Graphene oxide/light cured resin composite and its preparation method and application

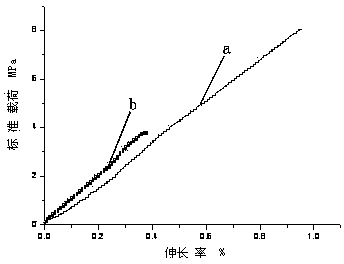

A technology of light-curing resin and composite material, applied in the field of graphene oxide/light-curing resin composite material and its preparation, can solve the problems of inability to print materials with 3D printers, difficult to achieve instant rapid curing, long curing time, etc. Elongation and maximum bending strain, good market application prospects, effect of improved impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of graphene oxide / cationic photocurable 3D printing material and preparation method thereof

[0045] 1. Dissolve 0.11g of graphene oxide in tetrahydrofuran to prepare a suspension in which the mass of graphene oxide accounts for 0.1wt% of the total mass of the suspension, and use an ultrasonic instrument with a power of 200W and a frequency of 21kHz to ultrasonically disperse at 0°C for 4 hours , to obtain a suspension of graphene oxide / tetrahydrofuran;

[0046] 2. Dissolve 100g of 3,4-epoxycyclohexylmethyl-3,4-epoxycyclohexyl carboxylate in 100g of tetrahydrofuran, and sonicate for 30min with an ultrasonic instrument with a power of 32W and a frequency of 40kHz;

[0047] 3. Mix the graphene oxide / THF suspension prepared in step 1 with the 3,4-epoxycyclohexylmethyl-3,4-epoxycyclohexyl carboxylate / THF solution prepared in step 2 in a beaker , using an ultrasonic instrument with a power of 32W and a frequency of 40kHz for 36 hours;

[0048] 4. Mix 5 g of sulfoniu...

Embodiment 2

[0050] A kind of graphene oxide / free radical photocurable 3D printing material and preparation method thereof

[0051] 1. Dissolve 0.11g of graphene oxide in tetrahydrofuran to make a suspension with graphene oxide mass accounting for 0.1wt% of the total mass of the suspension, and use an ultrasonic instrument with a power of 200W and a frequency of 21kHz to disperse at 0°C for 4 Hour, obtain the suspension of graphene oxide / THF;

[0052] 2. Dissolve 50g of polyether acrylate and 50g of tripropylene glycol diacrylate in 100g of tetrahydrofuran, and use an ultrasonic instrument with a power of 32W and a frequency of 40kHz for 30min;

[0053] 3. Mix the graphene oxide / tetrahydrofuran suspension prepared in step 1 with the mixed solution prepared in step 2 in a beaker, and use an ultrasonic instrument with a power of 32W and a frequency of 40kHz for 1.5 hours;

[0054] 4. Mix 4g of 1-hydroxycyclohexylacetophenone and 40g of tetrahydrofuran and add it to the mixed solution prepar...

Embodiment 3

[0056] A graphene oxide / free radical-cation hybrid light-cured 3D printing material and its preparation method

[0057] 1. Dissolve 0.11g of graphene oxide in tetrahydrofuran to prepare a suspension in which the mass of graphene oxide accounts for 0.1wt% of the total mass of the suspension, and use an ultrasonic instrument with a power of 200W and a frequency of 21kHz to ultrasonically disperse at 0°C for 4 hours , to obtain a suspension of graphene oxide / tetrahydrofuran;

[0058] 2. Dissolve 25g of 4,5-epoxycyclohexane-1,2-dicarboxylic acid diglycidyl ester, 25g of 4-vinyl epoxycyclohexane, and 50g of polyether acrylate in 100g of tetrahydrofuran, using a power of 32W, frequency of 40kHz ultrasound machine ultrasound 30min;

[0059] 3. Mix the graphene oxide / tetrahydrofuran suspension prepared in step 1 with the mixed solution prepared in step 2 in a beaker, and use an ultrasonic instrument with a power of 32W and a frequency of 40kHz for 2 hours;

[0060] 4. Mix 4g of 1-hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com