Patents

Literature

54results about How to "Increase the setting area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

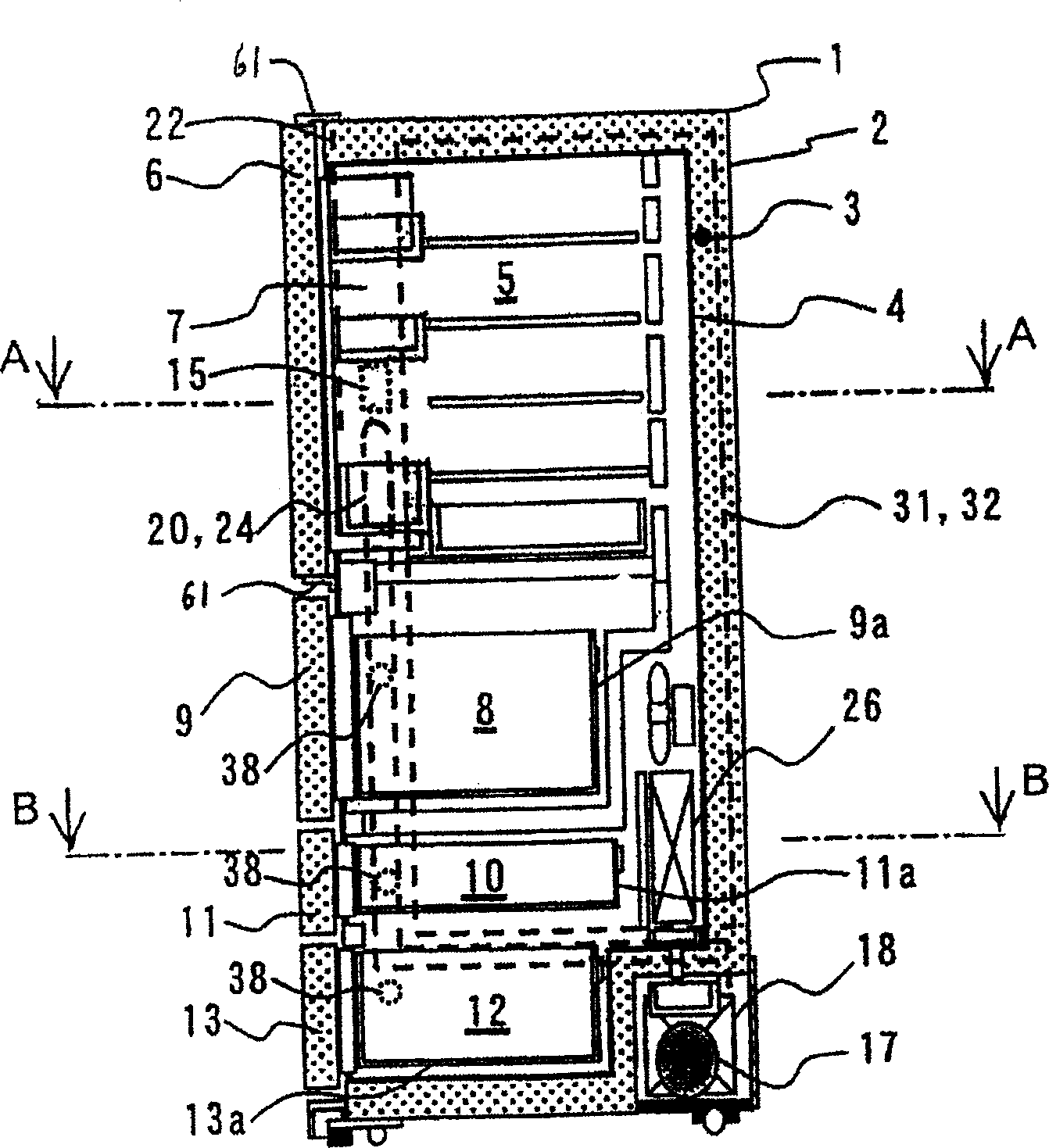

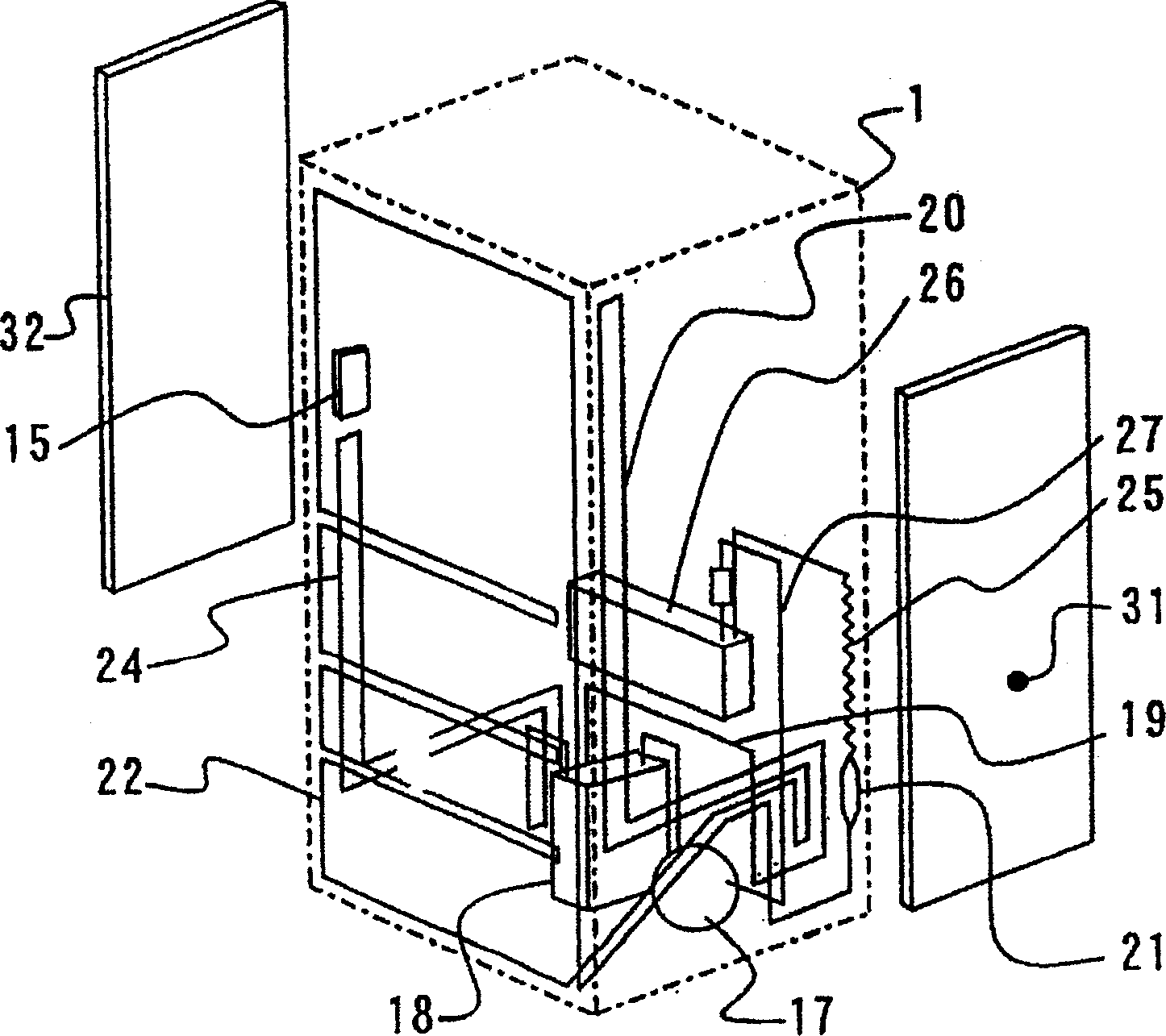

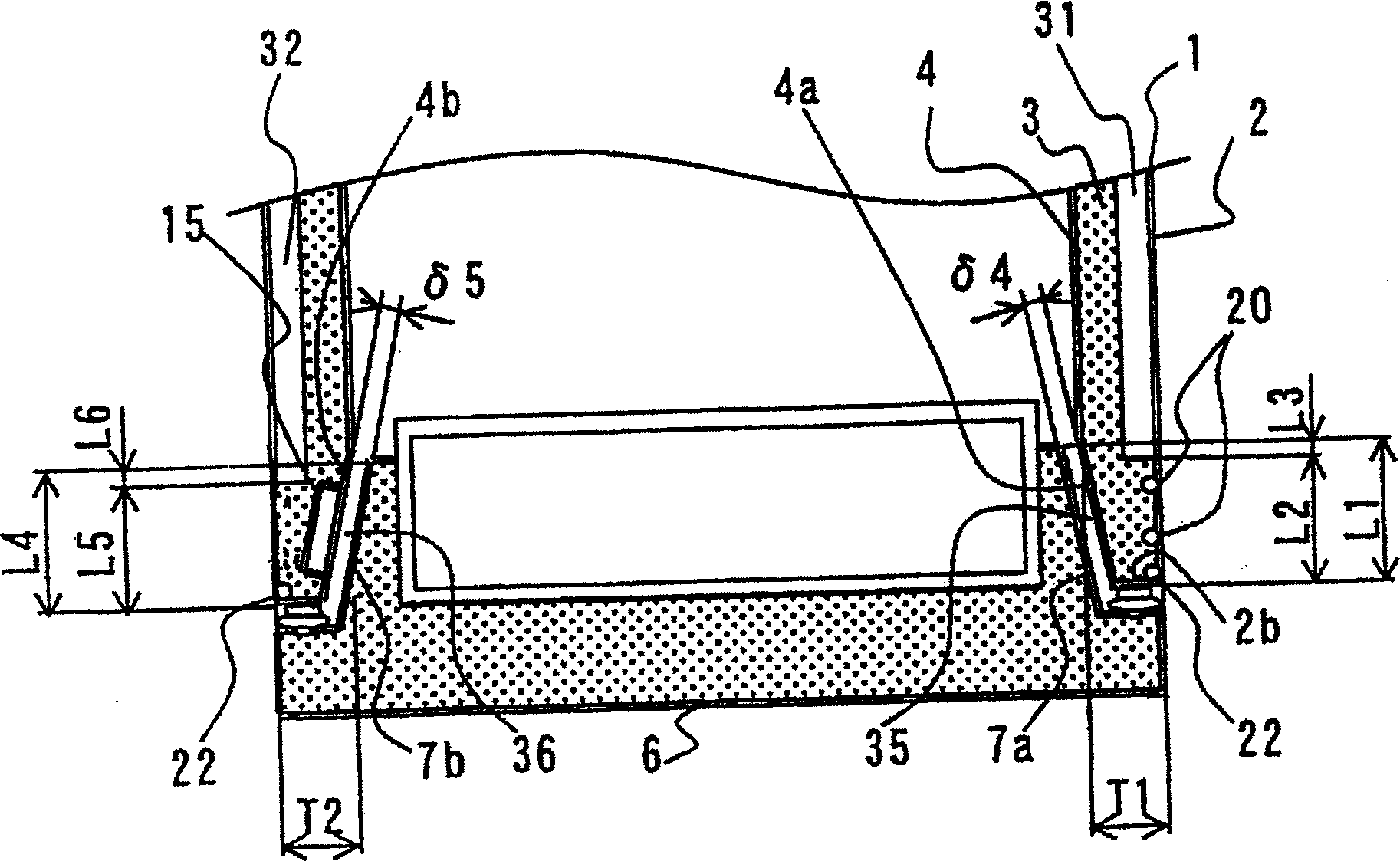

Refrigerator

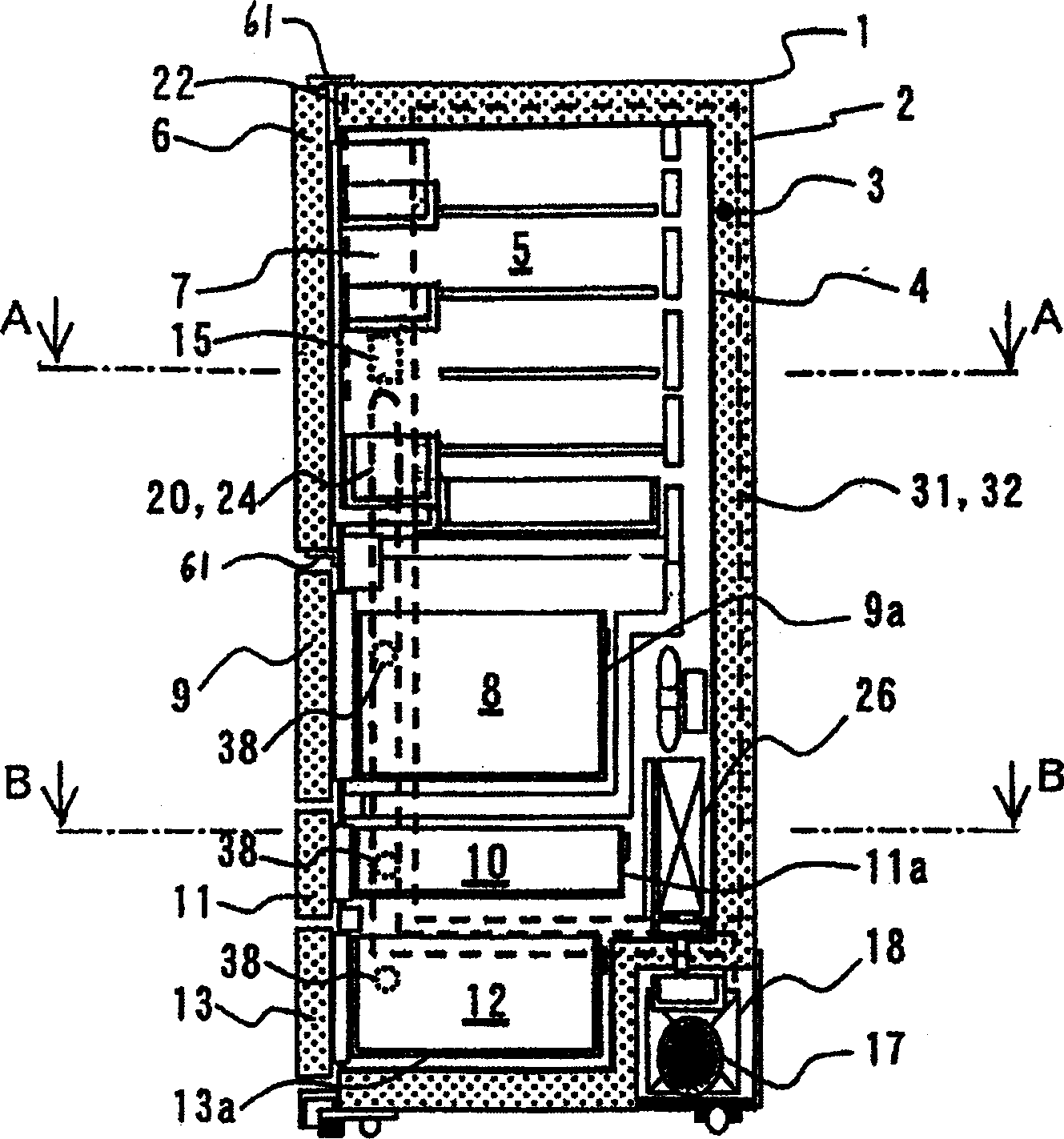

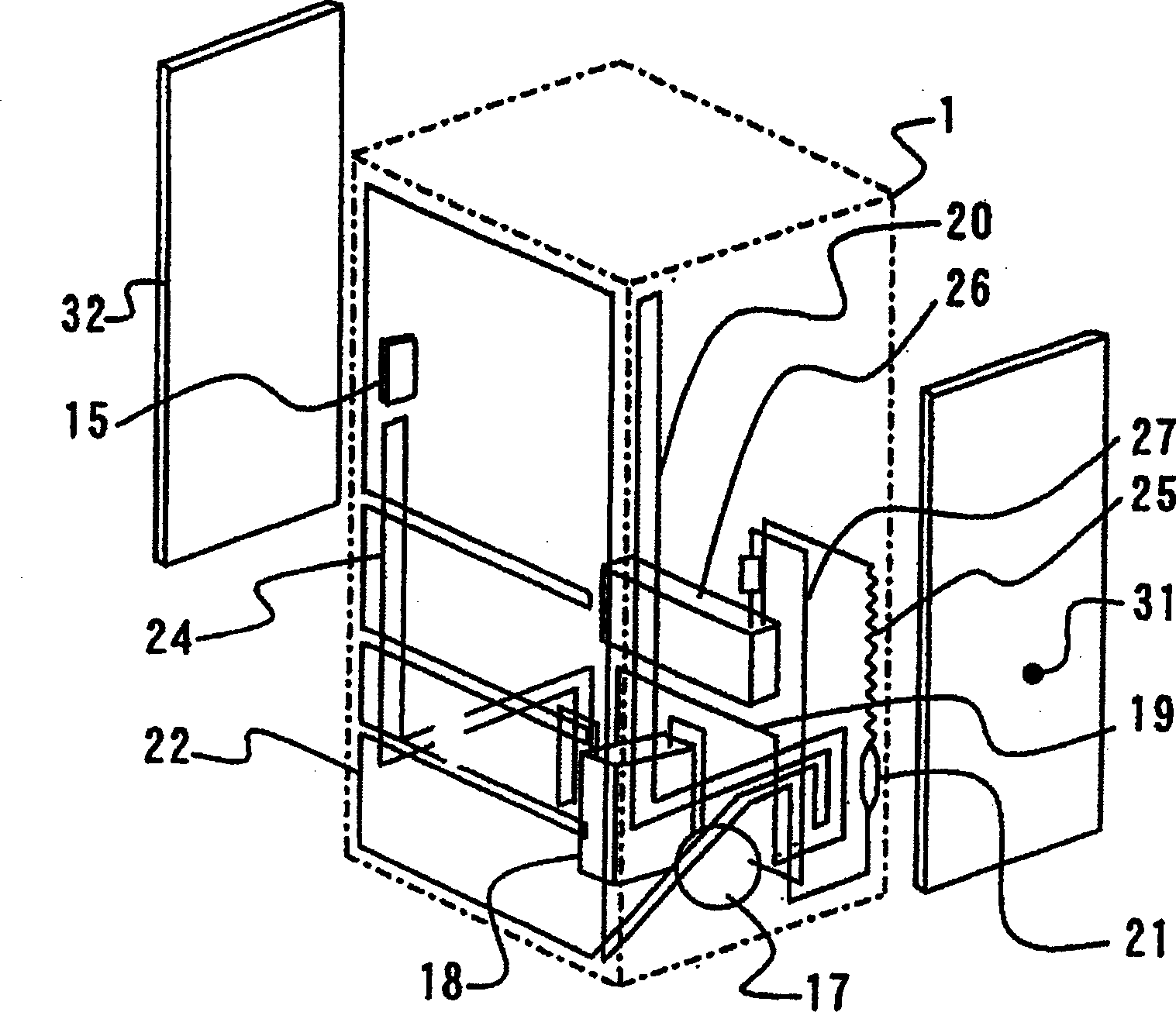

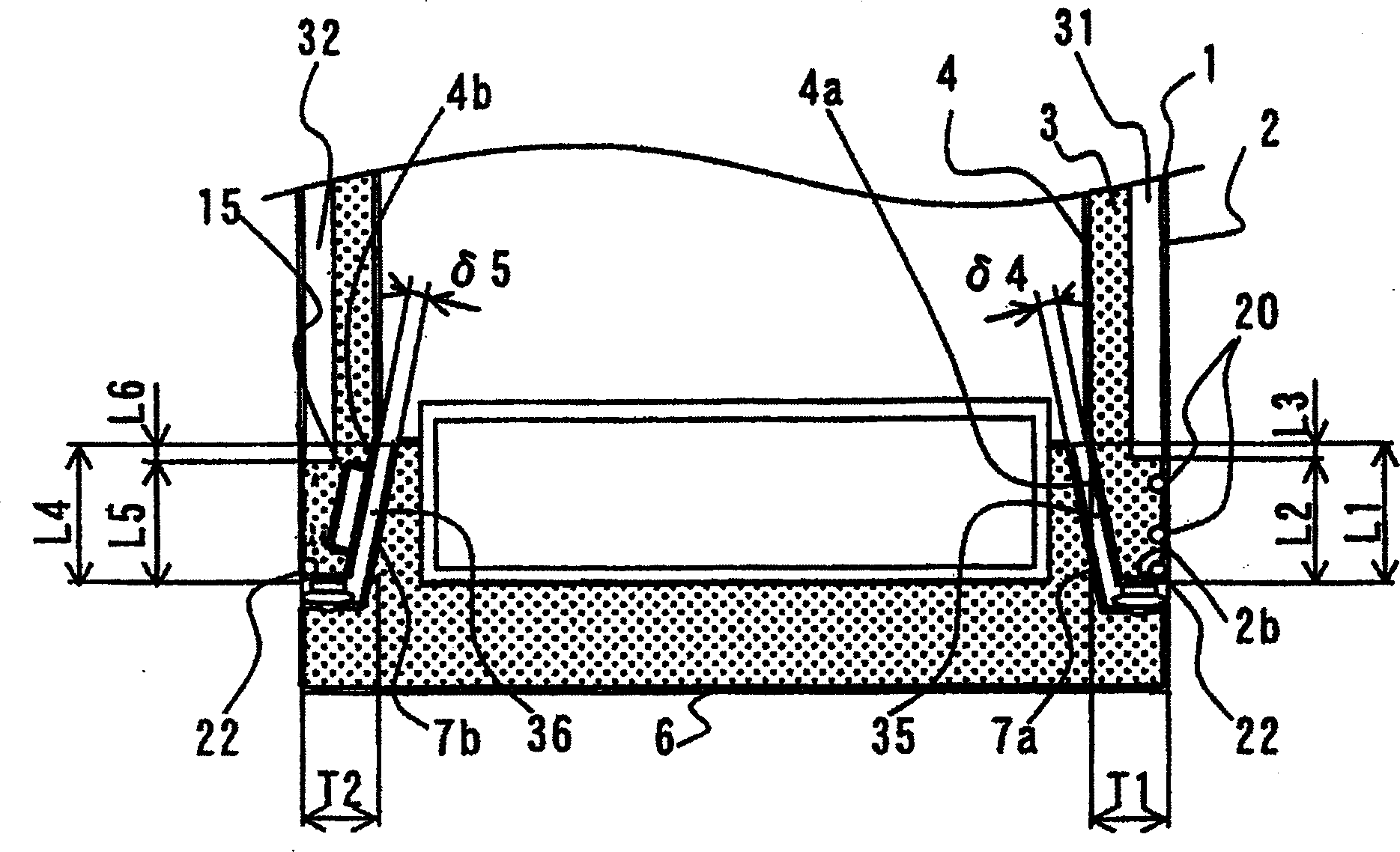

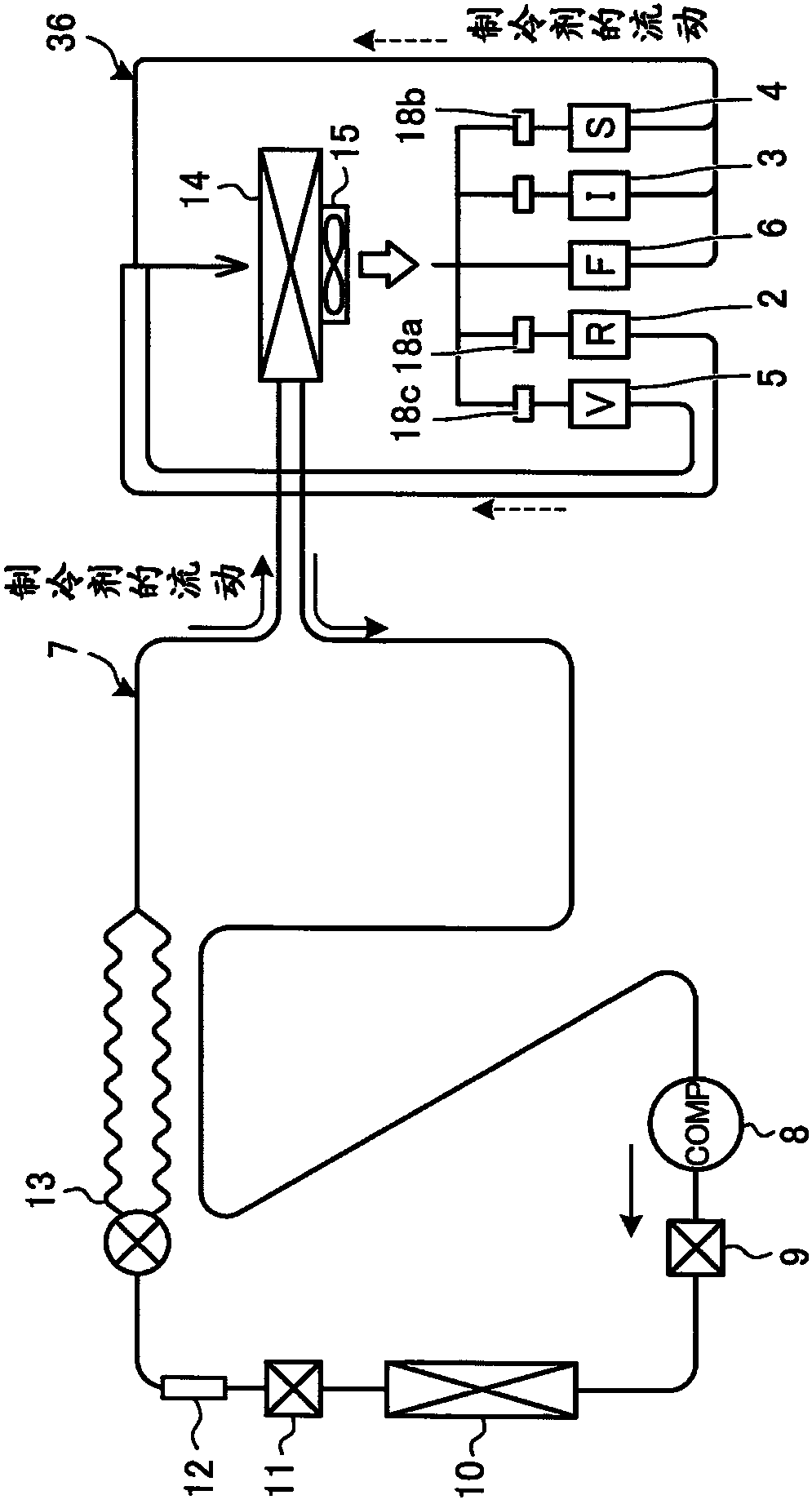

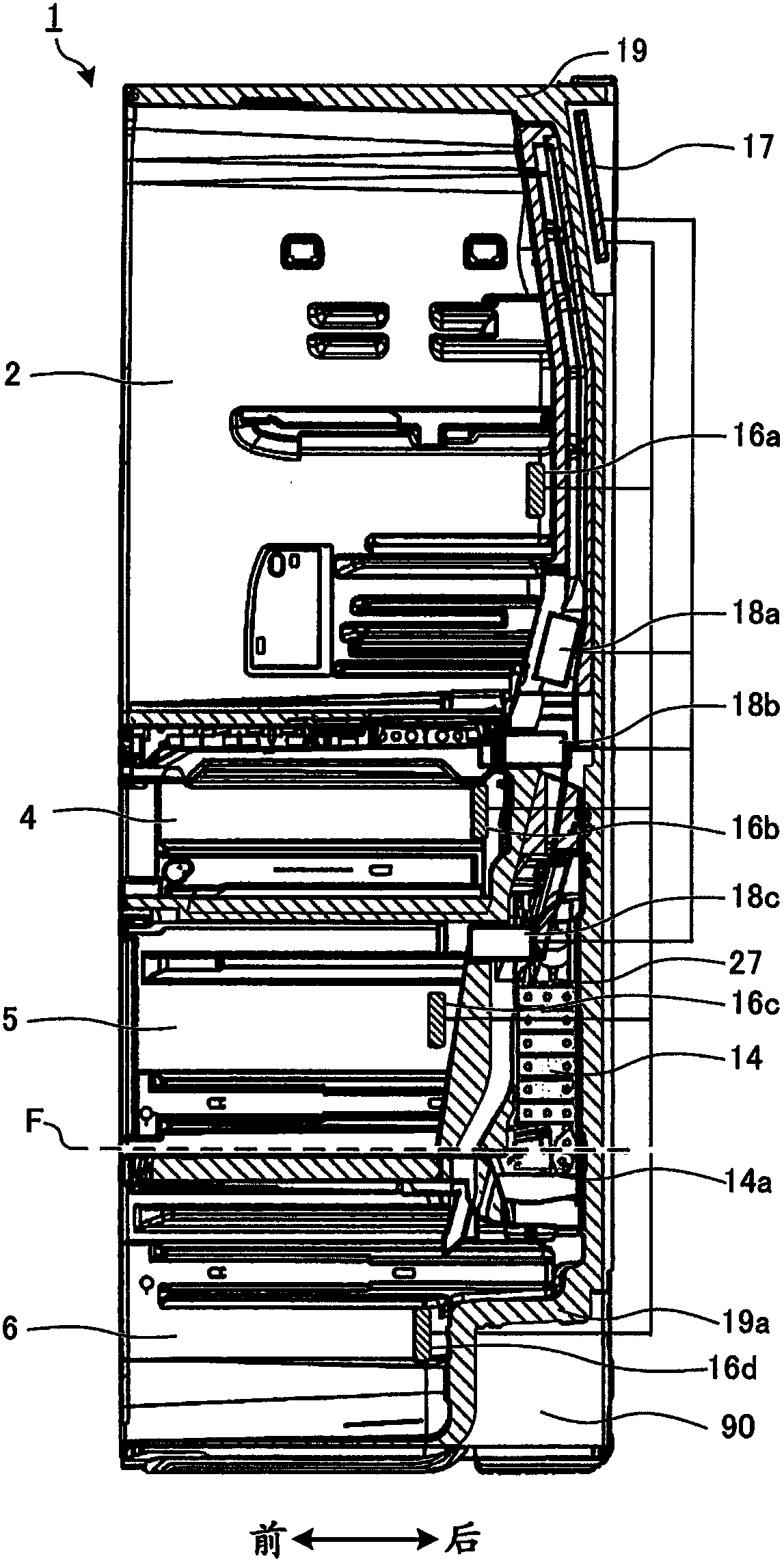

InactiveCN1590941AImprove performanceGood insulation performanceLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigerated temperature

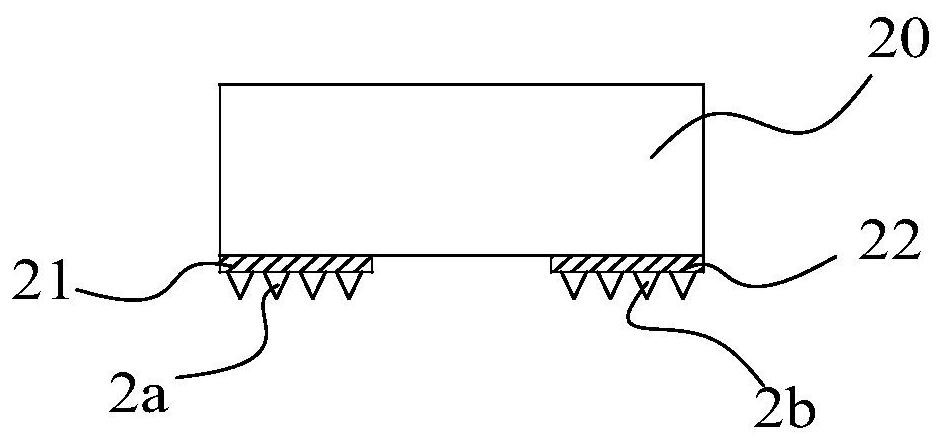

To improve performance of a freezing cycle by releasing heat from a pipe for heat release using a front part of a side face of an outer package and to improve heat insulating performance by extending a vacuum heat insulating material to a back face side of the outer package, in a refrigerator using the vacuum heat insulating material. In the refrigerator, a package body 1 is structured by providing the vacuum heat insulating material 31 on a back side of the side face of the outer package 2 and filling a foam heat insulating material 3 between the outer package 2 and an inner package 4, a dew preventive pipe 22 of the freezing cycle is provided on a back side of a front face flange of the outer package 2 and the heat releasing pipe 20 of the freezing cycle is provided on the back side of the side face of the outer package 2. The heat releasing pipe 20 is provided so that it vertically extends at a front part of the side face of the outer package 2 and the vacuum heat insulating material 31 is provided so that it extends to the back face side of the outer package 2 from behind the heat releasing pipe 20.

