Patents

Literature

122 results about "Maleamic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

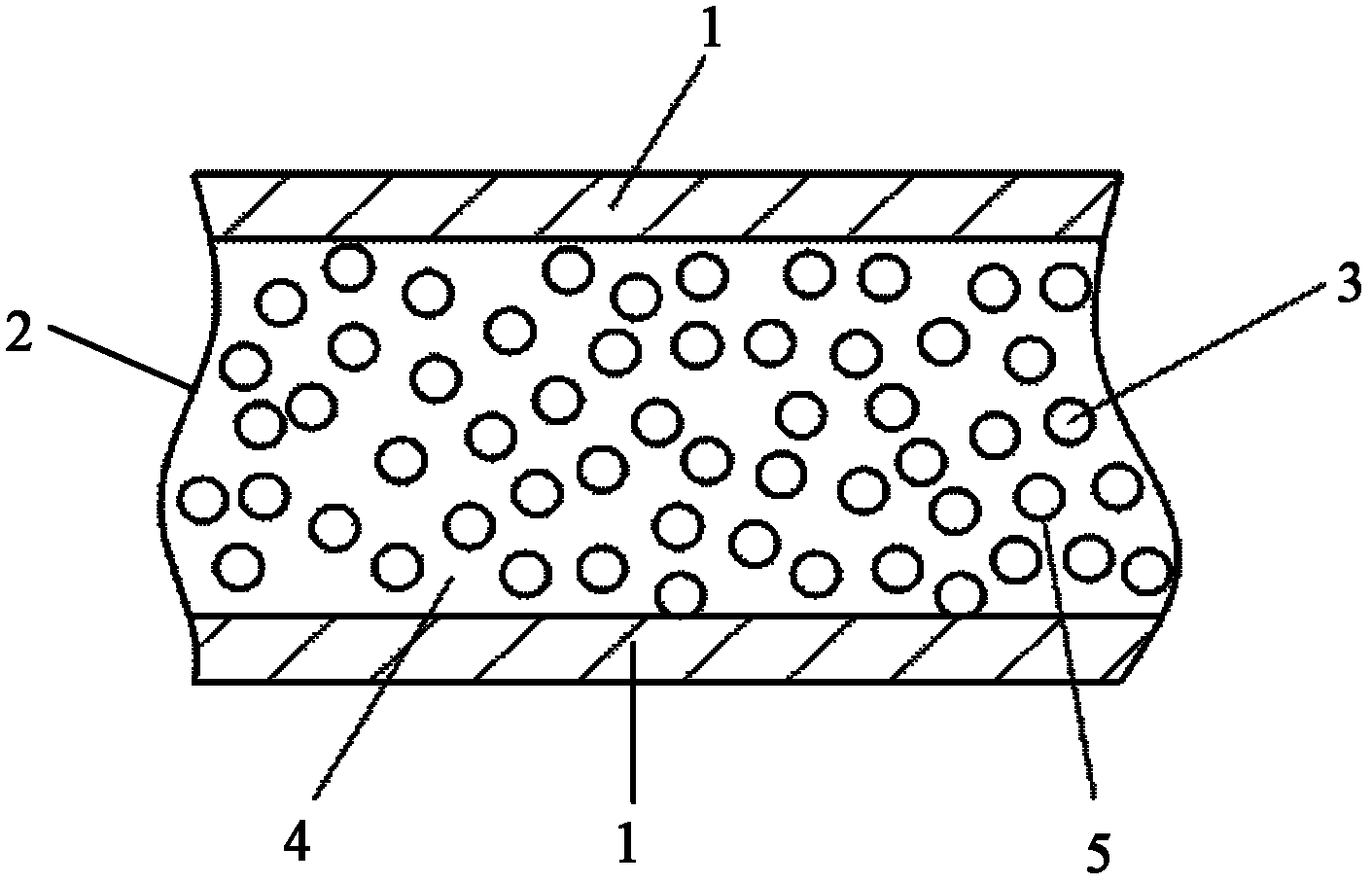

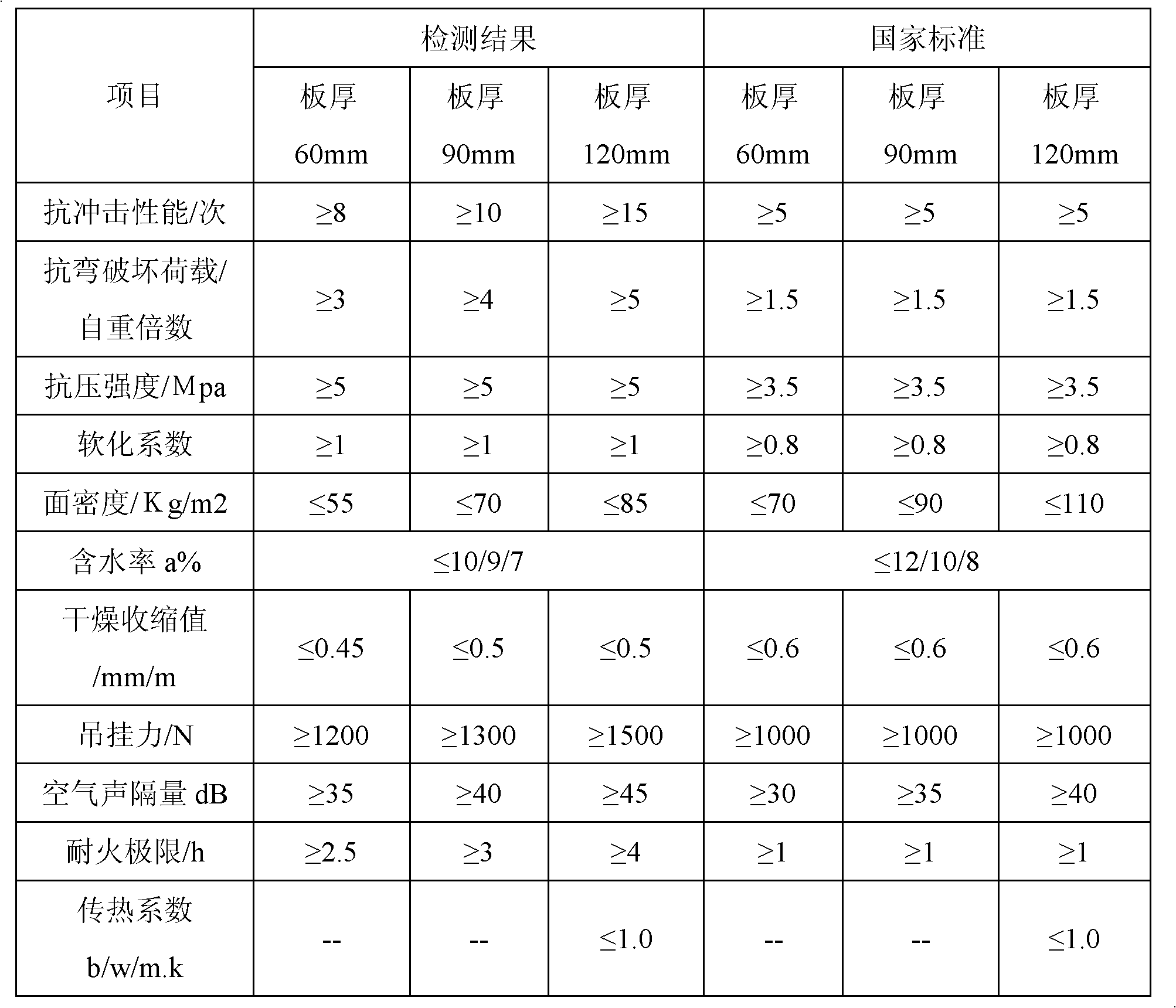

Composite heat-insulating wallboard and preparation method thereof

InactiveCN102505798AImprove interface compatibilityImprove physical and mechanical propertiesClimate change adaptationCeramic shaping apparatusCalcium silicateEmulsion

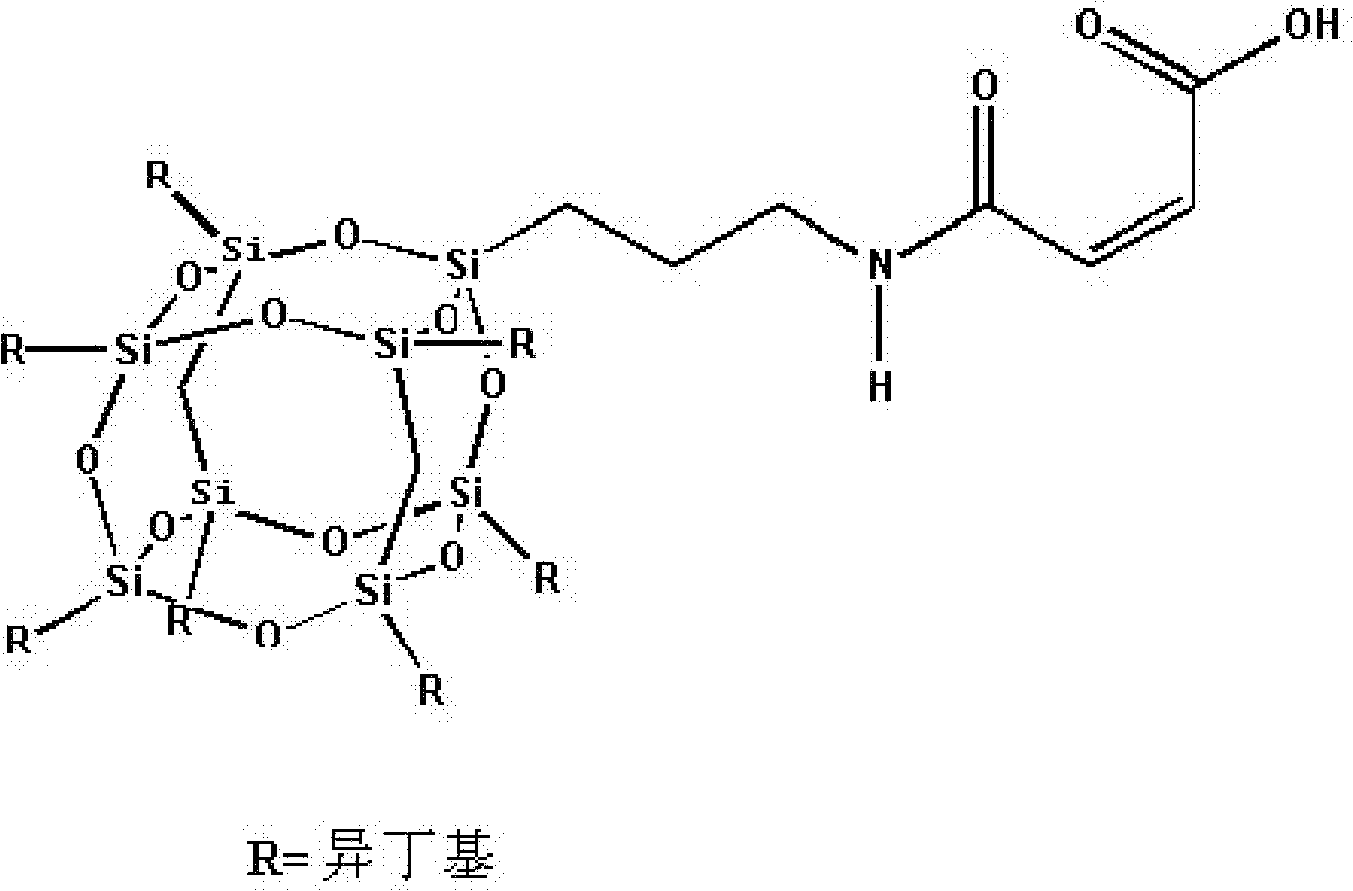

The invention discloses a composite heat-insulating wallboard and a preparation method thereof and relates to a heat-insulating wallboard. The heat-insulating wallboard is provided with two layers of calcium silicate plates, wherein a heat-insulating core material is clamped between the two layers of calcium silicate plates and is prepared from cement, coal ash, gypsum, expandable polystyrene (EPS), Maleamic Acid-Isobutyl Polyhedral Oligomeric Silsesquioxane (POSS), emulsion powder, a water reducing agent, a foaming agent and an early strength agent. Dry POSS powder is dissolved in normal hexane and then the solution is sprayed onto the surface of EPS particles to obtain substance A; the cement, the coal ash, the gypsum and the emulsion powder are drily stirred, water is added into the mixture, the mixture is stirred into paste, the substance A is added into the paste to form a slurry B; the foaming agent solution is stirred through a stirrer to form foam C; the slurry B and the foam C are mixed to obtain a heat-insulating core material slurry; the surfaces of the calcium silicate plates are brushed and washed, the calcium silicate plates are placed on the two sides of a fixed mold, the heat-insulating core material slurry is poured into the middle of the two calcium silicate plates, and the mold is vibrated to mold the slurry; and the mold is de-molded, and after watering to maintain, the wallboard is obtained.

Owner:XIAMEN UNIV +1

Silica reinforced rubber composition which contains stabilized unsymmetrical coupling agents and article of manufacture, including a tire, having at least one component comprised of such rubber composition

This invention relates to use of stabilized unsymmetrical coupling agents for use in conjugated diene-based rubber compositions reinforced with silica-based reinforcement, namely use of stabilized 2-benzothiazyl-3-(triethoxysilylpropyl) disulfide and 3-(triethoxysilyl)propyl-N-maleamic acid. Said stabilized unsymmetrical coupling agent materials may be provided for mixing with said diene-based rubber(s), for example, as individual materials, as at least one of said materials being pre-reacted with aggregates of precipitated silica, said precipitated silica having hydroxyl groups (e.g. silanol groups) on its surface. The invention includes an article of manufacture, including a tire, having at least one component comprised of such rubber composition.

Owner:THE GOODYEAR TIRE & RUBBER CO

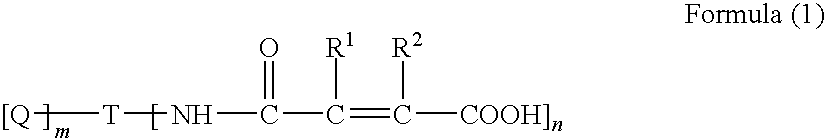

Liquid crystal alignment agent and liquid crystal alignment film formed therefore and manufacturing method thereof

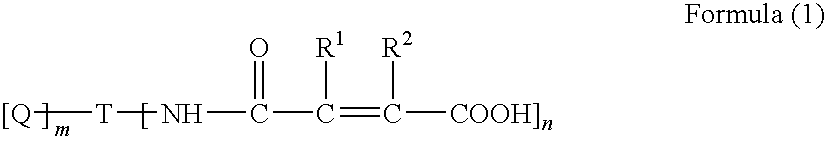

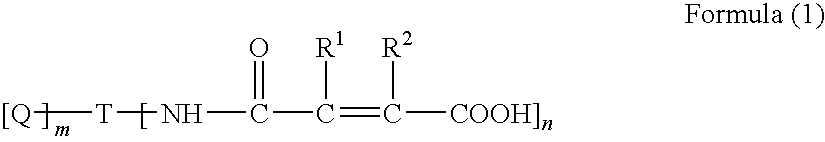

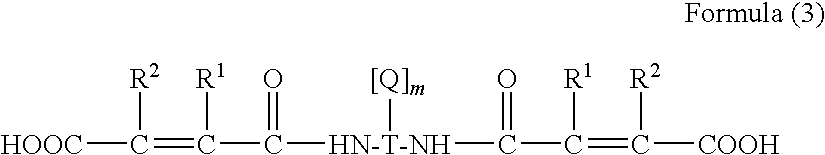

InactiveUS20090280236A1Good coating performanceEasy to controlPretreated surfacesSpecial surfacesPolyesterPolyamide

The present invention provides a free radical polymerizable liquid crystal alignment agent having superior coating ability, a manufacturing method, which comprises the process of coating the liquid crystal alignment agent onto a substrate, and processing the liquid crystal alignment agent with dehydration / ring-closure reaction and free radical polymerization, enables obtaining a liquid crystal alignment film with superior reliability, superior voltage holding ratio and easy control of pretilt angle, and enables the manufacture of a liquid crystal display element provided with a liquid crystal alignment film. The free radical polymerizable liquid crystal alignment agent comprises a molecular compound containing at least 2 polymerizable maleamic acid groups (A), a polymer (B) and an organic solvent (C), in which the polymer (B) comprises at least one kind of polymer obtained from condensation polymerization, which is selected from the groups consisting of polyester, polyesterimide, polyamide-imide acid, polyamide-imide, polyamide acid ester, polyamide and polyimide series polymer.

