Patents

Literature

2499 results about "Stationary phase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stationary phase (plural stationary phases) (chemistry) The solid or liquid phase of a chromatography system on which the materials are to be separated or selectively adsorbed.

Method of producing undifferentiated hemopoietic stem cells using a stationary phase plug-flow bioreactor

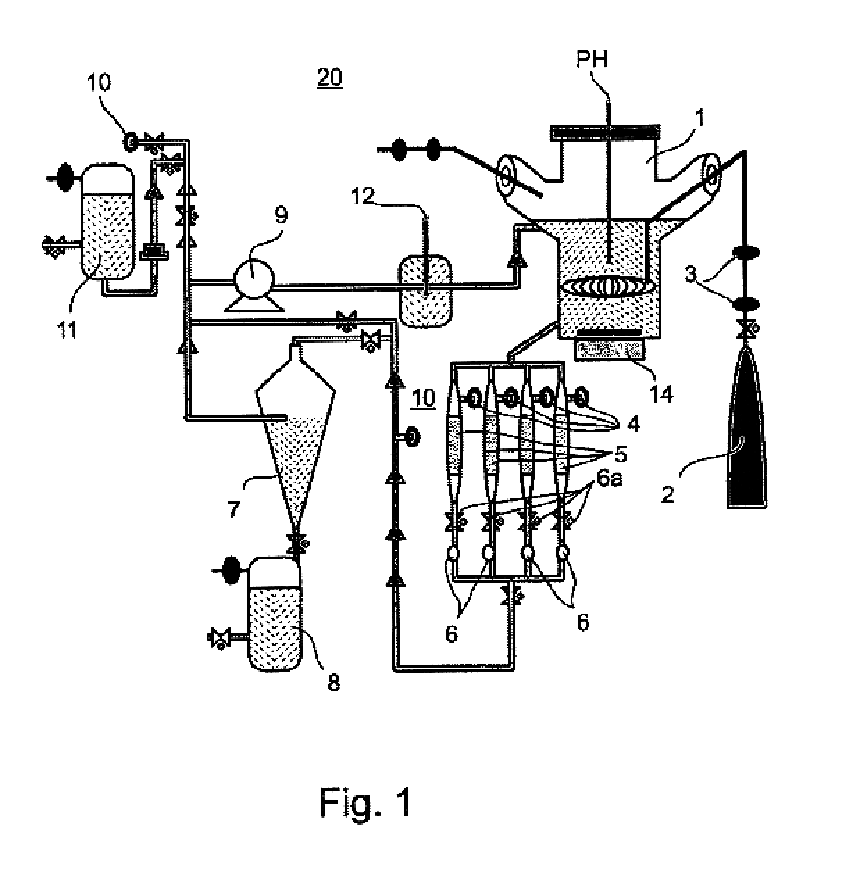

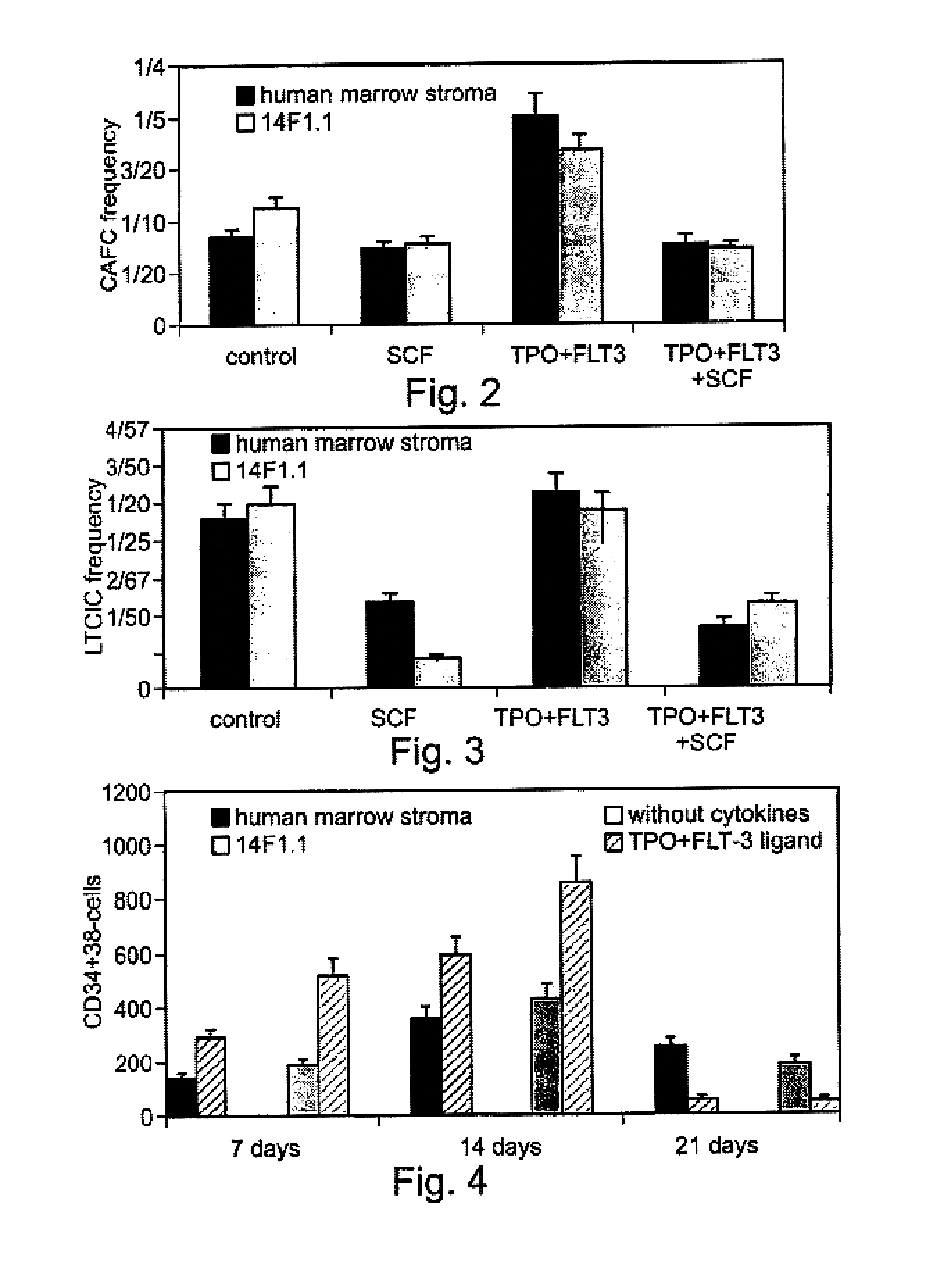

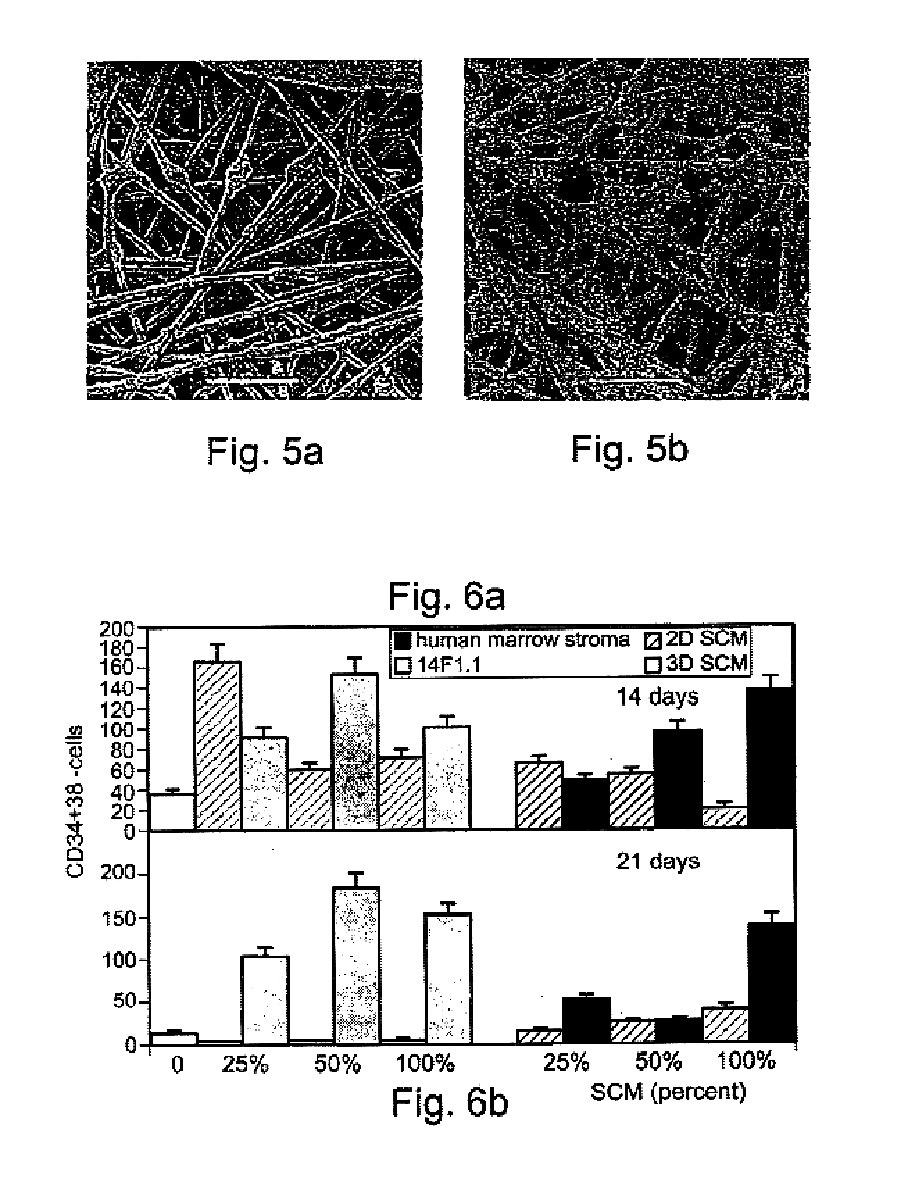

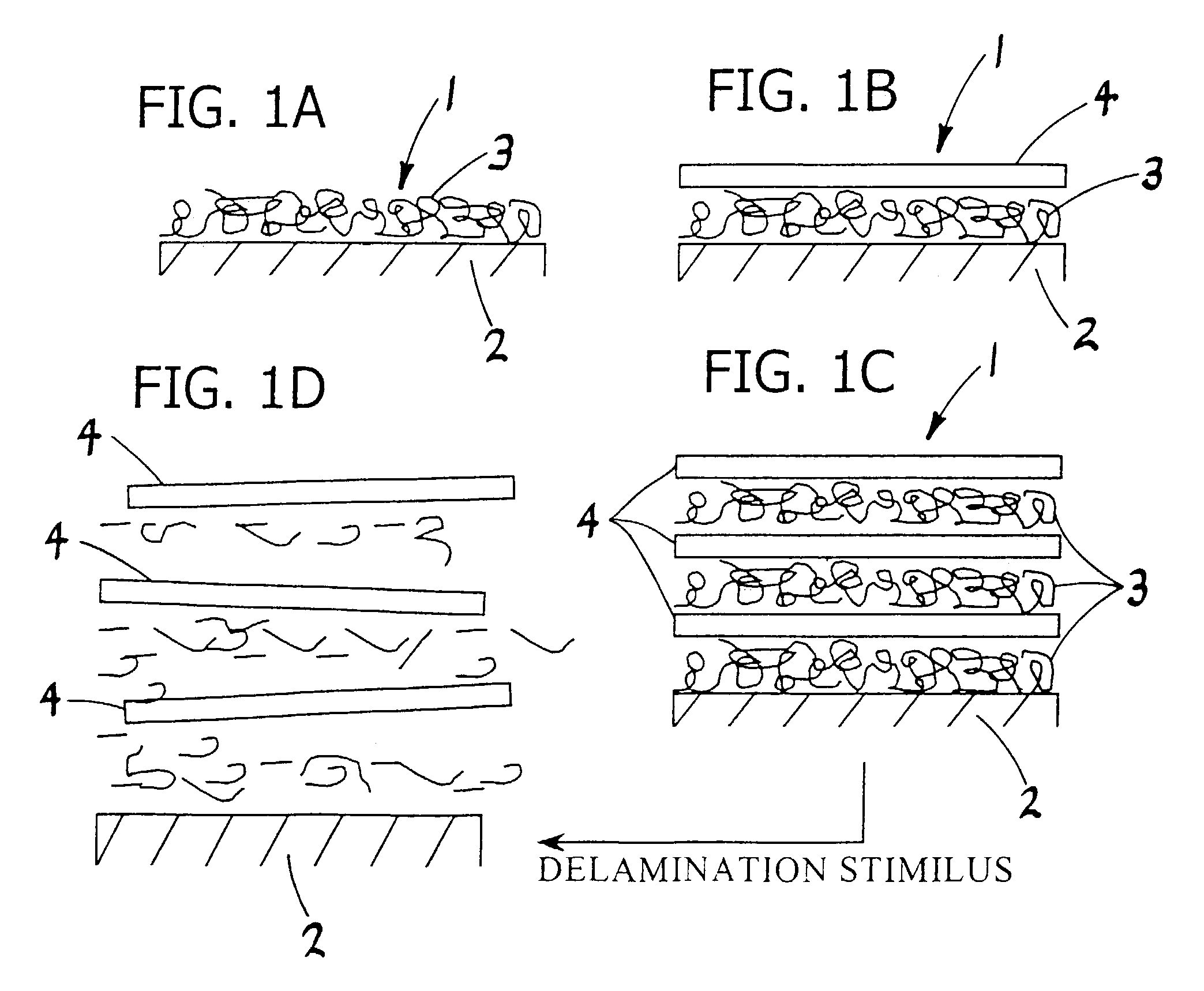

A method of expanding / maintaining undifferentiated hemopoietic stem cells or progenitor cells by obtaining undifferentiated hemopoietic stem cells or progenitor cells; and either seeding the undifferentiated hemopoietic stem cells or progenitor cells into a stationary phase plug-flow bioreactor in which a three-dimensional stromal cell culture has been pre-established on a substrate in the form of a sheet, the substrate including a non-woven fibrous matrix forming a physiologically acceptable three-dimensional network of fibers, thereby expanding / maintaining undifferentiated hemopoietic stem cells or progenitor cells, or culturing the undifferentiated hemopoietic stem cells or progenitor cells in conditioned medium obtained from such a reactor.

Owner:PLURISTEAM LTD +1

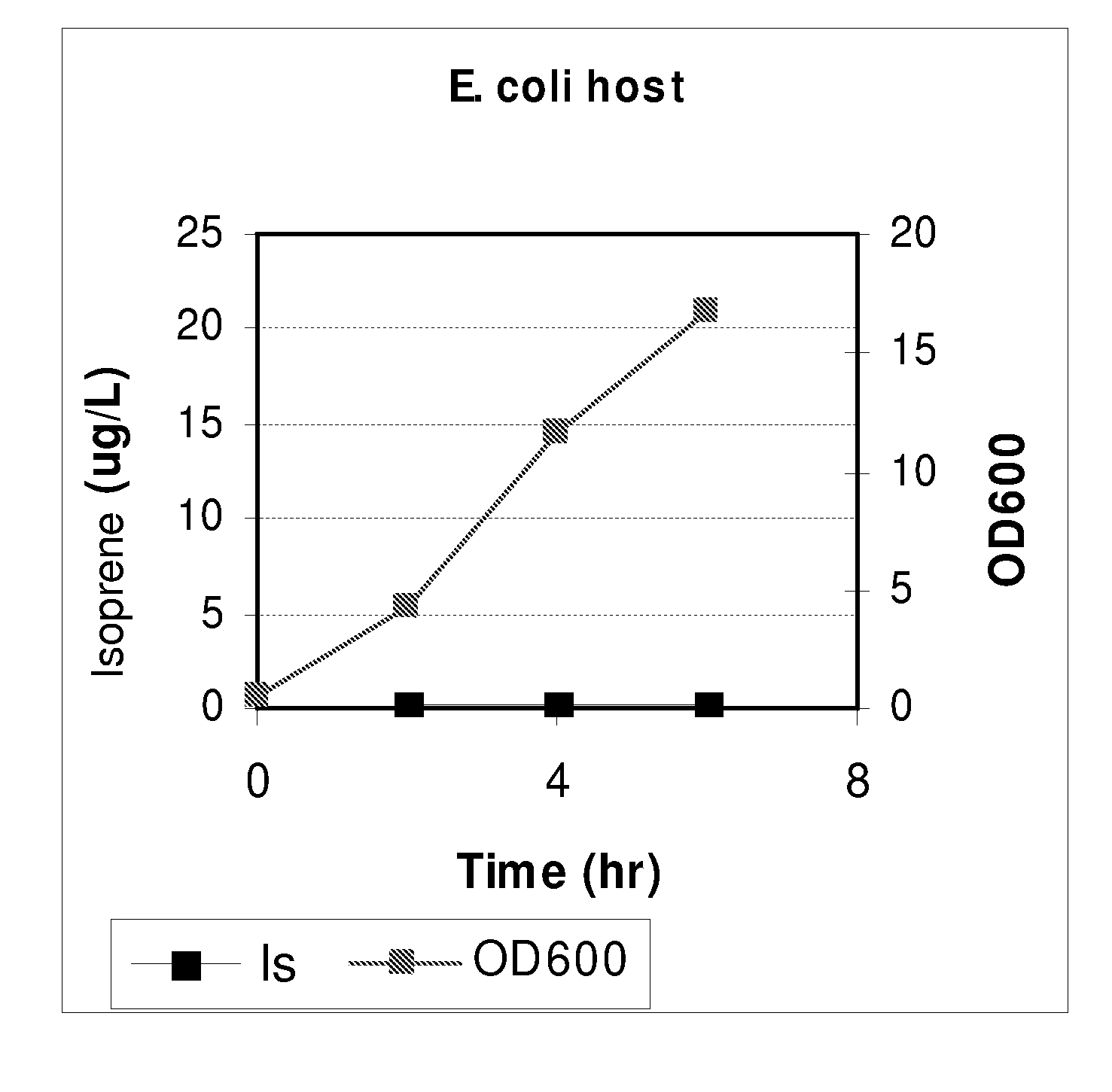

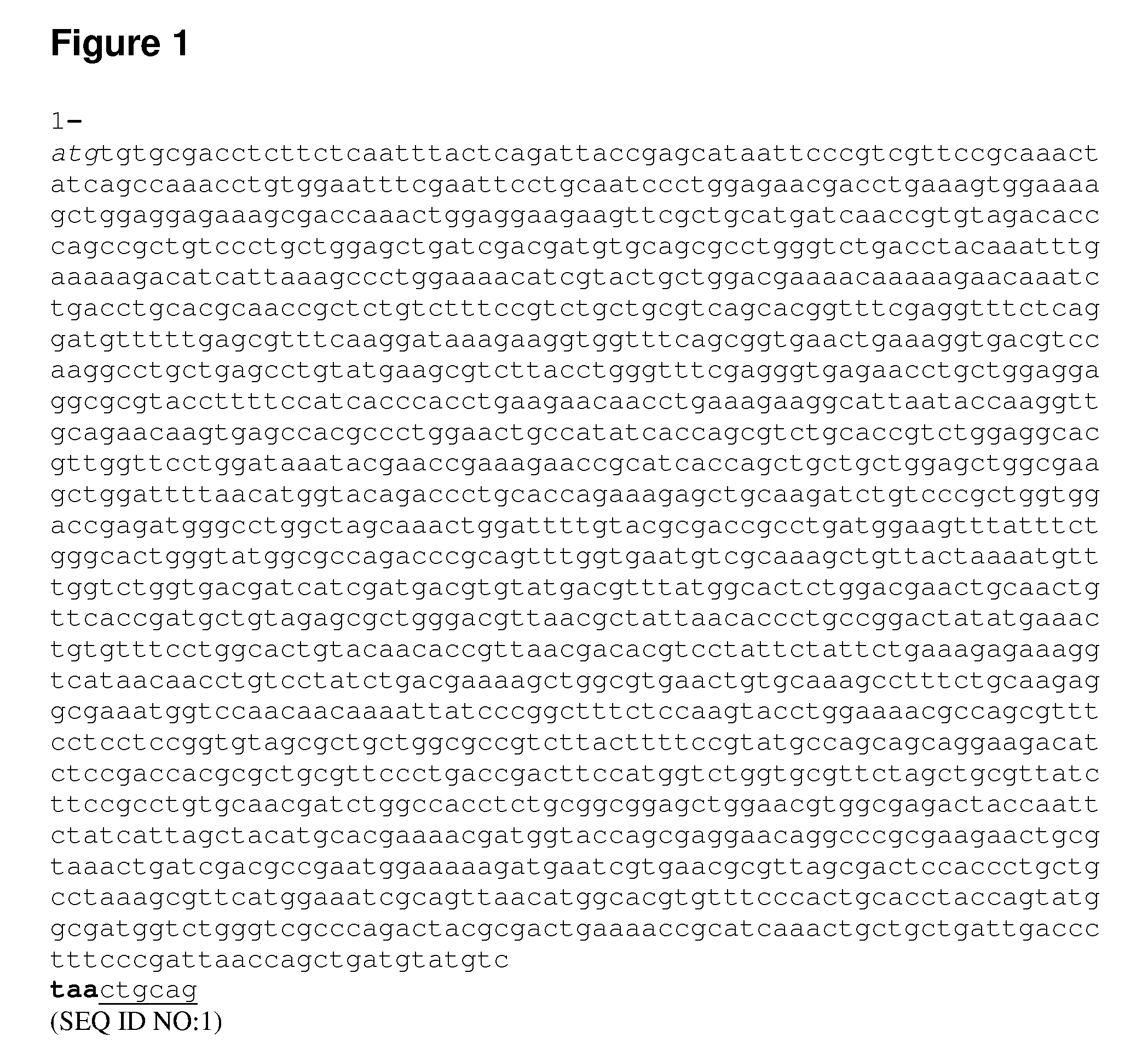

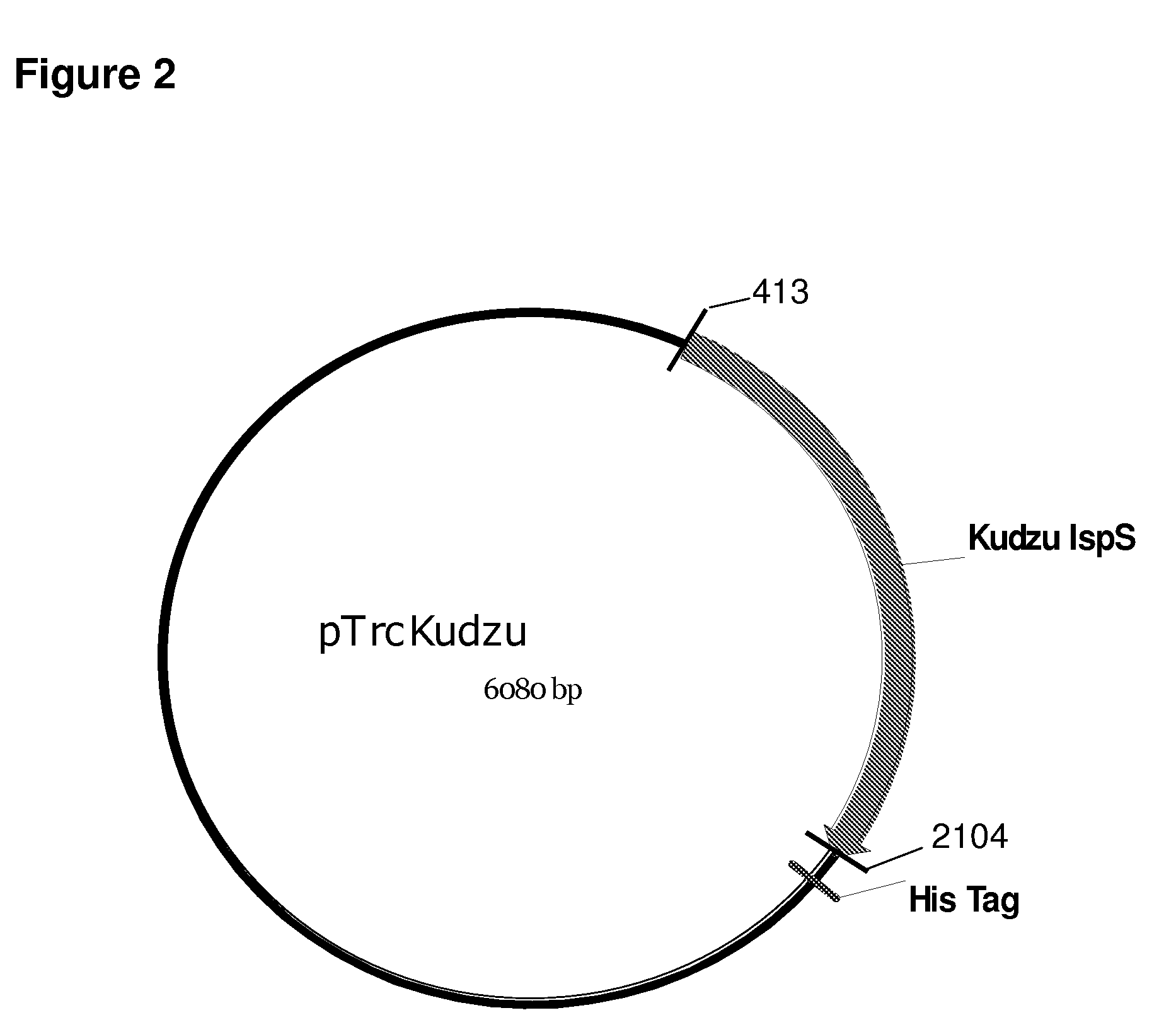

Compositions and methods for producing isoprene free of c5 hydrocarbons under decoupling conditions and/or safe operating ranges

The invention features methods for producing isoprene from cultured cells wherein the cells in the stationary phase. The invention also provides compositions that include these cultured cells and / or increased amount of isoprene. The invention also provides for systems that include a non-flammable concentration of isoprene in the gas phase. Additionally, the invention provides isoprene compositions, such as compositions with increased amount of isoprene or increased purity.

