Patents

Literature

35results about How to "Control the degree of hydrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

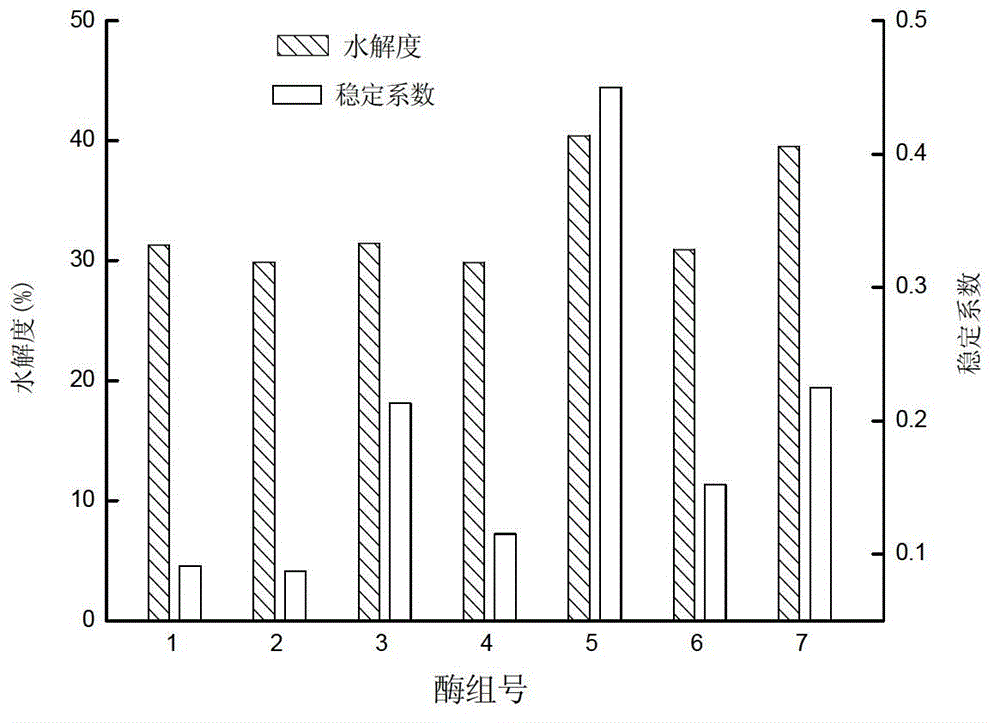

Method for preparing high-purity rice protein and high-purity rice peptide

InactiveCN102229643AHigh protein contentHigh in peptidesPeptide preparation methodsFermentationAmylaseFiltration

The invention relates to a method for preparing high-purity rice protein and high-purity rice peptide. Rice or broken rice is used as a raw material in the method; based on crude rice protein prepared by an alkali extraction and acid precipitation method, non-protein substances in the crude rice protein are removed by the impurity removing effect of an efficient composite enzyme consisting of amylase, cellulase and lipase, and then the high-purity rice protein with protein content of more than 90 percent is prepared; and based on the high-purity rice protein, the hydrolysis degree of the rice protein is controlled under the action of the composite enzyme by an alternated enzymolysis ultra-filtration coupling technology, and the high-purity rice peptide with protein content of over 90 percent, polypeptide content of more than 70 percent and 200 to 1,200Da oligopeptide content of over 50 percent is prepared by separation.

