Patents

Literature

181results about How to "Reduce oil production costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synthesis method of drilling fluid filtrate reducer

InactiveCN101805595ANo pollution in the processFast polymerization rateDrilling compositionSynthesis methodsOil phase

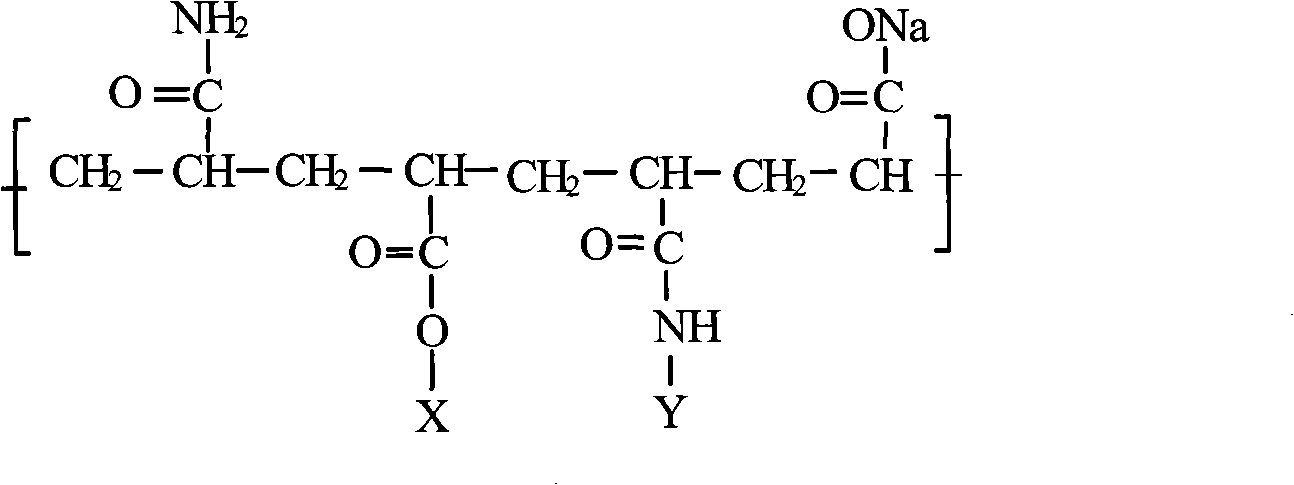

The invention relates to a synthesis method of drilling fluid filtrate reducer. The method comprises: a, nonionic compound emulsifying agent is dissolved in oil and oil phase is made up; a first monomer chosen from fumaric acid, maleic acid, itaconic acid or crylic acid, a second monomer chosen from N, N- dimethylacrylamide, N, N-diethylacrylamide or acrylamide and a third monomer chosen from 4-vinylbenzenesulfonic acid sodium salt, sodium allylsulfonate, 3-allyloxy-2-dydroxy-1-sodium allylsulfonate, 2- methacryloxypropyl-2-methyl propanesulfonic acid, 2-acrylamido-2-methyl propanesulfonic acid or SMAS are dissolved in water with the molar ratio of 1:1 to 5:1 to 5, the pH value of the solution is adjusted to be between 8 and 11, evocating agent is added and water phase solution is made up; and b, the water solution is added to the oil phase solution and the temperature rises to 40 to 70 DEG C for polymerization. The method of the invention has the advantages of fast polymerization speed, high outcome molecular weight and high outcome stability, good filtrate reducing performance, high temperature resistance and high salt resistant performance.

Owner:BEIJING UNIV OF CHEM TECH

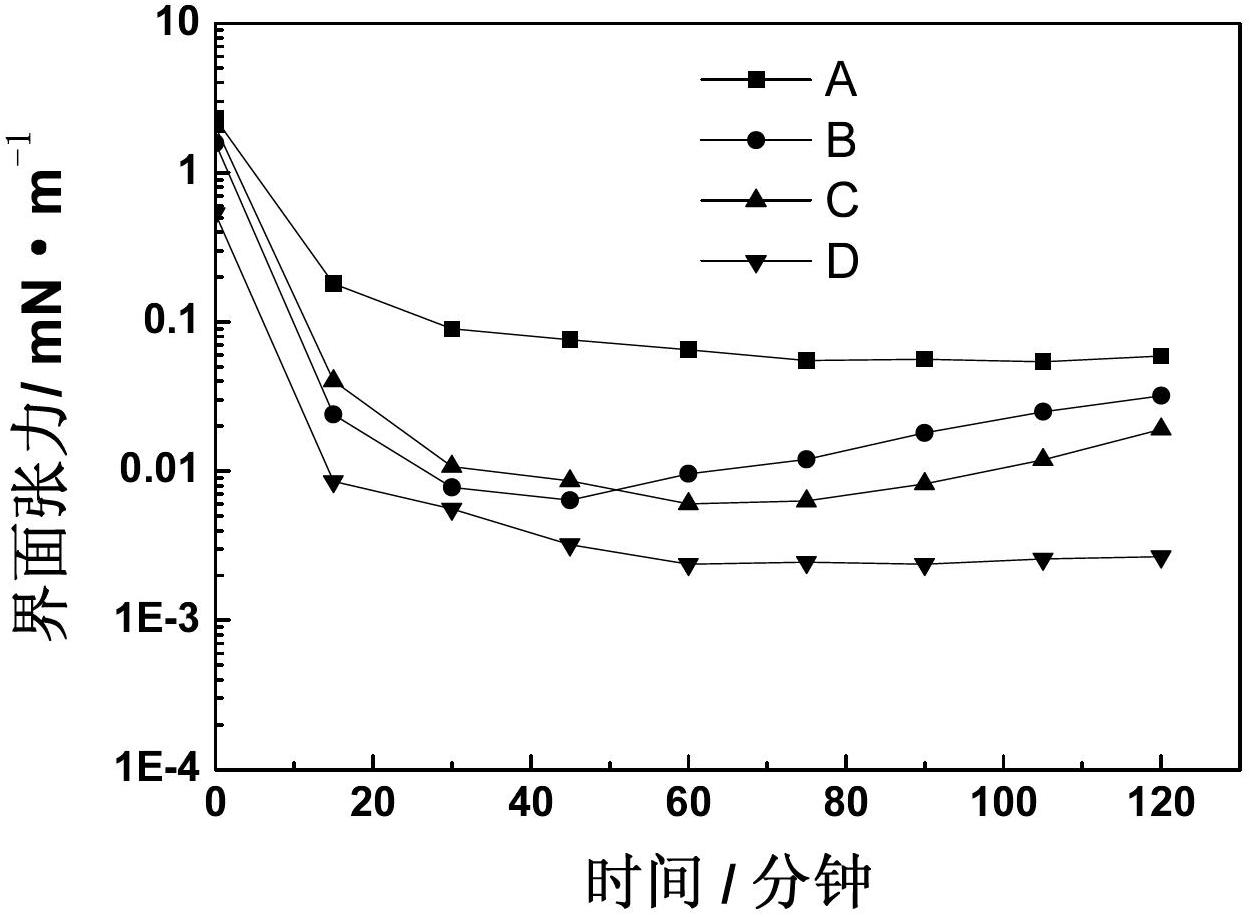

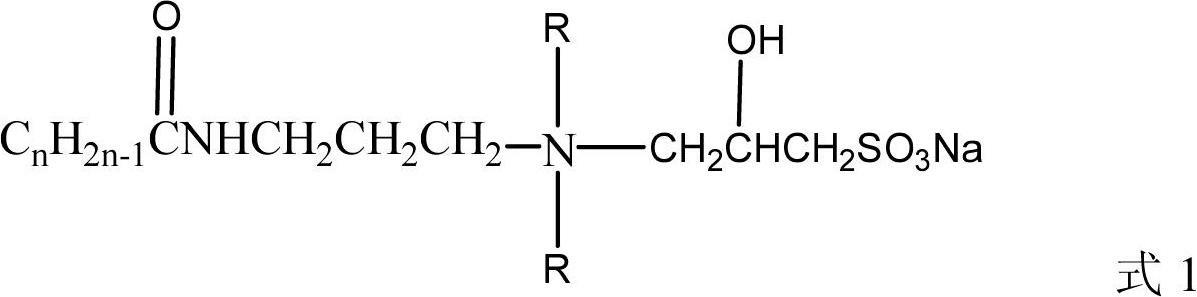

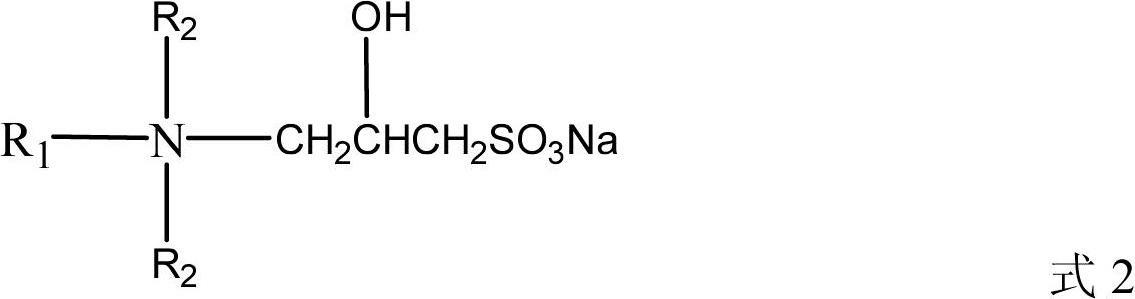

Binary alkali-free complex composition for flooding, suitable for high-temperature and high-salinity reservoir, and application thereof

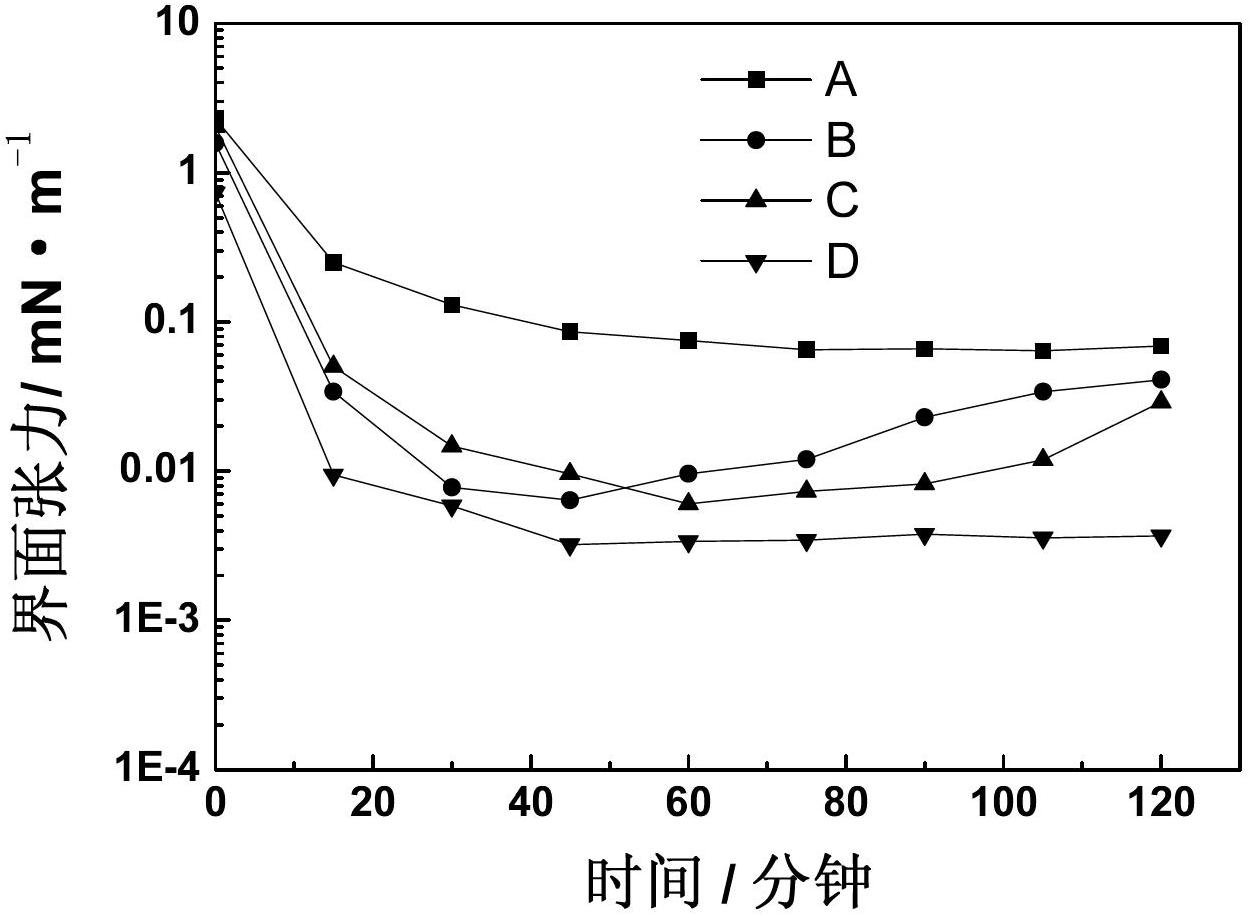

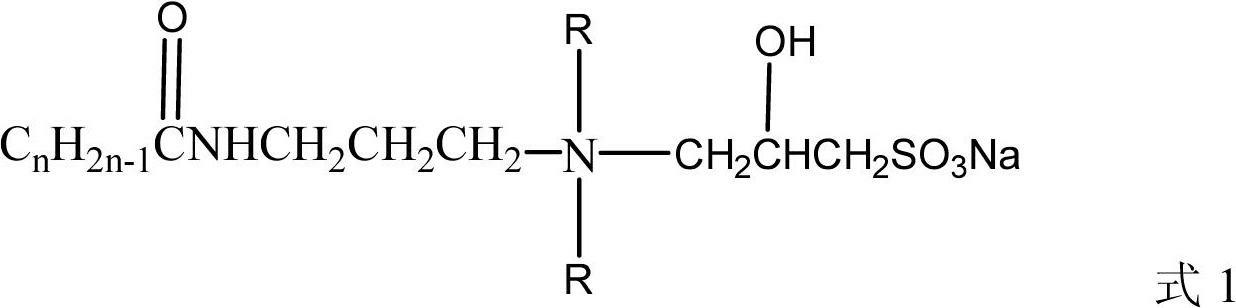

ActiveCN102690644ALow costOvercoming the defect of interfacial tension recoveryFluid removalDrilling compositionAlkali freeMass ratio

The invention relates to a binary alkali-free complex composition for flooding, suitable for high-temperature and high-salinity reservoir, and application of the composition. The binary alkali-free complex composition for flooding is composed of the following components measured by total weight of the binary alkali-free complex composition for flooding: 0.05-0.3% of complex surfactants, 0.1-0.25% of polymers and the balance of water; wherein the compound surfactants are composed of two kinds of hydroxysulfobetaine with different structures and a mass ratio of 9: 1-4: 6. The invention further provides the application of the binary alkali-free complex composition for flooding in tertiary oil recovery. According to the binary alkali-free complex flooding composition provided by the invention, interface performance exceeds the performance of the composition simply utilizing erucamide hydroxysulfobetaine as surfactants to achieve ultralow interfacial tension, and at the same time, the interfacial tension of the composition in a long term can be kept at an ultralow state; and oil recovery cost also can be reduced.

Owner:PETROCHINA CO LTD

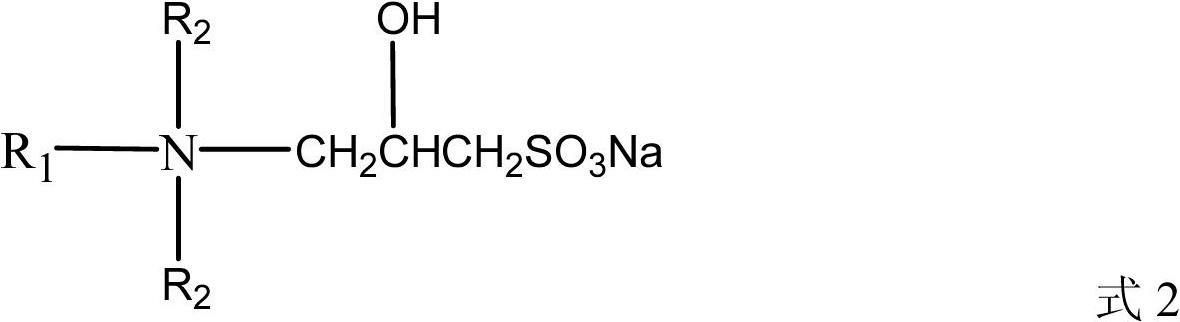

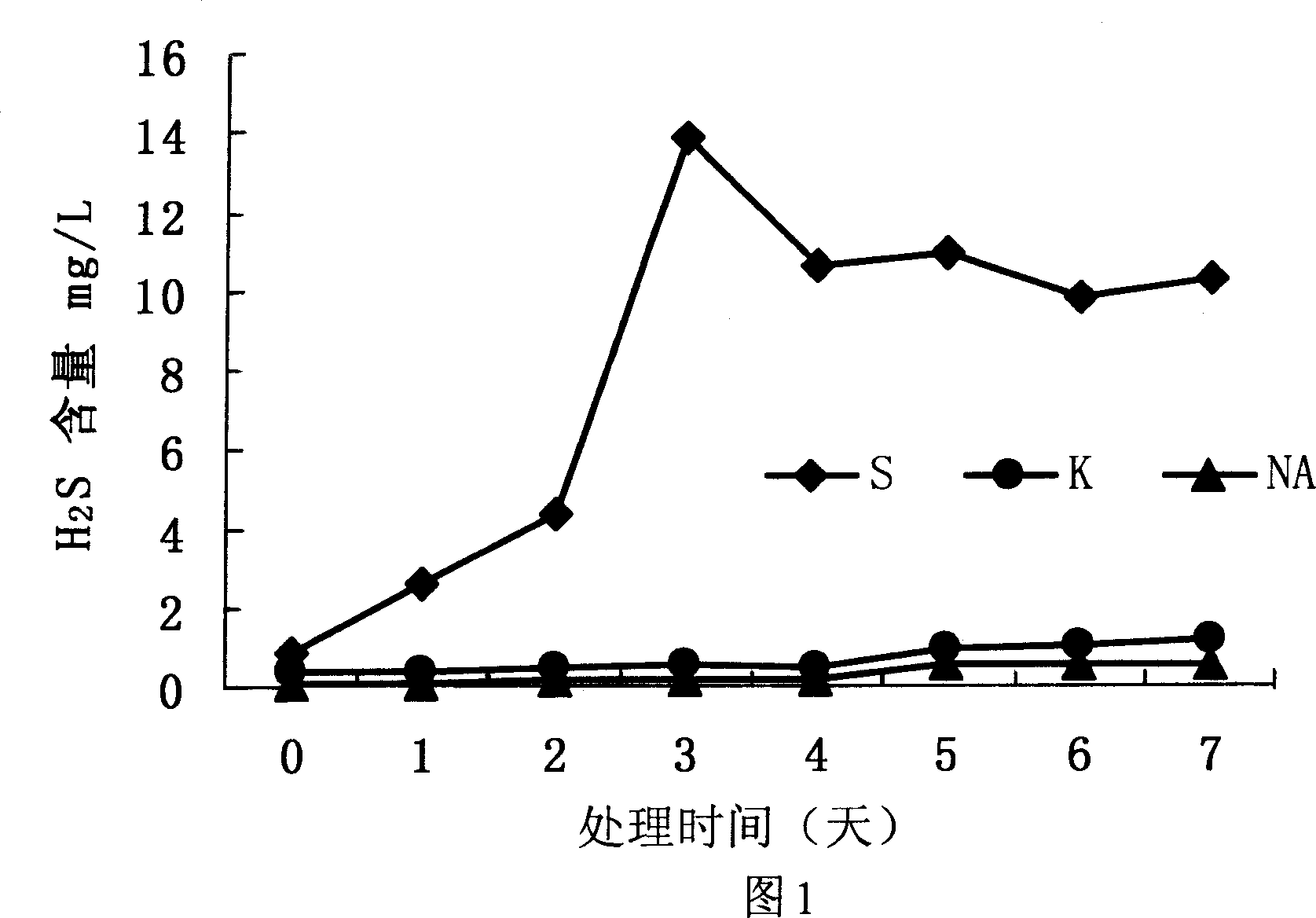

Microorganism for controlling harm of oil field sulfate reductive bacterium and application thereof

InactiveCN1920004AReduce corrosion costsEliminate pollutionBacteriaBiological water/sewage treatmentMetaboliteDenitrifying bacteria

The invention relates the microorganism agent used to control oil field sulfate-reducing bacteria and its application. The invention can used to control oil field secondary depletion sulfate-reducing bacteria and microorganism. The water outlet system of secondary depletion technology comprises sulfate-reducing bacteria, H2S and sulphide, which can cause corrosion and pollution of sulphide. Microorganism agent comprises denitrifying bacteria culture, nutrescin and synergic nutrescin. 0.01-1wt% denitrifying bacteria culture, 5-100g / L culture and 10-200ppm synergic nutrescin. Microorganism agent can avoid SRB growing, SRB producing H2S, and removing sulphide. At the same time, metabolite can improve recovery efficiency.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Oil-displacing agent and oil-displacing method for enhancing recovery ratio of high-temperature, high-salinity and high-hardness reservoir crude oil

ActiveCN103254883ALow critical micellar concentrationStrong ability to reduce interfacial tensionFluid removalDrilling compositionChemistryAlkylphenol

