Patents

Literature

229results about How to "Fast polymerization rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

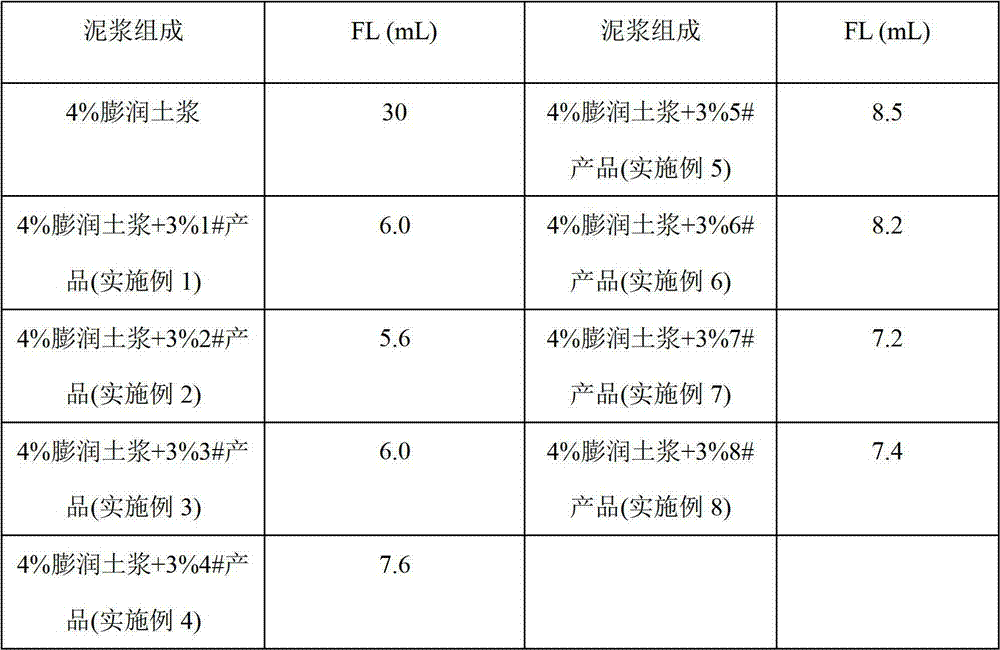

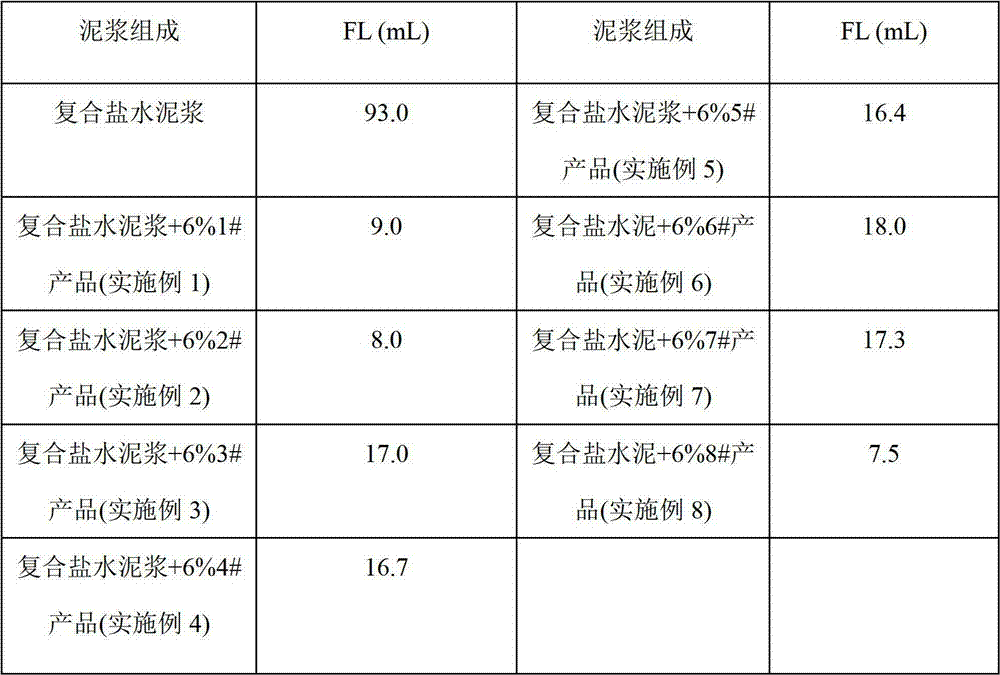

Synthesis method of drilling fluid filtrate reducer

InactiveCN101805595ANo pollution in the processFast polymerization rateDrilling compositionSynthesis methodsOil phase

The invention relates to a synthesis method of drilling fluid filtrate reducer. The method comprises: a, nonionic compound emulsifying agent is dissolved in oil and oil phase is made up; a first monomer chosen from fumaric acid, maleic acid, itaconic acid or crylic acid, a second monomer chosen from N, N- dimethylacrylamide, N, N-diethylacrylamide or acrylamide and a third monomer chosen from 4-vinylbenzenesulfonic acid sodium salt, sodium allylsulfonate, 3-allyloxy-2-dydroxy-1-sodium allylsulfonate, 2- methacryloxypropyl-2-methyl propanesulfonic acid, 2-acrylamido-2-methyl propanesulfonic acid or SMAS are dissolved in water with the molar ratio of 1:1 to 5:1 to 5, the pH value of the solution is adjusted to be between 8 and 11, evocating agent is added and water phase solution is made up; and b, the water solution is added to the oil phase solution and the temperature rises to 40 to 70 DEG C for polymerization. The method of the invention has the advantages of fast polymerization speed, high outcome molecular weight and high outcome stability, good filtrate reducing performance, high temperature resistance and high salt resistant performance.

Owner:BEIJING UNIV OF CHEM TECH

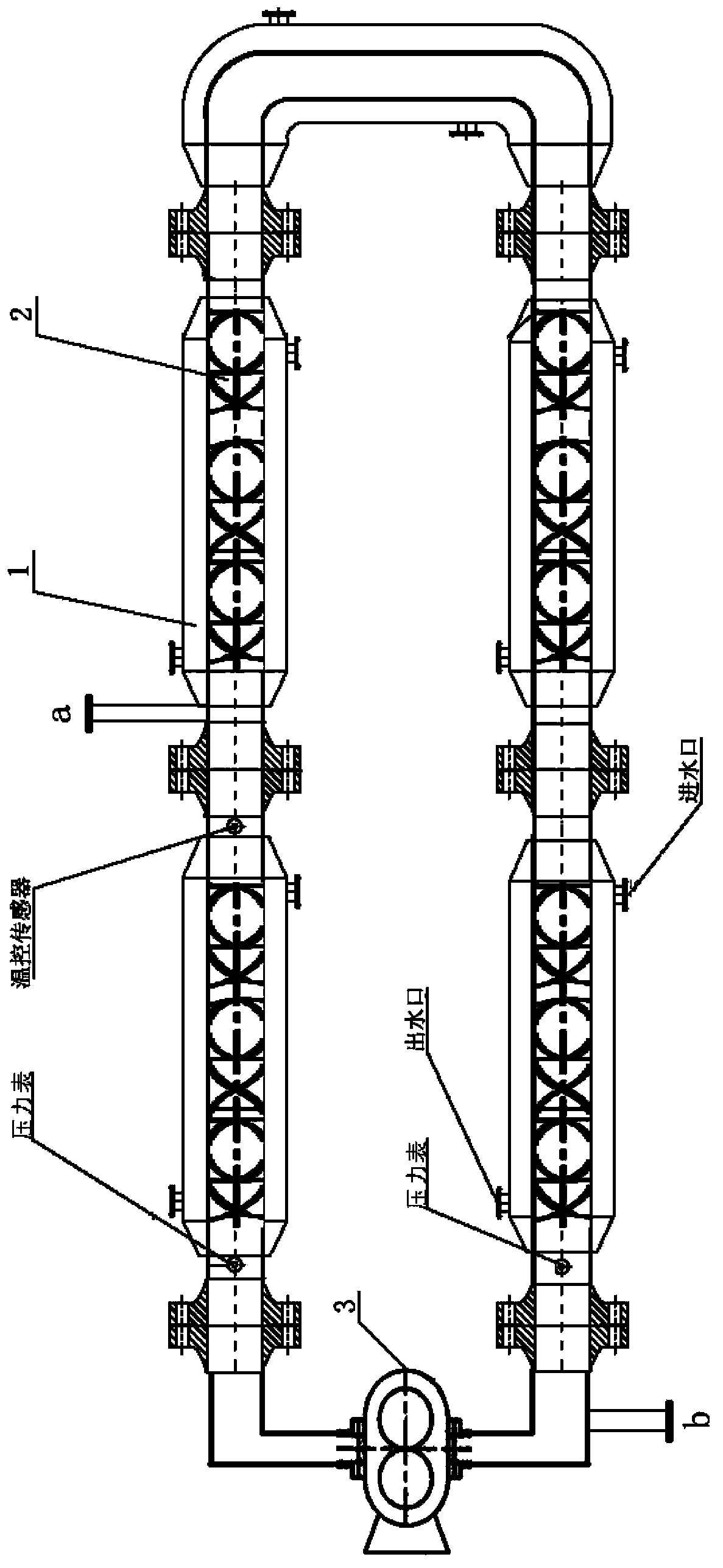

Method for preparing super-high molecular weight polyacrylonitrile-base carbon fiber spinning primary fluid

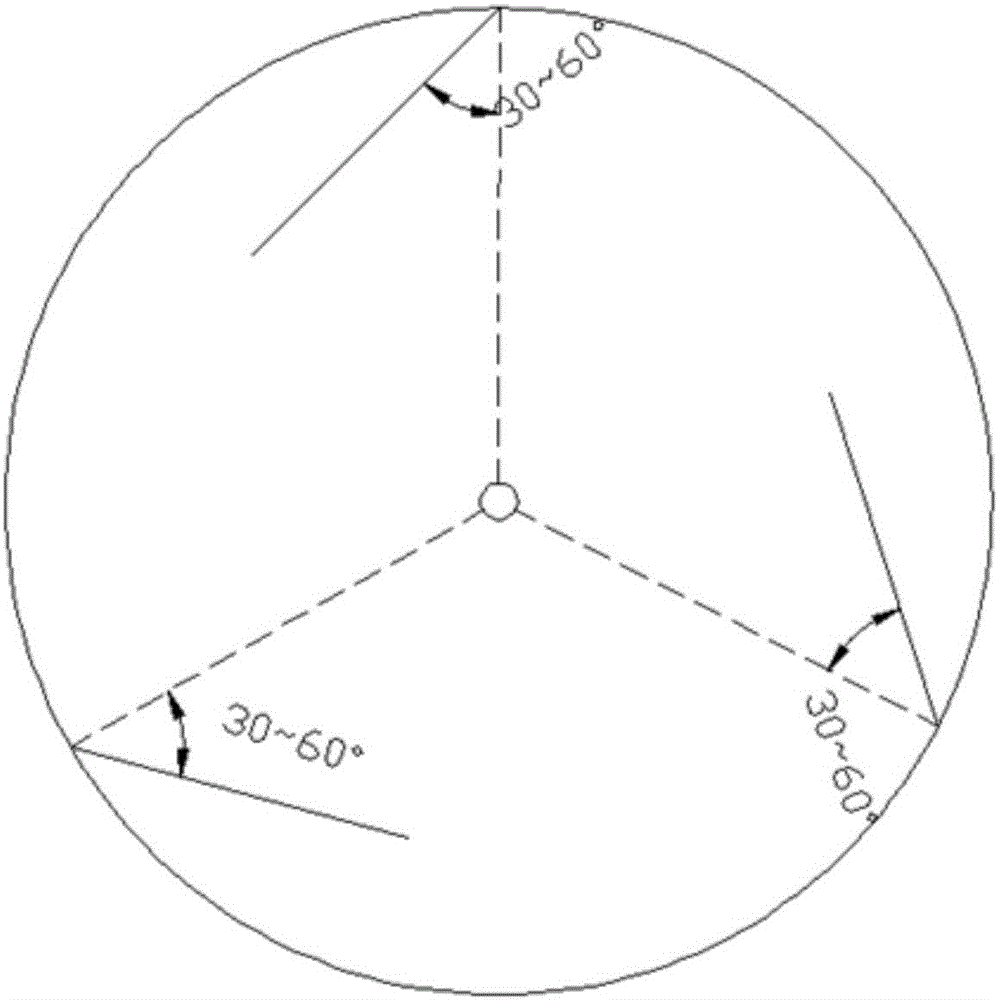

InactiveCN101260172AStir wellImprove heat transfer performanceFibre chemical featuresPolymer scienceNitrogen

