Patents

Literature

3375 results about "Laser soldering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

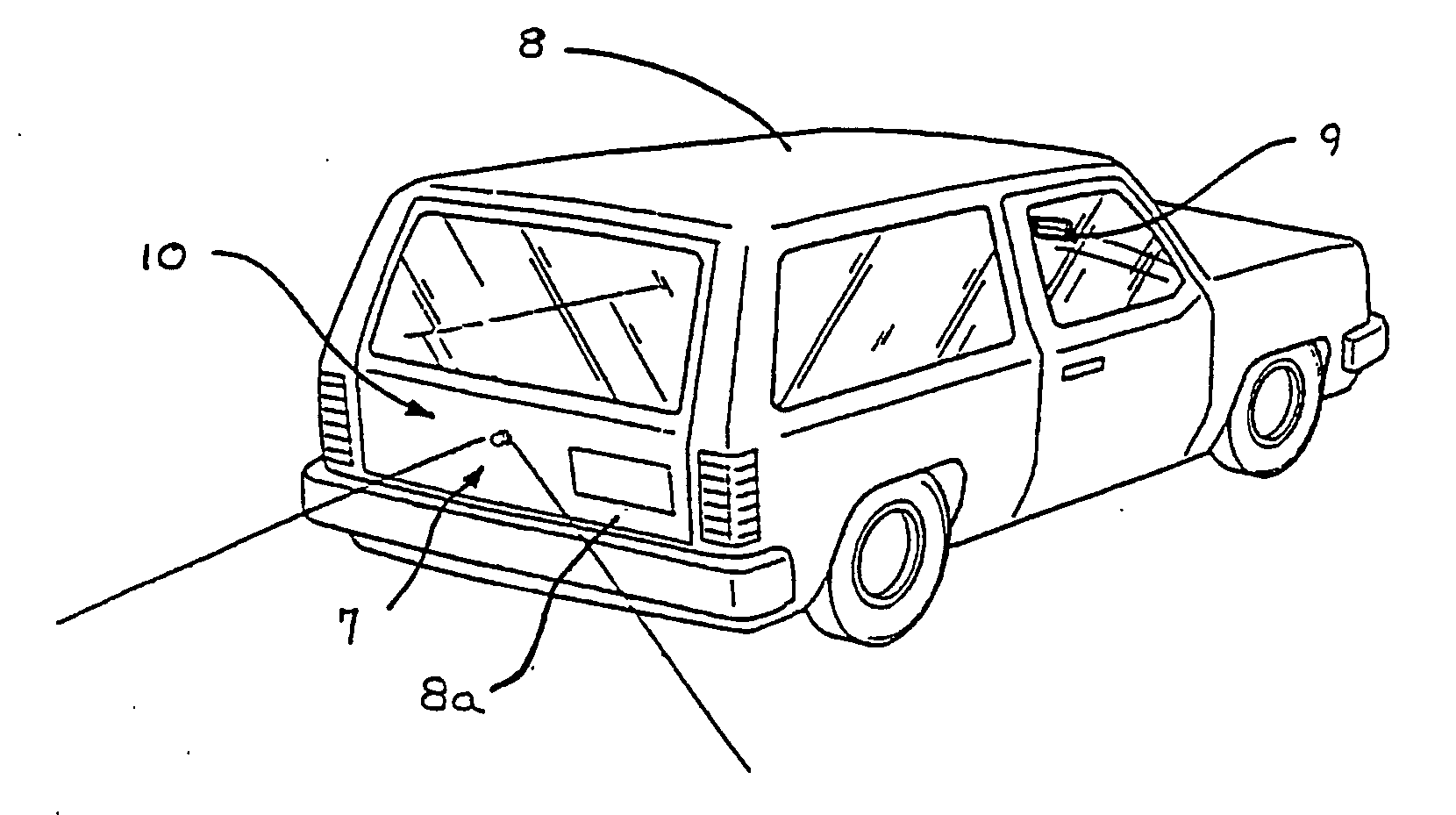

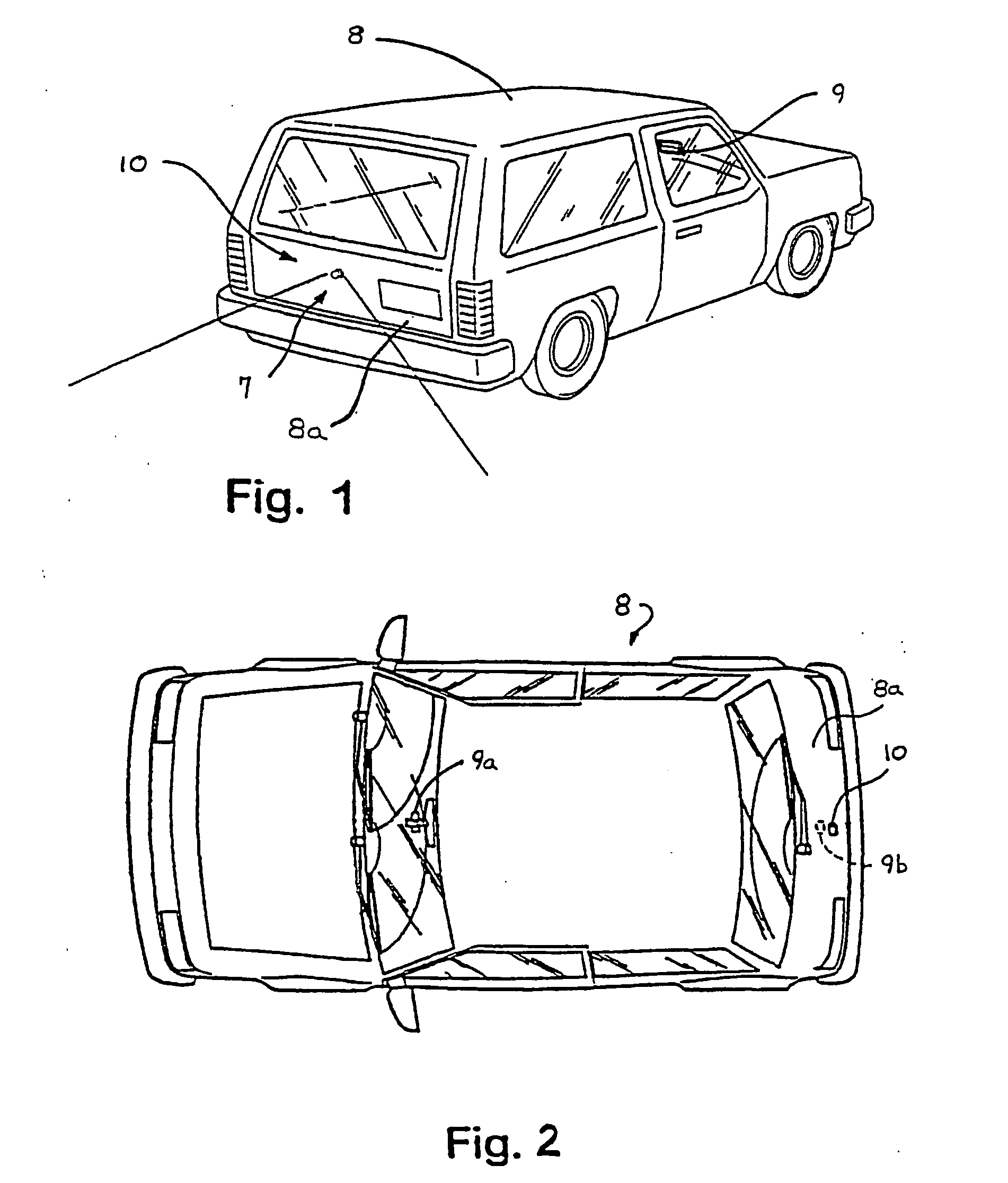

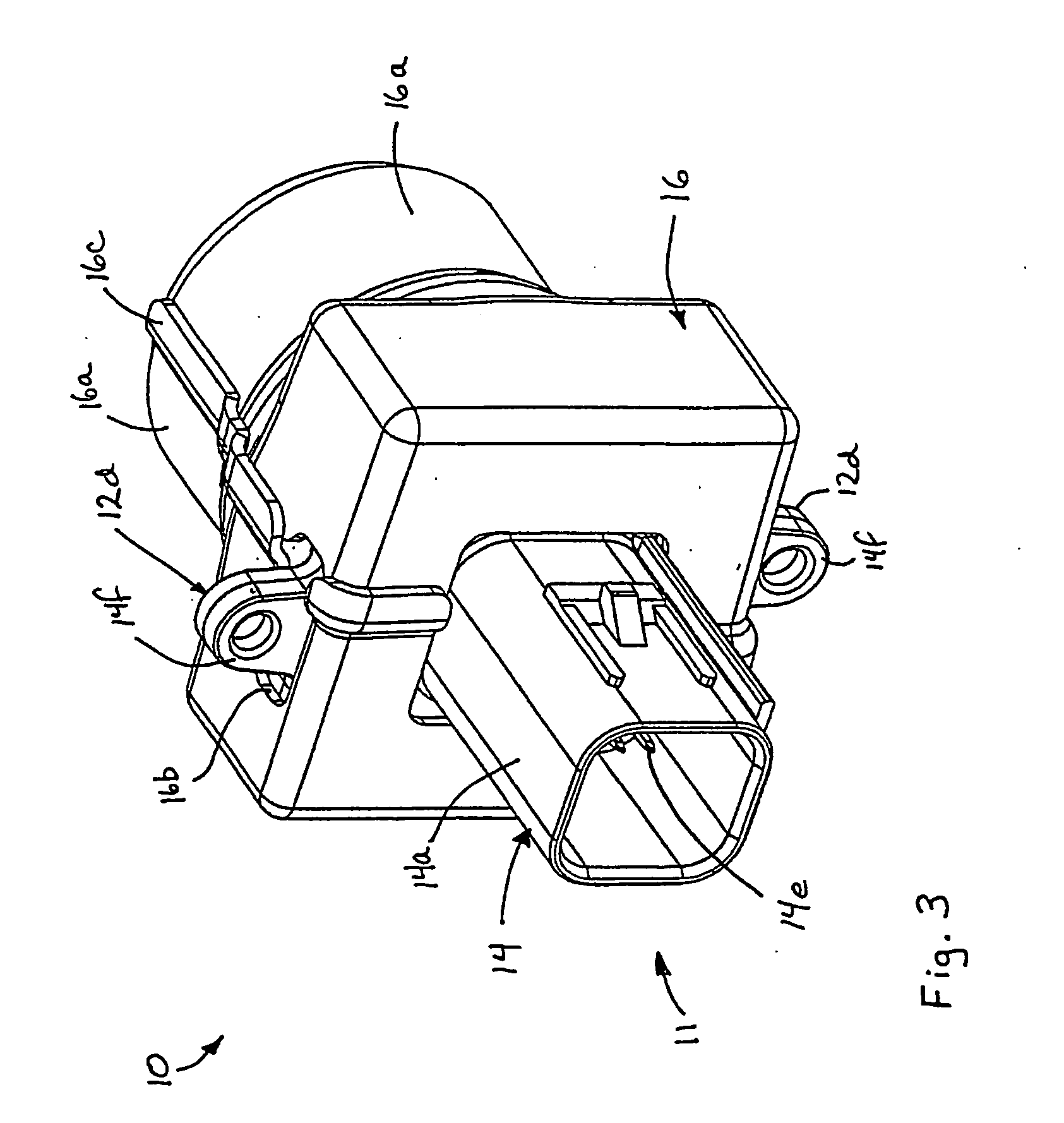

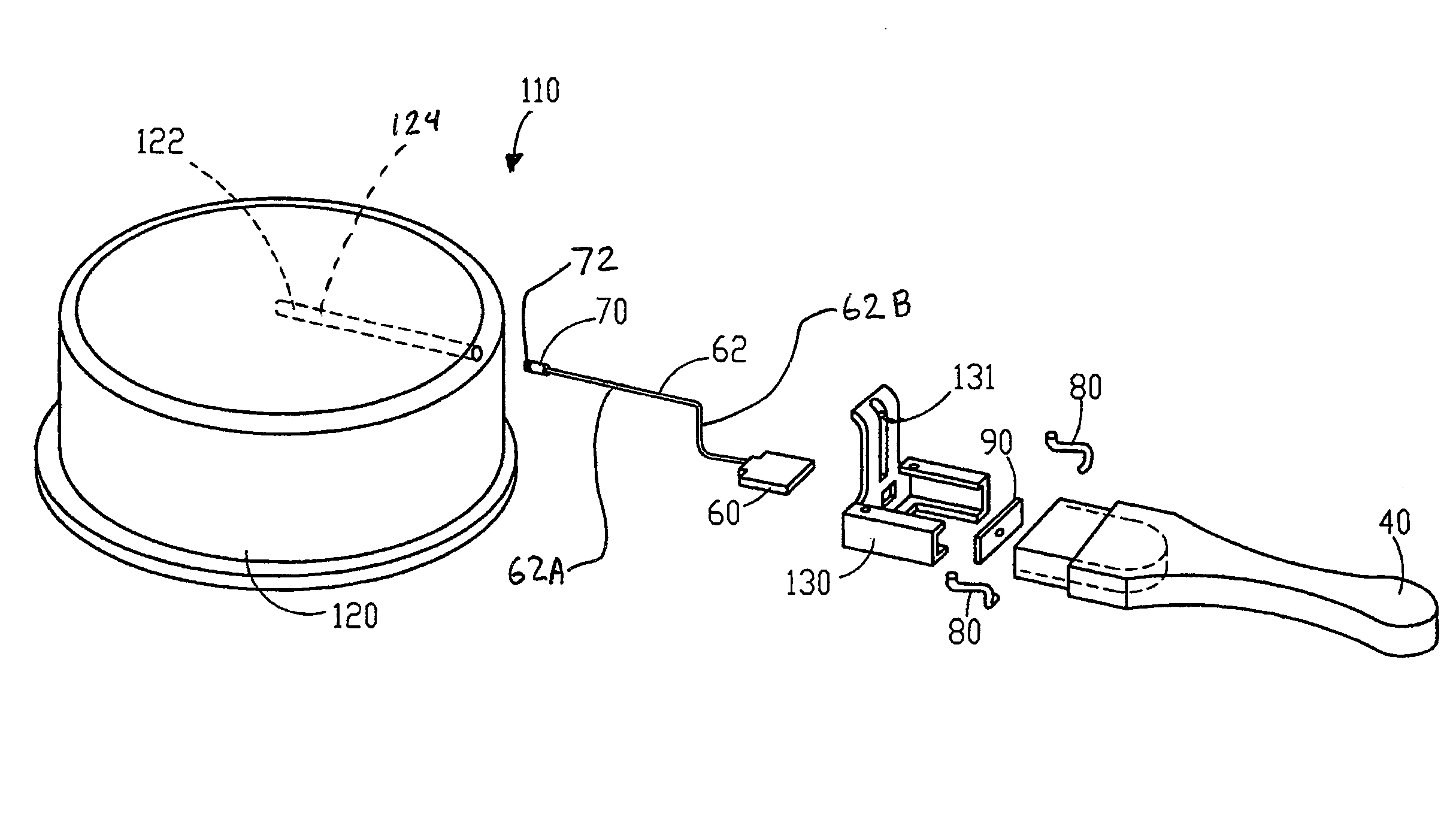

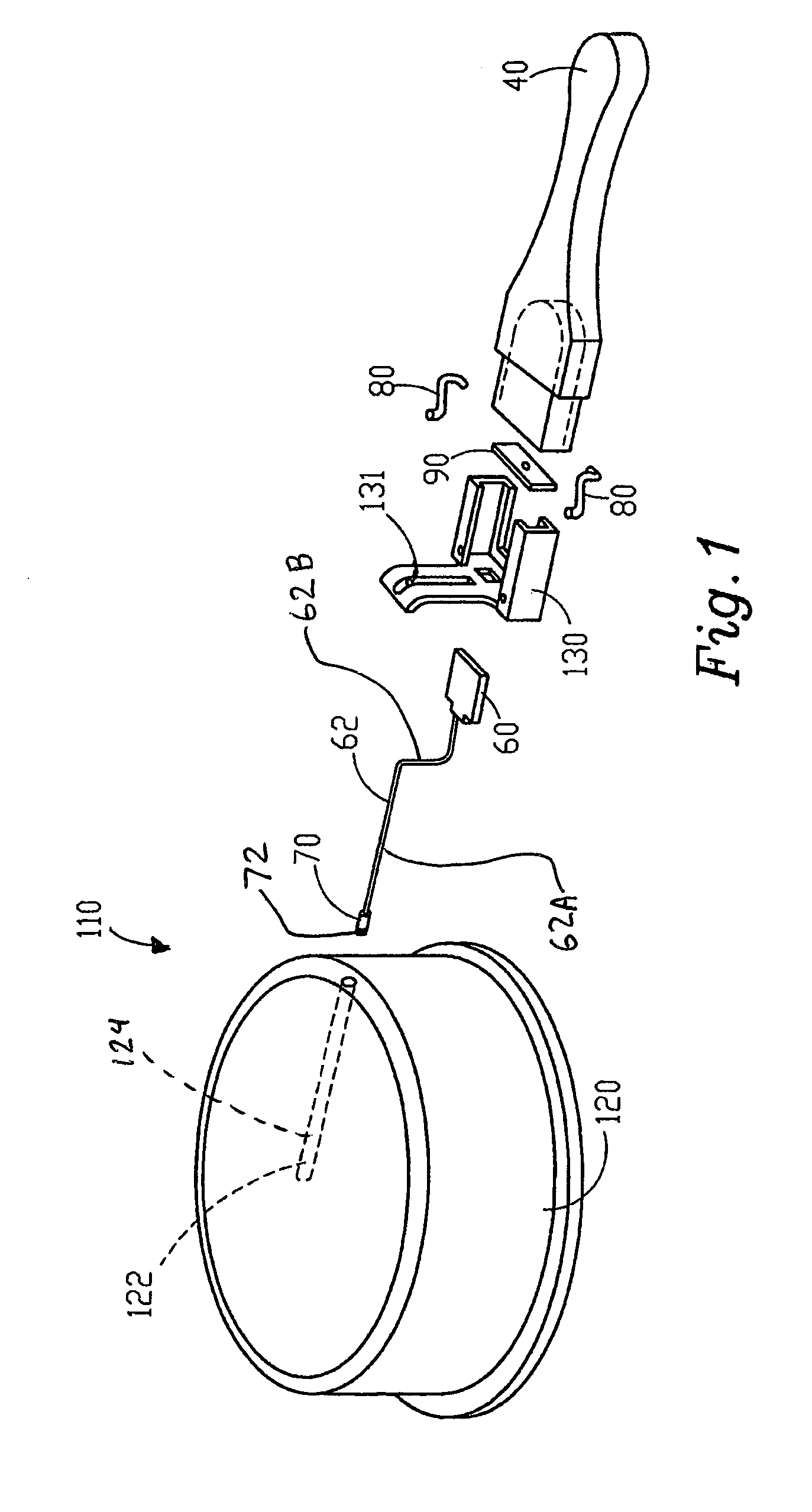

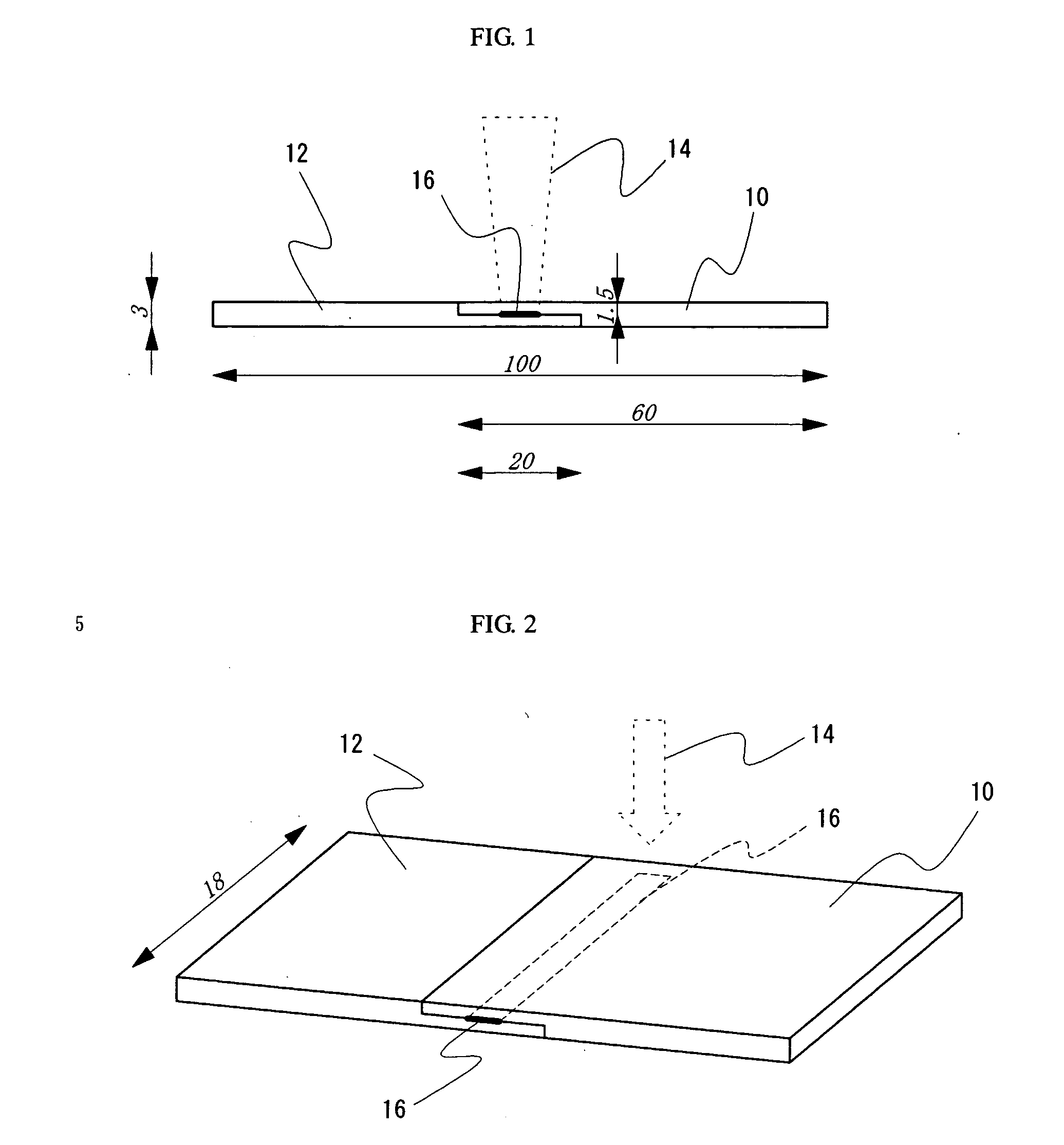

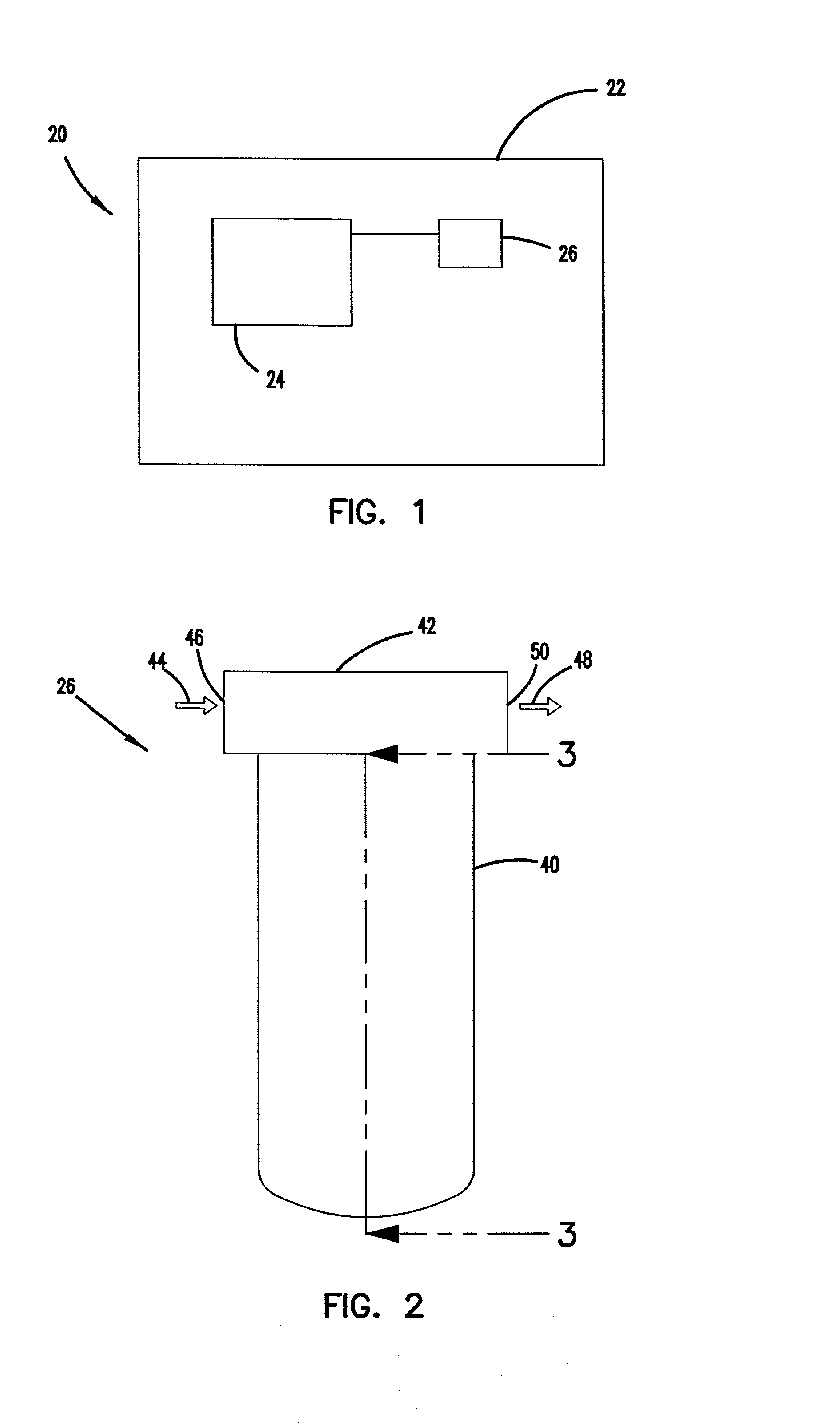

Imaging system for vehicle

ActiveUS20060171704A1Reduce vibration effectsReduce foggingTelevision system detailsPrintersWater vaporEngineering

An imaging system for a vehicle includes a camera module positionable at the vehicle and a control. The camera module includes a plastic housing that houses an image sensor, which is operable to capture images of a scene occurring exteriorly of the vehicle. The control is operable to process images captured by the image sensor. The portions of the housing may be laser welded or sonic welded together to substantially seal the image sensor and associated components within the plastic housing. The housing may include a ventilation portion that is at least partially permeable to water vapor to allow water vapor to pass therethrough while substantially precluding passage of water droplets and / or other contaminants. The housing may be movable at the vehicle between a stored position and an operational position, where the image sensor may be directed toward the exterior scene.

Owner:MAGNA ELECTRONICS

Tag assembly for radio frequency identification controlled heatable objects

ActiveUS7875836B2Improved operation/functionalityAdditional componentBoiling over preventionNear-field systems using receiversEngineeringRadio frequency

Components for use in a temperature controlled heatable object are provided in which a temperature sensor is connected to a transmitter such as a Radio Frequency Identification (RFID) tag. The RFID tag is encased in a protective overmolding and connected to the temperature sensor via a mineral insulated cable. An end cap containing a potting material (such as silicone or ceramic) is placed over the temperature sensor and laser welded to a sheathing of the mineral insulated cable. A potting material for use in a heatable object is also provided comprising a silicone-based material that is modified by adding bauxite to increase thermal conductivity.

