Patents

Literature

4068results about How to "Increase contact surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

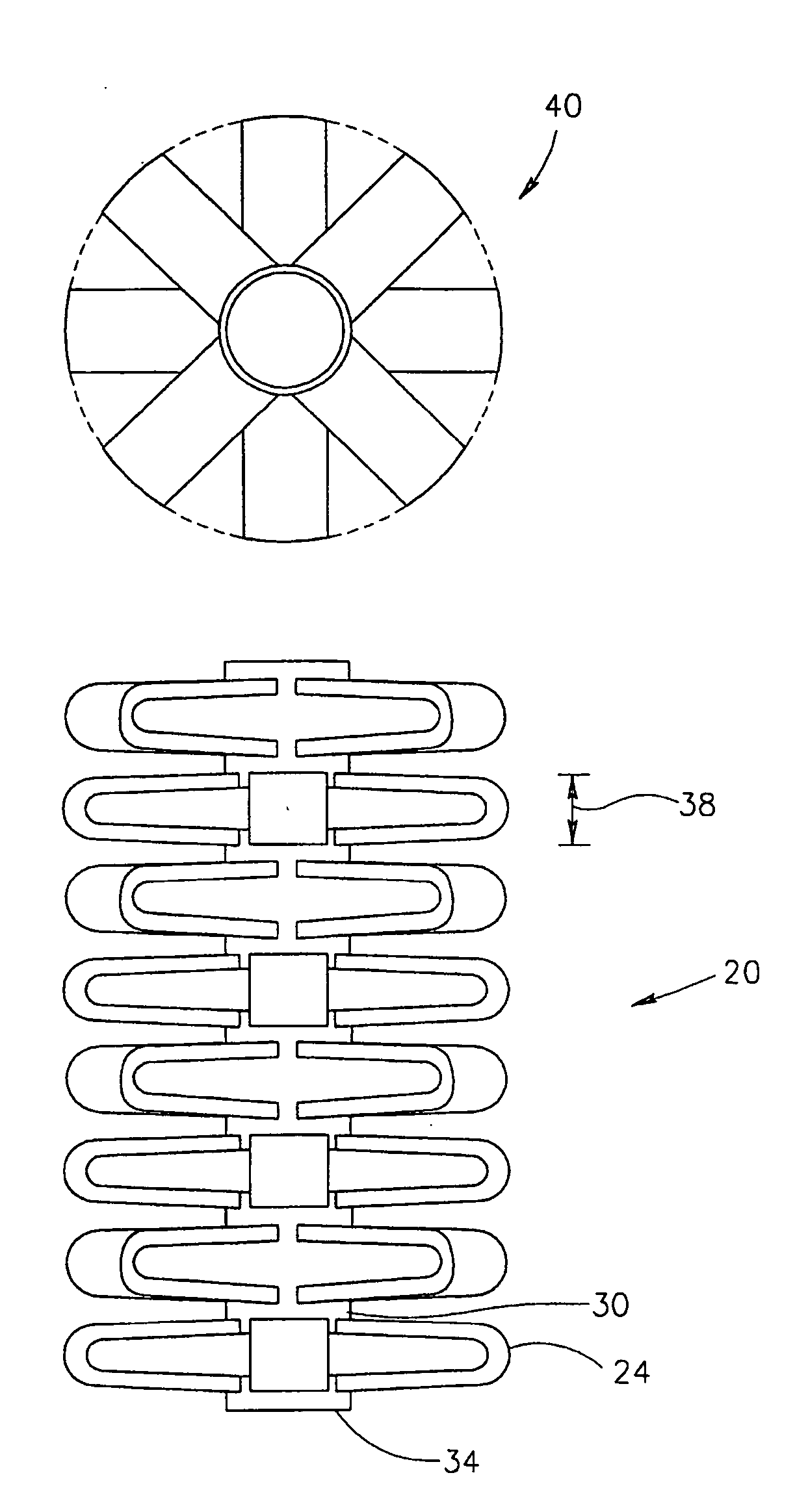

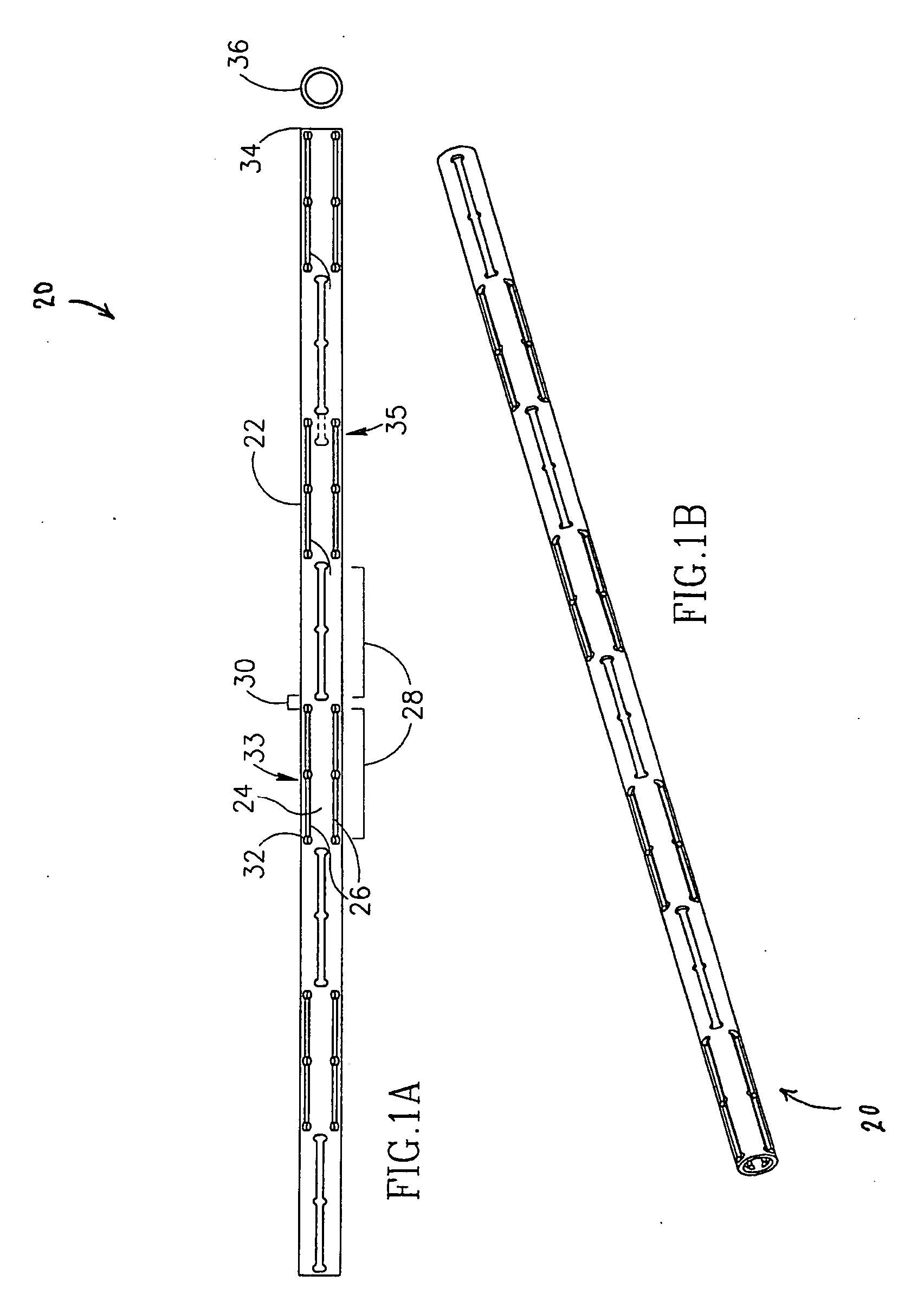

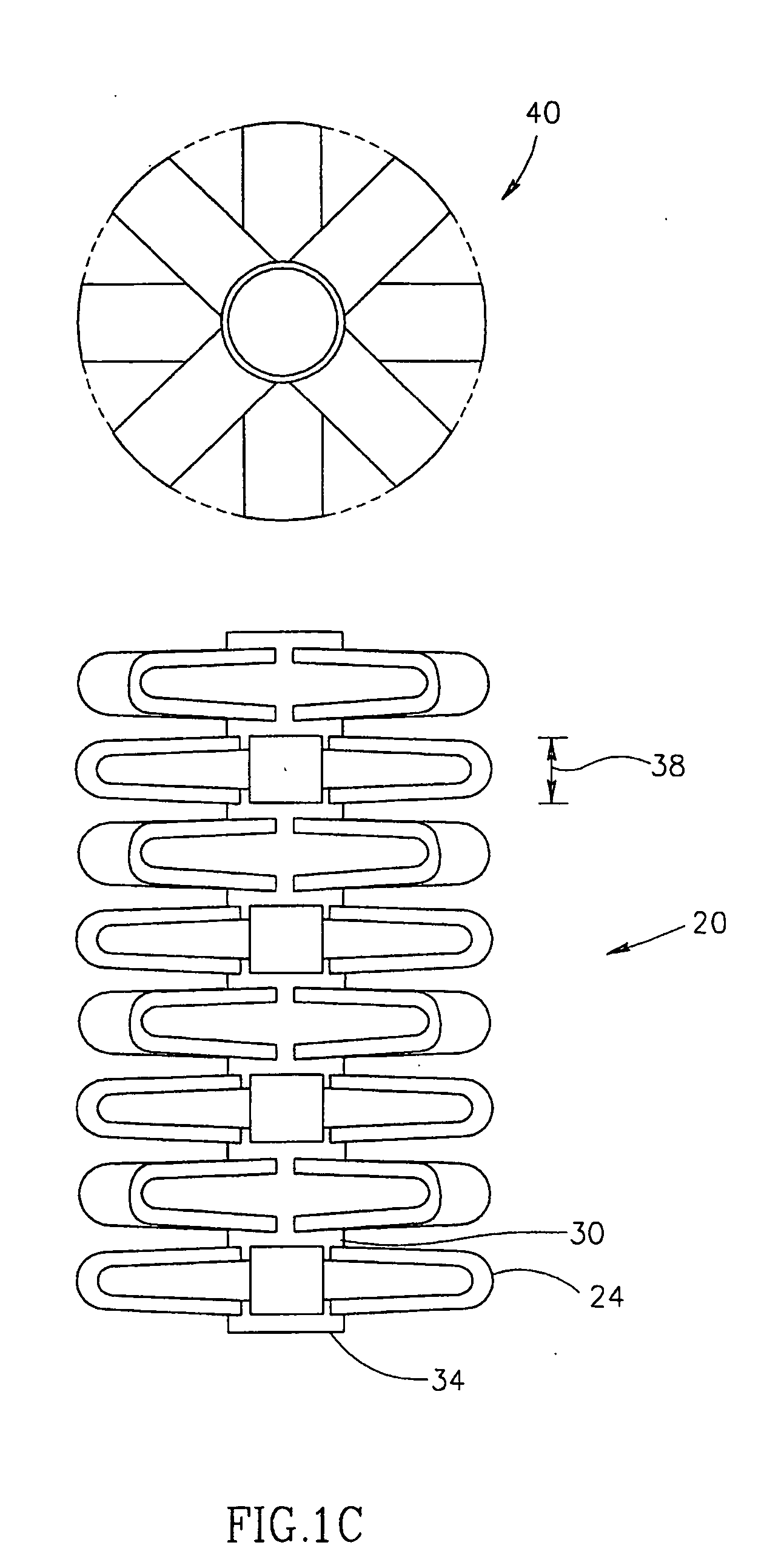

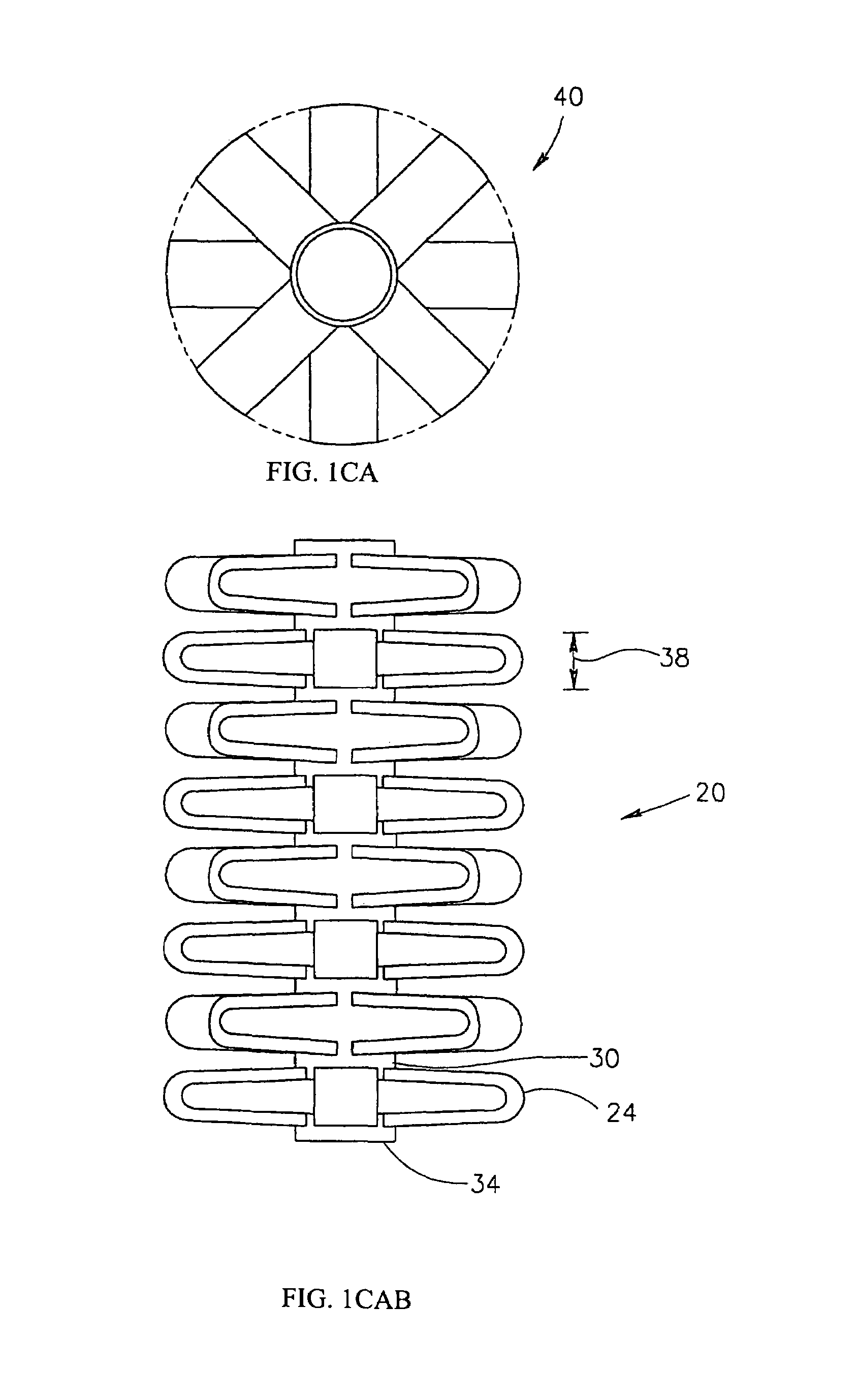

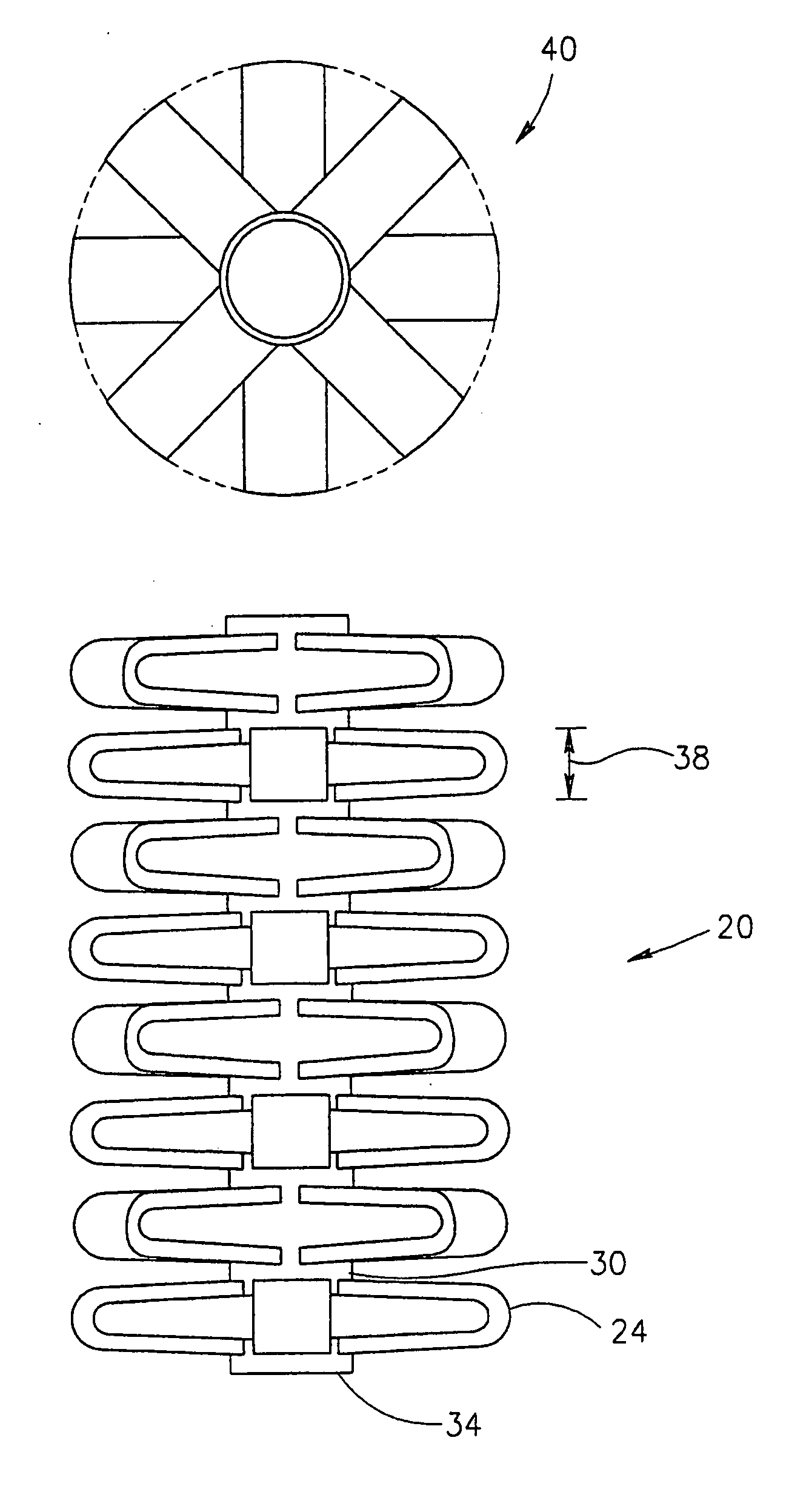

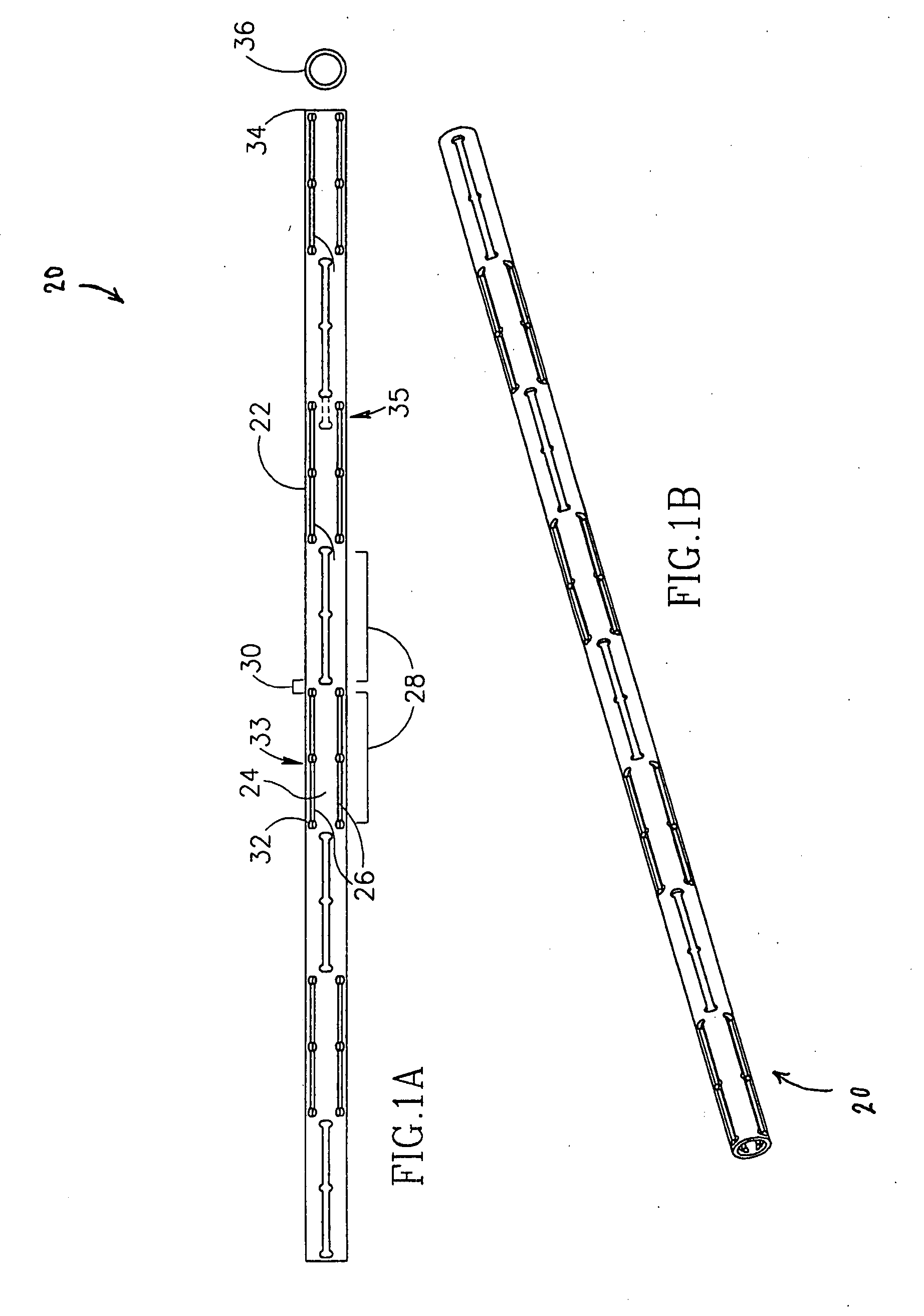

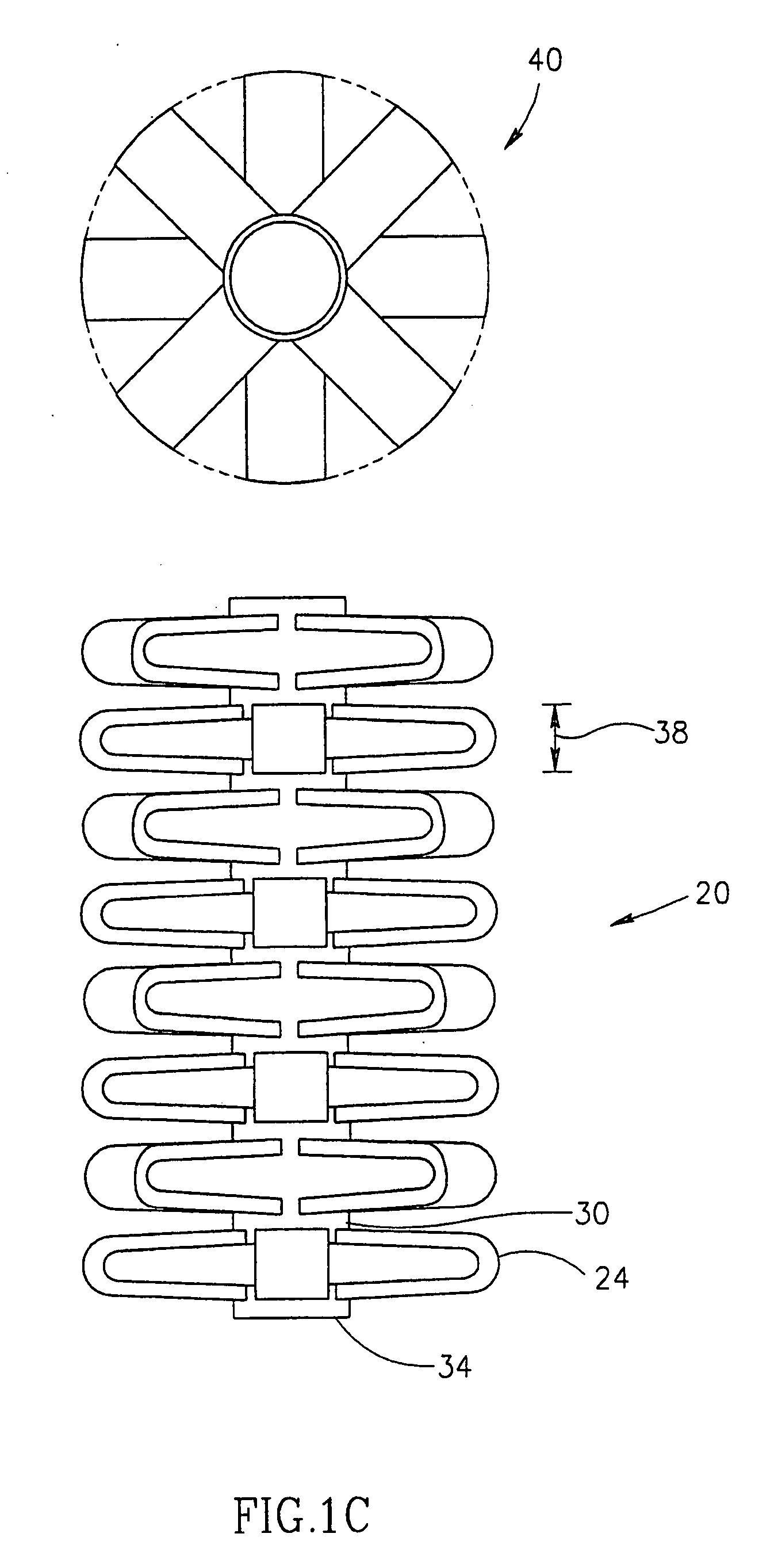

Expandable intervertebral spacer

ActiveUS20050143827A1Prevent crashIncrease contact surfaceDental implantsInternal osteosythesisBiomedical engineering