Owner:INST OF CHEM CHINESE ACAD OF SCI

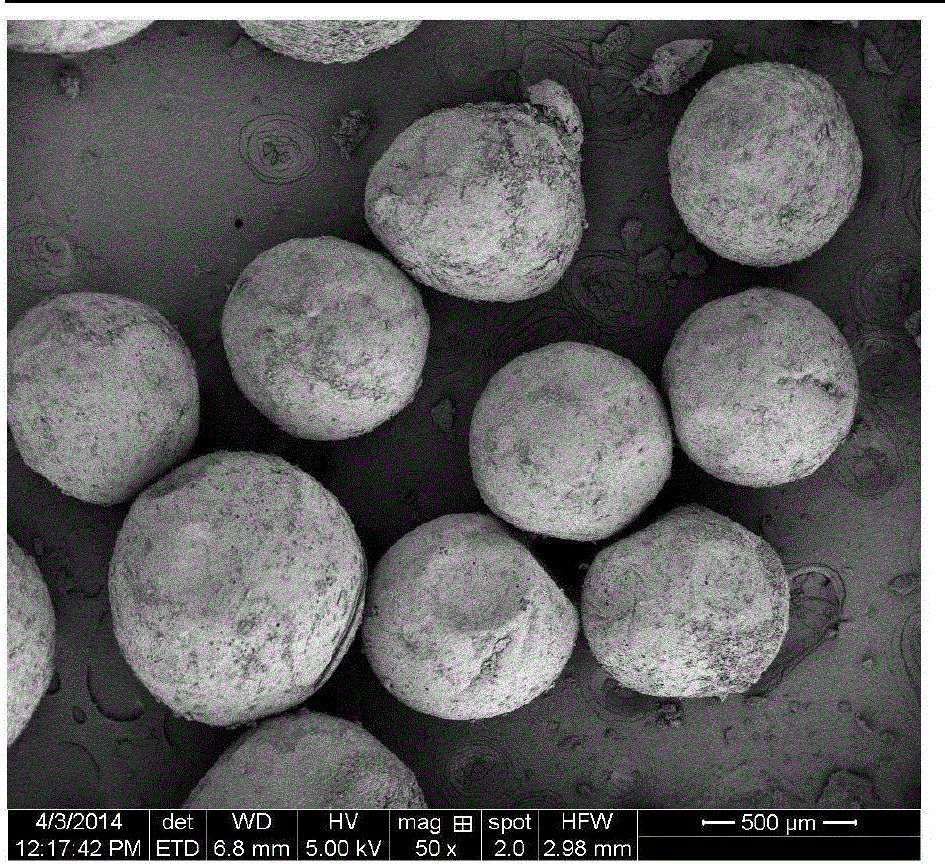

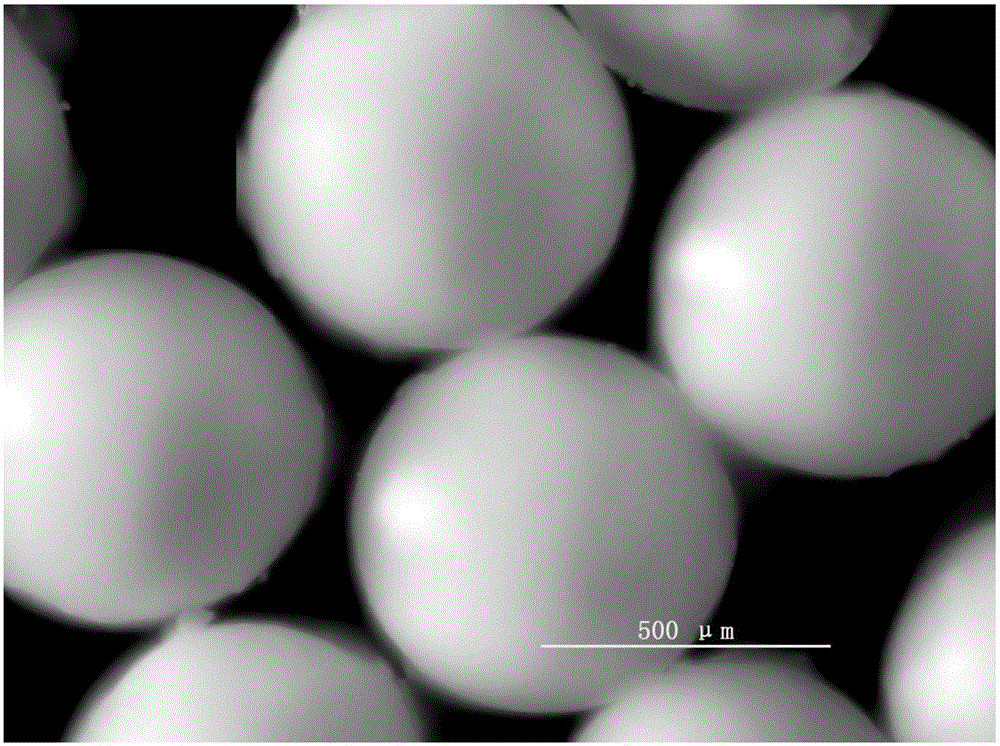

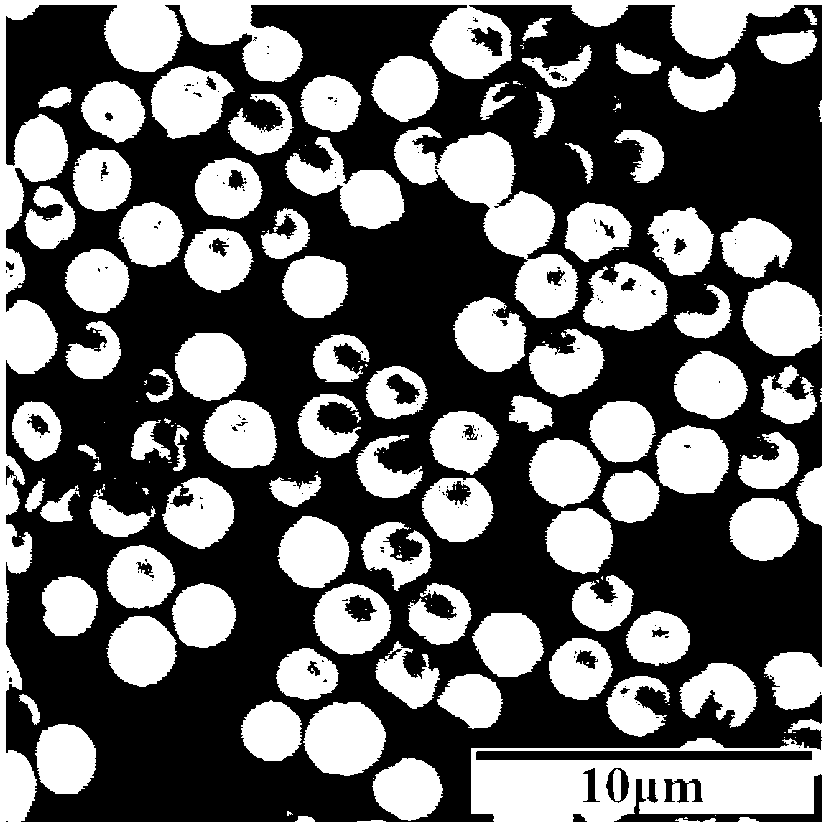

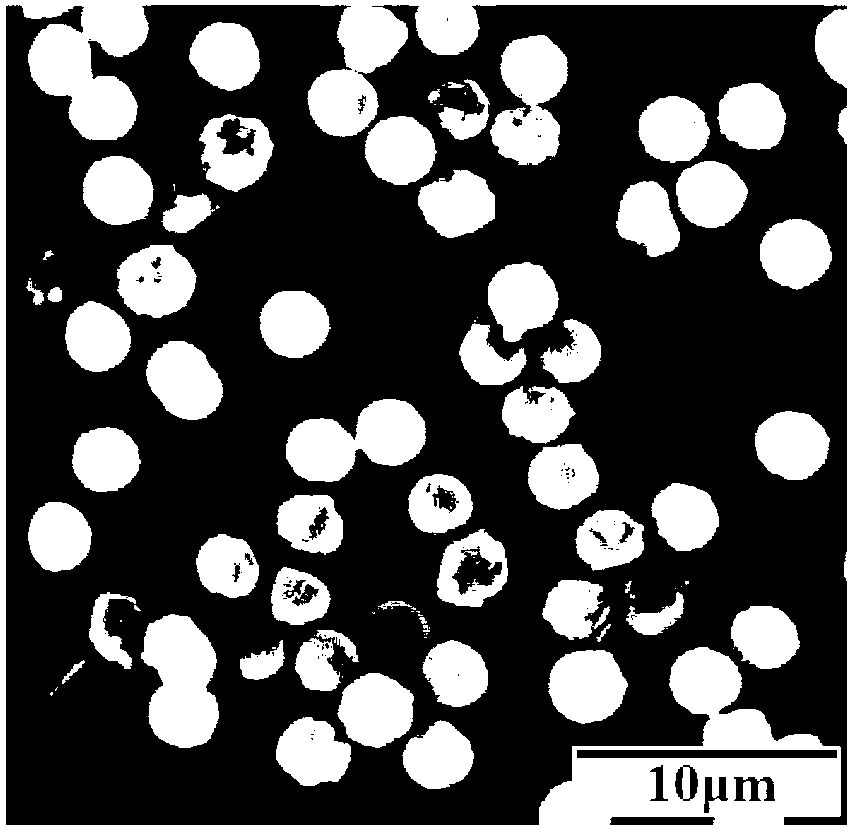

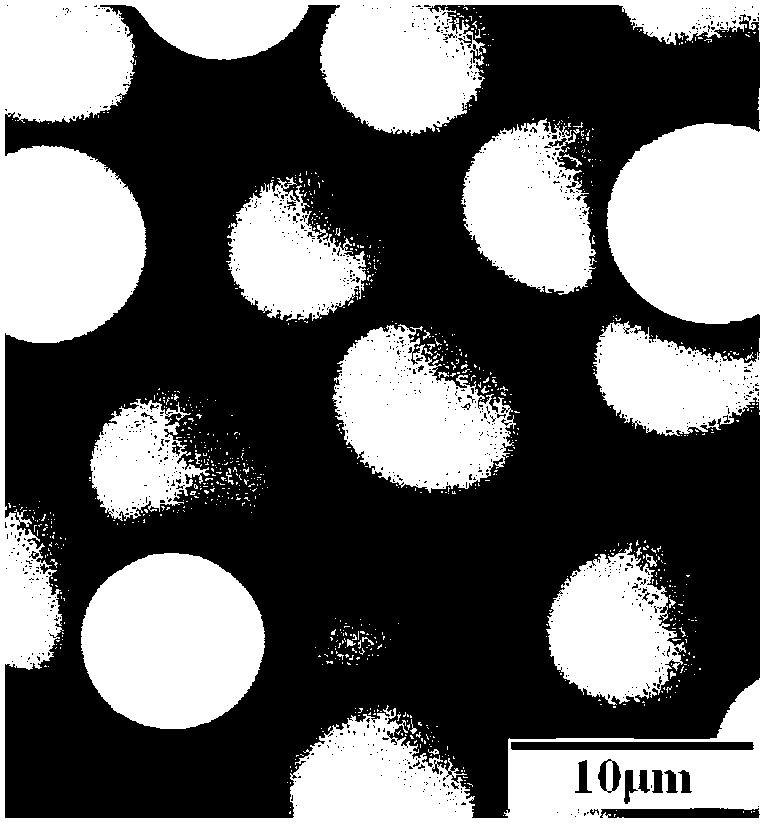

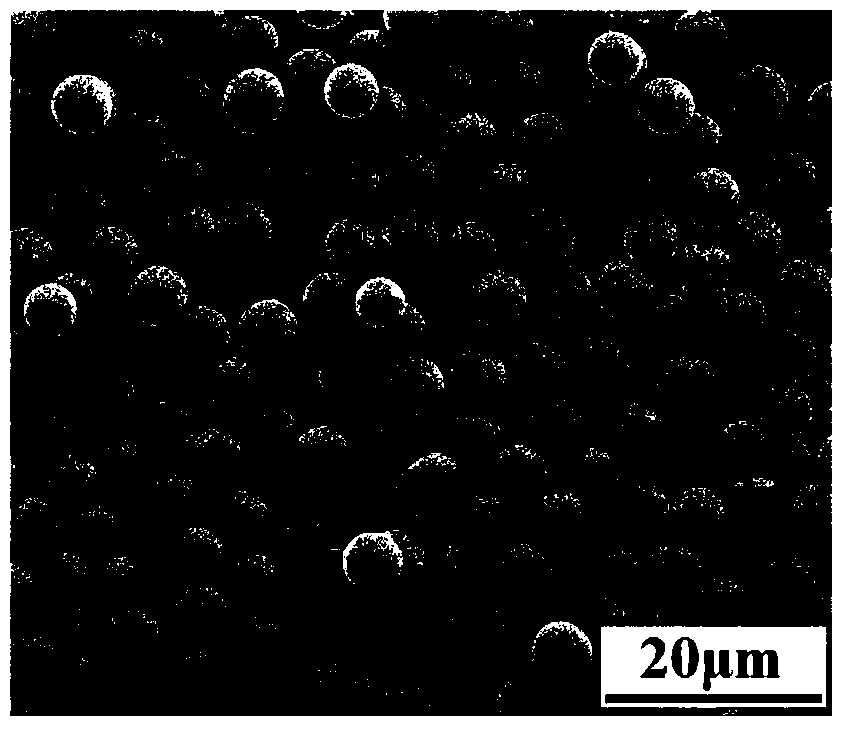

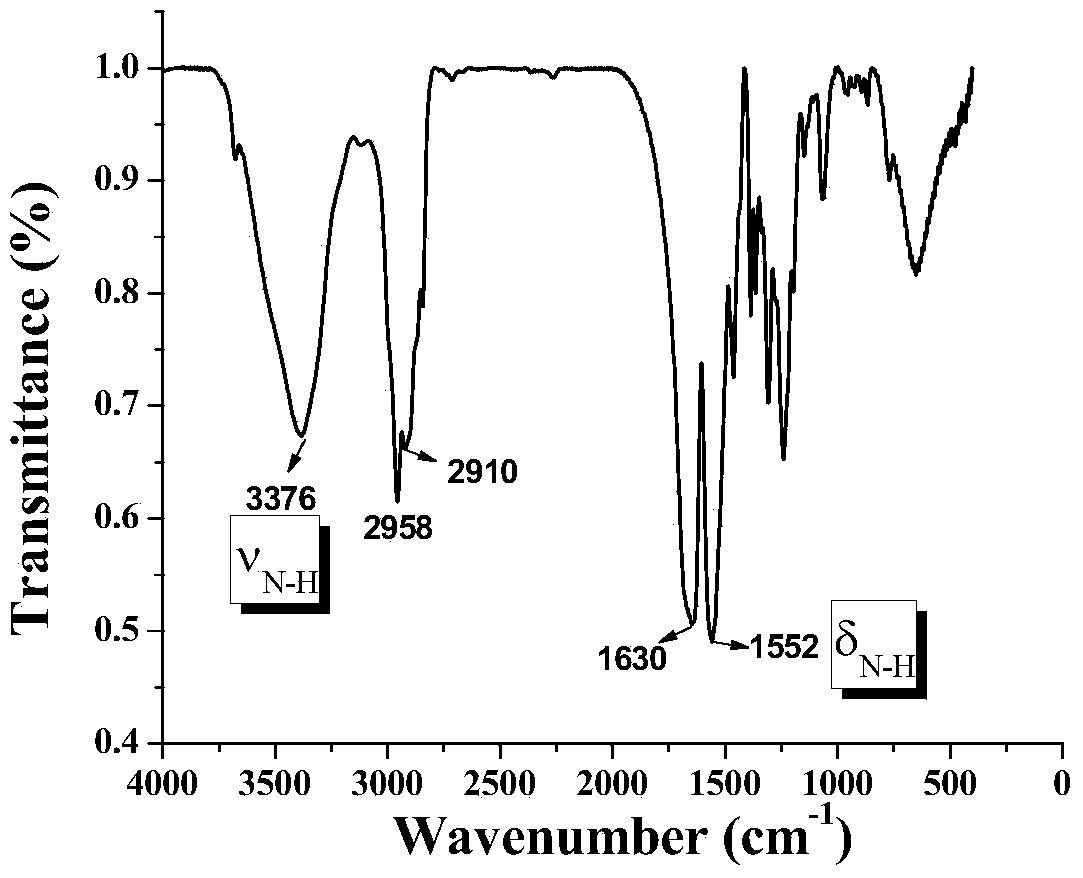

Preparation method for particle diameter controllable millimeter-scale polyurea monodisperse microsphere

InactiveCN104151516AMeet particle size requirementsNo pollutionMicroballoon preparationMicrocapsule preparationMicrospherePollution

The invention relates to a preparation method for a particle diameter controllable millimeter-scale polyurea monodisperse microsphere. The preparation method comprises the following steps: isocyanate compound is adopted as a monomer and is squeezed through syringe needles or capillary tubes to form liquid drops and the liquid drops are added into water or a polyamine aqueous solution for sedimentation and polymerization; during the settlement process of the liquid drops, the monomers on the surfaces of the liquid drops react with the water or the polyamine aqueous solution rapidly to form a gelatin layer or callus and the stability of particles is maintained. According to the method, as water is adopted as the dispersion medium, no pollution is generated; the polymerization reaction can be conducted under lower temperature, the equipment is simple and the manufacturing cost is low; the obtained microsphere is free from residual monomer and the post-processing is simple; no surface modified agent or pore-foaming agent is needed, porous polyurea microsphere with rich amino on the surface is prepared in one step; the method can be used in the fields of enzyme immobilization, chemocatalysis, dye, adsorption and separation of heavy metal ions and the like.

Owner:UNIV OF JINAN

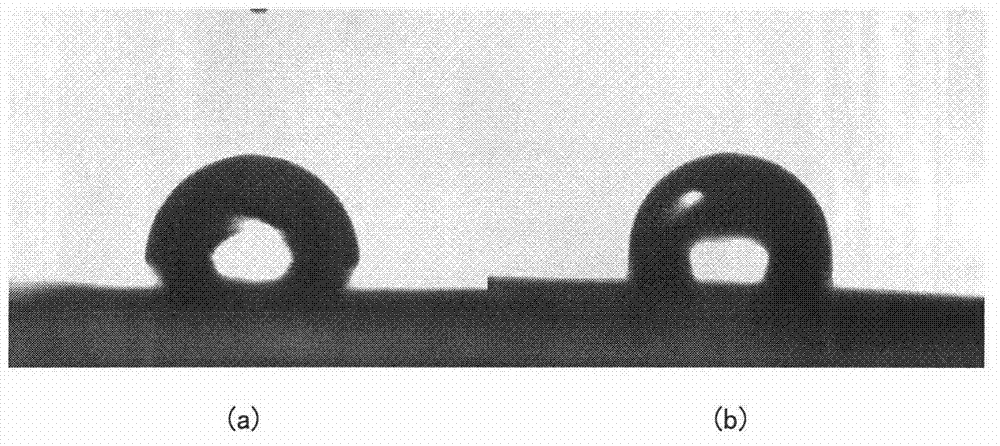

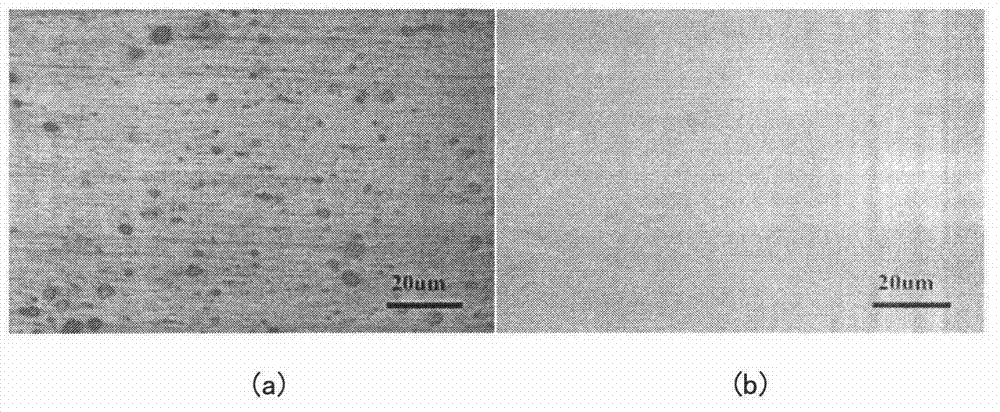

Preparation method for core-shell fluorinated polyurethane-acrylate latex

InactiveCN102924664AImprove grafting efficiencyFast polymerization rateCoatingsPolymer scienceFunctional monomer

The invention relates to a preparation method for core-shell fluorinated polyurethane-acrylate latex. The method comprises the following steps: placing polyether glycol and toluene diisocynate into a stirrer to prepare polyurethane; and emulsifying an emulsifier, butyl acrylate, methyl methacrylate, a functional monomer and a proper amount of water at high speed to prepare the core-shell fluorinated polyurethane-acrylate latex. By the method, the defects that the fluorinated acrylate in the prior art is independent of oil and water phases due to hydrophobicity and lipophobicity, effective micelle is difficult to form by the general surfactant and the grafting ratio is low are overcome. The core-shell fluorinated polyurethane-acrylate latex has a core-shell structure and the fluorinated acrylate is enriched in the shell, so a latex film has a large water contact angle. The using amount of the fluorinated acrylate monomer (G04) is 1 to 2 percent of the weight of the monomer and the using amount of polyurethane (PU) is 10 percent of the weight of a composite latex solid, so the preparation cost is low. The emulsifier does not need a fluorine-containing surfactant, so the polymerization rate is high, the grafting efficiency of the fluorinated acrylate monomer is high and the latex is stored stably.

Owner:江苏日出化工有限公司 +1

Preparation method of butyleneadipate-terephthalate with low terminal carboxyl group content

The invention belongs to the technical field of fully-biodegradable fat-aromatic copolyester, in particular to a preparation method of butyleneadipate-terephthalate with low terminal carboxyl group content. The preparation method comprises the following steps: mixing butanediol, adipic acid and terephthalic acid; after polyhydric alcohols are added, adding a water-soluble catalyst; stirring uniformly; performing esterification reaction under the protection of gas with inactive chemical property; then performing condensation polymerization so as to obtain butyleneadipate-terephthalate. The preparation method provided by the invention has the advantages that the operation is simple, the terminal carboxyl group content of butyleneadipate-terephthalate is lowered, heat resistance and processability of butyleneadipate-terephthalate are improved on the premise that the biodegradability of a polymer is not changed, the stability during the process of storage is improved, a non-poisonous pollution-free fourth monomer is added, so that rate of polymerization is increased, the terminal carboxyl group content of products is lowered, characteristics of green and environmental protection of the products are not affected, the dosage of a catalyst is less, and the production cost is reduced.

Owner:甘肃莫高聚和环保新材料科技有限公司

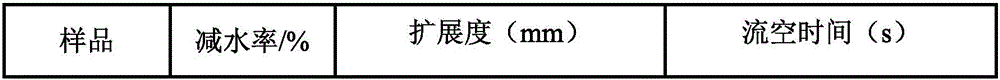

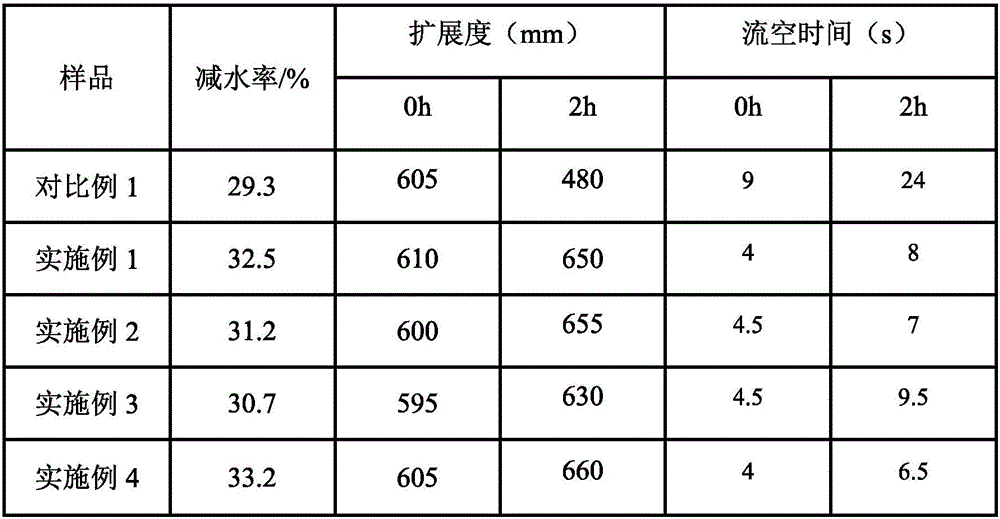

Preparation method of ester type viscosity reduction type polycarboxylate superplasticizer

ActiveCN106380554AImprove adsorption capacityIncrease electrostatic repulsionFunctional monomerSludge

The invention discloses a preparation method of an ester type viscosity reduction type polycarboxylate superplasticizer. The method comprises the following steps: (1) preparing an esterified monomer; (2) conducting the copolymerization reaction; (3) conducting the neutralization reaction. According to the technical scheme of the preparation method, methyl methacrylate and dimethylaminoethanol, remaining after the preparation of the esterified monomer, are subjected to ester exchange in the same condition of preparing the esterified monomer so as to obtain dimethylaminoethyl methacrylate as a functional monomer. Therefore, the preparation method is cost-saving and simple in operation. In addition, the functional monomer is directly introduced into the copolymerization reaction to react with other cationic monomers. During the polymerization process, anions, cations and tertiary amine groups are attached to polycarboxylic acid molecular chains, so that the surface adsorbability of cement particles can be improved. The electrostatic repulsion effect between cement particles is improved. Not only the ester type viscosity reduction type polycarboxylate superplasticizer is good in anti-sludge effect for sand and gravel materials high in cement content, but also the ester type viscosity reduction type polycarboxylate superplasticizer is good in dispersibility and viscosity-reducing effect.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Method for quickly preparing phase change energy storage microcapsule by ultraviolet light irradiation and polymerization

InactiveCN101628218AFast polymerization rateUniform productEnergy based chemical/physical/physico-chemical processesMicroballoon preparationIonEmulsion

The invention relates to a method for quickly preparing a phase change energy storage microcapsule by ultraviolet light irradiation and polymerization, which comprises the following steps: adding 100 parts of phase change energy storage material, 5-10 parts of surface active agent, 40-80 parts of monomer material and an ultraviolet light initiating agent being 2-5 percent of the monomer material into 500-1,000 parts of deionized water; stirring the materials at a certain rotating speed for 20-40 minutes and then homogenizing and dispersing the materials for 2-5min at the rotating speed of 6,000-12,000 by a homogenizer so as to prepare the materials into an emulsion; putting the emulsion under an ultraviolet light source of 500-1,000W, irradiating the emulsion for 20-40min to initiate the monomer material to polymerize and stirring the emulsion at lower rotating speed; and after finishing initiating, filtering the emulsion to obtain solid powder and washing and drying the solid powder. Because the wavelength of the ultraviolet light is concentrated, the initiation mode of the ultraviolet light to a reactant system is easy to control, and a large quantity of the ultraviolet light initiating agent can be decomposed to generate free radicals, therefore, the reaction speed of photopolymerization is many times higher than the reaction speed of a conventional thermal initiation polymerization mode, and the improvement of the reaction speed renders possible the continuous mass production.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

