Patents

Literature

400results about How to "Solve the problem of fragmentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light diffusion master batch for transparent plastics and preparation method thereof

ActiveCN103073867ASolve the problem of fragmentationAvoid the disadvantages of physical property degradationHigh concentrationAging resistance

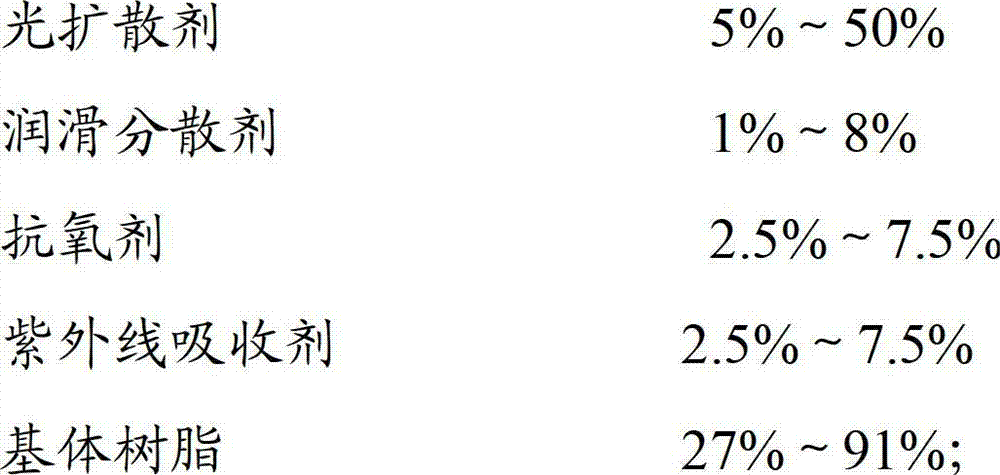

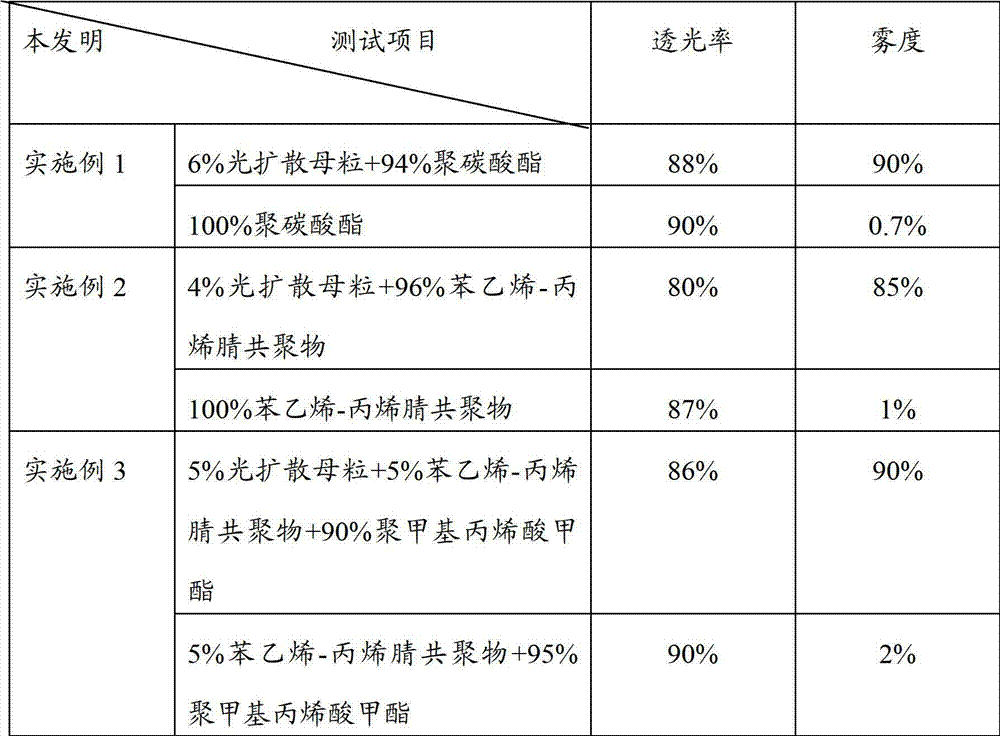

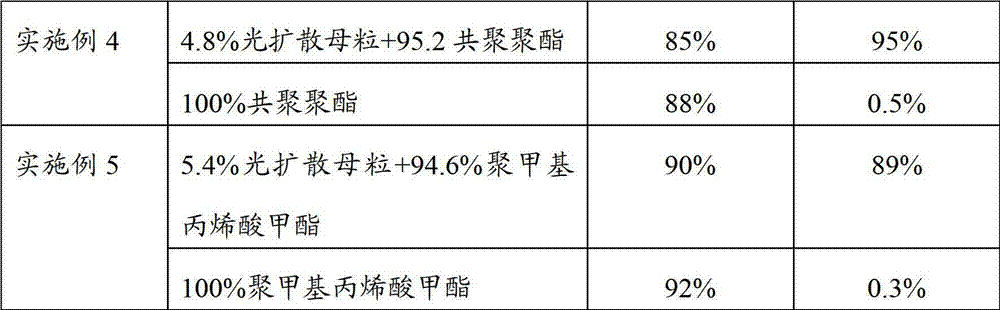

The invention relates to the technical field of functional master batches, in particular to a light diffusion master batch for transparent plastics and a preparation method thereof. The light diffusion master batch comprises the following components in percentage by weight: 5-50% of light diffusant, 1-8% of lubrication dispersant, 2.5-7.5% of antioxidant, 2.5-7.5% of ultraviolet light absorber and 27-91% of matrix resin; after being mixed, the components are placed in an extruder for being molten and extruded; and the extruded materials are cooled, pelletized and dried to prepare the product of light diffusion master batch. The light diffusion master batch has stable properties, high transparency and high haze; and as the master batch contains a light stabilizing agent and a heat stabilizing agent with high concentrations, plastic products produced thereby have excellent ageing resistance, and are suitable for long-time use in locations of natural illumination or manual illumination.

Owner:东莞市普凯塑料科技有限公司

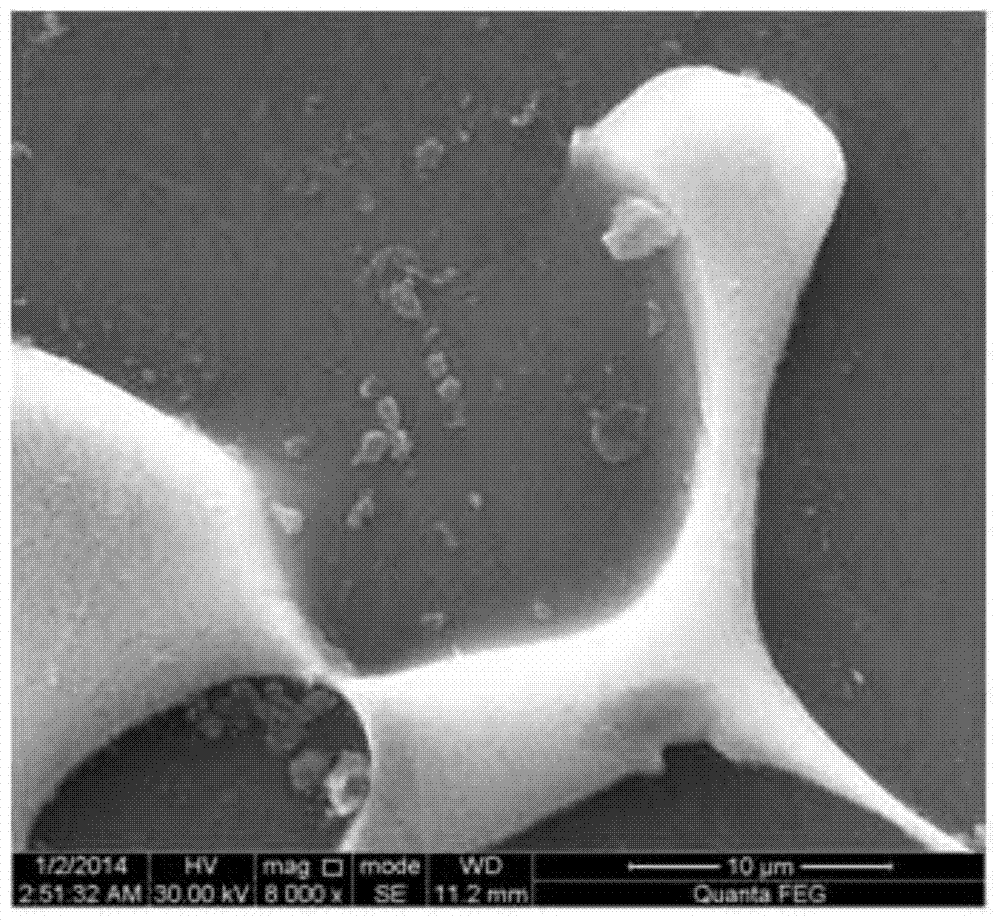

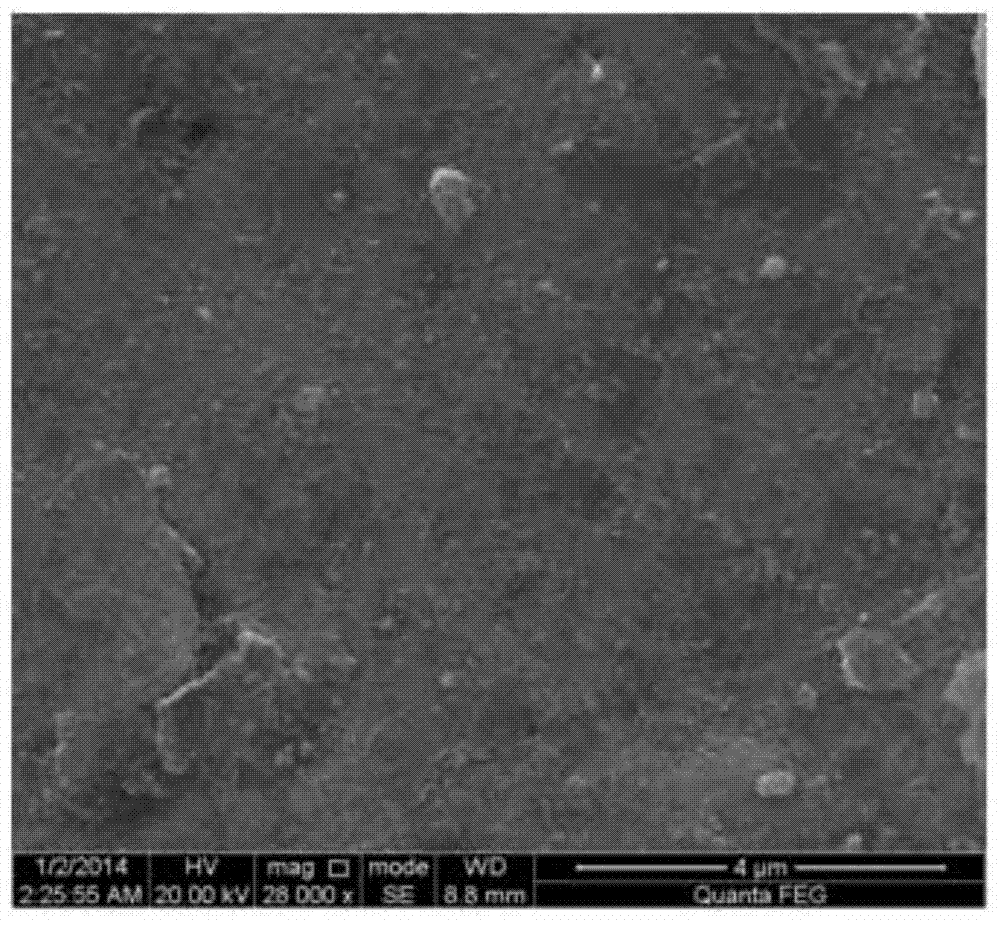

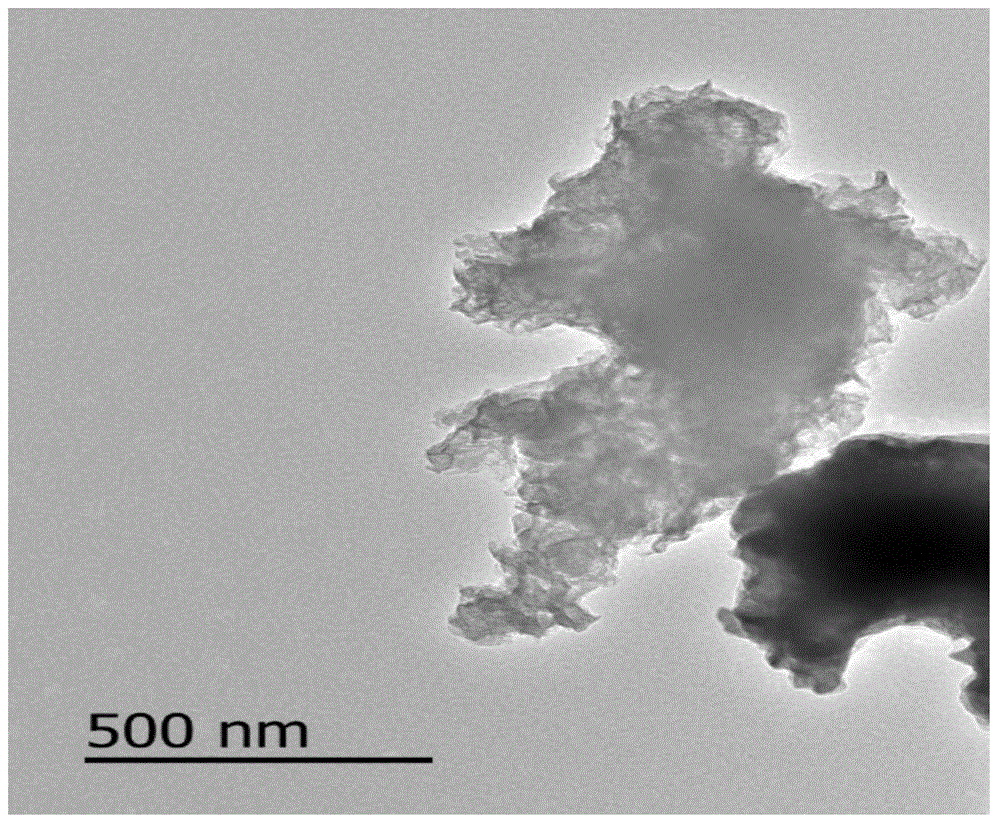

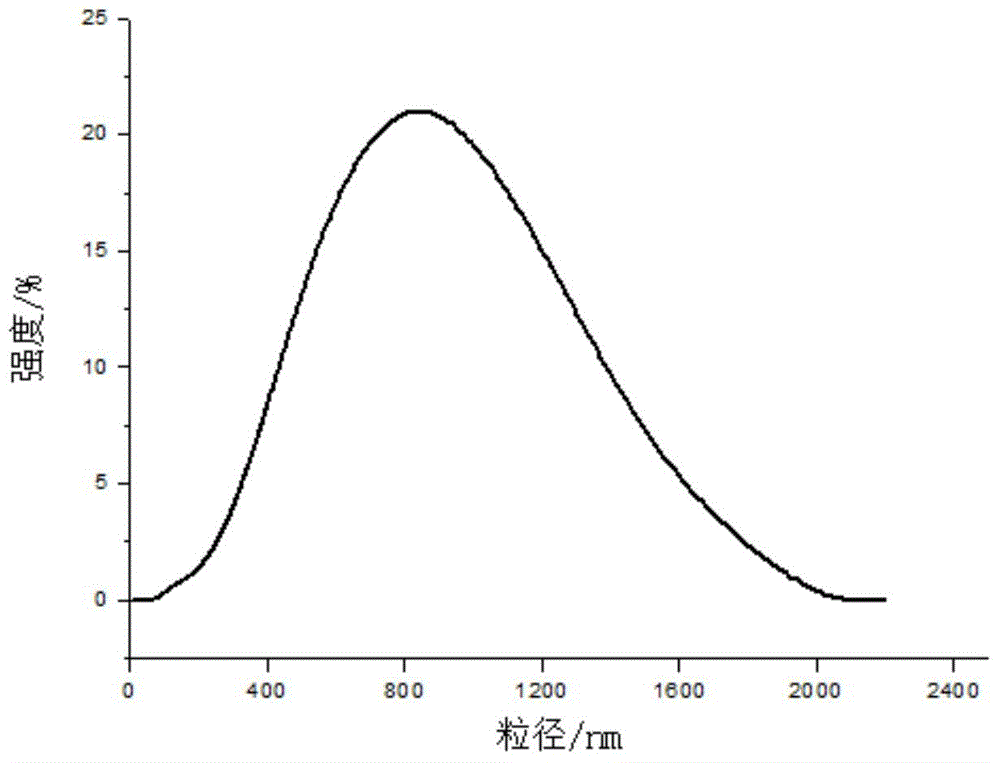

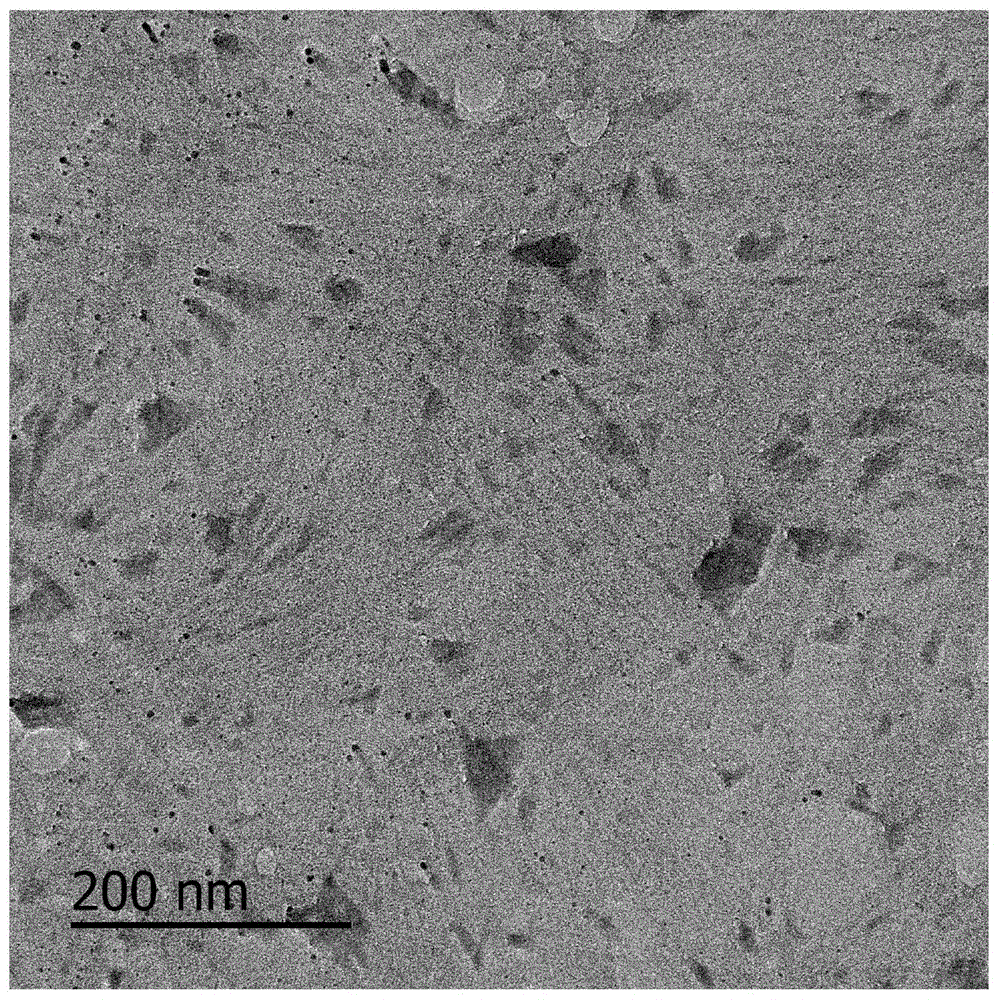

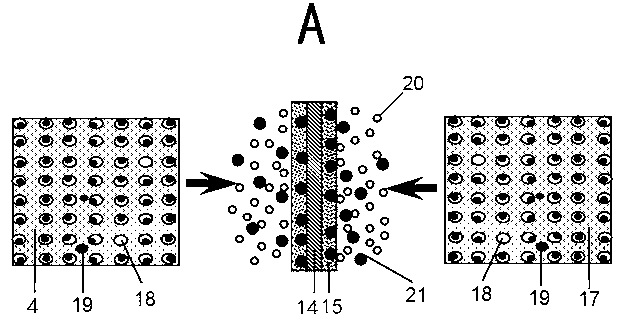

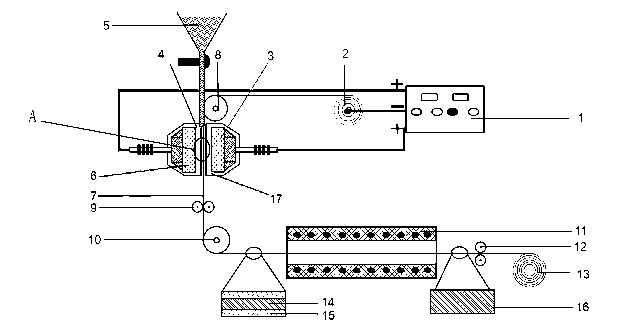

High-flux polyamide/ZIF-8 nanofiltration composite film and preparation method thereof