Owner:DANISCO US INC +1

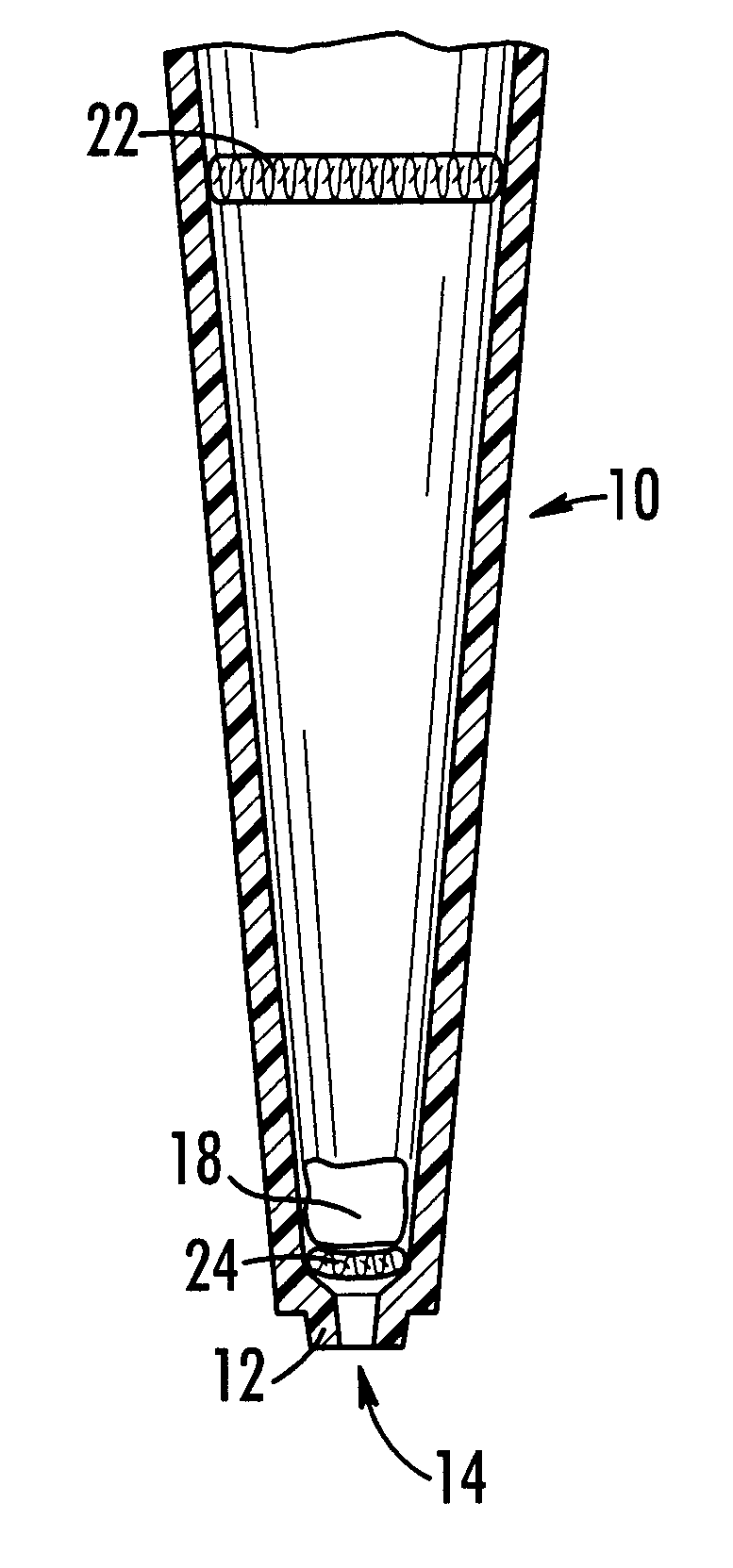

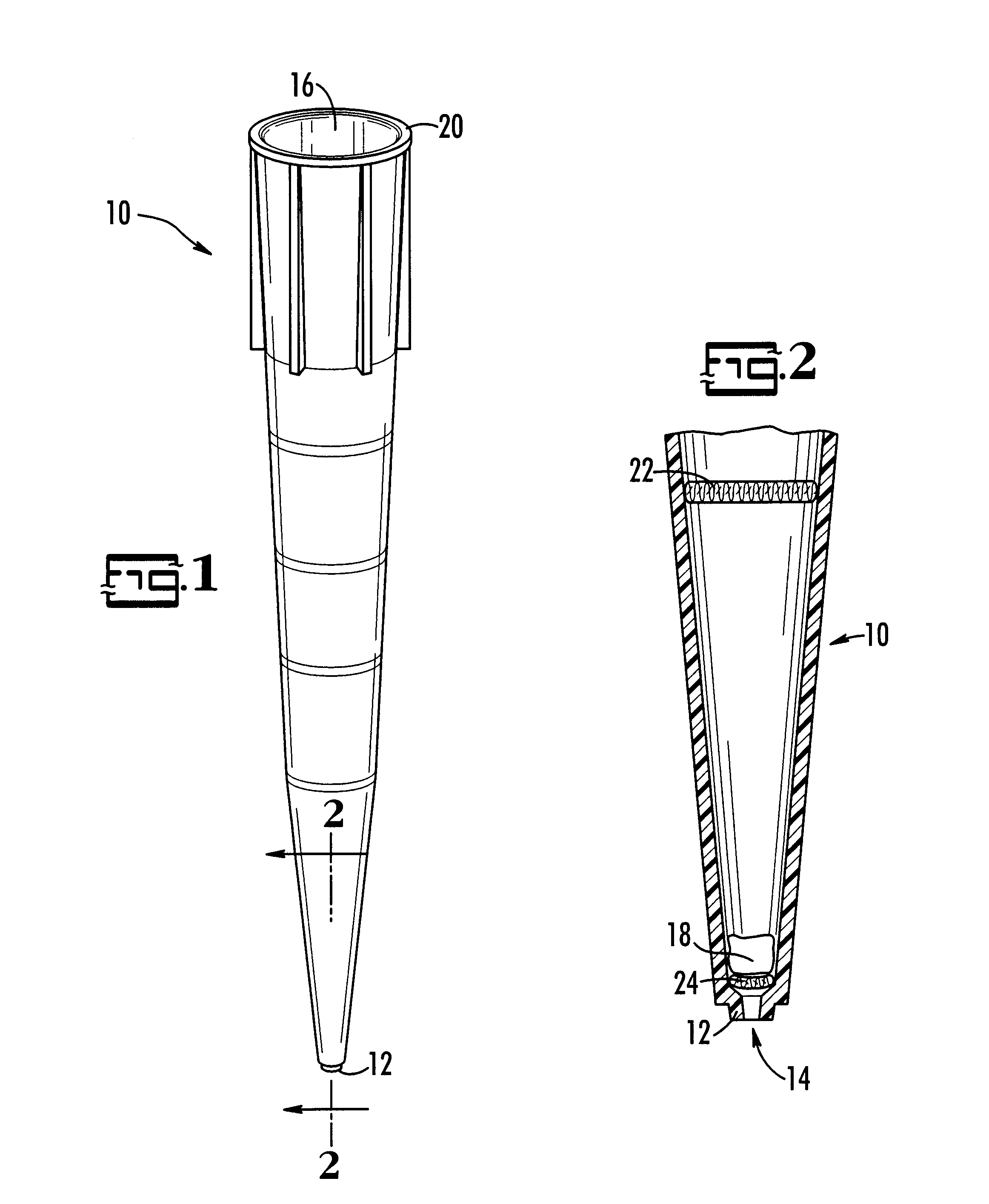

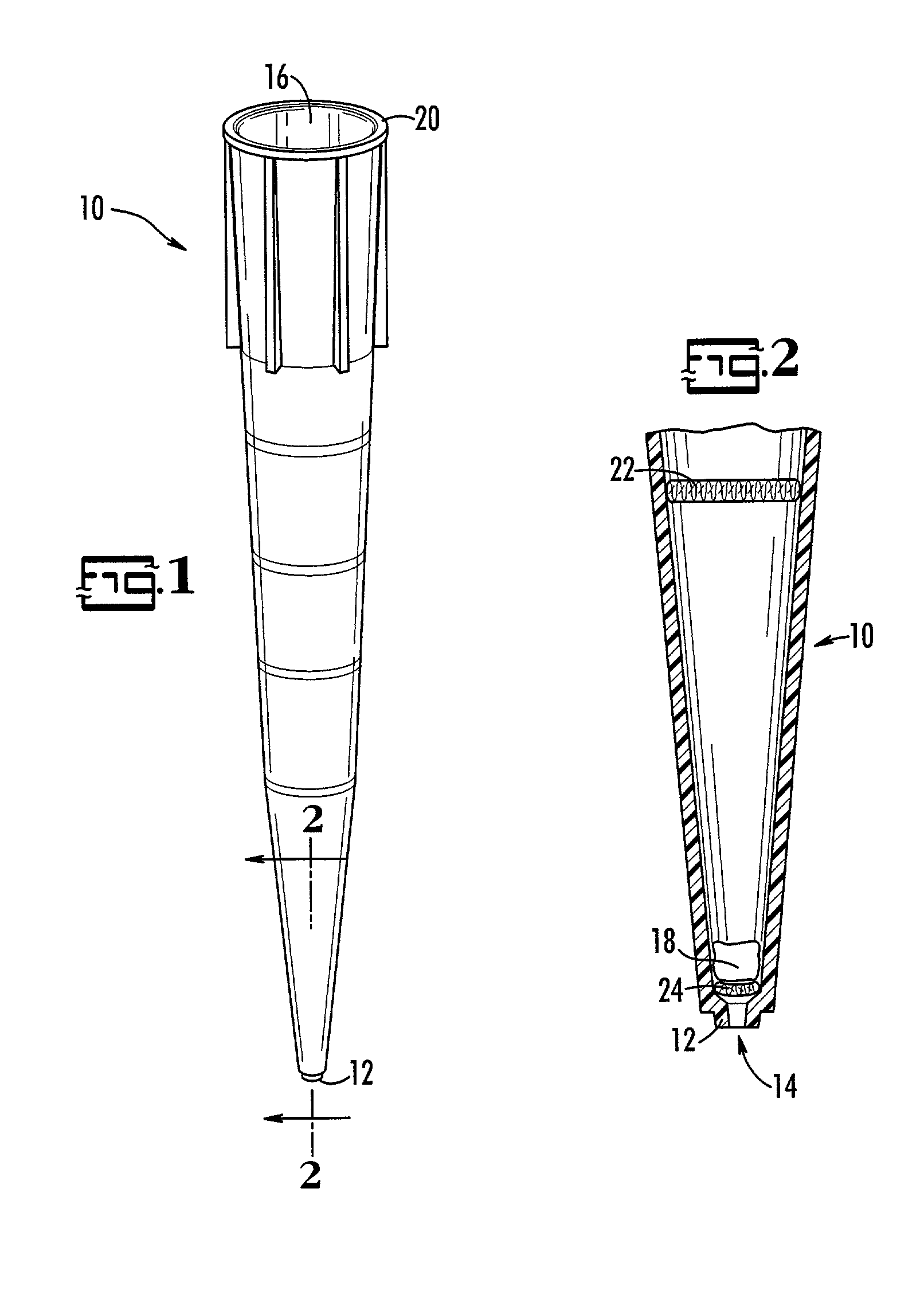

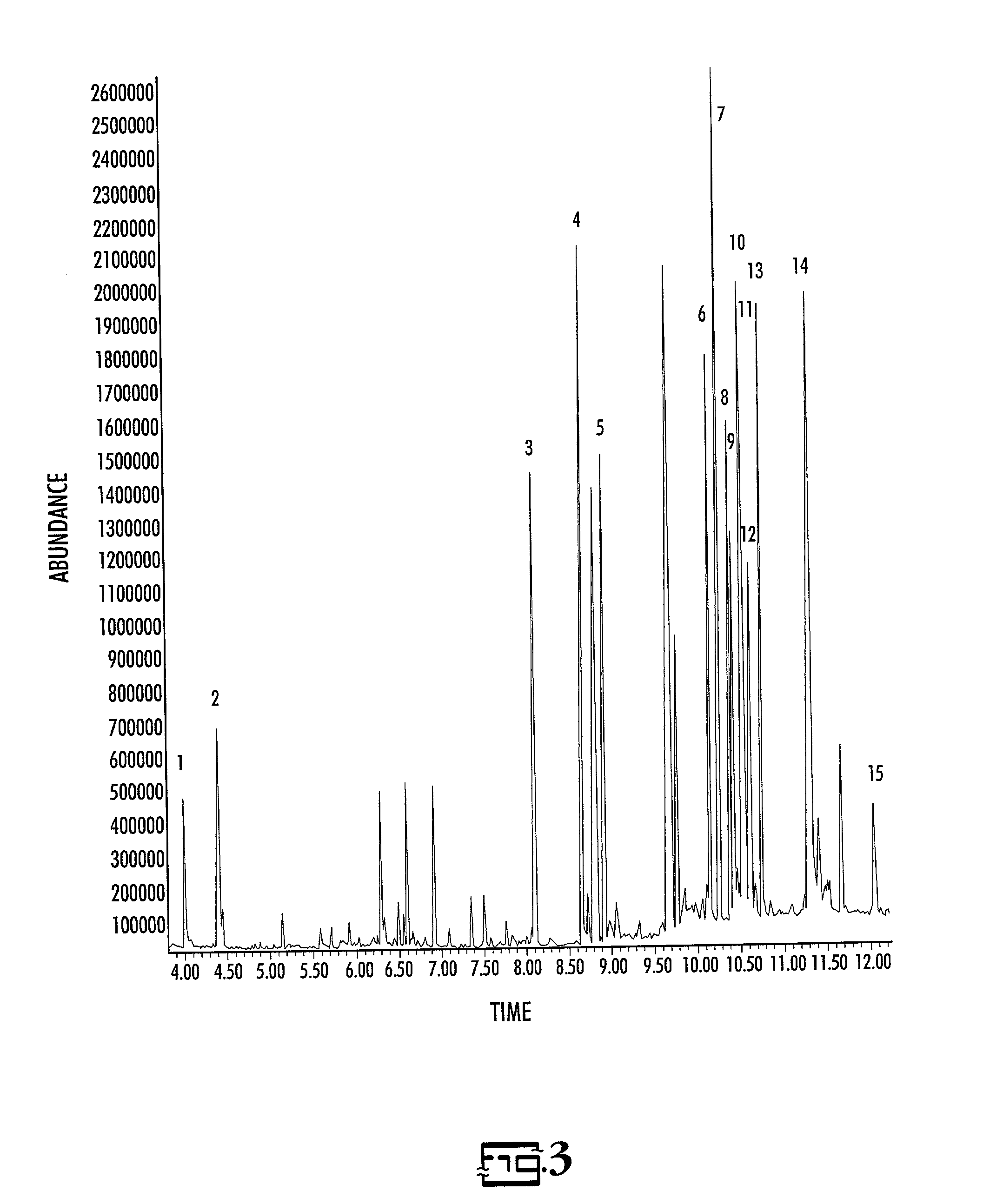

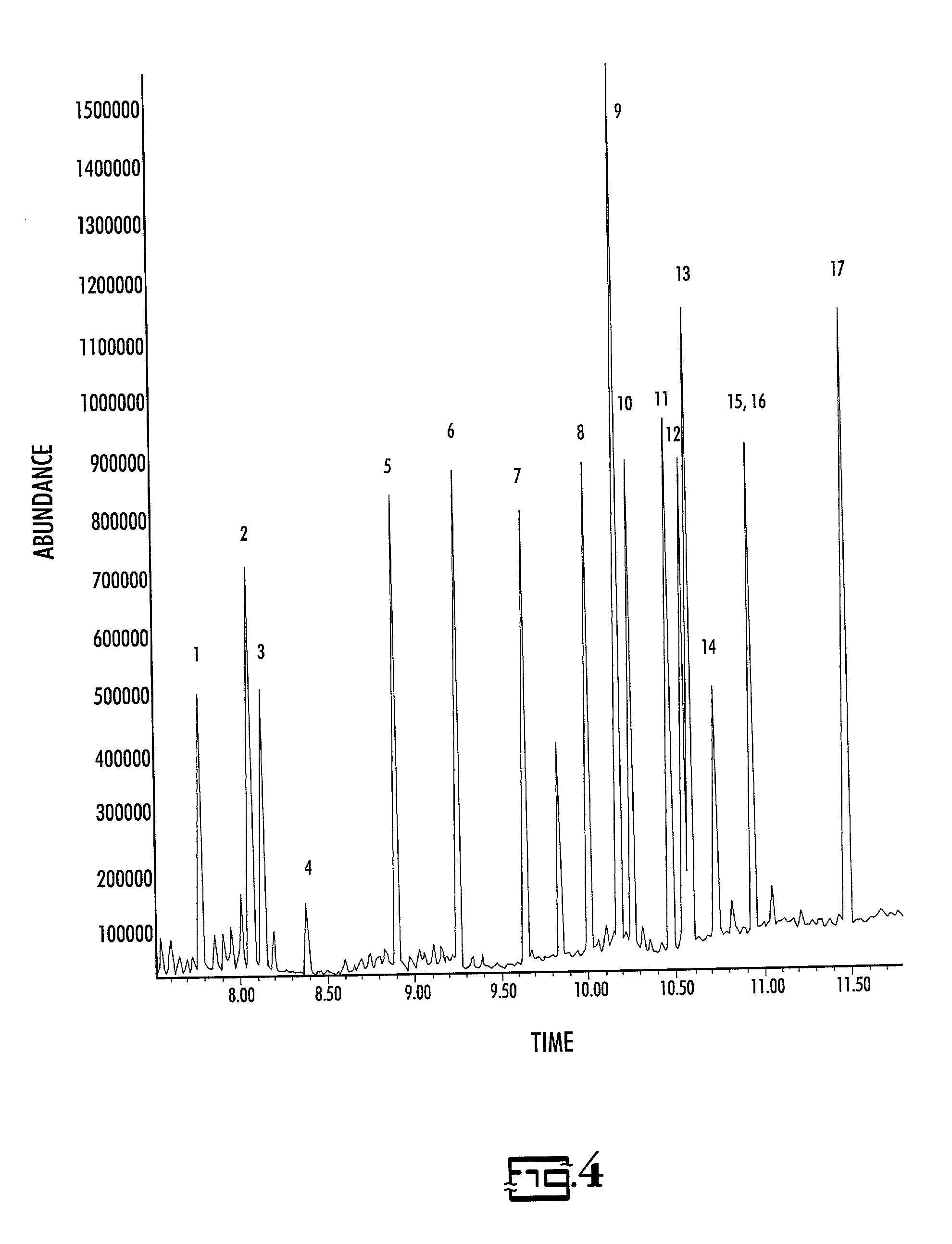

Disposable pipette extraction

Owner:BREWER WILLIAM E

Golf putting game with means for automatically monitoring the movement of the ball

InactiveUS7040998B2Undesired movementGymnastic exercisingBall sportsStationary phaseImage resolution

A golf game employing r.f-tag coded golf balls has a playing area with r.f. antennae located underneath to enable the number of strokes taken by a player to be counted. Separate antennae are provided for the tee area and hole, respectively, and the antennae around the hole are smaller to improve resolution. The antennae are connected to a computer which monitors successive moving and stationary phases of a golf ball to count the number of strokes taken by a player.

Owner:WORLD GOLF SYST

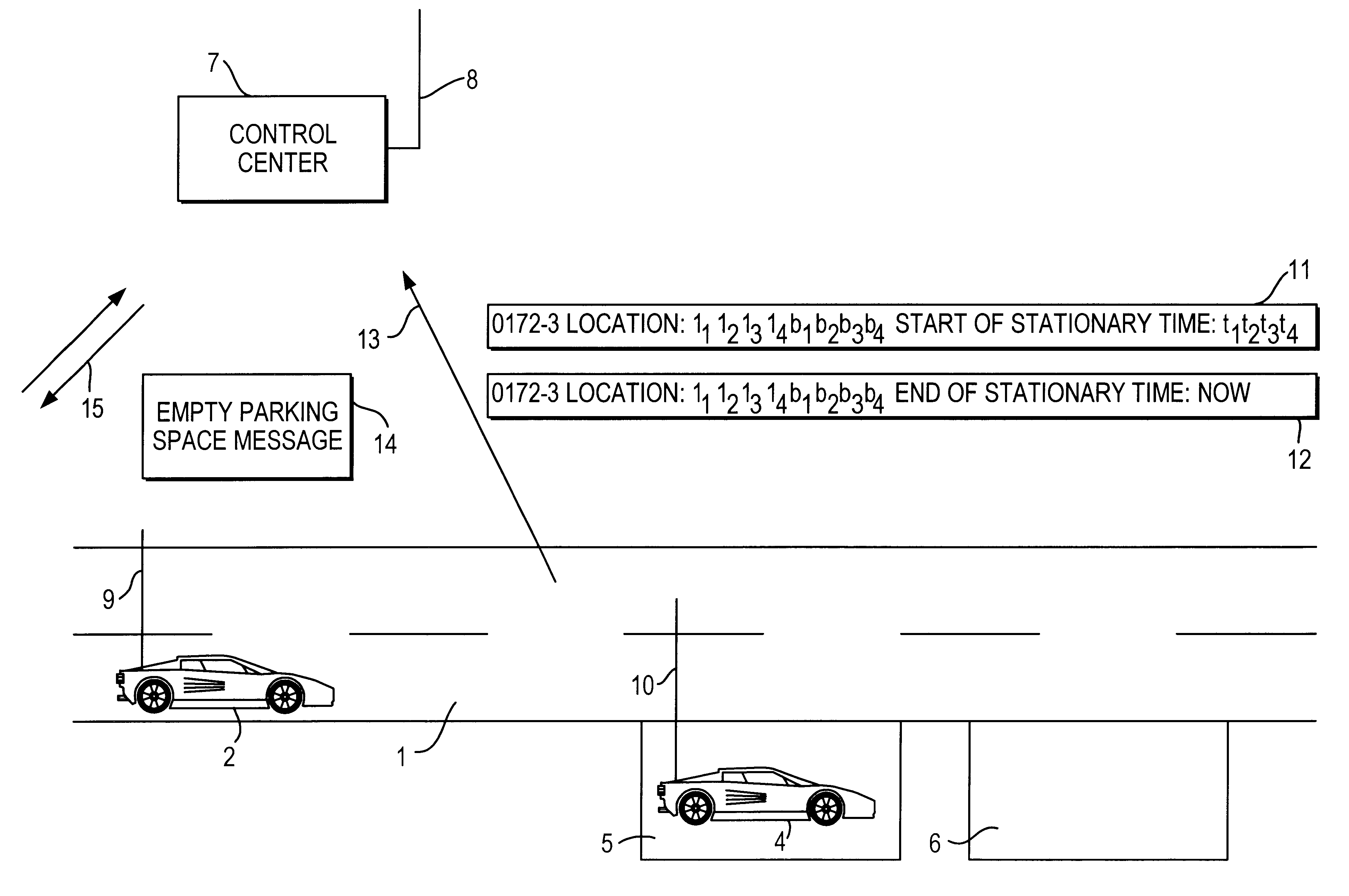

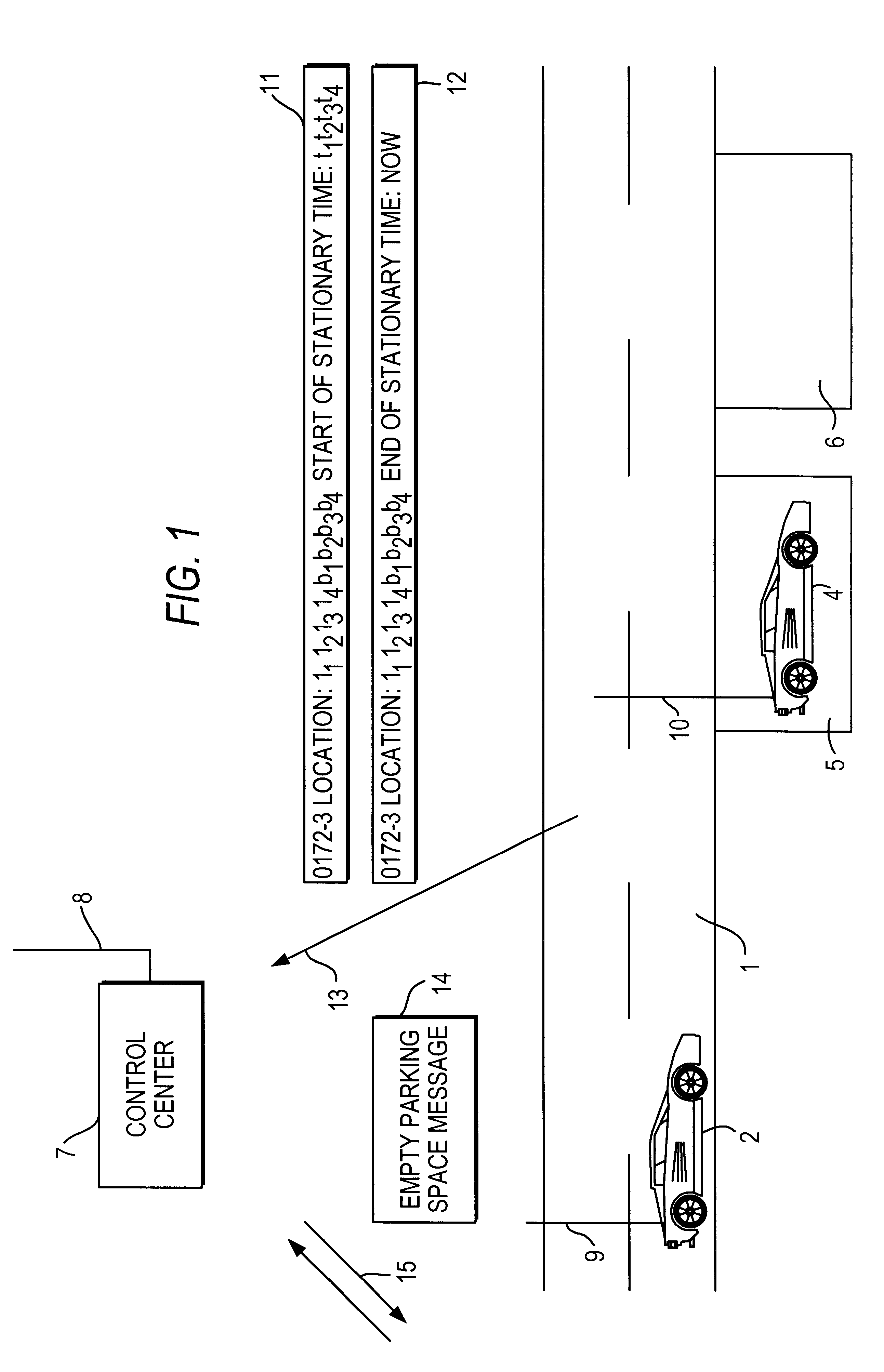

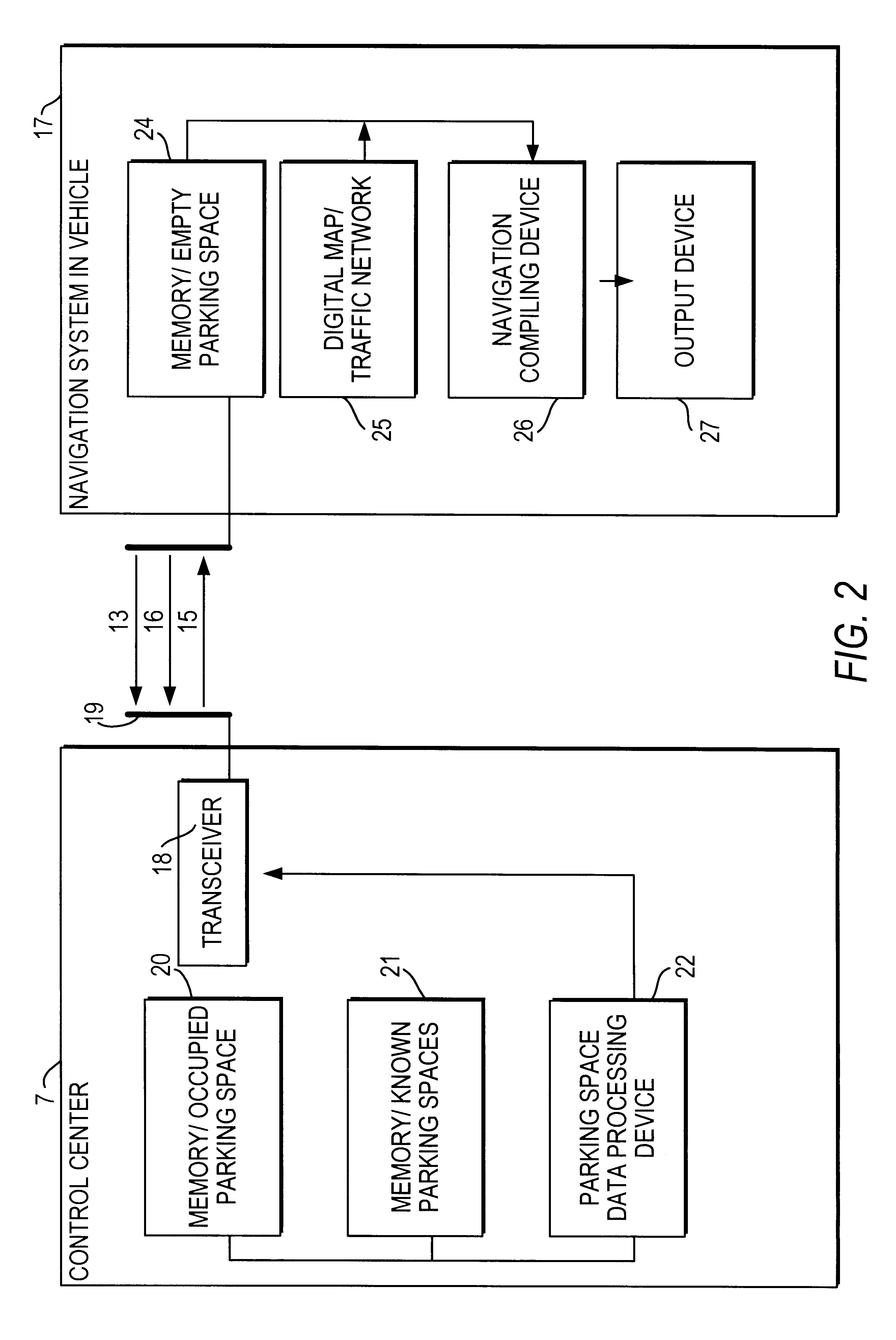

Parking space detection

InactiveUS6266609B1Effectively monitors the occupation proportion of parking spacesInstruments for road network navigationTicket-issuing apparatusStationary phaseTraffic network

A method for detecting information on occupied parking space in a traffic network, in particular a town, uses a parking space detection control center. Parking space information relating to a stationary phase of a vehicle and the vehicle location is transmitted to the control center from a navigation system at the vehicle. Information relating to empty parking space is generated by the control center and information relating to empty parking space is transmitted from the control center to a navigation system at the vehicle end.

Owner:DDG GES FUR VERKEHRSDATEN

Multicapillary device for sample preparation

InactiveUS20070017870A1Large specific surface areaLoad largeIon-exchange process apparatusComponent separationStationary phaseMICRO PIPETTE

A multicapillary sample preparation device, especially useful for handling biological samples, comprising a plurality of uniform capillary tubes coated with a stationary phase, and arranged in a monolithic element. The multicapillary device is suitable for attachment to a pipette, micropipette, syringe, or other analytical or sample preparation instrument.

