Patents

Literature

1885 results about "Fumaric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fumaric acid or trans-butenedioic acid is the chemical compound with the formula HO₂CCH=CHCO₂H. Fumaric acid has a fruit-like taste and has been used as a food acidulant since 1946. Its E number is E297.

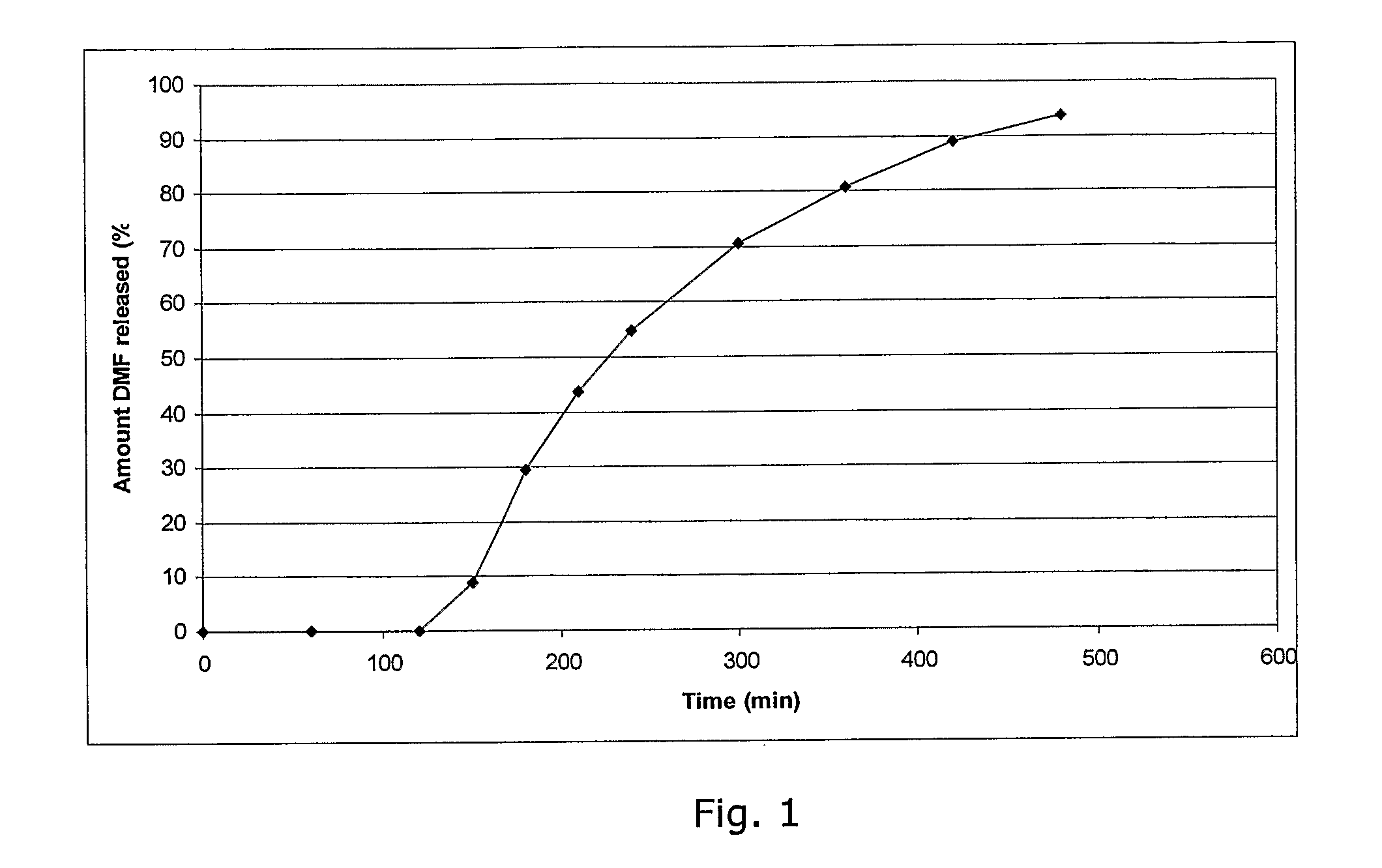

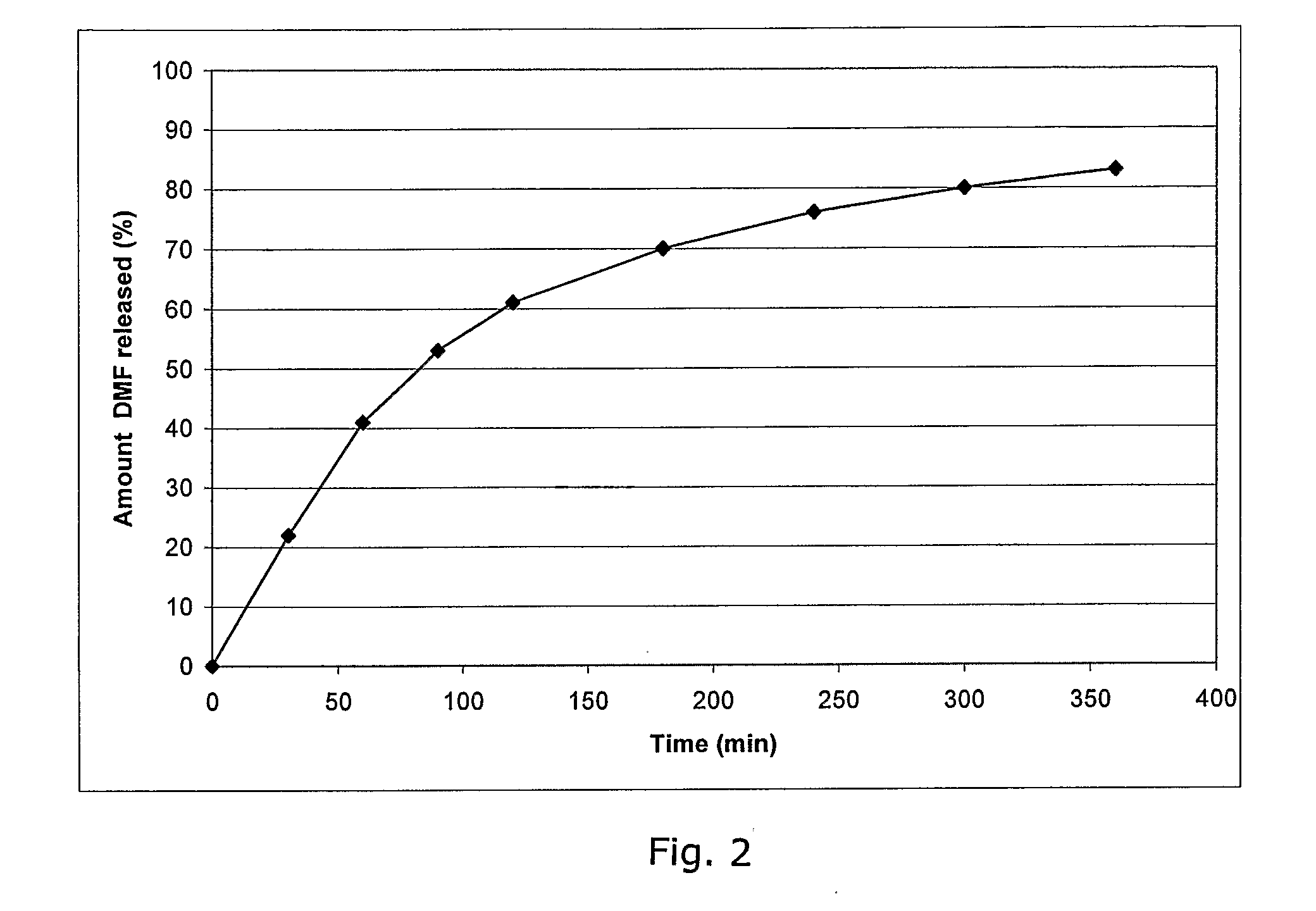

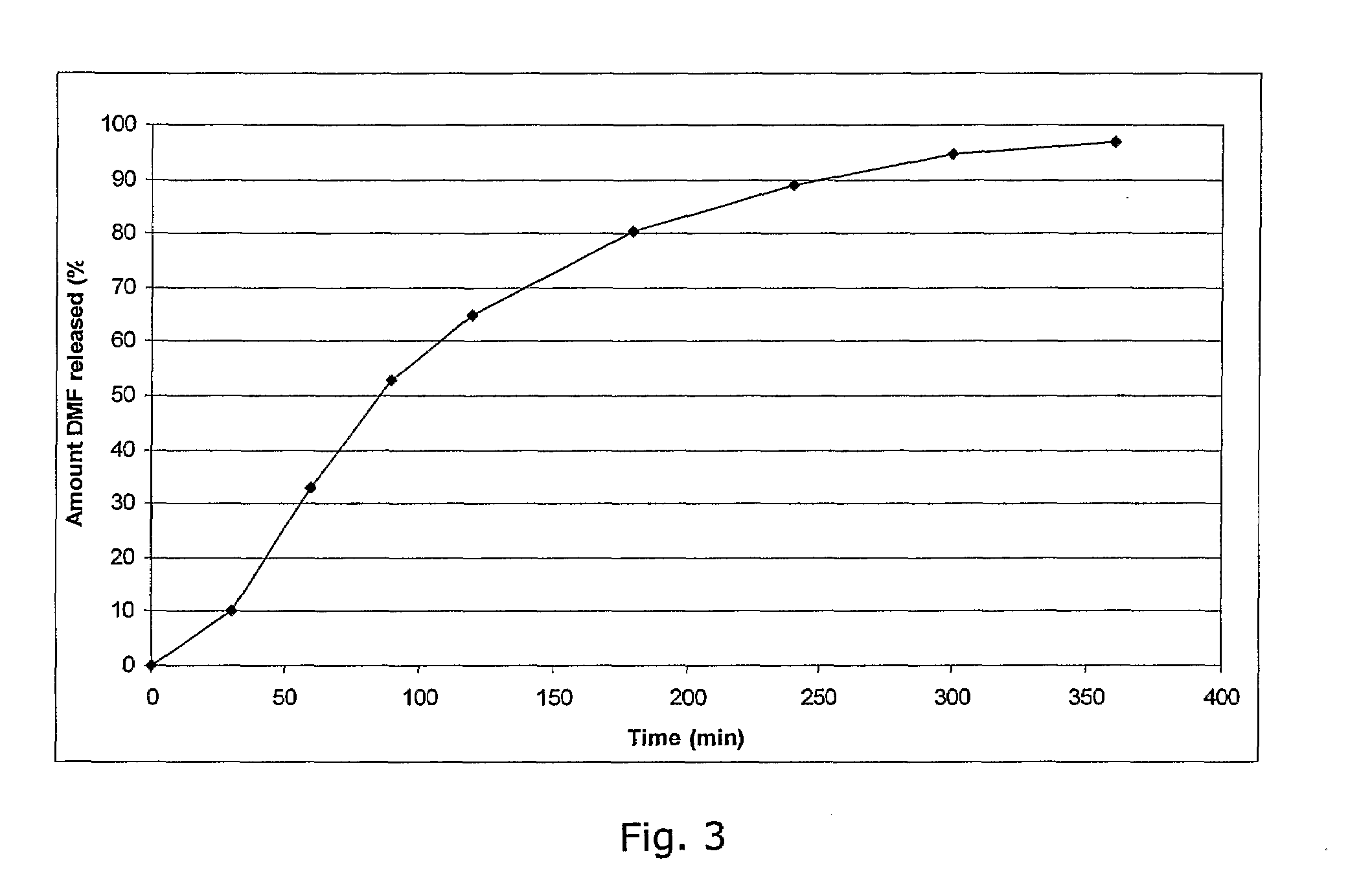

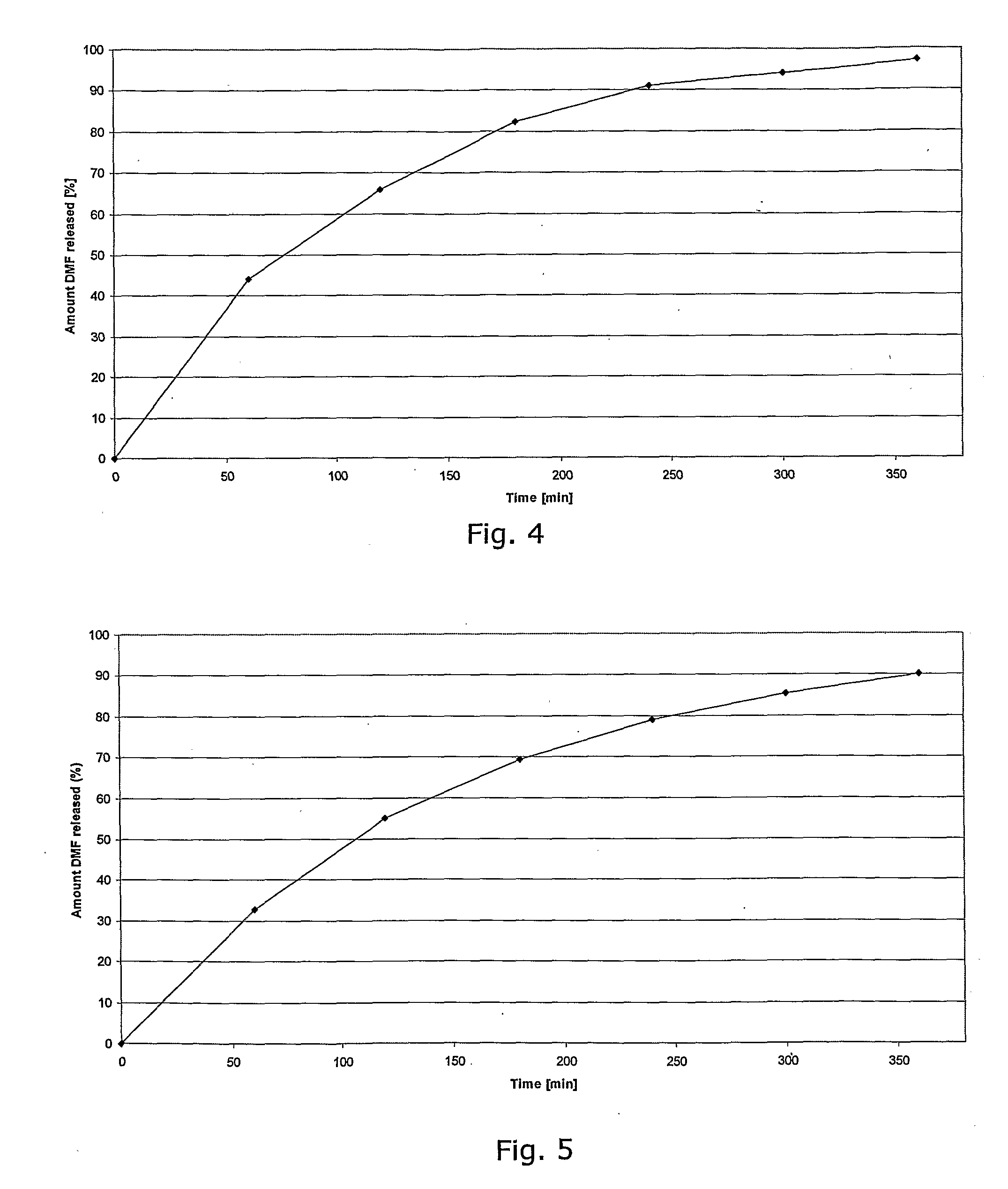

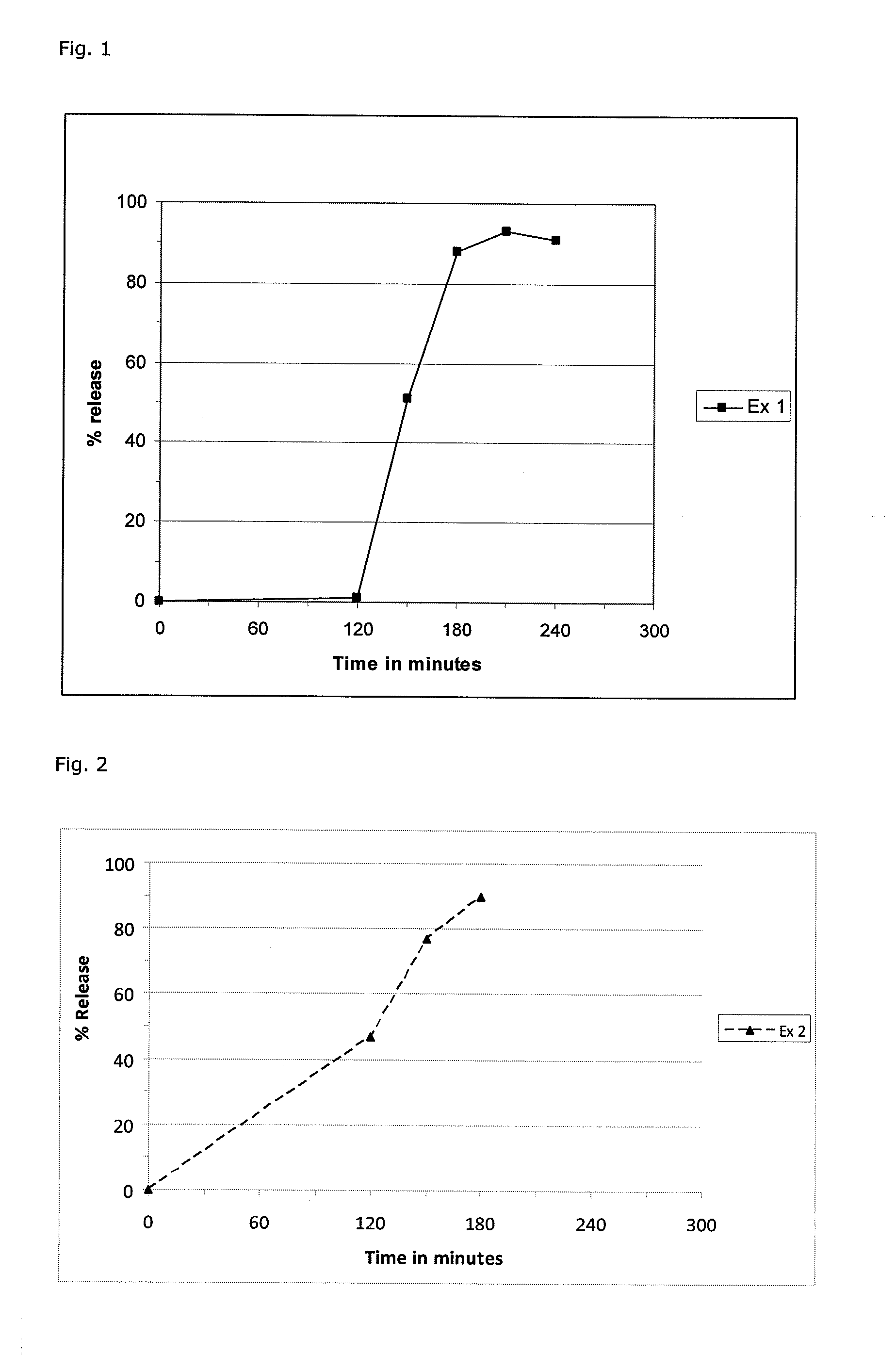

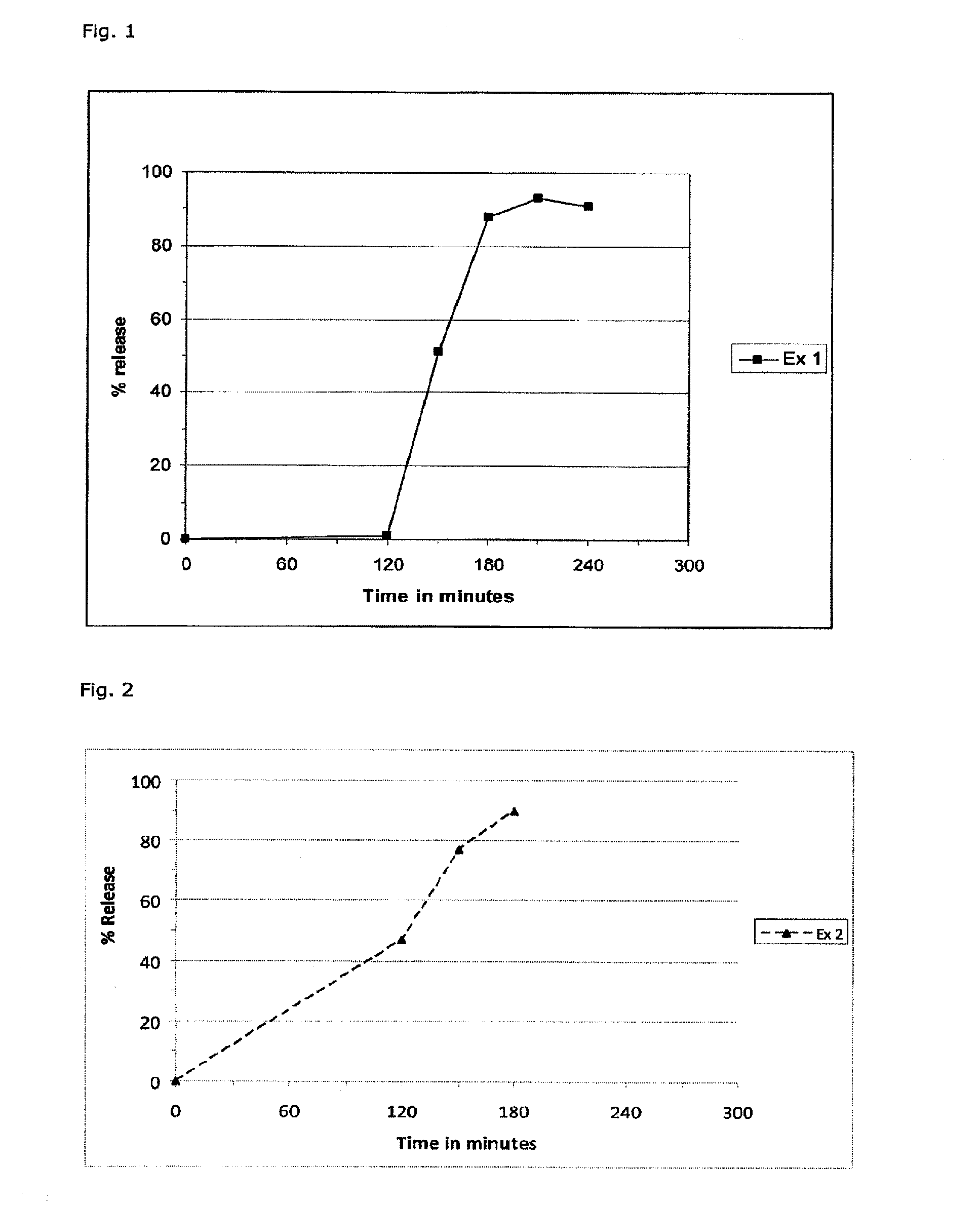

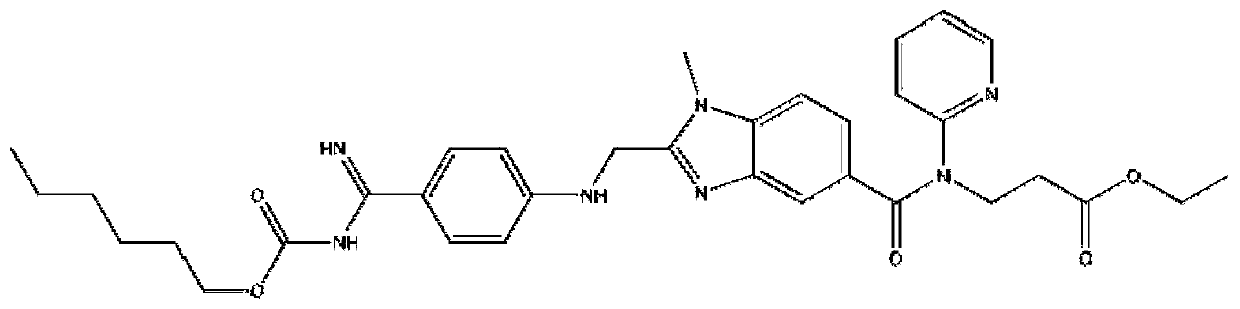

Controlled release pharmaceutical compositions comprising a fumaric acid ester

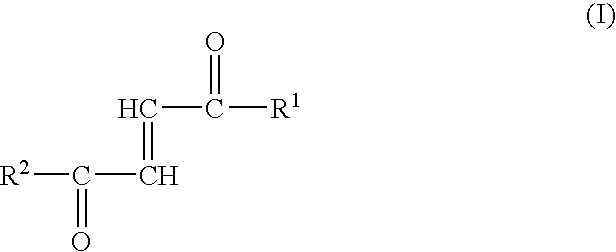

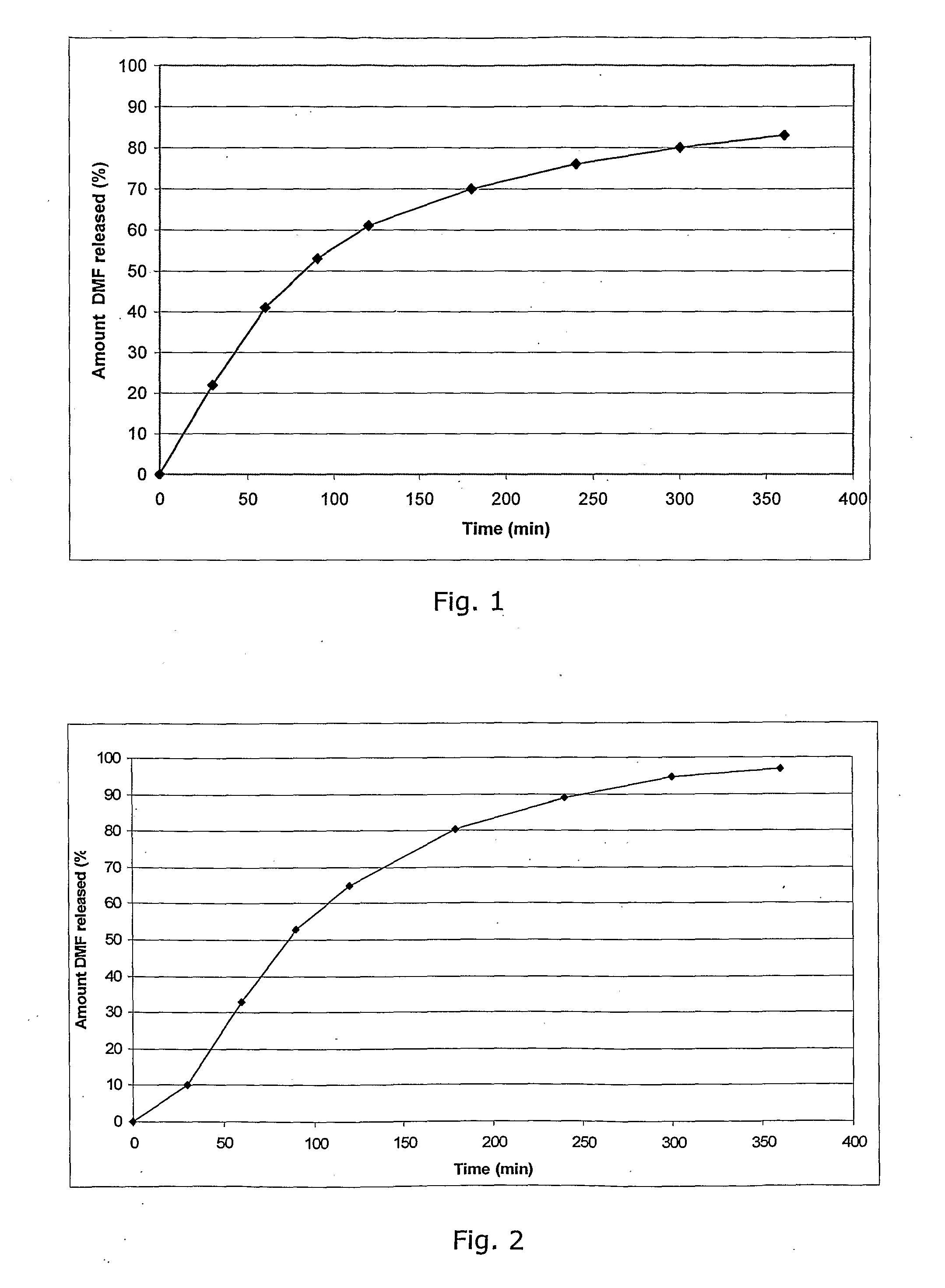

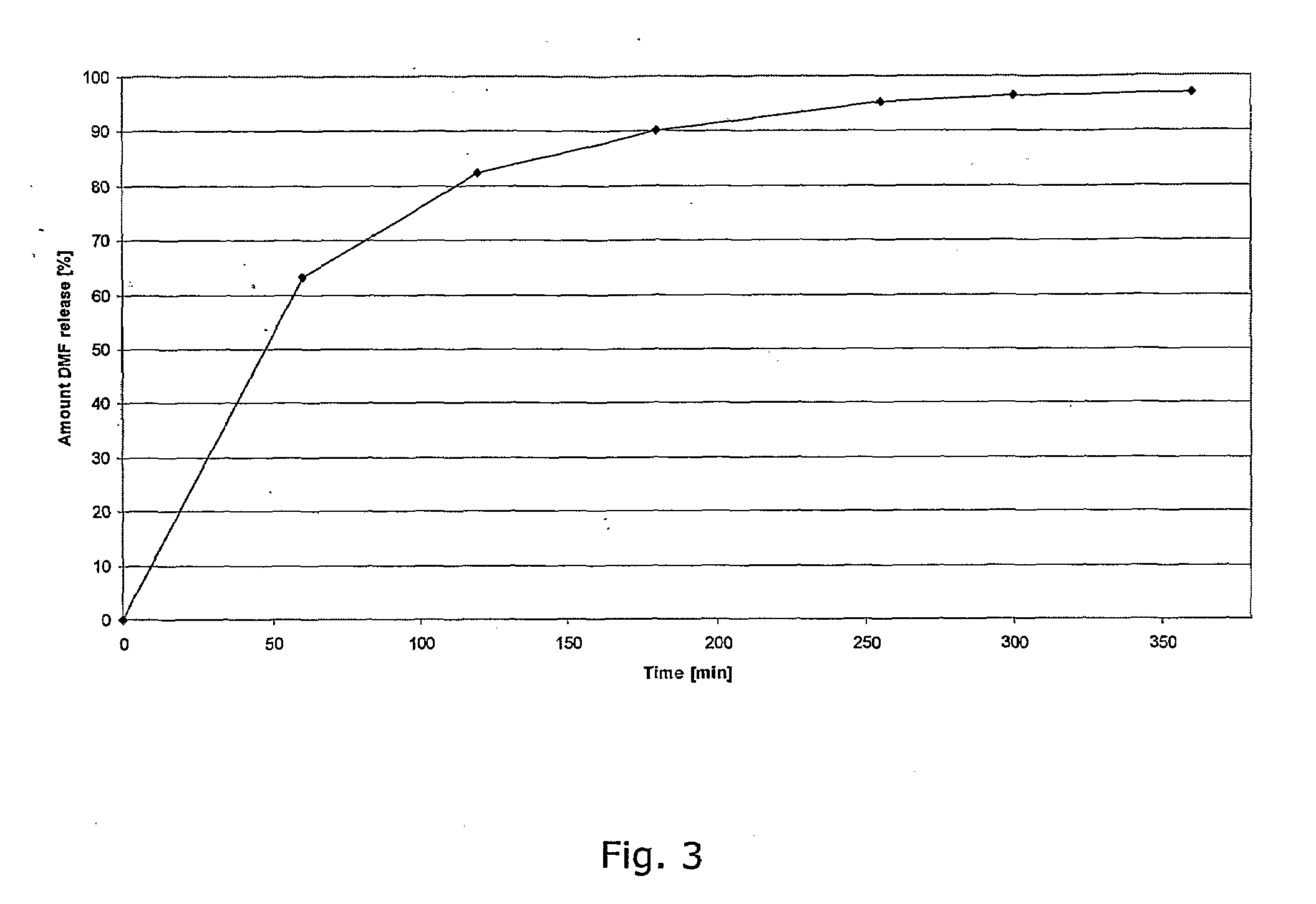

The present invention relates to controlled release pharmaceutical compositions comprising fumaric acid ester(s) as active substance(s). The compositions are suitable for use in the treatment of e.g. psoriasis or other hyperproliferative, inflammatory or autoimmune disorders and are designated to release the fumaric acid ester in a controlled manner so that local high concentrations of the active substance within the gastrointestinal tract upon oral administration can be avoided and, thereby, enabling a reduction in gastro-intestinal related side-effects.

