Economic active powder concrete mixed superfine cement

A technology of ultra-fine cement and active powder, applied in the field of concrete, can solve the problems of slow increase in the strength of active powder concrete, limited silica fume output, and lack of silica fume resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

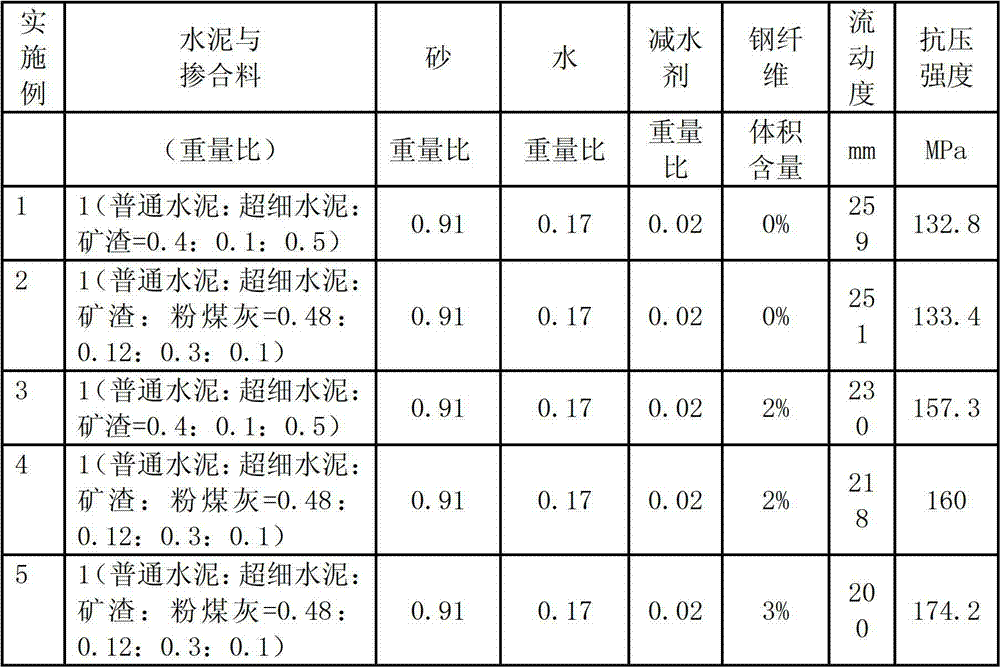

[0021] The typical material mix ratio that the present invention adopts, and the fluidity and strength of corresponding active powder concrete are shown in the following table:

[0022]

[0023] The slag powder in the above table is the abbreviation of granulated blast furnace slag powder;

[0024] The ultra-fine cement is an expansive ultra-fine portland cement with a specific surface area of 647m 2 / kg;

[0025] Described ordinary cement is 42.5 grades of early-strength ordinary Portland cement;

[0026] The grade of the granulated blast furnace slag powder is S95, and the density is 2.86g / cm 3 , specific surface area 408m 2 / kg;

[0027] Described fly ash is Class I fly ash, density 2.23g / cm 3 , specific surface area 278m 2 / kg;

[0028] The sand is natural quartz sand with a particle size ranging from 40 mesh to 70 mesh;

[0029] The water described complies with the provisions of JGJ 63-89 in the "Concrete Mixing Water Standard";

[0030] Described water red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com