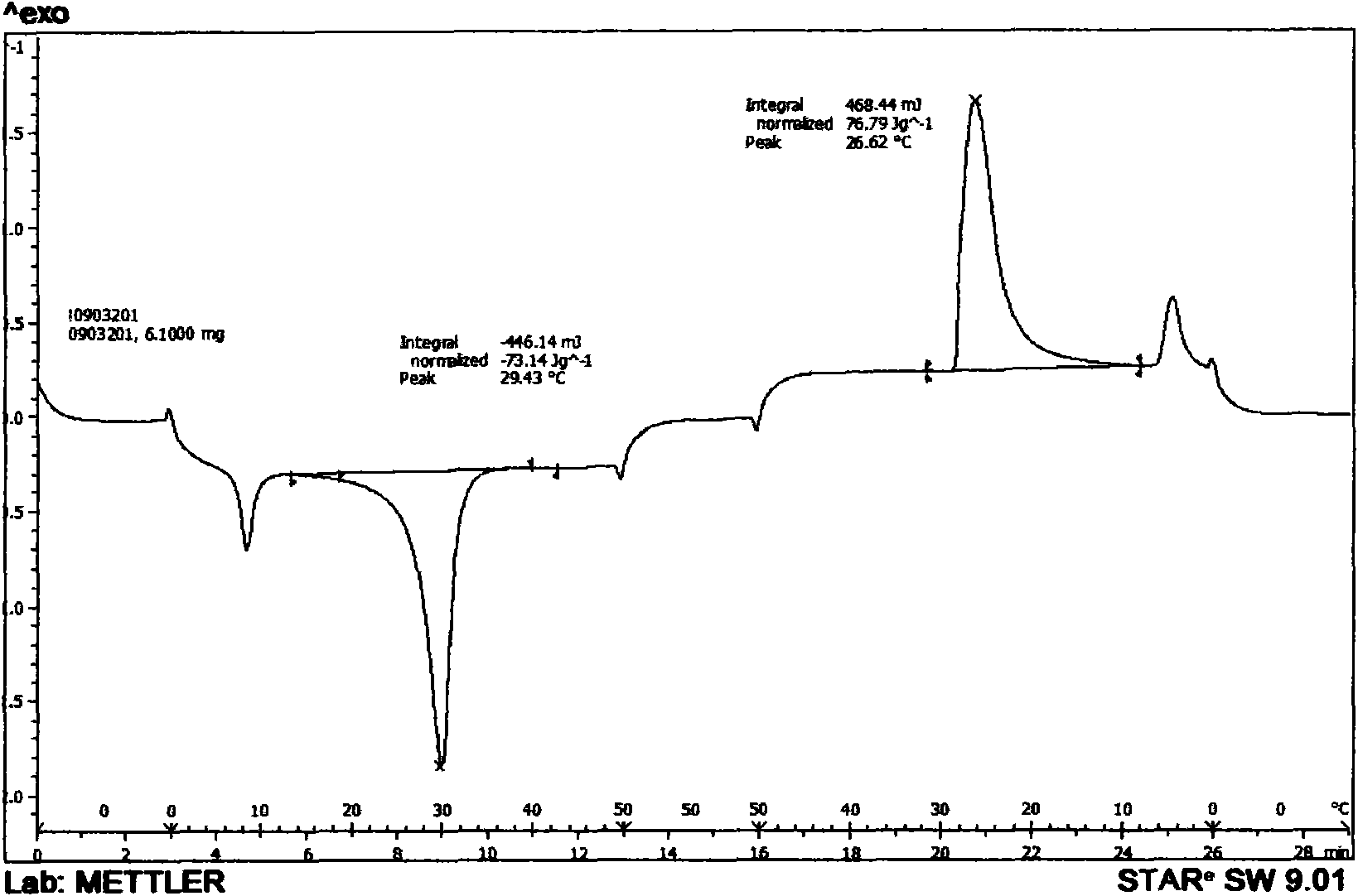

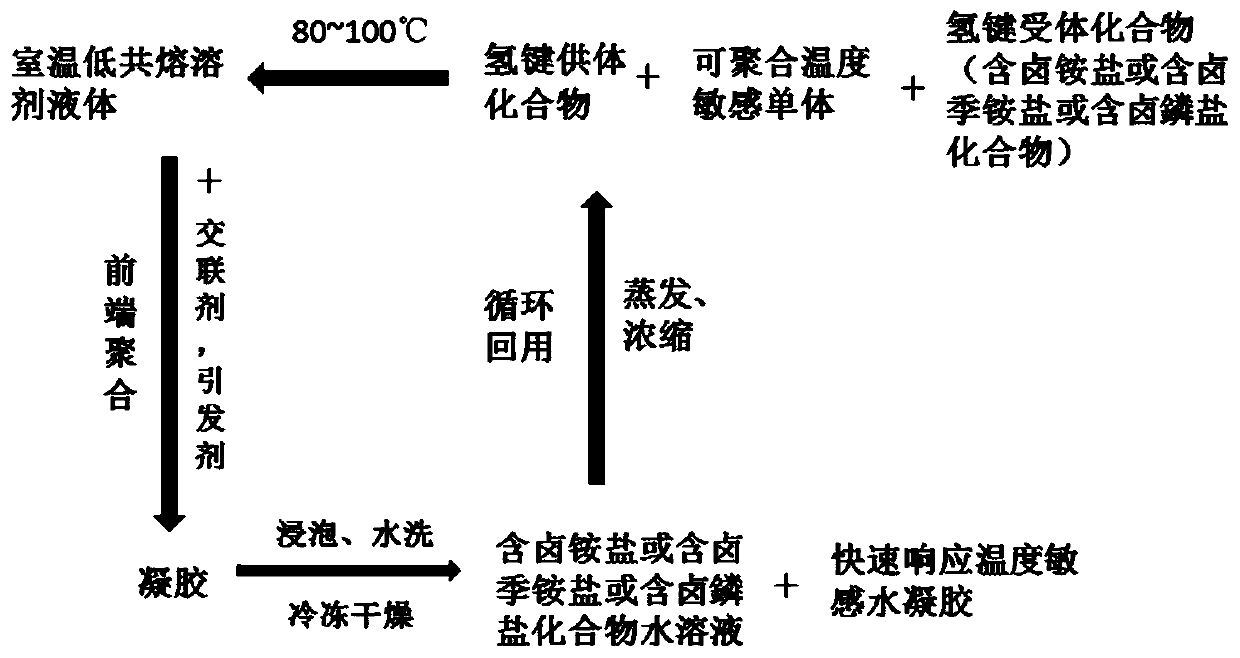

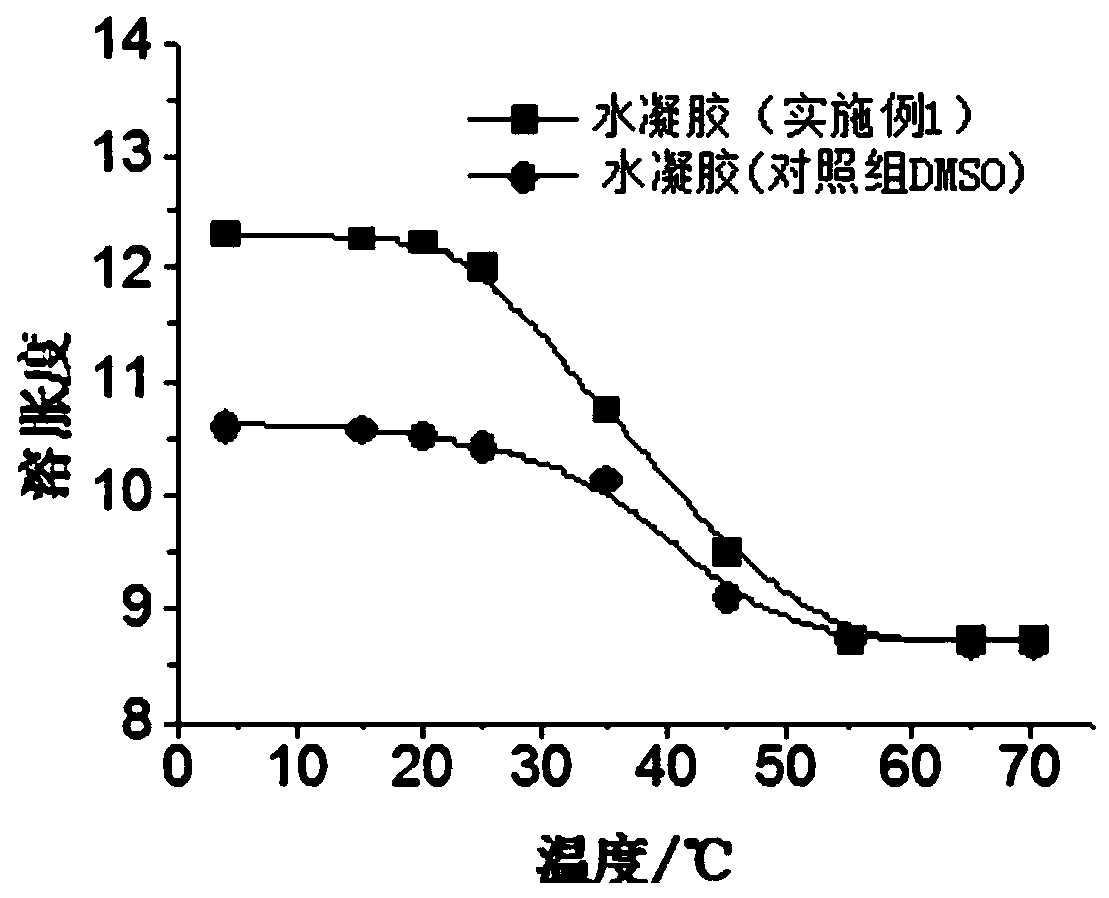

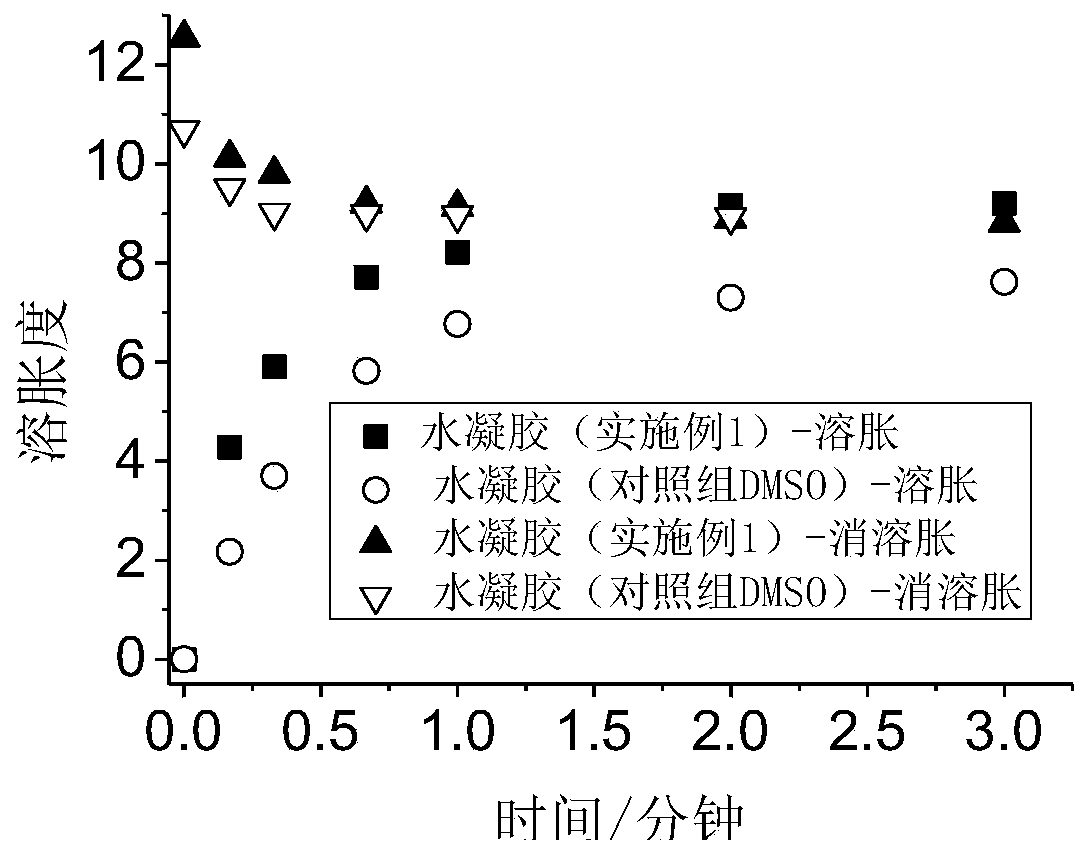

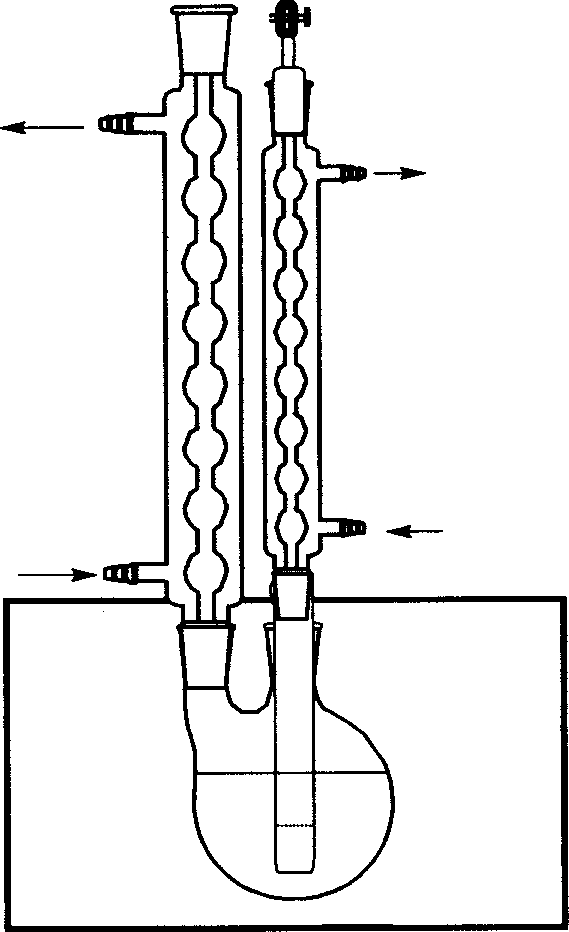

Method for preparing quick-response temperature-sensitive hydrogel by adopting room-temperature eutectic solvent liquid frontal polymerization

The invention discloses a method for preparing a quick-response temperature-sensitive hydrogel by adopting room-temperature eutectic solvent liquid frontal polymerization, and belongs to the technicalfield of preparation of functional polymer materials. The method comprises the following steps: mixing a polymerizable temperature-sensitive monomer, a hydrogen bond donor compound and a hydrogen bond acceptor compound, stirring at 80-100 DEG C until a transparent and clear liquid is formed, and cooling to room temperature to obtain a room-temperature eutectic solvent liquid; adding a cross-linking agent and an initiator into the room-temperature eutectic solvent liquid to form a mixture solution; transferring the formed mixture solution into a tubular reactor, initiating a reaction at the upper end or the lower end of the reactor by adopting a heat source or ultraviolet light, and removing the heat source or the ultraviolet light after the thermal initiation reaction is started until allthe raw materials in the whole reactor are converted into a polymer gel; and soaking and washing the obtained polymer gel with distilled water, and freeze-drying to obtain the target hydrogel. No extra liquid solvent is needed, the polymerization speed is high, the reaction time is short, and the energy consumption is low.

Owner:HUBEI POLYTECHNIC UNIV

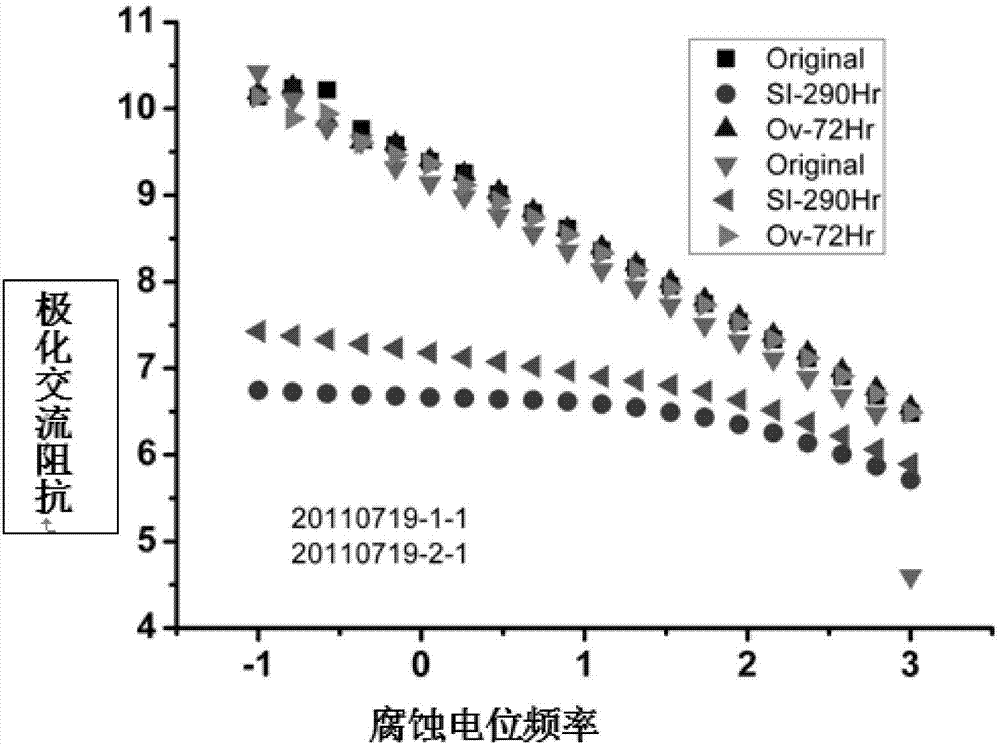

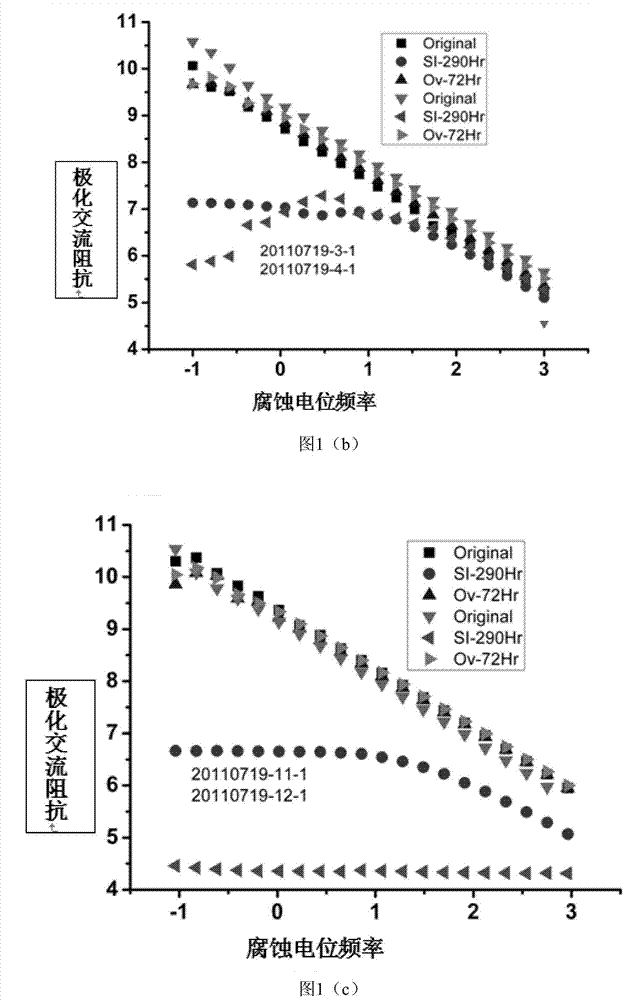

Special anticorrosion conductive powder coating for vertical shaft fluidized bed dip-coating as well as preparation method and application of coating

ActiveCN104710908AHigh glass transition temperatureLight weightAnti-corrosive paintsPolyurea/polyurethane coatingsNano al2o3Conductive materials

The invention relates to a special anticorrosion conductive powder coating for vertical shaft fluidized bed dip-coating. The special anticorrosion conductive powder coating is prepared from the following raw materials in parts by weight: 500-900 parts of film-forming resin and curing agent, 0-200 parts of glass flakes, 0-350 parts of filler, 15-50 parts of auxiliaries, 5-100 parts of conductive material and 1-5 parts of nanometer aluminum oxide or nano fumed silica. The powder coating has the characteristics of a high glass transition temperature, low specific gravity which is generally less than or equal to 1.1g / cm<3>, and easiness for fluidization; even though hundreds of tons of powder is added to a 20m deep well, the powder can be fluidized easily and uniformly; in case of too high specific gravity and difficult fluidization, the vertical shaft dip-coating method can not be utilized; the powder aims at a hot-dip coating construction process, and the film formed by the coating has surface conduction characteristics and high temperature water boiling resistance, and therefore, the coating is suitable for anti-corrosion coating of long linear workpieces such as mine mining anti-explosion gas pipelines, natural gas pipelines and liquefied gas pipelines; the coating is adaptive to the vertical shaft fluidized beds as deep as 20m, and still has good fluidity, which cannot be realized by common powders easily.

Owner:阜阳市诗雅涤新材料科技有限公司

Preparation method of ether viscosity reduction type polycarboxylate superplasticizer

The invention discloses a preparation method of an ether viscosity reduction type polycarboxylate superplasticizer, which comprises the following steps: (1) copolymerization reaction; and (2) neutralization reaction. According to the preparation method disclosed by the invention, amide groups are connected to superplasticizer molecules, and then a polycarboxylate molecular chain has anion and cation groups, so that adsorbability on the surfaces of cement particles can be increased, the electrostatic repulsion effect between the cement particles can be increased, and a better viscosity reduction effect on concrete is achieved. Moreover, the amide groups are hydrolyzed under alkaline conditions so as to release potential carboxyl groups again, thereby being favorable for improving the dispersibility and slump retentivity of the superplasticizer and realizing high adaptability to cement of different varieties.

