Patents

Literature

9109 results about "3d printer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

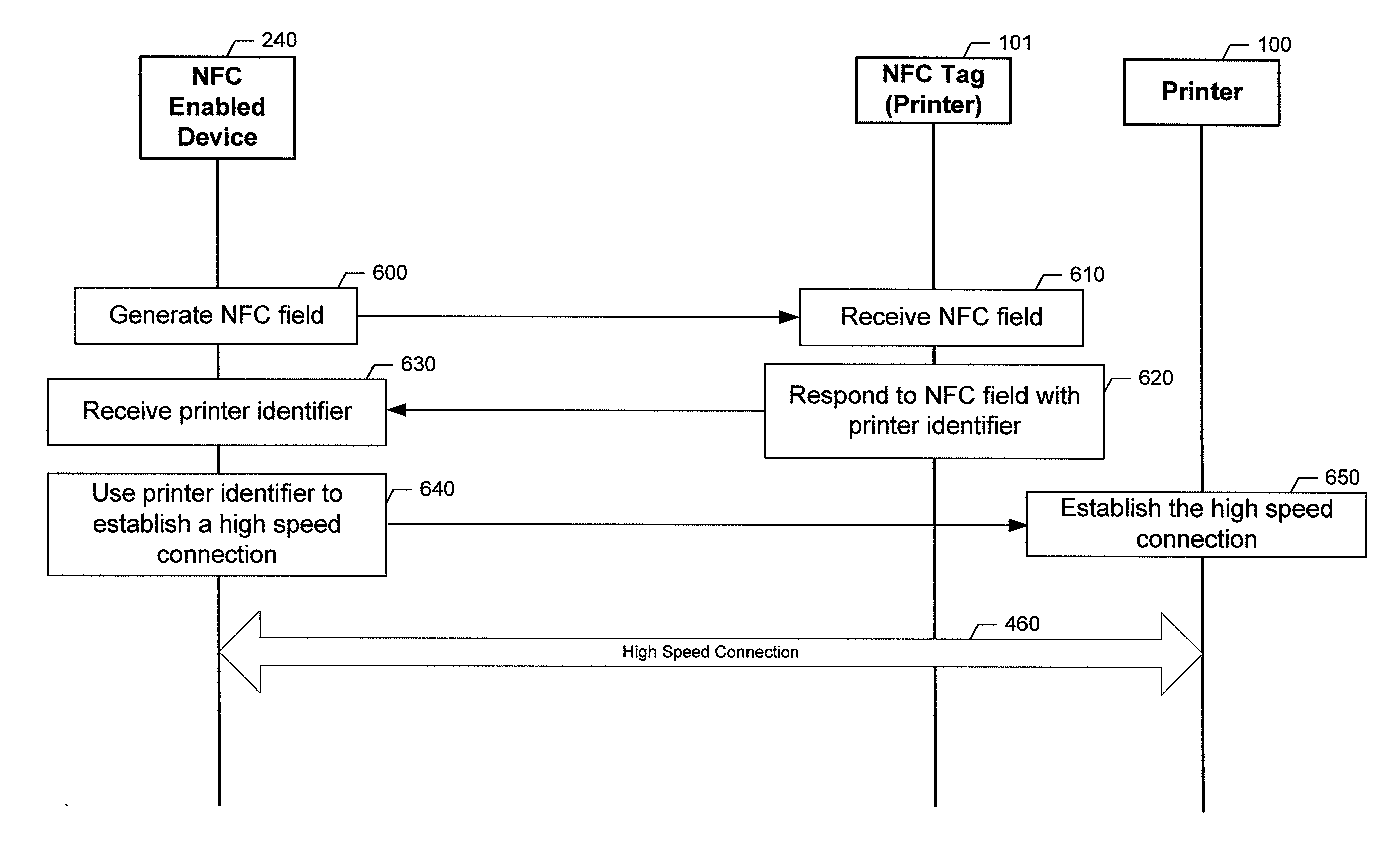

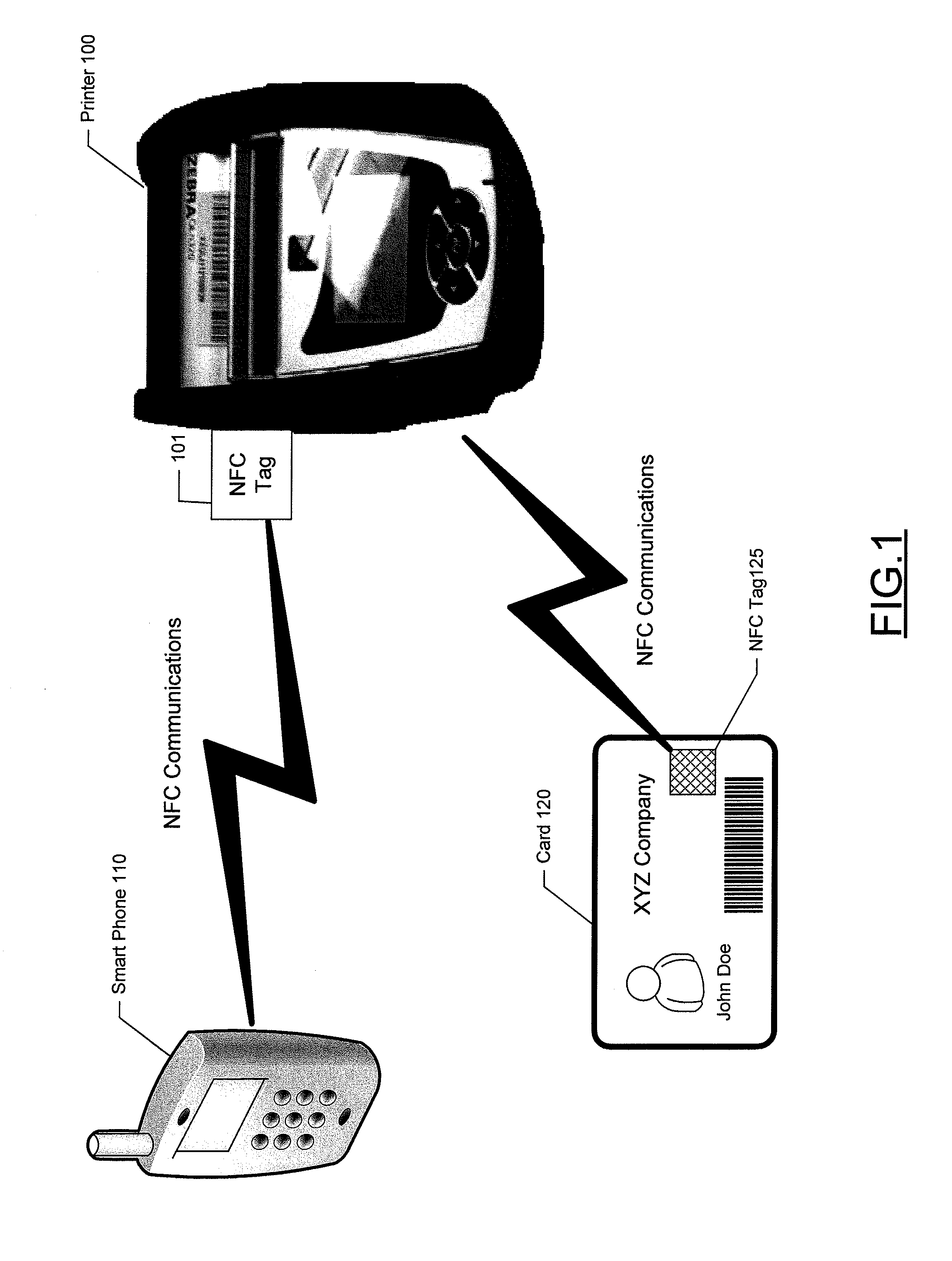

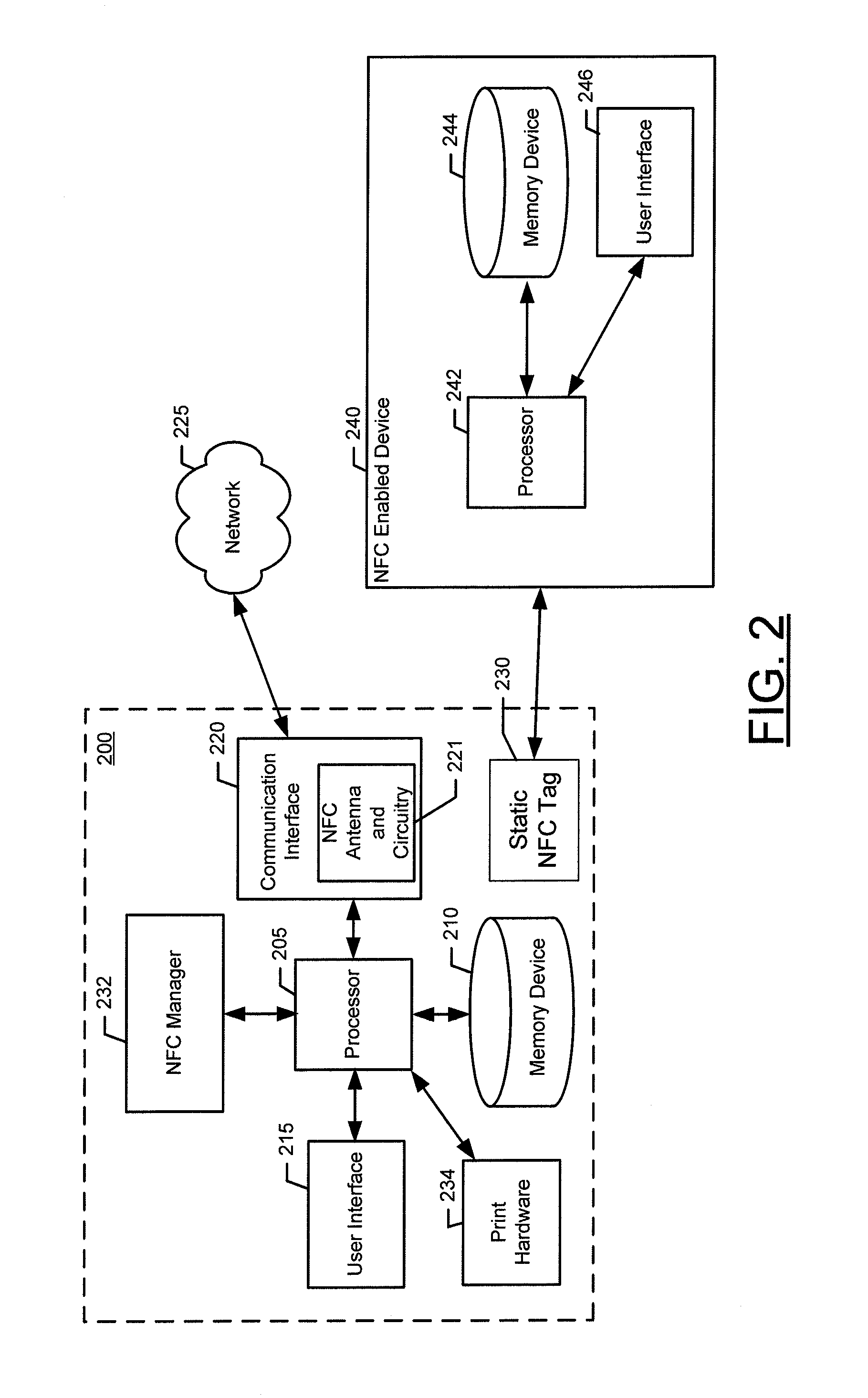

Method and apparatus for implementing near field communications with a printer

Aspects of the disclosure provide systems, methods, and apparatuses for leveraging near field communications (NFC) in conjunction with printer devices. Examples of the disclosure provide for novel methods of interfacing with printers configured to use near field communications using NFC enabled readers and output media. Examples include using a smart phone to access data stored on an NFC tag associated with the printer. The data provided by the NFC tag may include printer status information, printer configuration information, network information, or other data relating to operation and maintenance of the printer. The printer may also encode the NFC tag dynamically, including encoding data to NFC tags included on print media. The printer may encode an NFC tag associated with media with a variety of information in support of various use cases.

Owner:ZIH CORP

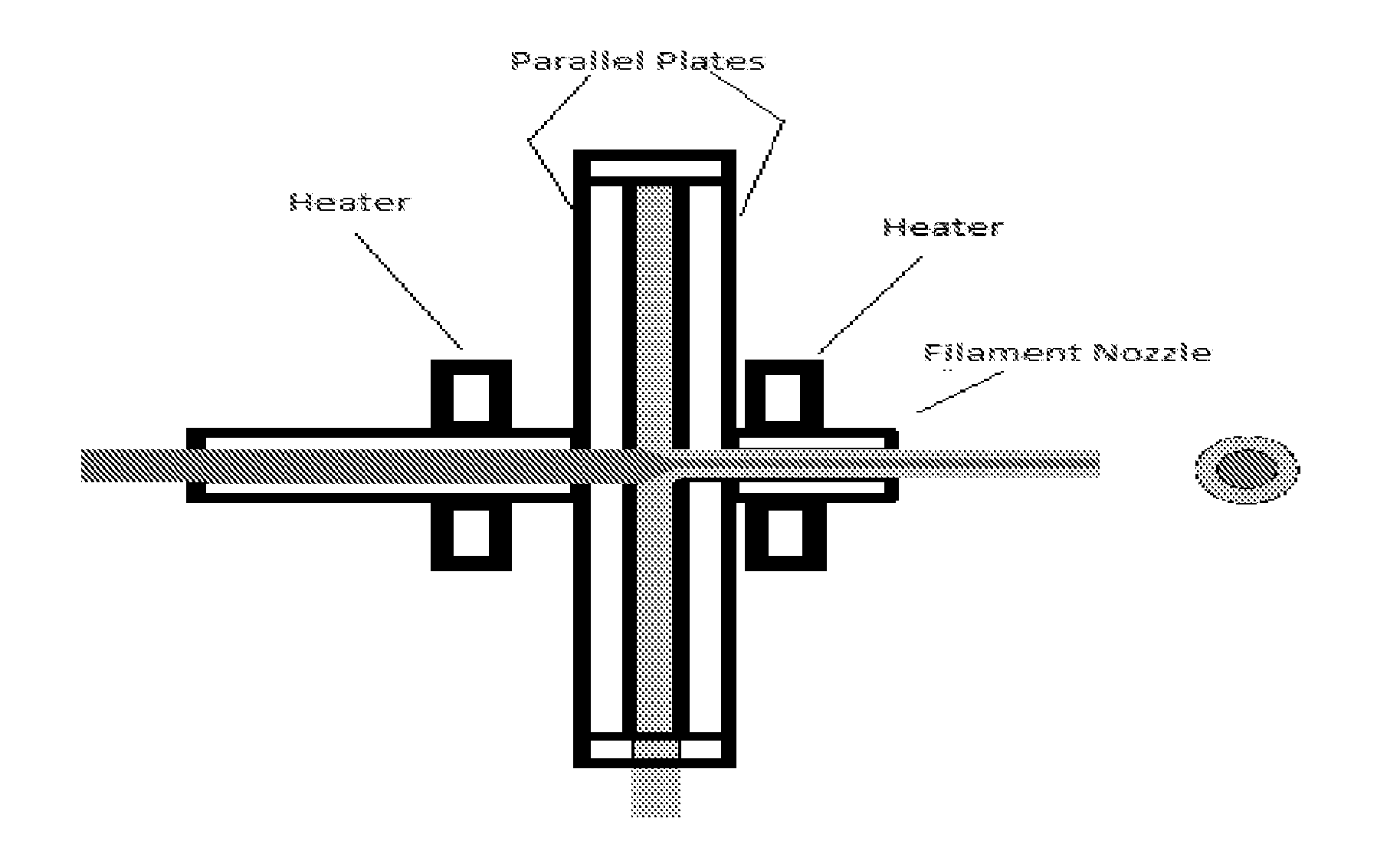

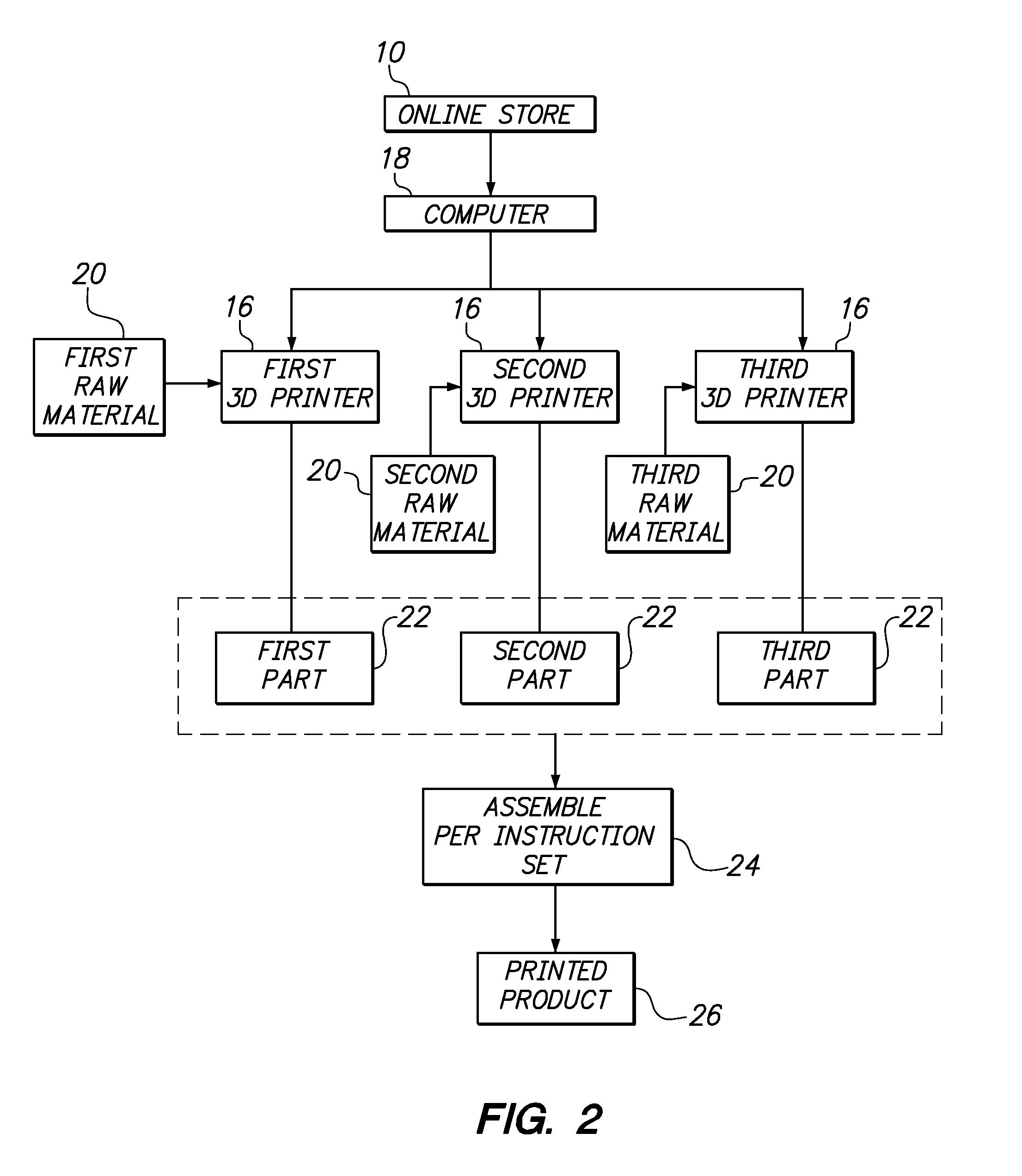

Coextruded, multilayer and multicomponent 3D printing inputs field

PendingUS20160297104A1Small sizeHigh viscosityAdditive manufacturing apparatusFilament/thread formingEngineering3d printer

The present invention relates to 3D printer inputs including filaments comprising separated layers or sections. These inputs particularly including filaments may be prepared by coextrusion, microlayer coextrusion or multicomponent / fractal coextrusion. These inputs and specifically filaments enable layering or combining different materials simultaneously through one or more nozzles during the so-called 3D printing process. These techniques facilitate smaller layer sizes (milli, micro, and nano) different layer configurations as well as the potential to incorporate materials that would otherwise not be usable in standard 3D printer methods.