Owner:HITACHI APPLIANCES INC

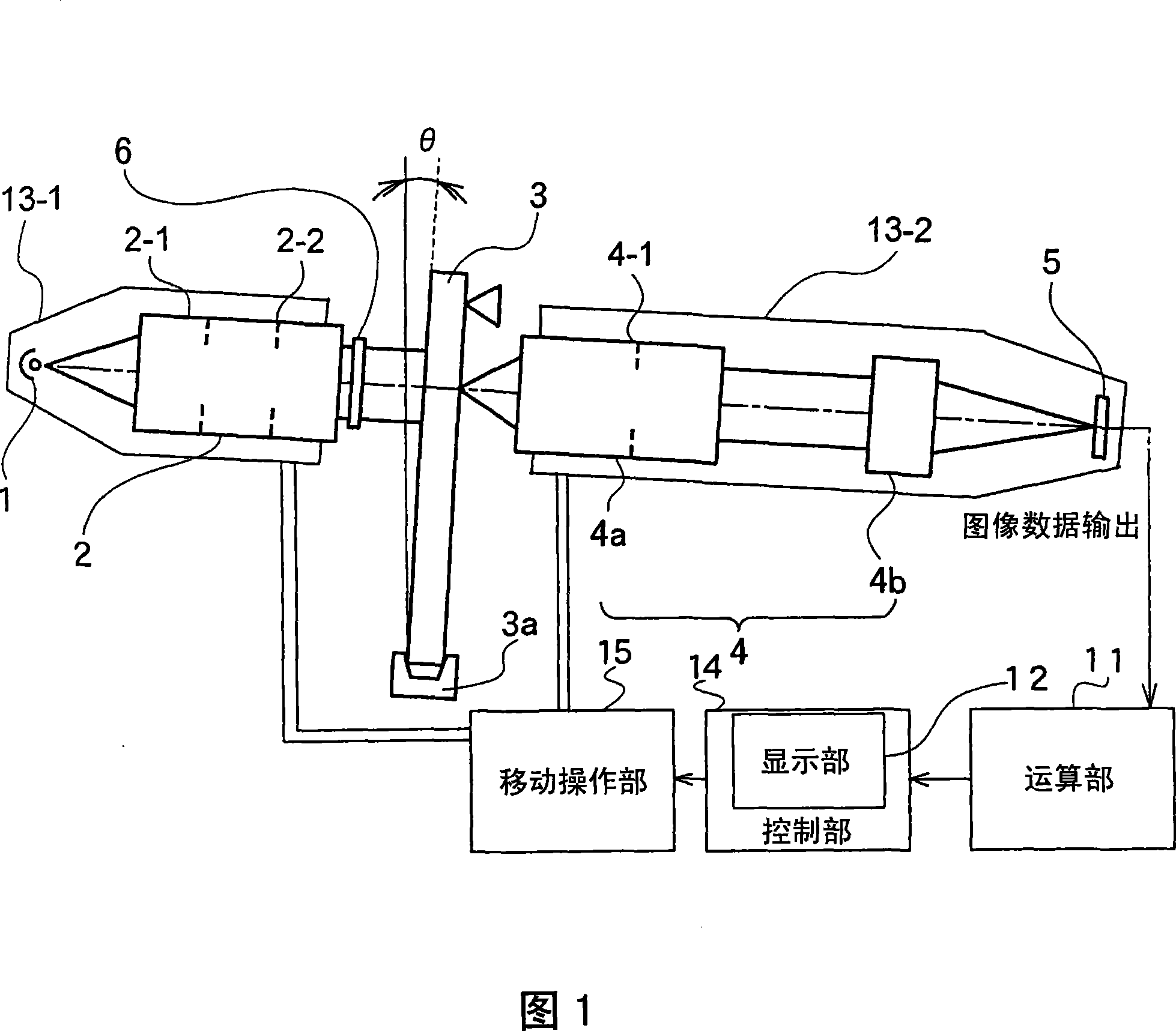

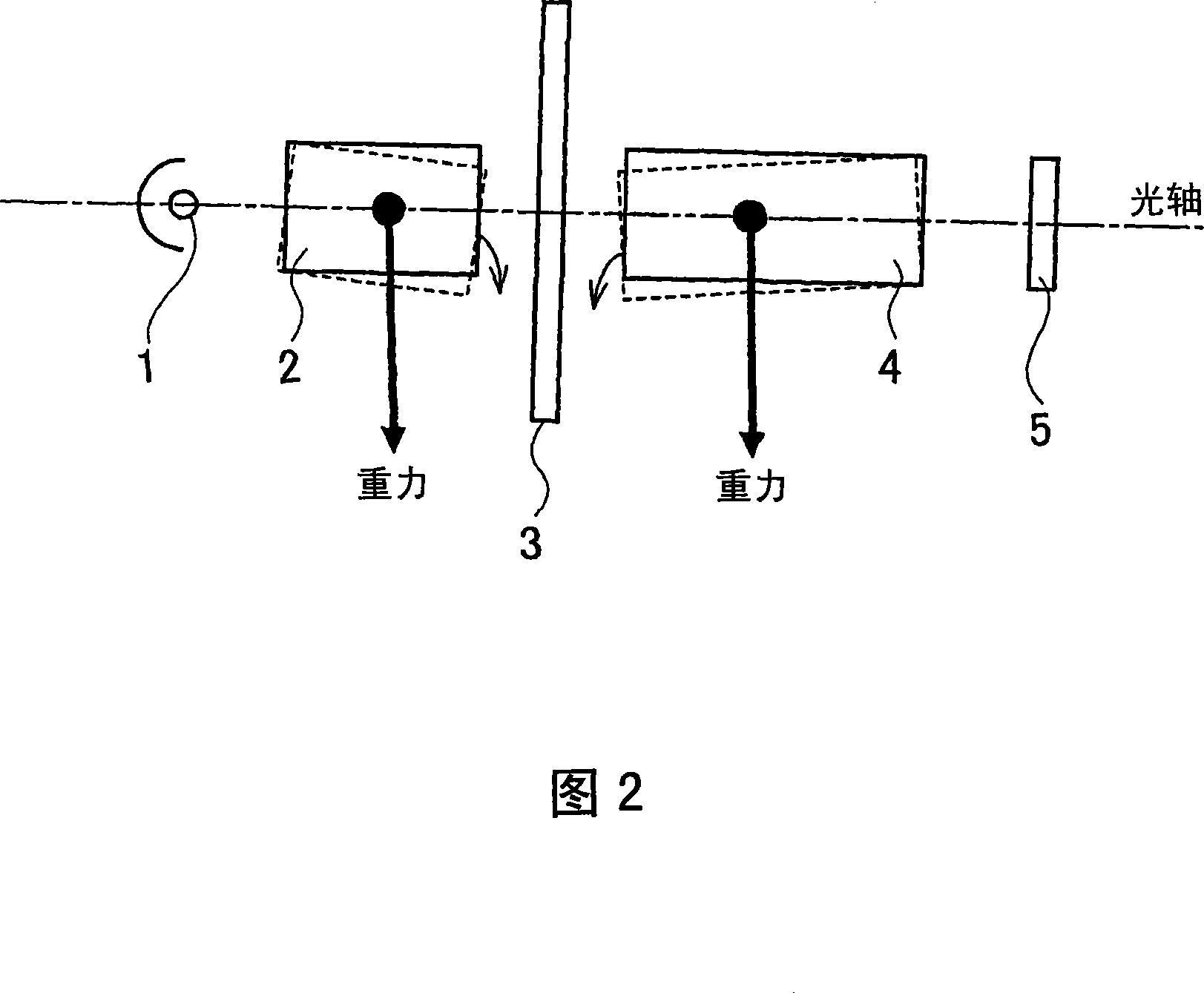

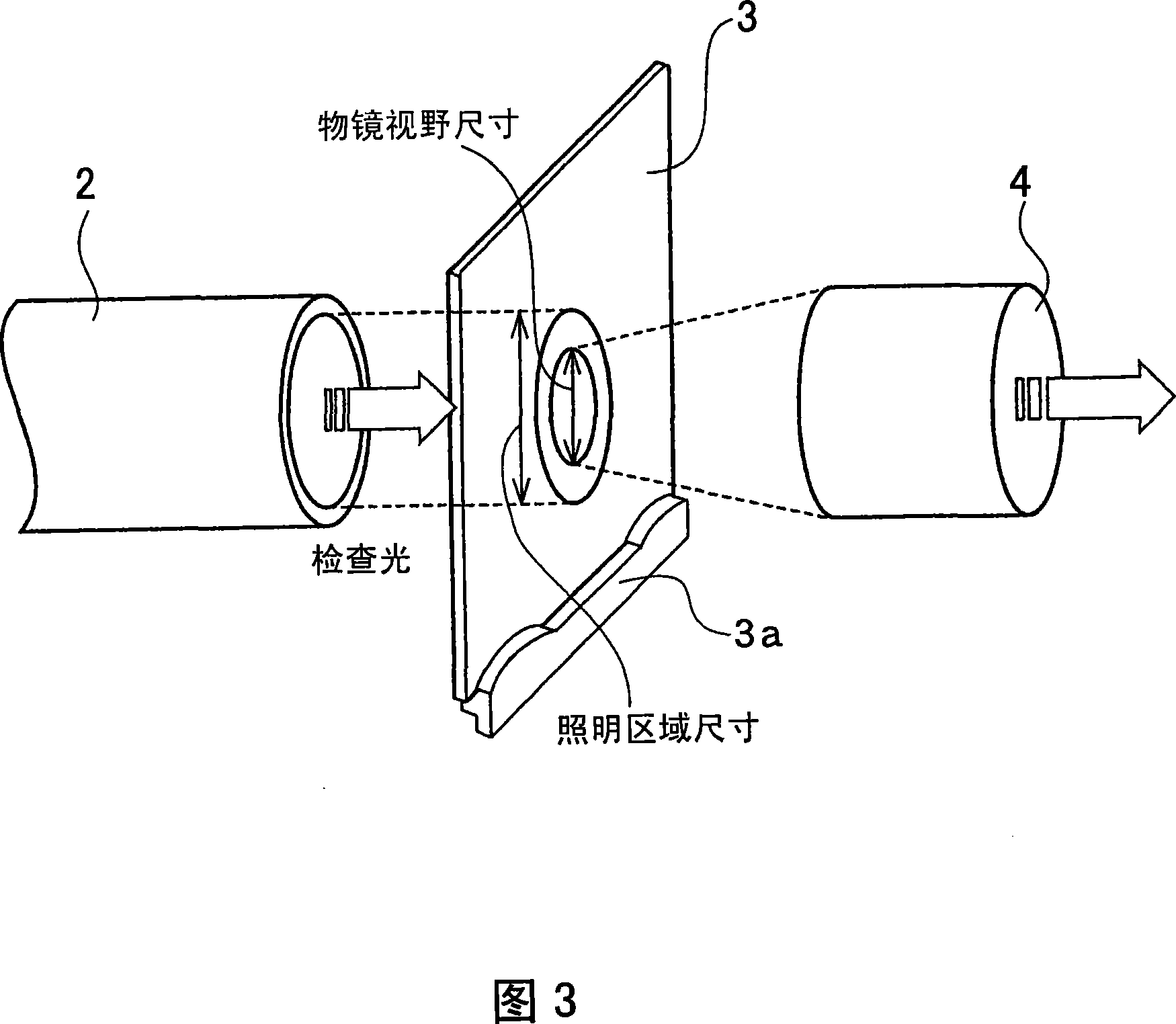

Detecting device, detecting method, manufacturing method and pattern transferring method for photomask

ActiveCN101196681AIncrease the setting areaSemiconductor/solid-state device testing/measurementMaterial analysis by optical meansOptical axisLight beam

In the photmask detecting device of the invention, the photomask holding part (3a) holds the photomask (3) which is irradiated with the light beam that comes from the light source (1) and has preset wavelength to the photomask (3) through the lamp optical system (2), and the image of the photomask (3) is shot by the camera shooting element (5) through the object lens system (4). The light axes ofthe lamp optical system (2), the object lens system (4) and the camera shooting element (5) are facilitated to consistent, the object lens system (4) and the camera shooting element (5) are moved andoperated independent with each other along the direction of the light axis to shoot the image of the photomask (3).

Owner:HOYA CORP

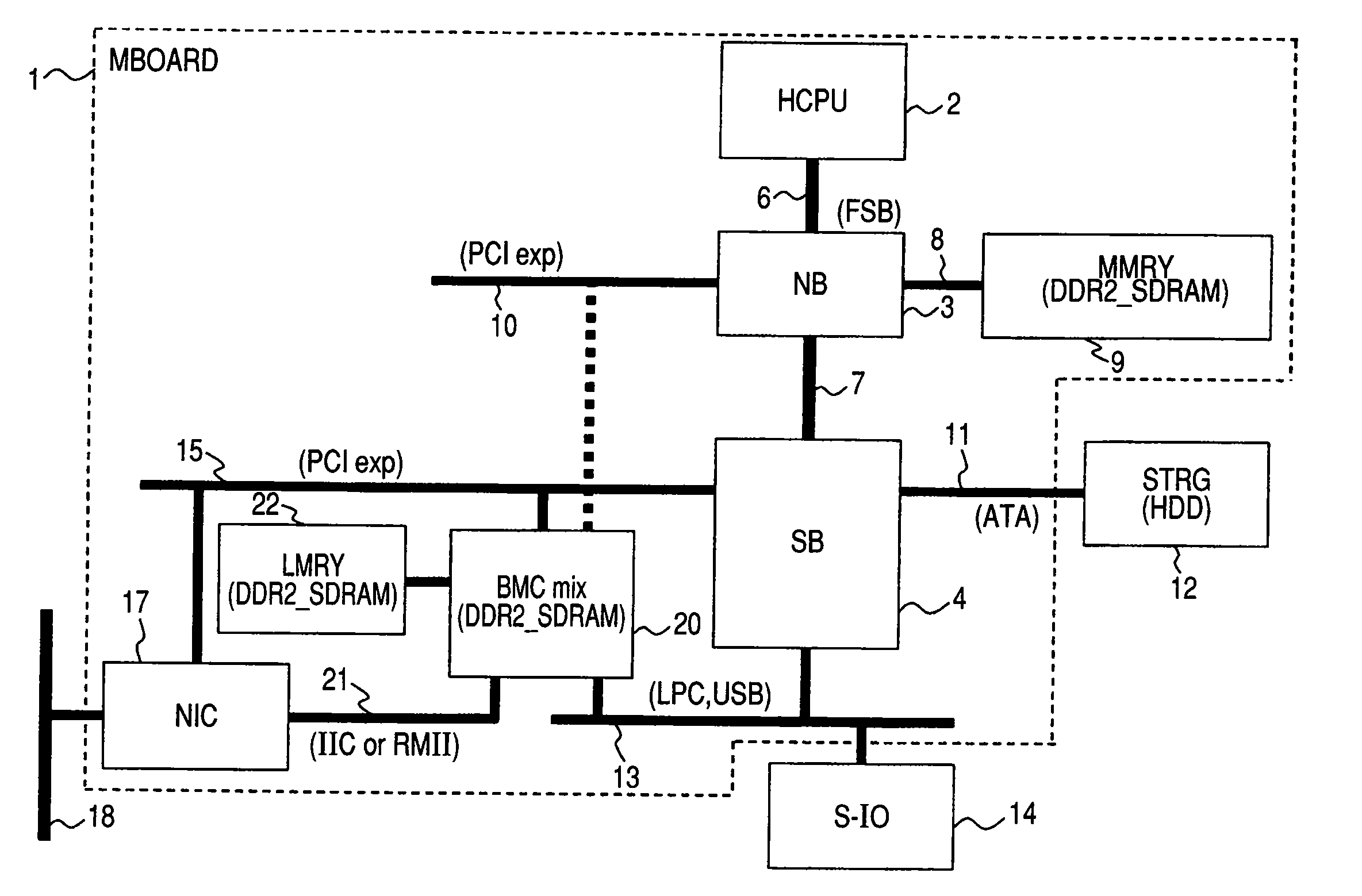

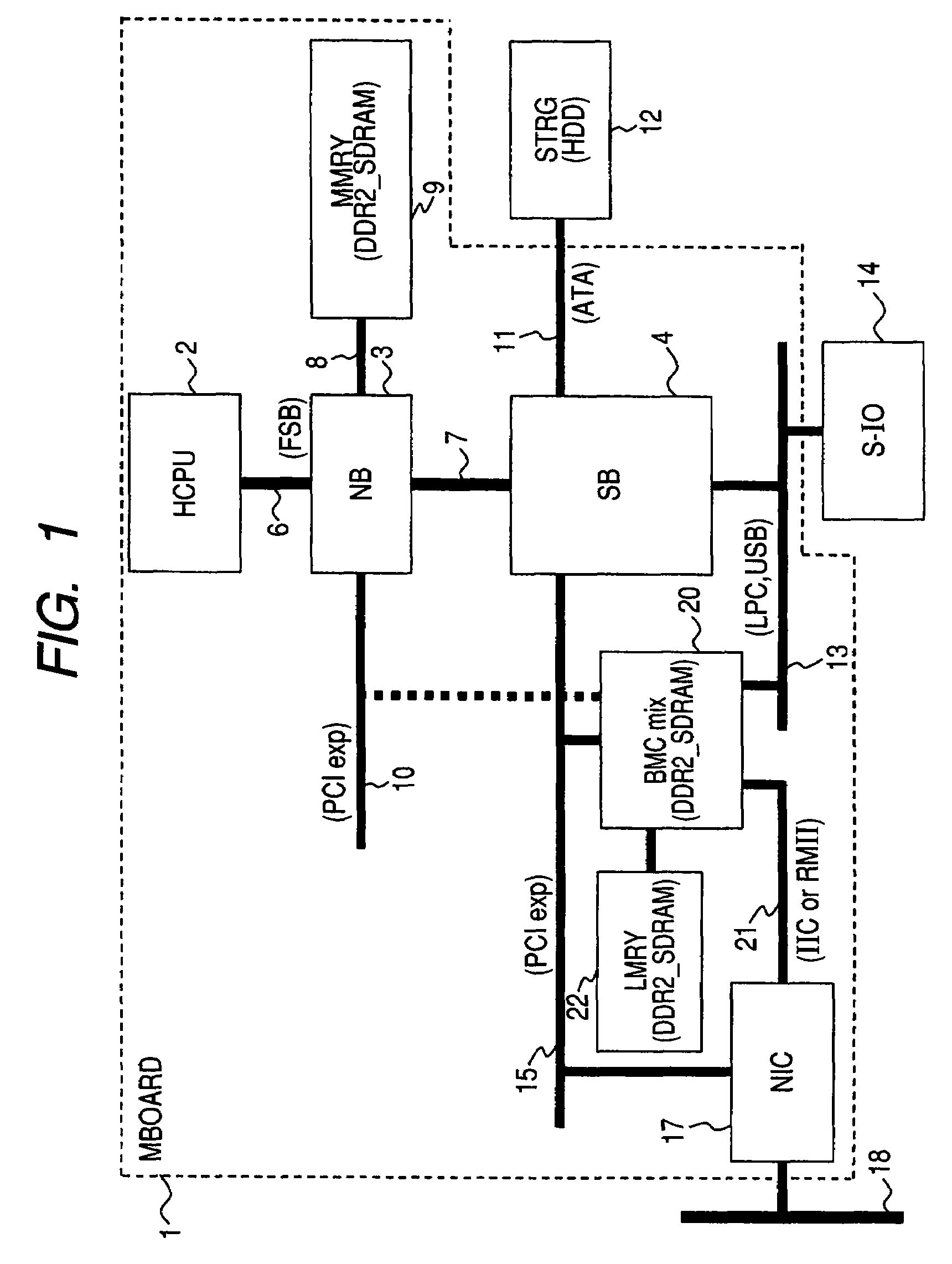

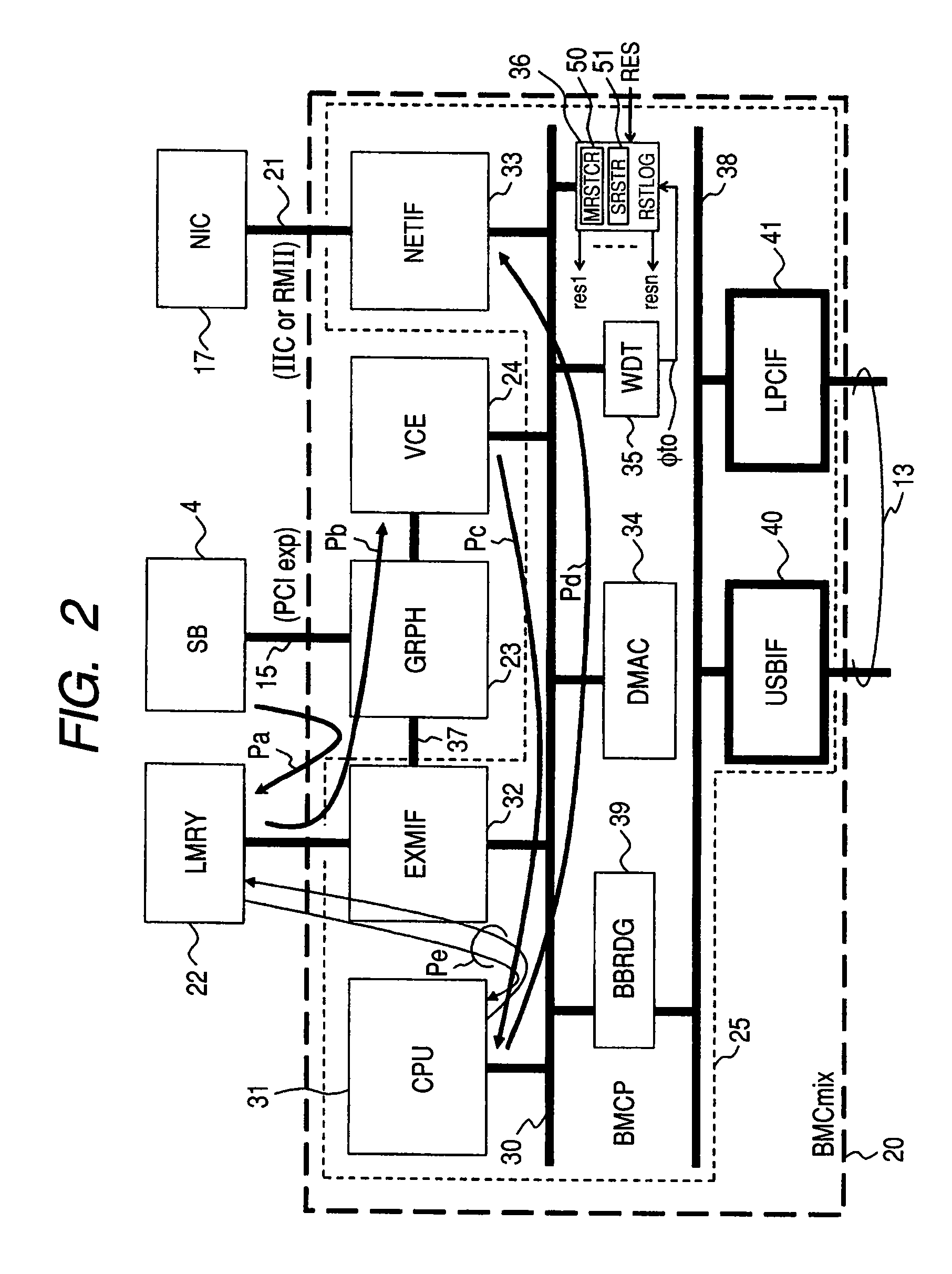

Semiconductor integrated circuit and data processing system

InactiveUS20080177912A1Increase data transmission rateIncrease loadNon-redundant fault processingData transmissionIntegrated circuit

To contribute to increase data transmission rate for server management without increasing load during normal operation.A semiconductor integrated circuit includes: a central processing unit; an external memory interface circuit; a network interface circuit; an image processing unit; and a data compression unit. The image processing unit performs image processing in response to an input from an external bus, the image processing unit is coupled to an external memory interface circuit through a dedicated internal bus, and the image processing unit stores an image data into an external memory via the dedicated internal bus. The compression unit is coupled to the image processing unit and is capable of compressing the image data supplied from the image processing unit. Since the dedicated internal bus, through which the image processing unit receives image information and stores the same into the external memory, is separated from the common internal bus, the data for image processing by the image processing unit that responds to an instruction from the outside will not conflict with the data for data processing by an instruction from the network interface circuit on the common internal bus.

Owner:RENESAS ELECTRONICS CORP

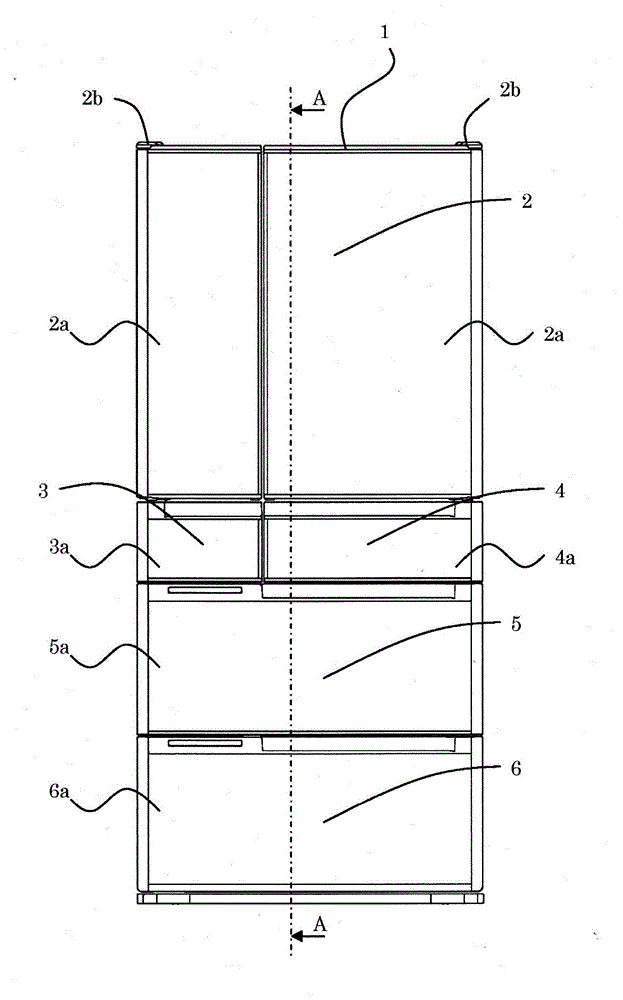

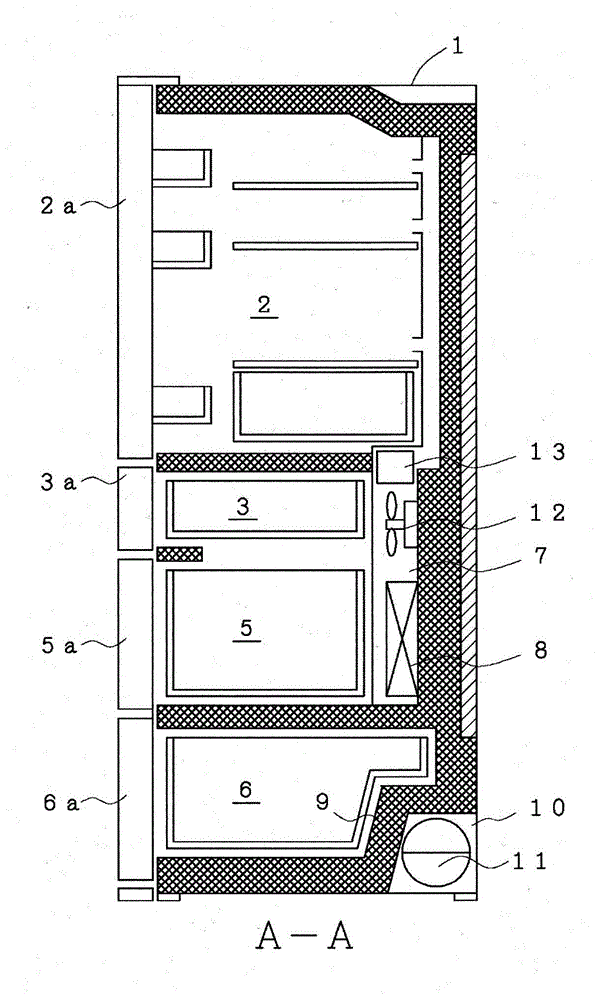

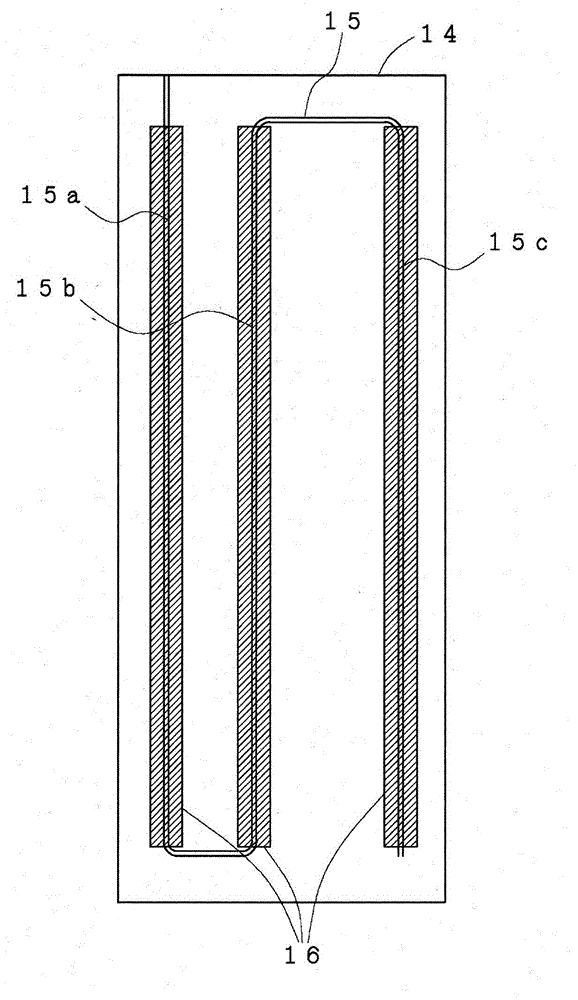

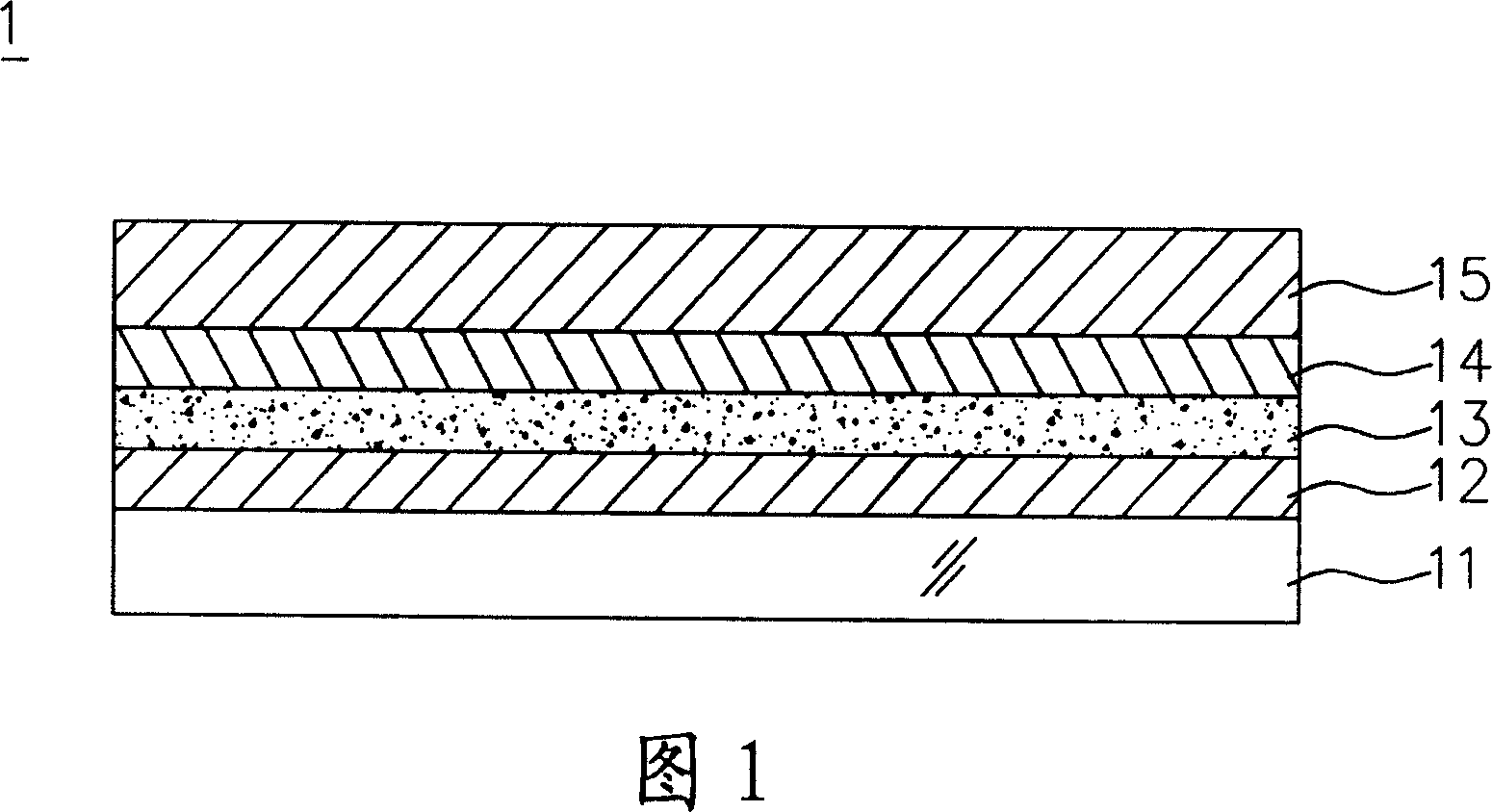

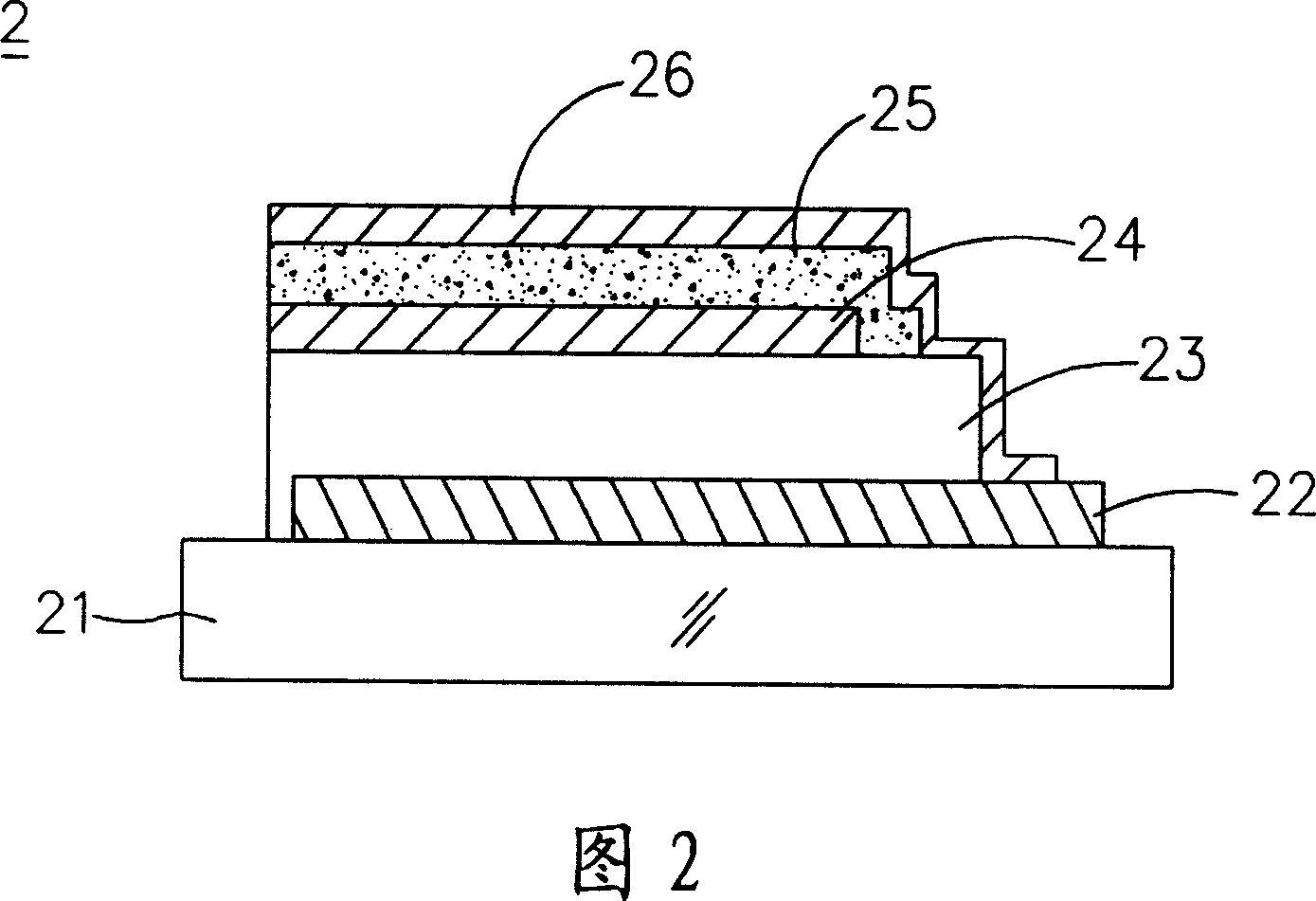

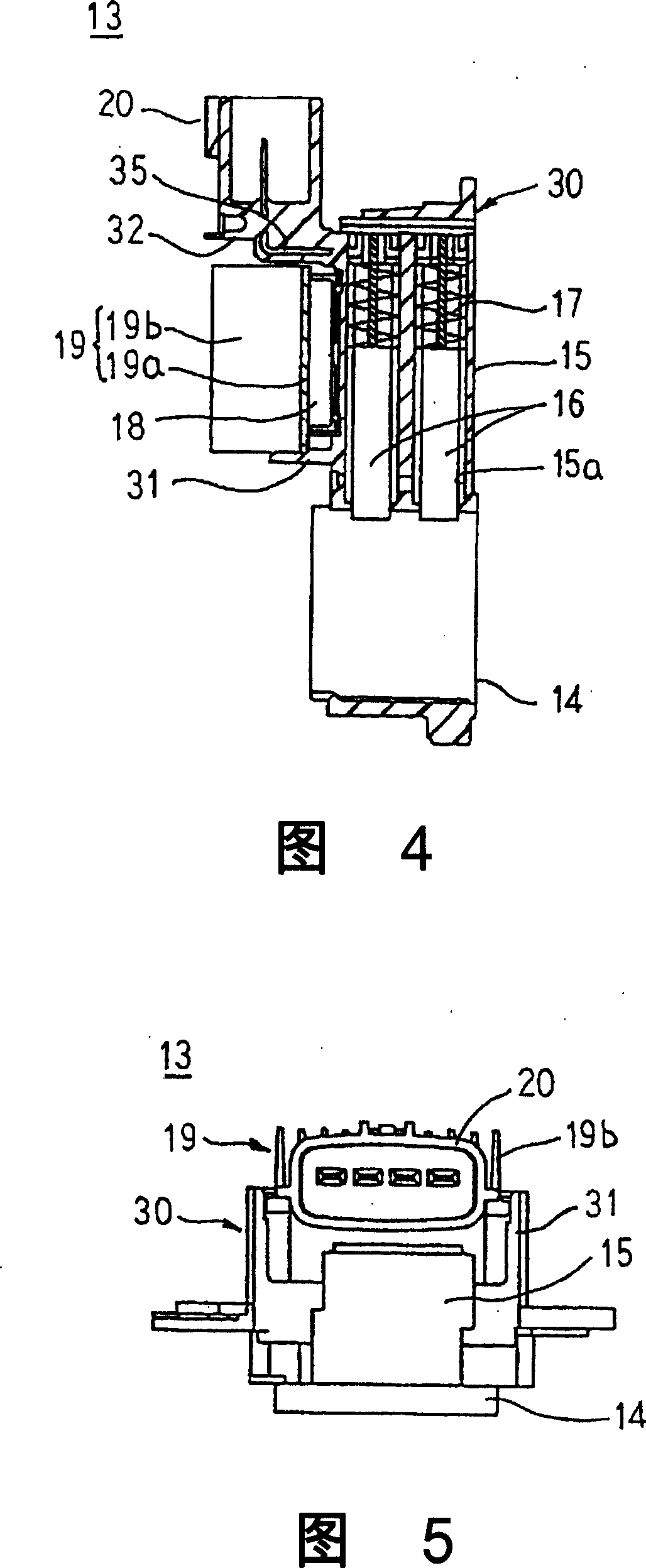

Vacuum heat insulating material and refrigerator

ActiveCN104421578AIncrease the setting areaClear structureThermal insulationDomestic cooling apparatusFiberEngineering

The invention aims to provide a refrigerator which does not impede foaming of polyurethane foam and can improve coverage of a vacuum heat insulating material on a heat insulating wall. The refrigerator comprises a cooling pipe (15) on the inner wall surface of an outer box (14), and a foam heat insulating material (21) and a vacuum heat insulating material (19) both inside the space formed between the outer box and an inner box. The vacuum heat insulating material (19) comprises a core material including a plurality of layers of fiber aggregates (22), and a wrapping material (23) which holds the core material and is decompressed inside. The vacuum heat insulating material (19) comprises a first groove (19a) formed by changing stacking thickness of the fiber aggregates (22), and a second groove (19b) formed by pressing the wrapping material (23) which is decompressed inside. The first groove (19a) is located in a thin wall part of the foam heat insulating material (21) where the thickness is reduced.