Owner:BIOGEN SWISS MFG GMBH

Fumaric acid amides

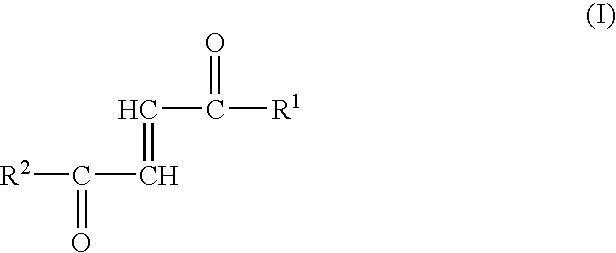

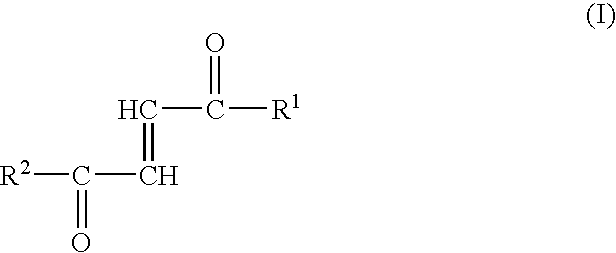

InactiveUS7157423B2More resistant to hydrolysisEasy to handleAntibacterial agentsSenses disorderDiseaseSide chain

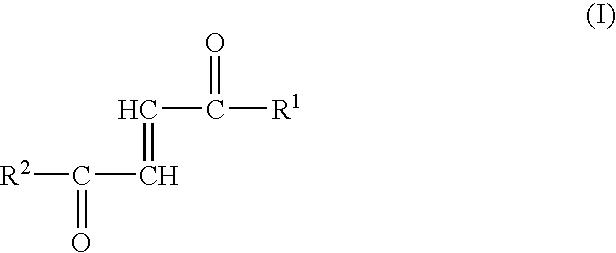

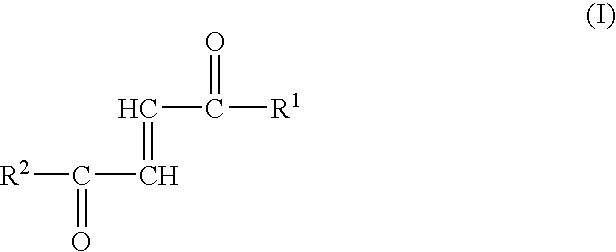

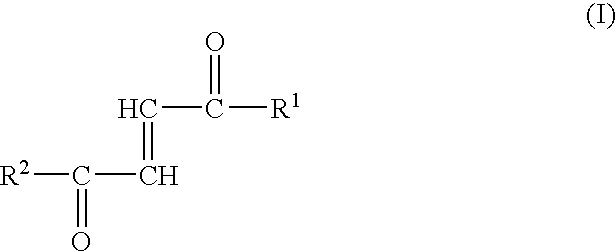

Fumaric acid amides of the general formula (I)wherein R1 represents OR3 or a D- or L-amino acid radical —NH—CHR4—COOH bonded via an amide bond, wherein R3 is hydrogen, a straight-chained or branched, optionally substituted C1-24 alkyl radical, a phenyl radical or C6-10 aralkyl radical and R4 is a side chain of a natural or synthetic amino acid and R2 represents a D- or L-amino acid radical —NH—CHR5—COOH bonded via an amide bond or a peptide radical comprising 2 to 100 amino acids bonded via an amide bond, wherein R5 is a side chain of a natural or synthetic amino acid, are used for preparing a drug (1) for the therapy of an autoimmune disease; (2) for use in transplantation medicine; (3) for the therapy of mitochondrial diseases; or (4) for the therapy of NF-kappaB mediated diseases.

