Patents

Literature

186 results about "Vacuum mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of preparing iolite honeycomb ceramics for automobile tail gas purifier

InactiveCN1785894AIncrease the volume fraction of the solid phaseHigh densityExhaust apparatusSilencing apparatusPtru catalystExhaust fumes

The present invention belongs to a ceramic material preparation process, and relates to a cordierite honeycomb ceramic preparation process. Said process includes the following steps: preparing material, synthesizing cordierite powder, wet mud-forming, vacuum mixing mud, vacuum extruding, microwave forming, drying in drying oven, processing blank body and high-temperature sintering. Said cordierite honeycomb ceramic can be used as carrier of catalyst, can be extensively used for purifying industrial noxious gas and auto exhaust gas, also can be used for making ceramic heat exchanger, etc.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

Method of preparing iolite honeycomb ceramic having relatively low thermel expansion coefficient

InactiveCN1785895AAdapt to the requirements of industrial productionSmall coefficient of thermal expansionExhaust apparatusSilencing apparatusMicrowaveMetallic materials

The present invention relates to an improvement on preparation method of lower thermal expansion coefficient cordierite honeycomb ceramic which can be used as auto exhaust gas purifier carrier. Its process includes the following steps: synthesizing cordierite powder, synthesizing zirconium tungstate powder, mixing components, vacuum mixing mud, vacuum extruding, microwave forming, drying in drying oven, processing blank, high-temperature sintering and checking.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

Magnesium jade porcelain formula and one-time calcining manufacture method

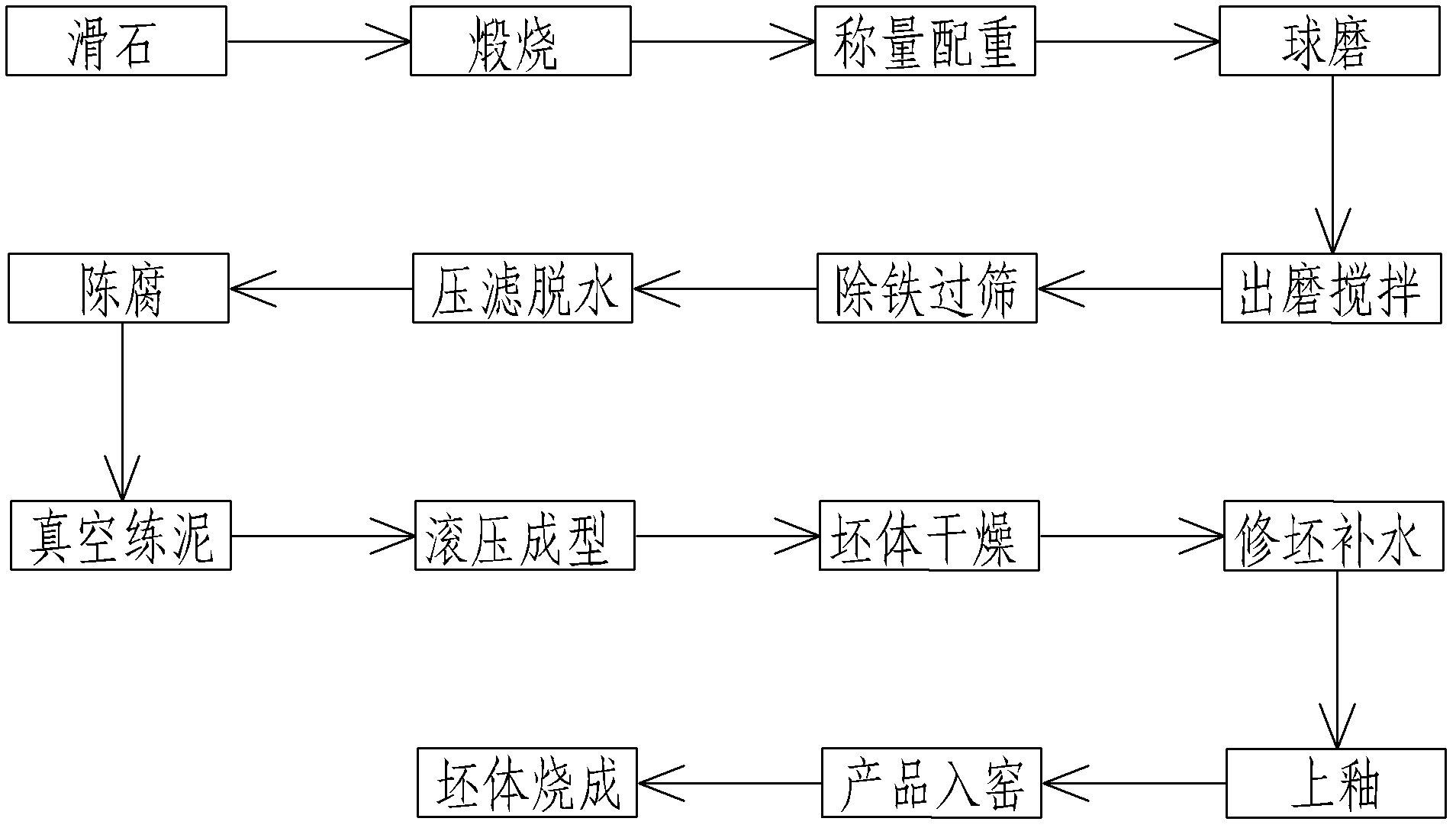

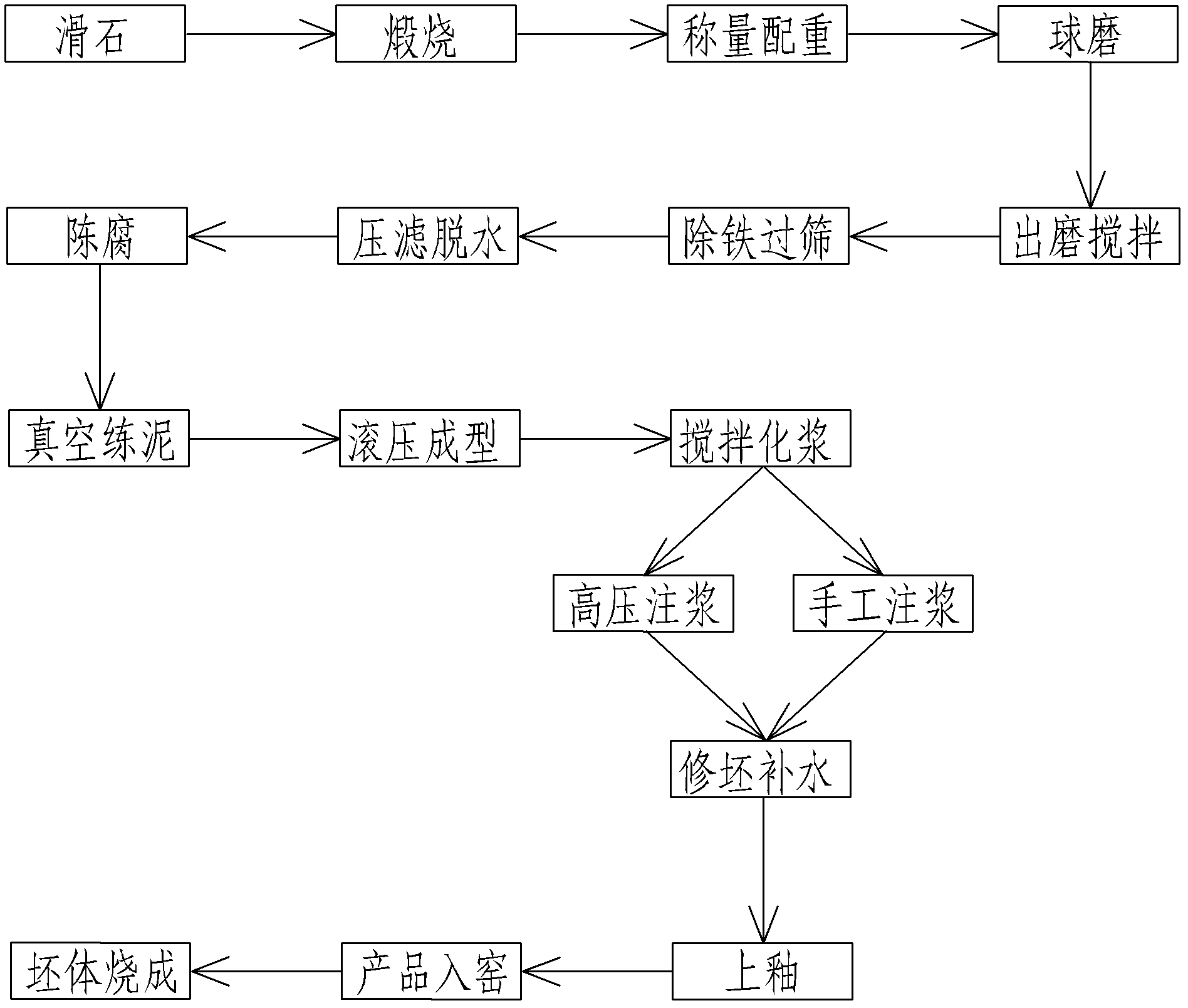

The invention relates to a magnesium jade porcelain formula and one-time calcining manufacture method, the raw materials are weighted according to the formula of a blank material and glaze, the method comprise the following steps: calcining a talcum raw material at the temperature of 1150-1250 DEG C; mixing 75-85% of calcined talcum, 5-15% of magnesian clay, 1-5% of feldspar, 1-5% of bentonite, 2-6% of kaolin, 0.1-0.3% of carboxymethylcellulose sodium for ball milling; stirring the clay after mixing and ball milling, deironing and sieving and controlling the particles in the clay less than 30 mum; carrying out press filtration, on the clay after deironing and sieving, dehydrating, aging, vacuum mixing and roll forming; preparing the clay after roll forming into biscuit, glazing, entering into a kiln and calcining a base substrate. One-time calcining of magnesium jade porcelain can be realized, and the problems of poor product regularity and thermal shock resistance performance generated by calcining temperature by using a lot of talcum material can be overcome and enhanced.

Owner:FUJIAN GUANFU IND CO LTD

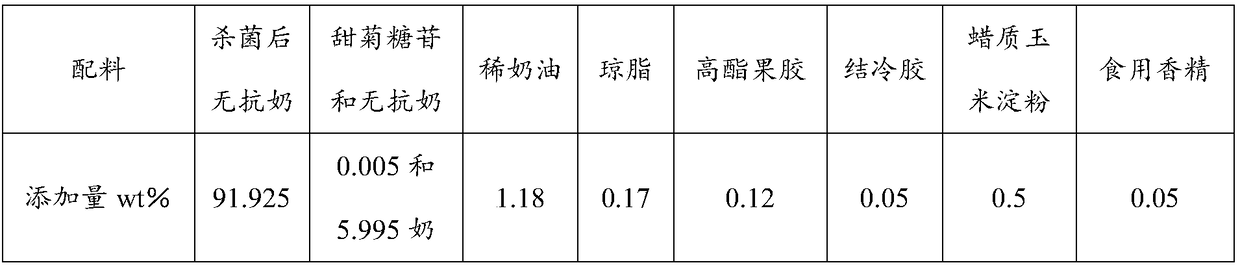

Normal-temperature yogurt and preparation method thereof

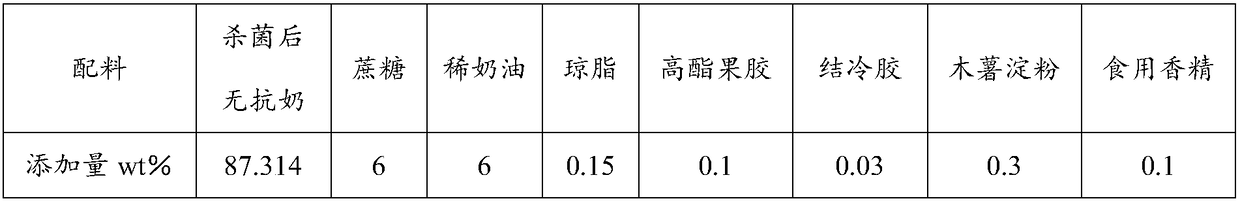

The invention discloses normal-temperature yogurt and a preparation method thereof. According to the normal-temperature yogurt, the viscosity is 200-250cp, the total protein content by mass percent is2.56%-3.03%, the fat content by mass percent is 3.5%-6.0%, the carbohydrate content by mass percent is 4.76%-12.14%, and the acidity is 70-90 degrees T. The preparation method of the yogurt comprisesthe following steps: uniformly mixing 81.491%-93.327% of pre-sterilized antibiotic-free milk, 4%-8% of a sweetening agent, 2.25%-8.61% of light cream and 0.42%-0.84% of a stabilizing agent by a vacuum mixing mode, homogenizing the mixed liquid, and performing pasteurization on the homogenized liquid, wherein the percentages are the mass percentages of the components in the mixed liquid; cooling the sterilized mixed liquid, adding 0.003%-0.009% of a starter and 0%-0.1% of essence, performing fermenting, wherein the percentage is the mass percentage of the starter in the mixed liquid, and performing emulsion breaking when the acidity reaches 70-90 degrees T to obtain a yogurt base material; and performing homogenization and pasteurization on the yogurt base material for the second time, wherein the sterilization temperature is 70-80 DEG C and the sterilization time is 10-40s, performing cooling to 20-30 DEG C after sterilization and performing nitrogen-filled filling. The product is high in fat content, suitable for young people to drink and smooth and delicate in mouthfeel.

Owner:BRIGHT DAIRY & FOOD

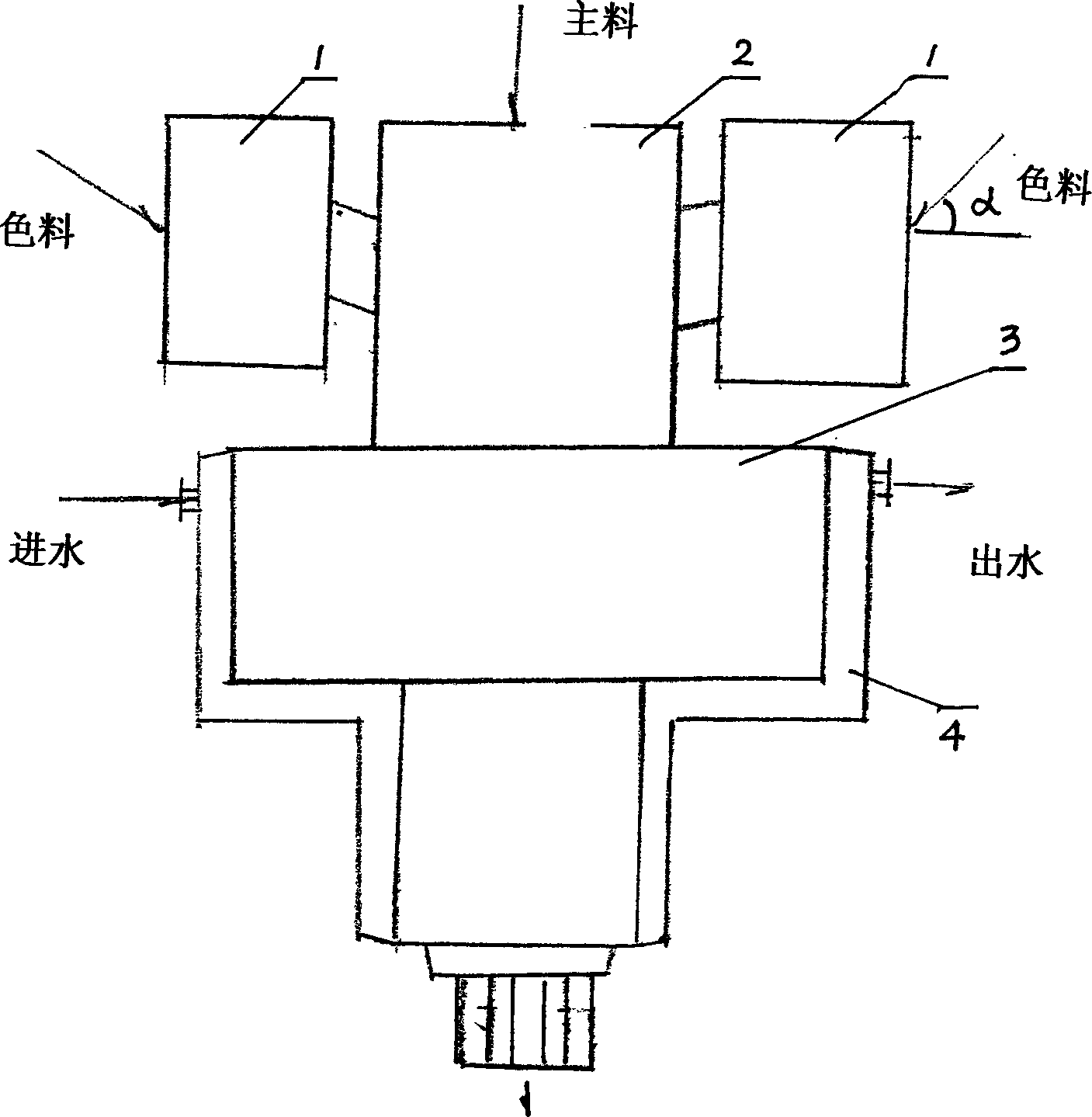

Method and equipment for producing art veins cleavage tile

InactiveCN1598214AEvenly distributedImprove plasticityCovering/liningsSurface layering apparatusCooking & bakingVein

The invention relates to a manufacturing method for artic texture brick and its device. The method includes material confection, grinding, squeezing, corroding, vacuuming, forming, drying, pasting, baking, selecting and separating, and packaging processes. The material is put into the grinder to be humidity grinded for 4-16 hours, the water content of mud pump is controlled from 30%-35%, the thinness after being grinded can reach 200 items and has error bout 1% to 15%; the mud material with two different colors are put into the vacuum squeezer, and they are blended together in the mixing box, and they are cooled by water around the spiral squeezer, the temperature of squeezed brick is controlled between 30deg.C and 60deg.C, cuts and abolishes the surface skin at two ends. Then uses mobile multi-layer pasting method to paste the brick, and bakes them.

