Patents

Literature

1201results about How to "Reduce heavy metal content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance water-based anticorrosion paint and preparation method thereof

InactiveCN102134410AReduce heavy metal contentImprove heat resistanceAlkali metal silicate coatingsAnti-corrosive paintsAviationWater based

The invention relates to a preparation method of high-performance water-based anticorrosion paint. The high-performance water-based anticorrosion paint comprises 30-60 parts of inorganic material resin, 0.5-30 parts of polyaniline-based nano composite material, 0-30 parts of curing agent, 0.1-1 part of defoaming agent, 0.1-1 part of dispersant and 0.1-1 part of leveling agent. Since the high-performance water-based anticorrosion paint does not contain organic resin or organic solvent, the paint has the advantages of heat resistance, wear resistance, weather resistance, oil resistance, fire resistance and environmental protection; the paint also has the advantages of simple preparation technique, strong binding force with metal, and low cost, can be cured at normal temperature, and can be widely used for corrosion protection in the fields of aviation, navigation, chemical engineering, electronics and the like.

Owner:济宁市产品质量监督检验所

Combined process for processing heavy oil

ActiveCN1844325AEasy to handleExtended service lifeTreatment with hydrotreatment processesKeroseneFuel oil

The invention discloses a group technology for heavy oil upgrading, in which the job steps include: (1) full or moiety of heavy oil individually or mixed with catalytic clarified oil entering solvent deasphalting plant, after the solvent deasphalting treatment, obtaining a deasphalted oil and a degreasing asphalt; (2) the degreasing asphalt obtained by step (1) individually or mixed with another moiety of heavy oil entering coking plant for coking treatment, in which the obtained tar heavy oil returns to solvent deasphalting plant or enters heavy oil hydrotreating plant, or moiety of tar heavy oil returns to solvent deasphalting plant and another moiety of tar heavy oil enters heavy oil hydrotreating plant, catalytic plant or hydrocracking plant; (3) the deasphalted oil obtained by step (1) individually or mixed with vacuum residual oil, non-pressure residual oil, pressure-relief residual oil, catalytic cycle stock and one or more than one heavy oil of tar heavy oil obtained by step (2) entering heavy oil hydrotreating plant for hydrotreatment, after hydrotreatment, obtaining fractions of benzin naphtha, plane kerosene and diesel and hydrogenating heavy oil. The invention can improve the charge-in nature, alleviate the operating condition and prolong the cycle length of the heavy oil hydrotreating plant, which provides better raw oil for downstream plants including catalytic plant.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

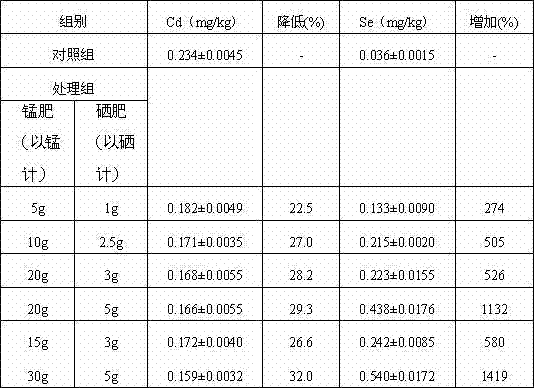

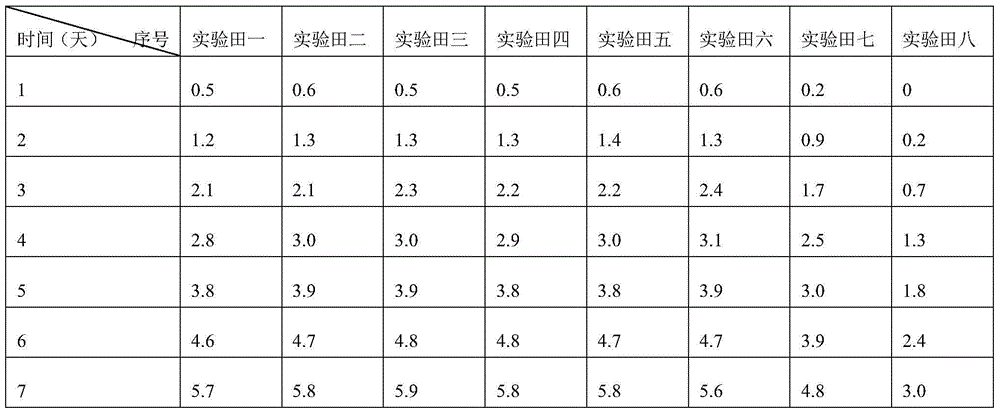

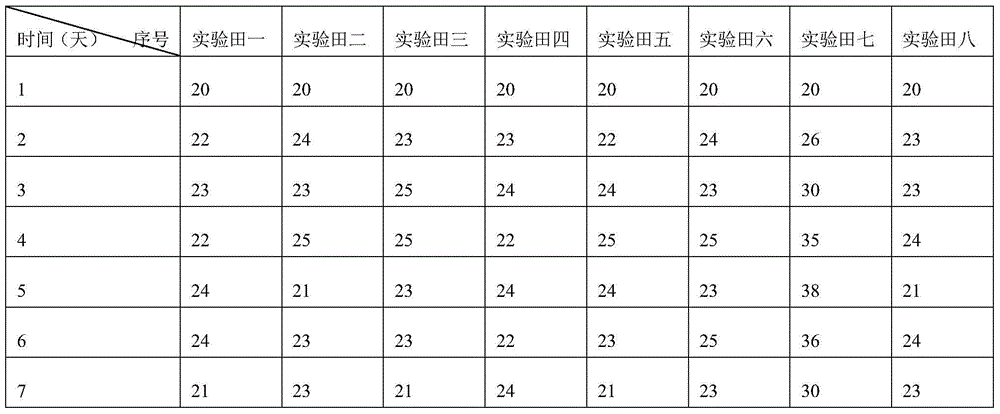

Method for reducing pollution caused by heavy metals including arsenic, lead, cadmium and mercury in paddy rice

InactiveCN102356739AReduce heavy metal contentNo pollution in the processFertilising methodsRice cultivationGramFertilizer

The invention discloses a method for reducing pollution caused by heavy metals including arsenic, lead, cadmium and mercury in paddy rice. The method comprises the following steps of: (1) spraying a bivalent manganese fertilizer in the amount of 2-30 grams per mu at the initial booting stage of paddy rice, and irrigating into a paddy field within 2-3 days; and (2) spraying a selenium fertilizer in the amount of 1-5 grams per mu at the full heading stage of the paddy rice. Due to the adoption of the method, the content of heavy metals in the paddy rice can be lowered, and the yield as well as the content of trace mineral nutritional elements in rice can be increased.

Owner:CHANGSHA SANYUAN AGRI TECH

A method for cultivating high-quality Pleurotus eryngii with waste mushroom residue

The invention discloses a method for culturing high-quality pleurotus geesteranus by using waste pleurotus eryngii residue. The method is characterized in that: when raw materials are prepared and treated, the culture material composition for production, namely the formula composition of raw materials, comprises the following raw materials in part by weight: 400 to 700 parts of waste pleurotus eryngii residue, 200 to 300 parts of sawdust, 300 to 500 parts of corn straw, 100 to 200 parts of cotton seed hull, 200 to 350 parts of bran, 10 to 20 parts of gypsum, 15 to 15 parts of lime, and 10 to 1 5 parts of white sugar. A proper amount of sodium selenite serving as a clearing auxiliary agent is added into each 100 kilograms of dry culture material. By the method, the waste is utilized, the cost of the raw materials is lowered, the resource waste is reduced, environmental pollution is lightened, the sources of the raw materials are easily solved, the process is simple, labor and effort are saved in management, and stable yield and high yield are achieved; and by adding a little amount of sodium selenite (Na2SeO3) serving as the clearing auxiliary agent, the cadmium content of the pleurotus geesteranus finished product is reduced, and the production and the export scale are enlarged.

Owner:INST OF SOIL & FERTILIZER FUJIAN ACADEMY OF AGRI SCI

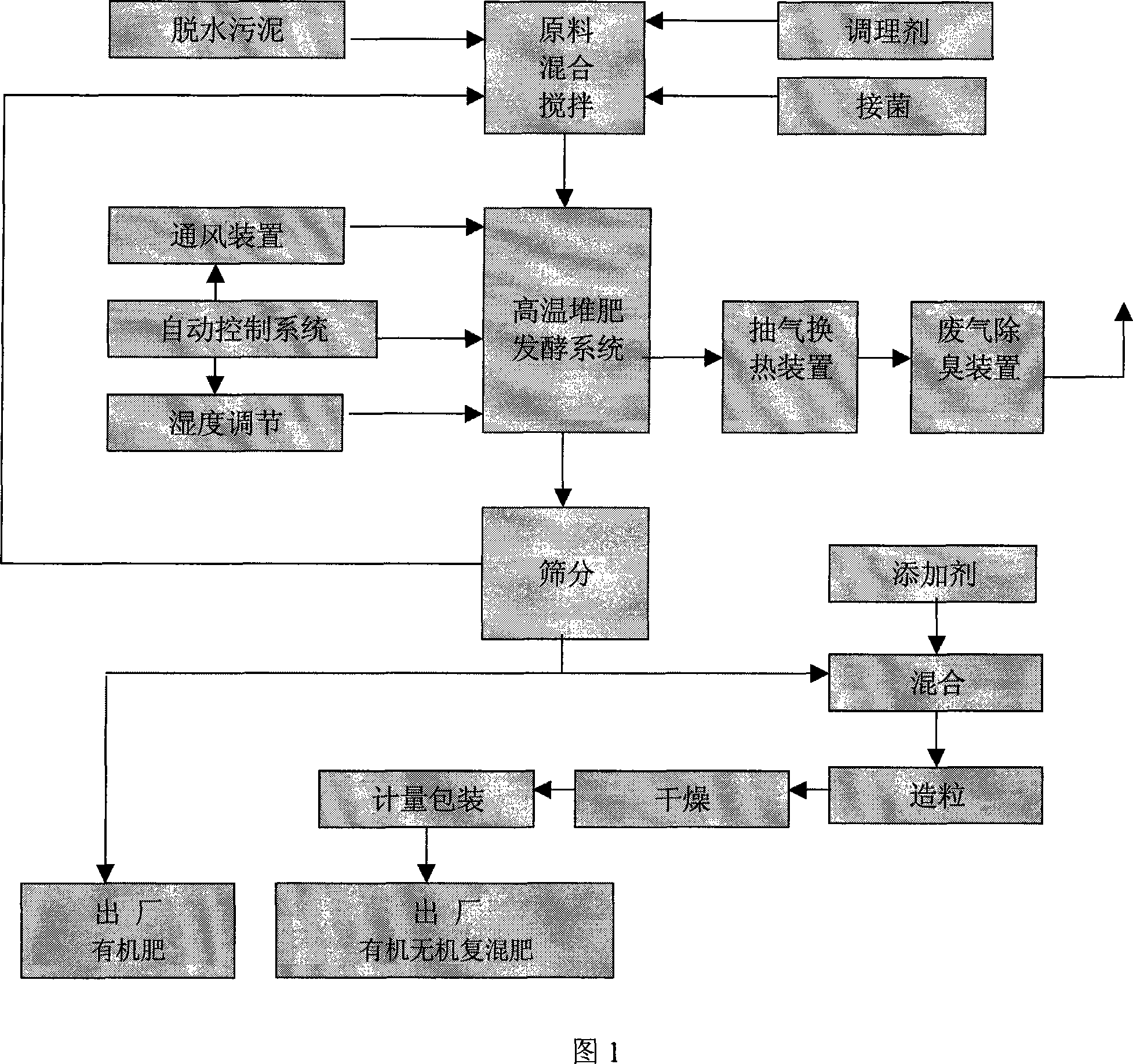

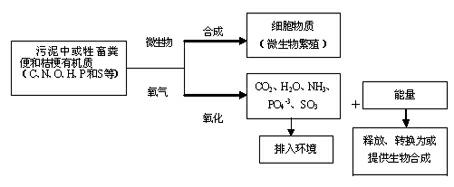

Method for producing compost

InactiveCN101215199AImprove resistance to pests and diseasesWide variety of sourcesBio-organic fraction processingOrganic fertiliser preparationOrganic baseOrganic content

The invention relates to a process for producing organic fertilizers, in particular to a process for producing composts by employing the method of compost fermentation, wherein the process comprises: selecting filthy mud as main fermenting raw materials, adding a conditioner in the filthy mud to adjust the carbon nitrogen ratio between 15 and 30, then adding catalytic bacteria, finally performing compost fermentation, wherein the conditioner is capable of employing castoffs as animal wastes, sawdust, wooden meals, traditional Chinese medicine dregs, straws, leave and the like and the castoffs have rich organic contents. The nutrition composition of organic base material which are fermented is more reasonable via controlling carbon nitrogen ratio in the invention, and the invention uses filthy mud which urgently needs to be handled to replace the conventional night soils and straws to be main raw materials of the composts, changes waste into valuable, and has certain effect for improving urban environment.

Owner:HANGZHOU NORMAL UNIVERSITY

Porous composite material for removing heavy metals in soil and preparation method thereof

InactiveCN104525123AGood chemical stabilityHigh mechanical strengthAgriculture tools and machinesOther chemical processesPorous compositeOrganic molecules

The invention discloses a preparation method of a porous composite material for removing heavy metals in soil, which comprises the following steps: mixing an inorganic material and an organic material, molding, drying, sintering and the like to prepare a porous material substrate; activating the porous material with acid; and finally, in an organic or inorganic solution, treating the porous material with a silane coupling agent or any other organic molecule with adsorption, complexing and chemical linkage function on heavy metals to obtain a functional molecular layer, thereby obtaining the required porous composite material. The porous composite material has the characteristics of high selectivity for heavy metals and high adsorption efficiency when being used for remediating heavy-metal-containing soil. The porous material has the advantages of low consumption and long service life (up to 3-5 years). The technique can be widely used for remediating farmland or cultivated soil without influencing the normal cultivation and production of crops.

