Patents

Literature

3351 results about "Fractionation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fractionation is a separation process in which a certain quantity of a mixture (gas, solid, liquid, enzymes, suspension, or isotope) is divided during a phase transition, into a number of smaller quantities (fractions) in which the composition varies according to a gradient. Fractions are collected based on differences in a specific property of the individual components. A common trait in fractionations is the need to find an optimum between the amount of fractions collected and the desired purity in each fraction. Fractionation makes it possible to isolate more than two components in a mixture in a single run. This property sets it apart from other separation techniques.

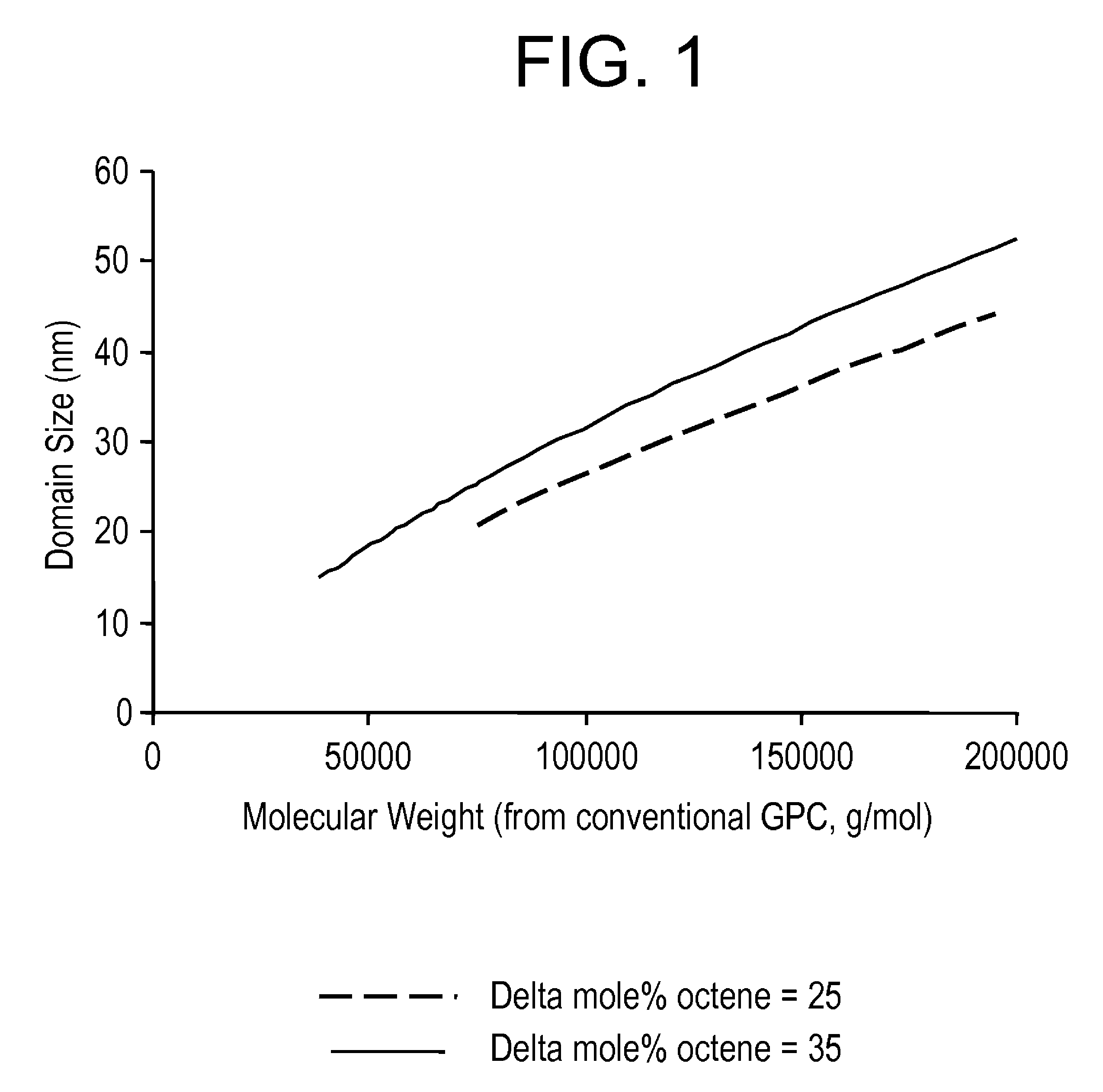

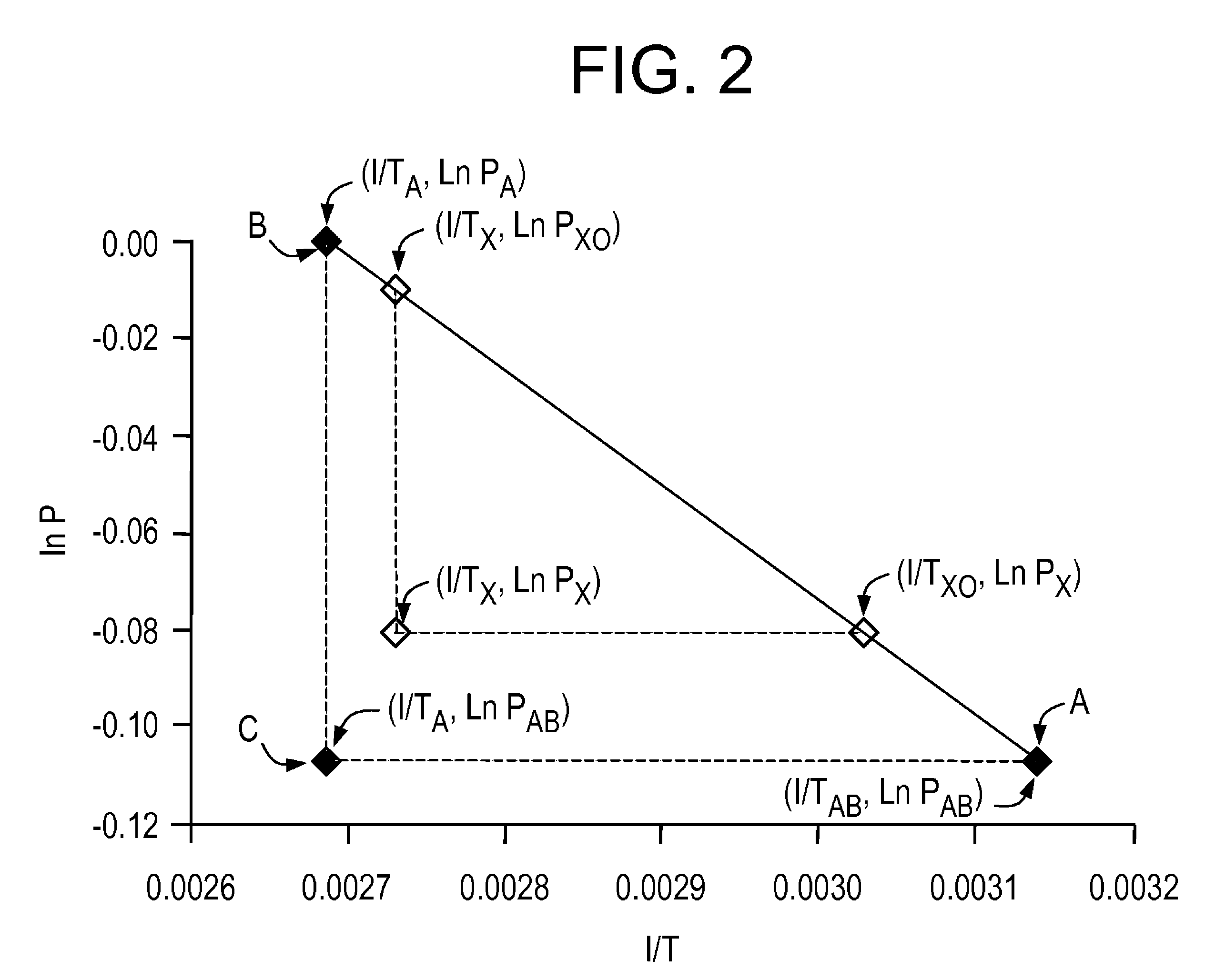

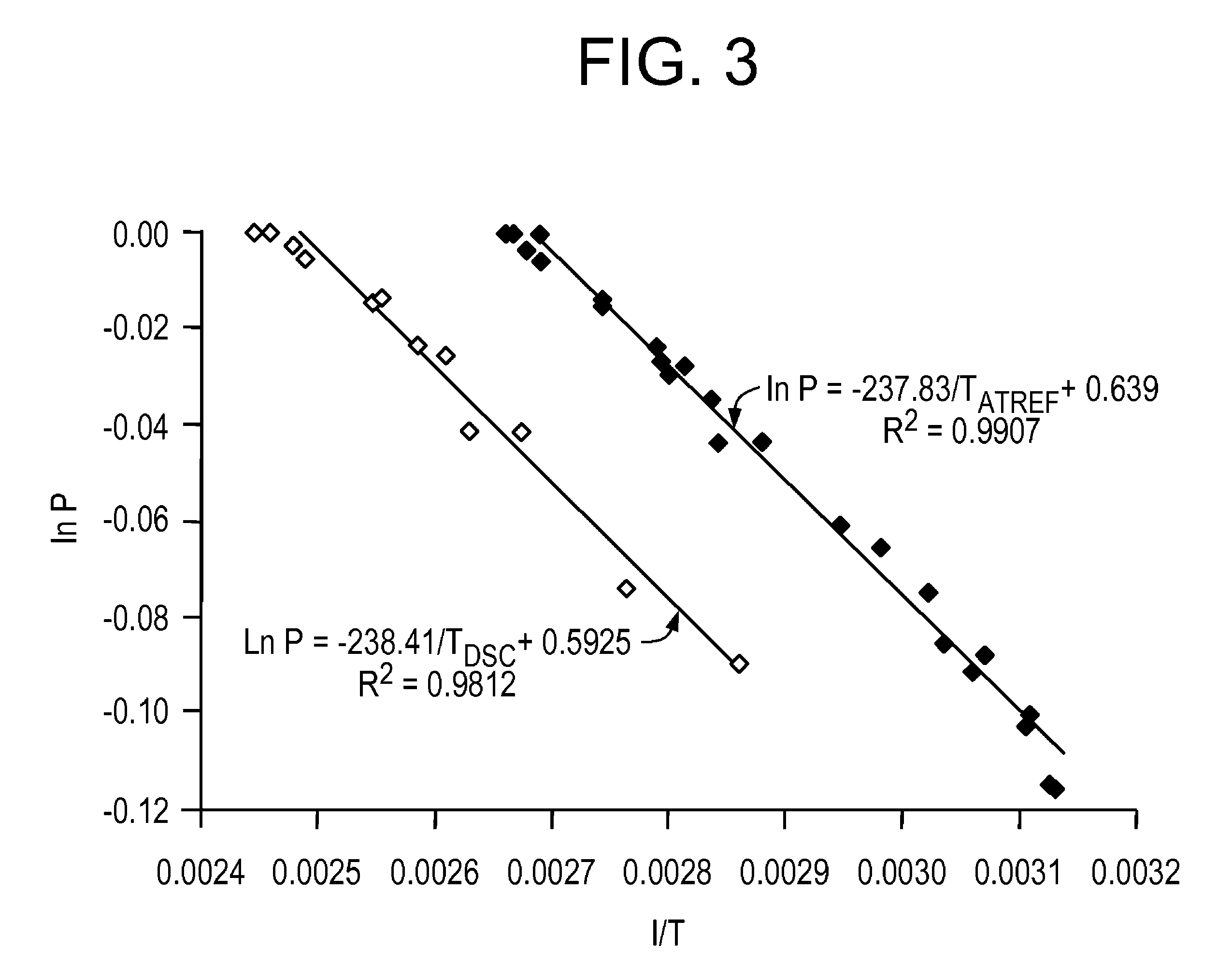

Ethylene/alpha-olefins block interpolymers

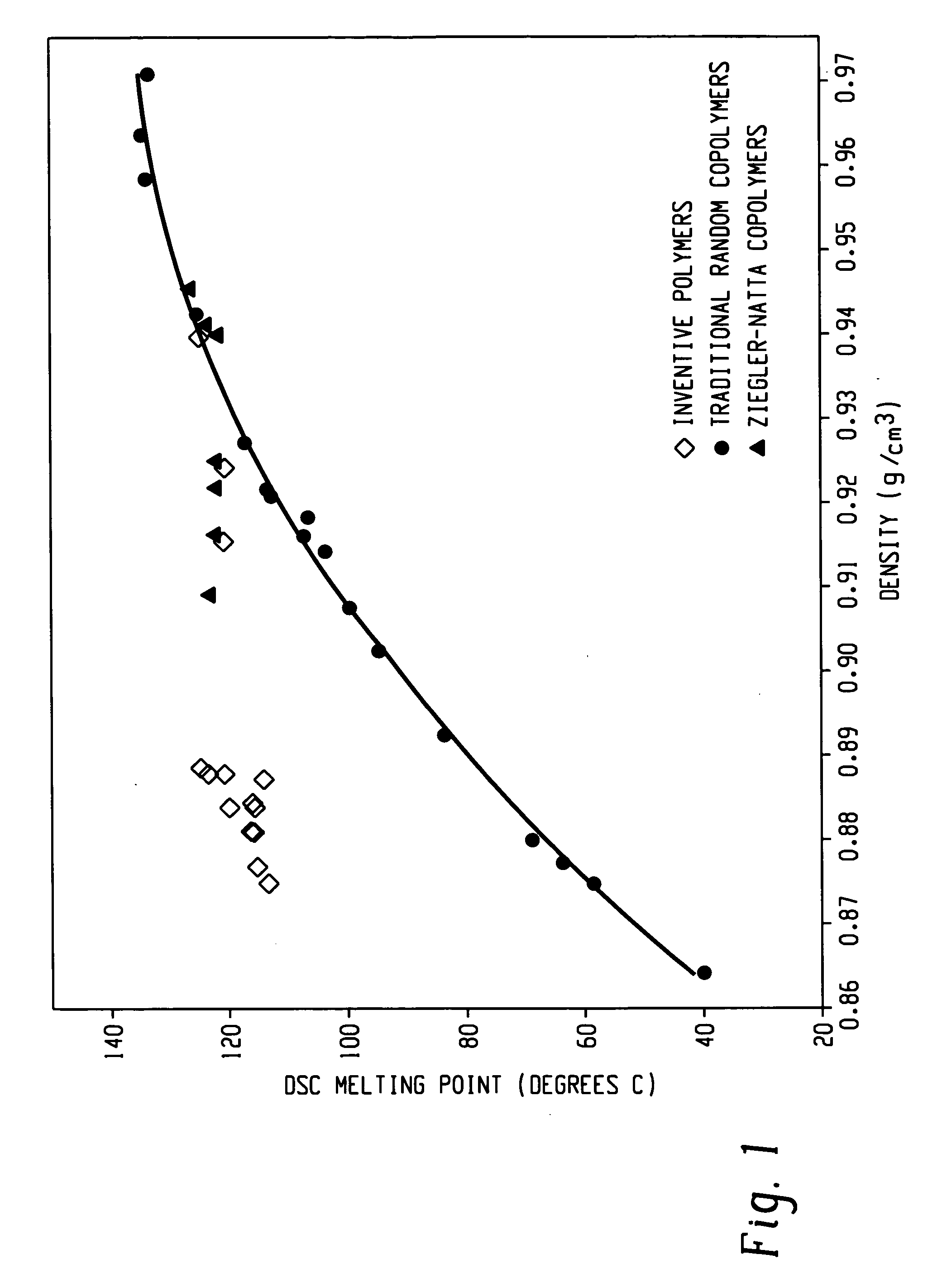

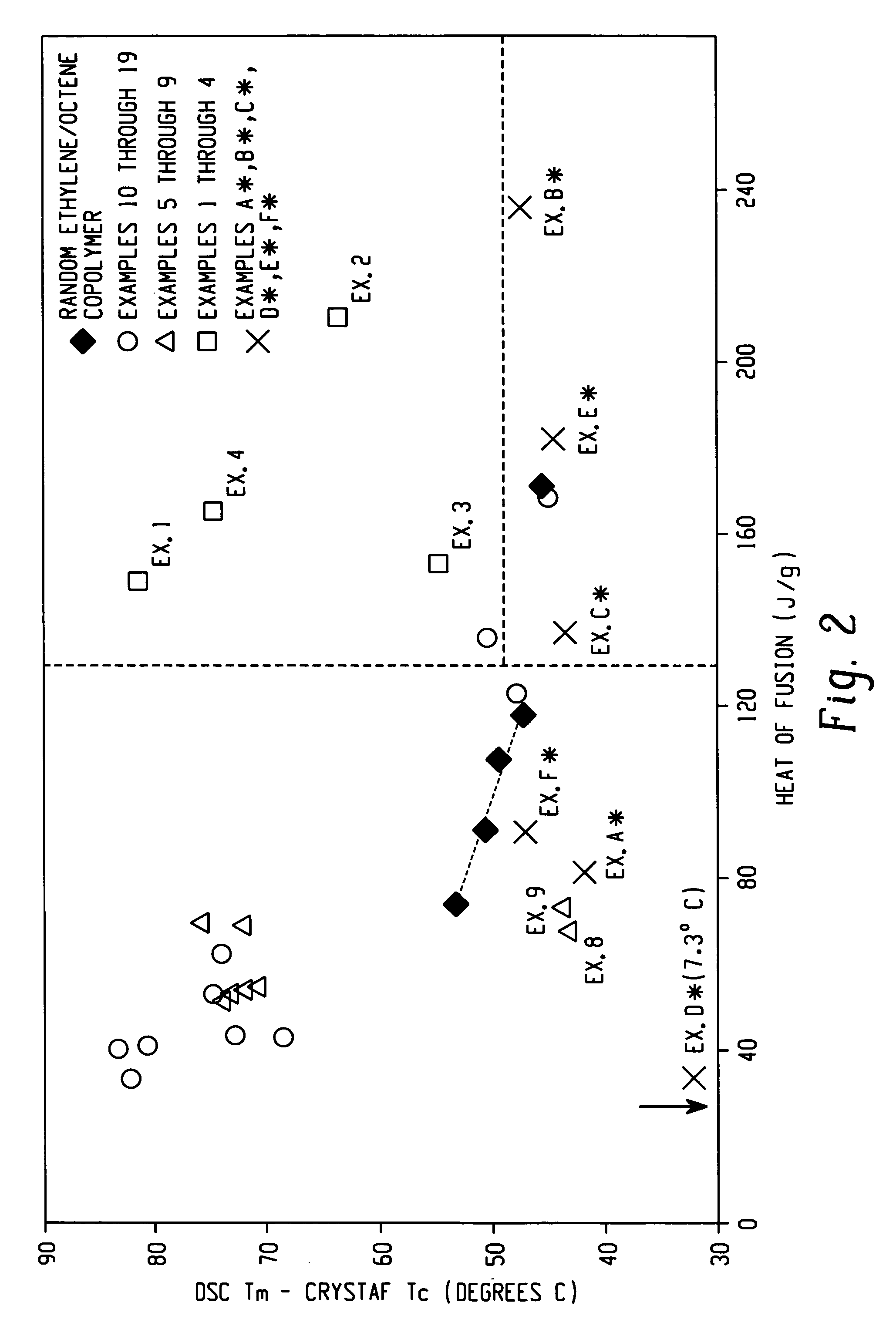

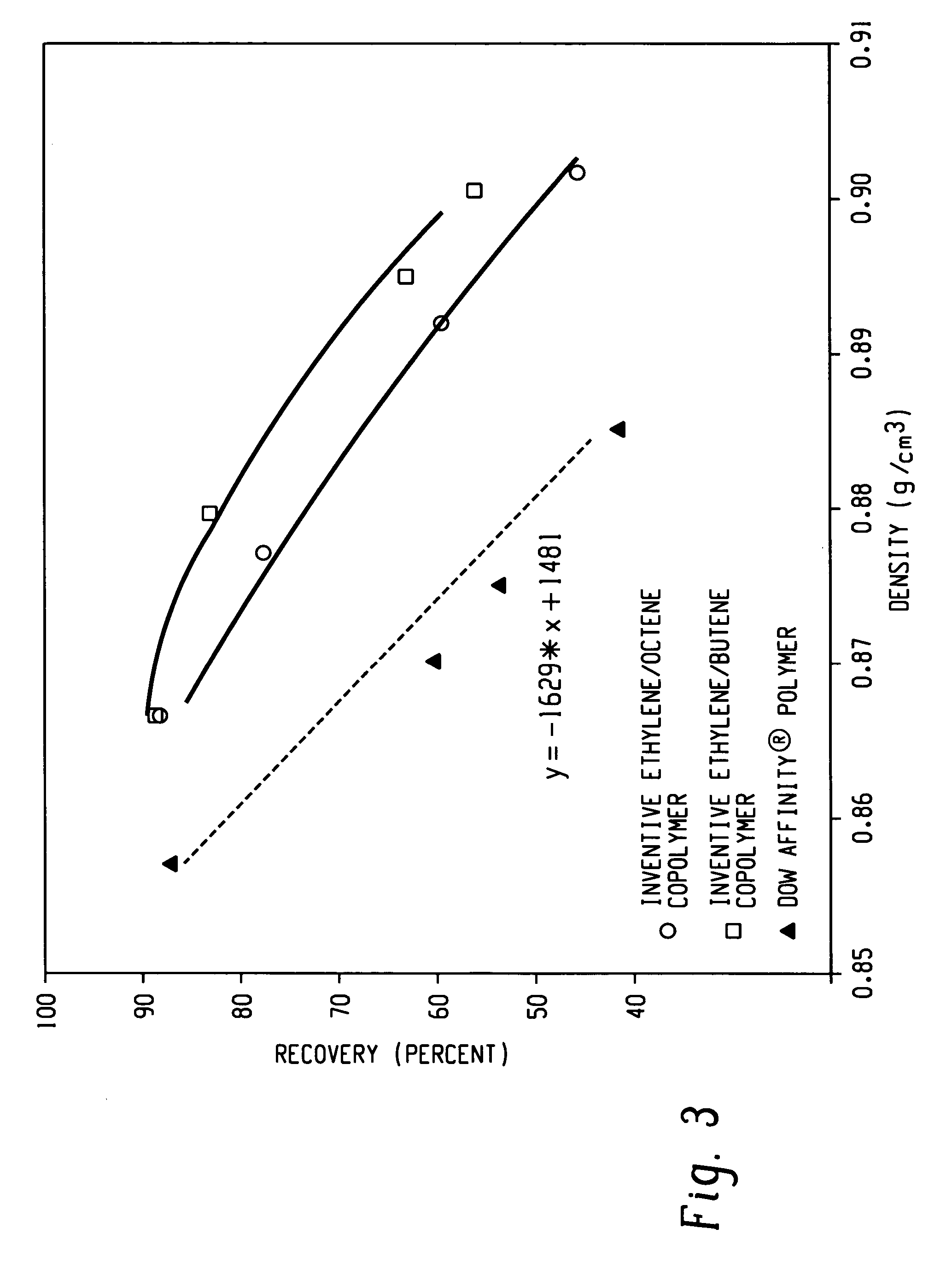

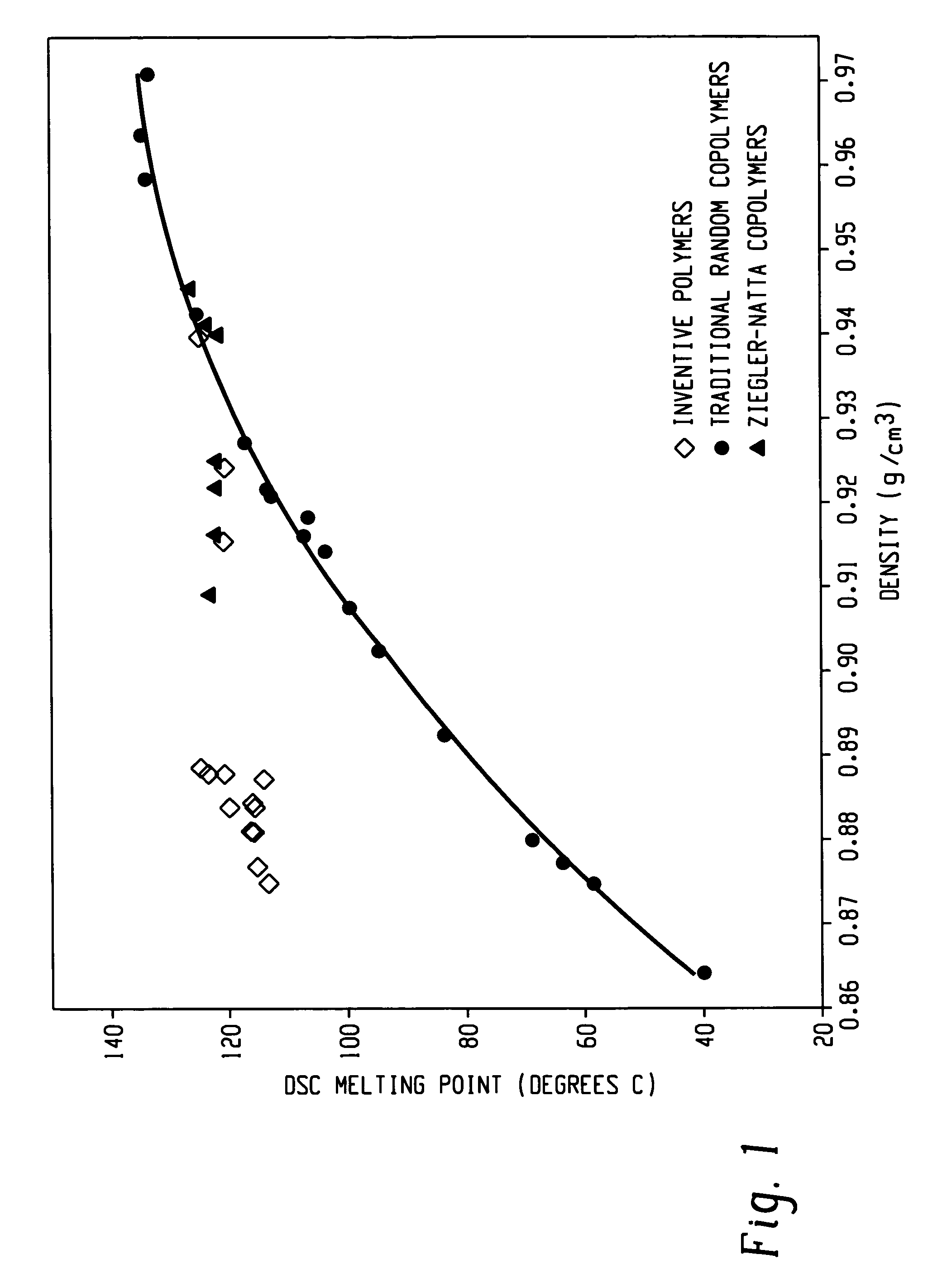

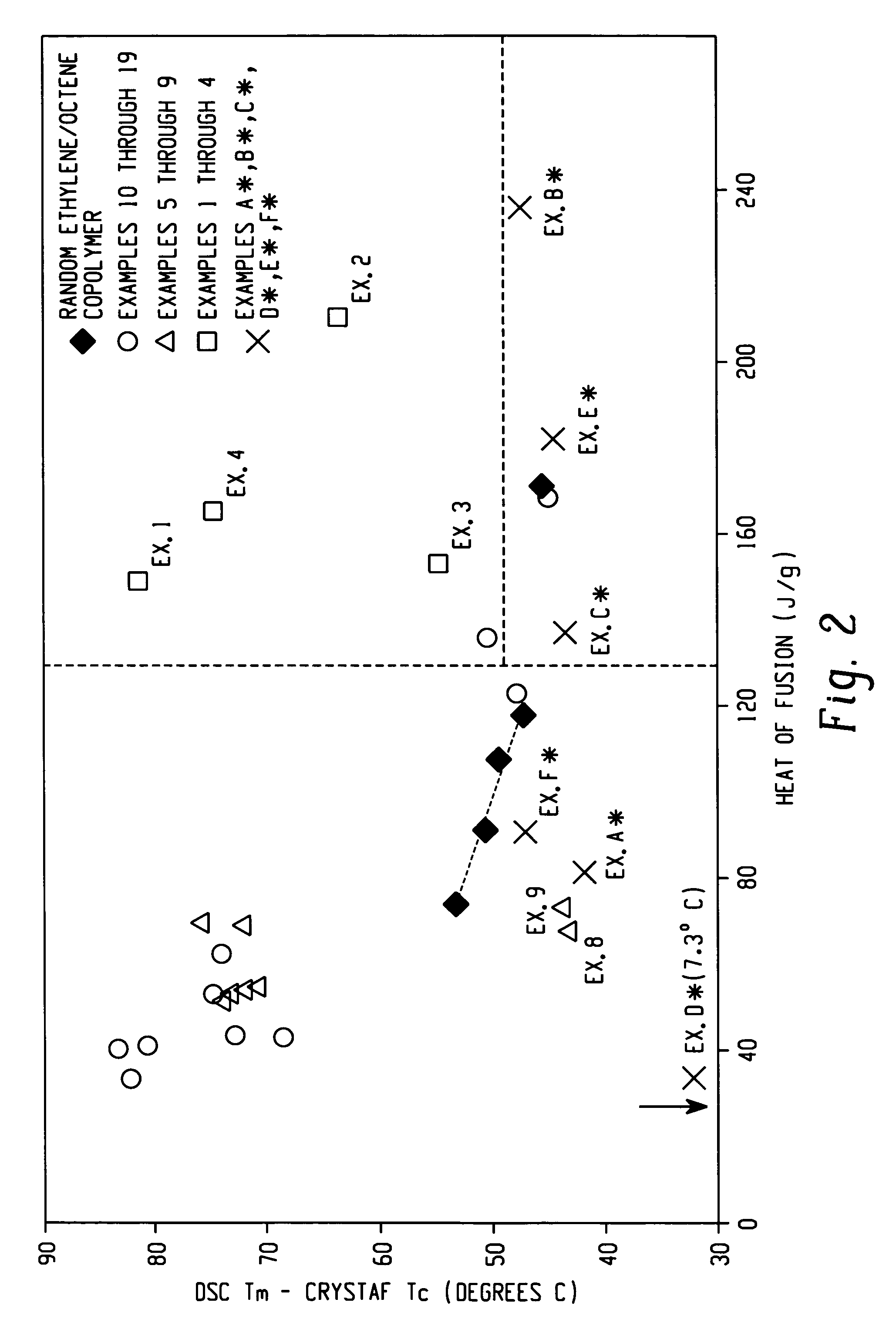

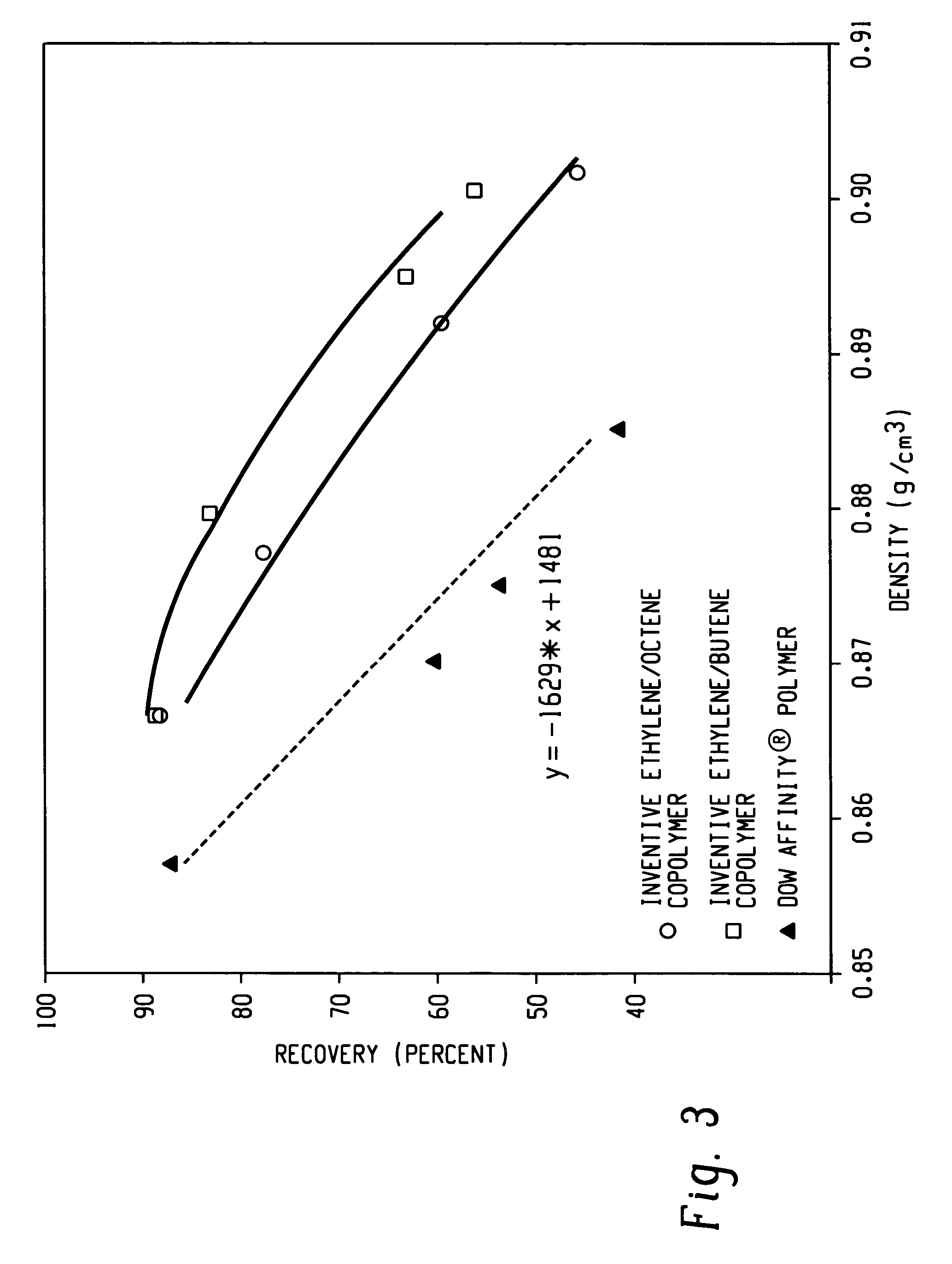

Embodiments of the invention provide a class of ethylene / α-olefin block interpolymers. The ethylene / α-olefin interpolymers are characterized by an average block index, ABI, which is greater than zero and up to about 1.0 and a molecular weight distribution, Mw / Mn, greater than about 1.3. Preferably, the block index is from about 0.2 to about 1. In addition or alternatively, the block ethylene / α-olefin interpolymer is characterized by having at least one fraction obtained by Temperature Rising Elution Fractionation (“TREF”), wherein the fraction has a block index greater than about 0.3 and up to about 1.0 and the ethylene / α-olefin interpolymer has a molecular weight distribution, Mw / Mn, greater than about 1.3.

Owner:DOW GLOBAL TECH LLC

Ethylene/alpha-olefins block interpolymers

Embodiments of the invention provide a class of ethylene / α-olefin block interpolymers. The ethylene / α-olefin interpolymers are characterized by an average block index, ABI, which is greater than zero and up to about 1.0 and a molecular weight distribution, Mw / Mn, greater than about 1.3. Preferably, the block index is from about 0.2 to about 1. In addition or alternatively, the block ethylene / α-olefin interpolymer is characterized by having at least one fraction obtained by Temperature Rising Elution Fractionation (“TREF”), wherein the fraction has a block index greater than about 0.3 and up to about 1.0 and the ethylene / α-olefin interpolymer has a molecular weight distribution, Mw / Mn, greater than about 1.3.

