Patents

Literature

110results about How to "Inhibited porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

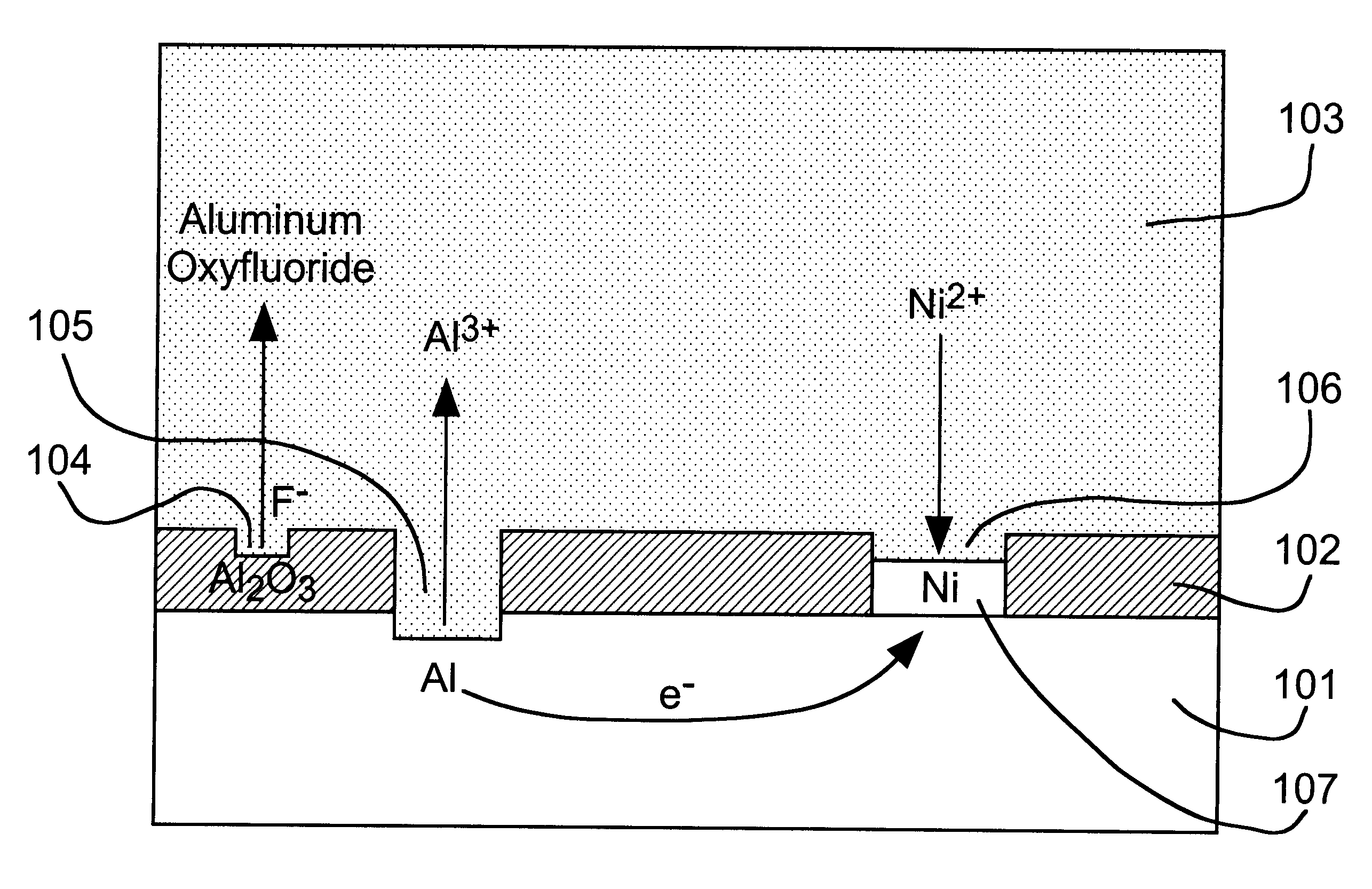

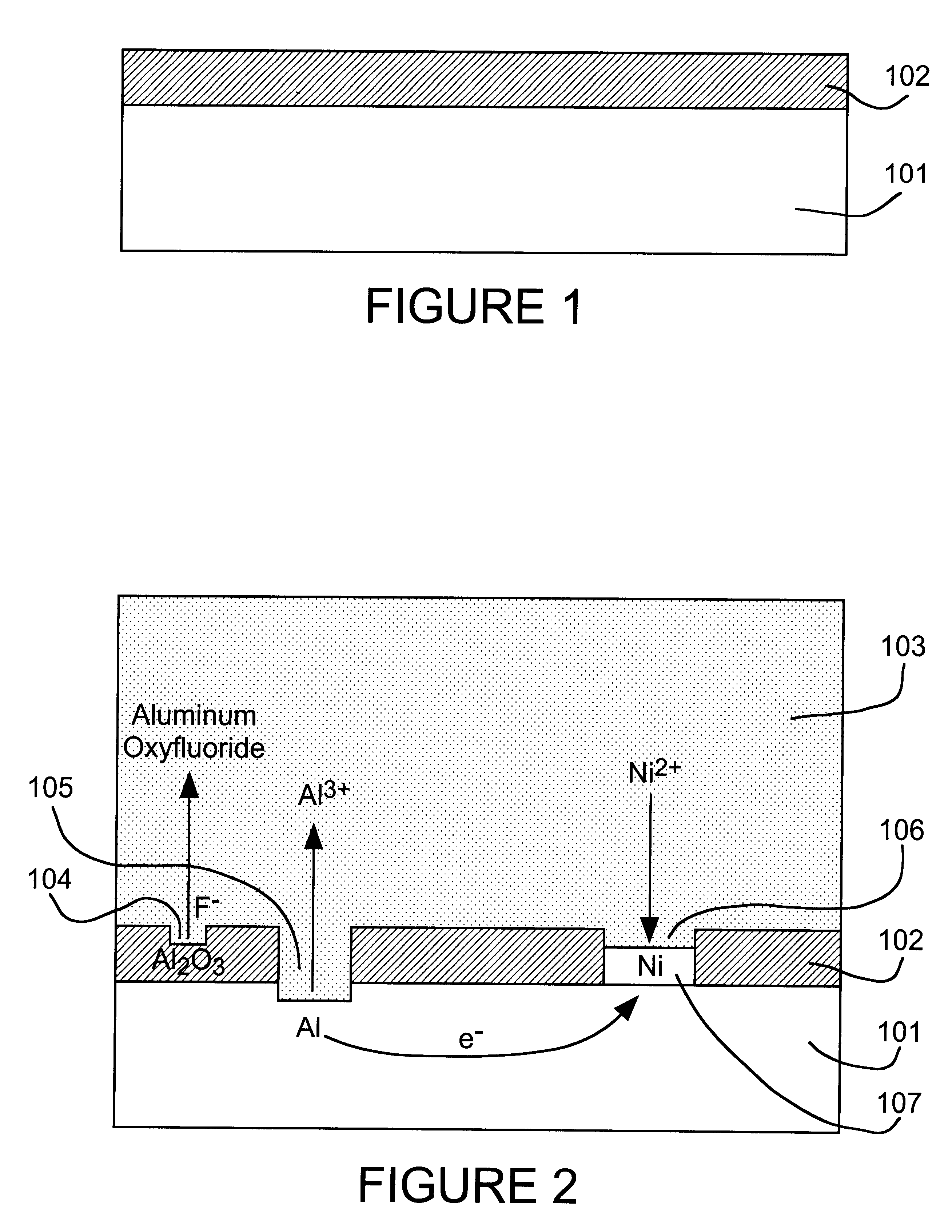

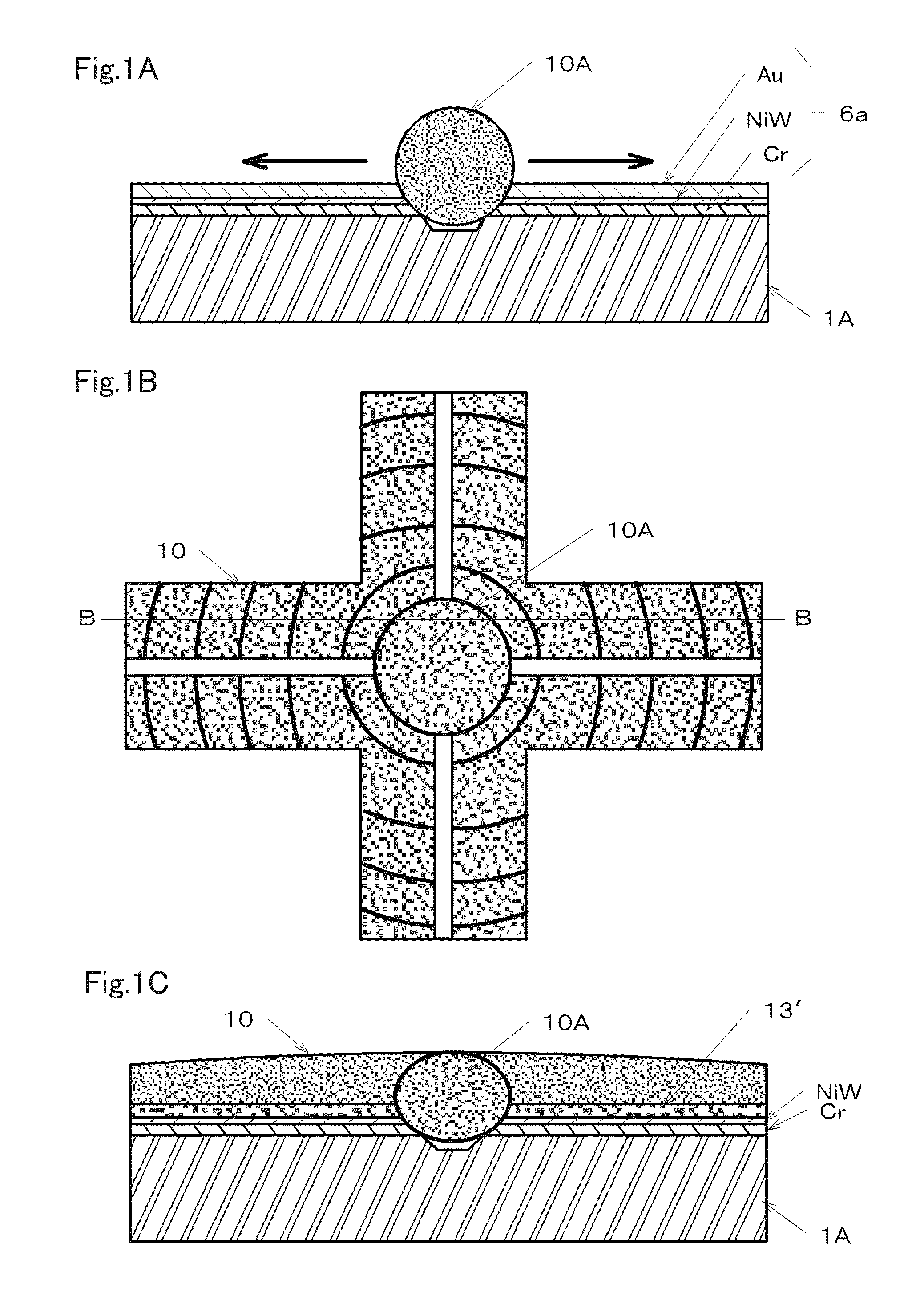

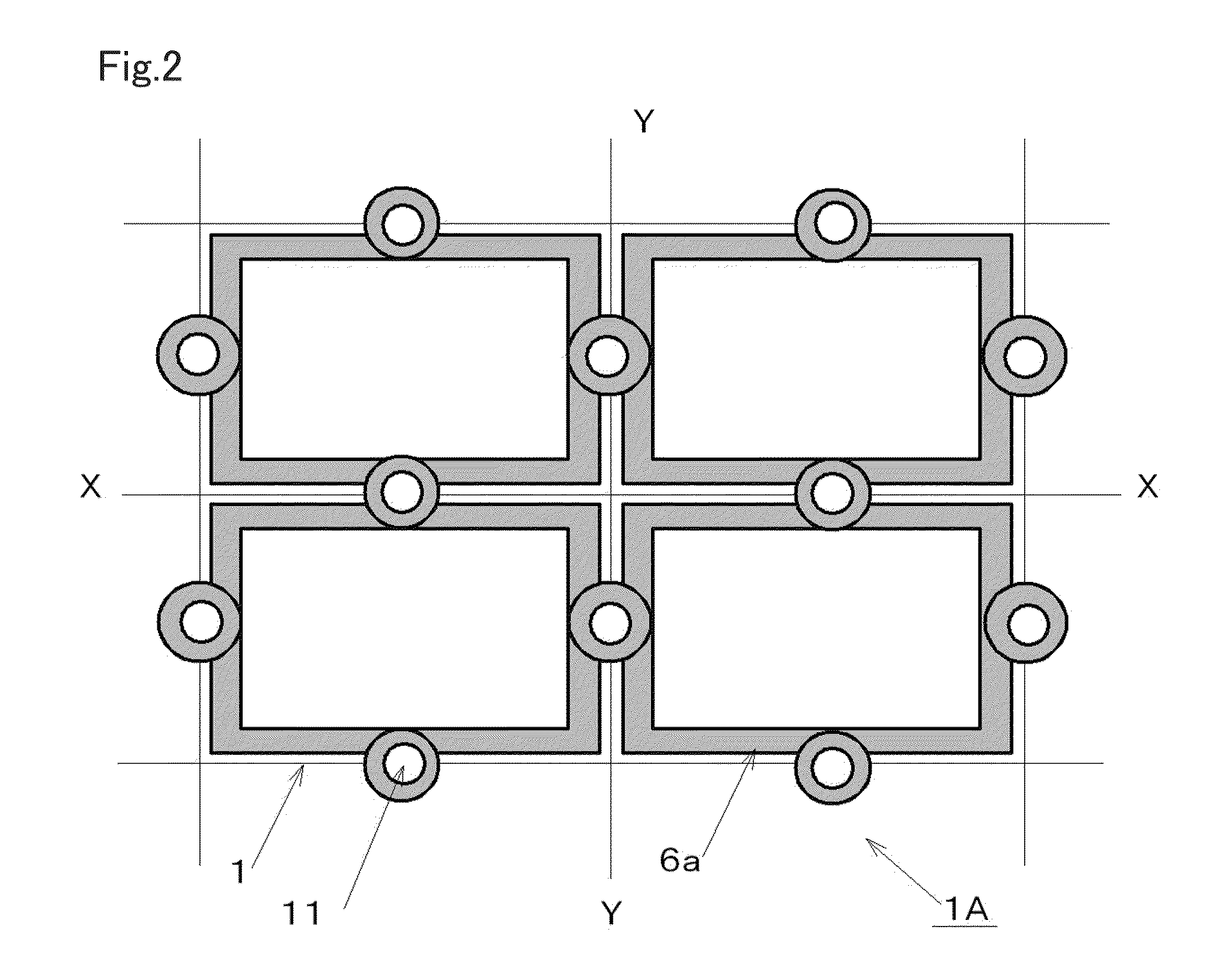

Controlled plating on reactive metals

InactiveUS6503343B1Avoid consumptionInhibited porositySolid-state devicesSemiconductor/solid-state device manufacturingElectroless nickelSolubility

A direct displacement plating process provides a uniform, adherent coating of a relatively stable metal (e.g., nickel) on a highly reactive metal (e.g., aluminum) that is normally covered with a recalcitrant oxide layer. The displacement reaction proceeds, preferably in a nonaqueous solvent, as the oxide layer is dissolved by a fluoride activator. Halide anions are used to provide high solubility, to serve as an anhydrous source of stable metal ions, and to control the rate of the displacement reaction. A low concentration of activator species and little or no solution agitation are used to cause depletion of the activator species within pores in the surface oxide so that attack of the reactive metal substrate is minimized. Used in conjunction with electroless nickel deposition to thicken the displacement coating, this process can be used to render aluminum pads on IC chips solderable without the need for expensive masks and vacuum deposition operations. Such coatings can also be used to preserve or restore wire bondability, or for corrosion protection of aluminum and other reactive structural metals and alloys. A thin layer of immersion gold can be used to protect the thickened coating from oxidation. The solderable aluminum IC chip pads provide the basis for a maskless bumping process for flip chip attachment.