Owner:GUILL TOOL & ENG

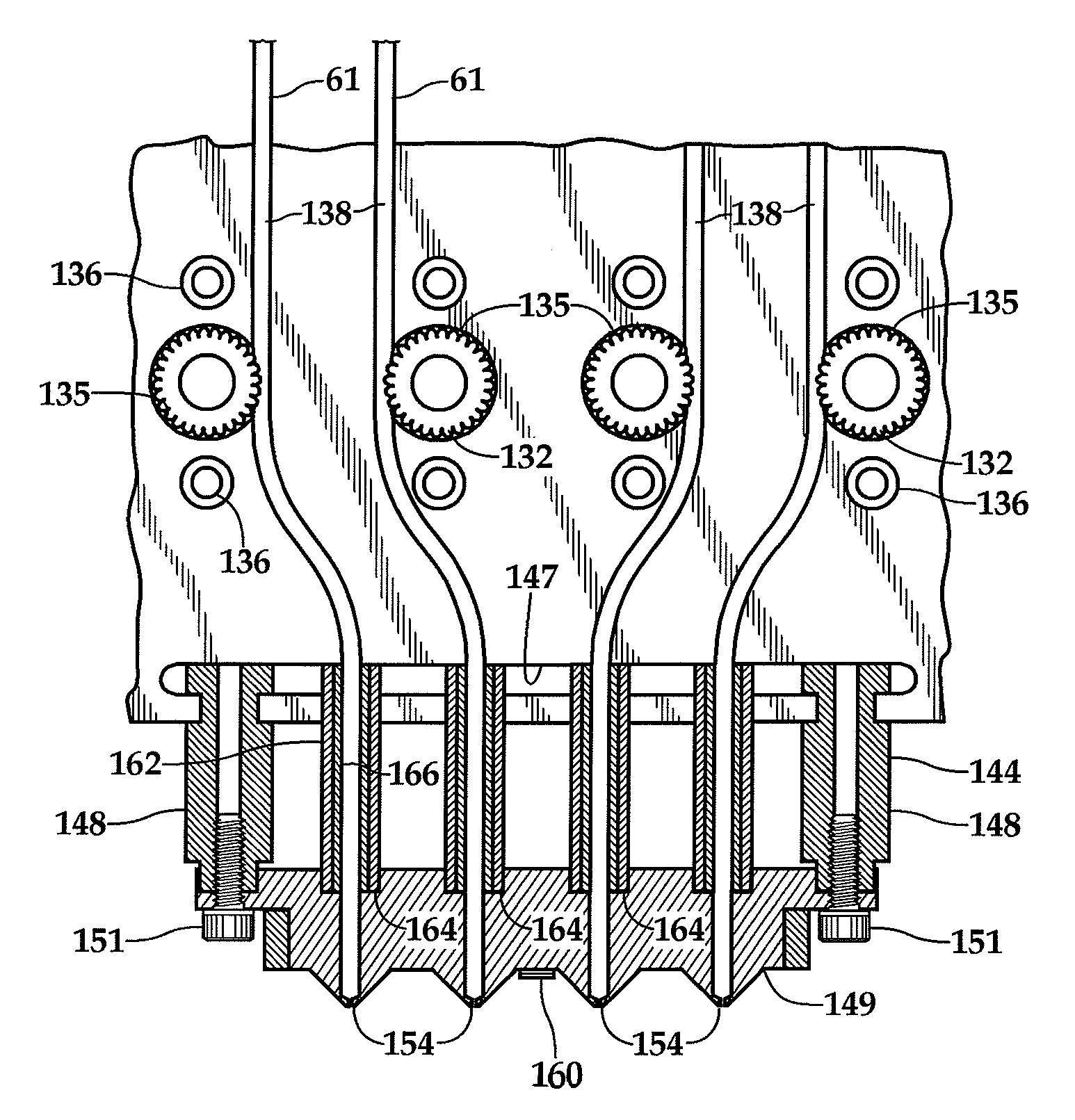

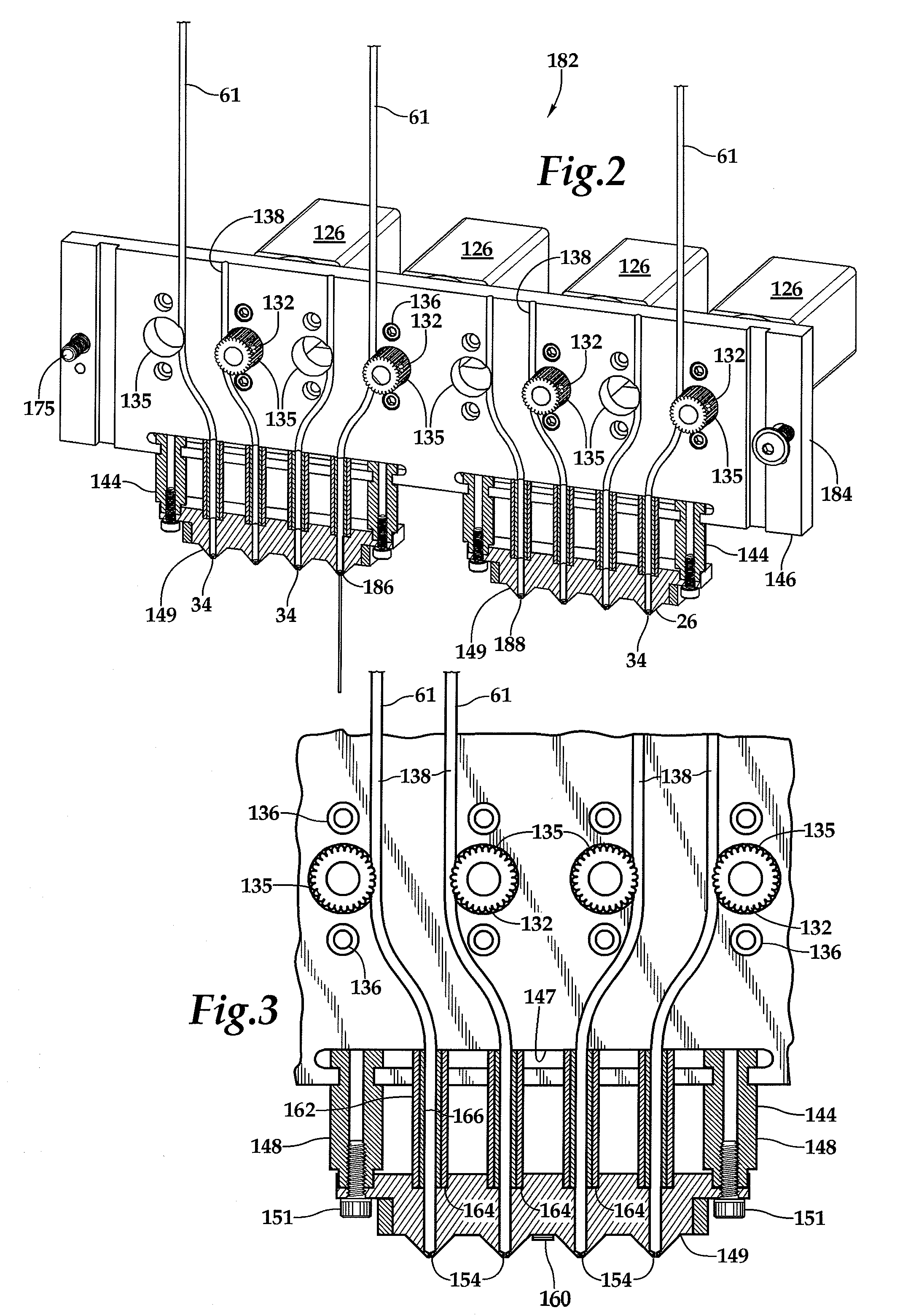

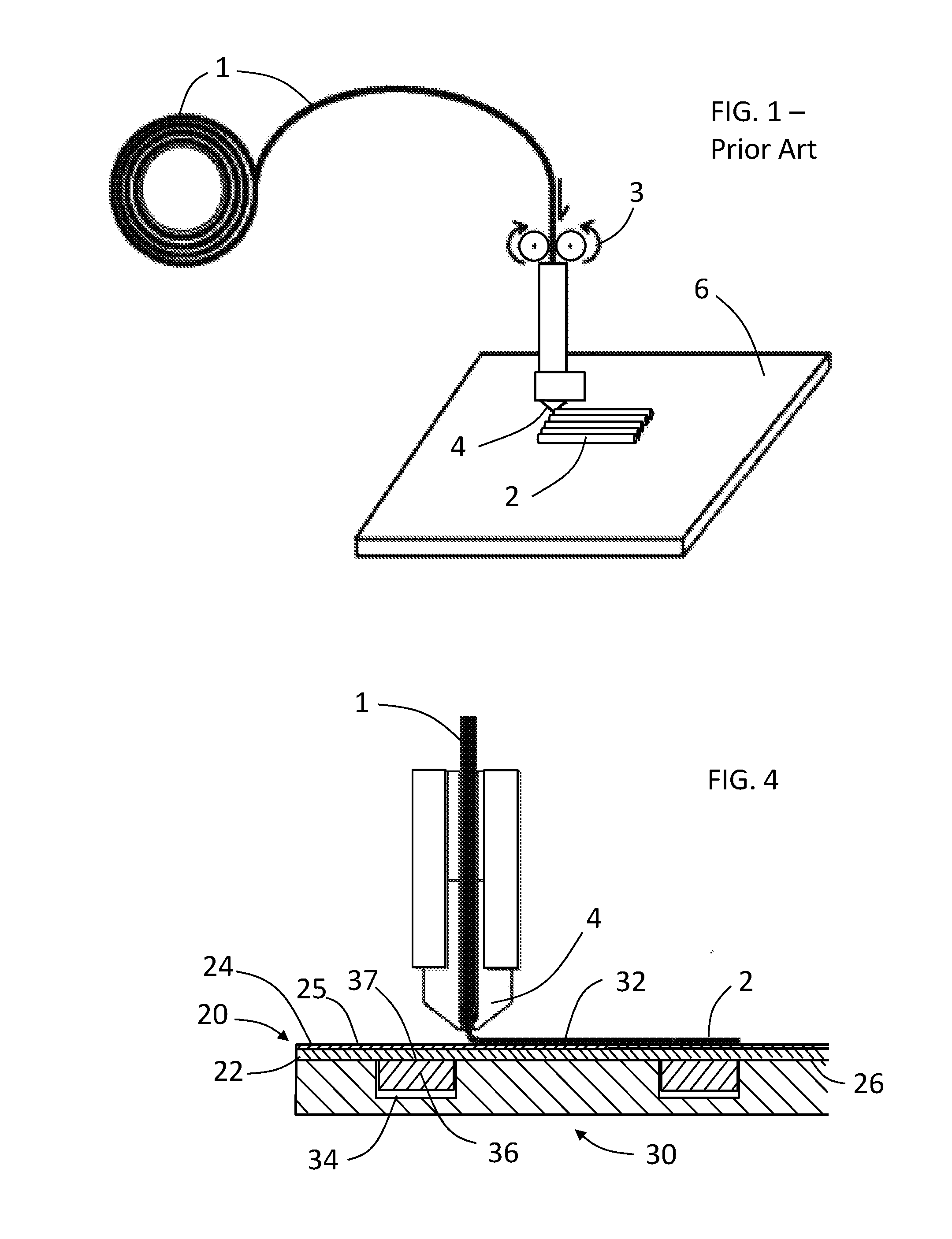

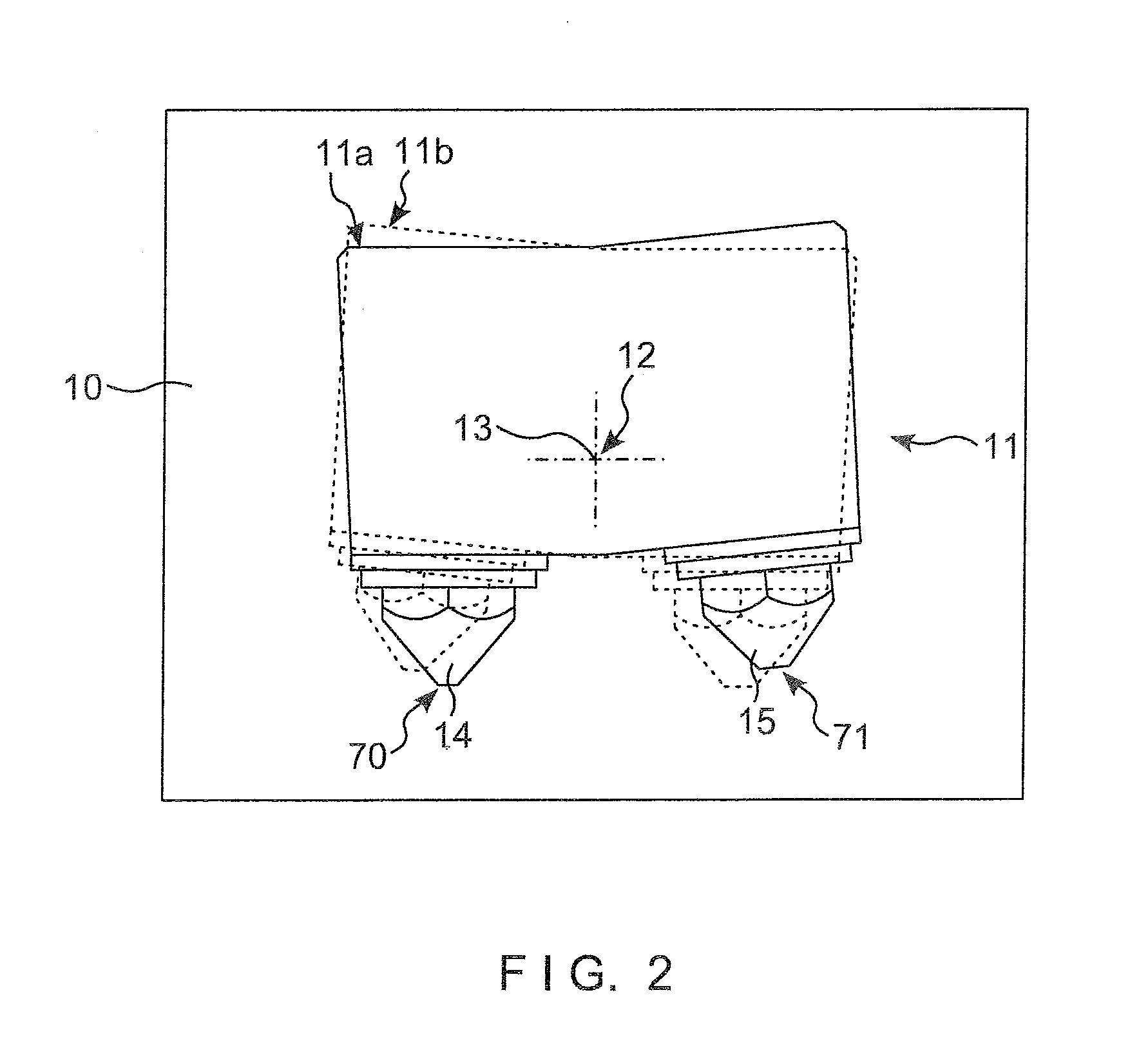

3D printer and printhead unit with multiple filaments

InactiveUS8827684B1Reduce complexityIncrease speedConfectionerySweetmeatsFused filament fabricationMetal filament

A fused filament fabrication printer has a fixed extrusion module having multiple printheads having print tips. The fixed arrangement of the printing heads allows the close spacing of multiple print tips in a printhead unit, and the simple routing of multiple plastic or metal filaments to the individual printing heads. The closely spaced print tips in the printhead unit share common components. An exemplary printhead unit has four printing heads which share a common heating block and heating block temperature sensor. The heating block incorporates a group of four print tips evenly spaced along a line. Each printing head has a separate filament which is controlled and driven by its own stepper motor through the heating block to one of the print tips. Printing of a part is by control of individual stepper motors which drive filaments through the heating block and through one of the printing tips.

Owner:RADIANT FABTION

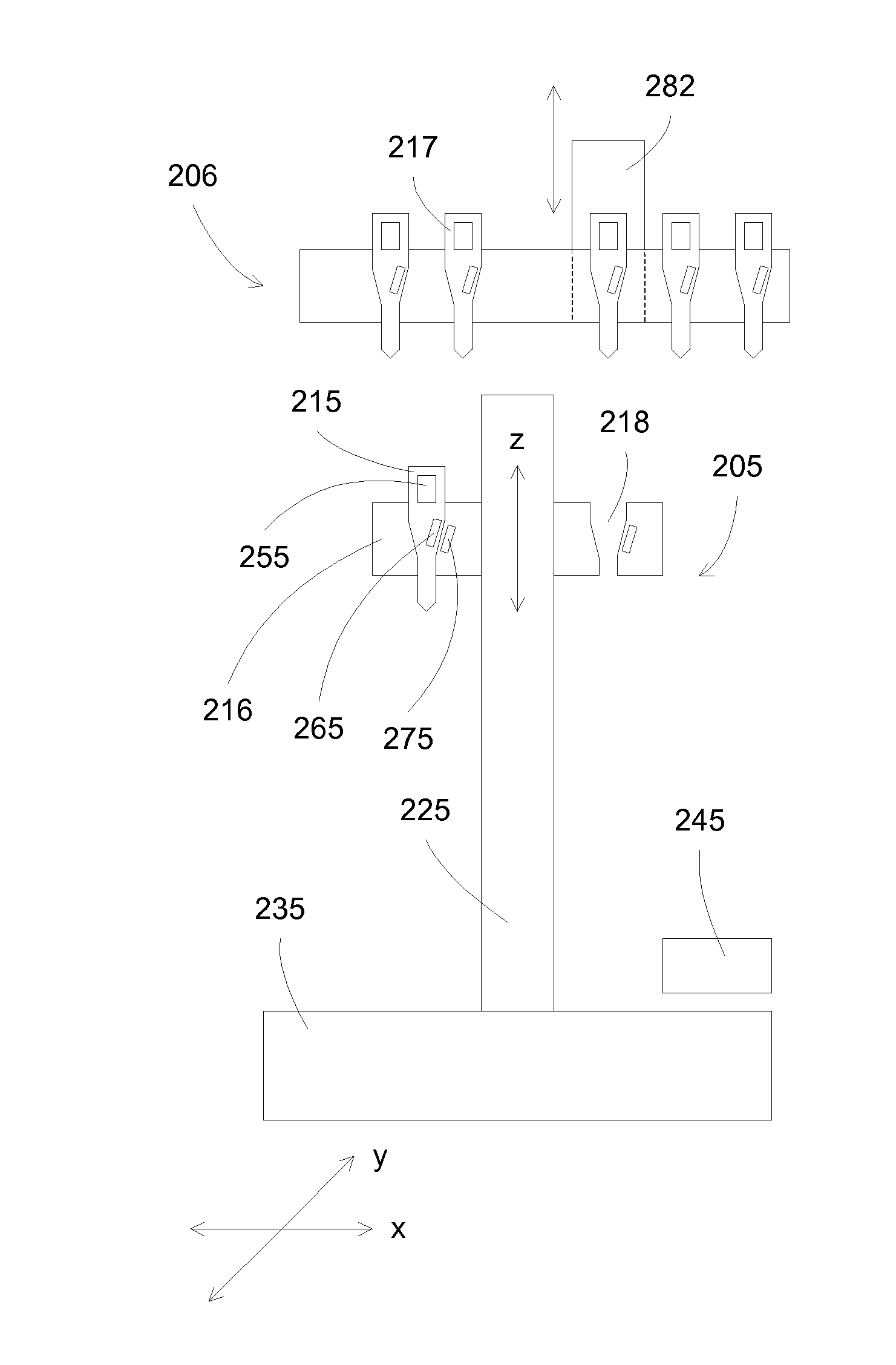

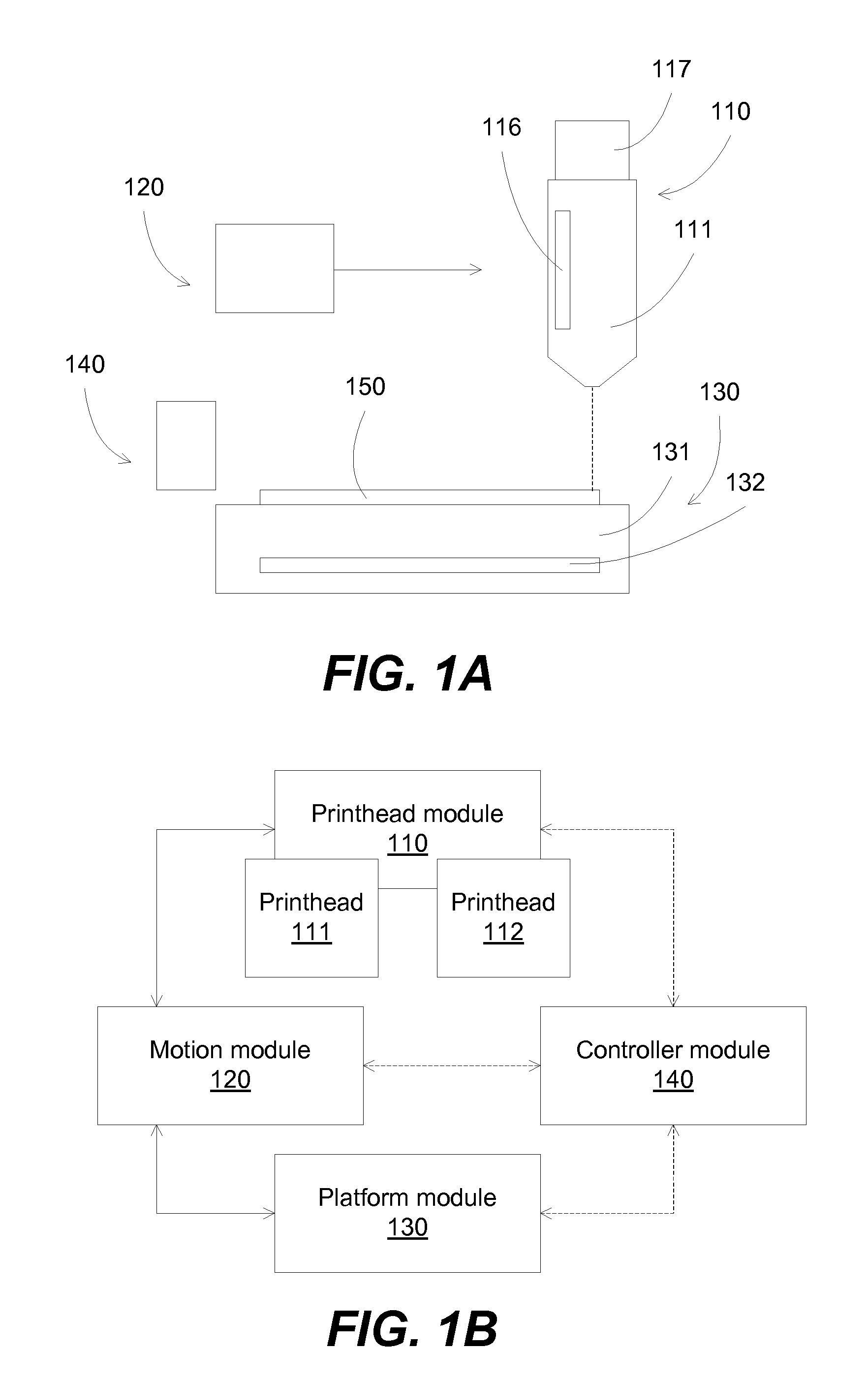

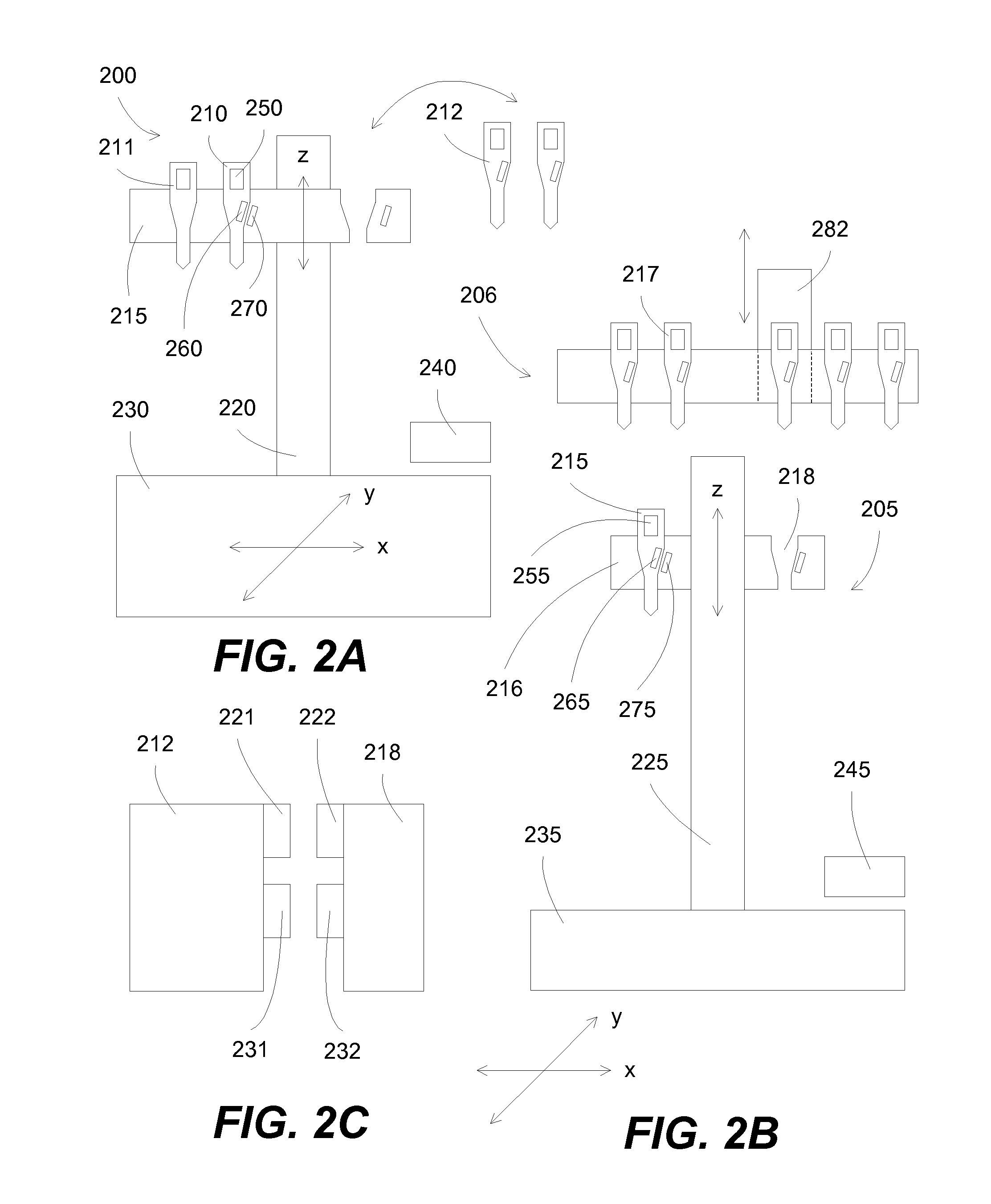

Systems and methods for 3D printing with multiple exchangeable printheads

A modular 3D printer system can include a base subsystem and multiple exchangeable components. The base subsystem can have a 3D motion module, a printhead module and a platform module. The multiple exchangeable components can include printheads having different configurations and functionalities, which can be exchangeably installed in the printhead module. The multiple exchangeable components can include platform supports having different configurations and functionalities, which can be exchangeably installed in the platform module.

Owner:GIFFORD KARL JOSEPH +3

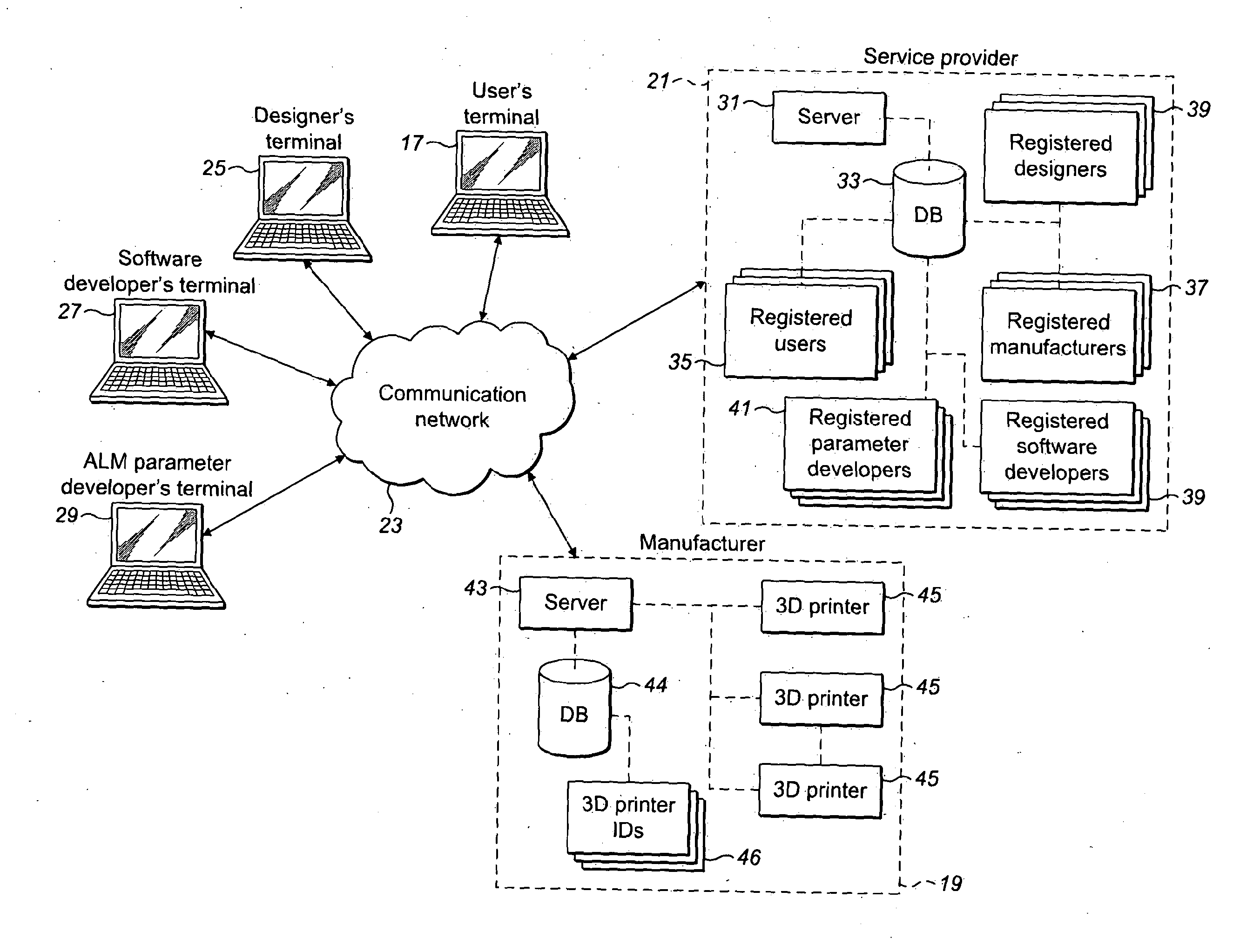

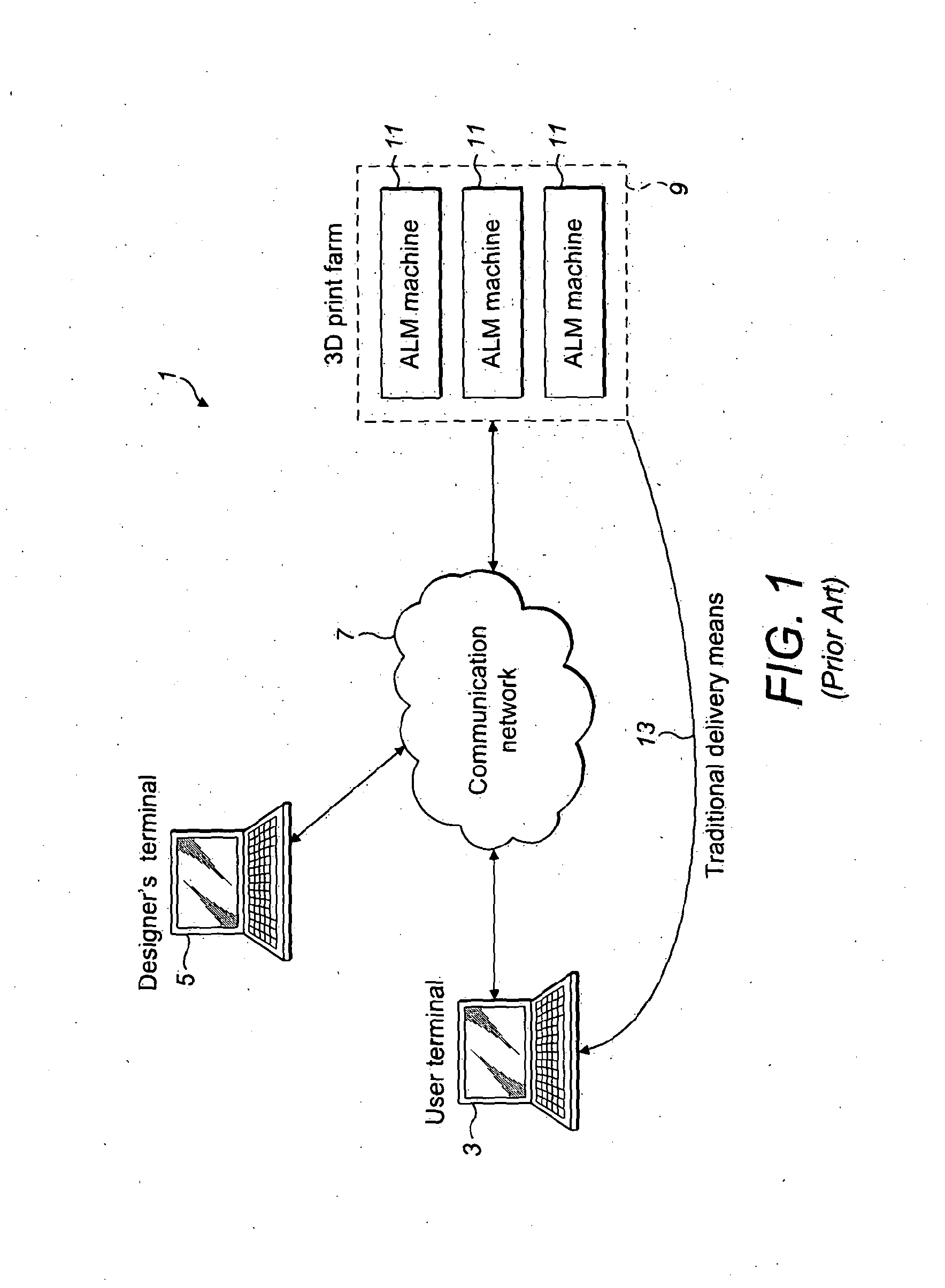

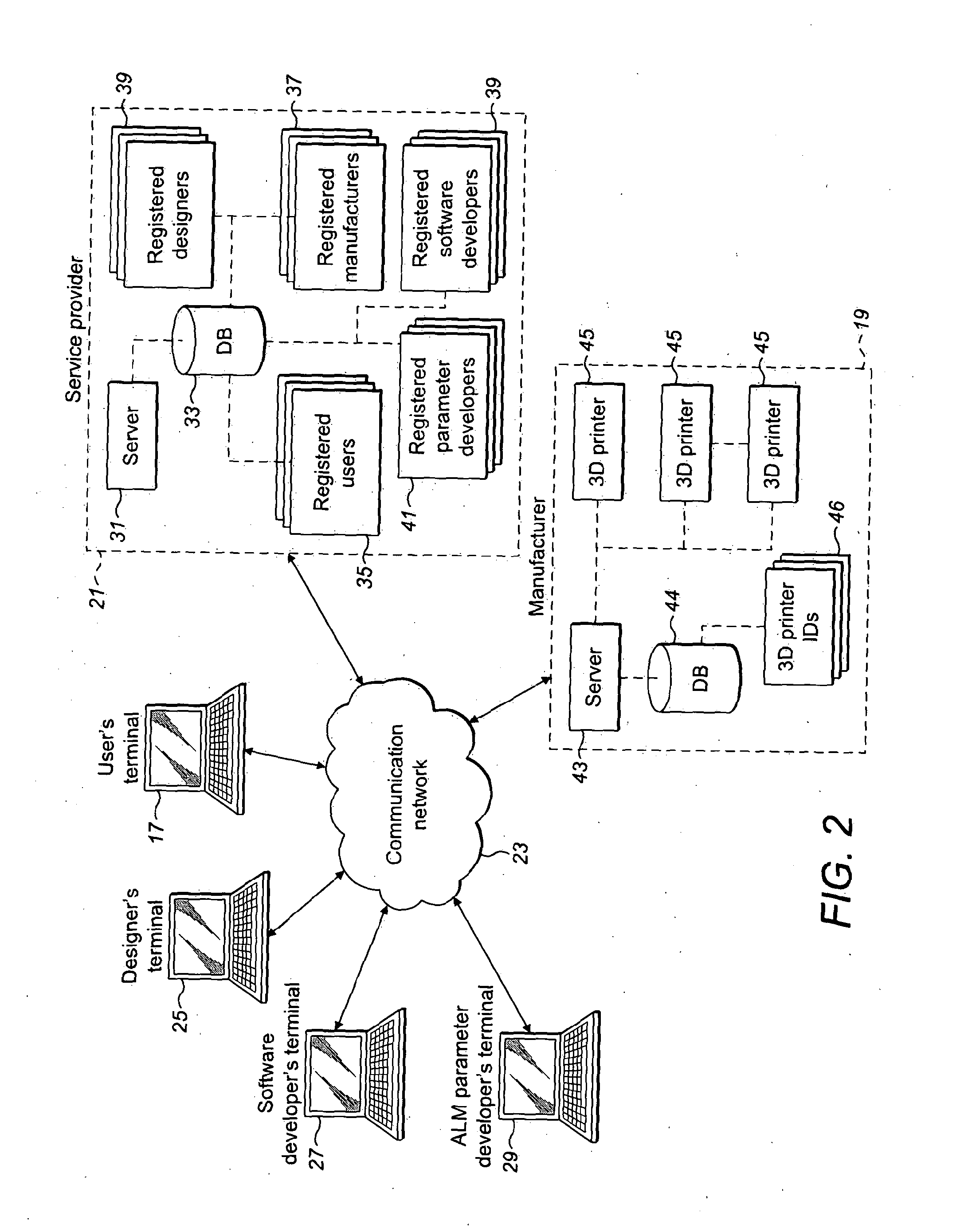

Three-dimensional design and manufacturing systems

ActiveUS20140156053A1Use directlyMinimize amount of processingAdditive manufacturing apparatusData processing applications3d print3d design

A method of authenticating the printing of a three-dimensional (3D) article at a 3D printer according to a 3D print file describing a three-dimensional design is described. The method comprises: receiving an authentication request from a 3D print server that is associated with the 3D printer, the request comprising a unique design identifier associated with a 3D design file and a unique 3D printer identifier associated with a 3D printer, the received unique 3D design identifier being related to the received 3D printer ter identifier in accordance with a first relationship; using at least one of the received unique identifiers to access a verifying 3D design identifier and a verifying 3D printer identifier, the verifying identifiers being related to each other in accordance with a second relationship; comparing the first and second relationships between the received and verifying identifiers; generating an authentication signal if the first relationship corresponds with the second relationship; obtaining a decryption key associated with the received identifiers in response to the authentication signal; and transferring the decryption key to the 3D print server to authenticate and enable the printing of the 3D article on the 3D printer.