Owner:TIANJIN UNIV OF SCI & TECH

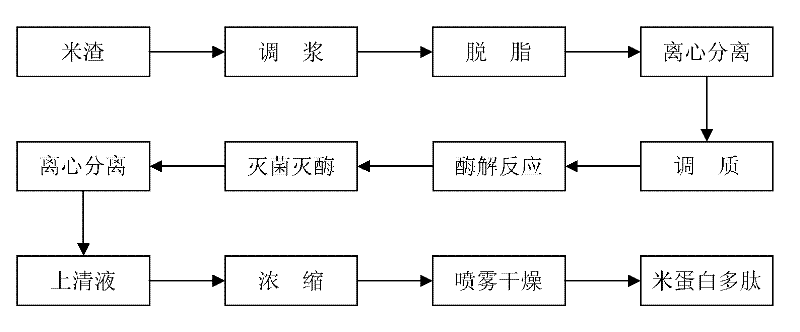

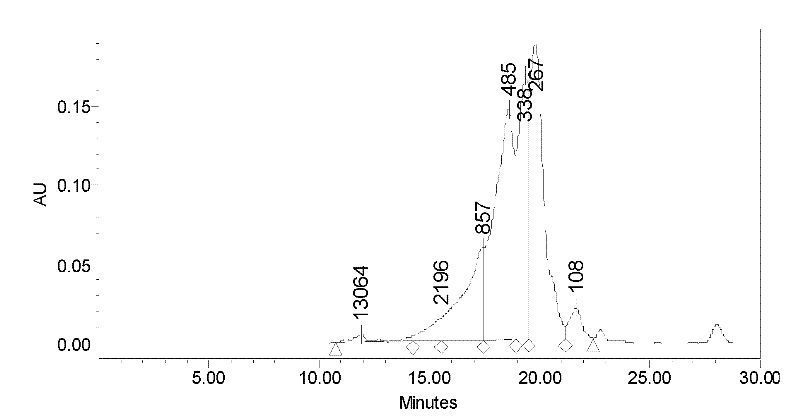

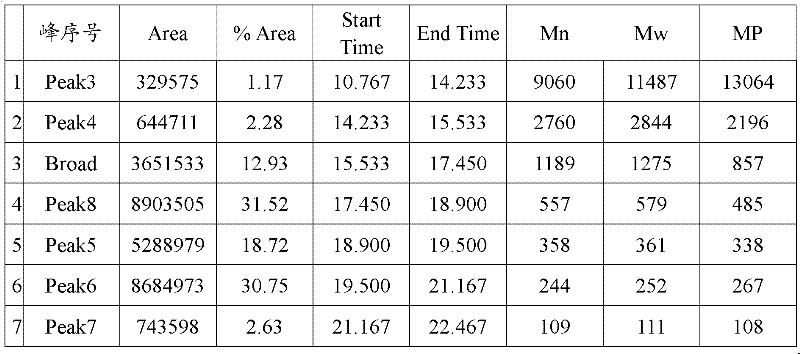

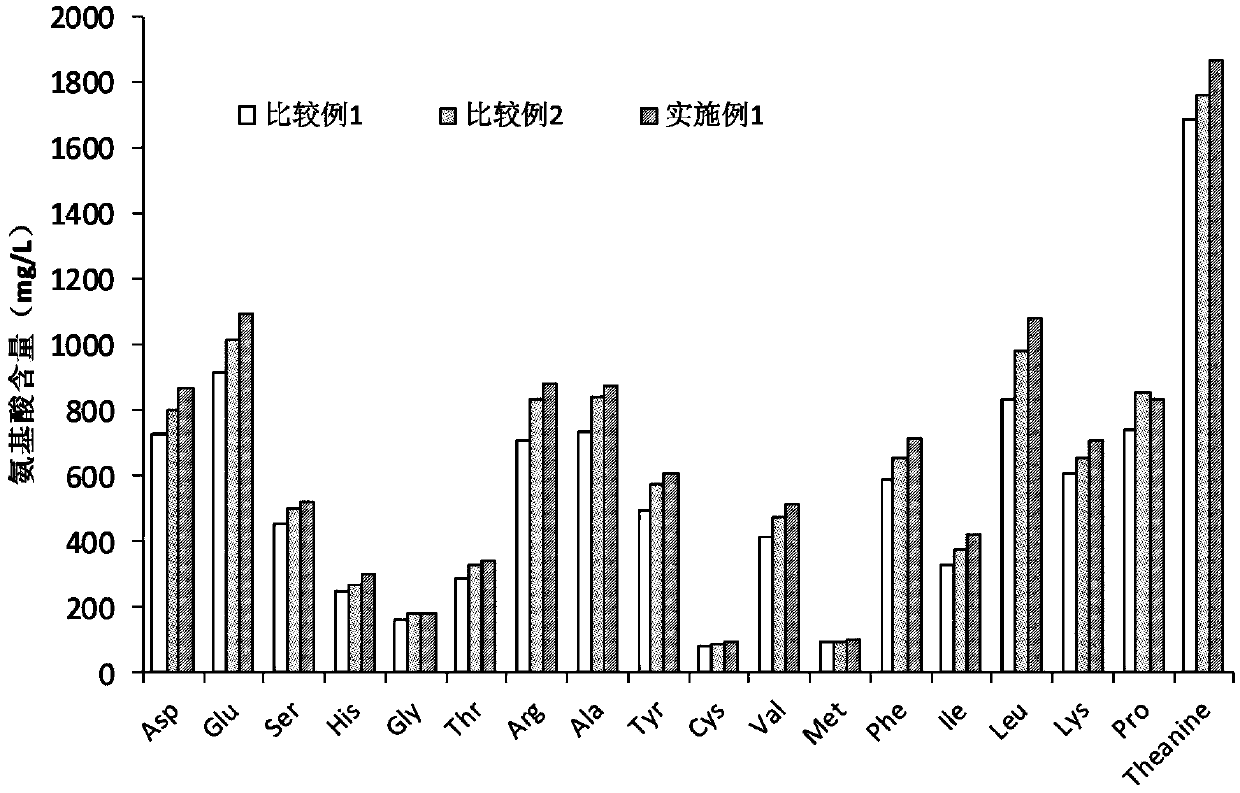

Rice protein polypeptide and preparation method thereof

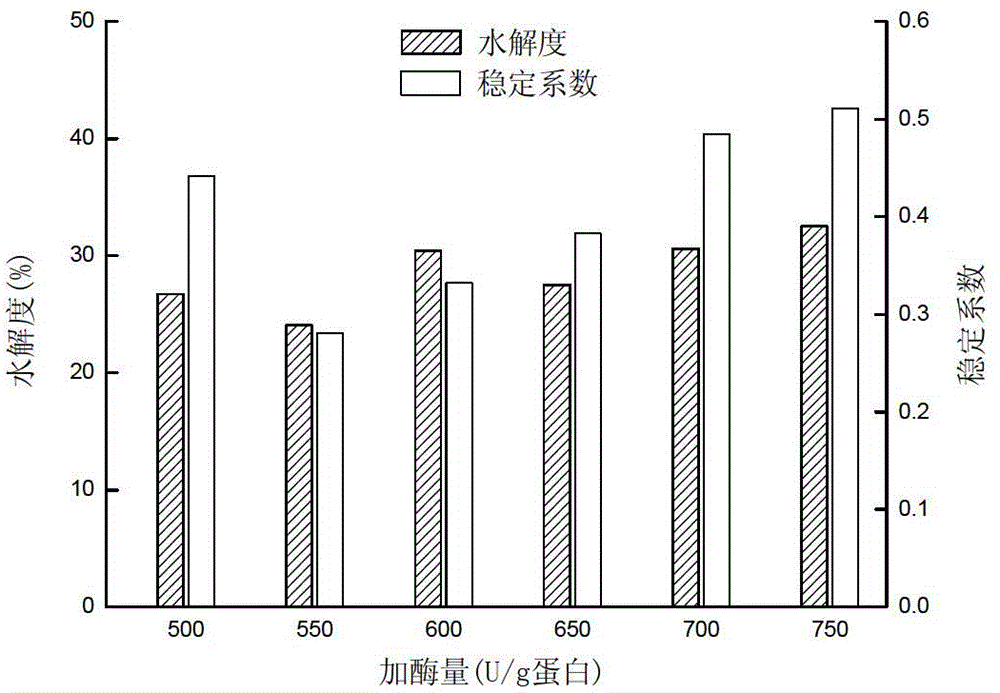

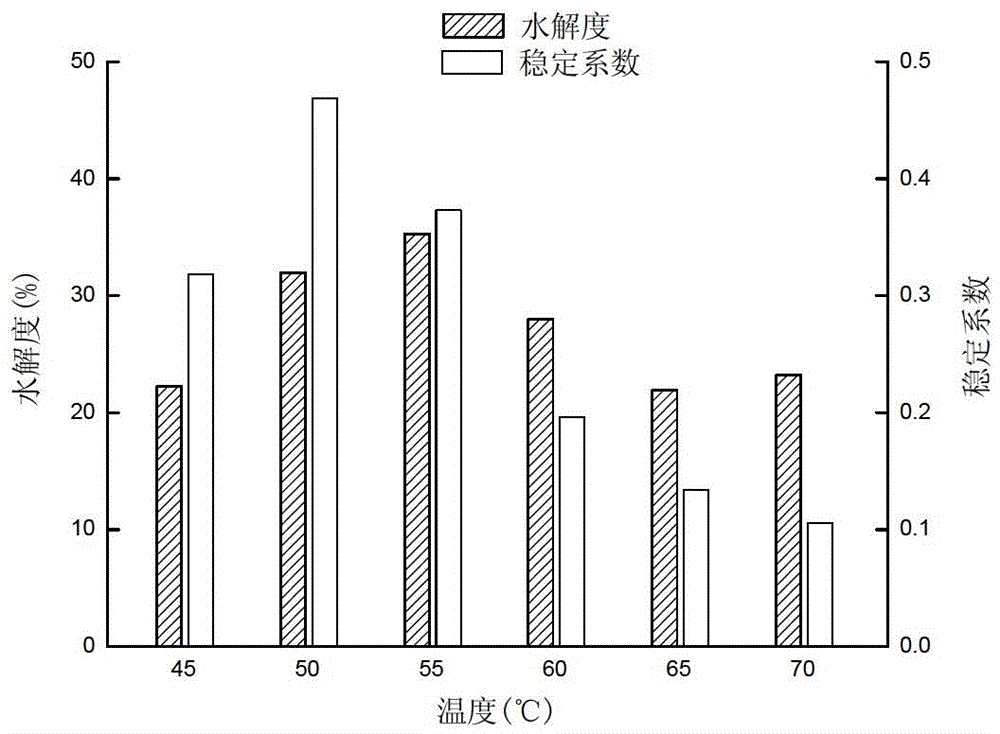

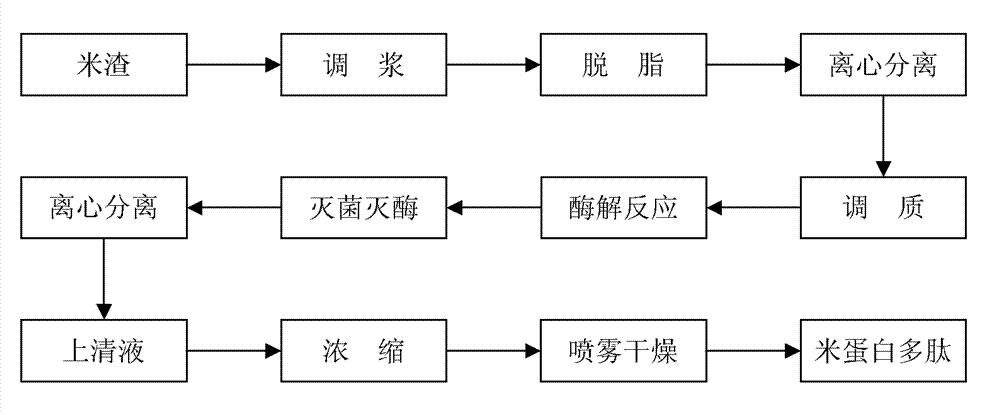

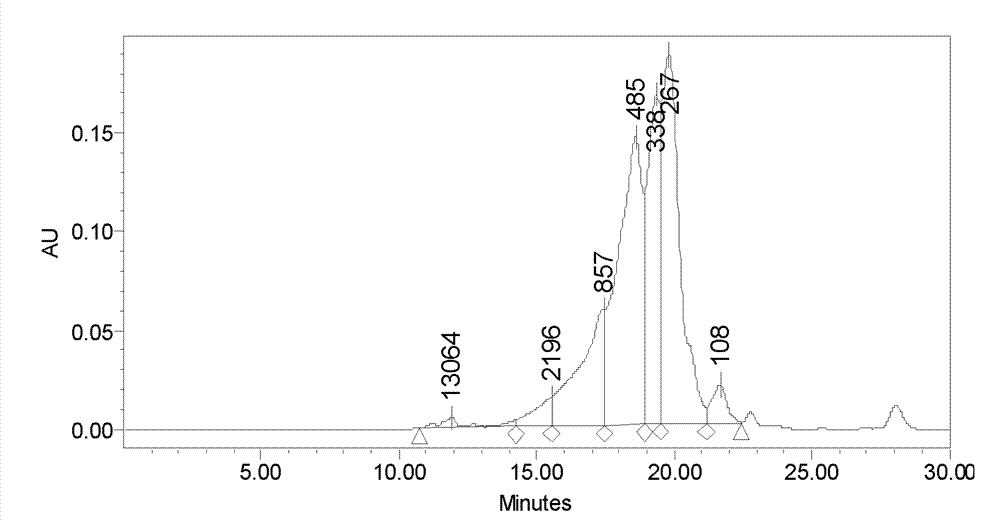

ActiveCN102212107AControl the degree of hydrolysisWide range of hydrolysis conditionsPlant peptidesFermentationTotal proteinRice protein

The invention relates to a rice protein polypeptide and also relates to a composite enzyme preparation method of the rice protein polypeptide. The preparation method comprises the following steps: size mixing, degreasing, centrifuging, homogenizing, enzymolysis reaction, sterilization and enzyme inactivation, centrifugal separation, concentration, drying and the like. The rice protein polypeptideprepared by using the preparation method has a protein content of 80% in percentage by weight and a fat content of 1% or below in percentage by weight, and has high bioactivity; the peptides of whichthe molecular weight distribution is 100-1000 Da account for more than 90% of the total protein content; and the product are completely soluble in water.

Owner:WUXI JINNONG BIOTECH CO LTD

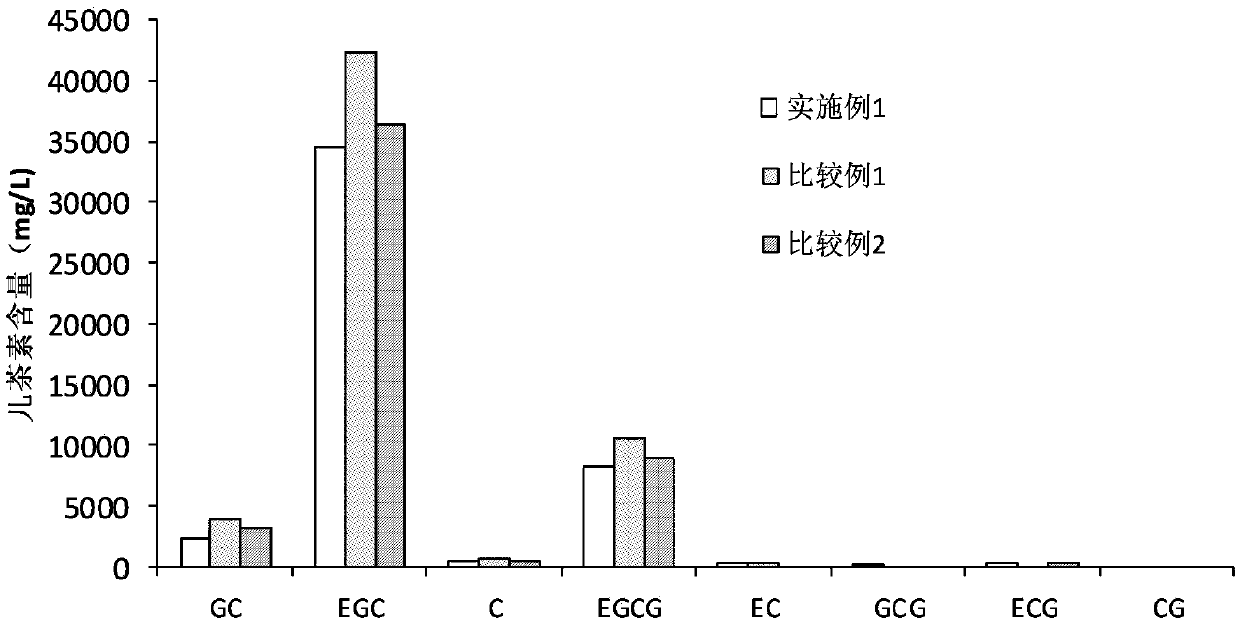

Preparing method of oolong tea concentrated solution

InactiveCN105494761AIncrease the content of amino acidsMellow and freshTea extractionFlavorTea leaf extract

The invention relates to a preparing method of an oolong tea concentrated solution. The preparing method comprises the following steps that firstly, oolong tea leaves are subjected to first-stage charging and extracting; secondly, enzymolysis is carried out, wherein a tea leaf extract solution is subjected to enzymolysis treatment, and wall-breaking enzyme, tannase and protease are used as an enzyme preparation; thirdly, the oolong tea leaves are subjected to second-stage charging and extracting; fourthly, separating and filtering are carried out; fifthly, concentration is carried out, wherein a tea extract solution is concentrated; sixthly, a finished product is sterilized, and thus the finished oolong tea concentrated solution is obtained. According to the method, by means of the synthetic effect of wall-breaking enzyme, tannase and protease with the combination of the tea two-stage charging method, the product yield and production efficiency within the same time can be increased; meanwhile, the oolong tea concentrated solution prepared though the method has high amino acid content with partial ester catechins reserved, and is full in tea sense and mellow in taste, the fresh and mellow sense and the tea sense of oolong tea are intensified, much feature flavor of the oolong tea is reserved, the taste of the oolong tea concentrated solution is upgraded, and diversity of the oolong tea concentrated solution varieties is improved.

Owner:康师傅饮品投资(中国)有限公司

Method for synthesizing polyaspartic acid by maleic anhydride and ammonia gas

ActiveCN104725634AAvoid it happening againProcess environmental protectionHydrolysisSodium hydroxide

The invention relates to a method for synthesizing polyaspartic acid by maleic anhydride and ammonia gas. The method comprises the following steps: performing substitution reaction of molten maleic anhydride and ammonia gas in a closed reactor and absorbing the residual gas after the completion of the substitution reaction; adding sodium hydrate solution into the reacted maleic anhydride and ammonia gas to perform neutrallzation reaction, so as to obtain a mixture of maleamic acid sodium and maleamic acid ammonium; directly heating the product in the closed reactor and performing condensation polymerization by stirring; steaming and drying the moisture after the completion of the condensation polymerization, so as to obtain the polysuccinimide solid; adding water in another reaction kettle and starting stirring; then adding the polysuccinimide solid into the reaction kettle and slowly adding sodium hydrate solution and heating to perform hydrolysis reaction, so as to obtain the polyaspartic acid solution. According to the method for synthesizing polyaspartic acid by maleic anhydride and ammonia gas, the production process is simplified and the polyaspartic acid prepared according to the method has a weight-average molecular weight of 2000-15000 and a molecular weight distribution index of 1.5-1.65, so that molecular weight requirements of various application domains are met and environment-friendly production process is realized.

