Preparation method of boron-doped diamond film electrode taking porous titanium as matrix

A boron-doped diamond and thin-film electrode technology, applied in the field of electrode materials, can solve problems such as the influence of electron transfer performance, poor conductivity of passivation film, and electrode film peeling off, and achieve the advantages of increasing binding force, wide potential window and improving stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

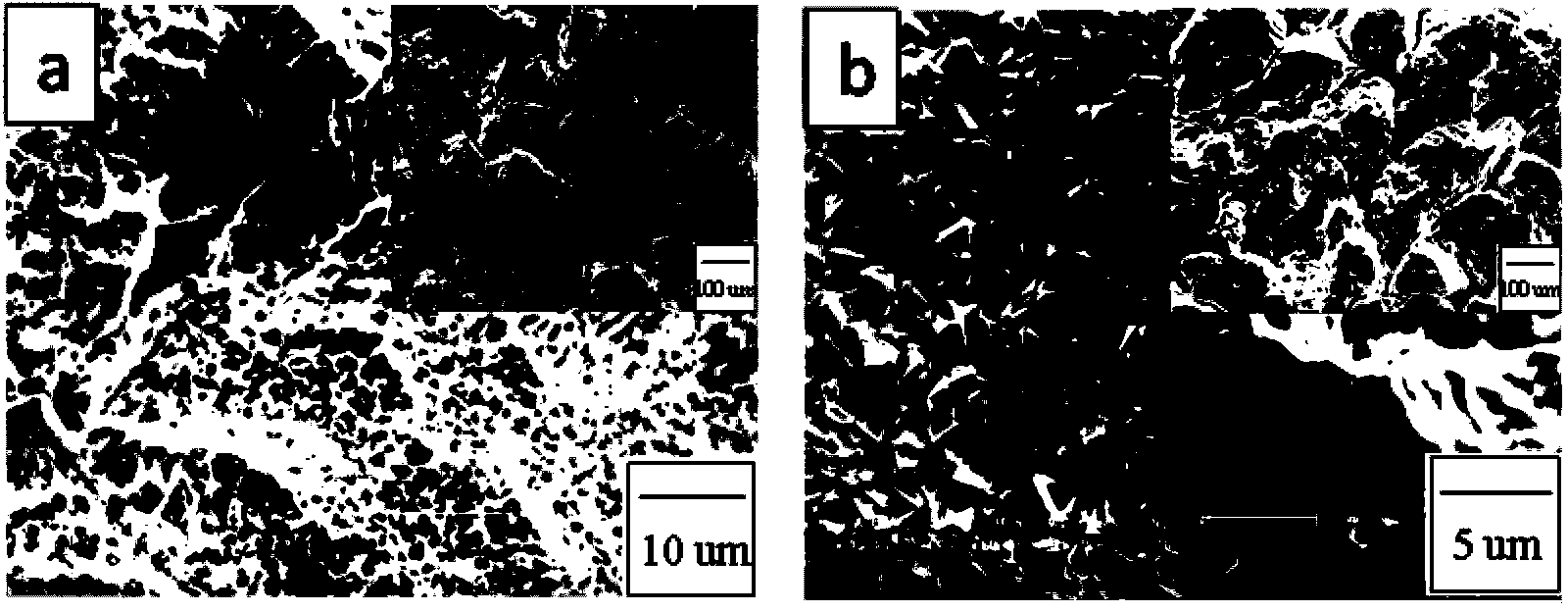

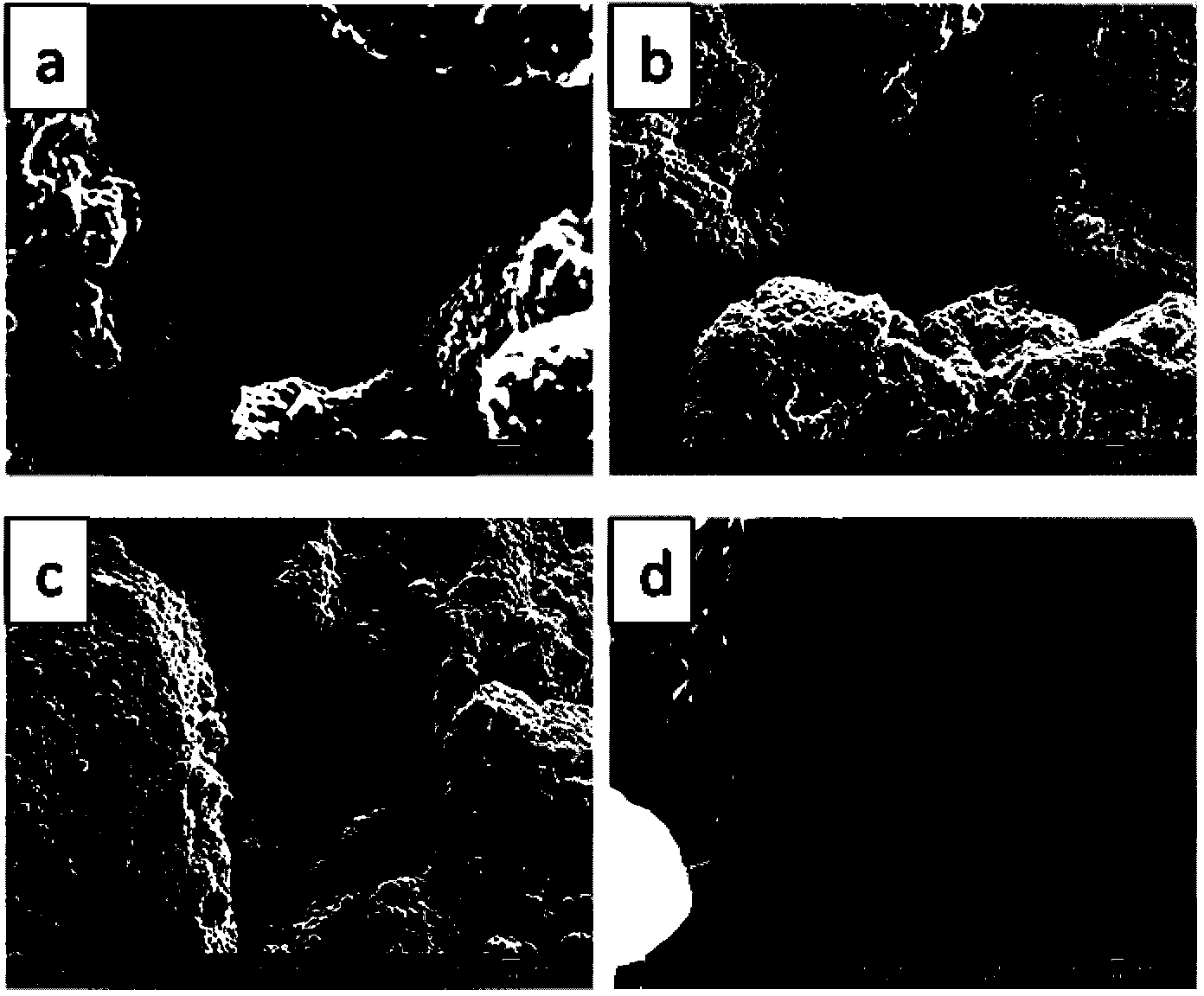

[0020] (1) The porous titanium matrix with a pore size of 15mm×15mm×1mm and a porosity of 60 μm and a porosity of 32% (measured by mercury porosimetry) is soaked in an aqueous NaOH solution with a mass fraction of 10% to fully deoil it, and degrease it with water. After ultrasonic cleaning of the final porous titanium substrate, put it into a beaker filled with 10% hydrochloric acid solution and heat it to a slight boiling state. Stir continuously until the solution gradually becomes light purple. Use deionized water to ultrasonically clean the porous titanium substrate for 5 minutes and rinse it clean. Then put it in deionized water for protection;

