Patents

Literature

777 results about "Total protein" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

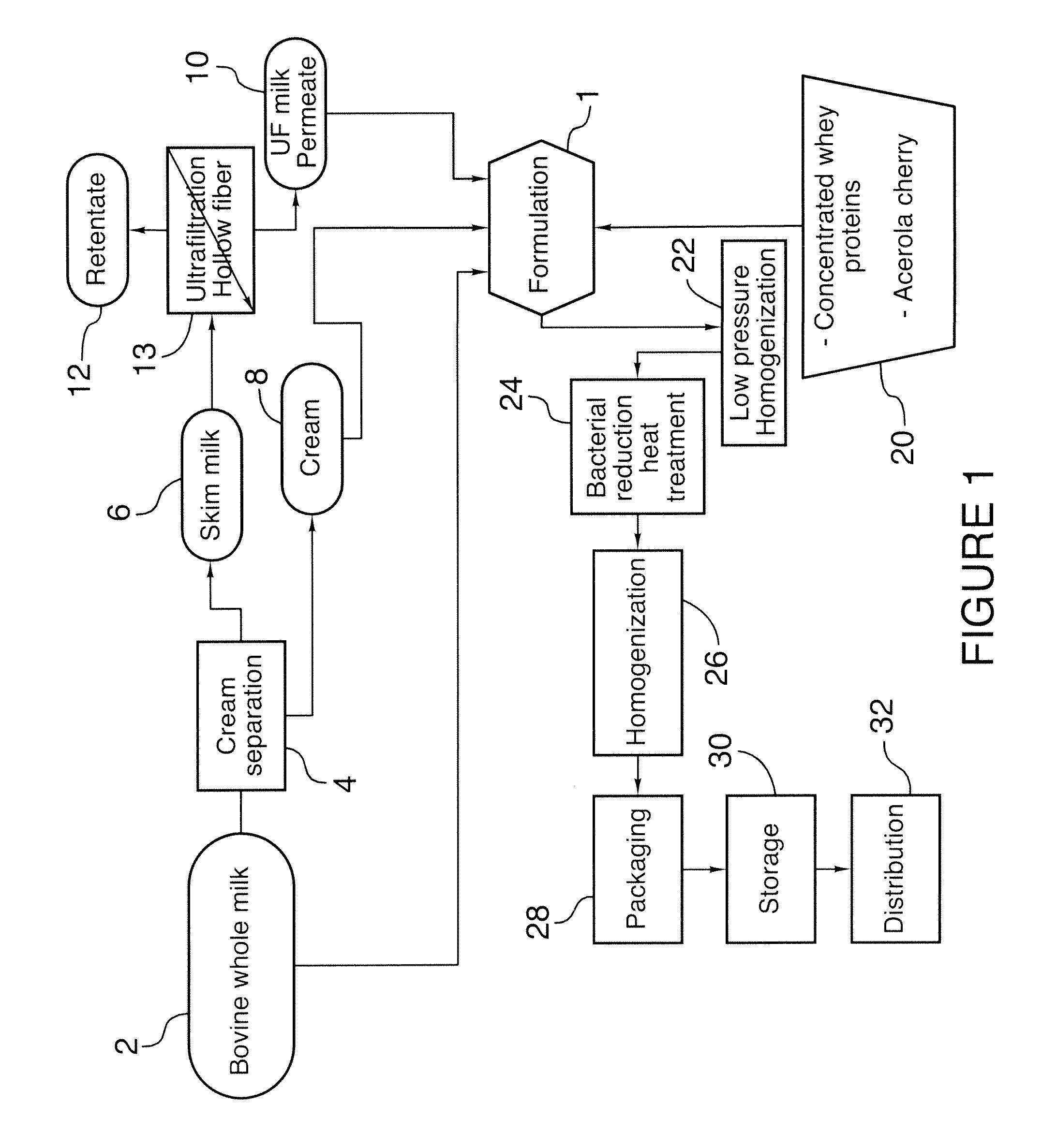

Whey protein product and a method for its preparation

InactiveUS20110097442A1Improve sensory propertiesImprove stabilityMilk preparationMetabolism disorderWhey proteinTotal protein

The invention relates to a whey protein product having a ratio of whey protein to casein in the range from about 90:10 to about 50:50 and the total protein content of at least 20% on dry matter basis, and a method for its preparation. The product has a favourable amino acid composition and is especially suitable for athletes.

Owner:VALIO OY

High protein beverage and method of producing same

A high-protein beverage is made with a protein content of at least 15% of the total product content. At least 10% of the total product consists of hydrolyzed gelatin. A method of producing a high-protein beverage product via UHT processing comprising at least 15% total protein also is disclosed.

Owner:TETRA LAVAL HLDG & FINANCE SA

High protein puffed food product and method of preparation

Disclosed are ready-to-eat puffed dried food products that are high both in protein and in fiber. The cereals contain sufficient amounts of at least one protein ingredient to provide a total protein content about 50% to 75% (dry weight) of the cooked food product; sufficient amounts of at least one dietary fiber ingredient to provide a total fiber content of about 1-45% (dry weight); and sufficient amounts of a starch containing ingredient to provide a starch content of about 5-45%. The food products have a crush strength raging from about 0.25 to 3.5 kg / cm3.

Owner:GENERAL MILLS INC

High protein puffed food product and method of preparation

Disclosed are ready-to-eat puffed dried food products that are high both in protein and in fiber. The cereals contain sufficient amounts of at least one protein ingredient to provide a total protein content about 50% to 75% (dry weight) of the cooked food product; sufficient amounts of at least one dietary fiber ingredient to provide a total fiber content of about 1-45% (dry weight); and sufficient amounts of a starch containing ingredient to provide a starch content of about 5-45%. The food products have a crush strength raging from about 0.25 to 3.5 kg / cm3.

Owner:GENERAL MILLS INC

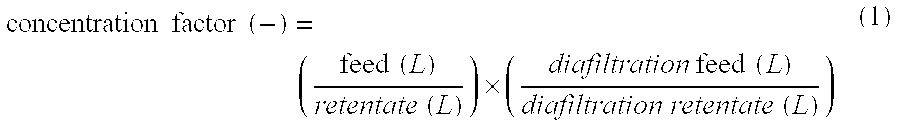

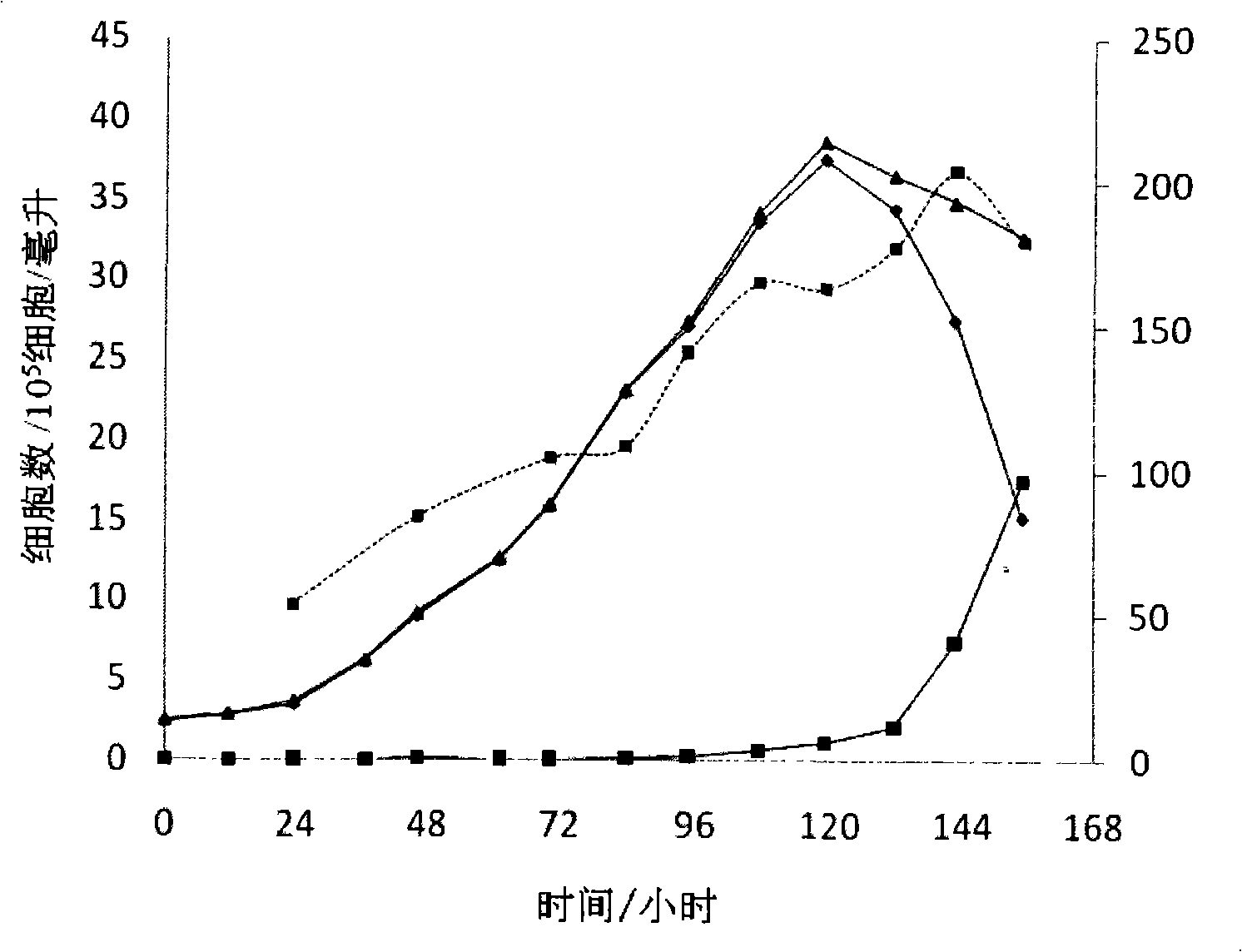

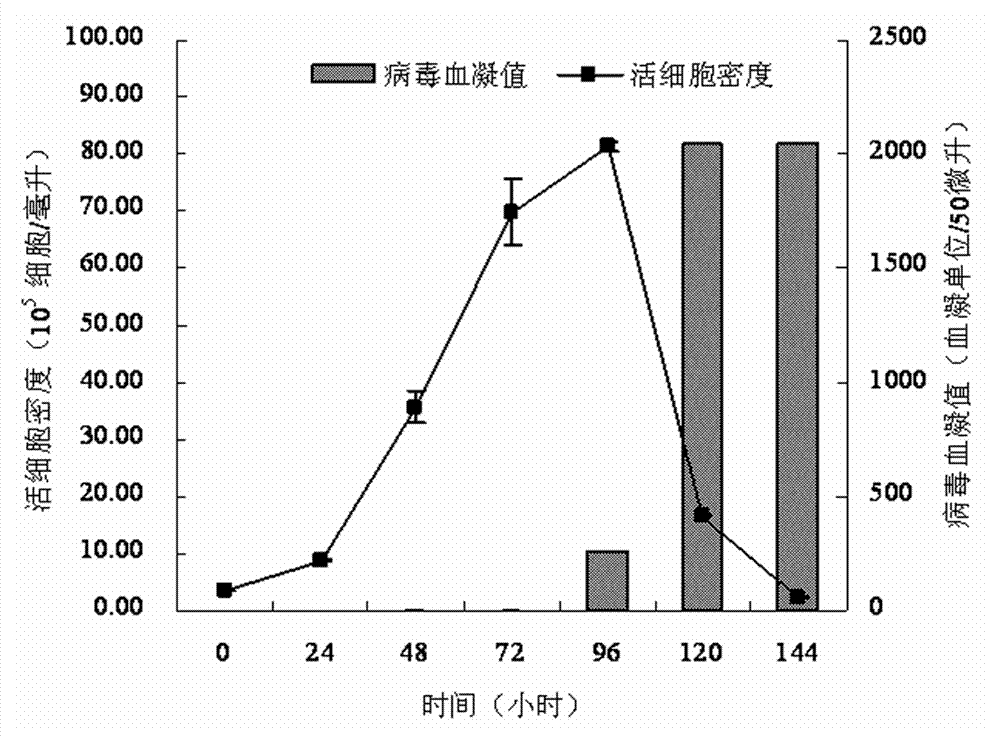

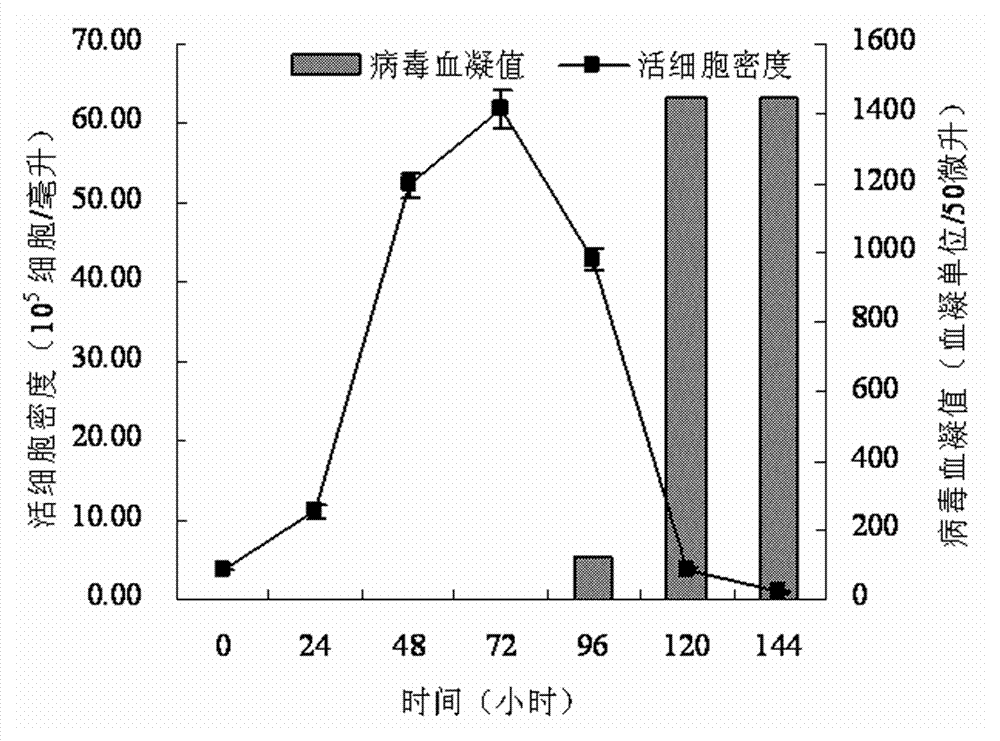

Inactivated Zika virus vaccine

ActiveCN105749268AEase the epidemicReduce the burden onSsRNA viruses positive-senseViral antigen ingredientsZika virusSide effect

The invention provides an inactivated Zika virus vaccine. The inactivated Zika virus vaccine is obtained by: performing ultrafiltration and concentration on Zika virus liquid after inactivation, centrifuging the concentrated virus liquid by adopting a sucrose density zone, performing ion exchange and concentration sterilization on a centrifugal product to obtain a Zika virus vaccine stock solution, diluting the vaccine stock solution until the total protein content is not more than 20mu g / ml, and adding an adjuvant to obtain a vaccine semi-finished product. The method for preparing the vaccine provided by the invention is simple, convenient and easy to operate, the cost is saved, the produced vaccine is suitable for Asian people, a unit dose of the Zika virus liquid is high in immunogenicity, the content of hybrid protein is low, the side effect after injection is small, and the safety is high, so that the vaccine is suitable for vaccination of fertile women before pregnancy, can avoid newborn Brazil microcephaly caused by infection of Zika virus, and is significant in social value and market efficiency.