Owner:HEBEI XIETONG ENVIRONMENTAL PROTECTION TECH CO LTD

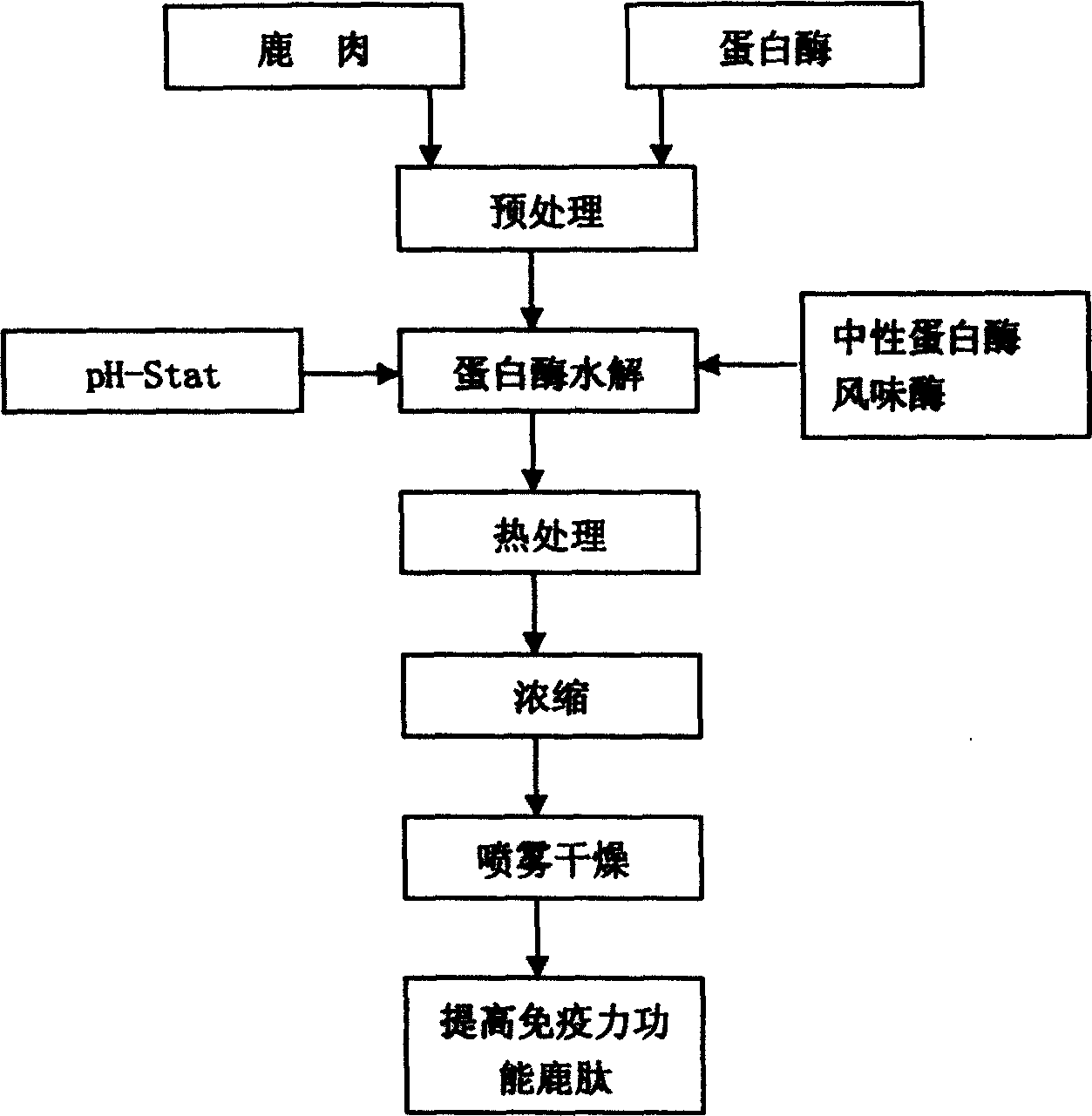

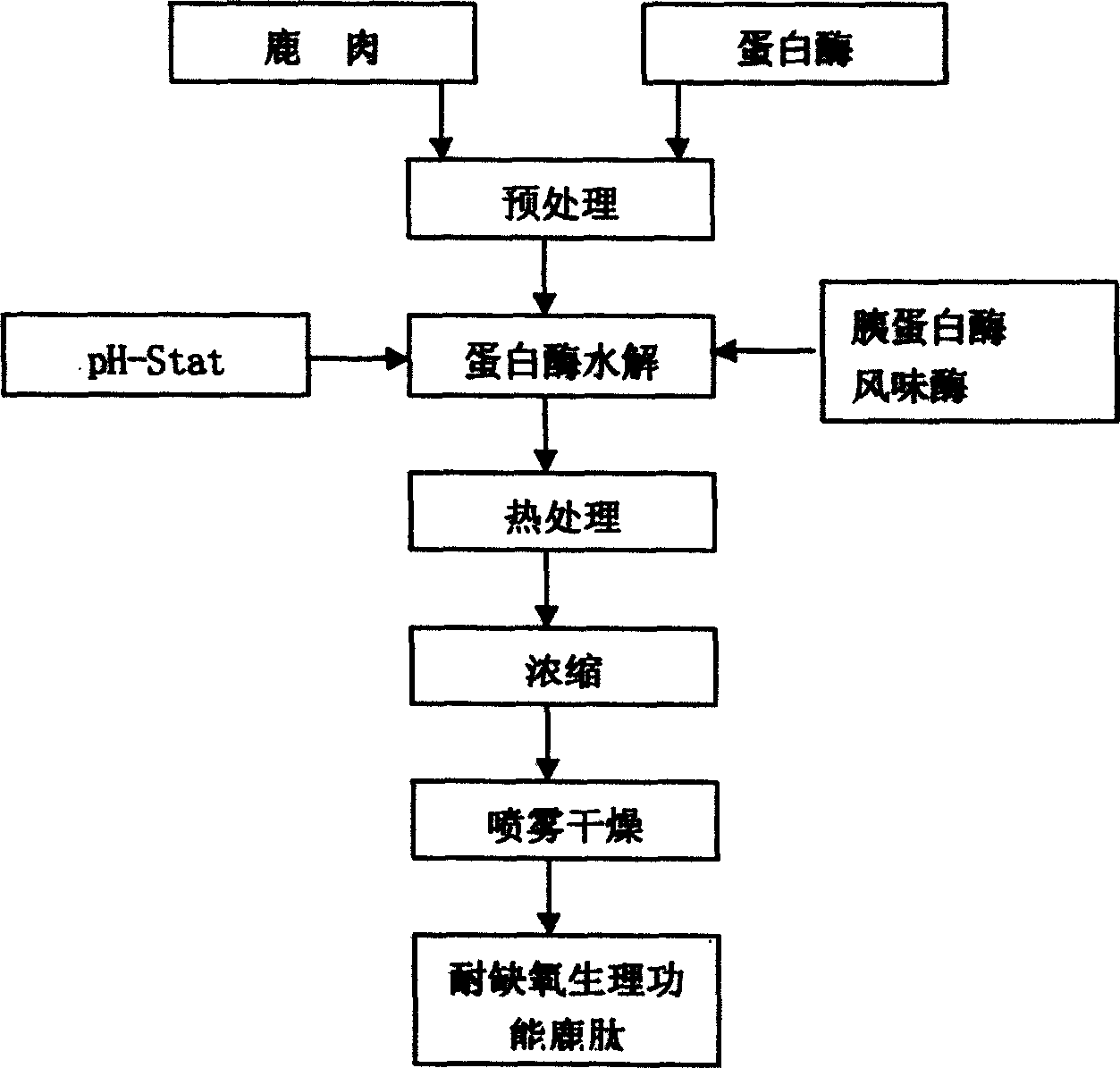

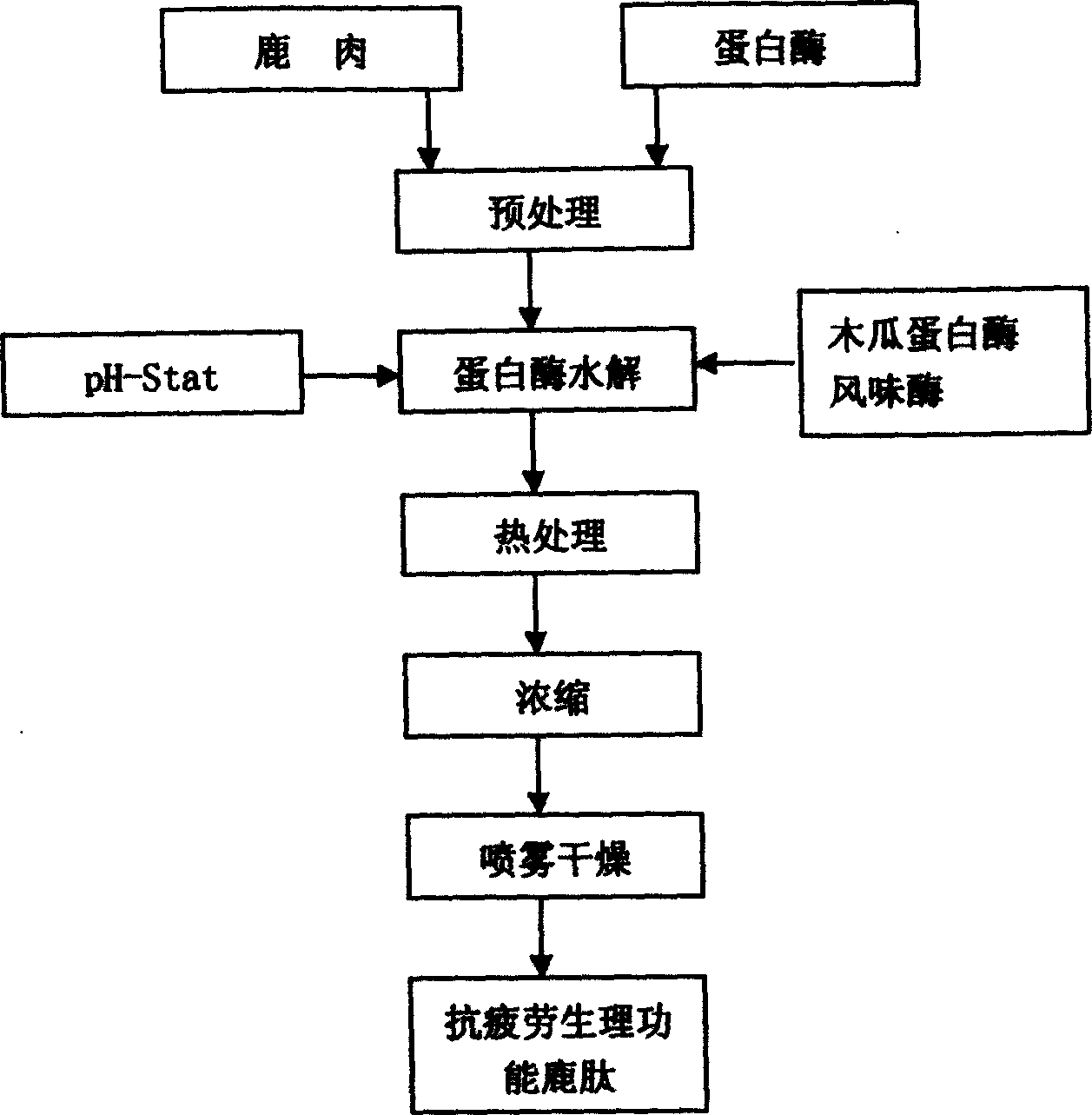

Physiological active buck peptide by compound proteinase catalysis and use of products thereby

InactiveCN1552892AIncrease valueExpand sourcePeptide/protein ingredientsImmunological disordersChemistryNeutral protease

This invention relates to preparation of deer peptide with biological activity by composite protease catalysis and its uses in human immunity, fatigue resistance and hypoxia tolerance. Products are obtained by heating deer meat paste as raw material, which is screened with 80 mesh, to 48-52 deg.C, regulating pH 6.8-7.2 with NaOH solution, stirring and adding neutral protease, papoid or trypsin, then adding fragrant protease after protein hydrolysis to 28-33%, controlling reaction with standard 2M NaOH to make protein hydrolysis to 34 -42%, heating enzymolysed liquid to 114-116 deg.C for 10-15 minutes, sharply cooling to atmosphere, solid-liquid separating, concentrating, and drying to obtain yellow powder or granular products of deer peptide.

Owner:JILIN UNIV

High-argillization coal washing agent

InactiveCN103977909AControl the degree of hydrolysisFully dispersedFlotationAluminium chlorideFoaming agent

The invention discloses a high-argillization coal washing agent. The high-argillization coal washing agent is characterized by comprising a collecting agent, a foaming agent and a flocculating agent, wherein the collecting agent is 390-440g / t of N9883; the foaming agent is 400-430g / t of fusel; the flocculating agent comprises polyacrylamide and polymeric aluminum; the control concentration of the polymeric aluminum is 0.5-1.2 percent; the preparation concentration of the polyacrylamide is 0.1-0.15 percent; the usage of the polyacrylamide is required to be controlled to be 0.1-1 percent according to a volume ratio. Compared with the prior art, the high-argillization coal washing agent has the advantages that slime water is timely clarified, so that coal can be washed by clean water, slime is recovered, and the coal washing water is recycled.

Owner:SHANDONG DONGSHAN WANGLOU COAL MINE

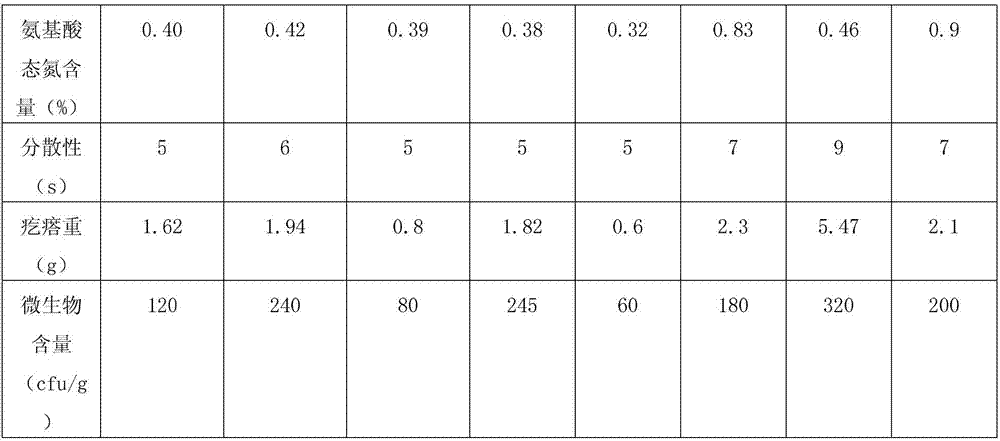

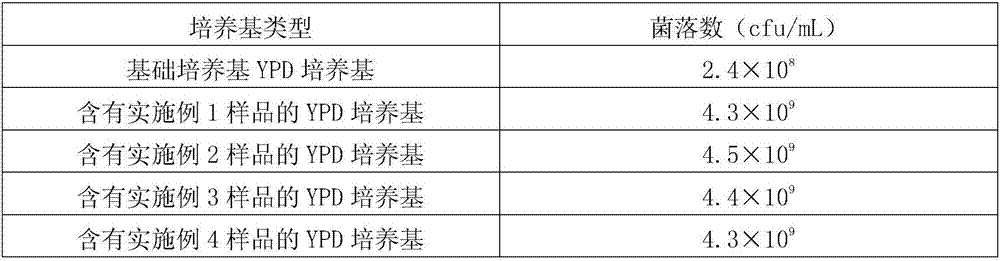

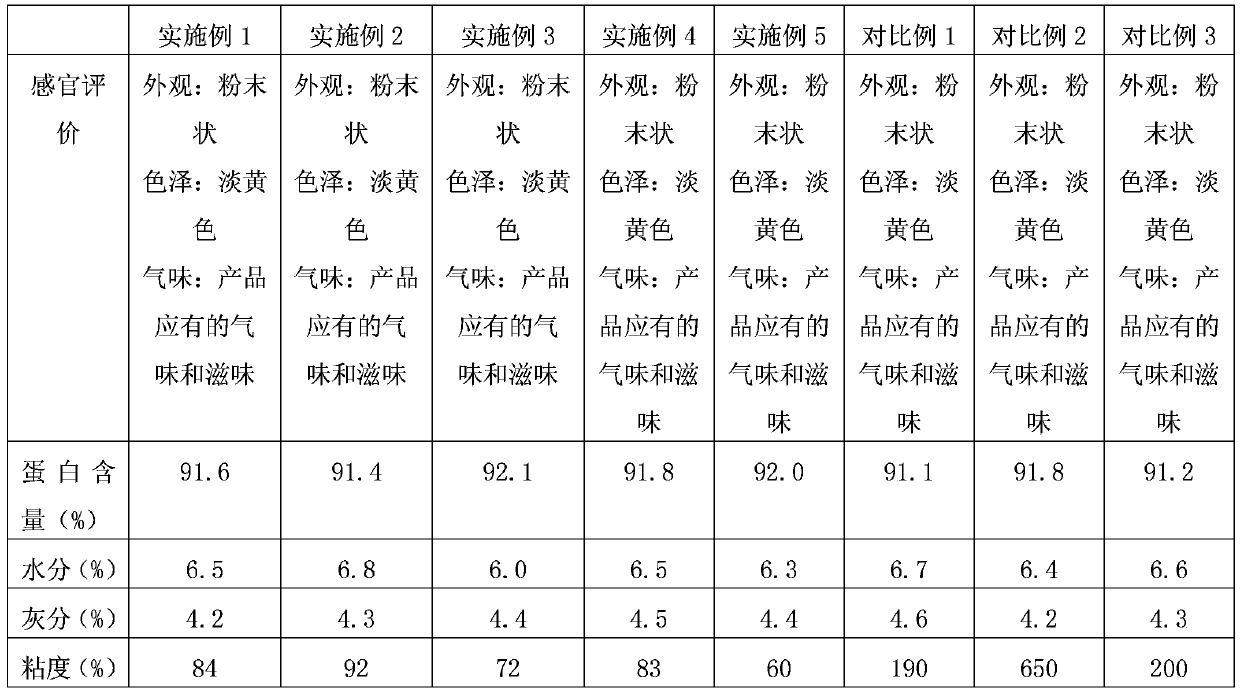

Method for preparing microorganism-dedicated soybean protein isolate

ActiveCN107312813AAppropriate degree of enzymatic hydrolysisAppropriate molecular weightPlant peptidesFermentationAlkaline proteaseNeutral protease

The invention discloses a method for preparing microorganism-dedicated soybean protein isolate. The method comprises the following steps: soaking low-temperature degreased soybean meal in an alkali solution with a pH value of 9.5 to 10.0 at a temperature of 50 to 55 DEG C, adjusting the pH value to 6.8 to 7.4, the sugar content to 8.0 to 9.0, stirring for 40 to 60min, and performing solid-liquid separation to obtain a crude protein extracting solution; adding an acid solution into the crude protein extracting solution at room temperature, stirring for 10 to 50min, and centrifuging to obtain acid-precipitated protein; dissolving the acid-precipitated protein in water at room temperature, adjusting the pH value to 6.00 to 6.30 and the sugar content to 18.0 to 19.5 to obtain an acid-precipitated protein solution; adding neutral protease and alkaline protease, reacting at 50 to 60 DEG C for 0.5 to 3h to obtain enzymatic hydrolysate; performing sterilization, flash treatment and spray drying to obtain the microorganism-dedicated soybean protein isolate. The soybean protein isolate prepared according to the invention has good dispersibility, low viscosity and suitable amino acid nitrogen, and has the advantages of simple process, easy operation, strong protein practicability, wide application in fermentation industry and better popularization value.