Owner:KZJ NEW MATERIALS GROUP CO LTD

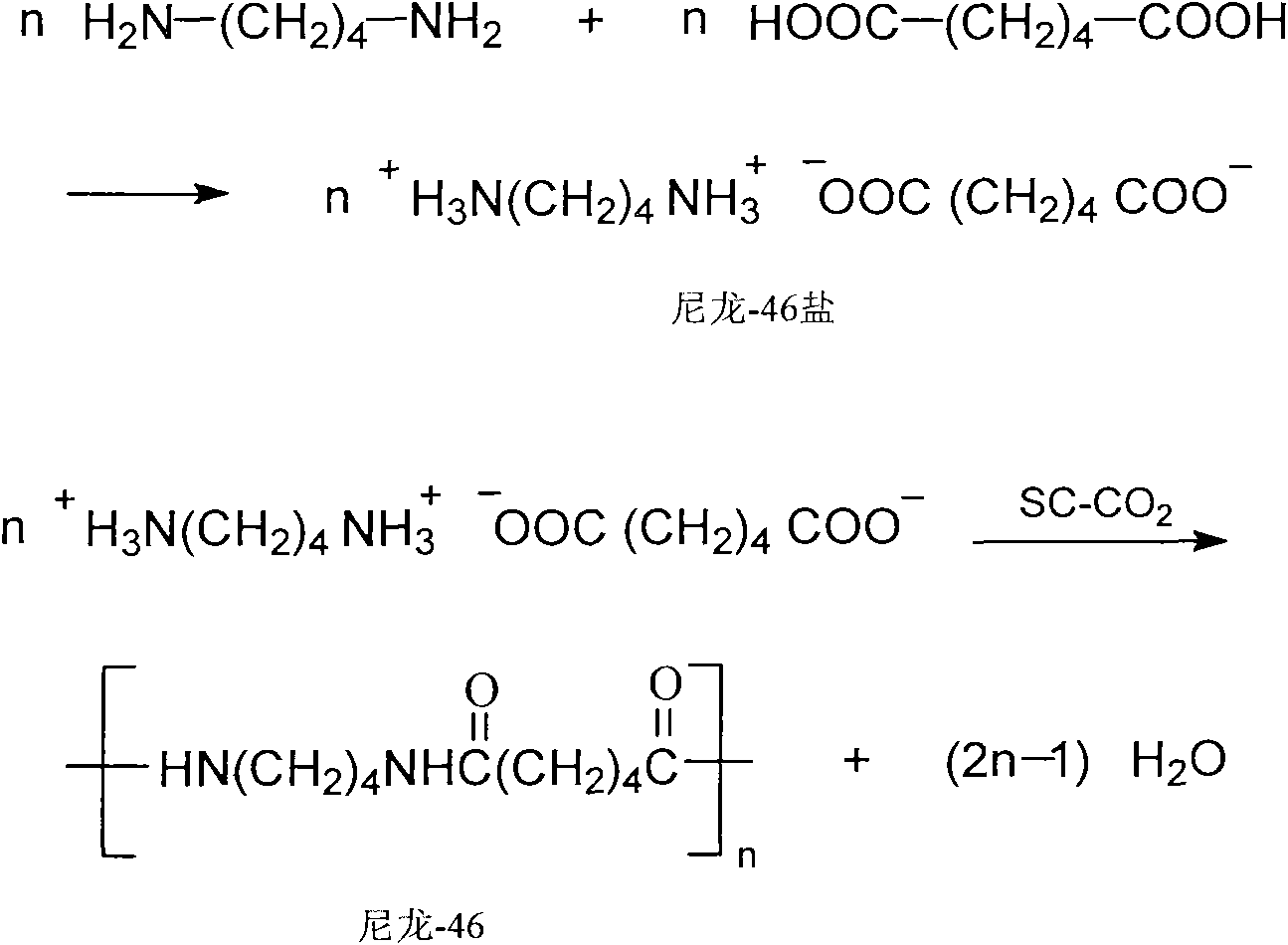

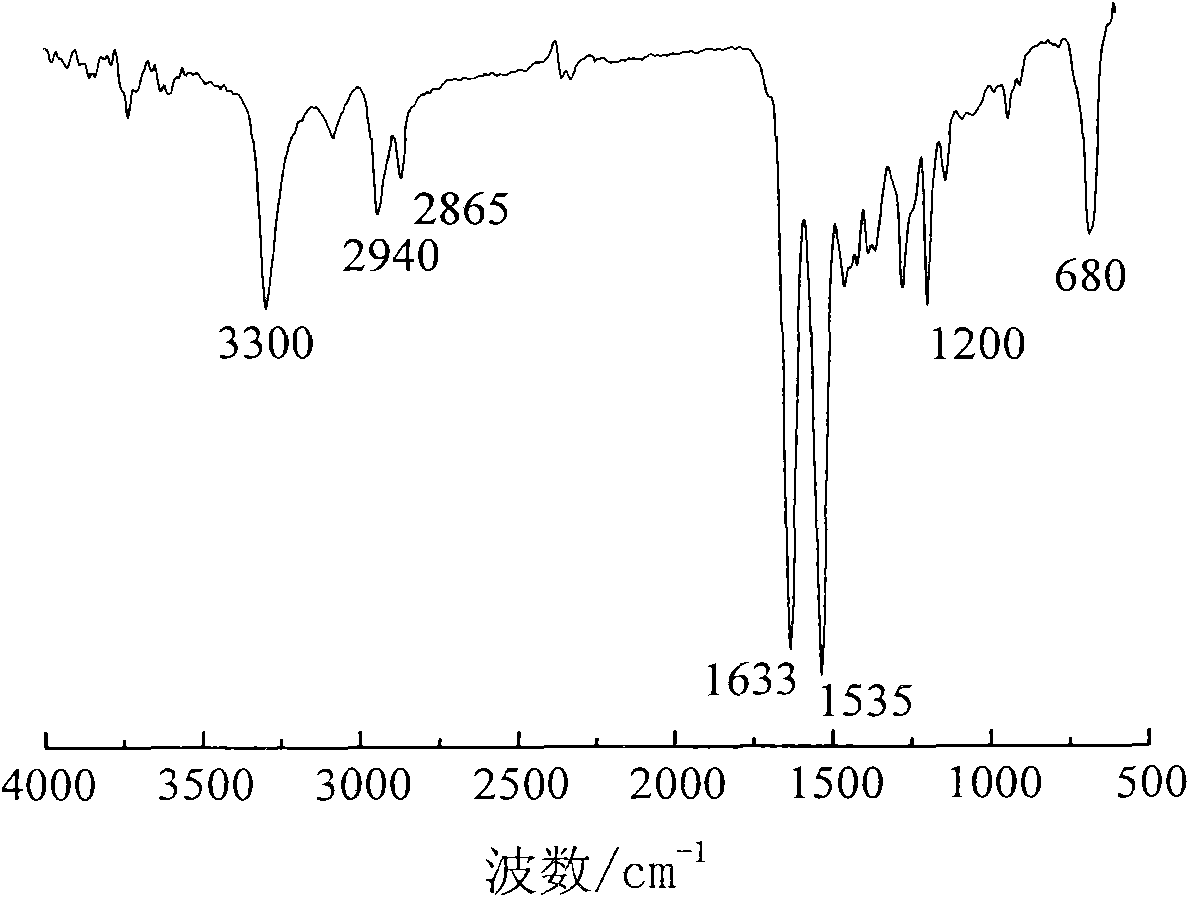

Method for preparing nylon-46 in supercritical carbon dioxide

ActiveCN101831069ALow melting pointLower glass transition temperatureBulk chemical productionVacuum pumpingRoom temperature

The invention discloses a new method for preparing nylon-46 in a supercritical carbon dioxide medium, which comprises the following steps of: adding a 1,4-butanediamine methanol solution into a 1,6-adipic acid methanol solution under the condition of stirring to obtain precipitates; filtering and drying to obtain nylon-46 salt; putting the nylon-46 salt into a reaction kettle, filling carbon dioxide for replacing the air in the kettle, carrying out vacuum-pumping operation, and pumping carbon dioxide; increasing temperature and pressure to enable the carbon dioxide in the kettle to be in a critical state, and carrying out polycondensation reaction of the one-step method in the existence of supercritical carbon dioxide; after the polycondensation reaction, cooling to room temperature, relieving the pressure, and opening the kettle to obtain nylon-46 products of the one-step method; crushing the polycondensation products of the one-step method, and putting the powder into the reaction kettle again to carry out the second-step polycondensation reaction in the existence of supercritical carbon dioxide; and after the second-step polycondensation reaction, cooling to room temperature, relieving the pressure, and opening the kettle to obtain nylon-46 products of a two-step method.

Owner:JINAN UNIVERSITY

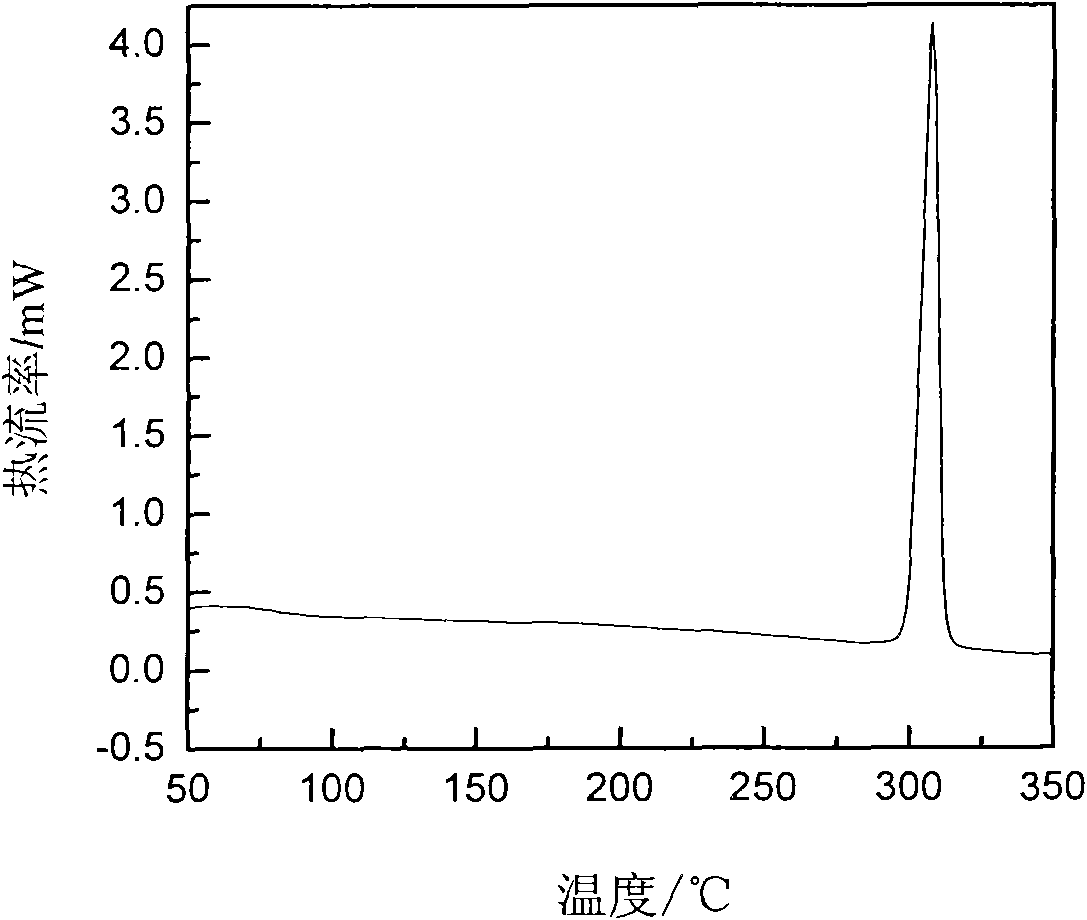

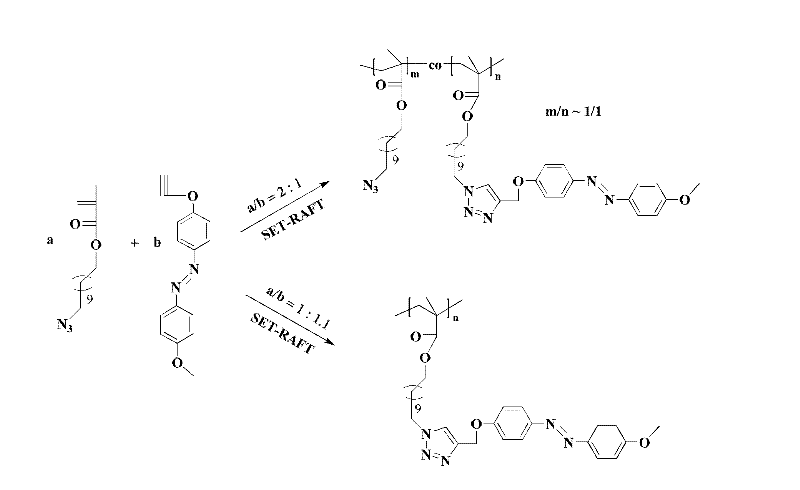

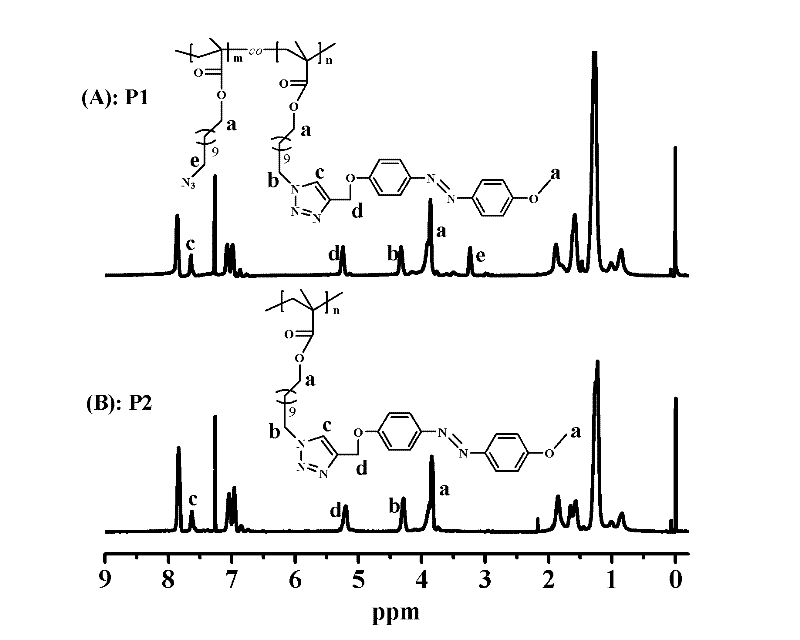

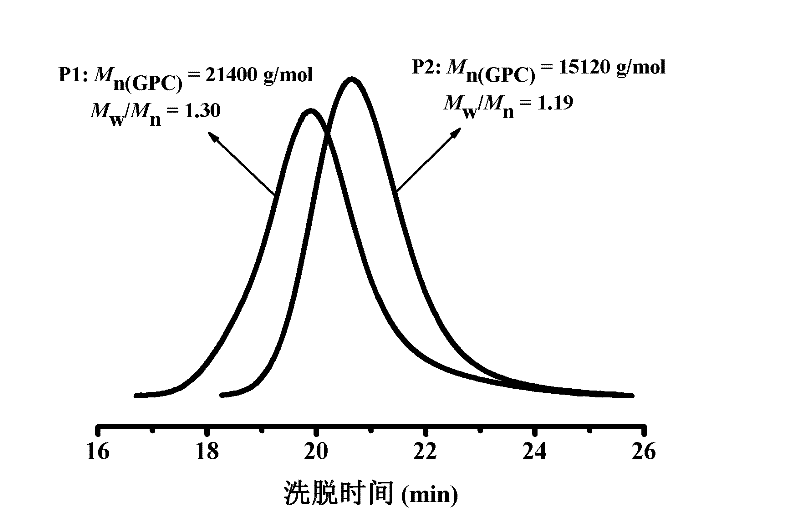

Side chain functional polymer and preparation method thereof

The invention discloses a side chain functional polymer and a preparation method thereof. A polymerization system consists of a monomer, an initiator, a chain transfer agent, a catalyst, a coordination agent and a coupling component, wherein the monomer is undecyl azidomethacrylic ester; the catalyst is copper; the coordination agent is N,N,N',N'',N''-pentamethyldiethylenetriamine; the coupling component is 4-methyoxyl-4'-propynyloxy azobenzene; single electron transfer (SET) is adopted for initiation to produce a free radical; polymerization reaction of the monomer is performed by a method for performing chain propagation in a reversible addition fragmentation chain transfer (RAFT) mode; meanwhile, click chemical reaction is performed; and monovalent copper is used for catalyzing an azide group and an alkynyl group in the coupling component to perform cycloaddition reaction so as to obtain the side chain functional polymer. Since the SET-RAFT method and the click chemical method are combined, the side chain functional polymer can be obtained by only one-step reaction; and thus, the reaction steps are reduced, the waste rate of the raw materials is reduced, rational utilization ofthe resources is realized, side reaction is basically avoided, and troublesome purification operation is avoided.