Owner:SINOVAC RES & DEV

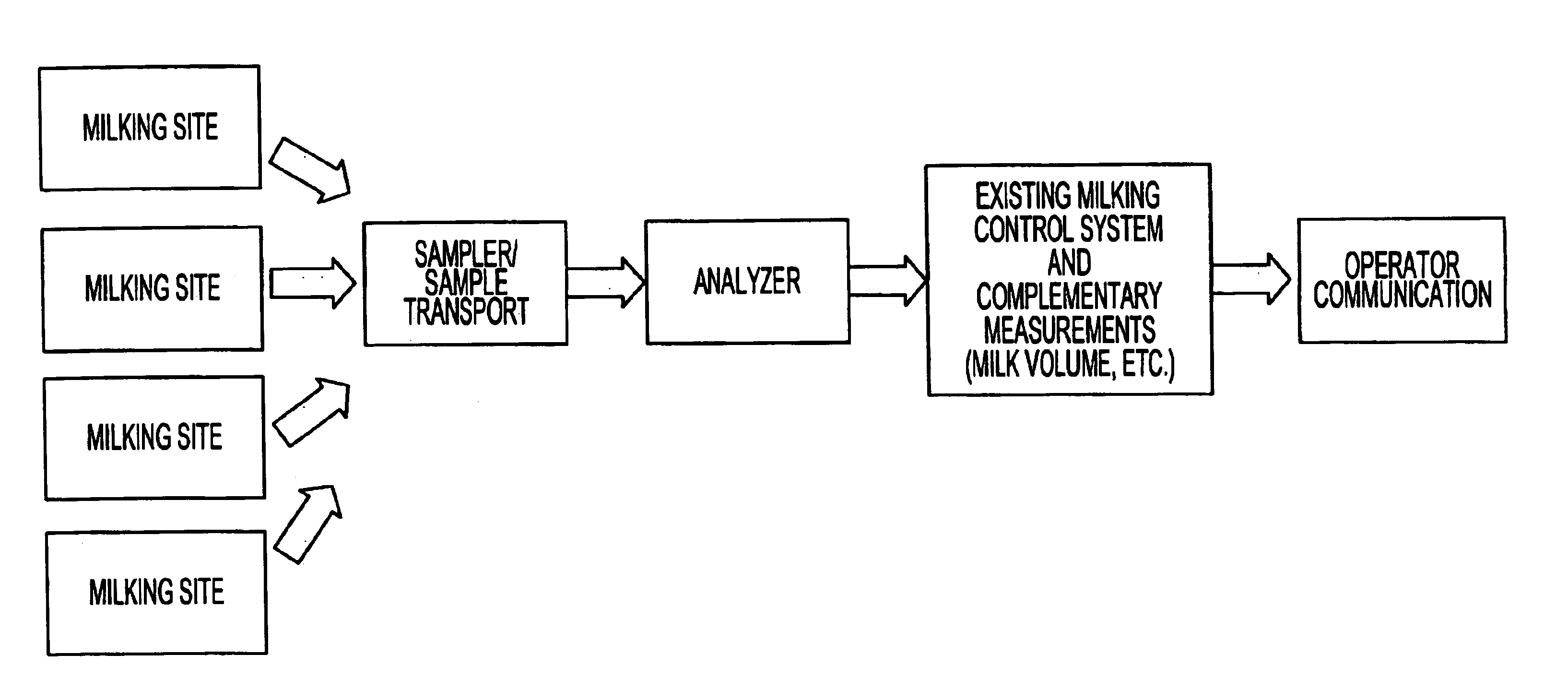

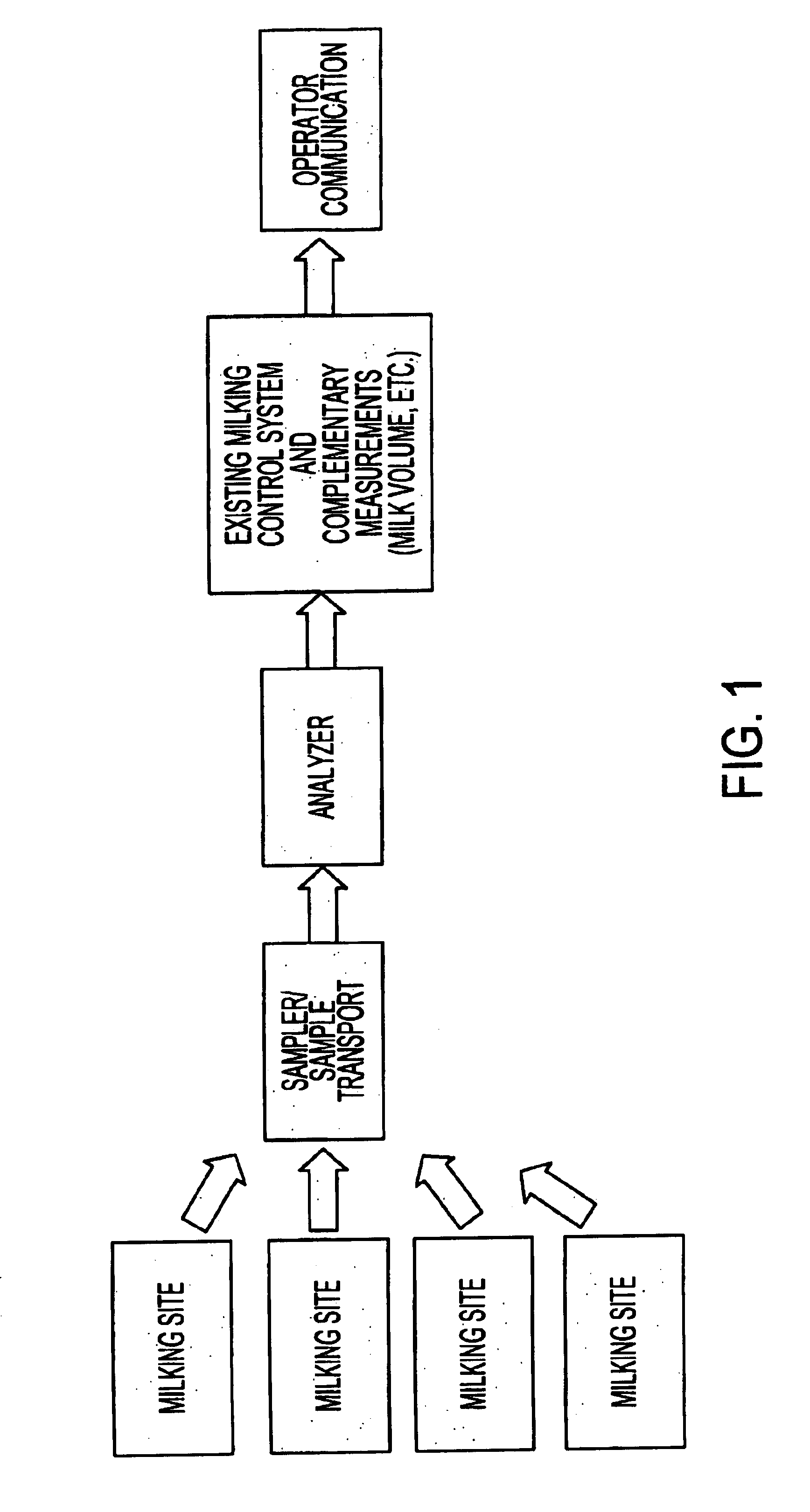

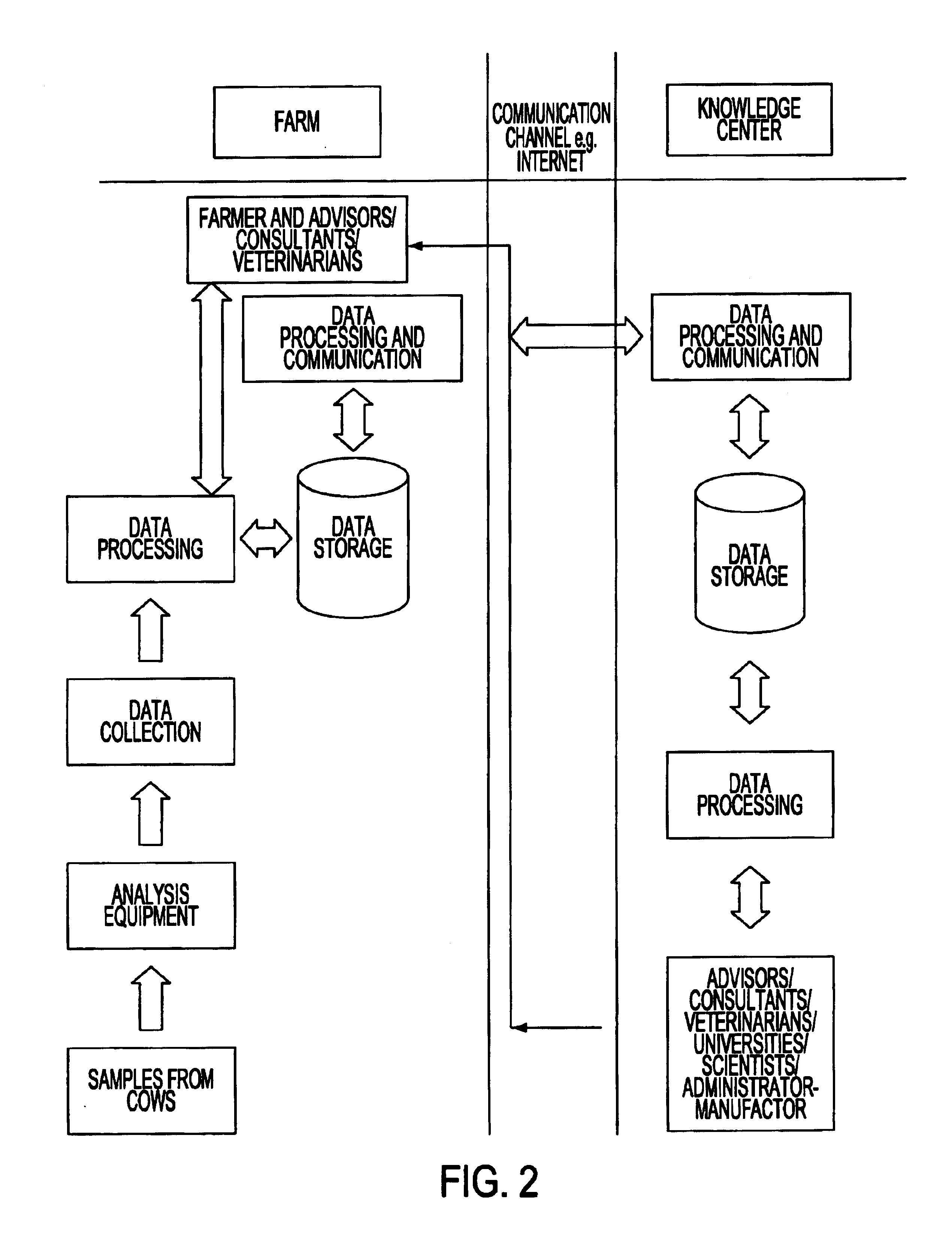

System for optimizing the production performance of a milk producing animal herd

InactiveUS6814025B2Increase productivityIncrease profitabilitySamplingCathetersLactate dehydrogenaseAgricultural science

Owner:LATTEC

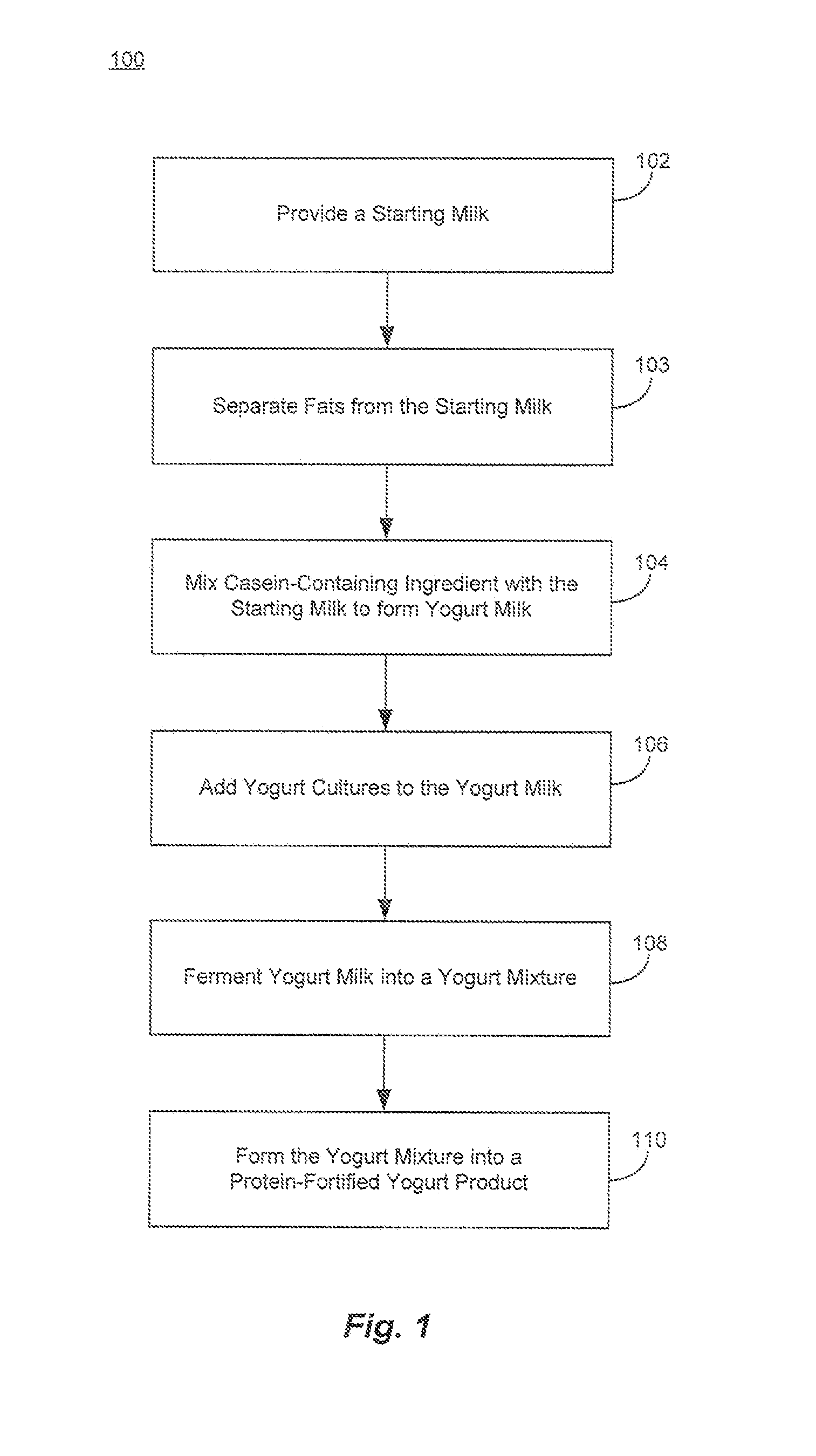

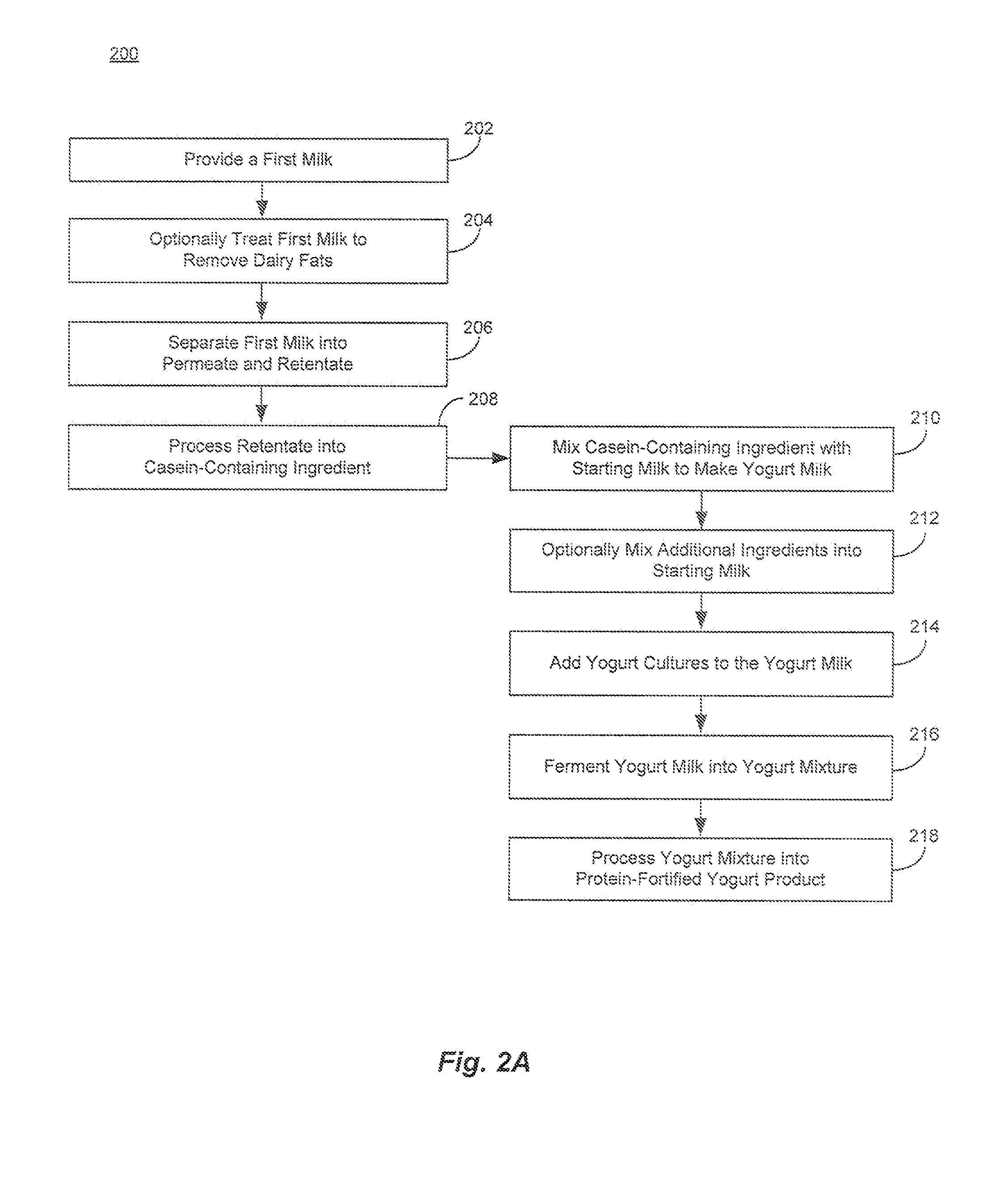

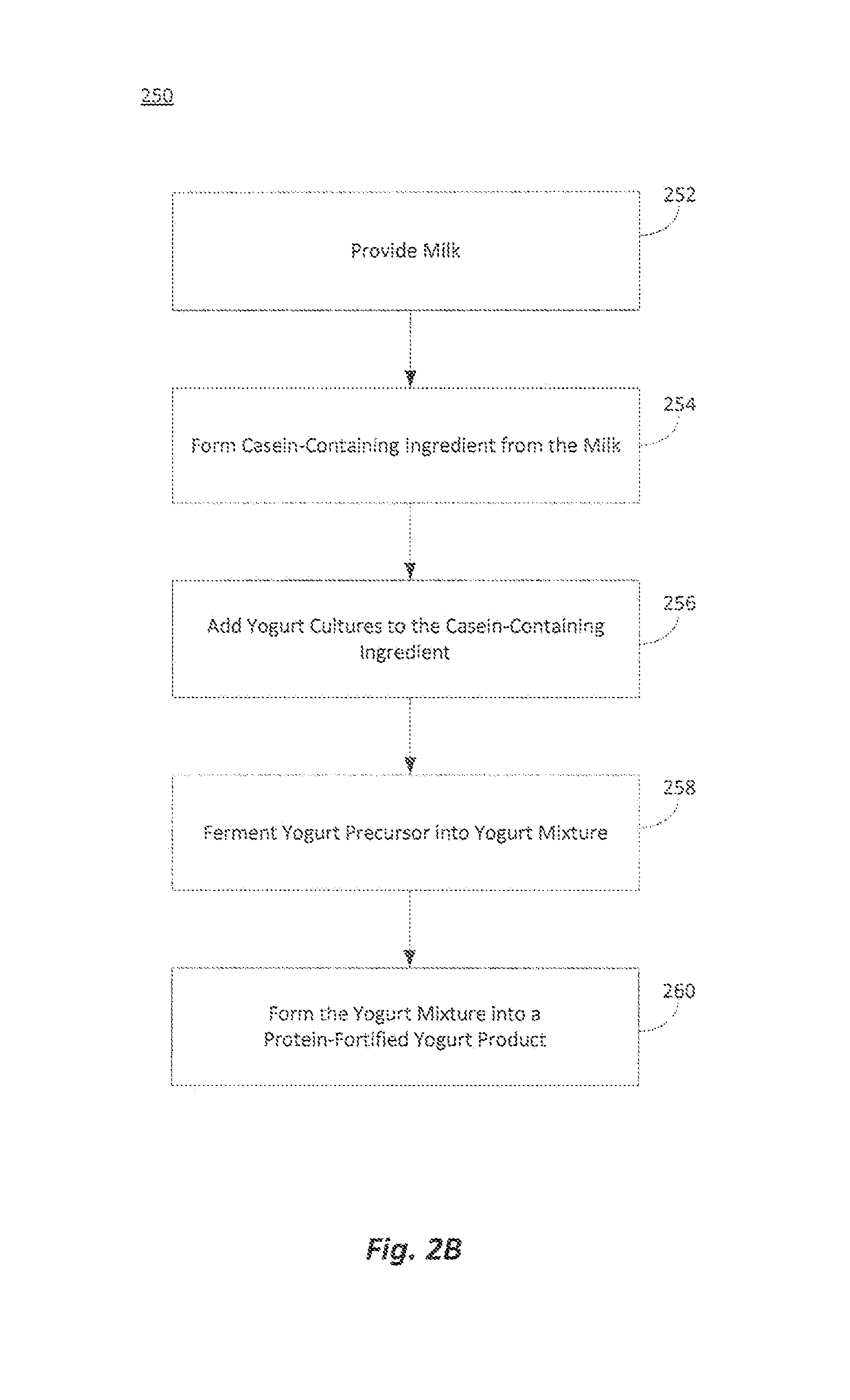

Protein fortified yogurts and methods of making

ActiveUS20140308398A1Improve production yieldMilk preparationOther dairy technologyAdditive ingredientWhey protein

Methods of making protein-fortified yogurt products are described. The methods may include mixing a casein-containing ingredient with starting milk to make a yogurt milk, where the casein-containing ingredient has a casein-to-whey protein ratio of 82:18 or greater. The yogurt milk may be fermented after adding yogurt culture to make a yogurt mixture. The yogurt mixture may then be formed into the protein-fortified yogurt product. The total protein concentration in the protein-fortified yogurt product may be 10 wt. % or more. One variety of the protein-fortified yogurt product is a spreadable yogurt product having the total protein concentration of 11 wt. % or more.

Owner:LEPRINO FOODS

Liquid nutritional compositions containing unsaturated fatty acids

ActiveUS20070048405A1Improve oxidation stabilityAdd flavorFood ingredient as taste affecting agentFood preparationLipid formationTotal protein

Disclosed are liquid nutritional compositions comprising: carbohydrate; lipid having from about 0.1% to about 20% of an n-3 polyunsaturated fatty acid, n-6 polyunsaturated fatty acid, or combinations thereof by weight of the composition; a protein matrix having from about 15% to about 50% of a whey protein fraction by weight of the total protein in the composition; and a limonene-containing material, cranberry oil, or combinations thereof. The compositions are preferably aseptically packaged, and provide enhanced oxidative stability, flavor, and aroma, especially when formulated with relative high polyunsaturated fatty acid concentrations.

Owner:ABBOTT LAB INC

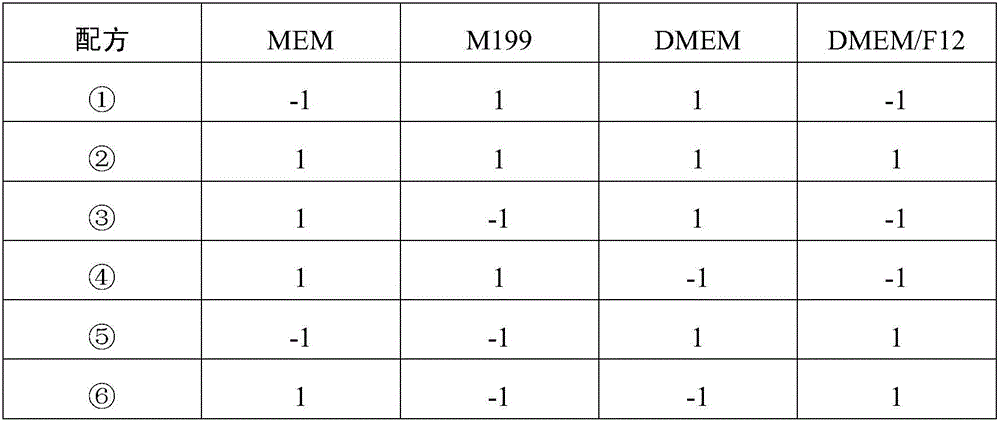

Animal origin-free low-protein culture medium suitable for animal cell product production

ActiveCN101603026AEasy to separate and purifySuitable for productionTissue cultureFermentationLipid formationAntioxidant

The invention relates to an animal origin-free low-protein culture medium suitable for animal cell product production, comprising 24 basic metabolism nutrients, 11 vitamins, 3 transferrin substitute compounds, 5 lipid compounds, 2 nucleic acid compounds, 4 hormones and growth factors, 3 antioxidants, 1 shear-resistant protective agent, 1 pH indicator, 2 pH buffers, 9 other inorganic salts, soy hydrolysates adopted to substitute animal origin component, and composition of ferrous sulfate, ferric nitrate and EDTA-2Na adopted to substitute transferrin. The culture medium can be made by dissolving the aforementioned components in triply distilled water. The positive effects of the culture medium are as follows: the culture medium contains no animal origin component, the total protein content is lower than 10mg / L, which helps separate and purify products and is suitable for production of recombinant protein medicaments; the culture medium supports normal growth and long-term subculturing of animal cells; the culture medium can be used without adaptation, is easily prepared and is suitable for massive production of animal cell products.