Owner:BIOGEN INT

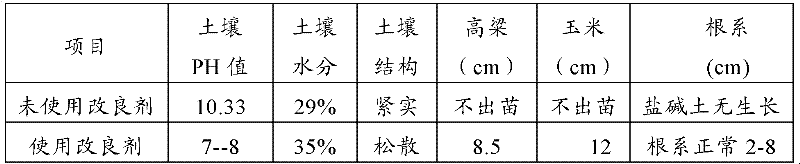

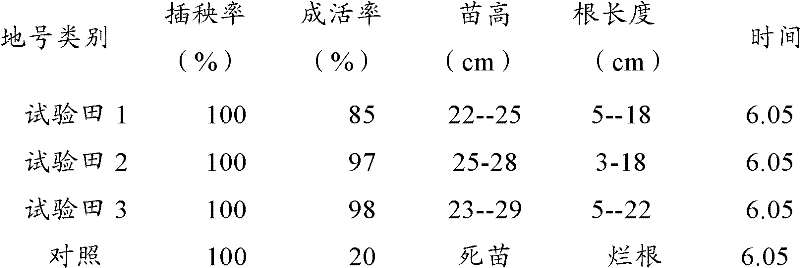

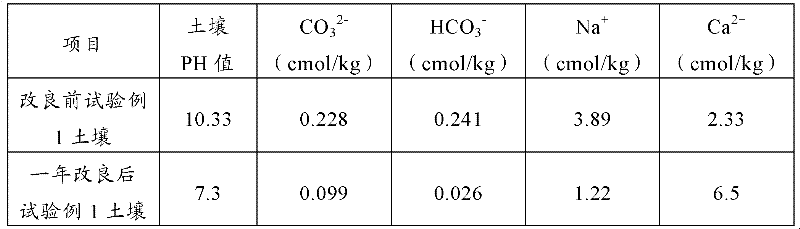

Saline-alkali soil improver

InactiveCN102517030ALower pHRaise the pHOther chemical processesOrganic fertilisersCis-Butenedioic AcidFatty alcohol

The invention relates to an improver for saline-alkali soil. The improver comprises a powder agent and a water agent, wherein the powder agent comprises the following components: organic matters, plant mycelium protein powder, active calcium, calcium superphosphate, aluminum sulfate, fatty alcohol polyoxyethylene ether ammonium sulfate, amino acid powder, bacillus subtilis and photosynthetic bacteria, and the water agent comprises the following components: citric acid, fulvic acid, humic acid, malic acid, maleic acid, fumaric acid, L-tartaric acid, pyrophosphoric acid, humic acid, lactic acid, oxalic acid, salicylic acid, sodium ion adsorbent, Tween-80 and water. The improver disclosed by the invention can improve the soil from multiple angles, namely soil structure, microorganism species, a chemical method and the like, obviously promote the release of iron and phosphorus in the soil, improve the soil structure, effectively reduce the content of sodium ions in the soil, reduce the pH value of the soil and restore land to a normal planting state after being used continuously for two years.

Owner:孙东军 +1

Use of fumaric acid derivatives for treating mitochondrial diseases

The present invention relates to the use of individual fumaric acid derivatives or mixtures thereof for preparing a pharmaceutical composition for treating mitochondrial diseases, especially for treating Parkinson's syndrome, Alzheimer's disease, Chorea Huntington disease, retinopathia pigmentosa and mitochondrial encephalomyopathy. Preferably, the fumaric acid derivative(s) is / are those selected from the group consisting of fumaric acid dialkyl esters or fumaric acid monoalkyl esters in the form of the free acid or a salt thereof.