Owner:SANXING COMMODITY TRADE LIUZHOU

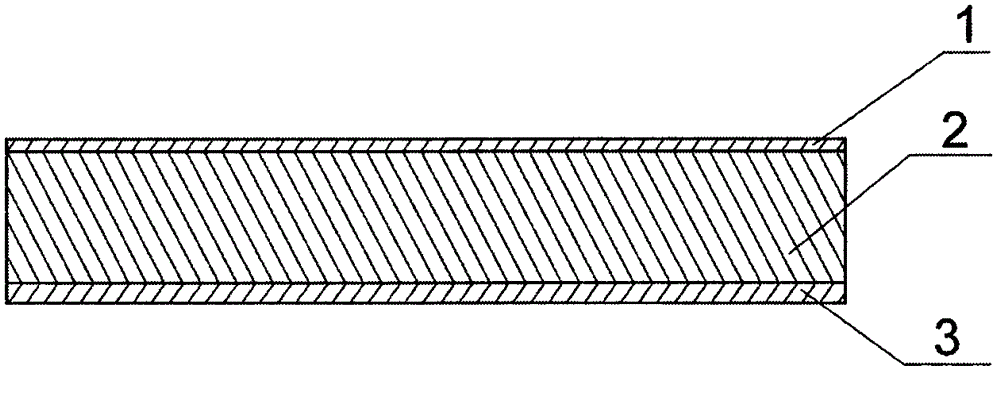

Medical cold compress plaster and preparation process thereof

InactiveCN105878217ASimple production processEase of mass productionAntipyreticAnalgesicsTriclosanVitamin C

The invention provides a medical cold compress plaster. The medical cold compress plaster is composed of a support layer, a gel layer and an isolating layer, and has the special shape according with the physiological curve of the applied part. An oil phase and a water phase forming the hydrophilic gel layer respectively comprise the following components in percentage by weight: the oil phase: 20-35% of a dispersing agent, 5-7% of macromolecule resin, 0.05-0.15% of dihydroxyaluminium aminoacetate, 0.01-0.15% of ethylene diamine tetraacetic acid, 0.15% of absolute ethyl alcohol, 0.04-0.1% of menthol, 0.1-1% of vitamin E, and 0.05-0.1% of triclosan; the water phase: 0.2-0.8% of tartaric acid, 1.2-2% of carbomer, 0.5-1% of sodium carboxymethylcellulose, 0.01-0.1% of vitamin C, the balance of medical purified water, and the total weight percentage is 100%. A preparation process comprises the following steps: dispersing all the components of the oil phase into the dispersing agent, and uniformly stirring the components; dissolving all the components of the water phase into water, and uniformly stirring the components; mixing the water phase and the oil phase, uniformly stirring the water phase and the oil phase in a vacuum mixing pot, thus obtaining the hydrophilic gel substrate of the medical cold compress plaster, coating the support layer with the hydrophilic gel substrate, meanwhile covering with the isolating layer, and carrying out cutting, solidifying and packaging to obtain the needed medical cold compress plaster product.

Owner:HANGZHOU JIERSI BIOTECH CO LTD

Preparation method of anode paste for lithium-ion power battery

InactiveCN105489844AReduce lossReduce the content of large particlesElectrode manufacturing processesSecondary cellsLithiumPower battery

The invention discloses a preparation method of an anode paste for a lithium-ion power battery. The anode paste is prepared from an active material, a conductive agent, a dispersing agent, a binder and a solvent; the preparation method comprises an order of mixing various components in the anode paste; and the method is characterized in that mixing is carried out by the following four steps: (1) carrying out high-speed stirring and dry mixing on the active material and the conductive agent; (2) adding the dispersing agent, and carrying out dry mixing on the dispersing agent and black powder obtained in the step (1); (3) adding the solvent, introducing condensate water, carrying out high-speed stirring and dispersing after low-speed stirring, carrying out fractioning and vacuum supply and further carrying out high-speed vacuum mixing; and (4) adding the binder, and dispersing and mixing the binder. A dry mixing technology is utilized; and the solvent is added once, so that the paste mixing time is shortened; the machine loss caused by a high solid content is reduced; the capacity is improved; and a relatively good mixing effect is obtained.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Method for preparing ceramic with pore gradient

InactiveCN1830902AImprove performanceEasy to operateCeramicwareClaywaresTetramethylammonium hydroxidePorosity

A process for preparing the porosity-gradient ceramic includes such steps as adding deionized water to ceramic powder and disperser, ball grinding to obtain slurry A, adding deionized water to solidifying organic substance (starch or modified starch), ultrasonic dispersing or ball grinding to obtain slurry B, vacuum mixing, fast filling the mixture in mould, solidifying, drying and sintering. Said ceramic powder is chosen from alumina powder, SiC powder and Si3N4 powder. Said disperser is chosen from ammonium citrate and ammonium tetramethyl hydroxide.

Owner:TSINGHUA UNIV

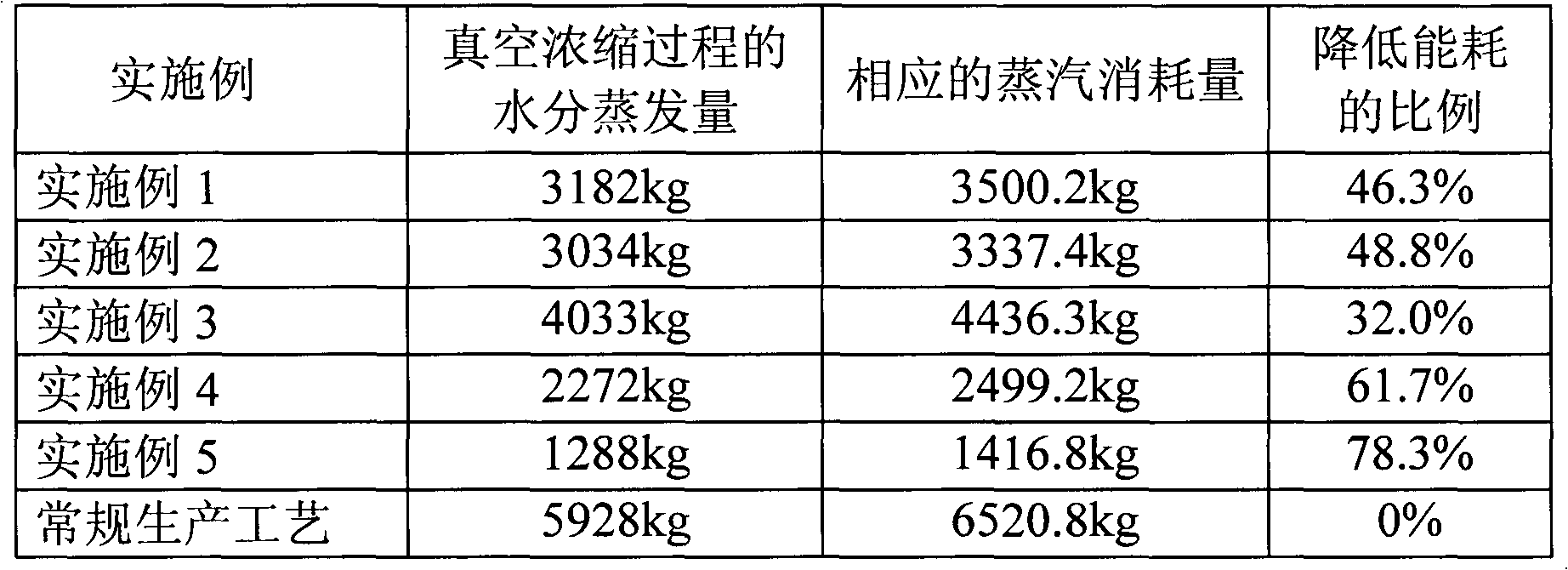

Production technology for formula milk powder

ActiveCN102986877AReduce water evaporationReduce production energy consumptionMilk preparationEvaporationWhey protein powder

A production technology of formula milk powder comprises the following steps: 1, dissolving an auxiliary material in pretreated raw milk A through utilizing a vacuum mixing method to obtain an auxiliary material solution, and carrying out vacuum concentration of pretreated raw milk B to obtain concentrated milk, wherein the solid concentration of the auxiliary material solution is 40-50wt%; 2, carrying out steam spraying sterilizing treatment of the auxiliary material solution obtained in step 1; 3, adding the auxiliary material solution obtained in step 2 to the concentrated milk obtained in step 1, uniformly mixing, and preheating to 65-75DEG C; and 4, carrying out spray drying to obtain the formula milk powder. The production technology only needs the raw milk B subjected to the vacuum concentration pretreatment, so the concentration evaporation amount is reduced, and the energy consumption is reduced; and simultaneously the vacuum concentration heat treatment of heat-sensitive raw materials comprising concentrated whey protein powder, vitamins and the like is avoided, so the protein heat denaturation and the heat losses of the heat-sensitive raw materials are reduced, and the nutritional quality of the formula milk powder is improved.

Owner:BRIGHT DAIRY & FOOD

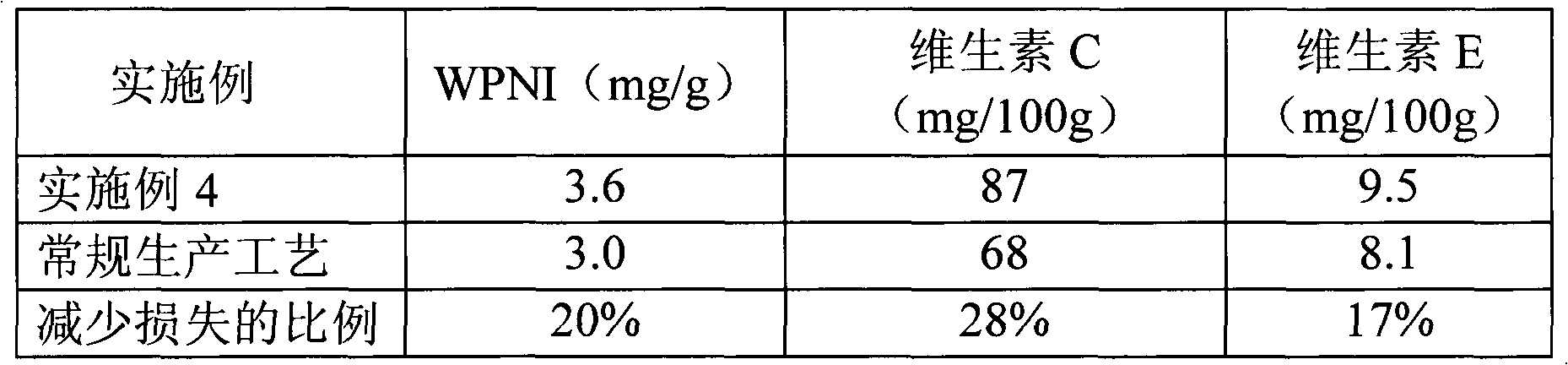

Method for preparing large-size ceramic grinding ball and mould

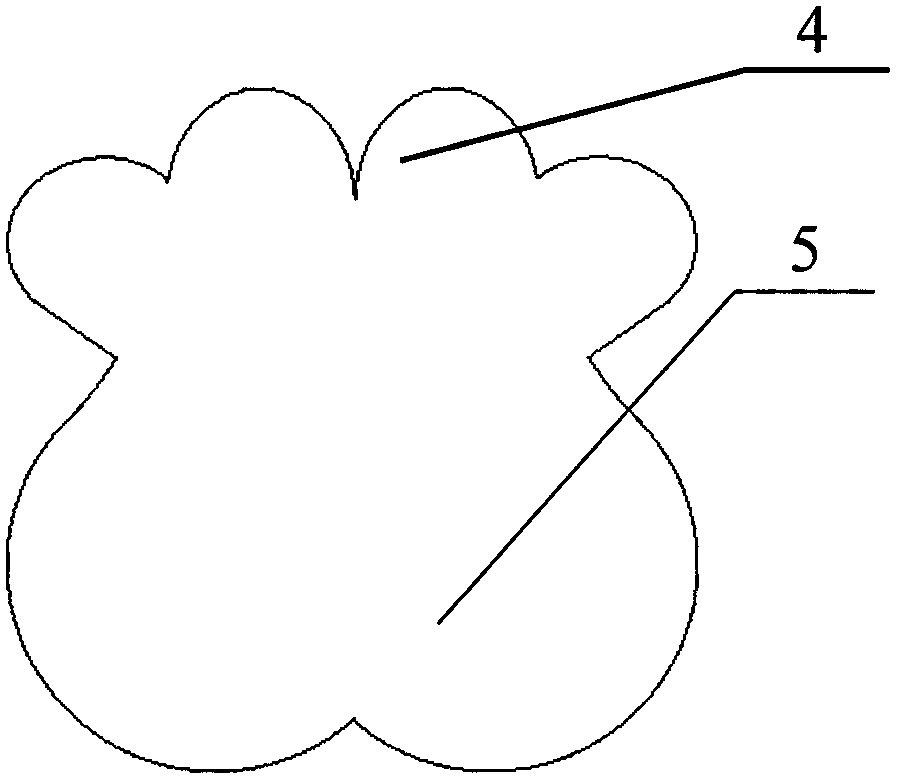

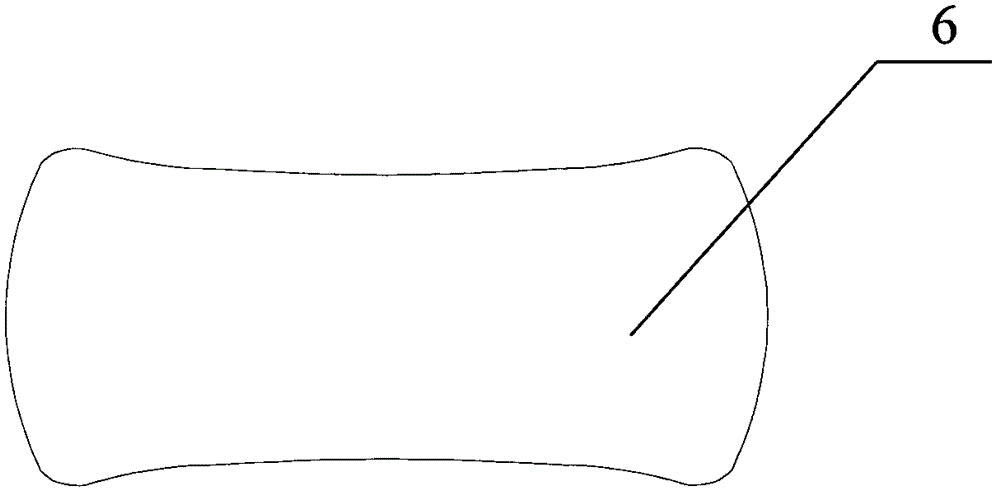

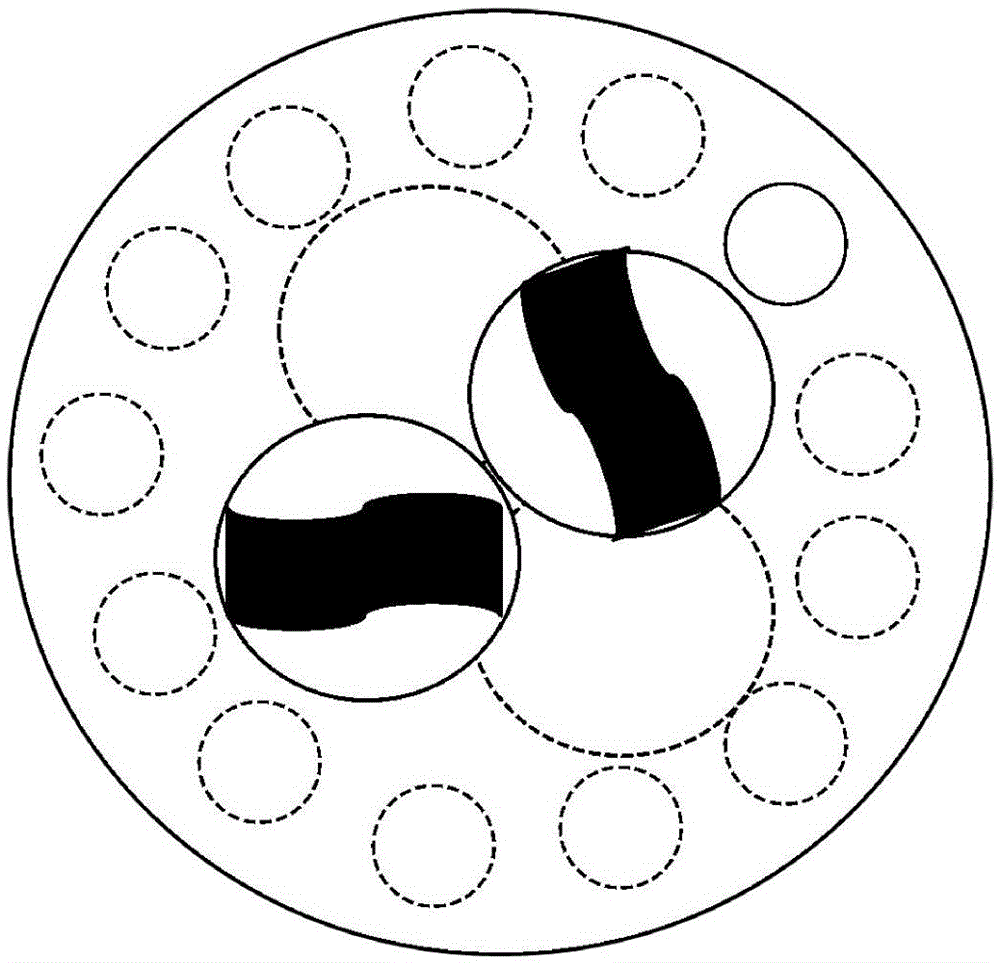

InactiveCN101302110ASmall sizeRealize one-time moldingCeramic shaping apparatusHardnessHigh intensity