Owner:EAST CHINA UNIV OF SCI & TECH

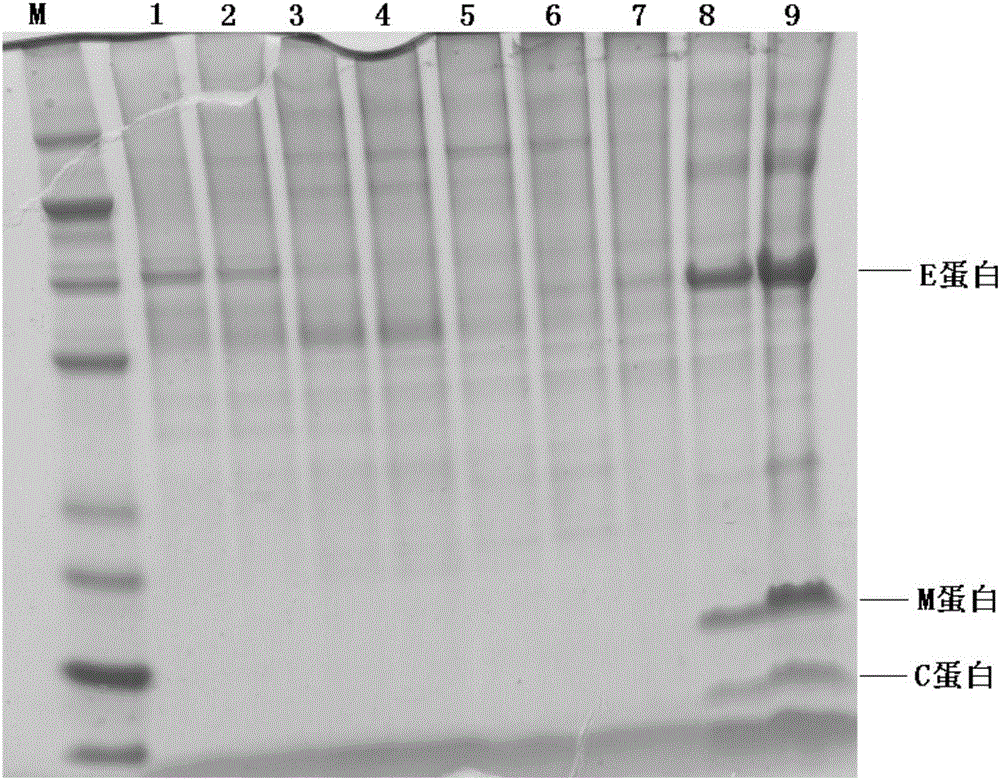

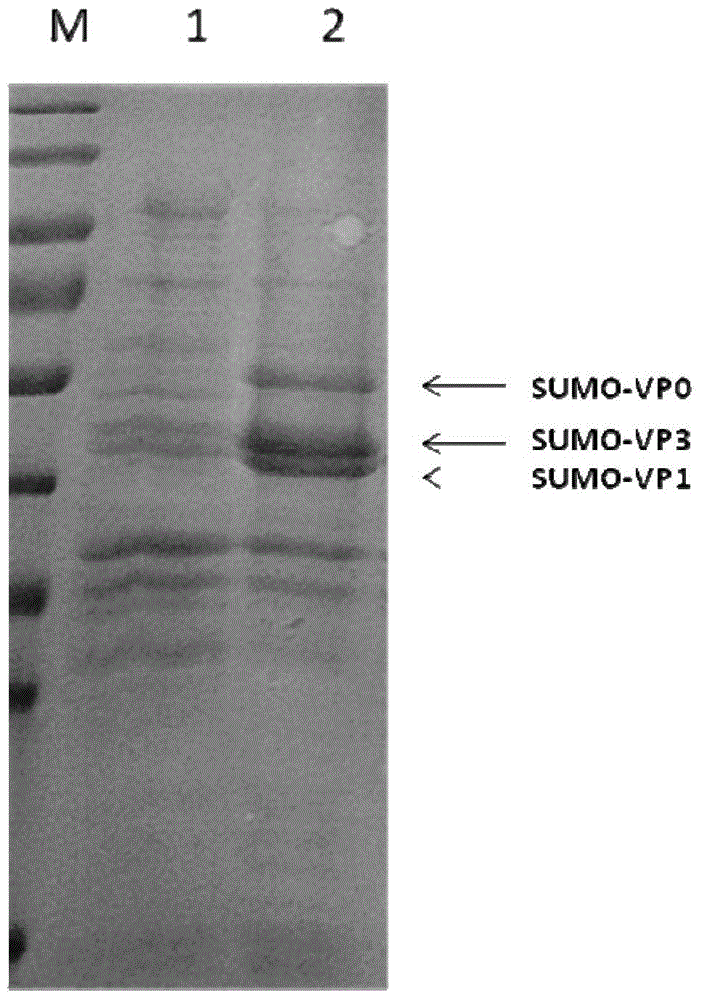

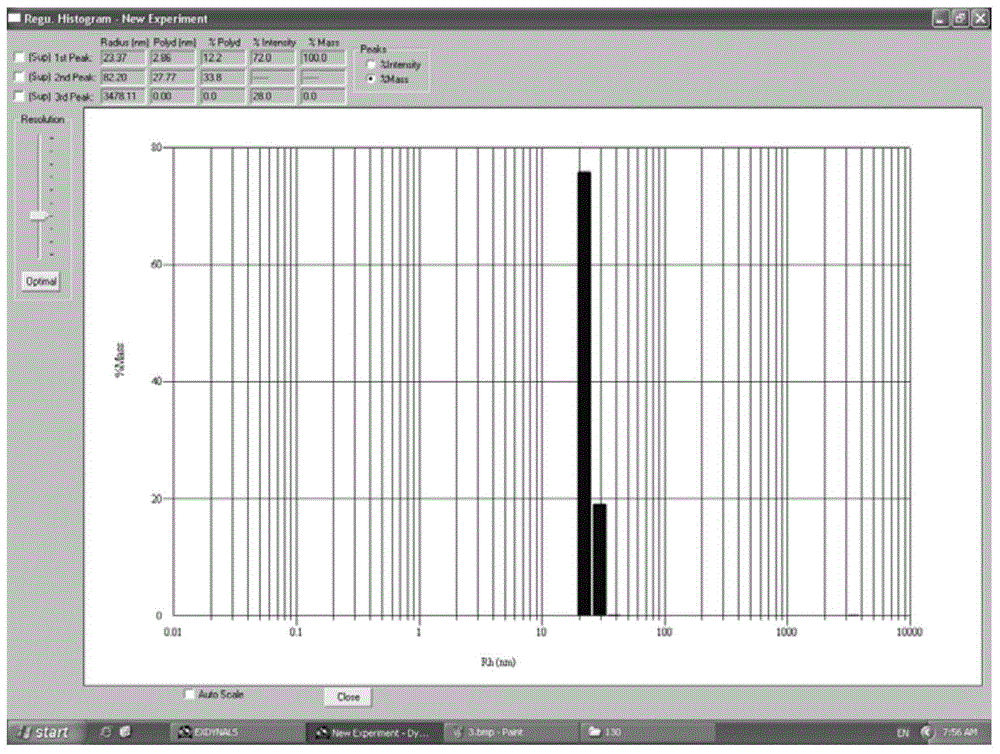

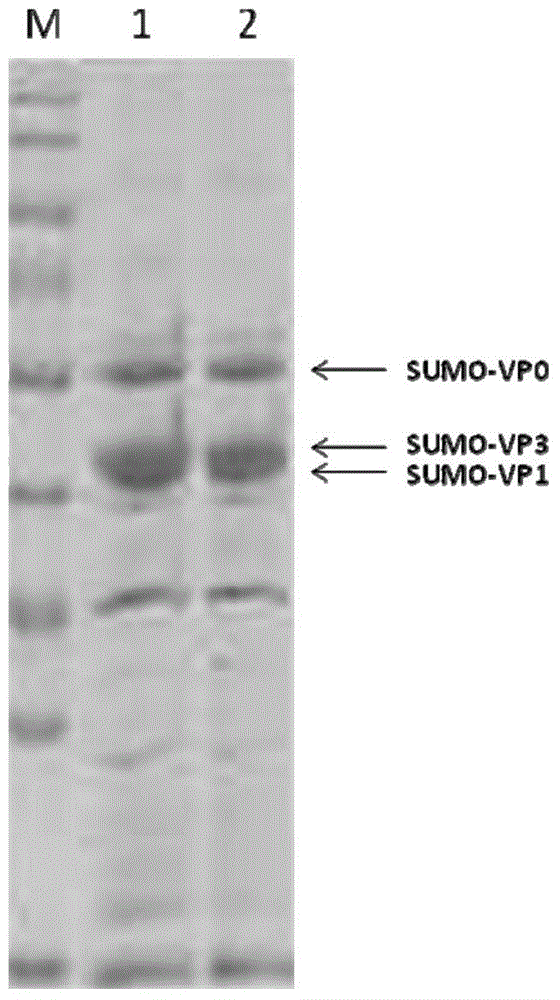

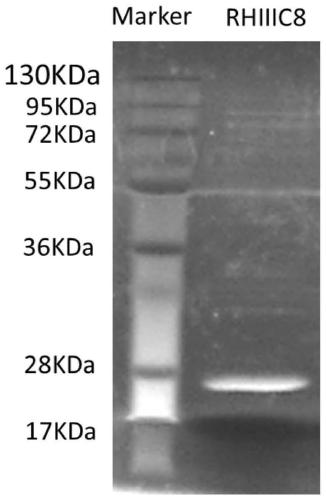

Foot-and-mouth disease virus capsid protein tandem coexpressions and virus-like particle preparation method

ActiveCN104404074AHigh activityNatural binding activityBacteriaInactivation/attenuationEscherichia coliVirus-like particle

The invention relates to escherichia coli-derived single-plasmid-tandem soluble coexpression foot-and-mouth disease virus capsid proteins VP0 (which is a VP4 and VP2 fusion gene), VP1 and VP3, and a foot-and-mouth disease virus capsid protein virus-like particle preparation method. Foot-and-mouth disease virus capsid protein virus-like particles can be used for preparation of a foot-and-mouth disease vaccine. According to the method, a plurality of aspects of escherichia coli-derived soluble coexpression foot-and-mouth disease virus capsid protein are studied, by comprehensive use of tandem coexpression and SUMO(suggested upper merged ontology) technology with a tag for soluble coexpression of the foot-and-mouth disease virus capsid proteins VP0 (which is the VP4 and VP2 fusion gene), VP1 and VP3, the ultimate objective protein accounts for about 20% of total bacterial protein, and the foot-and-mouth disease virus capsid proteins obtained by purification can be successfully assembled into the virus like particles.

Owner:SA BIOTECH (SUZHOU) PTE LTD

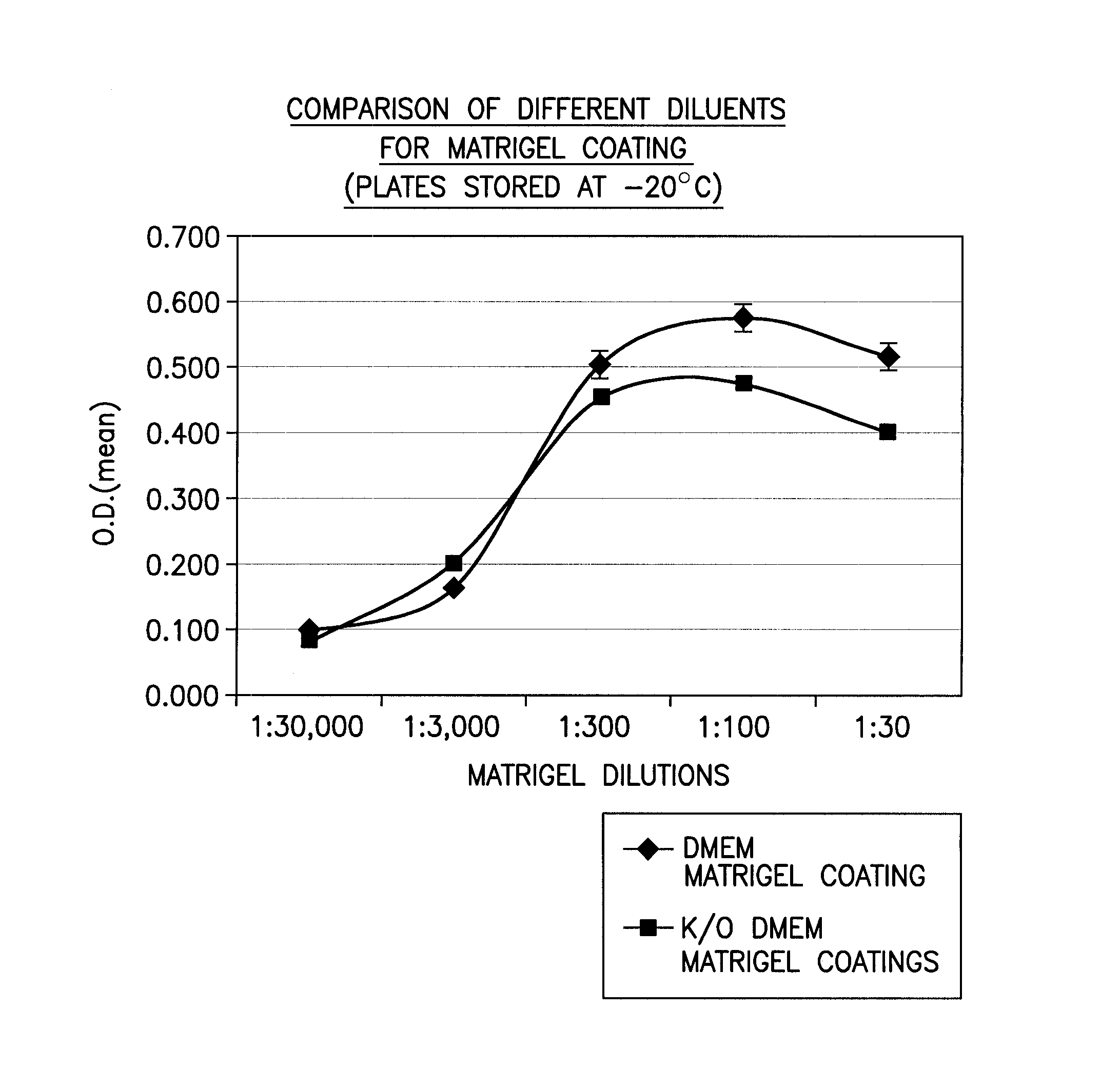

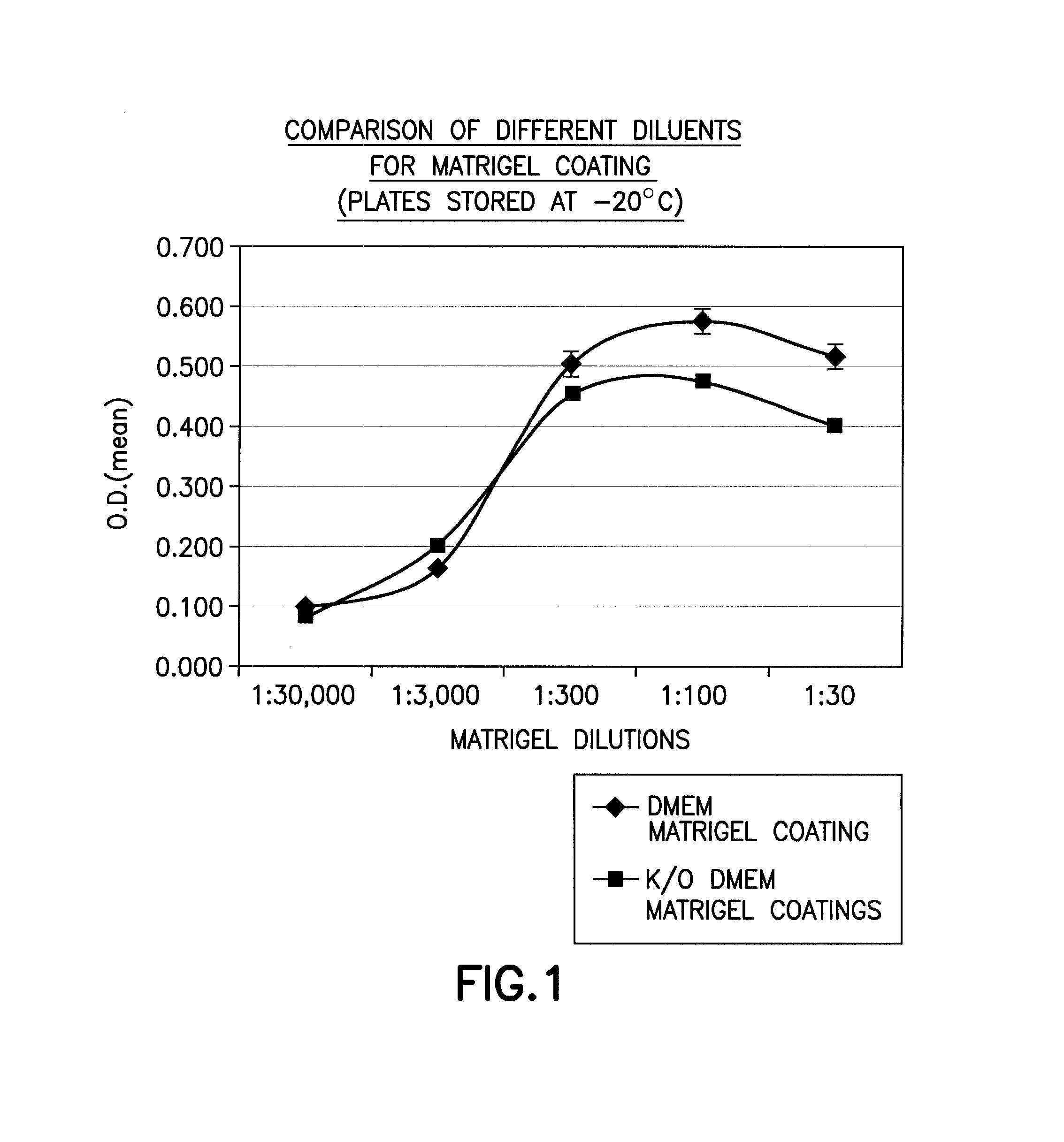

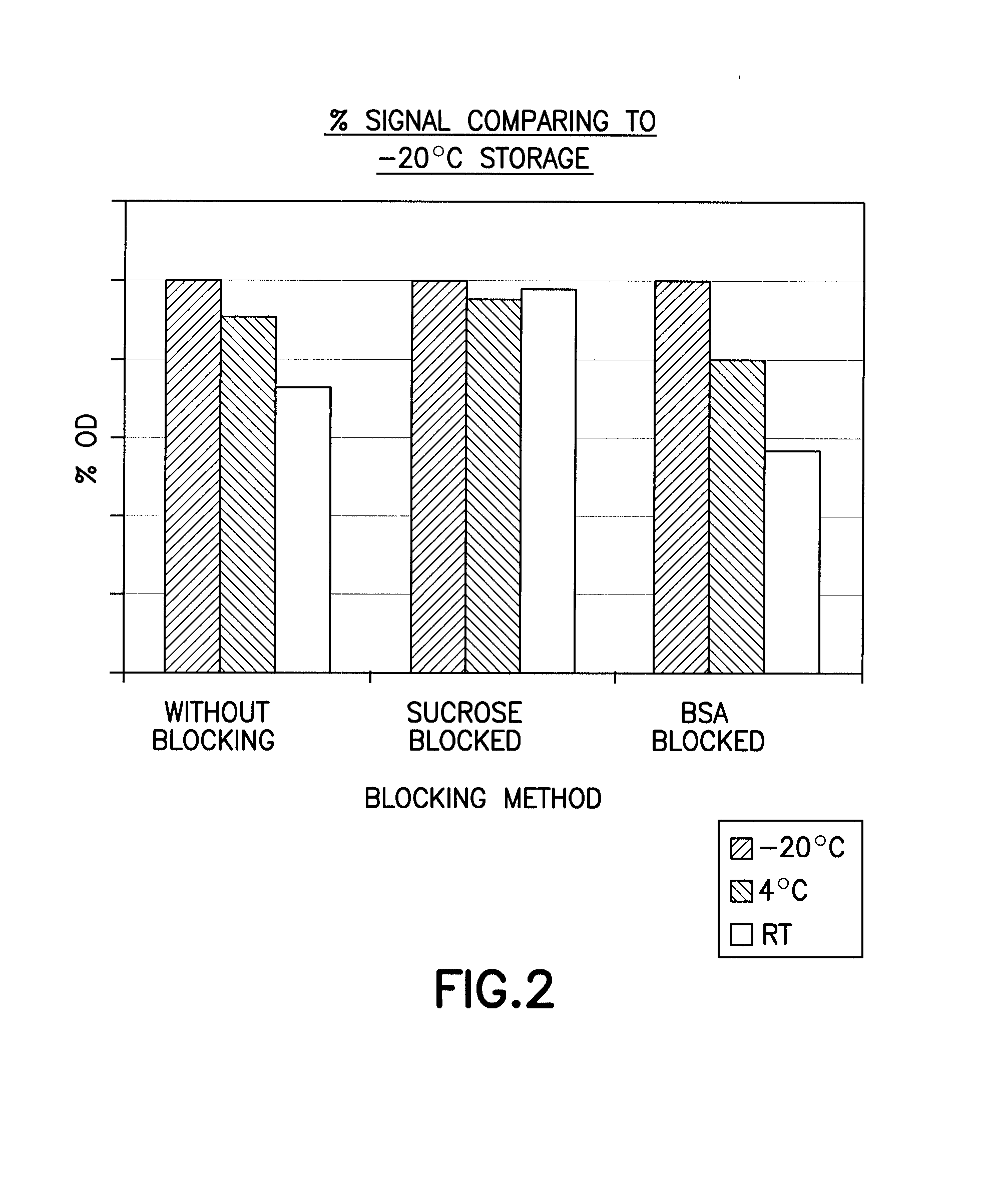

Extracellular matrix coated surface for culturing cells

ActiveUS20070269886A1Prevent excessive aggregationHigh amount of proteinBioreactor/fermenter combinationsBiological substance pretreatmentsCoated surfaceCell-Extracellular Matrix

A cell culture product is provided for propagating embryonic stem cells, and maintaining their self-renewal and pluripotency characteristics for extended periods of time in culture. The cell culturing, product includes a substrate; and a coating thereon deposited, from a coating solution. The coating solution includes a mixture of extracellular matrix proteins and an aqueous solvent, wherein the total protein concentration in the coating solution is about 10 μg / ml to about 1 mg / ml.