Owner:BIOGEN INT

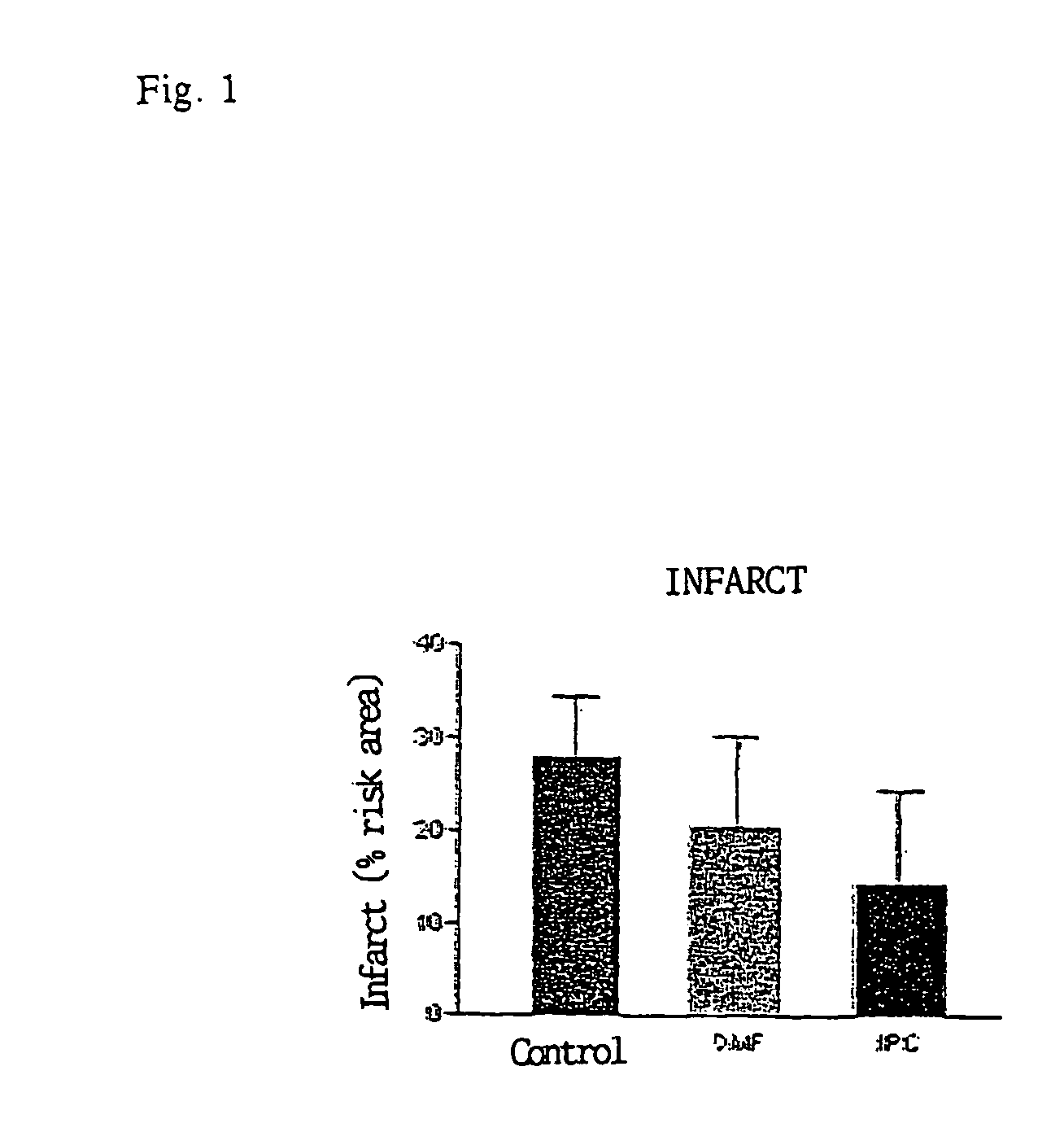

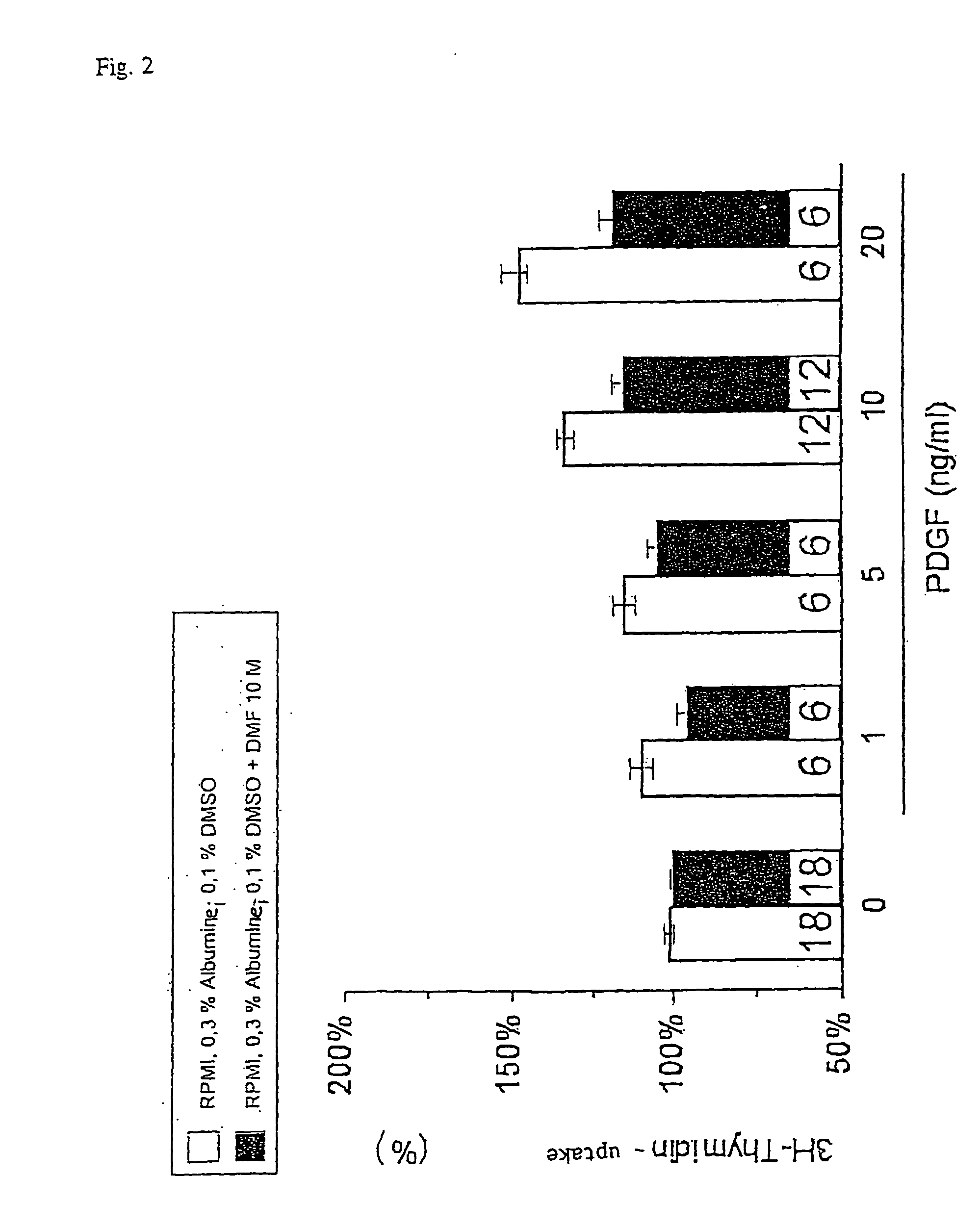

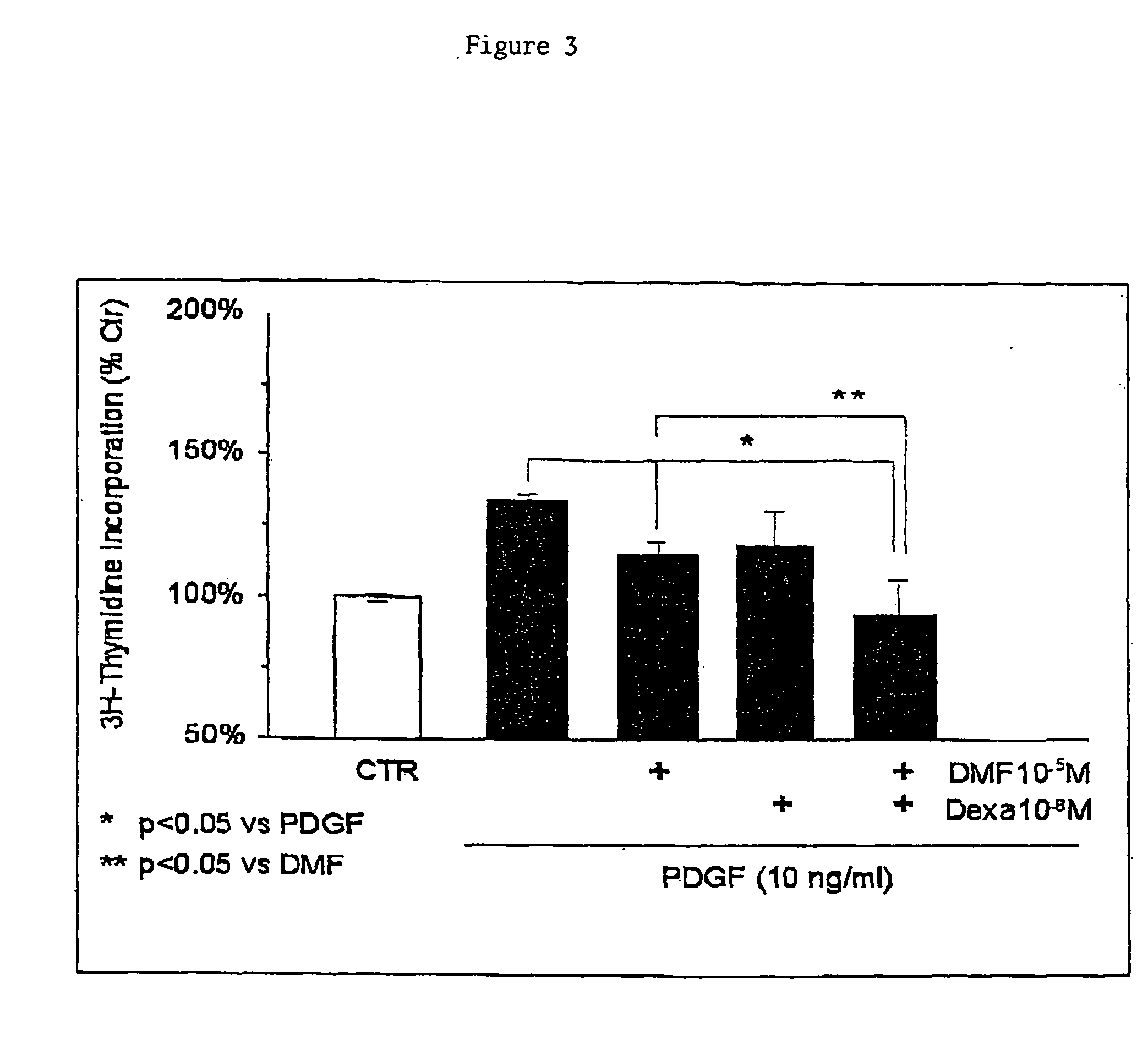

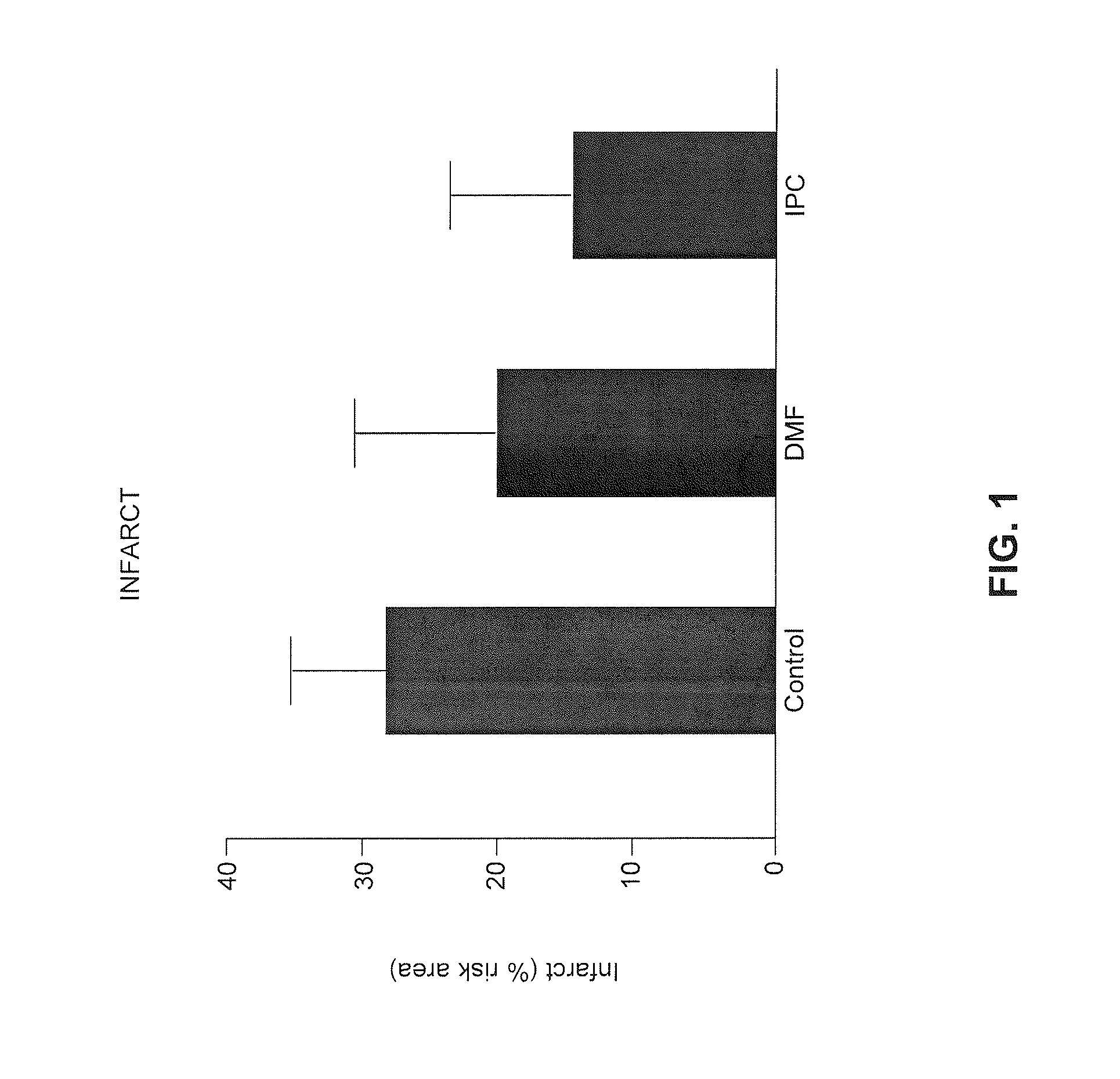

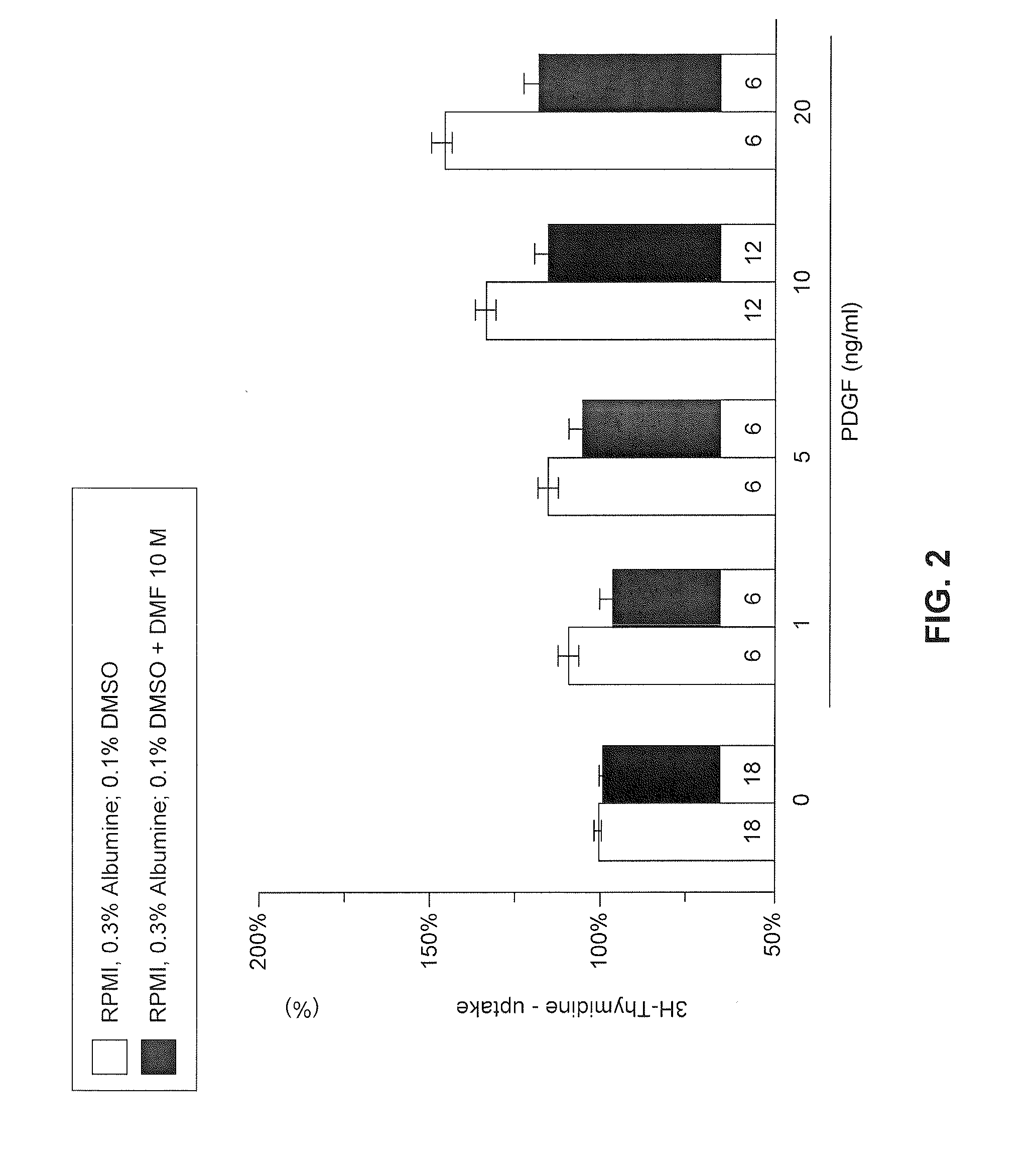

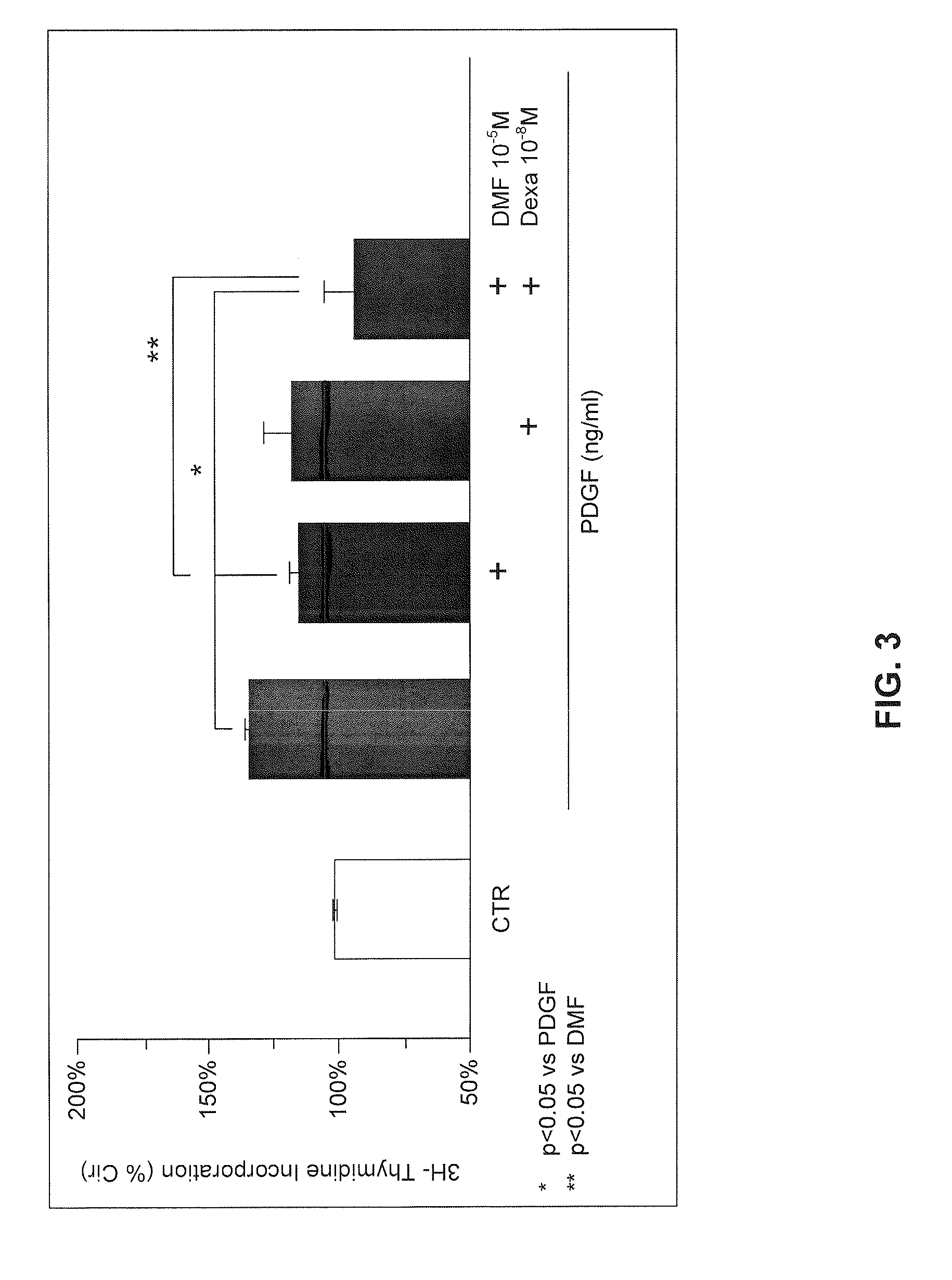

Use of fumaric acid derivatives for treating cardiac insufficiency, and asthma

According to a first aspect the invention relates to the use of fumaric acid derivatives selected from the group consisting of dialkyl fumarates, monoalkyl hydrogen fumarates, fumaric acid monoalkyl ester salts, fumaric acid monoamides, monoamido fumaric acid salts, fumaric acid diamides, monoalkyl monoamido fumarates, carbocyclic and oxacarbocyclic oligomers of these compounds and mixtures thereof for preparing a drug for the treatment or prevention of cardiac insufficiency, in particular left ventricular insufficiency, myocardial infarction and angina pectoris. According to a second aspect the invention relates to the use of fumaric acid derivatives, selected from the group consisting of dialkyl fumarates, monoalkyl hydrogen fumarates, fumaric acid monoalkyl ester salts, fumaric acid monoamides, monoamido fumaric acid salts, fumaric acid diamides, monoalkyl monoamido fumarates, carbocyclic and oxacarbocyclic oligomers of these compounds and mixtures thereof for preparing a drug for the treatment of asthma and chronic obstructive pulmonary diseases, especially asthma caused by allergies, infections, analgesics, job conditions or physical effort, mixed forms of asthma, or asthma cardiale.

Owner:FUMAPHAM AG

Fumaric Acid Amides

InactiveUS20060205659A1Easy to handleMore resistant to hydrolysisAntibacterial agentsOrganic active ingredientsAutoimmune conditionHydrogen

Fumaric acid amides of the general formula (I) wherein R1 represents OR3 or a D- or L-amino acid radical —NH—CHR4—COOH bonded via an amide bond, wherein R3 is hydrogen, a straight-chained or branched, optionally substituted C1-24 alkyl radical, a phenyl radical or C6-10 aralkyl radical and R4 is a side chain of a natural or synthetic amino acid and R2 represents a D- or L-amino acid radical —NH—CHR5—COOH bonded via an amide bond or a peptide radical comprising 2 to 100 amino acids bonded via an amide bond, wherein R5 is a side chain of a natural or synthetic amino acid, are used for preparing a drug (1) for the therapy of an autoimmune disease; (2) for use in transplantation medicine; (3) for the therapy of mitochondrial diseases; or (4) for the therapy of NF-kappaB mediated diseases.

Owner:BIOGEN INT

Aqueous dispersion for chemical mechanical polishing

InactiveUS6527818B2Pigmenting treatmentOther chemical processesColloidal silicaOXALIC ACID DIHYDRATE

There is provided an aqueous dispersion for CMP with an excellent balance between chemical etching and mechanical polishing performance. The aqueous dispersion for CMP of the invention is characterized by comprising an abrasive, water and a heteropolyacid. Another aqueous dispersion for CMP according to the invention is characterized by comprising an abrasive, water, a heteropolyacid and an organic acid. Yet another aqueous dispersion for CMP according to the invention is characterized by comprising colloidal silica with a primary particle size of 5-100 nm, water and a heteropolyacid. Preferred for the heteropolyacid is at least one type selected from among silicomolybdic acid, phosphorotungstic acid, silicotungstic acid, phosphoromolybdic acid and silicotungstomolybdic acid. Preferred for the organic acid is at least one selected from among oxalic acid, malonic acid, succinic acid, glutaric acid, adipic acid, maleic acid, fumaric acid, phthalic acid, malic acid, tartaric acid and citric acid.

Owner:JSR CORPORATIOON

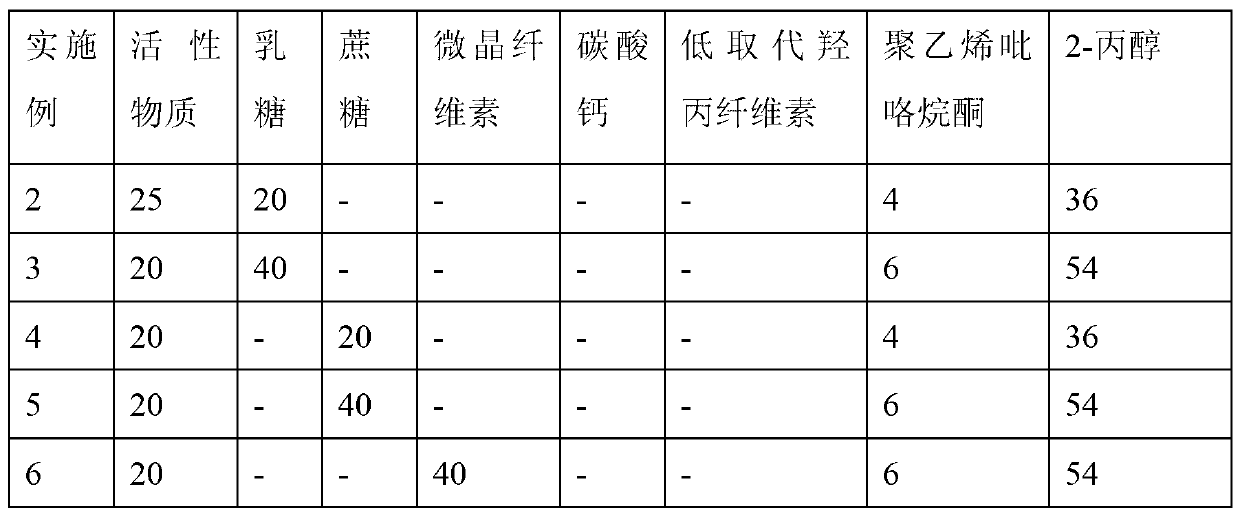

Controlled Release Pharmaceutical Compositions Comprising a Fumaric Acid Ester

InactiveUS20080299196A1Decrease glass transition pointLow film forming temperatureBiocideSenses disorderDiseaseHigh concentration

The present invention relates to controlled release pharmaceutical compositions comprising fumaric acid ester(s) as active substance(s). The compositions are suitable for use in the treatment of e.g. psoriasis or other hyperproliferative, inflammatory or autoimmune disorders and are designed to release the fumaric acid ester in a controlled manner so that local high concentrations of the active substance within the gastrointestinal tract upon oral administration can be avoided and, thereby, enabling a reduction in gastro-intestinal related side-effects.

Owner:BIOGEN SWISS MFG GMBH

Pvc/Wood Composite

InactiveUS20080261019A1Synthetic resin layered productsCellulosic plastic layered productsMethacrylateFibrous composites

The present invention relates to a thermoplastic / natural cellulosic fiber composite, and more specifically to a high molecular weight compatibilizer within that composite resulting in both a high flex strength and high modulus and significant reduction in water absorption. The compatibilizer is preferably a terpolymer comprising: a) 0.5-20 percent by weight of monomer units selected from the group consisting of maleic anhydride, substituted maleic anhydride, mono-ester of maleic anhydride, itaconic anhydride, maleic acid, fumaric acid, crotonic acid, acrylic acid and methacrylic acid; b) 0 to 40 percent by weight of monomer units selected from styrene and functionalized styrene; and c) 40 to 98.5 percent by weight of monomer units selected from the group consisting of C1-8 alkyl acrylates and methacrylates, and vinyl acetate.

Owner:ARKEMA INC

Polishing fluid and polishing method

ActiveUS20050181609A1Increase chanceSuperior in dimensional accuracy and electric characteristicOther chemical processesSemiconductor/solid-state device manufacturingDevice materialSlurry

A polishing slurry including an oxidant, a metal oxide dissolver, a metal inhibitor and water and having a pH from 2 to 5. The metal oxide dissolver contains one or more types selected from one or more acids (A-group) selected from acids of which the dissociation constant (pKa) of a first dissociable acid group is less than 3.7 and from which five acids of lactic acid, phthalic acid, fumaric acid, maleic acid and aminoacetic acid are excluded, ammonium salts of the A-group and esters of the A-group, and one or more types selected from one or more acids (B-group) selected from acids of which the dissociation constant (pKa) of a first dissociable acid group is 3.7 or more and the five acids, ammonium salts of the B-group and esters of the B-group. The metal inhibitor contains one or more types selected from the group consisting of aromatic compounds having a triazole skeleton and one or more types selected from the group consisting of aliphatic compounds having a triazole skeleton and compounds having any one of pyrimidine skeleton, imidazole skeleton, guanidine skeleton, thiazole skeleton and pyrazole skeleton. The polishing slurry having a high metal-polishing rate, reducing etching rate and polishing friction, results in the production, with high productivity, of semiconductor devices reduced in dishing and erosion in metal wiring.

Owner:HITACHI CHEM CO LTD

Pharmaceutical composition comprising one or more fumaric acid esters

InactiveUS20120034274A1Reduce degradationImprove toleranceOrganic active ingredientsBiocideControlled releaseFumaric acid

Owner:BIOGEN SWISS MFG GMBH

Slowly-released compound acidifier for poultry and livestock feed, preparation method thereof and feed

ActiveCN102578387AMatching scienceDefinitelyClimate change adaptationAnimal feeding stuffDiseaseFeed conversion ratio

The invention discloses a slowly-released compound acidifier for poultry and livestock feed, a preparation method thereof and feed containing the same. The compound acidifier comprises the following compositions in part by weight: 30 to 80 parts of complex organic acid, 15 to 50 parts of supplementary materials and 5 to 20 parts of coating agents. The complex organic acid is citric acid, fumaric acid, malic acid, lactic acid, linoleic acid, crataegolic acid, ursolic acid, chlorogenic acid, glycyrrhizic acid and oleanolic acid, and the supplementary materials are silicon dioxide, hydroxypropyl methylcellulose and ethyl cellulose. The acidifier is scientifically proportioned, has strong efficiency and is long-acting and slow-releasing, nutrients in the feed are free from being damaged, the acidifier has good fluidity and is easy to be uniformly mixed with the feed, the digestive absorption of nutrients can be promoted, the conversion rate of the feed can be improved, the productivity of poultry and livestock can be improved, the time for domestic animals for sale can be effectively shortened, the health of gastrointestinal mucosa of the animals can be protected, the immunologic function of the animals can be strengthened, and diseases can be prevented.

Owner:BEIJING DABEINONG ANIMAL HEALTH TECH +1

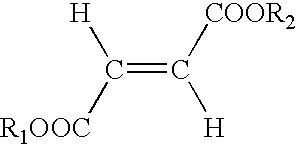

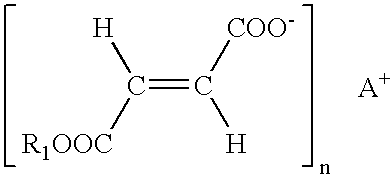

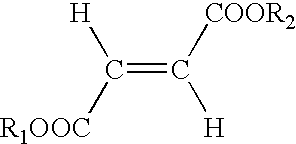

Synthesis method of drilling fluid filtrate reducer

InactiveCN101805595ANo pollution in the processFast polymerization rateDrilling compositionSynthesis methodsOil phase

The invention relates to a synthesis method of drilling fluid filtrate reducer. The method comprises: a, nonionic compound emulsifying agent is dissolved in oil and oil phase is made up; a first monomer chosen from fumaric acid, maleic acid, itaconic acid or crylic acid, a second monomer chosen from N, N- dimethylacrylamide, N, N-diethylacrylamide or acrylamide and a third monomer chosen from 4-vinylbenzenesulfonic acid sodium salt, sodium allylsulfonate, 3-allyloxy-2-dydroxy-1-sodium allylsulfonate, 2- methacryloxypropyl-2-methyl propanesulfonic acid, 2-acrylamido-2-methyl propanesulfonic acid or SMAS are dissolved in water with the molar ratio of 1:1 to 5:1 to 5, the pH value of the solution is adjusted to be between 8 and 11, evocating agent is added and water phase solution is made up; and b, the water solution is added to the oil phase solution and the temperature rises to 40 to 70 DEG C for polymerization. The method of the invention has the advantages of fast polymerization speed, high outcome molecular weight and high outcome stability, good filtrate reducing performance, high temperature resistance and high salt resistant performance.

Owner:BEIJING UNIV OF CHEM TECH

Antimicrobial perfume compositions

InactiveUS6479456B1Improve actionEasy to useCosmetic preparationsBiocideAdditive ingredientBULK ACTIVE INGREDIENT

Owner:FIRMENICH SA

Hot melt adhesive composition

A hot melt adhesive composition comprising: (a) a functional copolymer obtained from copolymerization of ethylene and a comonomer selected from maleic anhydride, citraconic anhydride, itaconic anhydride, tetrahydrophthalic anhydride, maleic acid, citraconic acid, itaconic acid, fumaric acid, tetrahydrophthalic acid, the corresponding salts, monoesters and diesters of these acids, and mixtures of any of these, wherein the functional copolymer is present in an amount from about 5 to about 95 weight % of the combined total amount of (a) and (b); and (b) at least one ethylene copolymer obtained from copolymerization of ethylene with a polar monomer wherein said polar comonomer is present in the copolymer in an amount of from 8 to 40 weight %, wherein said ethylene copolymer is selected from the group consisting of ethylene / vinyl acetate copolymers, ethylene / alkyl (meth)acrylate copolymers and ethylene / alkyl (meth)acrylate / carbon monoxide terpolymers, in an amount from about 5 to about 95 weight % of the combined total amount of (a) and (b); wherein the composition has a melt index of 100 grams / 10 minutes or higher. Articles comprising and process using the hot melt adhesive are also disclosed.