Owner:SUZHOU UNIV

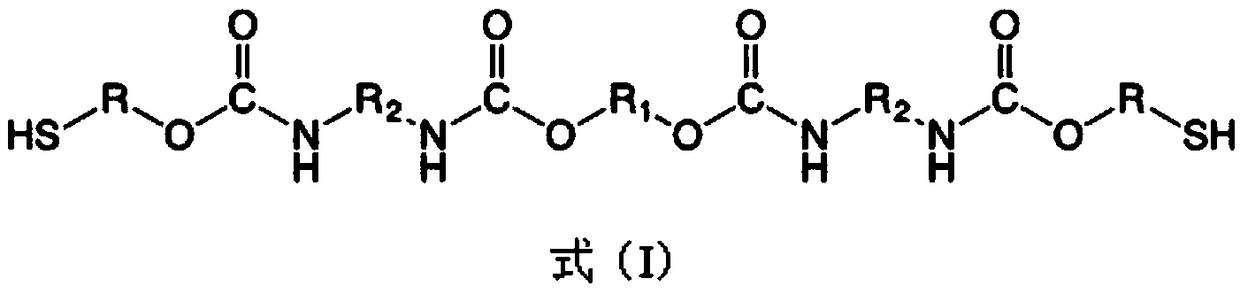

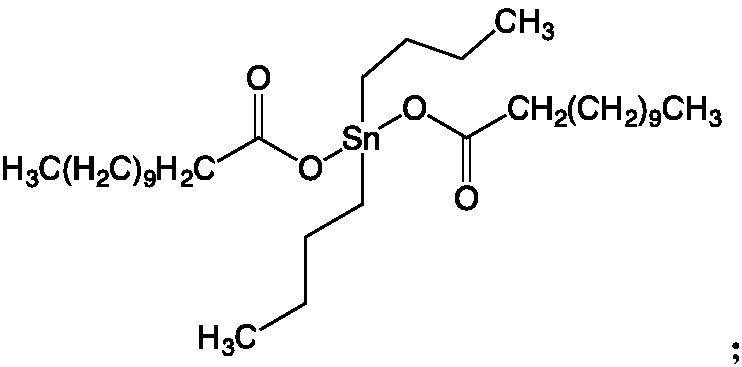

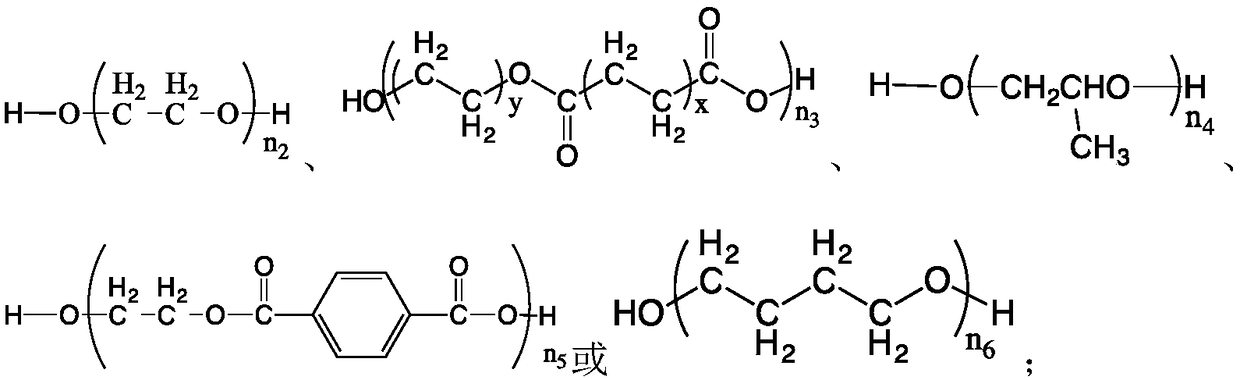

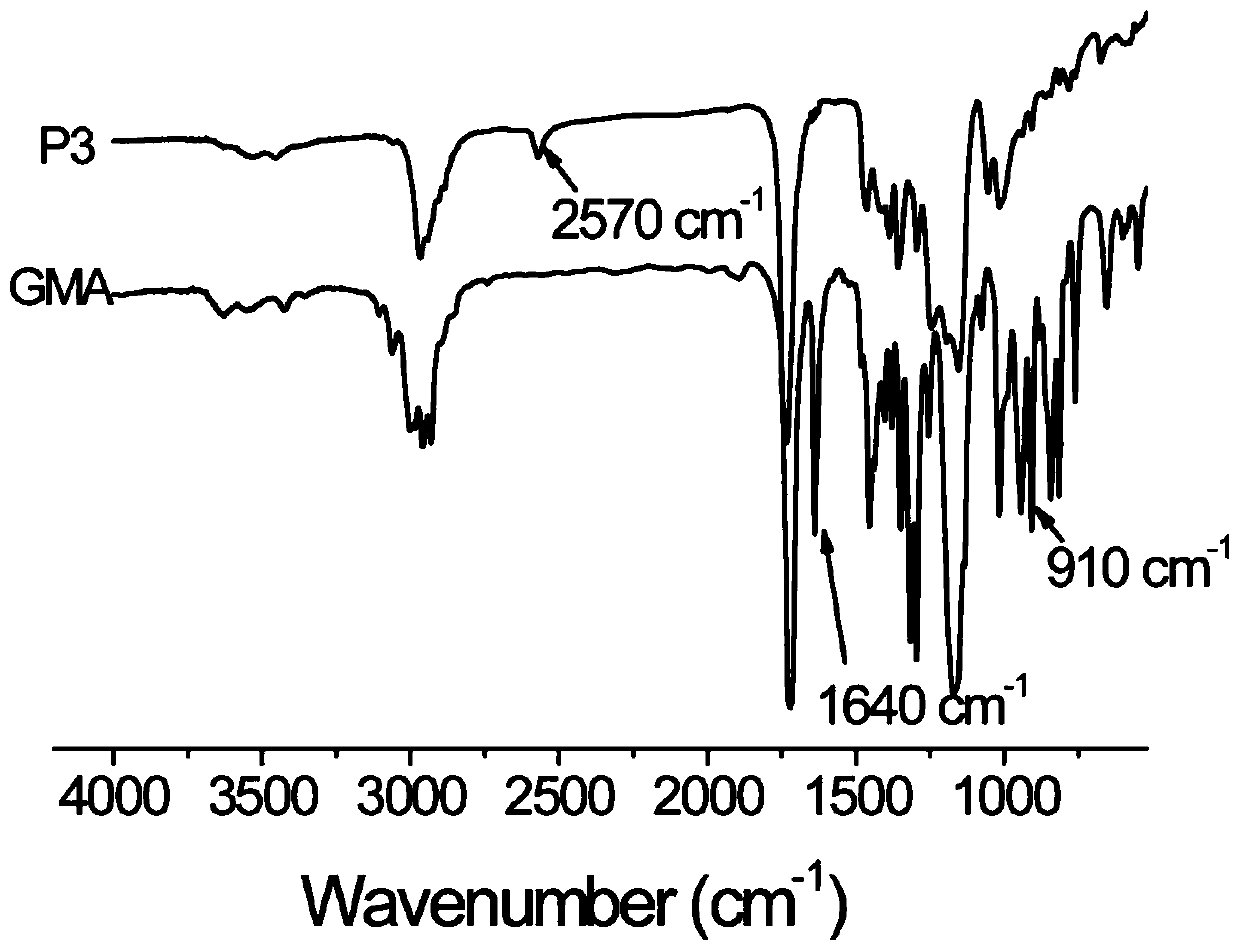

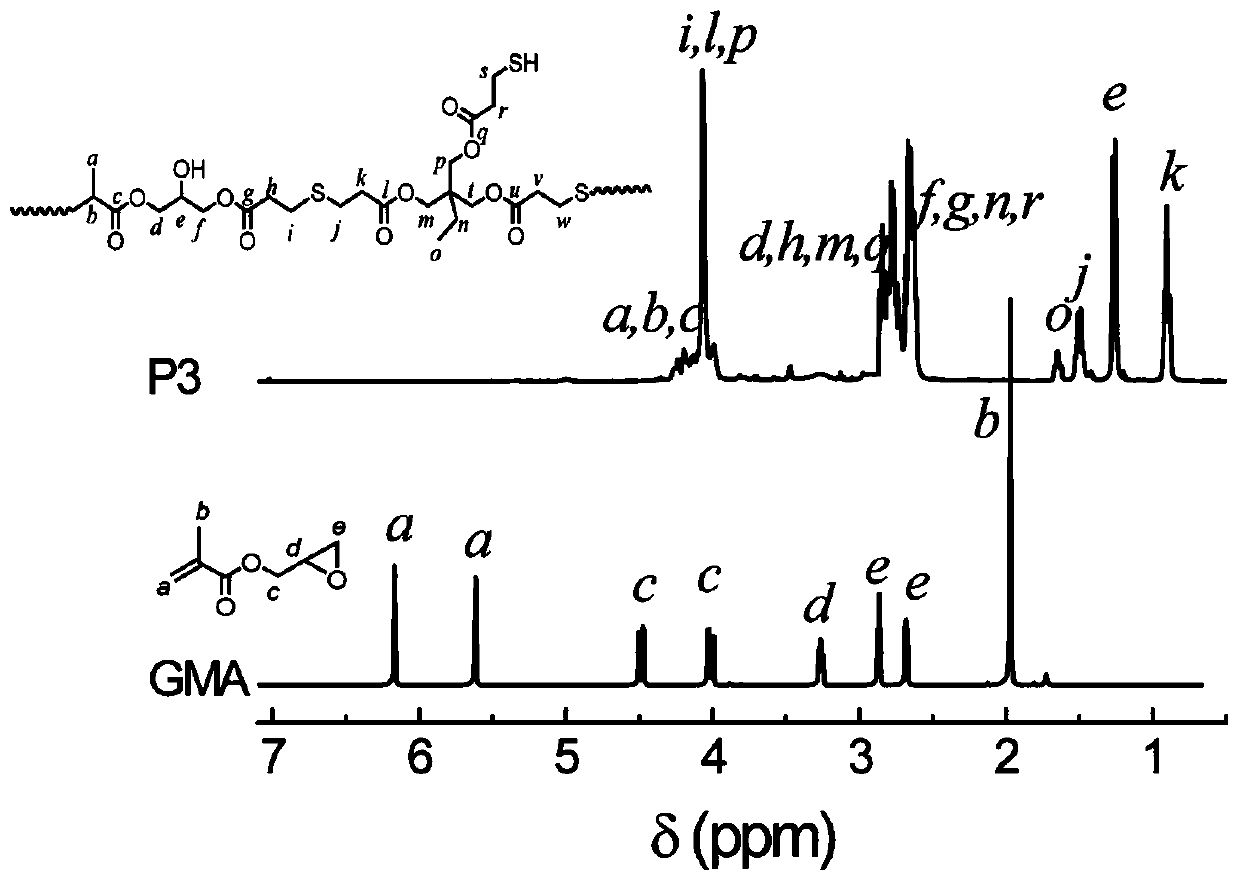

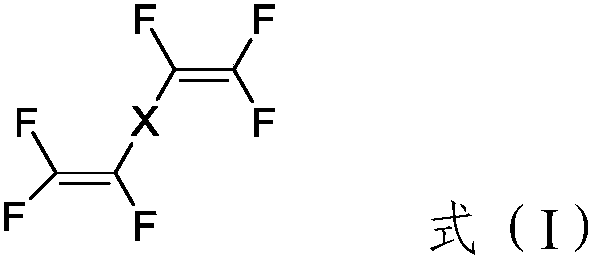

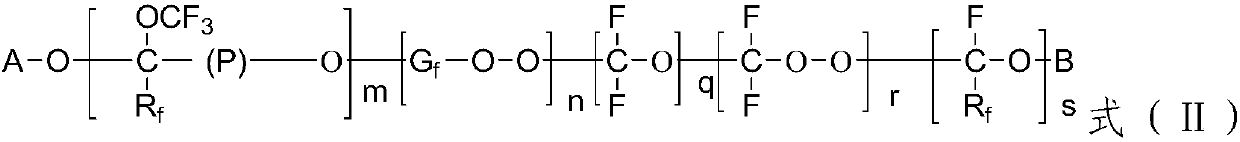

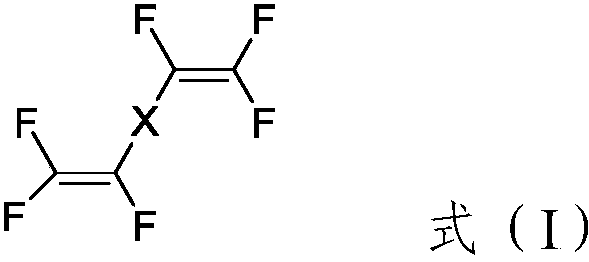

Polyurethane dithiol prepolymer, photosensitive resin composition as well as preparation method and application of prepolymer

The invention relates to a polyurethane dithiol prepolymer, a photosensitive resin composition as well as a preparation method and application of the prepolymer. The prepolymer is represented by a formula (I) (shown in the description), where R represents a formula (shown in the description), n1 is greater than or equal to 2 and less than or equal to 6, n2 is greater than or equal to 1 and less than or equal to 100, n3 is greater than or equal to 1 and less than or equal to 100, n4 is greater than or equal to 1 and less than or equal to 100, n5 is greater than or equal to 1 and less than or equal to 100, n6 is greater than or equal to 1 and less than or equal to 100, x is greater than or equal to 1 and less than or equal to 3, y is greater than or equal to 1 and less than or equal to 3, R2represents a formula (shown in the description). According to the polyurethane dithiol prepolymer through the increase of the length of a mercaptan alkyl chain and the substitution of a specific group, the mercaptan volatility is greatly weakened, the prepolymer has no pungent smell, and the photosensitive resin prepared from the prepolymer is odorless and relatively low in volume shrinkage speedand relatively high polymerization speed.

Owner:LINGNAN NORMAL UNIV

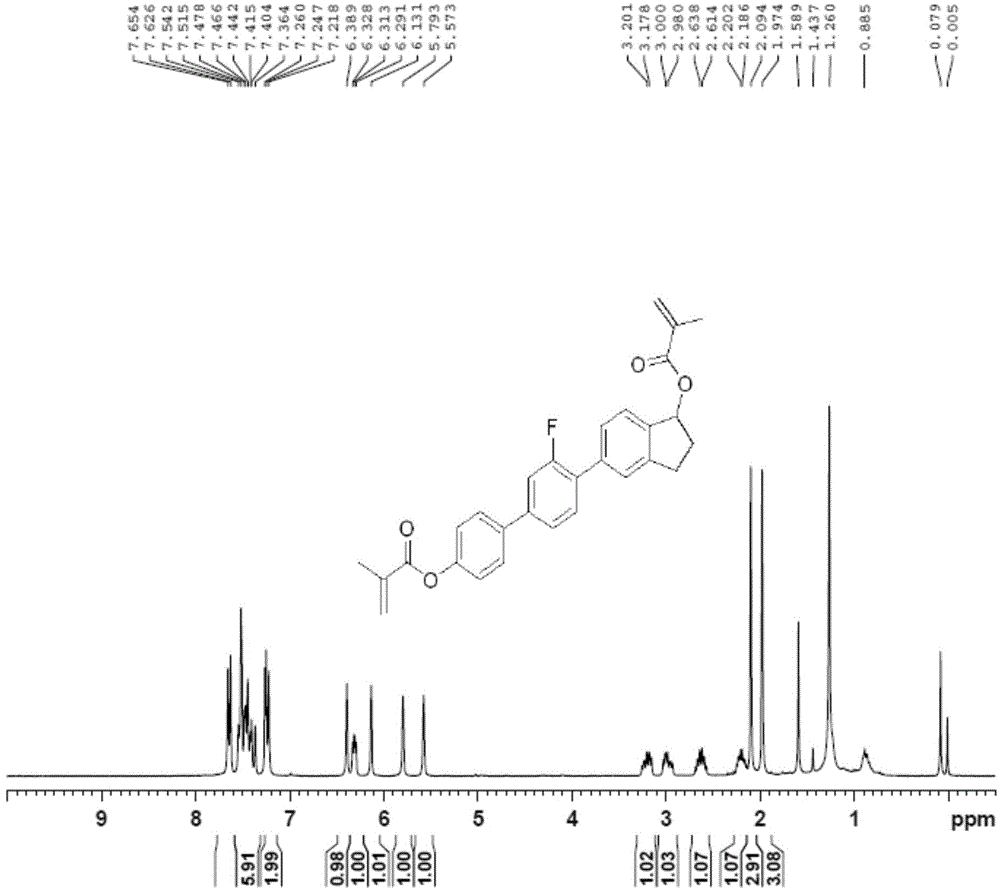

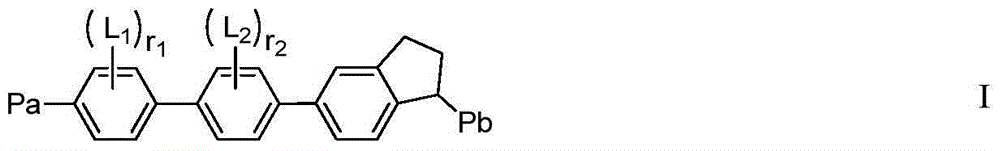

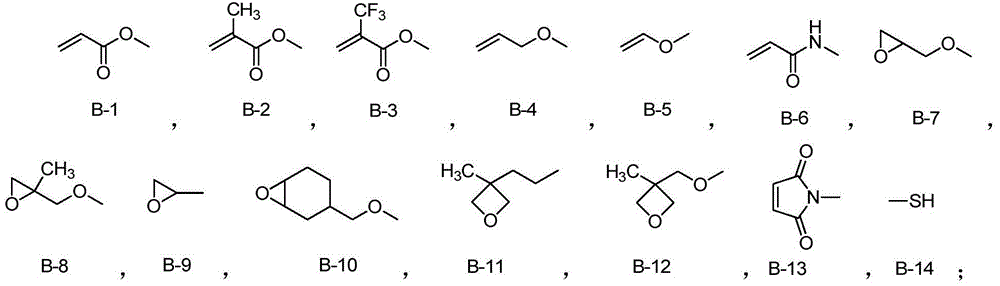

Polymerizable compound and its application in optical anisotropic body and liquid crystal display element

ActiveCN104557545AFully aggregatedImprove solubilityLiquid crystal compositionsOrganic chemistryCrystallographySolubility

The invention relates to a polymerizable compound with general formula I, also provides a polymerizable liquid crystal composition containing the polymerizable compound and a liquid crystal display element containing the polymerizable compound, and especially provides a liquid crystal display element used for PS or PSA (polymer stabilized or polymer stably-aligned) liquid crystal displays. The polymerizable liquid crystal compound has the advantages of good solubility, good orientation effect, fast polymerization rate, complete polymerization and low residue, so the bad display problem can be greatly improved.

Owner:JIANGSU HECHENG DISPLAY TECHCO

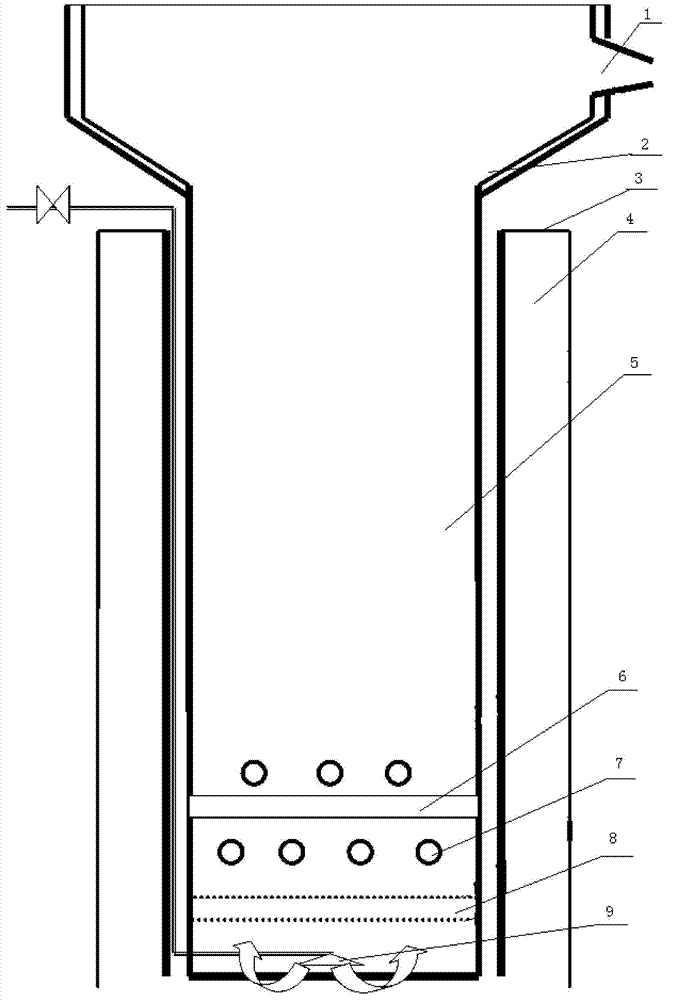

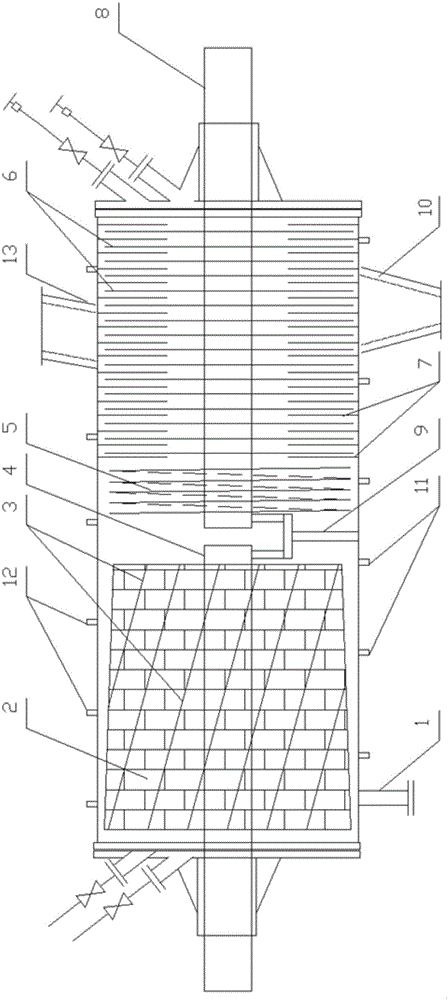

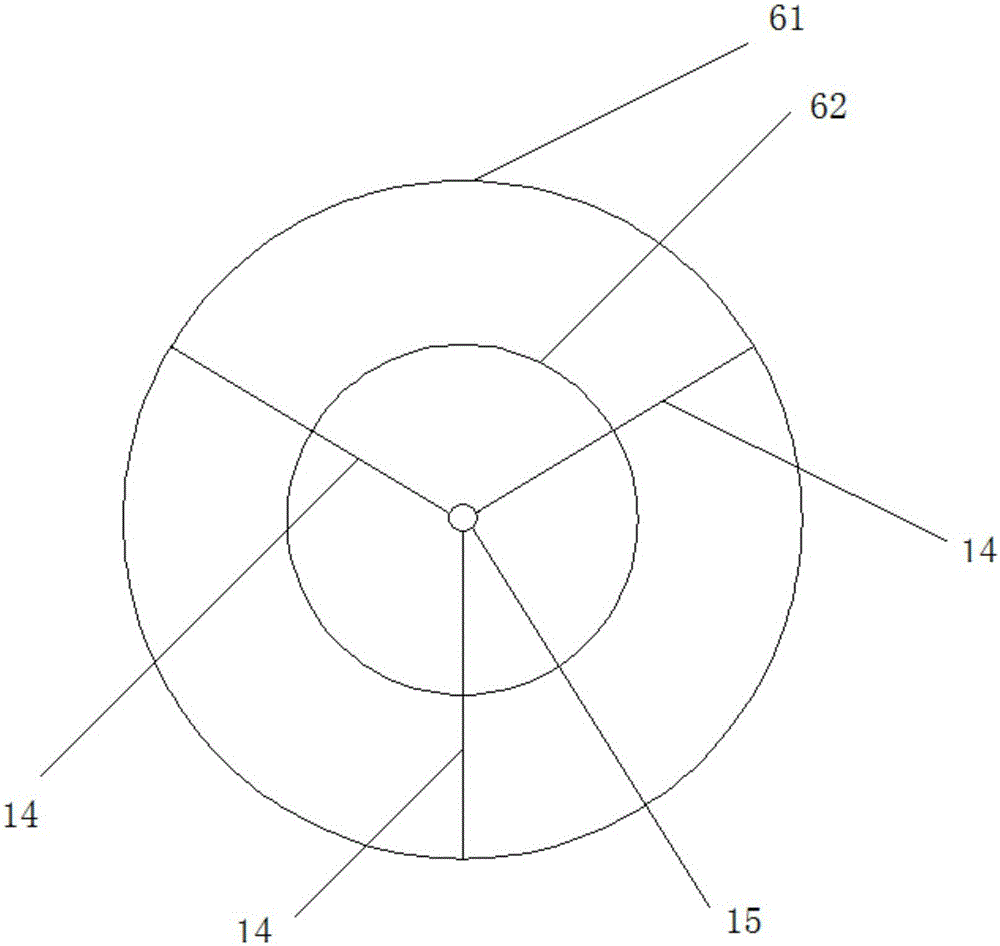

Polymeric reactor and polyester production method

ActiveCN106268591AHigh viscosityIncrease the devolatilization areaChemical/physical/physico-chemical stationary reactorsCircular discPolyester

The invention discloses a polymeric reactor and a polyester production method. The polymeric reactor comprises a closed horizontal cylinder. A front end rotating shaft is arranged at the portion, close to a material inlet, inside the cylinder. One end of the front end rotating shaft stretches out from the cylinder and is connected with a first power device. A rear end rotating shaft is arranged at the portion, close to a material outlet, of the cylinder, and one end of the rear end rotating shaft stretches out from the cylinder and is connected with a second power device. A supporting structure for supporting the front end rotating shaft and the rear end rotating shaft is arranged inside the cylinder. A cage frame type stirrer is arranged on the front end rotating shaft. A section of screw-type disc is arranged at the portion, close to the front end rotating shaft, of the rear end rotating shaft. A plurality of sets of coaxial circular rings are arranged at the other parts of the rear end rotating shaft. A plurality of scrapers parallel to the faces of the circular rings are arranged among the circular rings. According to the method, the polymeric reactor is used for performing polyester production to obtain a high-viscosity polyester melt. The cage frame type stirrer is arranged at the front end, the multiple circular rings are arranged at the rear end, and the devolatilization efficiency of equipment can be effectively improved.

Owner:SHANGHAI JUYOU CHEM ENG

Phosphate surfactant and method for preparing trifluorochlor oethylene polymer

The invention discloses a phosphate surfactant, of which the chemical formula is: H-(CF2)m-CH2-O-(CH2CH2O)n-PO(OM)2, wherein m is equal to 2, 4, 6 or 8, n is equal to 0 or 1, and M is NH4+ or Na+. The invention also discloses a method for preparing trifluorochlor oethylene polymer emulsion or solid with the phosphate surfactant as an emulsifier. The surfactant can be used for emulsion polymerization of fluoride-containing monomer. Used as the emulsifier, the surfactant can achieve a high polymerization rate, good dispersion stability, high yield, excellent copolymerization performance and / or multiple particle sizes (including small particle size). Besides, the method can realize polymerization by only using conventional equipment, is easy and convenient to operate and has a low cost, and does not cause environmental pollution during and after reaction.