Owner:IMURA INT USA

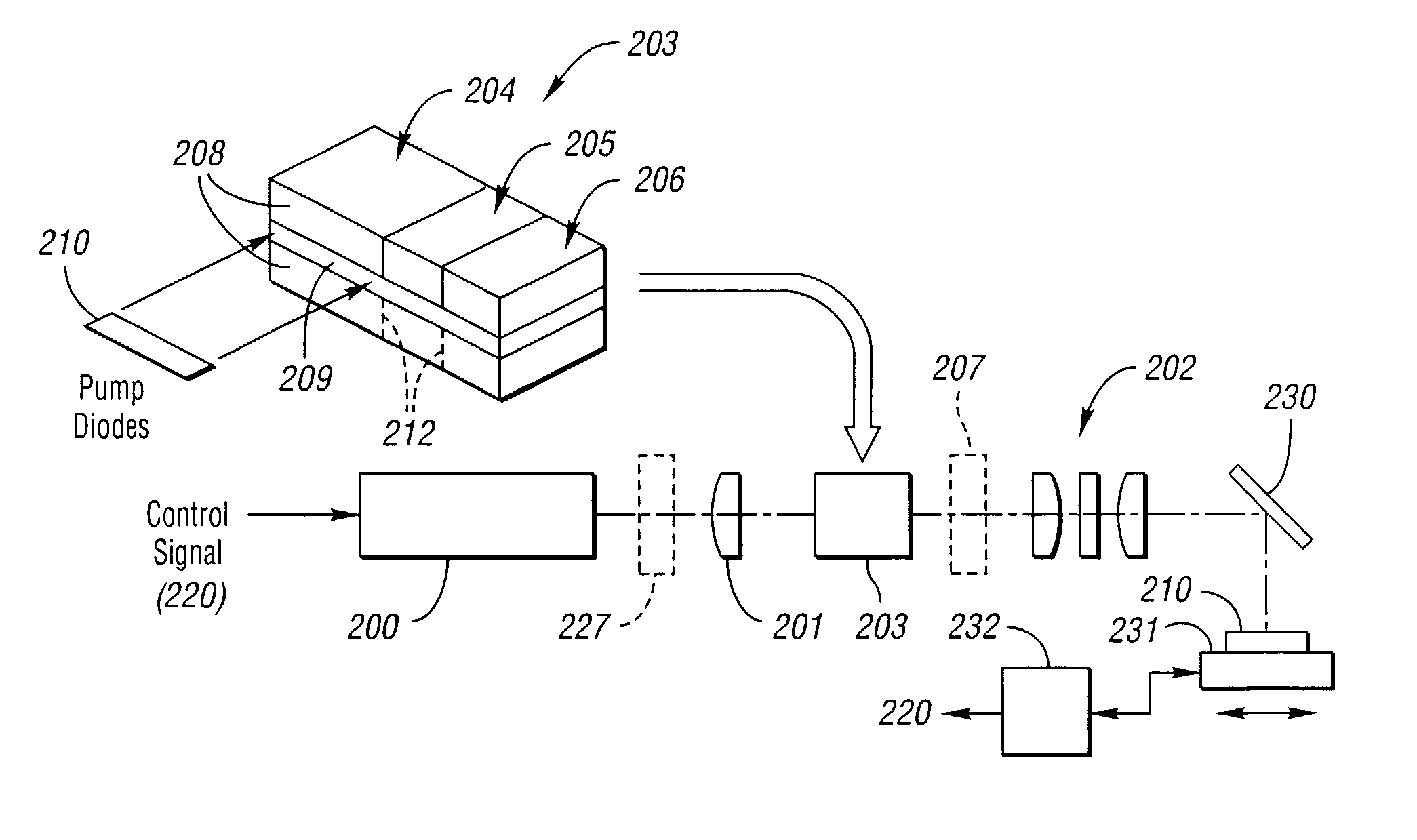

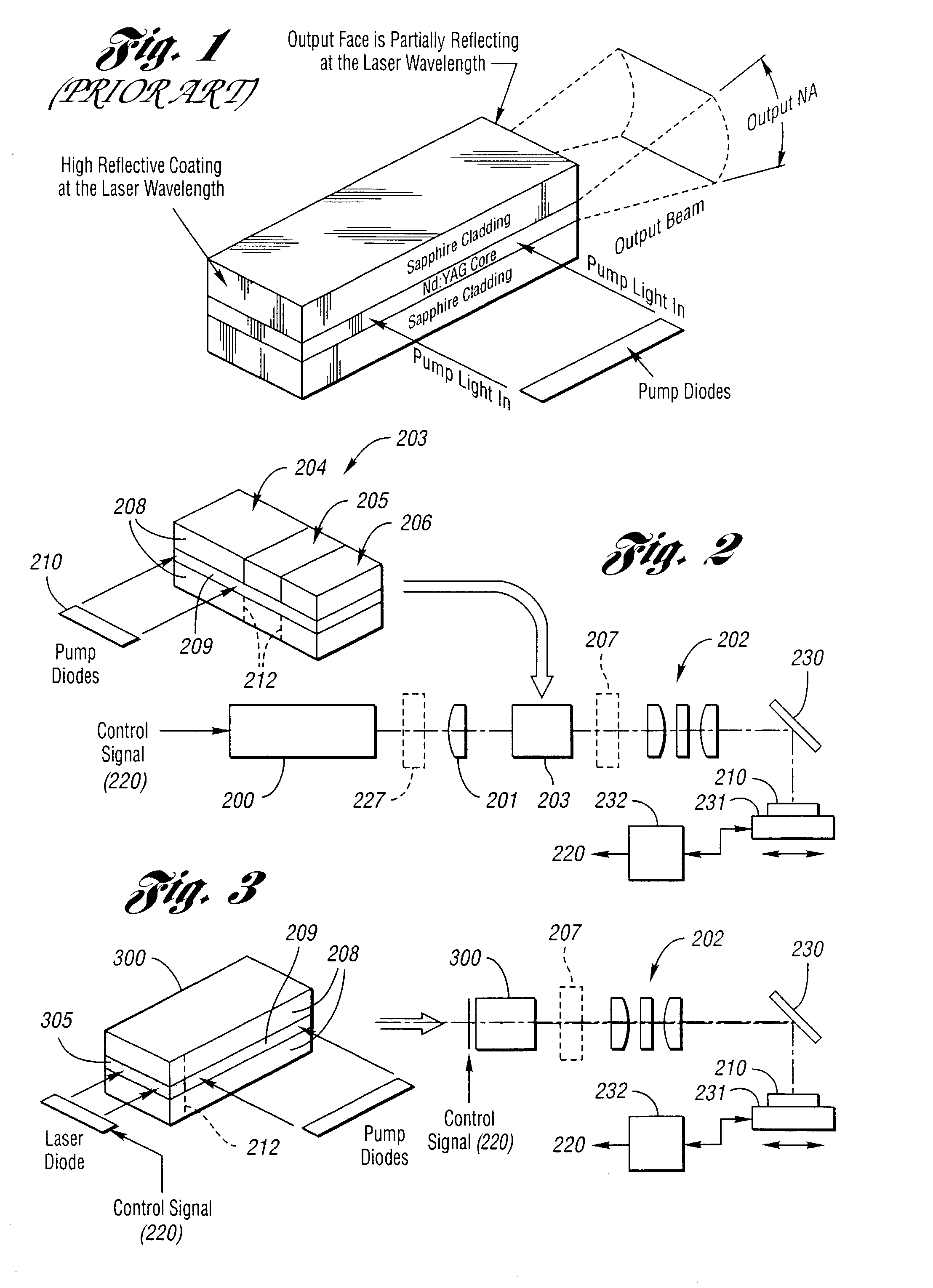

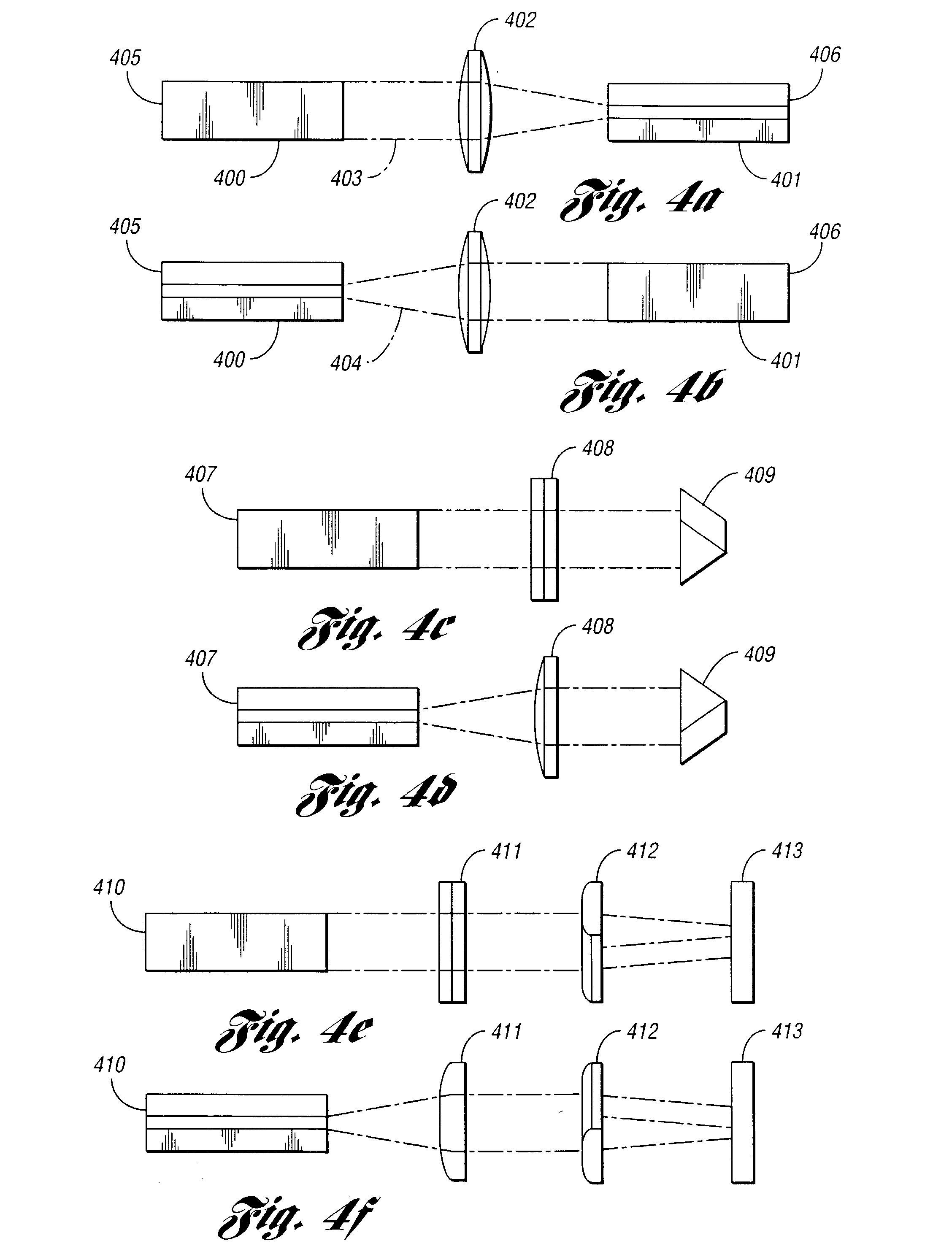

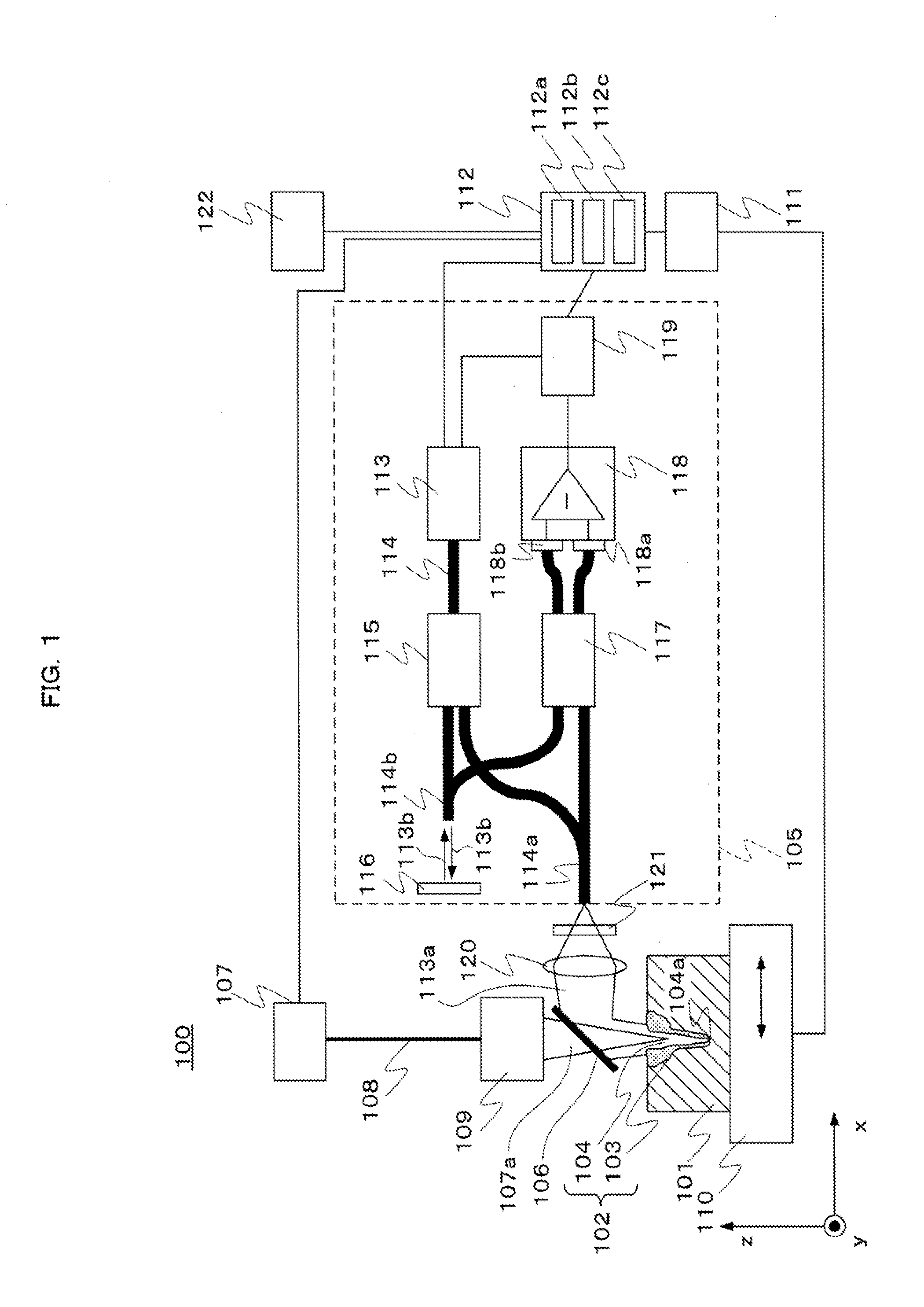

Waveguide architecture, waveguide devices for laser processing and beam control, and laser processing applications

InactiveUS20030161375A1Optical resonator shape and constructionActive medium shape and constructionEngineeringWaveguide

Methods and systems for laser-based processing of materials are disclosed wherein a scalable laser architecture, based on planar waveguide technology, provides for pulsed laser micromachining applications while supporting higher average power applications like laser welding and cutting. Various embodiments relate to improvements in planar waveguide technology which provide for stable operation at high powers with a reduction in spurious outputs and thermal effects. At least one embodiment provides for micromachining with pulsewidths in the range of femtoseconds to nanoseconds. In another embodiment, 100W or greater average output power operation is provided for with a diode-pumped, planar waveguide architecture.

Owner:GSI LUMONICS LTD

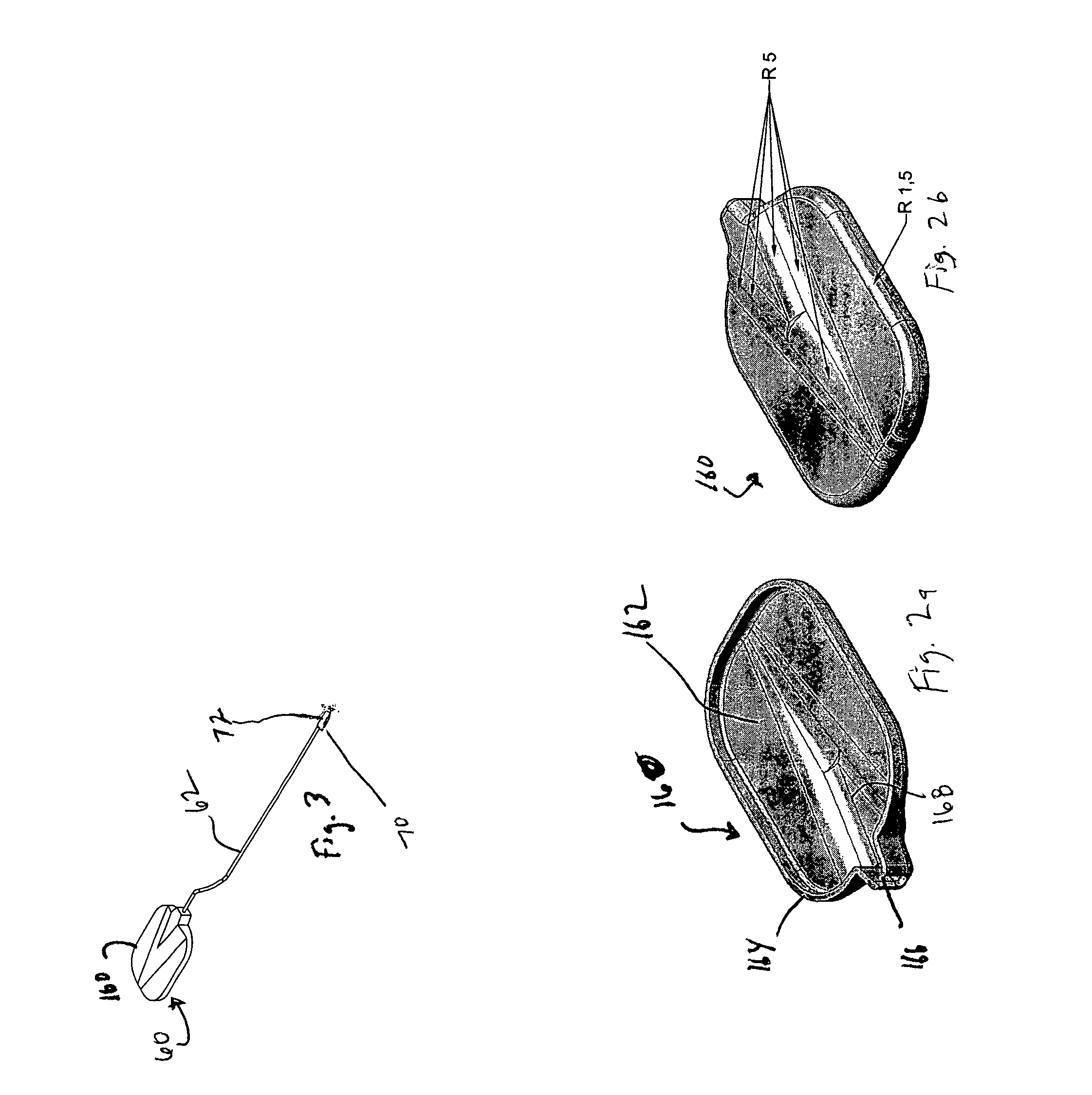

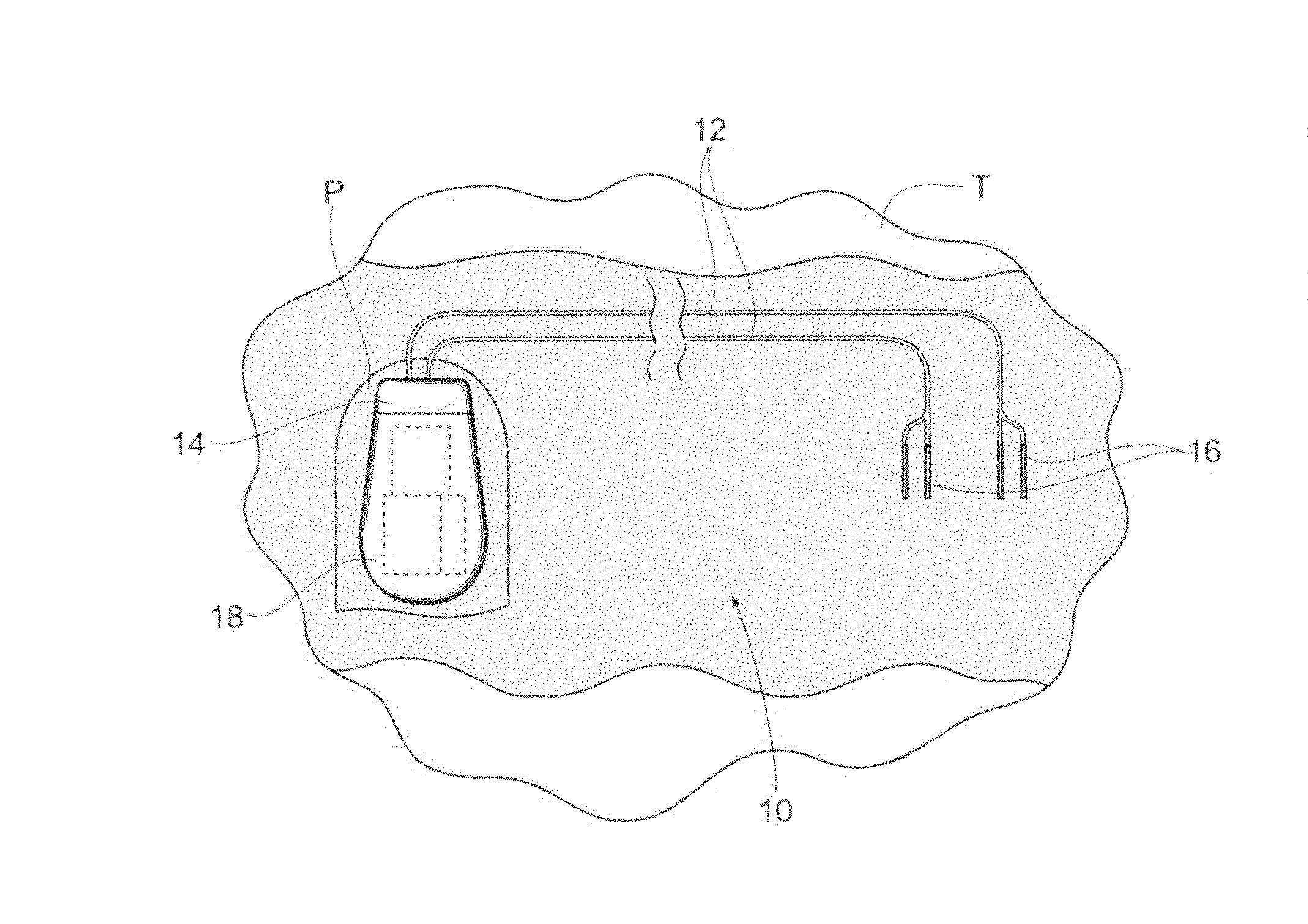

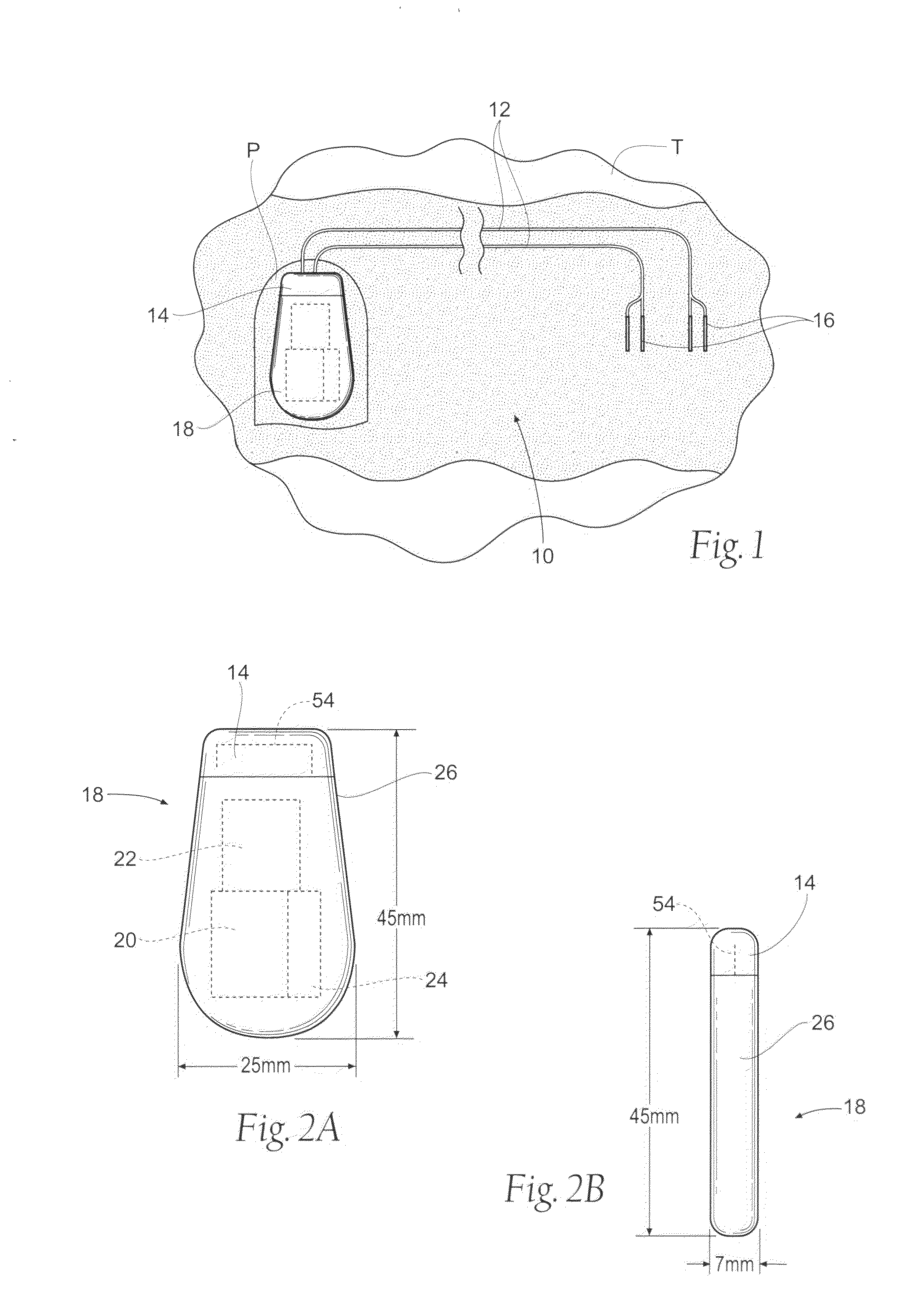

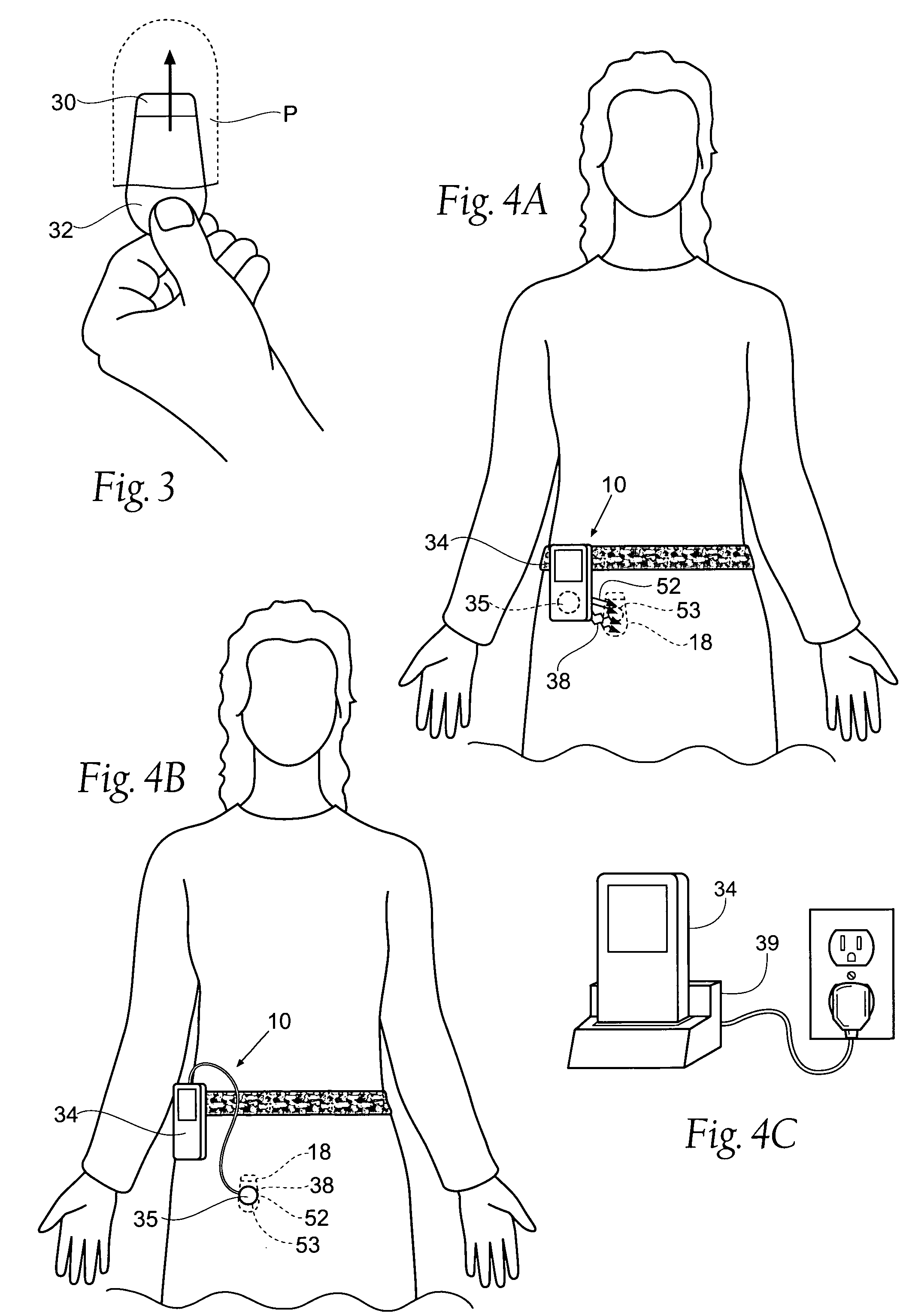

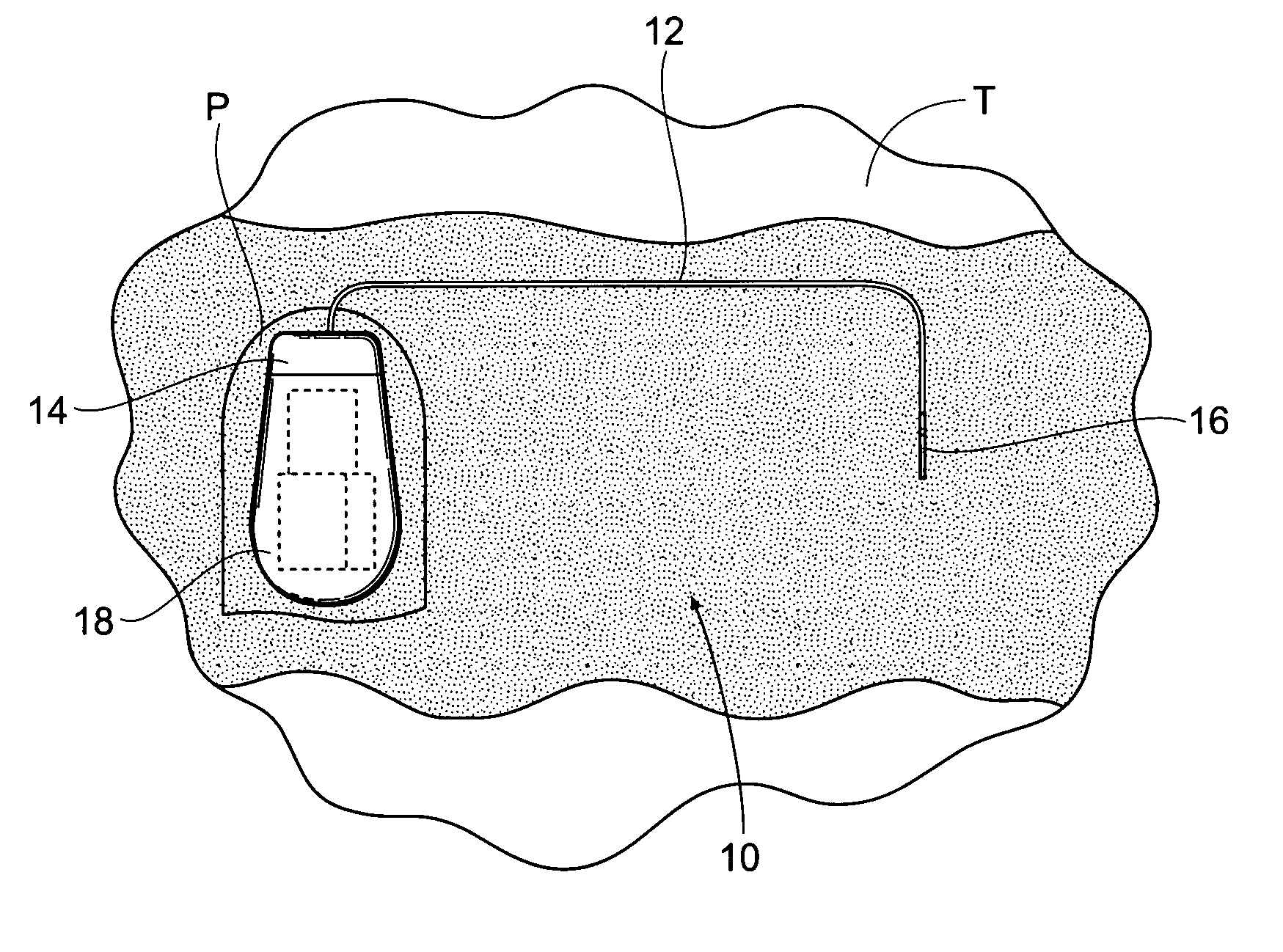

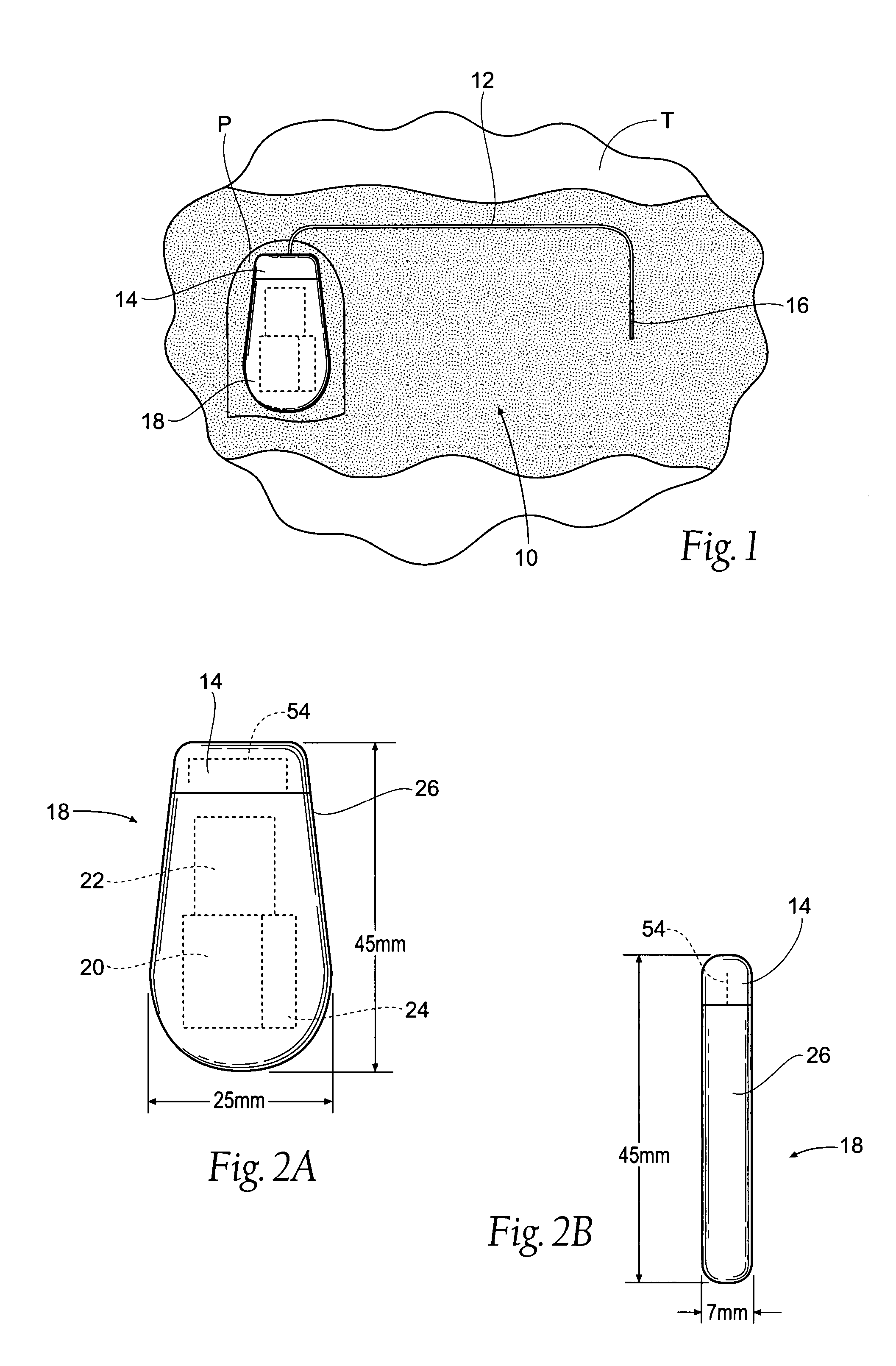

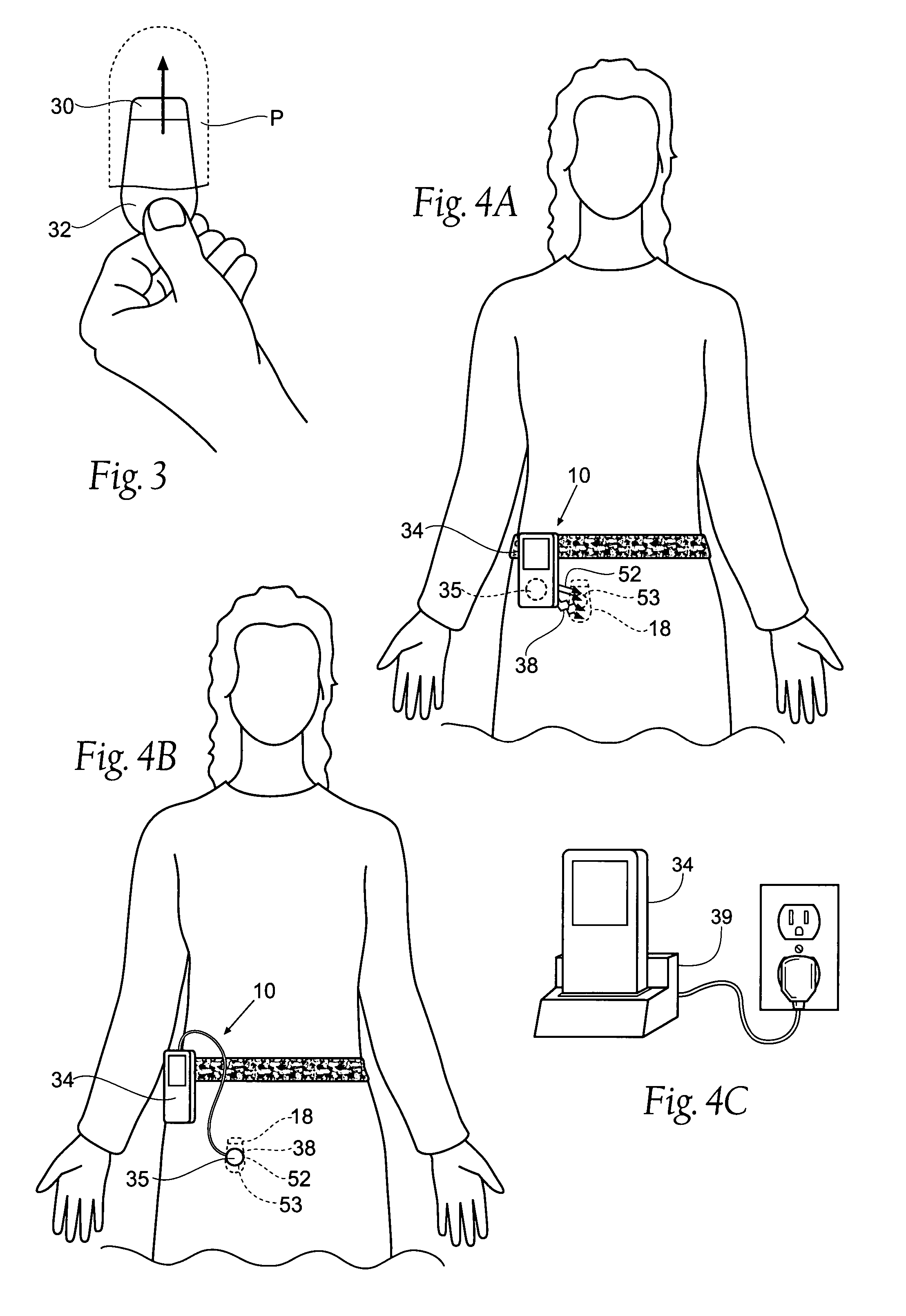

Implantable systems and methods for acquisition and processing of electrical signals for therapeutic and/or functional restoration purposes

ActiveUS20080132974A1Efficient chargingImprove the quality of lifeElectromyographyImplantable neurostimulatorsTitaniumRadio frequency

Improved assemblies, systems, and methods provide an electrical signal processor for acquisition and processing of electric signals from tissue. The electrical signal processor is sized and configured to be implanted in subcutaneous tissue. The electrical signal processor includes an electrically conductive case of a laser welded titanium material. Control circuitry is located within the case, the control circuitry including a rechargeable power source, a receive coil for receiving a first radio frequency wireless telemetry to recharge the power source, and an antenna for receiving a second radio frequency wireless telemetry for communication with the electrical signal processor.