Owner:格丰科技材料有限公司

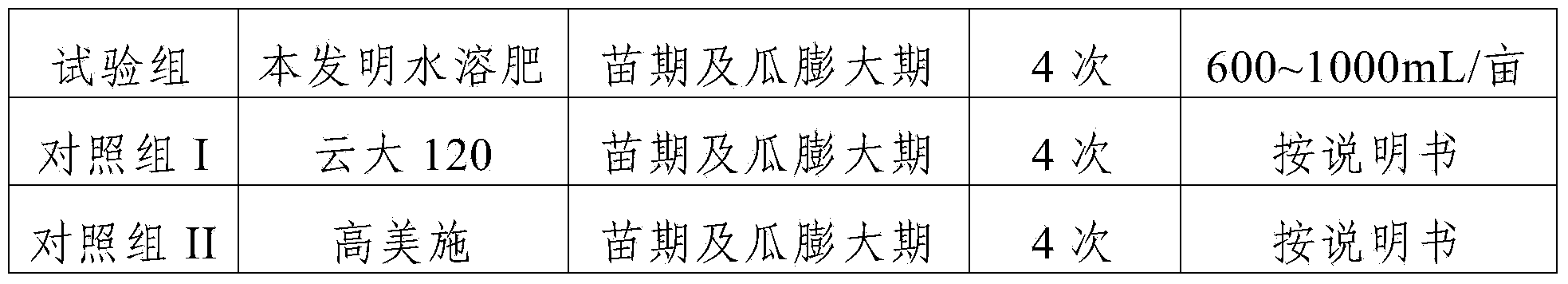

Water soluble fertilizer containing high-concentration humic acid and preparation method thereof

ActiveCN103408373AImprove buffering effectReduce heavy metal contentFertilizer mixturesDipotassium hydrogen phosphateHigh concentration

The invention provides a water soluble fertilizer containing high-concentration humic acid. The water soluble fertilizer comprises, by weight, 15-25 parts of a water soluble humic acid salt, 18-25 parts of urea, 9-15 parts of dipotassium hydrogen phosphate, 8-13 parts of potassium acetate, 0.5-2 parts of borax, 0.1-10 parts of polyglutamic acid, 1-5 parts of rhamnolipid, 5-10 parts of a hydroxymethyl cellulose aqueous solution and 30-40 parts of water. The water soluble fertilizer has humic acid content greater than or equal to 150g / L. The invention also provides a preparation method of the water soluble fertilizer containing high-concentration humic acid. The preparation method comprises the following steps of 1, carrying out heating stirring of the water soluble humic acid salt and water to obtain a humic acid salt solution, 2, adding dipotassium hydrogen phosphate, potassium acetate, borax, polyglutamic acid, rhamnolipid and urea into the humic acid salt solution, and carrying out heating stirring to obtain a mixed solution, and 3, carrying out emulsification of the hydroxymethyl cellulose aqueous solution and the mixed solution to obtain the water soluble fertilizer containing high-concentration humic acid. The water soluble fertilizer has obvious fertilizer efficiency, is environmentally friendly, stable and uniform and has a wide application range.

Owner:陕西鼎天济农腐殖酸制品有限公司

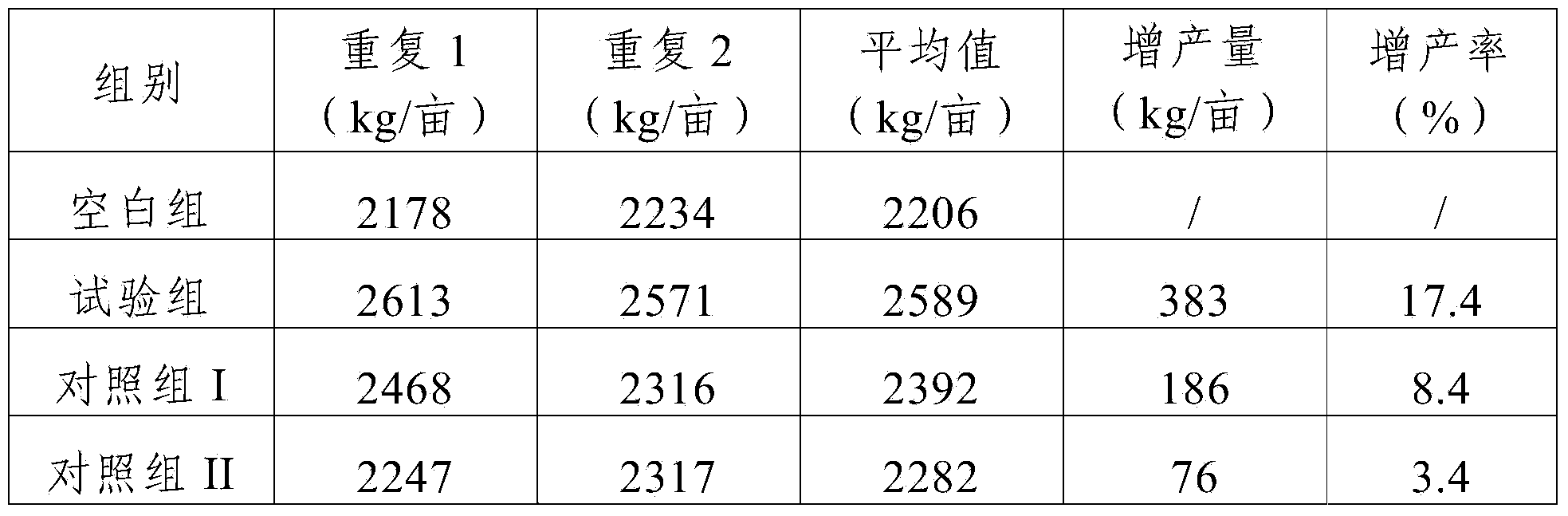

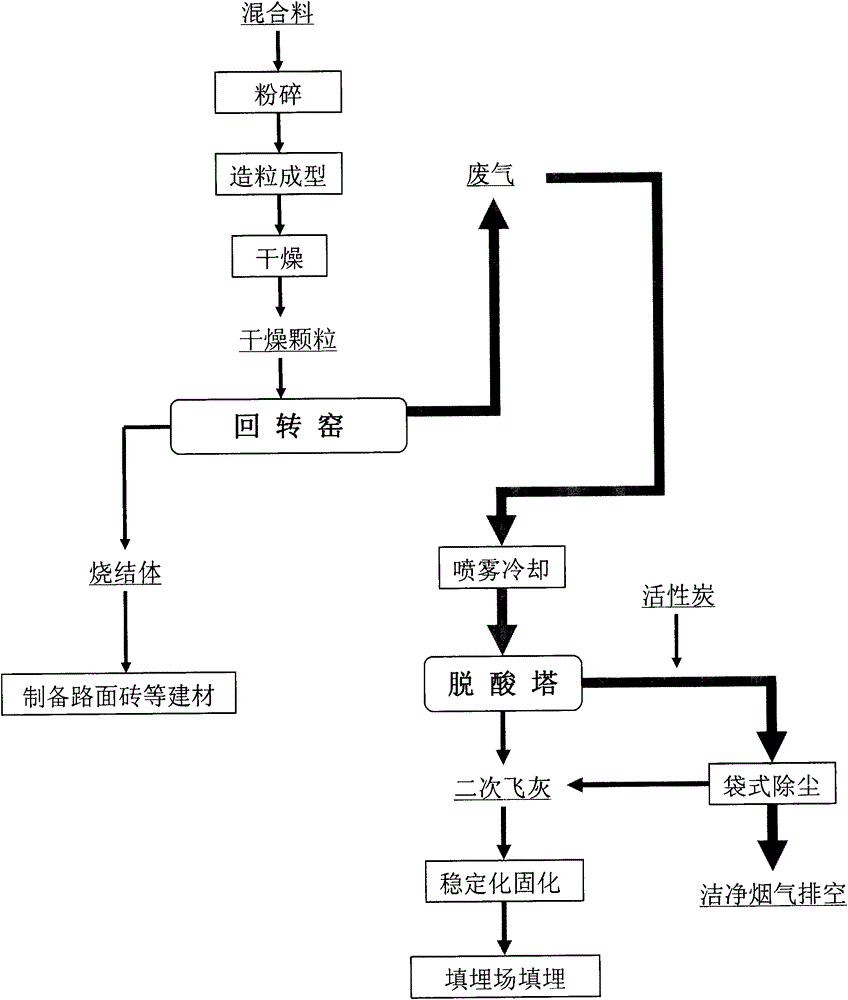

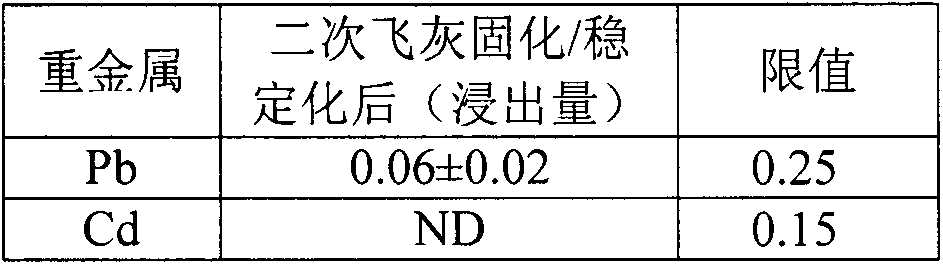

Garbage burning fly ash sintering harm-eliminating resource-utilization treatment system

The invention relates to a garbage burning fly ash sintering harm-eliminating resource-utilization treatment technology. According to the invention, garbage burning fly ash is mixed with premixed coal and auxiliary materials; the mixture is granulated and shaped; and the material is dried and is sintered in a rotary kiln. During the sintering process, when the temperature is increased and a coal ignition point is reached, the premixed coal is spontaneously combusted. Therefore, external coal dose can be reduced. Initial combustion of the premixed coal can provide a reductive atmosphere, such that dechlorination and detoxification of dioxin in fly ash can be benefited. Large amount of gas is produced by subsequent combustion, such that dust pores and holes are produced on inner and outer parts of the sintered body, and heavy metal volatilization can be promoted, and fly ash sintered body with low heavy metal content and leaching amount can be obtained. The sintered body has no potential harm to the environment, such that fly ash harm-eliminating and resource-utilization are sufficiently realized. During the processing process, smoke and secondary fly ash production amounts are low, and heavy metal and acidic component contents are high. In deacidification and heavy metal stabilization processes, agent utilization rate is improved. Compared with a traditional original fly ash curing / stabilizing process, a landfill amount can be reduced by 80-90%, such that pressure caused by serious landfill space shortage can be effectively relieved.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

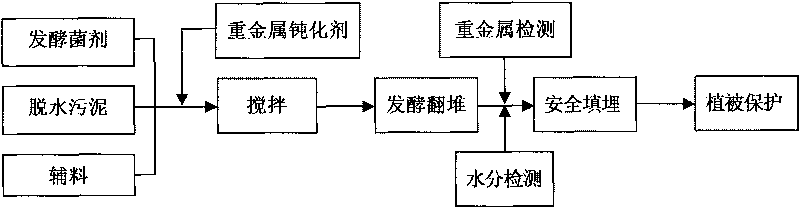

Method for treating sludge with heavy metals exceeding standard

InactiveCN101708936AReduced penetrationReduce land footprintSludge processingBiological sludge treatmentWater contentHelminth egg

The invention discloses a method for treating sludge with heavy metals exceeding the standard. The method comprises the following steps: mixing 2300 parts by weight of the sludge with water content of 80% (weight percentage) or below and heavy metal content exceeding the standard, 4.6-6.9 parts by weight of aerobic microbial agent, 690-805 parts by weight of auxiliary material and 184-276 parts by weight of heavy metal passivating agent and carrying out fermentation for 15-20 days for obtaining the sludge after the treatment; the aerobic microbial agent comprises the active ingredients of Bacillus subtilis, Bacillus stearothermophilus, Aspergillus niger, thermophilic sporotrichum and Saccharomyces cerevisiae; and the auxiliary material is one or any combination of shale, peat, sawdust, coco peat or cassava residue. The purpose of adding the aerobic microbial agent is to kill harmful microbes, pathogen and helminth eggs in the materials, decompose toxic and harmful organic matters and realize reduction, stabilization and harmless treatment of the materials; and the addition of the heavy metal passivating agent can transform the heavy metal form without causing the direct damage to organisms. The sludge after the treatment can be used for safe landfill, soil can be covered on a landfill field, and plants can be grown in the soil, thereby beautifying the environment and improving the ecology.

Owner:海南农丰宝肥料有限公司

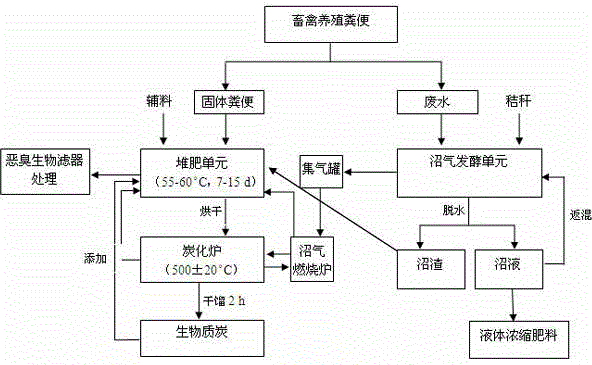

Resource utilization method of livestock and poultry breeding wastes

ActiveCN104150987AHigh calorific valueReduce moisture contentBio-organic fraction processingClimate change adaptationFecesResource utilization

The invention discloses a resource utilization method of livestock and poultry breeding wastes. The method comprises the following steps of carrying out solid-liquid separation on livestock and poultry breeding wastes to obtain solid manures and breeding wastewater, composting solid manures at a high temperature and carbonizing to prepare biomass carbon and carrying out biogas fermentation on the breeding wastewater and concentrating to obtain a liquid fertilizer. By adopting the method disclosed by the invention, livestock and poultry breeding wastes are subjected to optimal utilization in form of material and energy to obtain biomass carbon and the concentrated liquid fertilizer capable of being applied to the agricultural production and thus the resource utilization of wastes is achieved, and the recycling of resources can be realized inside a livestock and poultry breeding wastes treatment region to achieve the purposes of reducing energy consumption and pollutant emission.