Owner:CALLAHAN CELLULAR L L C

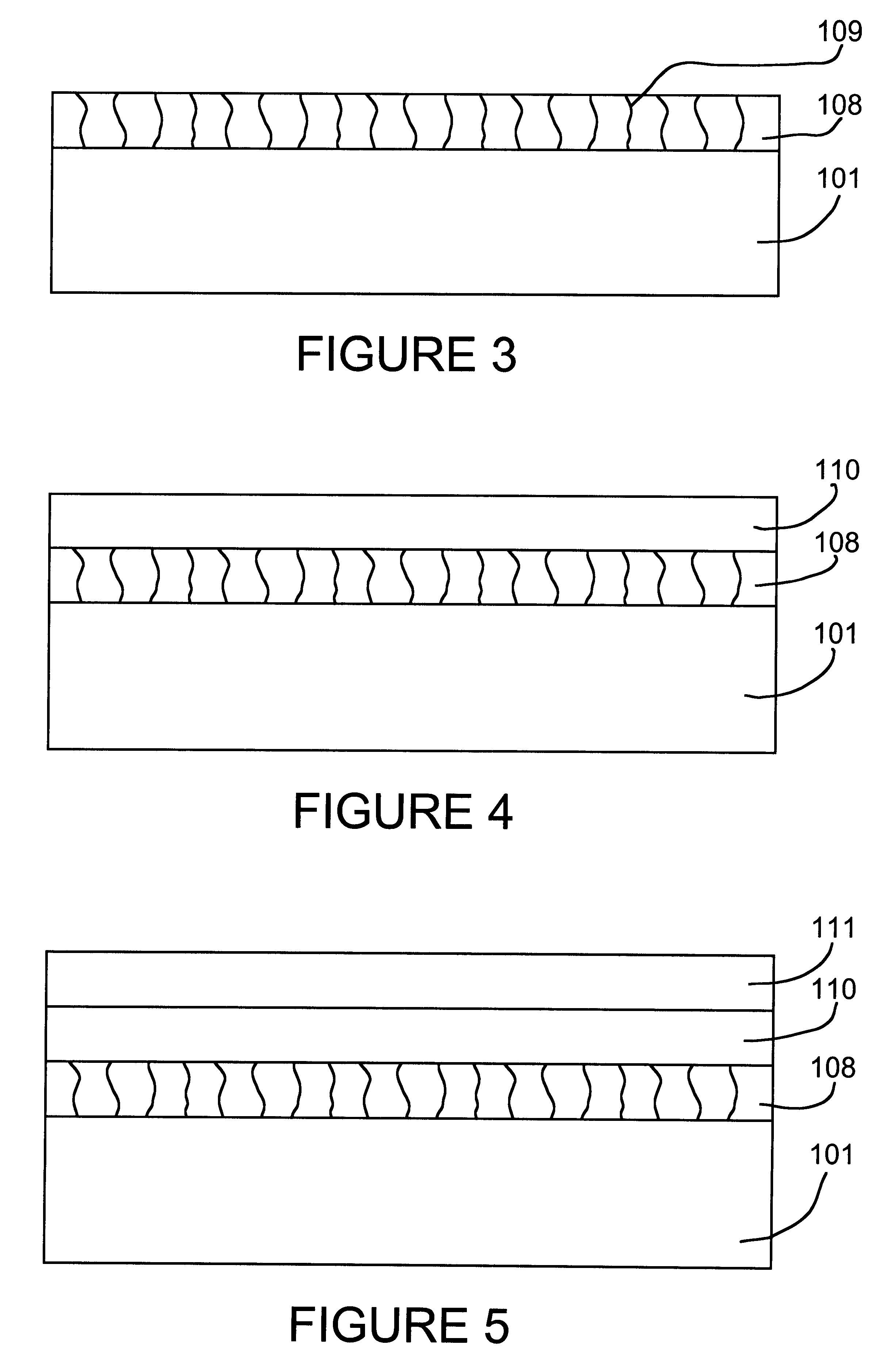

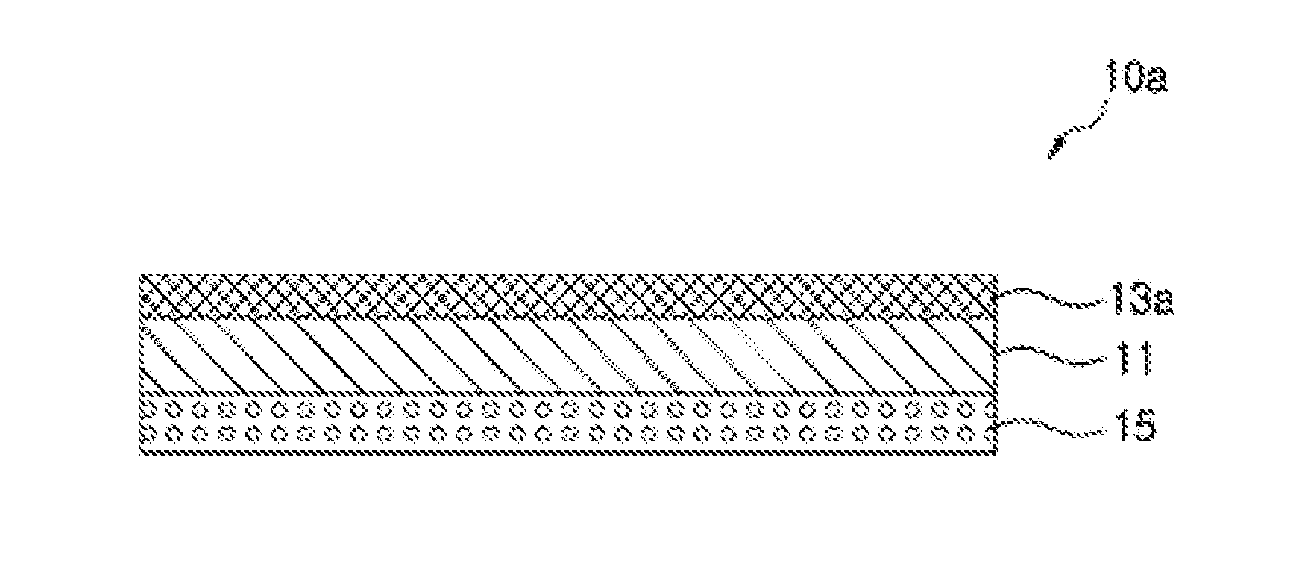

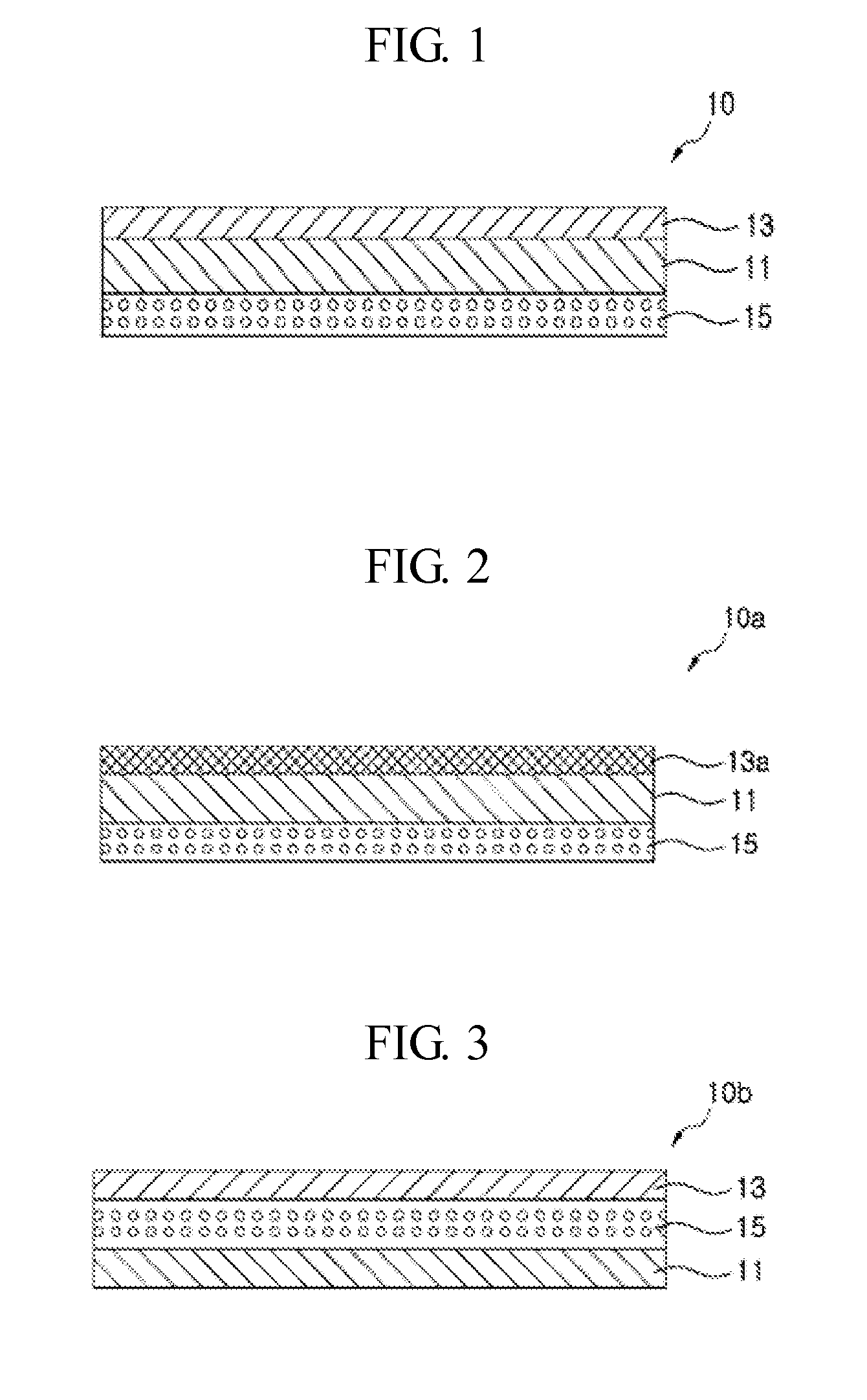

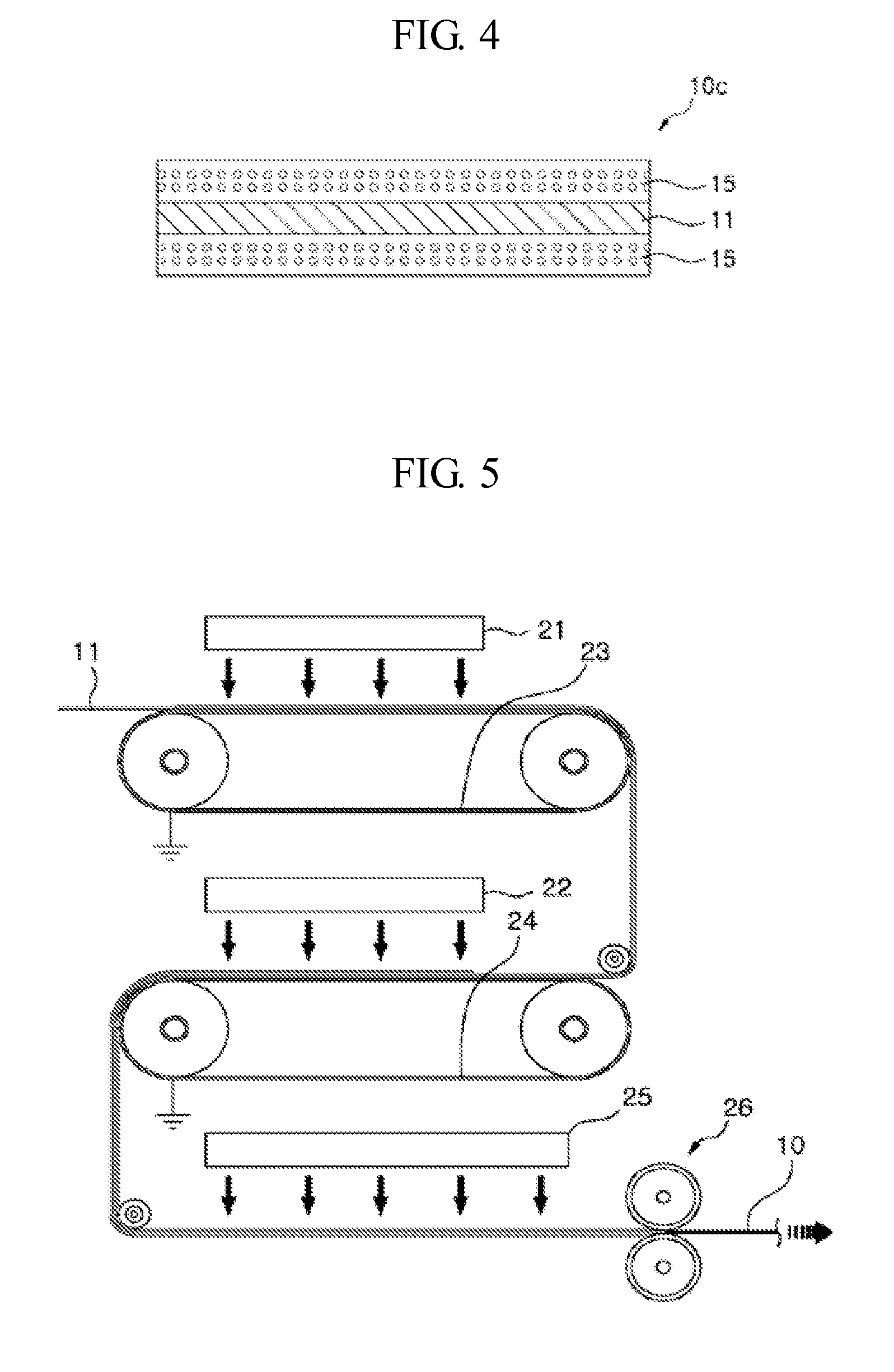

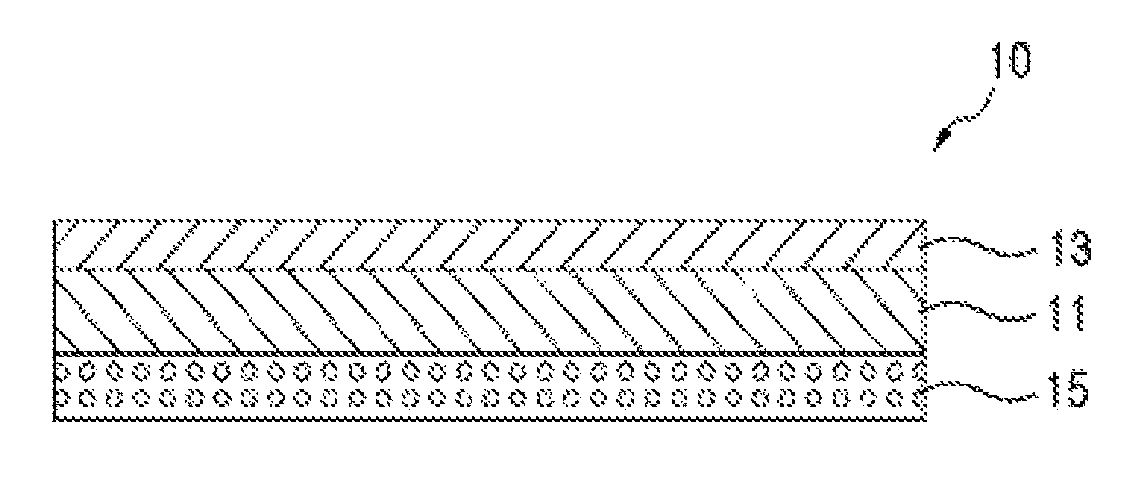

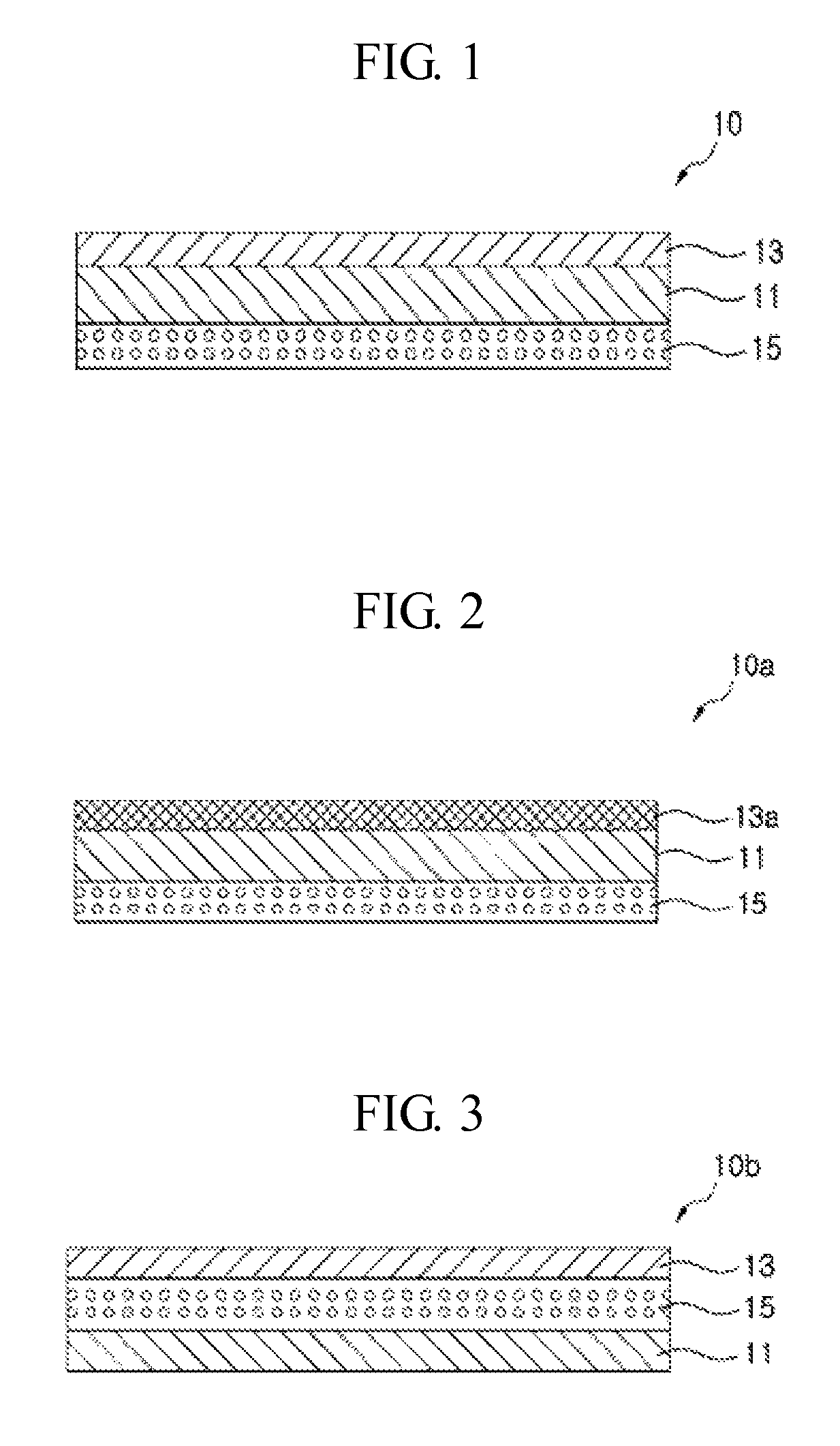

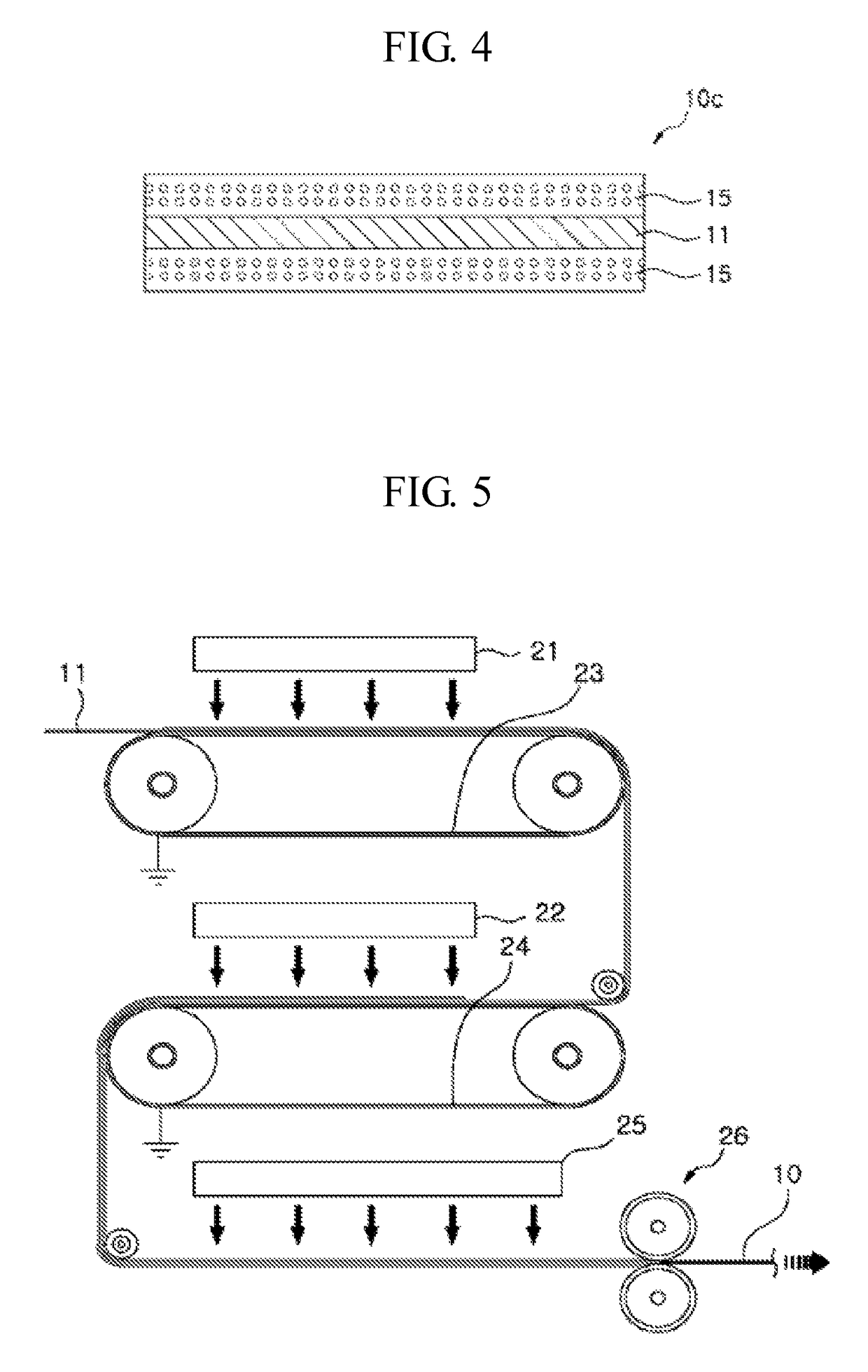

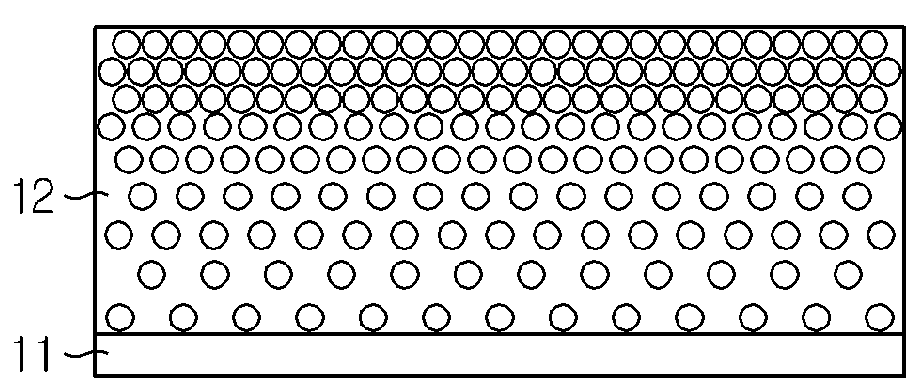

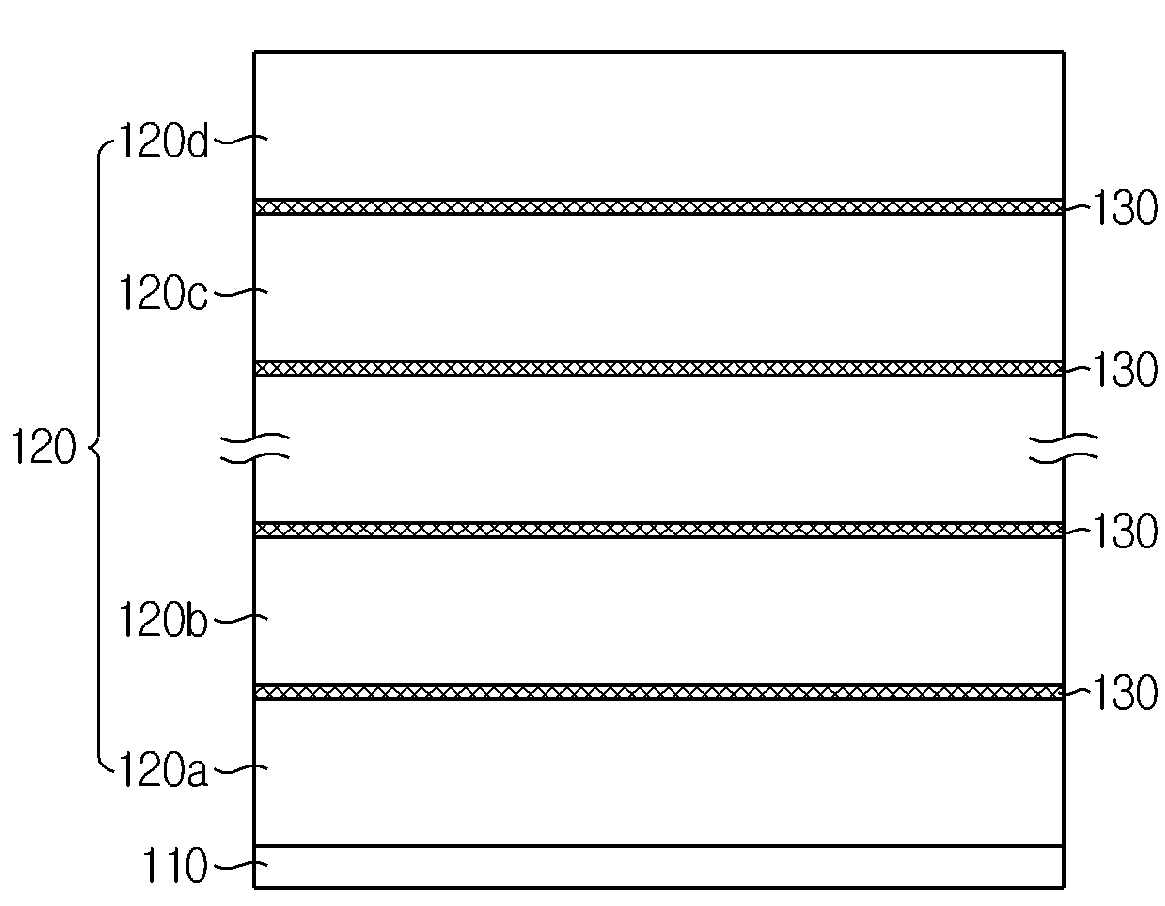

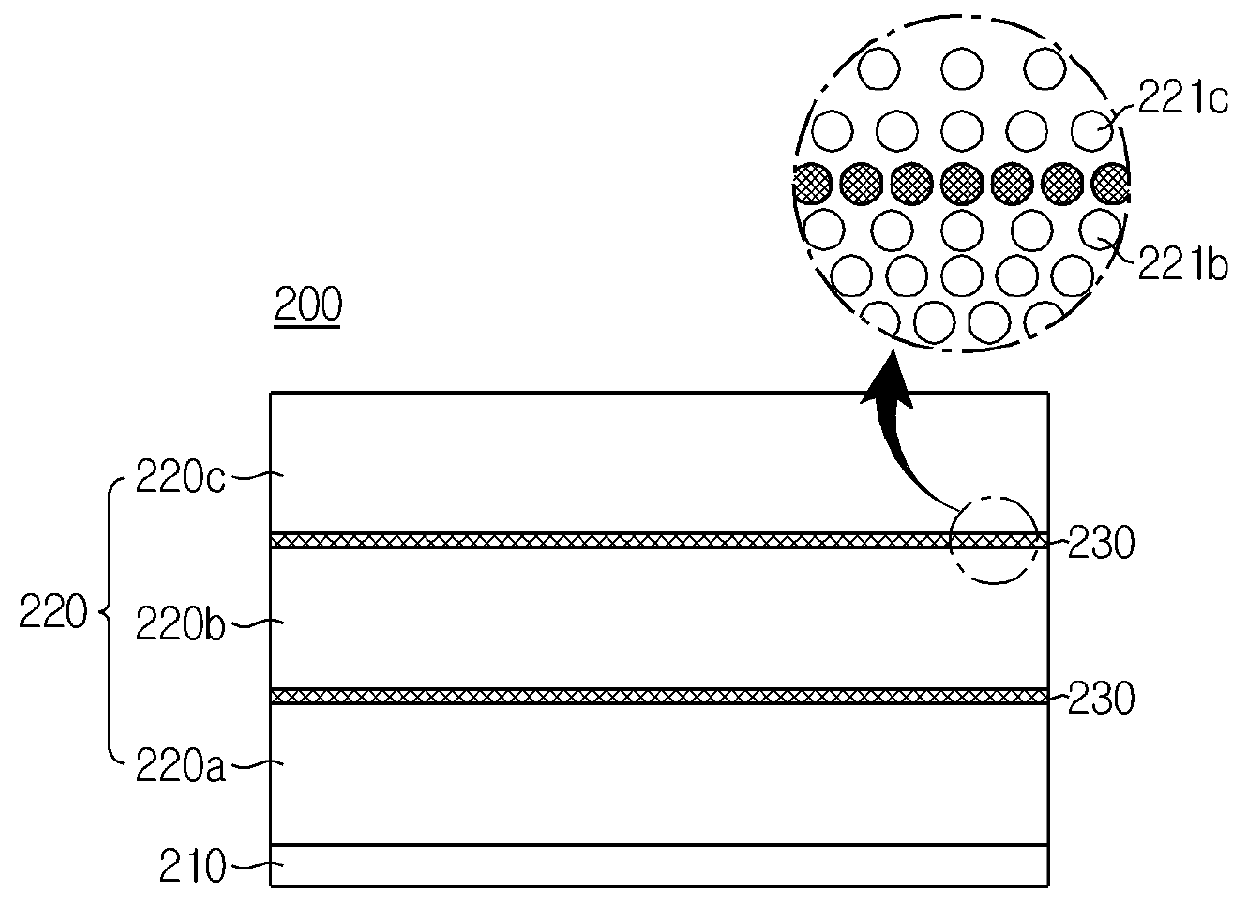

Composite porous separation membrane having shut-down function, method of manufacturing same, and secondary batteries using same

ActiveUS20150162588A1Inhibited porosityLow costFinal product manufactureLi-accumulatorsPorous substrateNanofiber

A composite porous separator includes: a porous substrate acting as a support and having a first melting point and a first porosity; a first porous polymer web layer that is laminated on one side of the porous substrate, and acts as an adhesive layer when being in close contact with an opposing electrode; and a second porous polymer web layer that is laminated on the other surface of the porous substrate, and is formed of nanofibers of a heat-resistant polymer, in which the first porous polymer web layer and the second porous polymer web layer have a melting point higher than the first melting point of the porous substrate and a porosity that is the same as or similar to the first porosity of the porous substrate, respectively.

Owner:AMOGREENTECH CO LTD

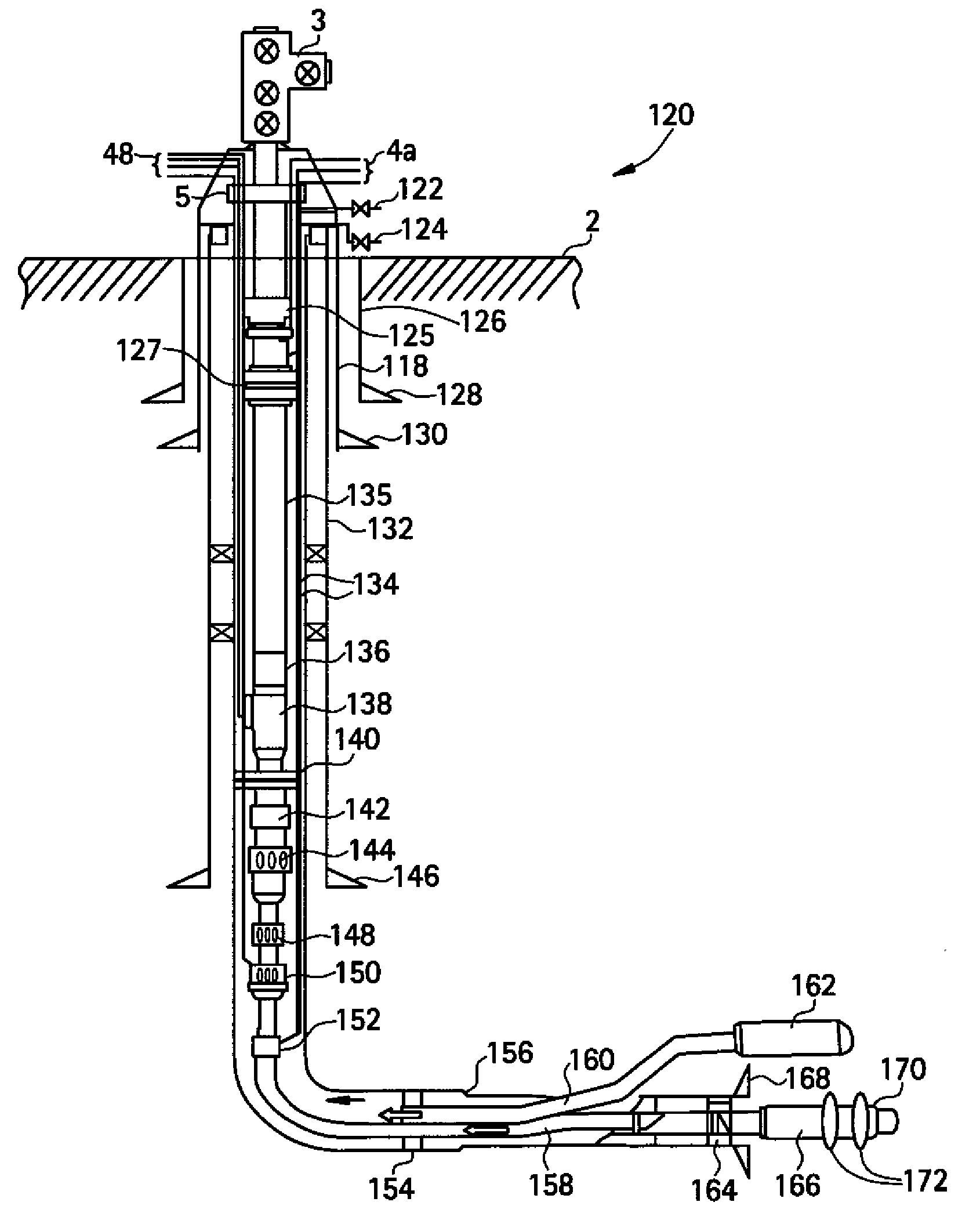

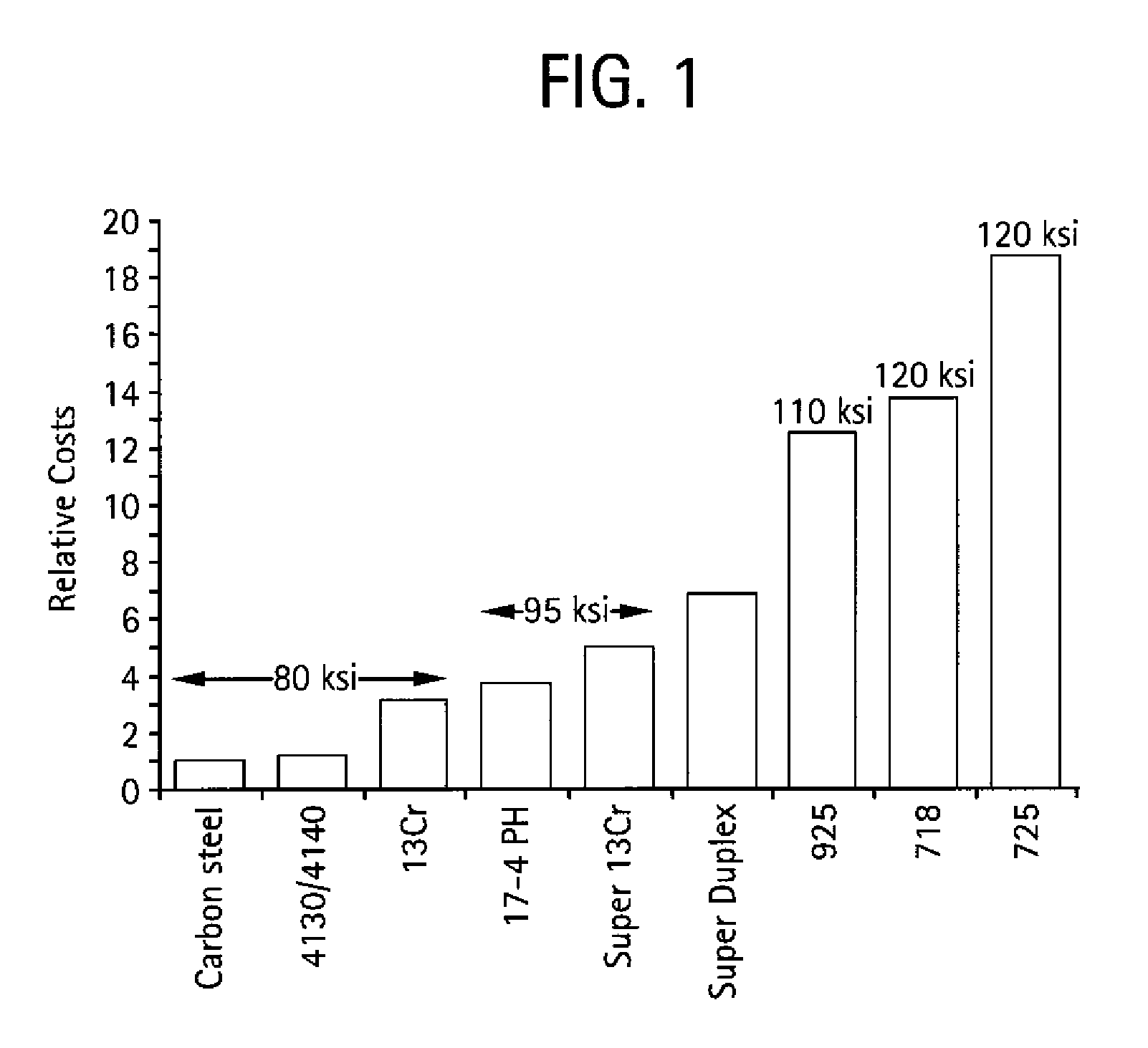

Interstitially strengthened high carbon and high nitrogen austenitic alloys, oilfield apparatus comprising same, and methods of making and using same

InactiveUS20080141826A1Material costHigh strengthQuenching agentsThin material handlingHigh carbonSubject matter

Novel carbon-plus-nitrogen corrosion-resistant ferrous and austenitic alloys, apparatus incorporating an inventive alloy, and methods of making and using the apparatus are described. The corrosion-resistant ferrous and austenitic alloys comprise no greater than about 4 wt. % nickel, are characterized by a strength greater than about 700 MPa (100 ksi), and, when being essentially free of molybdenum (<0.3 wt. %), have minimum Pitting Resistance Equivalence (PRE) numbers of 20 and minimum Measure of Alloying for Corrosion Resistance numbers (MARC) of 30 because of the use of both carbon and nitrogen. The ferrous and austenitic alloys are particularly formulated for use in oilfield operations, especially sour oil and gas wells and reservoirs. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims.