The invention provides a method for preparing a large size ceramic grinding ball and a mould for shaping the same, which belongs to the grinding media technical field. The method is as follows: firstly, monomer solution for gel-casting is prepared, added with ceramic powder to form a stable slurry with uniform stirring; catalyst and initiator are added to slurry with vacuum mixing; secondly, the slurry is cast in the mould, and is kept in a temperature till the complete reaction between the monomer and crosslinking agent to get a green ceramic grinding ball; finally, the green ceramic grinding ball is dried and sintered to obtain the ceramic grinding ball. The mould for shaping consists of upper and lower semi-norms of the same size, which are mismatched and provided with a plurality of hemispherical mode cavities. The ceramic grinding ball has the advantages of high strength, hardness, wear resistance, corrosion resistance and temperature stability; and the size of which can be controlled by that of the spherical mode cavity of the mould. The method is low in cost, easy for industrialization, and is especially suitable for a shaped large size ceramic grinding ball.

Owner:SHANGHAI JIAO TONG UNIV

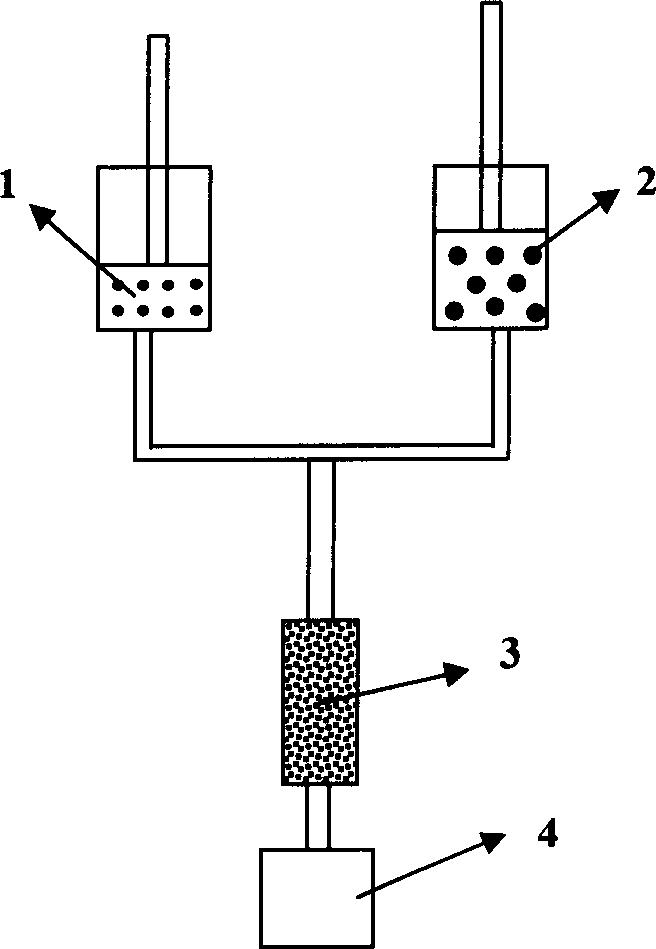

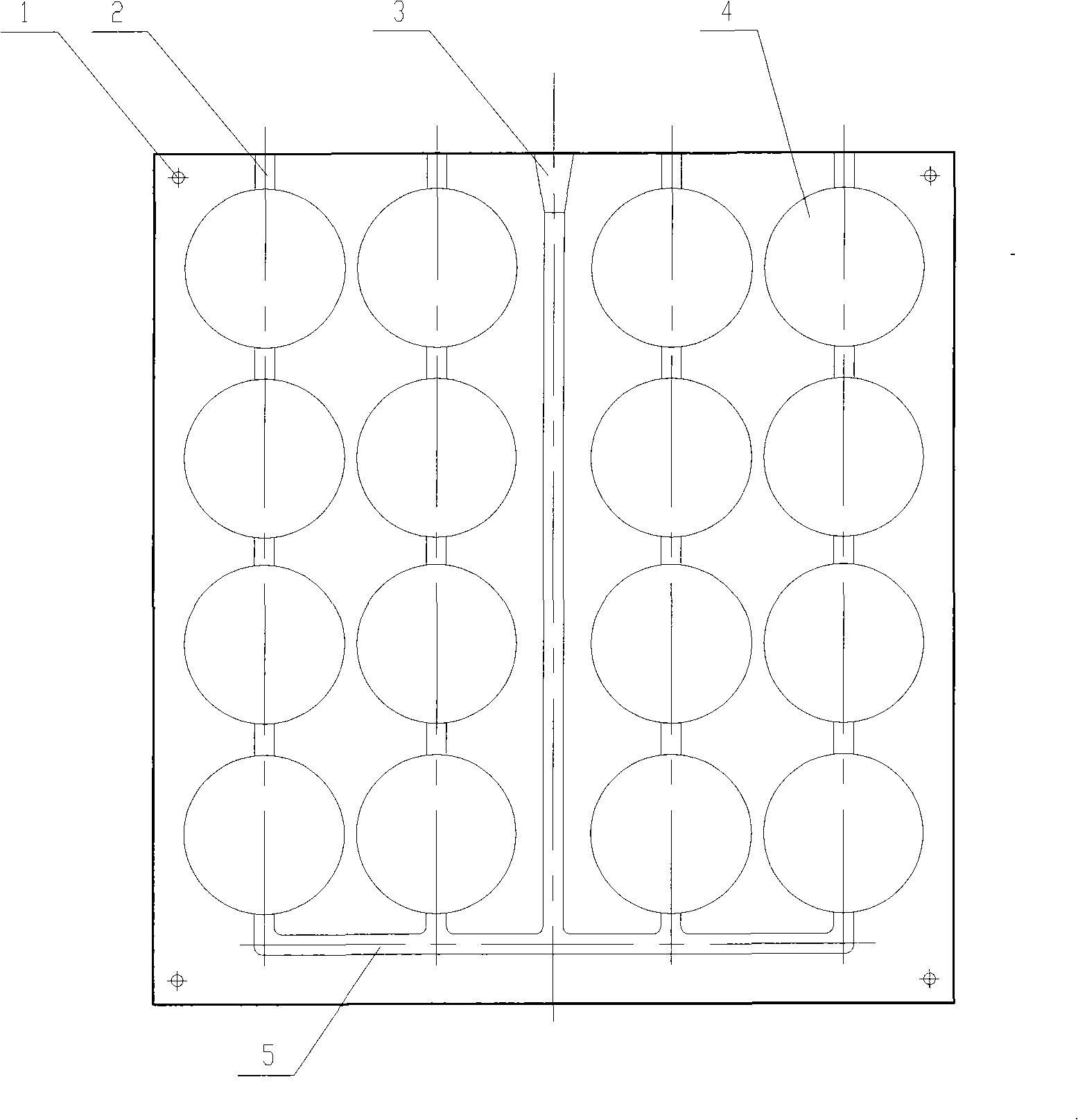

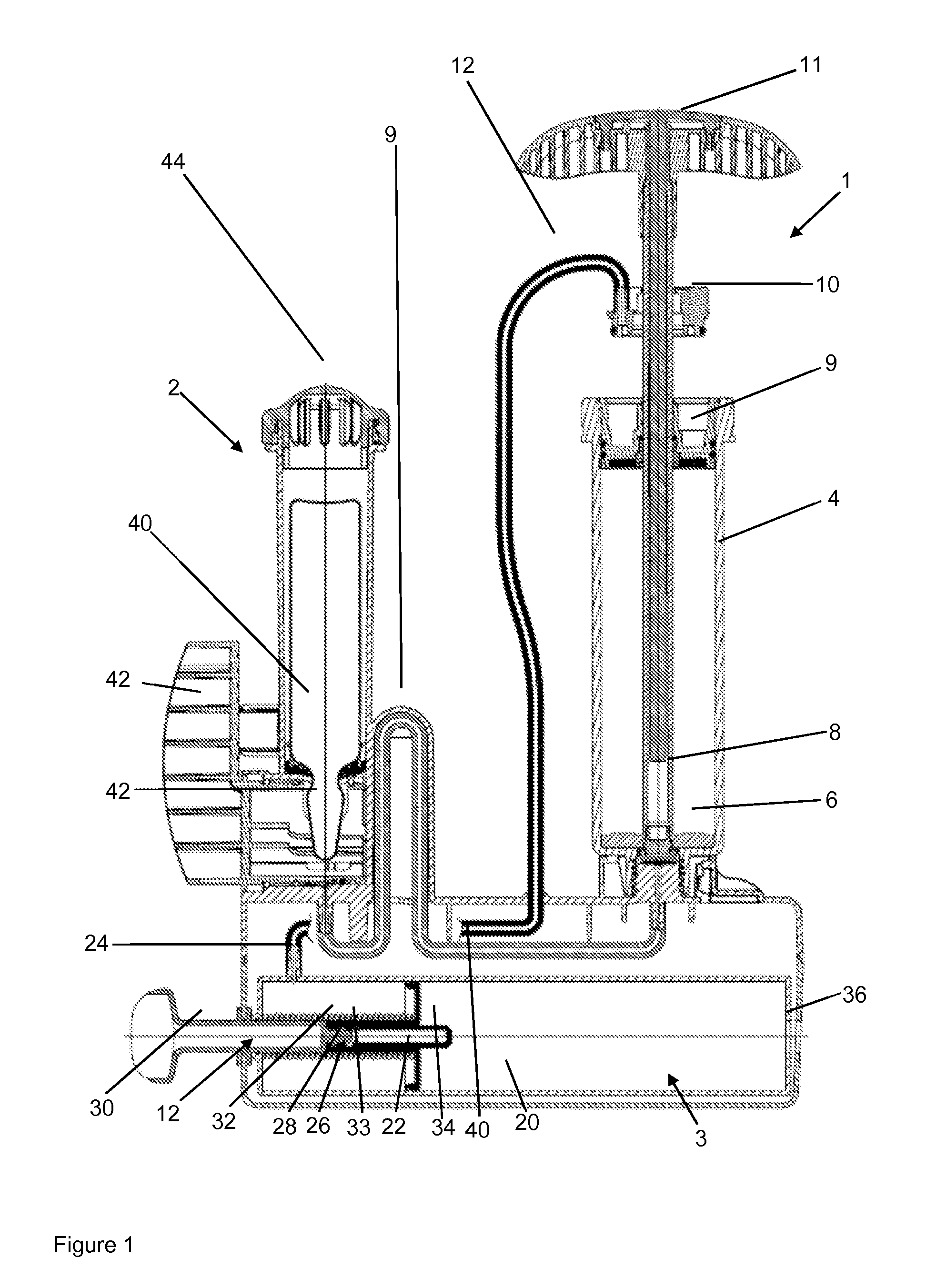

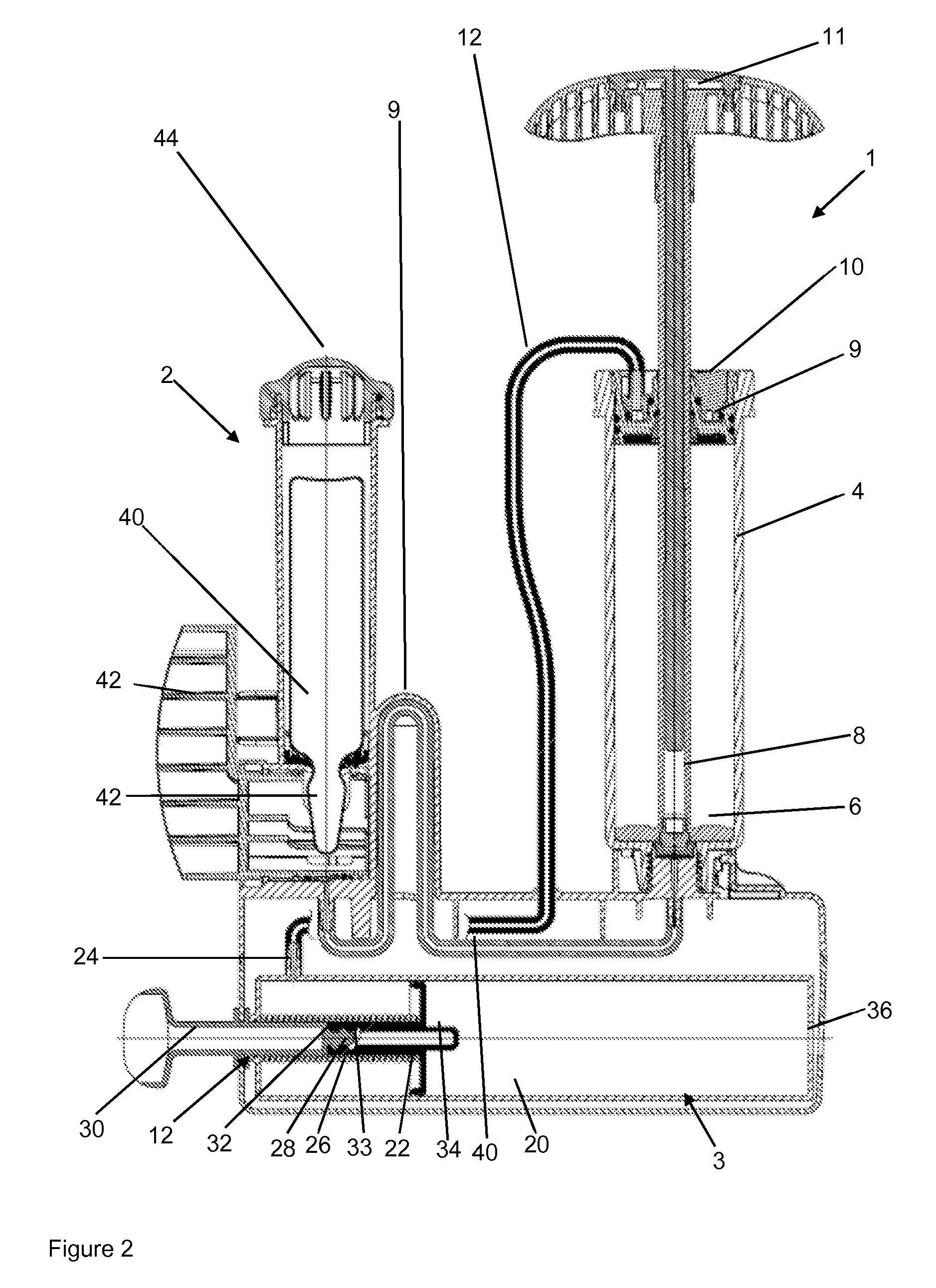

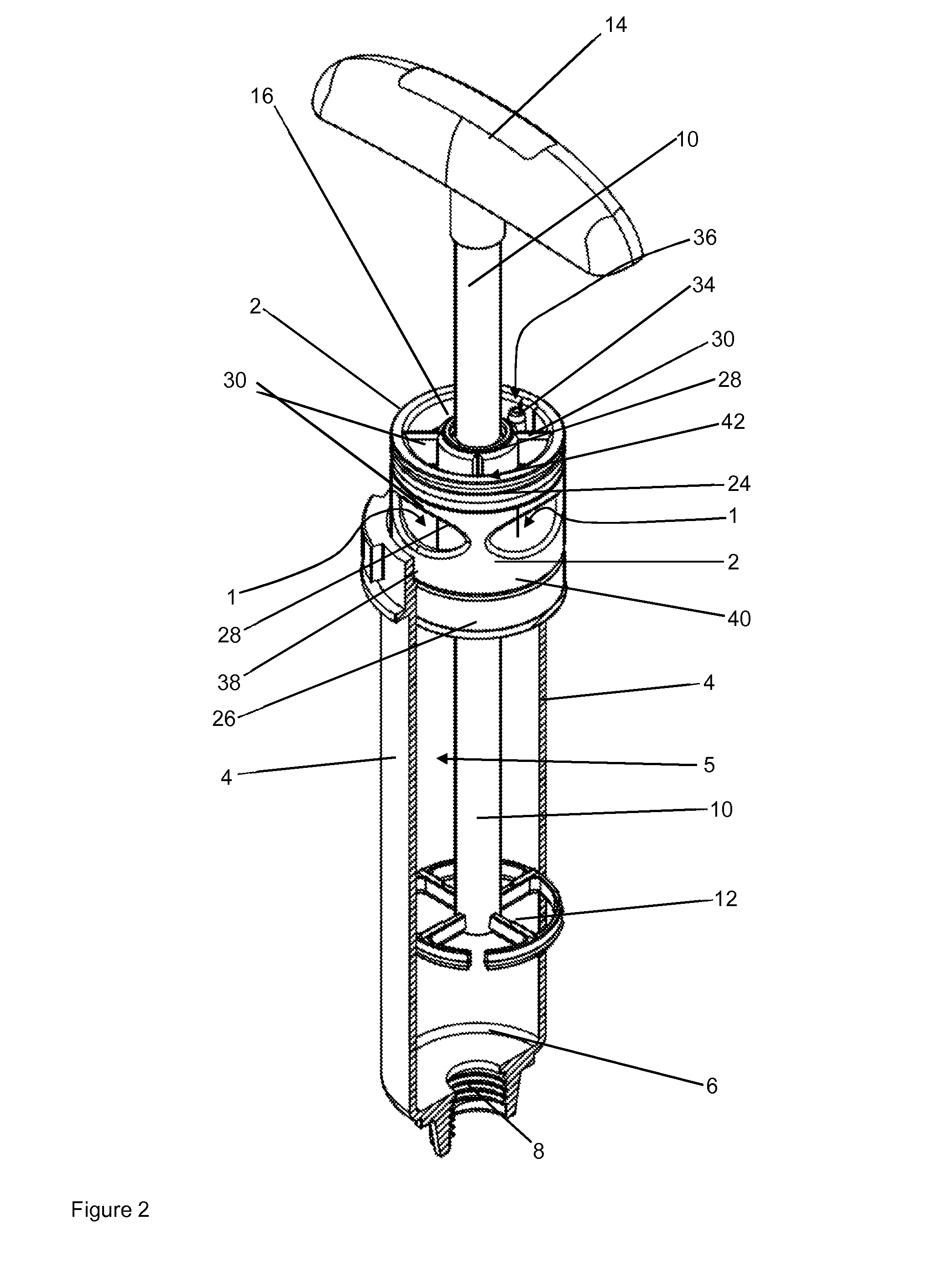

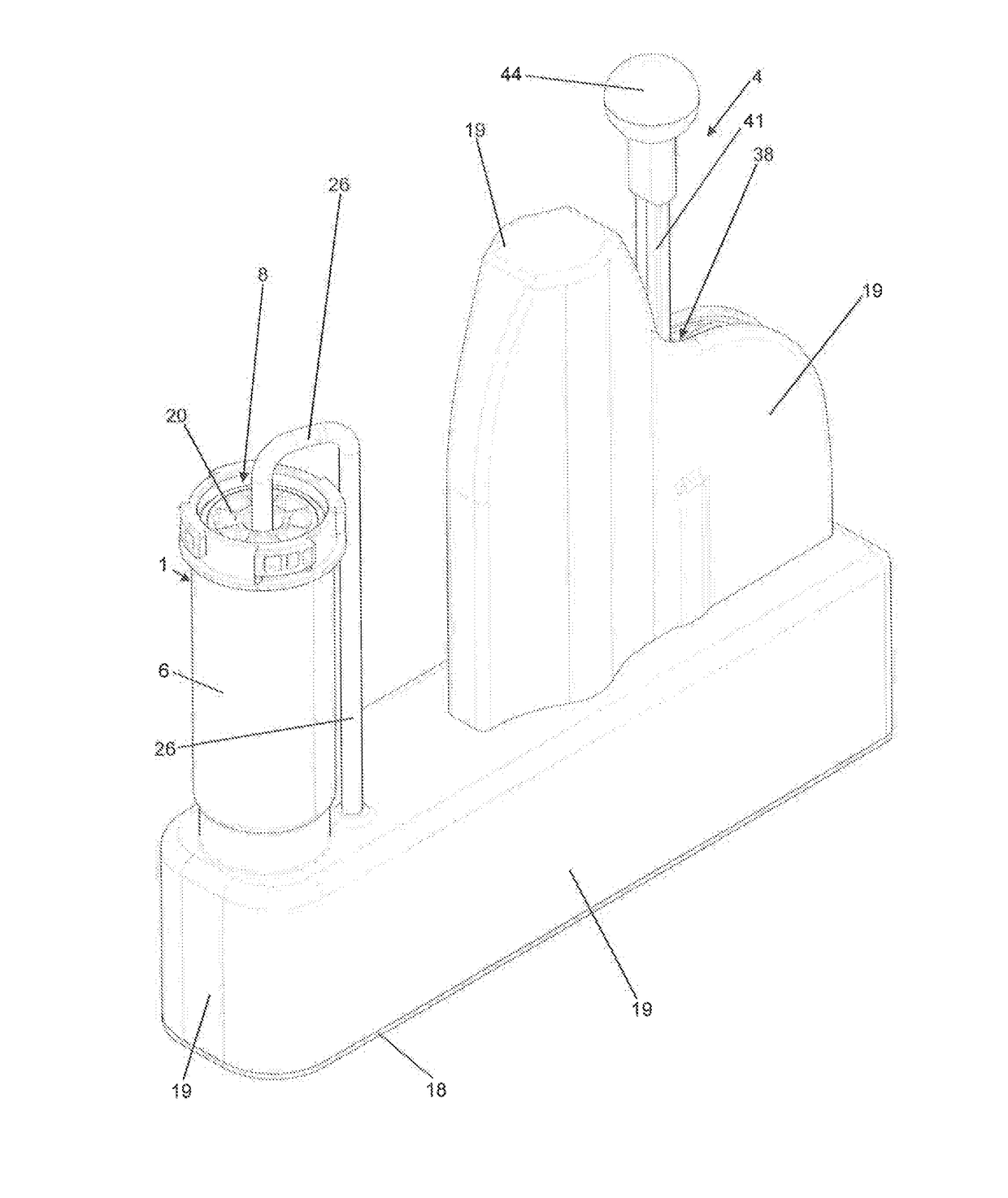

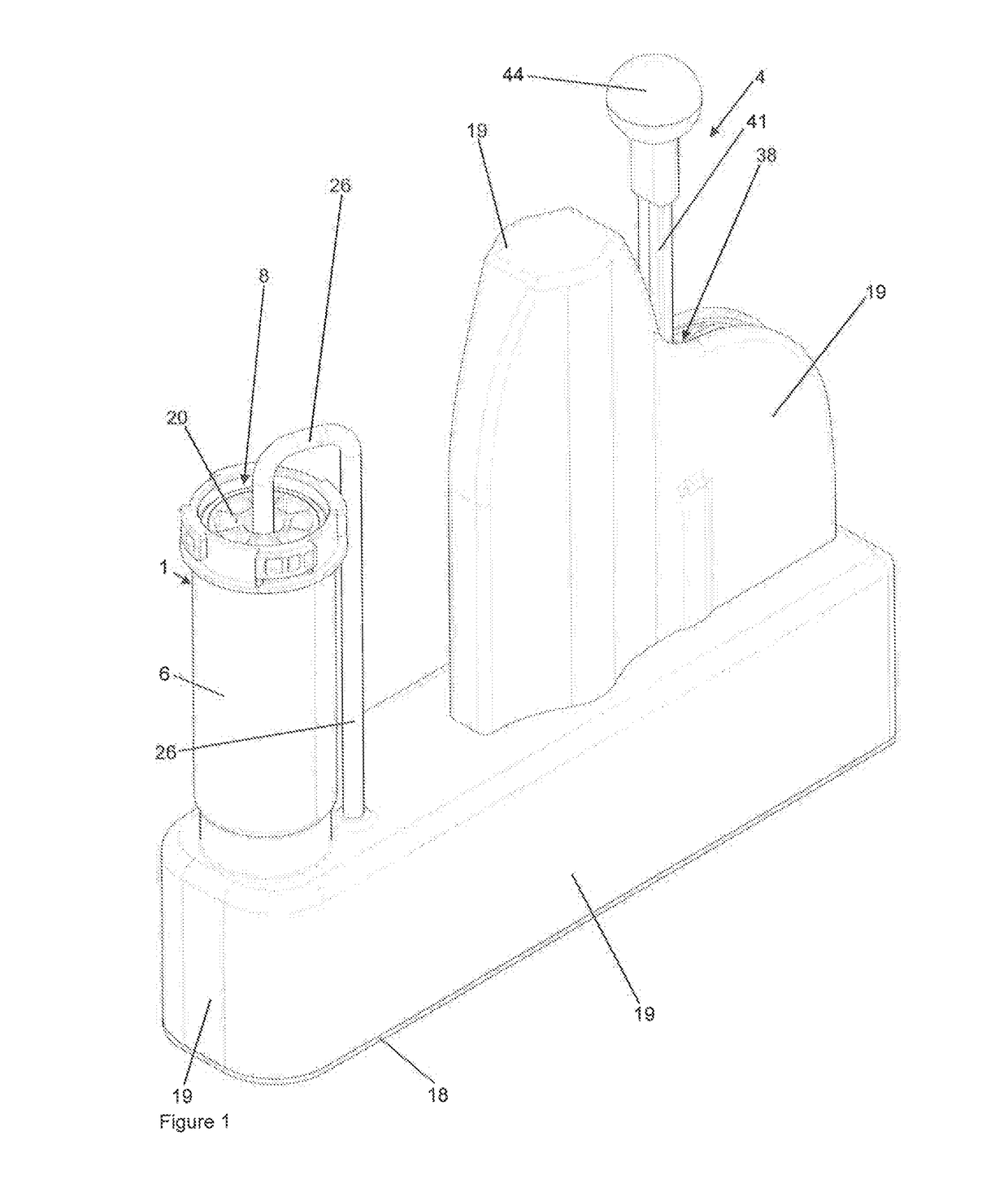

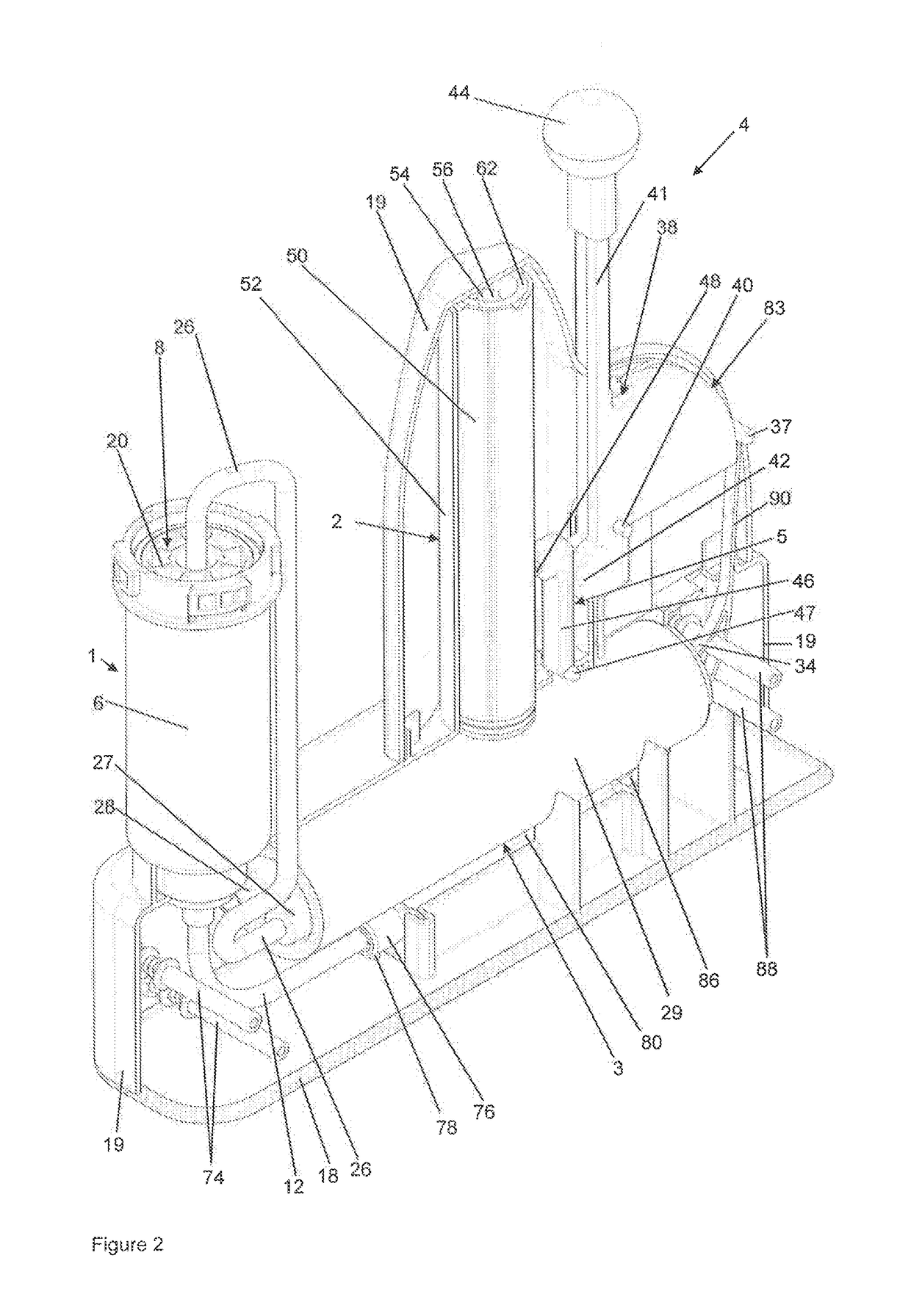

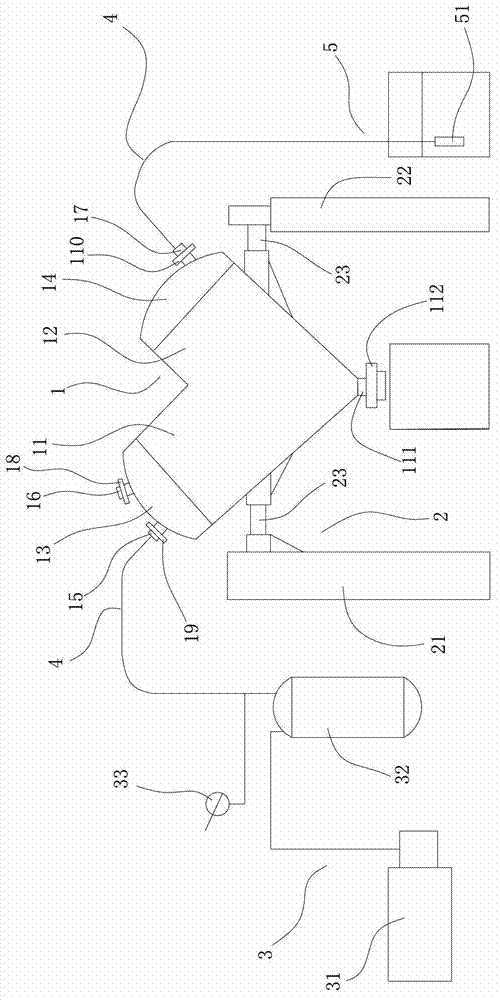

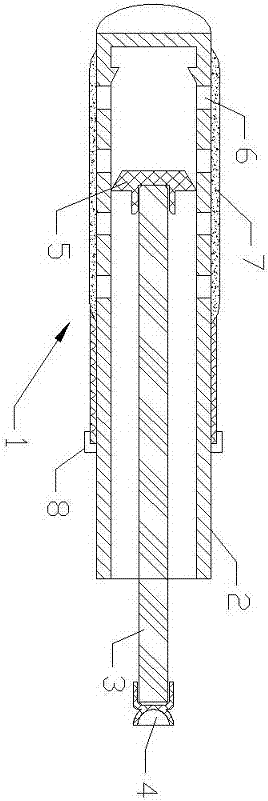

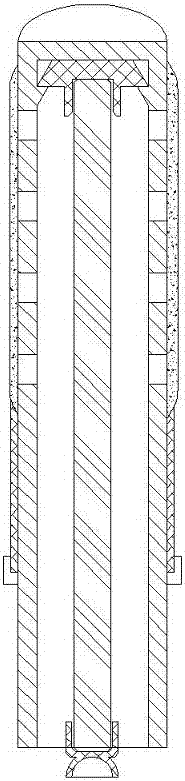

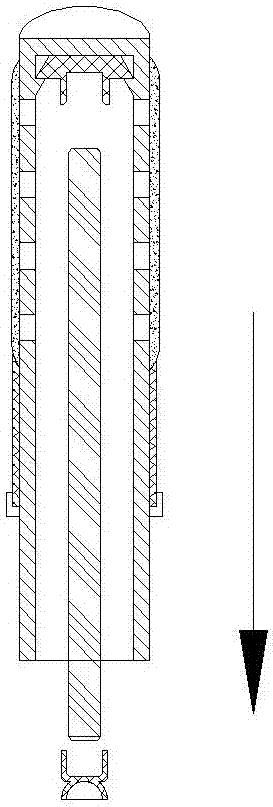

Vacuum mixing system and method for the mixing of polymethylmethacrylate bone cement

