Patents

Literature

795 results about "Triethyl citrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Triethyl citrate is an ester of citric acid. It is a colorless, odorless liquid used as a food additive (E number E1505) to stabilize foams, especially as whipping aid for egg white. It is also used in pharmaceutical coatings and plastics.

Well treatment fluid compositions and methods for their use

InactiveUS6983801B2High viscosityIncrease volumeFluid removalFlushingAlkaline earth metalCarboxylic acid

Owner:COMBINED SYST +1

Cooling compositons

The present invention relates to cooling compositions comprising a cooling agent (preferably menthyl lactate) together with an ester derivative (preferably tri-ethyl citrate). Such compositions deliver immediate and long lasting freshness sensation, while maintaining or even improving skin and / or mucosal membrane health to which they are contacted and deodorizing said skin and / or mucosal membrane.

Owner:THE PROCTER & GAMBLE COMPANY

Compositions and methods for controlling insects

Pest control compositions, blends, and formulations are disclosed. The blends contain, in a synergistic combinations, at least two ingredients such as Lilac Flower Oil, D-Limonene, Thyme Oil, Lime Oil, Black Seed Oil, Wintergreen Oil, Linalool, Tetrahydrolinalool, Vanillin, Isopropyl myristate, Piperonal (aldehyde), Geraniol, Geraniol 60, Triethyl Citrate, and Methyl Salicylate.

Owner:TYRATECH

A solvent for electronic cigarette liquid and an electronic cigarette liquid

InactiveUS20160366927A1Great amount of smokeConvenient amountTobacco treatmentPolyolElectronic cigarette

The present invention provides a solvent for electronic cigarette liquid, comprising triethyl citrate. In the present invention, triethyl citrate alone or in combination with a polyol is used as the solvent for the electronic cigarette liquid. Due to the effect of triethyl citrate, the electronic cigarette liquid which is prepared with the solvent for electronic cigarette liquid provided by the present invention generates relatively greater amount of smoke while being atomized, improves the experience of the smoker, who feels thick and full, neither too dry nor too wet, and has relatively higher comfort level. Furthermore, all the components of the solvent for electronic cigarette liquid provided by the present invention are of food grade, and are harmless to the body of the smoker.

Owner:KIMREE HI TECH

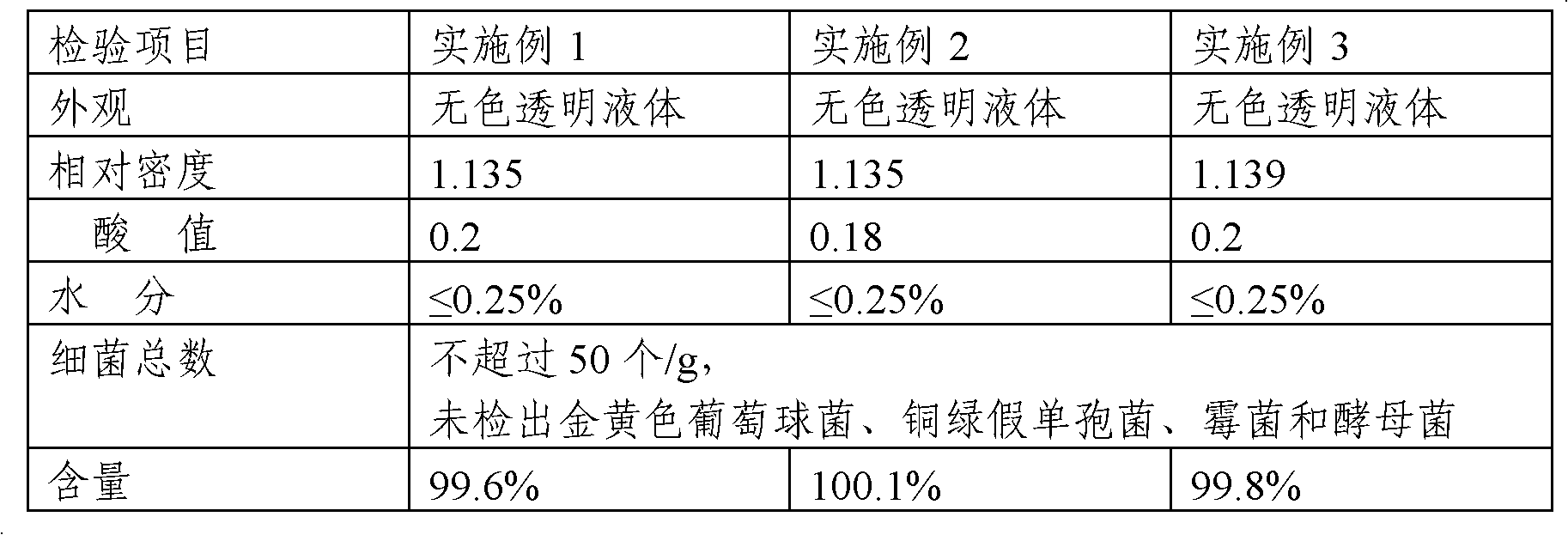

Preparation method of triethyl citrate

ActiveCN102079704ALess side effectsHarm reductionOrganic compound preparationCarboxylic acid esters preparationLiquid productPhenolphthalein

The invention relates to a preparation method of triethyl citrate. The preparation method is as follows: by deeply studying the preparation process of triethyl citrate, setting a reaction feed ratio; then adding catalyst to perform reflux reaction; then utilizing phenolphthalein as an indicator and sodium hydroxide to perform titration to determine the reaction end point; utilizing weak base to neutralize less acidic materials in the obtained product, and eluting sodium carbonate with purified water; and finally utilizing activated carbon to decolor, thus obtaining the pure triethyl citrate product. Compared with the prior art, the preparation method provided by the invention has the advantages that the reaction end point is strictly controlled, unnecessary side reactions are reduced, thereduction of the product quality and the waste of cost caused by inadequate reaction or too long reaction time can be avoided; by controlling the temperatures of the processing steps, the damages caused by side reactions are reduced as far as possible; by selecting the decoloring mode, an ideal, colorless and transparent liquid product can be obtained; and the product quality is above the national standard: especially the acid value is controlled to be about 0.2 while the acid value of the national standard is 1.0, and the stability of the product when stored for a long time is higher than those of the like products.

Owner:蚌埠丰原涂山制药有限公司

Montmorillonite/isotactic polypropylene/polylactic acid composite sound absorbing cotton and preparation method thereof

InactiveCN103696127ASimple production processRaw materials are cheap and easy to getSynthetic resin layered productsNon-woven fabricsAdditive ingredientPolypropylene

The invention discloses montmorillonite / isotactic polypropylene / polylactic acid composite sound absorbing cotton, which consists of a top surface layer, a back surface layer and a fiber cotton layer, wherein the fiber cotton layer is clamped and arranged between the top surface layer and the back surface layer, and the top surface layer and the back surface layer are made of non-woven fabric materials. The montmorillonite / isotactic polypropylene / polylactic acid composite sound absorbing cotton is characterized in that the non-woven fabric is prepared form the following ingredients in parts by weight by a melt blowing method: 100 parts of isotactic polypropylene, 10 to 12 parts of polylactic acid, 10 to 12 parts of montmorillonite powder, 5 to 7 parts of dilauryl thiodipropionate, 2 to 3 parts of zinc oxide, 12 to 15 parts of diethylene glycol dibenzoate, 4 to 6 parts of triethyl citrate, 2 to 3 parts of zinc chloride, 5 to 7 parts of chitosan, 2 to 3 parts of molecular sieves, 12 to 15 parts of yellow cinnamon leaf, 2 to 3 parts of rhizoma gastrodiae, 2 to 3 parts of mint, 2 to 3 parts of radix angelicae pubescentis and 4 to 5 parts of auxiliary agents. The montmorillonite / isotactic polypropylene / polylactic acid composite sound absorbing cotton has the advantages that the montmorillonite, the isotactic polypropylene and the polylactic acid are compounded for preparing the sound absorbing cotton by the melt blowing method, the production process is simple, the raw materials are easy to obtain, the cost is low, and the prepared product has the advantages that the air permeability and the oxygen permeability are good, the tensile strength and the extension degree are high, the sound absorbing effect is obvious, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