Owner:CHI MEI CORP

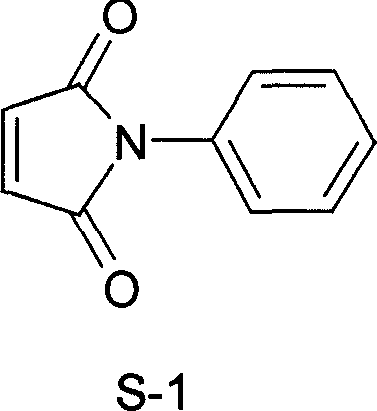

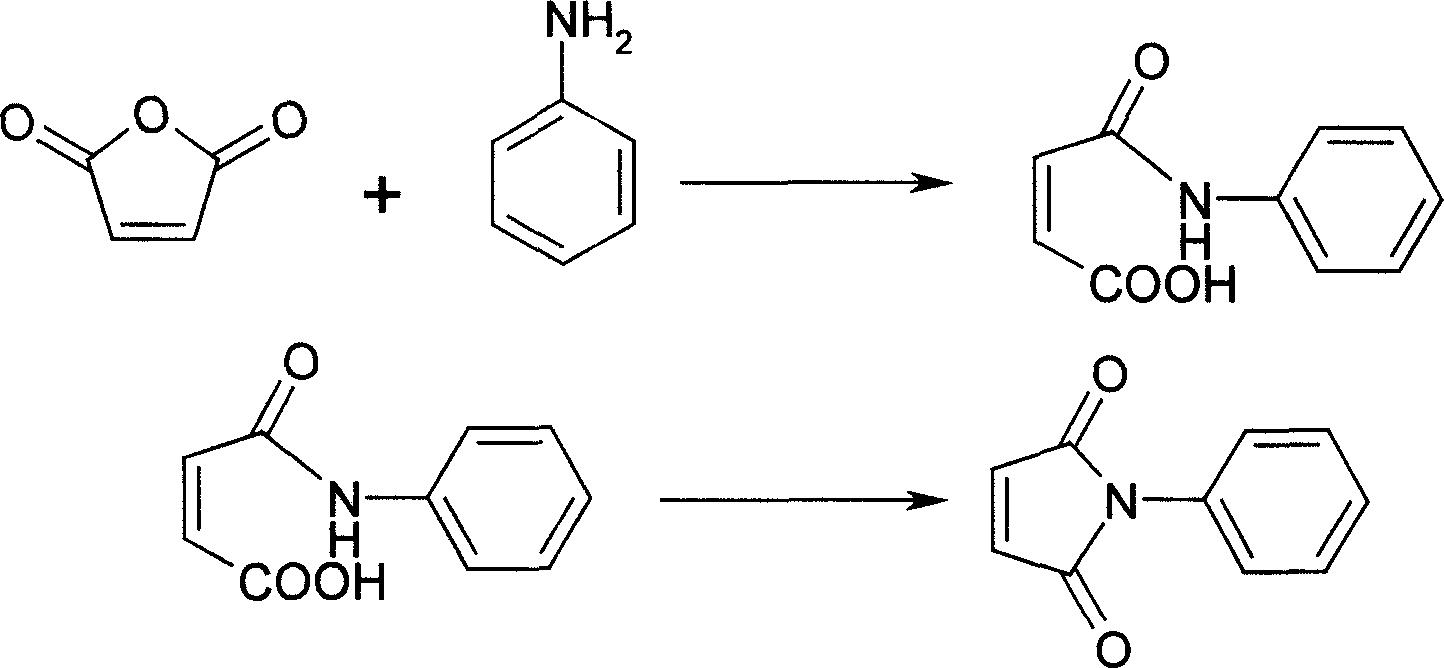

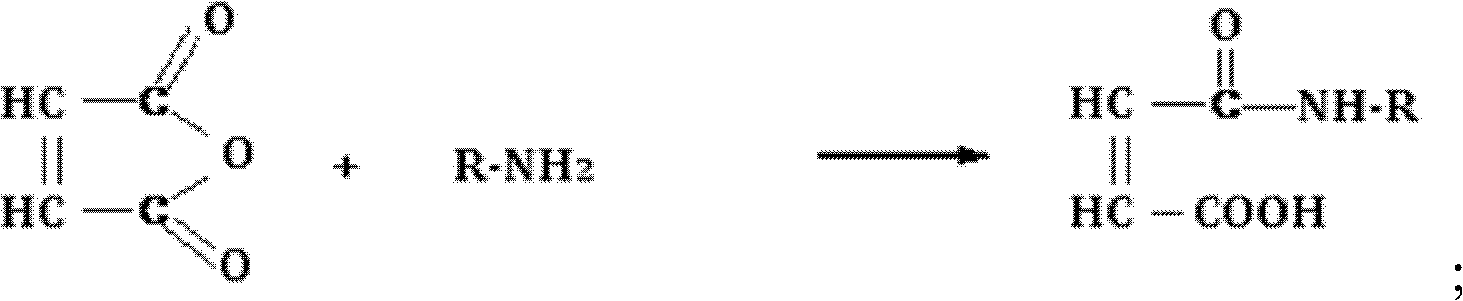

Process for preparing N-phenyl maleimide

The invention discloses a synthesizing method of N-phenyl maleimide, which comprises the following steps: 1) acylating the maleic anhydride and aniline in the solvent; 2) reacting N-phenyl maleamic acid with hydroquinone as inhibitor and p-toluenesulfonic acid and N-ethyl pyrrolidone as double catalyst; decompressing the liquid to remove solvent; obtaining the rought product; 3) recrystallizing to obtain the product.

Owner:ZHEJIANG UNIV

Phosphorus-free, green and environment-friendly slow-release scale inhibitor

InactiveCN105000683AWide variety of sourcesLow priceScale removal and water softeningSodium lactateStearate

The present invention discloses a phosphorus-free, green and environment-friendly slow-release scale inhibitor, which comprises the following raw materials in weight part: 5-20 parts of maleamic acid, 5-10 parts of chitosan, 2-5 parts of lignin, 1-10 parts of starch, 3-15 parts of sodium humate, 1-3 parts of polyacrylic acid, 2-10 parts of sodium molybdate, 1-5 parts of zine stearate, 4-10 parts of zinc borate, 3-12 parts of sodium lactate, 1-8 parts of triethanolamine, 3-10 parts of benzotriazol, 5-20 parts of polyaspartic acid, 3-12 parts of S-CETSA, 10-25 parts of polyepoxysuccinic acid, 2-15 parts of acrylic acid-2-acrylamide-2-methyl propane sulfonic acid copolymer and 50-70 parts of water. The phosphorus-free, green and environment-friendly slow-release scale inhibitor is phosphorus-free, non-toxic, green, environmentally-friendly, and good in scale-inhibition and slow-release effect.

