Coating material compositions

A composition and coating technology, which is applied in the direction of polishing composition, paper coating, anti-corrosion coating, etc., can solve the problem of not yet adopting precise classification, and achieve the effect of increasing spray absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

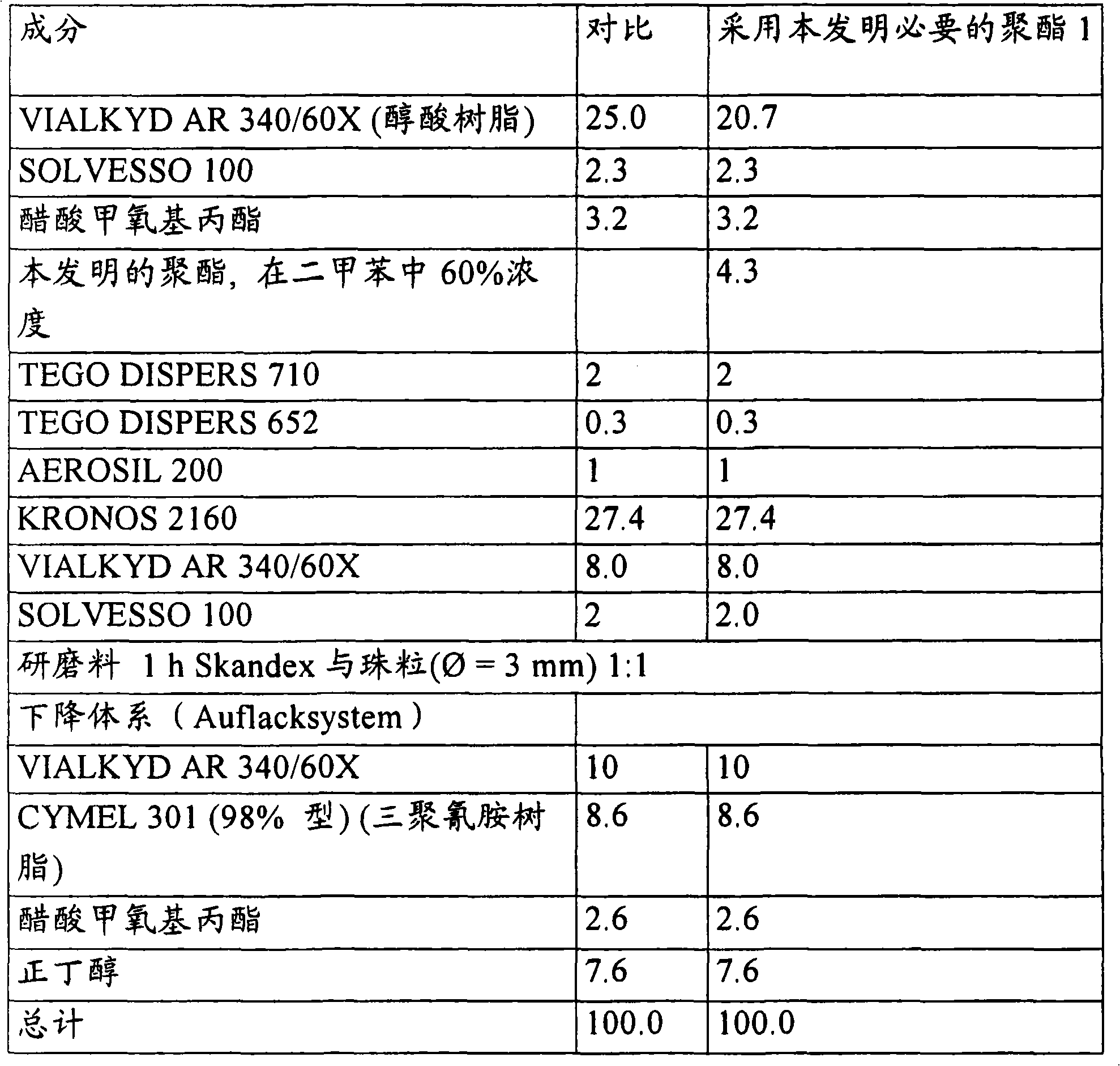

Embodiment 1

[0271] Embodiment 1 (essential polyester of the present invention)

[0272] 3.3 mol tricyclodecane dimethanol mixture, 2.1 mol phthalic anhydride and 1.1 mol maleic anhydride were reacted in a reaction flask equipped with a distillation unit, a stirrer and a thermometer at 210° C. under a nitrogen atmosphere until reaching 15.9 mg KOH / g acid value and 36.0 mg KOH / g OH number.

[0273] m n =2100g / mol M w = 7200 g / mol, polydispersity = 3.4, glass transition temperature 62°C (no crystallization peak), as a 60% solution in xylene, viscosity 960 mPa·s, as a 60% solution in xylene , Garnder color value before / after heat load is 0.1 / 0.2, benzene content: <2mg / kg, formaldehyde content: <1mg / kg.

Embodiment 2

[0274] Embodiment 2 (essential polyester of the present invention)

[0275] 5.3 mol tricyclodecane dimethanol mixture, 2.5 mol adipic acid and 2.5 mol maleic anhydride were reacted in a reaction flask equipped with distillation unit, stirrer and thermometer under nitrogen atmosphere at 210°C until 28 mg KOH / g acid value and 29 mg KOH / g OH number.

[0276] m n =2000g / mol M w =5200g / mol, polydispersity=2.6, glass transition temperature 9°C (no crystallization peak), as a 60% solution in xylene, viscosity 780mPa·s, as a 60% solution in xylene , Garnder color value before / after heat load is 0.1 / 0.1, benzene content: <2mg / kg, formaldehyde content: <1mg / kg.

[0277] The compatibility of the two inventive polyesters of Examples 1 and 2 was investigated. It has high compatibility with, for example, PVC, chlorinated rubber, nitrocellulose, ketone-aldehyde resins, alkyd resins, acrylate resins, polyesters, melamine resins, urea resins and polyisocyanates.

[0278] Resistance to ye...

Embodiment 3

[0281] Embodiment 3 (essential polyester of the present invention)

[0282] Put 9.9 mol tricyclodecane dimethanol mixture, 5.0 mol phthalic anhydride, 2.0 mol adipic acid and 3.0 mol maleic anhydride in a reaction flask equipped with a distillation unit, a stirrer and a thermometer at 210 ° C under a nitrogen atmosphere The reaction was carried out until the acid value of 32mgKOH / g and OH number of 27mgKOH / g were reached.

[0283] m n =2000g / mol M w =5900g / mol, polydispersity=3.0, glass transition temperature 46°C (no crystallization peak), as a 60% solution in xylene, viscosity 850mPa·s, as a 60% solution in xylene , Garnder color value before / after heat load is 0.1 / 0.2, benzene content: <2mg / kg, formaldehyde content: <1mg / kg.

[0284] The thus-prepared polyester essential to the present invention was melted at about 120° C. in an airtight container, mixed with dimethylethanolamine corresponding to a degree of neutralization of 1.0, and supplied with water, and vigorously ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com