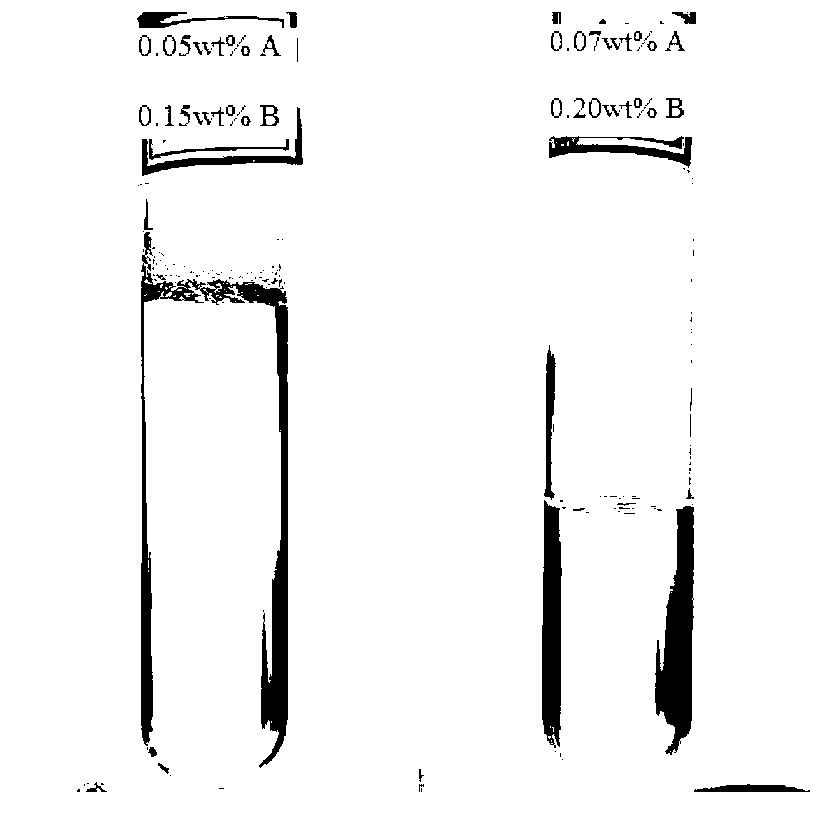

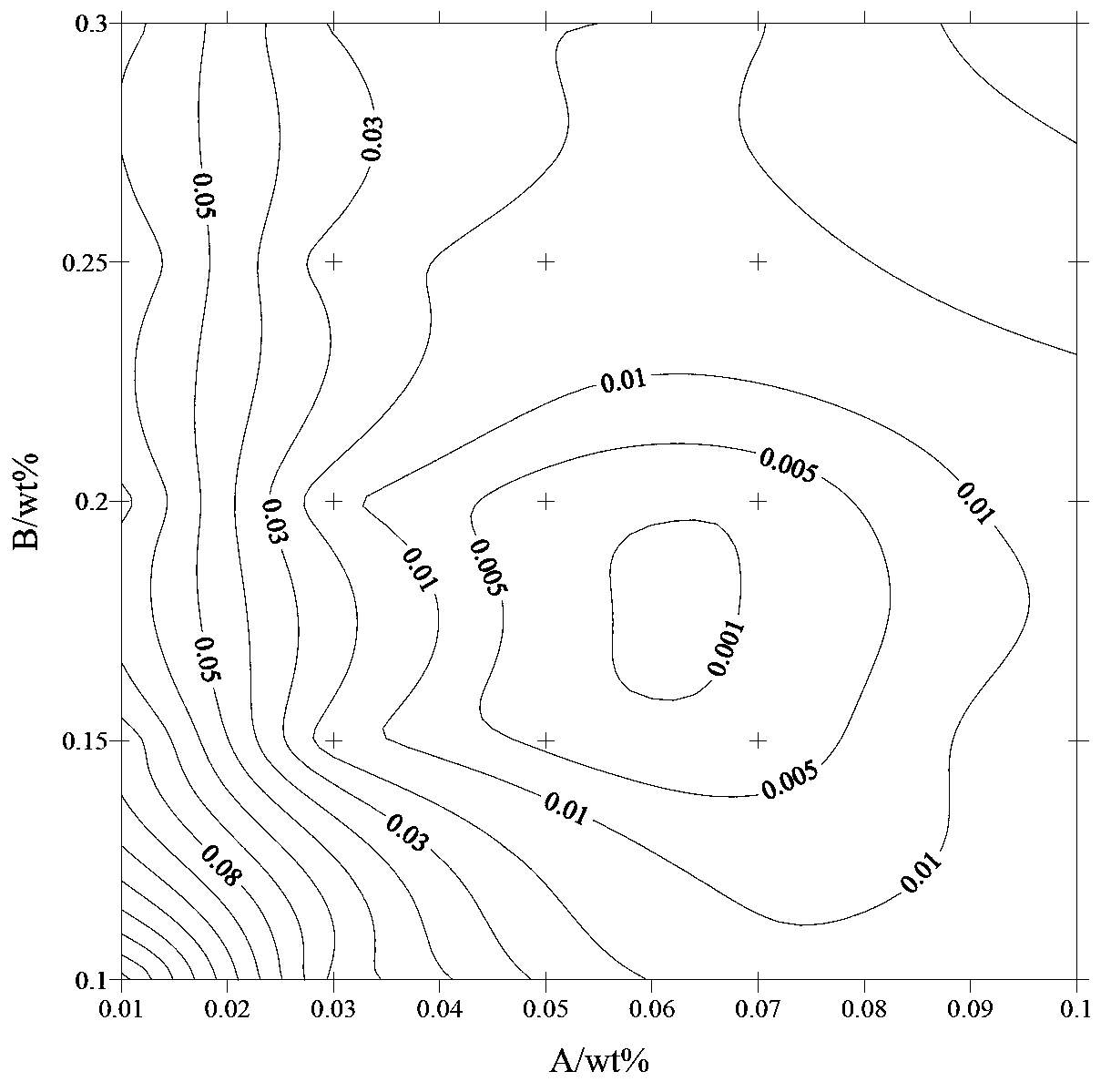

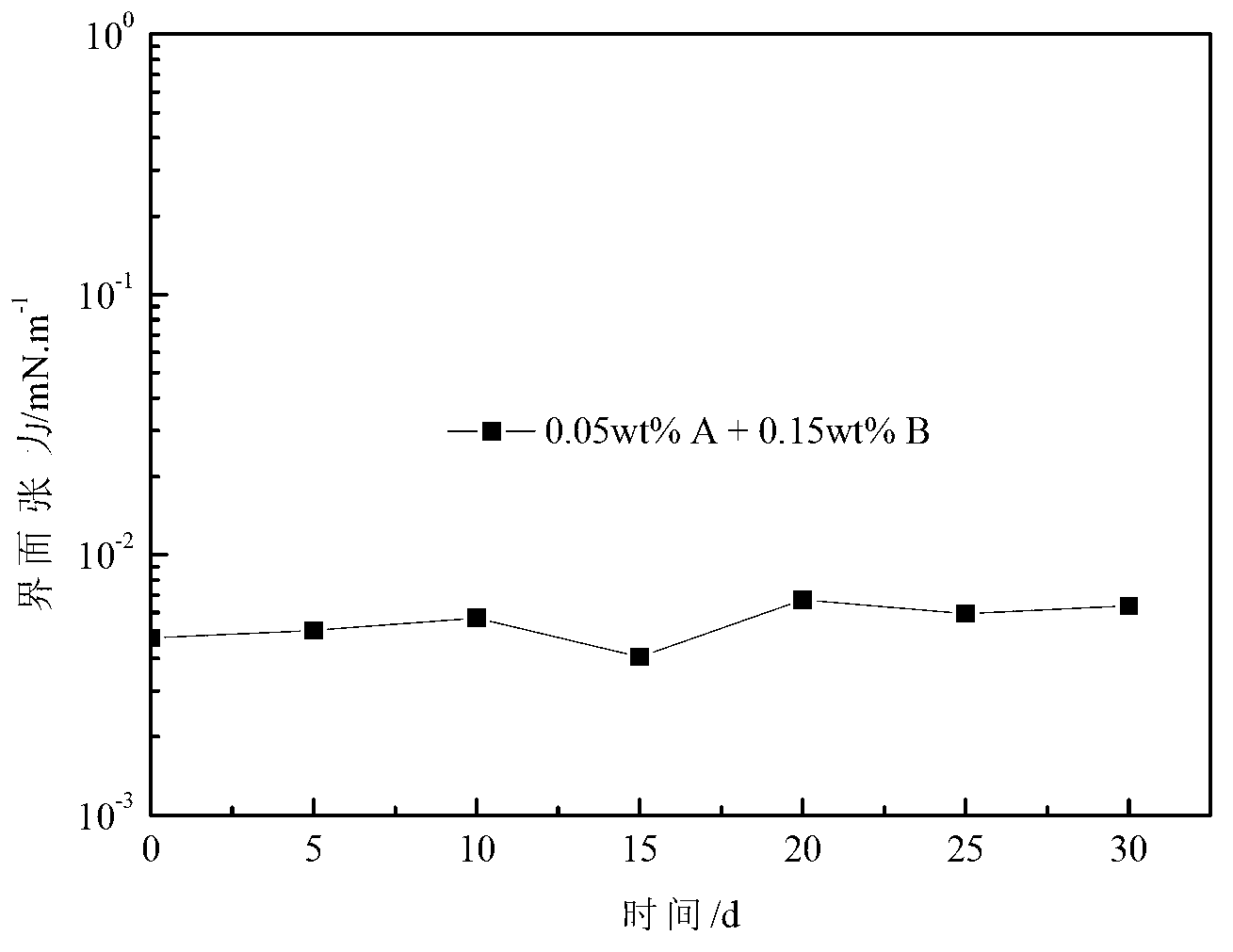

The invention relates to an oil-displacing agent and an oil-displacing method for enhancing the recovery ratio of high-temperature, high-salinity and high-hardness reservoir crude oil. The oil-displacing agent is composed of the following components in percentage by mass: A, 0.05-0.07% of an amine oxide type amphoteric surfactant; B, 0.15-0.20% of alkylphenol ethoxylate carboxylate; and C, the balance of water. The oil-displacing method disclosed by the invention is implemented through injecting the oil-displacing agent into a natural core subjected to oil-displacing under the conditions that the oil reservoir temperature is 100-120 DEG C, the total salinity of formation water is (10-15)*10<4> mg / L, and the amount of calcium-magnesium divalent metal ions is 7000-10000 mg / L, so that residual oil is in contact with the oil-displacing agent, and then the residual oil is fully displaced. The oil-displacing agent provided by the invention reaches the magnitude order of 10<-3> mN / m under the condition of high-temperature, high-salinity and high-hardness salt reservoirs, and the interfacial tension still can be maintained in an ultra-low interfacial tension state after the oil-displacing agent is aged for a long time under the condition of oil reservoirs, therefore, the oil-displacing agent is applied to the tertiary oil recovery production of oil fields.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

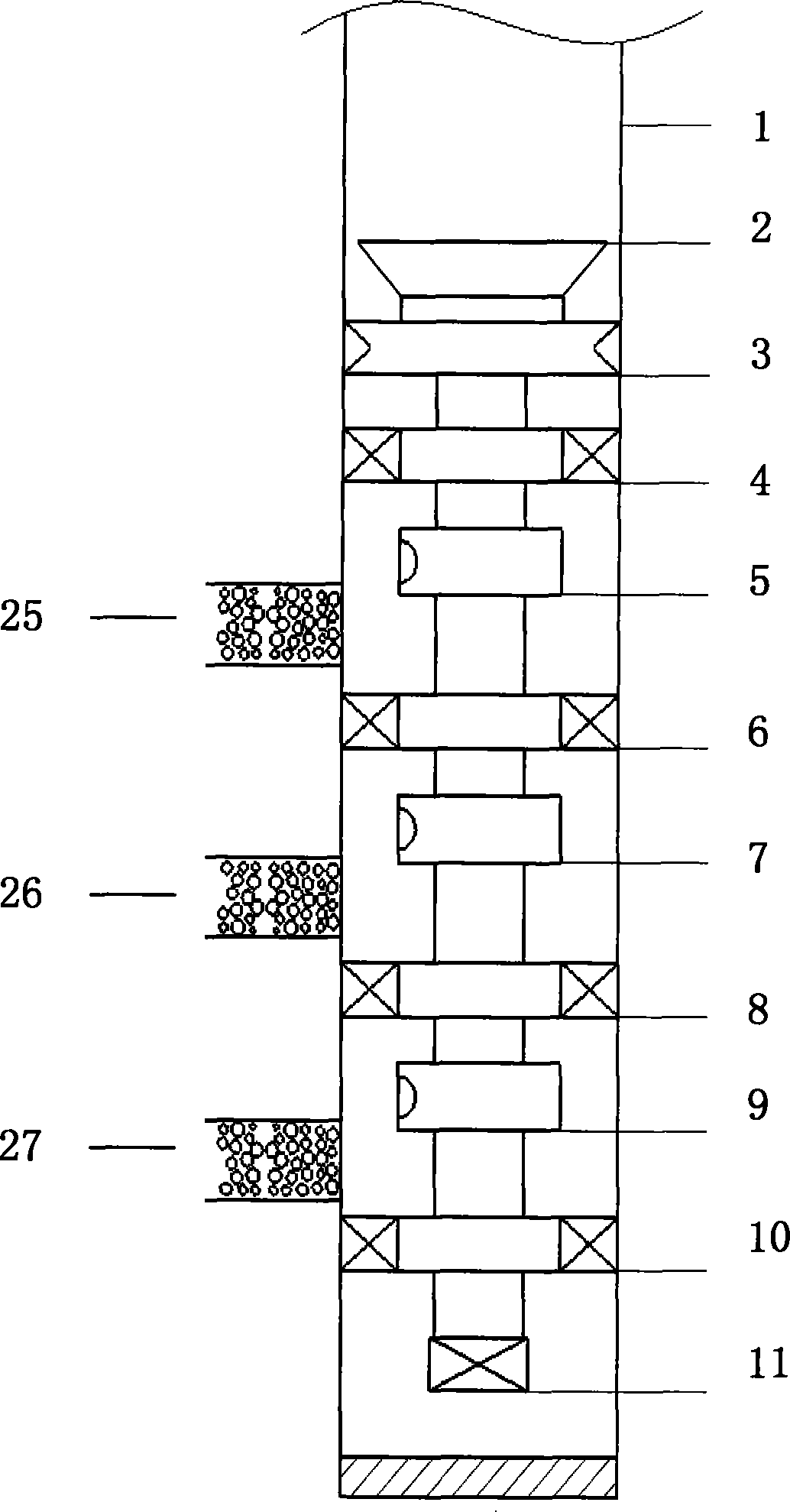

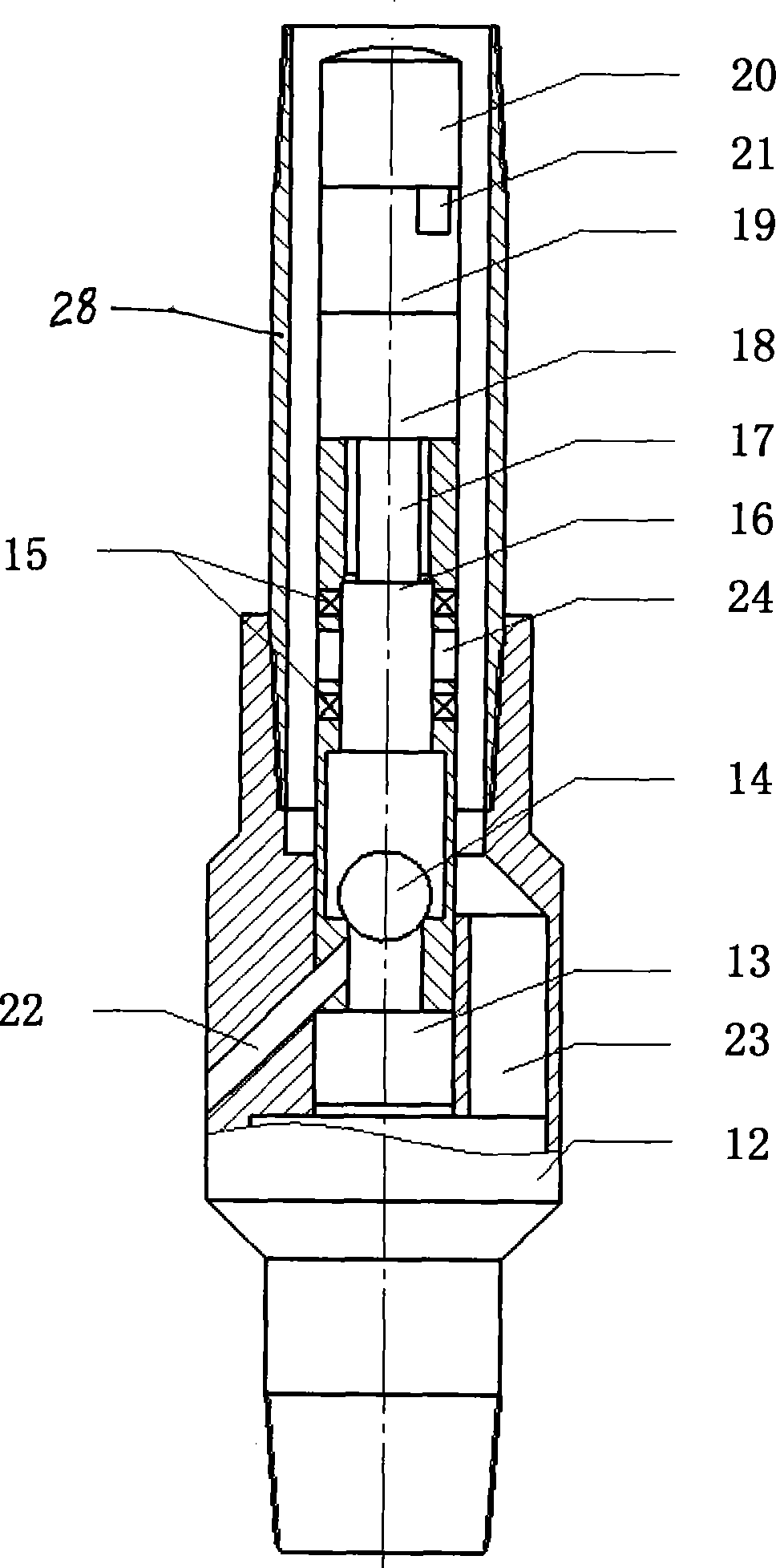

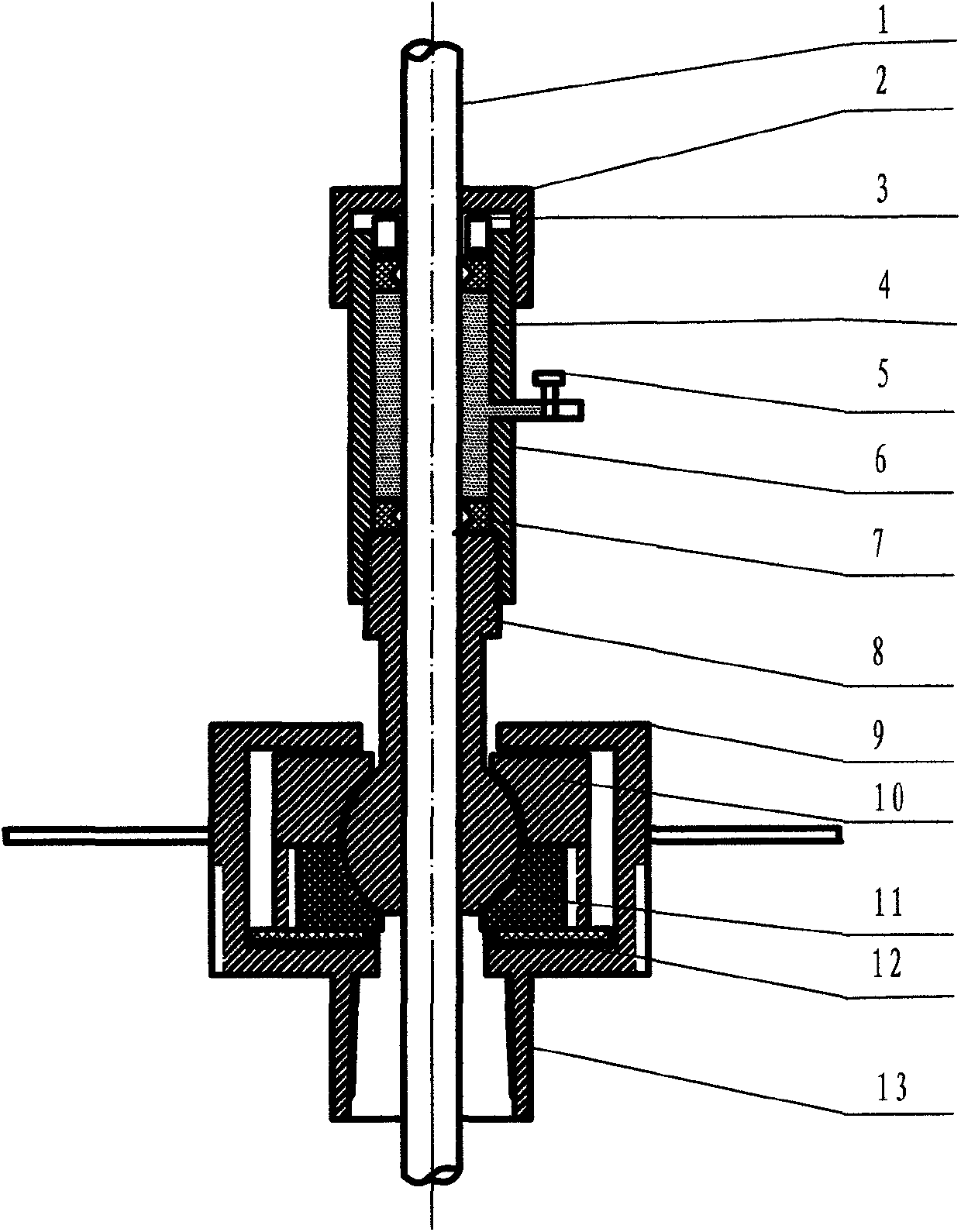

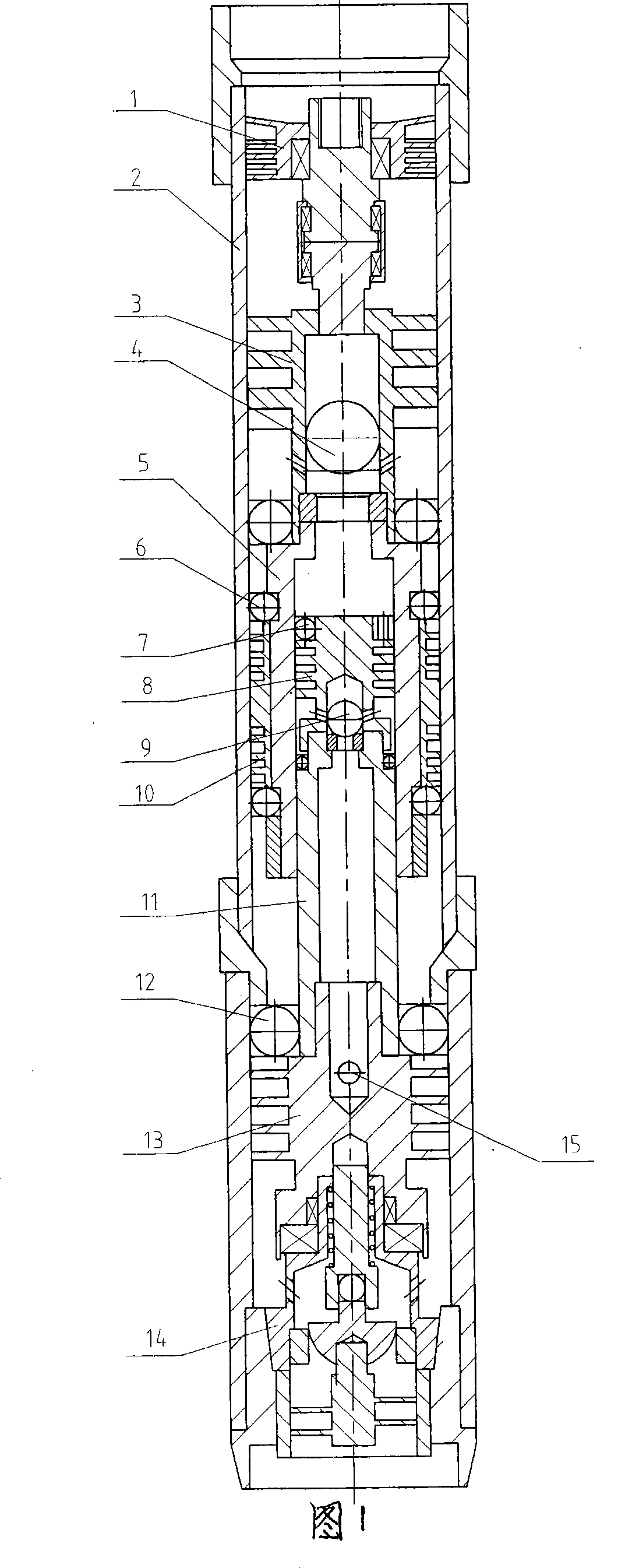

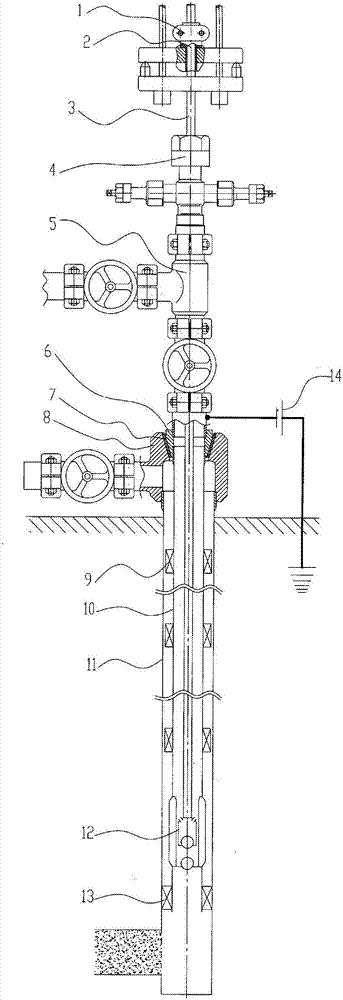

Method for testing and dislodging oil well intelligent delamination

The invention discloses a method of testing and exploiting an oil well intelligently and hierarchically, mainly comprising a releasing joint, a safety joint, a water shutoff packer and an intelligent switch which are connected via a tubing nipple from top to bottom. The method not only can finish the process of water finding and water plugging fitting one-trip strings, but also can realize the action of an underground intelligent switch by sending commands through ground remote control to finish closing and opening of a horizon. The intelligent switch is highly automated, low in construction cost, without a trip or string operation, has the advantages of being simple to operate, working reliably and high in success rate.

