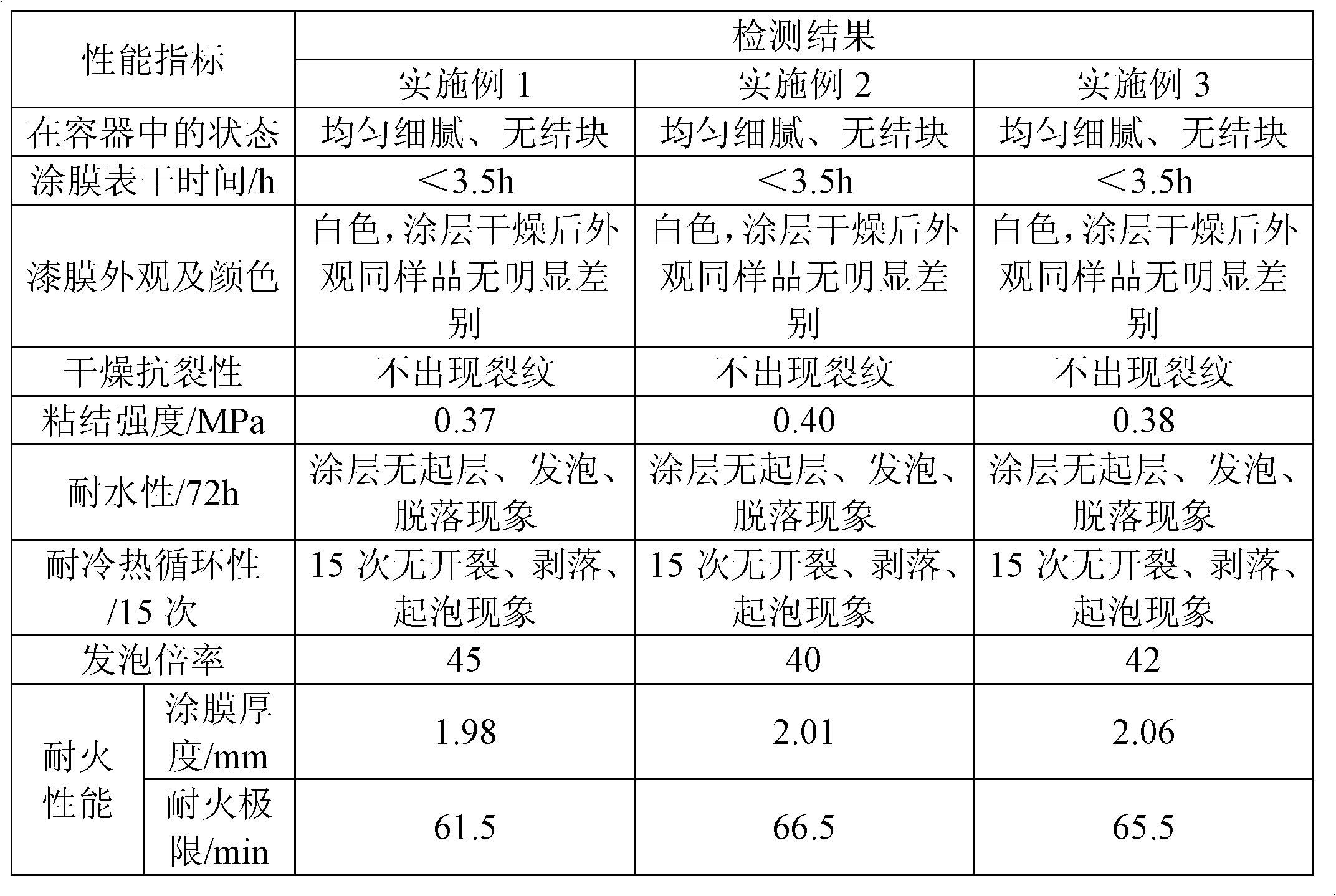

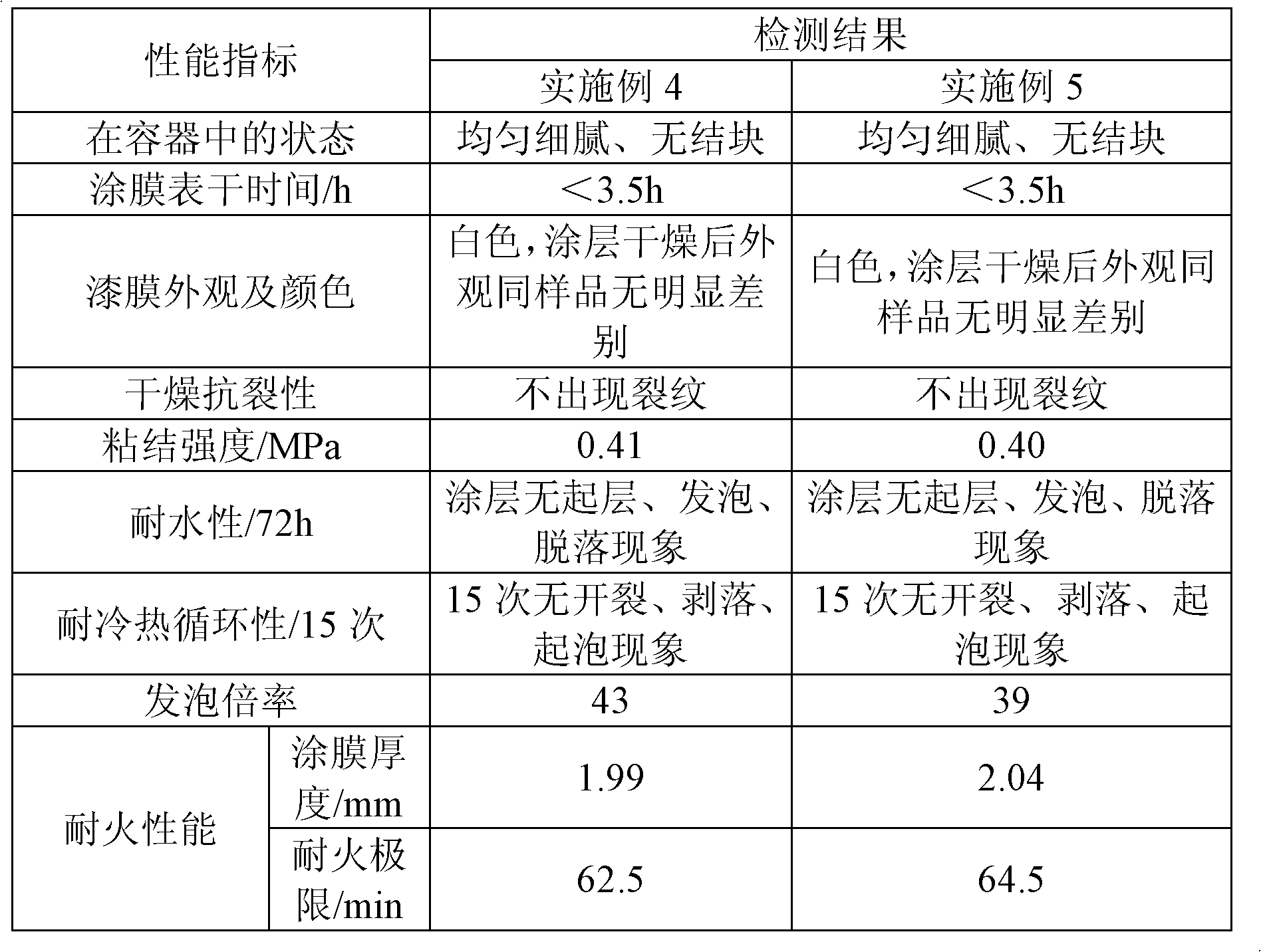

Patents

Literature

3468 results about "Chlorinated paraffins" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chlorinated paraffins (CPs) are complex mixtures of polychlorinated n-alkanes. The chlorination degree of CPs can vary between 30 and 70 wt%. CPs are subdivided according to their carbon chain length into short chain CPs (SCCPs, C10–13), medium chain CPs (MCCPs, C14–17) and long chain CPs (LCCPs, C>17). Depending on chain length and chlorine content, CPs are colorless or yellowish liquids or solids.

Resin composition for vibration-damping material, vibration-damping material, and sound-insulating member

InactiveUS7041377B2Reduce nipping temperatureGood release effectOther chemical processesFibre treatmentPolymer scienceChlorinated paraffins

The object of the invention is to provide sound insulating members exhibiting both high vibration damping performance and high sound insulation performance, a vibration damping material for affording such members and a resin composition for forming the vibration damping material. The invention provides a first resin composition for vibration damping materials which contains 100 parts by weight of a chlorine-containing thermoplastic resin, and 20 to 200 parts by weight of a chlorinated paraffin having 12 to 16 carbon atoms on average. The thermoplastic resin contains preferably 20 to 70 wt. %, more preferably 30 to 70 wt. %, of chlorine. The chlorinated paraffin is preferably 30 to 70 wt. %, more preferably 35 to 65 wt. %, in chlorination degree.

Owner:SEKISUI CHEM CO LTD

Lubricating material for cold rolling and its preparation method and use

ActiveCN103589491ASolving Stress Corrosion ProblemsHarm reductionLubricant compositionEmulsionChlorinated paraffins

The invention belongs to the technical field of lubricating materials and discloses a lubricating material for cold rolling and its preparation method and use. The lubricating material for cold rolling comprises, by mass, 20-60% of base oil, 0.3-1% of an anti-oxidant, 20-60% of a lubricant, 3-10% of an extreme pressure agent, 0-5% of an antirust agent, 1-3% of a purification dispersant, 3-9% of an emulsifier, and 2-6% of an anionic surfactant. The lubricating material is especially suitable for a four-roller four continuous rolling unit having the size of 650mm and high lubricity requirements, does not contain chlorinated paraffin, prevents stress corrosion on a cold-rolled finished product, and has excellent lubricity. Compared with the common emulsion on the current market, the lubricating material reduces a rolling force by 7-10%, prolongs a roller service life by 10-15%, reduces comprehensive energy consumption by 10-15% and effectively prolongs a rolling mill bearing service life.

Owner:GUANGZHOU MECHANICAL ENG RES INST

Expanded type aqueous facing fireproof coating and preparation method thereof

ActiveCN102675992AImprove fire resistanceImprove water resistanceFireproof paintsCelluloseChlorinated paraffins