Owner:UNIV OF JINAN

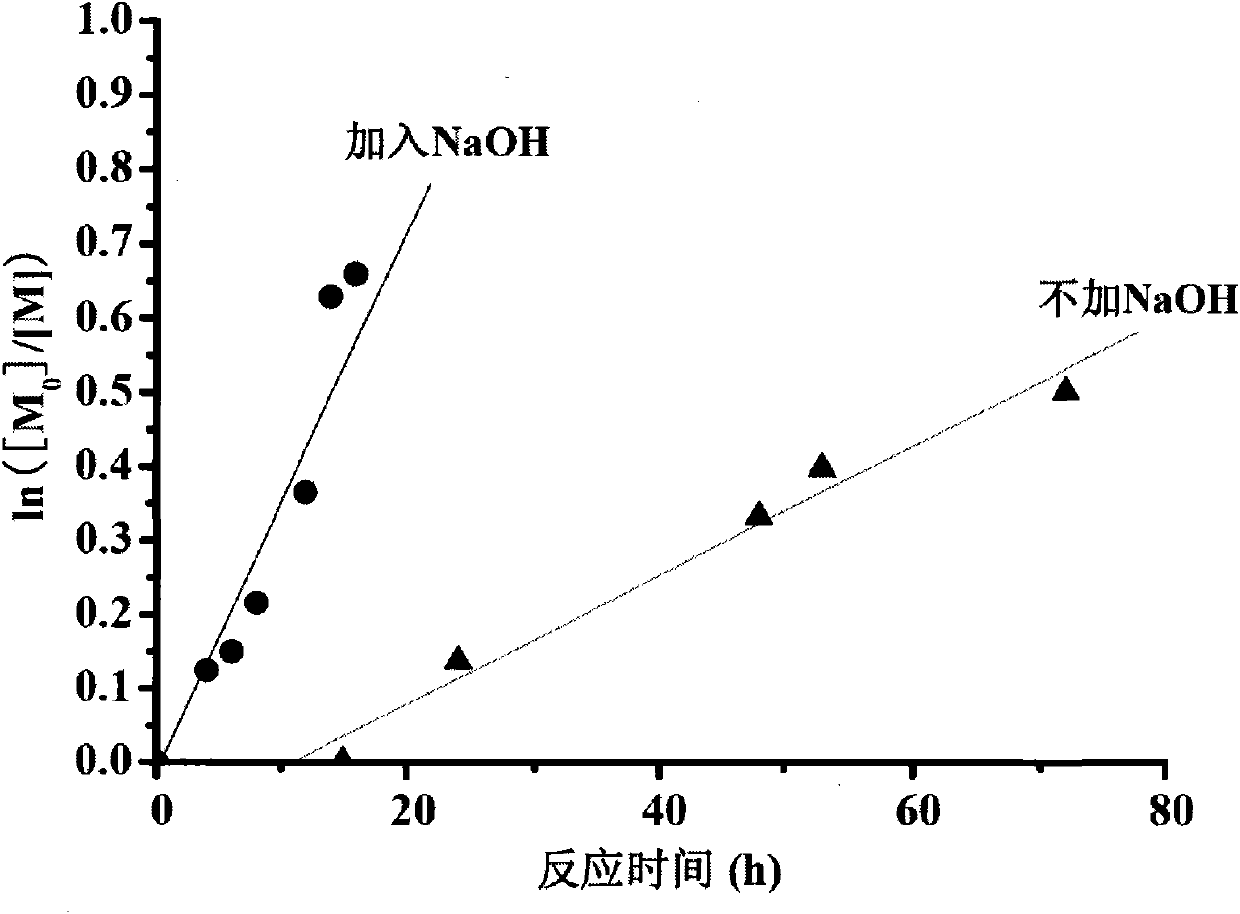

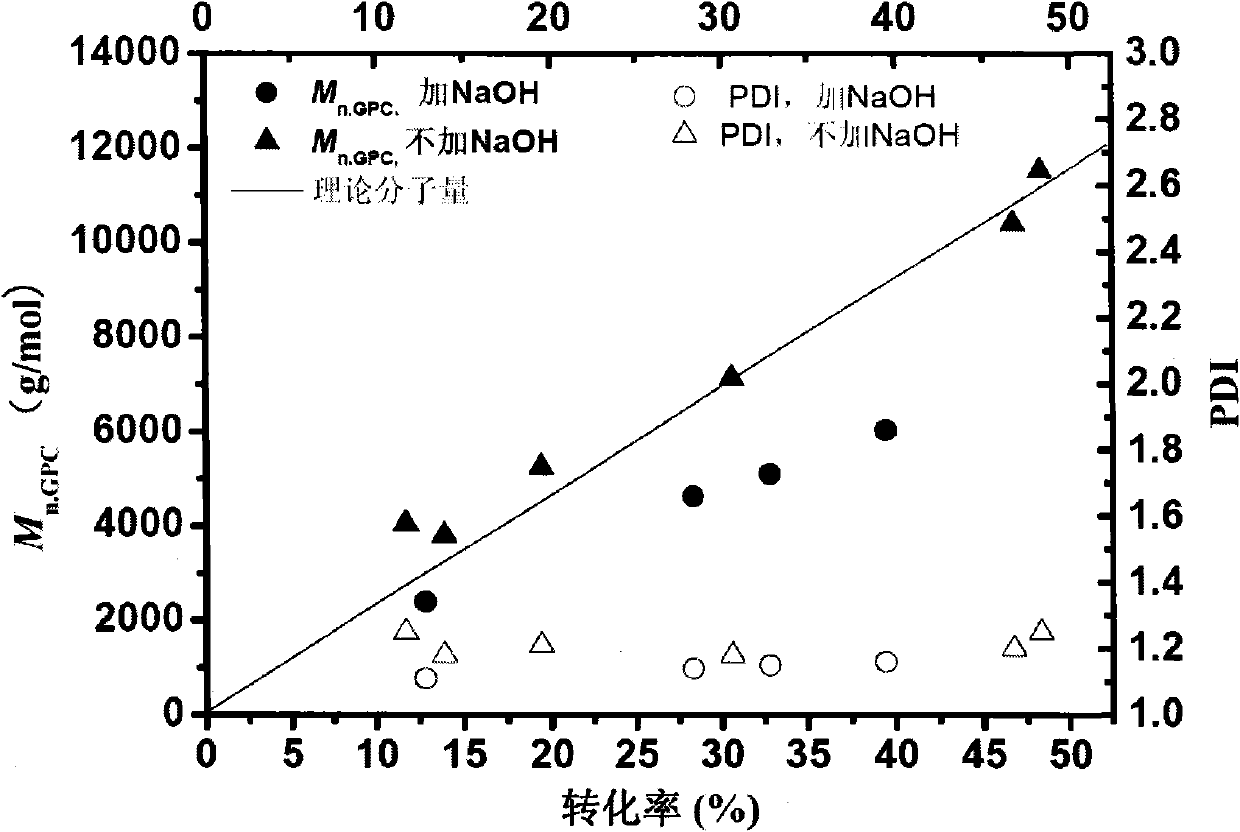

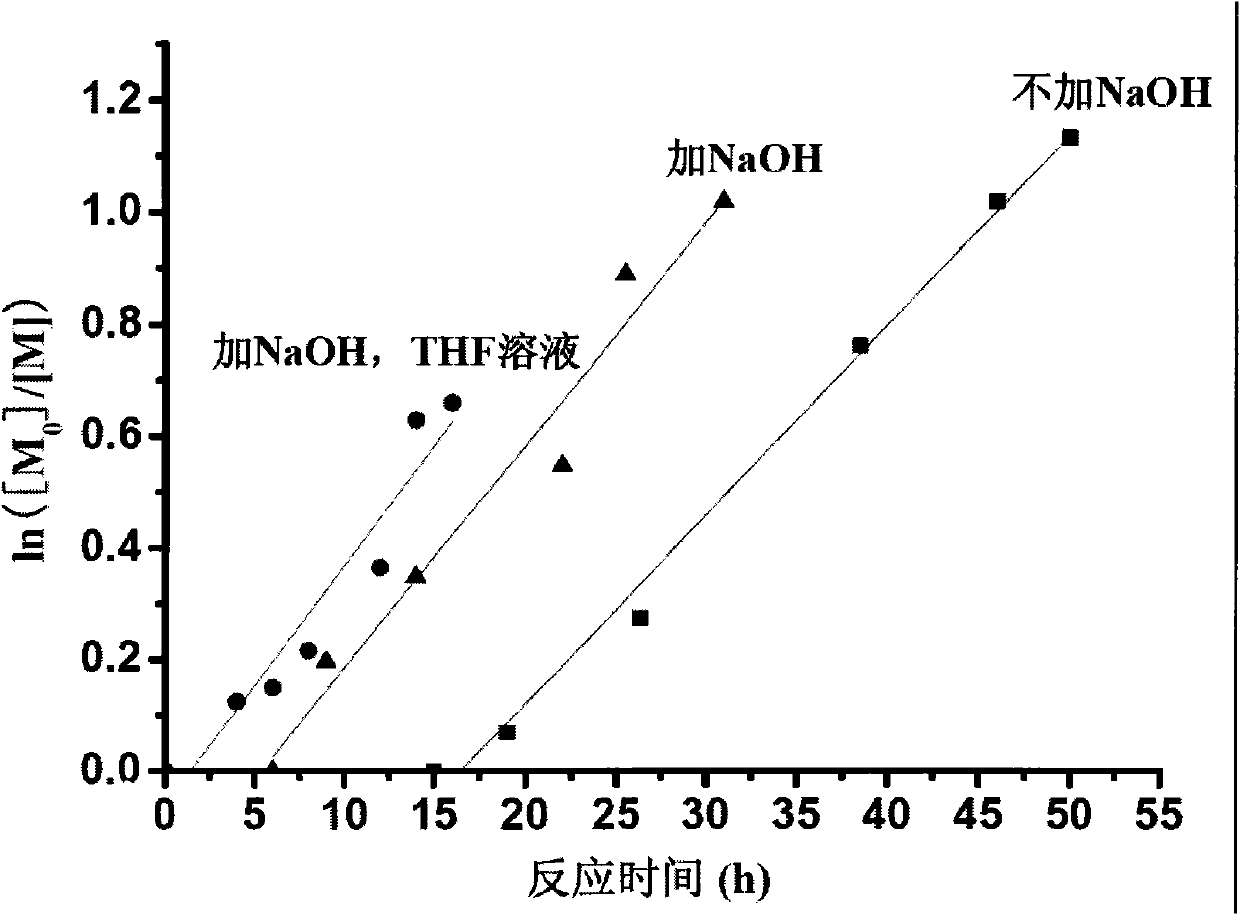

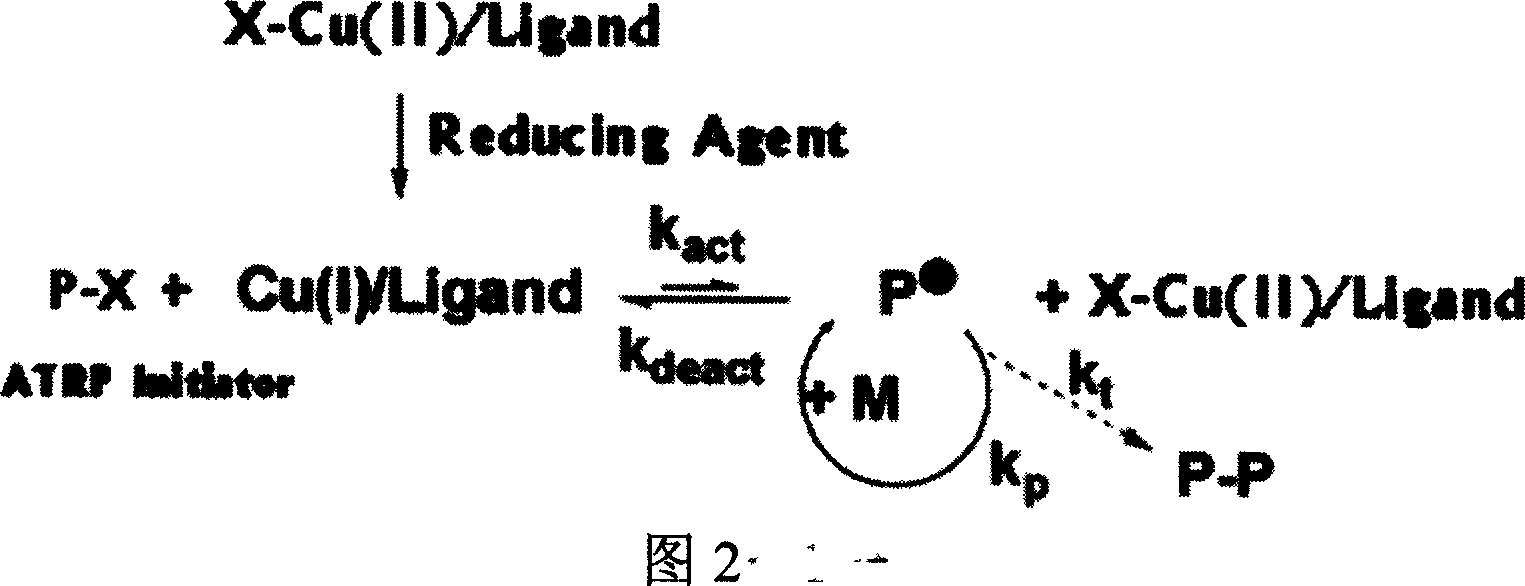

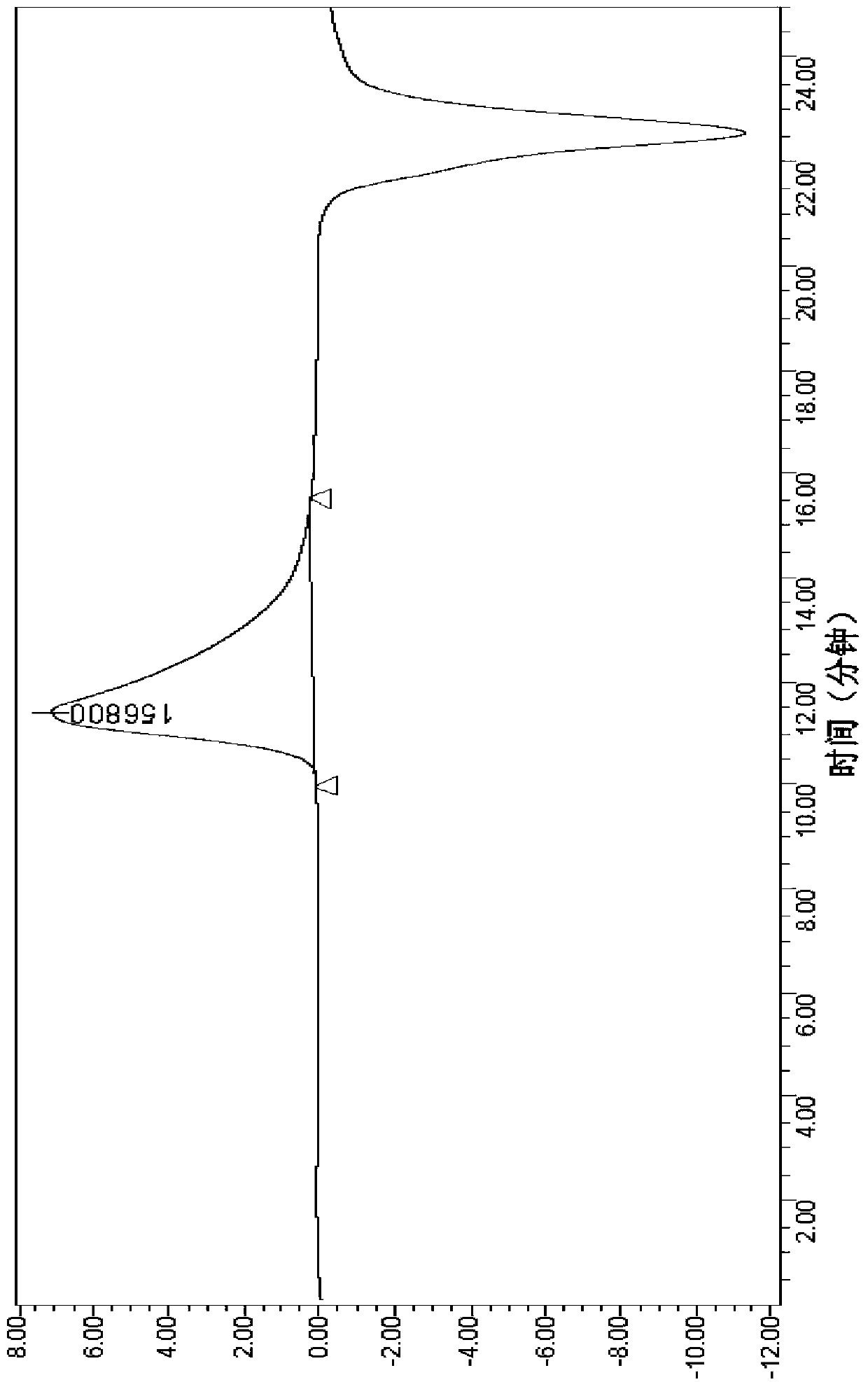

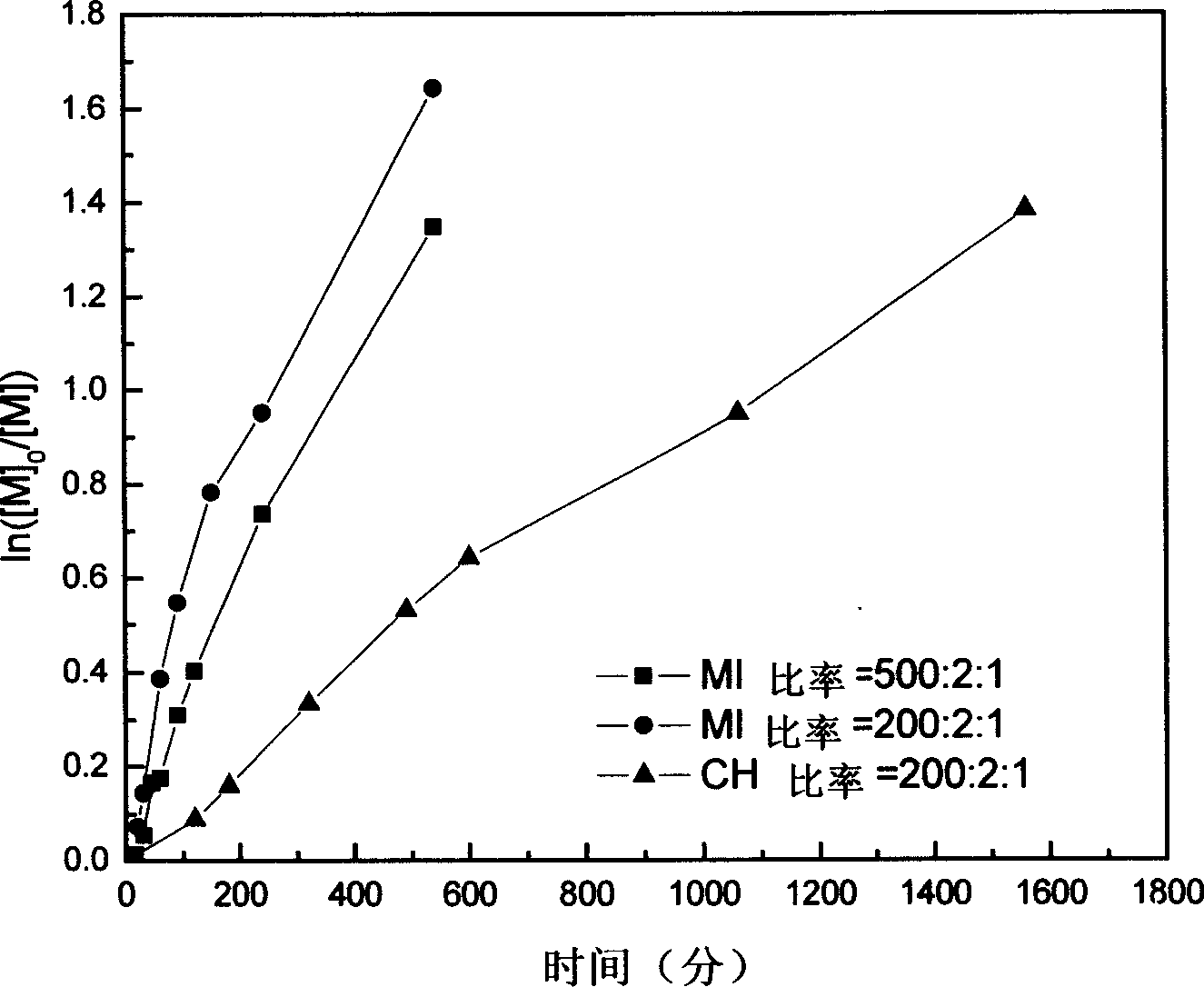

Polymerization system for atom transfer radical polymerization (ATRP) using activators generated by electron transfer (AGET)

The invention discloses a polymerization system for atom transfer radical polymerization (ATRP) using activators generated by electron transfer (AGET), comprising radical polymerization monomers, initiator, coordination agent, catalyst and reducer. The invention is characterized in that the polymerization system still comprises alkaline; the components are proportioned in mol as that monomers: initiator: alkaline equals to 100-1000: 1: 1-5; the catalyst is selected from Iron(III) chloride hexahydrate or iron bromide; and the alkaline is selected from one of sodium hydroxide (NaOH), sodium bicarbonate and ferric hydroxide (Fe (OH) 3). Because the alkaline with the same dose of the catalyst is added into the AGET ATRP polymerization system, the polymerization reaction rate is improved, a polymer with high percent conversion can be generated in a short time and the control performance of polymerization reaction is improved.

Owner:SUZHOU UNIV

Synthesis method of organosilicon drilling fluid water loss reducing agent

InactiveCN102816276AFast polymerization rateHigh molecular weightDrilling compositionSynthesis methodsUltraviolet lights

The invention relates to a synthesis method of an organosilicon drilling fluid water loss reducing agent, which comprises the following steps: adding 2-acrylamido-2-methylpropanesulfonic acid and acrylamide into an organic solvent, adding an organosilicon monomer and a photoinitiator, and carrying out ultrasonic treatment until all the solid matters are dissolved; irradiating under ultraviolet light for some time to obtain a gelatinous product; soaking the gelatinous matter in anhydrous alcohol for several hours; and taking out, carrying out vacuum drying, and grinding to obtain the white powdery product. The fluid loss agent prepared by the method provided by the invention has the advantages of favorable water loss reducing property, high temperature resistance, favorable salt resistance, high molecular weight and high stability; besides, the method provided by the invention has the advantage of high polymerization rate, and is simple; and the water loss reducing agent has favorable fluid loss reducing effect in both fresh-water drilling fluids and salt-water drilling fluids.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

Method of preparing hyperbranched polythioether

The invention relates to a method of preparing hyperbranched polythioether based on selective thiol-ene and thiol-epoxy click chemistry. According to the method, difunctional glycidyl acrylate monomers and trifunctional mercaptan are used as raw materials, and hyperbranched polythioether with a controlled skeleton and end group is synthesized by a one-pot method. The hyperbranched polythioether click chemical preparation method has the advantages that the raw material is easy to obtain, the steps are simple, the polymerization rate is rapid, the controllability is good, the skeleton of the prepared hyperbranched polythioether can be controlled, and the end group can be effectively controlled to be thiol or epoxy by using the monomeric molar ratio; functional modification can be further conducted, and the hyperbranched polythioether with particular characteristics is prepared.