Owner:MEDTRONIC URINARY SOLUTIONS

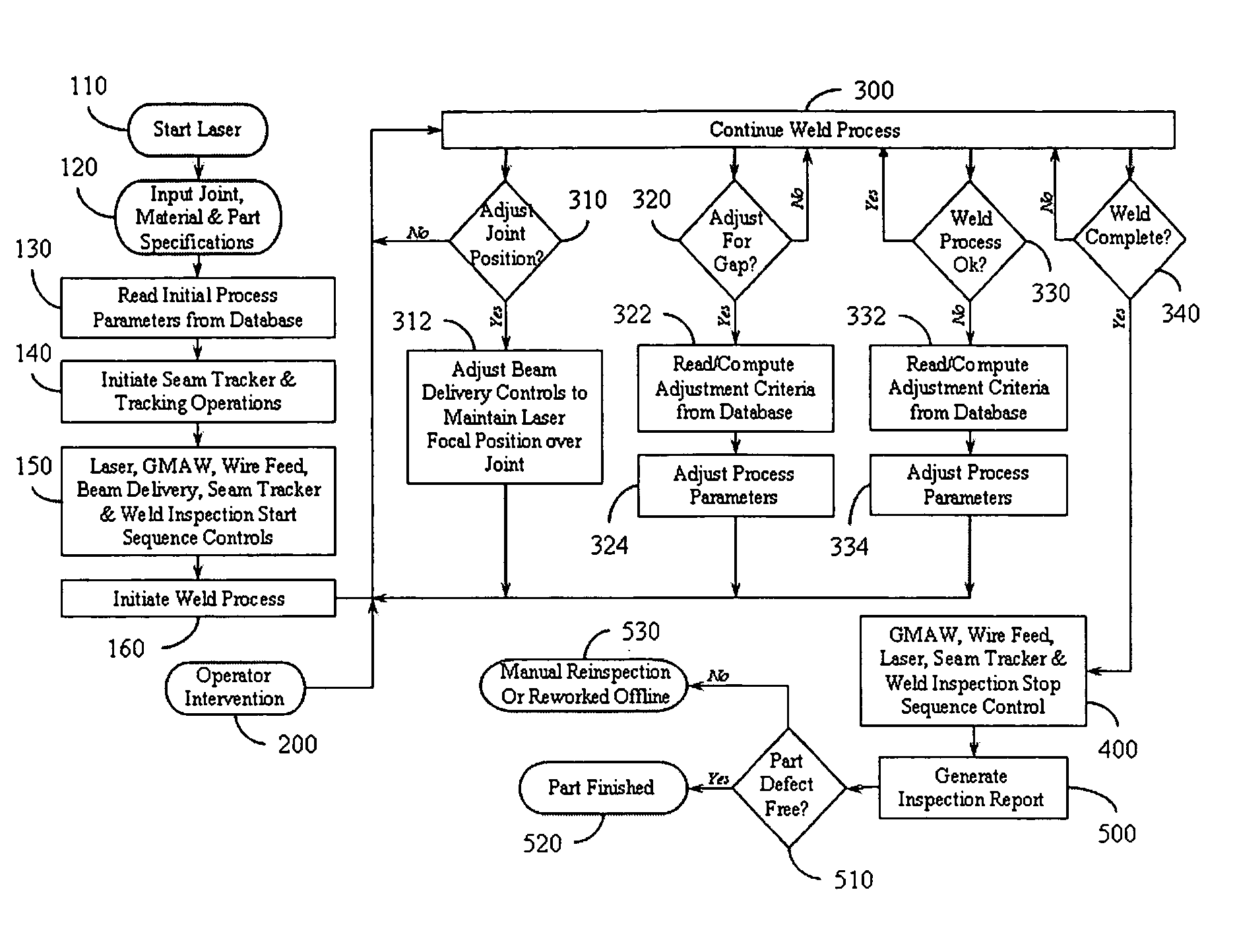

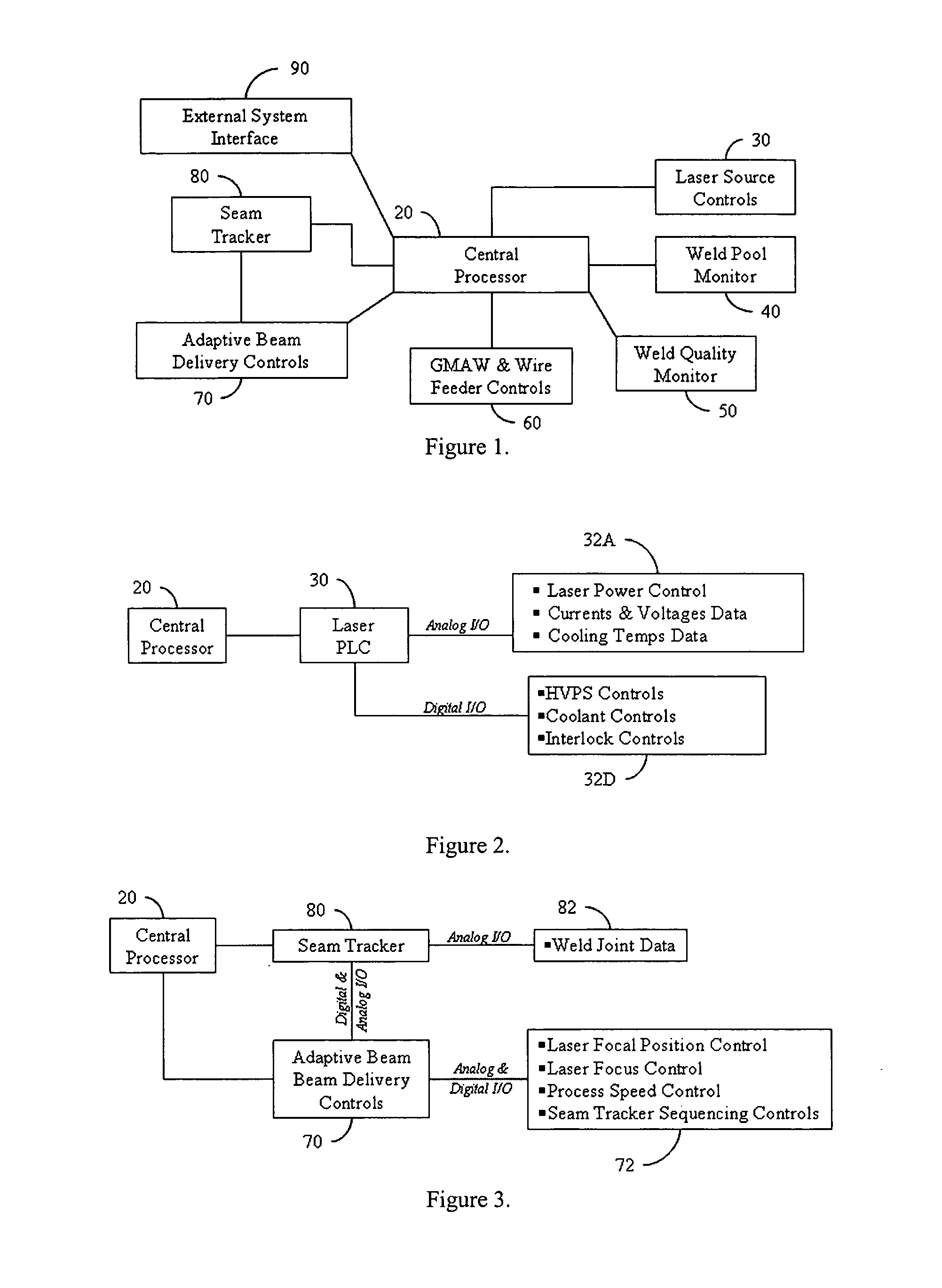

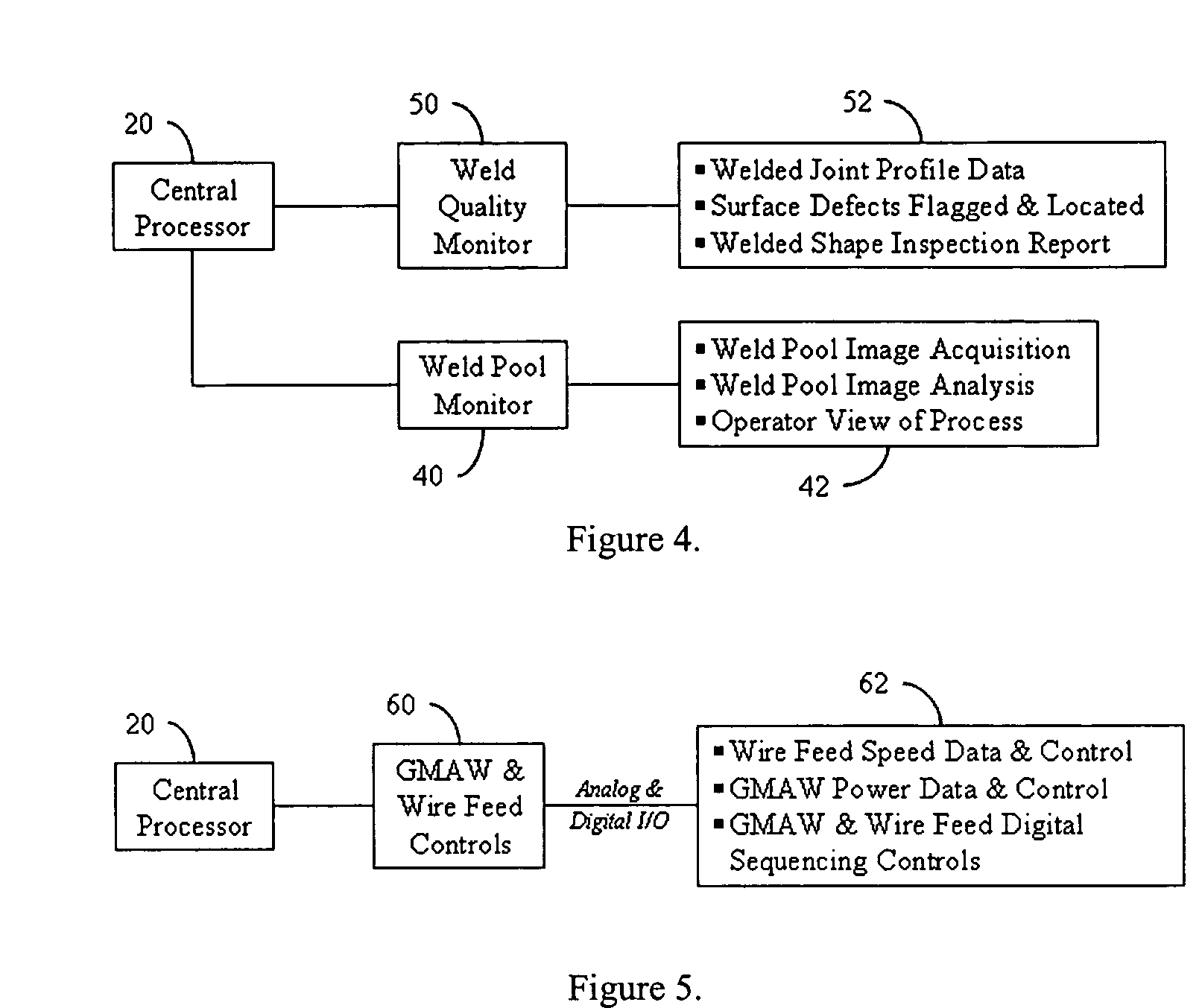

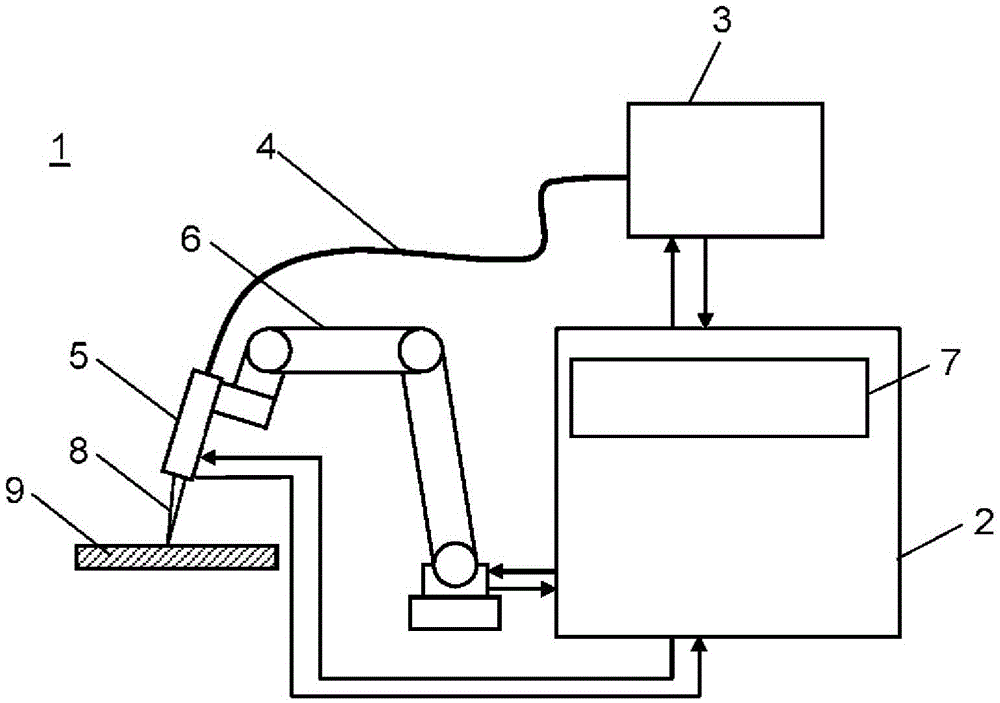

Laser welding control system

ActiveUS7107118B2Improve reliabilityReduce the amount requiredProgramme controlElectrical apparatusClosed loopVision based

A fully integrated automated laser weld process control system (LWPCS) and method of controlling the fabrication of structural parts, particularly for shipbuilding and other industries. The LWPCS defines joint and weld quality attributes as process control variables and integrates these weld quality variables, along with the more traditional process parameters such as laser power, wire feed, GMAW voltage and active seam tracking, into a closed-loop monitoring and control system. The LWPCS includes a central processor and a plurality of subsystems that control laser beam positioning, vision-based monitoring and image processing, active weld-quality monitoring and inspection, adaptive beam delivery, and seam tracking. Cross-communication between subsystems is managed by the central processor. In addition to process control, the system extracts weld quality attributes during the weld process and provides immediate documentation of the weld quality.

Owner:ESAB AB

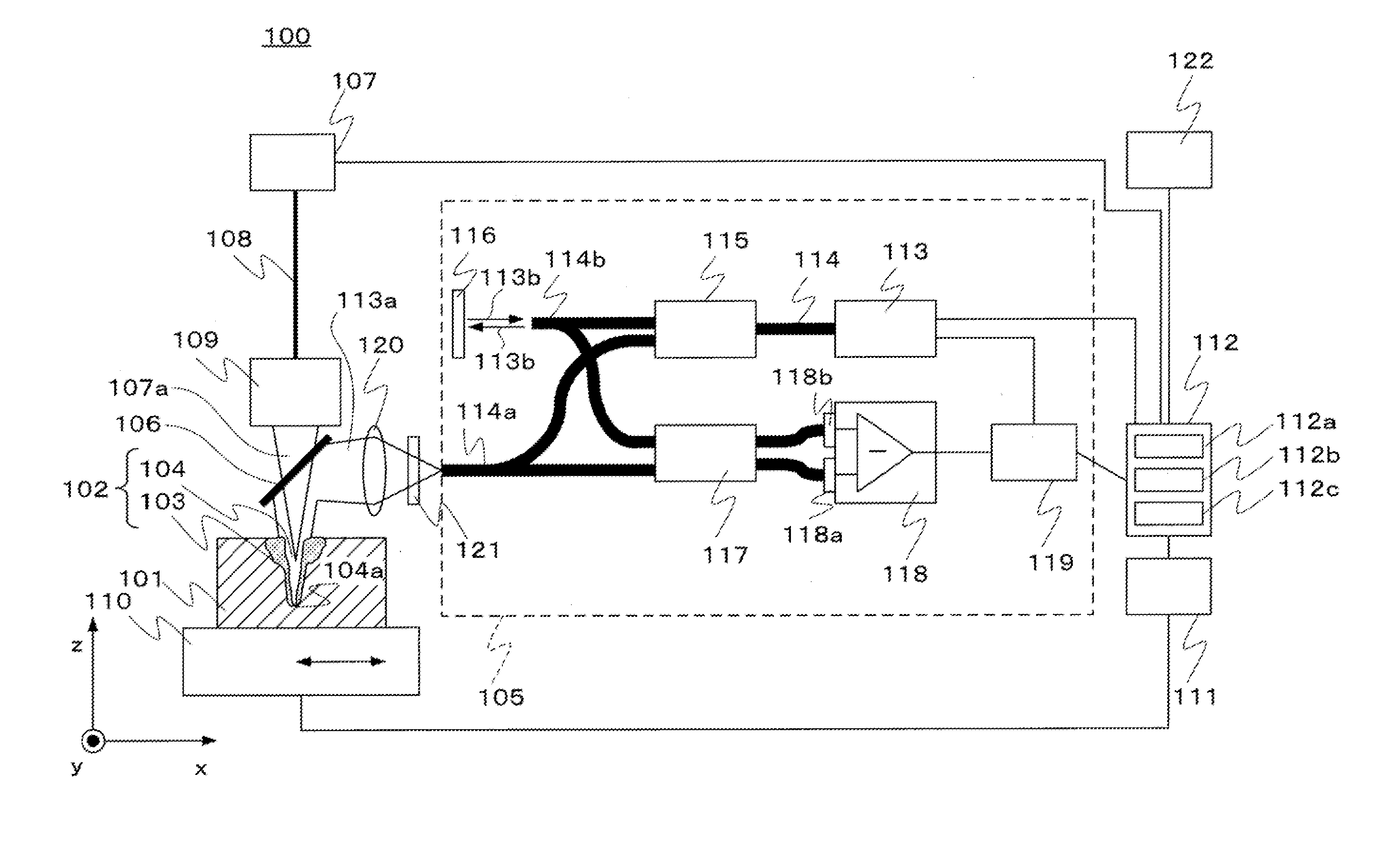

Laser welding apparatus and laser welding method

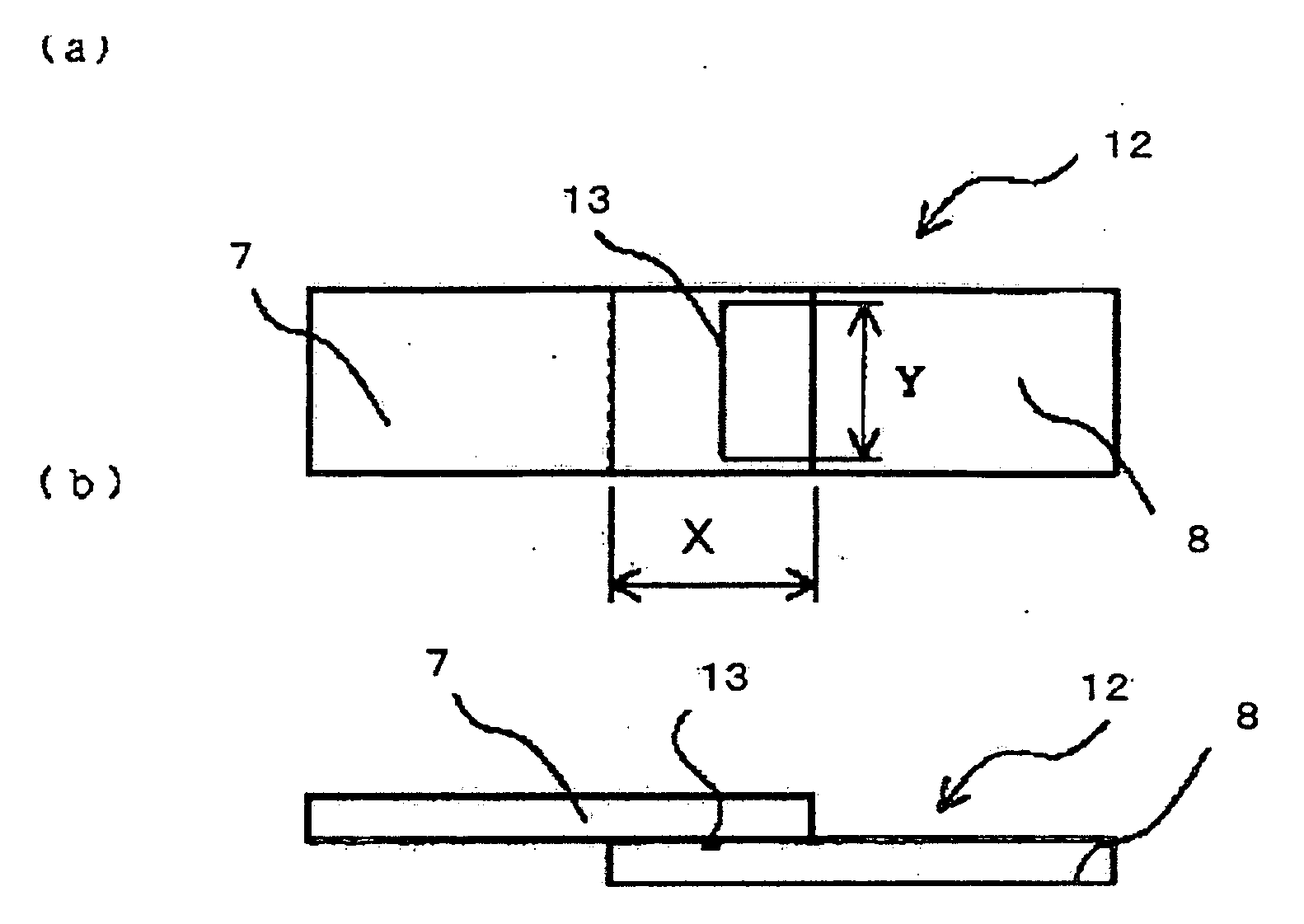

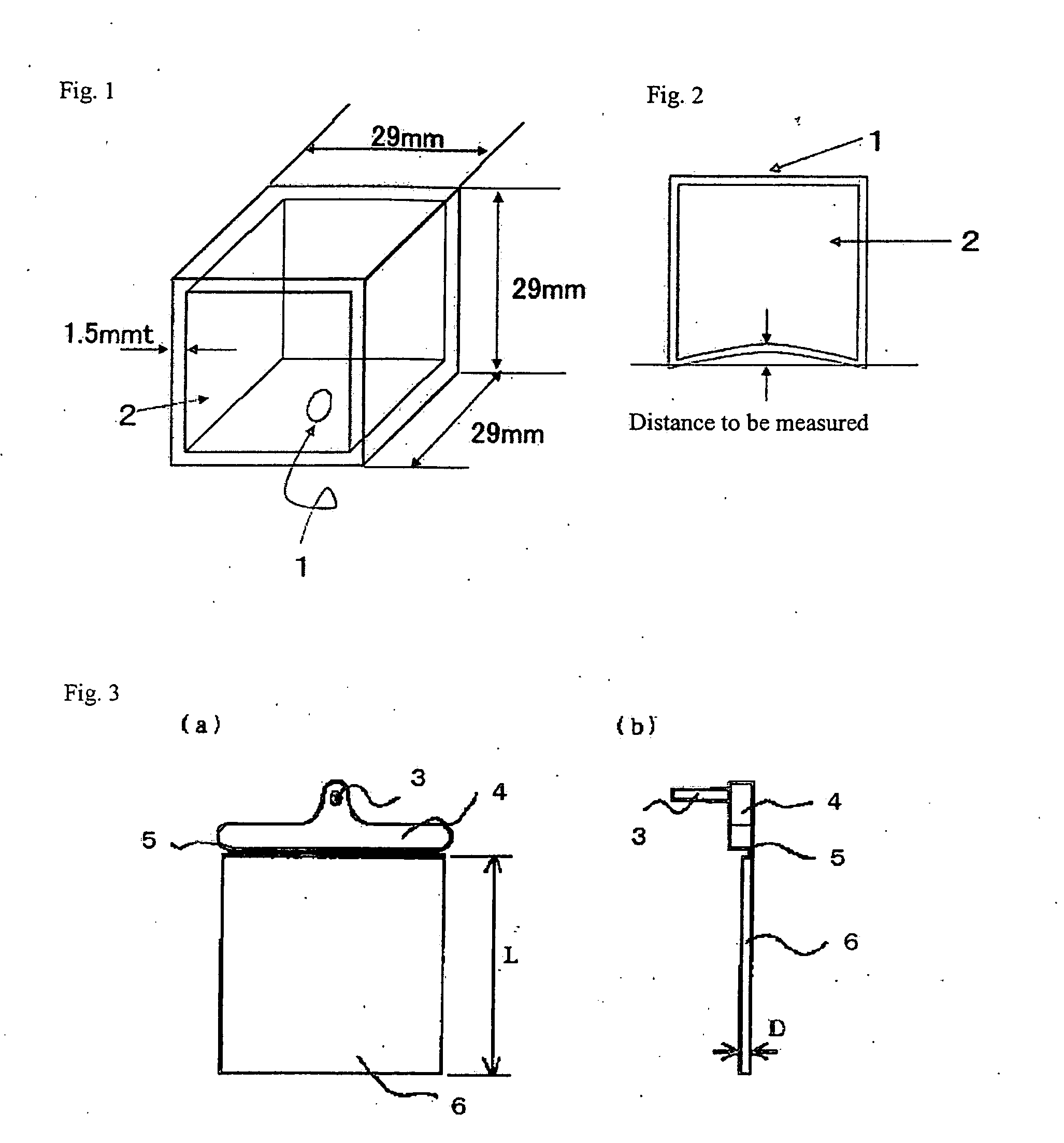

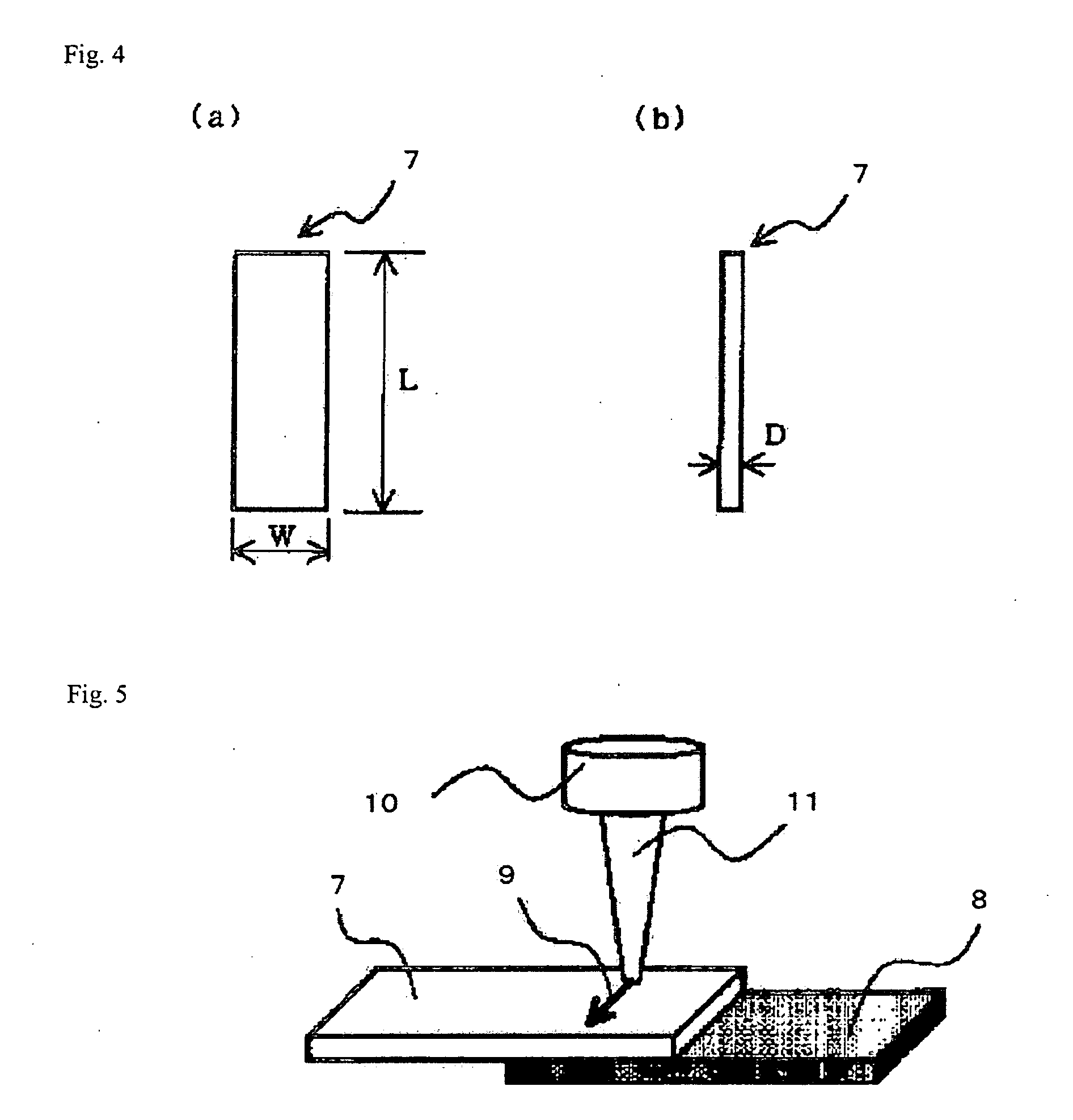

ActiveUS20120285936A1Improve accuracyUsing optical meansWelding/soldering/cutting articlesLight beamLaser light

A laser welding apparatus includes: a first optical element that coaxially emits, to a welded part, a laser beam emitted from a laser light source and an object beam having a different wavelength from the laser beam; a second optical element that causes the spot diameter of the object beam to be larger than the spot diameter of the laser beam on the welded part; an optical interferometer that emits the object beam to the first optical element, detects through the first optical element the object beam reflected on the welded part, and generates an electric signal based on the detected object beam; and a measuring unit that measures a penetration depth of the welded part based on the electric signal.

Owner:PANASONIC CORP

Implantable pulse generator for providing functional and/or therapeutic stimulation of muscles and/or nerves and/or central nervous system tissue

ActiveUS20070293910A1Efficient chargingImprove the quality of lifeElectrotherapyDiagnosticsElectricityMicrocontroller

Improved assemblies, systems, and methods provide an implantable pulse generator for prosthetic or therapeutic stimulation of muscles, nerves, or central nervous system tissue, or any combination. The implantable pulse generator is sized and configured to be implanted subcutaneous a tissue region. The implantable pulse generator includes an electrically conductive case of a laser welded titanium material. Control circuitry is located within the case, the control circuitry including a rechargeable power source, a receive coil for receiving an RF magnetic field to recharge the power source, and a microcontroller for control of the implantable pulse generator. Improved assemblies, systems, and methods also provide a stimulation system for prosthetic or therapeutic stimulation of muscles, nerves, or central nervous system tissue, or any combination. The stimulation system provides at least one electrically conductive surface, a lead connected to the electrically conductive surface, and an implantable pulse generator electrically connected to the lead.