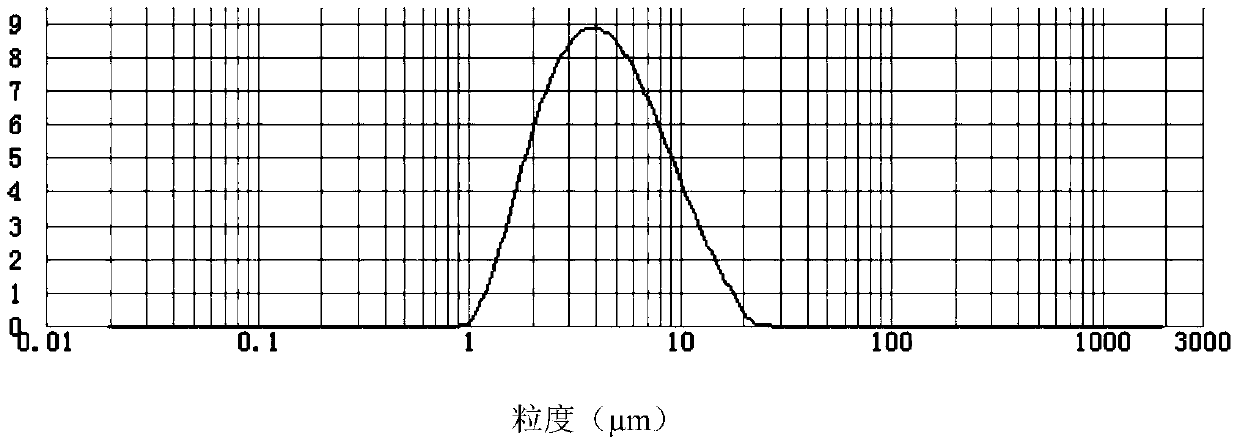

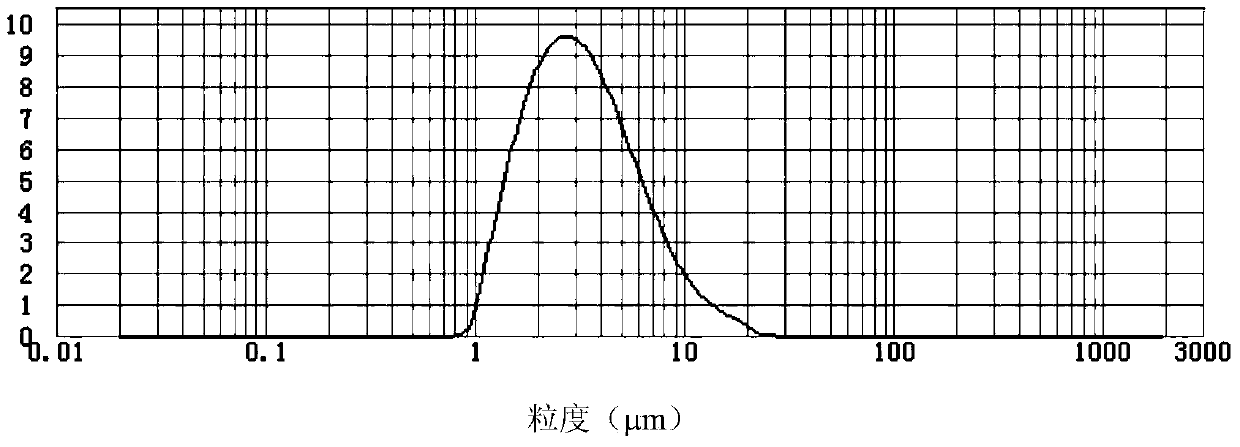

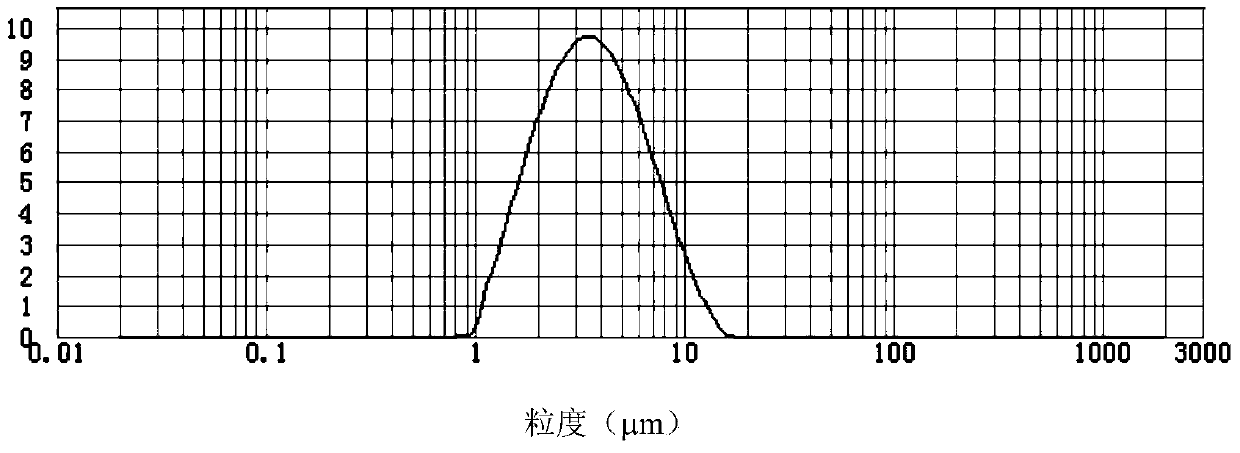

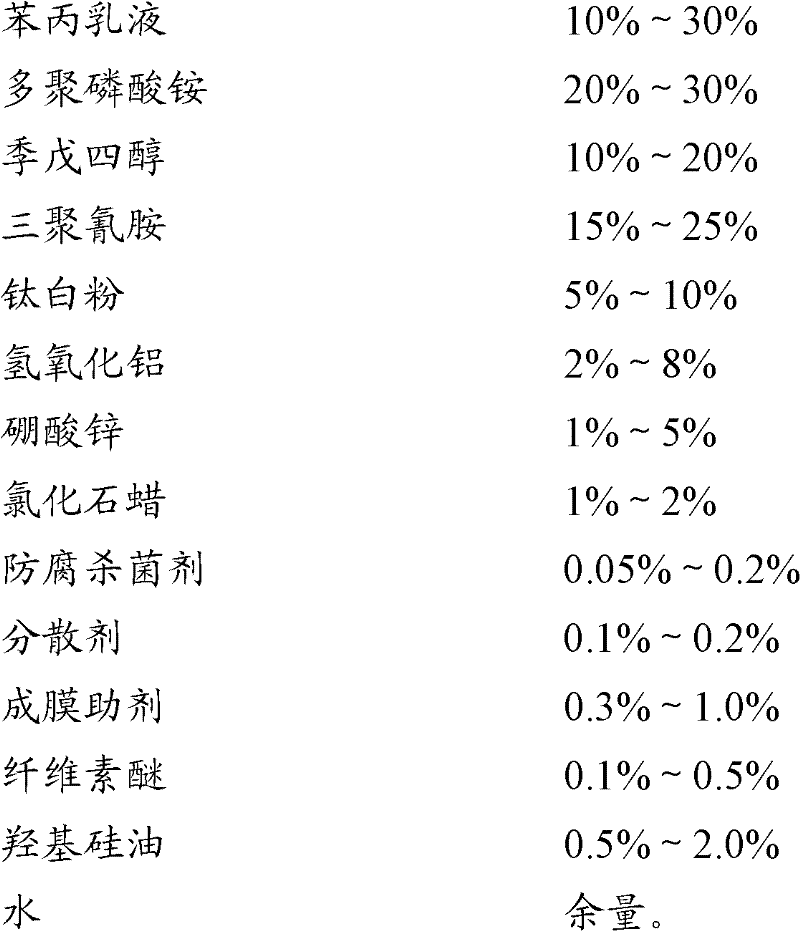

The invention provides an expanded type aqueous facing fireproof coating, which comprises the following components by weight: 10% to 30% of styrene-acrylic emulsion, 20% to 30% of ammonium polyphosphate, 10% to 20% of pentaerythritol, 15% to 25% of melamine, 5% to 10% of titanium dioxide, 2% to 8% of aluminum hydroxide, 1% to 5% of zinc borate, 1% to 2% of chlorinated paraffin, 0.05% to 0.2% of antiseptic, 0.1% to 0.2% of dispersing agent, 0.3% to 1.0% of film-forming auxiliary, 0.1% to 0.5% of cellulose ether, 0.5% to 2.0% of hydroxy silicone oil and the balance of water. The expanded type aqueous facing fireproof coating, provided by the invention, has the advantages of excellent water resistance and salt mist resistance, excellent adhesion and flexibility, good storage stability, no layering, no fineness change and no packing phenomenon, excellent waterproof resistance, smooth and fine coating film, no toxicity and pollution, and environment-friendliness.

Owner:CARPOLY CHEM GRP

Polyimide porous membrane and lithium ion battery comprising same

ActiveCN101665580AUniform hole diameter distributionImprove breathabilitySecondary cellsCell component detailsBenzoic acidChlorinated paraffins

The invention discloses a polyimide porous membrane and a lithium ion battery comprising the same. The polyimide porous membrane is prepared by the following method, and the method comprises the following steps: forming a polyamic acid membrane by using the mixture of a mixture containing polyamic acid, pore-forming substance and solvent, and subjecting the polyamic acid membrane to amidation at the temperature higher than the decomposing temperature of the pore-forming substance, wherein the solvent is a solvent which dissolves the polyamic acid but slightly dissolves or does not dissolve thepore-forming substance; and the pore-forming substance may be one or combination of benzoic acid polyol ester, phthalic acid dialkyl ester, polyprotic acid alkyl ester, phenyl alkysulfonate, chlorinated paraffin and epoxidized soybean oil. The service life and the processing yield of the lithium ion battery made of the polyimide porous membrane serving as a battery membrane are improved. Moreover, the polyimide porous membrane also has higher thermal stability, and greatly improves the safety performance of the battery.

Owner:BYD CO LTD

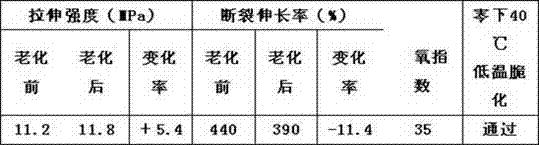

Cold-resistant rubber cable sheath material and preparation method

ActiveCN102399397AImprove low temperature performanceImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesParaffin waxActive agent

The invention discloses a cold-resistant rubber cable sheath material and a preparation method. The material comprises chlorinated polyethylene, ethylene-propylene-diene monomer (EPDM) rubber, lead oxide, calcium carbonate, N-isopropyl benzene-N'-phenyl p-phenylenediamine serving as an anti-aging agent, antimonous oxide, magnesium oxide, paraffin hydrocarbon oil, chlorinated paraffin, paraffin, carbon black, settled white carbon black, talc powder, gamma-aminopropyl triethoxysilane serving as a surfactant, dicumyl peroxide serving as a vulcanizing agent and triallyl isocyanurate serving as a co-vulcanizing agent. The low temperature performance of the material is improved by blending the chlorinated polyethylene and the EPDM rubber, and meanwhile, the flame-retardant performance of the rubber sheath material is improved by synergy of the antimonous oxide serving as a flame retardant and the chlorinated paraffin; experiments show that the rubber sheath material can pass low-temperature embrittlement test of 40 DEG C below zero, has excellent low-temperature resistance, has the oxygen index of more than 32 and has good flame-retardant performance; and the preparation method is simple and strong in operability.

Owner:JIANGSU HENGTONG POWER CABLE

Bi-component high-strength polyurethane waterproofing paint

ActiveCN101100582AImprove performanceQuality improvementAntifouling/underwater paintsPaints with biocidesExtensibilityToluene diisocyanate

A dual-component high-strength polyurethane water proof coating contains A and B components; A component consists of polyether dibasic alcohol 120-200 proportion, polyether trivalent alcohol 40-180 proportion, toluene diisocyanate 47-80 proportion, dibutyl ester 1.5-3 proportion, and tartaric acid 0.1-1 proportion. B component consists of filling oil 50-90 proportion, paraffin chloride 20-50 proportion, dibutyl ester 10-30 proportion, 3,3-dichloro-4,4-diphenyl-methane-diamine 45-70 proportion, poly-ether trivalent alcohol 60-360 proportion, hydrated magnesium silicate 50-60 proportion, kaolin 10-50 proportion, heavy calcium carbonate 50-60 proportion, iron oxide brown or carbon black 3.5-4.5 proportion, de-foaming agent 0.2-0.5 proportion, and dibutyltin dilaurate 0.2-0.5 proportion. It's convenient and cheap, has excellent adhesion, strength and extensibility and more solid content and no environmental pollution. It can be used for foundation construction and municipal traffic engineering.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

Latent curing single-component polyurethane water-proof coating and preparation method thereof

ActiveCN102807812AFast curingSolve the speed problemPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention discloses a latent curing single-component polyurethane water-proof coating and a preparation method thereof. The latent curing single-component polyurethane water-proof coating consists of the following components in parts by weight: 30-50 parts of diisocyanate, 150-190 parts of polyether polyol, 140-170 parts of chlorinated paraffin, 400-500 parts of a filler, 0.3-0.5 parts of a silane coupling agent, 8-15 parts of a latent curing agent, 0.8-1.1 parts of a catalyst and 120-165 parts of a diluting agent. The latent curing single-component polyurethane water-proof coating plays a role solving the problems of easiness in foaming in a crosslinking process and swelling and bubbling in a storing process existing in the conventional single-component moisture curing polyurethane water-proof coating, can be used for reducing the specific weight of polyurethane in the waterproof coating for reducing the cost, and has high mechanical property and low-temperature flexibility.

Owner:大岩(上海)建筑材料有限公司

Weather-resistant and fire-proof nanometer coating for expanding ultrathin steel structure and production thereof

The invention relates to the process of an inflatable ultrathin steel structural weather-fire resisting nanopaint. It is composed of acrylic resin:16-25; amine resin:5-8; epoxy modified high polymer: 5-8; nano-compound fire retardant:3-6; superfine compound fire retardant: 35-45; intensify spun glass: 4-7; smoke abatementer:2-4; chlorinated paraffin:2-4; rutile titanium white:3-5; elasticizer:2-4; antifoam agent:0.3-0.6; flow promoter:0.3-0.6; mixing solvent:15-20. The above mixture is lapped to 60um of diameter and we can get the product. The product has the good resistance of the fire, water, oil and salt.

Owner:中科纳米涂料技术(苏州)有限公司

Flame-retardant and environmentally-friendly polyurethane cable material and its preparation method

ActiveCN102977585AImprove flame retardant performanceExcellent non-flammabilityElastomerDecabromodiphenyl ether

The invention provides an flame-retardant and environmentally-friendly polyurethane cable material. The cable material is prepared from the following raw materials, by weight, 20-30 parts of chloroprene rubber, 60-80 parts of a polyurethane thermoplastic elastomer, 8-10 parts of acrylonitrile-butadiene rubber, 8-10 parts of chlorinated paraffin, 0.5-1.0 part of stearic acid, 1-3 parts of barium stearate, 4-6 parts of iron oxide, 0.5-1.0 part of ammonium trimolybdate, 30-50 parts of precipitated silica, 10-13 parts of modified argil, 0.5-1.0 part of capsaicin, 0.1-0.3 parts of an antioxidant AW, 0.5-1.5 parts of a promoter TMTD, 0.2-0.5 parts of sulfur, 8-10 parts of decabromodiphenyl oxide, 12-15 parts of antimony (III) oxide and 6-8 parts of zinc borate hydrate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good low temperature resistance, good oil resistance, and good abrasion resistance, and the cables processed through using the cable material can prevent the harms of mice and termites and simultaneously have the efficacies of low smoke, environmental protection and flame retardation.