Owner:DOW GLOBAL TECH LLC

Use of fumaric acid derivatives for treating cardiac insufficiency, and asthma

According to a first aspect the invention relates to the use of fumaric acid derivatives selected from the group consisting of dialkyl fumarates, monoalkyl hydrogen fumarates, fumaric acid monoalkyl ester salts, fumaric acid monoamides, monoamido fumaric acid salts, fumaric acid diamides, monoalkyl monoamido fumarates, carbocyclic and oxacarbocyclic oligomers of these compounds and mixtures thereof for preparing a drug for the treatment or prevention of cardiac insufficiency, in particular left ventricular insufficiency, myocardial infarction and angina pectoris.According to a second aspect the invention relates to the use of fumaric acid derivatives, selected from the group consisting of dialkyl fumarates, monoalkyl hydrogen fumarates, fumaric acid monoalkyl ester salts, fumaric acid monoamides, monoamido fumaric acid salts, fumaric acid diamides, monoalkyl monoamido fumarates, carbocyclic and oxacarbocyclic oligomers of these compounds and mixtures thereof for preparing a drug for the treatment of asthma and chronic obstructive pulmonary diseases, especially asthma caused by allergies, infections, analgesics, job conditions or physical effort, mixed forms of asthma, or asthma cardiale.

Owner:BIOGEN INT

Aqueous dispersion for chemical mechanical polishing

InactiveUS20010039766A1Improve balanceImprove accuracyPigmenting treatmentOther chemical processesOXALIC ACID DIHYDRATEColloidal silica

There is provided an aqueous dispersion for CMP with an excellent balance between chemical etching and mechanical polishing performance. The aqueous dispersion for CMP of the invention is characterized by comprising an abrasive, water and a heteropolyacid. Another aqueous dispersion for CMP according to the invention is characterized by comprising an abrasive, water, a heteropolyacid and an organic acid. Yet another aqueous dispersion for CMP according to the invention is characterized by comprising colloidal silica with a primary particle size of 5-100 nm, water and a heteropolyacid. Preferred for the heteropolyacid is at least one type selected from among silicomolybdic acid, phosphorotungstic acid, silicotungstic acid, phosphoromolybdic acid and silicotungstomolybdic acid. Preferred for the organic acid is at least one selected from among oxalic acid, malonic acid, succinic acid, glutaric acid, adipic acid, maleic acid, fumaric acid, phthalic acid, malic acid, tartaric acid and citric acid.

Owner:JSR CORPORATIOON

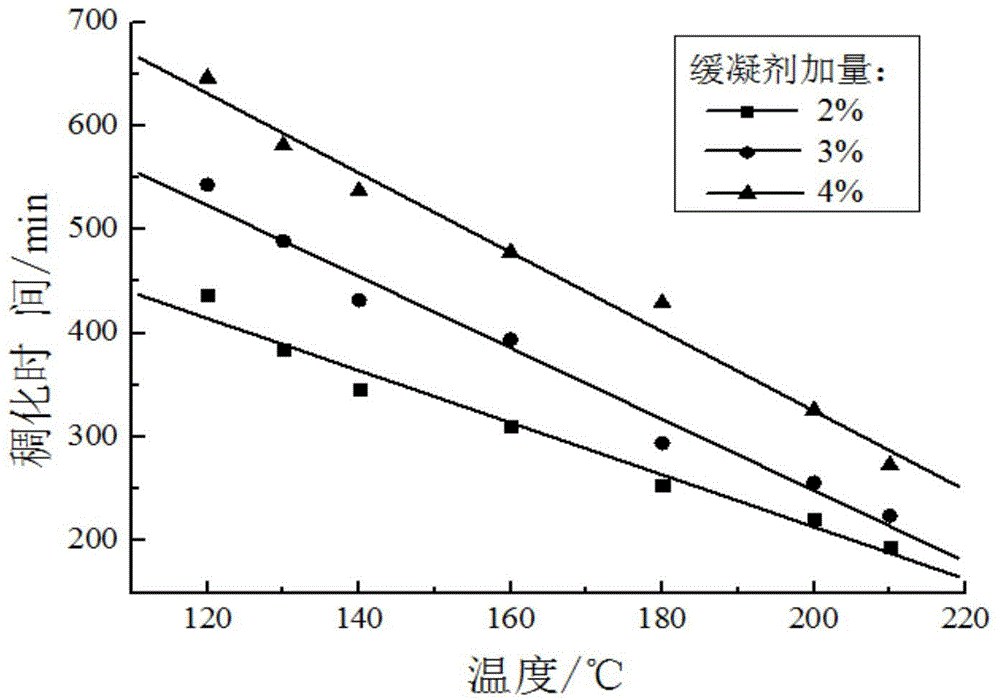

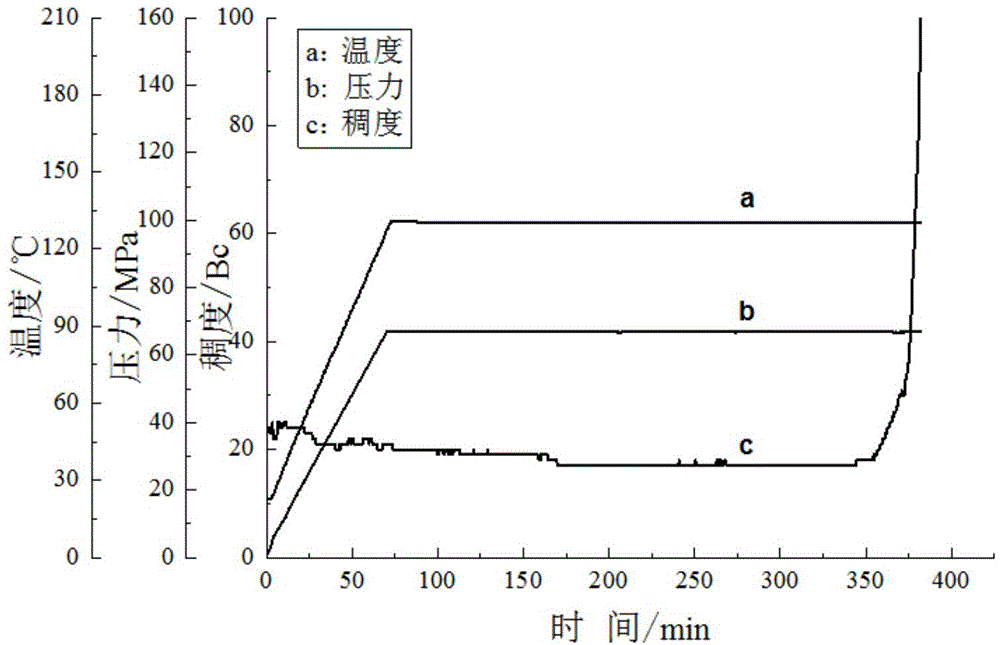

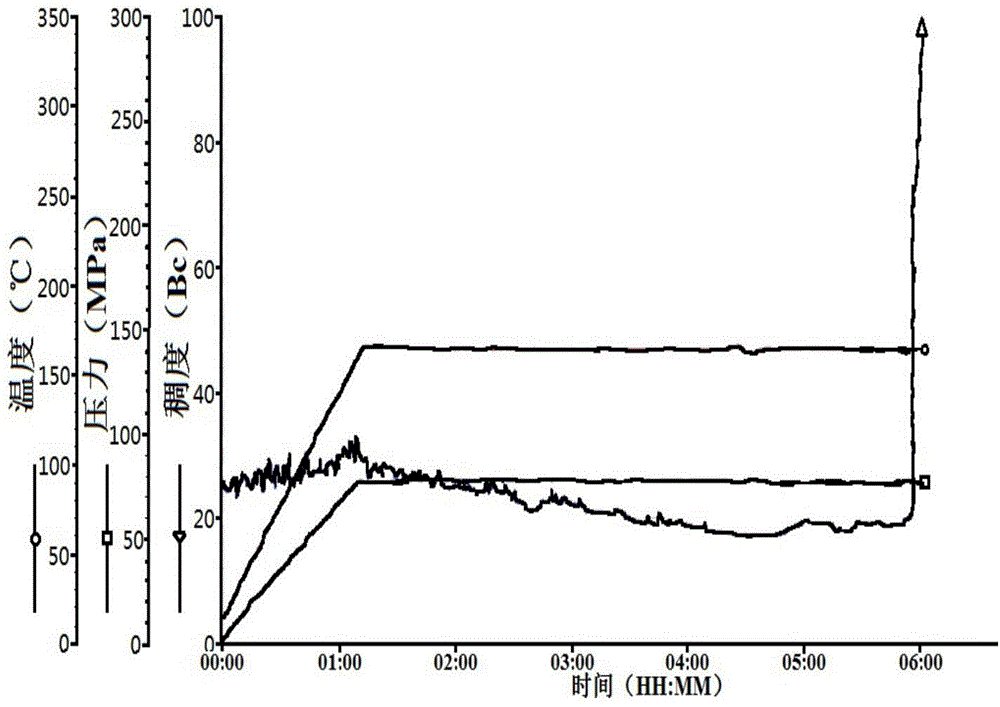

High-temperature-resistant copolymer oil well cement retarder and preparation method thereof

ActiveCN104403056AImprove performanceSolve the problem of severe subsidence at high temperatureDrilling compositionPolymer scienceFumaric acid

The invention relates to a high-temperature-resistant copolymer oil well cement retarder and a preparation method thereof. The preparation method comprises: respectively weighing four polymerization monomers such as 2-acrylamide-2-methylpropanesulfonic acid, diallyldimethylammonium chloride, maleic anhydride or itaconic acid or fumaric acid, and acrylic acid or methacrylic acid according to the mass ratio of 45-80:5-17:7-18:8-20, dissolving the first three monomers in water, then adding sodium polyphosphate and diphenylcarbazide, then successively adding a chain transfer reagent and an initiator, and finally dropwise adding the forth monomer, performing heating reaction and adjusting the pH value, so as to obtain the copolymer retarder. The invention also provides the high-temperature-resistant copolymer oil well cement retarder prepared by the above preparation method. The retarder is resistant to a high temperature up to 230 DEG C and is weak in dispersibility at a high temperature, the cement paste strength develops fast at a low temperature, the addition amount of the retarder has good linear relation with the cement paste hardening time, and the cement paste comprehensive performance is good.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

