Patents

Literature

6630 results about "Propane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Propane (/ˈproʊpeɪn/) is a three-carbon alkane with the molecular formula C₃H₈. It is a gas at standard temperature and pressure, but compressible to a transportable liquid. A by-product of natural gas processing and petroleum refining, it is commonly used as a fuel. Propane is one of a group of liquefied petroleum gases (LP gases). The others include butane, propylene, butadiene, butylene, isobutylene, and mixtures thereof.

Water-swellable copolymers and articles and coatings made therefrom

Owner:TYCO HEALTHCARE GRP LP

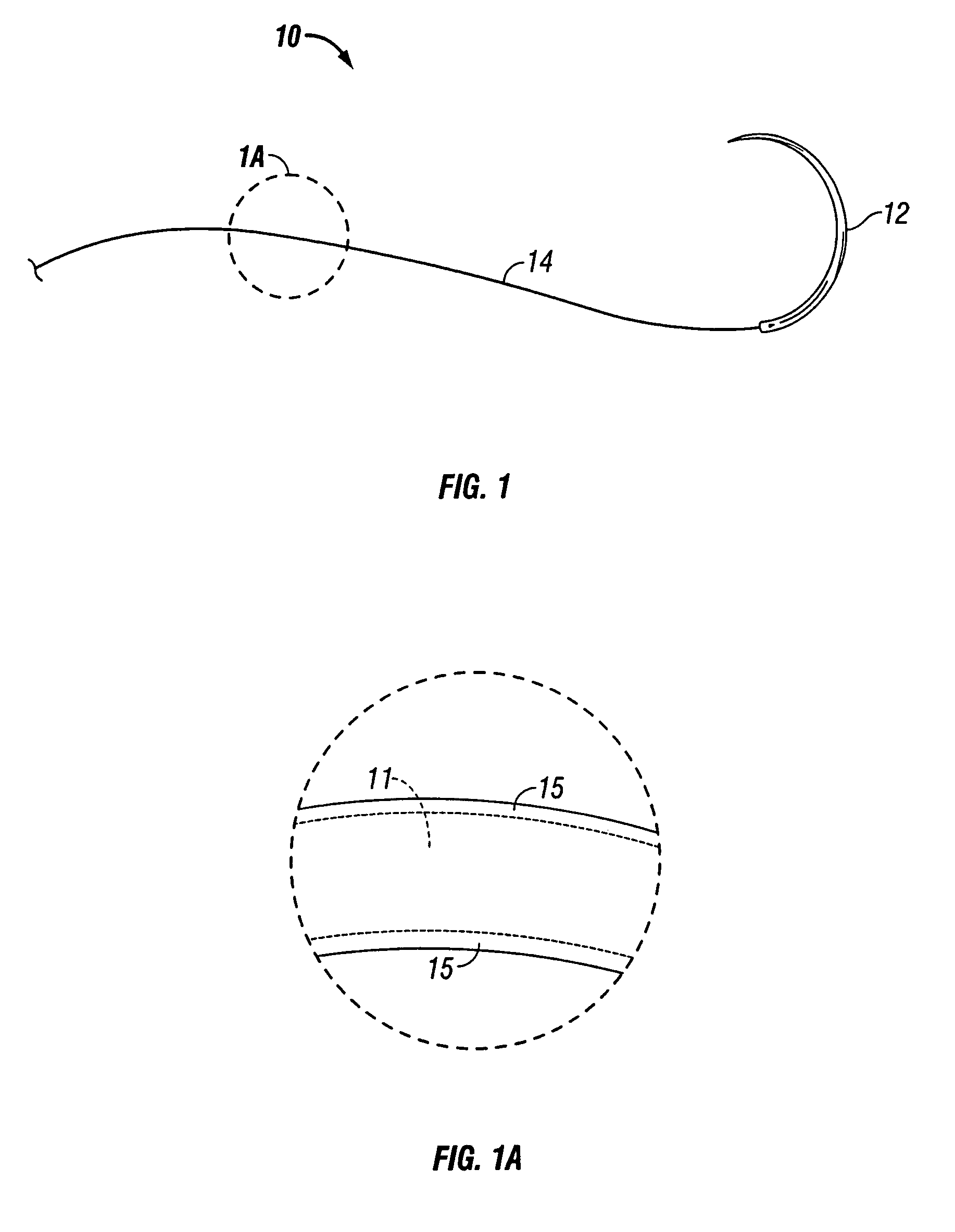

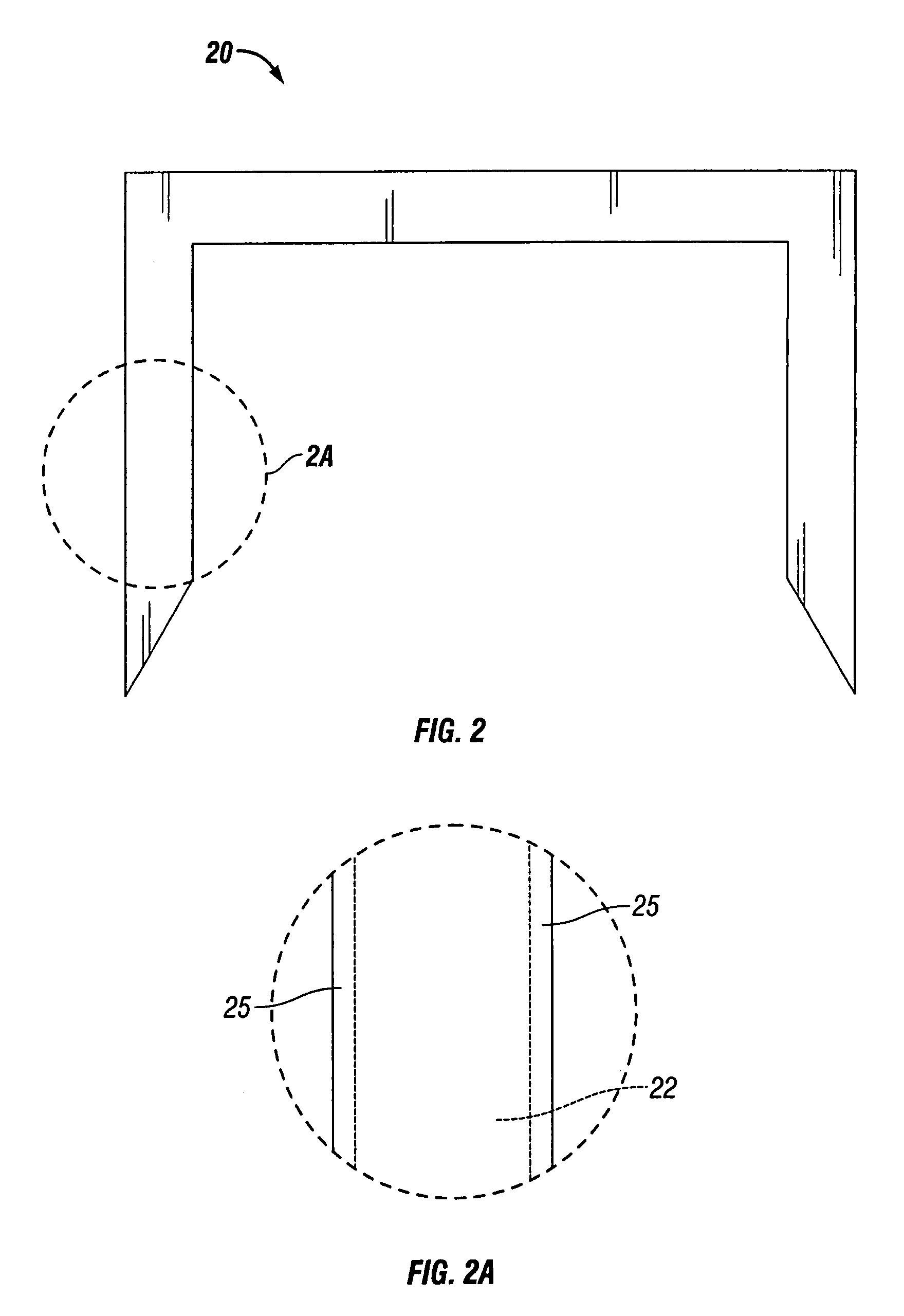

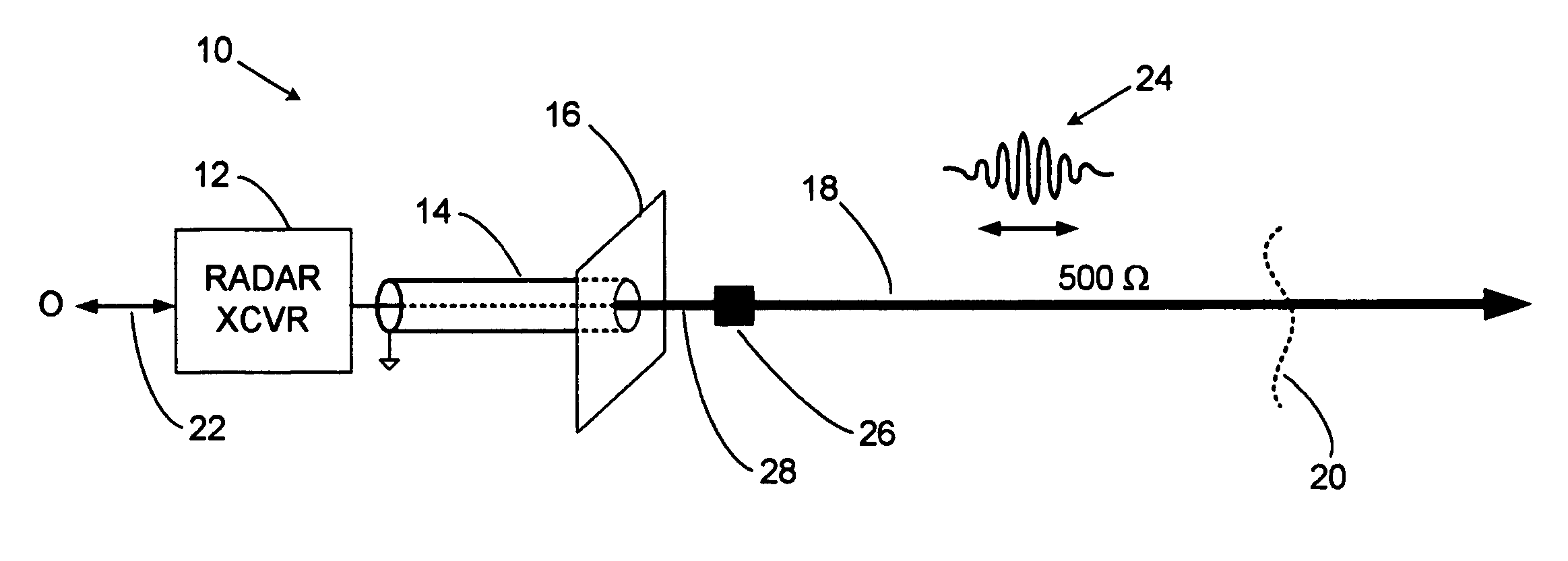

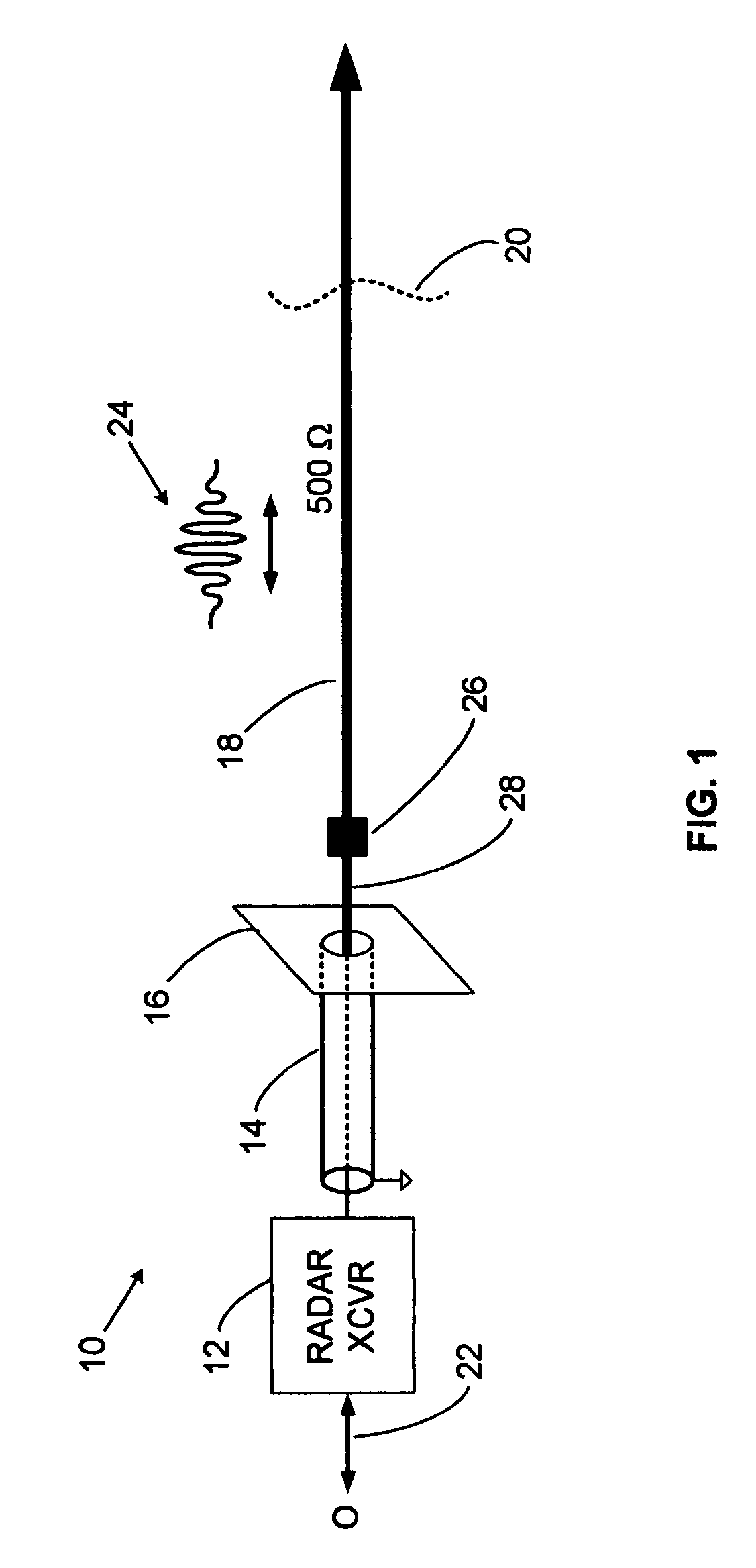

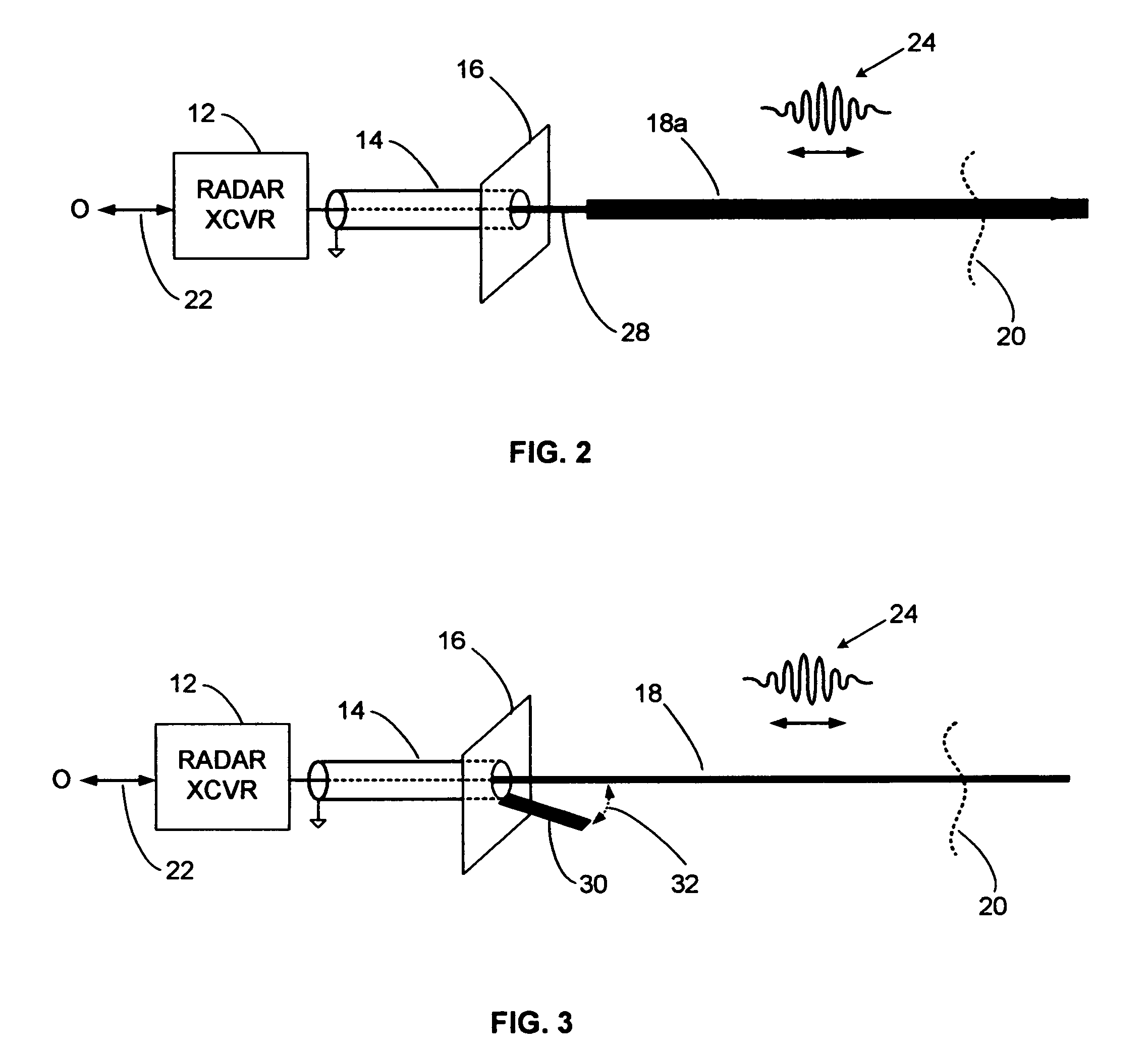

Reflection free launcher for electromagnetic guide wire

InactiveUS7345623B2Easy to measureSmall sizeMachines/enginesLevel indicatorsEngineeringImpedance matching

Guided wave radar (GWR) pulses are launched onto an electromagnetic guide wire using a compact launcher that includes