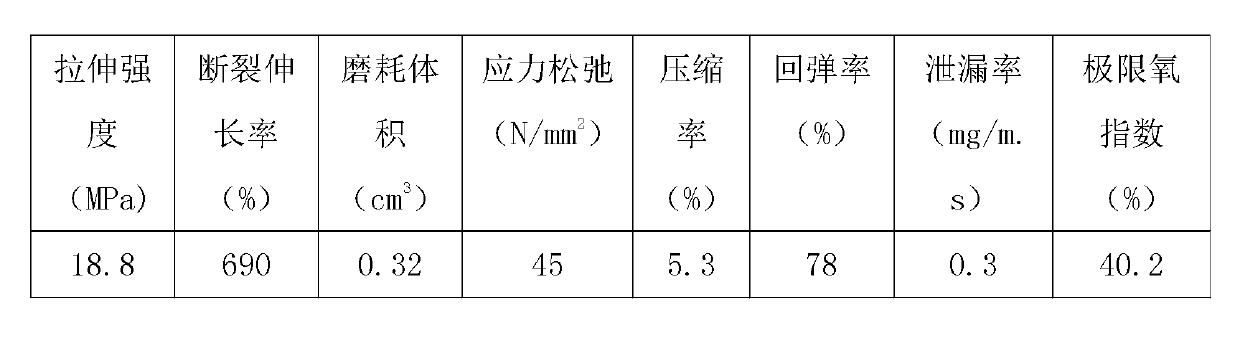

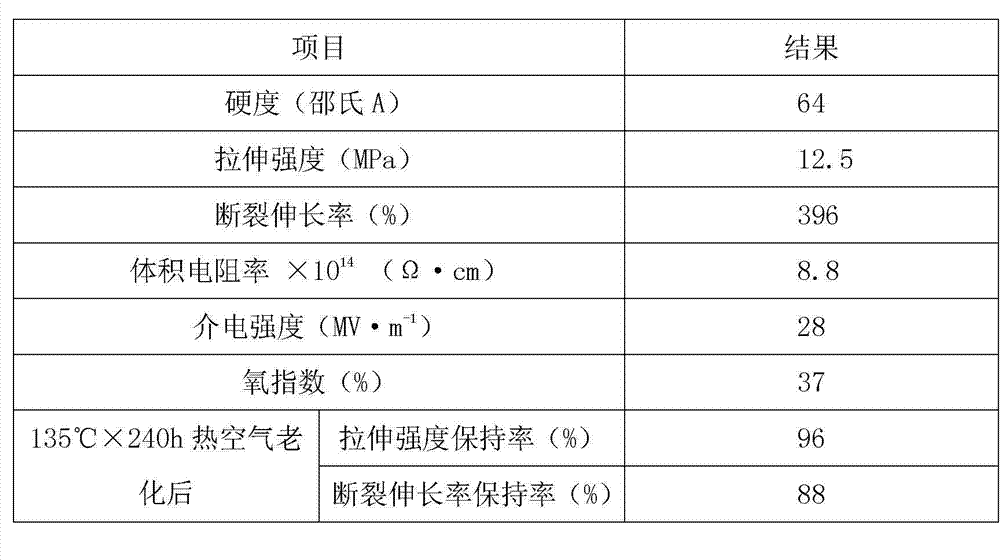

Leather cup rubber for laundry machine and preparation method thereof

The invention discloses leather cup rubber for a laundry machine. The leather cup rubber is prepared from the following raw materials in parts by weight: 30-40 parts of nitrile rubber, 20-30 parts of chlorosulfonated polyethylene rubber, 20-40 parts of ethylene propylene terpolymer 5962 (LANXESS Deutschland), 10-15 parts of fluorine rubber, 3-5 parts of natural rubber, 20-30 parts of high abrasion furnace black N330, 10-15 parts of modified white carbon black, 3-4 parts of zirconia, 8-10 parts of modified wood ash, 4-6 parts of attapulgite, 4-6 parts of meerschaum, 9-11 parts of modified iron tailing slag powder, 0.5-1 part of stearic acid, 0.5-1 part of isocyanate, 0.2-0.4 part of accelerant DM, 0.3-0.6 part of accelerant BZ, 1-2 parts of stearic acid, 2-4 parts of zinc oxide, 0.2-0.4 part of ferrocene, 1-2 parts of polyethylene wax, 1-2 parts of antioxidant DSTP, 1-2 parts of anti-aging agent NBC, 2-3 parts of gamma-methacryloxypropyl trimethoxysilane and 16-18 parts of triethyl citrate. The rubber disclosed by the invention has excellent ozone resistance, excellent low temperature resistance and heat resistance and is large in operating temperature range and environment-friendly in process, so that the rubber can be used for preparing various packing materials.

Owner:WUHU HENGKUN AUTO PARTS

Completely biological degradable polylactic coating materials

A fully biodegradable polylactic acid coating material for the coated paper consisting of paper substrate and coated plasticizing polylactic acid composition is disclosed. Said plasticizing polylactic acid composition contains proportionally polylactic acid, composite plasticizer chosen from polyethandiol, glucoside triacetate, triethyl citrate, tributyl citrate, triethyl acetylacetate, etc, lipoamide and inorganic filler. The coated paper features high resistance to water, oil and high temp, air tight, and antibacterial effect.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Irradiation crosslinking low-smoke halogen-free flame-retardant polyolefin cable material for photovoltaic cables

The invention provides an irradiation crosslinking low-smoke halogen-free flame-retardant polyolefin cable material for photovoltaic cables. The cable material is prepared from the following raw materials in parts by weight: 40-50 parts of polyethylene (PE), 30-40 parts of polyvinyl chloride resin, 20-30 parts of CSM2305, 10-12 parts of ethylene-acrylate copolymer, 10-15 parts of epichlorohydrin rubber T3100, 5-10 parts of epoxidized soybean oil, 2-3 parts of carbonyl iron powder, 10-12 parts of high abrasion carbon black N330, 5-10 parts of light calcium carbonate, 1-2 parts of zinc oxide, 5-10 parts of wollastonite powder, 4-5 parts of vermiculite, 1-2 parts of polytetrafluoroethylene micro powder, 1-2 parts of graphite, 1-2 parts of nano boron carbide, 2-3 parts of ferric oxide, 0.1-0.2 part of UV-O, 0.1-0.2 part of UV-53, 0.1-0.2 part of flame retardant TBC, 10-12 parts of aluminium hypophosphite, 5-8 parts of decabromodiphenyl ether, 8-10 parts of dioctyl terephthalate, 6-8 parts of trioctyl trimellitate, 8-10 parts of triethyl citrate, 1-2 parts of calcium stearate, 0.2-0.4 part of stearic acid, 0.1-0.2 part of oxidized polyethlene wax, 0.2-0.3 part of ethylene bis stearamide, 0.1-0.2 part of DCP, and 12-15 parts of modified filler. The cable material has the characteristics of high flame retardance, high ultraviolet resistance and high ageing resistance, and meanwhile, has a good mechanical property, and is environment-friendly.

Owner:温州市粤来电子加速器应用有限公司

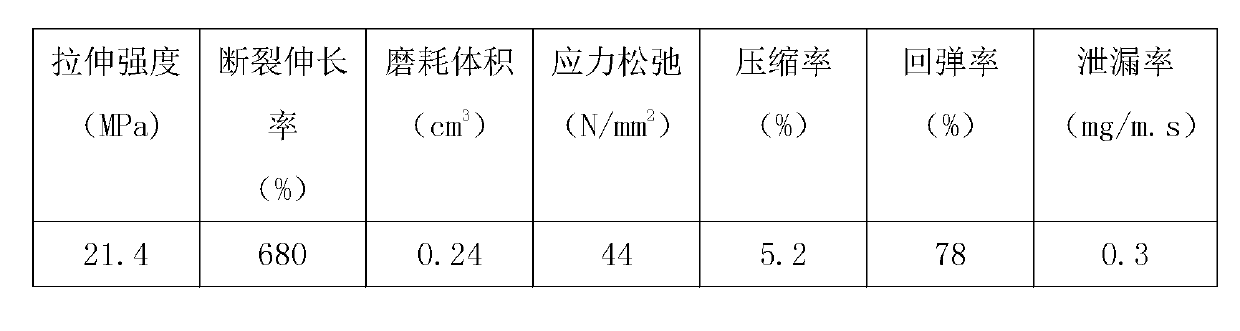

High-temperature oil resistant nitrile rubber gasket and preparation method thereof

The invention discloses a high-temperature oil resistant nitrile rubber gasket, comprising the following ingredients in parts by weight: 35-145 parts of nitrile rubber N411, 30-35 parts of active chloride type acrylic rubber, 10-15 parts of SG-1 type polyvinyl chloride, 2-5 parts of triethyl citrate, 3-5 parts of epoxy butyl oleate, and 2-5 parts of n-butyl methacrylate. The nitrile rubber gasket disclosed by the invention has excellent oil resistance and solvent resistance, also has excellent compressibility and rebound resilience and weak permanent deformation, does not soften and not decompose at high temperature, does not harden and not crack at low temperature, has excellent corrosion property, can work for a long time in mediums of acid, alkali, oil and the like, has small change in volume and rigidity and can adhered on metal surfaces, and has the following advantages of low friction coefficient, excellent wearing resistance, flexibility of being combined with a seal surface, excellent weather aging and ozone aging resistance, endurance, and the like.

