Burnthrough-resistant water-based fire retardant glue for spinning

A kind of flame retardant glue, water-based technology, applied in the direction of fire retardant coatings, coatings, etc., can solve the problem of high flame retardant cost, increase the coating amount of flame retardant glue, affect the flame retardant of flame retardant and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

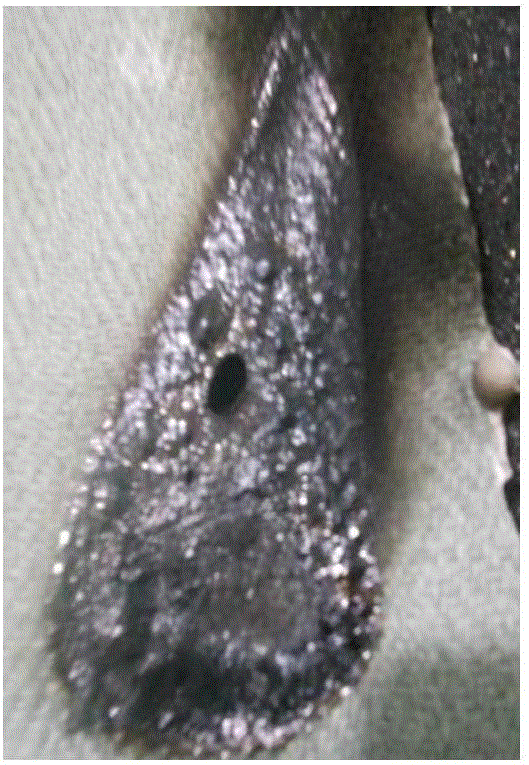

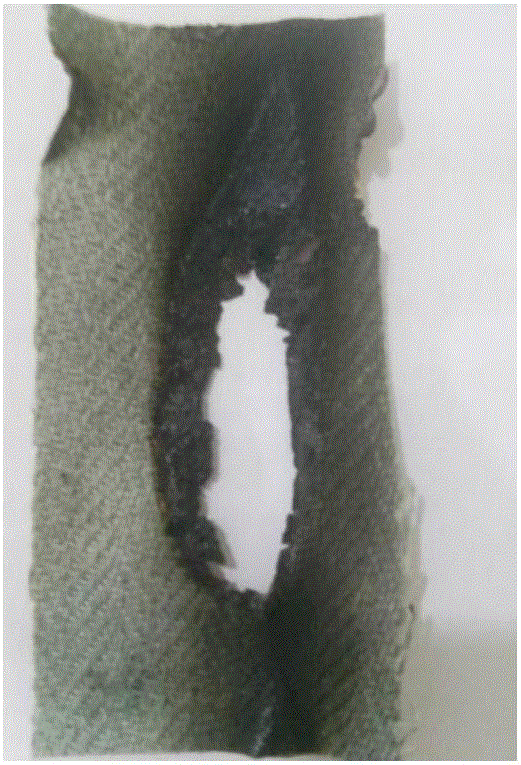

Image

Examples

preparation example Construction

[0073] The preparation steps of described polyacrylate are as follows:

[0074] (1) Mixing of raw materials: Add hydroxyl-containing acrylic resin, 1-isocyanato-3-isocyanatomethyl-3,5,5-trimethylcyclohexane, dibutyltin dioctoate, tert- Dodecyl mercaptan is uniformly mixed in a certain proportion, and the usage amount of the dibutyltin dioctoate is 0.1wt%;

[0075] (2) Polymerization reaction: add a certain amount of toluene in the reaction vessel, heat to the reflux state, keep the reflux state, and add the monomer mixture dropwise at a uniform speed in the reaction vessel, and the dropwise addition is completed within 3 hours, then adjust the reaction material to 80 ℃, and keep warm for 1 hour;

[0076] (3) Post-treatment: Use atmospheric pressure and vacuum distillation to remove the solvent, pour the material into an aluminum tray while it is hot, and cool to obtain the polyacrylate.

[0077] In the present invention, the isocyanate group of the polyfunctional isocyanate ...

Embodiment 1

[0142] A burn-through-resistant water-based flame-retardant adhesive for textiles, comprising: 60 parts of ethylene-vinyl acetate copolymer emulsion, 10 parts of polyacrylate emulsion, 30 parts of silicone modified polyurethane emulsion, 25 parts of ethylene Bistetrabromophthalimide, 30 parts ammonium polyphosphate (EPFR-APP241), 10 parts resorcinol bis(diphenyl phosphate), 5 parts antimony trioxide, 0.6 parts AEO-9, 1 part of sodium polyacrylate, 0.6 part of coupling agent 551, 0.4 part of hydroxyethyl cellulose, 0.6 part of sodium hydroxide, 8 parts of acrylic acid amide, 6 parts of triethyl citrate, 36 parts of water; the ethylene-vinyl acetate The solid content of the copolymer emulsion is 54.5%; the solid content of the polyacrylate emulsion is 30%; the solid content of the silicone modified polyurethane emulsion is 45%; the water-based adhesive (60 parts of ethylene-vinyl acetate copolymer emulsion, 10 parts of polyacrylate emulsion, 30 parts of silicone modified polyure...

Embodiment 2

[0156] A burn-through-resistant water-based flame-retardant adhesive for textiles, comprising: 70 parts of ethylene-vinyl acetate copolymer emulsion, 10 parts of polyacrylate emulsion, 20 parts of silicone modified polyurethane emulsion, 22.7 parts of tri( 2,3-Dibromopropyl) isocyanurate, 30 parts ammonium polyphosphate (EPFR-APP241), 5 parts resorcinol bis(diphenyl phosphate), 5 parts aluminum hydroxide, 0.6 parts AEO-9, 1 part of sodium polyacrylate, 0.6 part of coupling agent 551, 0.4 part of hydroxyethyl cellulose, 0.6 part of sodium hydroxide, 8 parts of acrylic acid amide, 6 parts of triethyl citrate, 36 parts of water; The solid content of ethylene-vinyl acetate copolymer emulsion is 54.5%; the solid content of the polyacrylate emulsion is 30%; the solid content of the silicone modified polyurethane emulsion is 45%; the water-based adhesive (70 parts of ethylene - The weight ratio of vinyl acetate copolymer emulsion, 10 parts of polyacrylate emulsion, 20 parts of silico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com