Owner:BIOEDGE

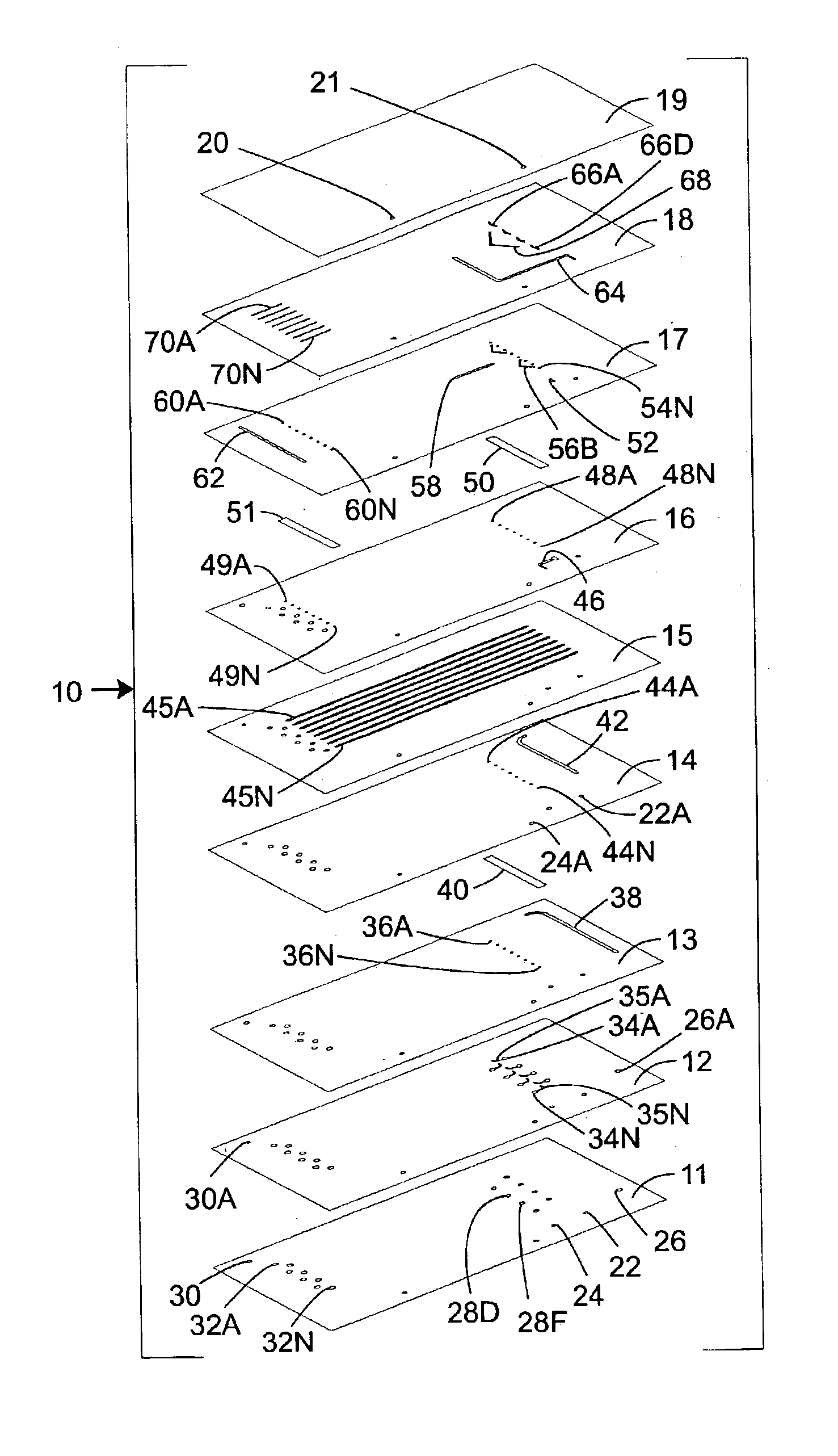

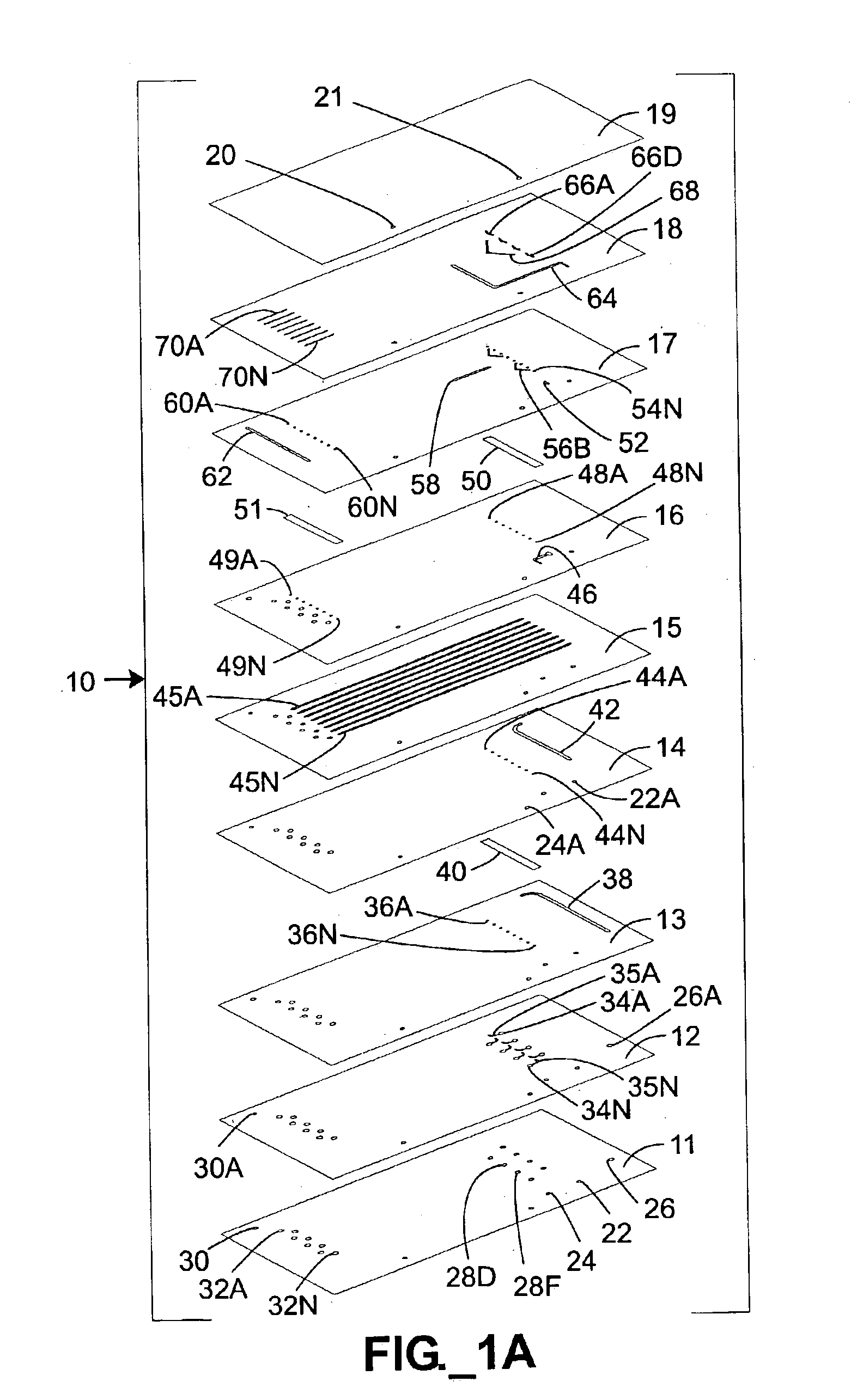

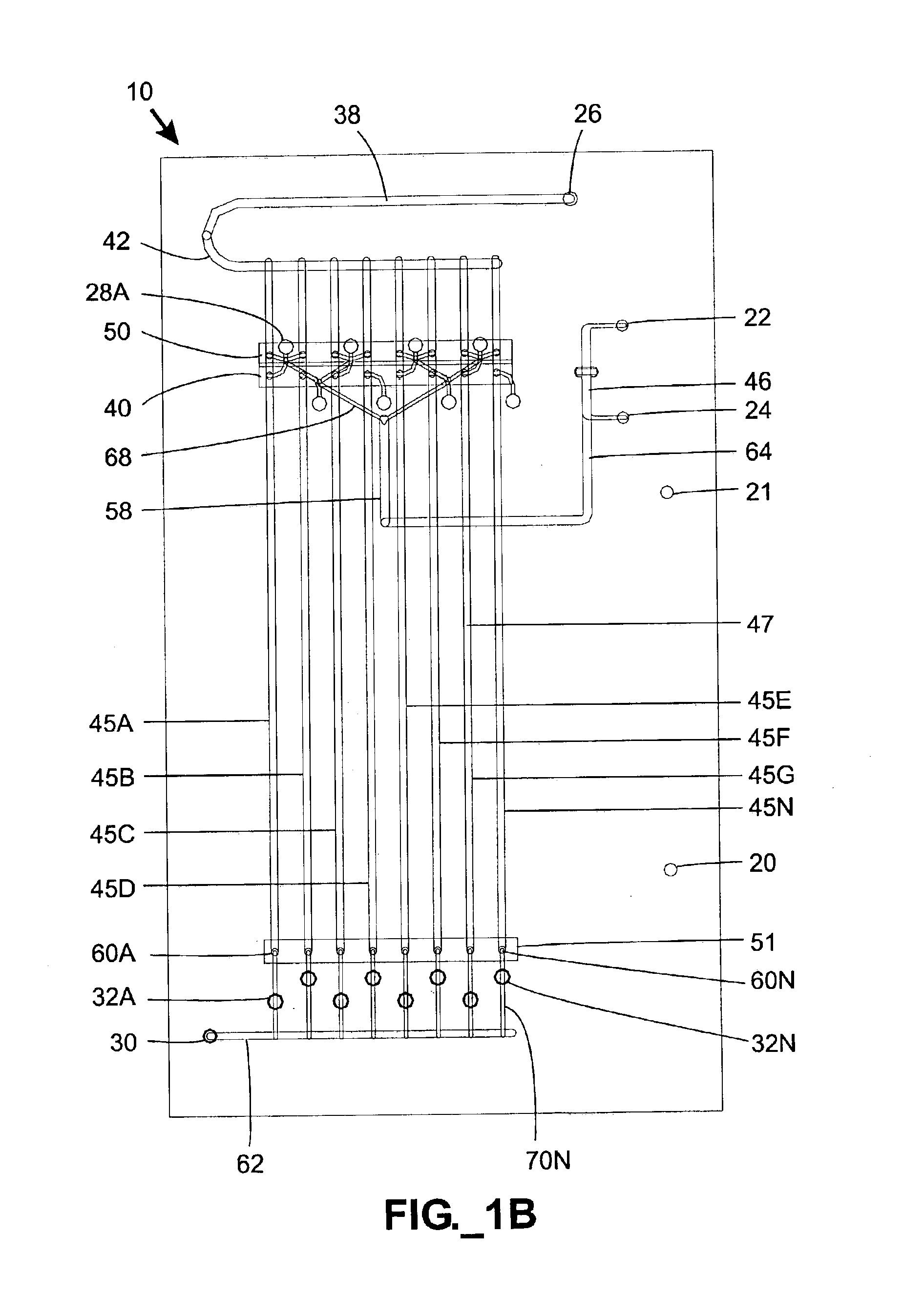

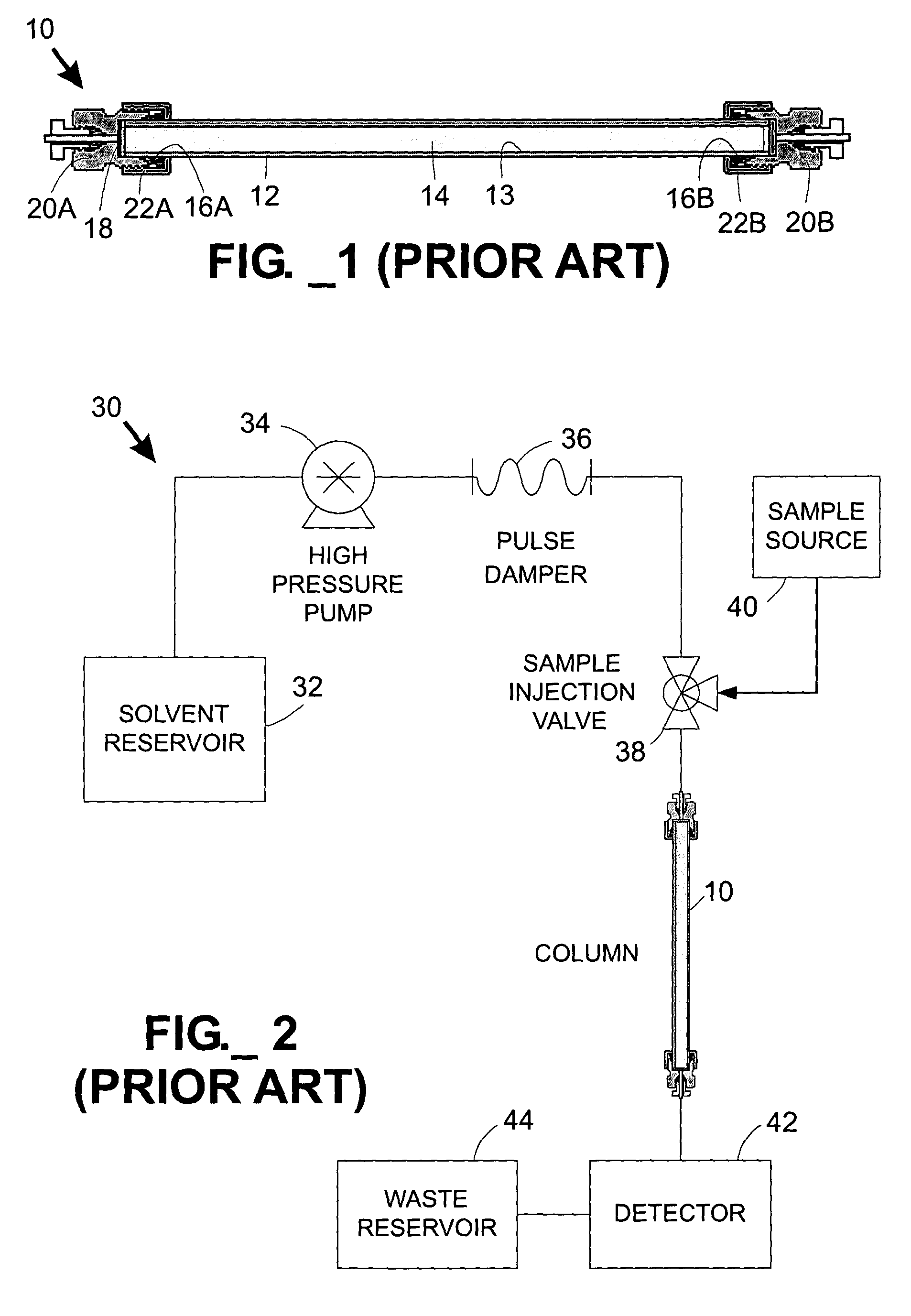

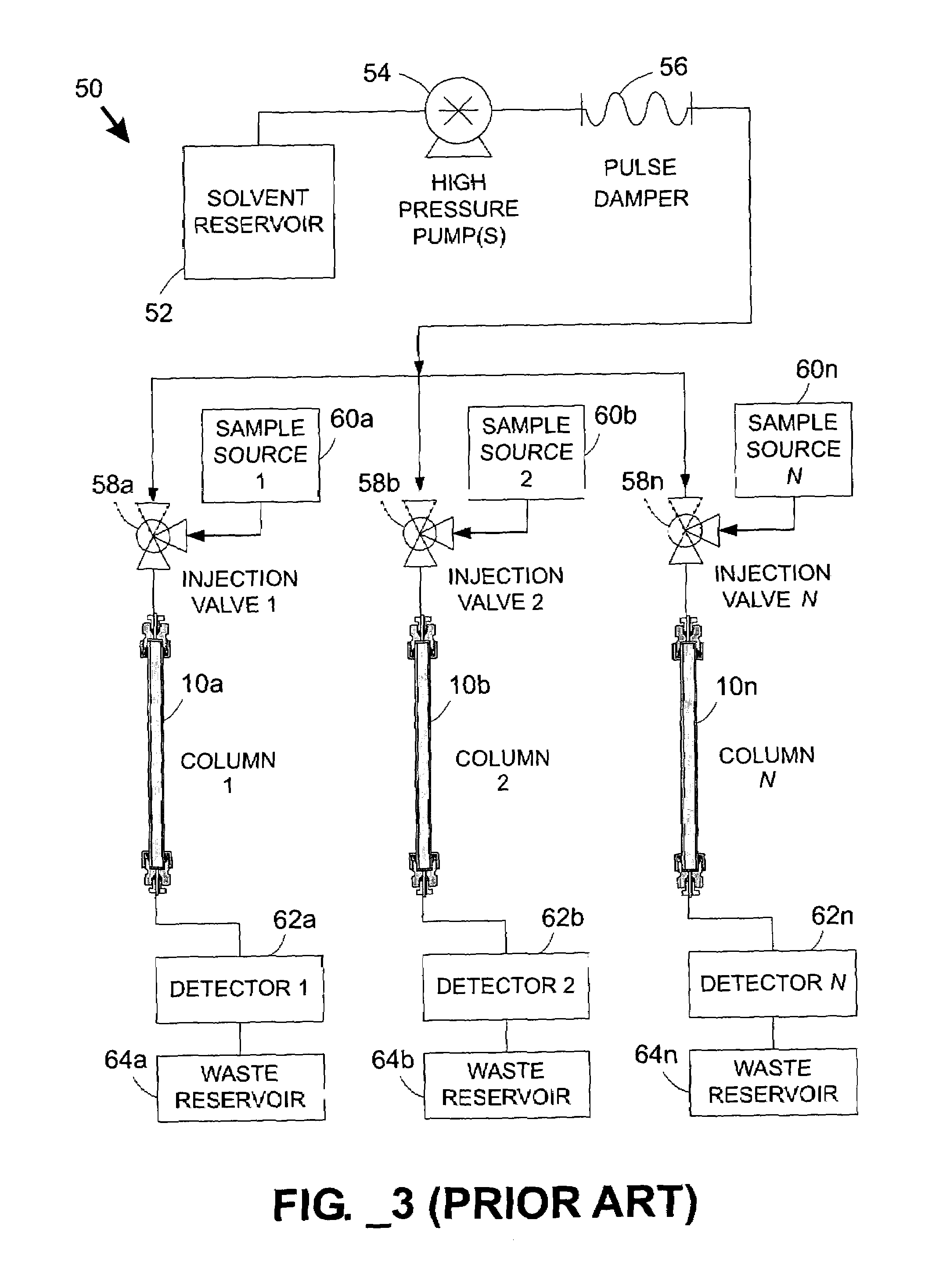

Separation column devices and fabrication methods

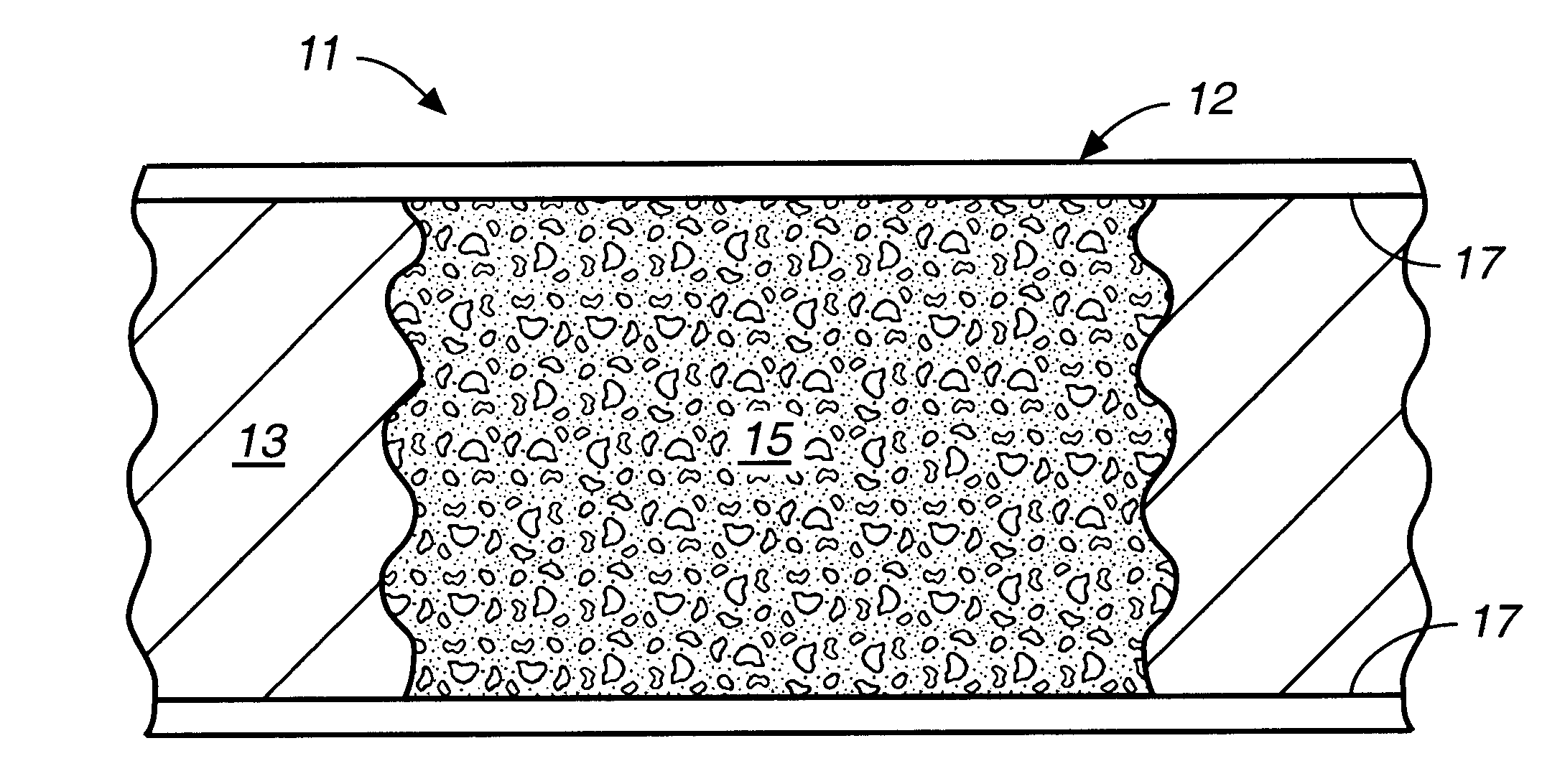

Pressure-driven microfluidic separation devices, such as may be used for performing high performance liquid chromatography, are provided. Multiple separation columns may be defined in a single device and packed with stationary phase material retained by porous frits. One or more splitters may be provided to distribute slurry and / or mobile phase among multiple separation columns. In one embodiment, separation devices are substantially planar and fabricated with multiple device layers. Systems and methods employing slurry for packing separation devices are also provided.

Owner:AGILENT TECH INC

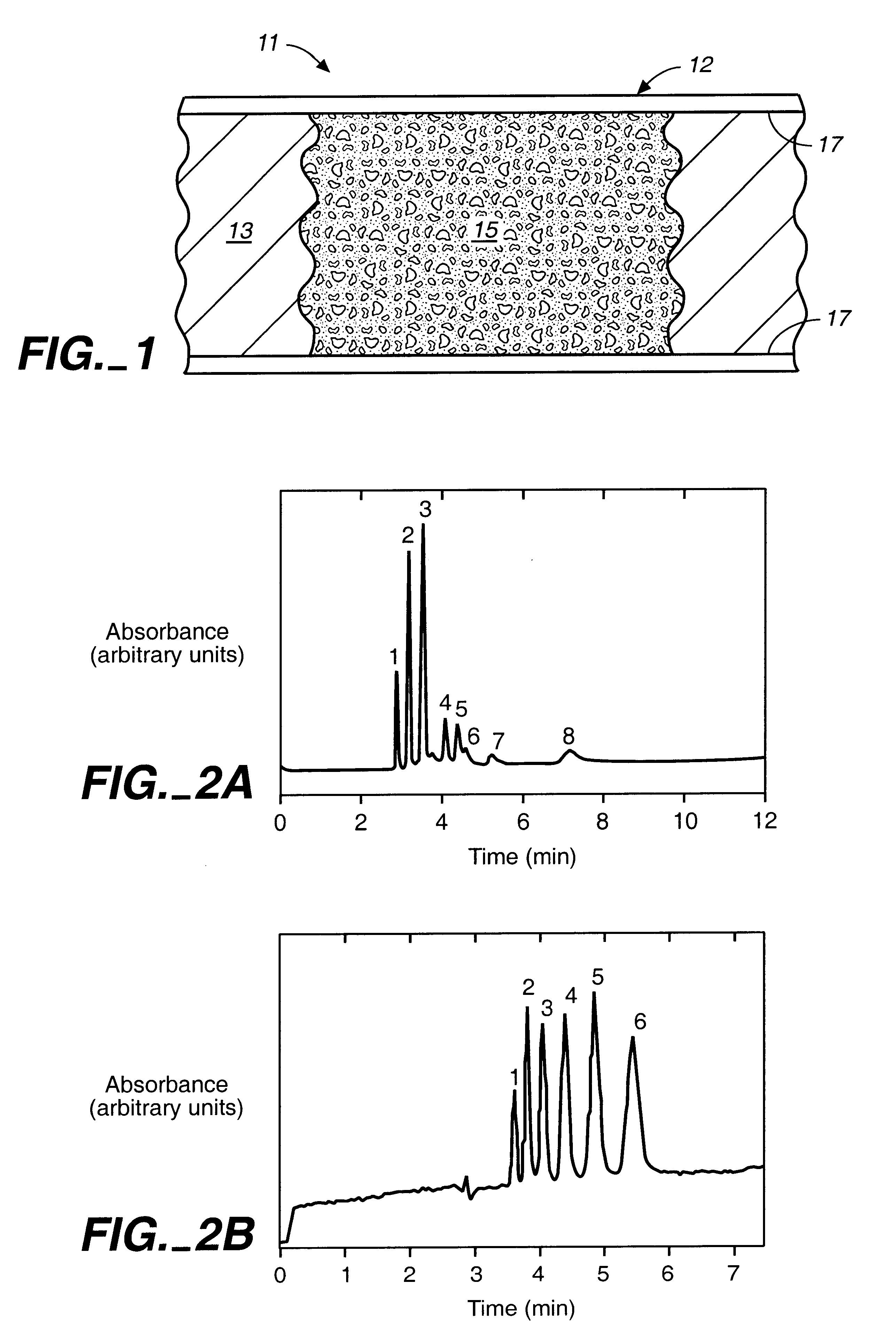

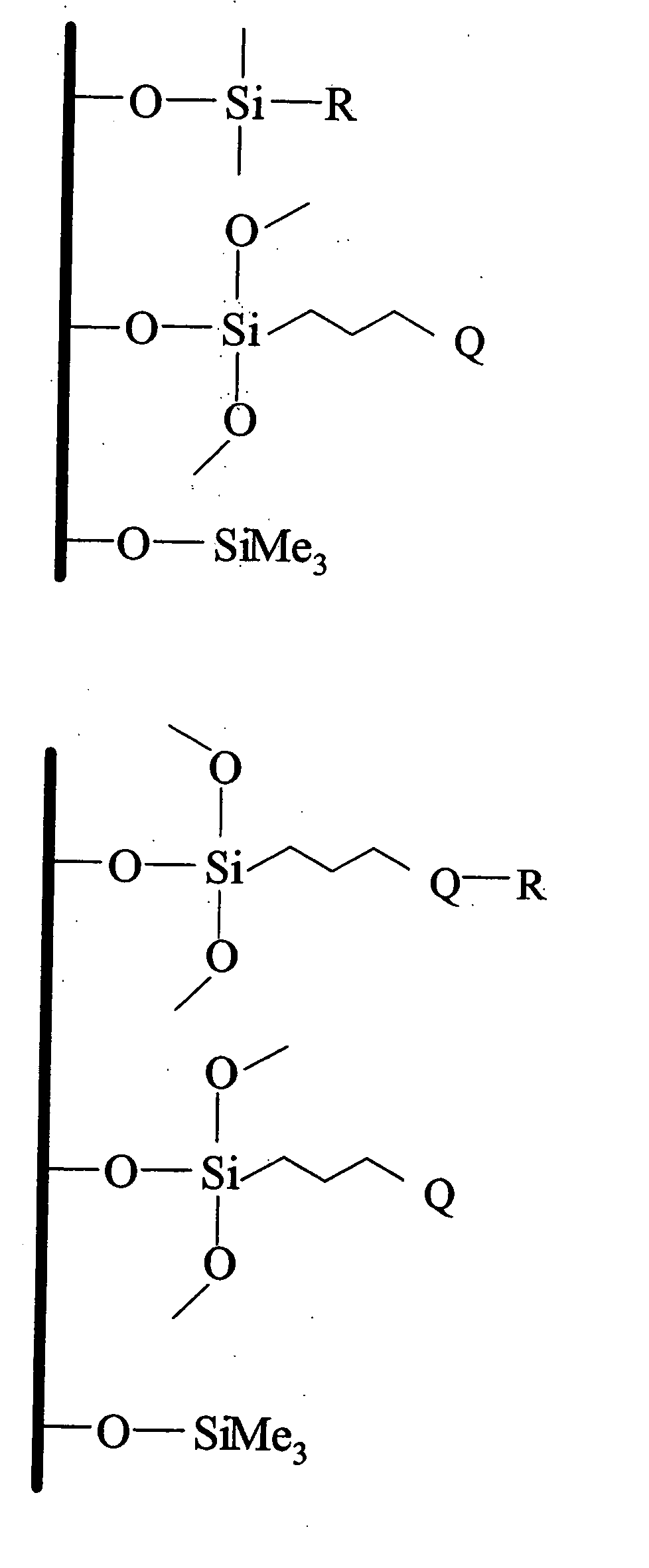

Polar-modified bonded phase materials for chromatographic separations

ActiveUS20060207923A1Good reproducibilityIon-exchange process apparatusOther chemical processesChromatographic separationStationary phase

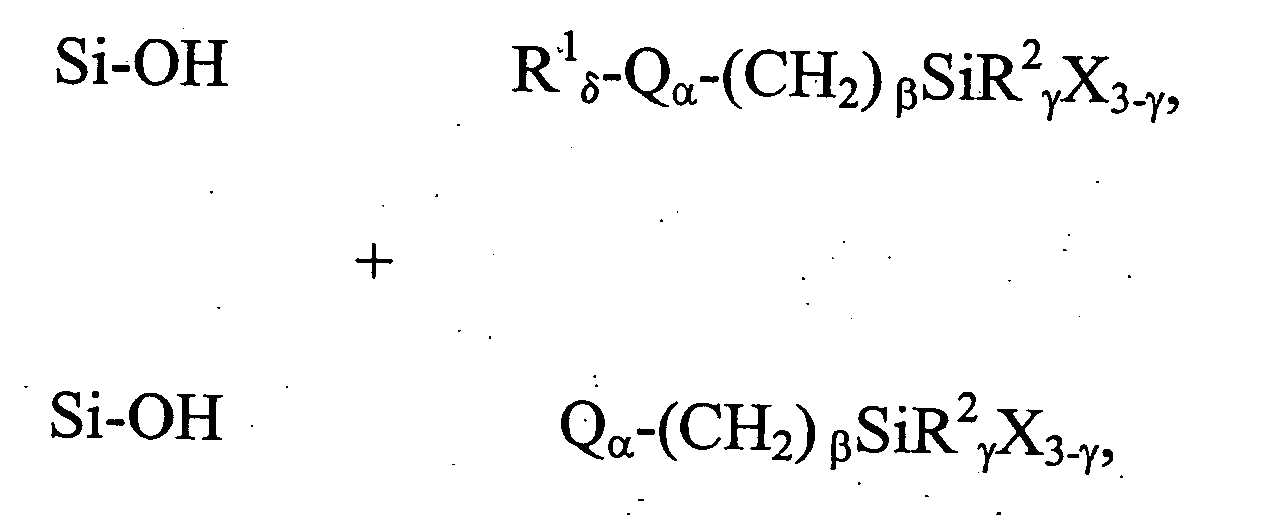

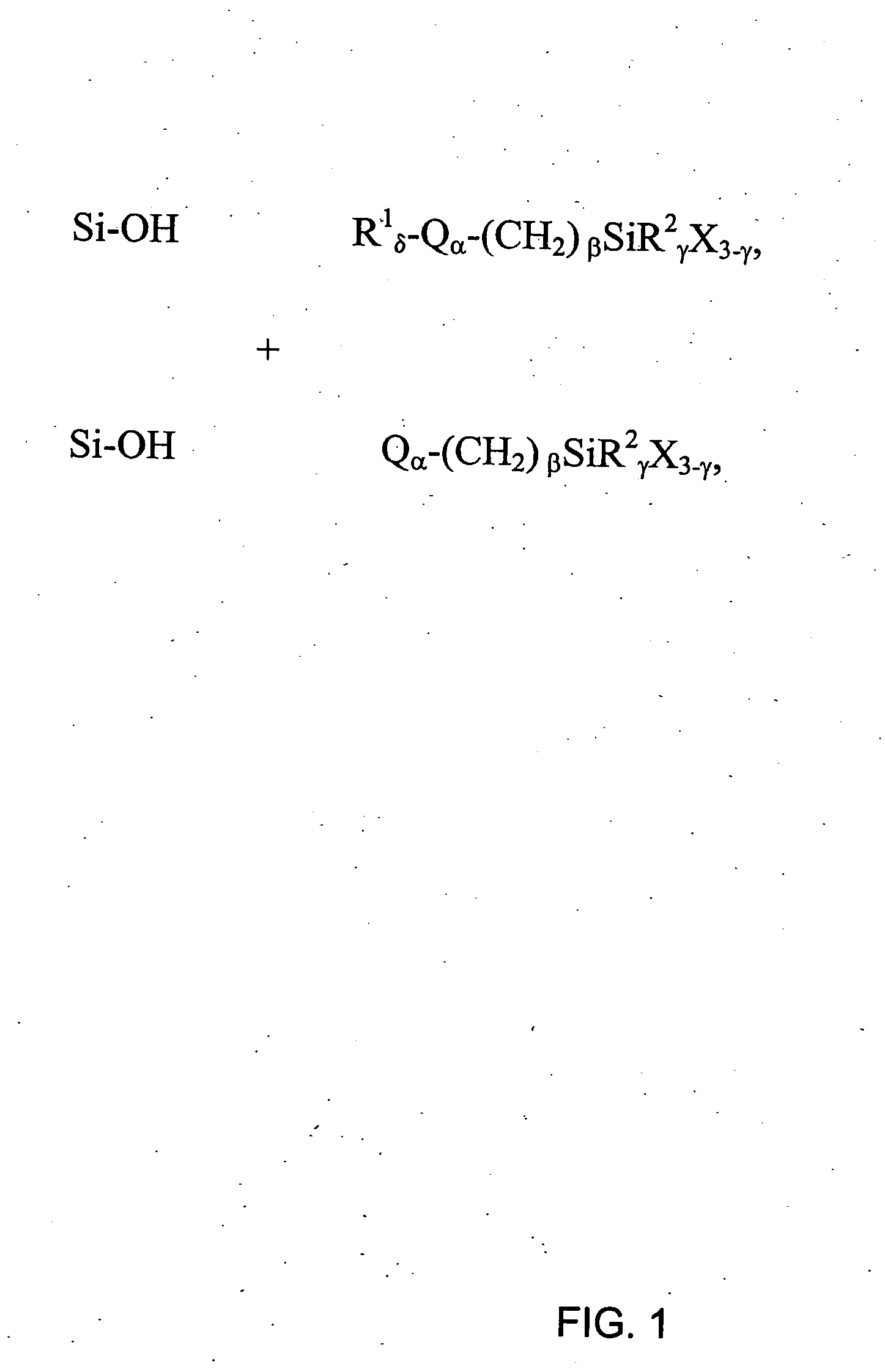

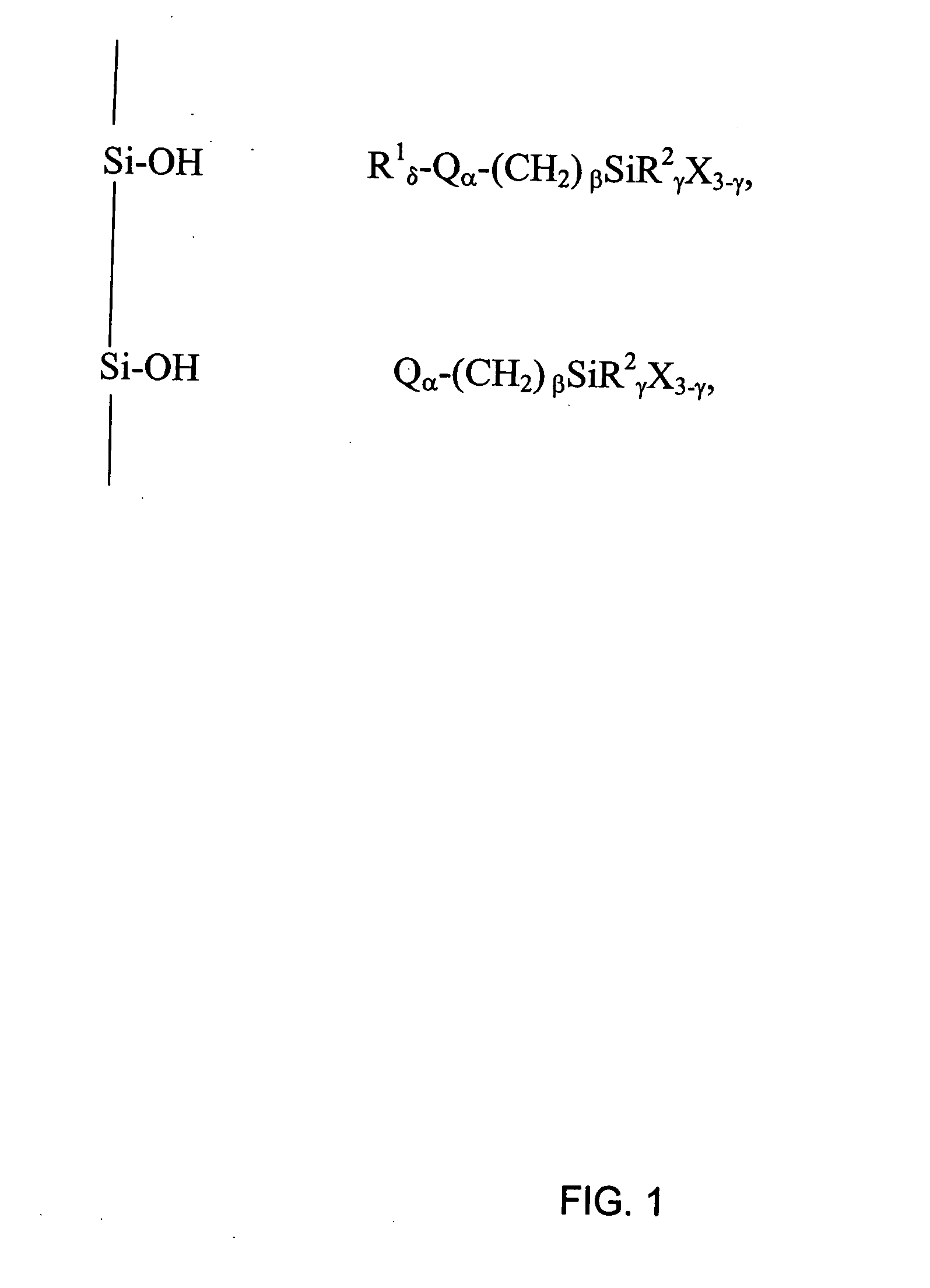

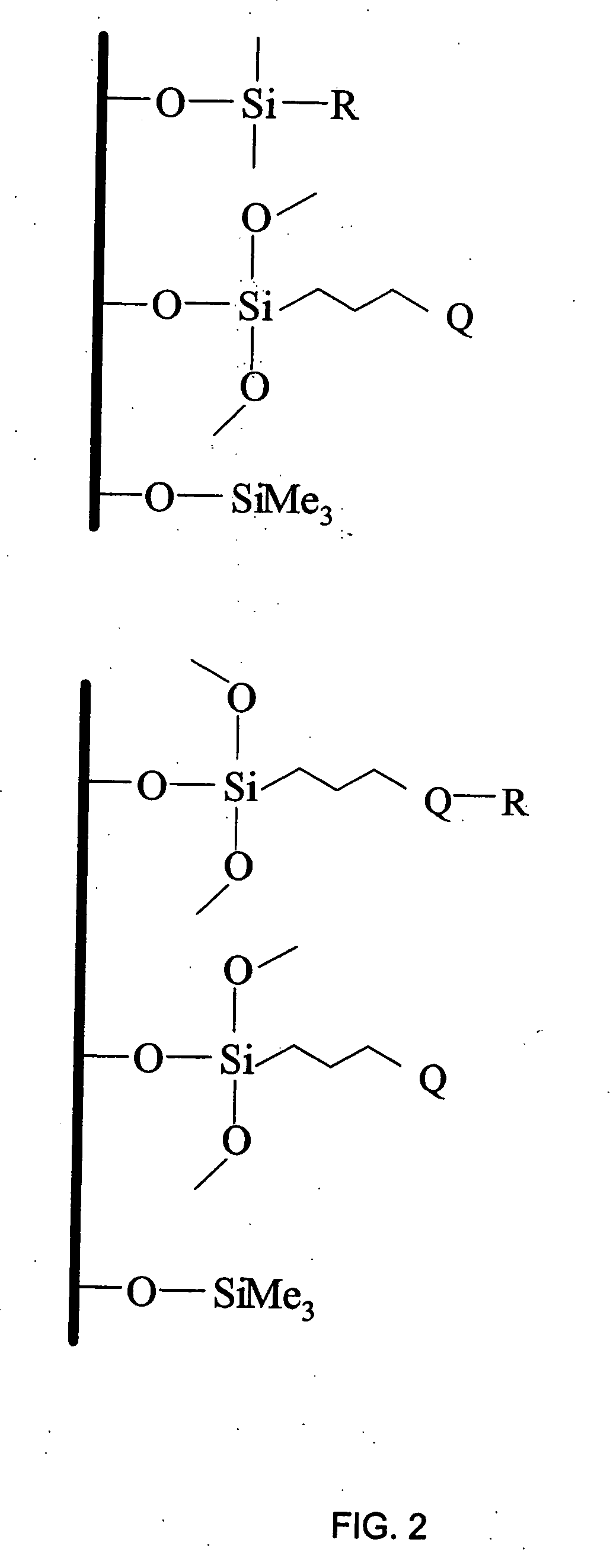

Novel compositions are disclosed for use as a stationary phase in chromatography comprising an inorganic substrate that is modified with at least one silane having the formula R1δ-Qα-(CH2)βSiR2γX3-γ. In a preferred embodiment, the inorganic substrate is silica gel and is modified with at least two silanes. Methods of preparation and use in chromatographic applications are disclosed. The novel compositions provide superior chromatographic performance, reduced silanol activity, enhanced stability, and reproducibility in preparation and performance.

Owner:AGILENT TECH INC

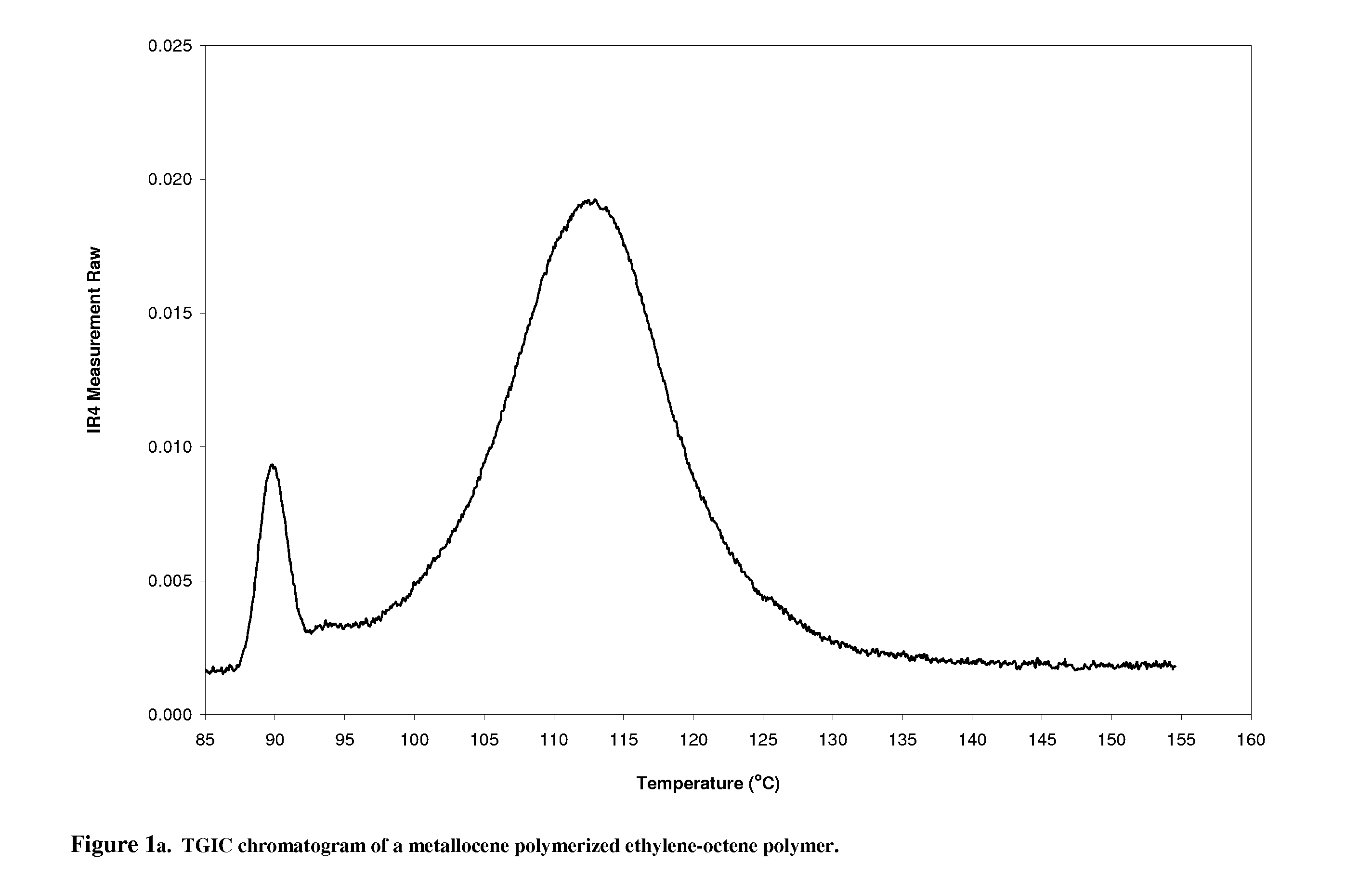

Multi-column separation devices and methods

InactiveUS7261812B1Ion-exchange process apparatusComponent separationChromatographic separationStationary phase

Chromatographic separation devices include multiple batch-processed columns joined by a body structure and adapted to perform parallel analyses. Both slurry-packed and monolithic column embodiments are provided. One or more liquid-permeable frits of various types may be used to retain stationary phase material within columns. A fluidic distribution network may be used to distribute stationary phase material and / or mobile phase solvents to multiple columns. Separation devices, including microfluidic embodiments, may be fabricated with various materials including polymers. Multi-column fabrication and separation methods are provided.