Owner:SCHLUMBERGER TECH CORP

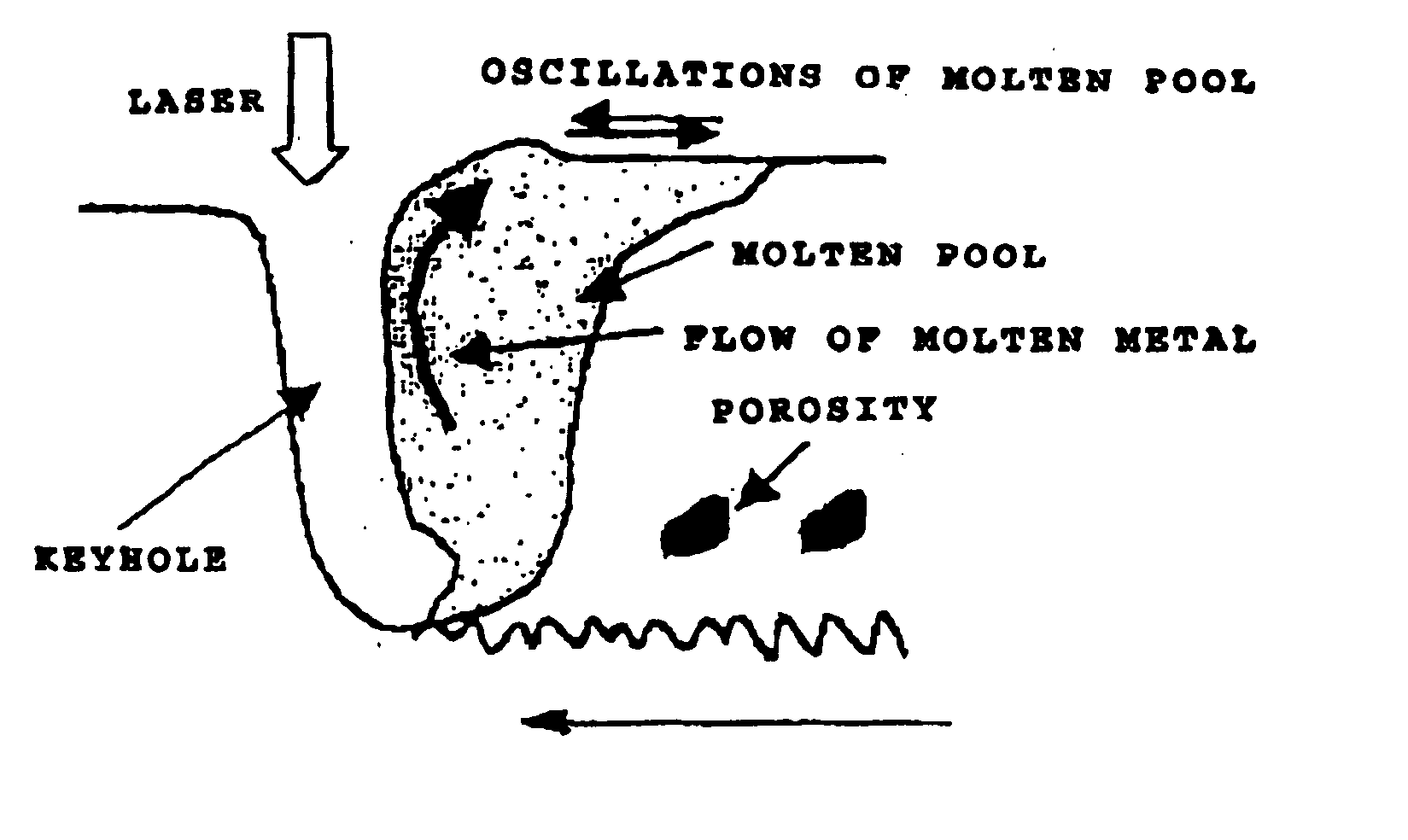

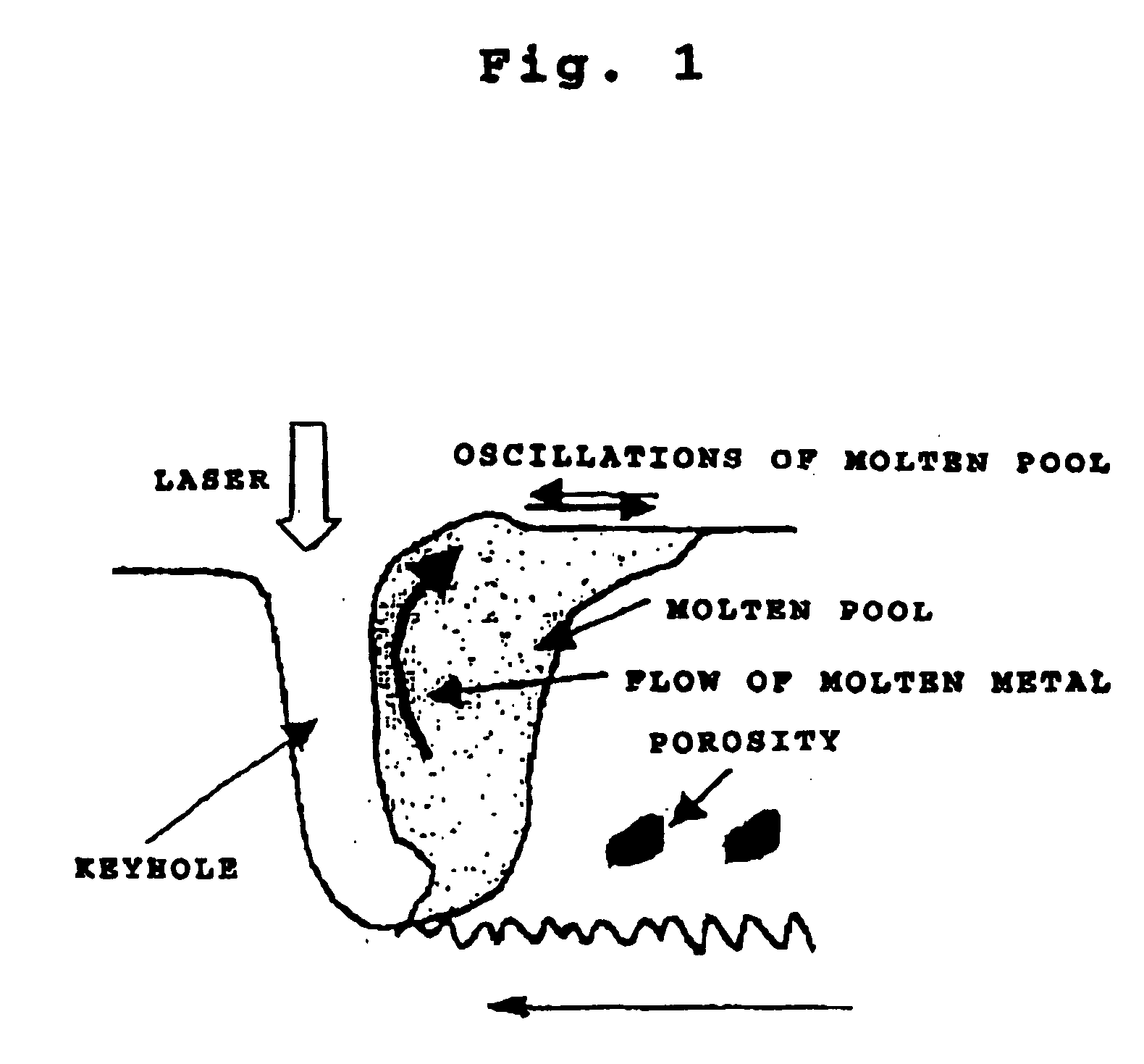

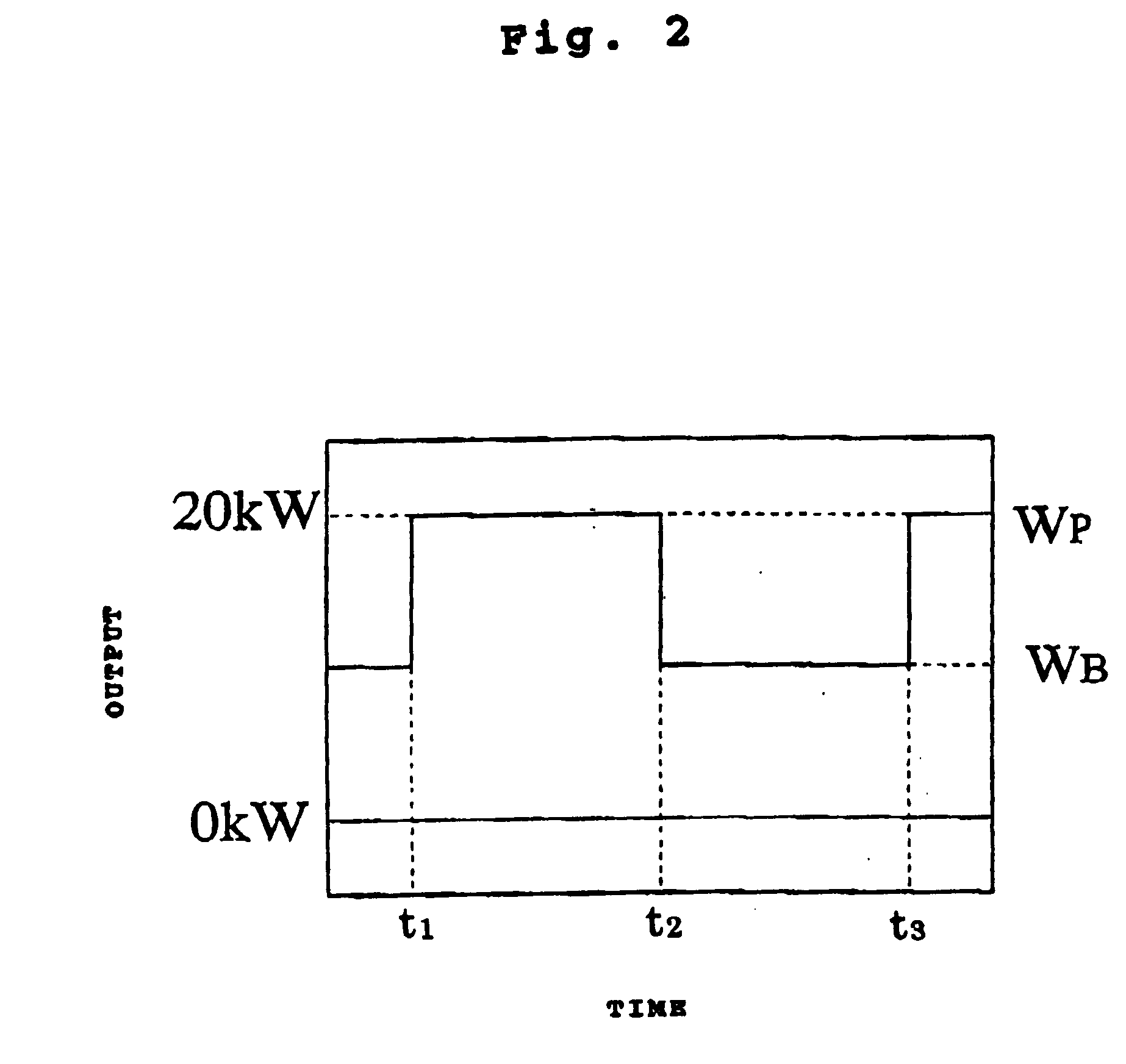

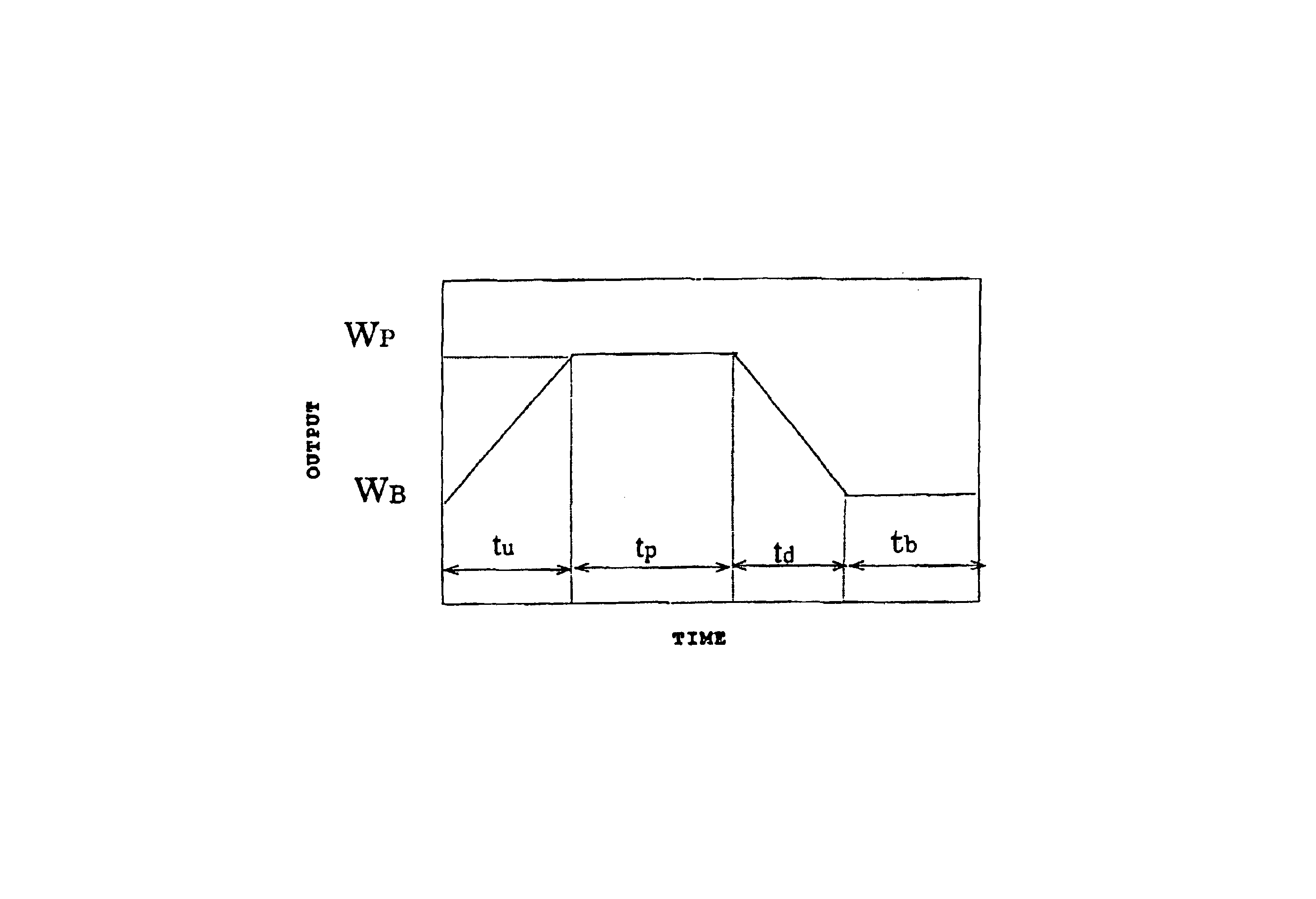

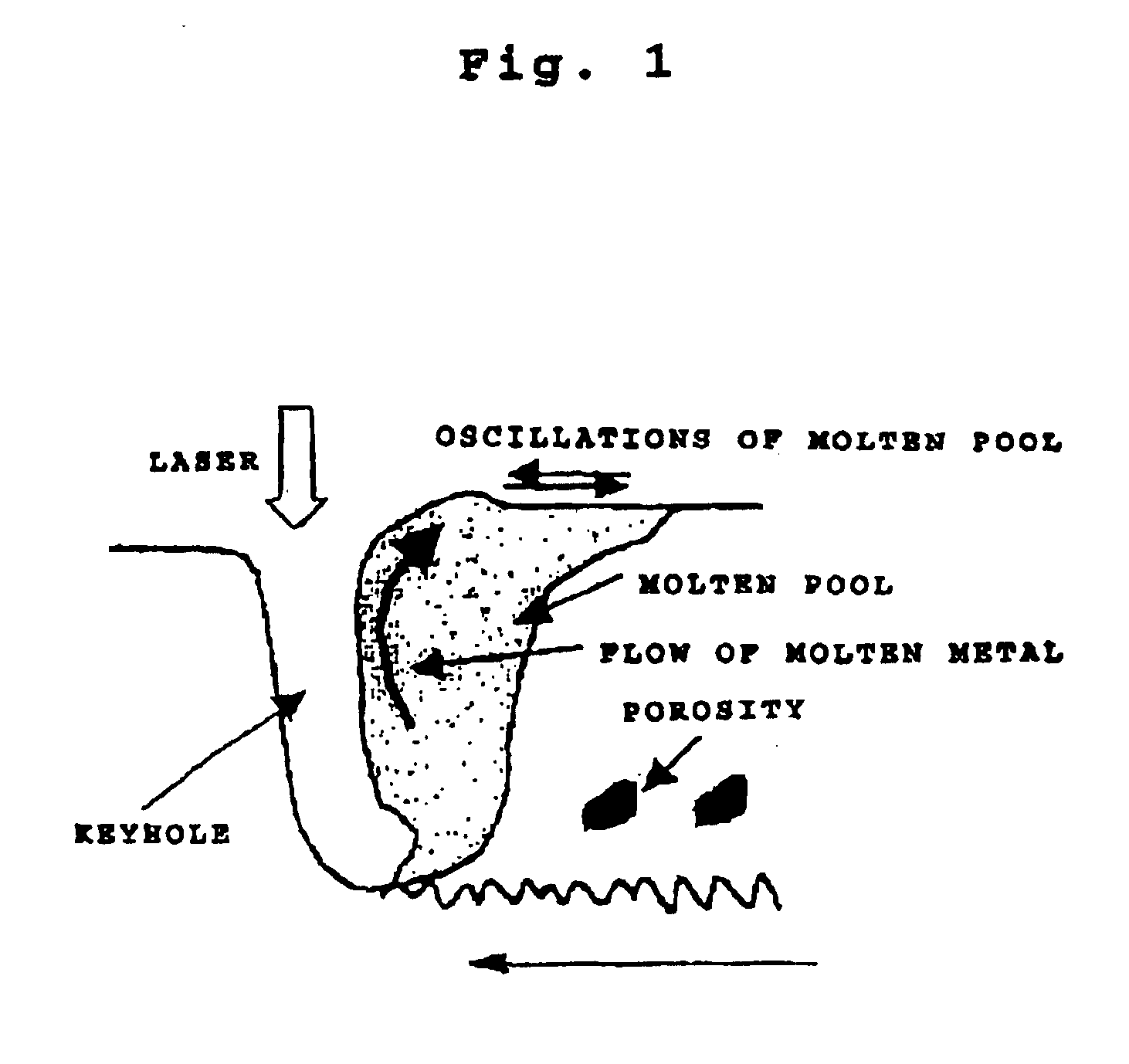

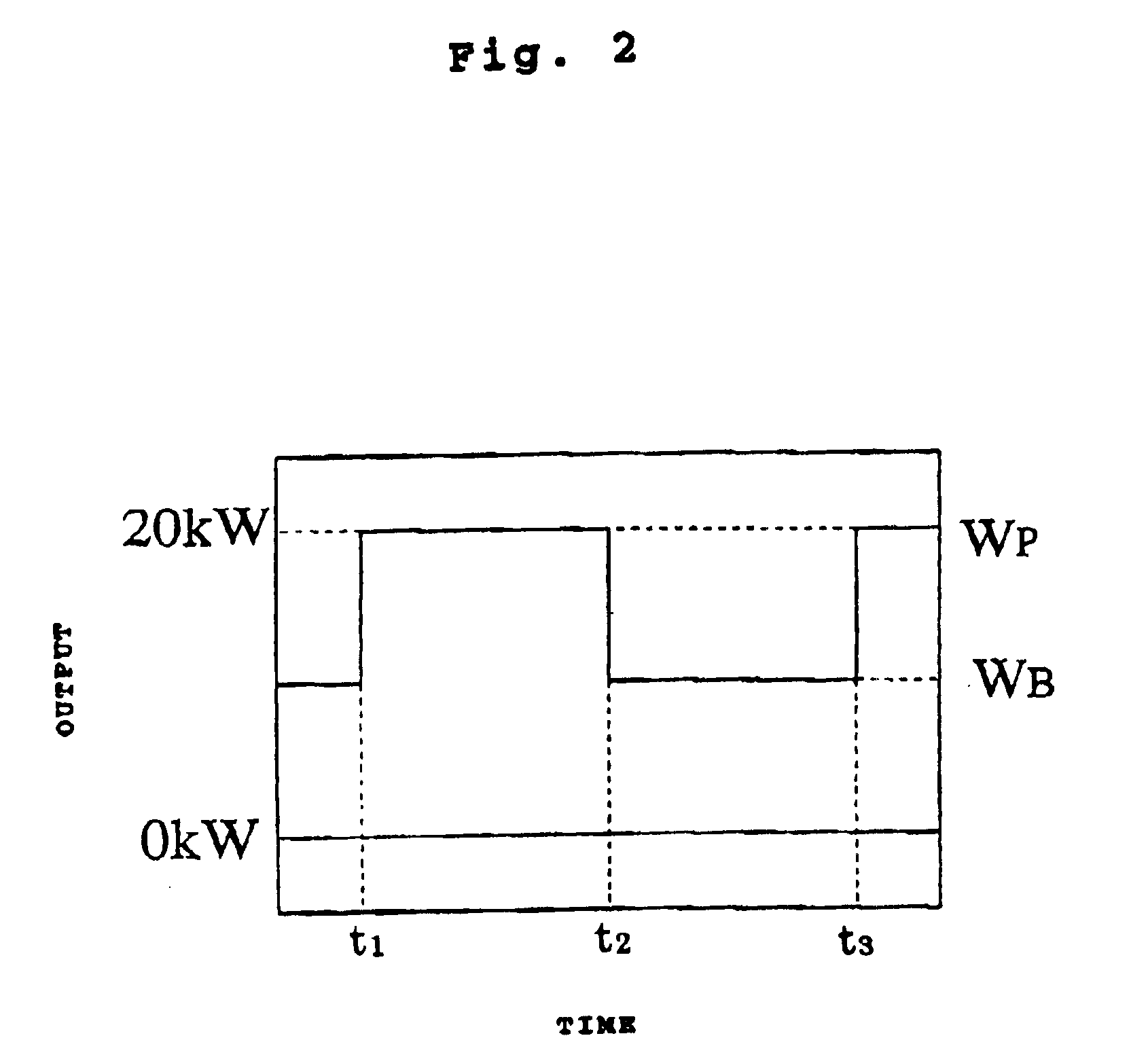

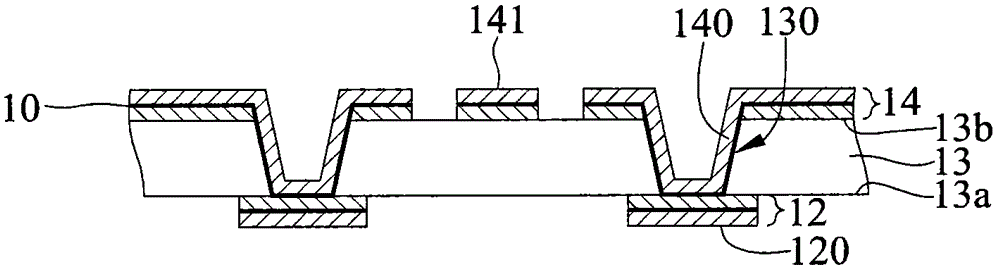

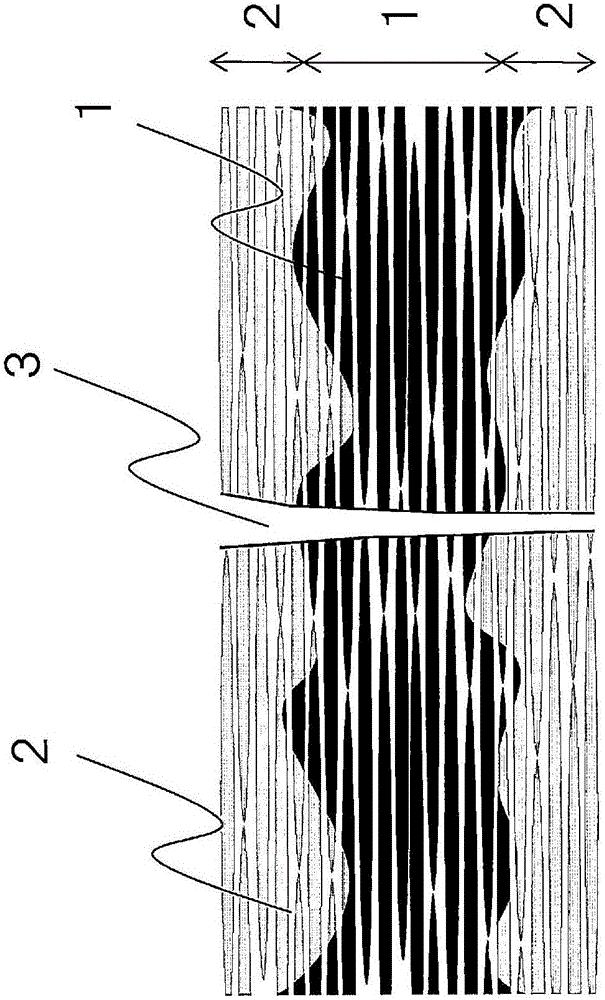

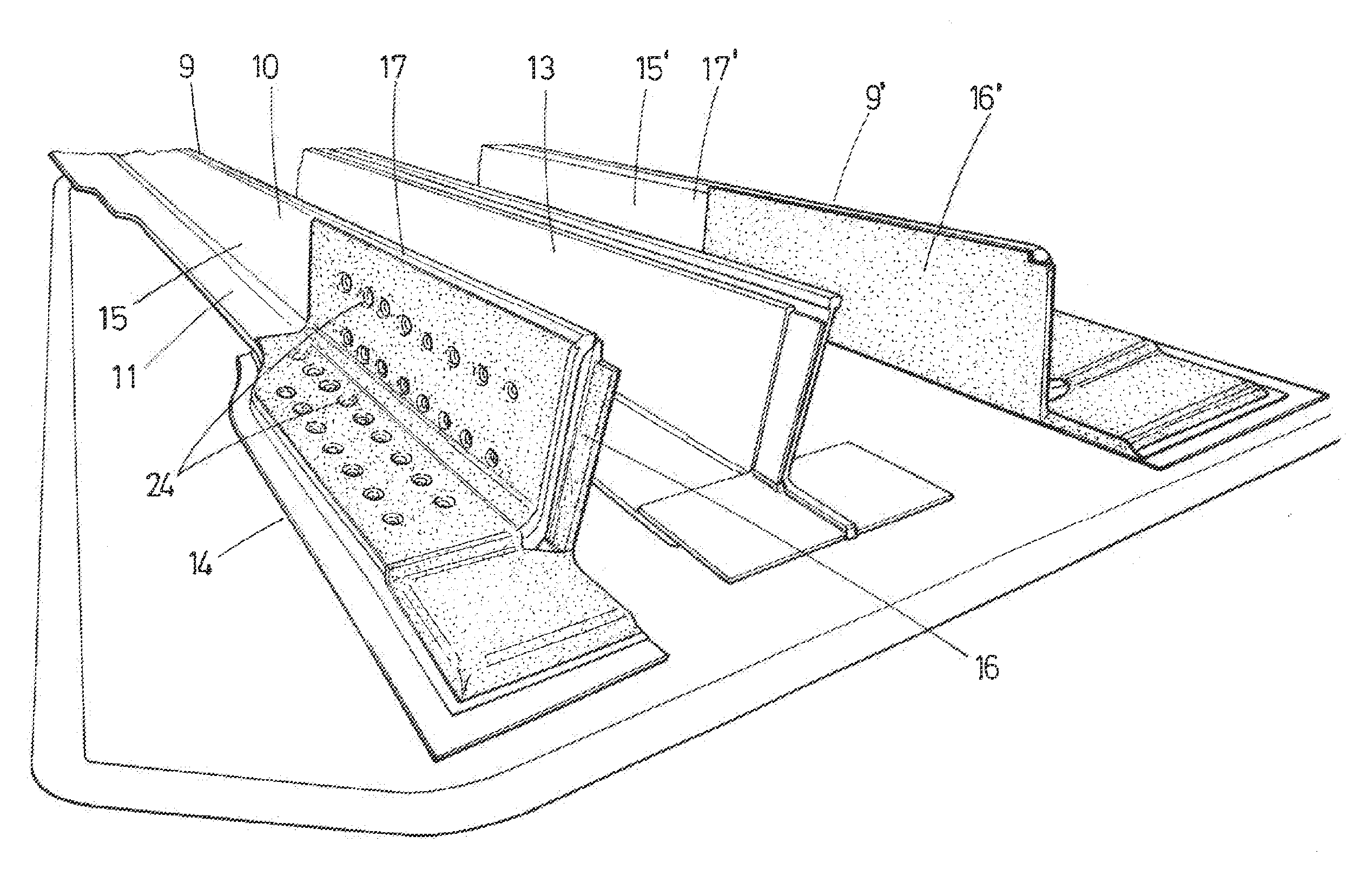

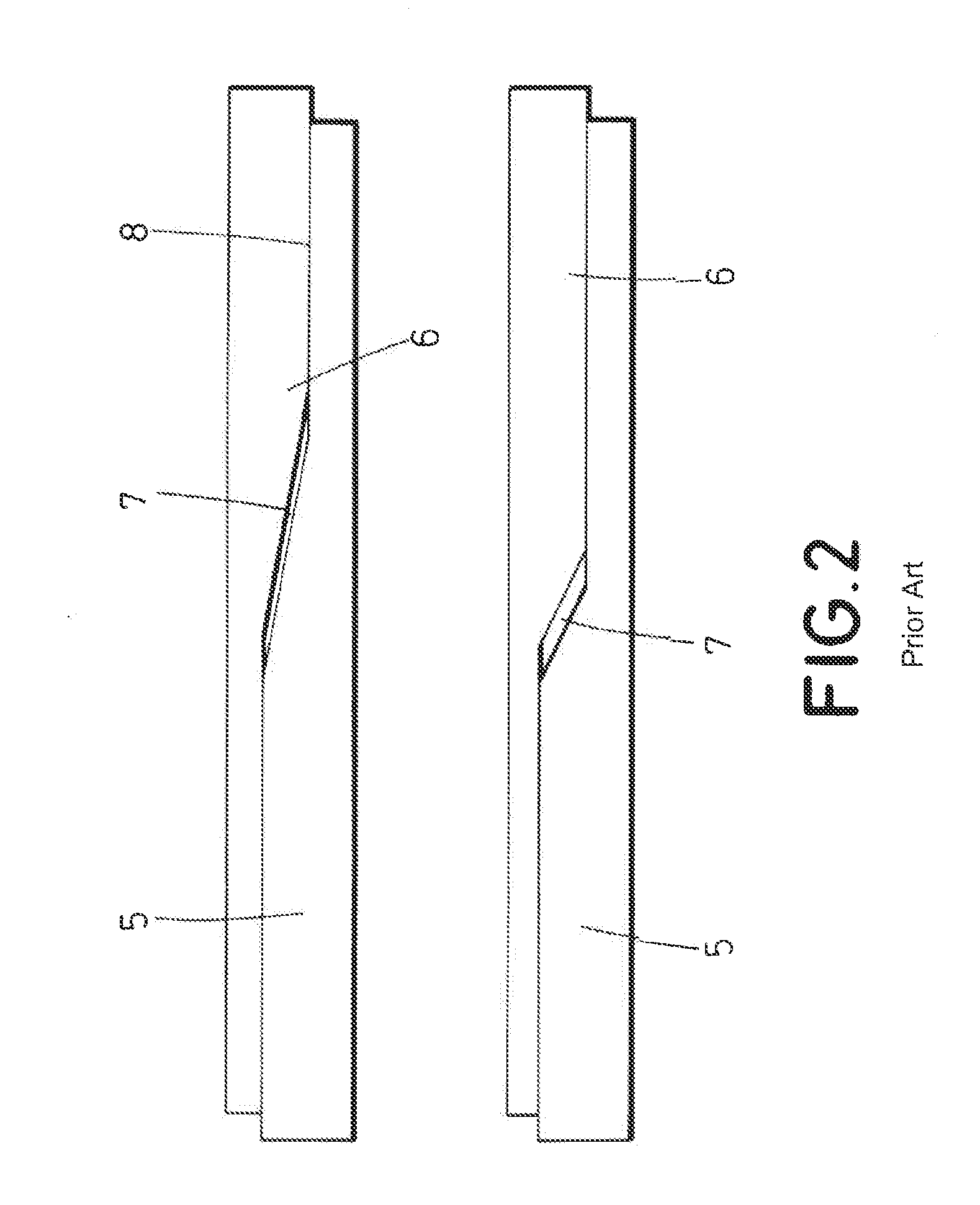

Laser welding processed

InactiveUS20040026381A1Avoid crackingInhibited porosityLaser beam welding apparatusMelting tankWelding defect

In a laser welding method, occurrence of weld defects is effectively prevented, and a high-quality weld joint is provided; and in addition, a wide range of material processes including a laser-using de p-penetration welding technique can be implemented. In keyhole welding using a laser performing output pulse modulation, the welding is conducted in accordance with a frequency conforming to a natural fr queucy of a metal molten pool.

Owner:NAT INST FOR MATERIALS SCI +1

Laser welding processed

InactiveUS6900410B2Avoid crackingInhibited porosityLaser beam welding apparatusMelting tankEngineering

In a laser welding method, occurrence of weld defects is effectively prevented, and a high-quality weld joint is provided, and in addition, a wide range of material processes including a laser-using de p-penetration welding technique can be implemented.In keyhole welding using a laser performing output pulse modulation, the welding is conducted in accordance with a frequency conforming to a natural frequency of a metal molten pool.

Owner:NAT INST FOR MATERIALS SCI +1

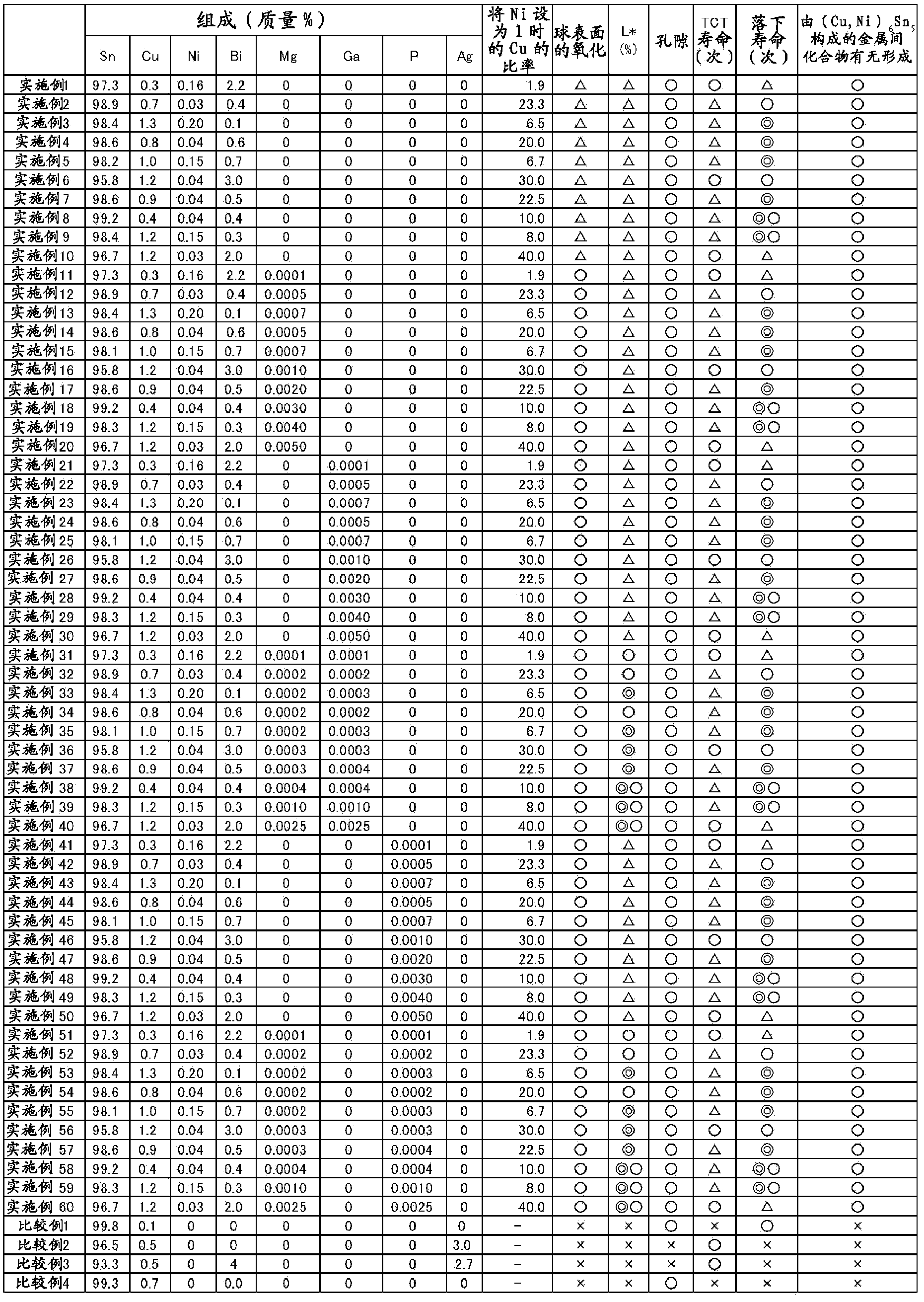

Lead-free solder alloy

ActiveCN101208174AAvoid yellowingInhibited porosityPrinted circuit assemblingWelding/cutting media/materialsDrop impactImpurity