Owner:杨红微

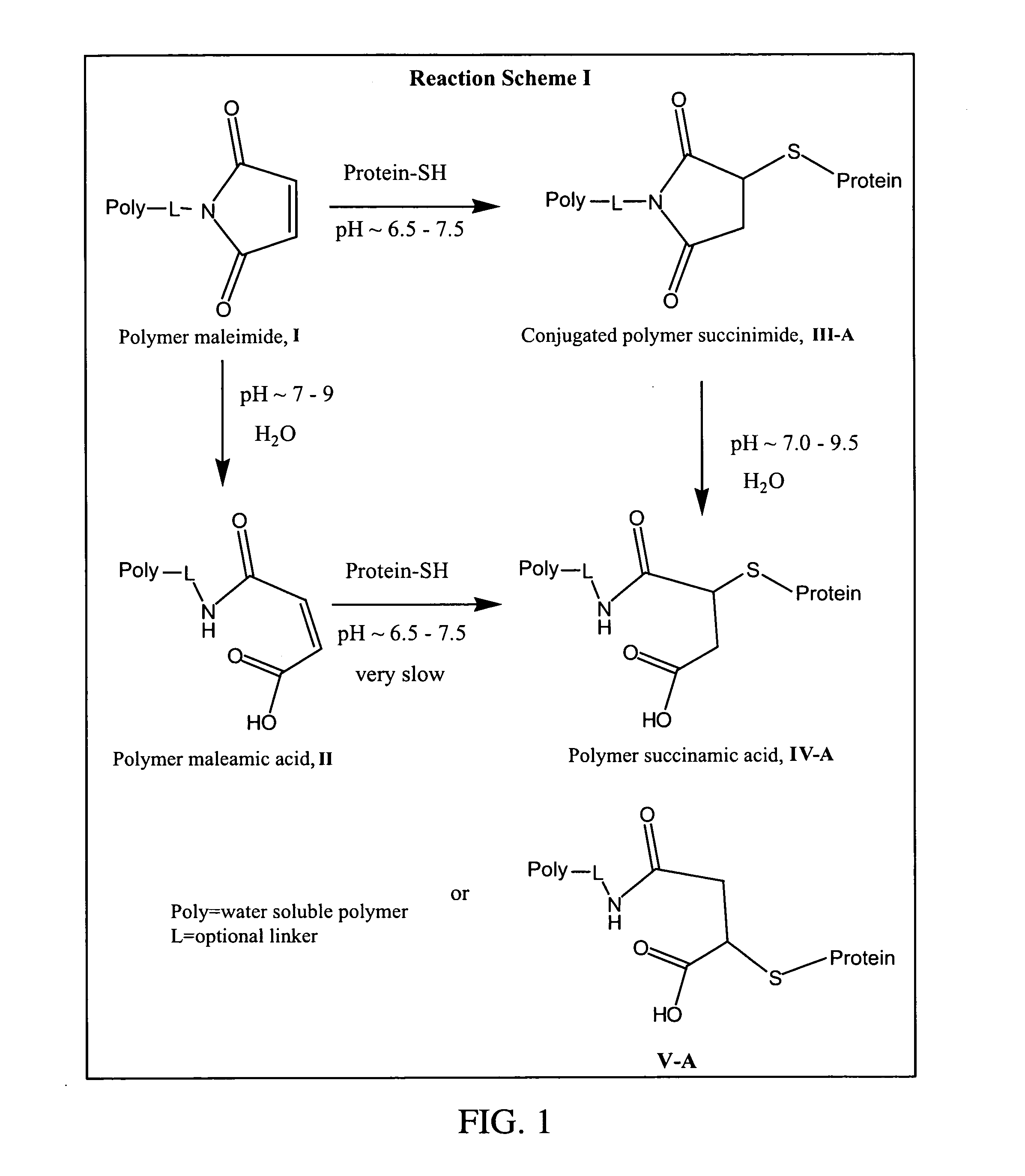

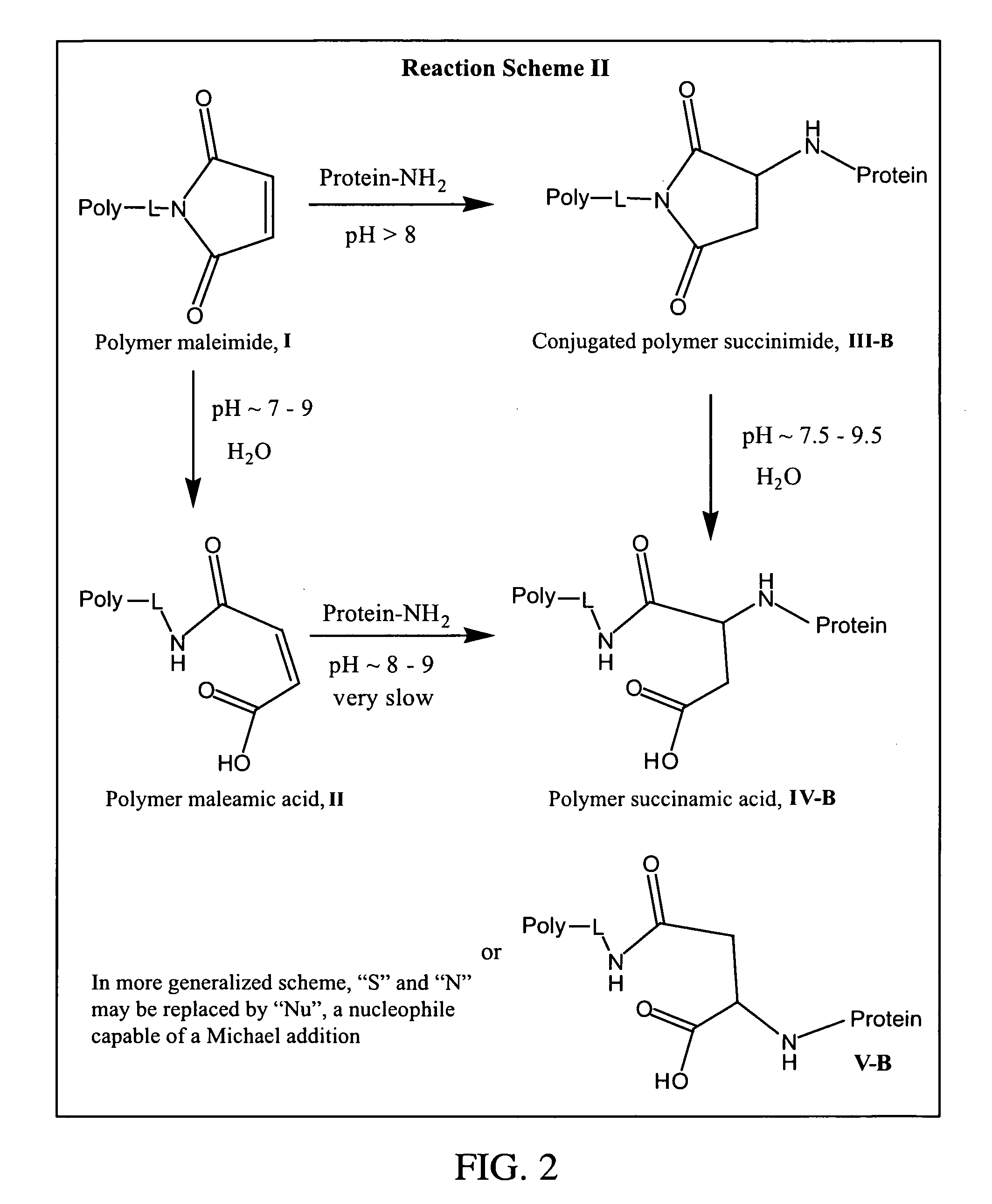

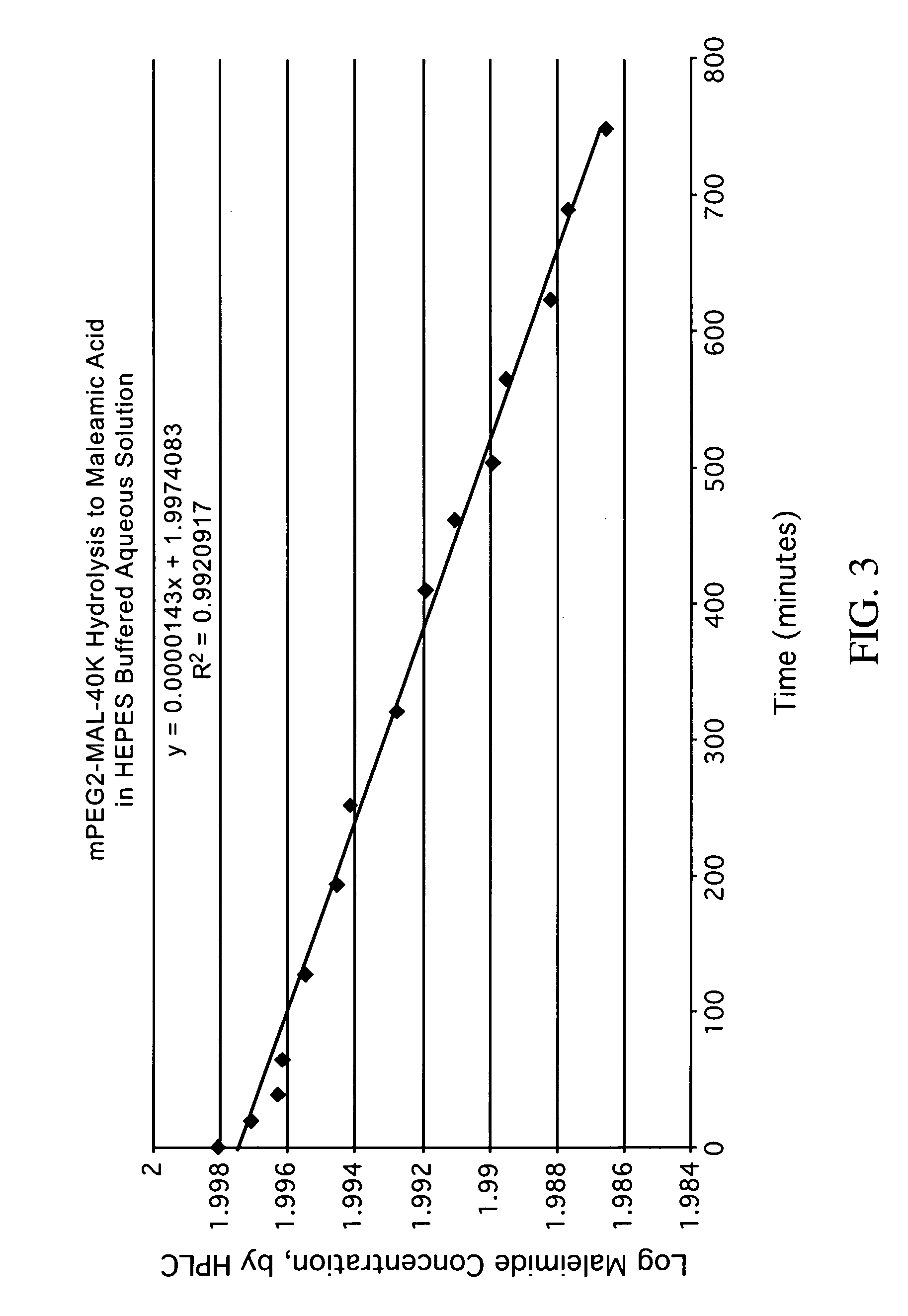

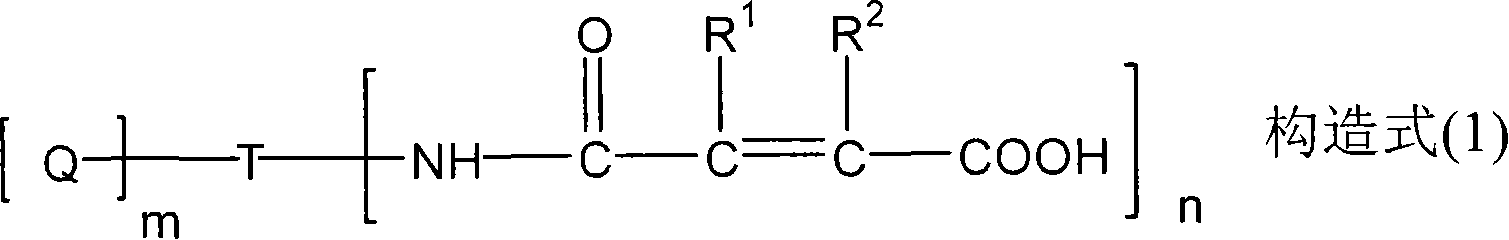

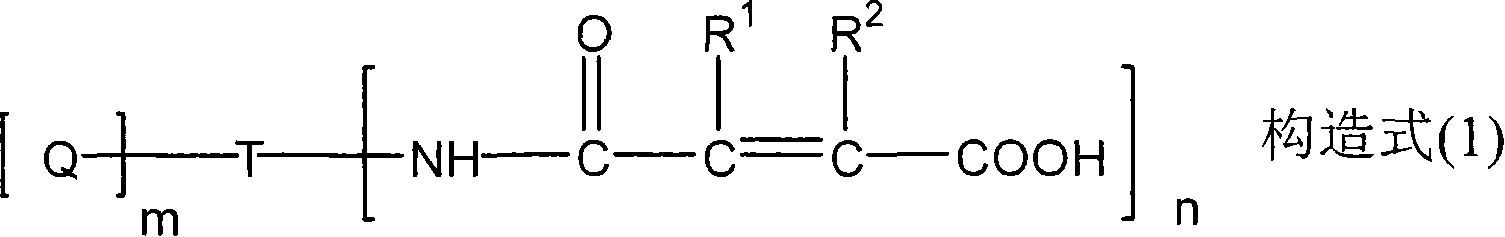

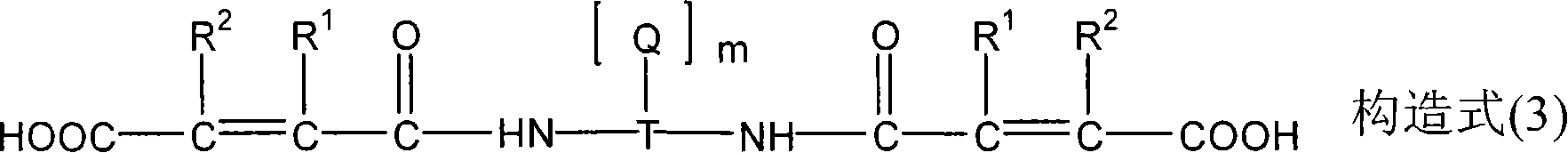

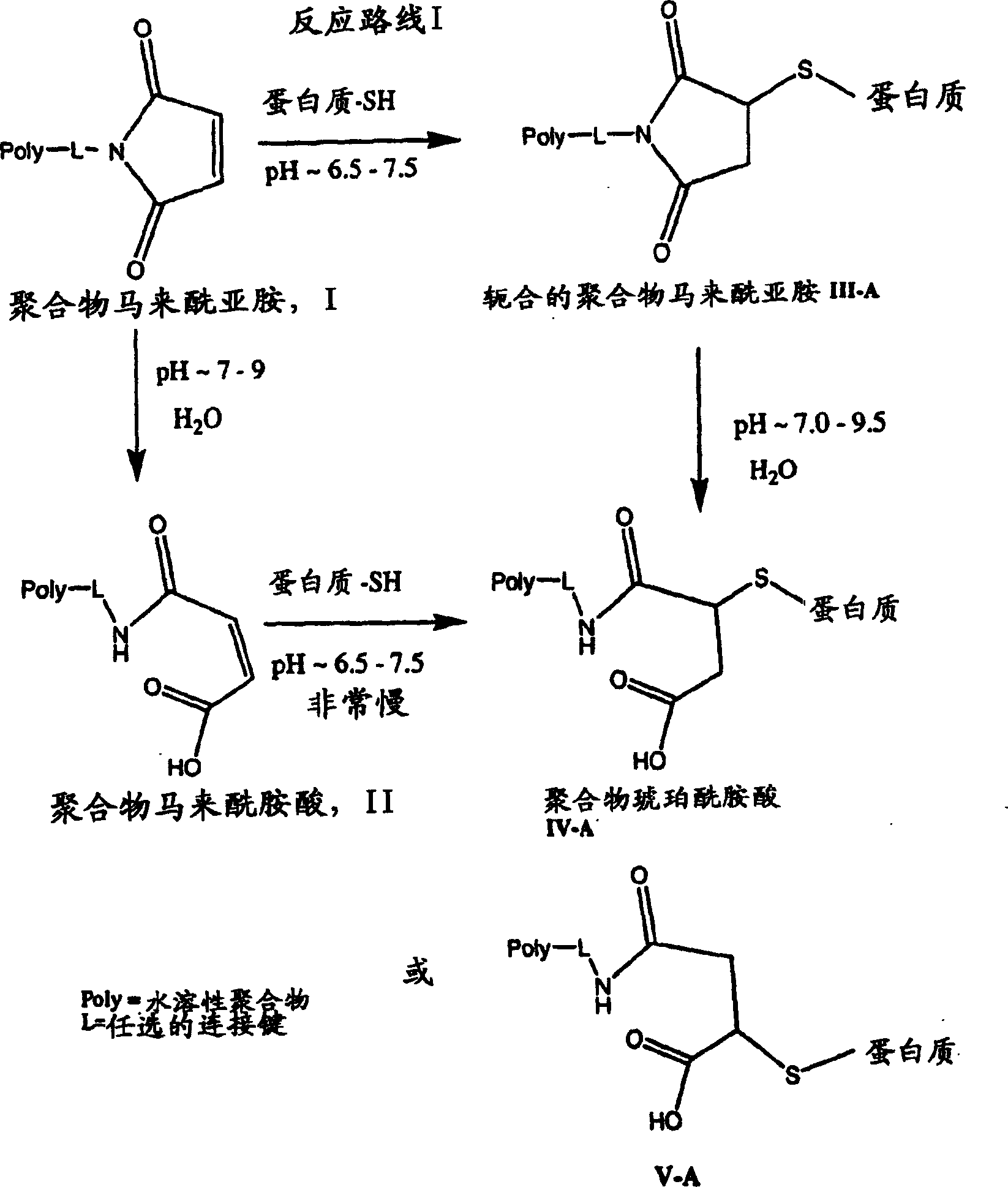

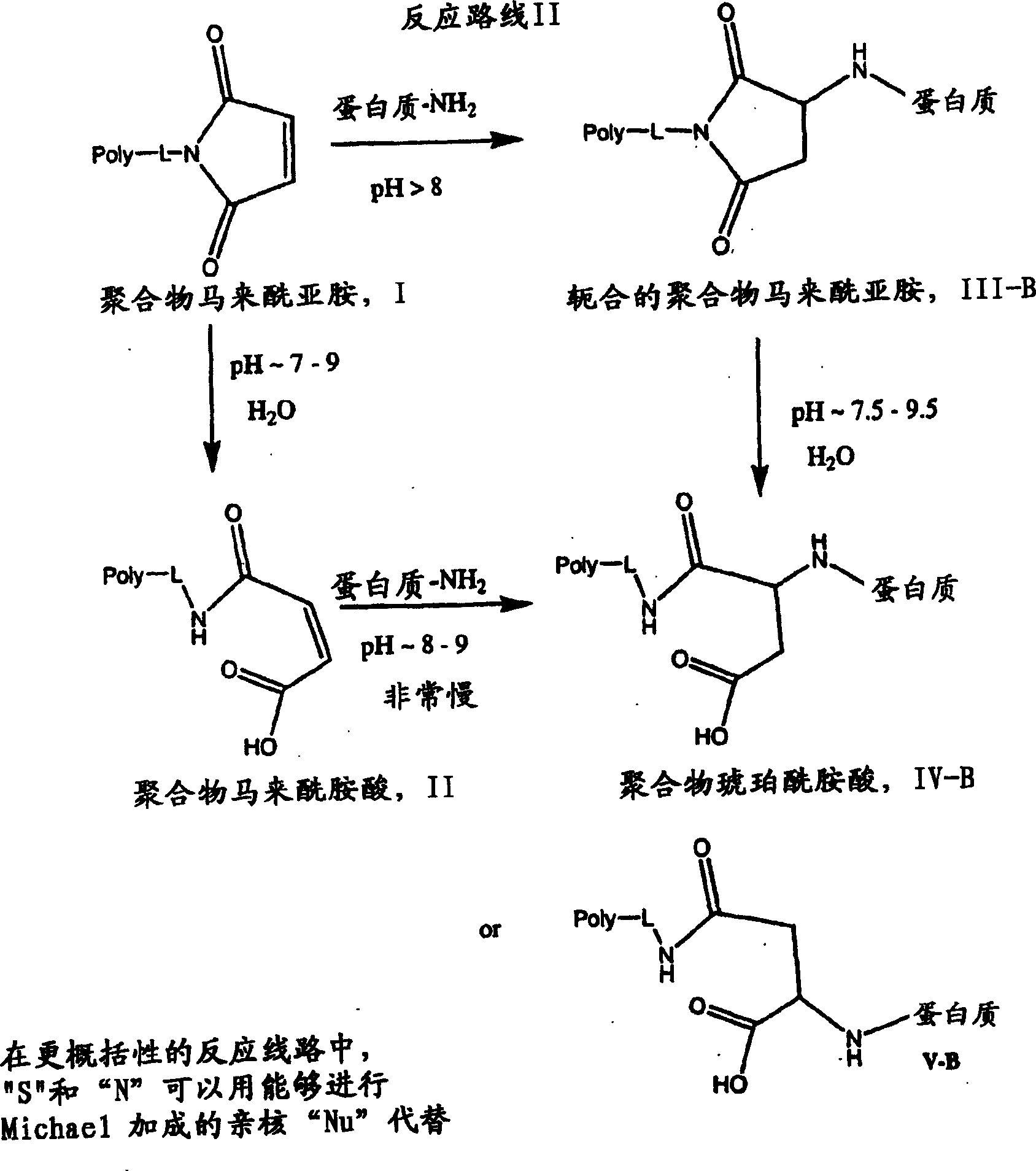

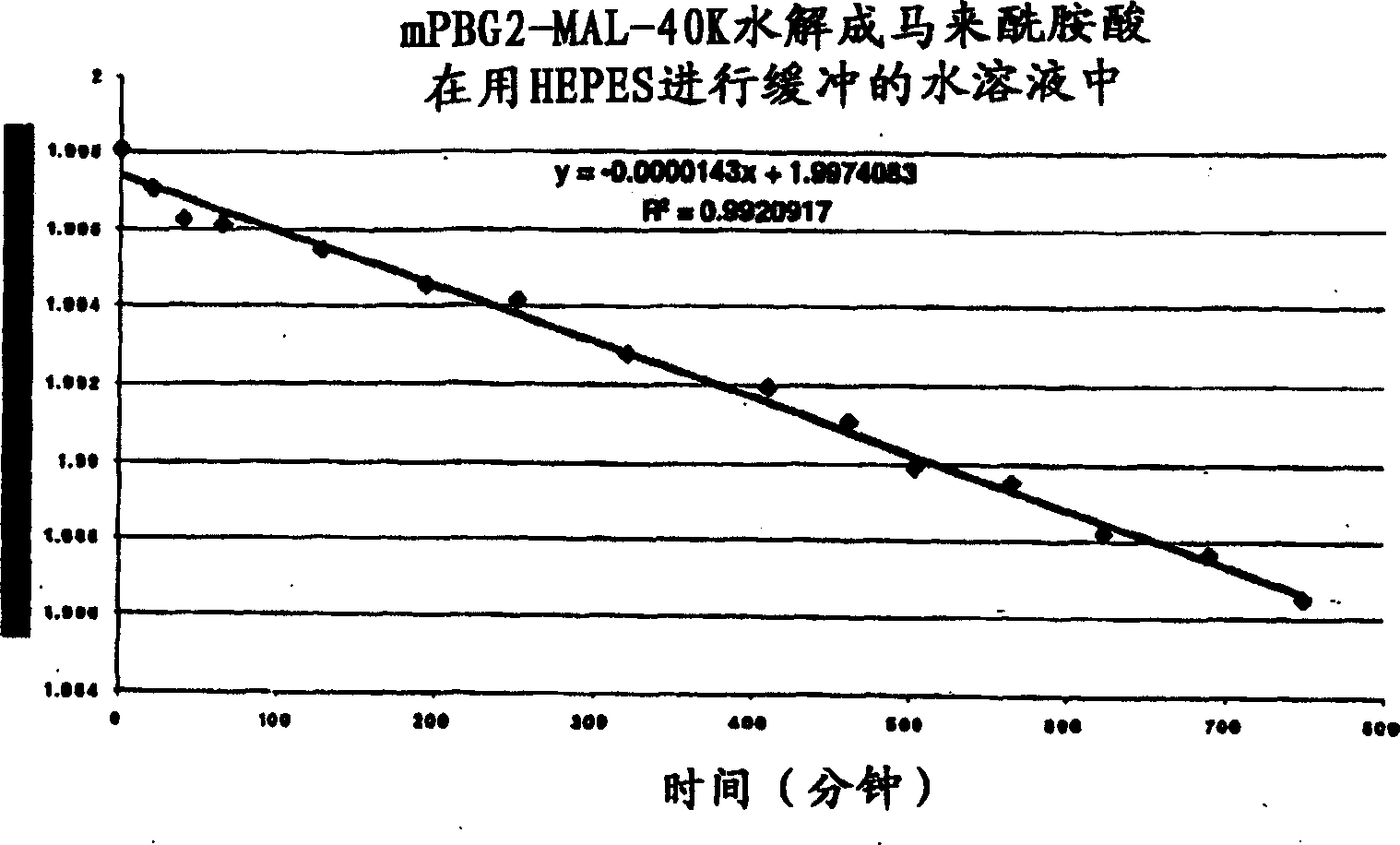

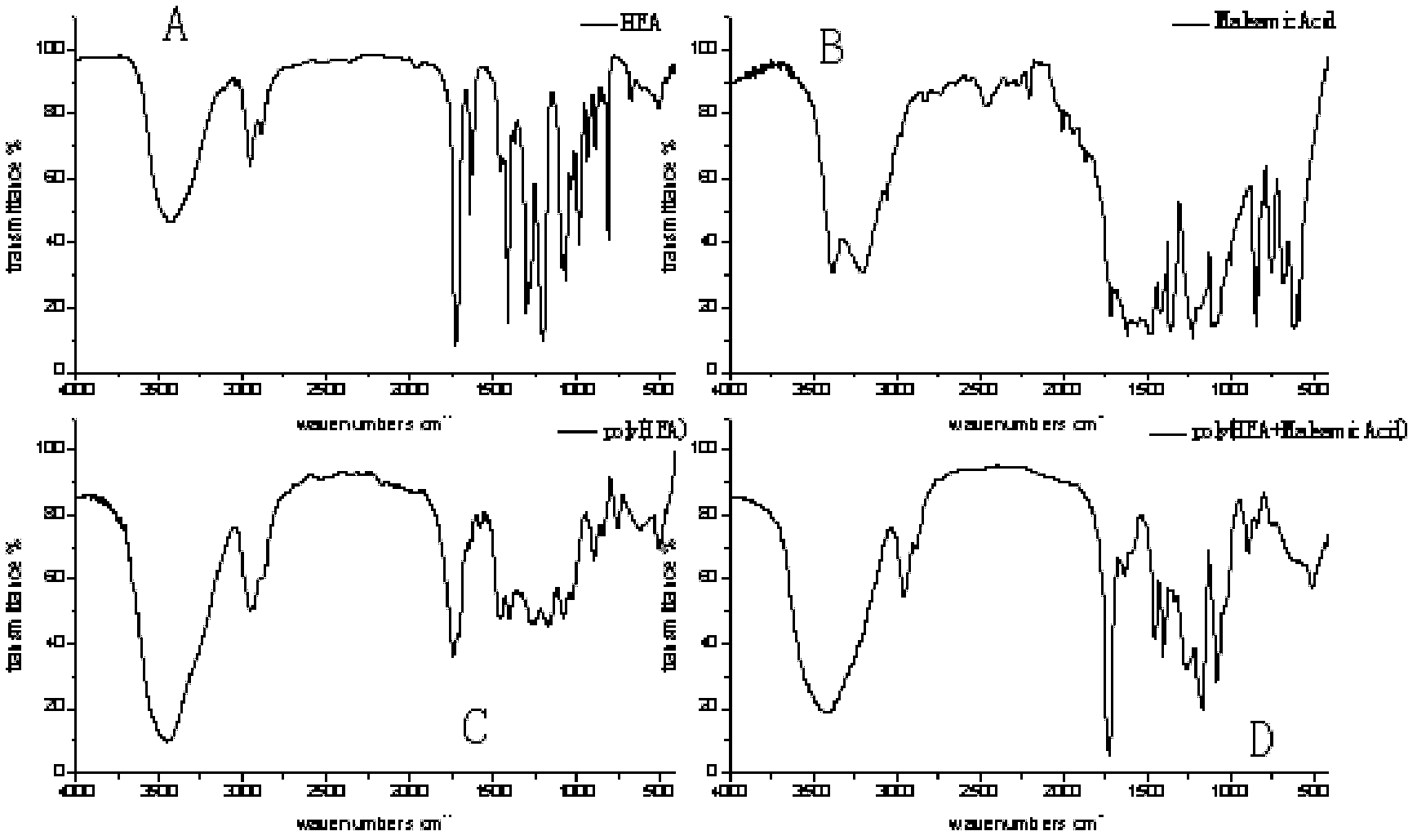

Maleamic acid polymer derivatives and their bioconjugates

The present invention is directed to maleamic acid derivatives of water soluble polymers, to chemically stable water-soluble polymer succinamic acid-active agent conjugates, and to methods for reproducibly preparing, characterizing and using such polymer reagents and their conjugates.