Owner:SHANDONG YUWANG ECOLOGY FOOD IND

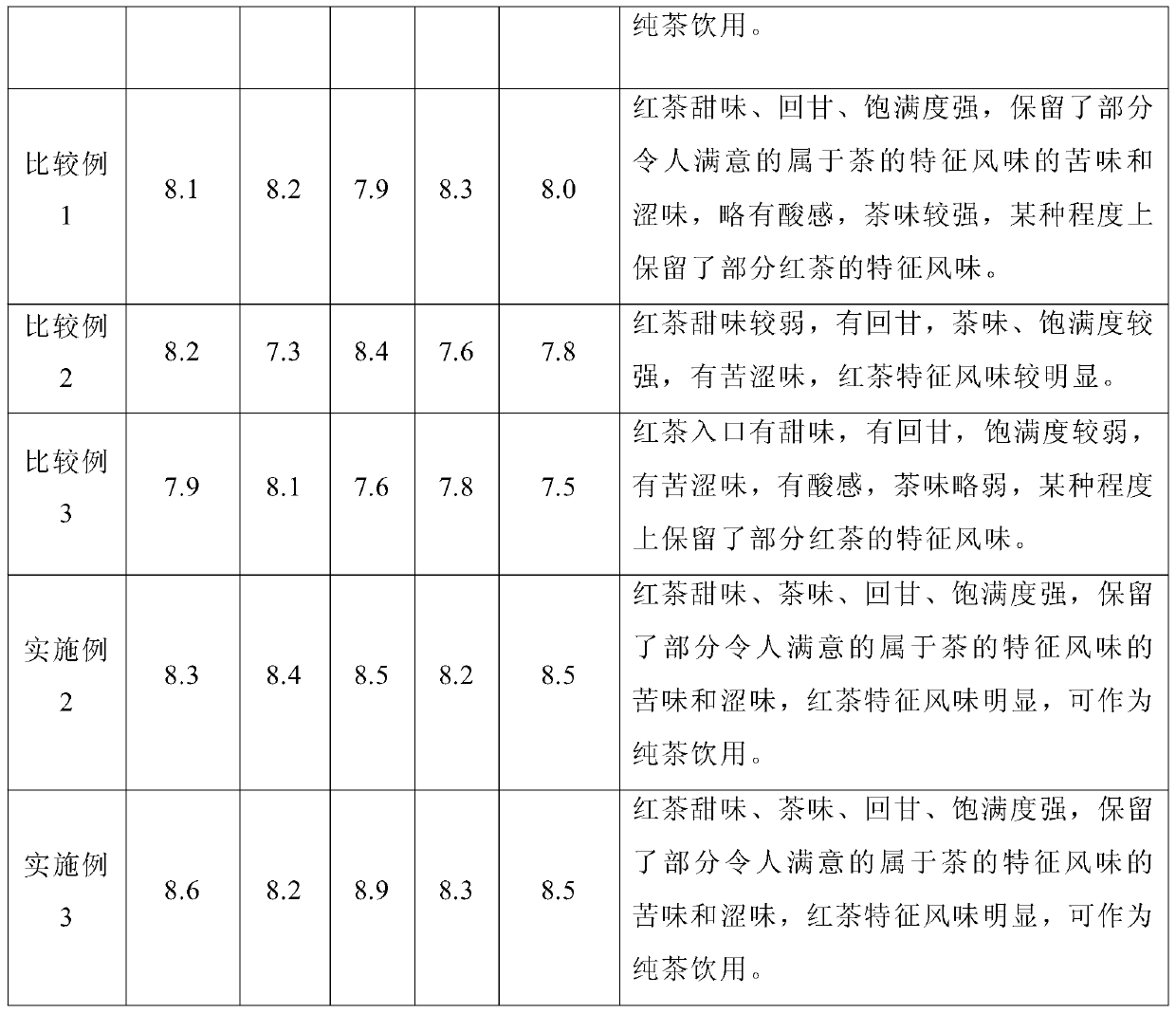

Method and device for producing methane gas and lignin from straws

InactiveCN104818298AImprove enzymatic hydrolysis efficiencyReduce inhibitionApparatus sterilizationGas production bioreactorsFiltrationHydrolysate

The invention discloses a method and device for producing methane gas and lignin from straws. The method comprises the following steps of removing impurities of straws, crushing the straws into straw powder, feeding the straw powder into a hydrolysis device, controlling a hydrolysis degree until all hemicelluloses is hydrolyzed and 20-100% of cellulose is hydrolyzed, feeding an upper hydrolysate into an anaerobic fermentation pool, carrying out fermentation to obtain crude methane gas, discharging lower lignin slurry, and carrying out filtration and drying to obtain lignin powder. Straw hydrolase comprises excision beta glucanase, incision beta glucanase, beta glucosidase and xylanase according to a mass ratio of 1: 1.2-10: 0.8-5: 1.5-8. The culture contains an inducer activator, and in use, the culture is added with a starter. The method and device used by the method fully utilize straws, produce methane gas and lignin, adjust a straw hydrolysis degree, produce marketable products and are suitable for different raw materials.

Owner:CATECH TECH

Preparation method of skim polypeptide cow milk

ActiveCN103329992AImprove nutritional statusPromote digestion and absorptionMilk preparationNeutral proteaseNutritional status

The invention discloses a preparation method of a skim polypeptide cow milk. By enzymolysis of skim milk, a high-quality functional liquid dairy product rich in milk protein peptides can be prepared. In the invention, a key enzyme system is directly employed to hydrolyze milk protein, and the optimal enzymolysis conditions of skim polypeptide cow milk are determined. Specifically, papain and neutral protease with an enzyme dosage of 750U / g protein are compounded in a ratio of 1U:1U, and the skim milk is hydrolyzed at 55DEG C for 25min, so that the hydrolysis degree of milk protein can reach the highest (44-45%). The method provided in the invention maintains the colloidal properties of milk while producing milk peptide, improves the nutritional status of protein in milk, enhances the product quality, and enables the product to be absorbed by the intestine more easily. The product has the efficacy of restoring physical power and promoting rapid energy replenishing of muscles. The functional polypeptide cow milk is suitable for all consumer groups, including rehabilitation patients, the elderly with declined digestive functions, infants with weak gastrointestinal functions and the like.

Owner:黑龙江省康平生物工程有限责任公司

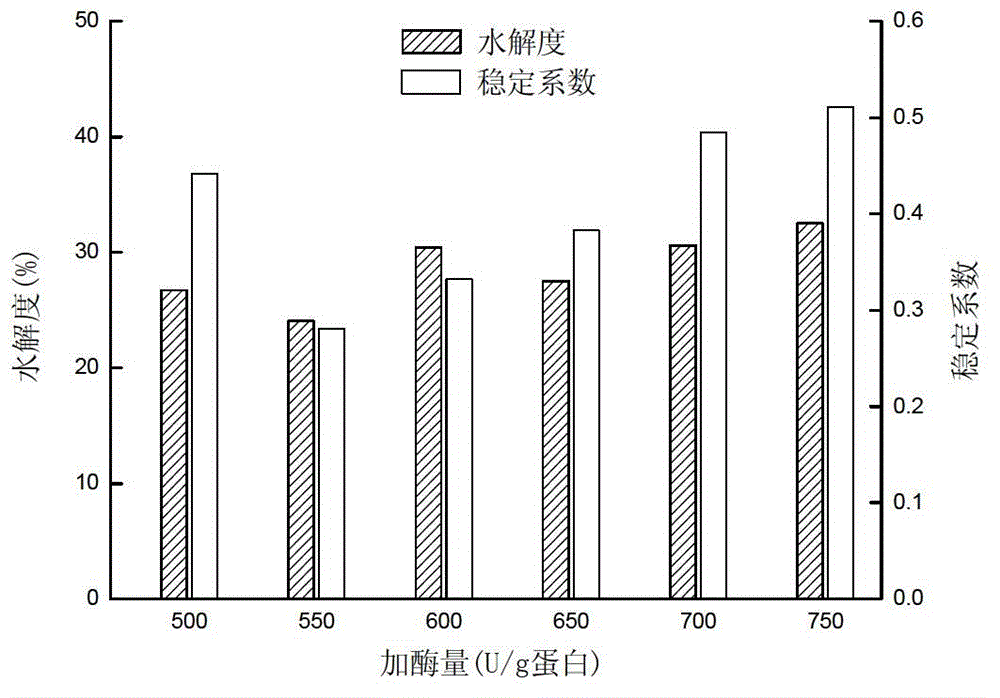

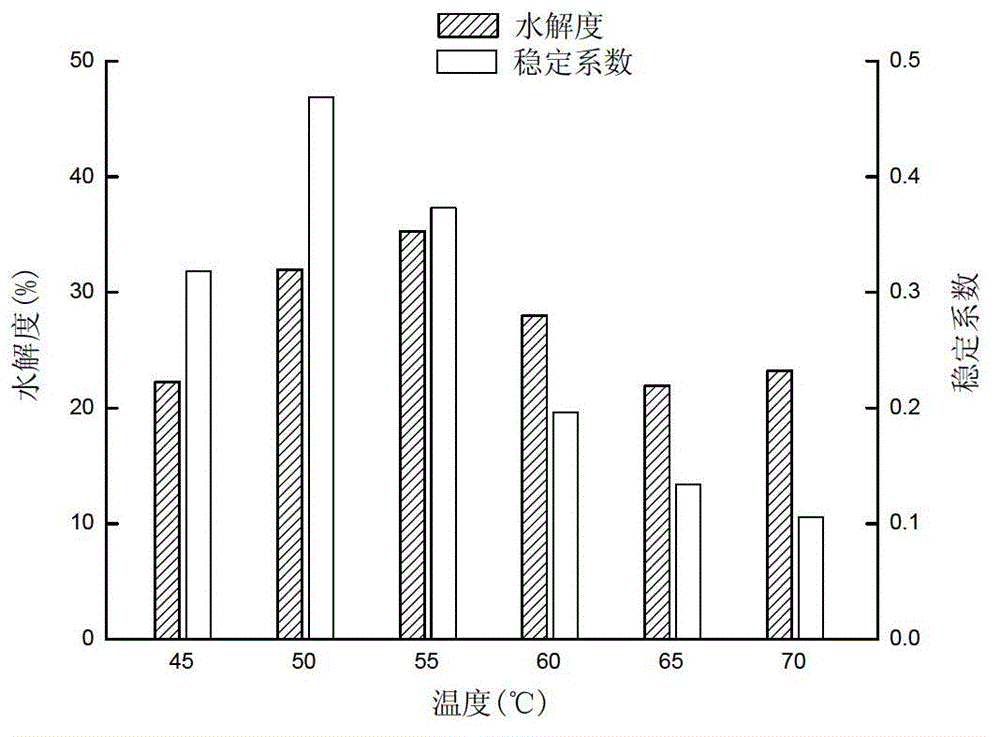

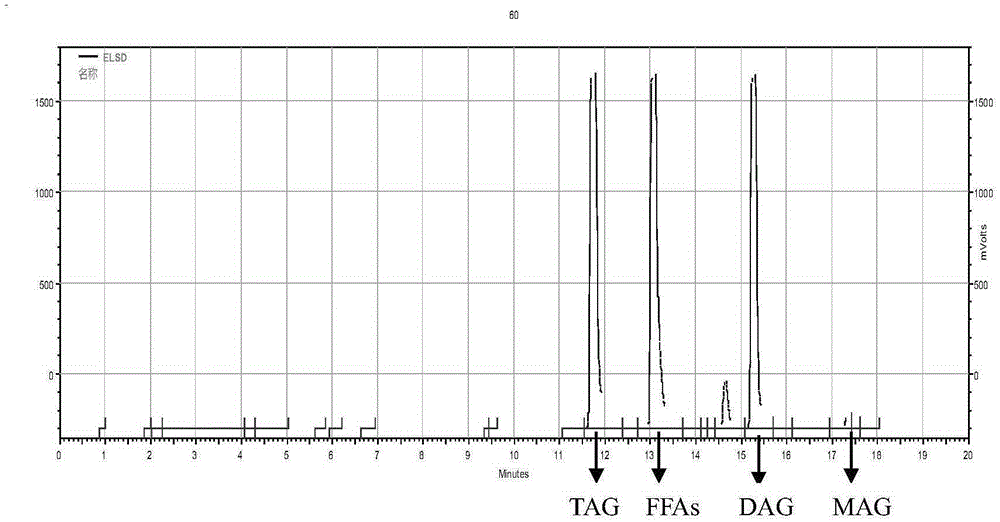

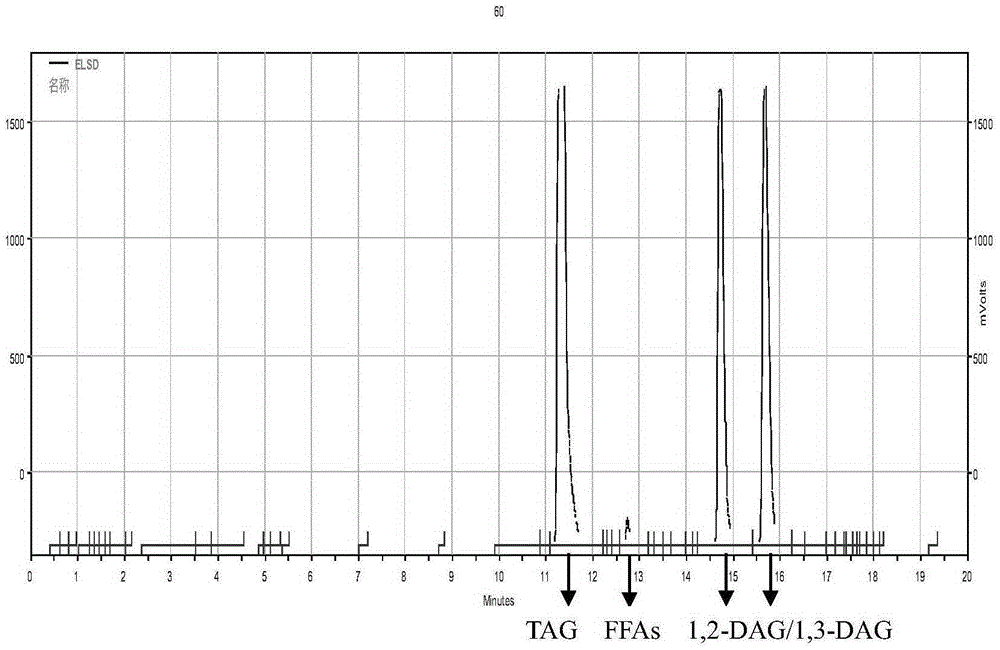

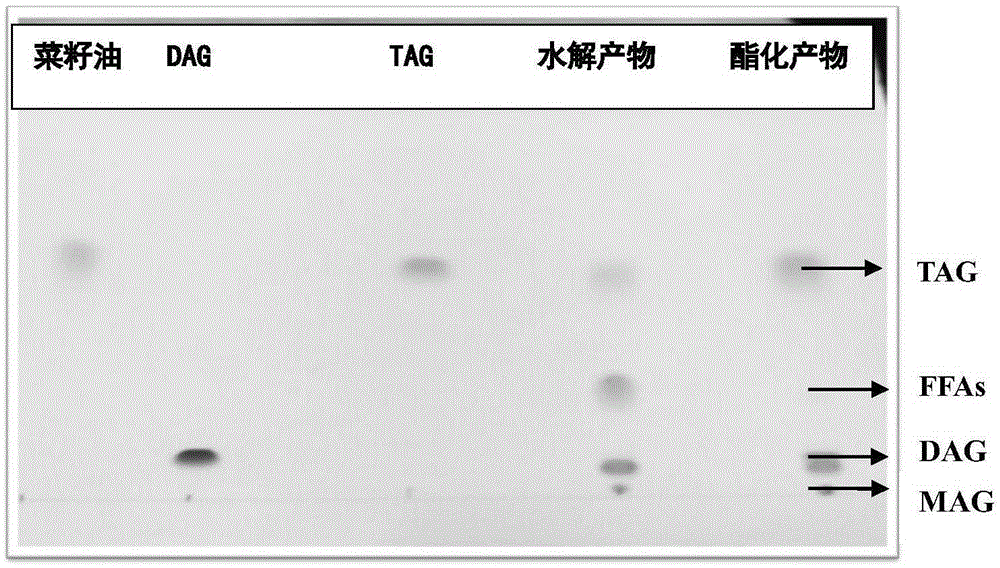

Method for preparing diglyceride through enzyme catalysis

The invention discloses a method for preparing diglyceride through enzyme catalysis. The method is characterized by including the following steps that firstly, grease parts are hydrolyzed, wherein edible oil is partially hydrolyzed through an enzyme catalysis hydrolysis method, hydrolysis products are obtained through dewatering, the content of diglyceride in the hydrolysis products ranges from 30.0wt% to 35.0wt%, and the content of free fatty acid ranges from 26.0wt% and 30.0wt%; secondly, esterification is performed, glycerin with the mass 2.5-4 times of that of the hydrolysis products is added in the hydrolysis products obtained in the first step, an esterification reaction is performed through an enzyme catalysis esterification method, diglyceride is synthesized, and the edible diglyceride is obtained after excessive glycerin is removed. According to the method, free fatty acid does not need to be independently prepared, and operation is easy; excessive hydraolysis can be avoided, and total controllability is high; besides, the method is high in diglyceride yield, the acid value is low, acid removing treatment does not need to be performed on finished products, preparation cost is substantially reduced, and the method is suitable for large-scale industrial production.