Owner:ANHUI RONGDA VALVE

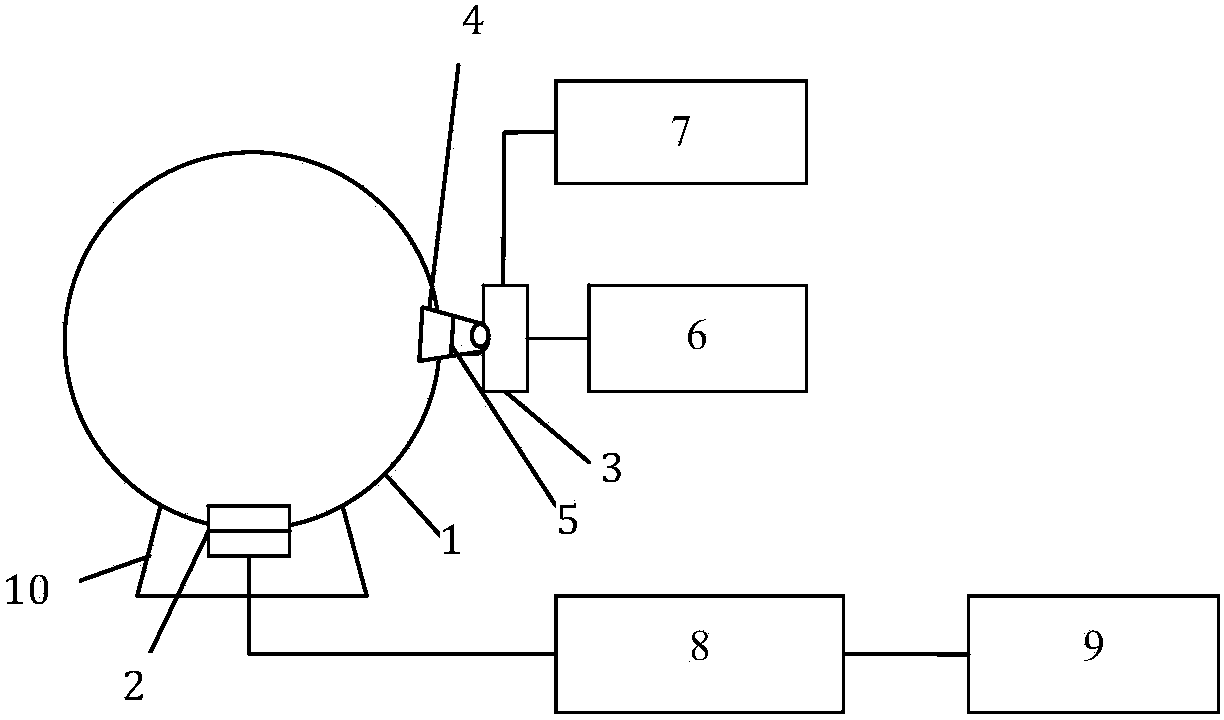

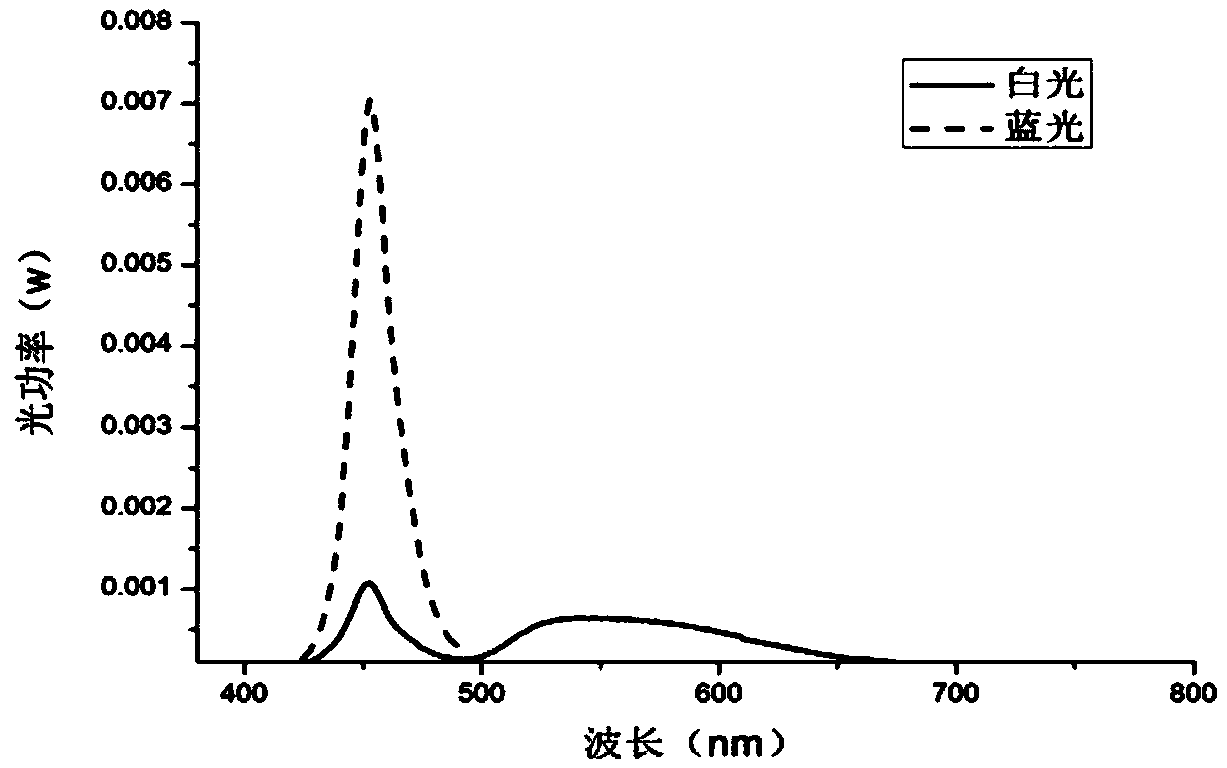

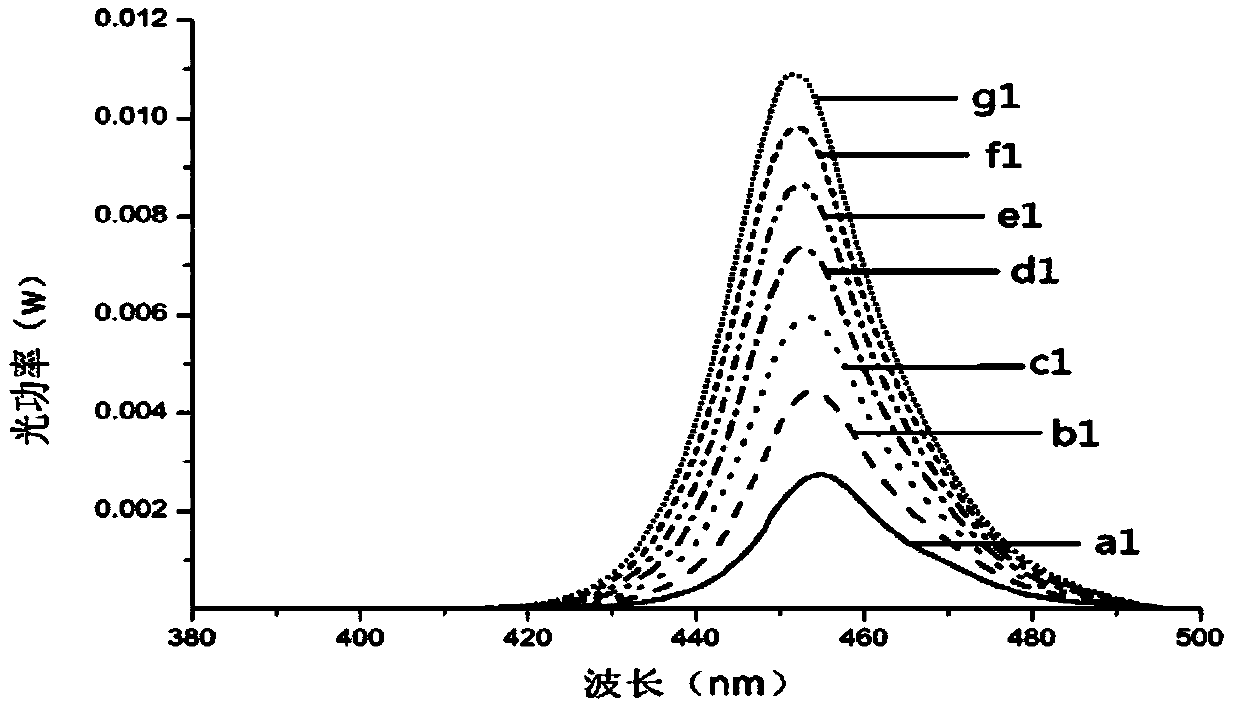

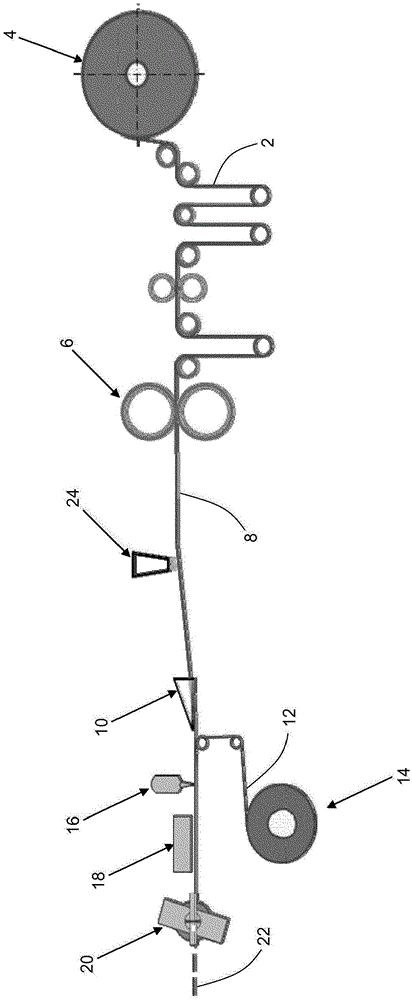

Remote fluorescent powder performance test device and test method

ActiveCN104198453AMeet the preparation conditionsGuaranteed uniformity of distributionFluorescence/phosphorescenceFluorescenceSilica gel

The invention discloses a remote fluorescent powder performance test device and a test method, and relates to fluorescent powder. The remote fluorescent powder performance test device is provided with an integration ball, a cosine collector, a blue light LED (light emitting diode) source, a light reflection cup, a fluorescent powder sheet / silica gel sheet, a TEC (triethyl citrate) temperature control clamp, a constant-current source, a spectrometer, a computer and a base, wherein the integration ball is fixed on the base and is provided with a light inlet and a light outlet; the cosine collector is connected with the spectrometer through an optical fiber at the light outlet and is used for collecting incident light; the output end of the spectrometer is connected with the computer and is used for spectrum collection and data analysis; the blue light LED source is connected with the constant-current source, serves as an exciting light source and is fixed on the TEC temperature control clamp, so that the stability of the light source is guaranteed through temperature control; the light reflection cup is fixed on the blue light LED source and achieves a light focusing effect; the fluorescent powder sheet / silica gel sheet is attached to the light reflection cup; the blue light LED source excites fluorescent powder to generate yellow light, and the yellow light and penetrating blue light are blended to synthesize white light.