Owner:KYPHON

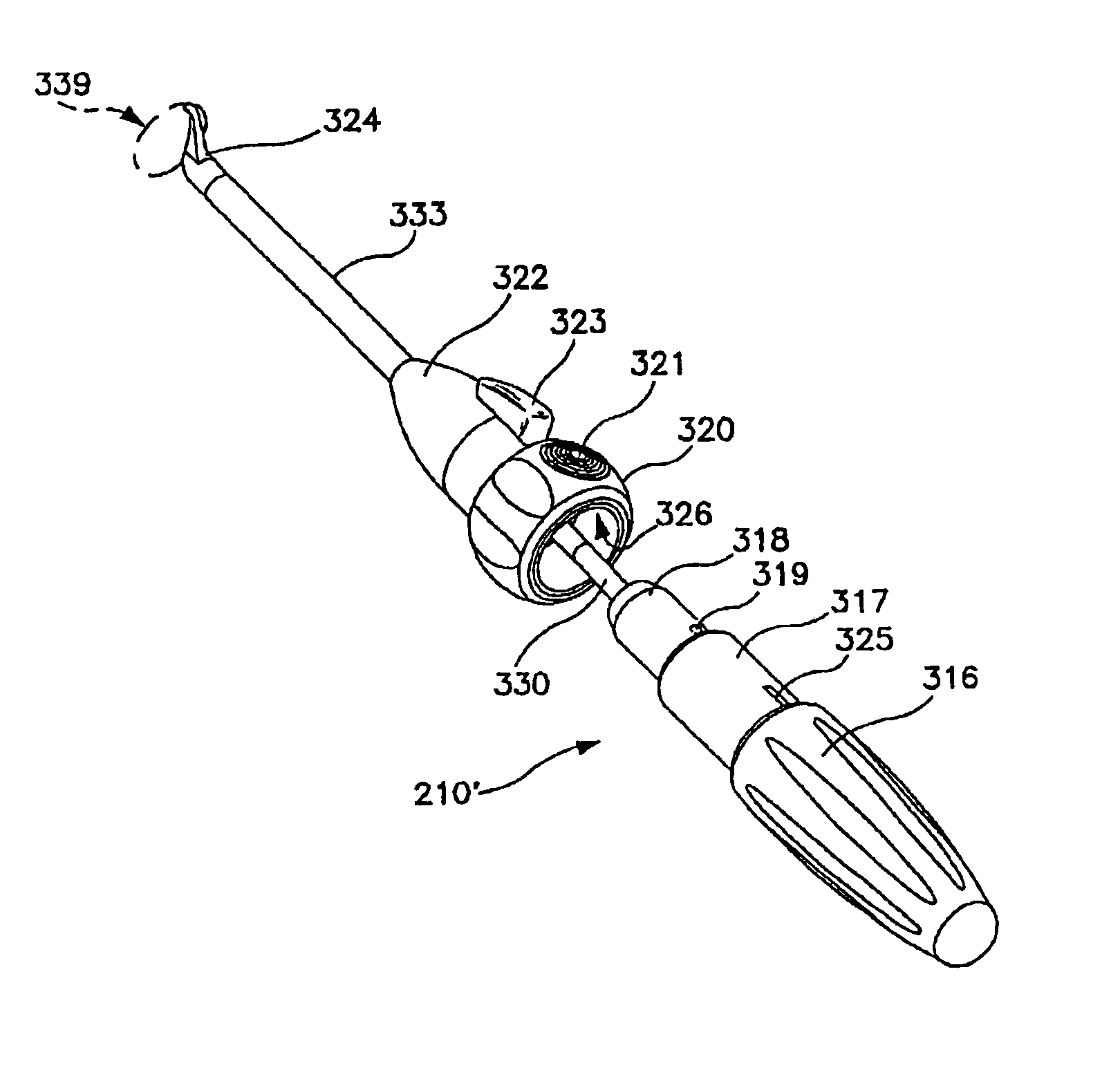

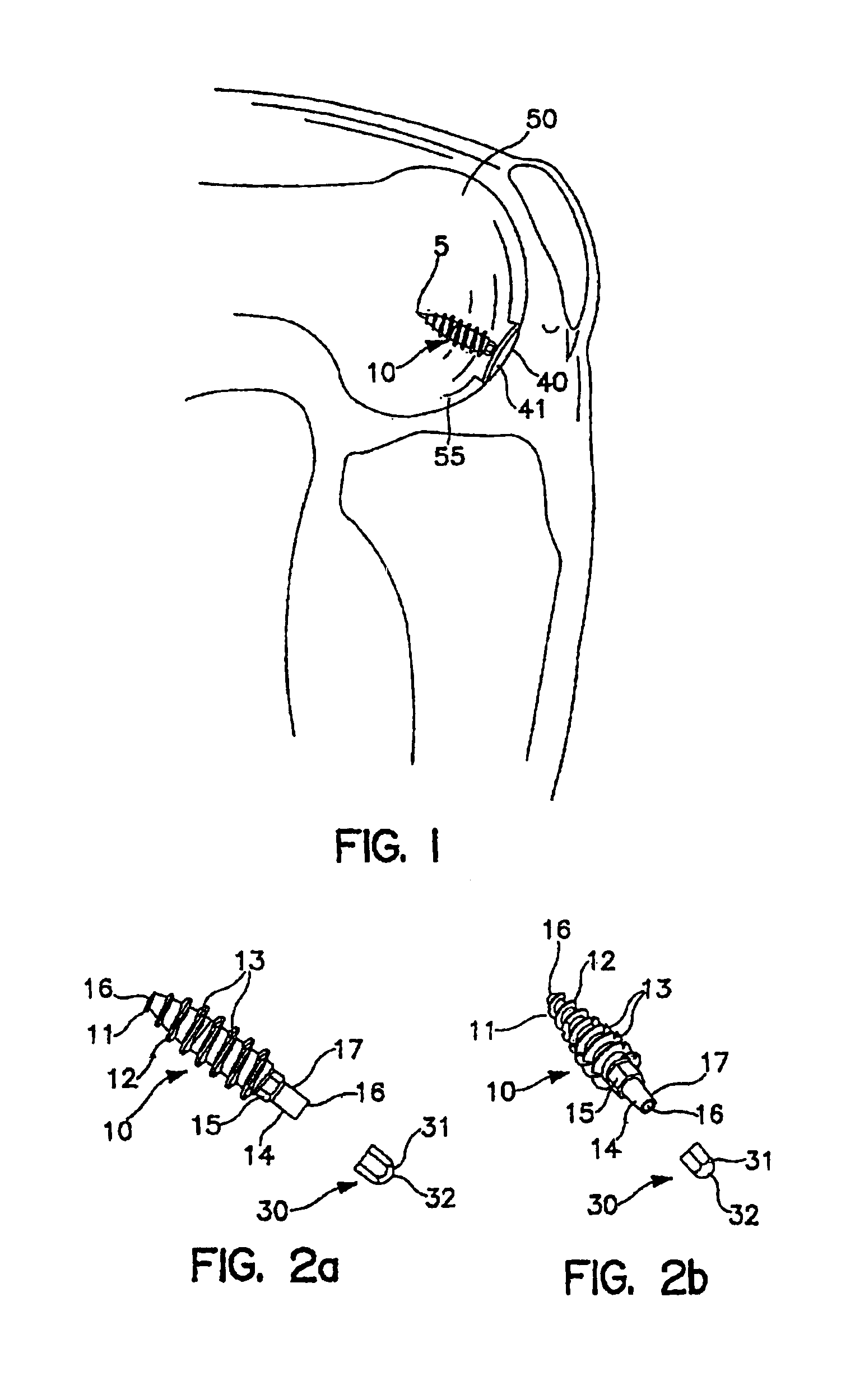

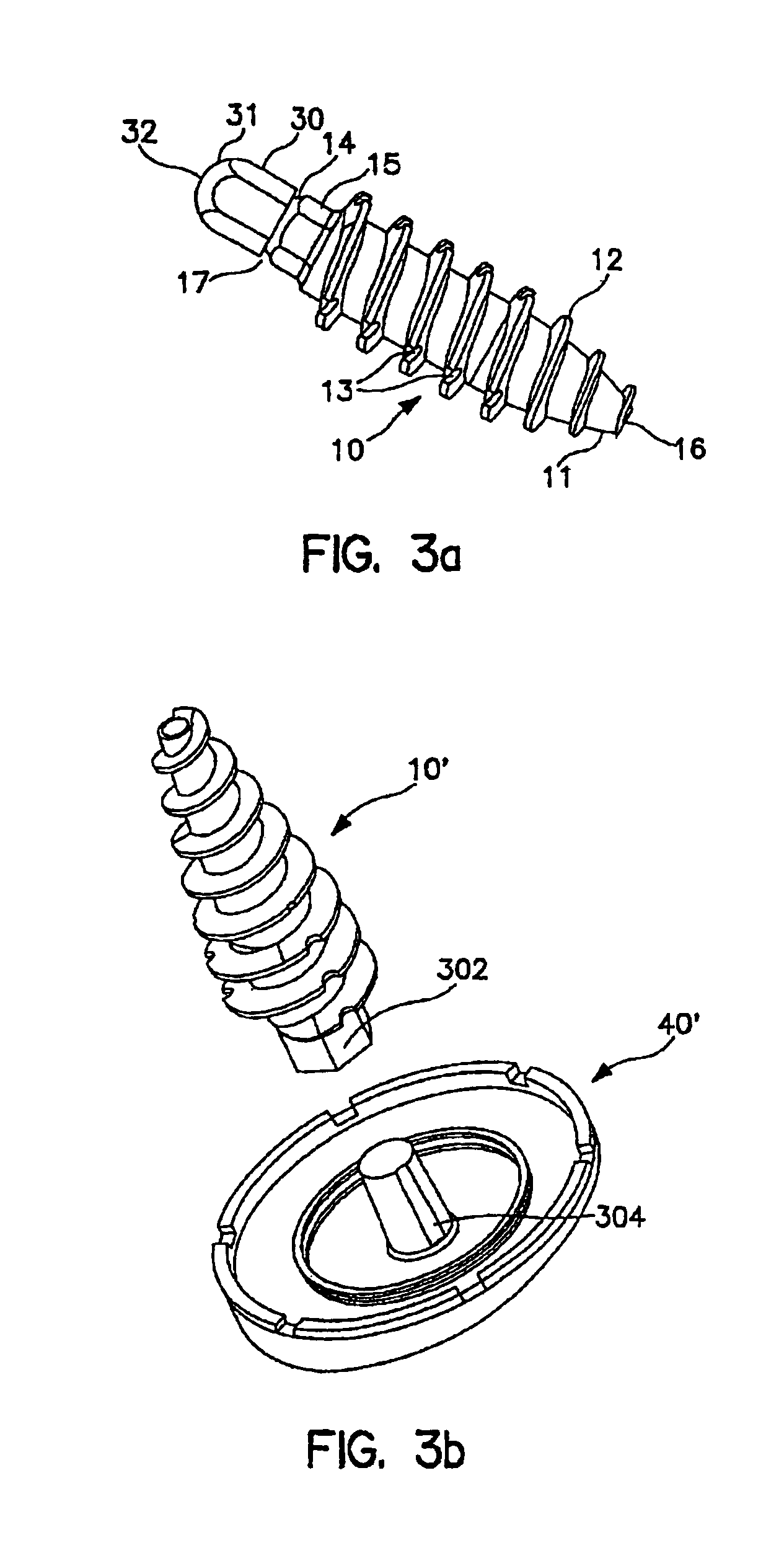

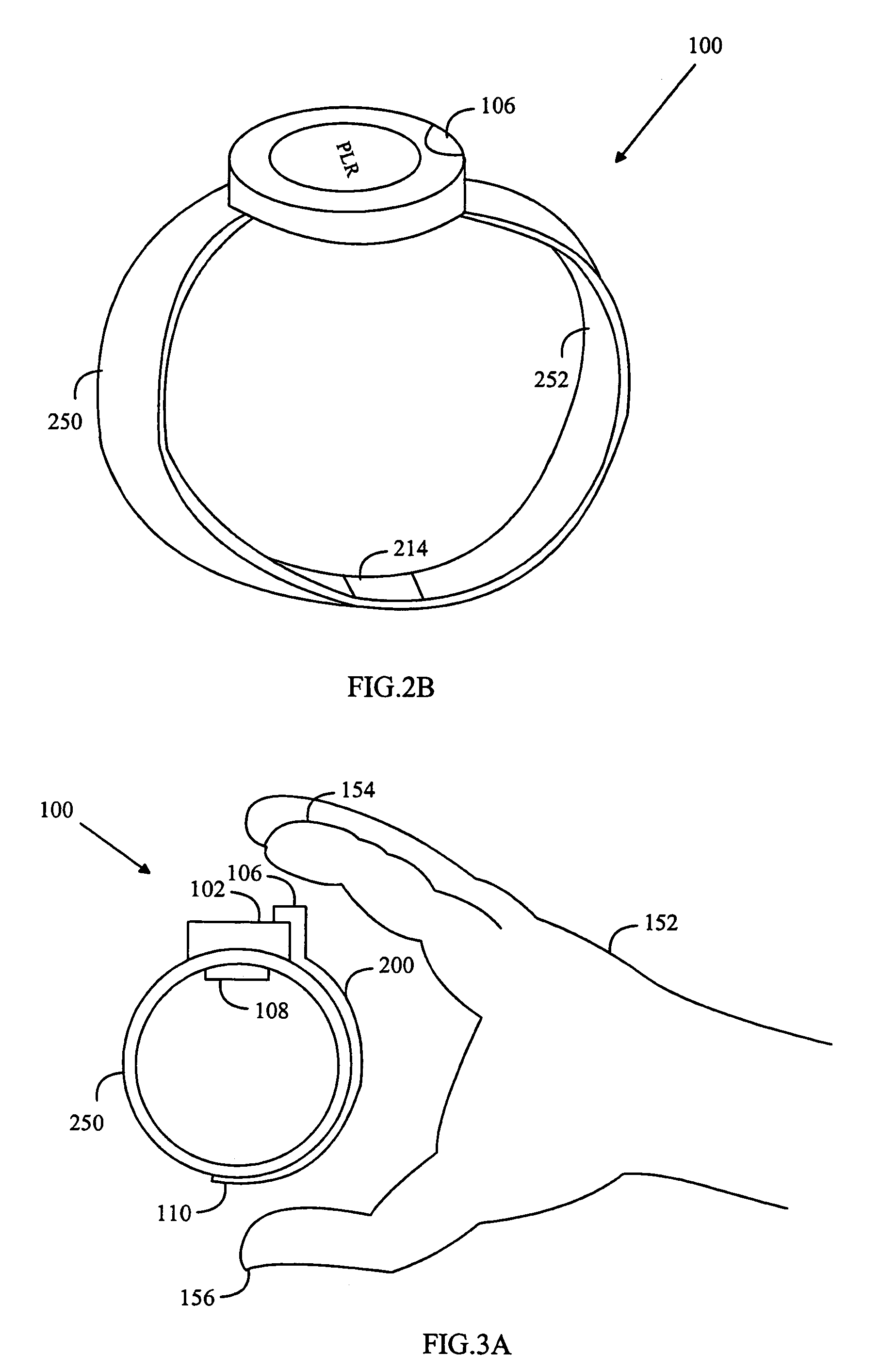

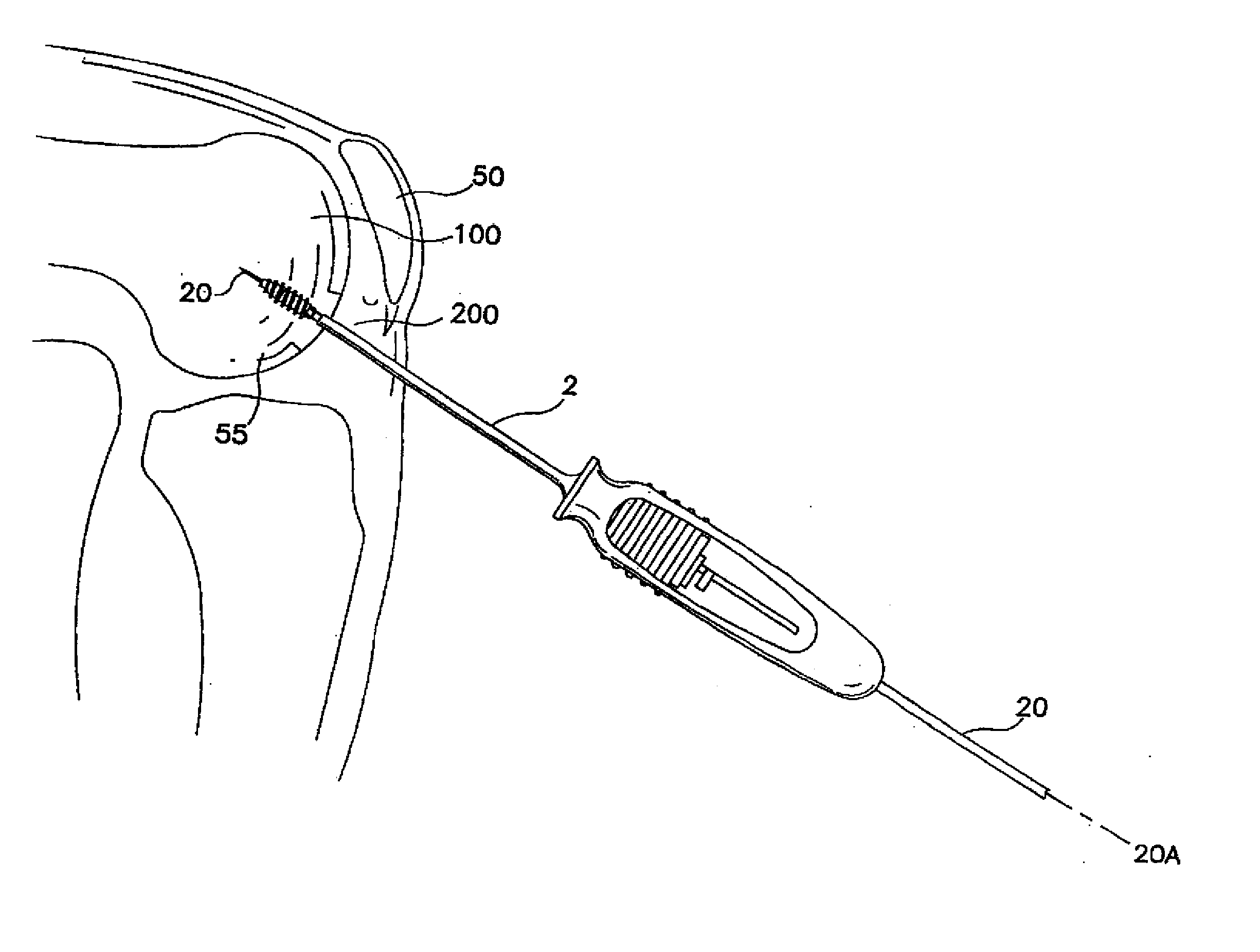

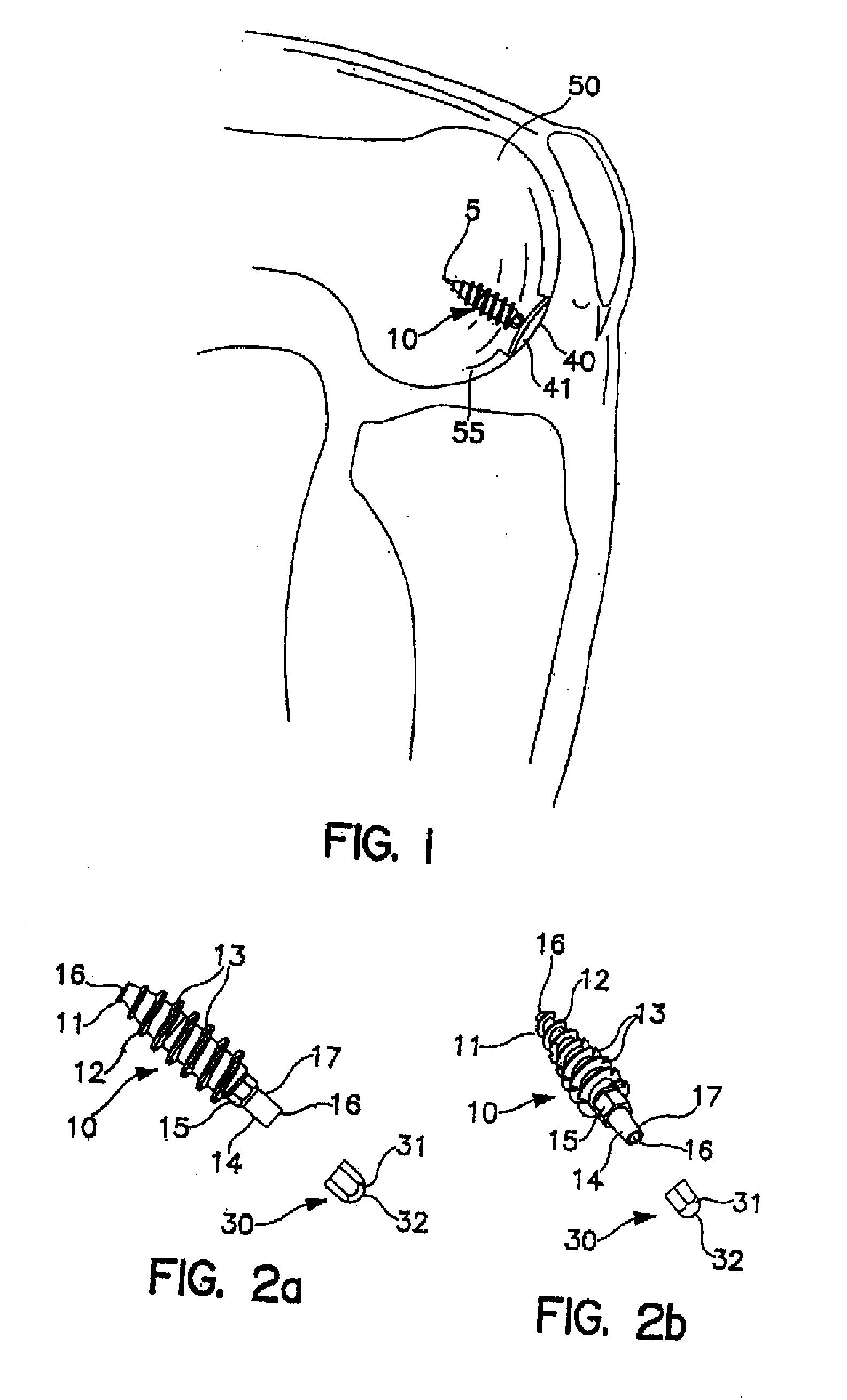

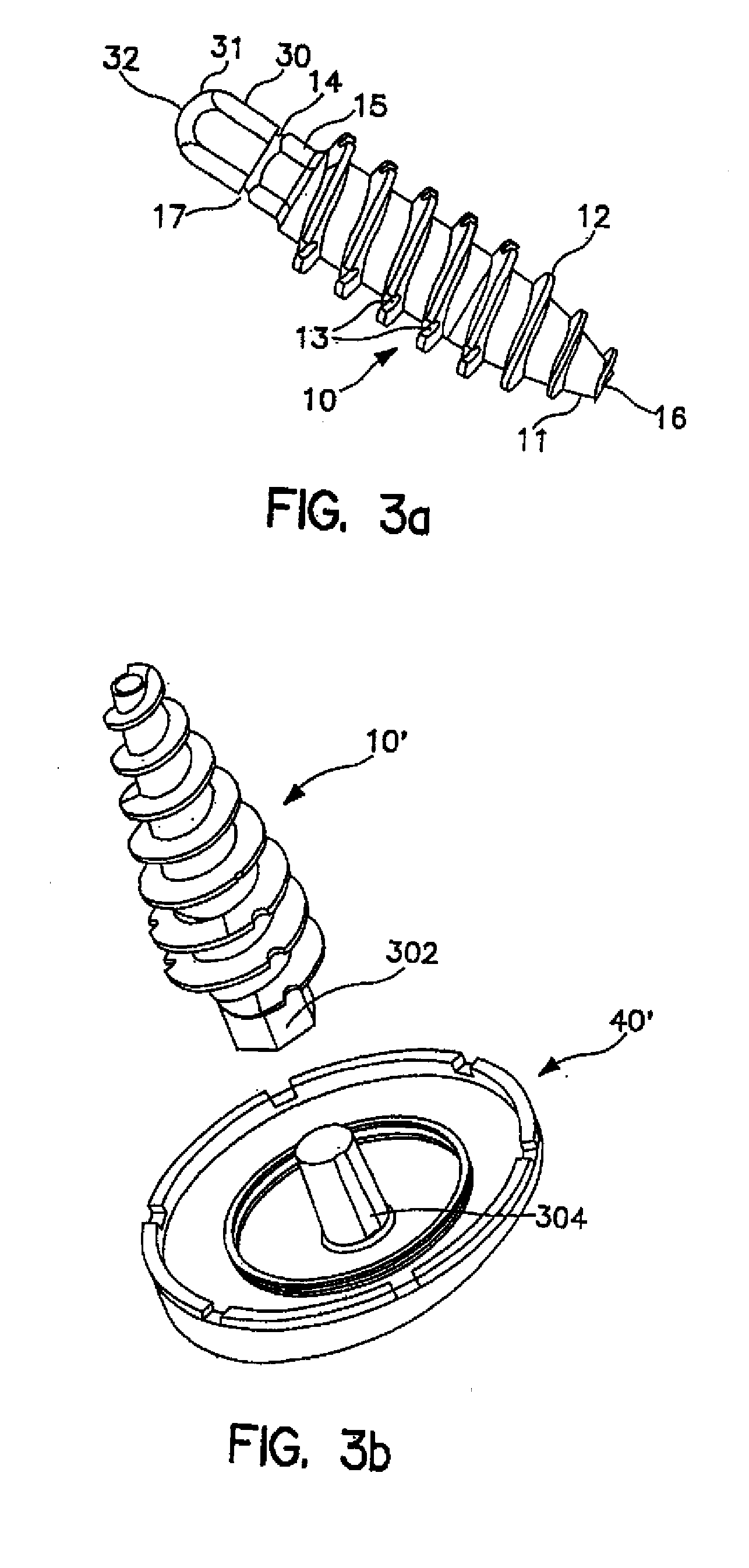

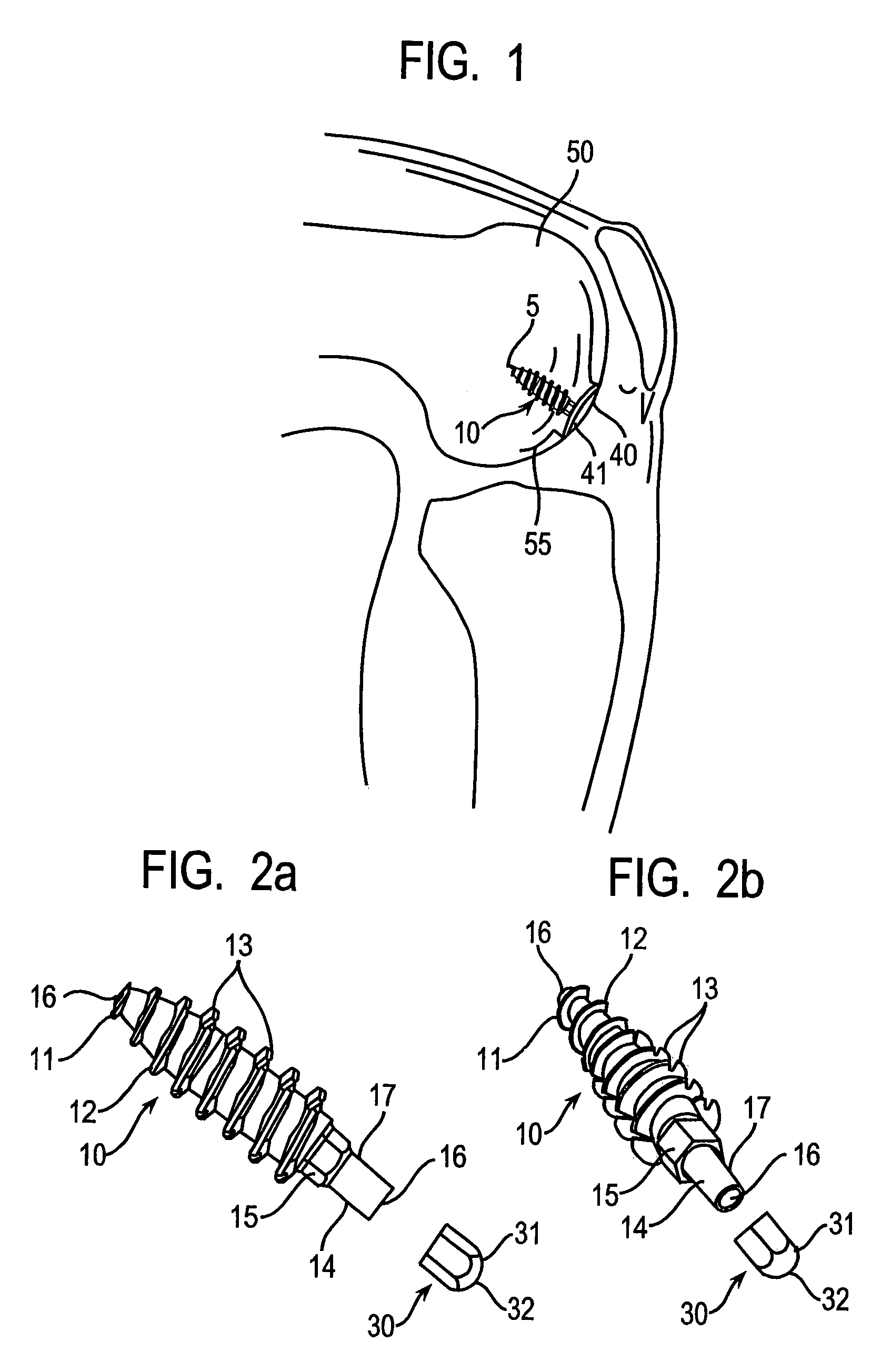

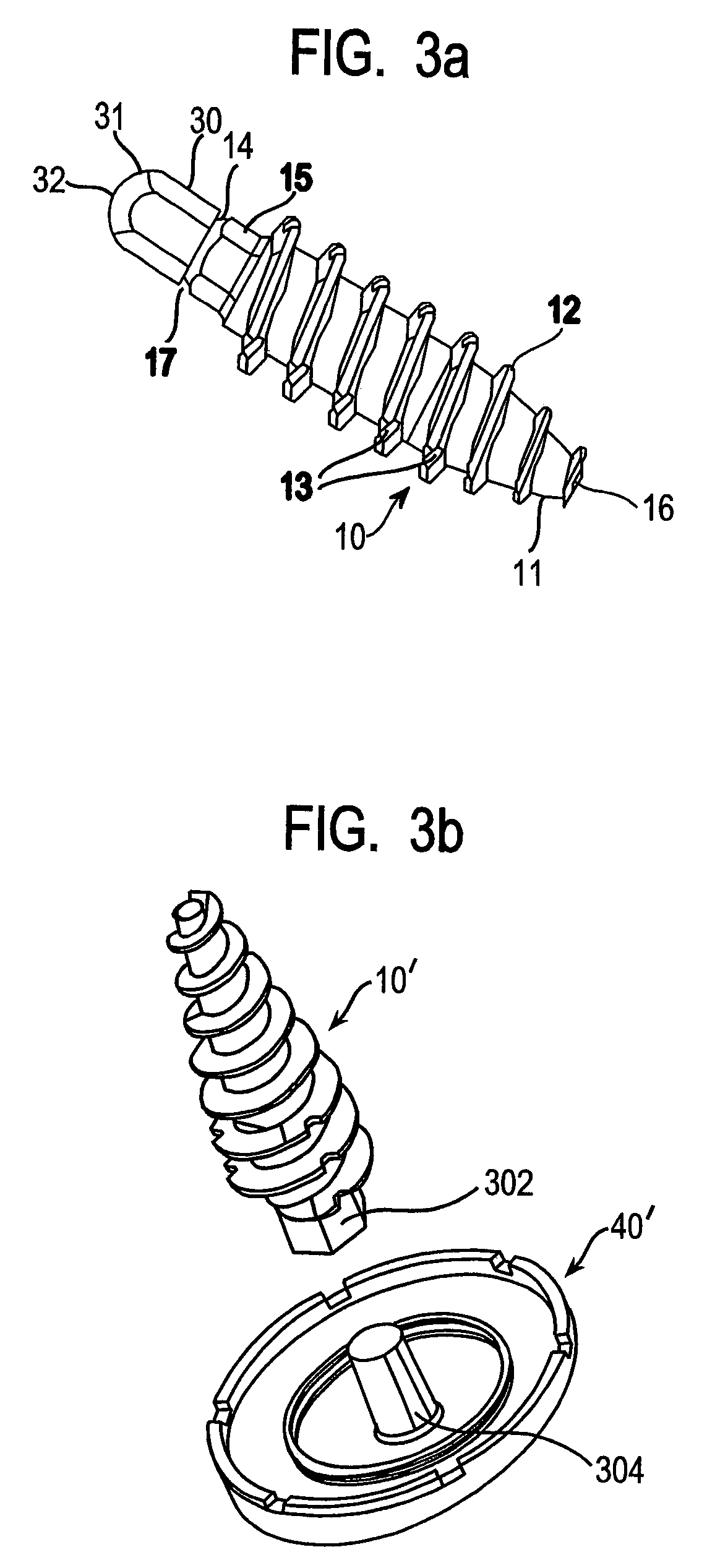

System and method for joint resurface repair

InactiveUS7029479B2Enhance transfer of loadIncrease rotational forceSuture equipmentsInternal osteosythesisBearing surfaceSacroiliac joint

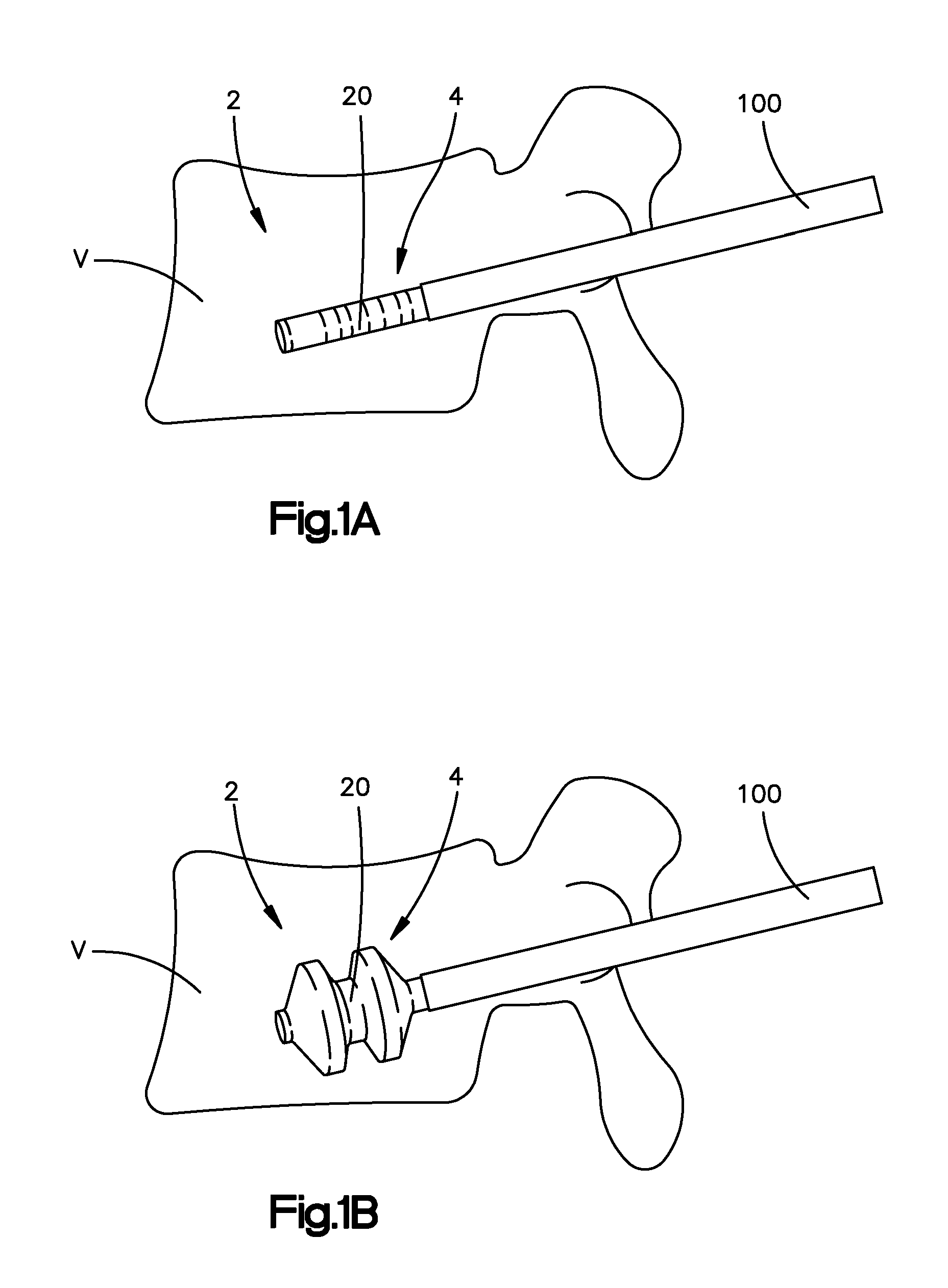

The present invention provides tools and methods for mapping and measuring the articular surface of a joint (or of any bony surface) and for fabricating a prosthetic device based on this recorded data. In one embodiment, once the defect of the chondral surface has been identified, a guide pin is inserted arthroscopically. A fixation screw is driven into the subchondral bone in relation to a reference axis that is approximately central to the defect, the fixation device also serving to define a tangent point to the surrounding articular surface. A further cylindrical proximal extension of the screw that eventually serves as a fixation element for the surface prosthetic is concealed with a cover or plug. The depth positioning of the cover or plug establishes an origin or reference point for all future measuring, cutting, and prosthetic machining operations. A measuring tool having a static post that establishes the axial location of origin is inserted on the reference axis. By rotating the outer arm or outrigger of the measuring tool relative to the static post while also maintaining contact with the articular surface, an axial displacement or Z dimension is established relative to the origin for any point along the known radial sweep of the outrigger to determine the final geometry of the prosthetic surface which fits within the defect. Data recorded during the mapping procedure is entered into parametric engineering design software or similar algorithm to define a three dimensional surface matched to the bearing surface geometry to be implanted and reproduce the anatomic contours mapped.

Owner:ARTHROSURFACE

Expandable intervertebral spacer

InactiveUS7621950B1Increase contact surfaceEasy to fillInternal osteosythesisBone implantBiomedical engineering

Owner:KYPHON

Expandable element

InactiveUS20070282443A1Prevent crashIncrease contact surfaceDental implantsInternal osteosythesisEngineeringBiomedical engineering

Owner:KYPHON

Porous containment device and associated method for stabilization of vertebral compression fractures

ActiveUS20100262240A1Restoring anatomyEasy to optimizeInternal osteosythesisDiagnosticsFilling materialsMedicine

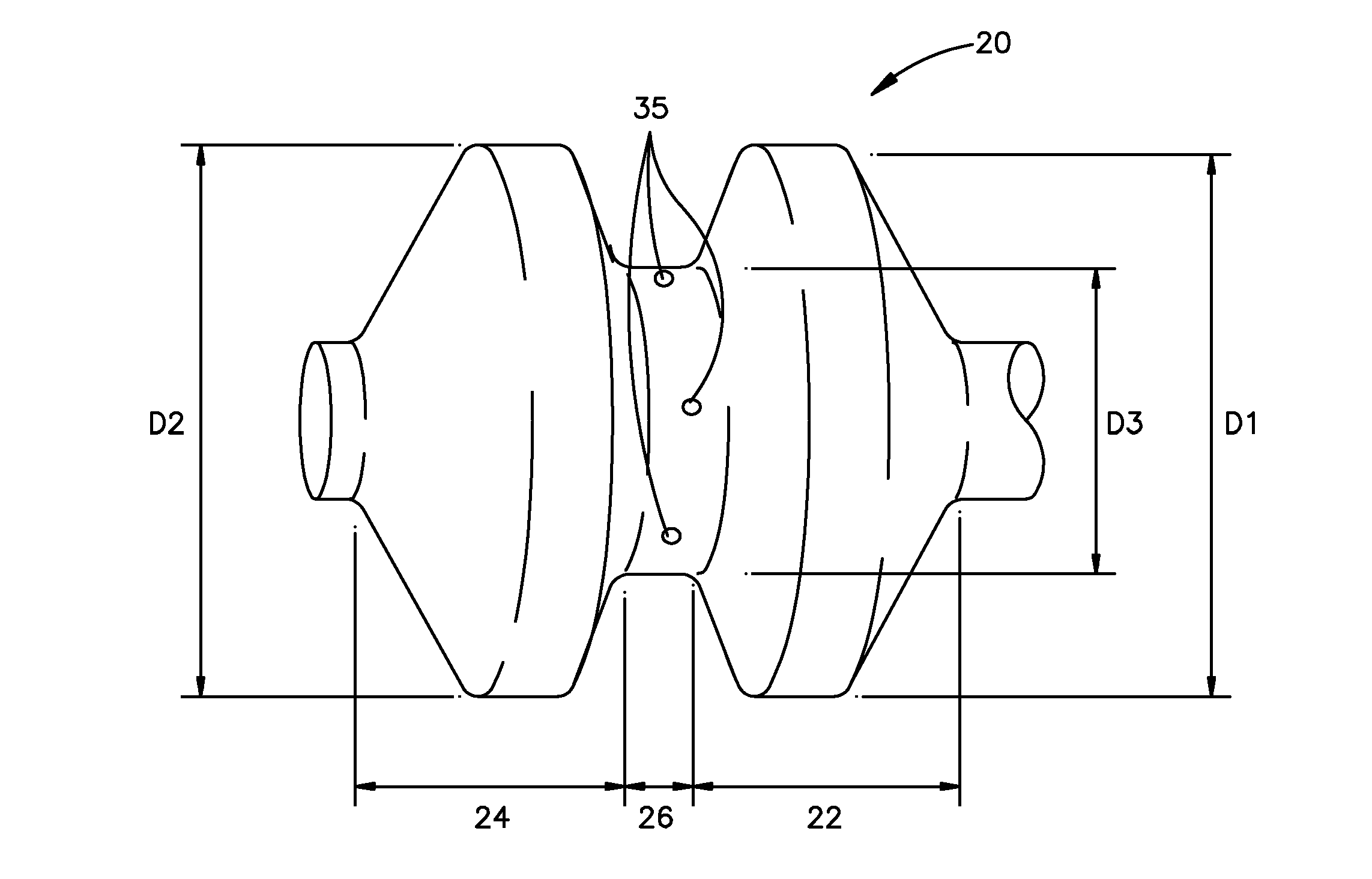

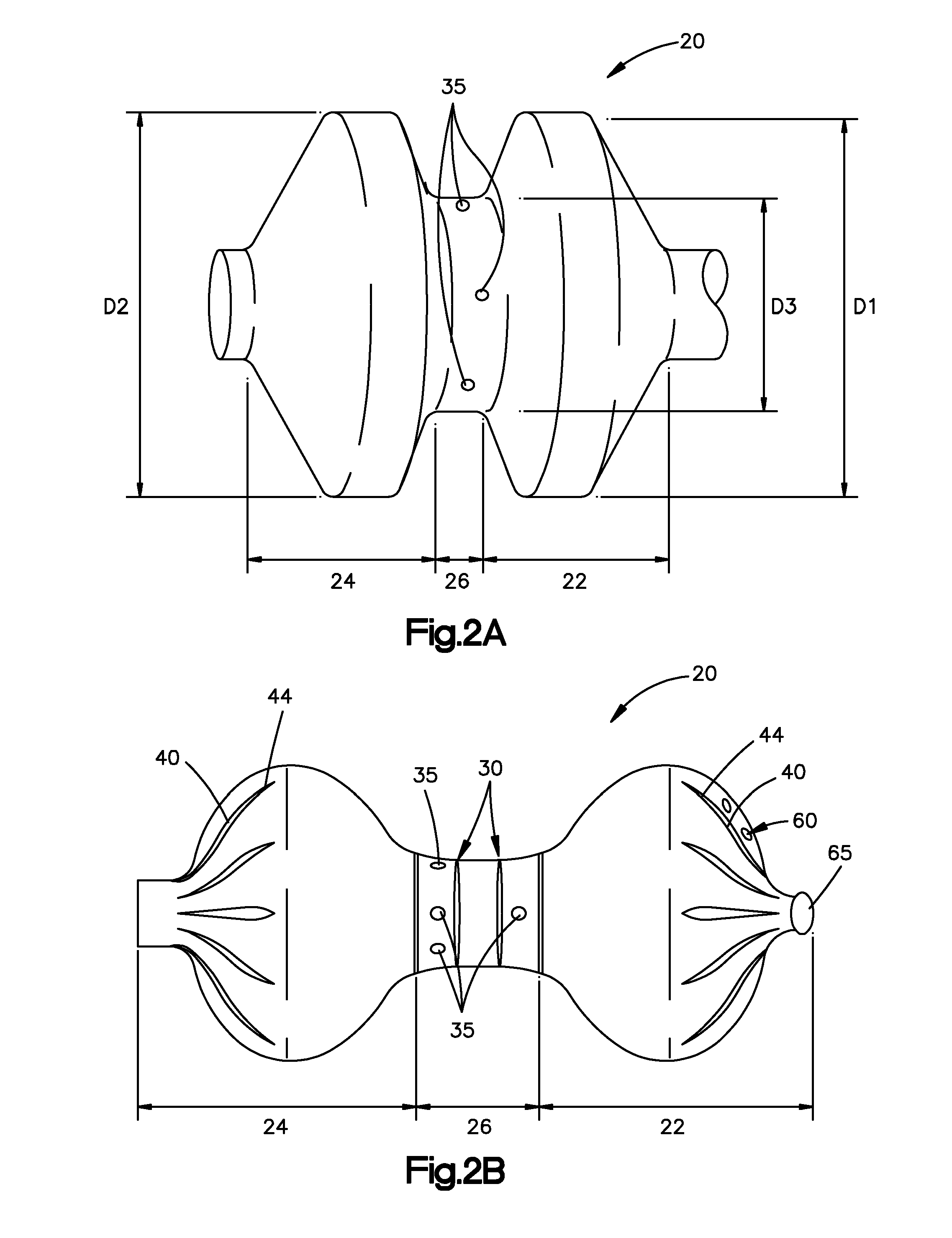

The present invention is directed to a porous or permeable containment device for implanting into the interior volume of a targeted vertebral body for use in restoring the anatomy of the targeted vertebral body. The containment device is expandable from an insertion configuration to an expanded configuration via, for example, a bone filler material. The containment device preferably permits the bone filler material to flow out of the containment device via, for example, one or more pores, one or more flow-directing tentacles, etc. so that the bone filler material may interdigitates with the surrounding bone tissue. The containment device is preferably configured to have a pre-determined, ‘dog-bone’ shape, when in the expanded configuration. The containment device preferably also includes one or more knobs or ribs to facilitate anchoring of the containment device to the surrounding bone tissue, one or more air or fluid evacuation pores to permit air or fluid from escaping from the interior volume of the containment device and / or one or more radiopacity rings or markers to enable a surgeon to locate and / or position the containment device under X-ray imaging.

