Resin line with peripheral openings

A resin tube and peripheral side technology, applied in the field of resin tubes, can solve the problem of expensive manufacturing of flexible spiral hoses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

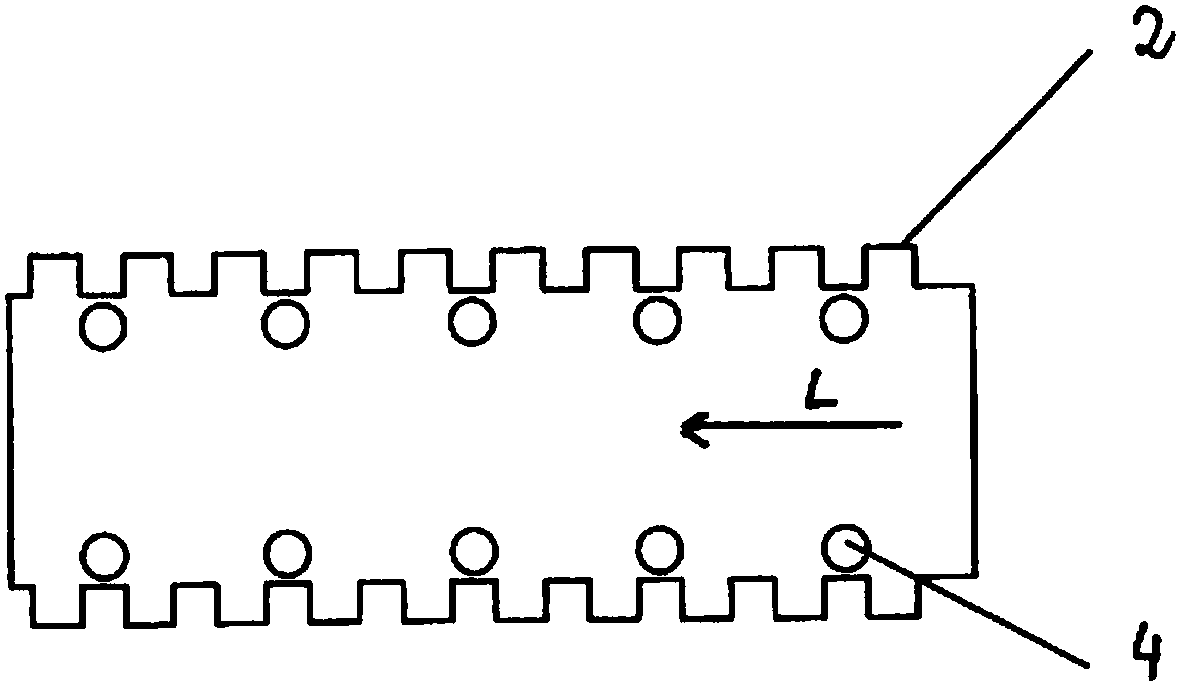

[0020] exist figure 1 The outline of the bellows 2 is schematically shown in . The perforations 4 are also shown schematically, which are located in the wall of the bellows 2 . In the depicted exemplary embodiment, the bellows 2 is formed from a series of parallel ring-shaped formations. In the exemplary embodiment, rings with an angular cross-sectional profile are shown, but these rings can also have a rounded cross-sectional shape, for example a semi-circular or semi-elliptical shape.

[0021] When the matrix material flows through the bellows 2 in the longitudinal direction L, the matrix material can flow outwards through the perforations 4 . When the corrugated tube 2 is placed in a mold for producing a fiber composite component, the matrix material can penetrate through the perforations 4 after leaving the corrugated tube into the reinforcing fibers placed in the mold and fill the mold.

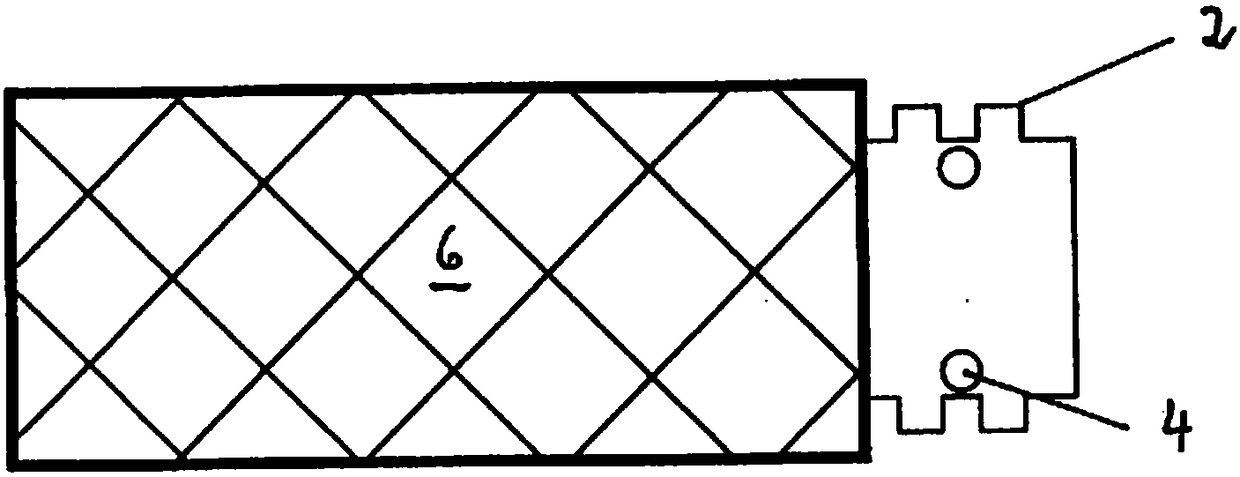

[0022] exist figure 2 A view towards the bellows which is at least partially sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com