Owner:DNA AM LTD

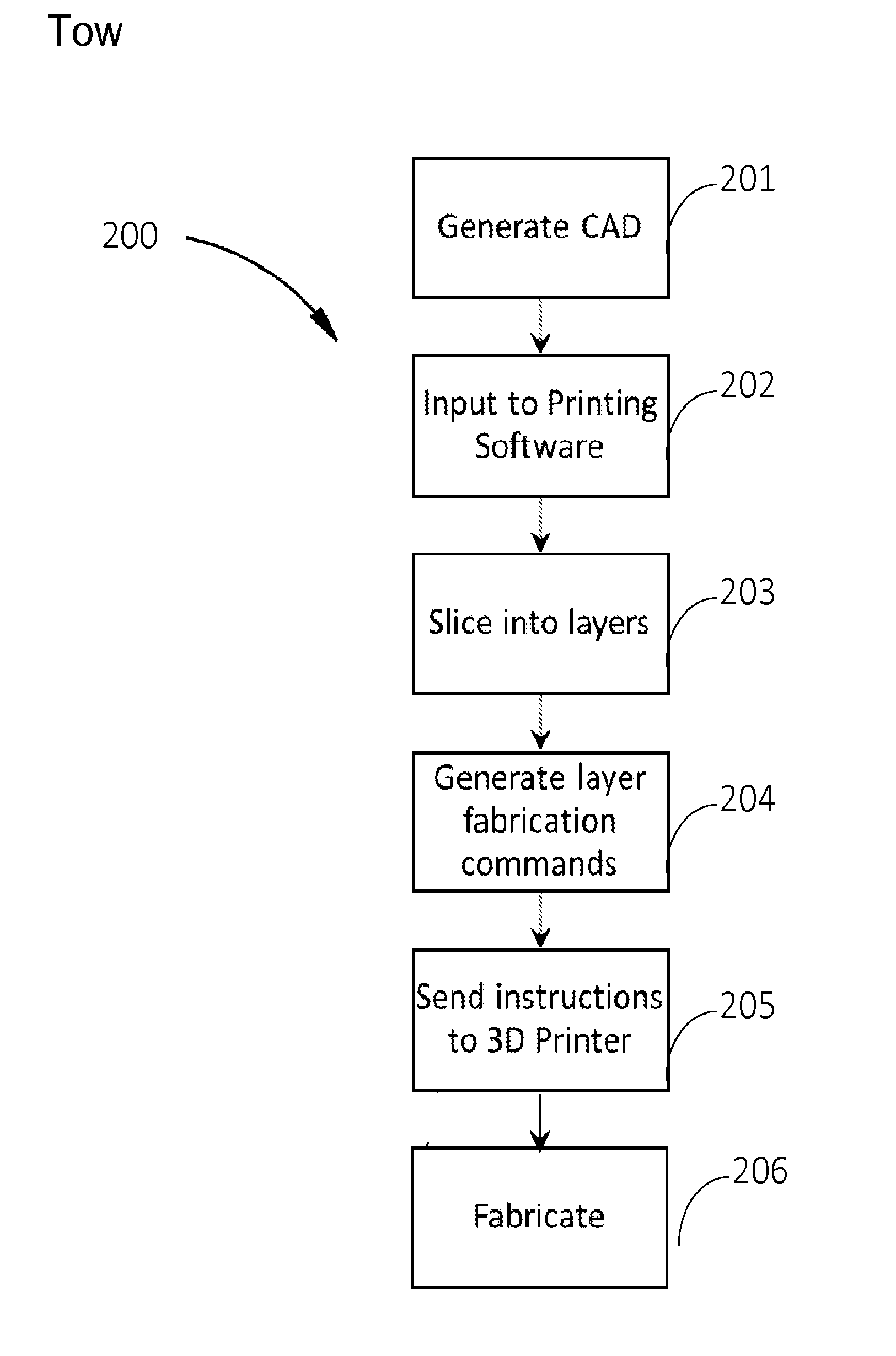

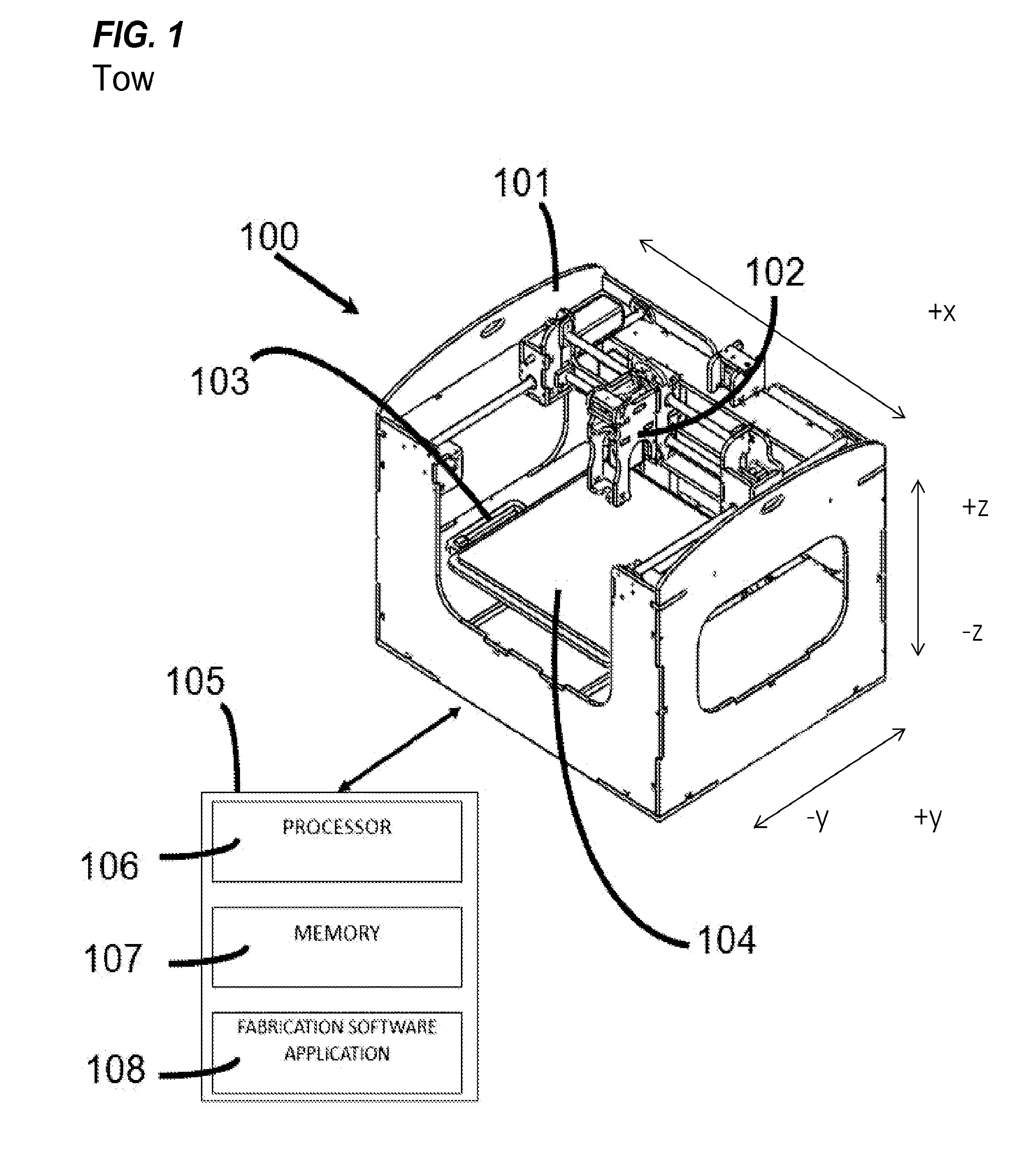

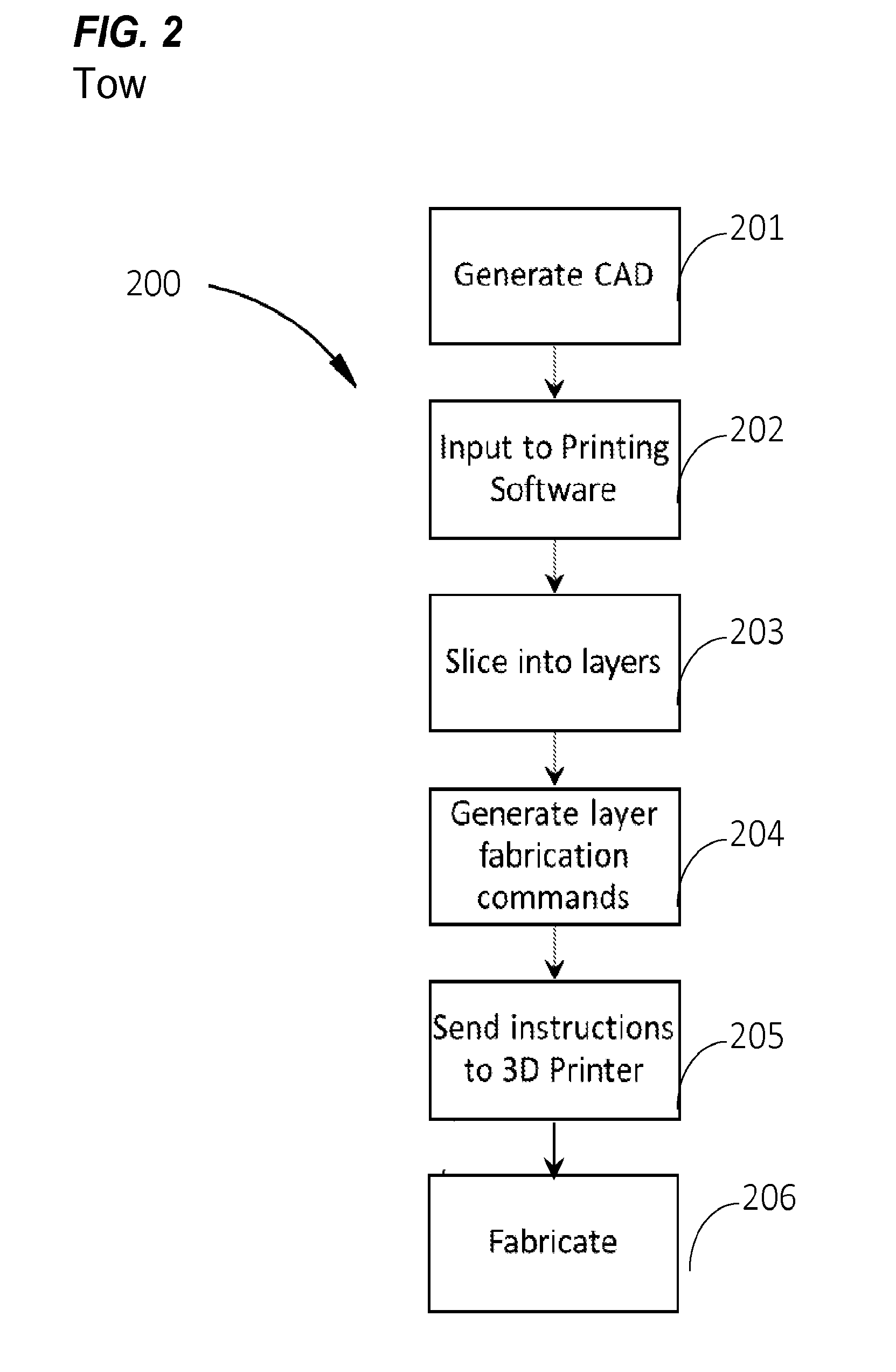

Systems and methods for manufacturing of multi-property anatomically customized devices

InactiveUS20150165690A1Increase productionOvercomes shortcomingAdditive manufacturing apparatusComputer controlMulti materialEngineering

Systems and methods for using a three dimensional fabrication device, like a 3D Printer, for novel automation and additive manufacturing techniques in manufacturing medical devices such as orthotics, customized for a particular person. The systems and methods may use a plurality of work surfaces on the three dimensional fabrication device. The systems and methods may use a plurality of materials or a plurality of fabrication tools and processes to manufacture the customized product.

Owner:TOW ADAM P

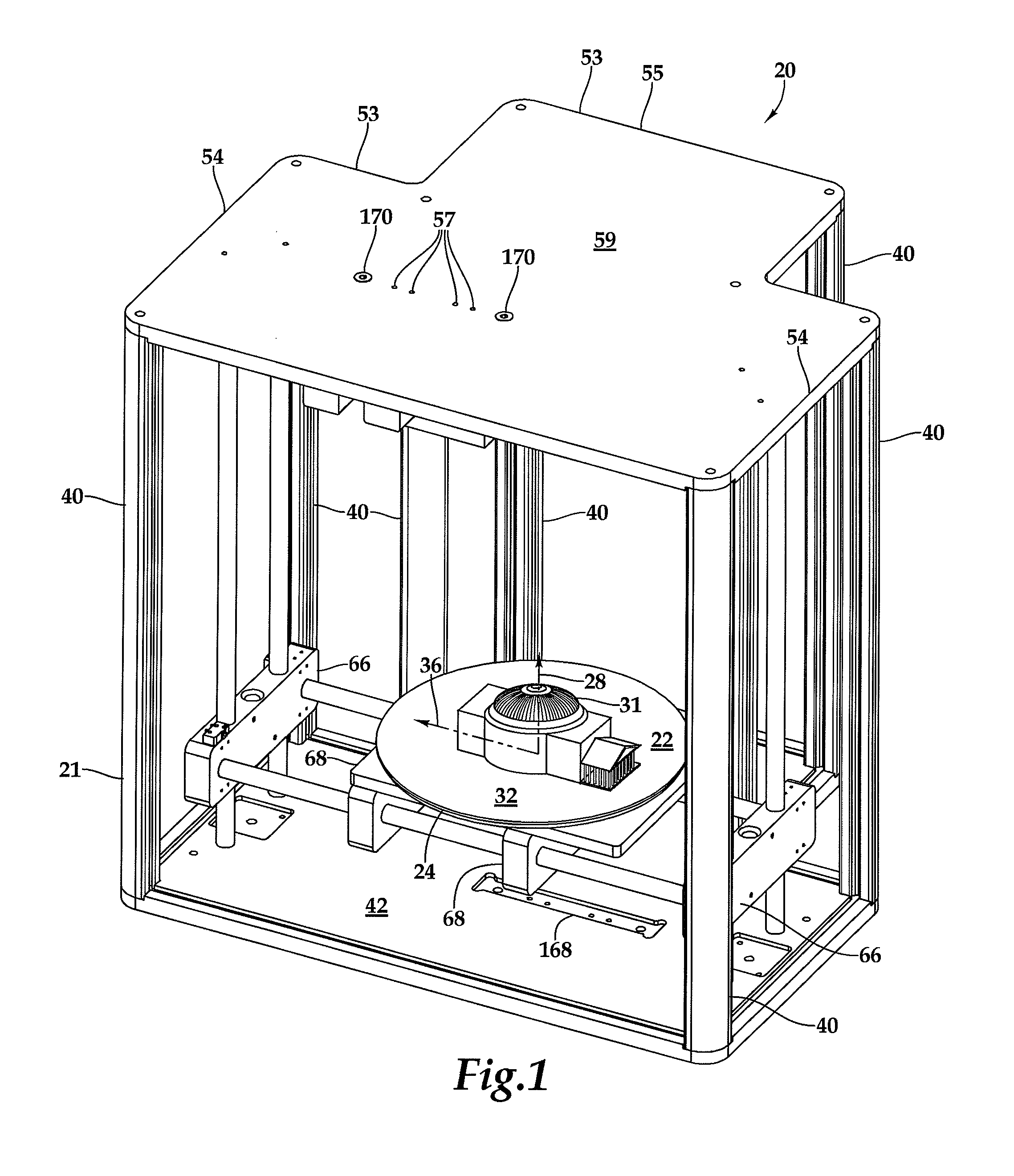

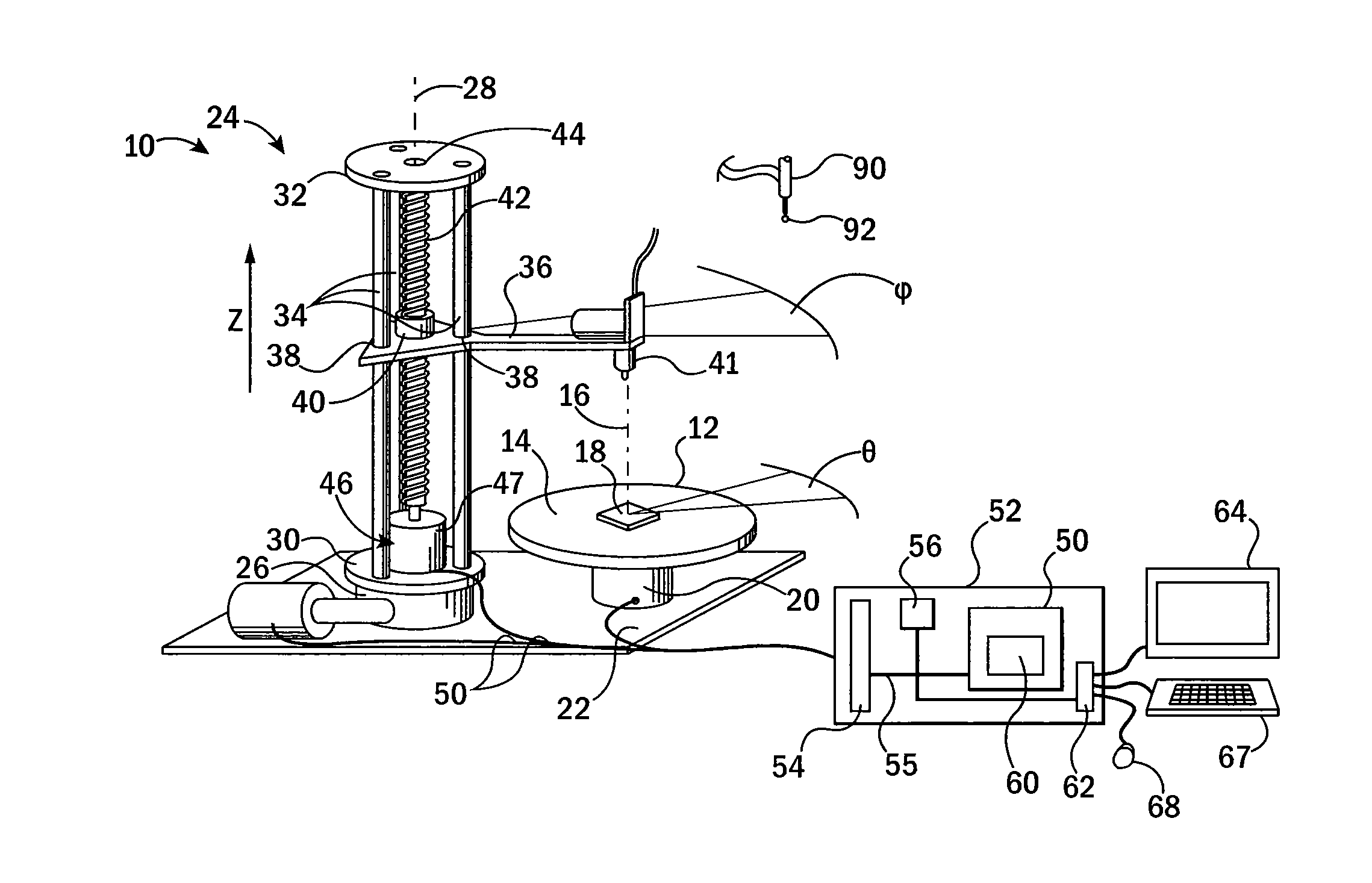

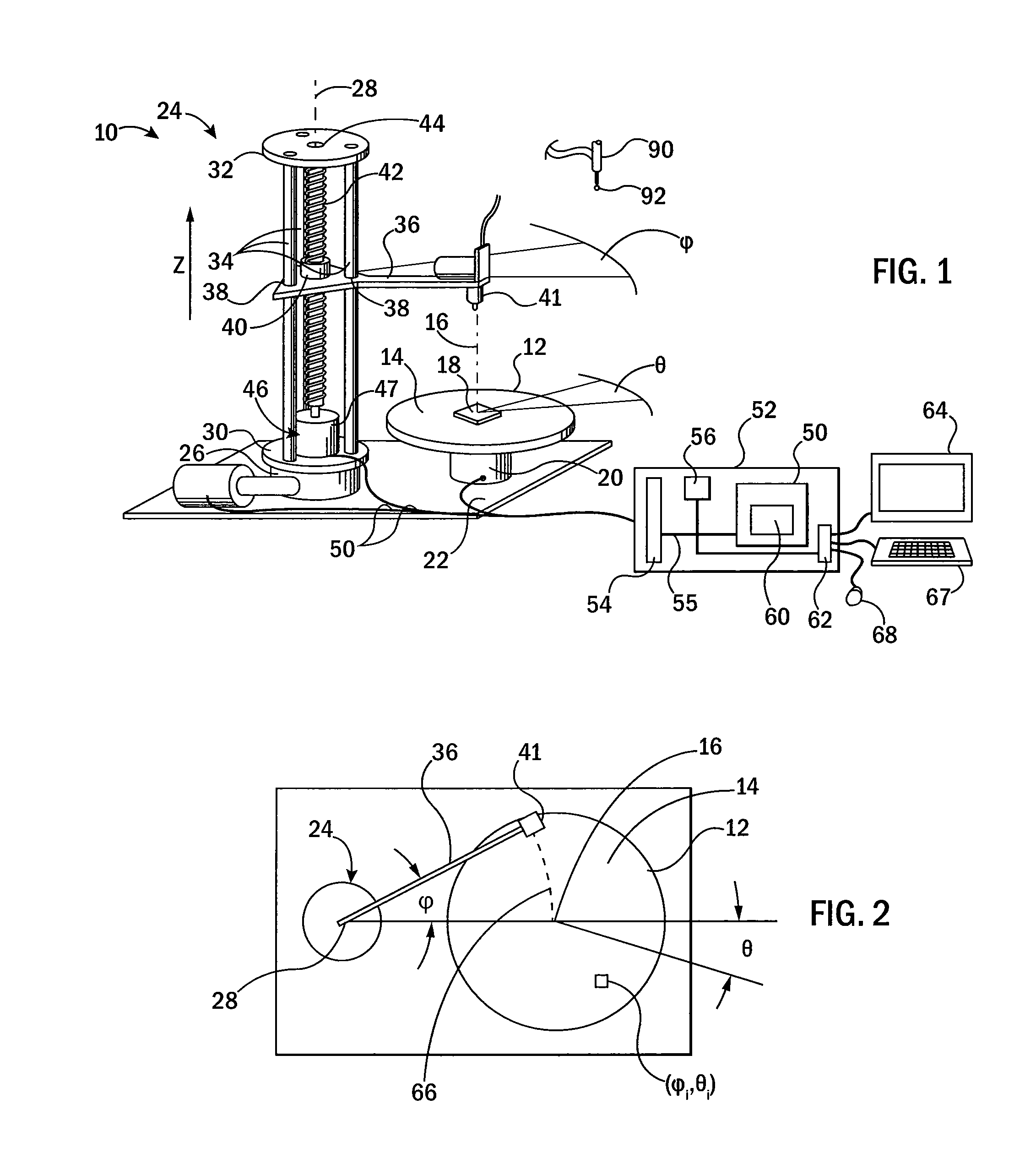

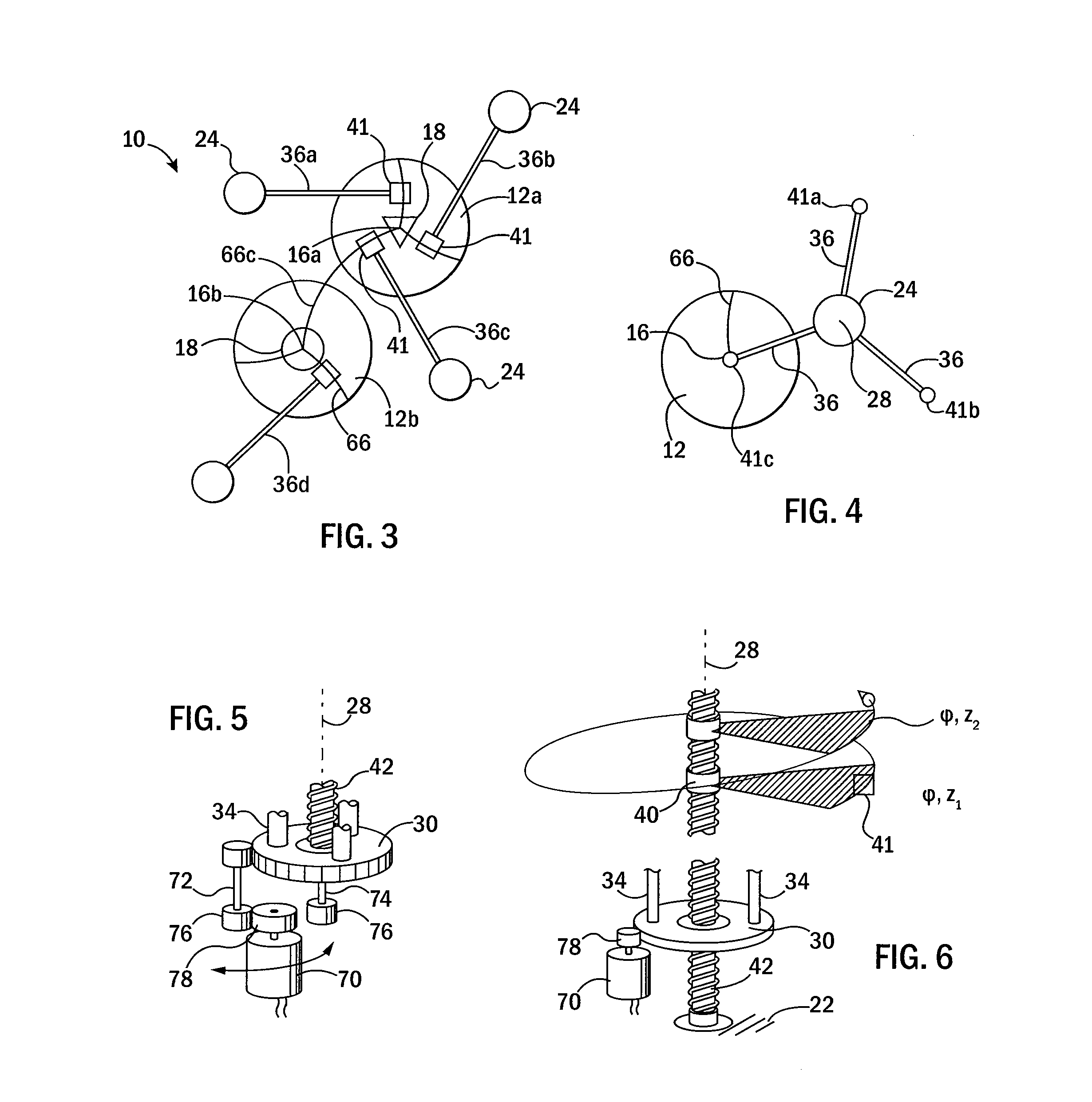

Three-Dimensional Printing System Using Dual Rotation Axes

ActiveUS20130189435A1Promote sportsImprove throughputAdditive manufacturing apparatusAdditive manufacturing with liquidsRotational axisLinear motion

A 3-D printer system moves a printed tool over a print surface with a mechanism controlling a rotational angle of an arm holding the print tool and a revolutionary angle of axis of rotation of the printable area to eliminate the disadvantages of conventionally used linear motion mechanisms