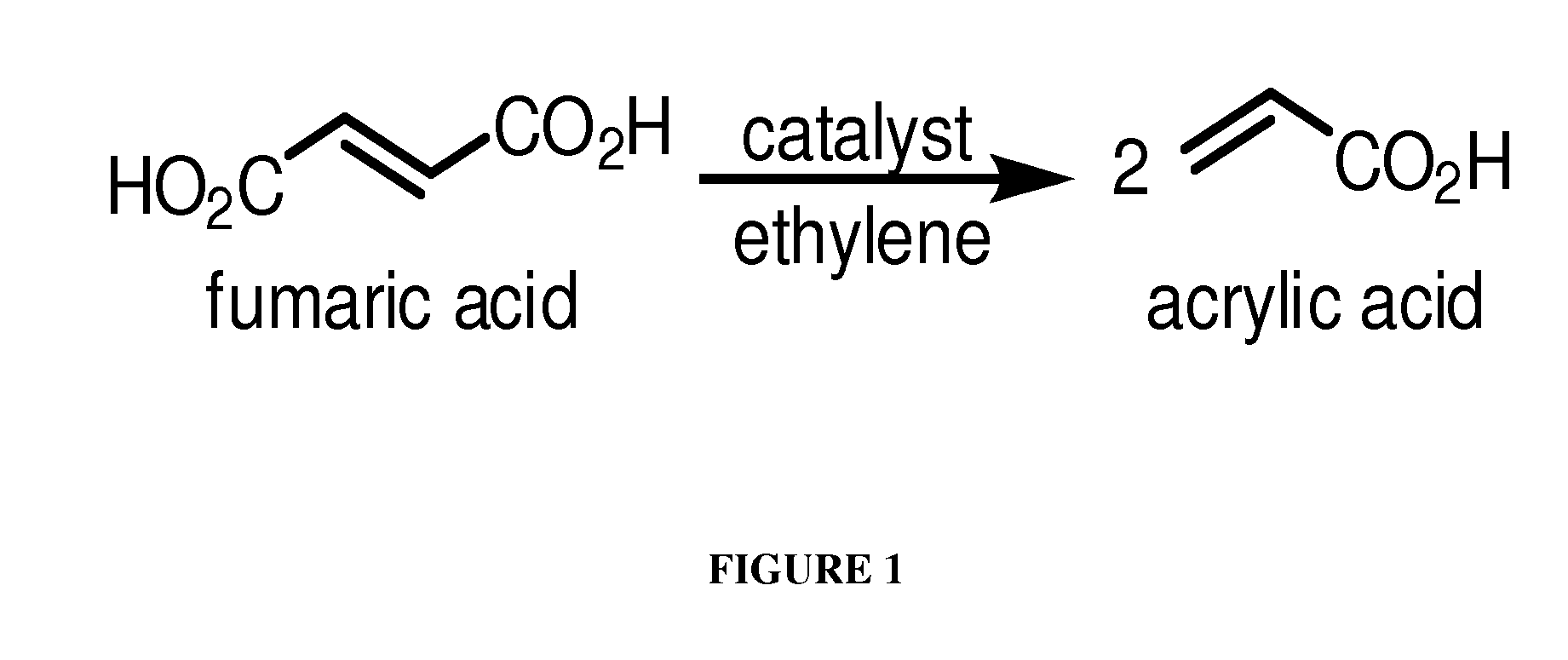

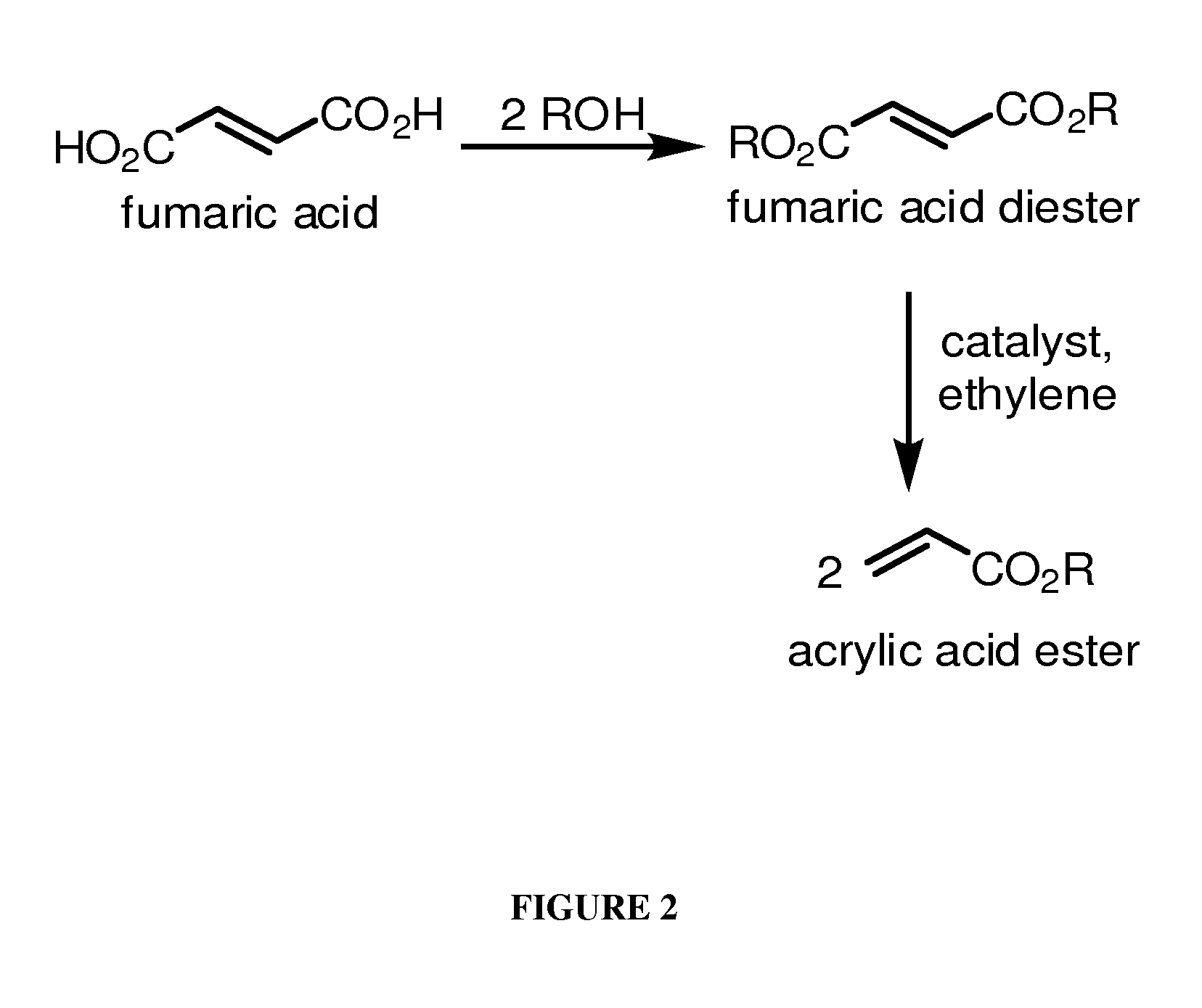

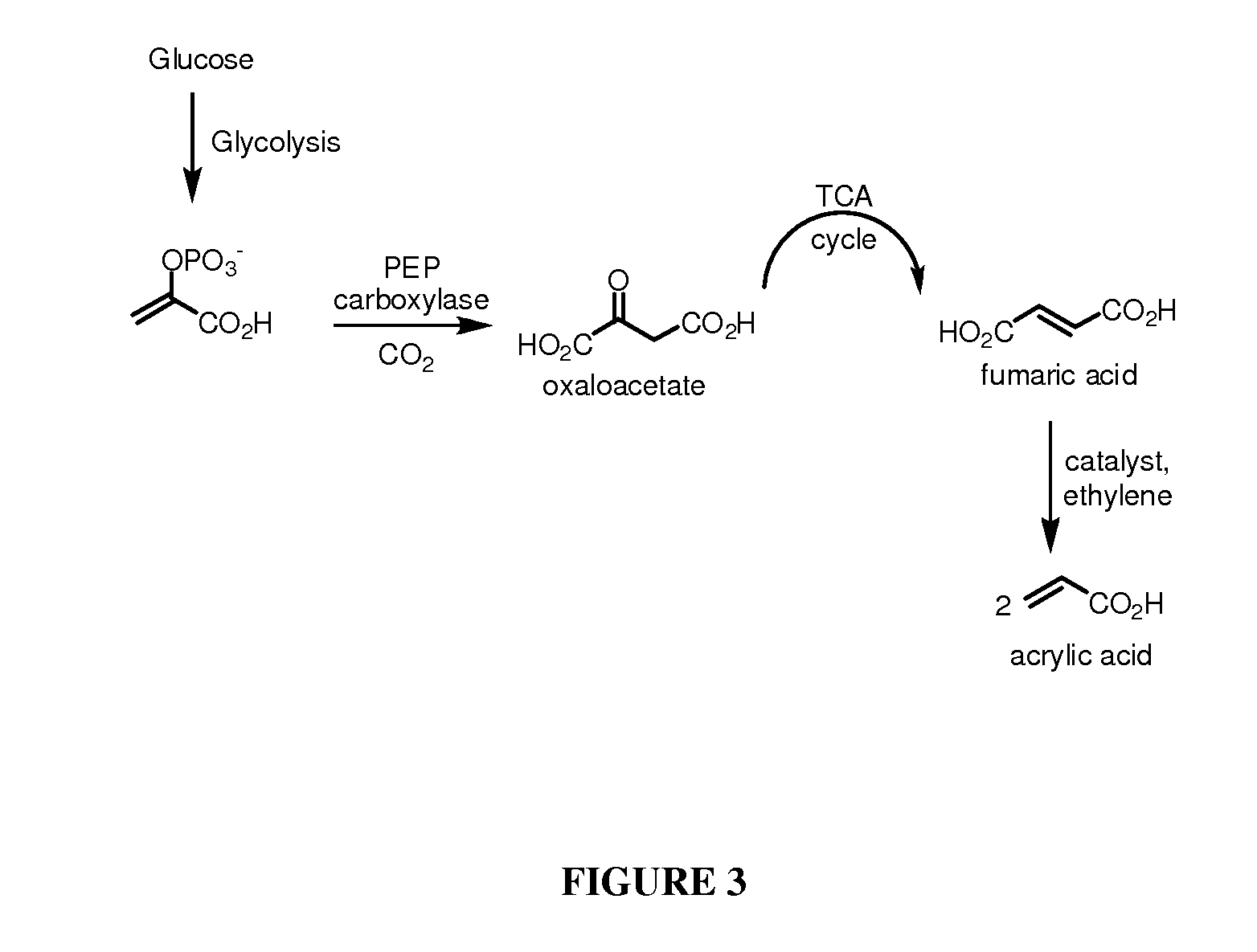

Methods for the synthesis of olefins and derivatives

The invention provides a method of producing acrylic acid. The method includes contacting fumaric acid with a sufficient amount of ethylene in the presence of a cross-metathesis transformation catalyst to produce about two moles of acrylic acid per mole of fumaric acid. Also provided is an acrylate ester. The method includes contacting fumarate diester with a sufficient amount of ethylene in the presence of a cross-metathesis transformation catalyst to produce about two moles of acrylate ester per mole of fumarate diester. An integrated process for process for producing acrylic acid or acrylate ester is provided which couples bioproduction of fumaric acid with metathesis transformation. An acrylic acid and an acrylate ester production also is provided.

Owner:GENOMATICA INC

Pharmaceutical composition comprising one or more fumaric acid esters

InactiveUS20130259906A1Reduce degradationImprove toleranceOrganic active ingredientsBiocideControl releaseFumaric acid

Owner:BIOGEN SWISS MFG GMBH

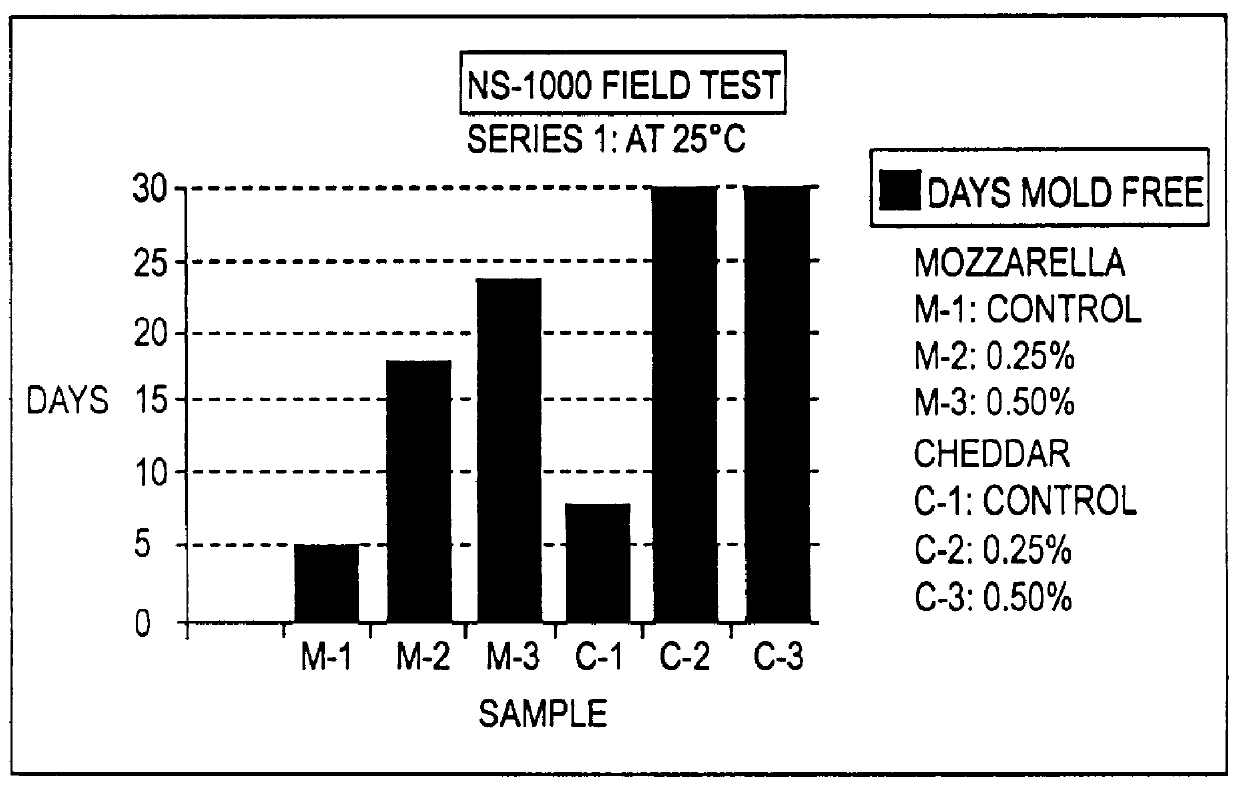

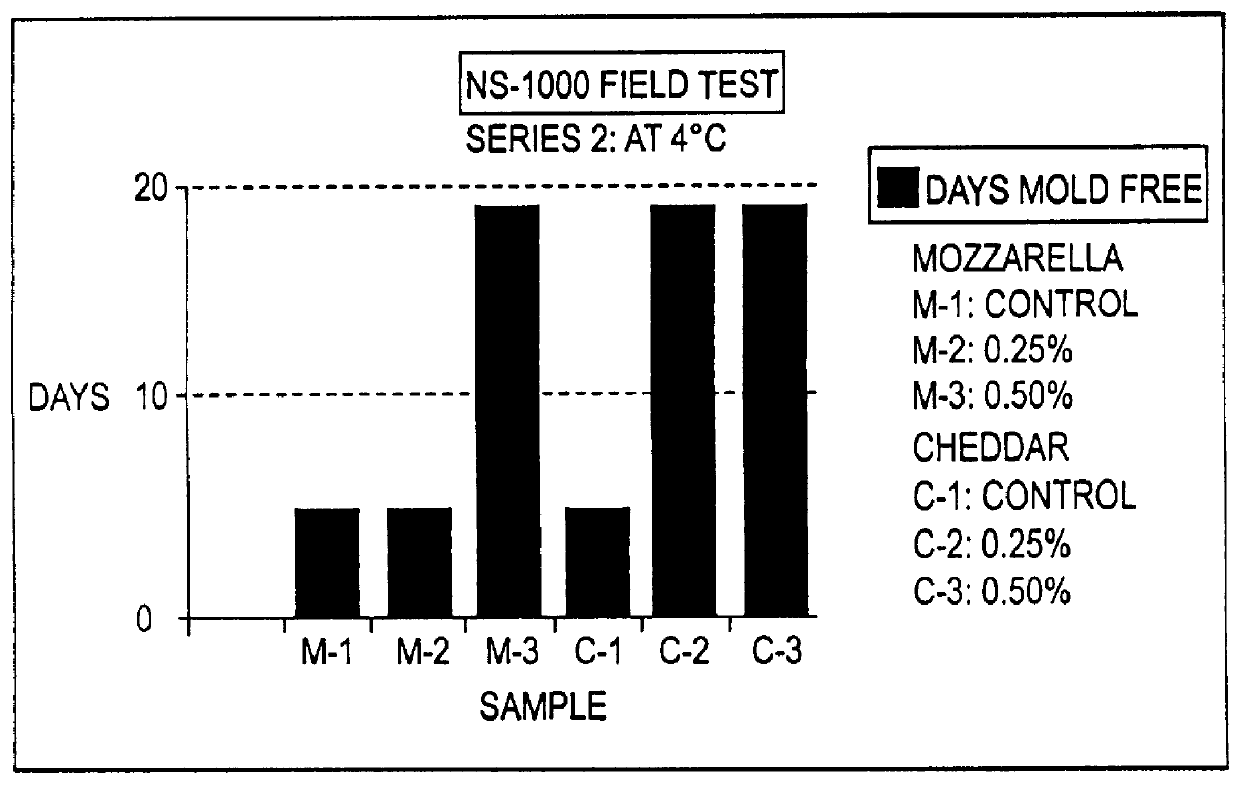

Methods of preparation and using antimicrobial products

InactiveUS6123973AEliminate bad tasteLower decomposition temperatureBiocideDough treatmentPropanoic acidSodium sorbate

Novel antimicrobial products and methods of making and using the same are shown, whereby the products can be used in the same or greater percentages as conventional microbial growth inhibitors without imparting an off-flavor, taste, color or odor to the products in which they are used. The antimicrobial products are formed by reacting azodicarbonamide or an ammonia gas with a compound selected from the group consisting of benzoic acid, sodium benzoate, calcium benzoate, potassium benzoate, acetic acid, sodium diacetate, paraben, niacin, calcium acetate, calcium diacetate, citric acid, lactic acid, fumaric acid, sorbic acid, sodium sorbate, calcium sorbate, potassium sorbate, propionic acid, sodium propionate, calcium propionate, potassium propionate and mixtures thereof. In one embodiment, the product is prepared by placing a layer of azodicarbonamide on a substrate and covering the layer with a gas permeable separator. The antimicrobial compound is then added on top of the separator, and the combination is heated to form the final product. In another embodiment, the product is prepared by exposing the antimicrobial compound to an ammonia gas. The ammonia gas reacts with free acids in the antimicrobial compound to convert the free acids into ammonium salts, thereby eliminating off-flavor and off-odor of the resulting antimicrobial product. The antimicrobial products prepared according to the present invention are suitable for use in foodstuffs, sanitation products, cosmetics, pharmaceuticals, and so forth.

Owner:TILLIN

Composition for prevention or treatment of an alcohol hangover

InactiveUS20050271754A1Relieve symptomsLittle and no toxicityBiocideDipeptide ingredientsNutritionSuccinic acid

The present invention represents a formulation and method for preventing or reducing the effects of veisalgia or alcohol “hangover.” More particularly, the present invention relates to a treatment which provides nutritional requirements in the form of L-glutamine, L-cysteine, fumaric acid, succinic acid, young barley grass juice powder, vitamin B-12, vitamin B-1, calcium ascorbate, and dextrose. The composition may be ingested before, before and during, or after consumption of ethyl alcohol. The composition of the present invention is made available in several forms including, but not limited to, capsule, tablet or liquid form suitable for administration for amelioration of alcohol induced hangover symptoms. This treatment enables rapid relief of symptoms in affected individuals by slowing or reducing the conversion of ethanol into acetaldehyde, a toxic substance resulting from alcohol metabolism. Additionally, the present invention also incorporates nutritional elements which are directed toward assisting in the conversion of acetaldehyde into acetic acid and the oxidative processes in the mitochondria responsible for decomposition of acetaldehyde.

Owner:CHEERZ USA

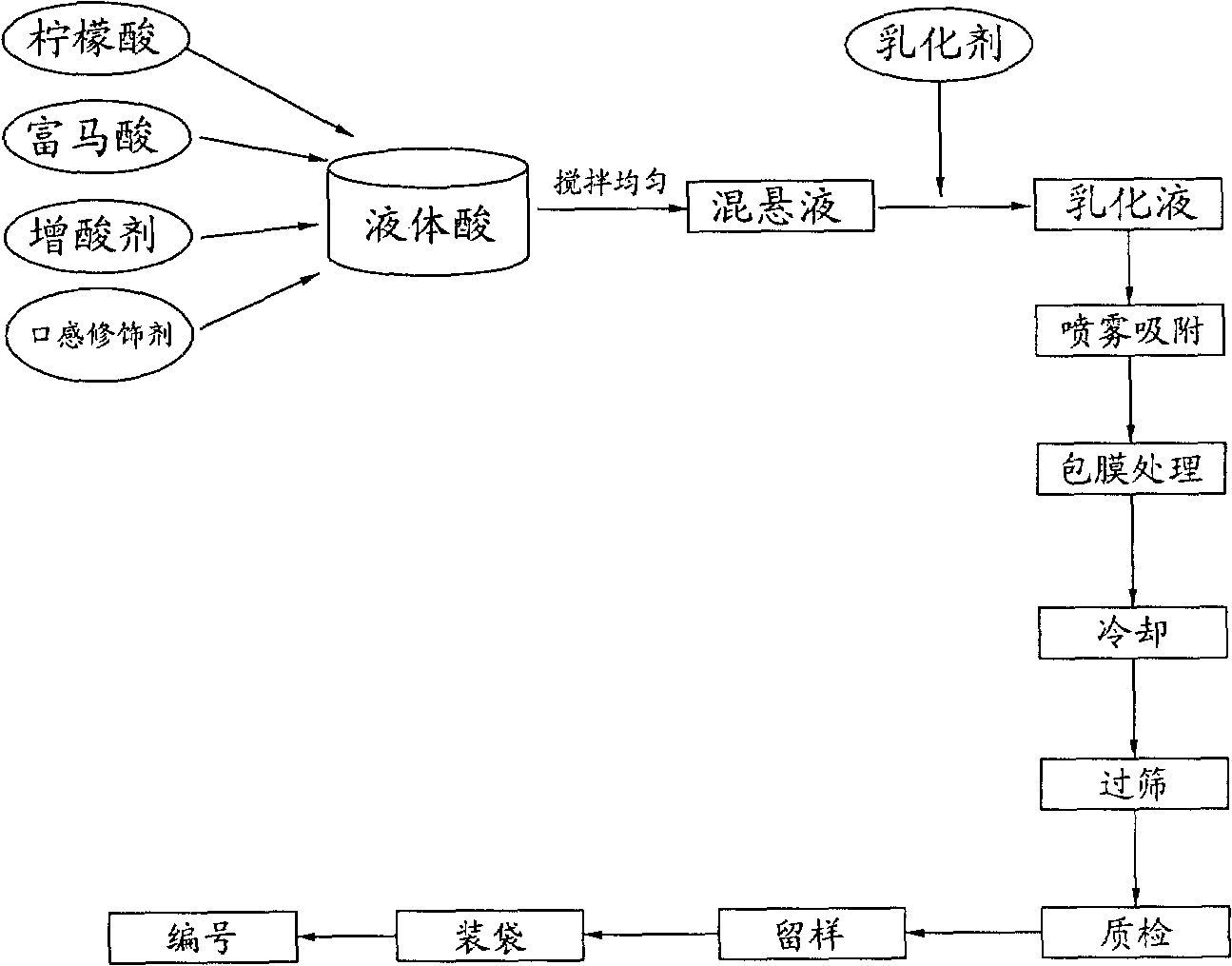

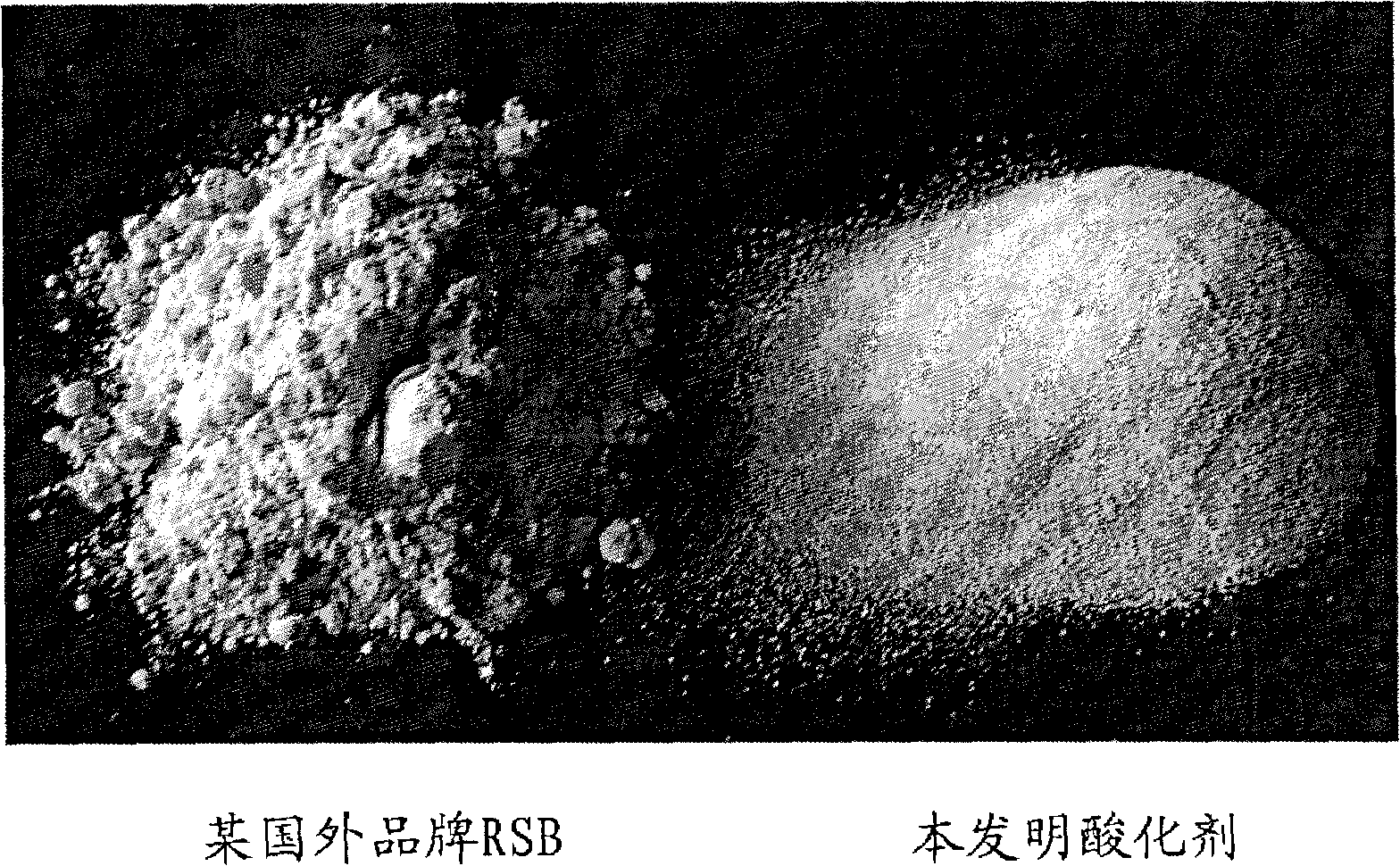

Feeding acidifier prepared by emulsifying technology and preparing method thereof

ActiveCN101513222AFully dispersedFully emulsifiedAnimal feeding stuffAccessory food factorsPhosphoric acidMoisture absorption

The present invention relates to a feeding acidifier prepared by emulsifying technology and a preparing method thereof. The invention belongs to the technical field of animal feed additive preparing. The feeding acidifier comprises the following components according to content: 8-20 parts of lemon acid; 5-20 parts of fumaric acid; 10-15 parts of phosphoric acid; 5-20 parts of malic acid; 15-25 parts of lactic acid; 6-15 parts of formic acid; 2-10 parts of acetic acid; 2-5 parts of mouthfeel modifying agent; and 3-5 parts of silicon dioxide. The invention provides a novel preparation form of acidifier and combines the physical and chemical properties of shaping material for developing the novel producing technique of acidifier according to the sustained-release control principle. The feeding acidifier prepared according to the emulsifying technique of the invention effectively settles the problem of stomach digesting of acidifier and the effect directly gets to the intestinal canal. The feeding acidifier prepared by emulsifying technology according to the invention has the advantages of reliable safety, excellent free-running property, strong moisture absorption resistance, convenient processing, growth promotion, diarrhea prevention, etc.