InactiveUS20150367301A1Reduce manufacturing costEasy to operate manuallyShaking/oscillating/vibrating mixersMixing methodsVacuum mixingBone cement

A vacuum mixing system for the mixing of polymethylmethacrylate bone cement, comprising at least one cartridge (4) having an evacuable internal space for mixing of the bone cement, a pump (18) for generating a negative pressure, and a connecting conduit (12) connecting the internal space of the at least one cartridge (4) to the pump (18) for generating a negative pressure, an integrated energy reservoir (28) for driving the pump (18) that is or can be connected to the pump (18) and has energy for at least one pumping process of the pump (18) stored in it, whereby a negative pressure can be generated by means of the pump (18) during the pumping process, which negative pressure can be used to evacuate gas from the internal space of the at least one cartridge (4) through the connecting conduit (12).

Owner:HERAEUS MEDICAL

Method of preparing anisotropic neodymium-iron-boron multi-pole magnetic ring

InactiveCN110415964AReduce frictionImprove fill rateMagnetic materialsPermanent magnet manufactureParaffin waxVacuum mixing

A method of preparing an anisotropic neodymium-iron-boron multi-pole magnetic ring comprises the following steps: (a) taking a number of types of anisotropic neodymium-iron-boron magnetic powder withdifferent particle sizes, sub-packaging and marking the magnetic powder, and mixing the magnetic powder to form mixed magnetic powder; (b) modifying the surface of the mixed magnetic powder by a silane coupling agent; (c) adding a binder to the surface-modified magnetic powder for vacuum mixing, and mixing the magnetic powder with paraffin wax; (d) pre-pressing the magnetic powder after mixing toform a preformed blank; (e) performing pulse multi-pole magnetic field orientation multiple times on the preformed blank in an orientation molding pressing mold to form multiple poles of a magnetic ring, and pressing the poles to form a magnetic ring; (f) demagnetizing the formed magnetic ring in the mold and removing the magnetic ring from the mold to obtain an anisotropic neodymium-iron-boron multi-pole magnetic ring blank; and (g) curing the neodymium-iron-boron multi-pole magnetic ring blank under the protection of inert gas in a vacuum curing furnace, and immersing the neodymium-iron-boron multi-pole magnetic ring blank in oil to obtain a finished anisotropic neodymium-iron-boron multi-pole magnetic ring.

Owner:DONGGUAN HAITIAN MAGNETIC IND CO LTD

Honeycomb producing process needing no tung oil and less cellulose

The process of producing honeycomb ceramic with no tung oil and less cellulose includes the following steps: 1. milling glutinous rice into powder, adding water and steaming; 2. adding wheat flour in 3-5 wt% and cooking into panada; 3. adding alumina sol or silicon sol in 20-30 wt% and milling slurry in a ball mill; 4. 80 mesh sieving the slurry serving as the temporary adhesive for honeycomb ceramic; and 5. adding the temporary adhesive in 18-23 wt% and carboxymethylcellulose in 0.5-0.8 wt% into compounded honeycomb ceramic material, kneading, vacuum mixing, extruding to form, drying and sintering to obtain honeycomb ceramic. The present invention has the advantages of environment friendship, low production cost, high heat shock resistance, high heat conductivity, etc.

Owner:潘国明

Method for extracting vitamin C from shine skin papayas

InactiveCN104610203ASimple extraction methodHigh in Vitamin COrganic chemistryVitamin CFreeze-drying

The invention discloses a method for extracting a vitamin C from shine skin papayas. The method comprises the following steps: (1) picking fresh shine skin papayas, cleaning the picked shine skin papayas, separately cutting the cleaned shine skin papayas in an extraction protective solvent, and deseeding the cut shine skin papayas; (2) adding the flesh of the cut shine skin papayas and the extraction protective solvent in a vacuum pulping machine together, and pulping the flesh of the cut shine skin papayas and the extraction protective solvent to obtain a sizing agent ; (3) adding the generated sizing agent after pulping to a vacuum mixer to perform vacuum mixing; (4) filtering the materials obtained in the step (3) to obtain a filtrate, standing the filtrate for layering, and performing separation to obtain an organic phase; (5) adding water of which the pH is smaller than 7 to the organic phase obtained in the step (4), and performing vacuum mixing for more than 2 hours; (6) standing a mixture for layering, and performing separation to obtain an aqueous phase; (7) performing vacuum concentration on the aqueous phase to enable the aqueous phase to be dried, and performing freeze drying so as to obtain the vitamin C crude product. The extraction method disclosed by the invention can extract the vitamin C in the shine skin papayas, the extraction method is simple, and the method is suitable for large-scale popularization and application. Extracts are high in the content of the vitamin C.

Owner:CHINA PAULOWNIA RES CENT

Preparation of radish red pigment

InactiveCN1510086ACompletely deodorizedShorten the production cycleNatural dyesFood preparationBetacyaninsVacuum mixing

A process for preparing the edible red pigment from the fresh red-core radish includes such steps as washing, slitting, leaching, extracting, macroreticular resin column adsorbing, concentrating, spray drying, vacuum mixing and drying, and deodoring. Its advantages are rich in fish pelargonium pigment glycoside and anthocyanidin glycoside, no radish odor, and high chromatic level greater than 60.

Owner:重庆武隆县祥宇农业发展有限公司

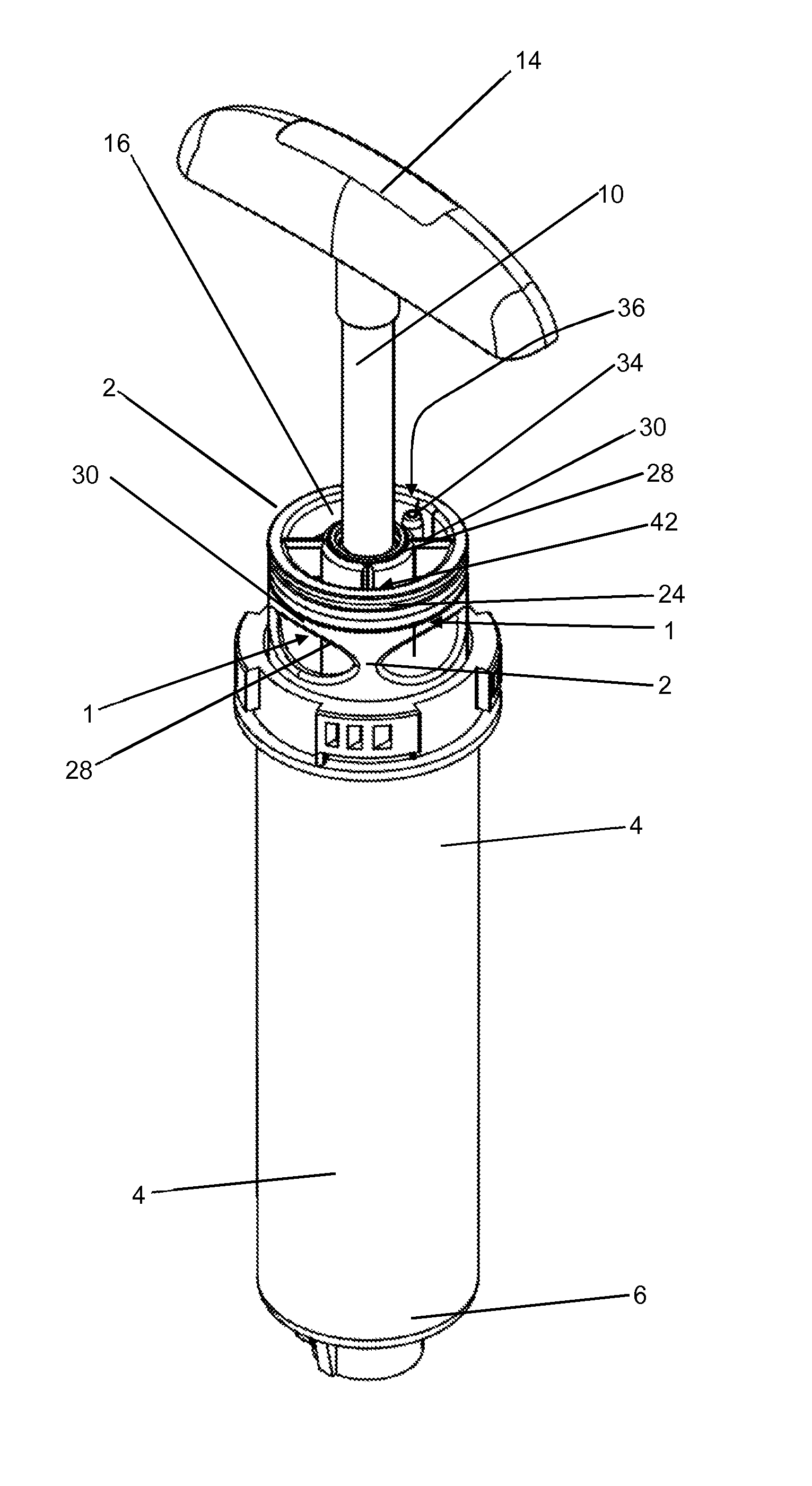

Vacuum mixing system and method for the mixing of polymethylmethacrylate bone cement

ActiveUS20160015854A1Easy to exportEasy to useImpression capsShaking/oscillating/vibrating mixersEngineeringVacuum mixing

A vacuum mixing system for the mixing of polymethylmethacrylate bone cement comprising at least one cartridge (4) having an evacuatable internal space (5) for the mixing of the bone cement, the internal space (5) of which comprises a cylindrical swept volume, a mixing element (12) that is arranged in the internal space (5) of the cartridge (4) such as to be mobile and can be operated from outside the vacuum mixing system in order to mix the content in the internal space (5) of the cartridge (4), and a dispensing plunger (2) having a cylindrical external circumference whose first base surface borders a base surface of the internal space (5) of the cartridge (4) and which can be or is locked to the cartridge (4) in detachable manner and which, in the detached state, is mobile in the cylindrical region of the internal space (5) of the cartridge (4).

Owner:HERAEUS MEDICAL

Normal-temperature yogurt containing fruit and vegetable granules and preparation method of normal-temperature yogurt

PendingCN108094543ACompliance with safety standardsGreat tasteMilk preparationAntibiotic freePasteurization

The invention discloses a preparation method of normal-temperature yogurt containing fruit and vegetable granules. The preparation method comprises the following steps of performing vacuum mixing on antibiotic-free milk, a sweetening agent, modified starch and a stabilizing agent which are presterilized, performing uniform mixing, performing homogenization, performing pasteurization, performing cooling on the mixed liquid after pasteurization, adding a fermentation agent for fermentation, and performing sterilization when the acidity reaches 70-90 DEG T to obtain a yogurt base material; and cutting at least one of fruits or vegetables to obtain fruit and vegetable granules, mixing the fruit and vegetable granules with white granulated sugar, the stabilizing agent, a flavouring essence anda PH regulator to obtain a mixture, performing boiling, performing sterilization after boiling, performing filling to obtain the fruit and vegetable granules, firstly performing static mixing, whereinthe mass ratio of the added yogurt base material to the added fruit and vegetable granules is (8-9)to(2-1), then performing dynamic mixing by stirring, and performing filling after mixing to obtain the product of namely the normal-temperature yogurt containing fruit and vegetable granules.

Owner:BRIGHT DAIRY & FOOD CO LTD

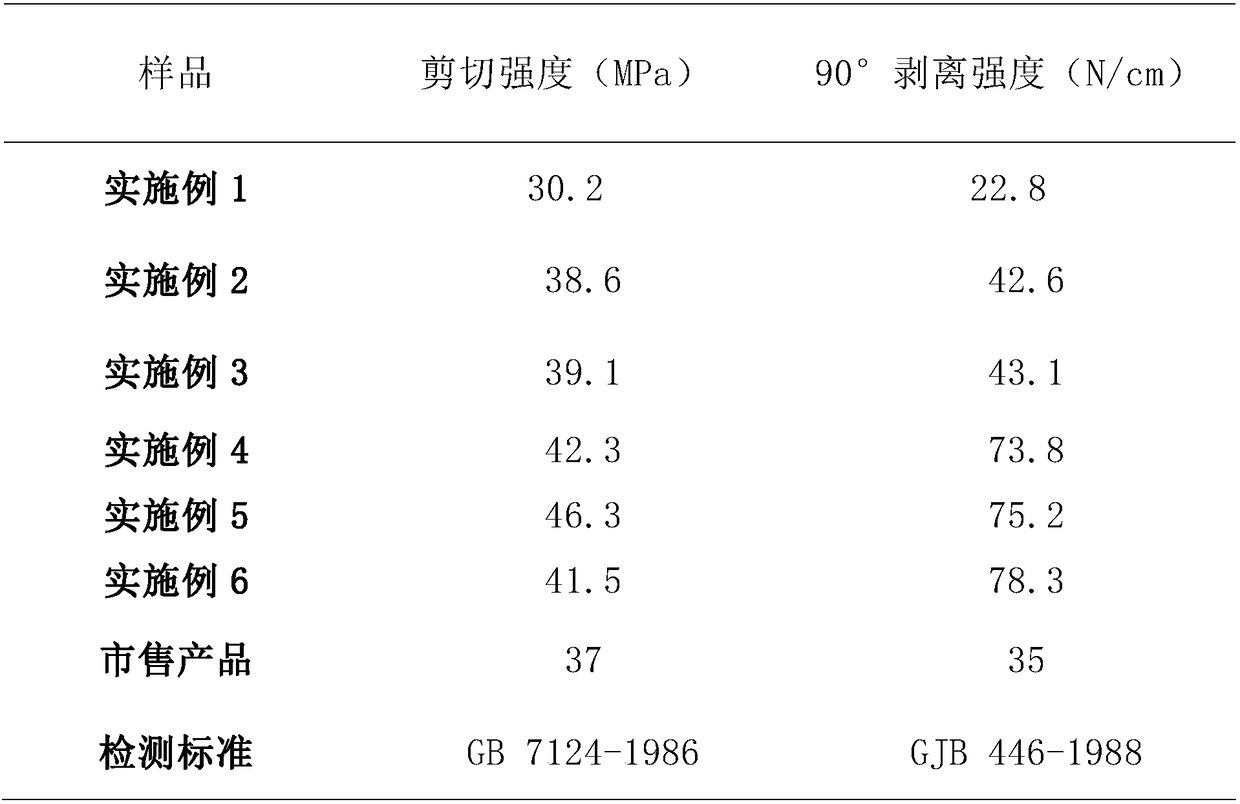

Single-component epoxy adhesive solution for impregnating glass fibers

The invention discloses a single-component epoxy adhesive solution for impregnating glass fibers. The single-component epoxy adhesive solution is prepared by carrying out vacuum mixing on the following raw materials in percentage by weight to form a solution, 35 to 75 percent of epoxy resin, 5 to 20 percent of toughening agent, 4 to 10 percent of curing agent, 0.1 to 1 percent of coupling agent, 0.1 to 2 percent of rheological additive and 1 to 5 percent of accelerant. The epoxy adhesive solution disclosed by the invention has the characteristics that 90-degree peel strength of stainless steels can reach 78.3 N / cm and shear strength at normal temperature can reach 41.5MPa.