Owner:DOW GLOBAL TECH LLC

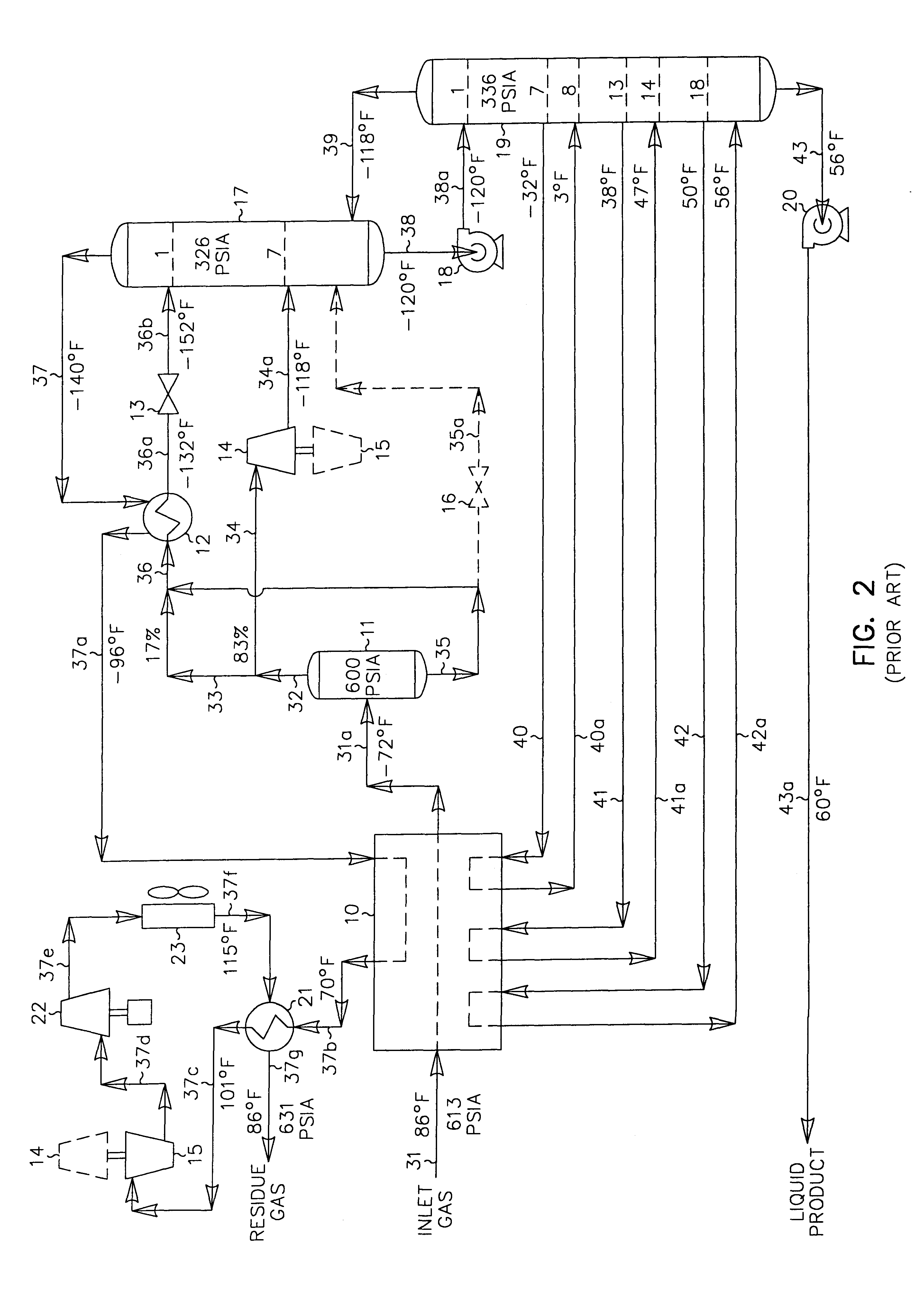

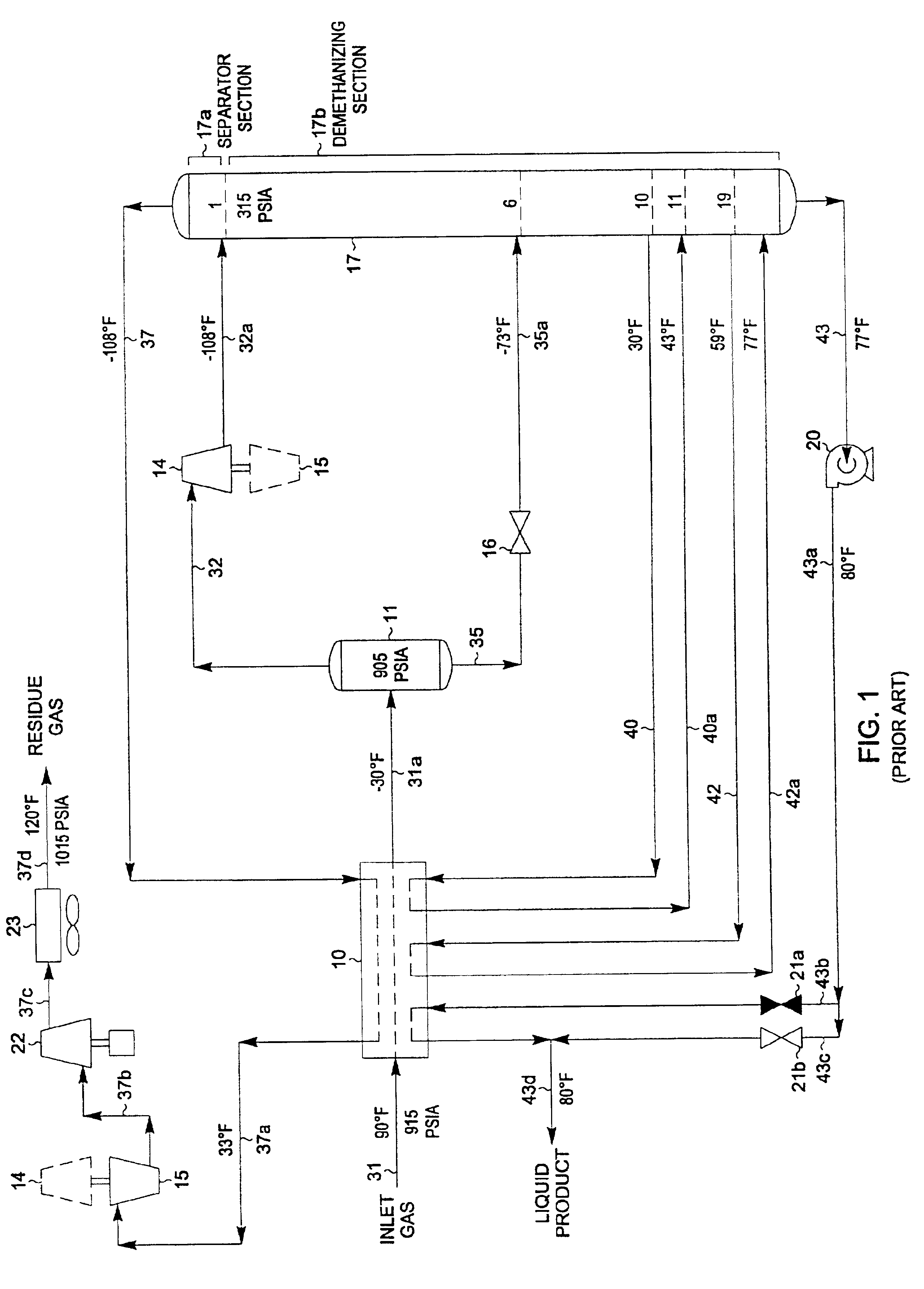

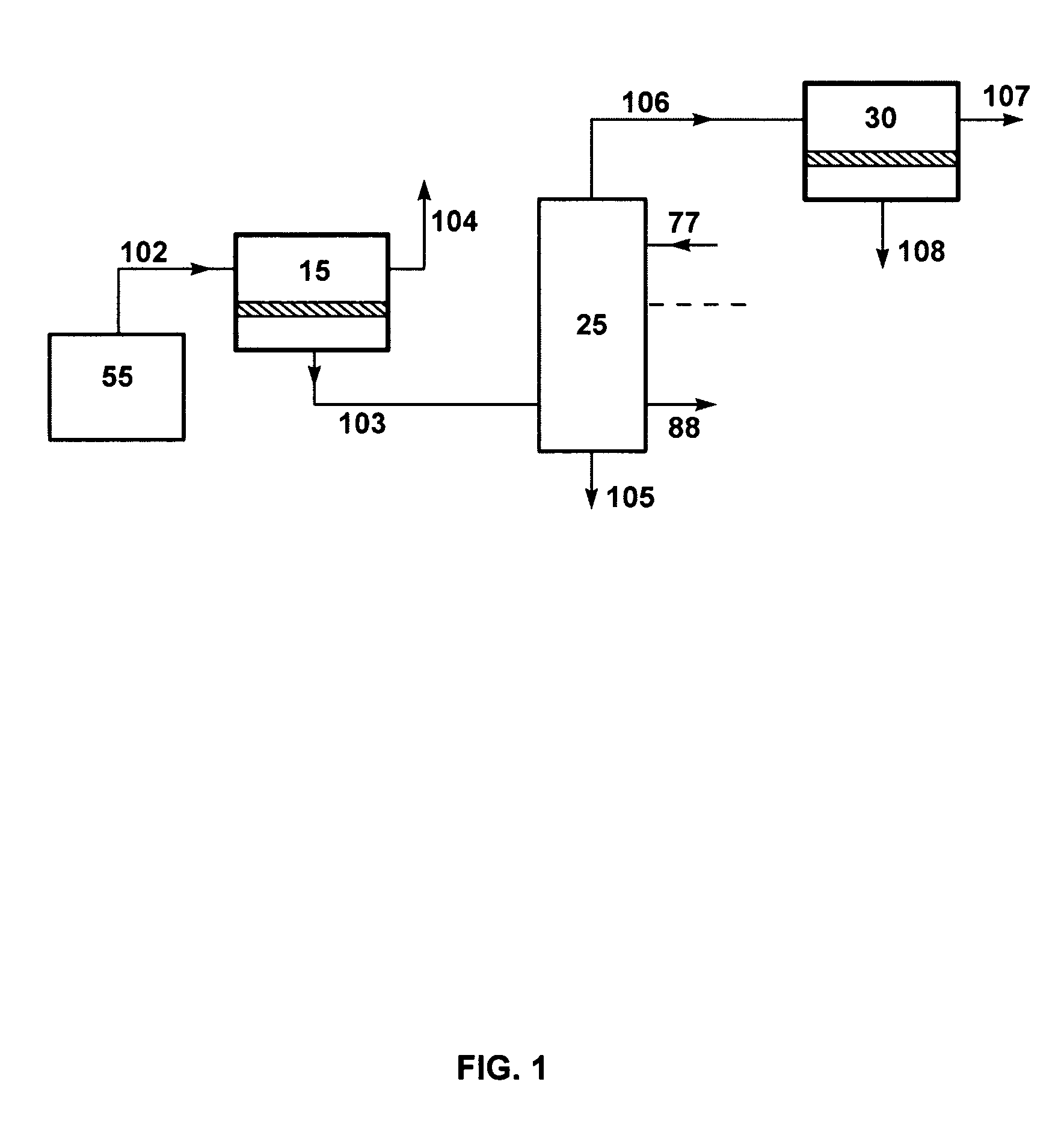

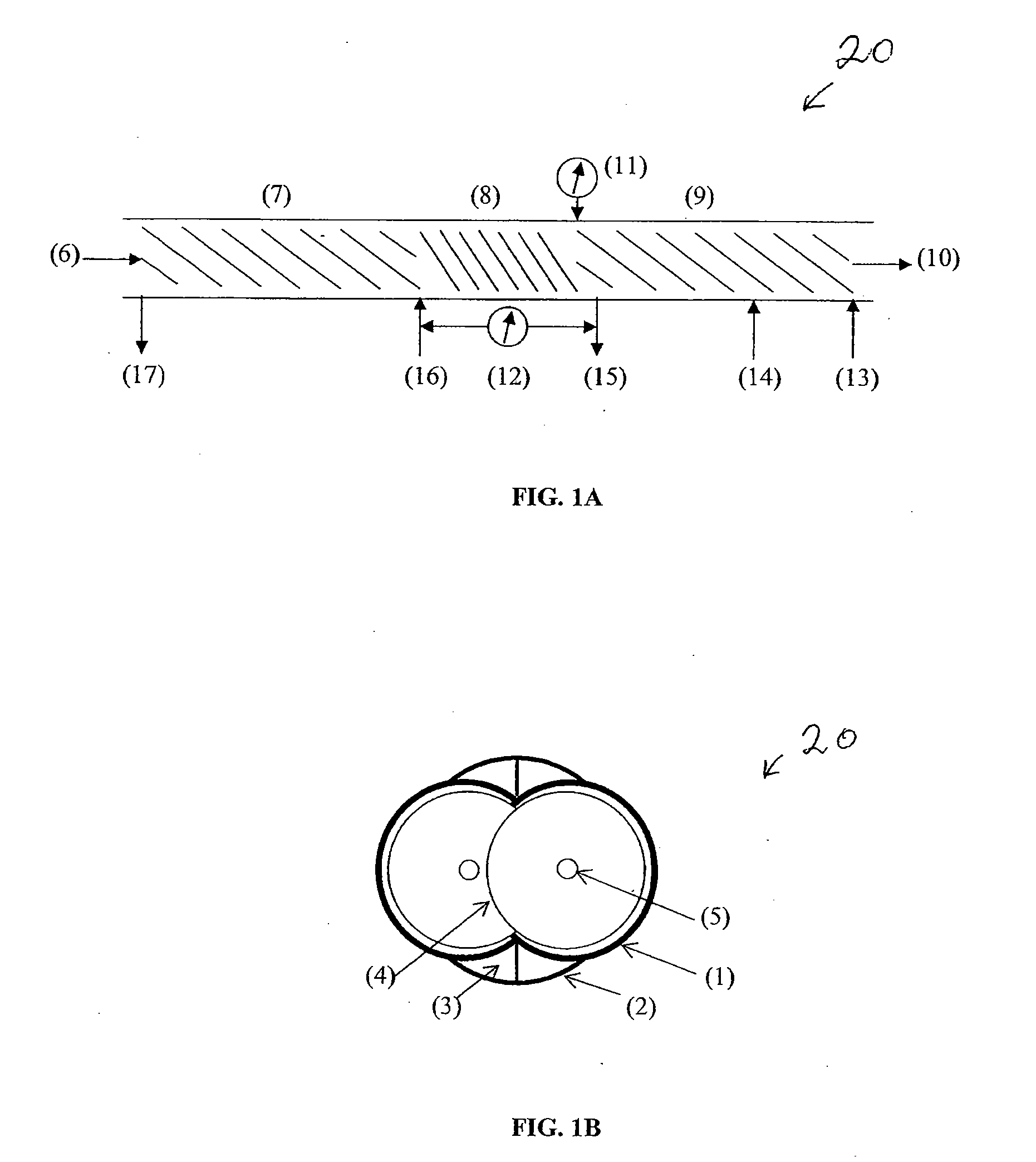

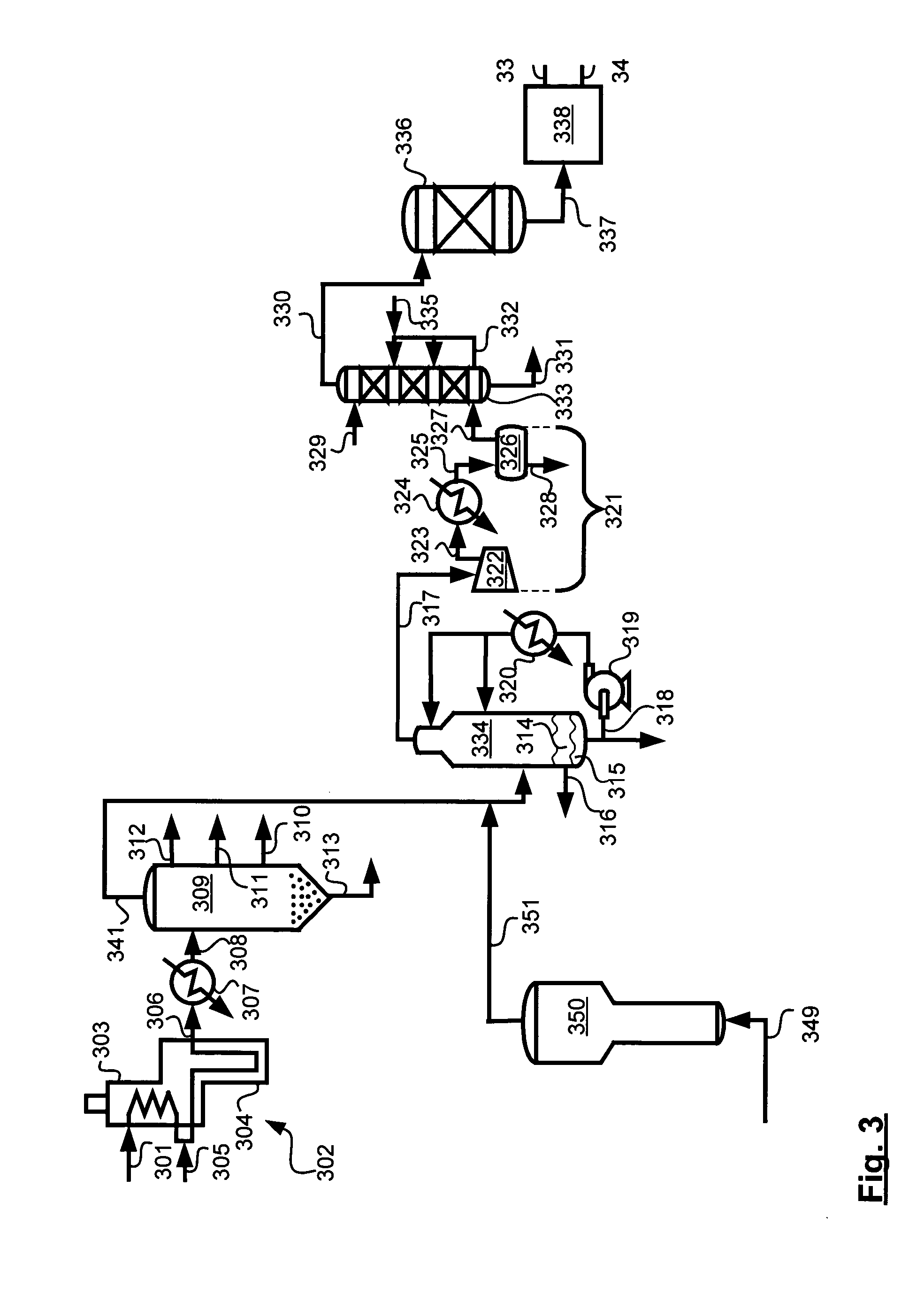

Hydrocarbon gas processing

A process for the recovery of ethane, ethylene, propane, propylene and heavier hydrocarbon components from a hydrocarbon gas stream is disclosed. In recent years, the preferred method of separating a hydrocarbon gas stream generally includes supplying at least portions of the gas stream to a fractionation tower having at least one reboiler, and often one or more side reboilers, to supply heat to the column by withdrawing and heating some of the tower liquids to produce stripping vapors that separate the more volatile components from the desired components. The reboiler and side reboilers (if any) are typically integrated into the feed stream cooling scheme to provide at least a portion of the refrigeration needed to condense the desired components for subsequent fractionation in the distillation column. In the process disclosed, the tower reboiling scheme is modified to use one or more tower liquid distillation streams from a point higher in the column than is used in the conventional reboiling scheme, providing colder stream(s) for the reboiler(s) that allow more effective cooling of the feed streams and thereby improve the efficiency with which the desired components are recovered. In addition, the tower liquid streams withdrawn from a higher point in the column contain larger quantities of the more volatile components, which when vaporized provide better stripping of undesirable components like carbon dioxide without reducing the recovery of the desired components. The heated distillation stream is returned to a lower point on the fractionation tower that is separated from the withdrawal point by at least one theoretical stage.

Owner:UOP LLC

Ethylene/α-olefin block copolymers

Embodiments of the invention provide a class of ethylene / α-olefin block interpolymers. The ethylene / α-olefin interpolymers are characterized by an average block index, ABI, which is greater than zero and up to about 1.0 and a molecular weight distribution, Mw / Mn, greater than about 1.3. Preferably, the block index is from about 0.2 to about 1. In addition or alternatively, the block ethylene / α-olefin interpolymer is characterized by having at least one fraction obtained by Temperature Rising Elution Fractionation (‘TREF’), wherein the fraction has a block index greater than about 0.3 and up to about 1.0 and the ethylene / α-olefin interpolymer has a molecular weight distribution, Mw / Mn, greater than about 1.4.

Owner:DOW GLOBAL TECH LLC

Enhanced purification of antibodies and antibody fragments by apatite chromatography

ActiveUS20090187005A1Peptide/protein ingredientsPeptide preparation methodsApatiteAntibody fragments

Methods are disclosed for use of apatite chromatography, particularly without reliance upon phosphate gradients, for purification or separation of at least one intact non-aggregated antibody, or at least one immunoreactive antibody fragment, from an impure preparation. Integration of such methods into multi-step procedures with other fractionation methods are additionally disclosed.

Owner:BIO RAD LAB INC

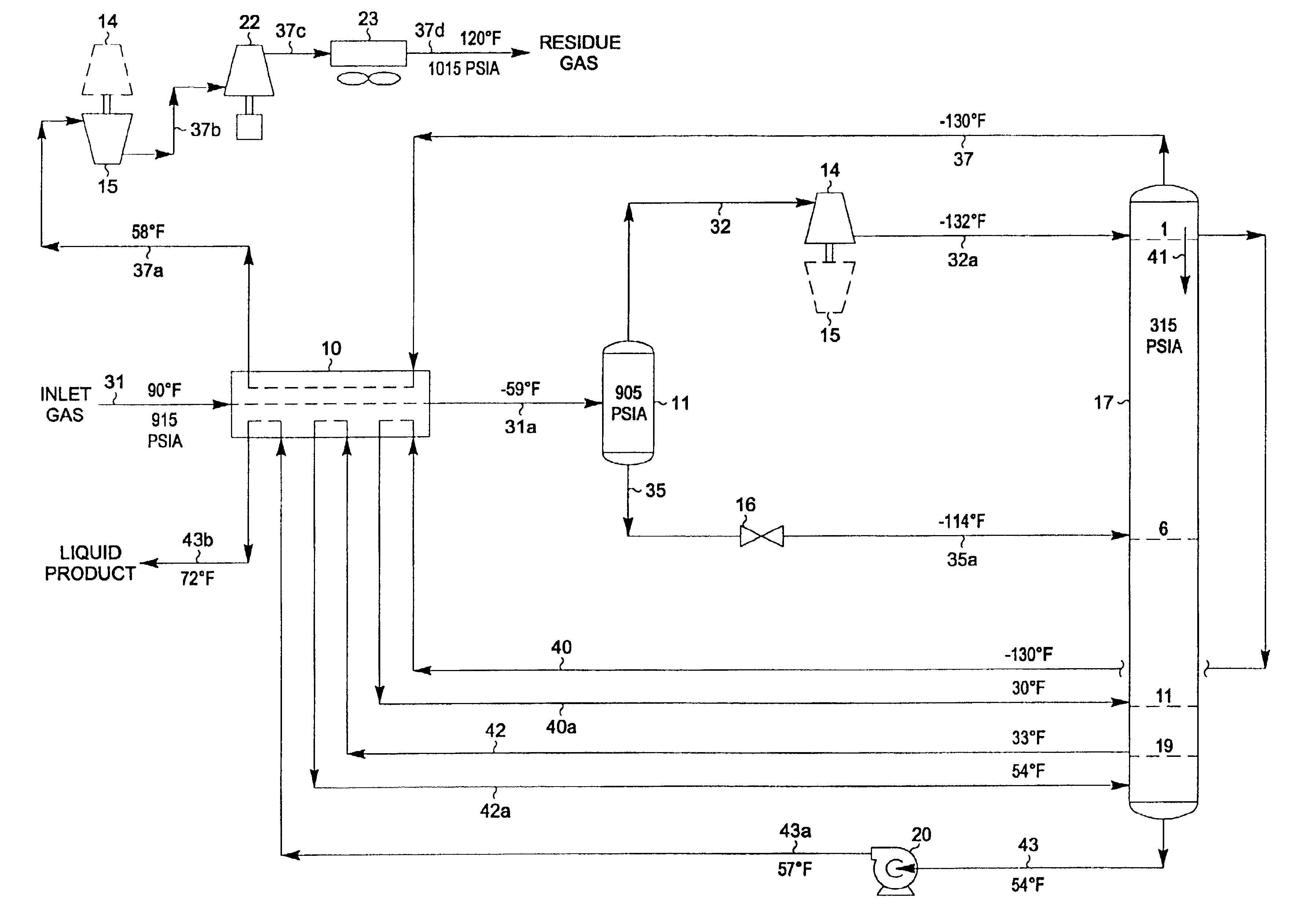

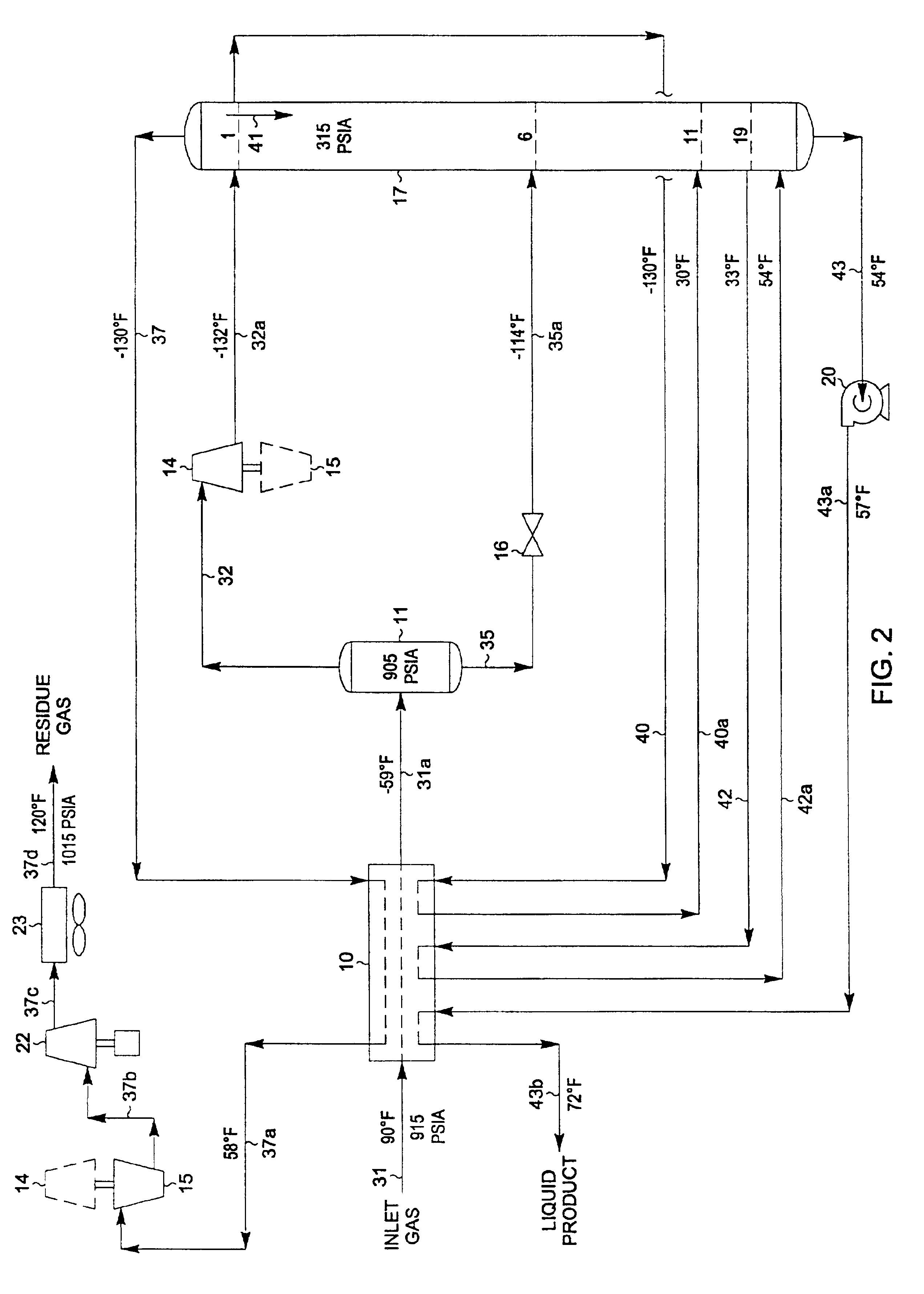

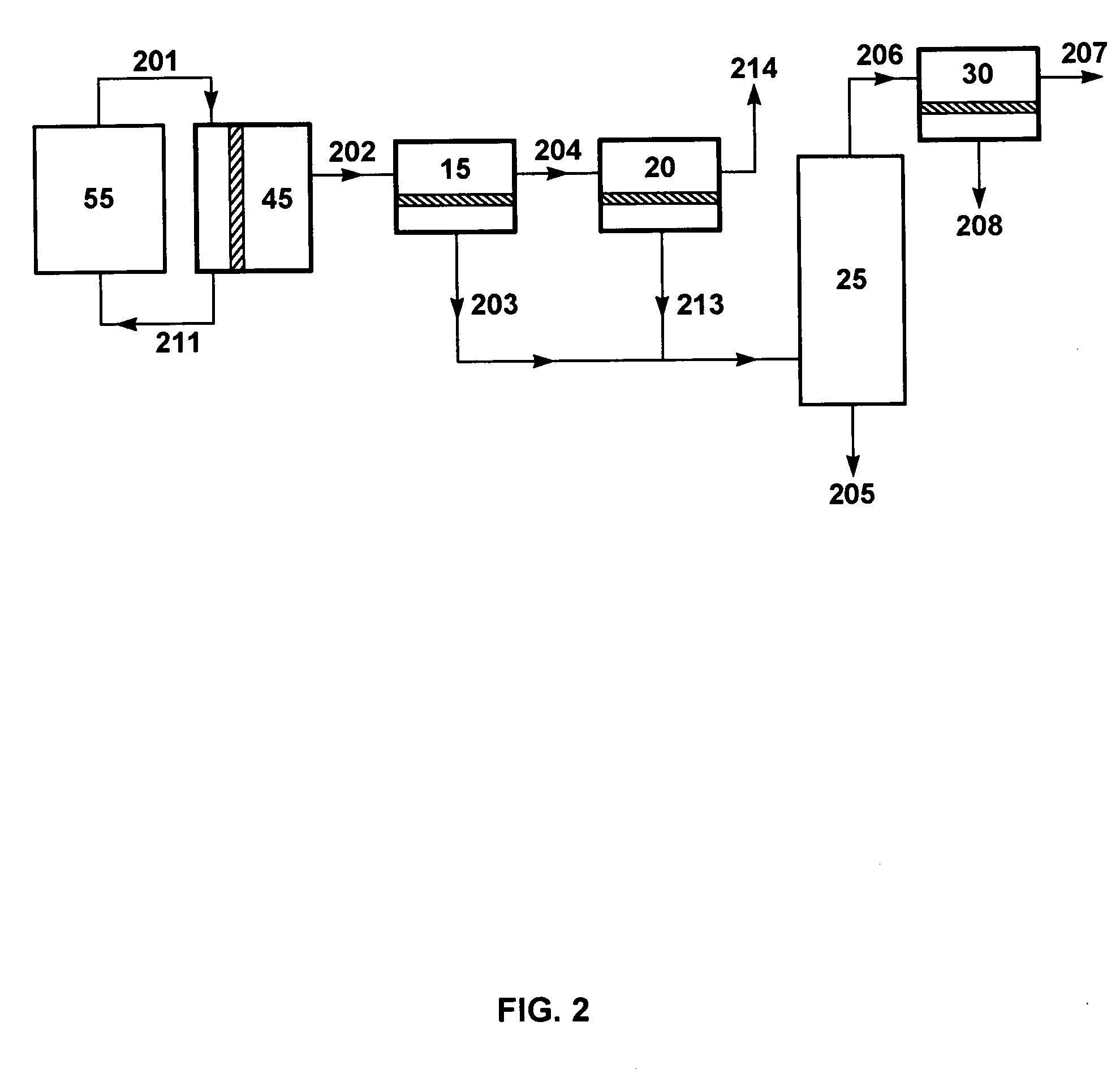

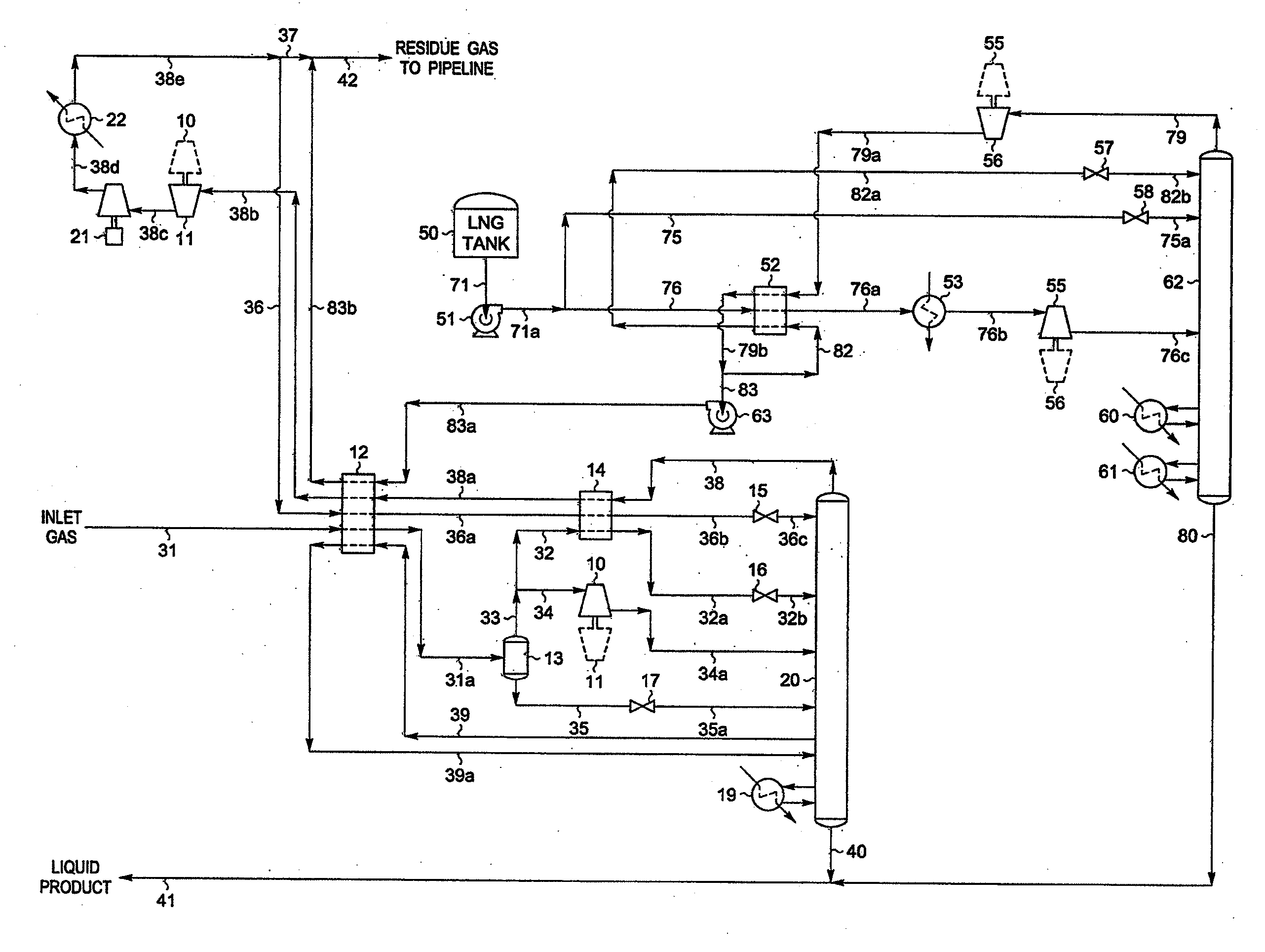

Hydrocarbon gas processing

ActiveUS20060283207A1Reduce the valueReduce investmentSolidificationLiquefactionFractionationFractionating column