Owner:HUAZHONG UNIV OF SCI & TECH

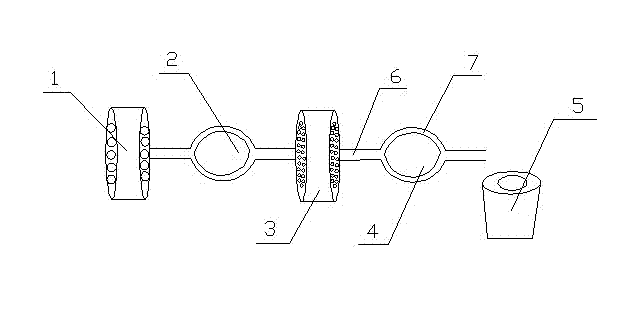

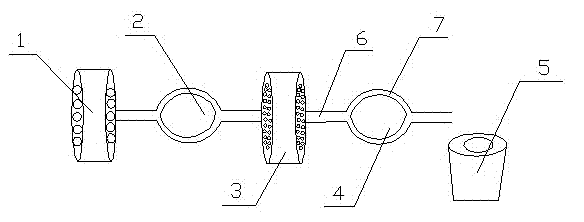

Method for evenly mixing wet gluten with alkali liquor

The invention discloses a method for evenly mixing wet gluten with alkali liquor, and the method is realized by virtue of a wet gluten and alkali liquor mixing device. The wet gluten and alkali liquor mixing device comprises a large-aperture perforated plate, a pipeline mixer I, a small-aperture perforated plate, a pipeline mixer II and a homogenizer, wherein the large-aperture perforated plate, the pipeline mixer I, the small-aperture perforated plate and the pipeline mixer II are connected in sequence. Because multi-path and multi-step mixing is adopted in the method, the large-aperture perforated plate and the pipeline mixer I are used for primary mixing; the small-aperture perforated plate and the pipeline mixer II are used for secondary mixing; and finally, the homogenizer is used for final mixing to achieve the purpose of mixing, thereby controlling the use amount of the alkali liquor, causing the degree of hydrolysis of the product to achieve the requirement, and preventing theash content from exceeding the standard. The method ensures the mixing effect of the wet gluten and the alkali liquor to be good, is convenient to operate and is convenient for mass production.

Owner:HENAN TIANGUAN GRP

Method for preparing antioxidant chicken protein polypeptide

PendingCN109055470AImprove cleanlinessImproves antioxidant activityPeptide preparation methodsFermentationProteinase activityHydrolysate

The invention discloses a method for preparing an antioxidant chicken protein polypeptide. The method comprises the following steps: 1. taking fresh chicken breast and chicken skeleton as raw materials, cleaning and removing blood water in chicken; 2. adding water to cook; 3. using a colloid mill to grind the cooked chicken breast and chicken skeleton; 4. weighing three proteases; 5. adjusting thepH value and temperature, adding the weighed proteases; 6. after the end of an enzymatic reaction, heating and killing the enzyme to obtain an enzymatic hydrolysate; 7. filtering and ultra-filteringthe enzymatic hydrolysate; 8. adding a filtrate obtained in step 7 to a mixing tank, and concentrating to obtain a concentrated liquid; 9. drying the concentrated liquid to obtain the antioxidant chicken protein peptide. The method for preparing the antioxidant chicken protein polypeptide disclosed by the invention can decompose the chicken protein into a polypeptide, has a good flavor, is rich innutrition, and has the characteristic of high antioxidant activity.

Owner:GUANGDONG CHUBANG FOOD

Method for preparing porous starch through enzyme method in high temperature

A process for preparing the porous starch by high-temp enzyme method includes such steps as proportionally mixing starch with water, regulating pH=1.5-12.5, adding the cross-linking agent with multiple function groups, stirring while reacting to obtain cross-linked starch, regulating pH=6-7, dewatering, washing, drying to obtain powdered cross-linked starch, regulating concentration of emulsion, adding amylase, enzymolyzing, regulating pH=6-7, filtering, washing, centrifugal dewatering, pulverizing filtered cake, and drying to obtain porous starch.

Owner:SOUTH CHINA UNIV OF TECH

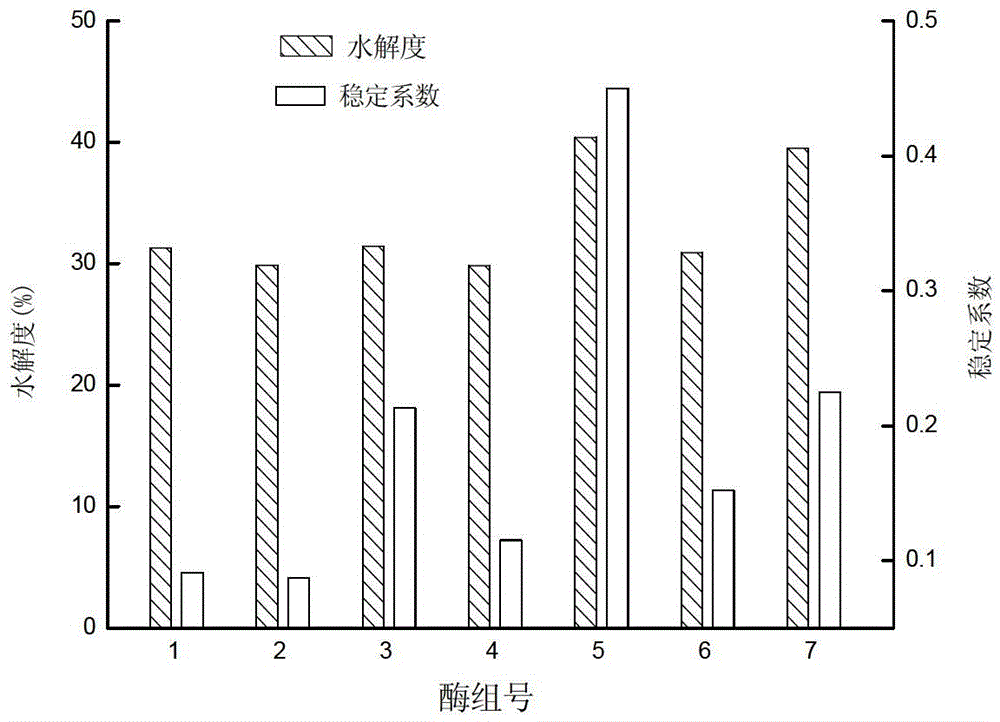

Preparation method of oligopeptide flavor enhancer by controllable enzymolysis proteins

InactiveCN102125251AIncrease hydrolysis rateHigh oligopeptide contentFood preparationChemistryMolecular weight cut-off

The invention provides a preparation method of an oligopeptide flavor enhancer by controllable enzymolysis proteins. The preparation method is characterized by comprising the steps of: (1) wetly smashing and degreasing pigeon meat; (2) adding the pigeon meat into an enzymolysis pot, and performing the enzymolysis by adding flavored protease and water, wherein the condition is that the temperature is 47-55 DEG C, the use level of the enzyme is 8-10% of the weight of the protein meat, the volume ratio of the protein meat weight to the water is 1: (3-4), the PH value is adjusted to be 6-7, and the reaction time is 3-3.5 hours; pumping the pigeon meat into an ultrafiltration membrane separating device with the cut-off molecular weight of 1000-20000 Da, feeding the pigeon meat proteins and the enzyme with large molecules in the enzymolysis pot for continuous enzymolysis; and repeating the steps till that the oligopeptide is generated wholly or the amino acid is generated partially; and (3) pumping the enzymolysis liquid obtained in the step (2) into a spray dryer, wherein the wind inlet temperature is 150-170 DEG C, the wind outlet temperature is 75-95 DEG C, and the pressure is 560-700 mm Hg. The method takes the pigeon meat or the chicken as a preparation raw material, and has the advantages of being high in pigeon meat protein enzymolysis speed rate and enzymolysis rate, short in enzymolysis time, and high in oligopeptide content in the product.