Owner:CHINA PETROLEUM & CHEM CORP

Ternary complex composition for flooding, suitable for high-temperature and high-salinity reservoir, and application thereof

ActiveCN102690642AImprove interface performanceGood emulsificationFluid removalDrilling compositionTernary complexMass ratio

The invention relates to a ternary complex composition for flooding, suitable for high-temperature and high-salinity reservoir, and application of the composition. The ternary complex composition for flooding is composed of the following components measured by total weight of the ternary complex composition for flooding: 0.05-0.3% of complex surfactants, 0.1-0.25% of polymers, 0.05-2.0% of alkaline matters and the balance of water; wherein the complex surfactants are composed of two kinds of hydroxysulfobetaine with different structures and a mass ratio of 9: 1-4: 6. The invention further provides the application of the ternary complex composition for flooding in tertiary oil recovery. The ternary complex flooding composition of the complex surfactants provided by the invention is featured with high flooding efficiency and low cost of oleamide hydroxysulfobetaine, and is capable of reducing flooding cost.

Owner:PETROCHINA CO LTD

Nano-surfactant for oil production and method for preparing the same

The invention provides a nanometer surface active agent for oil exploitation and method for making same, the surface active agent is prepared from nano material, 4A-zeolite, sodium carbonate, sodium sulfate, sodium silicate, polyoxythylene fatty alcohol ether sodium sulfate, dodecylbenzene sulfonic acid sodium, dodecylbenzene sulfonic acid and aromatic hydrocarbon dissolvent through mixing, heating, and stabilizing.

Owner:马冬兰

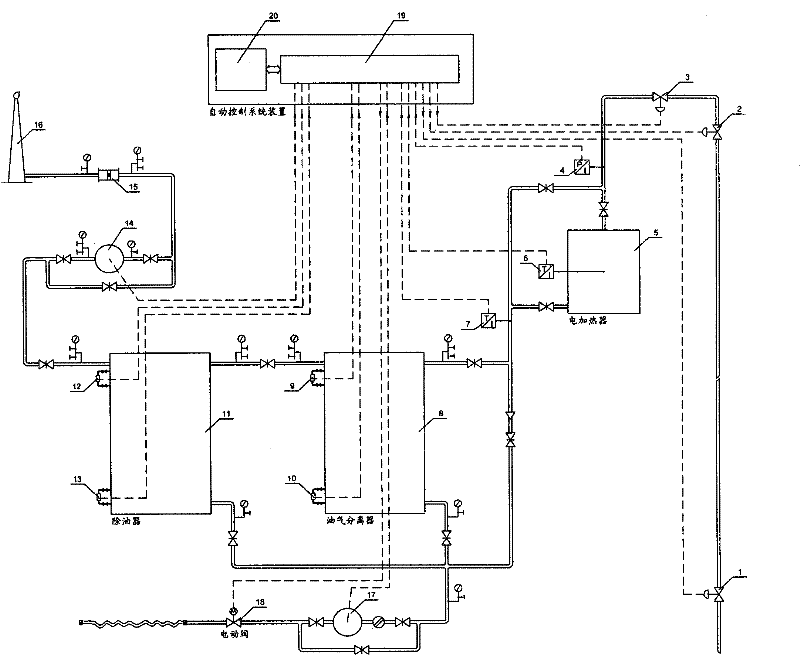

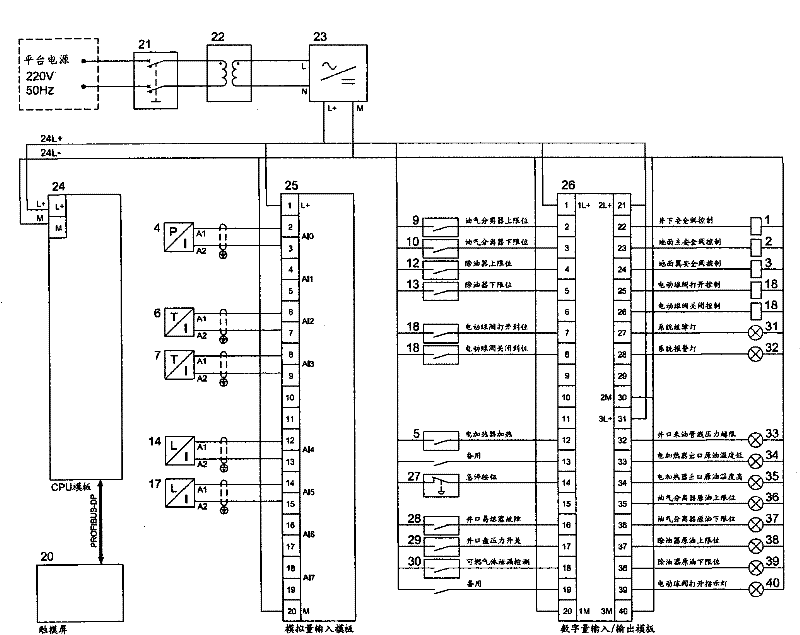

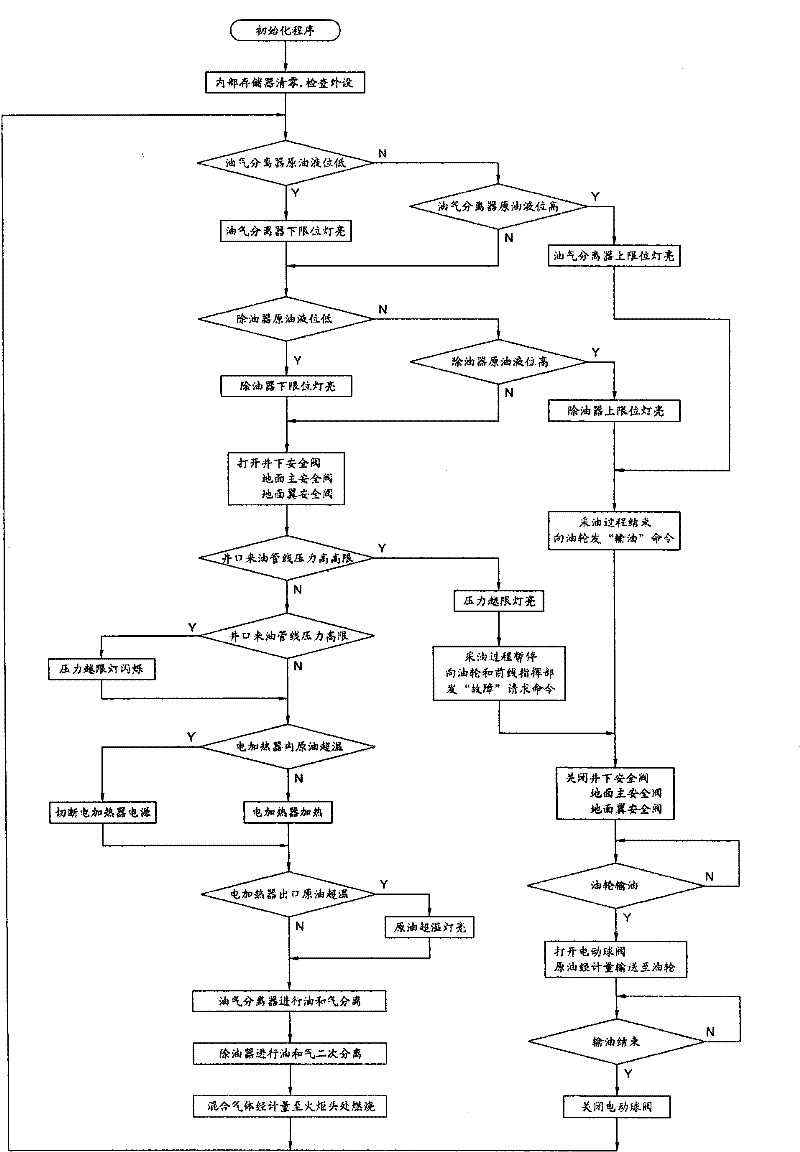

Automatic control system and method for offshore production platform

InactiveCN102337868AMeet unattended requirementsImprove working environmentFluid removalWell/borehole valve arrangementsAutomatic controlAutomated control system

The invention discloses an automatic control system and method for an offshore production platform. The system consists of an automatic control device, a crude oil treatment system and an oil transmission system, wherein the automatic control device consists of a PLC (programmable logical controller), a touch screen and peripheral test equipment; the crude oil treatment system comprises main devices such as an electrical heater, an oil-gas separator, an oil eliminator and the like; and the oil transmission system comprises an oil tanker, an oil transmission pipeline and an electric valve. The PLC and the touch screen which are positioned in the automatic control device are used for monitoring the process parameters of the production process through programming, treating the crude oil according to the crude oil treatment process flow and automatically controlling the oil tanker to collect the crude oil of the platform at fixed point; the PLC has perfect alarming, failure self-diagnosis and protection functions; and the touch screen can display the procedure parameters of the crude oil treatment in real time, perform manual intervention on the crude oil treatment procedure as well as automatically pop up the failure message screen in case of alarm and failure events. The data exchange can be realized between the PLC and the touch screen through a field bus.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

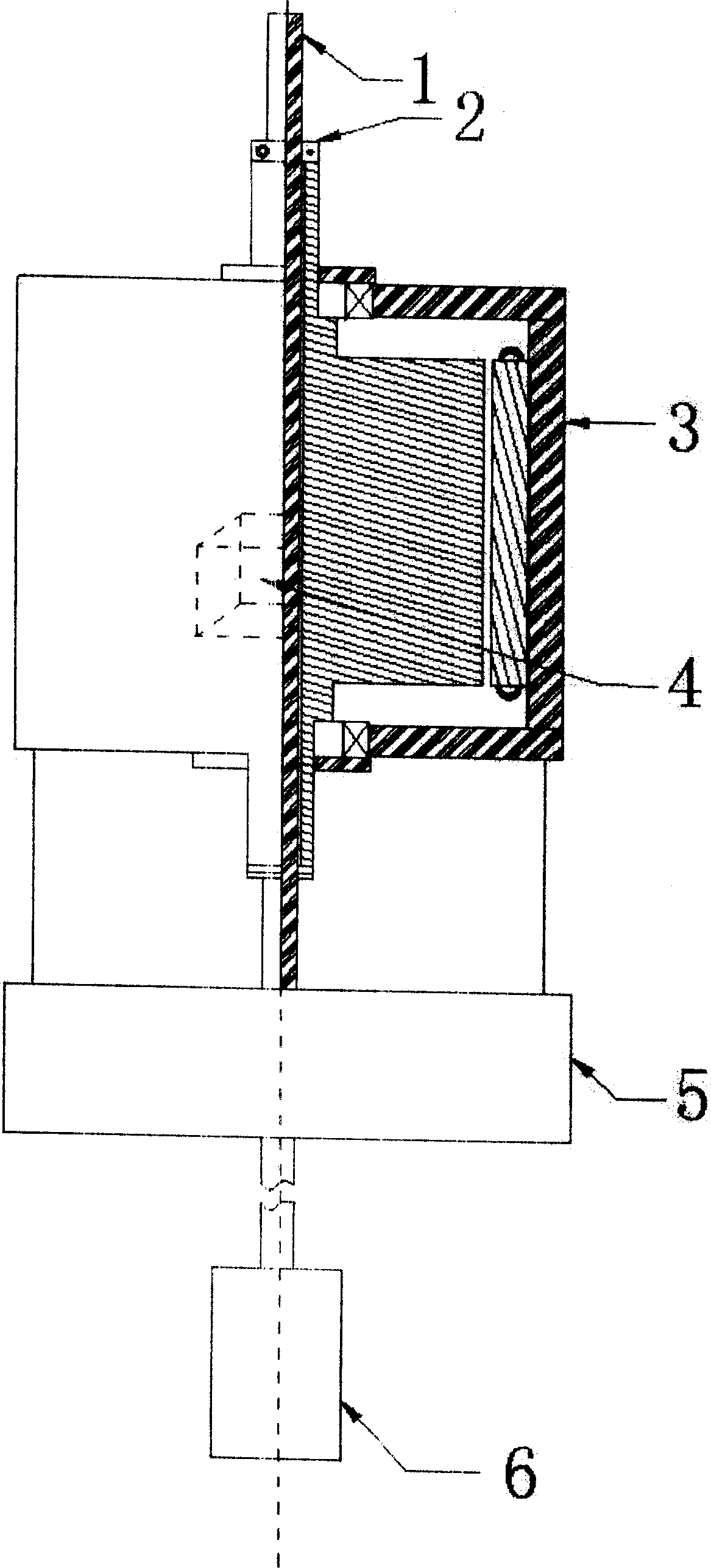

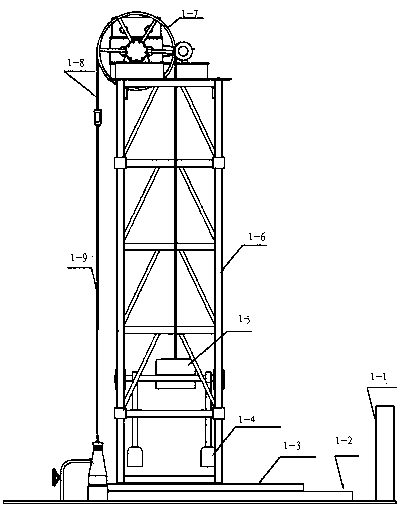

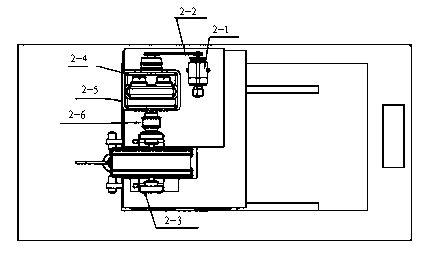

Directly driving screw pump device

InactiveCN1683791AEliminate Oil Spill ProblemsEliminate lossesFlexible member pumpsFluid removalLow speedEngineering

The directly driven screw pump device consists of polished rod, shaft coupler, low speed motor, motor controller, fixing seat and screw pump body. It features the hollow low speed motor shaft penetrating through the polished rod to connect integrally with the polished rod; the polished rod penetrating through the central hole in the fixing seat to connect to the shaft of screw pump in well; the low speed motor fixed on the fixing seat; the fixing seat fixed on the well head through support; and coaxiality of the polished rod, the low speed motor and the fixing seat with the well head.