Owner:蚌埠尚维知识产权运营有限公司

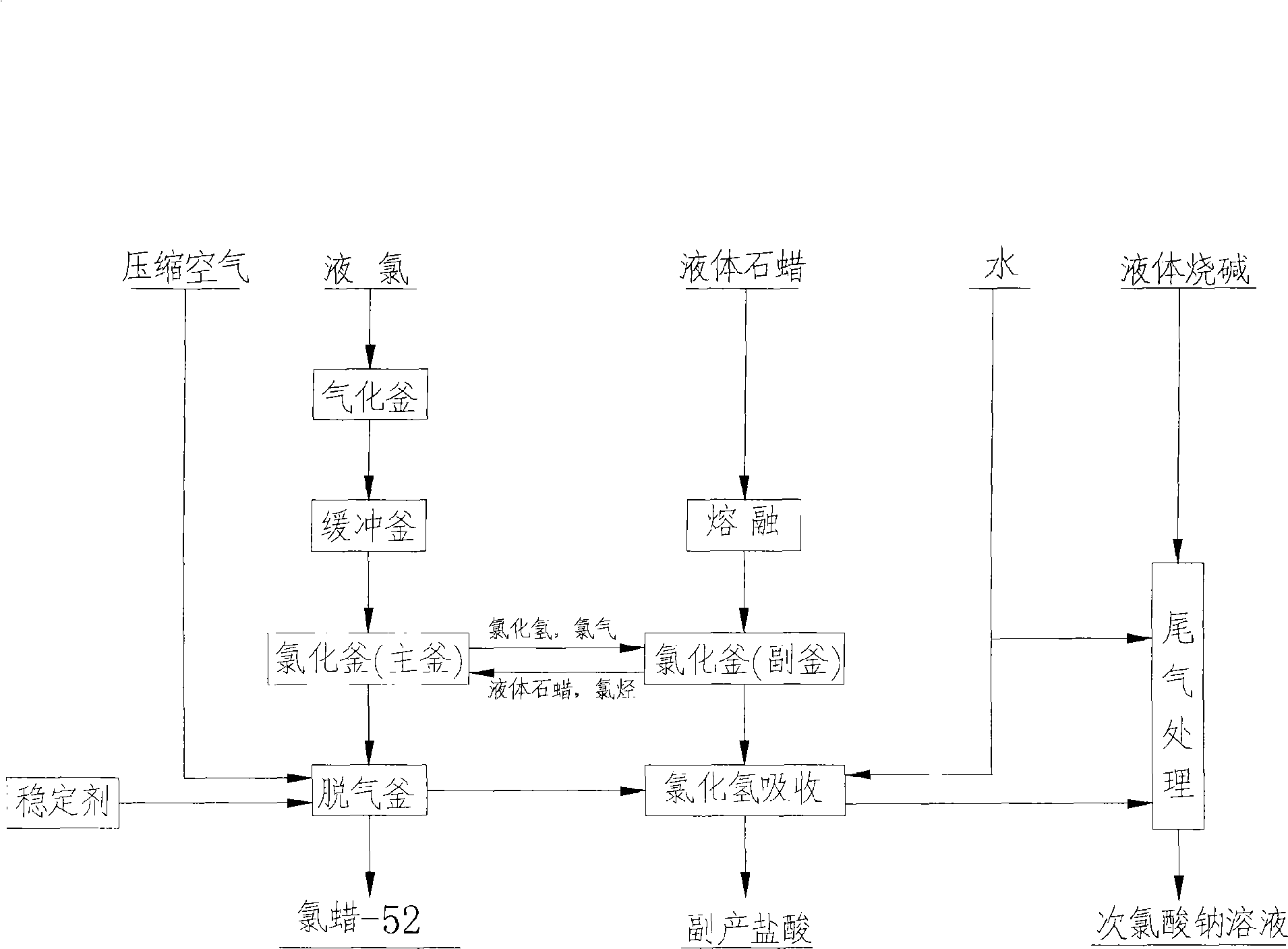

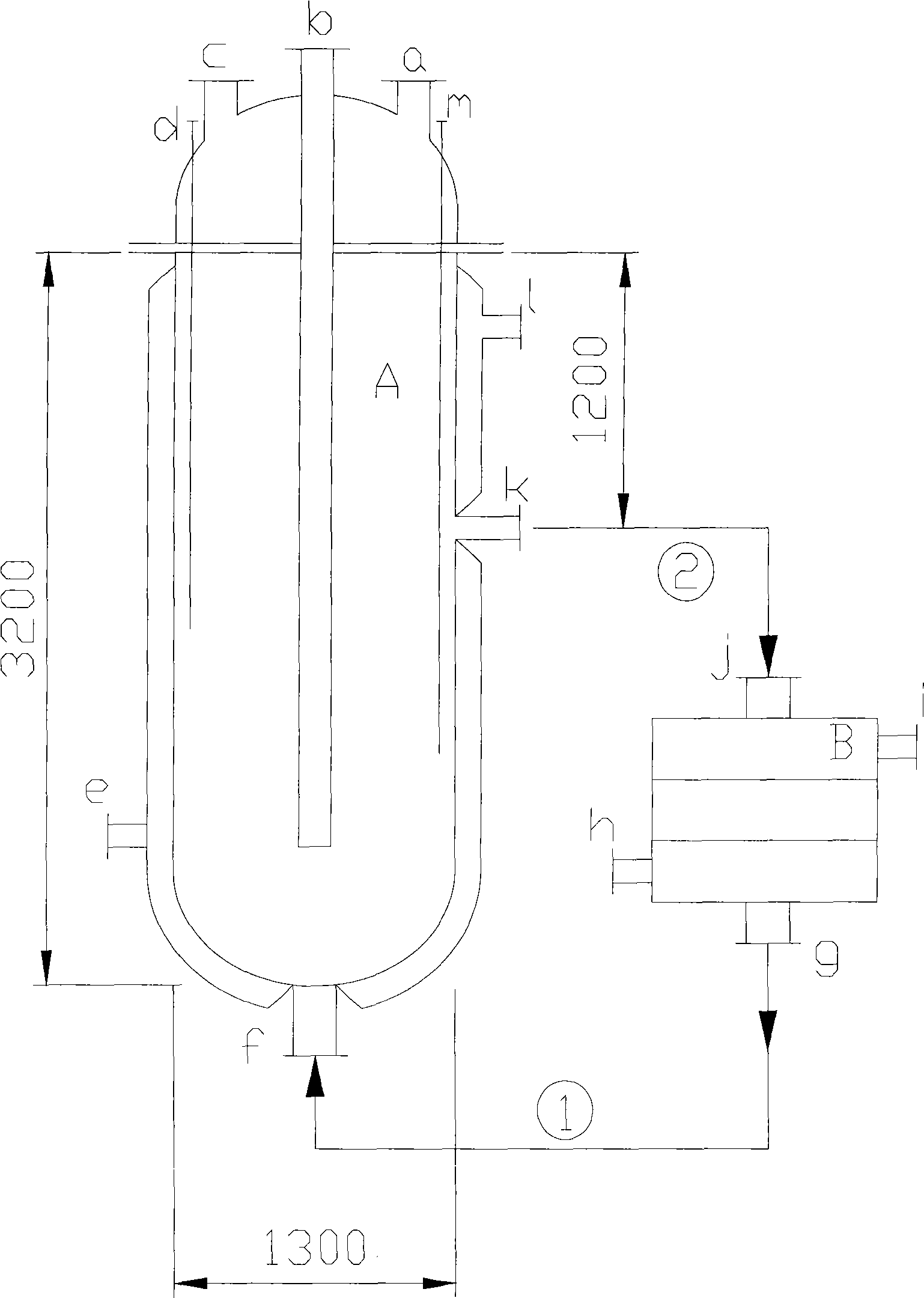

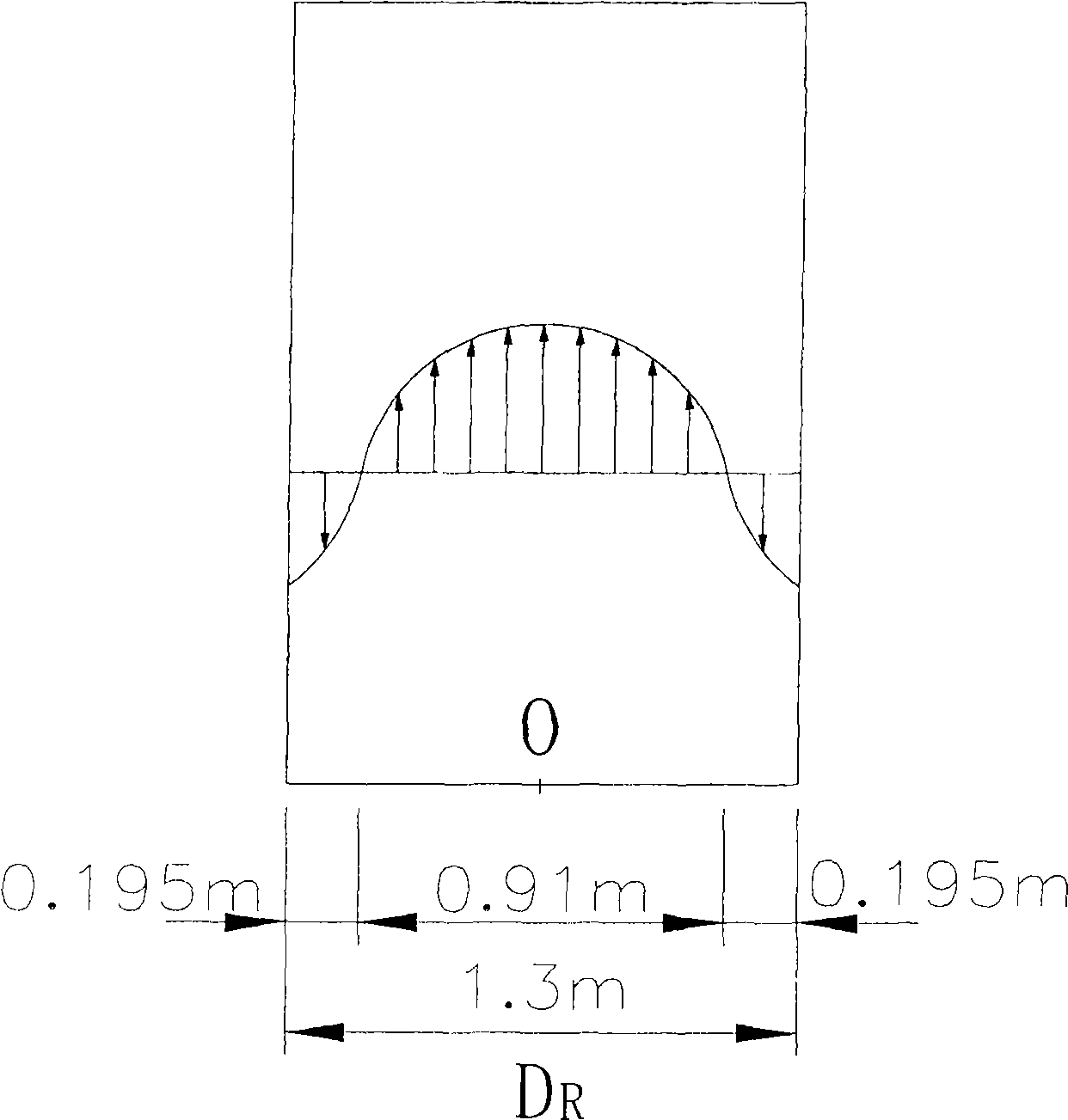

Self circulation heat exchange method for materials in production of chlorinating paraffin-52 and chlorination reaction device therefor

InactiveCN101544911AOrderly escapeNo reduction in mass transfer efficiencyPetroleum chemical modificationComing outParaffin wax

The invention provides a self circulation heat exchange method for materials in production of chlorinating paraffin-52 and a chlorination reaction device therefor. The method comprises the steps that: a, liquid paraffin is added into an automatic circulation main and auxiliary chlorination reaction kettle provided with a catalytic light source and a heat exchanger outside the kettle, and a catalytic light source lamp is turned on; b, liquid chlorine is introduced into a gasification kettle, stabilized by an accumulator still, and is introduced into a main kettle of the chlorination reaction kettle at a chlorine flowrate of between 200 and 230Kg / h, the chlorination temperature is controlled to be between 100 and 110 DEG C, the reaction is stopped when the chlorine content analyzed in a taken sample is between 50 and 54 percent to obtain a crude product of the chlorinating paraffin-52, dissolved chlorine and chlorine hydride in the crude product of the chlorinating paraffin-52 are removed by a degasification kettle, and then a stabilizing agent is added to obtain a finished product of the chlorinating paraffin-52; and c, gas coming out of the main kettle of the chlorination reaction kettle enters an auxiliary kettle of the chlorination reaction kettle, gas coming out of the auxiliary kettle of the chlorination reaction kettle passes through a graphitic absorber, a water falling film is used for absorbing the chlorine hydride in the gas to prepare hydrochloric acid, micro chlorine and chlorine hydride contained in tail gas which is discharged by the graphic absorber pass through a waste gas processor and are absorbed by water solution of sodium hydroxide to generate sodium hypochlorite and sodium chloride.

Owner:HENAN CHEM IND RES INST

High-temperature-resisting easy collapse molding sand and preparation method thereof

InactiveCN103495693AImprove breathabilityImprove liquidityFoundry mouldsFoundry coresWet bondingSodium metasilicate

High-temperature-resisting easy collapse molding sand is made from, by weight, 240-280 parts of quartz sand, 50-55 parts of lightweight calcium carbonate powder, 20-30 parts of hollow ceramic microspheres, 10-15 parts of hollow glass microspheres, 40-55 parts of aluminum silicate powder, 25-30 parts of titanium dioxide, 35-40 parts of fluorite nano-powder, 30-40 parts of gypsum whisker, 60-70 parts of expanded perlite, 10-15 parts of talcum powder, 2-4 parts of sodium metasilicate, 1-2 parts of glucose powder, 1-2 parts of urea, 1-2 parts of chlorinated paraffin, and a proper amount of water. The materials such as the hollow ceramic microspheres and the hollow glass microspheres are used, so that the molding sand is fine in breathability and fluidity; meanwhile, the lightweight calcium carbonate, the glucose, the urea and the like are used, so that the molding sand is fine in high temperature collapsibility, high dry strength of sand molds, high in wet bonding power, excellent in sticking resistance and applicable to various hardening manners; drying time after CO2 hardening is shortened, and reuse rate of used sand can be increased significantly.