Owner:DEPUY SYNTHES PROD INC

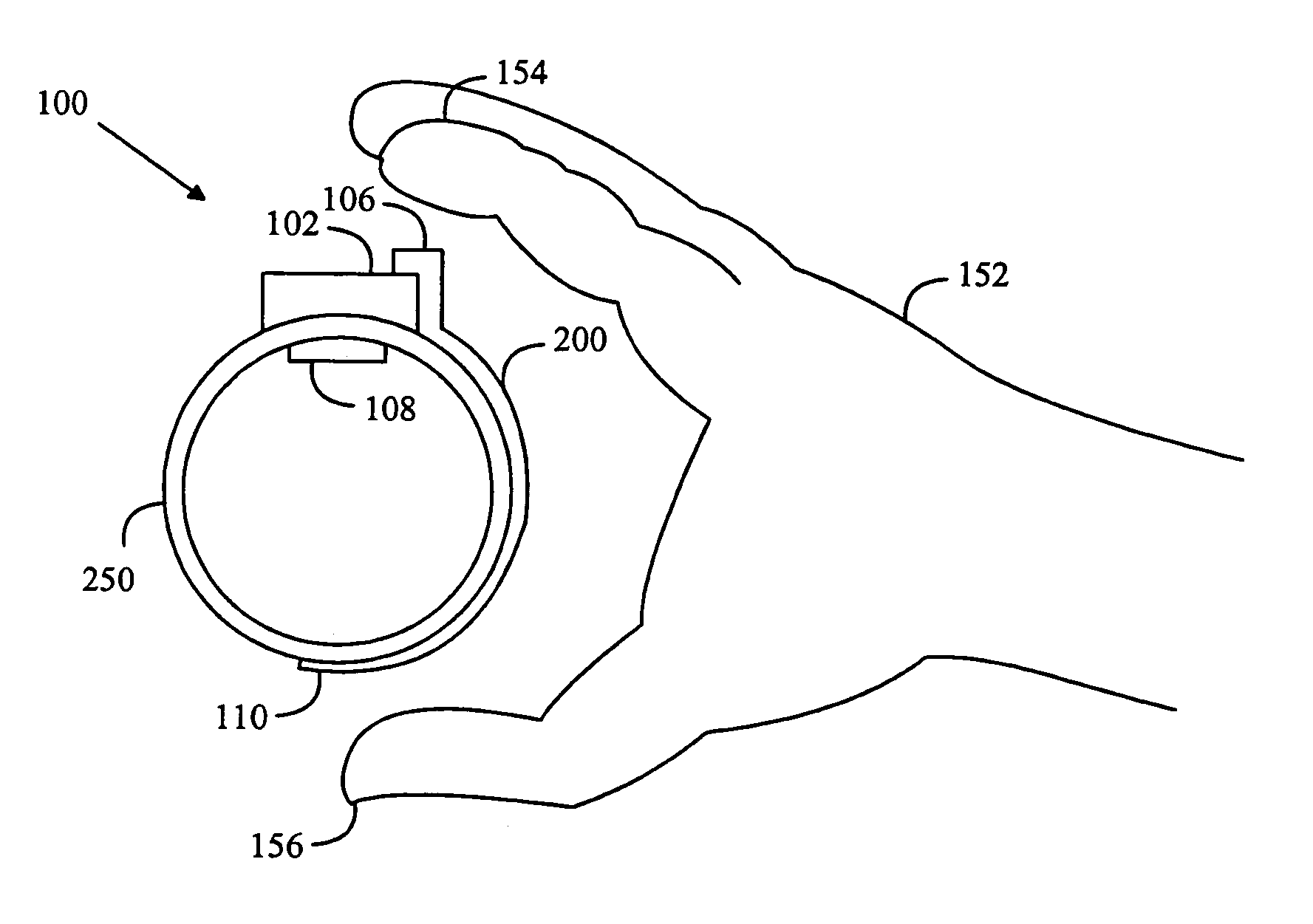

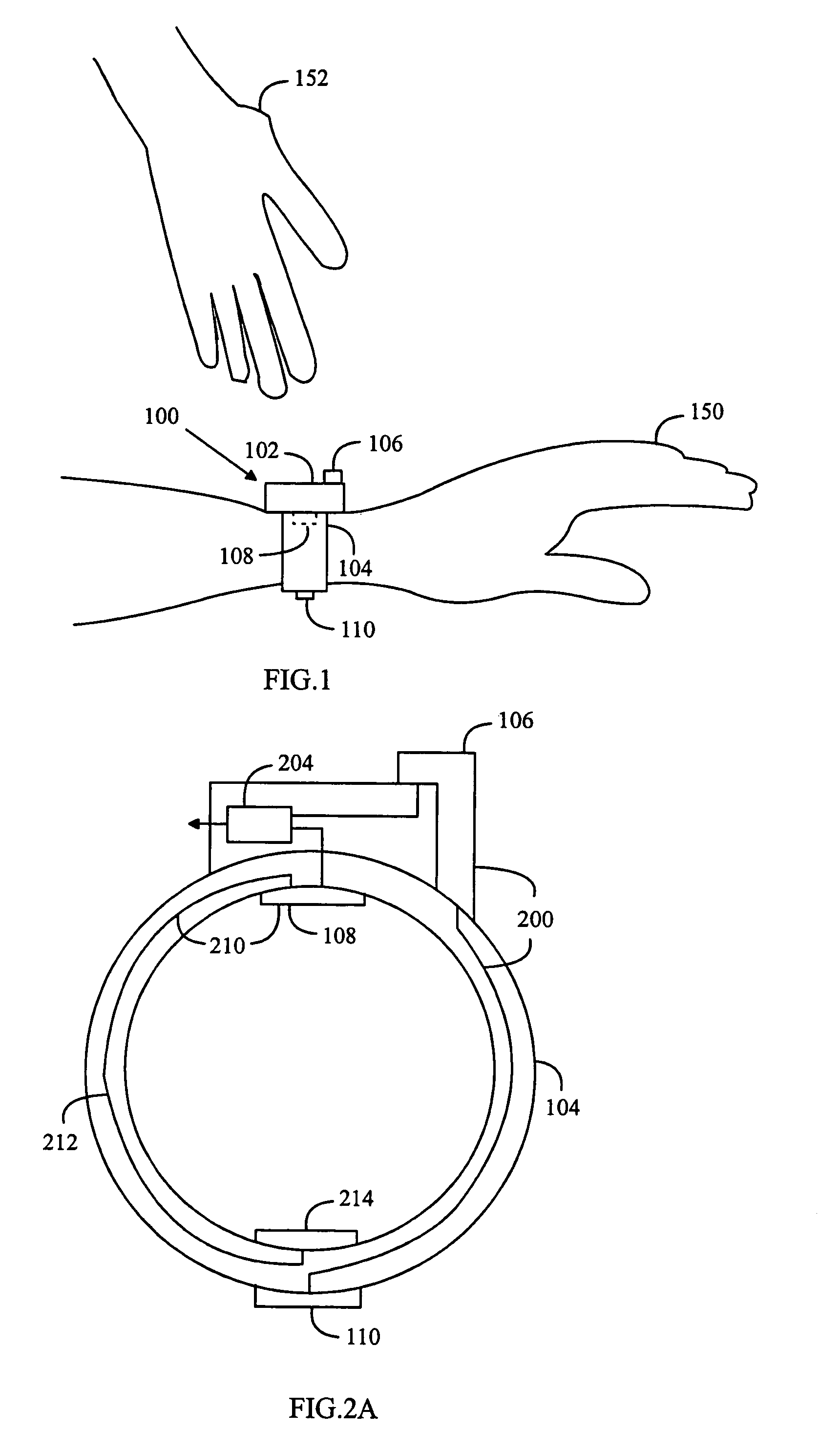

Method and device for measuring heart rate, and method for manufacturing the device

ActiveUS7171259B2Firm and convenient gripLower impedanceElectrocardiographySensorsMeasurement deviceStructure function

A heart rate measuring device is attached around a user's hand, the device having an inner surface, which is in contact with the skin on the hand to which it is attached, and an outer surface, which is other than the inner surface. The inner surface of the measuring device is provided with an electrically conductive inner structure, which functions as an electrode for a contact with the skin of the hand to which the device is attached. An electrically conductive outer structure functions as an electrode for a contact with the user's other hand and it is electrically isolated from the electrically conductive inner structure. The electrically conductive outer structure on the measuring device extends at least to opposite sides of the hand to which the device is attached, and at least part of the electrically conductive outer surface is on the outer surface of the measuring device, on opposite sides of the hand to which the device is attached. The electrically conductive outer structure and inner structure are connected to a measuring unit for heart rate measurement.

Owner:POLAR ELECTRO

System and method for joint resurface repair

InactiveUS20060190002A1Enhance load bearing and load transfer propertyImprove the immunitySuture equipmentsInternal osteosythesisArticular surfacesArticular surface

A system for positioning an element relative to an articular surface. An embodiment of the system may include a first element having a positional reference relative to an articular surface. The system may further include a second element capable of indicating the positional reference of the first element relative to said articular surface. Of course, many alternatives, variations, and modifications are possible without departing from this embodiment.

Owner:ARTHROSURFACE

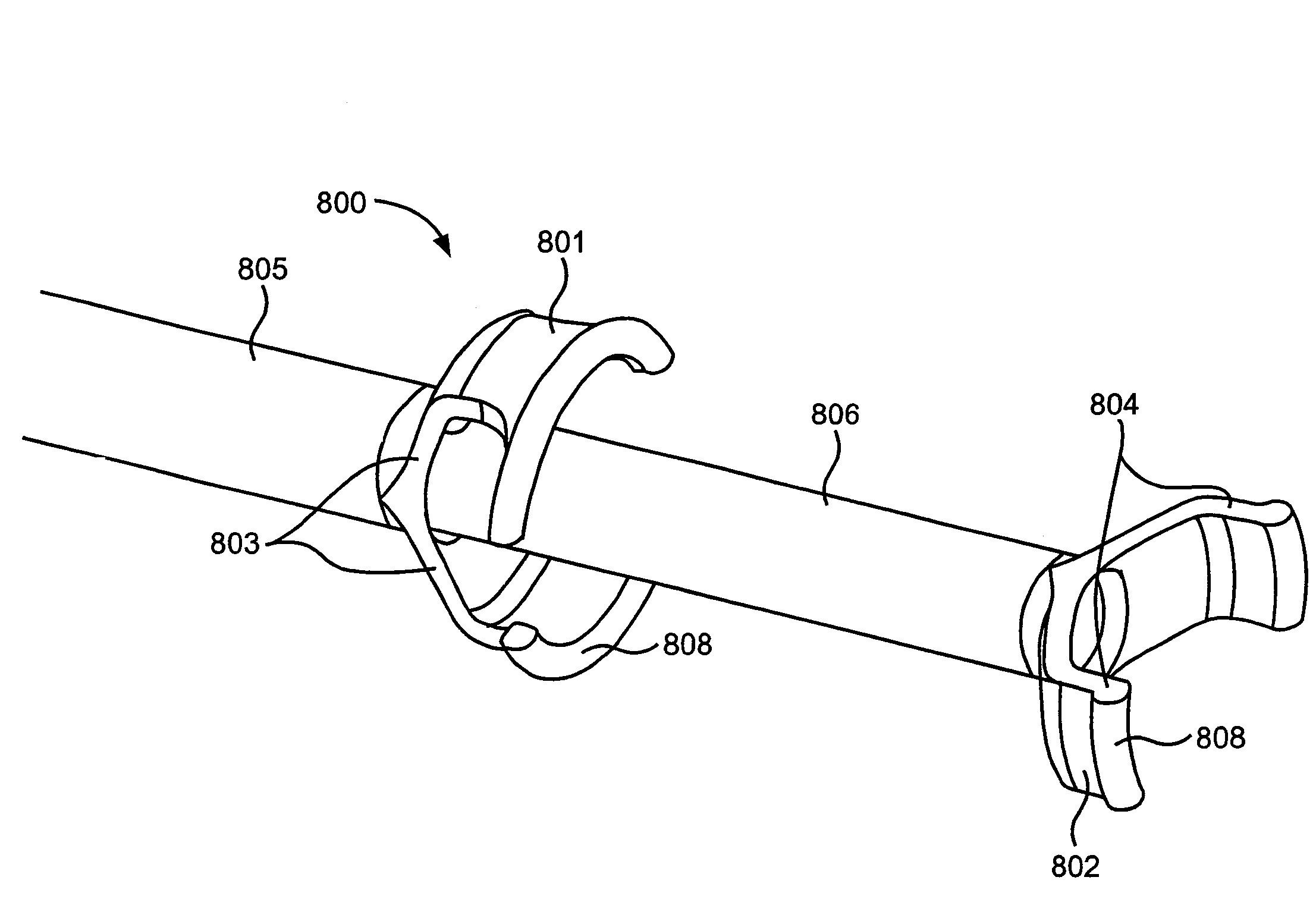

System and method for joint resurface repair

InactiveUS7510558B2Enhance load bearing and load transfer propertyImprove the immunitySuture equipmentsInternal osteosythesisArticular surfacesArticular surface

A generic bone implant, or set of standardized implants, is created based on using a guide device to develop an axis normal to an articular surface of bone and collecting only one or two data points. A generic cutting tool is used to cut the bone to a point where a generic implant can be used. Several improved tools relating to the procedure for using such an implant, as well as methods for using implants consistent with the invention are further described, including: single-axis and biaxial drill guide tools and methods, generic single-axis implant methods and devices, generic biaxial implant methods and devices, tools and methods for holding or delivering an implant, removal or revision tools and methods, digital measuring systems and methods, and set of measuring gauges for determining the appropriate implant dimensions.

Owner:ARTHROSURFACE

Continuous manufacturing method of rubber masterbatch and rubber masterbatch prepared by same

ActiveCN103113597AGood physical and mechanical propertiesQuality improvementMasterbatchPolymer science

The invention relates to a continuous manufacturing method of rubber masterbatch and rubber masterbatch prepared by the continuous manufacturing method. The invention discloses the continuous manufacturing method of rubber masterbatch. The continuous manufacturing method of rubber masterbatch comprises the following steps of: 1) adding stuffing into rubber liquor, and stirring to form a rubber / stuffing / solvent mixture; 2) feeding the rubber / stuffing / solvent mixture in step 1) to a flocculator, wherein the rubber / stuffing / solvent mixture is contacted and mixed with one or more of nitrogen, steam, stuffing aqueous slurry and oil, and flocculating to obtain a mixture of a rubber / stuffing compound and the solvent; and 3) removing the solvent and drying the mixture to obtain rubber / stuffing masterbatch. The invention further relates to masterbatch prepared by the method and a rubber product prepared by the masterbatch. Compared with the flocculating technology in current wet-method mixing, as no special requirements are posed to rubber and stuffing, the application range is wider. In addition, the manufacturing method is continuous in production process, efficient, low in energy consumption and less in labor, so that the cost is lower. Meanwhile, masterbatch prepared by the method is quite excellent in processability, physical and mechanical properties and product quality.

Owner:EVE RUBBER RES INST

Electric pressure cooker

InactiveCN100496350CSimple structureLow costCooking-vessel materialsElectric heatingElectricityEngineering

The present invention relates to a kind of electric pressure cooker and electric rice cooker. It includes outer shell, pot cover, inner pot, heating disk and temperature detection and control device of electric heating pot. The inner pot is placed in the upper portion of heating disk, and said inner pot is a stainless steel single-layer structure. The temperature detection and control device of invented electroheating pot is formed from heat sensing element and control circuit of electroheating pot, and said heat sensing element is fixed on the heating disk.

Owner:关国华

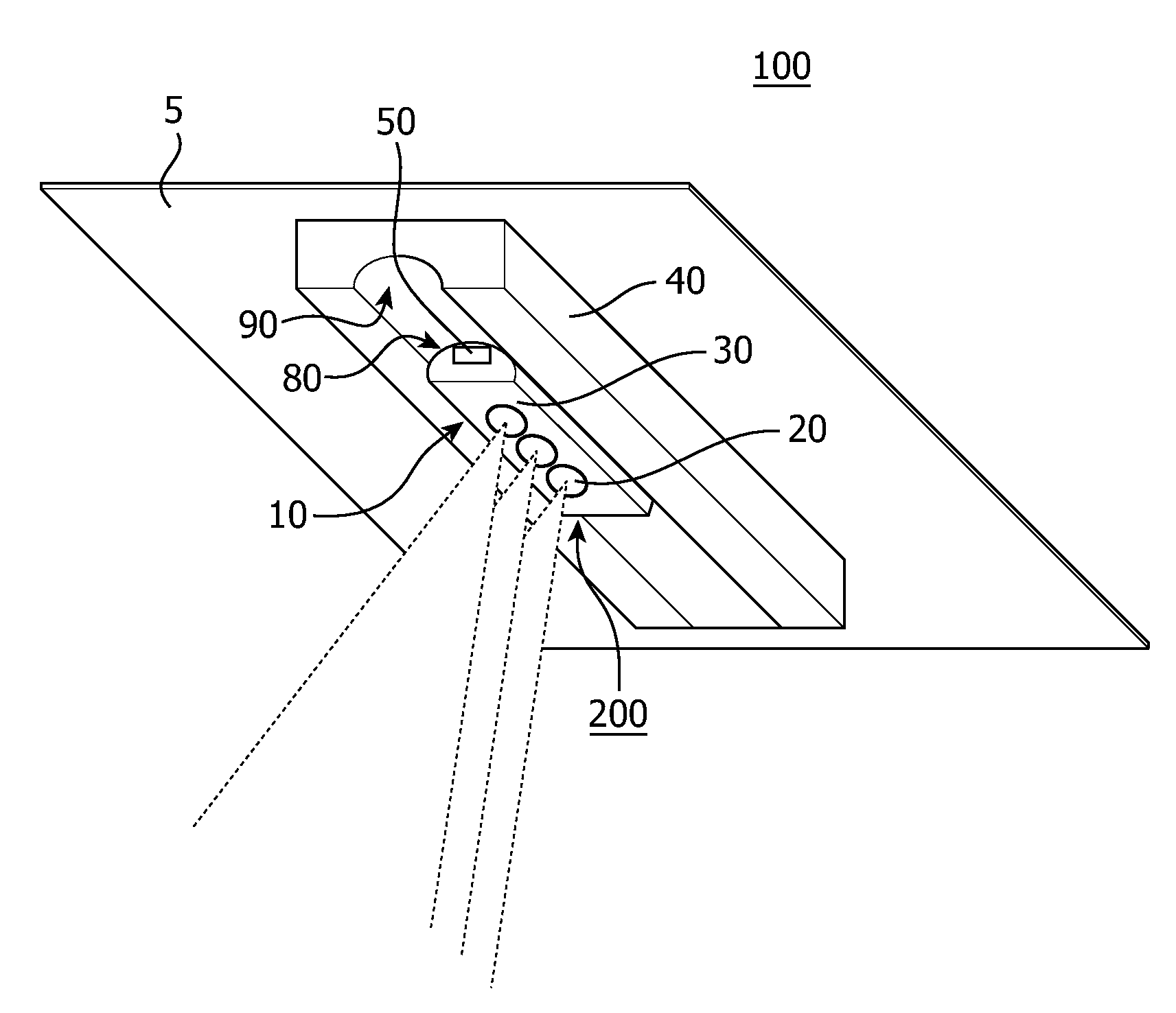

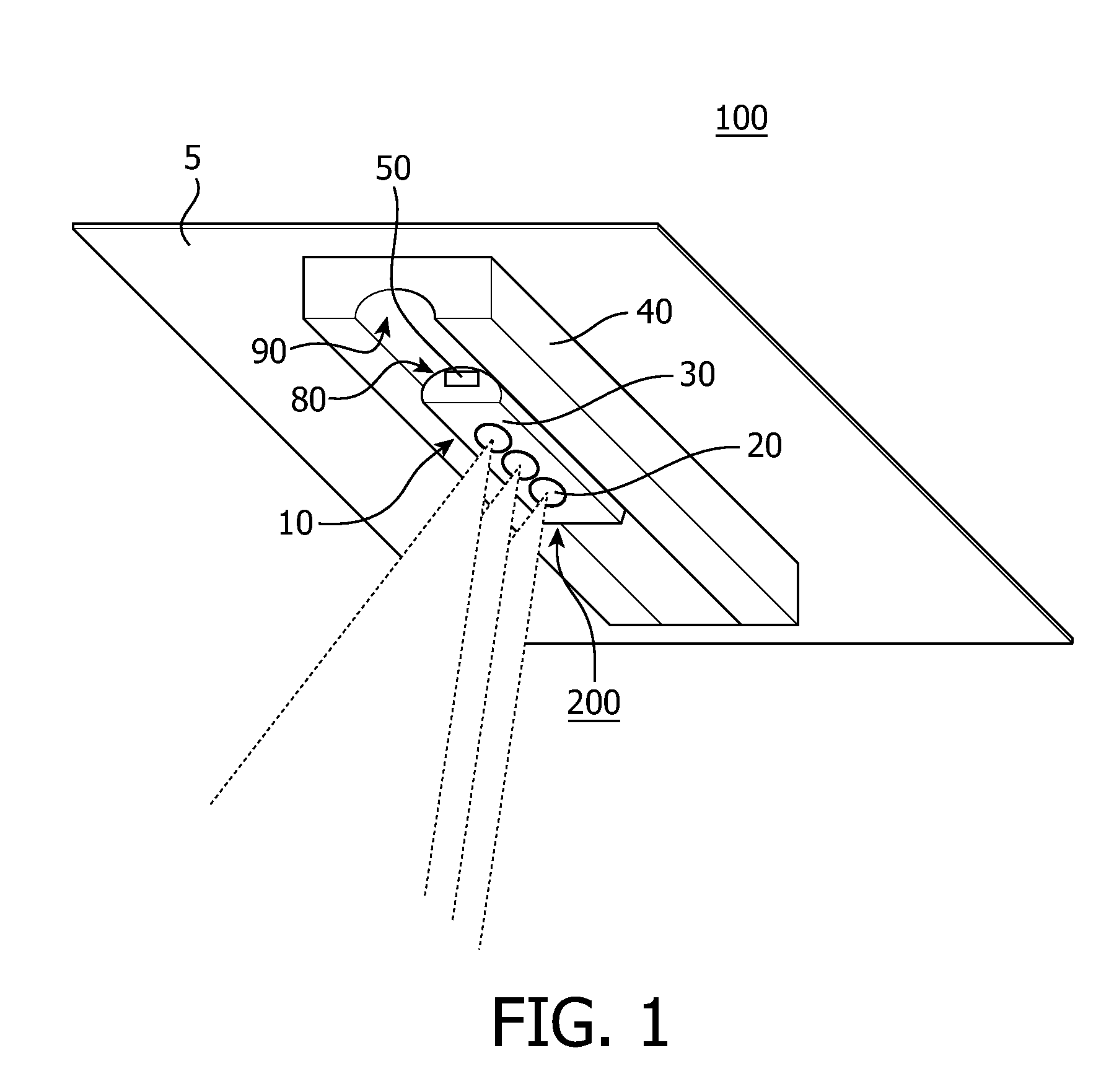

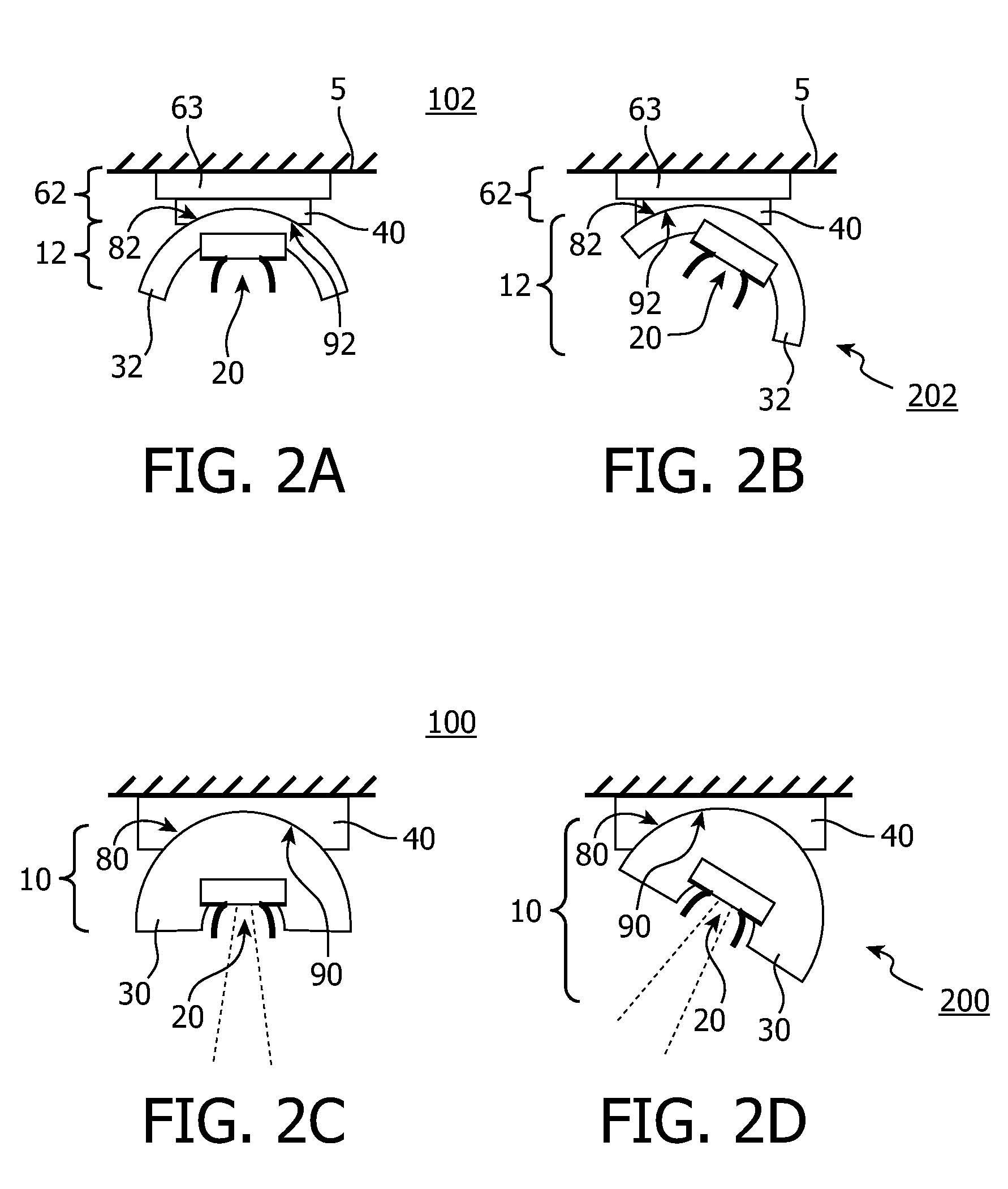

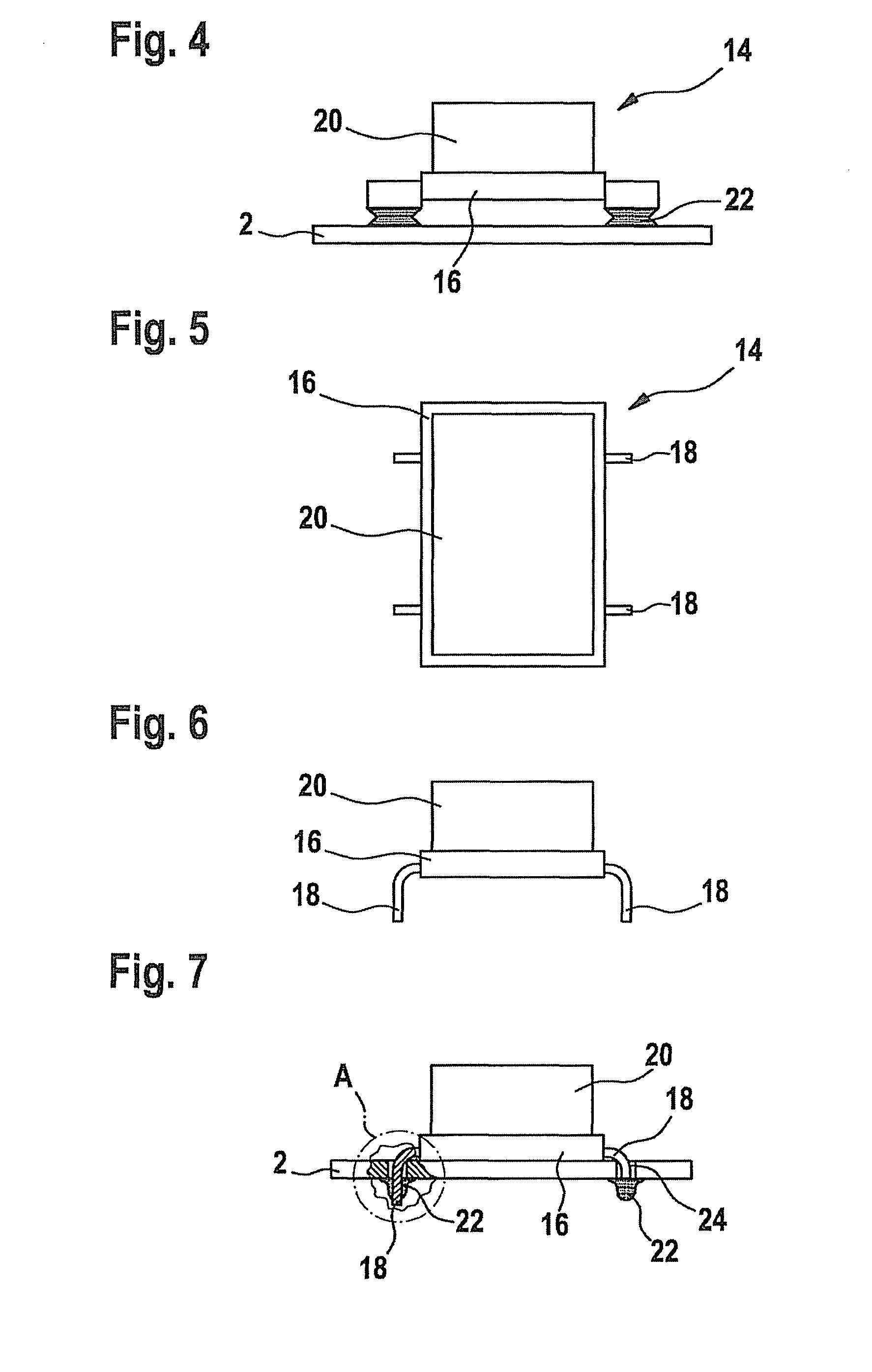

Directable magnetic mount for light emitter, a light source, a base and an illumination system

ActiveUS20120075857A1Improve cooling effectSolve insufficient capacityLighting support devicesPoint-like light sourceThermal energyEngineering

The invention relates to a directable magnetic mount (10) for a light emitter (20). The invention also relates to a light source (200), to a base (40) and to an illumination system (100). The directable magnetic mount comprises interface means (30) configured for conducting thermal energy away from the light emitter to a heat sink (40), and comprises a magnetic connector (50) configured for magnetically connecting the directable magnetic mount to the base. The magnetic connector is configured for thermally interconnecting the interface means and the heat sink. The interface means is configured for being thermally connected to the heat sink at a plurality of orientations of the interface means with respect to the heat sink. Each of the plurality of orientations of the interface means comprises a different emission direction of the light emitter.The effect of the measures according to the invention is that it enables to omit the need for a heat sink in the light source which enables to reduce the size of the light source while also allowing to reposition and redirect the light emitted from the illumination system.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