Owner:上海康达新材料科技有限公司

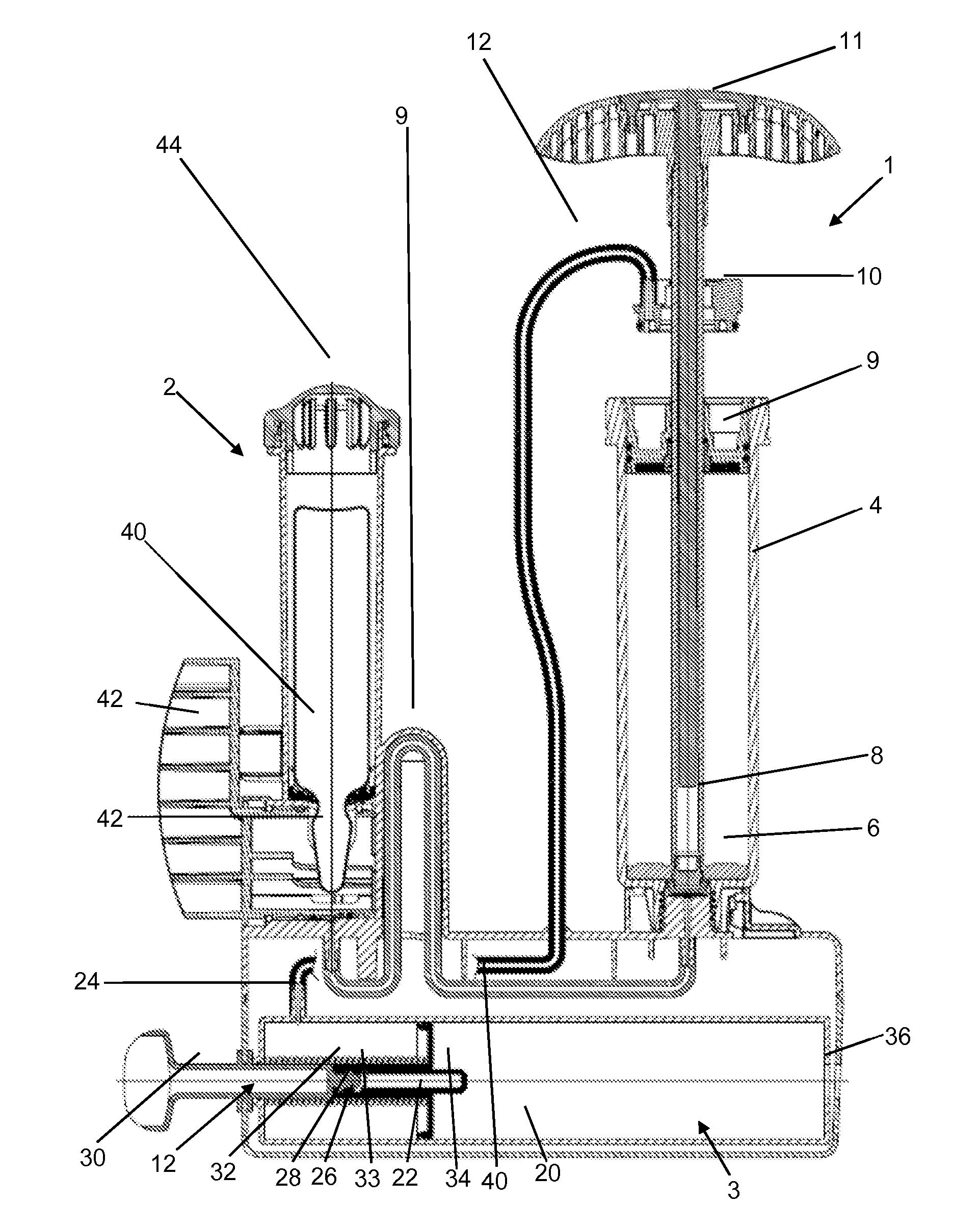

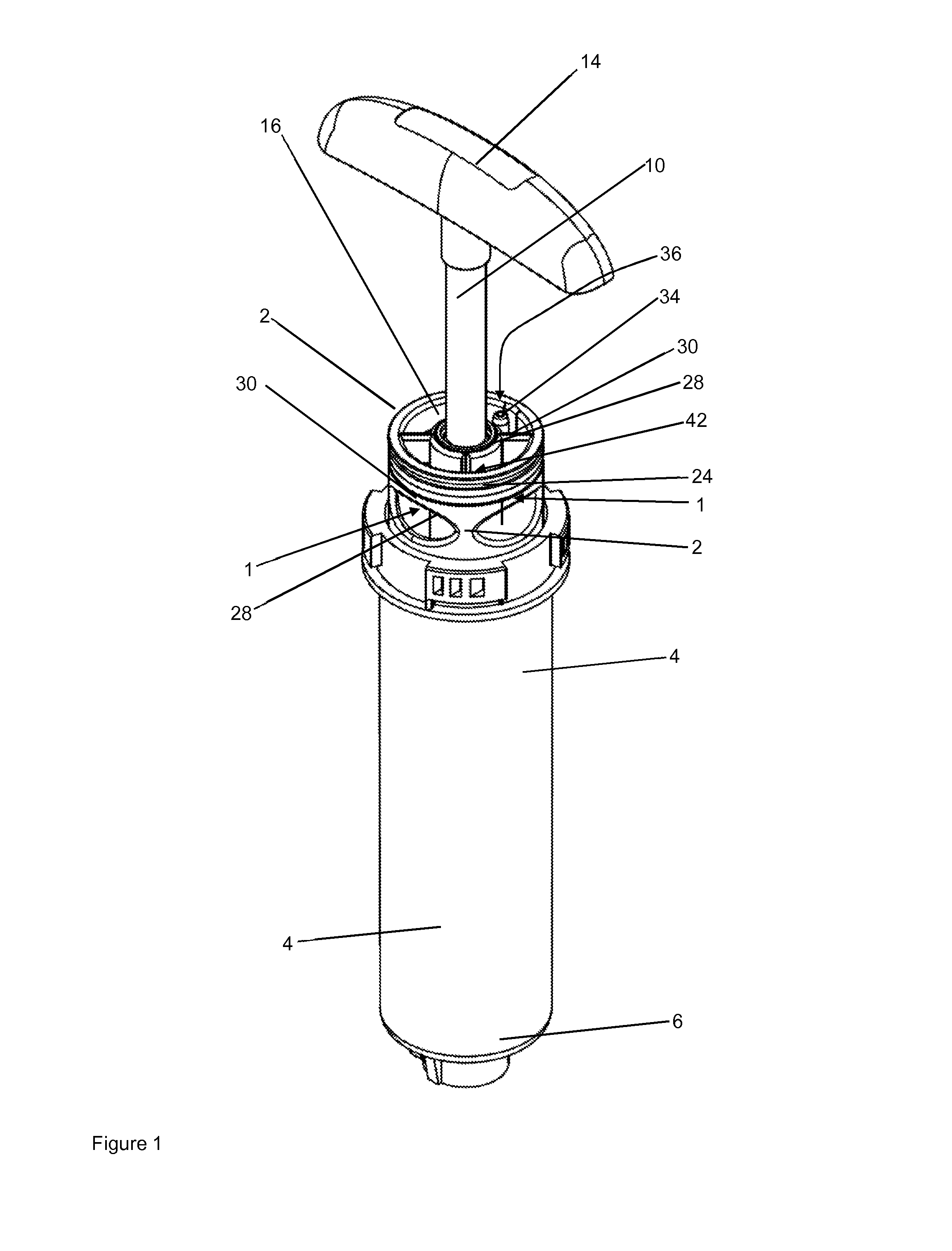

Vacuum mixing device with operating element, pressure pump, and vacuum pump for mixing polymethylmethacrylate bone cement

InactiveUS20170157579A1Improve patient safetyUse minimizedShaking/oscillating/vibrating mixersSurgical adhesivesPump chamberEngineering

A vacuum mixing device or system mixes polymethylmethacrylate bone cement from a monomer liquid and a cement powder. The device or system comprising at least one cartridge comprising an evacuable interior for mixing of the bone cement, a mixing device for mixing the content in the interior of the at least one cartridge, a receptacle for receiving a separate container containing the monomer liquid or comprising an integrated container containing the monomer liquid, an opening device, which is arranged in the region of the receptacle in a manner movable relative to the receptacle so that, by moving the opening device, a separate container arranged in the receptacle is openable by means of the opening device, or the opening device is arranged in the region of the integrated container in a manner movable relative to the integrated container so that, by moving the opening device, the integrated container is openable by means of the opening device, a vacuum pump, in which a movable vacuum plunger for generating a negative pressure is arranged and delimits a vacuum pump chamber of the vacuum pump, a pressure pump, in which a movable pump plunger for conveying a liquid is arranged and delimits a pressure pump chamber of the pressure pump, a connection line, and a fluid connection. The device or system further comprises an operating element that is operatable from outside, wherein, by means of the operating element, the vacuum plunger in the vacuum pump is movable manually, the pump plunger in the pressure pump is movable manually, the opening device is movable manually relative to the receptacle or relative to the integrated container, and the mixing device is movable manually in the interior of the cartridge.

Owner:HERAEUS MEDICAL

Material mixing process based on vacuum mixing drum

The invention discloses a material mixing process based on a vacuum mixing drum. The vacuum mixing drum comprises a mixing drum and an upper cover, wherein an extraction pipe and an air inlet pipe are arranged on the side wall of the mixing drum, a pneumatic cylinder used for lifting is arranged above the upper cover, and a discharge port and a pneumatic valve are formed in and arranged at the bottom of the mixing drum. Firstly, the upper cover is lifted to discharge by virtue of the pneumatic cylinder, then the upper cover is closed to exhaust, the mixing drum is vacuumized, and subsequently, air enters again after mixing for a certain time, so that air pressure in the mixing drum conforms to ambient pressure; when the air enters, the pneumatic valve is opened, materials flow out from the discharge port, and the pneumatic cylinder is driven by a part of air to lift the upper cover, so as to be convenient to discharge again. The whole process is automatically completed by air pressure, the problems of bad dust removing effect and non-uniform mixing of a traditional mixing drum are solved, the upper cover of the vacuum mixing drum can be quickly lifted with labor saving, and the working efficiency is improved.