InactiveCN104209022ASolve the problem of fragmentationImprove permeabilitySemi-permeable membranesInorganic saltsPolymer science

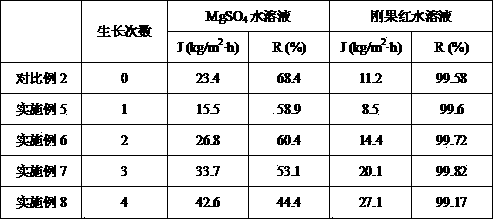

The invention discloses a preparation method of a high-flux polyamide / ZIF-8 nanofiltration composite film. The preparation method comprises the following steps of (1) growing a ZIF-8 type metal-organic framework material on an ultrafiltration bottom film in situ; (2) preparing a polyamide skin layer on the bottom film with ZIF-8 particles through interfacial polymerization; and (3) post-treating a primary composite film to obtain the polyamide / ZIF-8 nanofiltration composite film. A dense skin layer of the nanofiltration film consists of ZIF-8 and polyamide; by virtue of single or multiple in-situ growth, the ZIF-8 particles grow on the surface of the bottom film, and the polyamide skin layer is formed through interfacial polymerization, and the ZIF-8 particles on the surface of the bottom film are embedded into the polyamide layer. By use of a ZIF-8 multi-hole structure and a nano-grade channel size, the nanofiltration separation performance of the polyamide film of the prepared polyamide / ZIF-8 nanofiltration composite film can be improved. On the basis of the in-situ growth method, the operation of firstly synthesizing ZIF-8 and then adding into film preparation liquid is eliminated, so that the film preparation technology is simple; the performance of the polyamide / ZIF-8 film prepared by in-situ growth for multiple times is high; when the nanofiltration composite film is used for separating an inorganic salt aqueous solution system, the permeation flux can be increased; when the nanofiltration composite film is used for separating a congo red aqueous solution, the permeation flux and the retention rate can be increased at the same time.

Owner:BEIJING FORESTRY UNIVERSITY

Power distribution network overall planning method and system

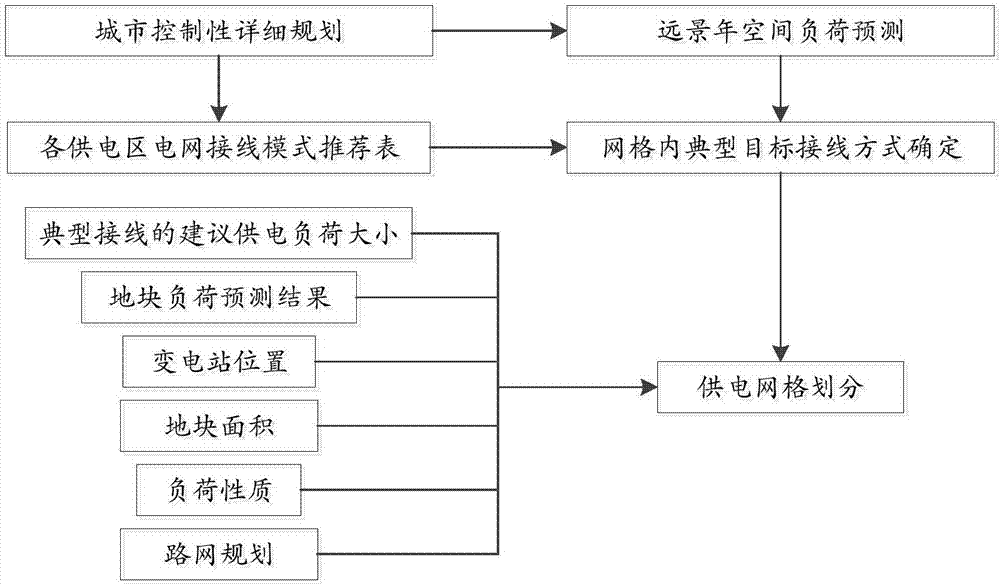

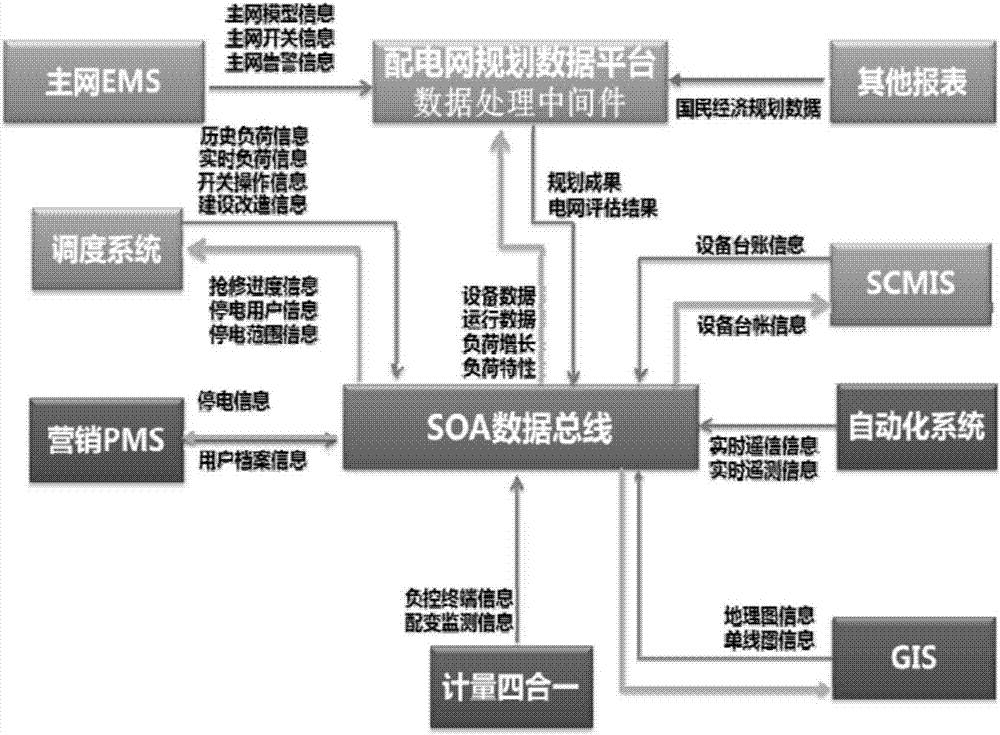

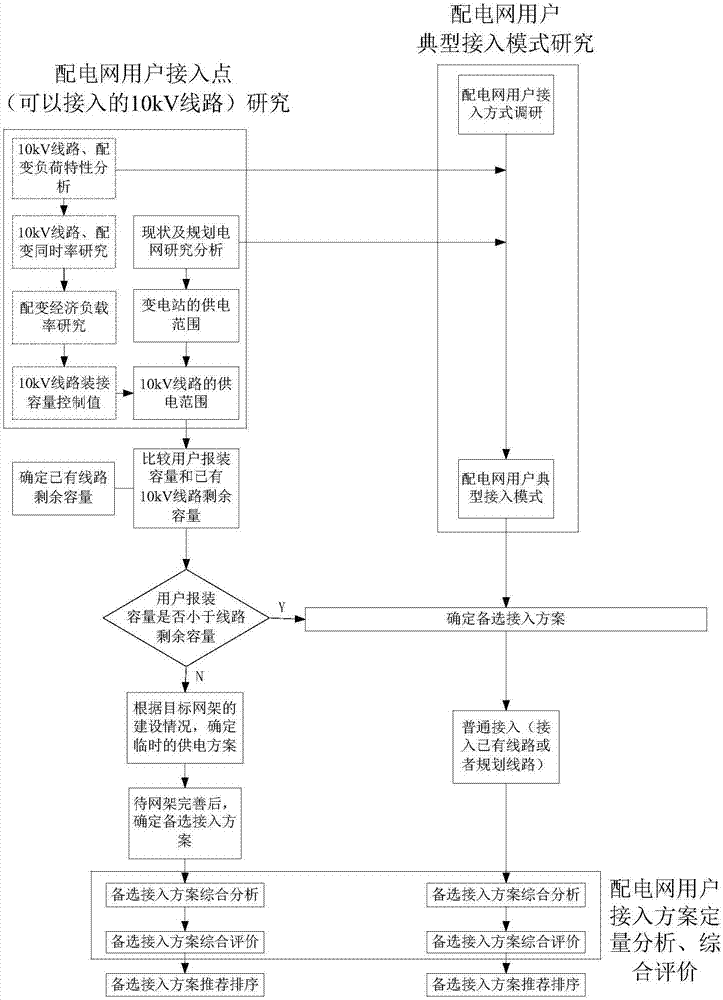

InactiveCN107038530AProper Load Transfer CapabilityReliable power supplyLoad forecast in ac networkForecastingSelf-healingWiring diagram

The invention provides a power distribution network overall planning method and system. The power distribution network overall planning method includes the steps: 1) dividing power supply areas; 2) determining the power supply area attribute and the planning strategy; 3) carding the present situation of grids; 4) predicting load; 5) determining the planning target; 6) dividing the power supply grids; 7) planning a power supply grid present situation wiring diagram and a target wiring diagram; 8) determining the planning scheme and the transitional scheme; 9) forming concrete implementation projects; and 10) compiling the line channel planning. The power distribution network overall planning method and system can systematically guide planning and construct a medium voltage power distribution network rack so as to guarantee reliability and firmness of the medium voltage power distribution network. The power distribution network overall planning method and system can construct a power distribution network with necessary capacity margin, proper load transferring capability, certain self-healing capability and emergency processing capability, and reasonable distributed power supply admission capability, and can safely, reliably and economically supply power for the user.

Owner:TIANDAQIUSHI ELECTRIC POWER HIGH TECH CO LTD

Aliphatic-aromatic copolyester, preparation method and application thereof

ActiveCN101717493AAvoid problems such as affecting performanceEvenly dispersedAdhesivesCarboxylic acid halidesMonomer

The invention provides aliphatic-aromatic copolyester, a preparation method and application thereof. Polymerization monomers comprise a compound selected from aliphatic dibasic acid, and naphthenic base dibasic acid or the ester, the anhydride and the acyl halide thereof, a compound selected from aromatic dibasic acid or the ester, the anhydride and the acyl halide thereof, a compound simultaneously with two functional groups selected from an amino-group, a mercapto group or a hydroxy or a compound of a derivative of the amino-group, the mercapto group or the hydroxyl with an epoxy group and an azepine ring, a compound selected from unsaturated acid with at least one C-C, C-O, C-N or C-S double bond and C-C or C-N triple bond or the ester, the anhydride and the acyl halide thereof and a compound of unsaturated alcohol with at least one C-C double bond or a C-C triple bond or an epoxide thereof. The aliphatic-aromatic copolyester is prepared by carrying out esterification and polycondensation after mixing the polymerization monomers, polymerizing the double bonds and / or the triple bonds on the polymerization monomers under the action of an initiator and then carrying out a graftingand / or coupling reaction.

Owner:HANGZHOU XINFU TECH CO LTD

Environment-friendly solar cell back film

ActiveCN102746754AReduce pollutionReduce harmSynthetic resin layered productsCoatingsWeather resistanceFluoropolymer

An environment-friendly solar cell back film comprises a substrate, a fluorine-containing polymer layer and an adhesive layer, wherein the fluorine-containing polymer layer is obtained by coating waterborne fluororesin coating solution on the surface of the substrate by means of curing, and the waterborne fluororesin coating solution comprises, by weight, 15-35 parts of fluororesin, 5-10 parts of modified resin A, 6-12 parts of modified resin B, 0.5-3 parts of polymer filler, 40-70 parts of water and 1-5 parts of cosolvents, wherein the weight ratio of the modified resin A to the modified resin B is 1:0.8-1:1.5. The environment-friendly solar cell back film is environment-friendly, low in production cost, excellent in performance, high in peeling strength and good in water resistance and weather resistance.

Owner:乐凯胶片股份有限公司

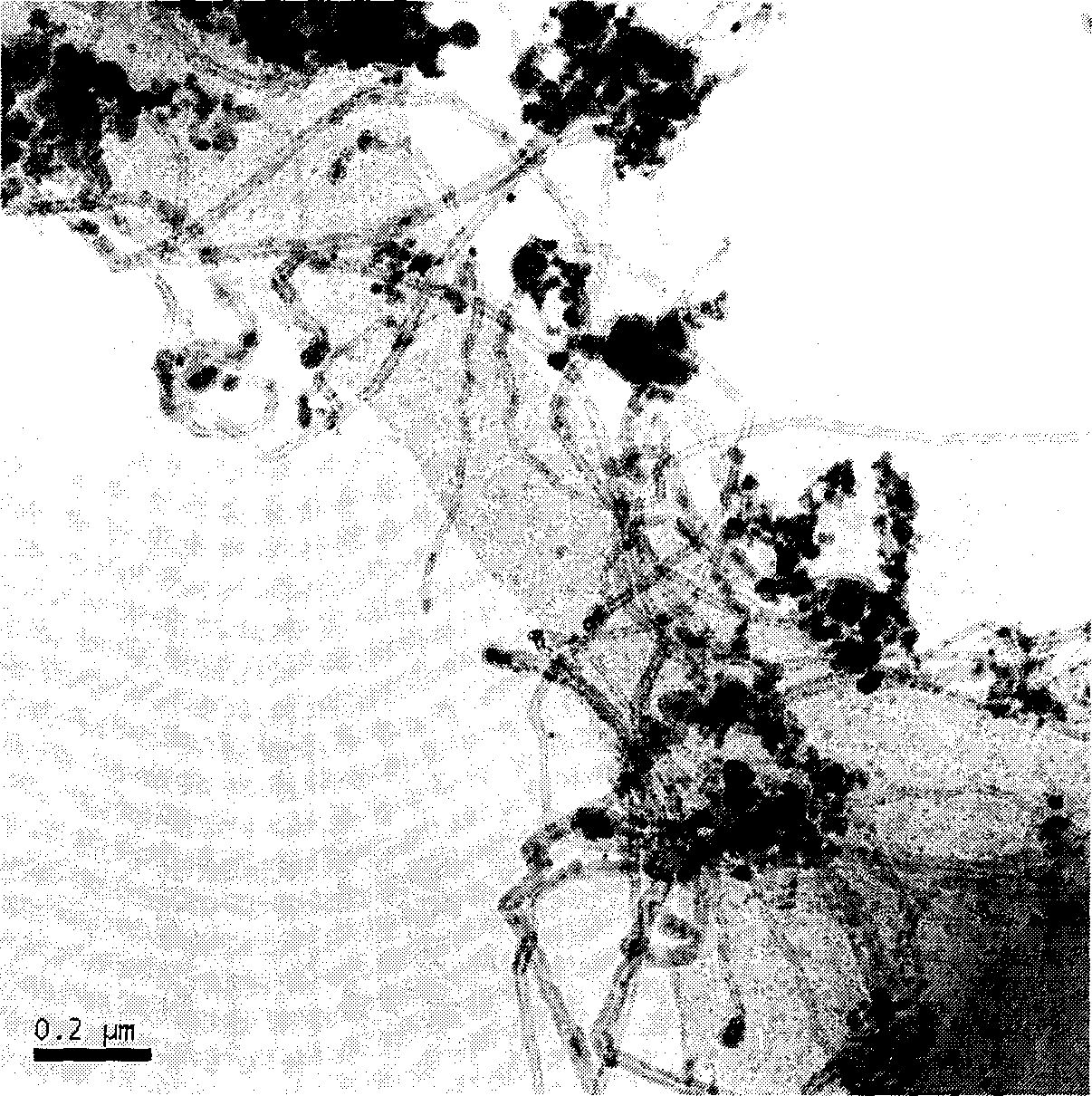

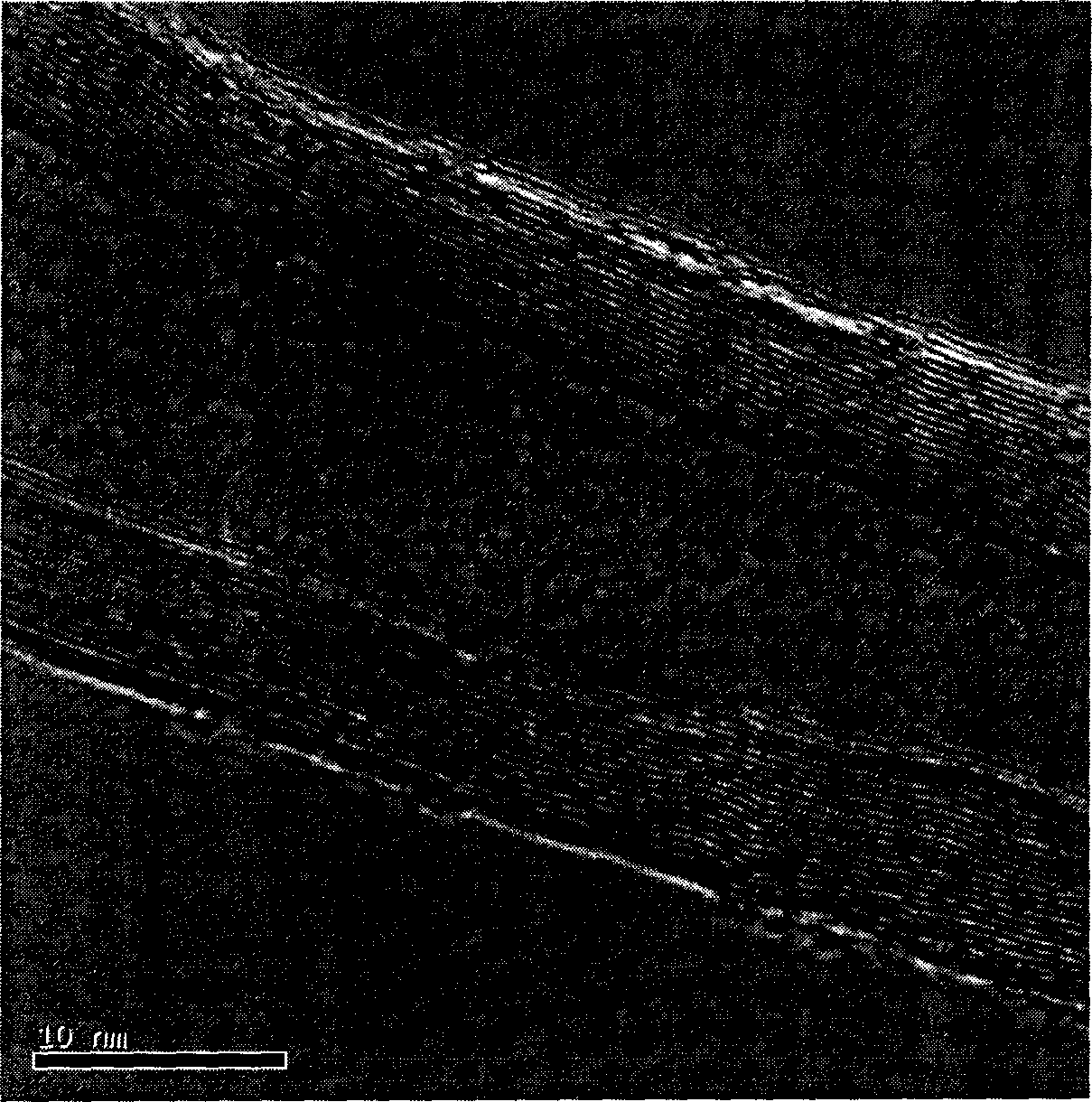

Vapor depositing in-situ reaction process for preparing carbon nanotube reinforced copper-base composite material

InactiveCN1888103ASolve the problem of fragmentationExcellent electrical performanceChemical vapor deposition coatingGas phaseCarbon nanotube

The present invention is preparation process of carbon nanotube reinforced copper-base composite material with high strength and high conductivity, and belongs to the field of copper-base composite material preparing technology. The preparation process includes the following steps: adding nickel nitrate hexahydrate, yttrium nitrate hexahydrate and ethanol soaked copper powder in certain weight proportion into distilled water to obtain nickel nitrate solution; dropping sodium hydroxide solution to the nickel nitrate solution to produce neutralizing reaction obtaining ternary Ni(OH)2 / Y(OH)3 / Cu colloid; washing, filtering, drying, grinding and calcining to obtain Ni / Y / Cu catalyst precursor; setting the precursor into reaction furnace, introducing H2 to reduce, and introducing N2 and reaction gas for catalytic cracking reaction to obtain composite carbon nanotube / Cu powder; initially pressing the composite powder, sintering and re-pressing to obtain carbon nanotube in-situ reinforced copper-base composite material.