Owner:NEKTAR THERAPEUTICS INC

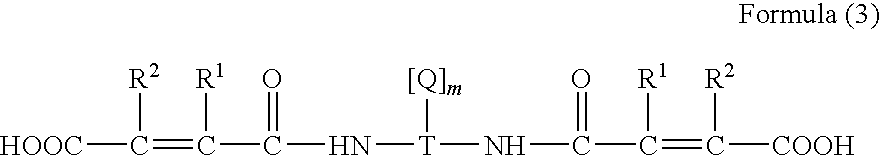

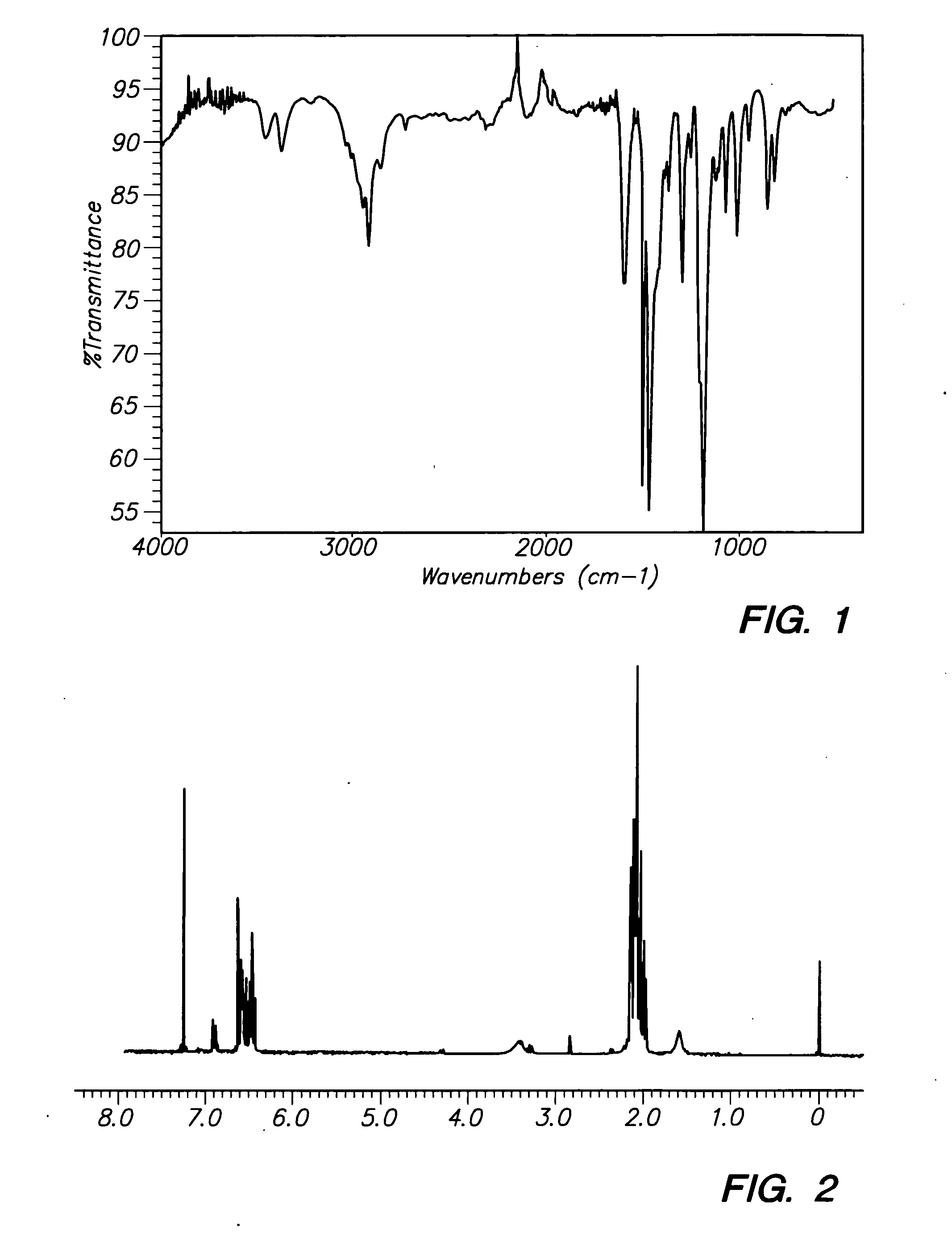

Bismaleamic acid, bismaleimide and cured product thereof

A bismaleamic acid obtained by reacting a bifunctional phenylene ether oligomer diamine, obtained by introducing aromatic amino groups into both terminals of a specific bifunctional phenylene ether oligomer, with maleic anhydride, a bismaleimide obtained from the bismaleamic acid as a raw material, which bismaleimide has high heat resistance, low dielectric characteristics and excellent solvent solubility and exhibits only a small change in dielectric characteristics even in high humidity, a curable resin composition containing the above bismaleimide and a cured product obtained by curing the curable resin composition.

Owner:MITSUBISHI GAS CHEM CO INC

Bismaleamic acid, bismaleimide and cured product thereof

InactiveCN101602704ALow dielectric propertiesImprove solubilityOrganic compound preparationCarboxylic acid amides preparationSolubilityOligomer

The invention provides bismaleamic acid, bismaleimide and cured product thereof. Particularly, the invention provides a bismaleimide having high heat resistance, a low dielectric constant, a low water absorption coefficient and excellent solvent solubility, a bismaleamic acid capable of generating the above bismaleimide, a cured resin composition containing the above bismaleimide and a cured product obtained by curing the above resin composition. Bismaleamic acid, bismaleimide, the cured resin composition containing the bismaleimide and the cured product obtained by curing the resin composition are obtained by reaction between diamine of bifunctional phenylene ether oligomer and maleic anhydride, wherein the diamine of bifunctional phenylene ether oligomer is obtained by introducing aromatic amino into two terminals of the bifunctional phenylene ether oligomer.

Owner:MITSUBISHI GAS CHEM CO INC

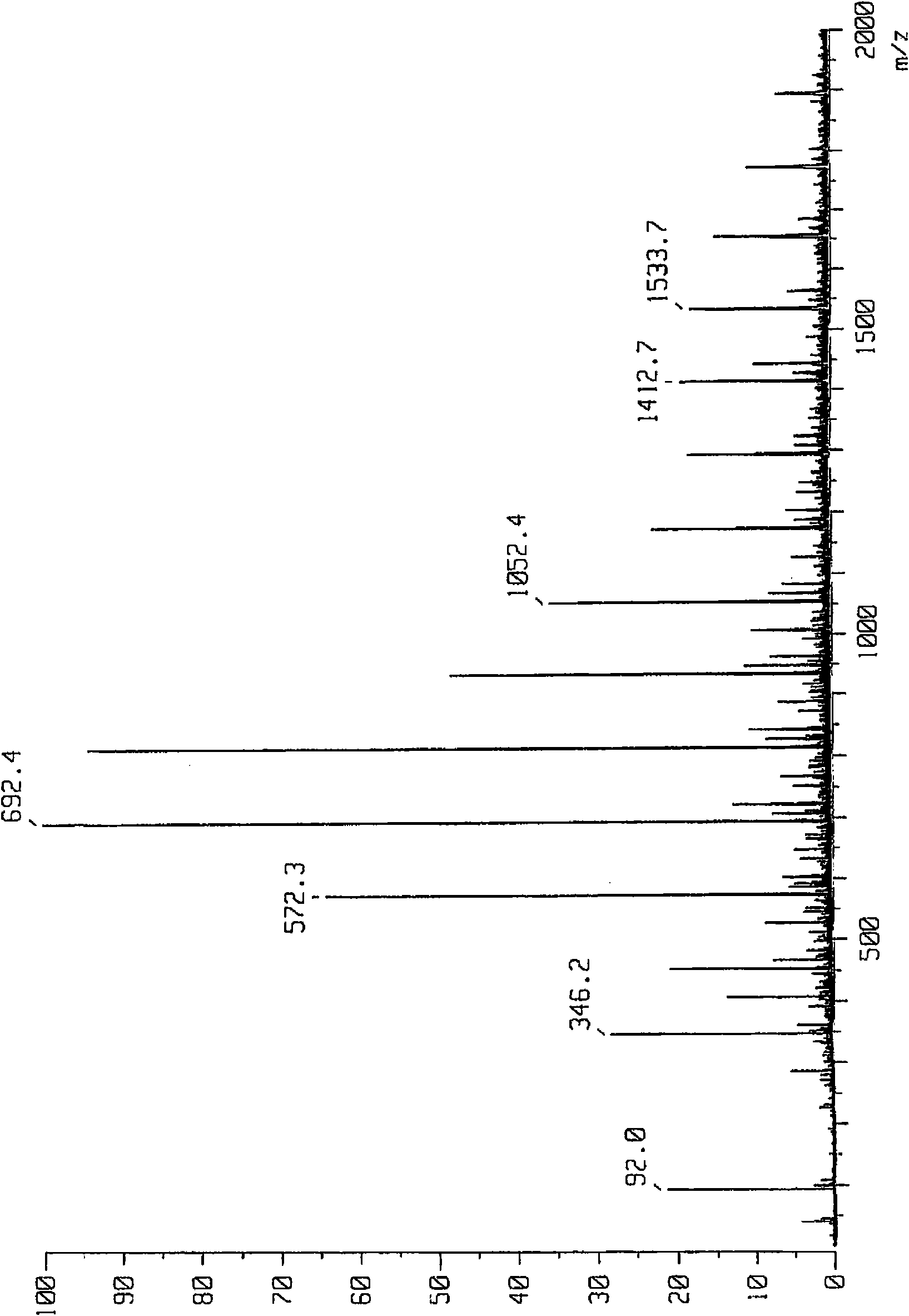

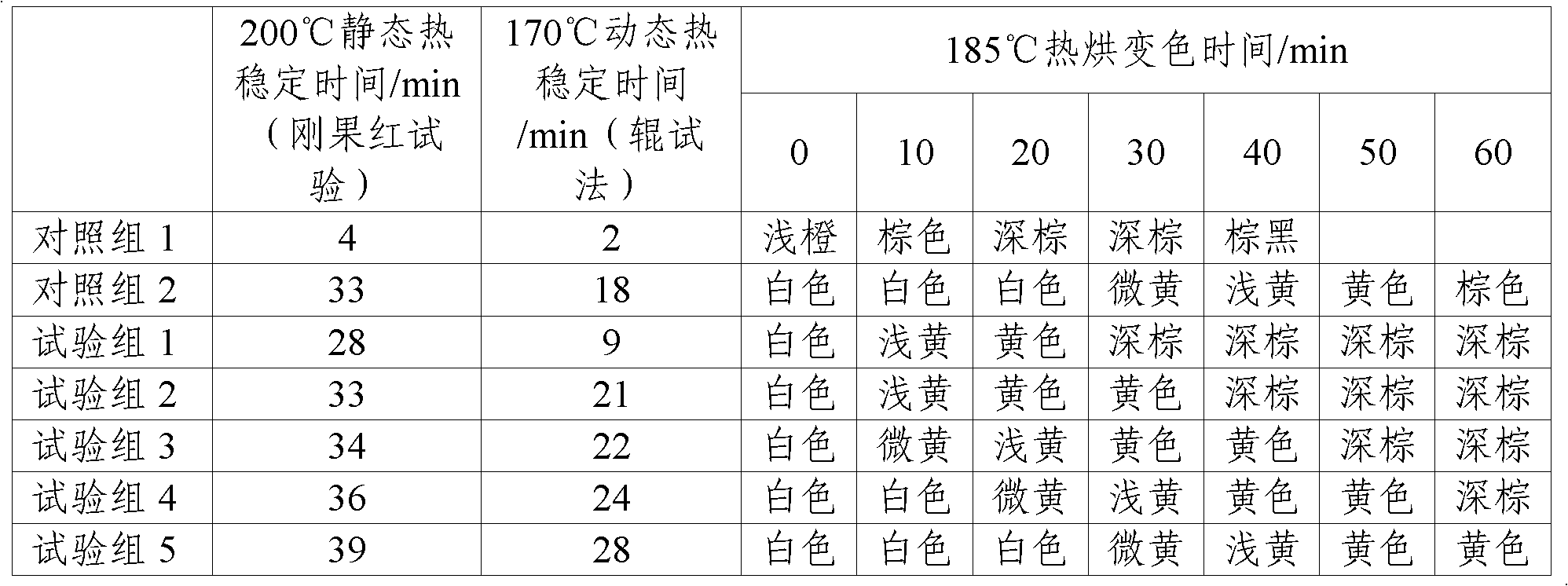

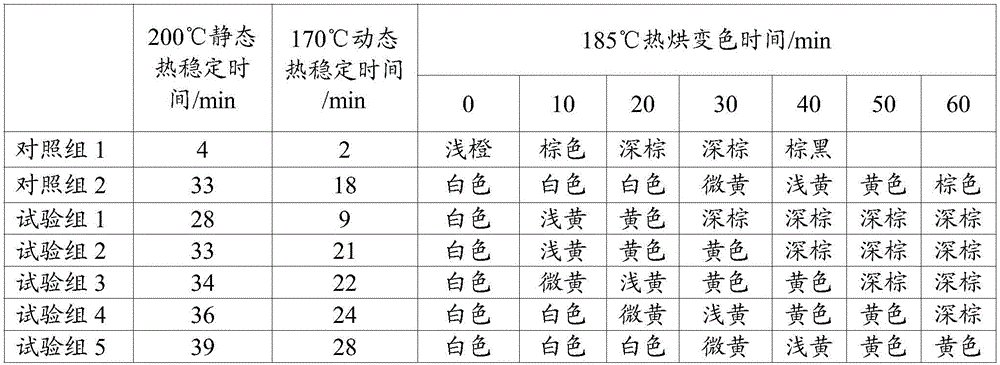

Rare earth complex and its preparation method and use

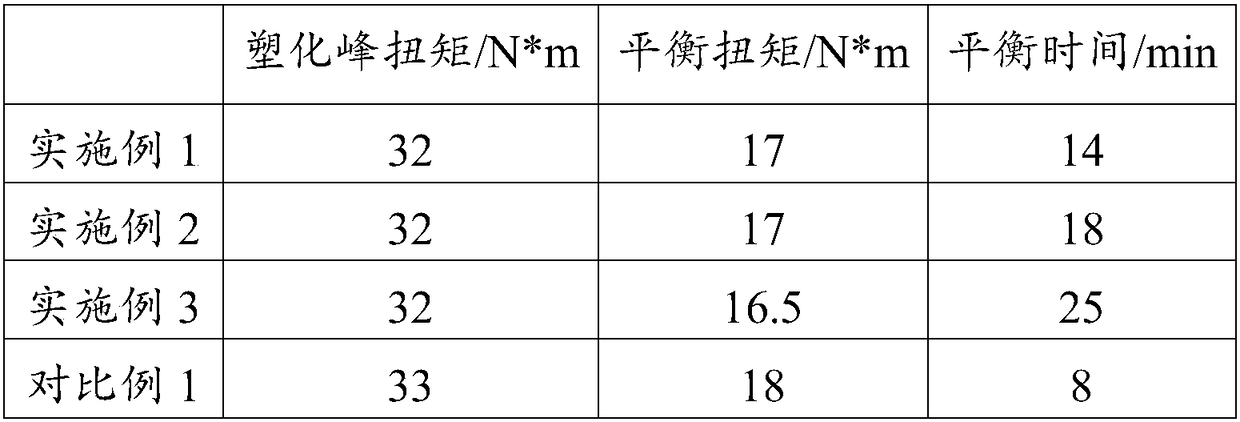

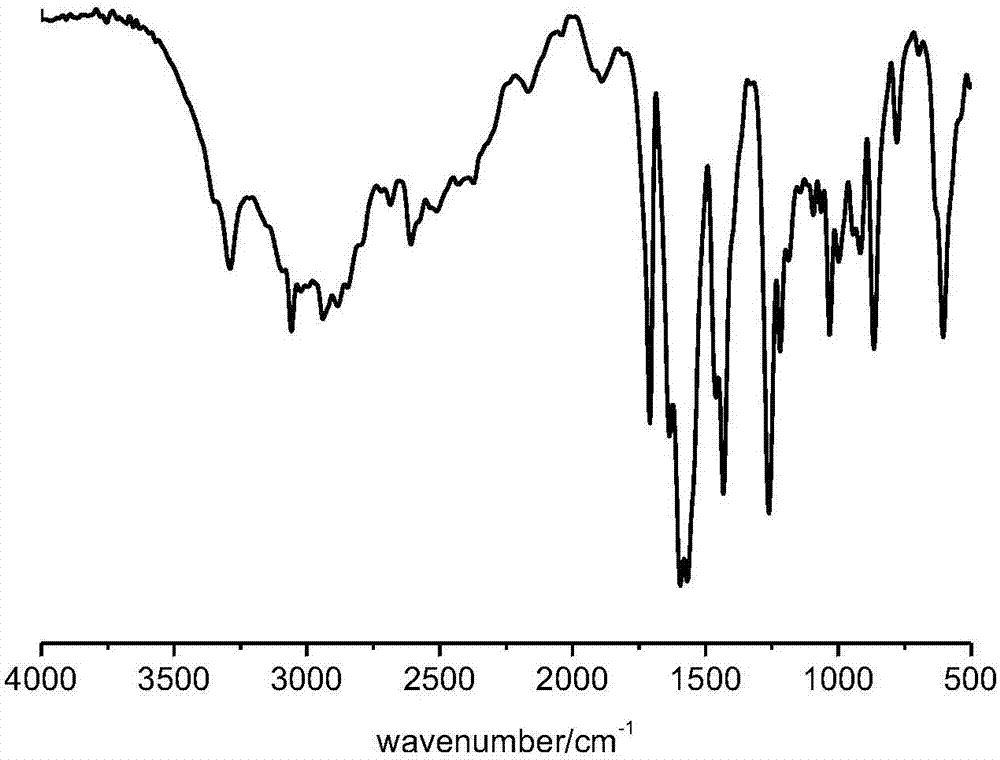

ActiveCN102627575AImprove thermal stabilityGood weather resistanceOrganic compound preparationCarboxylic acid amides preparationRare-earth elementPolyvinyl chloride

The invention discloses a rare earth complex. The rare earth complex is an N-alkyl maleamic acid-rare earth complex having a chemical formula of RE(OA)3.nH2O, wherein RE represents a rare-earth element; OA represents N-alkyl maleamic acid radical; and n is equal to 1 or 2. The invention also discloses a preparation method of the rare earth complex and a use of the rare earth complex in a polrvinyl chloride (PVC) heat stabilizer. The rare earth complex can be prepared by simple processes, and has a low cost and industrial application prospects. The rare earth complex or a composition of the rare earth complex as a PVC heat stabilizer overcomes the defects of the existing heat stabilizers, and improves primary dyeing properties and long-term thermal stability of PVC. Especially, the rare earth complex has good synergistic effects with calcium stearate, organic tin and pentaerythritol and thus under unified use, the thermal stability of PVC is improved. In addition, the rare earth complex can effectively improve mechanical properties of a PVC material.