Owner:MEDTRONIC URINARY SOLUTIONS

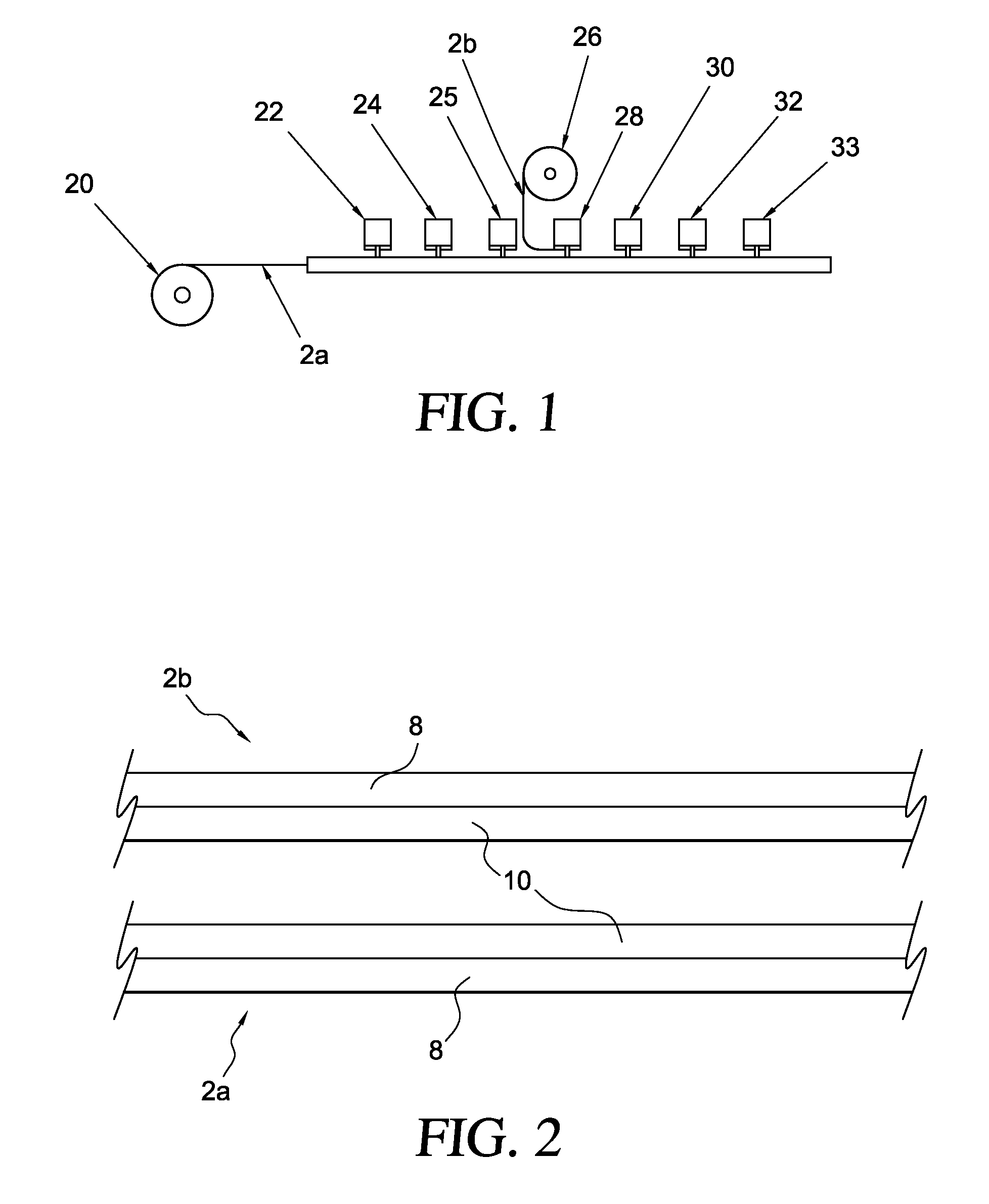

Fluid-containing pouches with reduced gas exchange and methods for making same

ActiveUS8216529B2Reduce penetrationReduce solubilityReagent containersClosure using stoppersUltrasonic weldingProduct gas

Owner:ABBOTT POINT CARE

Thermoplastic resin composition and molded article thereof

ActiveUS20090275678A1Excellent in flowability and mechanical propertyExcellent in flowabilityOrganic chemistryInksPolycarbonateTransmittance

A thermoplastic resin composition and a molded article thereof, respectively excellent in flowability and mechanical properties, and, in a preferred mode, also excellent in low warping property, laser transmittance and laser weldability, is obtained by mixing (B) 0.1 to 4 parts by weight of a polyfunctional compound having three or more functional groups, in which at least one of the terminal structures having the functional groups is a structure containing alkylene oxide units, with (A) 100 parts by weight of a thermoplastic resin, and further provides a molded particle thereof. It is preferred that the (A) thermoplastic resin is one or more selected from a polyester resin and polycarbonate resin.

Owner:TORAY IND INC

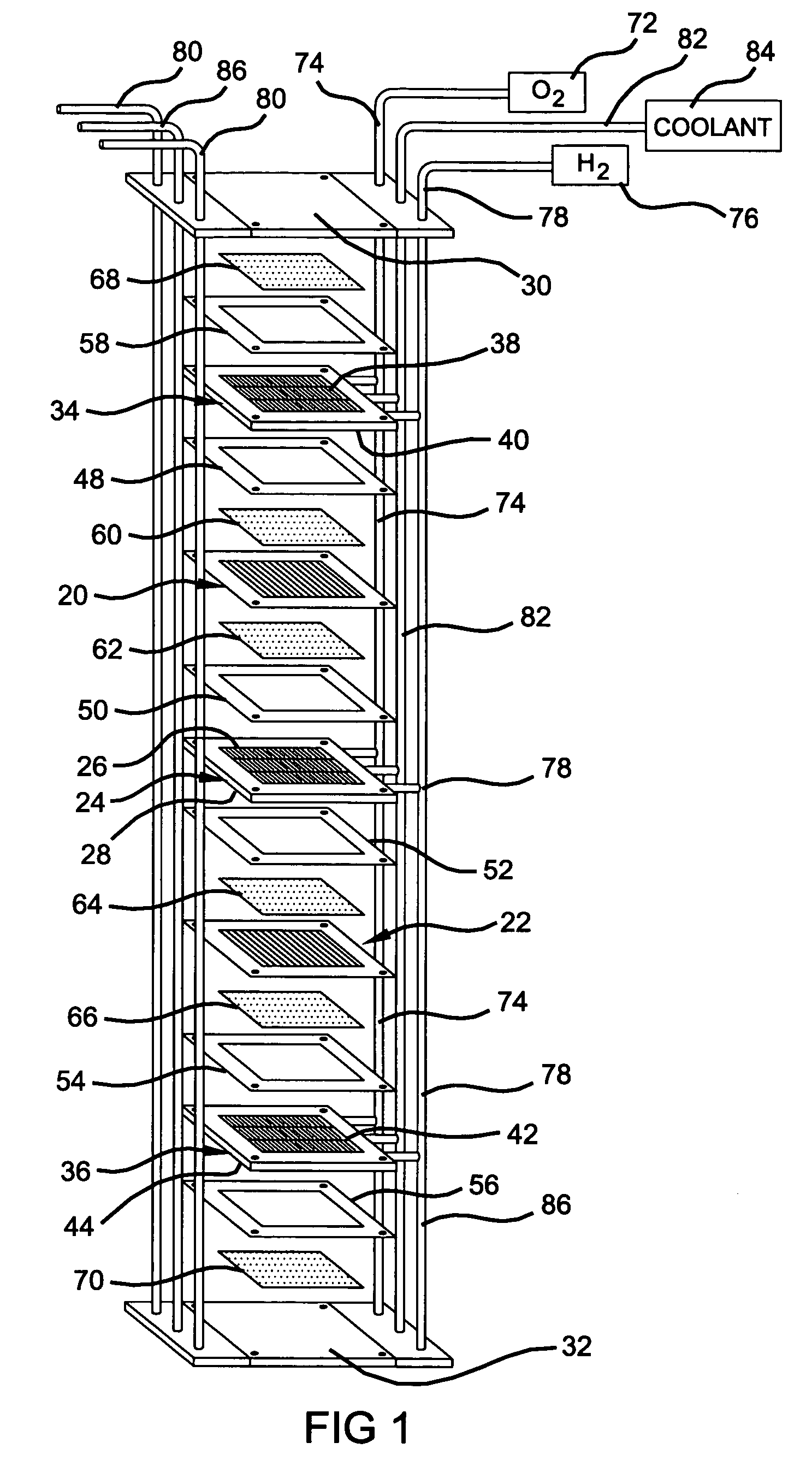

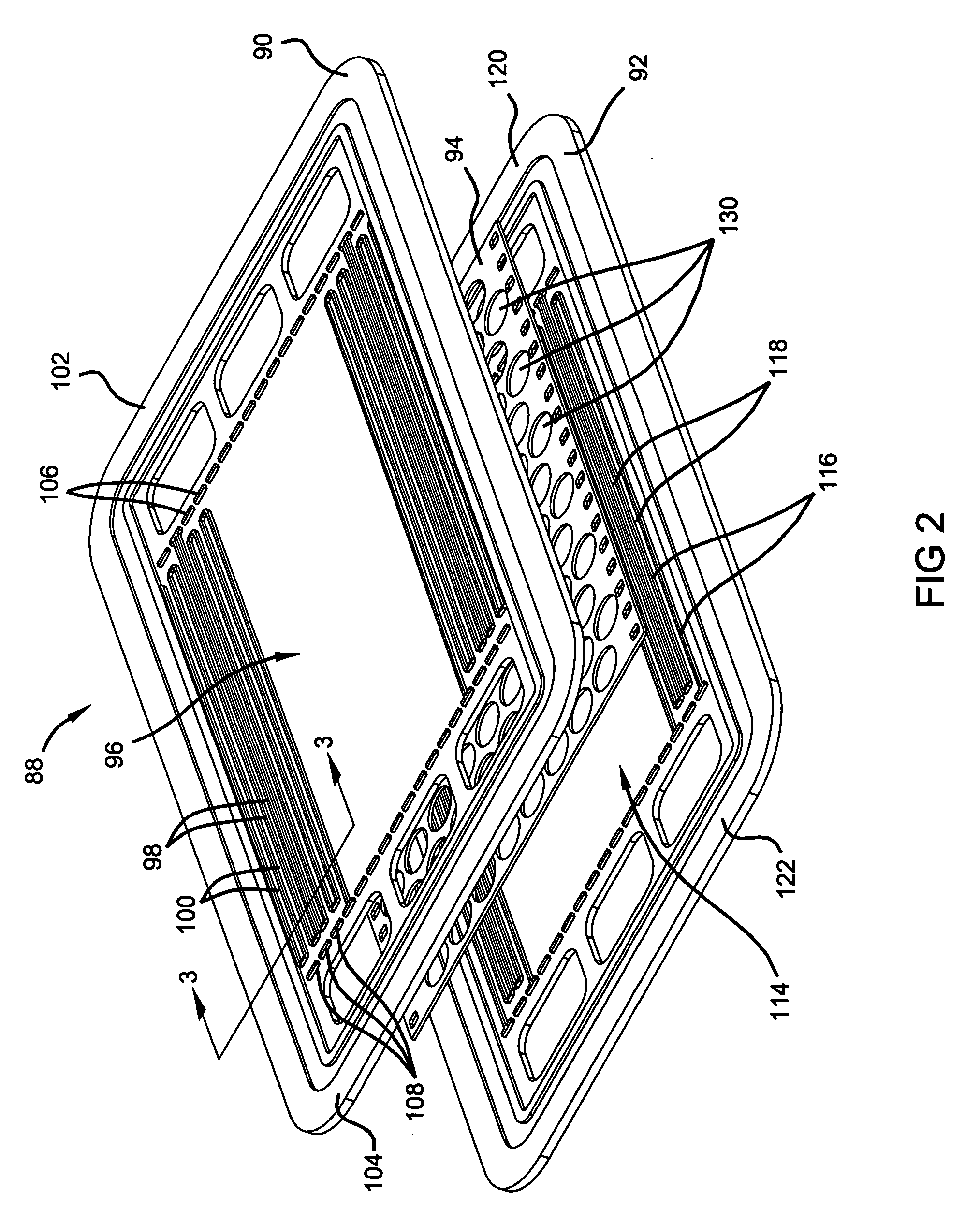

Laser welding of conductive coated metallic bipolar plates

ActiveUS20050252892A1Less corrosion resistantReduced corrosion resistanceFuel cells groupingFinal product manufactureFuel cellsEngineering

The present invention discloses a method of efficiently manufacturing fuel cells having coated bipolar plates. The present invention contemplates the laser welding together of individual plates already having a coating thereon to form the bipolar plates that are used in a fuel cell. The laser welding of the coated plates together does not result in sensitization of the plates to a magnitude sufficient to cause an undesirable level of corrosion resistance. This result is achieved regardless of the presence of the organic coating in the region of the plates being welded and regardless of the ablating of the organic coating by the laser beam.

Owner:GM GLOBAL TECH OPERATIONS LLC

Polybutylene terephthalate resin composition for fusion bonding with laser and molded article

InactiveUS20050165176A1Improve Laser Welding PerformanceImprove welding strengthPolytetramethylene terephthalatePolymer science

A laser weldable PBT-series resin composition comprises a polybutylene terephthalate (PBT)-series resin (A), and at least one resin (B) selected from the group consisting of a polycarbonate-series resin (b1), a styrenic resin (b2), a polyethylene terephthalate-series resin (b3) and an acrylic resin (b4). The PBT-series resin (A) may be a PBT homopolyester, or a PBT-series copolymer modified with not more than 30 mol % of a copolymerizable monomer (e.g., a bisphenol compound or an adduct thereof with an alkylene oxide, and an asymmetrical aromatic dicarboxylic acid). The ratio (weight ratio) of the resin (B) relative to the PBT-series resin (A) [the former / the latter] is about 0.1 / 1 to 1.5 / 1. The resin composition may comprise a glass fiber. The resin composition is excellent in laser weldability, and can improve in welding strength of a shaped article formed from the resin composition.

Owner:WIN TECH POLYMER LTD

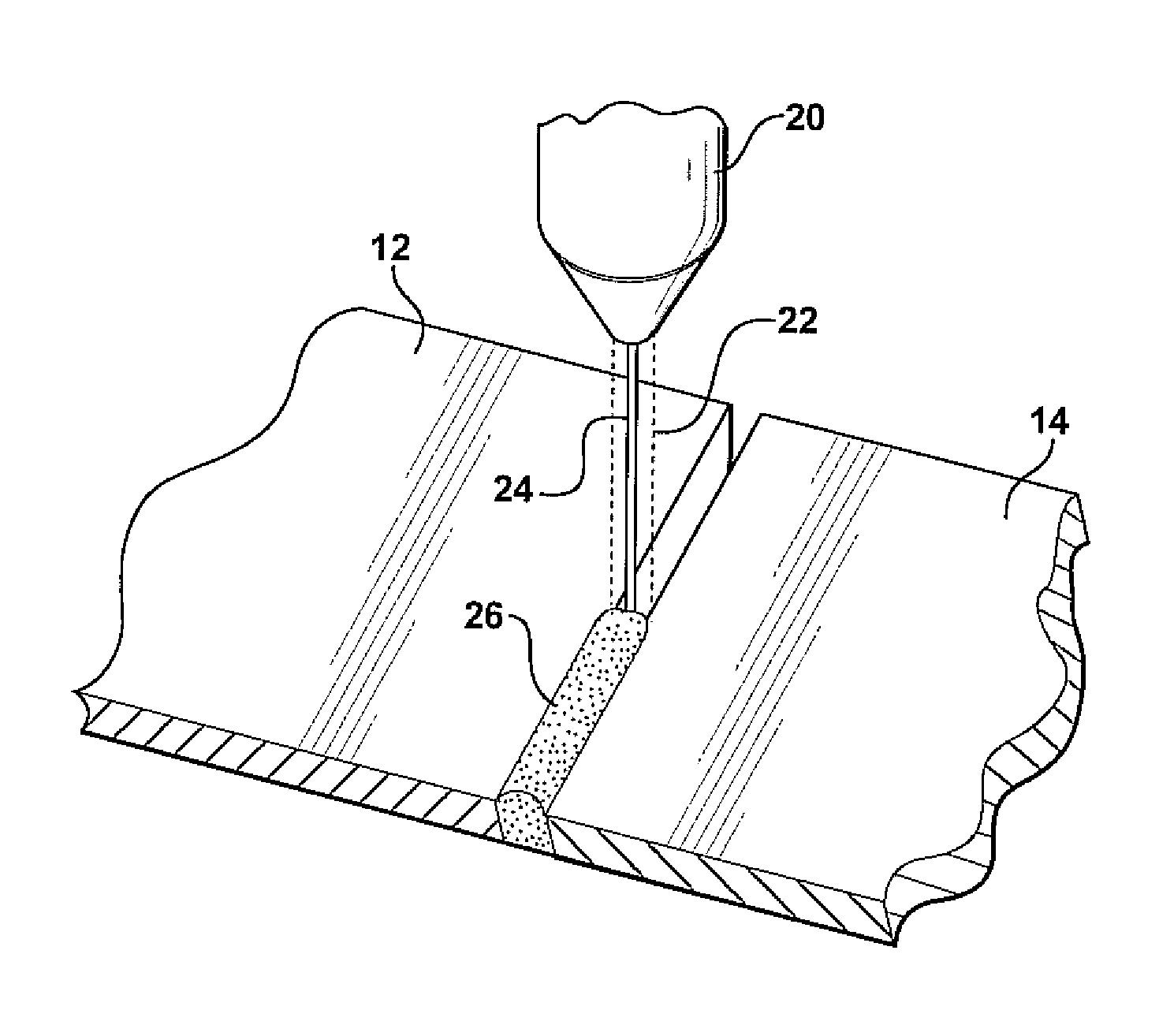

Method of manufacturing a welded metal panel having a high quality surface finish

InactiveUS20080128053A1Improve surface qualityReduce hardnessFurnace typesWelding/soldering/cutting articlesSurface finishWeld seam

In a method for preparing a welded metal panel having a high surface quality a first metal blank and a second metal blank are disposed so that edge portions of the blanks are in an abutting relationship. The blanks are laser welded together utilizing a powdered metal filler so as to produce a weld seam which is convex. A portion of the seam is removed to produce a flush weld seam between the blanks. The hardness of the weld seam is determined, and if the hardness of the weld seam is more than the hardness of the remainder of the panel, the weld seam is tempered so as to reduce its hardness. The thus produced welded metal panel may be subjected to a further shaping operation such as stamping, bending or the like. After shaping, the article may be plated, painted or otherwise finished.

Owner:NOBLE ADVANCED TECH

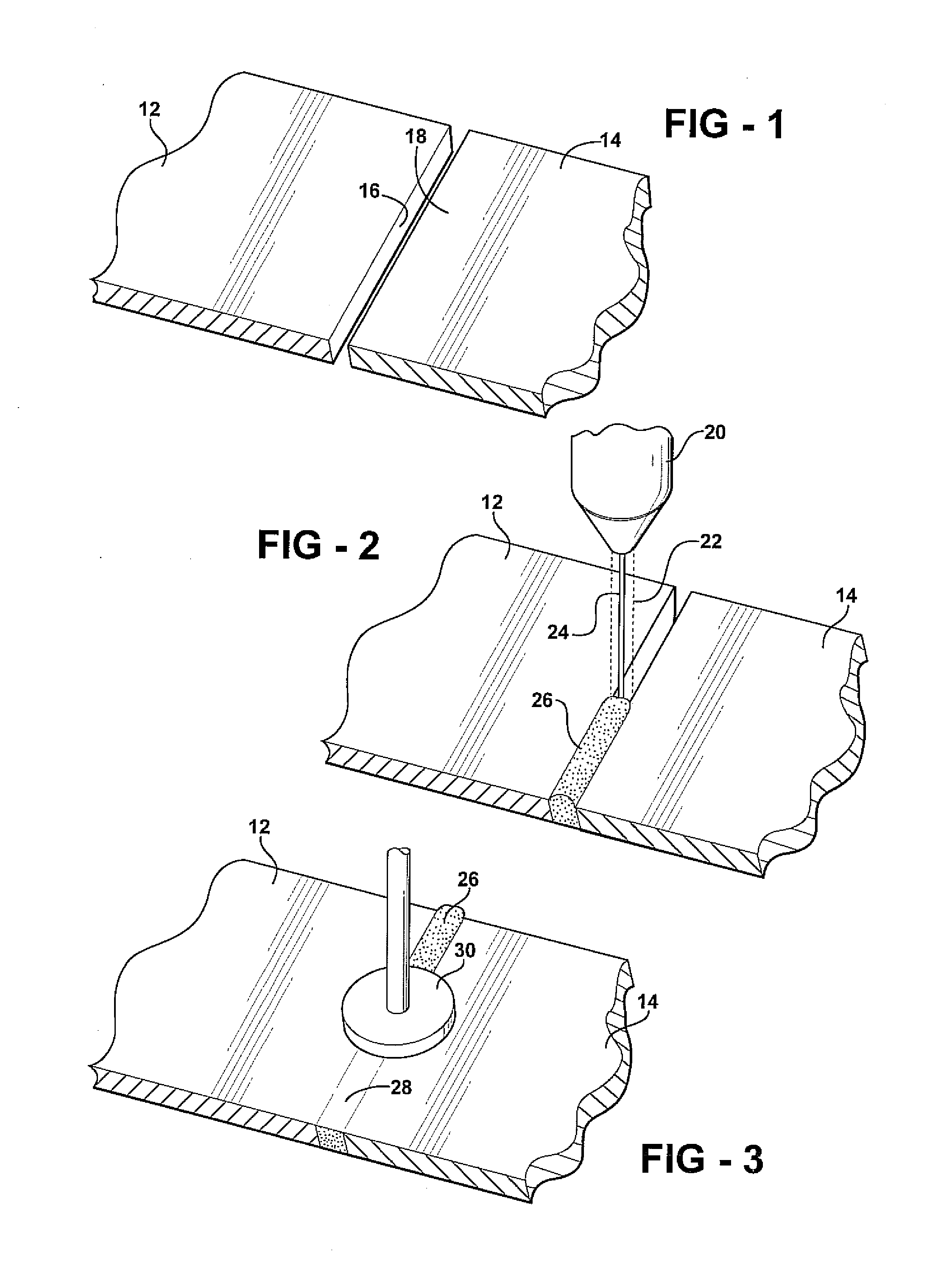

Laser-CMT welding aluminum alloy additive manufacturing method and forming system

PendingCN107283061AImprove stabilityImprove interlayer bonding performanceWelding/soldering/cutting articlesLaser beam welding apparatusSlag (welding)Molten bath

The invention discloses a laser-CMT welding aluminum alloy additive manufacturing method and a forming system. A laser and an electric arc are adopted as a composite heat source, the cold metal short circuiting transfer manner is adopted, and additive manufacturing forming for an aluminum alloy component is achieved. According to the provided laser-CMT welding additive manufacturing method, the problems that in the process of aluminum alloy component manufacturing through laser additive, the required laser power is high, and forming is difficult are solved, the problems that in the traditional process of aluminum alloy manufacturing through electric arc additive, the heat input amount is large, deformation is serious, and a molten bath is prone to overflowing or webbing are solved, and the problem that in the process of aluminum alloy manufacturing through CMT welding additive, incomplete fusion or slag inclusion or the like is likely to happen is solved; and the additive manufacturing method based on the laser-electric arc composite heat source principle is provided for additive manufacturing forming for the aluminum alloy component.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN +1

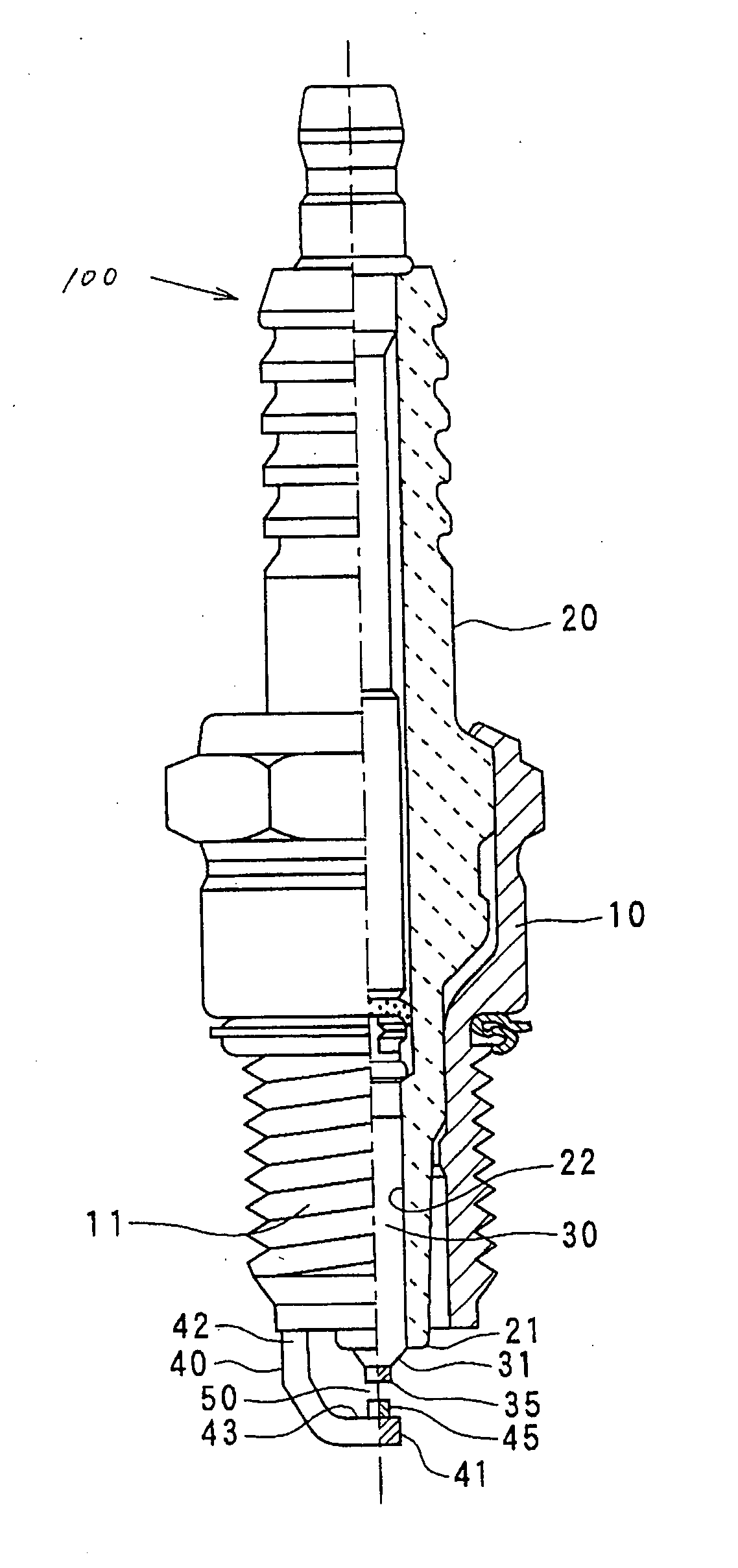

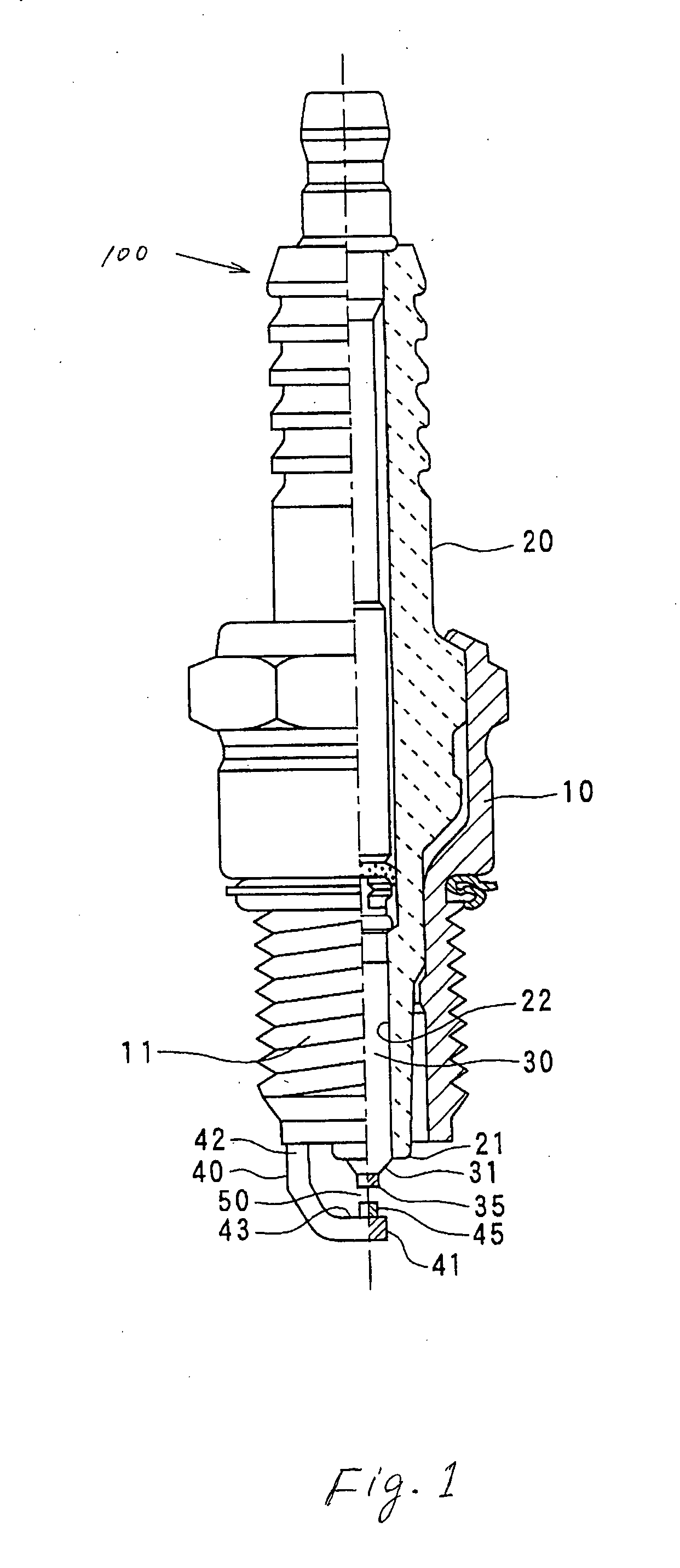

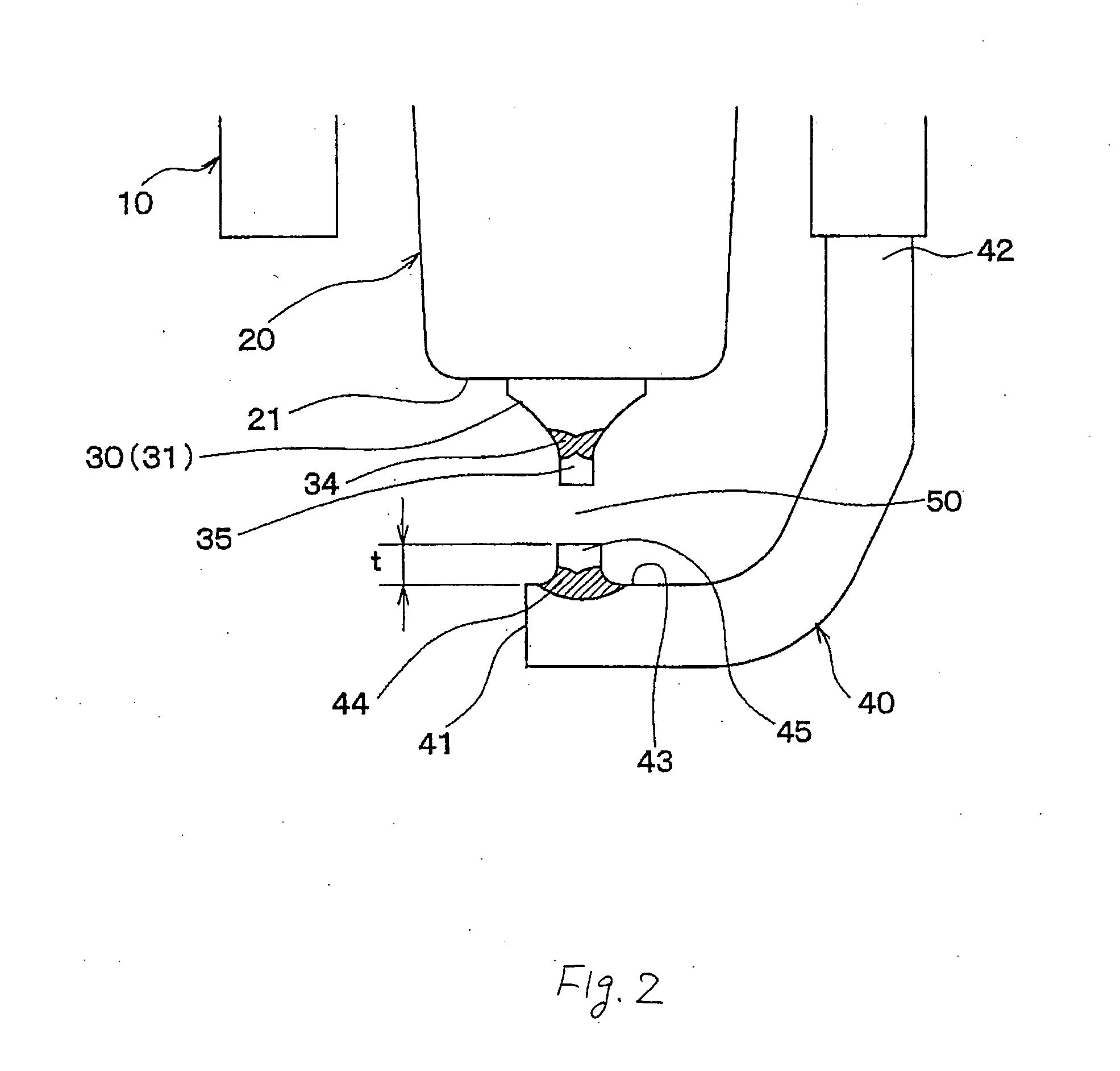

Spark plug with noble metal chip joined by unique laser welding and fabrication method thereof

ActiveUS20050023949A1Improve welding reliabilitySacrifice productivityFuel injection apparatusMachines/enginesMaterials scienceLaser soldering

A spark plug is provided which ensures the reliability of a weld between a noble metal chip and a ground electrode as well as higher durability and ignitability of fuel. The ground electrode is joined to a metal shell, after which the noble metal chip is laser-welded to the ground electrode. The laser welding is achieved by emitting laser beams around an interface between the noble metal chip and the ground electrode outside a given angular range within which the metal shell will be an obstruction to the traveling of the laser beams. Specifically, the laser beams are emitted without any optical interference with the metal shell. This permits the angle between the orientation of each of the laser beams and the surface of the ground electrode to be minimized regardless of the metal shell, thus ensuring a desired depth of the fused portions in the noble metal chip.