Owner:胜利油田胜利电器有限责任公司

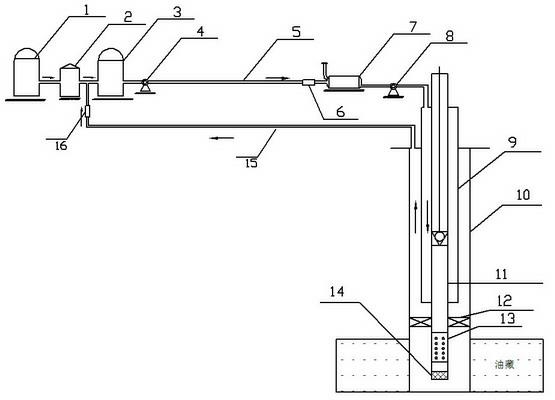

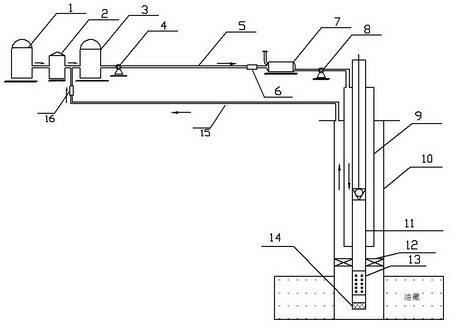

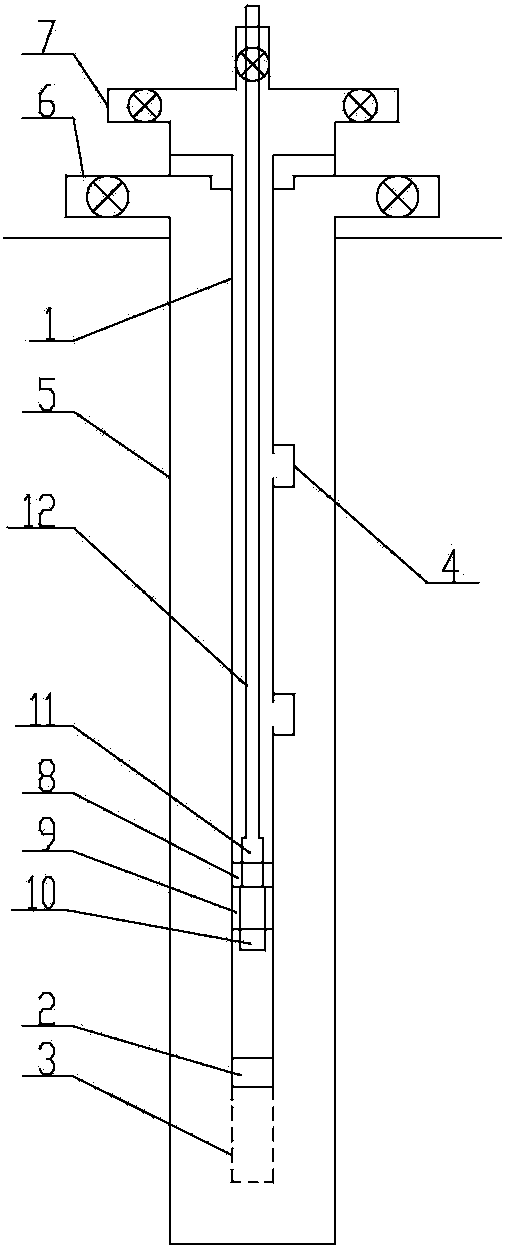

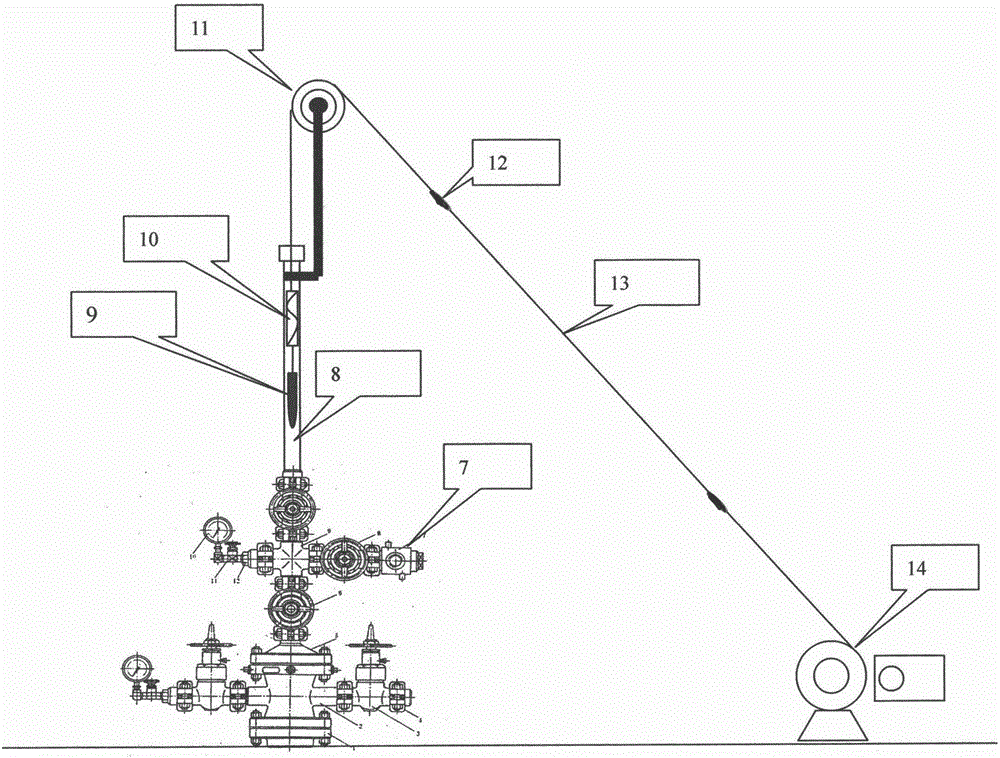

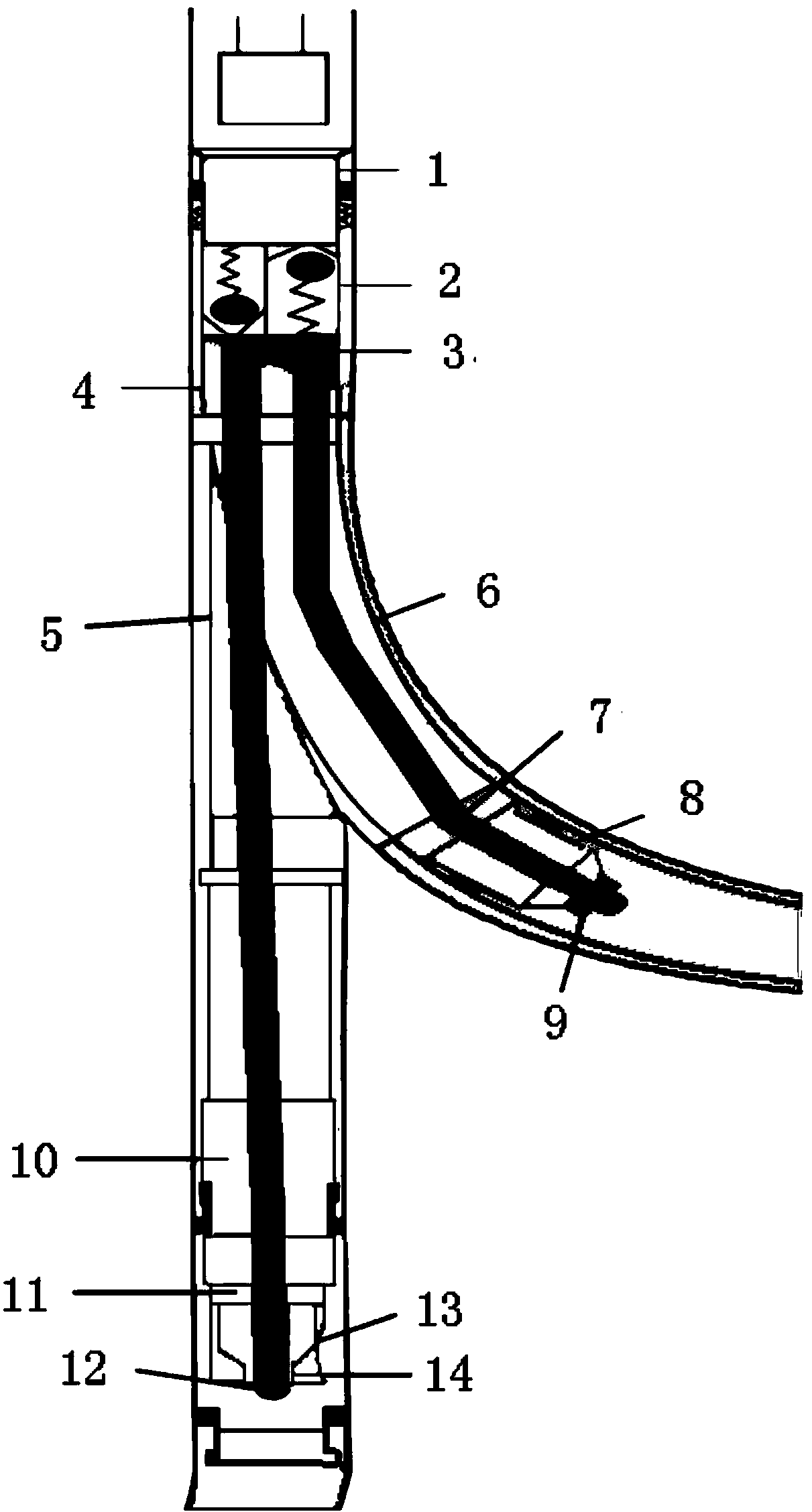

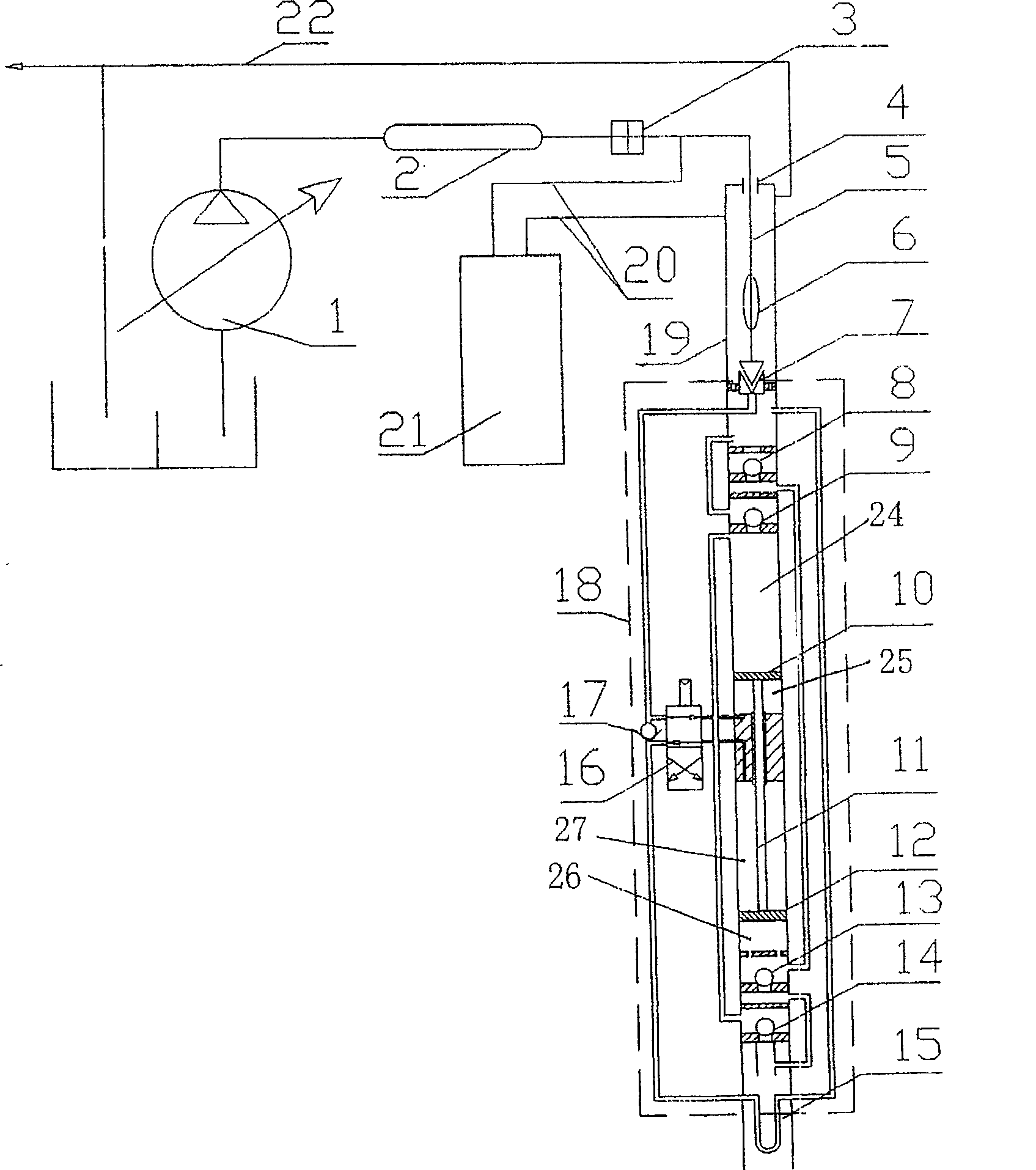

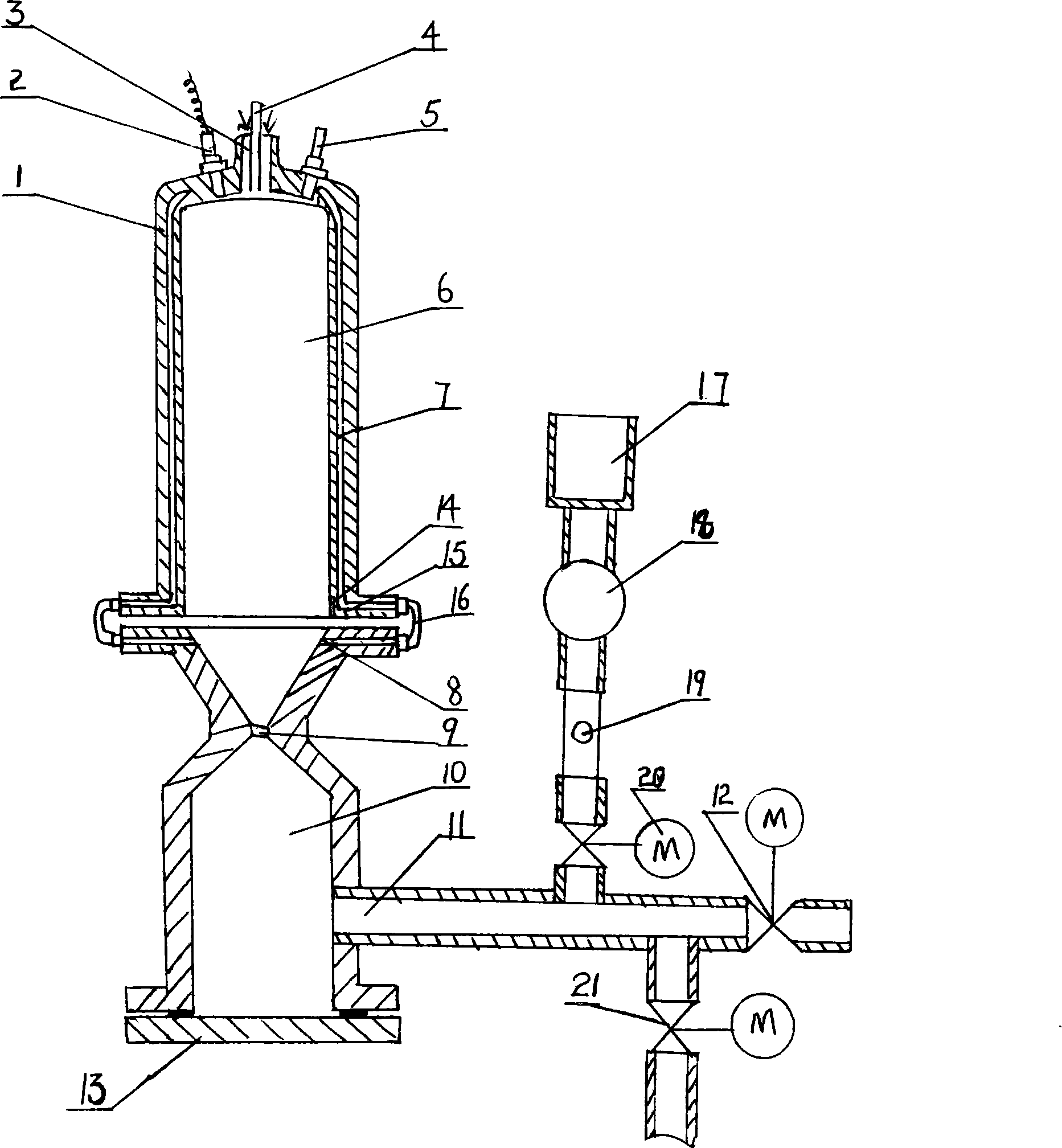

Hot water injection circulation viscosity reduction system for producing ultra-deep ultra-heavy oil and application method thereof

The invention relates to a hot water injection circulation viscosity reduction system for producing ultra-deep ultra-heavy oil and an application method thereof, belonging to the field of viscosity reduction production of heavy oil in an oilfield. The hot water injection circulation viscosity reduction system comprises a ground circulation system and an underground circulation viscosity reduction system, wherein the ground circulation system is formed by sequentially connecting a clear water tank, a water softening device, a softened water tank, a water supply pump, a magnetization device, a water jacket furnace and a water injection pump, which are arranged on a circulating injection pipeline, as well as a pressure relief valve on a circulating outflow pipeline; and the underground circulation system adopts a liquid injection and outflow pipeline constituted by a heat insulation oil pipe annulus, a sleeve annulus and a packer, as well as an inner-layer oil pipe, the packer, a sieve pipe and a screw plug to constitute an oil production pipeline. The hot water injection circulation viscosity reduction system according to the invention can reduce the viscosity of heavy oil, be conductive to production of the ultra-deep ultra-heavy oil and solve the problems of low effective pump efficiency, short pump inspection period of high energy consumption in a viscosity reduction process by light oil blending, and further has the advantages of low oil production cost, easiness in popularization and application and the like.

Owner:SOUTHWEST PETROLEUM UNIV

Protection coating for petroleum equipment and construction method thereof

ActiveCN102504678AImprove corrosion resistanceNo peeling, peeling phenomenonPretreated surfacesAnti-corrosive paintsAdhesion forceSand blasting

The invention which relates to a protection coating for petroleum equipment and a construction method thereof belongs to the technical field of chemical engineering coatings. The protection coating comprises, by mass, 70-99% of polyaryletherketone, 1-30% of a fluororesin, and 0-6% of an inorganic filler. The construction method comprises the following steps: 1, sand-blasting the surface of a workpiece; 2, spraying a powdery pure polyaryletherketone coating on the surface of the workpiece by utilizing an electrostatic spraying technology; 3, placing the workpiece in an oven to fuse the powdery pure polyaryletherketone coating; 4, spraying a powdery composite polyaryletherketone coating while hot by utilizing the electrostatic spraying technology, and fusing the powdery composite polyaryletherketone coating; and 5, cooling to 220-300DEG C, maintaining the temperature for 30-90min, and cooling to room temperature. According to the invention, the process flow can be reasonably controlled, and the operation is simple; and the obtained coating layer has the advantages of strong adhesion force, and excellent resistance, abrasion resistance and non-stick performance, so the service life of the petroleum equipment can be increased, thereby the oil extraction cost reduction purpose is reached.

Owner:吉林省奕彤新材料有限公司

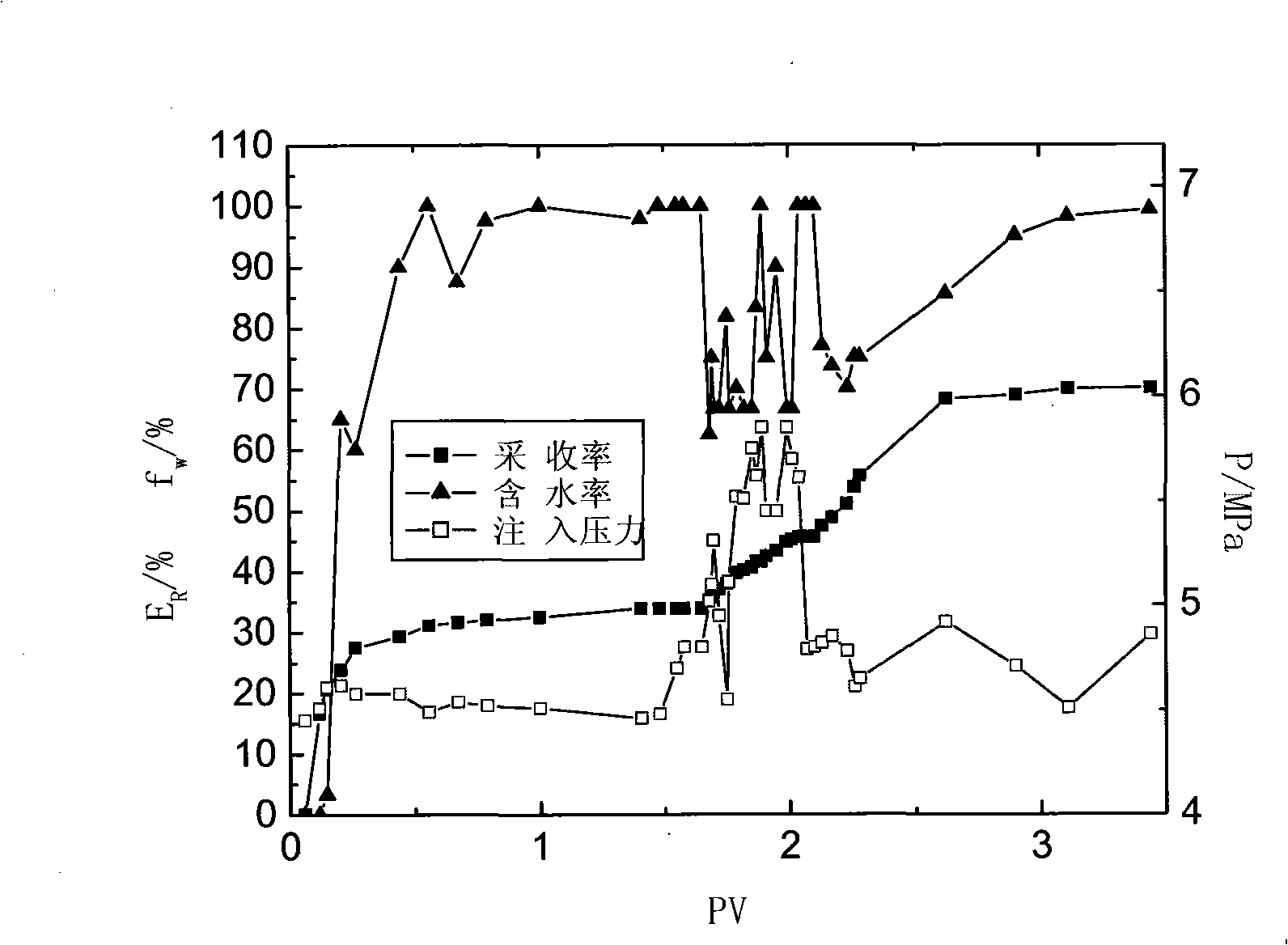

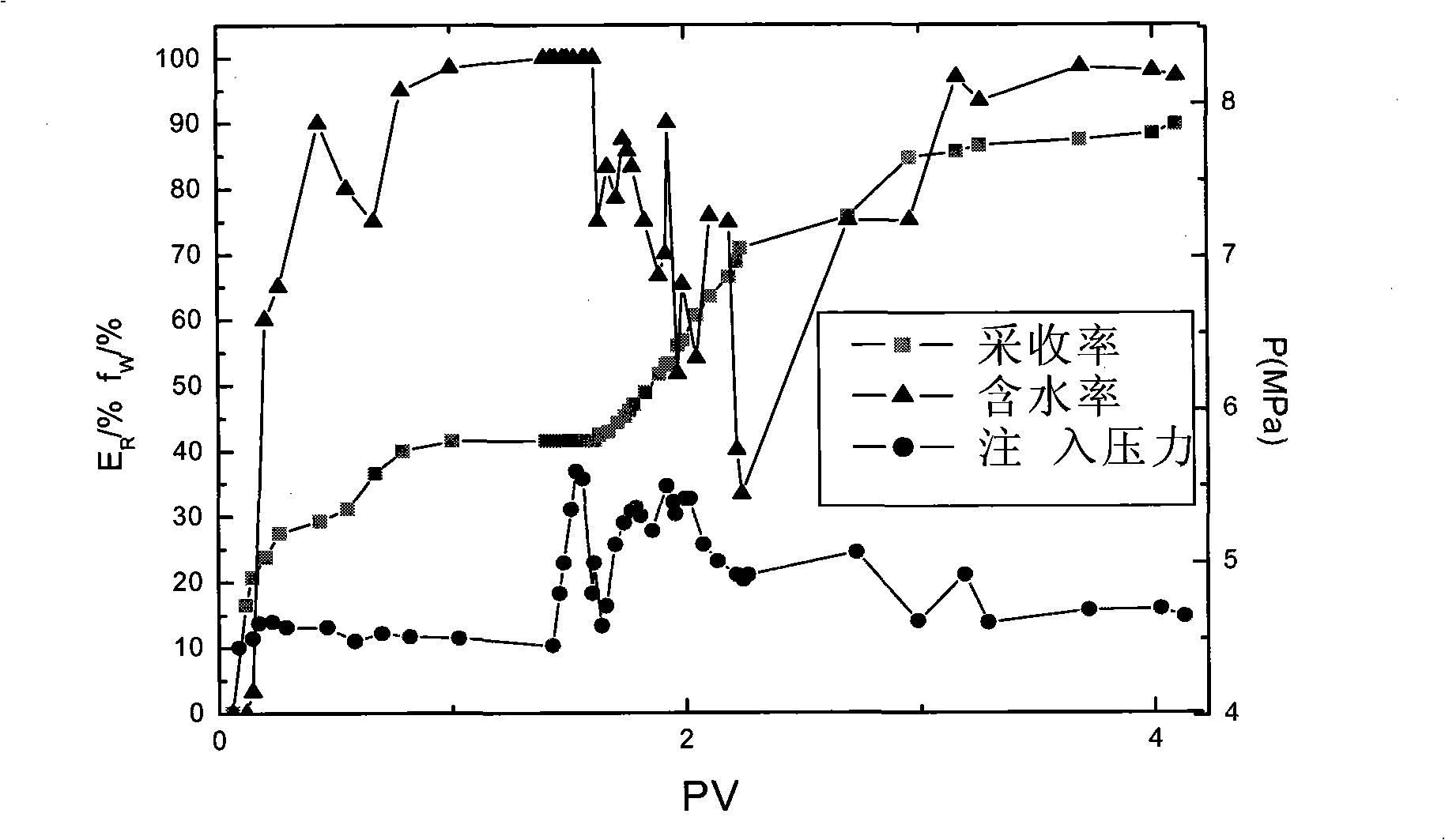

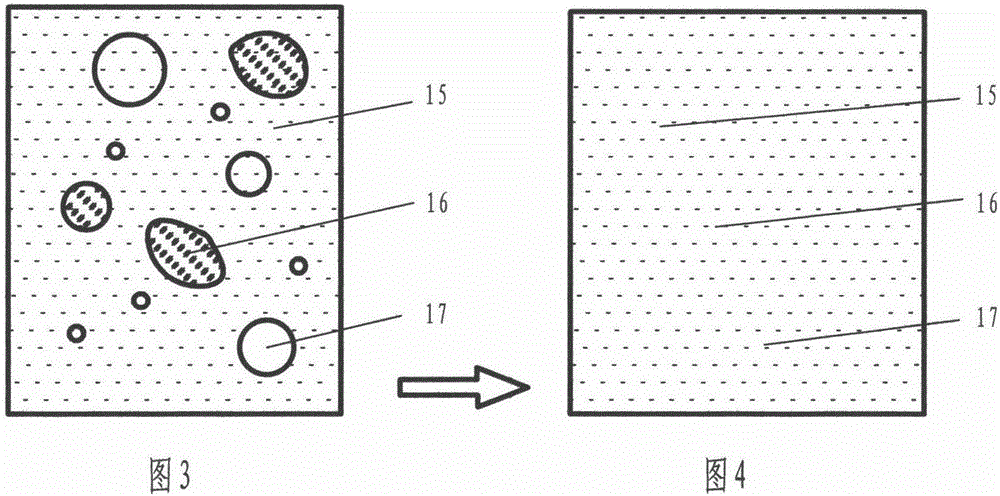

Microsphere oil displacement profile control agent, displacement of reservoir oil system and displacement of reservoir oil method

ActiveCN101314712AEnhanced overall recoveryImprove the spread factorFluid removalDrilling compositionMicrosphereEconomic benefits

The invention discloses a microsphere profile control and displacement agent used for petroleum exploitation, which is a dispersion system prepared from functional polymer solution and microspheres with diameter of 0.2 to 20 mum by mixing, wherein the microspheres have a concentration of 0.05 to 0.2wt percent. The invention further discloses a combined oil displacement system formed by using the foam profile control and displacement agent and a combined oil displacement method. The oil displacement is achieved by using a combined slug consisting of functional polymers from high viscosity to low viscosity and the microspheres, and is suitable for multiple kinds of anisotropic oil layers to effectively improve oil recovery, reduce ineffective water circulation, and improve economic benefits. Through the effective combination, the system can improve the recovery greatly, improve the total recovery to 70 to 89 percent or above and reduce the oil recovery cost greatly, and can be widely used for tertiary oil recovery.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