Owner:AGILENT TECH INC

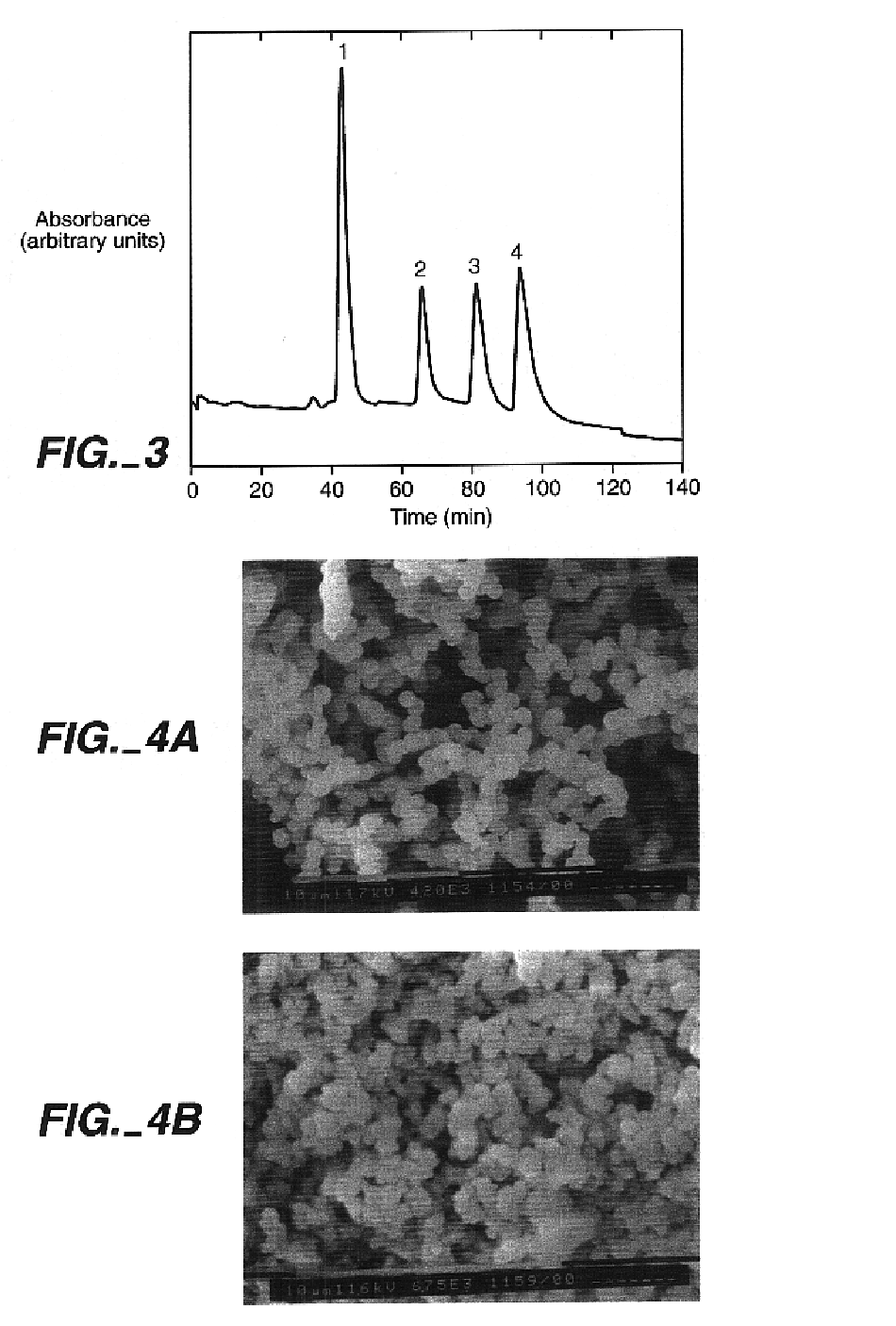

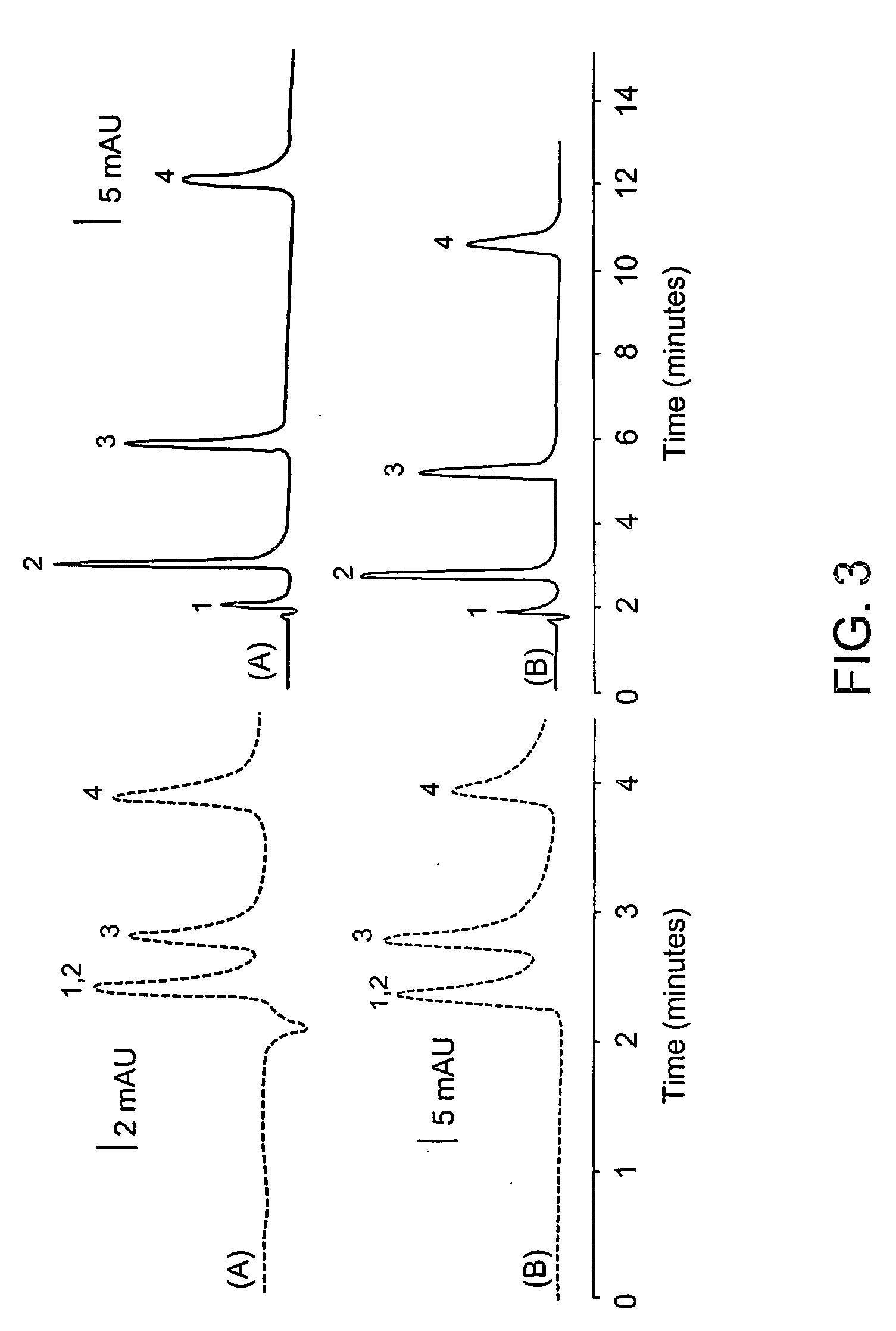

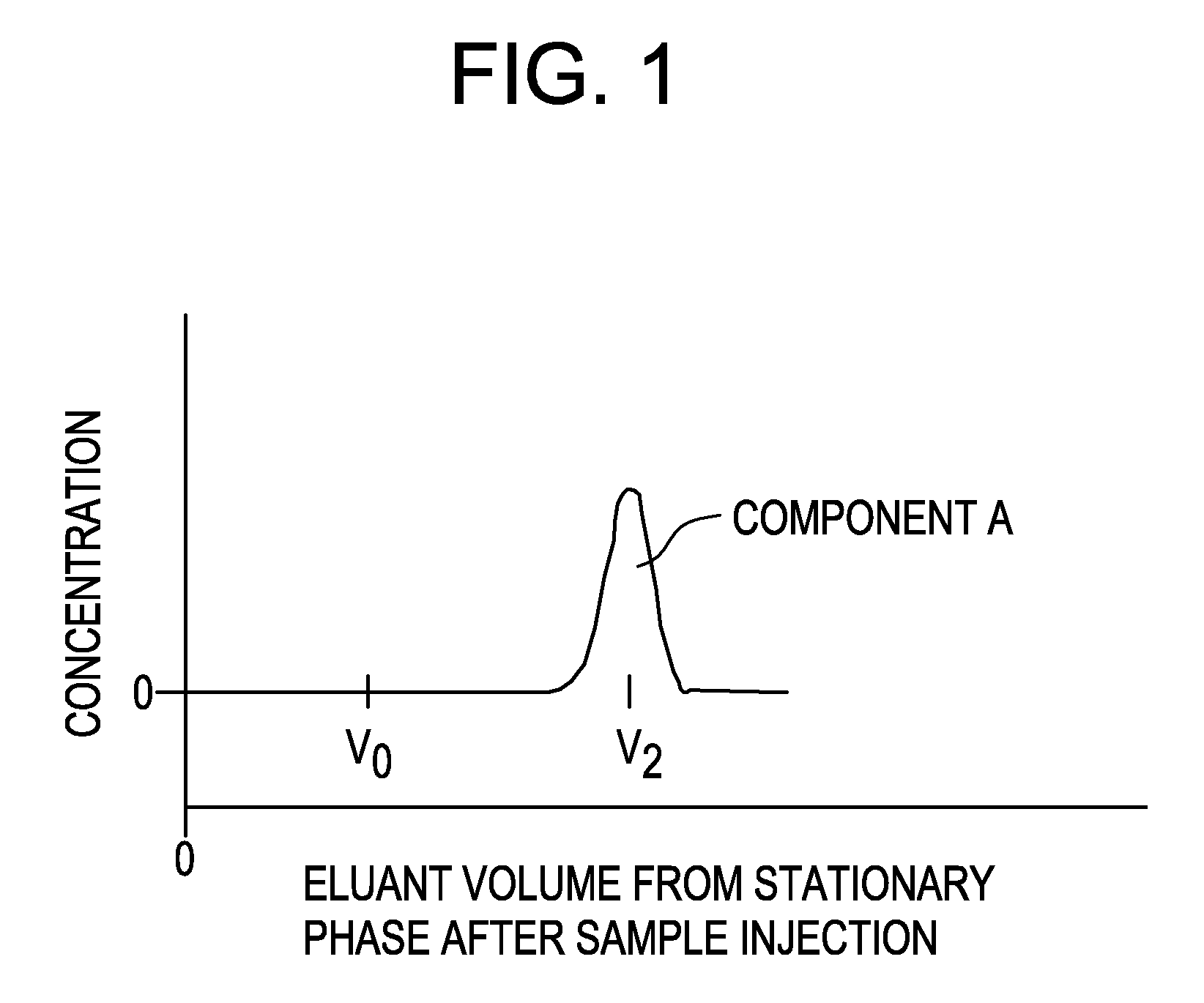

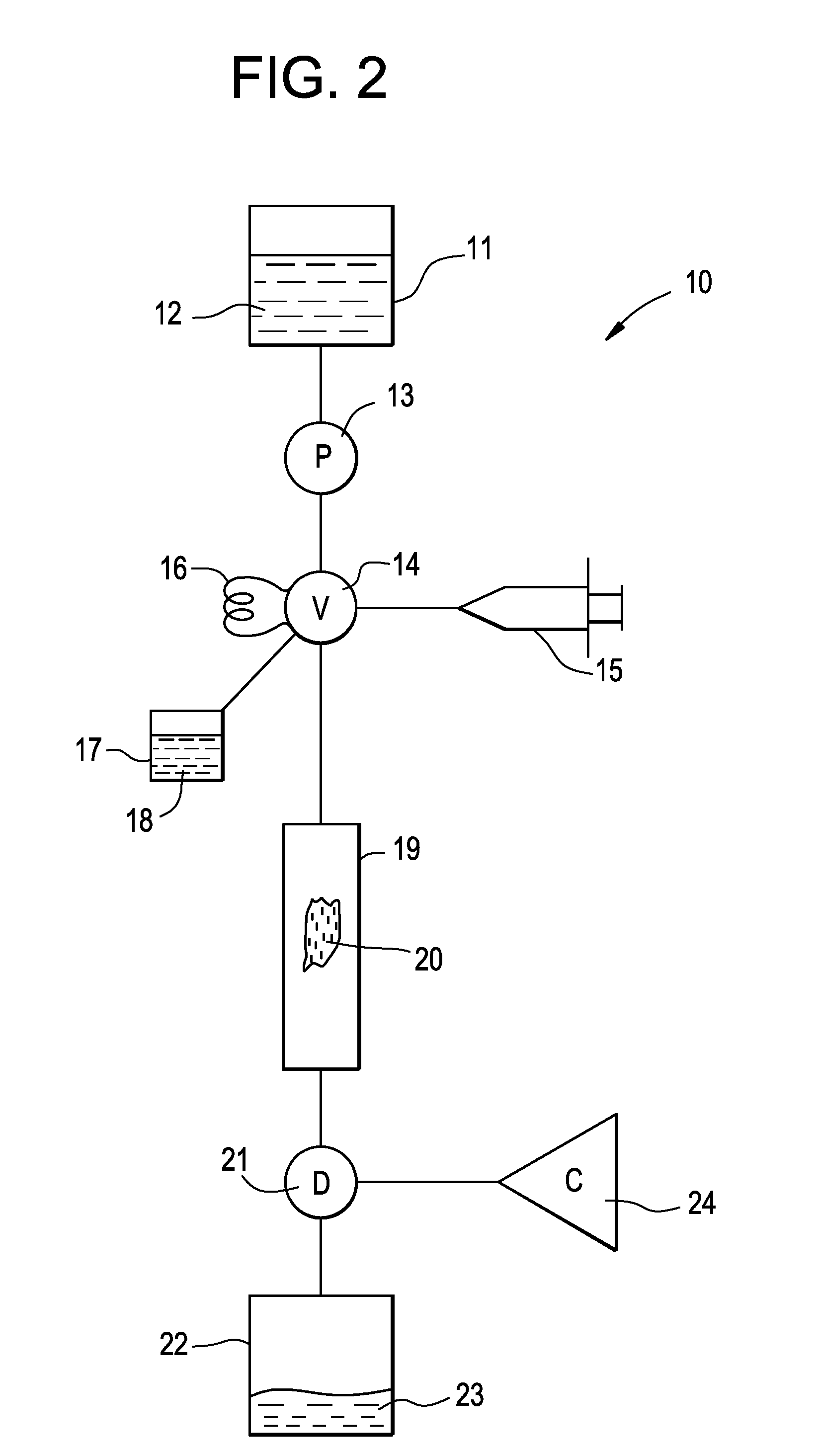

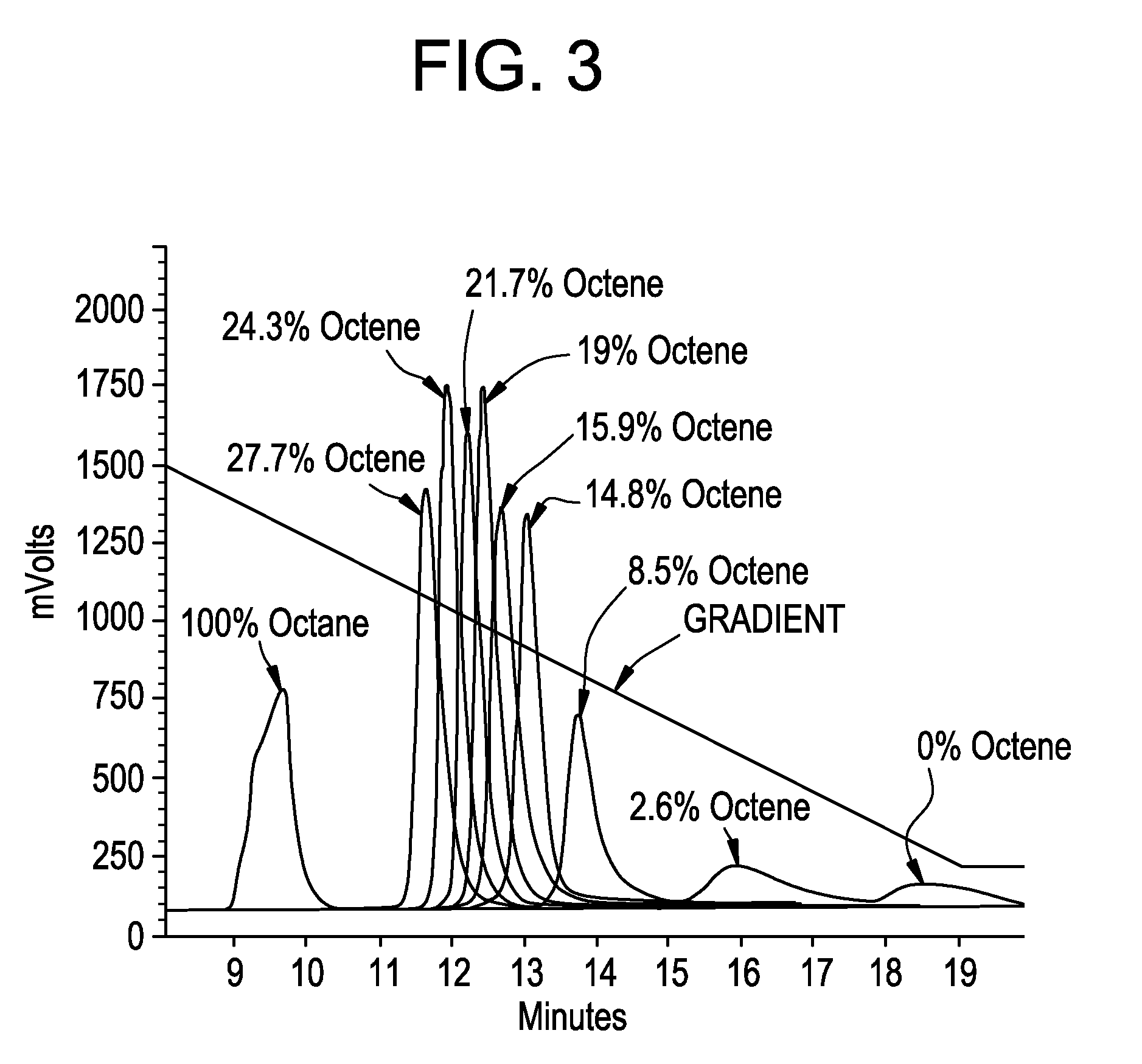

Chromatography of polyolefin polymers

A method for multi-dimensional chromatography of a polyolefin polymer, comprising introducing a solution of the polyolefin polymer into a liquid flowing through a first liquid chromatography stationary phase or a field flow fractionation device and subsequently flowing the solution through a second liquid chromatography stationary phase, the second liquid chromatography stationary phase comprising graphitic carbon, the polyolefin polymer emerging from the liquid chromatography stationary phase with a retention factor greater than zero.