Disclosed is a lead-free solder alloy exhibiting improved drop impact resistance even after thermal aging while being good in soldering properties, void formation and discoloration. Specifically disclosed is a solder alloy consisting essentially of, in mass %, (1) 0.8-2.0% of Ag, (2) 0.05-0.3% of Cu, (3) one or more elements selected from not less than 0.01% and less than 0.1% of In, 0.01-0.04% of Ni, 0.01-0.05% of Co and 0.01-0.1% of Pt, and if necessary (4) one or more elements selected from Sb, Bi, Fe, Al, Zn and P in an amount of not more than 0.1% in total, and the balance of Sn and unavoidable impurities.

Owner:SENJU METAL IND CO LTD

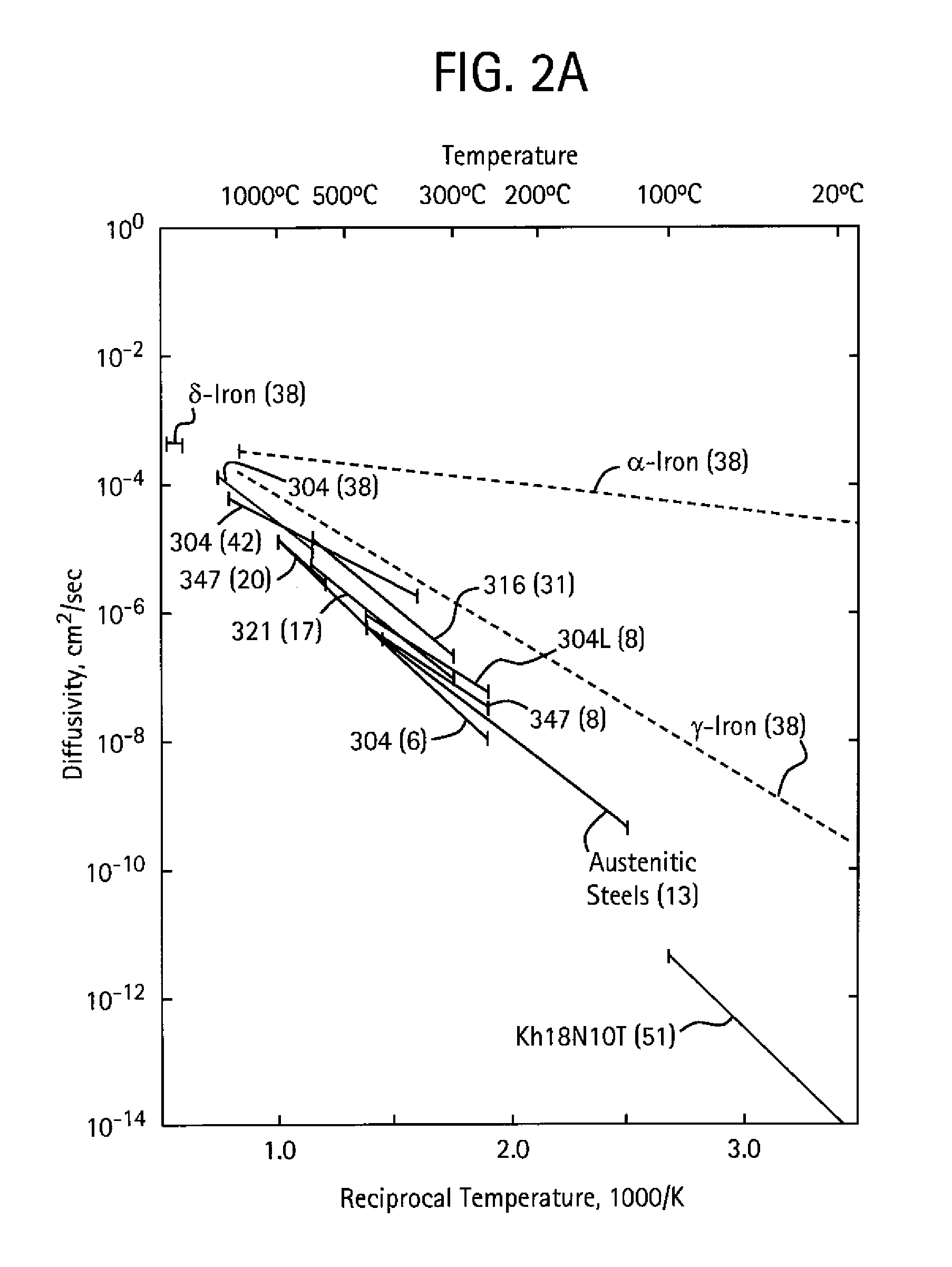

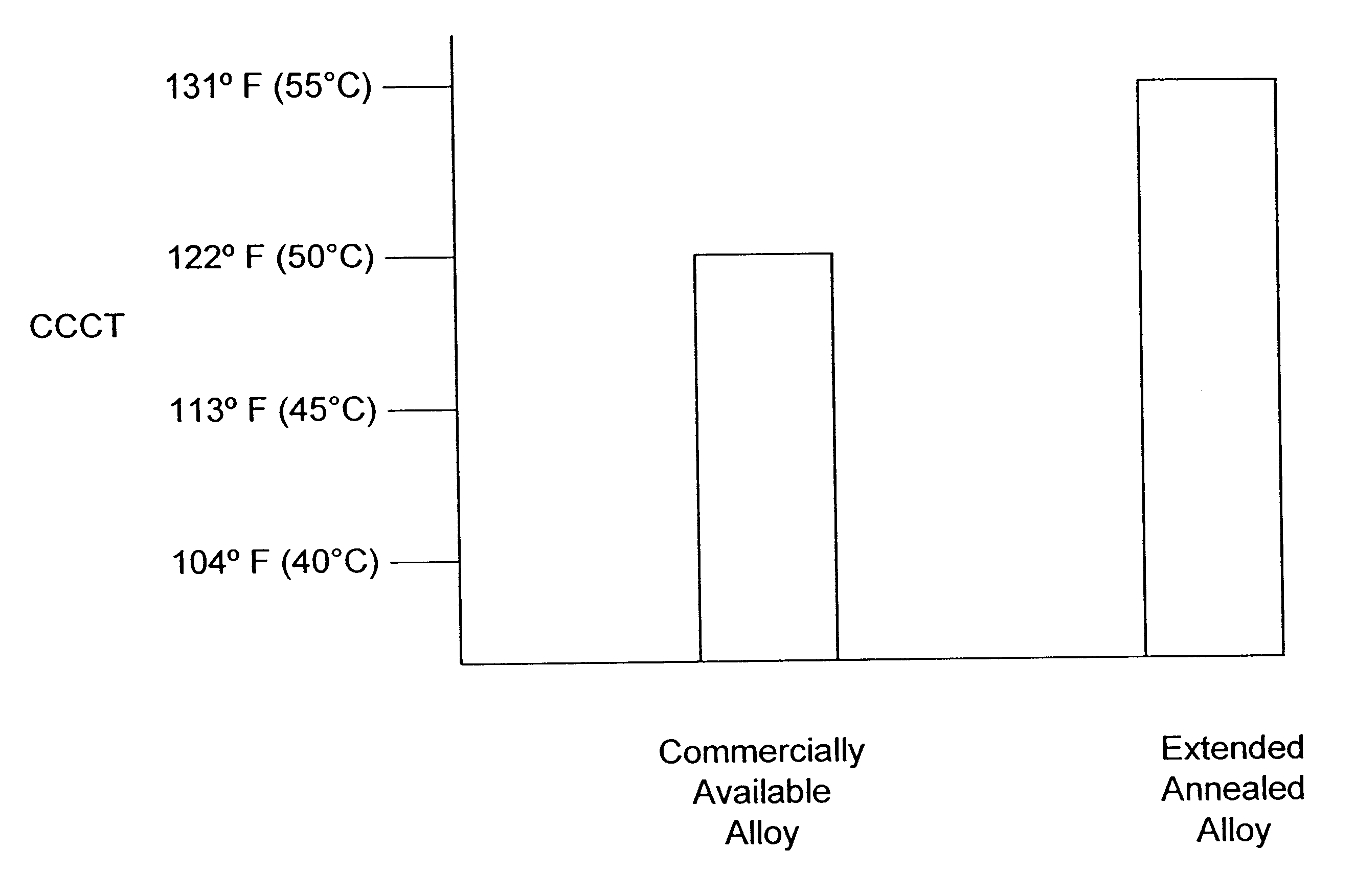

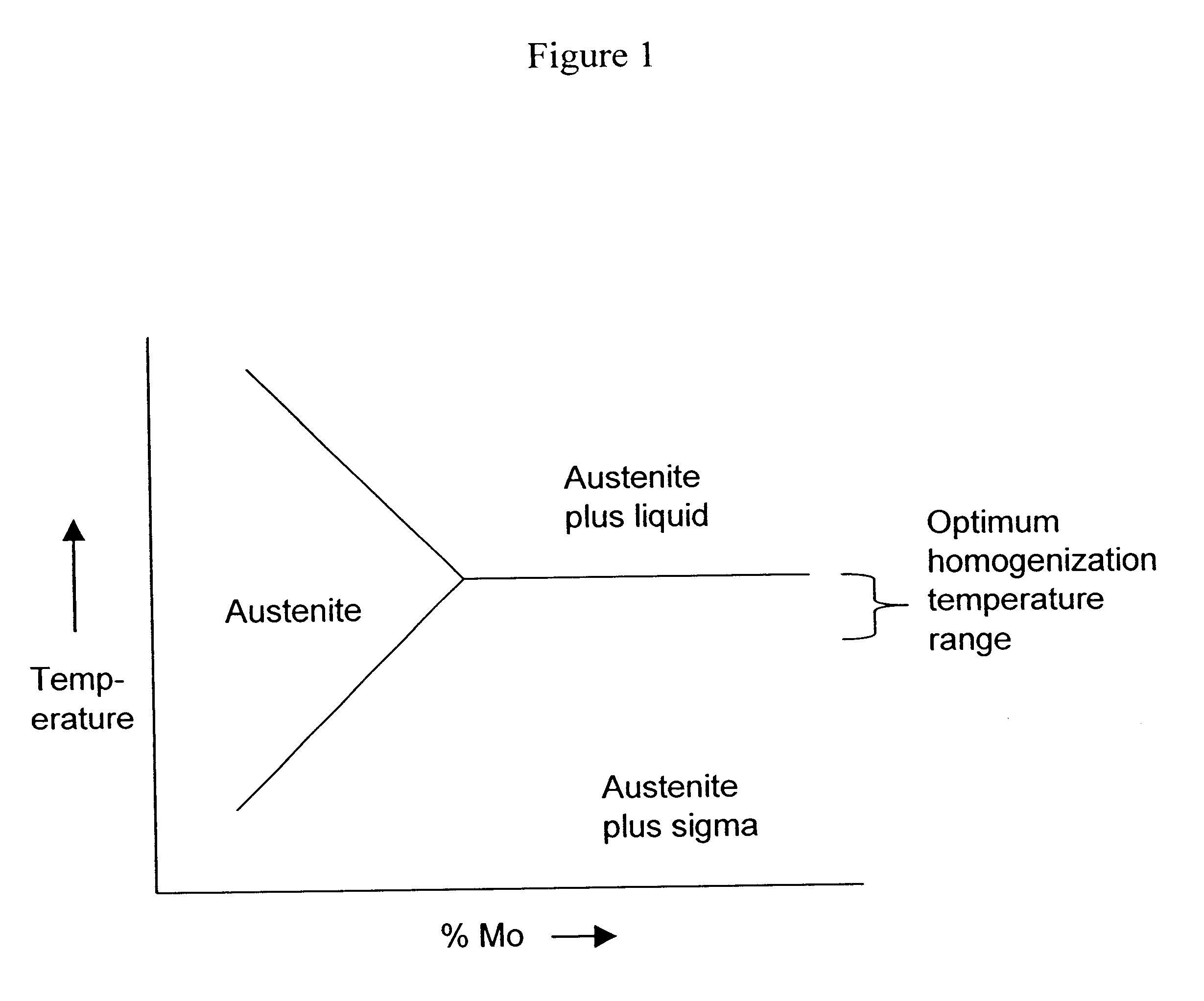

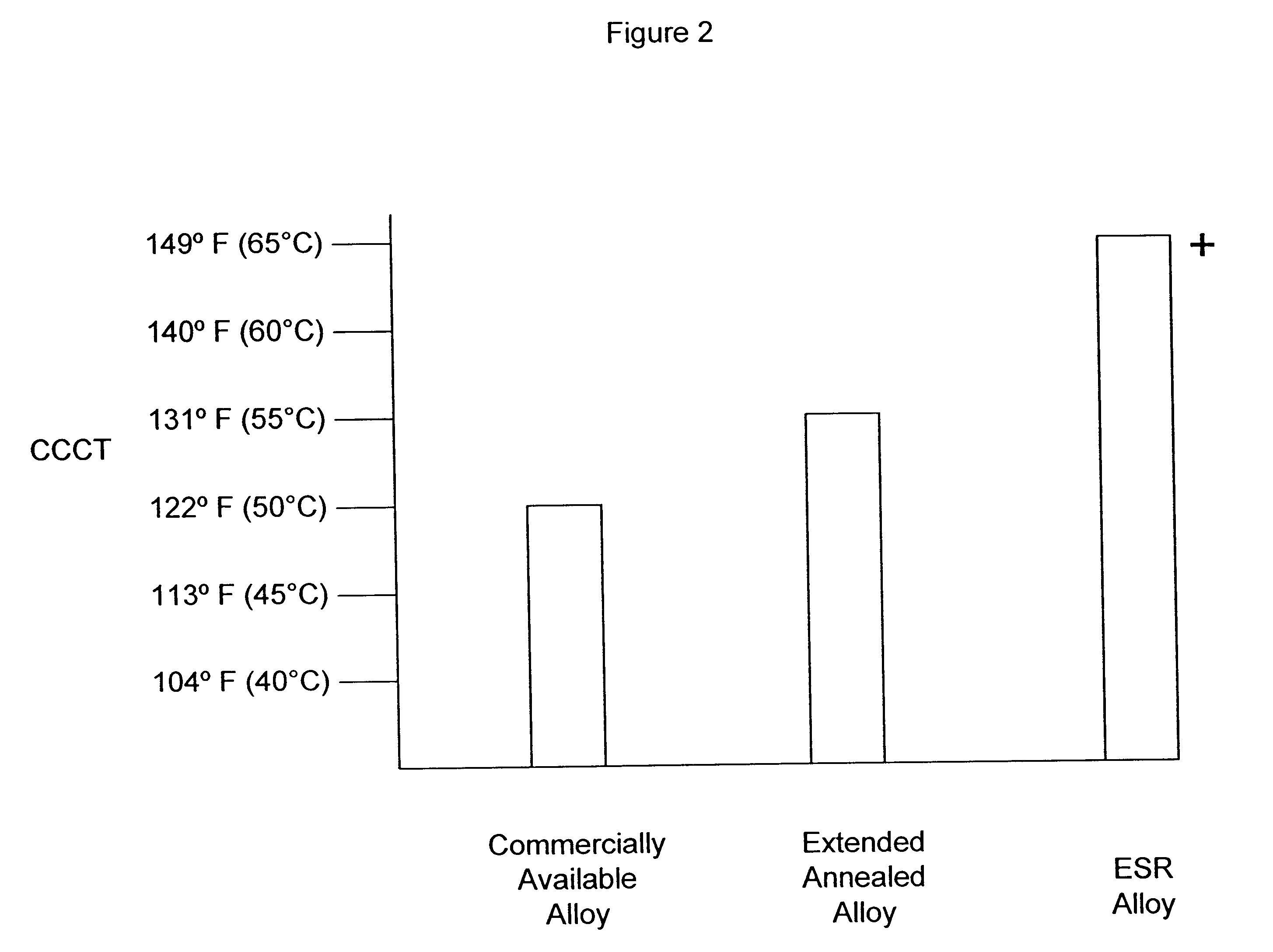

Method of producing stainless steels having improved corrosion resistance

InactiveUS6576068B2Improve the immunityImprove solubilityWelding/cutting media/materialsElectric furnaceNitrogenSS - Stainless steel

A method for producing a stainless steel with improved corrosion resistance includes homogenizing at least a portion of an article of a stainless steel including chromium, nickel, and molybdenum and having a PREN of at least 50, as calculated by the equation:where Cr is weight percent chromium, Mo is weight percent molybdenum, and N is weight percent nitrogen in the steel. In one form of the method, at least a portion of the article is remelted to homogenize the portion. In another form of the method, the article is annealed under conditions sufficient to homogenize at least a surface region of the article. The method of the invention enhances corrosion resistance of the stainless steel as reflected by the steel's critical crevice corrosion temperature.