Owner:JIANGXI XIANGCHU IND CO LTD

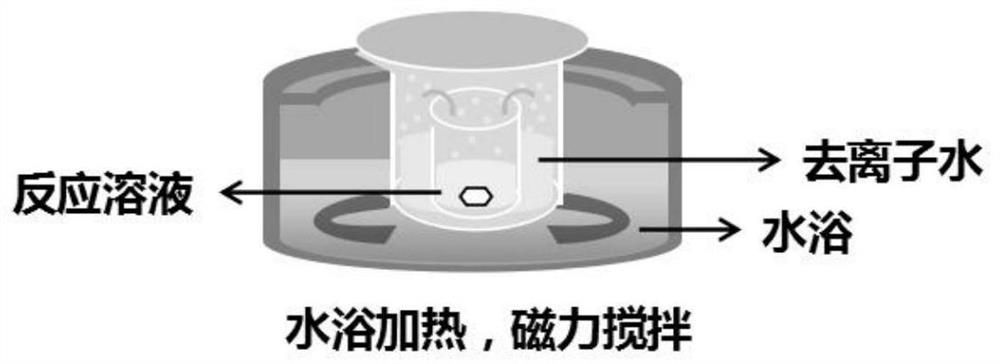

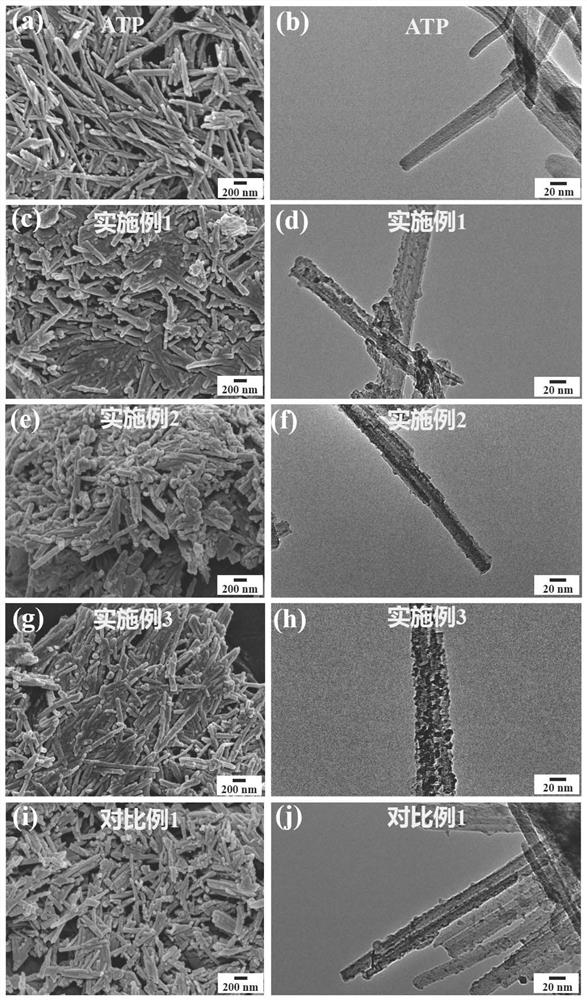

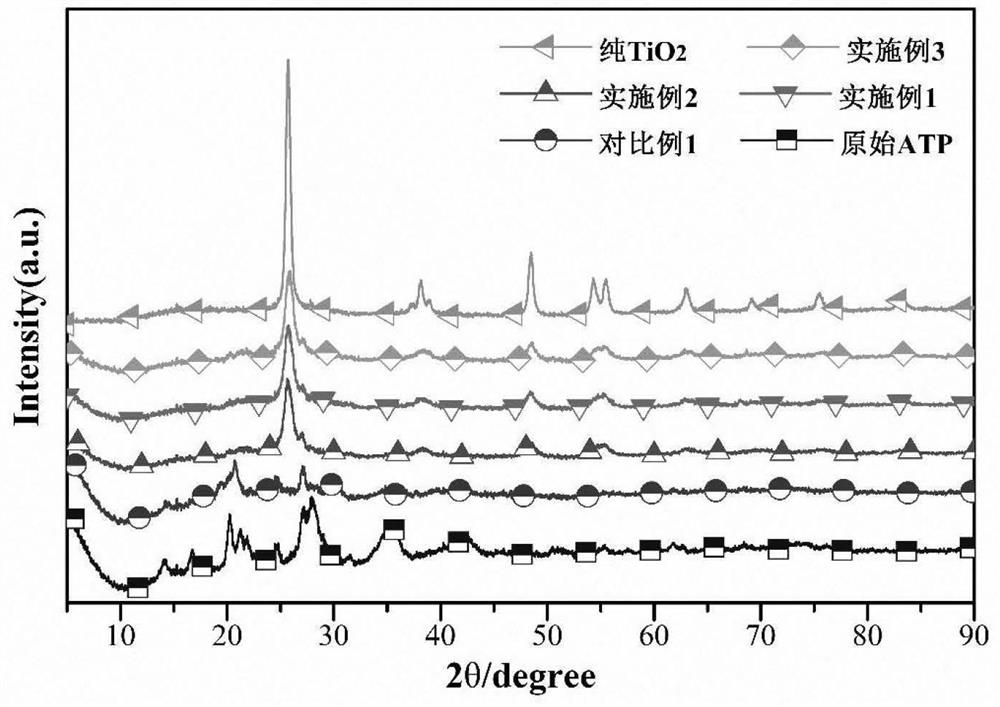

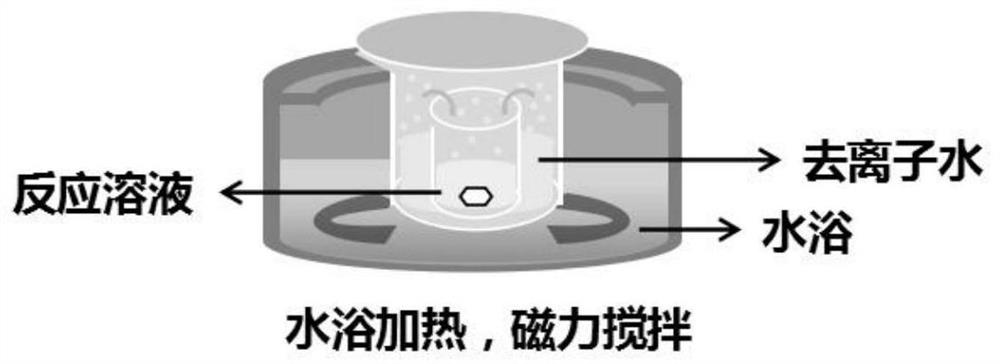

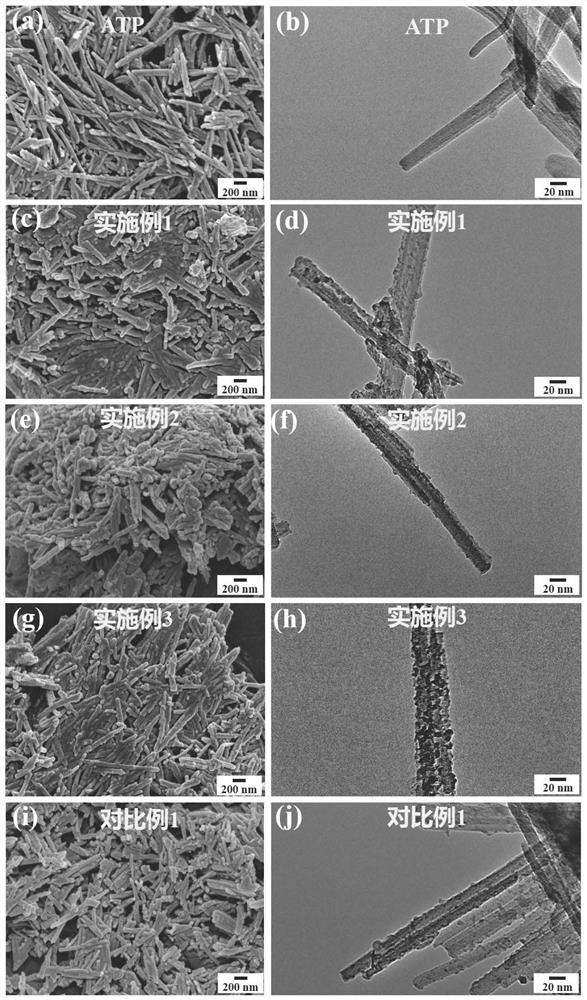

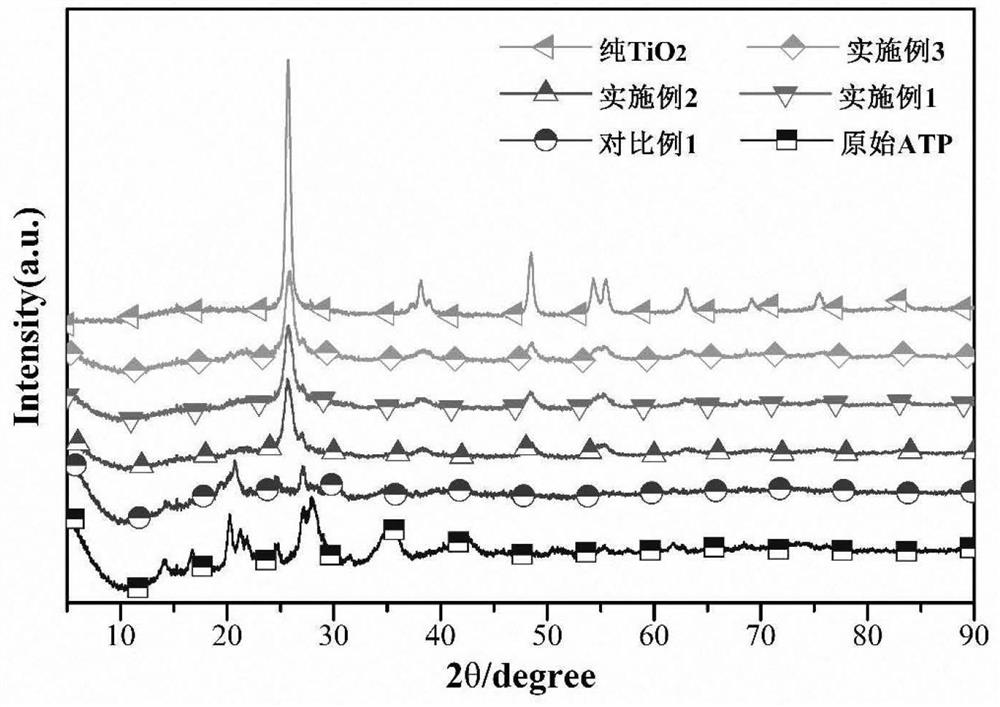

Method for uniformly preparing attapulgite-titanium dioxide composite material

ActiveCN112108137AEvenly distributedGuaranteed uniformityPhysical/chemical process catalystsEnergy based wastewater treatmentHybrid materialHydrolytic Process

The invention provides a method for uniformly preparing an attapulgite-titanium dioxide composite material, which belongs to the technical field of hybrid materials. A steam hydrolysis method is adopted, magnetic stirring is assisted in the whole hydrolysis process, hydrolysis is conducted through a water bath constant-temperature heating method, meanwhile, the stirring rotating speed and the water bath temperature are controlled, accordingly, the contact speed of attapulgite and water vapor and the hydrolysis degree of butyl titanate are controlled, the uniformity of titanium dioxide can be guaranteed, titanium dioxide in the obtained attapulgite-titanium dioxide composite material is uniformly distributed on the surface of attapulgite, and meanwhile, attapulgite in the composite materialstill keeps low agglomeration.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Water-soluble radix puerariae fiber oligosaccharide and preparing method thereof

ActiveCN105410948AImprove accessibilityImprove efficiencyFood ingredient functionsFood ultrasonic treatmentFunctional foodEnzymatic hydrolysis

The invention discloses water-soluble radix puerariae fiber oligosaccharide and a preparing method thereof. The preparing method includes the steps that 1, radix puerariae residues are adopted as a raw material, water is added, and the radix puerariae residues are smashed in a stirred mode to obtain radix puerariae residue pulp; 2, the radix puerariae residue pulp is placed in an electric heating oil bath pan for steam precooking, and radix puerariae fiber residues are obtained through suction filtration; 3, the radix puerariae fiber residues are prepared into radix puerariae fiber residue pulp; 4, the radix puerariae fiber residue pulp is subjected to enzyme hydrolysis for two times and treated ultrasonically and supplementarily to obtain radix puerariae fiber hydrolysate; 5, membrane separation is carried out on the radix puerariae fiber hydrolysate obtained after enzyme hydrolysis is conducted for two times, fiber oligosaccharide with the polymerization degree of 2-5 is enriched, and the good-water-solubility fiber oligosaccharide with the polymerization degree of 2-5 can be prepared. The water-soluble radix puerariae fiber oligosaccharide can serve as prebiotics to be applied to related functional food and medicine, new resources are developed, and a new way is provided for full utilization of radix puerariae.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI +1

Preserved egg protein polypeptide beverage and preparation method thereof

The invention provides a preserved egg protein polypeptide beverage. The beverage is prepared from a main material namely preserved egg protein enzymatic hydrolysate in mass concentration of 4-6% andauxiliary materials, wherein the auxiliary materials include, by mass of the preserved egg protein enzymatic hydrolysate, 0.75%-1.75% of concentrated lemon juice, 1%-3% of concentrated mango juice, 7.5%-17.5% of white granulated sugar, 7.5%-17.5% of brown granulated sugar, 2%-3% of complex gum and the balance water. The beverage is naturally brownish yellow in color, has a preserved egg flavor slightly and is sweet slightly, harmony in taste, free of off-odor, crystal bright in liquid, free of evident precipitates and layering and high in fluidity.

Owner:HUBEI SHENDAN HEALTHY FOOD

Preparation method of skim polypeptide cow milk

ActiveCN103329992BImprove nutritional statusPromote digestion and absorptionMilk preparationNeutral proteaseNutritional status

The invention discloses a preparation method of a skim polypeptide cow milk. By enzymolysis of skim milk, a high-quality functional liquid dairy product rich in milk protein peptides can be prepared. In the invention, a key enzyme system is directly employed to hydrolyze milk protein, and the optimal enzymolysis conditions of skim polypeptide cow milk are determined. Specifically, papain and neutral protease with an enzyme dosage of 750U / g protein are compounded in a ratio of 1U:1U, and the skim milk is hydrolyzed at 55DEG C for 25min, so that the hydrolysis degree of milk protein can reach the highest (44-45%). The method provided in the invention maintains the colloidal properties of milk while producing milk peptide, improves the nutritional status of protein in milk, enhances the product quality, and enables the product to be absorbed by the intestine more easily. The product has the efficacy of restoring physical power and promoting rapid energy replenishing of muscles. The functional polypeptide cow milk is suitable for all consumer groups, including rehabilitation patients, the elderly with declined digestive functions, infants with weak gastrointestinal functions and the like.

Owner:黑龙江省康平生物工程有限责任公司

Rice protein polypeptide and preparation method thereof

ActiveCN102212107BControl the degree of hydrolysisWide range of hydrolysis conditionsPlant peptidesFermentationTotal proteinRice protein

The invention relates to a rice protein polypeptide and also relates to a composite enzyme preparation method of the rice protein polypeptide. The preparation method comprises the following steps: size mixing, degreasing, centrifuging, homogenizing, enzymolysis reaction, sterilization and enzyme inactivation, centrifugal separation, concentration, drying and the like. The rice protein polypeptideprepared by using the preparation method has a protein content of 80% in percentage by weight and a fat content of 1% or below in percentage by weight, and has high bioactivity; the peptides of whichthe molecular weight distribution is 100-1000 Da account for more than 90% of the total protein content; and the product are completely soluble in water.

Owner:WUXI JINNONG BIOTECH CO LTD

A kind of preparation method of cyclodextrin

ActiveCN104531808BControl the degree of hydrolysisGood application effectFermentationAmylaseCyclodextrin

The invention relates to a preparation method of cyclodextrin, comprising the following steps: (1) preparing starch slurry; (2) adding α-amylase, glucosidase and pullulanase to the starch slurry, insulated for reaction, and then adding Cyclodextrin glucosyltransferase, react for 2 to 3 hours, stop the reaction, and prepare the cyclodextrin feed liquid; (3) add α-amylase, glucosidase and pullulanase to the cyclodextrin feed liquid, react 1.5 to 2 hours to obtain a cyclodextrin crude liquid; (4) add flocculant and activated carbon to the cyclodextrin crude liquid to decolorize, and then undergo separation and nanofiltration membrane filtration to obtain a cyclodextrin purified liquid; (5 ) Concentrate and dry the cyclodextrin purified liquid to obtain cyclodextrin. The present invention greatly increases the ratio of α and γ-cyclodextrin in cyclodextrin in the reaction product without using an organic solvent, while the content of β-cyclodextrin is relatively small, which greatly improves the ratio of cyclodextrin Application scope and application effect.