Owner:THE DOW CHEM CO

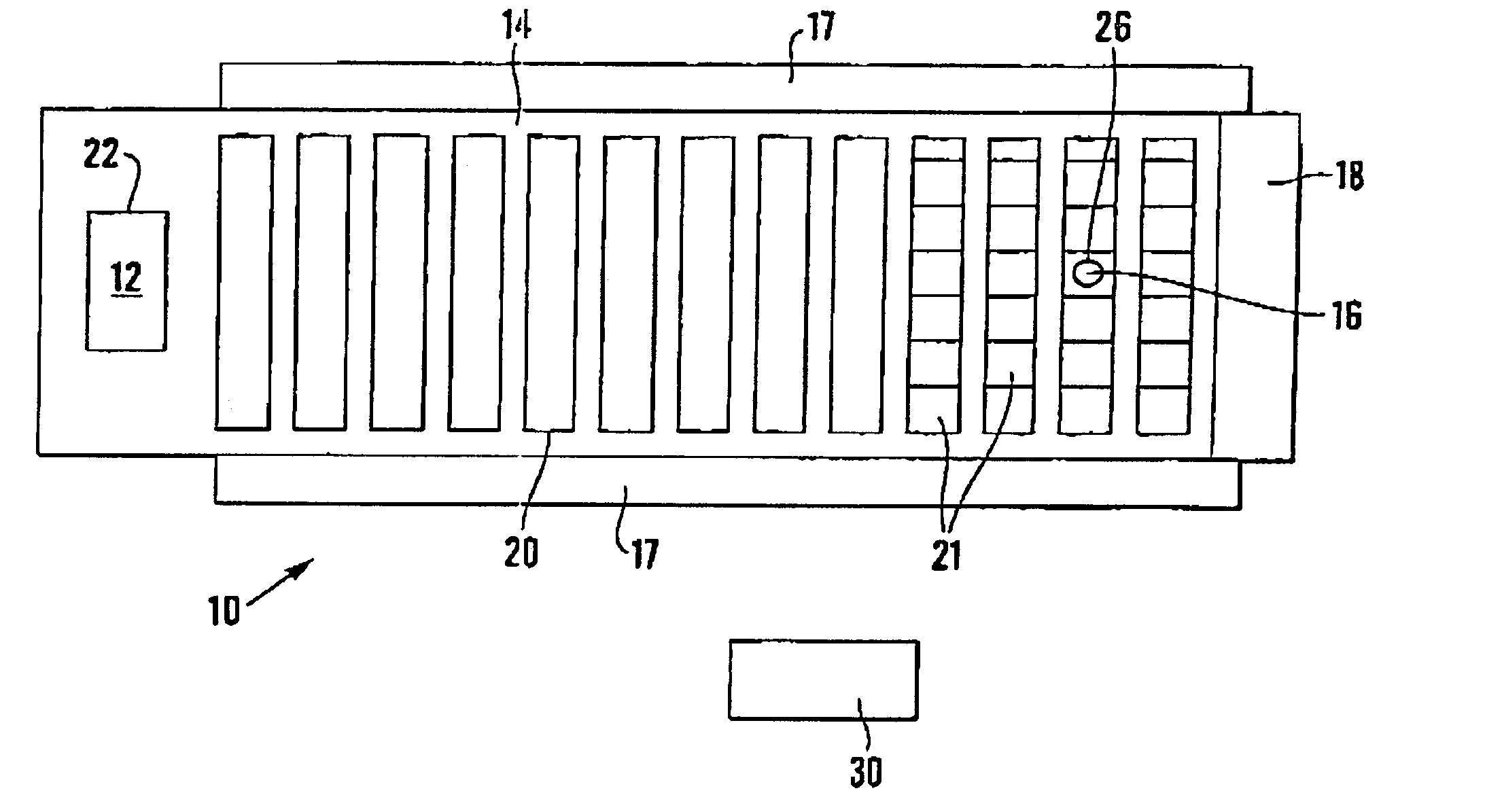

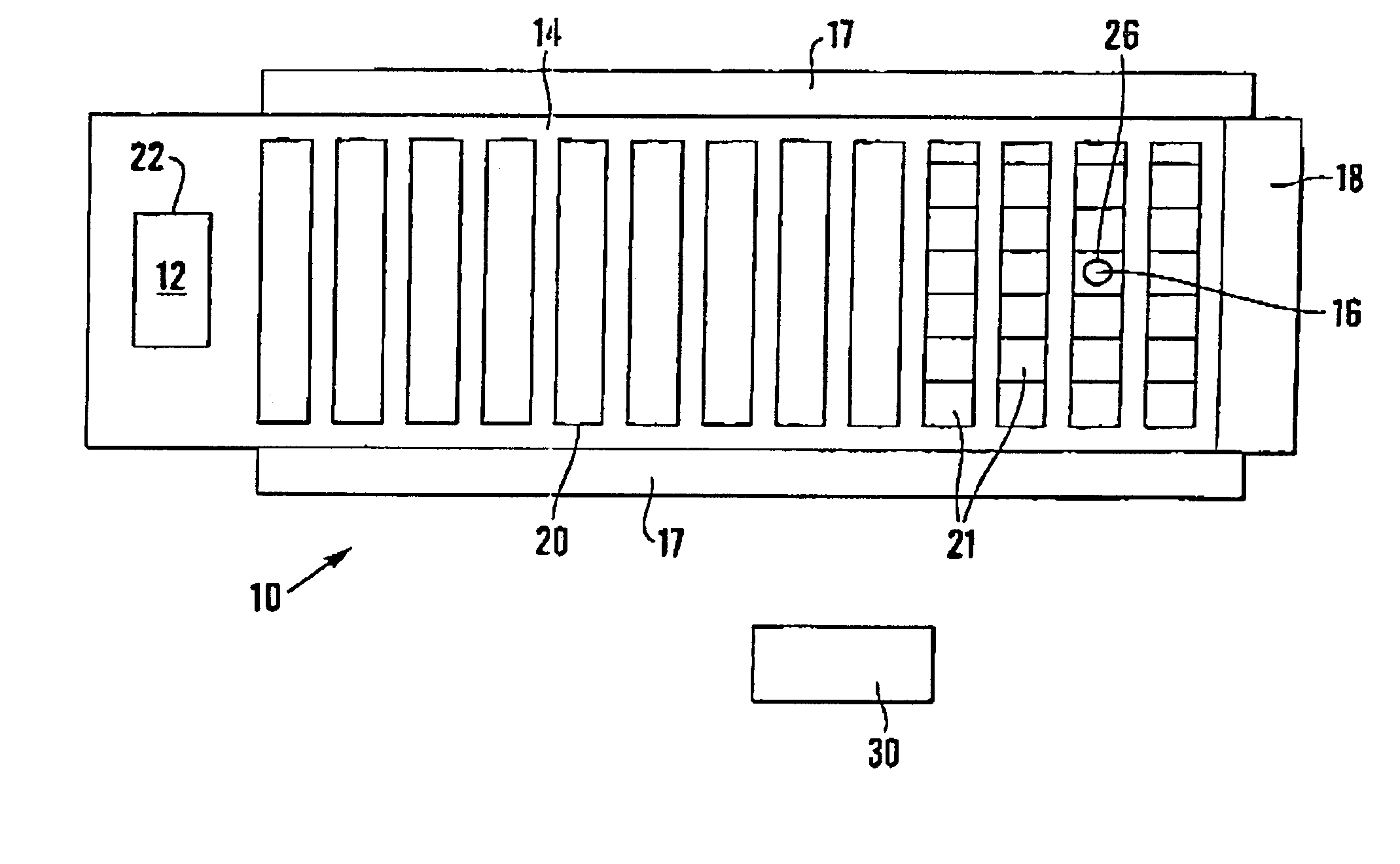

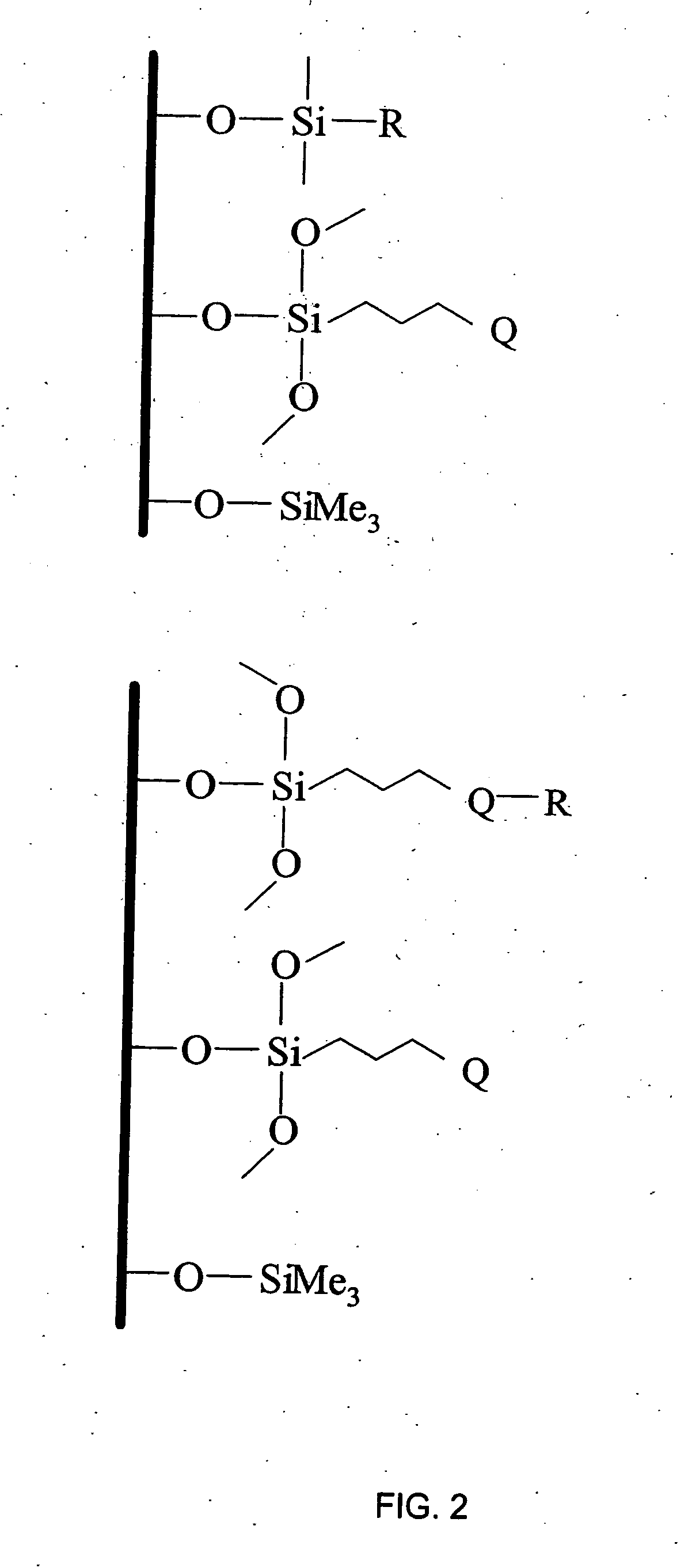

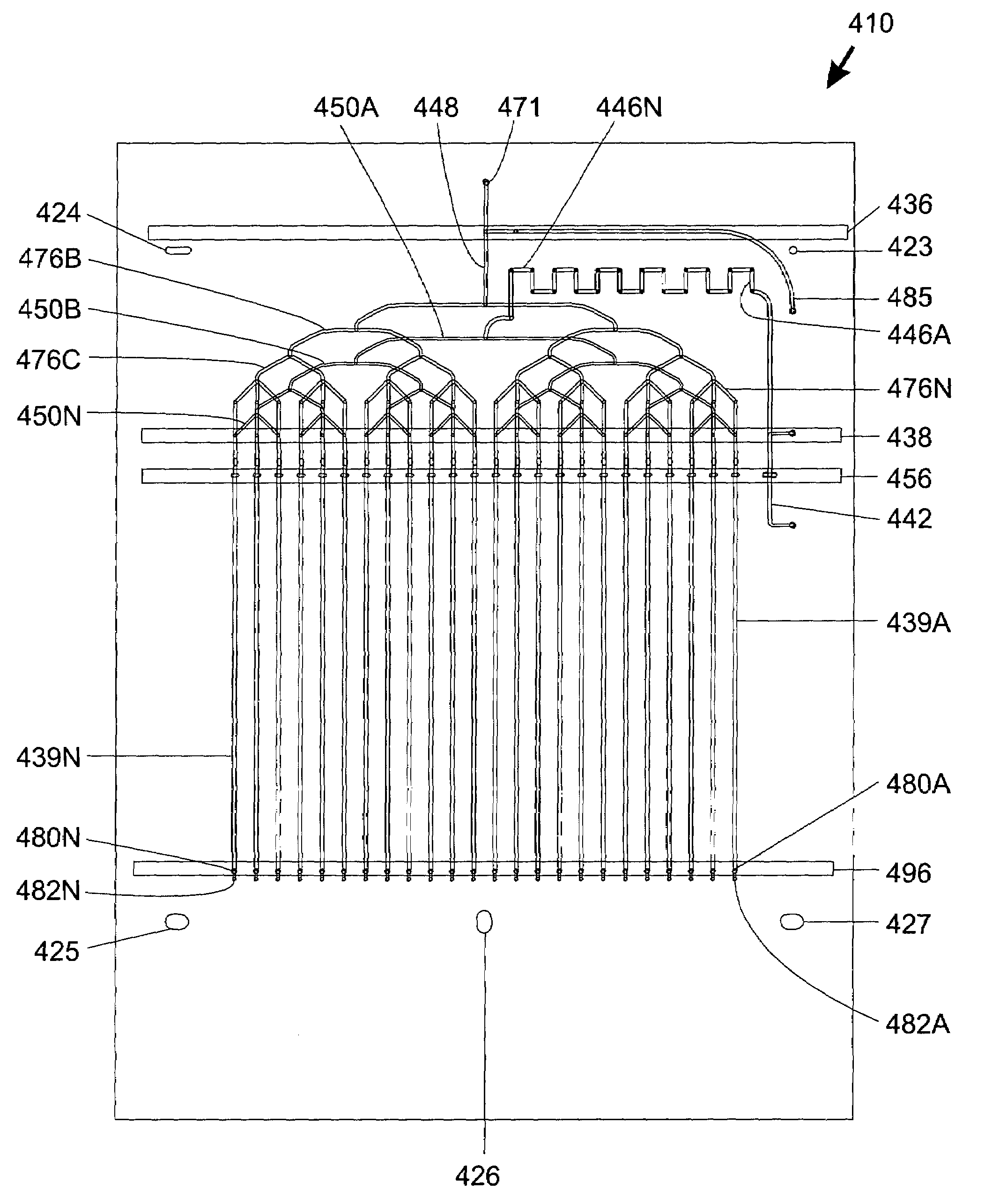

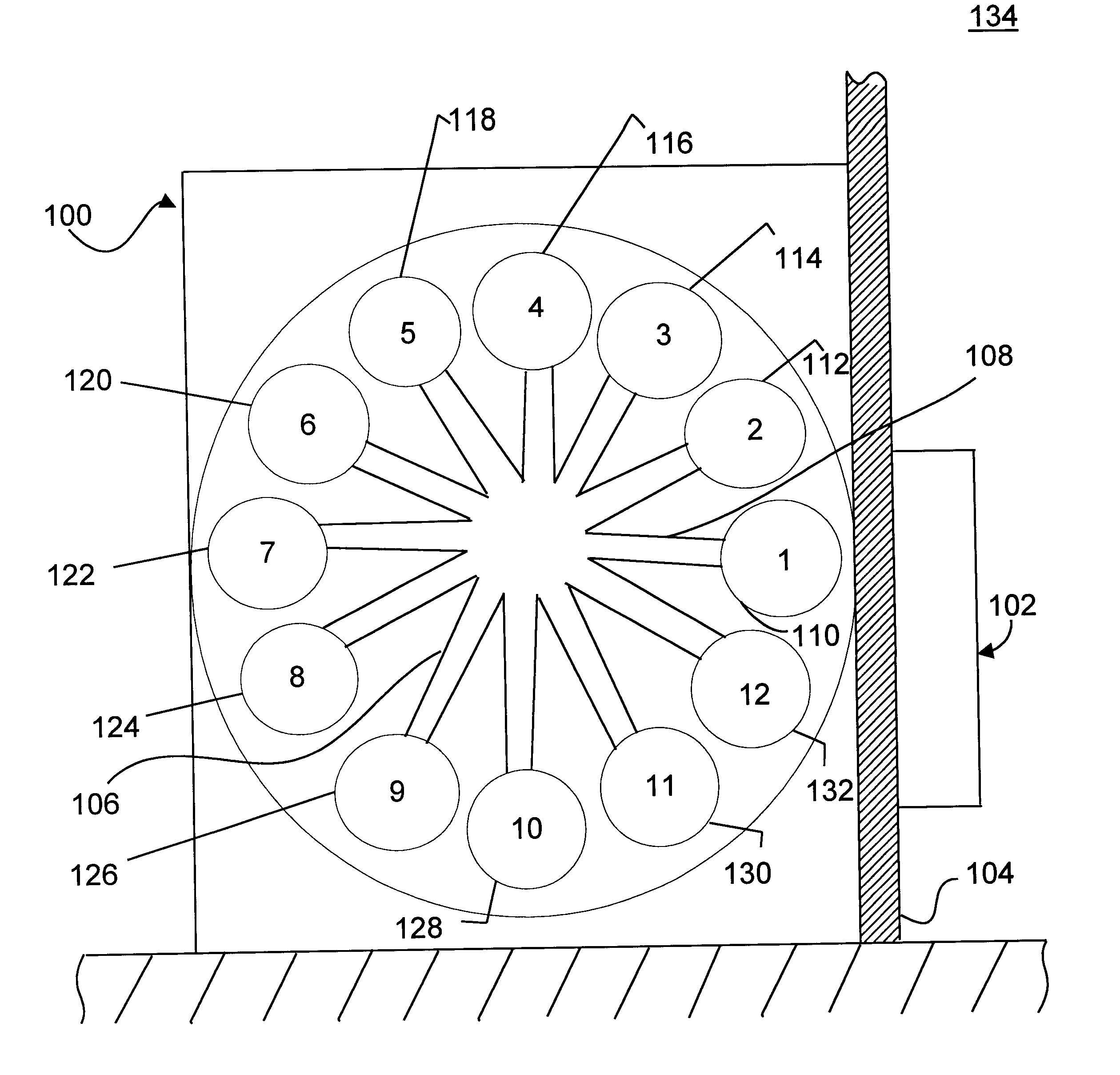

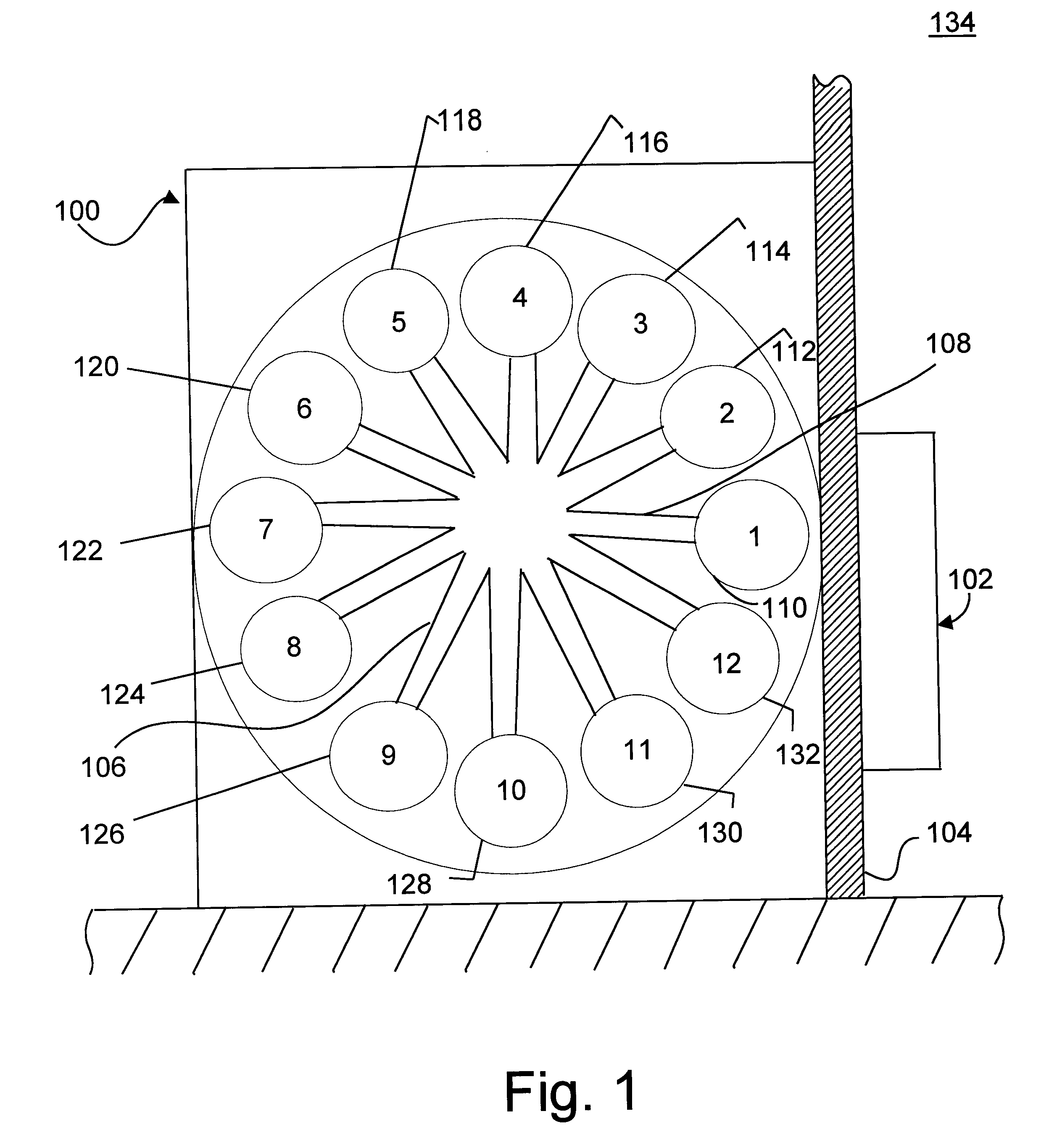

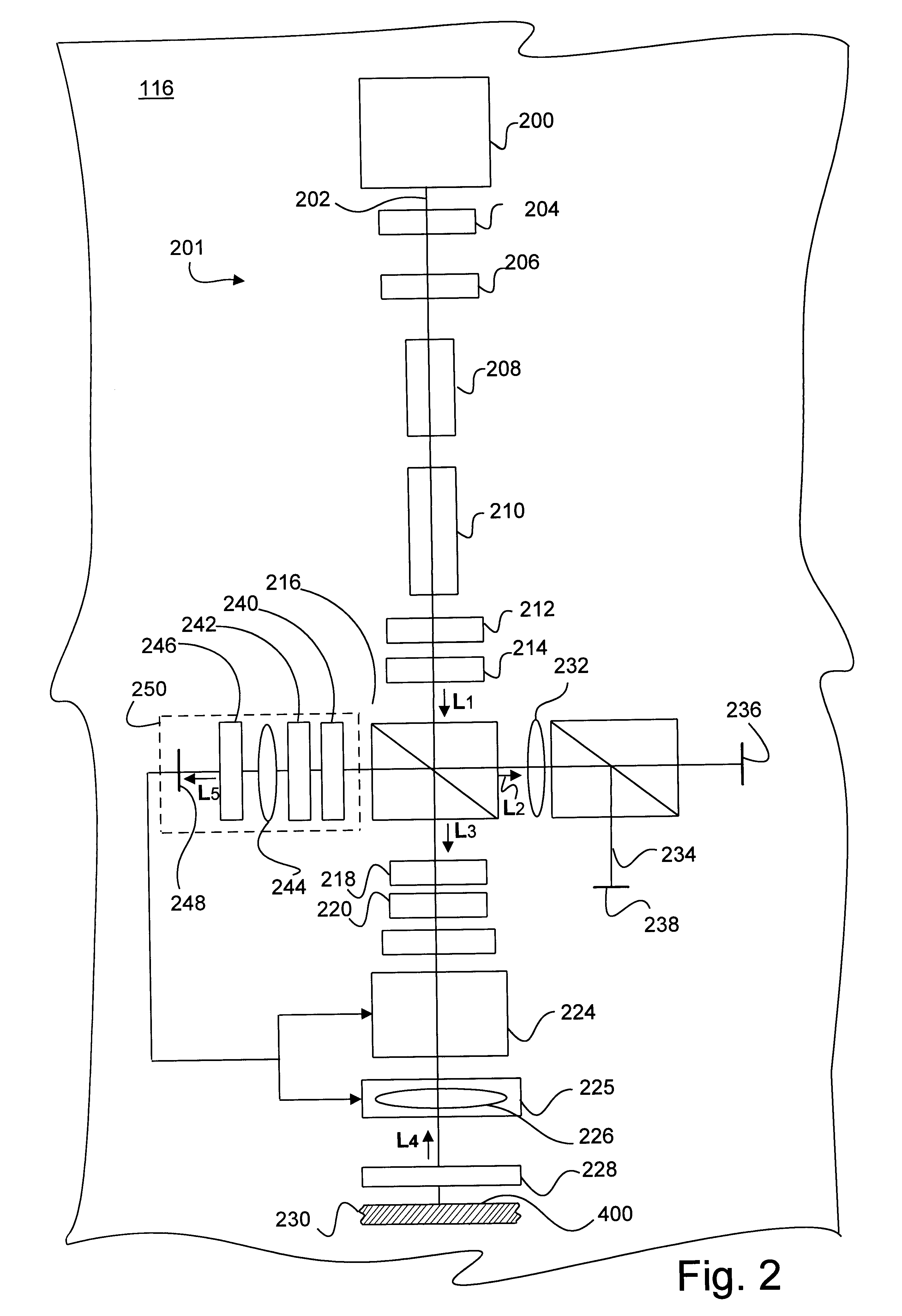

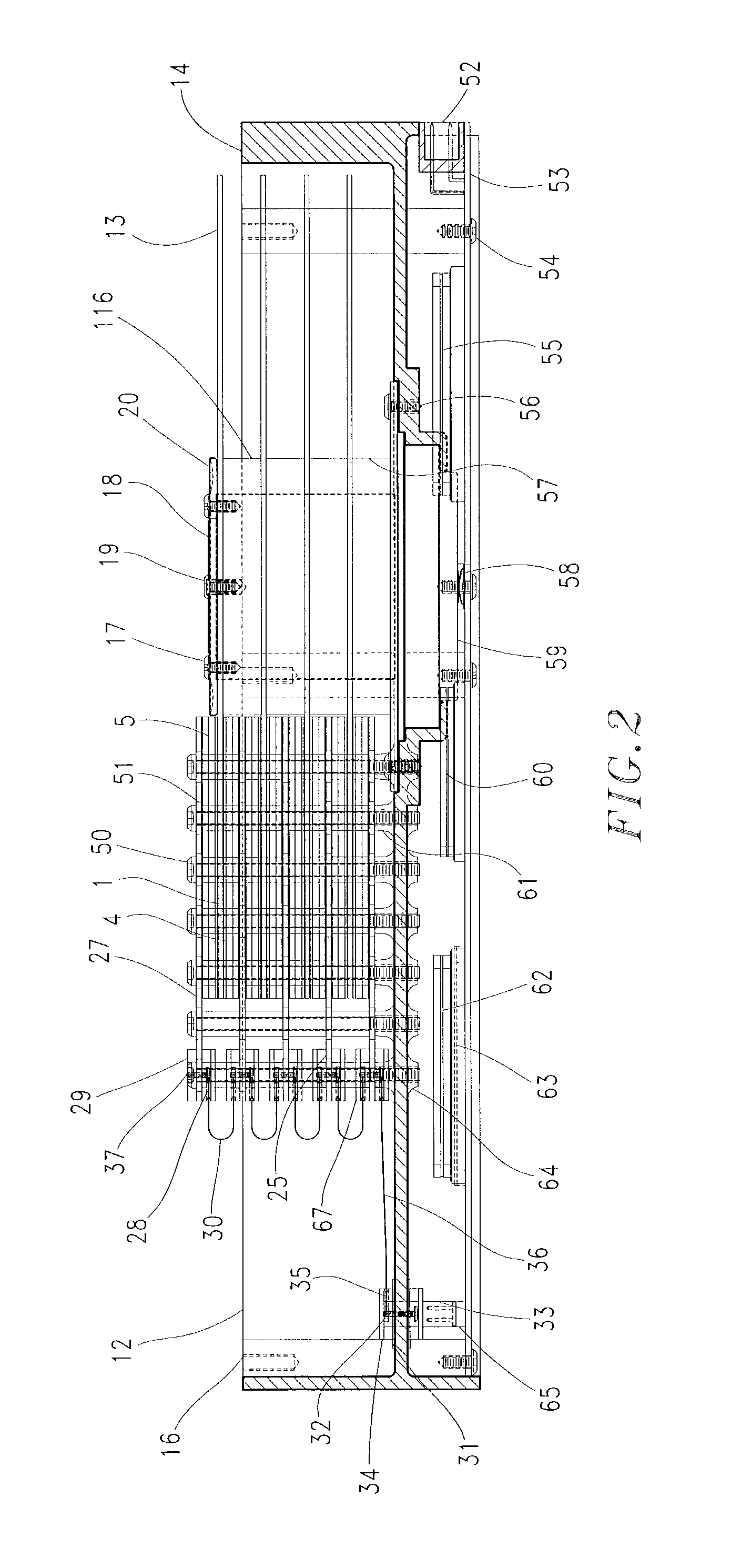

Multiple station vacuum deposition apparatus for texturing a substrate using a scanning beam

A stationary vacuum deposition machine for use in a method for processing substrates to make magnetic hard disks includes a series of stations and a transport. The series of stations includes an entrance station for receiving substrates into the machine and a predetermined station. The transport operates in a cycle with each cycle including a transport phase and a stationary phase. The transport causes all the substrates that are in the machine to be moved during the transport phase, and be temporarily held stationary during the stationary phase, such that during each stationary phase a predetermined one of the stations is occupied by one of the substrates while each of a plurality of others of the stations is occupied by a respective one of a plurality of others of the substrates. The machine further includes a plurality of vacuum deposition stations and a scanning beam generator. Each vacuum deposition station operates during each stationary phase such that each station causes a thin film to be deposited on a respective one of the substrates. The scanning beam generator directs a scanning beam at the substrate occupying the predetermined station while the substrate is held stationary to produce a textured pattern.

Owner:WESTERN DIGITAL TECH INC

Bonded phase photopolymerized sol-gel column and associated methods

InactiveUS6884346B2Preparation of a fritless separation mediumSimple preparation processIon-exchange process apparatusOther chemical processesStationary phaseAnalyte

A separation column and a method of making the separation column are provided. The separation column includes a separation channel and a separation medium in the channel. The separation medium includes a porous matrix, and the porous matrix includes a support and a stationary phase. The support includes a metal organic polymer, such as a photopolymer, and the stationary phase includes a bonded phase. The separation medium can be used to separate a sample of analytes.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Polar-modified bonded phase materials for chromatographic separations

ActiveUS20050178730A1Good reproducibilityIon-exchange process apparatusOther chemical processesChromatographic separationStationary phase

Novel compositions are disclosed for use as a stationary phase in chromatography comprising an inorganic substrate that is modified with at least one silane having the formula R1δ-Qα-(CH2)βSiR2γX3-γ. In a preferred embodiment, the inorganic substrate is silica gel and is modified with at least two silanes. Methods of preparation and use in chromatographic applications are disclosed. The novel compositions provide superior chromatographic performance, reduced silanol activity, enhanced stability, and reproducibility in preparation and performance.

Owner:AGILENT TECH INC

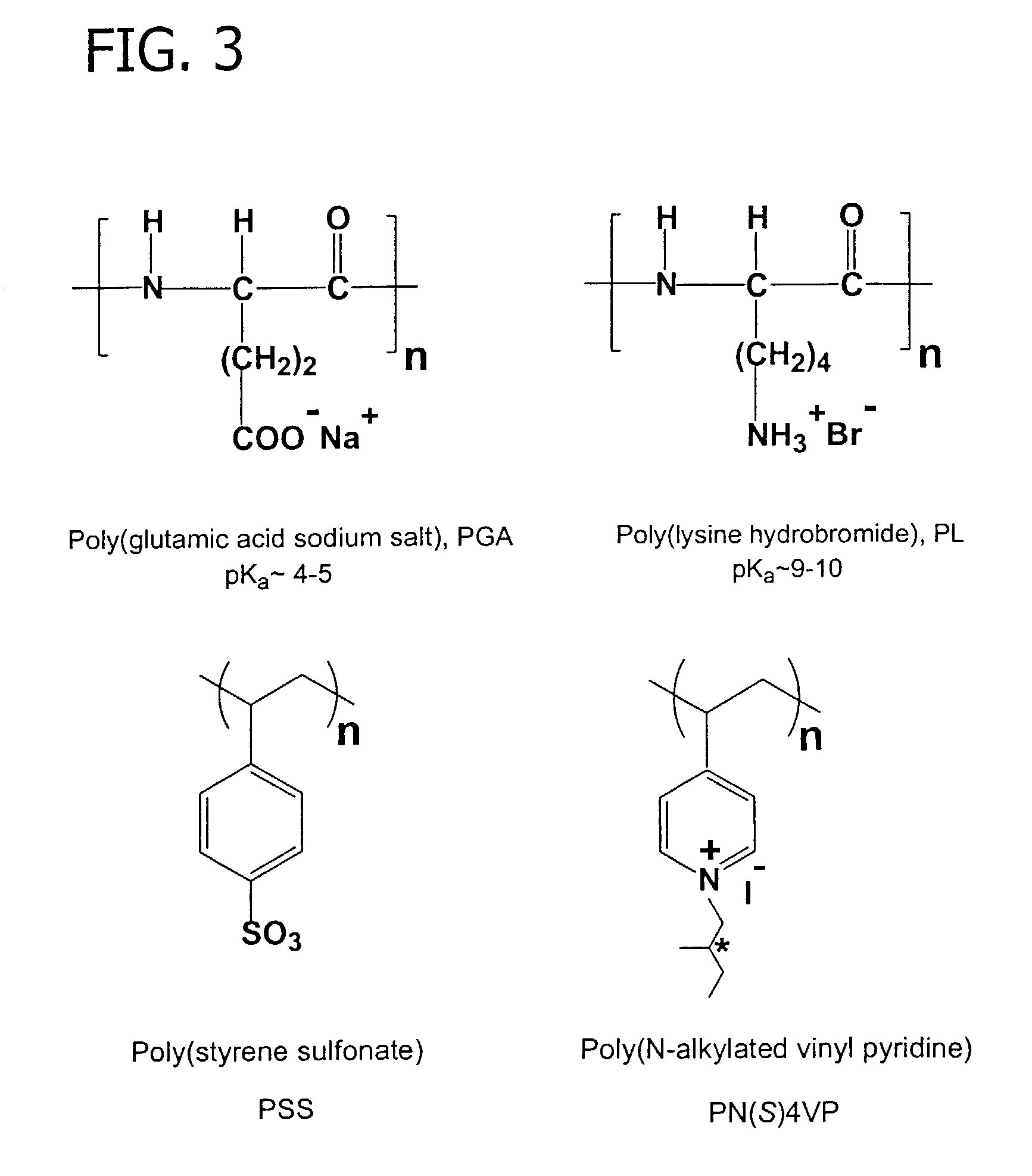

Polyelectrolyte complex films for analytical and membrane separation of chiral compounds

The present invention is directed to enantioselective polyelectrolyte complex films. Further, said films may be free or isolated membranes, or coatings on substrates such a porous substrates, capillary tubes, chromatographic packing material, and monolithic stationary phases and used to separate chiral compounds. The present invention is also directed to a method for forming such enantioselective polyelectrolyte complex films.

Owner:FLORIDA STATE UNIV RES FOUND INC

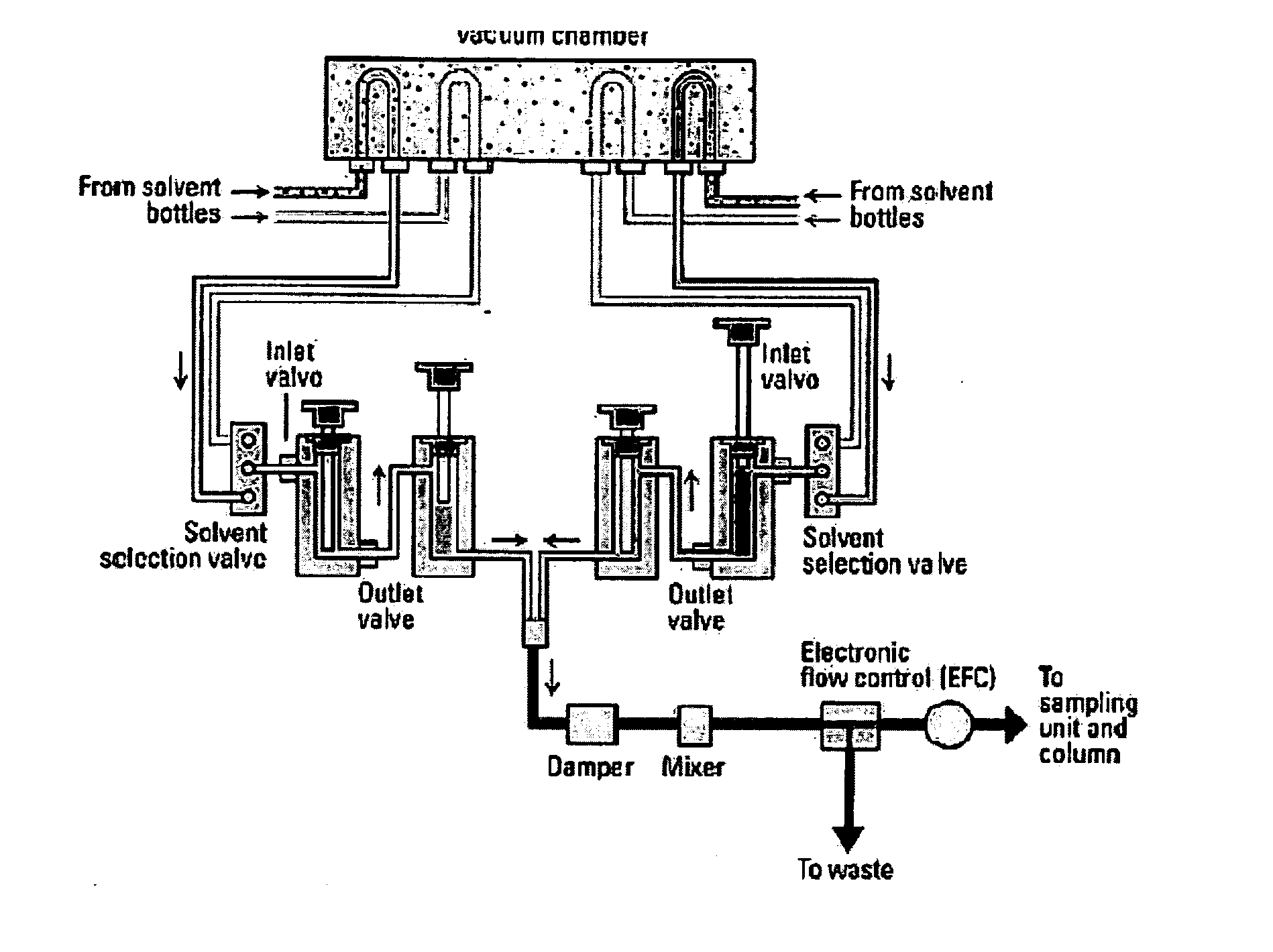

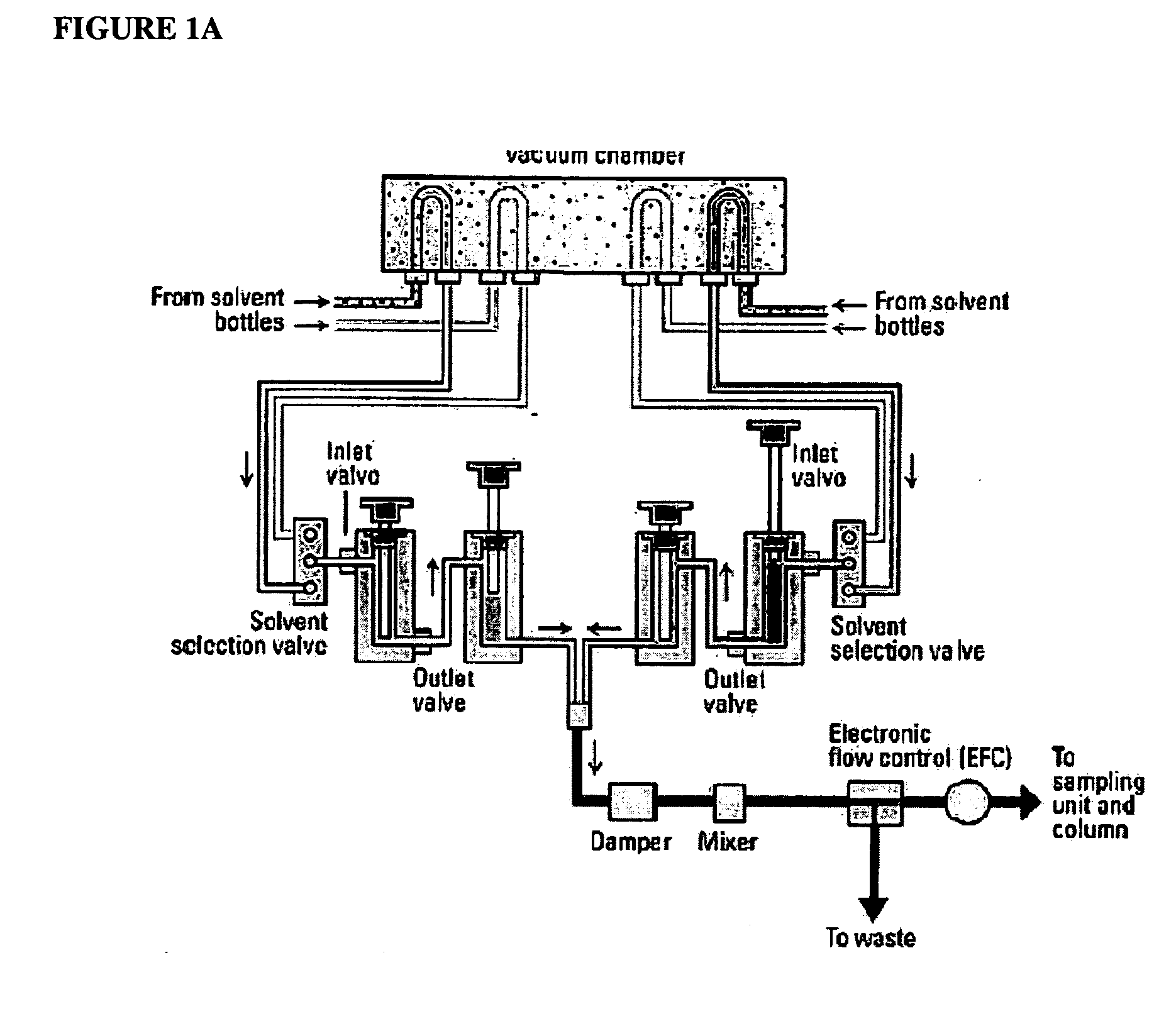

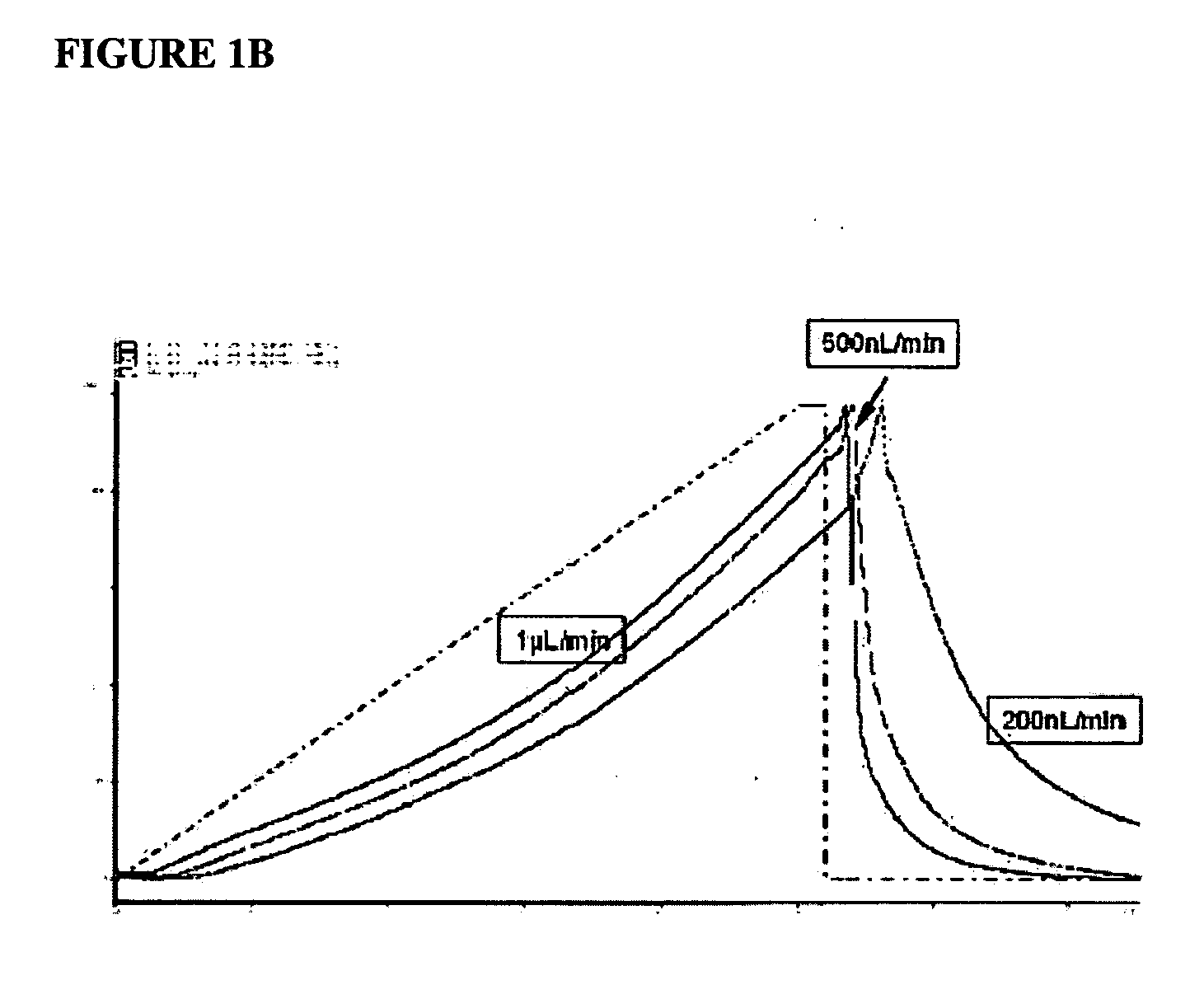

Devices, systems and methods for liquid chromatography

InactiveUS20060219637A1Increase flow rateIon-exchange process apparatusSamplingStationary phaseEngineering

Devices comprising a mechanism for selectively diverting a portion of a mobile phase flowing through a mobile-phase transporting conduit to a fluid-transporting conduit comprising a stationary phase for separating sample components are disclosed, as well as systems and methods for using the same.

Owner:AGILENT TECH INC

Elimination of trans-unsaturated fatty acid compounds by selective adsorption with zeolites

InactiveUS6229032B1Low yieldLow costFatty oils/acids recovery from wasteFatty acid hydrogenationPartial hydrogenationDouble bond

A novel process for the selective elimination of fatty acid compounds containing carbon-carbon double bonds in trans configuration from a substrate containing cis- and trans-isomers of said fatty acid compounds, by selective adsorption by a microporous zeolite material is disclosed. The pore size and shape of usable zeolite materials enable differentiation between cis- and trans-isomers of unsaturated fatty acid chains. The zeolite materials used have a selectivity ratio alphatrans / cis higher than 1.00; this ratio is defined based on the elution properties of cis and trans double bond containing fatty acid methylesters dissolved in n-hexane during a column chromatography experiment with the zeolite material as the stationary phase and n-hexane as the mobile phase. Besides selective adsorption of trans-unsaturated fatty acid compounds, simultaneous or subsequent total or partial hydrogenation of the double bonds in said compounds can be carried out while using the same or similar zeolite material, containing finely dispersed catalytic active metals. The majority of these catalytic active sites must be inside the pores.

Owner:K U LEUVEN RES & DEV

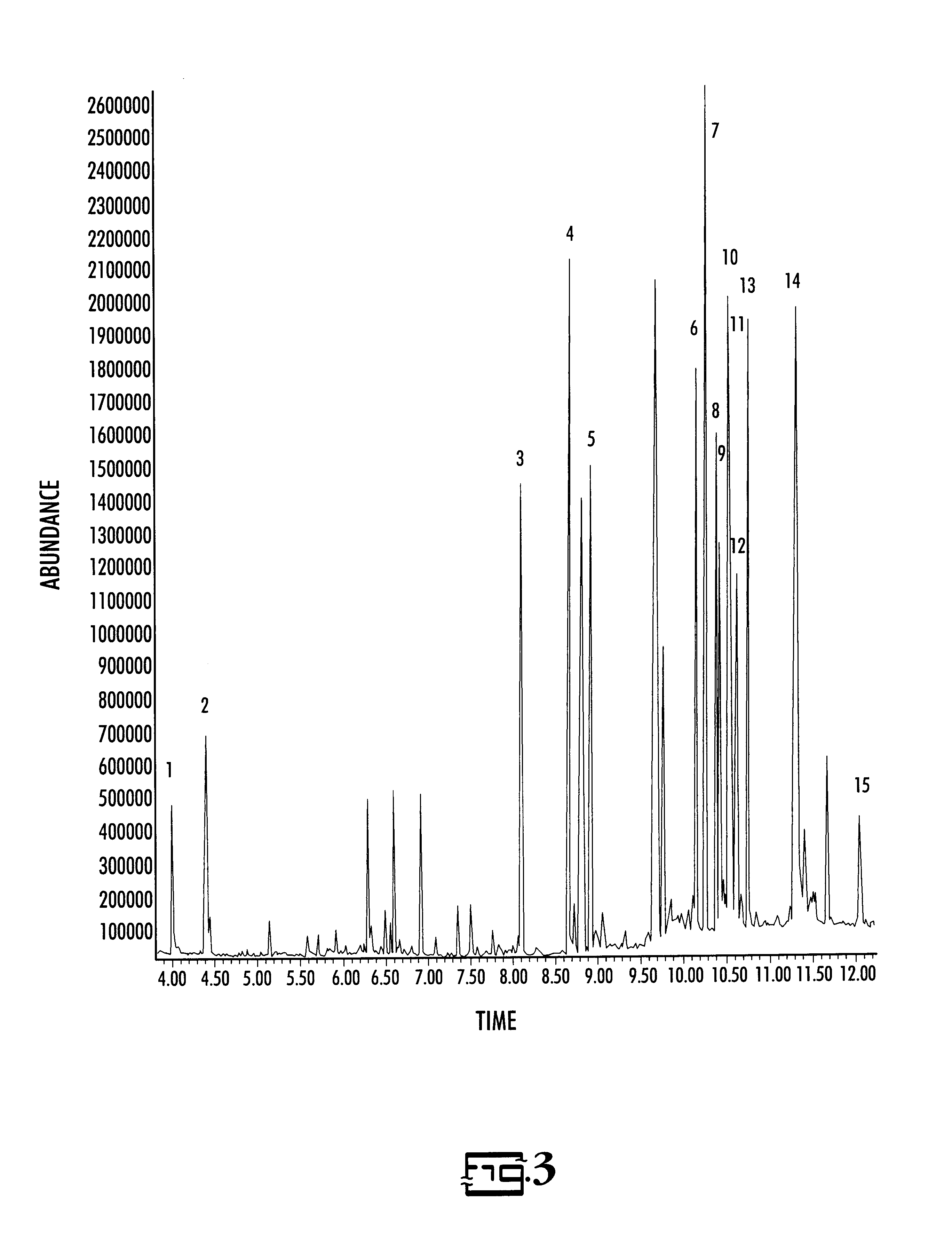

Method for producing purified tocotrienols and tocopherols using liquid chromatography

InactiveUS6395915B1Fatty oils/acids recovery from wasteOrganic compound preparationStationary phaseSolvent

A method separating tocotrienols from tocopherols and the isomers thereof on a large-scale or commercially feasible basis. Separation is accomplished using reverse phase partition liquid chromatography. The chromatography column is prepared using a stationary phase comprising a hydrophobic or aromatic reverse phase chromatography media. The mobile phase consists of a solvent which is capable of solubilizing the crude stock, tocotrienols and tocopherols. The chromatography column containing the stationary and mobile phases is loaded with a crude feed stock and the tocotrienols, tocopherols and / or isomers thereof are eluted at a predetermined linear velocity.

Owner:ASAHI KASEI TECHNROM

Methods and systems for on-column protein delipidation

ActiveUS7943046B2Minimal protein lossesGood reproducibilityIon-exchange process apparatusIon-exchanger regenerationStationary phaseAlcohol

Embodiments of the present invention provide a method of chromatographic delipidation comprising separating a lipid-containing sample on a superficially porous stationary phase at greater than about 70° C., at least about 80° C., having at least one mobile phase comprising an ion-pairing agent in water, an ion-pairing agent in an organic modifier, an acid in an organic modifier, and an alcohol. The invention provides minimal protein losses and high run-to-run reproducibility. The on-column delipidation method aventageously utilize reversed phase liquid chromatography.