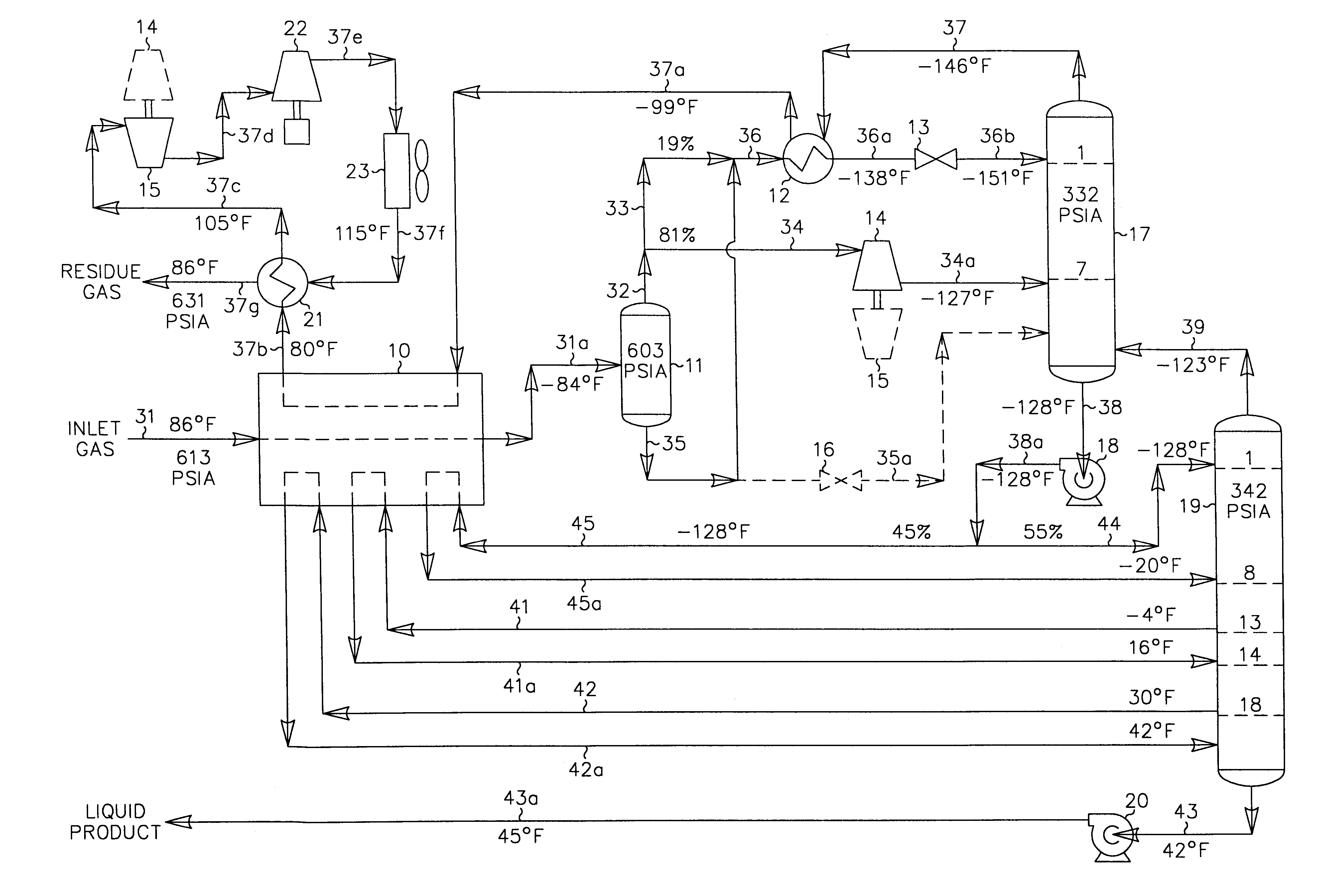

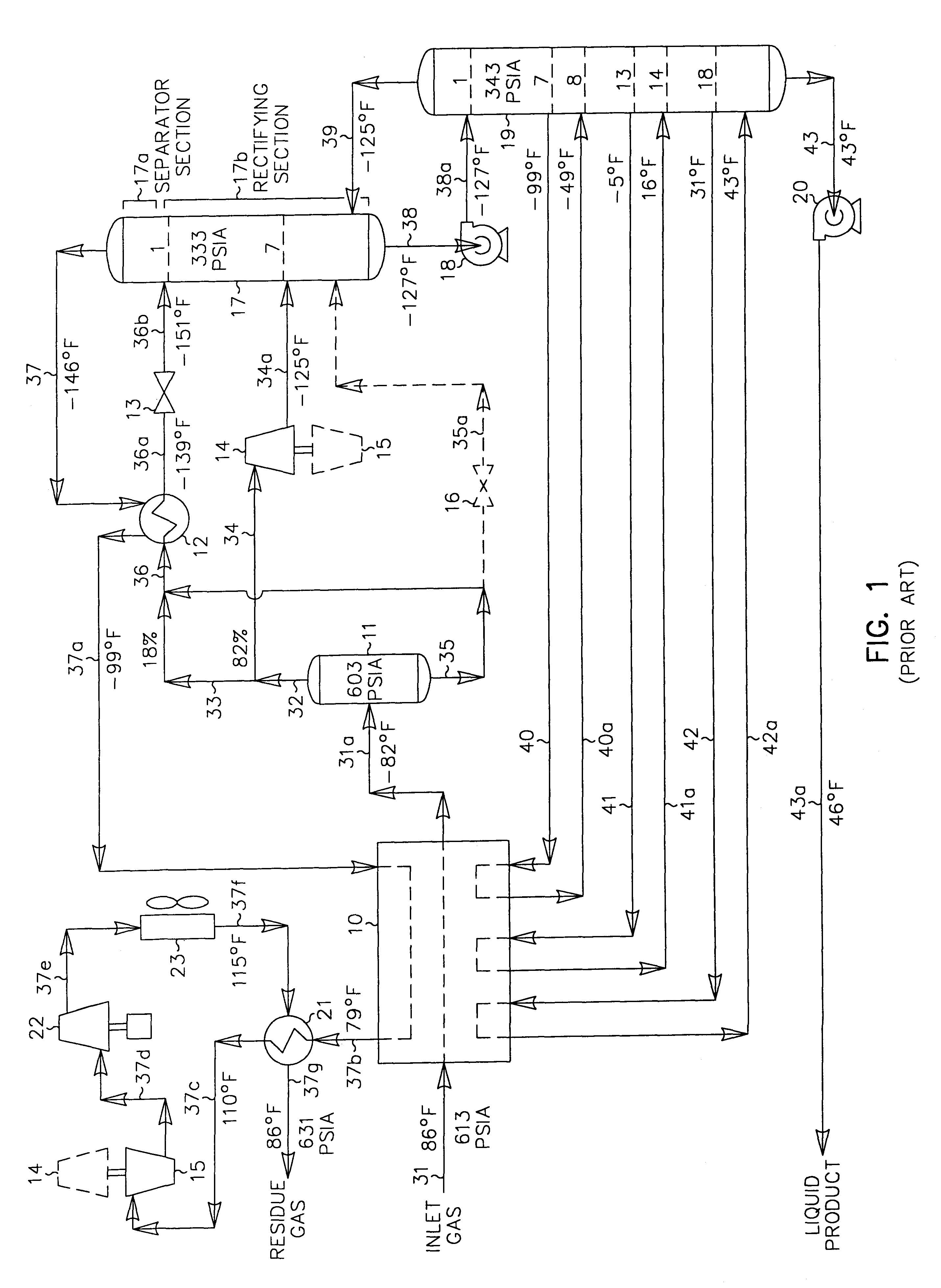

A process for the recovery of ethane, ethylene, propane, propylene, and heavier hydrocarbon components from a hydrocarbon gas stream is disclosed. The stream is cooled and is thereafter expanded to the fractionation tower pressure and supplied to the fractionation tower at a lower mid-column feed position. A distillation stream is withdrawn from the column below the feed point of the stream and is then directed into heat exchange relation with the tower overhead vapor stream to cool the distillation stream and condense at least a part of it, forming a condensed stream. At least a portion of the condensed stream is directed to the fractionation tower at an upper mid-column feed position. A recycle stream is withdrawn from the tower overhead after it has been warmed and compressed. The compressed recycle stream is cooled sufficiently to substantially condense it, and is then expanded to the pressure of the fractionation tower and supplied to the tower at a top column feed position. The quantities and temperatures of the feeds to the fractionation tower are effective to maintain the overhead temperature of the fractionation tower at a temperature whereby the major portion of the desired components is recovered.

Owner:UOP LLC

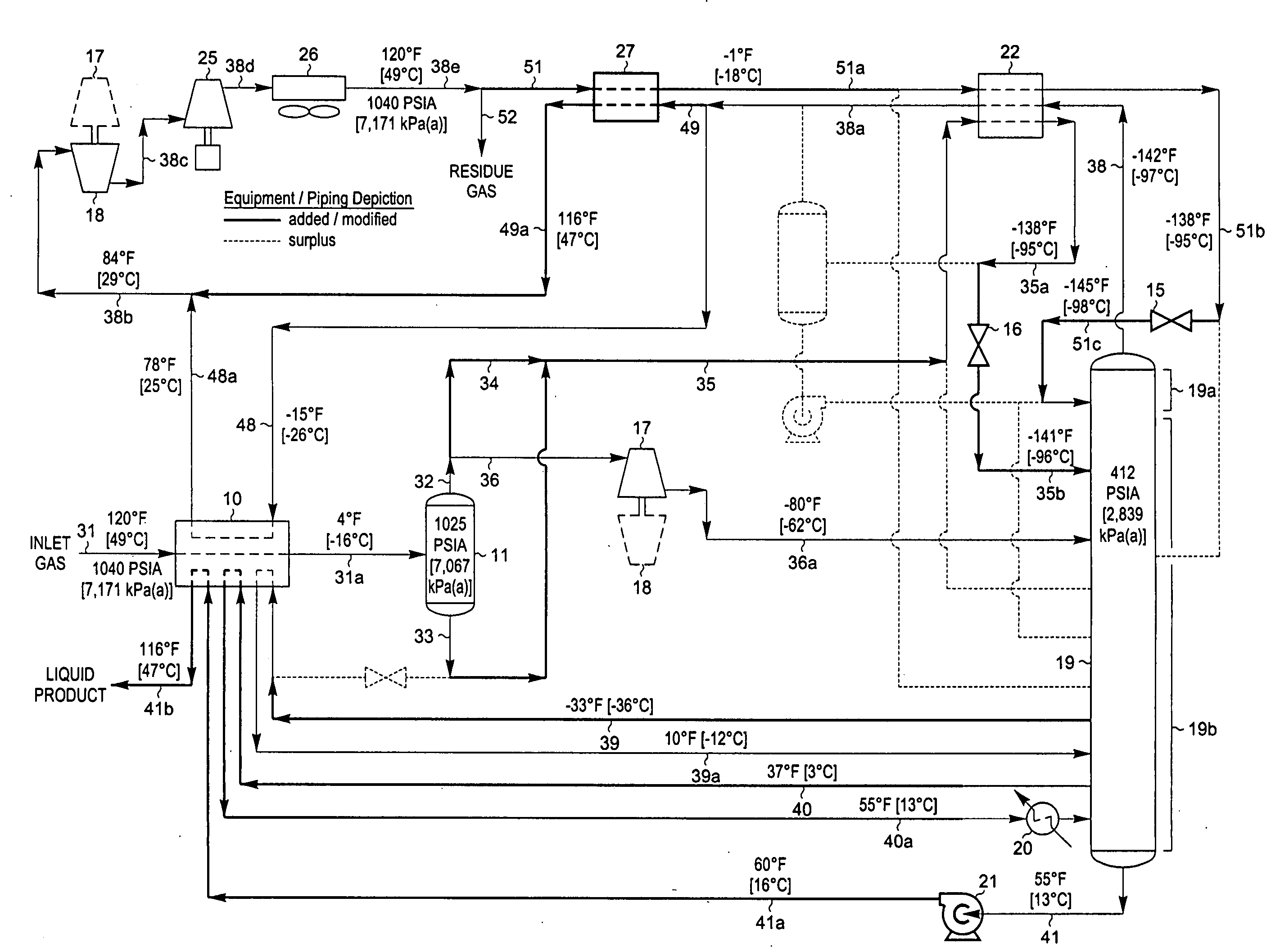

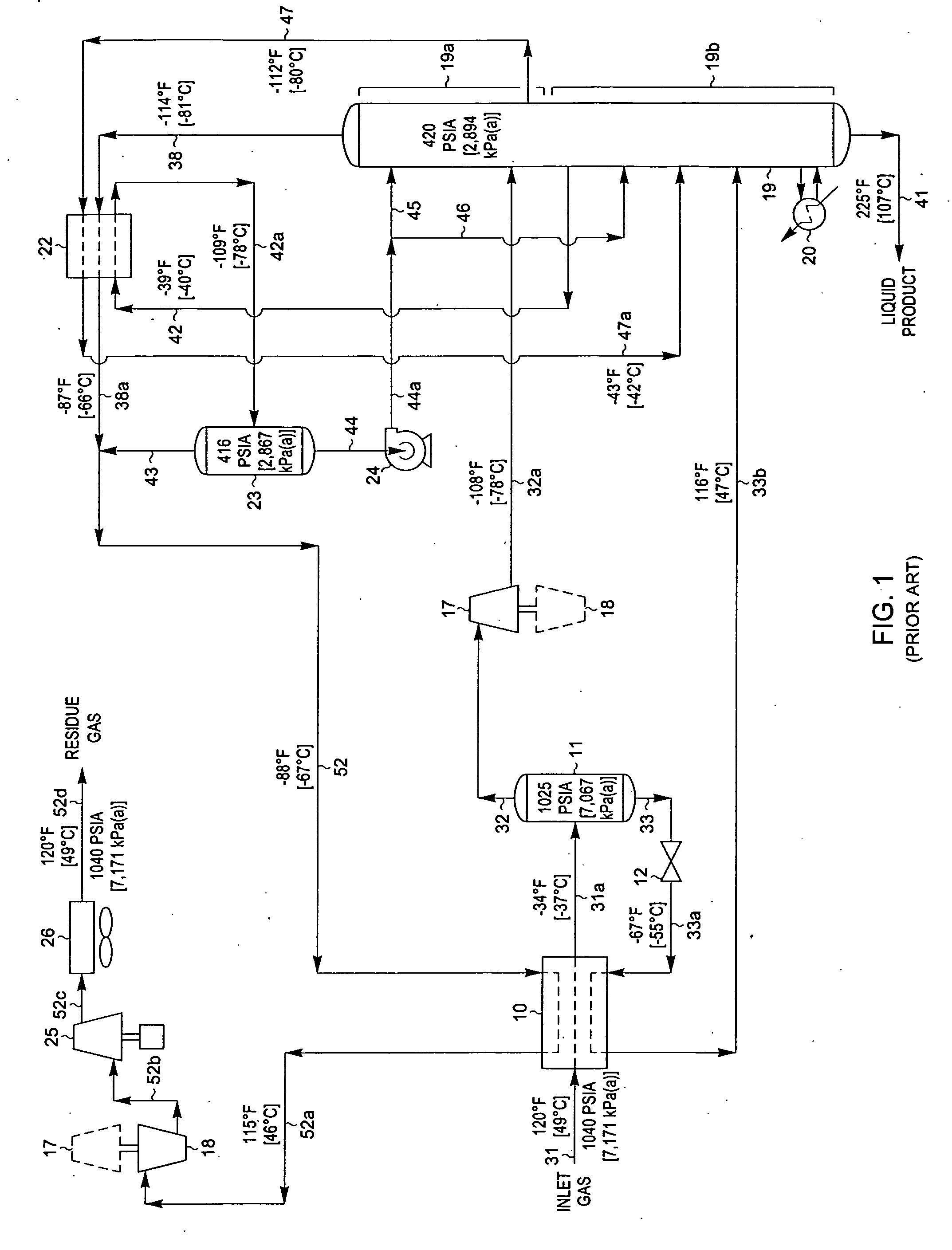

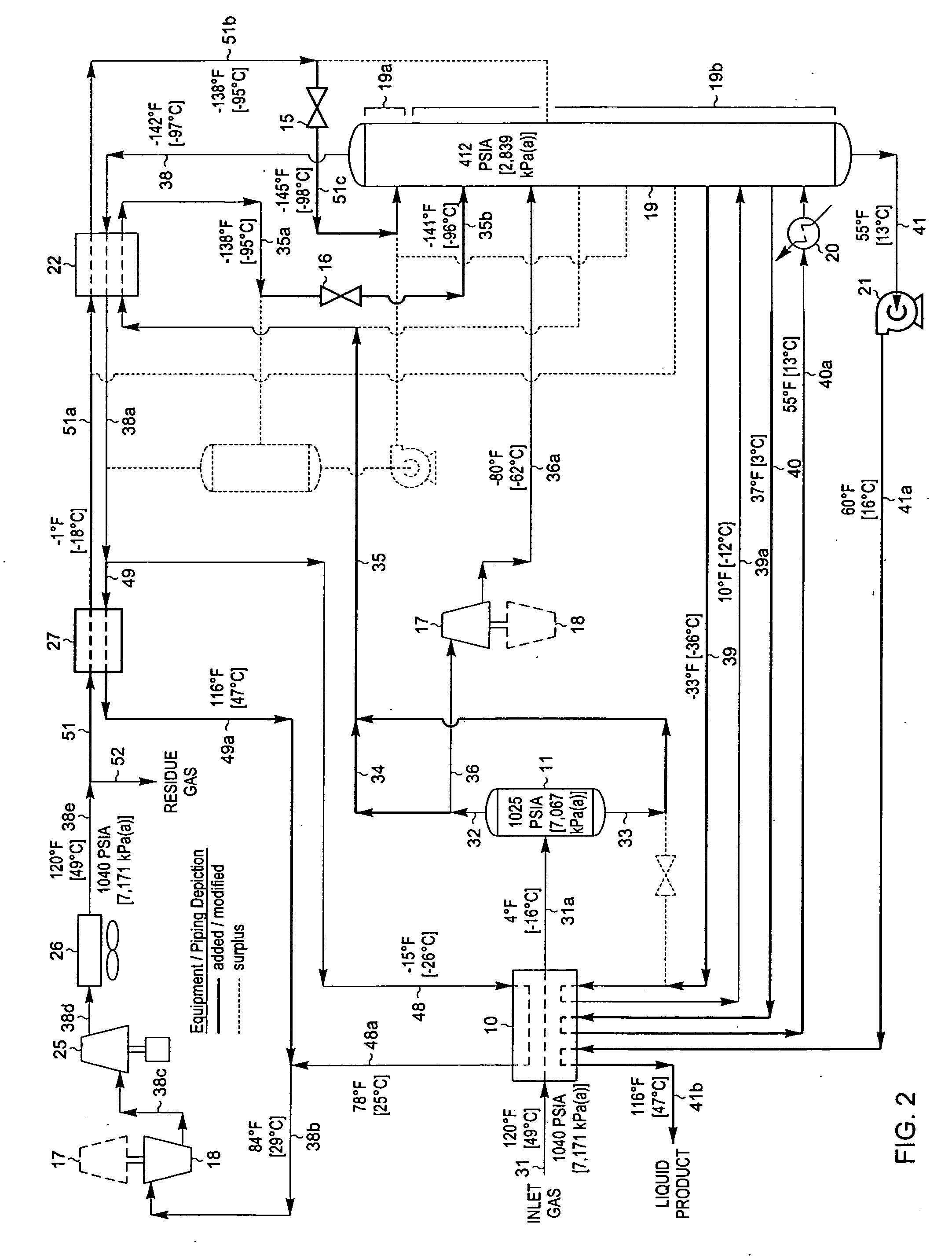

Hydrocarbon gas processing

A process for the recovery of ethane, ethylene, propane, propylene and heavier hydrocarbon components from a hydrocarbon gas stream is disclosed. In recent years, the preferred method of separating a hydrocarbon gas stream generally includes supplying at least portions of the gas stream to a fractionation tower having at least one reboiler, and often one or more side reboilers, to supply heat to the column by withdrawing and heating some of the tower liquids to produce stripping vapors that separate the more volatile components from the desired components. The reboiler and side reboilers (if any) are typically integrated into the feed stream cooling scheme to provide at least a portion of the refrigeration needed to condense the desired components for subsequent fractionation in the distillation column. In the process disclosed, the tower reboiling scheme is modified to use one or more tower liquid distillation streams from a point higher in the column than is used in the conventional reboiling scheme, providing colder stream(s) for the reboiler(s) that allow more effective cooling of the feed streams and thereby improve the efficiency with which the desired components are recovered. In addition, the tower liquid streams withdrawn from a higher point in the column contain larger quantities of the more volatile components, which when vaporized provide better stripping of undesirable components like carbon dioxide without reducing the recovery of the desired components. The heated distillation stream is returned to a lower point on the fractionation tower that is separated from the withdrawal point by at least one theoretical stage.