Owner:CORNING INC

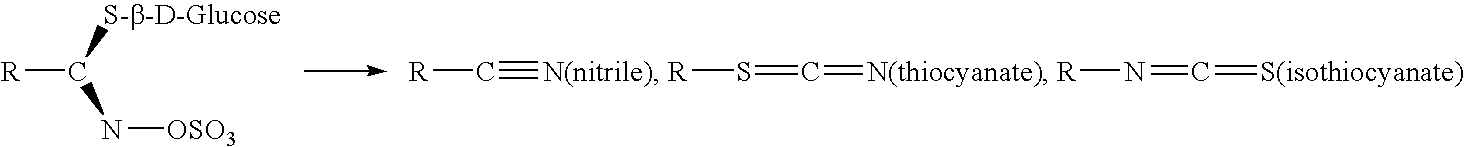

ITFM extraction of oil seeds

InactiveUS7156981B2Superior, high purity, bright proteinsIncrease in absorbable proteinHydrocarbon distillationEssential-oils/perfumesProtein insertionProtein isolate

A process for the producing edible protein-containing meal for human and animal consumption and high quality food grade oils from oil seed using iodotrifluoromathane as the solvent is shown. The meal has a significantly improved level of dietary available (absorbable) protein. The process involves the preparation of protein isolates by a procedure which is conducted at room temperature, thus decreases protein degradation and denaturing which is caused by elevated temperatures. The process also provides for extraction of substantially all oils and fats, which interfere with the formation of the protein micelle, from the protein meal providing a cleaner, purer product with high levels of absorbable protein. Such protein isolates can then be used as such or added to formulated foods in order to increase the total protein content of that food. The protein produced and the oils recovered have compositions which are also unique and unobtainable by prior processing methods.

Owner:BIO EXTRACTION INC

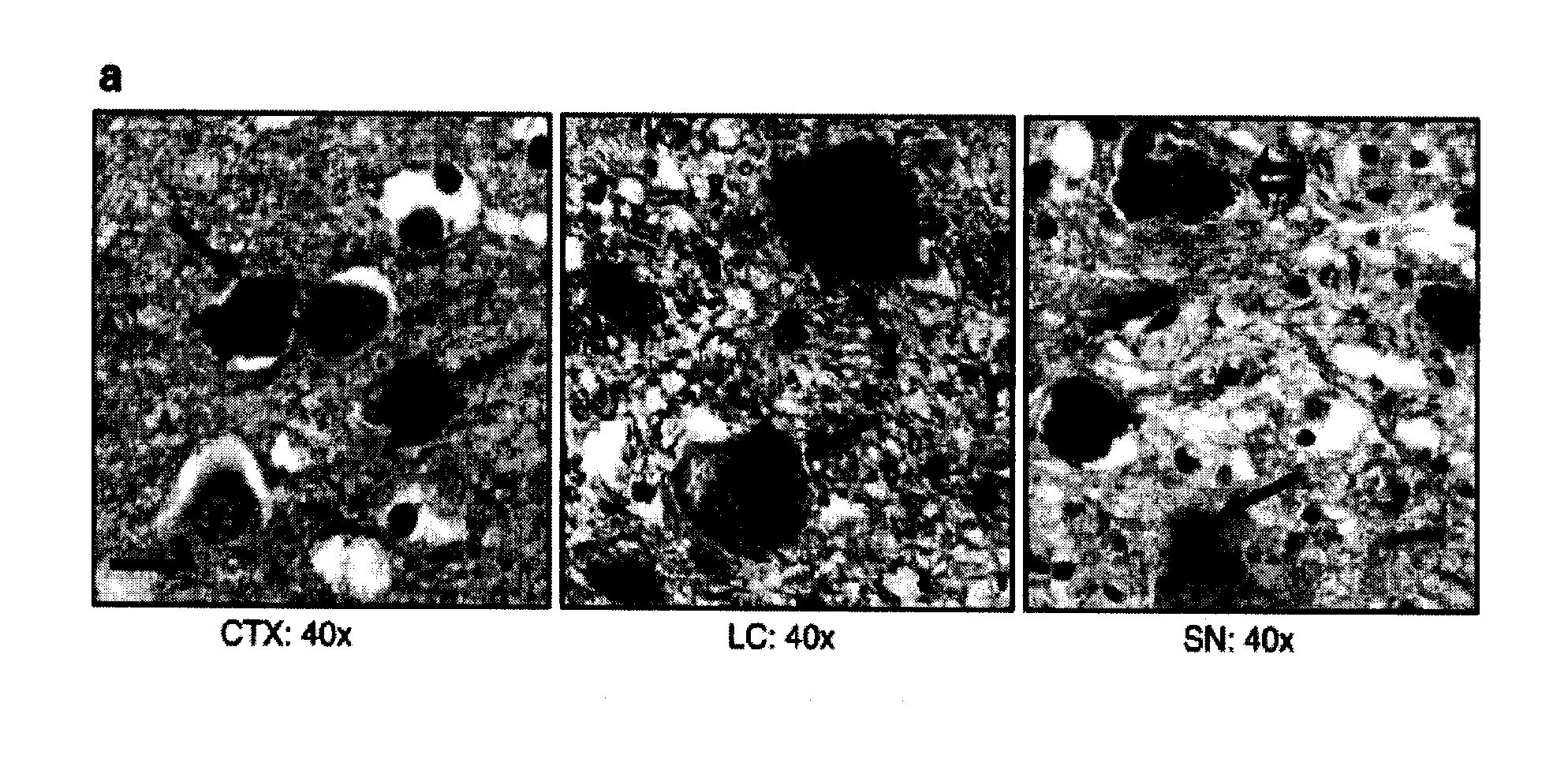

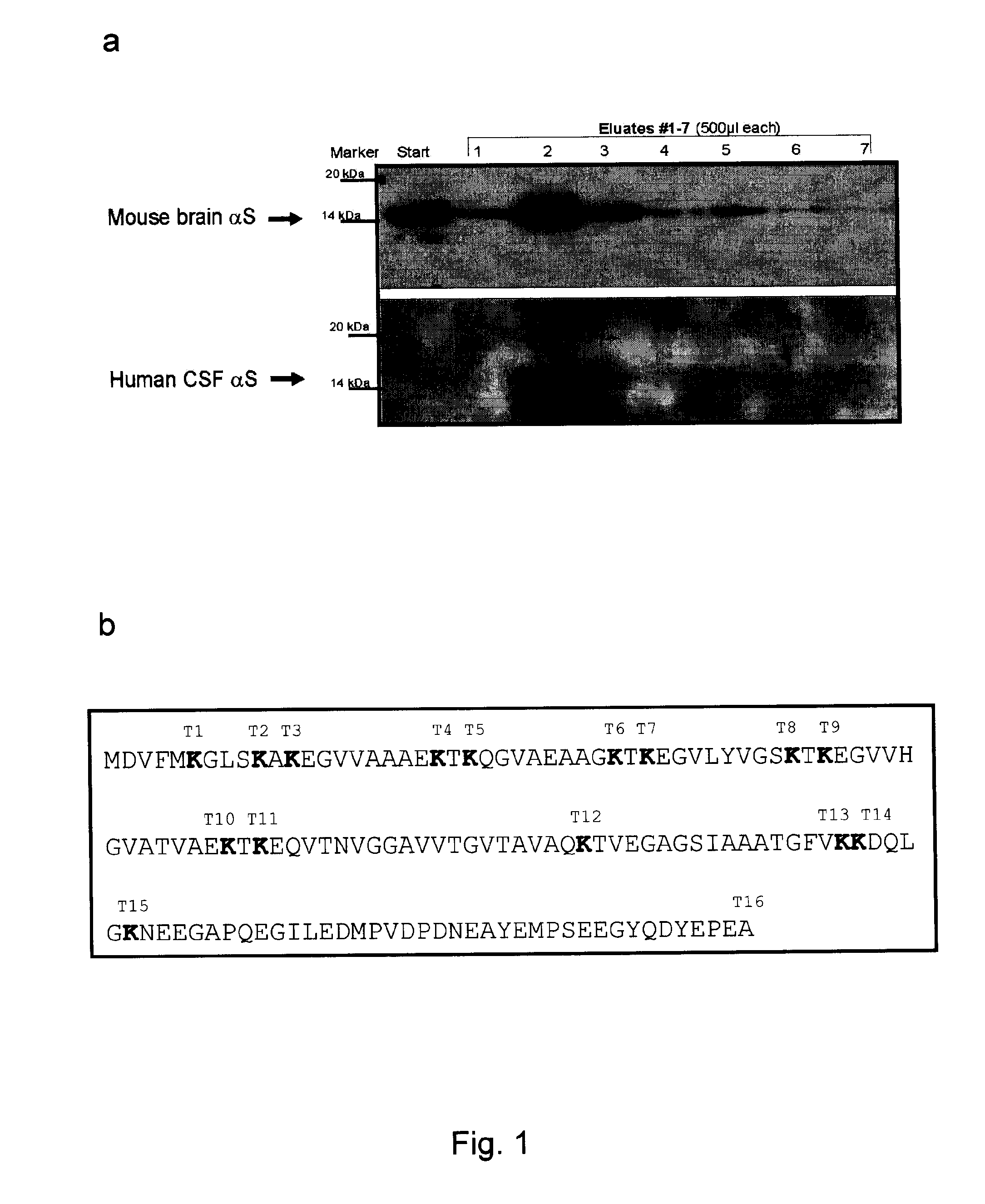

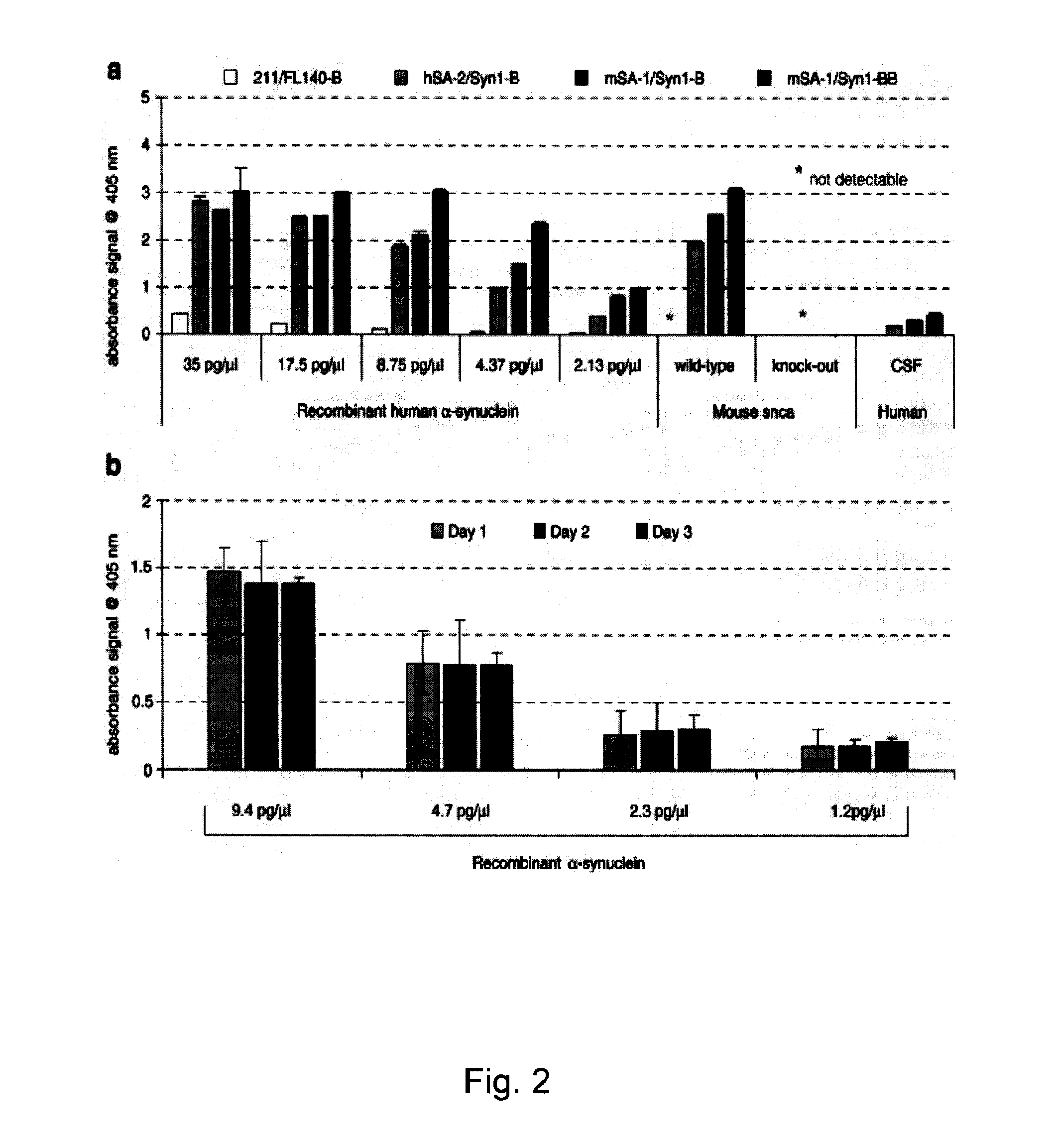

Methods and kits for diagnosing neurodegenerative disease

InactiveUS20110159527A1Prevent slaughterRaise the ratioMicrobiological testing/measurementDisease diagnosisDisease freeTotal protein

Methods and diagnostic kits for determining whether a subject may develop a or for diagnosing a neurodegenerative disease. The method includes quantitating the amount of alpha-synuclein and total protein in a cerebrospinal fluid (CSF) sample obtained from the subject and calculating a ratio of alpha-synuclein to total protein content; comparing the ratio of alpha-synuclein to total protein content in the CSF sample with the alpha-synuclein to total protein content ratio in CSF samples obtained from healthy neurodegenerative disease-free subjects; and (c) determining from the comparison whether the subject has a likelihood to develop neurodegenerative disease or making a diagnosis of neurodegenerative disease in a subject. A difference in the ratio of alpha-synuclein to total protein content indicates that the subject has a likelihood to develop a neurodegenerative disease or has developed a neurodegenerative disease.

Owner:SCHLOSSMACHER MICHAEL GEBHARD +2

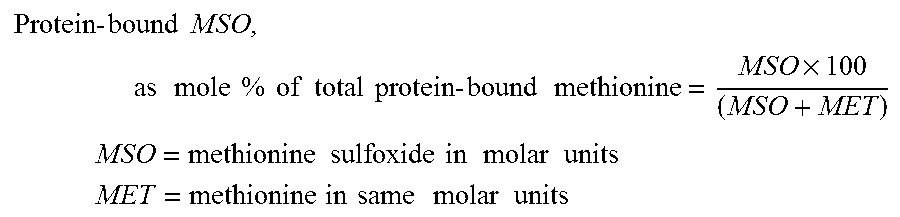

Induced-viscosity nutritional emulsions

InactiveUS20070141124A1Easy to optimizeInduced viscosityMetabolism disorderChewing gumTotal proteinMethionine biosynthesis

Disclosed are induced viscosity nutritional emulsions comprising (A) protein having a protein-bound methionine sulfoxide content of 8% or less of the total protein-bound methionine, on a molar basis, (B) fat, and (C) an induced viscosity fiber system that provides the emulsion with a packaged viscosity of less than 300 cps and an induced viscosity following consumption of at least 300 cps, wherein the induced viscosity nutritional emulsion is an oil-in-water emulsion. It has been found that product stability is improved and shelf-life increased by selection of those protein sources having a low methionine sulfoxide content.

Owner:ABBOTT LAB INC

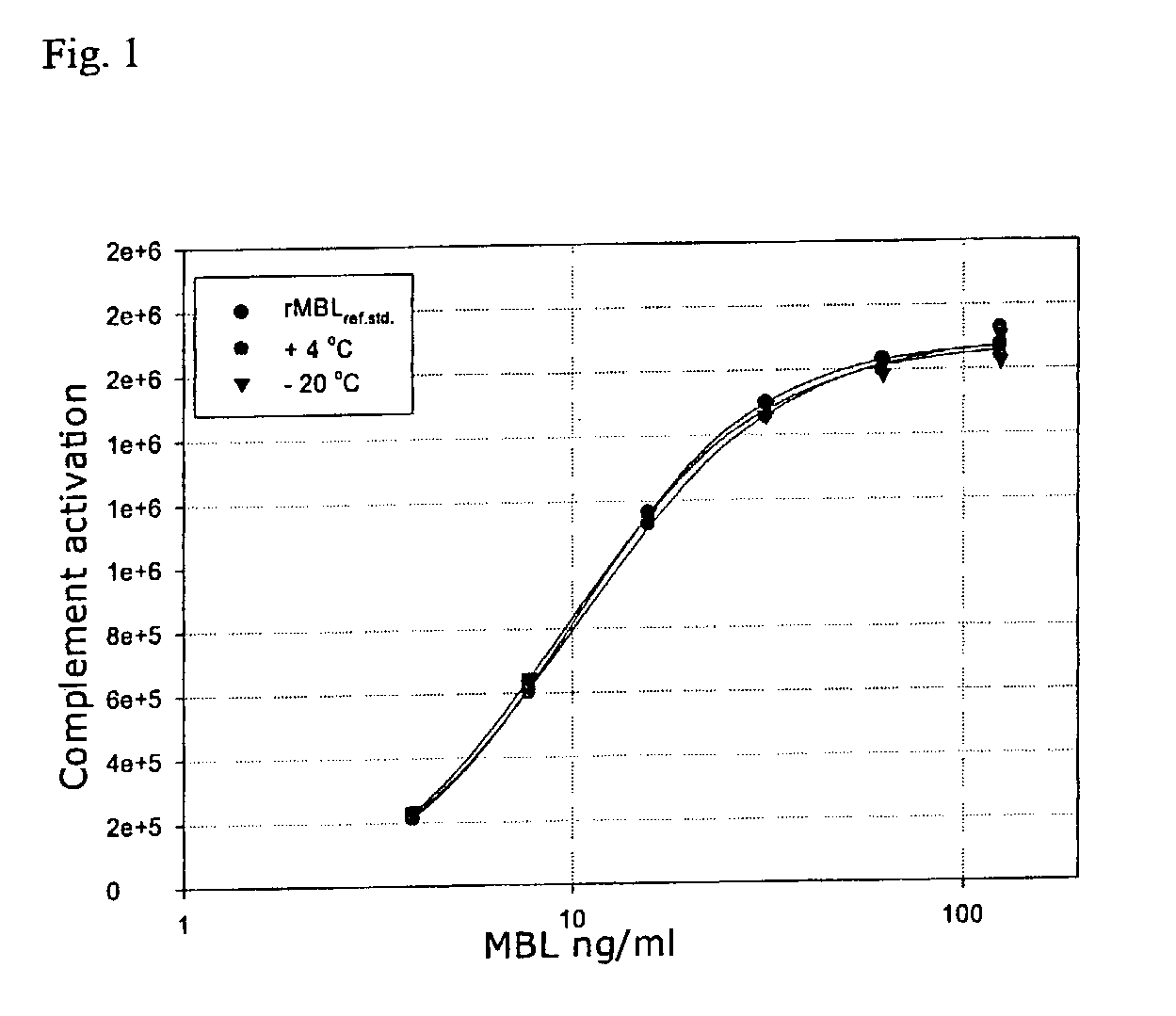

Pharmaceutical compositions comprising mannose binding lectin

InactiveUS7462596B2Increase concentrationAntibacterial agentsAntimycoticsTotal proteinProtein materials

The present invention relates to pharmaceutical compositions comprising MBL and / or MBL variants. In particular the invention relates to pharmaceutical compositions comprising at least 200 μg / ml protein containing material, wherein mannan binding lectin (MBL) and / or MBL variants constitutes at least 35% (w / w) of the total protein; or to compositions comprising at least 400 μg / ml mannan binding lectin (MBL) and / or MBL variants. In addition the invention relates to pharmaceutical compositions comprising MBL and / or MBL variants and divalent cations. The invention also describes methods of preparing said compositions.The pharmaceutical compositions according to the invention may for example be used in methods of treatment of a number of different clinical conditions including infections. Uses of the compositions for preparation of medicaments for treatment of a clinical condition are also described.