Owner:ATI PROPERTIES

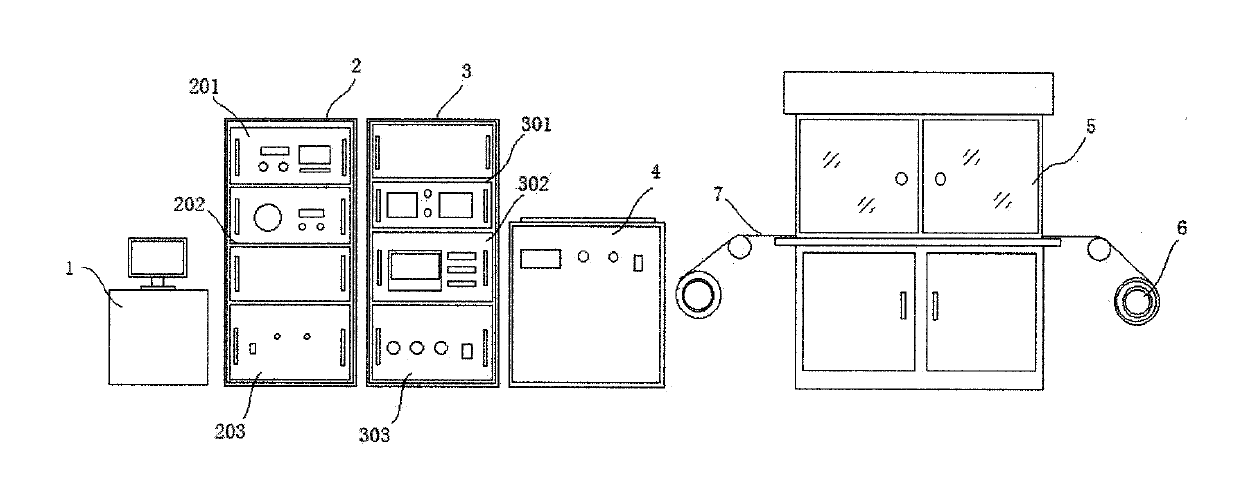

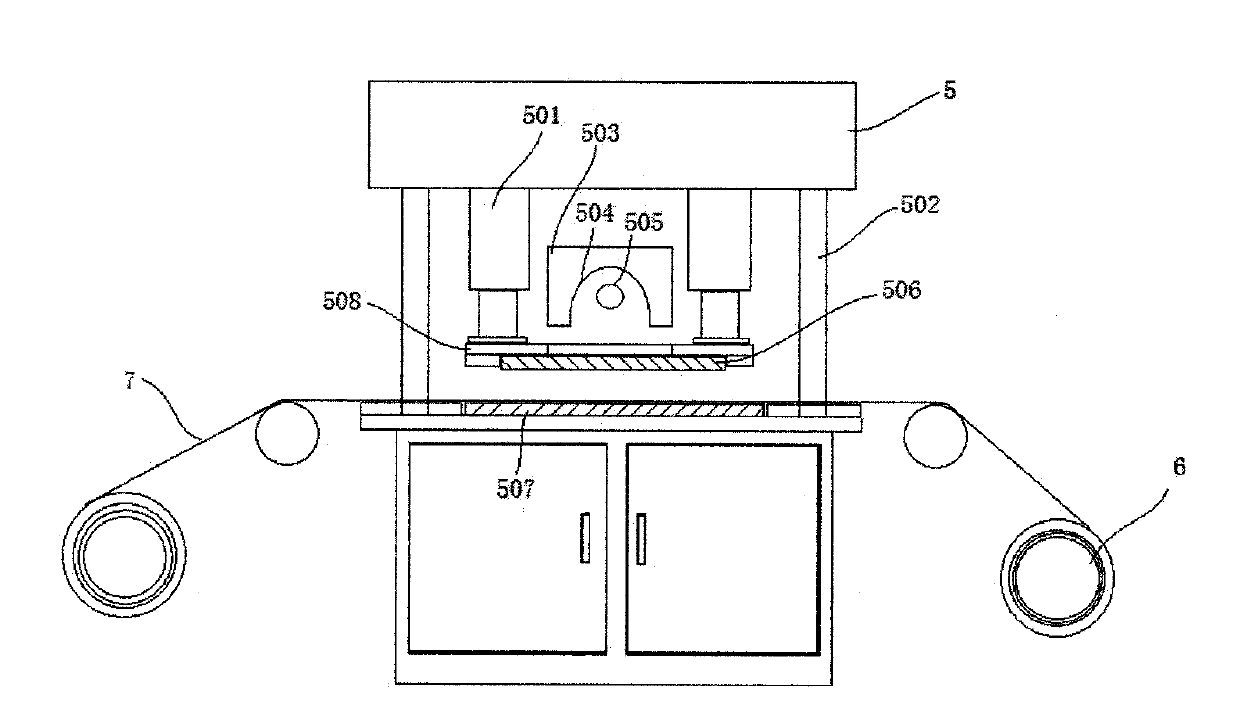

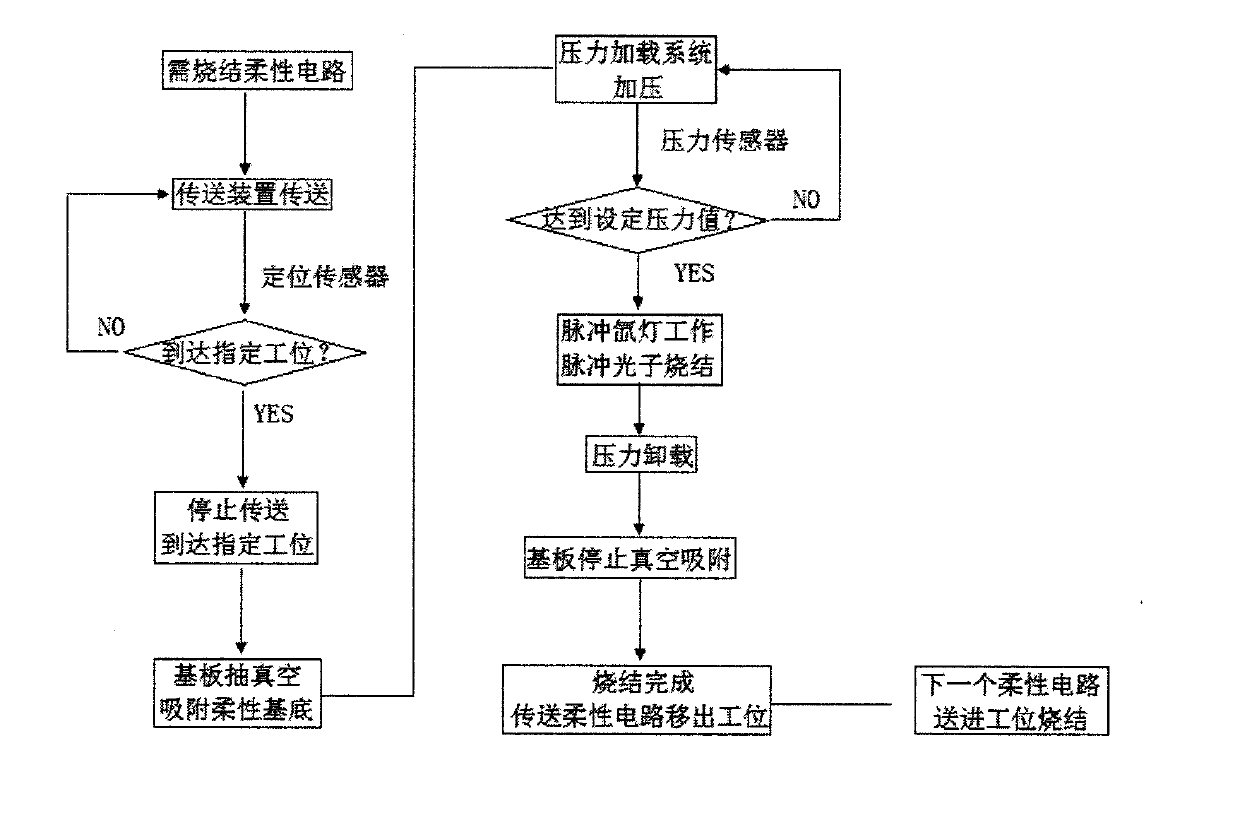

Manufacturing method and manufacturing device of flexible printed circuit

The invention discloses a manufacturing method and a manufacturing device of a flexible printed circuit. The method mainly includes the steps of providing an imaging flexible printed circuit substrate which is coated with nanometer conductive ink or sizing agents; exerting pressure to the flexible printed circuit substrate; and sintering the flexible printed circuit substrate by using xenon lamp sintering technology at the same time when the pressure is exerted and obtaining a target product. By means of the method, a printed circuit can be rapidly manufactured on a low temperature flexible substrate, a metal film which is good in binding force, electrical conductivity and compactness can be obtained, and manufacturing cost is low. The method avoids the processes such as photoetching in the manufacturing process of a traditional flexible printed circuit, rapid and pollution-free flexible printed circuit manufacturing is achieved, and the method is suitable for the production and the manufacture of the flexible printed circuit of the low temperature substrate.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Preparation method for gas separation composite membrane

ActiveCN102008909AImprove permeabilityEasy to separateSemi-permeable membranesDispersed particle separationCross-linkPlatinum complex

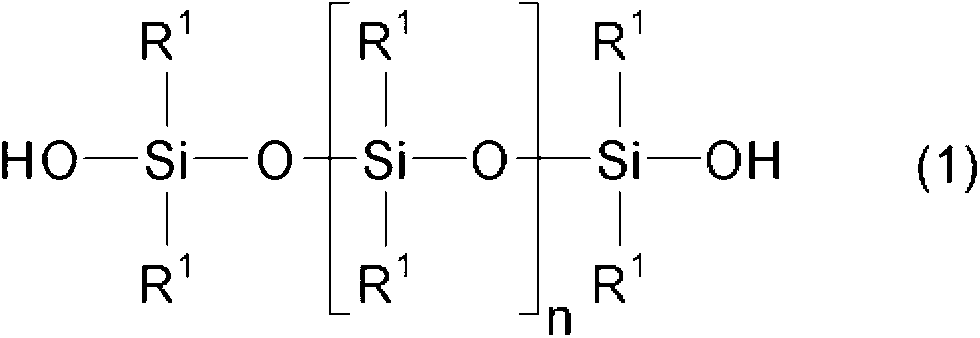

The invention discloses a preparation method for a gas separation composite membrane, comprising the following steps: dissolving a siloxane prepolymer in isooctane, adding a cross-linking agent (pelyntethylhydrosiloxane) and a catalyst (1,3-diethenyl-1,1,3,3-tetramethyldisiloxane platinum complex), stirring to prepare into separation layer membrane liquid; and evenly coating the separation layer membrane liquid on a polyacrylonitrile basement membrane, airing and performing thermal cross linking to obtain the gas separation composite membrane, wherein the adopted basement membrane is a commercialized polyacrylonitrile ultrafiltration membrane, the airing time is 2-20min, the thermal cross linking temperature is 60-120 DEG C, and the thermal cross linking time is 5-30 minutes. The permeation and separation properties of the gas separation composite membrane on O2, N2 and C2H6 determined under the temperature of 25 DEG C are respectively as follows: JN2>0.2m<3>.m<-2>.atm<-1>.h<-1>, alpha (O2 / N2)>2.3, and alpha (C3H6 / N2) >24. The preparation method for the composite membrane is also suitable to preparation of nanofiltration, hyperfiltration and pervaporation composite membranes.

Owner:DALIAN EUROFILM IND

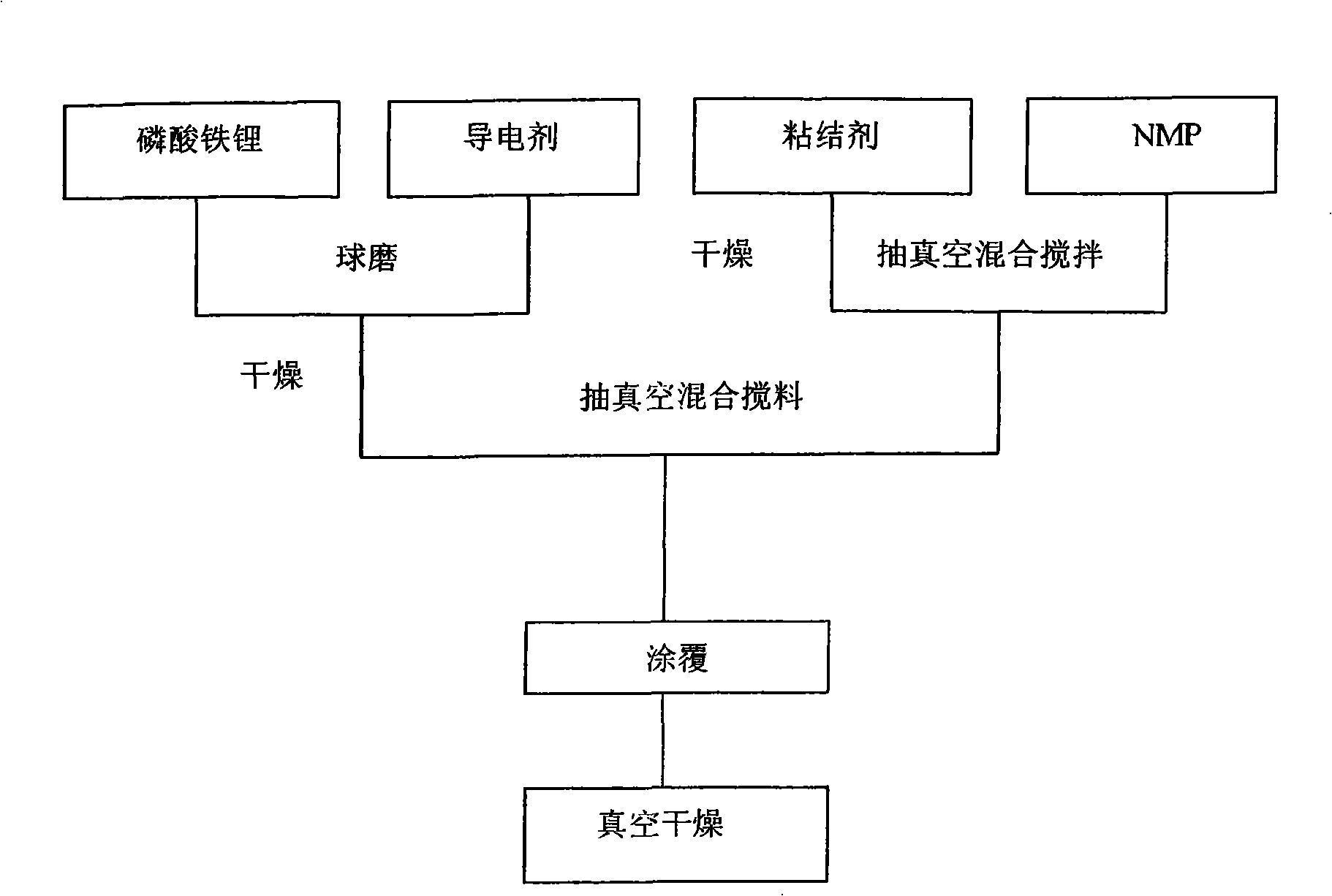

Method for vacuum mixing and coating material for lithium ion battery anode slice

InactiveCN101409343AWell mixedInhibited porosityElectrode manufacturing processesLithium iron phosphateAdhesive

The invention provides a method for coating a lithium ion battery anode plate by vacuum stirring materials. The method comprises the following steps: first, a binder and a solvent are evenly mixed by a certain proportion to obtain an adhesive; the prepared mixture of lithium iron phosphate and a conductive agent are added to the prepared adhesive to obtain a mixed slurry with the viscosity of 1000-10000mPas by vacuum mixing and stirring the materials, and then the slurry is coated by a coating machine to obtain an anode material plate. On the one hand, the anode material, the conductive agent and the binder can be evenly mixed by vacuum stirring the materials; on the other hand, air which results in blistering phenomenon on the plate surface while coating is prevented from being introduced into the slurry by a stirring blade at high-speed rotation by vacuum stirring the materials, thus enhancing the coating volume, mass and density of the material as well as enhancing the specific capacity and the cyclical stability of the anode material of the electrode plate.

Owner:KUNMING UNIV OF SCI & TECH

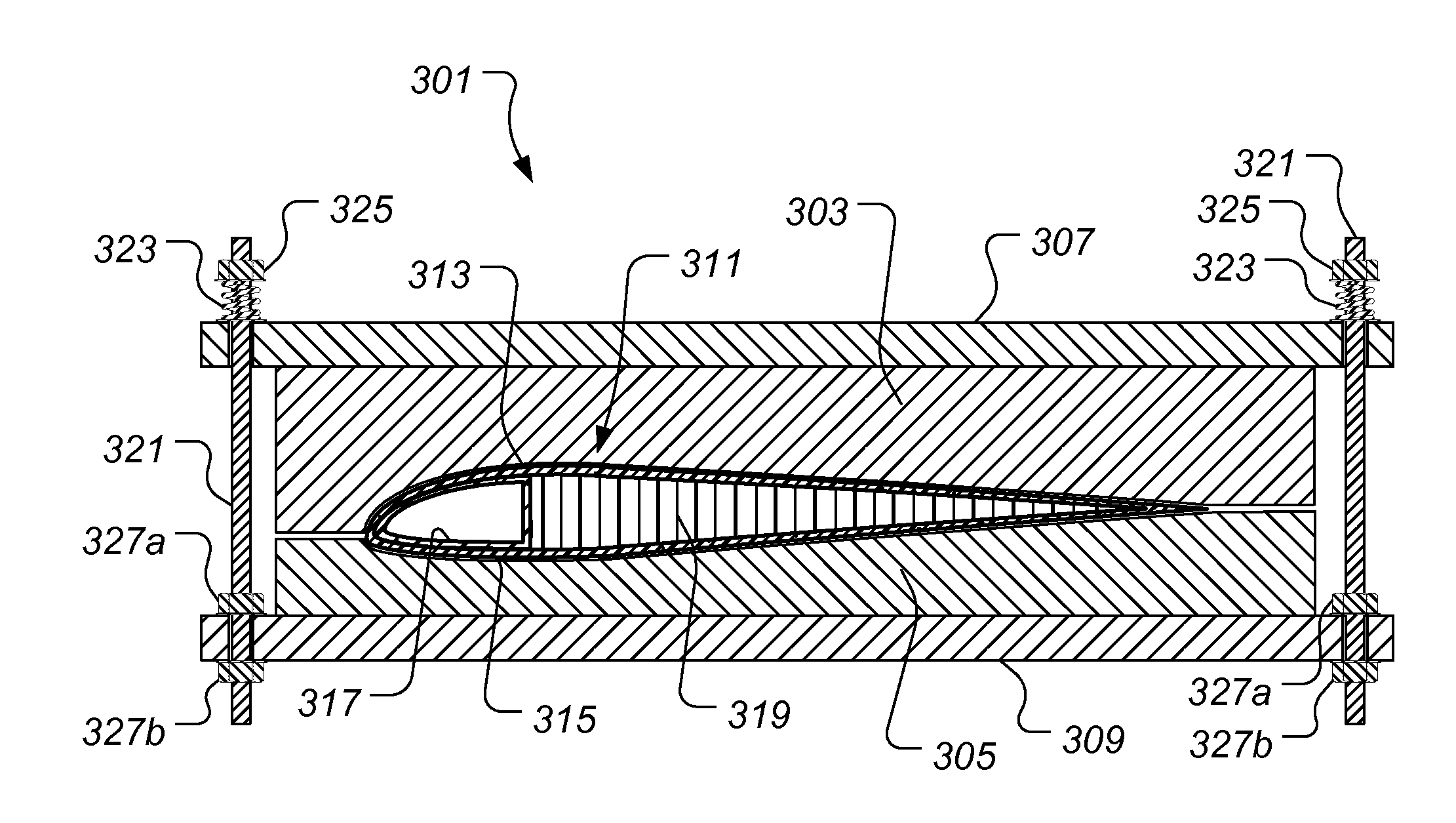

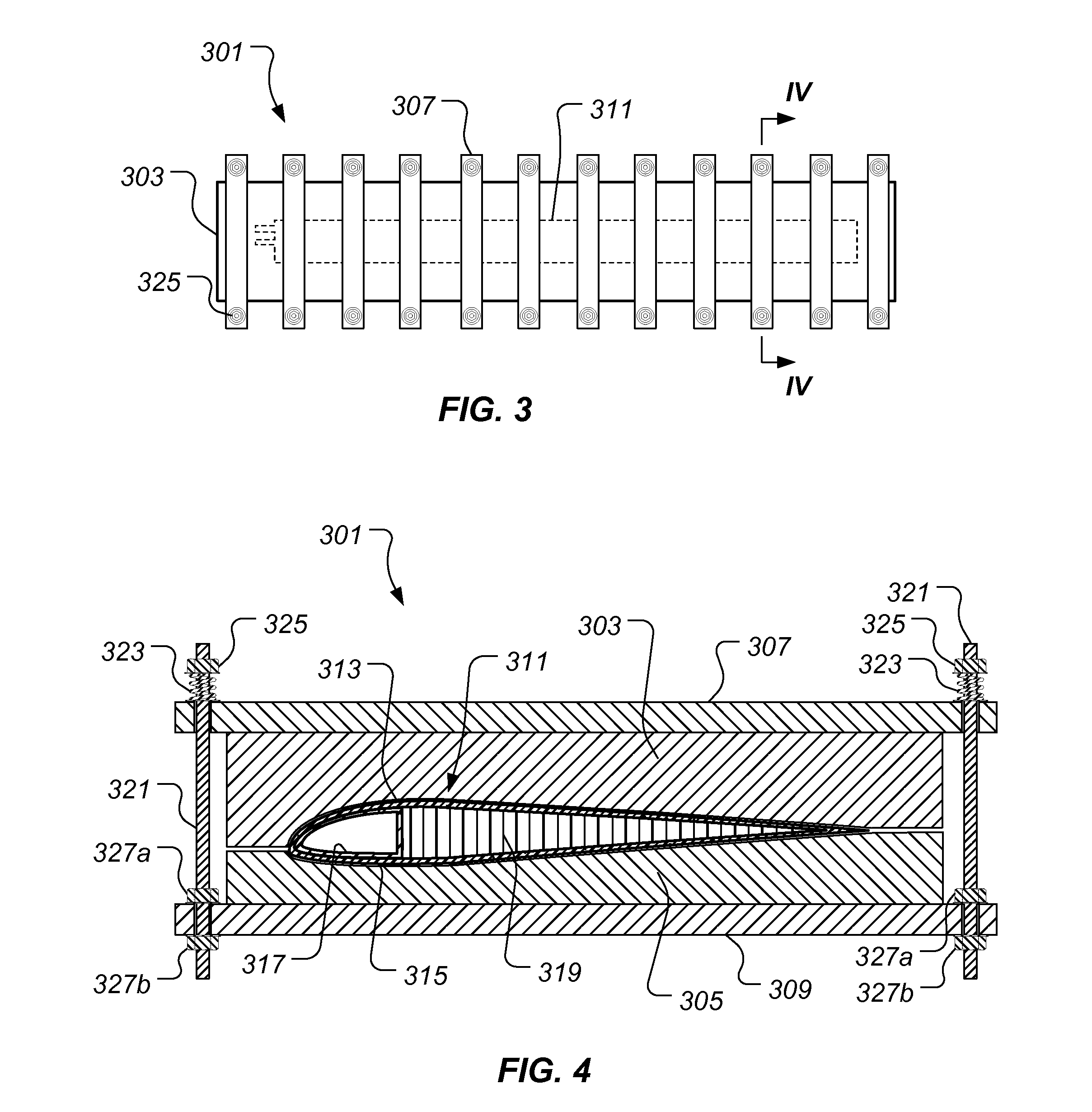

System and Method of Manufacturing a Composite Structure in a Closed Cavity Mold

ActiveUS20130221580A1Avoid developmentInhibited porosityConfectionerySweetmeatsPorosityMaterials science

The present application relates to a method and system that can be utilized to manufacturing composite structures in a closed cavity mold. The tool system includes a closed cavity tool with spring members that when in compression apply pressure to a preform located within the closed cavity mold. During a curing cycle, the spring members provide substantially constant pressure to the preform, thereby preventing voids and porosity in the cured composite structure. Further, the substantially constant pressure, provided by the spring members, acts to more effectively conform the preform to the geometry defined by a void in the closed cavity mold during the curing cycle.

Owner:TEXTRON INNOVATIONS

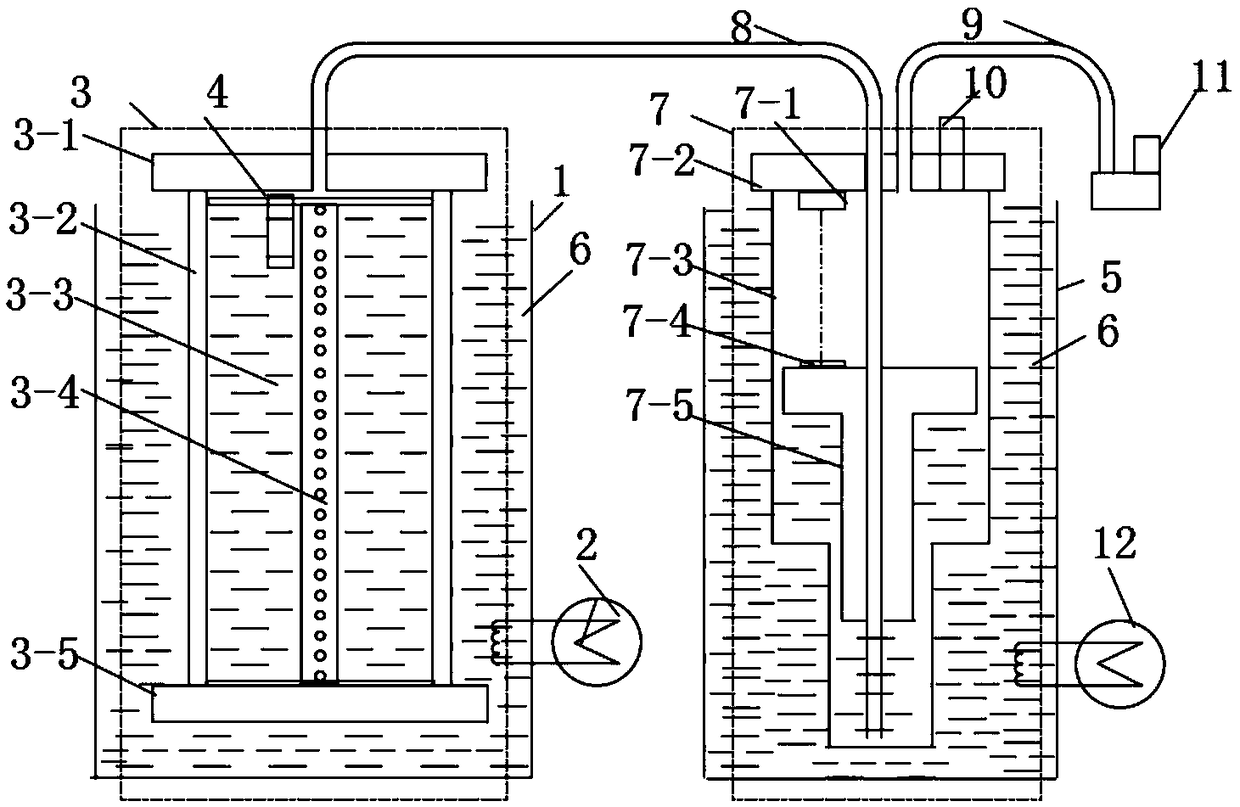

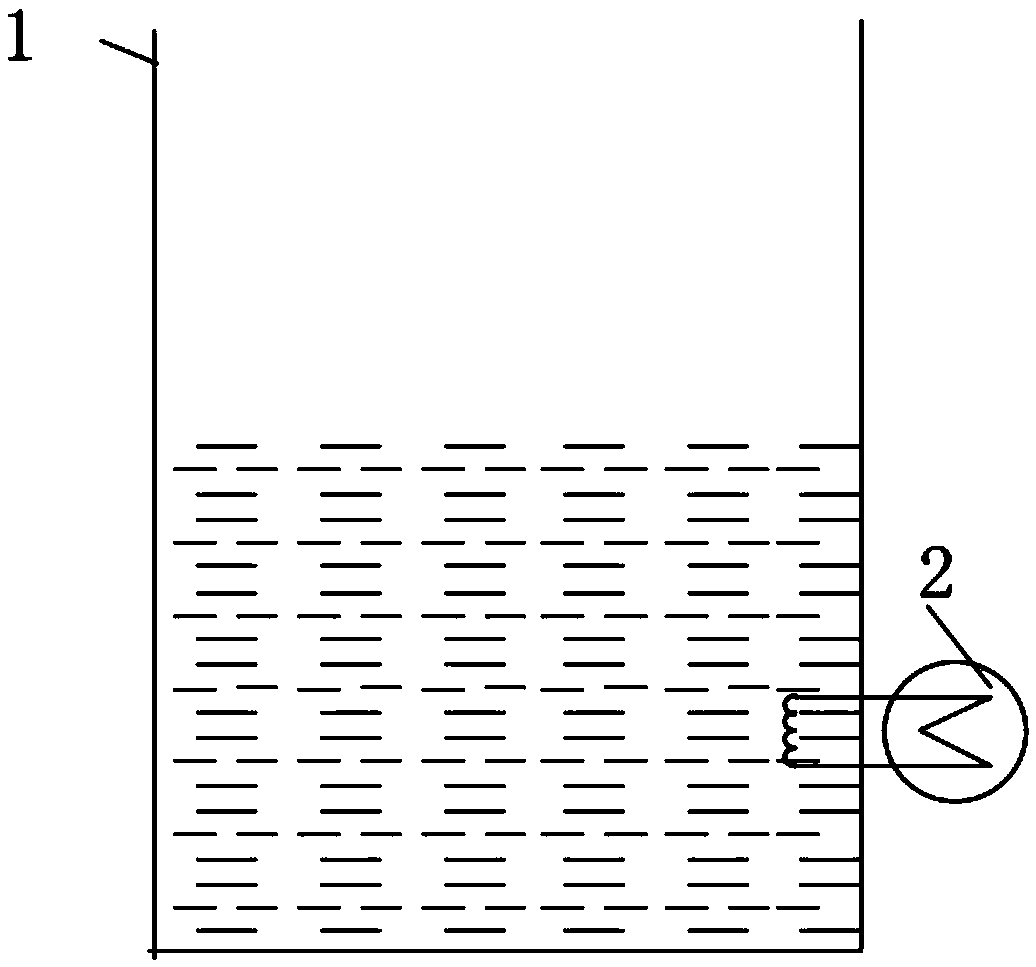

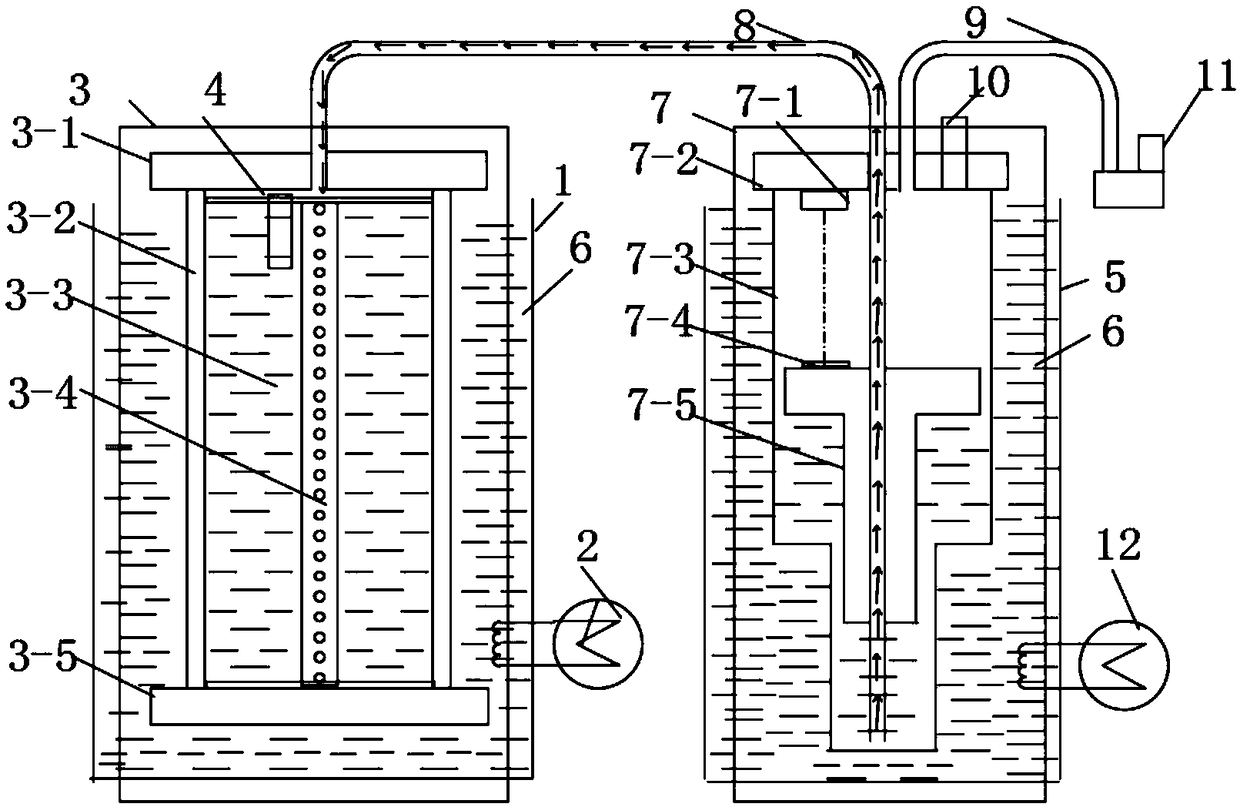

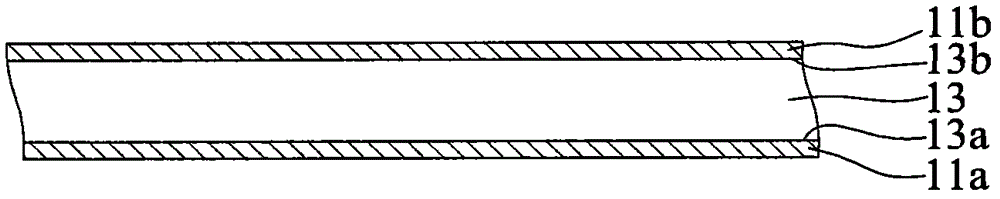

Device and method for measuring volume change rate of phase change power system

ActiveCN109164129AEasy to measureHigh degree of automationInvestigating phase/state changeControl systemEngineering