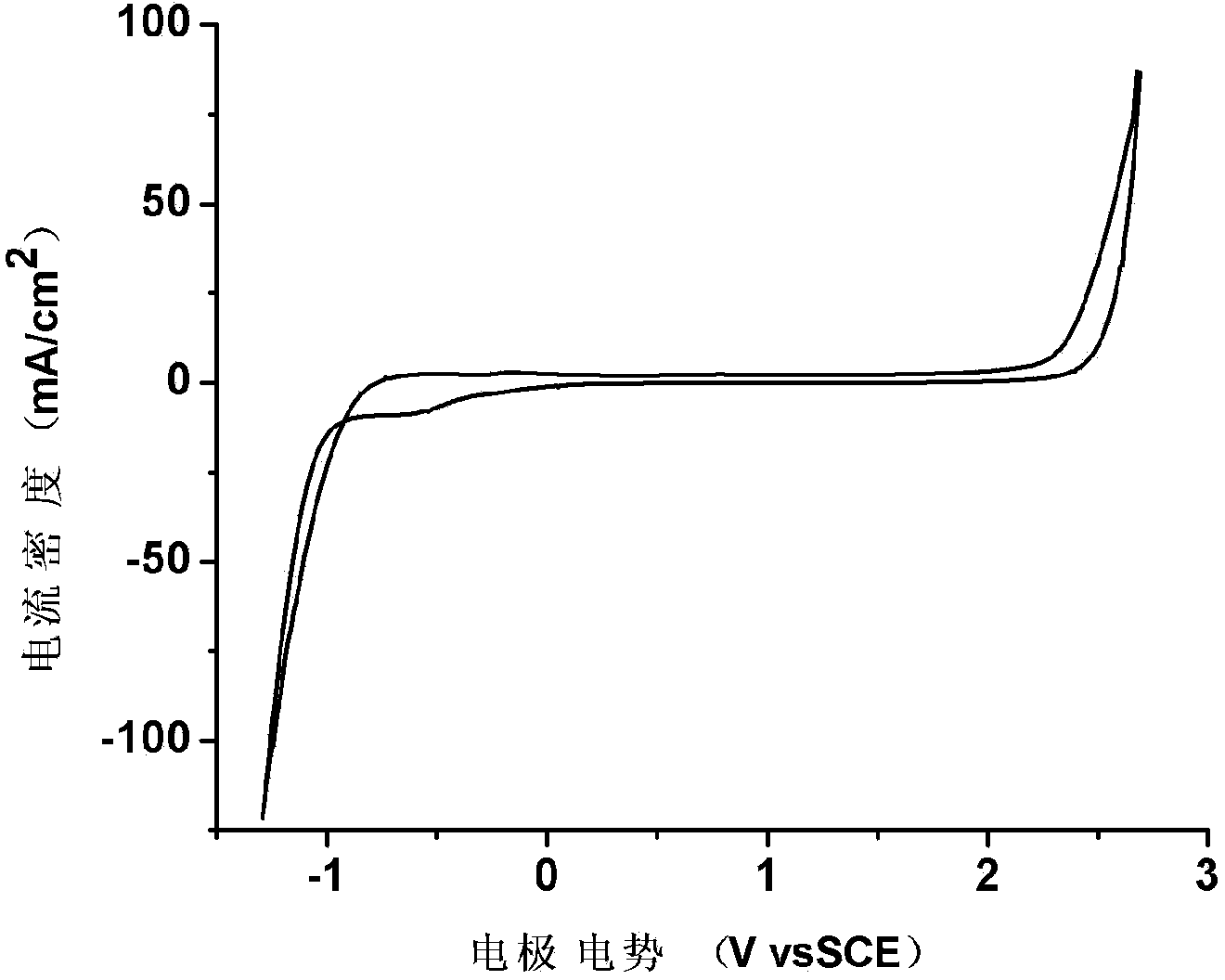

[0021] (2) The porous titanium processed in step (1) is used as the substrate, the tantalum wire is used as the hot wire, methane and hydrogen are used as the gas source, and trimethyl borate is used as the boron source. In the methane and hydrogen atmosphere, hot wire chemical vapor deposition is used. Method for growing boron-d...

Embodiment 2

[0027] (1) The porous titanium matrix with a pore size of 15mm×15mm×1mm and a porosity of 60 μm and a porosity of 32% (measured by mercury porosimetry) is soaked in an aqueous NaOH solution with a mass fraction of 10% to fully deoil it, and degrease it with water. After ultrasonic cleaning of the final porous titanium substrate, put it into a beaker filled with 10% hydrochloric acid solution and heat it to a slight boiling state. Stir continuously until the solution gradually becomes light purple. Use deionized water to ultrasonically clean the porous titanium substrate for 5 minutes and rinse it clean. Then put it in deionized water for protection;

[0028] (2) The porous titanium processed in step (1) is used as the substrate, the tantalum wire is used as the hot wire, methane and hydrogen are used as the gas source, and trimethyl borate is used as the boron source. In the methane and hydrogen atmosphere, hot wire chemical vapor deposition is used. Method for growing boron-dop...

Embodiment 3

[0034] (1) The porous titanium substrate with a size of 15mm×15mm×1mm, a pore size of 100μm, and a porosity of 27% (measured by mercury porosimetry) is soaked in an aqueous NaOH solution with a mass fraction of 10% to fully deoil it, and degrease it with water. After ultrasonic cleaning of the final porous titanium substrate, put it into a beaker filled with 10% hydrochloric acid solution and heat it to a slight boiling state. Stir continuously until the solution gradually becomes light purple. Use deionized water to ultrasonically clean the porous titanium substrate for 5 minutes and rinse it clean. Then put it in deionized water for protection;

[0035] (2) The porous titanium processed in step (1) is used as the substrate, the tantalum wire is used as the hot wire, methane and hydrogen are used as the gas source, and trimethyl borate is used as the boron source. In the methane and hydrogen atmosphere, hot wire chemical vapor deposition is used. Method for growing boron-dope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com