Owner:HITACHI APPLIANCES INC

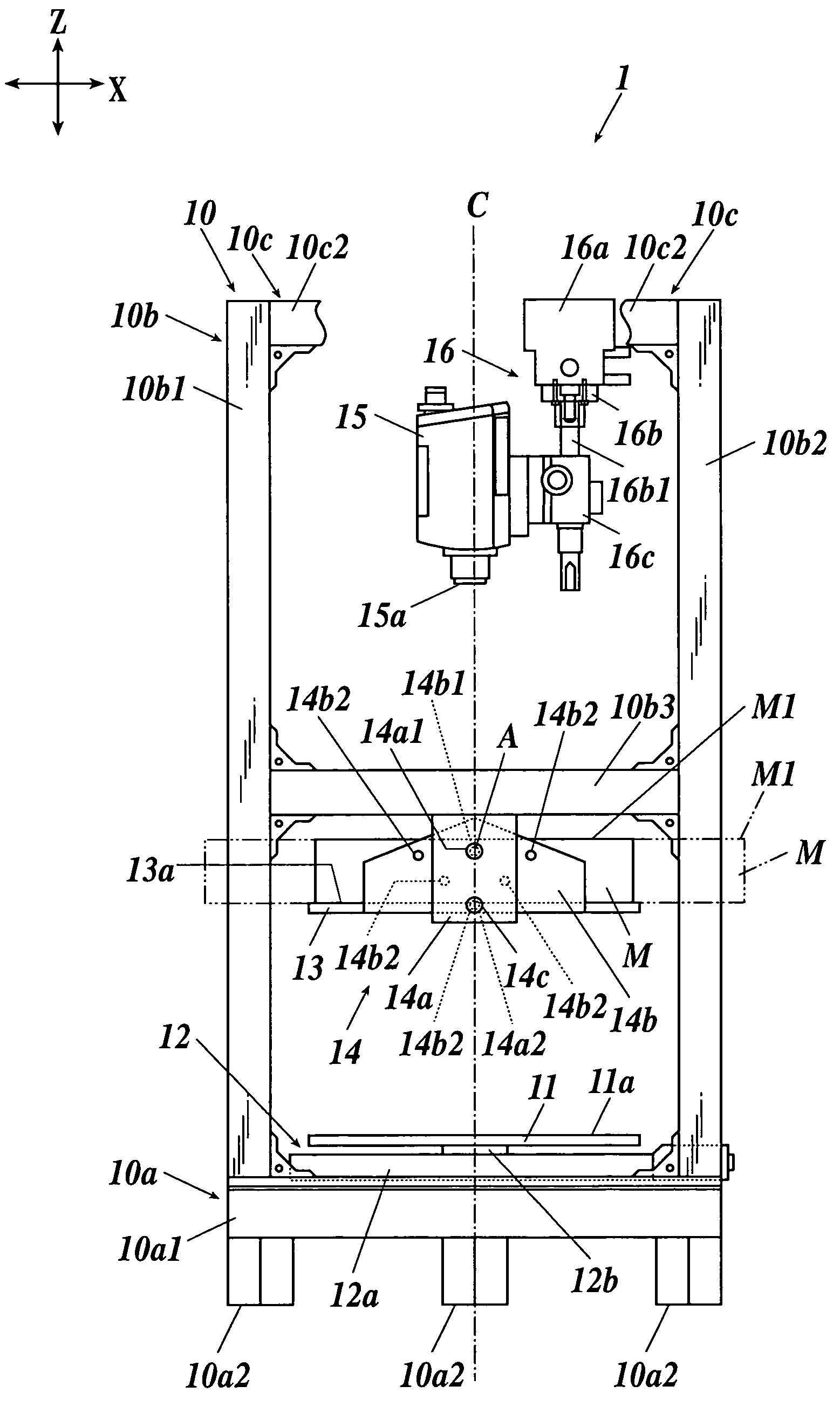

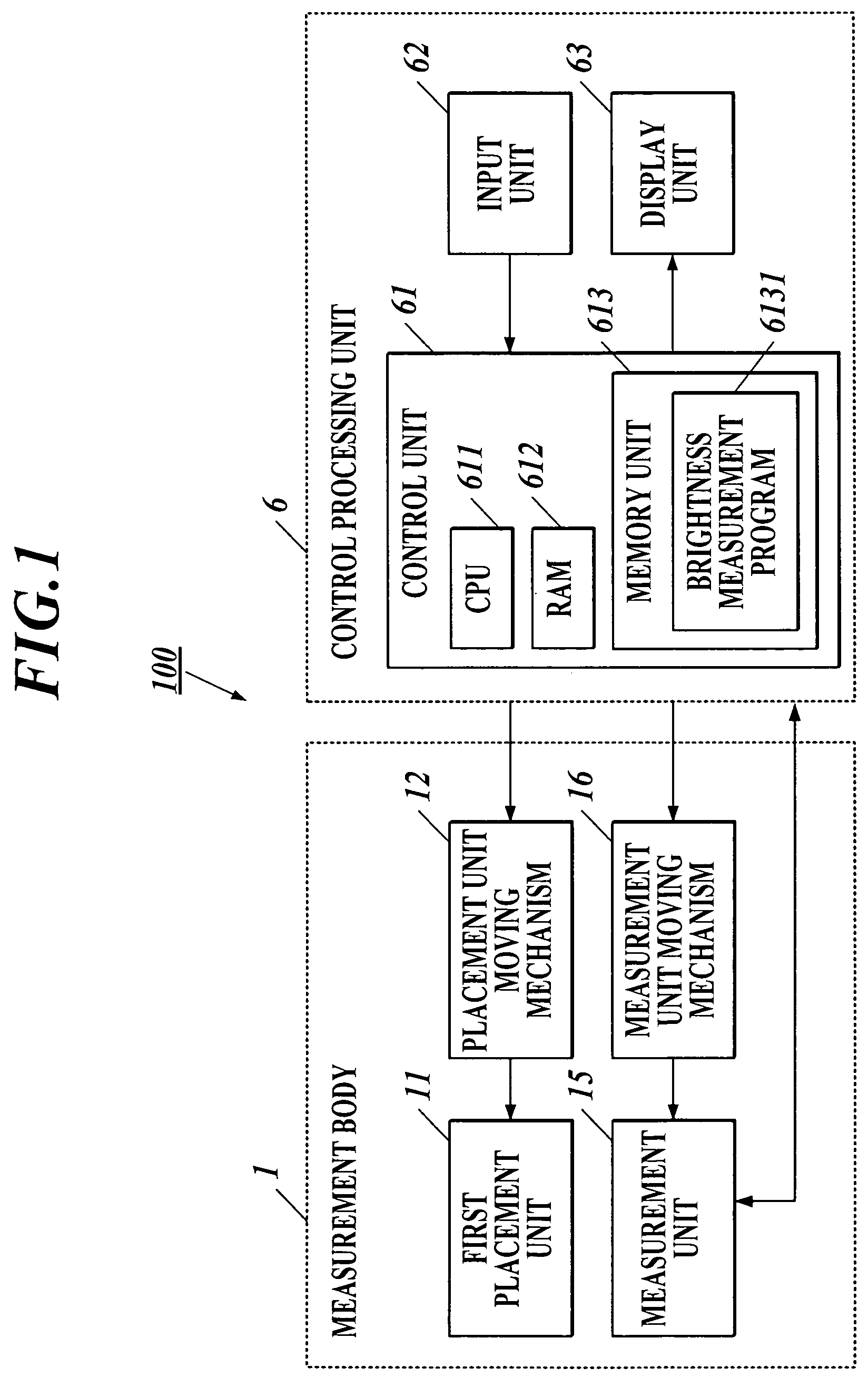

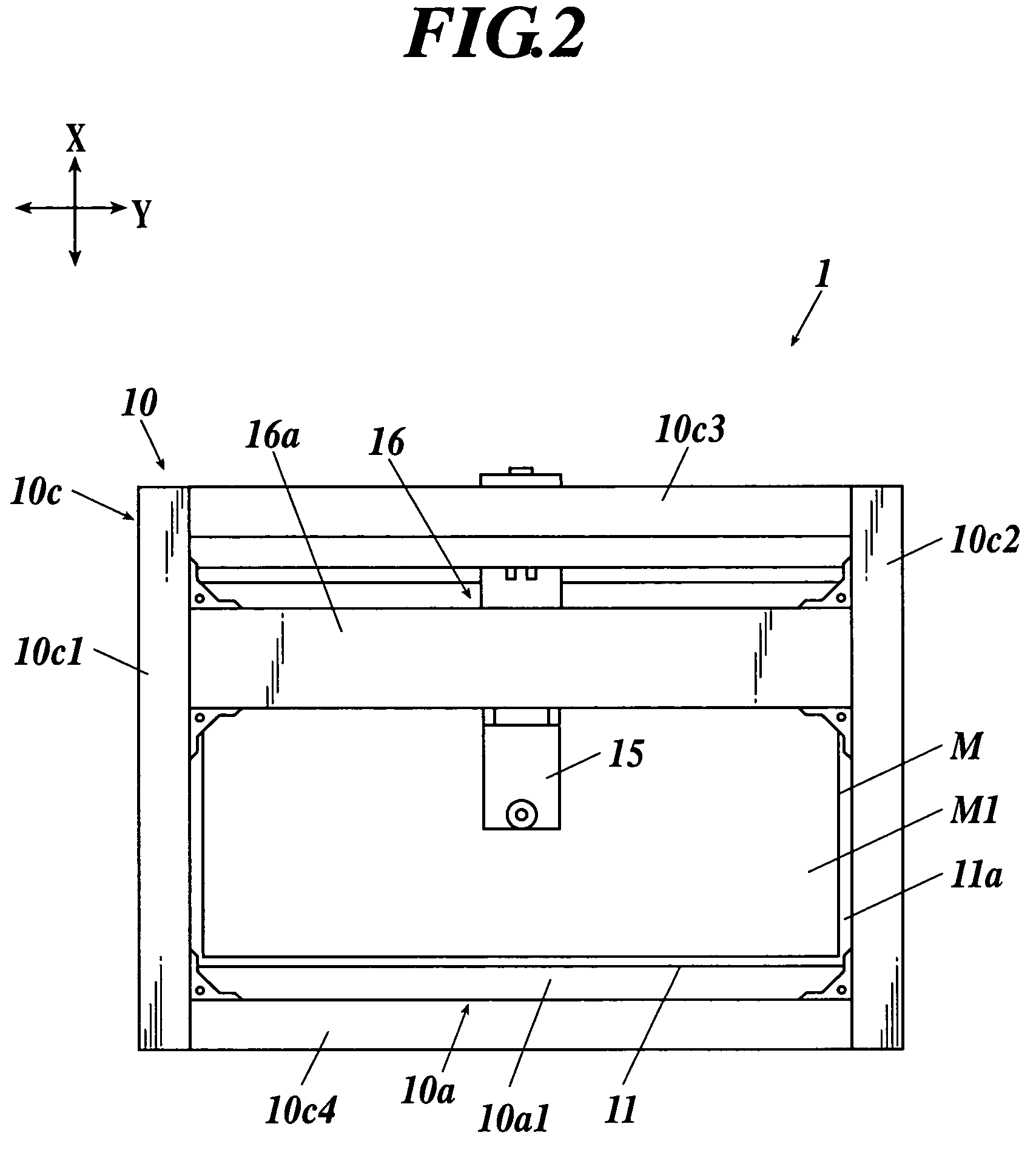

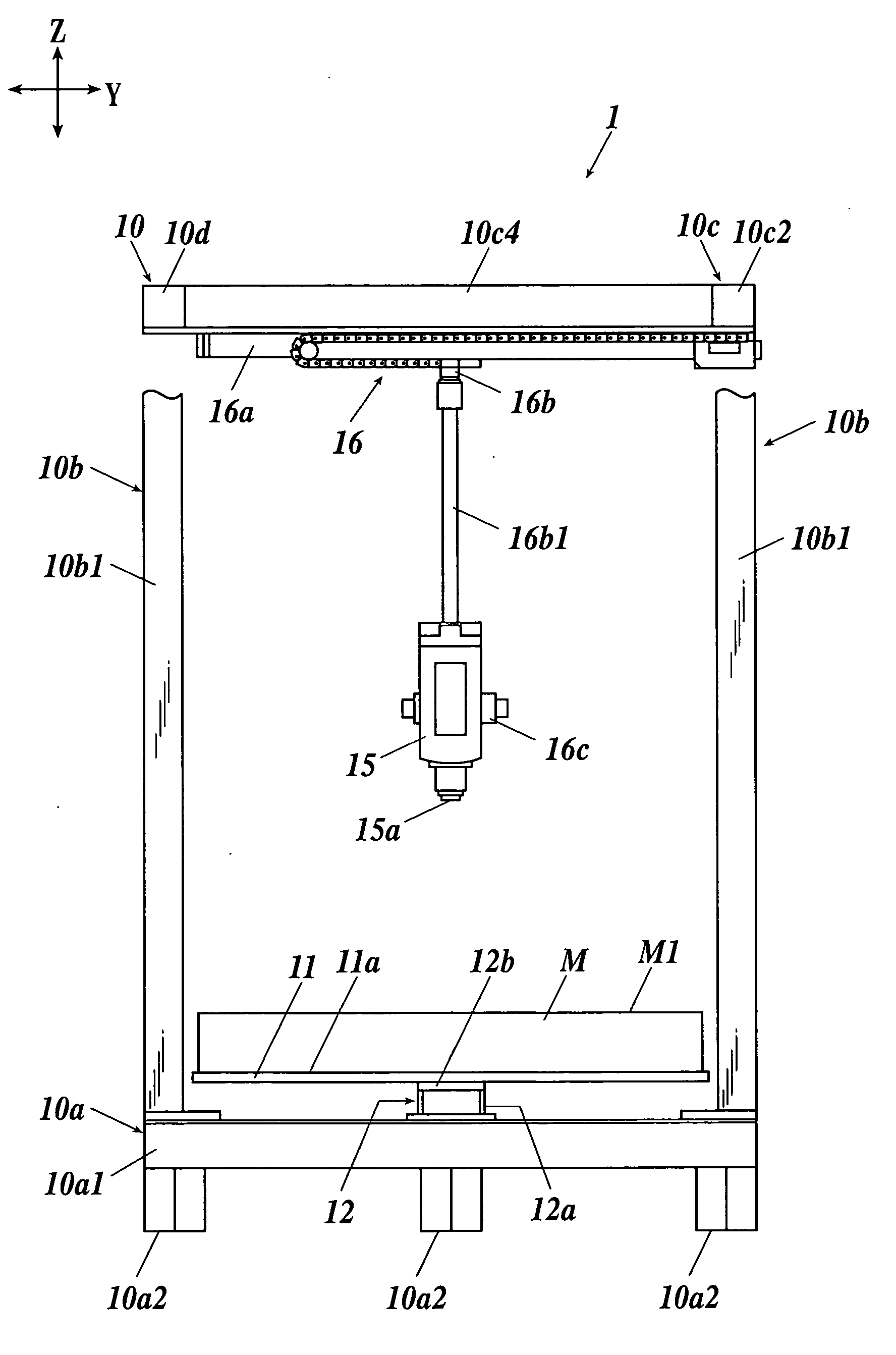

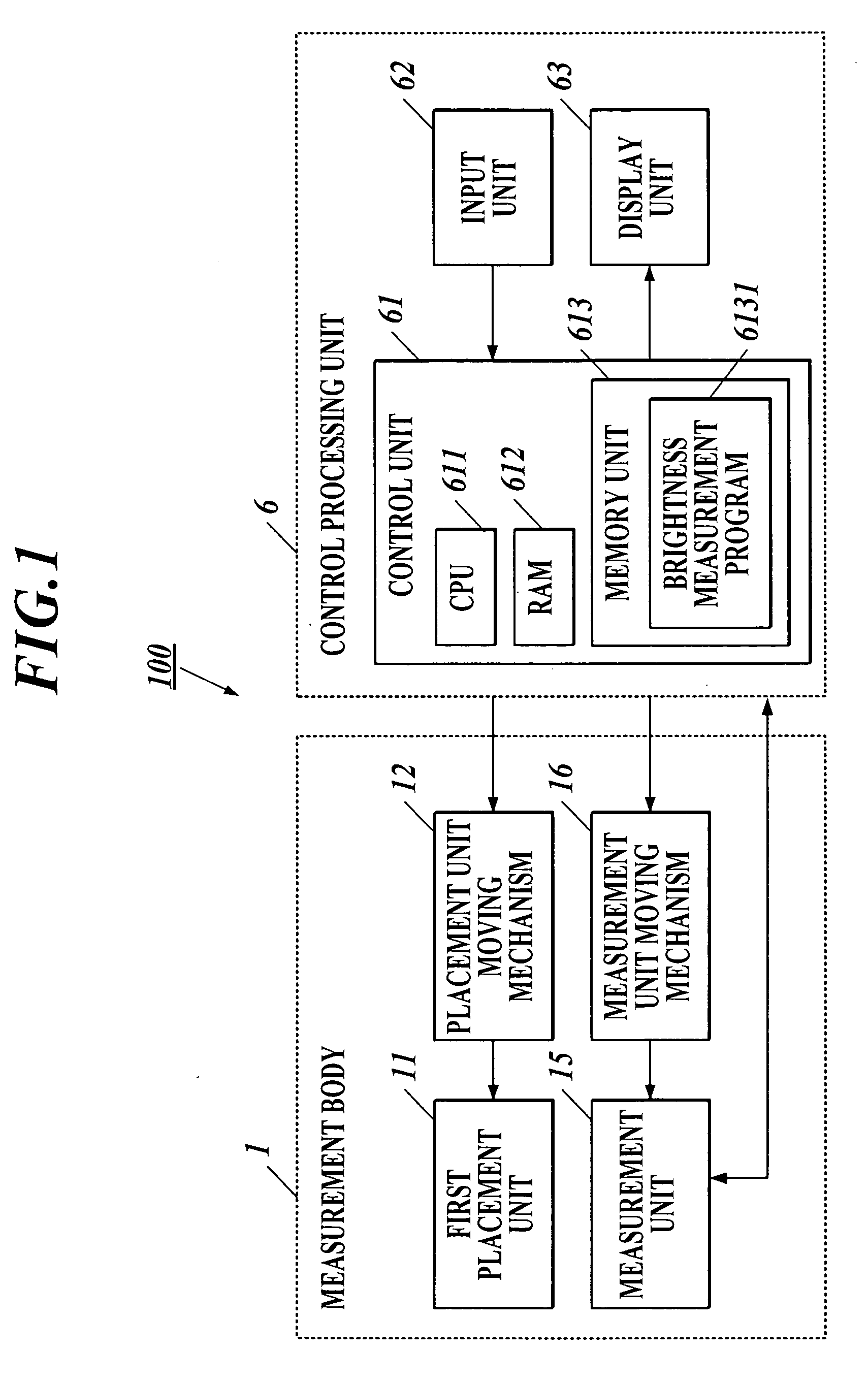

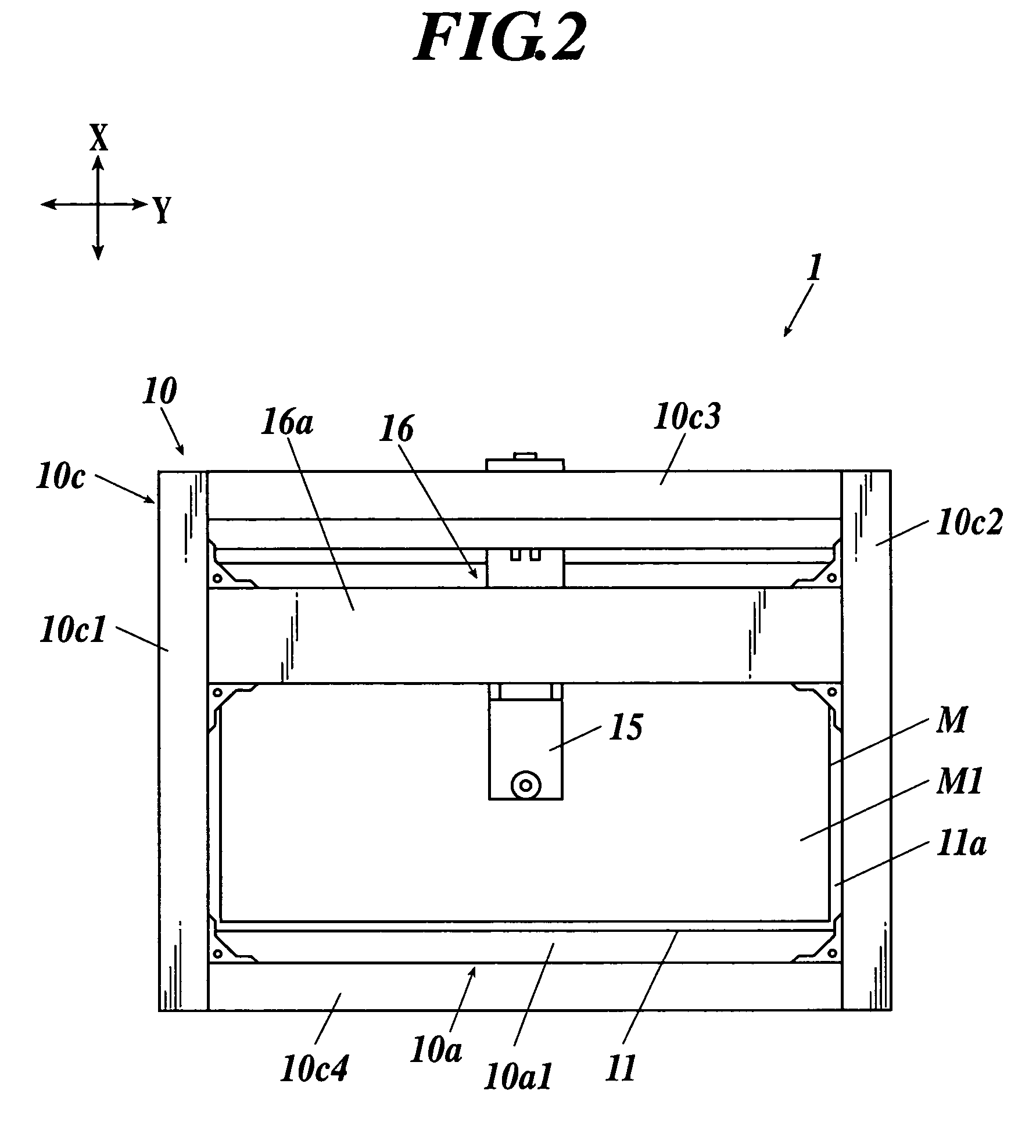

Liquid crystal module brightness measurement apparatus and brightness measurement apparatus

InactiveUS7426022B2Reduce the overall heightSmall range of movementUsing electrical meansLarge fixed membersLightnessBrightness perception

A brightness measurement apparatus which includes a placement unit on which an object to be measured is placed, a measurement unit for measuring brightness or chromaticity from an upper surface of the object placed on the placement unit, a placement unit moving mechanism for moving the placement unit in an x-axis direction, and a measurement unit moving mechanism for moving the measurement unit in a y-axis direction orthogonal to the x-axis direction.

Owner:FUNAI ELECTRIC CO LTD

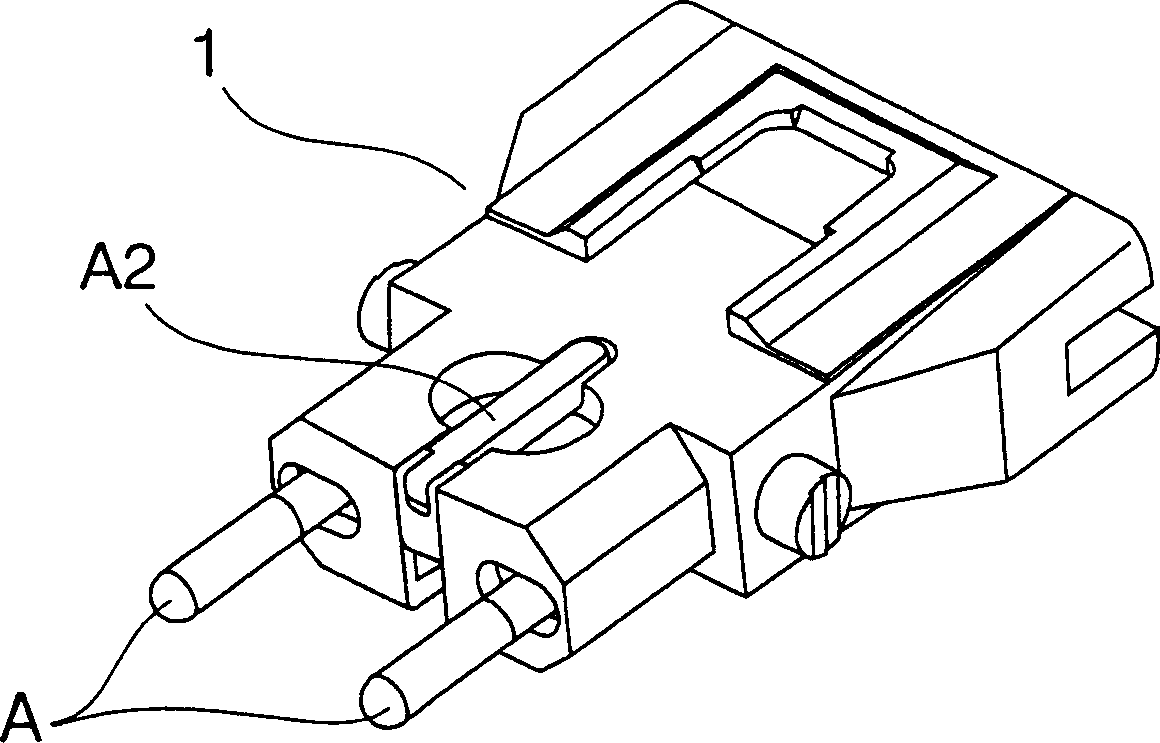

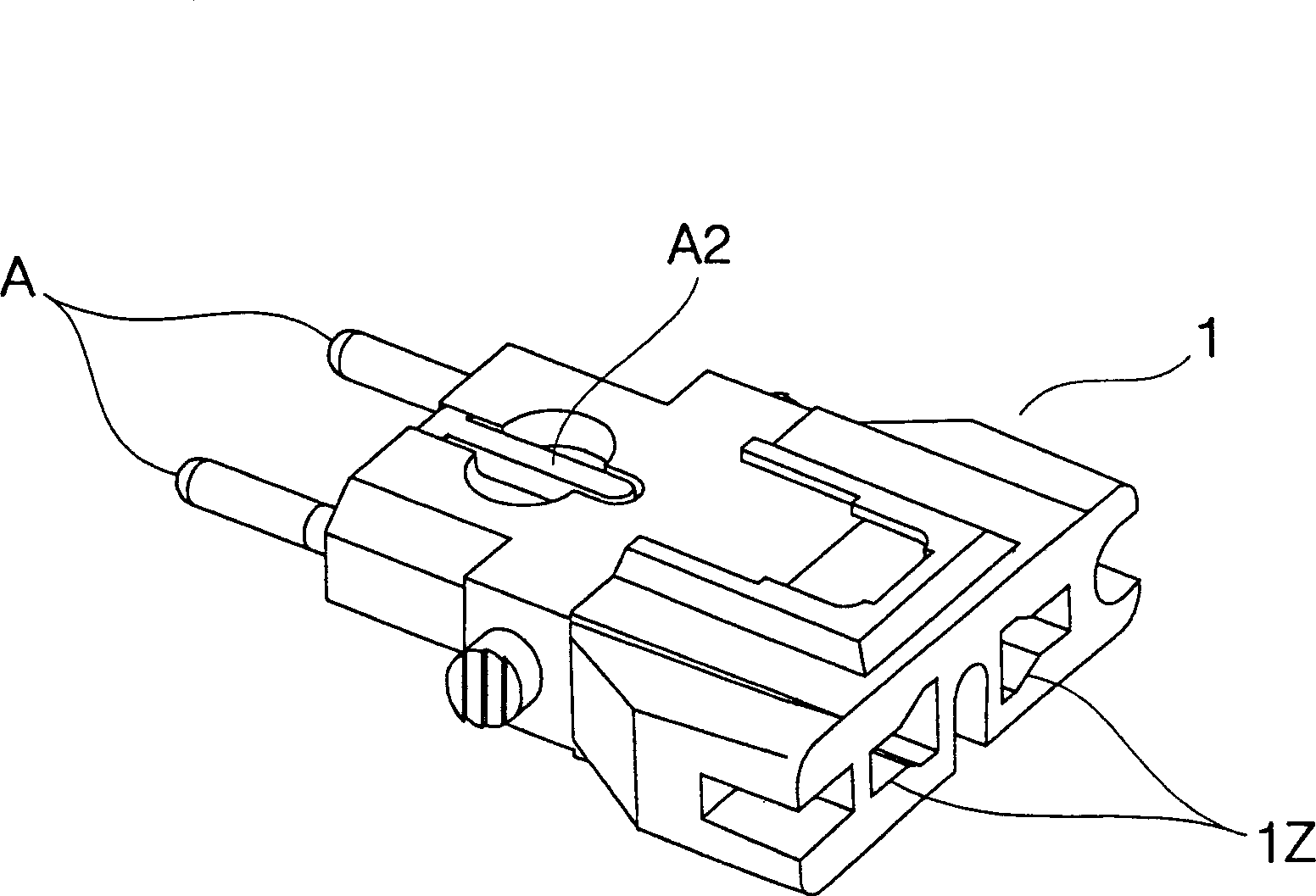

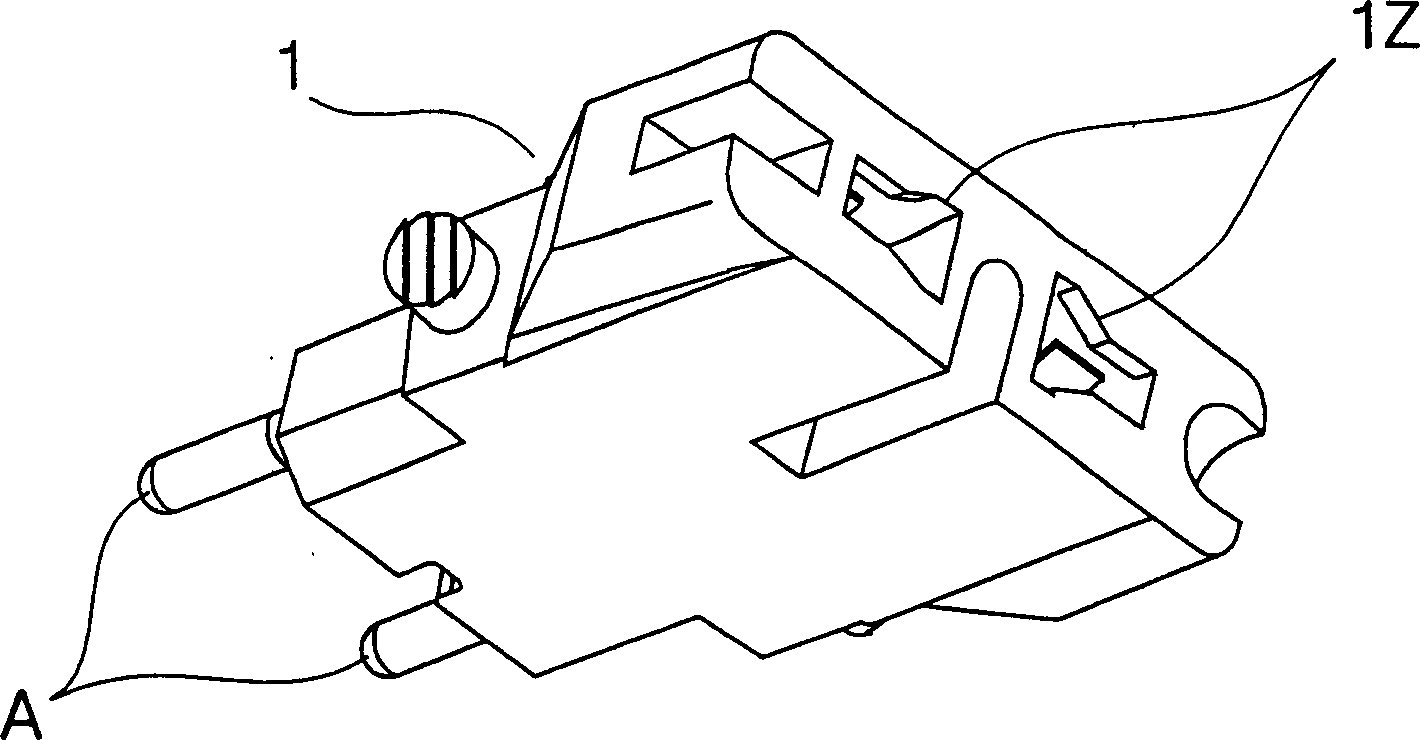

Combined power source adaptation plug connector

InactiveCN1503412AIncrease the setting areaGuaranteed stabilityTwo pole connectionsTwo-part coupling devicesRound barEngineering

A coalescent type power supply conversion plug is capable of connecting to different power supply plug sockets. The plug includes a first adapter having two round bar-shaped plug terminals so that a pitch width of plug terminals is adjustable. A pin for earth hole for B type, C type and SE type is foldably provided in the center portion of the plug terminals, and a plug-in port connectable to the sockets of all the types is provided in the rear end surface. Another pin for flat plate-shaped hole for BF type and a pin for round bar shaped earth hole for B3 type is foldably provided in a second adapter. Flat plate-shaped plug terminals and a pin for earth hole are provided in the plug terminals. A plug-in port connectable to the sockets of all kinds is provided in the rear end surface.