Owner:NATLMMUNE AS (DK) +1

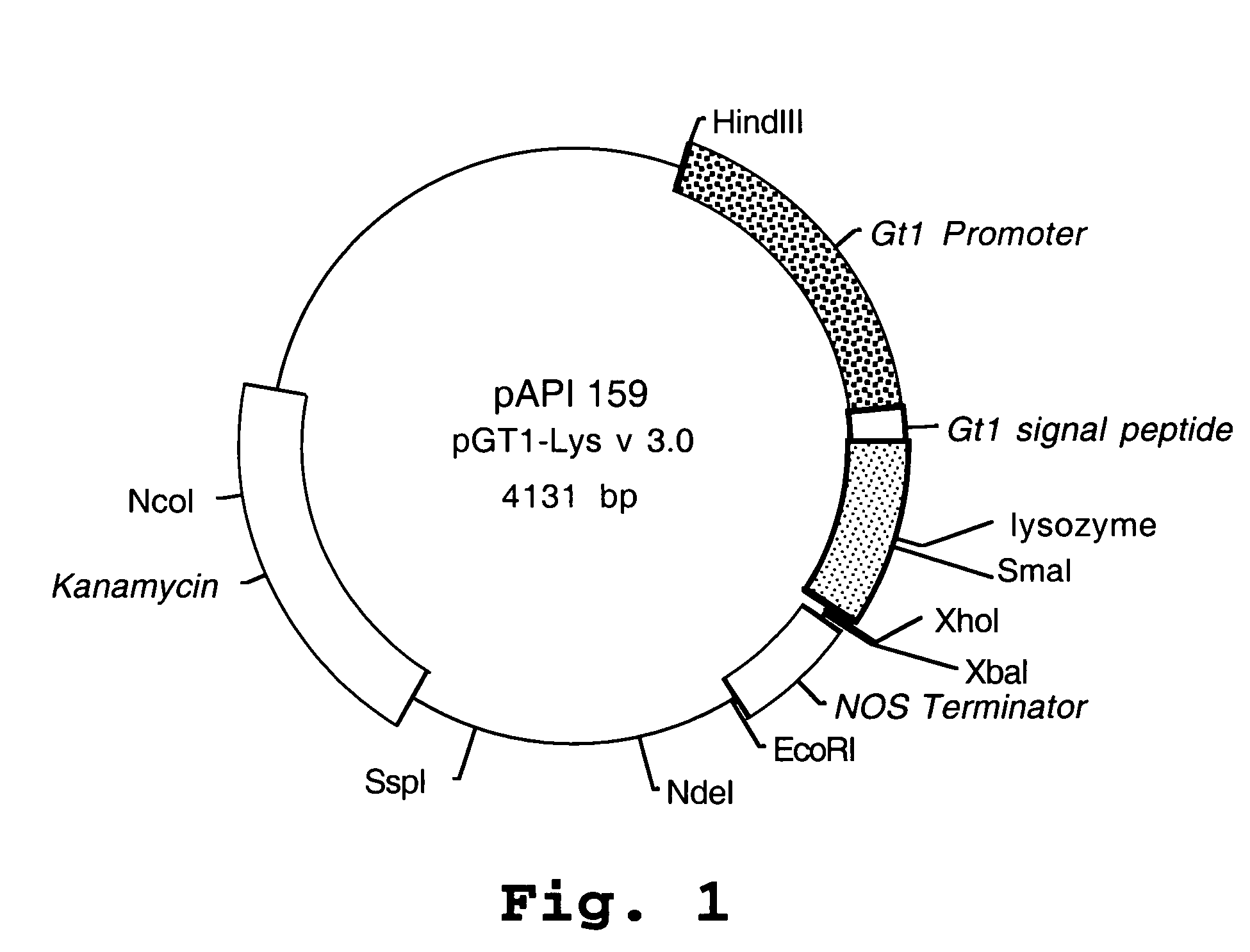

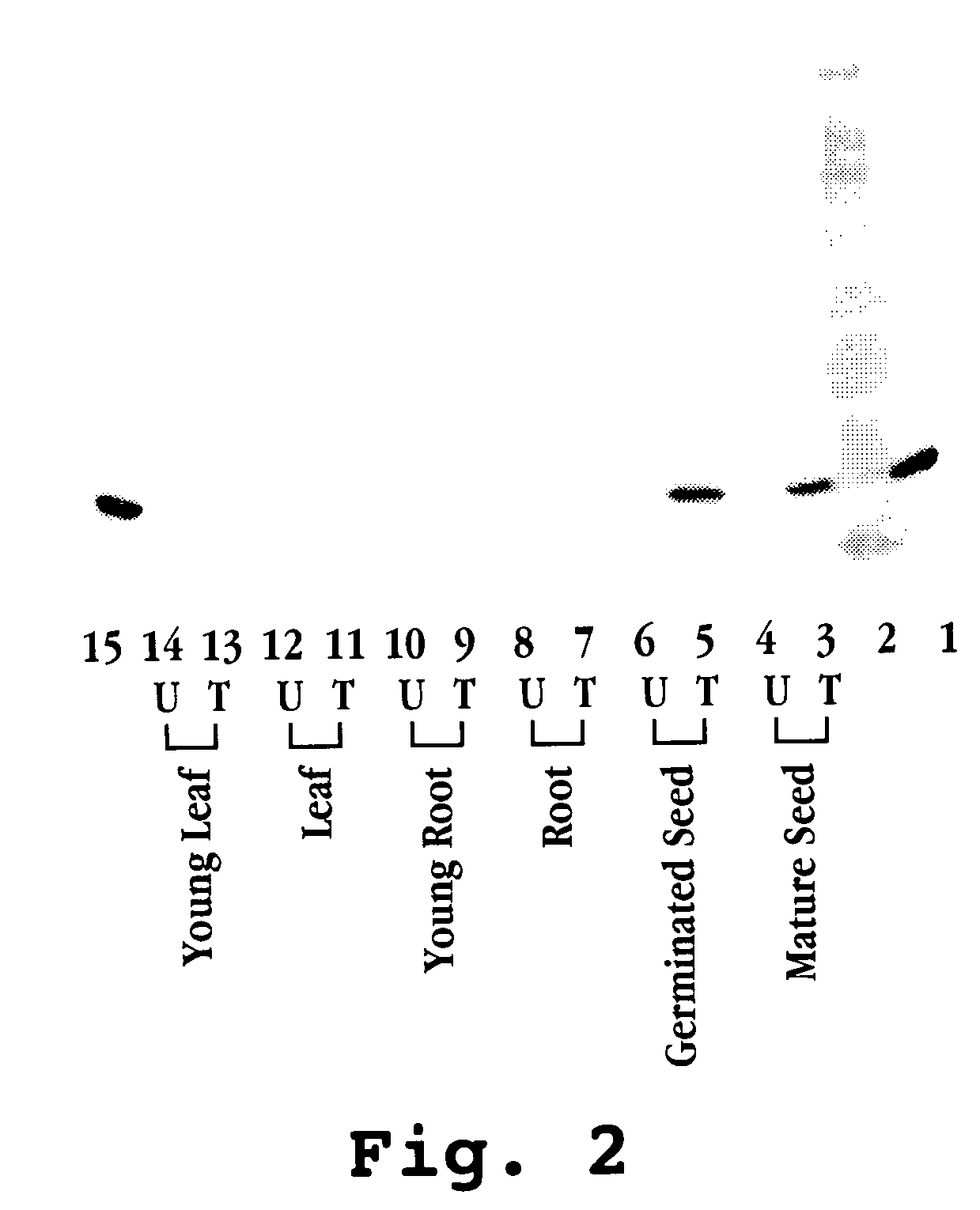

Expression of human milk proteins in transgenic plants

The invention is directed to seed and seed extract compositions containing levels of a human milk protein between 3-40% or higher of the total protein weight of the soluble protein extractable from the seed. Also disclosed is a method of producing the seed with high levels of extractable human milk protein. The method includes transforming a monocotyledonous plant with a chimeric gene having a protein-coding sequence encoding a protein normally present in human milk under the control of a seed maturation-specific promoter. The method may further includes a leader DNA sequence encoding a monocot seed-specific transit sequence capable to target a linked milk protein to a storage body.

Owner:VENTRIA BIOSCIENCE

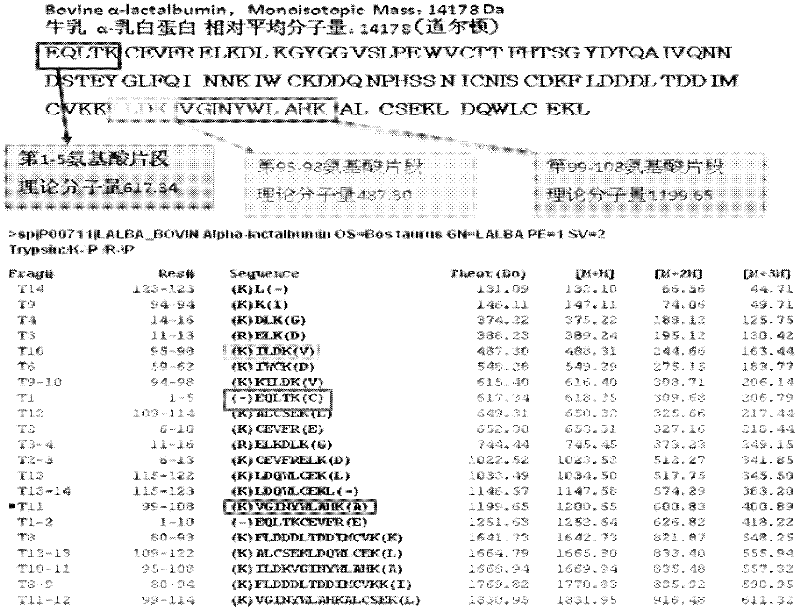

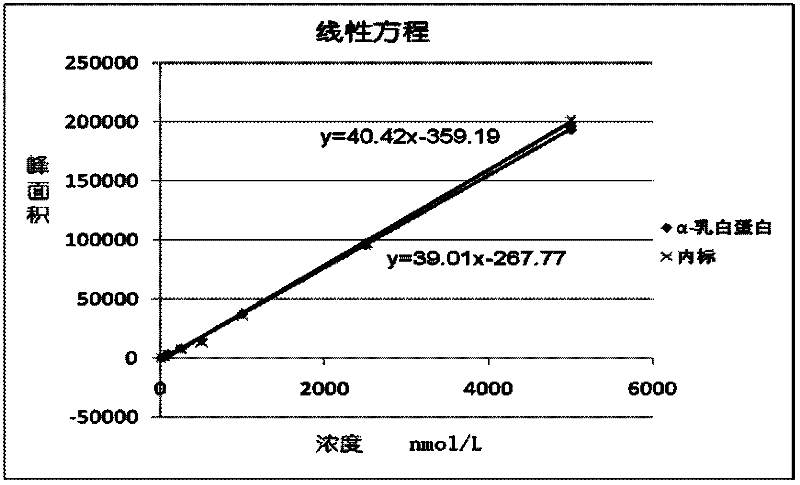

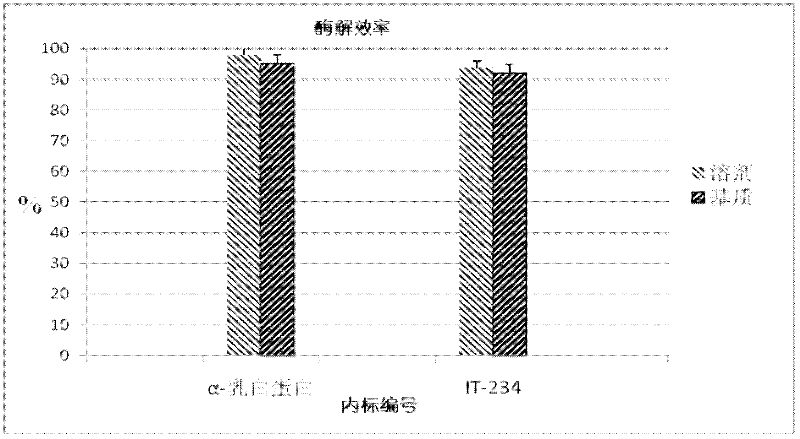

Quantitative detection method for bovine alpha-lactalbumin

InactiveCN102590413AEasy to operateGuaranteed reproducibilityComponent separationRelative standard deviationReversed-Phase Liquid Chromatography

The invention relates to a quantitative detection method for thermal-denaturation and non-denaturation bovine alpha-lactalbumin in milk and milk products by applying an enzymolysis-liquid chromatography and mass spectrometry combination technology. The quantitative detection method comprises the steps as follows: taking a certain amount of milk or milk samples, dissolving and diluting the milk or milk samples in water to obtain solution with total protein content being about 1mg / mL; after volume metering, correctly sucking 500 mu L, adding an internal standard substance, reacting disulfide bond with dithiothreitol (DTT), alkylating to protect sulfydryl produced in reaction by iodoacetamide (IAA), and then conducting constant-temperature and constant-time enzymolysis with trypsin; and separating enzymolysis products by reversed phase liquid chromatography, conducting detection with a mass spectrum multiple reaction monitoring (MRM) manner, and calculating the result by an internal standard method. The quantitation limit of the method is 0.001g / 100g; when adding amount is 0.2, 1.7 and 5.0g / 100g, the recovery rate is 98.9-110.8% (n is equal to 6) and repeatability: RSD (Relative Standard Deviation) is smaller than 7.6%; and the quantitative detection method can be applicable to the quantitative detection of samples with different contents of bovine alpha-lactalbumin.