Owner:ZHEJIANG UNIV

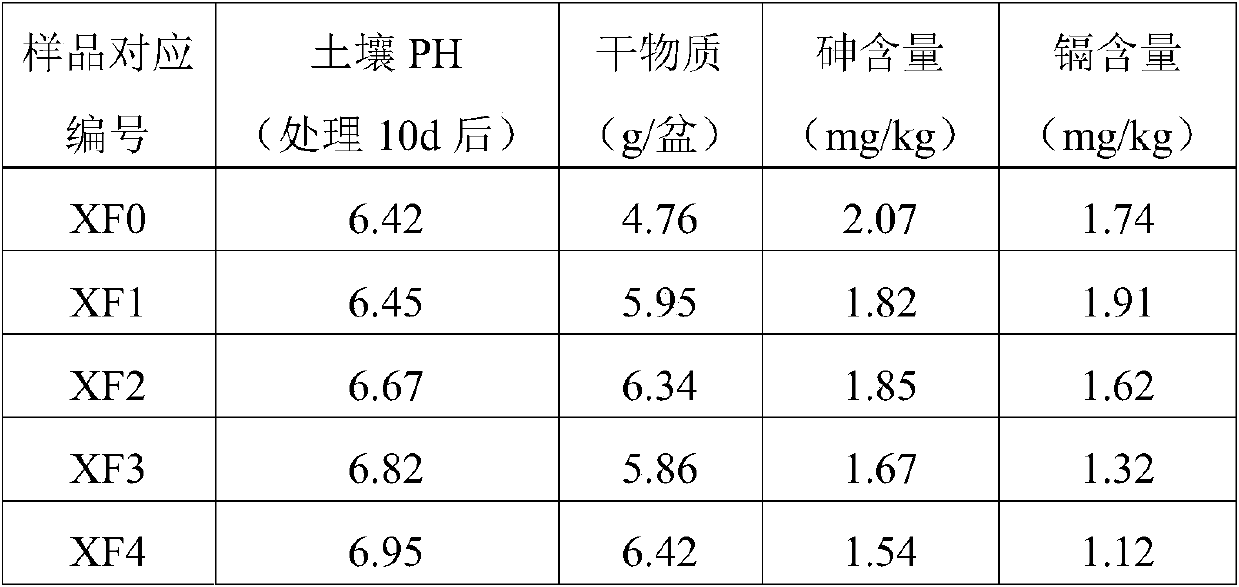

Mineral-based soil remediation agent, and preparation method thereof

ActiveCN107652976ARealize comprehensive utilizationRaise the pHAgriculture tools and machinesOther chemical processesSolubilitySoil remediation

The invention provides a mineral-based soil remediation agent, and a preparation method and application thereof. The mineral-based soil remediation agent is prepared by mixing calcium raw materials, sodium raw materials and silicate minerals, and then performing calcination and crushing; or further performing water immersion treatment on the mineral-based soil remediation agent, then performing solid-liquid separation, and then drying the obtained solid. The effective silicon content (solubility in citric acid) in terms of SiO2 is more than or equal to 20 wt%, and the effective calcium contentin terms of CaO is more than or equal to 40 wt%, and the content of harmful elements such as Hg, As, Cd, Pb and Cr is lower than 50 ppm.

Owner:HUNAN LONGE GALLOP TECH CO LTD

Slow control release biological inorganic and organic mixed fertilizer

InactiveCN101805227AMeet nutrient needsNutritional diversityFertilizer mixturesMicrobial agentPotassium

The invention belongs to the field of agriculture, which relates to a slow control release biological inorganic and organic mixed fertilizer. The mixing fertilizer is prepared by fully mixing the following components in percentage by weight: 3%-10% of beneficial microbial agent, 0.4%-1% of fertilizer slow control release agent, 5%-12% of organic matter, 0.2%-10% of plant growth stimulin, 15%-25% of nitrogen, 5%-12% of phosphorus, 6%-15% of potassium, and 2%-10% of middle trace element. The invention not only has the advantages of high nutrient concentration and simple production process, but also can enhance the utilization rate of the fertilizer, save the fertilizer, increase the output, improve the soil, and promote the sustainable development of agriculture and environment protection.

Owner:HEILONGJIANG JINSHIDA AGRI TECH DEV

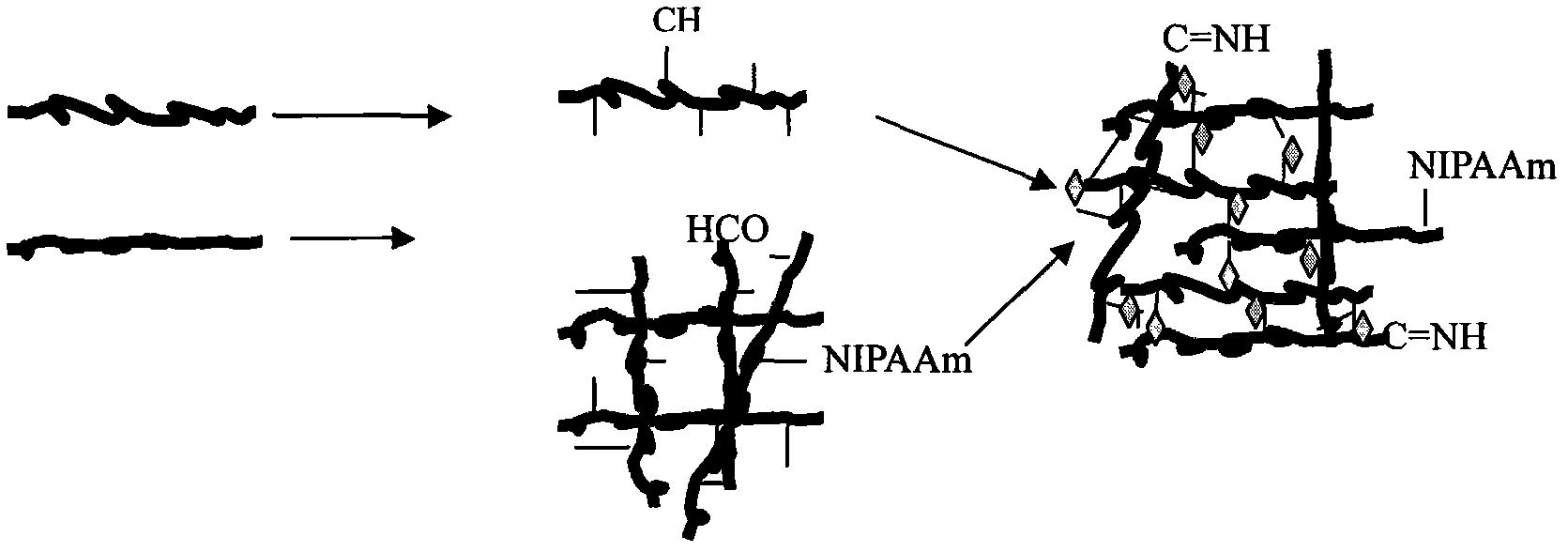

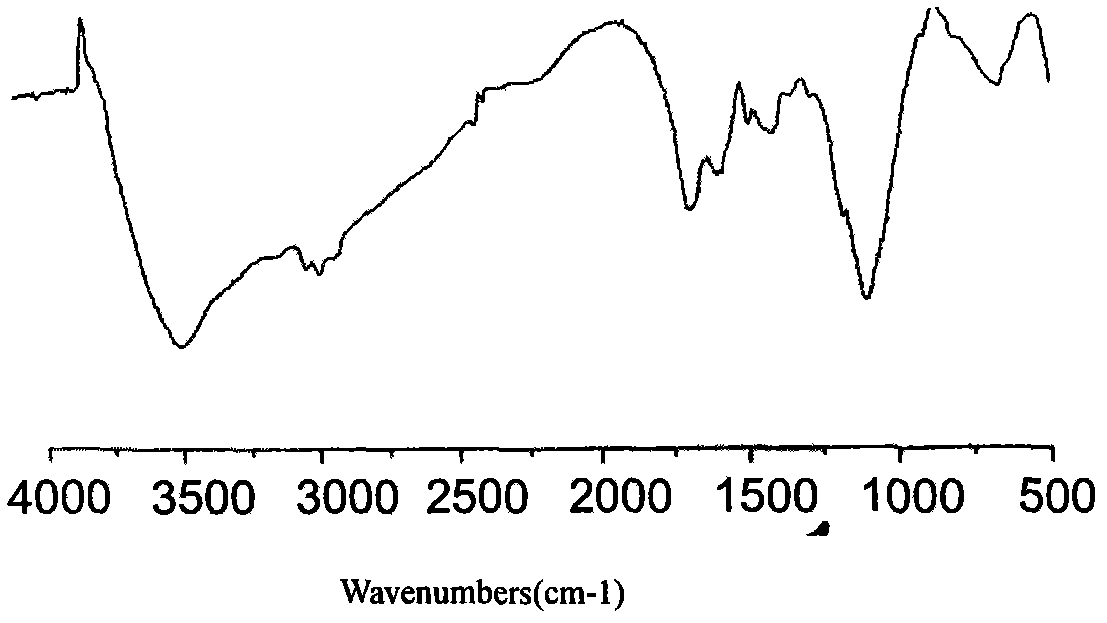

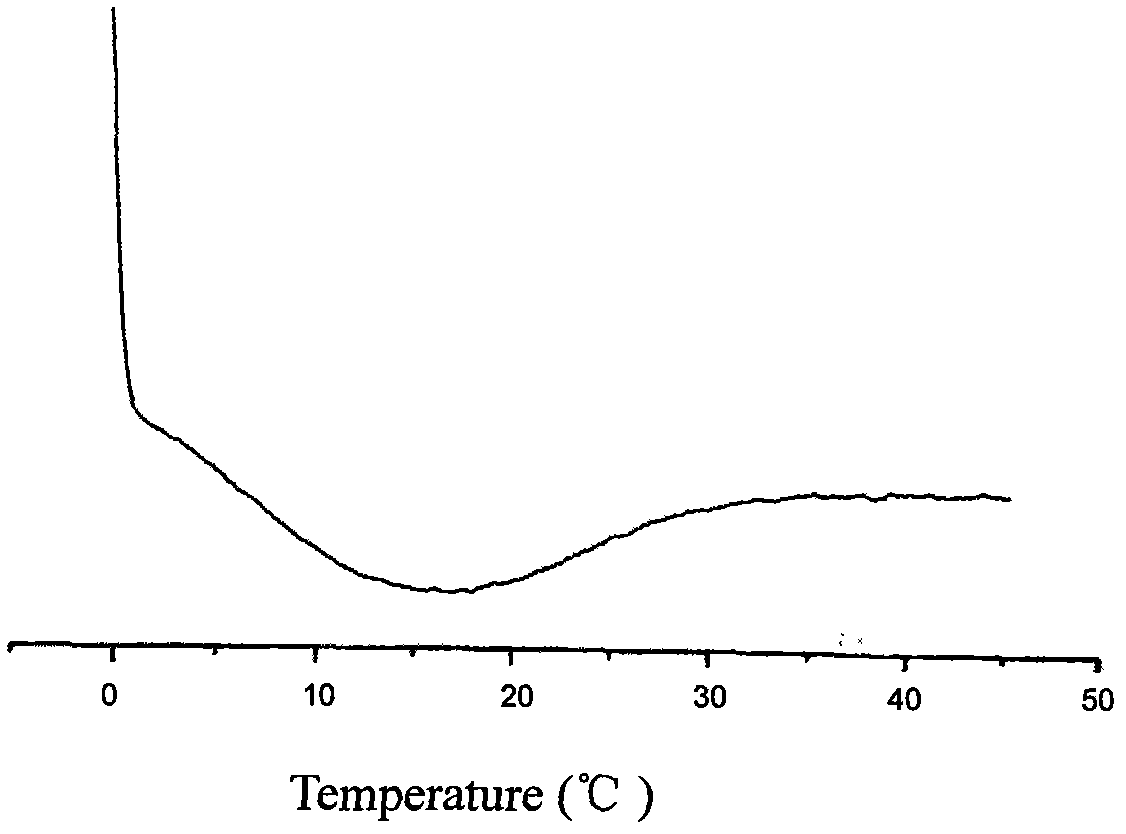

Injectable temperature sensitive gel used for filling and repairing damaged tissues

The invention relates to an injectable temperature sensitive gel used for filling and repairing damaged tissues. The gel is characterized in that: medical-grade hyaluronic acid and chitosan are used as gel raw materials; the gel swelling ratio is 2-500; and a temperature sensitive temperature is 32-37 DEG C. The gel provided by the invention has the advantages that the injection temperature sensitive gel has physical and chemical properties of a general gel, also has injectable and temperature sensitive properties and a good fluidity at a room temperature and is easy for injection; the formability in organisms is good and the degradation is slow so that the general gel can not be compared; a cross-linking agent is not used for the gel so that harms of the cross-linking agent to a human body are avoided; a gel system can prolong a persistence time of the gel in a body, and also can continuously stimulate the body to produce reactions so that the tissue in-situ regeneration and repair is promoted and the filling quality is increased; and the gel simultaneously has the advantages of reducing bacterial invansion, anticoagulation and low allergic reaction and the like.