Owner:SHIROSHITA INDAL

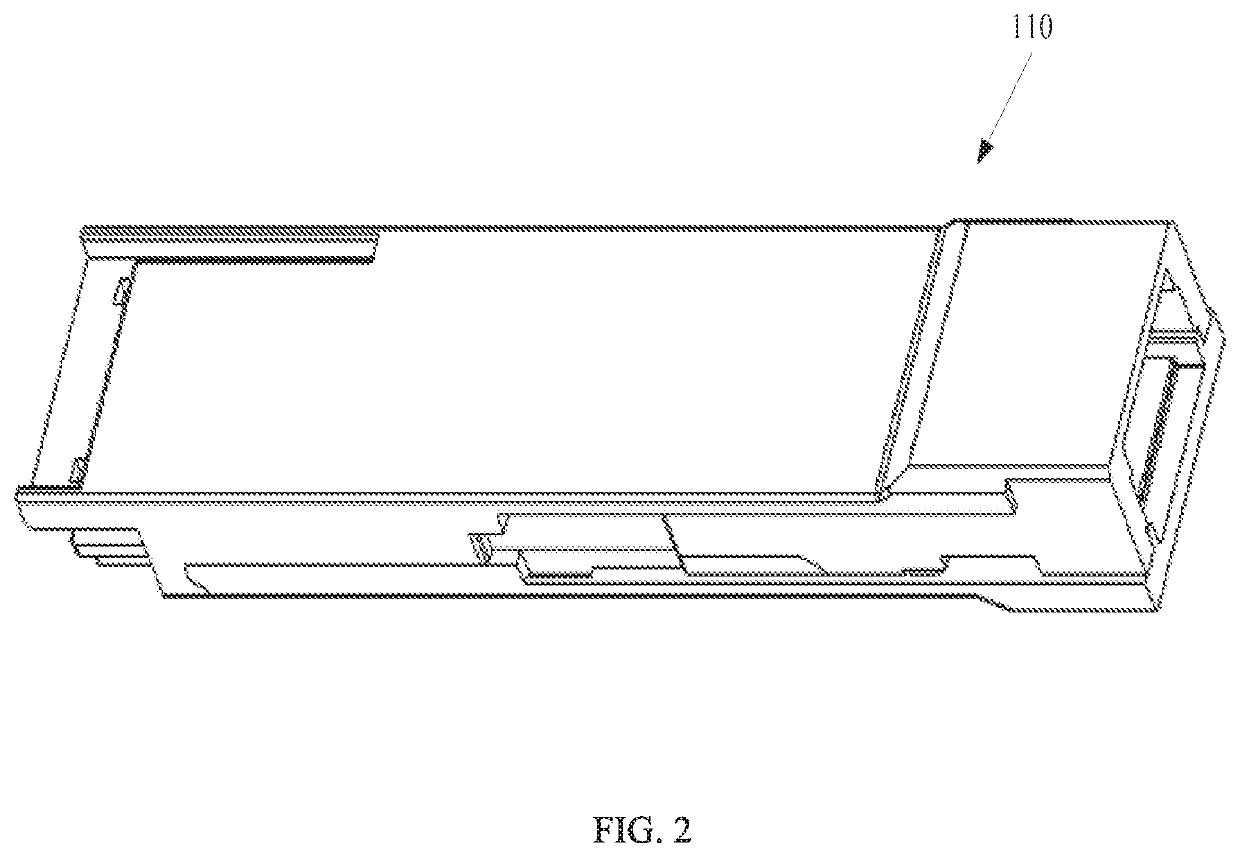

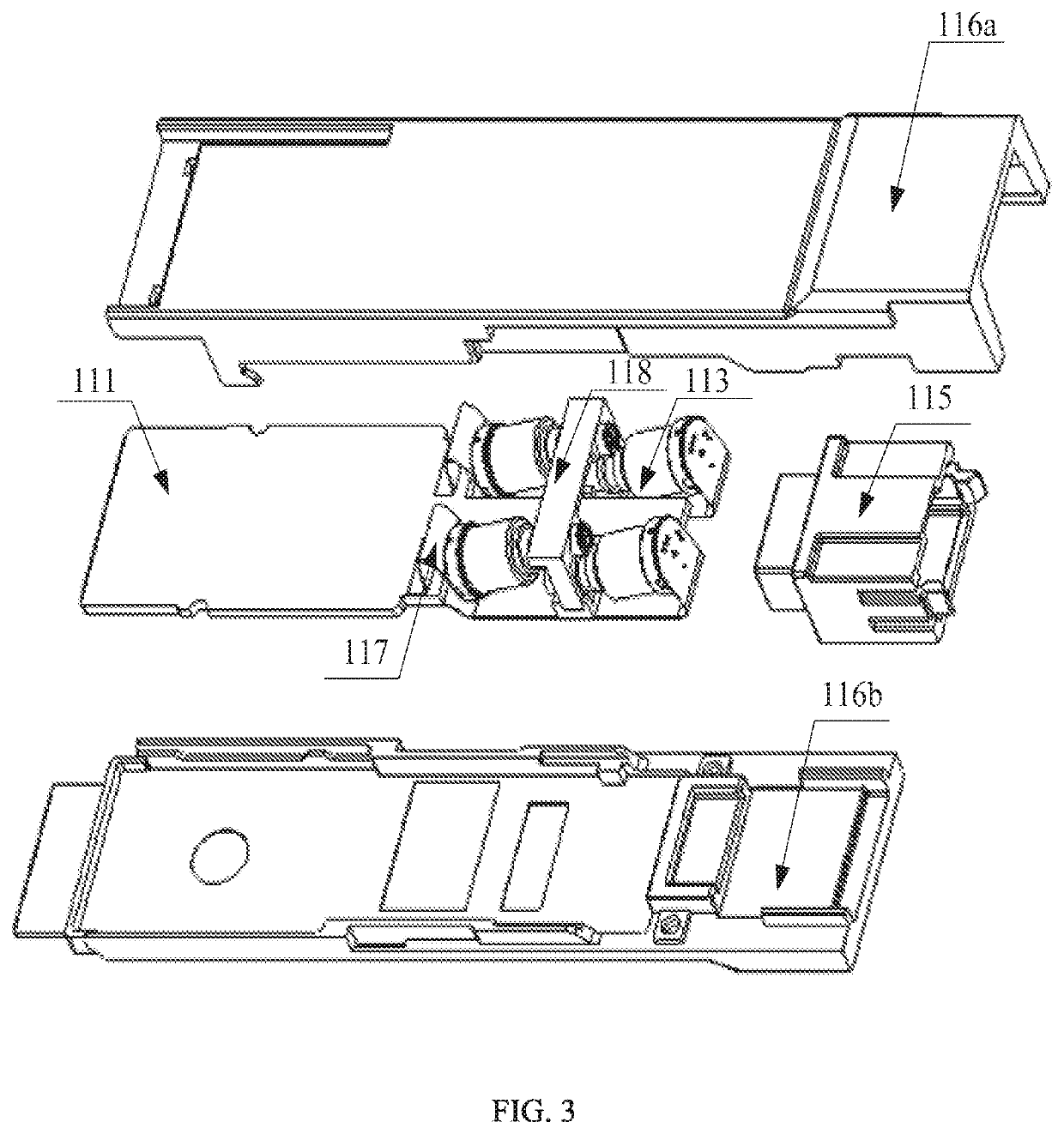

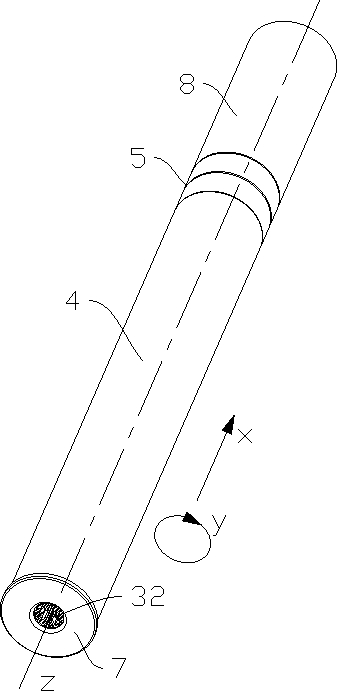

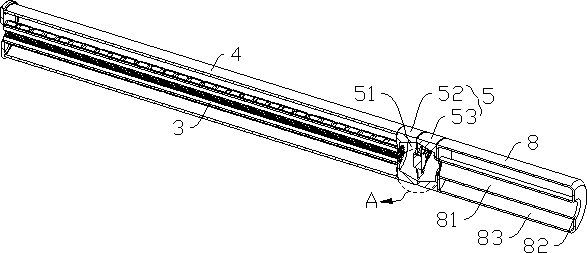

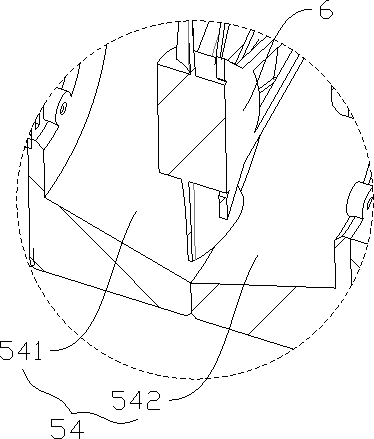

Optical transceiver module and optical cable module

ActiveUS20200301083A1Increase the setting areaSimple manufacturing structureCoupling light guidesElectromagnetic transceiversTransceiverEngineering

The present invention is to provide an optical transceiver module comprising a housing, a substrate, an optical receiving device and a plurality of optical transmitting devices. The substrate is disposed in the housing. The optical receiving device is disposed on the substrate. The plurality of optical transmitting devices are connected to the substrate, and there is a tilt angle between the optical transmitting devices and the substrate.

Owner:YU SHENG PHOTOELECTRIC CO LTD

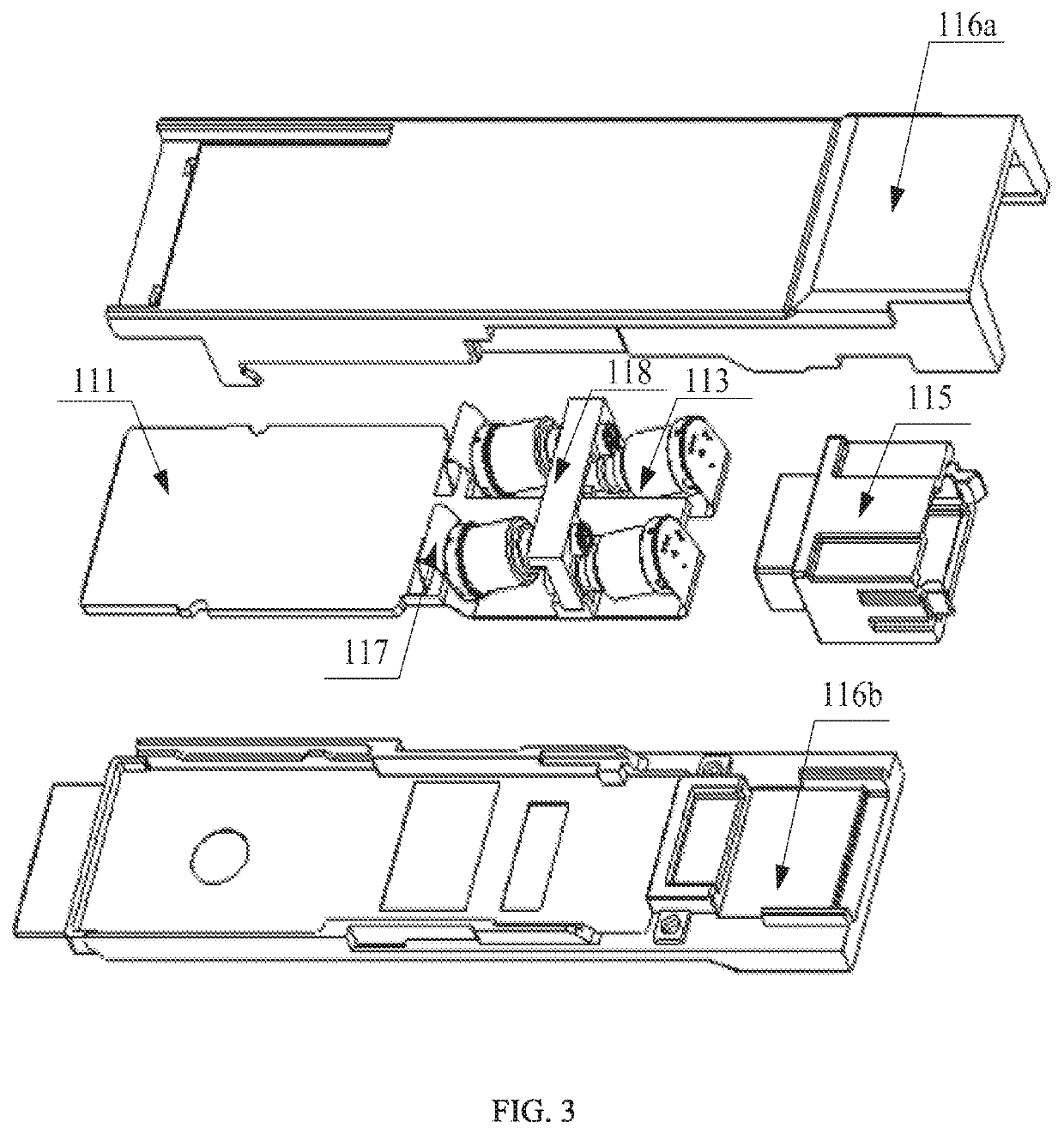

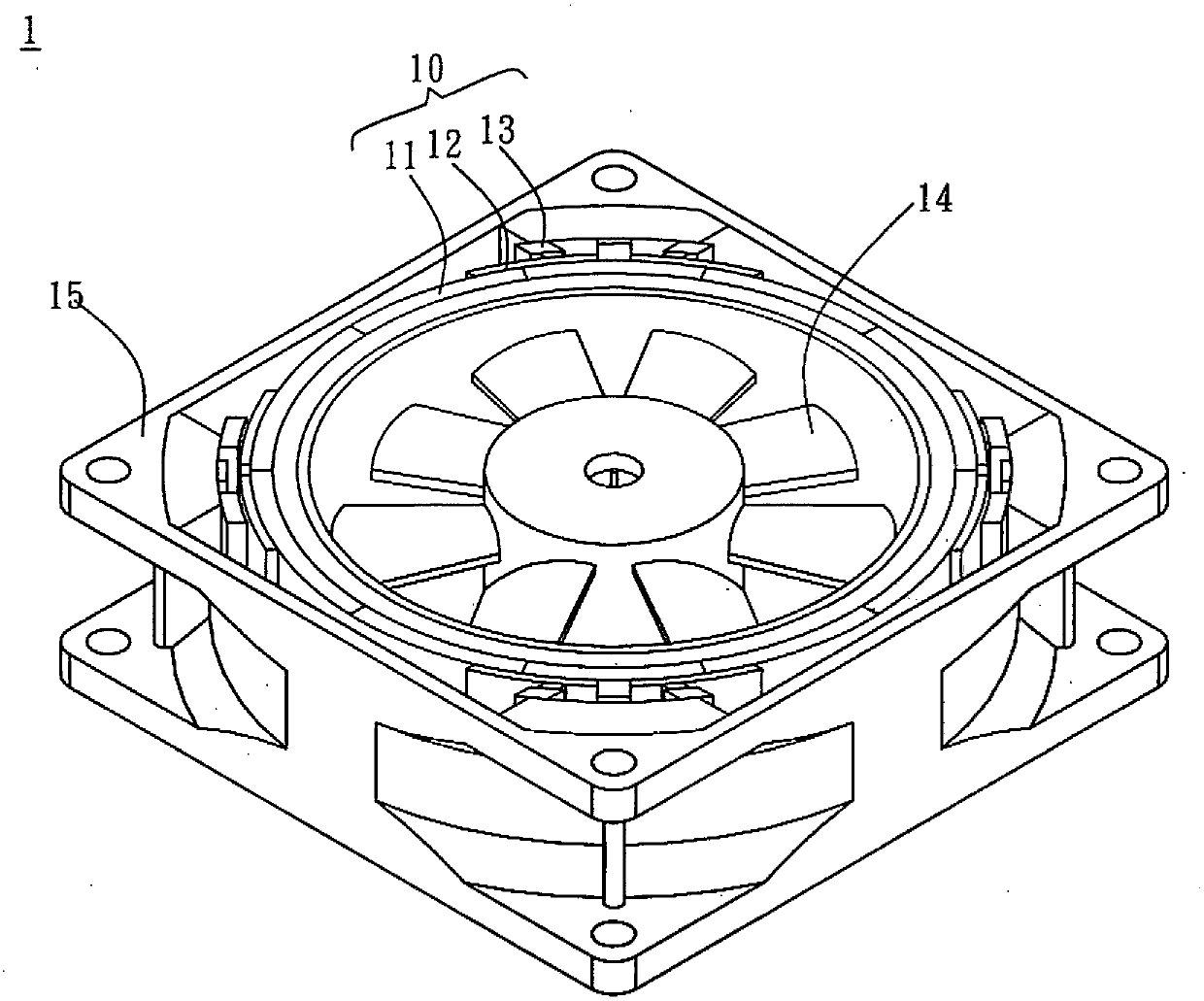

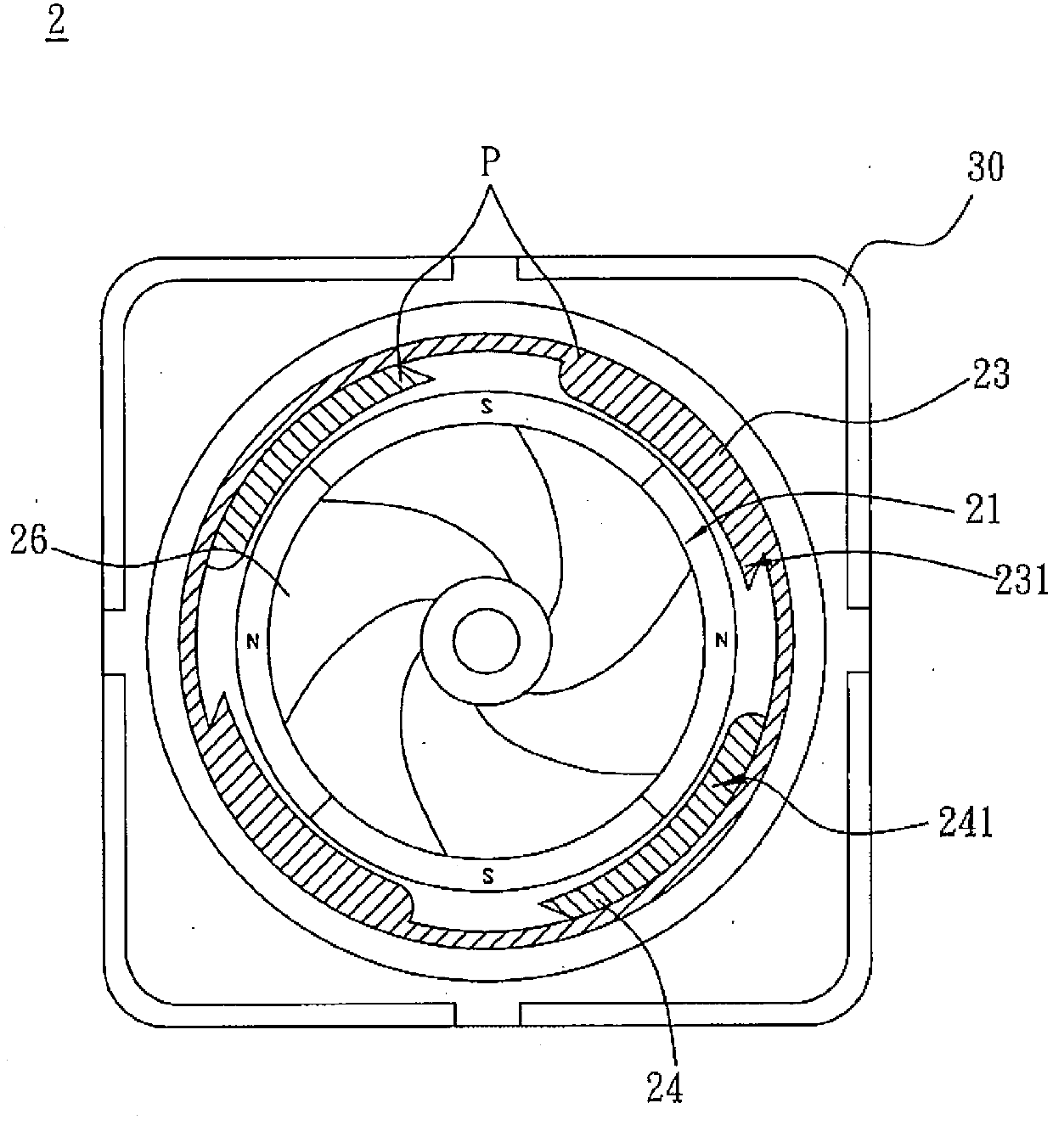

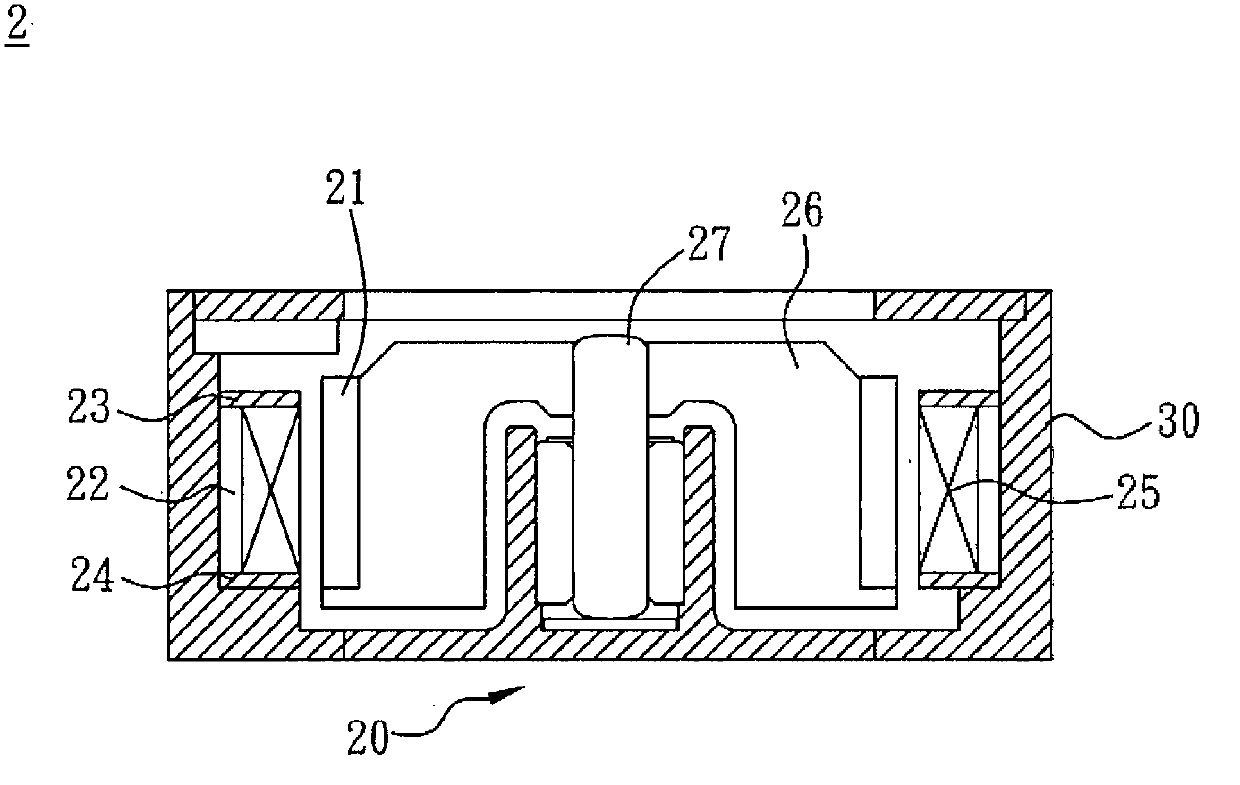

Fan and motor

InactiveCN103107648AReduce manufacturing costIncrease the setting areaMechanical energy handlingPump installationsRotor magnetsMagnetic poles

The invention discloses a motor which comprises a rotor magnet ring, a stator iron core, a first silicon steel sheet, and a second silicon steel sheet. The stator iron core is arranged outside the rotor magnet ring. The first silicon steel sheet is ring-shaped, arranged on an upper side of the stator iron core and provided with at least one first magnetic pole. The second silicon steel sheet is ring-shaped, arranged on a lower side of the stator iron core and provided with at least one second magnetic pole. The first magnetic pole and the second magnetic pole are arranged in the projection direction in a staggered mode. The invention further discloses a fan with the motor.

Owner:DELTA ELECTRONICS INC

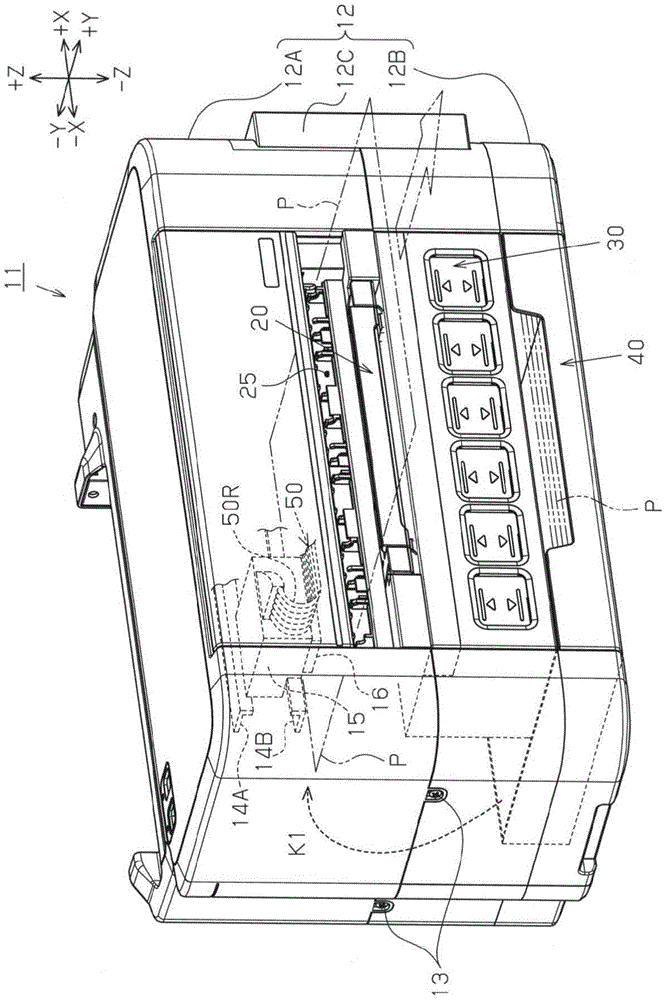

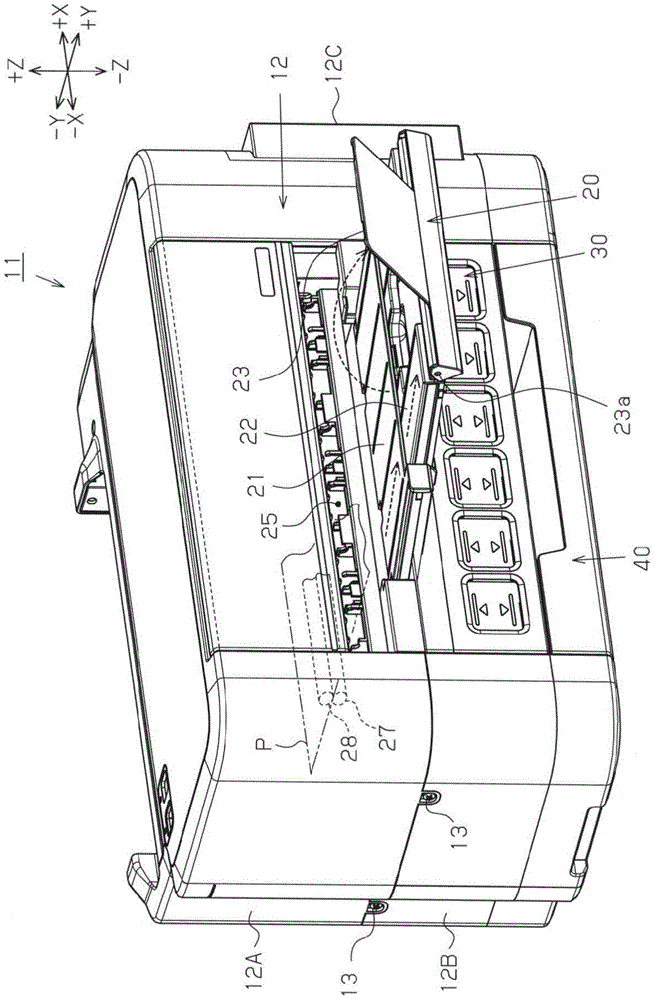

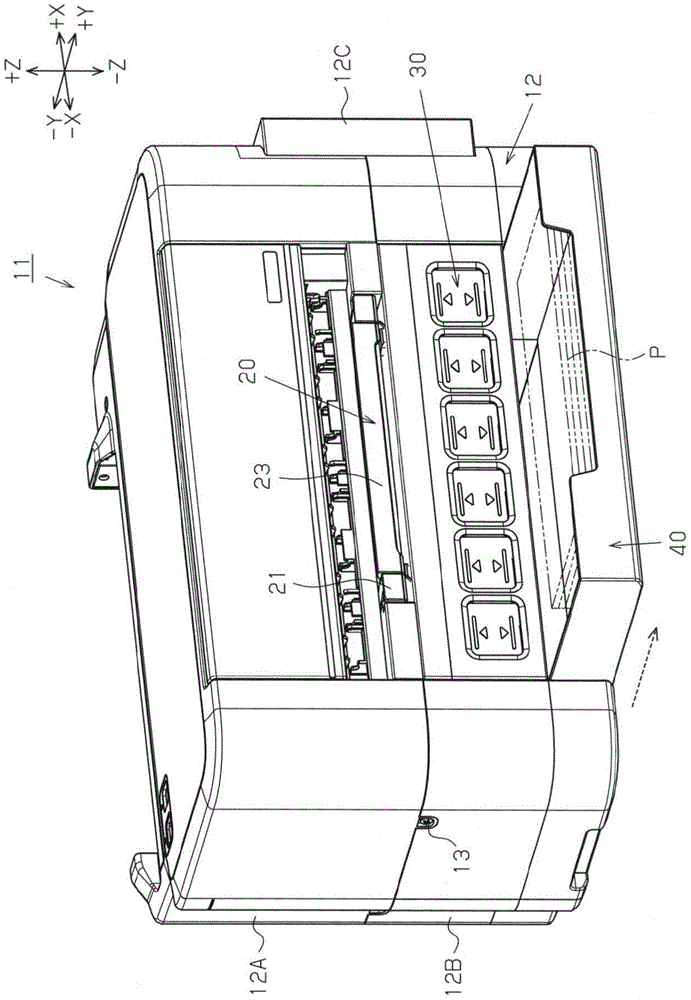

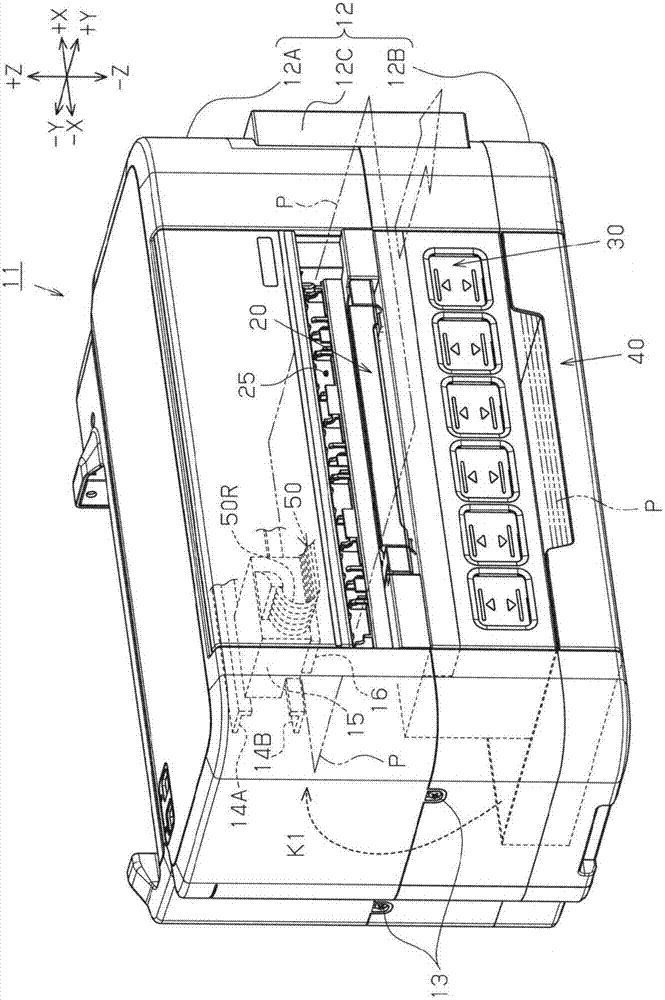

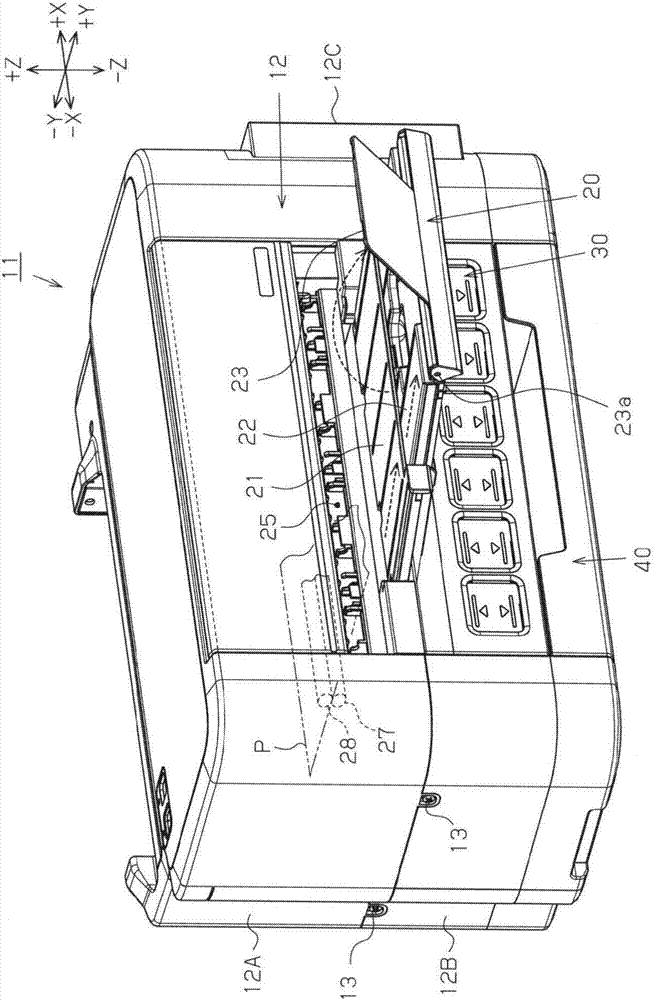

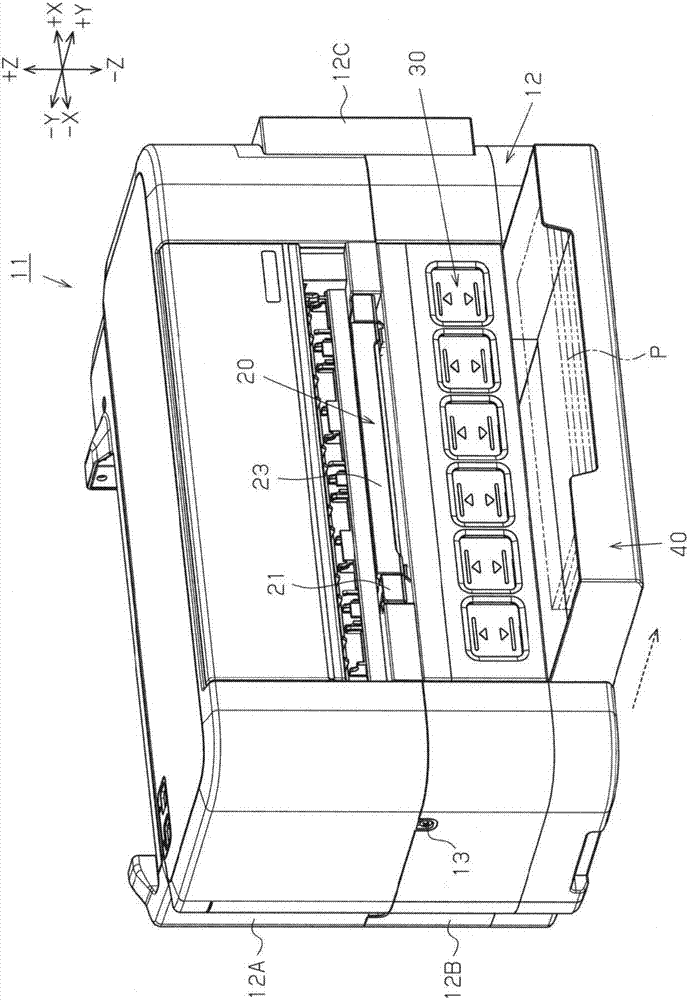

Recording device

Provided is a recording device which, while avoiding increases in the installation surface area, allows easy filling of a liquid storage unit with recording fluid. A printer main body (12) is provided with a liquid jetting head (16) which records by jetting ink against a paper (P), a discharge unit (20) in which a discharge port (25) is formed that includes a discharge region from which the paper is discharged on which recording was performed by the liquid jetting head, and a liquid housing unit (30) which can store the ink supplied to the liquid jetting head. The liquid storage unit is provided with an injection port which is disposed in a position below the discharge unit in the vertical direction (-Z direction) and overlapping the discharge unit in the vertical direction and which allows injection of ink into said liquid storage unit.