Owner:TIANJIN UNIV

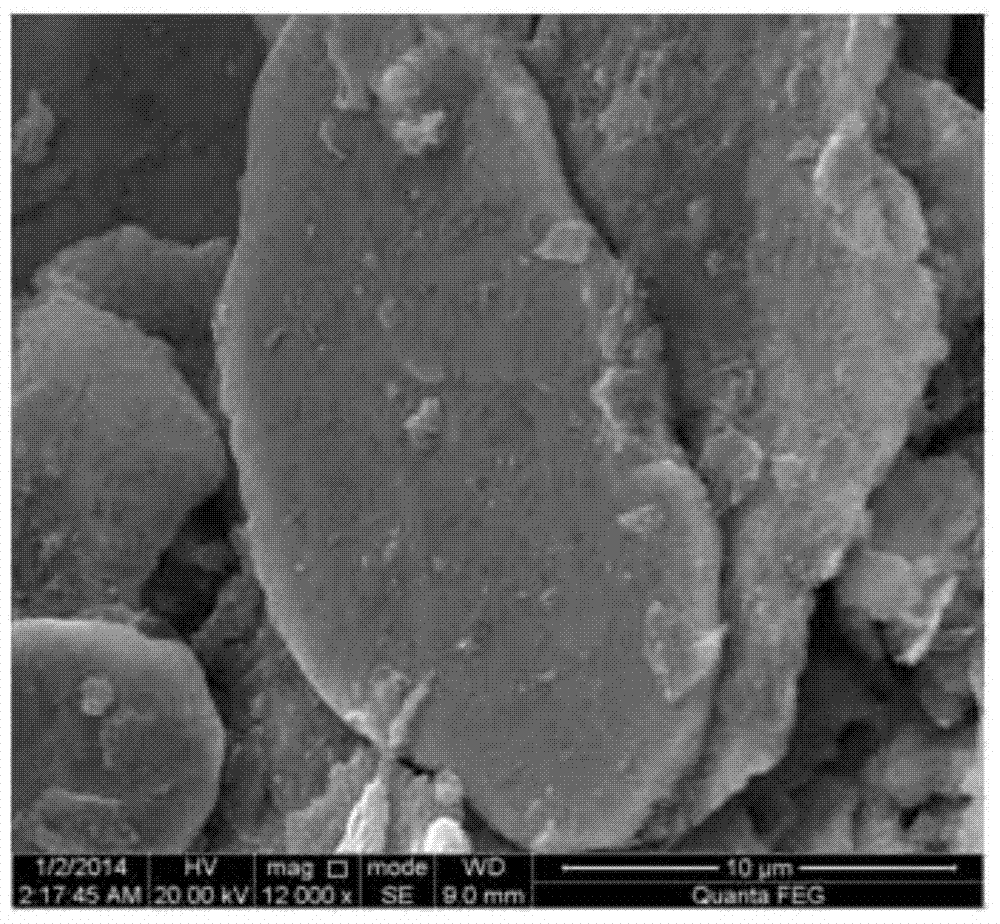

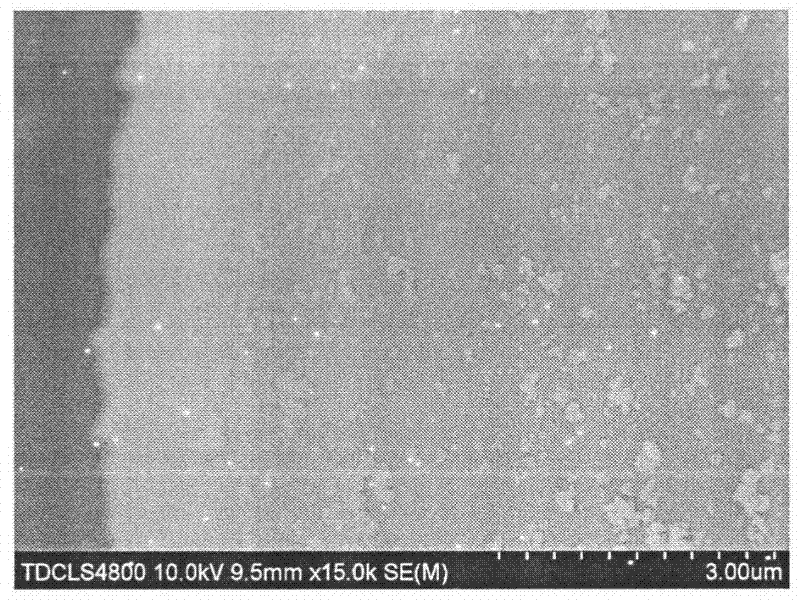

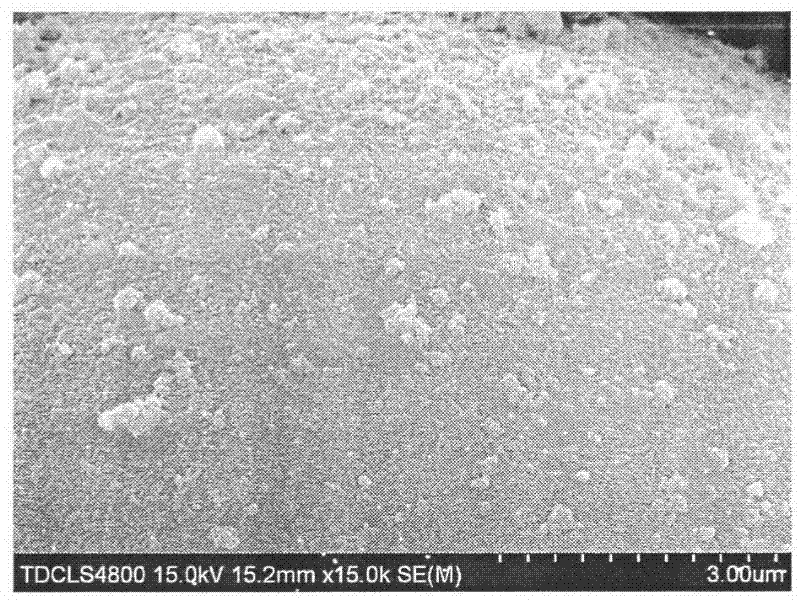

Preparation method of graphene enhanced magnesium-based composite material

The invention relates to a preparation method of a graphene enhanced magnesium-based composite material, and relates to a preparation method of a nanometer composite material. The invention aims at solving the technical problem of nonuniform dispersion of the traditional graphene in a matrix metal. The preparation method comprises the following steps of 1, mixing graphene with an alcohol dispersant in absolute ethyl alcohol, chemically dispersing under an ultrasonic condition to obtain chemically dispersed graphene; 2, mixing the chemically dispersed graphene with Zn powder for ball milling to obtain Gra@Zn composite powder; 3, adding Gra@Zn composite powder to a semi-solid state Mg-Zn alloy fusant for mechanical stirring, then increasing temperature till liquid state, and stretching an ultrasonic rod below an alloy liquid level for ultrasonic dispersion treatment to obtain an alloy fusant; 4, pouring the alloy fusant into a preheated mould, and then solidifying so as to prepare the graphene enhanced magnesium-based composite material. The preparation method disclosed by the invention is applied to the field of preparation of the nanometer composite material.

Owner:严格集团股份有限公司

Epoxy resin/carbon nanotube high-strength lightweight composite material, and preparation method thereof

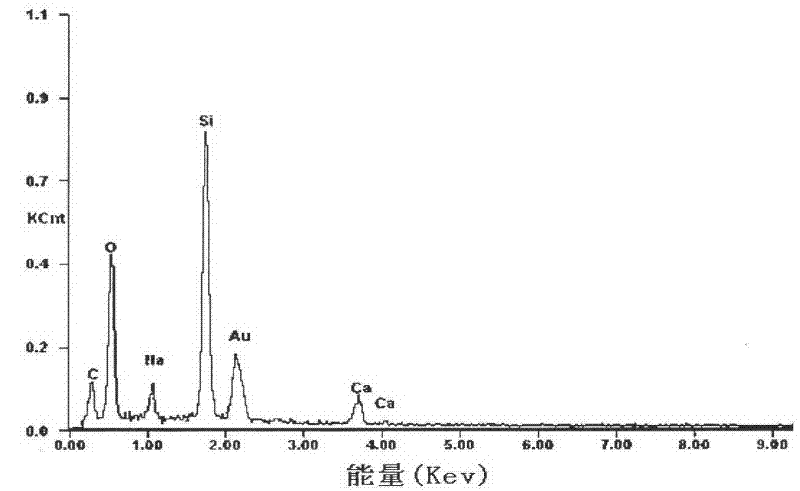

The invention relates to an epoxy resin / carbon nanotube high-strength lightweight composite material, and a preparation method thereof. The material comprises components of, by mass: 100 parts of epoxy resin, 30 parts of a curing agent, 10 to 60 parts of hollow glass microballoons, 1.0 to 6.0 parts of carboxylated carbon nanotubes, and 0.75 to 1.5 parts of an aminosilane coupling agent. The carboxylated carbon nanotubes are grafted on the surfaces of the hollow glass microballoons through chemical methods, and the materials are composed into epoxy resin. With good dispersibility of the hollowglass microballoons in epoxy resin, a dispersion problem of carbon nanotubes in epoxy resin is effectively solved, and mechanical intensity and conductivity of the composite material are improved. With the lightweight of the hollow glass microballoons, the density of the composite material is substantially reduced. The high-strength lightweight composite material produced with the method can be applied in the advanced material fields of aerospace, deep sea buoyancy materials, and wind power blades.

Owner:HEBEI BEISU PIPE IND

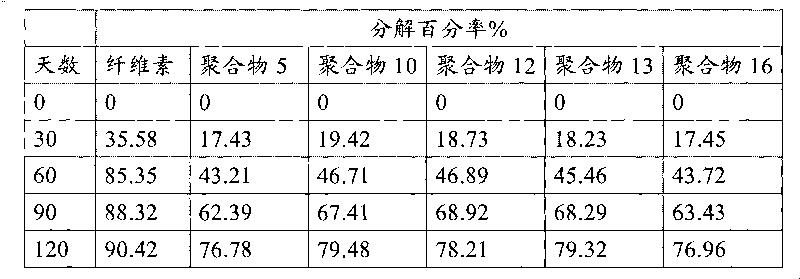

Fully biodegradable and multi-functional plastic mulch

ActiveCN103289134AFully biodegradableCreate pollutionClimate change adaptationPlant protective coveringsEcological environmentAdditive ingredient

The present invention provides fully biodegradable and multi-functional plastic mulch. The plastic mulch comprises, by weight percent: natural biopolymers of starch or derivatives thereof, biodegradable synthetic polymers, an interfacial reinforcer, a compound plasticizer with urea as a main ingredient, a nitrogen phosphorus and potassium compound fertilizer, pesticides, herbicides and trace fertilizers. The plastic mulch of the present invention not only has heat and moisture preservation functions, and is fully biodegradable after use, eliminating the contamination to soil causes by residual plastic mulch debris; and functional additives of fertilizers and nutrients, pesticides, herbicides etc. in the plastic mulch are sustainedly released as the plastic munch degrading, so the plastic mulch has long lasting effects of weed controlling, pest killing, and sustainedly released fertilizing, significantly reducing the use amount of fertilizers and pesticides, decreasing costs, and protecting the ecological environment. The invention also provides a method for preparing the multi-functional plastic mulch.

Owner:ANHUI XUELANG BIOTECHNOLOGY CO LTD

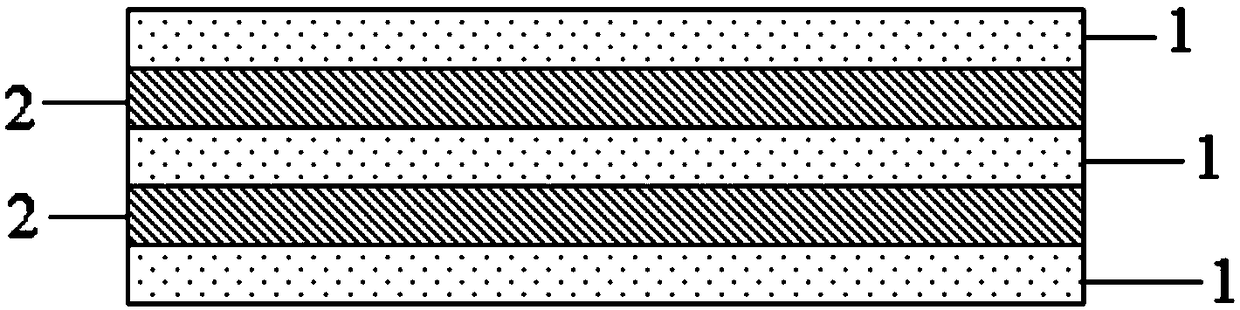

Graphene thermal-conductive film/thermal-conductive silica gel film composite material with layered alternative structure and preparation method of composite material

ActiveCN108819360AEfficient and uniform heat dissipationImprove tear resistance and mechanical propertiesLamination ancillary operationsLaminationCvd grapheneConductive materials

The invention discloses a graphene thermal-conductive film / thermal-conductive silica gel film composite material with a layered alternative structure and a preparation method of the composite material, and relates to the graphene / thermal-conductive silica gel composite material and the preparation method thereof. The invention aims to solve the technical problems that graphene in a current graphene / thermal-conductive silica gel composite material is difficult to disperse, and a stable and continuous thermal-conductive path is difficult to form. The composite material is composed of graphene thermal-conductive films and thermal-conductive silica gel films, and the graphene thermal-conductive films and the thermal-conductive silica gel films are alternately arranged. The preparation method of the composite material comprises the following steps: 1, preparing the graphene thermal-conductive film; 2, preparing thermal-conductive silica gel; and 3, preparing the graphene thermal-conductivefilm / thermal-conductive silica gel film composite material with the layered alternative structure. The method disclosed by the invention adopts a method of compounding nanocellulose and graphene to prepare the graphene thermal-conductive film, and utilizes an interface technology to compound the graphene thermal-conductive film with the thermal-conductive silica gel film to form the graphene / thermal-conductive silica gel film composite material with the layered alternative structure, and the composite material meets the requirements for high-performance thermal-conductive materials in the fields such as aviation, aerospace, electronic and electrical engineering.