Owner:CHANGXING HUAQIANG ELECTRONICS

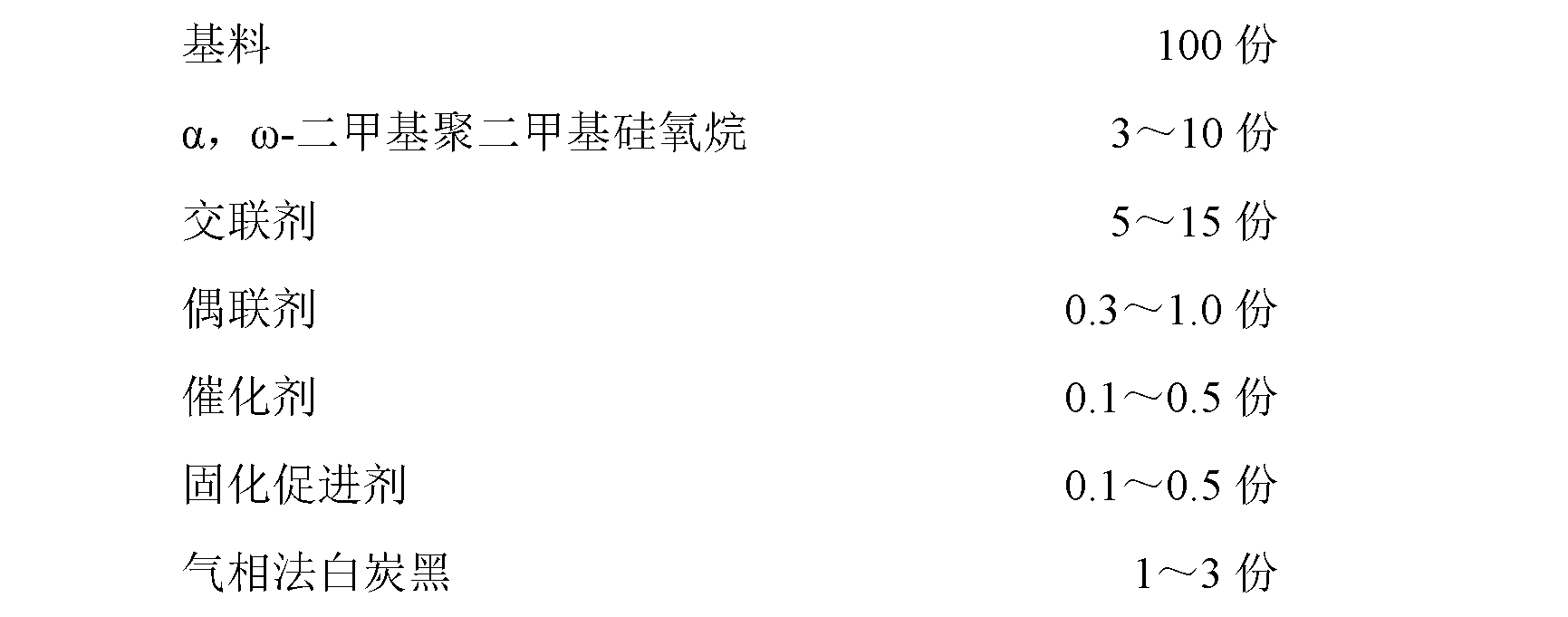

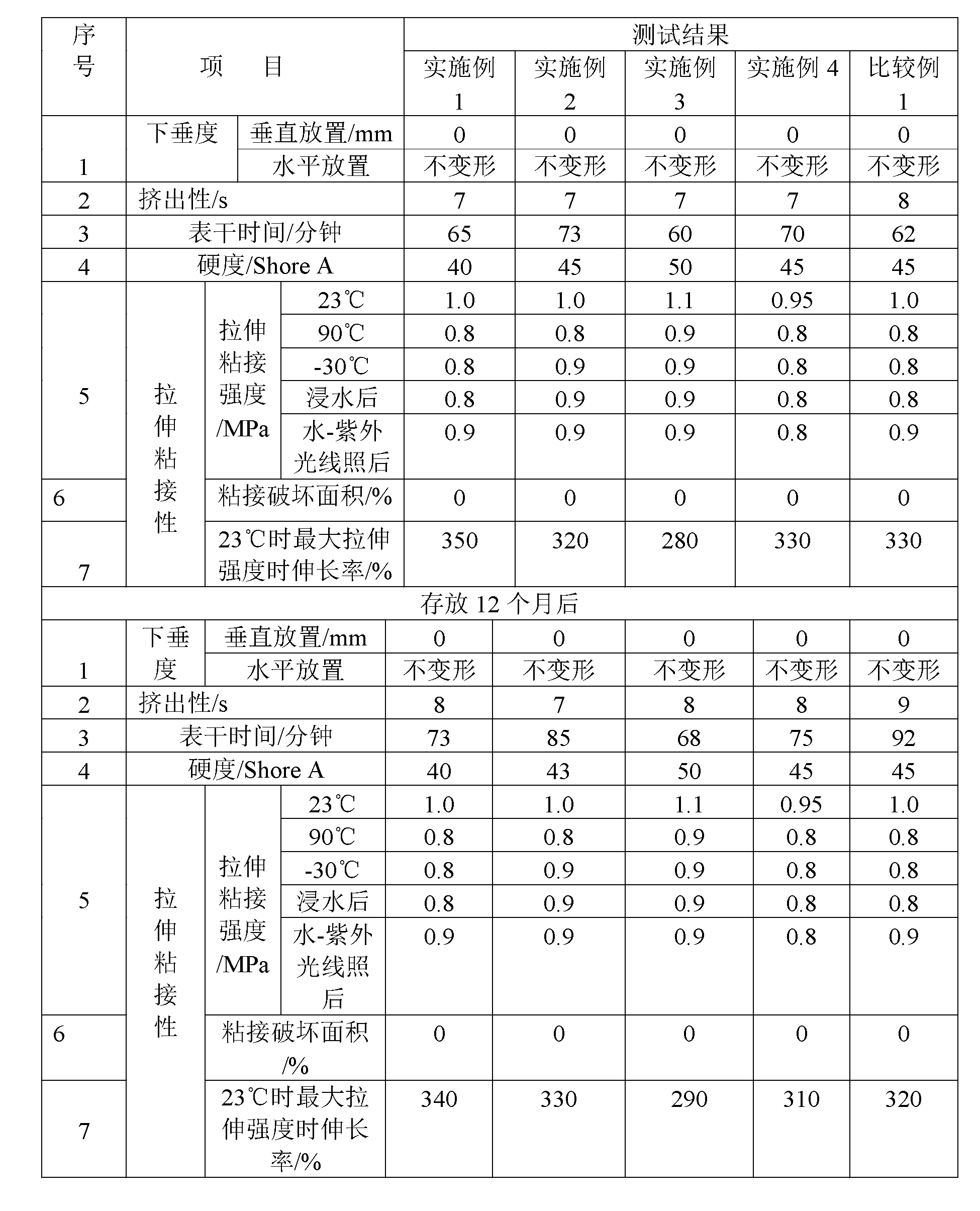

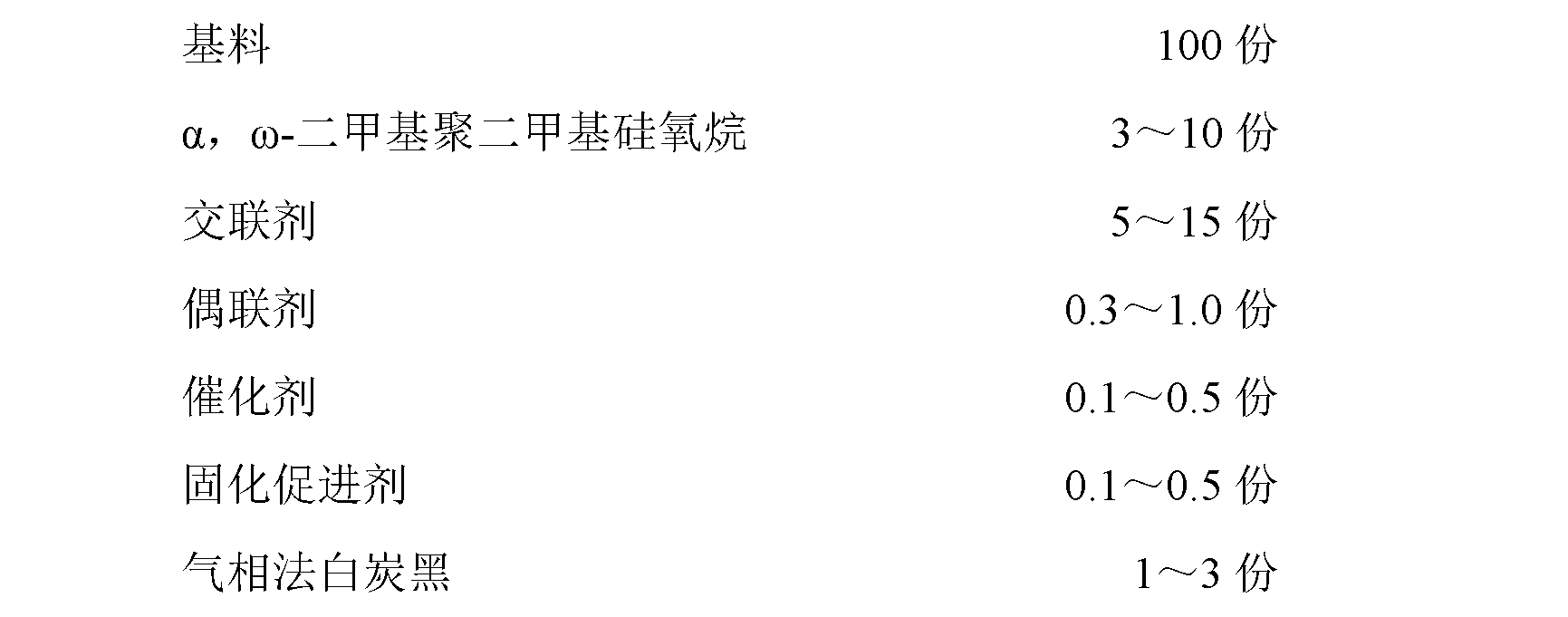

Environment-friendly organosilicone sealant and manufacturing method thereof

InactiveCN103013430AEnvironmentally friendly and healthyReduce dosageNon-macromolecular adhesive additivesOmegaSealant

The invention discloses an environment-friendly organosilicone sealant which is characterized in that 100 parts by mass of alpha,omega-dyhydroxyl polydimethylsiloxane and 50-150 parts by mass of packing are added into a vacuum kneader for dehydration and blending for 120-240min at 120-170 DEG C and at the vacuum degree of 0.06-0.099MPa, and a base stock is obtained. 100 parts by mass of base stock, 3-10 parts by mass of alpha,omega-dimethyl polydimethylsiloxane, 5-15 parts by mass of cross-linking agent, 0.3-1.0 parts by mass of coupling agent, 0.1-0.5 parts by mass of dimethylbis [(1-oxoneodecyl) oxy] stannane, neodecanoic acid zinc and organic bismuth, 0.1-0.5 parts by mass of curing accelerator and 1-3 parts by mass of fumed silica are added into a dispersion machine for vacuum mixing for 20-4040 at a room temperature and at the vacuum degree of 0.06-0.099MPa, and the environment-friendly organosilicone sealant is obtained. Various performances of the environment-friendly organosilicone sealant meet requirements of building sealants, and can be widely applied to the field of buildings.

Owner:CHENGDU GUIBAO SCI & TECH

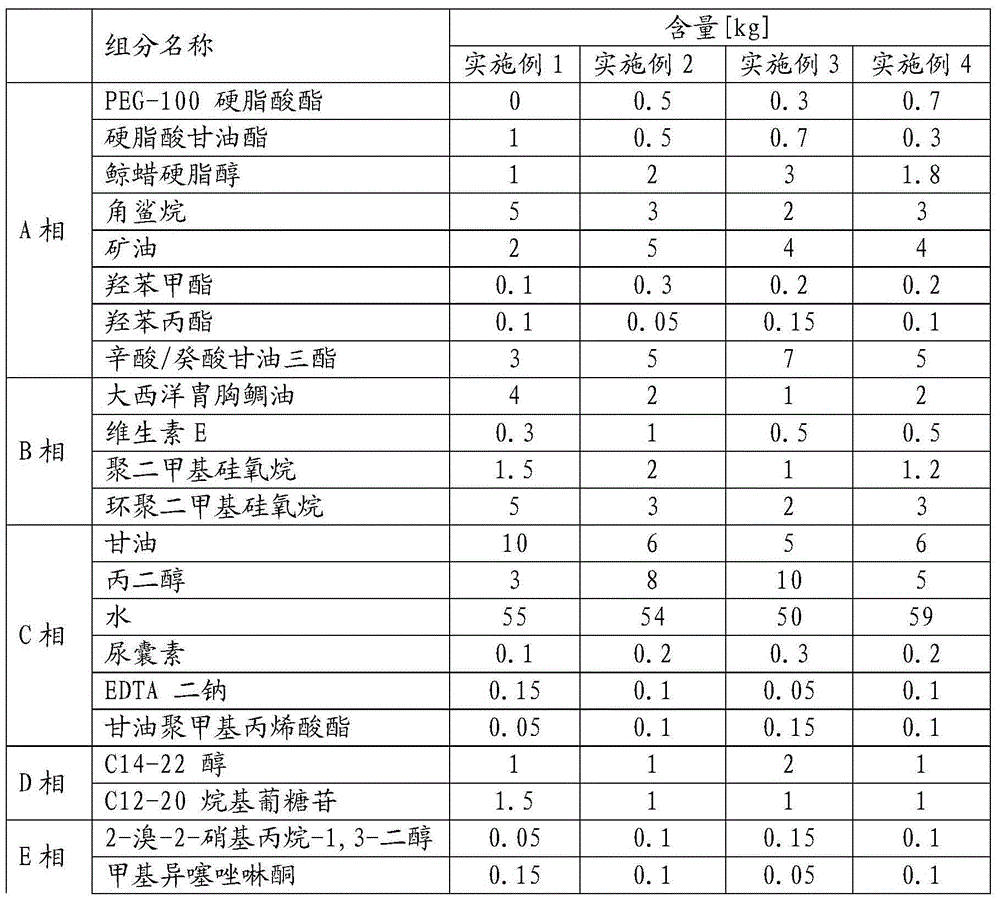

Hormone-free breast enlargement cream and preparation method thereof

InactiveCN104887606ANo side effectsQuick resultsCosmetic preparationsToilet preparationsWater basedBiological activation

Hormone-free breast enlargement cream comprises an A phase, a B phase, a C phase, a D phase and an E phase, wherein the A phase comprises a non-irritant emulsion matrix, methylparaben, and propyl hydroxybenzoate; the B phase comprises vitamin E and siloxane; the C phase comprises a water-based matrix and allantoin; the D phase is an emulgator and a stabilizing agent; the E phase comprises a bacteriostatic agent and a natural substance. Containing no hormone, artificially synthesized essence or bleaching components, the hormone-free breast enlargement cream is almost non-irritant for skin. The preparation method comprises four steps, namely, vacuum-mixing, emulsification homogenization, emulsion stabilization and compounding. By adopting the method provided by the invention, bacteria and bubbles are not easy to generate in the production process, and the prepared cream is fine and smooth in texture, and non-irritant for skin; the hormone-free breast enlargement cream provided by the invention has the basic function of moisturizing, further achieves the effects such as hematogenesis and blood activation, breast blood circulation improvement, cell nutrition supply and the cell growth promotion, and is supplemented by breast enlargement essence fragrance, so as to achieve multiple effects, and promote the second-time healthy development of breast.

Owner:广州市白云区天芳化妆品厂

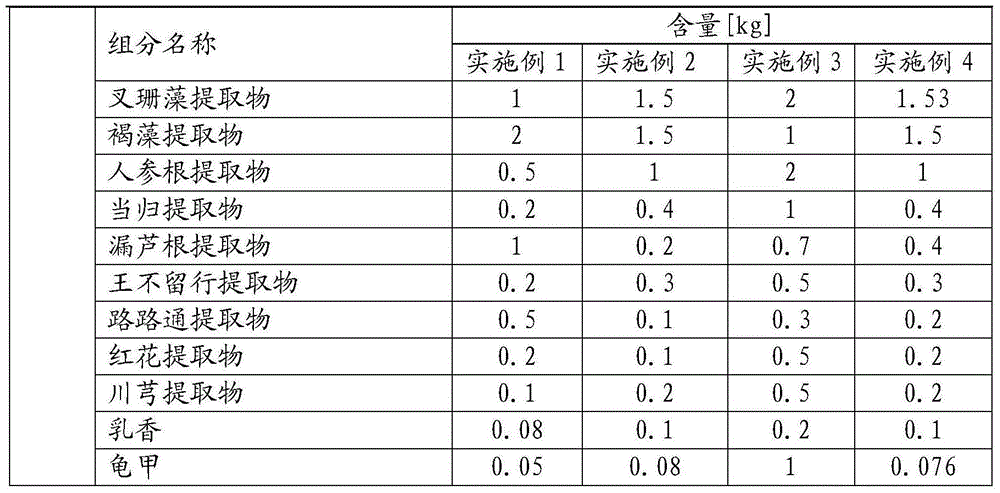

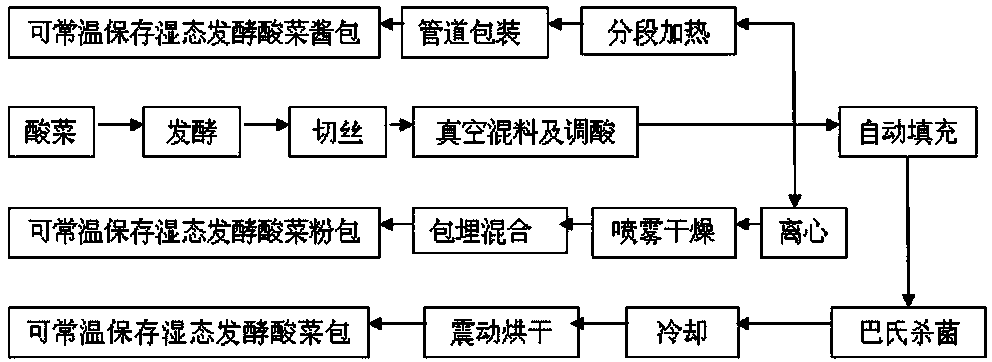

Wet fermentation pickled Chinese cabbage seasoning packet capable of being preserved at room temperature for instant noodles and production method thereof

ActiveCN103947996AGreat tasteQuality improvementFood thermal treatmentClimate change adaptationOxygenInstant noodle

The invention discloses a wet fermentation pickled Chinese cabbage seasoning packet capable of being preserved at room temperature for instant noodles and a production method thereof. The fermentation pickled Chinese cabbage is taken as a main raw material, the mixing uniformity is enhanced in a vacuum mixing manner, the possibility of oxidation and brown stain after contact of pickled Chinese cabbage and oxygen is reduced, the pH value achieves a low-acid value by adjusting an acidity regulator, sterilization is carried out by adopting a low-density heat sterilization process, and the pickled Chinese cabbage seasoning packet is free of a corrosion remover, is crisp and tender, sour and cool, and can be preserved at room temperature. In addition, the acid value and the water activity control are changed by adopting a segmented temperature control heating technology and an acid adjusting technology, the shelf life and the safety of the product can be effectively controlled, so as to obtain the wet fermentation pickled Chinese cabbage seasoning packet for instant noodles, which is strong in flavor and can be preserved at room temperature, and the shelf life can be up to over 10 months. The seasoning packet produced by the method disclosed by the invention is crisp and fresh, strong in sour fragrance, good in mouthfeel, stable in quality, and convenient to eat.