Owner:AGILENT TECH INC

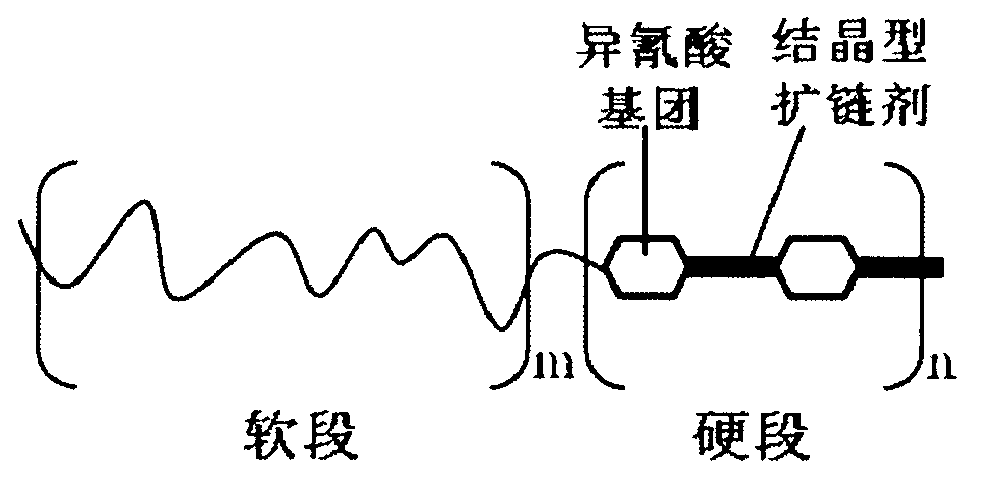

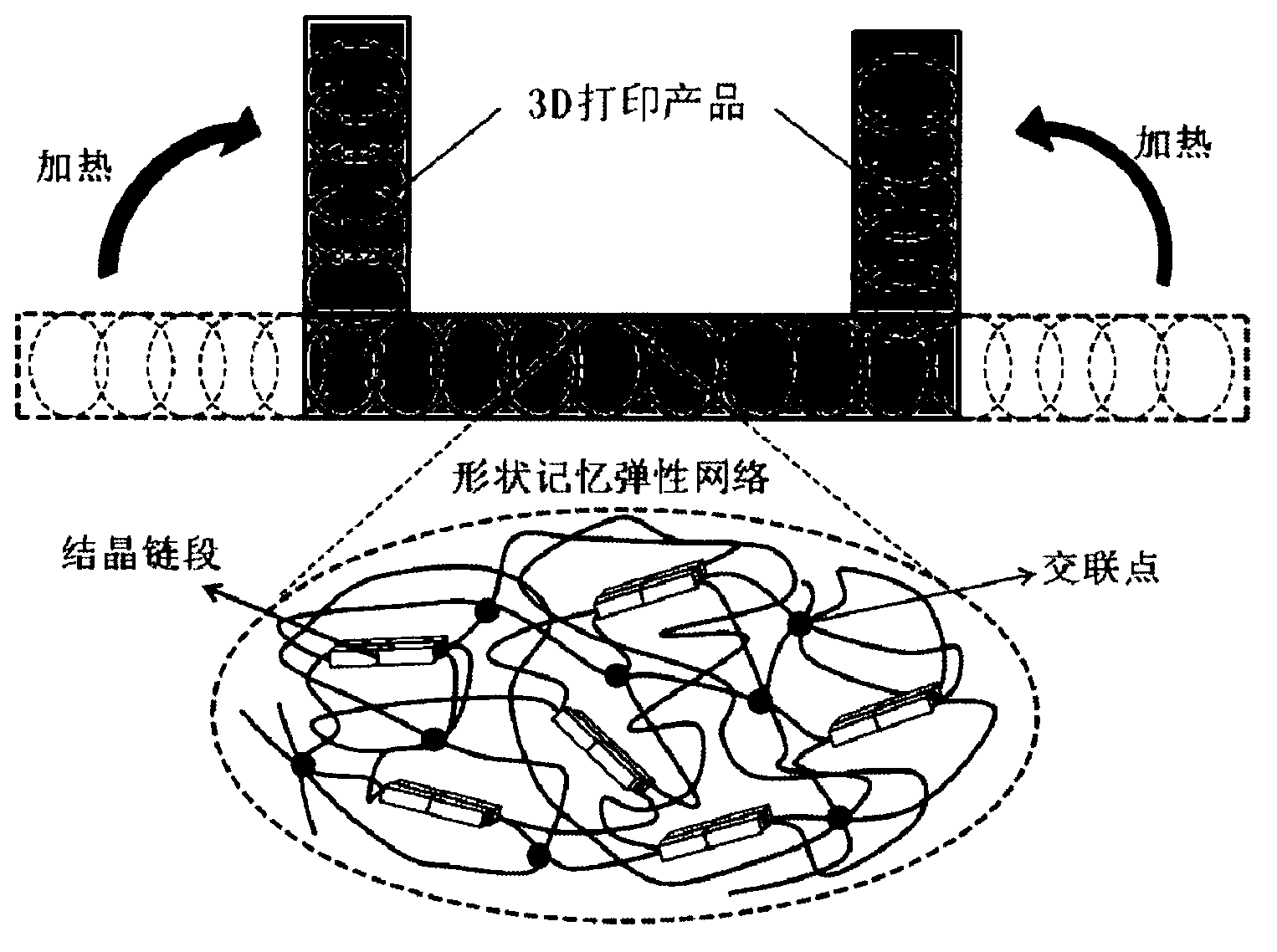

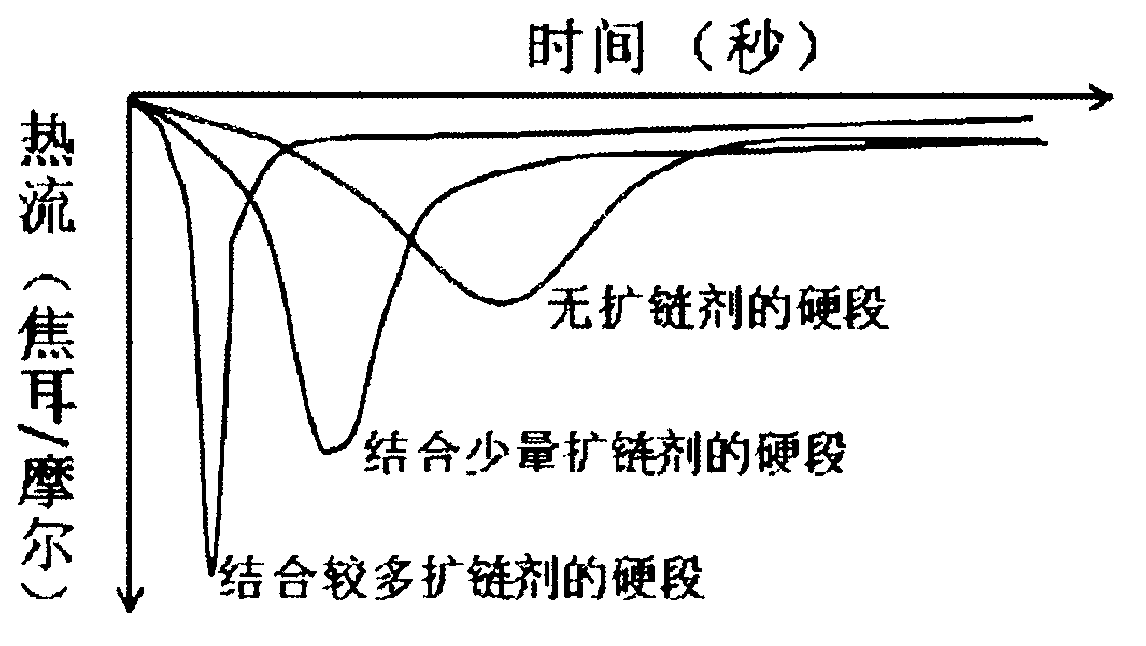

Rapid prototyping shape memory high polymer material and preparation method and application thereof

ActiveCN103160948AImprove cooling forming effectGuaranteed moldingMonocomponent synthetic polymer artificial filamentPolyesterCross-link

The invention discloses a rapid prototyping shape memory high polymer material and a preparation method and application thereof. The high polymer material comprises a physical cross-linking hard-segment structure which can be rapidly cooled and formed and a high polymer soft-segment structure which can be fixed and temporarily deformed, wherein the hard-segment structure is formed by combining diisocyanate and a crystallization type chain extender; the soft-segment structure is formed by combining polyester type or polyether type polyhydric alcohol with the crystallization type chain extender; and the molar ratio of hydroxyl in the polyhydric alcohol to diisocyanate group in the diisocyanate is 1:2-1:5. The material is functional, and the printed 3D product has the capability of self-deforming and restoring the time dimensionality; the material has good cooling forming performance, and the hard-segment part can rapidly form a physical cross-linking point in the temperature difference range of melt extrusion; the contained stationary phase and restoration phase double components are wide in material selection and low in price, a preparation process is simple, the defects that synthetic raw materials are expensive, the process is complex and the like in the prior art can be overcome, and the material is suitable for large-scale production.

Owner:JF POLYMERS (SUZHOU) CO LTD

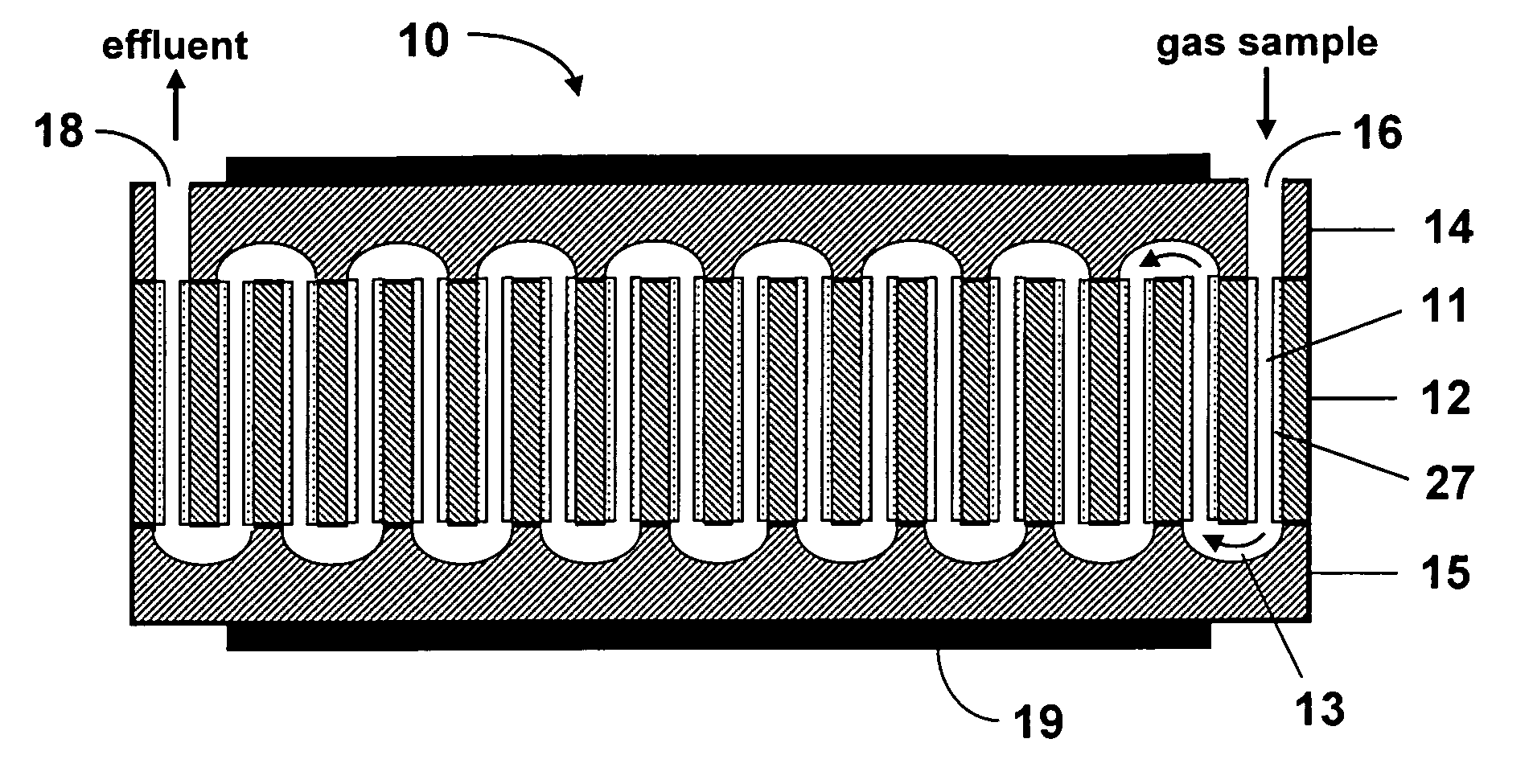

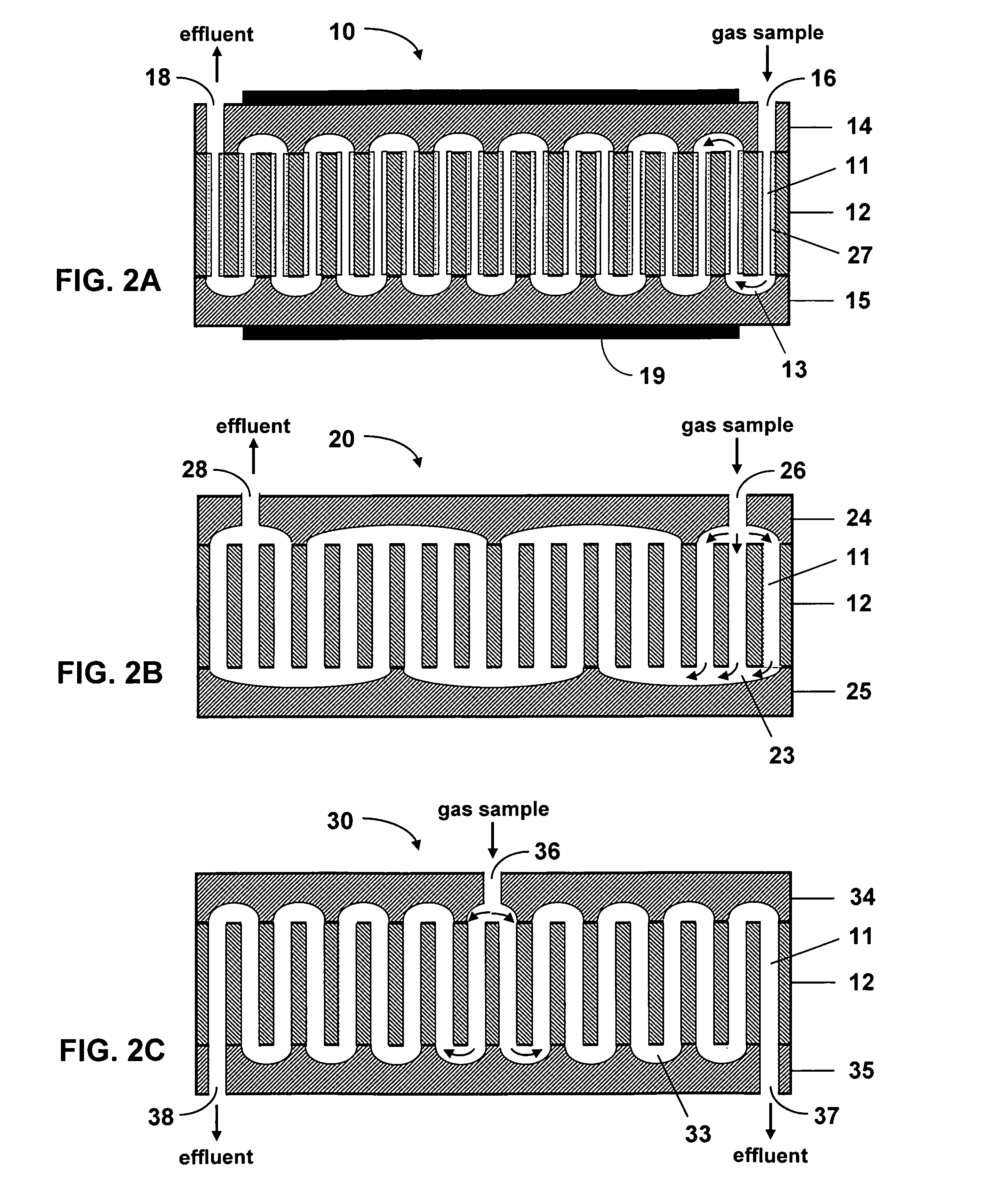

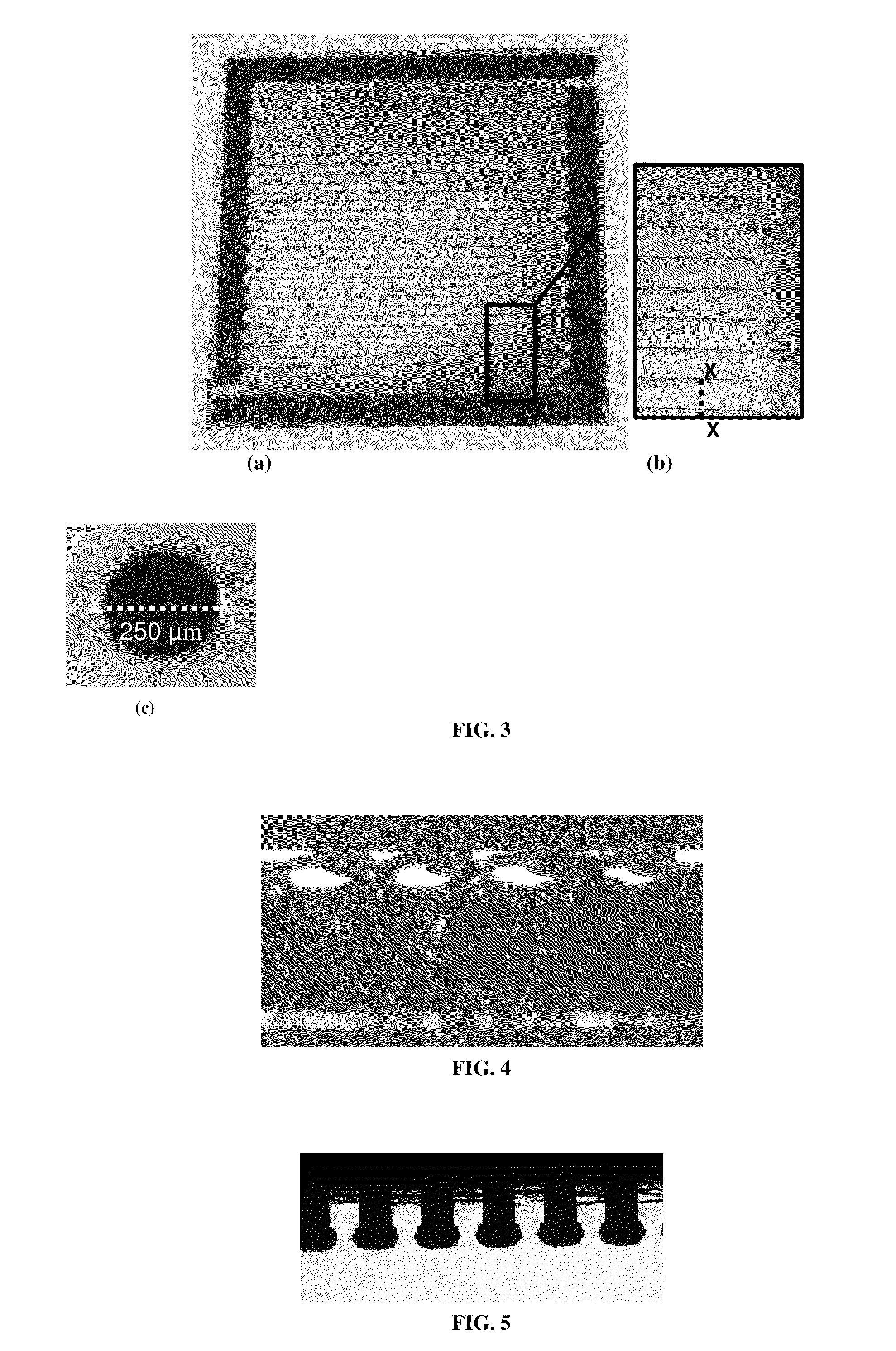

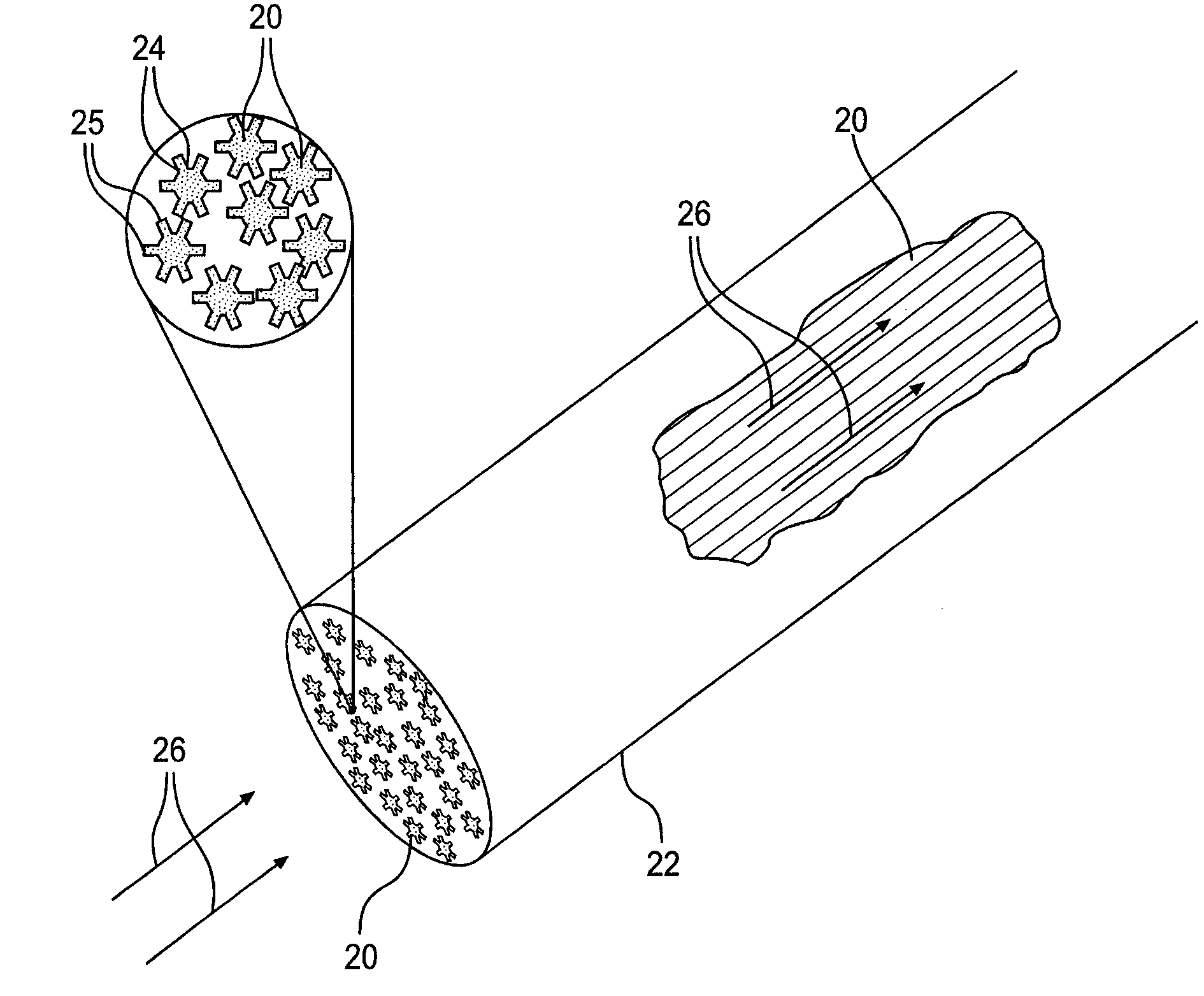

Non-planar microfabricated gas chromatography column

ActiveUS7273517B1Band broadening can be minimizedComponent separationDispersed particle separationStationary phaseAnalyte

A non-planar microfabricated gas chromatography column comprises a planar substrate having a plurality of through holes, a top lid and a bottom lid bonded to opposite surfaces of the planar substrate, and inlet and outlet ports for injection of a sample gas and elution of separated analytes. A plurality of such planar substrates can be aligned and stacked to provide a longer column length having a small footprint. Furthermore, two or more separate channels can enable multi-channel or multi-dimensional gas chromatography. The through holes preferably have a circular cross section and can be coated with a stationary phase material or packed with a porous packing material. Importantly, uniform stationary phase coatings can be obtained and band broadening can be minimized with the circular channels. A heating or cooling element can be disposed on at least one of the lids to enable temperature programming of the column.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

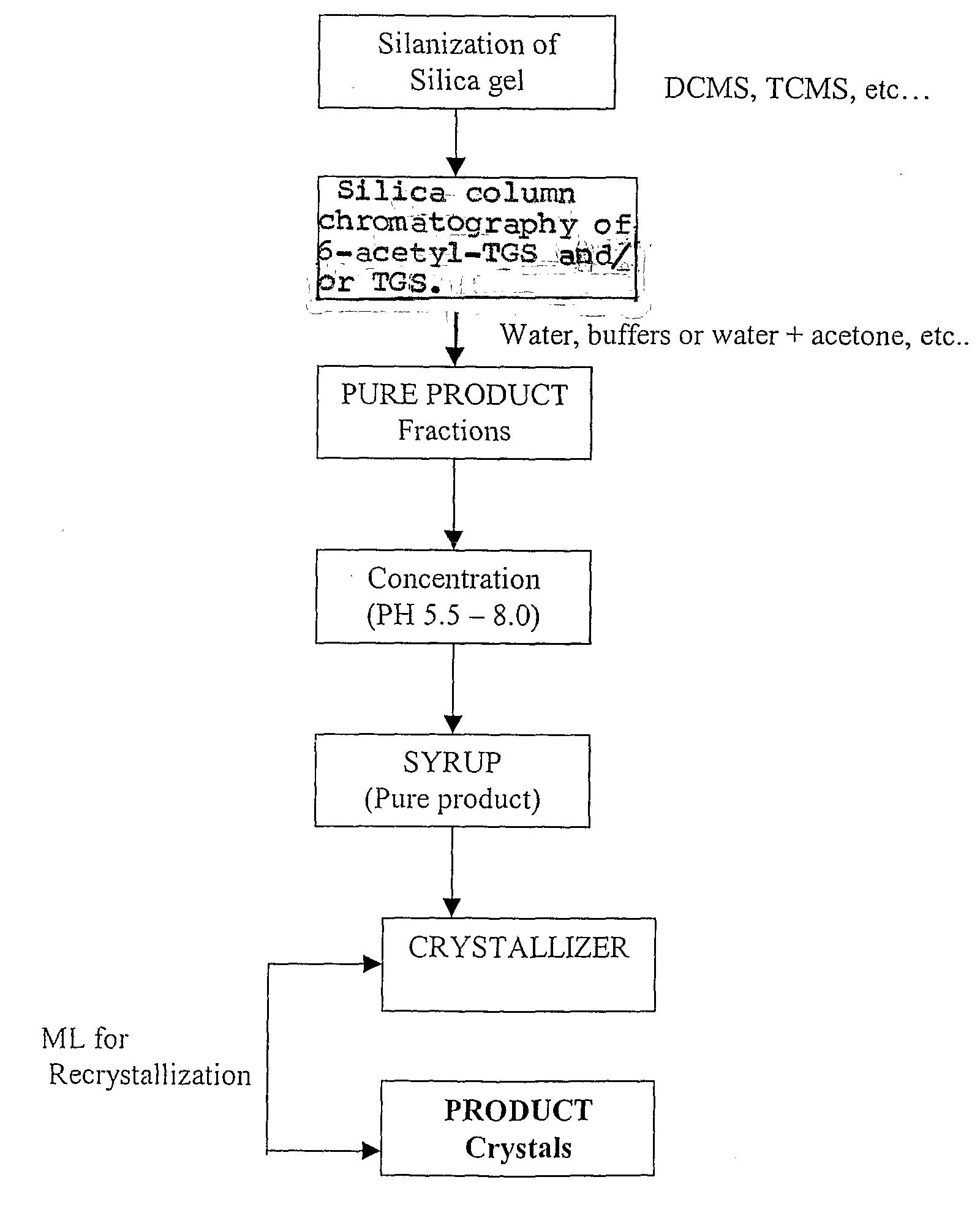

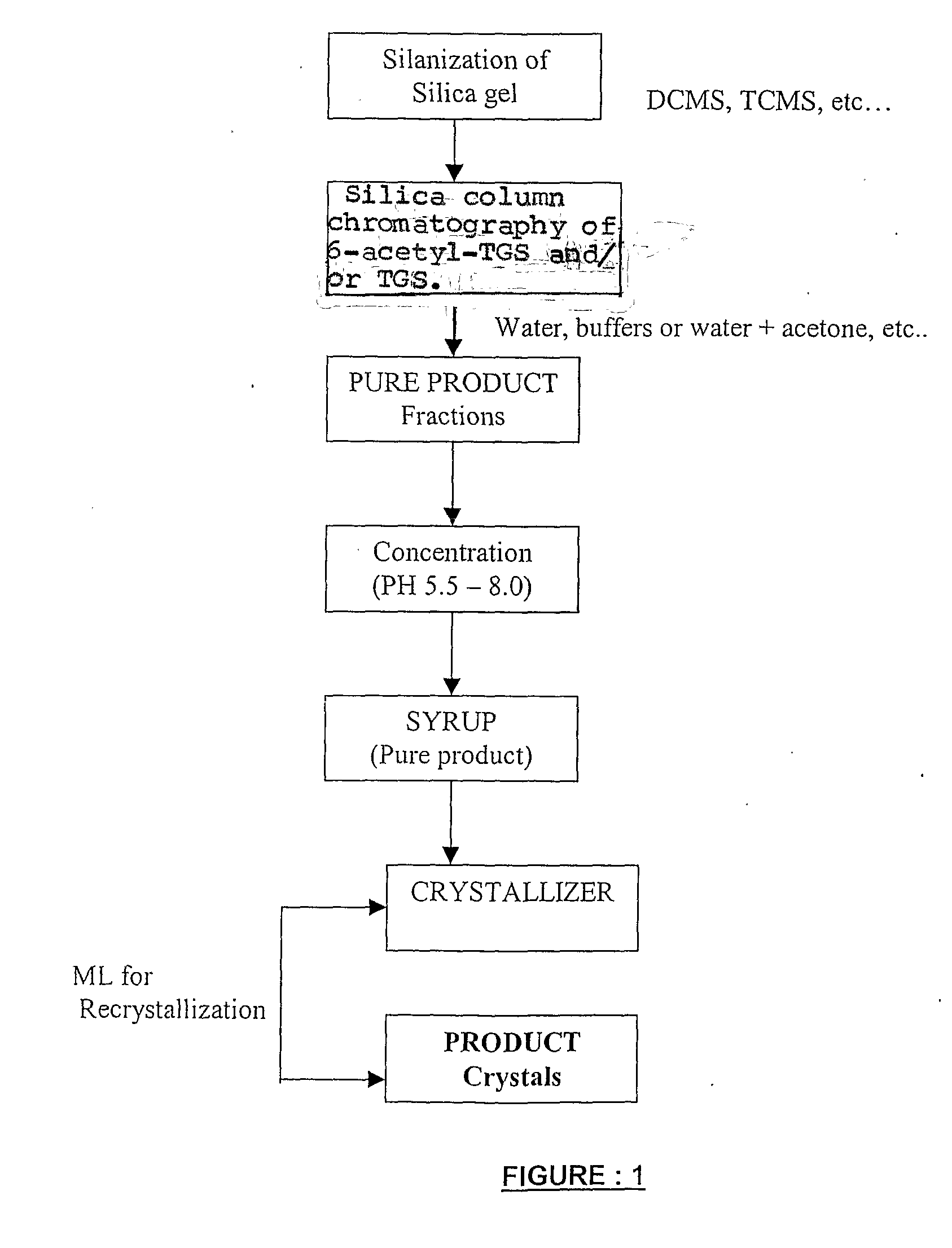

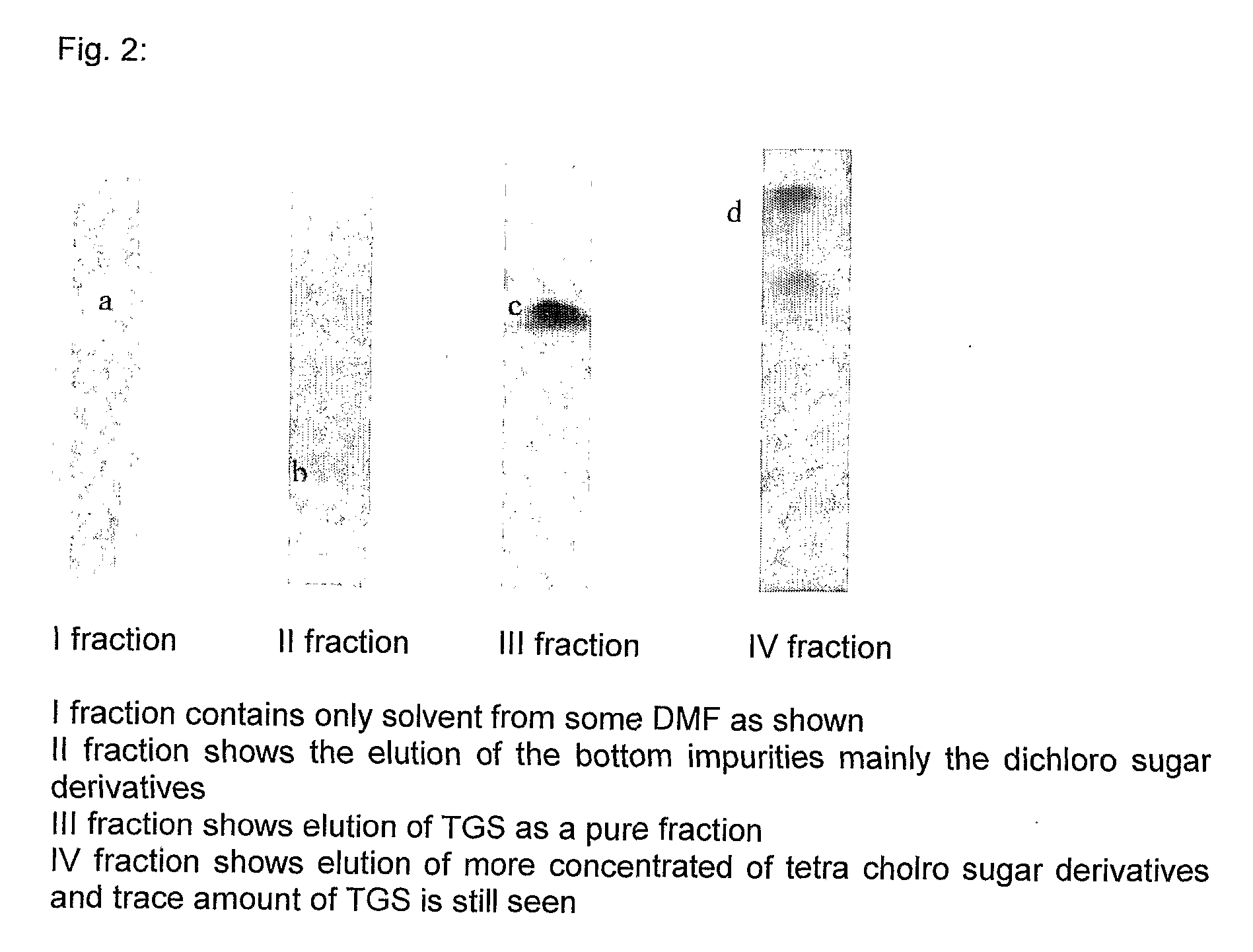

Process for Purification of 6 Acetyl 4,1', 6' Trichlorogalactosucrose and 4,1', 6' Trichlorogalactosucrose by Chromatography on Silanized Silica Gel

InactiveUS20070270583A1Purification using adsorption agentsSugar derivativesStationary phaseOrganic solvent

A reverse phase column chromatographic process of purification of 6-acetyl-4,1′,6′trichlorogalactose and 4,1′,6′trichlorogalactose is described which uses silanized silica as stationary phase and water or predominatly aqeous mixture derived from water and small proportion of organic solvents as a mobile phase.