Owner:HARBIN UNIV OF SCI & TECH

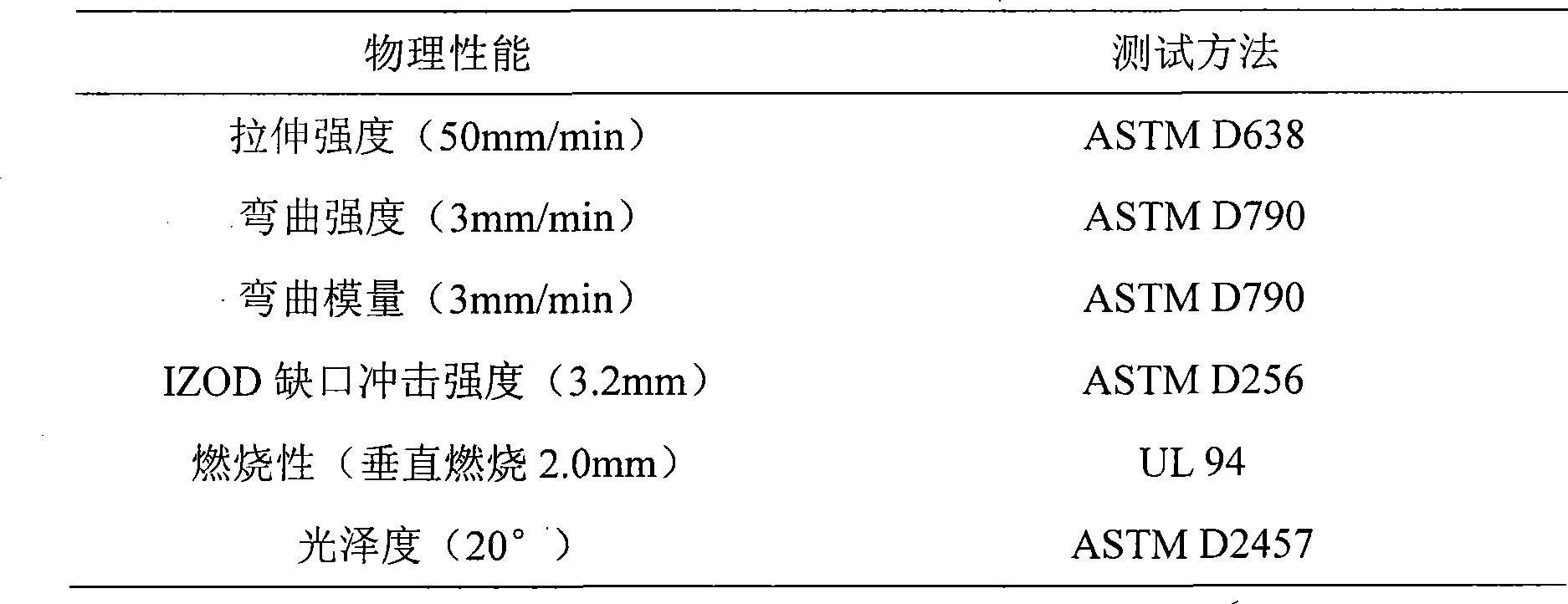

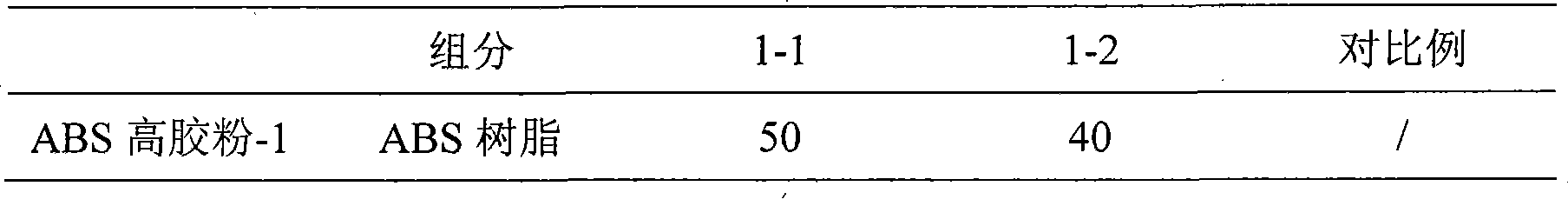

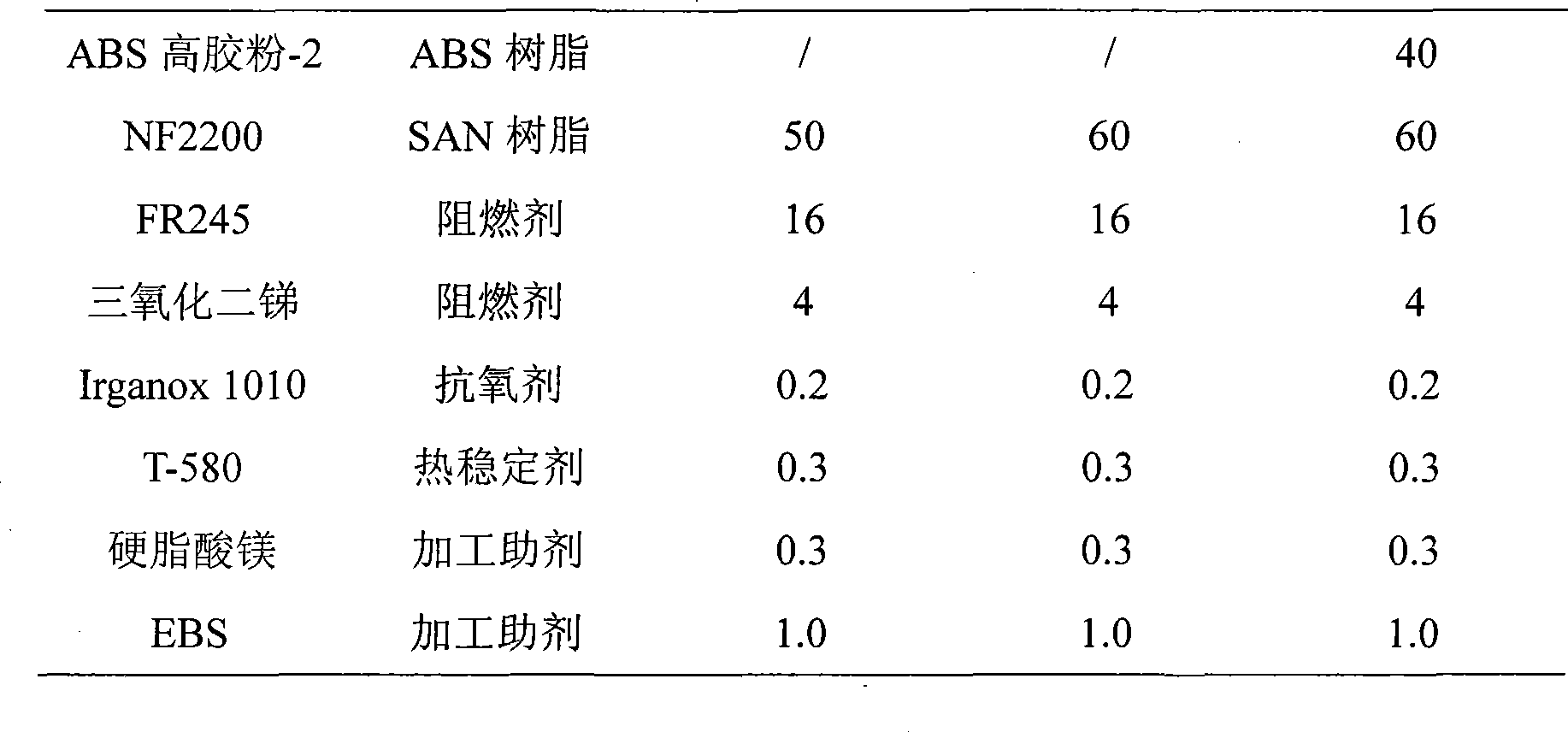

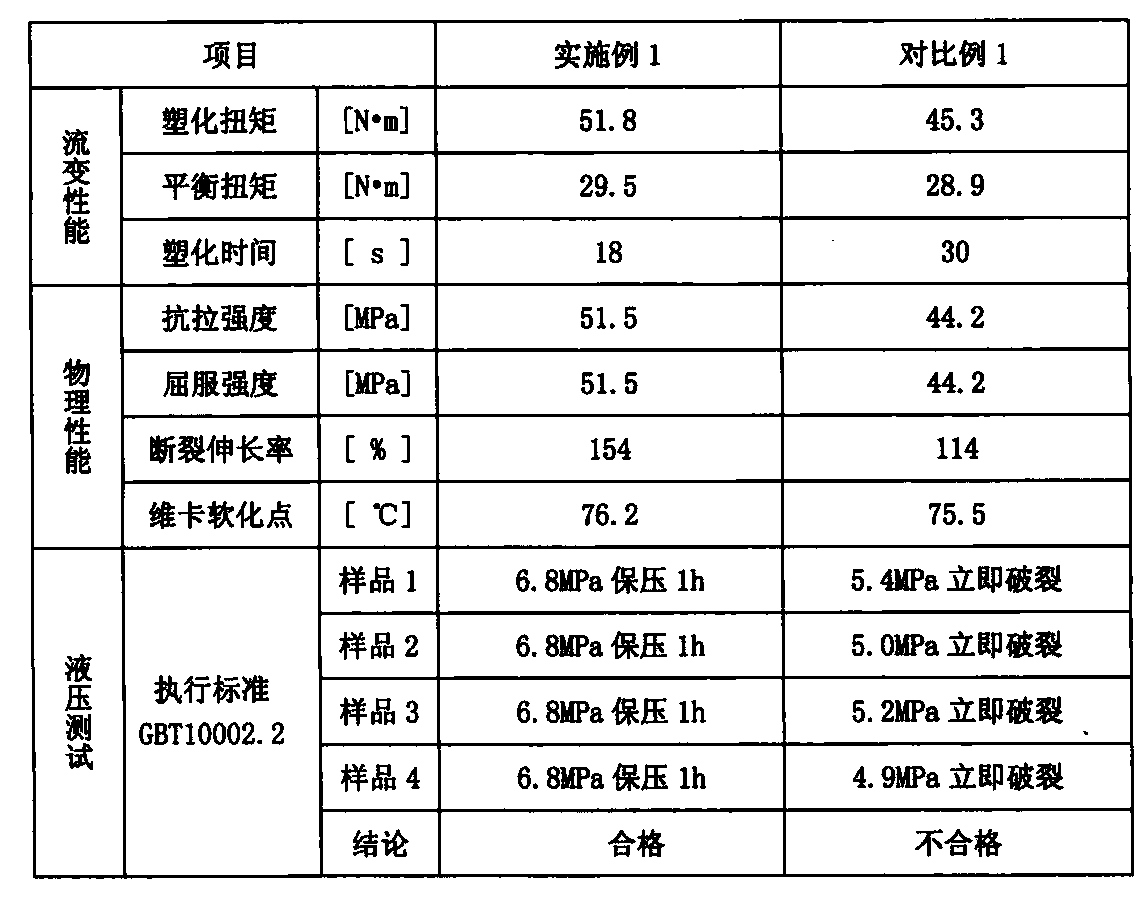

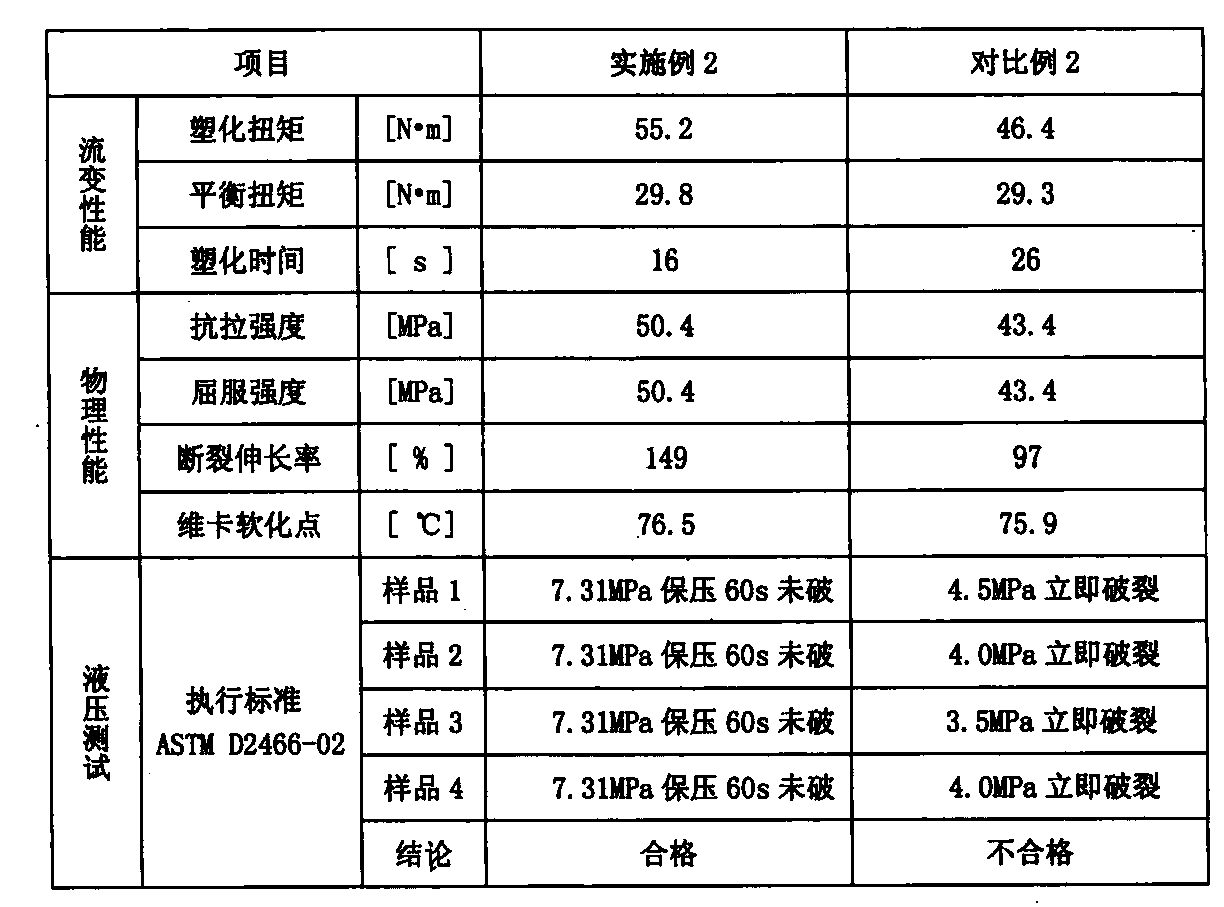

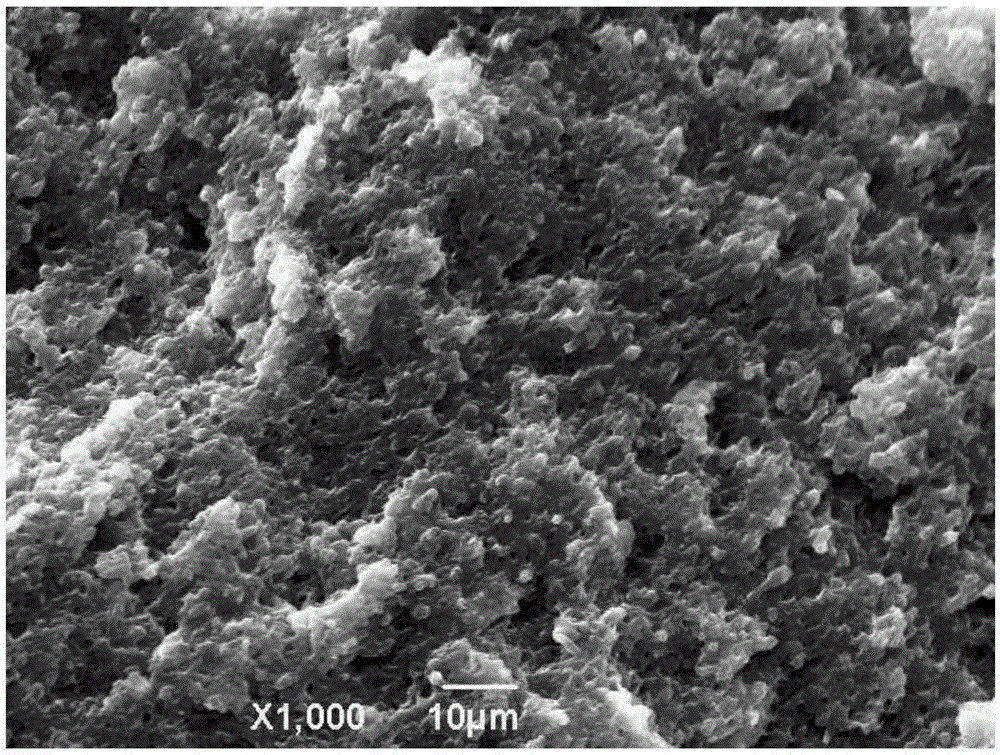

High gloss flame-retardant ABS modified resin and preparation thereof

The invention relates to the technical field of polymer material, in particular to a flame-retardant ABS modified resin having high glaze and a manufacturing method thereof. The invention provides the flame-retardant ABS modified resin having high glaze, which comprises ABS high glue powder, SAN resin, brominated flame retardant, antimonic flame retardant, antioxidizer, heat stabilizer and processing aid. The flame-retardant ABS modified resin is characterized in that the ABS has the rubber-particle size being less than 1mum. Based on maintaining excellent physical property of the original ABS resin, the flame-retardant ABS modified resin having high glaze has good flame retardant property and the high glaze of the surface. The flame-retardant ABS modified resin having high glaze can be prepared by traditional twin-screw extrusion process equipment, has the advantages of simple and continuous production flow, high production efficiency and stable product quality, and can be widely applied to the industries such as household electrical appliances having high glaze and flame-retardant requirements, automobile industry, etc.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

High-filling highly-pressure-resistant U-PVC water supply pipe fitting

ActiveCN103992600ASolve the problem of fragmentationImprove interface compatibilityRigid pipesMaleic anhydridePolypropylene

A high-filling highly-pressure-resistant U-PVC water supply pipe fitting is provided. Raw materials are uniformly mixed by a mixer, and subjected to injection moulding at 160-190 DEG C. The raw materials comprise 100 parts by weight of polyvinyl chloride resin, 1-10 parts by weight of a heat stabilizer, 0.1-4 parts by weight of a lubricant, 0-5 parts by weight of a processing modifier, 0-8 parts by weight of a shock-resistant modifier, 1-10 parts by weight of a compatilizer, and 5-50 parts by weight of a filing agent, with pigments not included. The heat stabilizer is one or more of organo-tin, a calcium-zinc composite heat stabilizer, and an organic or inorganic heat stabilizer. The lubricant is one or more selected from stearic acid and derivatives thereof, metallic soap, polyesters or a saturated hydrocarbon lubricant. The processing modifier is one or more of a processing modifier with ultra-high molecular weight or a common processing modifier. The anti-shock modifier is one or more of a scheduled elastomer anti-shock modifier, an unscheduled elastomer anti-shock modifier or a transitional anti-shock modifier. The compatilizer is one of maleic anhydride grafted polypropylene, silane grafted polypropylene, glycidyl methacrylate grafted polypropylene or methacrylic acid grafted polypropylene.

Owner:YONGGAO CO LTD

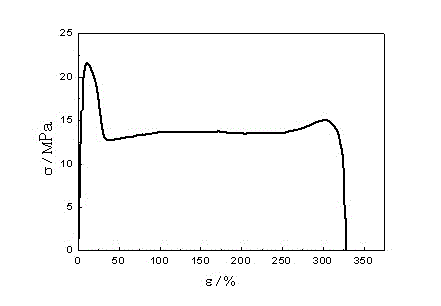

PLA (polylactic acid)/MMT (montmorillonite) degradation enhanced master batch blending modification PLA/PBAT (polyethylene terephthalate-adipic acid-butanediol copolyester) composite material and preparation method thereof

InactiveCN105199347AChange sizeReduce phase sizePolyethylene terephthalate glycolIn situ polymerization

The invention relates to a PLA (polylactic acid) / MMT (montmorillonite) degradation enhanced master batch blending modification PLA / PBAT (polyethylene terephthalate-adipic acid-butanediol copolyester) composite material and a preparation method thereof, belonging to the technical field of biodegradable materials. The method provided by the invention is characterized by taking PLA, PBAT and PLA / MMT degradation enhanced master batches as raw materials and uniformly mixing 10-90 parts of PLA, 10-90 parts of PBAT and 5-30 parts of PLA / MMT degradation enhanced master batches and then melting, blending and modifying PLA / PBAT to prepare the PLA / PBAT composite material with excellent performance, wherein the PLA / MMT degradation enhanced master batches are obtained by preparing organic MMT through ion exchange by using an intercalation agent and an intercalation assistant, increasing interlayer spacing among MMT and then intercalating monomer or polylactic acid molecular chains into the interlayer of MMT through melt in situ polymerization. The PLA / MMT degradation enhanced master batch blending modification PLA / PBAT composite material prepared by the method provided by the invention has excellent performance and can be used for production of daily supplies and packaging materials.