an impedance matching element. The impedance matching element produces reflections that cancel launcher reflections. Short range echoes can be accurately detected after impedance matching. GWR operation in small tanks and in tanks containing low dielectric constant materials, such as propane, can be enhanced with the compact impedance-matched launcher.

Owner:MCEWAN TECH

Method for producing fluorinated organic compounds

ActiveUS20070197842A1Preparation by hydrogen halide split-offPreparation by halogen replacementPtru catalystDistillation

Disclosed are processes for the production of fluorinated olefins, preferably adapted to commercialization of CF3CF═CH2 (1234yf). Three steps may be used in preferred embodiments in which a feedstock such as CCl2═CClCH2Cl (which may be purchased or synthesized from 1,2,3-trichloropropane) is fluorinated (preferably with HF in gas-phase in the presence of a catalyst) to synthesize a compound such as CF3CCl═CH2, preferably in a 80-96% selectivity. The CF3CCl═CH2 is preferably converted to CF3CFClCH3 (244-isomer) using a SbCl5 as the catalyst which is then transformed selectively to 1234yf, preferably in a gas-phase catalytic reaction using activated carbon as the catalyst. For the first step, a mixture of Cr2O3 and FeCl3 / C is preferably used as the catalyst to achieve high selectivity to CF3CCl═CH2 (96%). In the second step, SbCl5 / C is preferably used as the selective catalyst for transforming 1233xf to 244-isomer, CF3CFClCH3. The intermediates are preferably isolated and purified by distillation and used in the next step without further purification, preferably to a purity level of greater than about 95%.