Owner:SEIKO EPSON CORP

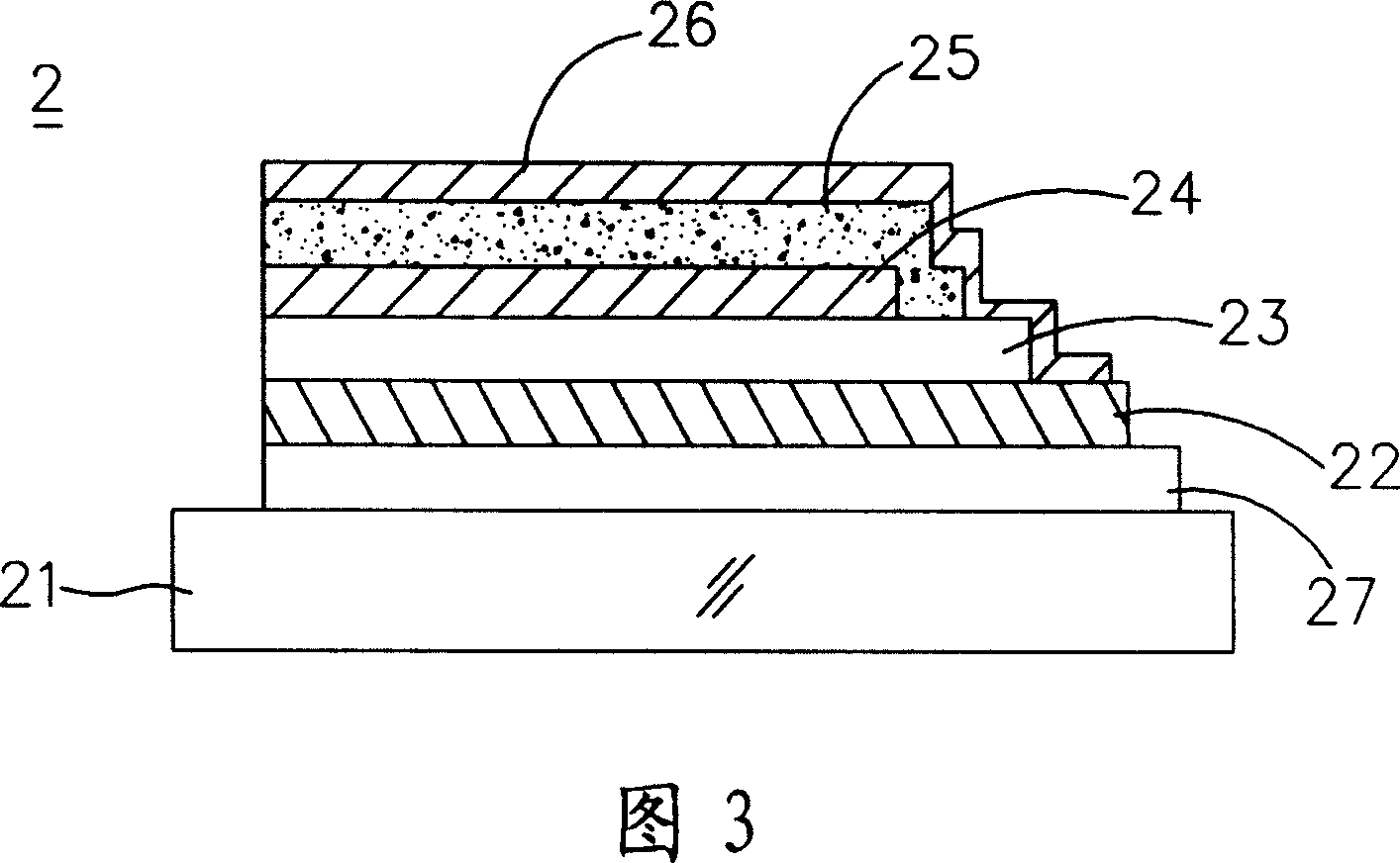

Organic luminescent device and electrode base plate

InactiveCN1942032AIncrease the setting areaDoes not affect aperture ratioElectrical apparatusElectroluminescent light sourcesInsulation layerOptoelectronics

The invention comprises a baseboard, an auxiliary electrode, an insulation layer, a first electrode, at least one organically-functionalized layer and a second electrode. The part of second electrode is connected to the auxiliary electrode.

Owner:RITDISPLAY

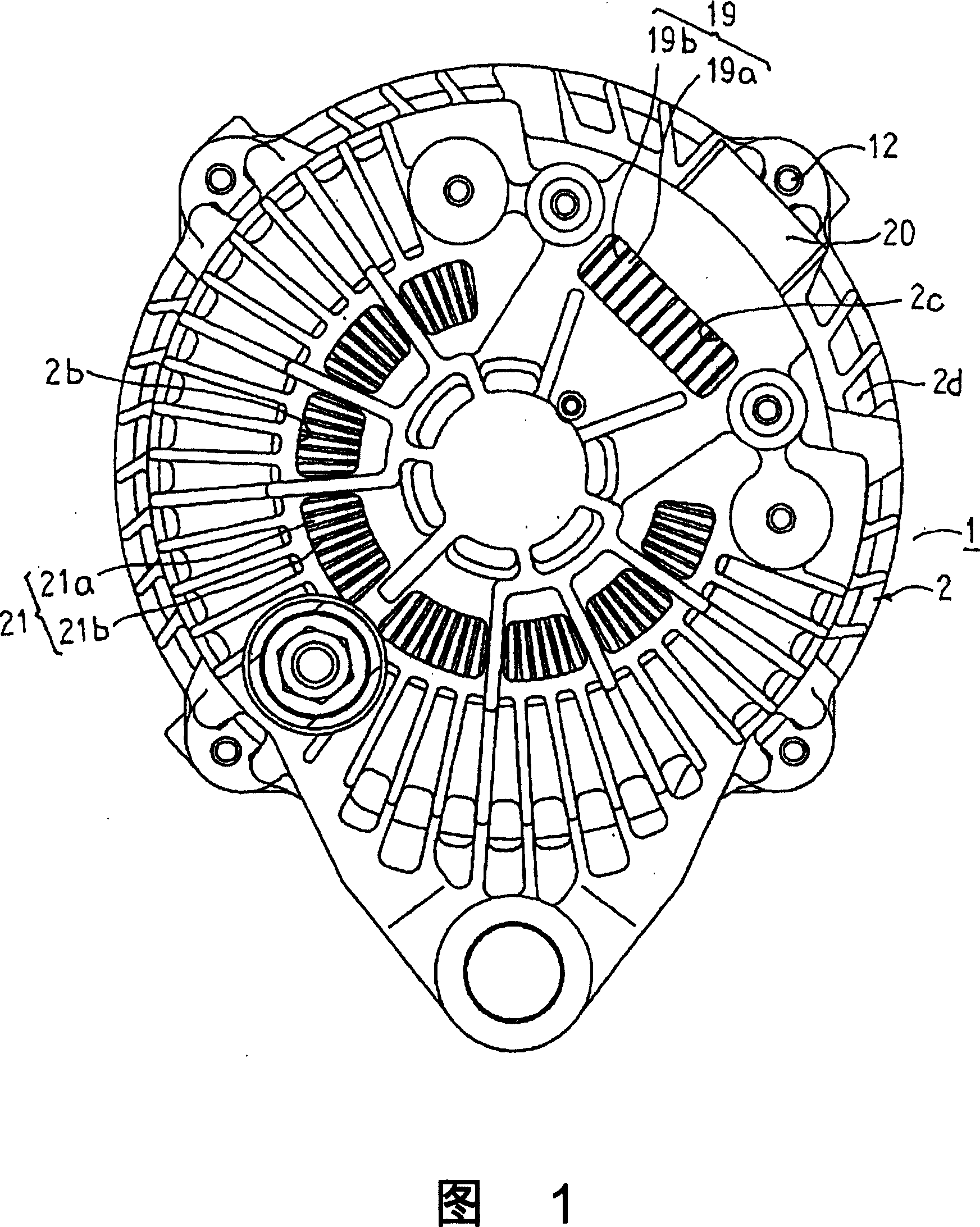

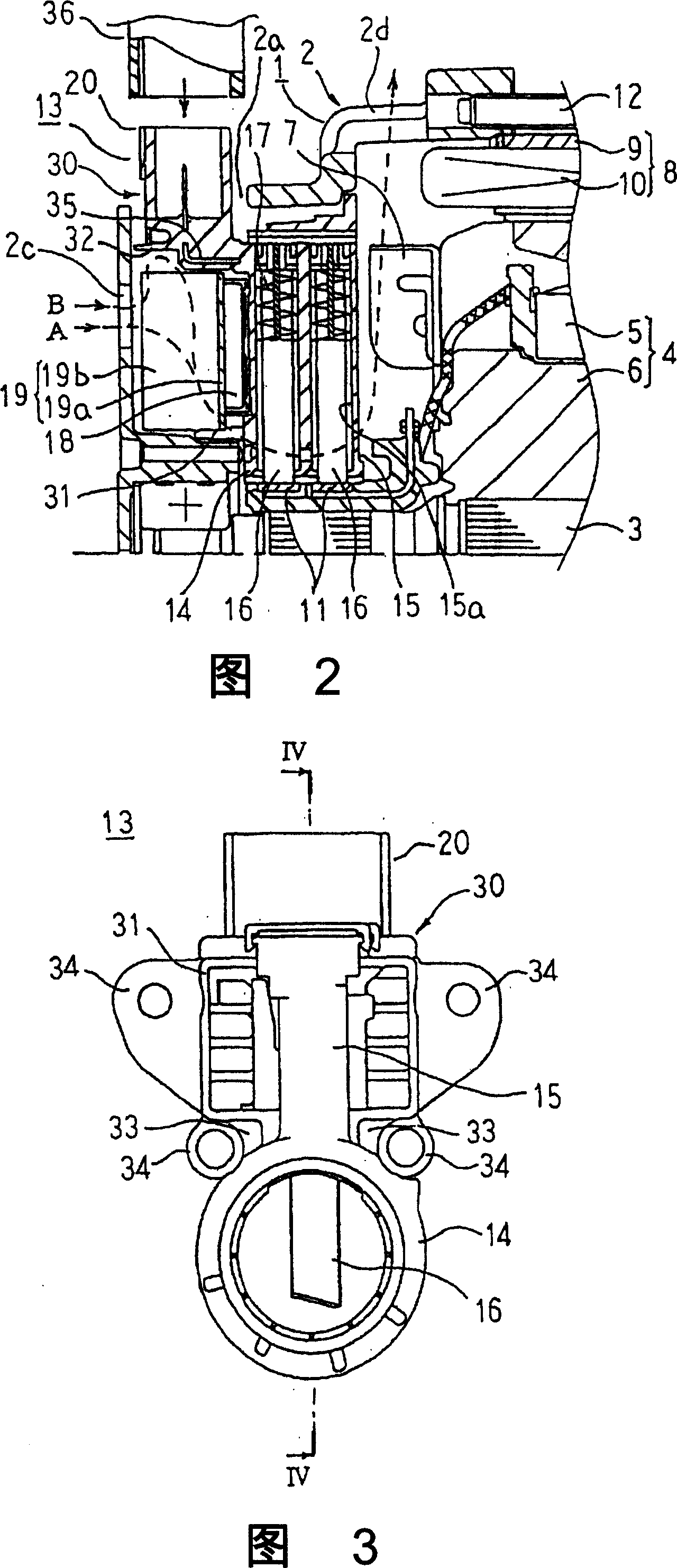

Generator for automobile

InactiveCN101090218AIncrease temperatureIncrease the setting areaPropulsion using engine-driven generatorsModifications for power electronicsRectifierHeat spreader

The present invention provides a vehicle alternator capable of suppressing deterioration of the cooling performance of a voltage regulator due to improvement of the cooling performance of the rectifier, suppressing temperature rises of the rectifier and the voltage regulator, and improving performance. The cooling air introduction guide part (32) ensures a predetermined gap with respect to the heat sink (19b) at the position facing the heat sink (19b) of the voltage regulator heat sink (19) of the connector (20), and along the heat dissipation The arrangement direction of the sheets (19b) extends. Then, an air suction hole (2c) is formed through the portion of the rear end cover (2) opposite to the heat sink (19) for the voltage regulator.

Owner:MITSUBISHI ELECTRIC CORP

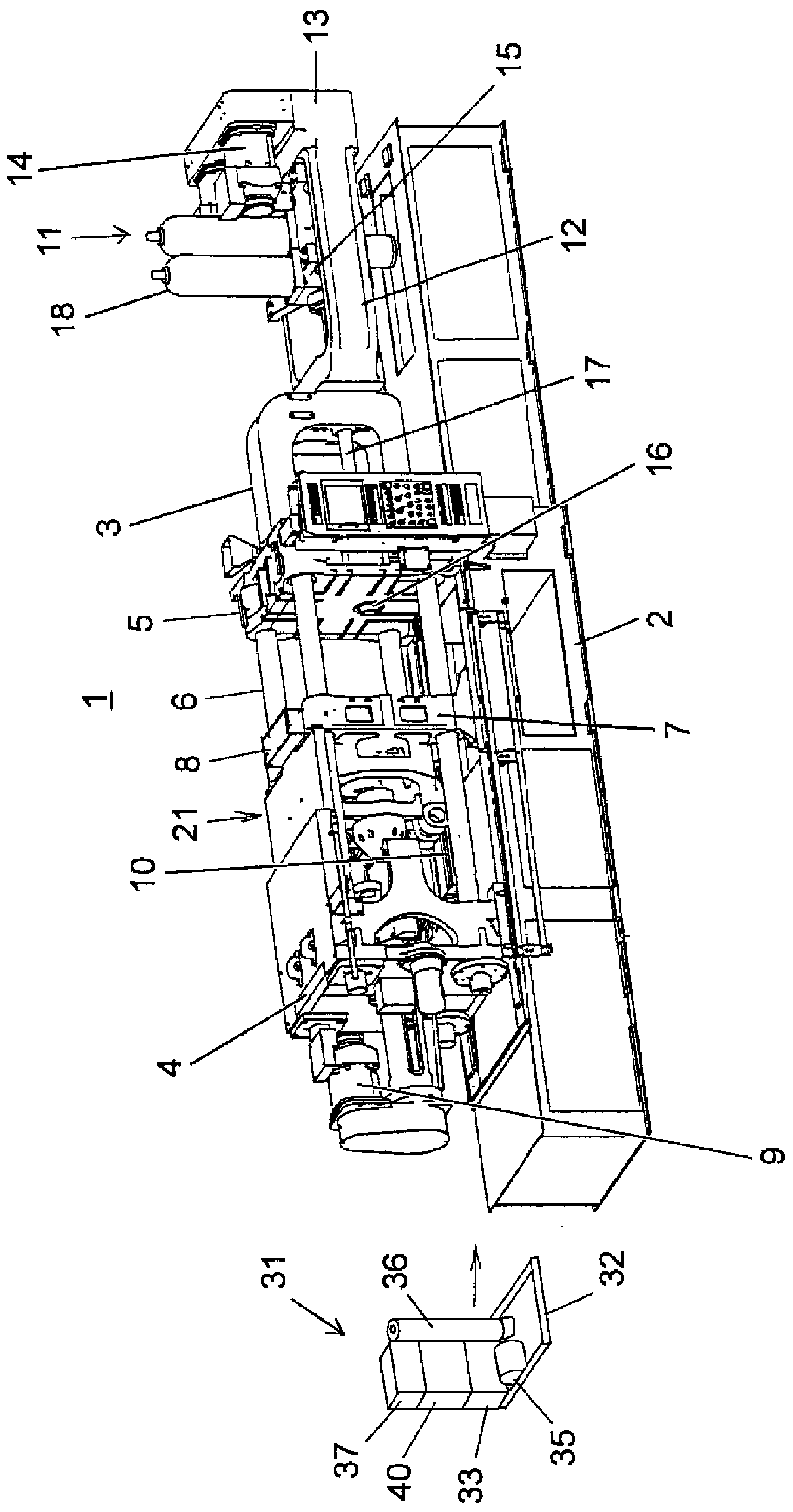

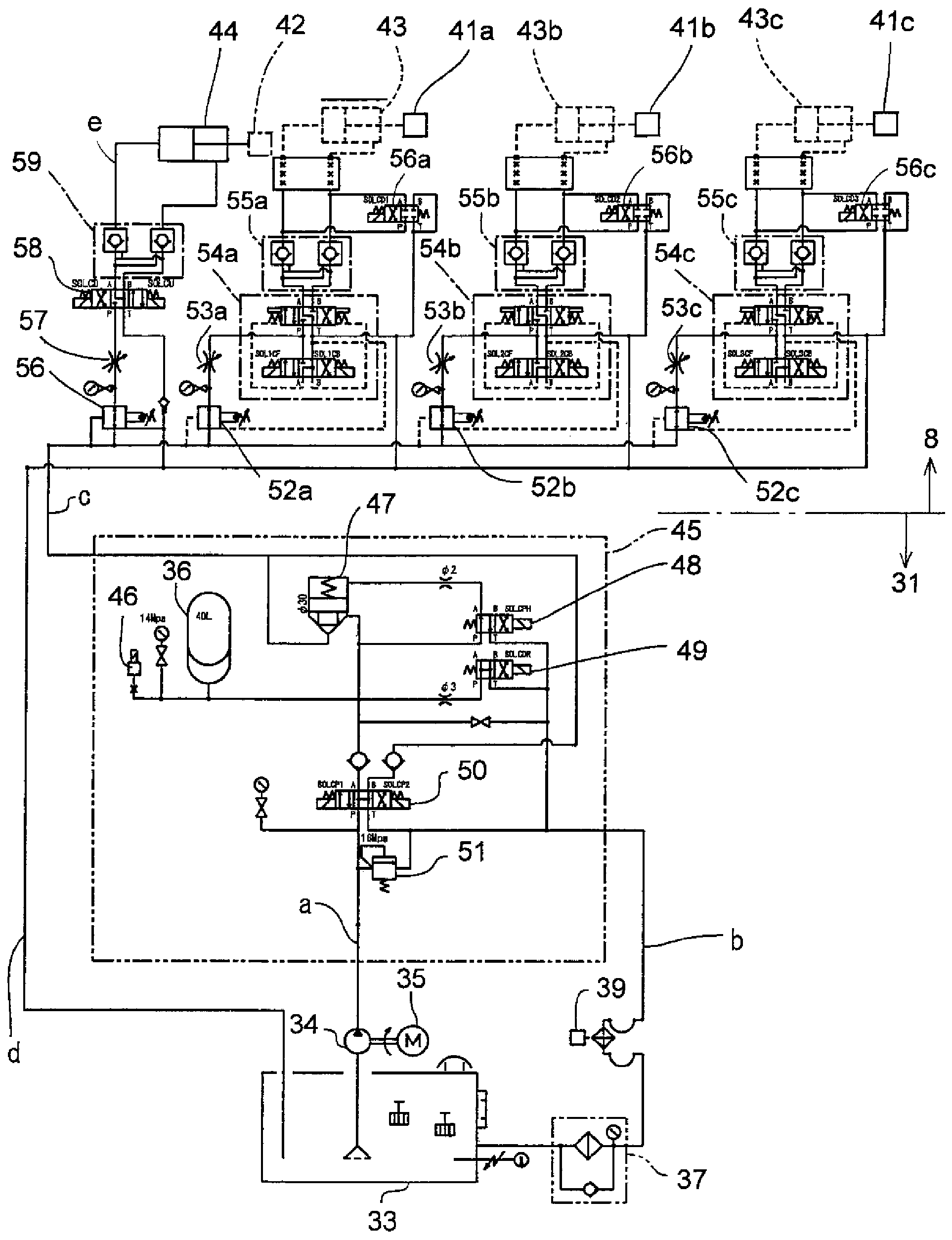

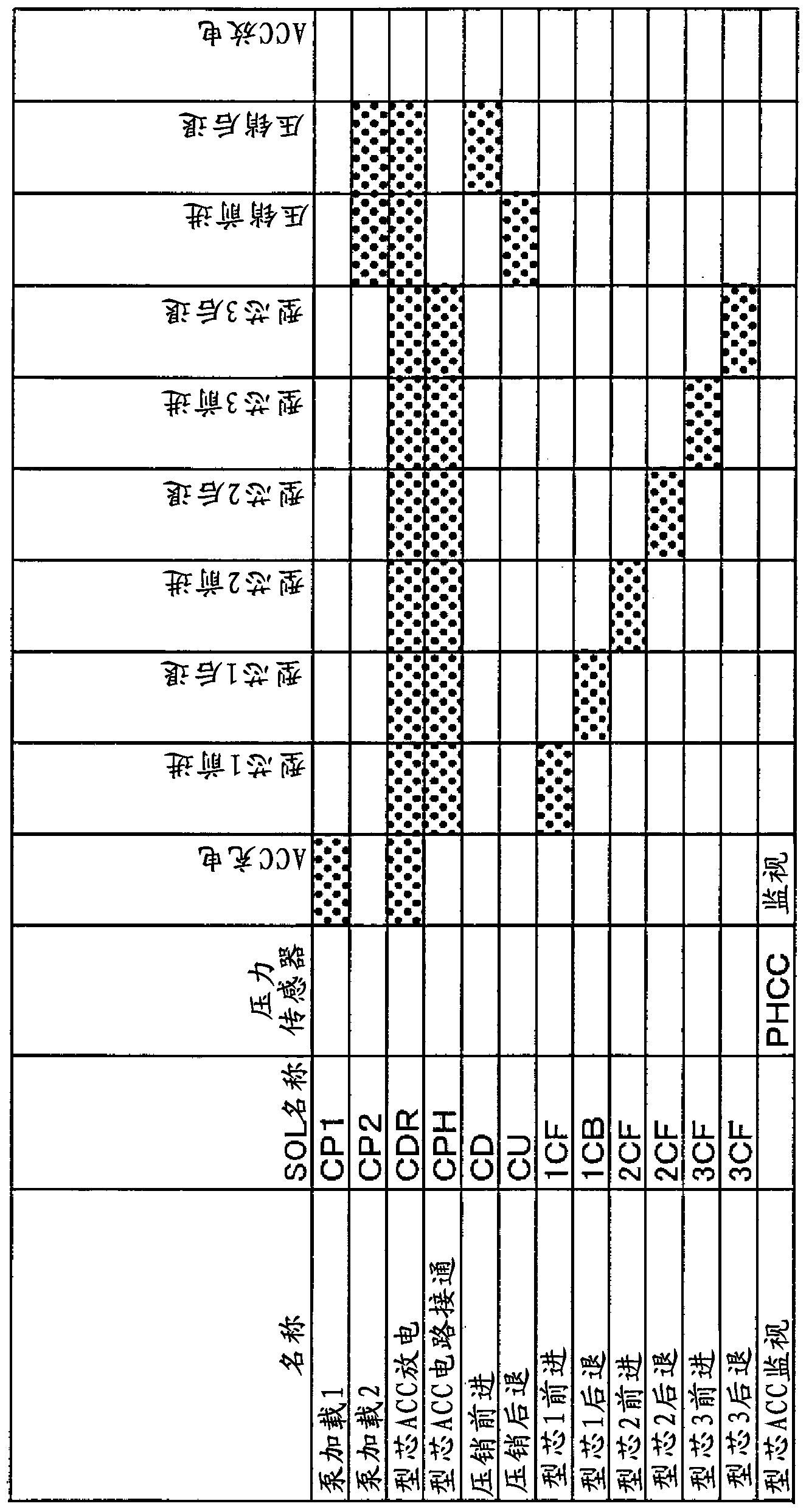

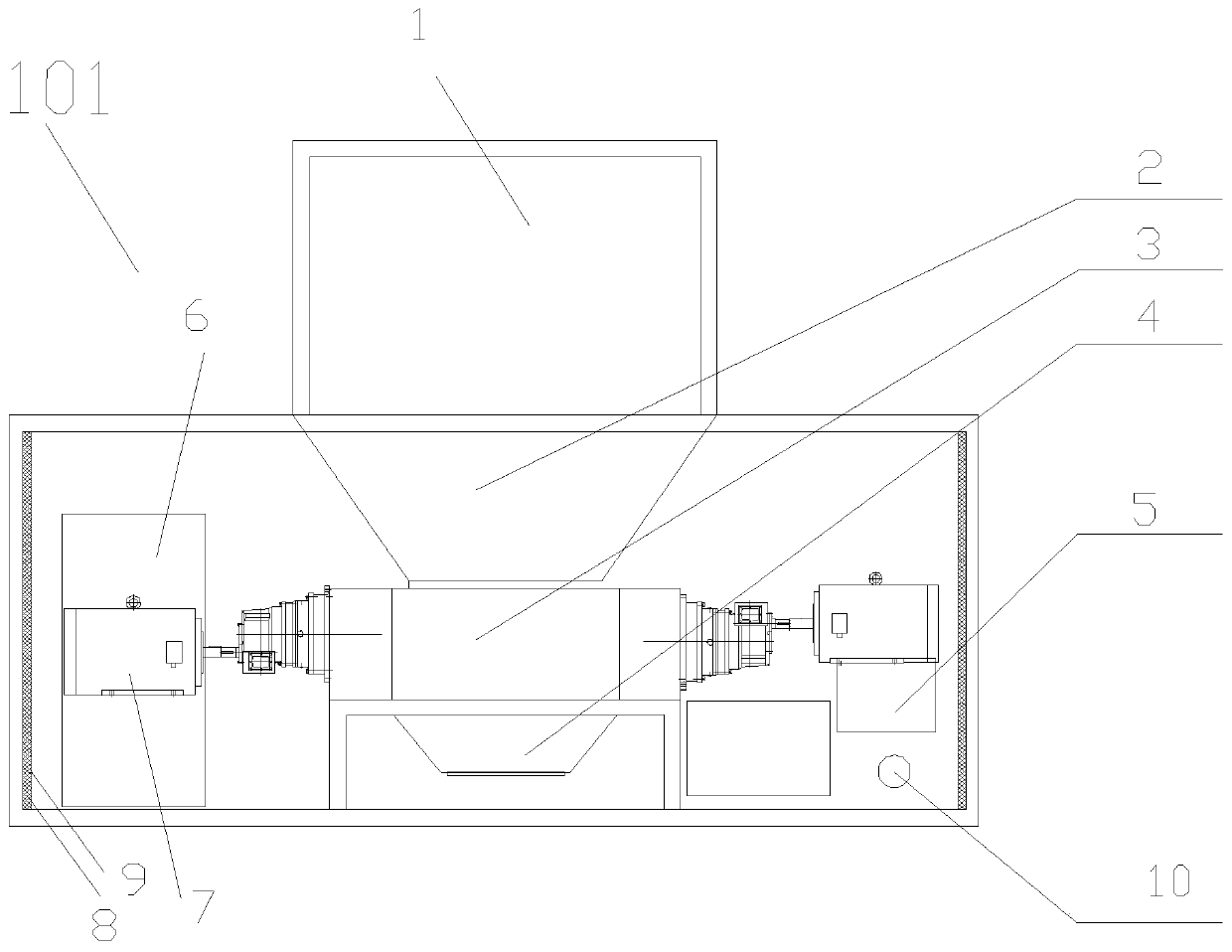

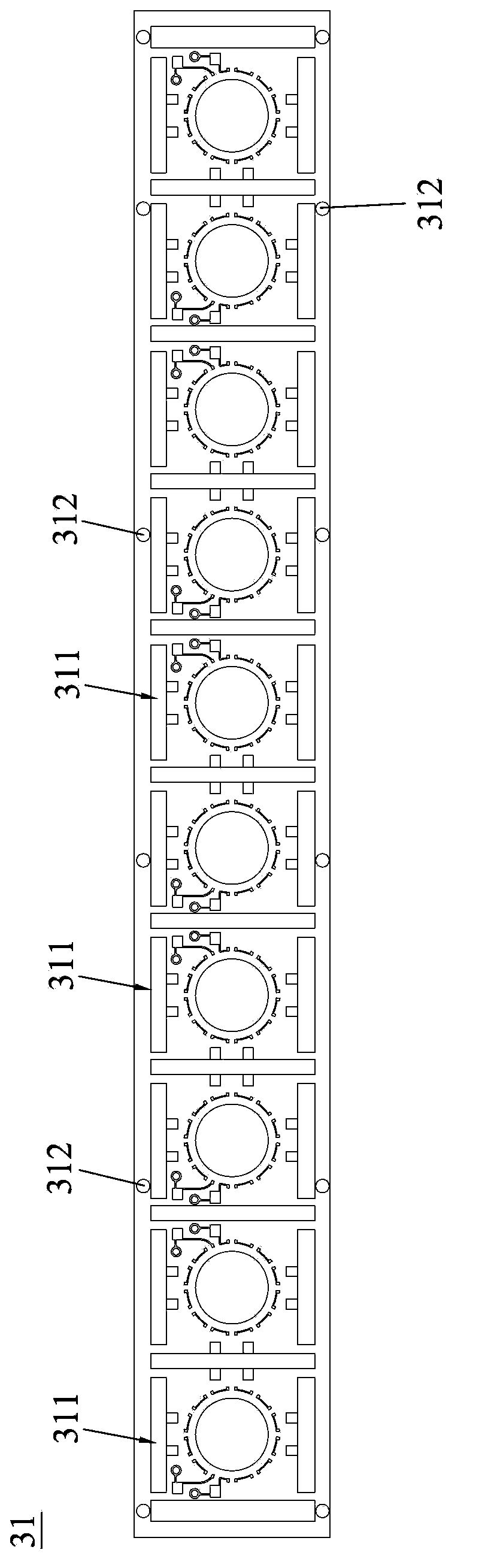

Electric die-casting machine with core-riving hydraulic unit

[Problem] To provide an electric die-casting machine equipped with a core-driving hydraulic unit, the electric die-casting machine being configured in a manner such that, although the electric die-casting machine is equipped with the hydraulic unit, the electric die-casting machine does not require a large installation area and the maintainability of the electric die-casting machine is not compromised. [Solution] A suitable core-driving hydraulic unit (31) is configured by integrating together an oil tank (33), a hydraulic pump (34), a hydraulic pump-driving motor (35), an accumulator (36), an oil cooler (37), valves (38) including a solenoid directional control valve, an oil cleaner (39), an electric box (40), etc. in such a manner that such components are disposed on a base plate (32) doubling as an oil pan. The core-driving hydraulic unit (31) is affixed to a predetermined position on a main base board (2) in such a manner that the hydraulic pump (34) and the hydraulic pump-driving motor (35) are located below a mold-clamping electric servomotor (22) and the remaining components are located at a side of the mold-clamping electric servomotor (22).

Owner:TOYO MACH & METAL CO LTD

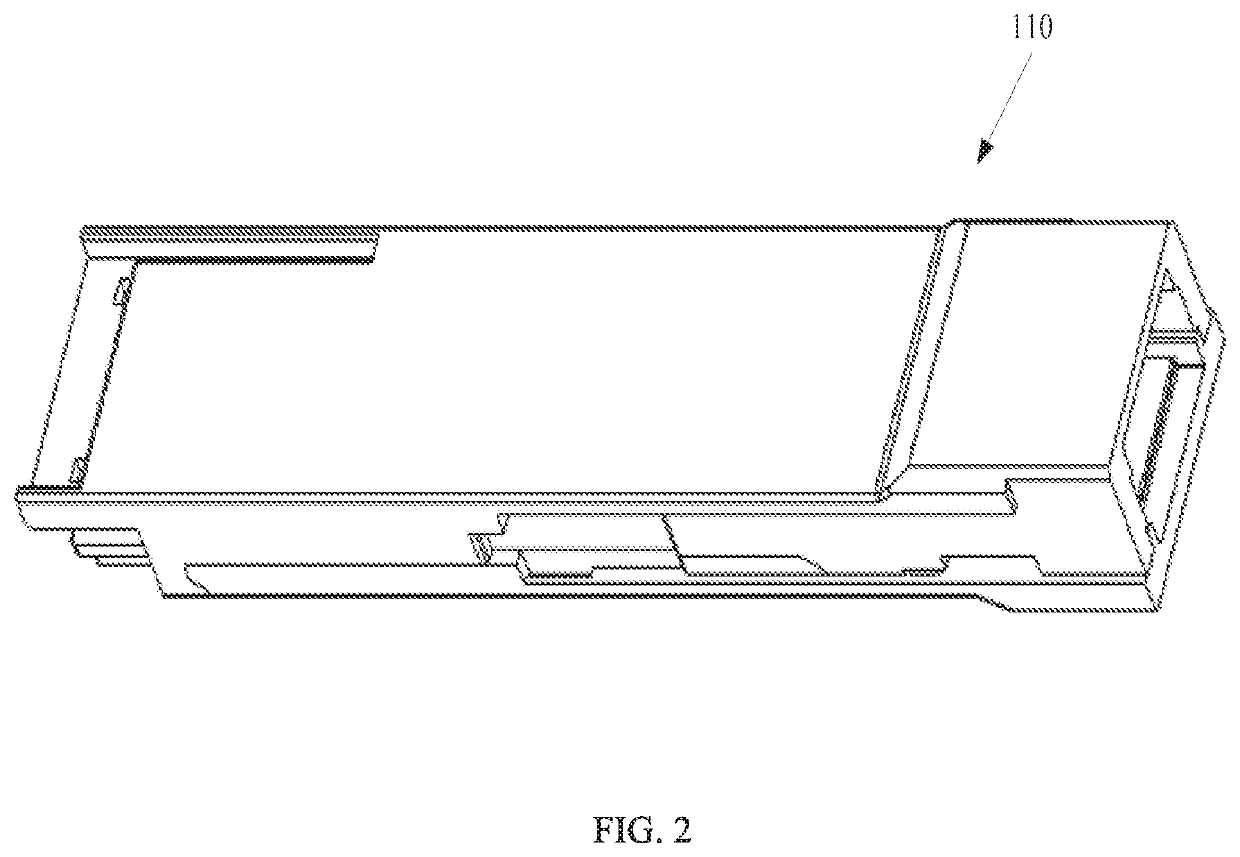

Optical transceiver module and optical cable module

ActiveUS11105990B2Increase the setting areaSimple manufacturing structureCoupling light guidesElectromagnetic transceiversTransceiverEngineering

The present invention is to provide an optical transceiver module comprising a housing, a substrate, an optical receiving device and a plurality of optical transmitting devices. The substrate is disposed in the housing. The optical receiving device is disposed on the substrate. The plurality of optical transmitting devices are connected to the substrate, and there is a tilt angle between the optical transmitting devices and the substrate.