Owner:XIAN UNIV OF SCI & TECH

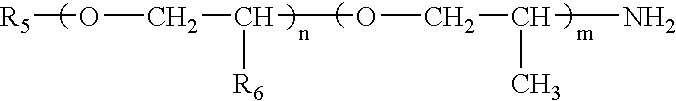

Liquid crystal oriented agent and method for manufacturing liquid crystal oriented film formed by same

The invention relates to a liquid crystal oriented agent and a manufacturing method, in particular to a free radical polymerized liquid crystal oriented agent with excellent coatability, a manufacturing method of a liquid crystal oriented film which has excellent reliability and voltage conservation rate and easily controlled pretilt angle and can be obtained by a dewatering closed-loop and free radical polymerization reaction after coating the liquid crystal orientation agent on a substrate, and a liquid crystal display element with the liquid crystal oriented film. The free radical polymerization liquid crystal orientation agent contains a compound (A) with a molecule containing two or more polymerized maleamic acid radicals, a polymer (B) and an organic solvent (C), wherein the polymer (B) is selected from at least one of polyester, polyurethane, polyamide imide acid, polyamide imide, polyamic ester, polyamide and polyimide polymer which are obtained by a polymerization reaction. The manufacturing method of the liquid crystal oriented film comprises the step that after the liquid crystal oriented agent is coated on the substrate, the dewatering closed-loop and free radical polymerized reaction are carried out.

Owner:CHI MEI CORP

Method for synthesizing polyaspartic acid by maleic anhydride and ammonia gas

ActiveCN104725634AAvoid it happening againProcess environmental protectionHydrolysisSodium hydroxide

The invention relates to a method for synthesizing polyaspartic acid by maleic anhydride and ammonia gas. The method comprises the following steps: performing substitution reaction of molten maleic anhydride and ammonia gas in a closed reactor and absorbing the residual gas after the completion of the substitution reaction; adding sodium hydrate solution into the reacted maleic anhydride and ammonia gas to perform neutrallzation reaction, so as to obtain a mixture of maleamic acid sodium and maleamic acid ammonium; directly heating the product in the closed reactor and performing condensation polymerization by stirring; steaming and drying the moisture after the completion of the condensation polymerization, so as to obtain the polysuccinimide solid; adding water in another reaction kettle and starting stirring; then adding the polysuccinimide solid into the reaction kettle and slowly adding sodium hydrate solution and heating to perform hydrolysis reaction, so as to obtain the polyaspartic acid solution. According to the method for synthesizing polyaspartic acid by maleic anhydride and ammonia gas, the production process is simplified and the polyaspartic acid prepared according to the method has a weight-average molecular weight of 2000-15000 and a molecular weight distribution index of 1.5-1.65, so that molecular weight requirements of various application domains are met and environment-friendly production process is realized.

Owner:HEBEI XIETONG ENVIRONMENTAL PROTECTION TECH CO LTD

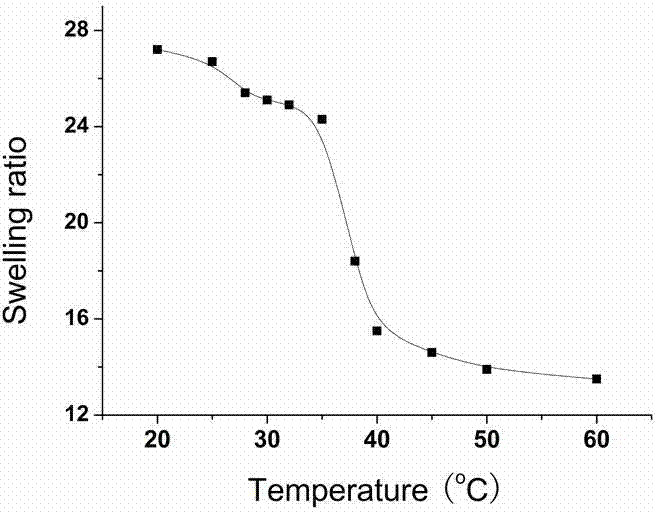

High-strength cellulose-based nanocomposite temperature and pH dual stimuli-responsive gel and preparation method thereof

InactiveCN105440296AGuaranteed biocompatibilityGuaranteed surface propertiesFilament/thread formingMonocomponent synthetic polymer artificial filamentCelluloseAntioxidant

The present invention relates to a preparation method of a high-strength and high-buffer POSS (polyhedral oligomeric silsesquioxane) hybridized polylactic acid foam material. The preparation method is characterized in that the foam material is prepared from main materials and auxiliary materials by compounding; the main materials comprise hydroxyl-terminated polylactic acid, thermoplastic polyurethane elastomer and polylactic acid; and the auxiliary materials comprise a compatibilizing agent such as eight-arm maleamic acid-based cage-like silsesquioxane, a condensation catalyst such as tetrabutyl titanate, as well as an antioxidant, a plasticizer, and an anti-UV agent. In the main materials, the mass ratio of the hydroxyl-terminated polylactic acid is between 45% and 65%, the mass ratio of the thermoplastic polyurethane elastomer is between 10% and 25%, and the mass ratio of polylactic acid is between 20% and 30%. In the auxiliary materials, the using amount of the compatibilizing agent such as eight-arm maleamic acid-based cage-like silsesquioxane accounts for 3.5%-6% of the mass of the hydroxyl-terminated polylactic acid in the main materials, the using amount of the condensation catalysts such as tetrabutyl titanate accounts for 0.5%-1.5% of the mass of the hydroxyl-terminated polylactic acid in the main materials, and the mass percentages of the antioxidant, the plasticizer, and the anti-UV agent all account for 1%-2% of the mass of the main materials. The foam material is prepared by adopting vapor extrusion foaming, and the process is simple. The material has good strength and buffer property, and is applicable to the fields of packaging and industry with requirements of high strength and high buffer property.

Owner:HUNAN UNIV OF TECH

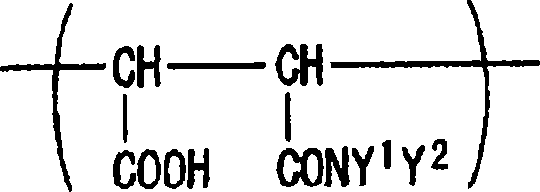

Rubber composition comprised of cis-1,4-polyisoprene and polymeric di-maleamic acid and articles, including tires, having at least one component comprised thereof

InactiveUS6297325B1Improve propertiesAdvantageously producedSpecial tyresTyre tread bands/patternsPolymer sciencePolyprenol

This invention relates to rubber compositions comprised of cis-1,4-polyisoprene and a polymeric di-maleamic acid and to articles of manufacture having at least one component comprised thereof, including tires. The polymeric di-maleamic acid has been observed to enhance green strength of such rubber composition.

Owner:THE GOODYEAR TIRE & RUBBER CO

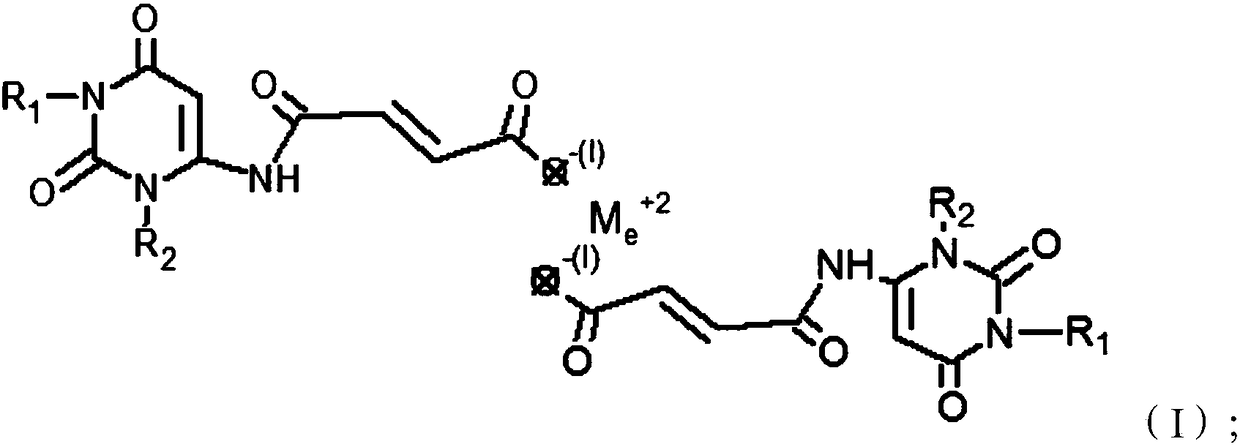

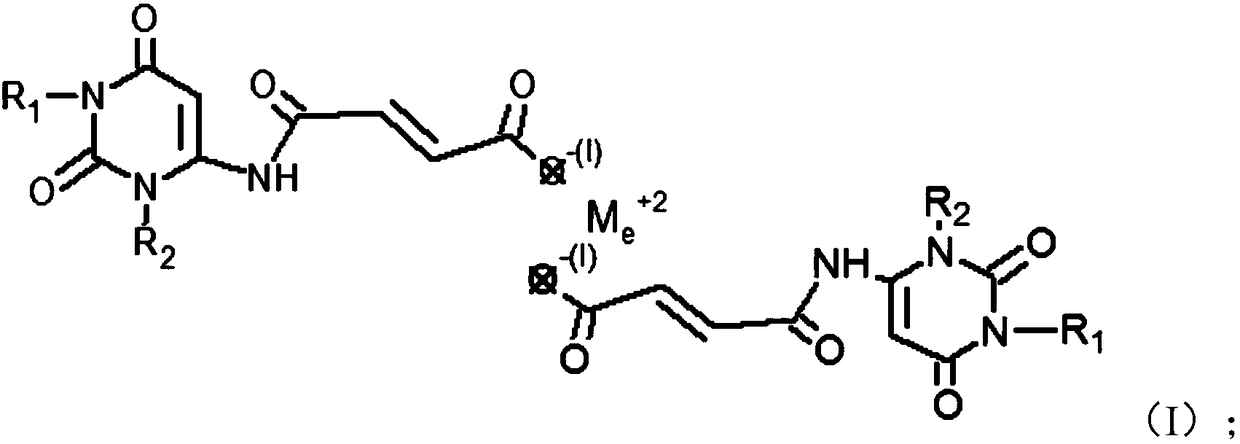

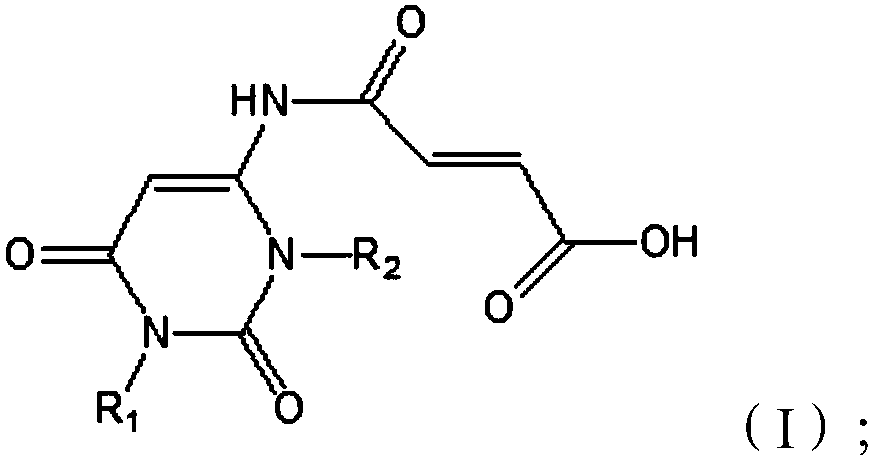

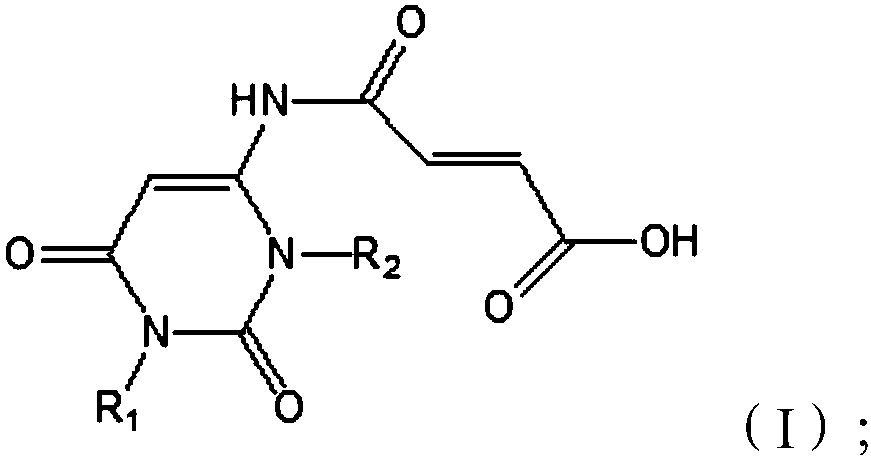

Aminouracil maleamate and preparation method as well as polyvinyl chloride heat stabilizer

The invention belongs to the field of fine chemistry and in particular relates to aminouracil maleamate and a preparation method as well as a polyvinyl chloride (PVC) heat stabilizer. The invention provides the aminouracil maleamate; the structure of the aminouracil maleamate is shown as a formula (I), wherein each of R1 and R2 is independently selected from hydrogen, alkyl and substituted alkyl;Me is selected from Zn, Mg, Ca, Ba and Sn. The aminouracil maleamate provided by the invention can be used for inhibiting further degradation and coloring of polyvinyl chloride; meanwhile, the aminouracil maleamate is bonded on a PVC molecular chain through a chemical bond and the stability in a product is improved, so that uracil is not easily separated out; the aminouracil maleamate belongs to amultifunctional heat stabilizer and has initial-stage and long-period stable effects; the problems that an existing heat stabilizer has poor compatibility with PVC and is easily bloomed and separatedout can be solved. The formula (I) is shown in the description.

Owner:GUANGDONG UNIV OF TECH

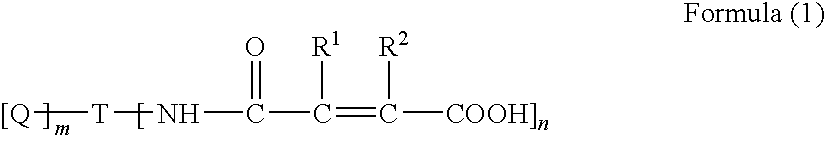

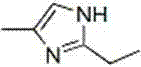

N-glucose hydrochloride-based maleamic acid monomer, and preparation method and application thereof

ActiveCN107286209AThe reaction conditions are simple and safeEasy to operateEsterified saccharide compoundsSugar derivativesFunctional monomerChemical products

The invention discloses an N-glucose hydrochloride-based maleamic acid monomer, and a preparation method and application thereof. The structure of the monomer is as follows: the formula is as shown in the description. The preparation method comprises the following steps: dissolving C mol of glucosamine hydrochloride into B mL of solvent; and dropwise adding A mol of maleic anhydride and B mL of solvent mixed solution while stirring until white powder is generated and white powder is not increased any more. The N-glucose hydrochloride-based maleamic acid synthesized by the method serves as a brand new amido acid compound, can serve as an intermediate of an imide chemical product and also can directly serve as a raw material of aqueous phase reaction or a functional monomer; furthermore, the reaction condition is simple, convenient and safe, operation is benefited, and the yield is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for Preparing N-Substituted Maleimides

The present invention relates to a method of preparing N-substituted maleimide in high purity and high yield, wherein, unlike a conventional method of preparing N-substituted maleimide after preparing N-substituted maleamic acid, an organic solvent, an acid catalyst, a dehydration co-catalyst and a stabilizer are added into a reactor without separately preparing N-substituted maleamic acid, and then a primary amine is added into the reactor to form an amine salt, maleic anhydride is added into the reactor, and the resulting mixture is subjected to a dehydration-cyclization reaction, wherein water produced during the reaction is azeotropically distilled with the organic solvent so as to effectively suppress formation of a maleimide polymer. Particularly, the invention simplifies the process, has high yield, minimizes side reactions, eliminates the introduction of expensive raw materials and the complicated treatment of the reaction solution and significantly shortens the time over which the raw materials and maleic anhydride are added.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

Liquid crystal alignment agent and liquid crystal alignment film formed therefore and manufacturing method thereof

InactiveUS20090226640A1Good coating performanceEasy to controlLiquid crystal compositionsPretreated surfacesLiquid-crystal displayOrganic solvent

The present invention provides a free radical polymerizable liquid crystal alignment agent having superior coating ability, a manufacturing method, which comprises the process of coating the liquid crystal alignment agent onto a substrate, carrying out dehydration / ring-closure and free radical polymerization, enables obtaining a liquid crystal alignment film with superior reliability, superior voltage holding ratio and easy control of pretilt angle, and enables the manufacture of a liquid crystal display element provided with a liquid crystal alignment film. The free radical polymerizable liquid crystal alignment agent comprises a molecular compound containing at least 2 polymerizable maleamic acid groups and an organic solvent.