Owner:冯淑芹

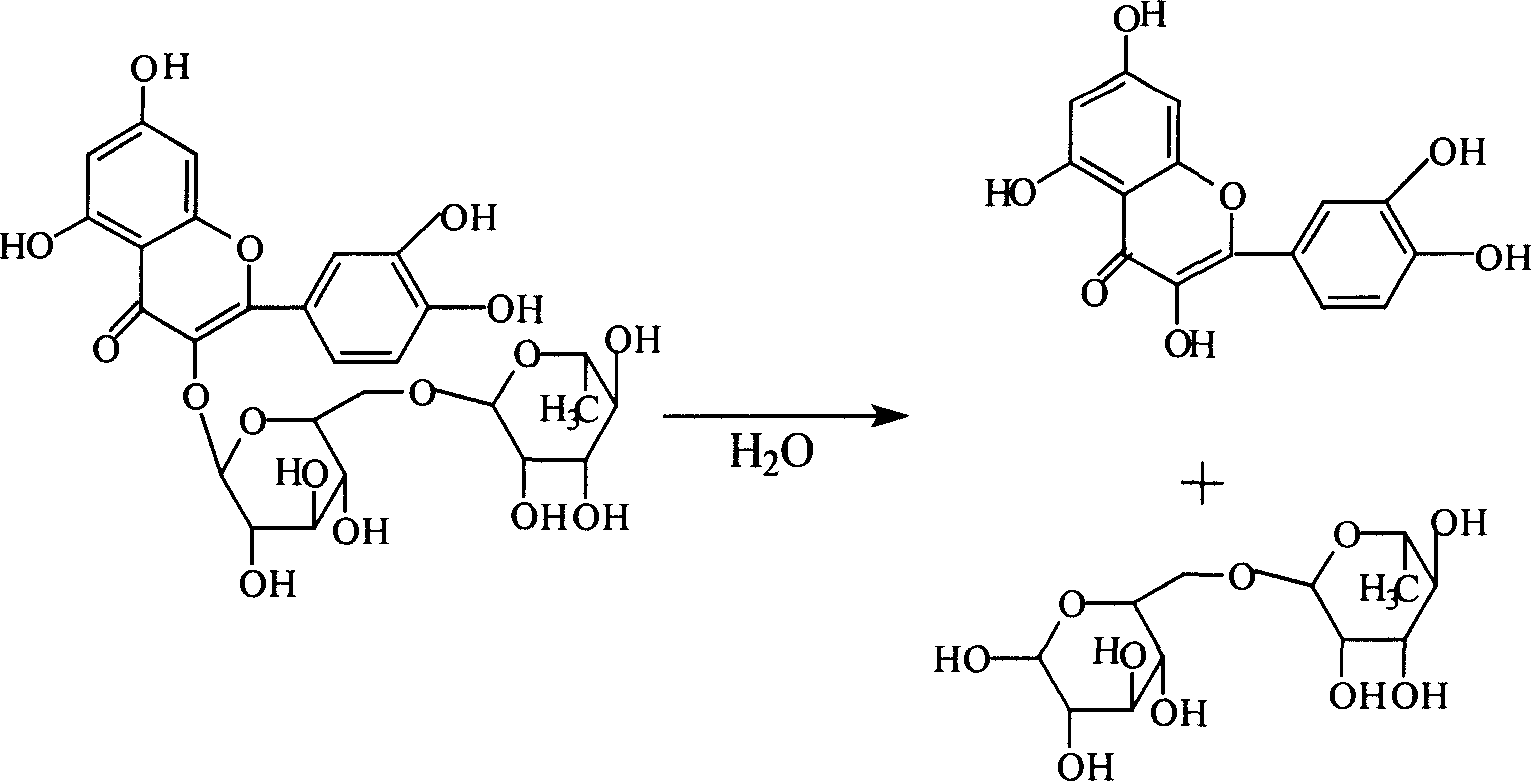

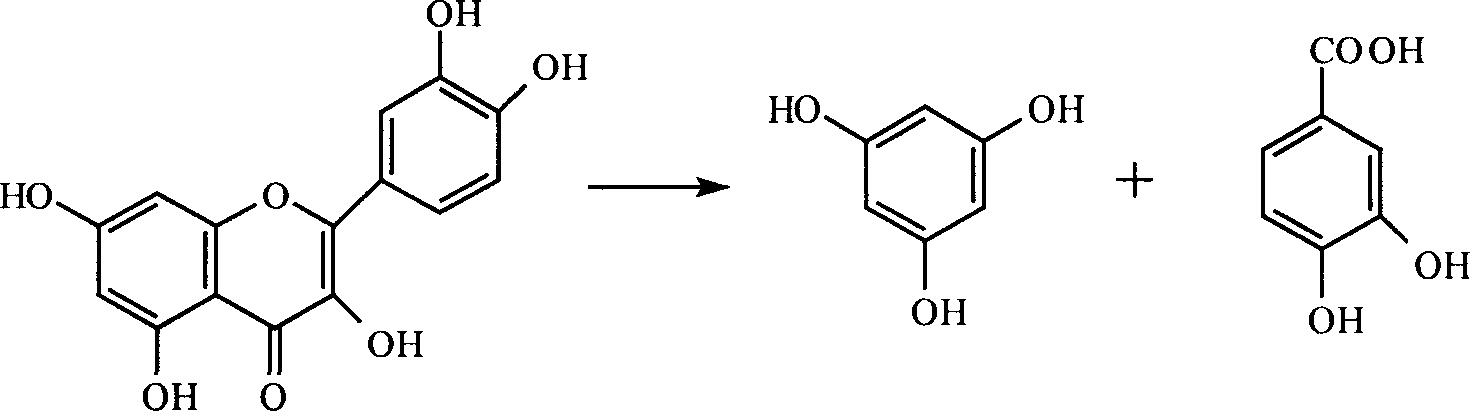

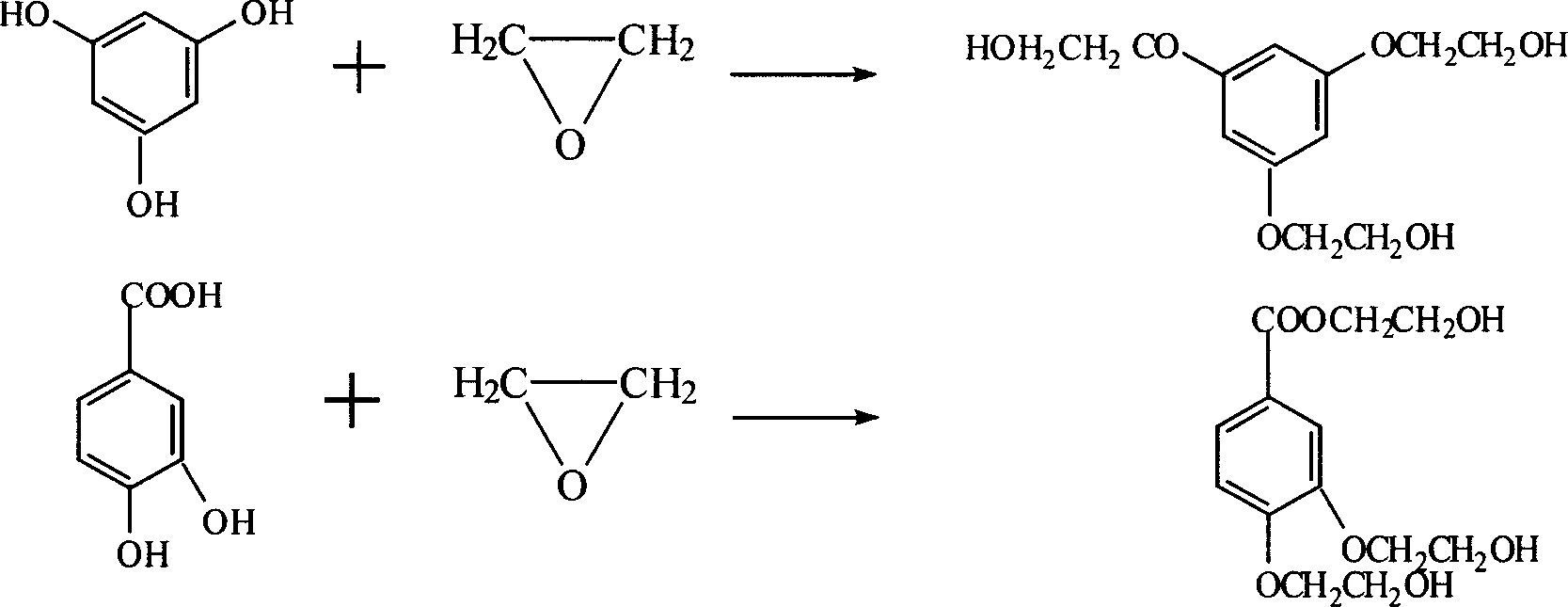

Method for preparing high-content troxerutin drug

ActiveCN1814613AHigh content and yieldReduce dosageOrganic active ingredientsSugar derivativesDrugSodium hydroxide

The invention offers 3', 4', 7-troxerutin synthetic method. It uses rutin and ethylene oxide to do hydroxyethylation reaction under the catalyzing of sodium hydroxide. Its features are that in the reaction, the weight ratio of rutin and water is 1:1-1:3; optimization is 1:1-1:1.5; the weight ratio of rutin and sodium hydroxide is 100:0.82-100:0.85; adding resin when the pH value of the reaction solution is 9.0-9.5 to adjust end point pH value to 9.5-10.3. The method can make high purity and high quality troxerutin. And its 3', 4', 7-troxerutin content is more than 78%; optimization is more than 80%; and the more optimization is more than 85%.

Owner:TOPFOND PHARMA CO LTD

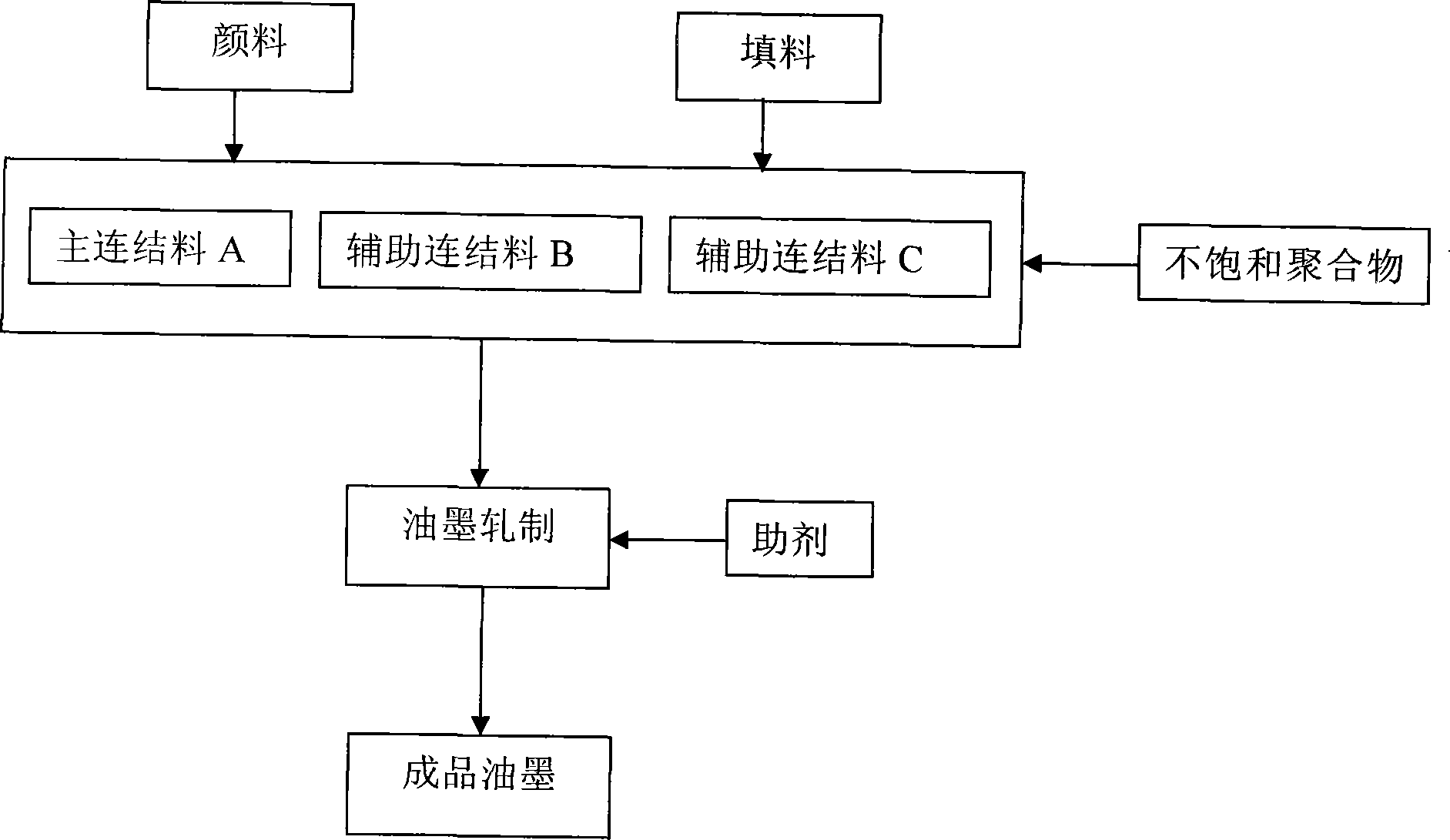

Soybean oil based protruding printing ink

ActiveCN101250350AImprove rheologyIncrease elasticityInksOther printing apparatusVegetable oilLetterpress printing

The invention relates to soybean oil base letterpress printing ink, which adopts modified phenolic with high viscosity and high dissolving ability, prepares resin oil through matching soybean oil with Chinese wood oil, regulates acid value with alkyd resin to improve appropriate hydrophilicity, uses gelatinizing agent to improve the rheological property of resin oil and increase elasticity, uses unsaturated polymer which can dissolve with vegetable oil to provide extra drying property as bonding material of printing ink. The printing ink solves the technical problem that harmful contamination in the air and the surface of printing which is caused by large amount of petroleum solvent comprised in current common letterpress printing ink can further dangers the health of producers and users, and has the advantages of small VOC content, low heavy metal content, excellent printability, set stability and processability after printed.

