High gloss flame-retardant ABS modified resin and preparation thereof

A technology of ABS resin and modified resin, which is applied in the field of high-gloss flame-retardant ABS modified resin and its preparation. Simple, the effect of improving flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

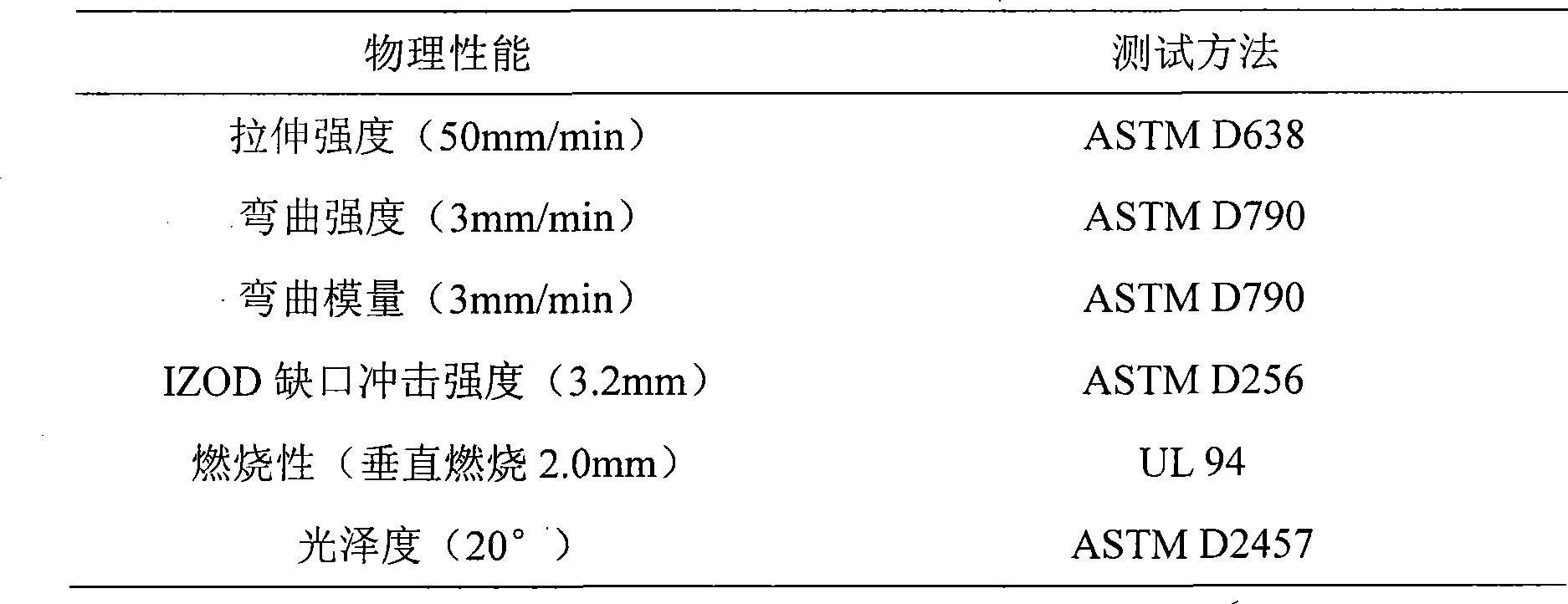

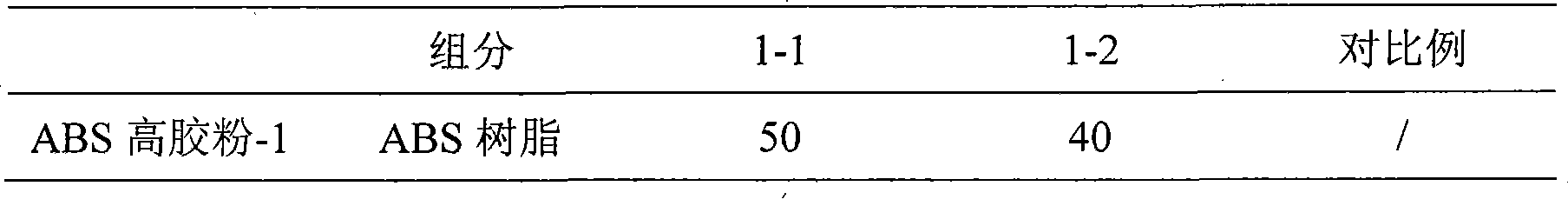

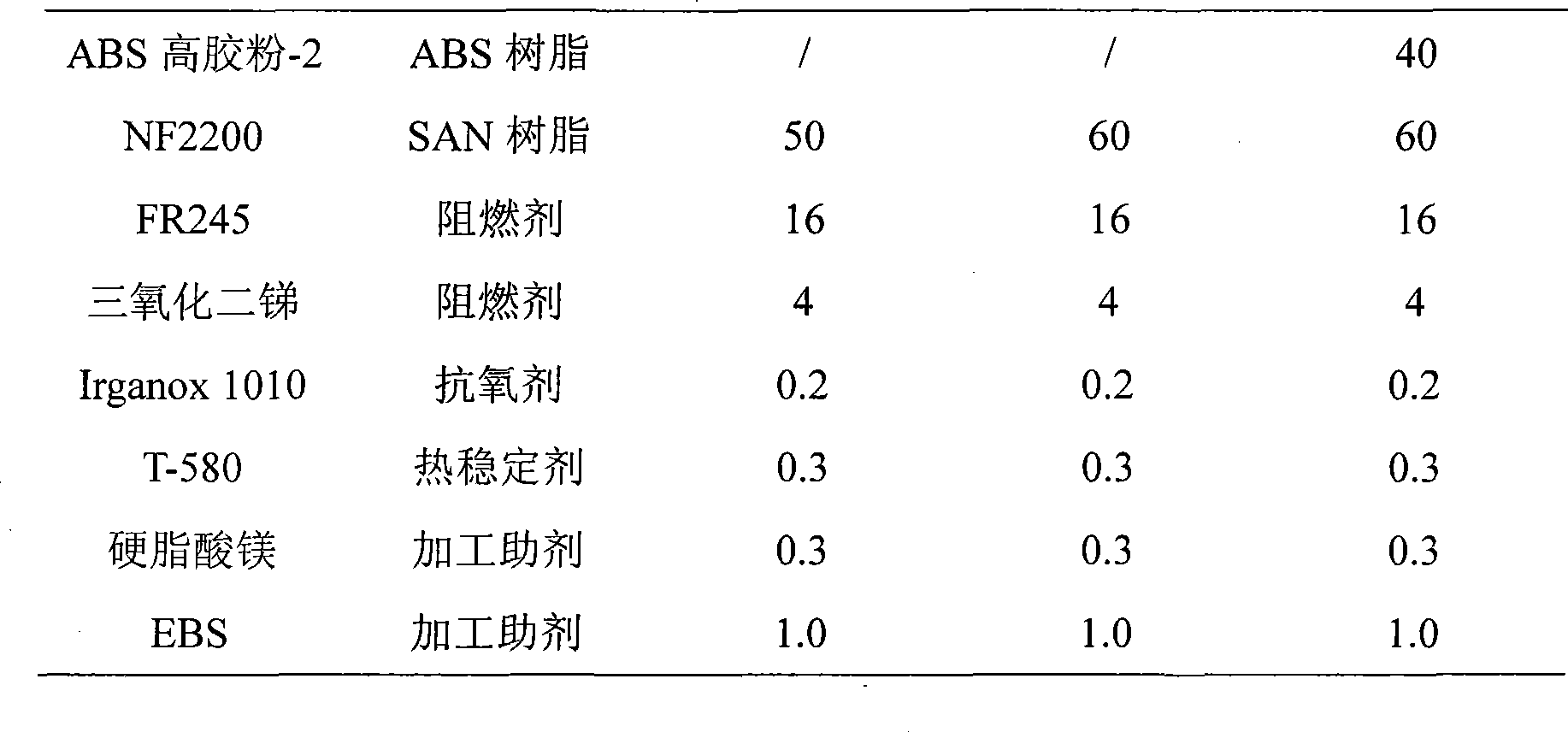

[0033] The preparation and physical properties of the high-gloss flame-retardant ABS modified resin of the present invention are shown in attached tables 2 and 3.

[0034] Wherein the ABS resin is ABS high rubber powder (recorded as ABS high rubber powder-1) with a particle diameter of 230nm, and the ABS high rubber powder (recorded as ABS high rubber powder-2) with a particle diameter of 1 μm, which is acrylonitrile-butadiene Diene-styrene graft copolymer, SAN resin, Taihua NF2200, which is an acrylonitrile-styrene copolymer; the flame retardant is FR245 (brominated phenol) from Nanjing Qixing and 2 trioxide from Huachang Antimony Industry. antimony; antioxidant is Irganox 1010 refined by CIBA; heat stabilizer is domestic organic tin stabilizer T-580; processing aids are domestic magnesium stearate and EBS (ethylene bis stearic acid amide).

[0035] The formula of Example 1 is shown in Table 2, all in parts by weight, and the test results are shown in Table 3.

[0036] Table...

Embodiment 2

[0042] The preparation and physical properties of the high-gloss flame-retardant ABS modified resin of the present invention are shown in attached tables 4 and 5.