Owner:CHI MEI CORP

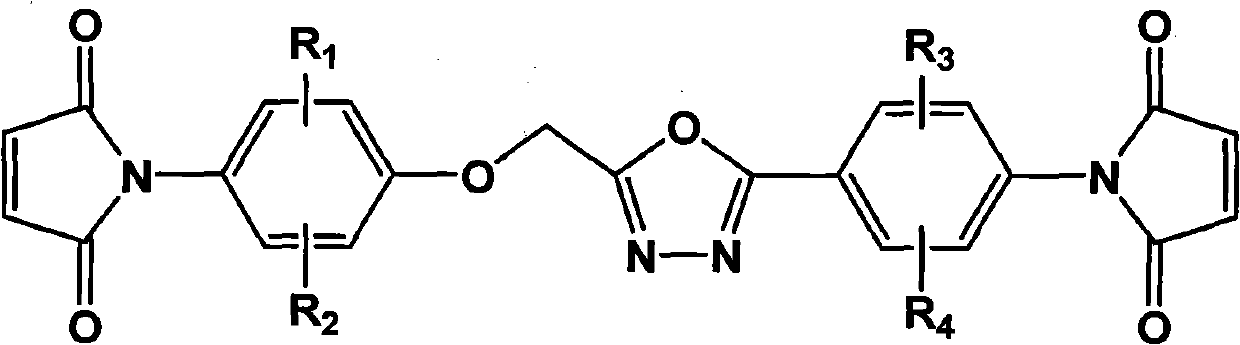

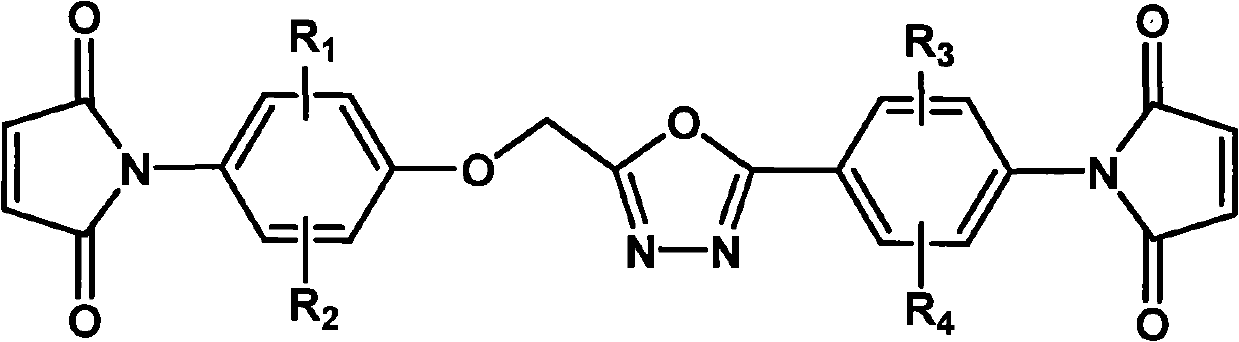

Bismaleimide containing 1,3,4-oxadiazole structure and preparation method thereof

InactiveCN101870693AImprove heat resistanceGood flexibilityOrganic chemistryAlkaneStructural formula

The invention relates to a bismaleimide containing a 1,3,4-oxadiazole structure and a preparation method thereof. In the structural formula of bismaleimide, substituents of R1 to R4 can be hydrogen atom, halogen atom, or same or different fat alkane of C1 to C20 and derivatives thereof, or same of different aromatic of C6 to C12 and derivatives thereof. The bismaleimide with a 1,3,4-oxadiazole structure is prepared by reacting diamine with a 1,3,4-oxadiazole structure with maleic anhydride to produce bismaleamic and performing imide cyclization reaction under the action of catalyst and dehydrating agent. The bismaleimide containing the1,3,4-oxadiazole structure has an asymmetric structure; and two reactive groups have different reaction activities in different chemical environments and can successively react at different curing temperatures. In addition, the cured product of the bismaleimide with a 1,3,4-oxadiazole structure has excellent heat resistance and is suitable for being used as a high-performance polymer composite matrix.

Owner:DALIAN UNIV OF TECH +1

Personal care products

ActiveUS20040042987A1Excellent high humidity curl retention properties,Improve adhesionCosmetic preparationsHair removalCarboxylic acidNatural fiber

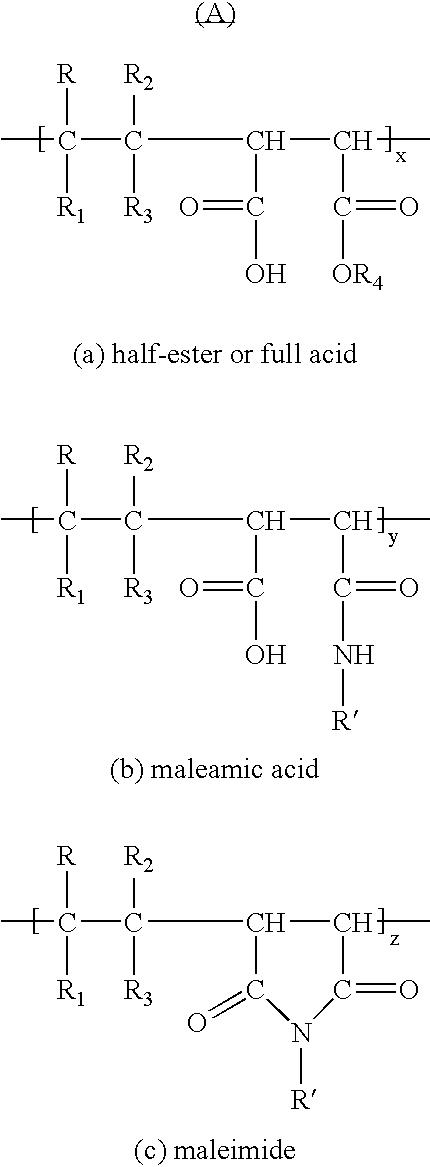

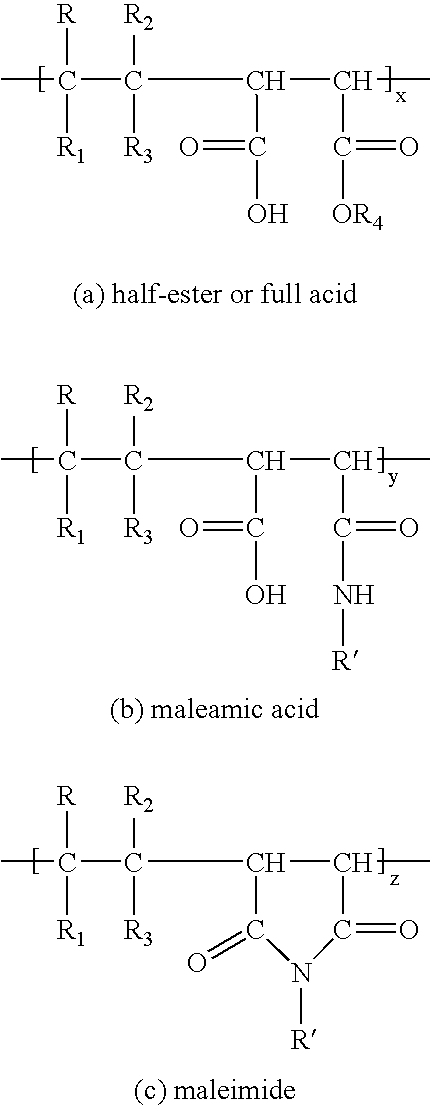

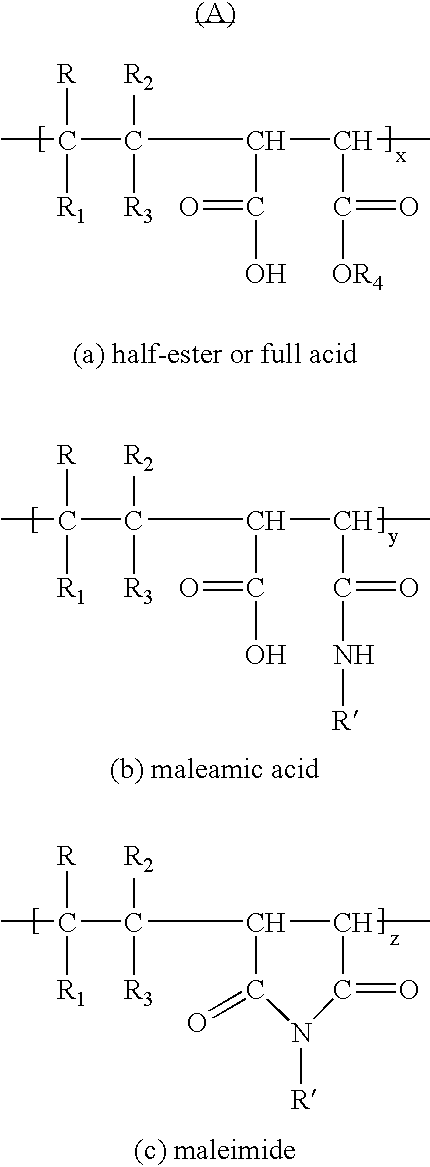

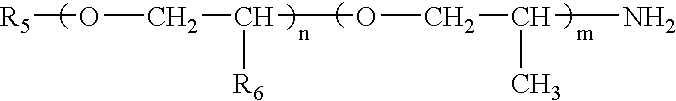

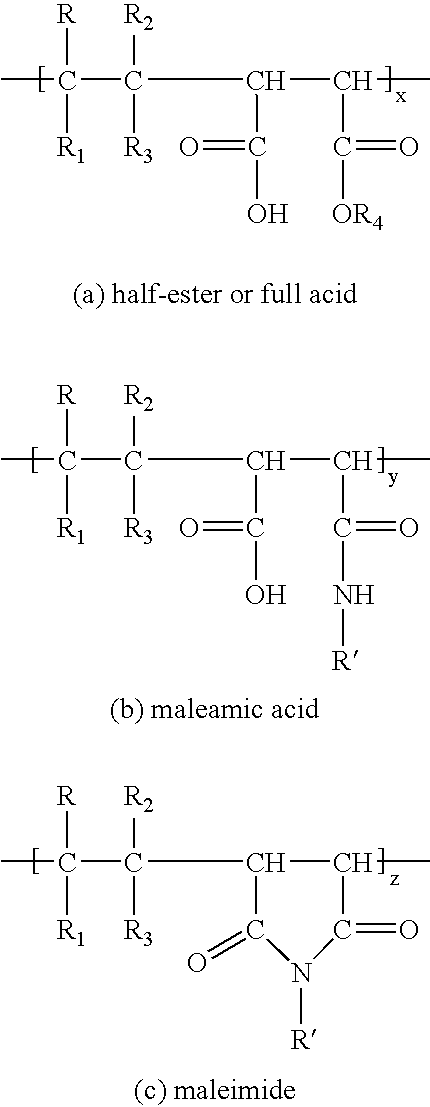

Personal care products, particularly hair care products, are made herein by mixing (A) a polymer having defined repeat units of a monomer (e.g. alpha-olefin) maleic anhydride alkyl half-ester or full acid, maleamic acid and maleimide, which is derivatized with an amine, and (B) a compound or polymer having a carboxylic acid functionality. These products exhibit excellent high humidity curl retention properties, as well as an advantageous blend of toughness and cohesiveness, and a strong affinity to natural fibers, when applied to keratin-based fibers, e.g. hair, skin, or textiles, e.g. cotton, wool; and also they are water-soluble and water-resistant.

Owner:ISP INVESTMENTS LLC

Medical antibacterial PVC catheter material and preparation method

The invention discloses a medical antibacterial PVC catheter material which is prepared by taking PVC resin and high density PVC as main components and adding calcium lignosulfonate, linolenic acid, bismaleamic acid, polymethyl methacrylate, octenyl succinic starch ester, (3,4-dimethylbenzylidene) sorbitol, epoxidized soybean oil, barium stearate, nanometer zinc oxide, chitosan fibers, sea-foam stone powder, propolis, a plasticizer and a dispersant under the assistance of processes of ball milling, ultrasonic dispersion, high-temperature stirring, twin-screw extrusion and the like. The prepared catheter material is high in antibacterial performance and biocompatibility, and has considerable mechanical strength and broader application prospect, and the requirement of the industry can be met.

Owner:胡何辉

Personal care products

Owner:ISP INVESTMENTS LLC

Synthesis method of N-phenyl-maleimide

The invention discloses a synthesis method of N-phenyl-maleimide, which comprises three steps of: 1. carrying out acylation on maleic anhydride and phenylamine in solvent to obtain N-phenyl-maleamic acid; 2. dehydrating the N-phenyl-maleamic acid in the solvent with hydroquinone and molecular sieve attached with phosphoric acid to obtain a crude product; and 3. adding activated clay and apply acid agent into the solvent of the crude product to obtain the product by refining. After the technology is adopted, the synthesis method is environment-friendly, simple in technology and low in cost.