Owner:UOP LLC

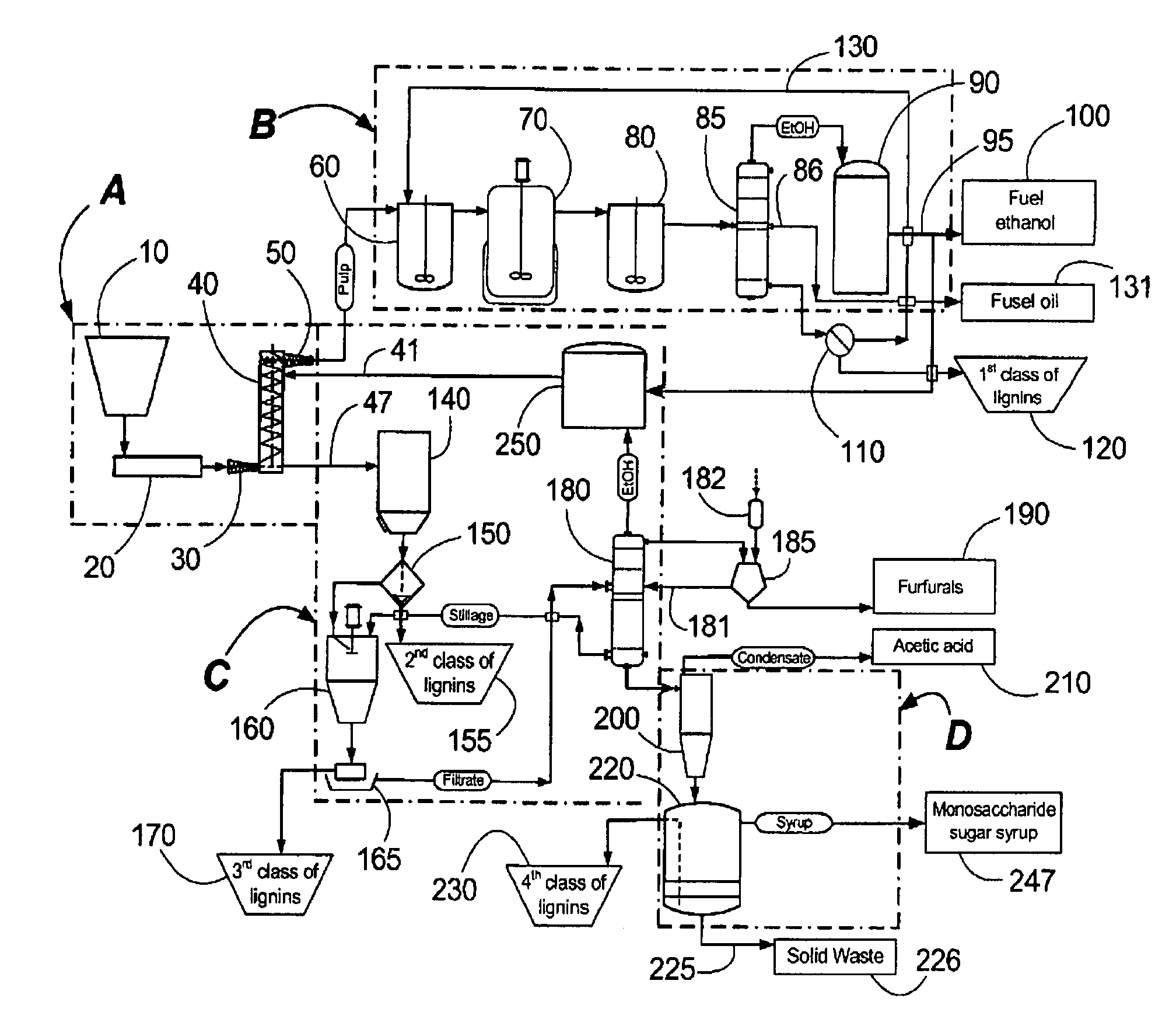

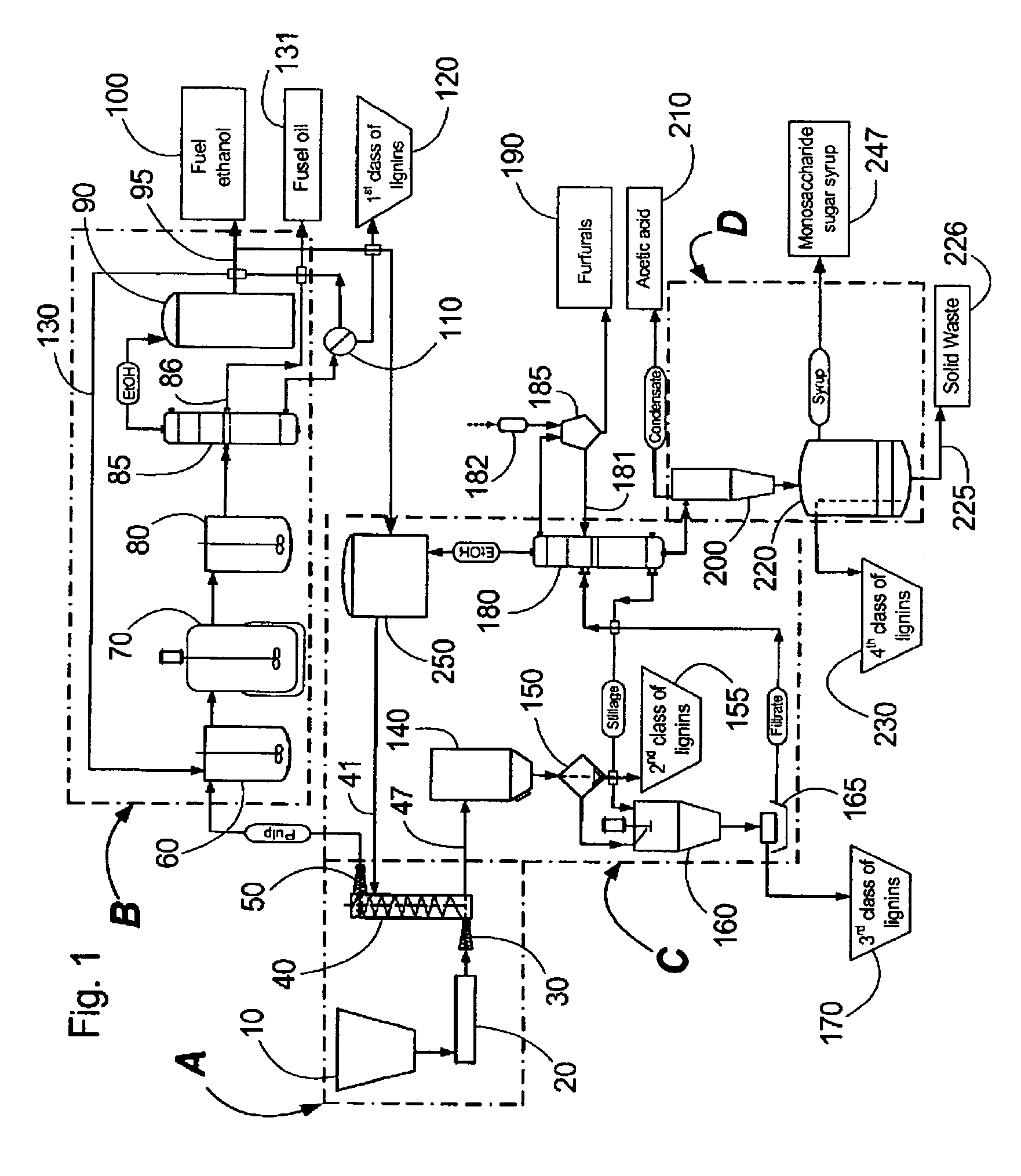

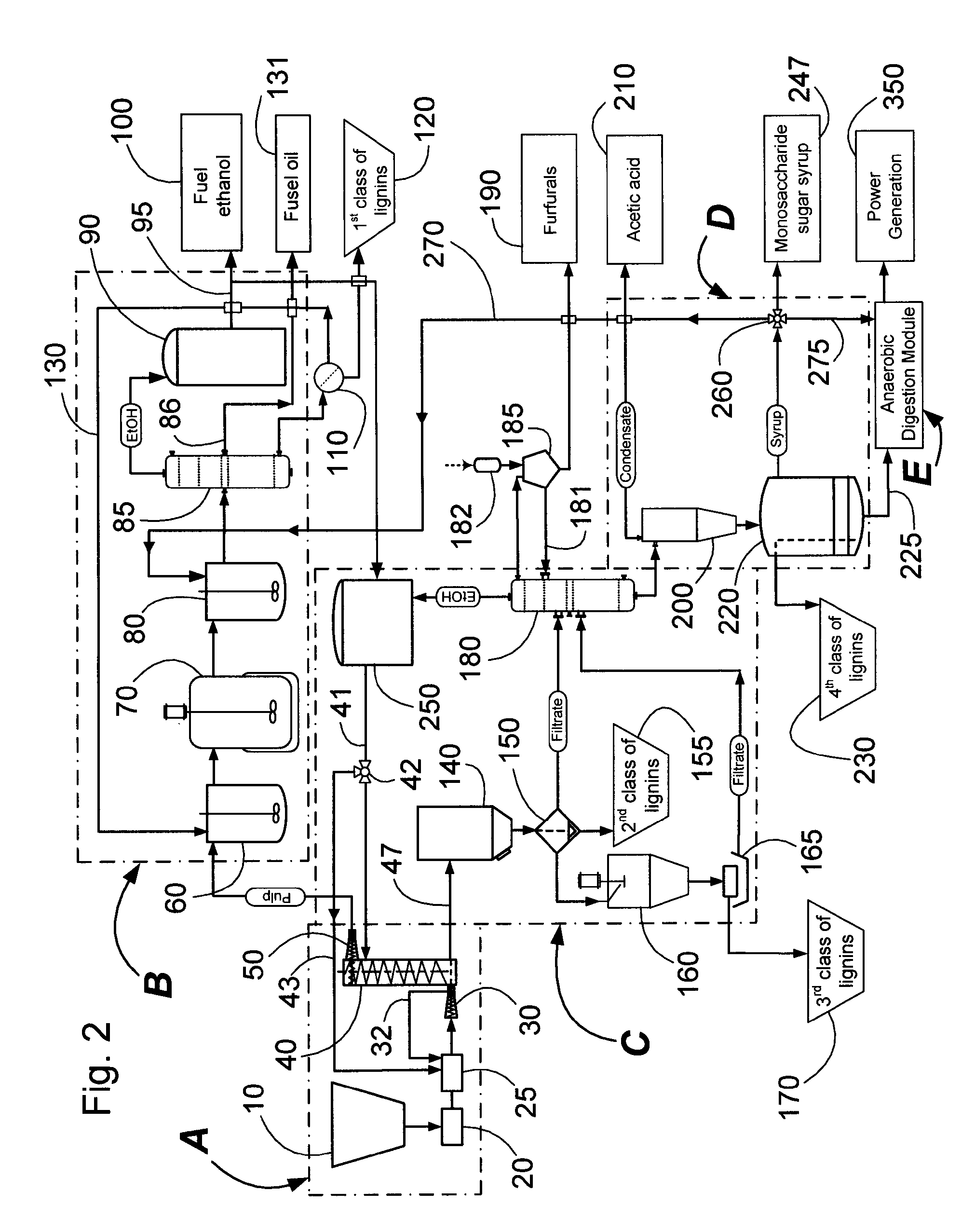

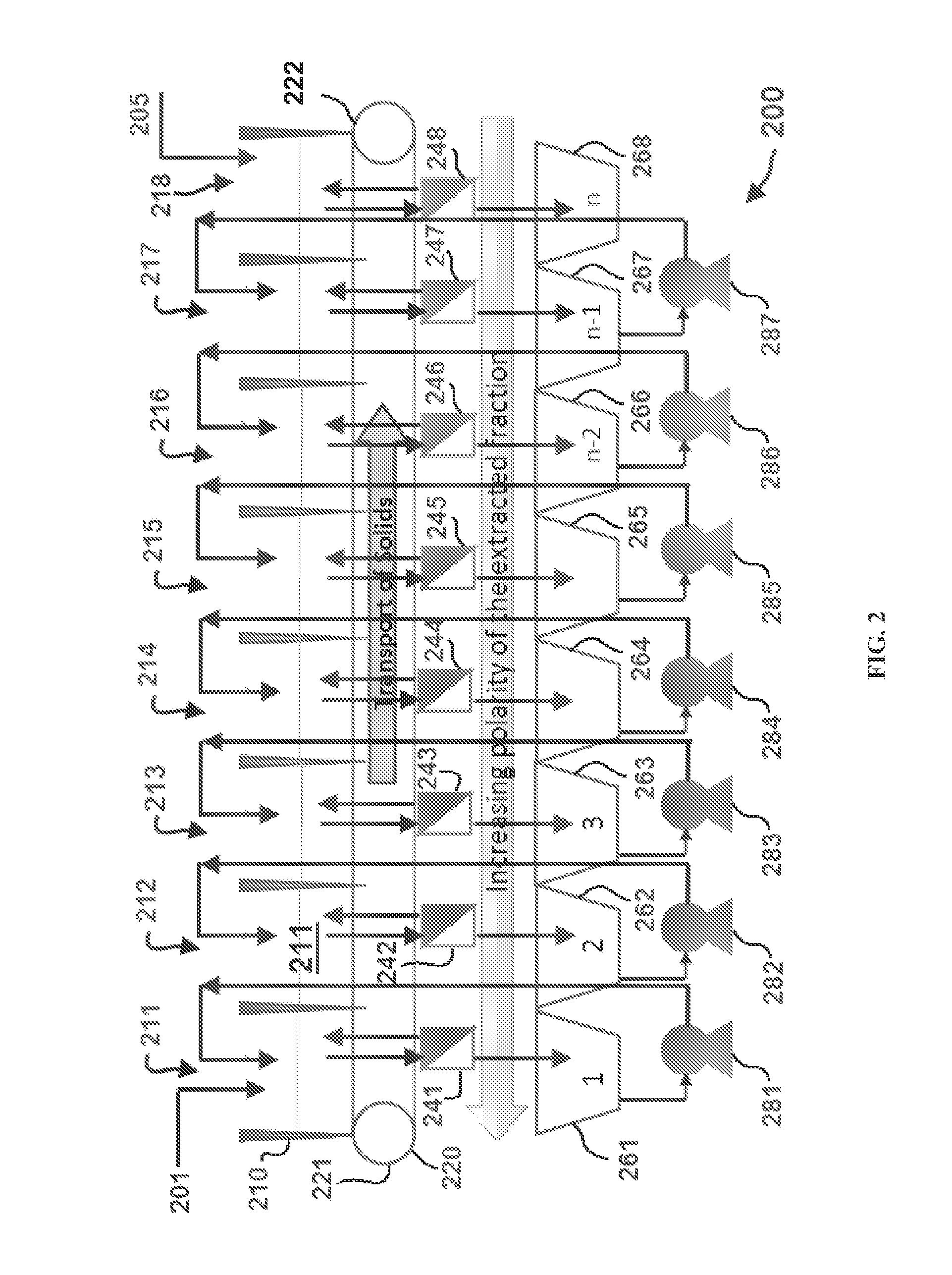

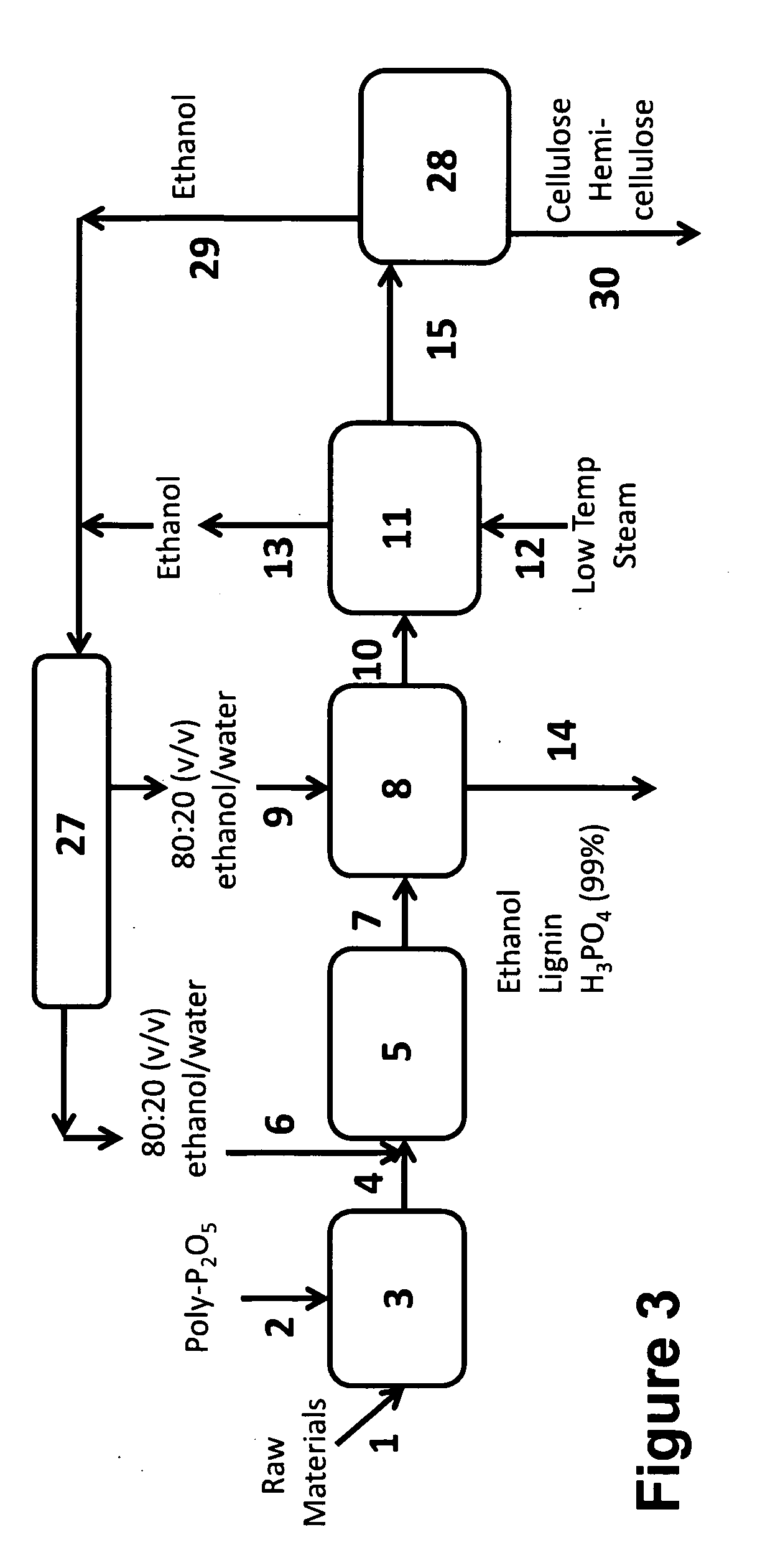

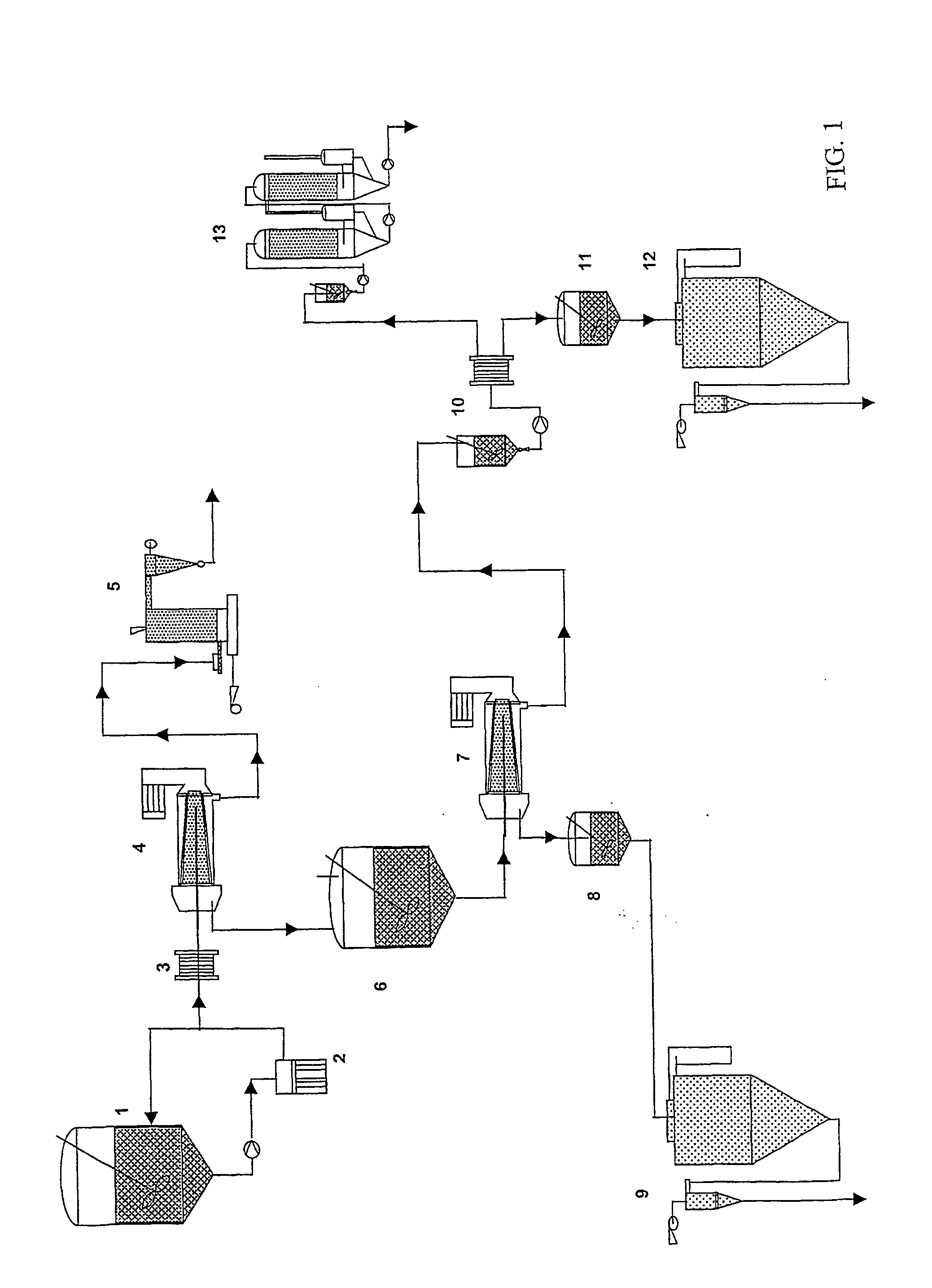

Continuous counter-current organosolv processing of lignocellulosic feedstocks

InactiveUS7465791B1Low viscosityNon-fibrous pulp additionBiological substance pretreatmentsFractionationOrganosolv

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into at least fuel-grade ethanol and four classes of lignin derivatives. The modular process comprises a first processing module configured for physico-chemically digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for producing at least a fuel-grade ethanol and a first class of novel lignin derivatives from the cellulosic solids fraction, a third processing module configured for separating a second class and a third class of lignin derivatives from the liquid fraction and further processing the liquid fraction to produce a distillate and a stillage, a fourth processing module configured for separating a fourth class of lignin derivatives from the stillage and further processing the stillage to produce a sugar syrup.

Owner:SUZANO CANADA INC

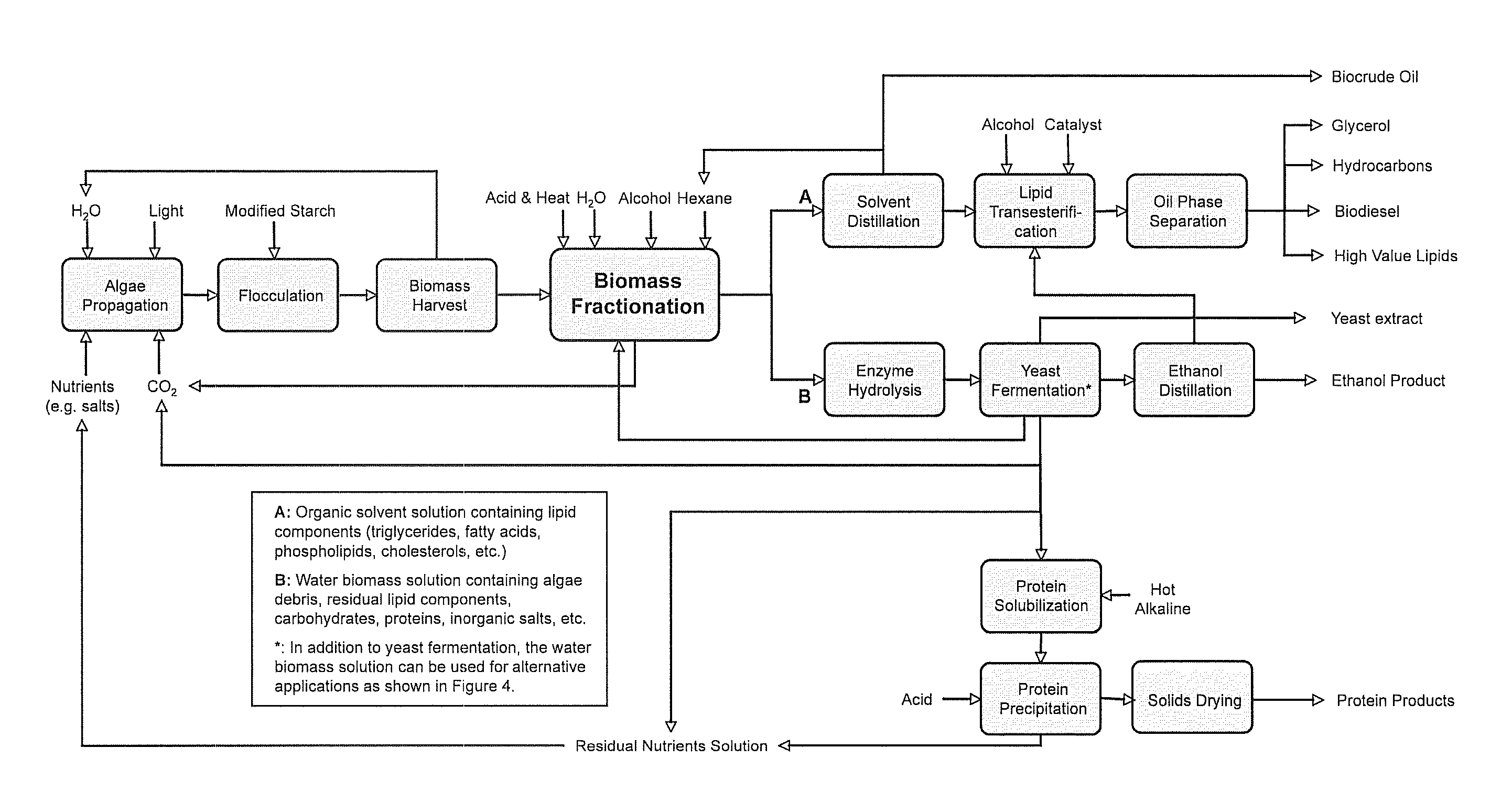

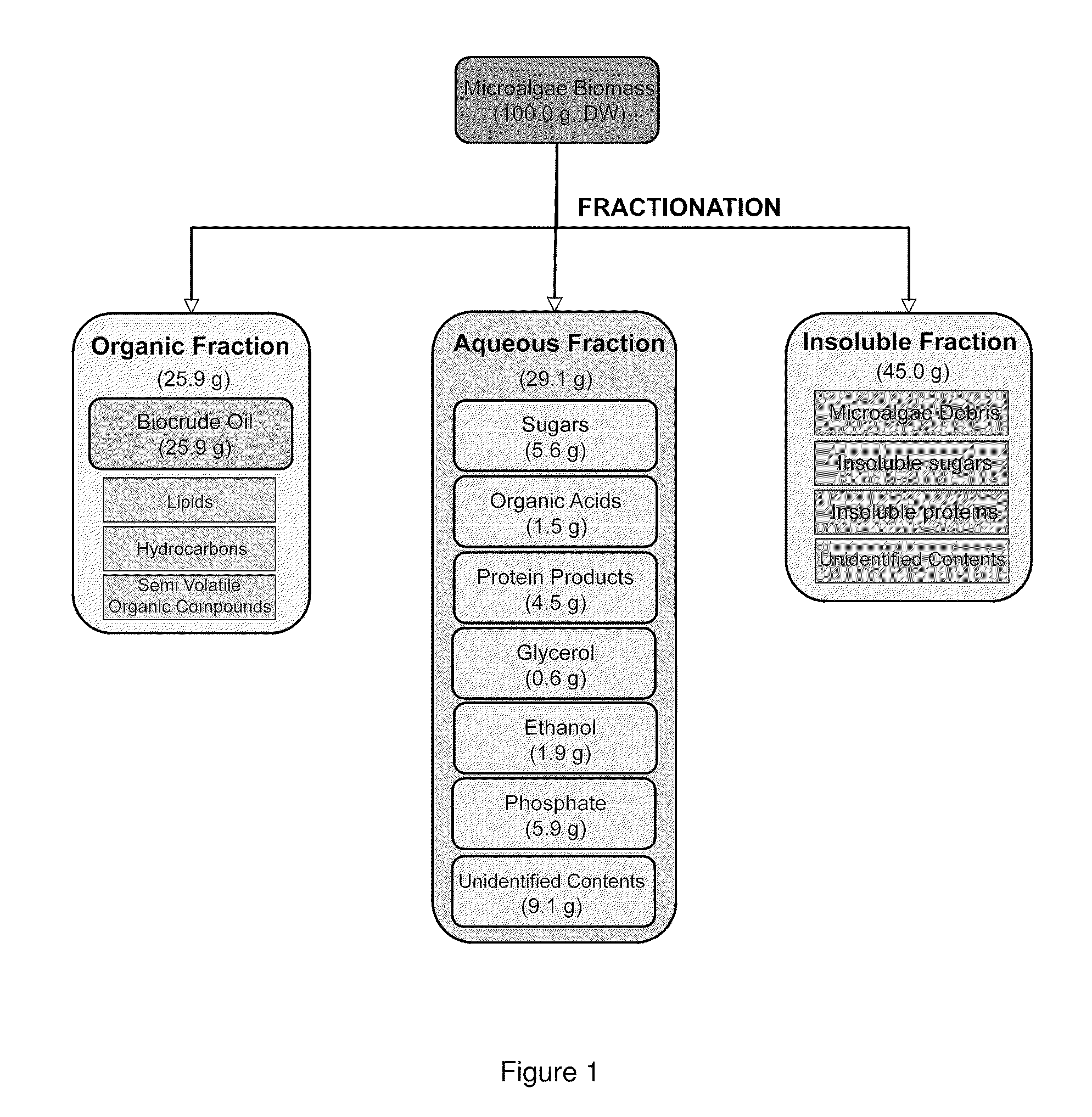

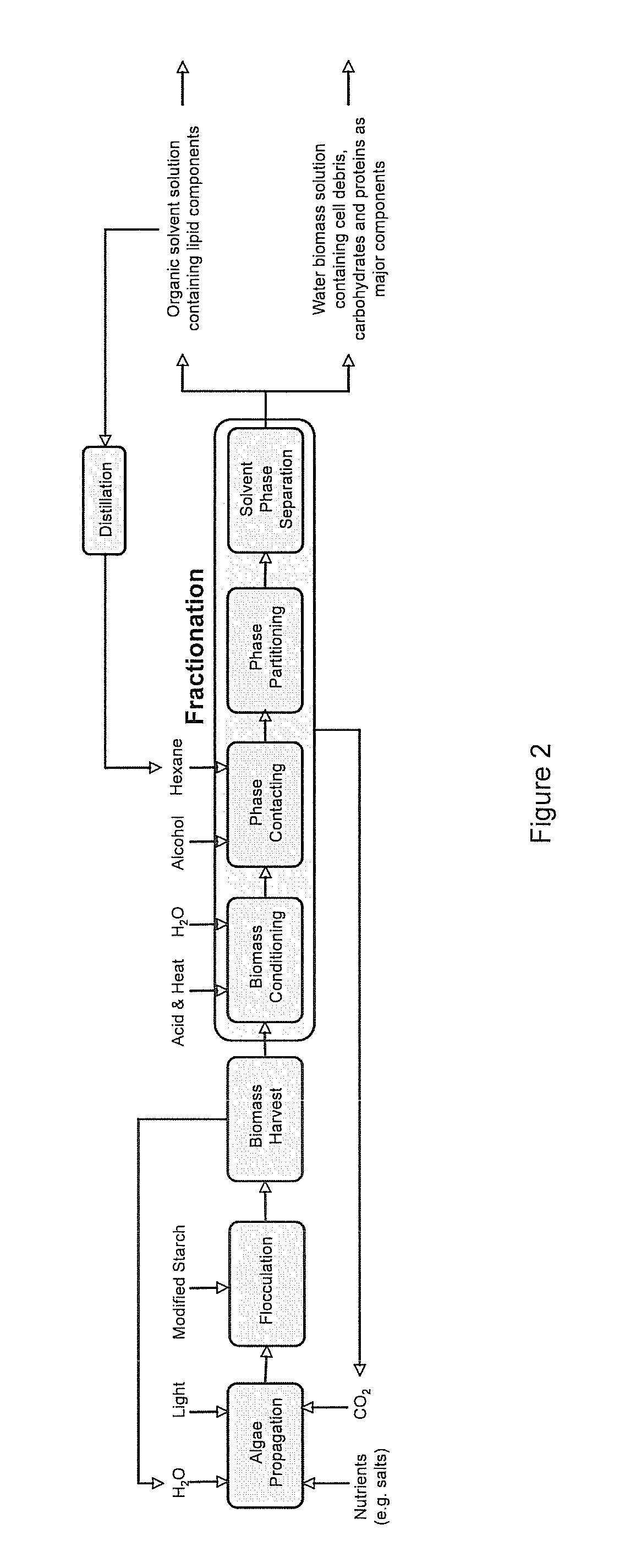

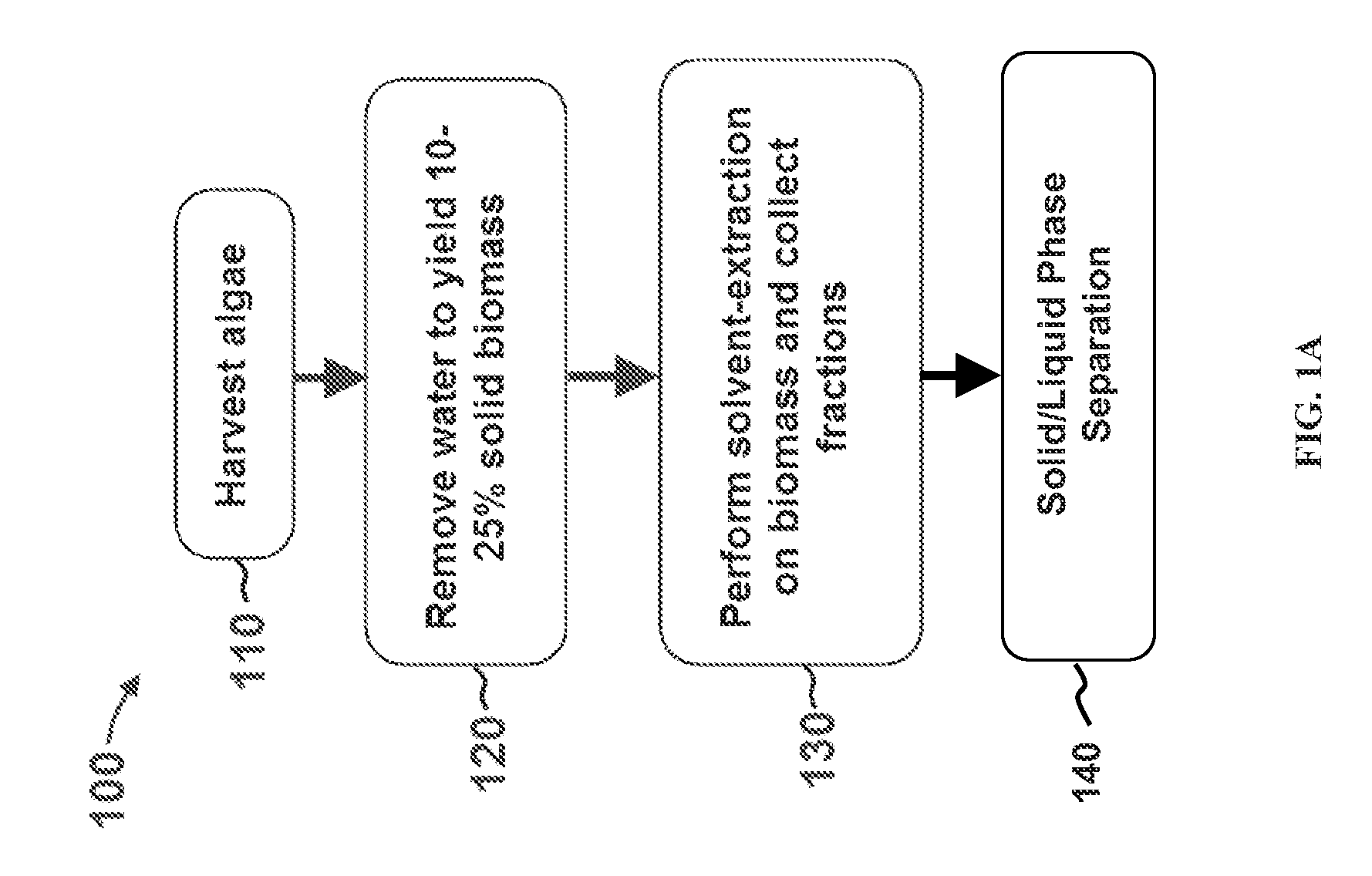

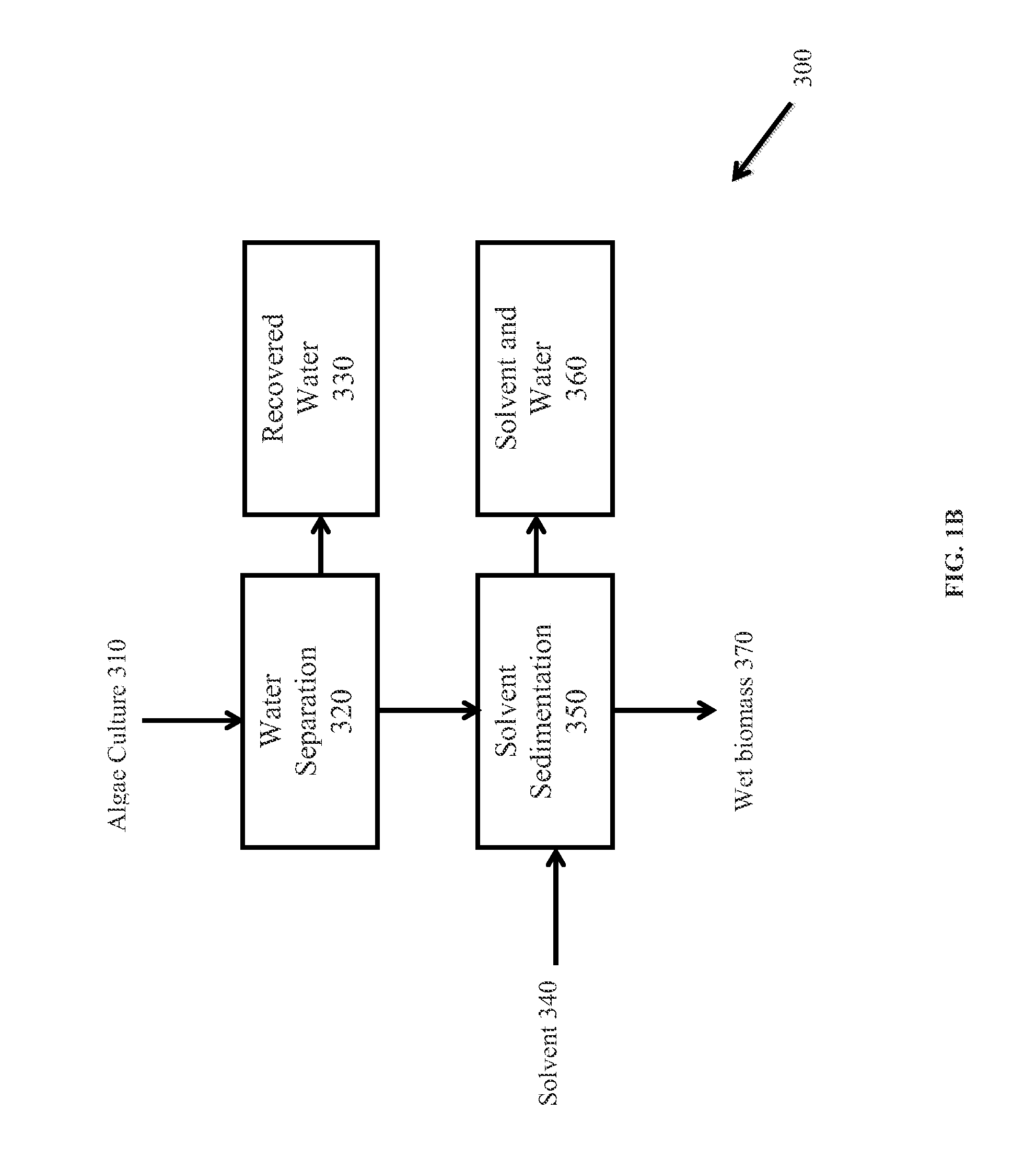

Algae biomass fractionation

A method of fractionating biomass, by permeability conditioning biomass suspended in a pH adjusted solution of at least one water-based polar solvent to form a conditioned biomass, intimately contacting the pH adjusted solution with at least one non-polar solvent, partitioning to obtain an non-polar solvent solution and a polar biomass solution, and recovering cell and cell derived products from the non-polar solvent solution and polar biomass solution. Products recovered from the above method. A method of operating a renewable and sustainable plant for growing and processing algae.

Owner:VALICOR

Ethanol recovery process

ActiveUS20070031954A1Permeate pressureSimple equipmentMembranesFermented solutions distillation/rectificationAlcoholFractionation

A process for producing and recovering light alcohols, particularly ethanol, alcohol mixtures containing ethanol, and ABE mixtures (alcohol mixtures containing acetone, butanol and ethanol), using a combination of steps including fermentation, first membrane separation, dephlegmation and dehydration by second membrane separation.

Owner:MEMBRANE TECH & RES

Premium synthetic lubricants

InactiveUS6475960B1Refining to change hydrocarbon structural skeletonHydrocarbon purification/separationAntioxidantBoiling point

Premium synthetic lubricants comprise a synthetic isoparaffinic hydrocarbon base stock and an effective amount of at least one, and typically a plurality of lubricant additives such as a detergent, dispersant, antioxidant, antiwear additive, pout point depresant, VI improver and the like. The base stock is derived from a waxy, paraffinic, Fischer-Tropsch synthesized hydrocarbon feed fraction having an initial boiling point in the range of about 650-750° F. and continuously boiling up to at least 1050° F., by a process which comprises hydroisomerizing the feed and dewaxing the isomerate. The waxy feed has a T90-T10 temperature difference of at least 350° F. and is preferably hydroisomerized without any pretreatment, other than optional fractionation. The lubricant may also contain hydrocarbonaceous and synthetic base stock material. Lubricants, such as fully formulated multigrade automotive crankcase and transmission oils formed by adding a suitable additive package to the isoparaffinic base stock have exhibited performance superior to similar fully formulated oils based on both PAO and conventional, petroleum derived base stocks.

Owner:EXXON RES & ENG CO

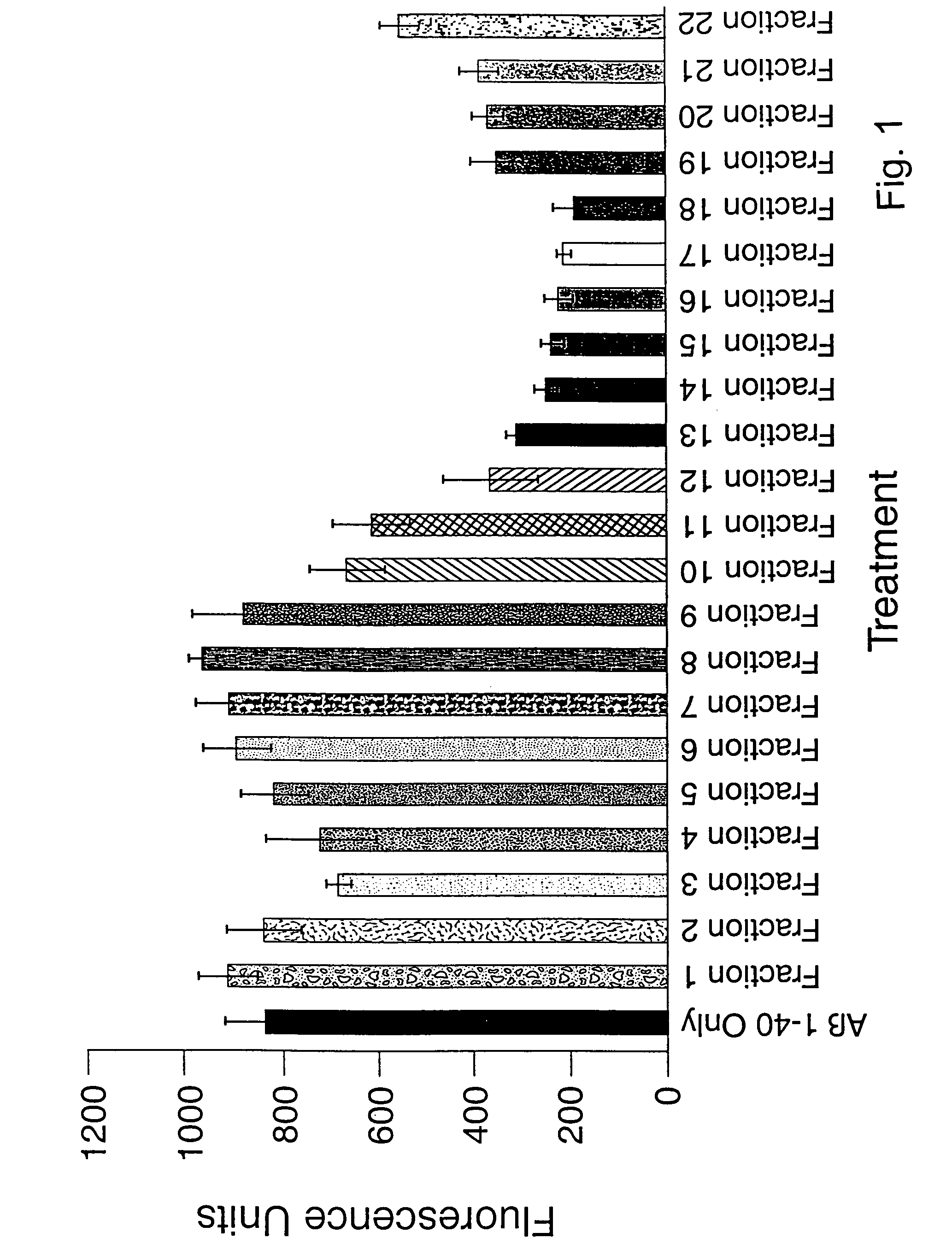

Methods of isolating amyloid-inhibiting compounds and use of compounds isolated from Uncaria tomentosa and related plants

InactiveUS7285293B2Inhibition formationPromote mental alertnessBiocideNervous disorderAdditive ingredientFractionation