Owner:WISCONSIN ALUMNI RES FOUND

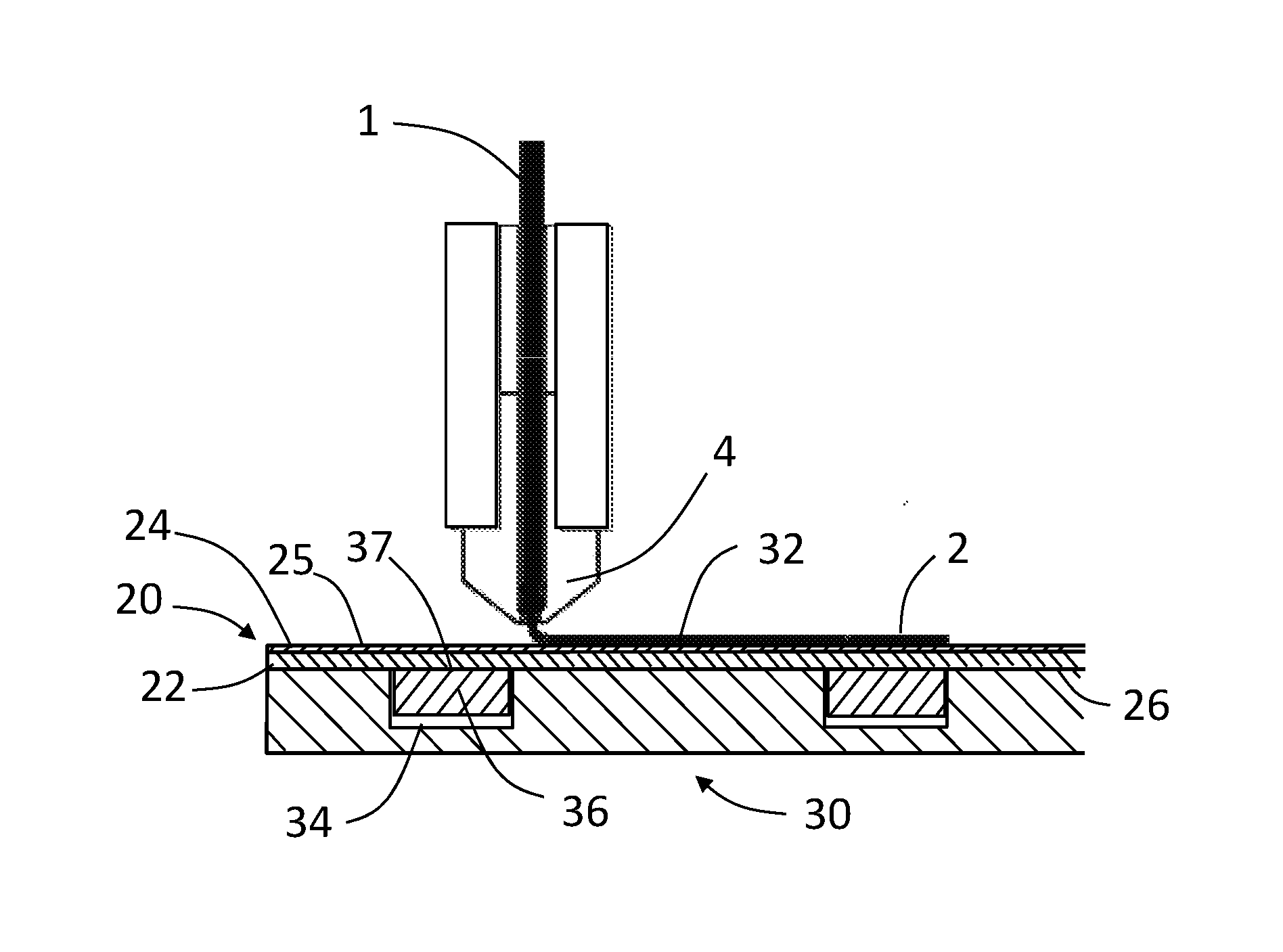

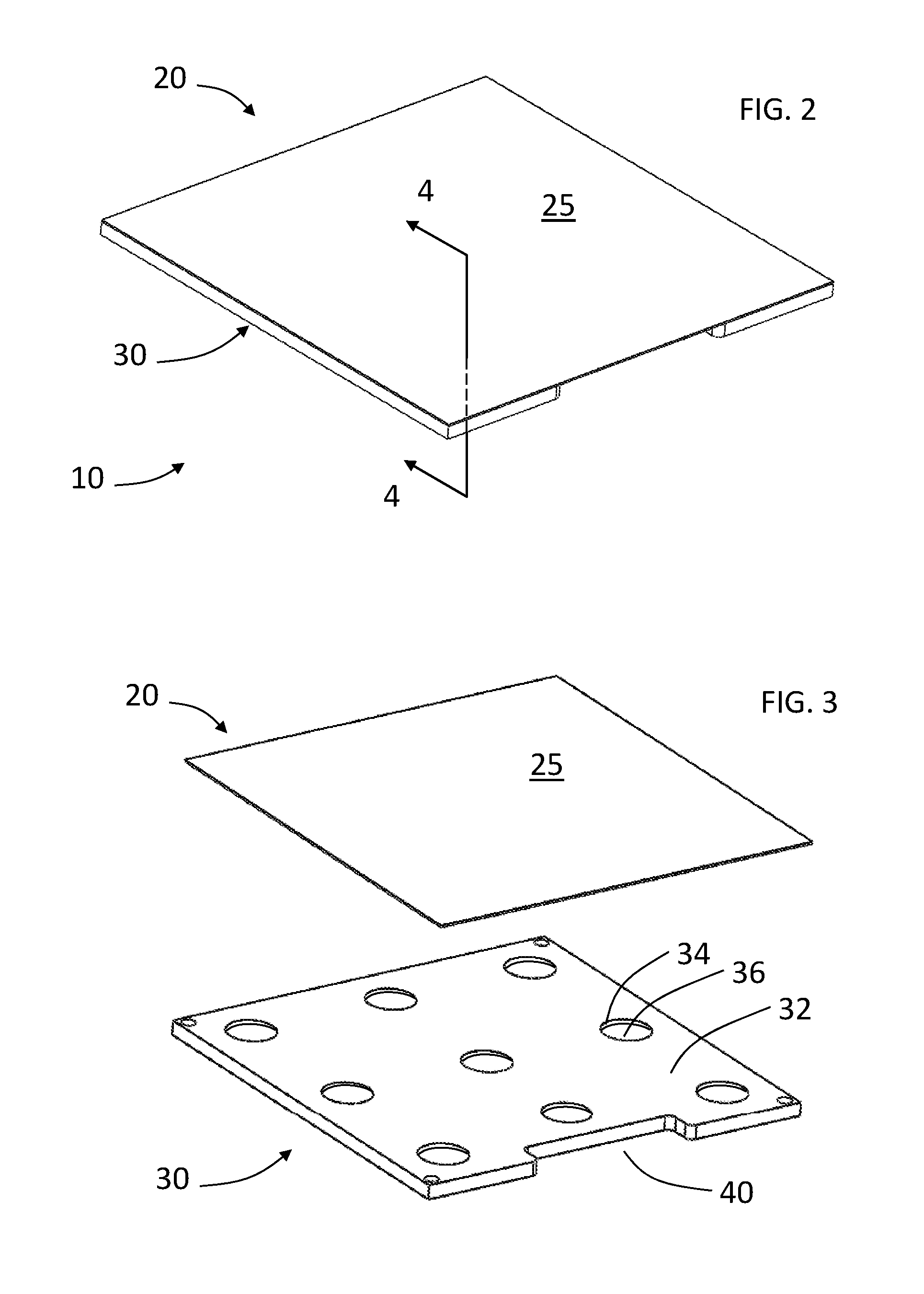

3D Print Bed Having Permanent Coating

PendingUS20170036403A1Improve adhesionSufficient level of adhesionManufacturing platforms/substratesPretreated surfacesEpoxyWater based

A coated print bed for a 3D printer having a permanent print-surface coating permanently secured to a print bed substrate plate, having a smooth, planar surface that provides an adhesive interface layer between a first layer of an applied plastic print material and the coated print bed. The coating contains a matrix-forming compound, such as a solvent- or water-based epoxy resin, an adhesive material, and optionally a filler. The user can print a series of print object directly onto the permanent print surface coating of the coated print bed, without having to refresh or refurbish the print surface, such as by applying to the print bed surface a temporary coating such as painter's tape, or a liquid adhesive.

Owner:EZ PRINT

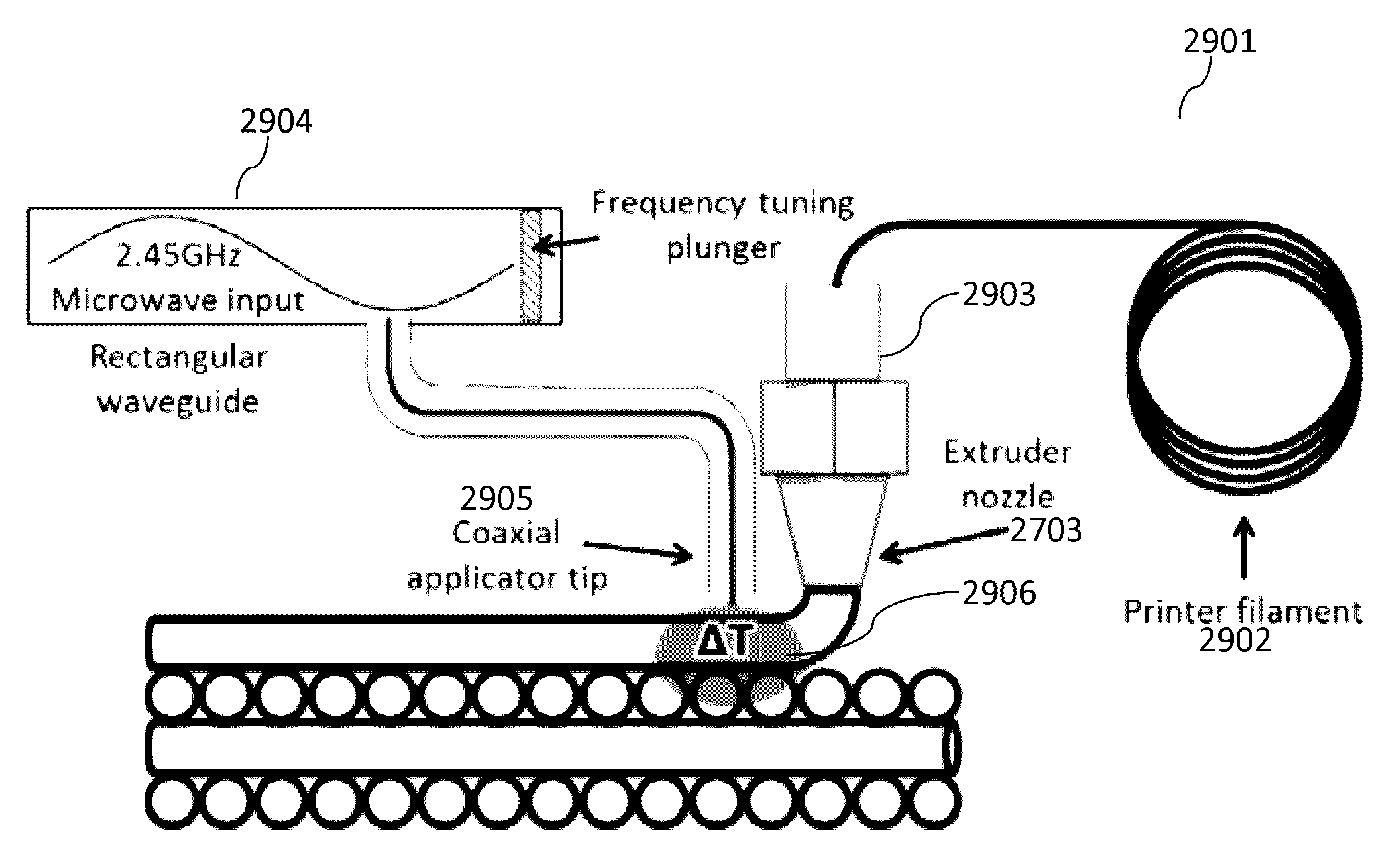

Microwave-induced localized heating of cnt filled polymer composites for enhanced inter-bead diffusive bonding of fused filament fabricated parts

ActiveUS20160325491A1Increase inter-bead bond strengthImprove mechanical propertiesMaterial nanotechnologyElectroconductive/antistatic filament manufacture3d printCarbon nanotube

A microwave-induced heating of CNT filled (or coated) polymer composites for enhancing inter-bead diffusive bonding of fused filament fabricated parts. The technique incorporates microwave absorbing nanomaterials (carbon nanotubes (CNTs)) onto the surface or throughout the volume of 3D printer polymer filament to increase the inter-bead bond strength following a post microwave irradiation treatment and / or in-situ focused microwave beam during printing. The overall strength of the final 3D printed part will be dramatically increased and the isotropic mechanical properties of fused filament part will approach or exceed conventionally manufactured counterparts.