Owner:ZHEJIANG CENT FOR DISEASE CONTROL & PREVENTION

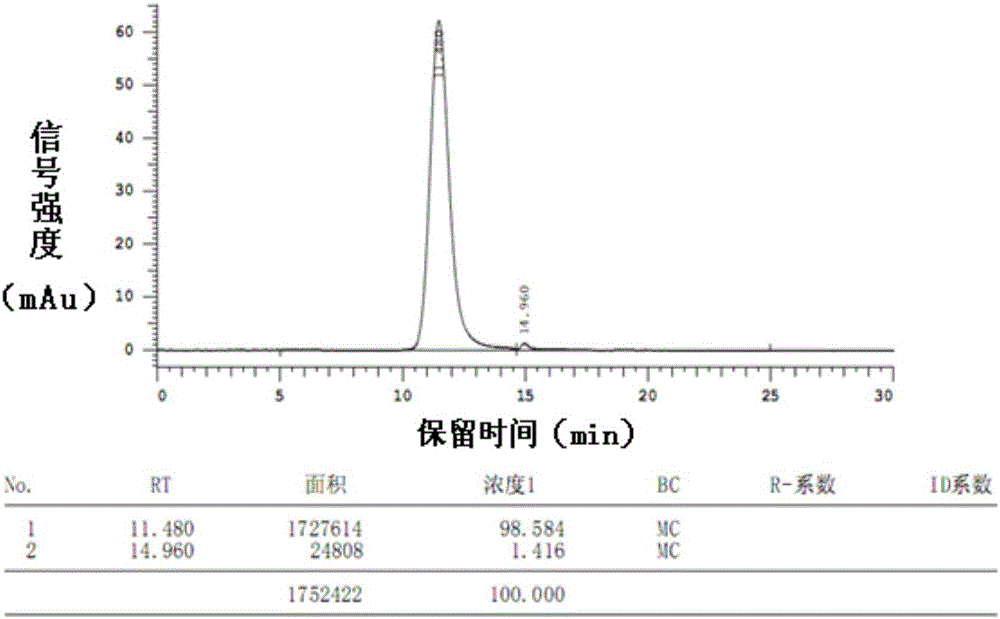

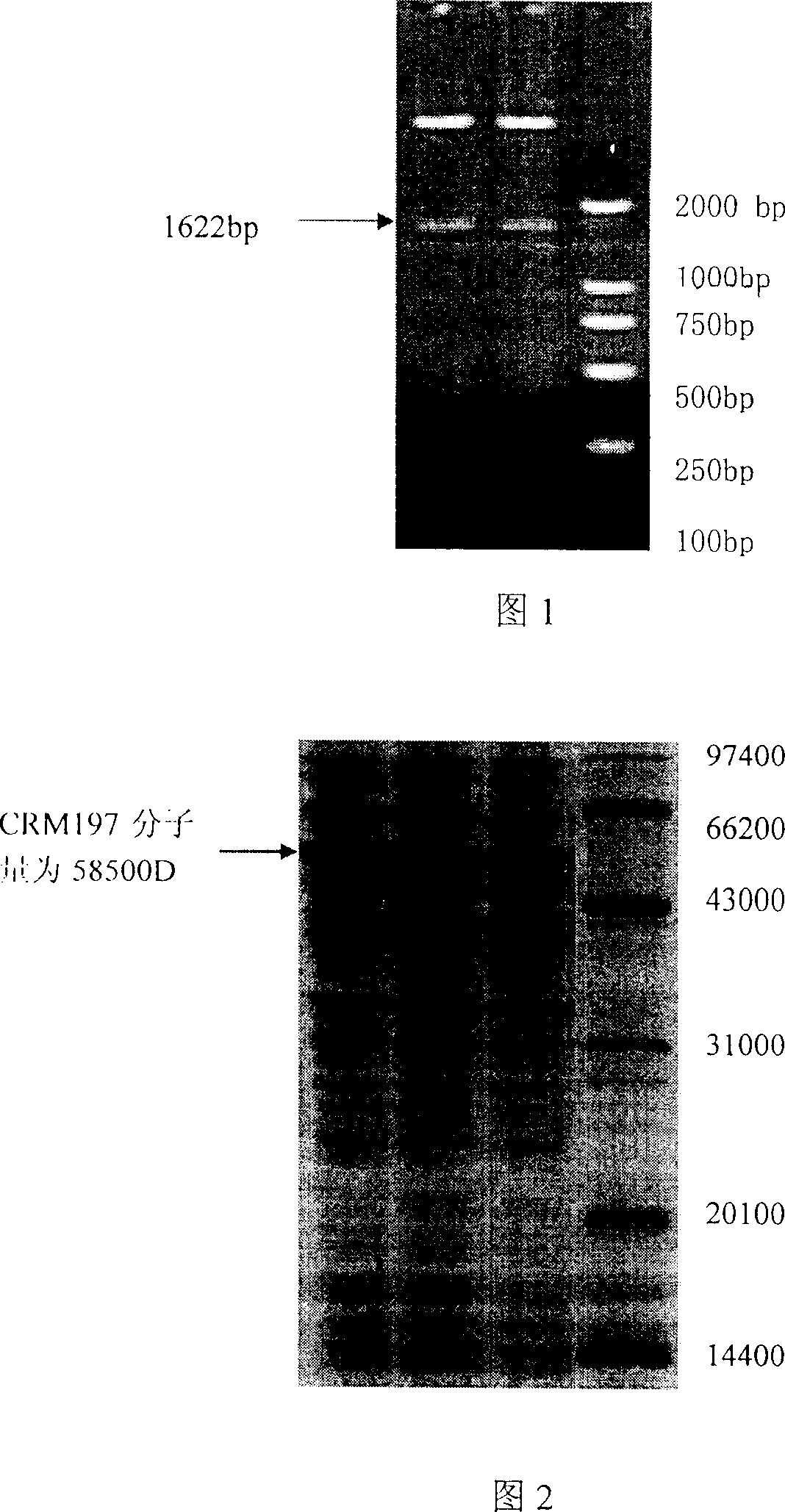

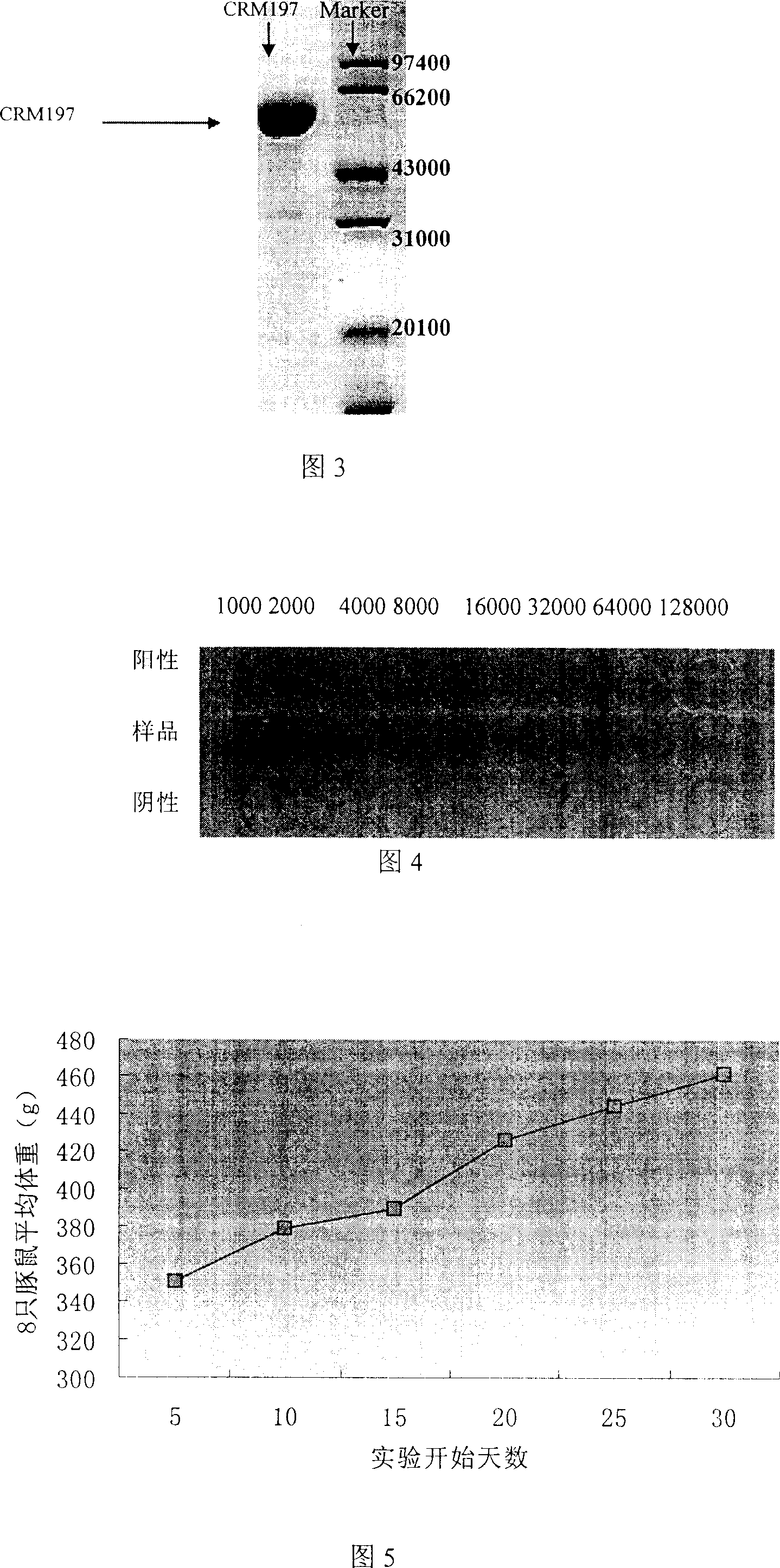

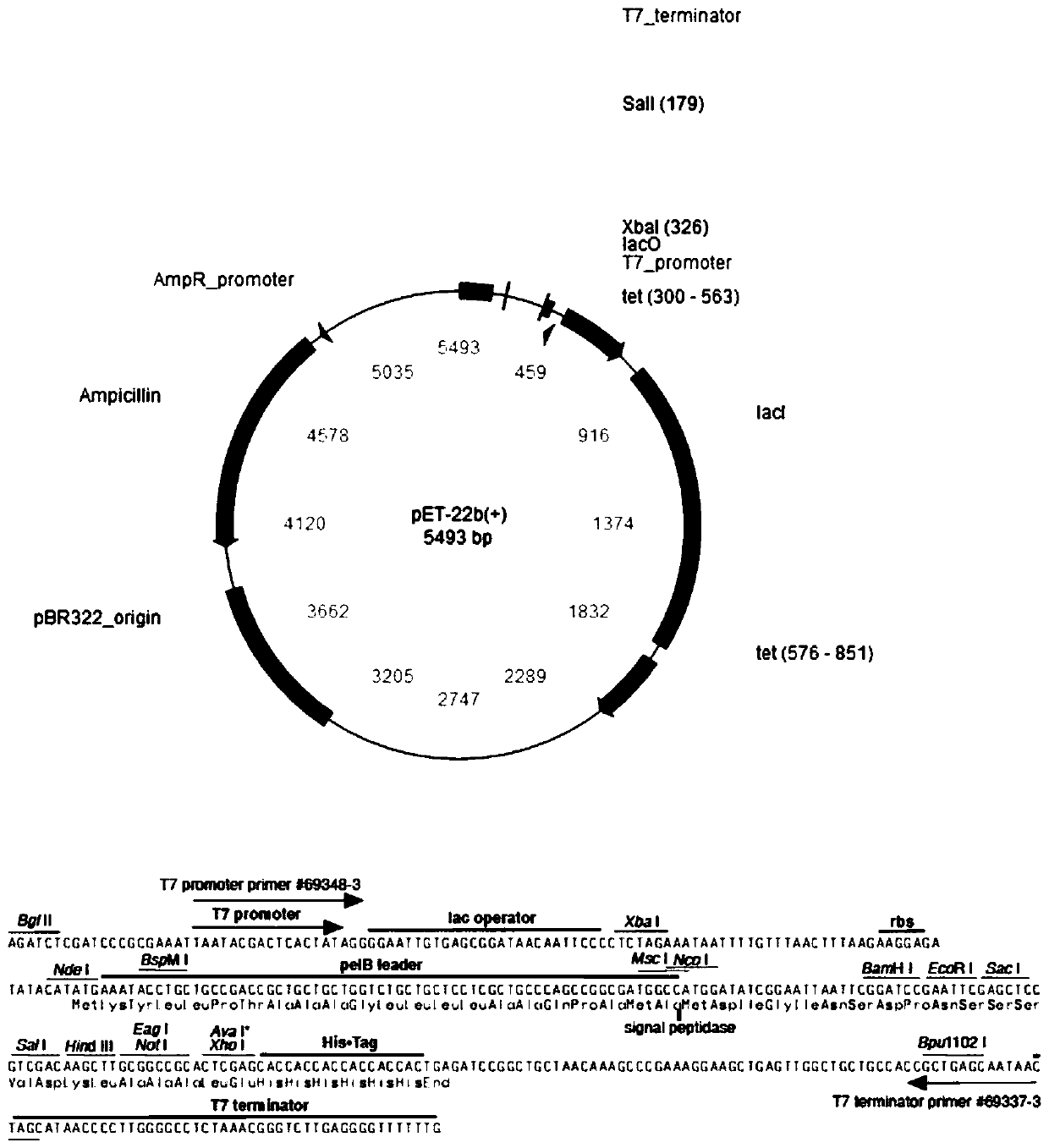

Diphtheria toxin muton CRM197 and its preparation process

The present invention is diphtheria toxin mutant CRM197 and its preparation process, and belongs to the field of immune protein carrier technology. The diphtheria toxin mutant CRM197 is expressed in colibacillus in the form of inclusion body, and the target product has sequence length of 536 amino acids, the immunogenicity the same as that of diphtheria toxin and no toxicity similar to that of diphtheria toxin. The present invention clones gene coding CRM197, constructs recombinant expression plasmid expressing CRM197 and transforms to colibacillus host for expression in the form of inclusion body. The present invention has target protein accounting for over 24 % of total protein content, high CRM197 purity over 95 % and high target protein recovering rate. The preparation process is simple, low in cost and suitable for industrial production.

Owner:QILU PHARMA HAINAN

Large scale preparation of alpha-1 proteinase inhibitor and use thereof

ActiveUS7879800B2Inhibition capacityAvoid flowPeptide/protein ingredientsInactivation/attenuationSource materialTotal protein

A process suitable for processing scaled-up amounts of source material in the range of tens of kilograms for the purification of alpha-1 proteinase inhibitor (API) from a mixture of unpurified proteins is provided. More particularly, a process for the purification of API from blood plasma or from plasma fractions to obtain pharmaceutical grade API on a commercial scale is provided. The API produced by the process is highly pure (at least 90% API out of the total protein) and highly active (at least 90% active API). Pharmaceutical compositions comprising the purified API and methods of using same are also described.

Owner:KAMADA

Substantially clear nutritional liquids comprising calcium hmb and soluble protein

ActiveUS20110305799A1Reduce nutrient availabilityEffective shelf-lifeMilk preparationWhey manufactureIsomaltuloseTotal protein

Disclosed are substantially clear nutritional liquids comprising protein and calcium HMB wherein soluble protein represents from about 65% to 100% by weight of total protein. The liquids have a pH of from about 2.8 to about 4.6 and may be manufactured as a hot fill product. The substantially clear nutritional liquids may also have a weight ratio of calcium HMB to soluble calcium of from 4.5:1 to 7.3:1. In some embodiments, the substantially clear nutritional liquids are substantially free of fat, and may optionally include isomaltulose and / or beta alanine.

Owner:ABBOTT LAB INC

Methods for Promoting Health or Wellness in Adult Animals

ActiveUS20080317905A1High retention rateReadily apparentMilk preparationMetabolism disorderAnimal scienceNitrogen

Methods for promoting health or wellness, regulating food intake, and increasing nitrogen retention in an adult animal by feeding the animal a food containing lysine in an amount of at least about 3% by weight of total protein. Also, kits containing lysine and a food suitable for consumption in separate packages and instructions for how to combine the lysine and food are provided.

Owner:HILLS PET NUTRITION INC

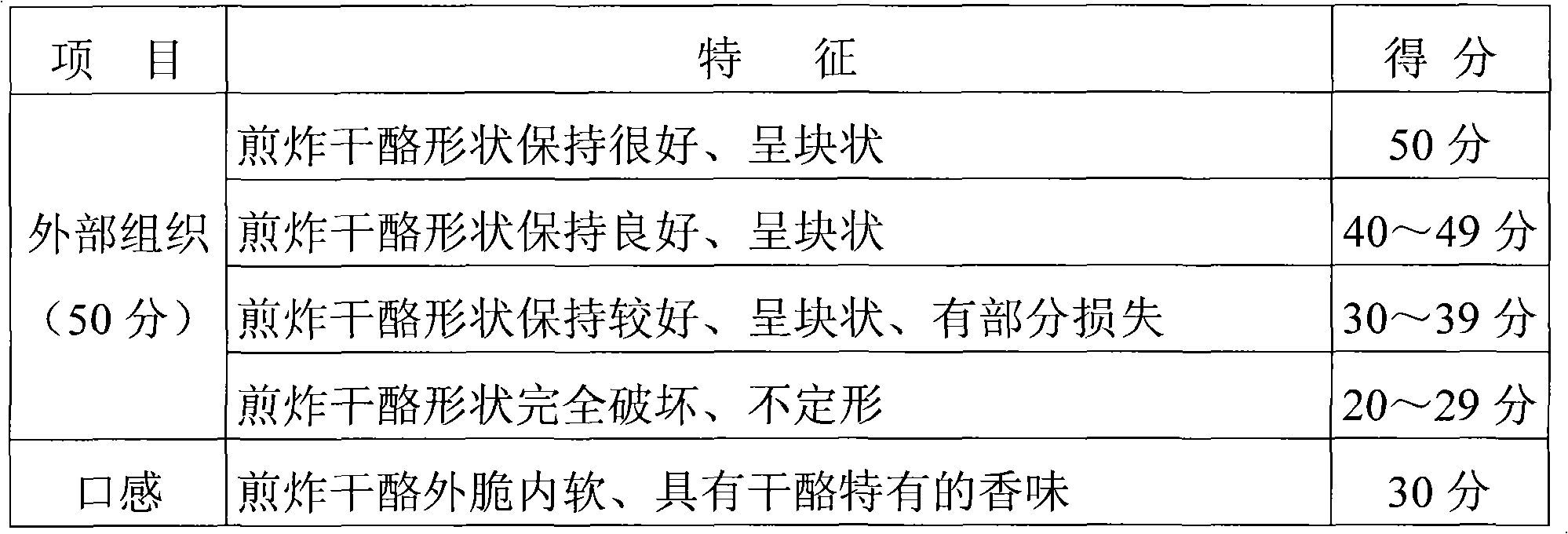

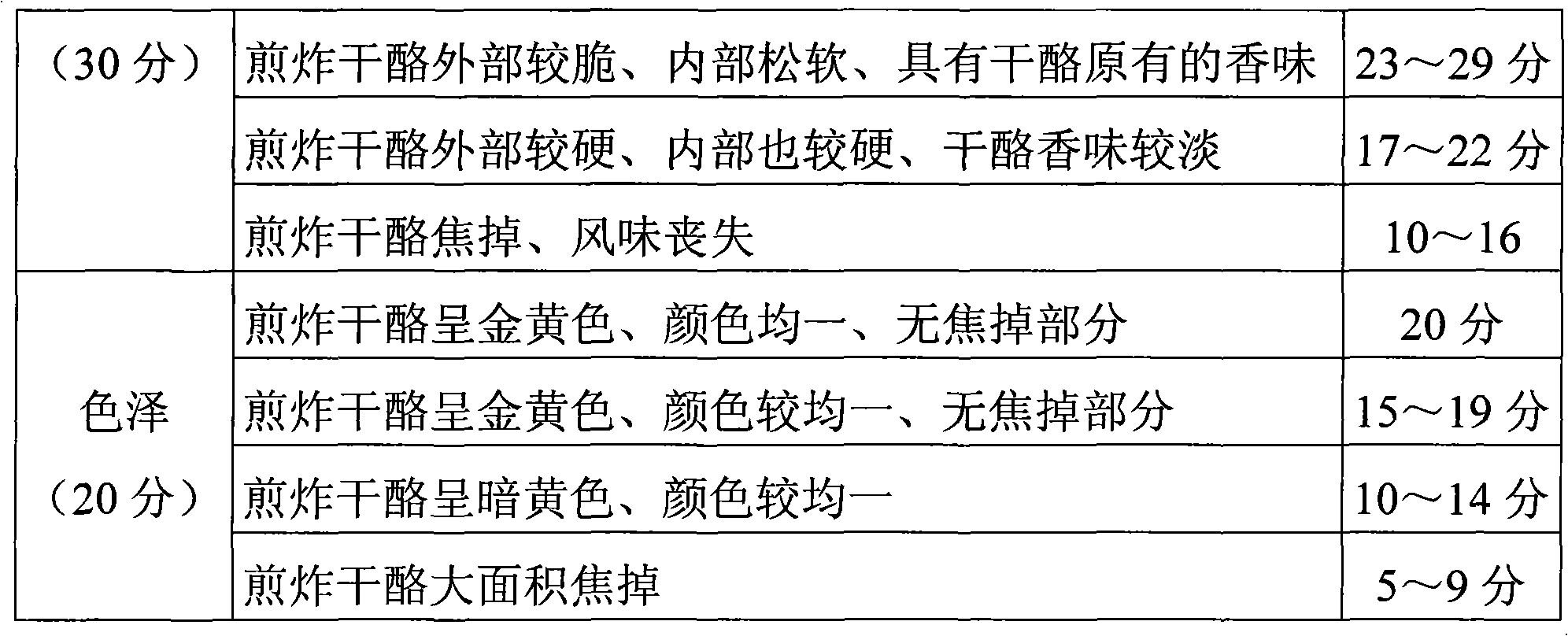

Processed cheese and preparation method thereof

The invention discloses processed cheese and a preparation method thereof. The processed cheese comprises the following materials in percentage by mass: 16 to 26 percent of protein, 20 to 30 percent of fat, 37 to 50 percent of water and 1 to 3 percent of emulsifying salt, wherein complete casein accounts for 75 to 90 mass percent of total protein. The invention provides the processed cheese which can be fried, roasted, or subjected to microwave heating for the first time. After being fried, roasted or subjected to microwave heating, the processed cheese can still keep the external form of a solid phase instead of becoming fluid. The processed cheese is crisp outside and tender inside and delicious after being fried at a high temperature, can completely meet the requirement of frying, roasting or microwave operation, and has wide market prospect.

Owner:BRIGHT DAIRY & FOOD

Process technique for preparing wheat gluten powder peptide by fermentation and enzymolysis method

InactiveCN104263794AIncrease vitalityGood effectMicroorganism based processesFermentationBiotechnologyTotal protein

The invention discloses a process technique for preparing wheat gluten powder peptide by a fermentation and enzymolysis method. A wheat gluten powder active peptide product with relatively high antioxidant activity is obtained by using a microbial fermentation and enzymolysis method, hoping for providing technique support for industrial production of preparing antioxidative peptide by using wheat gluten powder, thereby expanding the application range of the wheat gluten powder and improving the production additional value of the wheat gluten powder. The wheat gluten powder product obtained by adopting ultrasonic-assisted enzymolysis and an aerobic anaerobic two-step fermentation process is white in color and luster, powdery and free from impurities and bitter taste. The total protein content is greater than or equal to 97%, and the content of peptide with the molecular weight which is smaller than 1000 Dalton in total protein is greater than or equal to 98%. The reducing capacity of the wheat gluten powder peptide reaches 0.486 and the ABTS free radical scavenging capacity reaches 1.85mmol / L Trolox. The method disclosed by the invention is short in production period, low in cost and free from generation of any toxic and harmful substances. The obtained product is high in safety and good in functional activity and can be widely applied to the fields such foods, drugs, health products and biological synthesis.