Owner:DENSO CORP

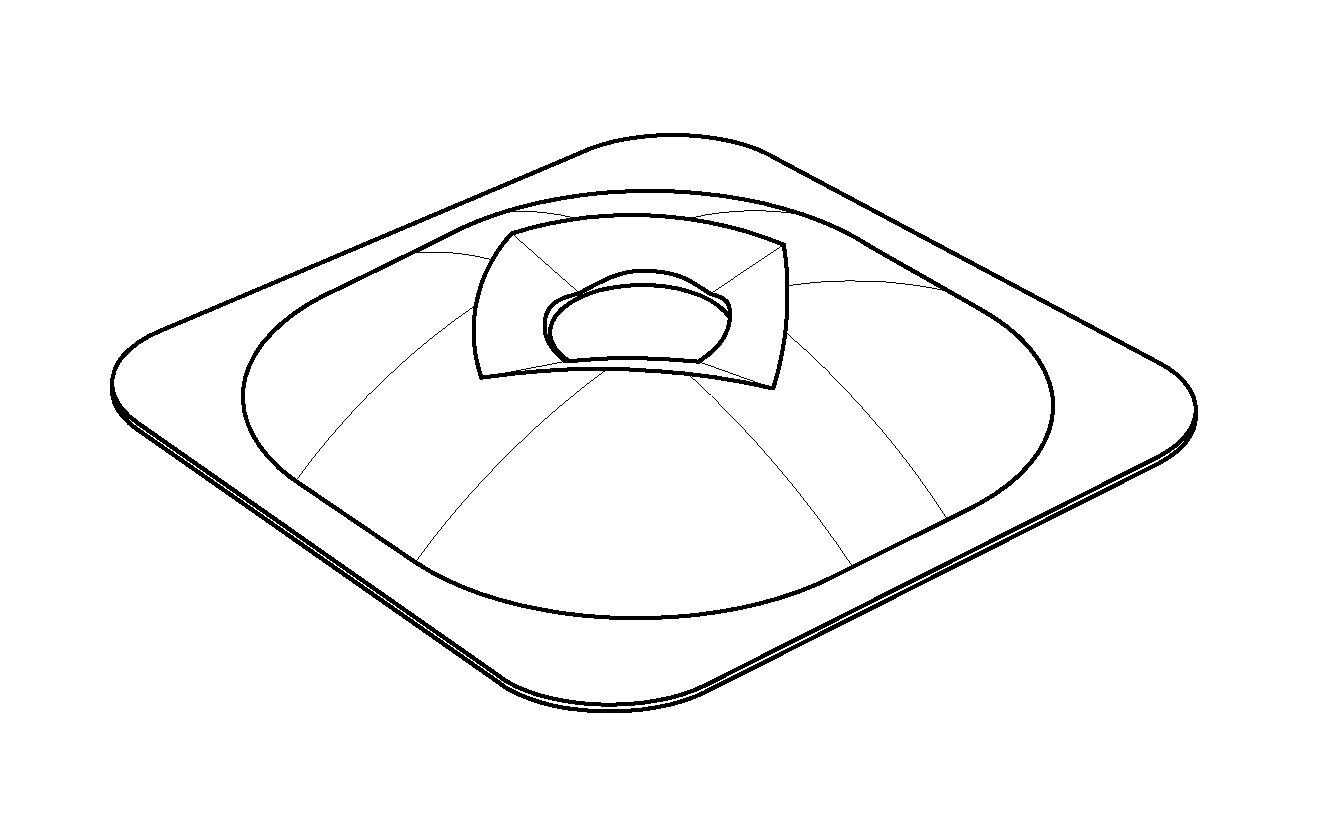

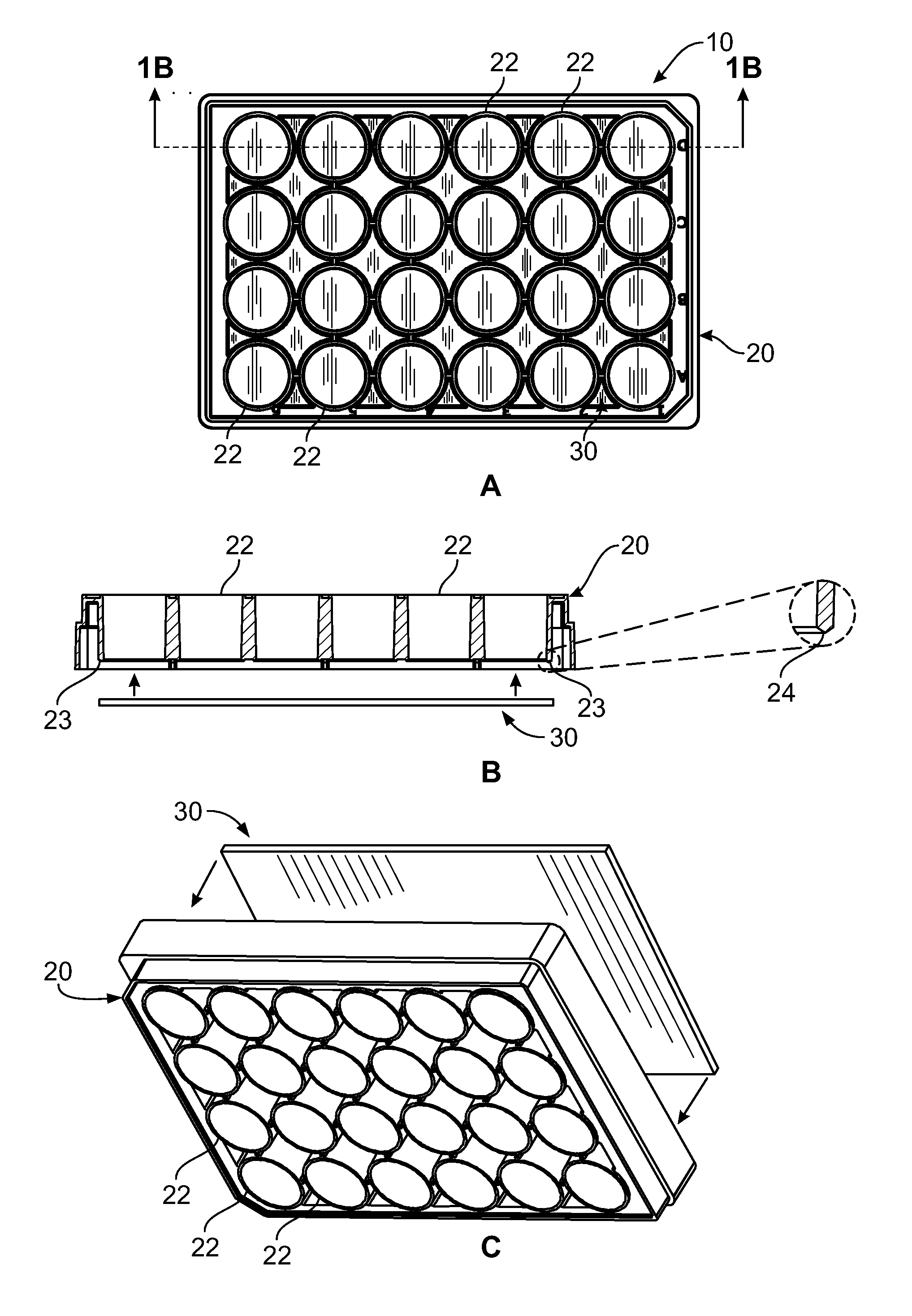

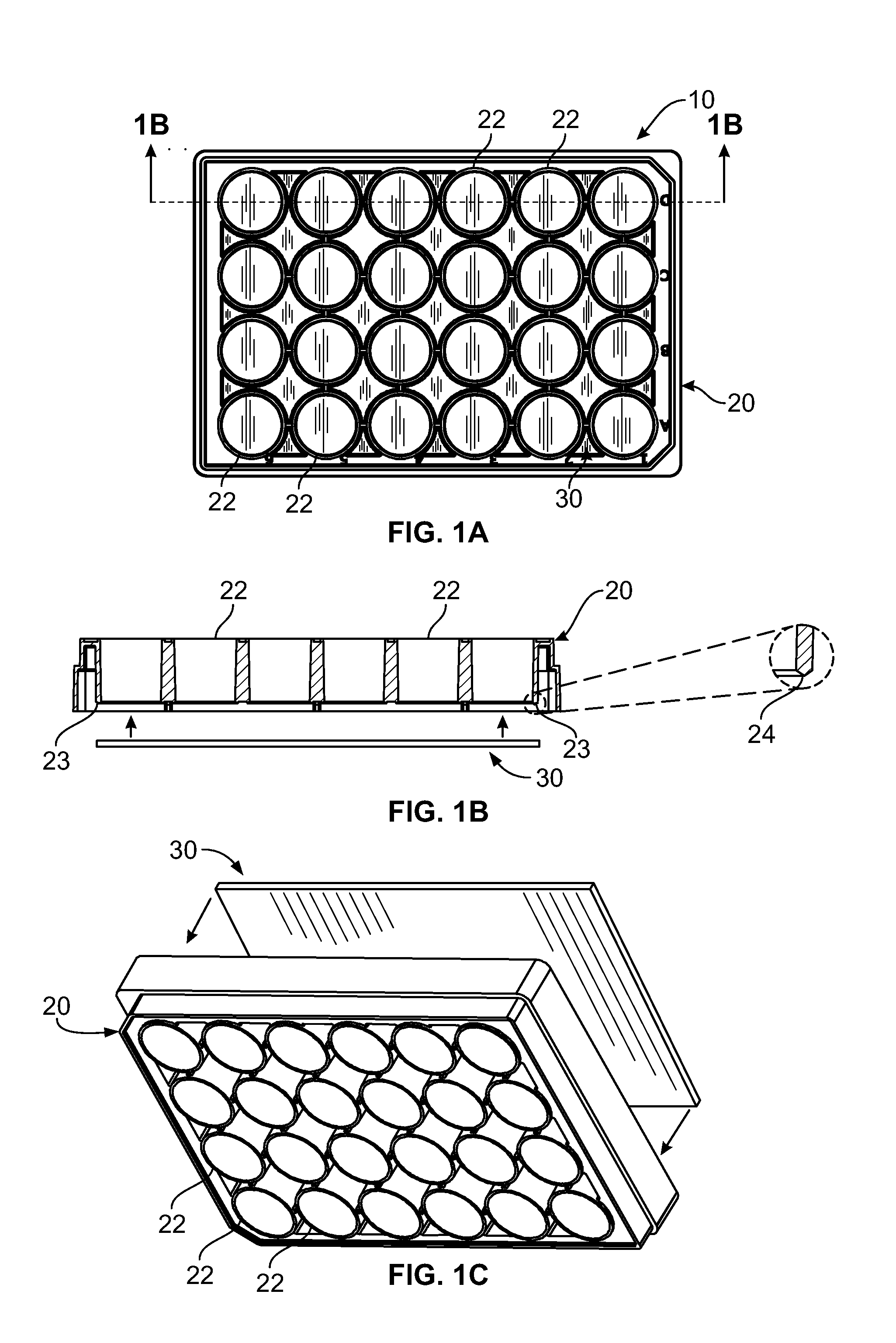

Culture plate with fiber-coated bottom surface

ActiveUS20140057346A1Bioreactor/fermenter combinationsBiological substance pretreatmentsFiberBiological cell

A cell culture plate that includes an upper portion having at least one discrete chamber with a top edge and a bottom edge; a substantially flat lower portion, wherein at least one layer of polymer fibers has been deposited on the upper surface of the lower portion, and wherein the at least one layer of polymer fibers is conducive to the growth of biological cells thereon; and wherein the bottom edge of the at least one discrete chamber is hermetically sealed to the fiber-coated upper surface of the lower portion to form a well using adhesives, laser welding, or ultrasonic welding.

Owner:NFS IP HLDG LLC

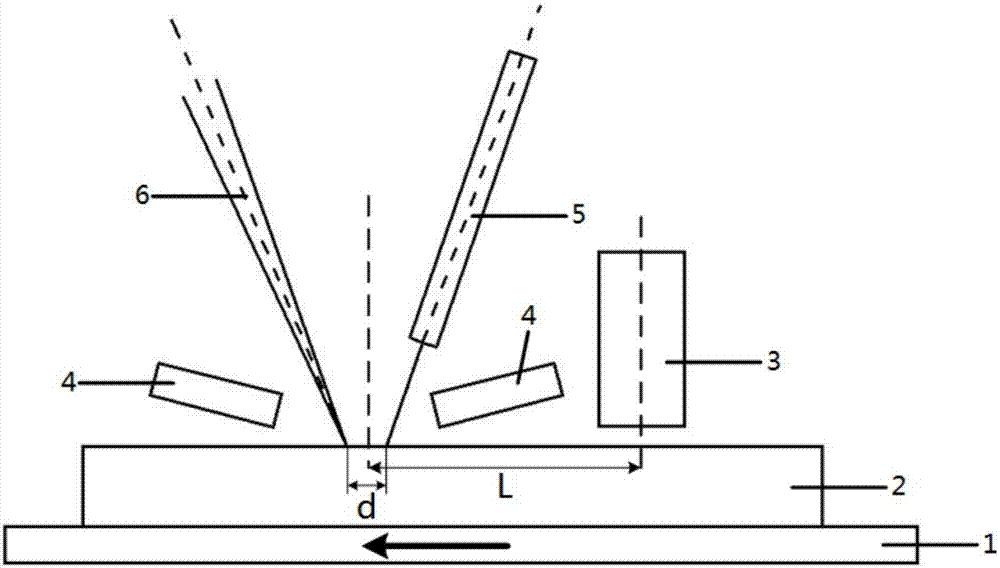

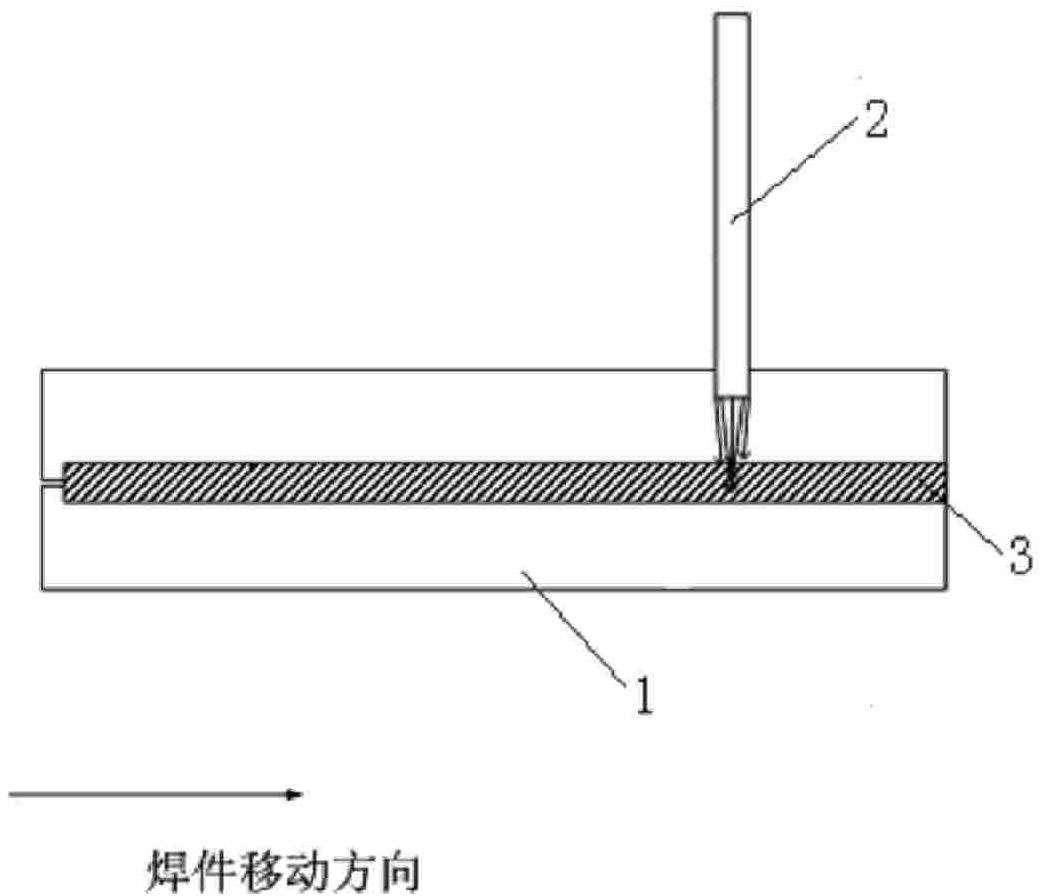

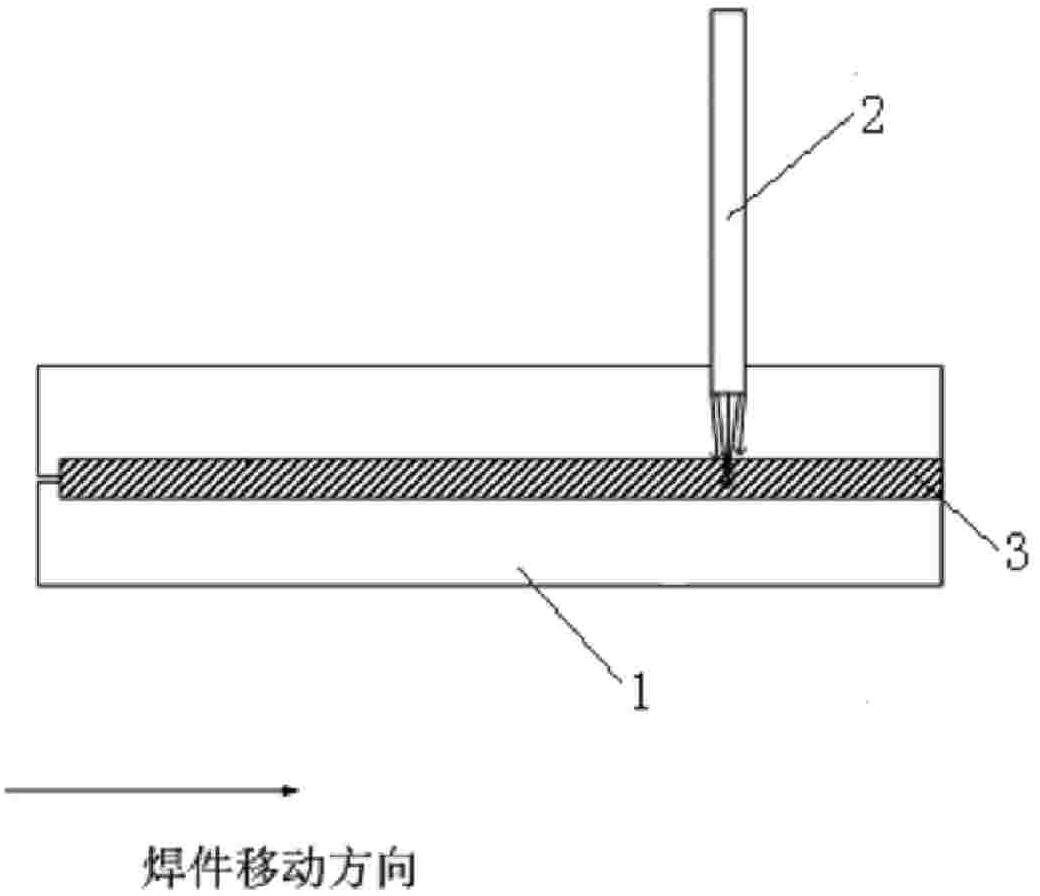

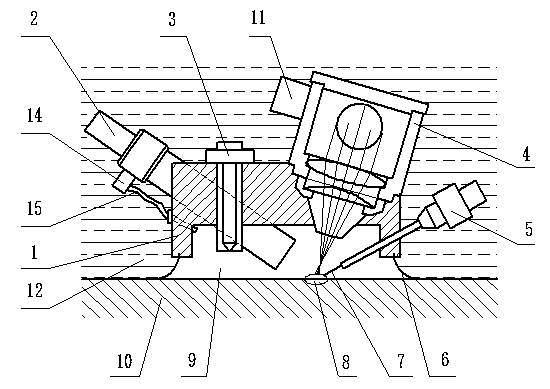

Hybrid welding method and hybrid welding equipment for laser electromagnetic pulse

ActiveCN103737176AImprove adoption efficiencyReduce welding defectsLaser beam welding apparatusStructural deformationMetallic materials

The invention discloses a hybrid welding method and hybrid welding equipment for laser electromagnetic pulse. The method can be used for laser seam welding and laser spot welding technology, a pulsed high magnetic field is applied to a welding region during the process of laser welding on a workpiece with the effect of laser beams so as to mutually react with an induced plasma, a welding pool and a stress strain field through welding and complete welding task. The equipment comprises a laser device, an electromagnetic pulse generator, a numerical control system, an optical transmission system and a laser electromagnetic pulse combined machining head. The combined machining head is used for integrating the laser beams with the pulsed high magnetic field and adjusting the distance between an electromagnetic conversion device and the workpiece; the combined machining head is arranged on a machine tool. The structural deformation can be reduced, the welding quality and machining efficiency are improved, and insurmountable technical problems when a metallic material structure is manufactured through existing single welding technology are solved.