Owner:HUBEI UNIV OF TECH

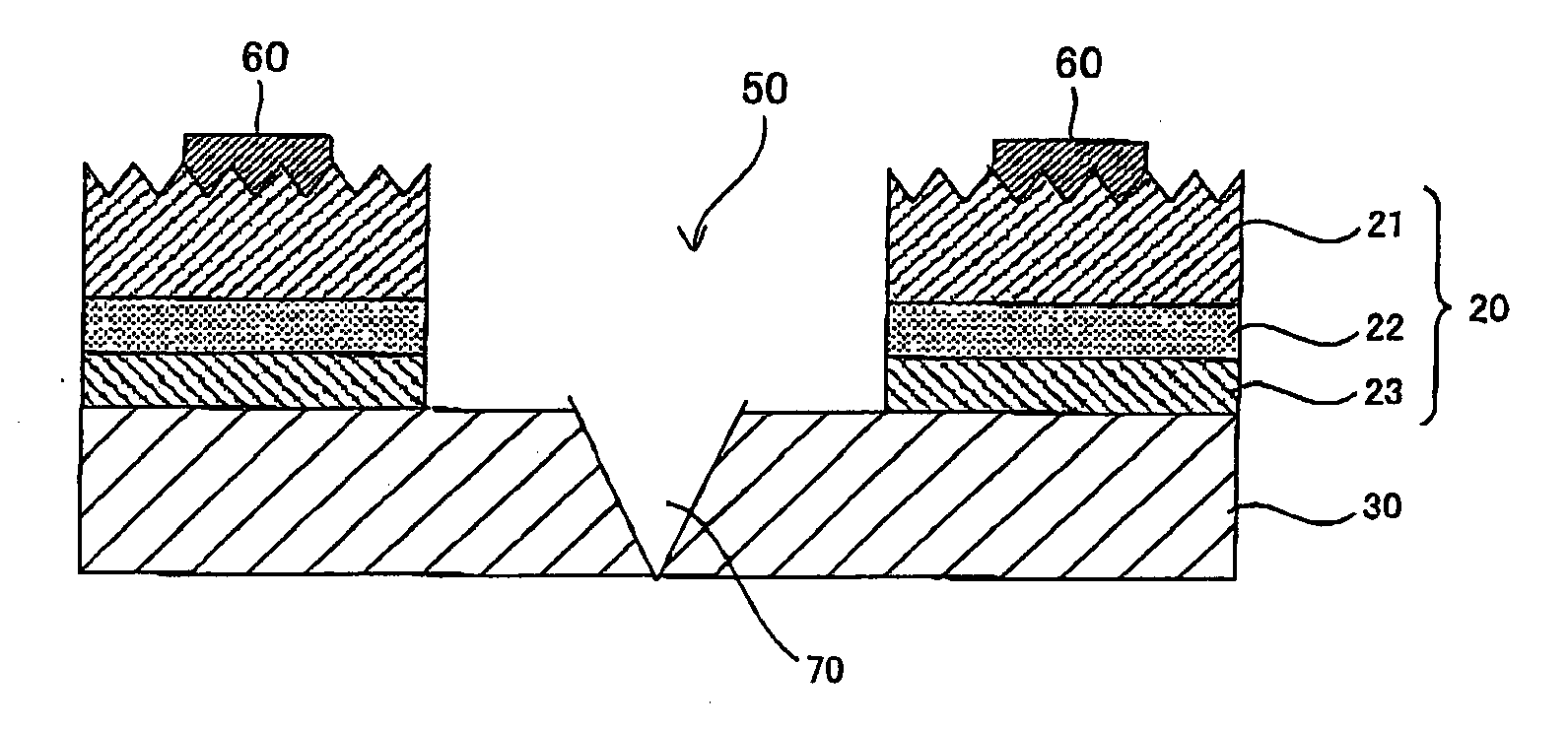

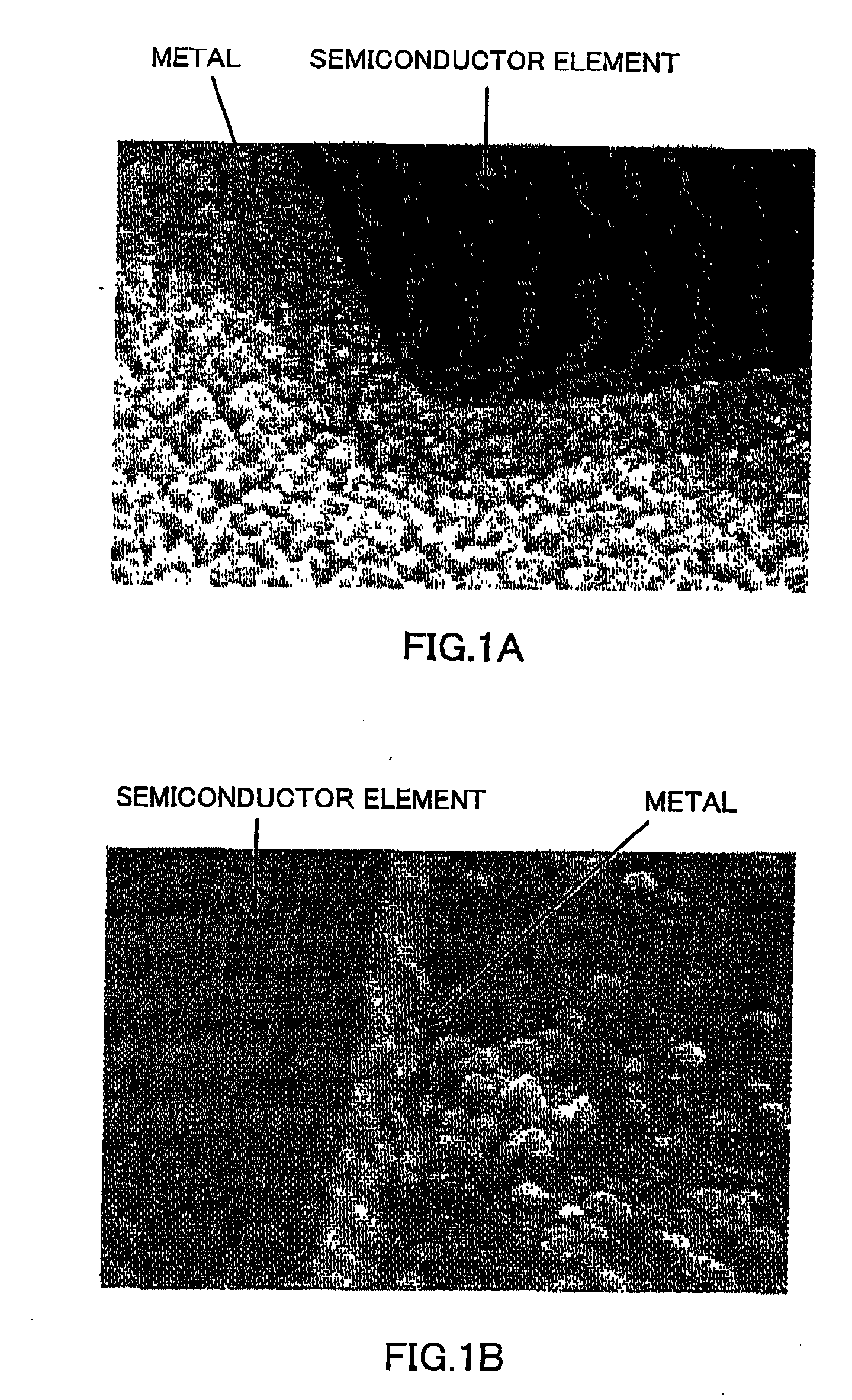

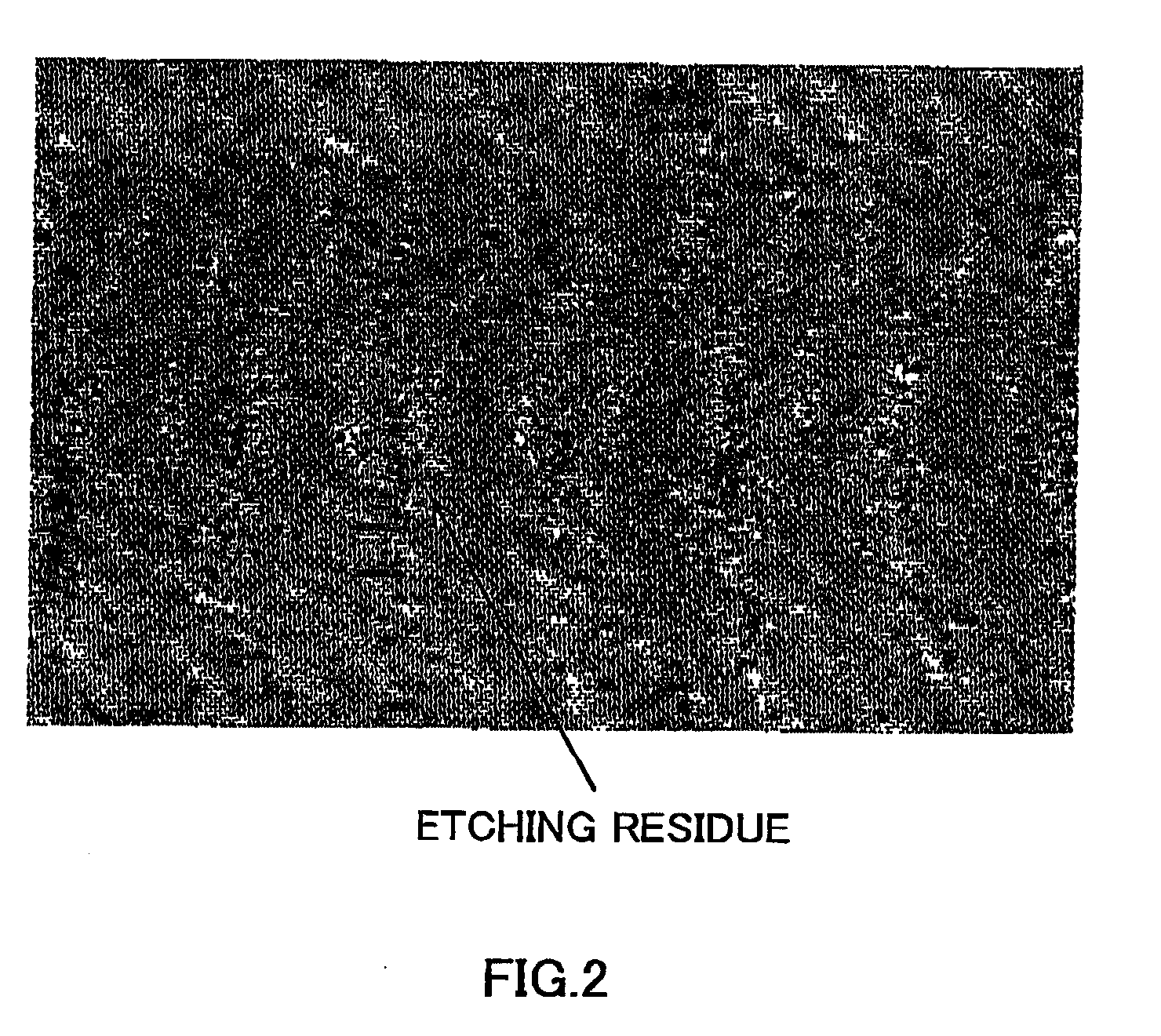

Method of manufacturing semiconductor devices

InactiveUS20100120237A1Reduce processing timeAvoid it happening againSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSemiconductor

A growth substrate is removed from a semiconductor film, and a surface of the semiconductor film exposed by removing the growth substrate is flattened. The semiconductor film along device division lines are partially etched by dry etching to form grooves in a lattice that form streets, not reaching the metal support in the semiconductor film. The surface of the semiconductor film at the bottom of the grooves is flattened. The semiconductor film along the device division lines at the bottom of the grooves are further etched by wet etching to expose the metal support at the bottom of the grooves to finish the streets.

Owner:STANLEY ELECTRIC CO LTD

Method for preparing pretreated white carbon black/natural rubber composite material

The invention relates to a method for preparing a pretreated white carbon black / natural rubber composite material, relates to the technical field of property improvement on natural rubber composite materials, and is used for solving the problem that natural latex is easy to be cured at an early stage in an experiment process. Firstly, the white carbon black is treated by using a coupling agent to organize the surface of the white carbon black, so that the mutual action between the white carbon black and the rubber is improved; secondly, a white carbon black / rubber nano composite material is obtained through flocculation, washing and drying processes. The method comprises the following steps: firstly, normally stirring and premixing the white carbon black with water, subsequently dropping the coupling agent to modify, further mixing with the natural latex, and finally flocculating, washing and drying so as to obtain the white carbon black / rubber nano composite material. As the white carbon black is uniformly dispersed in natural rubber liquid slurry added with the white carbon black, the white carbon black / rubber nano composite material can be directly used for machining and preparing rubber products such as vulcanized natural rubber which is modified by the white carbon black.

Owner:BEIJING UNIV OF CHEM TECH

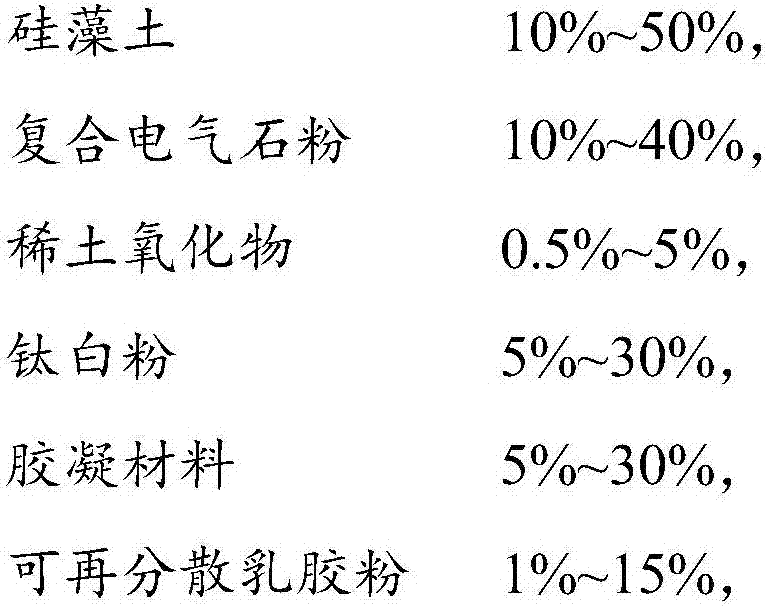

Diatom ooze capable of releasing anions and preparation method of diatom ooze

The invention relates to diatom ooze capable of releasing anions and a preparation method of the diatom ooze. The diatom ooze is prepared from the following raw materials in percentage by weight: 10-50% of kieselguhr, 10-40% of composite tourmaline powder, 0.5-5% of rare earth oxide, 5-30% of titanium dioxide, 5-30% of a cementing material, 1-15% of redispersible powder and 0.1-2% of cellulose, wherein the composite tourmaline powder is mainly prepared from the following raw materials in percentage by weight: 50-80% of tourmaline powder, 10-40% of nanometer titania, 1-10% of sodium silicate and 0.5-1% of a surfactant. The diatom ooze is capable of continuously releasing the anions and a far infrared ray, has good air purification effect and human health effect, is high in purification efficiency and purification persistence and has good adhesive force.

Owner:北京科技大学广州新材料研究院

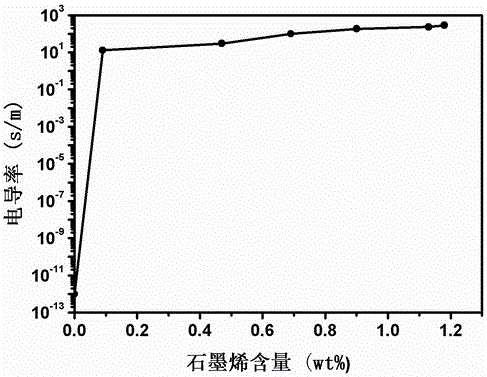

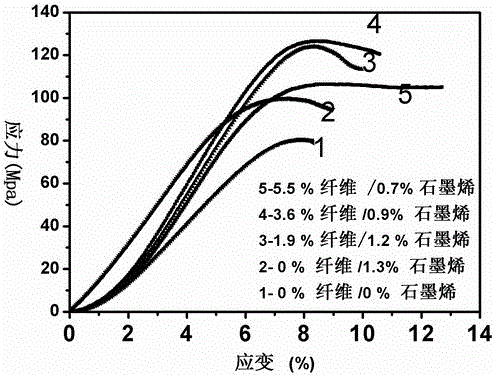

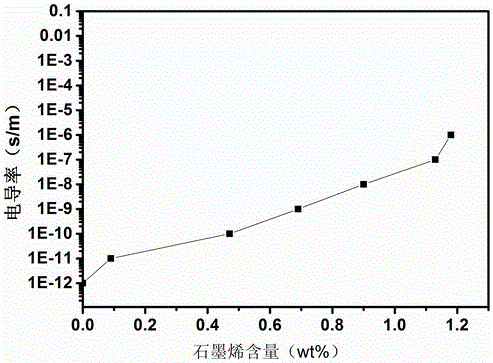

Aramid fiber reinforced 3D graphene/epoxy resin composite material as well as preparation method and application thereof

ActiveCN106832774AHigh compressive strengthImprove conductivityMagnetic/electric field screeningNon-conductive material with dispersed conductive materialEpoxy resin compositeGraphene

The invention relates to an aramid fiber reinforced 3D graphene / epoxy resin composite material and a preparation method thereof. Aramid fibers are uniformly distributed and loaded on 3D graphene, and the composite material has electrical conductivity of 102S / cm or higher and compressive strength of 115MPa or higher. The aramid fiber reinforced 3D graphene / epoxy resin composite material has high comprehensive strength and high electrical conductivity, and can be used as a conducting material or electromagnetic shielding material with good buffering capacity.

Owner:BEIJING UNIV OF CHEM TECH

Rubber composite material of waste cotton material-based nano-microcrystalline cellulose and preparation method of rubber composite material

InactiveCN104530504AThe reaction steps are simpleShort reaction timeLiquid crystallinePolymer science

The invention discloses a rubber composite material of waste cotton material-based nano-microcrystalline cellulose and a preparation method of the rubber composite material. The method comprises the following steps: stirring natural rubber latex, adding cotton nano-microcrystalline cellulose to the natural rubber latex, stirring and mixing, so as to obtain a cotton nano-microcrystalline cellulose / natural rubber mixture; laying, carrying out demulsification coprecipitation, washing participation, and drying until the weight is constant, so as to obtain a solid cotton nano-microcrystalline cellulose / natural rubber mixture; and mixing with white carbon black, so as to obtain the required product. The nano-microcrystalline cellulose disclosed by the invention can be used as a novel reinforcing material for rubber, and has the characteristics of renewability, small density, high strength, biodegradability, biocompatibility, liquid crystalline property and the like; the preparation method is simple and convenient; the raw materials are cheap and available; the reinforcing effect of the cotton nano-microcrystalline cellulose on the rubber is superior to that of the white carbon black; the mechanical property of the rubber is well improved; and the nano-microcrystalline cellulose / white carbon black / rubber composite material can be applied to manufacturing of various vulcanized rubber products.

Owner:SOUTH CHINA UNIV OF TECH

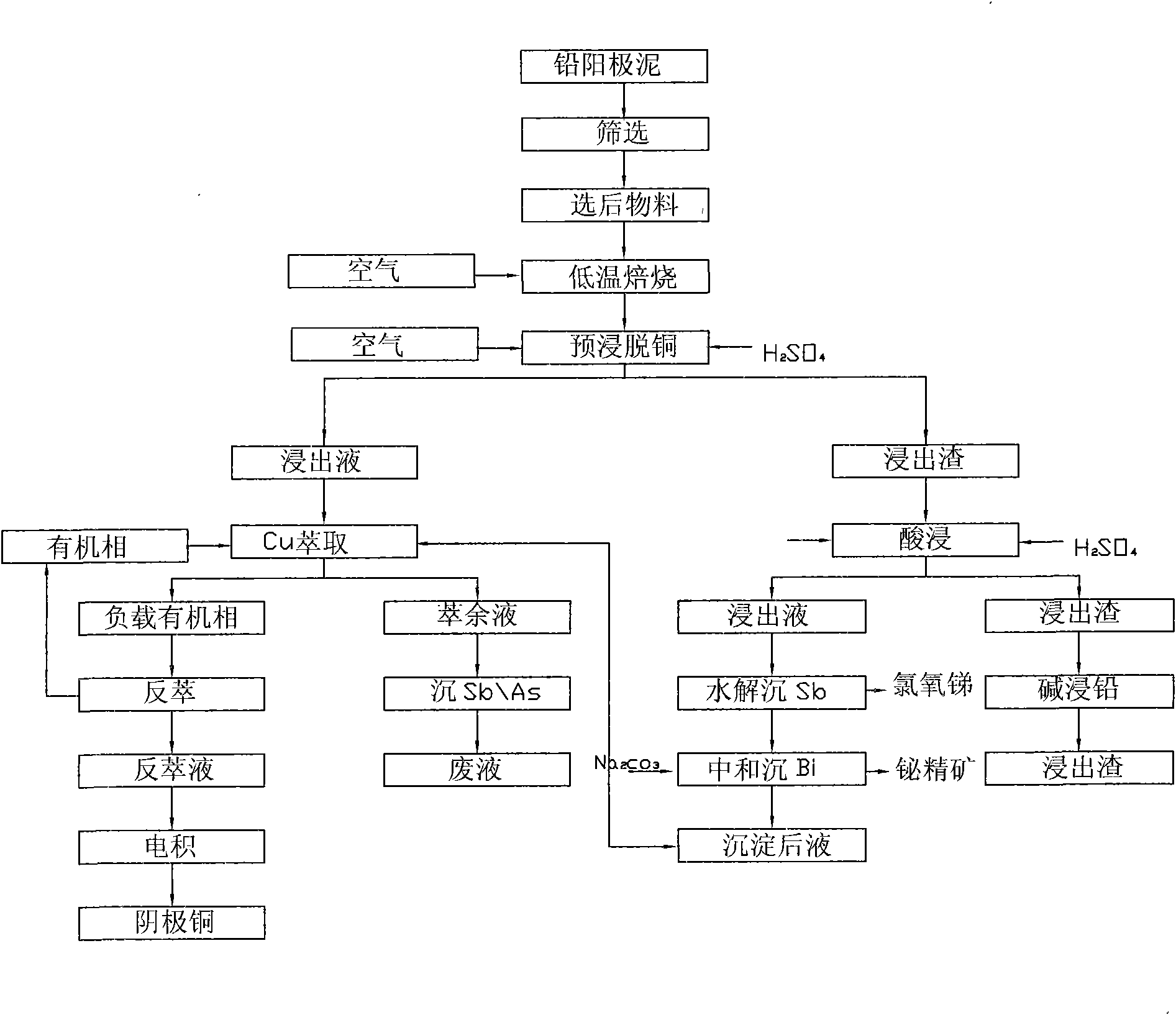

Method for recycling multiple precious metals from anode mud

InactiveCN101597690AAddressing Arsenic PollutionAddressing Adaptive IssuesPhotography auxillary processesProcess efficiency improvementArsenic pollutionAntimony

The invention discloses a method for recycling multiple precious metals from anode mud, comprising a step of smelting and filtering the anode mud in a smelting furnace, cooling the smelted material and then preliminarily immersing and removing copper to obtain extract and leached mud, conveying the leached mud to acid leaching tank to obtain extract and leached mud again, conveying the extract to the hydrolysis tank to process neutralization precipitation, conveying the leached mud to alkaline leaching lead tank, processing smelting method to the processed leached mud. The extract is conveyed to copper extraction tank to process back extract by the organic substances of organic box. Copper-contained material and extract residual are obtained after extraction. The copper-contained material is conveyed to the load organic box to process back extract; after the back extract, the material part is conveyed to the organic box to reprocess; the rest back extract liquid is conveyed to the electrodeposition tank to process electrodeposition to obtain cathode copper. The extract residual liquid obtained from copper extraction box is conveyed to a sedimentation tank to settle; and the waste liquid is conveyed to waste water treatment system to treat. The invention uses wet leaching method to separate precious metals, combines the advantages of fire and wet production and solves the problems of arsenic pollution, long production process, bad raw material applicability, long production period and lower comprehensive recovery in the fire smelting. The recycling yield of gold, silver, copper, antimony, bismuth, arsenic and lead reaches up to 95%.