Owner:如皋市油脂化工有限责任公司

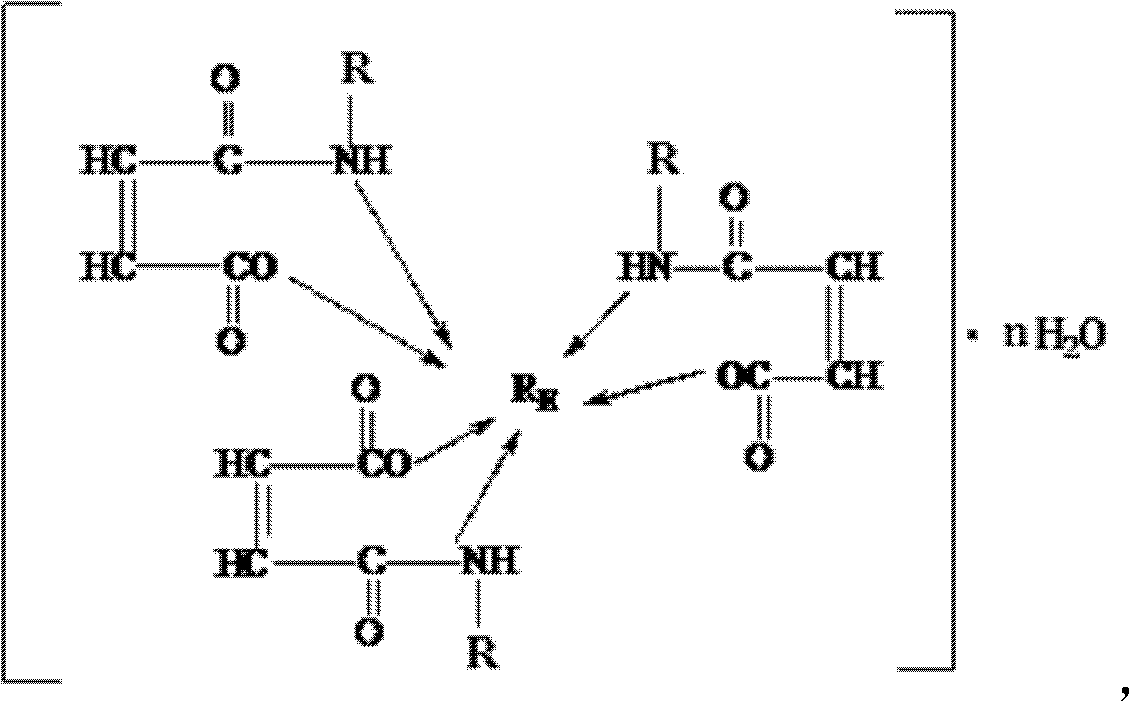

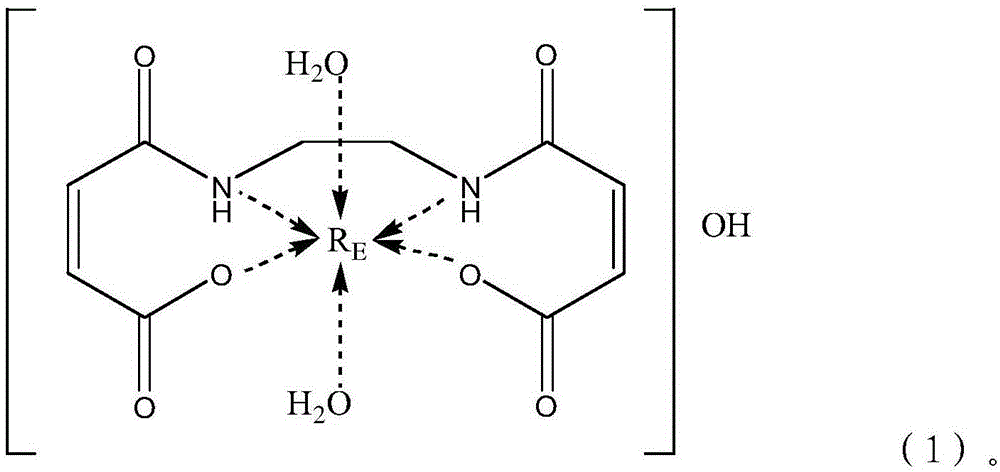

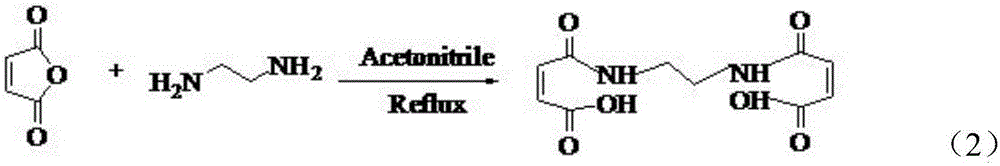

Rare earth complex, preparation method and applications thereof

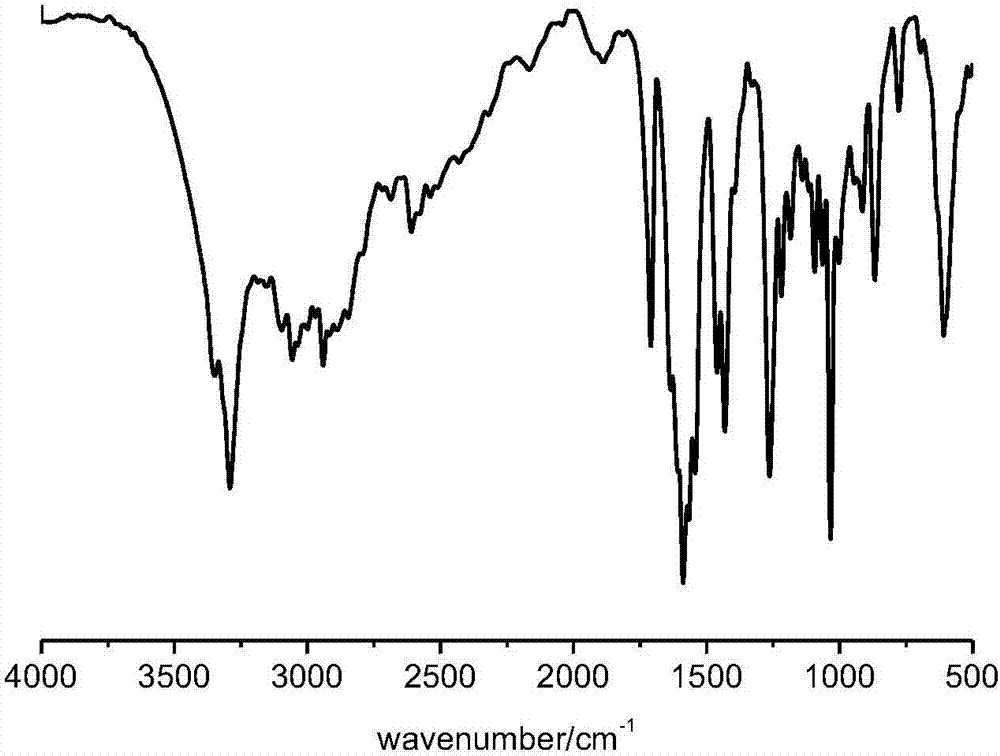

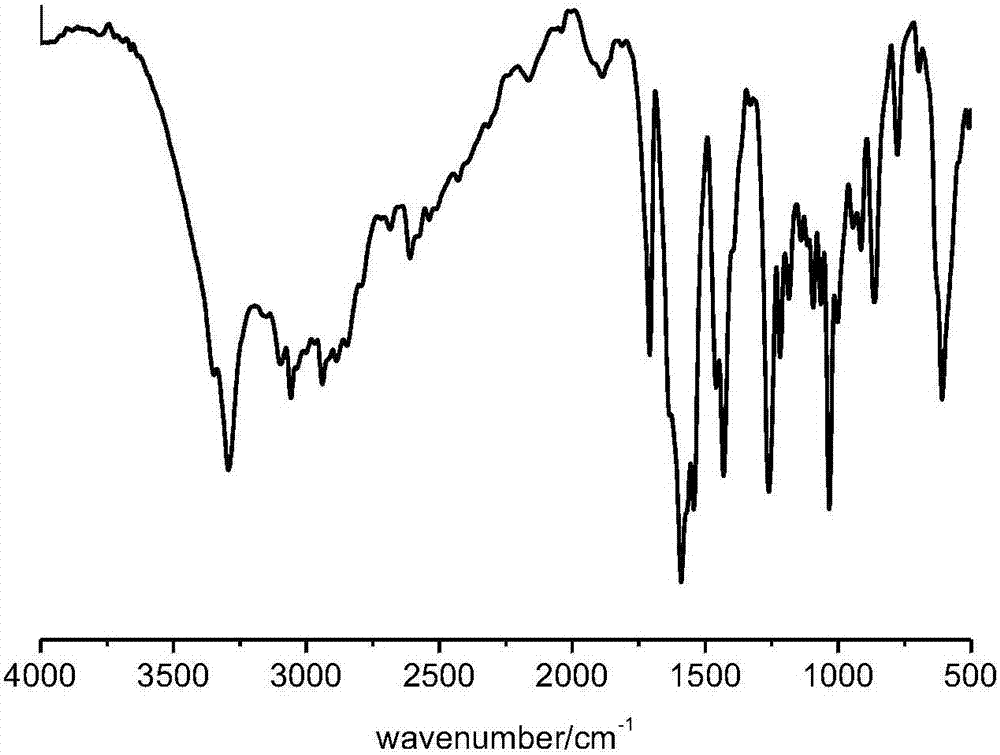

ActiveCN105936680AImprove thermal stabilityGood weather resistanceOrganic compound preparationCarboxylic acid amides preparationRare-earth elementPolyvinyl chloride

The invention provides a rare earth complex. The rare earth complex is an ethylene diamine bis(maleic amide) rare earth complex, and the chemical formula of the rare earth complex is [RE(H2O)2.L]OH, wherein RE represents a rare earth element and L represents an ethylene diamine bis(maleic amide) group. The invention also provides a preparation method and an application of the rare earth complex as a polyvinyl chloride (PVC) stabilizing agent. The preparation method is simple, the cost is low, and thus the rare earth complex has an industrial application prospect. The provided rare earth complex or a composition thereof can be used as a PVC stabilizing agent, the shortages of conventional thermal stabilizing agents can be overcome, moreover, the primary coloring performance and long term stability of PVC are both improved; the rare earth complex, calcium stearate, organic tin, and pentaerythritol can generate a good synergetic effect and are capable of cooperatively improving the thermal stability of PVC; and at the same time, the mechanical properties of PVC are effectively improved.

Owner:XIAN UNIV OF SCI & TECH

Aminouracil maleamic acid as well as preparation method thereof and polyvinyl chloride heat stabilizer

The invention belongs to the field of fine chemistry, and particularly relates to aminouracil maleamic acid as well as a preparation method thereof and polyvinyl chloride heat stabilizer. The invention provides aminouracil maleamic acid, and a structure of the aminouracil maleamic acid is as shown by the general formula (I), wherein R1 and R2 are respectively and independently selected from hydrogen, alkyl or substituent alkyl. The aminouracil maleamic acid of the invention can inhibit the further degradation and coloring of polyvinyl chloride and is bonded onto a PVC molecular chain by virtueof a chemical bond, and the stability of the aminouracil maleamic acid in a product is improved, so that the uracil is unlikely to precipitate, the polyvinyl chloride heat stabilizer is a multifunctional heat stabilizer integrating a primary stabilizing effect and a long-term stabilizing effect and can be used for solving the problems that the existing heat stabilizer is poor in compatibility with the PVC and easy to precipitate in a spraying manner. (the formula (1) is shown in the description).

Owner:GUANGDONG UNIV OF TECH

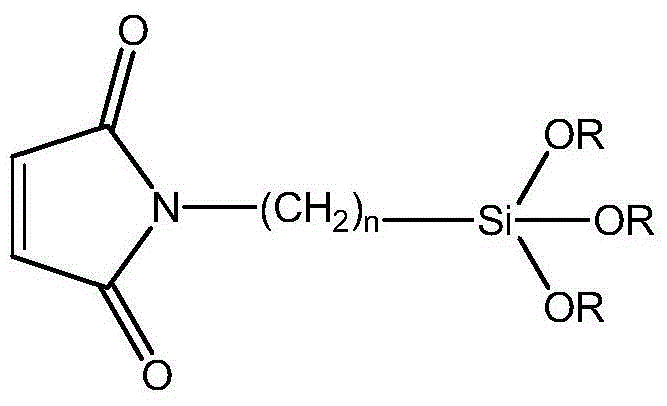

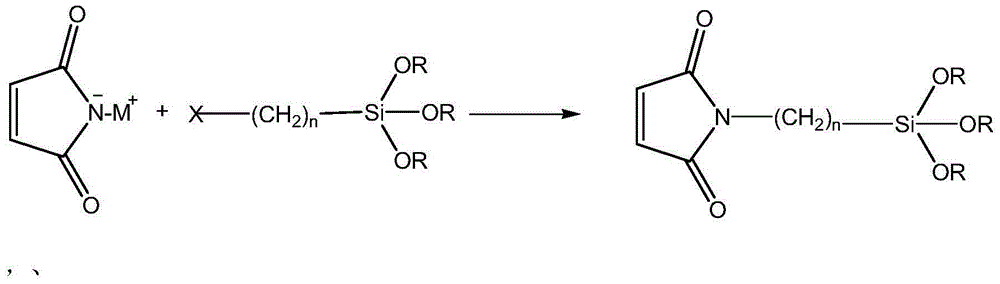

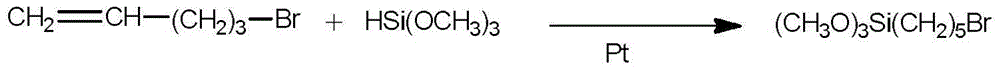

Synthesis method of siloxane-substituted maleimide

InactiveCN104447849AOvercome cumbersomeOvercome the disadvantages of siloxane hydrolysis easily caused by the dehydration processGroup 4/14 element organic compoundsGlass fiberImide

The invention belongs to the field of synthesis of polymer monomers, and specifically relates to a synthesis method of siloxane-substituted maleimide which can be used as an active coupling agent of glass fibers for greatly improving the combination force of the glass fibers and organic resins. The traditional manufacturing method of such coupling agent is a two-step method and comprises the steps of enabling amino alkyl siloxane and maleic anhydride to react to generate maleamic acid alkyl siloxane; synthesizing the siloxane-substituted maleimide through amic acid under the effect of a dehydrating agent. The invention provides a novel synthesis method for preparing a target product through raw materials that are alkali metal salt of maleimide and halogen alkyl siloxane by an one-step mode in the presence of a polar aprotic solvent, aims at overcoming the shortages that the traditional synthesis method is cockamamie in process and the dehydrating easily leads to hydrolyzing of siloxane. The method, by being compared with the traditional synthesis method, has the advantages that the after-treatment is convenient, the siloxane is avoided electrolyzing, and the product is high in purity.

Owner:SHANGHAI AIMO JINSHAN PHARM CO LTD

High-affinity medical antibacterial glycolide material and preparation method thereof

The invention discloses a high-affinity medical antibacterial glycolide material. The material is prepared from, by weight, 45-55 parts of polyglycollide, 40-50 parts of N,N'-ethylene hisstearamide, 40-50 parts of collagen, 35-45 parts of 1,6-ethylene glycol dimethacrylate, 25-35 parts of N,N'-ethylene hisstearamide, 20-26 parts of bi-maleamidic acid, 18-22 parts of polyvinyl alcohol condensed glyoxal, 10-12 parts of glass fiber, 10-12 parts of fimbrin, 5-8 parts of wollastonite powder, 4-6 parts of nano titanium dioxide, 4-6 parts of aluminum silicate ceramic fiber, 3-5 parts of acetyl triethyl citrate, 2-4 parts of stabilizer and 2-4 parts of coupling agent. The prepared high-affinity medical antibacterial glycolide material is good in biocompatibility and antibacterial performance, has certain flexibility and mechanical strength and can meet industrial requirements. Meanwhile, the invention further discloses a corresponding preparation method.