Owner:HEFEI CITY TENVER PRECISION CASTING

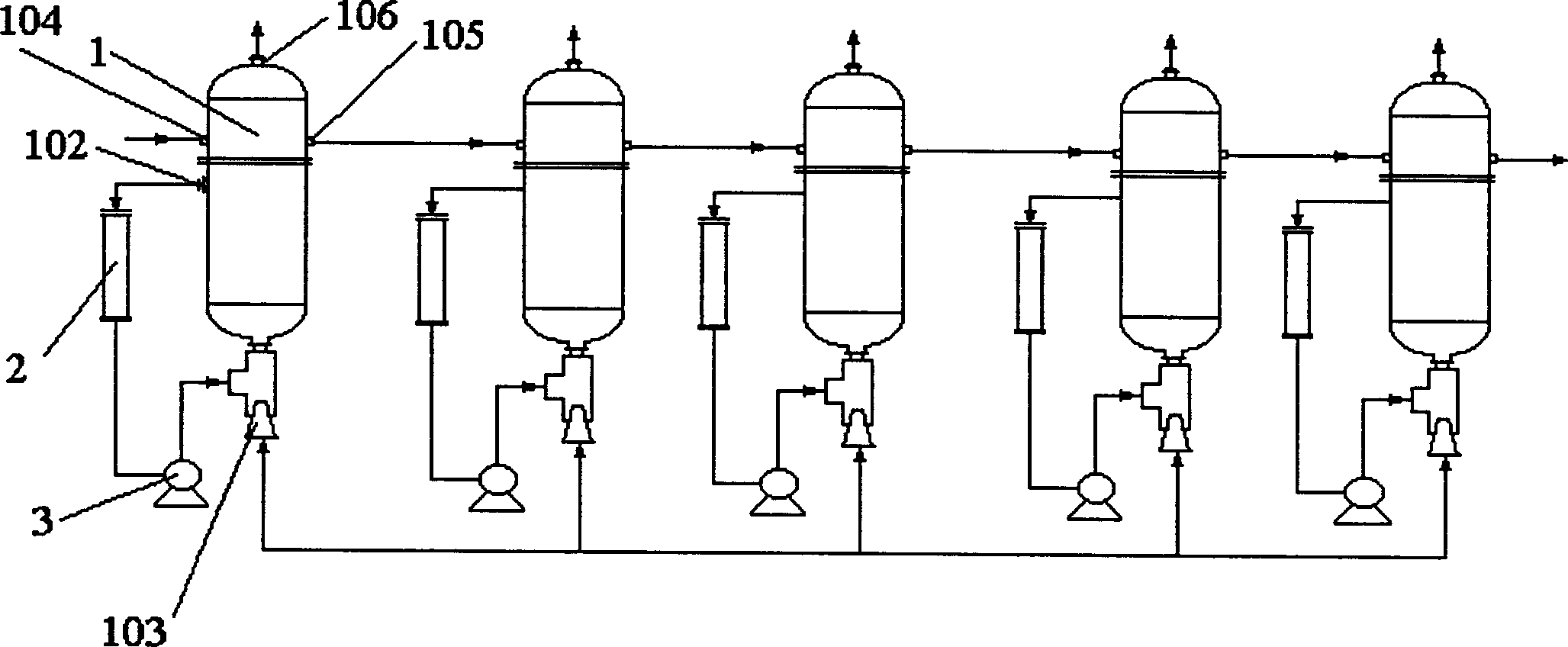

Continuous production method of chlorinated paraffin

InactiveCN1824737APrevent burning phenomenonAvoid production accidentsPetroleum chemical modificationParaffin oilsChlorinated paraffins

The present invention discloses a method for continuously producing chloroparaffine. Said method includes the following steps: making paraffin oil be passed through paraffin oil inlet and continuously fed into reactor; making chlorine gas be passed through circulation material and chlorine gas feeding device and fed into reactor from bottom portion of said reactor; under the catalysis of UV light making them implement chlorination reaction; making reaction product of the prior-stage be fed into reactor of next-stage to make continuous reaction, making the reaction product of the last reactor be fed into subsequent work-shop section to make refinement; making the reaction product overflowed from upper portion of reactor be fed into inlet of external cooling device, cooled, then passed through circulating pump, conveyed and premixed with chlorine gas, then fed into reactor.

Owner:SHANGHAI CHLOR ALKALI CHEM

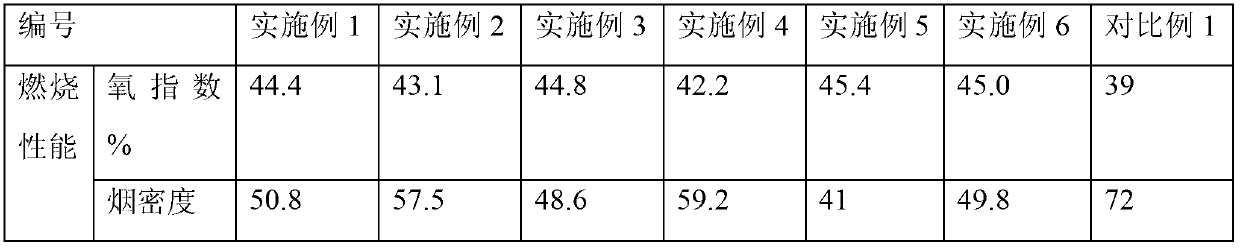

High flame retardancy type soft foam plastic insulation product and preparation method thereof

ActiveCN103102533AHigh oxygen indexImprove flame retardant performancePolyvinyl chloridePolyethylene glycol

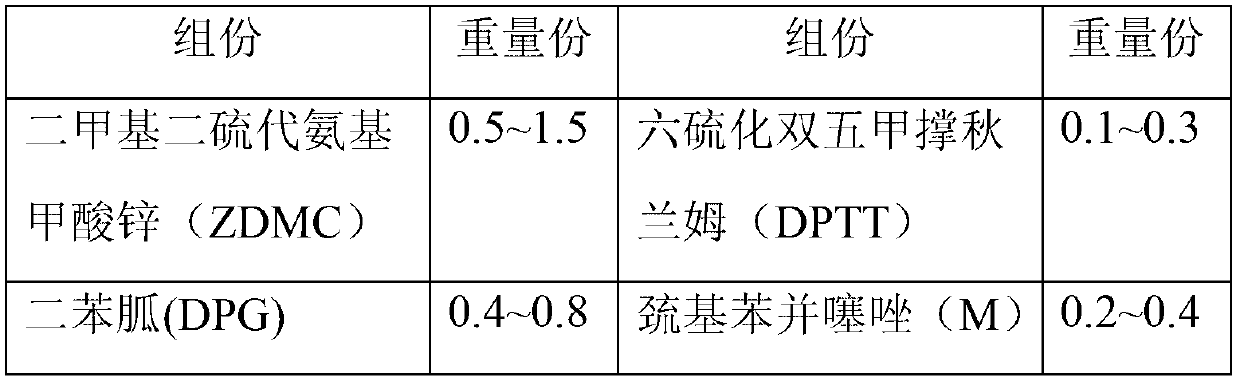

The invention provides a high flame retardancy type soft foam plastic insulation product and a preparation method thereof. The product comprises the following components in parts by weight: 12 to 15 parts of nitrile rubber, 8 to 10 parts of talcum powder, 0.5 to 0.8 parts of polyethylene glycol, 0.2 to 0.4 parts of antiager 4020, 15 to 20 parts of chlorinated paraffin, 0.6 to 0.9 parts of paraffin, 1 to 2 parts of epoxidized soybean oil, 0.1 to 0.3 parts of antiager RD, 0.4 to 0.7 parts of carbon black, 7 to 10 parts of polrvinyl chloride, 26 to 36 parts of fire retardant based on the total amount, 2 to 5 parts of dioctyl ester, 8 to 12 parts of azodicarbonamide, 0.2 to 0.5 parts of stearic acid, 0.4 to 0.7 parts of zinc oxide, 0.4 to 0.7 parts of sulphur, and 1.3 to 1.8 parts of accelerant based on the total amount. By adopting the high flame retardancy type soft foam plastic insulation product, the technical problem that the oxygen index and the smoke density are mutually conflicted in the technological manufacture is solved, and the bottleneck due to mutual limitation is broken through.

Owner:HEBEI HUAMEI CHEM & BUILDING MATERIALS GRP

Fire-proof water paint for wood and its preparing process

A fire-proof water paint used for coating it on the trunk of growing tree is prepared from ammonium polyphosphate, tripolycyanoamine, pentaerythritol, chlorinated paraffin wax, titanium oxide powder / iron oxide red, talc powder, carboxyethyl cellulose, water and water-base resin / emulsion through dispersing, stirring and grinding. Its advantages are high fire-proofing effect, no influence to growth of tree and no environmental pollution.

Owner:许勇

Machine-applied controlled-release fertilizer special for winter wheat and preparation method thereof

The invention discloses a machine-applied controlled-release fertilizer special for winter wheat and a preparation method thereof. The machine-applied controlled-release fertilizer special for the winter wheat is prepared from the following raw materials: by weight, 30-35 parts of ammonium bicarbonate, 10-12 parts of urea, 15-18 parts of monoammonium phosphate, 4-6 parts of potassium chloride, 1-2 parts of ammonium molybdate, 2-3 parts of manganese sulfate, 1-2 parts of borax, 1-2 parts of ferrous sulphate, 4-6 parts of bamboo charcoal powder, 3-4 parts of meerschaum powder, 1-2 parts of barite powder, 1-2 parts of silane coupling agent KH550, 2-3 parts of humic acid, 1-2 parts of waste engine oil, and proper amounts of chlorinated paraffin and wintergreen oil. In the formula of the machine-applied controlled-release fertilizer special for the winter wheat, the bamboo charcoal powder and the meerschaum powder can absorb trace elements and play a slow-release effect. The urea is melted and coats the trace elements, so that the urea and the trace elements can be simultaneously released so as to benefit synergy among fertilizers. The waste engine oil coats the trace elements so as to play the slow-release effect. When the fertilizer is applied, compared with a traditional fertilizer, the machine-applied controlled-release fertilizer special for the winter wheat can be used in single-dose application without additional fertilization. Wheat yield can be increased by 16% to 28%, and soil fertility also can be improved.

Owner:倪群

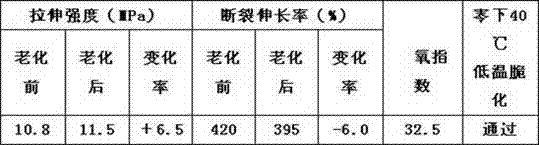

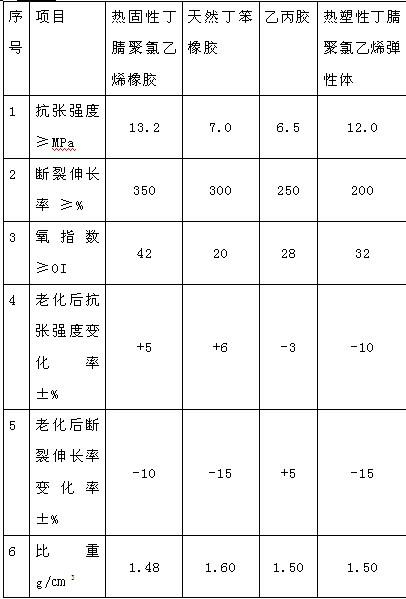

Flame-retardant thermosetting nitrile/polyvinyl chloride (PVC) rubber for wires and cables

ActiveCN102050971AHigh strengthGood elongationInsulated cablesInsulated conductorsThermoplasticParaffin wax

The invention discloses a flame-retardant thermosetting nitrile / polyvinyl chloride (PVC) rubber for wires and cables, which is characterized by comprising the following raw materials in parts by weight: 50-70 parts of nitrile rubber powder, 30-50 parts of PVC resin powder, 2-3 parts of vulcanizing agent, 2.5-4.5 parts of accelerant, 4-6 parts of zinc oxide, 2-3 parts of stearic acid, 1-3 parts of coumarone resin, 2-4 parts of anti-aging agent, 20-40 parts of chlorinated paraffin wax, 7-10 parts of antimony trioxide, 4-6 parts of zinc borate, 50-70 parts of aluminum hydroxide and 40-70 parts of carbon black. After exceeding a certain temperature, the flame-retardant thermosetting nitrile / PVC rubber disclosed by the invention can only be cured and charred, but can remain a certain insulating property; the strength, elongation and flame retardance of the flame-retardant thermosetting nitrile / PVC rubber are better than those of common rubber and thermoplastic nitrile / PVC rubber; and the flame-retardant thermosetting nitrile / PVC rubber also has the advantages of oil resistance, wear resistance and softness in the common rubber and thermoplastic nitrile / PVC rubber.