Owner:YU SHENG PHOTOELECTRIC CO LTD

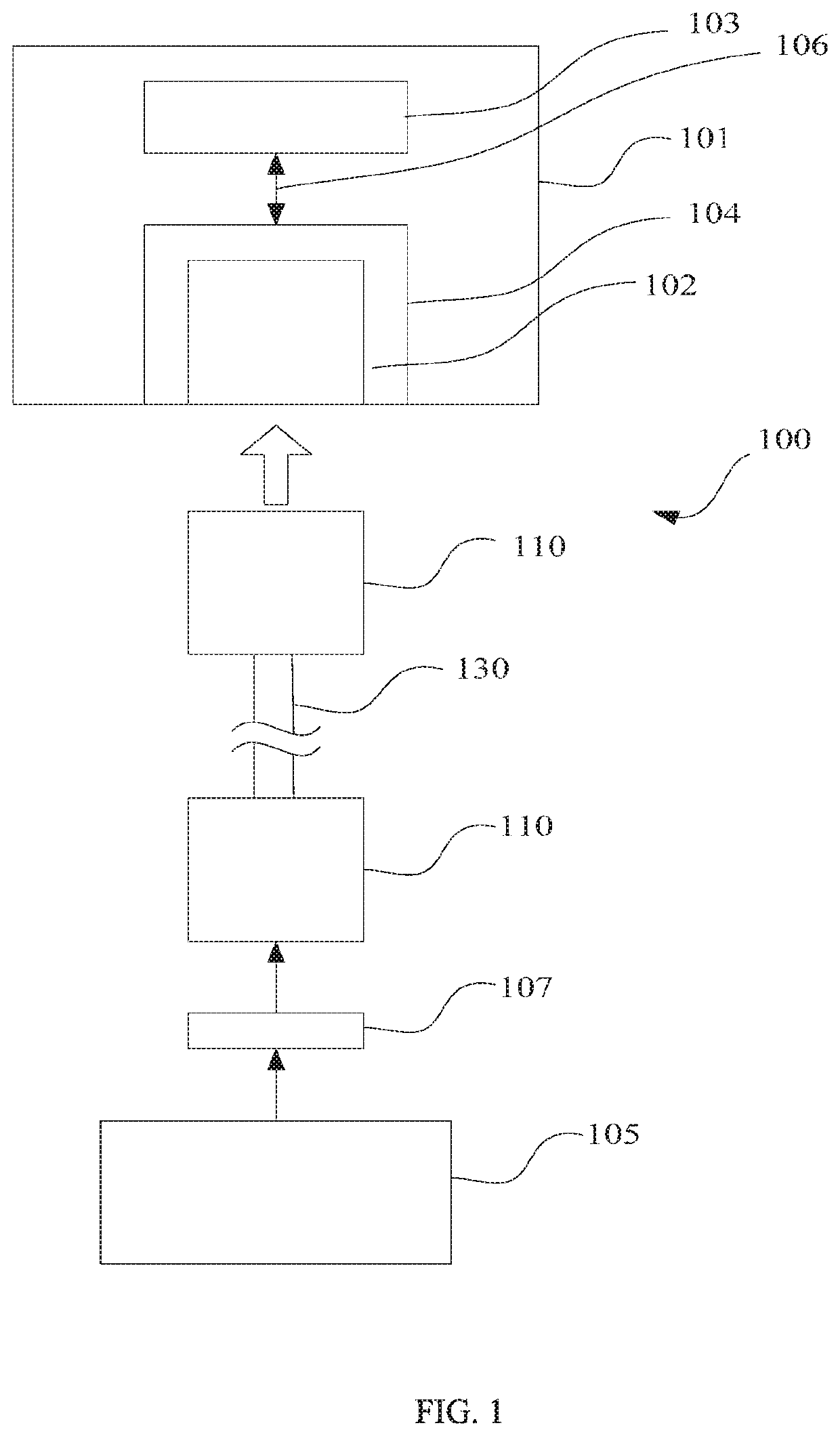

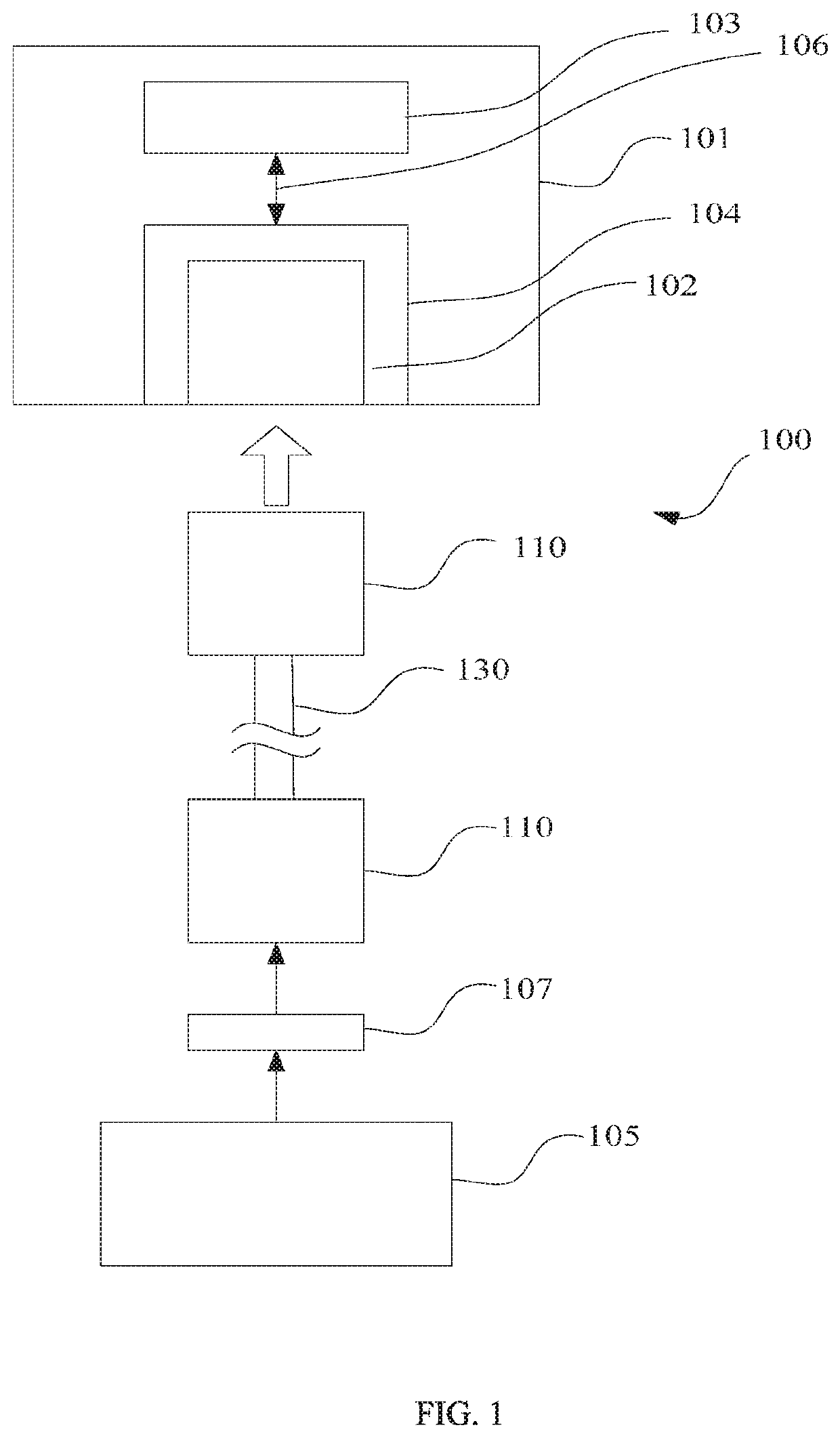

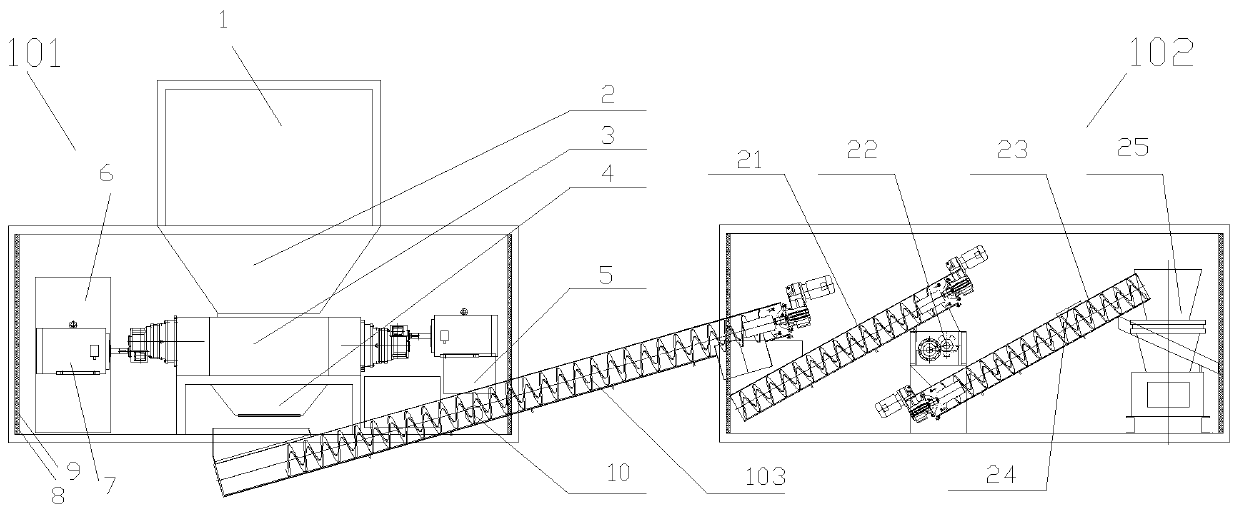

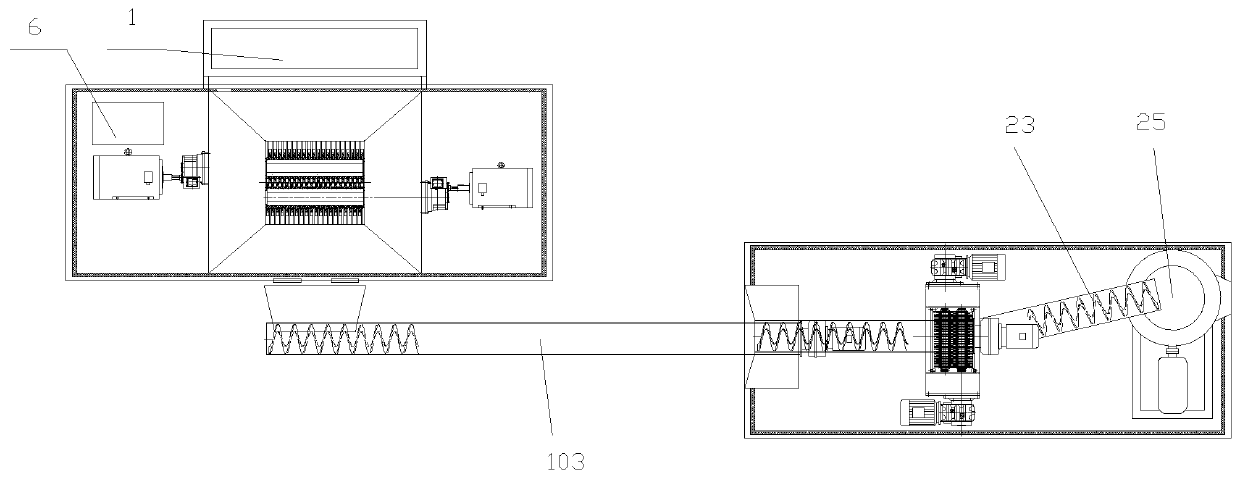

Integrated type solid waste garbage disposal system

PendingCN110052323AHigh degree of automationReduce shipping costsGrain treatmentsHandling systemGarbage disposal

The invention provides an integrated type solid waste garbage disposal system. The integrated type solid waste garbage disposal system comprises a first-stage device (101) used for carrying out first-stage disposal on solid waste garbage, a second-stage device (102) arranged on the downstream portion of the first-stage device (101) and used for carrying out second-stage disposal on solid waste garbage and a connecting conveyor (103) arranged between the first-stage device (101) and the second-stage device (102) so as to convey a discharged material from the first-stage device (101) to the second-stage device (102). The integrated type solid waste garbage disposal system can mechanically dispose garbage, two stages of smashing devices are integrated, and the whole disposal system is relatively small in occupied area, high in work efficiency and low in running cost.

Owner:李震

Recording apparatus

ActiveCN107097522AIncrease the setting areaOther printing apparatusEngineeringPerpendicular direction

Owner:SEIKO EPSON CORP

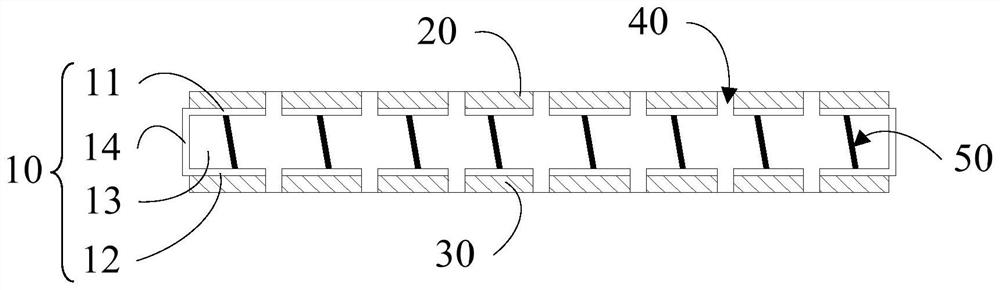

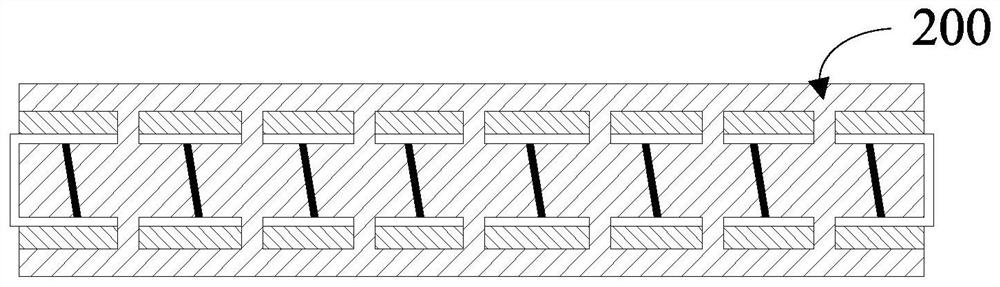

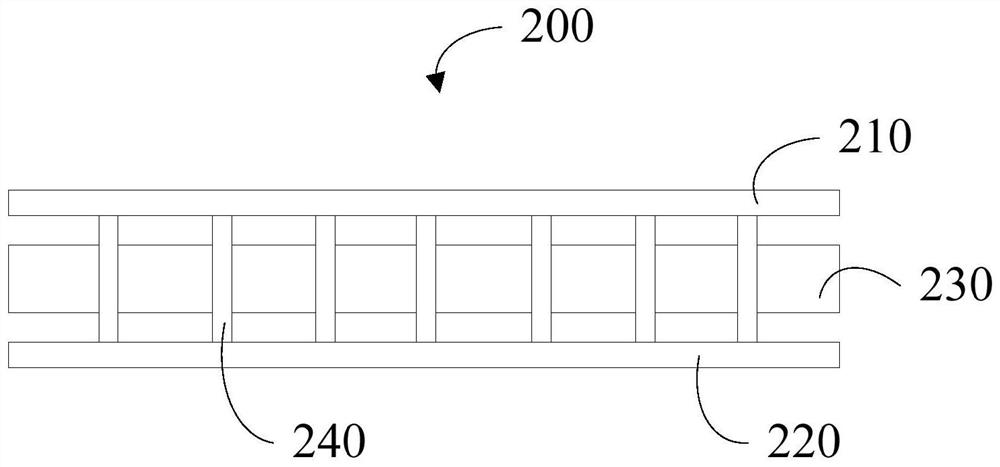

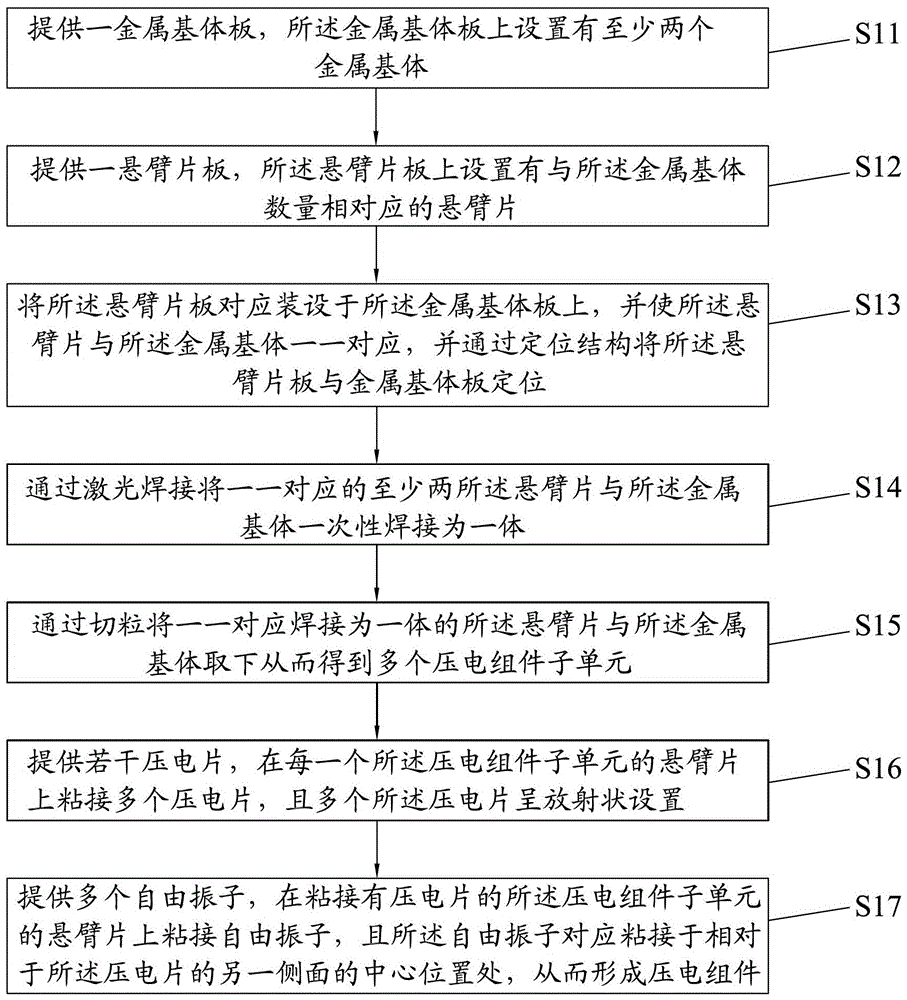

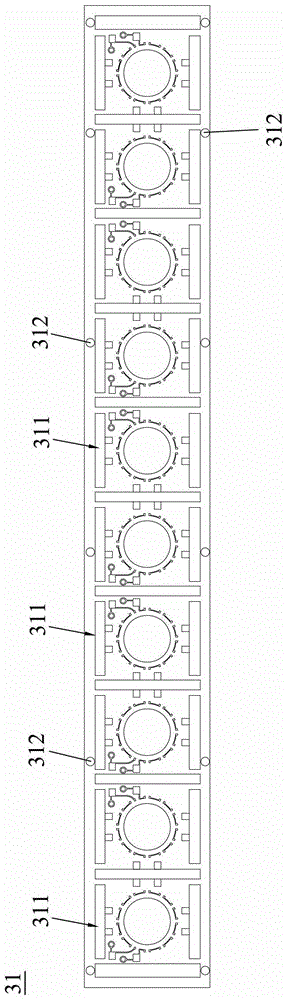

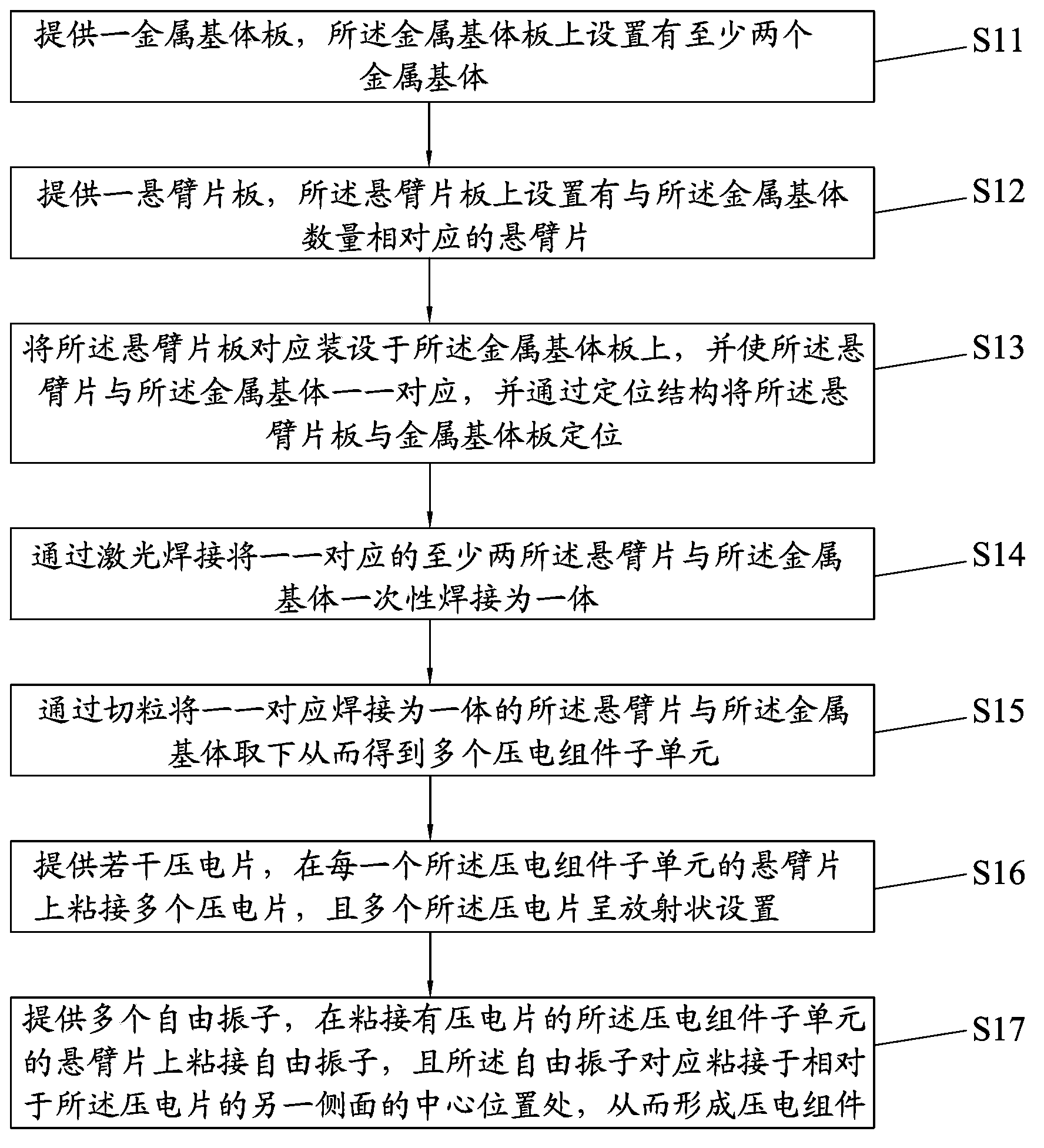

Piezoelectric vibration generating set and manufacturing method thereof

InactiveCN103916049AIncrease the areaImprove power generation efficiencyPiezoelectric/electrostriction/magnetostriction machinesFall protectionElectricity

The invention discloses a piezoelectric vibration generating set which comprises bottom caps, a base, at least two generating units and at least two conductive welding pins. The generating units are arranged on the base in parallel and overlaid modes, the two bottom caps are arranged at the two ends of the base respectively in a covering mode to seal a containing cavity, and the conductive welding pins are connected with the generating units and penetrate through one bottom cap to form a conductive electrode. Each generating unit comprises an elastic plate, a piezoelectric plate and a free vibrator, the elastic plates are supported at the end of the base, the free vibrators are bonded in the middles of the elastic plates, and the piezoelectric plates are bonded on the side faces, opposite to the free vibrators, of the elastic plates. The base and the bottom caps cover the generating units to form the piezoelectric vibration generating set, the functions of self-electricity-generating and anti-falling protection in multiple space angles are achieved, generating efficiency is high, the structure is simple, the size is small, thickness is small, and cost is low. In addition, the invention further discloses a manufacturing method for the piezoelectric vibration generating set.

Owner:BEIJING JIAYUE TONGLEJI ELECTRONICS

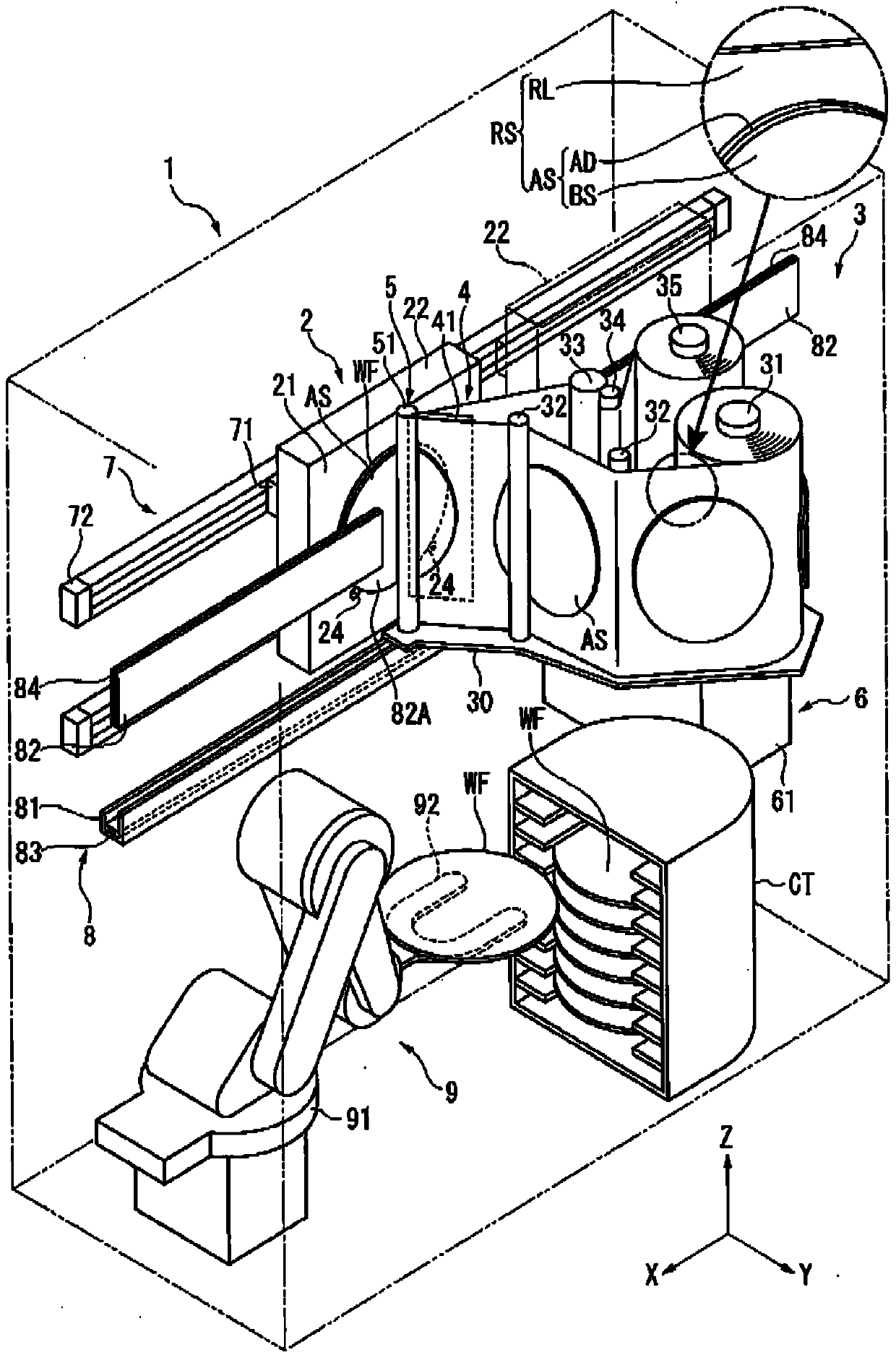

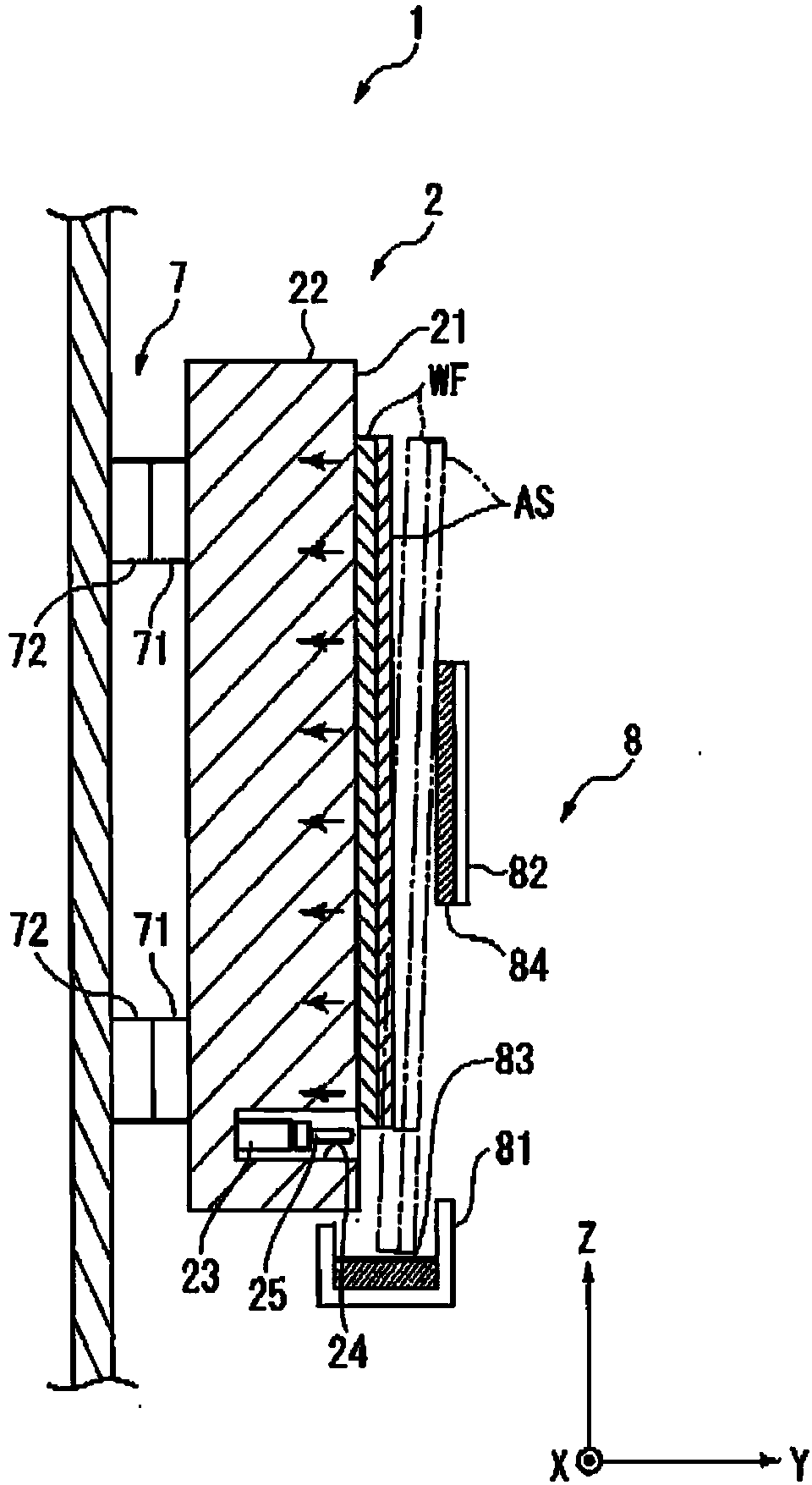

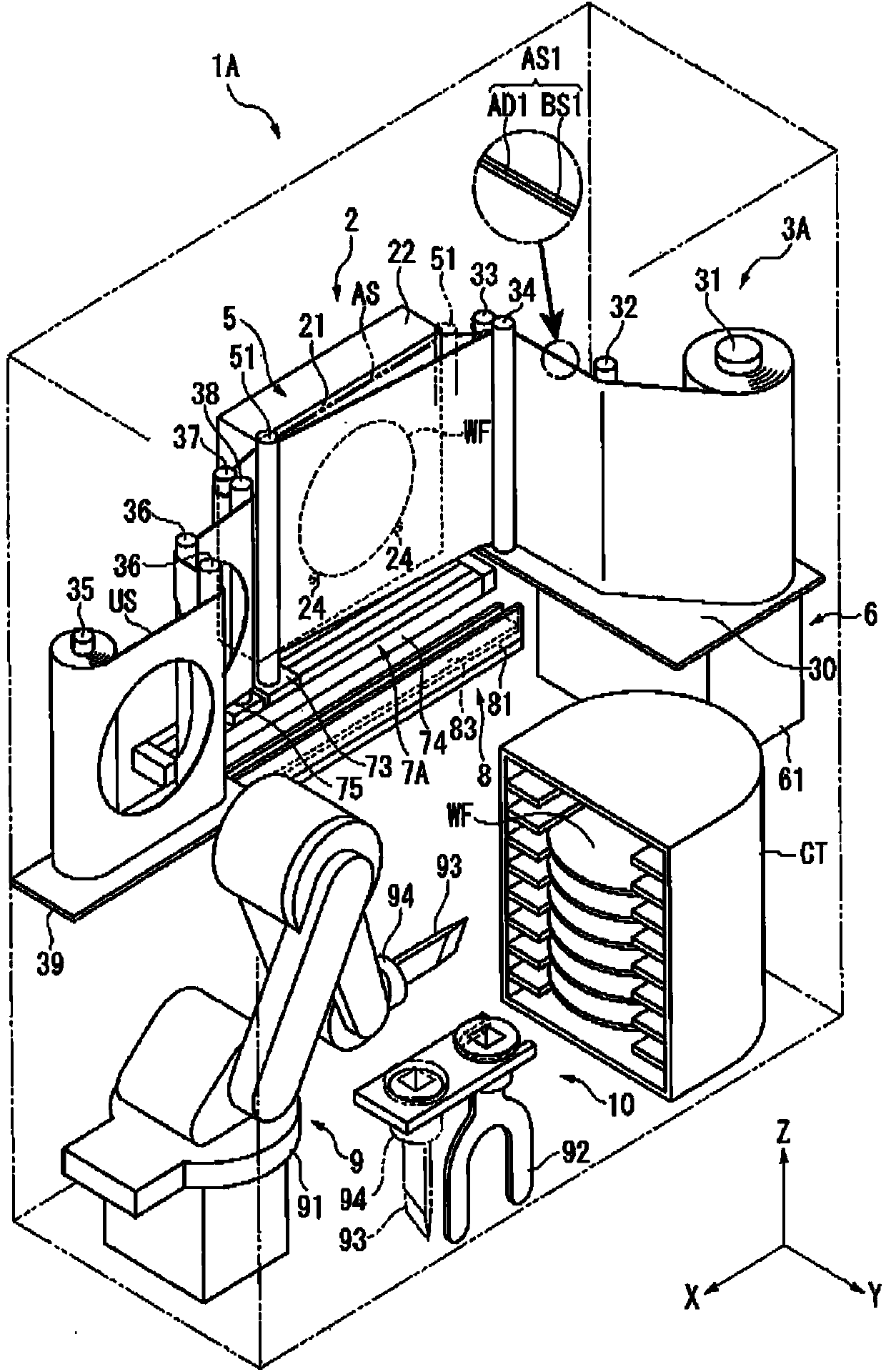

Sheet application device and application method

ActiveCN104221139AIncrease the setting areaReduce mixing into plate partsSemiconductor/solid-state device manufacturingIn planeEngineering

The invention provides a sheet application device and an application method. This sheet application device (1) is equipped with: a supporting means (2) that has a tilted surface (21) which is tilted with respect to a horizontal plane and is for supporting a plate-like member (WF) by means of the tilted surface (21); a feeding means (3) for feeding a rolled sheet (RS), which is obtained by temporarily adhering an adhesive sheet (AS) to one surface of a belt-like backing sheet (RL), as an object to be fed; a detaching means (4) for detaching the adhesive sheet (AS) from the backing sheet (RL) of the rolled sheet (RS) which is fed by the feeding means (3); a pressing means (5) for pressing the adhesive sheet (AS), which is detached by the detaching means (4), against the plate-like member (WF); and a moving means (7) for moving the supporting means (2) and the pressing means (5) relative to each other in the in-plane direction of the tilted surface (21) in order to apply the adhesive sheet (AS) to the plate-like member (WF).