Owner:永兴县元泰应用材料有限公司

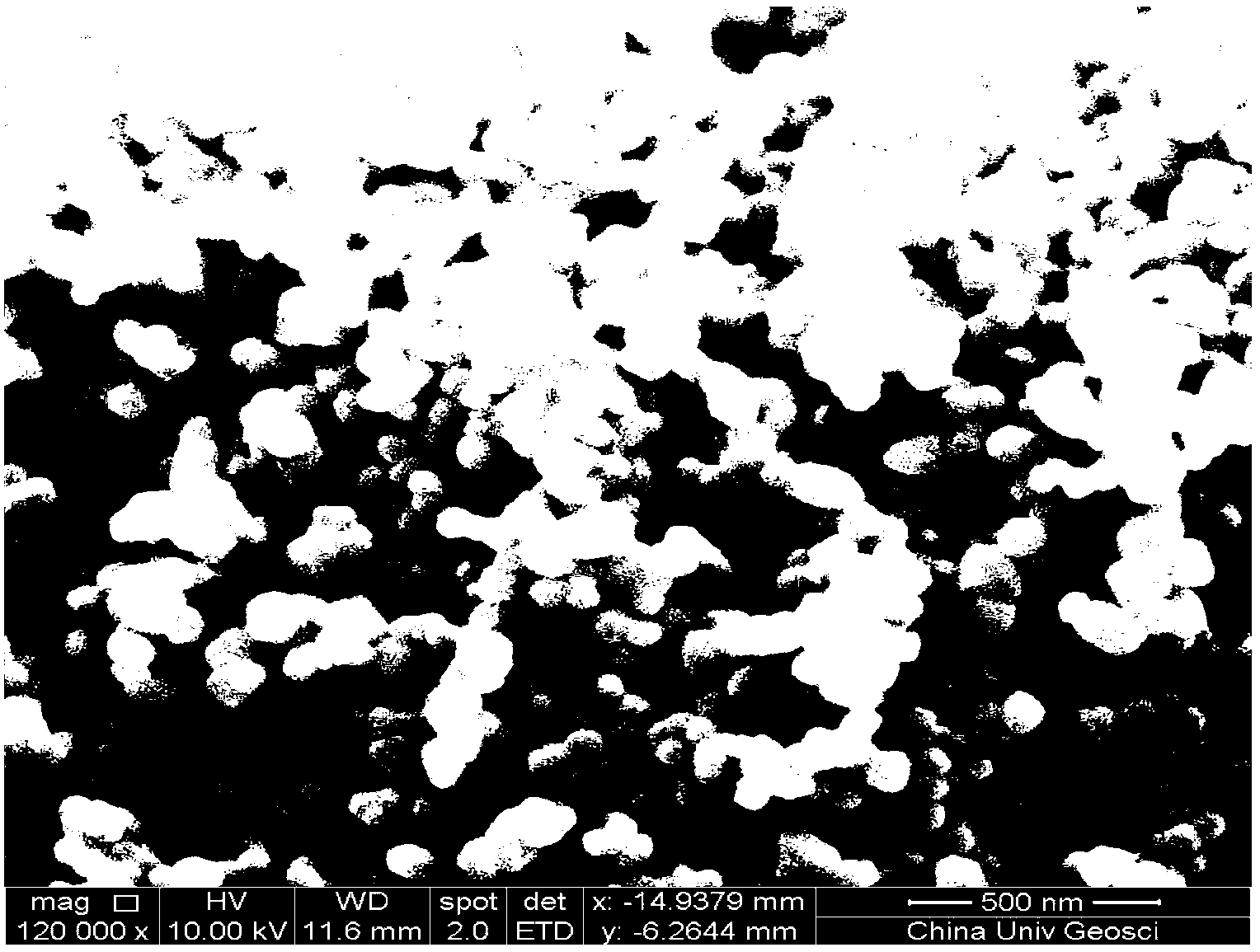

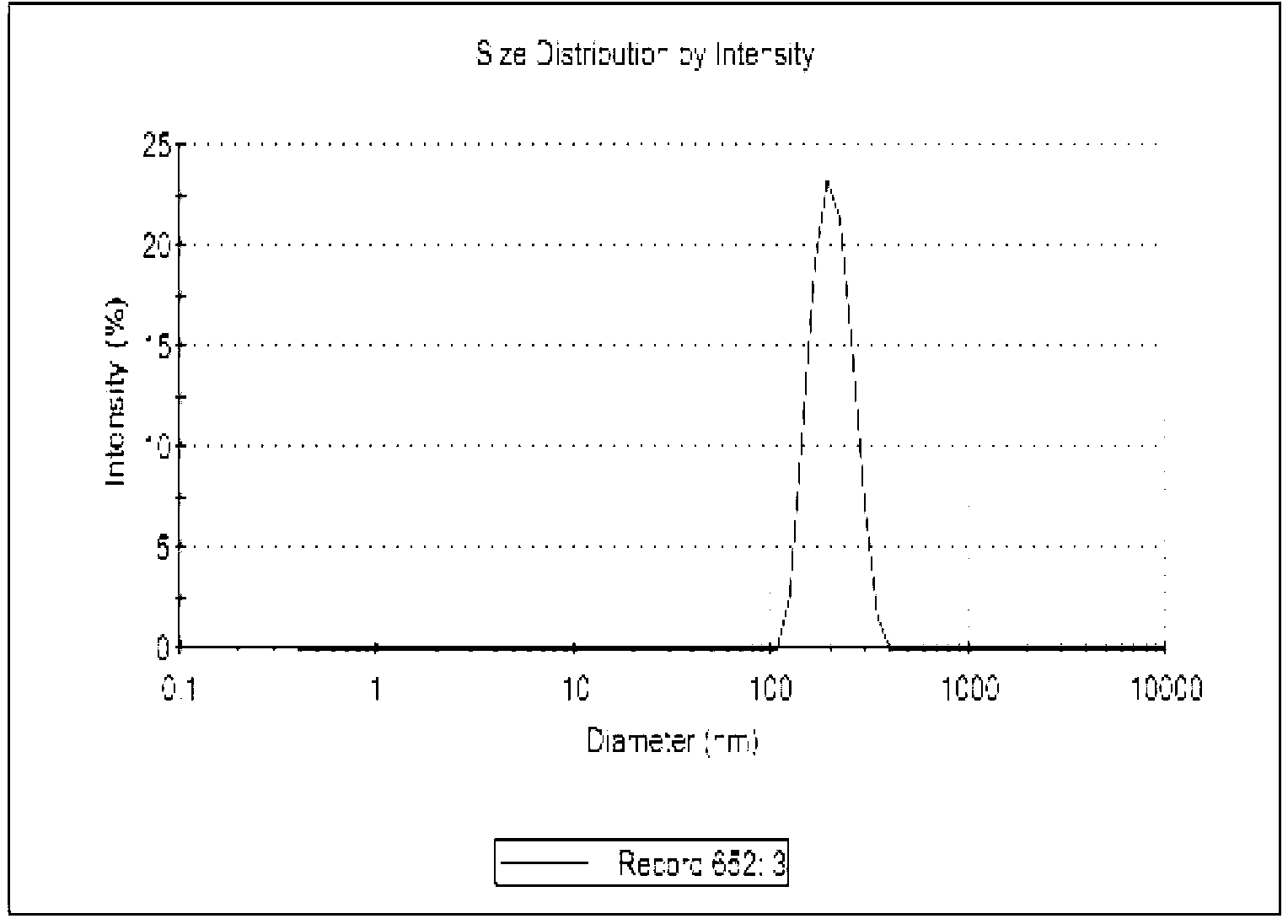

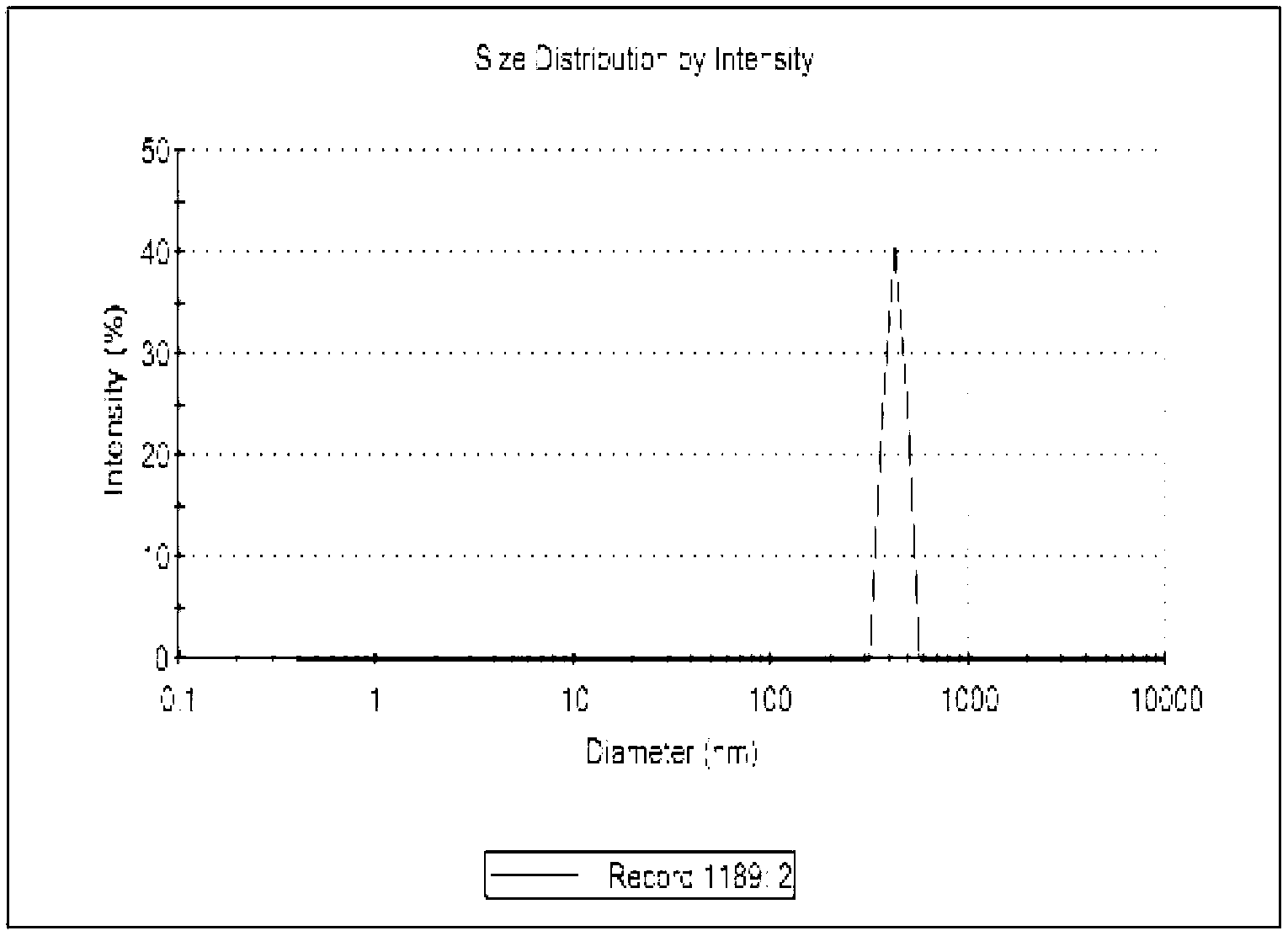

Method for dispersing nano calcium carbonate powder material in aqueous solution

ActiveCN103301763AImprove stabilitySolve the problem of fragmentationMixing methodsPorosityUltrasonic dispersion

The invention provides a method for dispersing a nano calcium carbonate powder material in an aqueous solution, wherein the nano calcium carbonate powder material is dispersed into a nanometer level in the aqueous solution by means of cooperative utilization a dispersing agent and a stabilizer, high speed stirring and shearing functions and ultrasonic dispersion, and the stability of the nano calcium carbonate powder material is maintained; and the dispersing agent is composed of an anionic surfactant, a nonionic surfactant and a cationic surfactant. The method provided by the invention can be used for dispersing the nano calcium carbonate powder to the nanometer level in the aqueous solution, namely, the particle diameter is smaller than 100nm; the stabilization effect of the stabilizer is obvious, and the stabilizer is cooperatively used with the dispersing agent to prompt the dispersion effect; and the method provided by the invention solves the problem of dispersing the carbon nano calcium carbonate powder material in the aqueous solution and lays a good foundation for expanding the application of the carbon nano calcium carbonate powder material in oilfield chemistry and particularly in protection of low-porosity low-permeability oil and gas reservoirs.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

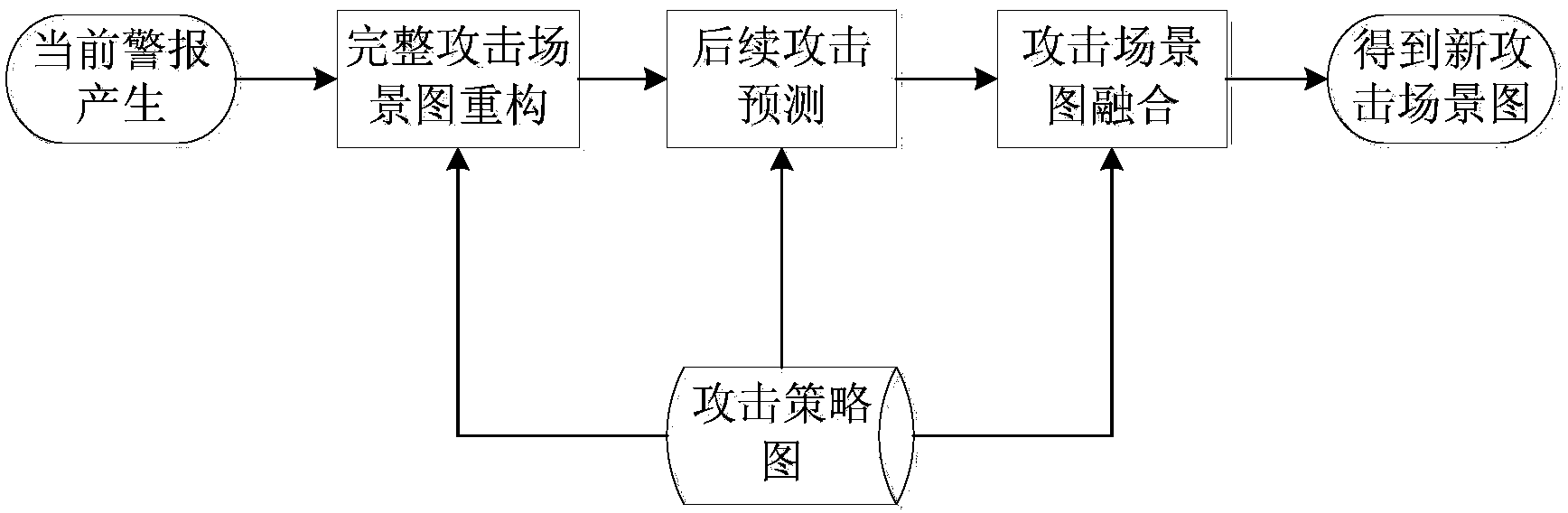

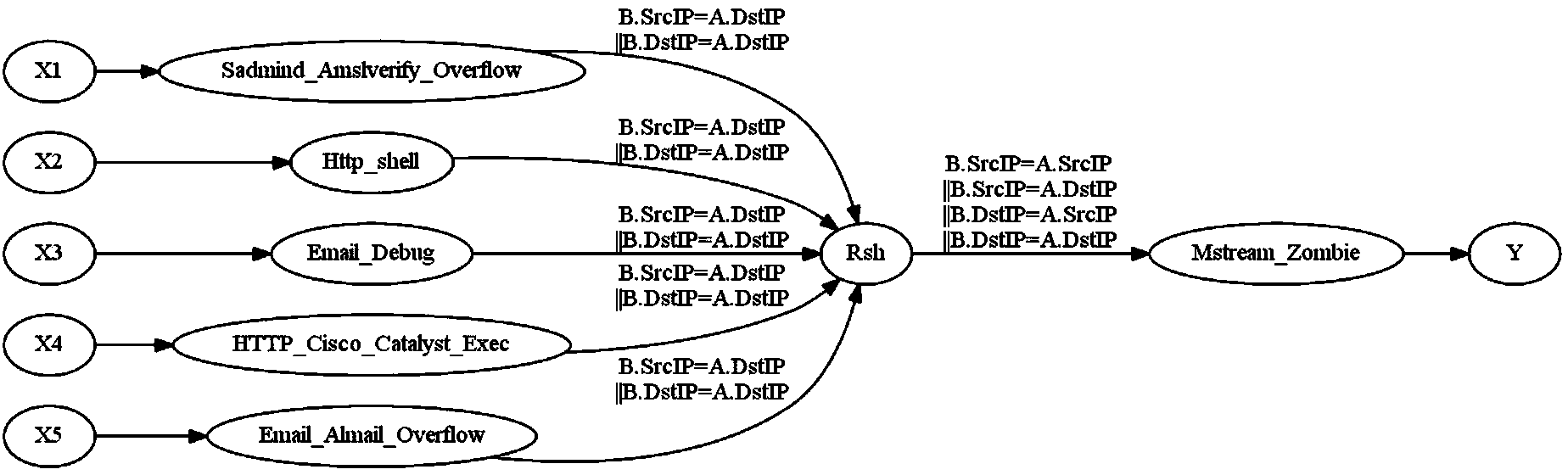

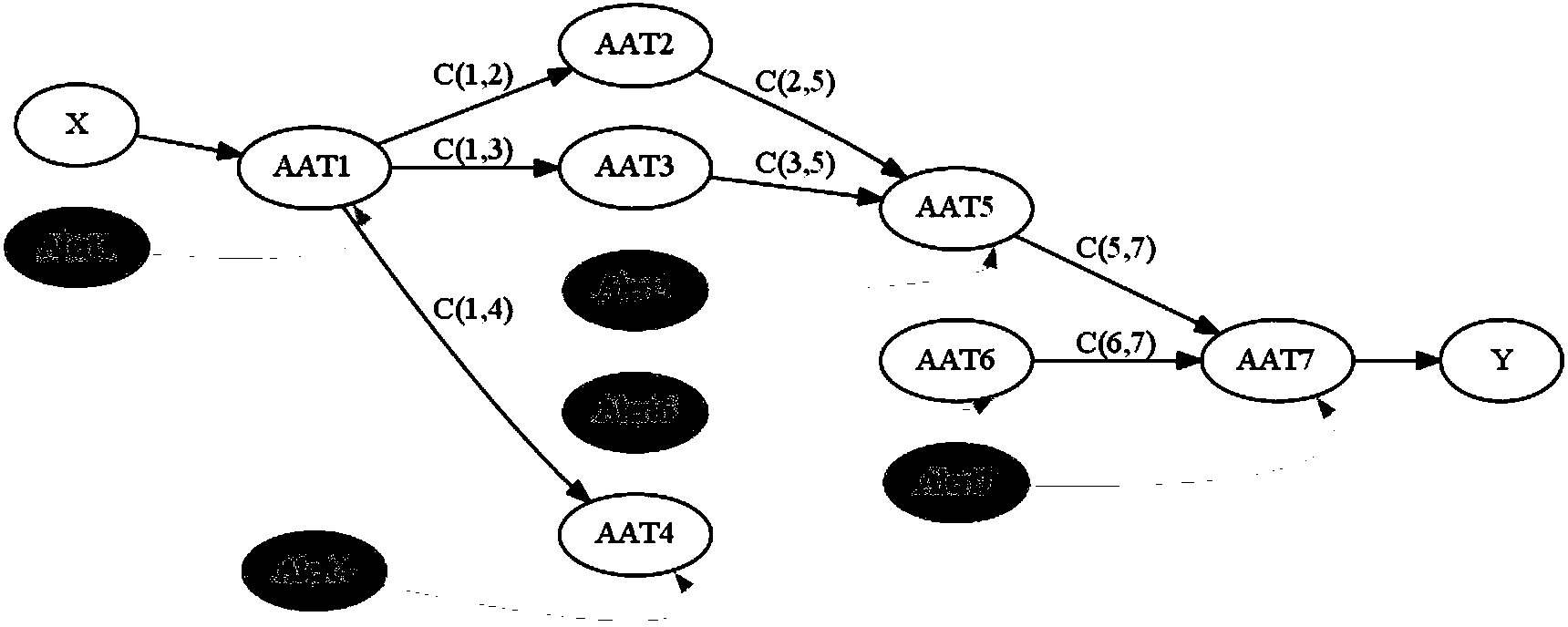

Method for comprehensively analyzing and processing real-time alarms on basis of attack strategy graphs and intrusion detection system thereof