[0043]Wherein ABS resin is ABS high rubber powder-1 (with embodiment 1), and it is acrylonitrile-butadiene-styrene graft copolymer, SAN resin, Taihua NF2200, and it is acrylonitrile-styrene copolymer; The flame retardant is Tetrabromobisphenol A (TBBA) from Weifang Kesheng Chemical Co., Ltd. and Hunan Anhua Wenwei’s nano-scale antimony trioxide and colloidal antimony pentoxide; the antioxidant is Irganox 1010 refined by CIBA; thermally stable The agent is domestic organic tin stabilizer T-580; the processing aid is domestic magnesium stearate and EBS (ethylene bis stearic acid amide).

[0044] The formula of Example 2 is shown in Table 4, all in parts by weight, and the test results are shown in Table 5.

[0045] Table 4

[0046]

[0047] table 5

[0048]

Embodiment 3

[0050] The preparation and physical properties of the high-gloss flame-retardant ABS modified resin of the present invention are shown in attached tables 6 and 7.

[0051] Wherein the ABS resin is ABS high-glue powder-1 (with embodiment 1), the ABS high-glue powder (particle diameter 150nm accounts for 35%, and particle diameter 380nm accounts for 65%) (recorded as ABS high-glue powder) Powder-3), it is acrylonitrile-butadiene-styrene graft copolymer, SAN resin, is ultra-high flow SAN, is denoted as SAN-1, and it is acrylonitrile-styrene copolymer; Flame retardant is Tetrabromobisphenol A (TBBA) from Weifang Kesheng Chemical and nano-scale antimony trioxide and colloidal antimony pentoxide from Hunan Anhua Wenwei; the antioxidant is Irganox 1010 refined by CIBA; the heat stabilizer is domestic Organotin stabilizer T-580; processing aids are domestic magnesium stearate and EBS (ethylene bisstearic acid amide).

[0052] Table 6

[0053]

[0054] Table 7

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com