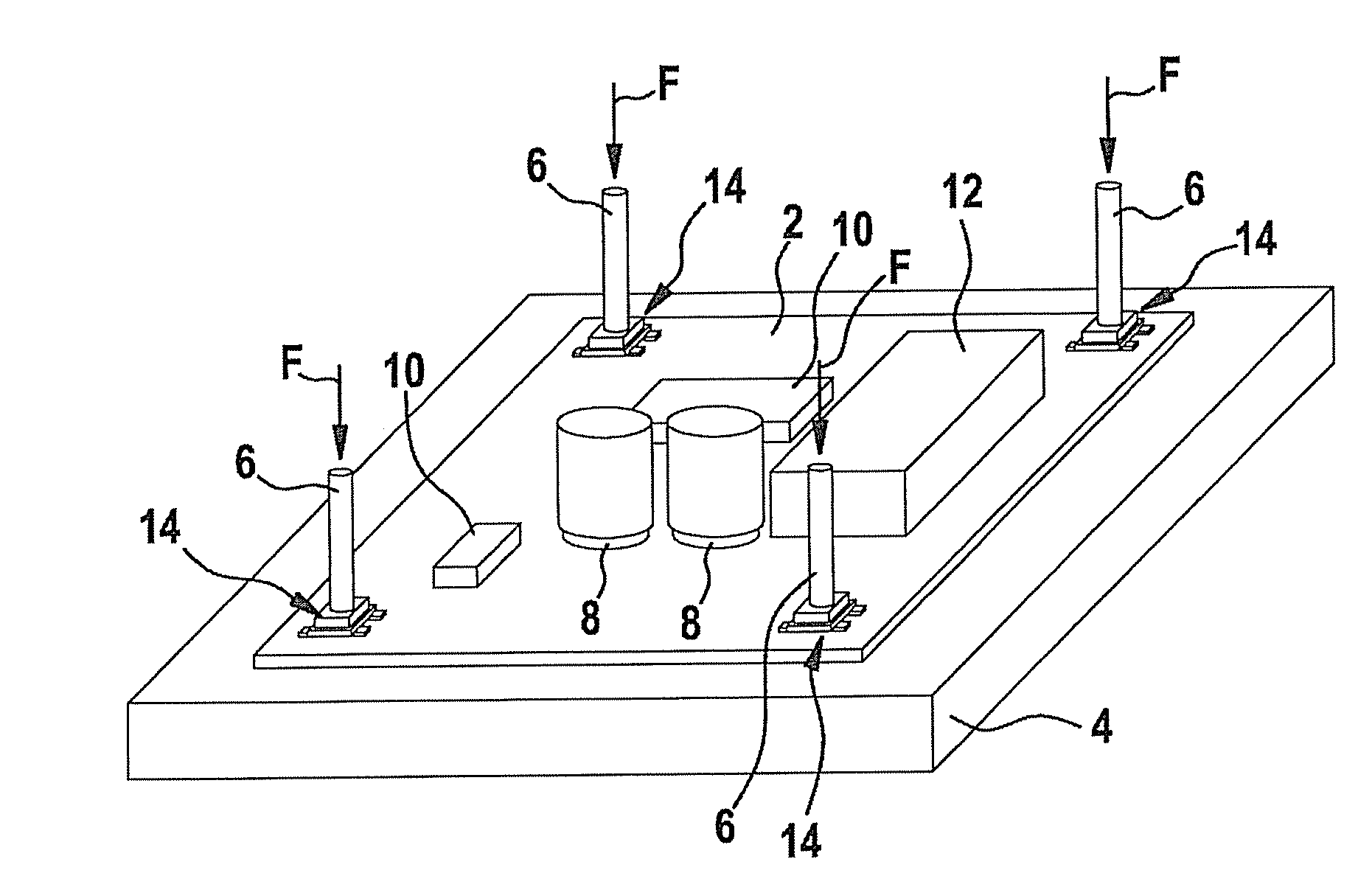

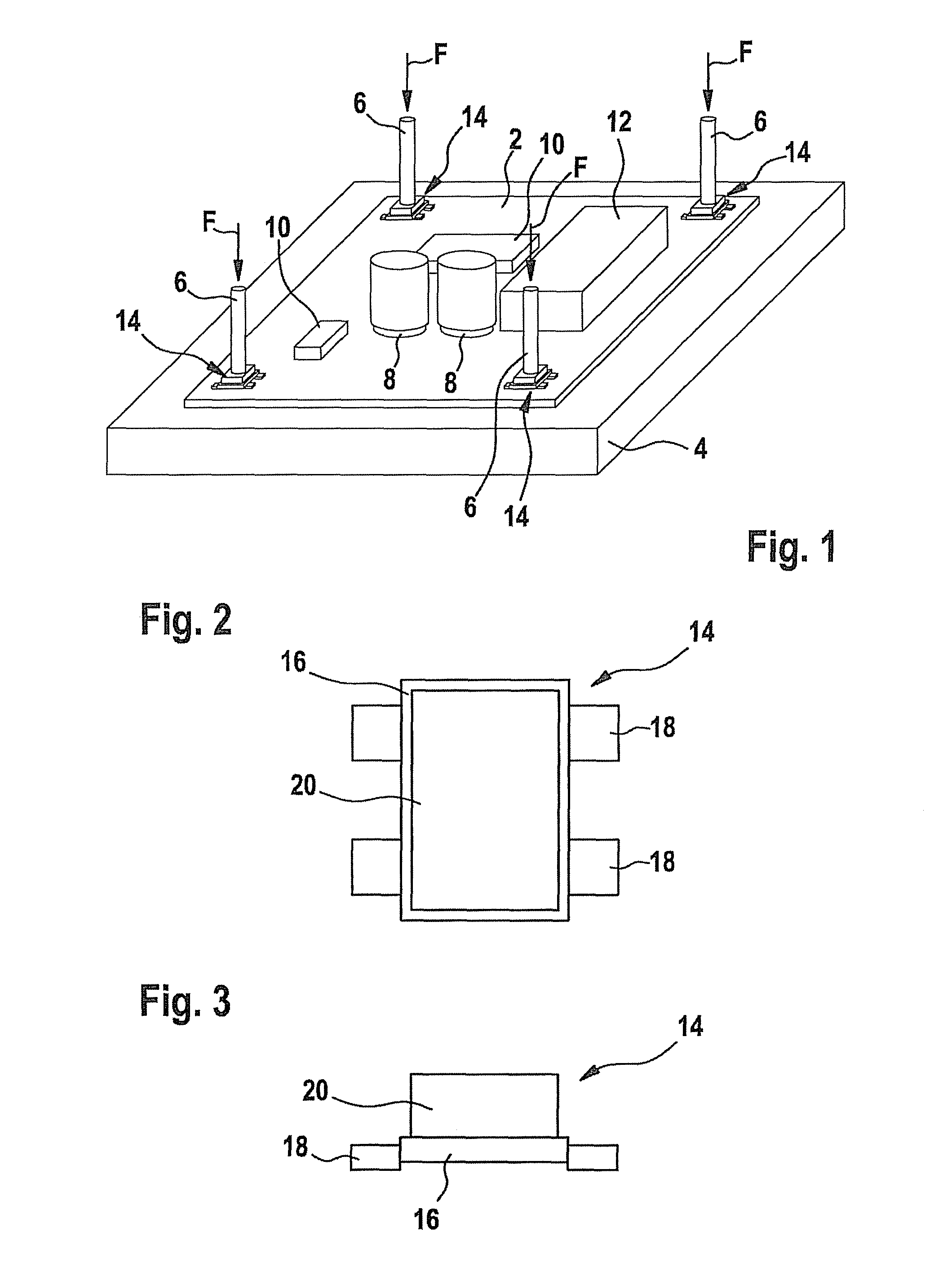

Method for fixing an electrical or an electronic component, particularly a printed-circuit board, in a housing and fixing element therefor

InactiveUS8331099B2Extended service lifeReduce componentsFinal product manufactureSecuring/insulating coupling contact membersStructural engineeringElectronic component

In a method for fixing an electrical or an electronic component, particularly a printed-circuit board, in a housing used to accommodate the component, and a fixing element for fixing the component by clamping it in place, the component is fitted with at least one fixing element, which includes an elastically yielding press-on part which, during the clamping in place of the component in the housing, is brought to lie against a part of the housing and is pressed against it while being deformed.

Owner:ROBERT BOSCH GMBH

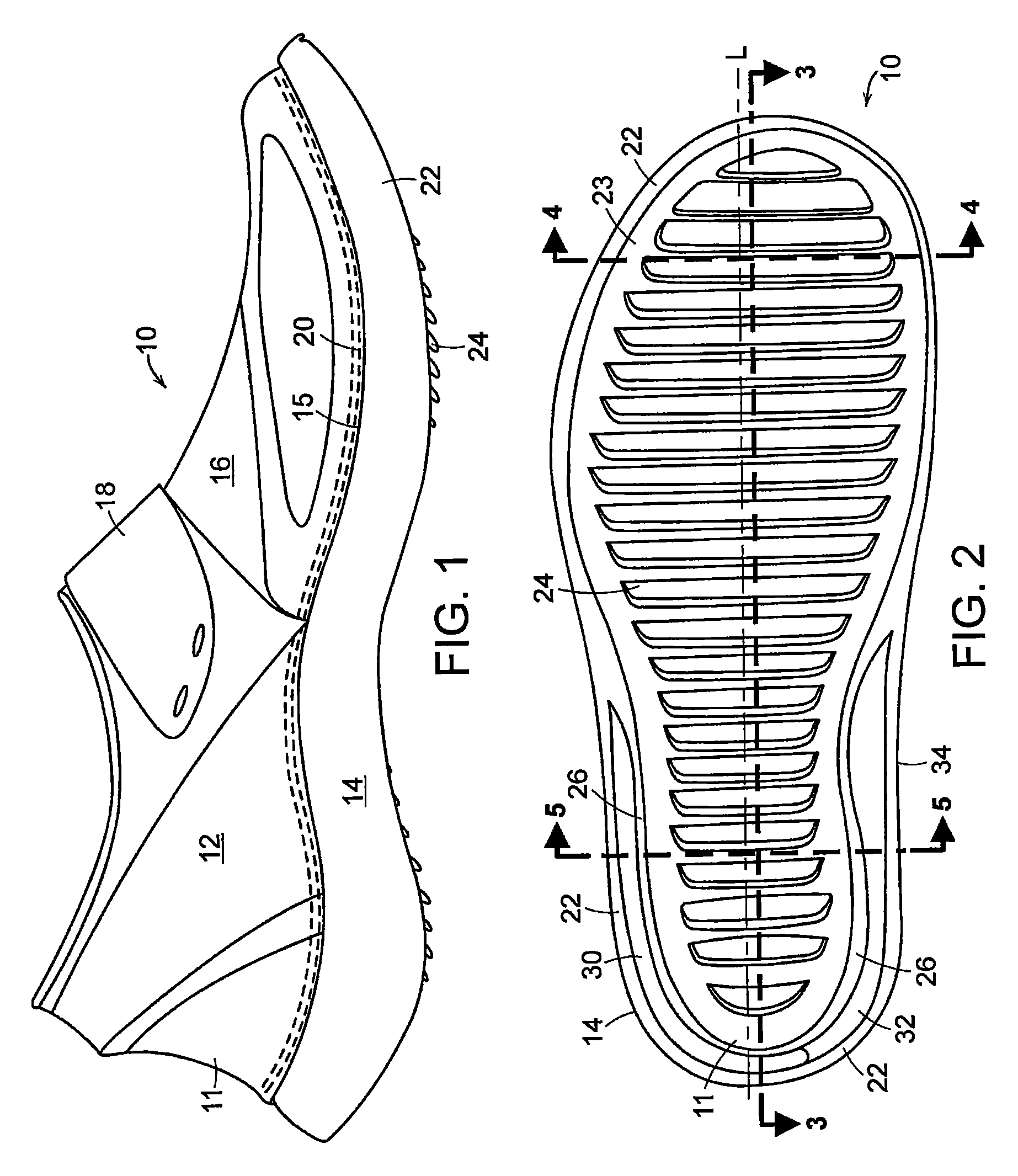

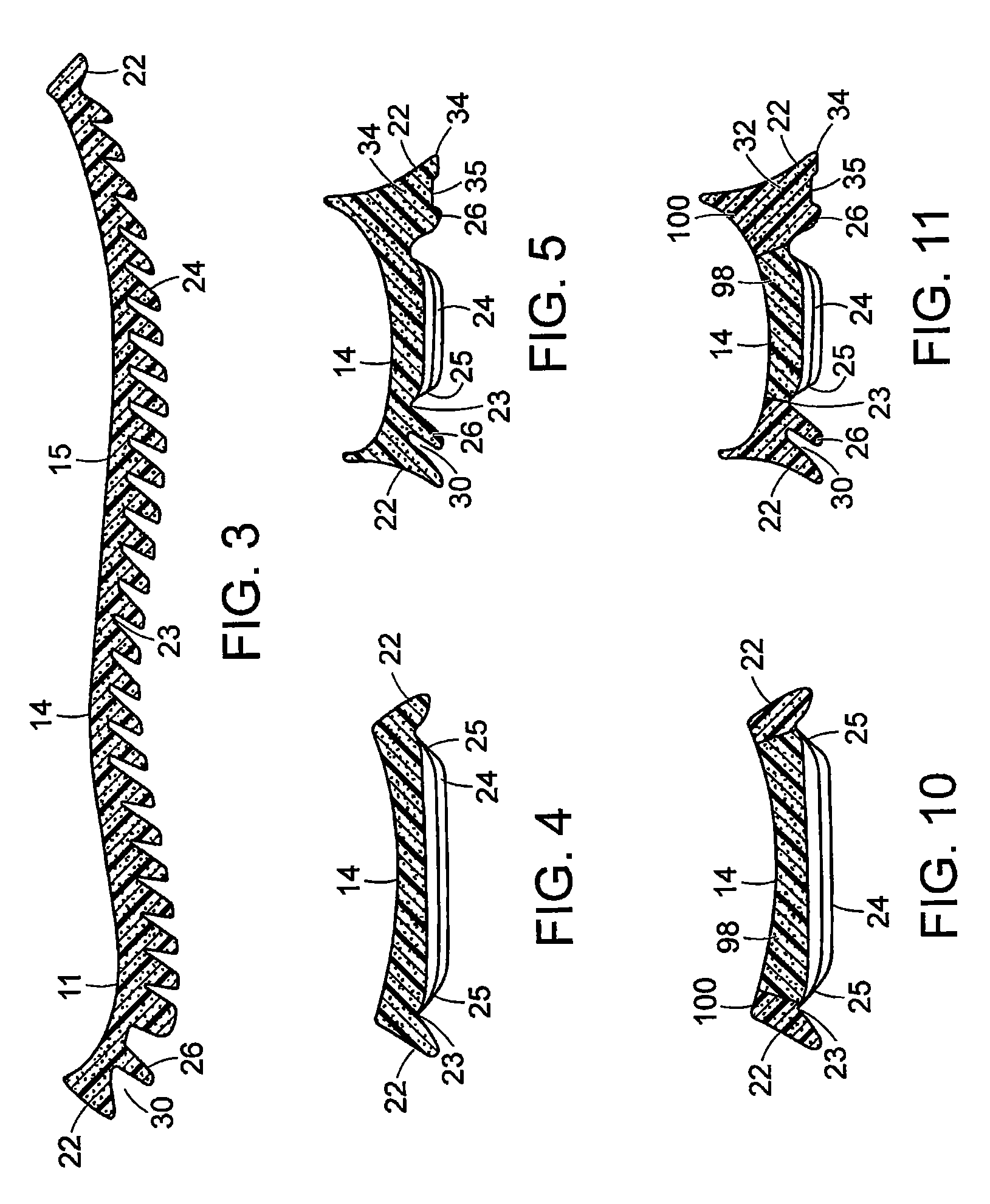

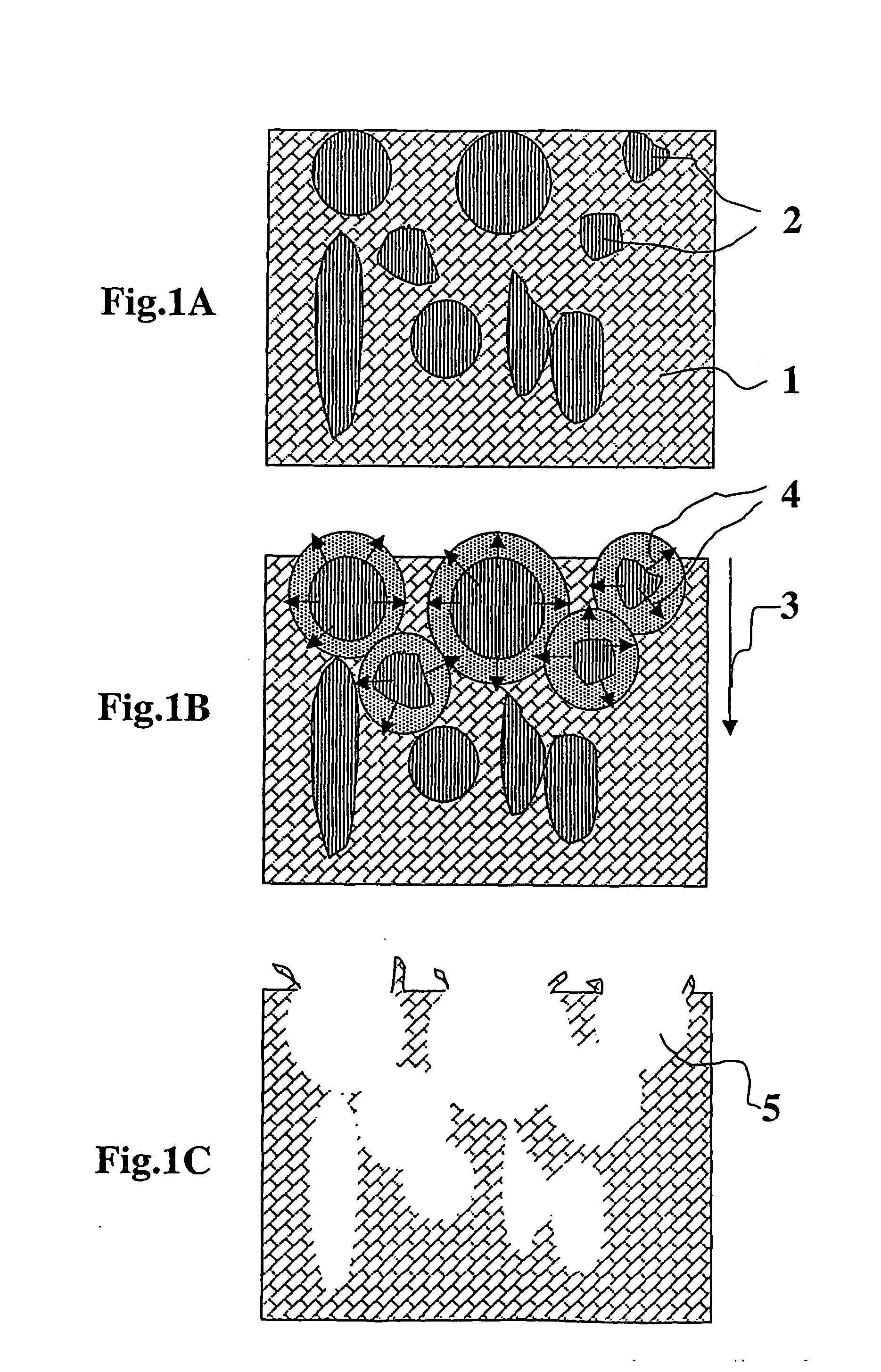

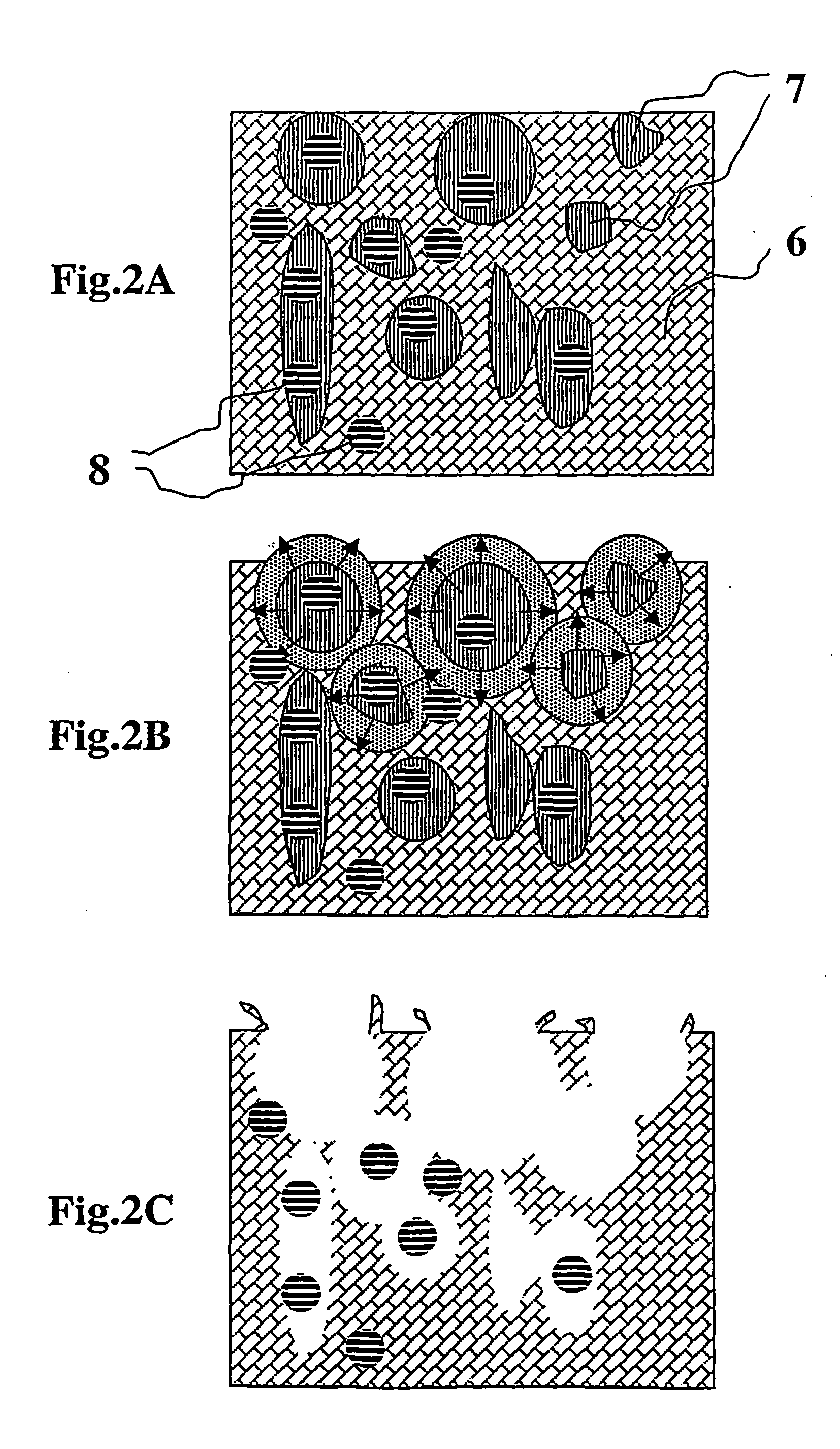

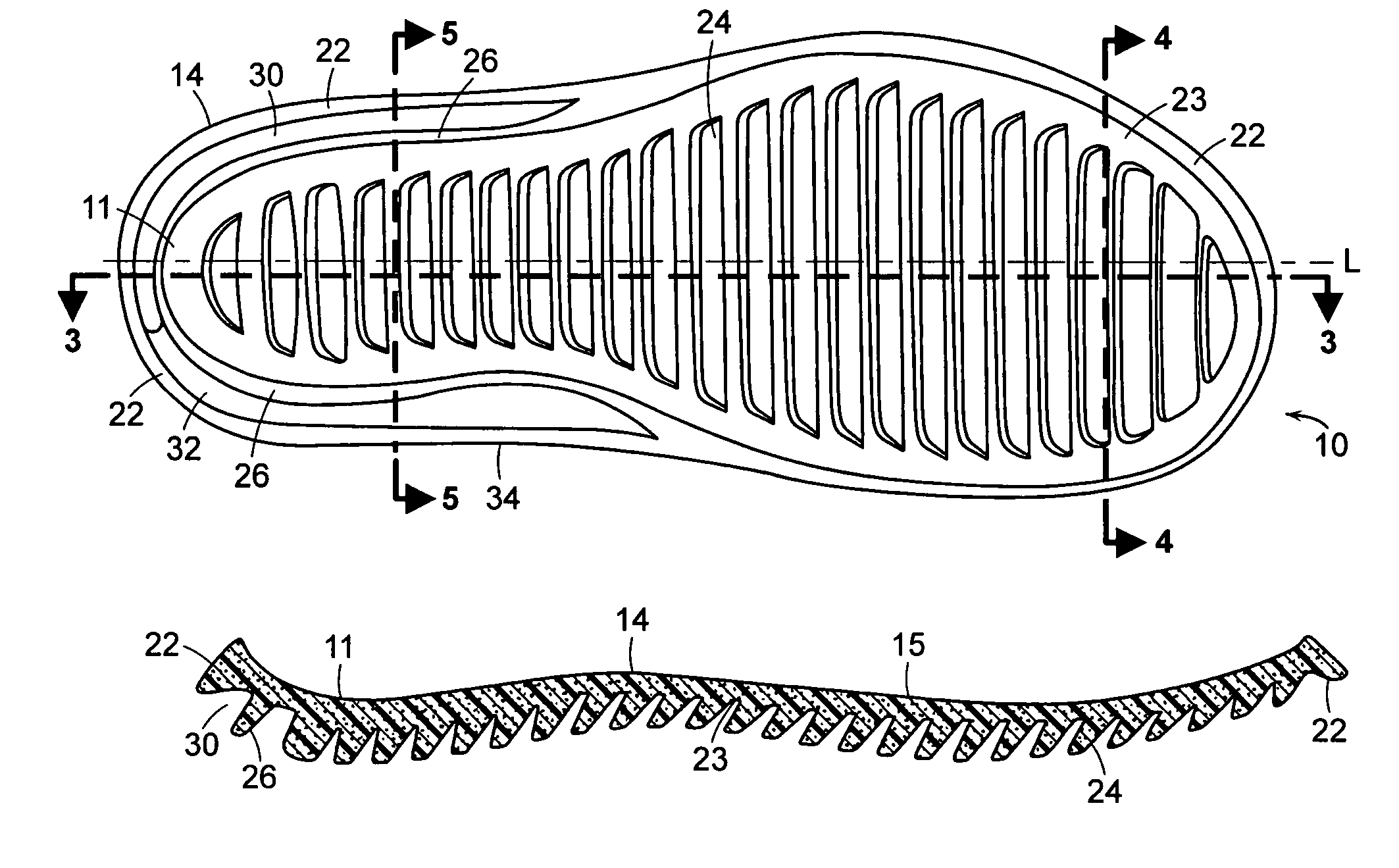

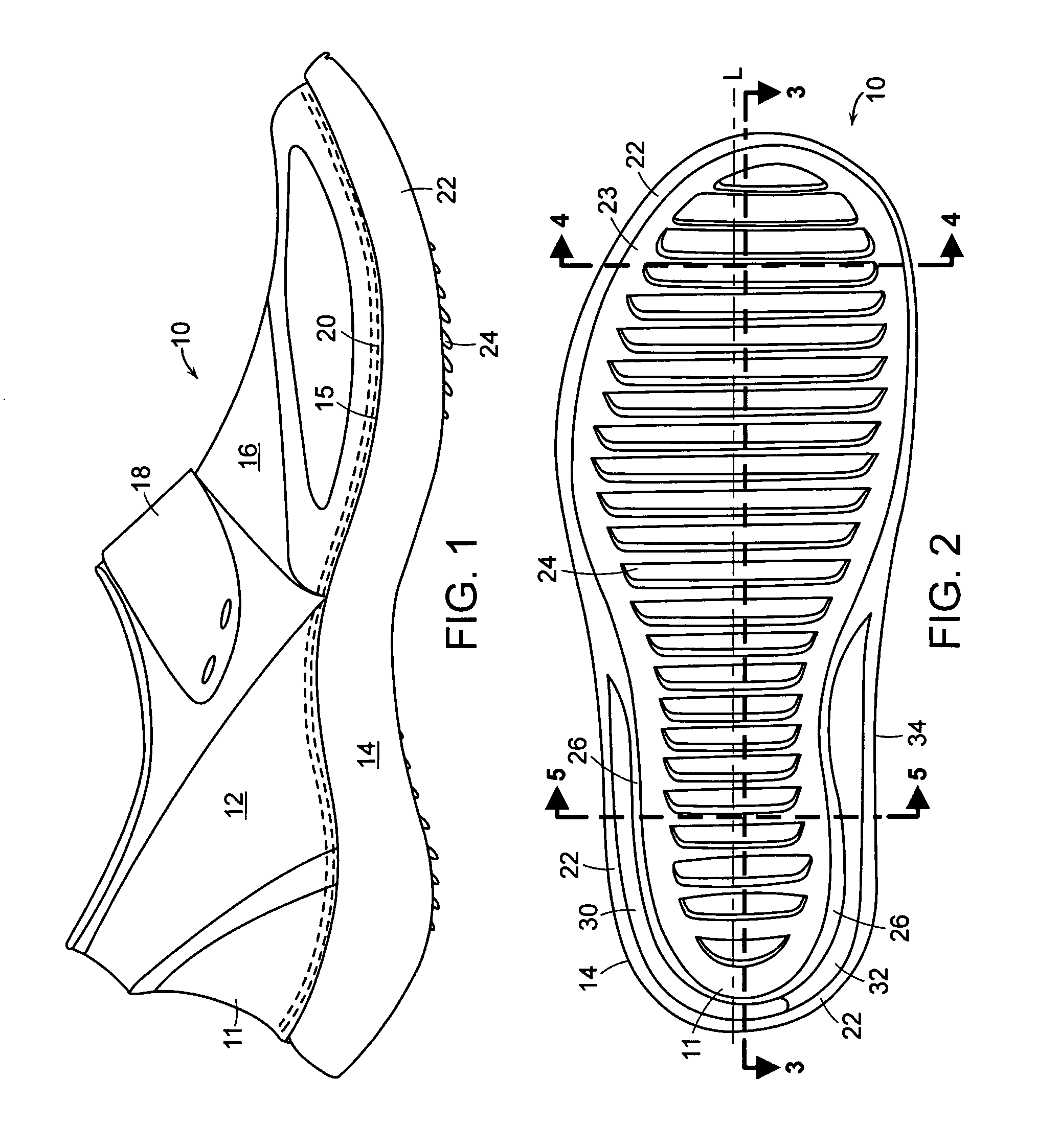

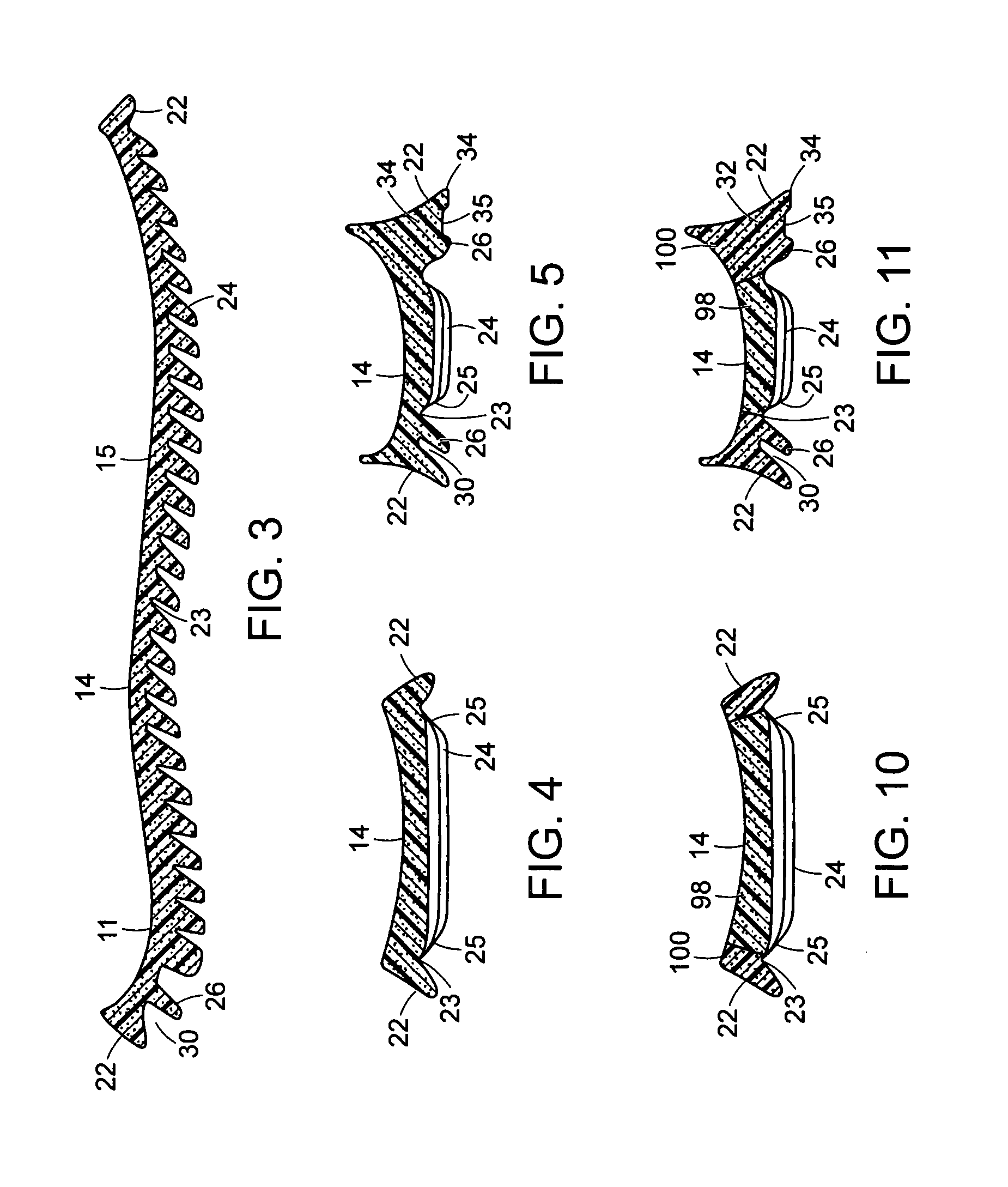

Sole for article of footwear for granular surfaces

A sole for an article of footwear to be used on a granular surface includes a sole of compressible material having an upper surface and a lower surface. A peripheral lip projects downwardly and outwardly from the lower surface of the sole. A plurality of fins projects downwardly from the lower surface of the sole.