Owner:XIAMEN UNIV

Attapulgite-modified polyvinyl chloride synthetic leather and manufacturing method thereof

InactiveCN102995446AGood flexibilityHas a natural and comfortable feelSynthetic resin layered productsLaminationEpoxySurface layer

The invention discloses attapulgite-modified polyvinyl chloride (PVC) synthetic leather. The attapulgite-modified PVC synthetic leather comprises a surface layer, a foamed layer, a bonding layer and a brushing fabric, and is characterized in that the surface layer is prepared by mixing the following raw materials in parts by weight to form slurry: 70 to 80 parts of SG-2 type PVC resin, 30 to 40 parts of SG-5 type PVC resin, 10 to 15 parts of triethyl citrate, 30 to 35 parts of epoxy butyl oleate, 20 to 25 parts of n-butyl methacrylate, 5 to 6 parts of PVC color paste, 1 to 2 parts of dibasic lead phosphate, 1 to 2 parts of tribasic lead sulfate and 5 to 10 parts of modified diatomite. Through the improvements of the formula and the process, the flexibility of the synthetic leather is improved, and the synthetic leather has a natural comfortable hand feeling similar to that of natural leather and is difficult to damage or tear after being used for 3 to 5 years.

Owner:HEFEI ANSHAN COATING FABRICS

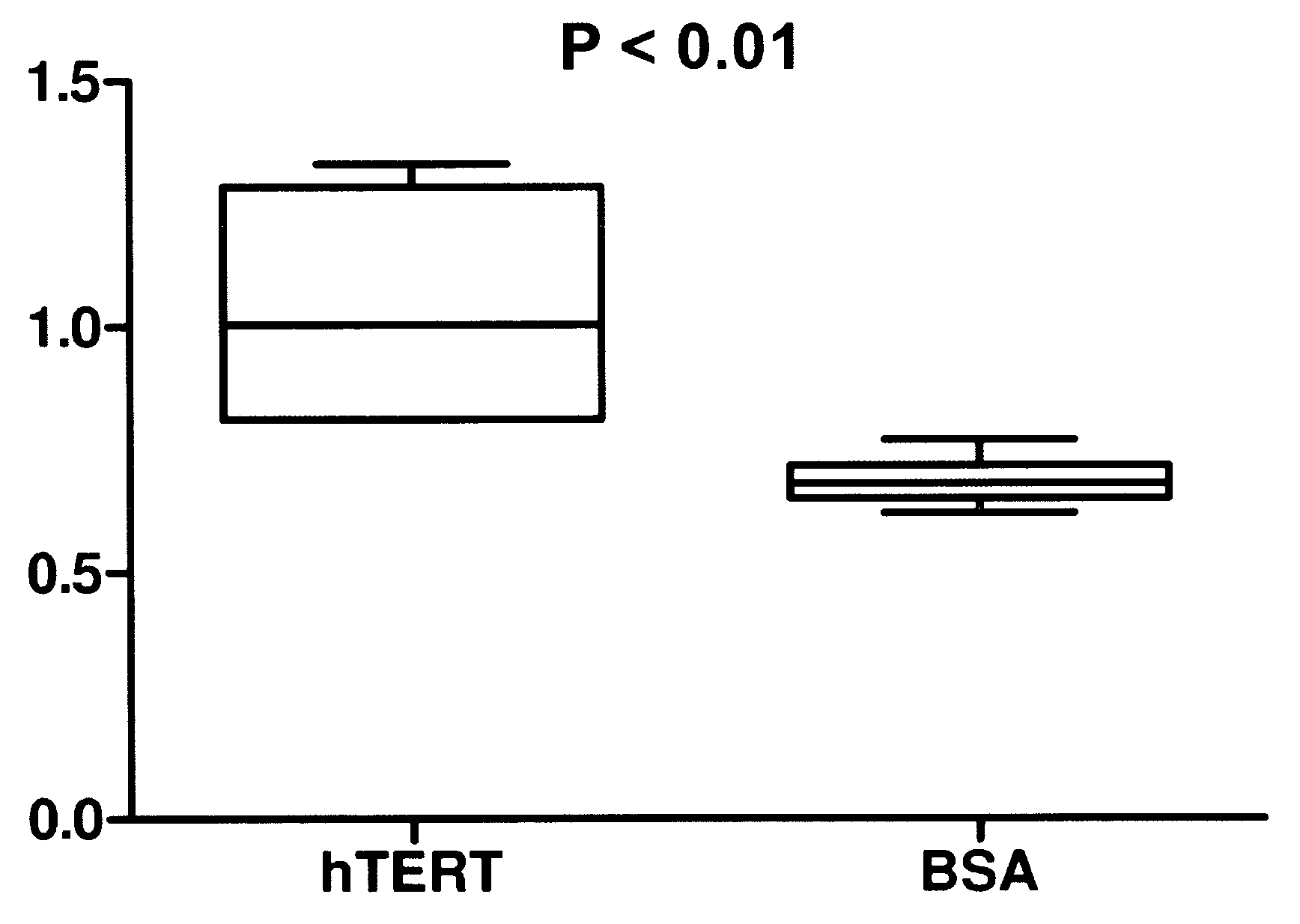

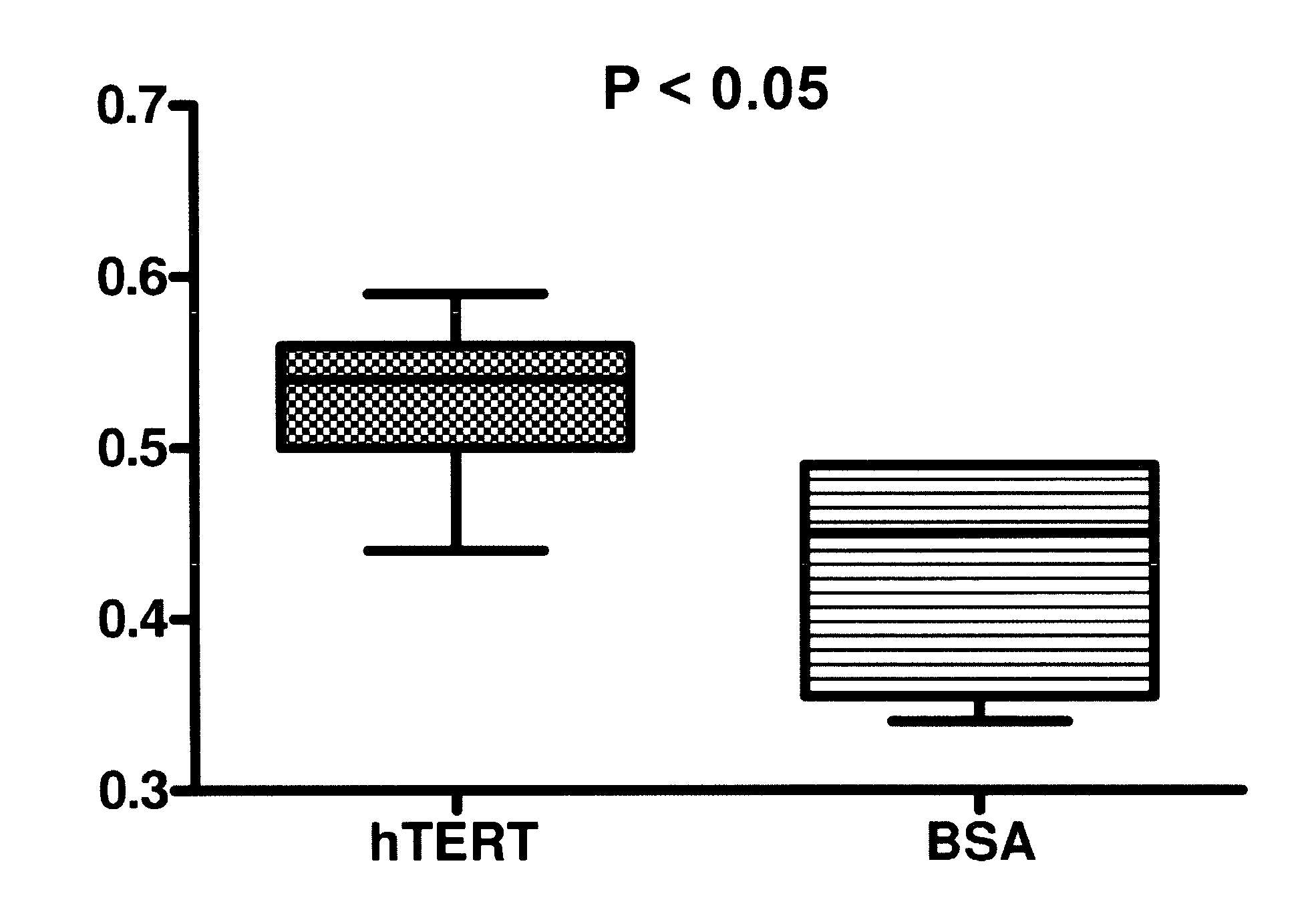

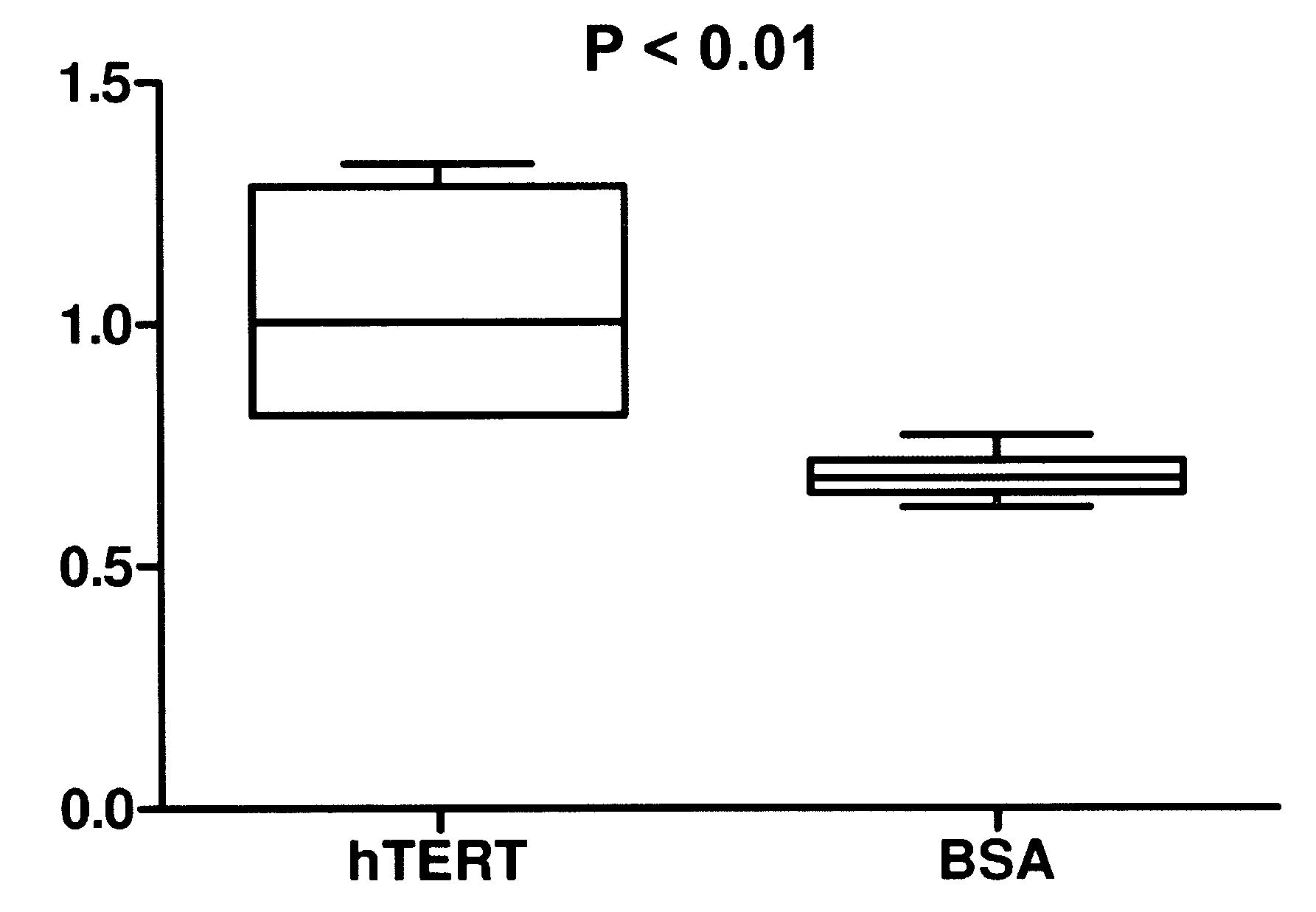

Telomerase delivery by biodegradable Nanoparticle

InactiveUS20090142408A1Effectively crossControl releasePowder deliveryPeptide/protein ingredientsAge related diseaseHydrophilic polymers