Owner:LINTEC CORP

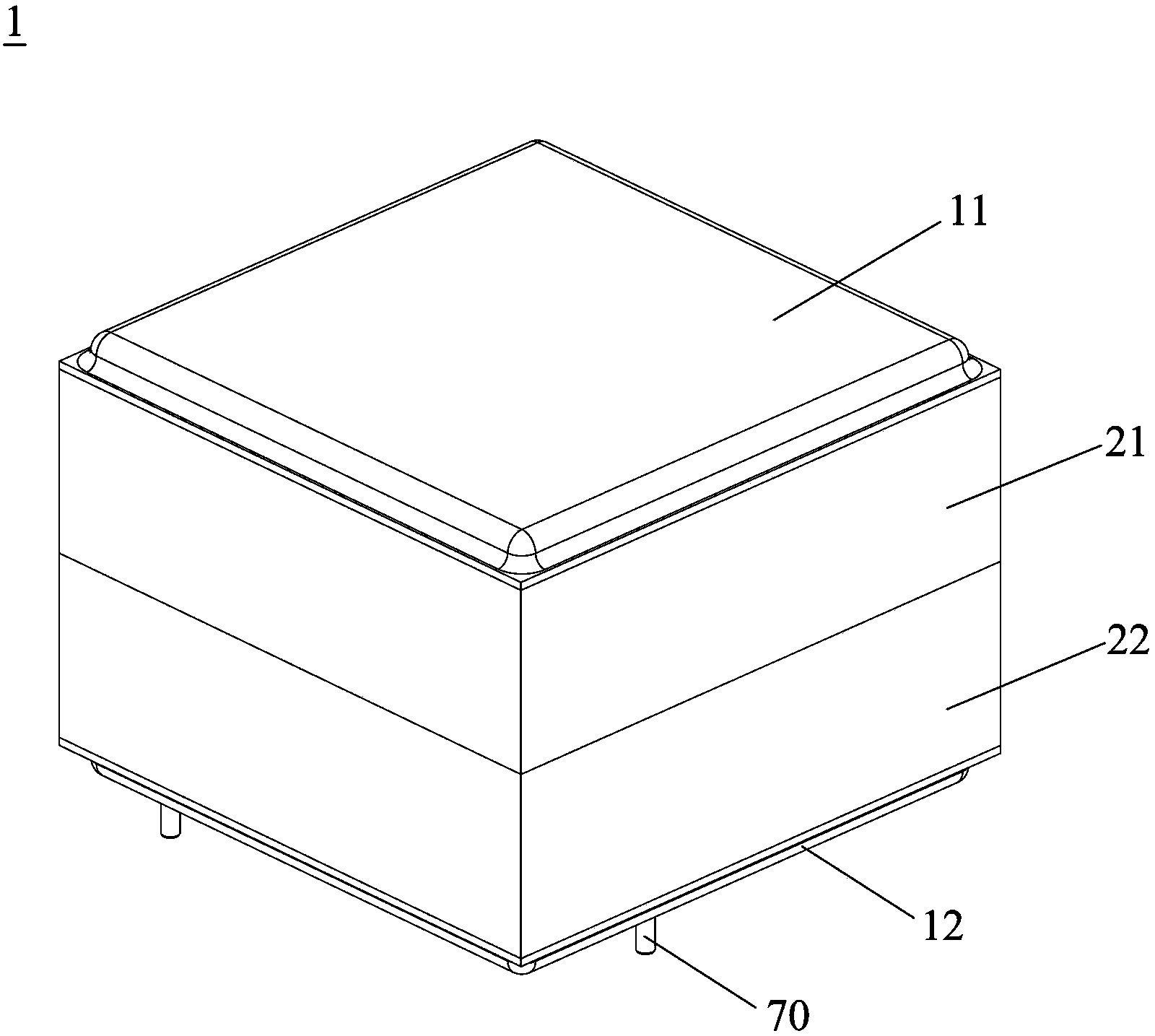

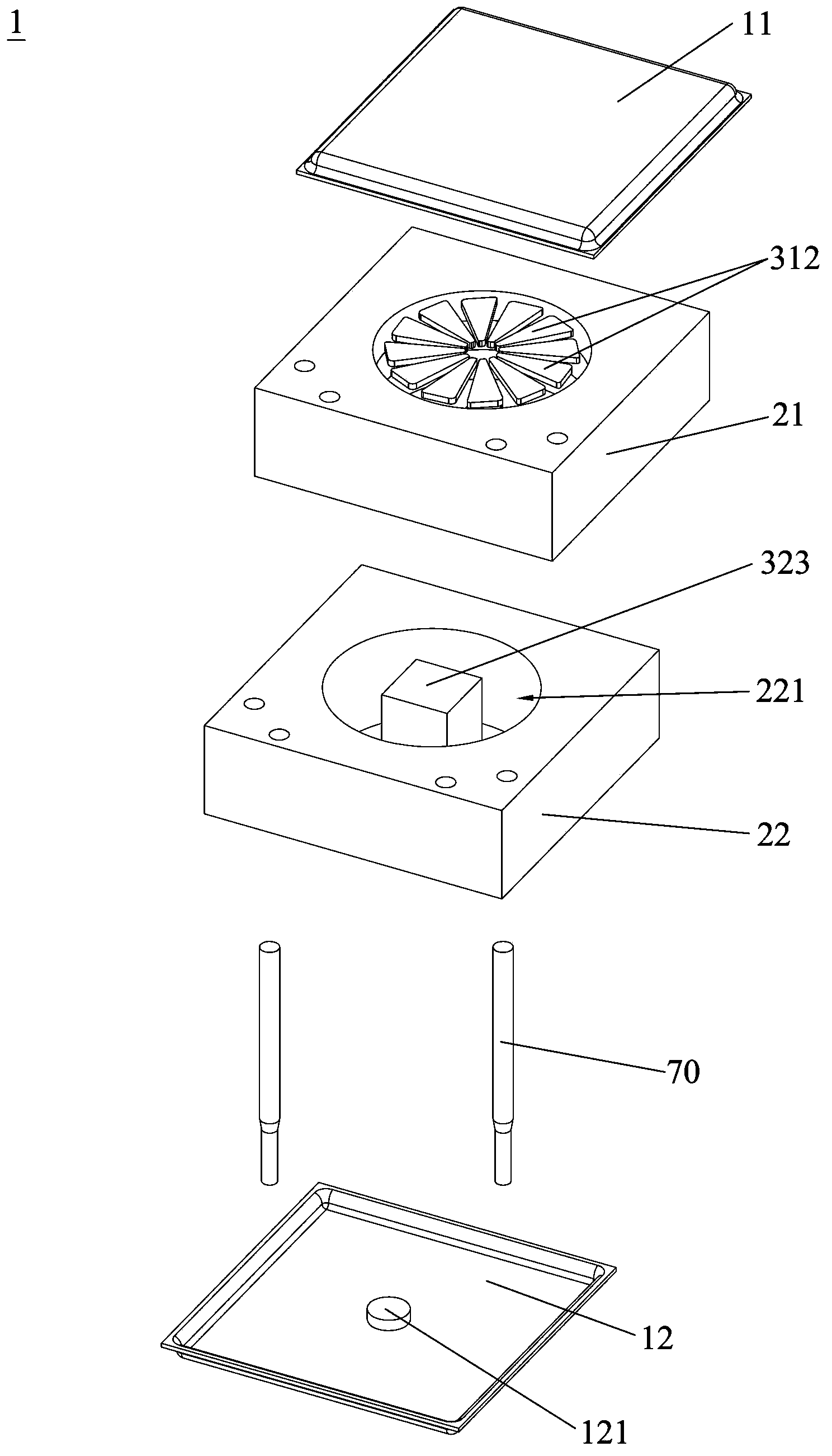

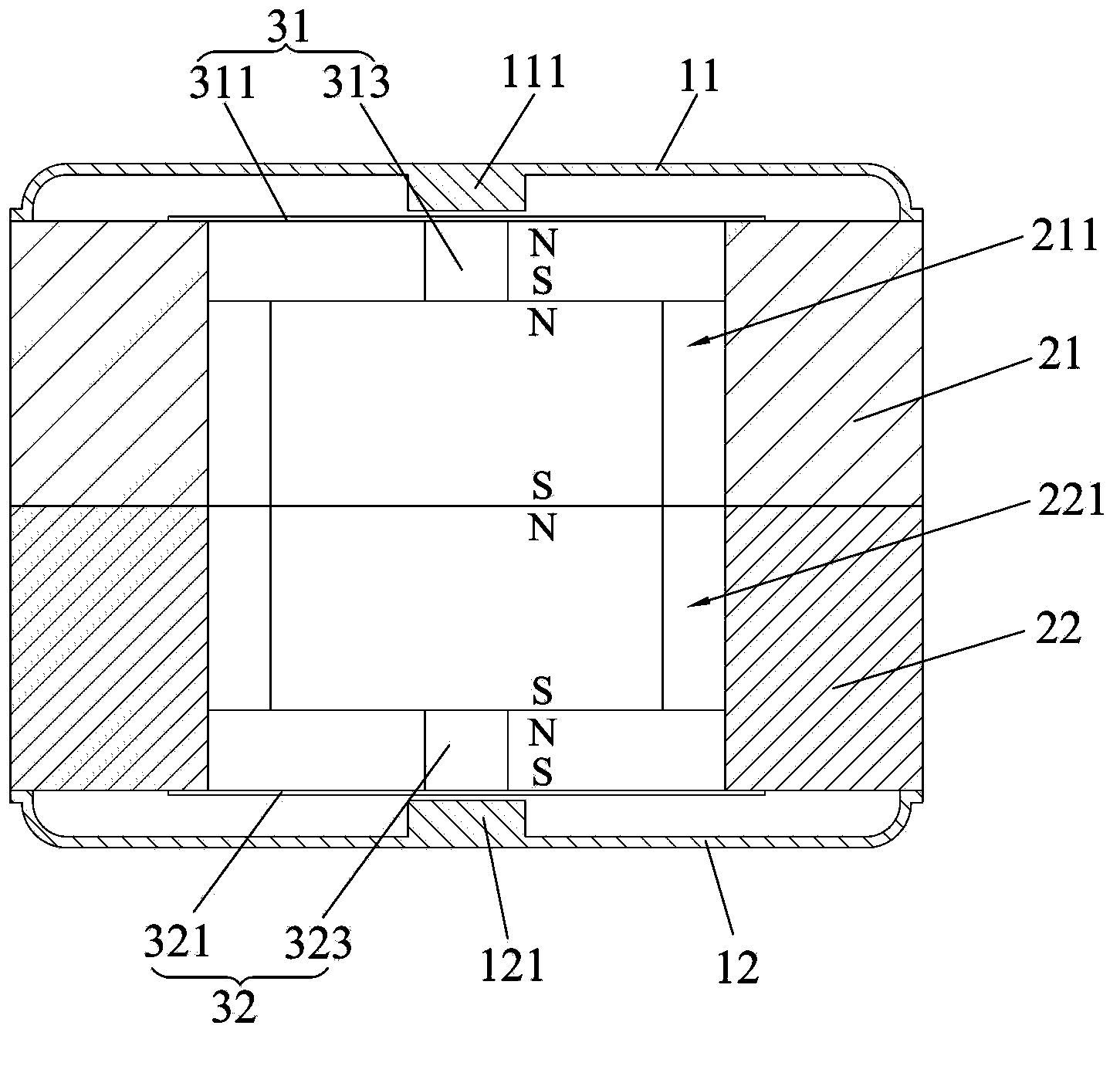

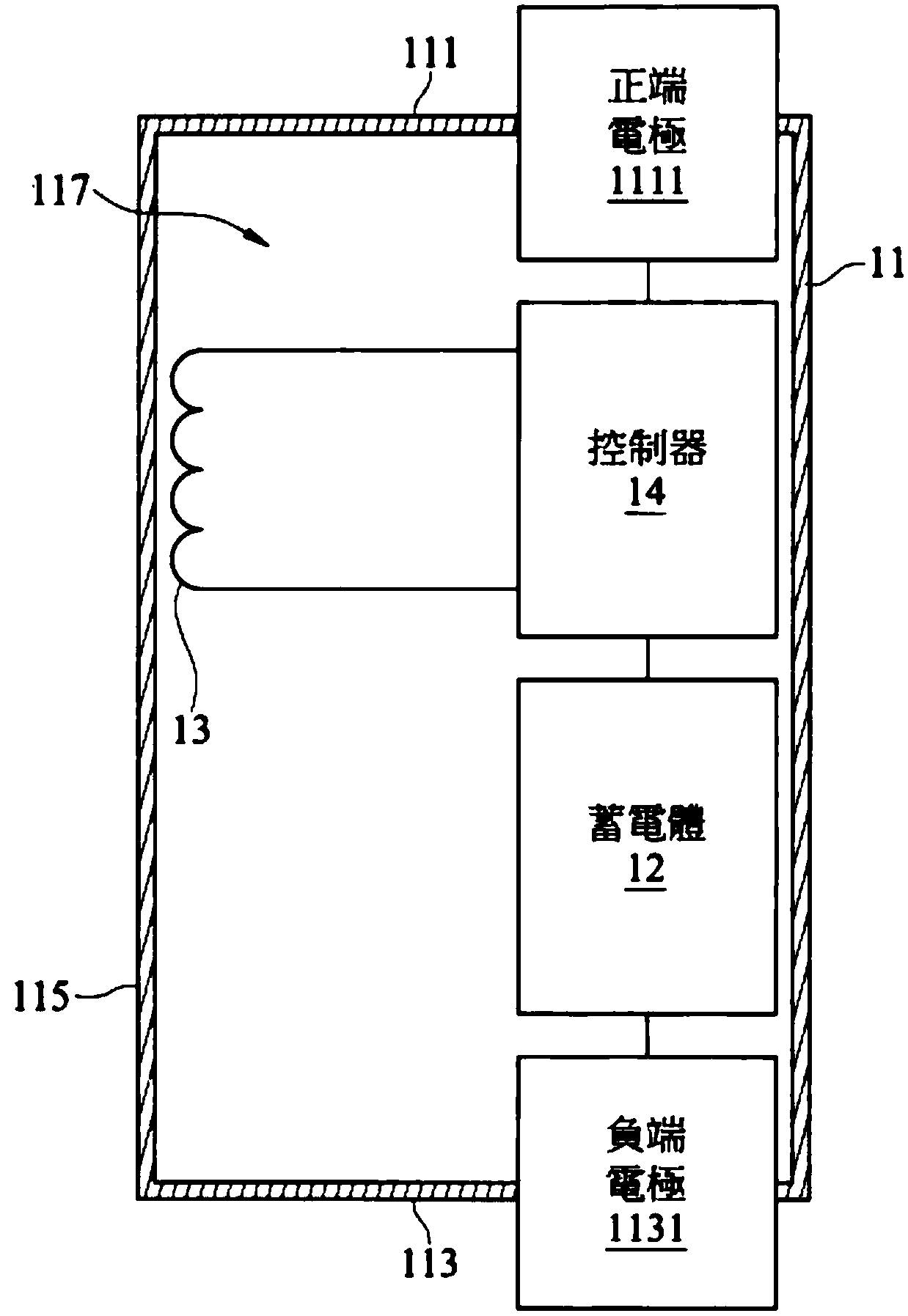

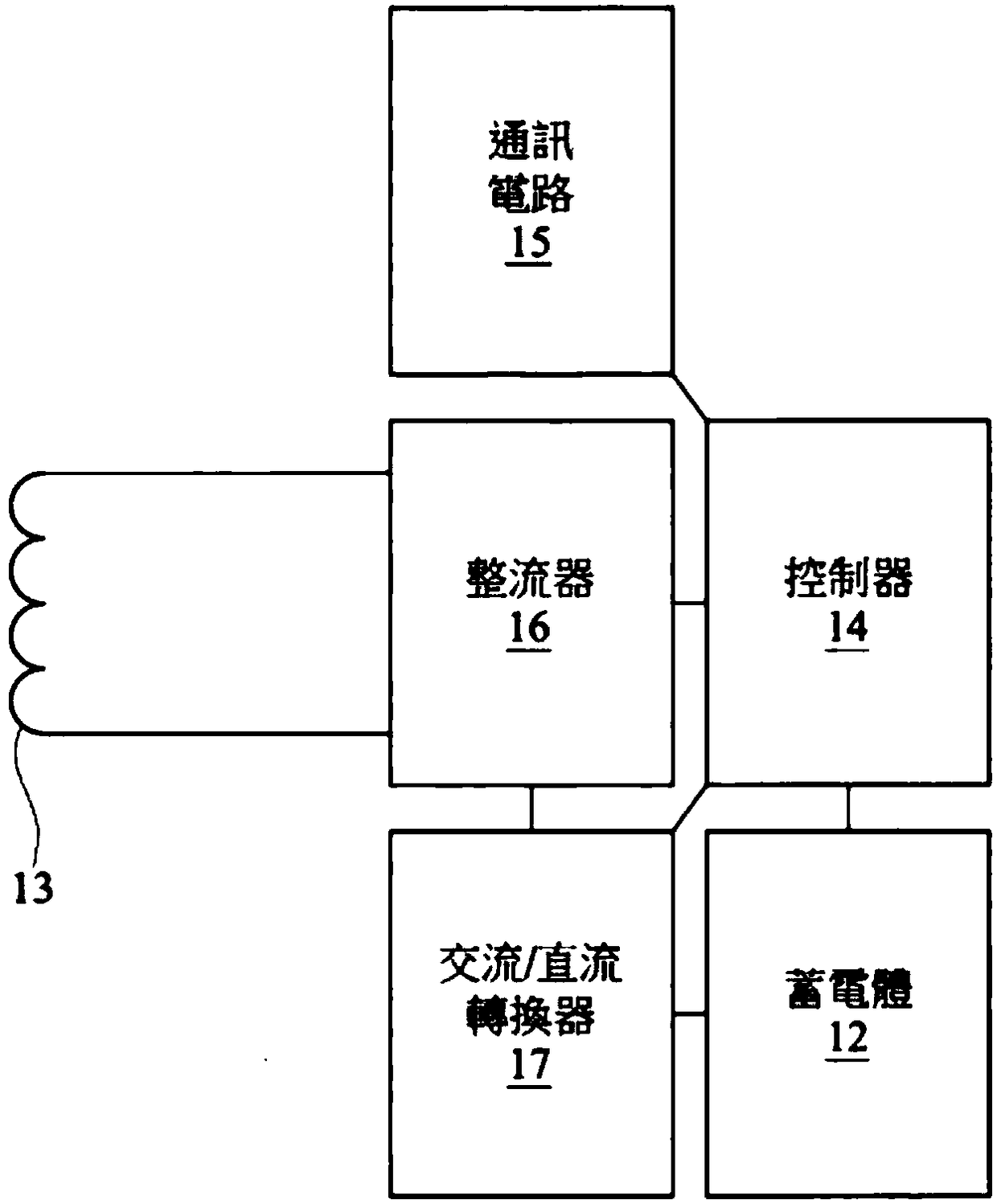

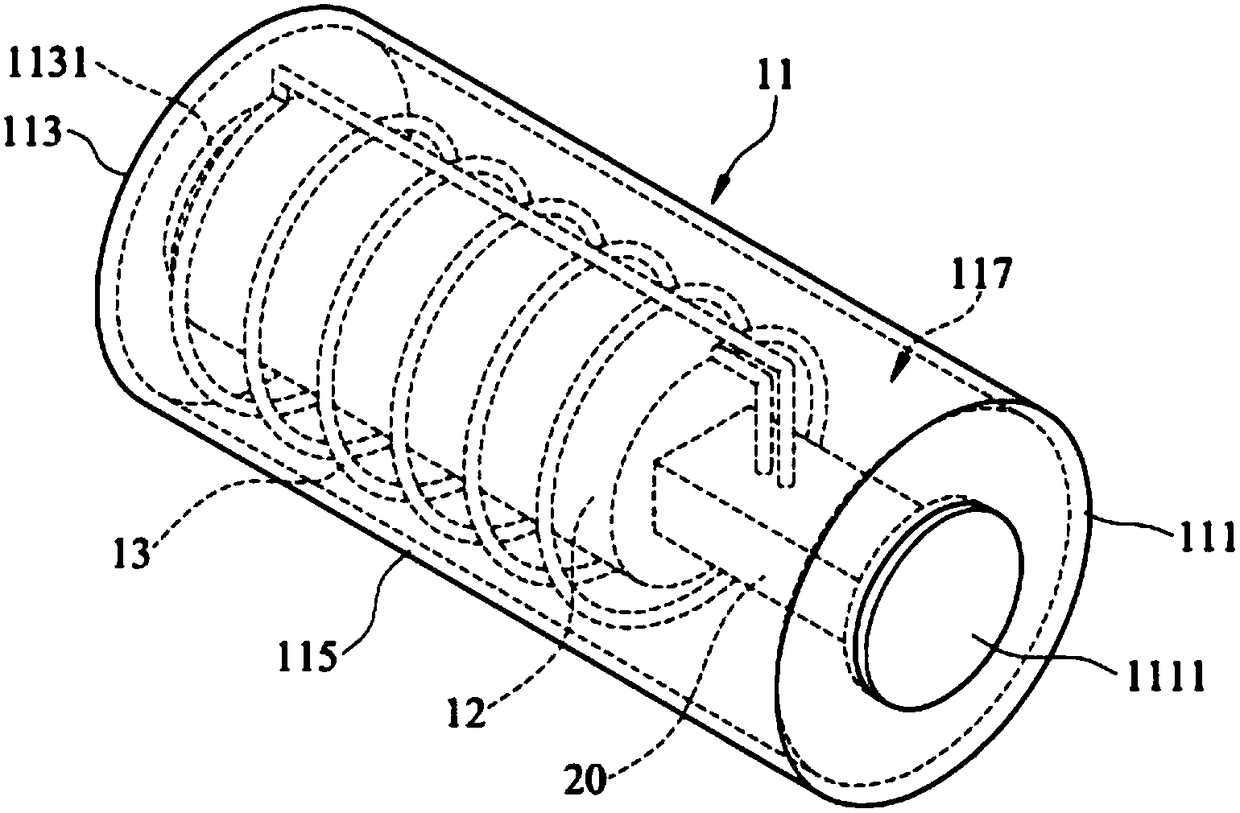

Wireless rechargeable battery

InactiveCN108134457AIncrease the setting areaIncrease the number of turnsCircuit monitoring/indicationDifferent batteries chargingEngineeringElectric power

The invention discloses a wireless rechargeable battery, and the rechargeable battery comprises a housing, a power storage body, a coil, and a controller. The housing is provided with a first end cover and a second end cover which are set at an interval, and is also provided with a side wall extending from the first end cover to the second end cover. The first end cover, the second end cover and the side wall form an accommodation space, and the first end cover comprises a positive electrode and the second end cover comprises a negative electrode. The power storage body is disposed in the accommodation space, and is electrically connected to one of the positive and negative electrodes. A coil is disposed around the power storage body, and is used for sensing the changes of an environment magnetic field to generate power. A controller is disposed in the accommodation space, is electrically connected to the other one of the positive and negative electrodes, the power storage body and thecoil, and selectively controls the supply of the power to the power storage body according to the power capacity of the power storage body.

Owner:APO INT CO LTD

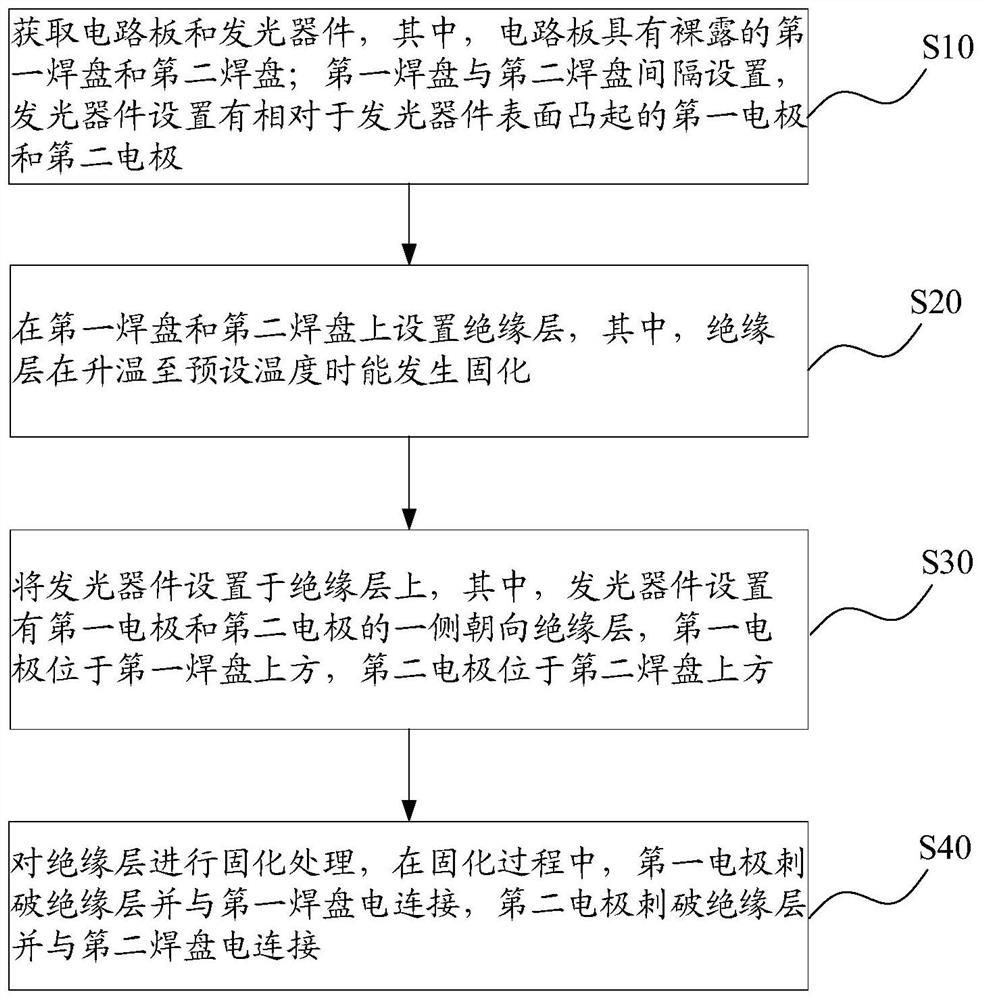

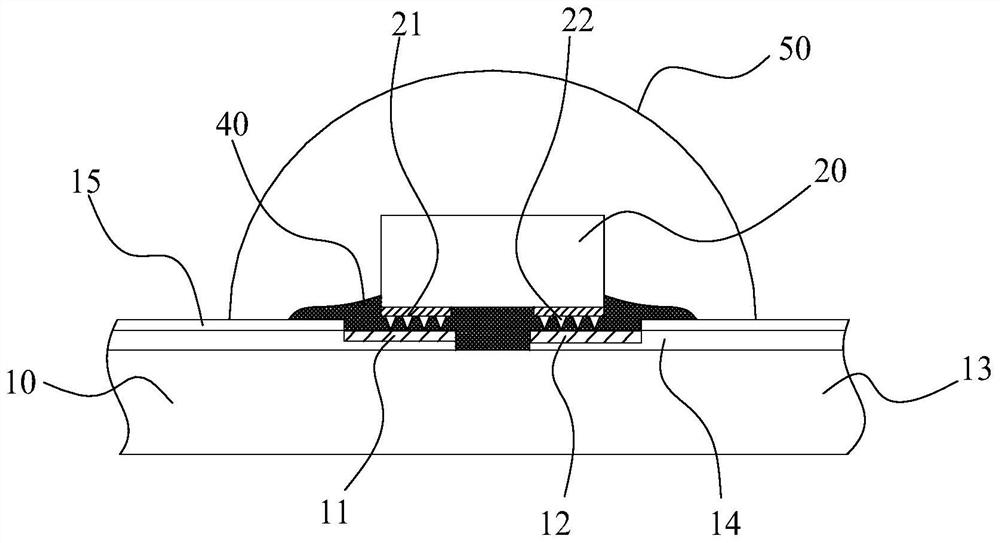

Preparation method of backlight source

PendingCN114007342ARequirements for reduced setup accuracyIncrease the setting areaPrinted circuit assemblingNon-linear opticsElectrical connectionDie bonding

The invention provides a preparation method of a backlight source. The preparation method comprises the following steps that: a circuit board and a light emitting device are obtained, wherein the circuit board has a first bonding pad and a second bonding pad which are exposed; the first bonding pad and the second bonding pad are arranged at an interval, and the light emitting device is provided with a first electrode and a second electrode which protrude relative to the surface of the light emitting device; an insulating layer is arranged on the first bonding pad and the second bonding pad, and the insulating layer can be solidified when the temperature rises to a preset temperature; the light emitting device is arranged on the insulating layer, the side, provided with the first electrode and the second electrode, of the light emitting device faces the insulating layer, the first electrode is located above the first bonding pad, and the second electrode is located above the second bonding pad; and the insulating layer is cured, in the curing process, the first electrode punctures the insulating layer and is electrically connected with the first bonding pad, and the second electrode punctures the insulating layer and is electrically connected with the second bonding pad. With the preparation method of the backlight source adopted, the problems that an LED chip is low in die bonding yieldand high in repair rate when an existing backlight source is manufactured can be solved.