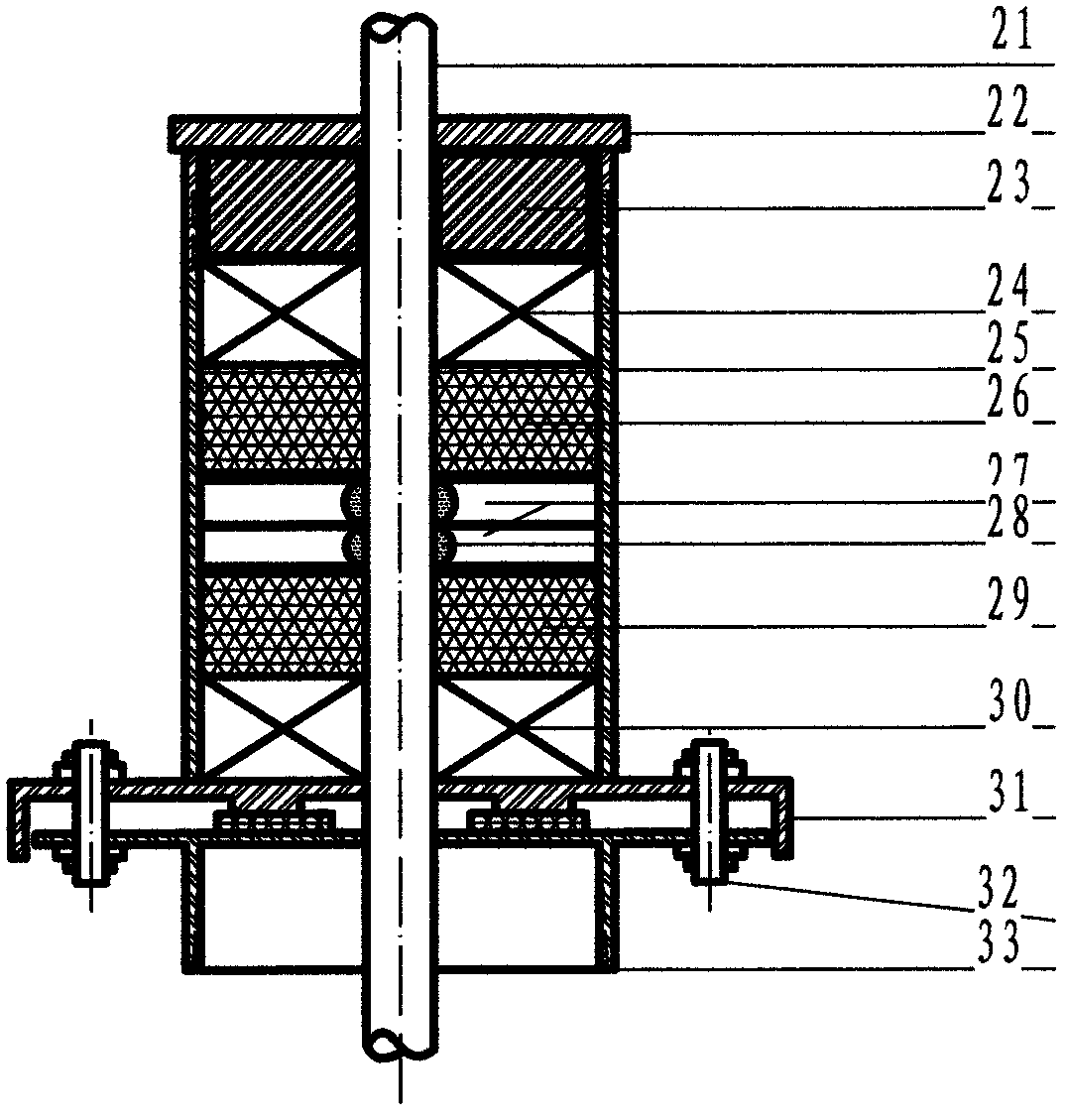

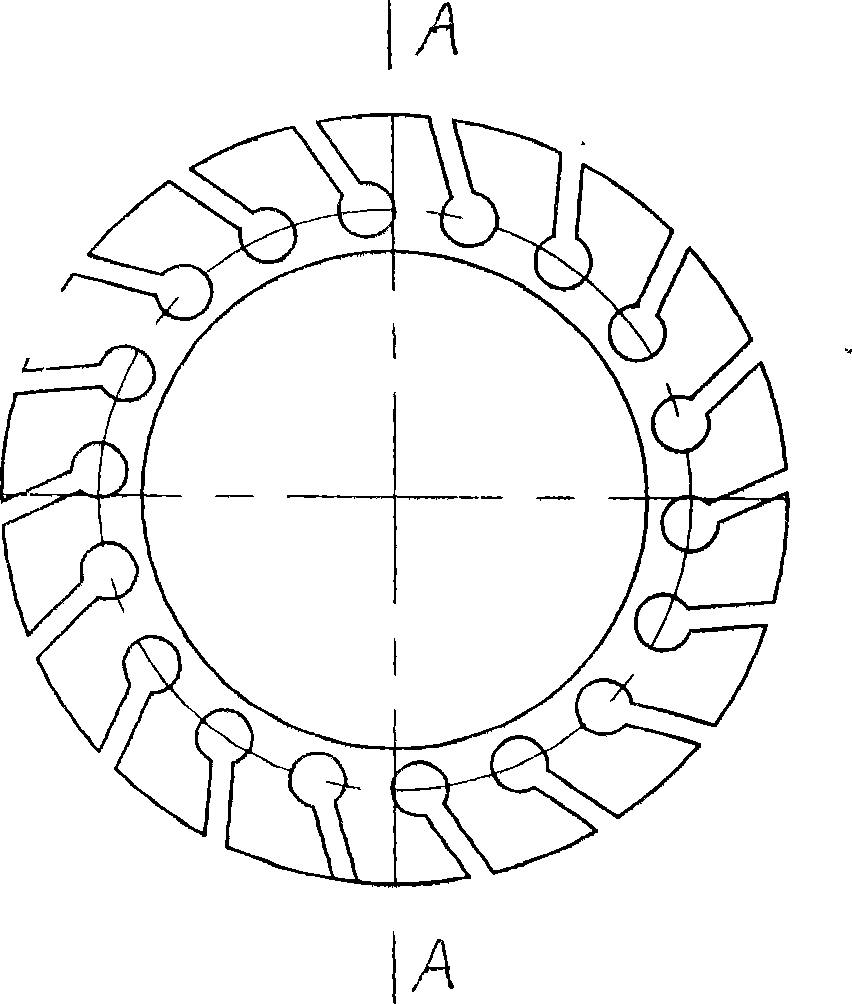

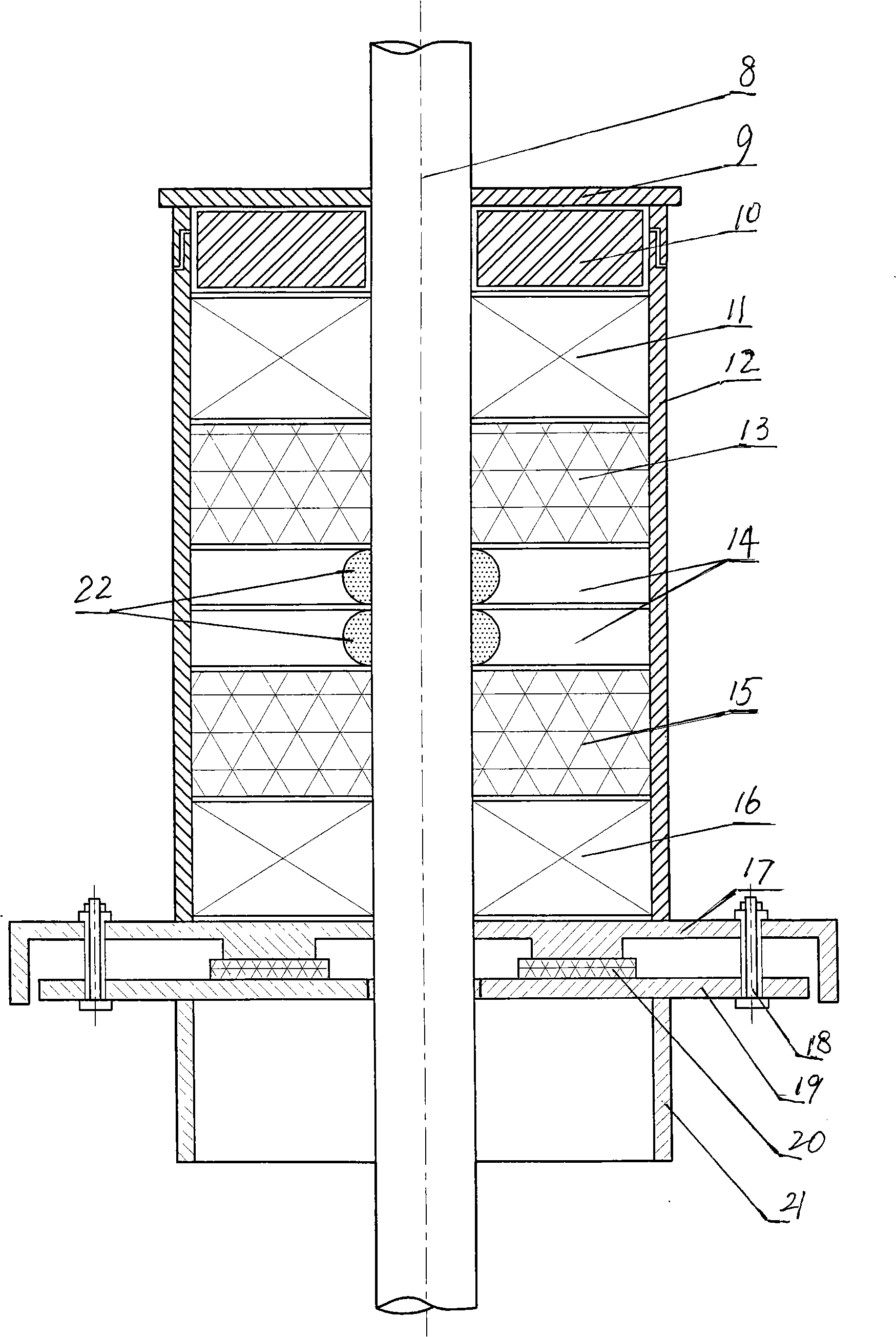

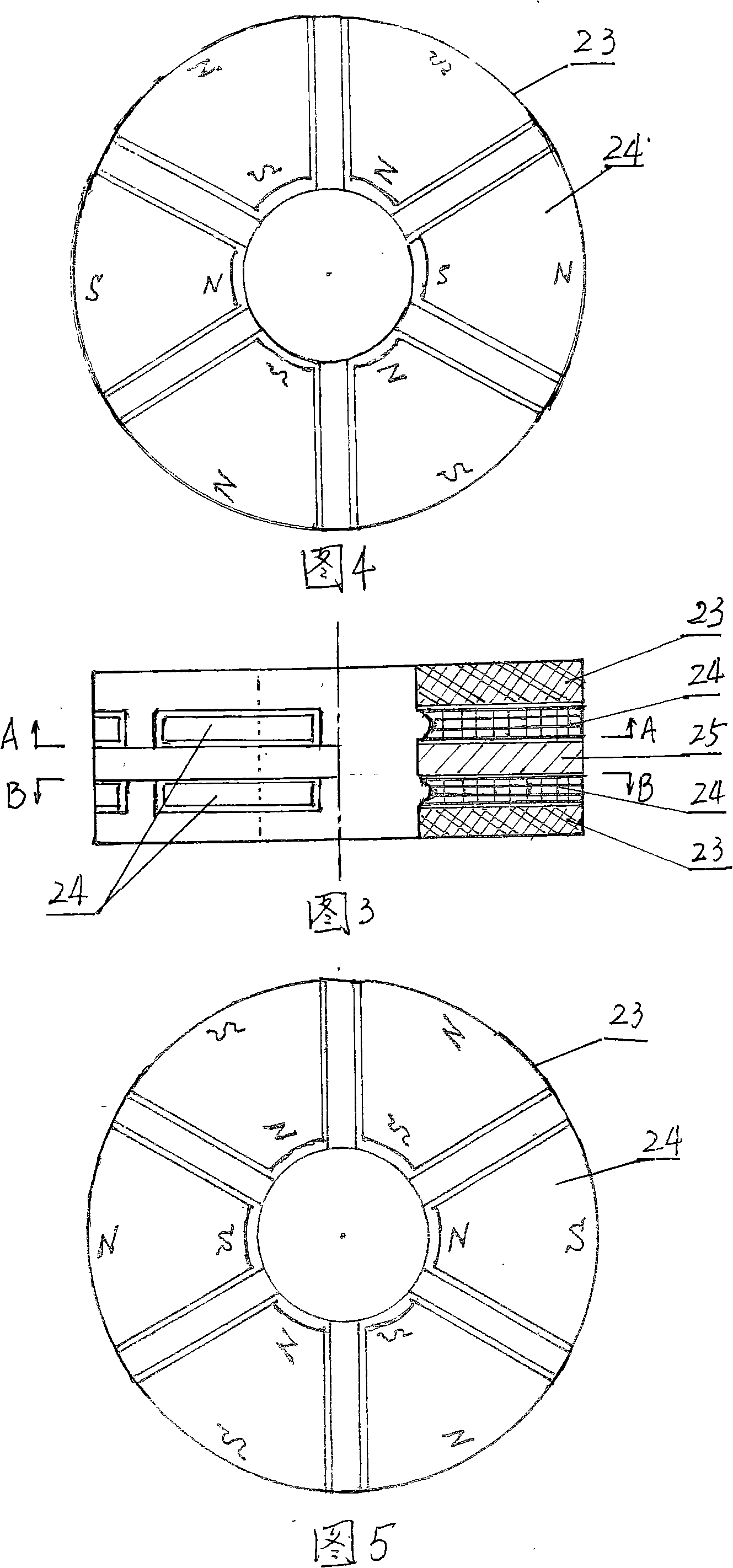

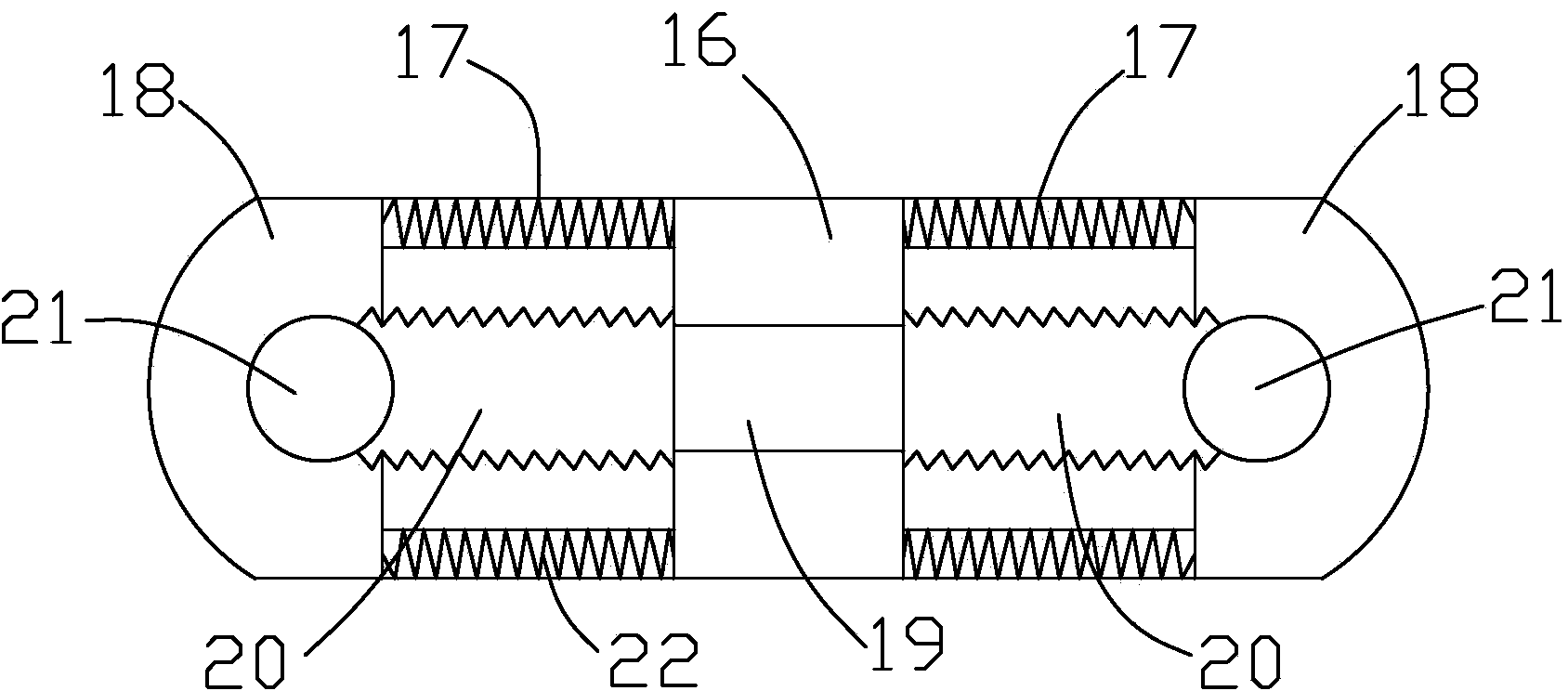

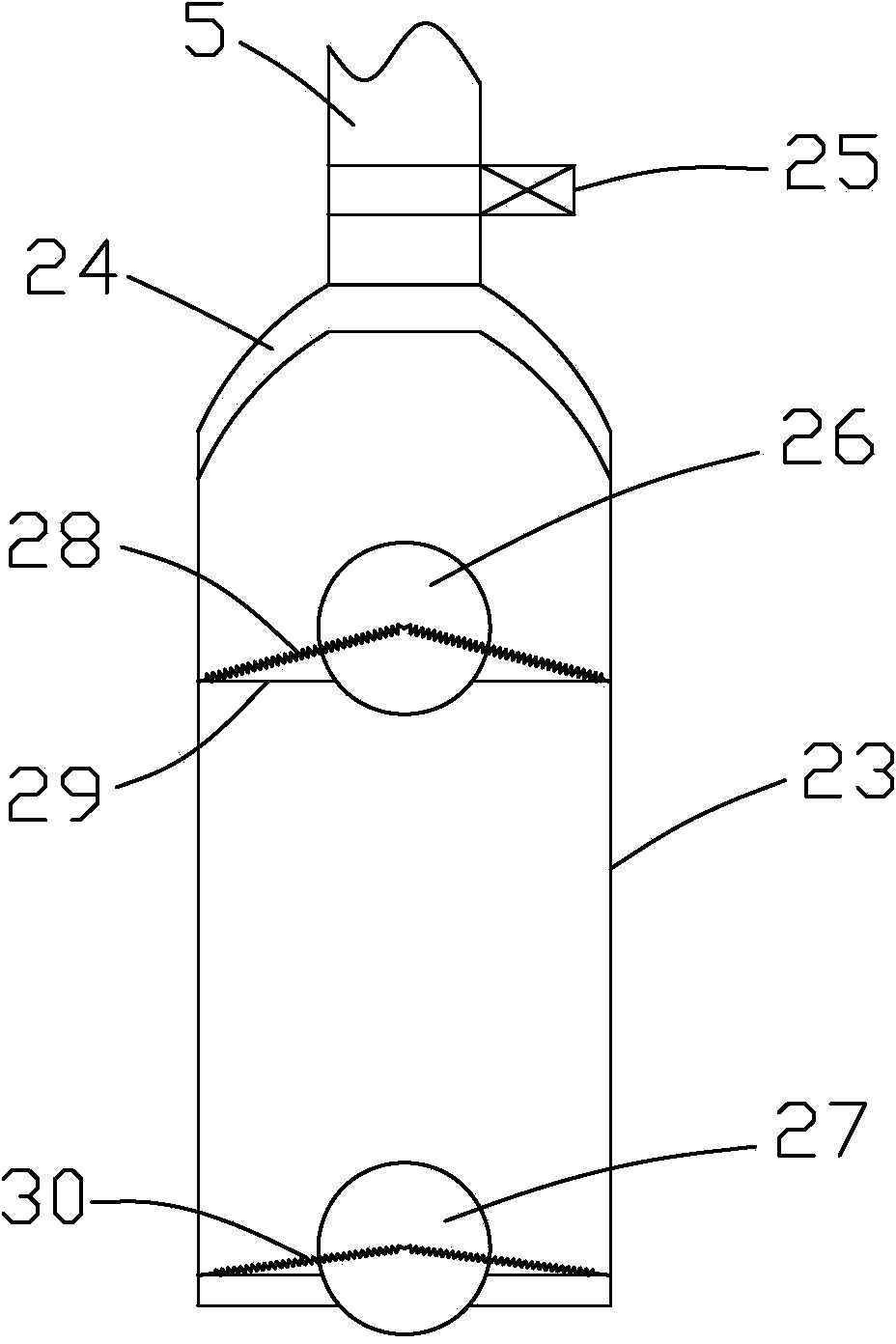

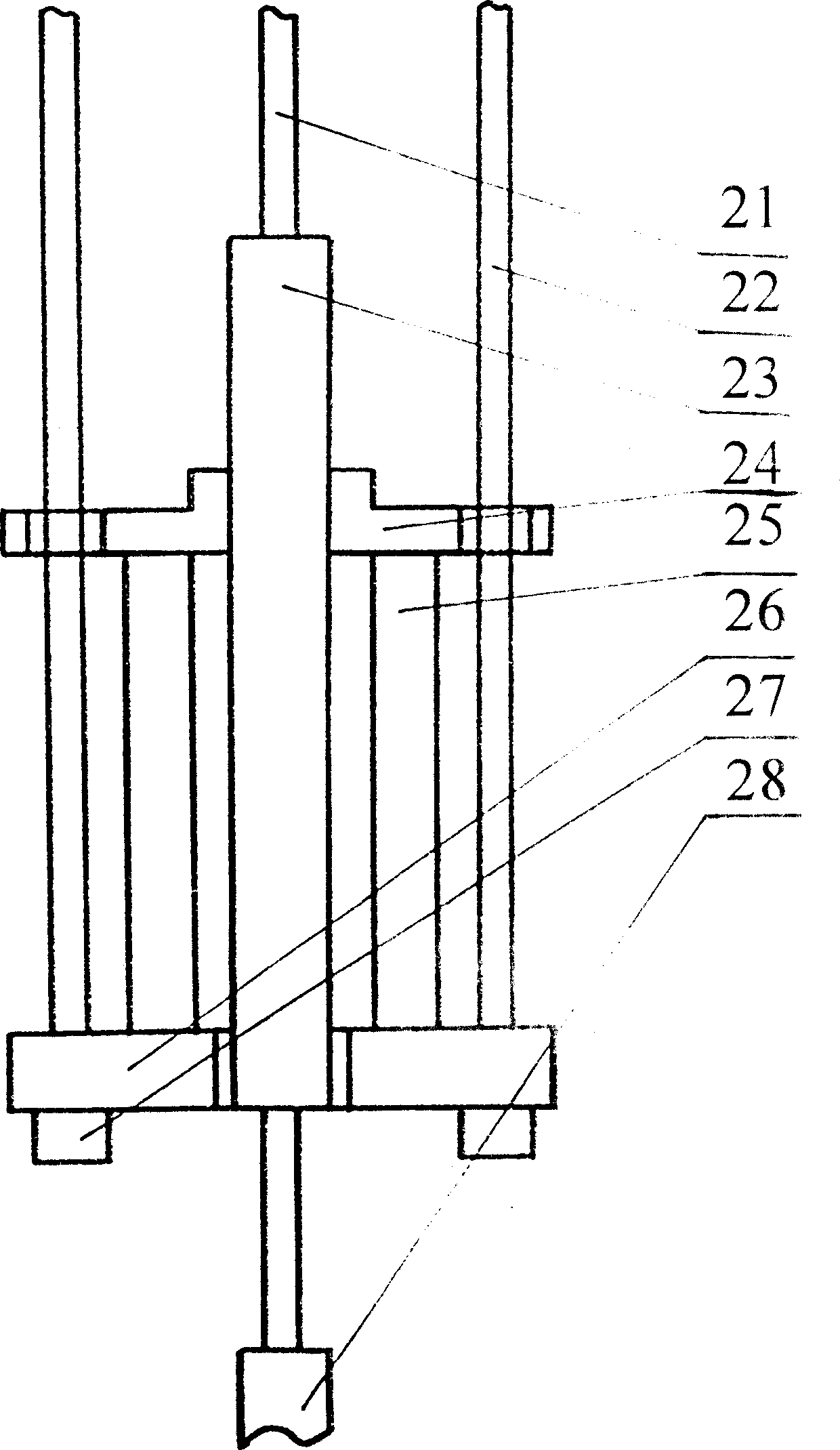

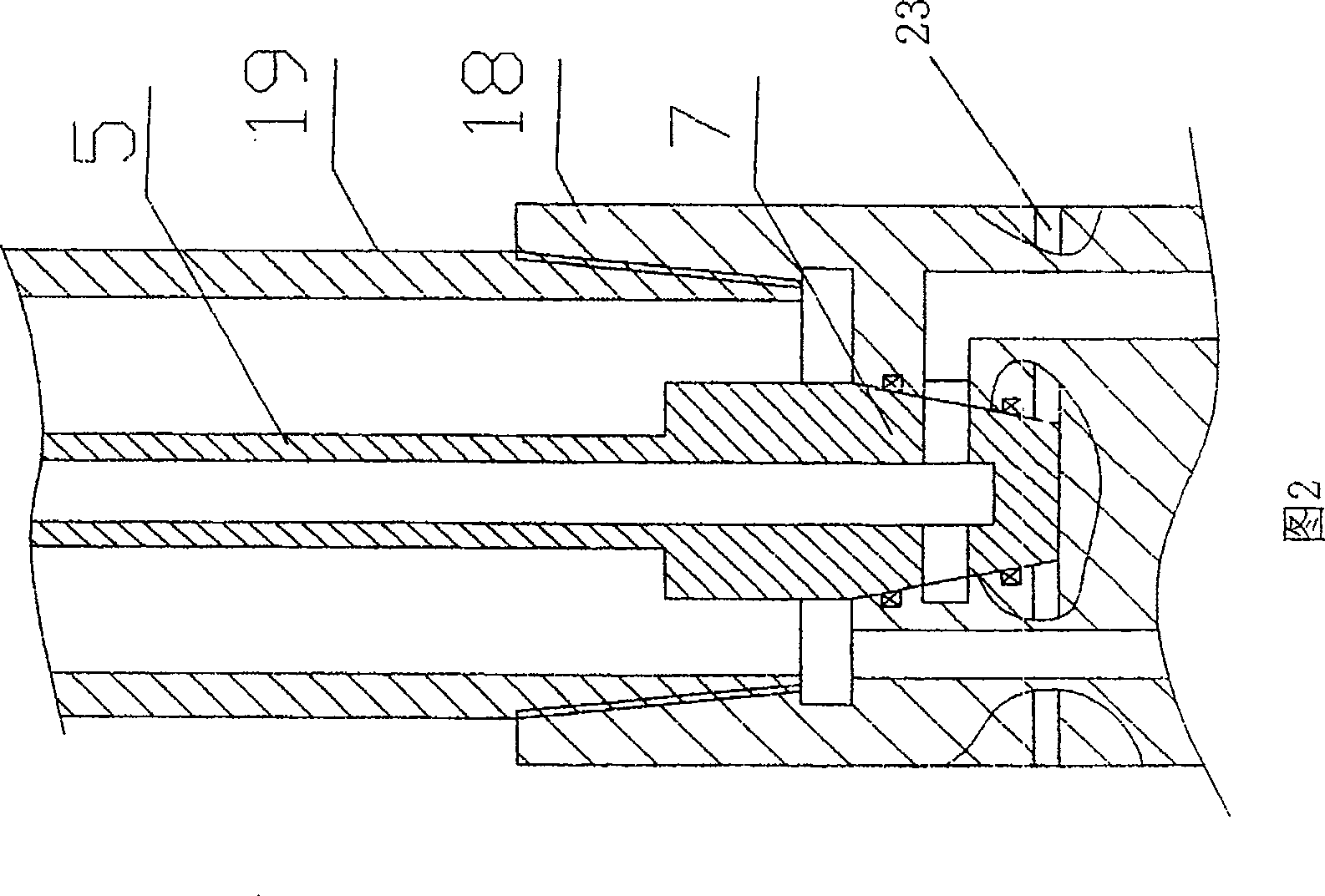

Universal random deviation rectification outside injected magnetic fluid polished rod sealing device

Provided is a universal random deviation rectification outside injected magnetic fluid polished rod sealing device applied for oil extraction in the oil field. The universal random deviation rectification outside injected magnetic fluid polished rod sealing device comprises a polished rod sealing culvert at the upper portion, wherein an upper and a lower group of permanent magnets are arranged in the culvert, an injection hole is formed in the middle portion capable of Is capable of injecting and supplying magnetic fluid into a cavity in due time to conduct a dynamic sealing to the polished rod, and a universal-joint mechanism at the lower portion is capable of rectifying deviation randomly in radial and axial three-dimensional space. A polished rod sealing culvert assembly is arranged above the random deviation rectification mechanism. The universal random deviation rectification outside injected magnetic fluid polished rod sealing device thoroughly resolves problems that production halts often occur due to applying packing polished rod sealing device in the existing oil extraction with huge energy consumption and easy damage, causing emitting, dipping and leakage of well mouth pressed oil, gas and water and accompanying serious environmental pollution, potential safety hazard and other world class problems, and can be widely applied in well mouth polished rod sealing of oil field sucker-rod pump oil extractor.