A therapeutic compound consisting of human telomerase, its catalytic subunit hTert, or a known variant of either, and a biodegradable nanoparticle carrier, which can be administered to cells in a cell culture or in a living animal, is provided herein. The therapeutic compound is envisioned as a method for treating a wide variety of age-related diseases such as idiopathic pulmonary fibrosis, aplastic anemia, dyskeratosis congenita, arteriosclerosis, macular degeneration, osteoporosis, Alzheimer's, diabetes type 2, and any disease that correlates with telomere shortening and may be corrected or ameliorated by lengthening telomeres. The therapeutic compound is also envisioned as method for potentially treating more generic problems of human aging. The nanoparticle carrier is comprised of certain biodegradable biocompatible polymers such as poly(lactide-co-glycolide), poly(lactic acid), poly(alkylene glycol), polybutylcyanoacrylate, poly(methylmethacrylate-co-methacrylic acid), poly-allylamine, polyanhydride, polyhydroxybutyric acid, polycaprolactone, lactide-caprolactone copolymers, polyhydroxybutyrate, polyalkylcyanoacrylates, polyanhydrides, polyorthoester or a combination thereof. The nanoparticle may incorporate a targeting moiety to direct the nanoparticle to a particular tissue type or a location within a cell. The nanoparticle may incorporate a plasticizer to facilitate sustained release of telomerase such as L-tartaric acid dimethyl ester, triethyl citrate, or glyceryl triacetate. A nanoparticle of the present invention can further contain a polymer that affects the charge or lipophilicity or hydrophilicity of the particle. Any biocompatible hydrophilic polymer can be used for this purpose, including but not limited to, poly(vinyl alcohol).

Owner:SARAD MATTHEW

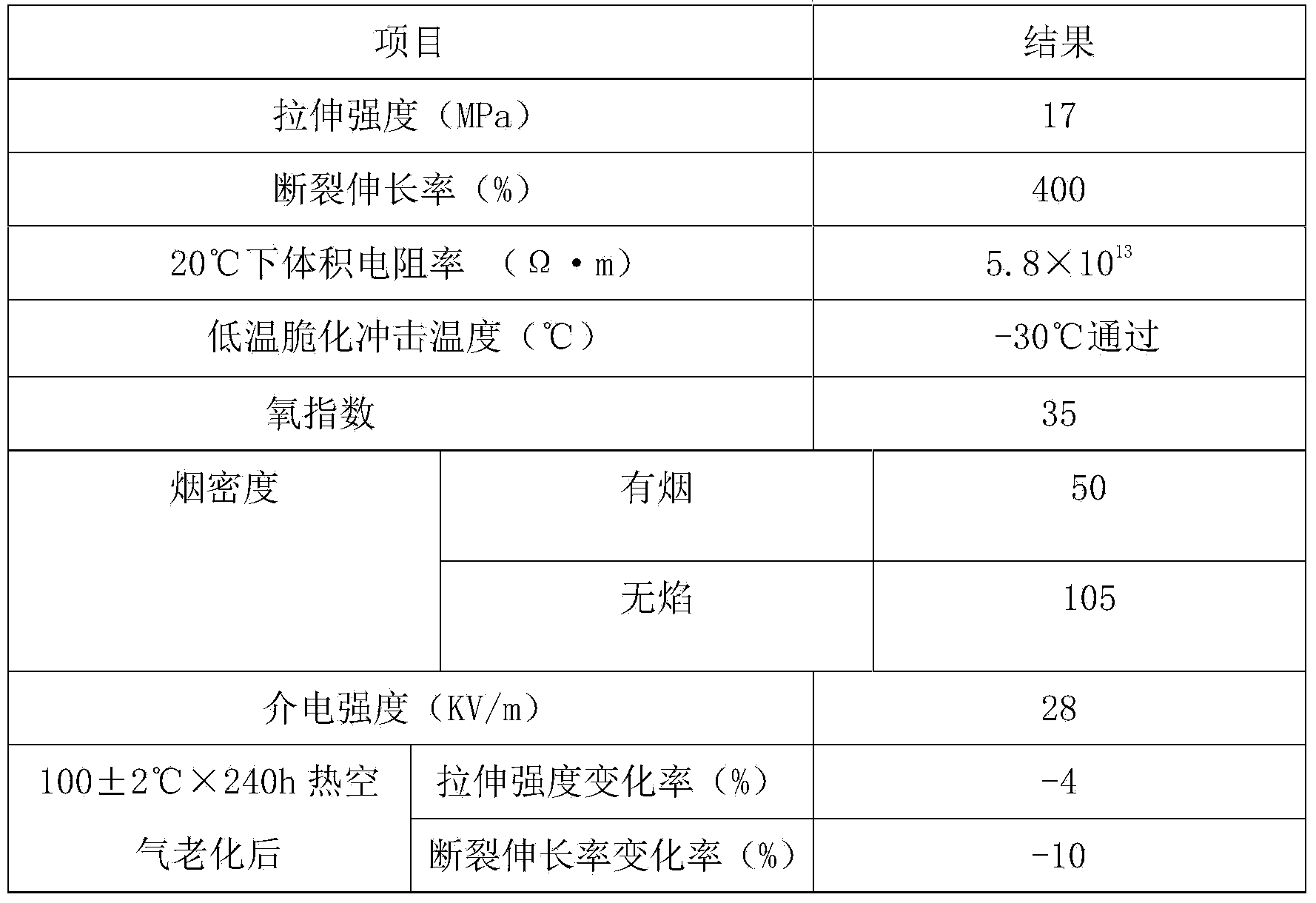

Incinerated pottery clay modified ethylene propylene diene copolymer cable material

ActiveCN102964699AImprove flame retardant performanceImprove heat resistanceParaffin waxPolymer science