Owner:TEXAS TECH UNIV SYST

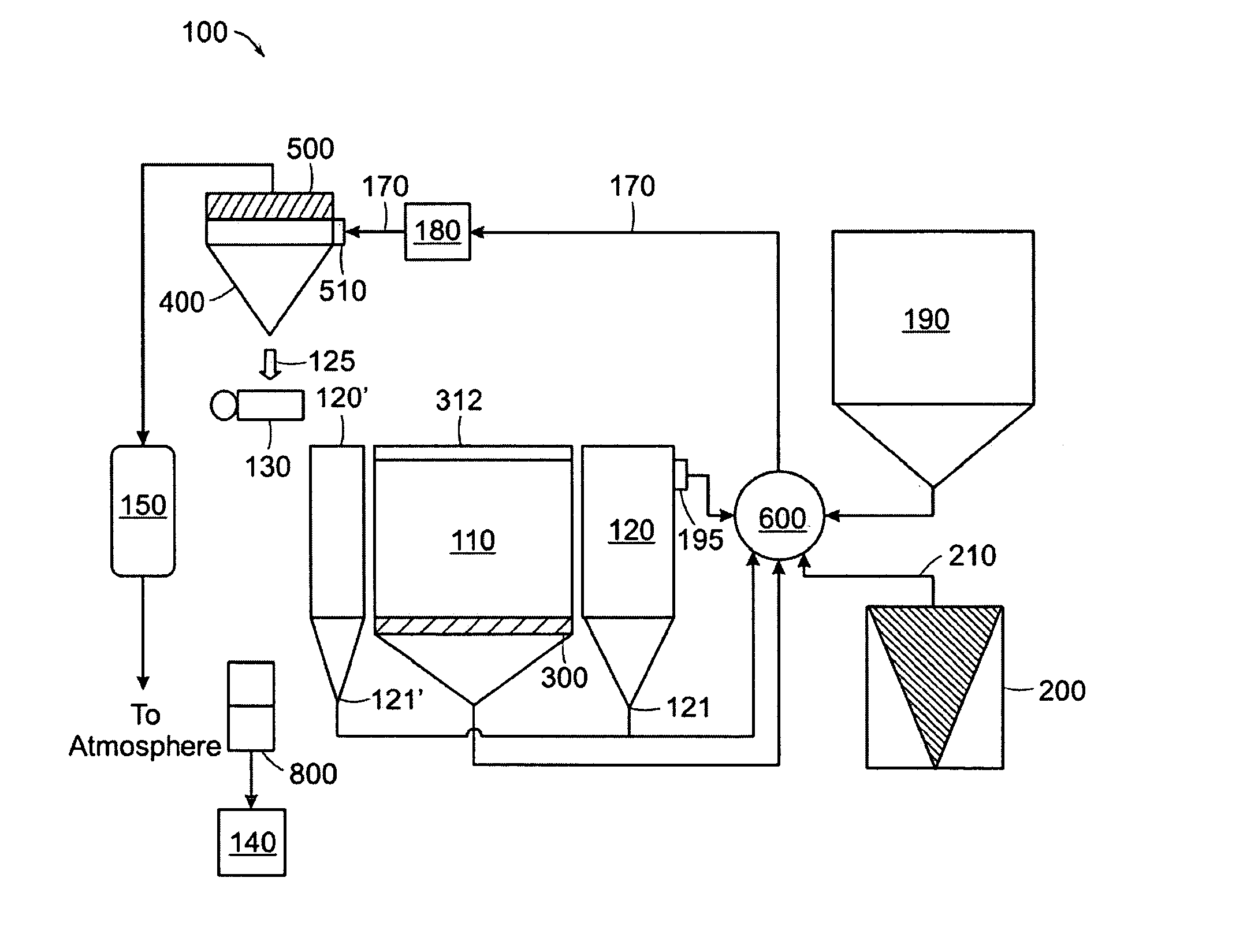

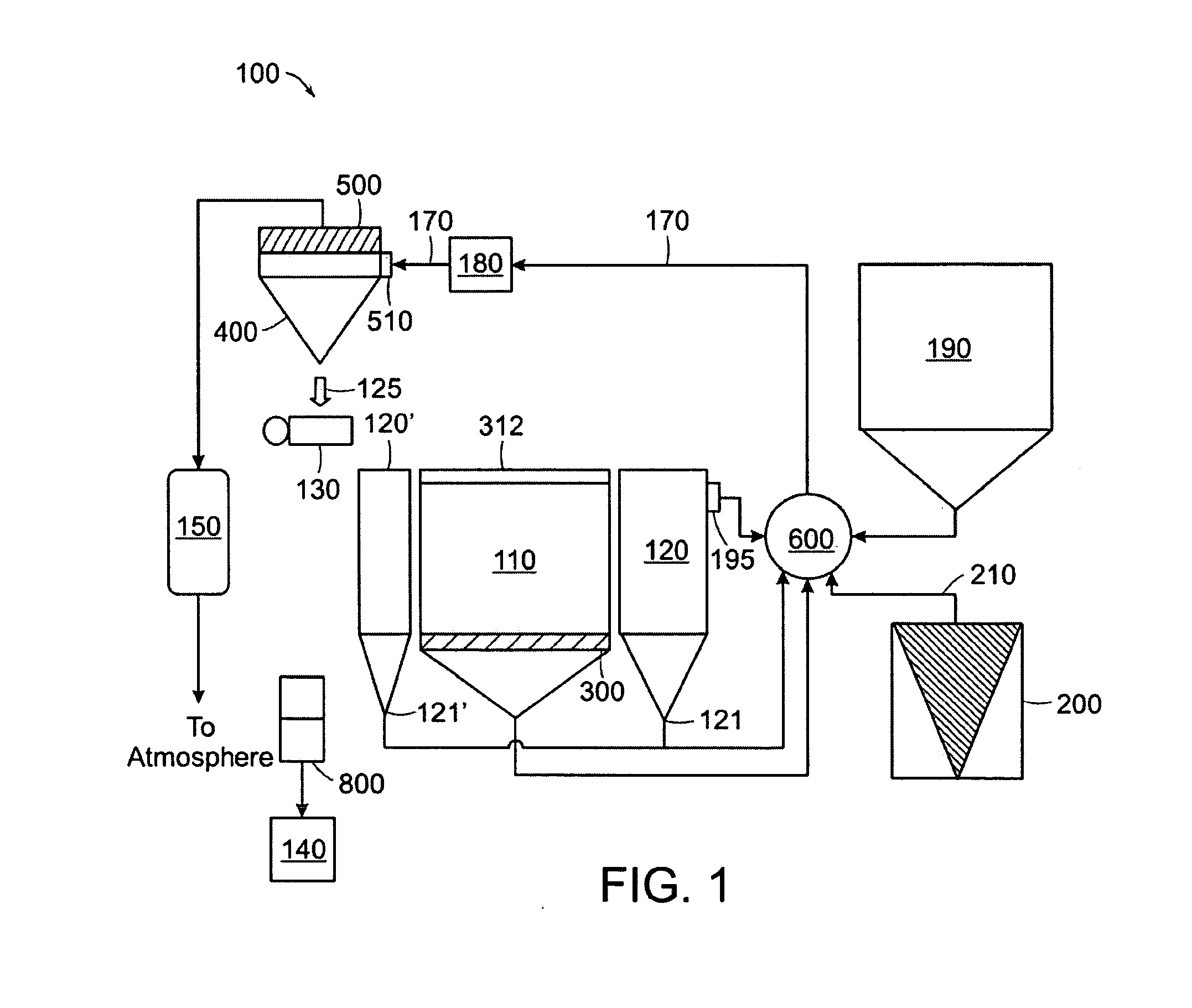

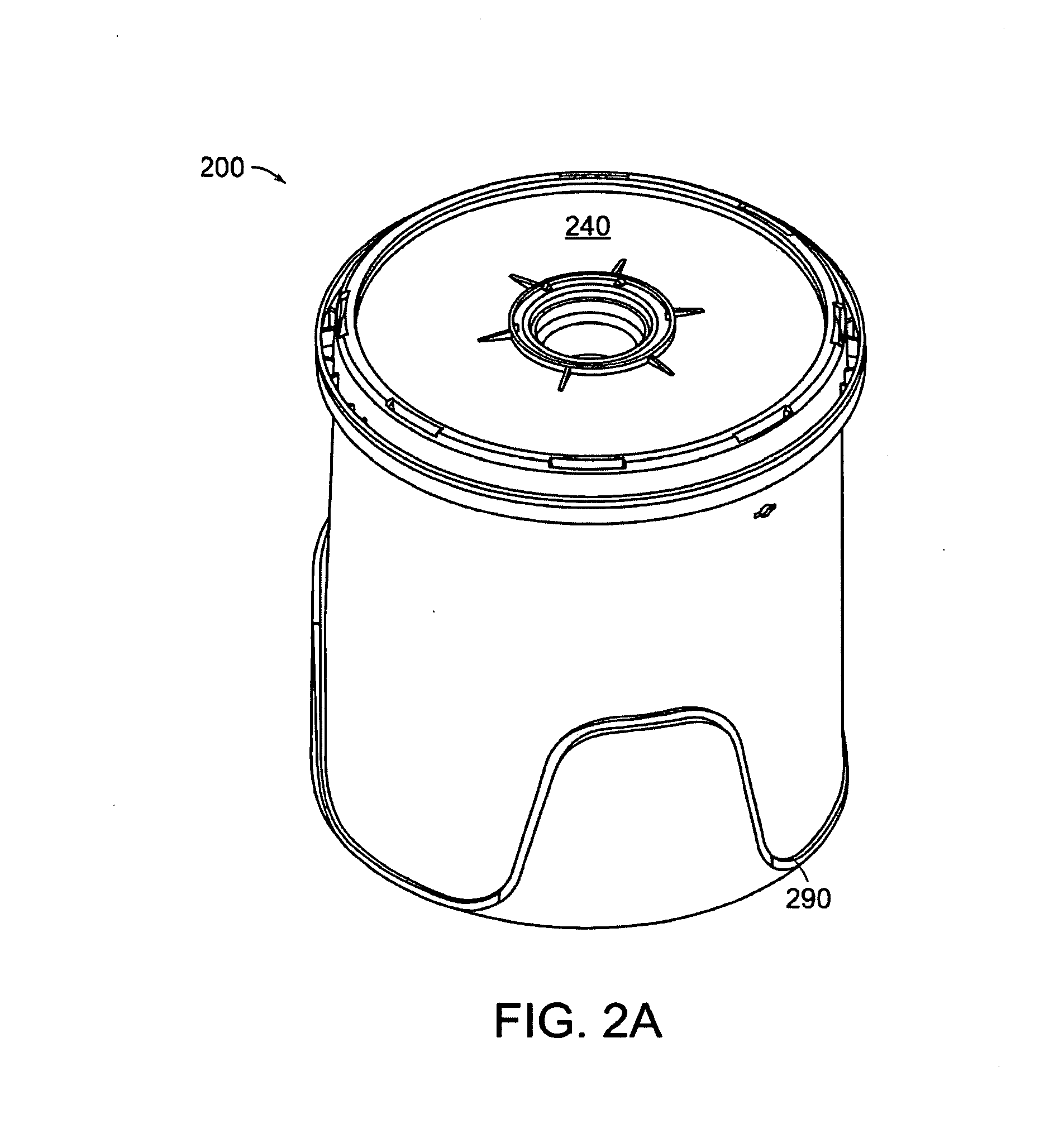

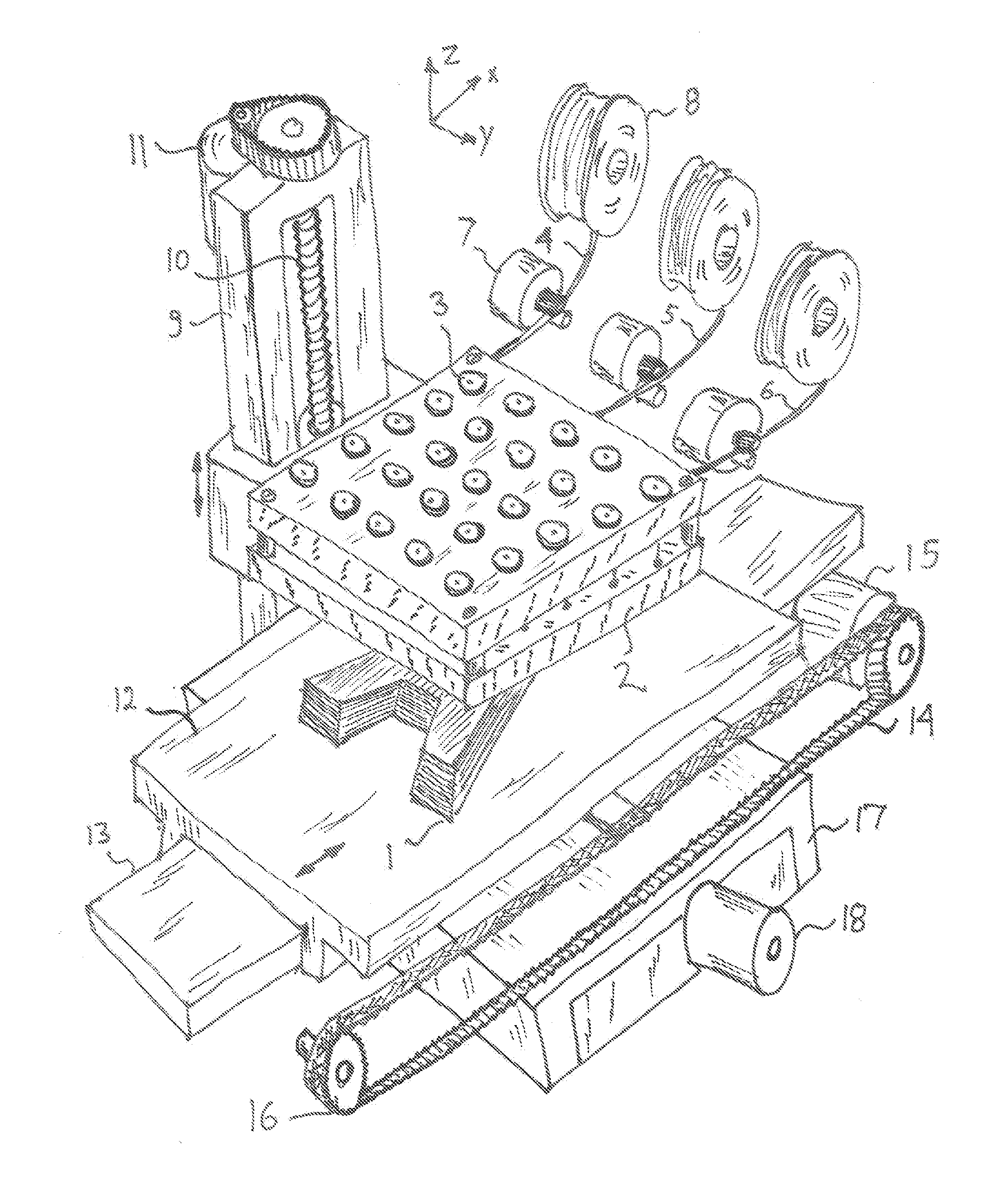

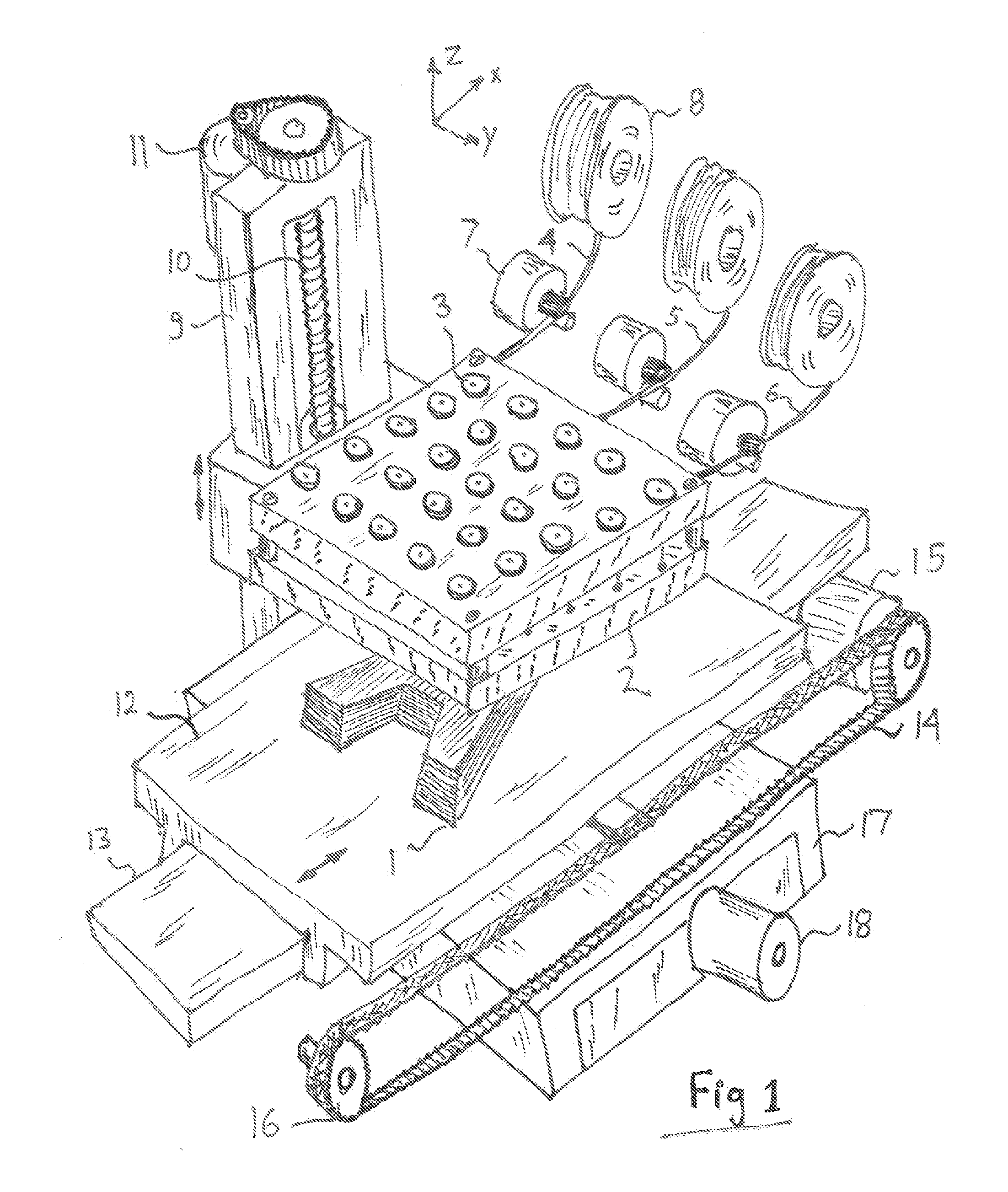

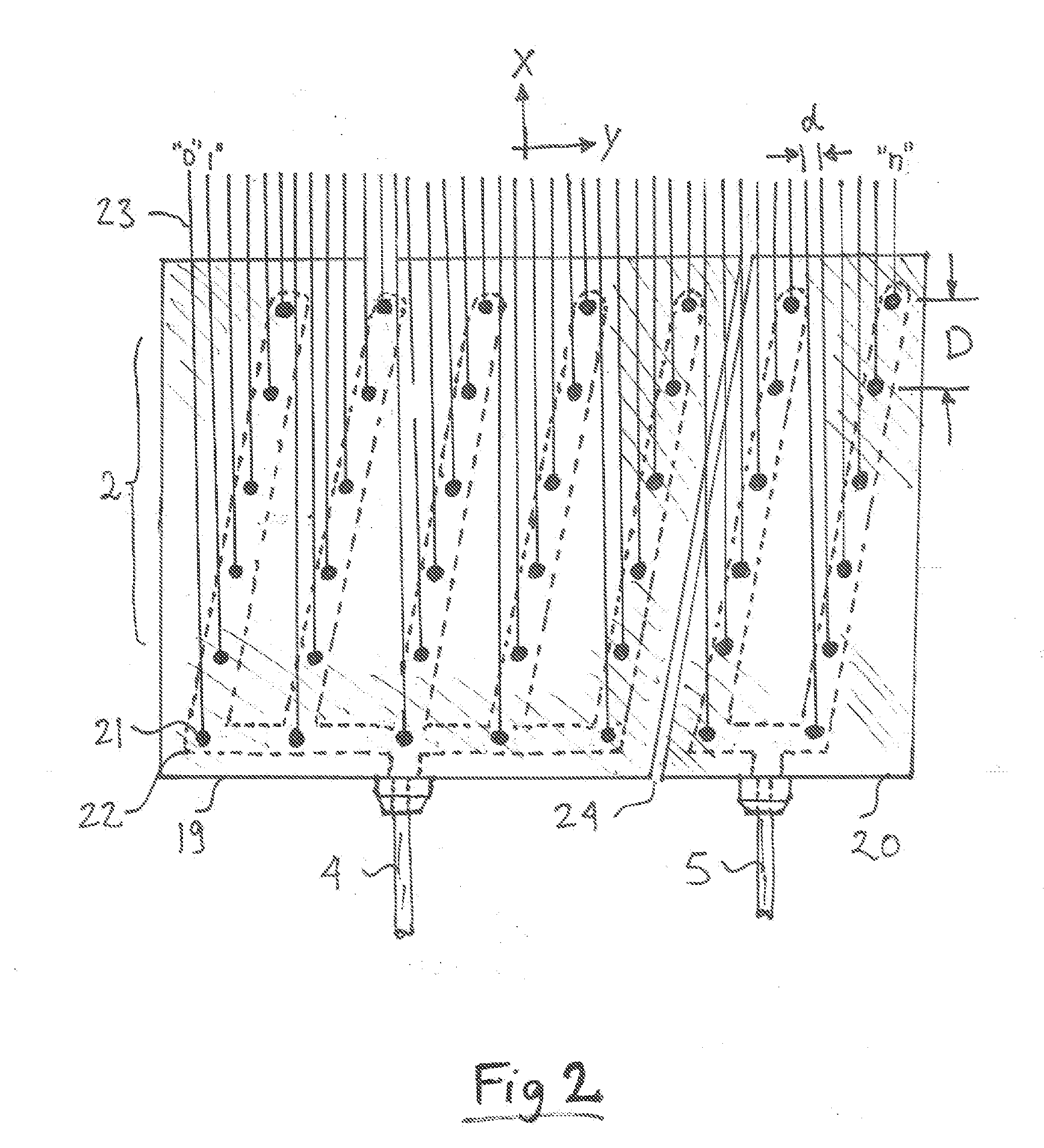

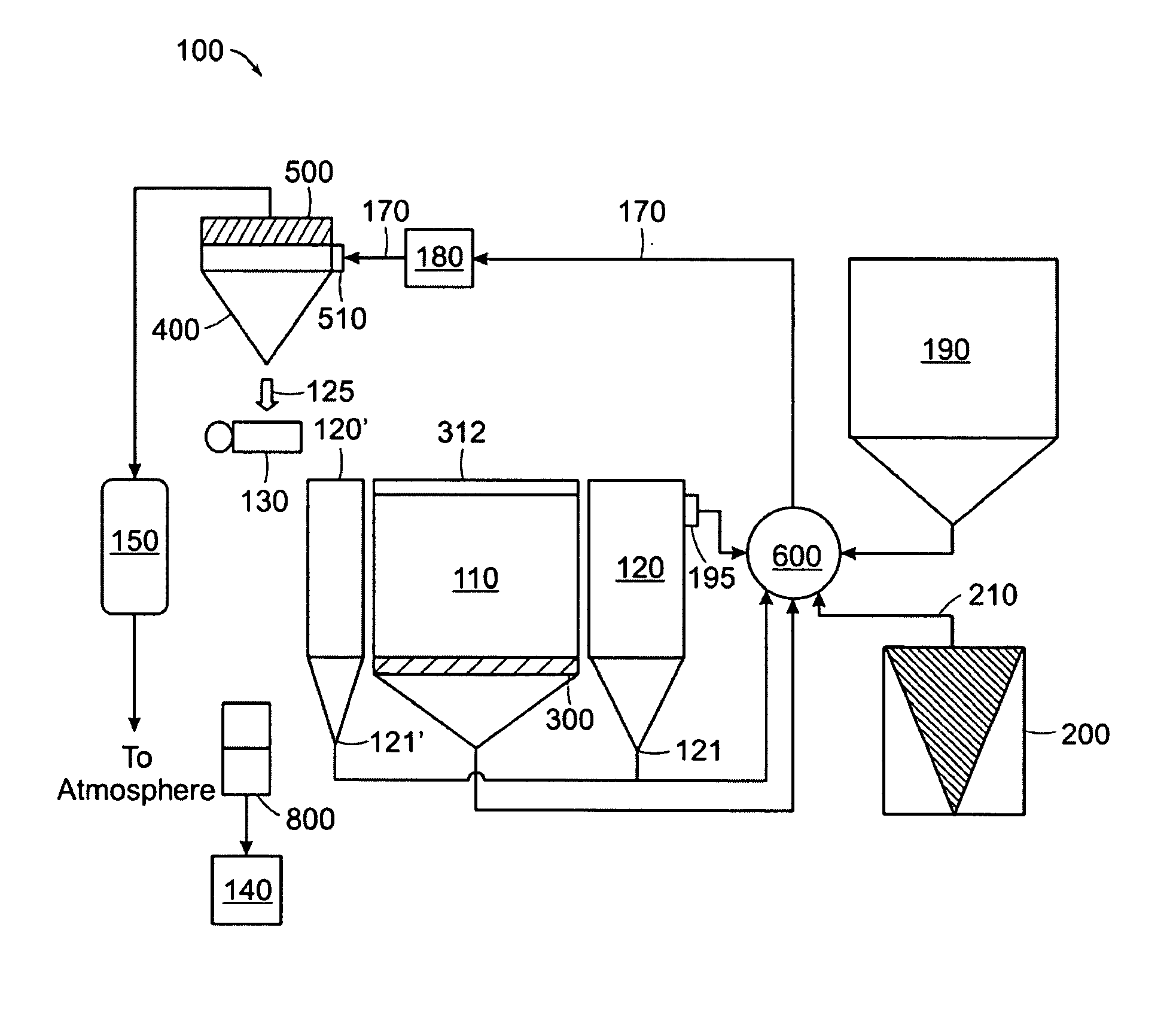

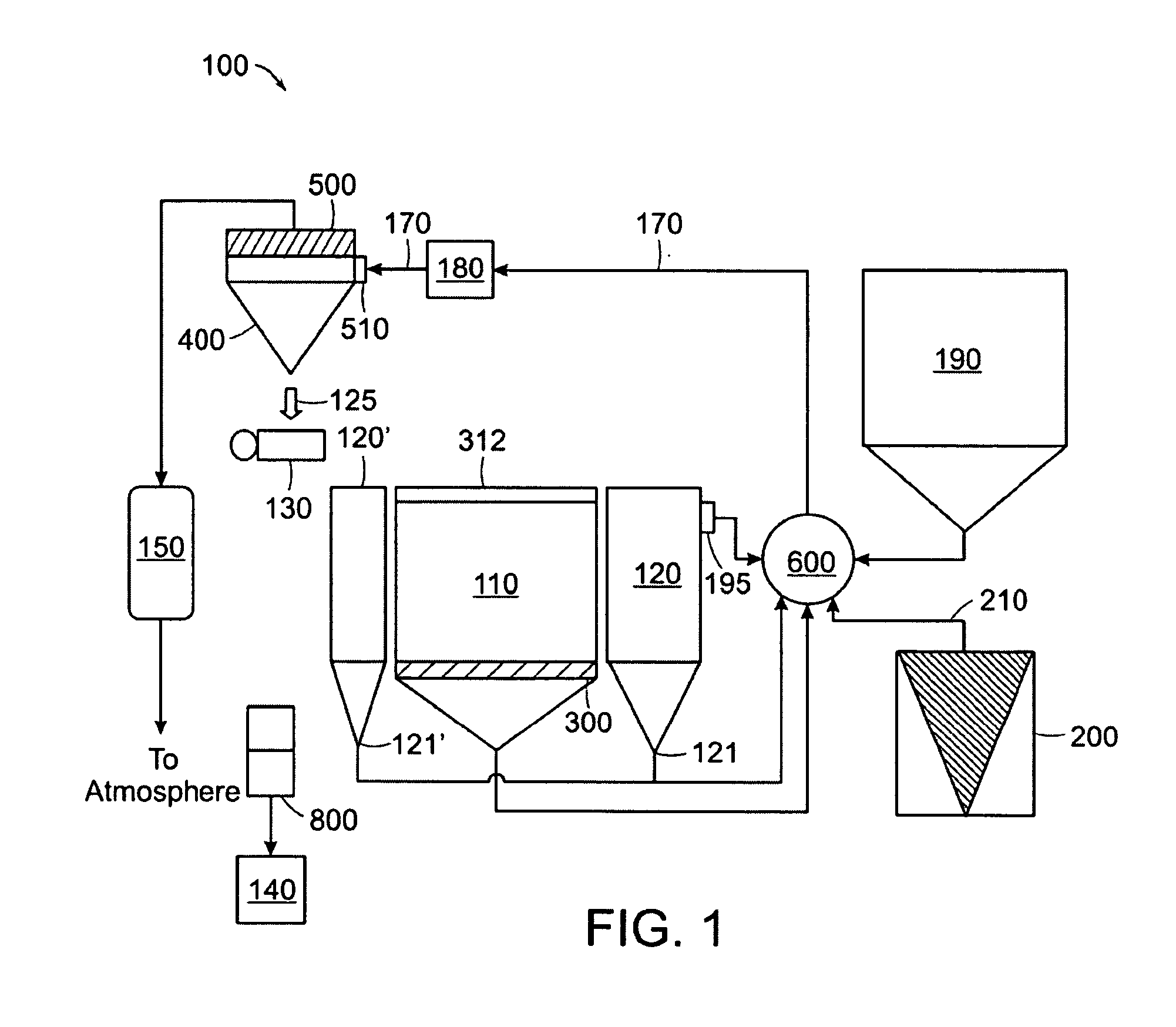

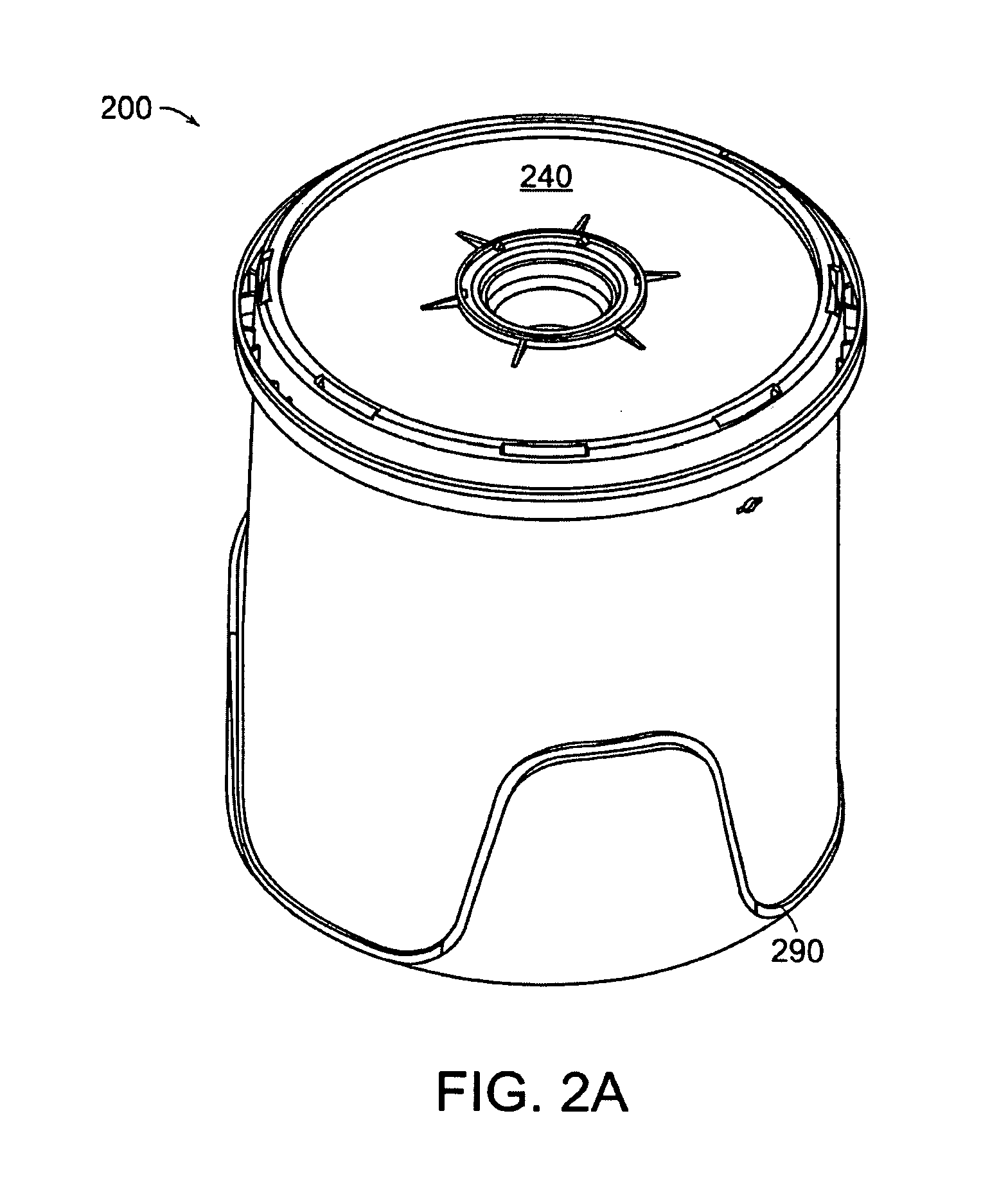

Apparatus and methods for handling materials in a 3-D printer

ActiveUS20080006334A1Improve efficiencyProcess uneconomicalLiquid surface applicatorsPowdered material dispensingComputer printing3d printer

The present invention is directed towards methods and apparatus for handling powder in a 3D printer. The invention includes a means of transporting powder from multiple sources to a powder dispensing apparatus with minimal user intervention, thus reducing contamination of the 3D printer and surrounding area with loose powder, while also providing a means of improving the recycling of powder for re-use.

Owner:3D SYST INC

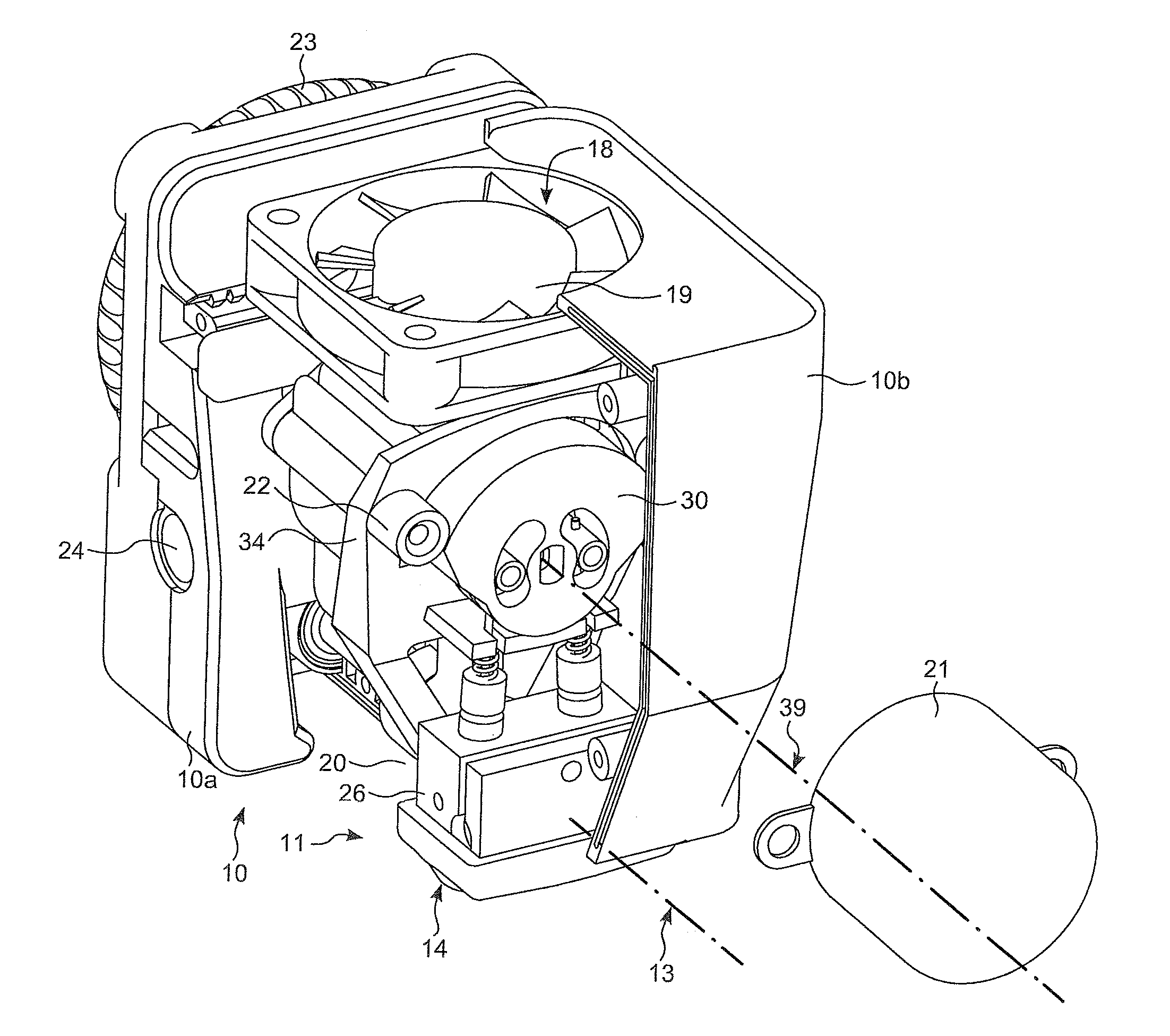

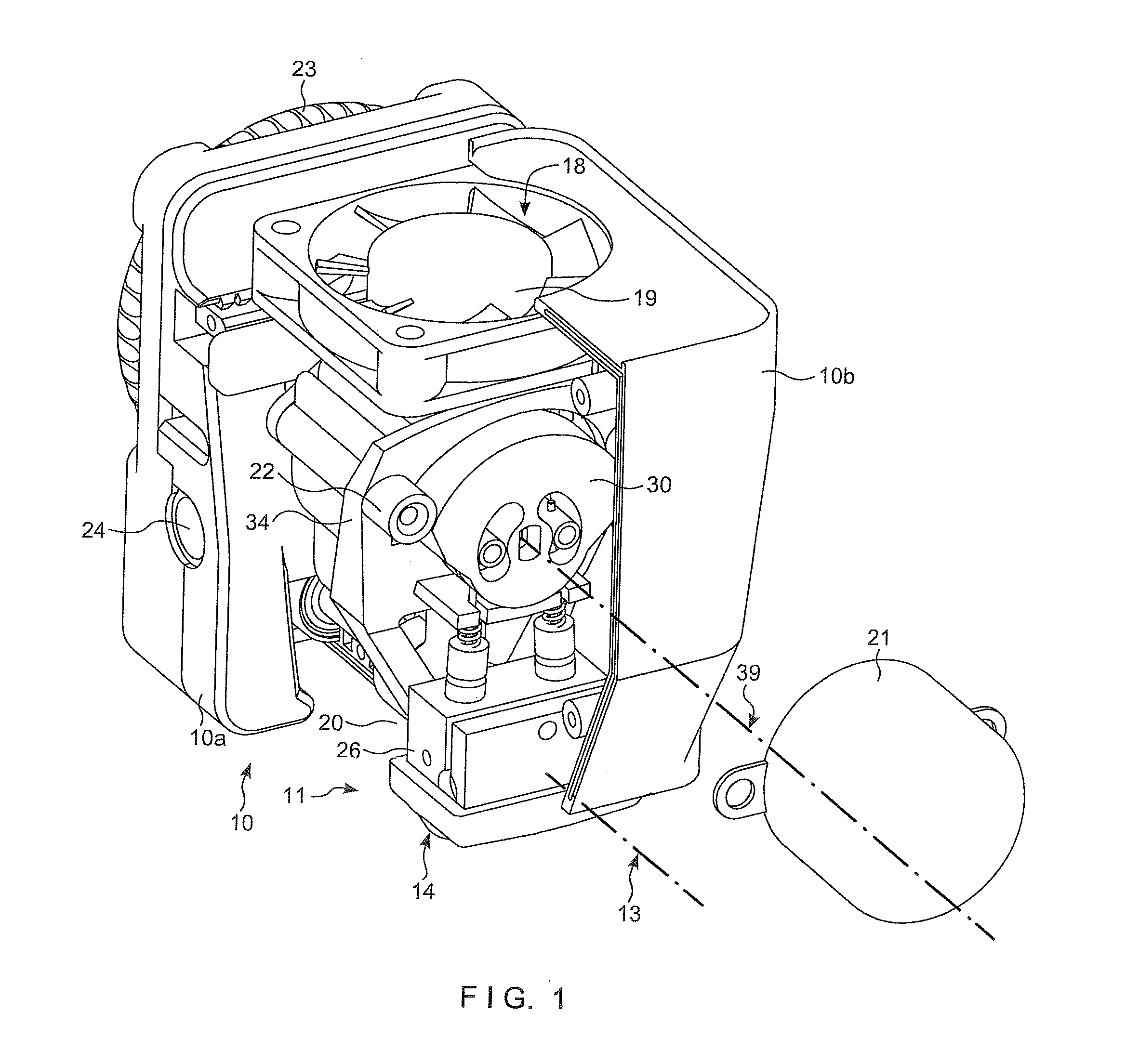

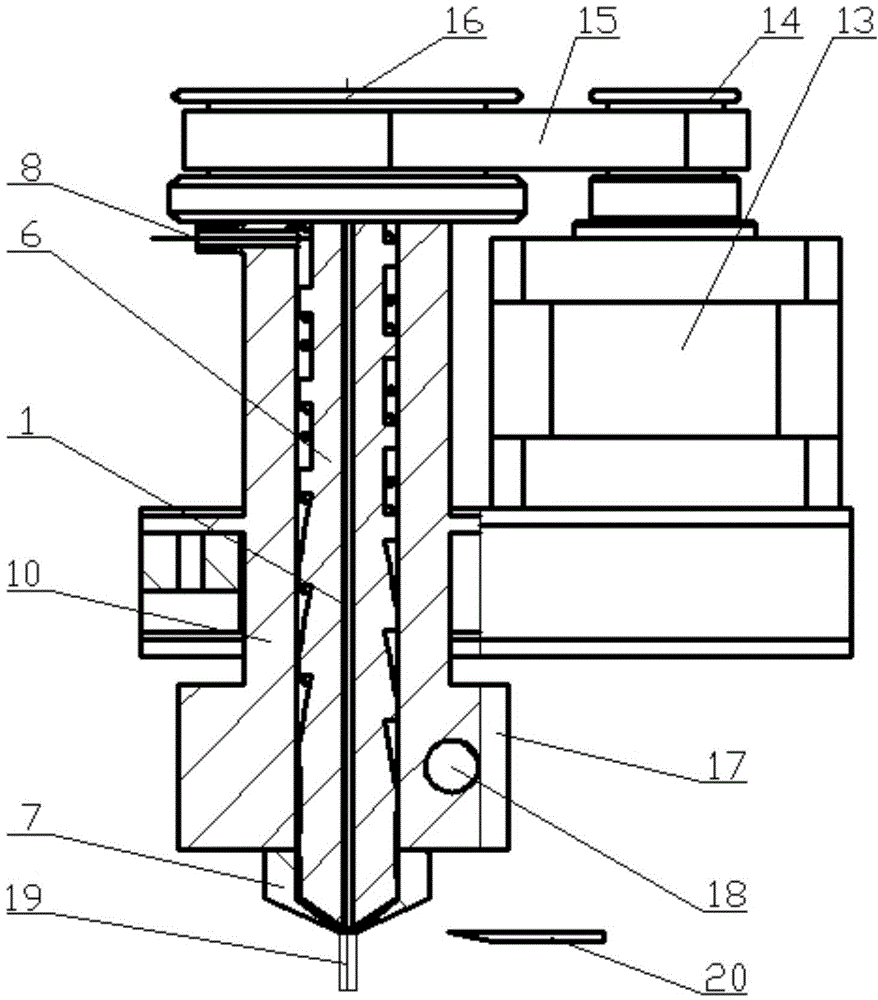

Fluid-dispensing head for a 3D printer

ActiveUS20140242208A1Readily switched into operationIncrease flexibilityConfectionerySweetmeatsInfill3d printer

A head assembly for an extrusion-based 3D printer includes: a fluid-dispensing head having a manifold and at least two fluid-dispensing nozzles, of different sizes, which are mounted in communication with a melt chamber in a manifold. Outlets of each nozzle are closed by respective valve members. A rocker serves both to pivot the nozzles to their lowermost nozzle-operating position and to actuate the valve members, for ready switching between the valves, such that the smaller nozzle can be used for high resolution work, and the larger nozzle can be used for bulk infill.

Owner:CEL TECH

Cement-based composite material used for 3D printing technology as well as preparation method and application thereof

ActiveCN104310918AEasy to get materialsLow costSolid waste managementHouse buildingConstruction 3D printing

The invention provides a cement-based composite material used for a 3D printing technology as well as a preparation method and application thereof. The cement-based composite material is prepared from the following raw materials based on the total weight of the composite material: 33%-40% of cement, 0%-8% of inorganic powder, 32%-38% of tailing machine-made sand, 2.5%-3% of a high-molecular polymer, 0.1%-0.5% of a water reducing agent and 16.7%-20% of mixing water; a composite thickening time control agent, a thixotropic agent, a volume stabilizer and the like are added into a mixture to prepare an inorganic composite material; and then the inorganic composite material can be directly pumped into a 3D printer for building to be applied to construction. The cement-based composite material is an inorganic material and the materials are easily available; a lot of industrial waste materials can be used; therefore, the cement-based composite material is low in cost, energy-saving and environment-friendly; the condensation time can be flexibly controlled, and the material has super early strength, good caking property and strong stability; the requirements of 3D printing construction continuity of the building and the building strength are met so that the house building has good global stability and use safety; and the application and popularization of 3D printing technology can be greatly promoted.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Use and production of coated filaments for extrusion-based 3D printing processes

ActiveUS20140134335A1Additive manufacturing apparatusFilament manufacturePolymer sciencePrinting press