Owner:邓海波

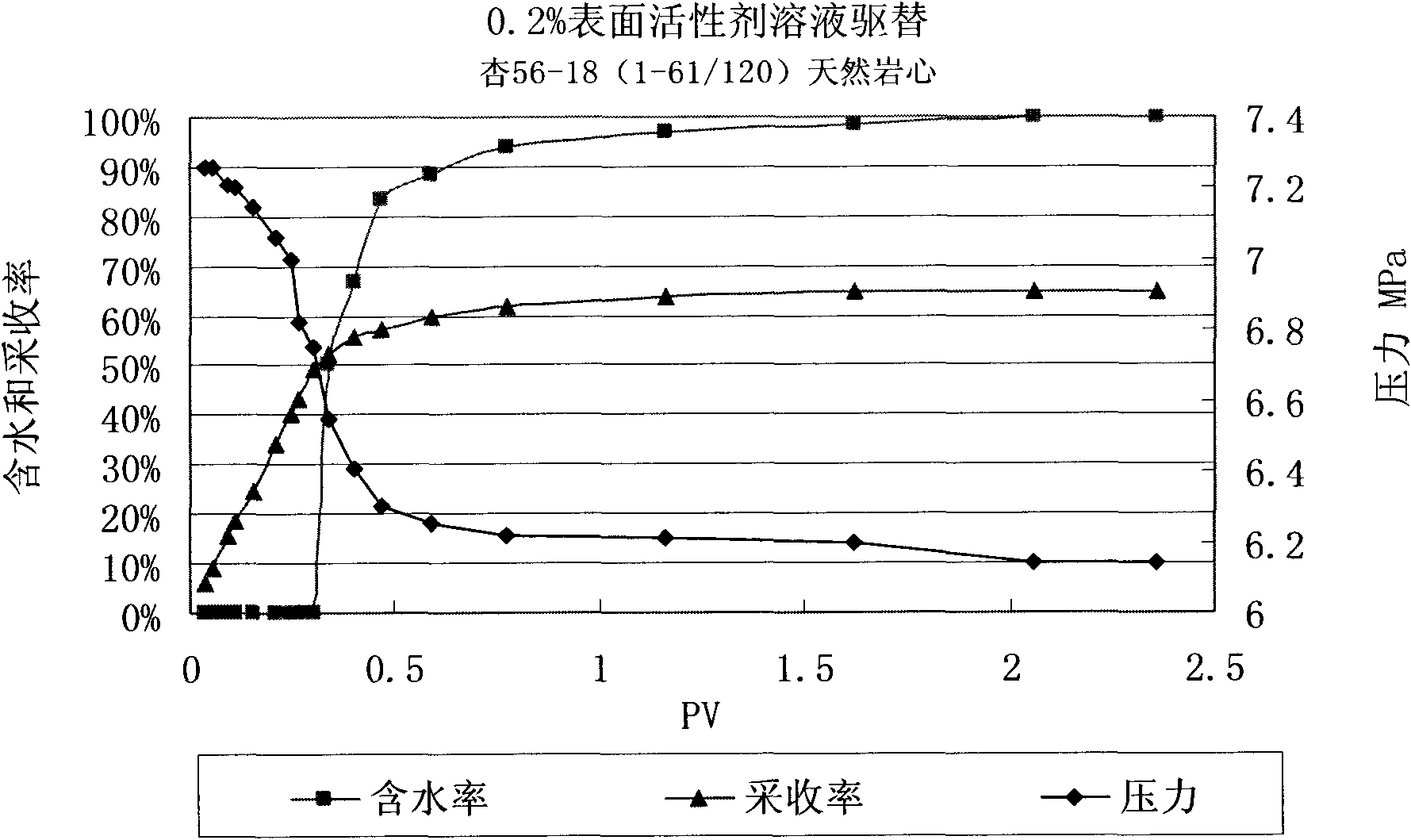

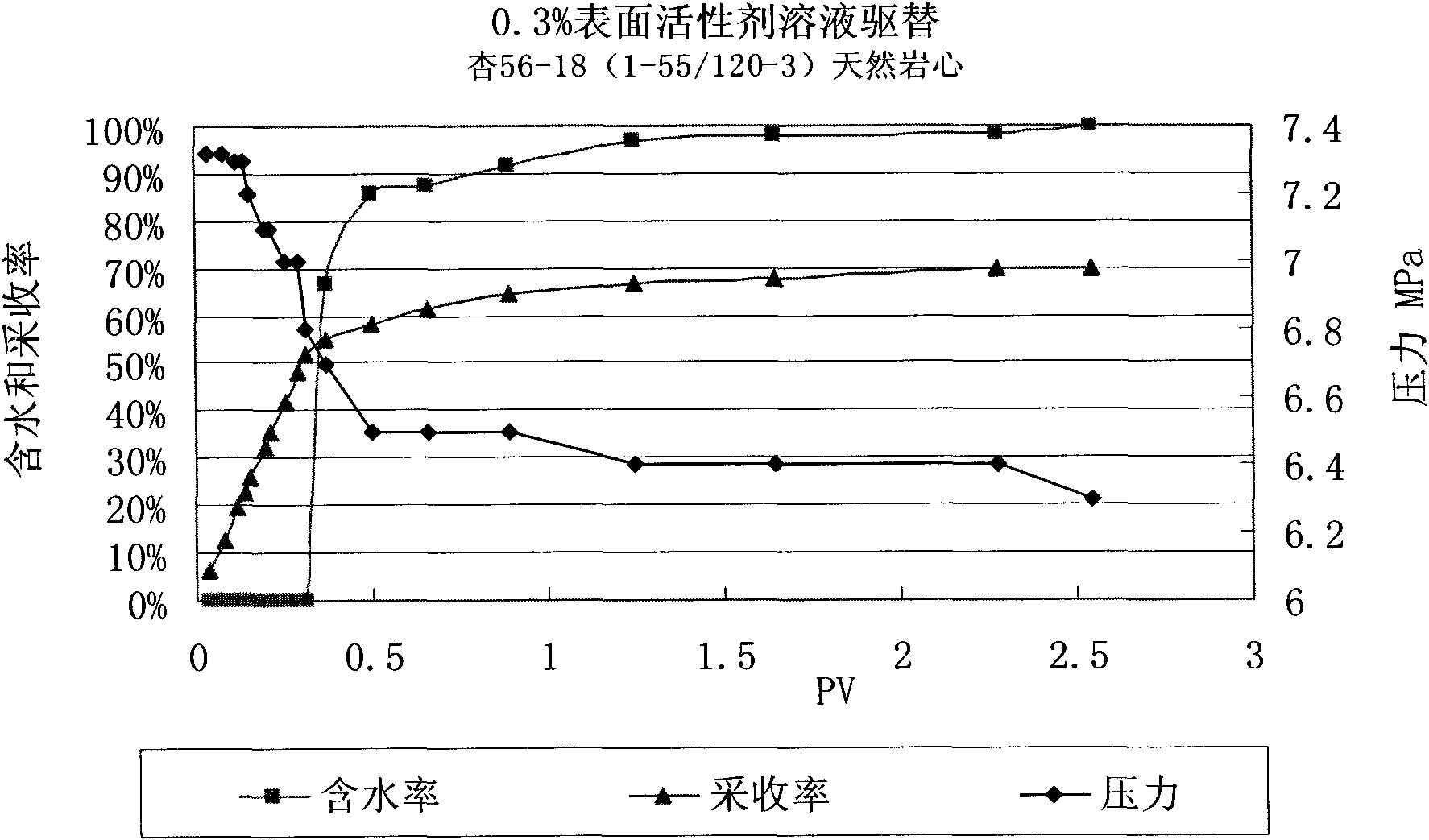

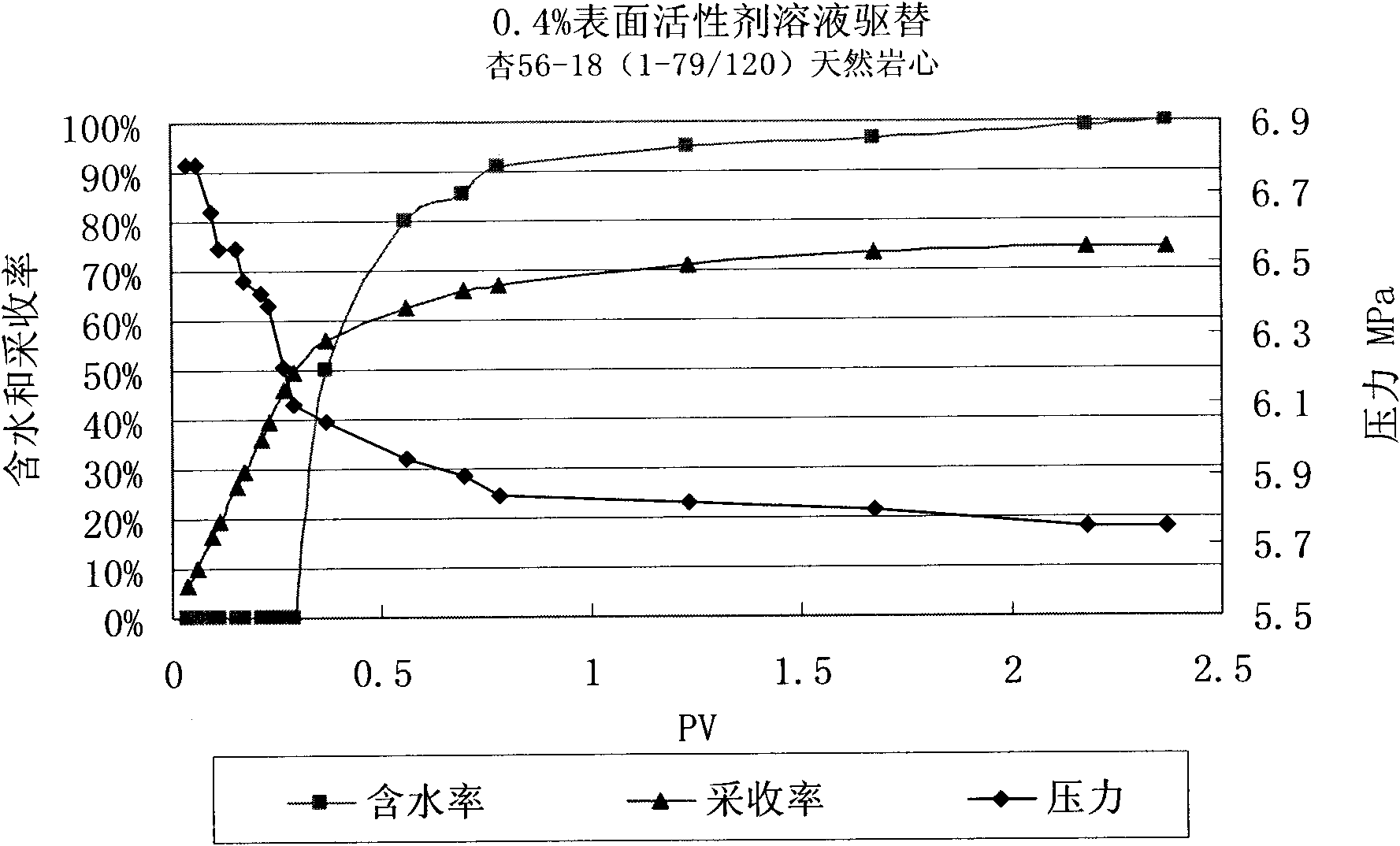

Oil-field largest swept volume chemical-flooding oil production method

The invention relates to an oil-field largest swept volume chemical-flooding oil production method, which is applied to the technical field of oil production in oil fields. The method is applicable to all reservoirs which can be exploited by water flooding but are not exploited by water flooding. When oil is exploited, the self energy of the strata of a reservoir is first utilized to carry out flowing production or swabbing production; when an oil field adopting flowing production or swabbing production reaches the economic benefit limit of production, flowing production or swabbing production is ended, subsequent water-flooding production is not carried out any more, but chemical flooding injecting surfactant as main agent is directly adopted to intensify oil production. The method has the following advantages that: at the moment, the swept volume of the displacement of the chemical displacing fluid is the largest, which is best favorable for the exertion of the oil-washing effect ofthe surfactant, and thereby the yield of oil production can be increased to the max.

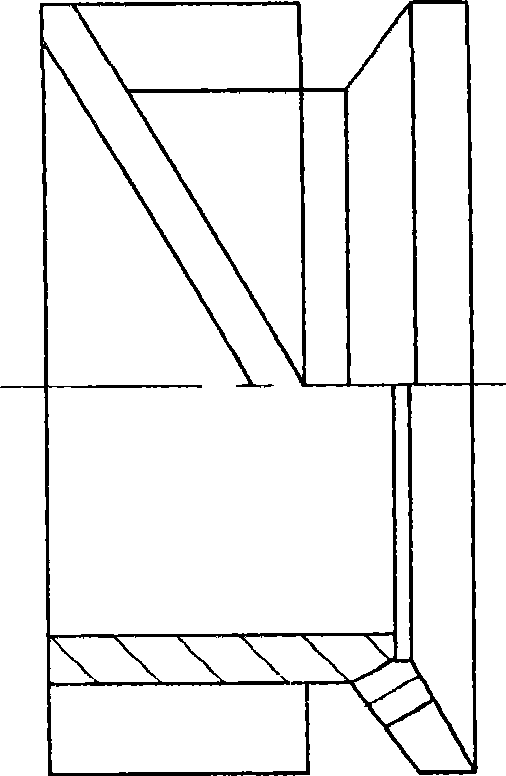

Movable barrel type rotary plunger oil well pump

InactiveCN101440798ANo sand burialReduce energy savingPositive displacement pump componentsFlexible member pumpsEngineeringMechanical engineering

The invention provides an actuating cylinder-type rotary plunger defueling pump and relates to a rotary plunger pump. The invention aims to provide an actuating cylinder-type rotary plunger defueling pump with no generation of sand stuck, energy conservation and low cost of oil extraction. The key points of the technical proposal comprise: an actuating cylinder and a plunger are arranged in a pump barrel; the plunger body is provided with an upper thruster and a lower thruster; the actuating cylinder is provided with a thruster and a rotary sealer; and a centering mechanism is arranged between the plunger and the actuating cylinder. The pump is used for a defueling machine.

Owner:新乡市乔山机械设备有限公司

Method for underbalanced tubing descending, non-well-killing gas lifting, rotary pumping, pump maintaining and tubing maintaining

ActiveCN103452531AGood productivity improvement effectShorten the working cycleFluid removalFlushingWell drillingGas lift

The invention relates to the technical field of underbalanced well completion and oil production, in particular to a method for underbalanced tubing descending, non-well-killing gas lifting, rotary pumping, pump maintaining and tubing maintaining. The method includes the steps: firstly, fixedly mounting an in-tubing blowout preventer and a lifting basket at the bottom end of a tubing string in sequence from top to bottom, and mounting a float valve in the in-tubing blowout preventer. The in-tubing blowout preventer is fixedly mounted at the bottom of the tubing string, so that tubing descending operation can be completed smoothly in the well completion phase, a gas lift liquid discharge or production passage can be established during gas-lift oil production, tubing descending, gas-lift oil production, oil pumping, oil-well pump maintenance and tubing maintenance can be closely integrated, operation cycle is shortened, operation of putting into production is simplified, reservoir protection effect of underbalanced well drilling is enhanced, oil-gas wells can be put into production timely to keep an excellent productivity increase effect, further competitiveness of the underbalanced technique is improved, and oil production cost is lowered.

Owner:CNPC XIBU DRILLING ENG

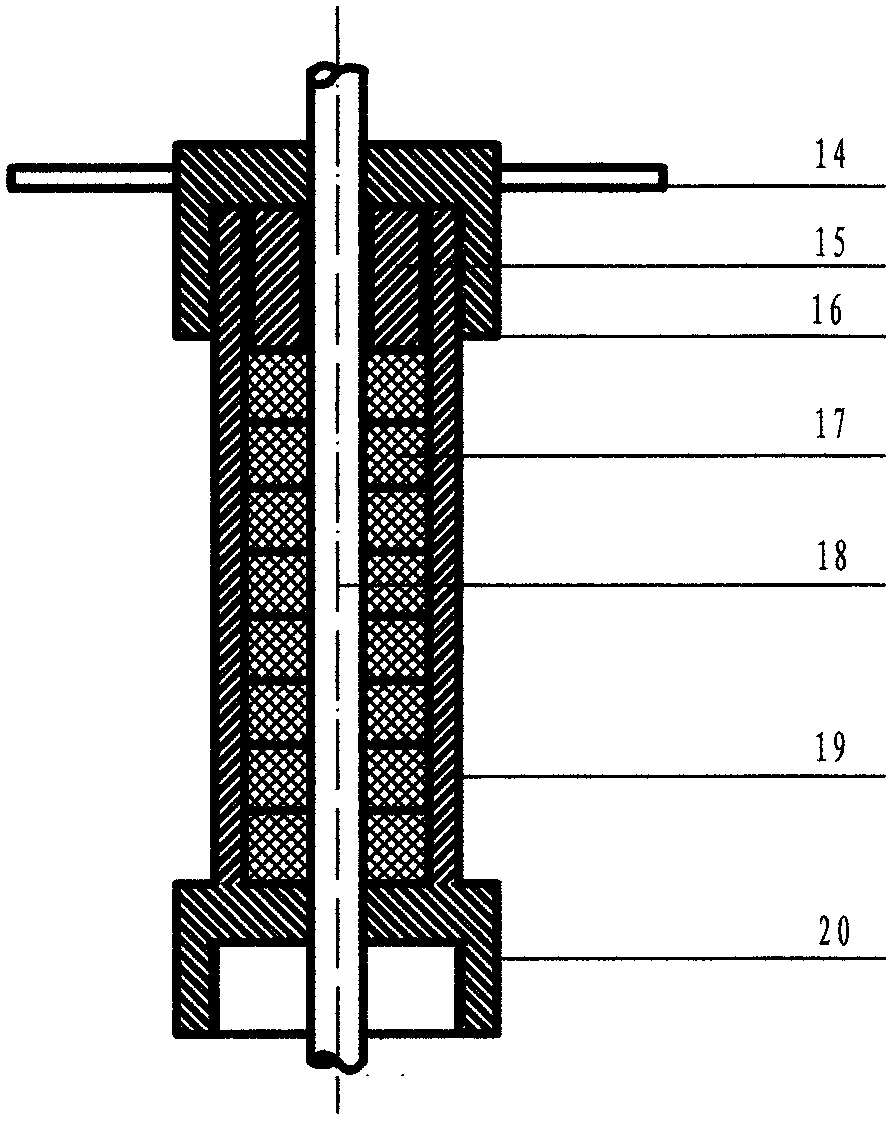

Magnetic fluid polished rod sealer for oil production in oilfield

The invention provides a magnetofluid polished rod sealer used for oil production in an oil field, comprising a housing; the lower end of the housing is enclosed, the upper end is provided with gram and a gland bush and the gland bush is sheathed on the outside of a polished rod; particularly, a magnetic sleeve gasket is arranged in the housing, the inner ring surface of the magnetic sleeve gasket is provided with a fill area opposite to the polished rod and the fill area is filled with magnetofluid; the upper end and the lower end of the magnetic sleeve gasket are respectively provides with an upper sleeve gasket and a lower sleeve gasket. The invention completely solves the long-standing problems of high power consumption, vulnerableness, 'running', 'emitting', 'dropping' and 'leaking' of oil-gas-water and harm on safety and environment protection of the existing oil producing sealer and the like; the sealer can be widely used for sucker-rod pumping wells in the oil field.

Owner:邓海波

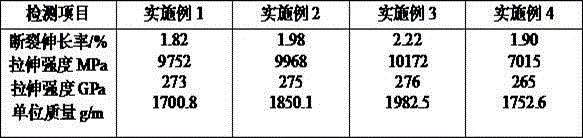

Method for manufacturing oil-gas-exploration special fiber rope

The invention provides a method for manufacturing a special carbon fiber rope, and belongs to the field of high polymer materials. The method includes the steps that 500k carbon fibers are firstly preprocessed through acetone ultrasounds and then coarsened, wherein impurities on the surface of the carbon fibers are removed, the superficial area of the carbon fibers is increased, the surface is coarsened, and the combining force between the carbon fibers and epoxy resin is increased; gum dipping is carried out on the preprocessed carbon fibers, and precuring is carried out for 1.5 hours; curing is carried out 1 hour again after twisting is carried out through a twisting machine, stranding is carried out after coating processing is carried out, and the special carbon fiber rope is manufactured. The strength of the special carbon fiber rope is about 10,000 MPa and is about ten times that of a steel cable, the density is about 150 g / m<2>, and the resin content is about 30%. The manufactured carbon fiber rope is mainly used for the oil-gas exploration field.

Owner:四川鑫达企业集团有限公司

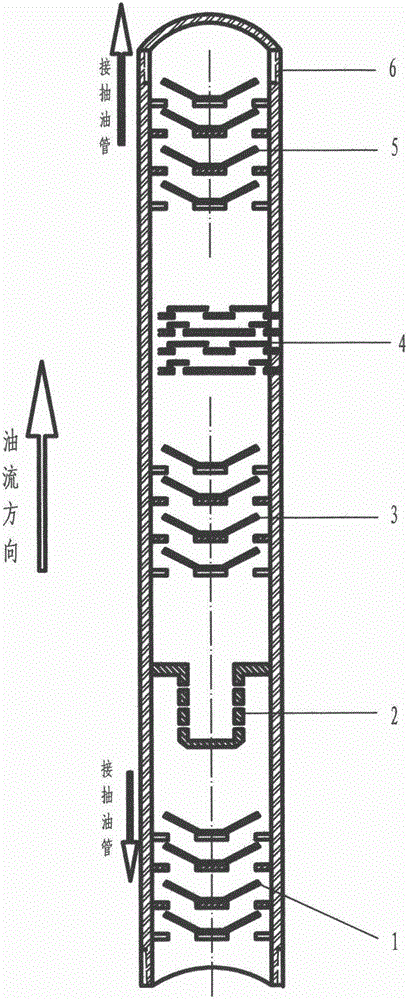

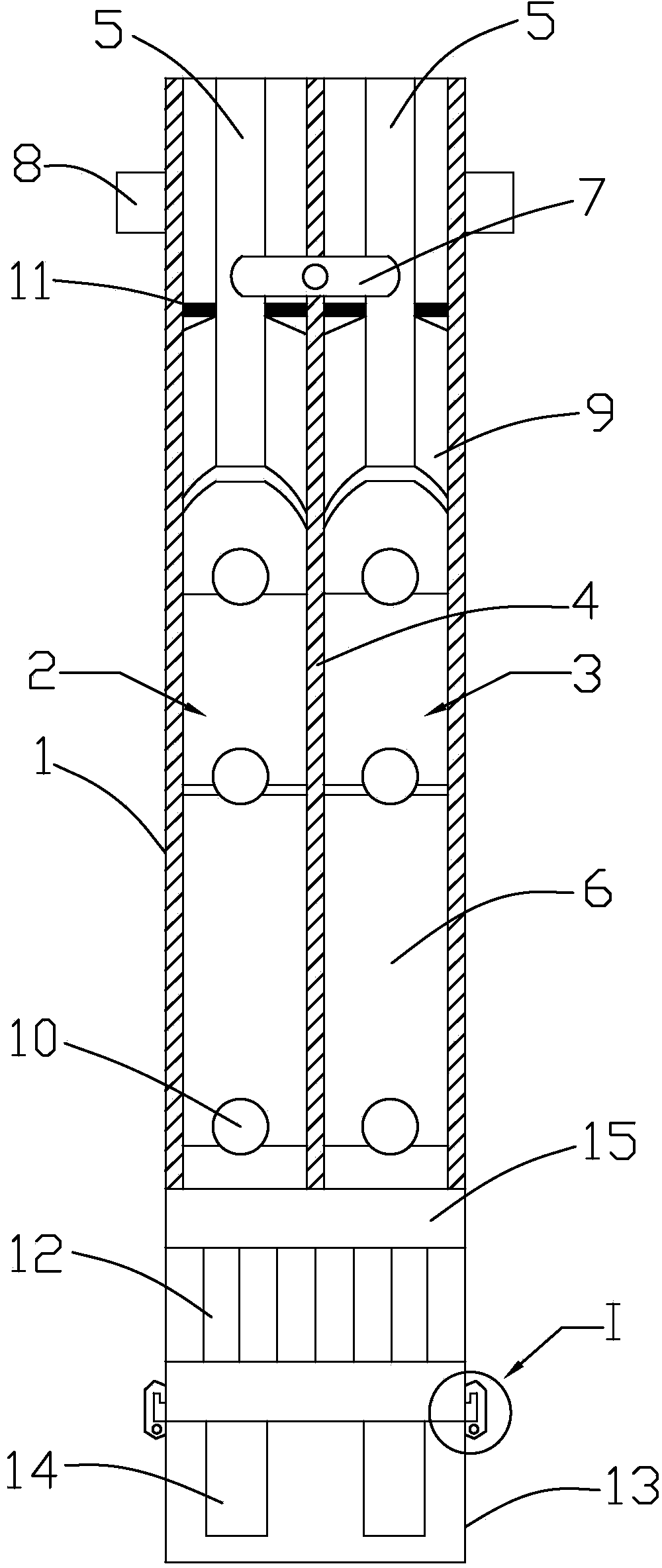

Paraffin-prevention and viscosity-reduction rectifier of oil field flowing well

PendingCN105909204AAchieve decentralizationRealize the shielding effectCleaning apparatusVibration devicesWaxPhase mixing

A paraffin-prevention and viscosity-reduction rectifier of an oil field flowing well is suitable for extracting oil from an oil field high-pressure well, and the long-standing, big and difficult problem that paraffin and scale of a flowing well are scraped and removed through manual work since the beginning of the oil exploitation history is solved. The rectifier is a tubular tool and mounted in the position about one thousand meters under a paraffin-troubled well section of the well. A first-level vortex rectifier body, an impinging stream phase mixing device, a second-level vortex rectifier body, an impact type acoustic oscillator and a third-level vortex rectifier body are mounted in the rectifier from bottom to top, a large-cluster laminar-flow condensed phase state of flowing oil, gas and water can be treated to form a fine-cluster milky eddying turbulence phase state, all heterogeneous components are made to wrap one another, refining, scattering and shielding of paraffin crystals and scale crystals are achieved, the physical state, the physical property, the flow state and the flow speed of produced liquid are optimized, and the phenomenon that the well is blocked by gathered paraffin and scale crystals on the oil tube wall is fundamentally eliminated; and meanwhile, the viscosity of the produced liquid is greatly lowered, the in-well burble procedure is effectively prolonged, manual paraffin and scale scraping and removing are omitted, workover treatment is reduced, oil extraction cost is lowered, and production and efficiency are improved.