The invention discloses an incinerated pottery clay modified ethylene propylene diene copolymer cable material, which is prepared from the following raw materials in parts by weight: 100-120 parts of Lanxess Deutschland ethylene propylene diene copolymer 3950, 20-30 parts of nitrile butadiene rubber N41, 10-15 parts of chlorosulfonated polyethylene rubber CSM2305, 10-15 parts of diisodecyl phthalate; 2-5 parts of epoxidized triglyceride, 2-5 parts of triethyl citrate, 5-8 parts of chlorinated paraffin wax, 0.5-1.0 part of stearic acid, 2-3 parts of calcium stearate, 1-2 parts of sulphur, 3-5 parts of zinc oxide, 30-40 parts of incinerated pottery clay, and the like. The cable material not only has excellent flame retardance and incombustibility, but also has the advantages of good high and low temperature resistance, corrosion resistance, water resistance, wear resistance, ozone resistance, ageing resistance and the like at the same time, and is durable in use.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

Capacitor film with metallocene line-shaped low-density polyethylene resin as base body and preparation method thereof

InactiveCN103102574AImprove barrier propertiesImprove air tightnessFixed capacitor dielectricLow-density polyethyleneEpoxy

The invention discloses a capacitor film with metallocene line-shaped low-density polyethylene resin as a base body and a preparation method thereof. The capacitor film is prepared from the following raw materials in parts by weight: 45-55 parts of metallocene line-shaped low-density polyethylene resin, 30-35 parts of LDPE (low-density polyethylene), 10-15 parts of homo-polypropylene, 3-5 parts of epoxy flaxseed oil, 2-3 parts of polyving akohol, 1-2 parts of calmogastrin, 1-2 parts of polyisobutene, 8-12 parts of diatomite, 1-2 parts of ferrocene, 0.8-1.2 parts of poly-4-methyl-1-amylene, 0.1-0.3 parts of polytetrafluoroethene, 9-11 parts of blanc fix, 0.6-0.8 part of antioxygen 1010, 0.3-0.5 part of triethyl acetyl citrate, 0.5-0.7 parts of fumarat, 3-5 parts of calcium stearate, 1.5-2.5 parts of N-2(amino ethyl)-3-ammonia propyl trimethoxy silane, and 1.4-1.8 parts of modified tree ash. The metallocene line-shaped low-density polyethylene resin serving as a primary raw material; the low-density polyethylene resin serving an auxiliary raw material and a plurality of auxiliary material additives are blended, extruded and subjected to film blowing, shaping and cuting to prepare the capacitor film. The capacitor film is simple in preparation method; and the diatomite, the blanc fixe and the modified tree ash are added to the raw materials at the same time. Therefore, the barrier property and the gas tightness of the film are increased; and the capacitor film has good resistance to pressure and shock resistance, and has the characteristics of high heat sealing strength and good heat sealing property at the same time.

Owner:TONGLING YIHENGDA ELECTRONICS

Solid gas generator and preparation method thereof

The invention provides a solid gas generator and a preparation method thereof. The solid gas generator comprises 12 to 23% of a polyether adhesive, 1.2 to 3.6% of a curing agent, 50 to 80% of an oxidizing agent, 0 to 5% of a plasticizer, 0 to 30% of a cooling agent, 0 to 5% of a combustion conditioning agent and 0 to 2% of other additives, wherein the polyether adhesive is one or a composition of more than one selected from the group consisting of ethylene oxide tetrahydrofuran copolyether and propylene oxide tetrahydrofuran copolyether, the curing agent is one or a composition of more than one selected from the group consisting of toluene diisocyanate, isophorone diisocyanate and multifunctional aliphatic diisocyanate, and the plasticizer is one or a composition of more than one selected from the group consisting of dioctyl sebacate, acetyl triethyl citrate and triethyl glycerin tricarbonate. The solid gas generator provided by the invention has a negative pressure exponent of 0 to - 0.30 and provides a power source for attitude control and orbit control power systems of light-weight kinetic kill vehicles (KKV).

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Chloroprene rubber gasket with high abrasion resistance and preparation method thereof

InactiveCN102993517AImprove flame retardant performanceAccelerated corrosionLow-density polyethylenePolymer science

The invention discloses a chloroprene rubber gasket with high abrasion resistance. The chloroprene rubber gasket comprises the following raw materials in parts by weight: 135-145 parts of chloroprene rubber (CR)121, 10-15 parts of butyl rubber CBK139, 20-25 parts of low density polyethylene, 3-5 parts of acetyl triethyl citrate, 2-5 parts of dibutyl maleate, 1-2 parts of isooctyl dimercaptoacetate di-n-octyl tin and the like. The chloroprene rubber gasket has the beneficial effects that the gasket has good high temperature resistance, sealability, flame retardance and corrosion resistance and can work in such medias as acid, alkali and oil for a long time; the volume and hardness of the gasket are small in variation; the gasket does not adhere to metal surfaces; and the gasket has small friction coefficient and good abrasion resistance and has the advantages of softness of bonding with sealing surfaces, good weathering aging and ozone aging resistance, durability and the like.

Owner:ANHUI RONGDA VALVE

Toughened and reinforced polylactic acid nano composite material and preparation method thereof

InactiveCN101037532AGood adhesionIntercalation effect improved significantlyALUMINUM STEARATESFunction group

The invention relates to method of preparing secondary functionalization organic modified montmorillonite (TFC), toughening and reinforcement biodegradable polylactic acid nano composite material using the organic montmorillonite and preparing method thereof. The novel double-function group organic modified montmorillonite (TFC) enhances adhesion force between montmorillonite and polymer molecule and obviously increases property of the composite material. The toughening and reinforcement biodegradable polylactic acid nano composite material is prepared by using polylactic acid as main raw material, and adding certain poly(epsilon-caprolactone) and lactic acid-epsilon-caprolactone copolymer; plasticizer selects acetyl tri-n-butyl citrate, tri-n-butyl citrate, triethyl citrate, dioctyl phthalate, and dibutylphthalate; lubricant selects aluminum stearate and calcium stearate; heat stabilizer selects maleic anhydride and epoxy soybean oil (EOS); and intensifier selects TFC montmorillonite (MMT). The prepared composite material possesses high strength and good toughness, and is hopeful of replacing traditional non-degradable material to be applied in field such as packaging, medical, and engineering for solving environment problems generated by white pollution.

Owner:SHANGHAI UNIV

High-strength tear-resistant rubber sealing gasket and preparation method thereof

The invention discloses a high-strength tear-resistant rubber sealing gasket and a preparation method thereof. The high-strength tear-resistant rubber sealing gasket is prepared from raw materials, namely chlorosulfonated polyethylene rubber, silicon rubber, bisphenol A type polycarbonate, cashew nut shell oil modified phenolic resin, hexamethylenetetramine, dicumyl peroxide, spray carbon black, modified nano ceramics, silicon-magnesium-calcium crystal whiskers, nanometer wollastonite, zinc methacrylate, magnesium oxide, stearic acid, vinyl silicone oil, chlorinated paraffin 4-7, triethyl citrate and the like. According to the high-strength tear-resistant rubber sealing gasket and the preparation method thereof disclosed by the invention, the organic composite modification is carried out by adopting multiple nano ceramic powder, namely nanometer aluminum nitride, nanometer titanium carbide and nanometer zirconium boride, so that the compatibility of the nano ceramic powder and rubber can be enhanced; the modified nano ceramic powder, the silicon-magnesium-calcium crystal whiskers, the nanometer wollastonite and the like are filled in a modified rubber material together to prepare the sealing gasket, so that the mechanical strength, impact resistance and especially tear resistance of the sealing gasket can be remarkably improved; the heat resistance, abrasion resistance and the like of the rubber can also be improved.

Owner:WUHU YINHONG HYDRAULIC COMPONENTS

Pliable tough cold-resistant anti-aging modified acrylate rubber cable material

ActiveCN103589102AImprove performanceGood mechanical propertiesRubber insulatorsPlastic/resin/waxes insulatorsWear resistantPolyvinyl chloride

The invention relates to a cable material, and specifically relates to a pliable tough cold-resistant anti-aging modified acrylate rubber cable material. The cable material comprises the following raw materials in parts by weight: 25-30 parts of acrylate rubber, 15-20 parts of epichlorohydrin rubber, 12-15 parts of fluororubber, 23-26 parts of precipitation-process white carbon black, 18-20 parts of polystyrene, 15-18 parts of polyvinyl chloride, 12-15 parts of wollastonite powder, 2-3 parts of anti-aging agnet KY-405, 1-2 parts of anti-aging agent MB, 1-2 parts of anti-oxidant 1035, 3-4 parts of magnesium oxide, 4-5 parts of stearic acid, 1-2 parts of promoter PZ, 5-7 parts of acetyl triethyl citrate, 5-6 parts of dibutyl maleate, 30-34 parts of spraying carbon black, 4-5 parts of engine oil, 2-3 parts of sulphur, 2-3 parts of zinc oxide and 4-5 parts of an auxiliary agent. The cable material combines the advantages of acrylate rubber, epichlorohydrin rubber, fluororubber, polystyrene, polyvinyl chloride and the like, so that the properties of conventional acrylate rubber cable materials are improved; and the cable material provided by the invention has good mechanical properties, is pliable, tough, wear-resistant, low temperature resistant, anti-aging and long in service life, is capable of being adaptive to specific usage environment conditions, and has wide market application prospect.