Owner:JIANGNAN UNIV

Volume expansion type efficient slug gel plugging agent and preparation method thereof

ActiveCN112877045AGel forming time is controllableWide temperature adaptabilityDrilling compositionPolymer scienceCross linker

The invention provides a volume expansion type efficient slug gel plugging agent and a preparation method thereof. The volume expansion type efficient slug gel plugging agent is prepared from the following raw materials in parts by mass: 10-35 parts of a polymerization reaction agent, 1-3 parts of a cross-linking agent a, 0.02-0.5 part of a suitable-temperature initiator, 0.5-5 parts of a water-soluble resin flexibilizer, 0.5-5 parts of a composite inorganic flexibilizer, 2-8 parts of modified starch, 2-10 parts of a volume expansion reaction agent and 2-8 parts of a rheological modifier, wherein the volume expansion reaction agent is prepared from the following raw materials through an inverse emulsion polymerization method: a water-soluble polymeric monomer, a dispersion medium, an emulsifier, an oil-phase initiator and a cross-linking agent b. The plugging agent disclosed by the invention has the advantages of capability of underground crosslinking gel forming, flexible and adjustable gel forming time, high pressure bearing capacity after gel forming, relatively high water absorption expansibility, excellent mechanical strength after water absorption and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

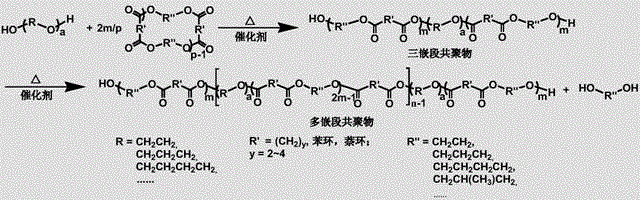

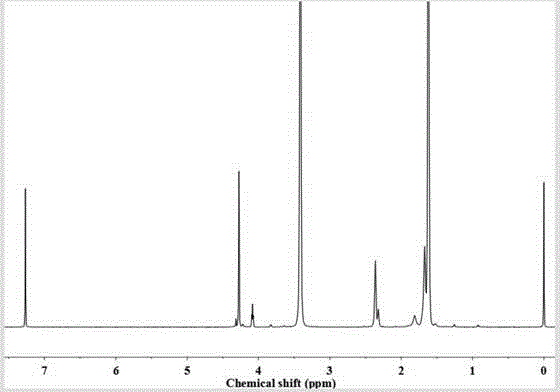

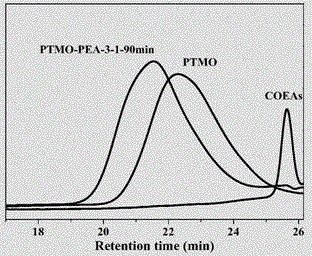

Preparation method of polyether ester multi-block alternating copolymer

InactiveCN104693447ALow reaction temperatureFast polymerization rateOligoesterSolution polymerization

The invention discloses a preparation method of a polyether ester multi-block alternating copolymer. The preparation method comprises the following steps: 1) adding a cyclic oligoester and polyether glycol to a reaction device, stirring mechanically and vacuumizing; step 2) heating to the range of 120-180 DEG C, adding a catalyst after the reactants are mixed evenly, and vacuumizing; 3) increasing the temperature to the range of 220-280 DEG C for reacting, performing ring opening polymerization on the cyclic oligoester in the presence of the polyether glycol, thereby obtaining a polyether ester three-block copolymer, and then performing condensation polymerization on the three-block copolymer to obtain the polyether ester multi-block alternating copolymer. The polyether ester multi-block alternating copolymer identified in structure is obtained by performing ring-opening condensation polymerization on the cyclic oligoester monomers by use of the polyether glycol in vacuum; the preparation method has the advantages of simple reaction, few by-products and no aftertreatment; besides, the product can be directly used without being purified.

Owner:SUZHOU UNIV

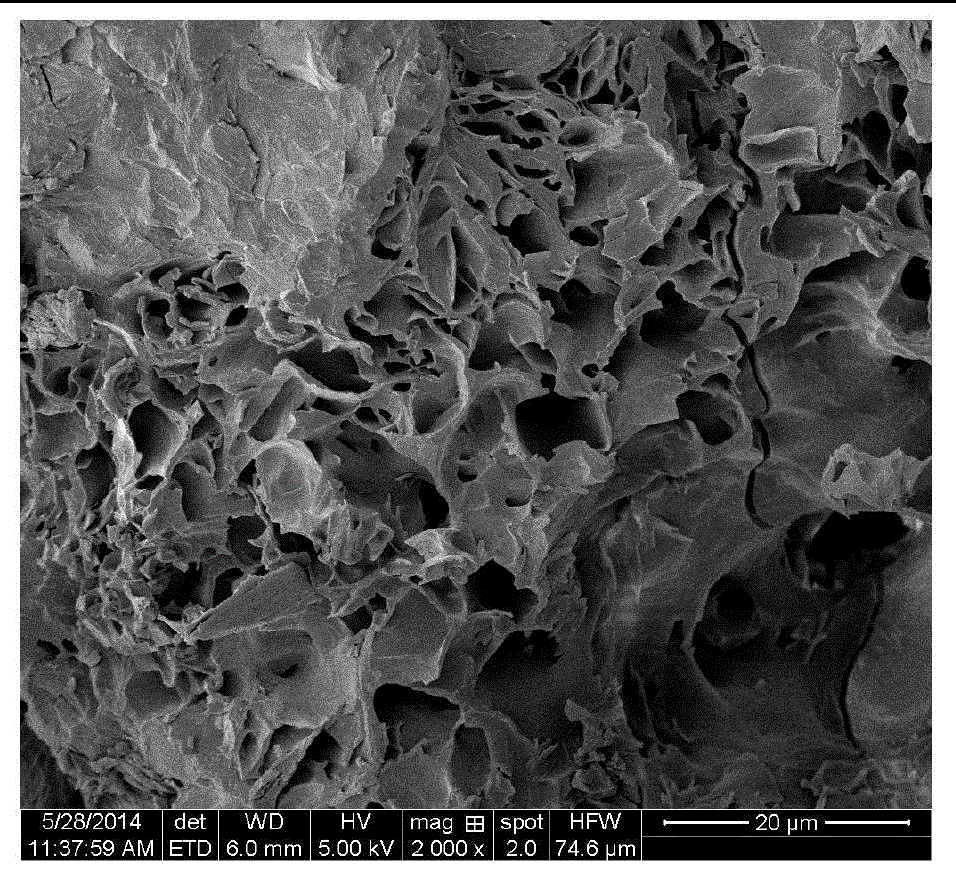

Method for preparing micro-sized monodisperse polyurea microsphere in static condition

The invention relates to a method for preparing micro-sized monodisperse polymer microspheres in static condition. The method comprises the steps that diisocyanate monomers and a water-acetone mixed solvent are added into a reaction bottle, wherein the mass ratio of water to acetone ranges from 20 / 80 to 60 / 40, and the diisocyanate compound accounts for 0.5-13.0% of the total mass of the polymerization system; after the reaction bottle is sealed and the mixed solvent is shaken up, the reaction bottle is placed in thermostatic waterbath of 20-80 DEG C for polymerization; after polymerization, the products are centrifugalized and dried to obtain the micro-sized monodisperse polyurea microspheres. The method for preparing micro-sized monodisperse polymer microspheres in static condition has the advantages that one monomer is used for precipitation polymerization completely in static condition without any stirring or oscillation, so that the reaction time is short, the monomer can be transformed completely, the yield of microspheres is high, and the operation is simple; the method is conducive to scale production of monodisperse microspheres; and the produced microspheres have clean surfaces and a large amount of amido, and can be used in various fields of protein adsorption and separation, enzyme immobilization, chromatographic analysis and the like..

Owner:UNIV OF JINAN

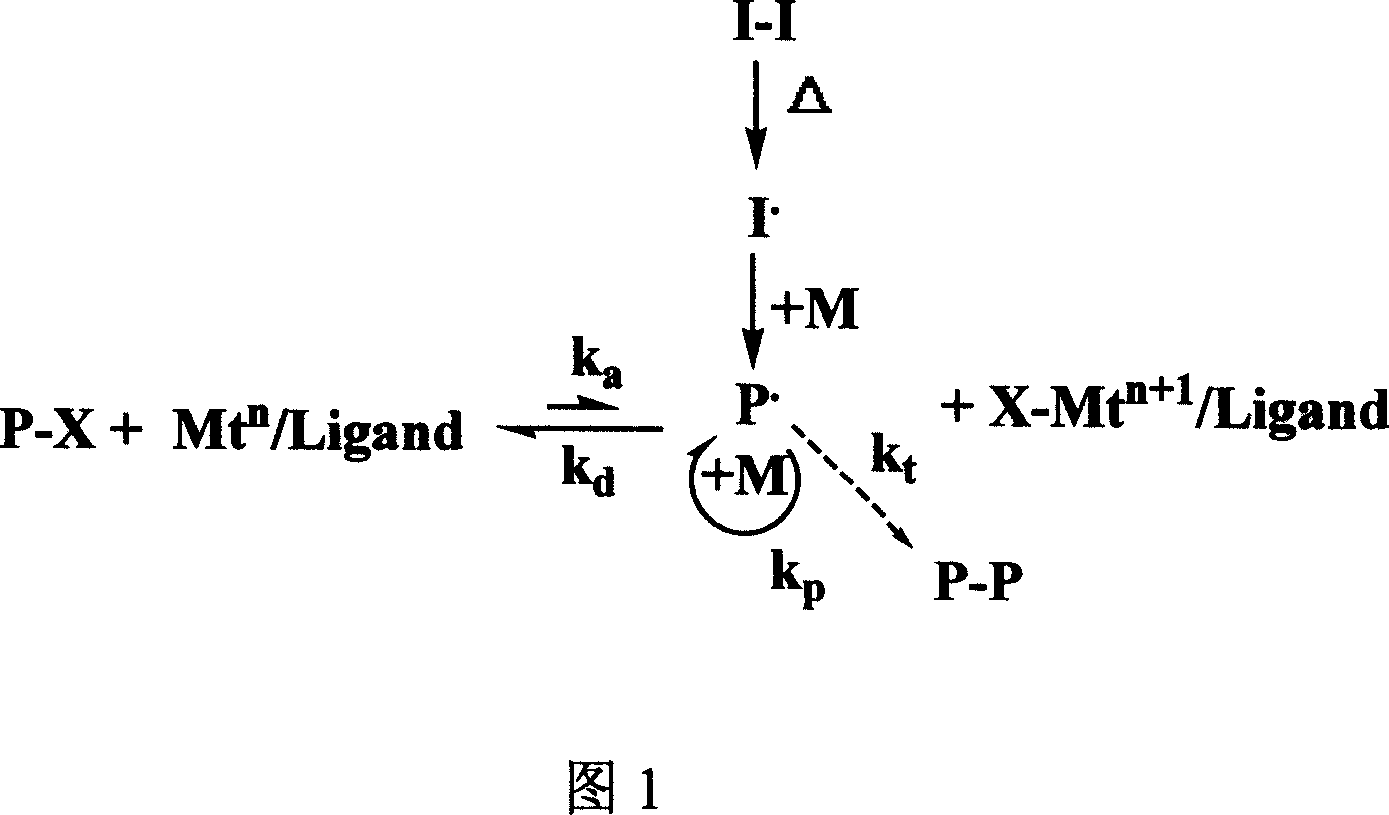

Atom transition free radical polymerization initiation system and application of the same for preparing macromolecular compound

InactiveCN101033269ALower synthesis costAvoid pollutionPolymer scienceAtom-transfer radical-polymerization

This invention relates to an atom transfer radical polymerization initiating system and its application in the preparation of polymers. The technical problem it needs to solve is to provide an initiating system with less catalyst, cost and environmental pollution. The method is characterized with the general formula [Hmim][RCOO] / PX / hydroquinone / MX1n, in which, [Hmim][RCOO] is methylimidazol organic acid salt ion liquid and R is alkyl, PX is a initiator with R1 of alkyl and X of halogen, catalyst MX1n is tall-price transition metal mineral salt, hydroquinone is a reductor, and oxygen has no effect on the polymerization system. The polymerization polymer of a monomer prepared from reaction of the above system and the monomers can react with different shapes of initiator obtaining linear, stellate and other polymers.

Owner:HANGZHOU NORMAL UNIVERSITY

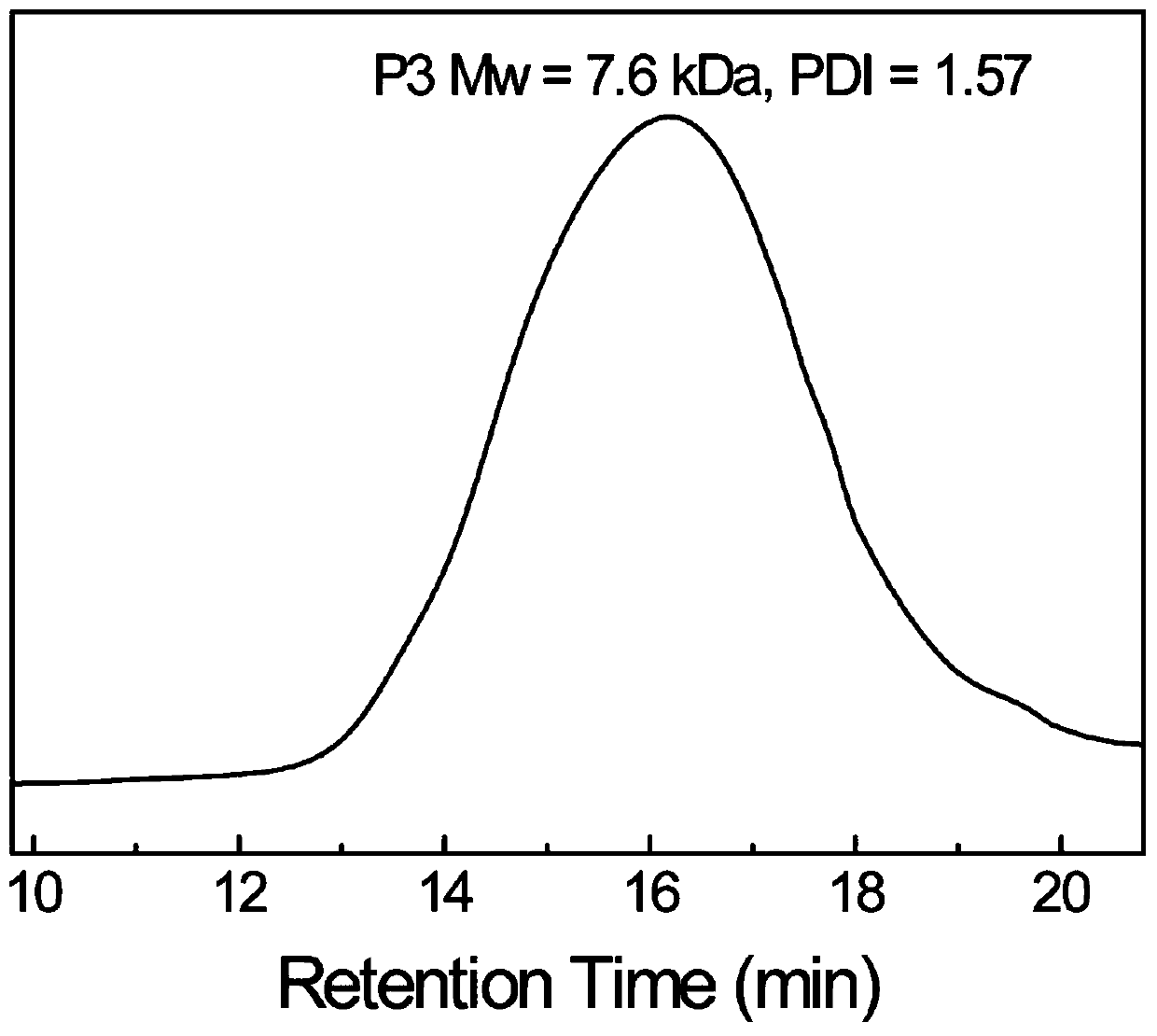

Polyacrylonitrile copolymer spinning solution and preparation method thereof

ActiveCN103421141AImprove the forceEnhanced mass transferFibre chemical featuresSpinning solutions preparationPolymer scienceAcrylonitrile

The invention relates to a polyacrylonitrile copolymer spinning solution and a preparation method thereof. In the invention, copolymerization reaction is performed on acrylonitrile in a tubular reactor containing a static mixer component; the tubular reactor, which contains the static mixer component and has the characteristics of mass transfer, efficient heat transfer, continuous and stable reaction and no mechanical stirring, is adopted to prepare the polyacrylonitrile copolymer spinning solution with high molecular weight and narrow molecular weight distribution. The polyacrylonitrile copolymer spinning solution is obtained after copolymerization reaction is performed on reaction liquid composed of monomers, a radical initiator and a solvent, wherein the percent concentration by weight of the monomers in the reaction liquid is 15% to 20%; the weight of the radical initiator is 0.4% to 1% of that of the monomers; the solvent is in balancing amount; the monomers are an acrylonitrile monomer and a comonomer. The dynamic viscosity of the polyacrylonitrile copolymer spinning solution provided by the invention is 200 to 800 Pa.S, and the molecular weight distribution is 1.5 to 2.6.

Owner:INST OF CHEM CHINESE ACAD OF SCI

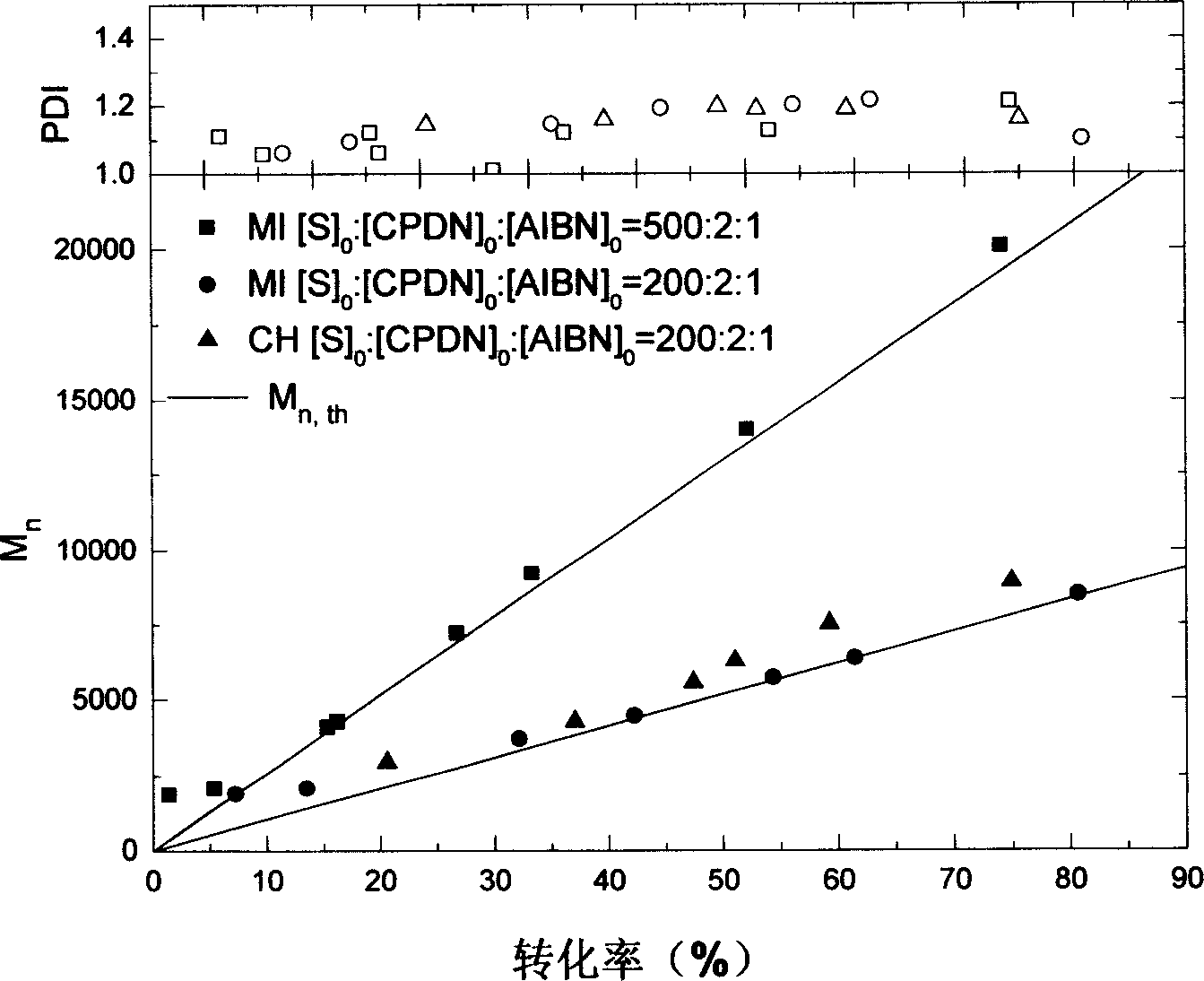

Reversible addition-fragmentation chain transfer free radical polymerization method

The invention discloses a reversible addition-fragmentation chain transfer free radical polymerization method, wherein characterized in that, microwave radiation heating can be used for polymerization, and it is possible not to use initiating agent . The invention can greatly increase polymerization speed, andconveniently control molecular weight of polymerization product.