Owner:MYRON XIAMEN BIOTECH

Article comprising ionomer and polyamide

InactiveUS20090298372A1Synthetic resin layered productsCellulosic plastic layered productsPolyamideCarboxylic acid

A multilayer structure comprises a surface layer, a substrate, and optionally additional layers wherein the surface layer comprises or is produced from a blend comprising an ionomer and a polyamide; the ionomer is or must be derived from at least three repeat units derived from ethylene, an α,β-unsaturated C3-C8 carboxylic acid, and a dicarboxylic acid or its derivative; and the dicarboxylic acid or its derivative is maleic acid, fumaric acid, itaconic acid, maleic anhydride, fumaric anhydride, itaconic anhydride, maleic acid monoester, fumaric acid monoester, itaconic acid monoester, or combinations of two or more thereof.

Owner:PERFORMANCE MATERIALS NA INC

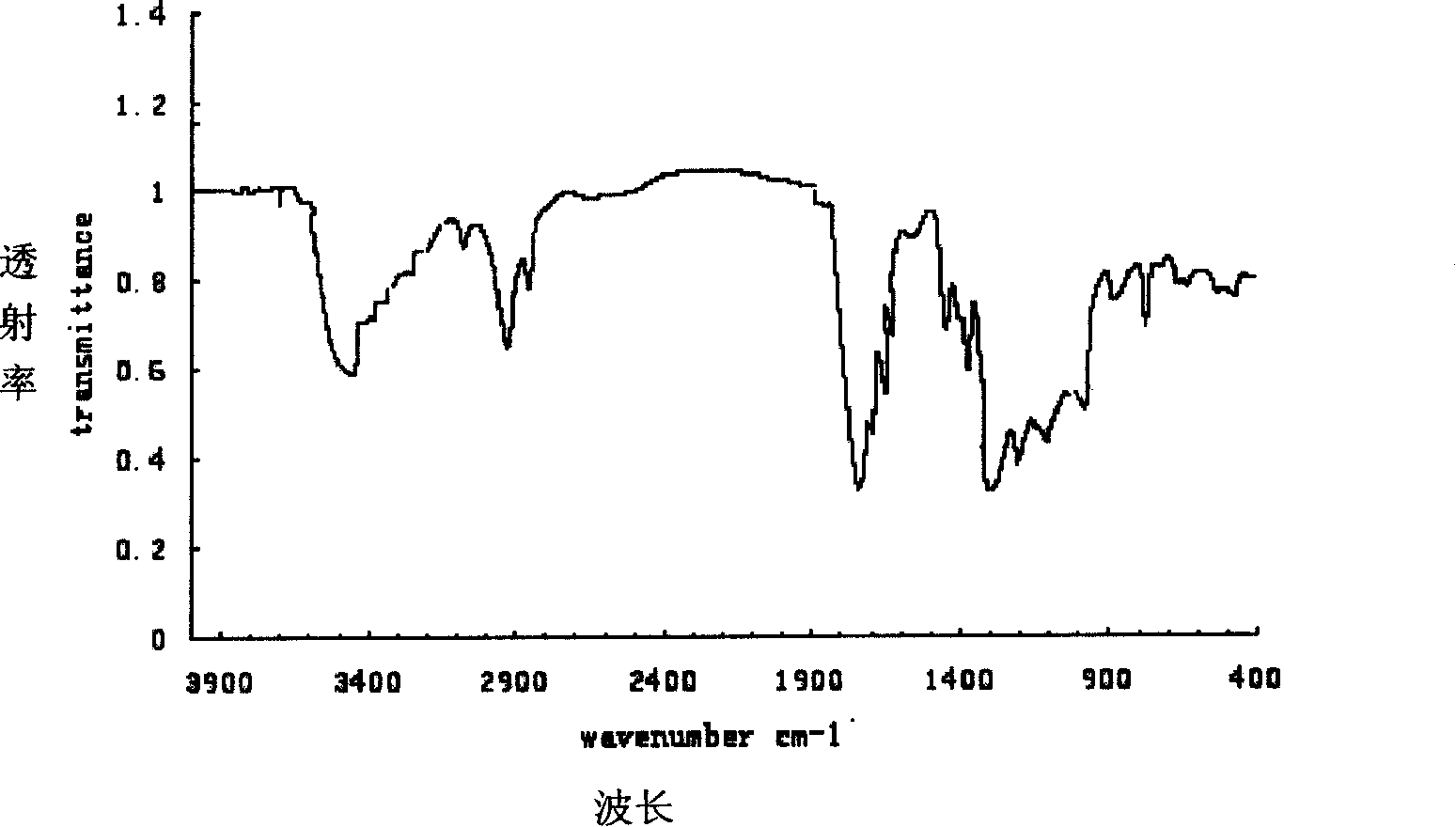

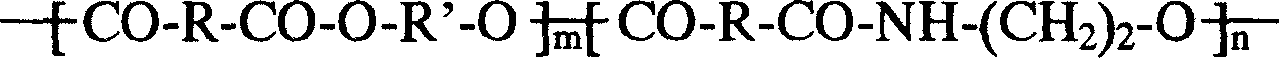

Degradable unsaturated polyesteramide resin and synthesis method thereof

The invention adopts a melt polycondensation method. A few of monomers of C2-5 aliphatic dibasic alcohol, diethylene glycol, polyglycol, fumaric acid, maleic anhydride, lactic acid, glycolic acid, ethanolamine, C2 to C12 aliphatic diamine, glutamic acid, lysine, glycine, etc. are taken as basic materials to be synthesized to obtain non toxic unsaturated polyester-amide resin with adjustable degradation rate and lower cost; wherein, the partial fumaric acid or maleic anhydride can be replaced with phthalic anhydride, isophthalic acid, or adipic acid. The resin yearns for being used as matrix resin of medical bone internal fixation material, tissue engineering scaffold material, bone tissue temporary substitutes, environmental protection type bonding agent, environmental protection type fiberglass reinforced plastics, environmental protection type coating material, disposable tableware, packing material, shopping bags, disposable bags, drug coating or capsule, drug delivery (controlled-release) material, agricultural mulching films, etc., and can be recovered to be utilized.

Owner:HUNAN UNIV

Pharmaceutical composition containing dabigatran etexilate or salt and hydrate thereof

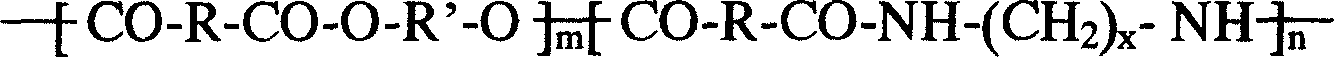

ActiveCN103127109AImprove solubilityHigh dissolution rateOrganic active ingredientsCapsule deliverySolubilityDissolution

The invention discloses a pharmaceutical composition containing dabigatran etexilate or salt and hydrate of the dabigatran etexilate. The pharmaceutical composition comprises an active substance pill core material containing the dabigatran etexilate or its pharmaceutically acceptable salt or hydrate and a filling agent and / or a bonding agent,and an organic acid or an organic acid material layer, the organic acid is arranged outside the active substance pill core materials, the organic acid material layer contains the organic acid, and the organic acid is selected from tartaric acid, succinic acid, citric acid, glutamic acid, fumaric acid, malic acid, aspartic acid or their hydrates or salts. After screening, the dabigatran etexilate active substance is prepared into a pill core, the organic acid material layer is added in an integrated mode, and meanwhile, an isolated layer is applied between the dabigatran etexilate active substance pill core and the organic acid material layer. The prepared dabigatran etexilate oral drugs composition has the advantages that solubility and dissolution rate are good, and bioavailability effect is prominent.

Owner:NANJING HUAWE MEDICINE TECH DEV

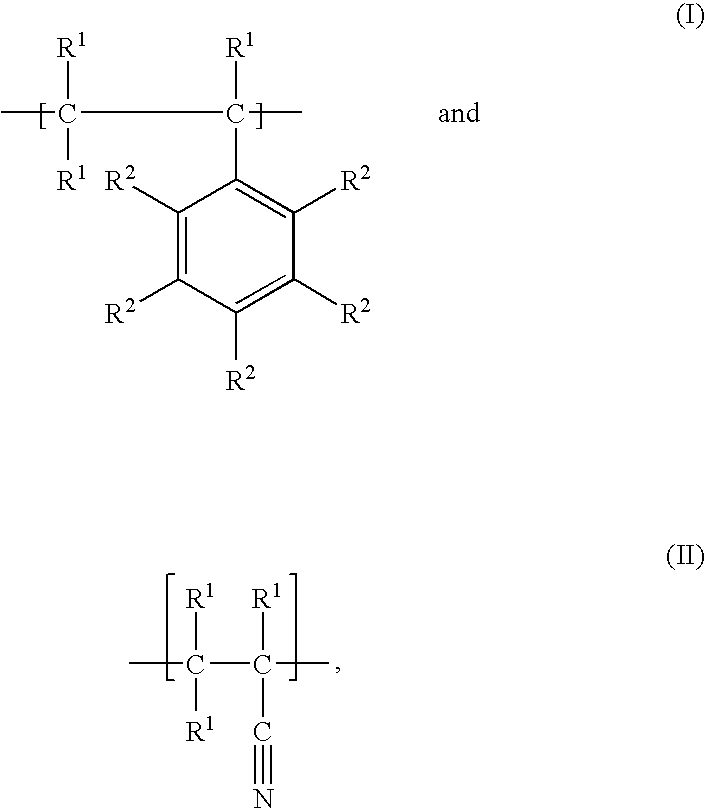

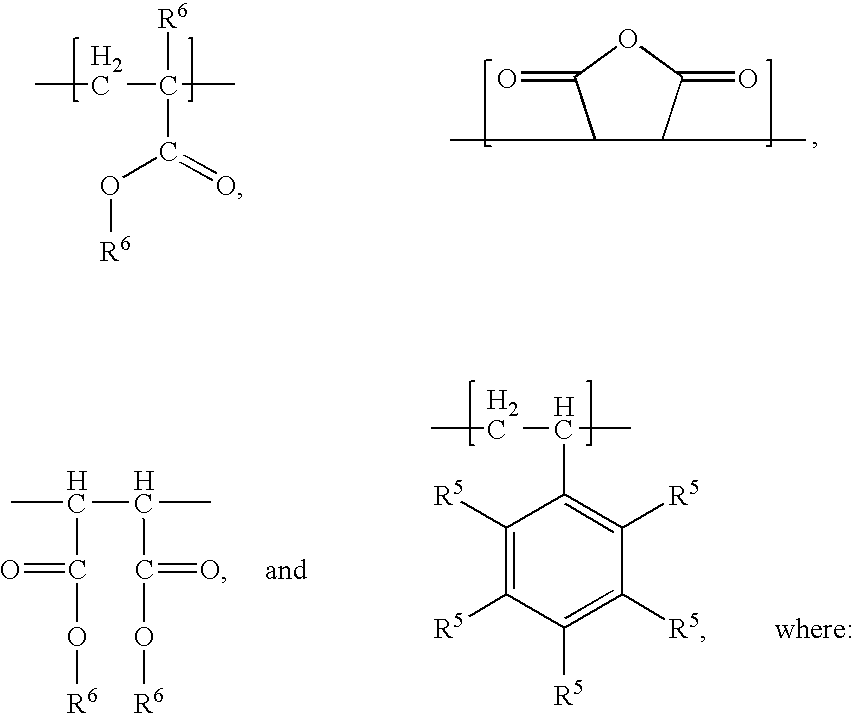

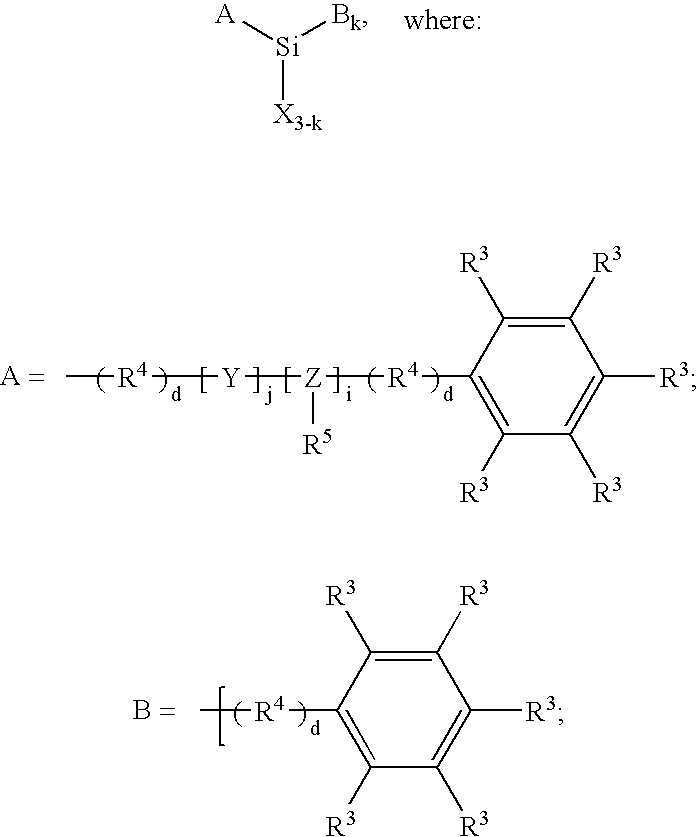

Spin-on protective coatings for wet-etch processing of microelectronic substrates

ActiveUS20050158538A1Easy to disassembleProtection formSynthetic resin layered productsSemiconductor/solid-state device manufacturingMethacrylateSilane compounds

New protective coating layers for use in wet etch processes during the production of semiconductor and MEMS devices are provided. The layers include a primer layer, a first protective layer, and an optional second protective layer. The primer layer preferably comprises an organo silane compound in a solvent system. The first protective layer includes thermoplastic copolymers prepared from styrene, acrylonitrile, and optionally other addition-polymerizable monomers such as (meth)acrylate monomers, vinylbenzyl chloride, and diesters of maleic acid or fumaric acid. The second protective layer comprises a highly halogenated polymer such as a chlorinated polymer which may or may not be crosslinked upon heating.