Owner:邓海波

Preparation method of petroleum propping agent

The invention discloses a preparation method of a petroleum propping agent. The method comprises the main steps that S1, firstly, raw materials are smashed and screened, raw materials with the grain size being not larger than 5.5 mm are collected, and the raw materials not meeting the requirement for the grain size continues to be subjected to the smashing process for use; S2, according to the weight component, the prepared raw materials are ground, screened and heated to 300-350 DEG C for use; S3, the materials in S2 are stirred and heated under the constant temperature of 150 DEG C, then, acuring agent, a lubricating agent and a surface active agent are added in sequence, and stirring continues to be performed for 2 min for use; S4, the materials in S3 are cooled, smashed and screened to obtain a finished product.

Owner:南通市飞宇石油科技开发有限公司

Blowout prevention oil well pump for oil field

InactiveCN104358677AImprove continuityImprove oil recovery efficiencyPositive displacement pump componentsFlexible member pumpsEconomic benefitsOil field

The invention discloses a blowout prevention oil well pump for an oil field, which comprises a pump body, wherein the pump body is internally provided with an oil pumping mechanism and a blowout prevention device; the oil pumping mechanism comprises a first oil pumping part and a second oil pumping part; the second oil pumping part comprises a second oil pumping device, an oil pipe and a pump cylinder; the first oil pumping device and the second oil pumping device comprise plungers and valve rods; oil-collecting hoods are arranged at the tops of the plungers; a connection bracket is arranged between every two adjacent valve rods and comprises a rotation support block, a telescopic connecting rod and a locating block; and the blowout prevention device comprises a housing; the housing is internally provided with a one-way guide plate; a buffer plate is arranged on the one-way guide plate; and an oil nipple and a filter screen are arranged at the bottom of the pump body. The oil recovery efficiency of the oil well pump is improved, continuous oil recovery is realized, simultaneous oil production of the double valve rods is realized, the oil production efficiency is improved, the oil recovery cost is lowered, and the economic benefit is significant.

Owner:HANGZHOU HELLER SCI & TECH

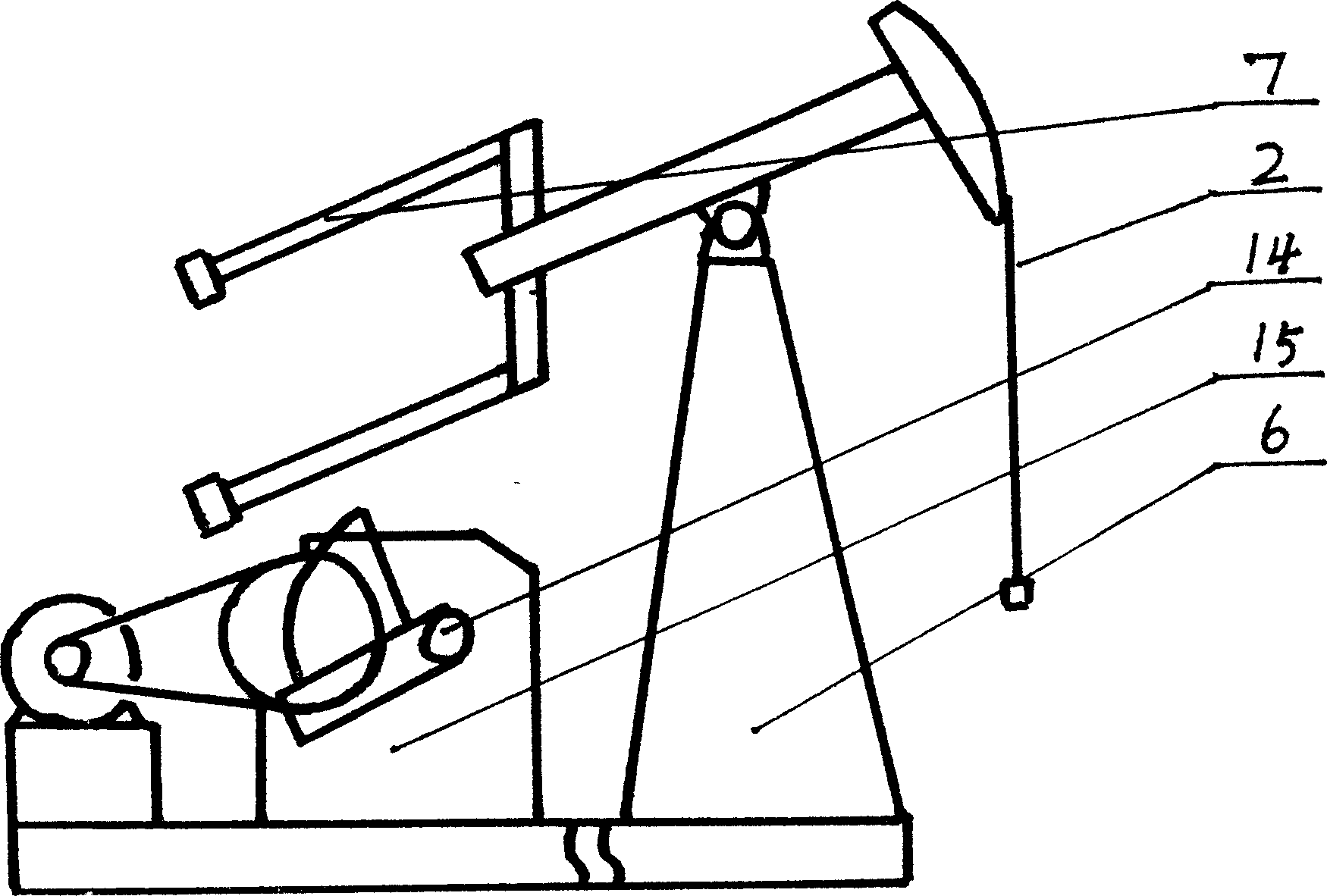

Single crank double distance flexible type beam-pumping unit

InactiveCN1793602AReduce weightReduce construction costsGearingFluid removalHigh energyReduction drive

Owner:DAQING OILFIELD CO LTD

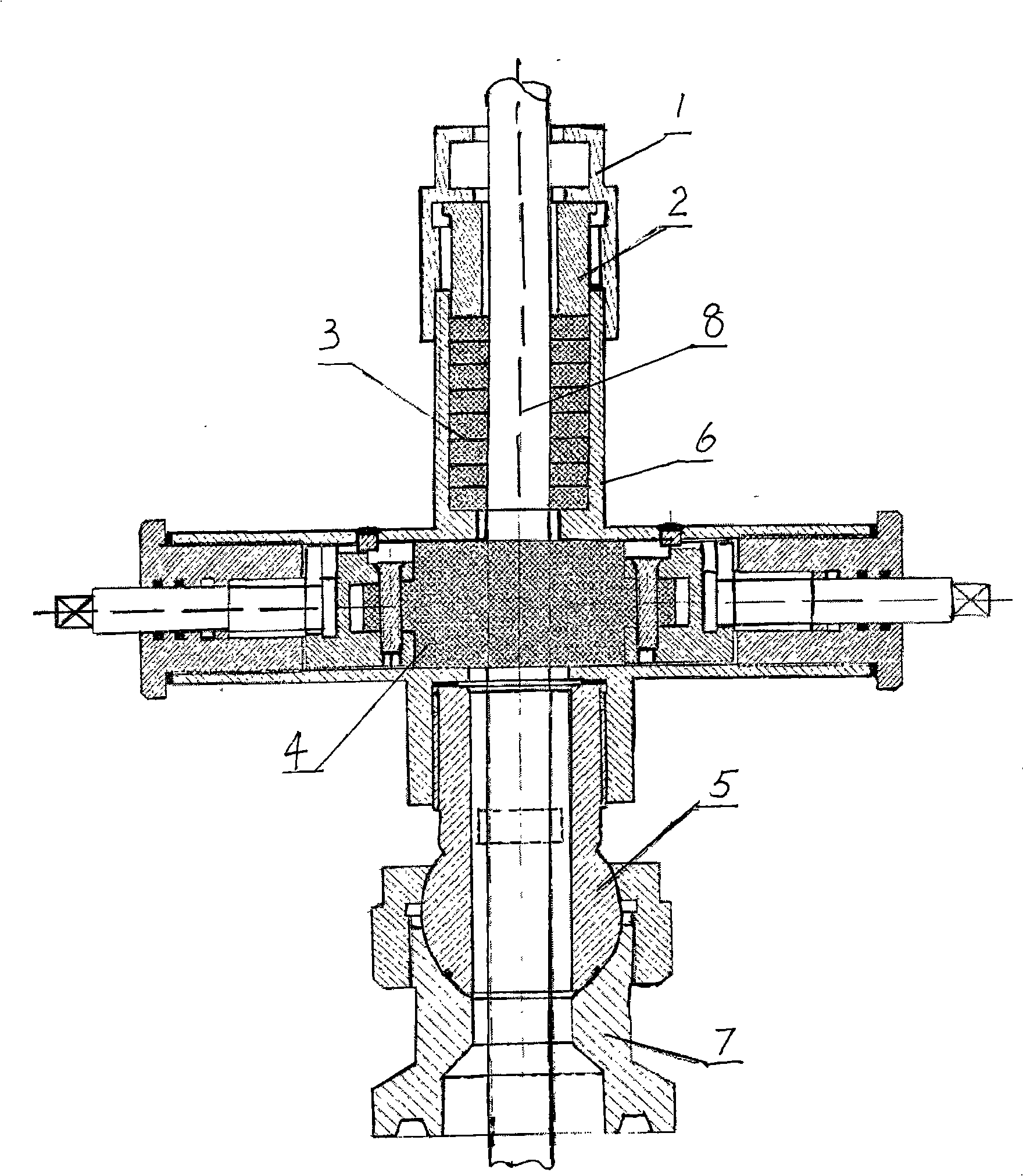

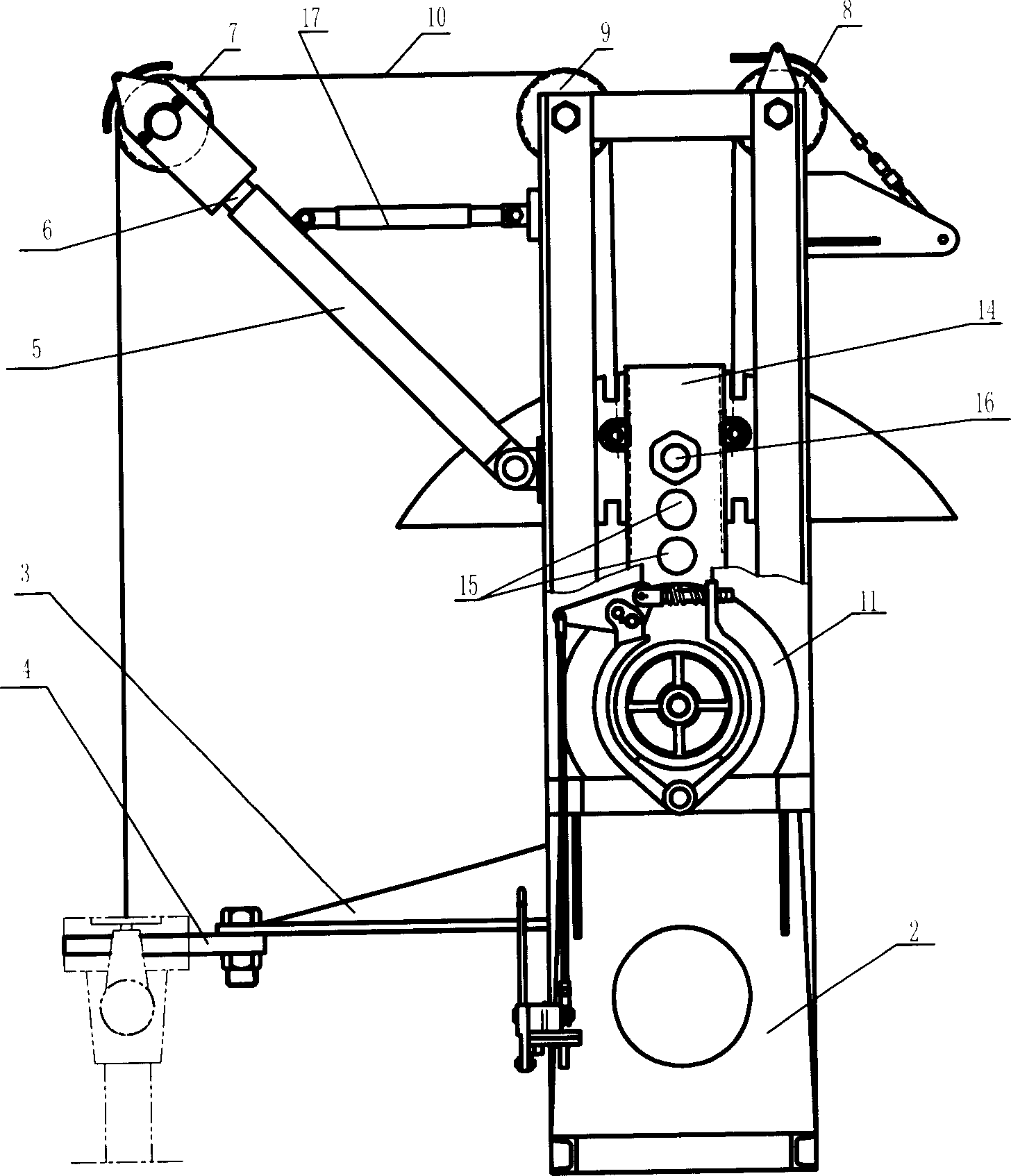

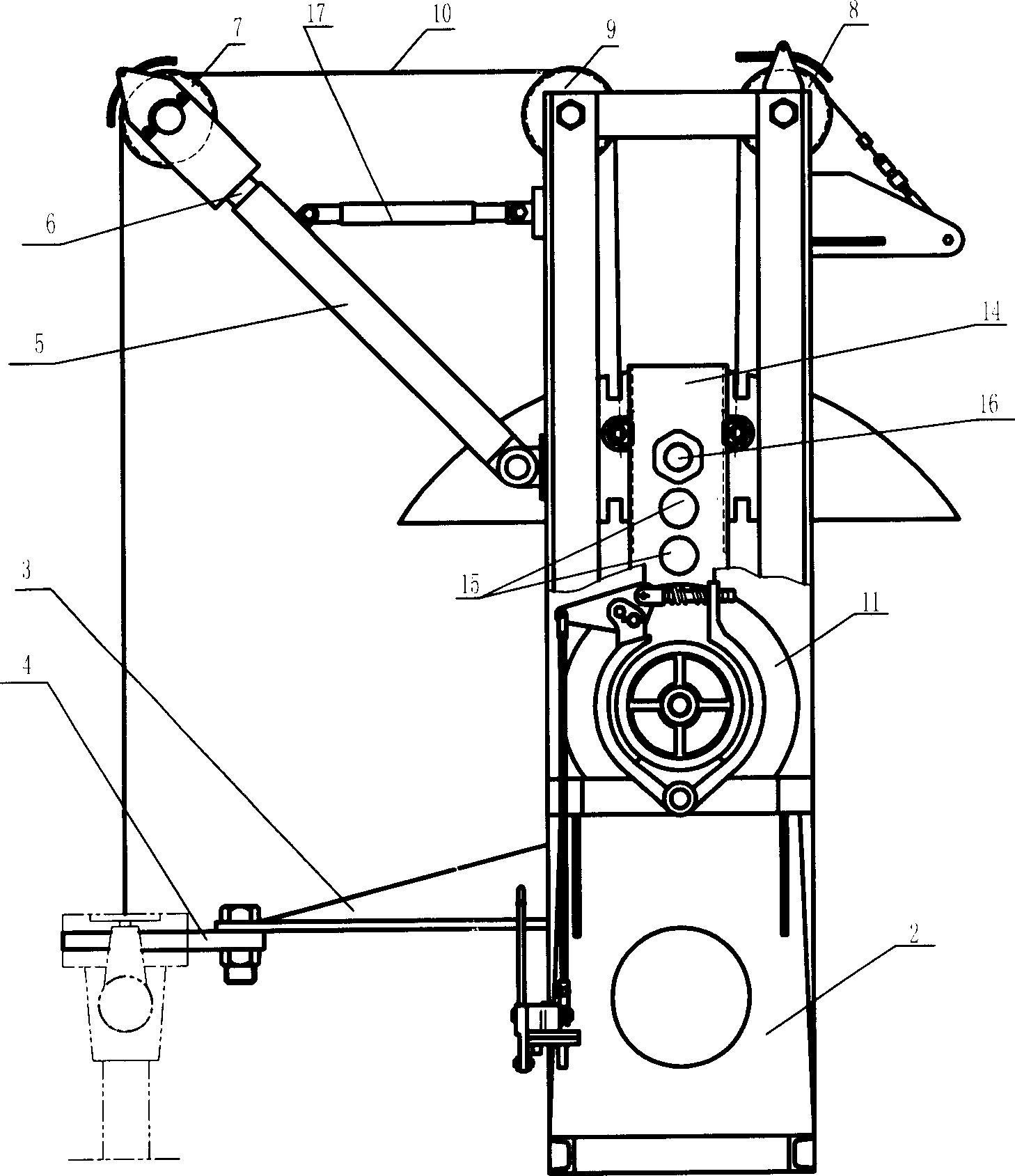

Method and equipment for equipotential self-balancing pumping unit in cluster wells

An equipotential self-balance petroleum pumping unit for cluster well is disclosed, which is suitable for the beam-type pumping unit. Its advantages are low cost, long service life and high reliability. The methods and apparatus for the contacting shaft with pump, the multifunctional sealing of bare rod sealer, exchanging said sealer without stopping production, regulating the horizontal angle of said sealer, and recovering leaked oil and preventing blowout are also disclosed.