The invention discloses a device and a method for measuring a volume change rate of a phase change power system. The device comprises a phase change power system, a phase change rehydration system anda variable temperature and variable pressure control system, wherein the phase change power system comprises an adiabatic top cover, heat conductive pipes, a phase change material, an adiabatic rehydration column, an adiabatic bottom cover and a first connecting tube; the phase change rehydration system comprises a laser displacement sensor, a rehydration tube adiabatic top cover, a rehydration tube, a reflector, a floating column and liquid; the variable temperature and variable pressure control system comprises a thermostatic water tank, a first cold-heat exchanger, a second cold-heat exchanger, a temperature sensor, a rehydration thermostatic water tank, a second connecting pipe, a pressure sensor and an air pump; By adopting the device, various constant phase-transition temperature conditions can be set through the cold-hot water exchangers; various pressure conditions of a phase change process can be set by the air pump, so that the measurement of the volume change rate of the phase change power system under different temperatures and pressures can be realized. The position of the floating column is measured by the laser displacement sensor, so that the acquisition of the liquid level change of the phase change material can be realized.

Owner:TIANJIN UNIV

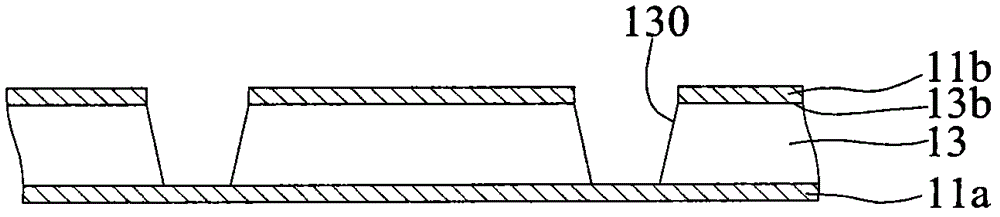

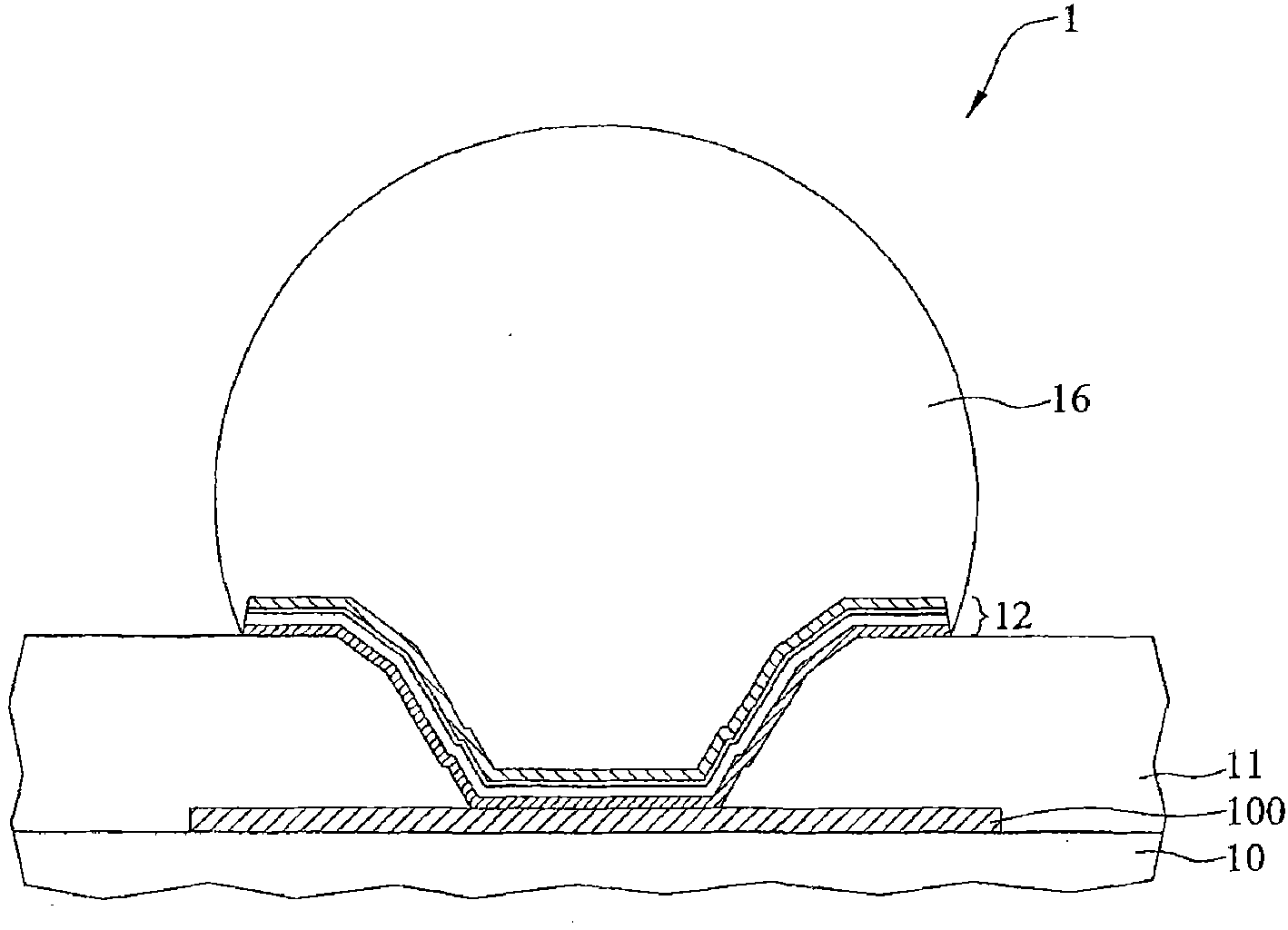

Packaging substrate and packaging structure provided with supporting body and manufacture method thereof

ActiveCN103066048AHigh strengthAvoid breakingSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectric contact

The invention discloses a packaging substrate and a packaging structure provided with a supporting body and a manufacture method thereof. The packaging substrate comprises the supporting body, a first electric contact pad arranged on the supporting body, a core layer of the first electric contact pad arranged on the supporting body in a burying mode, a circuit layer arranged on the core layer, a plurality of electric blind holes arranged in the core layer, and an insulation protective layer disposed on the core layer. Due to the fact that the supporting body is combined with one side of the packaging substrate, the packaging substrate is prevented from being broken during transportation or packaging because the packaging substrate is too thin.

Owner:UNIMICRON TECH CORP

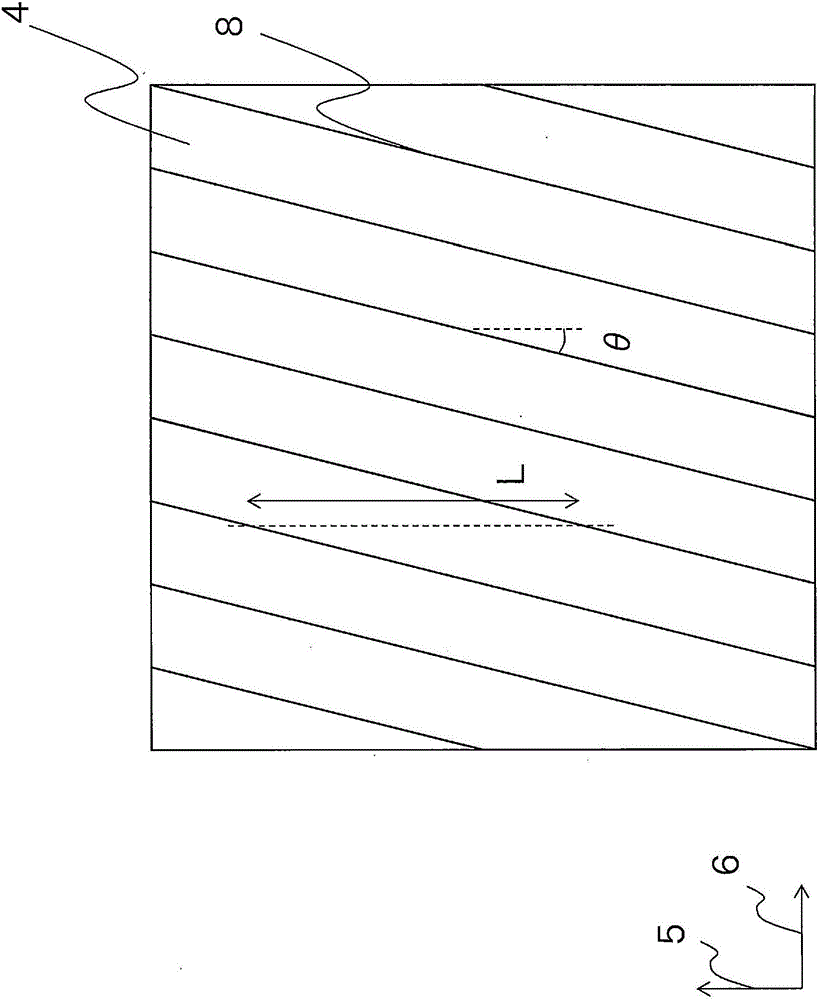

Notched pre-preg and notched pre-preg sheet

ActiveCN106715547AImprove molding stabilitySuppression of molding defects that reduce strengthSynthetic resin layered productsPaper/cardboard layered productsWrinkle skinLow pressure molding

The purpose of the present invention is to provide: an intermediate substrate that has excellent handleability and followability for complex shapes, and also achieves good yield, excellent mechanical properties and low variation thereof, as well as excellent dimensional stability as a result of strength-reducing moulding defects, such as wrinkles and voids, occurring less readily when used in a fibre-reinforced plastic, even with low-pressure moulding; and a method for manufacturing a fibre-reinforced plastic, the intermediate substrate being used in said method. This pre-preg, which has a layer that contains reinforcing fibres impregnated with a resin composition, is characterised by: being a notched pre-preg; the rate of impregnation by the resin composition in the pre-preg being within a prescribed range; comprising reinforcing fibres, at least a portion of which is of a prescribed fibre length due to a plurality of notches; and having a reinforcing-fibre volume content Vf that is within a prescribed range.

Owner:TORAY IND INC

Solder composition and electronic board

ActiveCN107262968APrintable enoughInhibited porosityWelding/cutting media/materialsSoldering mediaBoiling pointRosin

A solder composition of the invention includes: a flux composition containing a component (A) in a form of a rosin-based resin, a component (B) in a form of an activator, a component (C) in a form of a solvent and a component (D) in a form of a thixotropic agent; and a component (E) in a form of a solder powder. The component (C) in a form of the solvent contains a component (C1) in a form of a isobornyl cyclohexanol and a component (C2) in a form of a solvent whose viscosity at 20 degrees C. is 10 mPa s or less and whose boiling point ranges from 220 degrees C. to 245 degrees C.

Owner:TAMURA KK

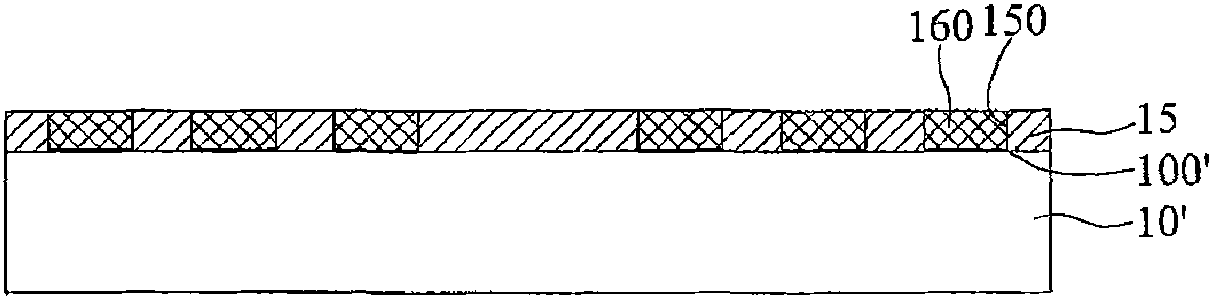

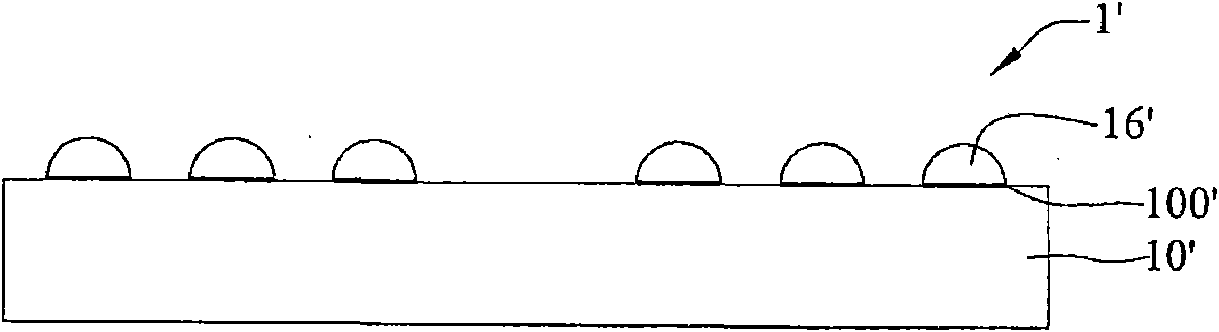

Semiconductor substrate and preparation method thereof

ActiveCN102487049AInhibit sheddingAvoid problems such as crackingSemiconductor/solid-state device detailsSolid-state devicesSolder ballSemiconductor

The invention relates to a semiconductor substrate and a preparation method thereof. The semiconductor substrate comprises a substrate, a first insulating protective layer, a metal layer, a second insulating protective layer, and a solder ball. More particularly, an electrical contact pad is arranged on the surface of the substrate; the first insulating protective layer is arranged on the substrate and enables the electrical contact pad to be exposed; the metal layer is arranged on the exposed electrical contact pad; the second insulating protective layer is arranged on the first insulating protective layer and enables a portion of the metal layer to be exposed; and the solder ball is arranged on the exposed metal layer. Because the second insulating protective layer is covered on a portion of the metal layer, when a temperature test is carried out on the semiconductor substrate, problems that the solder ball drops off or fractures and the like can be solved. Furthermore, the invention also provides a preparation method of the semiconductor substrate.

Owner:SILICONWARE PRECISION IND CO LTD

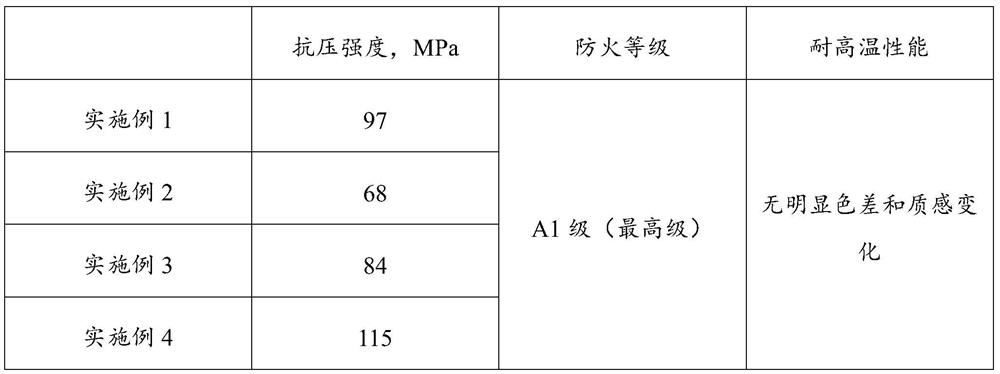

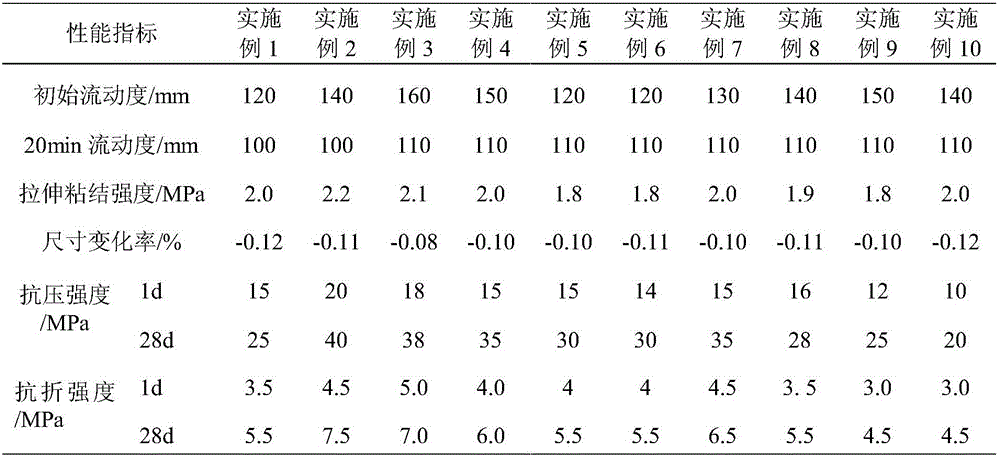

Solid waste-based inorganic artificial stone plate and preparation method thereof

The invention belongs to the technical field of building materials, and particularly relates to a solid waste-based inorganic artificial stone plate and a preparation method thereof. The solid waste-based inorganic artificial stone plate comprises, by weight, 46-66 parts of a solid waste-based material, 90-165 parts of quartz sand, 4-12 parts of an excitant, 7-16 parts of water, 0-2 parts of a water reducing agent and 0-10 parts of an inorganic pigment. The water consumption is low, generation of pores in the product due to excessive moisture is avoided, and the strength and other mechanical properties of the plate are improved; reinforcing materials such as fibers, resin and polyvinyl alcohol do not need to be additionally added, the chemical activity of solid waste is fully utilized, allthe raw materials are matched and used in proportion, that is, the solid waste-based inorganic artificial stone plate with high polymerization degree, high compactness and high strength can be generated in situ through the coordination effect of all the components, the mechanical property requirement of the artificial stone plate is met, the economic cost is effectively reduced, no free formaldehyde is released, and the solid waste-based inorganic artificial stone plate is more environmentally friendly, better in fireproof and high-temperature-resistant performance and wide in application prospect.

Owner:UNIV OF JINAN

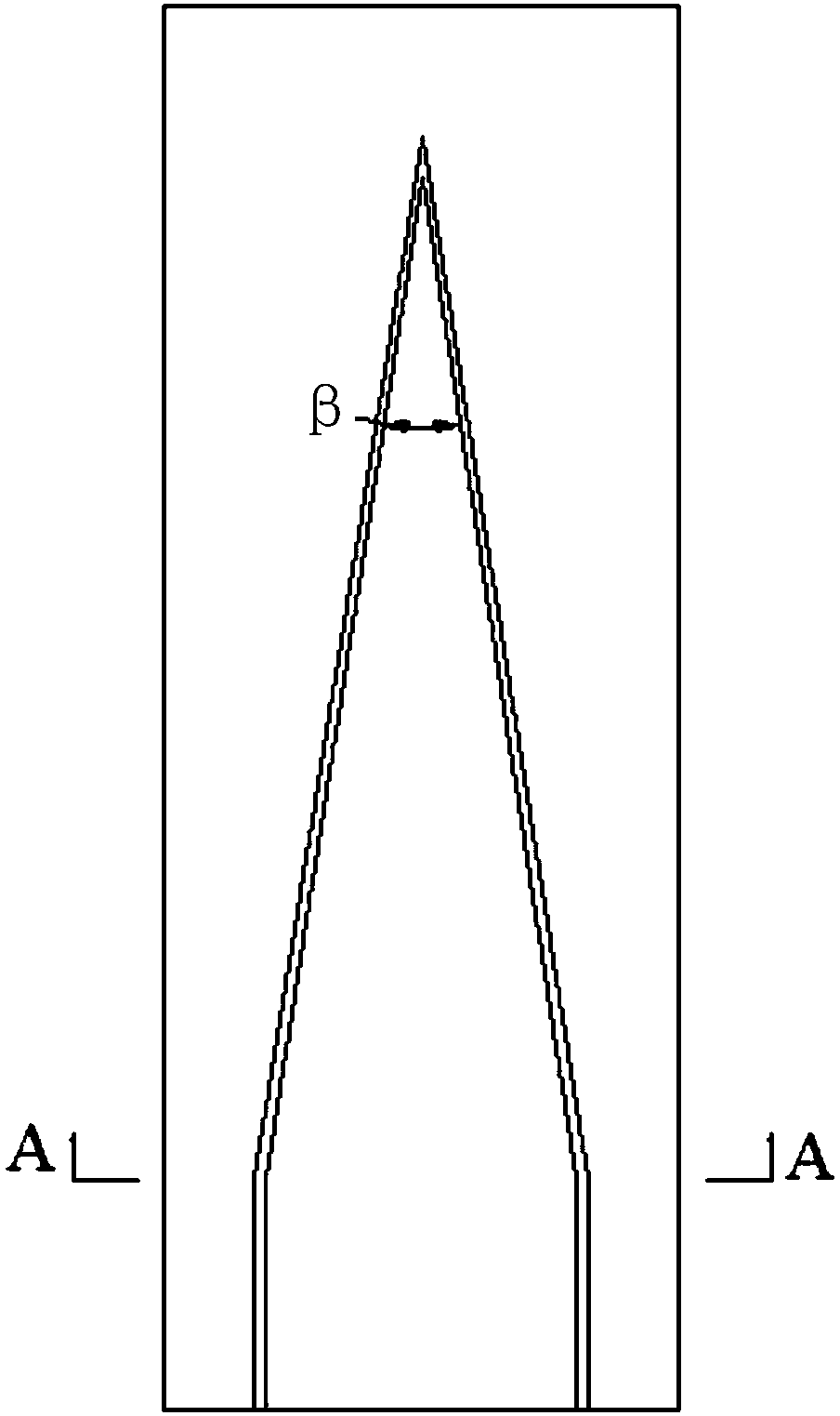

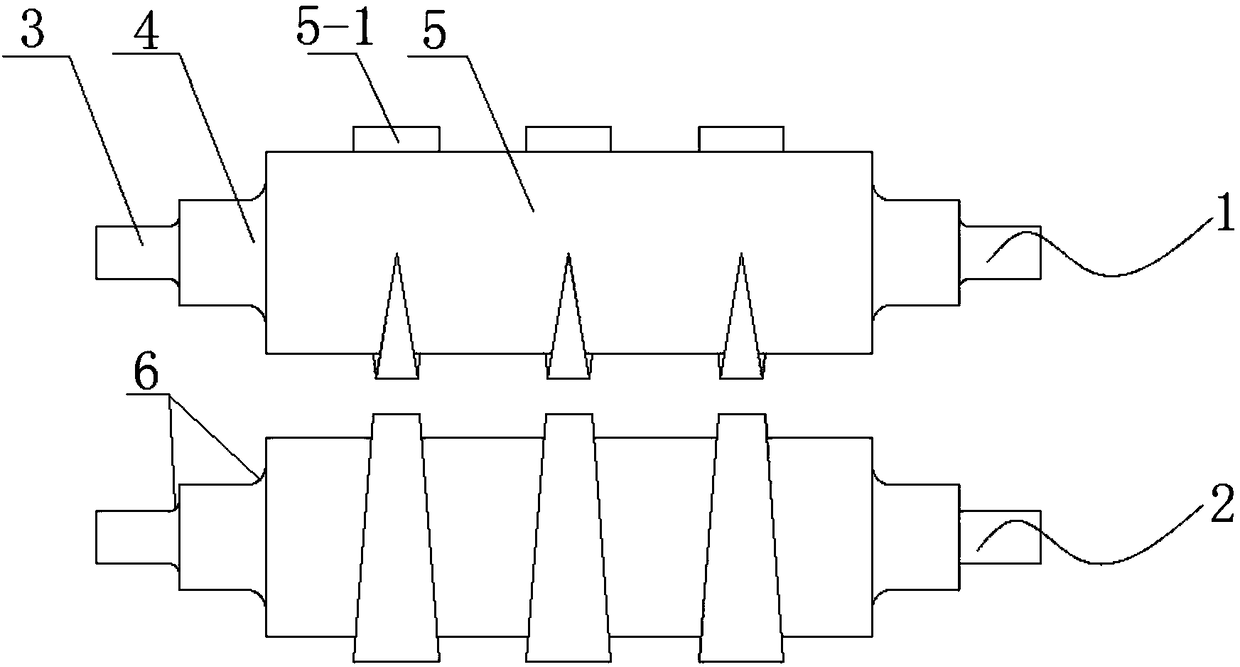

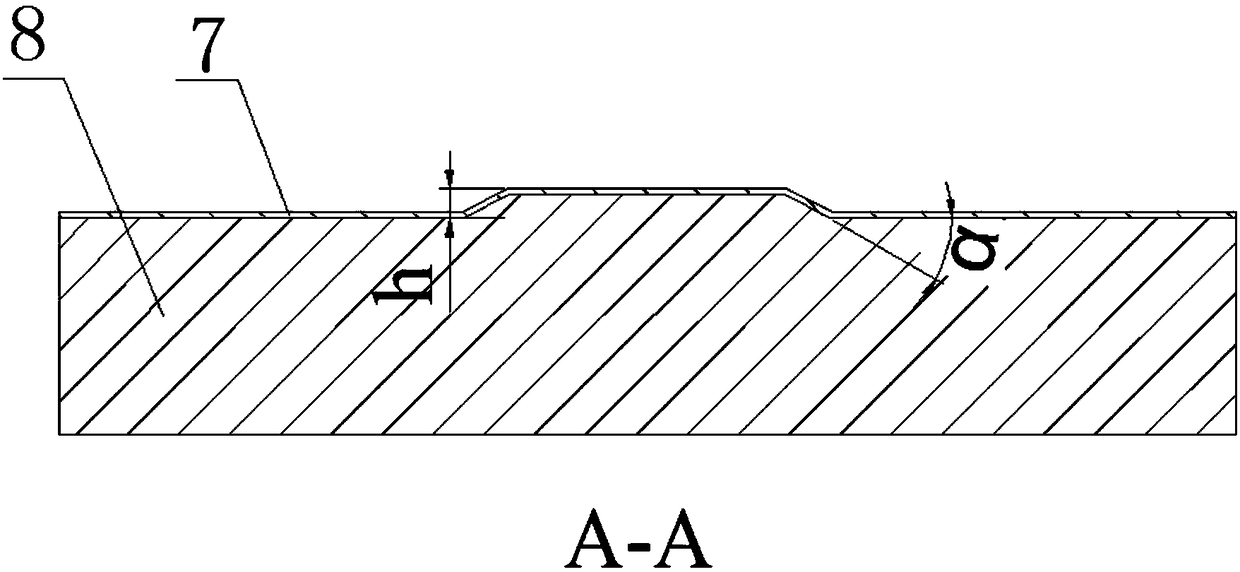

Roller applicable to cross wedge rolling shaft type parts and production technology

The invention relates to a roller and a production technology, in particular to a roller applicable to cross wedge rolling shaft type parts and a production technology. The roller is prepared from chemical ingredients comprising 1.8-2.2% of C, 0.4-0.60% of Si, 0.8-1.2% of Mn, 0.03% or less of P, 0.025% or less of S, 1.2-1.6% of Cr, 1.6-2.0% of Ni, 0.6-0.8% of Mo, 0.2-0.4% of V, 0.2-0.4% of Nb andthe balance Fe and a small amount of residual elements, then, two-furnace smelting is carried out, yttrium-based rare earth alterant is added, and a special heat treatment technology is carried out, so that the roller is obtained. The phenomenon that carbide exists in a discontinuous (granular) state is changed by optimally allocating the chemical ingredients, particularly adding niobium and vanadium, and the microscopic structure of the roller is improved. Meanwhile, by adding the yttrium-based heavy rare earth alterant for purifying molten steel in the steel melting process, the purity is improved, the comprehensive mechanical property of the roller is improved, the yield and quality of rolled products are improved, the service life of the roller is prolonged, and the purposes of cost decreasing and benefit increasing for enterprises are achieved.

