Aliphatic-aromatic copolyester, preparation method and application thereof

An aromatic and copolyester technology, applied in the direction of adhesives, etc., can solve the problems of easy aging, easy hydrolysis, low melting point, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

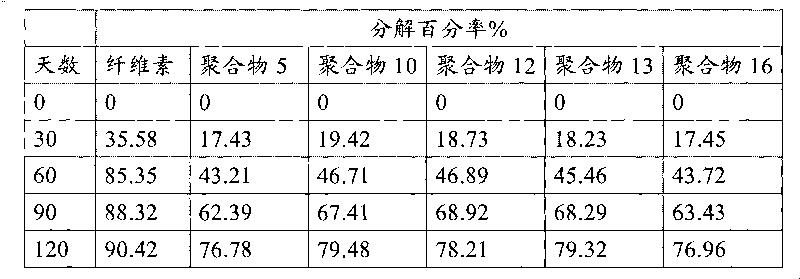

Examples

Embodiment 1

[0049] Add 1000ml of chloroform, 507.5 grams of terephthaloyl chloride and 387.5 grams of succinoyl chloride in the reaction flask, stir well, add dropwise a mixture of 450 grams of butanediol and 11.6 grams of monoethylene glycol acrylate under stirring, and control the reaction temperature at 0~40°C, after the dropwise addition is completed, continue to stir for 60 minutes to complete the reaction. The hydrogen chloride produced in the reaction was absorbed with NaOH solution.

[0050] After the reaction is complete, distill off the chloroform, add 0.5-1 g of tetrabutyl titanate, stir thoroughly for 20 minutes after melting, fill the bottle with nitrogen to replace the air in the bottle, reduce the pressure to 100-1000 Pa, continue to heat up to 180-250 °C, and stir After reacting for 60-120 minutes, light yellow to white polymer 1 was obtained. The GPC method determined that the molecular weight was 65,300 for Mn, 140,400 for Mw, and the molecular weight distribution was 2...

Embodiment 2

[0052] Add 1000ml of chloroform, 507.5 grams of terephthaloyl chloride, 387.5 grams of succinoyl chloride and 4.5 grams of acryloyl chloride into the reaction flask and stir evenly, then add dropwise 62 grams of ethylene glycol, 270 grams of butanediol, 95 grams of hexanediol, Mixture of 80 grams of polyethylene glycol, control reaction temperature at 0~40 ℃, dropwise, continue to stir for 60 minutes to make reaction complete. The hydrogen chloride produced in the reaction was absorbed with NaOH solution.

[0053] After the reaction is complete, distill off the chloroform, add 0.5-1 g of tetrabutyl titanate, stir for 20 minutes, fill the bottle with nitrogen to replace the air in the bottle, reduce the pressure to 100-1000 Pa, continue to heat up to 180-250 ° C, and react for 60-120 minutes , to obtain light yellow to white polymer 2. The GPC method determined that the molecular weight was 58,200 for Mn, 134,500 for Mw, and a molecular weight distribution of 2.31.

Embodiment 3

[0055] Add 1000ml of chloroform, 507.5g of terephthaloyl chloride, 457.5g of adipoyl chloride and 4.5g of acryloyl chloride into the reaction bottle, stir evenly, add dropwise a mixture of 441g of butanediol and 100g of polyethylene glycol under stirring to control the reaction The temperature is 0-40°C, after the dropwise addition is completed, the stirring is continued for 60 minutes to complete the reaction. The hydrogen chloride produced in the reaction was absorbed with NaOH solution.

[0056] After the reaction is complete, distill off the chloroform, add 0.5-1 g of tetrabutyl titanate, stir thoroughly for 20 minutes after melting, fill the bottle with nitrogen to replace the air in the bottle, reduce the pressure to 100-1000 Pa, continue to heat up to 180-250 °C, and stir After 60-120 minutes of reaction, polymer 3 was obtained. The GPC method determined that the molecular weight was 49,600 for Mn, 137,900 for Mw, and the molecular weight distribution was 2.78.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com