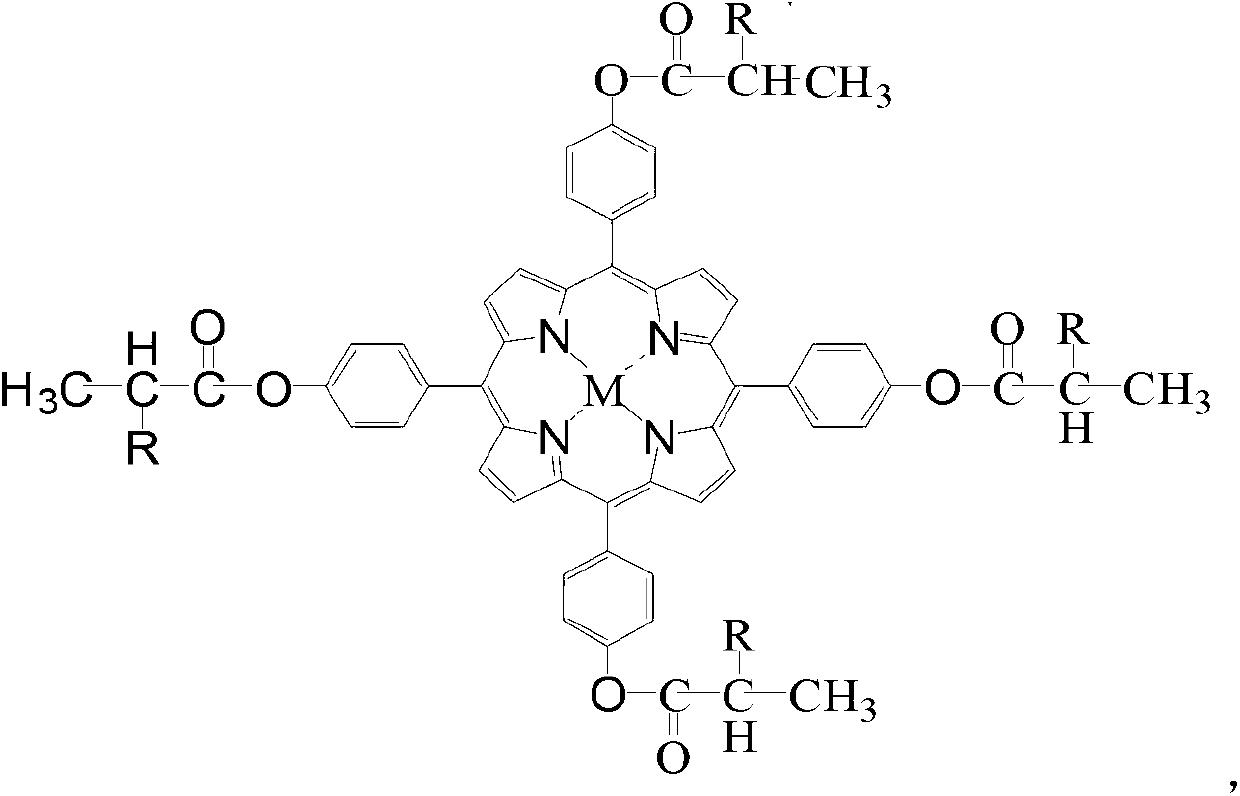

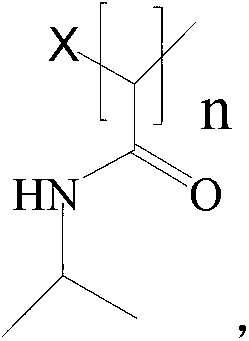

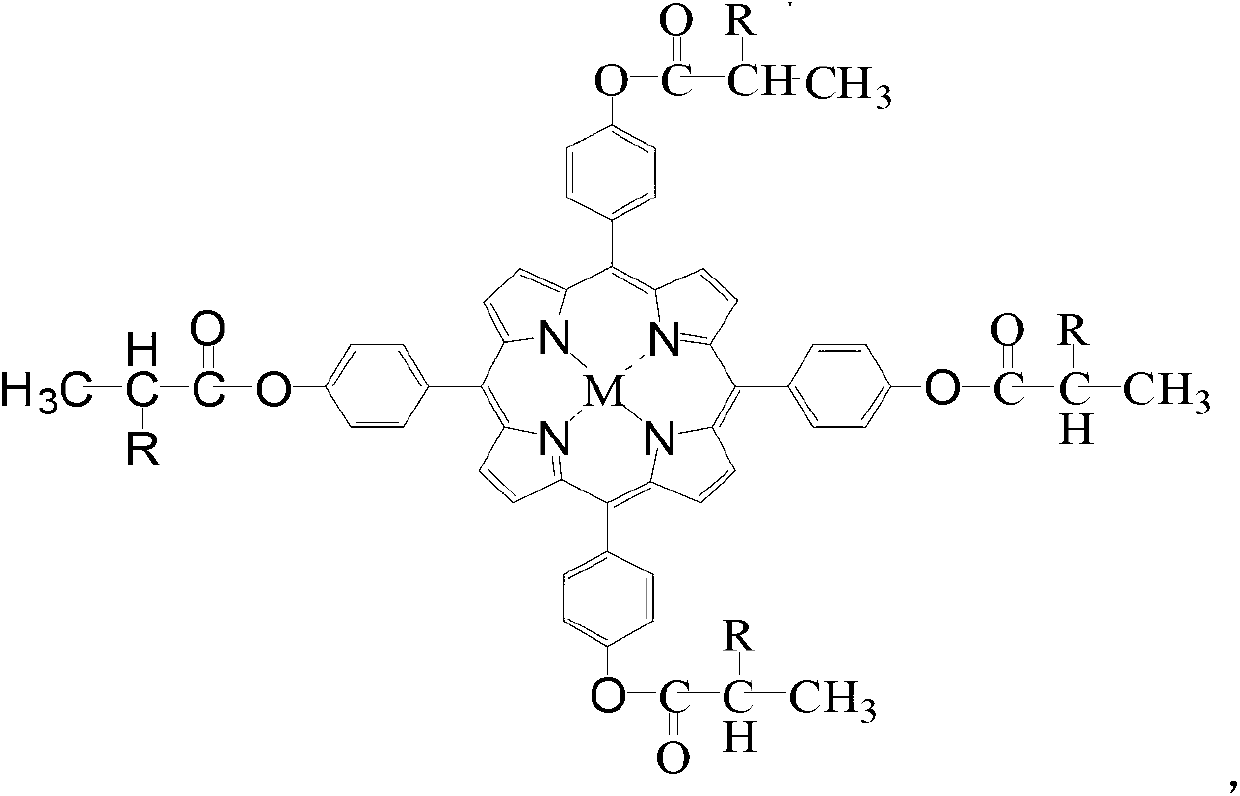

Thermosensitivity recyclable metalloporphyrin visible light degradation catalyst and preparation method thereof

A technology of metalloporphyrin and visible light, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc. Problems such as application restrictions, to achieve the effect of reducing treatment costs and solving secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preparation method of the temperature-sensitive recyclable metalloporphyrin visible light photodegradation catalyst of the present invention will be described in detail below.

[0017] First, 5,10,15,20-tetra-p-hydroxyphenylporphyrin reacts with zinc acetate to form a porphyrin metal complex. The specific process is as follows:

[0018] Put 10ml of N,N-dimethylformamide (DMF) in a three-necked flask, blow nitrogen gas, and heat to reflux for 15 minutes. Under the protection of nitrogen, 0.001mol of 5,10,15,20-tetra-hydroxyphenylporphyrin and equimolar zinc acetate were added, and reflux was continued in the dark. Monitor once with UV-Vis spectrum at regular intervals until the reaction is complete, remove the nitrogen, cool to room temperature, evaporate most of the solvent under reduced pressure, perform column chromatography with silica gel as the stationary phase and chloroform as the eluent, and collect the second After evaporating most of the solvent, carry o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com