Owner:EVONIK OPERATIONS GMBH

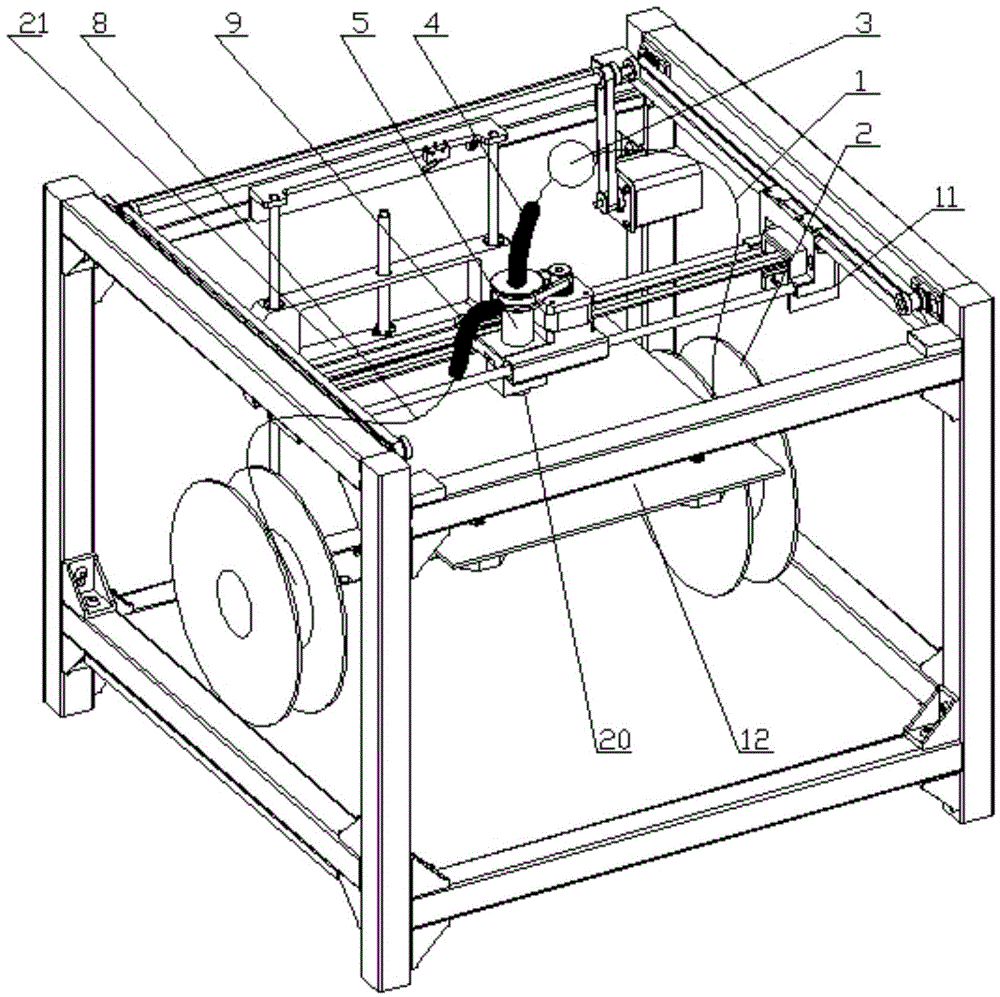

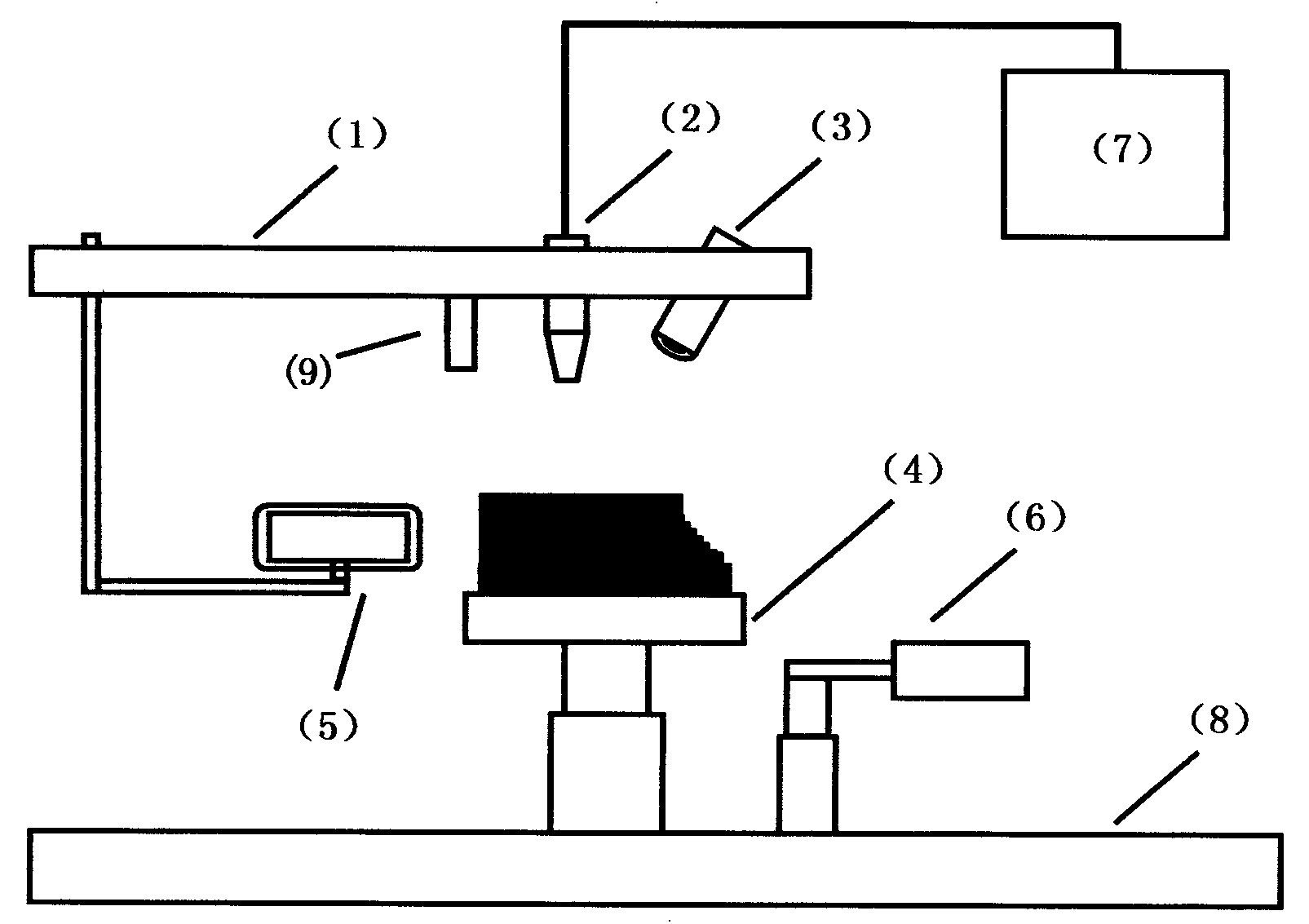

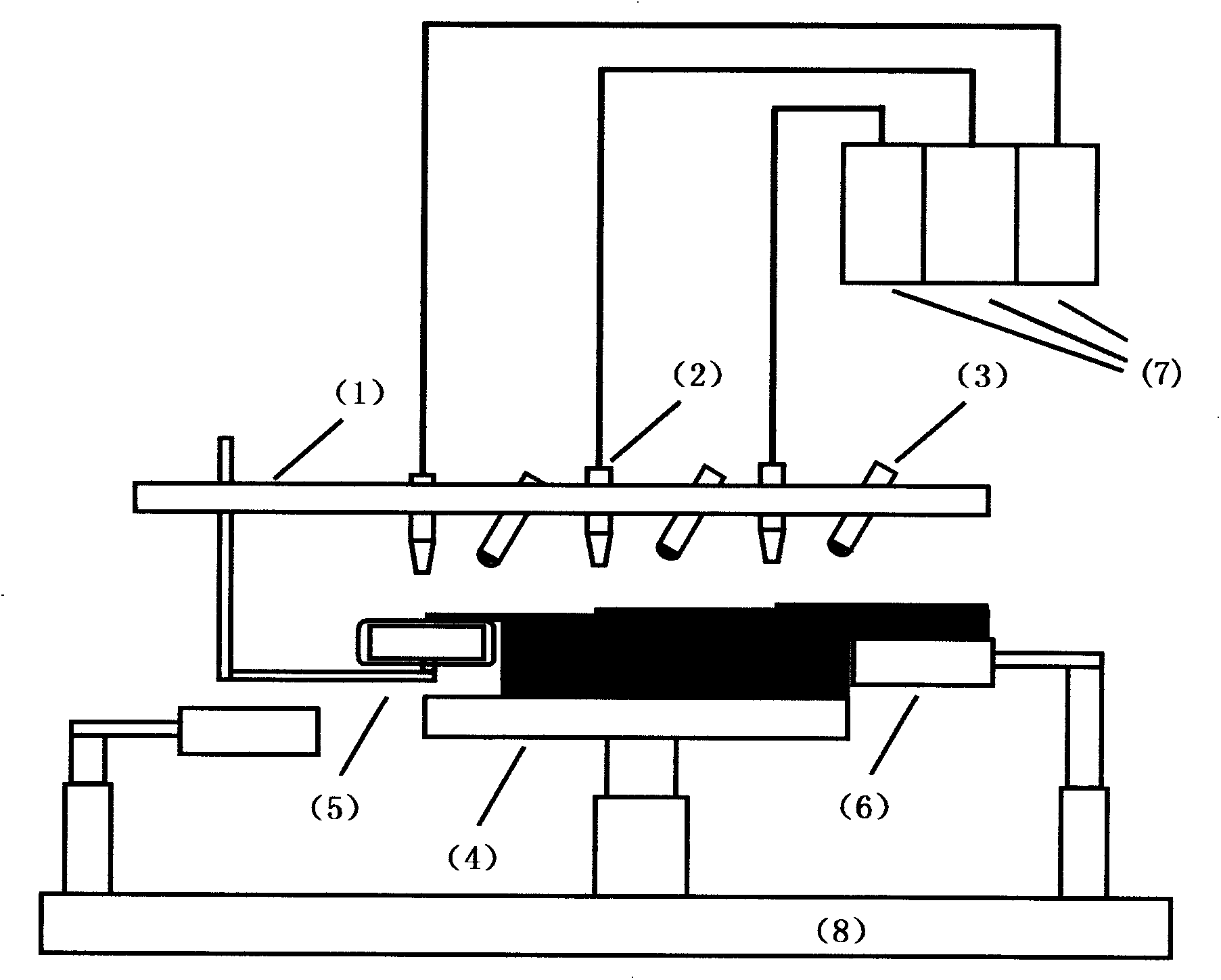

Continuous long-fiber reinforced-type composite material 3D printer and printing method thereof

The invention provides a continuous long-fiber reinforced-type composite material 3D printer and a printing method thereof. The 3D printer and the printing method are characterized in that the combination of the 3D printing technology and the composite material fiber placement technology achieves the 3D printing of a resin-based continuous long-fiber reinforced-type composite material, and the process does not need a die that is customized in advance and a pre-treated fiber pre-soaking belt, so that the cost is greatly decreased; meanwhile, the 3D printing method enables well and convenient control of the directions of the reinforced fibers in a manufactured part, and moreover, a composite material part with the customized mechanical property can be obtained easily, and the composite material part with a complex structure can be quickly manufactured; and compared with the original composite material fiber placement process, the printing method has the advantages that the application scope is wide, and the production efficiency is high.

Owner:XI AN JIAOTONG UNIV

3D Printer Based on a Staggered Nozzle Array

InactiveUS20160325498A1Increase deposition rateIncrease pressureAdditive manufacturing with liquids3D object support structuresGratingEngineering

A 3D printer is based on a two dimensional staggered nozzle array, depositing each layer in a raster scan mode. Each nozzle contains an individually controlled mechanical high speed valve, and multiple nozzles are fed from a constant pressure reservoir, typically containing molten polymer.

Owner:GELBART DANIEL

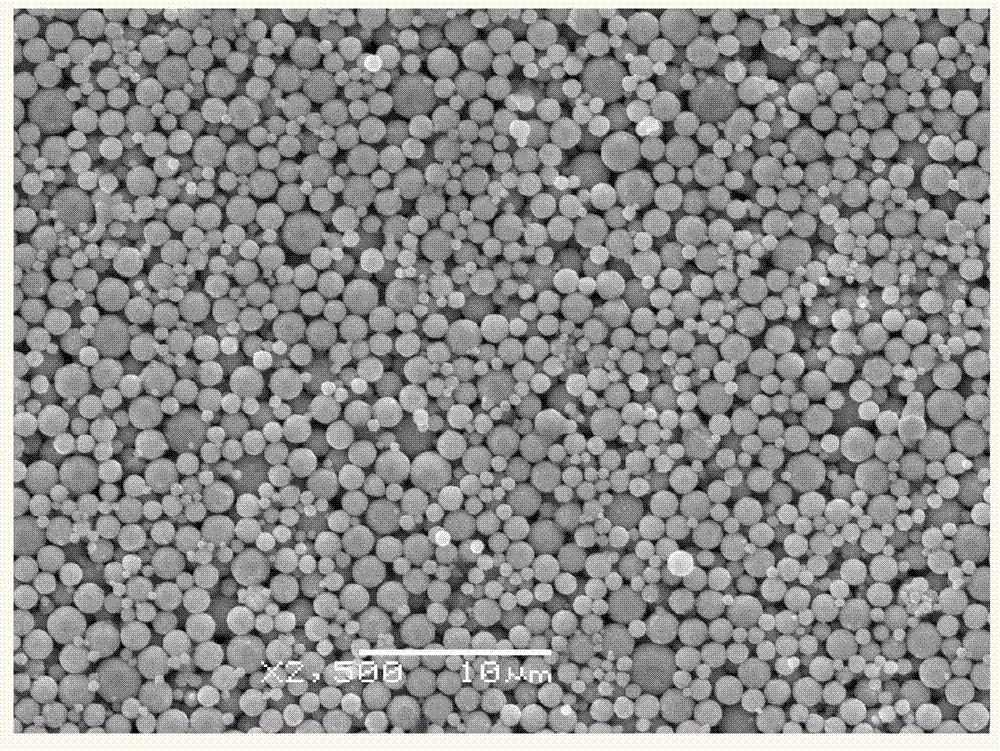

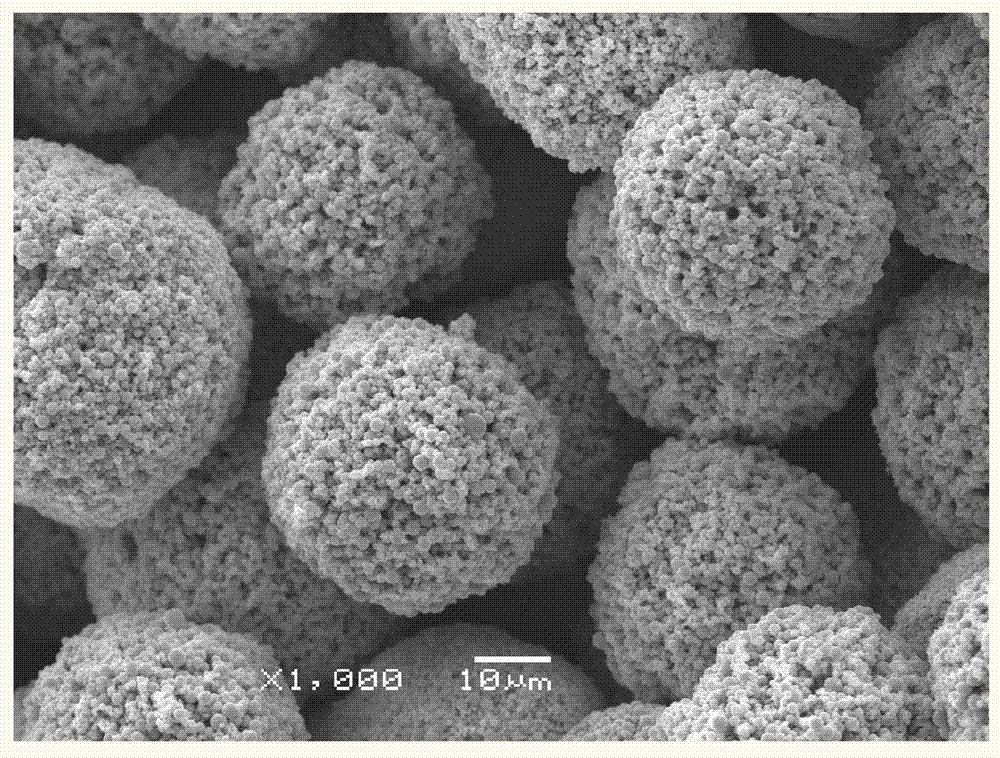

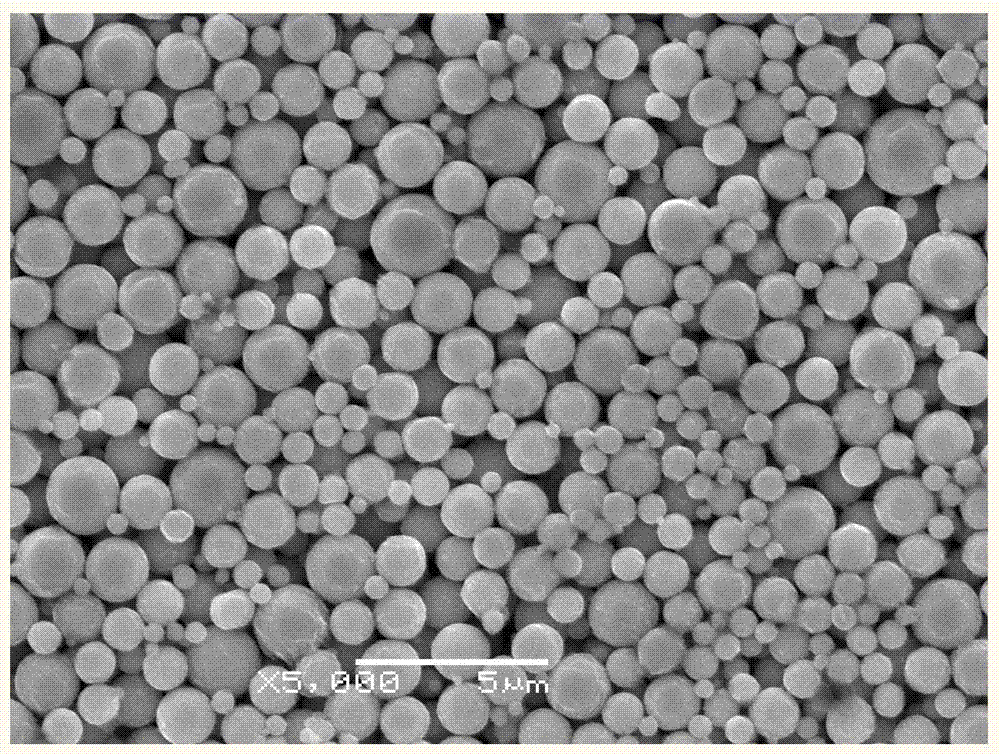

Metal powder for 3D printer and preparing method thereof

ActiveCN103785860AHigh sphericityUniform compositionAdditive manufacturing apparatusTransportation and packagingDispersityMetal particle

