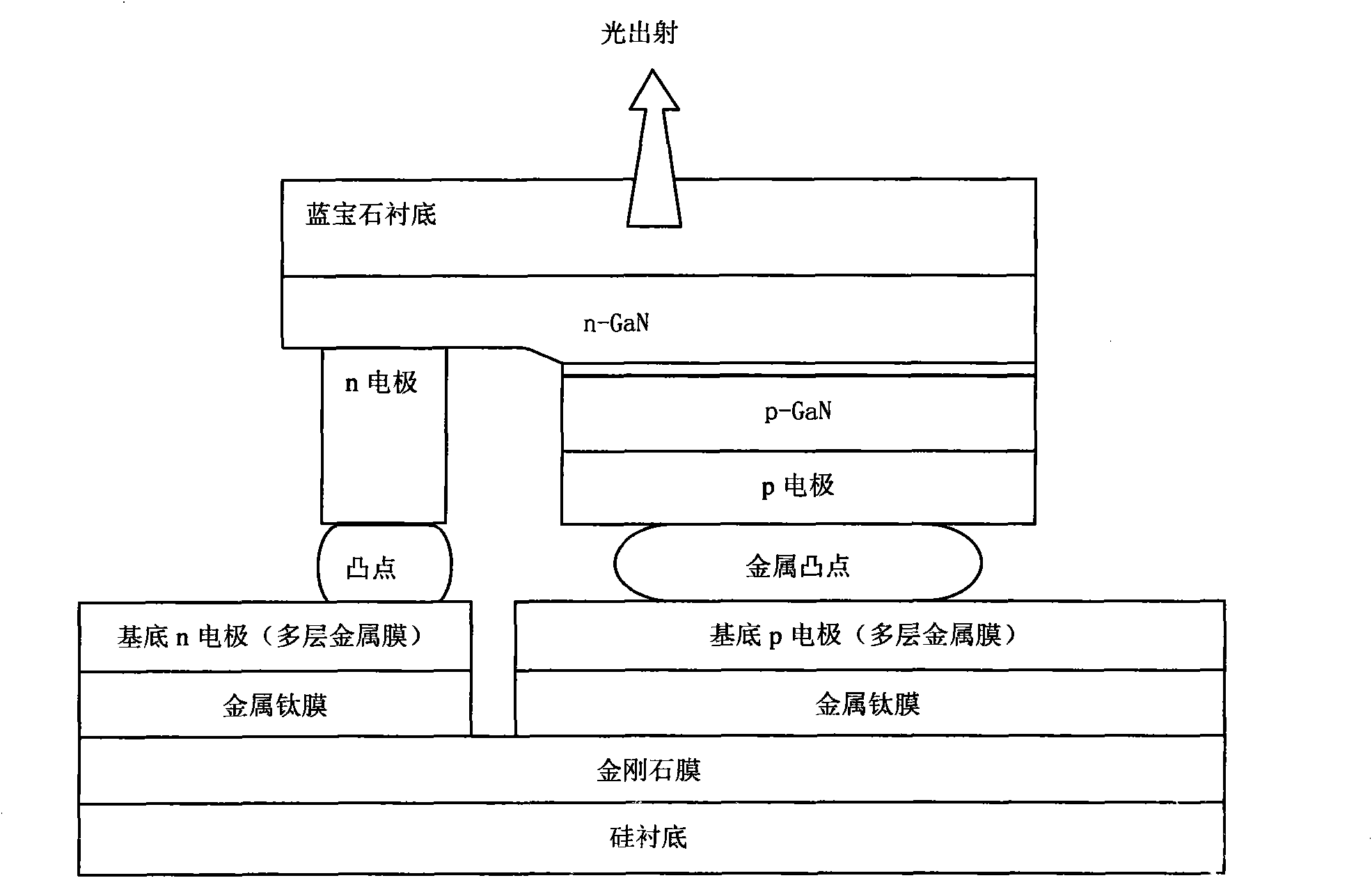

LED (light-emitting diode) radiating substrate based on diamond film and manufacturing method thereof

ActiveCN102130244AShorten the transmission distanceImprove adhesionSemiconductor devicesSurface roughnessLight-emitting diode

The invention relates to a radiating substrate based on a diamond film, comprising a silicon substrate, the diamond film and a transition layer, wherein the diamond film prepared on the silicon substrate has a diamond-on-silicon (DOS) structure; after an end-sealing top layer is removed and surface planarization is carried out, the roughness of the surface of the diamond film is at the nano orderand surface modification is carried out; and the transition layer is a Ti film, and is firstly deposited on the diamond film with a modified surface before metal bumps are prepared. The radiating substrate has the advantages that the diamond film with highest heat conductivity is adopted as a radiating layer of the LED (light-emitting diode) base to form the DOS structure, so that the radiating efficiency is greatly improved; simultaneously, the metal bumps for welding are directly manufactured on a radiating sink, so that the heat transfer distance is shortened; the thermochemical and mechanical planarization is utilized for carrying out surface modification and planarization on the surface of a diamond, so that the roughness of the surface is improved, and the valence bonds of the surface are activated, so that the adhesion among the diamond film and the metal bumps is improved, and the defects of generating air bubbles in the middle of a contact interface and the like are prevented; and due to the formed good contact interface, the heating resistance can be reduced and the radiating efficiency can be improved.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Diamond films and methods of making diamond films

InactiveUS7306778B2Performance advantageUltra-high pressure processesLayered productsGraphiteNanocrystal

The present invention provides films and substrates coated with films that comprise a nano-crystalline diamond matrix that is substantially free of graphite inclusions. The present invention also provides a method of chemical vapor deposition to prepare the films. The method of chemical vapor deposition operates at a DC bias voltage that substantially precludes the formation of a plasma ion capable of causing a region of a nano-crystalline diamond matrix within a forming film to allotrope when the plasma ion collides with the film.

Owner:NANOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com