Owner:QINGDAO JIARUI BIOLOGICAL TECH

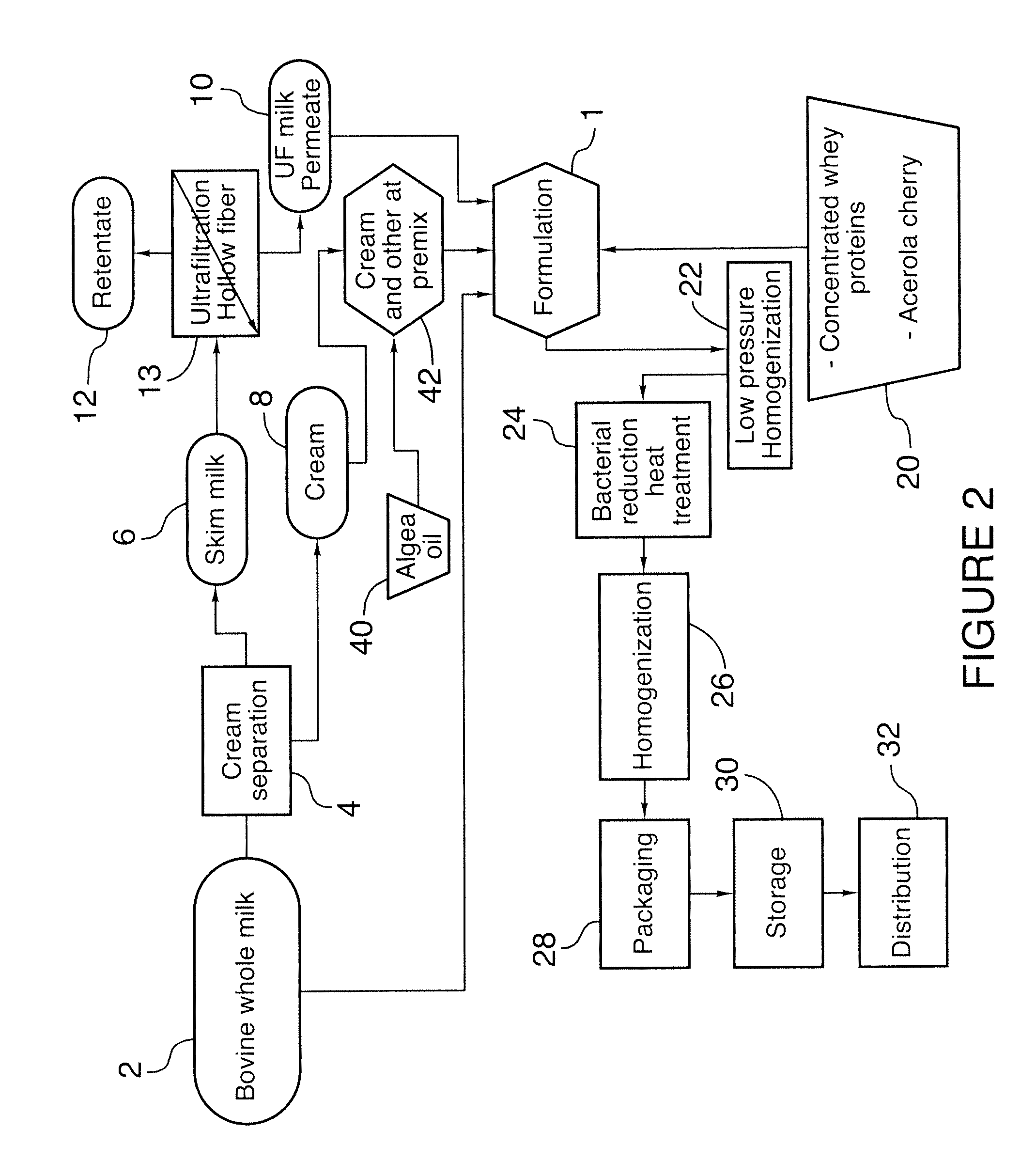

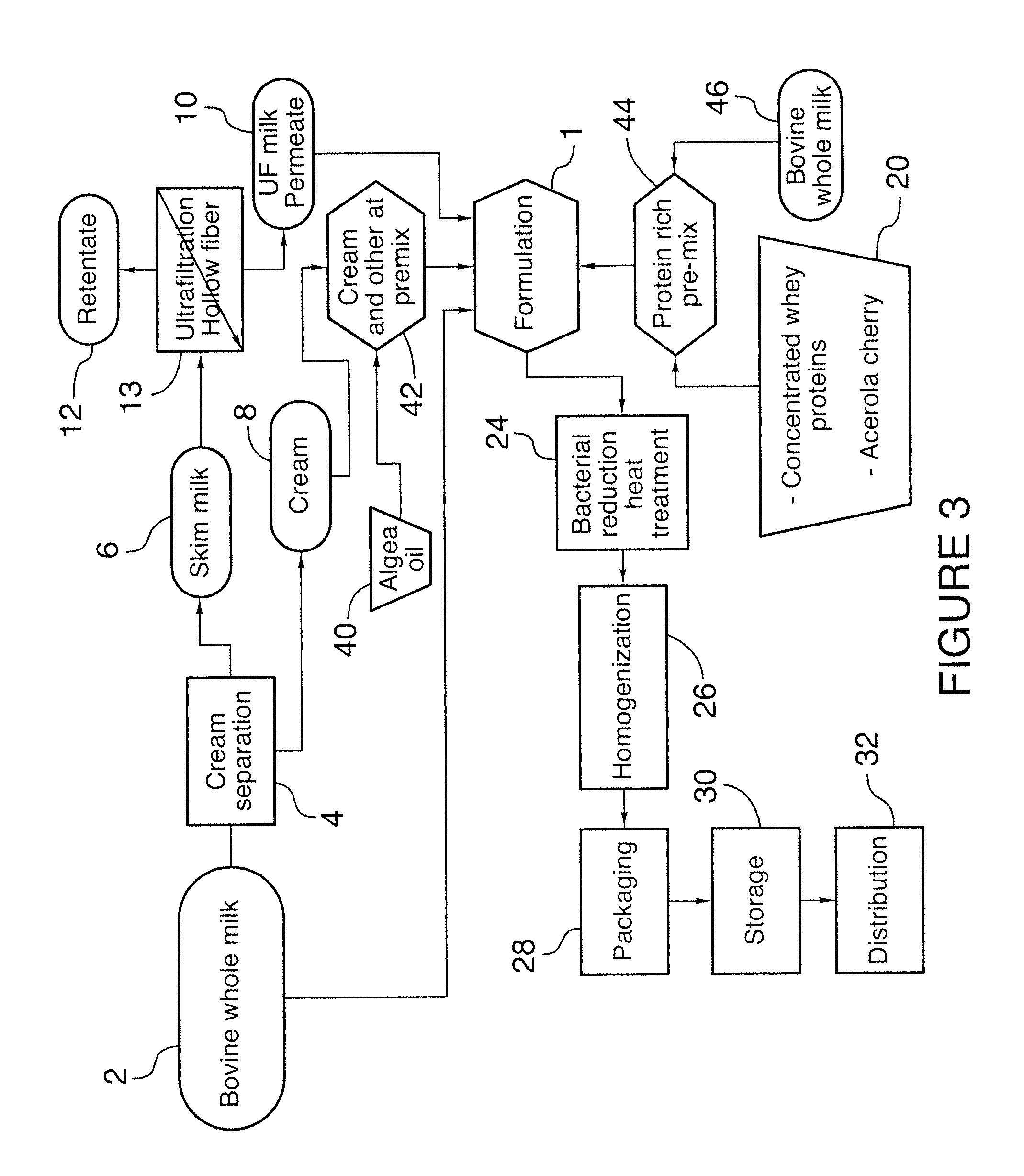

Liquid Milk Beverage For Toddlers

InactiveUS20130064923A1Less-expensive to manufacturePromote digestionMilk preparationVitamin food ingredientsFormula feedingWhey protein

Described herein are a liquid milk beverage for toddlers comprising non-hydrolyzed, non-fermented and protein-rebalanced cow's milk, processes for making same and methods of uses. The non-hydrolyzed, non-fermented rebalanced cow's milk comprises a reduced weight / weight proportion of casein:whey proteins when compared to untreated cow's milk. The non-hydrolyzed, non-fermented rebalanced cow's milk may further comprises a reduced total protein concentration when compared to untreated cow's milk. The reduced proportion and / or reduced total concentration of proteins facilitate digestion of the liquid milk beverage by infant and toddlers. Also described are methods for providing nutrition to a toddler, methods for facilitating transition from breast feeding and / or artificial formula feeding of a child towards drinking of cow's homogenized milk, and methods for increasing digestion of cow's milk in an individual.

Owner:AGROPUR COOP

Recombinant human collagen and application thereof

InactiveCN110194795AHigh purityIncrease productionConnective tissue peptidesBacteriaBiotechnologyProtein target

The invention discloses a recombinant human collagen and an application thereof. An amino acid sequence of the protein is shown as SEQ ID NO. 3, the nucleotide sequence of the protein-coding gene is shown as SEQ ID NO. 1. The recombinant human collagen of the invention has very good hydrophilicity and stability, and the amino acid composition thereof is 100% identical to the corresponding amino acid sequence of the natural collagen, and the amount of expressed protein can account for about 25% of the total protein of the thalline, per milliliter of the bacteria liquid precipitate contains 0.25mg of the target protein, and the production cost is very low and the cycle is short. The prepared collagen is applied to the human body without immunological rejection and allergic reaction, and canbe widely applied to the biomedicine and cosmetics industries.