Owner:JIANGSU BOQIAN NEW MATERIALS CO LTD

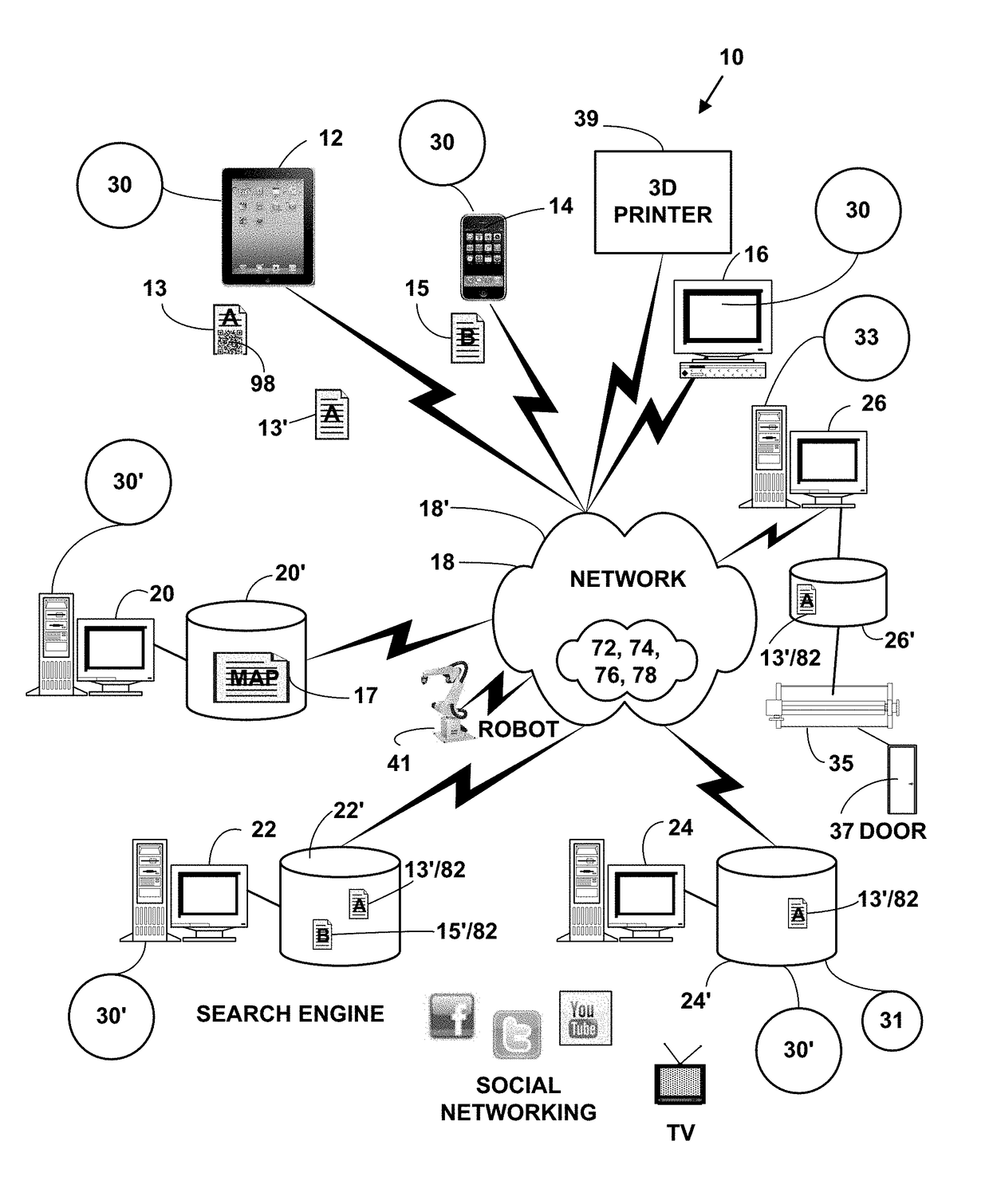

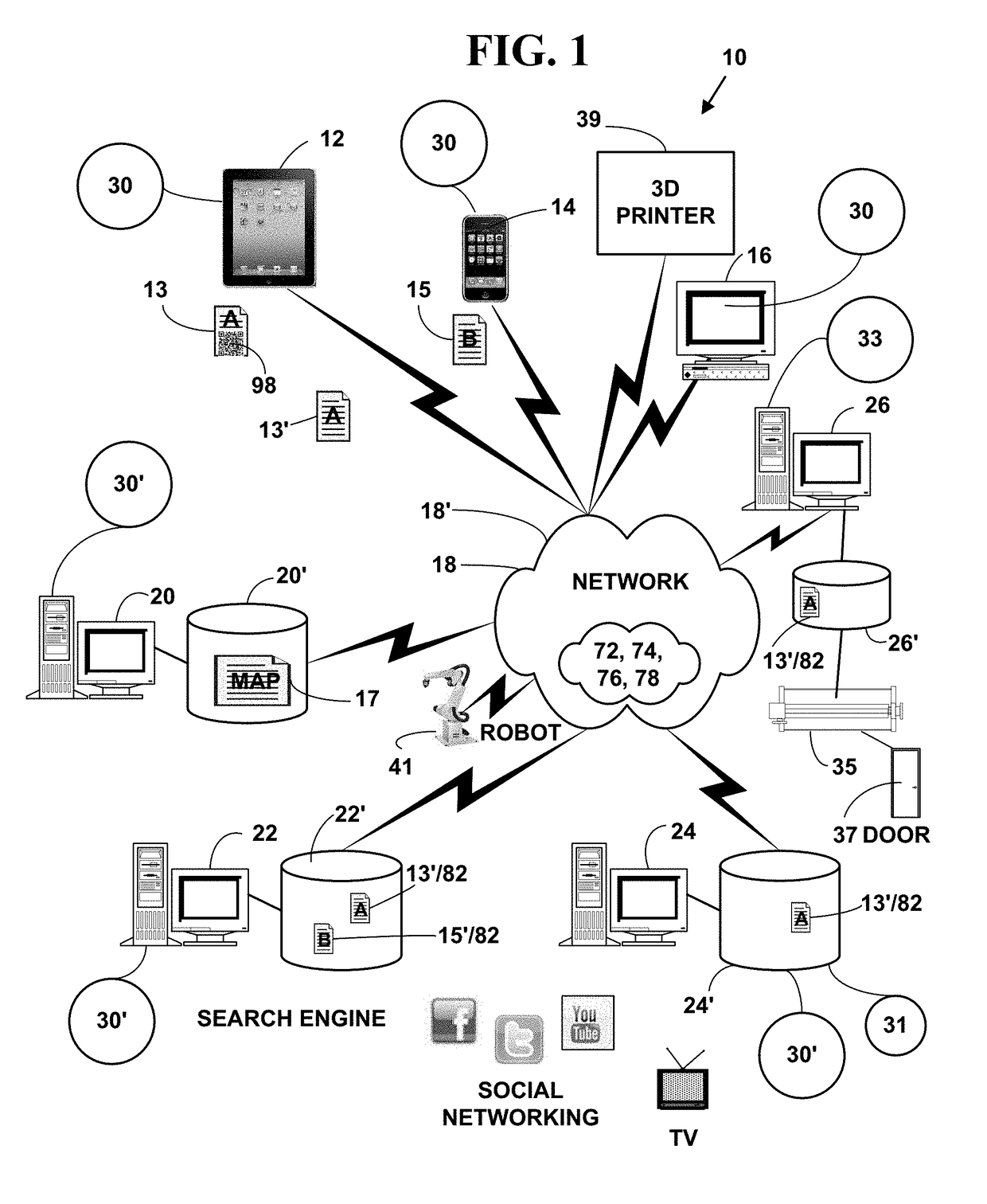

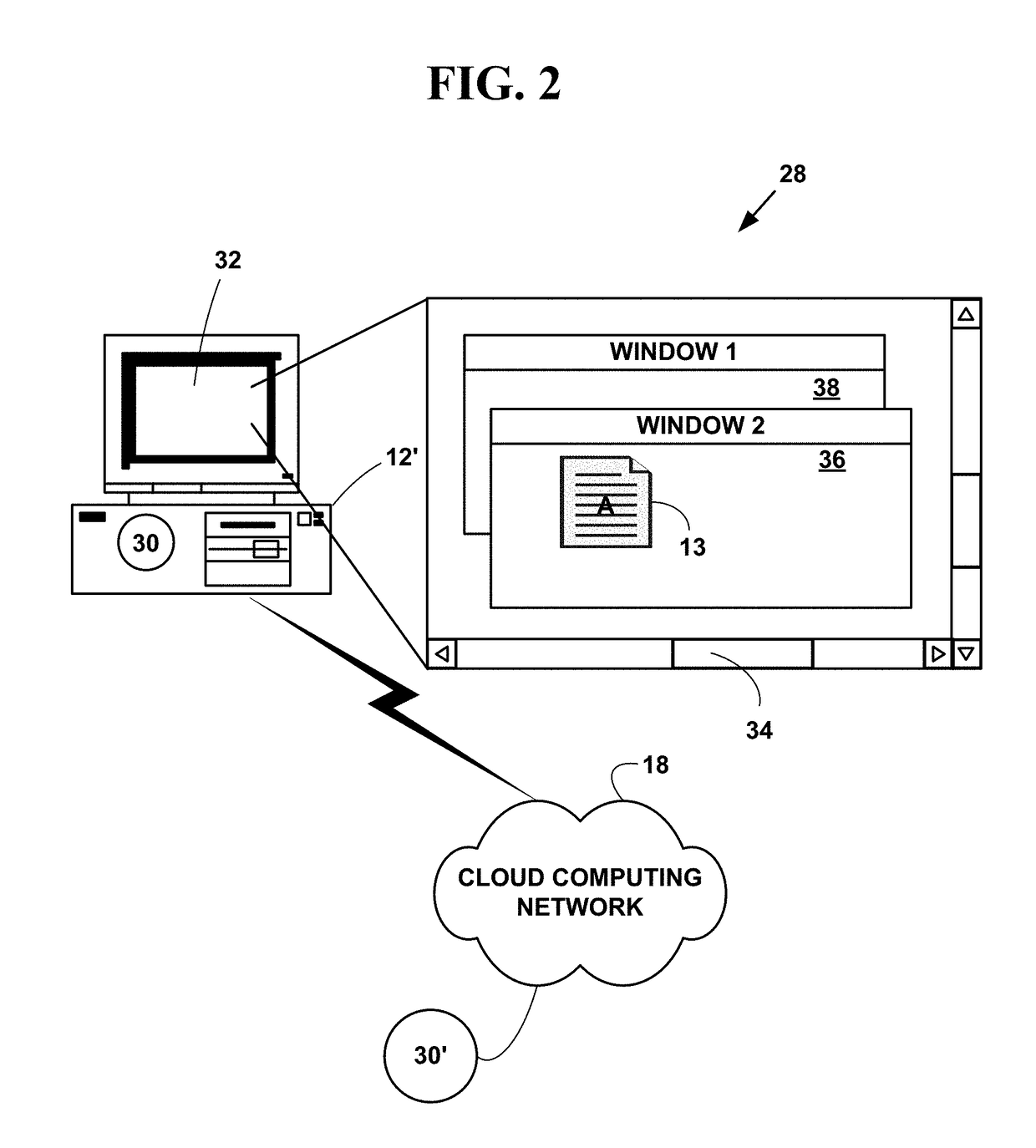

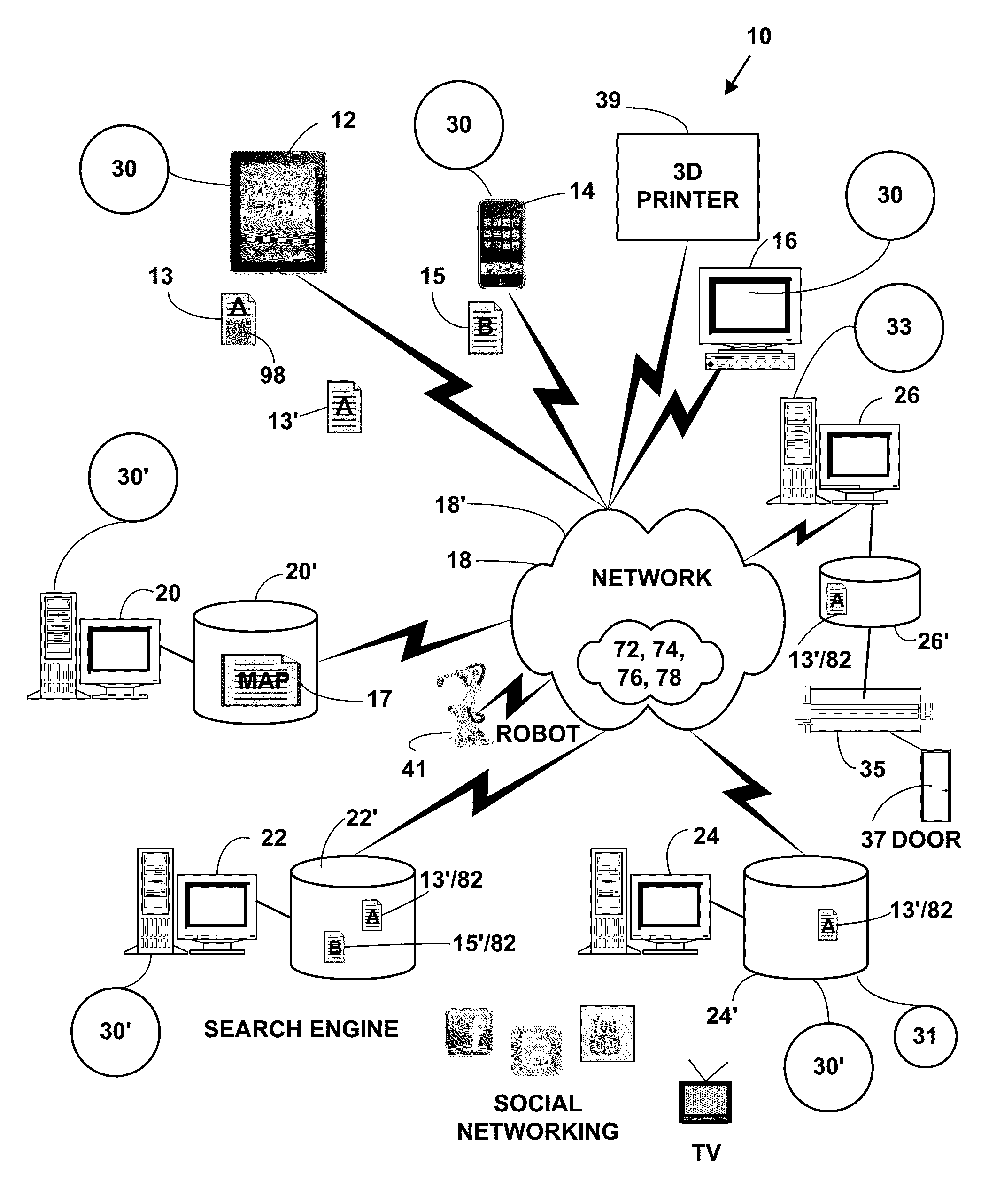

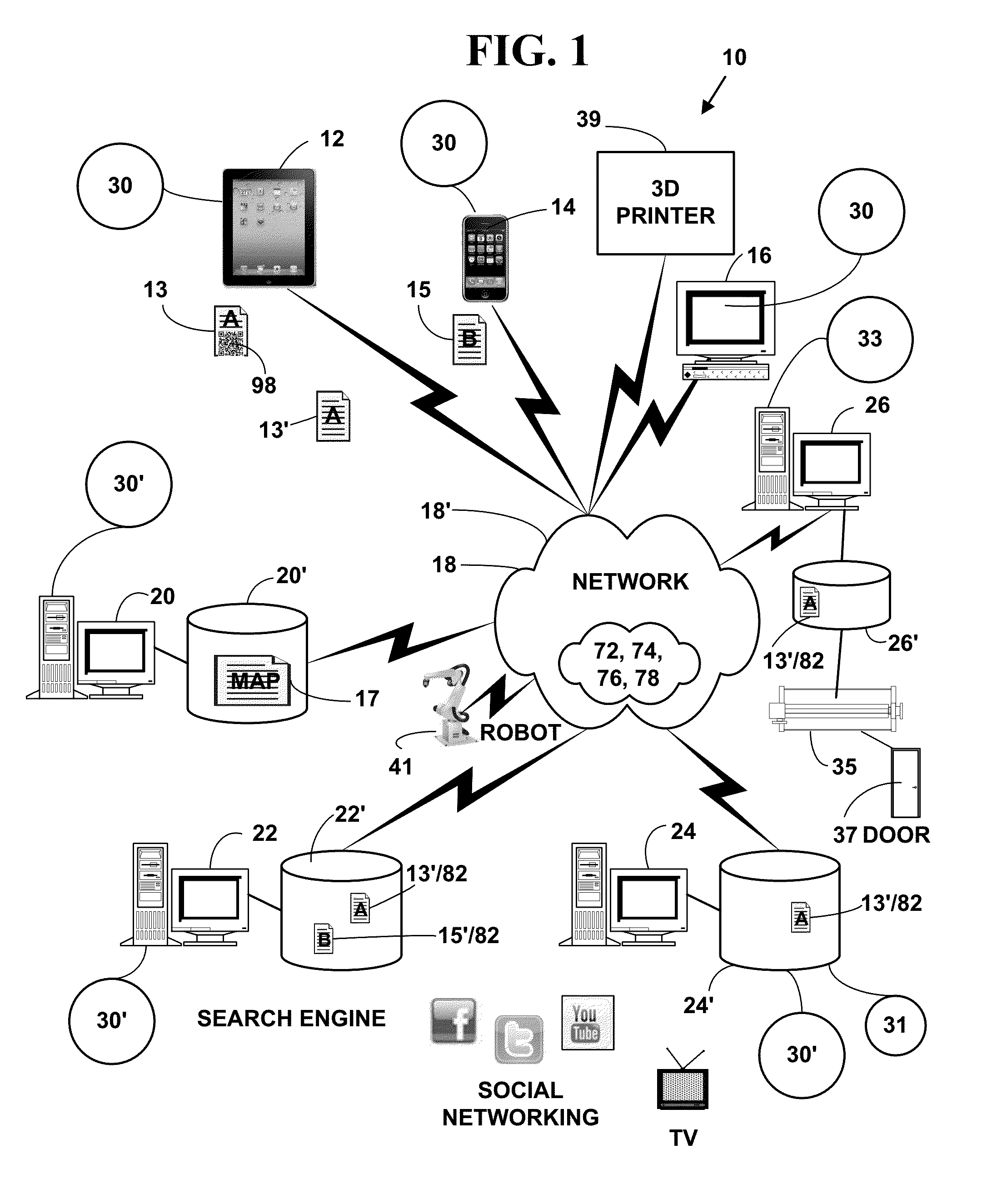

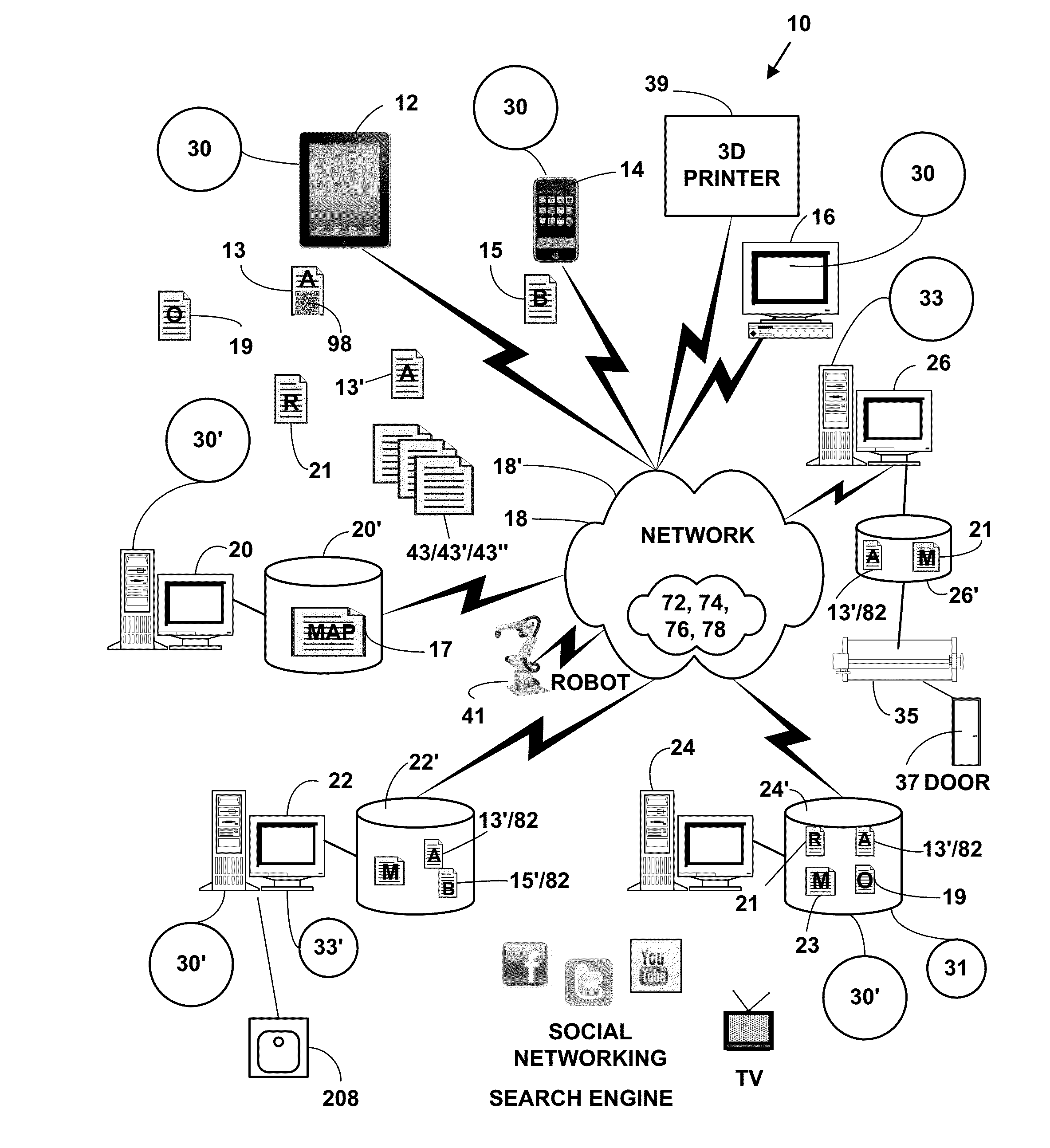

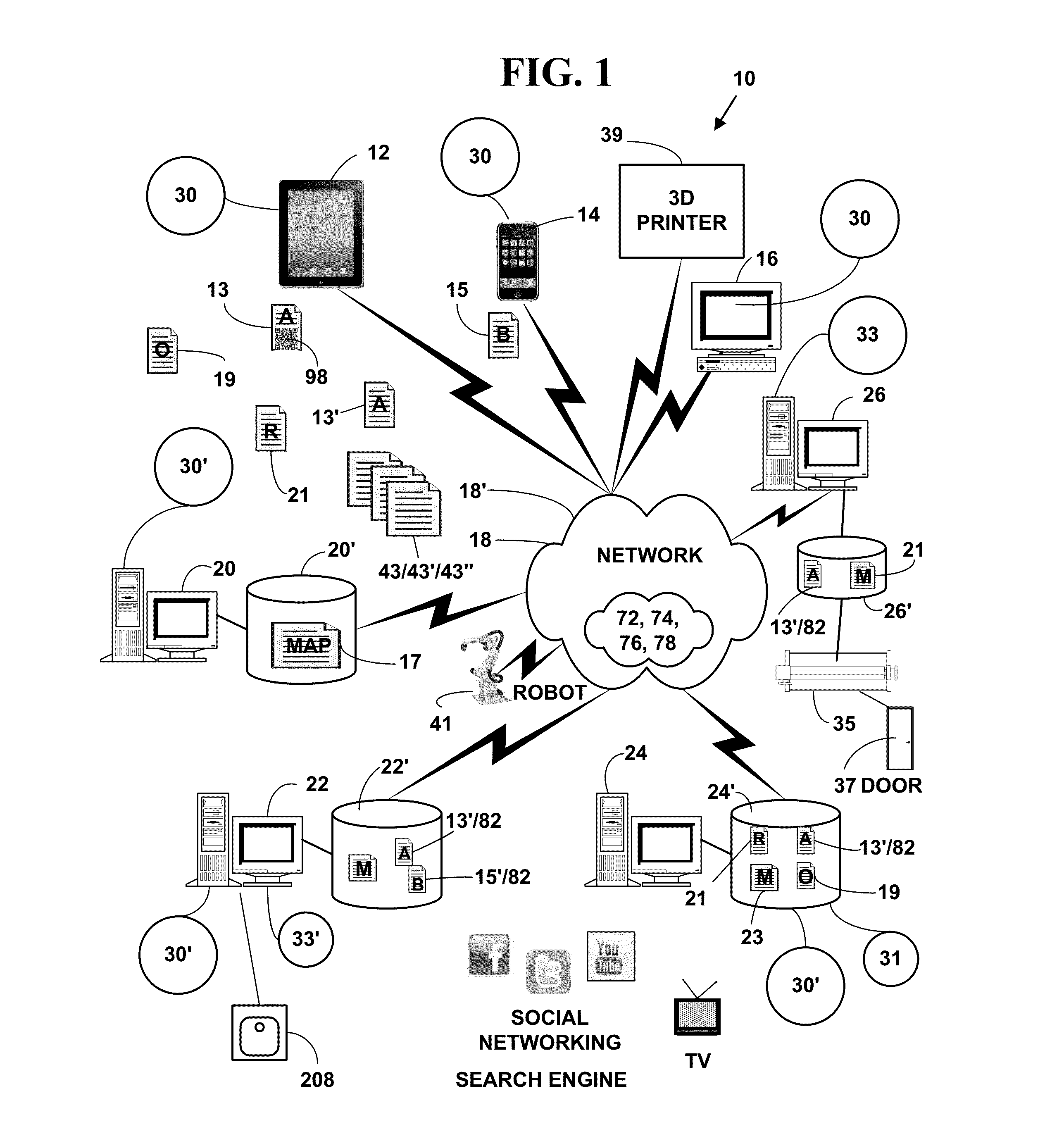

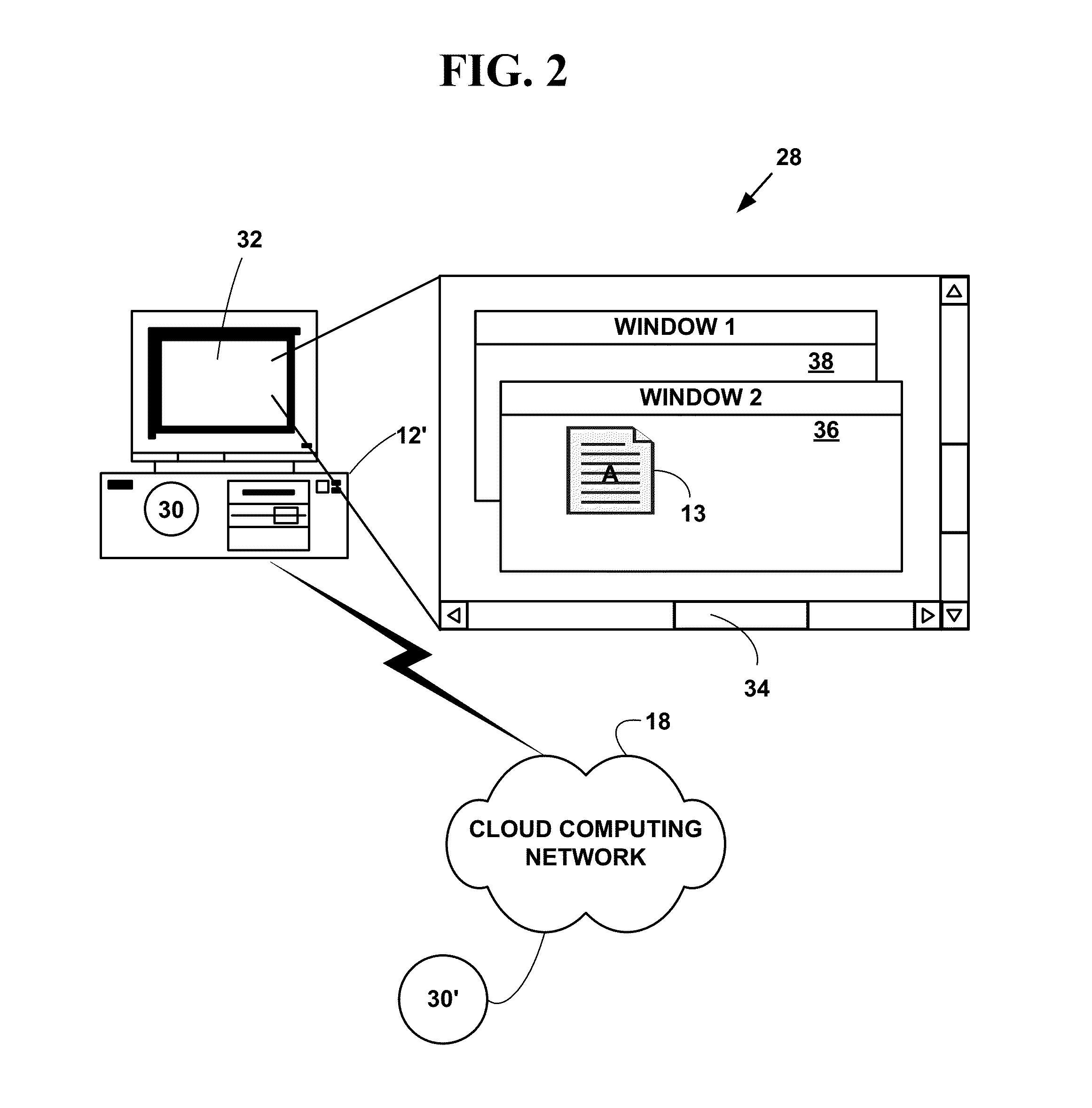

Method and system for creating 3D models from 2D data for building information modeling (BIM)

ActiveUS9817922B2Computer aided designSpecial data processing applicationsSimulationHigh dimensional

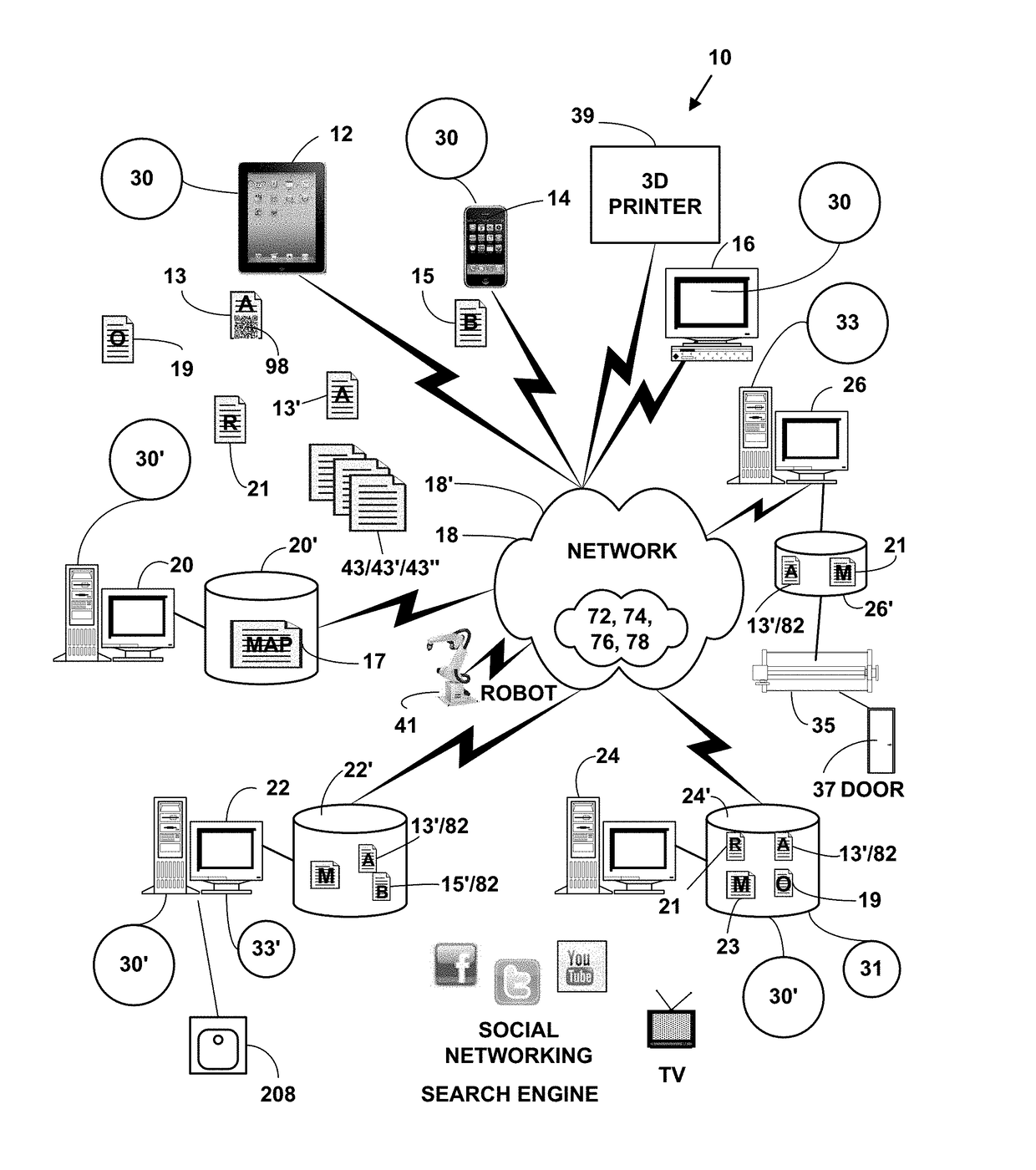

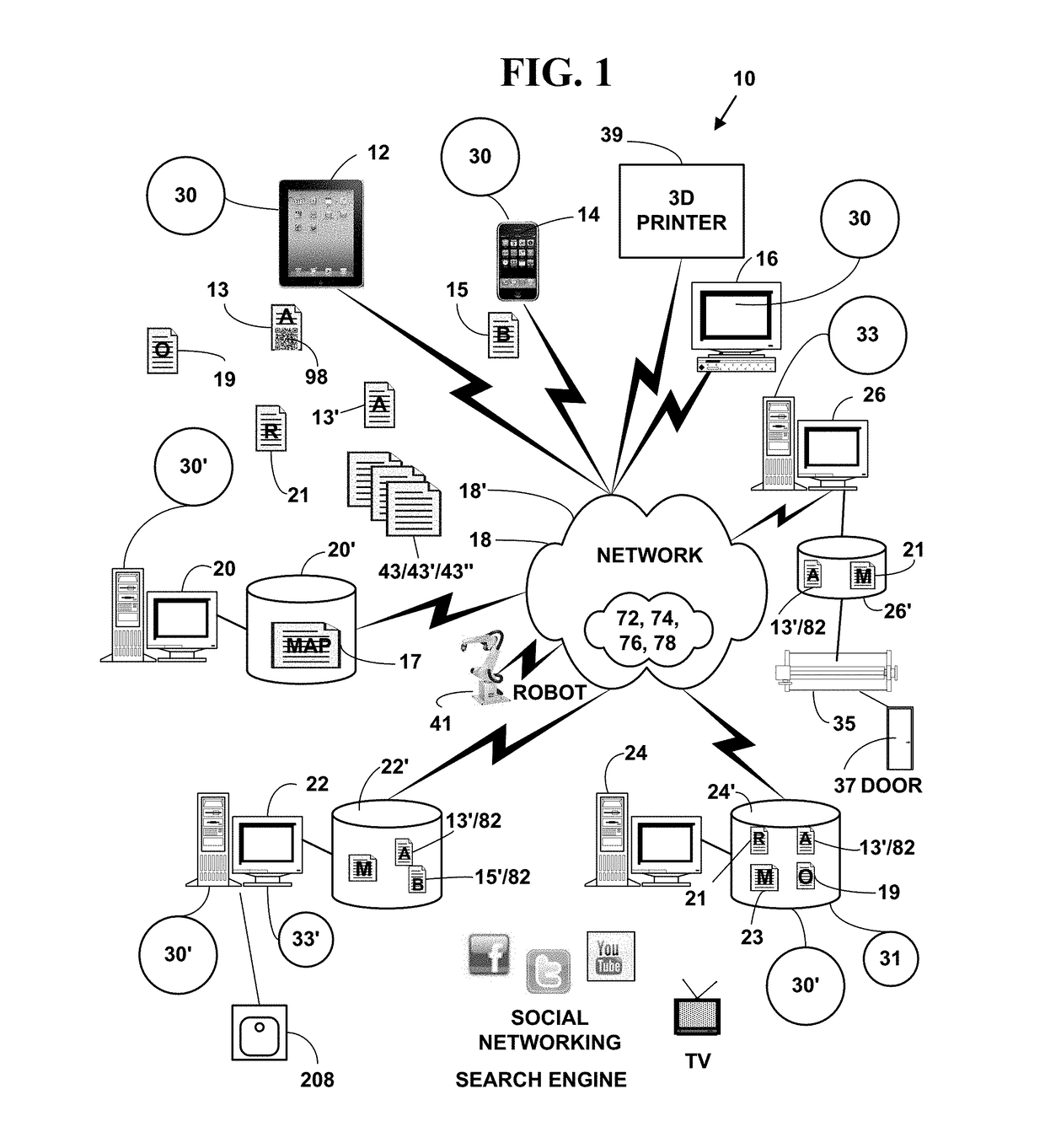

A method and system for creating three dimensional (3D) models from two dimensional (2D) data for building information modeling (BIM). The method and system allow new, 2D, 3D and higher dimensional models to be created for existing 3D modeling programs (e.g., AUTODESK REVIT, AUTOCAD, VECTORWORKS, MICROSTATION, ARCHICAD, etc.). The new models are used to enhance and extend existing 3D modeling programs. The new models can also be used to directly create physical objects (e.g., windows, doors, etc.) represented by the new models with robots, 3D printers and manufacturing machines.

Owner:ANGULERIS TECH

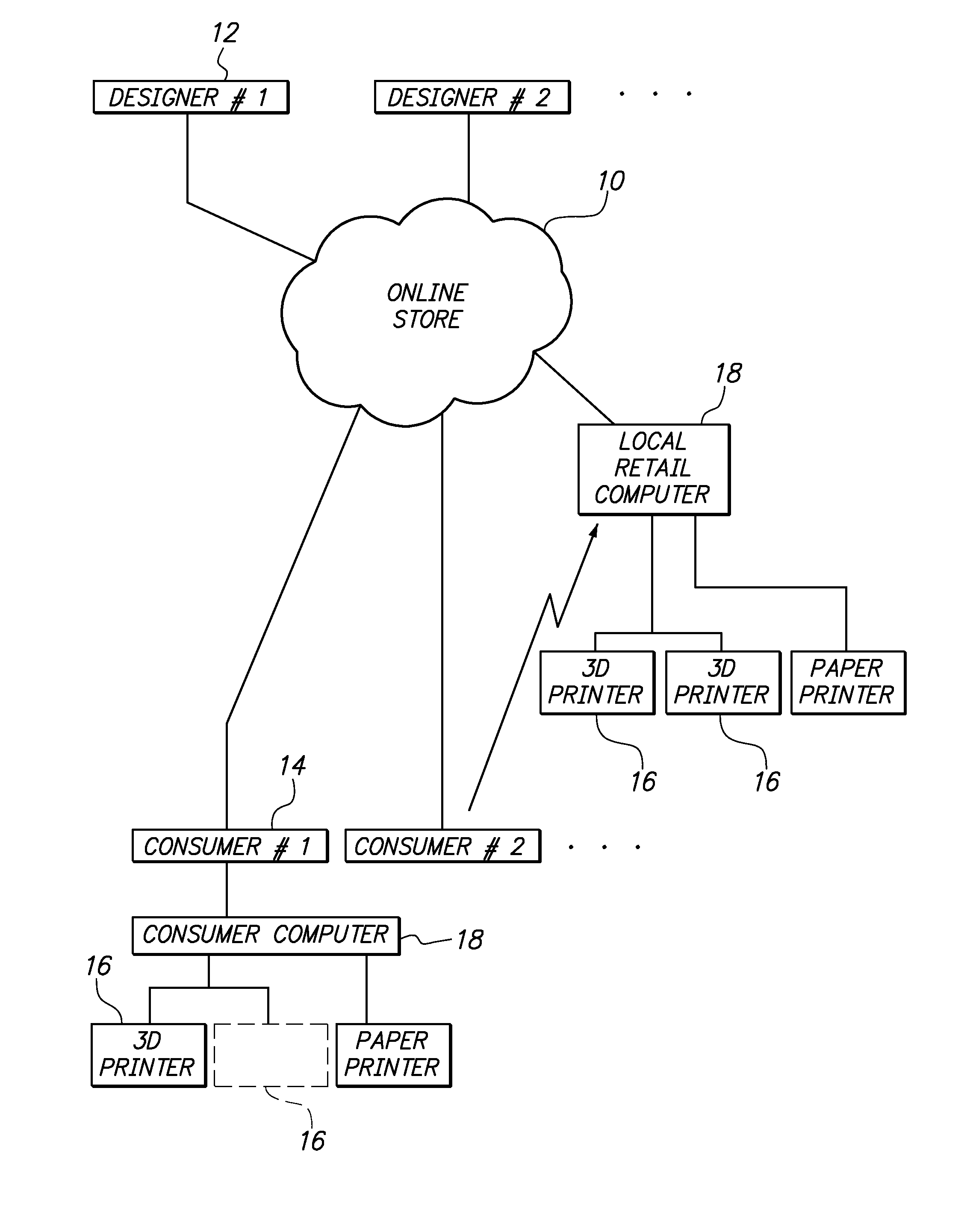

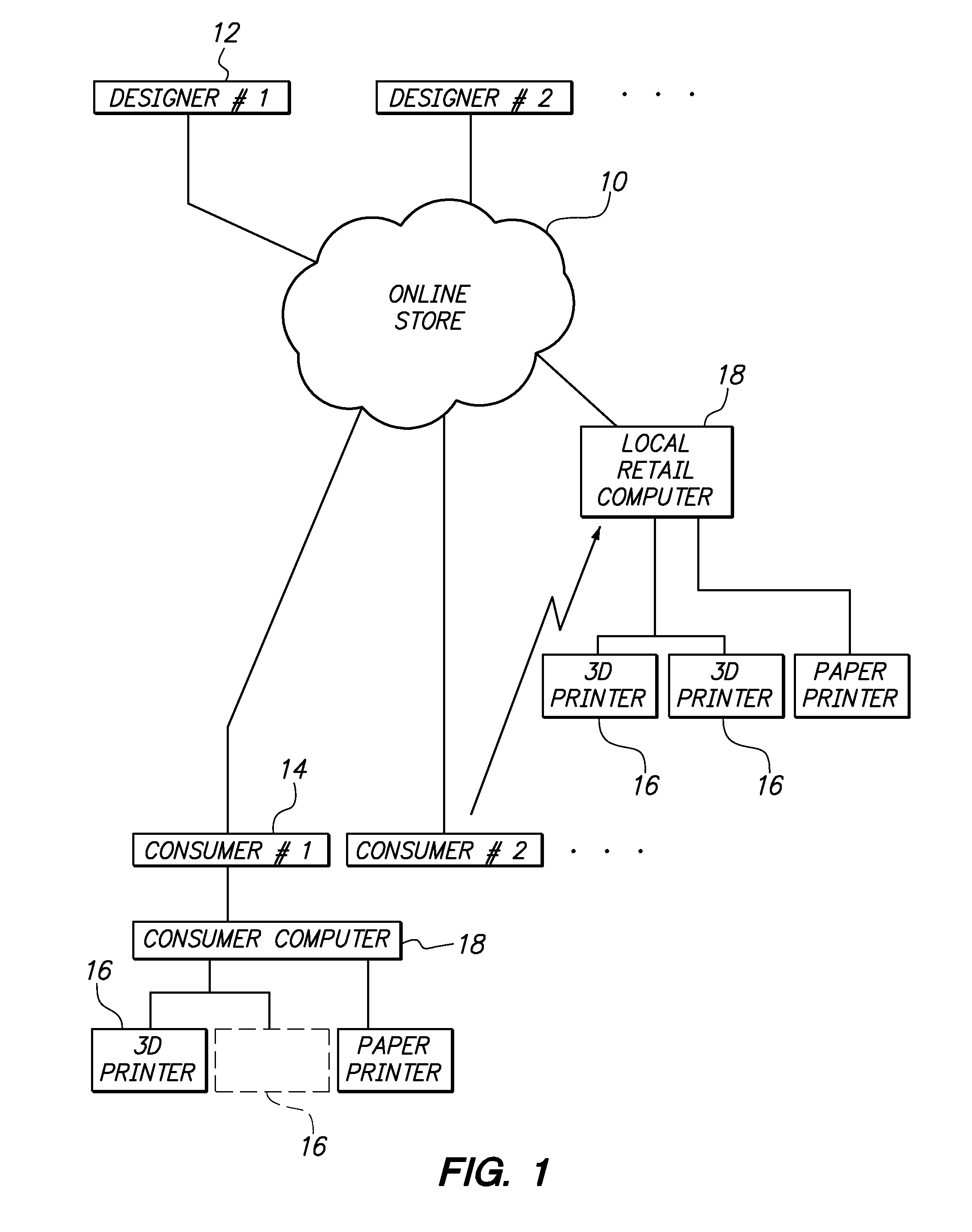

Online exchange for 3-d printable products

InactiveUS20140067609A1Taking mostEliminate storageAdditive manufacturing apparatusBuying/selling/leasing transactionsDistribution system3d printer

A method and system for eliminating storage and transportation of products within a product distribution system is disclosed saving money and time since businesses do not need to have products shipped and stored. The method and system includes an online store through which designers can upload electronic files of printable products and consumers can view the printable products for purchase, download and printing on a 3D printer. The method and system also allows for implementation of protection systems for designers with the option of insuring the final design is not tampered with by anyone other than the designer.