Owner:UNI PRESIDENT ENTERPRISES CHINA INVESTMENT CO LTD KUNSHAN RES & DEV CENT +1

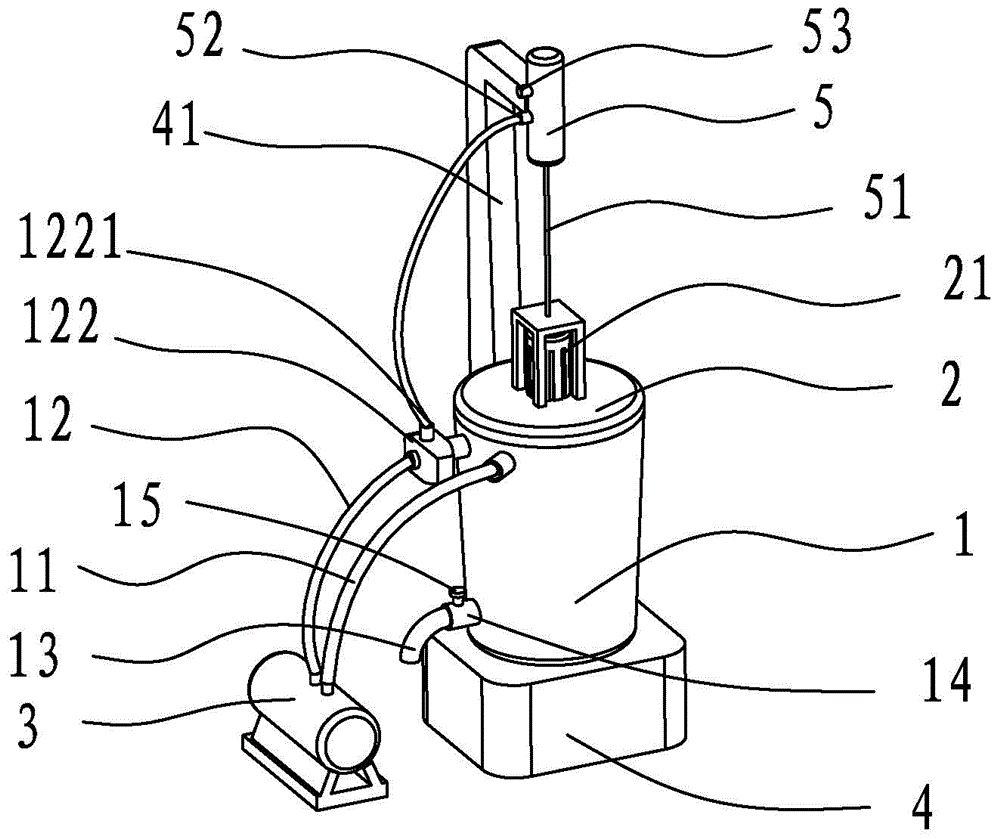

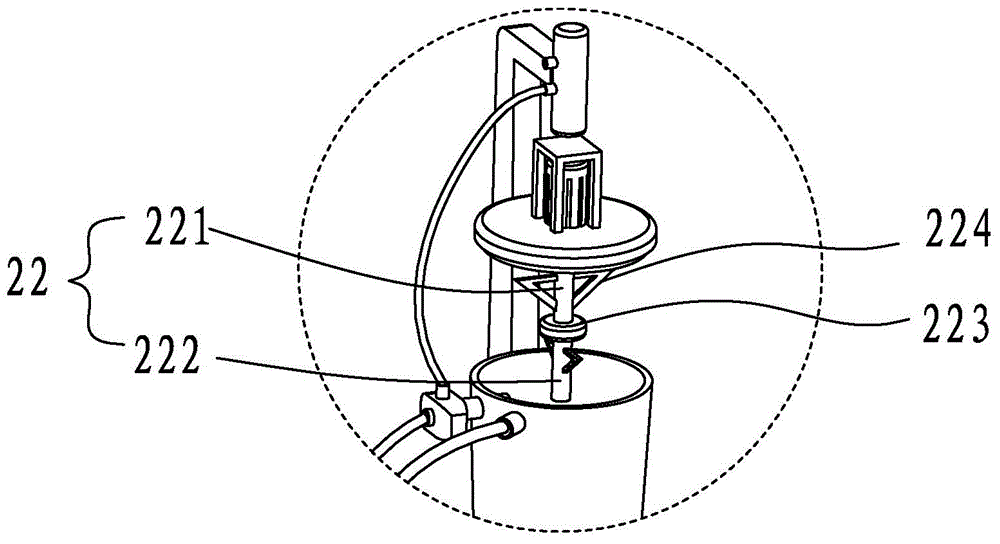

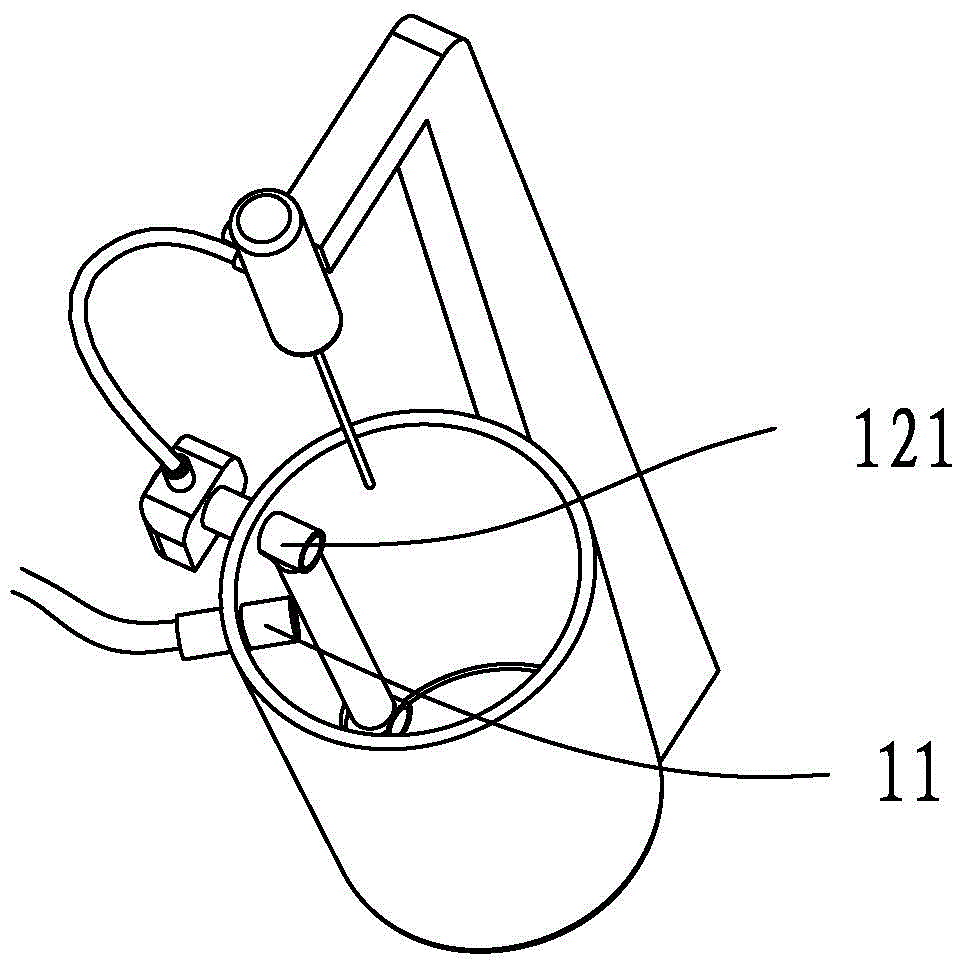

Vacuum mixing method and system

The invention discloses a vacuum mixing method which comprises the following steps of: arranging a mixing bin, a power mechanism, a vacuumizing device, a feeding device and a control system; placing a charging bucket filled with materials on one side of the mixing bin; extending a feeding suction nozzle into the materials in the charging bucket; extracting gas in the mixing bin by the work of the vacuumizing device; sucking the materials into the mixing bin by the feeding suction nozzle through a flexible pipeline due to the fact that the atmospheric pressure is higher than the atmospheric pressure in the mixing bin; transmitting an instruction by the control system to close a first electronic valve at a feeding port in the mixing bin; continuously vacuuizing the mixing bin by the vacuumizing device; when the atmospheric pressure in the mixing bin reaches the vacuum standard, closing a second electronic valve at an exhaust opening in the mixing bin; and enabling the power mechanism to act at the rotating speed of 250-350t / m for 20 minutes to finish the mixing operation process. The invention also discloses a vacuum mixing system implementing the method.

Owner:梁首强

Normal temperature manufacturing process for MMA high-intensity artificial stone special-shaped pot/trough

InactiveCN101474827AWell mixedEfficient mixingStone-like material working toolsMechanical propertyMaterials science

The present invention discloses a technique for manufacturing MMA high-strength artificial stone special-shaped basin / groove at normal temperature. The methyl methacrylate resin, arenaceous quartz, accelerating agent and solidifying agent are executed with mixing, injection molding and solidifying forming. The mixing is vacuum mixing which is executed in a mixer with a vacuum degree of 8MPa. The vibration is executed while the squeezing is executed for pouring into the mold for completing injection molding. The mould is closed to a static solidifying exothermic peak, and mould removing and baking are executed. The invention aims at the disadvantages of high cost and hard mould removing of prior art. The invention provides a technique for manufacturing MMA high-strength artificial stone special-shaped basin / groove at normal temperature. The cost is reduced on one hand. On the other hand the mechanical property of product is increased. The technique of the invention has the following remarkable effects: adoption of normal temperature pouring for replacing the previous high temperature pouring, low energy consumption and convenient construction; and 2. adoption of vacuum mixing, excellent texture of finished product, and beautiful external appearance.

Owner:SHANGHAI MOERSHU CORP DEVING

Bioglass dressing used for promoting healing of cervix uteri wound and drug delivery device

InactiveCN106924867AUnique formulaGood moist airtight healing environmentMedical devicesAdhesive dressingsIrritationPolyvinyl alcohol

The invention discloses a bioglass dressing used for promoting the healing of the cervix uteri wound and a drug delivery device. For the bioglass dressing and the drug delivery device, the bioglass dressing comprises 45-70 % of an A component and 30-55 % of a B component, wherein the A component contains 3-20 % of bioactive glass (actimins), 55-70 % of medical liquid paraffin, and 3-10 % of polyethylene glycol; the B component contains 0.3-15 % of carboxymethyl chitosan, 0.05-3 % of sodium hyaluronate, 0.001-0.005 % of nano-silver ions, 60-80 % of purified water, and 5-15 % of polyving akohol. The A component and the B component are subjected to vacuum mixing under a specific condition to form gel, after the steps of high-temperature sterilization, disinfection and the like, the drug delivery device for the cervix uteri wound of the department of gynecology is well designed, and specifically, the gel is subjected to sterile filling; the bioactive glass is mixed with the functional components including silver ions, chitosan and the like, the scheme is applied to the medical apparatus for realizing drug delivery to the cervix uteri wound, through the manner of gel, the drug delivery is mild, the curative effects are obvious, the wound can be well covered, and the clinical problems that the powder delivery in the cavity is difficult and the powder has large irritation are solved.

Owner:连光

Preparation method of monodispersed fluorescent microsphere

ActiveCN105859973AUniform particle sizeParticle size controllableLuminescent compositionsSolventVacuum mixing

The invention discloses a preparation method of a monodispersed fluorescent microsphere. The preparation method comprises the following steps: 1, preparing a fluorescent monomer, and adding the fluorescent monomer to a dispersant / solvent to be stirred uniformly to obtain a fluorescent monomer suspension; adding polymer seeds to a dispersant containing aqueous solution to obtain a seed suspension; adding an initiator to the dispersant containing aqueous solution to obtain an initiator suspension; then adding the initiator suspension and the fluorescent monomer suspension to the seed suspension to react, and then placing a polymer microsphere suspension at the temperature of 25 to 40 DEG C to be subjected to vacuum mixing for 0.5 to 2 hours to obtain a monodispersed fluorescent microsphere suspension. The fluorescent microsphere prepared by the method has uniform particle size, controllable particle diameter, strong stability, high fluorescence efficiency, and potential application values in biological medicine fields of labeling, tracing, detection and the like.

Owner:SUZHOU KNOWLEDGE & BENEFIT TECH CO LTD

Improved processing method of plant insulating oil

ActiveCN104987949AShorten the timeImprove processing efficiencyFatty-oils/fats refiningVacuum mixingImpurity

The invention discloses an improved processing method of plant insulating oil. The method includes the first step of coalescence dewatering, the second step of vacuum dewatering and the third step of vacuum mixing and refined filtering so that plant insulating oil can be obtained. The water content of the plant insulating oil processed through the improved processing method is smaller than 50 mg / kg, and 100 ml oil contains 2000 or less of impurity particles with diameter larger than 5 microns.

Owner:GUANGZHOU POWER SUPPLY CO LTD +1

Expanded graphite flame-retardant fire-extinguishing material and preparation method thereof

InactiveCN108864839AWith flame retardant self-extinguishing performanceWell mixedFireproof paintsEpoxy resin coatingsHeat conductingGraphite

The invention discloses an expanded graphite flame-retardant fire-extinguishing material and a preparation method thereof. The expanded graphite flame-retardant fire-extinguishing material is preparedfrom the following components in parts by weight: 5-40 parts of organic resin, 0.5-30 parts of expanded graphite powder, 10-80 parts of heat conducting and electric conducting powder, 1-10 parts of coupling agent, 0.5-5 parts of curing agent and 0.5-5 parts of auxiliary agent. The expanded graphite flame-retardant fire-extinguishing material utilizes that expanded graphite can be rapidly expandedunder heating at a high temperature, and the expansion multiple can be up to tens and thousands of times. The apparent volume of the expanded graphite can reach 250 ml or above after expansion, and alarge number of unique network-like microporous structures are formed inside. Then the graphite is compounded with an organic resin such as silicone resin to form a sheet, coiled material or irregular shaped member with flame-retardant self-extinguishing properties at a certain temperature; at the same time, high-speed dynamic vacuum mixing technology is used for accelerating system mixing, preventing agglomeration, and improving dispersion effect, sufficiently mixing the expanded graphite with the resin.

Owner:HUIZHOU KINGBALI TECH

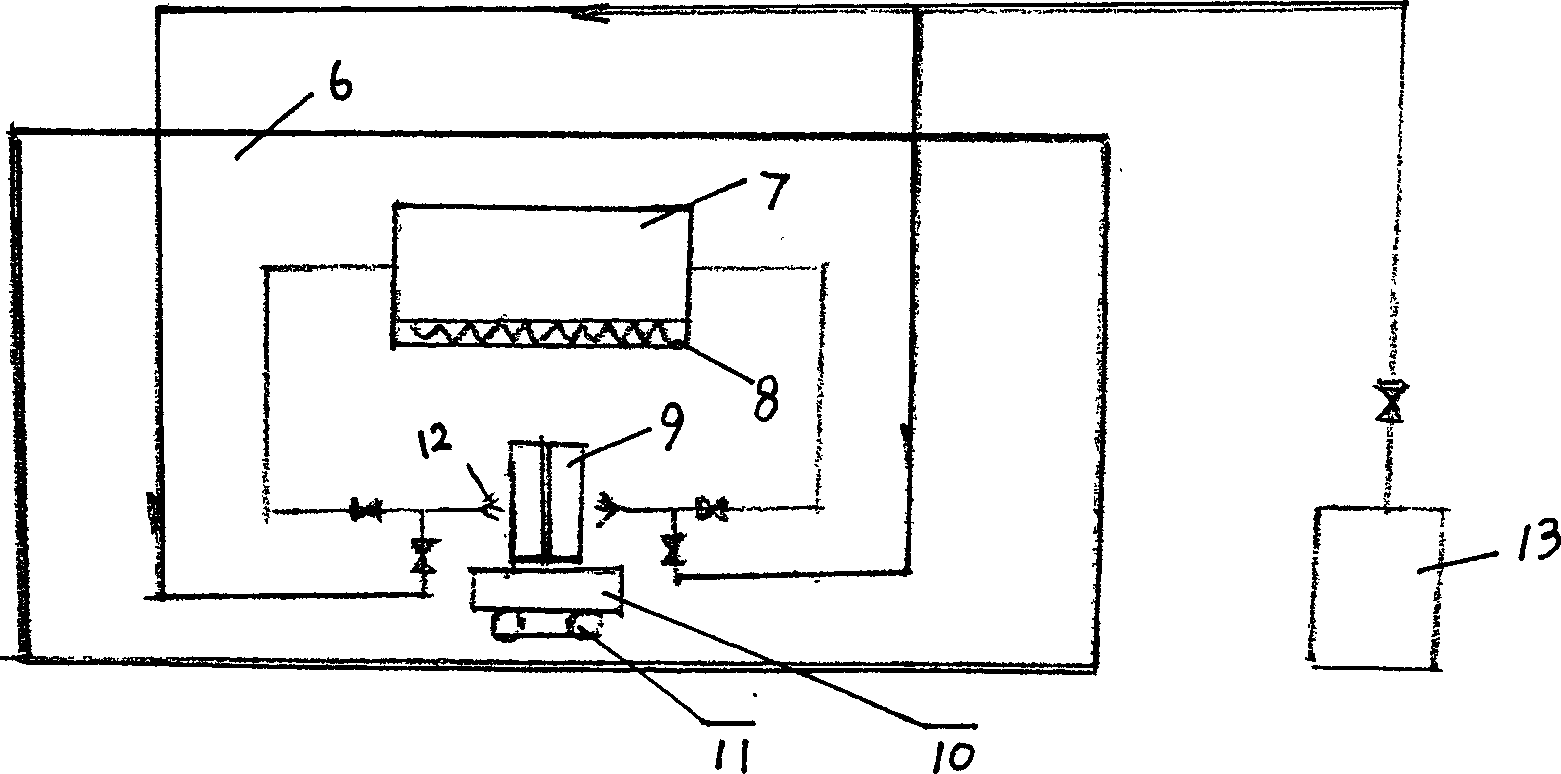

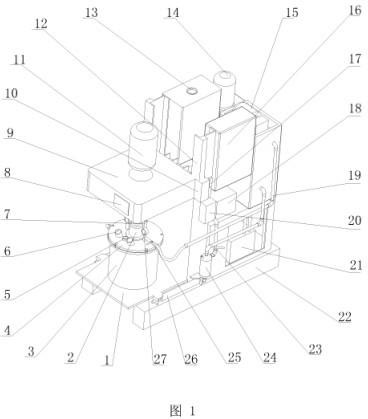

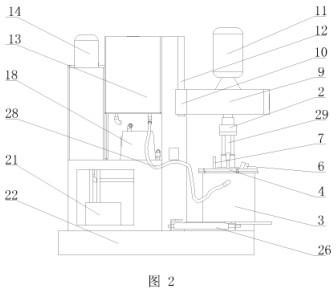

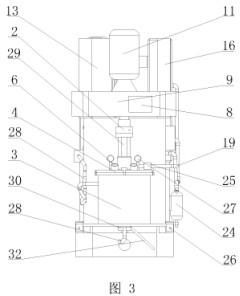

Magnetic powder vacuum mixer

ActiveCN102294190AUniform inclusionPrevent oxidationRotary stirring mixersTransportation and packagingHeat conductingElectric control

The invention discloses a magnetic powder vacuum mixer. The mixer comprises a frame, a mixing device, a hydraulic driving device, a condensation recovering device, a heating device and an electric controlling device. The mixing device comprises a material chamber, a lifting platform, a main motor, a transmission shaft, a stirring mechanism, a material chamber cap and a discharging port. The hydraulic driving device comprises a hydraulic oil pump, a sliding plate, a horizontal hydraulic cylinder, a slideway, a sliding sleeve and a lifting hydraulic cylinder. The condensation recovering device comprises a condensing machine set, a vacuum pump, a vacuum valve, a recovering tank and pipelines. The heating device comprises a heater, a heat circulating pump and a heat conducting water pipe. Theelectric controlling device comprises an electric controlling box and a frequency converter. The material chamber cap is provided with a gas discharging valve, two through holes and a camera hole. A display screen is arranged on one side of the lifting platform. With the mixer provided by the invention, magnetic powder can be prevented from being oxidized during a mixing procedure, the cost of nitrogen protection can be saved, and the product quality can be ensured. With the condensation recovering device, acetone can be recovered and reused, such that the production cost is saved, and the production process is green and environment-friendly.

Owner:潍坊德诺磁业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com