Owner:NIKE INC

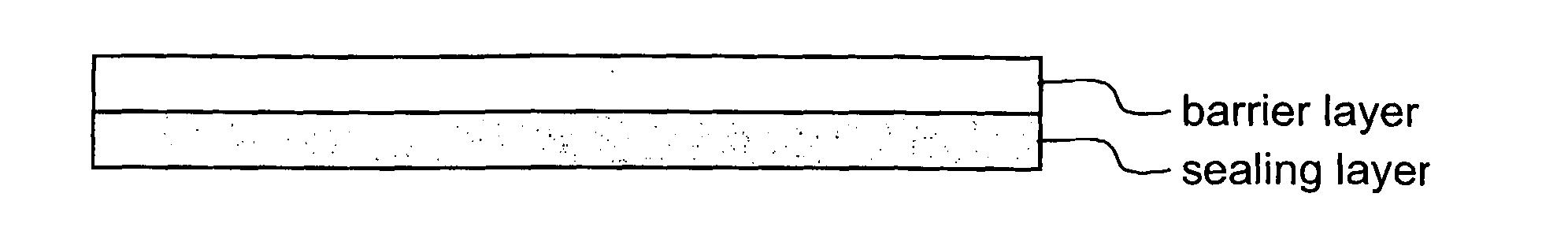

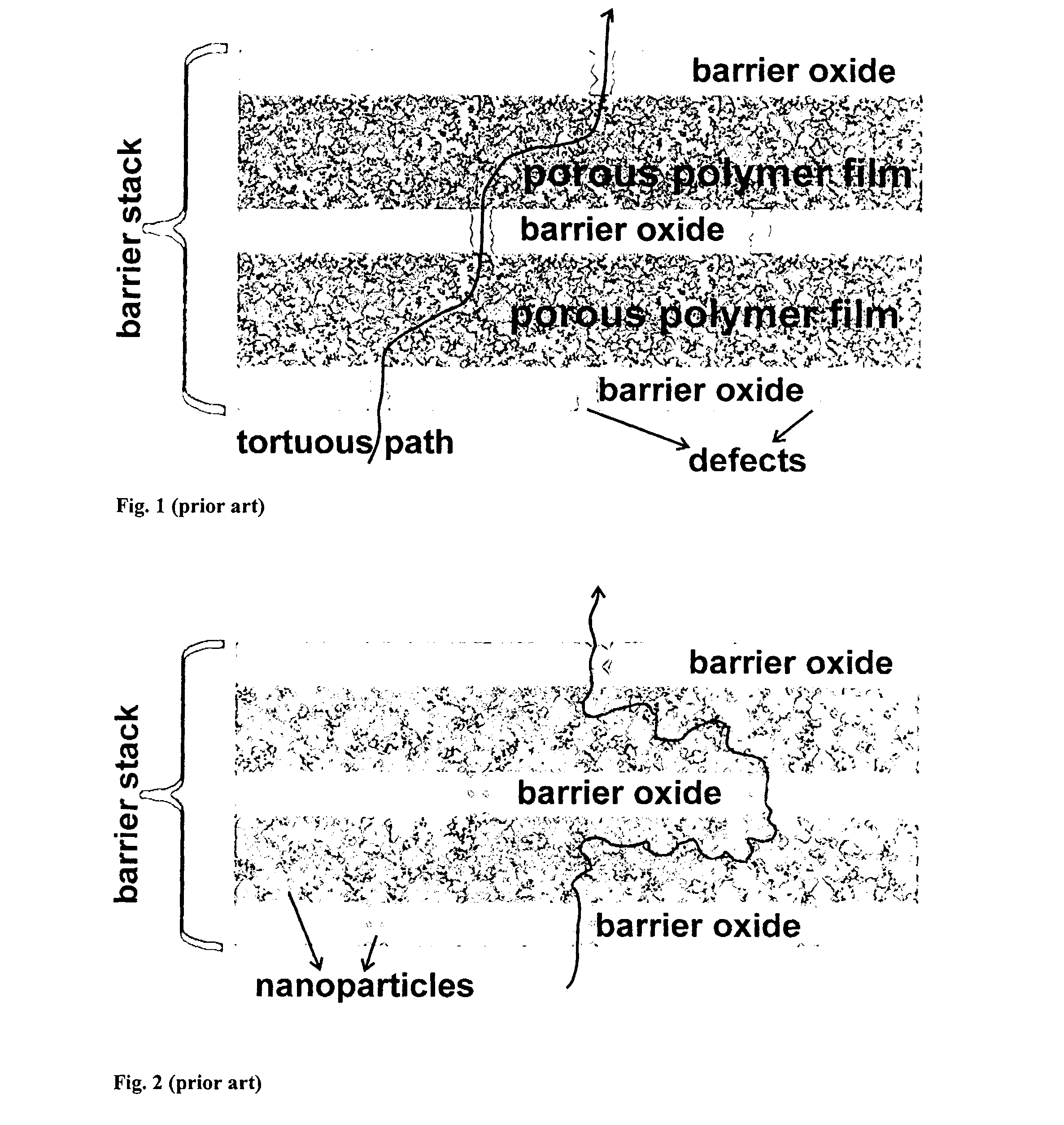

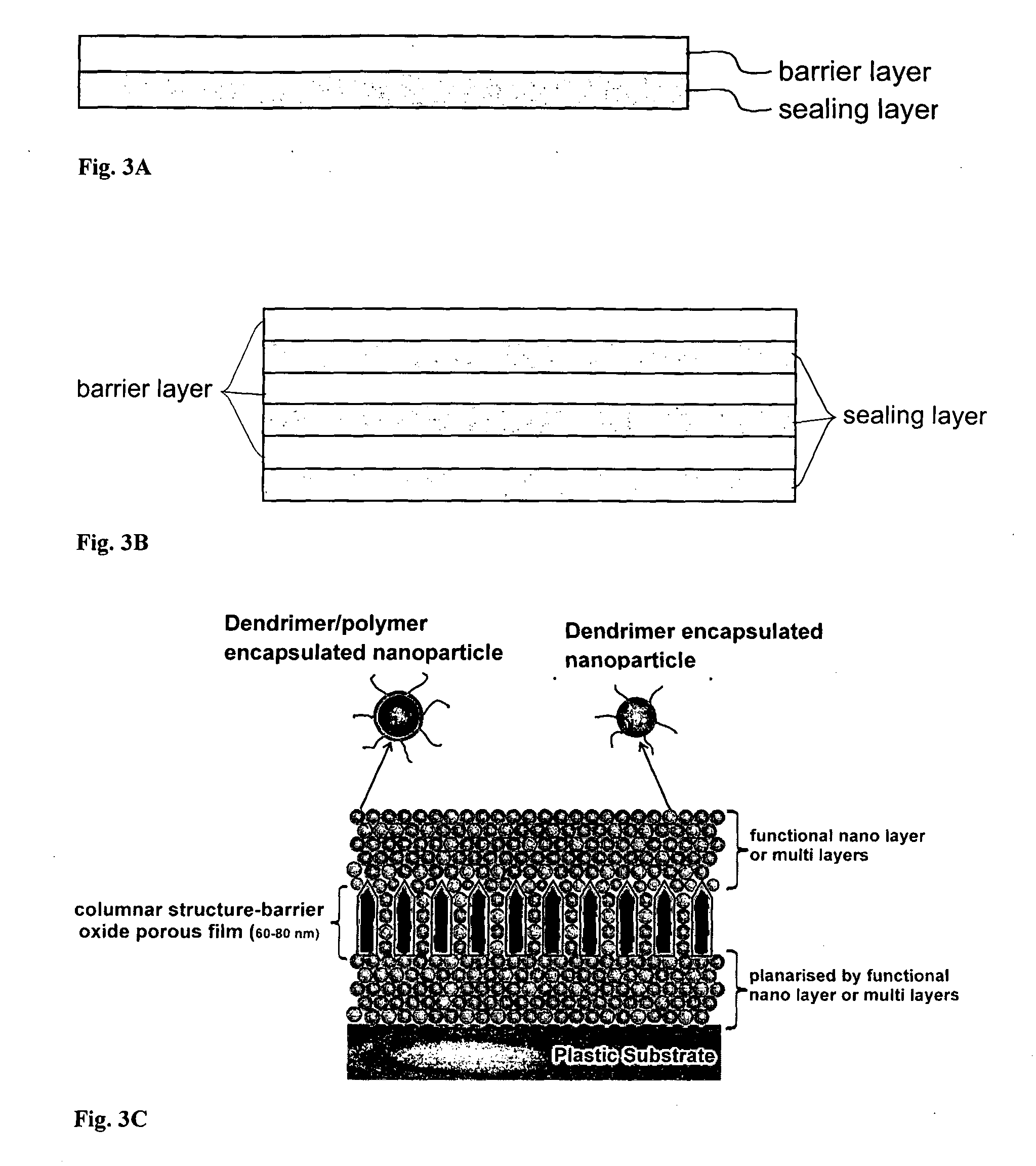

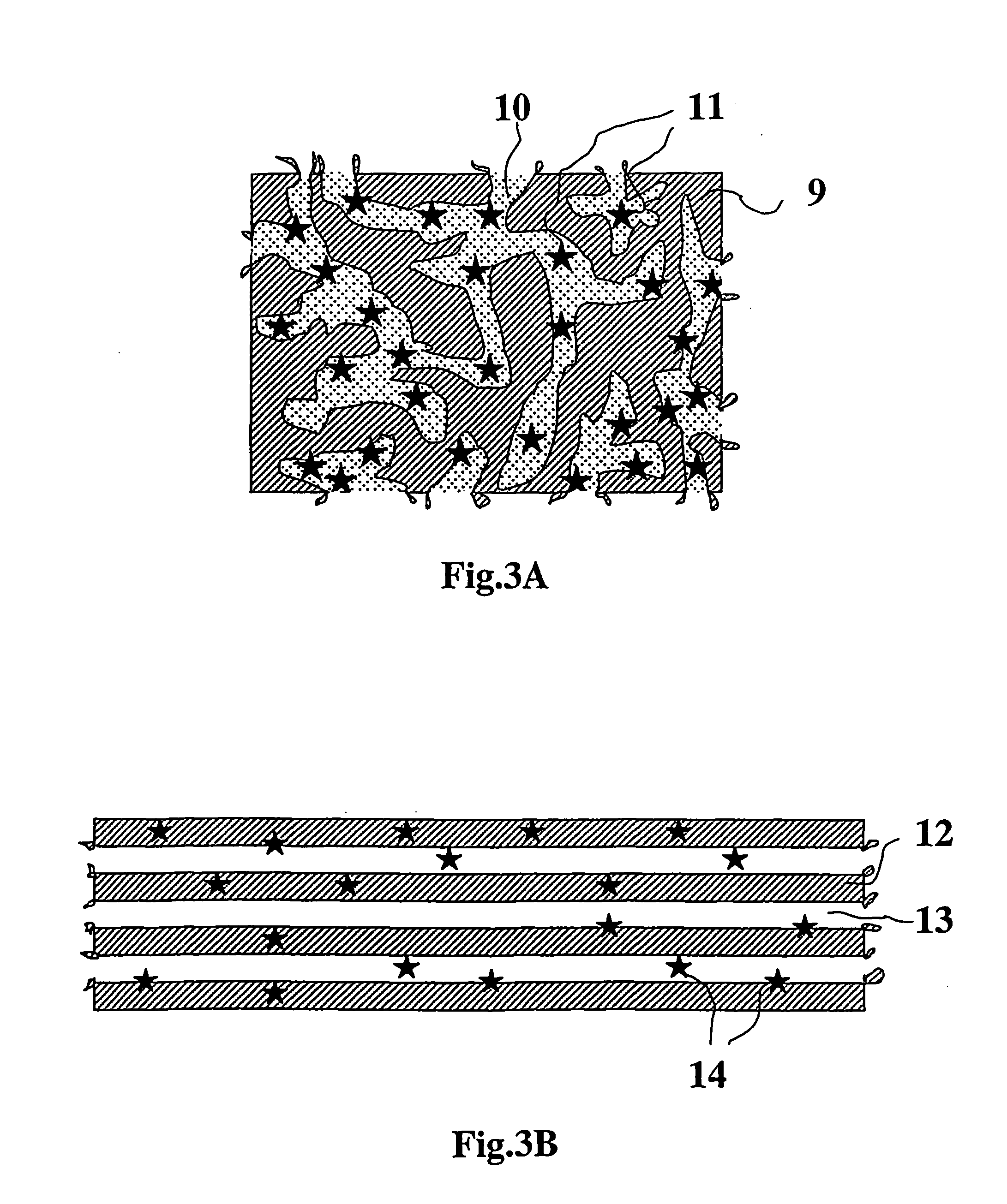

Encapsulation barrier stack comprising dendrimer encapsulated nanop articles

InactiveUS20160088756A1Reduce porosityHigh bonding strengthMaterial nanotechnologyFinal product manufacturePermeationMoisture

Disclosed is an encapsulation barrier stack, capable of encapsulating a moisture and / or oxygen sensitive article and comprising a multilayer film, wherein the multilayer film comprises: one or more barrier layer(s) having low moisture and / or oxygen permeability, and one or more sealing layer(s) arranged to be in contact with a surface of the at least one barrier layer, thereby covering defects present in the barrier layer, wherein the one or more sealing layer(s) comprise(s) a plurality of dendrimer encapsulated nanoparticles, the nanoparticles being reactive in that they are capable of interacting with moisture and / or oxygen to retard the permeation of moisture and / or oxygen through the defects present in the barrier layer.

Owner:TERA BARRIER FILMS

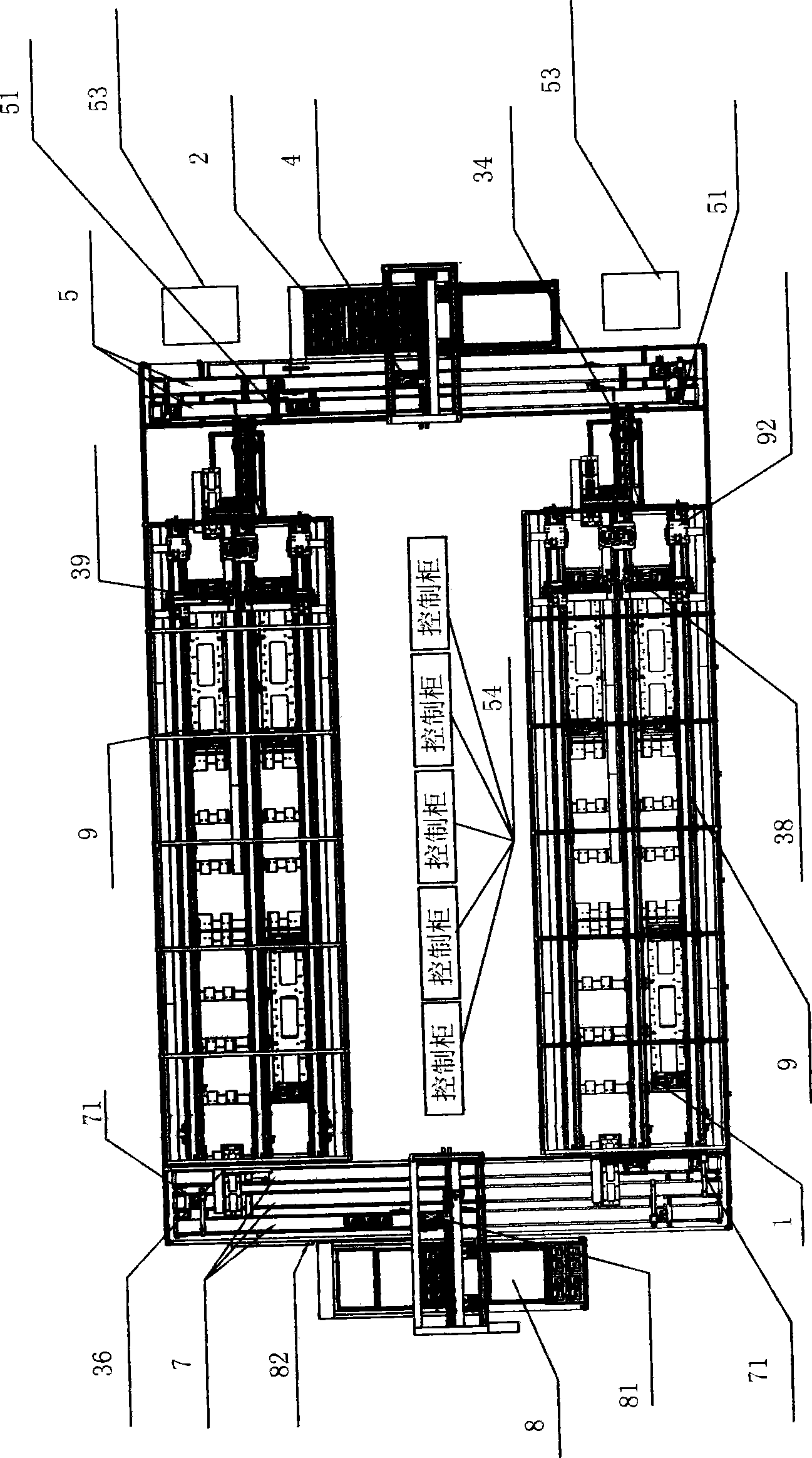

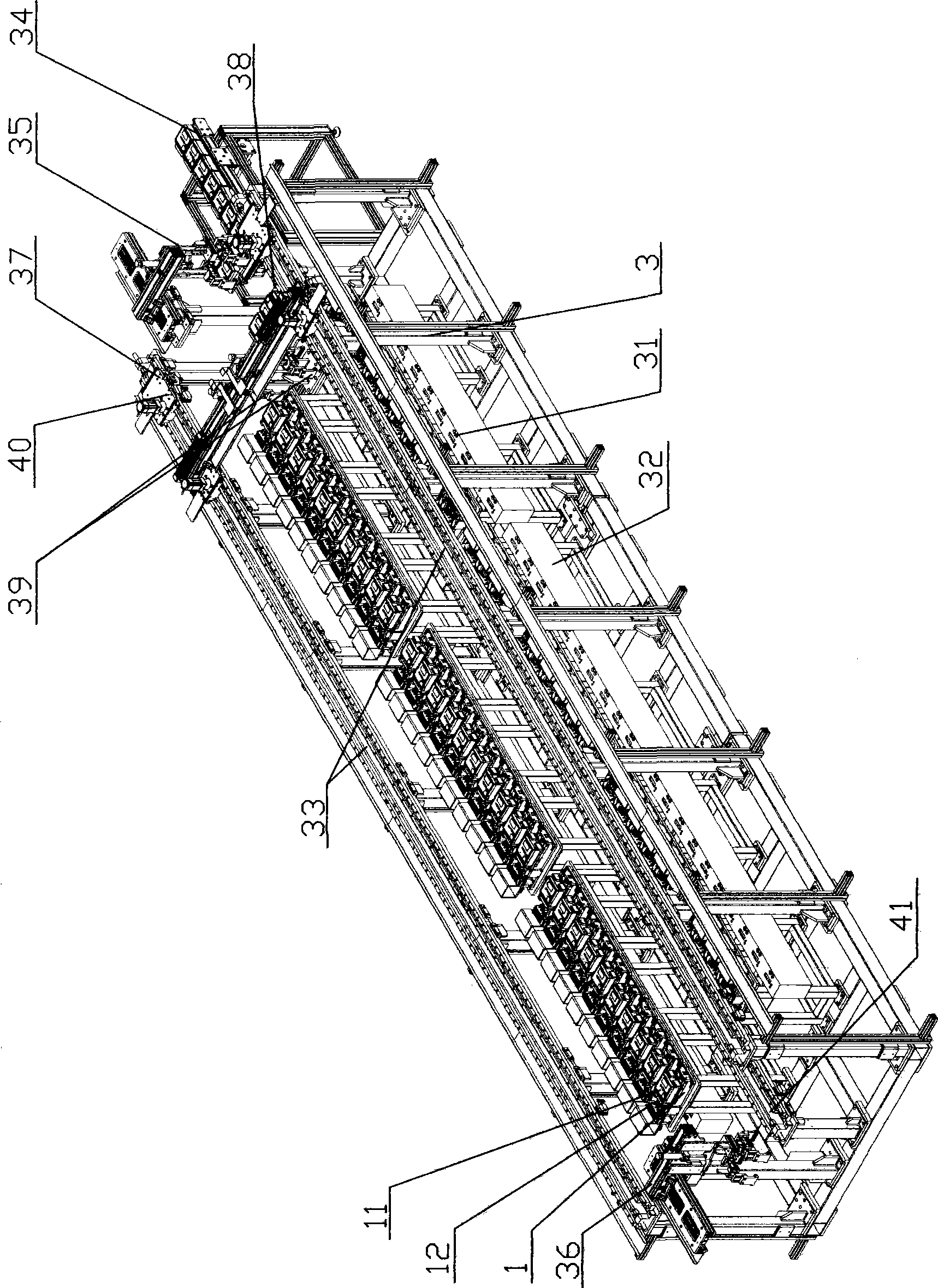

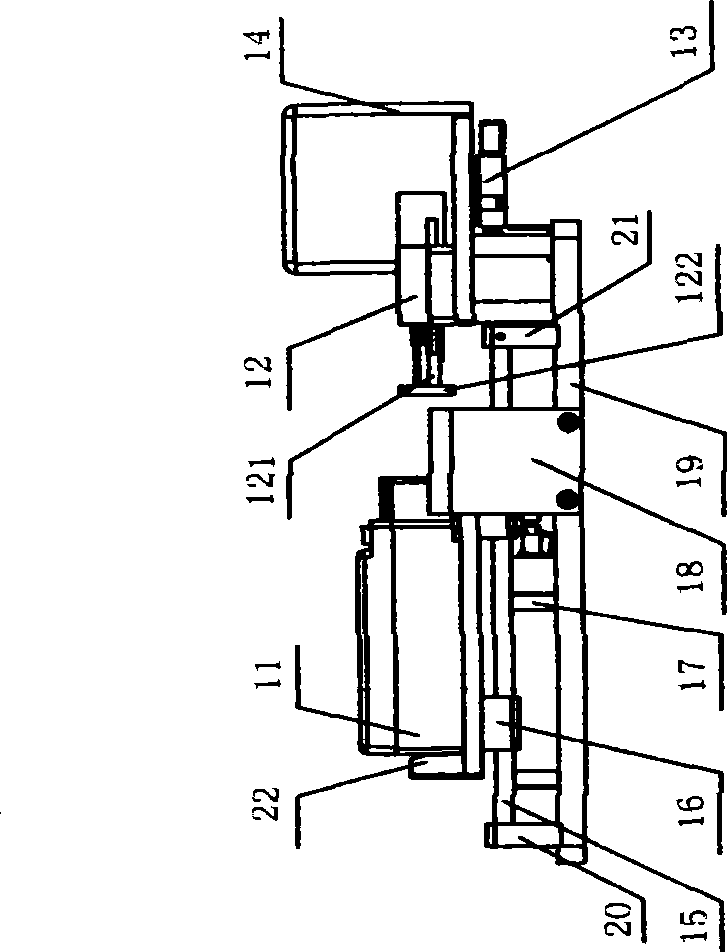

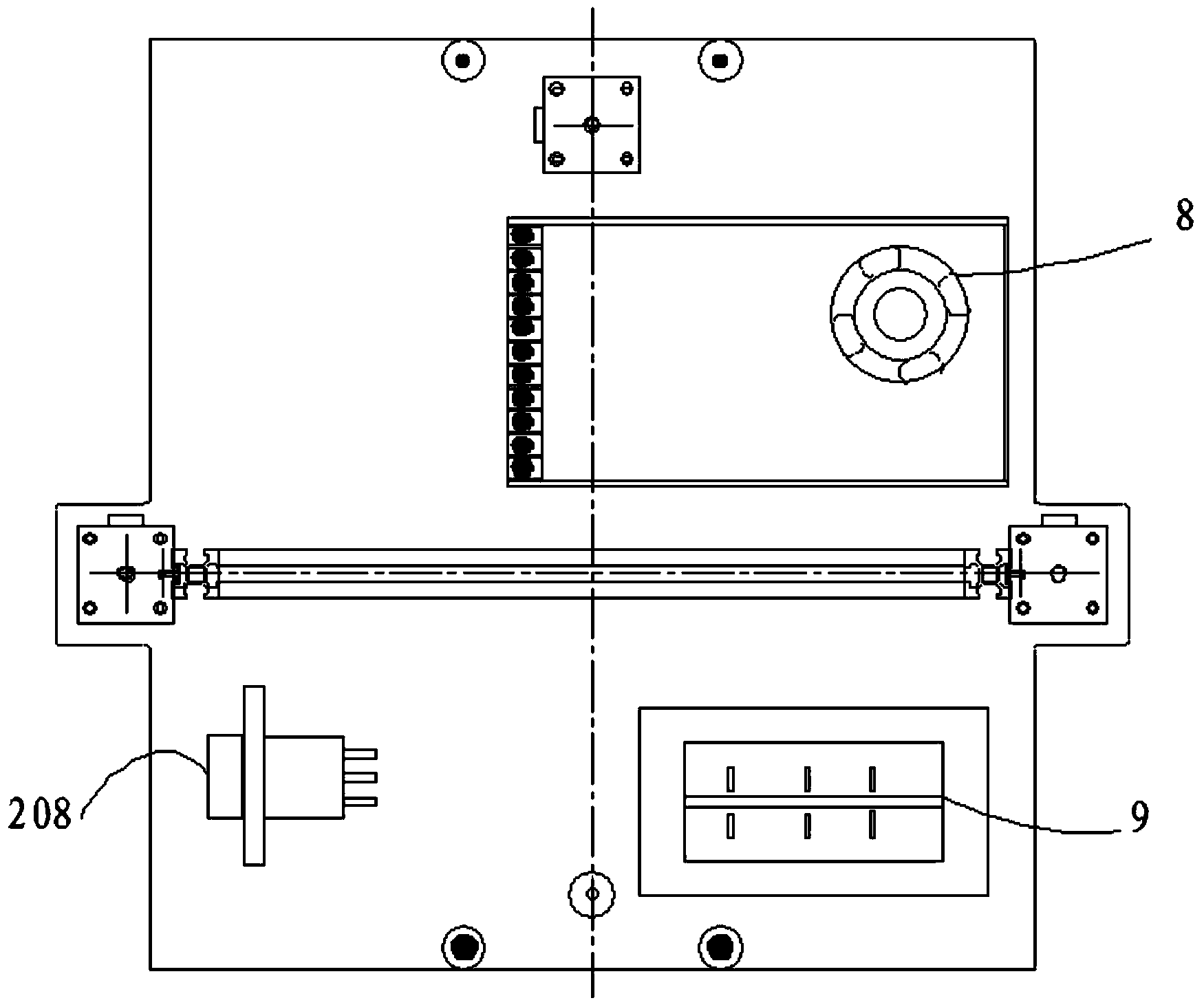

Automatic assembly line standard apparatus for electric energy meter calibration

ActiveCN101464504ARealize automatic feeding processAchieve contactElectrical measurementsProduction lineElectrical connection

The invention discloses an automatic production line standard device detected by an electric energy meter, which comprises a loading platform, a feeding loop line belt and an electric energy meter automatic standard device. The loading platform is connected with the feeding loop line belt; a material taking manipulator and a bar code reader are mounted on the feeding loop line belt; the feeding loop line belt is connected with the electric energy meter automatic standard device; the electric energy meter automatic standard device is simultaneously connected with a blanking conveying loop line belt; a loading manipulator and another bar code reader are mounted on the blanking conveying loop line belt; the loading manipulator is connected with an electric energy meter feeding box; an unqualified product outlet is formed on the blanking conveying loop line belt; the working process of the whole production line in the whole device is controlled by a computer program through a production line control cabinet; and the calibration / detection of the electric energy meter is controlled by a computer calibrating procedure through a calibrating control cabinet. The invention has the advantages of completely improving the calibrating / detecting work efficiency, reducing the labor intensity, improving the work quality, achieving the reliability and the safety of electrical connection, etc.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD SHAOXING POWER SUPPLY CO +1

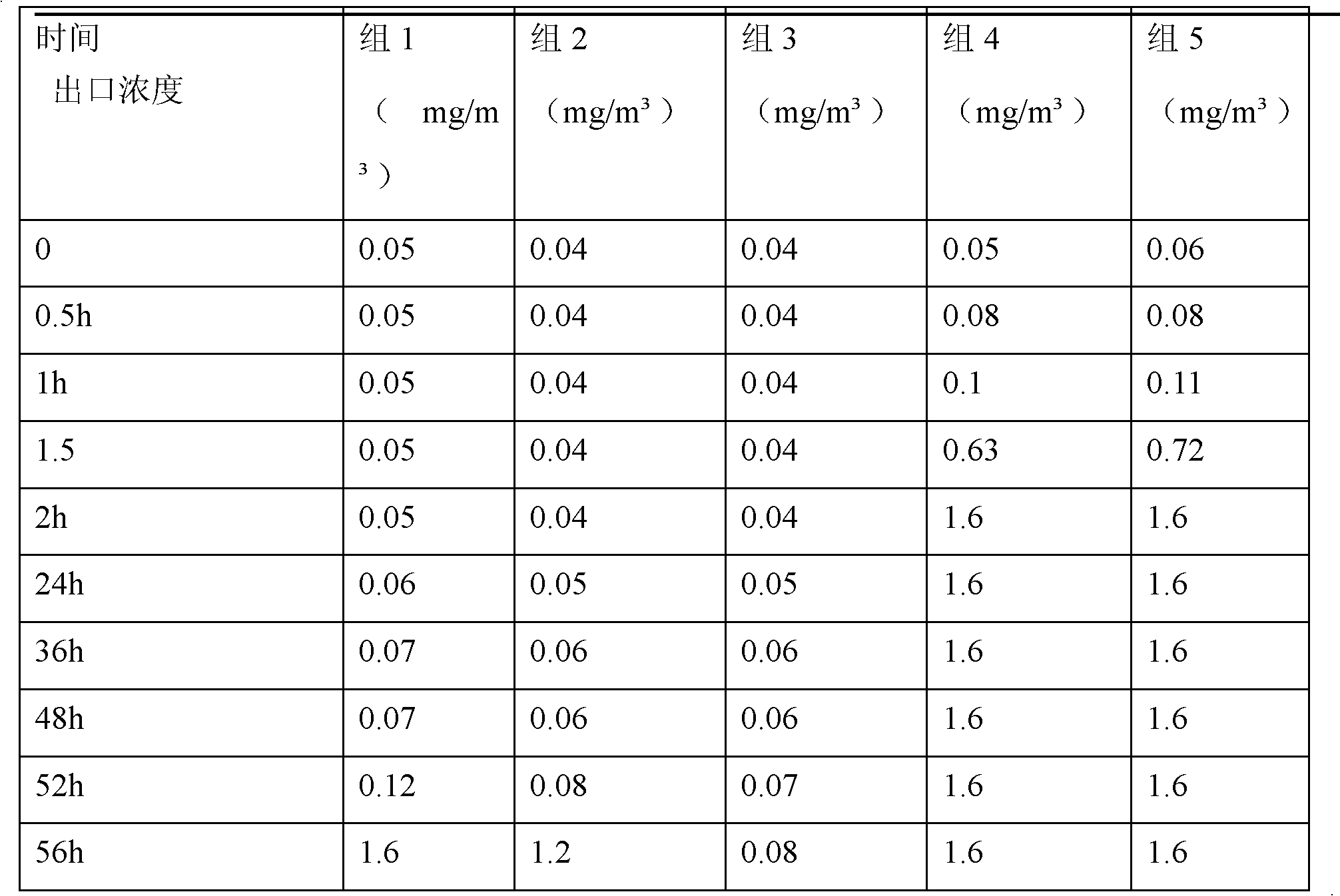

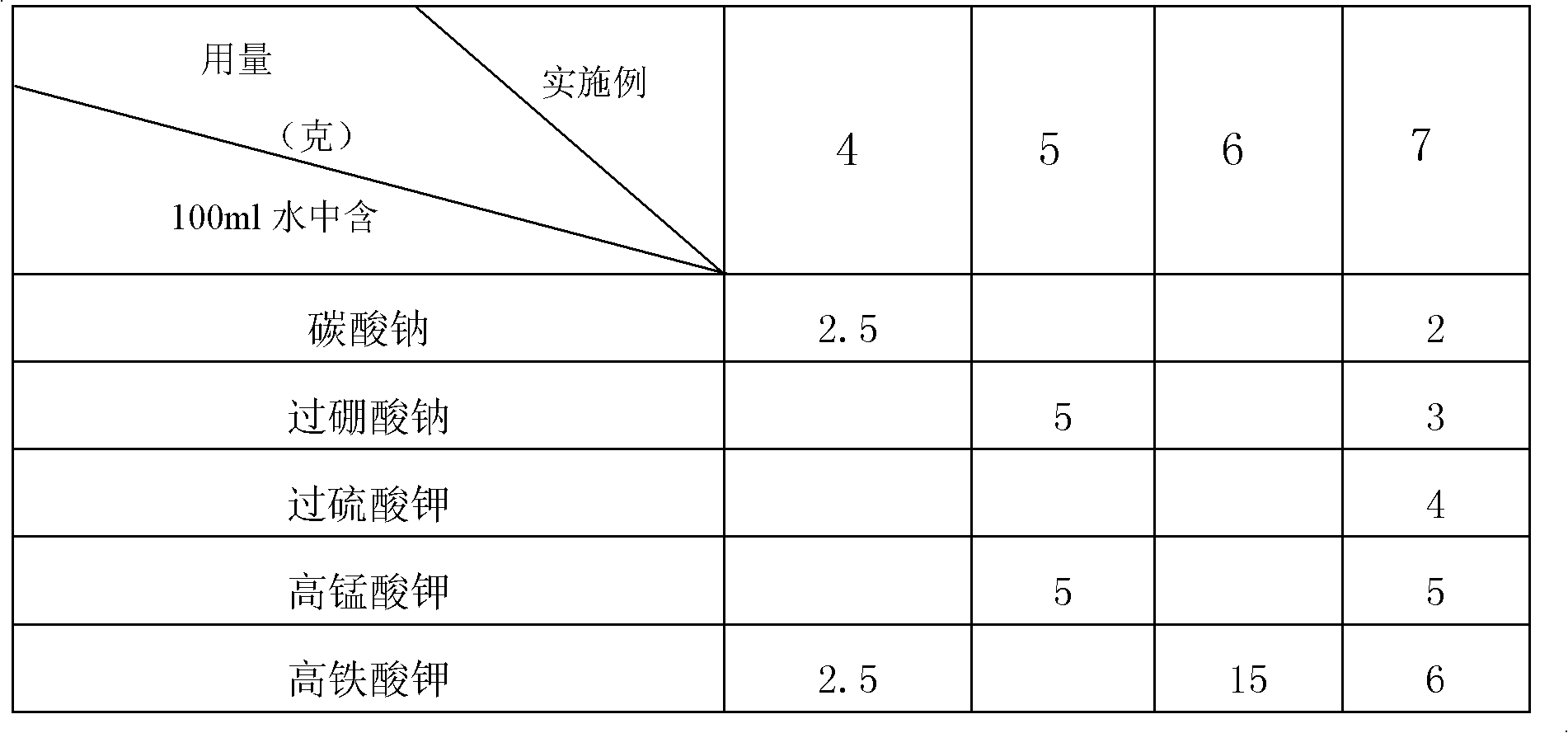

Oxidation type air purifying material and preparation method thereof

InactiveCN102101008ASolve the secondary release of harmful gasesSolve the purificationDispersed particle separationAir cleaningAqueous solution

The invention discloses an oxidation type air purifying material which has low cost and good air purifying effect and does not have secondary pollution. The oxidation type air purifying material is formed by loading an inorganic oxidant on an inorganic adsorbing material. The invention provides a method for preparing the material simultaneously, which comprises the following steps of: drying the inorganic adsorbing material till the moisture of the inorganic adsorbing material is less than 4 percent; preparing aqueous solution, which is at the concentration of between 5 and 20 percent (g / ml), of the inorganic oxidant; and immersing the aqueous solution of the inorganic oxidant in the inorganic adsorbing material for 18 to 36 hours, draining redundant liquid, and drying in a drying oven at the temperature of between 50 and 130 DEG C.