Owner:V B MEDICARE PVT LTD

Nanometer size chemical modified materials and uses

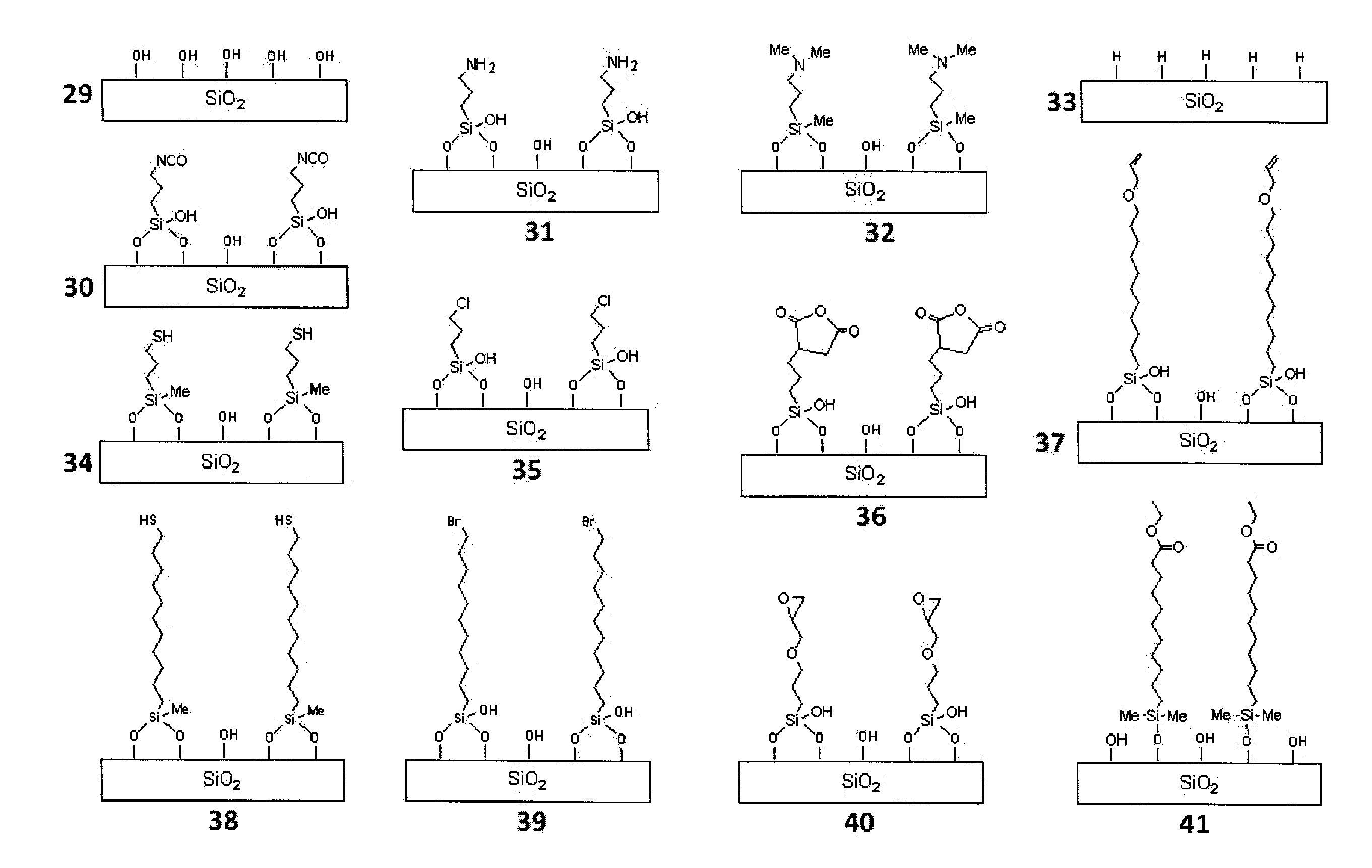

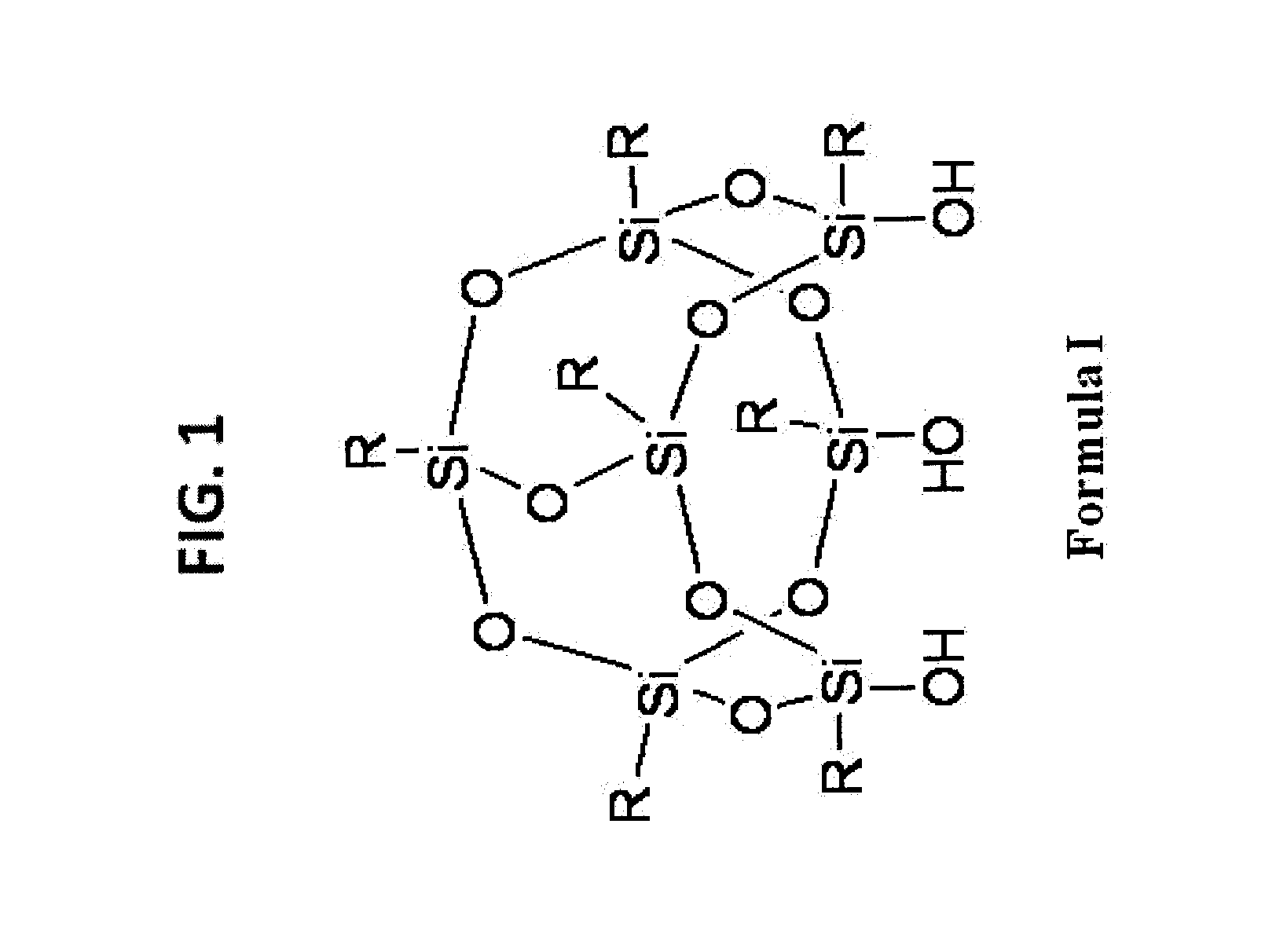

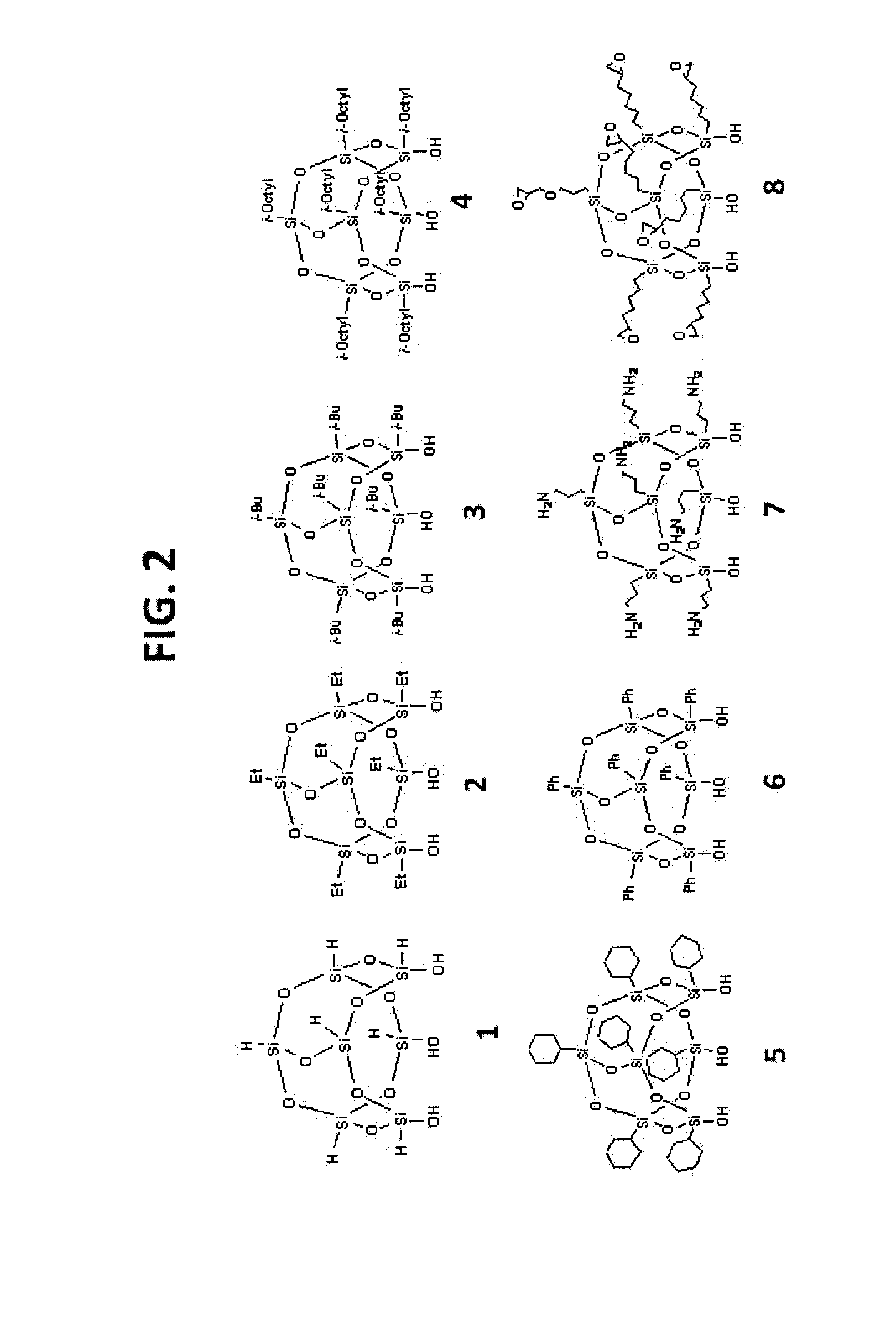

InactiveUS20120205315A1Improve hydrolytic stabilityImprove hydrophobicityIon-exchange process apparatusSilicon organic compoundsStationary phaseSilsesquioxane

There are provided ligand compositions and stationary phases comprising a polyhedral oligomeric silsequioxane moiety. Also provided are chromatographic devices comprising the stationary phases, and methods of making and using the ligands, stationary phases and chromatographic devices of the invention.

Owner:DIONEX CORP

Polymeric solid supports for chromatography nanocolumns

ActiveUS20060144770A1Ion-exchange process apparatusAnalysis using chemical indicatorsStationary phaseParticulates

Nanocolumn chromatography devices useful, e.g., in CEC and nanoLC are disclosed. An exemplary chromatography device of the invention includes a nanocolumn, e.g., a capillary, packed with a particulate stationary phase material and a solid support. The solid support, or in situ frit, is adjacent to and integral with the stationary phase material. An in situ frit of the invention may be a mixture of the stationary phase material and a polymeric network of cross-linked poly(diorganosiloxane), e.g., poly(dimethylsiloxane), which may optionally be sintered. The invention also provides methods of making and using such devices.

Owner:WATERS TECH CORP

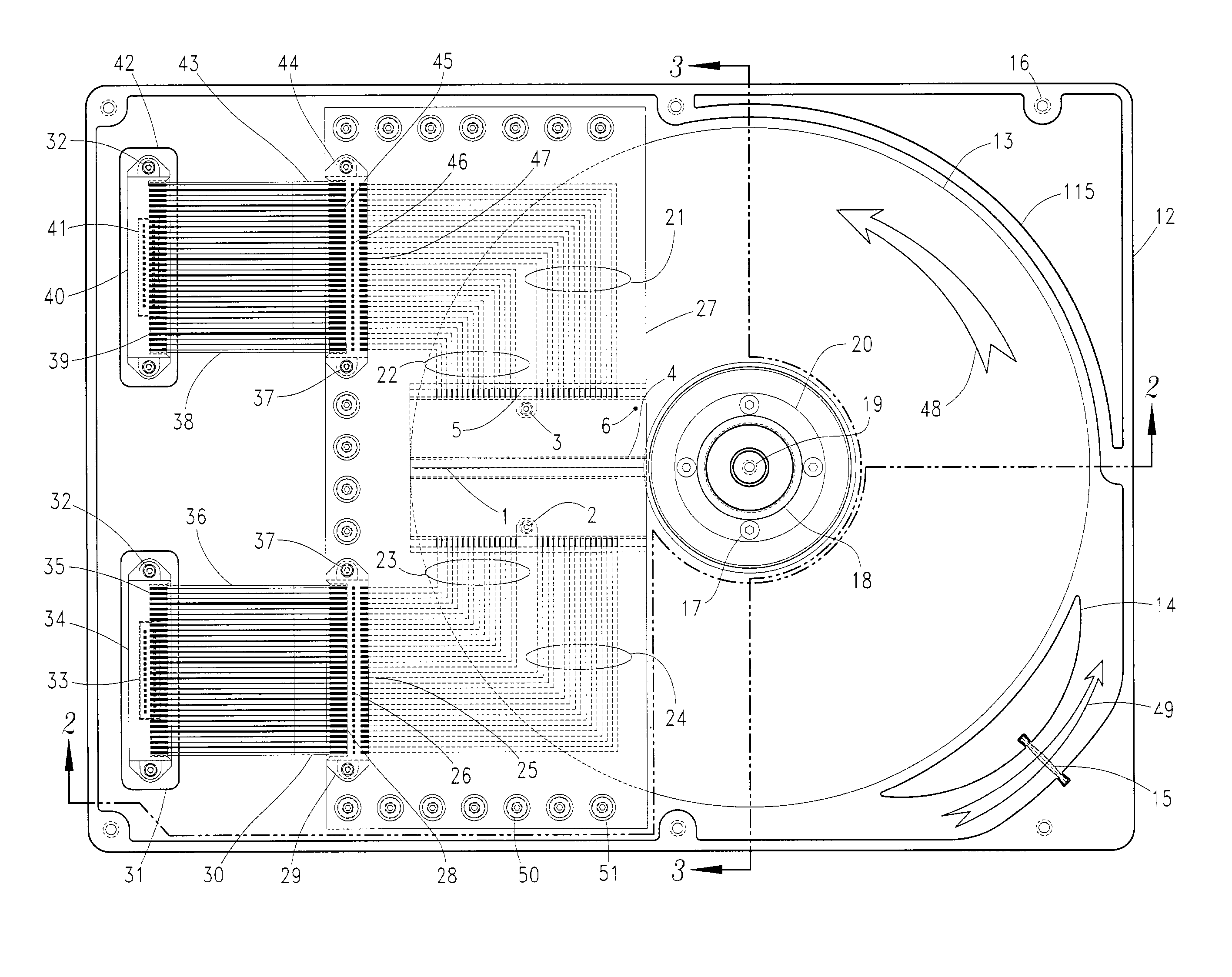

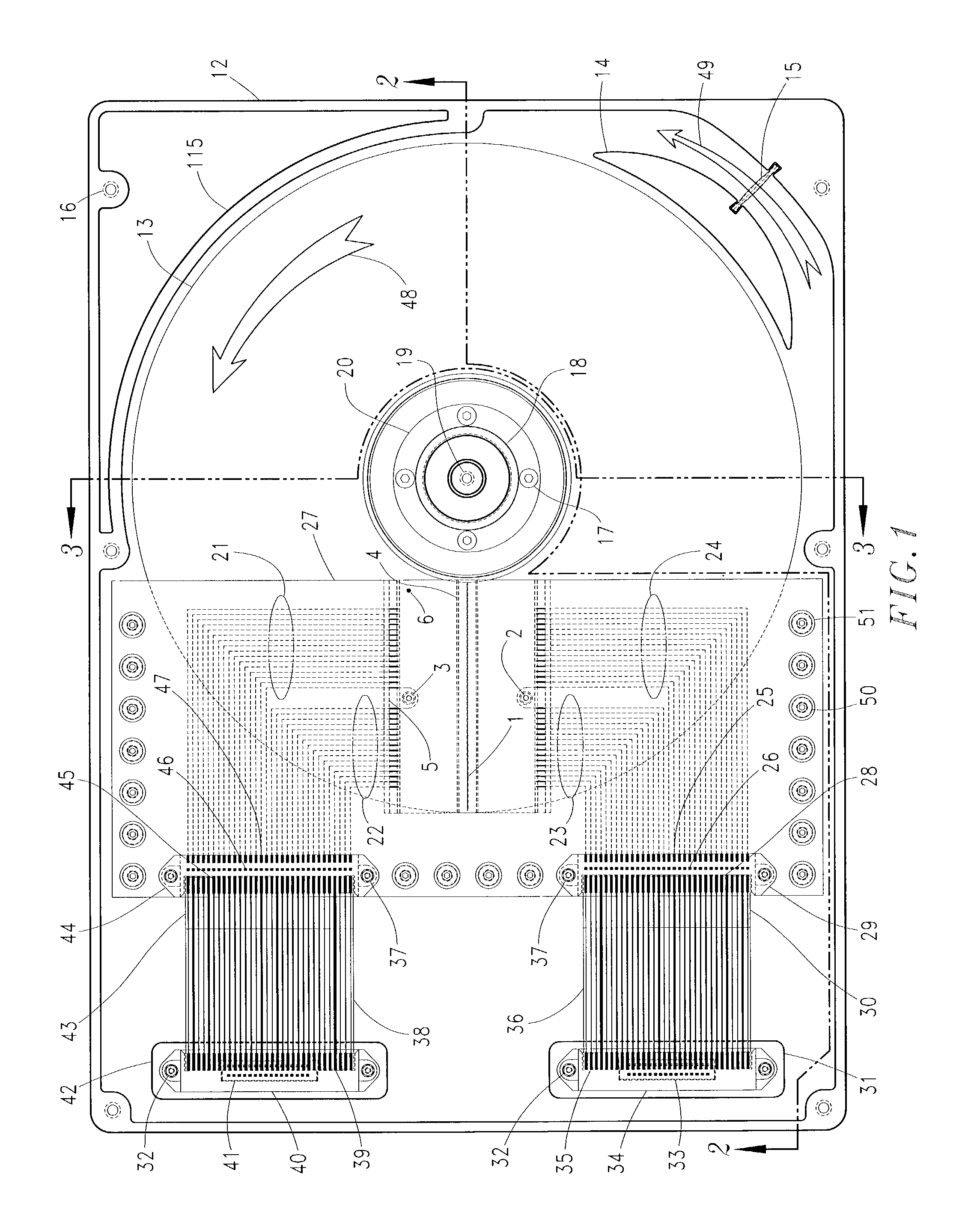

Phase-change microhead array chip hard disk drive

InactiveUS20030161245A1Electron beam carrier recordingOptical beam sourcesStationary phaseEngineering

An optical data-storage hard disk drive that uses stationary Phase-Change Microhead Array Chips in place of conventional flying-heads, rotary voice-coil actuators, or other similar types of servo-tracking mechanisms to simultaneously record and / or reproduce data to and / or from a multitude of data-tracks located across the data-surfaces of a multitude of phase-change based disc media using a multitude of microheads.

Owner:OPTICAL STORAGE DEVICES

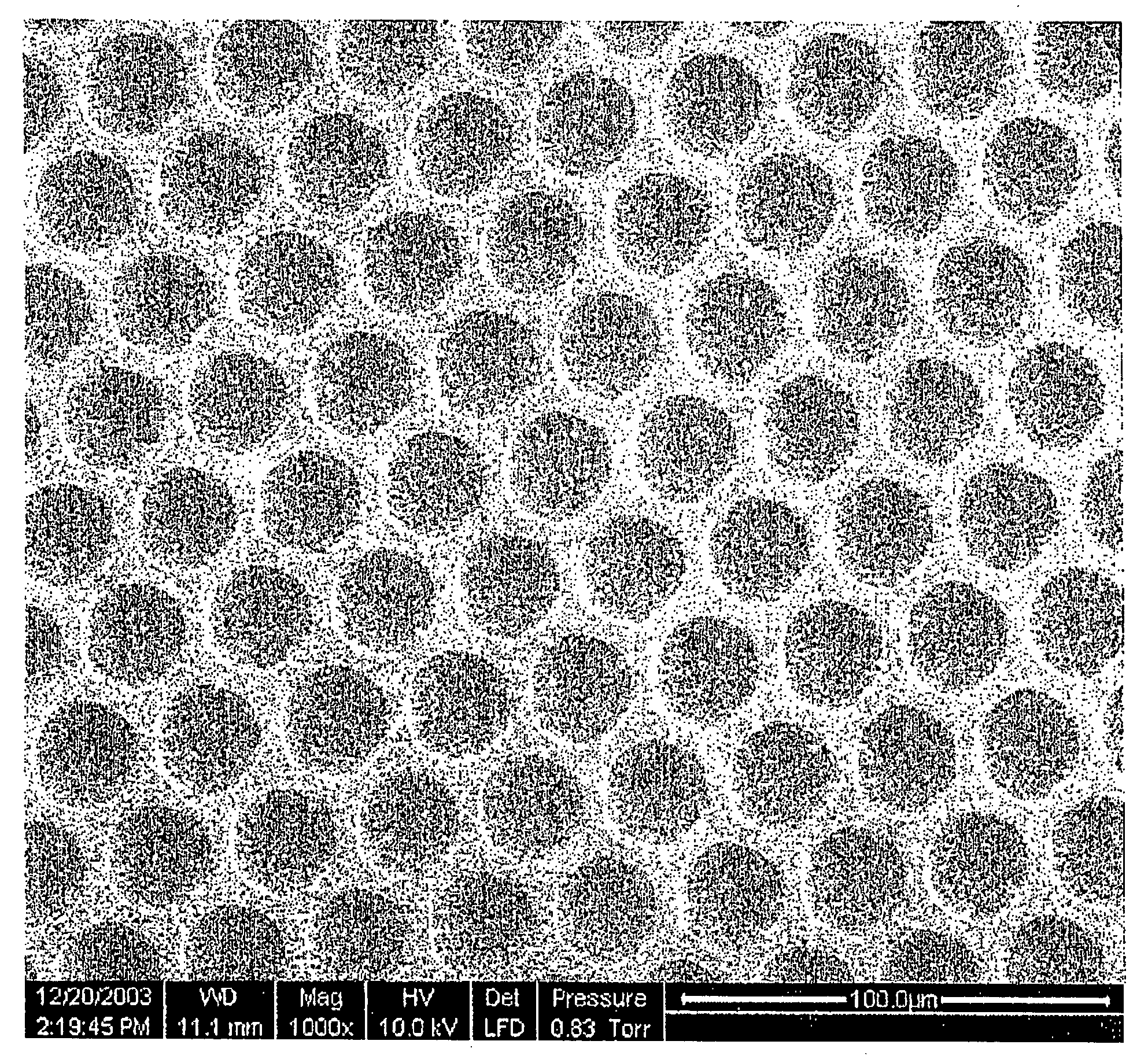

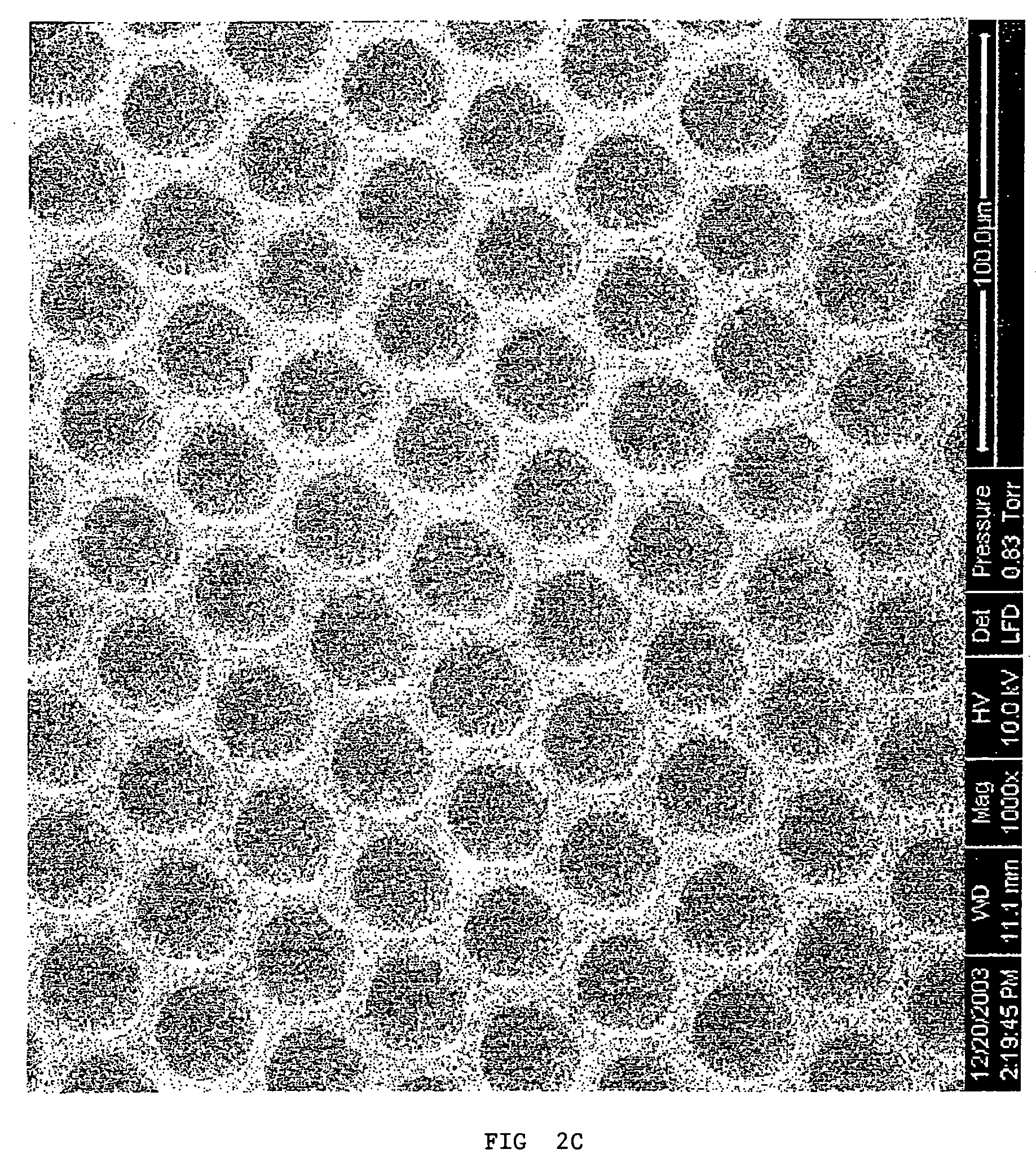

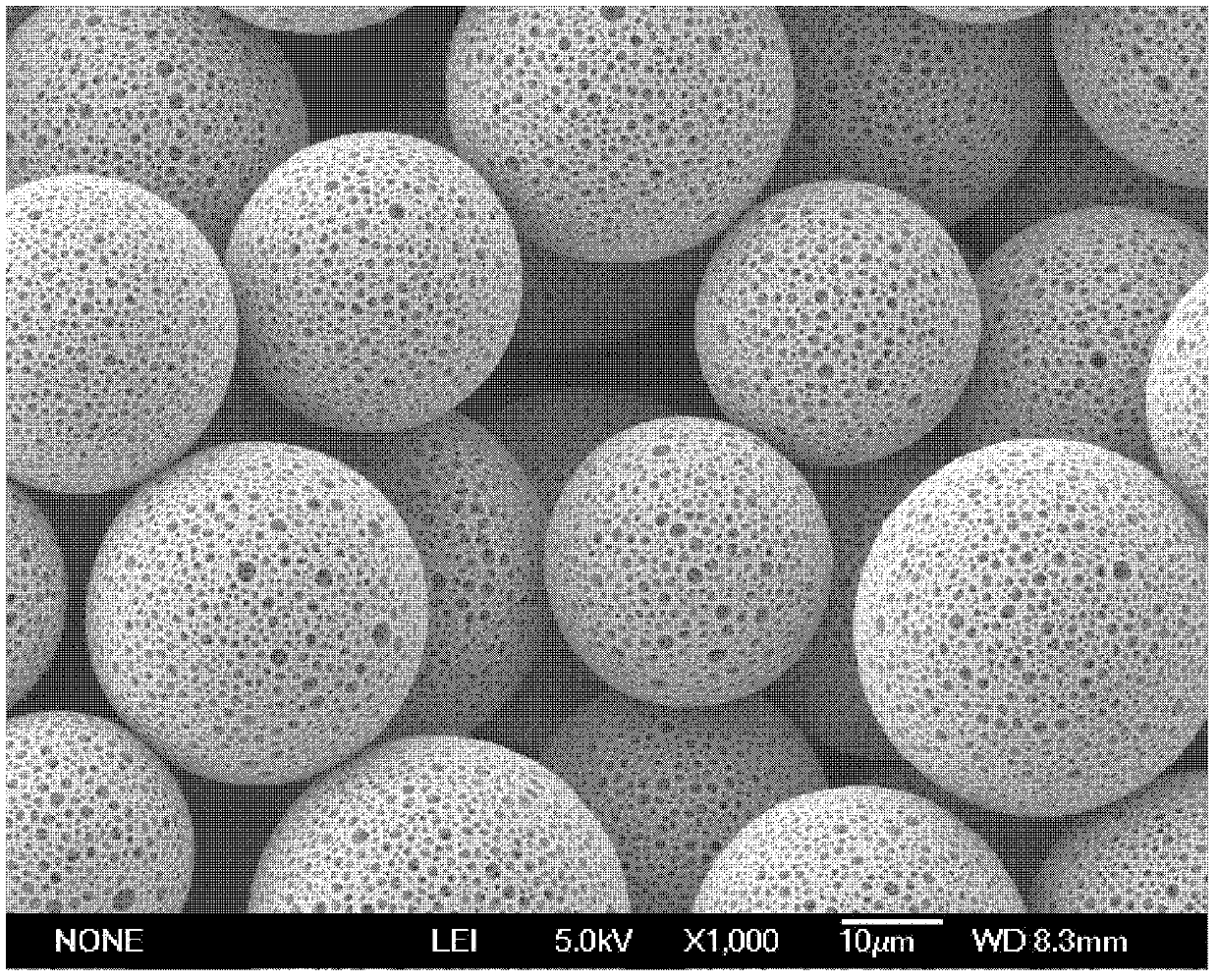

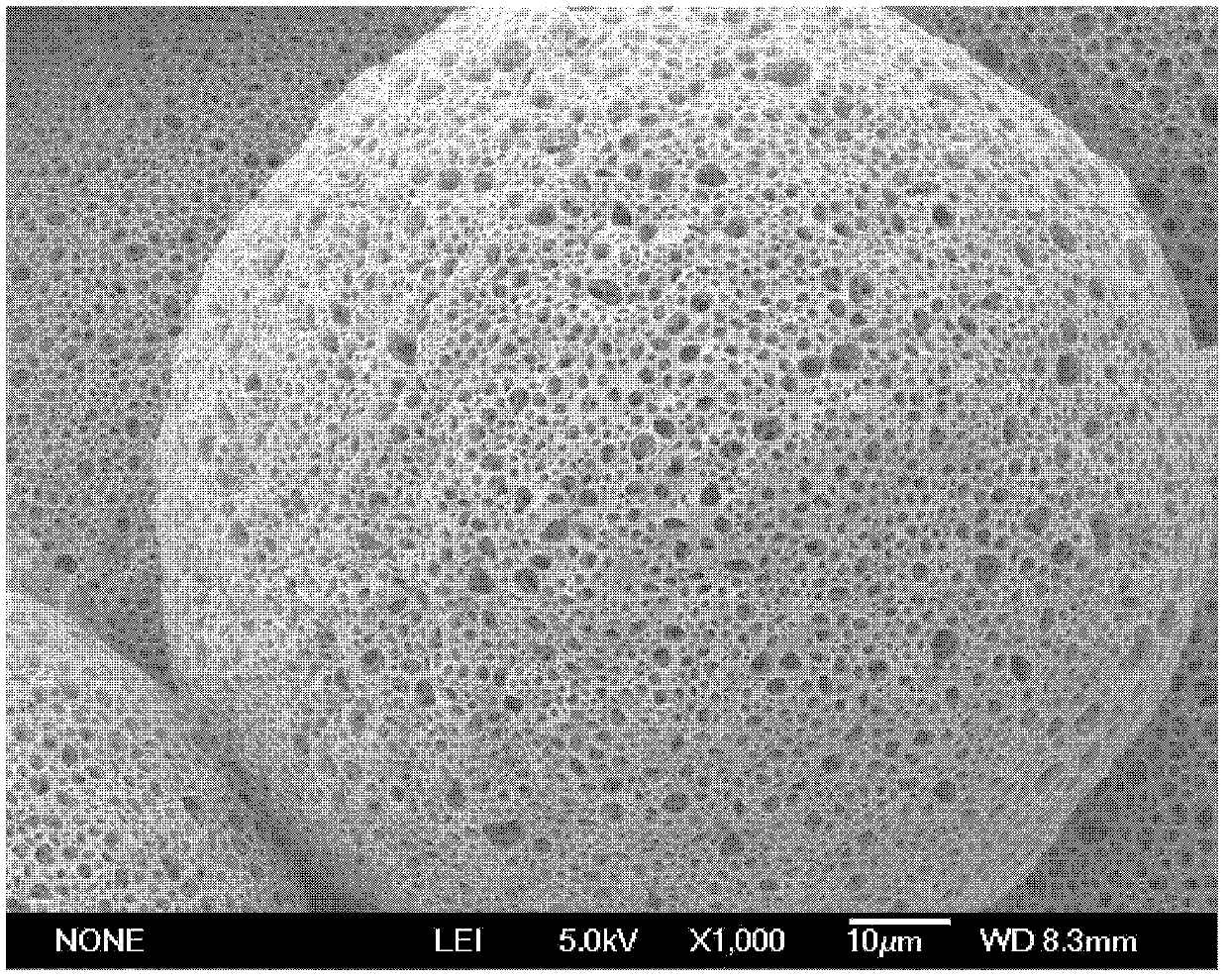

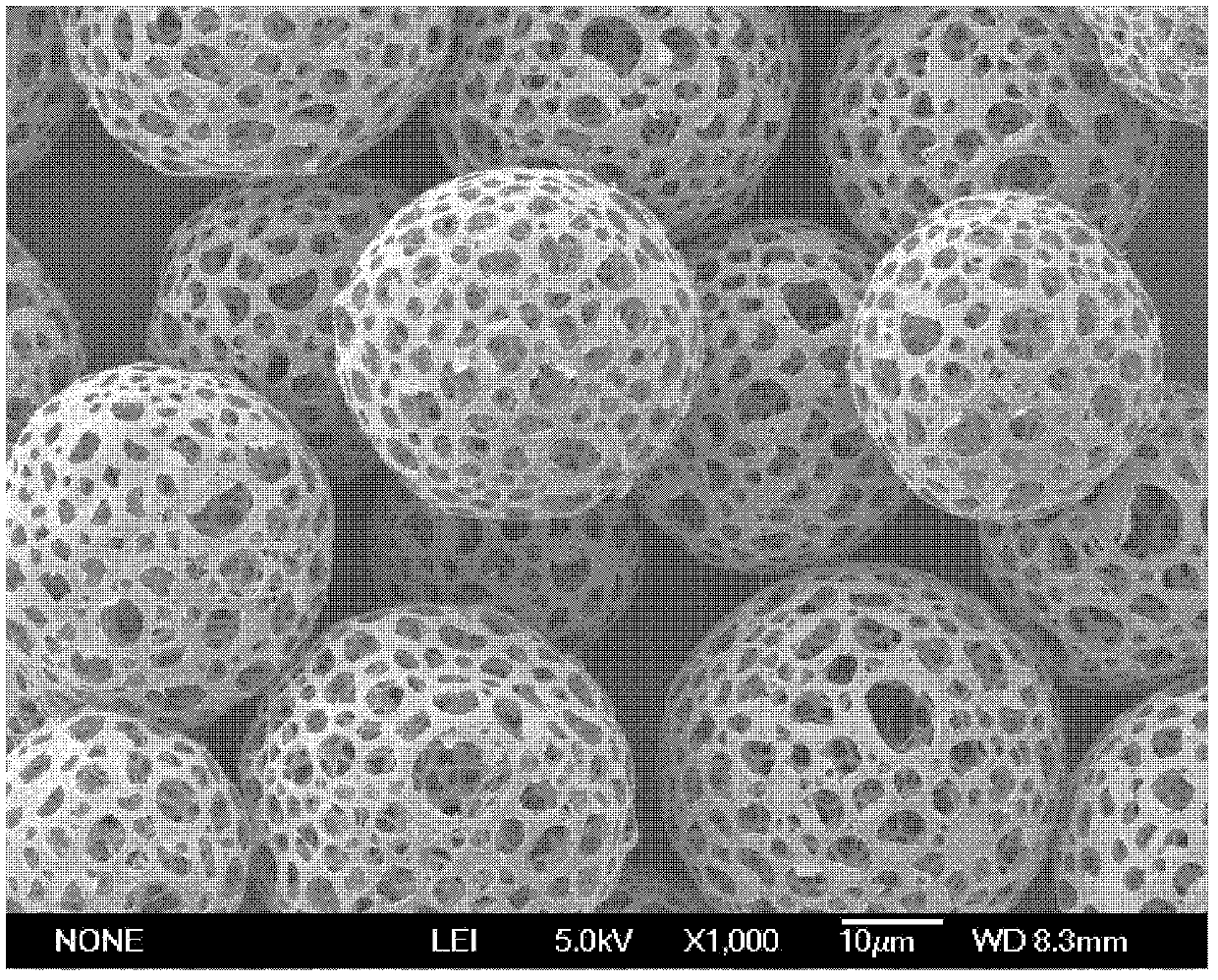

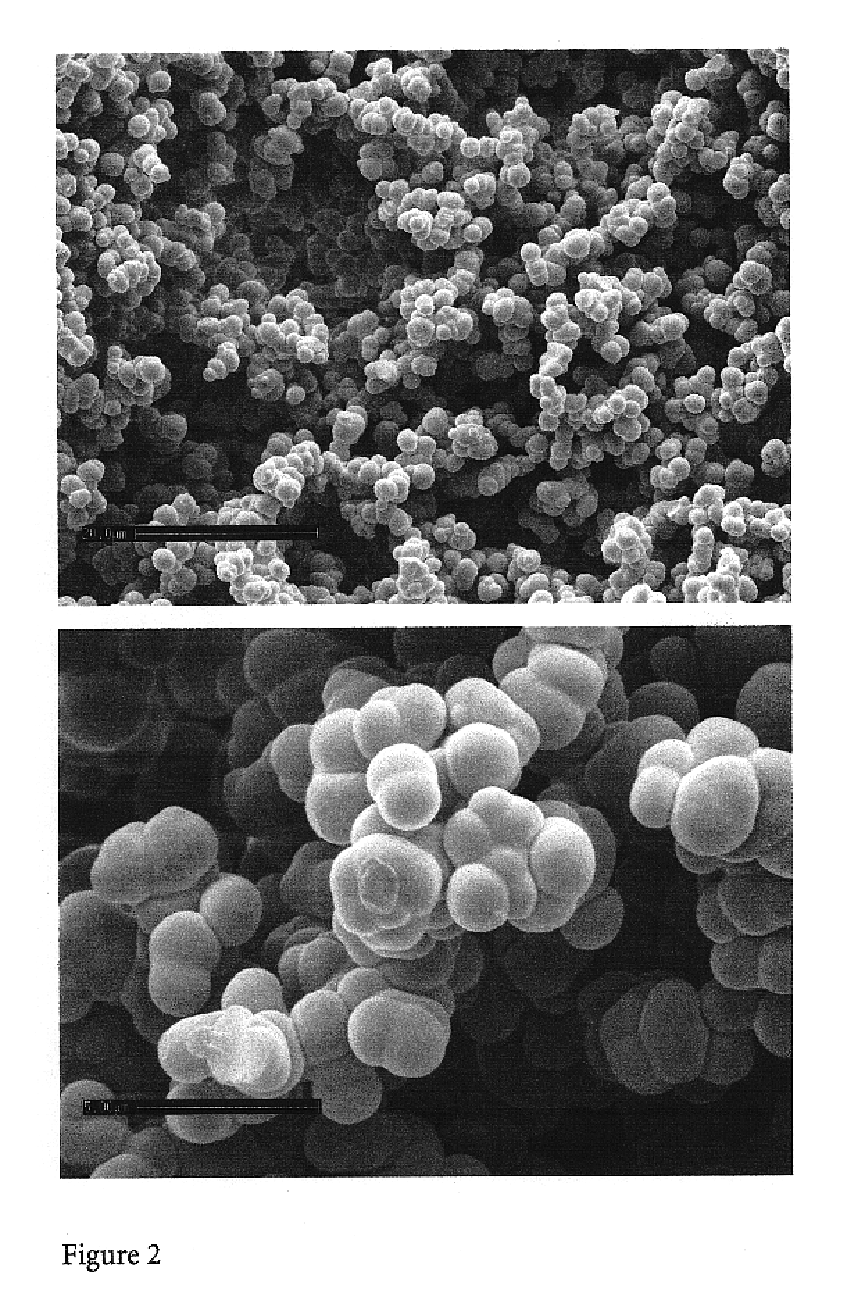

Super macroporous polymer microspheres and preparation method thereof

ActiveCN103374143AControl areaEasy to controlOther chemical processesTissue culturePorosityChromatographic separation