Owner:UNIV OF WASHINGTON +1

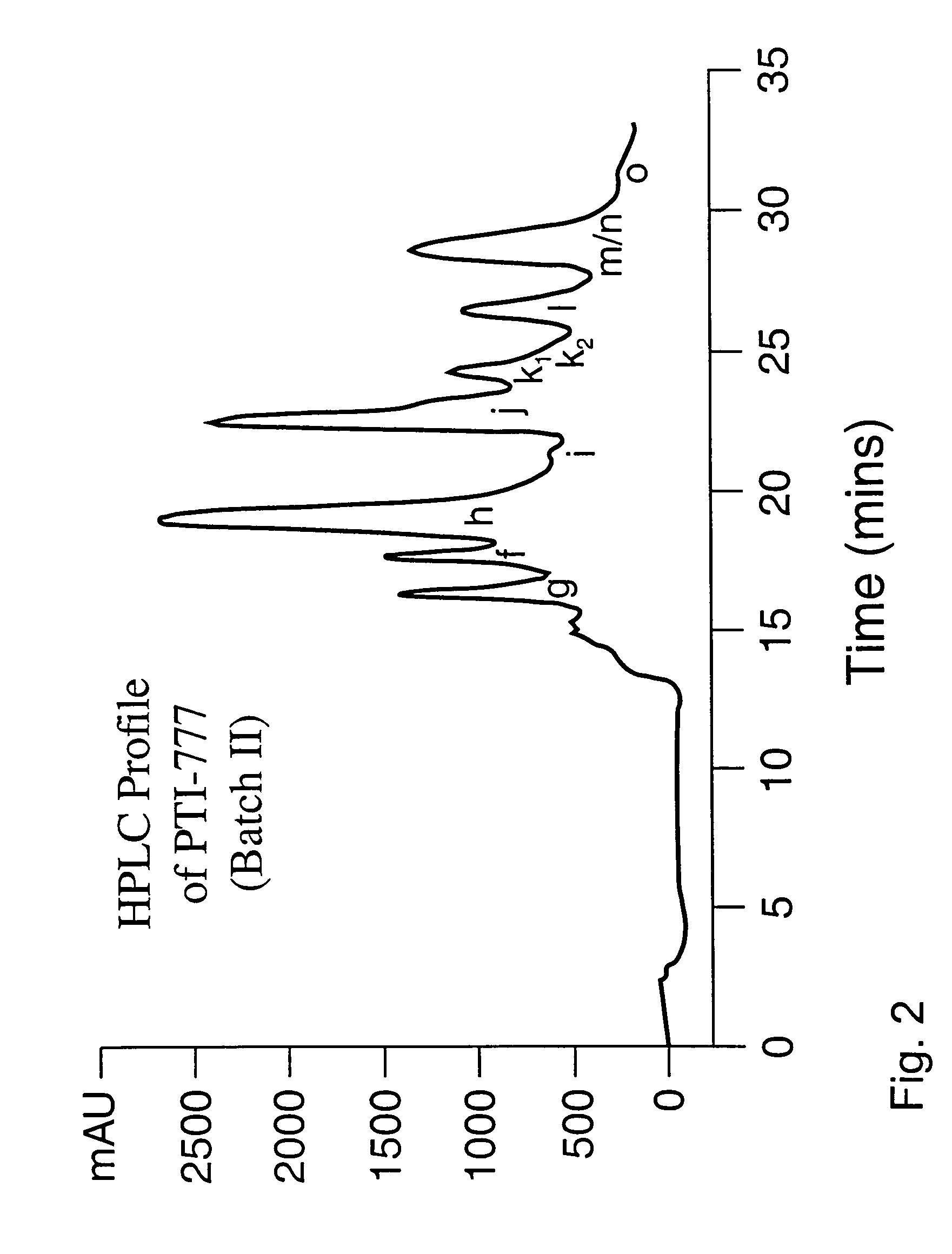

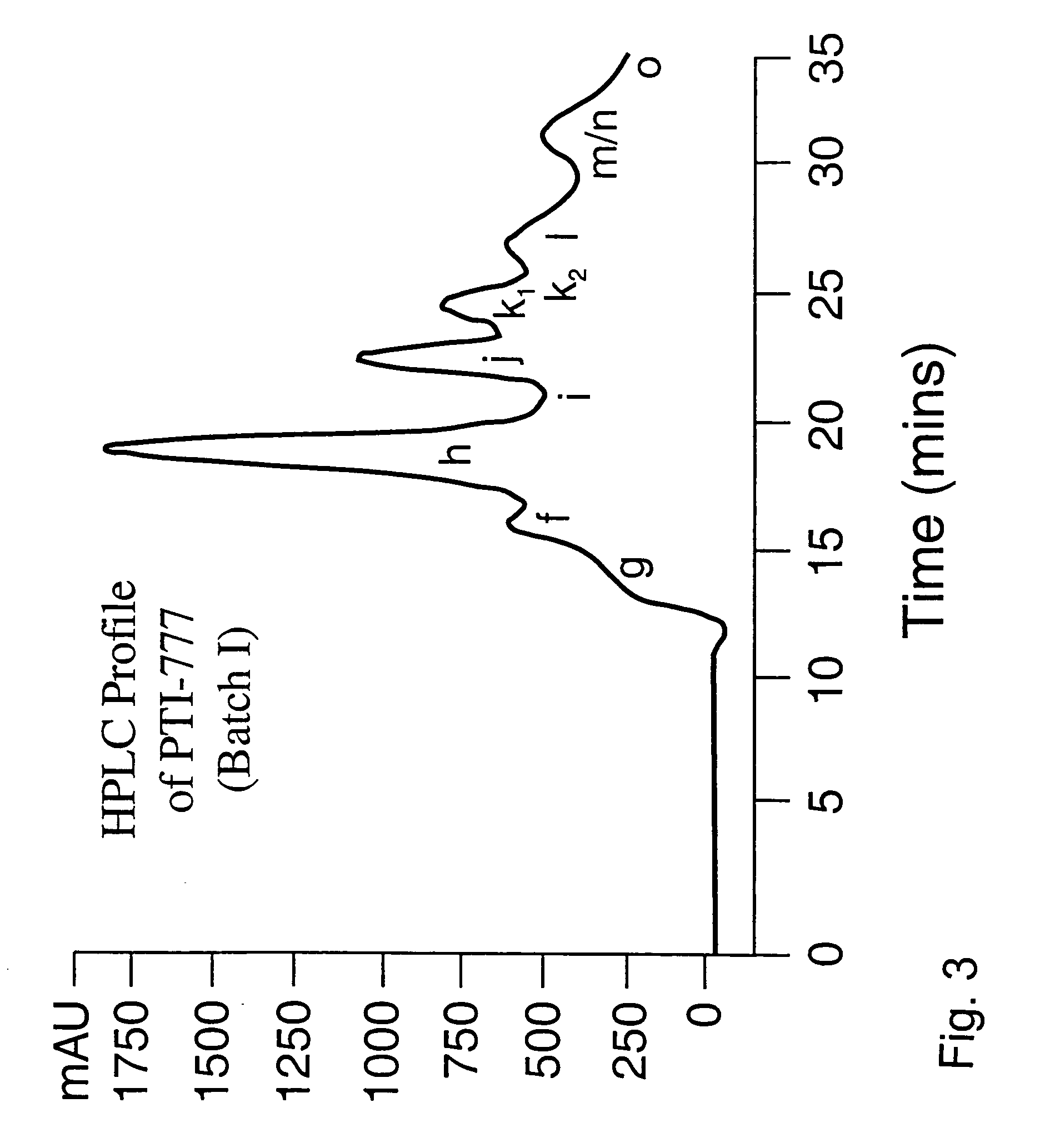

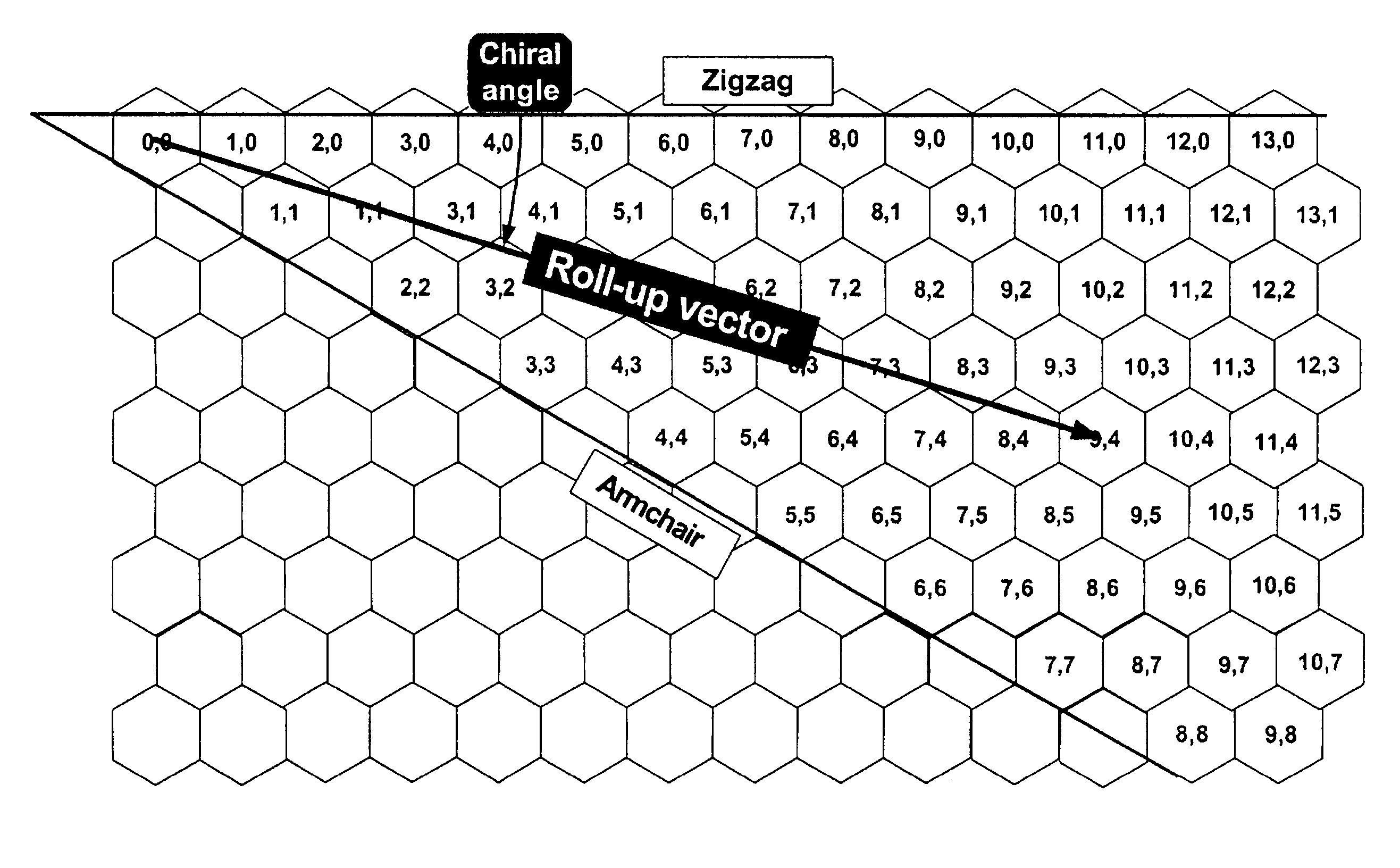

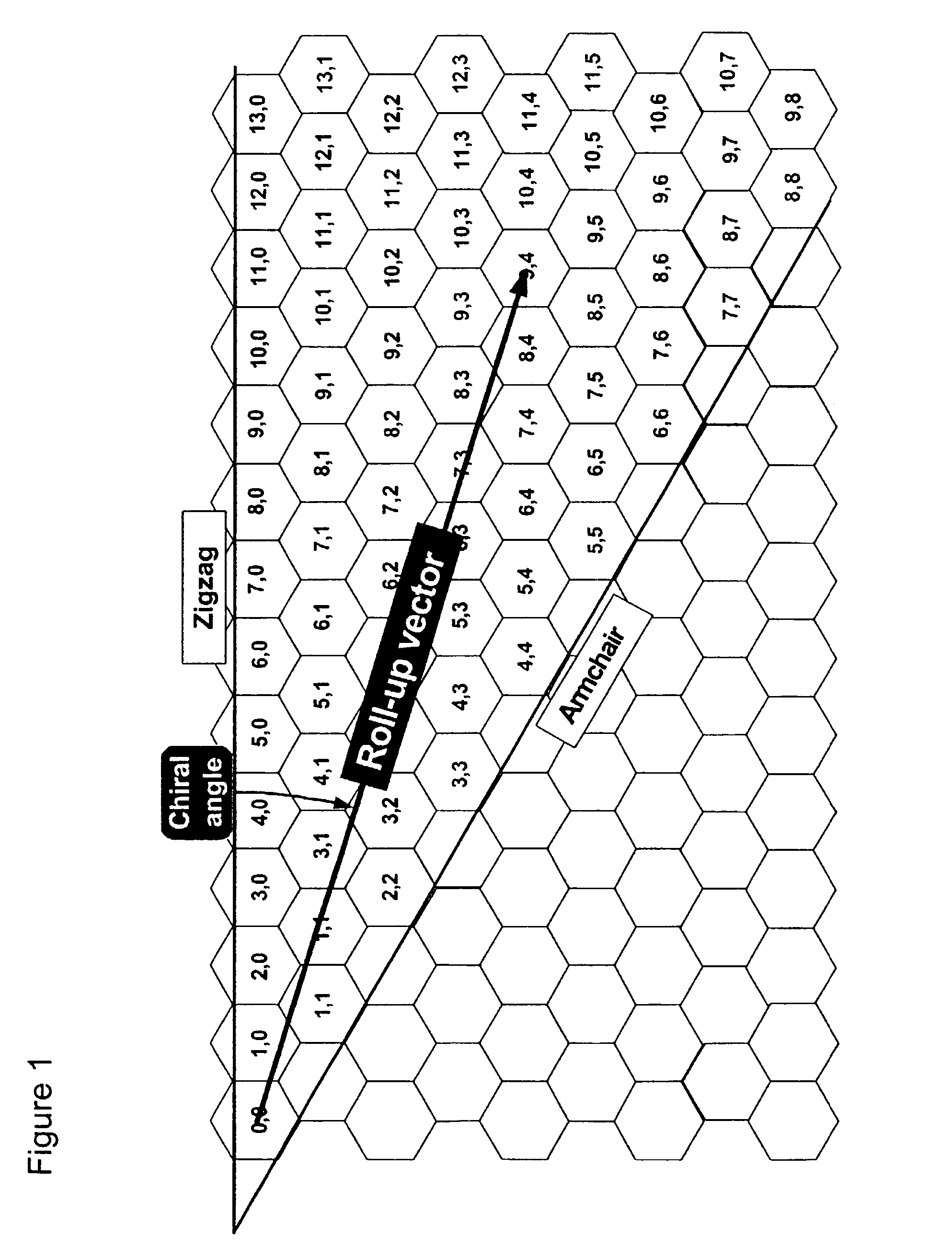

Method for separating single-wall carbon nanotubes and compositions thereof

The invention relates to a process for sorting and separating a mixture of (n, m) type single-wall carbon nanotubes according to (n, m) type. A mixture of (n, m) type single-wall carbon nanotubes is suspended such that the single-wall carbon nanotubes are individually dispersed. The nanotube suspension can be done in a surfactant-water solution and the surfactant surrounding the nanotubes keeps the nanotube isolated and from aggregating with other nanotubes. The nanotube suspension is acidified to protonate a fraction of the nanotubes. An electric field is applied and the protonated nanotubes migrate in the electric fields at different rates dependent on their (n, m) type. Fractions of nanotubes are collected at different fractionation times. The process of protonation, applying an electric field, and fractionation is repeated at increasingly higher pH to separated the (n, m) nanotube mixture into individual (n, m) nanotube fractions. The separation enables new electronic devices requiring selected (n, m) nanotube types.

Owner:RICE UNIV

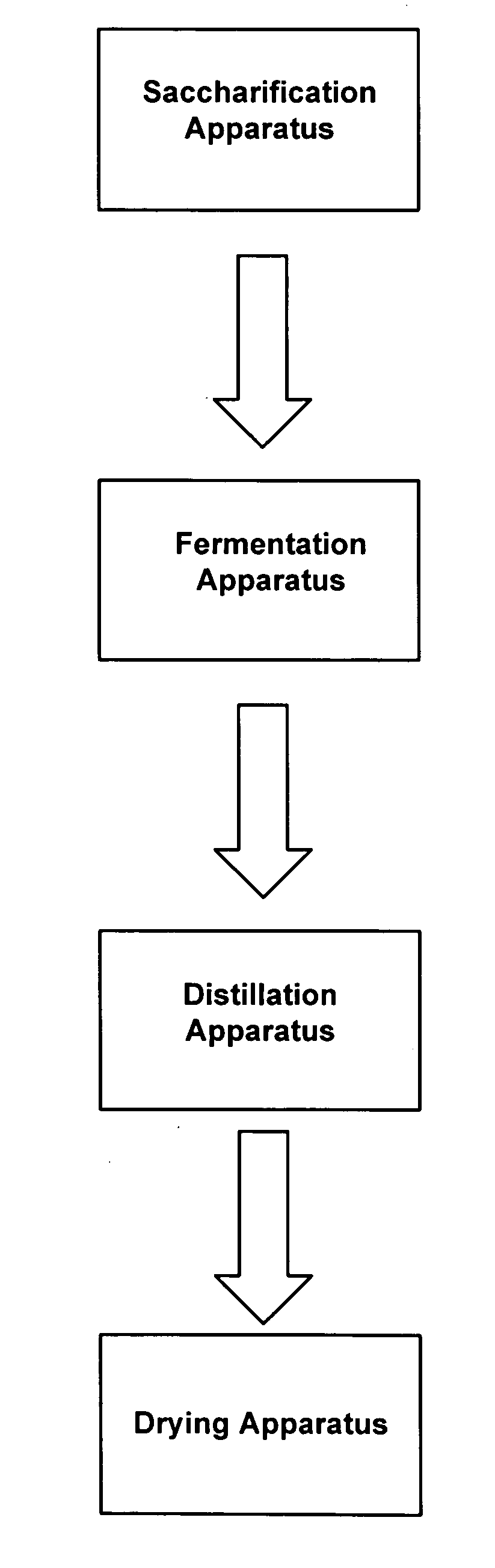

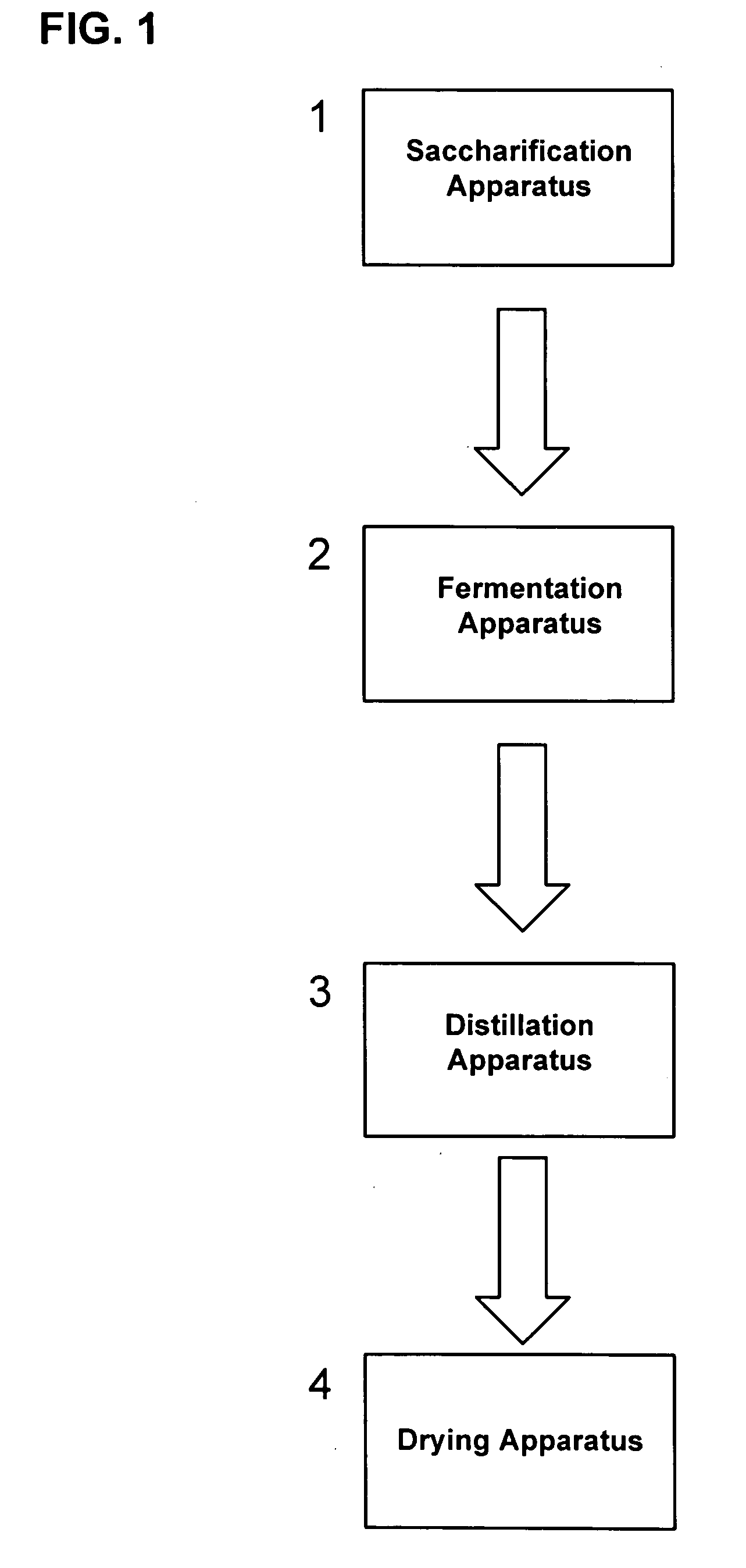

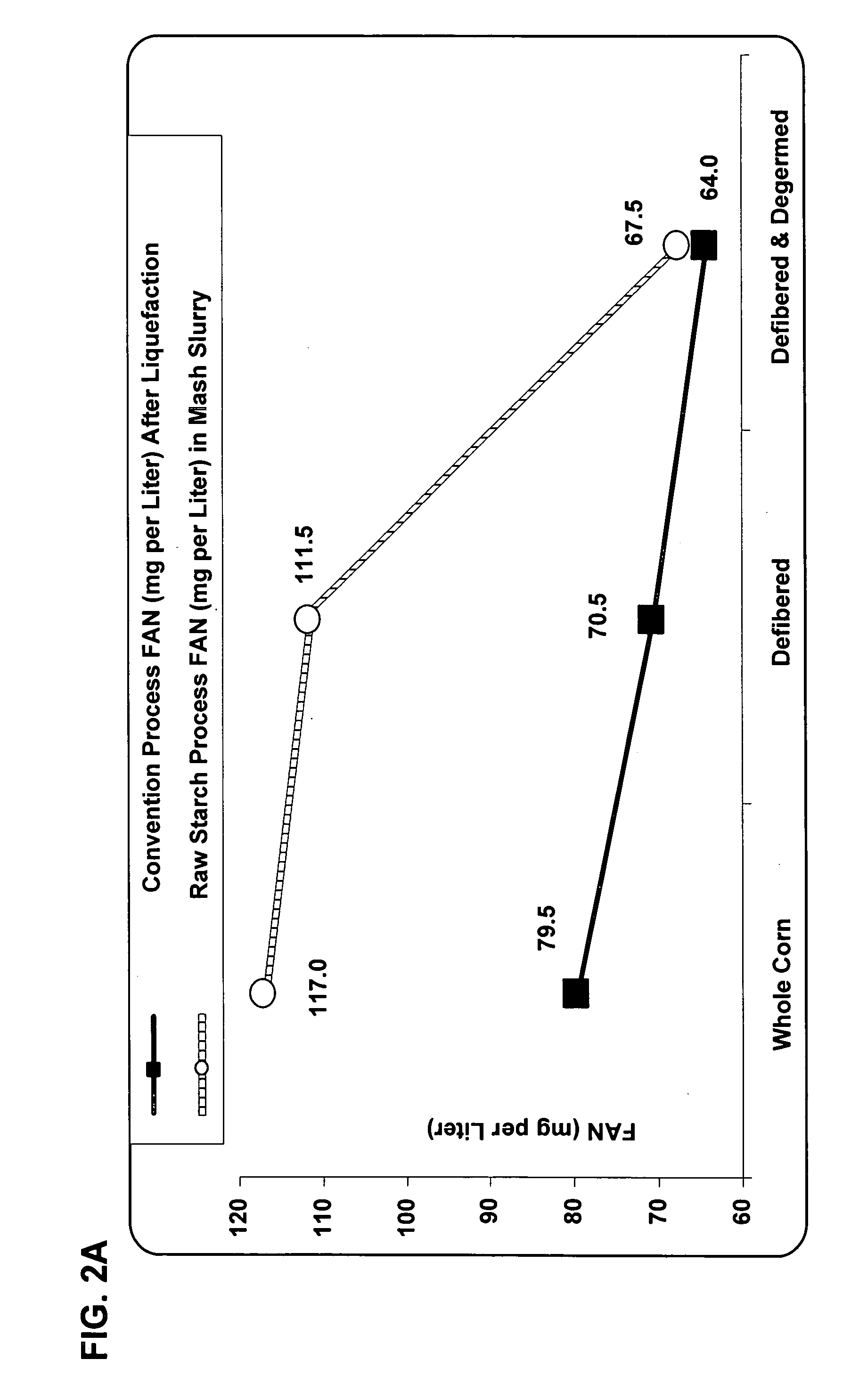

Methods and systems for producing ethanol using raw starch and fractionation

InactiveUS20070037267A1Improve the level ofImprove the immunityBiofuelsFermentationFluidized bed dryingHigh alcohol beer

The present invention relates to methods for producing high levels of alcohol during fermentation of plant material, and to the high alcohol beer produced. The method can include fractionating the plant material. The present invention also relates to methods for producing high protein distiller's dried grain from fermentation of plant material, and to the high protein distiller's dried grain produced. The method can include drying a co-product by ring drying, flash drying, or fluid bed drying. The present invention further relates to reduced stack emissions from drying distillation products from the production of ethanol.

Owner:BROIN & ASSOC

Polypropylene block-copolymer resin and process for producing it

Polypropylene block-copolymer resin exhibiting high melt tension and improved moldability with balanced stiffness and impact resistance may be molded at high speed into large-sized articles, including, stretched films, with good appearance and resistance to deformation. The block copolymer includes a higher molecular weight polypropylene segment, a lower molecular weight polypropylene segment and an ethylene alpha-olefin copolymer segment. When subjected to dissolution fractionation m paraxylene, a large proportion is insoluble at 23° C. but soluble at 135° C., and a smaller portion is soluble at 23° C. The block copolymer has a melt flow rate of 0.01 to 5 g / 10 min at 230 C. (2.16 kg) and a molecular weight distribution Mw / Mn of 6-20 and Mz / Mw of at least 3.5. A continuous multistage polymerization may be used to form the block copolymer.

Owner:PRIME POLYMER CO LTD

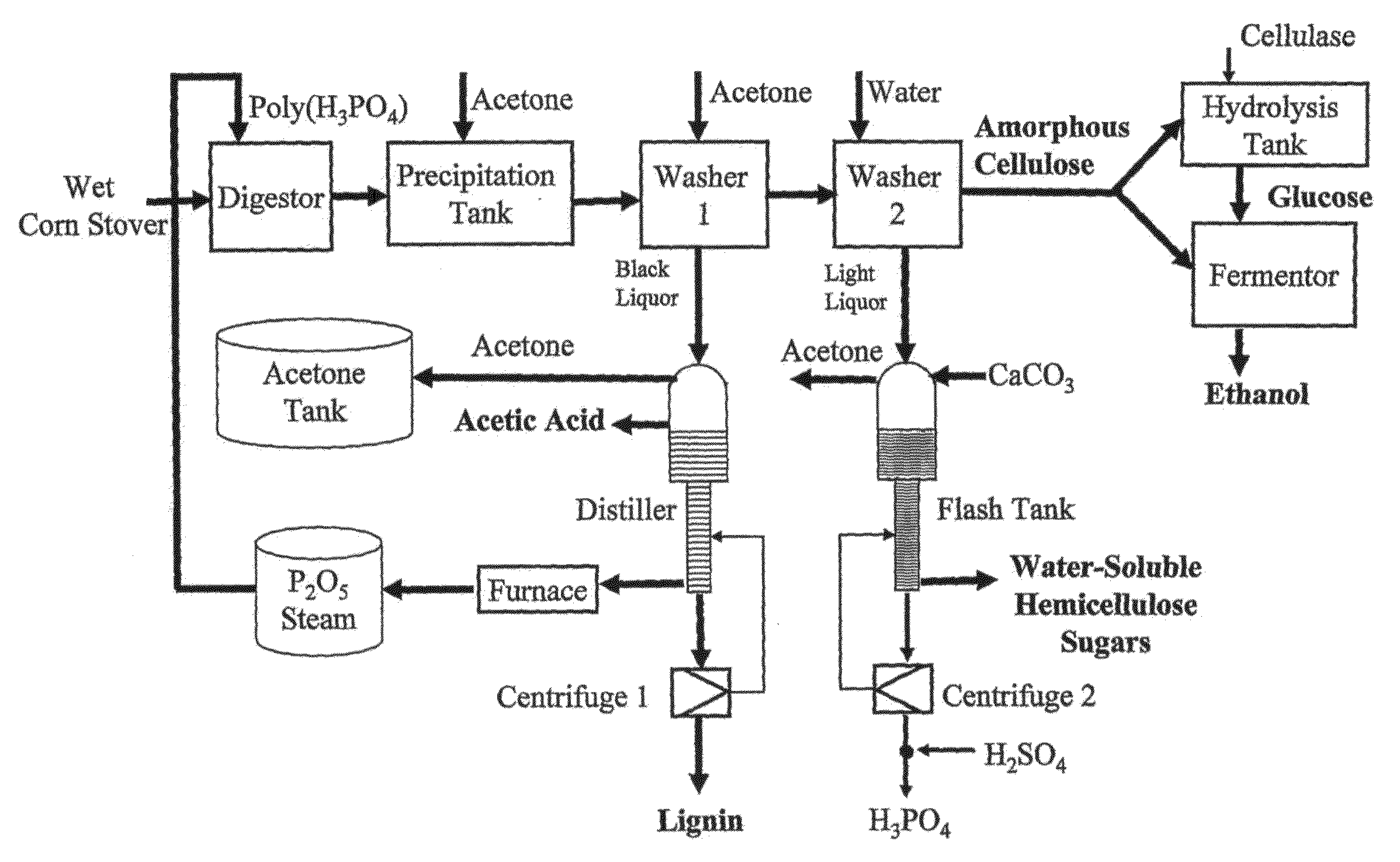

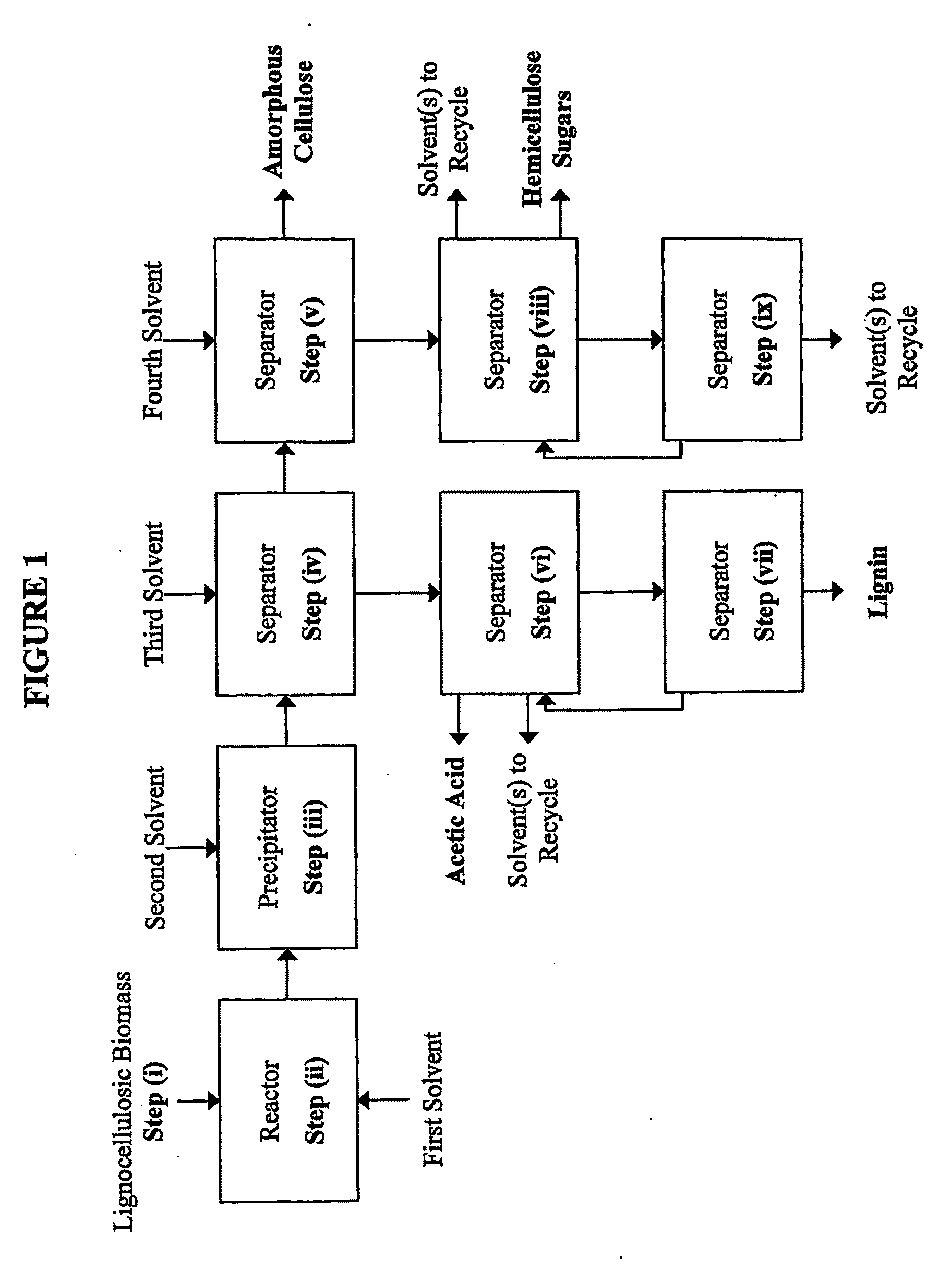

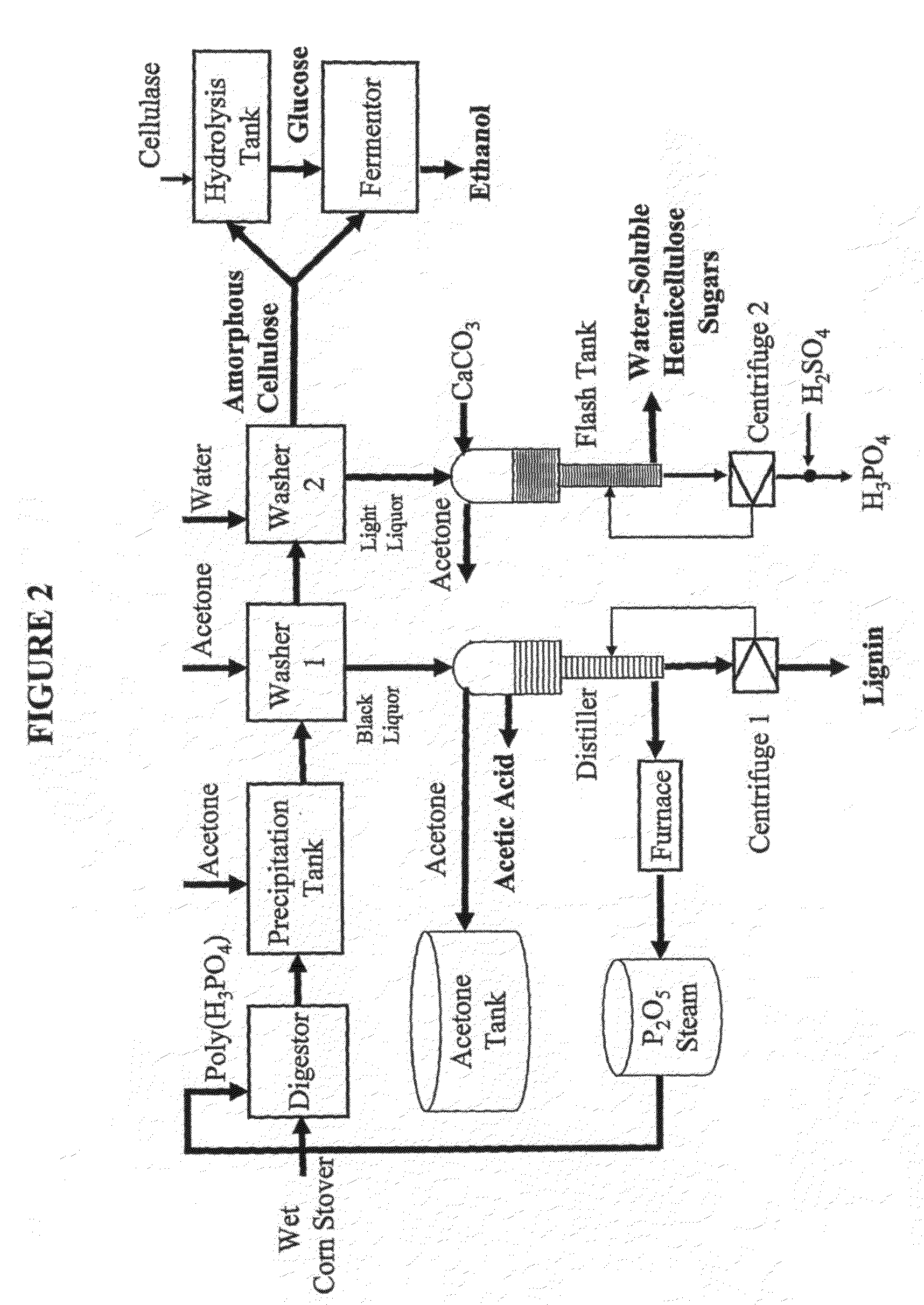

Cellulose-solvent-based lignocellulose fractionation with modest reaction conditions and reagent cycling

InactiveUS20100170504A1Lower cost of capitalReduce operating costsBiofuelsChemical recyclingFractionationProcessing cost

Embodiments of the present invention overcome the well-known recalcitrance of lignocellulosic biomass in an economically viable manner. A process and system are provided for the efficient fractionation of lignocellulosic biomass into cellulose, hemicellulose sugars, lignin, and acetic acid. The cellulose thus obtained is highly amorphous and can be readily converted into glucose using known methods. Fermentable hemicellulose sugars, low-molecular—weight lignin, and purified acetic acid are also major products of the process and system. The modest process conditions and low solvent / solid ratios of some embodiments of the invention imply relatively low capital and processing costs.

Owner:VIRGINIA TECH INTPROP INC

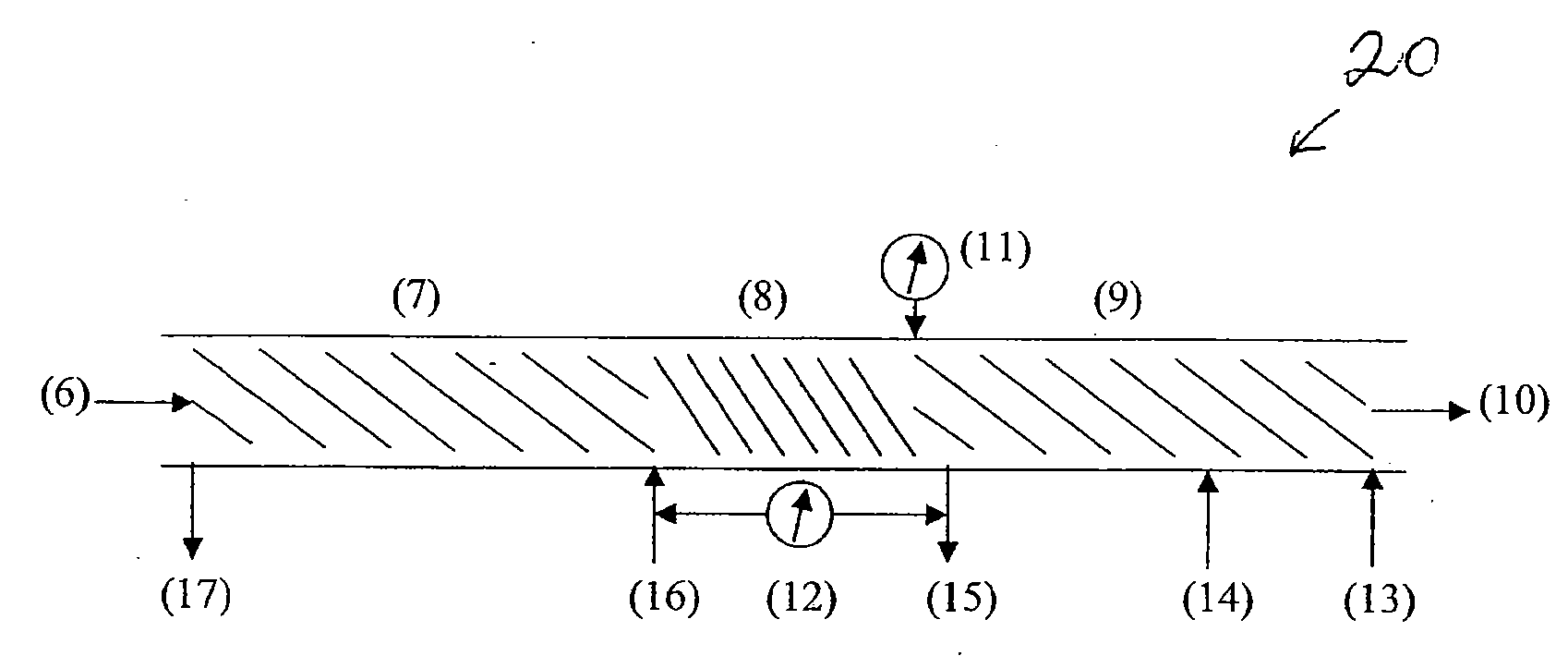

Moving bed biomass fractionation system and method

InactiveUS20080029233A1Improve production yieldIncrease pressureWashing/displacing pulp-treating liquorsDigestersChemical reactionFiltration

Countercurrent extraction of lignocellulosic biomass such as trees, grasses, shrubs, and agricultural residues or waste involves the separation of cellulose fibers from other constituents, for subsequent use in the manufacture of paper, plastics, ethanol, and other industrial chemicals. Systems and methods involve continuous, multiple processing steps that may include chemical reactions with mixing at elevated temperature and / or pressure, efficient reagent or solvent utilization, filtration at elevated temperature and / or pressure, controlled discharge of liquid and solid products, and energy recuperation.

