Oil-field largest swept volume chemical-flooding oil production method

A chemical flooding, the largest technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of shortening crude oil production time, long water flooding development time, and reducing oil production cost, so as to achieve low cost, free The effect of using polymer and alkali and short operation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1: Using the natural rock core of Changqing Oilfield, adopting the reservoir conditions such as crude oil, formation water, temperature, crude oil saturation of Changqing Oilfield, using the maximum sweep volume chemical flooding recovery method, to carry out indoor physical simulation oil displacement test as an example, The invention is described in further detail.

[0065] A. Changqing Oilfield has not been developed for a long time. There are many newly added geological reserves every year, as well as newly drilled oil production wells and new development blocks. The new blocks are very suitable for the use of maximum swept volume chemical flooding. These new blocks are sandstones with low permeability, all of which can be developed by water flooding but have not yet been developed by water flooding. Firstly, the energy of the reservoir formation itself is used for oil recovery by swabbing. When the oil field for oil extraction by swabbing reaches the eco...

Embodiment 2

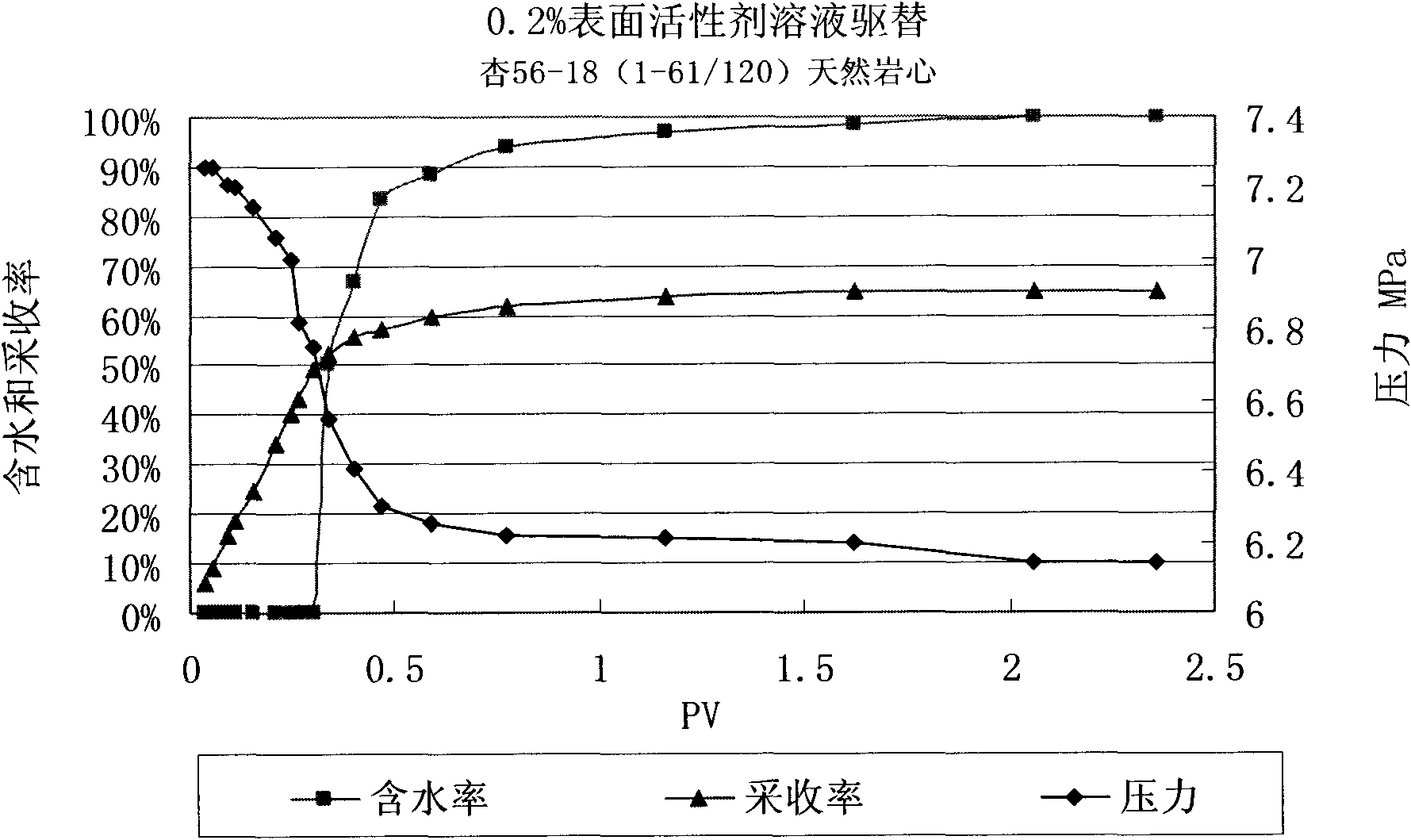

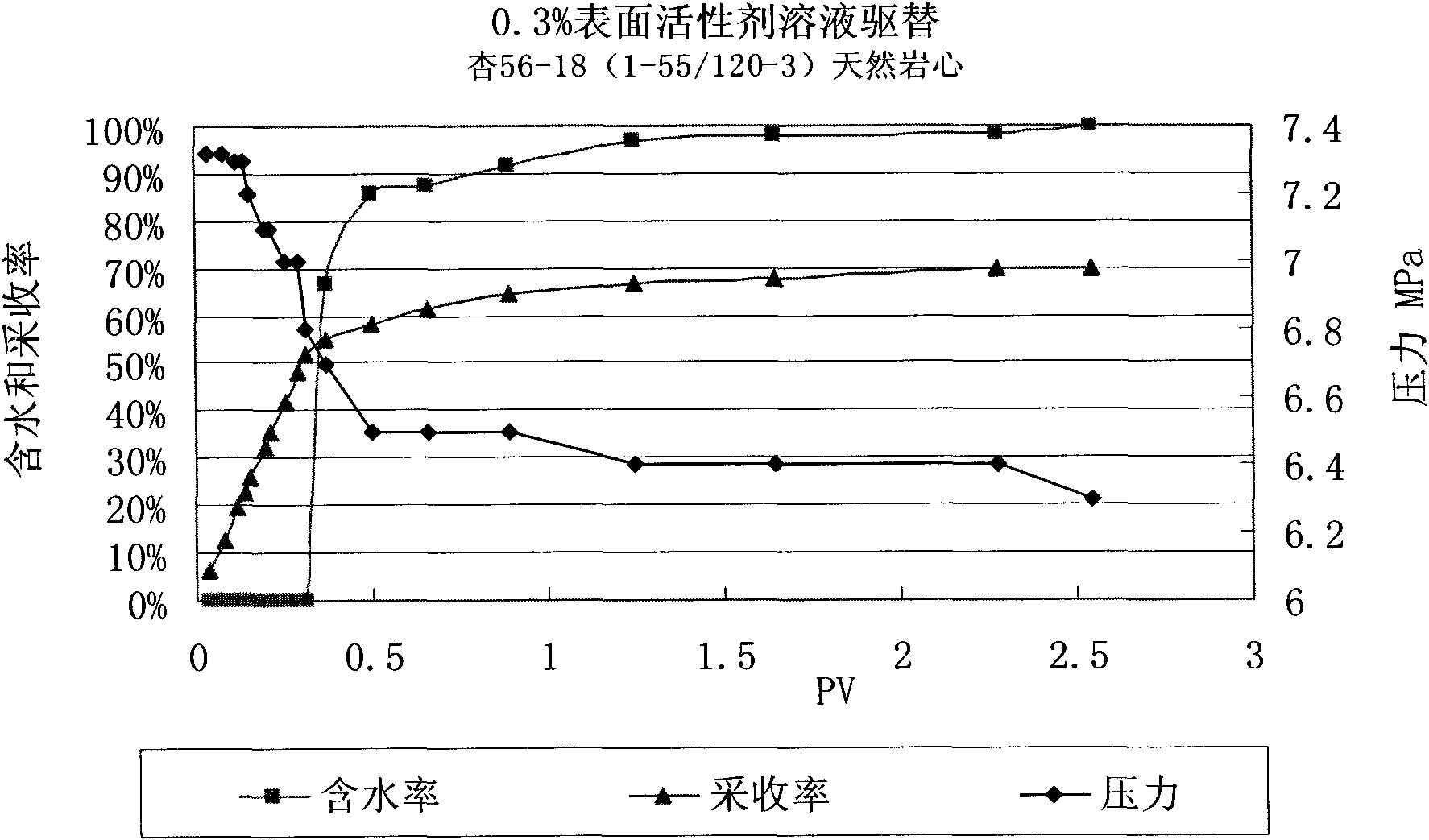

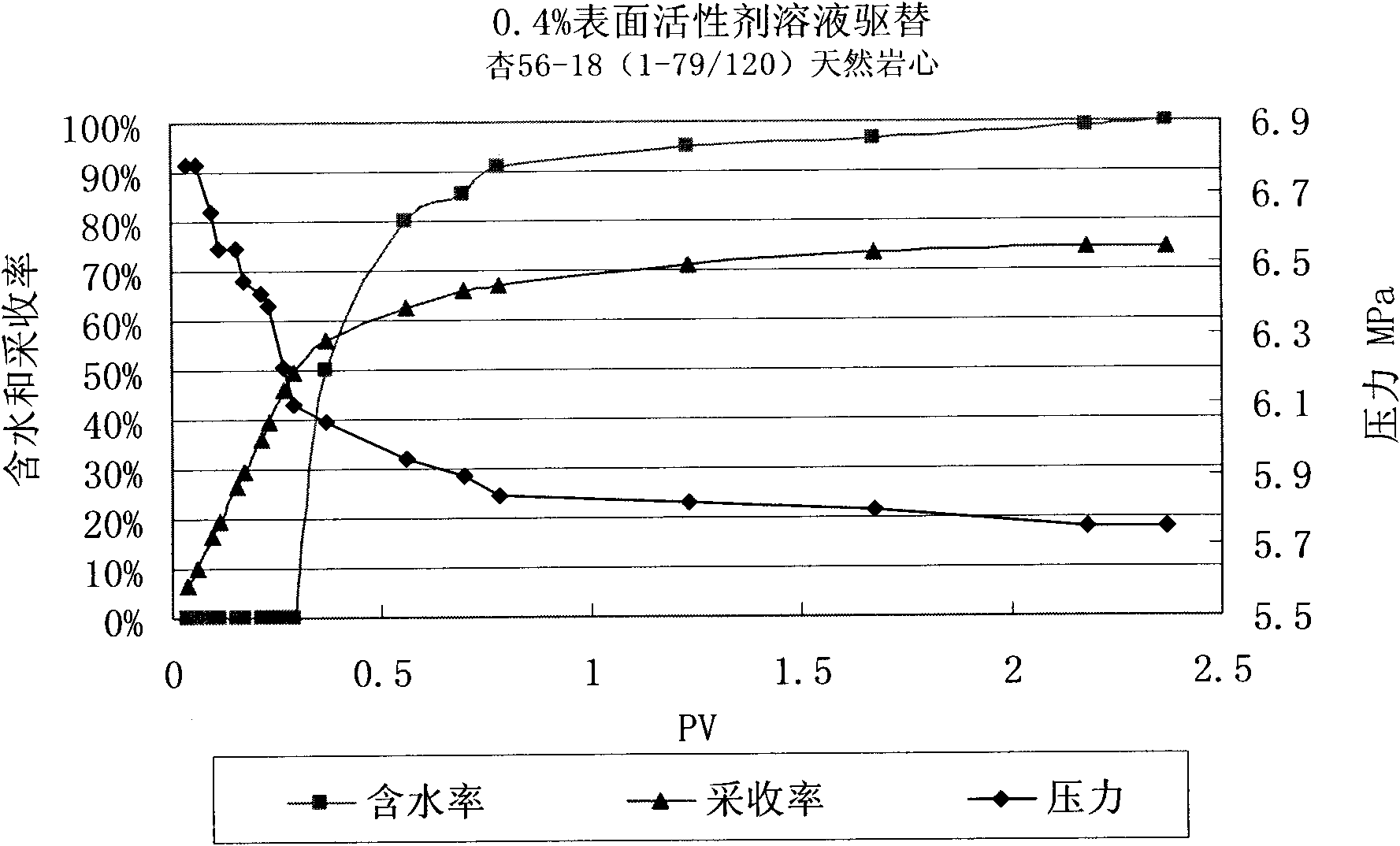

[0081] Example 2: In the initial stage of a certain oil reservoir exploitation, the self-spraying oil production is carried out by using the energy of the reservoir formation itself. When no oil is produced by the self-spraying oil production, the self-spraying oil production is terminated, and the conventional water flooding oil recovery is not carried out, but directly Enhanced oil recovery by flooding with injected surfactant solution.

[0082] The injected surfactant used is: a surfactant with emulsifying properties (water-in-oil or oil-in-water emulsification), specifically nonylphenol polyoxyethylene ether. The concentration of nonylphenol polyoxyethylene ether is 0.2% (w / w), and the solvent used is water.

Embodiment 3

[0083] Embodiment 3: When exploiting a certain oil reservoir, first use the energy of the reservoir formation itself to carry out oil extraction by swabbing, and when the oil field for oil extraction by swabbing reaches the limit of economic benefits of extraction, that is, when the input production cost is close to or equal to the output cost, the process ends Swabbing oil recovery does not carry out conventional water flooding oil recovery, but directly uses the displacement fluid injected with surfactant and added a small amount of additives for enhanced oil recovery.

[0084]The displacement fluid used to inject a surfactant and add a small amount of auxiliary agent is: two kinds of surfactants with different oil recovery properties are compounded and a small amount of alkali is added. The weight percentage of each component is:

[0085] Betaine: 86% (w / w)

[0086] Petroleum Sulfonate: 12% (w / w)

[0087] Alkali - sodium carbonate: 2% (w / w)

[0088] When in use, two kinds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com