Owner:CHINA BANKNOTE PRINTING & MINTING

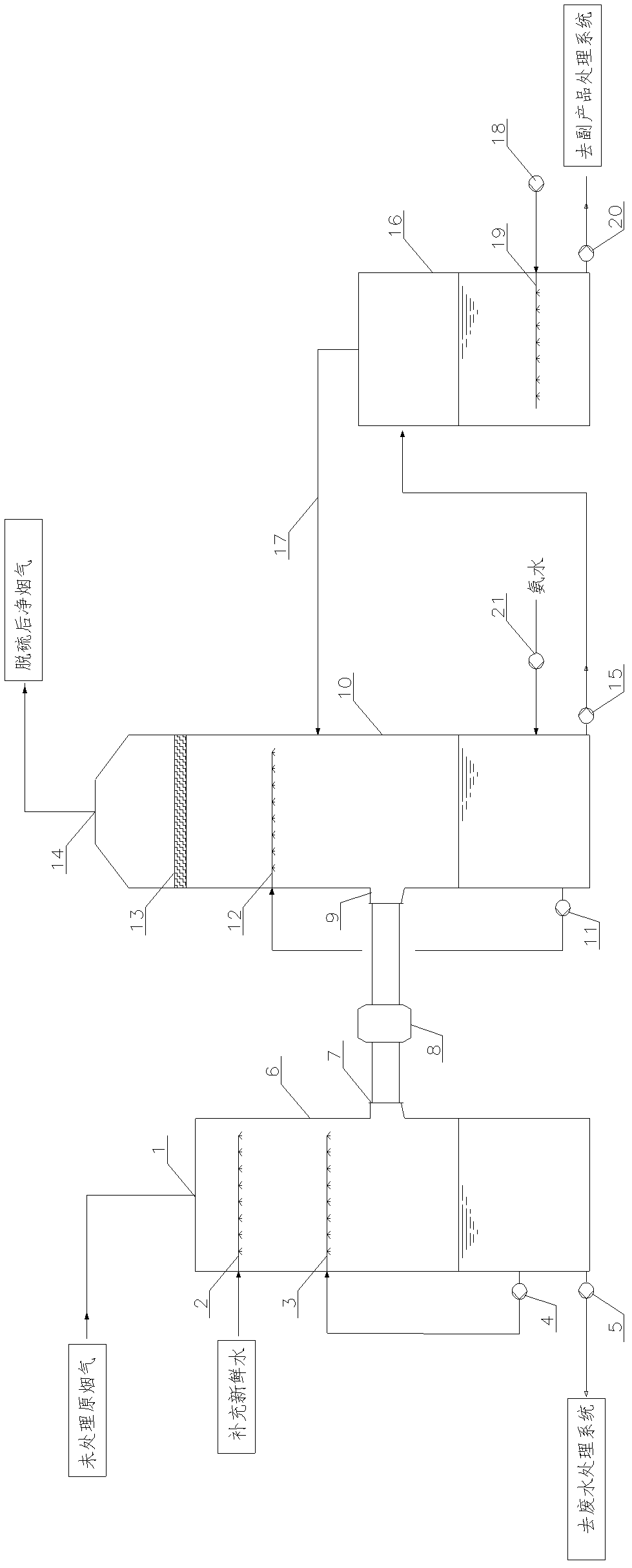

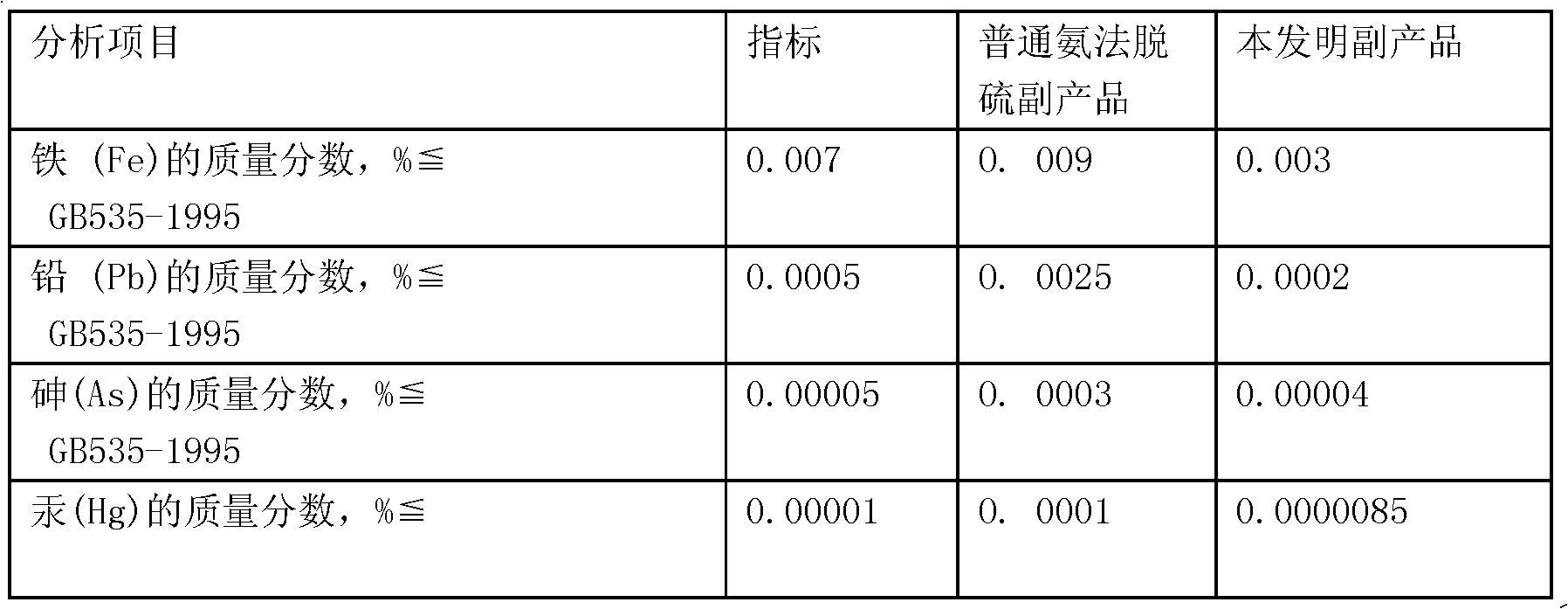

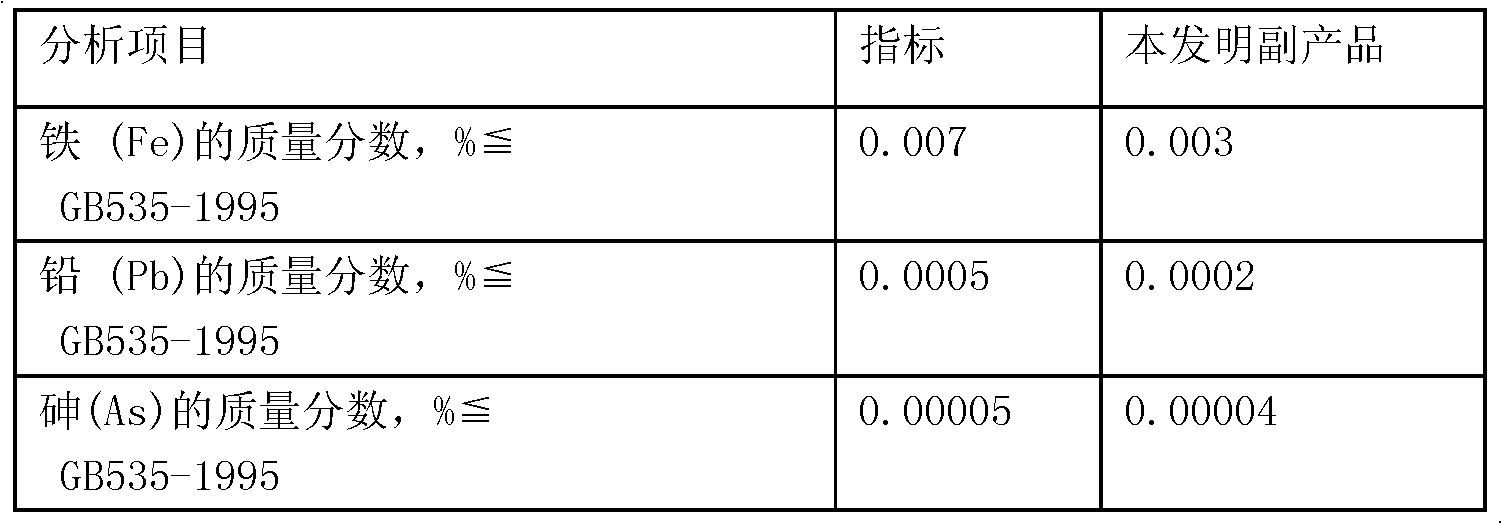

Ammonia desulfurization method for effectively removing chlorine and fluorine ions and heavy metal ions

InactiveCN102423613AAvoid secondary pollutionReduce heavy metal contentCombination devicesPerfluorocarbons/hydrofluorocarbons captureWater dischargeSlurry

The invention relates to an ammonia desulfurization method for effectively removing chlorine and fluorine ions and heavy metal ions. The invention is characterized in that prewashing is carried out before flue gas enters into a desulfurization tower, industrial water and / or circulating water can be used as washing liquid in a prewashing tower, circular spraying and washing are performed, 90-95% Cl<-> and F<-> in flue gas are removed, 70%-80% soluble metal ions Fe<3+>, Hg<2+> and Pb<2+> can be removed, 70%-80% of dust is removed, the washed pollutant is sent to a waste water treatment system through slurry-containing waste water discharged from the bottom of the tower for treating to reach the standard and then discharge. The ammonia desulfurization method of the invention can thoroughly eliminate the problems that severe equipment corrosion is caused by enrichment of Cl<-> and F<-> on the desulphurization system, and heavy metal of the finished product fertilizer exceeds the standard.The desulphurization byproduct ammonium sulfate fertilizer obtained by the method can reach or exceed the quality standard of the national standard superior products.

Owner:赵加勇

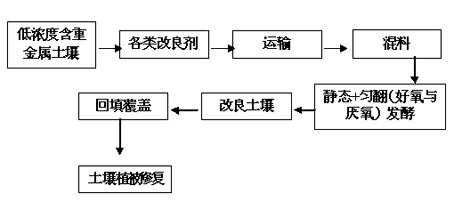

Method for comprehensively utilizing low-concentration heavy metal-containing soil improvement and repairing damaged soil by plants after detoxification of contaminated field

InactiveCN102319726AQuality improvementSimple structureContaminated soil reclamationSludgeAdditive ingredient

The invention relates to a method for comprehensively utilizing low-concentration heavy metal-containing soil improvement and repairing damaged soil by plants after detoxification of a contaminated field. The method comprises the following steps of: conveying of low-concentration soil after heavy metal-containing soil is detoxified, sludge and pulverized fuel ash; principal fermentation, mixing of various ingredients; primary fermentation; static state of post-fermentation (secondary fermentation); uniform turning (aerobic and anaerobic) fermentation; conveying of improved soil; and vegetation repairing (woody and herbaceous plants) planting for the contaminated soil. In the method, a modifier is added for modification, so that the content of heavy metals in the soil is reduced, the structure and pores of the damaged soil are repaired, and the permeation and air permeability of the soil are improved; and organic matters and other noxious matters in sludge and soil are decomposed and degraded in a certain condition by utilizing microbes in the sludge to reduce volume weight and compactness, so that the improved soil forms a substance similar to humus soil to serve as a biochemical process of the improved soil and fertilizer. According to the method, the planted vegetation growing environment of the land which uses the improved soil as a soil base material is ensured, so that the waste is used to treat waste, and the comprehensive utilization is improved.

Owner:姜桂荣 +1

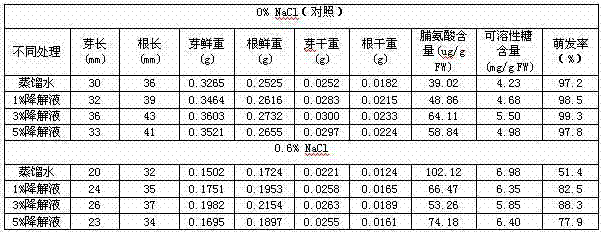

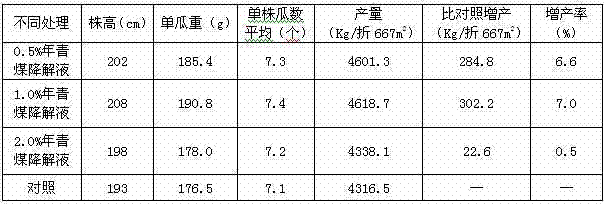

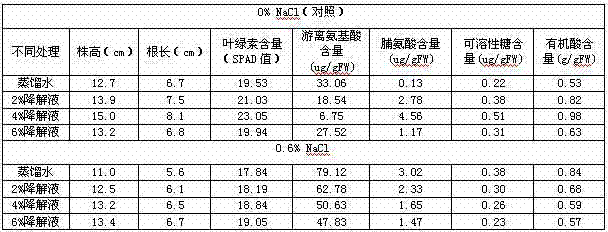

Production method and application of low-rack coal degradation liquid

InactiveCN103749538AReduce dosageRaw materials are easy to getBiocidePlant growth regulatorsPlant regulatorsPtru catalyst

The invention relates to a production method of low-rack coal degradation liquid. Low-rack coal used as a raw material is added with 2-10% of mixed oxidizing agent, 0.1-0.6% of negative catalyst and 0.2-0.5% of stabilizer to oxidize and degrade the low-rank coal, and the mixture is subjected to oxidation reaction, centrifugalization, filtering and vacuum rotating evaporation to obtain colourless low-rack coal degradation liquid. The colourless low-rack coal degradation liquid used as a new product has good effects in promoting growth and development of crops, increasing crop output, improving the crop quality, improving the seed germination rate, improving the plant salt resistance and the like, and is a multi-functional crop conditioner (plant conditioner); the process is simple, energy-saving and environment-friendly, and high in efficiency; one set of equipment can produce the low-rack coal degradation liquid and fulvic acid simultaneously, and the low-rack coal degradation liquid is safe and non-toxic, has strong appetency to plants, can take effect rapidly and is convenient for use.

Owner:KUNMING UNIV OF SCI & TECH TECH IND SALES MANAGEMENT

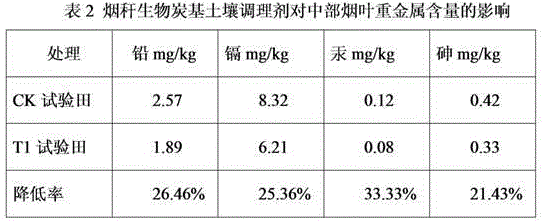

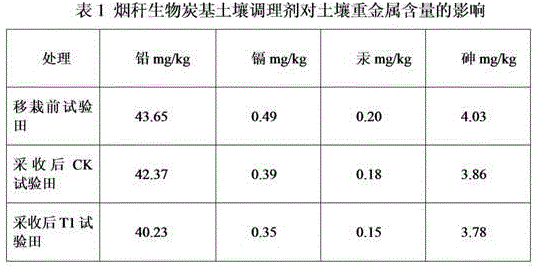

Tobacco stalk biochar soil conditioner and improvement method for tobacco field soil

ActiveCN104789229AReduce heavy metal activityEnhance metabolic functionOrganic fertilisersSoil conditioning compositionsSoil scienceEnvironmental engineering

The invention discloses a tobacco stalk biochar soil conditioner capable of reducing the content of heavy metals in tobacco, improving the tobacco quality and improving the soil environment, as well as an improvement method for tobacco field soil. The tobacco stalk biochar soil conditioner is prepared by mixing the following raw materials in parts by weight: 40-60 parts of tobacco stalk biochar and 40-60 g of a passivant. The tobacco stalk biochar soil conditioner is easy to obtain raw materials, simple in preparation method and low in cost, can effectively reduce the content of heavy metals in tobacco, and can improve the quality of tobacco field soil; a large number of waste tobacco stalks generated in tobacco growing areas are adopted as the raw material, the resource recycling of waste materials is realized, the sustainable development of the tobacco industry is facilitated, and the tobacco stalk biochar soil conditioner is suitable for large-scale popularization and application in the field of tobacco growing.