Owner:PUREVISION TECH

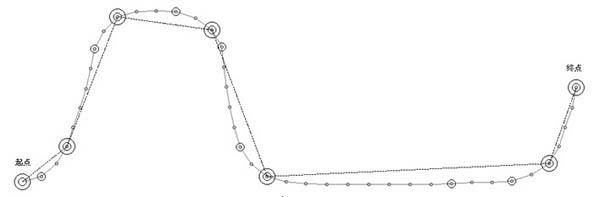

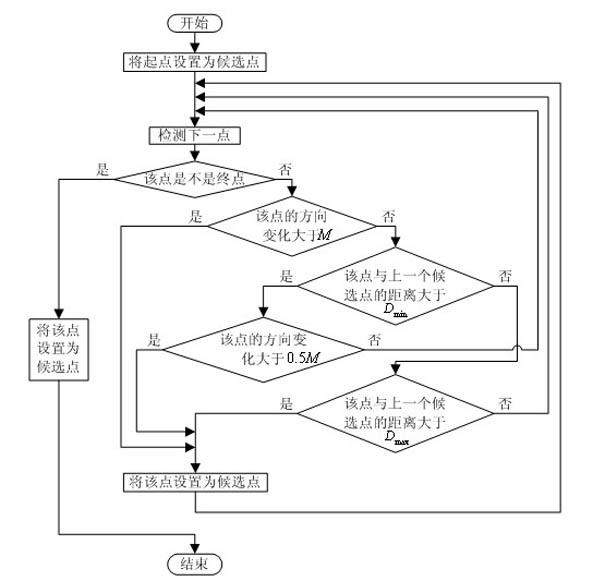

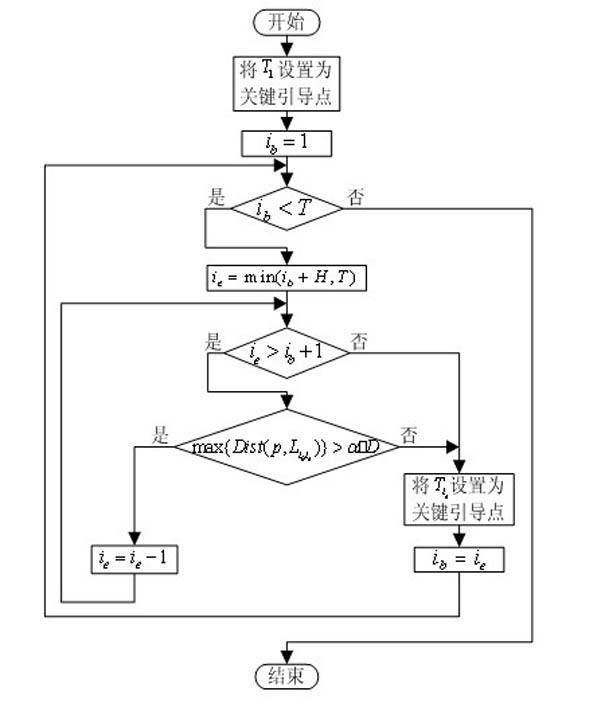

Vision navigation method of mobile robot based on hand-drawing map and path

InactiveCN102087530AAvoid dynamic obstaclesImprove robustnessInstruments for road network navigationPosition/course control in two dimensionsFractionationReference image

The invention relates to a vision navigation method of a mobile robot based on a hand-drawing map and path. The method comprises the following steps of: firstly, extracting a key leading point in an operation path according to a principle of less bias and dividing an original path into a plurality of segments; then, matching corresponding reference images in a pre-drawn environmental map and information collected in real time by a robot camera in various operation processes to estimate an image most possibly existing in the current field of view; detecting the characteristics of the image by utilizing a SURF (Selective Ultraviolet Radiation Fractionation) algorithm and rapidly solving matching points by relying on a KD-TREE (K-Dimension Tree) method; solving a projection conversion matrix of the reference image and a real-time image by adopting an RANSAC (Random Sample Consensus) algorithm, further acquiring the position of the reference image in the real-time image and merging milemeter data to acquire the reference position of the robot; and finally, calculating the operation direction of the next segment according to the acquired reference position of the robot until the robot moves to the last reference point. The robot can run to an appointed region without the needs of accurate environmental map and accurate operation path and dodge a dynamic obstacle.

Owner:SOUTHEAST UNIV

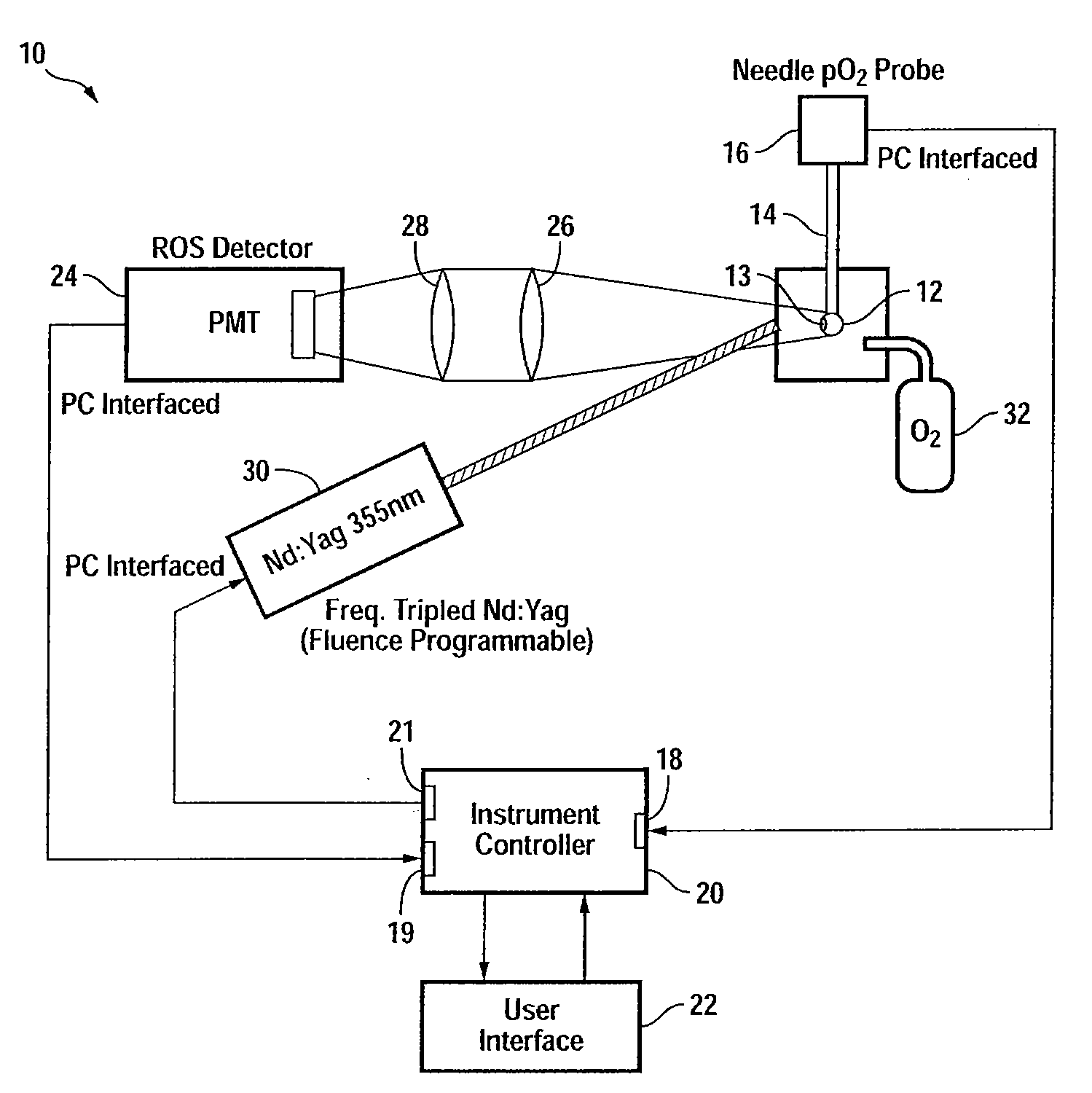

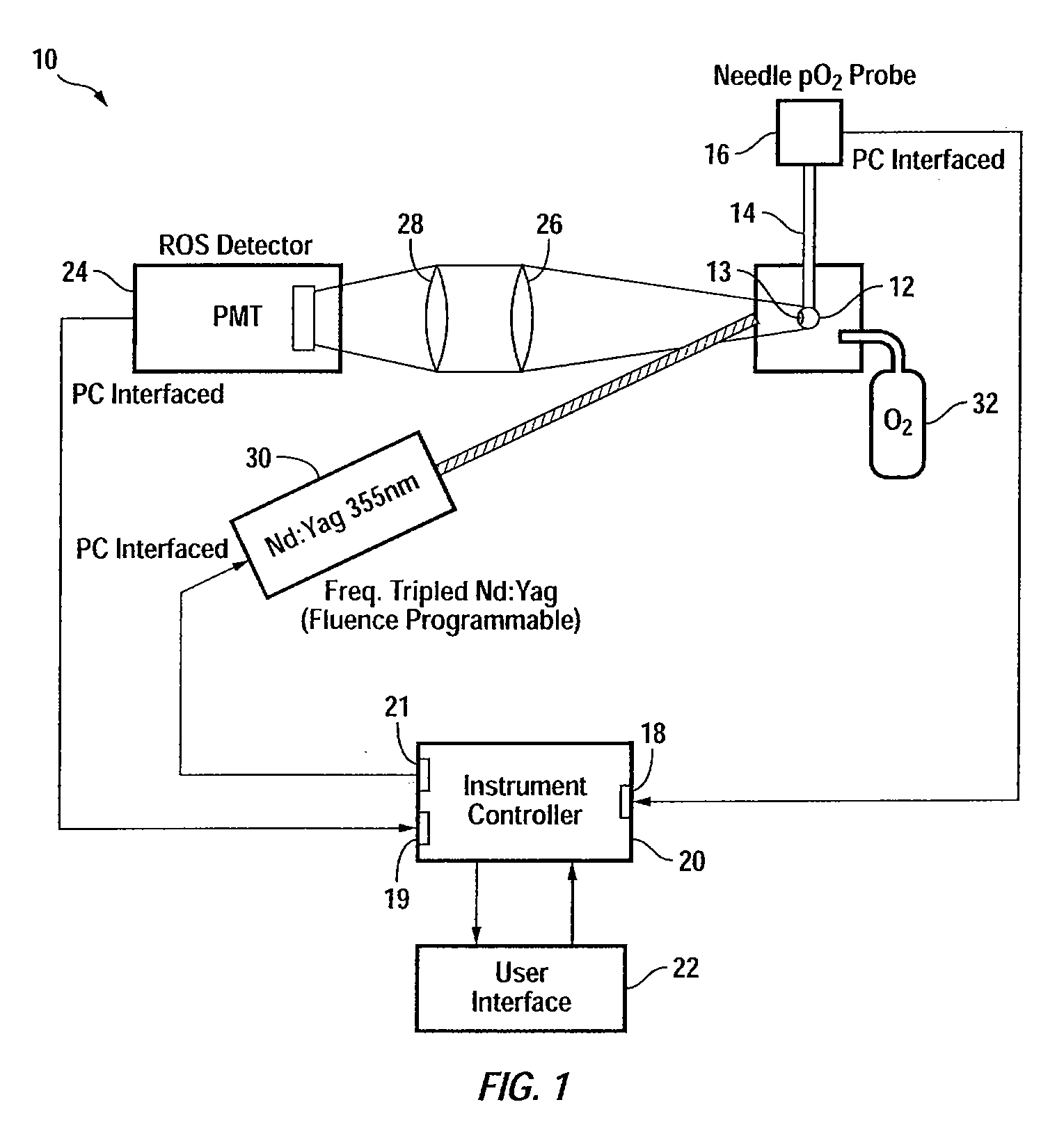

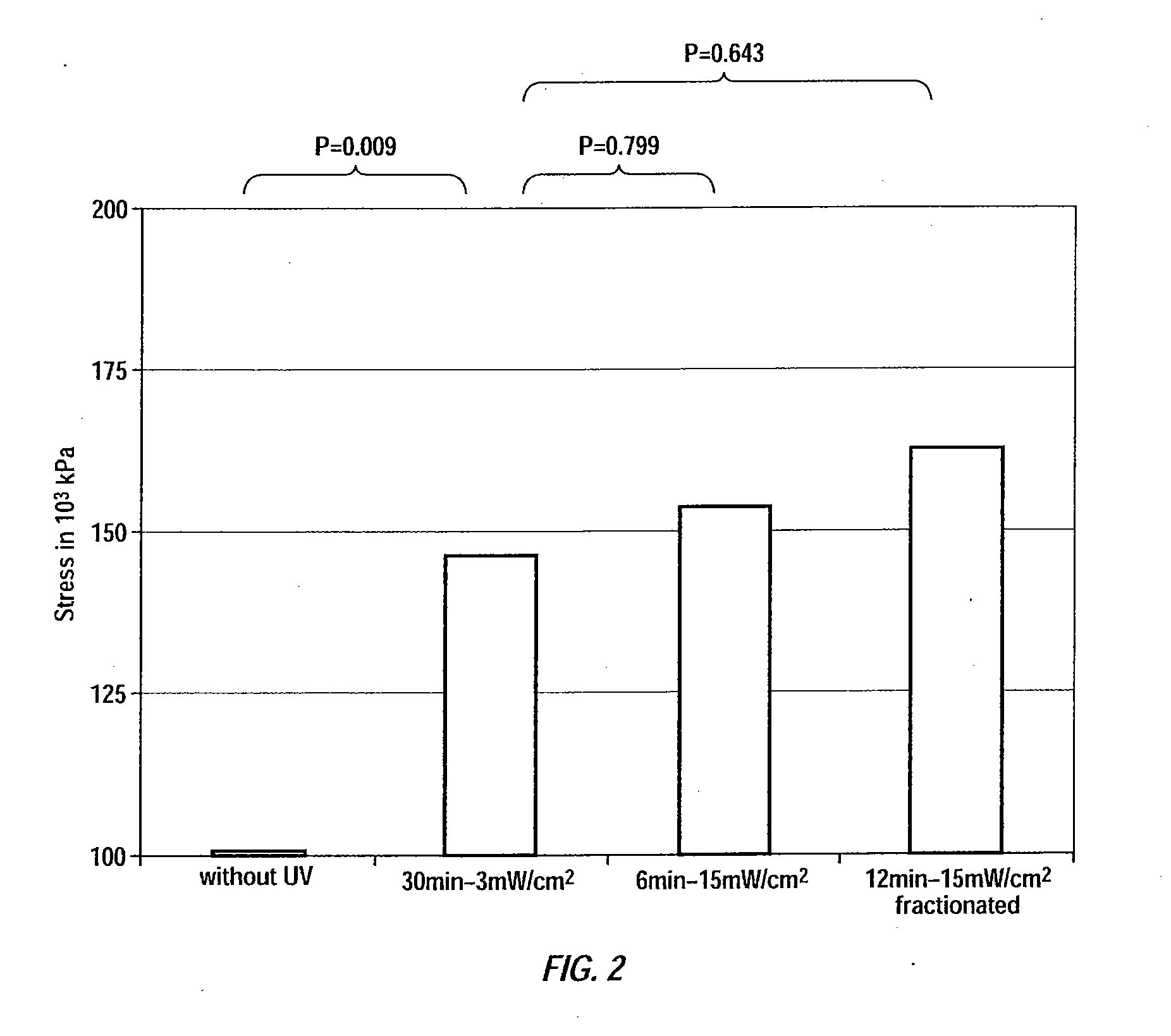

Method for equi-dosed time fractionated pulsed uva irradiation of collagen/riboflavin mixtures for ocular structural augmentation

InactiveUS20090149923A1Fast cross-linkingImprove cross-linking efficiencyLaser surgeryLight therapyCross-linkMedicine

Equi-dosed time-fractionated pulsed UVA is employed to irradiate a class of riboflavin / collagen mixture in the presence of copious oxygen to cause rapid crosslinking causing gelation of the riboflavin / collagen mixture in situ and to effect adhesion to underlying structure specifically ocular tissue such as scleral and corneal tissue. Irradiation according to an embodiment of the invention results in depletion of dissolved oxygen at a rate inversely related to irradiance and more particularly depletion of dissolved oxygen occurs rapidly during the process of generation / cross-linking of reactive oxygen species (ROS), specifically singlet oxygen, such that the pulsed fractionation of UVA radiation exposure increases cross-linking efficiency by allowing the re-diffusion of oxygen during pauses in exposure.

Owner:SEROS MEDICAL

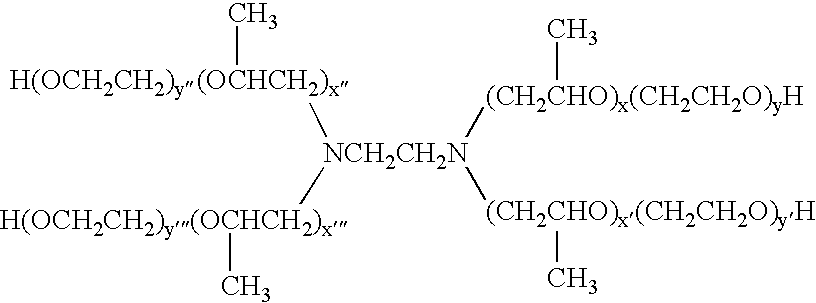

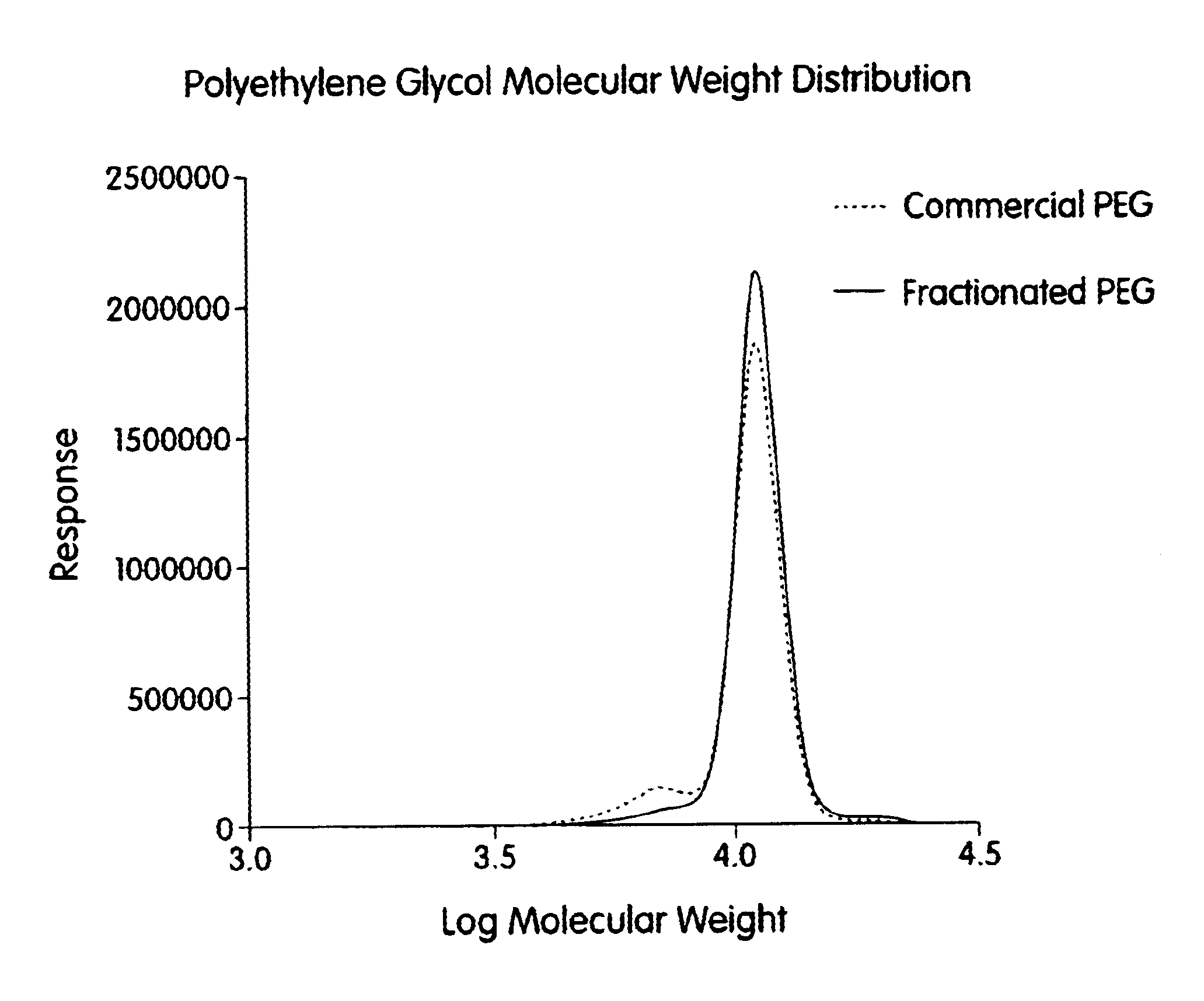

Process for the fractionation of polymers

A process for the purification or fractionation of aqueous soluble polymers using an aqueous two-phase system is described. The concentrations of the polymer to be fractionated and of an aqueous soluble salt, and the temperature of the aqueous fractionation medium are adjusted so that two phases form, the lower molecular weight polymer molecules partition into the high salt concentration phase, and the higher molecular weight polymer molecules partition into the low salt concentration phase. The resulting high molecular weight polymers are characterized by a higher average molecular weight and a narrower molecular weight distribution and decreased unsaturation than the unfractionated polymers. After being subjected to the fractionation process, polyol polymers that form hydrogels in aqueous solution exhibited higher viscosities and a liquid to gel transition over a narrower temperature range than the unfractionated polyol polymers.

Owner:HINSBERG MICHAEL G +1

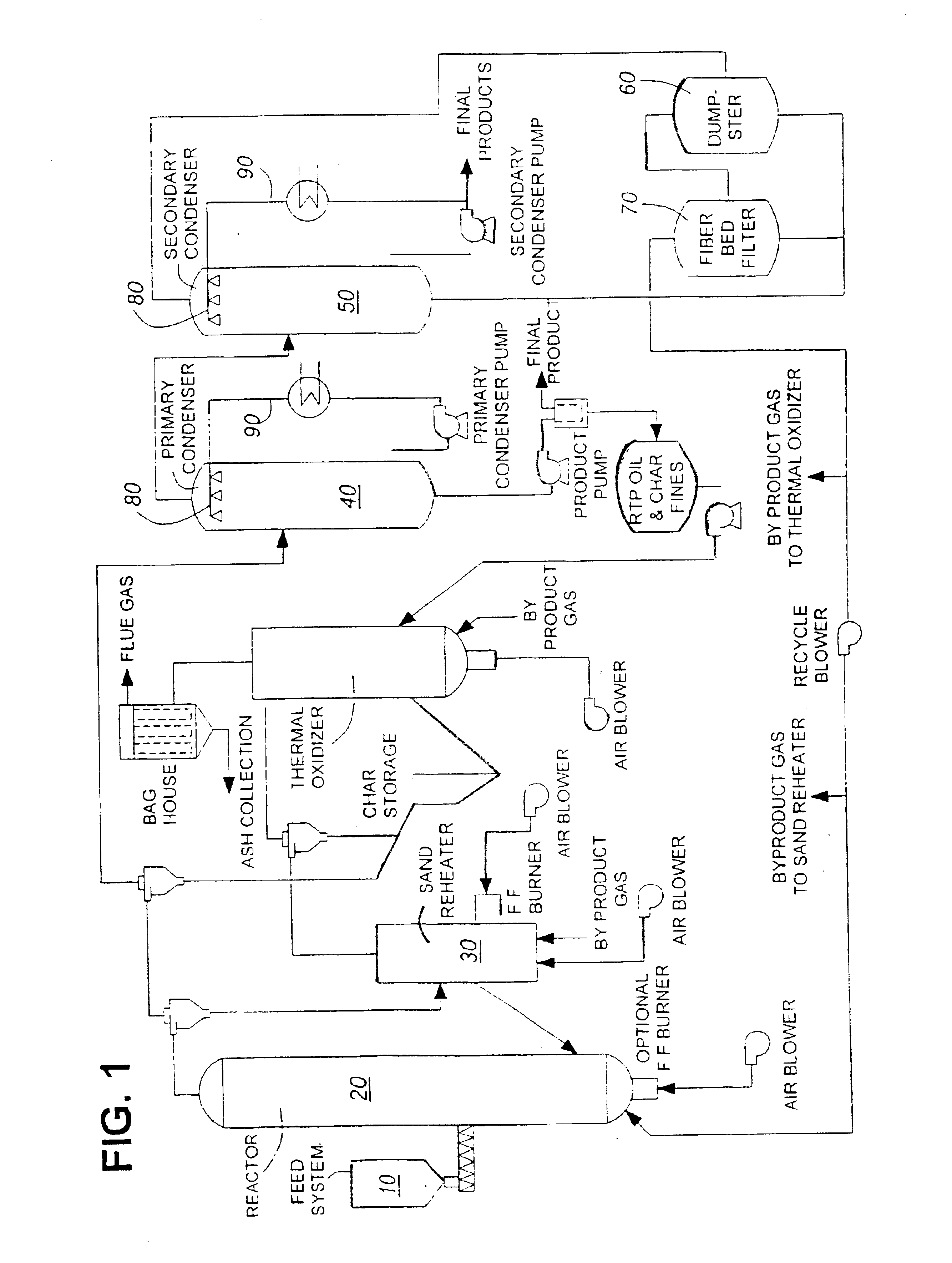

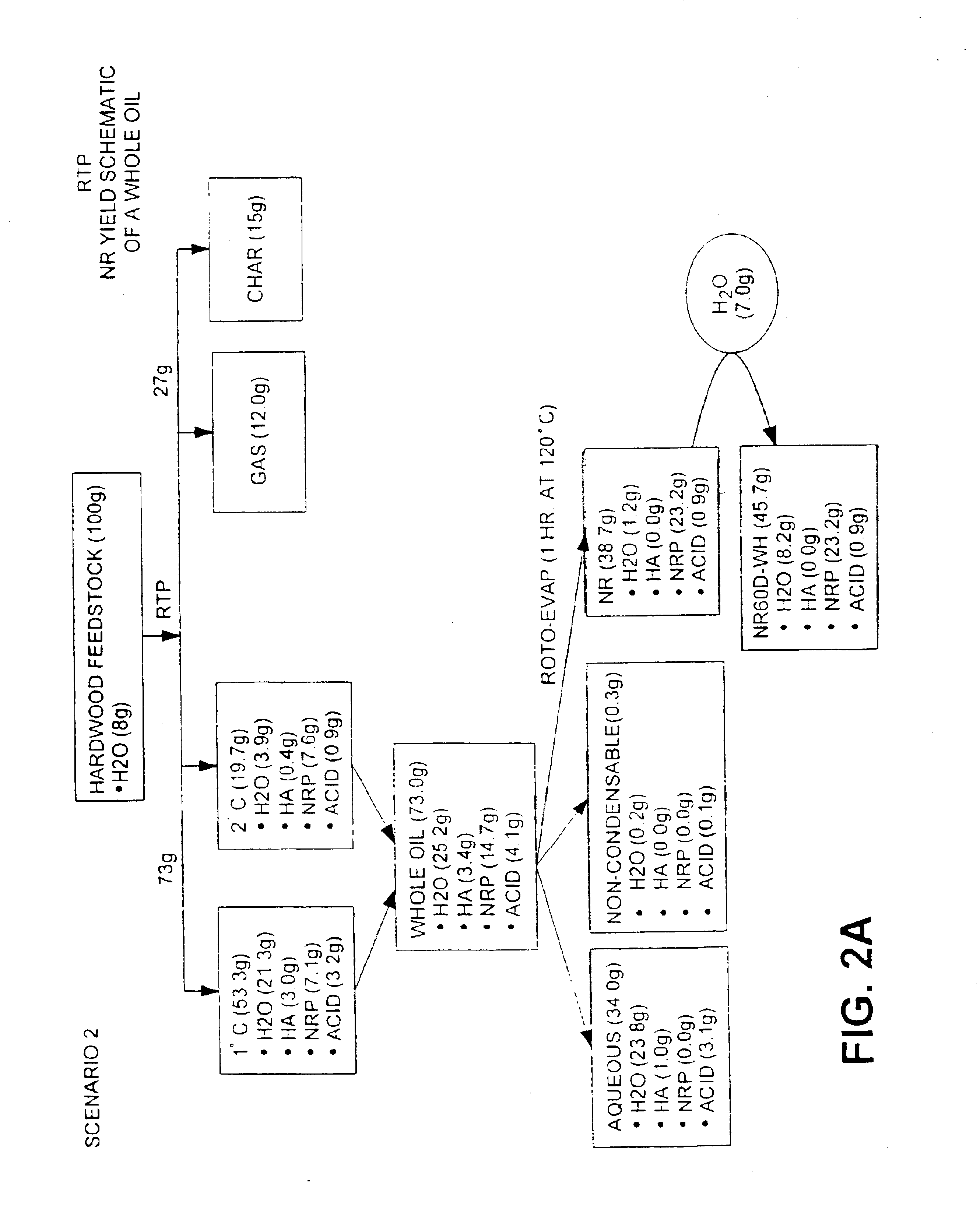

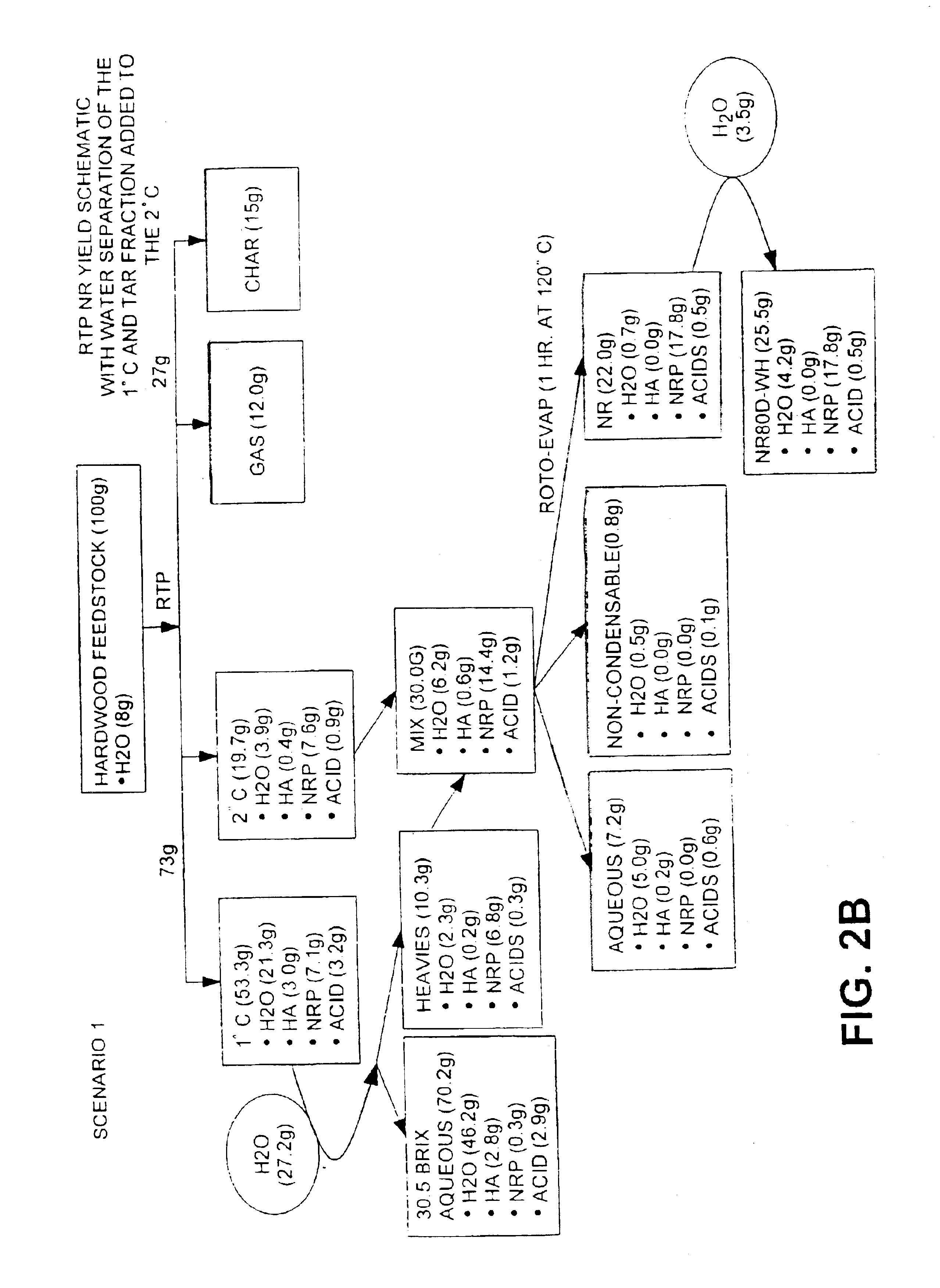

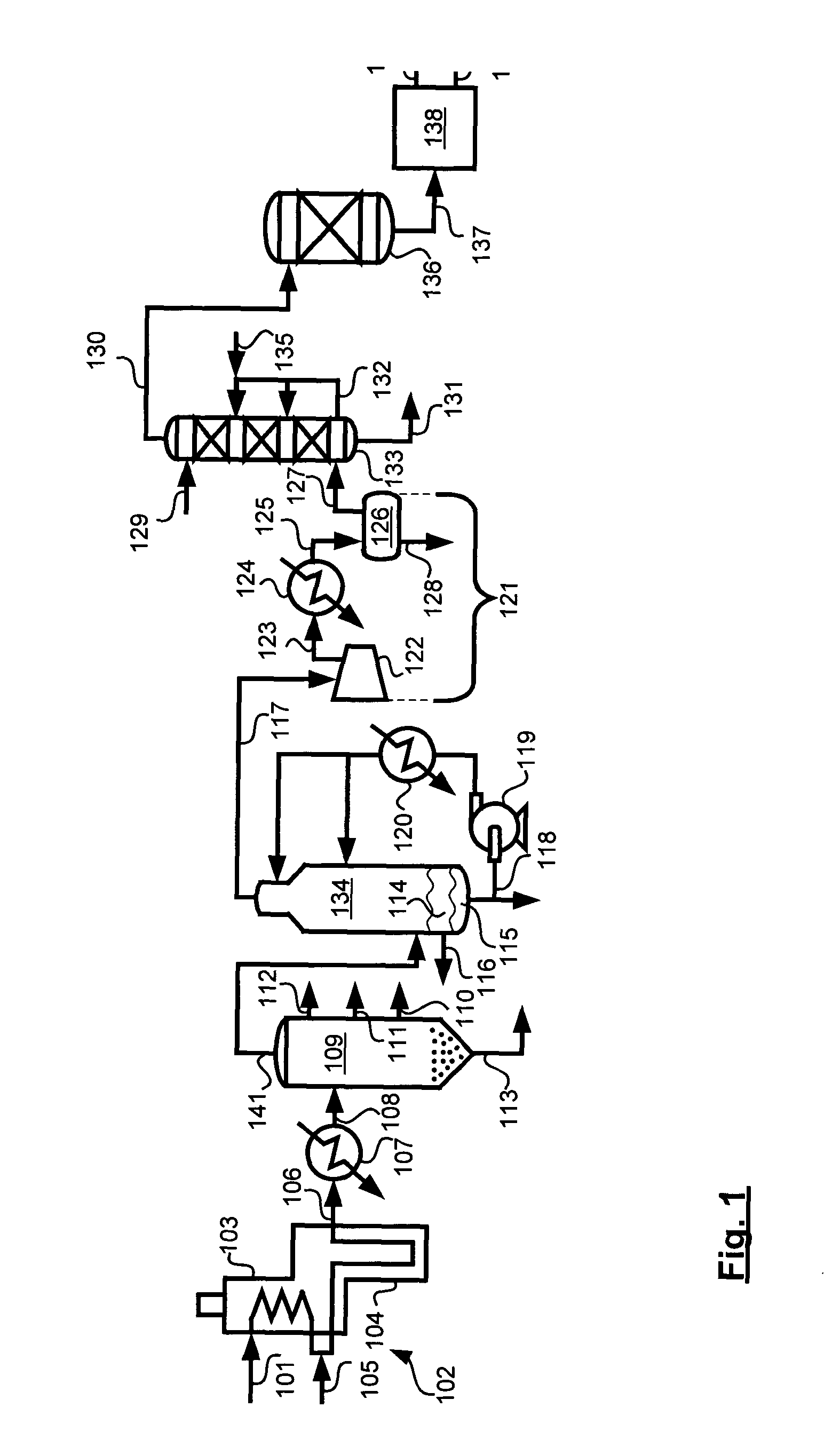

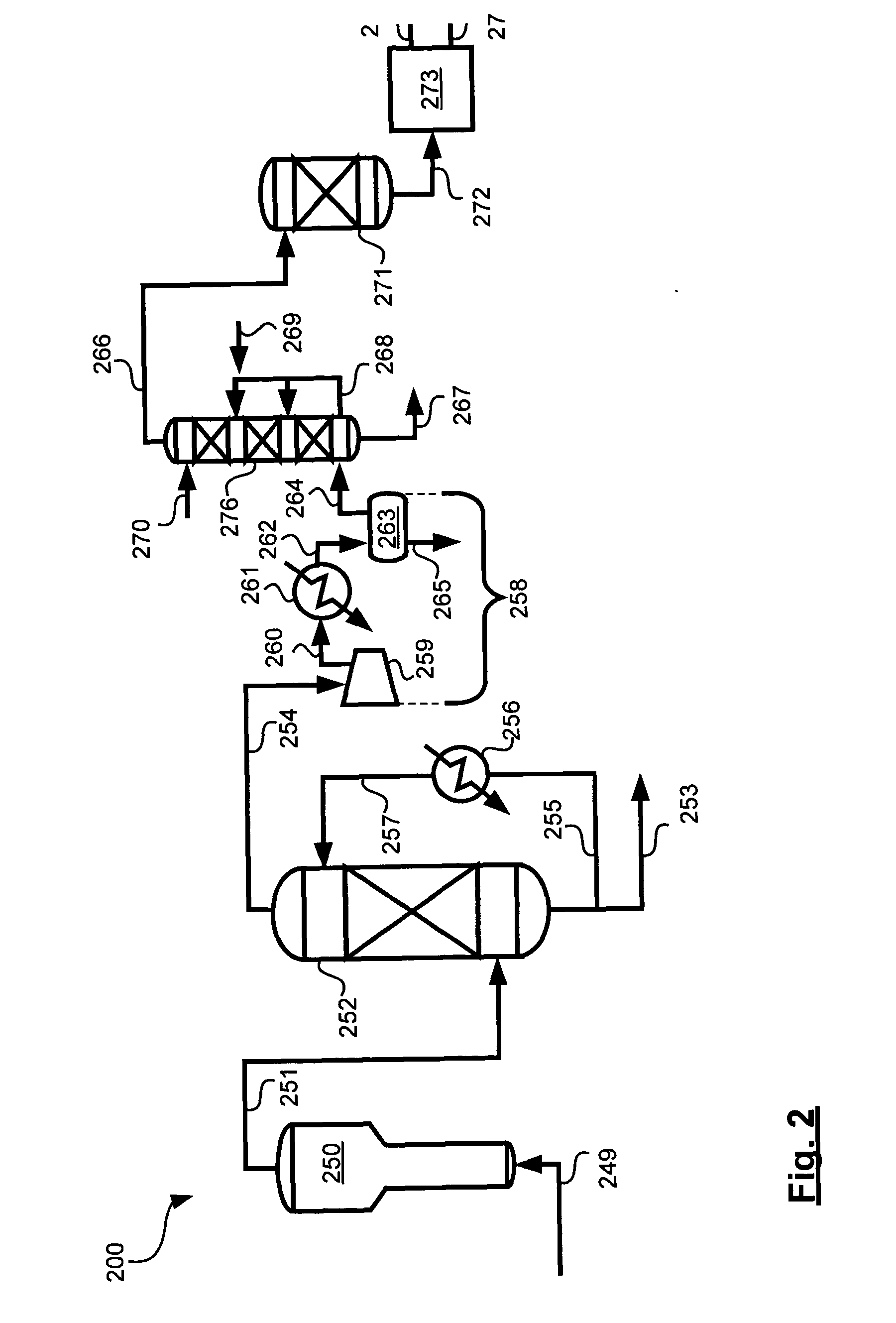

Natural resin formulations

InactiveUS6844420B1Low viscosityImprove liquidityFatty oils/acids recovery from wasteBiofuelsNatural resinDistillation