Owner:GUANGDONG RIFENG ELECTRIC CABLE

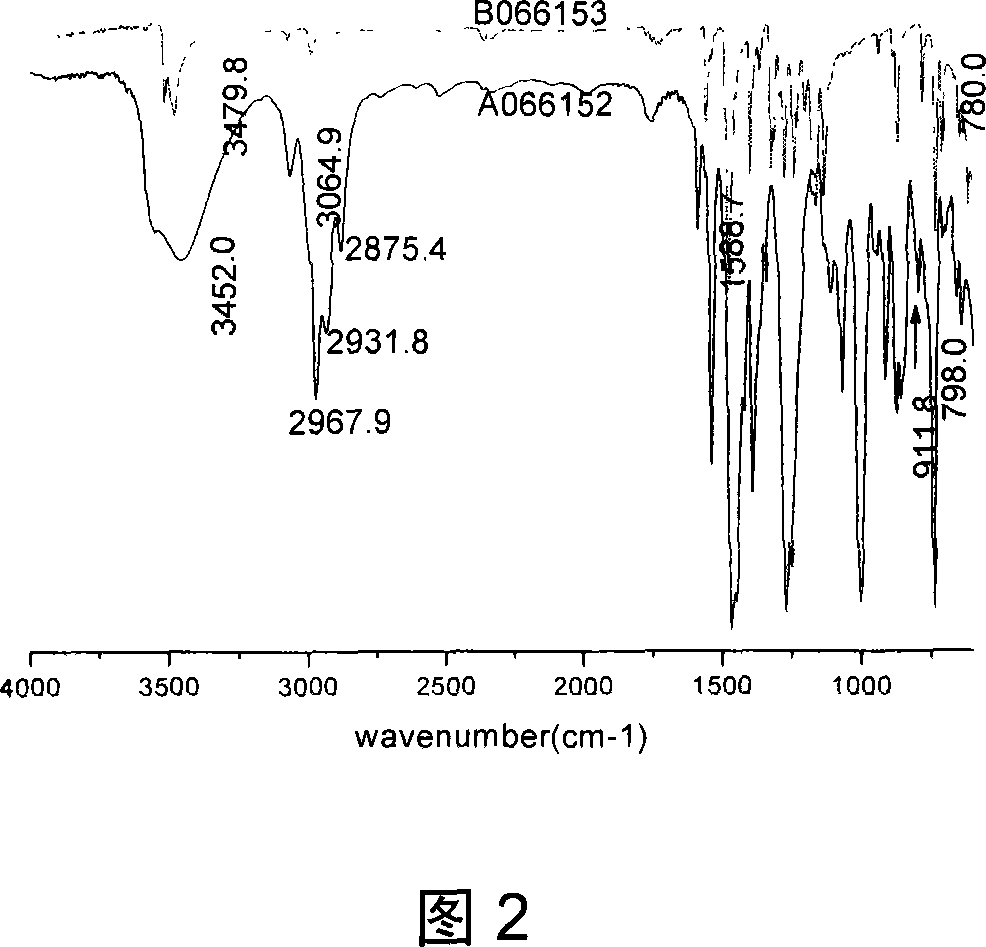

Fireproof paint for super-thin steel structure and preparation method thereof

InactiveCN101058693AStrong adhesionGood film formingFireproof paintsLiquid surface applicatorsTetrabromobisphenol APolyvinyl chloride

The invention discloses a method preparing for an ultra-thin inflatable steel structure fire-proof paint, which is characterized by the following: the allocation of tetrabromo-bisphenol A epoxide resin contains epichlorohydrin and tetrabromo-bisphenol A with weight rate at 1. 3-1. 5:1 and epichlorohydrin and sodium hydroxide with weight rate at 1. 0-1. 05:1; the allocation of fireproof painting is tetrabromo-bisphenol A epoxide resin and hyperchlorinated polyvinyl chloride with weight rate at 3: 1, polyphosphate, melamine, pentaerythritol with weight rate at 3:2:1, antimony trioxide and paraffin chloride with weight rate at 3:7, aluminium hydroxide and zinc borate smoke suppressor with weight rate at 10: 3. The method comprises the following steps: adding epichlorohydrin and tetrabromo-bisphenol A to the autoclave; mixing and heating at 90 Deg. C; adding caustic soda solution; keeping 7. 5 hours; washing and removing thylbenzene by heating;getting tetrabromo-bisphenol A epoxide resin; adding the mixed solvent to tetrabromo-bisphenol A epoxide resin and perchlorinated polyethylene; mixing and dissolving; adding ammonium polyphosphate, melamine, pentaerythrite, titanium dioxide, antimony oxide, aluminum hydroxide, zinc borate separately, adding chlorcosane; grinding after high-speed dispersing uniformly; mixing polyamide uniformly according to 10:1; getting the fire-proof paint.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

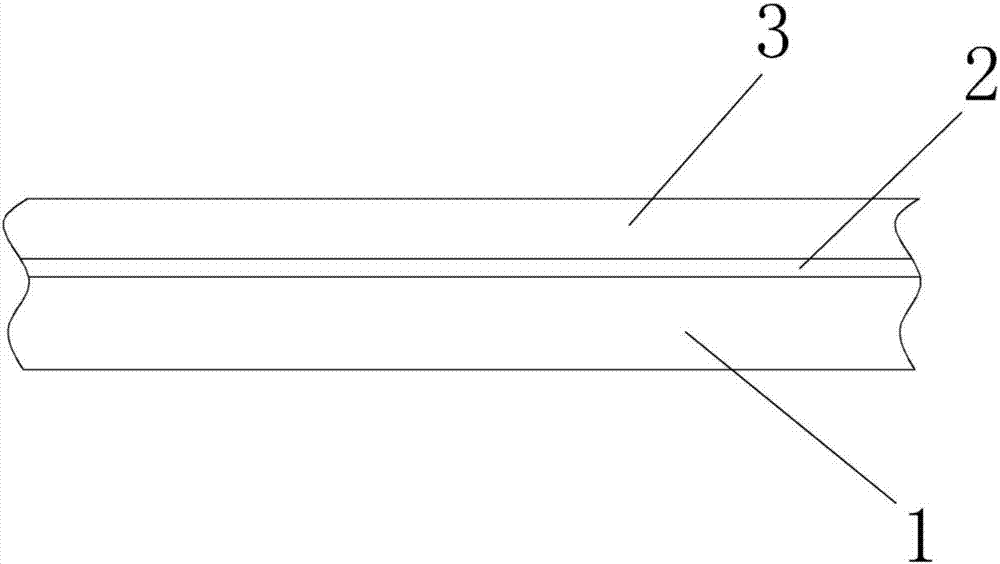

Stain-resistant and oil-resistant wallpaper and preparation method thereof

The invention discloses stain-resistant and oil-resistant wallpaper. The stain-resistant and oil-resistant wallpaper comprises a substrate layer, a stain-resistant layer and an oil-resistant layer, wherein the outer periphery of the substrate layer is coated with the stain-resistant layer, and the outer periphery, far away from the substrate layer, of the stain-resistant layer is coated with the oil-resistant layer; the oil-resistant layer is prepared from the raw materials: acrylic perfluoroalkyl ester, alkyd resin, polyester resin, perfluoroalkyl acrylate, butyl acrylate, hydroxyethyl acrylate, aluminum tripolyphosphate, nano zinc borate, potassium persulfate, hydroxymethyl cellulose, nano zinc oxide, nano titanium dioxide, diatomite, magnesium hydroxide, aluminum oxide, organobentonite, sericite powder, perfluorocarbon, ferric phosphate, sodium molybdate, sodium persulfate, chlorinated paraffin, silane coupling agent KH-560, dibutyltin dilaurate, octadecyl trimethyl ammonium chloride, polyethylene glycol, fluorosilicon oil, a thickener, an antifoamer, a curing agent and modifying auxiliaries. The invention further provides a preparation method of the stain-resistant and oil-resistant wallpaper. The prepared wallpaper has excellent stain resistance and oil resistance.

Owner:安徽易有墙纸有限公司

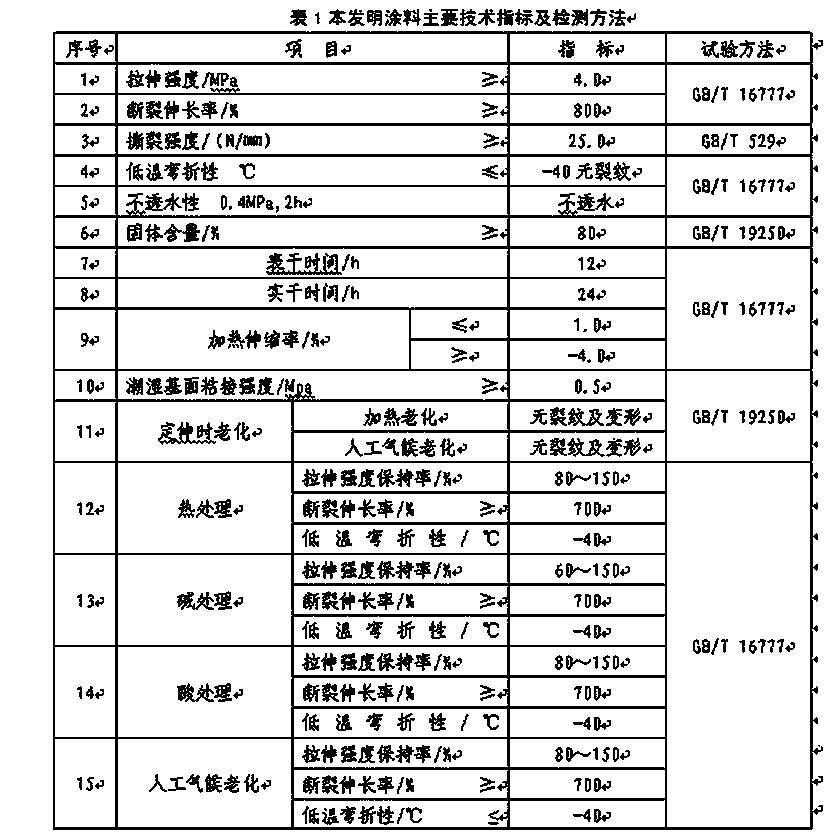

Latent-curing single-component color polyurethane waterproofing paint and preparation method thereof

ActiveCN103740260AHigh elongation at breakImprove impermeabilityPolyurea/polyurethane coatingsPolymer scienceChlorinated paraffins

The invention relates to the technical field of polyurethane waterproofing paint, and provides latent-curing single-component color polyurethane waterproofing paint. The latent-curing single-component color polyurethane waterproofing paint comprises the following components by weight: 18-22 parts of polyether 2000, 5-7 parts of polyether 330N, 18-22 parts of chlorinated paraffin, 28-32 parts of powder, 0.8-1.2 parts of dispersing agent, 6-10 parts of MDI-50, 0.8-1.2 parts of catalyst, 3-5 parts of latent curing agent, 3-5 parts of chain extender, and 6-8 parts of solvent. The latent-curing single-component color polyurethane waterproofing paint has such advantages as high strength, good toughness, good flexibility, low-temperature resistance, strong adhesive power with the basal plane, good adaptability, wide application field, convenience for construction and low dependency on the operation proficiency. The latent-curing single-component color polyurethane waterproofing paint not only satisfies the application field of the original single-component polyurethane waterproofing paint, but also can be suitable for the waterproofing requirements in such special fields as larger-deformation areas and low-temperature areas, so that the latent-curing single-component color polyurethane waterproofing paint has strong adaptability and strong market competitive advantages, and meets the higher and higher requirements of the market to the products.

Owner:郑家玉

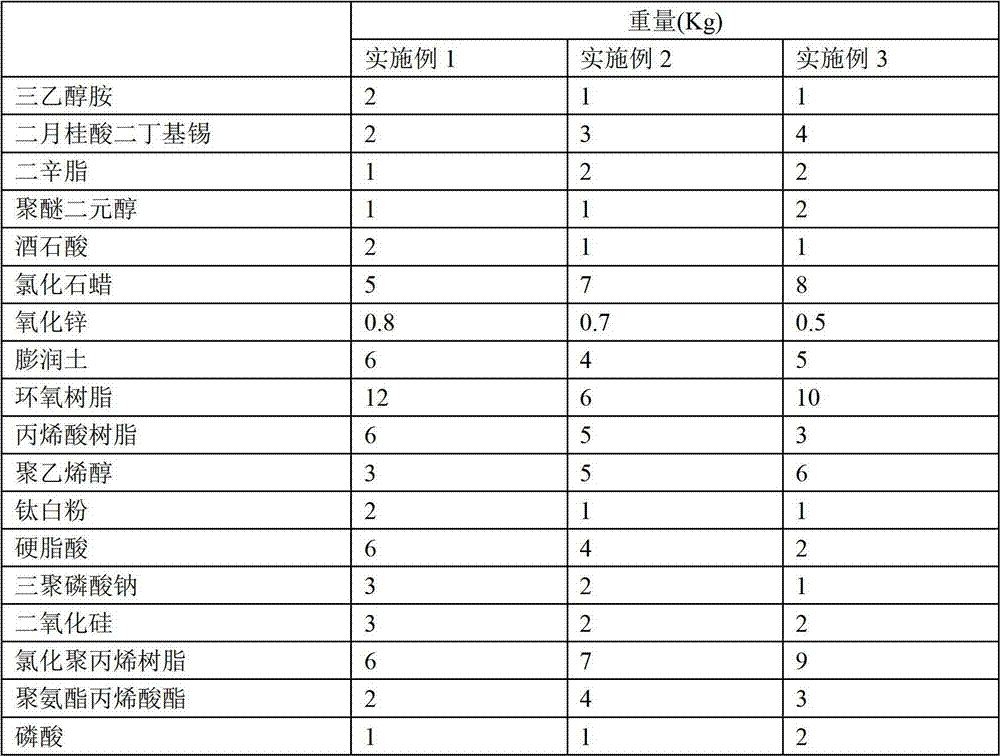

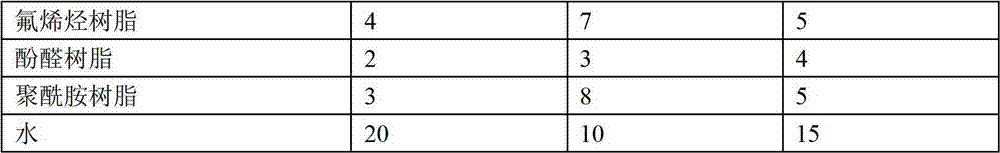

Waterproof coating

ActiveCN102850909AImprove liquidityIncrease breathabilityPolyamide coatingsEpoxy resin coatingsEpoxyAcrylic resin

The invention provides a waterproof coating, which belongs to the technical field of coatings. The waterproof coating comprises, by weight, 1 to 2 parts of triethanolamine, 2 to 4 parts of dibutyltin dilaurate, 1 to 2 parts of DOP, 1 to 2 parts of polyether glycol, 1 to 2 parts of tartrate, 5 to 8 parts of chlorinated paraffin, 0.5 to 0.8 part of zinc oxide, 4 to 6 parts of bentonite, 6 to 12 parts of epoxy resin, 3 to 6 parts of acrylic resin, 3 to 6 parts of polyvinyl alcohol, 1 to 2 parts of titanium dioxide, 2 to 6 parts of stearic acid, 1 to 3 parts of sodium tripolyphosphate, 2 to 3 parts of silica, 6 to 9 parts of chlorinated polypropylene resin, 2 to 4 parts of polyurethane acrylate, 1 to 2 parts of phosphoric acid, 4 to 7 parts of fluoro-olefin resin, 2 to 4 parts of phenolic resin, 3 to 8 parts of polyamide resin and 10 to 20 parts of water. The waterproof coating provided by the invention has excellent waterproof performance and strong adhesion with a substrate.