Owner:HENAN AGRICULTURAL UNIVERSITY

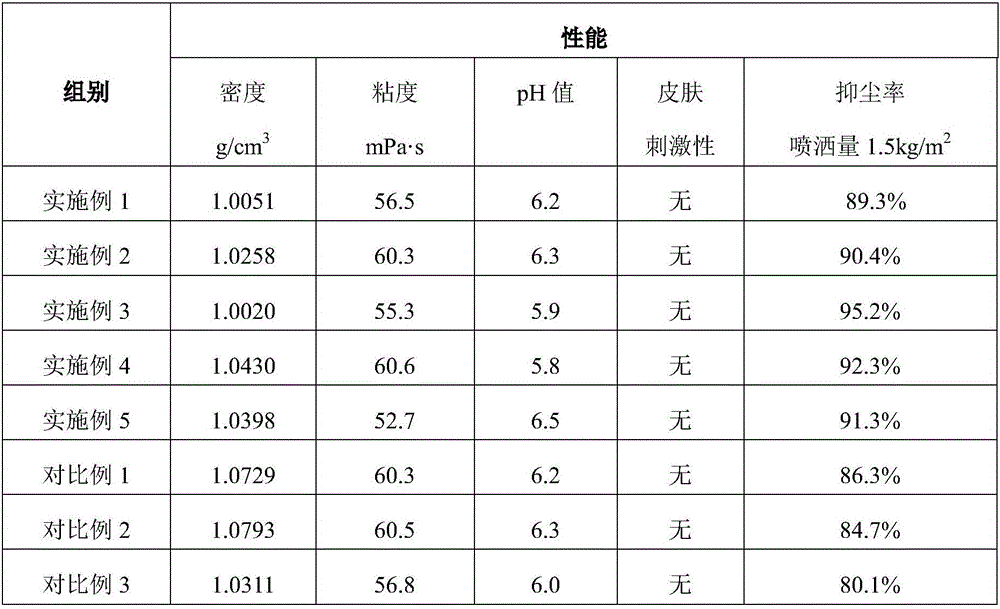

Road dust suppressant, and preparation and construction method thereof

ActiveCN106701024AStable stateEffective complexation adsorptionOther chemical processesRoad cleaningHazardous substanceSorbent

The invention discloses a road dust suppressant, and preparation and construction methods thereof, and belongs to the field of environmental protection and dust suppression. The road dust suppressant consists of the following components in percentage by weight: 0.1-2 percent of dispersible emulsion powder, 0.1-10 percent of an emulsion, 0.2-5 percent of a hygroscopic moisturizer, 0.01-0.5 percent of an absorbent, 2-10 percent of an anti-freezing agent, 0.1-0.2 percent of a wetting agent, 1-25 percent of filler and the balance of water. The road dust suppressant, and preparation and construction methods thereof disclosed by the invention have the benefits that inhalable particulate matters, nitric oxide, sulfide and other harmful matters on roads can be effectively reduced; the road dust suppressant has the characteristics that the environment is friendly, the hygroscopicity and the moisture retention are strong, the corrosion to vehicles and the roads is weak, and the road potential safety hazards cannot be caused.

Owner:UNIV OF JINAN

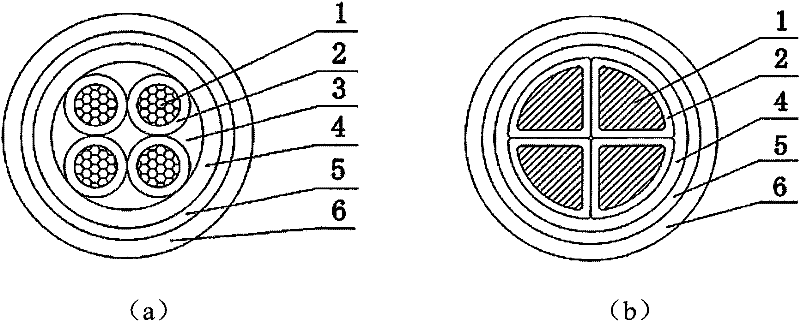

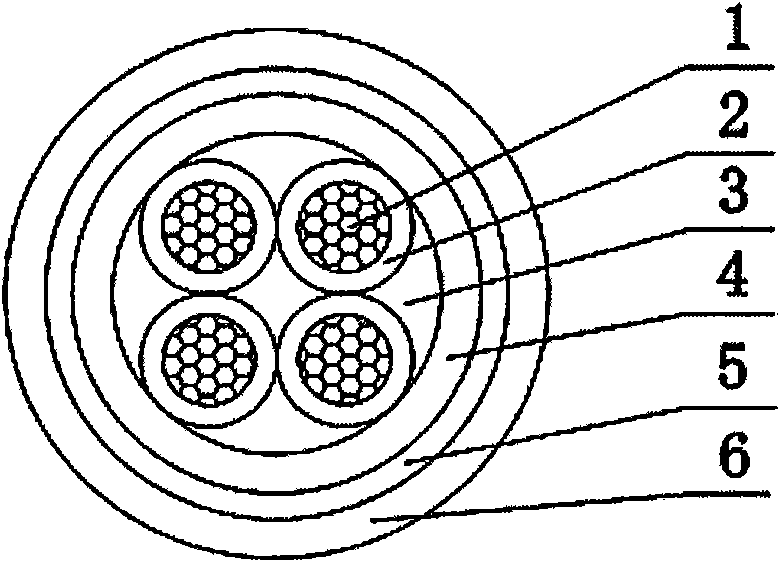

Expansion type environment-friendly halogen-free high-flame retardant and fire-resistant cable and method thereof

InactiveCN102306513AEasy to processImprove mechanical propertiesFlexible cablesCable/conductor manufactureEnvironmental resistanceInsulation layer

The invention relates to an expansion type environment-friendly halogen-free high-flame retardant and fire-resistant cable and a method thereof. The cable is characterized in that: each core sequentially consists of conductors, a silicon rubber insulating layer, a filler, a flame retardant oxygen separation layer, an aluminum-plastic composite tape insulation layer and an expansion type fire-resistant outer protective layer made of low-smoke halogen-free flame retardant polyolefin from inside to outside, and adopts a fire-resistant cable structure formed by combining the expansion type fire-resistant outer protective layer made of the low-smoke halogen-free flame retardant polyolefin, the aluminum-plastic composite tape insulation layer and the silicon rubber insulating layer; and a flame retardant oxygen separation layer structure is formed by a halogen-free high-flame retardant material coated with metal hydrates. The preparation method comprises the following steps of: drawing single lines, performing annealing, twisting the conductors, insulating silicon rubber, cabling, and preparing the flame retardant oxygen separation layer, the aluminum-plastic composite tape insulation layer and the expansion type refractory outer protective layer made of the low-smoke halogen-free flame retardant polyolefin. The cable provided by the invention is easy to process, the external diameter of the cable is smaller than that of the traditional cable by 2 to 4 millimeters, and the structure can be obviously lightened.

Owner:南洋电缆集团有限公司

Maotai-flavor distiller's grain organic fertilizer and preparation method thereof

InactiveCN104909854AReduce total usageEfficient use ofBio-organic fraction processingOrganic fertiliser preparationFlavorOrganic fertilizer

The invention discloses a Maotai-flavor distiller's grain organic fertilizer and a preparation method thereof. The fermentation raw material of the organic fertilizer comprises the following components: 80-90 parts of Maotai-flavor distiller's grains, 5-10 parts of rape seed cake, 4-8 parts of bone meal, 3-4 parts of straw, 3-4 parts of sawmilling powder, 5-10 parts of corncob core, 2-4 parts of egg shell, 1-2 parts of quicklime, 0.1-0.2 part of decomposing microbial inoculum and 2-4 parts of kitchen waste. The organic fertilizer contains few heavy metals and enough nutrients. The preparation method of the organic fertilizer comprises the steps of raw material crushing, raw material mixing, microbial inoculum inoculation, fermentation and granulation, drying and the like; and the preparation method realizes thorough composting and can avoid secondary fermentation after the organic fertilizer is applied to soil.

Owner:ZUNYI LIANGU AGRI TECH

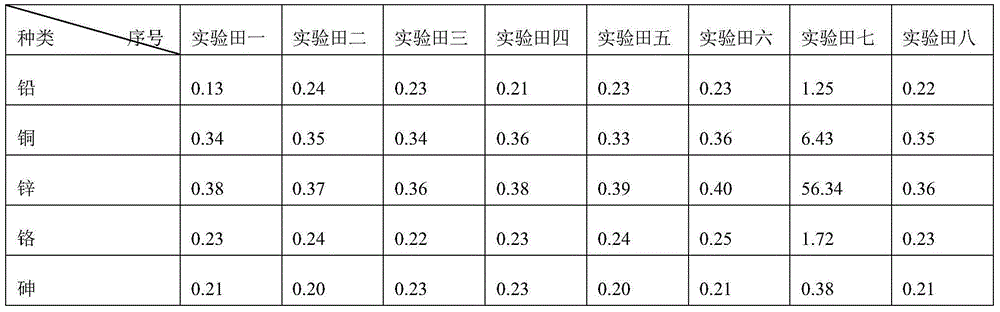

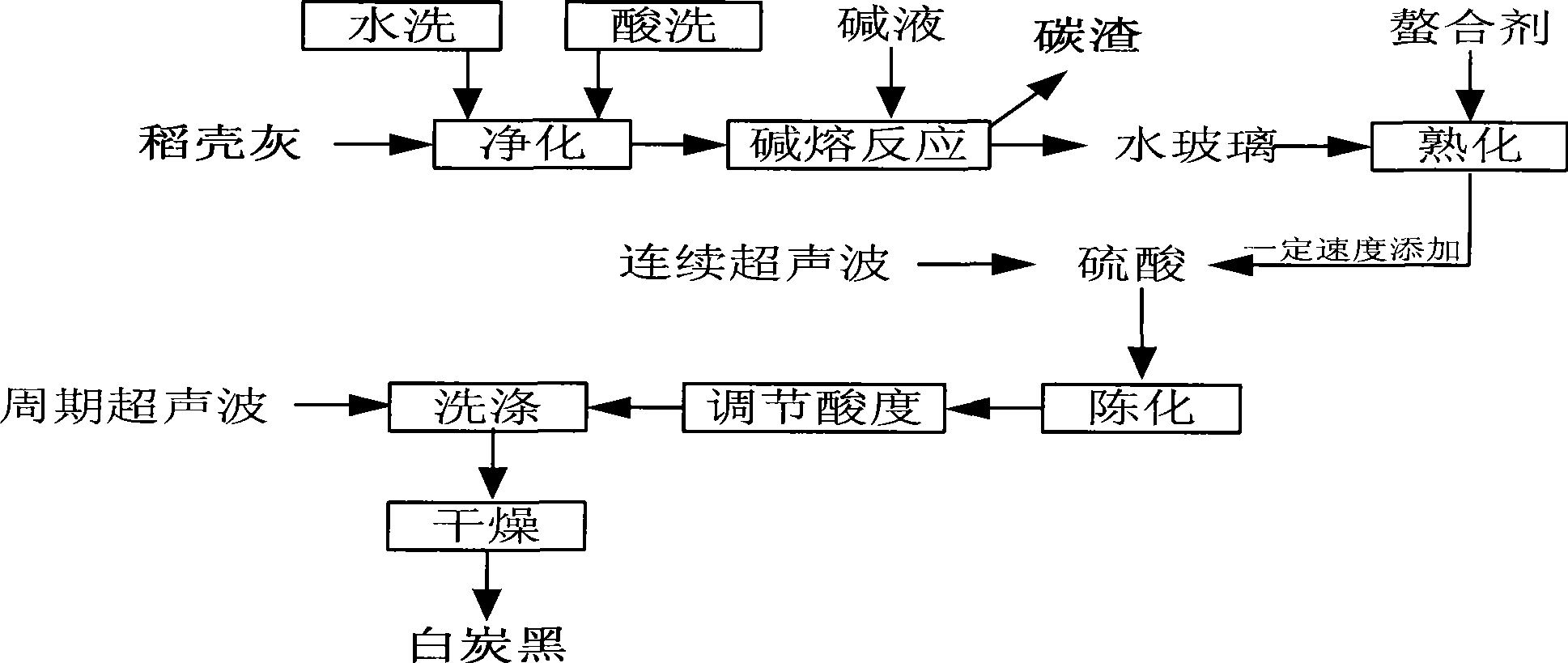

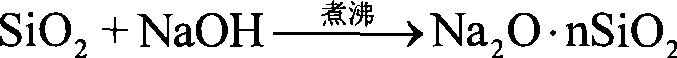

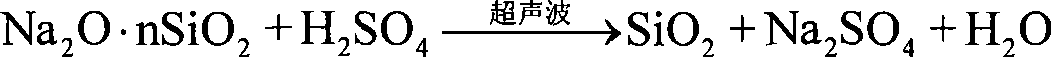

Method for preparing high-purity siliceous reinforcing agent by using rice hull ash as raw material

The invention relates to a method for preparing high purity silica white by using rice husk ash as a raw material, belonging to the field of fine inorganic chemical technology. The invention is characterized by comprising the following steps: taking the rice husk ash and water for washing under constant stirring, separation, pickling, leaching, and then undertaking washing till the lavage liquid is neutral and drying; taking the dried rice husk ash for being mixed and reacted with the sodium hydroxide solution, through leaching and washing; collecting filtrate and washing liquid so as to be condensed and obtain water glass; diluting the water glass which is obtained from the condensation and adding metal ion chelating agent, and next carrying out precipitation reaction after being fully dissolved, then a sediment is obtained by centrifugal separation; using ultrasound-assisted washing treatment, and then undertaking centrifugal separation and repeated washing; placing the washed sediment into a drying oven and then crushing and packaging the sediment so as to obtain the silica white product. The invention has simple process flow, easy operation, can improve the purity of the silica white, and is suitable for commercial process; moreover, the heavy metal content is less, which can completely replace or is even better than the market silica white product and also eliminates the environmental pollution of the rice husk ash.