Owner:SHANDONG BAILONG CHUANGYUAN BIO TECH

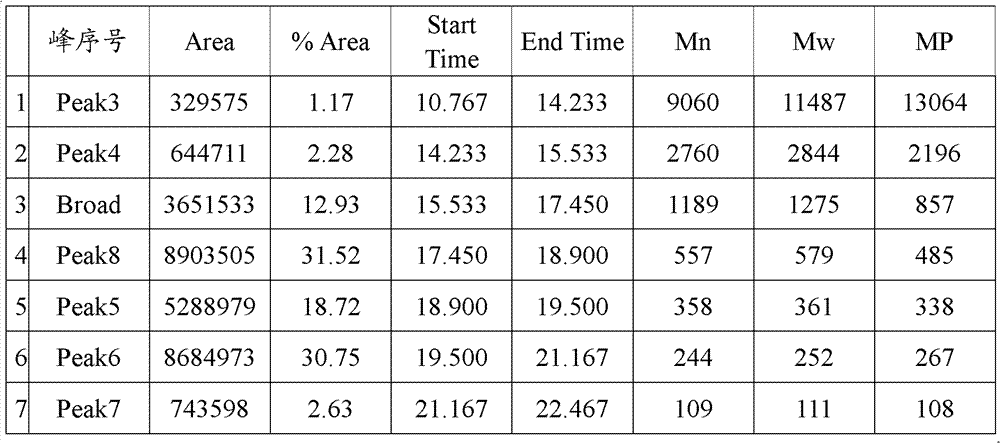

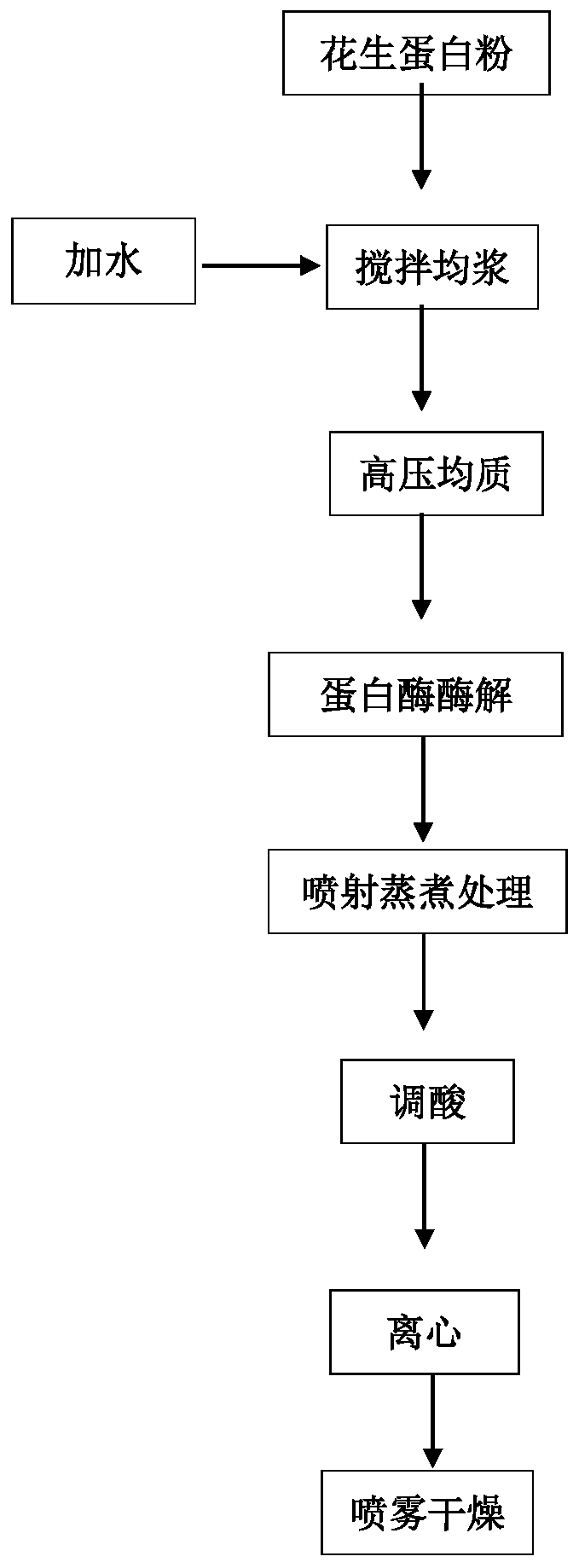

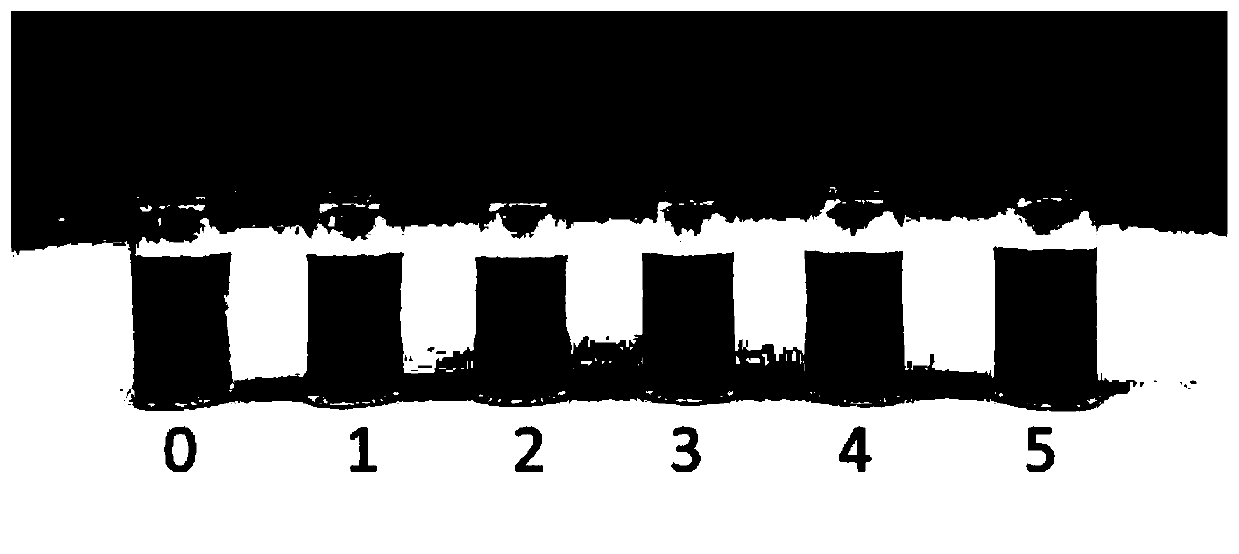

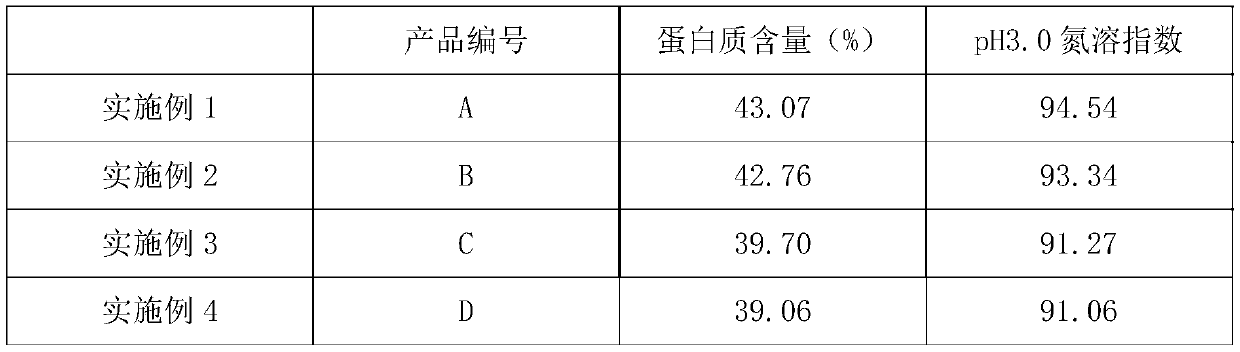

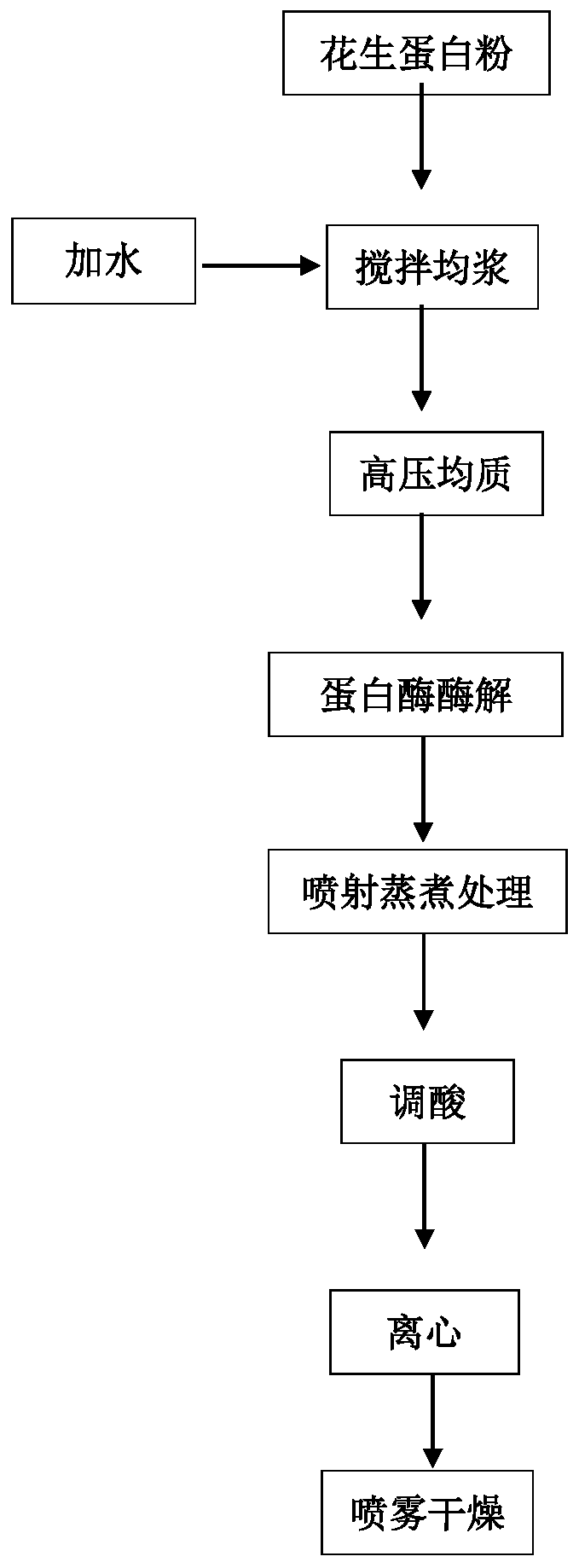

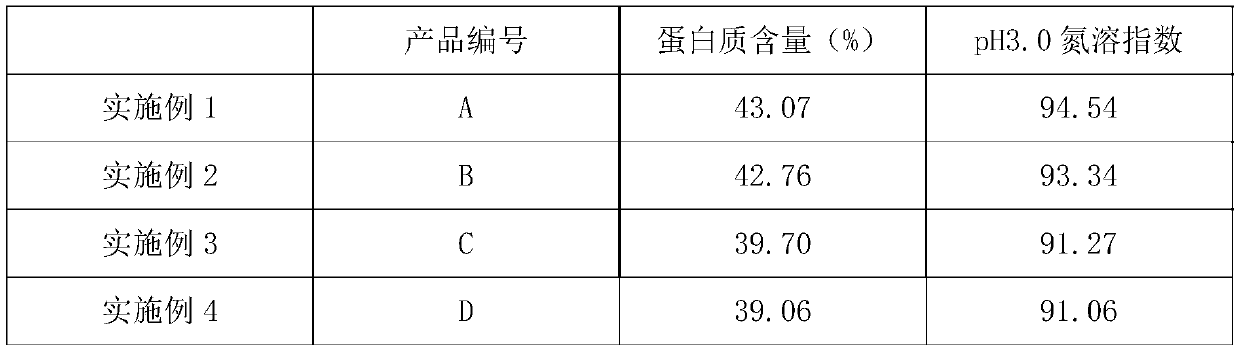

Acid-soluble peanut protein and preparation method and application thereof

ActiveCN110100947ASuitable for industrial productionControl the degree of hydrolysisFood ingredientsVegetable proteins working-upProtein solutionNeutral protease

The invention relates to an acid-soluble peanut protein and a preparation method and application thereof. The preparation method comprises the following steps that 1, peanut protein slurry is subjected to high-pressure homogenization to obtain a peanut protein solution; 2, the peanut protein solution is subjected to enzymolysis at 20-70 DEG C for 10-50 minutes by using 200-1000 U / g neutral protease; 3, the peanut protein solution obtained after enzymolysis is subjected to injection cooking for 60-180 seconds at 100-180 DEG C; 4, the peanut protein solution obtained after injection cooking is subjected to acidity adjustment until the pH value is 2.0-4.0. The acid-soluble peanut protein prepared through the method is almost free of bitterness and astringency, and the nitrogen dissolution index of the acid-soluble peanut protein is not lower than 91% when the pH value is 3.0; the acid-soluble peanut protein can be applied to processing of acid beverages.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

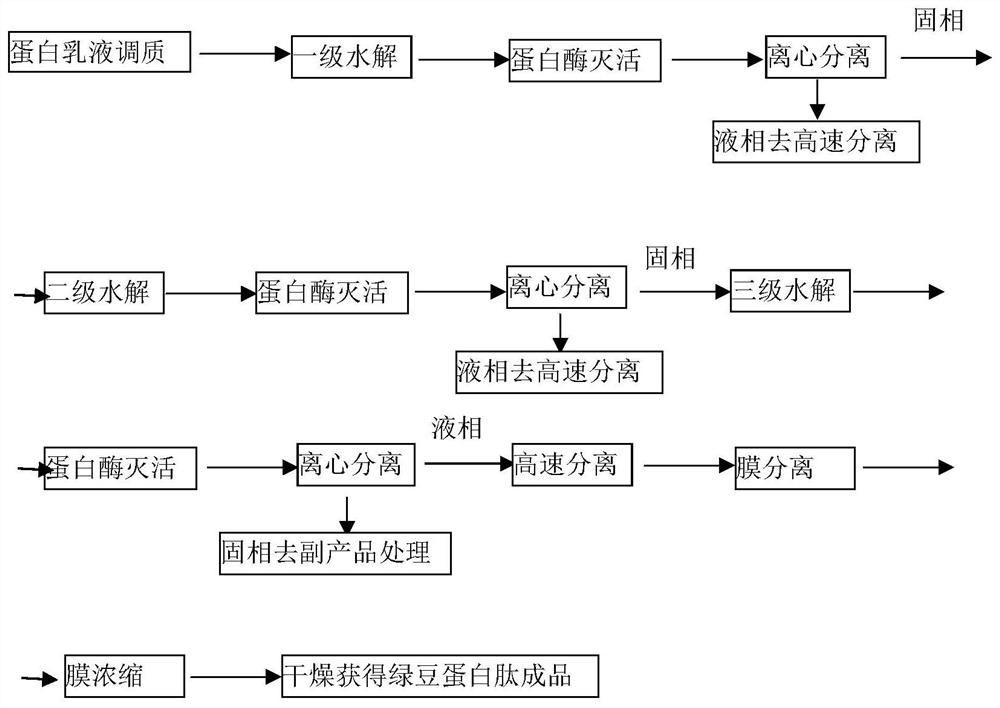

Mung bean protein peptide preparation method

InactiveCN112877392AIncrease hydrolysis rateControl the degree of hydrolysisPeptide preparation methodsFermentationFluid phaseUltrafiltration

The invention discloses a mung bean protein peptide preparation method, which belongs to the technical field of protein peptide processing, and comprises the following steps: (1) conditioning protein emulsion; (2) conducting primary hydrolysis; (3) conducting protease hydrolysis; (4) conducting centrifugal separation; (5) carrying out high-speed separation on a liquid phase, and carrying out secondary hydrolysis on a solid phase; (6) carrying out protease inactivation; (7) carrying out centrifugal separation; (8) carrying out high-speed separation on the liquid phase, and carrying out third decomposition on the solid phase; (9) carrying out protease inactivation; (10) performing centrifugal separation, removing by-products from the solid phase, and performing high-speed separation on the liquid phase; (11) performing membrane separation; (12) performing membrane concentration; and (13) drying to obtain a mung bean protein peptide finished product. According to the method, the peptide conversion rate of the mung bean protein is increased through fractional hydrolysis, ultrafiltration membrane separation and nanofiltration membrane concentration, the peptide content of a product is stabilized, the proportion of small molecule peptides less than 500d is increased, the peptide activity is improved, and the evaporation energy consumption is reduced.