Owner:何仁英

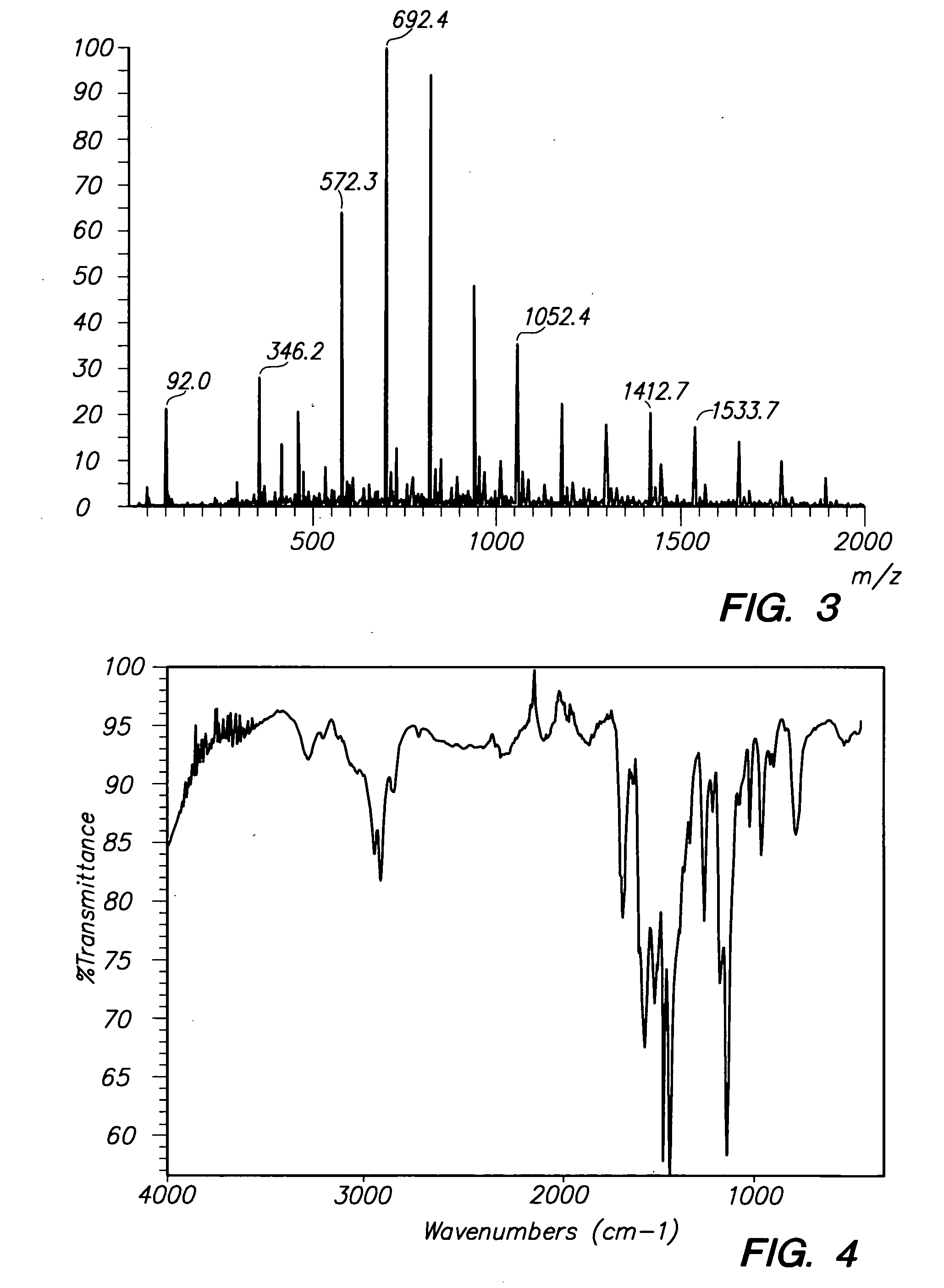

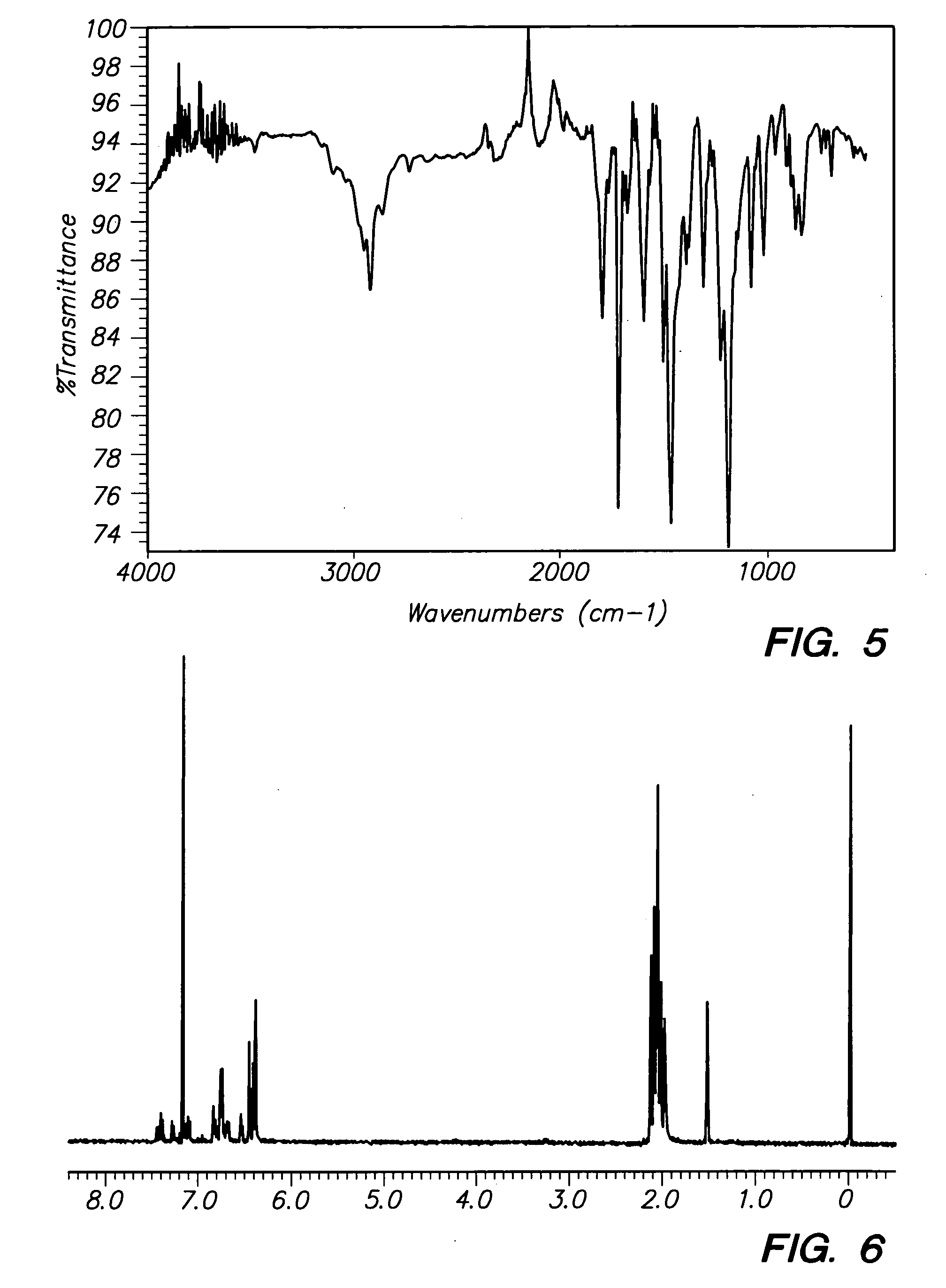

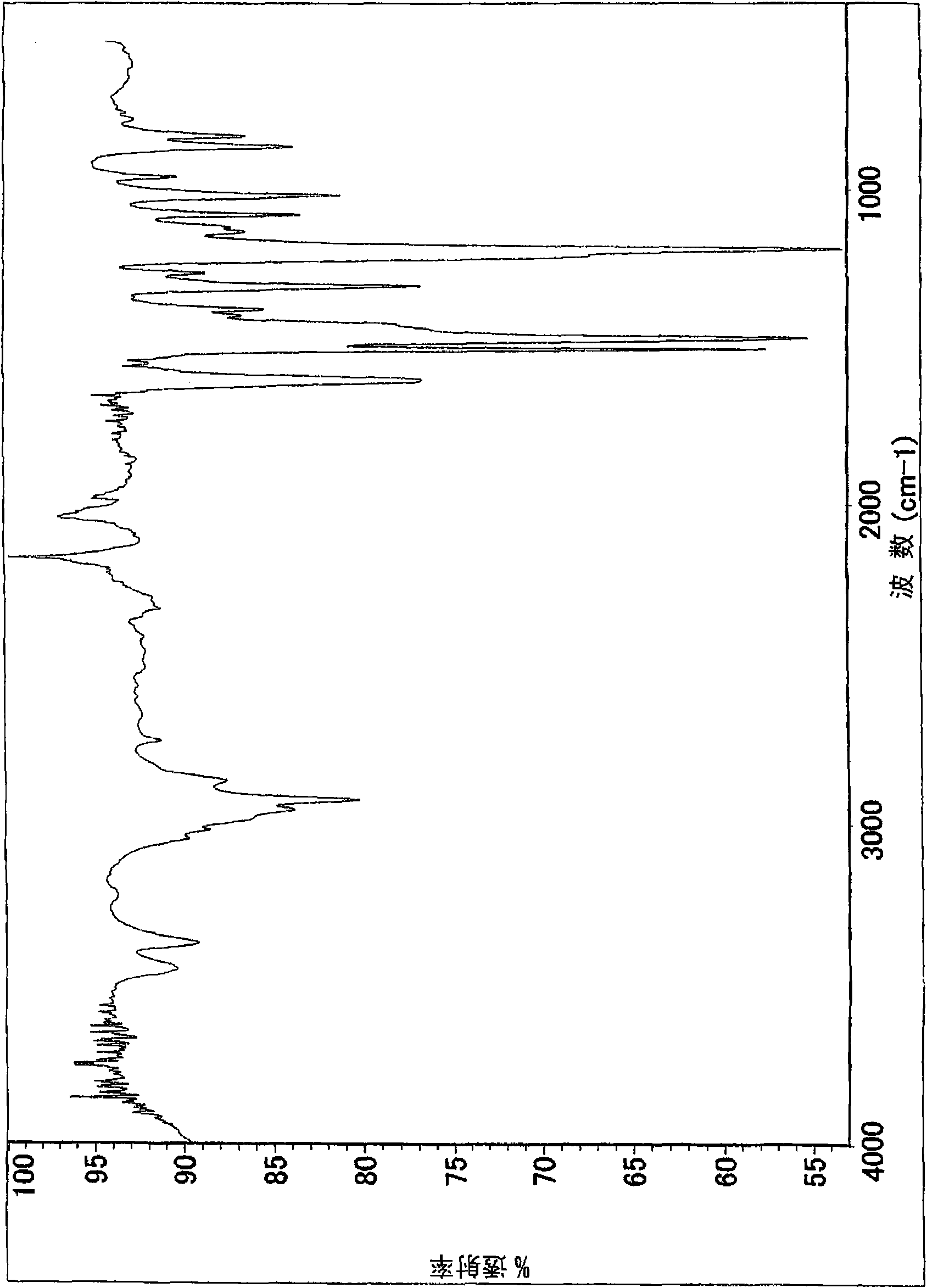

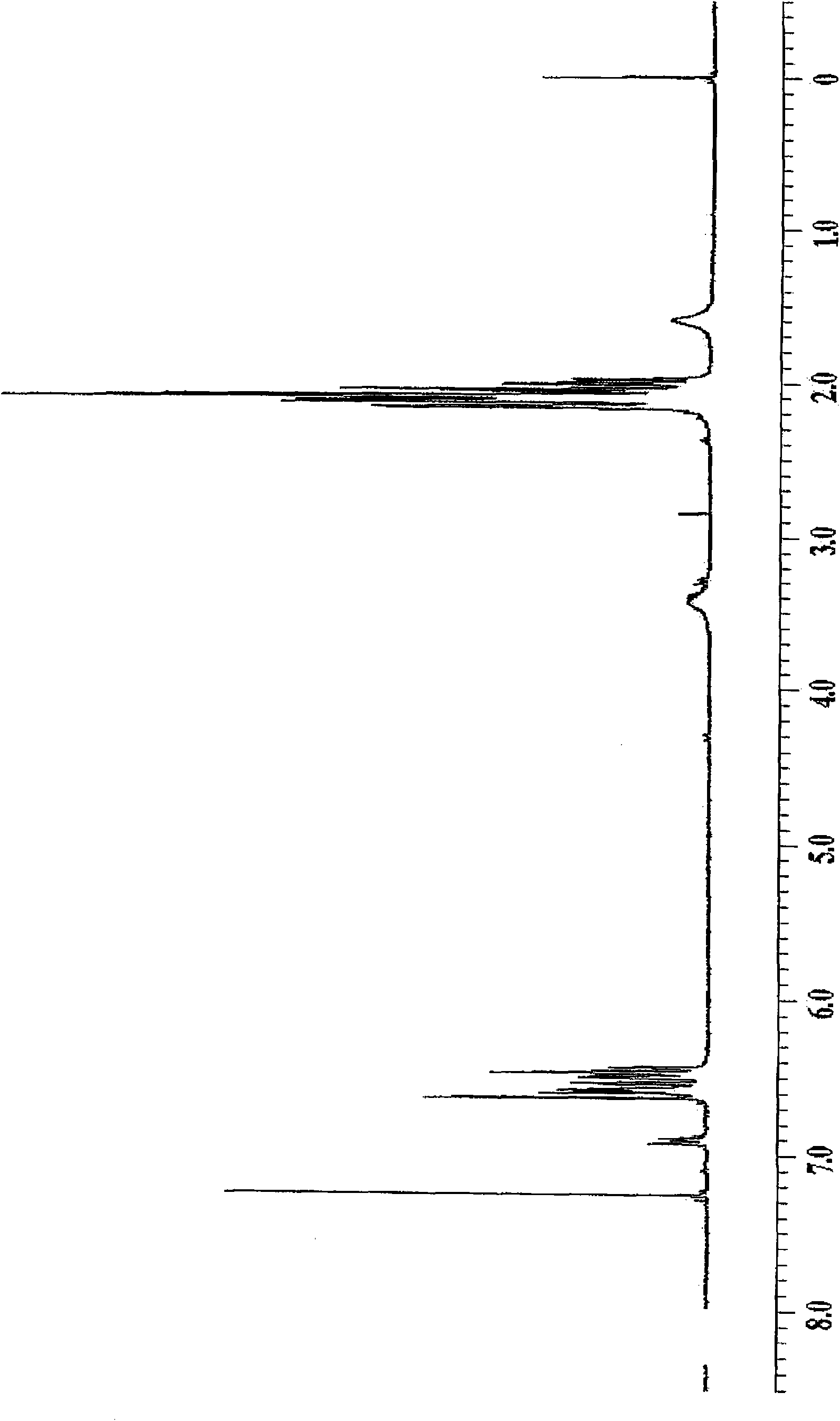

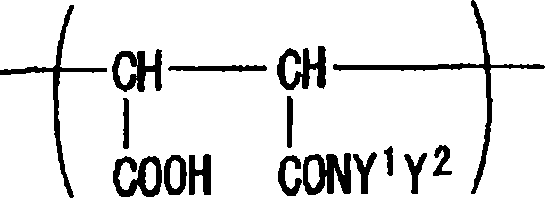

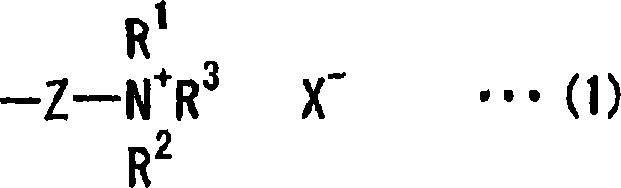

Maleamic acid polymer derivatives and their bioconjugates

The present invention is directed to maleamic acid derivatives of water soluble polymers, to chemically stable water-soluble polymer succinamic acid -active agent conjugates, and to methods for reproducibly preparing, characterizing and using such polymer reagents and their conjugates.

Owner:NEKTAR THERAPEUTICS INC

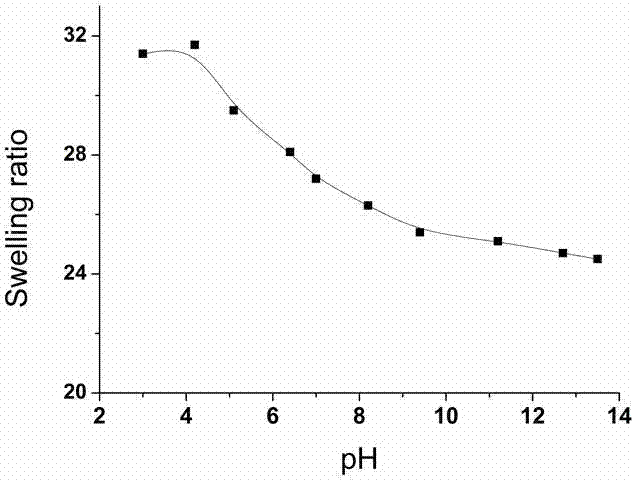

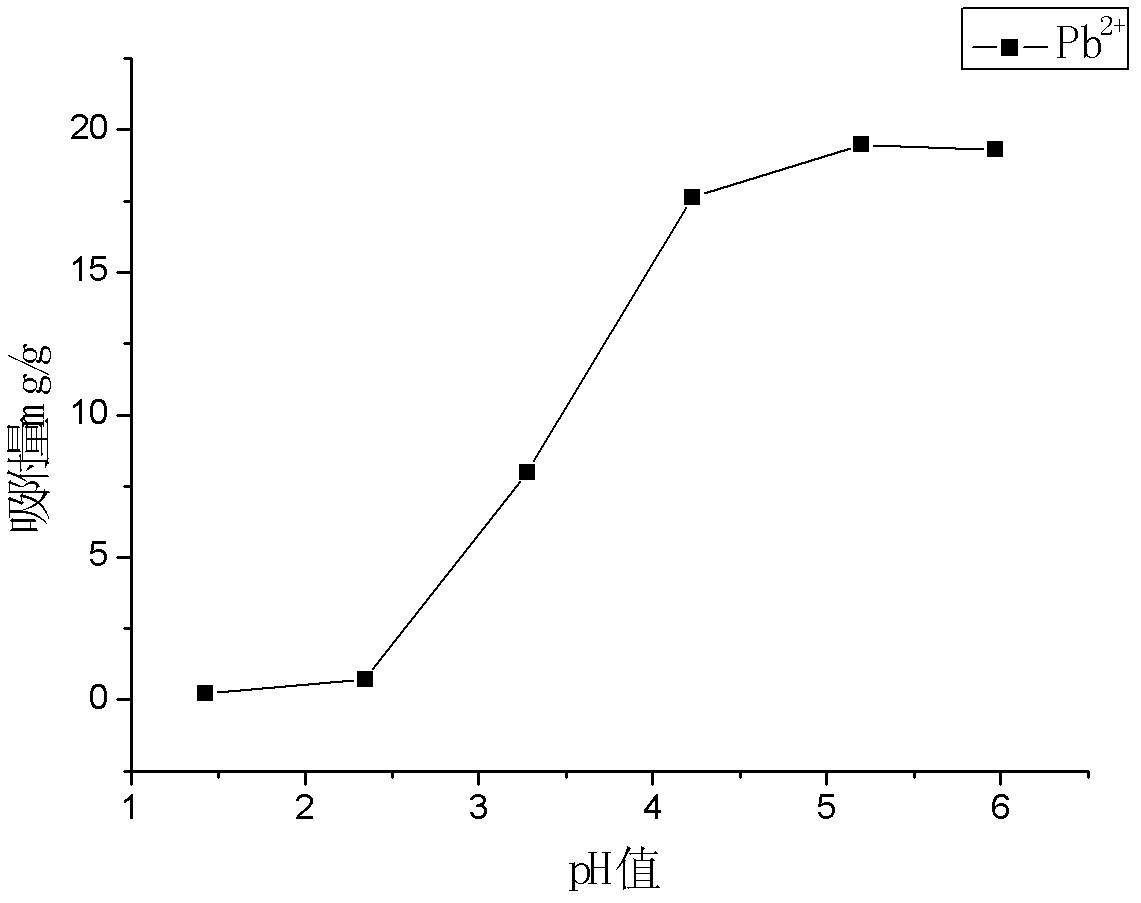

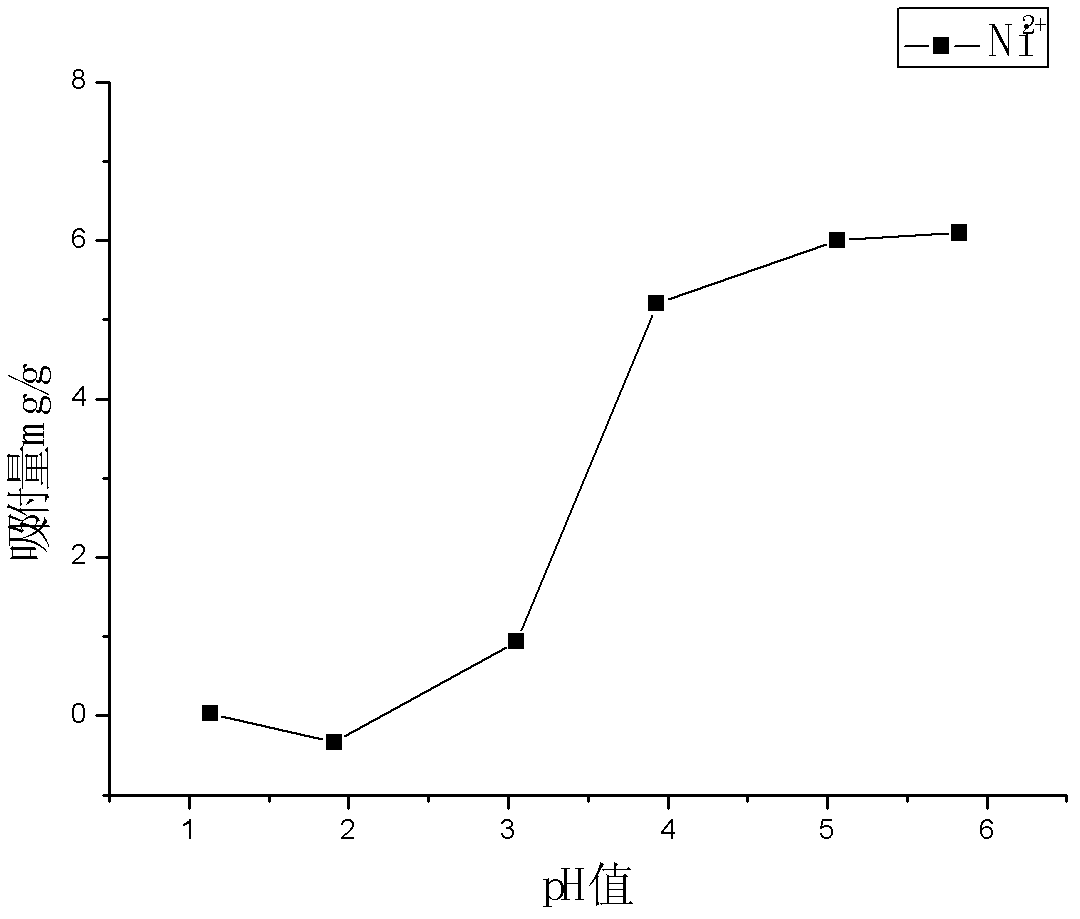

Hydrogel, its preparation method and its application in heavy metal waste water treatment

InactiveCN102492088AHave mechanical strengthWorks well for adsorption applicationsOther chemical processesAlkali metal oxides/hydroxidesRadiation DosagesIndustrial waste water

The invention relates to a polymer hydrogel, which comprises the following components and a preparation method: 1) uniformly mixing acrylic acid, hydroxyl ethyl, maleamic acid and deionized water according to a certain proportion; wherein the volume ratio of maleamic acid and hydroxyethyl acrylate to water is 2:8 to 4:6, the mol ratio of maleamic acid to hydroxyethyl acrylate is 1:9 to 9: 1; 2) mixing and carrying out ultrasonic treatment for 7-13 minutes; 3) filling nitrogen in a mixture in the step 1) for ensuring an anoxic state; 4) using high energy ray irradiation polymerization for forming the hydrogel at the temperature of -63 to -95 DEG C. The high energy ray preferably selects Gamma ray or electron beam with energy of more than 2 MEV, the radiation dosage preferably selects 1*10<3>-1*10<6>Gy; the radiation time is 14-34 hours. The obtained polymer hydrogel possesses adsorption application on the heavy metal ions in industrial waste water, life sewage and nature water body treatment.

Owner:NANJING UNIV

Lithographic printing plate precursor

InactiveCN101027611APhotosensitive materials for photomechanical apparatusForme preparationHydrogen atomOnium

To provide a lithographic printing plate precursor which generates no stains in the non-image area and is also excellent in development latitude. Disclosed is a lithographic printing plate precursor comprising a support and a photosensitive layer, said lithographic printing plate precursor further comprising a subbing layer containing a maleamic acid (co)polymer, in which at least one hydrogen atom on a nitrogen atom is substituted with an onium group, provided between the photosensitive layer and the support.

Owner:EASTMAN KODAK CO

Lithographic Printing Plate Precursor

InactiveUS20080261146A1Good development spaceNo stainsPhotosensitive materialsSemiconductor/solid-state device manufacturingHydrogen atomNitrogen

To provide a lithographic printing plate precursor which generates no stains in the non-image area and is also excellent in development latitude. Disclosed is a lithographic printing plate precursor comprising a support and a photosensitive layer, said lithographic printing plate precursor further comprising a subbing layer containing a maleamic acid (co)polymer, in which at least one hydrogen atom on a nitrogen atom is substituted with an onium group, provided between the photosensitive layer and the support.

Owner:KODAK POLYCHROME GRAPHICS JAPAN +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com