Owner:郭伟

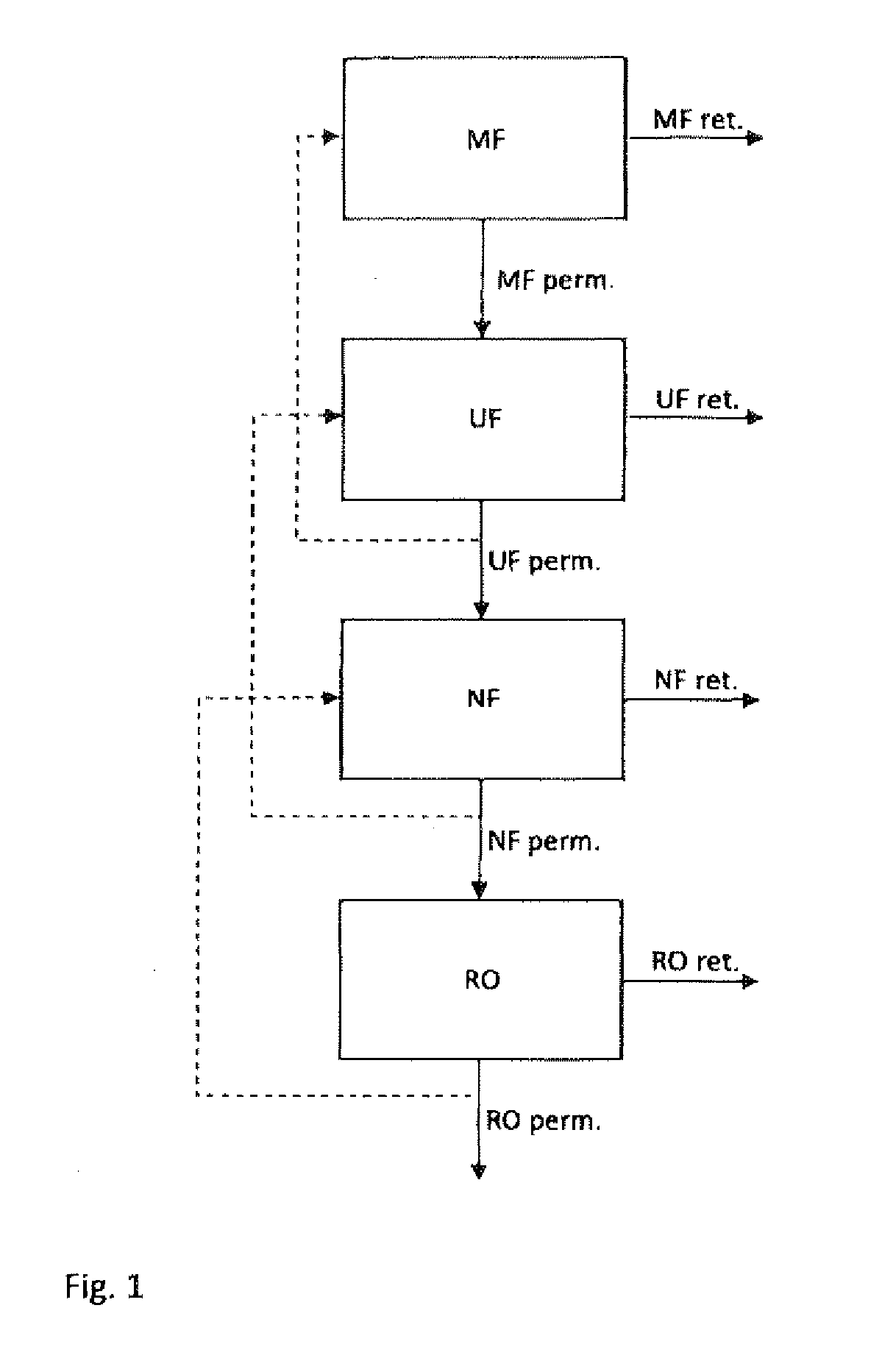

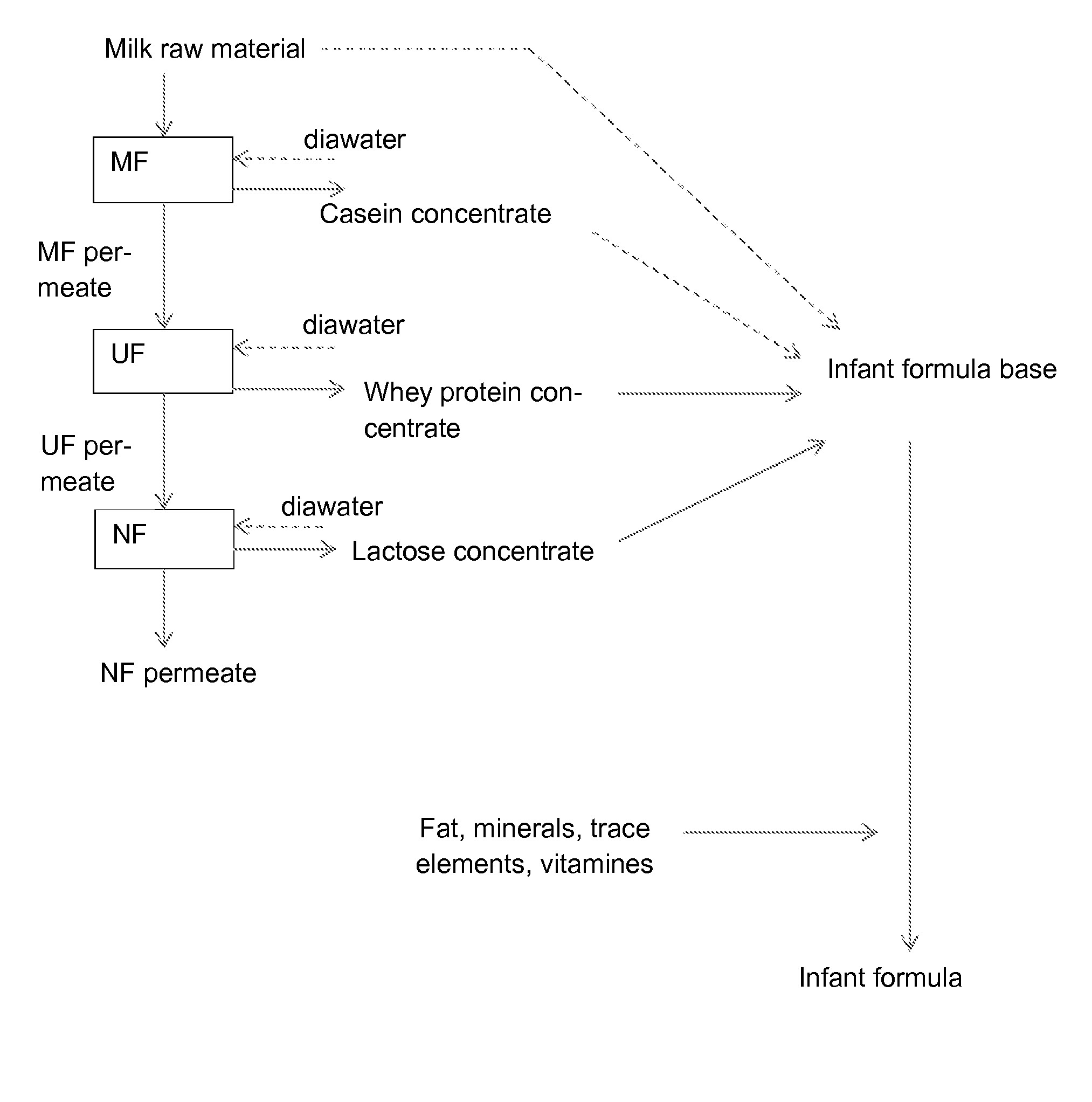

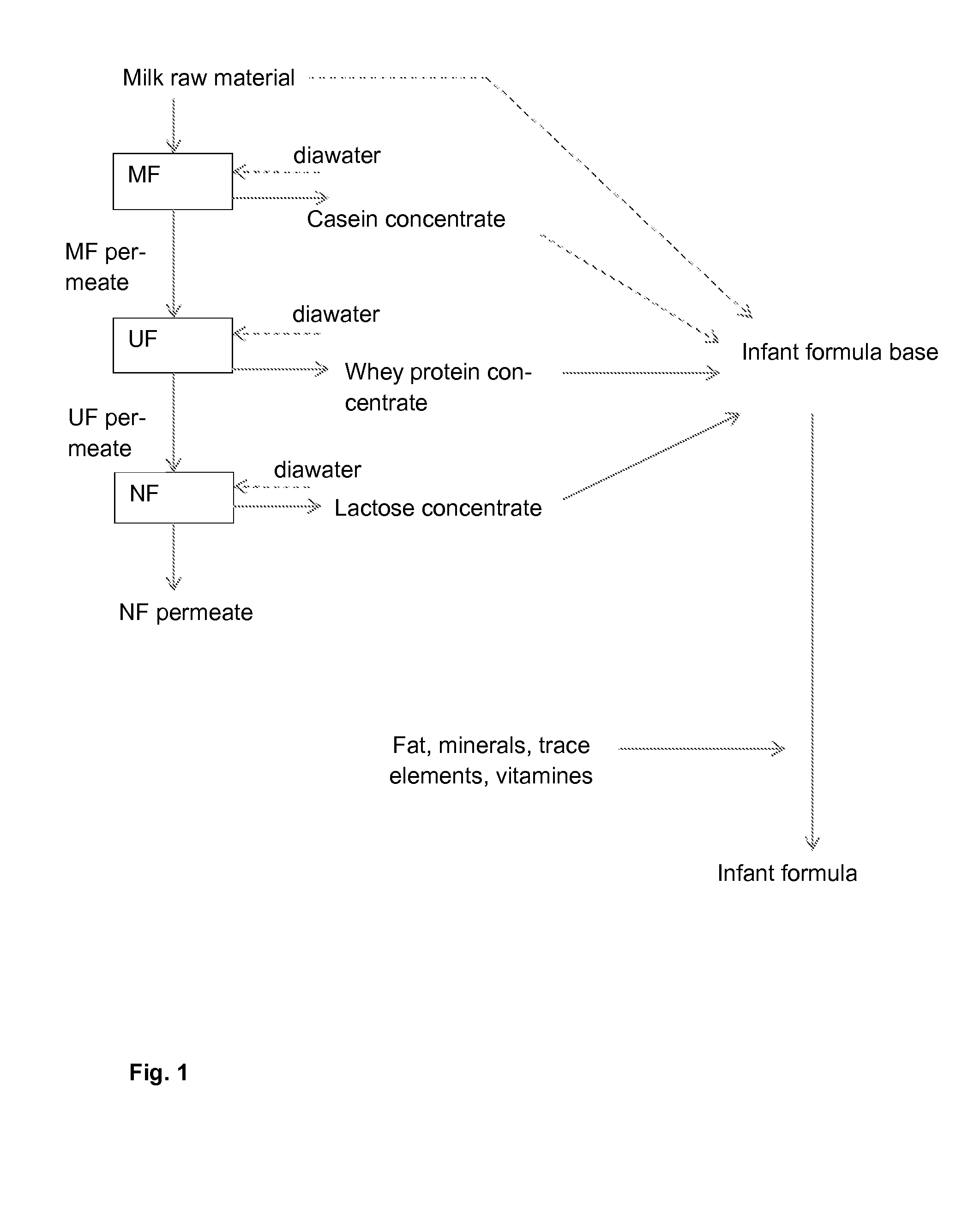

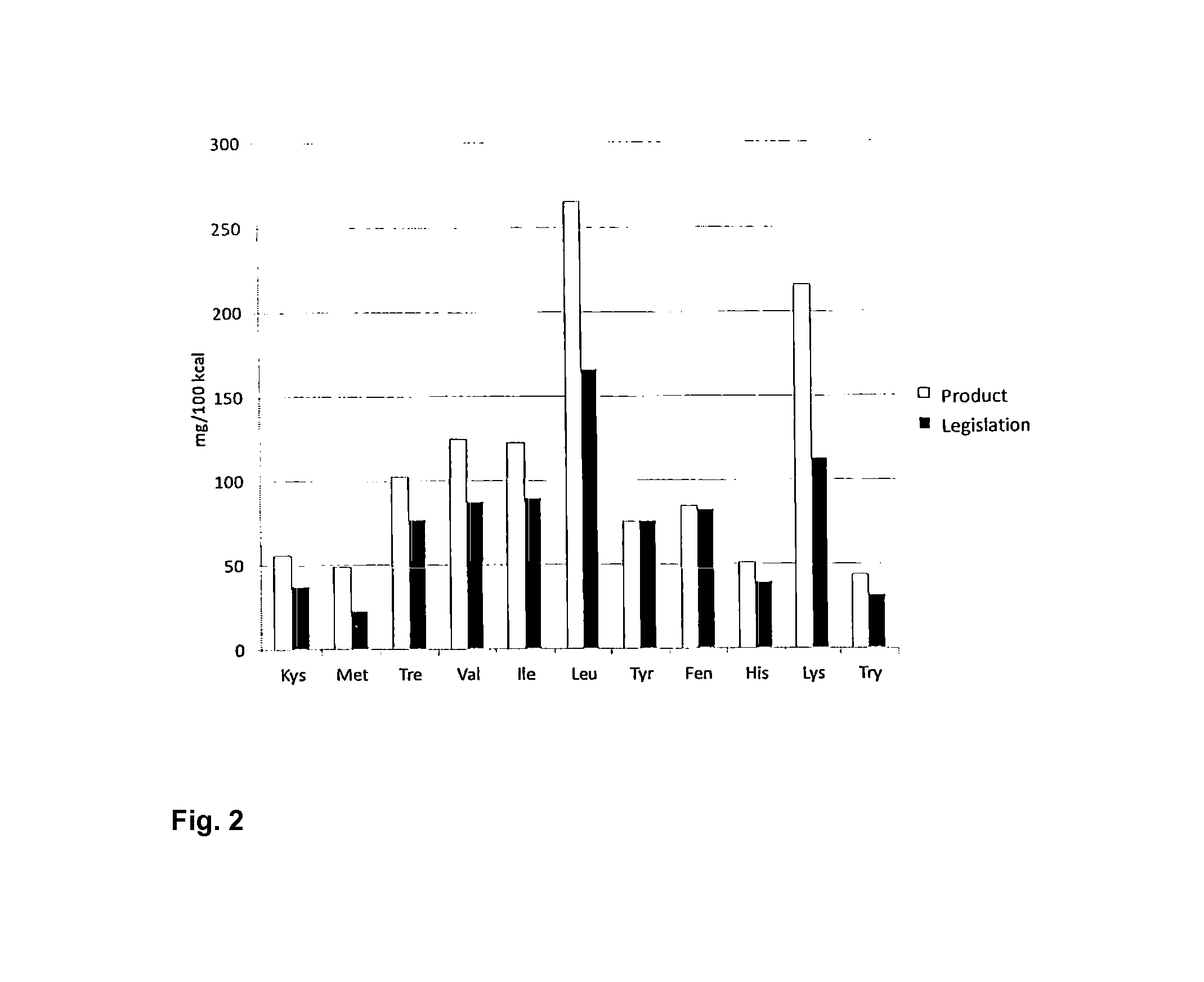

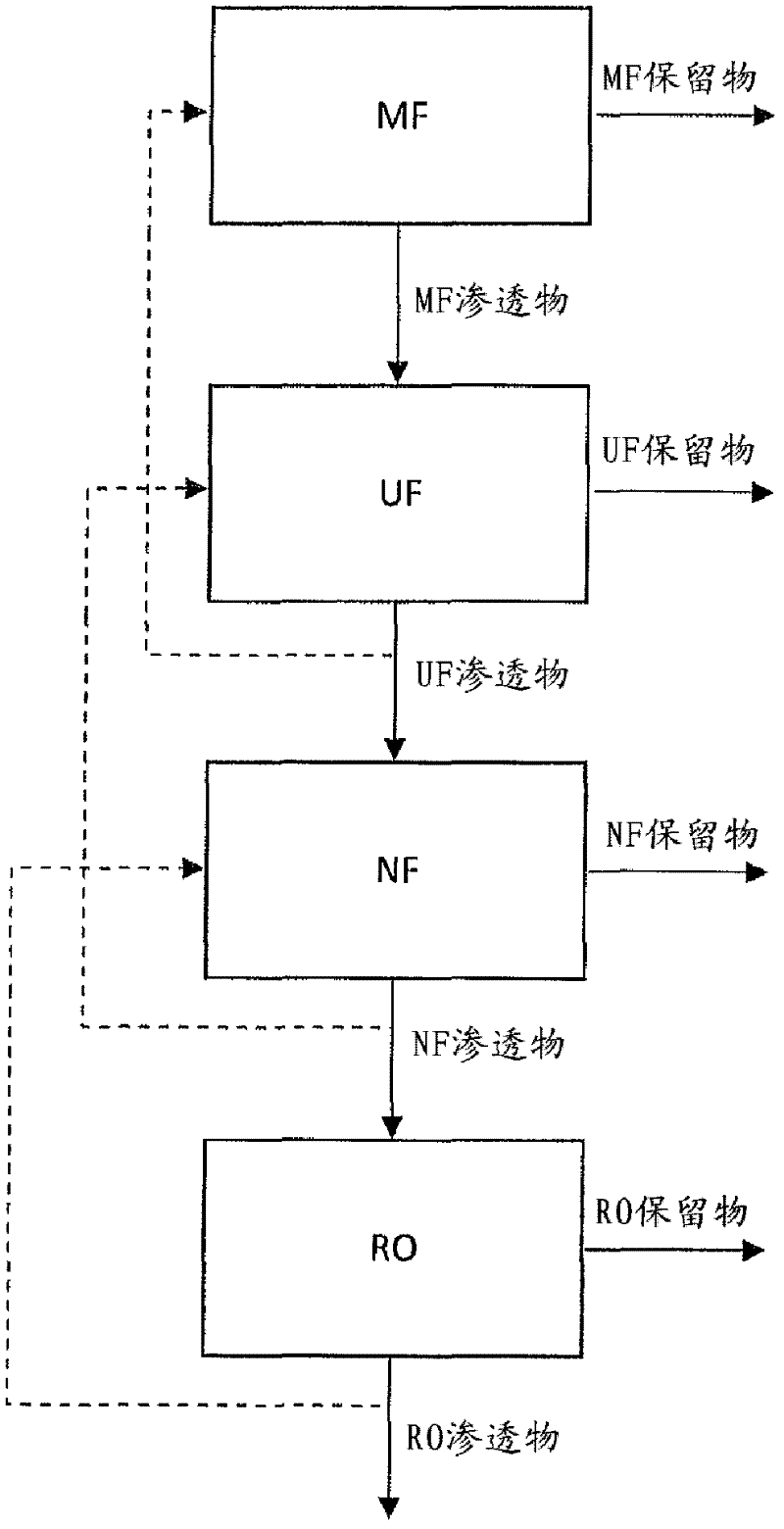

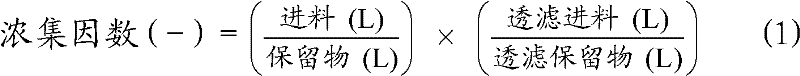

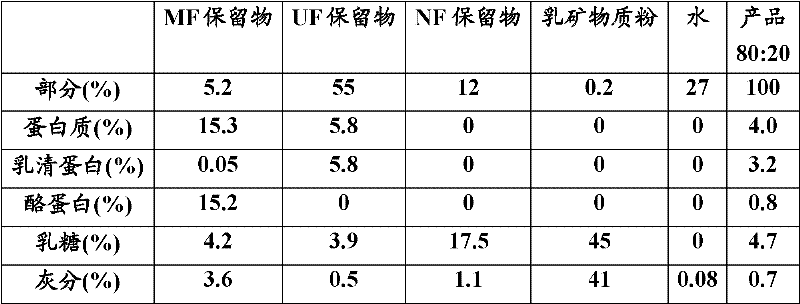

Method for producing a milk product

InactiveUS20140302219A1Excellent amino acid compositionDecreases protein concentrationProtein composition from fishMilk preparationWhey proteinTotal protein

A method is disclosed for producing an infant formula base, wherein by means of microfiltration, ultrafiltration, and nanofiltration the components of milk are separated into a casein fraction, a whey protein fraction, and a lactose fraction to produce, by suitably combining, a composition in which the amino acid composition is close to that of human milk. An infant formula base having a total protein concentration of about 1.0 to about 1.5% and a β-casein concentration of at least about 11% of the total protein concentration is also disclosed. The infant formula base is suitable for the production of an infant formula.

Owner:VALIO LTD

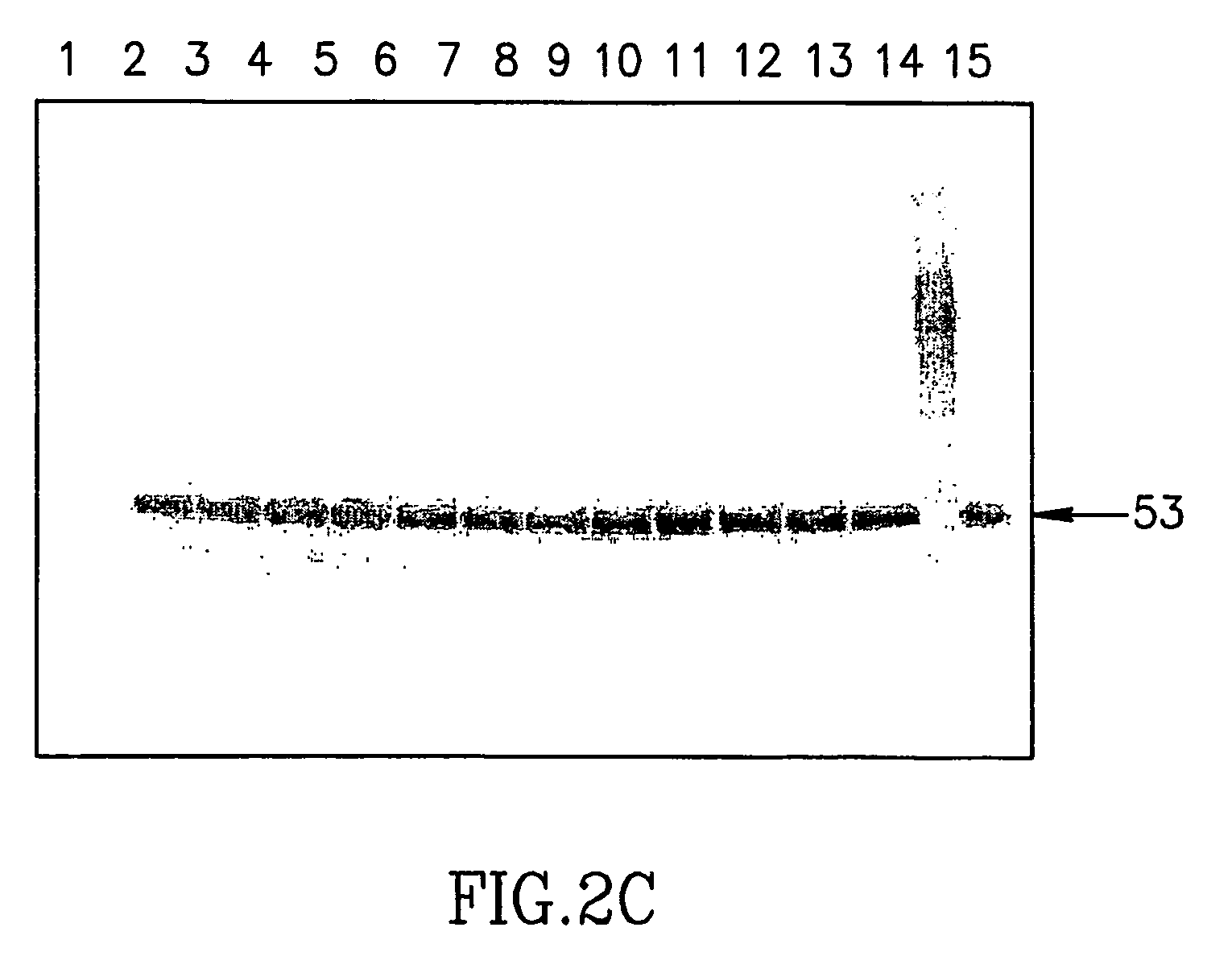

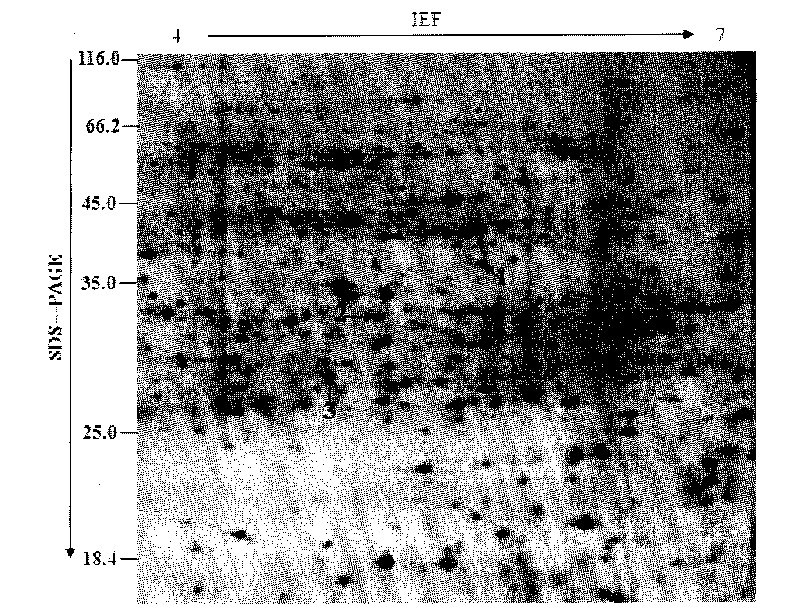

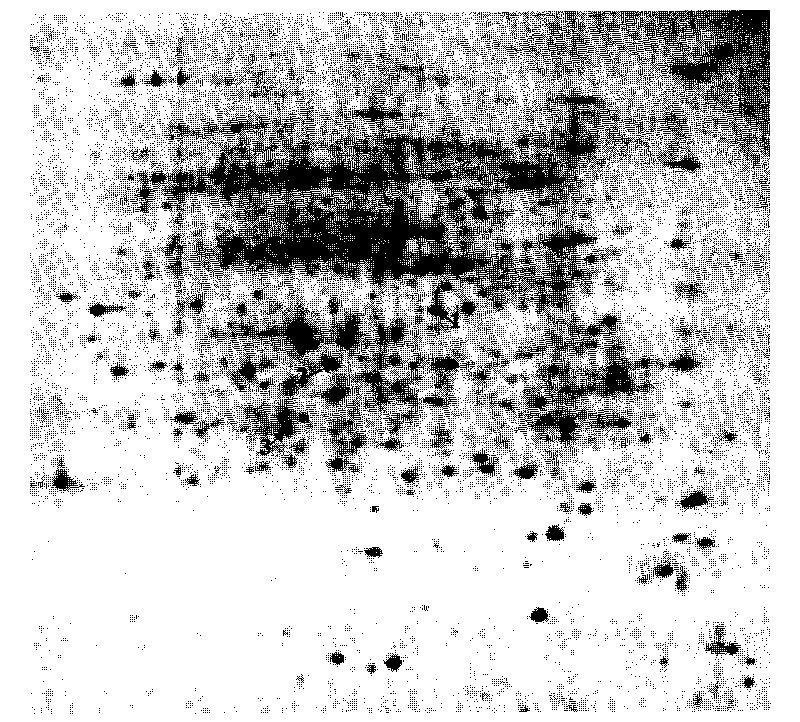

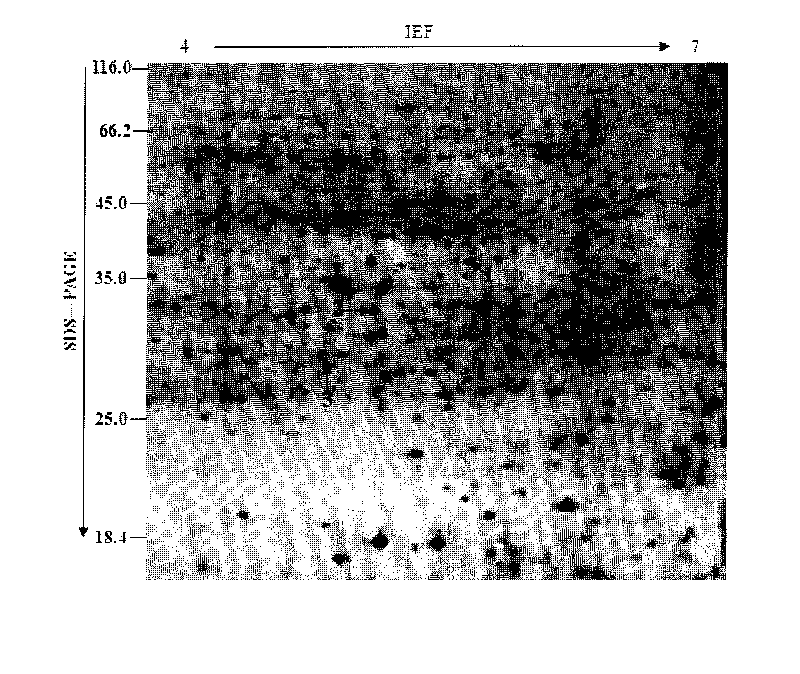

Dimensional electrophoresis method for total protein of jute root system

InactiveCN101718745AThe spectrum is clearNo horizontal and vertical stripesPreparing sample for investigationMaterial analysis by electric/magnetic meansBiotechnologyTotal protein

The invention relates to a dimensional electrophoresis method for a total protein of a jute root system, belonging to the field of biotechnology. The total protein of the jute root system capable of existing in the coastal beach is separated by the dimensional electrophoresis technique, and by adopting the technical scheme, the jute root system existing in the coastal beach is tested with good effect. At present, repeated experiments prove that the jute root system is separated by the dimensional electrophoresis method to obtain more protein points; and after detected by PDQuest software, the protein points are more than 1100, the map is clear without transverse and longitudinal grains, the protein points are circular, and the repeatability is good, thus the invention is a dimensional electrophoresis method suitable for the analysis of the total proteomics of the jute root system.

Owner:NANJING AGRICULTURAL UNIVERSITY

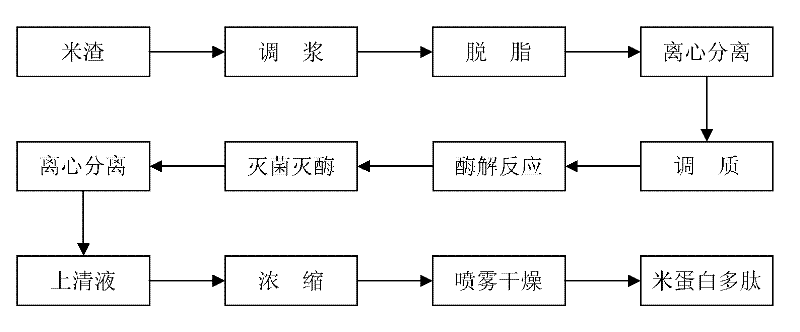

Rice protein polypeptide and preparation method thereof

ActiveCN102212107AControl the degree of hydrolysisWide range of hydrolysis conditionsPlant peptidesFermentationTotal proteinRice protein

The invention relates to a rice protein polypeptide and also relates to a composite enzyme preparation method of the rice protein polypeptide. The preparation method comprises the following steps: size mixing, degreasing, centrifuging, homogenizing, enzymolysis reaction, sterilization and enzyme inactivation, centrifugal separation, concentration, drying and the like. The rice protein polypeptideprepared by using the preparation method has a protein content of 80% in percentage by weight and a fat content of 1% or below in percentage by weight, and has high bioactivity; the peptides of whichthe molecular weight distribution is 100-1000 Da account for more than 90% of the total protein content; and the product are completely soluble in water.

Owner:WUXI JINNONG BIOTECH CO LTD

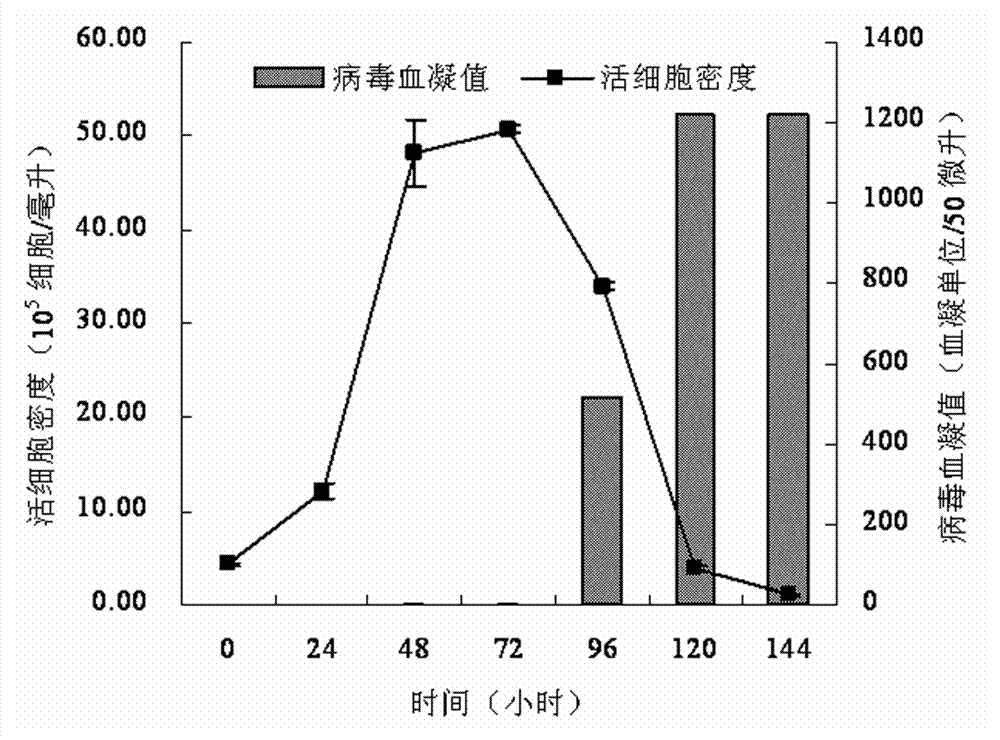

Serum-free medium suitable for large-scale production of influenza vaccines

ActiveCN103045533AEasy to separateEasy to purifyArtificial cell constructsVertebrate cellsBiotechnologyNutrition

The invention relates to the technical field of culture medium development and research of biotechnology and discloses a serum-free medium suitable for large-scale production of influenza vaccines. The serum-free medium comprises 23 basic metabolism nutrients, two nucleic acid compounds, 6 vitamins, 9 inorganic salt compounds, a shear force protective agent, two acidity and alkalinity buffer agents, an acidity and alkalinity indicator, 10 virus reproduction promoters and three additives. The conventional preparation method of the serum-free medium comprises the following steps of: dissolving the components in ultrapure water without a heat source so as to prepare the serum-free medium. The using method is a conventional method. The serum-free medium has the beneficial effects that the serum is not contained, the total protein content is lower than 10mg per liter, separation and purification of the product are promoted, and the serum-free medium is suitable for production of influenza vaccines, supports the normal growth and long-term continuous cell culture of animal cells and can be used without adaption; and moreover, because the components are clear, the serum-free medium is convenient to prepare, controllable in cost and suitable for large-scale production of the influenza vaccines.

Owner:EAST CHINA UNIV OF SCI & TECH

Whey protein product and a method for its preparation

InactiveCN102595915ASimple structureImprove stabilityMilk preparationMetabolism disorderWhey proteinTotal protein

The invention relates to a whey protein product having a ratio of whey protein to casein in the range from about 90:10 to about 50:50 and the total protein content of at least 20% on dry matter basis, and a method for its preparation. The product has a favourable amino acid composition and is especially suitable for athletes.

Owner:VALIO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com