Owner:东莞市胜牌电线电缆有限公司

Process for producing acet-tributyl citrate

InactiveCN101402571AEmission reductionReduce lossOrganic compound preparationCarboxylic acid esters preparationWater rinsingWastewater

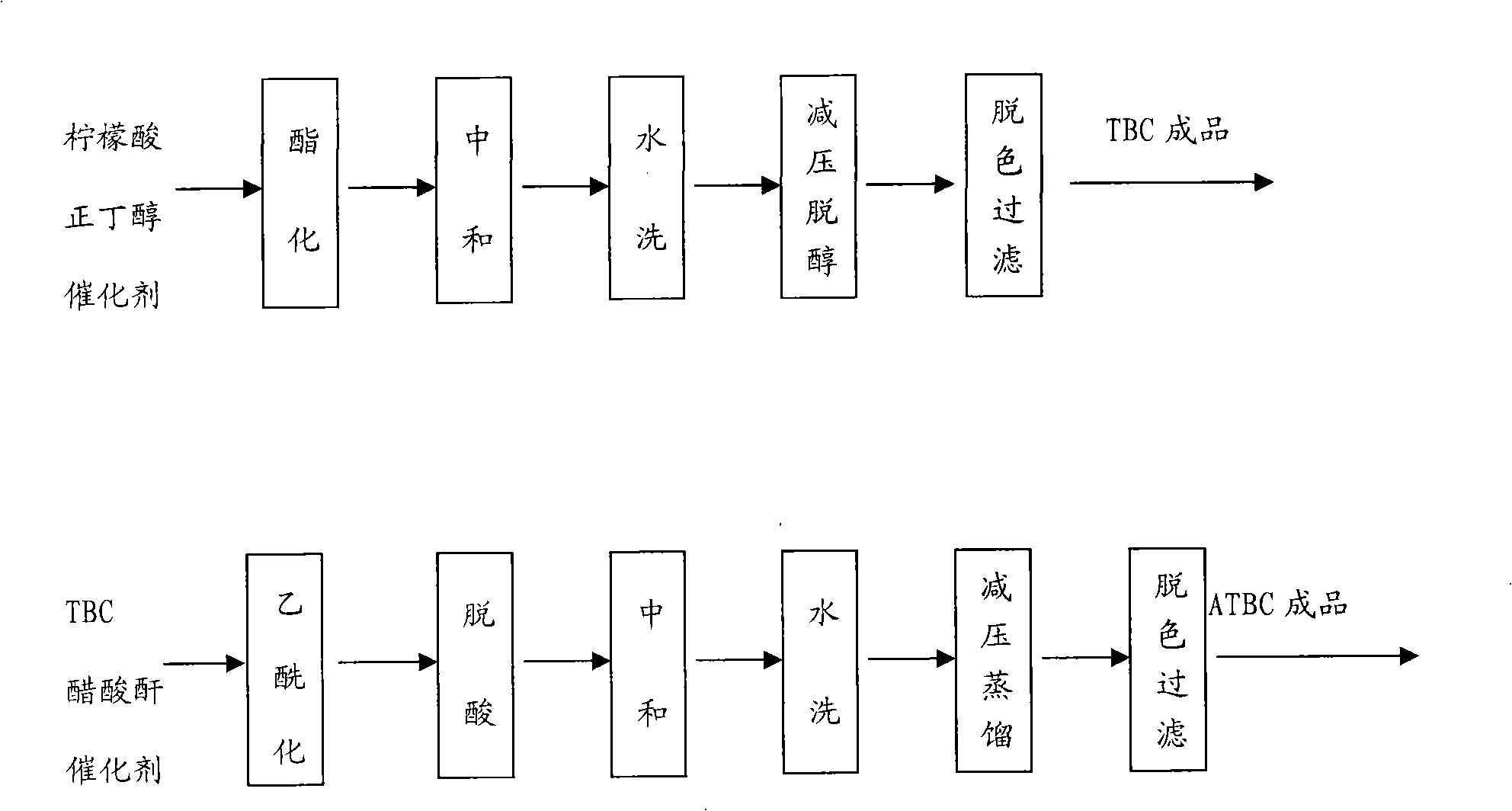

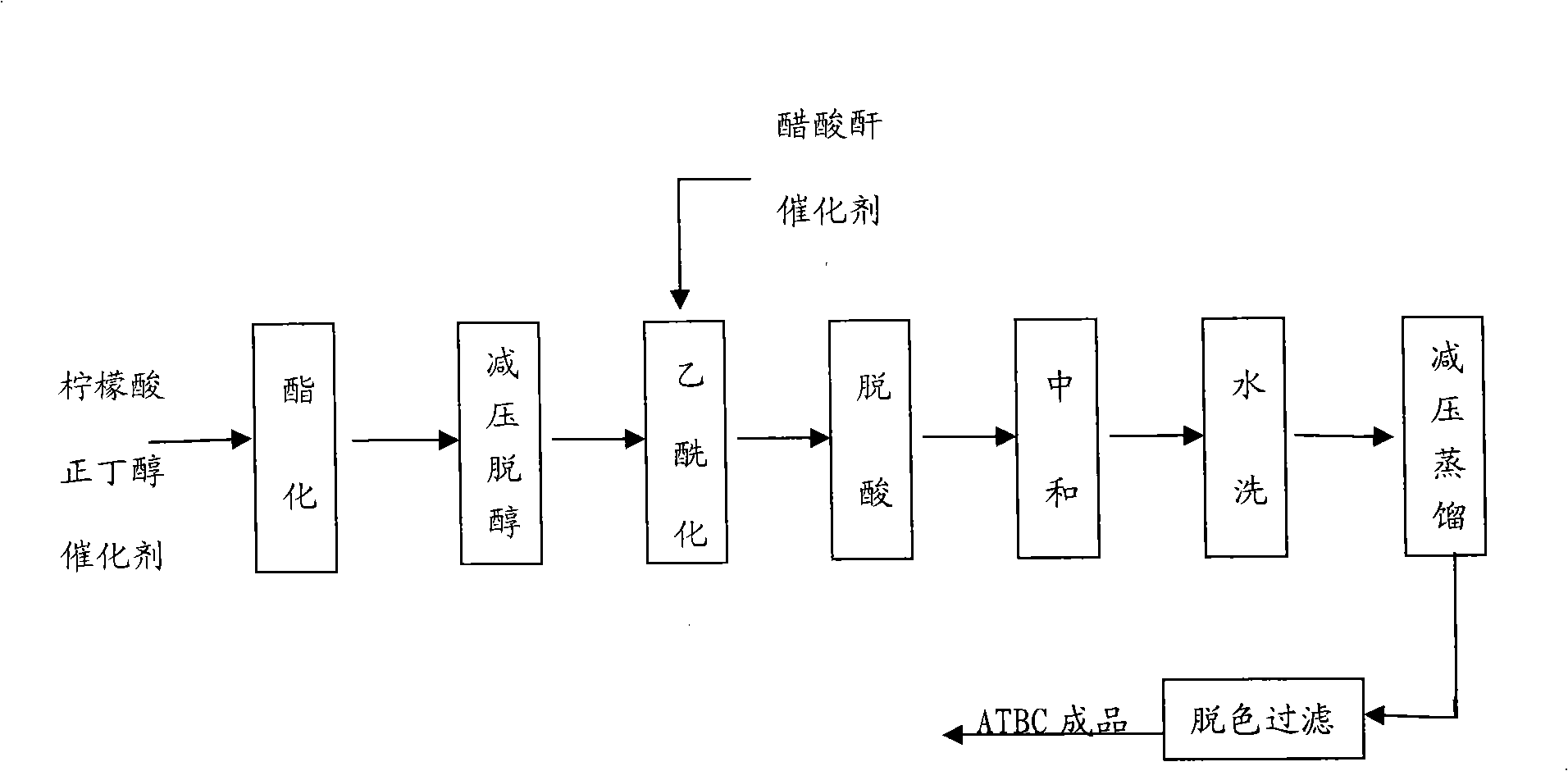

The invention relates to a process for producing acetyl triethyl citrate. The method comprises the following steps: using citric acid and n-butanol as raw materials, firstly carrying out esterification reaction under the action of a catalyst, directly using waste heat to reduce pressure and remove alcohol after carrying out the esterification reaction completely, so as to obtain a crude product of triethyl citrate, and then carrying out acetylation reaction, and finally carrying out the processes of removing acid, neutralizing, water rinsing, reducing pressure and distilling, decoloring and filtering, so as to obtain the acetyl triethyl citrate. The process has the advantages of consice process, short production period reduced about 3h, low equipment investment, low discharge amount reduced about 30 percent, low energy consumption, and production cost reduced about 10 to 20 percent.

Owner:河南庆安化工高科技股份有限公司

Flame-retardant, environmentally-friendly and safe polyolefin sheath material and its preparation method

ActiveCN102977466AImprove flame retardant performanceExcellent non-flammabilityPlastic/resin/waxes insulatorsInsulated cablesPolymer scienceAntimony trioxide

The invention provides a flame-retardant, environmentally-friendly and safe polyolefin sheath material. The polyolefin sheath material is prepared from the following raw materials, by weight, 20-30 parts of ethylene propylene diene monomer, 60-80 parts of high-density polyethylene, 8-10 parts of acrylonitrile-butadiene rubber, 8-10 parts of a rubber smoked sheet, 0.5-1.0 part of bisphenol A, 1-3 parts of modified tree ash, 20-30 parts of triethyl citrate, 4-6 parts of magnesium oxide, 0.5-1.0 part of molybdenum trioxide, 30-50 parts of fumed silica, 10-13 parts of nanometer calcium carbonate, 0.5-1.0 part of capsaicin, 0.1-0.3 parts of an antioxidant AW, 0.5-1.0 part of a promoter MBTS, 0.2-0.5 parts of a promoter TMTD, 0.2-0.5 parts of sulfur, 8-10 parts of decabromodiphenylethane, 12-15 parts of antimony (III) oxide and 6-8 parts of zinc borate hydrate. The polyolefin sheath material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good low temperature resistance, good oil resistance, good abrasion resistance, and good prevention performance.