Owner:HEGER CHAD BUEGE

Coextruded, multilayer and multicomponent 3D printing inputs

ActiveUS20160136887A1Superior D object performanceHigh viscosityAdditive manufacturing apparatusMouldsEngineering3d printer

The present invention relates to 3D printer inputs including filaments comprising separated layers or sections. These inputs particularly including filaments may be prepared by coextrusion, microlayer coextrusion or multicomponent / fractal coextrusion. These inputs and specifically filaments enable layering or combining different materials simultaneously through one or more nozzles during the so-called 3D printing process. These techniques facilitate smaller layer sizes (milli, micro, and nano) different layer configurations as well as the potential to incorporate materials that would otherwise not be usable in standard 3D printer methods.

Owner:GUILL TOOL & ENG

Method and system for creating composite 3D models for building information modeling (BIM)

A method and system for creating composite three dimensional (3D) models for building information modeling (BIM). The method and system provides the creation of new composite 3D and higher dimensional models from plural different 3D models from plural different manufacturers for existing 3D modeling (e.g., AUTODESK REVIT, AUTODESK INVENTOR, AUTOCAD, SKETCHUP, VECTORWORKS, MICROSTATION, ARCHICAD, SOLIDWORKS, PROE, etc.) The new composite 3D models are used to enhance and extend existing 3D modeling programs. The new models can also be used to directly create new physical objects (e.g., windows, doors, etc.) that never existed before with robots, 3D printers and manufacturing machines.

Owner:ANGULERIS TECH

High-toughness photosensitive resin for 3D printing and preparation method thereof.

The invention provides a high-toughness photosensitive resin for 3D printing and a preparation method thereof. The photosensitive resin comprises a photosensitive resin (maleable photosensitive resin and rigid photosensitive resin), an active diluent, a light initiator and an additive. The method first synthesizes the toughness photosensitive resin (maleable polyurethane acrylate and epoxy modified polyurethane), and then the maleable photosensitive resin is mixed with the rigid photosensitive resin, active diluent, light initiator and additive. The maleable photosensitive resin is prepared from a polymer soft segment, which is a mixture of one or more selected from of polypropyleneoxide glycol ether, PTMG, hydroxyl-terminated polybutadiene, hydroxyl-terminated styrene butadiene rubber, hydroxyl-terminated butadiene acrylonitrile rubber and hydroxyl-terminated polysiloxane, and a polymer hard segment of toluene diisocyanate or isophorone diisocyanate, through hydroxyethyl acrylate or epoxypropanol termination. The photosensitive resin is applicable to DLP or SLA type 3D printers for modification of the existing 3D printing photosensitive resin, has excellent bending strength, and can directly print out elastic models.

Owner:QINGDAO UNIV OF SCI & TECH

Method and system for creating 3D models from 2d data for building information modeling (BIM)

ActiveUS20150248503A1Computer aided designSpecial data processing applicationsSimulationHigh dimensional

A method and system for creating three dimensional (3D) models from two dimensional (2D) data for building information modeling (BIM). The method and system allow new, 2D, 3D and higher dimensional models to be created for existing 3D modeling programs (e.g., AUTODESK REVIT, AUTOCAD, VECTORWORKS, MICROSTATION, ARCHICAD, etc.). The new models are used to enhance and extend existing 3D modeling programs. The new models can also be used to directly create physical objects (e.g., windows, doors, etc.) represented by the new models with robots, 3D printers and manufacturing machines.

Owner:ANGULERIS TECH

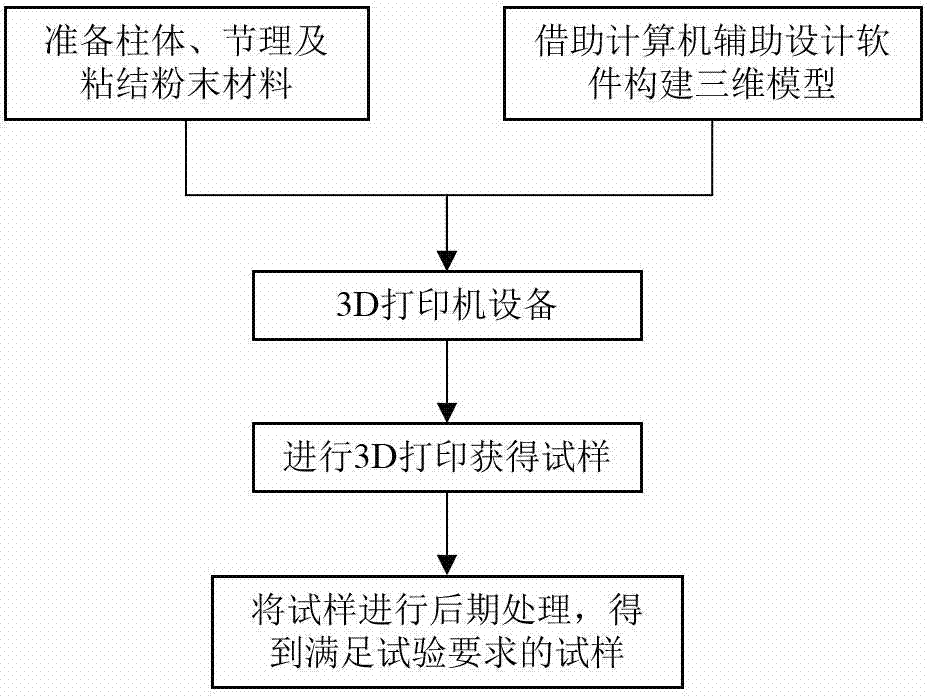

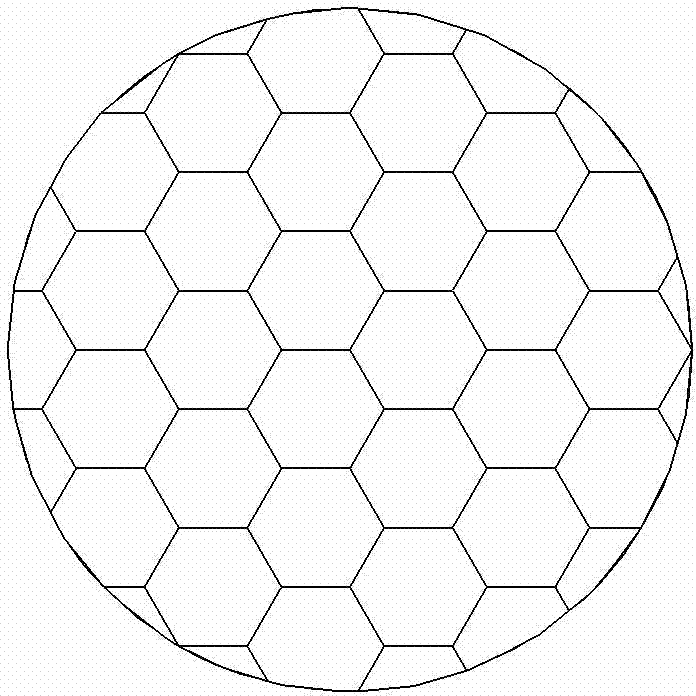

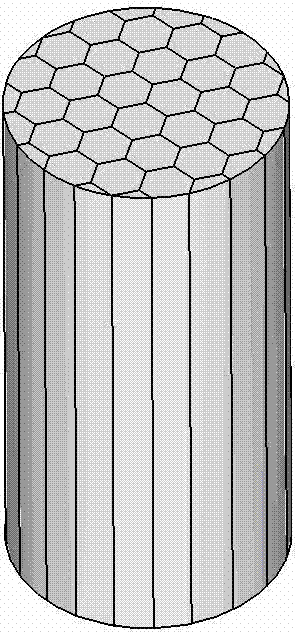

Method for preparation of columnar jointed rock mass similar material sample by 3D printing technology

InactiveCN104515696ASimple preparation processIncrease productivityPreparing sample for investigationAfter treatment3d printer

The invention discloses a method for preparation of a columnar jointed rock mass similar material sample by a 3D printing technology. The method includes: preparing powdered 3D printing raw materials: powder, columnar jointed column powder, joint needed powder and cementing bonding powder; loading the powdered materials into a 3D printer; establishing a columnar jointed sample three-dimensional model, and inputting the model into the 3D printer to conduct 3D printing; and carrying out after-treatment on the sample at the end of printing. The method provided by the invention applies the 3D printing technology into rock mechanical test for the first time, uses a similar material to simulate the basic characteristics of a columnar jointed rock mass in actual engineering, and has the advantages of simple preparation process, higher production efficiency than artificial sample preparation, and high yield, etc.

Owner:HOHAI UNIV

Method and system for creating composite 3D models for building information modeling (BIM)

A method and system for creating composite three dimensional (3D) models for building information modeling (BIM). The method and system provides the creation of new composite 3D and higher dimensional models from plural different 3D models from plural different manufacturers for existing 3D modeling (e.g., AUTODESK REVIT, AUTODESK INVENTOR, AUTOCAD, SKETCHUP, VECTORWORKS, MICROSTATION, ARCHICAD, SOLIDWORKS, PROE, etc.) The new composite 3D models are used to enhance and extend existing 3D modeling programs. The new models can also be used to directly create new physical objects (e.g., windows, doors, etc.) that never existed before with robots, 3D printers and manufacturing machines.

Owner:ANGULERIS TECH

Apparatus and methods for handling materials in a 3-D printer

InactiveUS20080047628A1Improve efficiencyProcess uneconomicalAdditive manufacturing apparatusSolid material3d printerBiomedical engineering

The present invention is directed towards methods and apparatus for handling powder in a 3D printer. The invention includes a means of transporting powder from multiple sources to a powder dispensing apparatus with minimal user intervention, thus reducing contamination of the 3D printer and surrounding area with loose powder, while also providing a means of improving the recycling of powder for re-use.

Owner:3D SYST INC

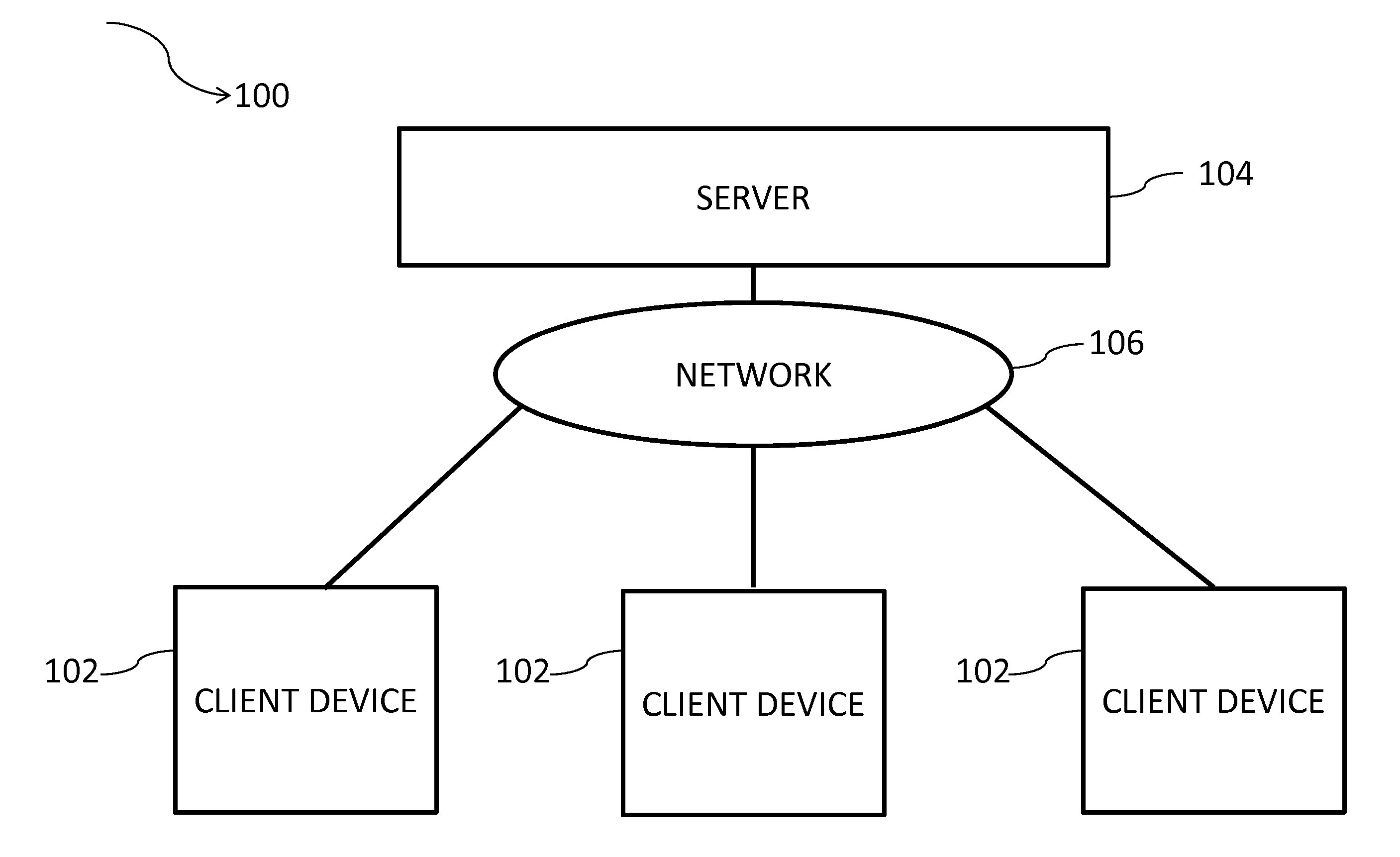

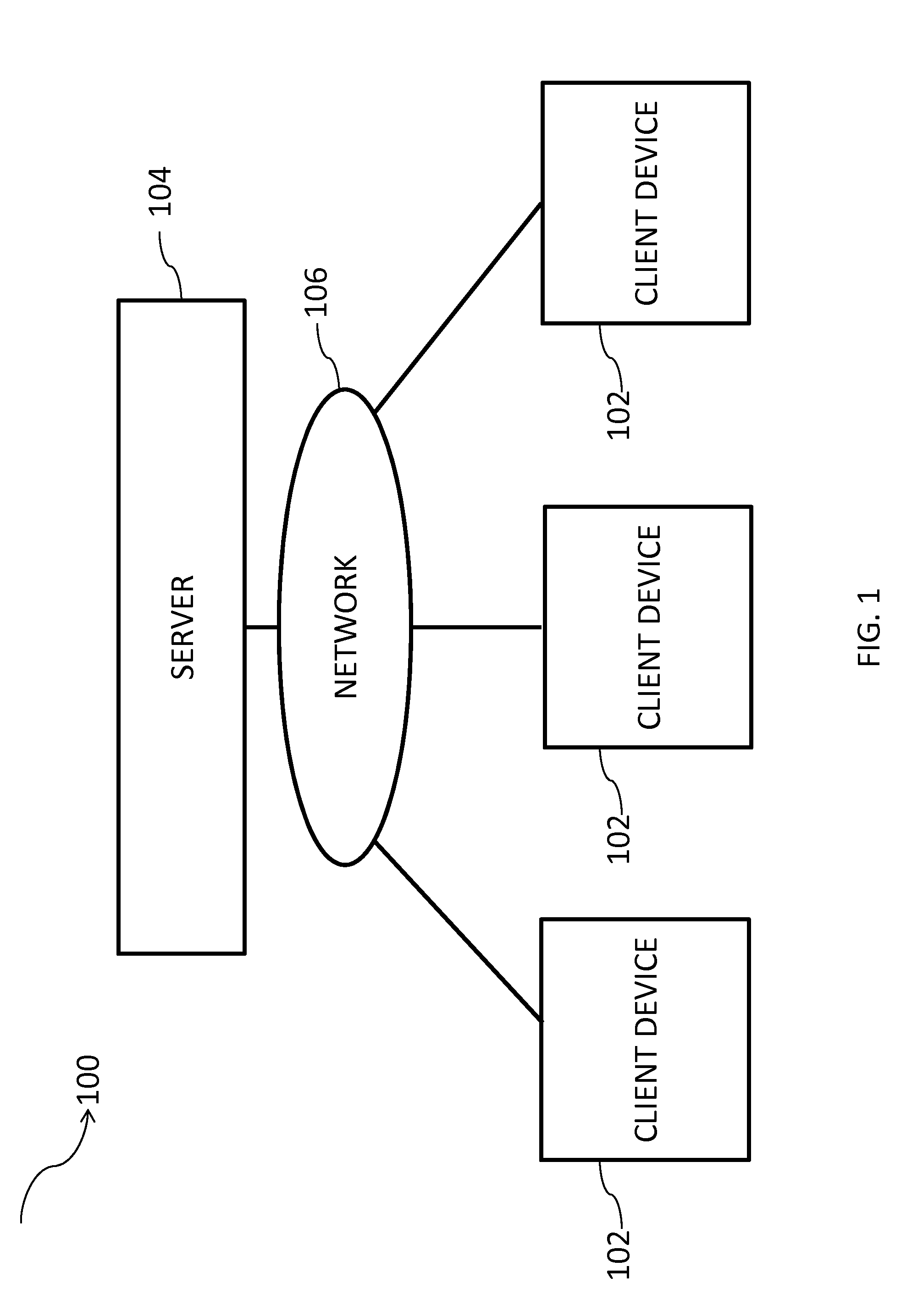

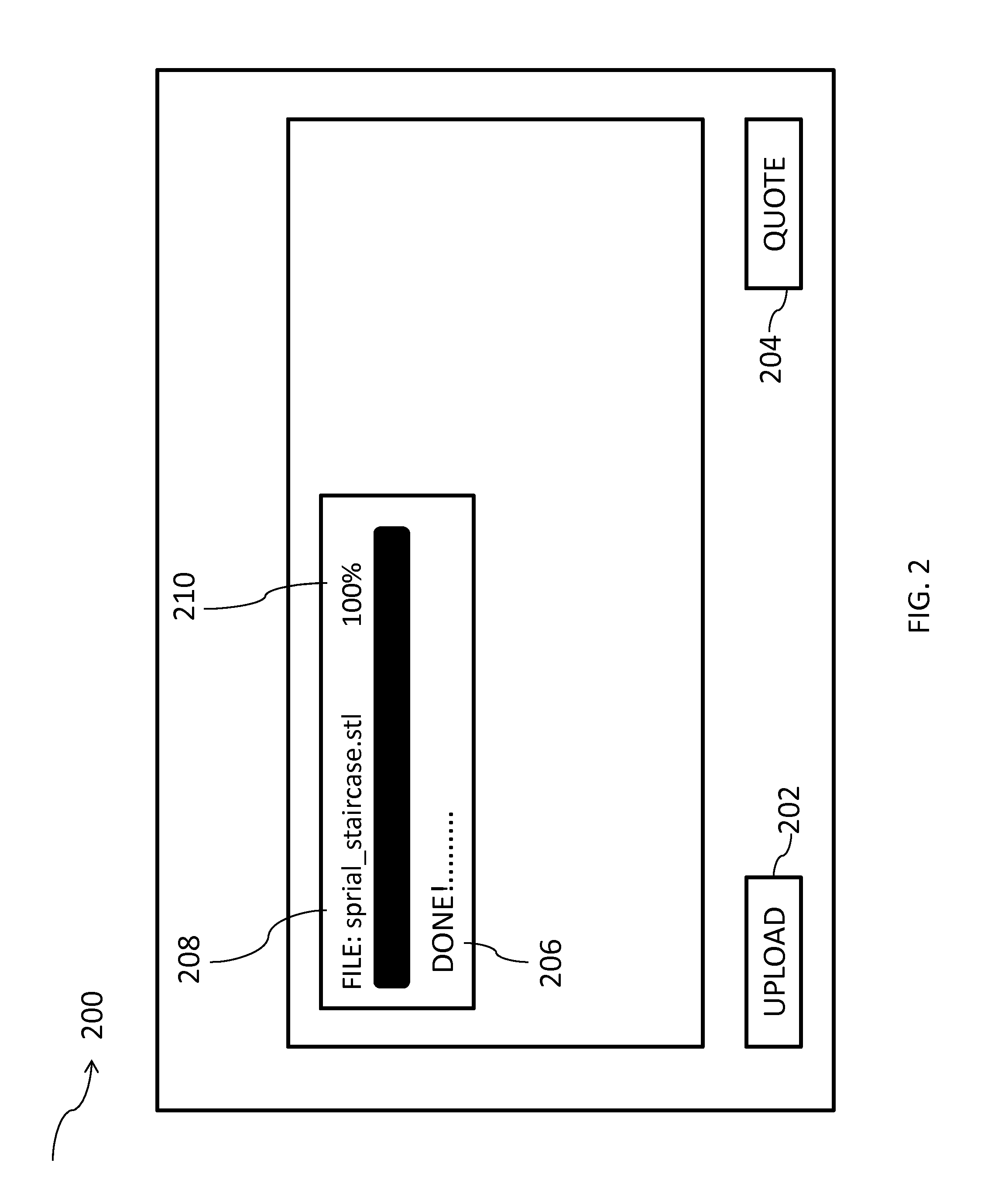

Systems and methods for providing price quotes for 3D objects

ActiveUS20140279177A1Quickly and easily costCost of productionAdditive manufacturing apparatusBuying/selling/leasing transactionsComputer graphics (images)Price quote

Systems and methods for providing price quotes for 3D objects are described herein. In one embodiment, costs related to generating a 3D object molded from a 3D printer mold may be based on various parameters. The process for generating a price quote may include uploading an initial file to a server and converting that file into a 3D CAD file. The method may also include selecting units, materials, a finish, and / or a quantity of objects to be made. Based on the selections, the server may generate a price quote to produce the one or more objects, and a checkout option may be provided allowing the user to purchase the one or more objects.

Owner:KEMEERA INC

Bi-component cement based composite material for 3D printing as well as preparation method and application thereof

The invention discloses a bi-component cement based composite material for 3D (three dimensional) printing as well as a preparation method and application thereof. The bi-component cement based composite material for 3D printing comprises a component A and a component B, wherein the component A is prepared from 34 to 40 percent of sulphate aluminium cement, 0 to 6 percent of inorganic powder, 40 to 44 percent of tailing machine-made sand, 2.5 to 3 percent of high-molecular polymer and the balance of a retarder, a water reducer, a size stabilizer, a defoaming agent and water, the pumping performance can be well kept for a long time, an industrialized process of pre-stirring production in a mixing plant, transportation, and using in a construction site can be realized; the B component is prepared from a coagulate promoting agent, a thixotropic agent, a defoaming agent and water, the component is stable in form and can be stored for a long time or produced in a concentrated manner. After A and B are respectively pumped in a 3D printer, through high-speed stirring and being mixed by an extrusion head, the composite printing material can be extruded out, the time of coagulation is short, the strength is high, the adhesion is good, the stability is strong, the constructive continuity and building strength requirements of building 3D printing can be met, the industrial production and promotion of the cement based 3D printing material are facilitated, and the application of a 3D printing technology in buildings can be effectively promoted.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

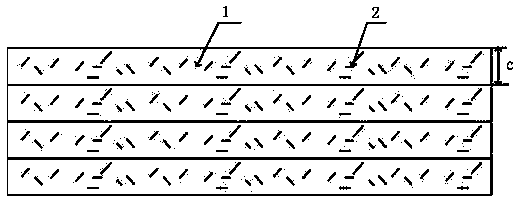

Three-dimensional (3D) printer and method for preparing three-dimensional products by use of 3D printer

The invention discloses a three-dimensional (3D) printer, the 3D printer comprises an X-Y working platform, spray heads installed on the X-Y working platform, light-emitting diode (LED) ultraviolet (UV) light sources, moving supporting frames, a base, fixed supporting frames, a supporting platform and UV resin material-feeding units, wherein the fixed supporting frames and the supporting platform are installed on the base, and the spray heads are connected with the UV resin material-feeding units. Through use of the 3D printer, one-way single-layer printing and one-way multi-layer printing can be carried out, multi-material printing, color printing, coating printing and other effects can be realized, and the printing efficiency is improved by times compared with that of the traditional 3D printers.

Owner:徐州泰铭电气有限公司

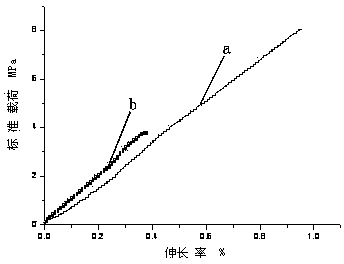

Graphene oxide/light cured resin composite and its preparation method and application

The invention provides a graphene oxide / light cured resin composite and its preparation method and application, the graphene oxide / light cured resin composite comprises two phases of graphene oxide and light cured resin, the graphene oxide is evenly dispersed in the light curing resin, the content of the graphene oxide is 0.1-1wt%, and the light cured resin comprises an oligomer, a light initiator and an active diluent. A graphene oxide nano material is dispersed in the light curing resin to obtain the graphene oxide / light cured resin nano composite, elongation at break and maximum bending strain of ordinary light cured resin is improved to a certain extent, and the impact strength of a coating film is increased by 2 times, so that a part printed by a 3D printer has better mechanical property.

Owner:QINGDAO UNIV OF SCI & TECH

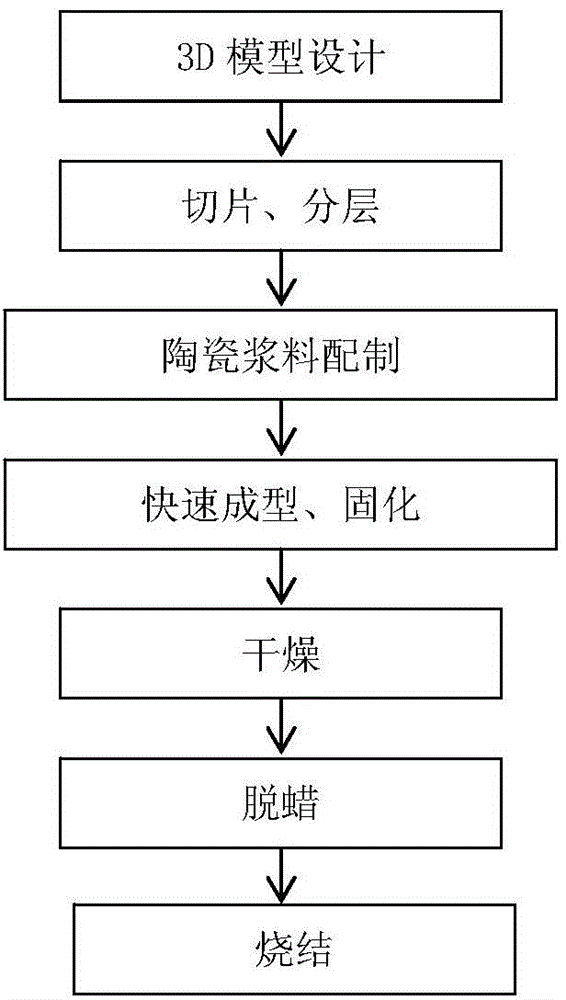

Method for 3D ceramic printing forming

ActiveCN104526838ARapid Dieless ManufacturingShorten the development cycleCeramic shaping apparatusSlurry3d printer

The invention discloses a method for 3D ceramic printing forming. The method comprises the following steps that (1) a 3D model of a target part is established; (2) layering processing is performed, and layered data are imported into a manufacturing program; (3) ceramic slurry is prepared; (4) the prepared ceramic slurry is added into a 3D printer to be made into a ceramic green body quickly formed; (5) the green body is cured at curing temperature for 10 min-60 min and then is placed in a drying oven for drying; (6) the dried green body is dewaxed and sintered to be made into the target part. The method is simple in technology and low in equipment cost; the distance between powder particles in the ceramic slurry can be reduced in the extrusion process, and therefore density is high; besides, the method is not limited by the type of ceramic particles and the shape of the part and is suitable for manufacturing ceramic products made of various ceramic materials and in various complex shapes.

Owner:NINGBO VULCAN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com