The invention provides super macroporous polymer microspheres and a preparation method thereof. The preparation method comprises the following steps of: firstly, preparing an oil-in-water in-water composite emulsion as a template for super macroporous microspheres through a two-step emulsion process; then, solidifying an oil phase by using a solvent removal method to form super macroporous microspheres provided with inner-outer through pore passages; and finally, after molding the microspheres, further crosslinking microsphere skeleton molecules to obtain microspheres with rigid resin structures. The microspheres prepared by the method have a through pore passage structure, the controllable particle size range is 0.1-300 microns, the controllable pore size range is 0.09-90 microns, and the controllable porosity range is 10-90%. Super macroporous structures are beneficial for biological macromolecules to penetrate through and enter the microspheres, the mass transfer by convection in the microspheres can be realized, and the rigid structure can tolerate higher pressure and higher flow velocity. The super macroporous polymer microspheres can be used as stationary phase fillers for chromatographic separation, immobilized carriers of enzymes, cell culture micro-carriers, tissue engineering micro scaffold materials, adsorbing materials and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

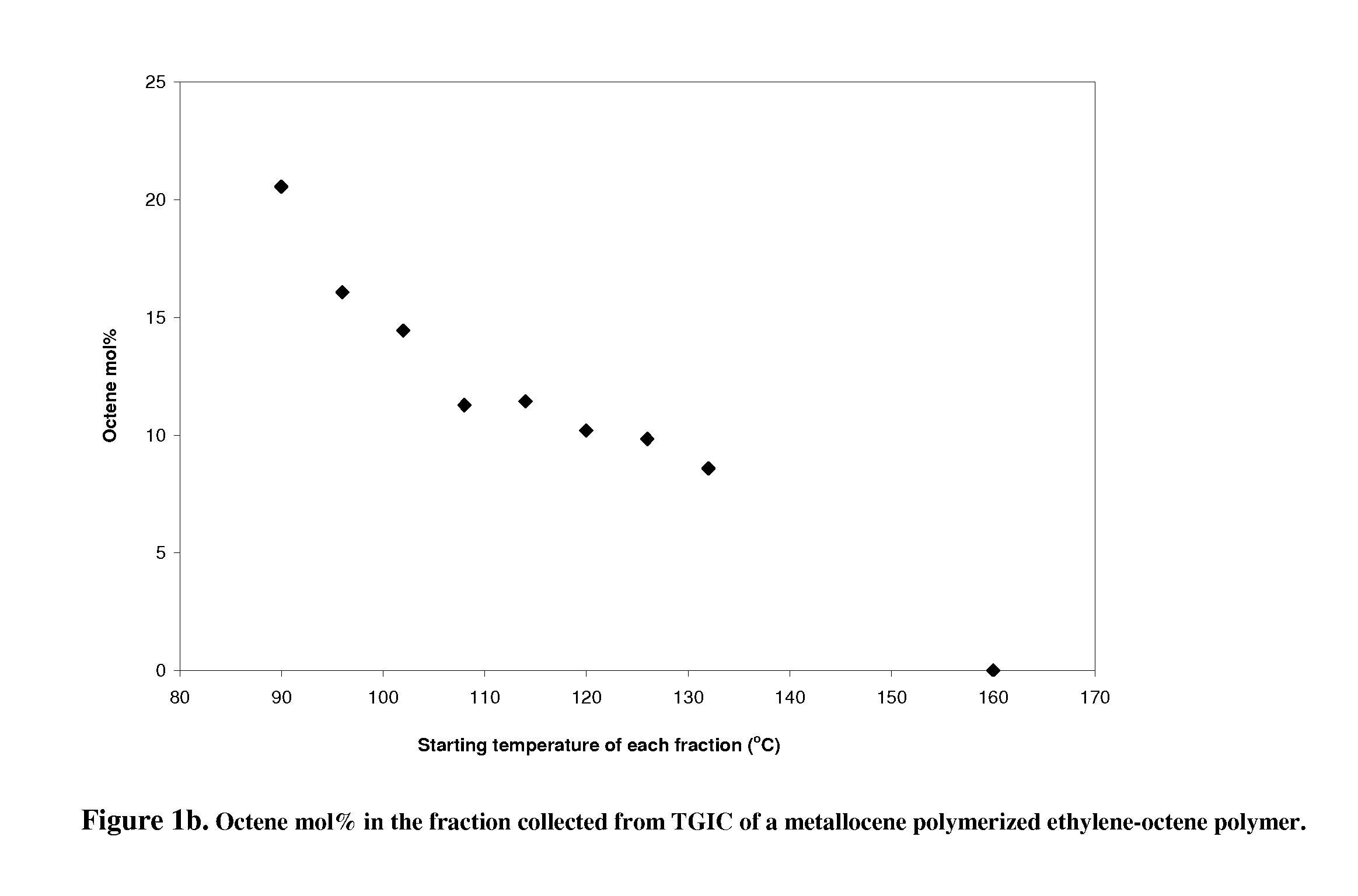

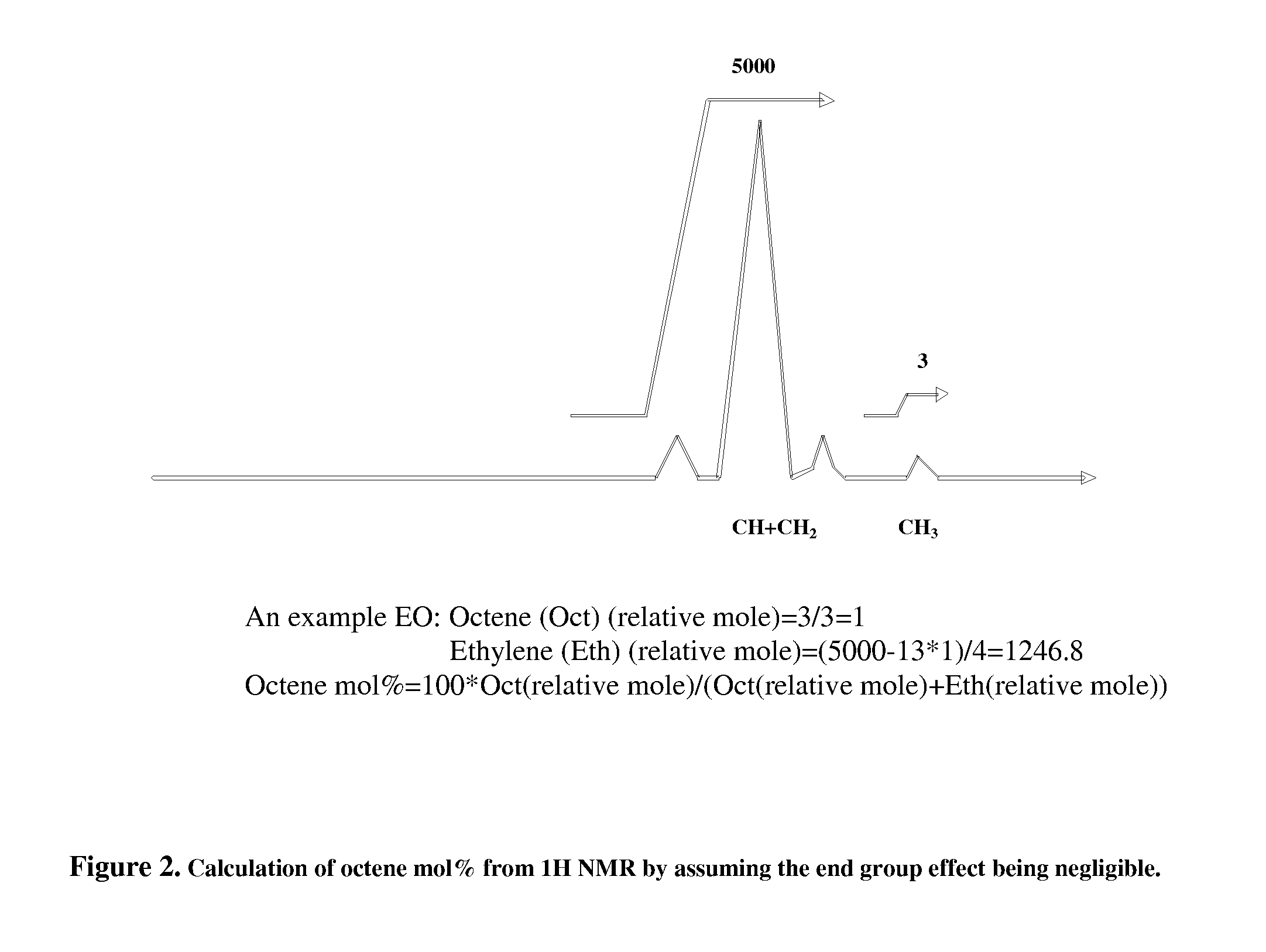

Chromotography of polyolefin polymers

ActiveUS8076147B2Separation efficiency can be improvedIon-exchange process apparatusComponent separationStationary phasePolymer science

A method and apparatus for chromatography of a polyolefin polymer by flowing a solution of the polyolefin polymer through liquid flowing through a graphitic carbon liquid chromatography stationary phase. The method can be used to determine the monomer to comonomer ratio of a polyolefin copolymer such as a copolymer of ethylene and 1-octene or a copolymer of propylene and ethylene.

Owner:THE DOW CHEM CO

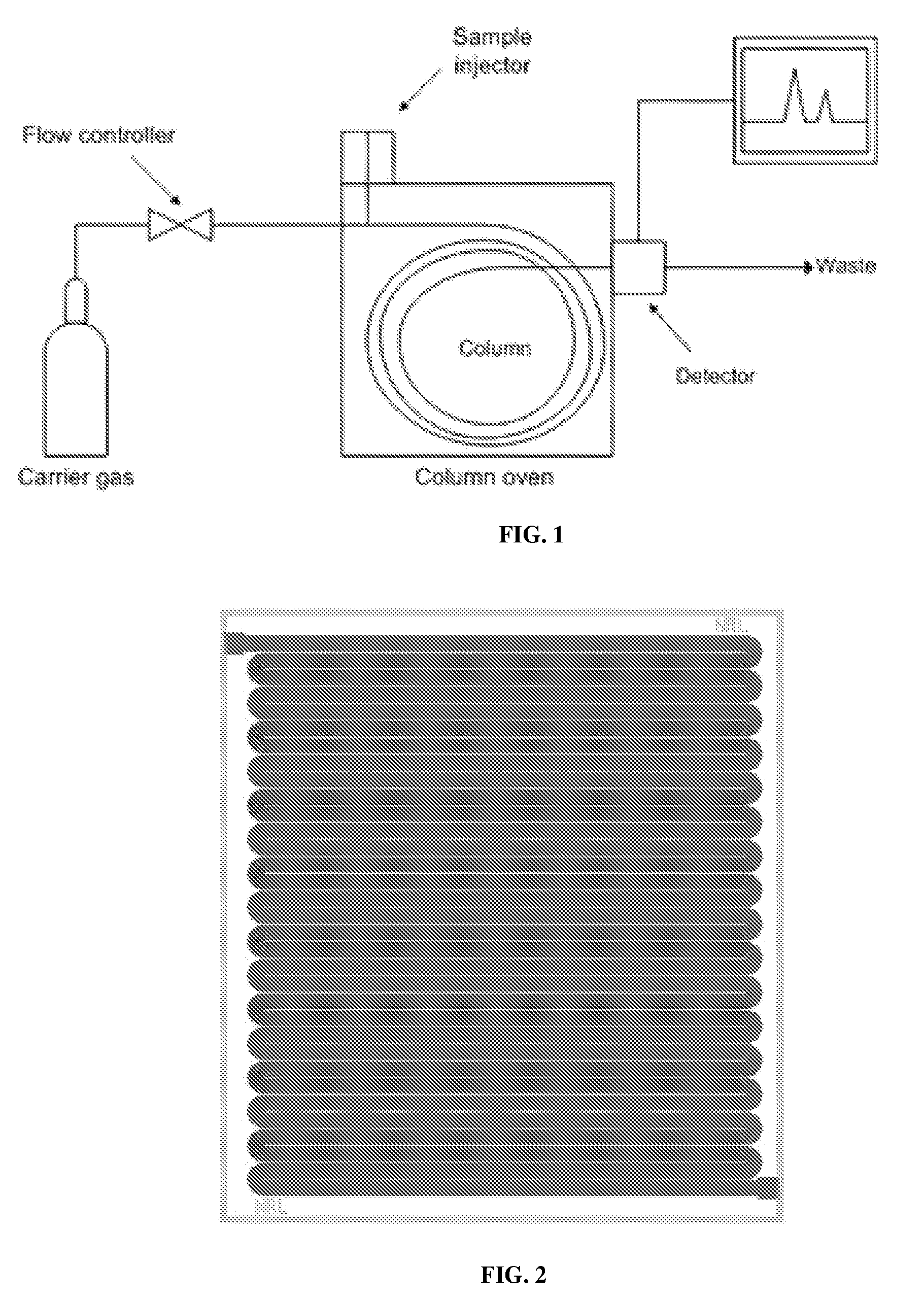

Microfabricated gas chromatograph

ActiveUS20090272270A1Mitigate band broadeningMitigate tailing problemLamination ancillary operationsComponent separationStationary phaseContinuous flow

The present invention is generally directed to a microfabricated gas chromatograph column having two patterned substrates, each optionally having a stationary phase material coating, bonded together to provide a continuous flow channel. The flow channel can have a serpentine arrangement or a modified serpentine arrangement comprising alternating series of consecutive turns in one direction where each series has enough turns to move carrier gas and analyte molecules from the center of the column cross section to an outer wall of the channel or from one outer wall of the channel to the opposite outer wall. Different portions of the substrates can be coated with differing thicknesses of stationary phase material and / or with different stationary phase materials. The column can have a circular cross-section or a semi-circular cross-section where the flat portion of the cross-section has grooves. Also disclosed is the related method of making the microfabricated gas chromatograph column.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

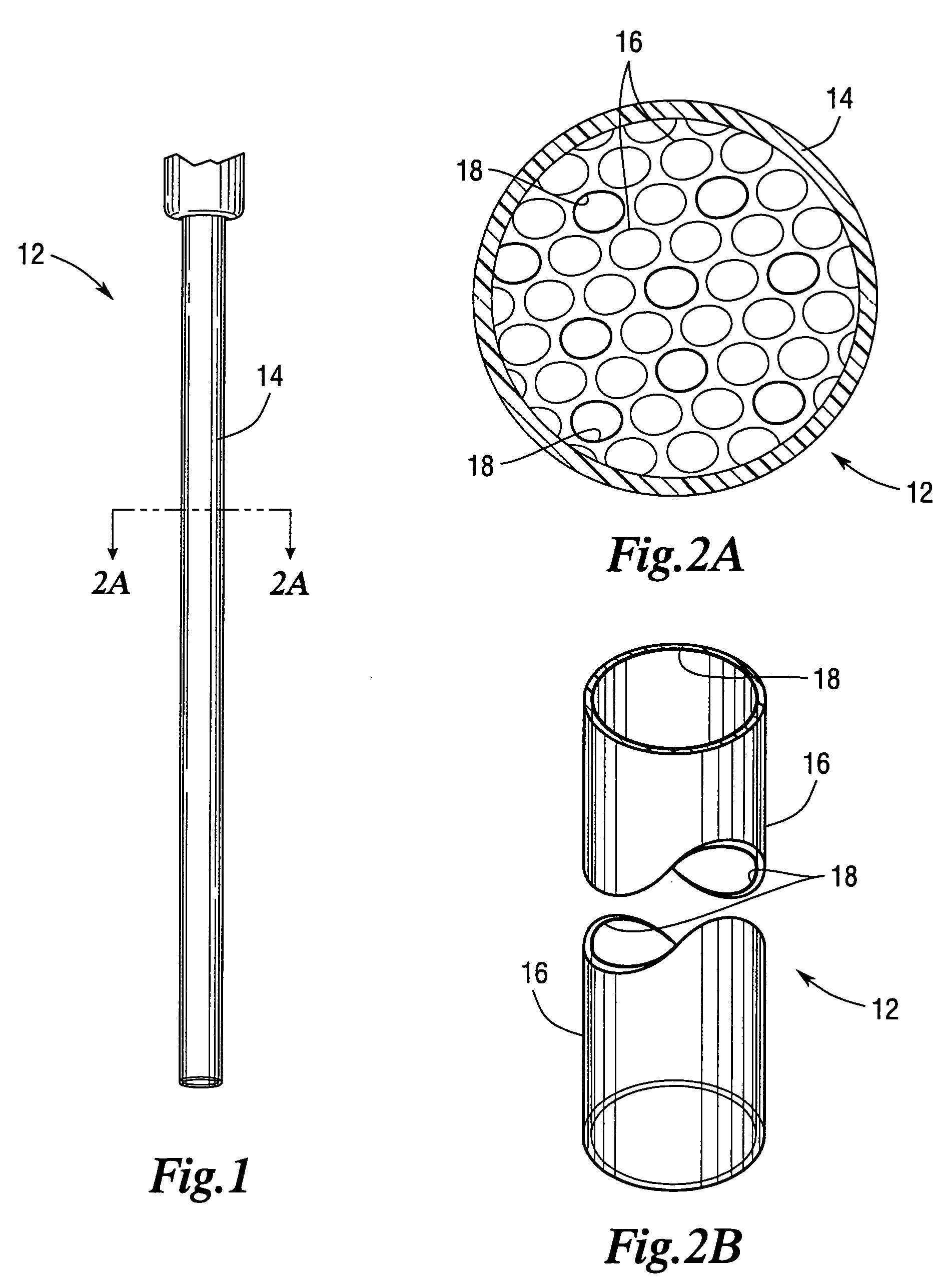

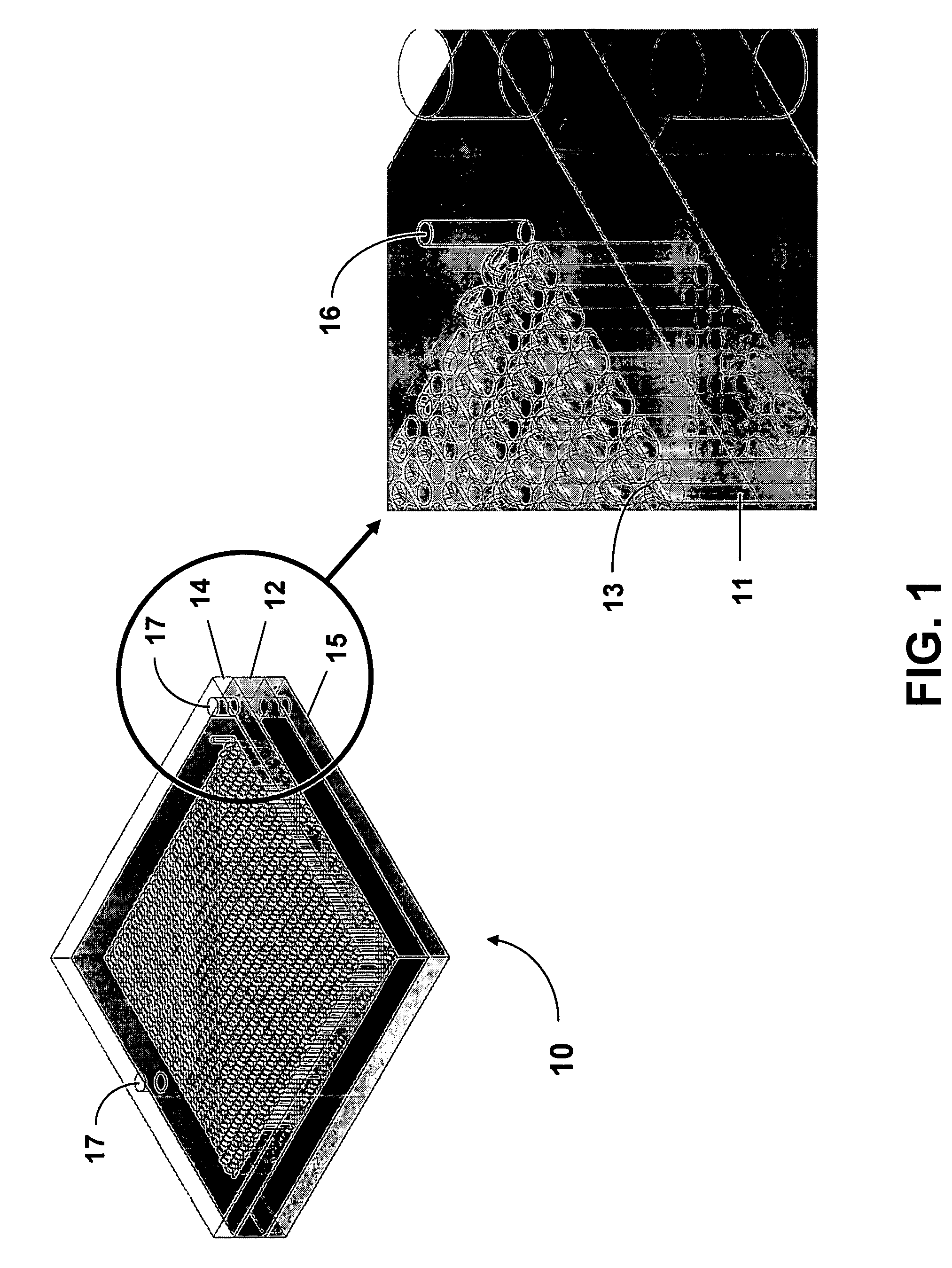

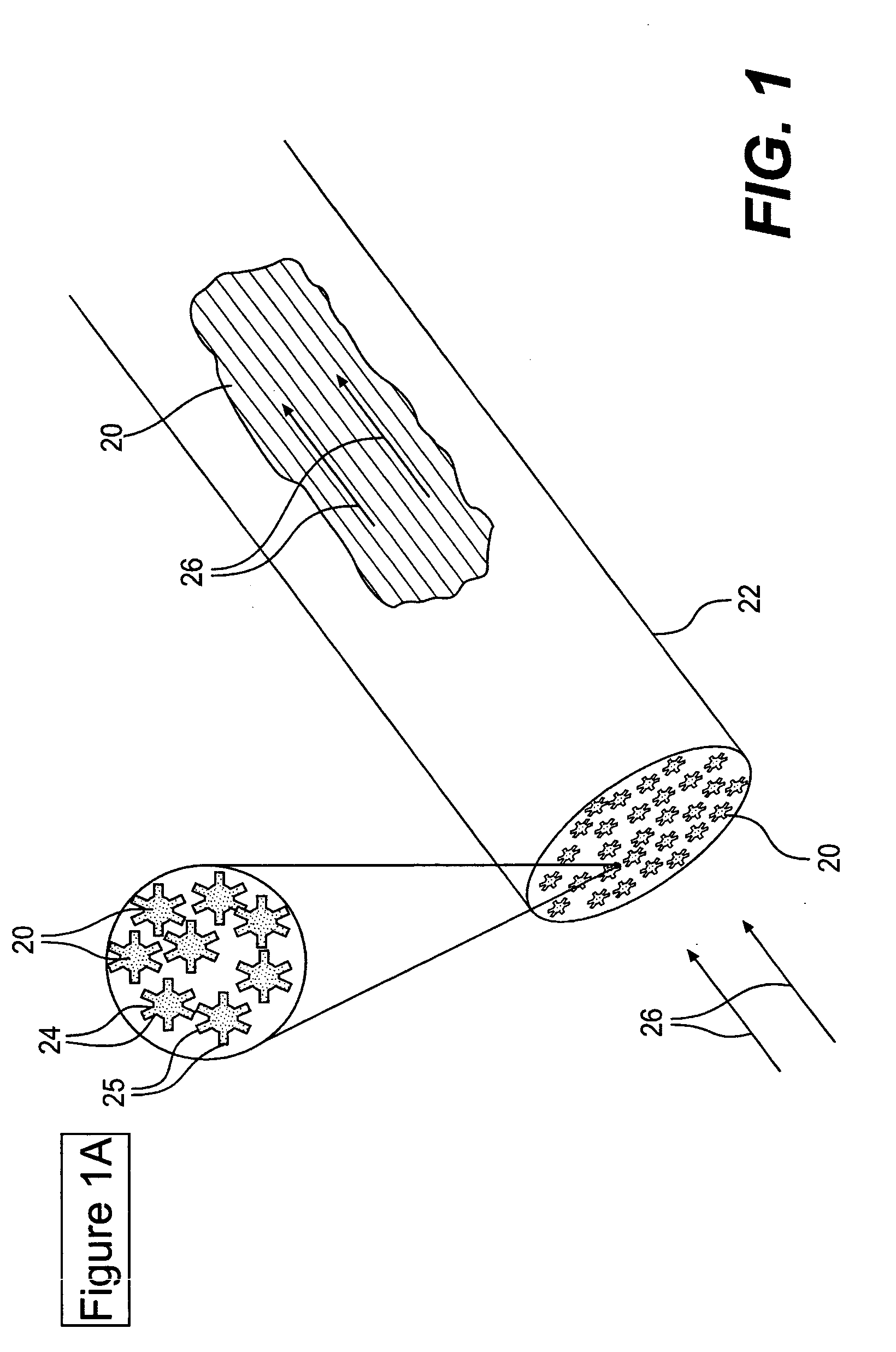

Monolithic structures comprising polymeric fibers for chemical separation by liquid chromatography

Monolithic cartridges including a plurality of nominally aligned polymer fibers can be used as stationary phase materials for liquid chromatography separations. Bundles of fibers are packed together so as to form capillary channels between the fibers. Different polymer compositions permit the “chemical tuning” of the separation process. The fibers can be physically or chemically bonded at spaced locations throughout the cartridge or can be packed together under pressure by use of an encasing wrap to form the capillary channels. Use of fibers allows a wide range of liquid flow rates with very low backpressures. Applications in HPLC, cap-LC, prep-scale separations, analytical separations, waste remediation / immobilization, extraction of selected organic molecules / ions from solution, purification of liquid streams (process waste, drinking water, pure solvents), selective extraction of cell matter and bacteria from growth media, and immobilization of cell matter and bacteria are envisioned.

Owner:CLEMSON UNIVERSITY

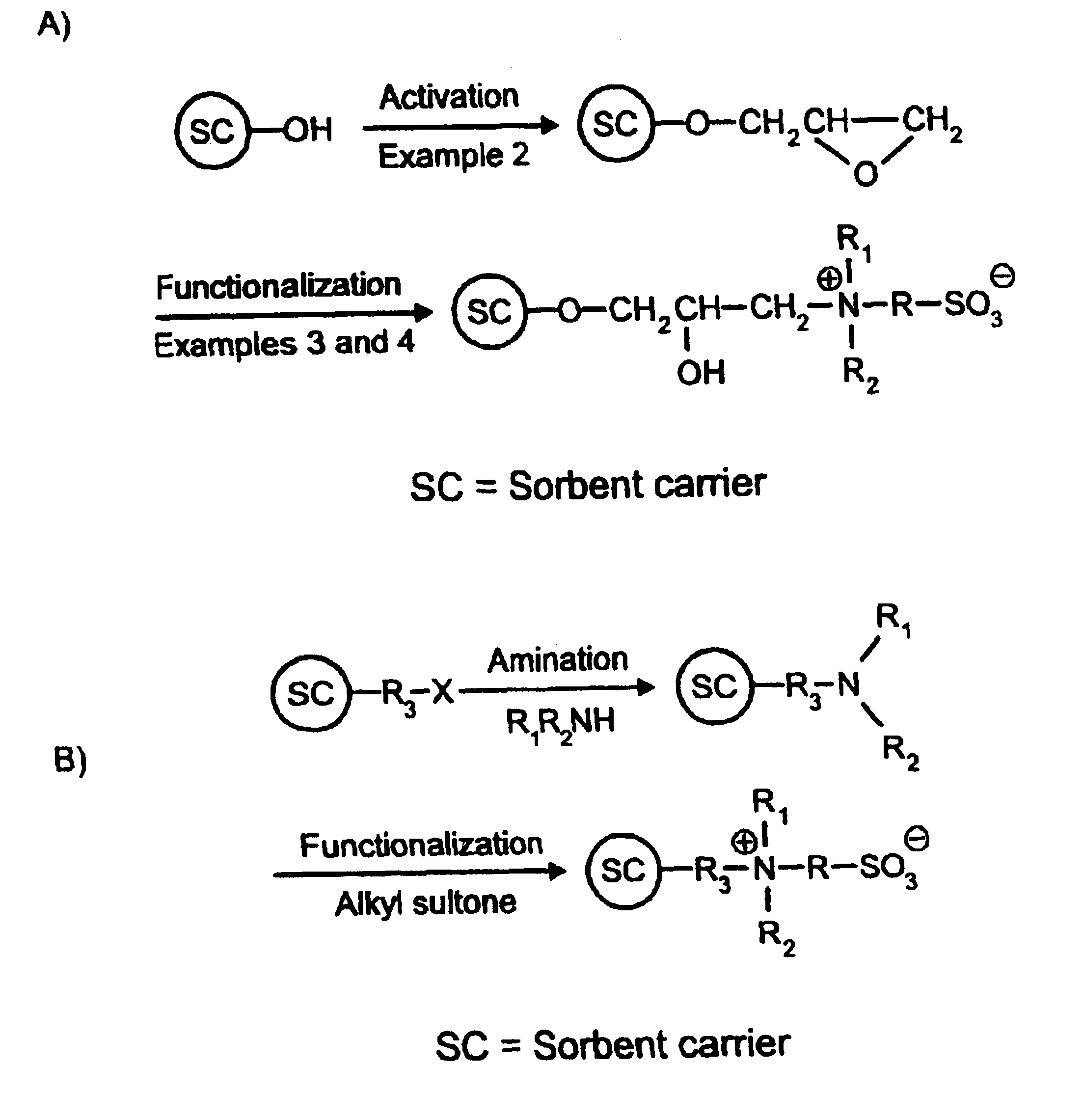

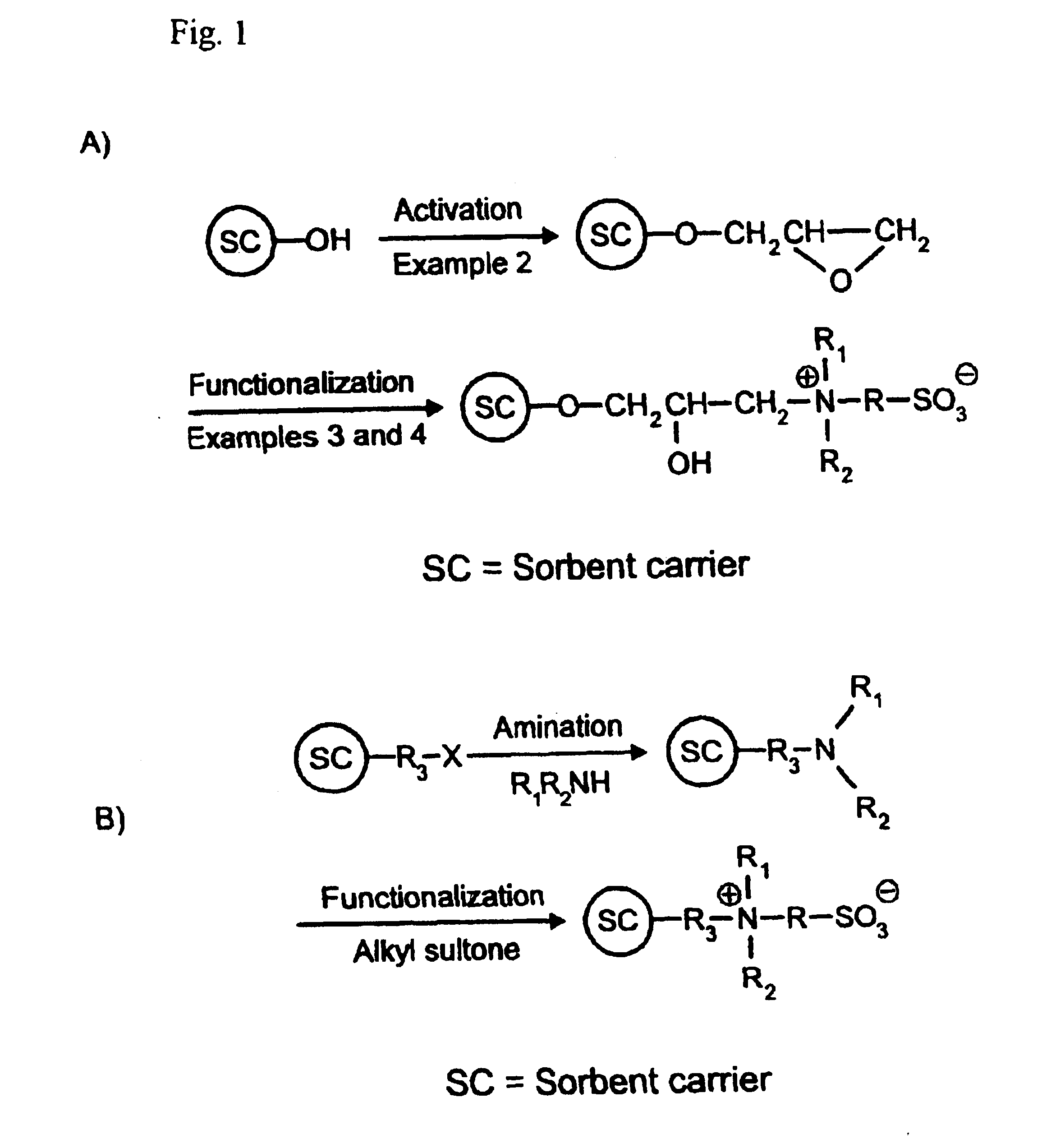

Chromatography method and a column material useful in said method

InactiveUS6884345B1Chromatographic cation exchangersCation exchanger materialsNatural sourceStationary phase

A novel sorbent suitable for use as a stationary phase in a chromatography column, the core of which consists of an organic polymer of synthetic or natural origin. Further, the carrier exhibits a plurality of covalently bonded non-aromatic zwitterionic groups on its surface. Additionally, the invention also relates to a method for purifying a particular biological macromolecule, such as a protein or a nucleic acid, by zwitterionic ion exchange chromatography as well as an ion exchange column suitable for use in the zwitterionic ion exchange chromatography.

Owner:MERCK PATENT GMBH

Disposable pipette extraction

The present invention is a disposable apparatus for the rapid, low-volume solid phase extraction of analytes from a variety of sources. The apparatus of the present invention is configured as a pipette tip and contains a loosely confined stationary phase. The mobility of the stationary phase particles enables rapid mixing and equilibration with a sample solution during agitation. The analyte may thereby be extracted in less time with less solvent, removing the need for a separate concentration step.

Owner:BREWER WILLIAM E

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com