Owner:刘尚顺

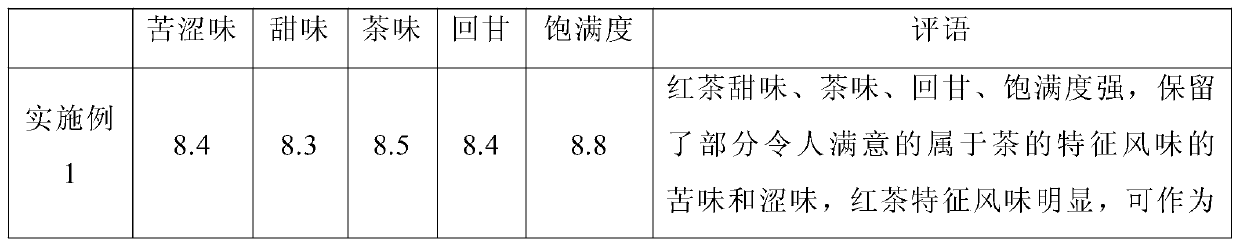

A kind of preparation method of black tea concentrate

ActiveCN105076580BPreserve the characteristic flavorIncrease the sweetness of the entranceTea extractionAmylaseEnzymatic hydrolysis

The invention relates to a preparation method of a black tea concentrated solution. The method includes the steps that firstly, tea leaves are extracted, wherein after tea leaf raw materials are thrown in, RO water at the temperature of 70-95 DEG C is added, and the tea leaf raw materials are extracted; secondly, enzymolysis reaction is performed, wherein tannase, lyticase, amylase and protease are sequentially added, enzymatic hydrolysis reaction lasts for 4-8 hours, and then circumscribed protease is added; thirdly, separation and filtration are performed; fourthly, the pH value of a black tea extracting solution is adjusted, NaHCO3 is added in the black tea extracting solution, the pH value is adjusted to be 5.0-6.0, and a black tea solution is obtained; sixthly, the black tea concentrated solution is obtained after concentration. The method takes the black tea leaves as raw materials, water serves as solvents in the whole production process, a unique enzymolysis technology is adopted, enzyme preparations can play the maximum application effect, the yield of the product is increased, taste components become richer, the sweet feeling is improved when the black tea concentrated solution enters the mouth, the sweetness after taste is improved, the characteristic flavor of black tea is reserved, and the black tea concentrated solution has tea feeling, and is natural plant extracts and is a high added-value product.

Owner:康师傅饮品投资(中国)有限公司

Method for Synthesizing Polyaspartic Acid Using Maleic Anhydride and Ammonia

ActiveCN104725634BAvoid it happening againProcess environmental protectionStyrene maleic anhydrideHydrolysis

The invention relates to a method for synthesizing polyaspartic acid by using maleic anhydride and ammonia gas. The molten maleic anhydride and ammonia gas are subjected to a substitution reaction in a closed reactor. After the substitution reaction is completed, the remaining gas is absorbed; Sodium solution, carry out neutralization reaction to obtain a mixture of sodium maleamate and ammonium maleamate; directly heat up the product in a closed reactor, and carry out polycondensation reaction under stirring. After the polycondensation reaction is completed, evaporate the water to obtain polysuccinate imide solid; add water to another reaction kettle, start stirring, add polysuccinimide solid, slowly add sodium hydroxide solution, heat up for hydrolysis reaction, and obtain polyaspartic acid solution; the present invention simplifies production The weight average molecular weight of the obtained polyaspartic acid is 2000-15000, and the molecular weight distribution index is 1.5-1.65, which can meet the molecular weight requirements of different application fields, and the production process is environmentally friendly.

Owner:HEBEI THINK DO ENVIRONMENT CO LTD

A method and device for producing methane gas and lignin by using straw

InactiveCN104818298BImprove enzymatic hydrolysis efficiencyReduce inhibitionApparatus sterilizationGas production bioreactorsHydrolysateFiltration

The invention discloses a method and device for producing methane gas and lignin from straws. The method comprises the following steps of removing impurities of straws, crushing the straws into straw powder, feeding the straw powder into a hydrolysis device, controlling a hydrolysis degree until all hemicelluloses is hydrolyzed and 20-100% of cellulose is hydrolyzed, feeding an upper hydrolysate into an anaerobic fermentation pool, carrying out fermentation to obtain crude methane gas, discharging lower lignin slurry, and carrying out filtration and drying to obtain lignin powder. Straw hydrolase comprises excision beta glucanase, incision beta glucanase, beta glucosidase and xylanase according to a mass ratio of 1: 1.2-10: 0.8-5: 1.5-8. The culture contains an inducer activator, and in use, the culture is added with a starter. The method and device used by the method fully utilize straws, produce methane gas and lignin, adjust a straw hydrolysis degree, produce marketable products and are suitable for different raw materials.

Owner:CATECH TECH

A method for uniformly preparing attapulgite-titanium dioxide composite material

ActiveCN112108137BEvenly distributedGuaranteed uniformityPhysical/chemical process catalystsEnergy based wastewater treatmentHybrid materialHydrolytic Process

The invention provides a method for uniformly preparing attapulgite-titanium dioxide composite material, which belongs to the technical field of hybrid materials. The present invention adopts the steam hydrolysis method, supplemented by magnetic stirring in the whole hydrolysis process, hydrolysis is carried out through the method of constant temperature heating in water bath, and at the same time, the stirring speed and the temperature of water bath are controlled, so as to control the contact speed of attapulgite and water vapor and the contact speed of butyl titanate The degree of hydrolysis can ensure the uniformity of titanium dioxide, so that the titanium dioxide in the obtained attapulgite-titania composite material is evenly distributed on the surface of the attapulgite, and at the same time, the attapulgite in the composite material still maintains low agglomeration.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of acid-soluble peanut protein and its preparation method and application

ActiveCN110100947BControl the degree of hydrolysisImprove solubilityFood ingredientsVegetable proteins working-upBiotechnologyProtein solution

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Gravure freezing point snowflake ink and preparation method thereof

The invention relates to the technical field of printing ink, and in particular relates to gravure freezing point snowflake ink and a preparation method thereof. The gravure freezing point snowflake ink comprises acrylic resin, tetra-n-butyl titanate, an organic solvent, deionized water, a catalyst and a light initiator. The preparation method of the gravure freezing point snowflake ink comprises the following steps: step one, adding tetra-n-butyl titanate, the organic solvent and the catalyst into a reaction kettle, heating, and slowly adding deionized water into the reaction kettle for hydrolysis reaction to obtain hydrolysate; step two, adding the acrylic resin into the hydrolysate, and after raising the temperature, carrying out polycondensation reaction to obtain condensation polymer; step three, adding the light initiator into the condensation polymer, and stirring evenly to prepare the gravure freezing point snowflake ink. The gravure freezing point snowflake ink has the advantages of high glossiness, moderate viscosity, and good adhesion and friction resistance, so that printed matter is not easy to wear or scratch in the process of production and use, and the market competitiveness of the printed matter is greatly enhanced.

Owner:东莞智源彩印有限公司

A kind of preparation method of microorganism-specific soybean protein isolate

ActiveCN107312813BAppropriate degree of enzymatic hydrolysisControl the degree of hydrolysisPlant peptidesFermentationBiotechnologyProtein solution

The invention discloses a method for preparing microorganism-dedicated soybean protein isolate. The method comprises the following steps: soaking low-temperature degreased soybean meal in an alkali solution with a pH value of 9.5 to 10.0 at a temperature of 50 to 55 DEG C, adjusting the pH value to 6.8 to 7.4, the sugar content to 8.0 to 9.0, stirring for 40 to 60min, and performing solid-liquid separation to obtain a crude protein extracting solution; adding an acid solution into the crude protein extracting solution at room temperature, stirring for 10 to 50min, and centrifuging to obtain acid-precipitated protein; dissolving the acid-precipitated protein in water at room temperature, adjusting the pH value to 6.00 to 6.30 and the sugar content to 18.0 to 19.5 to obtain an acid-precipitated protein solution; adding neutral protease and alkaline protease, reacting at 50 to 60 DEG C for 0.5 to 3h to obtain enzymatic hydrolysate; performing sterilization, flash treatment and spray drying to obtain the microorganism-dedicated soybean protein isolate. The soybean protein isolate prepared according to the invention has good dispersibility, low viscosity and suitable amino acid nitrogen, and has the advantages of simple process, easy operation, strong protein practicability, wide application in fermentation industry and better popularization value.

Owner:SHANDONG YUWANG ECOLOGY FOOD IND

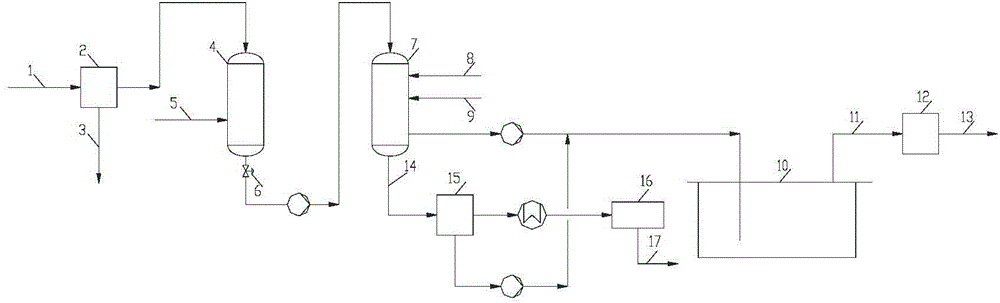

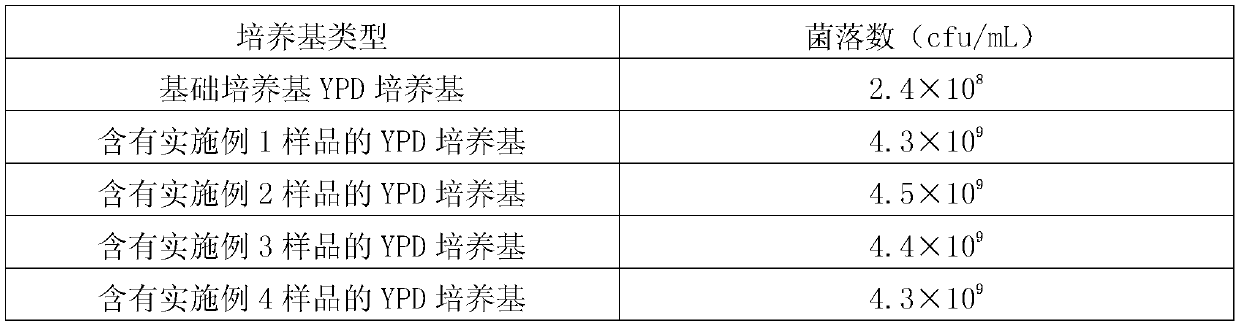

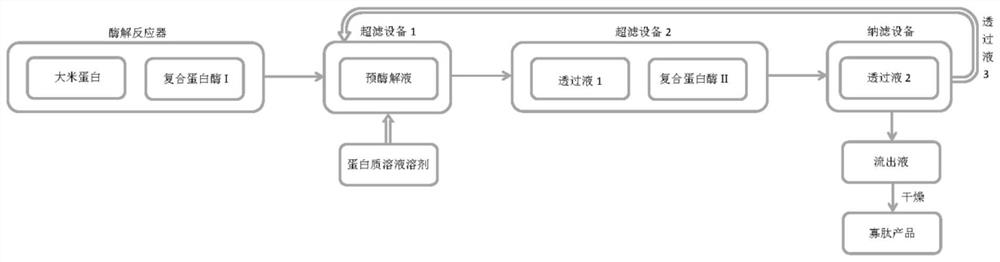

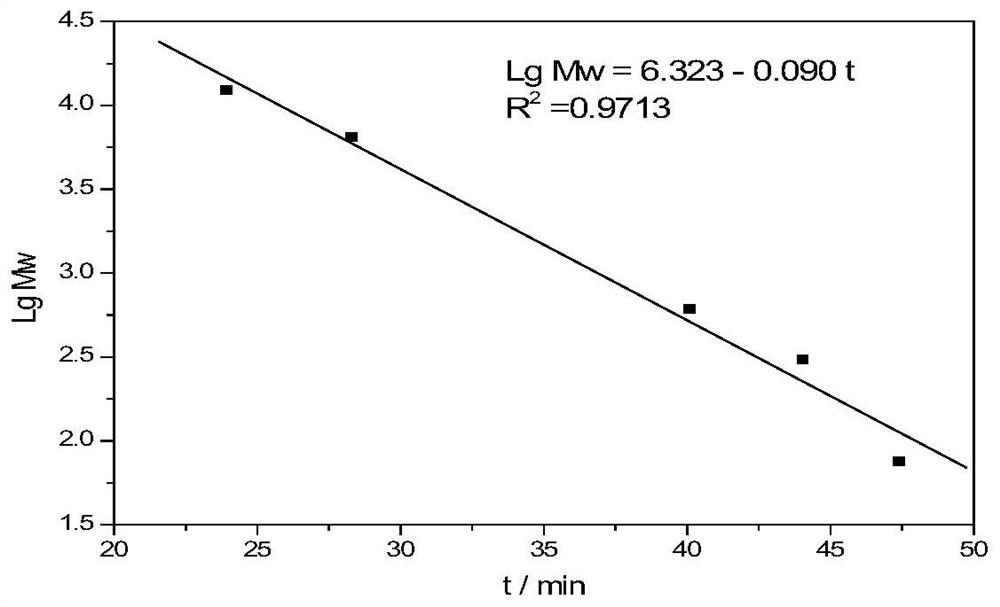

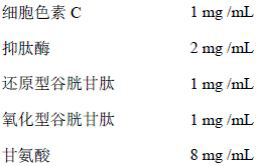

A kind of preparation method of active oligopeptide

ActiveCN110804637BIncrease contentHigh yieldCosmetic preparationsToilet preparationsProtein solutionEnzymatic hydrolysis

The invention provides a preparation method of oligopeptides: pre-enzymolyze the protein solution; then perform the first filtration: pump the pre-enzymolyzed solution into the ultrafiltration device 1, and obtain the permeate 1 after enzymolysis; the permeate 1 enters Ultrafiltration equipment 2, add compound protease II to obtain permeate 2 after enzymolysis; permeate 2 is subjected to nanofiltration to obtain permeate 3 and effluent, collect effluent (solution containing oligopeptides), and permeate 3 Flow back to the ultrafiltration device 1; then repeat the cycle: continuously replenish the solvent of the protein solution to the ultrafiltration device 1, and continuously obtain the permeate 1, permeate 2, permeate 3 and effluent; the concentration of oligopeptides in the effluent If it is less than the set threshold, pump the pre-enzymatic hydrolysis solution again. The preparation method of the present invention controls the degree of hydrolysis of proteins and polypeptides, extracts oligopeptides to the greatest extent, and improves the utilization rate of raw materials through two kinds of compound proteases and tandem ultrafiltration coupling enzymolysis. The preparation method has simple steps, and the obtained product oligopeptide has high content and high yield, and is suitable for industrial production.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com