Owner:王福成

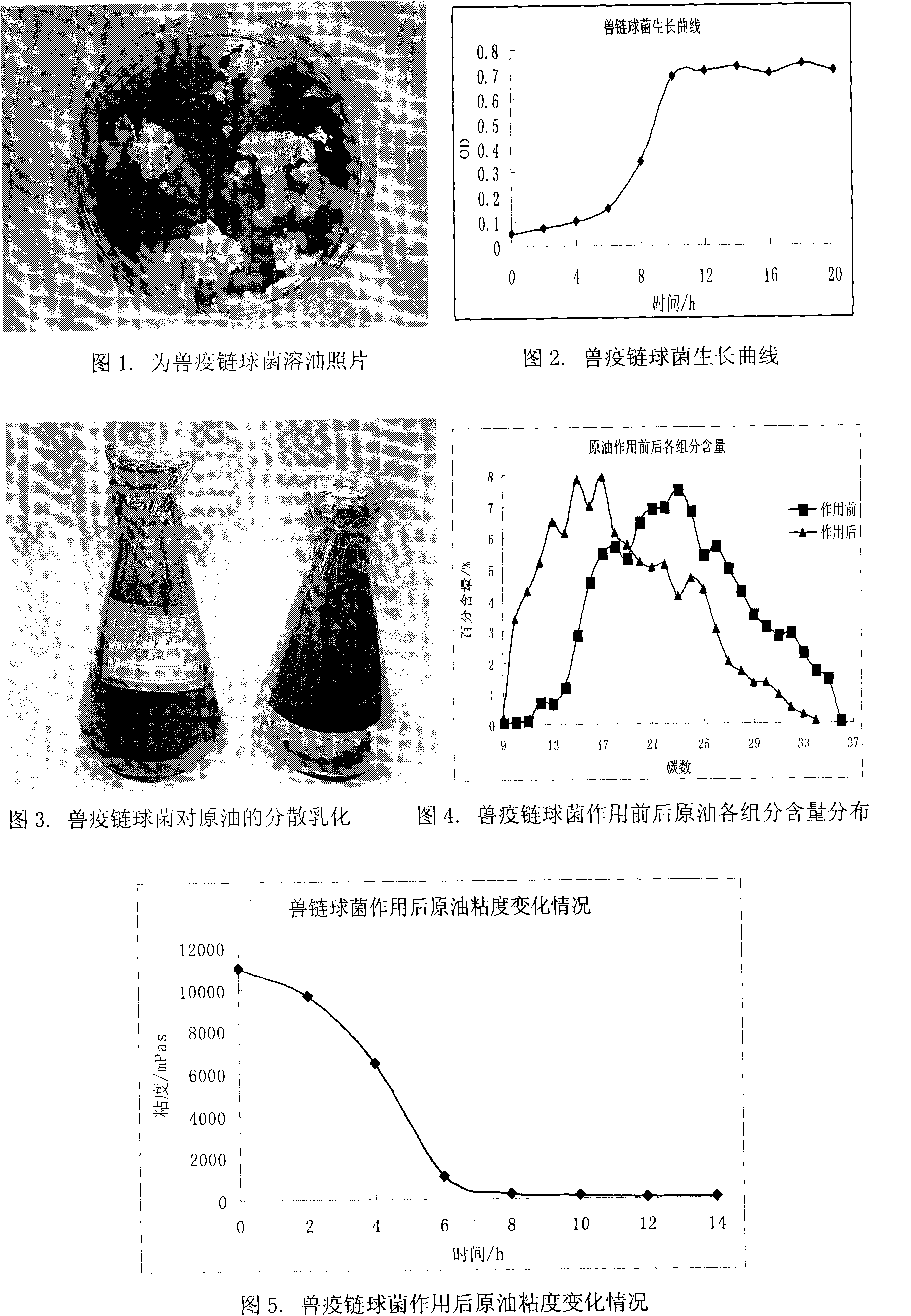

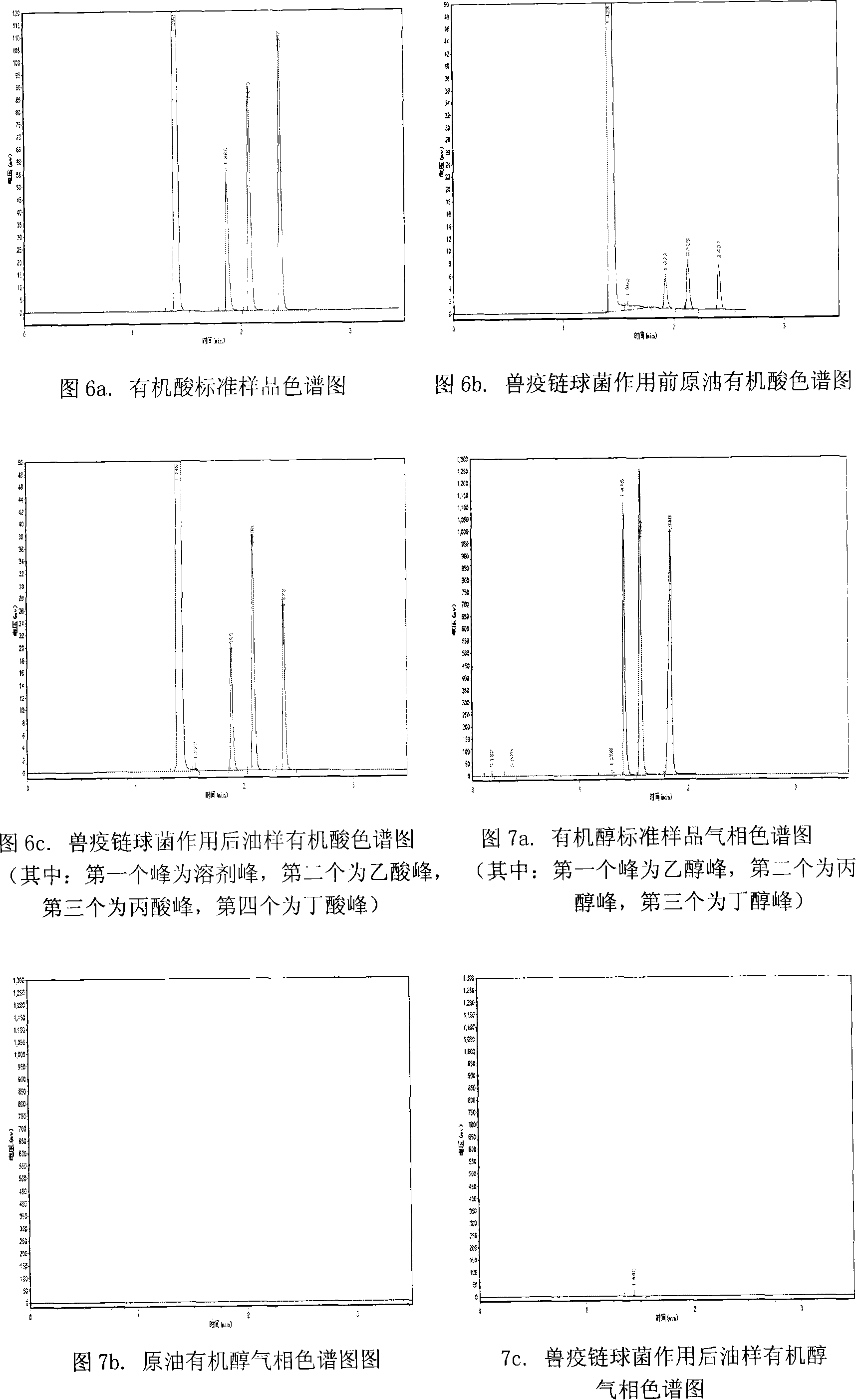

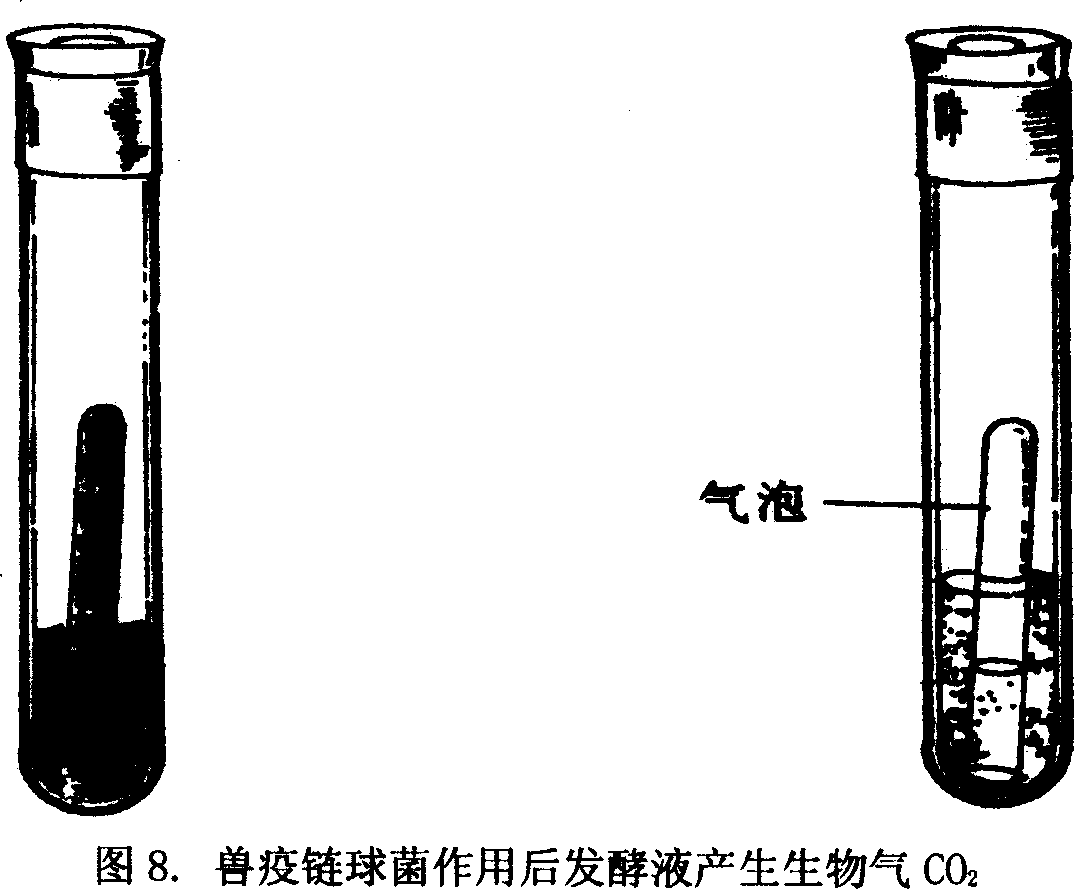

Viscosity reduction bacteria for increasing recovery ratio of petroleum, and application

InactiveCN101092602AIncrease vitalityReduce oil production costsBacteriaMicroorganism based processesStreptococcus zooepidemicusOil production

This invention discloses Streptococcus zooepidemicus (CGMCC No.1988) for reducing petroleum viacosity and increasing petroleum yield, and its application. Streptococcus zooepidemicus is applied by: inoculating in petroleum, and fermenting at 20-60 deg.C for 8-72 h. Streptococcus zooepidemicus can reduce petroleum viacosity from 8000-15000 mPa.s to 50-250mPa.s, increase petroleum acid value by 8-15 times and light component contents, reduce wax and glue contents by 50-95%, improve rheological property of petroleum, reduce interfacial tension between water and oil, increase organic acid contents in fermented petroleum, and increase oil layer pressure and petroleum fluidity. Besides, CO2, biogas and hyaluronic acid are generated during the fermentation process, thus fermented petroleum is easy to emulsify, moisten and disperse. Streptococcus zooepidemicus can be used in oil production, especially microbe-enhanced oil production and petroleum transportation.

Owner:厦门绿启源生物科技有限公司

Steam assisted gravity drainage technology of double-branch horizontal well

The invention relates to a thermal recovery technology of a branched horizontal well, in particular to a steam assisted gravity drainage technology of a double-branch horizontal well. The steam assisted gravity drainage technology of the double-branch horizontal well comprises the following steps that (1) in the process of well completion of the double-branch horizontal well, an upper directional horn-shaped opening is installed, and the slope direction of the upper directional horn-shaped opening is kept to be consistent with the direction of a hollow inclination guiding device; (2) a packer and a seal joint are installed in a branch well Z1 and a branch well Z2 respectively, and are used for sealing the branch well Z1 and enabling the branch well Z2 to form an annular space, and pressure leakproofness is kept. According to the steam assisted gravity drainage technology of the double-branch horizontal well, due to the fact that the technical advantages of the double-branch horizontal well are made full use of, the purposes that the recovery ratio of heavy oil and the recovery ratio of super heavy oil are increased, the oil production rate of heavy oil and the oil production rate of super heavy oil are increased, the well drilling cost and the oil production cost are reduced, the hard-to-recover reserve is used economically, and the workload of two common horizontal wells is accomplished through one double-branch horizontal well are achieved. The defects that according to an existing SAGD technology, two horizontal wells need to be drilled, and the well drilling cost and the oil production cost are high are overcome.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Device for preventing corrosion through impressed current method for oil pumping well

PendingCN107313721AAvoid corrosionExtended service lifeDrilling rodsDrilling casingsOil fieldMechanical engineering

The invention relates to a corrosion prevention device on an oil pumping well of an oil field, in particular to a device for preventing corrosion through an impressed current method for an oil pumping well. The device comprises a beam hanger, a sucker rod string, an oil outlet pipeline, an oil pipe, a sleeve, an oil well pump and a direct-current power source; the sleeve is mounted in a wellbore; the oil well pump is mounted on the oil pipe, then the oil pipe with the oil well pump is put in the sleeve, and the upper portion of the oil pipe is in insulated connection with the sleeve; the lower portion of the oil outlet pipeline is connected with the oil pipe; the sucker rod string is put in the oil pipe, and the lower portion of the sucker rod string is connected with a piston of the oil well pump; the upper portion of the sucker rod string penetrates through the oil outlet pipeline to be in insulated connection with the beam hanger; a plurality of non-conducting centering devices are mounted on the oil pipe at intervals; the negative pole of the direct-current power source is connected to the oil outlet pipeline, and the positive pole of the direct-current power source is connected to the ground; and the tail end of the oil pipe and the sleeve communicate through contacting to form a closed loop. The service lives of a sucker rod, the oil pipe, the oil well pump, the sleeve and downhole tools of the oil pumping well are prolonged, and the economic benefits of the oil well are improved.

Owner:PETROCHINA COALBED METHANE +2

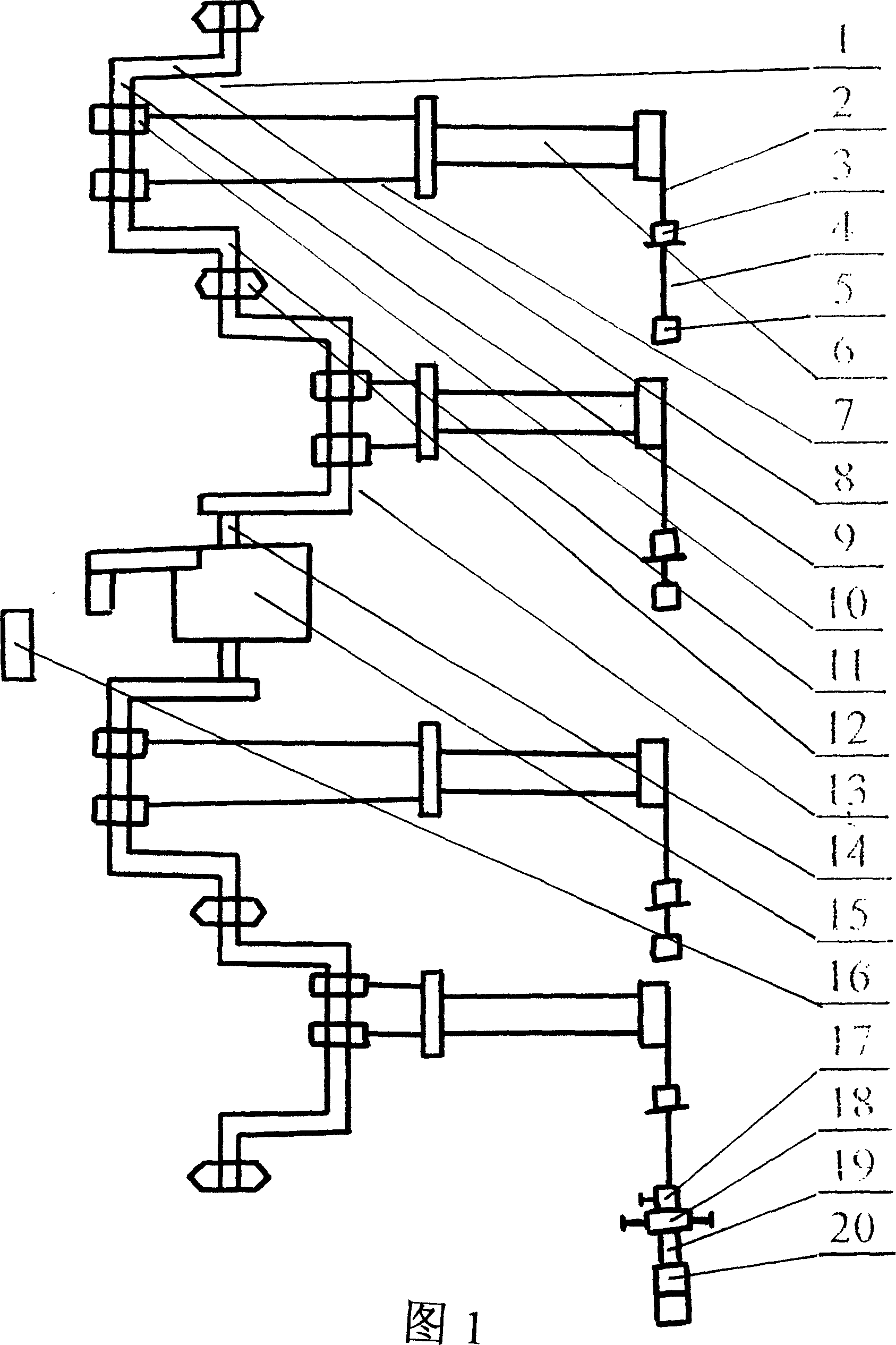

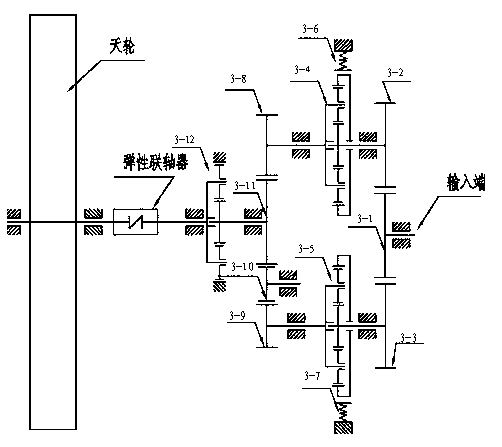

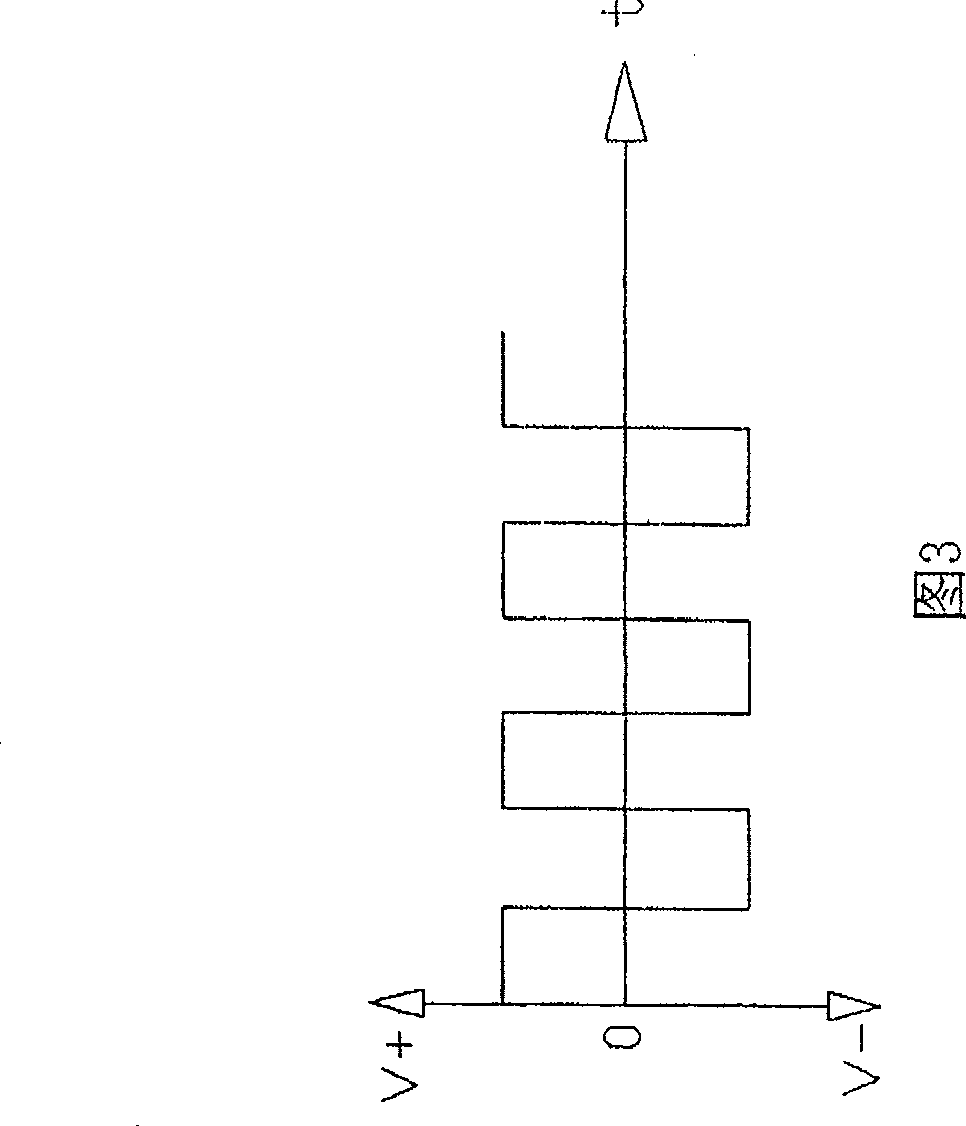

Novel vertical mechanical reversing energy-saving pumping unit

ActiveCN103216216ALess actual stroke lossActual stroke loss is smallToothed gearingsFluid removalStored energyGear drive

The invention relates to a novel vertical mechanical reversing energy-saving pumping unit. The novel vertical mechanical reversing energy-saving pumping unit is characterized in that a transmission system adopts a mechanical reversing, two-way gear drive and oil-immersed lubrication fully-enclosed reduction gearbox for realizing the positive and negative rotation of a head sheave of the pumping unit, to ensure the immense inertia of a pumping rod and a counterweight to decelerate, buffer until stop before the pumping unit runs to an upper dead point or a lower dead point, a crank buffer device is arranged so that the impact energy is smoothly absorbed and stored, the stored energy is released after passing through the upper dead point and the lower dead point, and a motor is started at an upper dead point or a lower dead point under the conditions of basically smooth input speed and torque. Through the adoption of mechanical reversing and closed oil-immersed lubrication, the adaptability of the pumping unit to the harsh environment is higher; as the motor runs in the same direction all the time, a complex electric control system is not provided, the reliability is high, and the servicing, the maintenance and the repair are simple; and the equipment is controlled to run by a PLC (programmable logic controller), and importantly, the system adopts a two-way backup, and therefore, both the reliability and the stability of the pumping unit are enhanced.

Owner:常州新槃威智能科技有限公司

Synthesis method of quaternary copolymerized salt-resistant and temperature-resistant polyacrylamide

InactiveCN107987211AImprove salt and temperature resistanceThe synthesis method is simpleDrilling compositionFunctional monomerSynthesis methods

The invention discloses a synthesis method of quaternary copolymerized salt-resistant and temperature-resistant polyacrylamide. The synthesis method comprises the following steps: firstly, adding acrylamide, a salt-resistant functional monomer, a temperature-resistant functional monomer, a pH buffering monomer and deionized water into a reaction device to prepare a mixed aqueous monomer solution,adjusting the pH value to be 5 to 8, inflating nitrogen to remove oxygen, and adding azodiisobutylimidazoline hydrochloride; after the oxygen content is lower than 0.1mg / L, controlling the temperatureto be at 0-8 DEG C, and reacting for 4-8 hours in a sealed state; then, crushing colloid, mixing with a hydrolyzing agent, preserving heat at 60-80 DEG C, reacting for 4-8 hours, drying and crushingto obtain a finished product. The synthesis method has the advantages as follows: the synthesis method is simple, and the synthesized finished product changes a single molecular structure of the conventional polyacrylamide; the functional monomers are introduced into a main chain to generate special functional groups, so that the sensitivity of the polyacrylamide to salt and the temperature is reduced, therefore, the salt resistance and the temperature resistance of the polyacrylamide are greatly improved, and the quaternary copolymerized salt-resistant and temperature-resistant polyacrylamidecan be better applied to tertiary oil recovery of a high-salt and high-temperature reservoir of an oilfield; moreover, sewage can be used for preparing the quaternary copolymerized salt-resistant andtemperature-resistant polyacrylamide, so that the oil recovery cost is effectively reduced.

Owner:HENAN ZHENGJIA ENERGY ENVIRONMENTAL PROTECTION CO LTD

Hydraulic oil production method and device

InactiveCN100497882CReduce wearNo pollutionFlexible member pumpsFluid removalPipe fittingHydraulic pump

The hydraulic oil extraction device comprise a ground hydraulic power for supplying high temperature and high pressure power liquid, a ground heater, a hydraulic power pipe that connects through a hollow oil extracting pole in the oil pipe and a stroke change-over valve nested the piston rod on the dual direction hydraulic pump with the piston rod having pistons at both ends. From bottom to up of the upper pump, there exists an upper pump outlet valve and a bottom pump valve, which connect respectively with the oil pipe and the outlet of the inlet valve of the bottom pump below the bottom pump cavity. Inlet of the upper outlet valve connects with the outlet of the upper pump inlet valve under the bottom pump let valve though pipe fittings. Discharging end of the adynamia hydraulic pipe connects with one of the channel of the stroke change-over valve, and the discharging end connects with the oil pipe through the pump heating tail pipe. When the upper pump discharges oil, the bottom pump absorbs oil or vice versa. This continuous alternating circulation carries the crude oil to the ground, improves the oil extraction efficiency and it applies to all kinds of oils.

Owner:李莉 +1

Steam injection technology method of high-temperature mixer generators

InactiveCN101182763AThe combustion process and the vaporization mixing process are fullyImprove cooling effectFluid removalElectric machineryInjector

A steam injection technique of a high-temperature mixer generator includes: a one-way gas injection valve is connected with the entrance of an underground oil layer; the fuel is ejected from a fuel nozzle and is mixed with the air entering through a high-pressure air nozzle and then is ignited by a high-pressure sparking plug so as to combust in a combustion chamber; before leaving the combustion chamber and entering a subsonic nozzle, the gas is mixed with the atomized water injected by a gasified water injector and then is accelerated by the subsonic nozzle so as to enter a buffer chamber for gasified mixing; the high-temperature composite gas after gasified mixing is injected into an oil layer in a high speed through a one-way gas injection valve from the buffer chamber; then a chemical drug injection device is used to inject the chemical drug into the well when the gas is injected into the well for chemical oil displacing; at the same time, the frequency conversion of a plunger pump motor is utilized to control the flow of a blister and make supplies at regular intervals, which are injected into the well after a gas bubble plug is formed with alternated gas section and bubble section, thus extending the oil-yielding time and achieving the aim of simultaneous and composite proceedings of gas oil extraction and chemical oil extraction.

Owner:SHENYANG MINGDA OIL EXTRACTION NEW TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com