Owner:SUZHOU UNIV

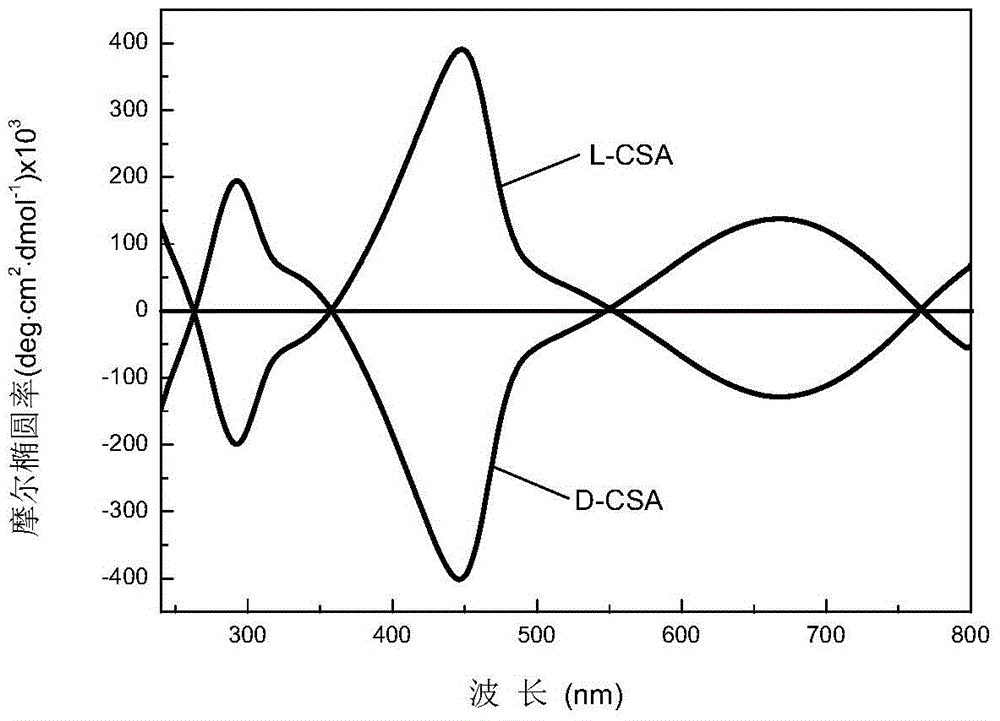

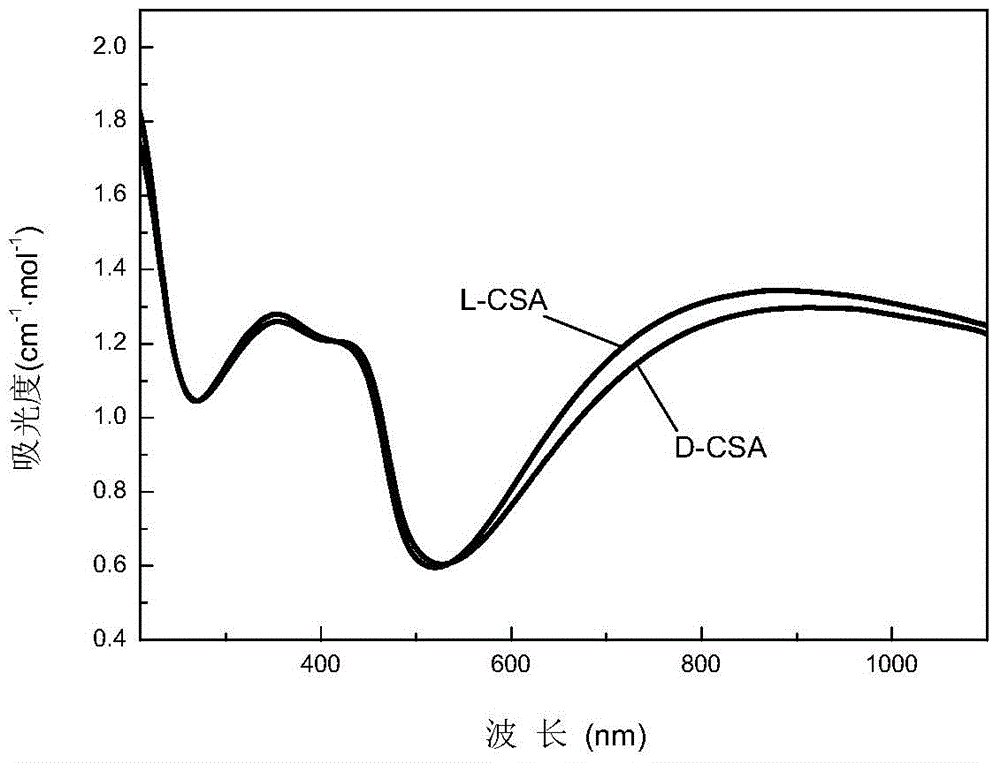

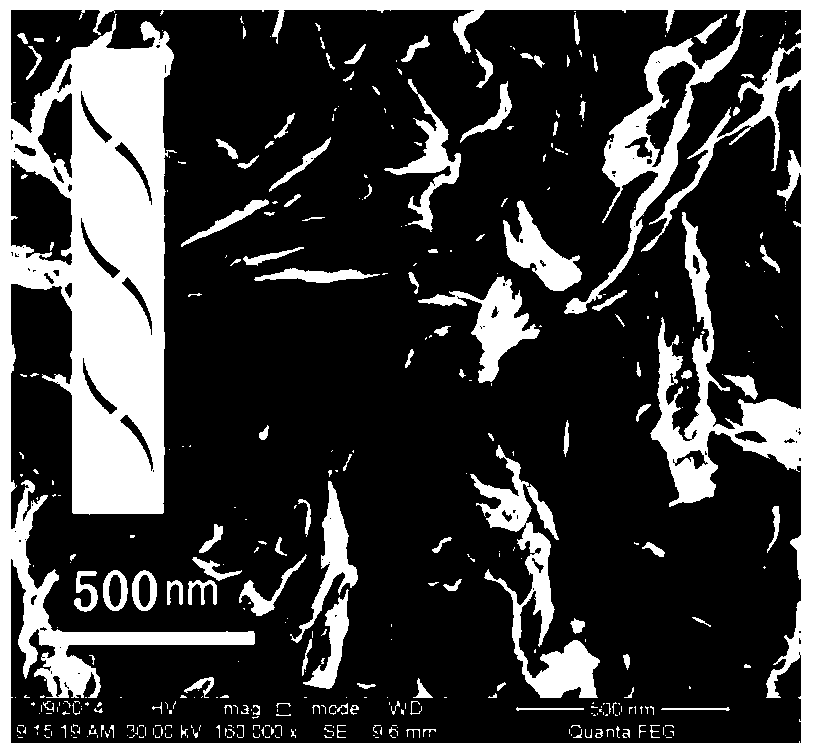

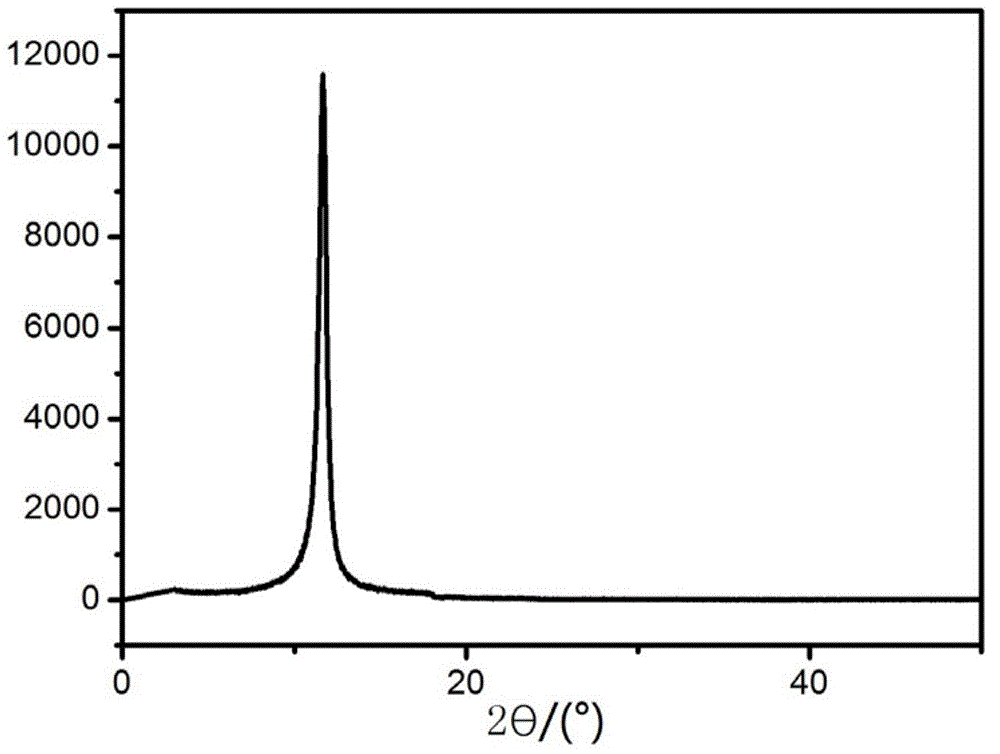

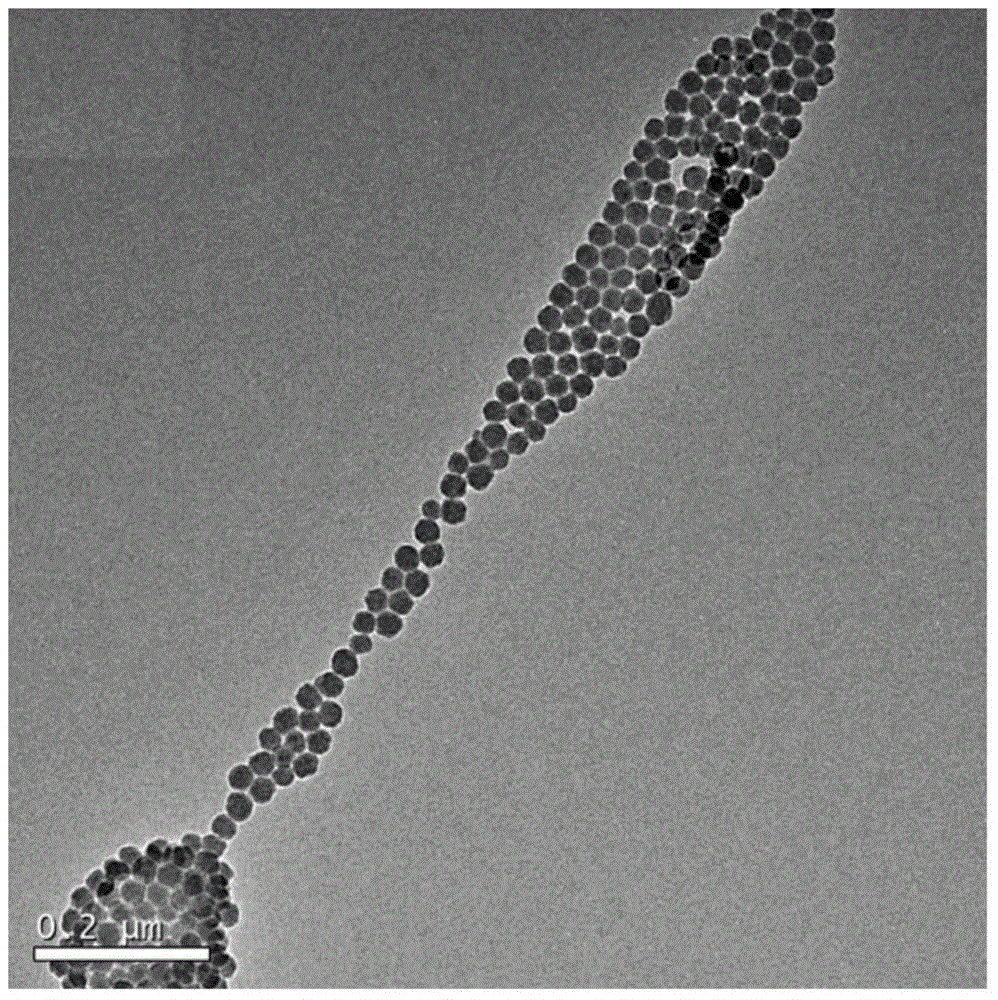

Synthetic method of polyaniline nanofiber with helical structure

The invention provides a synthetic method of polyaniline nanofiber with a helical structure. The method comprises the following steps: firstly synthesizing N, N'-2(4-phenylene diamine)-1 and 4-phenylene diamine; secondly taking N, N'-2(4-phenylene diamine)-1 and 4-phenylene diamine as a polymerization reaction catalyst, chiral camphor sulfonic acid as an inducer and a doping agent, and ammonium persulfate as an oxidizing agent; finally synthesizing the polyaniline nanofiber with the helical structure through adopting the chemical oxidative polymerization. According to the synthetic method, the chiral camphor sulfonic acid is adopted as the doping agent to be interacted with the polyaniline main chain and to induce the polyaniline main chain to form the helical structure, and meanwhile, N, N'-2(4- phenylene diamine)-1 and 4-phenylene diamine with the oxidation potential lower than that of monomer aniline is further added to serve as a 'seed' and catalyze the polymerization reaction, so that the polymerization rate is greatly increased with the addition of phenylene diamine, and besides, heterogeneous nucleation is under restriction in the polymerization process, giving rise to the predominance of homogeneous nucleation, so that secondary growth is inhibited, the formation of the polyaniline helical structure is facilitated, and the optical activity of polyaniline is greatly improved.

Owner:HARBIN ENG UNIV

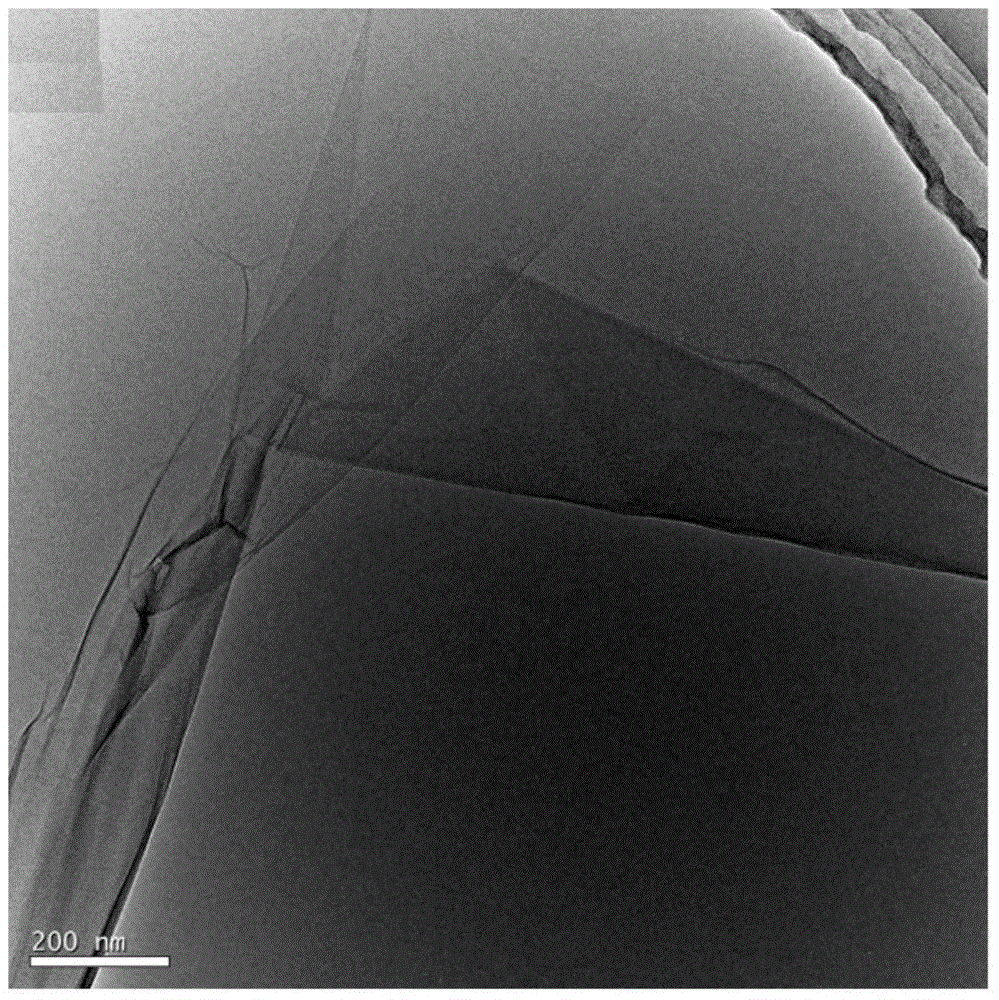

Polyethylene catalyst carrier material with ultrahigh molecular weight and preparation method thereof

The invention provides a polyethylene catalyst carrier material with an ultrahigh molecular weight and a preparation method thereof. The preparation method comprises the following steps: mixing a graphene oxide aqueous solution with a silica sol to obtain a mixed dispersion solution; spraying the mixed dispersion solution into liquid nitrogen, performing atomization, then curing instantly, volatizing to remove the liquid nitrogen, and performing vacuum drying to remove water so as to obtain a sample; heating the sample to perform activation reaction, thereby obtaining a graphene oxide / silicon dioxide spherical catalyst carrier material; mixing the graphene oxide / silicon dioxide spherical catalyst carrier material with butyl magnesium chloride in a tetrahydrofuran solution, and stirring for reaction to obtain a reaction product; and cleaning the reaction product, and heating at 600 DEG C for 2 hours to obtain the polyethylene catalyst carrier material with the ultrahigh molecular weight. The catalyst carrier provided by the invention can effectively reduce entanglement of polymer molecular chains, so that a graphene / ultrahigh-molecular-weight polyethylene composite material can be prepared.

Owner:PETROCHINA CO LTD +1

High-yield preparation method of functional monodisperse polyurea microspheres

The invention relates to a high-yield preparation method of functional monodisperse polyurea microspheres. The method adopts a precipitation polymerization process and comprises the following step: with water and acetonitrile as solvents and isophorone diisocyanate as monomers, reacting isocyanate with the water to prepare the monodisperse polyurea microspheres with rich amine groups on the surfaces. According to the method, single raw material is used, the reaction time is short, the monomers are completely converted, and the monomer content and the microsphere yield during preparation of the monodisperse microspheres are remarkably increased; the microsphere preparation process can be carried out in a complete standing condition, the functional polyurea microspheres can be obtained in one step without any surface modification, the process is simple, and the obtained microspheres can be used in the fields of enzyme immobilization, chemical catalysis, chromatographic analysis and the like.

Owner:UNIV OF JINAN

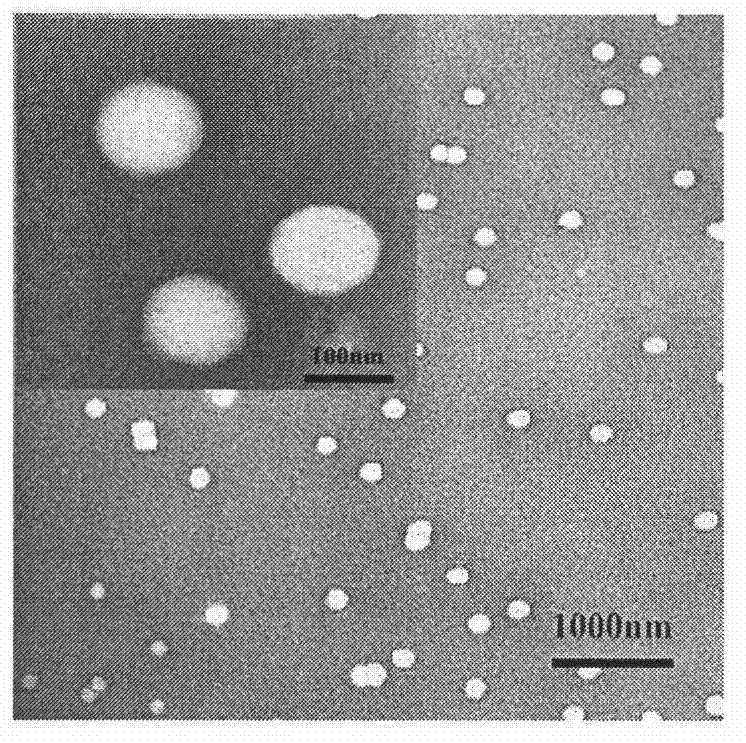

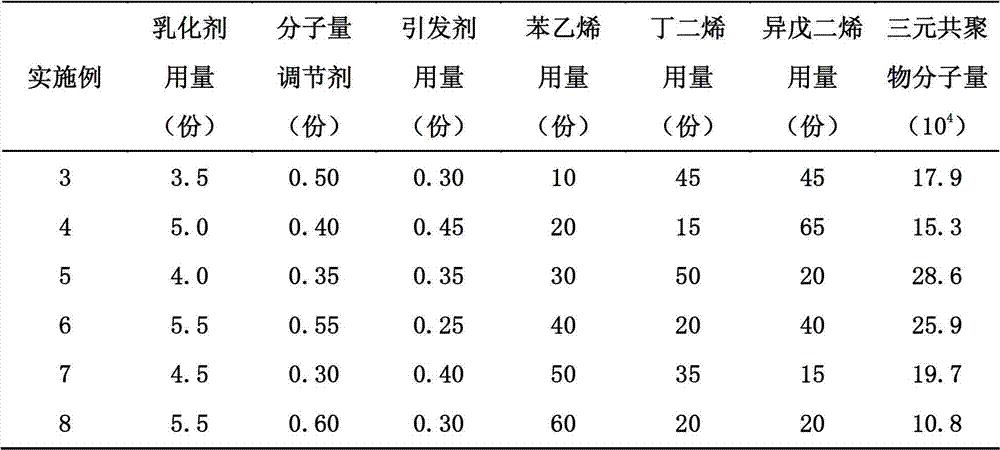

Styrene-butadiene-isoprene terpolymer integrated latex and preparation method thereof

The invention relates to a styrene-butadiene-isoprene terpolymer integrated latex and a preparation method thereof. The latex is characterized in that: the latex has a number-average molecular weight of 3*104-35*104; based on 100% of a total monomer, the latex comprises 10-65% of combined styrene, 10-70% of butadiene, and 10-70% of isoprene; and the particle size of the latex is 50-200 nm. The latex disclosed herein combines the characteristics of traditional polybutadiene rubber latex, polyisoprene latex, and styrene-butadiene latex, can replace natural latex and polyisoprene latex to be used for preparing high-grade latex products, and can replace traditional polybutadiene rubber latex and butylbenzene latex to prepare high-performance ABS resion by emulsion graft polymerization.

Owner:DALIAN UNIV OF TECH

Aqueous fluorine-containing dispersion solution as well as preparation method and application thereof

ActiveCN107778412AAchieve synergyAchieve modificationAntifouling/underwater paintsPaints with biocidesChemical industryPolymer science

The invention relates to the technical field of fluorine chemical industry and particularly relates to an aqueous fluorine-containing dispersion solution as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) taking fluorine-containing olefin monomers and perfluorinated diene as raw materials and carrying out emulsion polymerization to obtain a fluorine-containing seed polymer emulsion; and (2) taking the fluorine-containing seed polymer emulsion and fluorine-free olefin monomers as the raw materials and carrying out emulsion polymerization to obtain the aqueous fluorine-containing dispersion solution. According to the preparation method, unsaturated side chains can be formed on fluorine-containing seed polymer particles in the step (1), so that the combination of the fluorine-containing seed polymers and the fluorine-free olefin monomers is effectively improved; the modification action of fluorine-free olefin on fluorine-containing polymers can be better achieved; the synergistic action between two types of monomers is achieved, so that the negative influence of fluorine-free monomers on weather resistance and the negative influence of the fluorine-containing monomers on adhesion performance are reduced. The aqueous fluorine-containing dispersion solution has high pollution resistance, stain removal performance, adhesion, weather resistance and chemical resistance; the coating of the aqueous fluorine-containing dispersion solution has high glossiness and hardness.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com