InactiveCN103914649AImprove accuracySolve the split problemPlatform integrity maintainanceTransmissionGraphicsAlgorithm

The invention provides a method for comprehensively analyzing and processing real-time alarms on the basis of attack strategy graphs and an intrusion detection system thereof; splitting of attack scene graphs can be effectively prevented, the complete attack scene graphs can be reconstructed, the subsequent attack can be predicted, attack scenes can be fused with one another, and alarm information capable of being directly utilized can be accurately provided for analysts. The method for comprehensively analyzing and processing the real-time alarm includes steps of (1), constructing the attack strategy graphs; (2), reconstructing attack scene graphs, adding missing alarms or inferences of attack links omitted deliberately by an attacker, utilizing inference results as inference alarms and adding the inference alarms into alarm sets to be associated; (3), predicting subsequent attacks; (4), fusing the attack scene graphs, expressing fused associated records by graphs, and acquiring fresh attack scene graphs. The method and the intrusion detection system have the advantages that splitting of attack scene graphs can be effectively prevented, and analyzing accuracy can be improved. The intrusion detection system is used for analyzing and processing safety events to alarms generated by the system by the analyzing and processing method.

Owner:XIDIAN UNIV

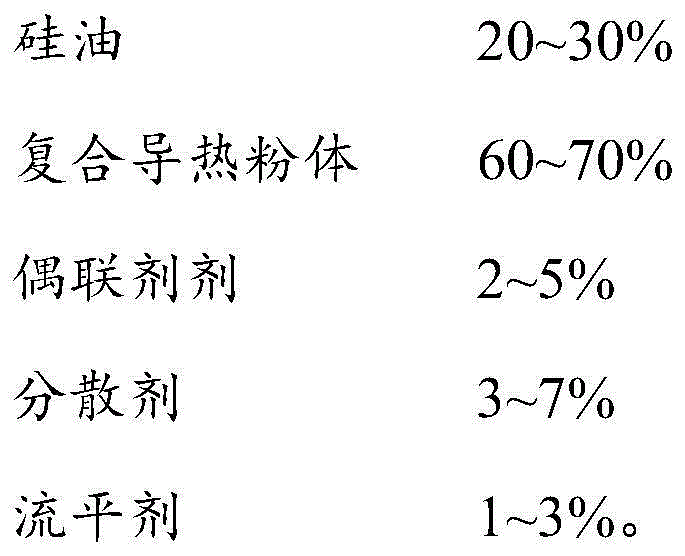

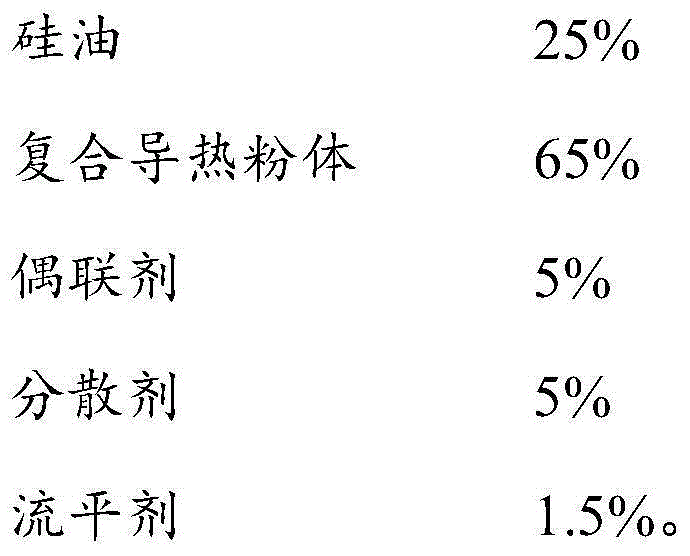

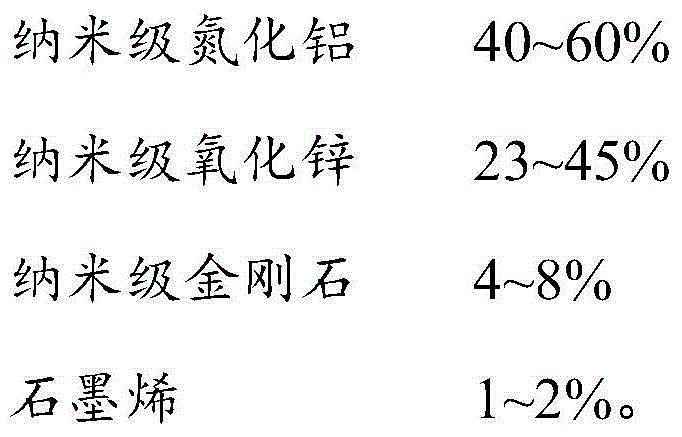

High thermal conductive paste

InactiveCN105086950AImprove thermal conductivityArchitecture StableHeat-exchange elementsConductive pasteScreen printing

The invention relates to the field of thermal conductive materials, and particularly discloses high thermal conductive paste. The high thermal conductive paste comprises, by weight, 20%-30% of silicone oil, 60%-70% of composite thermal conductive powder, 2%-5% of a coupling agent, 3%-7% of a dispersing agent and 1%-3% of a flatting agent. The invention further discloses a preparation method for preparing the high thermal conductive paste. The thermal conductive paste is high in thermal conductive coefficient, can be used on various components for thermal conduction and can be used for silk-screen printing.

Owner:HUIZHOU KECHENGTONG TECH CO LTD

Solvent-free static electricity conductive anticorrosive paint for oil storage tank and production method

InactiveCN101294044AGood physical and mechanical propertiesLow viscosityLarge containersAnti-corrosive paintsPolyesterBisphenol A

The invention relates to a solvent-free electrostatic conducting anti-corrosive coating for oil tanks and the preparation method thereof. The solvent-free electrostatic conducting anti-corrosive coating comprises a solution A prepared from bisphenol A type liquid-state epoxy resin, epoxy-containing polyol ether, titanium dioxide, precipitated barium sulfate, talcum powder, acidic polyester and polyamide, fluorocarbon-modified siloxane, polyacrylate-modified fluorocarbon polymer, poly-carboxylate, light-colored conductive powder and alkanolamine solution of unsaturated acidic carboxylate, and a solution B prepared from polyamide resin, N,N-dimethyl benzyl amine and poly-carboxylate. When in use, the solution A and the solution are mixed and solidified to form a coating. The solvent-free electrostatic conducting anti-corrosive coating has constructability and storage stability similar to those of solvent electrostatic conducting coatings, and no discharge of volatile organic solvent in the production and the construction process. The coating has the advantages of good electrostatic conductivity, high chemical resistance and good oil resistance, and can be applied to steel surfaces of different parts in the oil tanks, such as bottom plates, inner walls, floating cabins, floating roofs and pillars, to prevent corrosion.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

Grafting-modified rubber and preparation method thereof

The invention discloses a grafting-modified rubber and a preparation method thereof. The grafting-modified rubber is prepared by graft polymerization of rubber latex (1) and a nano-silica / poly(conjugated diene) composite emulsion (2) in the presence of an initiator, wherein a mass ratio of the dry basis of the rubber latex to the dry basis of the nano-silica / poly(conjugated diene) composite emulsion is 100: (0.1 to 100); based on the dry basis of the nano-silica / poly(conjugated diene) composite emulsion, the nano-silica / poly(conjugated diene) composite emulsion comprises 0.1 to 5 parts of surface functionalization-modified nano-silica; the nano-silica / poly(conjugated diene) composite emulsion has granularity of 50 to 80nm, number-average molecular weight of 100000 to 120000 and molecular weight distribution of 2 to 3; and the rubber latex is a homopolymer or a copolymer containing a poly(conjugated diene) compound and is prepared by emulsion polymerization.

Owner:PETROCHINA CO LTD

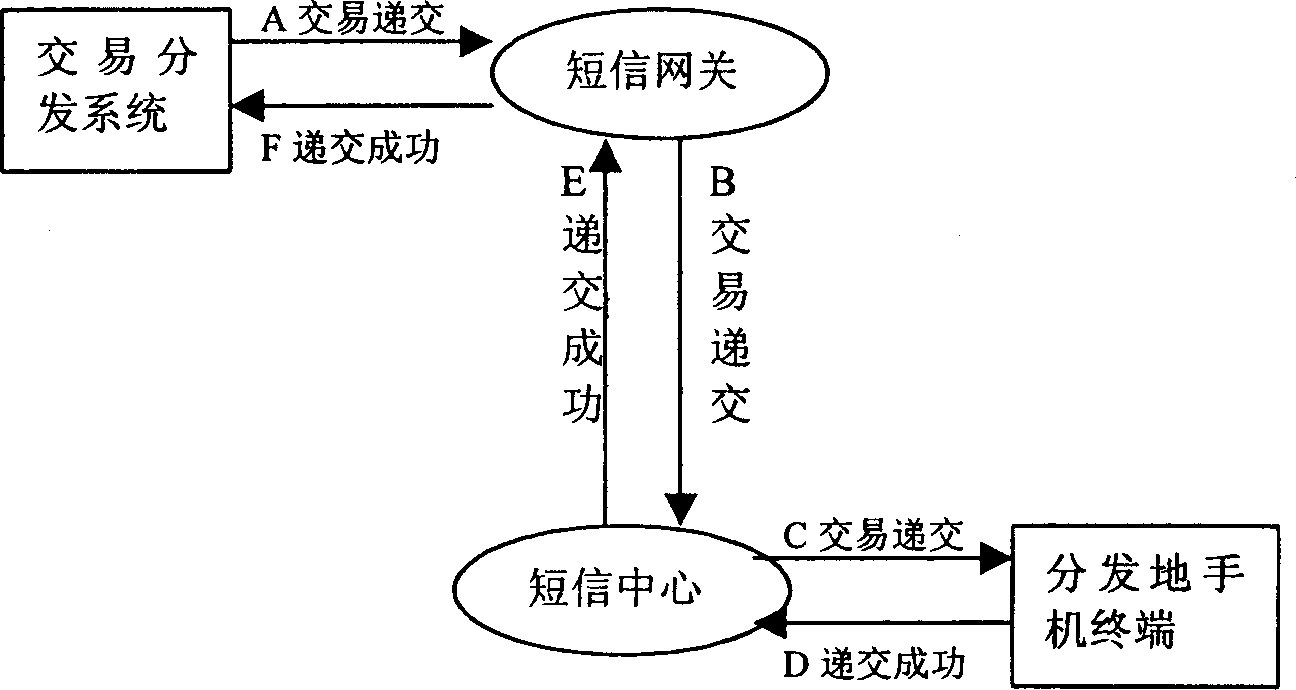

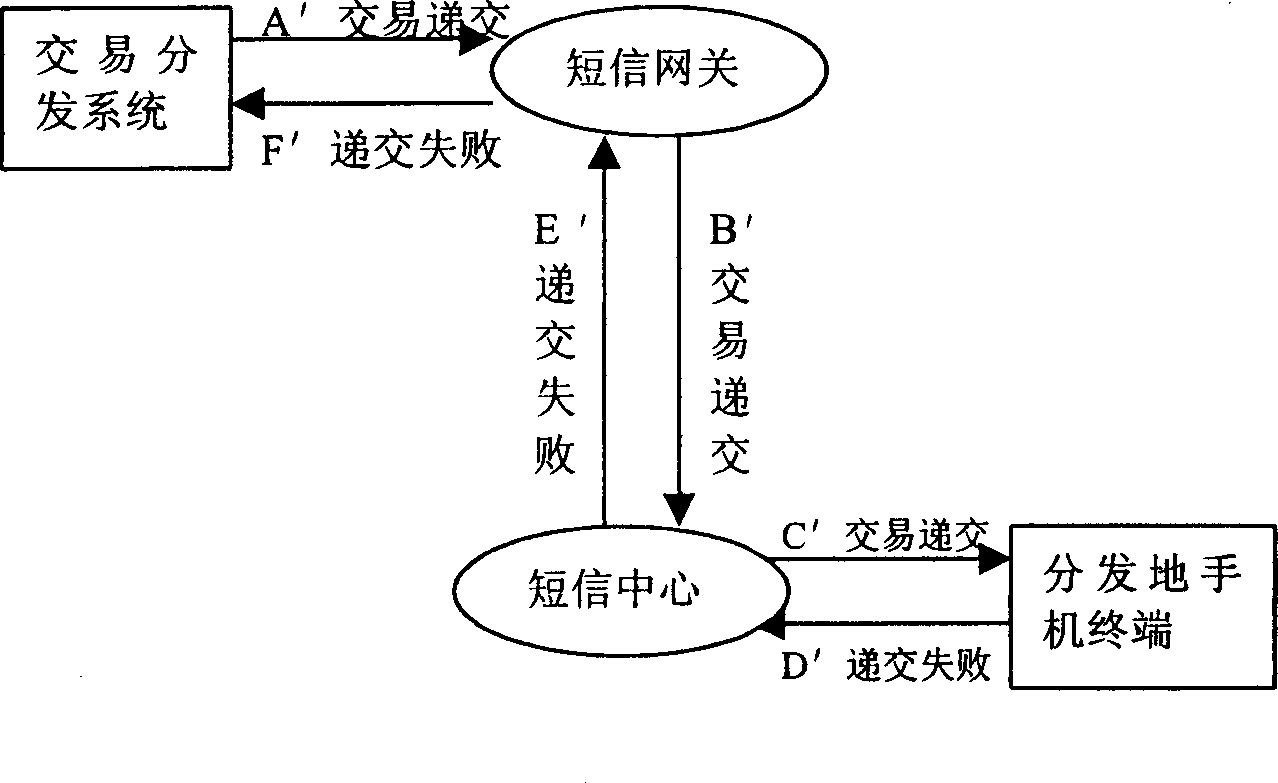

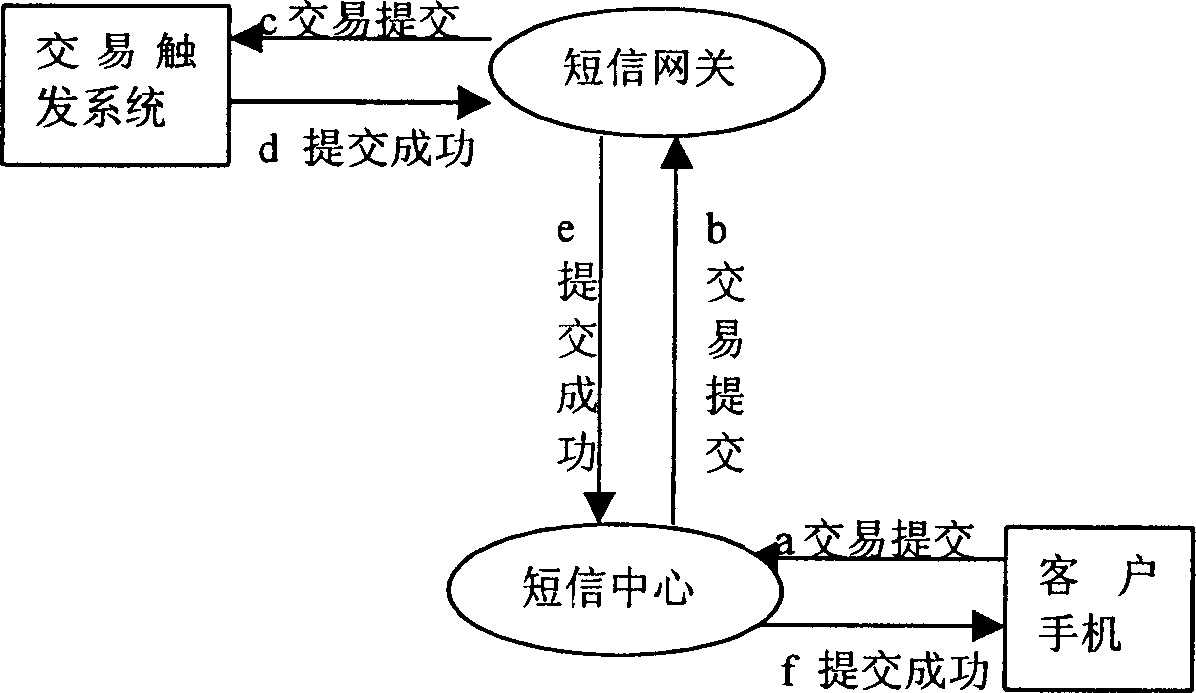

Method for implementation of electronic trade system

InactiveCN1417731ASolve the problem of fragmentationAvoid lostPayment architectureRadio/inductive link selection arrangementsShort Message ServiceFinancial transaction

The present invention features that the short message service of mobile network is used in trade dispatching and triggering treatment. Each trade message includes one specific trade number designatedby the trade triggering treatment system. During trade, the trade dispatching system checks the position information of dispatching place and finds out the nearest dispatching place mobile phone terminal based on the trade place. The trade dispatching system will re-sends the trade delivery information or alters the trade business destination in case of no response in certain time. It is suitablefor business with dispersed and mobile trade dispatching places and can save cost.