Owner:HUIZHOU VISION NEW TECH CO LTD

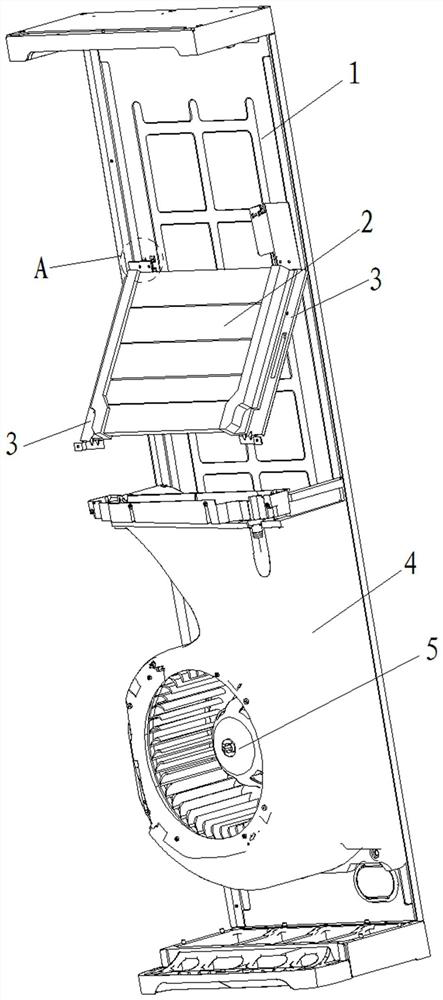

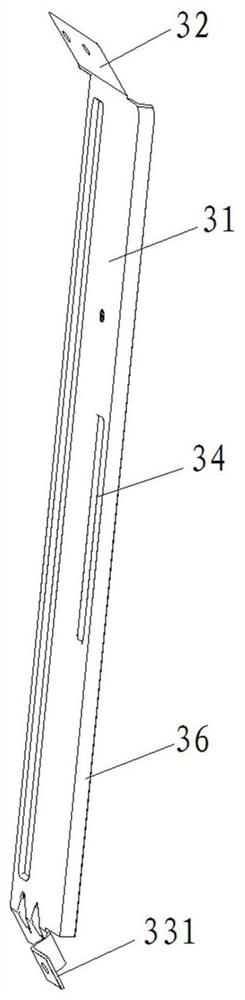

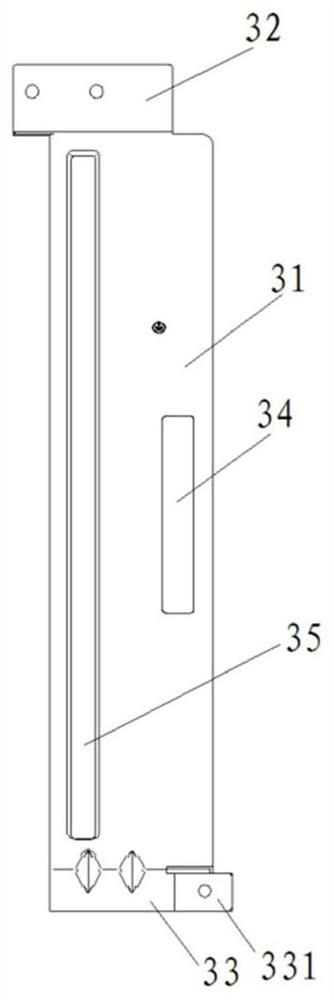

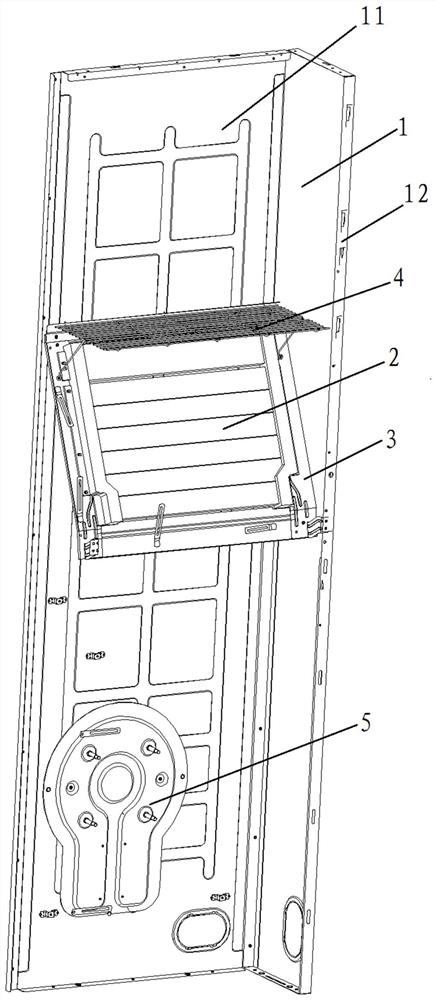

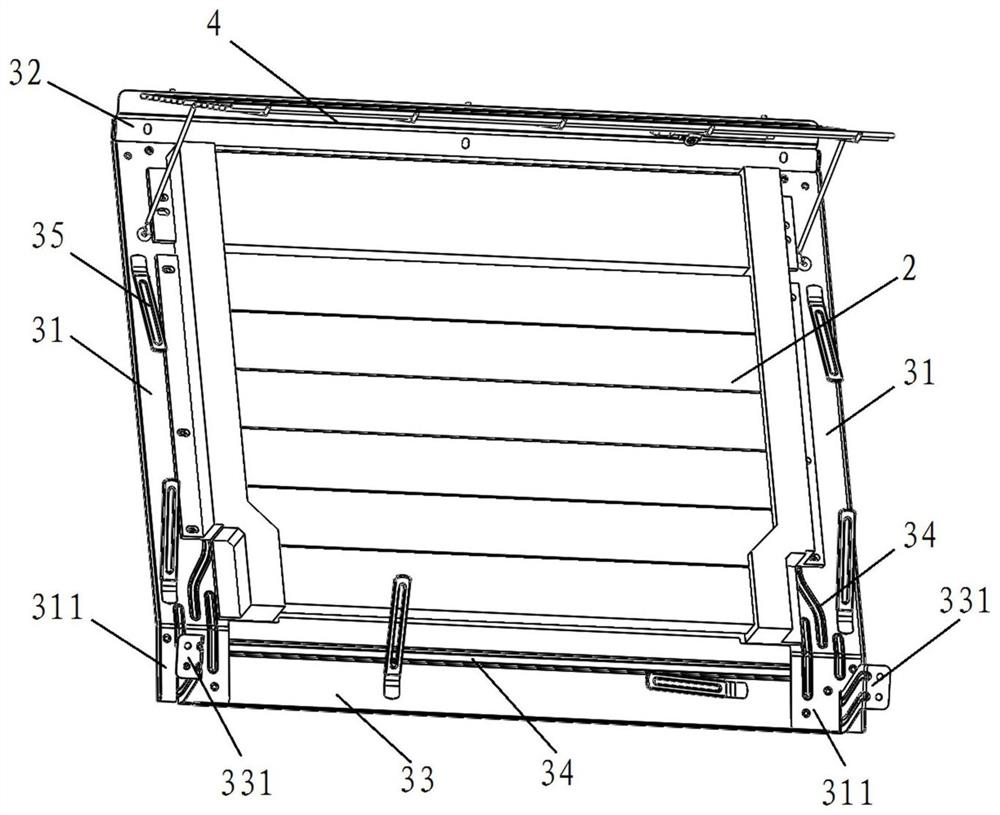

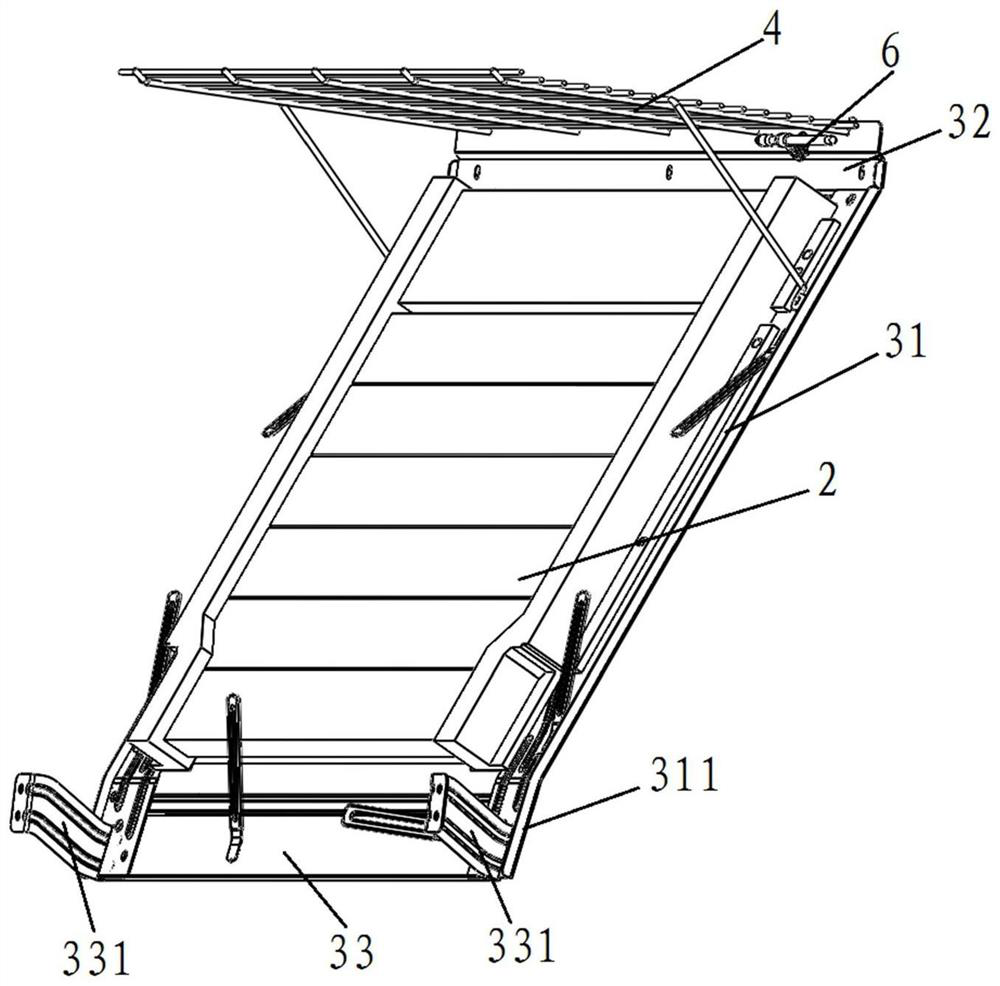

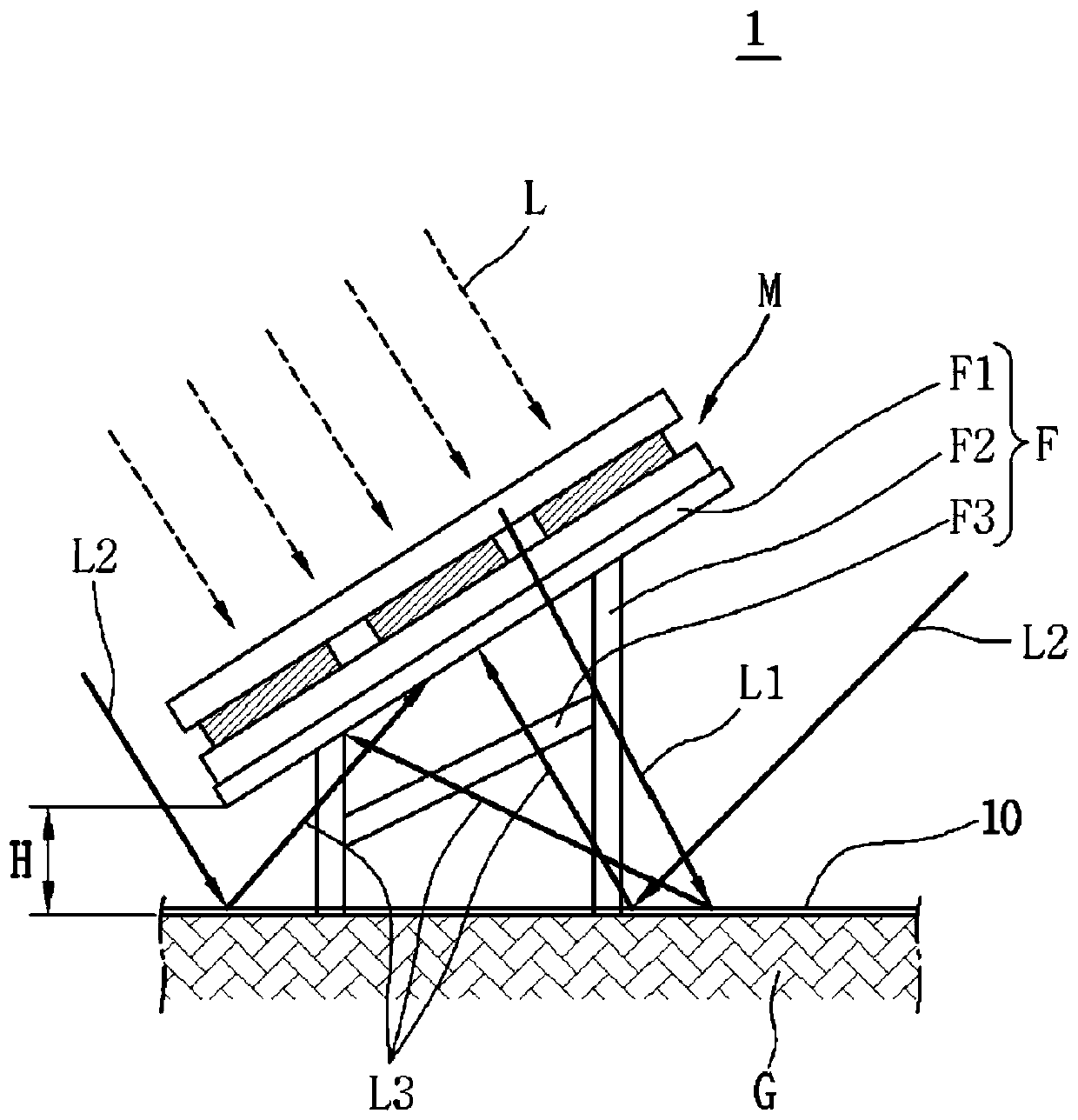

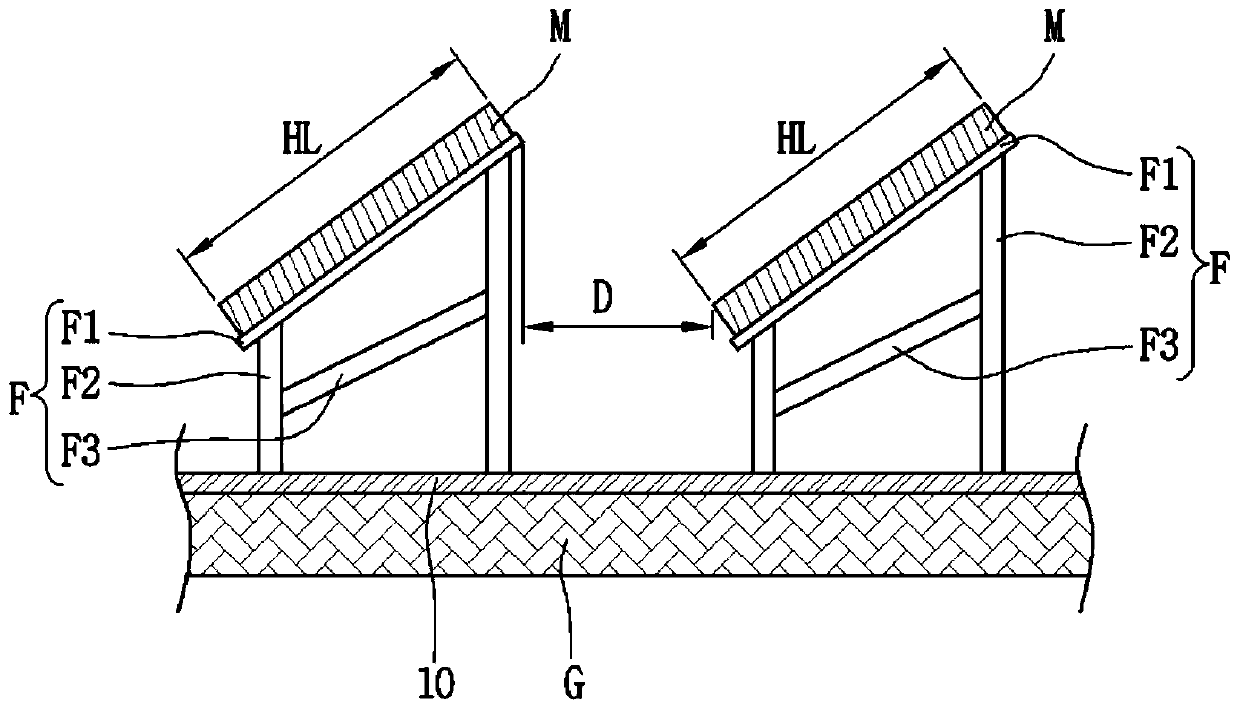

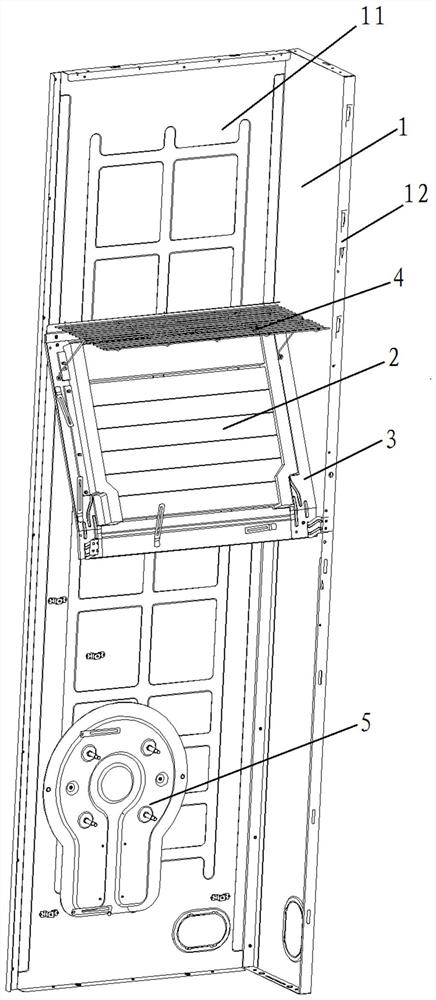

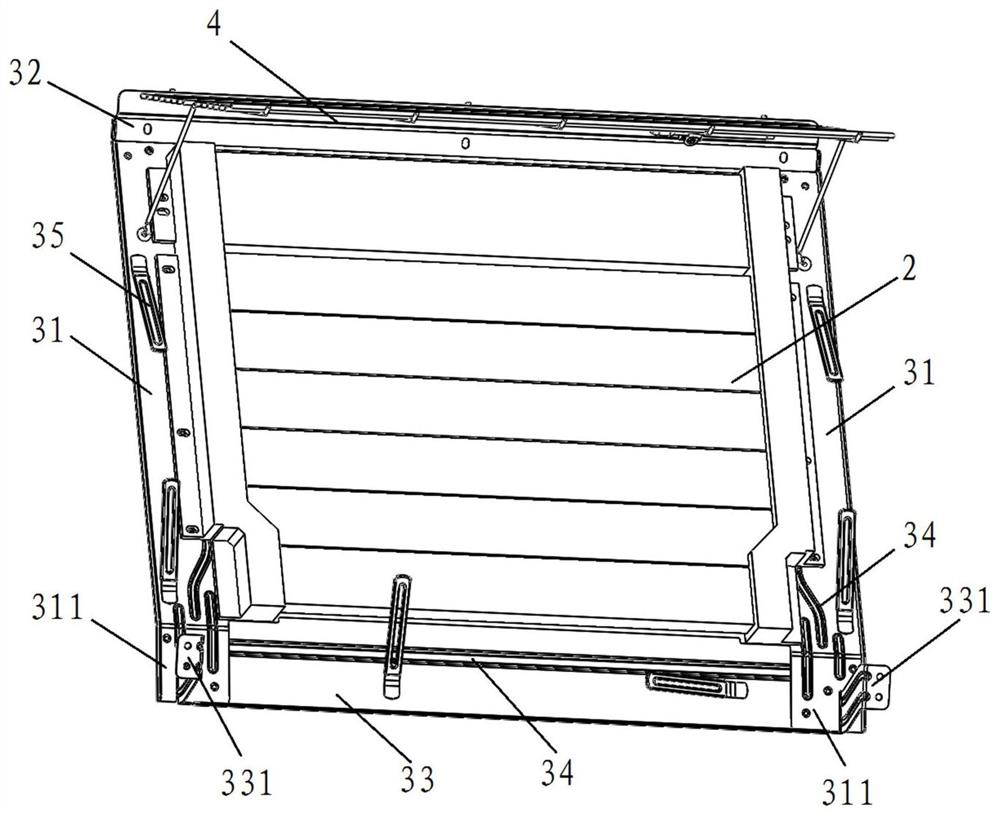

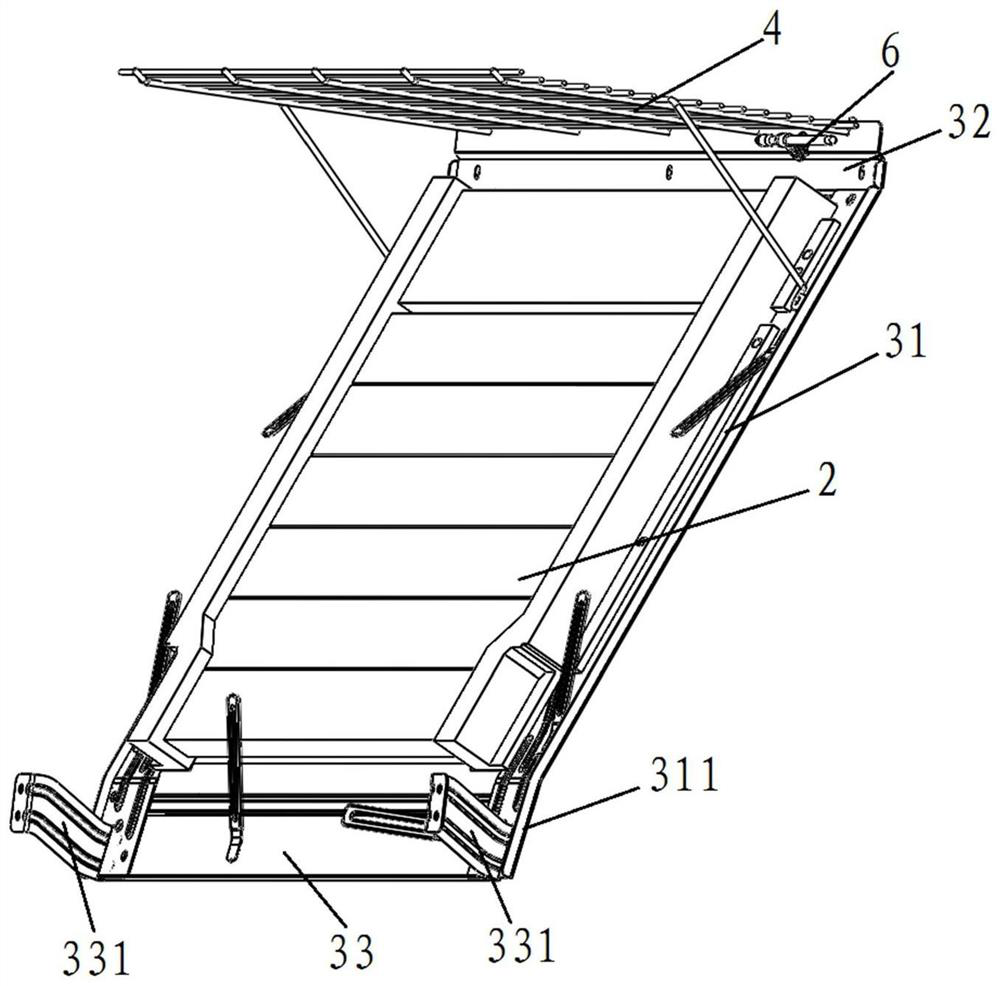

Heating element fixing structure of air treatment equipment and air treatment equipment

The invention relates to the technical field of air treatment equipment, and discloses a heating element fixing structure of air treatment equipment and the air treatment equipment. A heating element is fixed in a machine shell of the air treatment equipment; the heating element fixing structure comprises supporting plate assemblies respectively arranged at two sides of the heating element; each supporting plate assembly comprises a supporting plate body; the back end of the supporting plate body is connected to the back side of the machine shell; the front end of the supporting plate body is connected with the front side of the machine shell; the two sides of the heating element are correspondingly supported and placed on the supporting plate bodies at two sides; and the supporting plate bodies are obliquely arranged relative to the horizontal direction. The heating element fixing structure of the air treatment equipment and the air treatment equipment provided by the invention have the advantages that the supporting plate assemblies are correspondingly arranged at the two sides of the heating element to support and fix the heating element, the structure is simple, and the heating element can be conveniently installed; and in addition, the heating element is arranged to be in an inclined state through the supporting plate assemblies, the arrangement area of the heating element is increased, the heat supply amount is favorably increased, and the heat supply effect is guaranteed.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

Heating element mounting structure of warm air blower and warm air blower

ActiveCN113091317AEasy to installMeet high temperature installation requirementsAir heatersHeat resistanceAir treatment

The invention relates to the technical field of air treatment equipment, and discloses a heating element mounting structure of a warm air blower and the warm air blower. The warm air blower comprises a machine shell, wherein a heating element is arranged in the machine shell. The mounting structure comprises a supporting plate frame, wherein the rear end of the supporting plate frame is connected to the rear side of the machine shell, and the front end of the supporting plate frame is connected to the front side of the machine shell; the supporting plate frame is obliquely arranged in the front-back direction; the supporting plate frame comprises two supporting plates which are parallel to each other and are arranged front and back, a first connecting plate connected between the higher ends of the two supporting plates and a second connecting plate connected between the lower ends of the two supporting plates; and the two supporting plates are used for being correspondingly connected with the two sides of the heating element. According to the heating element mounting structure of the warm air blower and the warm air blower, the supporting plate frame is arranged to support and fix the heating element, the high-temperature mounting requirement of the heating element can be met through heat resistance of the supporting plate frame, and the heating element can be conveniently mounted due to a simple connecting structure.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

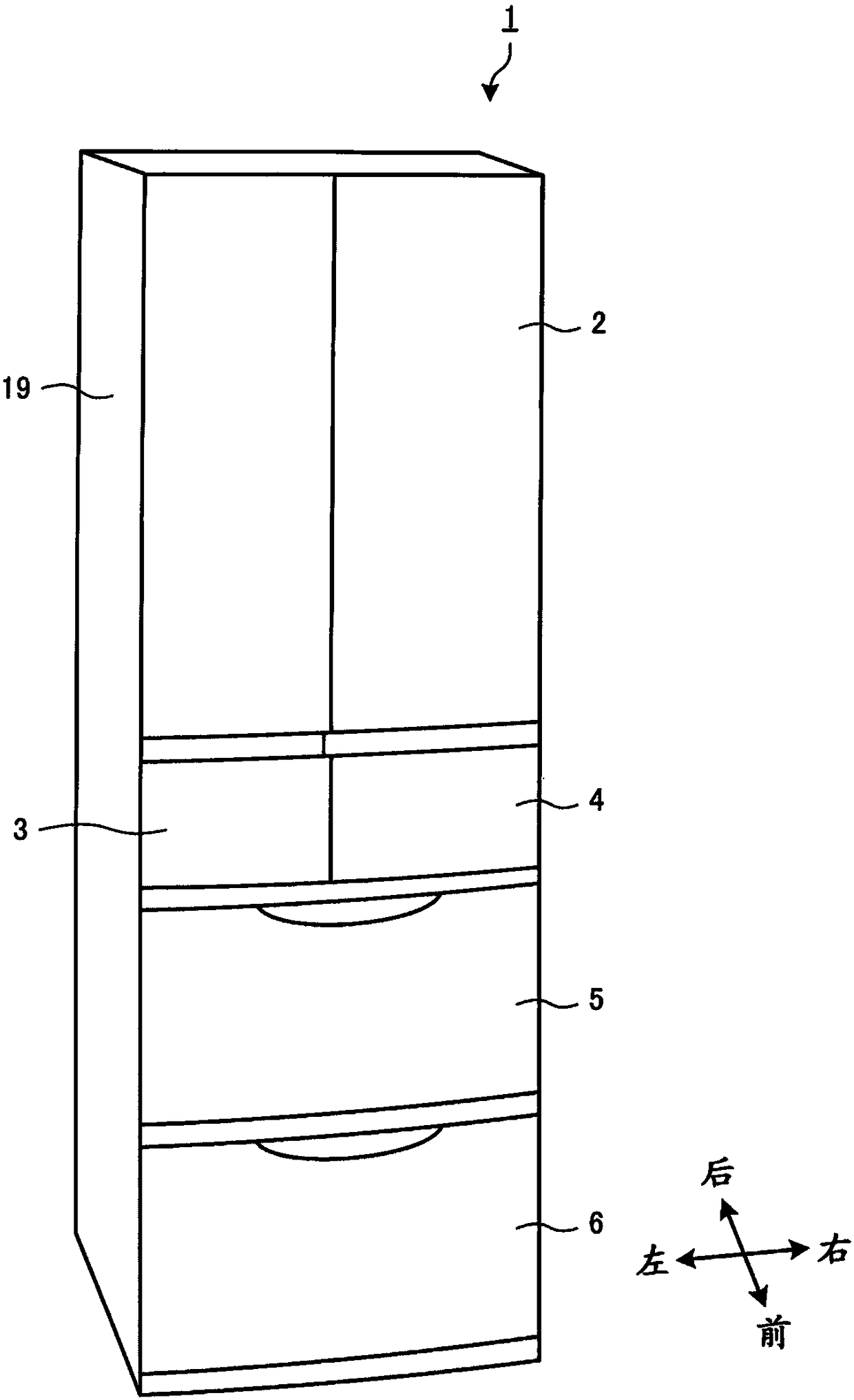

Refrigerator

ActiveCN108286854AIncrease the setting areaInhibition of soakingLighting and heating apparatusIce productionCold airThermal insulation

A refrigerator is provided with: a thermal insulation casing which is provided with an inner housing, an outer housing and a heat insulating material between the inner housing and the outer housing; amachine room which is formed by causing a lower back surface portion of the thermal insulation casing to be depressed inwards and in which a compressor is disposed; a cooler room which is formed above the machine room and in the thermal insulation casing and in which a cooler for generating cold air is disposed; a water receiving unit which is provided below the cooler in the cooler room and which receives water from the cooler; and a discharge channel having an inlet provided to the water receiving unit and an outlet protruded to the machine room, the discharge channel penetrating a thermalinsulation wall intervened between the cooler room and the machine room so as to cause the cooler room and the machine room to communicate. On the inlet side, a cross-sectional area of the discharge channel is gradually reduced toward a downstream side, and a center position of the cross section approaches a back surface side. The discharge channel is configured integrally from the inlet to the outlet. As a result, it is possible to provide a refrigerator with good water discharge performance while maintaining thermal insulation.

Owner:MITSUBISHI ELECTRIC CORP

Liquid crystal module brightness measurement apparatus and brightness measurement apparatus

InactiveUS20070132986A1Reduce the overall heightSmall range of movementPhotometry using electric radiation detectorsOptical apparatus testingSurface measurementBrightness perception

A brightness measurement apparatus which includes a placement unit on which an object to be measured is placed, a measurement unit for measuring brightness or chromaticity from an upper surface of the object placed on the placement unit, a placement unit moving mechanism for moving the placement unit in an x-axis direction, and a measurement unit moving mechanism for moving the measurement unit in a y-axis direction orthogonal to the x-axis direction.

Owner:FUNAI ELECTRIC CO LTD

Refrigerator

InactiveCN1301394CImprove performanceGood insulation performanceLighting and heating apparatusDomestic refrigeratorsEngineeringMechanical engineering

To improve performance of a freezing cycle by releasing heat from a pipe for heat release using a front part of a side face of an outer package and to improve heat insulating performance by extending a vacuum heat insulating material to a back face side of the outer package, in a refrigerator using the vacuum heat insulating material. In the refrigerator, a package body 1 is structured by providing the vacuum heat insulating material 31 on a back side of the side face of the outer package 2 and filling a foam heat insulating material 3 between the outer package 2 and an inner package 4, a dew preventive pipe 22 of the freezing cycle is provided on a back side of a front face flange of the outer package 2 and the heat releasing pipe 20 of the freezing cycle is provided on the back side of the side face of the outer package 2. The heat releasing pipe 20 is provided so that it vertically extends at a front part of the side face of the outer package 2 and the vacuum heat insulating material 31 is provided so that it extends to the back face side of the outer package 2 from behind the heat releasing pipe 20.

Owner:HITACHI GLOBAL LIFE SOLUTIONS INC

Current collector, battery pole piece and method for making current collector

ActiveCN113036150BReduce compacted densityIncrease the setting areaElectrode carriers/collectorsPositive electrodesEngineeringPole piece

The application discloses a current collector, a battery pole piece and a method for making the current collector, which belong to the technical field of batteries. The current collector includes: a first current collector layer, a first coating layer, a second coating layer and a second current collector layer stacked in sequence, there is an inner cavity between the first coating layer and the second coating layer, and the The first coating layer and the second coating layer are supported and connected by supporting columns; wherein, the current collector further includes through holes, and the through holes sequentially penetrate through the first current collector layer, the first coating layer, and the second coating layer. The plating layer and the second current collector layer, and the through hole communicates with the inner cavity. In this way, the compaction density of the active material on the current collector can be reduced, the polarization of the battery can be reduced, and the purpose of improving the charging and discharging performance of the battery can be achieved.

Owner:ZHUHAI COSMX BATTERY CO LTD

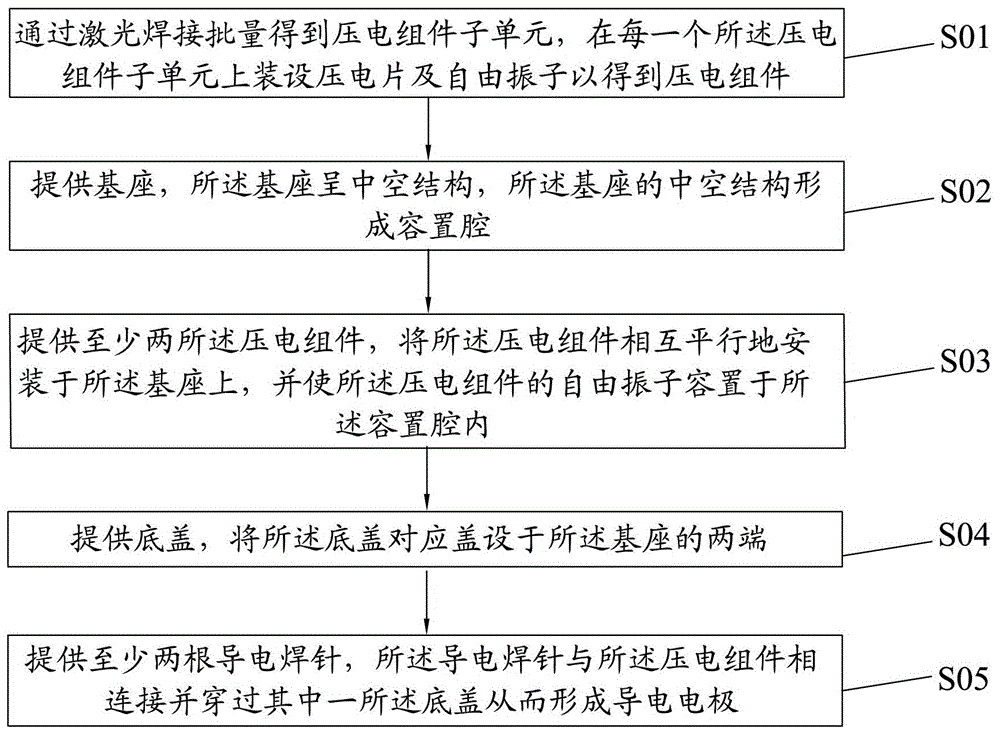

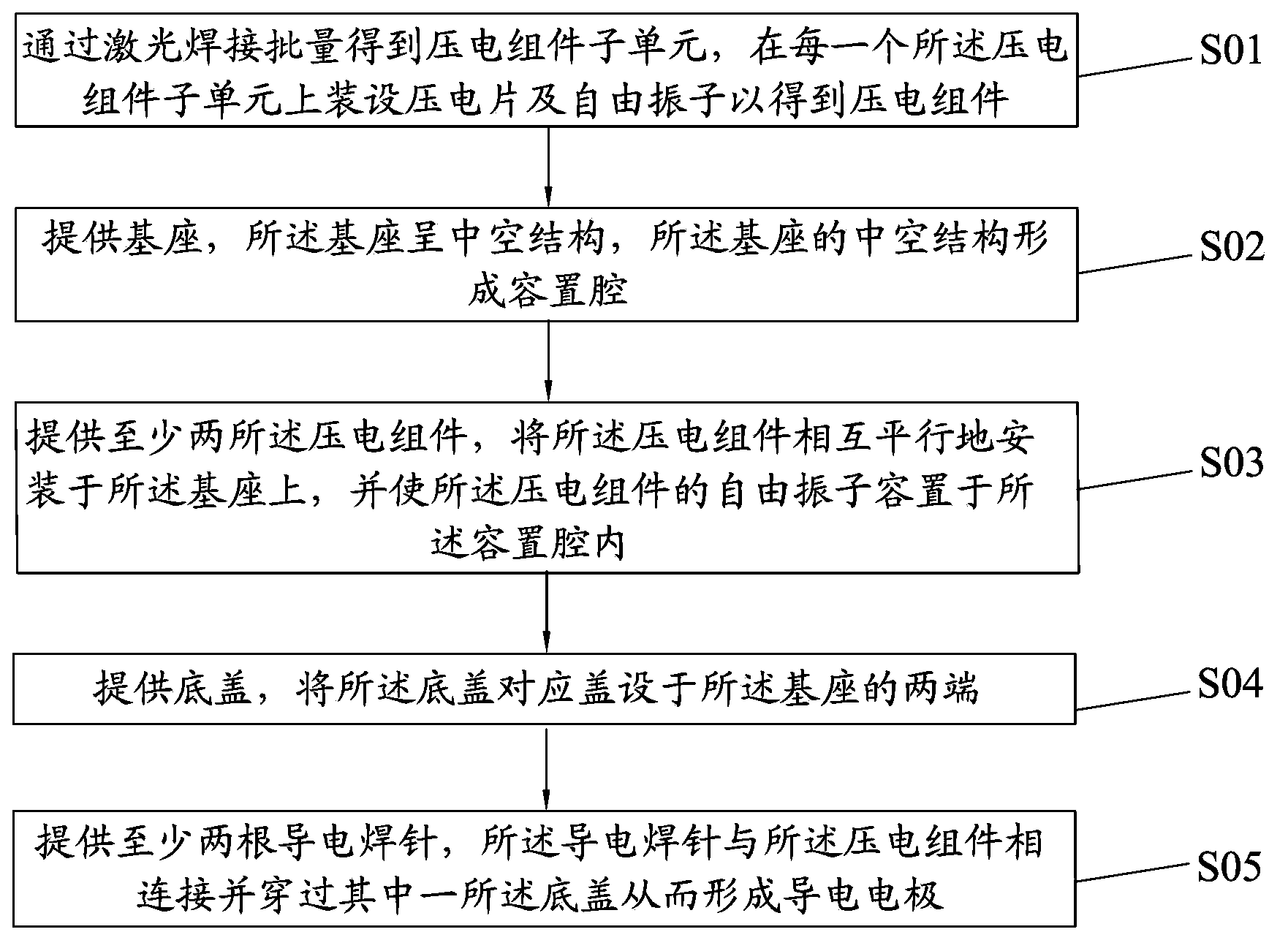

Piezoelectric vibration power generation device and manufacturing method thereof

InactiveCN103916048BAccurateImprove assembly accuracyPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEngineeringLaser soldering

The invention discloses a manufacturing method of a piezoelectric vibration power generation device, which includes: (1) Obtaining piezoelectric component subunits in batches through laser welding, and installing piezoelectric sheets and free vibrators on each piezoelectric component subunit to obtain piezoelectric components. component; (2) Provide a base with a hollow structure, and the hollow structure of the base forms a receiving cavity; (3) Provide at least two piezoelectric components, install the piezoelectric components on the base parallel to each other, and make the piezoelectric components The free vibrator of the component is accommodated in the accommodation cavity; (4) Provide a bottom cover, and set the corresponding covers of the bottom cover on both ends of the base; (5) Provide at least two conductive soldering pins, conductive soldering pins and piezoelectric components Connect and pass through one of the bottom covers to form a conductive electrode. Since laser welding is used to obtain piezoelectric component subunits in batches, precise alignment is facilitated during the assembly and production process, thereby improving assembly accuracy. Mass production greatly improves production efficiency, thereby reducing production costs. In addition, the invention also discloses a piezoelectric vibration power generation device.

Owner:BEIJING JIAYUE TONGLEJI ELECTRONICS

Piezoelectric vibration generating set and manufacturing method thereof

InactiveCN103916048AAccurateImprove assembly accuracyPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEngineeringLaser beam welding

The invention discloses a manufacturing method of a piezoelectric vibration generating set. The method comprises the steps that (1) piezoelectric component sub units are obtained in batches through laser welding, a piezoelectric plate and a free vibrator are mounted on each piezoelectric component sub unit to obtain a piezoelectric component; (2) a base of a hollow structure is provided, and the hollow structure of the base forms a containing cavity; (3) at least two piezoelectric components are provided and mounted on the base in parallel, and the free vibrators of the piezoelectric components are contained in the containing cavity; (4) bottom caps are provided and arranged at the two ends of the base in a covering mode correspondingly; (5) at least two conductive welding pins are provided to be connected with the piezoelectric components and penetrate through one bottom cap to form a conductive electrode. Due to the fact that laser welding is adopted to obtain the piezoelectric component sub units in batches, in the assembling and producing processes, accurate alignment is facilitated, assembling accuracy is improved, production efficiency is improved greatly through batch production, and therefore production cost is lowered. In addition, the invention further discloses the piezoelectric vibration generating set.

Owner:BEIJING JIAYUE TONGLEJI ELECTRONICS

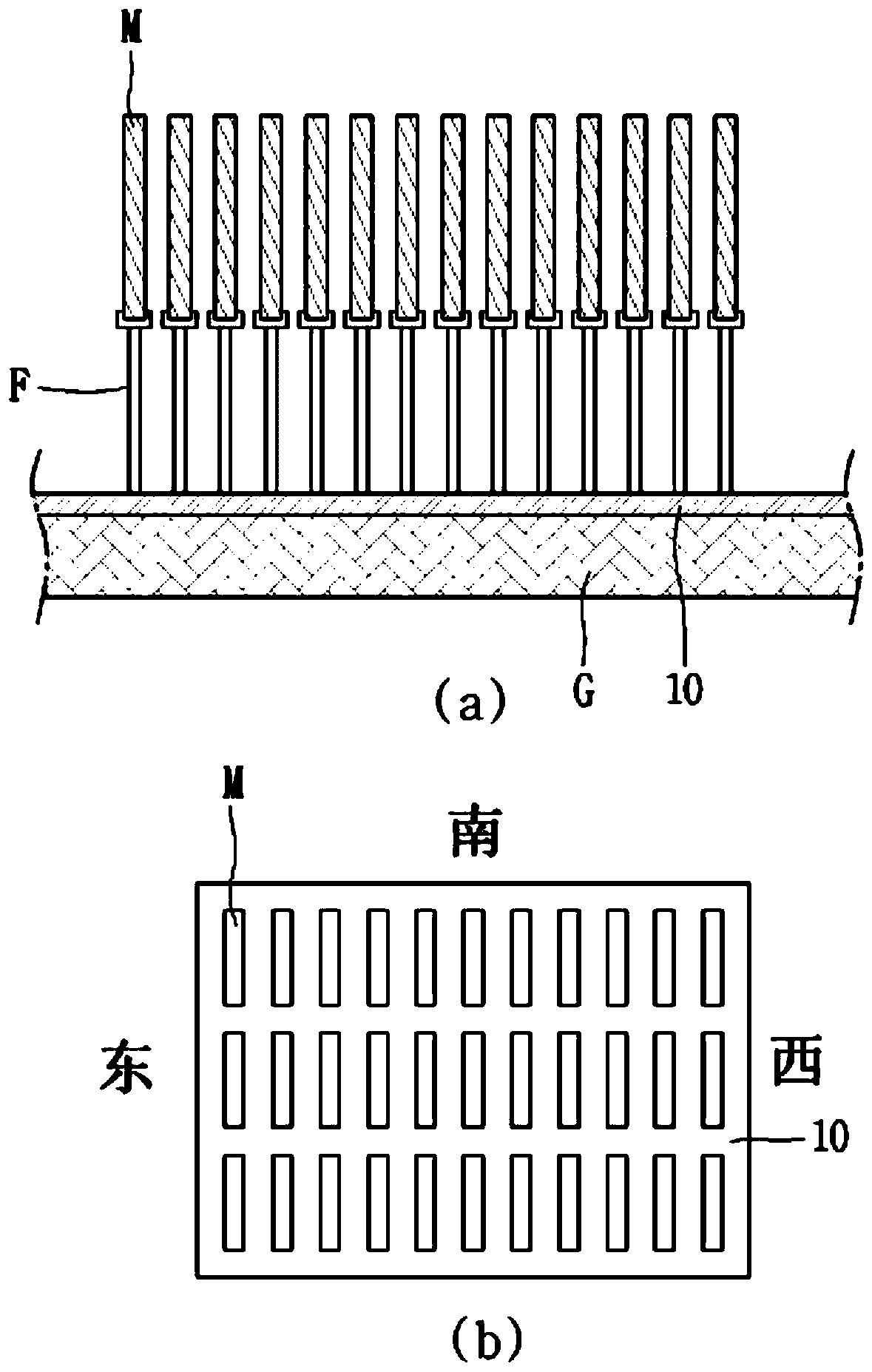

Solar light reflecting system

PendingCN111147005AIncrease diffuse reflectanceIncrease power generationPhotovoltaic supportsPhotovoltaic energy generationSolar lightEngineering

A solar light reflecting system is characterized by including a double-sided light-receiving solar cell module provided on a roof; a frame for arranging the double-sided light-receiving solar cell module provided on the roof; and a reflective layer which is positioned on the rear side of the double-sided light-receiving solar cell module provided on the roof and which is arranged on the bottom surface of the roof, wherein the reflective layer has heat insulation and waterproof functions, and conducts diffuse reflection of 380-1100nm sunlight with the wavelength range of 85% or more that avoidsthe double-sided light-receiving solar cell module to directly enter the bottom surface of the roof or that passes through the double-sided light-receiving solar cell module to enter the bottom surface of the roof to the rear side of the double-sided light-receiving solar cell module.

Owner:株式会社太阳能研究所

Lighting device

ActiveCN113946083AIncrease lighting brightnessIncrease the setting areaPhotographyEngineeringMaterials science

The invention relates to the technical field of lighting, and particularly discloses a lighting device which comprises a base, a first lamp bead, a second lamp bead with the color temperature different from that of the first lamp bead and a diffusion cover. The base extends along a first direction and is provided with a plurality of mounting surfaces which are arranged around the first direction and face different directions. The first lamp beads are arranged on the mounting face in the first direction, and the second lamp beads and the first lamp beads are arranged at intervals. On each mounting surface, the vertical distance from the end face, deviating from the mounting surface, of the first lamp bead to the center of the base is equal to the vertical distance from the end face, deviating from the mounting surface, of the second lamp bead to the center of the base, and the end faces of the first lamp bead and the second lamp bead on the two spaced mounting surfaces have an intersection line. The diffusion cover is arranged in the light emitting direction of the first lamp bead and the second lamp bead in a surrounding and covering mode, and the distance between the diffusion cover and the center is not less than the distance between the intersection line and the center. By means of the arrangement, the light emitting brightness and the light emitting range of the lighting device can be increased, and the lighting device has the better light mixing effect.

Owner:APUTURE IMAGING IND CO LTD

A heating element installation structure of a heater and the heater

ActiveCN113091317BEasy to installMeet high temperature installation requirementsAir heatersHeat resistanceAir treatment

The invention relates to the technical field of air treatment equipment, and discloses a heating element installation structure of a fan heater and the fan heater, wherein the fan heater includes a casing, a heating element is arranged inside the casing, and the installation structure includes: a supporting plate frame, a supporting plate frame The rear end is connected to the rear side of the casing, the front end of the supporting plate frame is connected to the front side of the casing, and the supporting plate frame is inclined along the front and rear directions; A first connecting plate between the upper ends of the two support plates and a second connecting plate between the lower ends of the two support plates for corresponding connection with both sides of the heating element . The invention provides a heating element installation structure for a fan heater and the fan heater. A support plate frame is provided to realize the support and fixation of the heating element. The support plate frame can meet the high temperature installation requirements of the heating element with heat resistance, and the connection structure is simple and convenient. Installation of heating elements.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com