Owner:苏州市德莱尔建材科技有限公司

Wear-resistant and heatproof modified polyurethane rubber cable material

InactiveCN105602238AImprove performanceGood wear resistance and heat resistancePlastic/resin/waxes insulatorsPolymer sciencePolyvinyl alcohol

The invention discloses a wear-resistant and heatproof modified polyurethane rubber cable material which comprises the following raw materials: modified polyurethane, acrylate rubber, ethylene-propylene-diene monomer, nitrile butadiene rubber, epoxy resin, polyether glycol, toluene diisocynate, polyvinyl alcohol, diisobutyltin dilaurate, polyvinyl chloride, hydroxyl-terminated polybutadiene, hydroxyl-terminated polyalcohol, isocyanate, vinyltriethoxysilane, dibutyltin dilaurate, silicone oil, a carbon nanotube, organic modified montmorillonoid, nano alumina powder, talc powder, bamboo carbon fiber, chlorinated paraffin, silicon dioxide, zinc oxide, stearic acid, nano aluminum hydroxide, a flame retardant, an anti-aging agent, a plasticizer, an antioxidant and an accelerant. The modified polyurethane rubber cable material disclosed by the invention has excellent wear-resistant and heatproof properties.

Owner:ANHUI DUJIANG CABLE GROUP

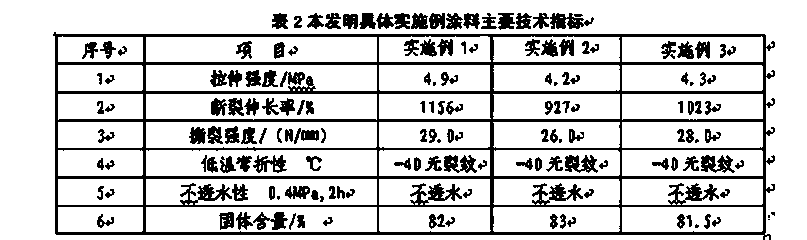

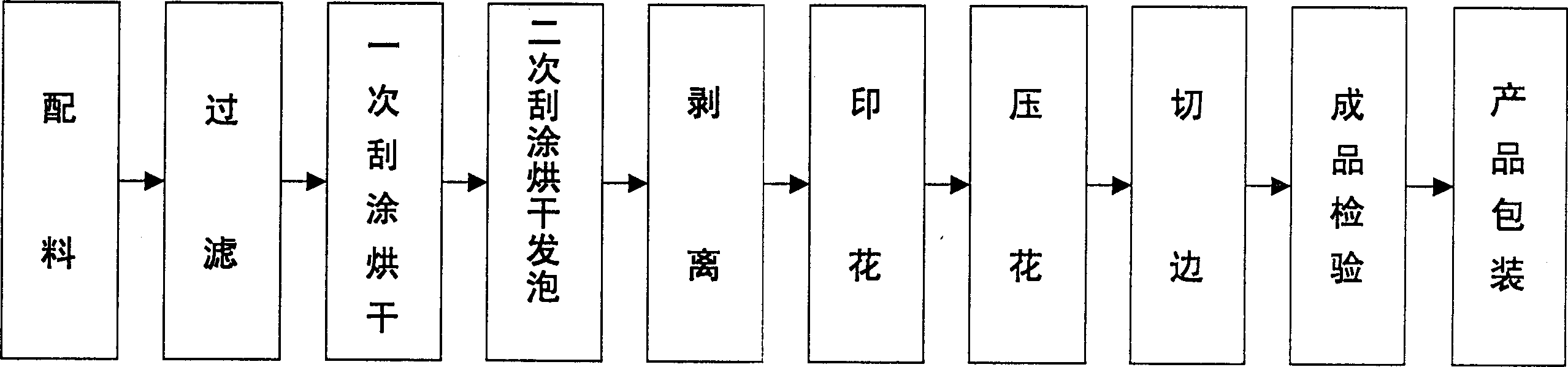

Decorative wall leather and its making method

InactiveCN1404989AImprove flame retardant performanceGood anti-mold and moisture-proof performanceSynthetic resin layered productsParaffin waxSurface layer

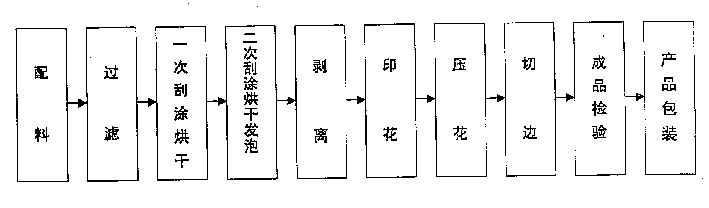

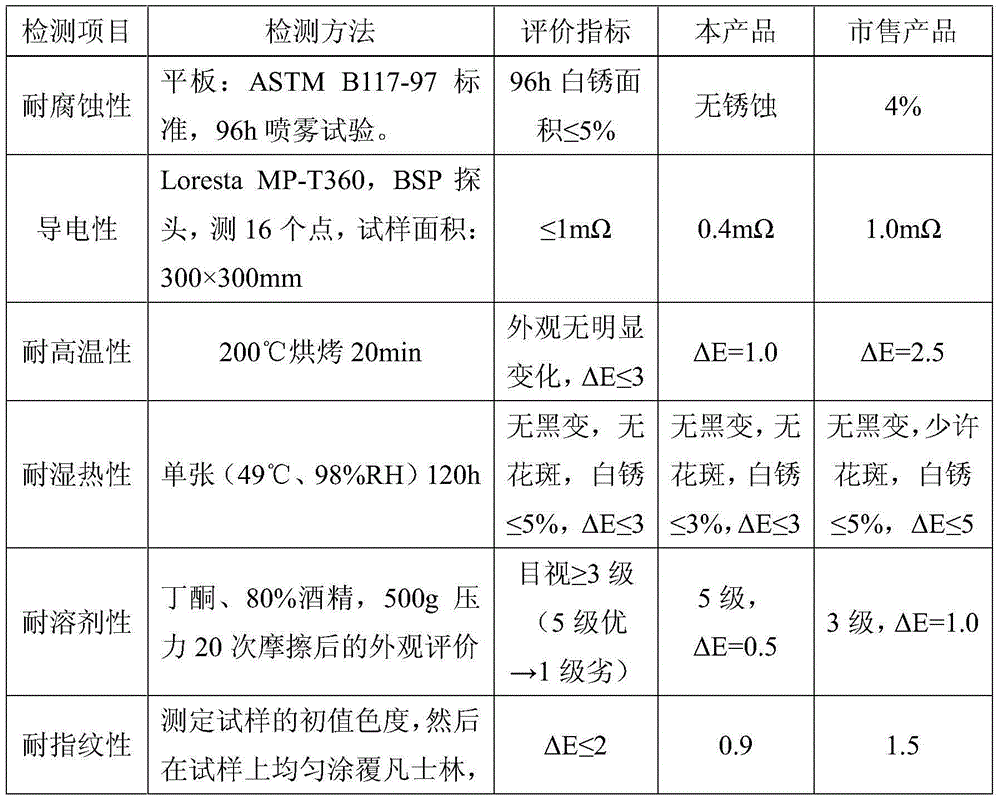

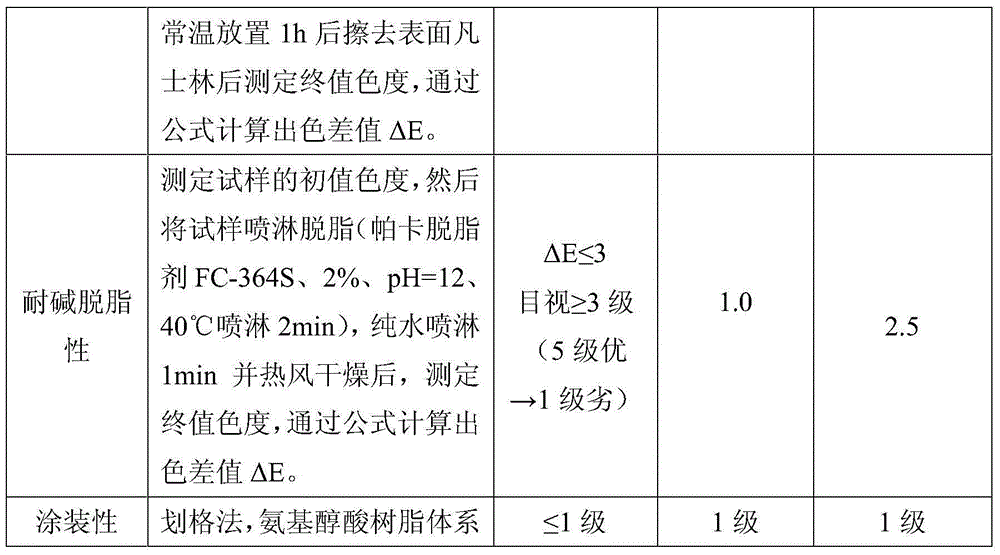

The decorative wall leather is formed from surface layer and bottom layer, the composition of surface layer comprises PVC base material 100, diisodecyl phthalate 30-60, chlorinated paraffin wax 0-25, barium-zinc liquid compound stabilizer 1-2, azoformamide 0-3, antimony oxide 0-5 and oil soluble dry film mildew inhibitor 0.2-1.5, and the composition of bottom layer contans PVC base material 100, diisodecyl phthalate 40-62, chlorinated paraffin wax 0-25, barium-zinc liquid compound stabilizer 1.5-3.5%, azoformamide 2-6, antimony oxide 2-8 and oil soluble dry film mildew inhibitor 0.2-2. Its preparation process includes the following steps: preparing materials, filtering, first knife coating, drying, secondary knife coating, drying, foaming, stripping, printing, embossing, edge-cutting, check finished product and packaging.

Owner:SICHUAN JINLU GRP

Two-component polyurethane waterproof coating and preparation method thereof

InactiveCN101418184AHigh solid contentHigh strengthPolyurea/polyurethane coatingsPolymer scienceToluene diisocyanate

The invention discloses a bicomponent polyurethane waterproof paint, which consists of a component A and a component B in weight portion, wherein the component A consists of 60 to 70 portions of toluene di-isocyanate(TDI), 7 to 10 portions of polyether N-330, 16.8 to 30.9 polyether N-220, 2 to 3 portions of amine-terminated polyether resin and 0.1 to 0.2 portion of stabilizing agent tartaric acid; and the component B consists of 20 to 30 portions of polyether N-330, 0.5 to 1 portion of antioxidant, 3 to 5 portions of tinting color, 4 to 8 portions of vulcanizing agent MOCA, 10 to 20 portions of vacuum distillate 4 line oil, 8 to 20 portions of chlorcosane, 4 to 8 portions of plasticizing agent DOP and 15 to 20 portions of sericite in powder. The invention also discloses a preparation method for the paint. The bicomponent polyurethane waterproof paint has the advantages of high solid content, high strength, and high elongation at break, and is especially suitable to be used as a waterproof layer of concrete bridge decks of high-speed railways, highways, lines for passenger transportation and lines for both passenger and freight transportation.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

Water-based chromium-free fingerprint-resistant paint for galvanized steel plate

InactiveCN104449154AReduce consumptionWeather resistantAntifouling/underwater paintsPaints with biocidesWater basedPhosphate

The invention discloses water-based chromium-free fingerprint-resistant paint for a galvanized steel plate. The paint comprises raw materials in parts by weight as follows: 30.0-55.0 parts of a fluorine-modified water-based self-crosslinking acrylate emulsion, 0.1-1.5 parts of a neutralizer, 0.5-1.0 part of a silane coupling agent, 0.1-0.2 parts of laurocapram, 0.6-1.0 part of chlorinated paraffin, 4.0-8.0 parts of inorganic sol, 1.5-3.5 parts of metal salt, 0.1-0.3 parts of glycerin, 0.1-0.2 parts of sodium carboxymethylcellulose, 0.1-0.2 parts of polydimethylsiloxane, 1.5-5.5 parts of a cosolvent, 1.0-2.5 parts of aluminium dihydrogen phosphate and 40-50 parts of water; the curing temperature is as low as 40-60 DEG C, and energy consumption is reduced. The fluorine-modified water-based self-crosslinking acrylate emulsion is adopted to enable a film to have weather-resistant, waterproof and self-cleaning performance and the like, the film has a self-repairing function when damaged, and the forming processability is greatly improved. Low VOC (volatile organic compounds) emission is realized, and the problem of chromium passivation pollution is solved.