Owner:湖州中杭轧辊有限公司

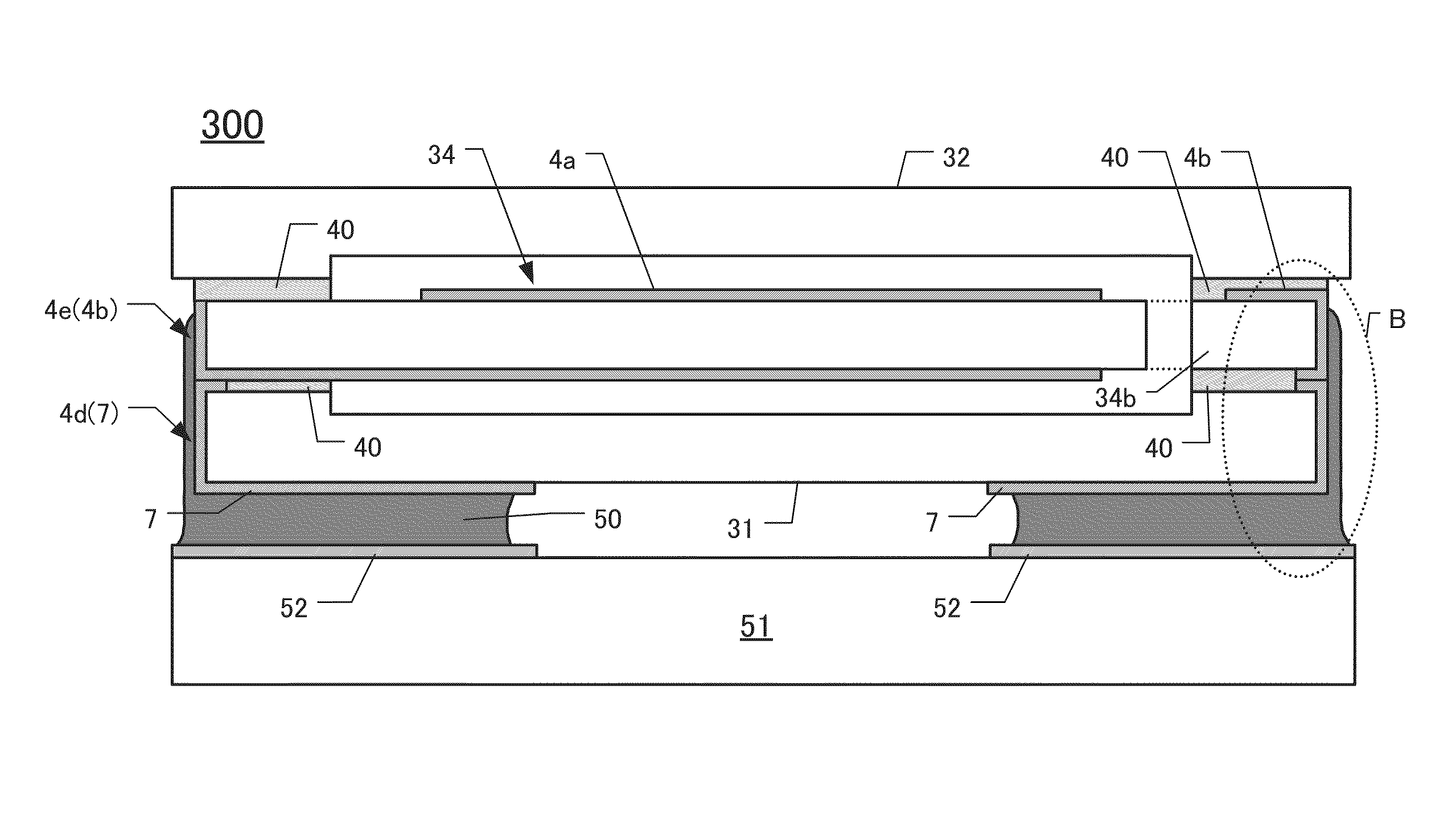

Surface-mountable piezoelectric devices including eutectic-bonded packages

InactiveUS8531092B2Avoid failureInhibition strengthImpedence networksPiezoelectric/electrostriction/magnetostriction machinesEngineeringAlloy

Piezoelectric devices are disclosed that are mountable on the surface of a printed circuit board or the like. An exemplary device comprises a piezoelectric vibrating piece enclosed and sealed within a package including at least a cover and a base-substrate formed of glass or piezoelectric material. The package includes frame-shaped metallic films formed in peripheral regions of inner main surfaces of the cover and / or the base substrate. The frame-shaped metallic films are used for sealing the package using a eutectic material (e.g., solder). At least one mounting terminal is provided on the outer (bottom) main surface of the base-substrate. At least one of the frame-shaped metallic films and mounting terminals includes a chromium foundation layer formed on the surface of the glass or piezoelectric material, a middle layer of NiW alloy formed on the surface of the chromium layer, and a gold layer formed on the surface of the middle layer.

Owner:NIHON DEMPA KOGYO CO LTD

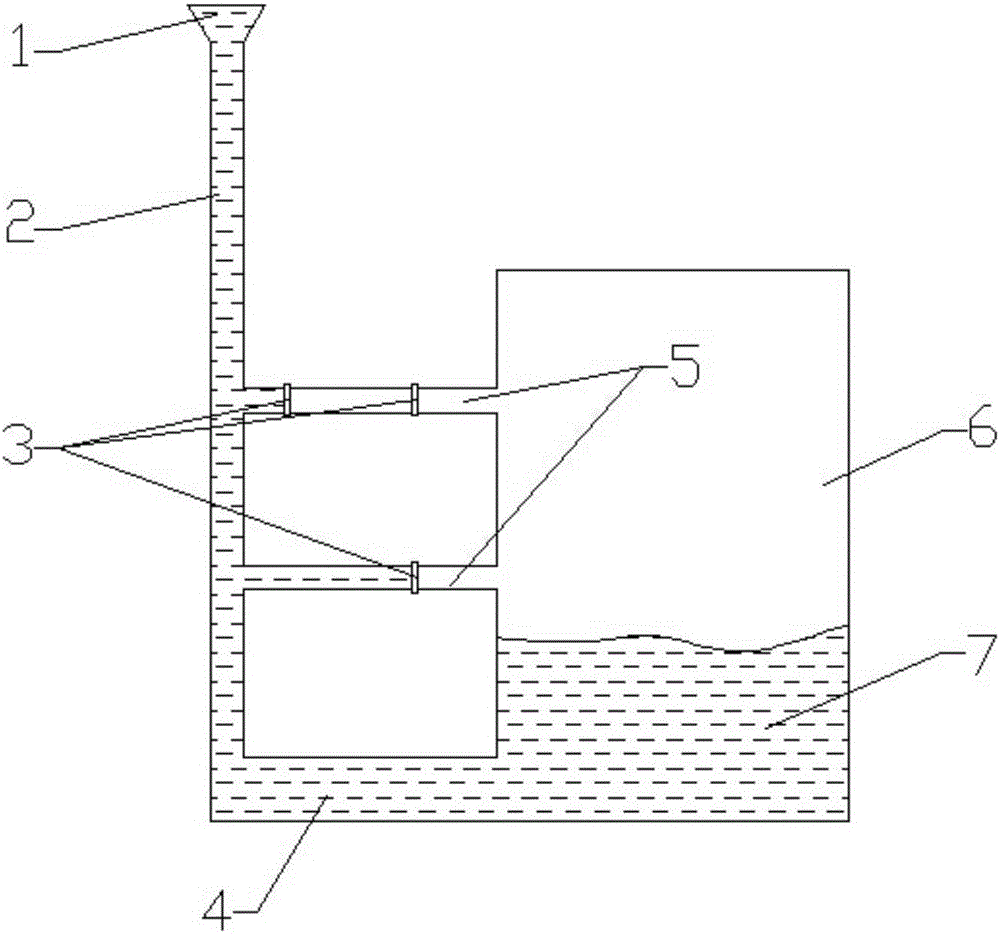

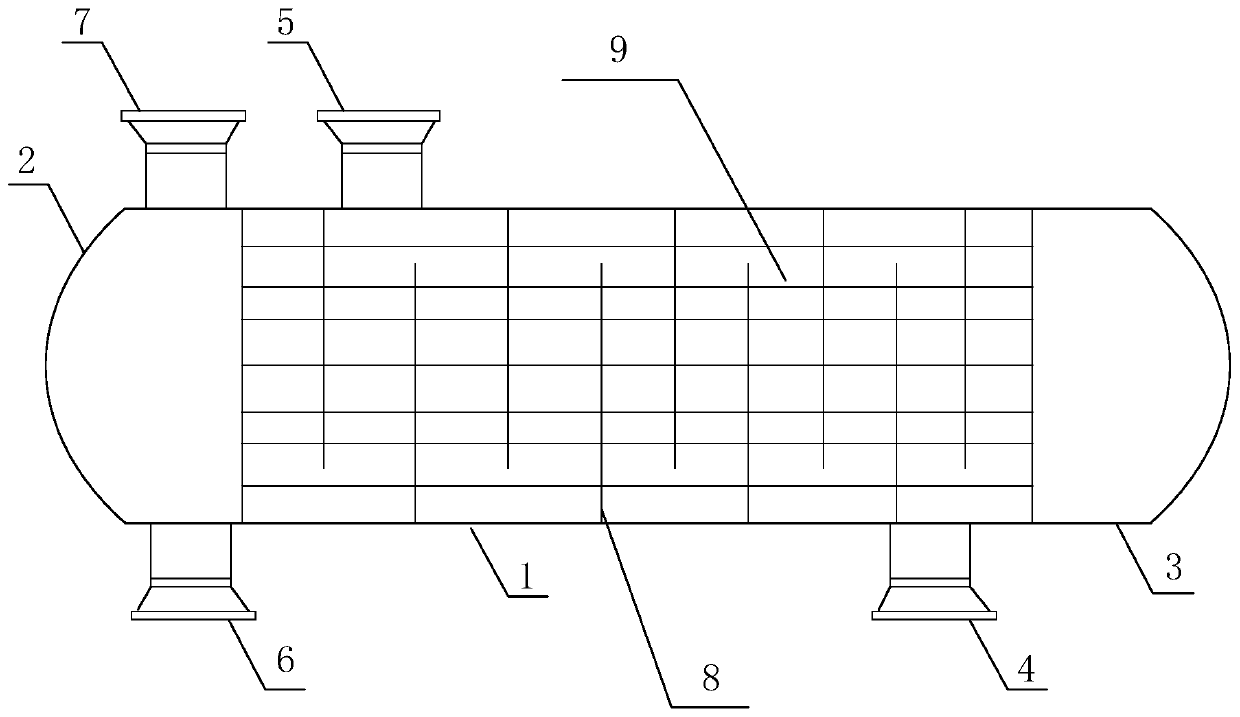

Control method capable of independently controlling on-time opening and closing of runners in pouring system

ActiveCN106216606AImplement layered importHierarchical introduction worksFoundry mouldsFoundry coresEngineeringMolten metal

The invention discloses a control method capable of independently controlling on-time opening and closing of runners in a pouring system. The pouring system comprises a pouring cup, a straight runner, a horizontal runner, an inner runner and other runners; flow blocking pieces are arranged in part of the runners in advance. The flow blocking pieces are arranged in the runners, required to be controlled, in the pouring system firstly in advance, in the initial stage of the filling process, the flow blocking pieces block the runners, the effect of locking and closing the runners is achieved, after the preset melting breaking time, the flow blocking pieces are broken in a melting manner under the high-temperature effect of molten metal, the function of blocking the runners is lost, the runners are opened, and the function of independent on-time opening and closing of the runners in the pouring system is achieved.

Owner:芜湖市原本机械制造有限公司

High-strength gradient full-absorption artificial ligament and preparation method thereof

ActiveCN108434530AHigh Strength Mechanical PropertiesFavorable for oriented growthTissue regenerationYarnFiberArticular cavity

The invention discloses a high-strength gradient full-absorption artificial ligament and a preparation method of the high-strength gradient full-absorption artificial ligament. The artificial ligamentcomprises an articular cavity free section and marrow channel woven sections at the two ends of the articular cavity free section, wherein the marrow channel woven sections are of sheath-core double-layer tube-shaped structures, and the sheath-core double-layer tube-shaped structures are composed of sheath layers and core layers. The preparation method comprises the following step: preparing themarrow channel woven sections of the sheath-core double-layer tube-shaped structures by adopting a weaving, knitting or braiding integrated forming technology, wherein weft yarns are not arranged at the articular cavity free section, namely, parallel free yarns not participating in weaving are adopted. The adopted yarns are formed by twisting and compounding fibers with different degrading periodsat the specific ratio, after implantation, a three-dimensional spiral through porous channel can be constructed through gradient degrading, thus the oriented growth of host cells is induced, and meanwhile, the requirement for the mechanical property needed during the tendon-bone healing process is met.

Owner:DONGHUA UNIV

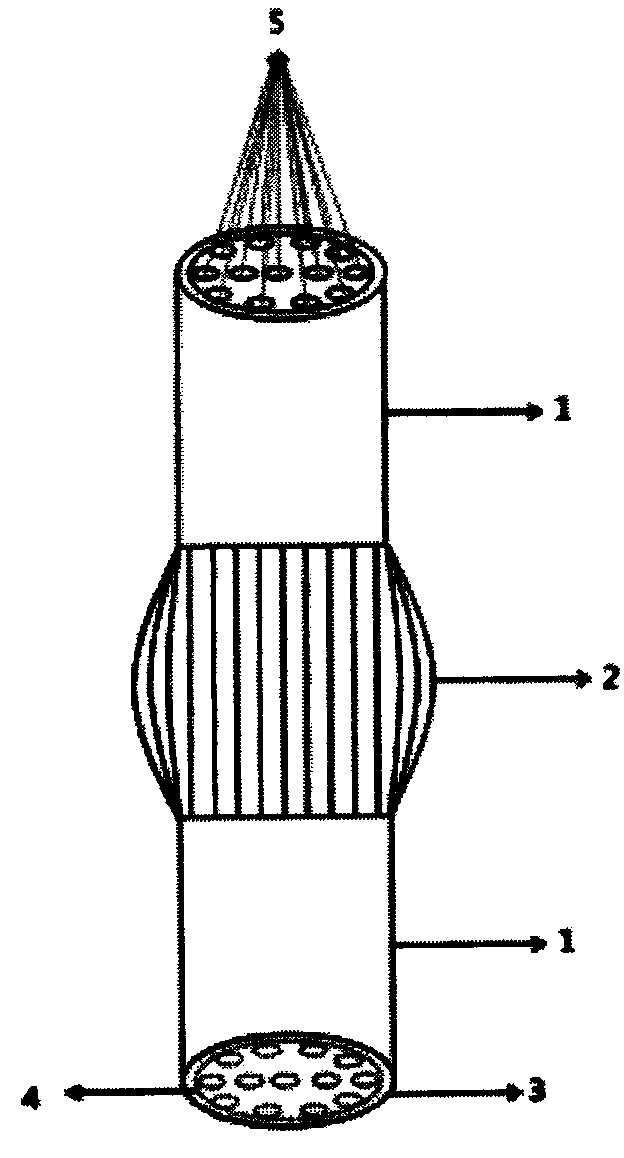

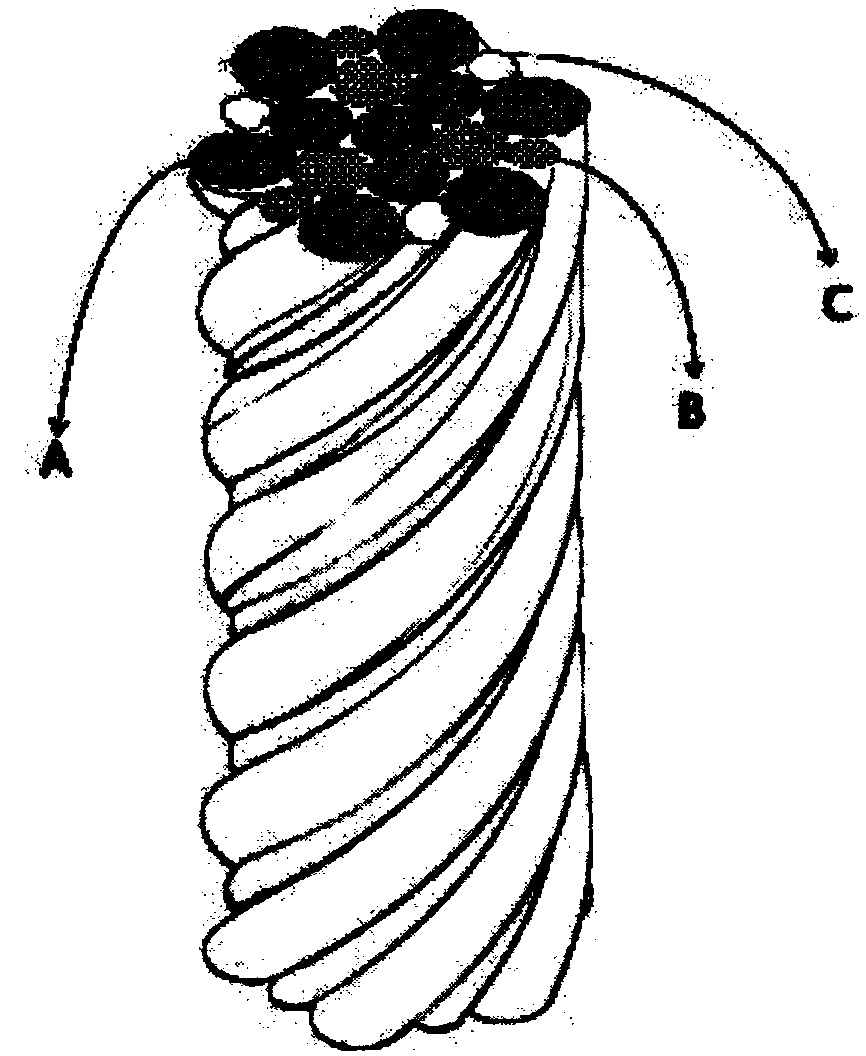

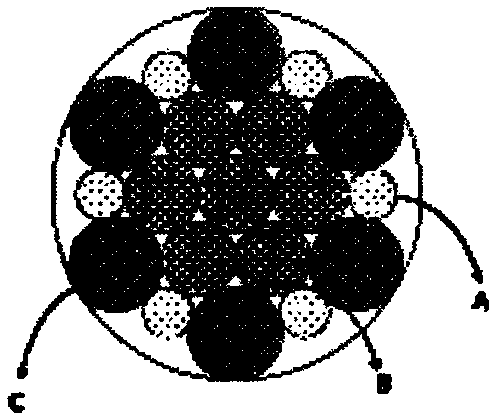

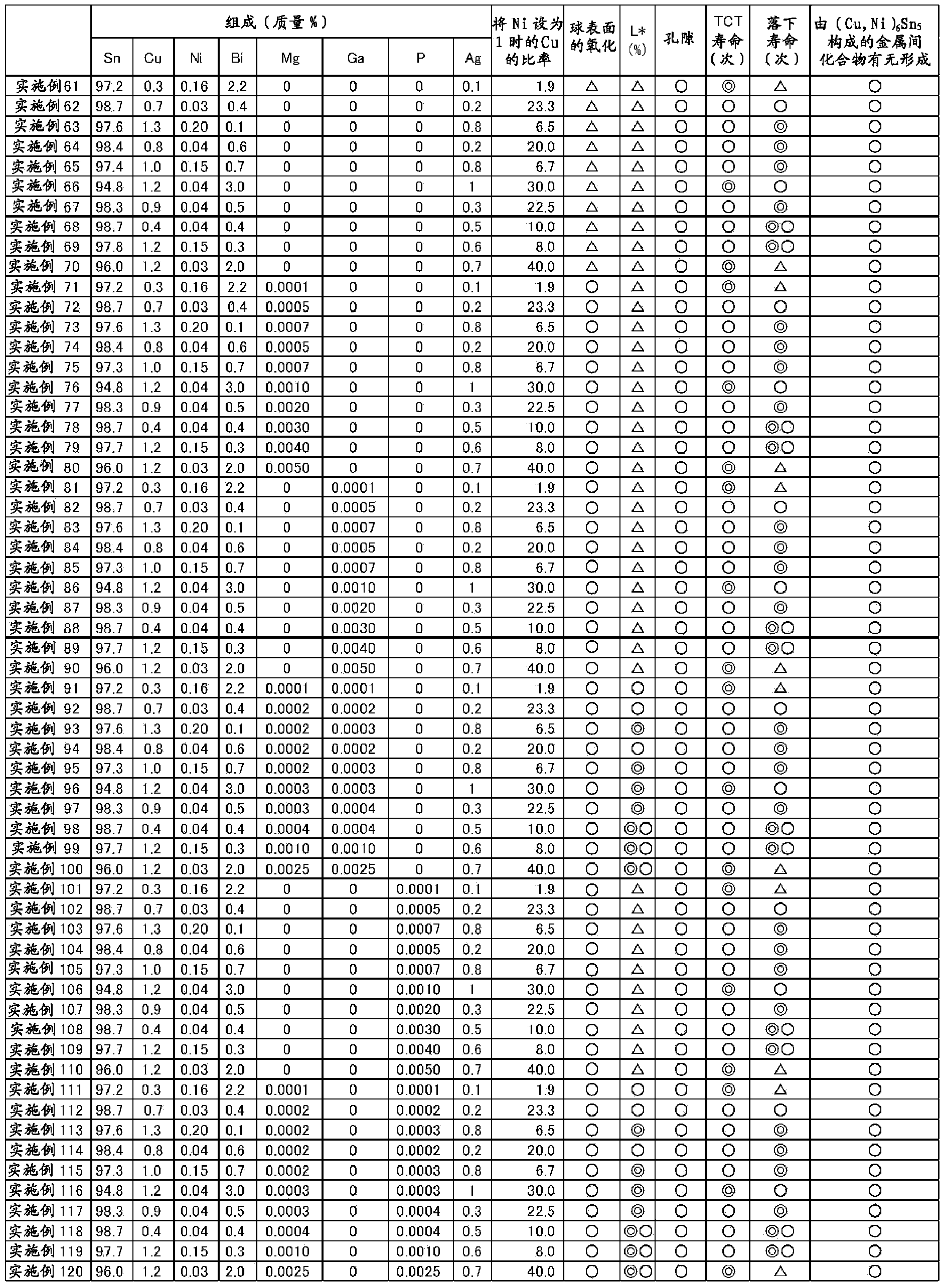

Solder ball and electronic member

InactiveCN104395035AExcellent drop impact resistanceInhibited porosityPrinted circuit assemblingWelding/cutting media/materialsThermal fatigueDrop impact

Provided are: a solder ball which is capable of achieving excellent thermal fatigue characteristics and good drop impact resistance characteristics, while suppressing generation of voids in a joined part; and an electronic member which uses this solder ball. This solder ball is formed of an Sn-Bi system alloy, which is mainly composed of Sn and contains 0.3-2.0% by mass of Cu, 0.01-0.2% by mass of Ni and 0.1-3.0% by mass of Bi, and is configured such that an intermetallic compound composed of (Cu, Ni)6Sn5 is formed in the Sn-Bi system alloy. Consequently, this solder ball is capable of achieving excellent thermal fatigue characteristics and good drop impact resistance characteristics, while suppressing generation of voids in a joined part in cases where this solder ball is joined to an electrode.