Owner:武汉飞能达激光技术有限公司

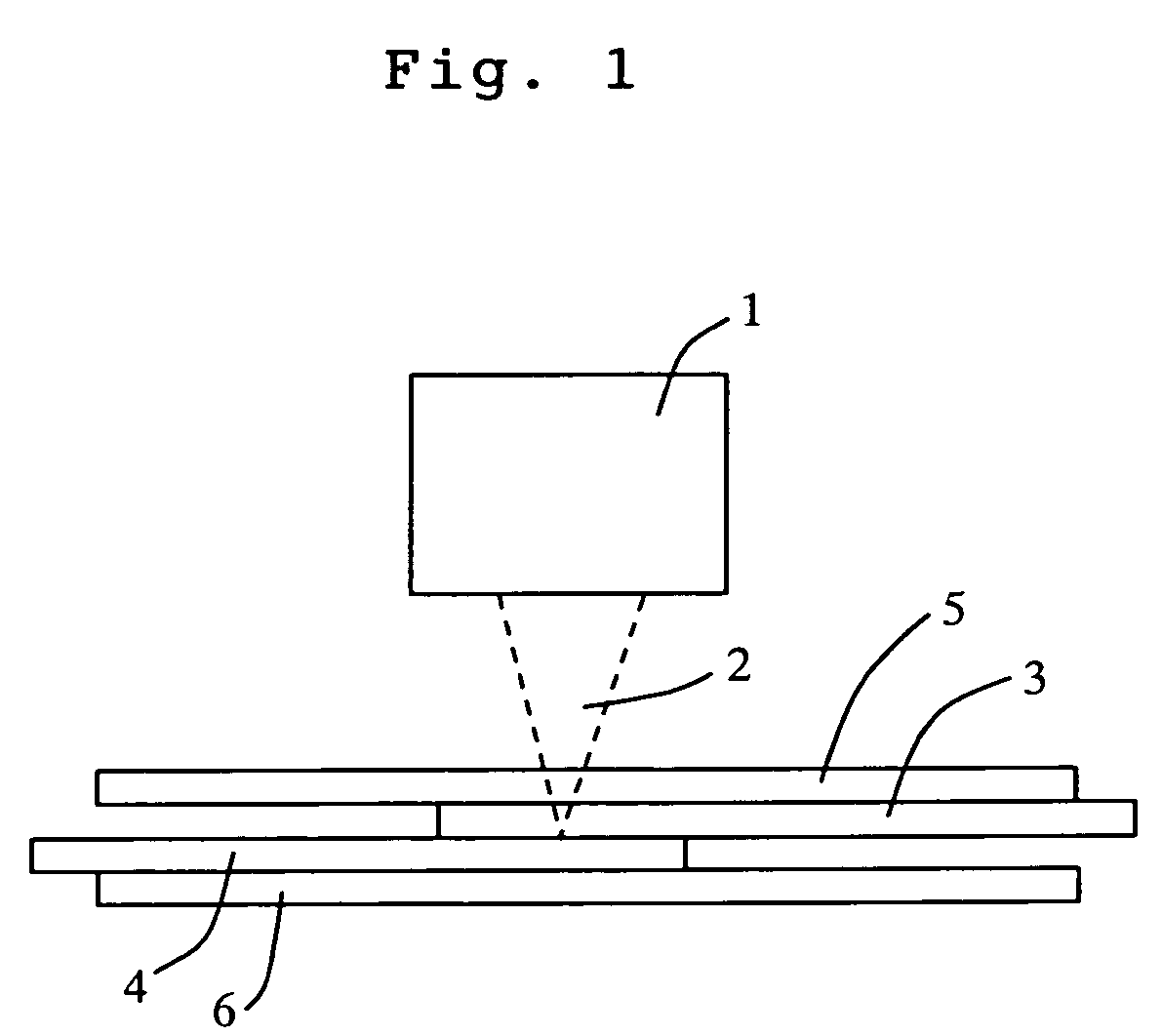

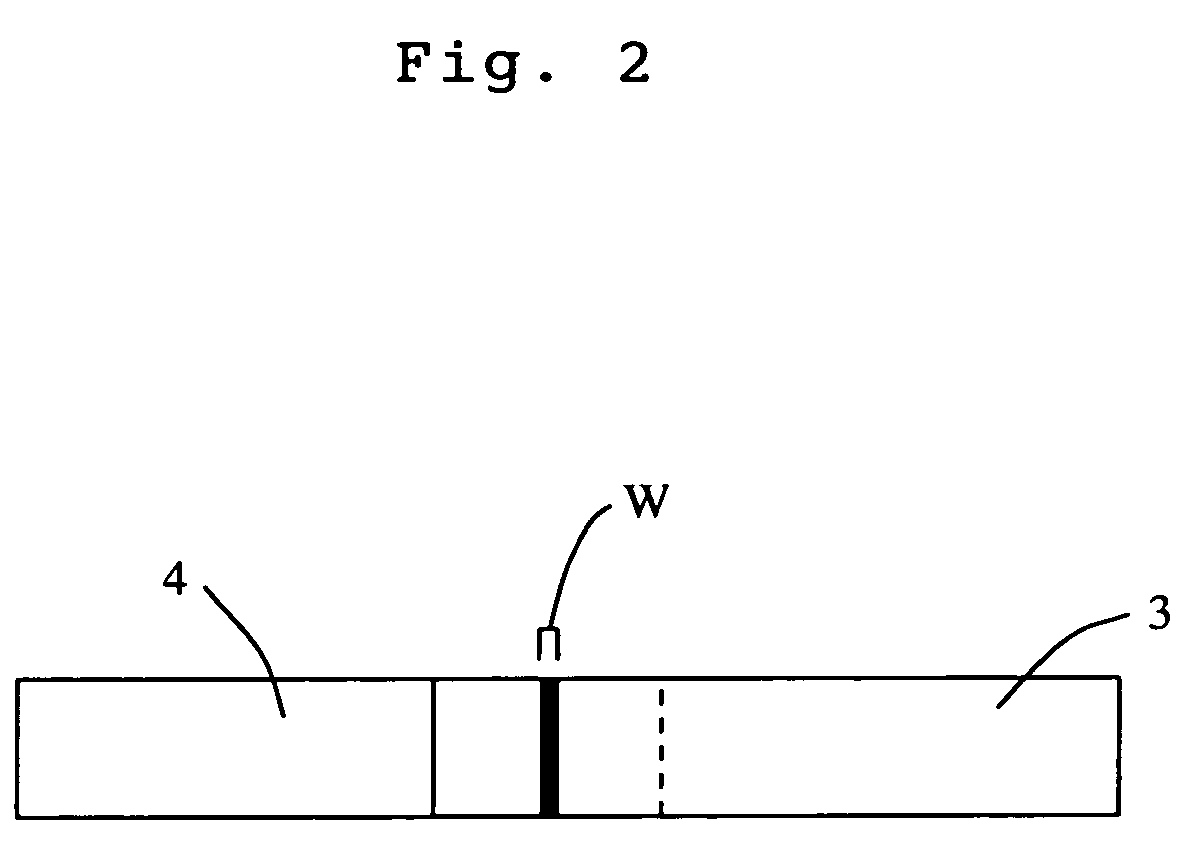

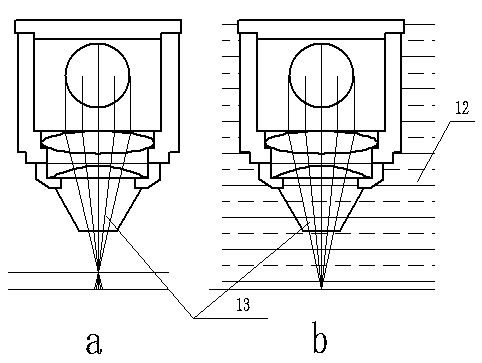

Laser soldering method

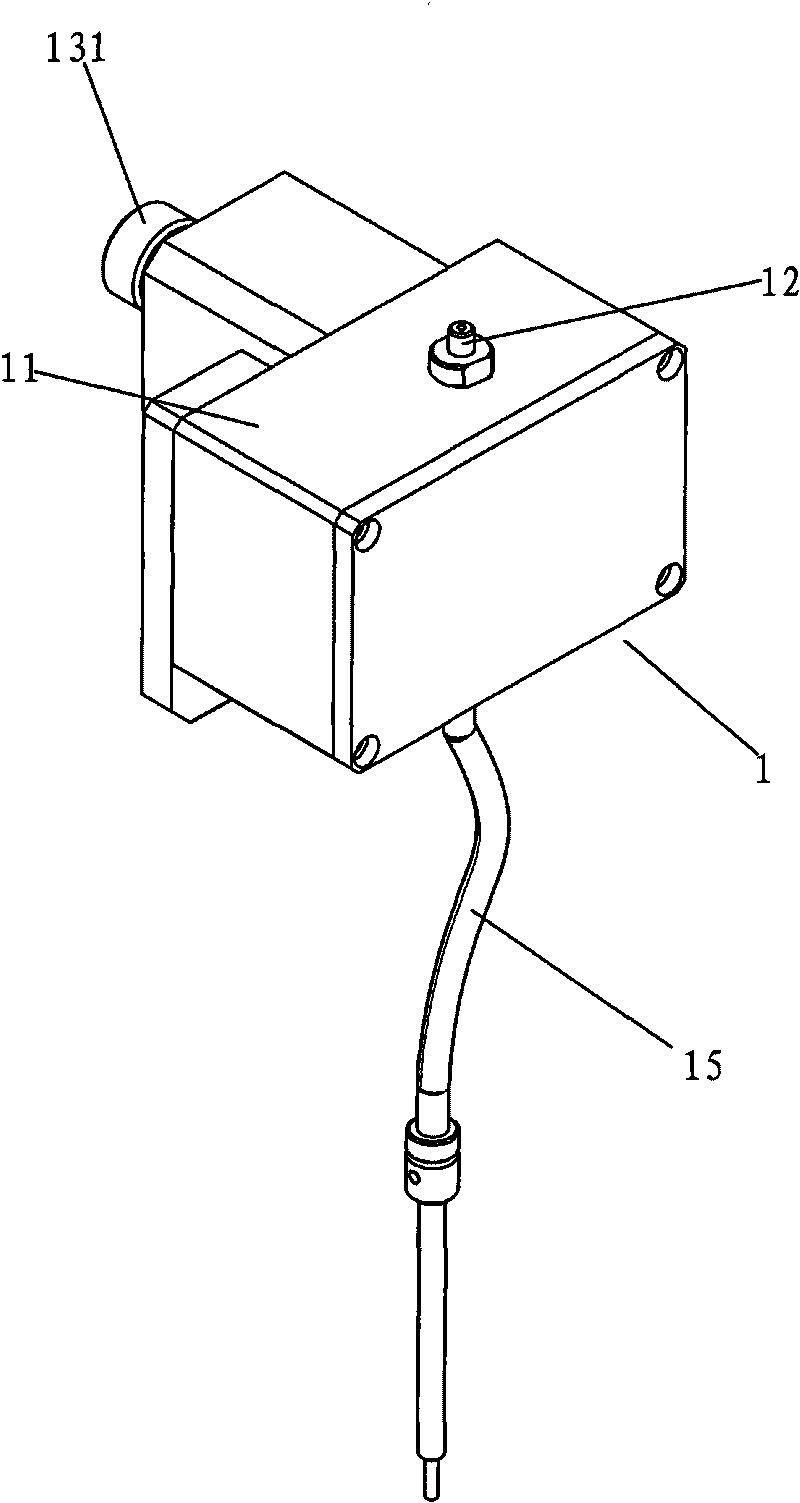

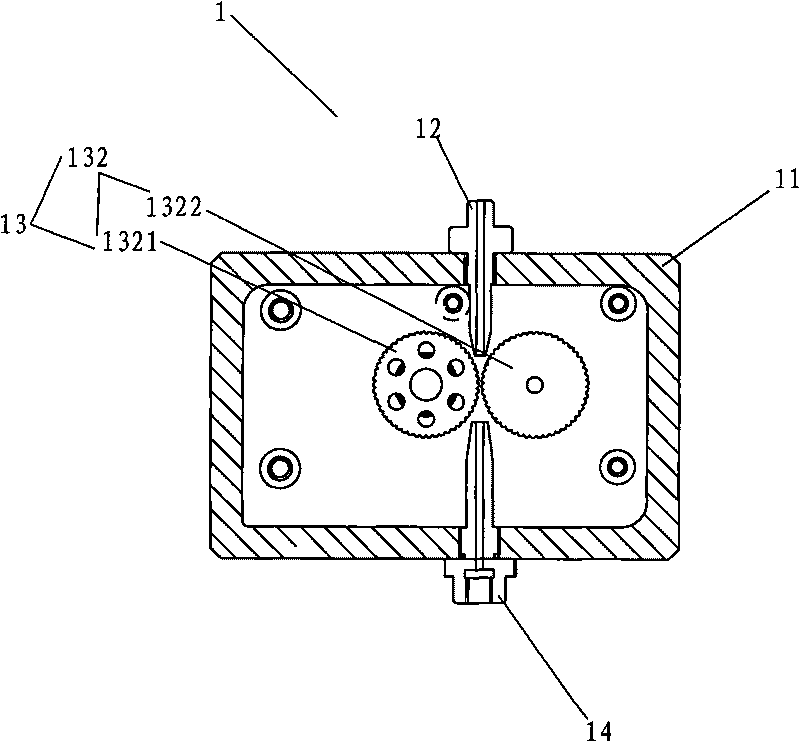

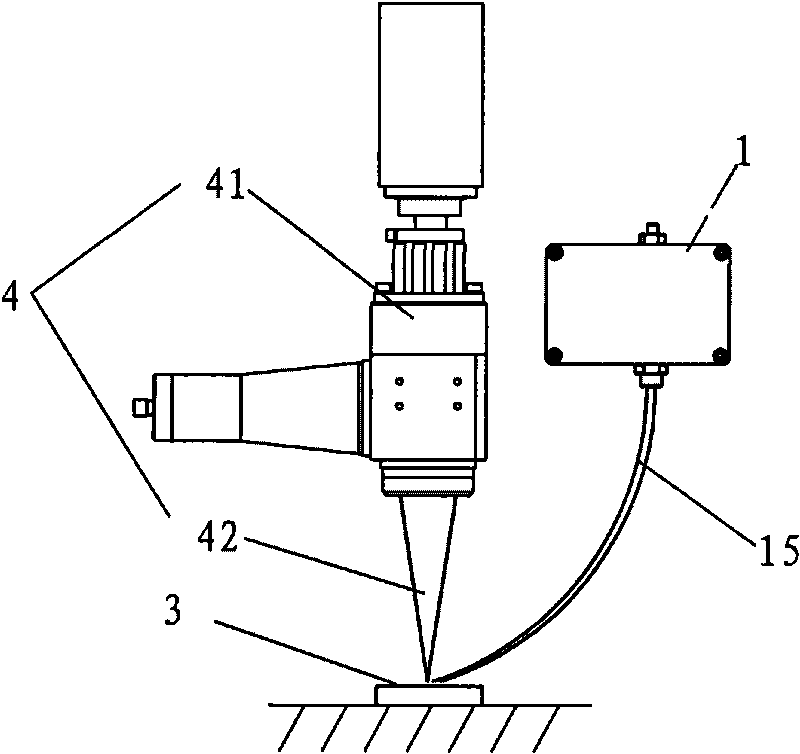

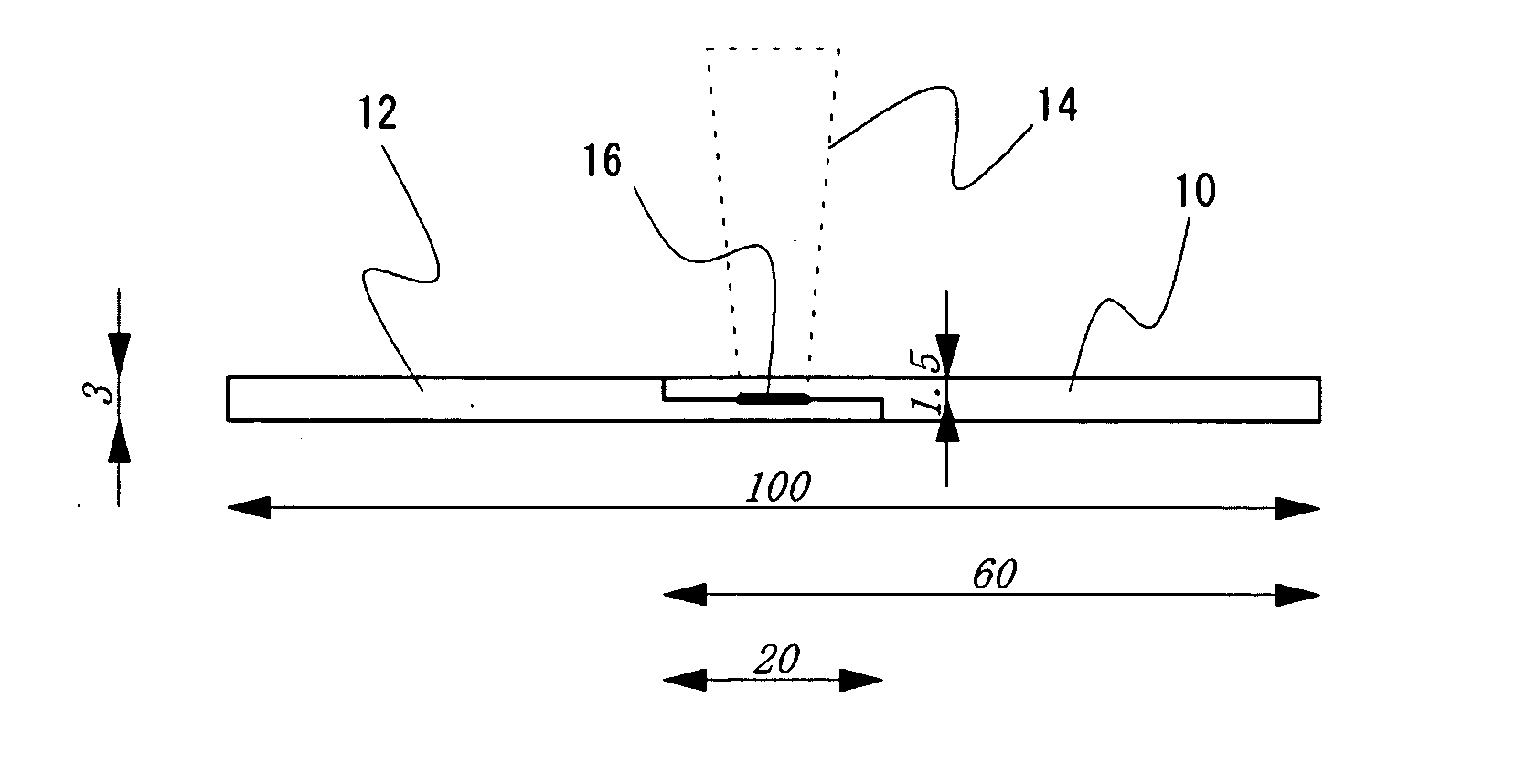

InactiveCN101745711AEasy to controlPrecise positioningSoldering apparatusLaser beam welding apparatusHeat lossesSoldering

The invention discloses a laser soldering method, comprising the following steps: (1) a semiconductor laser radiates a PCB pad with set energy so that the surface of the PCB pad reaches certain preheating temperature; (2) solder wires are fed to the surface of the PCB pad by a wire feeding mechanism on condition of certain feeding parameters; (3) under the action of laser radiation, the solder wires are molten and the molten tin spreads and moistens over the surface of the PCB pad; (4) the solder wires are withdrawn and removed from the pad; (5) the semiconductor laser continues radiating the pad so that the solder wires spread over the surface of the pad fully; and (6) the laser is closed and the tin is naturally cooled to form soldering points. During the use of the method, laser is used as soldering heat source, solder wires which are used as brazing filler metal are conveyed by wire feeder, and soldering connection is realized through the action of radiation of the laser to the tin wires and the PCB pad. Due to the characteristics of local heating, rapid heating, rapid cooling and the like during soldering, the method can effectively reduce heat loss of elements and greatly enhance the qualified rate of soldering.

Owner:HANS LASER TECH IND GRP CO LTD

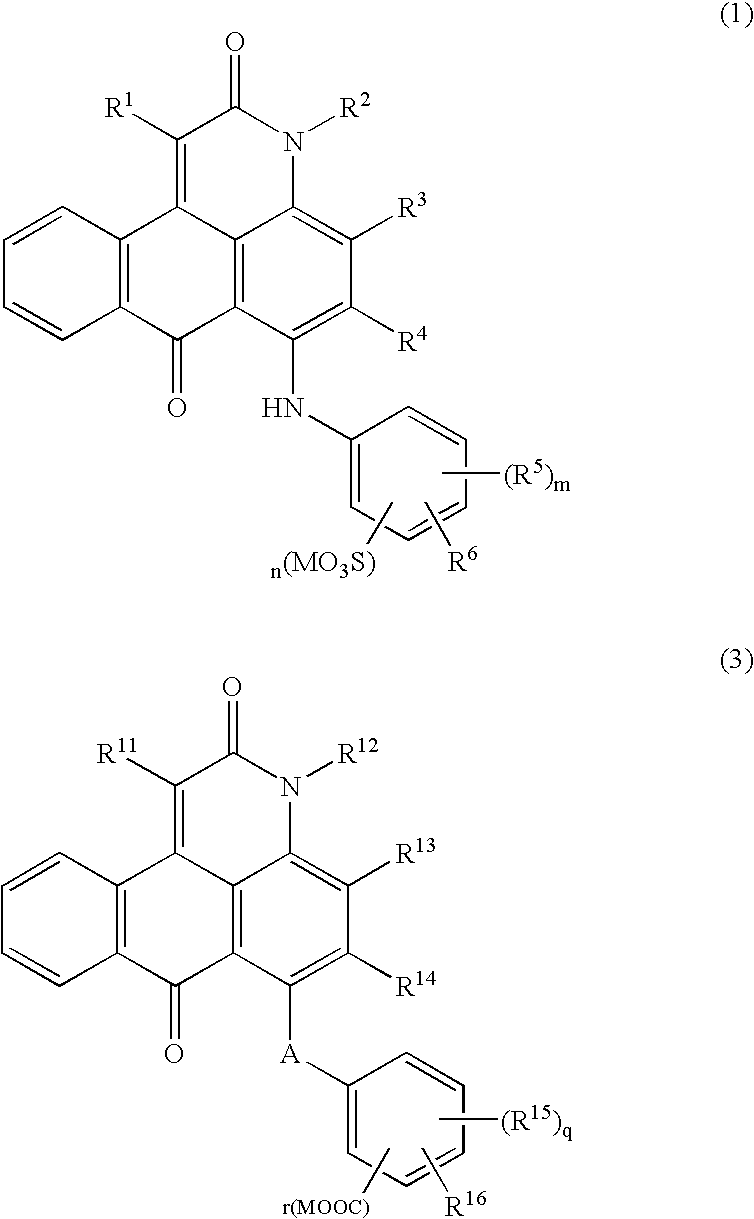

Laser ray transmitting colored thermoplastic resin composition and method of laser welding

InactiveUS20050003301A1High fastnessGood anti-migration propertyPhotomechanical apparatusPhotosensitive material auxillary/base layersOptoelectronicsIrradiation laser

A laser ray transmitting colored thermoplastic resin composition containing an anthrapyridone acid dye represented by formula (1) or (3); method of laser welding wherein a contact portion of a laser ray transmitting material of the laser ray transmitting colored thermoplastic resin composition and a laser absorbent material is welded by irradiating laser ray so that the laser ray transmits the laser ray transmitting material and is absorbed in the laser absorbent material with the laser ray transmitting material and the laser absorbent material in contact with each other.

Owner:ORIENT CHEM INDS

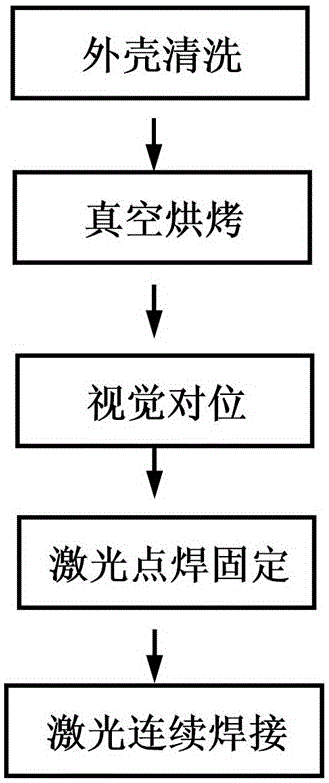

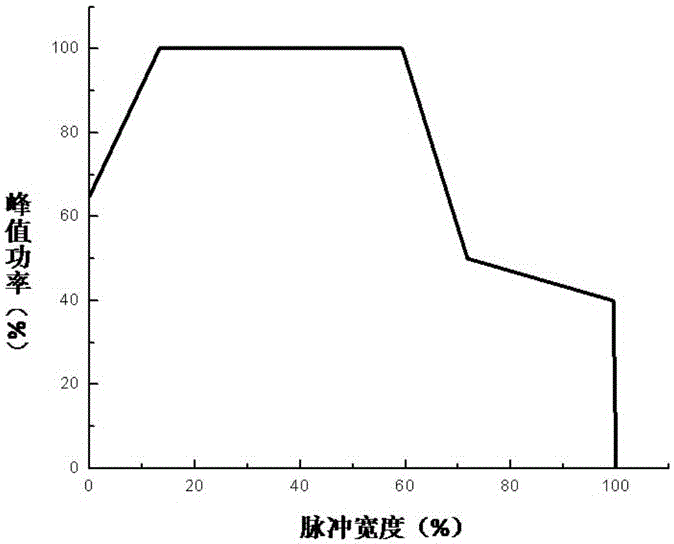

Laser seal welding technique for 3A21 aluminum alloy casing

ActiveCN105081573ASmall heat affected zoneSmall thermal deformationWelding/soldering/cutting articlesMetal working apparatusWeld seamSpot welding

The invention discloses a laser seal welding technique for a 3A21 aluminum alloy casing. The laser seal welding technique comprises the following steps of visual alignment, laser spot welding location and laser seal welding. The technological parameters of the laser seal welding are that the laser pulse peak power is 3000W-3500W, the impulse waveform is preheating thermal-insulation wave, the pulse width is 4ms-8ms, the pulse repetition frequency is 10Hz-20Hz, the welding speed is 108mm / min-180mm / min, and the defocusing amount is -1mm to -2mm. The laser seal welding technique for the 3A21 aluminum alloy casing can effectively remove cracks and air holes on welding seams of laser welding of the 3A21 aluminum alloy casing. The sealed 3A21 aluminum alloy casing has the beneficial effects of being attractive in welding seam appearance, high in air tightness, high in reliability, high in efficiency and low in cost.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Method of manufacturing a fluid dynamic bearing applicable to a disk drive that includes welding a cover member to a cylindrical wall of a shaft base

A method of manufacturing a fluid dynamic bearing in which a stopper is fixed by welding. The bearing comprises a hub, a shaft erected on the hub, a sleeve, a cylindrical wall erected on the hub, and the stopper mounted on the cylindrical wall. The method comprises a first step to hold oil in the bearing gap, and a second step to locate the stopper on the peripheral wall being apart from the interface of the oil to fix the stopper by LASER welding.

Owner:NIDEC CORP

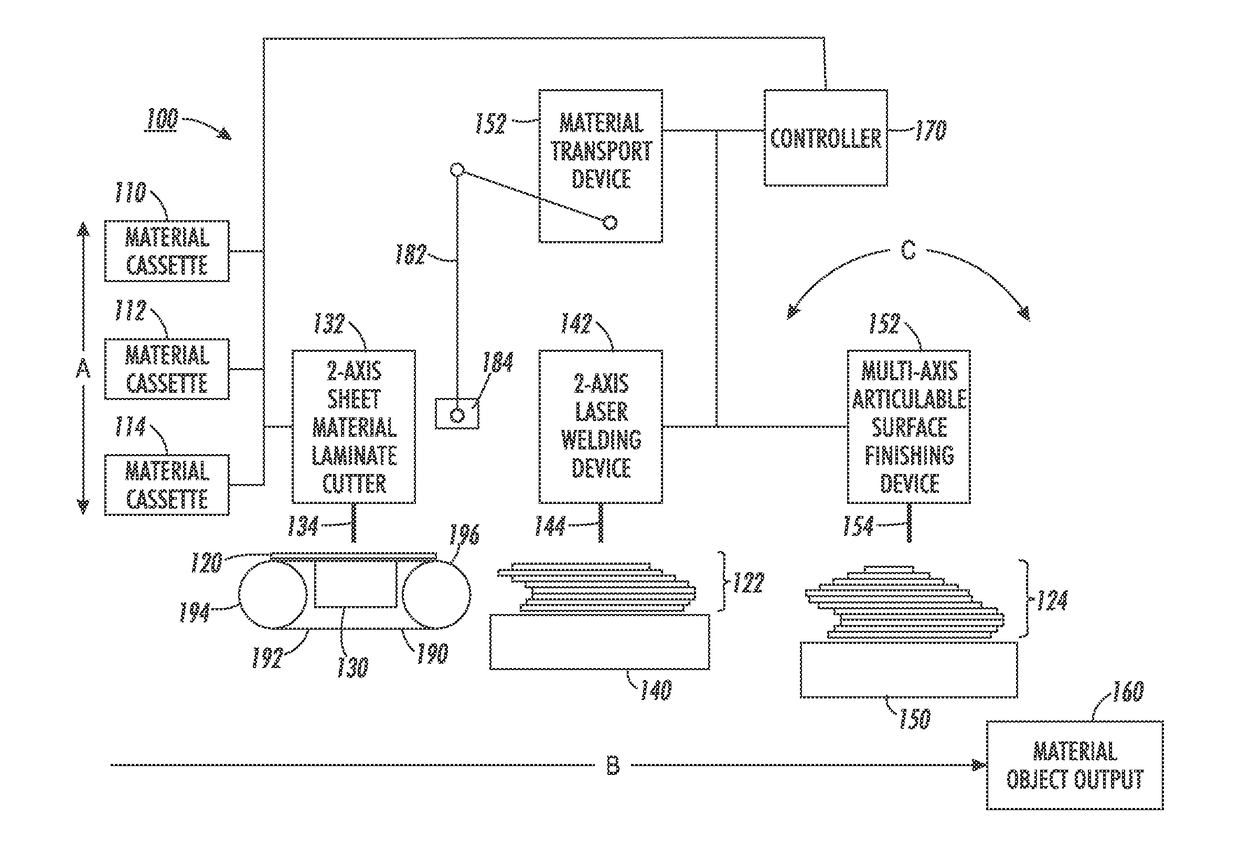

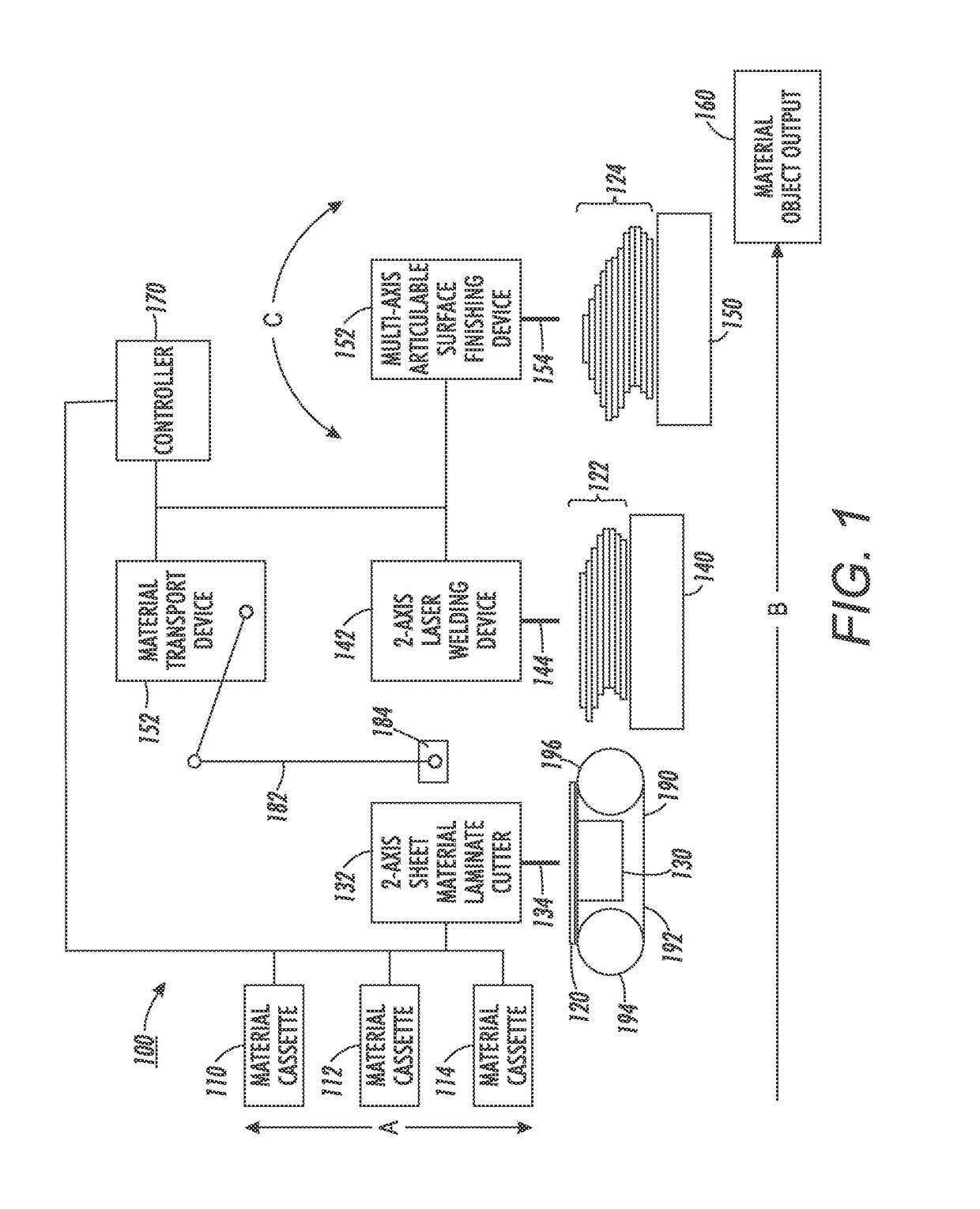

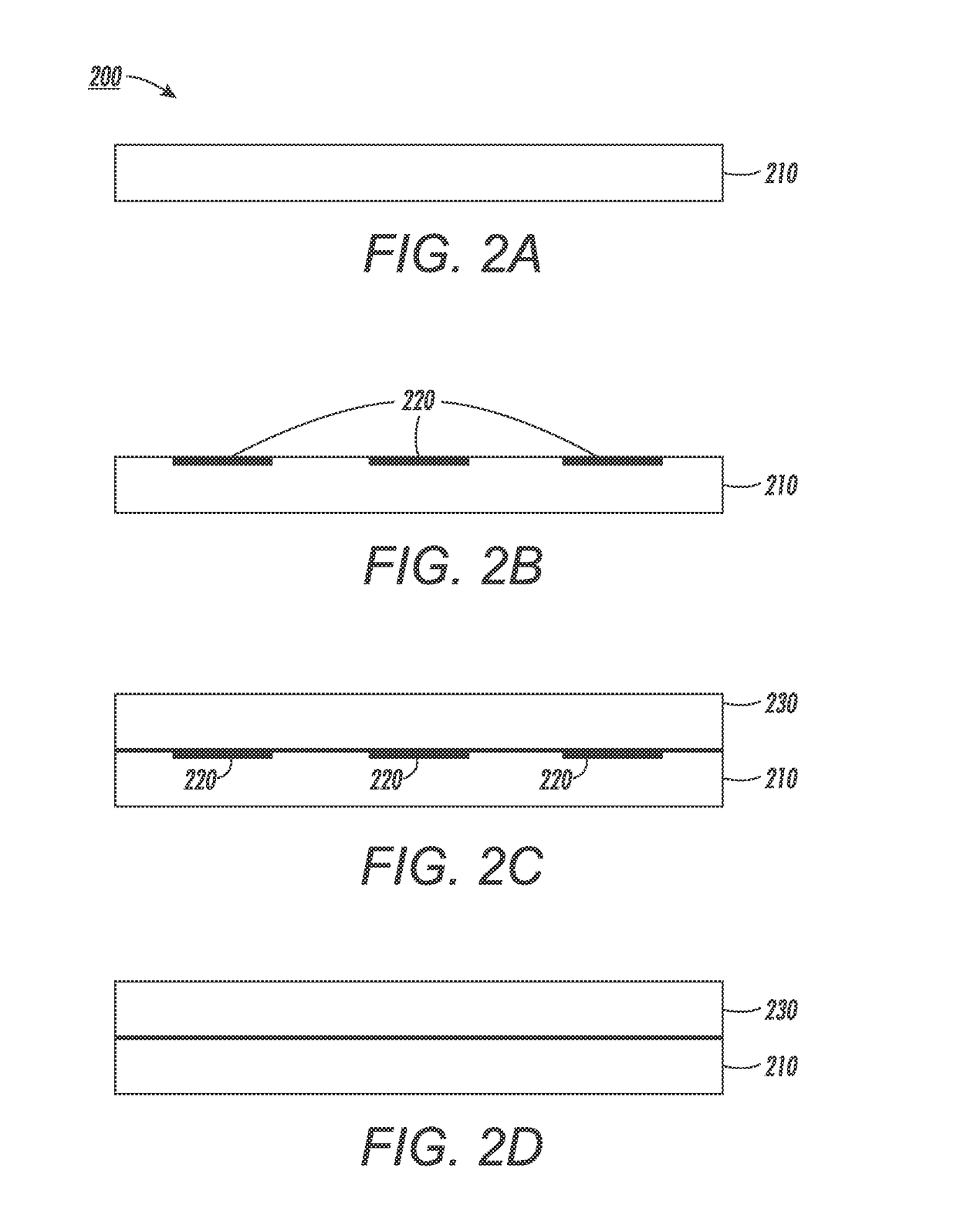

Systems and methods for implementing three dimensional (3D) object, part and component manufacture including locally laser welded laminates

ActiveUS20170144370A1High build rateSolve the slow construction speedAdditive manufacturing apparatus3D object support structuresSurface finishMachining

A system and method are provided for implementing localized and directed laser welding joining techniques in a process of building up laminate layers to form and / or manufacture three-dimensional objects, parts and components (3D objects). A multi-stage 3D object forming scheme is described involving steps of laminate cutting (with lasers or other cutting devices); laminate transport between processing stations (including using one or more of conveyors, robotic pick and place devices and the like); laminate stacking, clamping and adhering through a targeted laser welding technique; and mechanical surface finishing (via CNC machining or other comparable process).

Owner:XEROX CORP

Aluminum alloy laser welding method

InactiveCN102079013AImprove absorption rateImprove organizationLaser beam welding apparatusHeat-affected zoneYttrium

The invention relates to an aluminum alloy laser welding method. The method comprises the following steps: firstly carrying out nanometer metal oxide pretreatment on a part to be welded, namely, coating or spraying a nanometer metal oxide layer on the welding bead of an aluminum alloy weldment, wherein the nanometre metal oxide is nanometer yttrium oxide preferably; and then carrying out laser welding. By utilizing the method, the absorptivity of the aluminum alloy surface for laser can be greatly increased up to about 90%, thereby increasing the effective heating depth of the laser, deepening the weld penetration of a welding seam, effectively decreasing the width of the welding seam and the width of a thermal influence area, and improving the structure of the welding seam metal; the crystalline grain of an aluminum alloy welding joint under the action of the nanometre metal oxide can be refined, and finally the weld penetration can be relatively deep. Moreover, the thermal influence area is very small, and the weldment is beautiful in appearance and has fine inner structures.