Owner:JIANGNAN UNIV

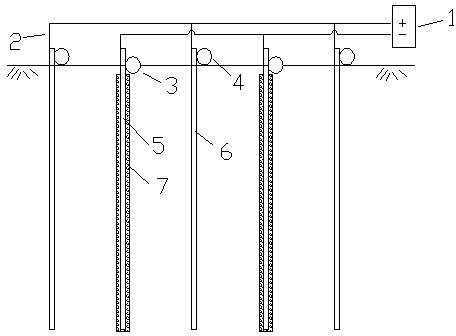

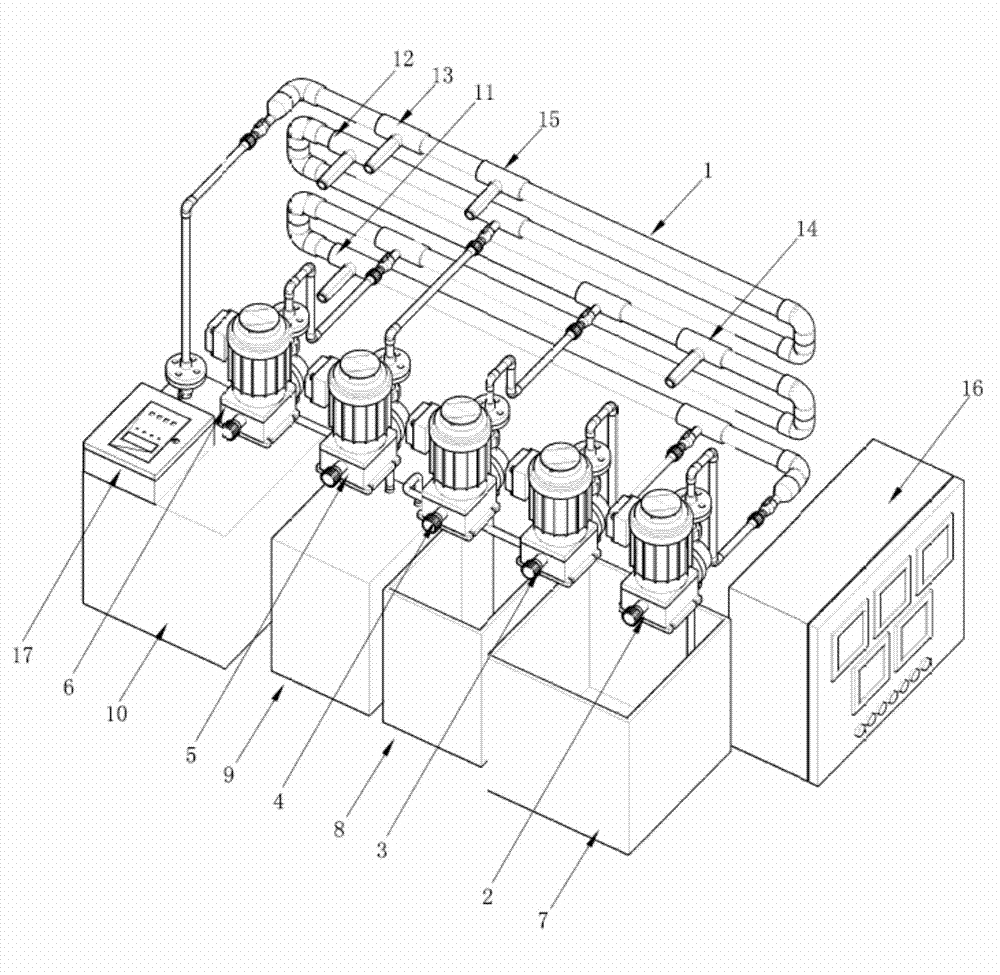

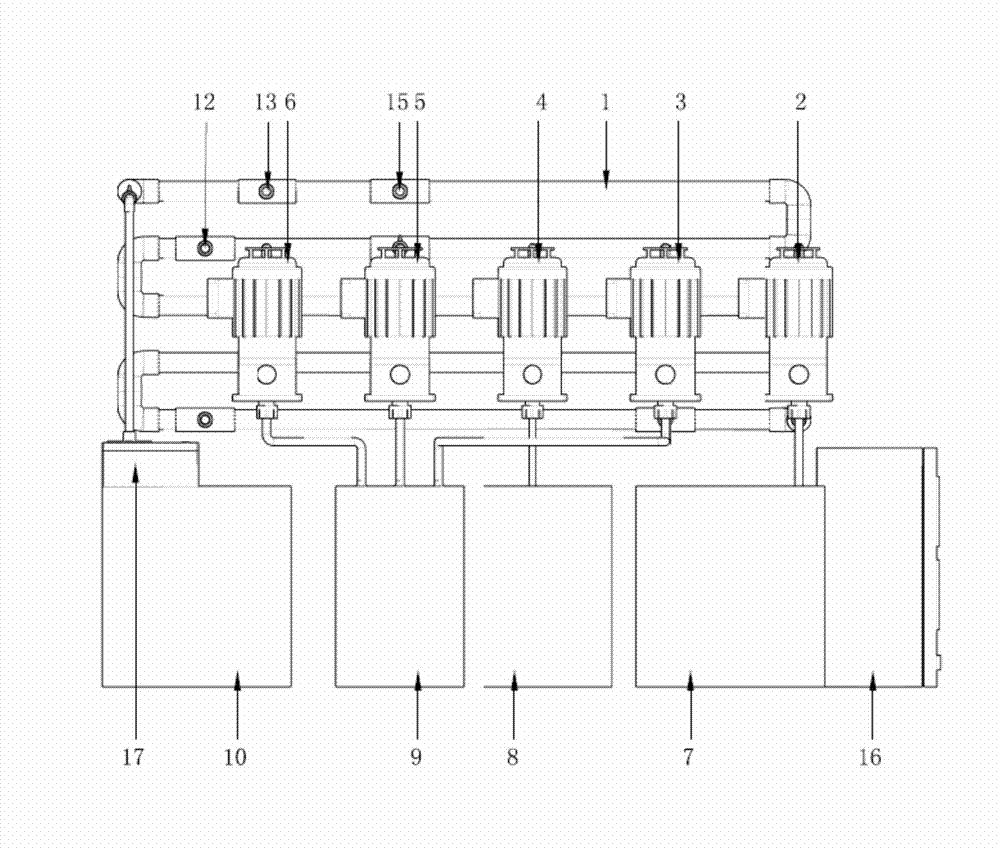

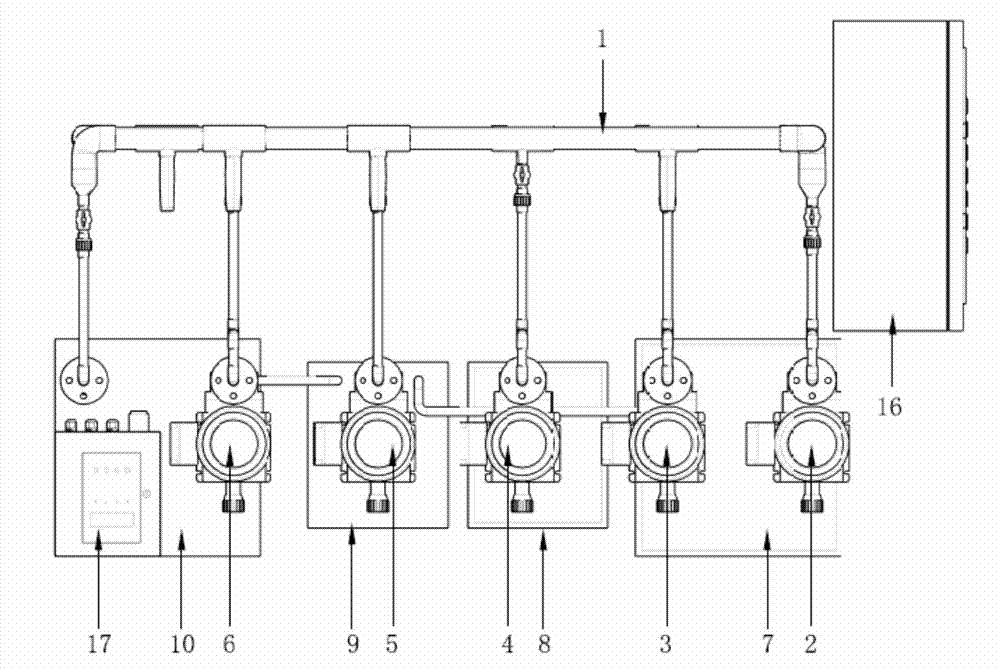

In-situ treatment method for electrically repairing heavy metal contaminated soil based on plastic electrode

InactiveCN104368596AEfficient removalEasy to operateContaminated soil reclamationWater dischargeElectrokinetic remediation

The invention relates to an in-situ treatment method for electrically repairing heavy metal contaminated soil based on a plastic electrode. The in-situ treatment method is characterized by comprising the following steps: step I, determining the treatment depth of contaminated soil by performing soil experiment; step II, leveling ground; step III, performing water irrigation and pre-soaking on soil with the water content of less than 30%; step IV, distributing an anode plastic electrode (6) and a cathode plastic electrode (5); step V, distributing a water discharge pipe (3) and a water filling pipe (4); step VI, respectively connecting the cathode plastic electrode (5) and the anode plastic electrode (6) by using conducting wires (2), and gathering the cathode plastic electrode (5) and the anode plastic electrode (6) to be connected to positive and negative electrodes of a direct current power supply (1); and step VII, powering on the direct current power supply (1), and starting electro-osmosis treatment. The in-situ treatment method for electrically repairing the heavy metal contaminated soil based on the plastic electrode, disclosed by the invention, has the advantages that the in-situ treatment method can be used for rapidly reducing the heavy metal content of a soil body, and is relatively high in environmental protection performance.

Owner:江阴市华宏盈飞电渗科技有限公司

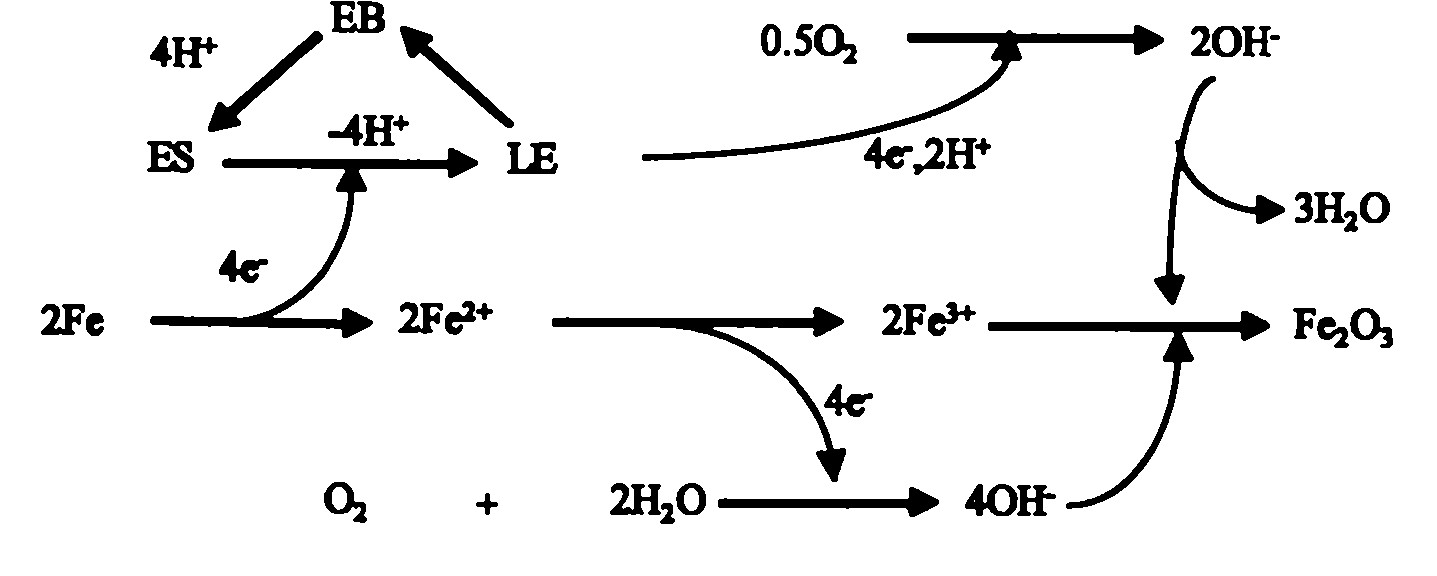

Treatment method of arsenic wastewater

ActiveCN103112974AShort process routeShort construction periodMultistage water/sewage treatmentFlocculationResource recovery

The invention discloses a treatment method of arsenic wastewater. The treatment method comprises the following steps: optionally adding acid liquor into the arsenic wastewater to adjust the pH value to 0-5; introducing the arsenic wastewater into a reaction unit, continuously removing arsenic by adding sulfide in multistage manner; carrying out solid-liquid separation on the effluent after reaction, recycling the separated arsenic slag; adding alkali into the separated effluent to perform electrochemical advanced treatment, wherein the electrochemical advanced treatment includes an electrolytic coagulation step, an electrolytic flotation step and an electrolytic oxidation reduction step, in the electrolytic coagulation, cations are generated by the electrolyzation of a soluble anodic iron plate for flocculation; carrying out aerated oxidation on the effluent after flocculation to generate floc and micelle sediment including ferric ions, and then carrying out solid-liquid separation, wherein the liquid supernatant after separation can be recycled or reach the standard and drain outwards. The treatment method of arsenic wastewater has the advantages of simple technology, low investment, low cost and high resource recovery and recycling rate, and being green and environment-friendly, and being capable of treating continuously and the like.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

Solid waste biological treatment technology based on earthworm breeding

InactiveCN106106372AIncrease contentLow costFood processingClimate change adaptationSludgeHazardous substance

The invention discloses solid waste biological treatment technology based on earthworm breeding. The invention discloses a method for treatment of sludge and solid waste and the like through earthworm breeding in combination with harmless biological treatment so that contents of nitrogen, phosphorus, potassium, amino acid, crude proteins and other nutrients can be improved after bio-fermentation technology and earthworm coelomic digestive treatment. Therefore, a large number of harmful substances and heavy metal content (lower than an NY 525-2012 agricultural industry standard), earthworm cats are raw material for organic fertilizers with high quality. Raw material is low in cost. Process is simple and easy to master. The purpose of eco-environment protection is fulfilled. The technology belongs to circular economy which is an industry greatly supported by China. The technology is suitable for scale production and promotion.