Owner:河北亚太环境科技发展股份有限公司

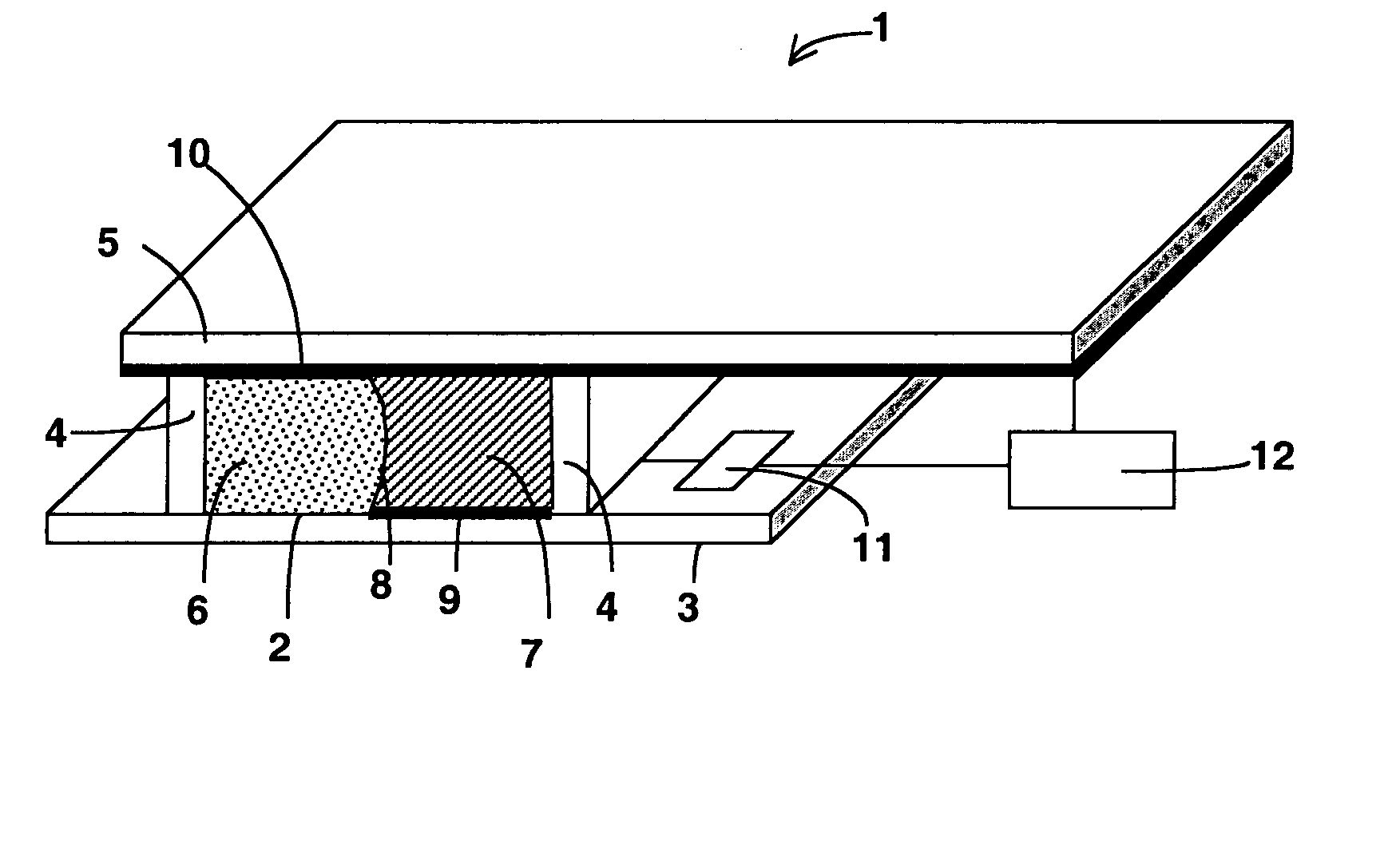

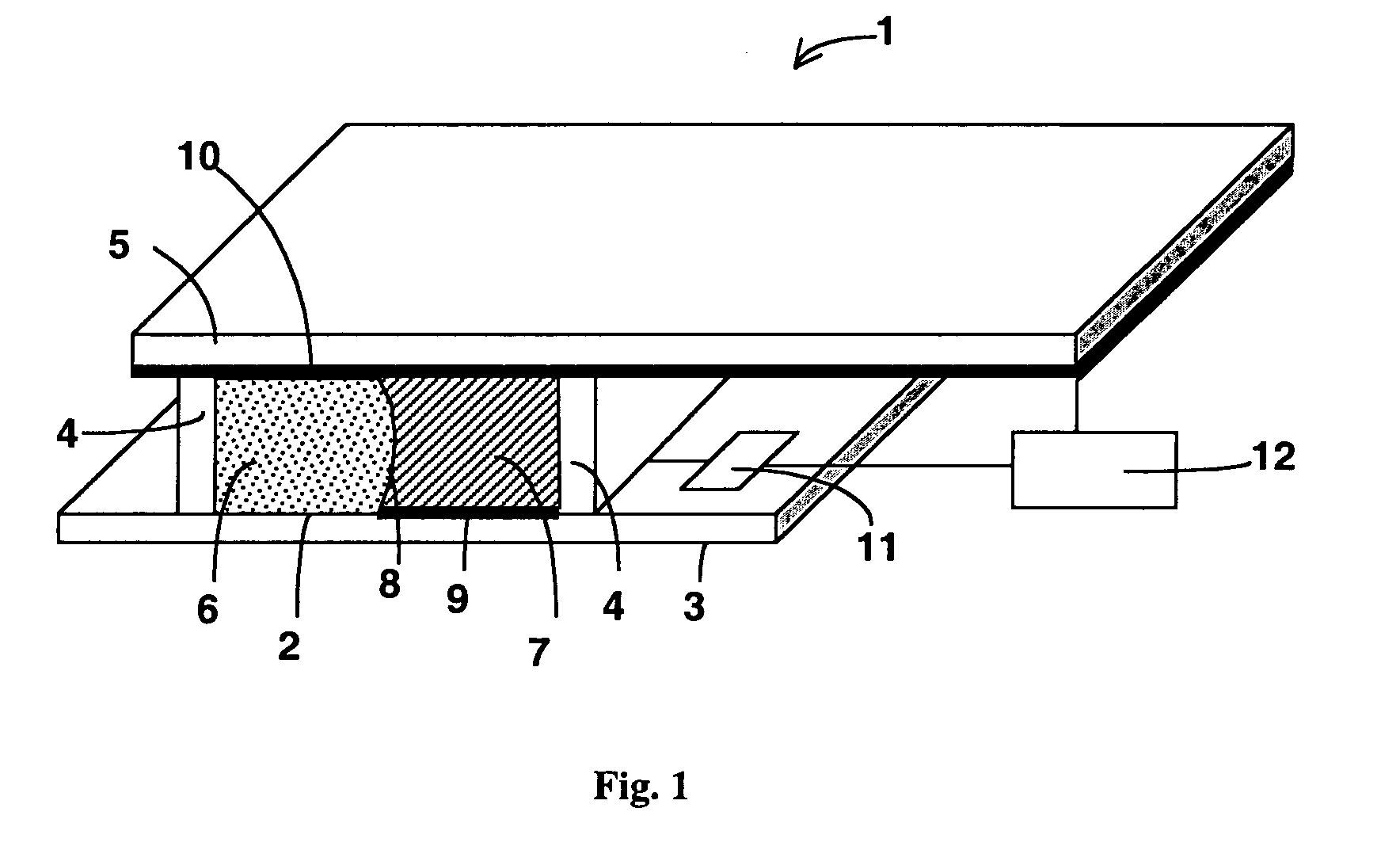

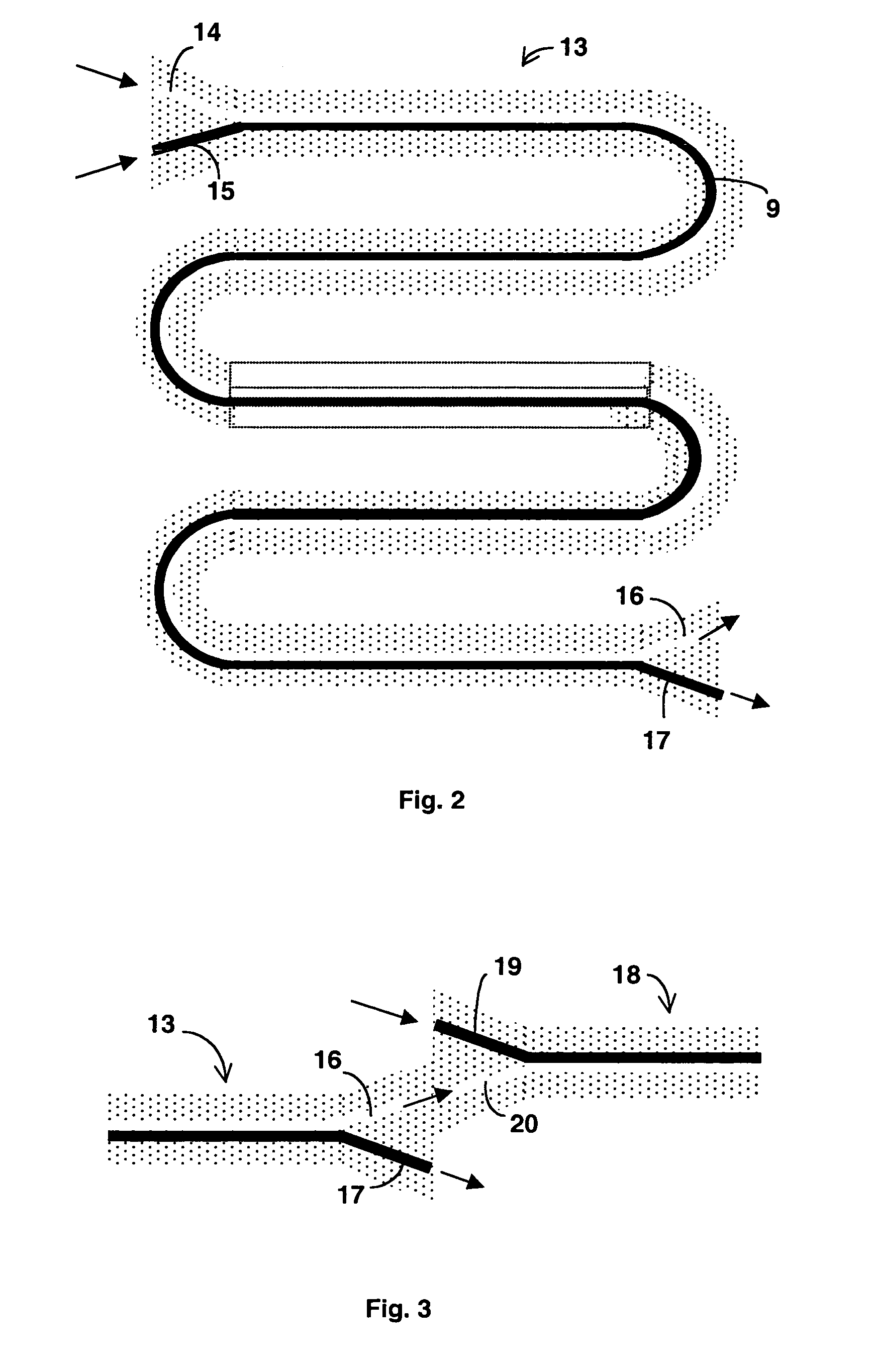

Microfluidic device wherein the liquid/fluid interface is stabilized

InactiveUS7591936B2Easy to implementIncrease contact surfaceCellsSludge treatmentFluid interfaceBiomedical engineering

The microfluidic device comprises at least one microchannel bounded by a bottom wall, side walls and a top wall and which is designed to contain at least one liquid and at least one fluid non-miscible with the liquid. The microfluidic device comprises means for stabilizing the interface between the liquid and the fluid. The means for stabilizing comprise at least one electrode arranged on at least one part of a first wall of the microchannel, over the entire length thereof, and at least one counter-electrode arranged over the entire length of the microchannel, on at least one part of a second wall, arranged facing the electrode. The electrode and counter-electrode are preferably respectively arranged on the bottom and top wall of the microchannel.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Lithium electrode and lithium secondary battery comprising the same

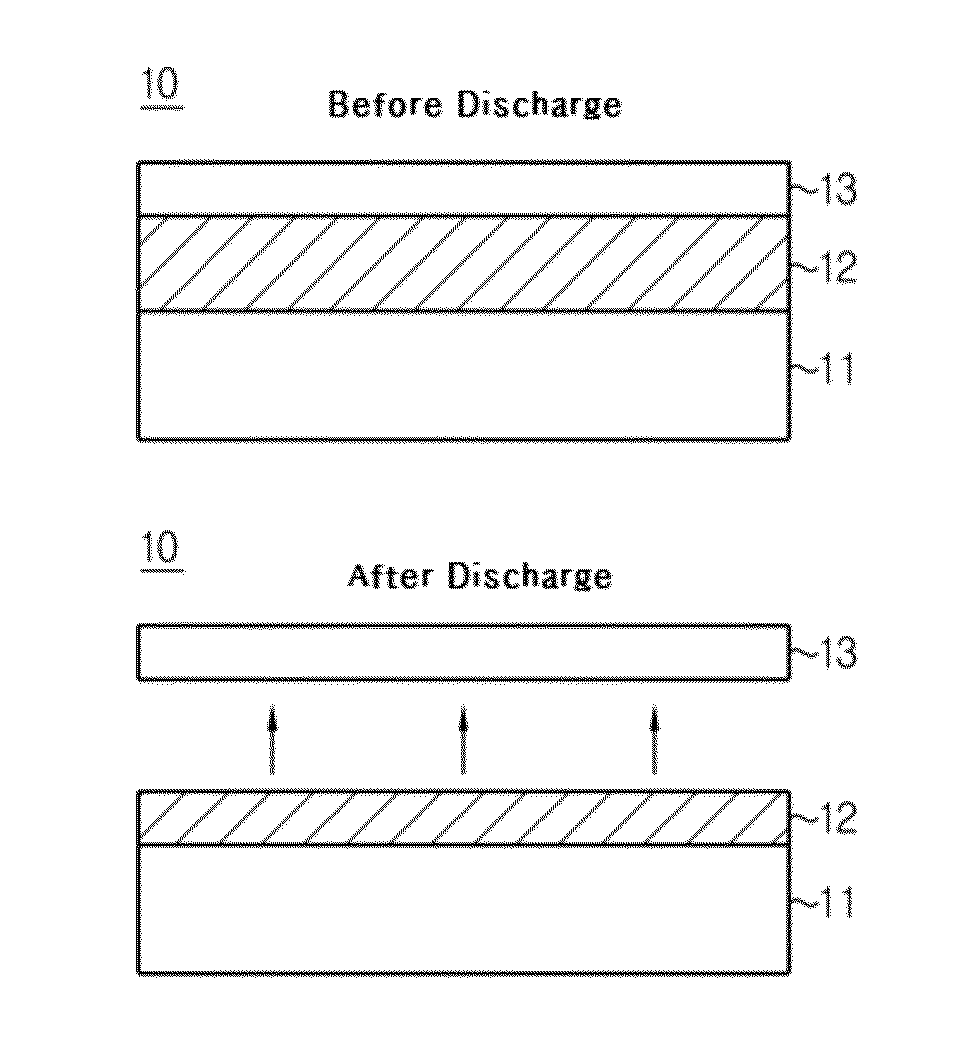

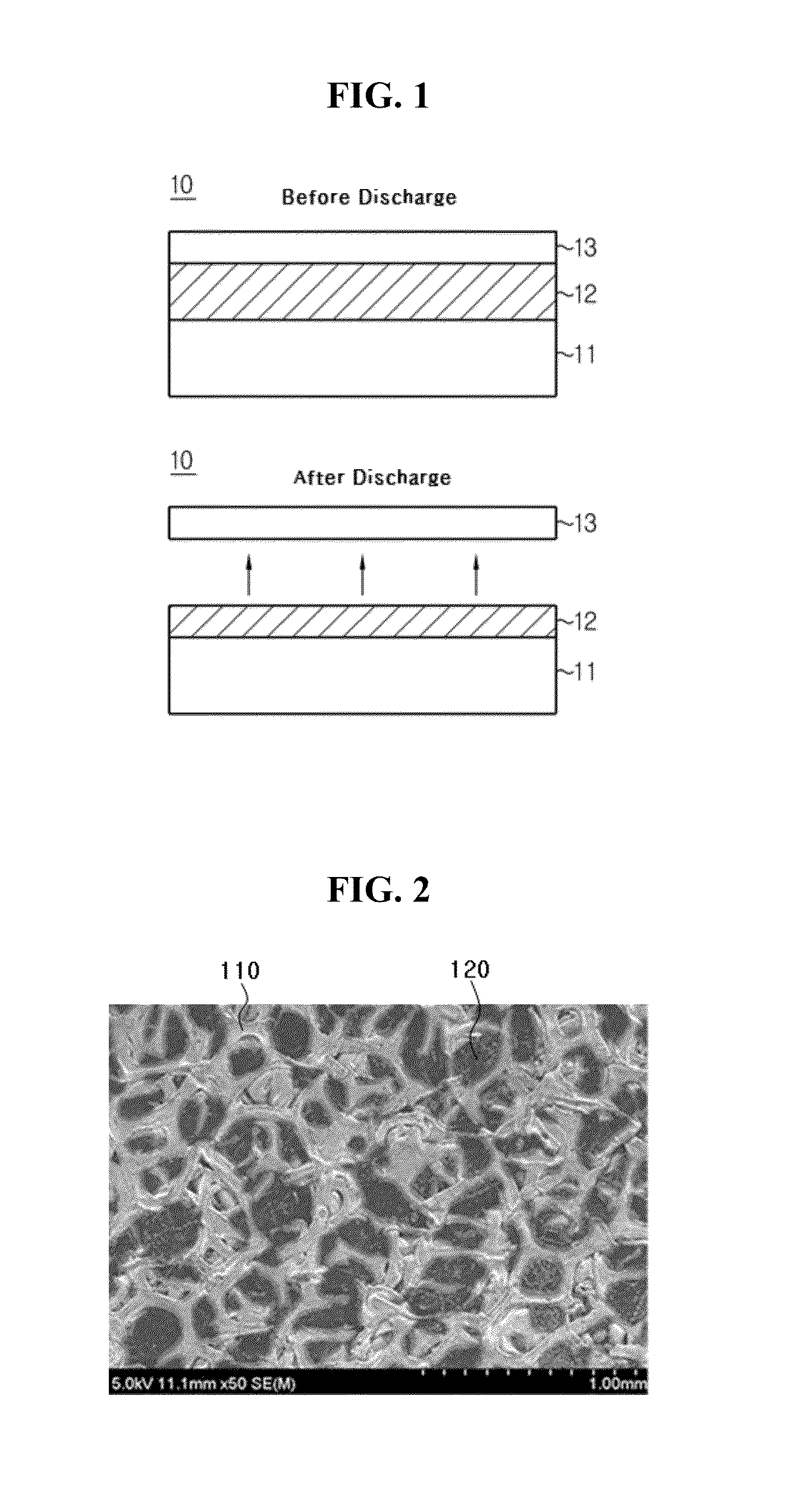

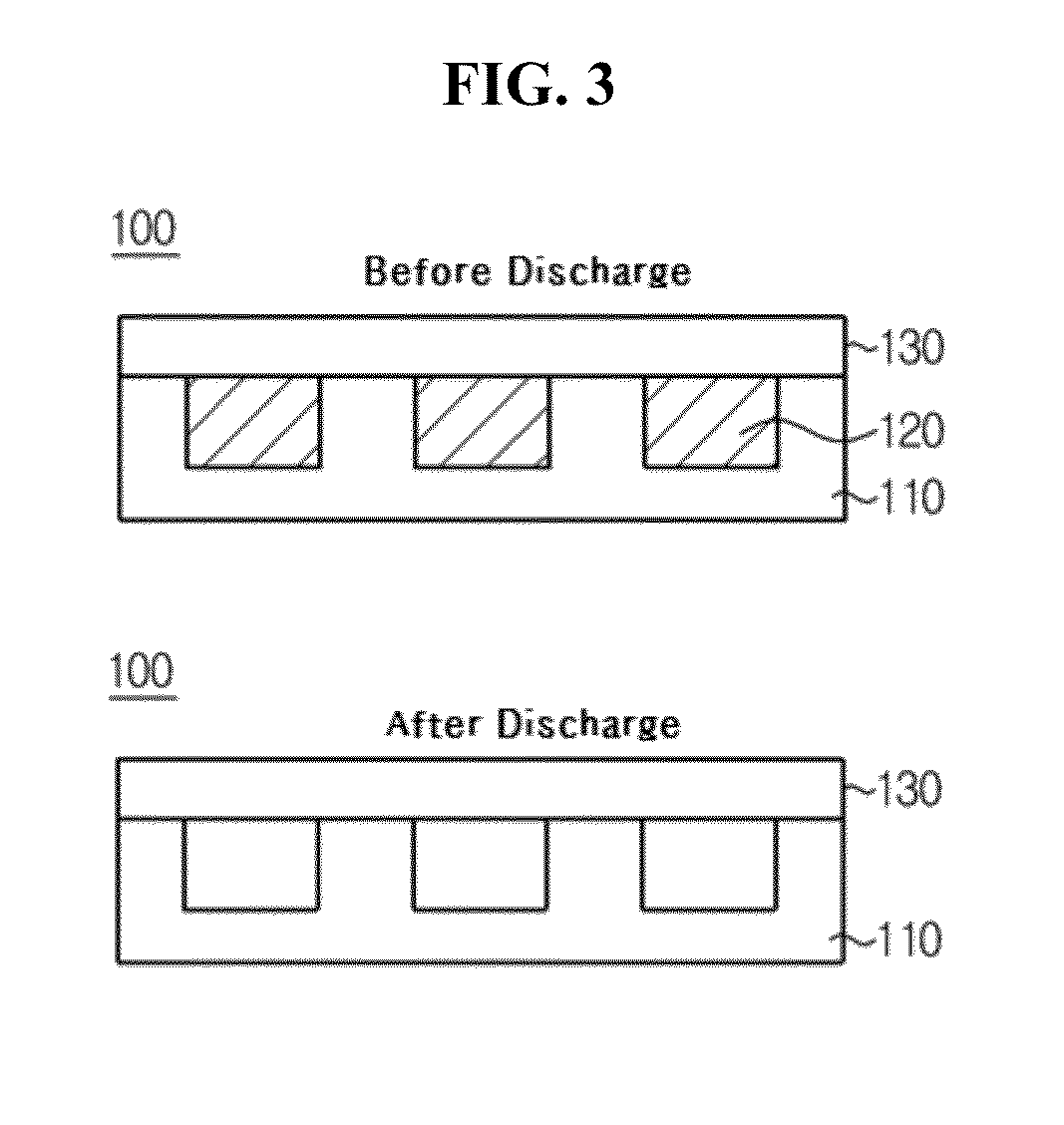

ActiveUS20150295246A1Improve performanceIncrease contact surfaceCell seperators/membranes/diaphragms/spacersSmall-sized cells cases/jacketsTectorial membraneLithium metal

The present disclosure relates to a lithium electrode, comprising an electrode composite comprising a porous metallic current collector, and lithium metal inserted into pores present in the metallic current collector; and a protective membrane for lithium ion conduction, the protective membrane being formed on at least one surface of the electrode composite.The lithium electrode according to the present disclosure can increase contact surface between lithium metal and a current collector to improve the performances of a lithium secondary battery, and can exhibit uniform electron distribution therein to prevent the growth of lithium dendrites during the operation of a lithium secondary battery, thereby improving the safety of a lithium secondary battery. Furthermore, even though the lithium electrode is coated with a protective membrane for lithium ion conduction on the surface thereof, the protective membrane can be prevented from being peeled off during the charge and discharge of a lithium secondary battery.

Owner:LG ENERGY SOLUTION LTD

Method for degrading organic pollutants in water body through activator composite material and activating persulfate

InactiveCN104129841AIncrease the areaHigh activityWater/sewage treatment by oxidationPollutantActivated persulfate

The invention discloses a method for degrading organic pollutants in a water body through an activator composite material and activating persulfate, belonging to the technical field of water pollution control. According to the method, the activator composite material comprises nano zero-valent iron and biochar; the activator composite material and persulfate react with the organic pollutants when being existent at the same time so as to degrade the organic pollutants in the water body. The method comprises the following concrete steps: 1, adding persulfate into the water body containing the organic pollutants, wherein the molar ratio of persulfate to the organic pollutants is (20 : 1) to (200 : 1); 2, adding the activator composite material while stirring, wherein the molar ratio of the activator composite material and persulfate is 1 : 1. The method has the advantages that generated free radicals are good in oxidation property, a reaction system is stable, the pH range is wide, the utilization rate of an oxidant is high, and the like; in addition, the method has wide application prospects on aspect of repairing the organic polluted water body.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

