Irradiation crosslinking low-smoke halogen-free flame-retardant polyolefin cable material for photovoltaic cables

A technology of polyolefin cable materials and photovoltaic cables, which is applied in the direction of circuits, electrical components, insulators, etc., can solve the problems of poor compatibility, lower mechanical properties and processing properties of materials, and achieve good compatibility, excellent mechanical properties, and excellent The effect of flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

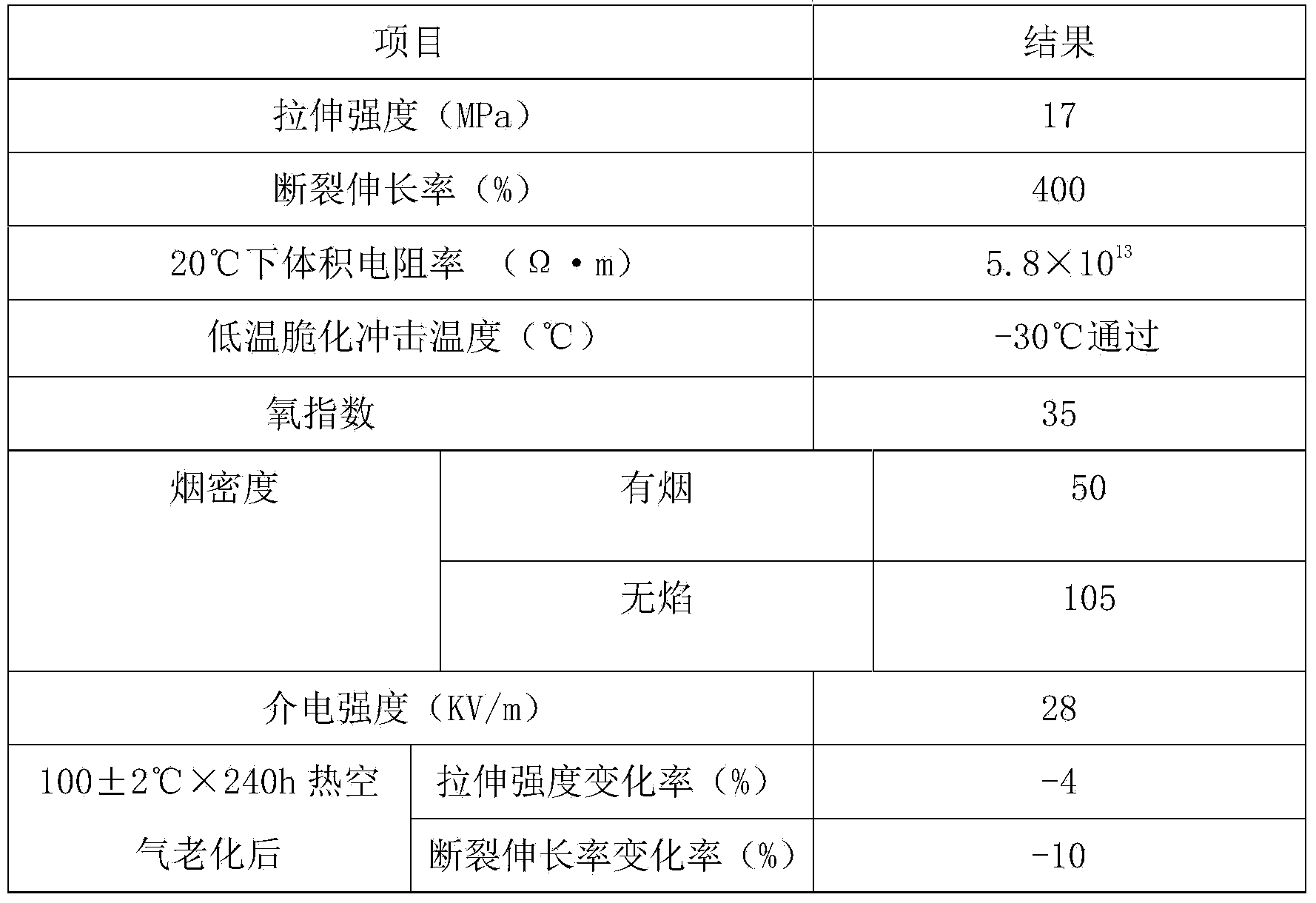

Examples

Embodiment Construction

[0017] A radiation cross-linked low-smoke halogen-free flame-retardant polyolefin cable material for photovoltaic cables, which is prepared from the following component raw materials in weight (kg):

[0018] Polyethylene PE 45, polyvinyl chloride resin 35, chlorosulfonated polyethylene rubber CSM2305 26, ethylene and acrylate copolymer 11, epichlorohydrin rubber T3100 13, epoxy soybean oil 7, carbonyl iron powder 3, high wear-resistant carbon black N330 11, light calcium carbonate 8, zinc oxide 1, wollastonite powder 6, vermiculite 4, polytetrafluoroethylene powder 1, graphite 1, nano boron carbide 1, iron oxide 2, ultraviolet absorber UV-O 0.1, ultraviolet light Absorbent UV-531 0.2, flame retardant TBC 0.1, aluminum hypophosphite 12, decabromodiphenyl ether 7, dioctyl terephthalate 9, trioctyl trimellitate 7, triethyl citrate 9, Calcium stearate 2, stearic acid 0.3, oxidized polyethylene wax 0.1, ethylene bisstearamide 0.3, dicumyl peroxide DCP 0.1, modified filler 14,

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com