Owner:刘建忠

Method for planting ganoderma tsugae by imitating wild growth in forest land

The invention discloses a method for planting ganoderma tsugae by imitating wild growth in a forest land and belongs to the technical field of edible fungus cultivation. The method is finished by the steps of preparing ganoderma tsugae strains, preparing fungus sections in a production season, earthing in the forest land, managing grown ganoderma tsugae, managing during an underground fungus growing period, an overwintering period and a ganoderma tsuga growing period, controlling and preventing pests and diseases, and the like. The prepared fungus strains comprise a mother strain culture medium, a stock strain culture medium and a planting strain culture medium, wherein the mother strain culture medium comprises 200g of potato, 20g of glucose, 18 to 20g of agar and 1,000ml of water; the stock strain culture medium and the planting strain culture medium comprise 40 percent of broadleaf hard miscellaneous wood chips, 38 percent of pinevood chips, 20 percent of bran, 1 percent of white sugar and 1 percent of gypsum powder. According to the method provided by the invention, the quality and the medical components of lucid ganoderma can be effectively guaranteed, and the method is suitable for wide application.

Owner:JILIN AGRICULTURAL UNIV

Artificial cultivation method for savatier monochasma herb

InactiveCN104782367AImprove survival rateImprove yield per unit areaClimate change adaptationPlant cultivationPesticide residueQuality control

The invention discloses an artificial cultivation method for savatier monochasma herb. The method comprises the aspects of planting base establishing, breeding, planting, field managing, harvesting, processing, storing and seed reserving. By adopting the cultivation method, the survival rate of medicine materials is high, the per unit area yield is high, the content of the flavonoid and other effective components is high, the quality of the medicine materials is stable, the pesticide residue does not exist, the pollution does not exist, the heave metal content is low, the quality control is easy to carry out during large-area generalizing and planting, the environmentally-friendly Chinese medicine materials are achieved, the medicine material products are accordant with the standard in the Chinese pharmacopoeia in the 2010 edition.

Owner:湖南华宝通制药有限公司

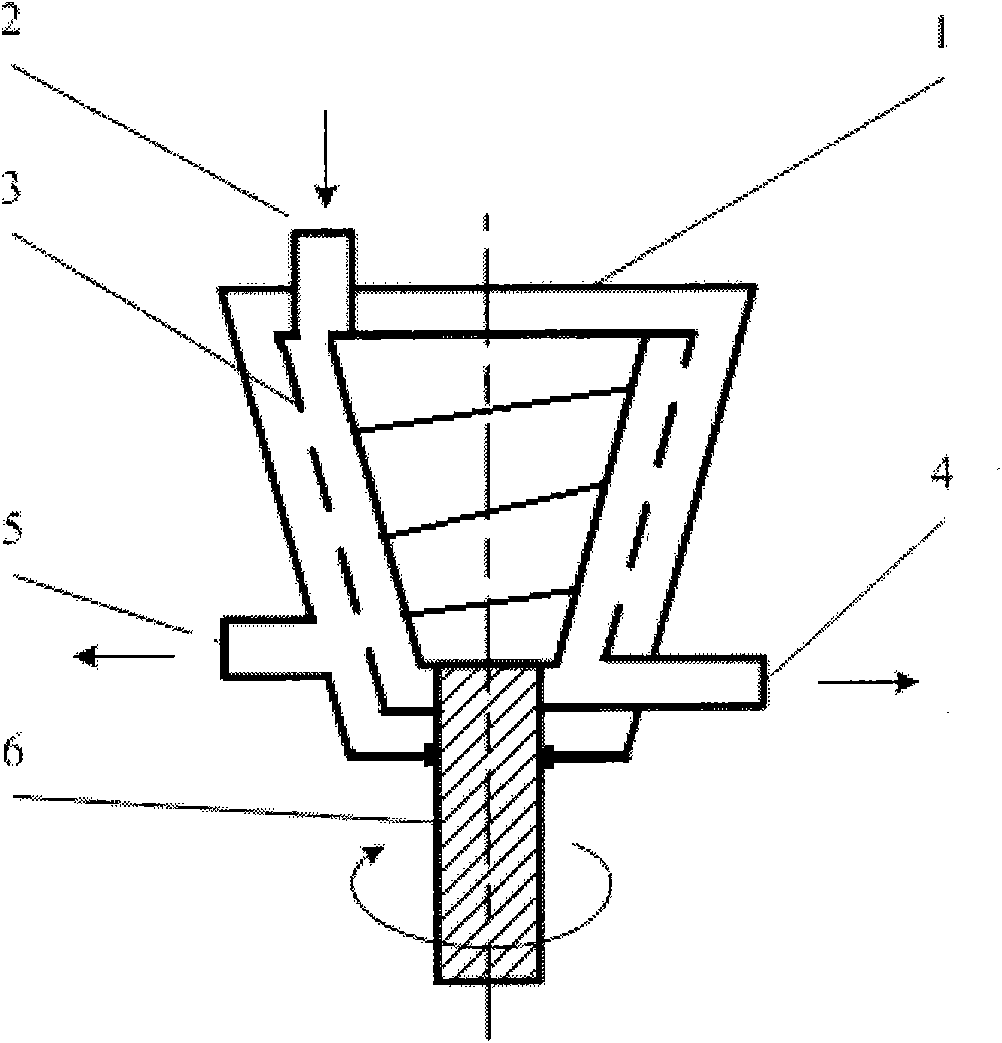

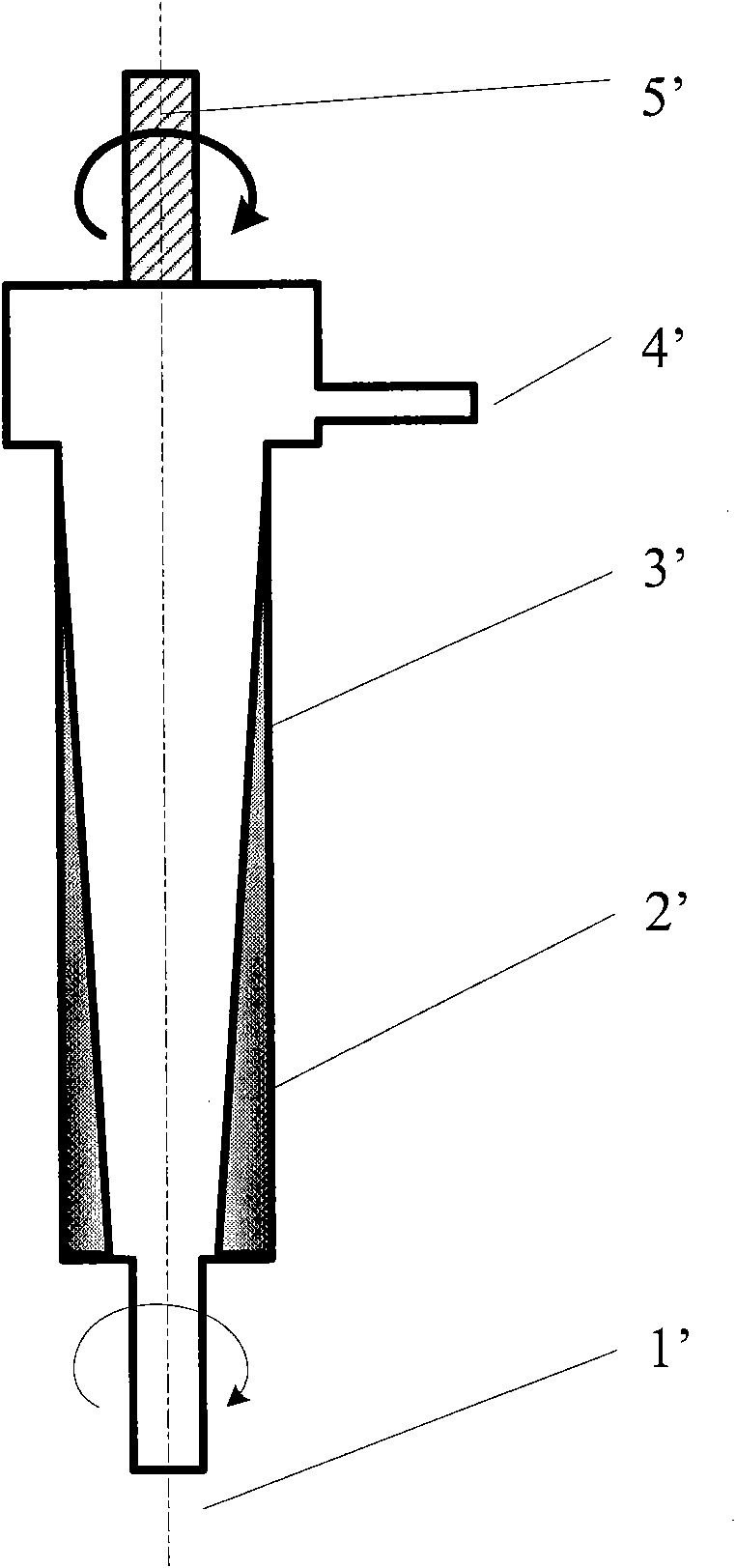

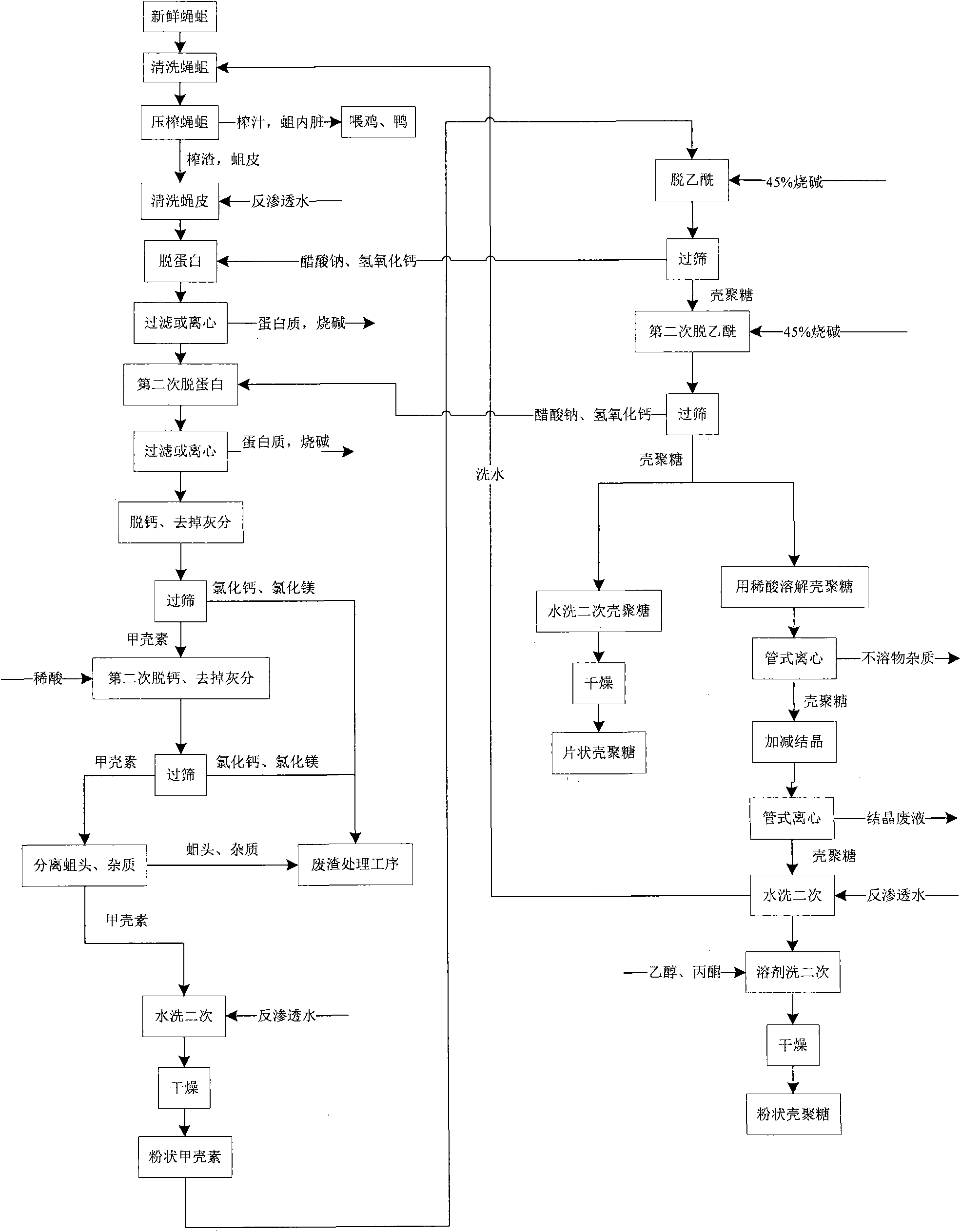

Preparation method of fly maggot chitosan

The invention relates to a method of preparing chitosan by using fly maggots, which comprises the followings steps that: firstly, the skin of a maggot is separated from entrails by pressing the fly maggot, an alkali solution is used to remove protein, a dilute acid solution is used to de-ash, and the impurities of the head of the maggot are removed by a physical method to obtain chitin; secondly, the chitin is deacetylated by 40-55% (W) of caustic soda solution, and then is separated to obtain a filter cake chitosan; and the chitosan is repeatedly washed until the PH value is equal to 7; thirdly, the cleaned chitosan adopts two processing methods: one method is to obtain flaky chitosan by drying, and the other method is that the chitosan is dissolved in dilute acid and centrifugally separated by a tube type centrifuge to obtain filtrate a chitosan solution; alkali is added in the filtrate until the PH value is equal 7-7.5, the chitosan is precipited and is separated by the tube type centrifuge to obtain a filter cake chitosan, and powdery chitosan is obtained after drying. The invention has the characteristics that: water can be saved, the chitosan product has low heavy metal content, low toxic content and stable product quality, the productivity is high and the production cost is low.

Owner:ZHEJIANG PUJIANG CHENGYUE PLANTATION +1

Soil conditioner for treating saline-alkali soil

The invention discloses a soil conditioner for treating saline-alkali soil, and belongs to the technical field of agricultural production. The soil conditioner is prepared by diatomite, attapulgite, halophilic bacteria, humic acid, fulvic acid and biological floras, 300 kilograms of water is added into fungi in the biological floras to prepare an aqueous solution, and the diatomite, the attapulgite and the halophilic bacteria are added into the aqueous solution; then the humic acid and the fulvic acid are mixed to be added into the aqueous solution to be mixed, and therefore particles are obtained. In tillage, the soil conditioner is applied along with bottom fertilization in soil turning, and can promote rapid growth of crops and increase the yield and incomes, and the quality of fruits is remarkably improved.

Owner:张大奇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com