Owner:林铭

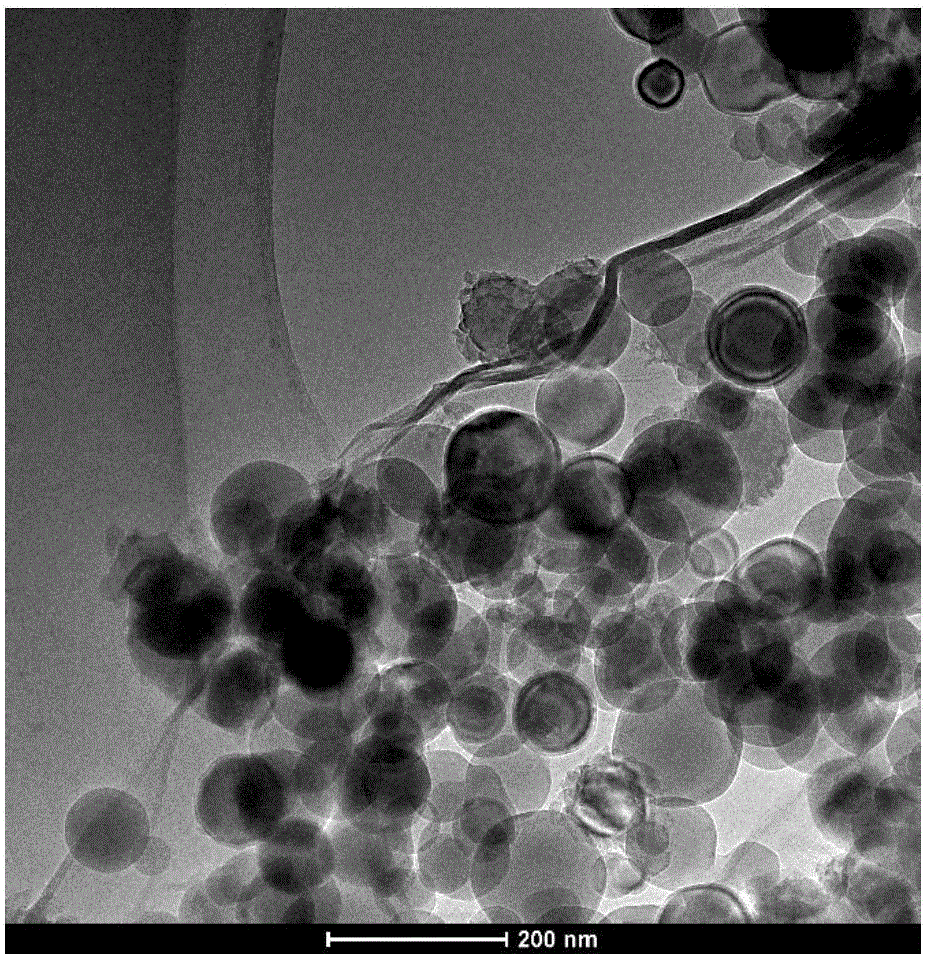

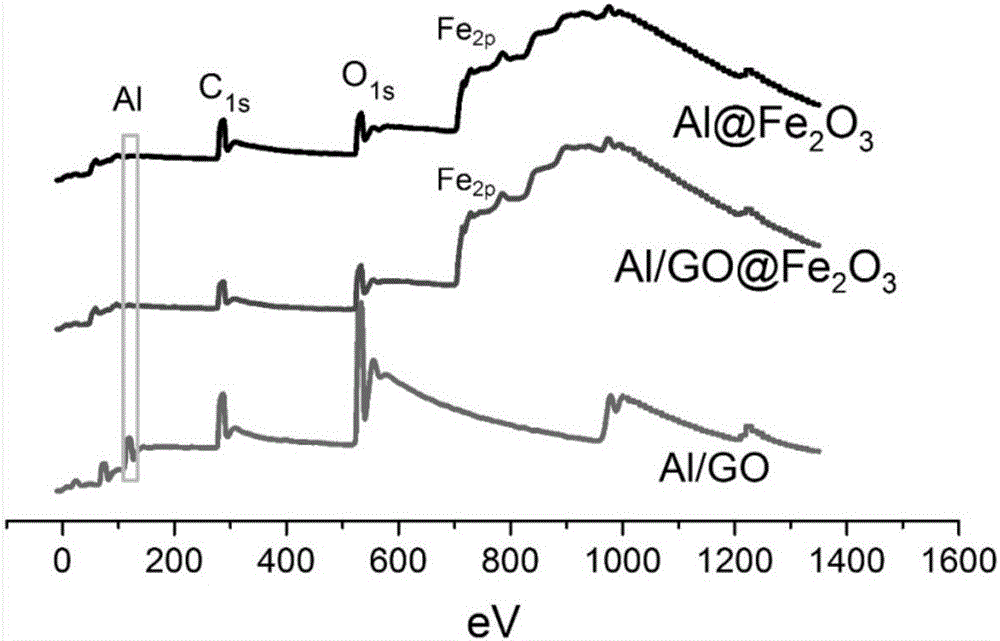

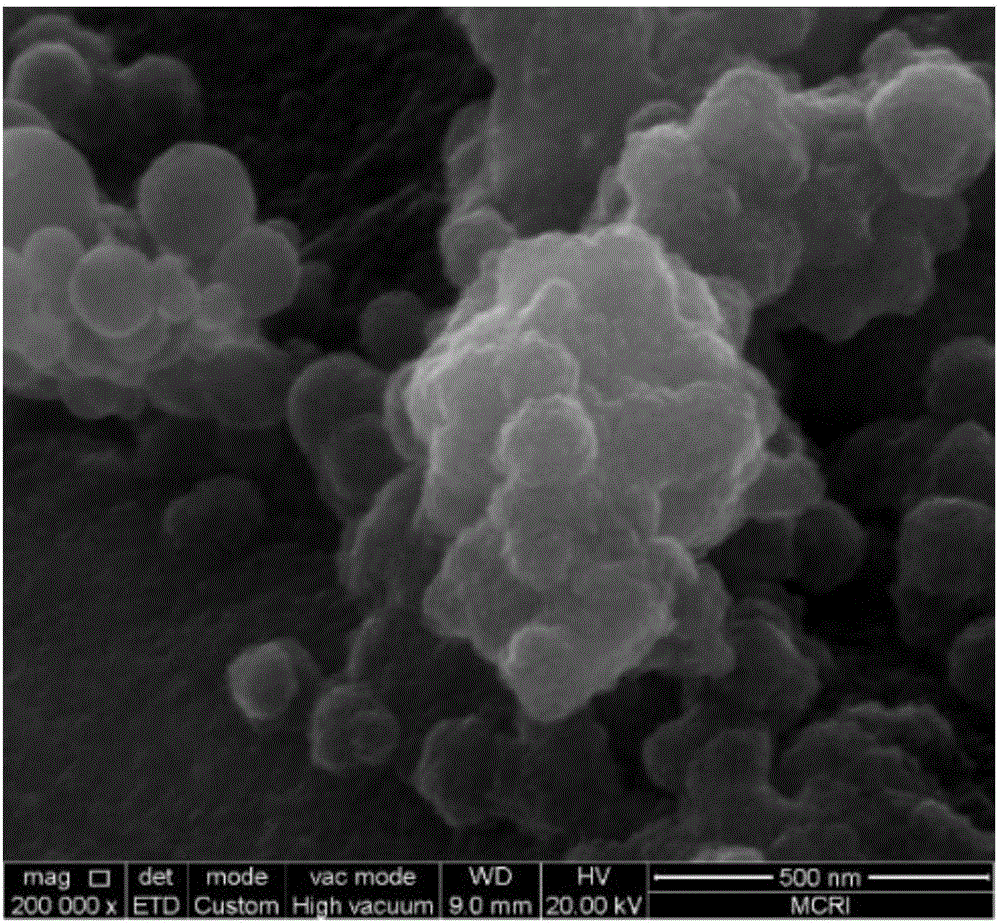

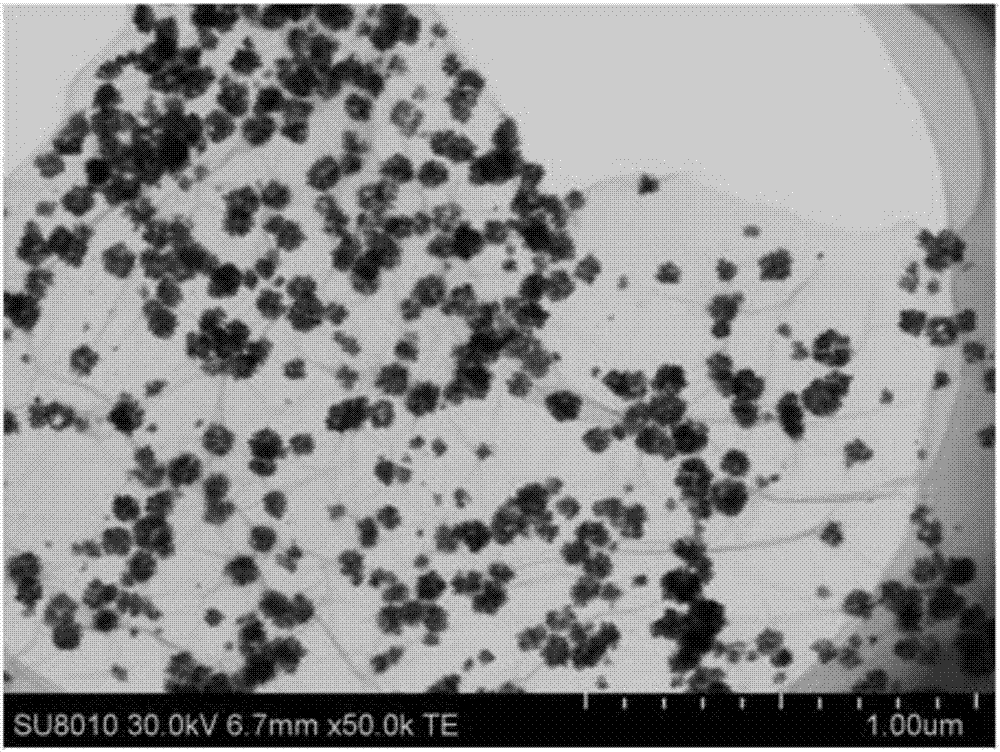

Method for preparing graphene nano-composite energetic material through atomic-layer deposition technology

ActiveCN105839078ASolve the problem of fragmentationEvenly dispersedNanotechnologyChemical vapor deposition coatingChemical reactionGas phase

The invention discloses a method for preparing a graphene nano-composite energetic material through an atomic-layer deposition technology. The method includes the steps that graphene loaded nanometer metal compound powder is prepared through an ultrasonic-assisted solution mixing and in-situ reduction method, so that even scattering of nanometer metal on the surface of graphene is achieved; and then, the gas-phase atomic-layer deposition technology is adopted, two different precursors pass through a reaction cavity alternately, the precursors make contact with the surface of the graphene / nanometer metal compound powder fully, a chemical reaction is set off, and oxides are generated. By means of the method, the oxides wrap the graphene surface and the nanometer metal surface evenly. According to the graphene nano-composite energetic material prepared through the method, the affinity between the oxides and the nanometer metal surface is increased, and spatial arrangement is improved. Due to the addition of the graphene, the scattering situation of the nanometer metal is improved, and the energy release rate of the energetic material is increased. The method is high in automation degree and good in safety, the material can be directly used without after-treatment, and mass production of the graphene nano-composite energetic material is achieved easily.

Owner:XIAN MODERN CHEM RES INST

Preparation method of modified diatomite/polyethylene composite plastic

The invention belongs to the field of composite materials and particularly relates to a preparation method of modified diatomite / polyethylene composite plastic. The preparation method comprises the steps as follows: drying superfine diatomite and then mixing the dried superfine diatomite and alcohol, conducting ultrasonic dispersion, adding a modifier, mechanically stirring, centrifugally separating, and conducting vacuum drying on a solid product obtained by separation for 1-24h to obtain the modified diatomite; or directly mixing the modifier and the alcohol, uniformly spraying a mixed solution onto the surface of the cooled diatomite to obtain the modified diatomite, adding the modified diatomite and polyethylene to an internal mixer for blending, and then conducting hot pressing with a plate vulcanizing machine to fabricate a diatomite / polyethylene composite plastic plate. The method adopts superfine and surface modification technologies to prepare the novel low-carbon, low-emission and environment-friendly polyethylene plastic which can be used for replacing a calcium carbonate filler in plastics.

Owner:YINGKOU DONGSHENG IND +1

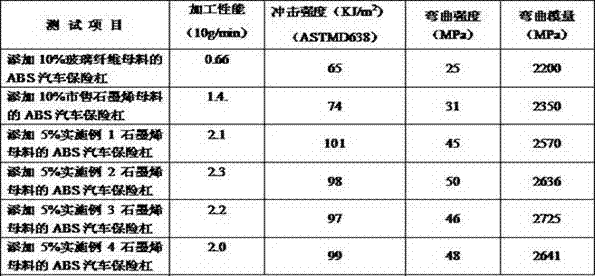

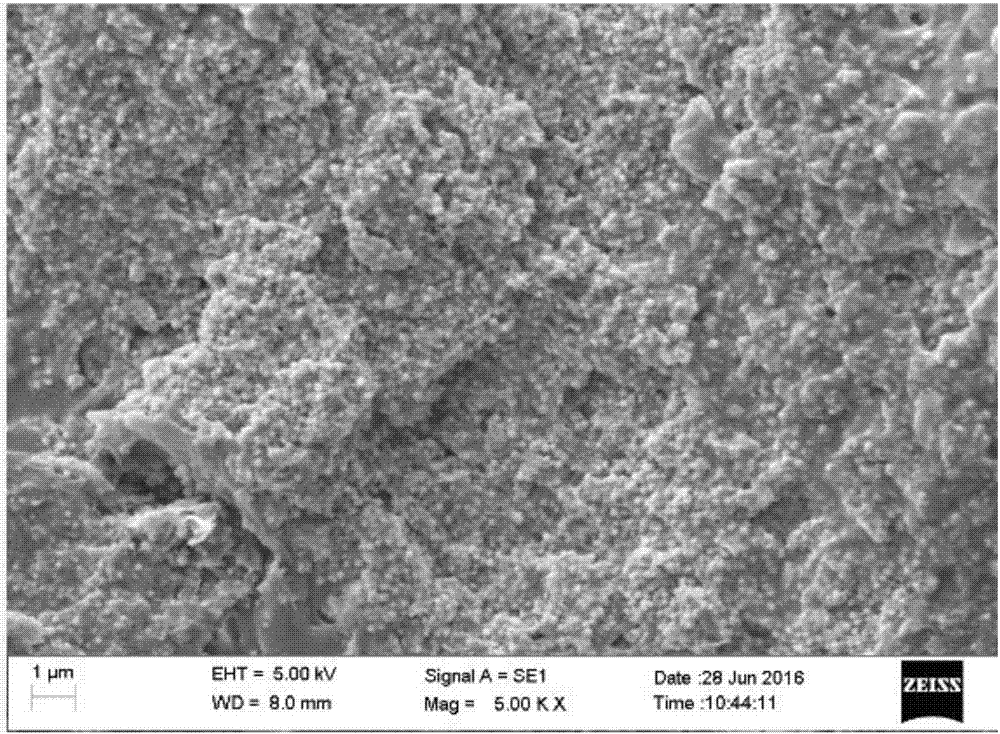

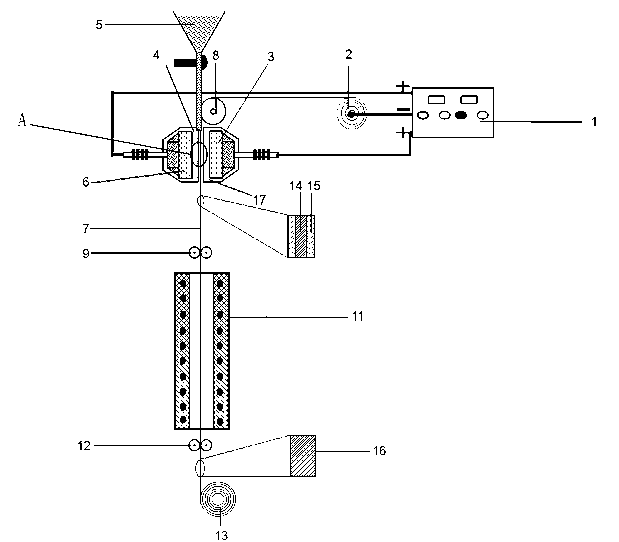

Preparation method of special graphene master batch for automobile engineering plastic

ActiveCN107022183ASolve the problem of fragmentationImprove processing fluiditySilanesEngineering plastic

The invention provides a preparation method of a special graphene master batch for automobile engineering plastic. The preparation method comprises the following steps of enabling graphene slurry to pre-compound with porous microspheres, enabling the porous microspheres to carry graphene, adding silane-terminated polyurethane prepolymer, and performing high-pressure spraying and polymerizing connection; dispersing into carrier resin, and granulating, so as to obtain the graphene master batch. The preparation method has the advantages that the technical defect of failure to effectively improve dispersion property in the production, processing and use process of the automobile engineering plastic in the prior art is overcome, the good dispersion effect in the automobile engineering plastic is realized, the high-strength reduction function in the automobile engineering plastic is realized, and the graphene master batch is the key material for the automobile engineering plastic; in particular, the graphene master batch has high fluidity due to existence of microsphere with high degree of sphericity, is especial for the automobile engineering plastic, and can overcome the defect of difficulty in flowing and dispersion of the conventional graphene master batch; the preparation technology is simple, and the scaled industrialized production can be easily realized.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Resin wave absorption paint and preparation method thereof

ActiveCN106977986AGood solution to the dispersion problemSolve the problem of fragmentationRadiation-absorbing paintsEpoxy resin coatingsHigh intensitySolvent

The invention provides resin wave absorption paint, which is prepared from resin, graphene and ferroferric oxide compounded material, dispersing agents, anti-settling agents and solvents. The paint is characterized in that the addition mode of graphene materials in the resin wave absorption paint is creatively changed; firstly, the graphene is compounded with a hard material of ferroferric oxide in the paint to obtain the graphene and ferroferric oxide compounded material; then, the graphene and ferroferric oxide compounding material is combined with the other ingredients to obtain the resin wave absorption paint. The graphene dispersing problem can be better solved; the complete realization of the excellent performance is ensured; the problem of mixing nonuniformity of flexible graphene materials in a paint system is solved; in addition, the uniform dispersion of ferroferric oxide nanometer particles on the surface of the graphene can be realized; the performance is better achieved; more importantly, the specific ingredients are matched to be used, so that the prepared resin wave absorption paint has the advantages of thin film layer, high intensity, strong wave absorption capability, wide wave absorption frequency band and low cost; wide application prospects are realized.

Owner:SHANDONG OBO NEW MATERIAL CO LTD

Method for preparing high-silicon steel ribbon through using electric brush composite plating method and continuous silicon steel ribbon preparing device

ActiveCN103320842AAvoid adverse effectsHigh cell voltageElectrolytic coatingsCarbon steelSilicon particle

The invention discloses a method for preparing a high-silicon steel ribbon through using an electric brush composite plating method. The method is characterized in that a pure iron ribbon, a low-carbon steel ribbon or a low-silicon steel ribbon is used as a cathode plating piece ribbon, an electric brush plating anode plate is used as an anode, a layer of iron-silicon iron particle composite plating layer is coated on the cathode plating piece ribbon through using an electric brush composite silicon plating process, a composite plating layer steel ribbon adopting a steel-ribbon substrate as a core part is formed, then the uniform dispersion heat treatment is carried out, silicon-contained particles in the iron-silicon iron particle composite plating layer are uniformly dispersed into the steel ribbon substrate of the core part, and the high-silicon steel ribbon can be continuously prepared. The invention also discloses a continuous silicon steel ribbon preparing device which comprises an unreeling guide device, a conveying device, an electroplating device, a dispersion heat treatment device and a rolling device. The high-silicon plating layer is electrically plated on the cathode plating piece ribbon, then the high-silicon steel ribbon with an excellent magnetic conduction performance is obtained through using a heat treatment process, the simplicity in operation can be realized, characteristics such as high efficiency and continuity in preparation can be achieved, and the preparation cost also can be greatly reduced.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com