Owner:BREWER SCI

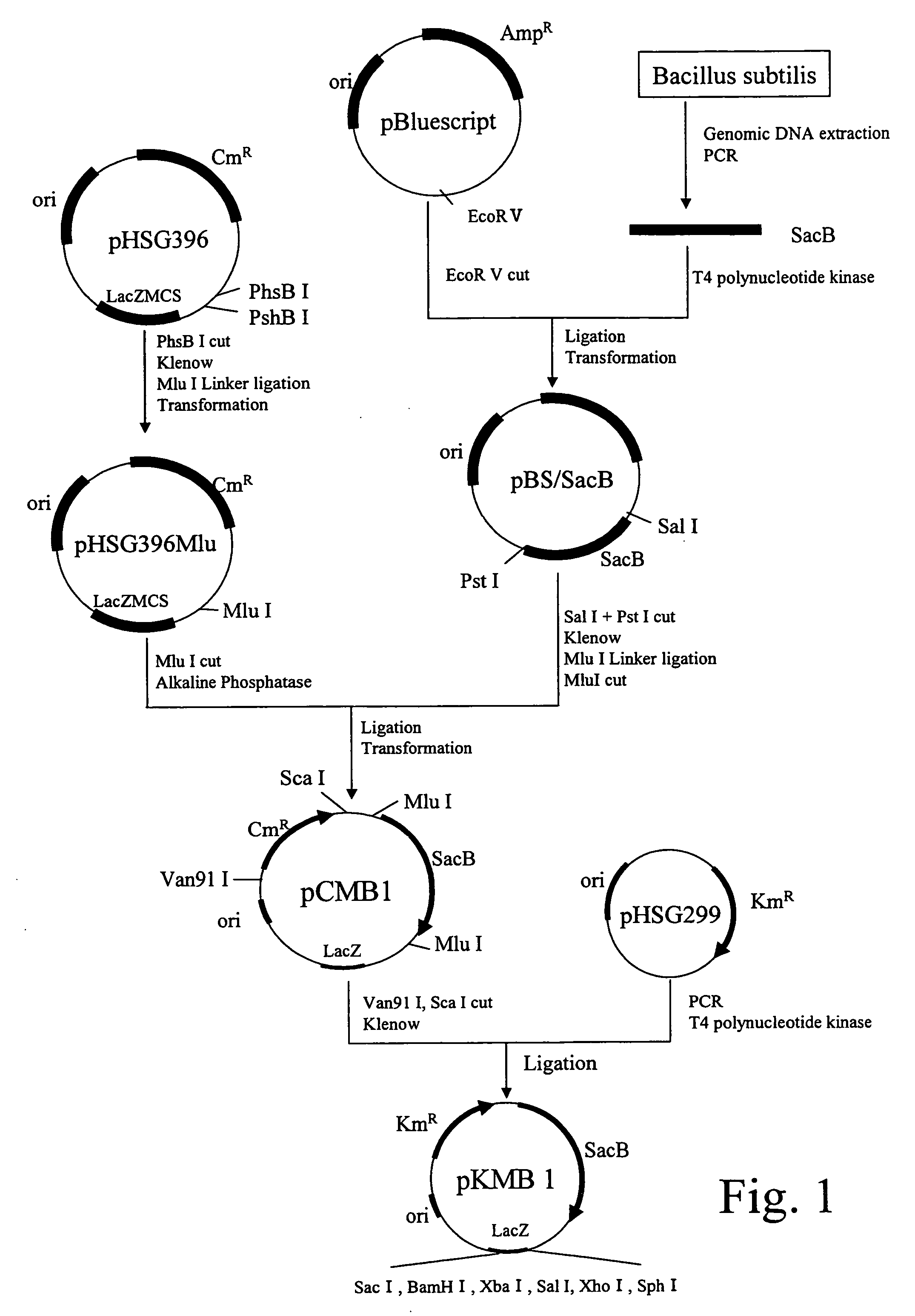

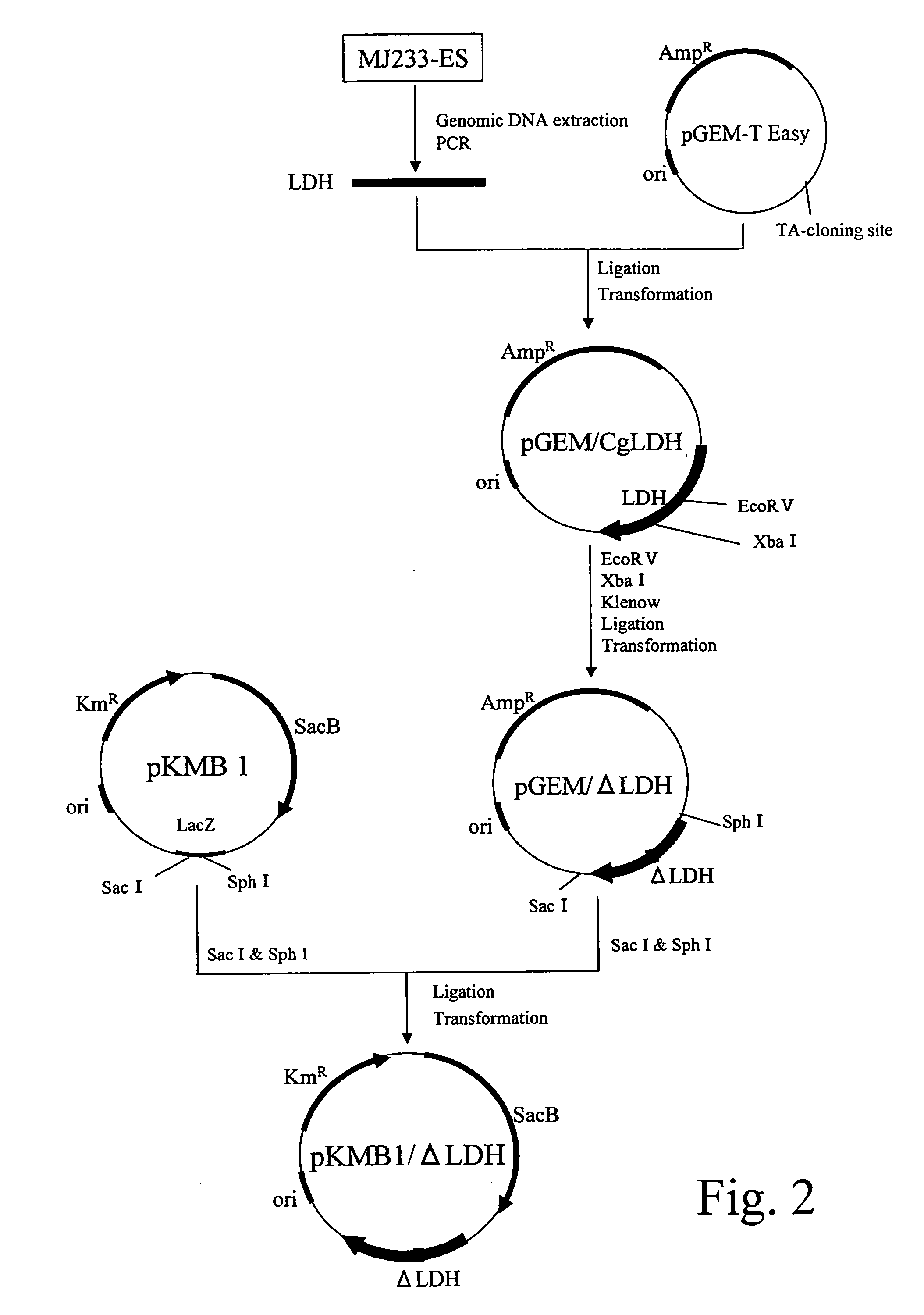

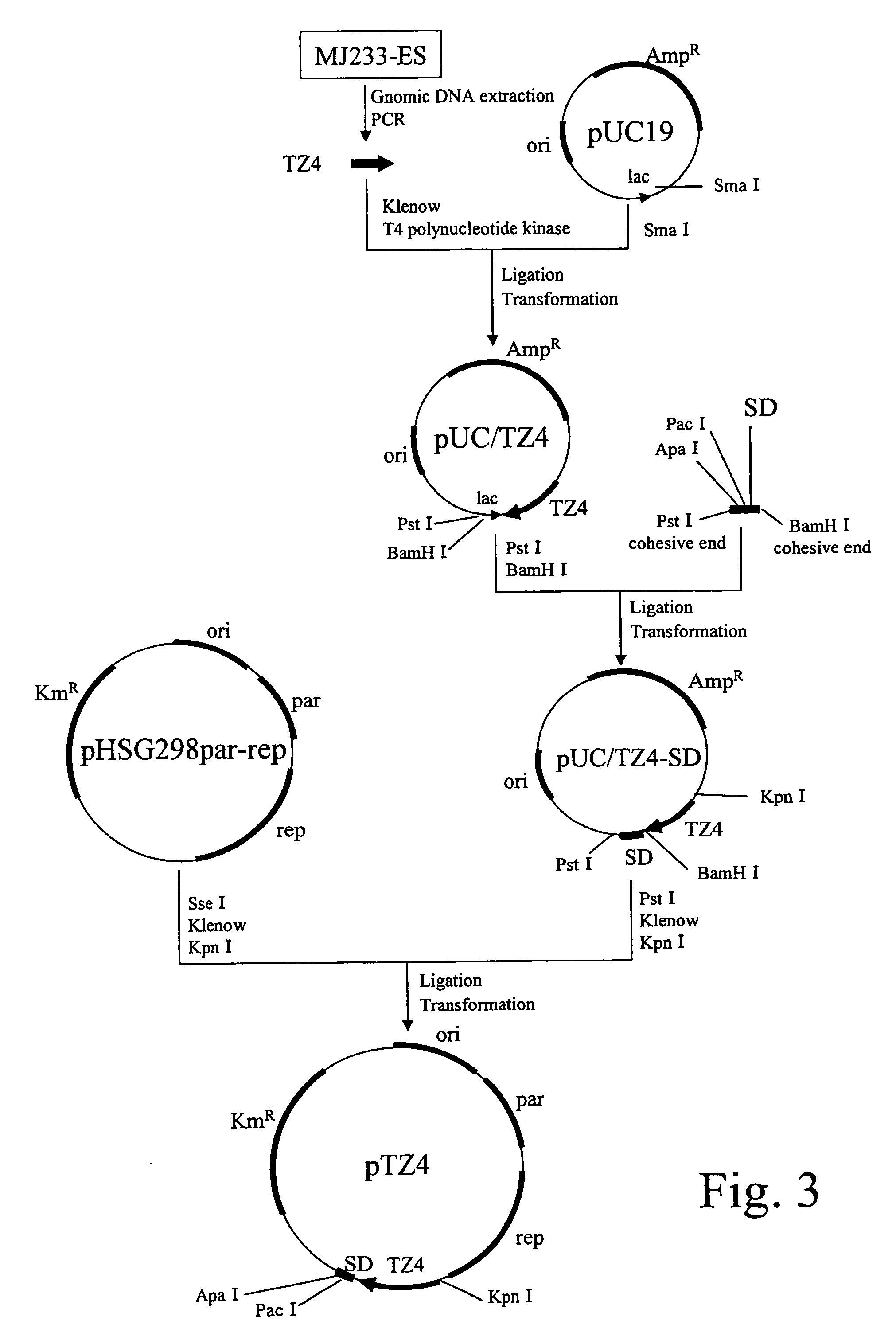

Process for producing succinic acid

ActiveUS20060205048A1Improve productivityProducing succinicBacteriaSugar derivativesPyruvate carboxylaseLactate dehydrogenase

Succinic acid is produced by allowing a bacterium modified to enhance fumarate reductase activity or cell preparation thereof to react with an organic raw material in a reaction solution containing one of a carbonate ion, a bicarbonate ion, and carbon dioxide gas to generate succinic acid. More preferably, succinic acid is produced by allowing a bacterium modified to enhance activities of fumarate reductase and pyruvate carboxylase and decrease lactate dehydrogenase activity or cell preparation thereof to react with an organic raw material in a reaction solution containing one of a carbonate ion, a bicarbonate ion, and carbon dioxide gas to generate succinic acid. Succinic acid is obtained by collecting the produced succinic acid.

Owner:AJINOMOTO CO INC

Fumaric acid producing strain and its mutagenesis screening method and application

InactiveCN101100645ANutritional Requirements SimpleFungiMutant preparationSubmerged fermentationScreening method

A (Rhizopus Oryzae)ME-F11, its mutation screening method and method for fermenting fumaric acid are disclosed. The preserving code is CCTCC NO: M 207066. The fumaric acid concentration reaches to 90-120g / L, total yield reaches to 90-95 wt% . It's simple and can be used for industrial production.

Owner:NANJING UNIV OF TECH

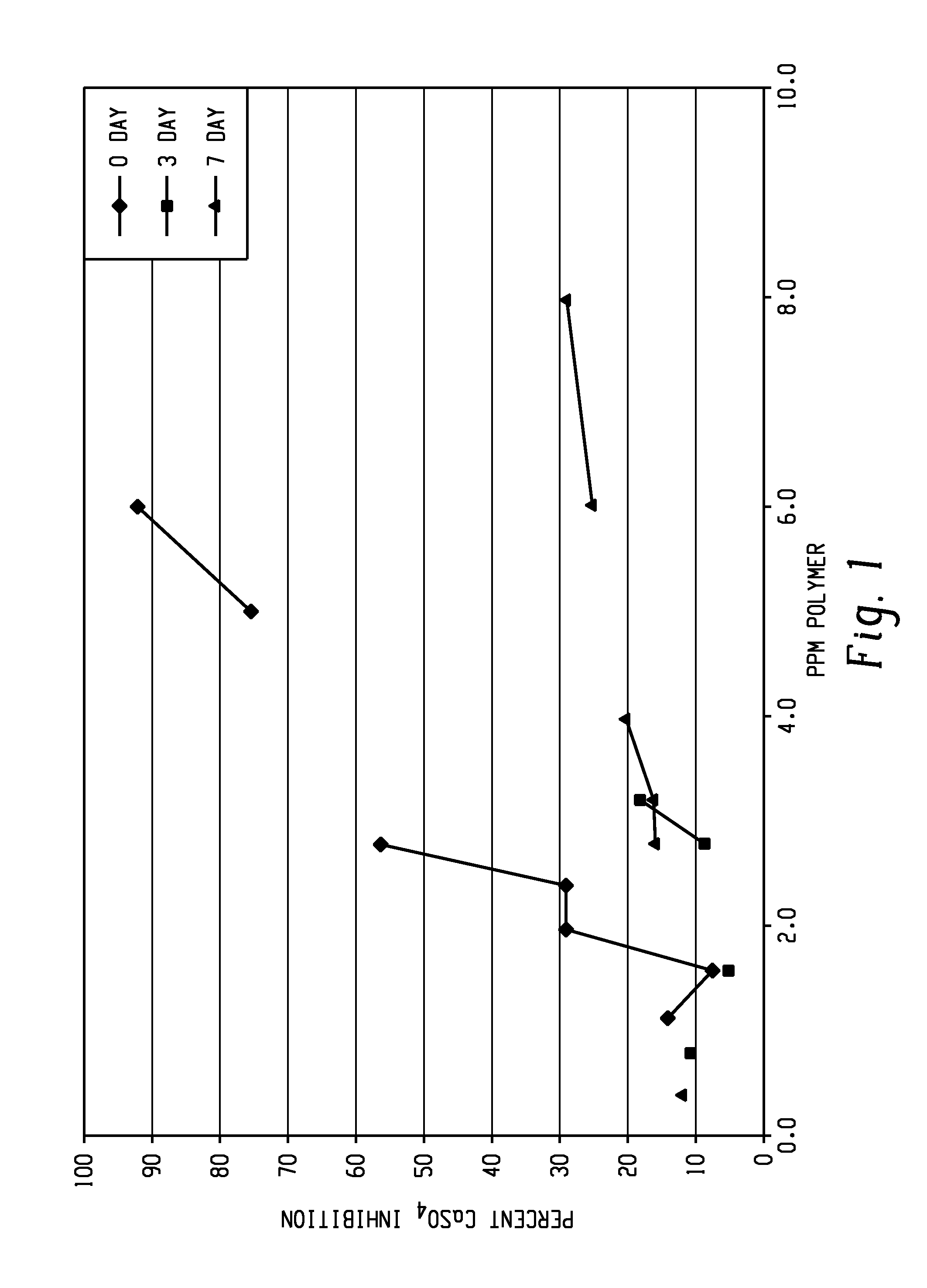

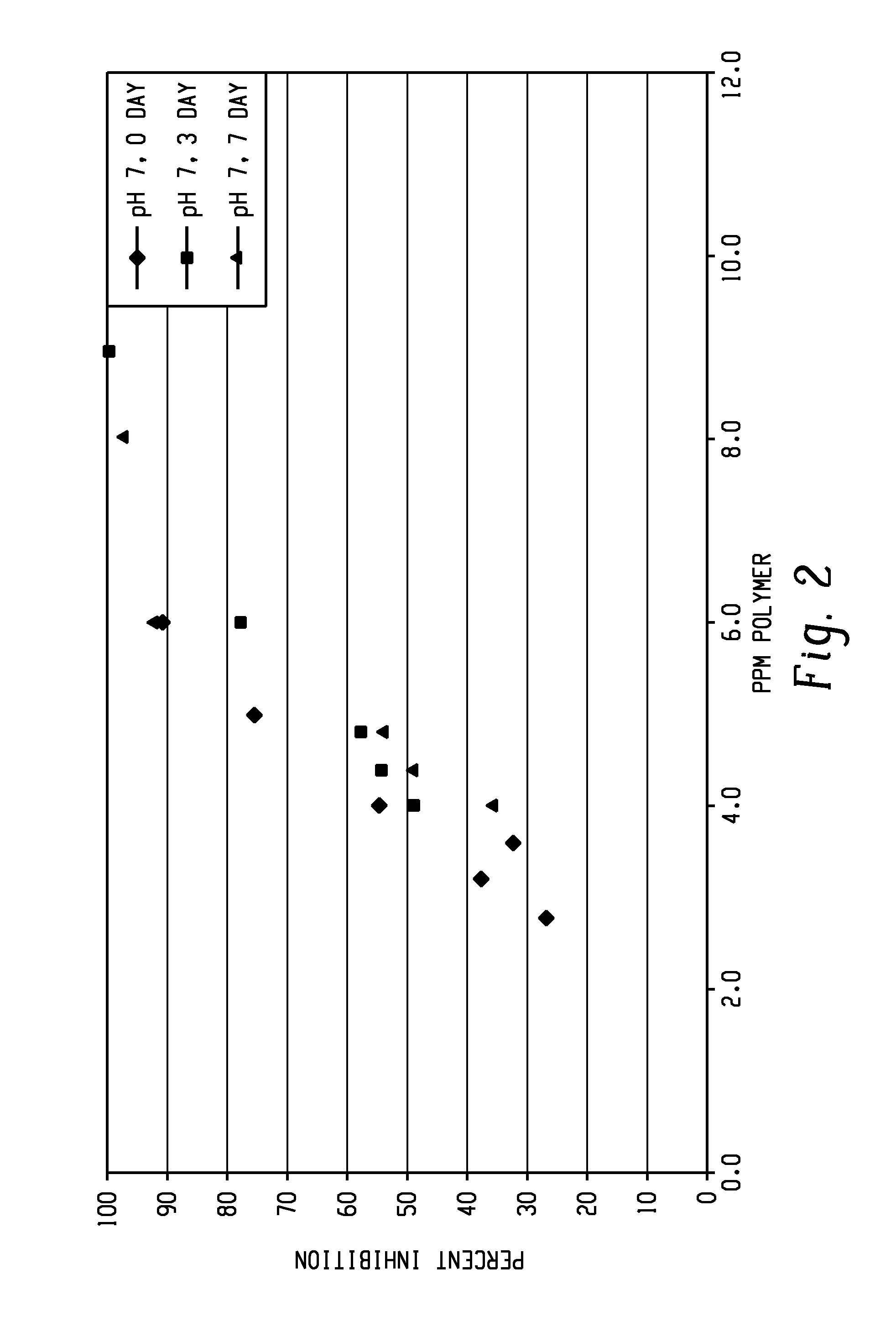

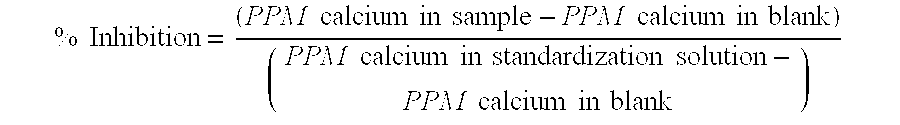

Thermally Stable Scale Inhibitor Compositions

InactiveUS20120118575A1Prevent scalingEasy to understandWaste water treatment from quariesWater treatment parameter controlVinylsulfonic acidMaleic anhydride

Methods for scale inhibition treatment of oil or gas production wells generally include injecting a scale inhibition composition into the oil or gas production well, wherein the scale inhibition composition comprises one or more polymers, each polymer comprising recurring units of a first monomer and a second monomer, wherein: (i) the first monomer is selected from maleic acid, maleic anhydride, fumaric acid, acrylic acid, salts thereof, or combinations thereof; and (ii) the second monomer is selected from vinyl sulfonic acid, allyl sulfonic acid, methallylsulfonic acid, salts thereof, or combinations thereof; wherein the concentration of the polymers in the composition is about 10 to about 60 percent of the polymers by weight of the composition; and wherein the composition has a pH of about 7 to about 8.5.

Owner:KEMIRA OY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com