Owner:NIPPON STEEL CHEM &MATERIAL CO LTD +1

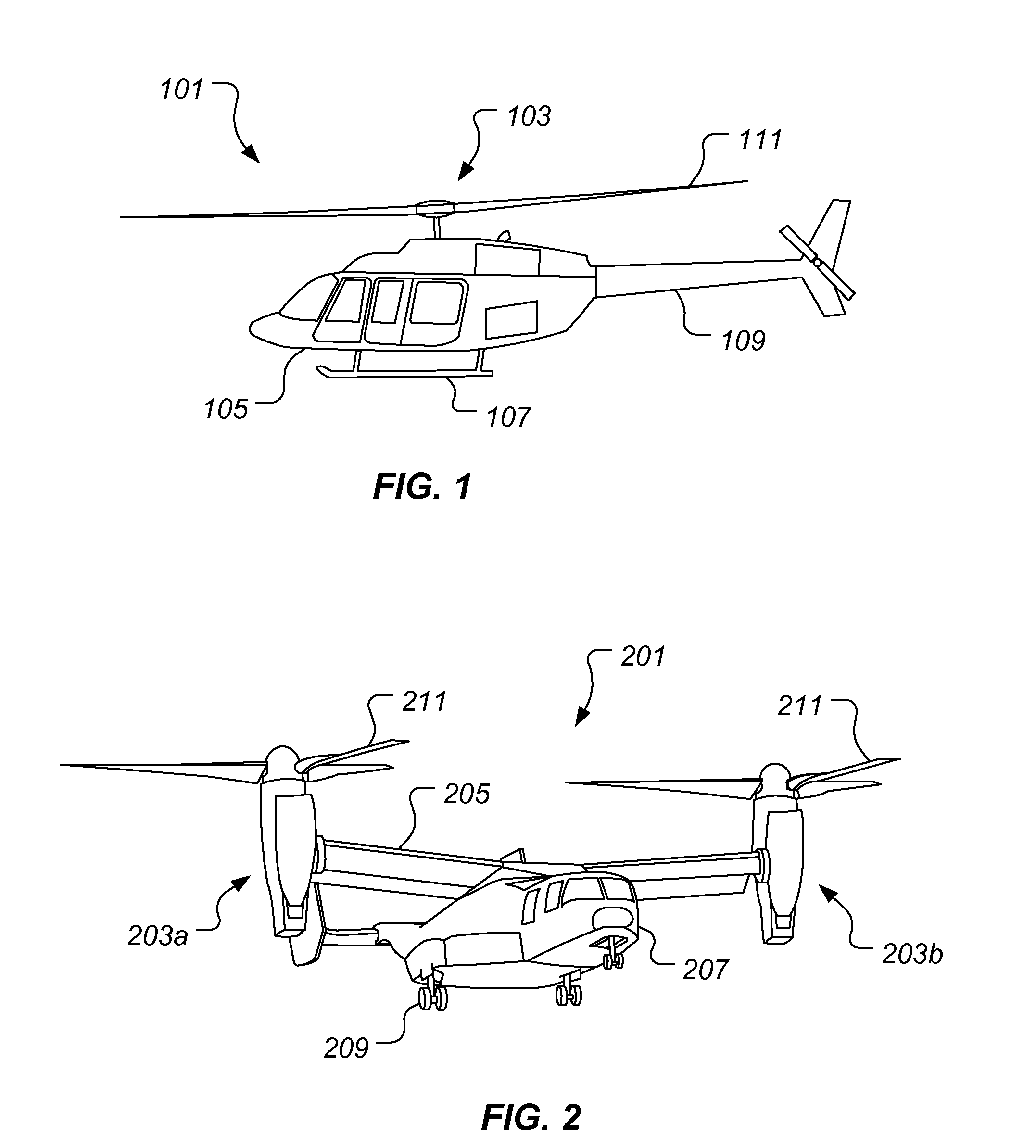

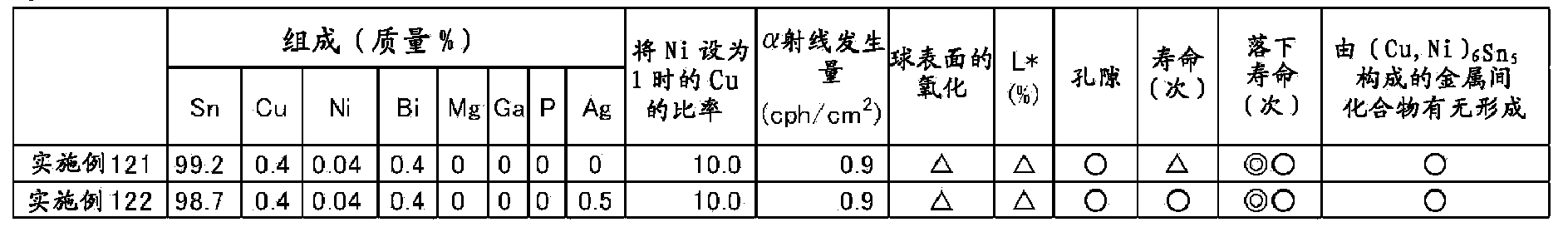

Hybrid tool for curing pieces of composite material

ActiveUS20140352877A1Repeat usagePorosity problem is preventedLamination ancillary operationsLaminationMetalMaterials science

A hybrid tool for curing composite structures for aircrafts, such as stringers, torsion boxes, skin panels, wing surfaces, horizontal tail or vertical stabilizers, etc. The hybrid tool comprises a metallic portion and an elastic portion arranged on a surface of the metallic portion. The elastic portion and the metallic portion are permanently joined to each other so that the metallic portion and the elastic portion together define a surface having a shape which copies at least part of a surface of a piece of composite material to be cured. The tool is capable of satisfactorily curing pieces of composite material which have a minimum thickness and / or a very aggressive change of thickness.

Owner:AIRBUS OPERATIONS SL

Composite porous separation membrane having shut-down function, method of manufacturing same, and secondary batteries using same

ActiveUS9601740B2Inhibited porosityLow costFinal product manufactureLi-accumulatorsFiberPorous substrate

A composite porous separator includes: a porous substrate acting as a support and having a first melting point and a first porosity; a first porous polymer web layer that is laminated on one side of the porous substrate, and acts as an adhesive layer when being in close contact with an opposing electrode; and a second porous polymer web layer that is laminated on the other surface of the porous substrate, and is formed of nanofibers of a heat-resistant polymer, in which the first porous polymer web layer and the second porous polymer web layer have a melting point higher than the first melting point of the porous substrate and a porosity that is the same as or similar to the first porosity of the porous substrate, respectively.

Owner:AMOGREENTECH CO LTD

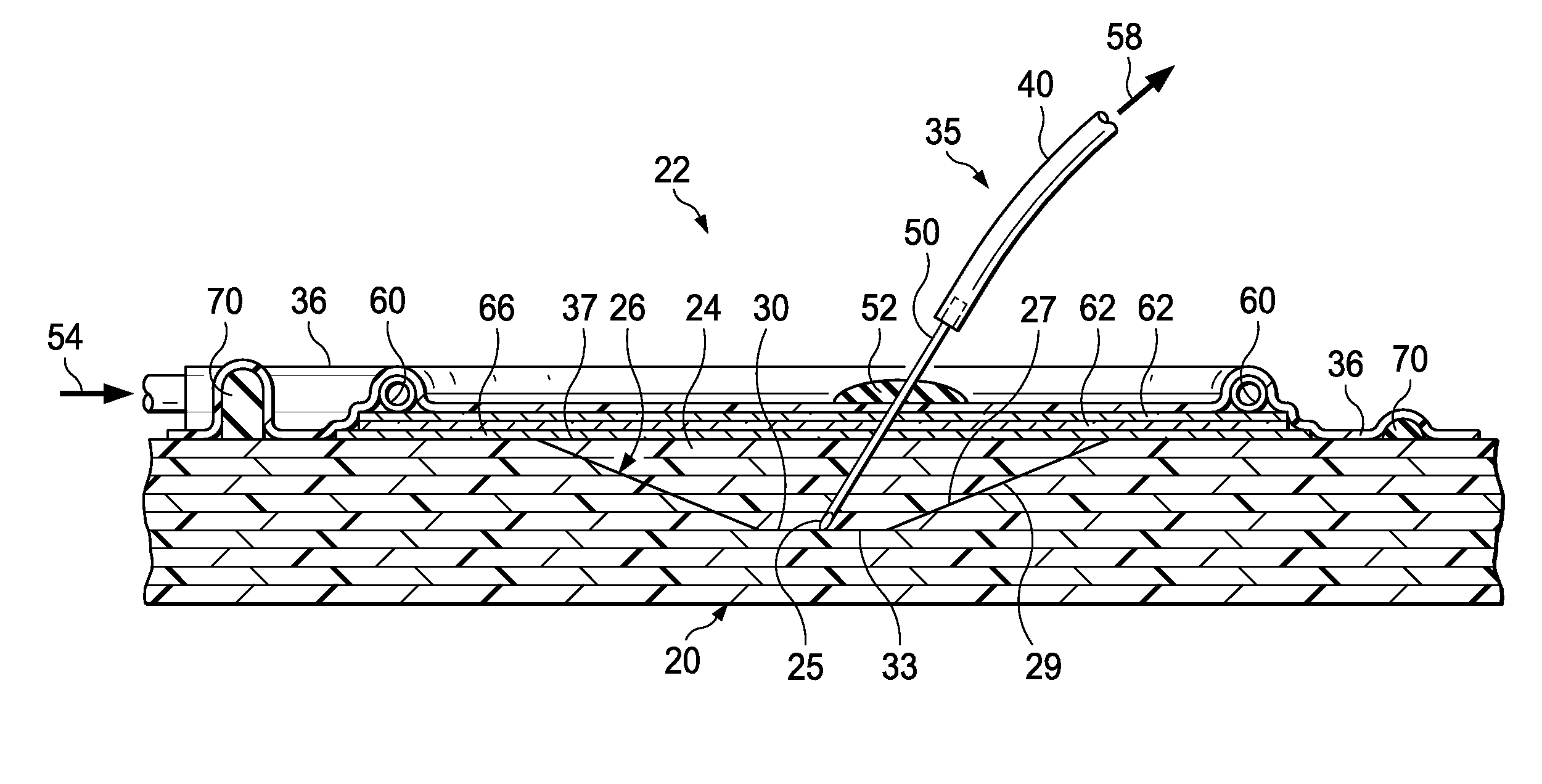

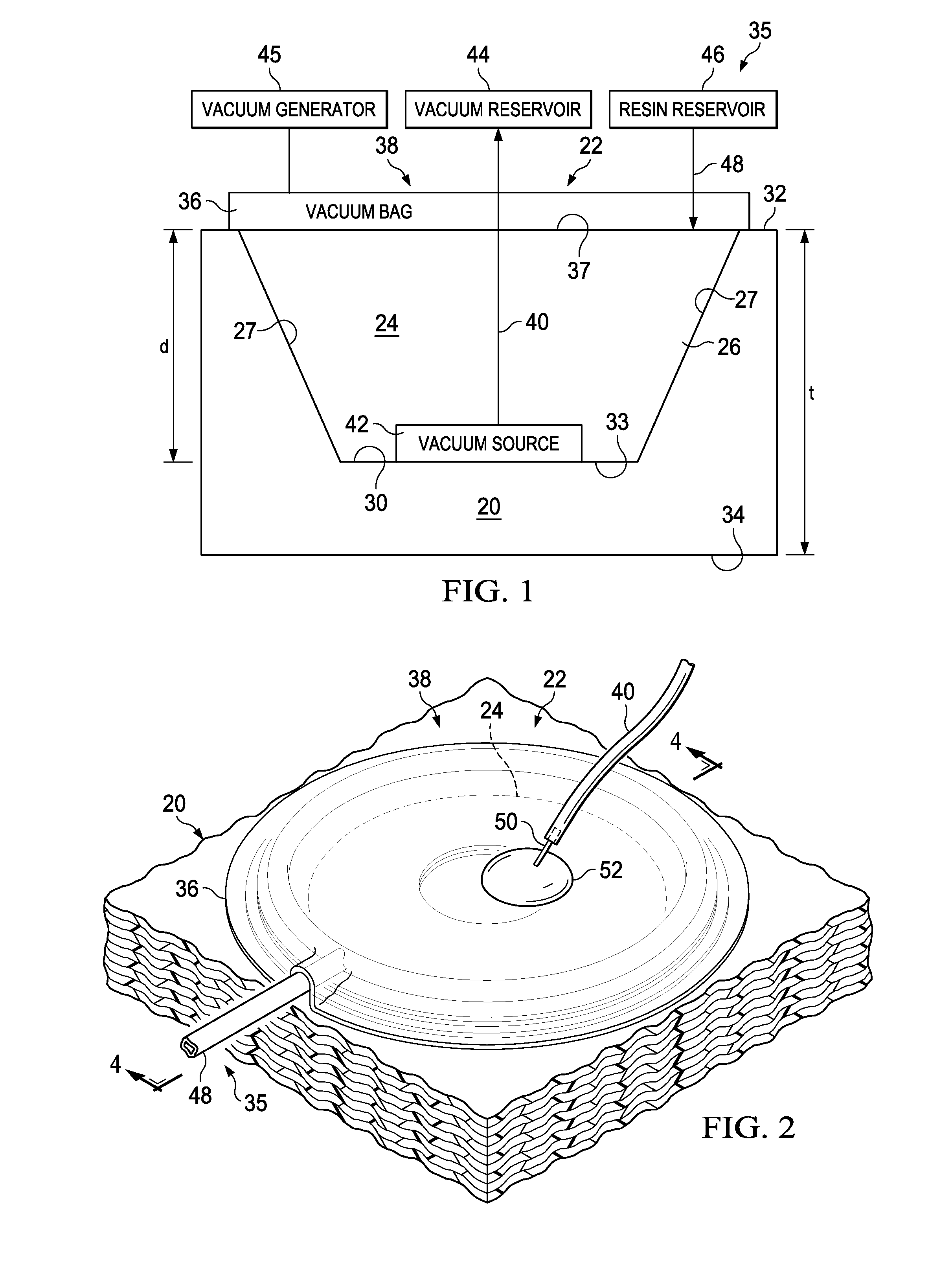

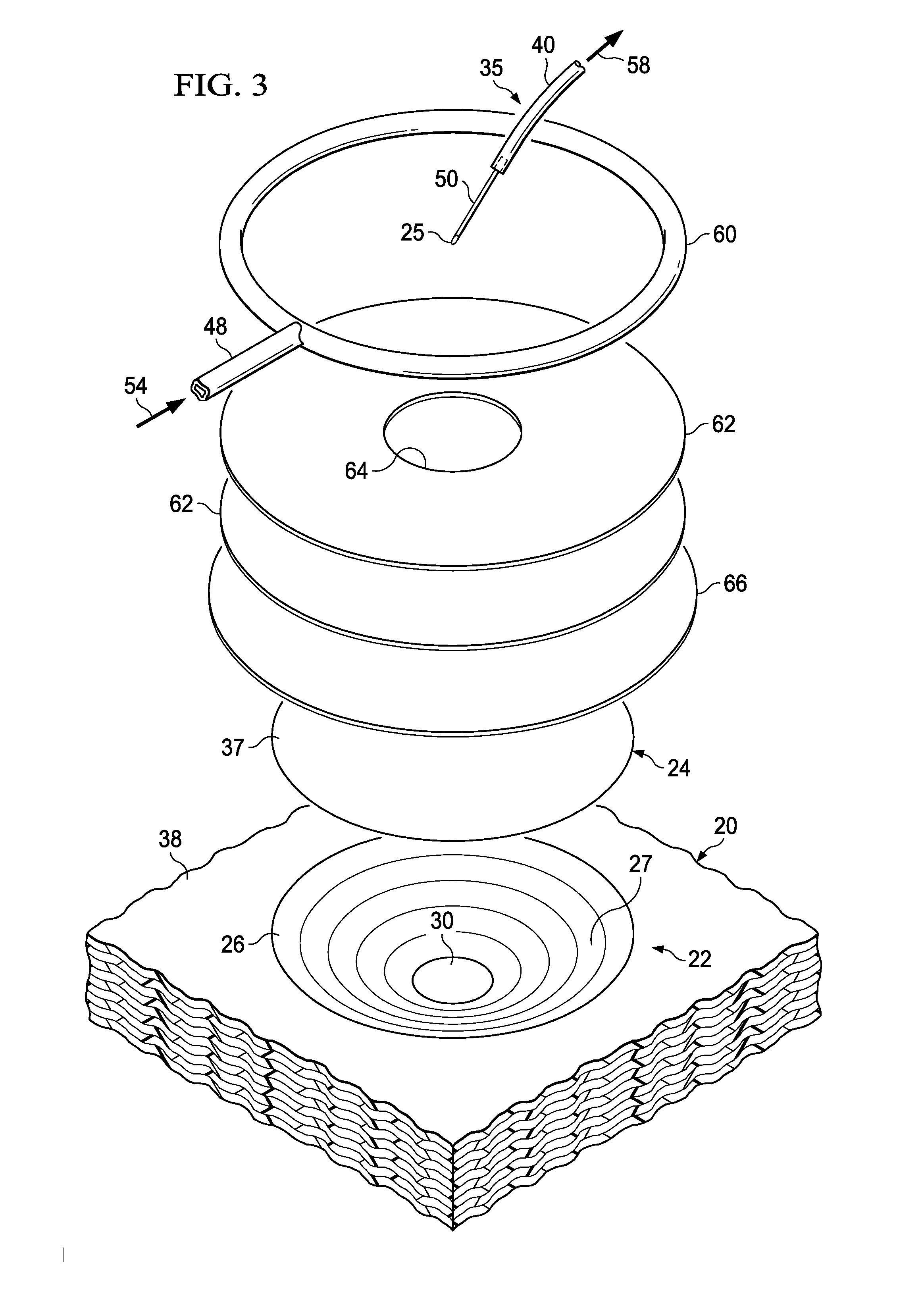

Method and apparatus for reworking structures

ActiveUS9579873B2Inhibited porosityReduce laborLamination ancillary operationsLaminationFiberEngineering

An area of a structure is reworked from one side of the structure using resin infusion of a dry fiber patch. Entrapped air and excess resin is removed from the patch during the infusion process by inserting a vacuum device into the patch, and forcing the area resin through the vacuum device.

Owner:THE BOEING CO

Electrode for electrochemical device and method for manufacturing electrode

ActiveUS20180097255A1Improved cycling characteristic and output characteristicInhibited porosityFinal product manufactureSecondary cellsPorosityElectrochemical cell

The present invention relates to an electrode for an electrochemical device and a method for manufacturing the same. More specifically, the present invention relates to an electrode for an electrochemical device having excellent electrolyte impregnation and improved battery output and lifecycle properties, and a method for manufacturing the electrode. The electrode according to the present invention enables an electrolyte to easily permeate into the electrode, thereby remarkably improving a lifecycle property or an output property due to high electrolyte impregnation. In addition, the method for manufacturing an electrode, according to the present invention, does not cause the deterioration of porosity of a lower electrode active material monolayer, the deterioration being caused by a step performed during the formation of an upper electrode active material monolayer.

Owner:LG ENERGY SOLUTION LTD

Preparation method of PDMS-PP composite membrane and application of PDMS-PP composite membrane to MDI waste brine treatment

ActiveCN110075721AHigh bonding strengthHigh permselectivitySemi-permeable membranesMembranesRubber membranePre treatment

The invention relates to a preparation method of a PDMS-PP composite membrane and application of the PDMS-PP composite membrane to MDI waste brine treatment. The preparation method comprises the following steps: pretreating a PP supporting base membrane, performing plasma treatment, preparing a silicone rubber membrane solution, coating the PP supporting base membrane with thesilicone rubber membrane solution, and drying to obtain the composite membrane. Waste brine treatment comprises the following steps: 1), conveying MDI waste brine into an extracting membrane tube of membrane extraction equipment, conveying an extractant into a shell layer of the membrane extraction equipment, and extracting to obtain crude brine, wherein the extracting membrane tube is produced from the PDMS-PP composite membrane; 2), mixing the crude brine with an oxidant, sending into an oxidation reactor, and reacting to obtain refined brine; 3), reducing excess oxidant in the refined brine by using a reducingagent to obtain qualified brine. A treatment method has the advantages of low energy consumption, simple technological process, low equipment investment and the like; by the treatment method, TOC in the waste brine can be treated till the concentration is lower than 10 ppm.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +1

Gel casting method of aluminum oxide-zirconium dioxide composite ceramic

The invention belongs to the field of ceramics, and particularly relates to a gel casting method of aluminum oxide-zirconium dioxide composite ceramics, which comprises the following steps: adding aluminum chloride into absolute ethyl alcohol, uniformly stirring, adding zirconium oxychloride, and carrying out low-temperature ultrasonic dispersion to form a mixed solution; adding ethyl cellulose into the mixed solution to be subjected to ultrasonic dispersion for 2-4 h, and obtaining a dispersed alcohol solution; blending ammonia gas and water vapor to form a mixed gas, slowly introducing the mixed gas into the dispersed alcohol liquid until no precipitate is generated, so as to obtain a suspended dispersion liquid, and then carrying out reduced pressure distillation for 3-6 hours, so as toobtain viscous slurry; and injecting the viscous slurry into a mold, carrying out a constant-temperature and constant-pressure reaction to form a dry material, carrying out a constant-temperature andconstant-pressure reaction in an illumination system for 2-4 h, and sintering in a muffle furnace for 6-10 h to obtain the alumina-zirconium dioxide composite ceramic. The problem that the ceramic prepared by the existing gel casting process is easy to peel off is solved, ethyl cellulose is used as an adhesive, light degradation in the pressing process is realized while viscosity is realized, andpore forming of organic matters in the sintering process is prevented.

Owner:无锡特科精细陶瓷有限公司

Using method of geopolymer based self-levelling ground material

The invention relates to the technical field of building materials, and aims to provide a using method of a geopolymer-based self-levelling ground material. The material includes a geopolymer, an expanding agent, a redispersible latex powder, a reinforcing fiber, a defoaming agent, a water reducing agent, water and an aggregate; the geopolymer is composed of an aluminum-silicon raw material and an alkali activator. The using method includes the steps: firstly, dissolving the alkali activator in water and placing for 24 h; followed by successively adding the rest of raw material components, stirring for 2-10 min by a mortar stirrer, then casting the ground, self-levelling, molding, and curing to form the ground material. With the geopolymer as a cementitious material, the method has the advantages of less energy consumption and less environmental pollution; the formula is reasonable in design, the expanding agent and the reinforcing fiber can decrease shrinkage and cracking of the ground material, the redispersible latex powder can improve the toughness and surface smoothness of the ground material, the defoaming agent can prevent the ground material from generating a hole structure, and thus the application of the geopolymer material in the engineering construction field is developed.

Owner:ZIGONG INNOVATION CENT OF ZHEJIANG UNIV

Light emitting diode device and method of producing the same

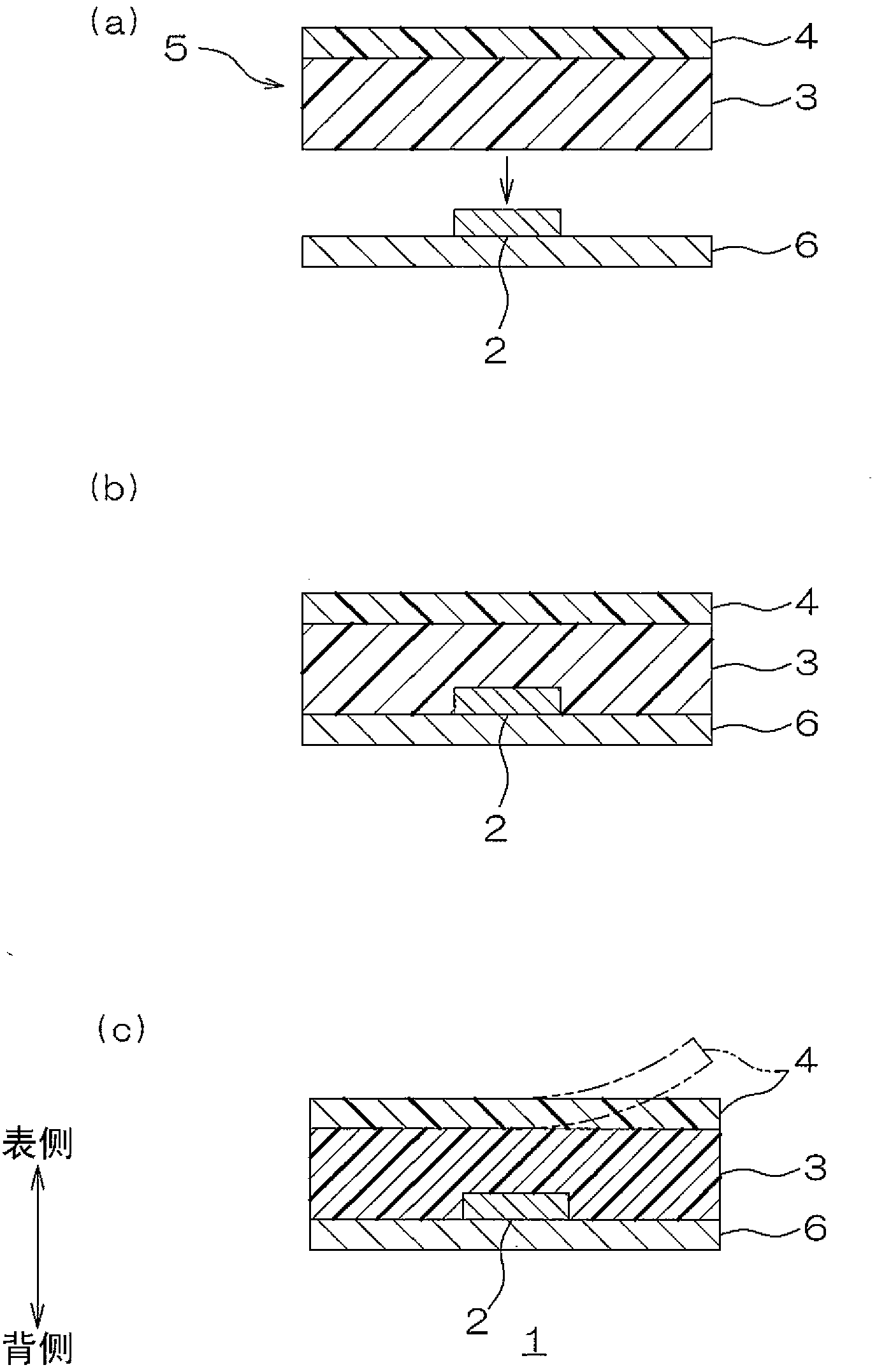

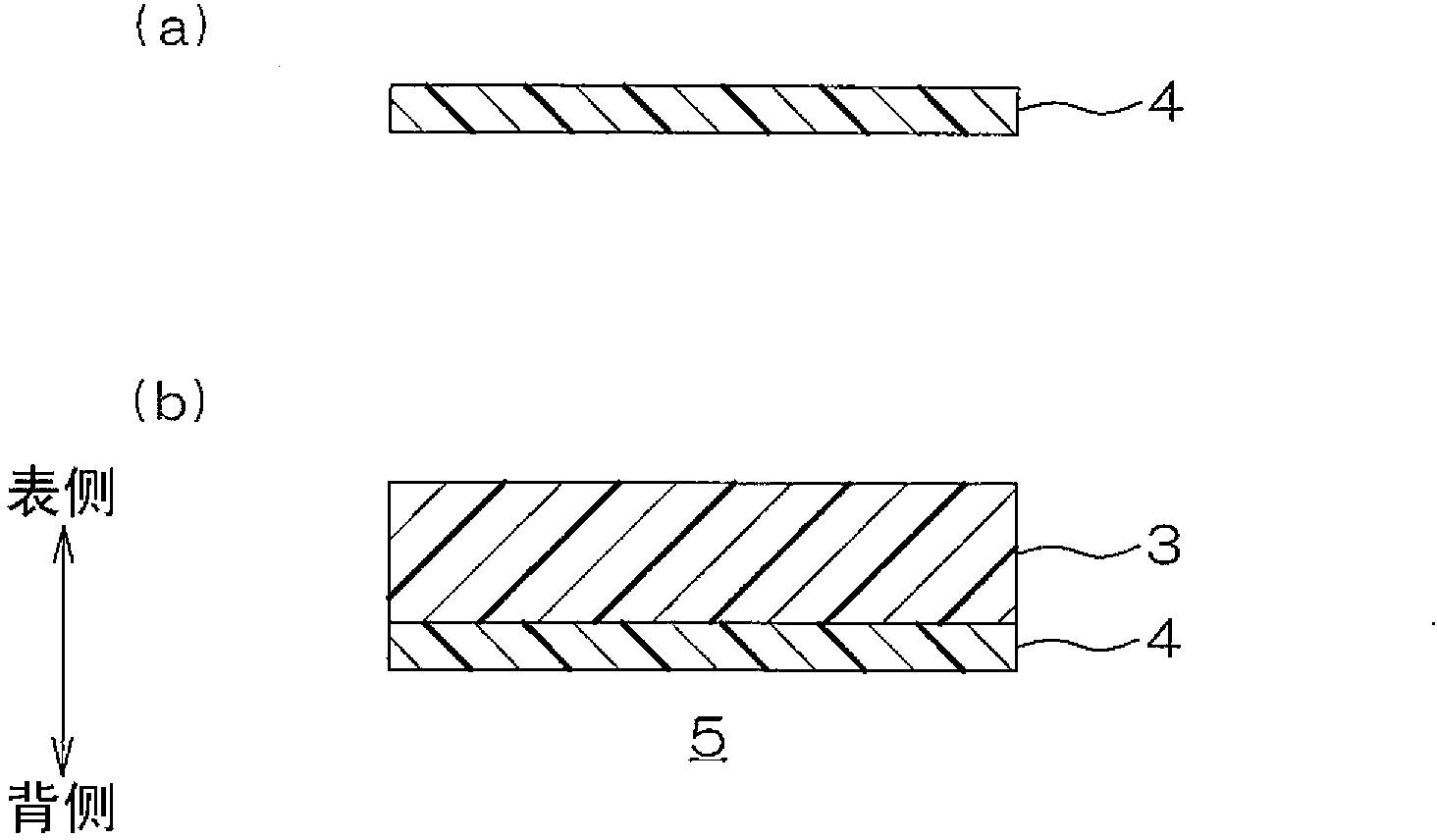

A method of producing a light emitting diode device (1) includes preparing an encapsulating resin layer; embedding a light emitting diode element in the encapsulating resin layer; and heating while pressing with gas the encapsulating resin layer having the light emitting diode element being embedded therein.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com