Owner:HEFEI UNIV OF TECH

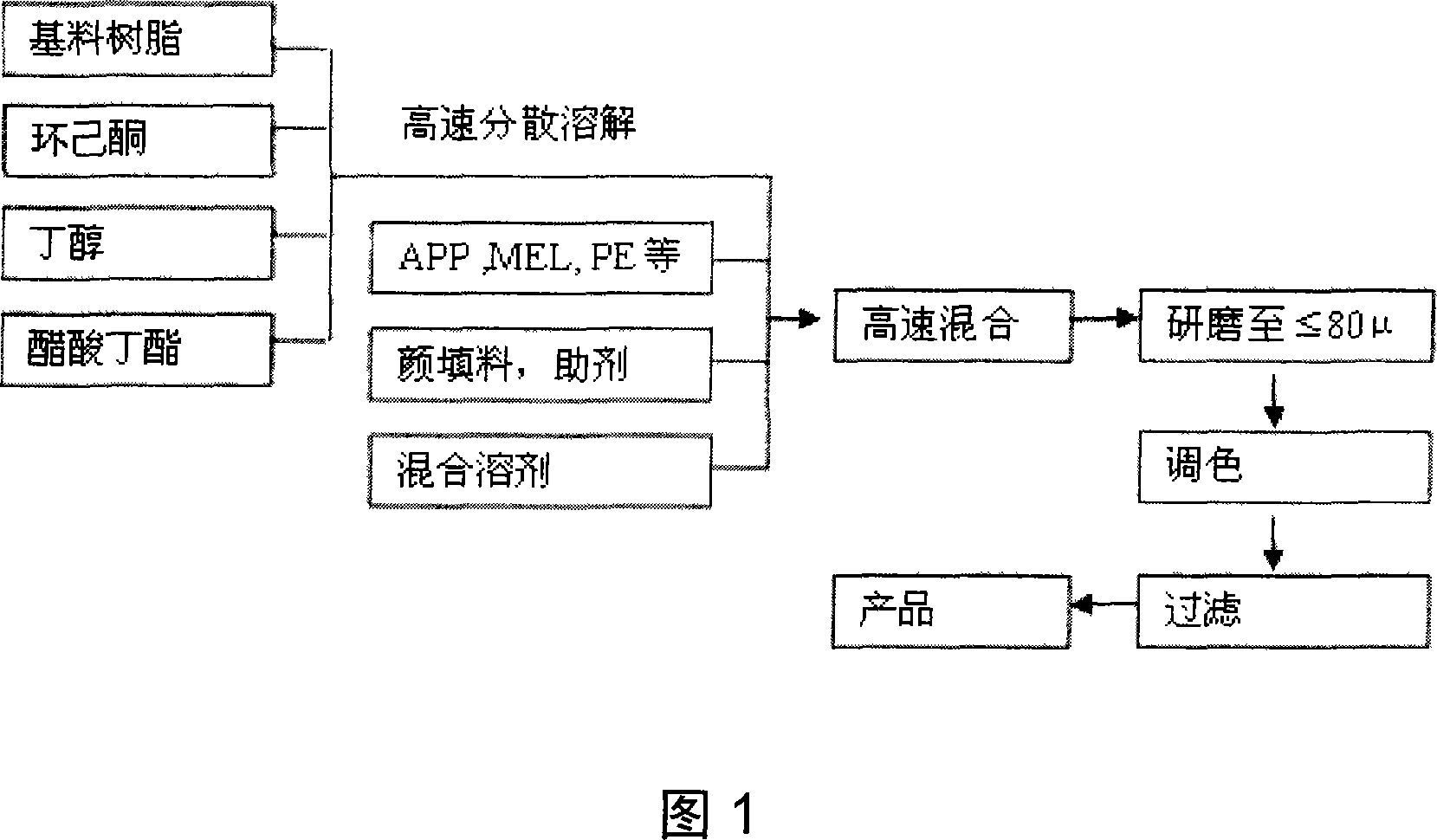

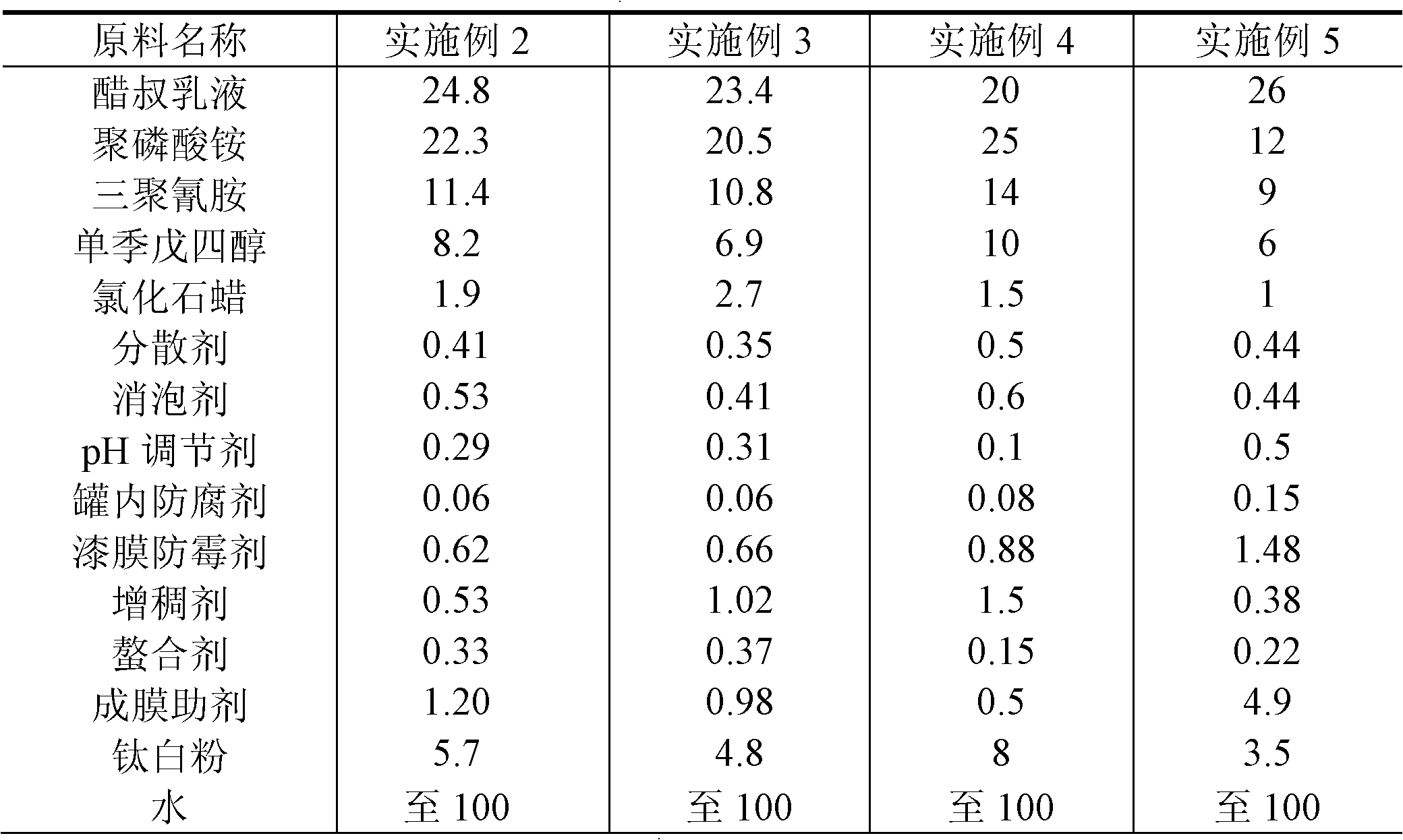

Aqueous ultrathin steel structure fire-retardant coating and preparation method thereof

InactiveCN102627891AImprove thixotropy"The effect of opening the can is goodFireproof paintsAntifouling/underwater paintsEnvironmental resistanceChlorinated paraffins

The invention relates to the field of preparation technologies of functional coatings, in particular to an aqueous ultrathin steel structure fire-retardant coating and a preparation method thereof. The coating comprises a vac-veova emulsion, chlorinated paraffin, ammonium polyphosphate, mono-pentaerythritol, melamine, a defoaming agent, a dispersant, a thickening agent, a chelating agent, a pH regulating agent, a film forming aid, a tank preservative, a paint film mold inhibitor, titanium pigment and water. In the aqueous ultrathin steel structure fire-retardant coating disclosed by the invention, the film forming agent with low glass transition temperature and flame retardant series and aid series with high mutual matching properties are adopted, so that the obtained fire-retardant coating has the excellent characteristics of high thixotropic property, good 'tank opening effect', high foaming performance and high flame retardance; and the preparation method of the fire-retardant coating has the advantages of readily-available raw materials, simple steps, low cost, convenience, environmental friendliness and high construction property.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

Ultrathin expansion steel-structure fireproofing coating

InactiveCN1488692AGood fire and heat insulationImprove adhesionFireproof paintsPolymer scienceAcrylic resin

The present invention provides a fire-retardant coating capable of forming ultrathin coating layer and having high fire-resisting limit. Its composition comprises (by weight portion) 50-60 portions of modified acrylic resin, 12-16 portions of pentaerythritol, 9-12 portions of trimeric cyanamide, 19-21 portions of polyammonium phosphate, 6-8 portions of zinc borate, 9-11 portions of titanium pigment, 1.25-15 portions of chlorinated paraffin (in which chlorine content is 70%) and 8-15 portions of 200# solvent gasoline. The above-mentioned modified acrylic resin is a chlorinated rubber modified acrylic resin made up by using 1.4-1.8 portions of chlorinated rubber, 2.2-2.7 portions of xylene, 0.9-1.1 portions of hexamethylene-diisocyanate and 1.6-1.8 portions of hydroxyl-bearing acrylic resin. Its coating layer thickness is 1.71-2.69 mm, and its fire-resisting limit can be up to 69-147 min.

Owner:应急管理部四川消防研究所

Burnthrough-resistant water-based fire retardant glue for spinning

The invention provides burnthrough-resistant water-based fire retardant glue for spinning. The burnthrough-resistant water-based fire retardant glue is prepared from the following components in parts by weight: 100 parts of a water-based adhesive, 10 to 100 parts of a halogen flame retardant, 3 to 100 parts of a synergistic flame retardant, 0 to 30 parts of an auxiliary and 0 to 100 parts of water, wherein the water-based adhesive is prepared from ethylene-vinyl acetate copolymer emulsion and an auxiliary adhesive; the solid content of the ethylene-vinyl acetate copolymer emulsion is 20 to 56 percent; the weight ratio of the water-based adhesive to the halogen flame retardant is (1 to 8) to 1; the halogen flame retardant is prepared from one or more of decabromodiphenyl ether, decabromodiphenyl ethane, tri(2,3-dibromo propyl) isocyanuric acid ester, tri(tribromophenyl) cyanurate, ethylene bis (tetrabromophthalimide), tetrabromo bisphenol A, hexabromocyclododecane, octo-bromo-ether, chlorine ester resin, ploy (vinylidene chloride) resin, brominated styrene, brominated epoxy resin, polyvinyl chloride, chlorinated paraffin and methyl chloride.

Owner:WUJIANG HONGYUAN SPRAY WEAVING CO LTD

Carbon crystal composite microporous ceramic filter core and preparation method thereof

ActiveCN103381326AInhibition of reproductionHigh temperature resistantOther chemical processesFiltration separationFiltrationChlorinated paraffins

The invention provides a carbon crystal composite microporous ceramic filter core and a preparation method thereof. The invention is characterized in that the ceramic filter core is prepared from the following raw materials by weight: 12 to 14 parts of light calcium carbonate, 9 to 12 parts of kaolin, 7 to 9 parts of diatomite, 10 to 12 parts of bamboo charcoal powder, 4 to 6 parts of charcoal dust, 1 to 2 parts of straw ash, 12 to 14 parts of celestine powder, 6 to 8 parts of talcum powder, 3 to 5 parts of mica powder, 10 to 12 parts of chlorinated paraffin, 12 to 14 parts of ethanol, 25 to 35 parts of modified bentonite and a proper amount of water. The ceramic filter core provided by the invention has a plurality of functions like filtration, adsorption and suppression of bacterial reproduction and has the protruding advantages of high purification efficiency, high temperature resistance, small pressure loss, corrosion resistance, a long service life, removal of dust in air, etc.