This invention is directed to a method of preparing a natural resin by liquefying wood, bark, forest residues, wood industry residues, or other biomass using rapid destructive distillation (fast pyrolysis). Fast pyrolysis produces both vapors and char from biomass, and following removal of the char from the product vapors, a liquid pitch product is recovered and processed by distillation, evaporation, or a combination thereof, in order to obtain a natural resin which may be in either liquid or solid form. The natural resin comprises a total phenolic content from about 30% to about 80% (w / w), and is a highly-reactive ligninic compound that has been found to be suitable for use within resin formulations without requiring any further extraction or fractionation procedures. Resins comprising up to 60% natural resin have been prepared and tested in board production and found to exhibit similar properties associated with commercially available resins. The natural resin may substitute for phenol, or for both phenol and formaldehyde within phenol-containing resins. Similarly, the natural resin can replace a substantial part of the components within urea-containing resins.

Owner:ENSYN RENEWABLES

Integrating a methanol to olefin reaction system with a steam cracking system

InactiveUS20050038304A1Shorten the counting processReduce the amount requiredThermal non-catalytic crackingMolecular sieve catalystOxygenateFractionating column

The present invention provides an integrated system for producing ethylene and propylene from an oxygenate to olefin (OTO) reaction system and a steam cracking system. In a preferred embodiment, at least a portion of an effluent stream from a steam cracking furnace is combined with at least a portion of an effluent stream from an OTO reaction system. Preferably the combined effluent stream is processed by one or more quench units, compression units, and / or fractionation columns. By integrating a steam cracking system with an OTO reaction system, equipment count can be reduced at a significant commercial savings. Compressor efficiency per pound of ethylene and propylene can also be advantageously increased over conventional steam cracking systems. Moreover, the amount of pollutants produced per pound of ethylene and propylene produced can be significantly reduced over the amount of pollutants produced per pound of ethylene and propylene produced in a steam cracking system.

Owner:EXXONMOBIL CHEM PAT INC

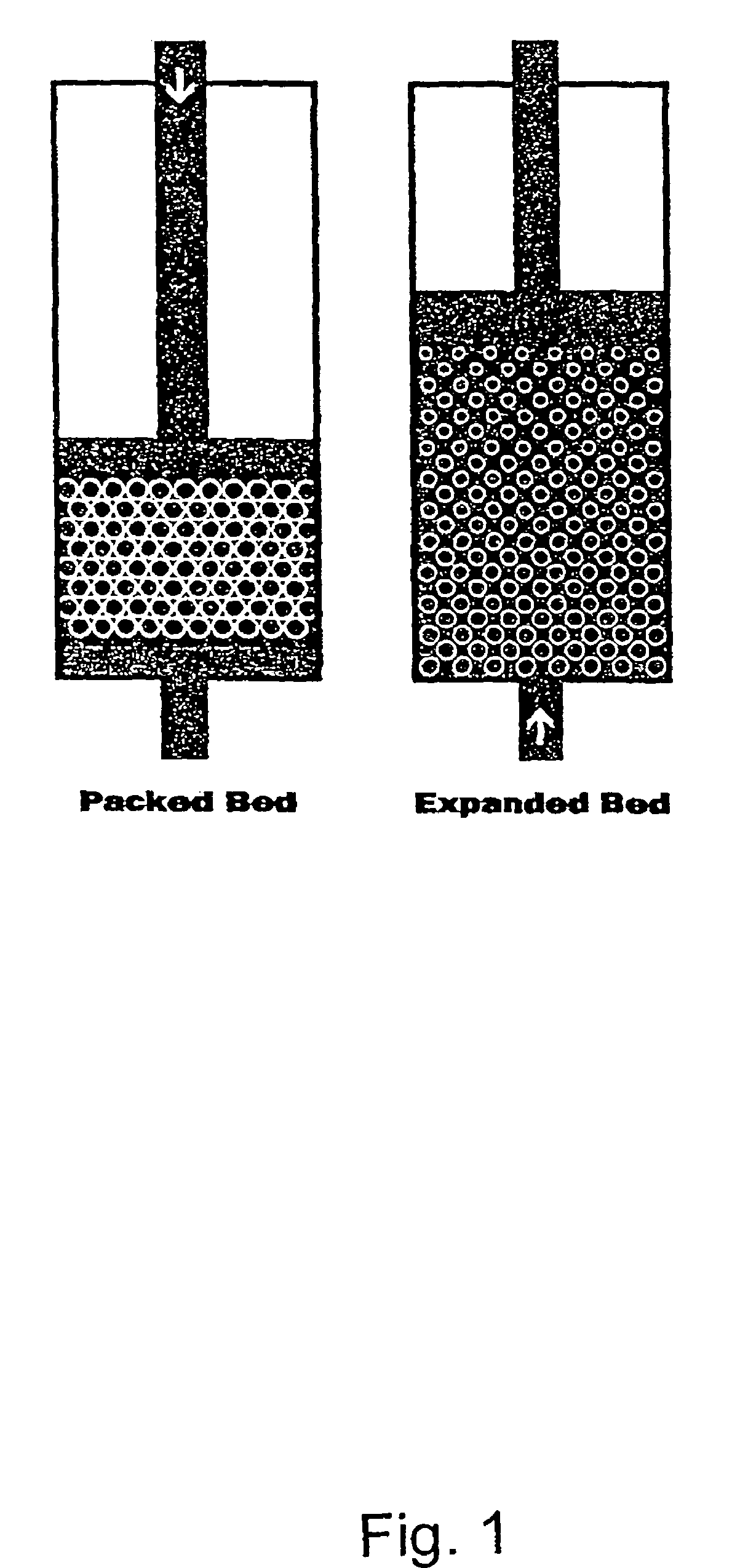

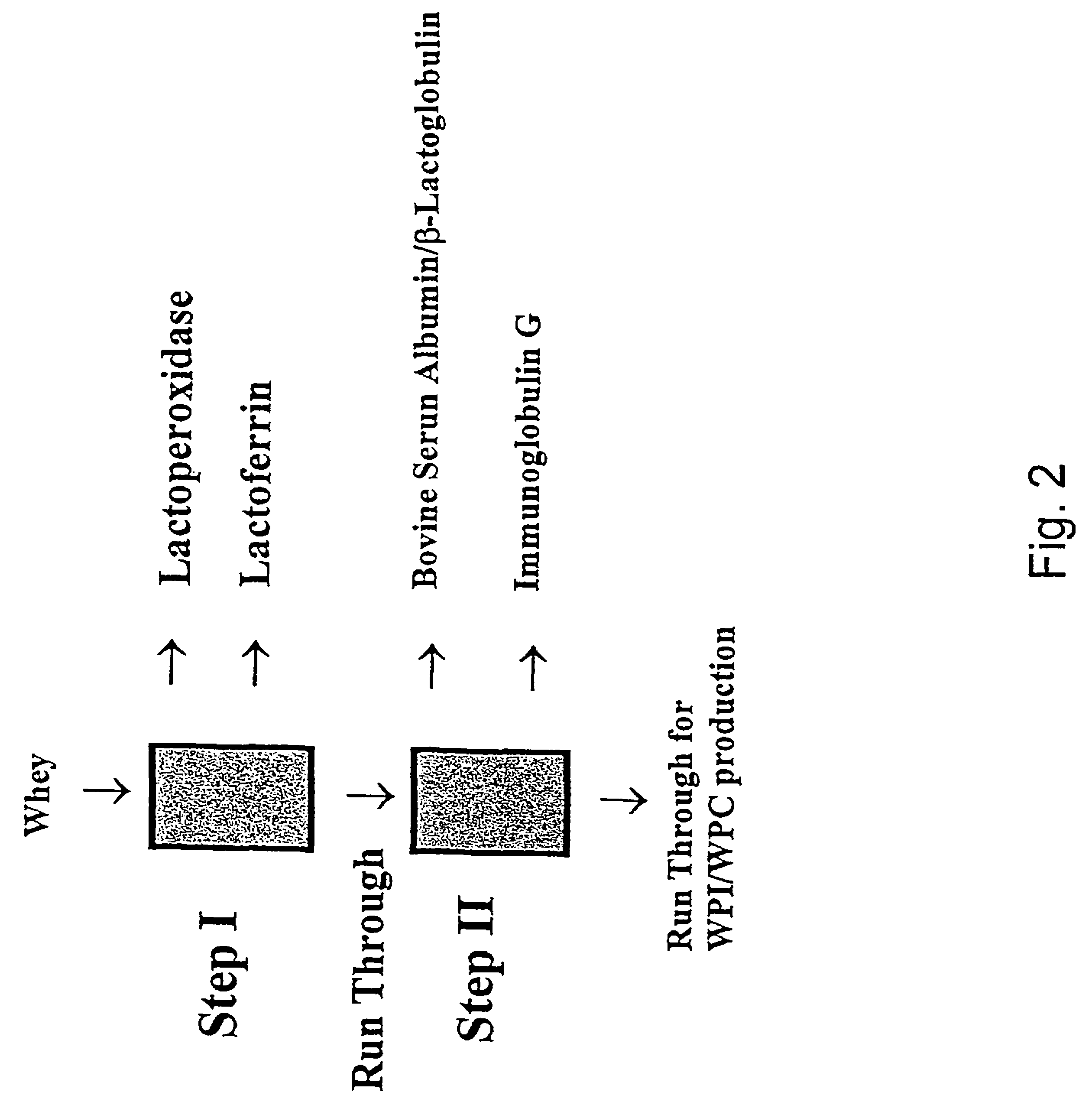

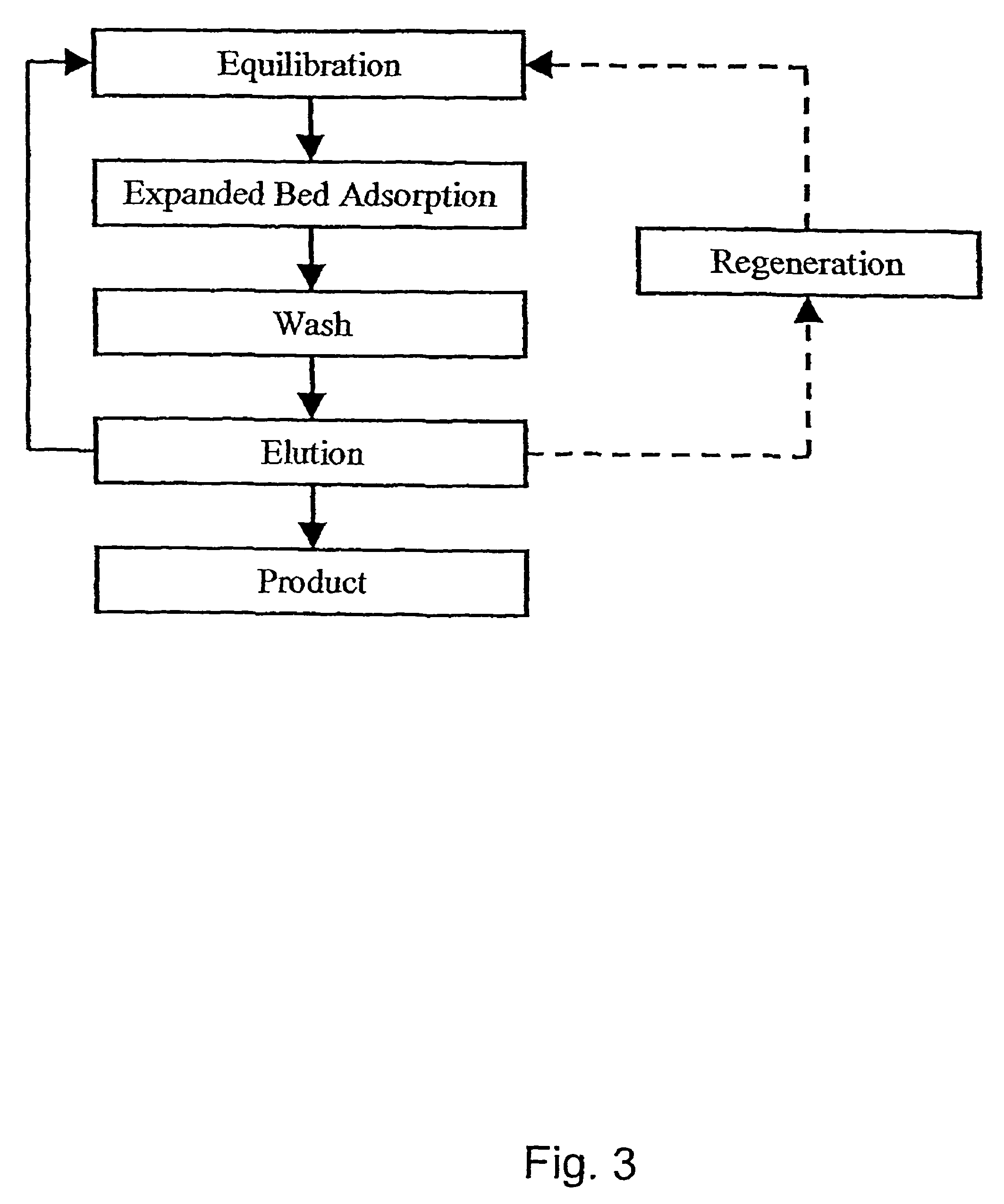

Fractionation of protein containing mixtures

InactiveUS7812138B2Easy to operatePeptide/protein ingredientsIon-exchanger regenerationHigh densitySorbent

Thus, a primary aspect of the present invention relates to a method for the fractionation of a protein-containing mixture wherein the protein-containing mixture is selected from the group consisting of milk, milk derived products, milk derived raw materials, vegetable derived products, vegetable derived extracts, fruit derived products, fruit derived extracts, fish derived products, and fish derived extracts, the method comprising the steps of: a) optionally adjusting the pH of the mixture; b) applying the mixture to an adsorption column comprising an adsorbent, the adsorbent comprises a particle with at least one high density non-porous core, surrounded by a porous material, the adsorbent having a particle density of at least 1.5 g / ml and a mean particle size of at most 150 μm; c) optionally washing the column; d) eluting at least one protein from the adsorbent.

Owner:UPFRONT CHROMATOGRAPHY

Extraction with fractionation of oil and proteinaceous material from oleaginous material

Methods for selective extraction and fractionation of algal lipids and algal products are disclosed. A method of selective removal of products from an algal biomass provides for single and multistep extraction processes which enable efficient separation of algal components. Among these components are neutral lipids synthesized by algae, which are extracted by the methods disclosed herein for the production of renewable fuels.

Owner:HELIAE DEVMENT

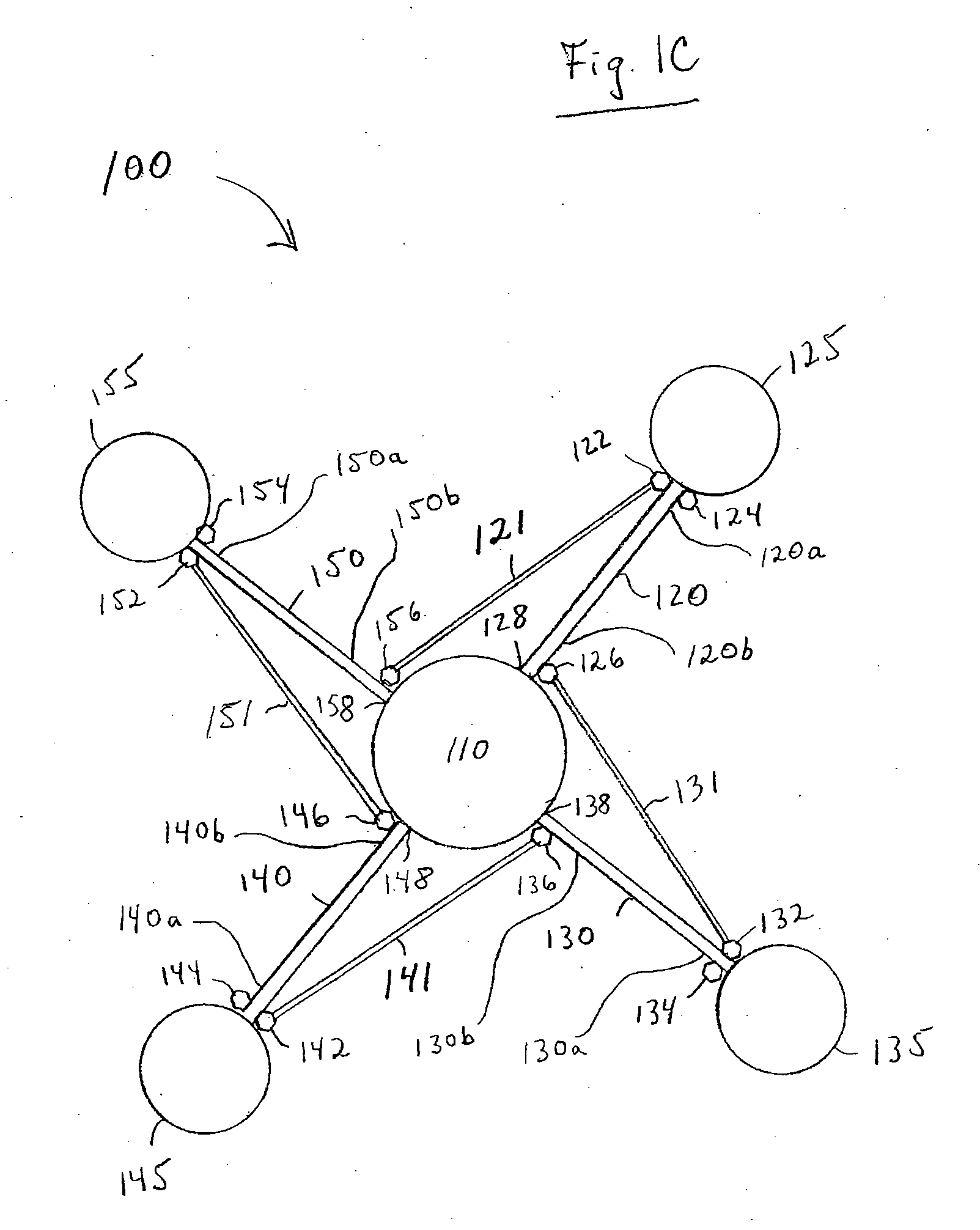

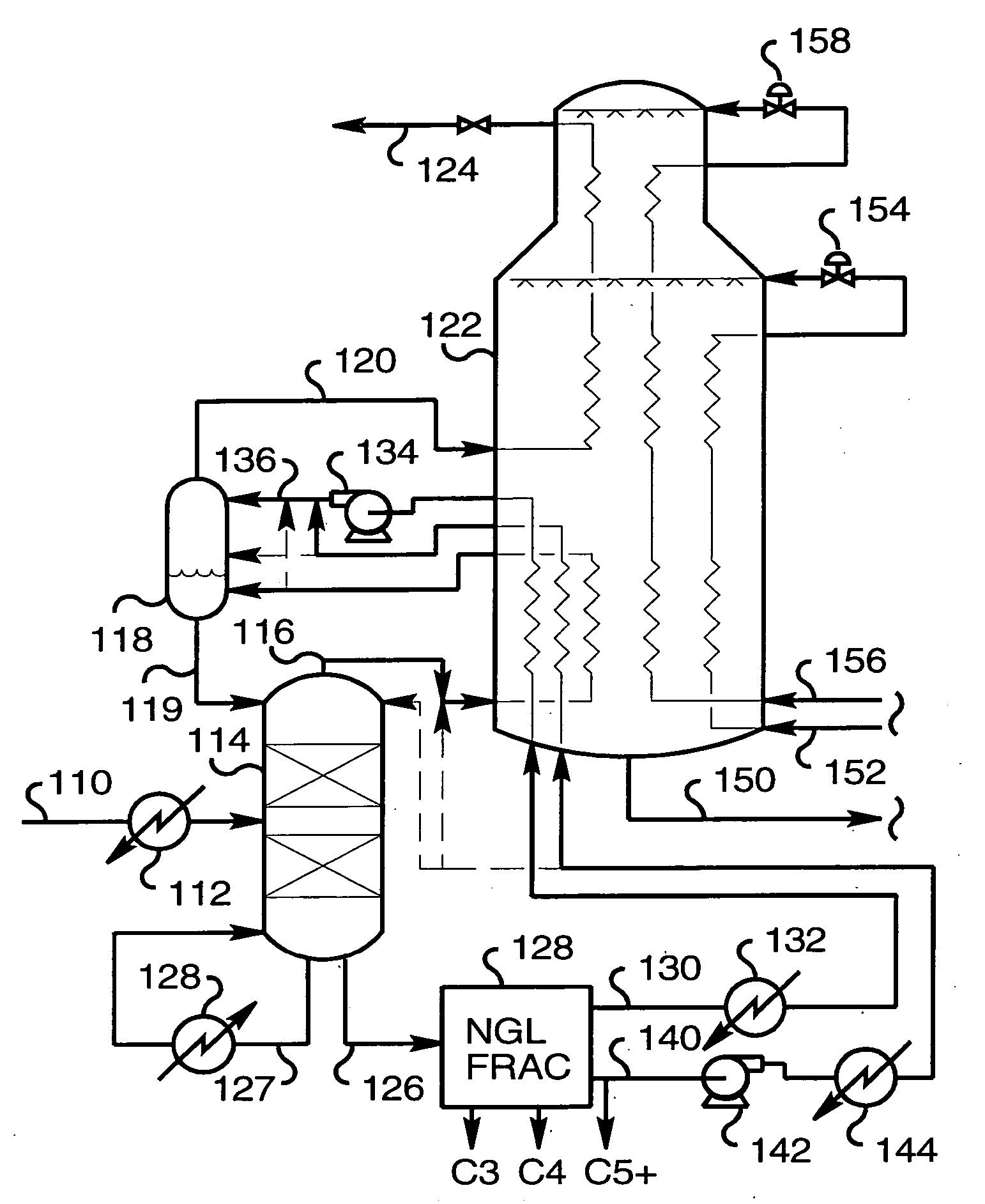

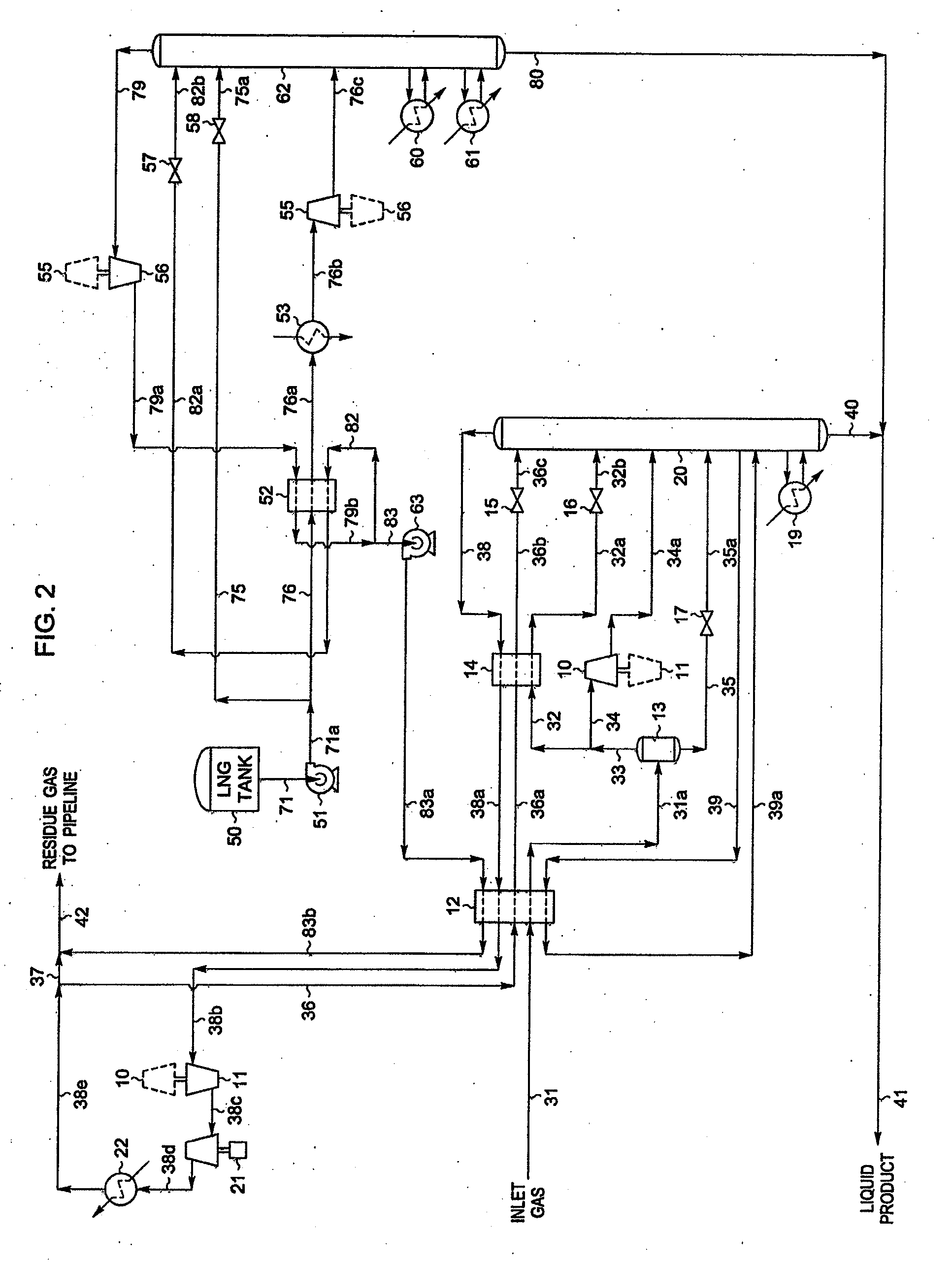

Integrated NGL recovery and liquefied natural gas production

InactiveUS20060260355A1Improves ethane-propane separationMaximize the benefitsSolidificationLiquefactionHydrocotyle bowlesioidesFractionation

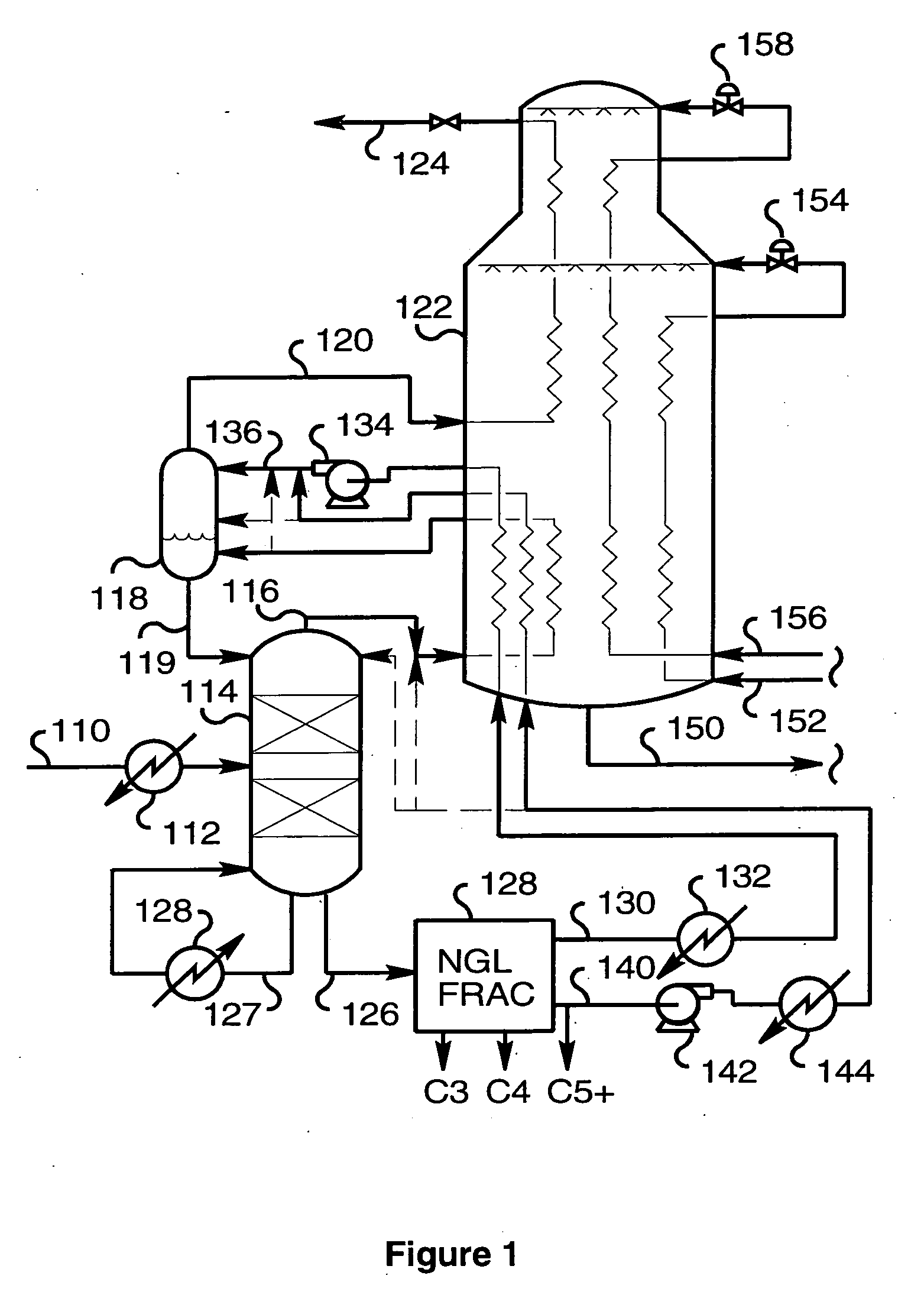

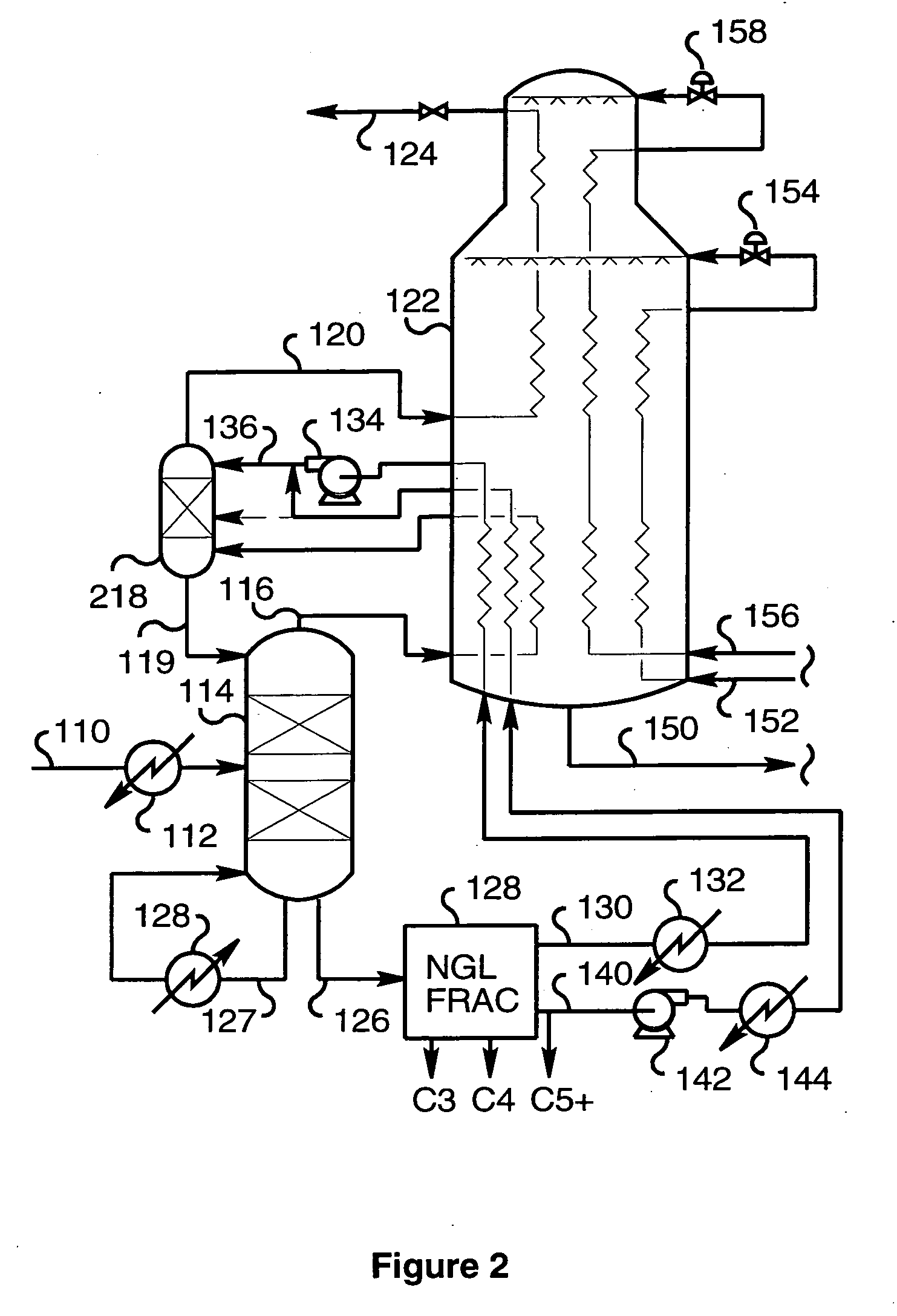

The separation of methane from an admixture (110) with ethane and higher hydrocarbons, especially natural gas, using a scrub column (114), in which the admixture is separated into a methane-rich overhead (116) that is partially condensed (122) to provide reflux to the column (114) and liquid methane-depleted bottoms liquid (126), is improved by providing additional reflux (136) derived from an ethane enriched stream (130) from fractionation (128) of the bottoms liquid. Preferably, absorber liquid (140) from the fractionation (128) also is introduced into the scrub column. The vapor fraction (120) remaining after partial condensation can be liquefied (122) to provide LNG product (124).