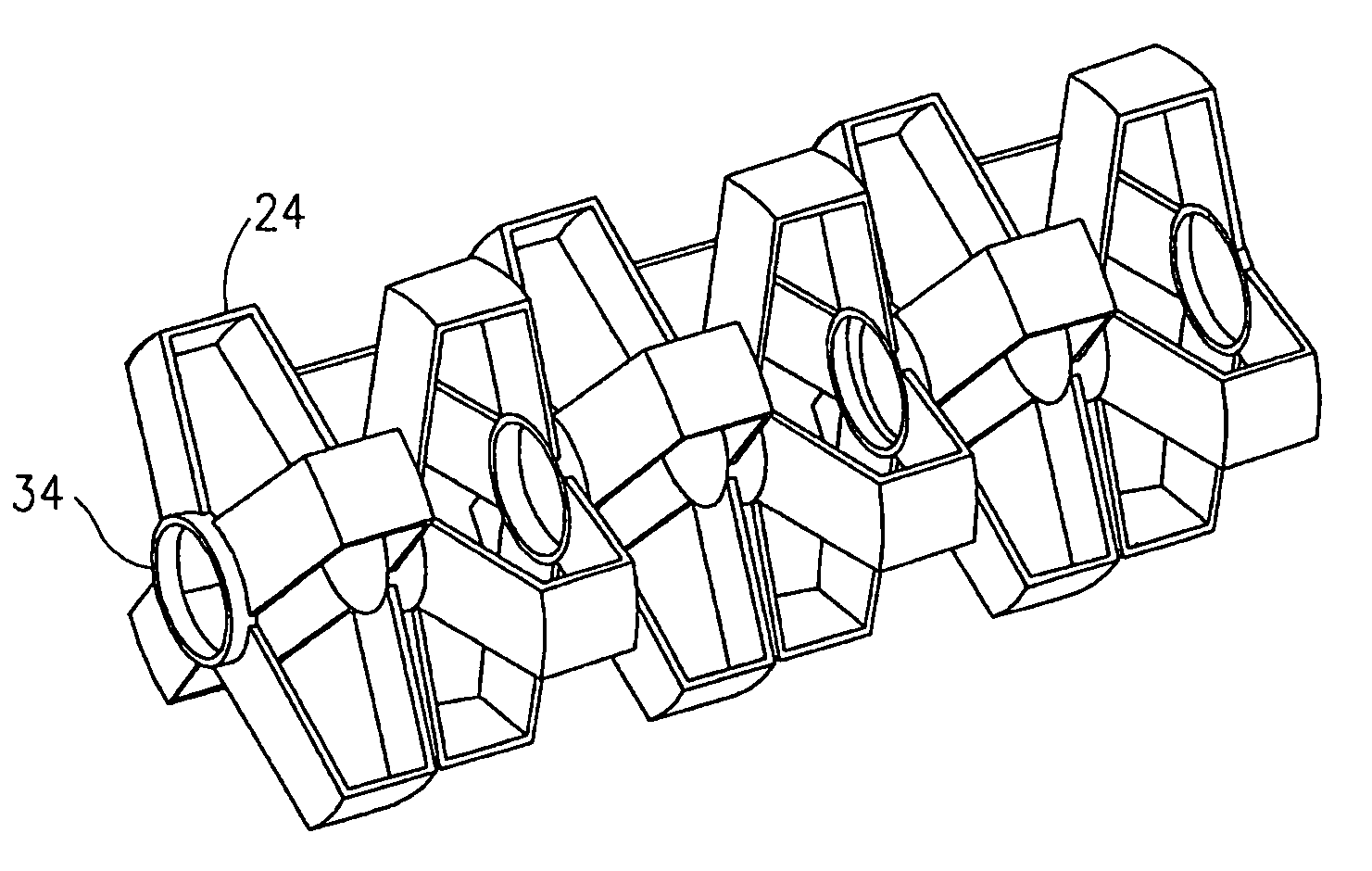

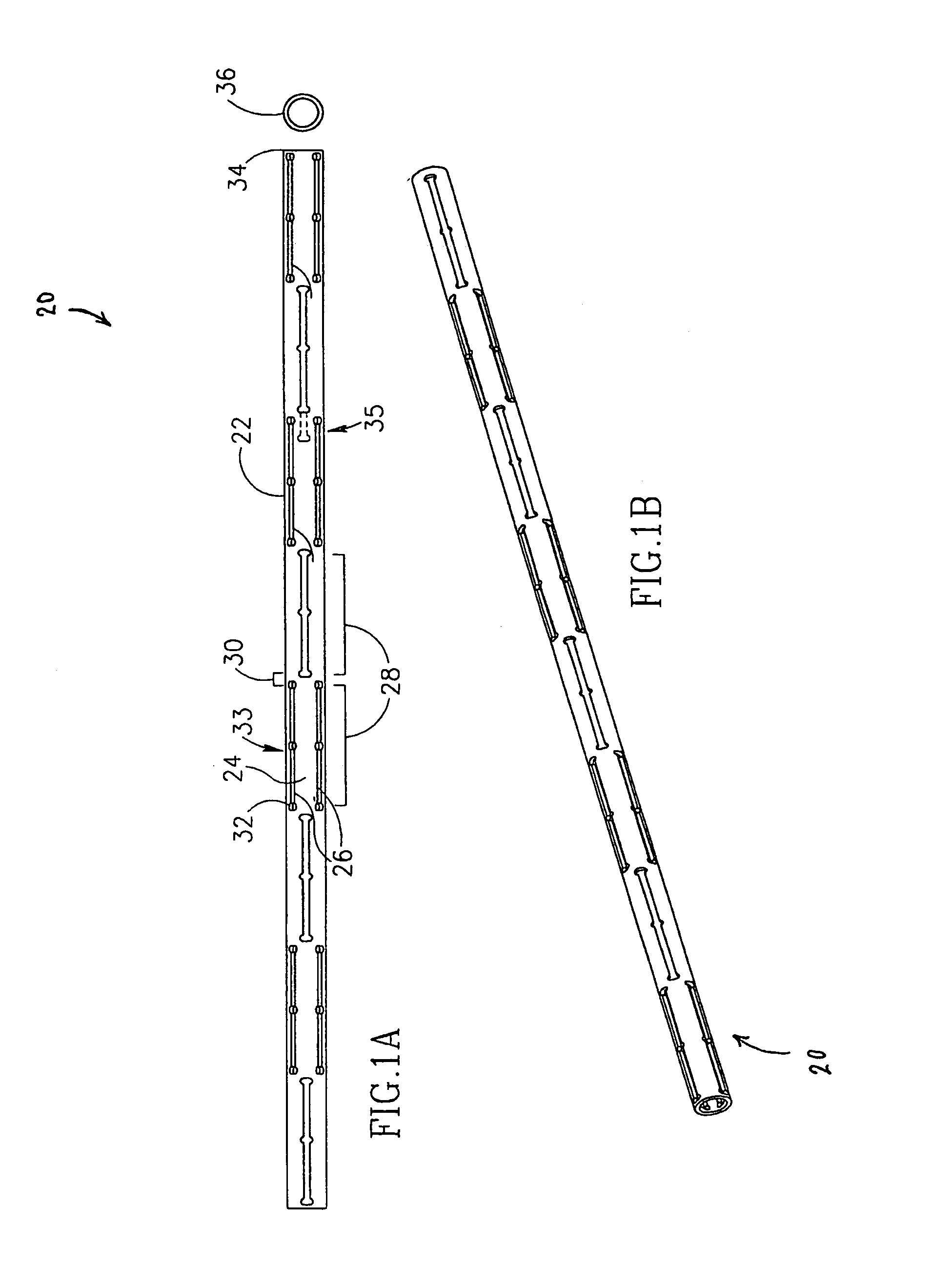

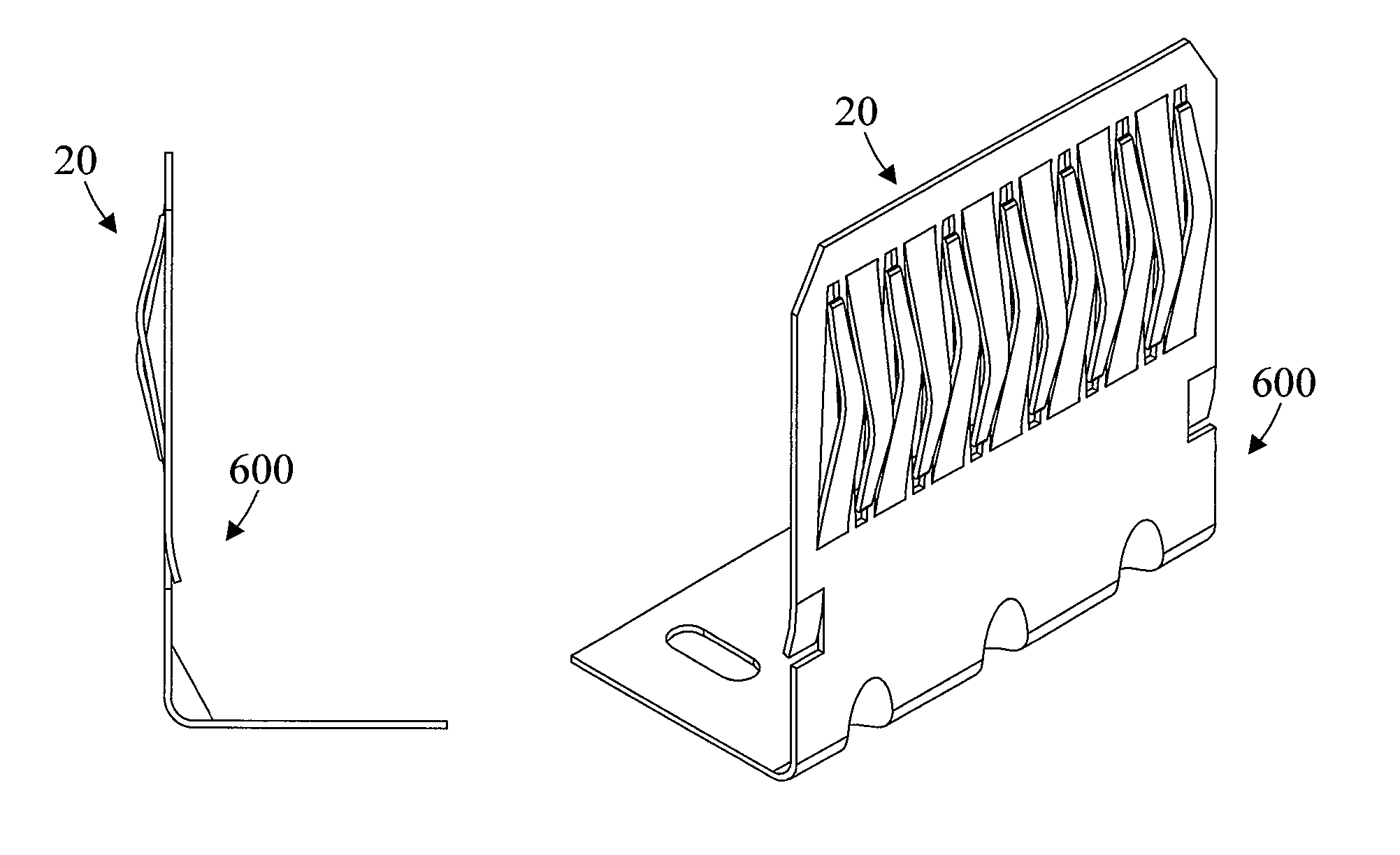

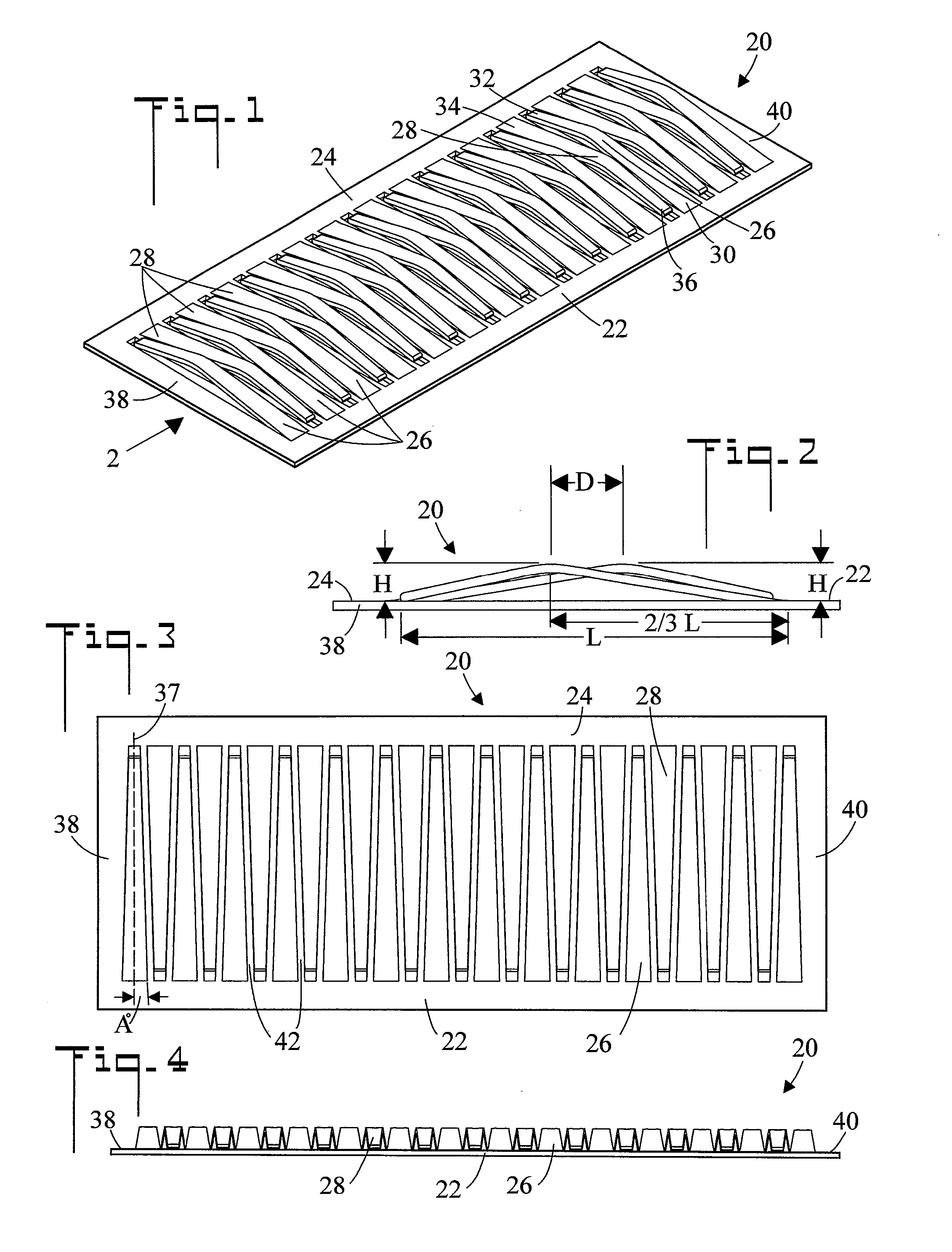

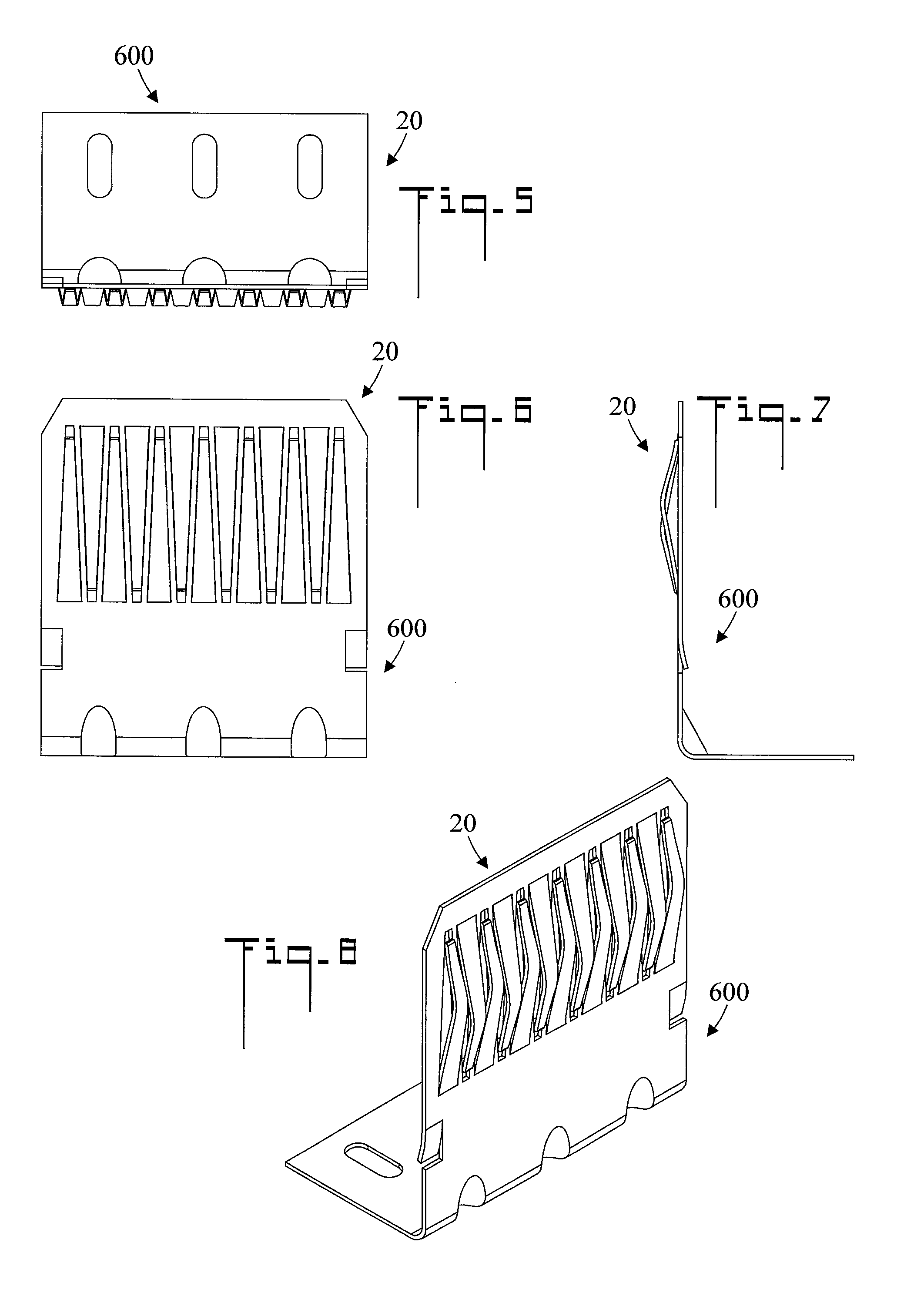

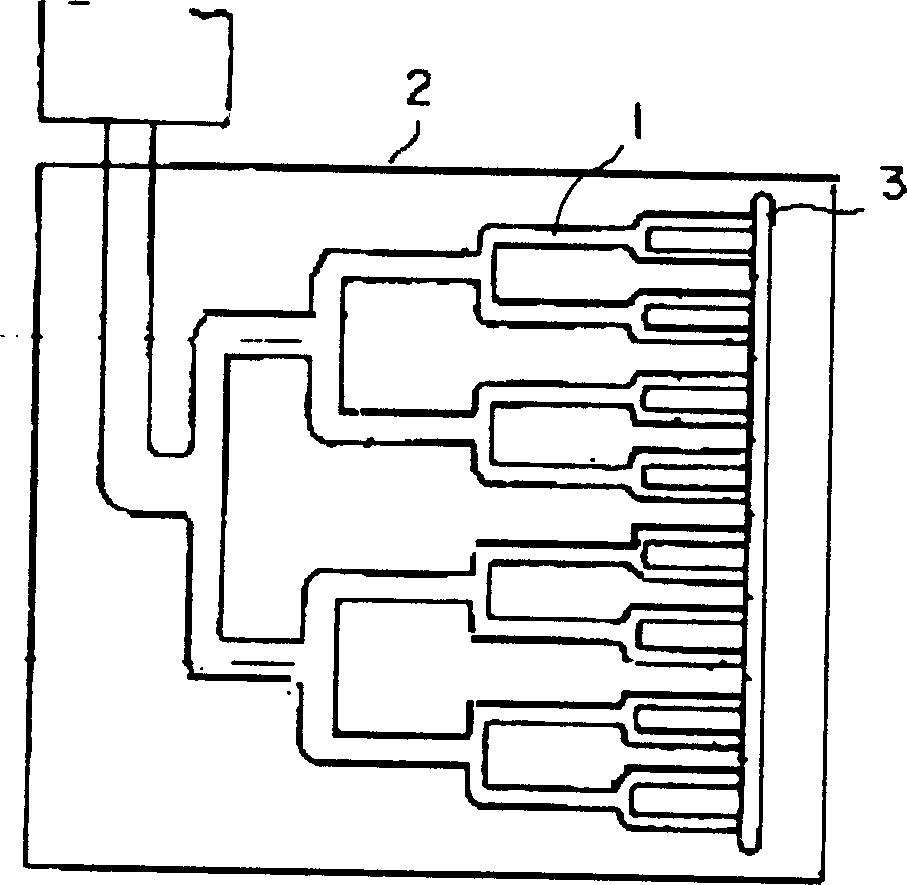

Electrical contact having multiple cantilevered beams

ActiveUS8821170B1Small insertion forceHigh currentElectrically conductive connectionsCoupling device detailsCantilevered beamEngineering

An electrical contact includes a first set of spaced apart cantilevered beams connected to a first rail, and a second set of cantilevered beams connected to a second rail. The first set of cantilevered beams project toward the second rail, and the second set of cantilevered beams project toward the first rail, wherein the first and second sets of cantilevered beams reside in alternating relationship. Each cantilevered beam is bowed and is outwardly tapered from its connected proximal to its unconnected distal end.

Owner:BELLWETHER ELECTRONIC CORP

Composite for attaching, growing and/or repairing of living tissues and use of said composite

InactiveUS20040115240A1Decrease flexuralDecrease compressive propertySkin implantsTeeth fillingPorosityMaterials science

Owner:VIVOXID

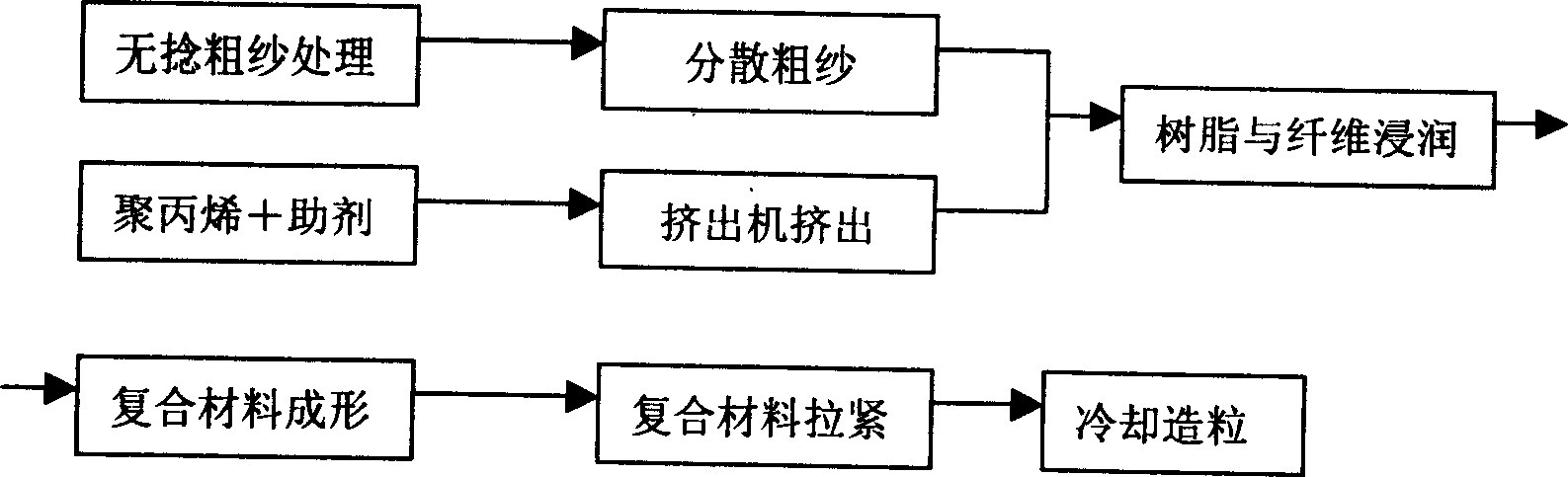

Continuous fiber reinforced composite materials, its production method and special equipment therefor

The invention relates to a glass fiberreinforced thermoplastic composite and a continuous fiber-reinforced composite, which are prepared with the following raw materials percentagewise by weight: 35-60 % of resin, 35-60 % of dip treated glass fiber and 0.5-5 % of auxiliary agent. The invention adopts resin and dip treated glass fiber as main raw materials, mixtures of antioxidant, ultraviolet absorbent and light-stability agent as main auxiliary agents, with logical formulations, eliminates the damage to glass fibrous surface caused by twin-screw with continuous fiber-reinforced composite producted by this manufacturing technique, improves product lustrous surface, binding properties between fiberglass and resins by a treatment for glass fibrous surface and mechanical properties of products, protects the materials for long periods from destruction because of addition of various stabilizing agents, and solves the limitation that general materials can not be used for a long time in extreme conditions such as high temperature, high humidity, radiation and so on.

Owner:JIANGSU QIYI TECH

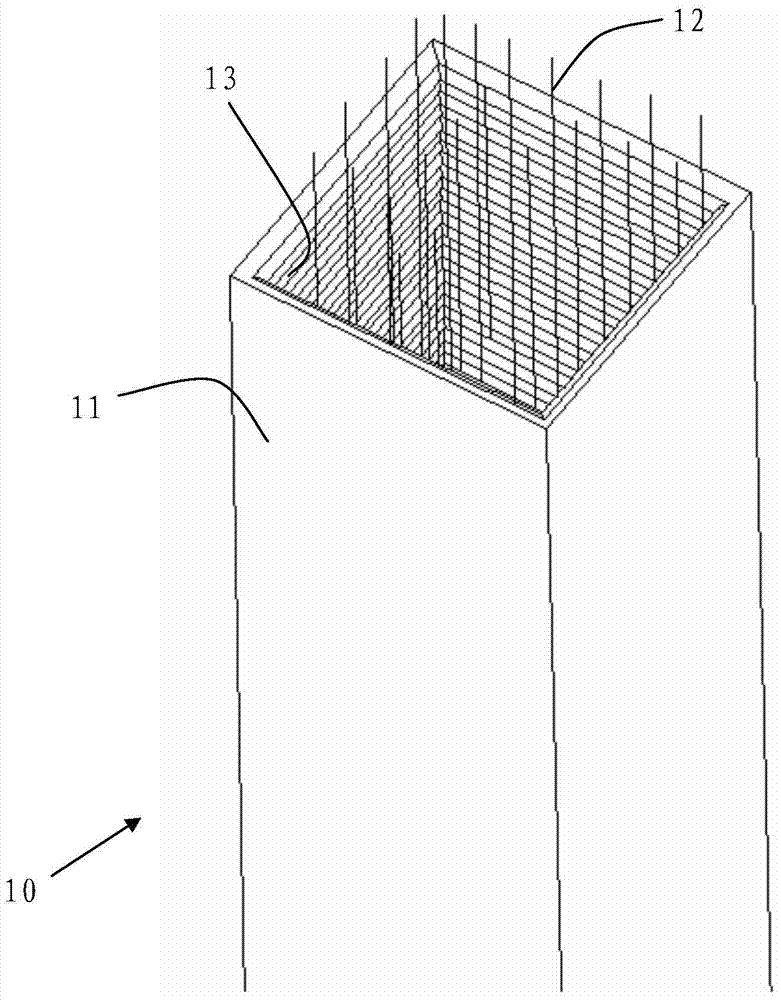

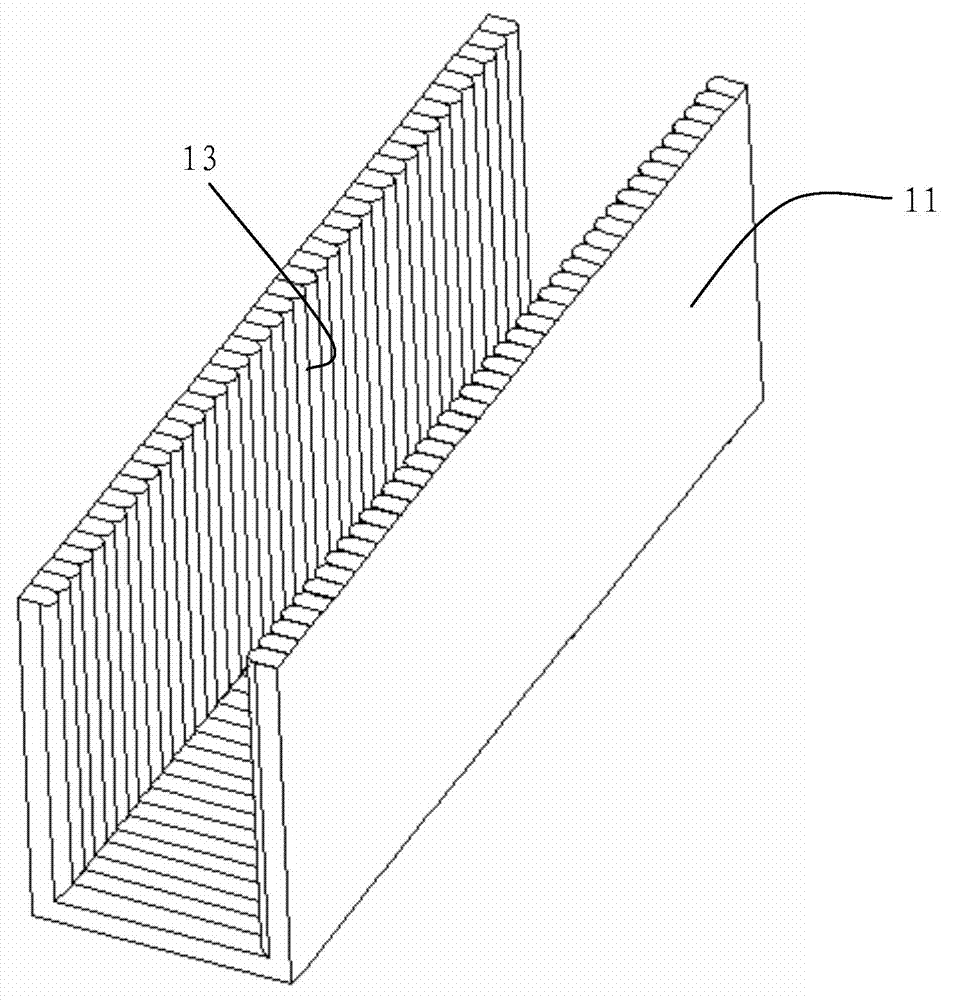

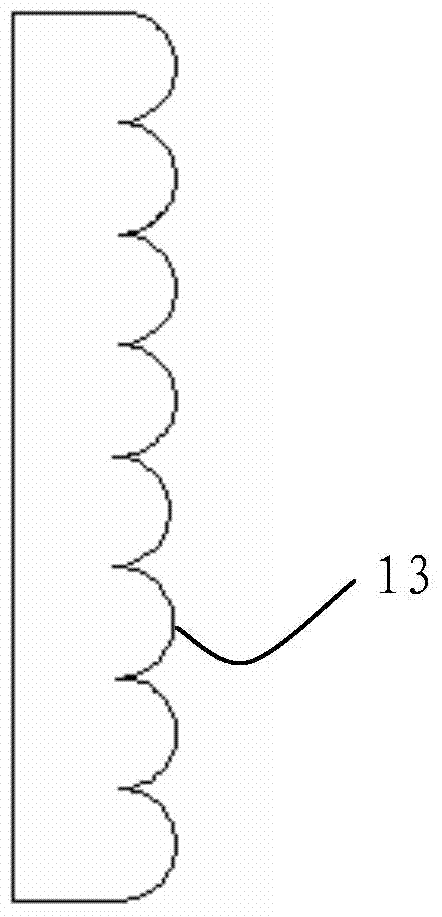

Reinforced concrete structure based on 3D printing and structure construction method

The invention discloses a reinforced concrete structure based on 3D printing and a structure construction method. The method comprises the following steps that a foundation bottom plate is constructed, and a connection section is reserved on the foundation bottom plate; a steel bar structure of a structural column is bound to the connection section; a first prefabricated concrete outer shell is manufactured by adopting 3D printing, and concave-convex lines are formed in the inner surface of the first prefabricated concrete outer shell; the first prefabricated concrete outer shell is arranged on the steel bar structure of the structural column in a sleeved mode; a steel bar structure of a structural beam is bound, and the steel bar structure of the structural beam is bound to the steel bar structure of the structural column; a second prefabricated concrete outer shell is manufactured by adopting 3D printing; the second prefabricated concrete outer shell is mounted on the steel bar structure of the structural beam; concrete is poured in the second prefabricated concrete outer shell, and the structural beam and the structural column are completed. The prefabricated concrete outer shells are formed integrally by adopting a 3D printing technology, the continuous concave-convex lines are formed in the inner surfaces of the prefabricated concrete outer shells, the contact surfaces between the concrete poured in the prefabricated concrete outer shells and the inner surfaces of the prefabricated concrete outer shells are enlarged, compared with a smooth inner surface, friction is increased, bonding strength is improved, and a shell disengagement phenomenon is avoided.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

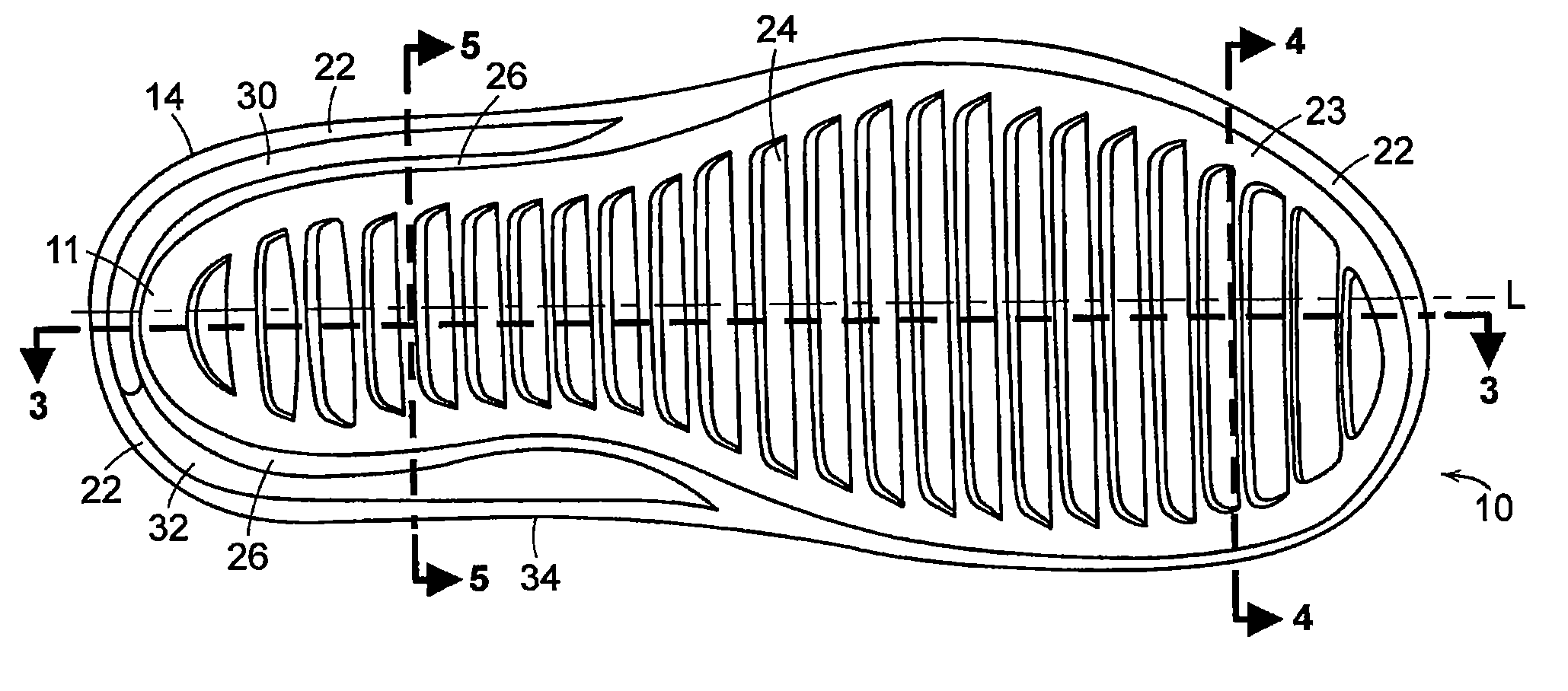

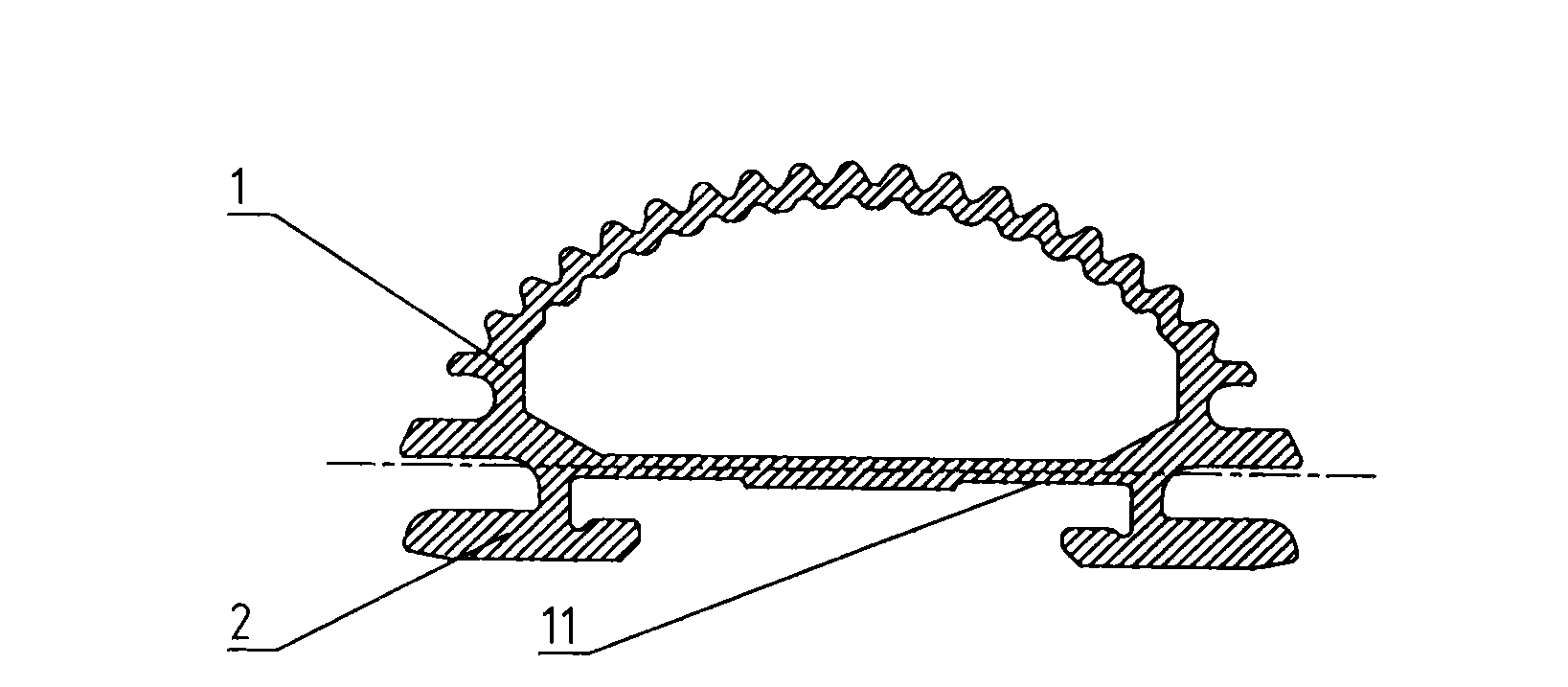

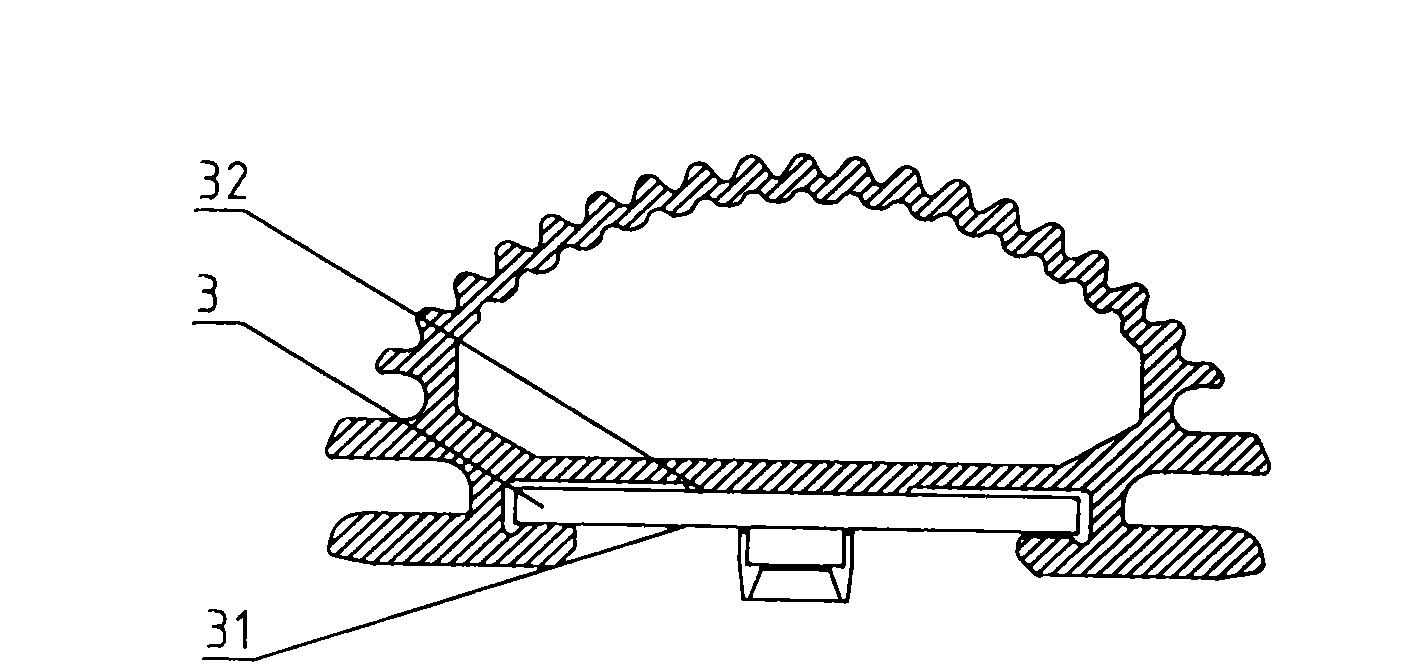

Sole for article of footwear for sand surfaces

A sole for an article of footwear to be used on a sand surface includes a sole of compressible material having an upper surface and a lower surface. A peripheral lip projects downwardly and outwardly from the lower surface of the sole. A plurality of fins projects downwardly from the lower surface of the sole.

Owner:NIKE INTERNATIONAL LTD

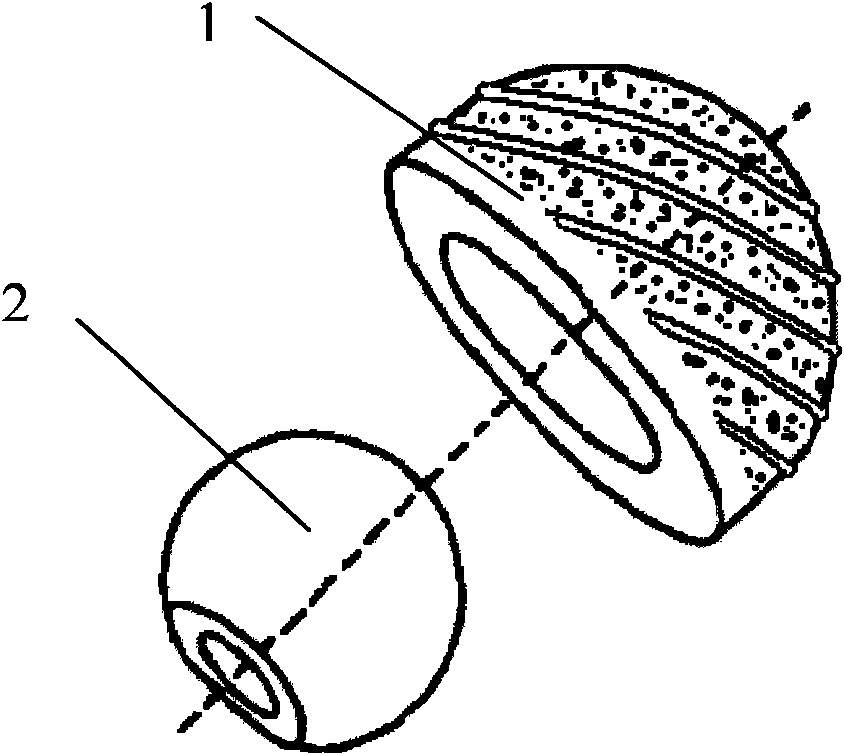

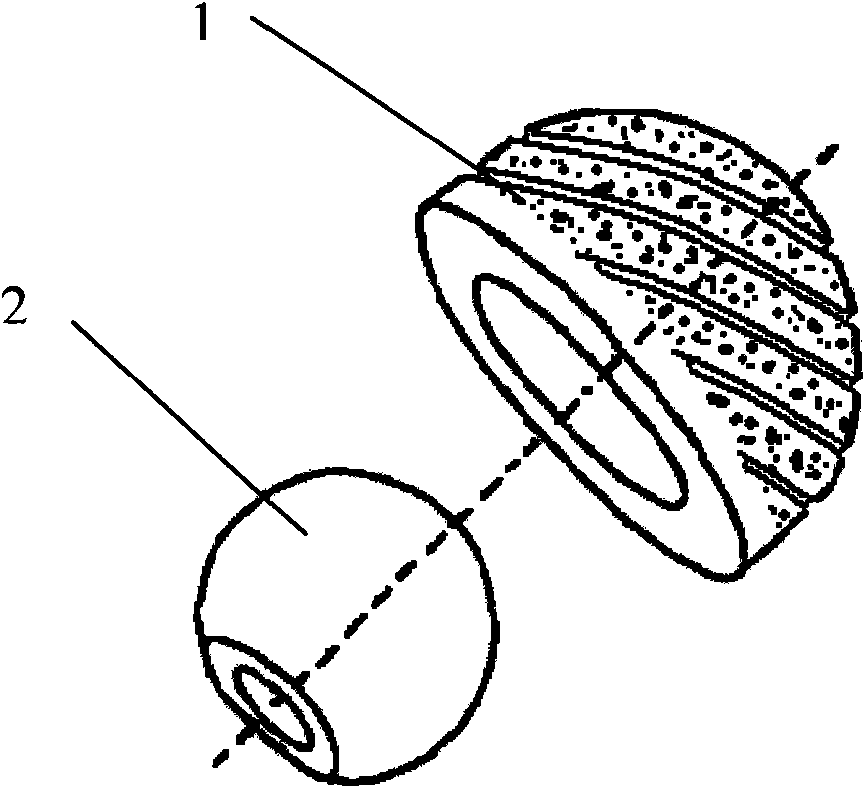

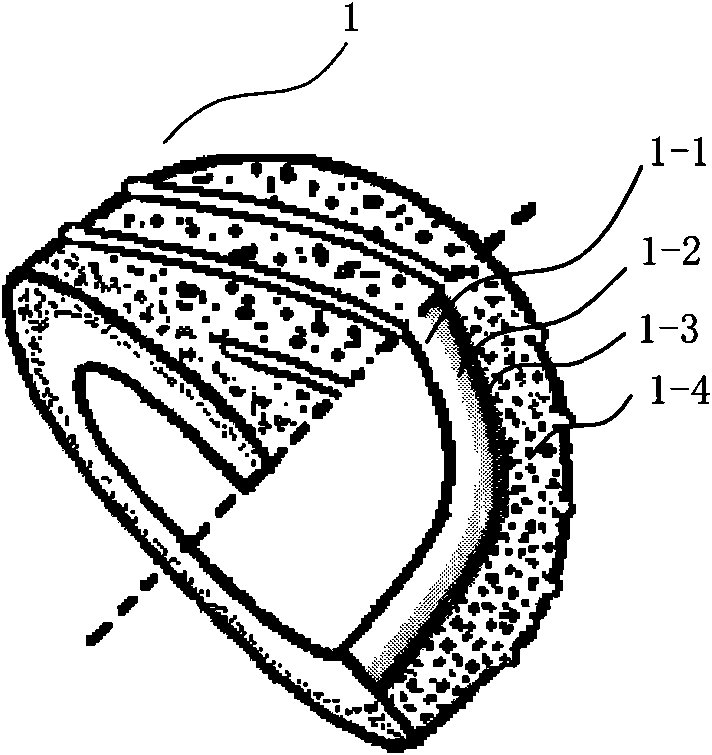

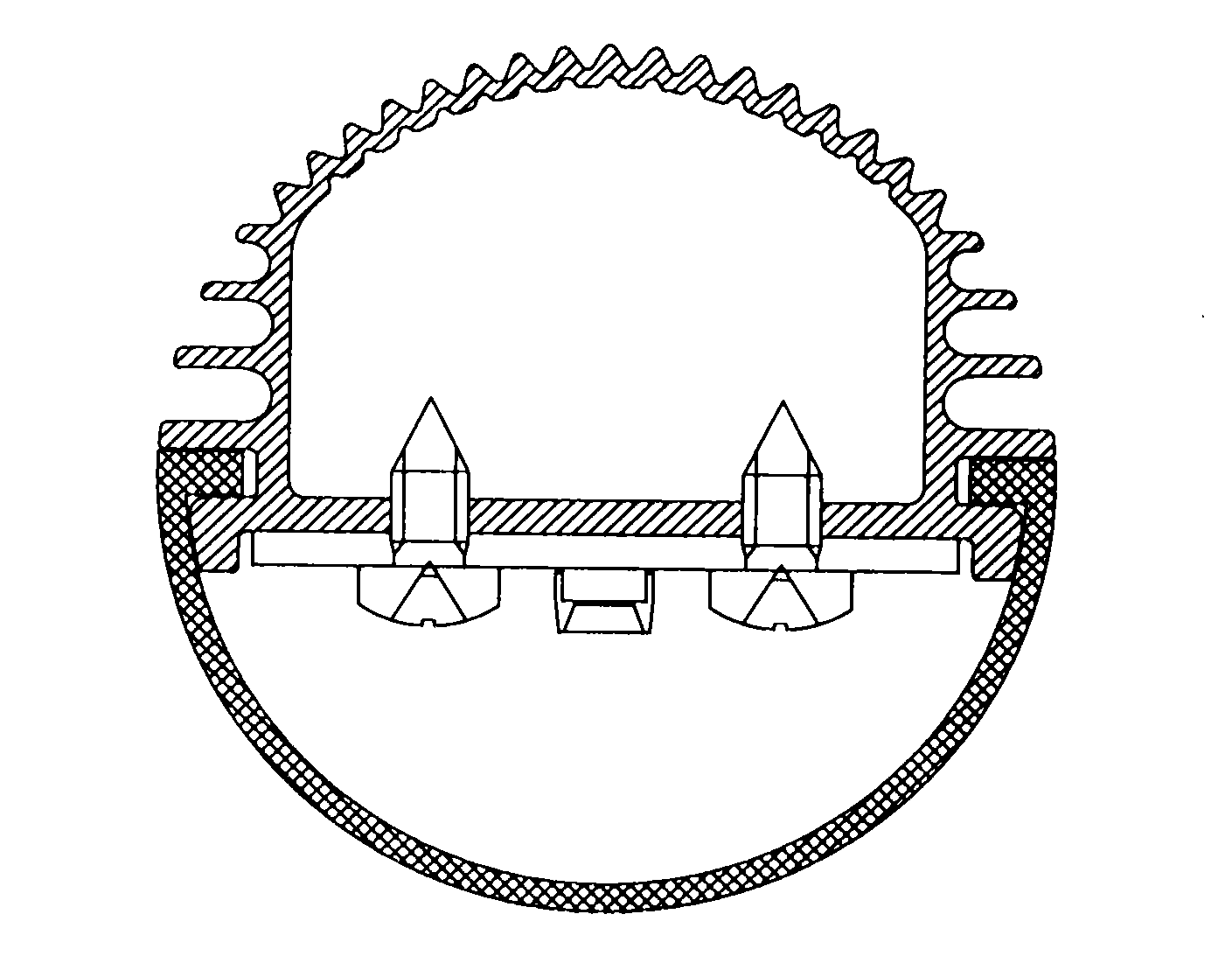

Artificial hip joint consisting of multilayer shell core composite structural components

The invention discloses an artificial hip joint consisting of multilayer shell core composite structural components. The artificial hip joint comprises an artificial acetabulum and an artificial thigh bone. The artificial hip joint is characterized in that: the artificial acetabulum has a multilayer shell core composite structure and consists of a ceramic acetabulum lining, a transition layer, a porous metal, a porous alloy or a porous toughened ceramic acetabulum shell; the artificial thigh bone has a multilayer shell core composite structure and consists of a ceramic spherical shell layer, a transition layer and a toughened ceramic inner core. The ceramic acetabulum lining and the spherical shell layer of the artificial thigh bone have high hardness, corrosion resistance and abrasion resistance; the artificial acetabulum shell layer and the inner core of the thigh bone have high toughness and impact resistance; and the transition layers are made of gradient composite materials between the materials for the shell layer and the inner core layer, and have the functions of increasing the bonding strength between the shell layer and the inner core layer, reducing the interface stressbetween the shell layer and the inner core layer and the like. The artificial hip joint has the characteristics of long service life, high reliability, high performance and the like.