Owner:CRRC QINGDAO SIFANG CO LTD

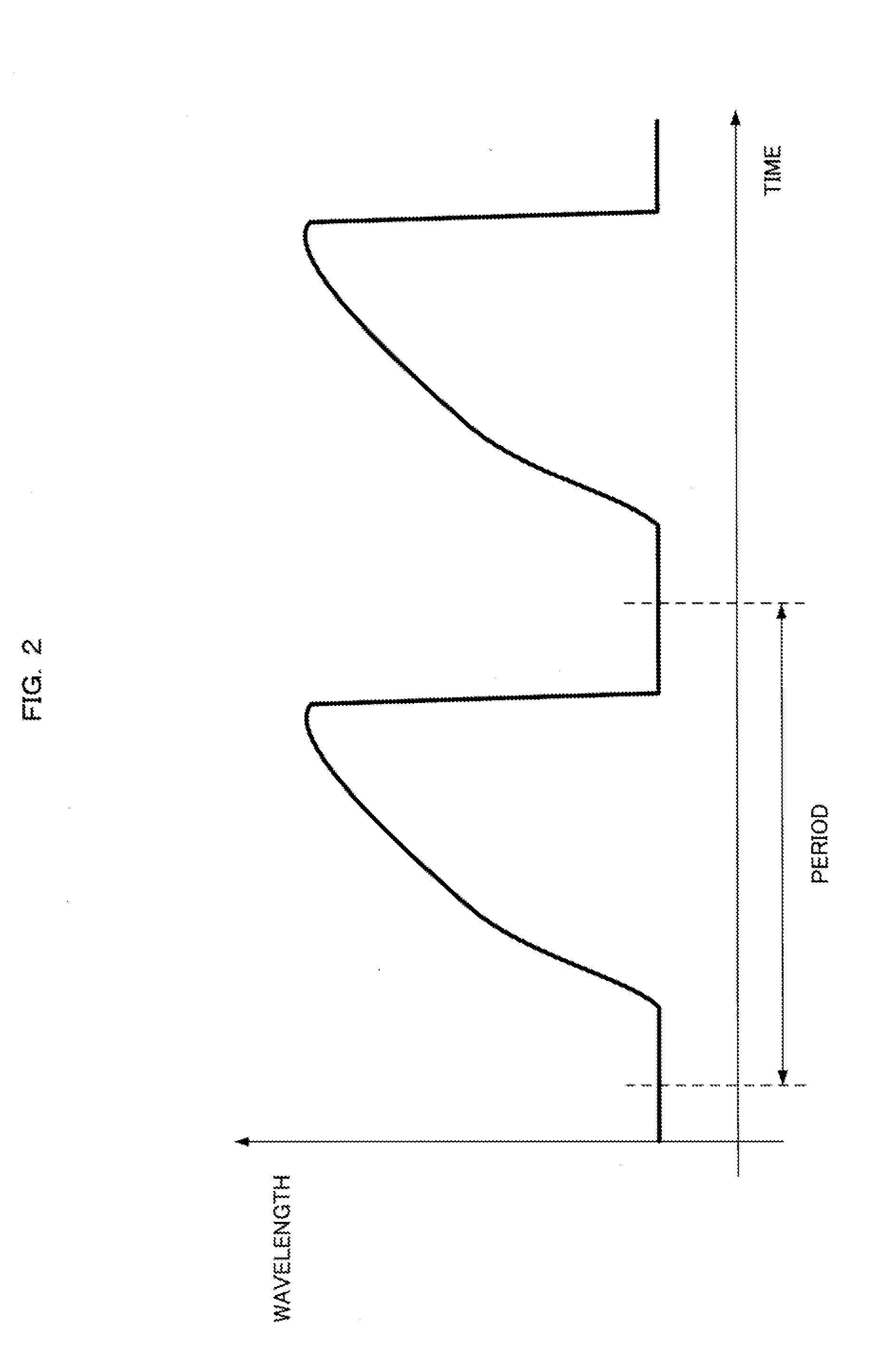

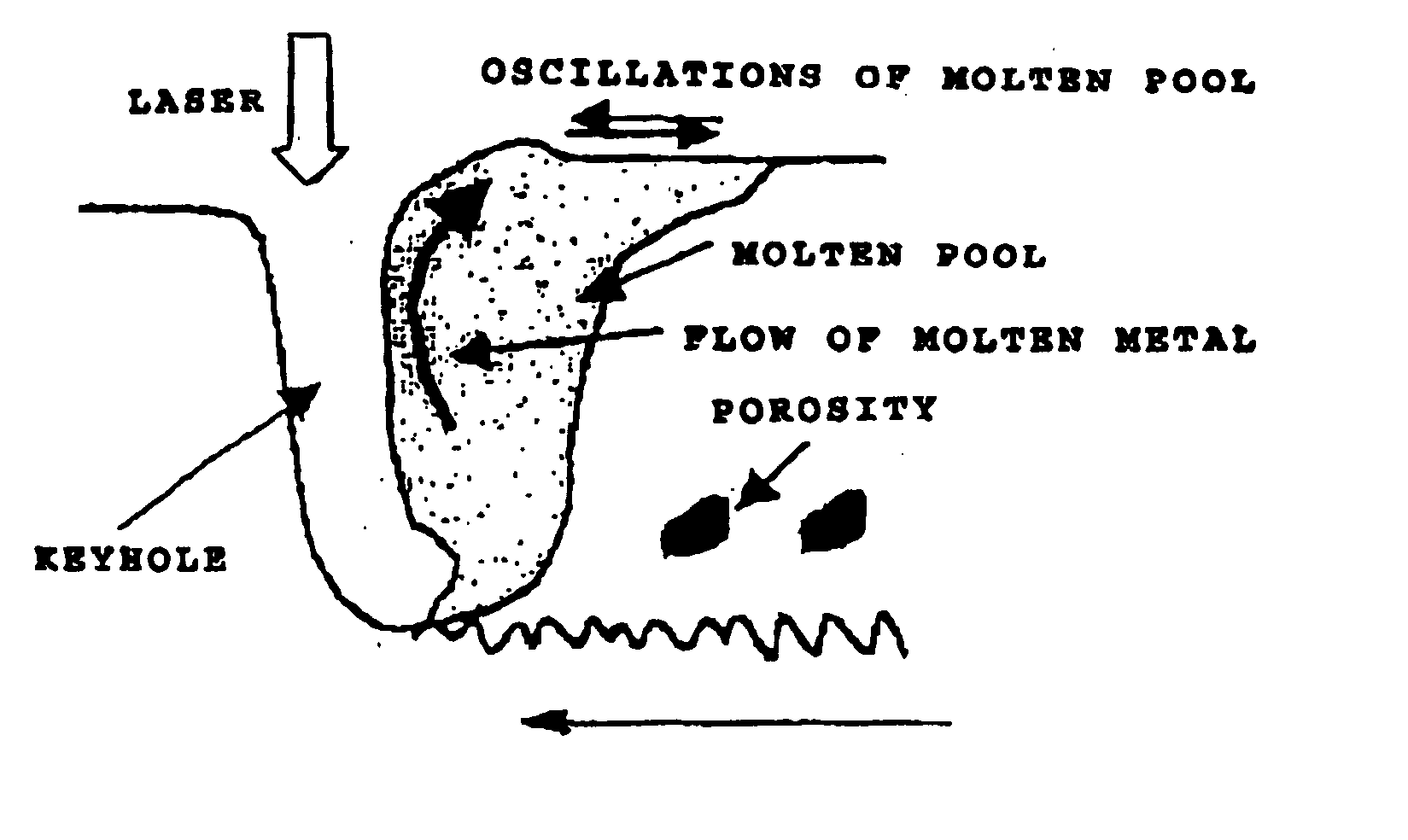

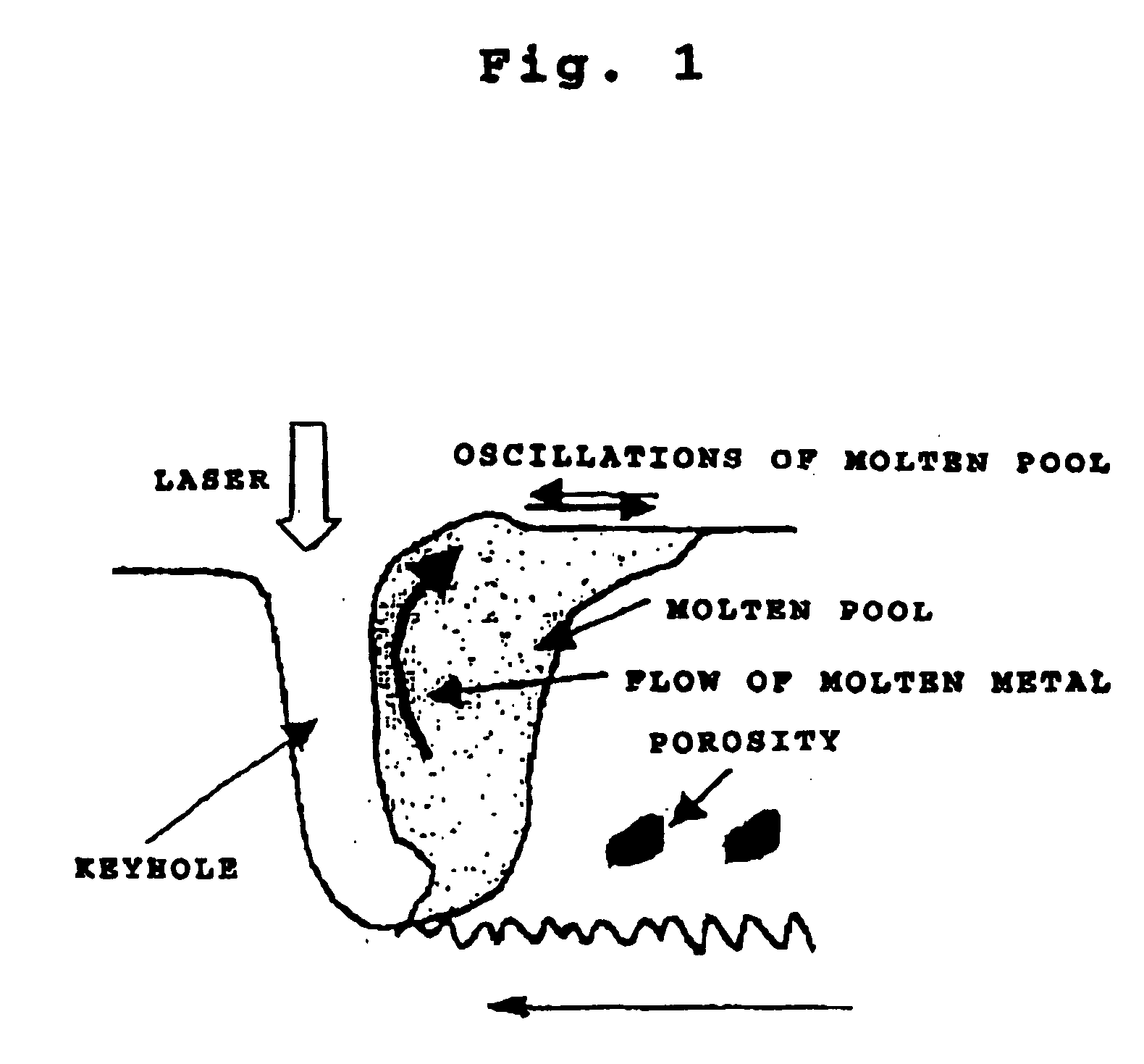

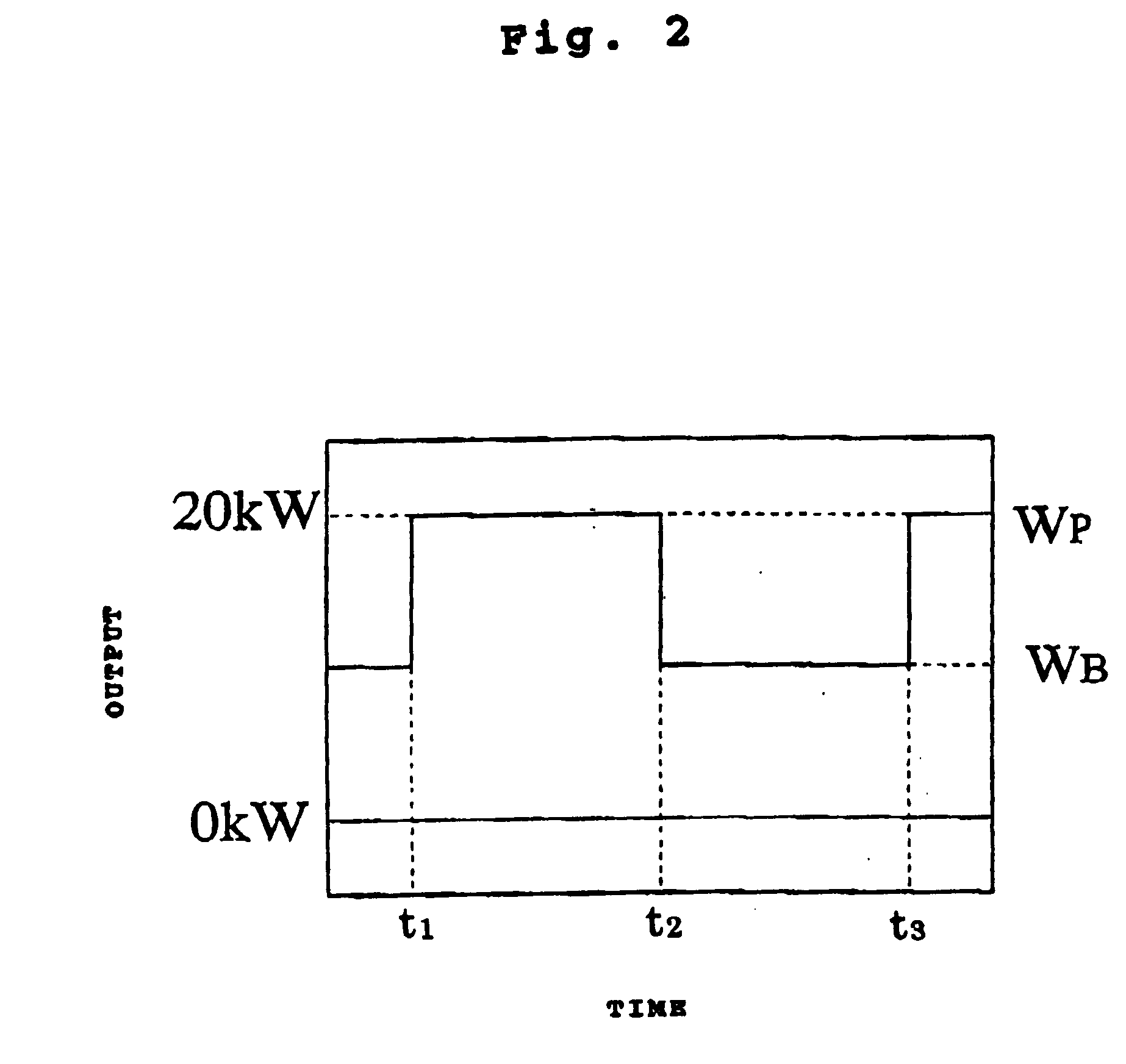

Laser welding processed

InactiveUS20040026381A1Avoid crackingInhibited porosityLaser beam welding apparatusMelting tankWelding defect

In a laser welding method, occurrence of weld defects is effectively prevented, and a high-quality weld joint is provided; and in addition, a wide range of material processes including a laser-using de p-penetration welding technique can be implemented. In keyhole welding using a laser performing output pulse modulation, the welding is conducted in accordance with a frequency conforming to a natural fr queucy of a metal molten pool.

Owner:NAT INST FOR MATERIALS SCI +1

Active agent for laser welding and method for laser welding by utilizing same

InactiveCN102179645AStrong penetrating powerIncrease profitWelding/cutting media/materialsSoldering mediaAluminium chlorideLithium chloride

The invention discloses an active agent and a method for carrying out surface treatment on materials to be welded of aluminium and aluminium alloys so as to improve the energy utilization rate of the aluminium and the aluminium alloys, deepen the fusion depth of welding seams and further obtain higher welding quality. The active agent for laser welding consists of a chloride and a fluoride, wherein the mass ratio of the chloride to the fluoride is (1-2): (1-4); the chloride is at least one of lithium chloride, sodium chloride, potassium chloride, zinc chloride, magnesium chloride, aluminium chloride, calcium chloride or tin chloride; and the fluoride is at least one of lithium fluoride, sodium fluoride, magnesium fluoride or calcium fluoride. When the surface treatment is carried out, firstly the fluoride and the chloride are mixed fully and uniformly, water is added to form a supersaturated solution, then the supersaturated solution is coated on the surface of a welded test piece as a coating agent, then drying is carried out, and finally laser welding is carried out under the condition of gas protection.

Owner:TIANJIN UNIV

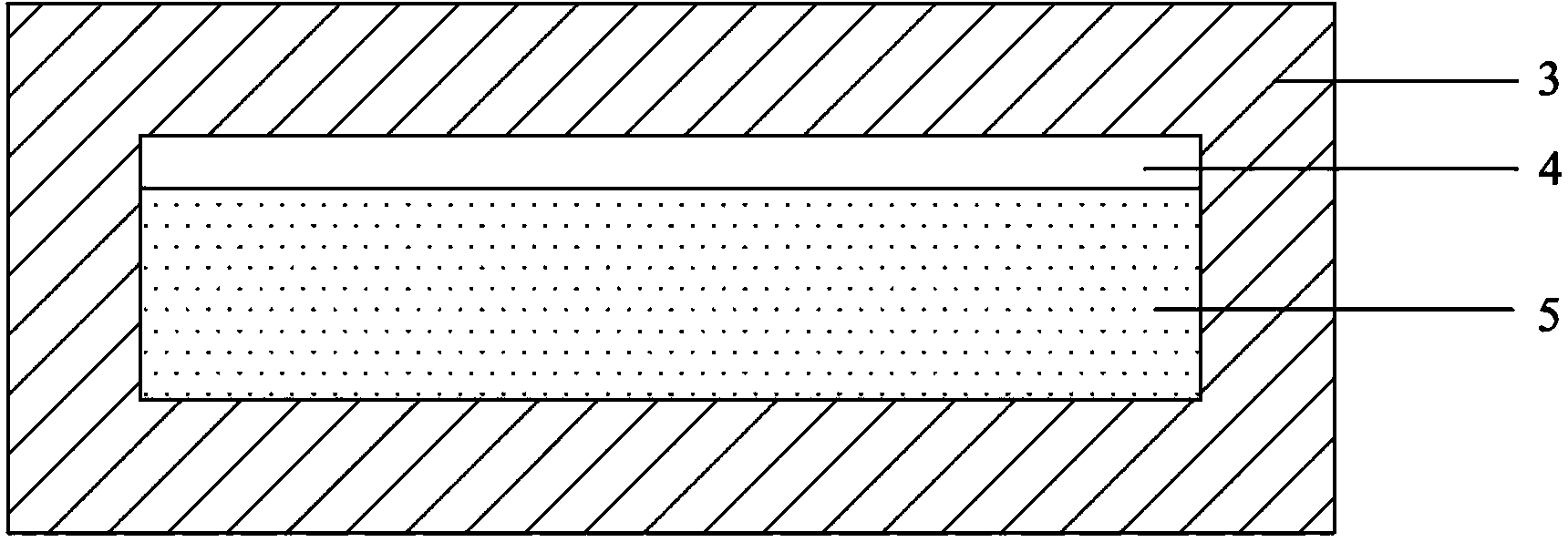

Aluminum silicon carbide composite material with laser welding layer and preparing method of aluminum silicon carbide composite material

ActiveCN103367270AImprove thermal conductivityReduce bloatSemiconductor/solid-state device detailsSolid-state devicesThermal dilatationCarbide silicon

The invention discloses an aluminum silicon carbide composite material with a laser welding layer and a preparing method of the aluminum silicon carbide composite material. The composite material is composed of the laser welding layer and an aluminum silicon carbide layer, the laser welding layer is composed of pure aluminum or aluminum alloy comprising silicon and aluminum, the volume fraction of the silicon in the aluminum alloy is a, the volume fraction of the aluminum in the aluminum alloy is b, the a is greater than 0 and less than or equal to 30%, and the b is greater than or equal to 30% and less than 100%. The aluminum silicon carbide layer is composed of silicon carbide and pure aluminum or aluminum alloy, and the volume fraction of the silicon carbide ranges from 30% to 70%. The preparing method comprises the steps that silicon carbide pelleting powder is prepared firstly, then silicon carbide preformed parts are prepared, and the aluminum silicon carbide composite material with the laser welding layer is prepared in the vacuum pressure impregnation method finally. The aluminum silicon carbide composite material is good in weldability and gas tightness, high in heat conductivity, low in coefficient of thermal expansion, simple in preparing method, efficient and low in cost.

Owner:NAT UNIV OF DEFENSE TECH

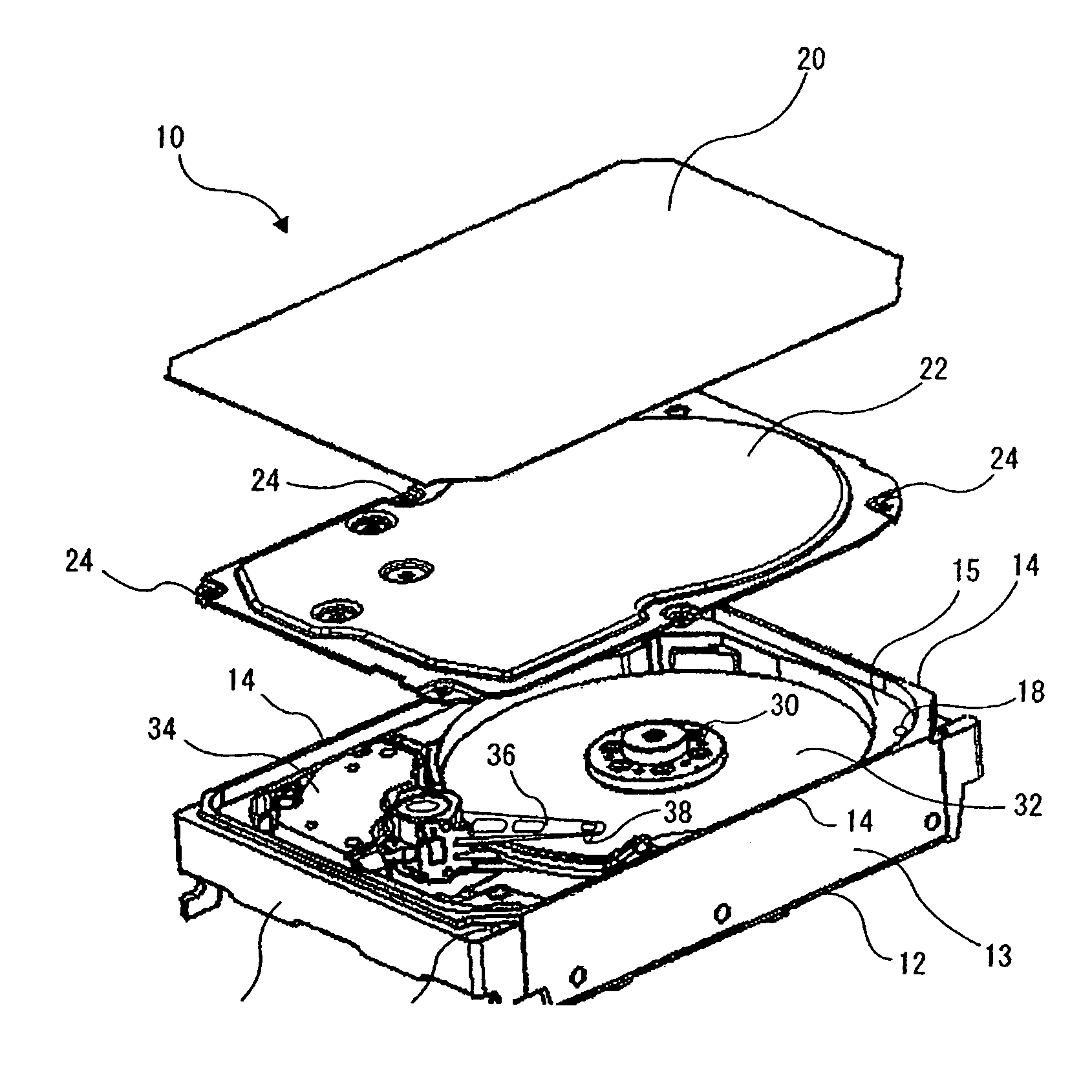

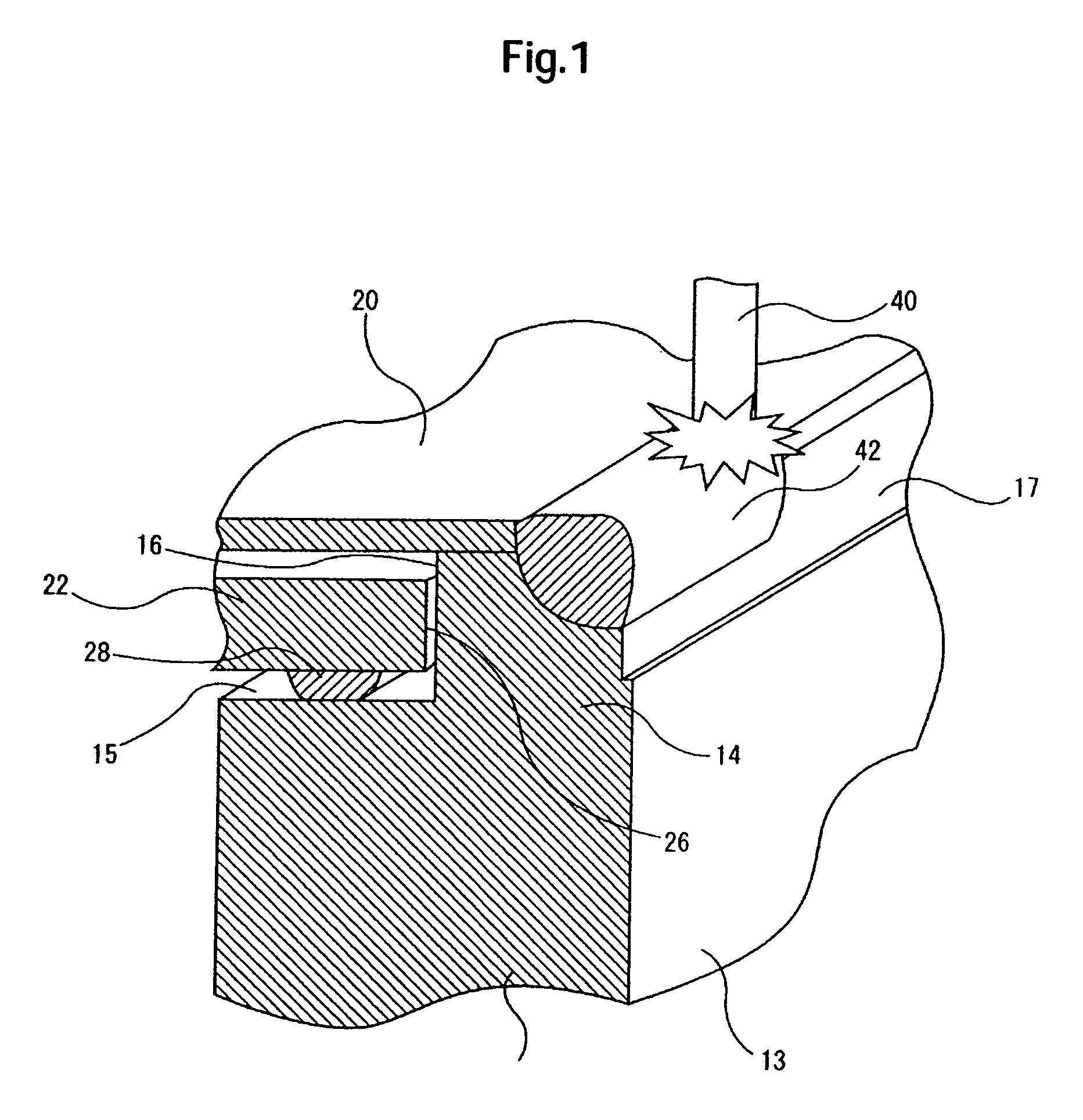

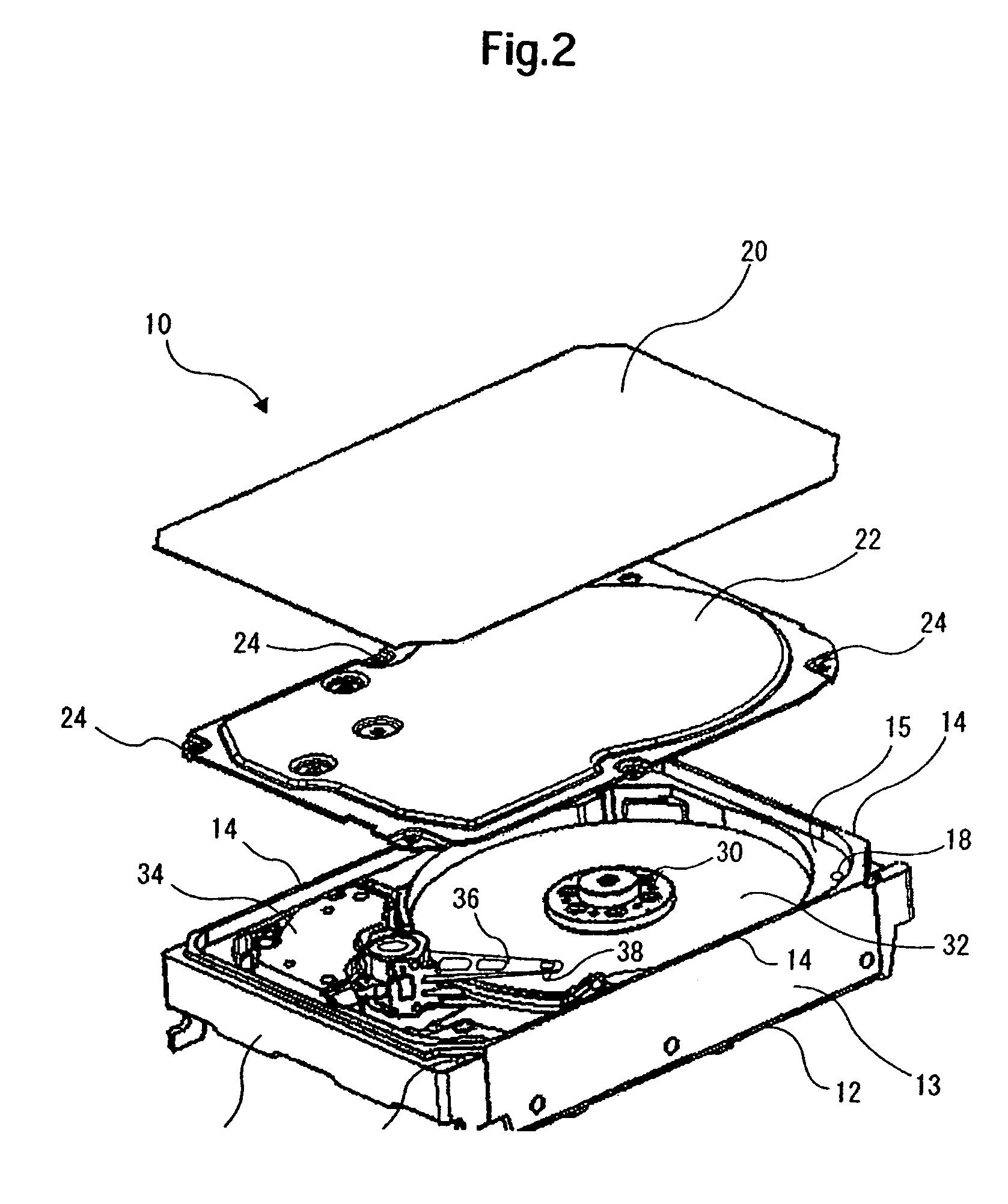

Magnetic disk drive and method for production thereof

ActiveUS7957092B2Prevent leakageApparatus modification to store record carriersUndesired vibrations/sounds insulation/absorptionEngineeringLow density

Embodiments of the present invention help to provide a magnetic disk drive in which the base and the lid are securely welded together, so that the low-density gas sealed therein is protected from leakage. According to one embodiment, the peripheral surface of the rib of the base is machined to form the surface, which is free of electrocoating and weld surface. The outer lid, which completely conforms to the contour of the base, is placed on the rib, and the laser beam is directed onto the outer lid. Thus the position of laser beam irradiation varies within only ±0.05 mm for both the base and the lid. Laser welding in this manner yields the bead invariably, which makes the enclosure completely sealed without helium leakage.

Owner:WESTERN DIGITAL TECH INC

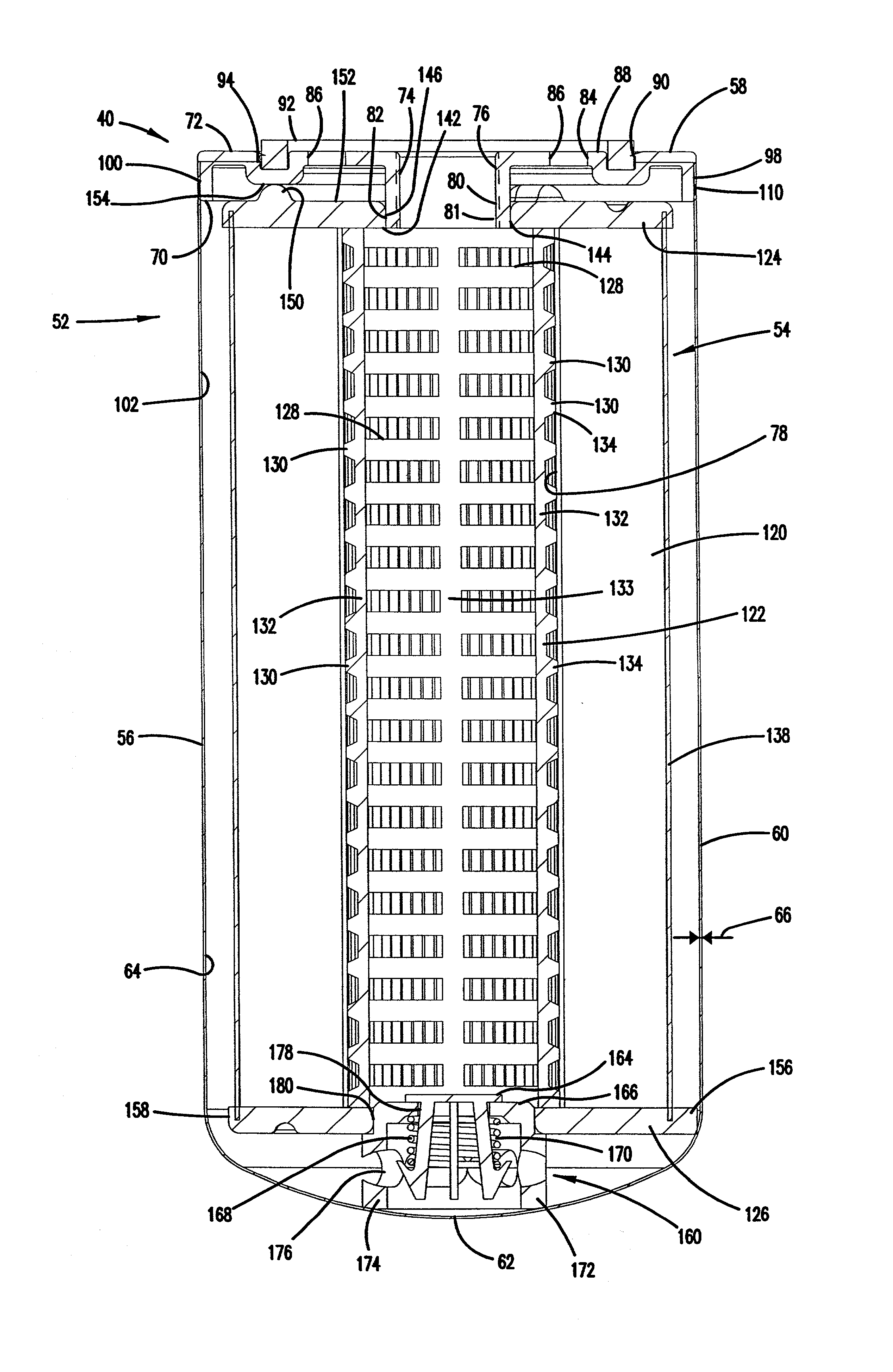

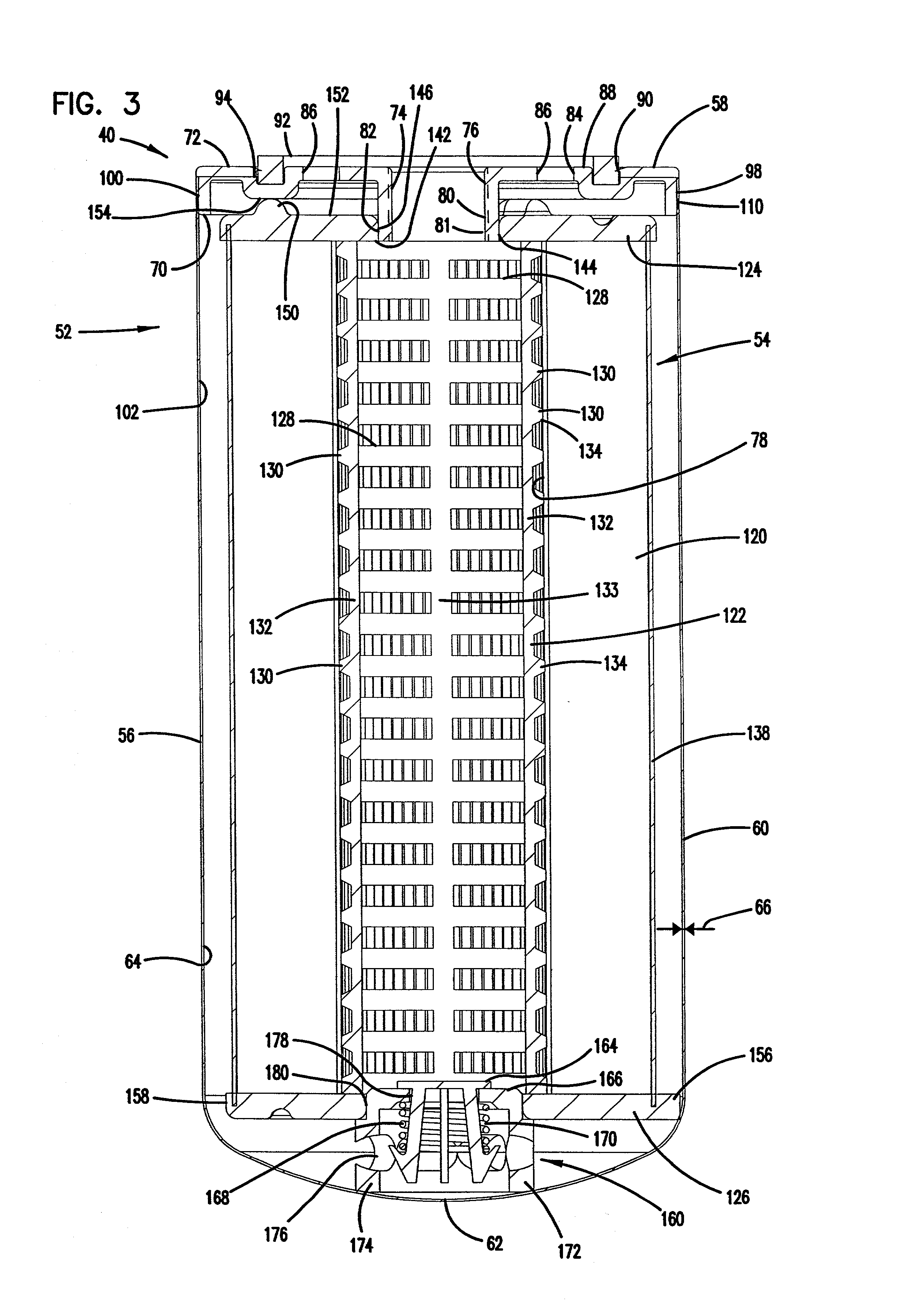

Liquid filter construction and methods

Liquid filter constructions include a baffle plate secured to a can, by way of laser welding. A filter element is operably oriented within the interior of the can. The filter element includes a first end cap and a media pack secured to the first end cap. In some embodiments, the first end cap radially abuts an outer, annular surface of a tubular member of the baffle plate to form a radially directed seal between the first end cap and the tubular member. Liquid filter constructions of this type have a burst strength between 500-800 psi (about 3.4-5.5 MPa), along a longitudinal section of the can wall. Constructions of this type eliminate a roll or lock seam, an inner gasket, an inner compressive spring, and a gasket retainer. Systems for using liquid filters are described herein. Methods of constructing and using these types of filter arrangements are also described.

Owner:DONALDSON CO INC

Combination device capable of achieving underwater laser welding and laser shot blasting

InactiveCN103521919AReduce volumeAdaptableLaser beam welding apparatusLasing wavelengthLaser peening

The invention discloses a combination device capable of achieving underwater laser welding and laser shot blasting. A laser welding-shot blasting component, an ultrasound detecting device, a water-argon inlet and a welding strip filling device are mounted on the same sealing cover which is placed underwater. Two functions of laser welding and laser shot blasting are achieved, and laser ultrasound detecting can be directly carried out on a workpiece after processing. By setting different laser wavelengths and sealing cover cavity inner environments, different functions can be used. During laser welding, a sealing cover cavity is filled with argon through the water-argon inlet. During laser shot blasting, the sealing cover cavity is filled with water through the water-argon inlet. The combination device is ingenious in structure, easy to operate, strong in adaptability, high in machining efficiency, capable of being used for alternating or continuous working of underwater welding and laser shot blasting and especially suitable for working under a special environment and defect repairing under the situation that the face where a defect exists is small in area.