Owner:宝新高分子科技(广州)有限公司

PET (polyethylene glycol terephthalate) fiber/mineral cotton fiber composite sound absorbing cotton and preparation method of PET fiber/mineral cotton fiber composite sound absorbing cotton

InactiveCN102965844AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsSound producing devicesPolymer scienceAntioxidant

The invention discloses PET (polyethylene glycol terephthalate) fiber / mineral cotton fiber composite sound absorbing cotton, which is prepared from the following ingredients in pars by weight: 70 to 80 parts of PET fibers, 40 to 50 parts of mineral cotton fibers, 10 to 15 parts of emulsifying agents OP-7, 5 to 10 parts of peregal O-20, 80 to 100 parts of PP (propene polymer), 30 to 40 parts of EPDM (ethylene propylene diene monomer), 15 to 20 parts of calcined clay, 10 to 15 parts of modified kieselguhr, 2 to 3 parts of stearic acid, 5 to 8 parts of triethyl citrate, 4 to 6 parts of pentabromophenyl ethane, 2 to 3 parts of glycerin monostearate, 1 to 2 parts of isopropyl distearyl oxyaluminate, 2 to 3 parts of zinc stearate, 1 to 2 parts of calcium stearate, 0.5 to 1.5 parts of anti-aging agents TPPD and 1 to 2 parts of antioxidants 1035. The sound absorbing cotton prepared by the invention has the advantages that the appearance evenness is good, the thickness is uniform, the hand feeling is soft, the product bonding degree is good, the tensile performance is high, the sound absorbing performance is excellent, the flame retardant effect is good, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

Diatomite modified polyvinyl chloride synthetic leather and manufacturing method thereof

InactiveCN102995445AGood flexibilityHas a natural and comfortable feelSynthetic resin layered productsLaminationPolyesterPolyvinyl chloride

The invention discloses diatomite modified polyvinyl chloride synthetic leather. The diatomite modified polyvinyl chloride synthetic leather comprises a surface layer, a foaming layer, a bonding layer and a brushing fabric and is characterized in that the surface layer is manufactured by blending the following raw materials in parts by weight into slurry: 40-50 parts of SG-1 type PVC (Polyvinyl Chloride) resin, 70-80 parts of SG-6 type PVC resin, 15-20 parts of sebacic acid propylene glycol polyester, 10-15 parts of acetyl triethyl citrate, 20-25 parts of di-n-butyl maleate, 5-6 parts of PVC color paste, 1-2 parts of imarcaptoacetate dioctyltin, 1-2 parts of dibasic lead phosphate, 1-2 parts of zinc stearate, 5-10 parts of nanometer calcium carbonate and 15-20 parts of modified attapulgite. Through an improvement of a formula and a technology, the flexibility of the synthetic leather is increased, and the diatomite modified polyvinyl chloride synthetic leather has the natural comfortable hand feel similar to that of natural leather and is not easily damaged or torn.

Owner:HEFEI ANSHAN COATING FABRICS

Biological degradable thin film material for transfusion bag and its preparing method

InactiveCN1821303AAdjustable degradation rateLower glass transition temperaturePharmaceutical containersMedical packagingPolyethylene glycolAluminum Stearate

The present invention relates to a kind one biodegradable film material for transfusion bag and its preparation process. The new type of medical film is prepared with polylactic acid as main material; proper amount of polyepsilon-caprolactone and lactic acid-epsilon-caprolactone copolymer; medical plasticizer tributyl acetylcitrate, tributyl citrate, triethyl citrate or polyglycol; defoaming agent methyl silicon oil or tributyl phosphate; lubricant aluminum stearate or calcium stearate; heat stabilizer maleic anhydride or EOS; and strengthening agent MMT. The biodegradable film material for transfusion bag has excellent flexibility, physical and chemical performance, and biological performance, and is expected to replace non-degradable film to avoid í‹white pollutioníŒ.

Owner:SHANGHAI UNIV

Leather cup rubber material for brake of automobile and preparation method thereof

The invention discloses a leather cup rubber material for a brake of an automobile. The leather cup rubber material is prepared from the following raw materials in parts by weight: 40-50 parts of nitrile rubber, 20-30 parts of chlorosulfonated polyethylene rubber, 10-30 parts of ethylene propylene terpolymer 5962 (LANXESS Deutschland), 10-15 parts of fluorine rubber, 3-5 parts of natural rubber, 30-40 parts of high abrasion furnace black N330, 15-20 parts of modified white carbon black, 3-4 parts of graphite, 8-10 parts of modified wood ash, 4-6 parts of vermiculite, 4-6 parts of quartz sand, 9-11 parts of modified iron tailing slag powder, 0.5-1 part of stearic acid, 0.5-1 part of sulfur, 0.2-0.4 part of accelerant DM, 0.3-0.6 part of accelerant BPP, 1-2 parts of stearic acid, 2-4 parts of zinc oxide, 0.2-0.4 part of ferrocene, 1-2 parts of lignite wax, 1-2 parts of antioxidant DSTP, 1-2 parts of anti-aging agent RD, 2-3 parts of phenyl triethoxysilane and 16-18 parts of acetyl triethyl citrate. The rubber material disclosed by the invention has excellent ozone resistance, excellent low temperature resistance and heat resistance and is large in operating temperature range and environment-friendly in process, so that the rubber material can be used for preparing various packing materials.

Owner:WUHU HENGKUN AUTO PARTS

High-strength wear-resisting nitrile butadiene rubber cable material

InactiveCN103554570AImprove performanceHigh strengthInsulated cablesInsulated conductorsLow-density polyethyleneLinear low-density polyethylene

The invention relates to a cable material, and in particular relates to a high-strength wear-resisting nitrile butadiene rubber cable material. The cable material is prepared from the following raw materials in parts by weight: 35-40 parts of nitrile butadiene rubber (3304), 1-2 parts of sulphur, 4-5 parts of polyacrylonitrile, 6-8 parts of ABS (Acrylonitrile Butadiene Styrene) high rubber powder, 30-34 parts of metallocene linear low-density polyethylene, 12-14 parts of butadiene rubber, 3-4 parts of stearic acid, 1-2 parts of oxalic acid, 25-28 parts of N330 carbon black, 5-8 parts of dioctyl adipate, 5-7 parts of triethyl citrate, 6-8 parts of zinc oxide, 2-4 parts of magnesium oxide, 28-32 parts of N550 carbon black, 1-2 parts of accelerant DM and 4-5 parts of auxiliary. According to the cable material, the advantages of the raw materials of nitrile butadiene rubber, butadiene rubber, ABS high rubber powder, metallocene linear low-density polyethylene and the like are combined, the properties of the conventional nitrile butadiene rubber cable material are improved, the cable material is enabled to have the advantages of high strength, good tension property, external impact resistance, wear resistance and the like, can meet the application requirements in special situations, is harmless to environment and human bodies, and is wide in application prospect.

Owner:安徽文峰电子科技集团有限公司

Rubber composition of nitrile rubber and epoxidized natural rubber

The invention discloses a rubber composition of nitrile rubber and epoxidized natural rubber. The rubber composition is prepared from nitrile rubber 3345, epoxidized natural rubber, antioxidant RD, antioxidant MB, stearic acid, sulfur powder, microcrystalline wax, zinc oxide, processing aid WB212, white carbon black, carbon black N330, triethyl citrate, promoter TMTD, promoter CZ, promoter DM, nanometer barite, light calcium carbonate, chalk, high styrene resin, benzoic acid, etc. The rubber composition provided in the invention has low permanent compression deformation, good elasticity and high hardness; the composition is used for fabricating rubber products like sealing rings, having the advantages of conservation of cost and excellent performance.

Owner:CGP WUHU SEALING

Formula of glass fiber composite

The invention discloses a formula of a glass fiber composite, and relates to the field of glass fiber. The composite comprises the following raw materials by weight: 12 to 13 parts of EW-200 glass fiber plain cloth, 14 to 16 parts of phenolic resin, 10 to 12 parts of barium titanate powder, 9 to 12 parts of a coupling agent, 7 to 9 parts of bamboo fiber felt, 6 to 8 parts of triethyl citrate, 3 to 5 parts of polypropylene powder, 7 to 9 parts of epoxidized soybean oil, 12 to 13 parts of bisphenol epoxy resin, 15 to 18 parts of dicumyl peroxide, 14 to 16 parts of maleic anhydride grafted polypropylene, and 20 to 25 parts of glass fiber. The glass fiber composite prepared according to the formula is light in weight, high in strength, and high-temperature resistant; due to the addition of barium titanate powder, the dielectric constant of the glass fiber composite is improved. The preparation method of the glass fiber composite is simple in process, and can be carried out on conventional equipment; the glass fiber composite is excellent in strength, rigidity and impact strength; the process is simple; the cost is low; the production efficiency is high.

Owner:ANHUI DANFENG ELECTRONICS MATERIAL

Heated aerosol-generating articles comprising improved rods

A heated aerosol-generating article comprises an aerosol-generating substrate, wherein the aerosol-generating substrate comprises a rod comprising a gathered sheet of homogenised tobacco material circumscribed by a wrapper. The sheet of homogenised tobacco material comprises one or more plasticisers and at least about 5 percent by weight triethyl citrate on a dry weight basis. The one or more plasticisers are preferably selected from the group consisting of propylene glycol, sugars and polyhydric alcohols. The sheet of homogenised tobacco material is preferably crimped or otherwise textured.

Owner:PHILIP MORRIS PROD SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com