Owner:SUZHOU DINGAN ELECTRONICS TECH

Manufacturing method of lamp-cover-supporting LED tubular lamp with self-clamping heat transmission substrate

InactiveCN103411140AAbsorb moreReduce absorptionPoint-like light sourceLighting heating/cooling arrangementsHeat transmissionEffect light

The invention discloses a manufacturing method of a lamp-cover-supporting LED tubular lamp with a self-clamping heat transmission substrate, and belongs to the technical field of supporting or hanging or connecting of lighting devices. The manufacturing method of the LED tubular lamp includes the steps that S1, the heat transmission substrate is inserted into strip-shaped clamping grooves from side ports of the strip-shaped clamping grooves; S2, after the heat transmission substrate is installed in the strip-shaped clamping grooves, a lamp cover covers a radiator; S3, the lamp cover exerts two acting forces on two T-shaped hooks, and the heat transmission substrate is installed in the strip-shaped clamping grooves in a clamped mode; S4, the radiator, the heat transmission substrate and the lamp cover form a lamp tube of the LED tubular lamp, and two end covers are installed at the two ends of the lamp tube of the LED tubular lamp. According to the lamp-cover-supporting LED tubular lamp with the self-clamping heat transmission substrate, the heat transmission substrate can be arranged in the strip-shaped clamping grooves in the clamped mode because the strip-shaped clamping grooves are formed in an installing part of the heat transmission substrate, heat dissipation efficiency can be improved, and the heat transmission substrate is prevented from thermal deformation.

Owner:辽宁三维传热技术有限公司 +1

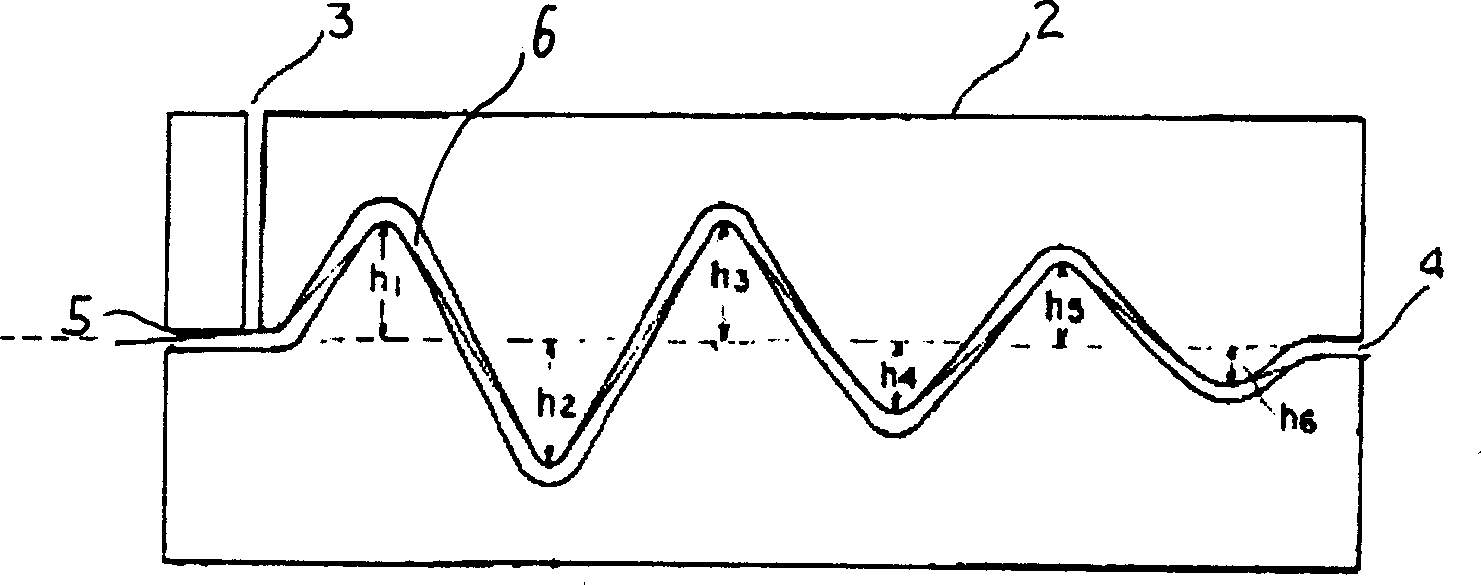

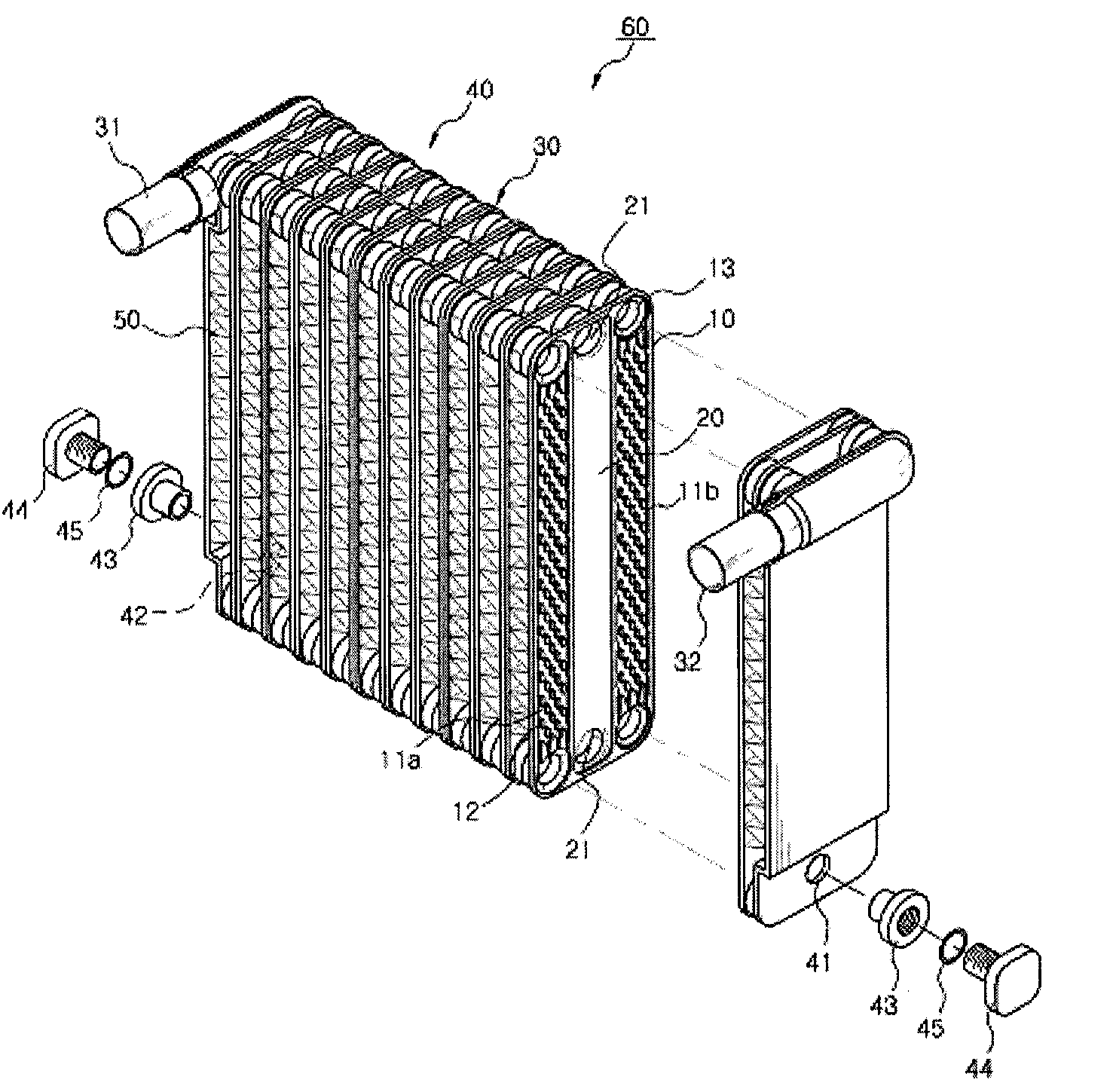

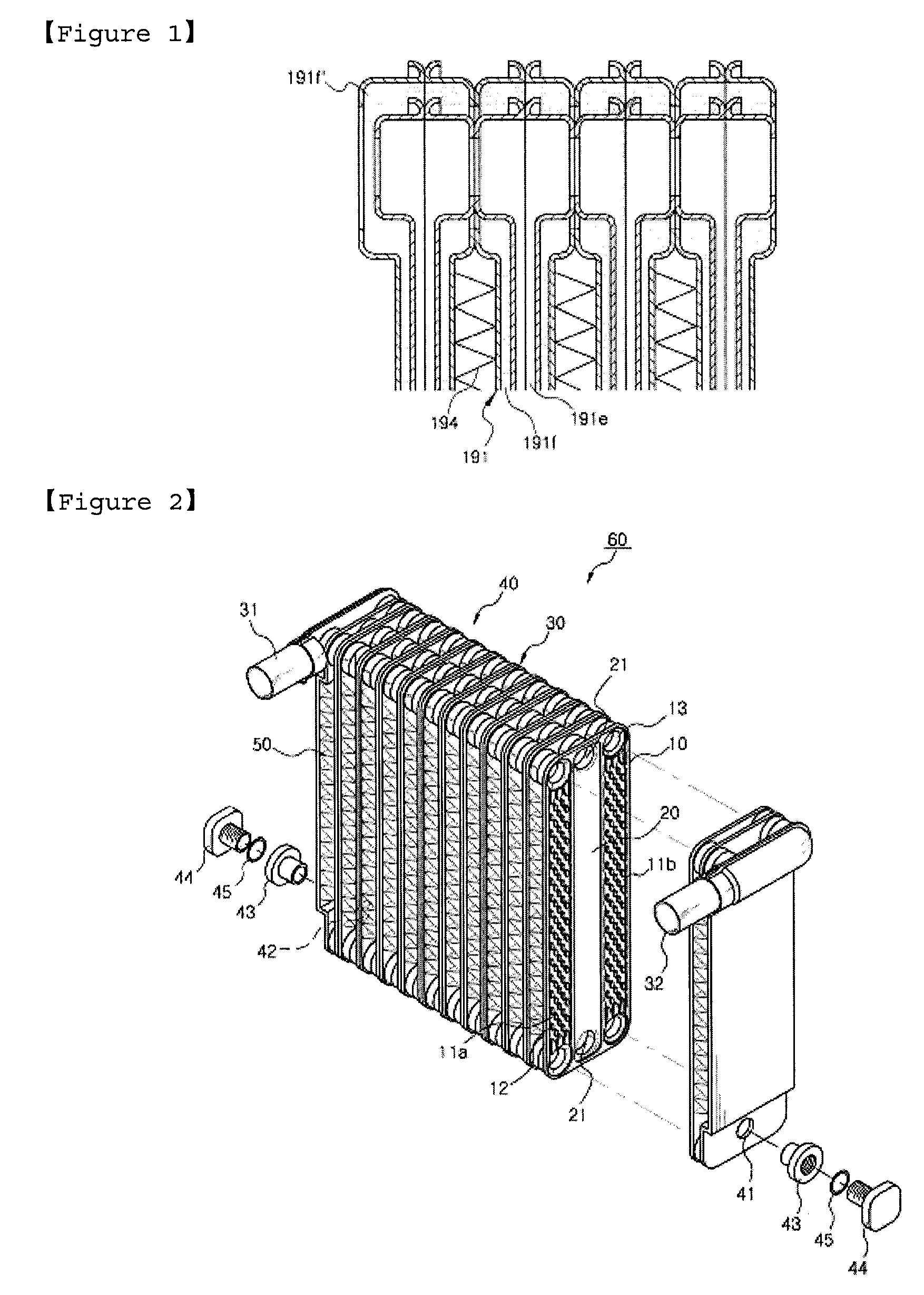

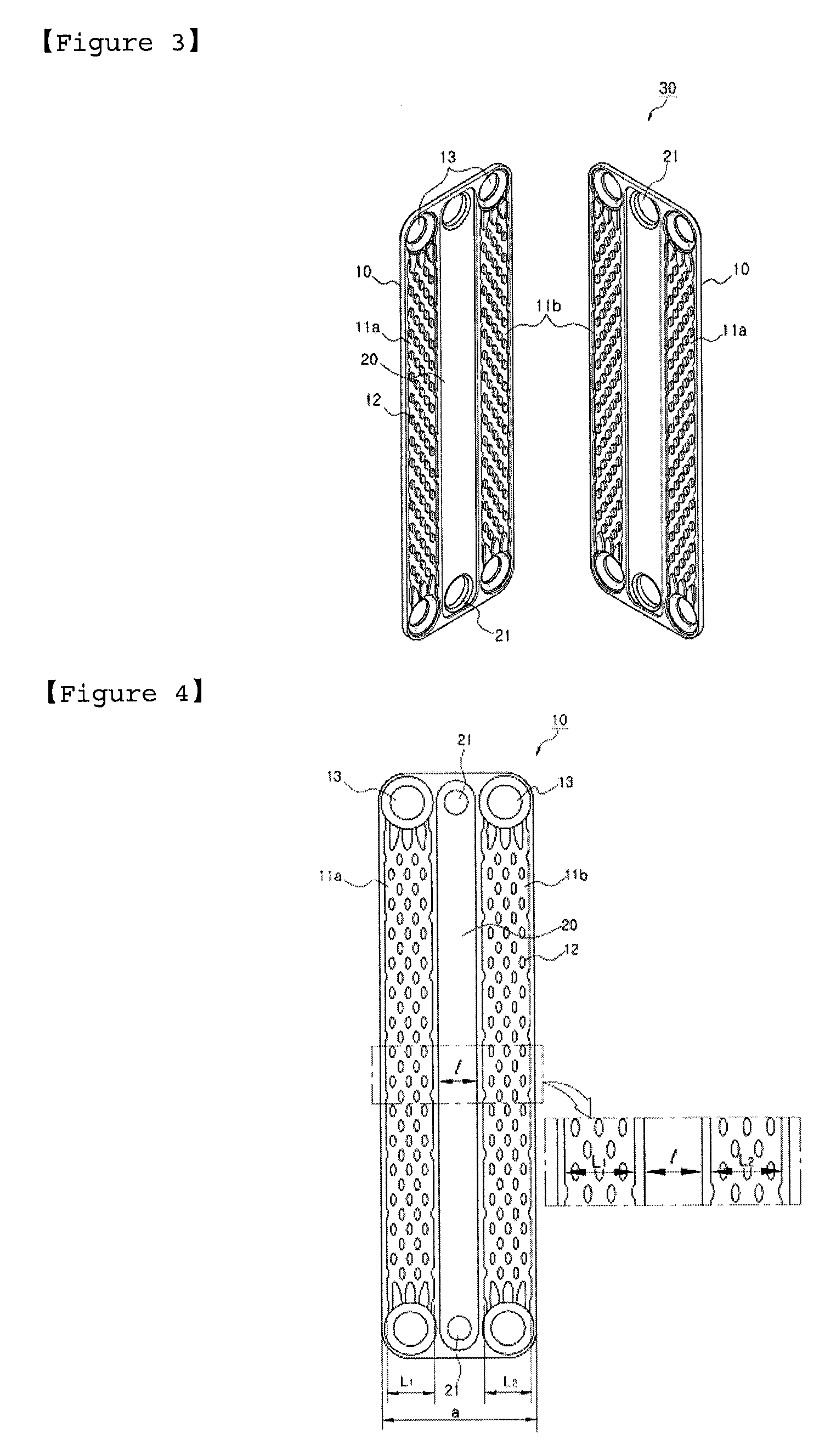

Cold reserving part equipped evaporator

ActiveUS20090120624A1Avoid temperature riseRapidly reserveHeat storage plantsEvaporators/condensersEngineeringRefrigerant

The present invention provides an evaporator in which a plurality of tubes (30), in which a pair of plates (10) forming independent refrigerant passages (11a) and lib are respectively coupled to both sides thereof, are laminated in a row, and a tank (40) communicated with the tube (30) is formed at an upper or lower side of the tube (30), and the tank (40) is provided with an inlet pipe (31) and an outlet pipe (32), and a plurality of fins (50) are formed between the tubes (30), characterized in that a cold reserving part (20) for storing a cold reserving material is formed between the refrigerant passages (11a) and lib of the tube (30), and integrally formed with the plate (10).

Owner:HANON SYST

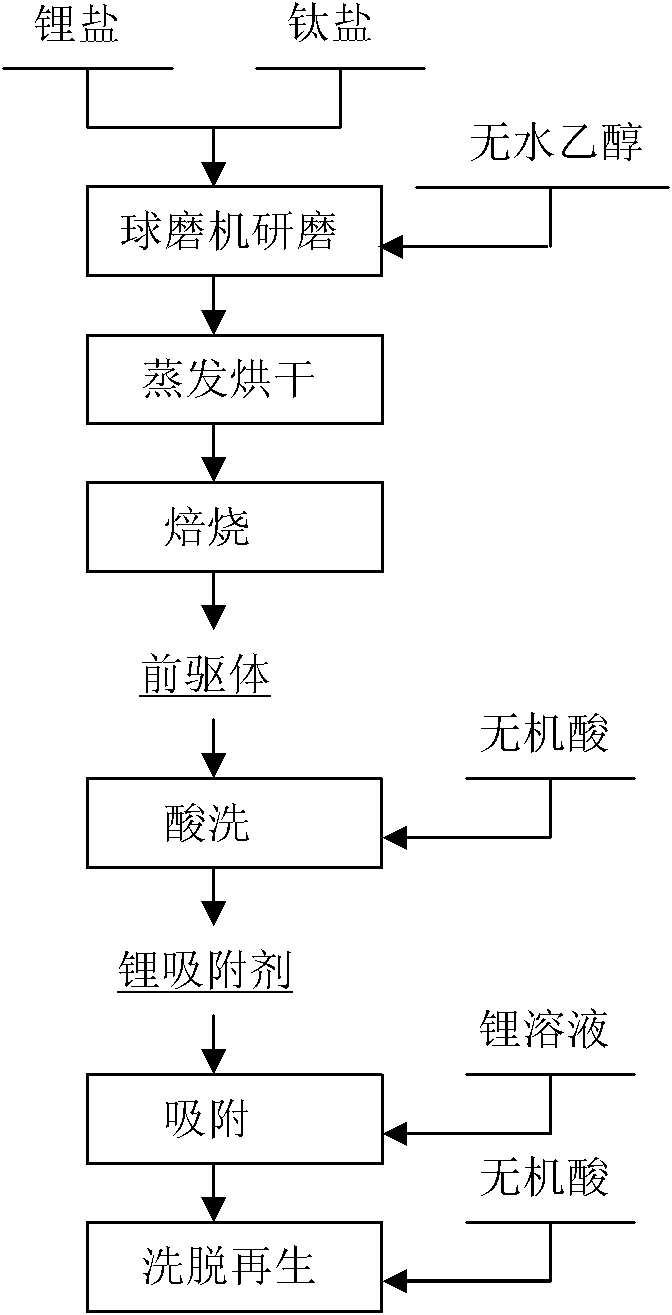

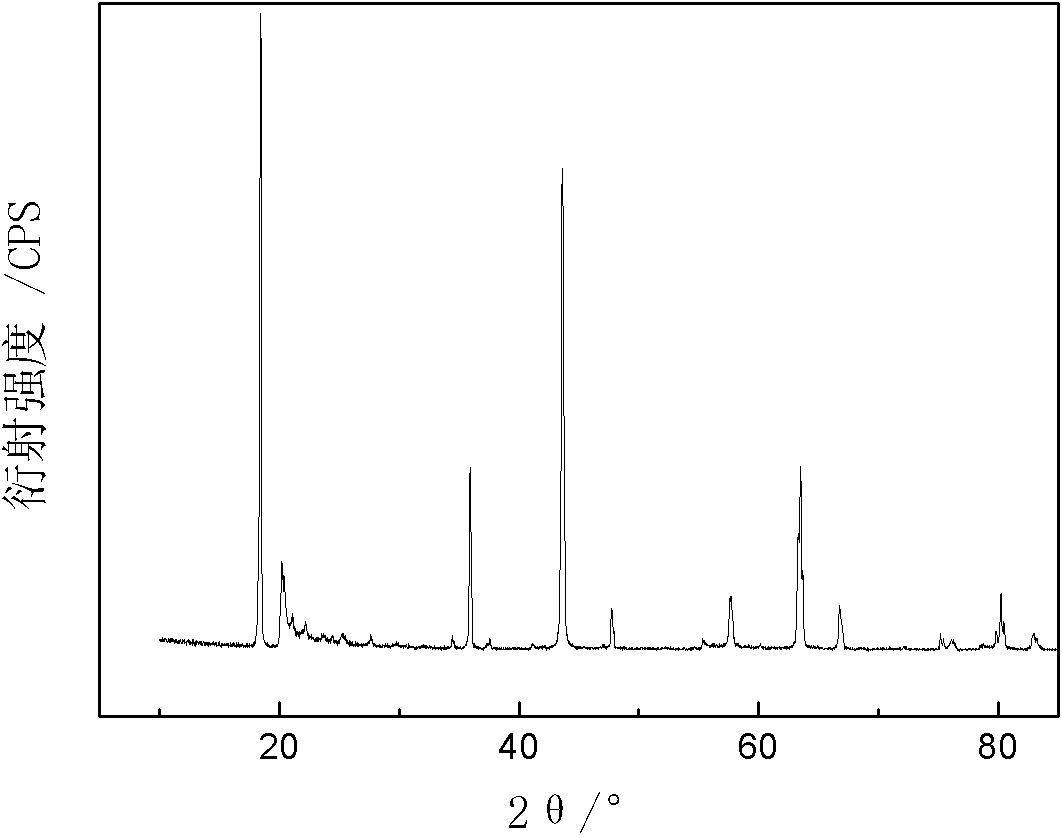

Lithium-titanium oxide type lithium ion sieve absorbent and method for preparing precursor thereof

InactiveCN101944600AWell mixedIncrease contact surfaceCell electrodesTitanium compoundsSalt lake brineTitanium oxide

The invention discloses a lithium-titanium oxide type lithium ion sieve absorbent and a method for preparing a precursor thereof, and relates to a method for preparing an inorganic absorbent for absorbing enriched lithium from salt lake brine, seawater and other liquid lithium resources. The method is characterized in that: titanium dioxide and lithium salt are taken as raw materials, ground by a ball grinder and dried so as to prepare a precursor Li2TiO3 of an ion sieve through a high-temperature solid-phase roasting method; and the lithium is eluted from the precursor Li2TiO3 by inorganic acid to prepare an ion sieve H2TiO3. The method has the advantage of simple technology, and the obtained ion sieve has the advantages of low solution loss and high adsorption capacity.

Owner:CENT SOUTH UNIV

Photo-curable 3D (three-dimensional) printing aluminum-base ceramic slurry and method for preparing ceramic mold cores

ActiveCN108083777AImprove liquidityEvenly dispersedAdditive manufacturing apparatusFoundry mouldsSlurryViscosity

The invention discloses photo-curable 3D (three-dimensional) printing aluminum-base ceramic slurry and a method for preparing ceramic mold cores. The photo-curable 3D printing aluminum-base ceramic slurry comprises ceramic formula powder, photo-curable resin systems and additives. The photo-curable 3D printing aluminum-base ceramic slurry and the method have the advantages that the photo-curable 3D printing aluminum-base ceramic slurry is high in solid phase content, low in viscosity and applicable to photo-curable 3D printing photo-polymerization, the problems of high viscosity and poor flowability of existing slurry for photo-curable 3D printing ceramics, easiness in agglomerating ceramic particles in the existing slurry, uneven dispersion of the ceramic particles, low solid phase contents and the like can be solved, and application of photo-curable 3D printing to ceramic precision components can be expanded.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

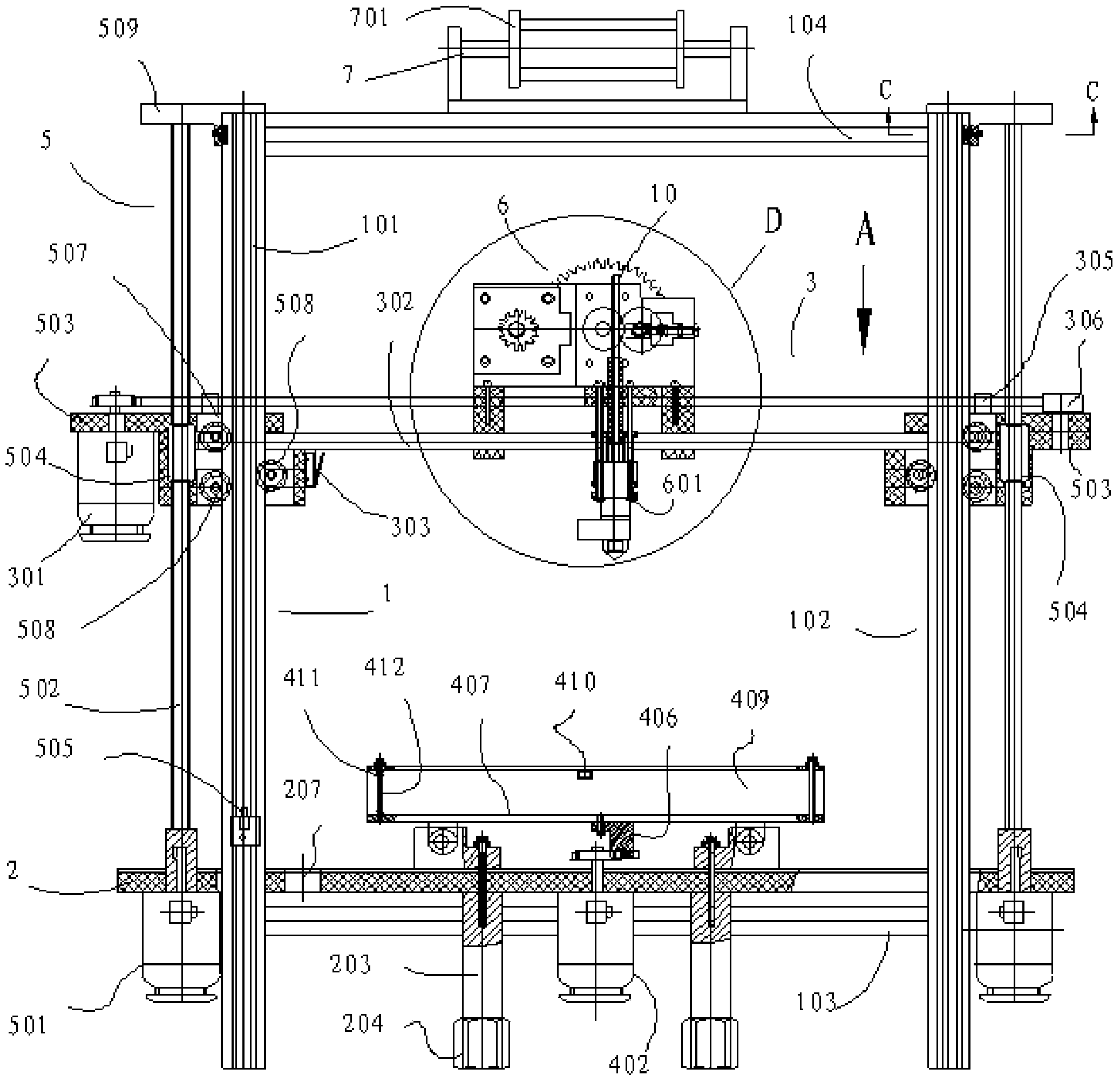

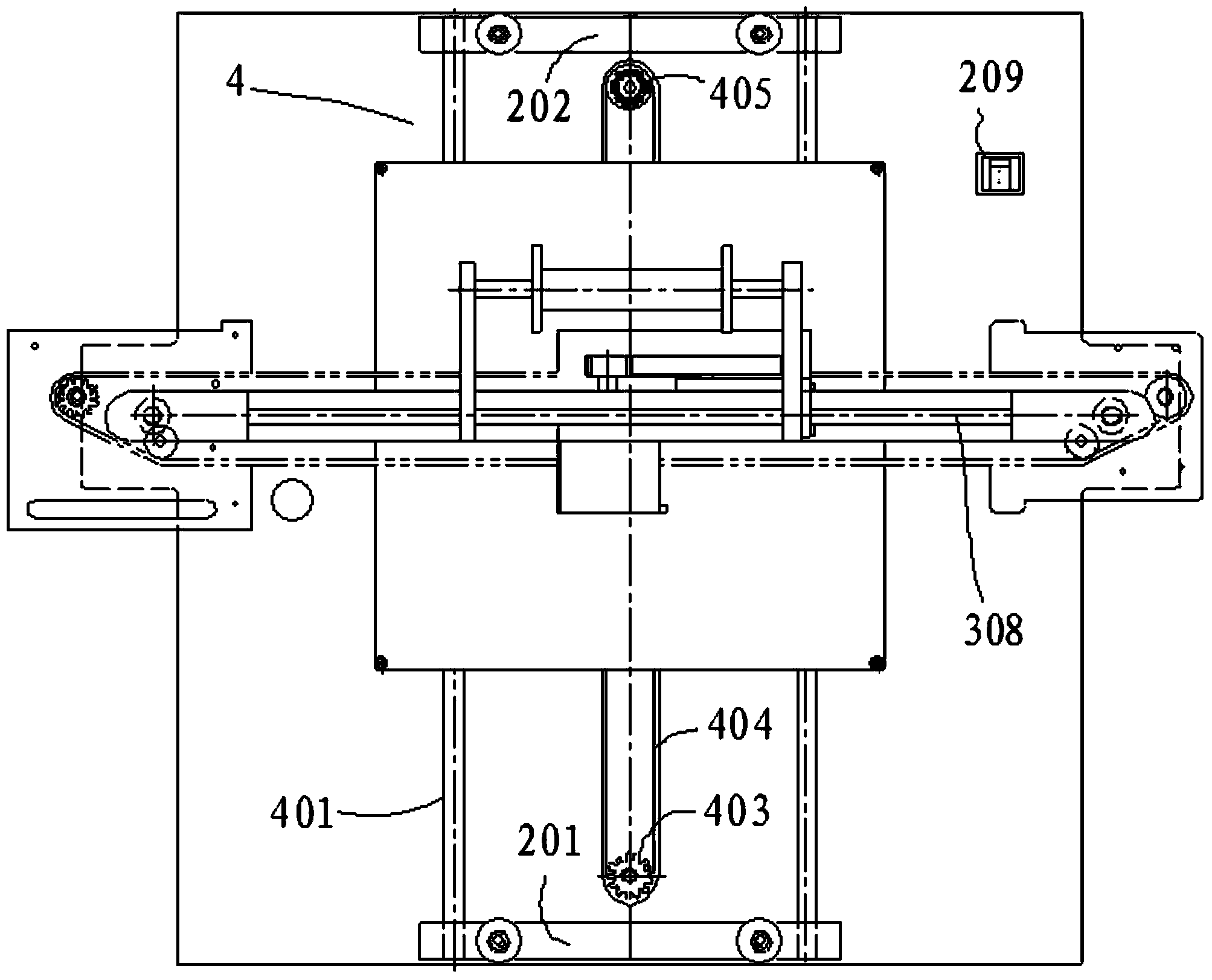

Three-dimensional (3D) printer

The invention discloses a three-dimensional (3D) printer which comprises a rack, a base, an X-axis movement system, a Y-axis movement system, a Z-axis movement system and a printing device, wherein the rack comprises a left upright post, a right upright post, an upper connecting plate and a lower connecting plate; the upper connecting plate and the lower connecting plate are connected with the left upright post and the right upright post, respectively; the base is connected with the lower connecting plate; the upper connecting plate is connected with a printing supplies connecting rack; the printing supplies connecting rack is connected with a printing supplies fixing disc; the printing device is connected with the X-axis movement system; the X-axis movement system is connected with the Z-axis movement system; the Z-axis movement system is connected with a guide rail of the left upright post and the right upright post; the Y-axis movement system is connected with the base; the X-axis movement system is provided with an X-axis movement guide rail through which the printing device moves; a power supply and a controller which are connected with each other are arranged at the bottom of the base; the controller is connected with the X-axis movement system, the Y-axis movement system, the Z-axis movement system and the printing device. The 3D printer is simple and compact in structure, small in size and low in manufacturing cost.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com