Owner:JIANGSU UNIV

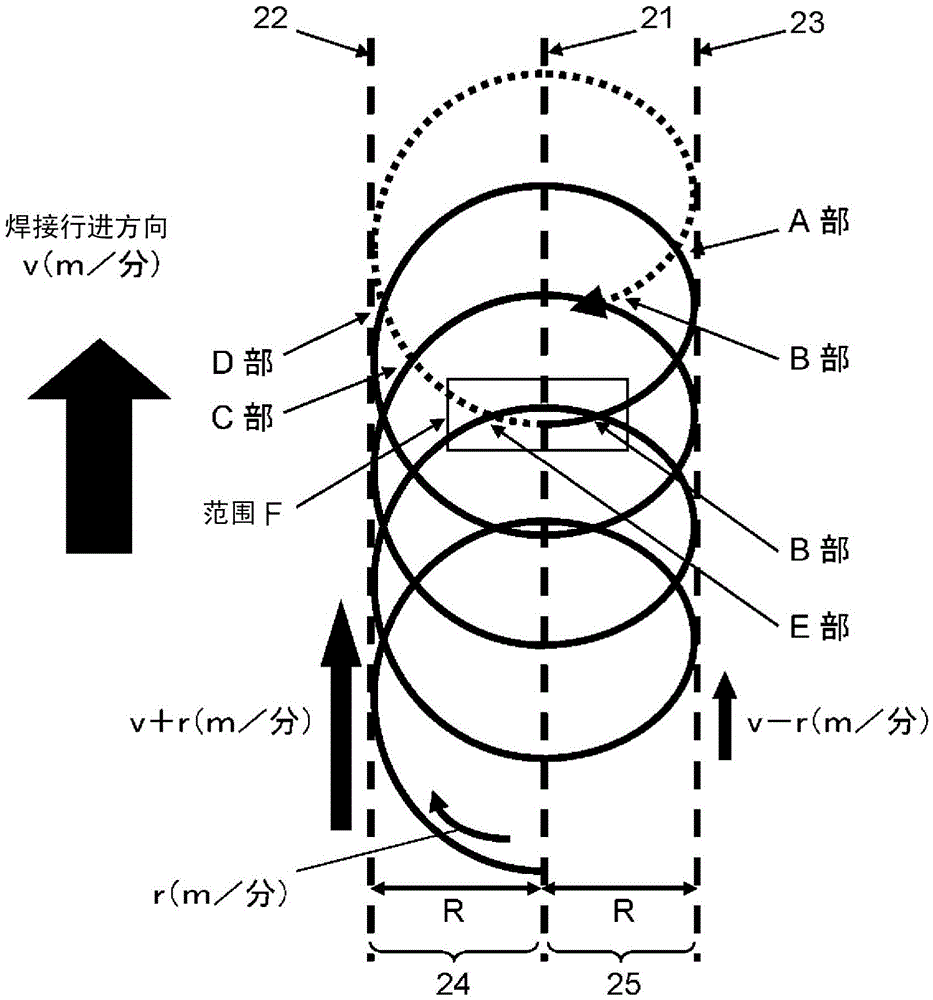

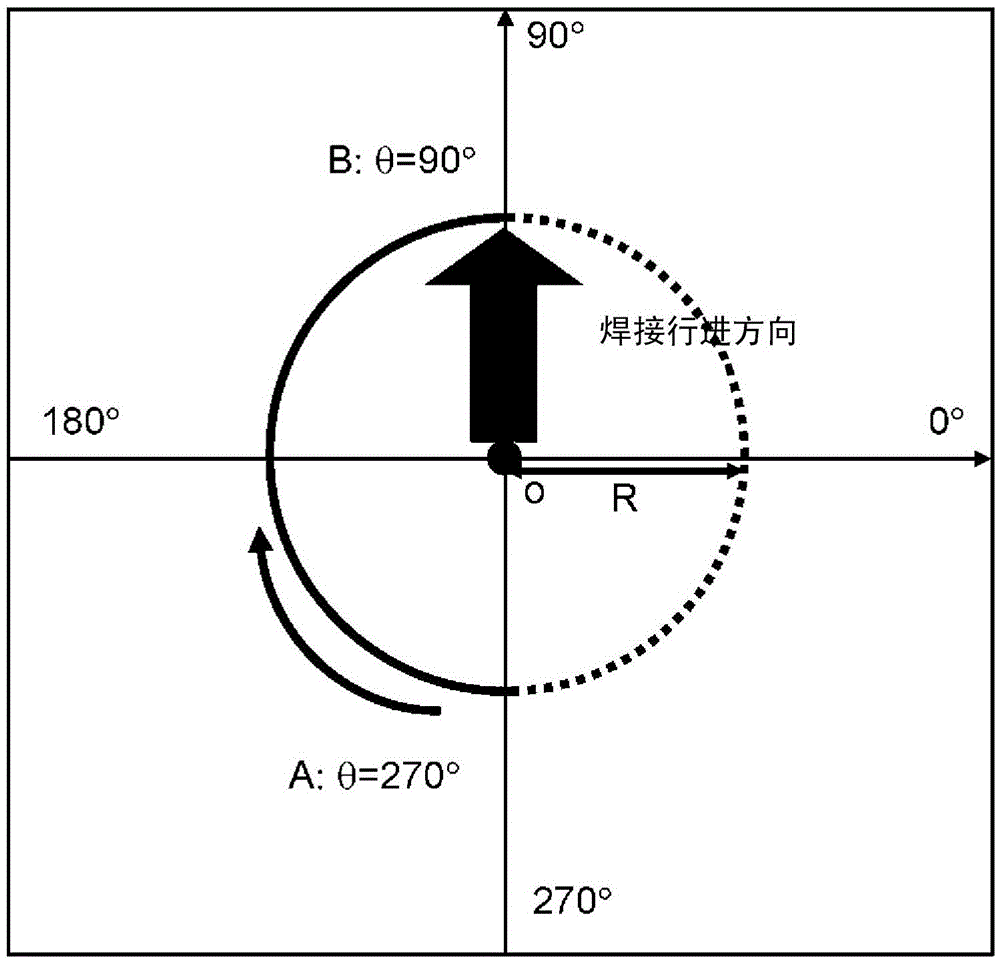

Laser welding method

ActiveCN105555465AInhibit burn throughWelding/soldering/cutting articlesMetal working apparatusLaser lightOptoelectronics

The invention provides a laser welding method. The laser welding method according to the present disclosure has a step for emitting laser light in a spiral shape along the welding site on a workpiece. The spiral shape is obtained by combining a circular path, in which a laser beam is moved in a circular shape, and a moving path, in which the laser beam is moved in the advancing direction along the welding site. First energy of the laser beam moving in the circular path so as to have an advancing-direction component is greater than second energy of the laser beam moving in the circular path so as to have a component in the direction opposite the advancing direction.

Owner:PANASONIC INTPROP MANAGEMENT CO LTD

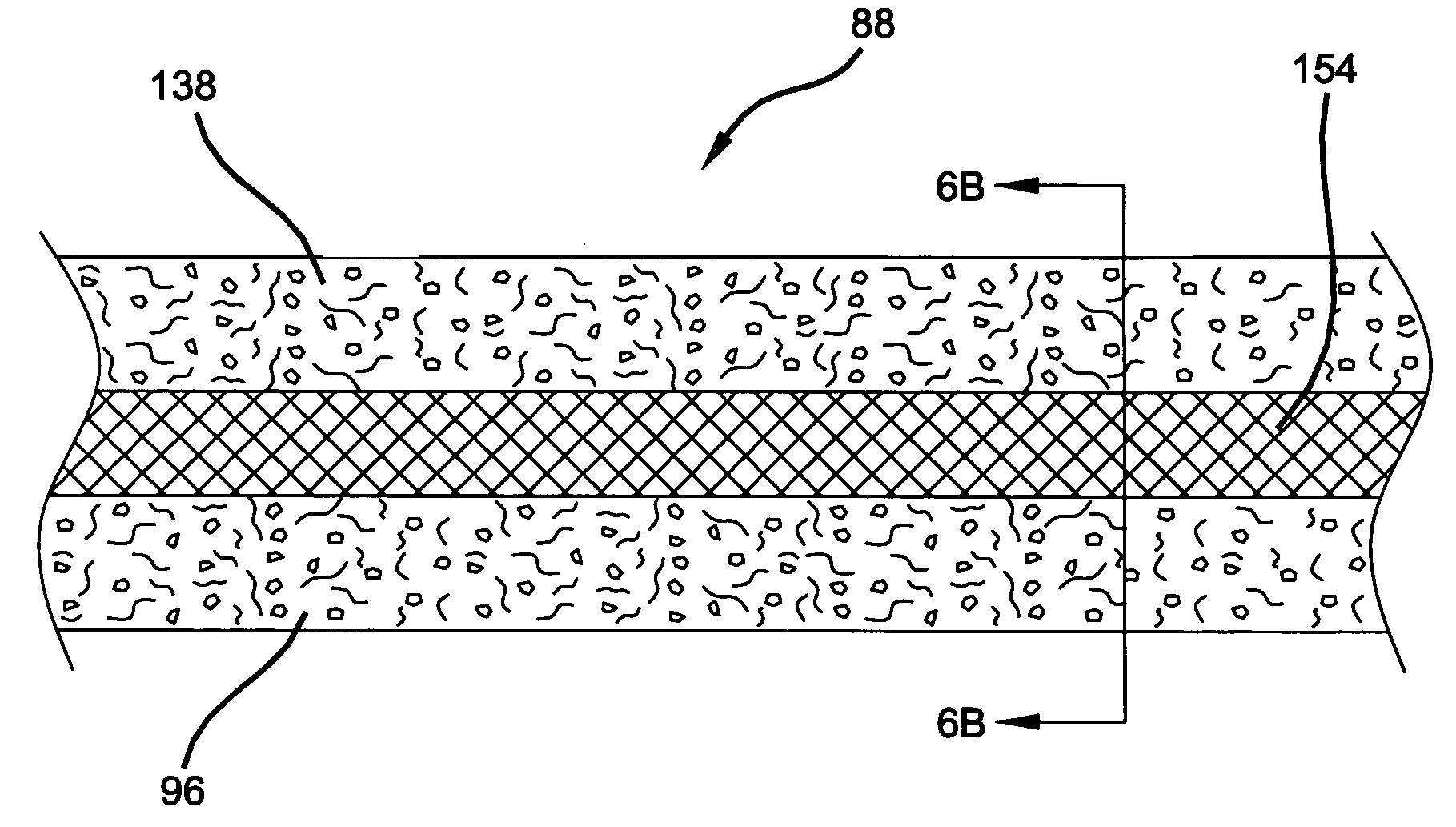

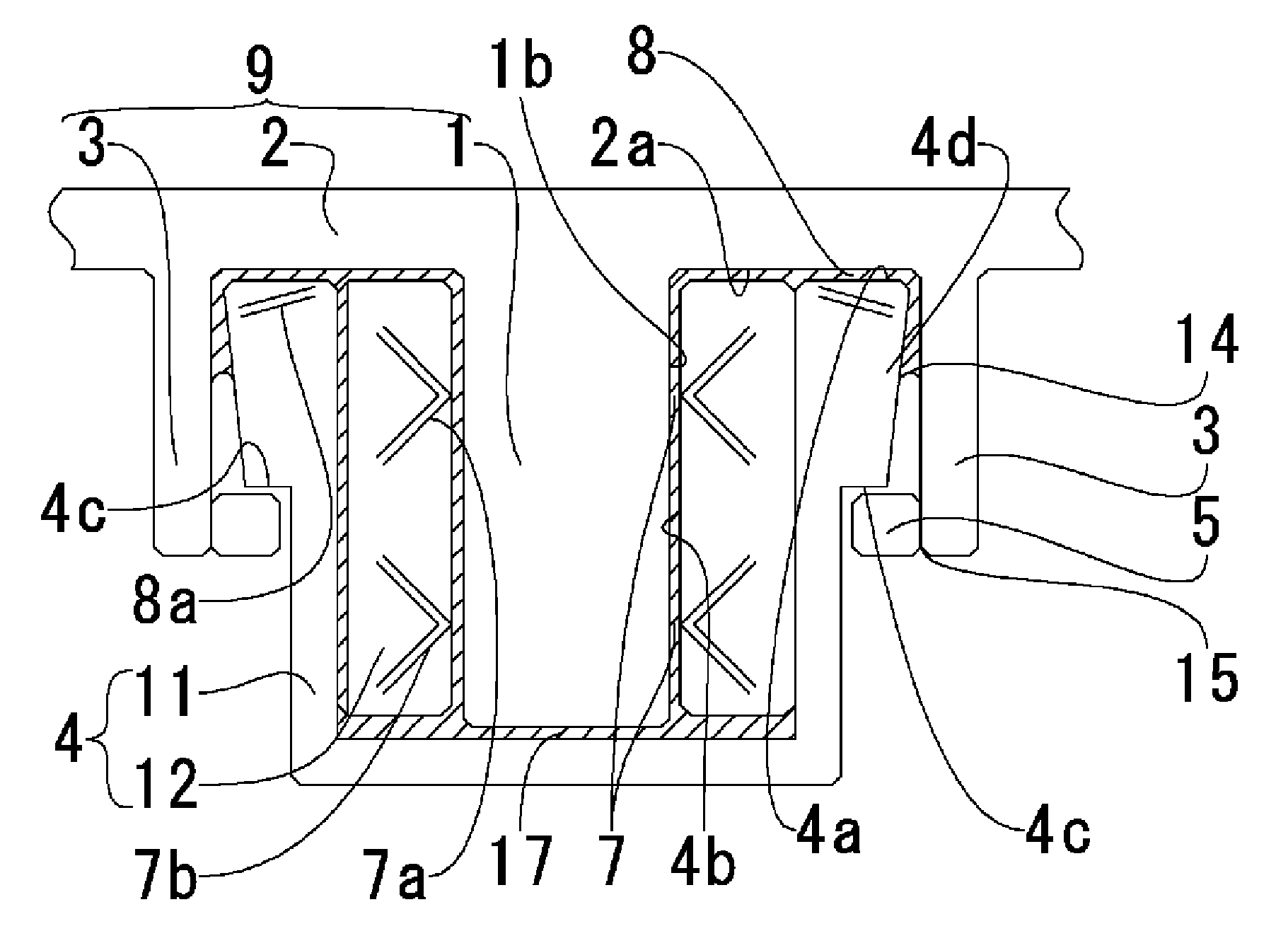

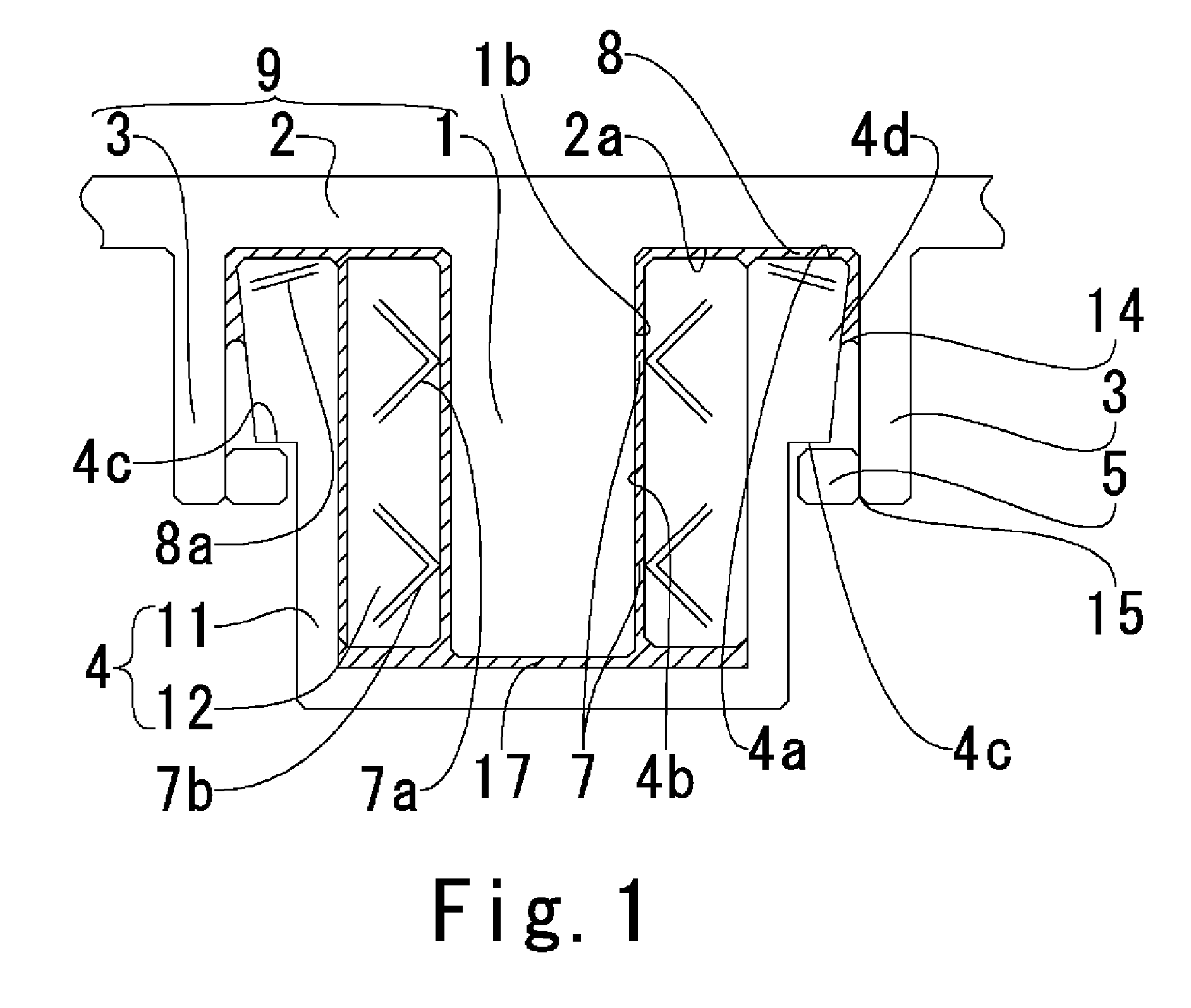

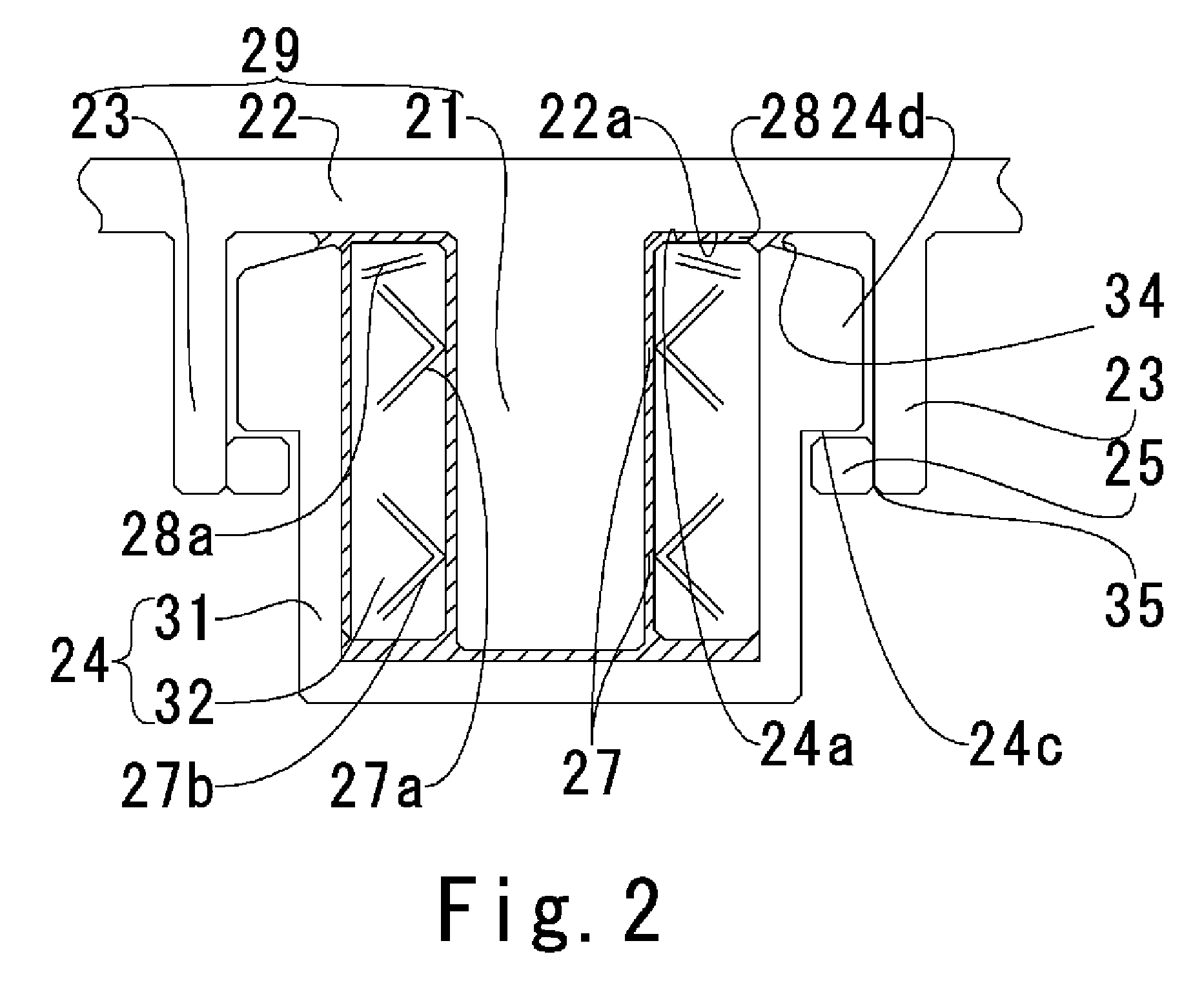

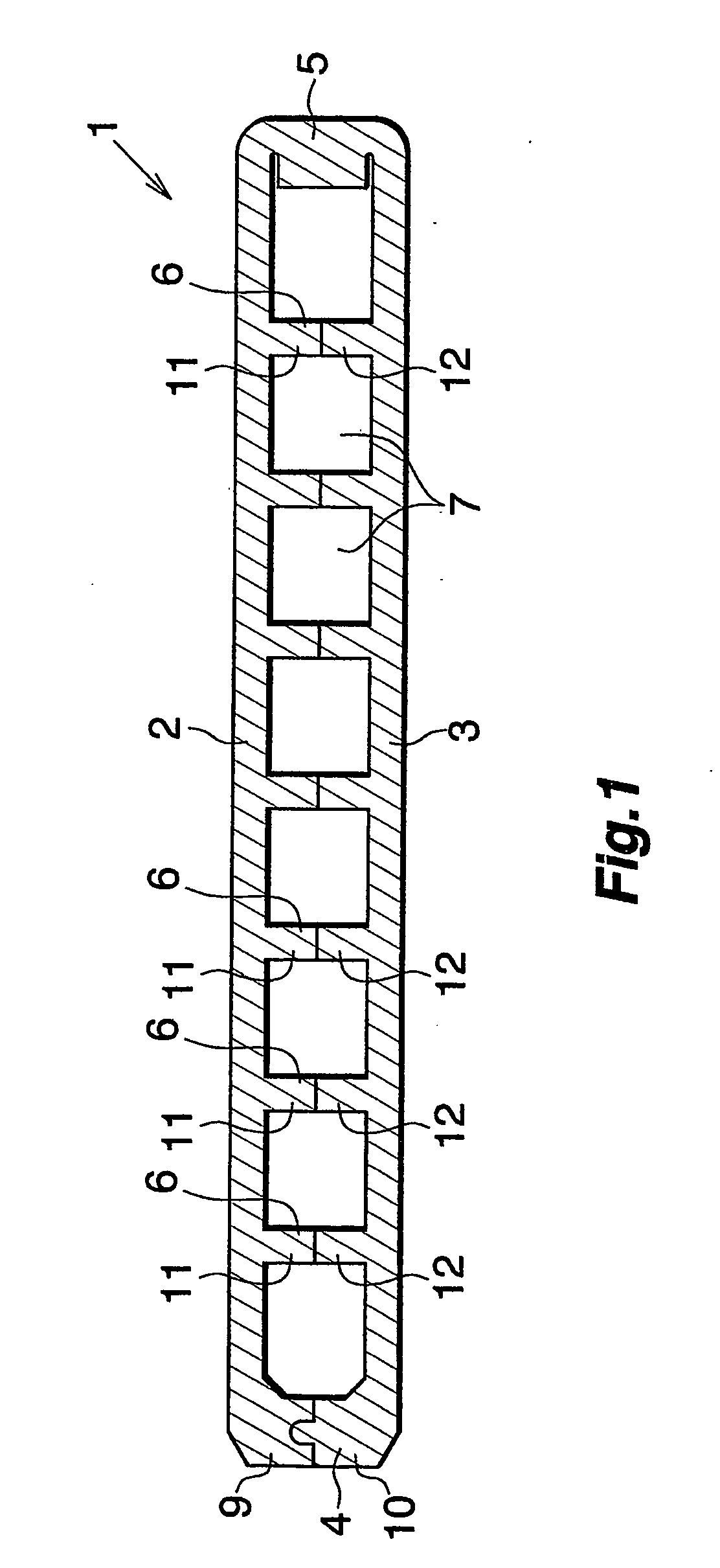

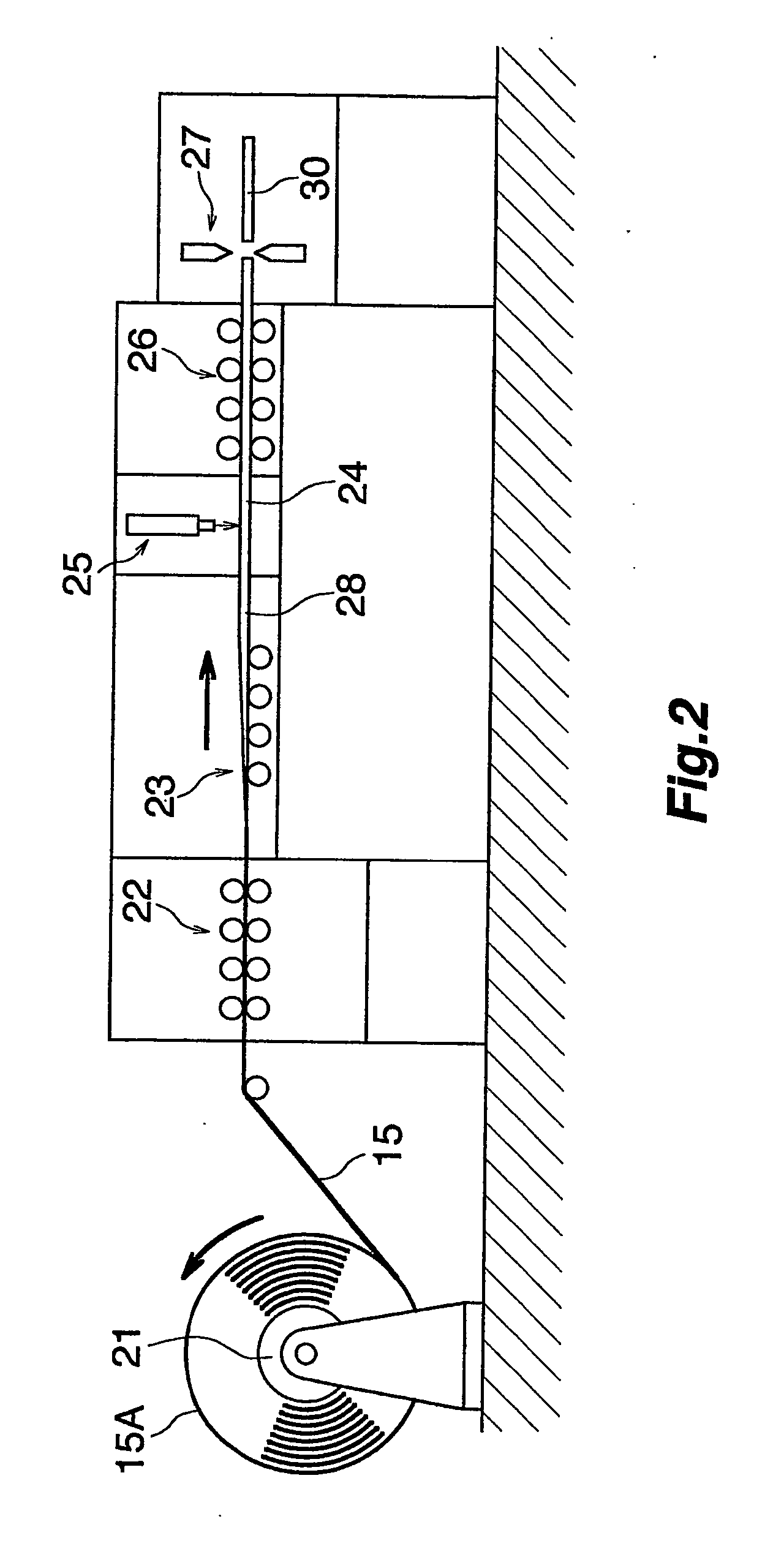

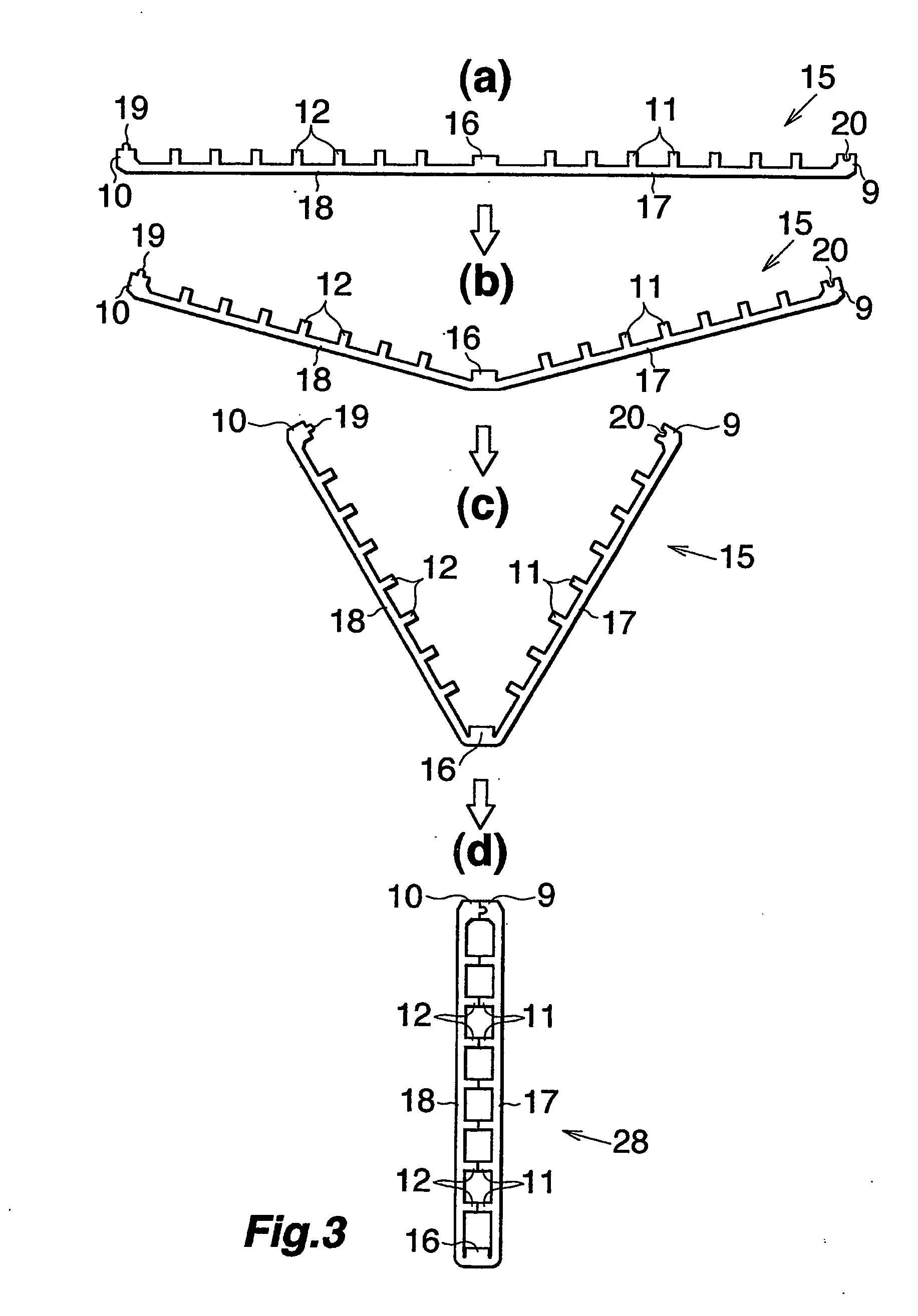

Semifinished flat tube, process for producing same, flat tube, heat exchanger comprising the flat tube and process for fabricating the heat exchanger

InactiveUS20070051499A1Improve rigidityAvoid deformationStationary conduit assembliesHeat exchanger fasteningEngineeringMetal

A semifinished flat tube 30 is for use in producing a flat tube 1 comprising an upper and a lower wall 2, 3 opposed to each other, and left and right opposite side walls 4, 5 interconnecting the upper and lower walls 2, 3 at opposite side edges thereof. The semifinished flat tube is produced from a metal plate 15 having two flat first portions 17, 18 for making the upper and lower walls 2, 3, a second portion 16 interconnecting the two first portions 17, 18 integrally for forming the right side wall 5, and two third portions 9, 10 projecting upward from the respective first portions 17, 18 integrally with the first portion each at a side edge thereof opposite to the second portion 16 for making the left side wall 4, by bending the metal plate 15 to the shape of a hairpin at the second portion 16 to cause the third portions 9, 10 to butt against each other. The two third portions 9, 10 arc joined to each other by laser welding intermittently from outside at a plurality of portions spaced apart longitudinally thereof.

Owner:SHOWA DENKO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com