Owner:AIR PROD & CHEM INC

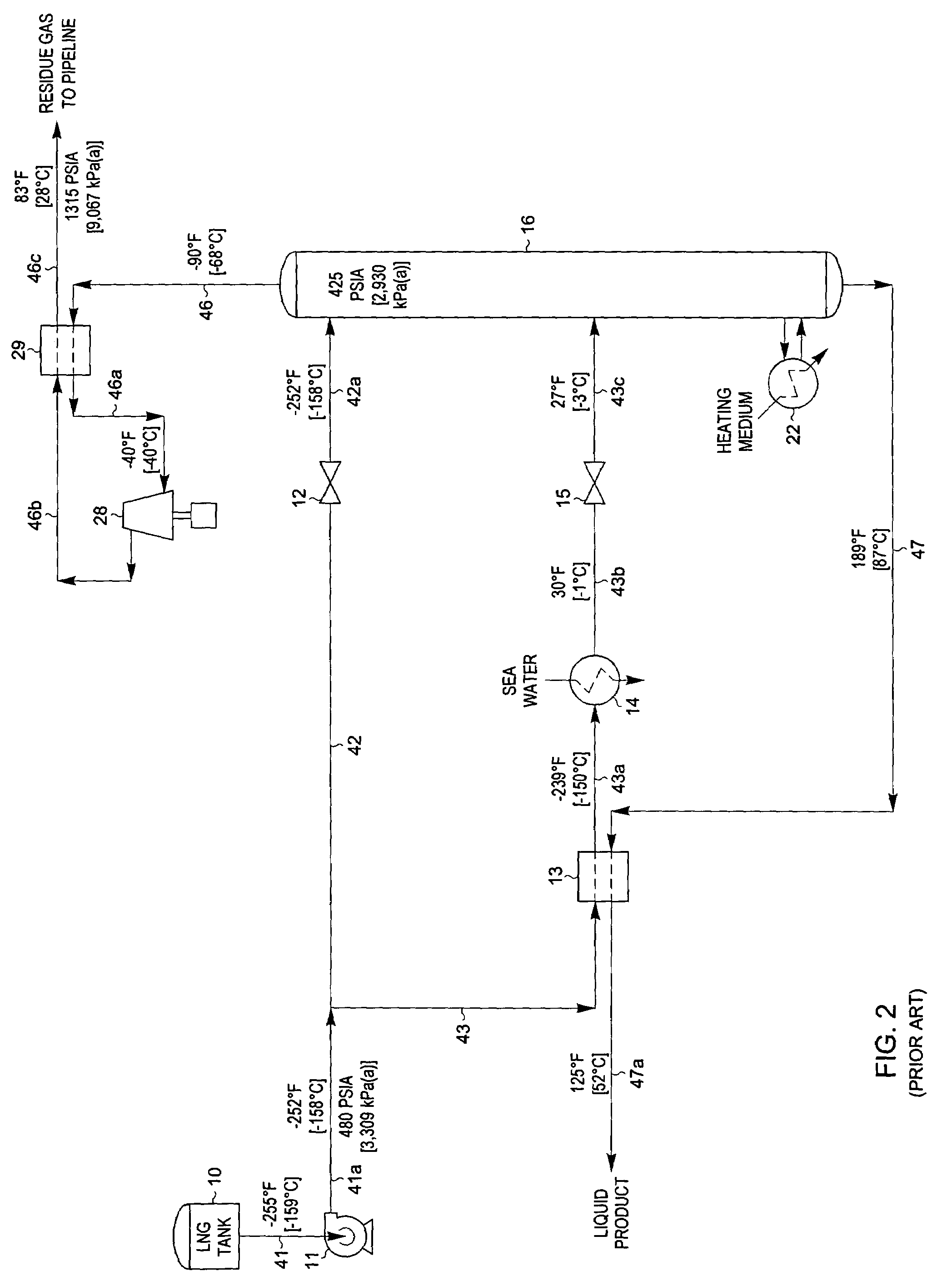

Liquefied natural gas processing

Owner:UOP LLC +1

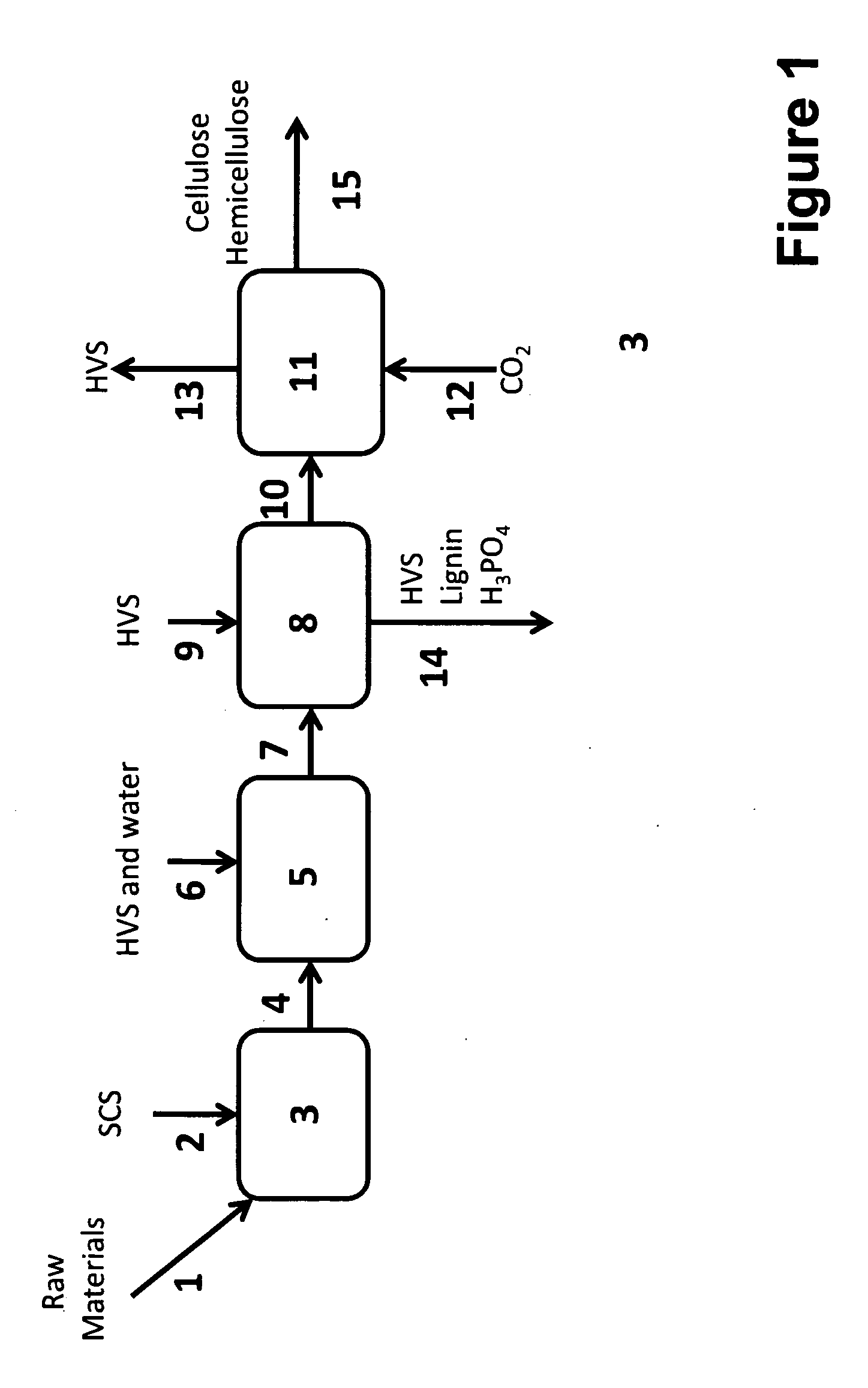

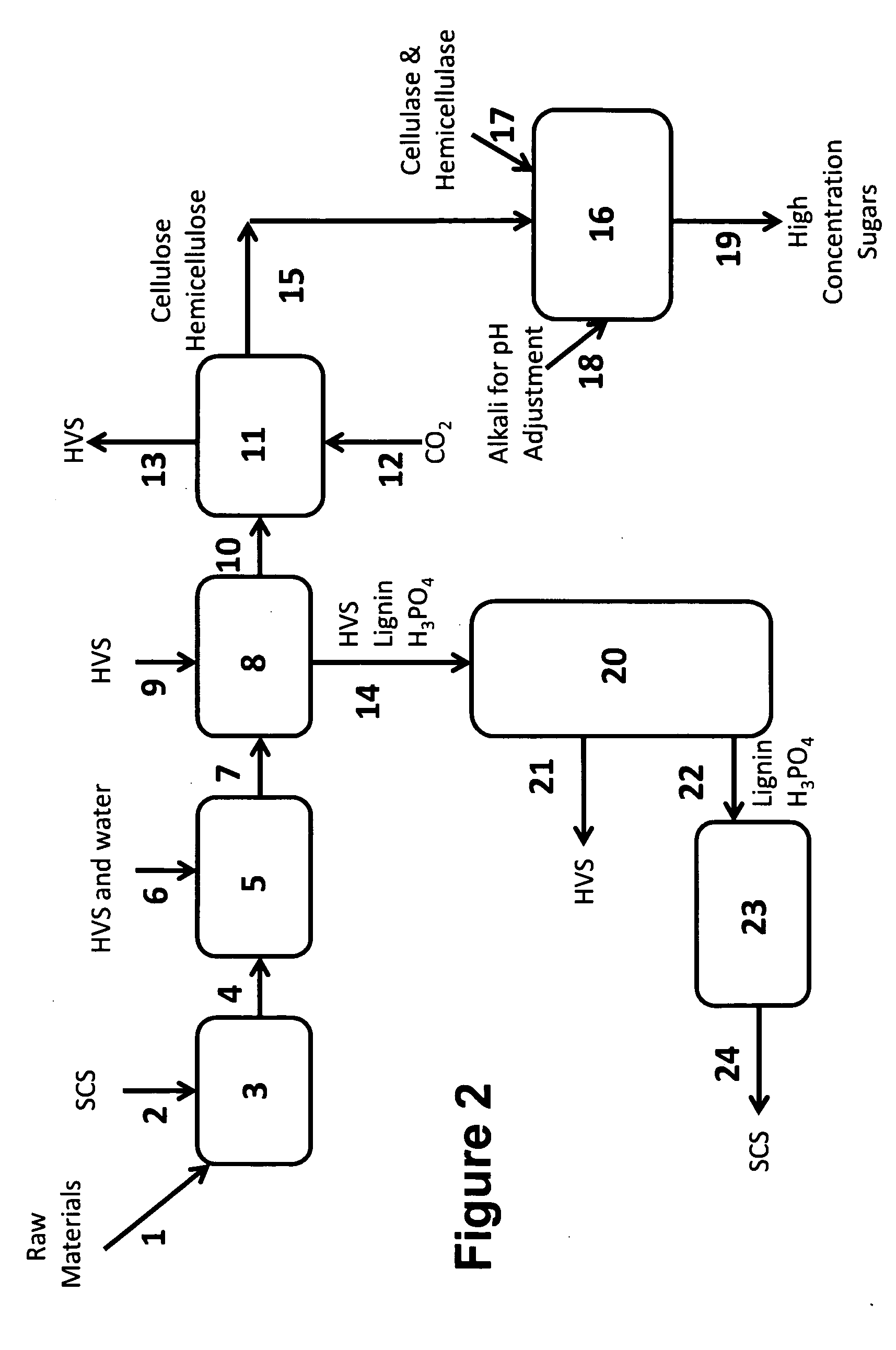

Method and apparatus for lignocellulose pretreatment using a super-cellulose-solvent and highly volatile solvents

InactiveUS20090229599A1Overcome shortcomingReduce solvent usagePressurized chemical processBiofuelsAlcoholGram

Embodiments of the present invention overcome the well-known recalcitrance of lignocellulosic biomass in an economically viable manner. A process and a system are provided for the efficient fractionation of lignocellulosic biomass into cellulose, hemicellulose, and lignin. The cellulose and hemicellulose thus obtained are highly amorphous and can be readily converted into highly concentrated mixtures of five and six carbon sugars using known methods. Typical yields of sugars exceed 100 grams of sugars per liter of sugar solution. Other products, such as alcohols, can easily be prepared according to methods of the invention. The modest process conditions and low solvent / solid ratios of some embodiments of the invention require relatively low capital and processing costs.

Owner:VIRGINIA TECH INTPROP INC

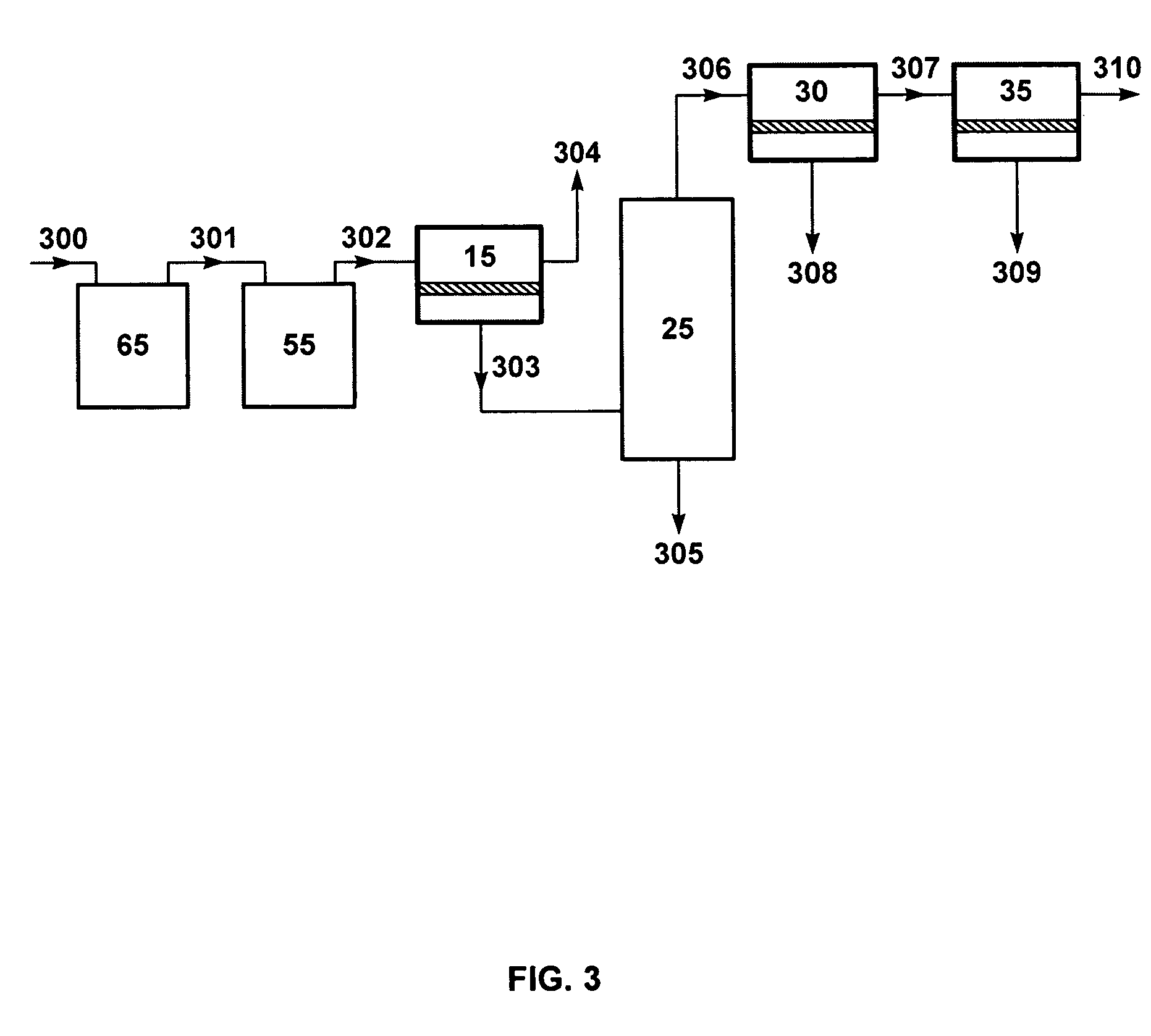

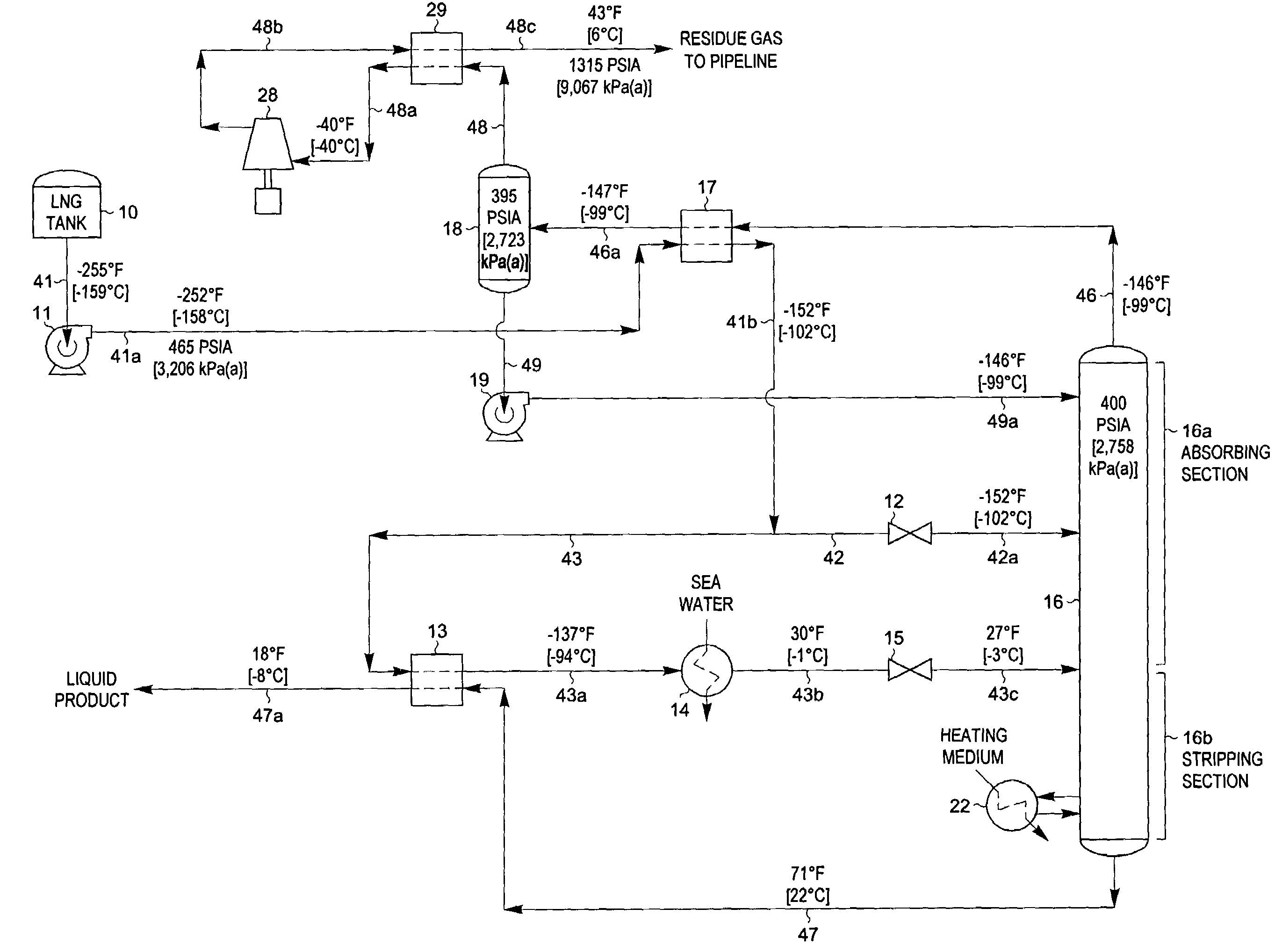

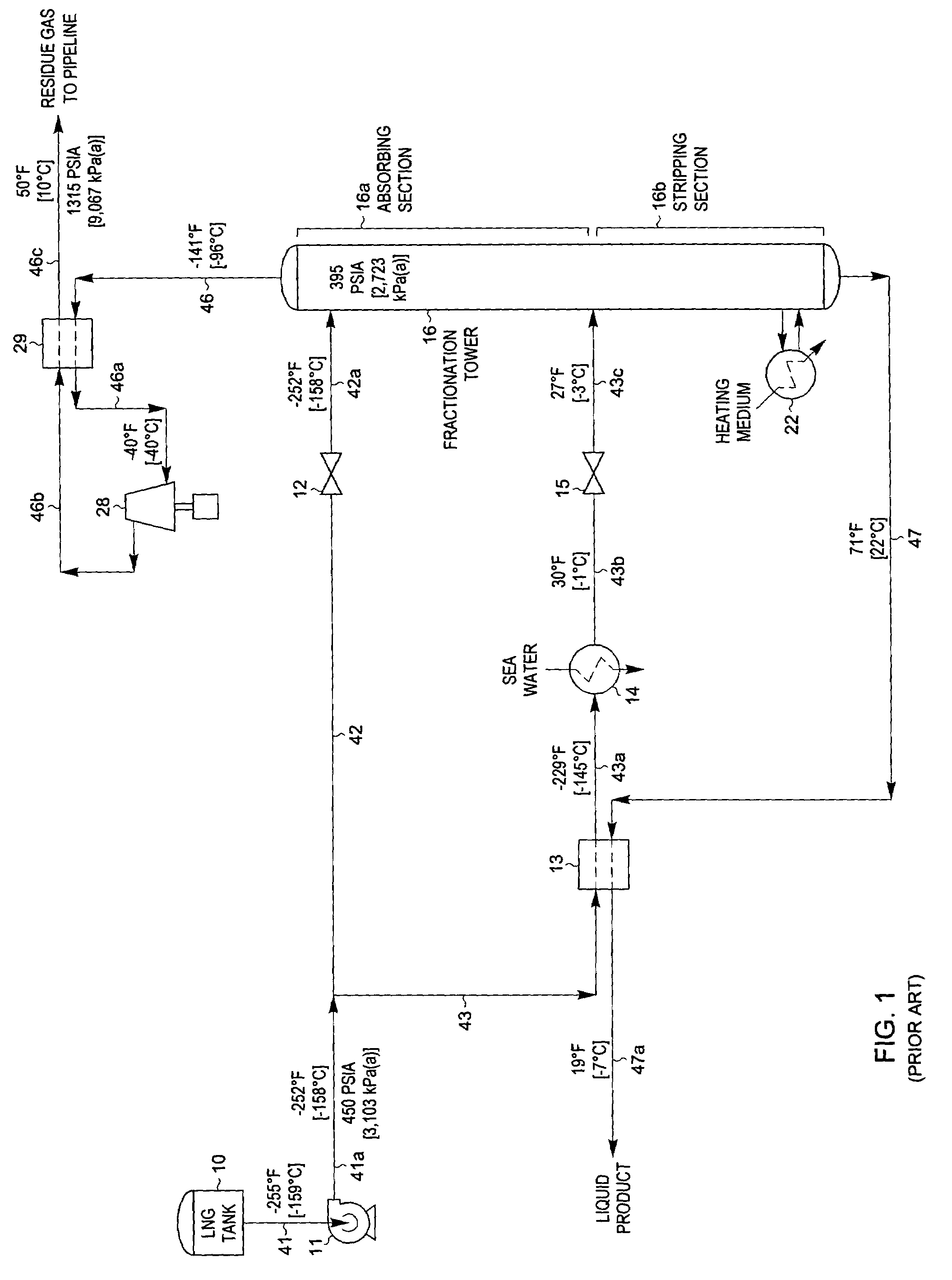

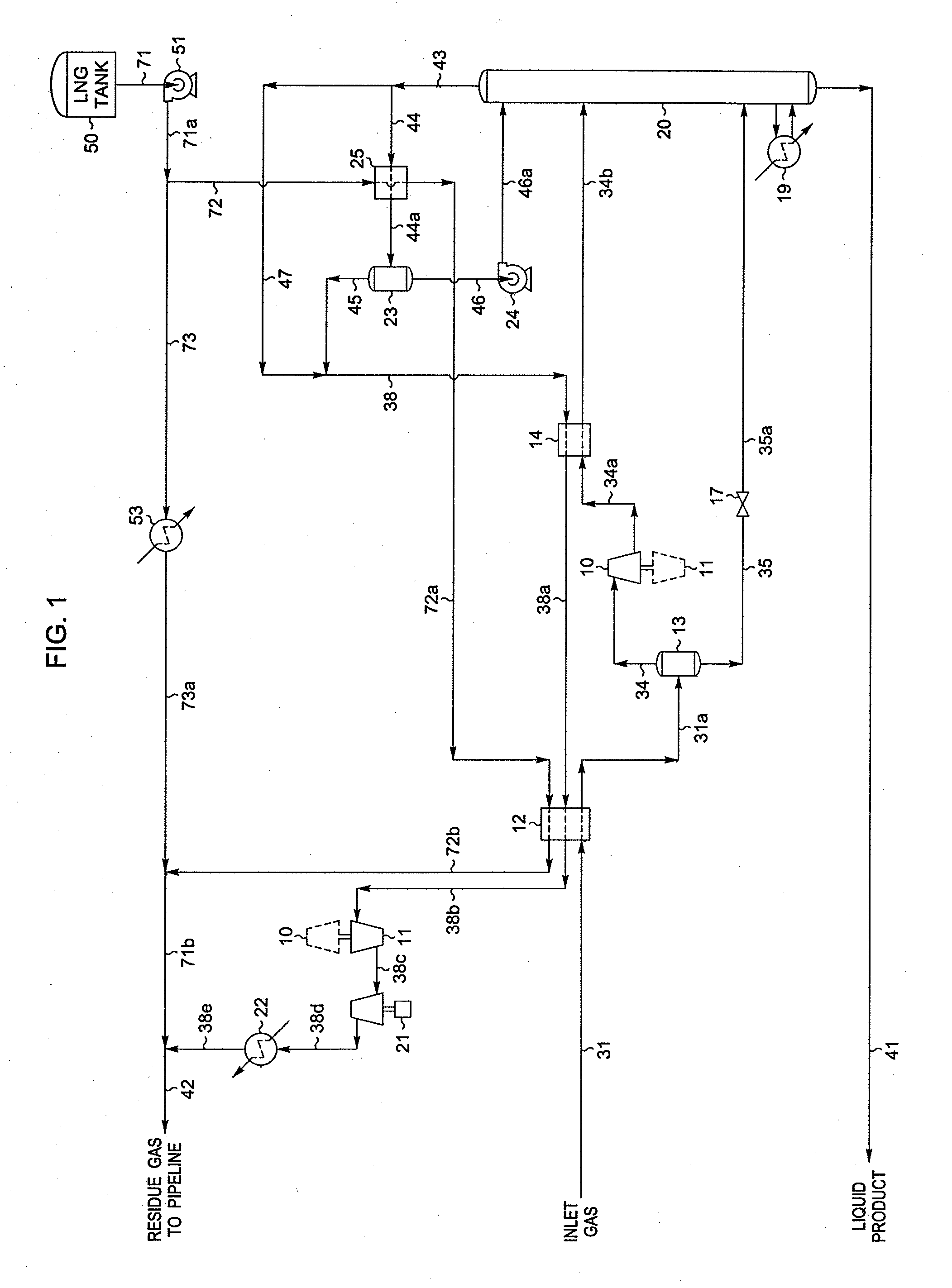

Liquefied Natural Gas and Hydrocarbon Gas Processing

A process for the recovery of ethane, ethylene, propane, propylene, and heavier hydrocarbons from a liquefied natural gas (LNG) stream and a hydrocarbon gas stream is disclosed. The LNG feed stream is divided into two portions. The first portion is supplied to a fractionation column at a first upper mid-column feed point. The second portion is directed in heat exchange relation with a first portion of a warmer distillation stream rising from the fractionation stages of the column, whereby the LNG feed stream is partially heated and the distillation stream is totally condensed. The condensed distillation stream is divided into a “lean” LNG stream and a reflux stream, whereupon the reflux stream is supplied to the column at a top column feed position. The second portion of the LNG feed stream is heated further to partially or totally vaporize it and thereafter supplied to the column at a first lower mid-column feed position. The gas stream is divided into two portions. The second portion is expanded to the operating pressure of the column, then both portions are directed in heat exchange relation with the lean LNG stream and the second portion of the warmer distillation stream, whereby both portions of the gas stream are cooled, the lean LNG stream is vaporized, and the second portion of the distillation stream is heated. The first portion of the gas stream, which has been cooled to substantial condensation, is supplied to the column at a second upper mid-column feed point, and the second portion is supplied to the column at a second lower mid-column feed point. The quantities and temperatures of the feeds to the column are effective to maintain the column overhead temperature at a temperature whereby the major portion of the desired components is recovered in the bottom liquid product from the column.

Owner:ORTLOFF ENGINEERS

Method of producing fuel oil by coal tar hydrogenation modifying

ActiveCN1903994AReduce temperature riseReduce coking rateTreatment with hydrotreatment processesGasoline stabilisationLow nitrogenSulfur

The present invention relates to a method for producing fuel oil by utilizing coal tar. It is characterized by that said method includes the following steps: after the whole coal tar in which the moisture and ash are removed and diluting oil are mixed according to a certain mixing ratio, making the obtained mixture be successively passed through a shallow hydrogenation unit with hydrogenation protecting agent and prehydrogenation catalyst and a deep hydrogenation unit with main hydrogenation catalyst, then making the product obtained after deep hydrogenation undergo the processes of high-pressure separation, low-pressure separation and fractionation so as to obtain light-oil fraction, medium-oil fraction and tail-oil fraction, namely obtain low-sulfur low-nitrogen fuel oil and light oil product.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

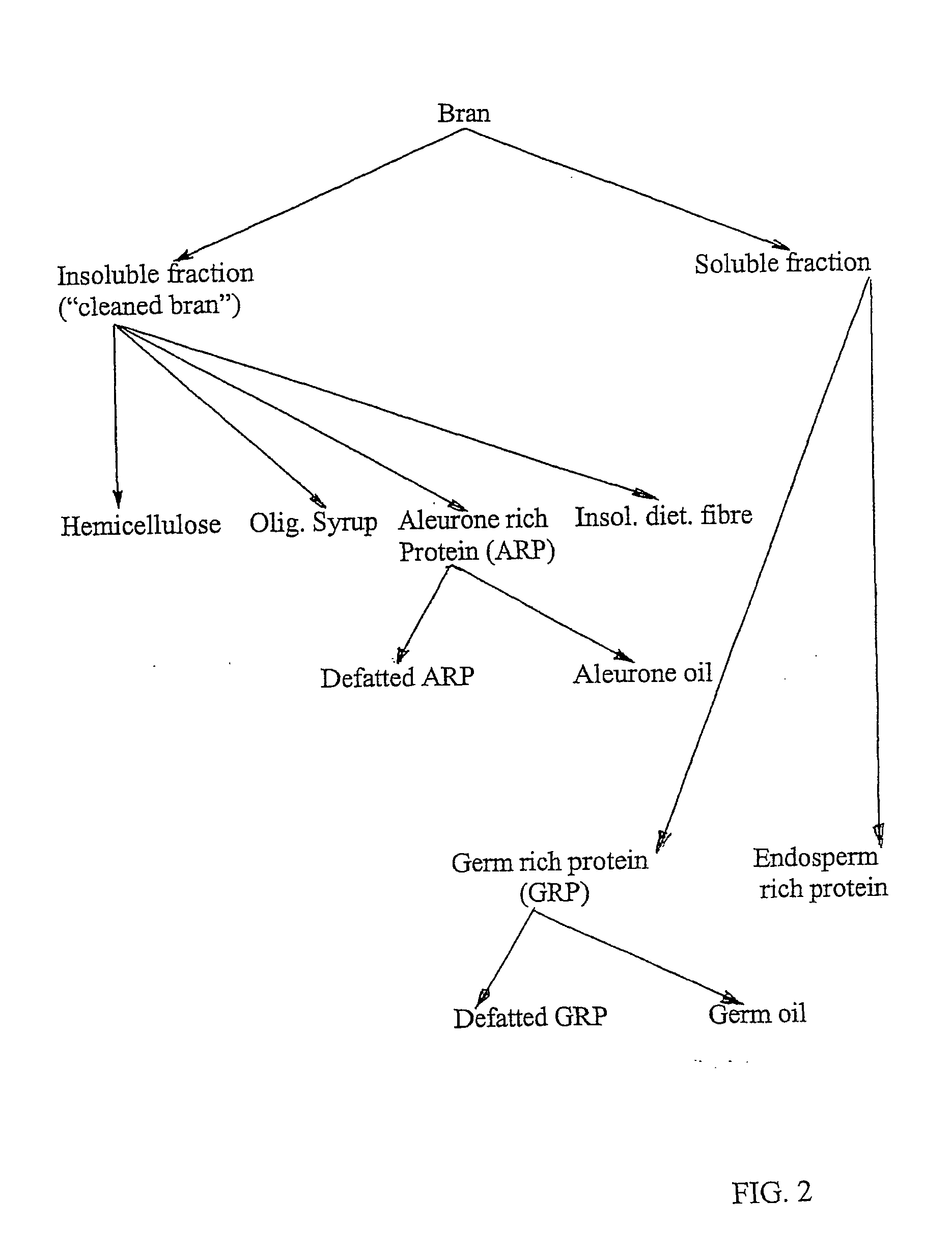

Process for the fractionation of cereal brans

InactiveUS20050089602A1Minimal contaminationImprove efficiencyTea extractionProtein composition from vegetable seedsUltrafiltrationHordeum vulgare

A process for the fractionation of valuable fractions from cereal brans (e.g. wheat, barley and oat brans, and rice polish) is described. In particular, this invention describes a two step process, in which the said bran is first subjected to a combination of enzymatic treatment and wet milling, followed by sequential centrifugation and ultrafiltration, which aims at physically separating the main bran factions, i.e. insoluble phase (pericarp and aleurone layer), germ-rich fraction, residual endosperm fraction and soluble sugars. A second step consists of fractionating cereal brans substantially free of soluble compounds, hence insoluble phase from the above-mentioned first step, by enzymatic treatment with xylanases and / or beta-glucanase and wet milling, followed by sequential centrifugation and ultrafiltration, which aims at physically separating the main fractions, i.e. insoluble phase (remaining cell wall components), protein-rich fraction, soluble hemicellulose and oligosaccharide, and therefore maximizes the extraction rate of valuable cell wall components and aleurone cells from previously cleaned bran.

Owner:LANTMANNEN OATS AB

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com