Injectable temperature sensitive gel used for filling and repairing damaged tissues

A temperature-sensitive gel and damaged tissue technology, applied in medical science, prosthesis, etc., can solve problems such as lack of thermodynamic reversibility, achieve prolonged retention time, low heavy metal content, and promote in situ regeneration and repair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

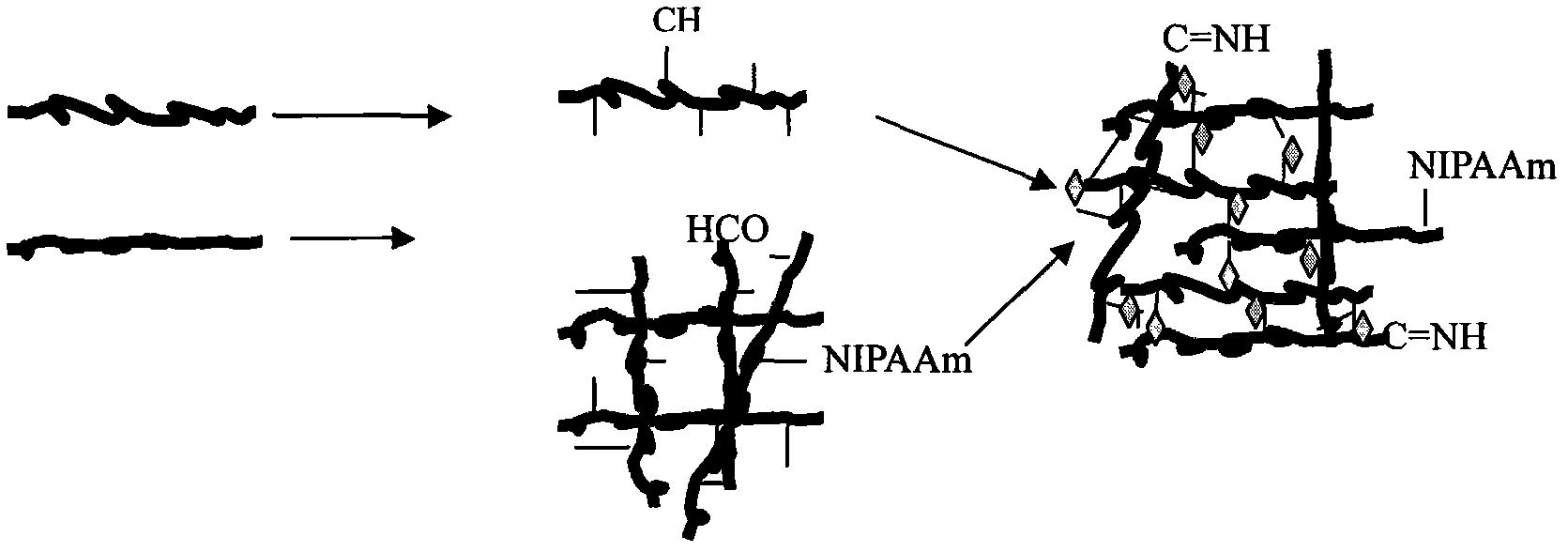

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of active aldehyde hyaluronic acid:

[0037] Mix the raw material hyaluronic acid and deionized water according to the ratio of 0.01g / 100ml, add 0.1M, 100mL sodium periodate aqueous solution, stir and react in the dark at room temperature, add ethylene glycol solution, stir and react at room temperature, and prepare Get aldehyde hyaluronic acid;

[0038] (2) soaking, washing, and extracting the prepared gel with absolute ethanol to remove unreacted monomers and other impurities, then dialysis and purification of the solution, and freeze-drying to obtain a pure gel product;

[0039] (3) Preparation of thermosensitive chitosan:

[0040] Dissolve 0.2 g of CS in 1% acetic acid solution, slowly add 0.2 g of N-isopropylpropionamide (NIPAAm) and 4 mg of potassium persulfate (KPS), stir and dissolve at room temperature, and then blow in nitrogen to stir the reaction. The above reactant was precipitated with acetone and filtered. Vacuum drying to obtain a gel ...

Embodiment 2

[0045] (1) Preparation of hyaluronic acid with active aldehyde groups:

[0046] Mix the raw material hyaluronic acid and deionized water according to the ratio of 1g / 100ml, add 0.5M, 5mL sodium periodate aqueous solution, stir and react at room temperature in the dark, add ethylene glycol solution after the reaction, stir and react at room temperature . Prepare hyaluronic acid gel;

[0047] (2) soaking, washing, and extracting the prepared gel with absolute ethanol to remove unreacted monomers and other impurities, then dialysis and purification of the solution, and freeze-drying to obtain a pure gel product;

[0048] (3) Preparation of thermosensitive chitosan:

[0049] Dissolve 0.2 g of chitosan in 5% acetic acid solution, slowly add 2 g of N-isopropylpropionamide (NIPAAm) and 4 mg of azobisisobutyronitrile, stir and dissolve at room temperature, and then feed nitrogen to stir the reaction. The above reactant was precipitated with acetone and filtered. Vacuum drying to o...

Embodiment 3

[0054] (1) Preparation of hyaluronic acid with active aldehyde groups:

[0055] Mix the raw material hyaluronic acid and deionized water according to the ratio of 20g / 100ml, add 10M, 100ml sodium periodate aqueous solution, stir and react at room temperature in the dark, add ethylene glycol solution after the reaction, stir and react at room temperature. Prepare hyaluronic acid gel;

[0056] (2) soaking, washing, and extracting the prepared gel with absolute ethanol to remove unreacted monomers and other impurities, then dialysis and purification of the solution, and freeze-drying to obtain a pure gel product;

[0057] (3) Preparation of thermosensitive chitosan:

[0058] Dissolve 0.2 g of CS in 98% acetic acid solution, slowly add 18 g of N-isopropylpropionamide (NIPAAm) and 1 mg of potassium persulfate (KPS), stir and dissolve at room temperature, and then blow in nitrogen to stir the reaction. The above reactant was precipitated with acetone and filtered. Vacuum drying t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com