Owner:ANHUI PHOENIX INT CO LTD

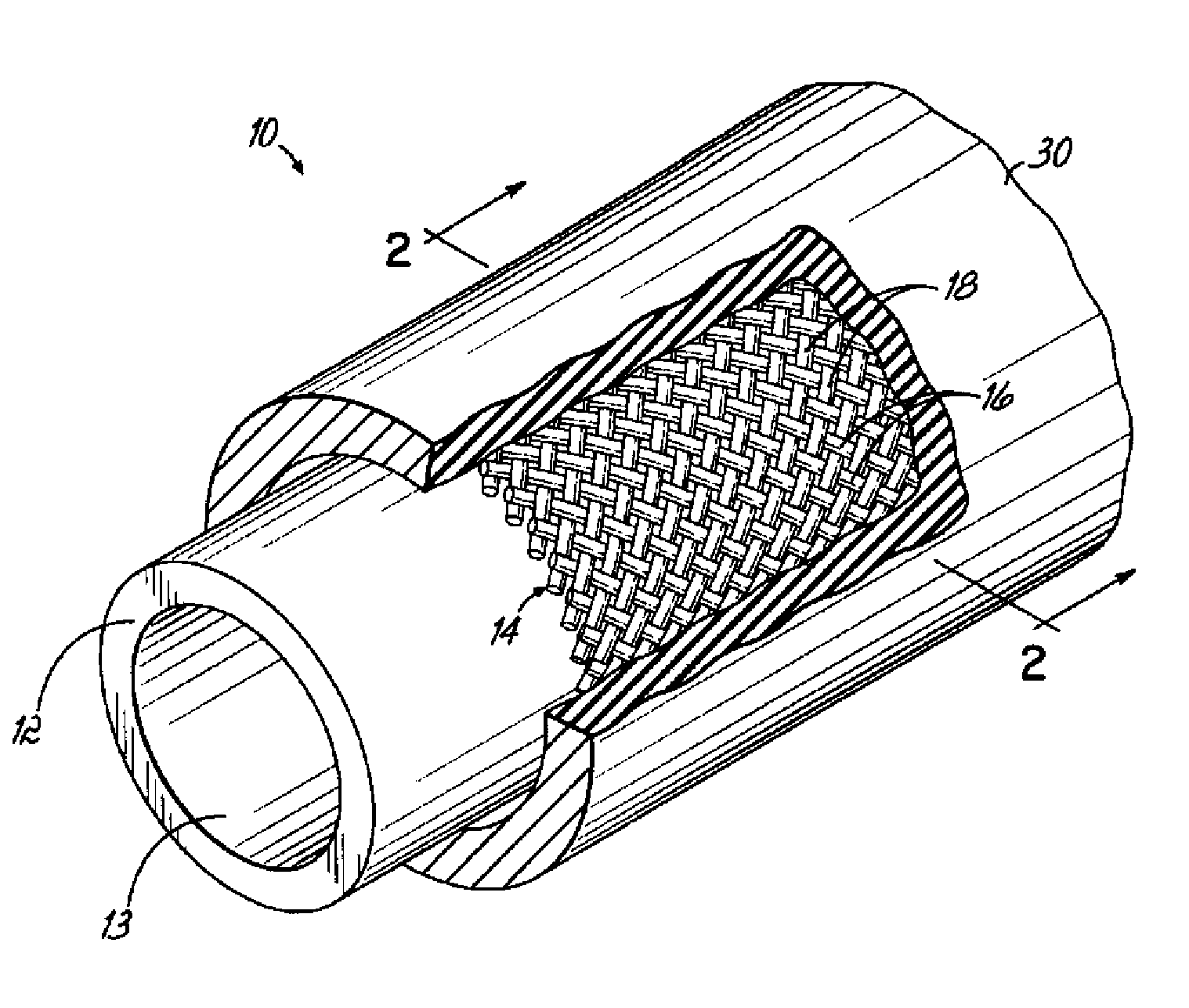

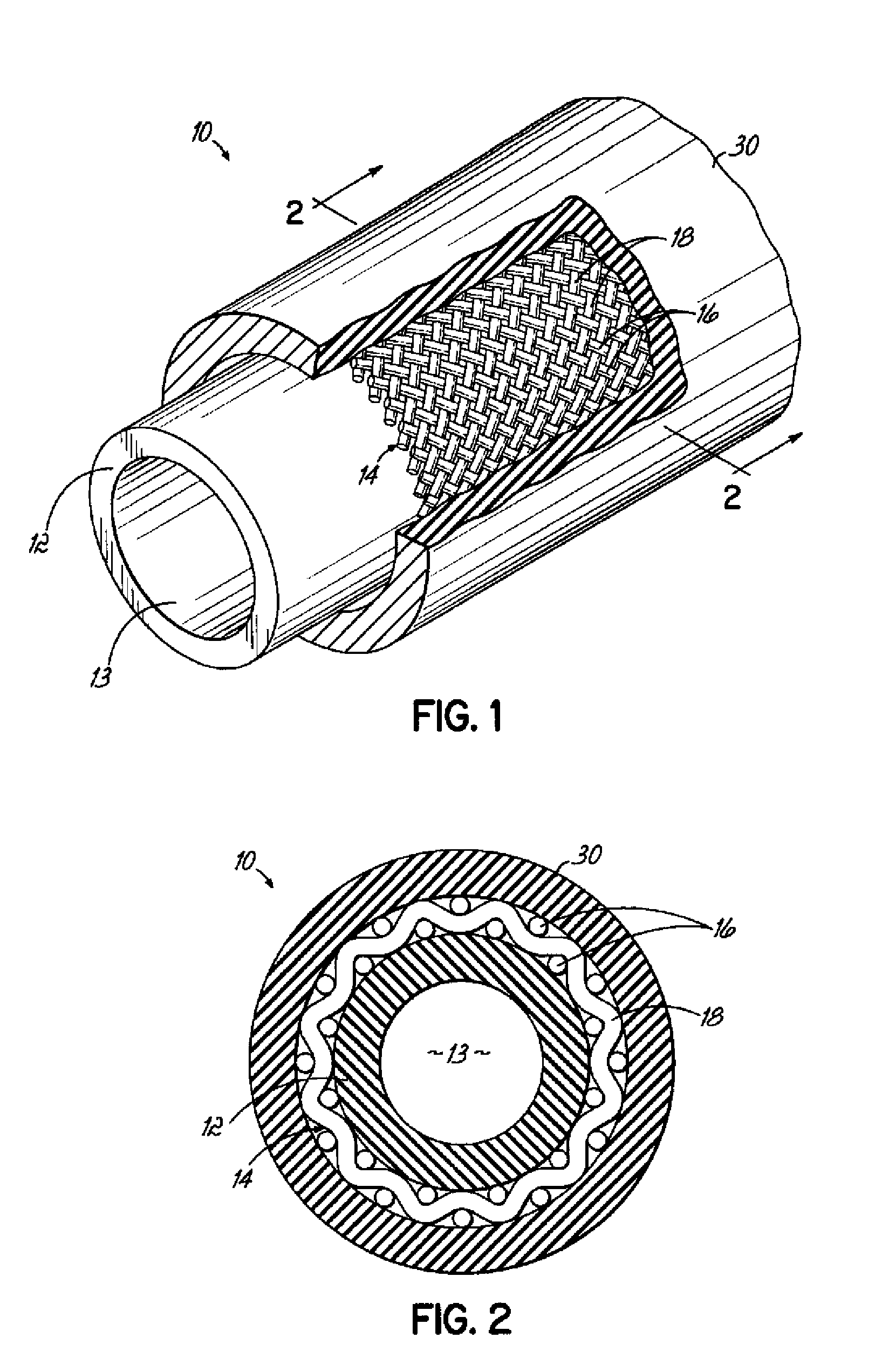

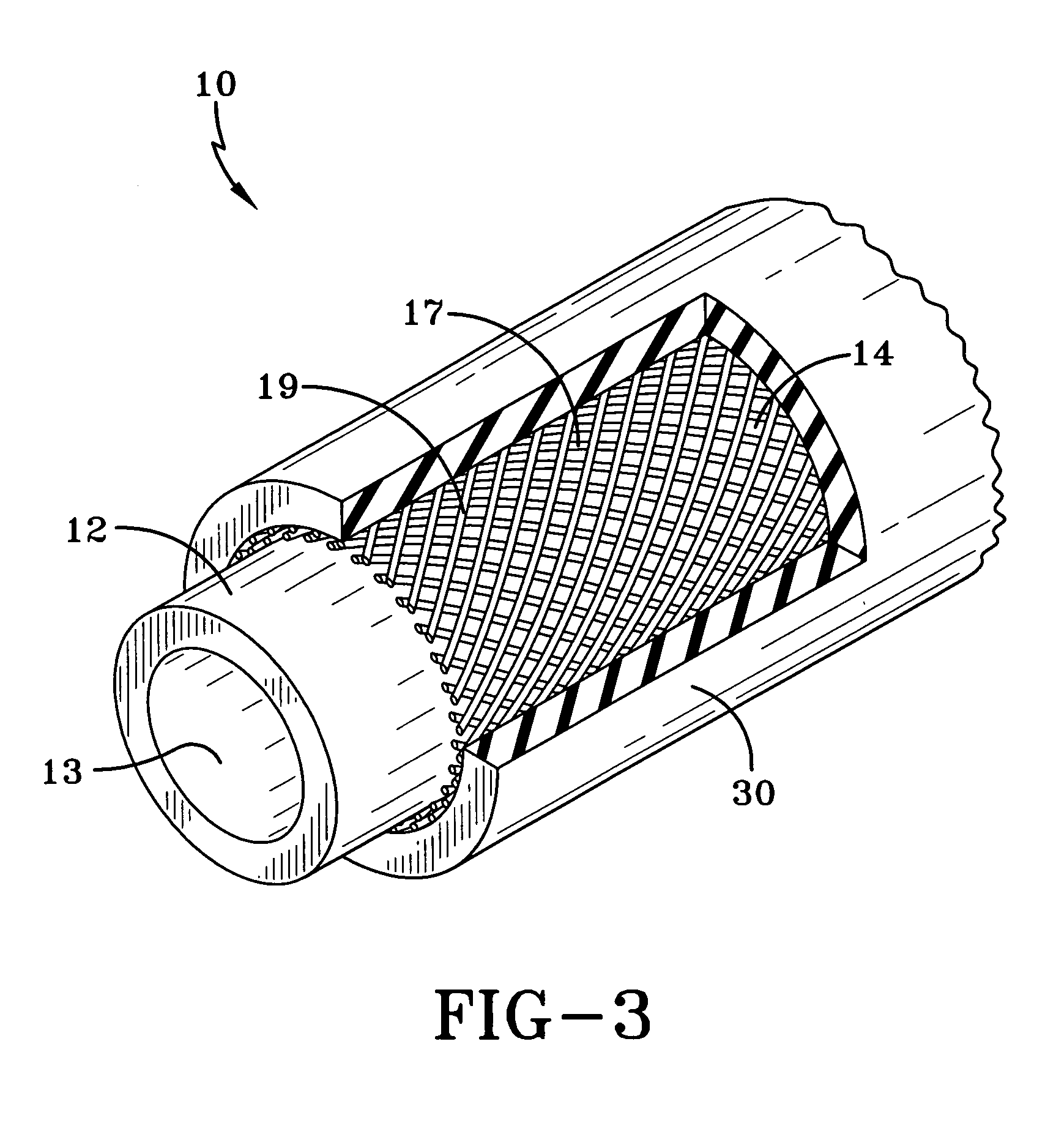

Fluid resistant high temperature hose

InactiveUS20120090720A1Improve the immunityWithout compromising flexural characteristic and burst strengthSynthetic resin layered productsFlexible pipesElastomerBursting strength

The present invention is based on the unexpected discovery that the fluid resistance of hoses can be greatly enhanced by adding a chlorinated paraffin to a chlorinated polyethylene elastomer or a chlorosulfonated polyethylene elastomer which is used as the tubular inner core layer of the hose. Hoses made using this approach offer the advantage of having improved resistance to modern automotive fluids, including power steering fluid, transmission fluid, and the like, without compromising flexural characteristics or burst strength. Accordingly, the hoses of this invention provide a longer service life and better reliability then hoses made utilizing conventional technology. The present invention more specifically discloses a hose which is comprised of (1) an elastomeric tubular inner core layer defining a lumen, (2) a friction layer, and (3) an elastomeric cover, wherein the elastomeric tubular inner core layer is comprised of (i) a chlorinated elastomer selected from the group consisting of epichlorohydrin, polychloroprene, chlorinated polyethylene and chlorosulfonated polyethylene, (ii) 1 phr to 50 phr of a chlorinated paraffin, and (iii) 30 phr to 120 phr of carbon black. It is typically preferred for the chlorinated elastomer to be chlorinated polyethylene or chlorosulfonated polyethylene.

Owner:CONTITECH USA INC

Thermal weld EPT rubber water-proof coiled material

InactiveCN101486892AHigh bonding strengthOther chemical processesRoof covering using flexible materialsParaffin waxSulfur

The invention discloses a thermal welding ethylene-propylene-diene rubber waterproof coiled material which is produced by raw materials of POE, ethylene-propylene-diene rubber, APP, light calcium carbonate, carbon black, chlorinated paraffin wax, DOP, sulfur, anti-aging agent and TMTD; the raw materials are put into a banburying device; the banburying time is 12 minutes, and the banburying temperature is 130 to 150 DEG C; the mixing is even; discharging is carried out, and the glue is poured on a 560 mill; strip discharging is carried out after the temperature is reduced to lower than or equal to 90 DEG C; the impurities are filtrated by a glue filtering machine and strip discharging is carried out after thinning and even mixing are carried out on a 450 mill; extrusion molding is carried out by an extruder; the molded coiled material goes through a continuous vulcanizing tank with the length of 20 meters and is vulcanized under 160 DEG C and 0.3 MPa, and then the finished product is produced; and the waterproof coiled material is an integrated waterproof layer which improves the adhesive strength.

Owner:曹天志 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com