Owner:HONEYWELL INT INC

Tobacco processing

InactiveUS6895974B2Lower Level RequirementsInhibition formationTobacco preparationTobacco treatmentTobacco-specific nitrosaminesEngineering

Owner:R J REYNOLDS TOBACCO COMPANY

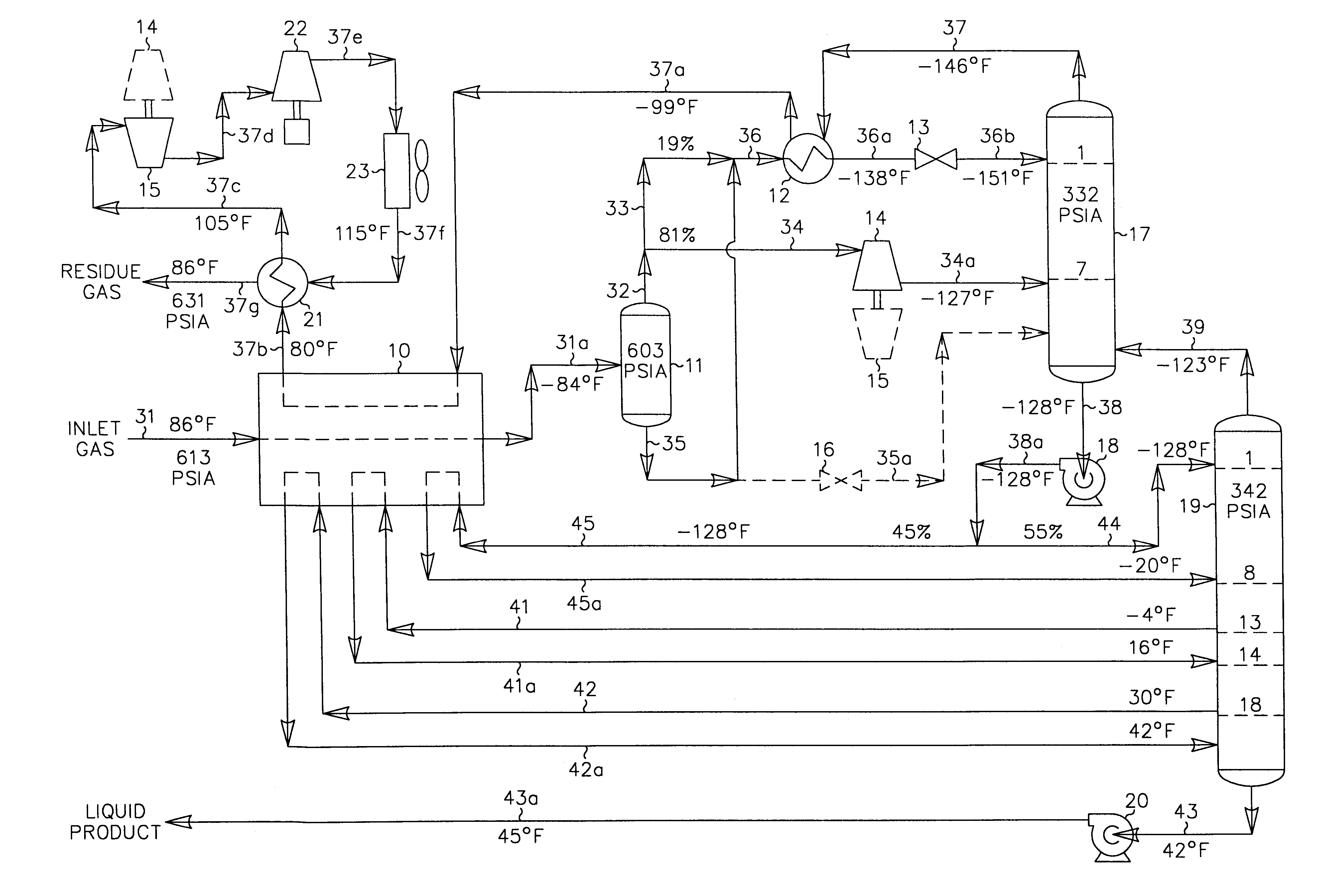

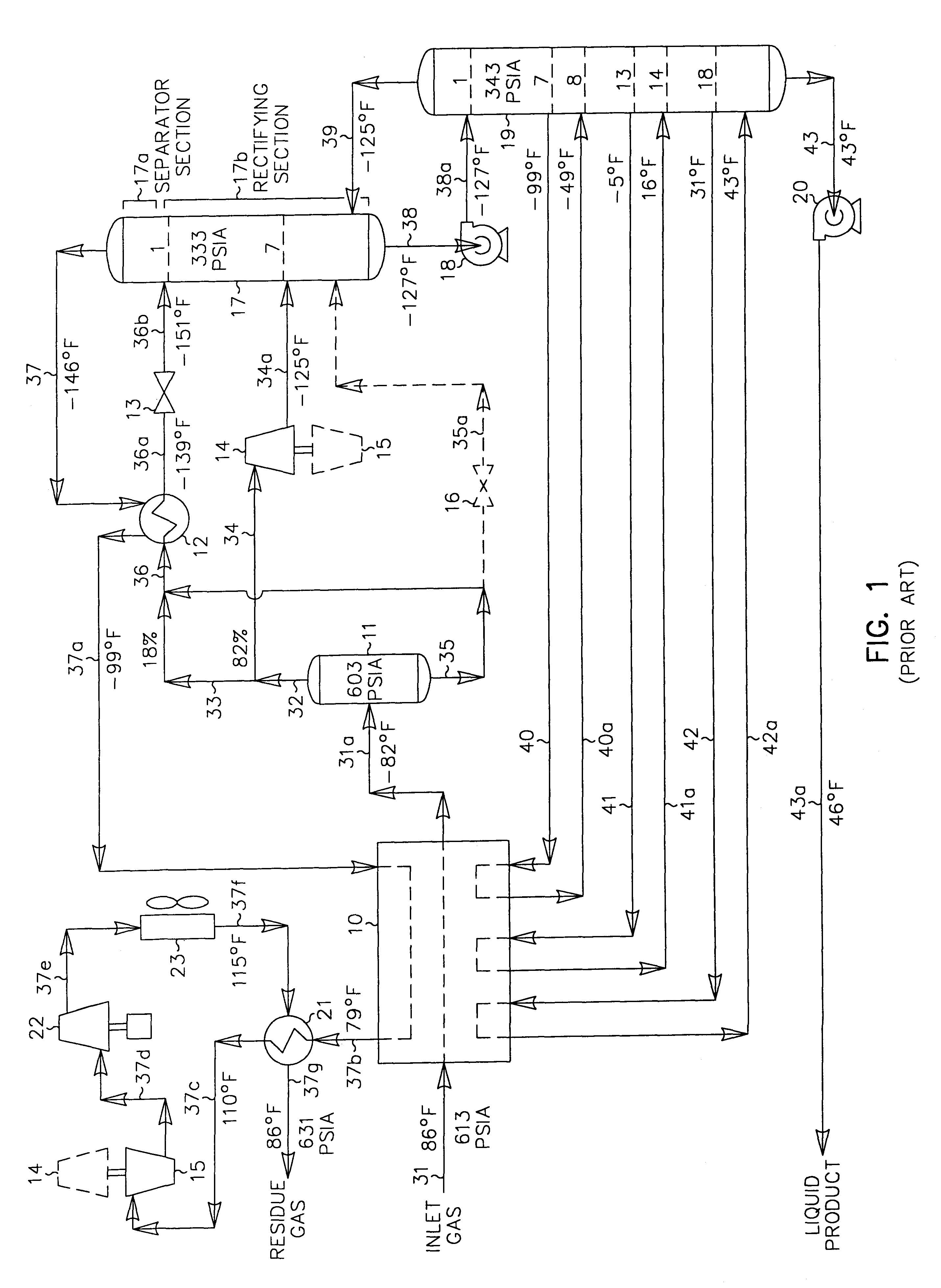

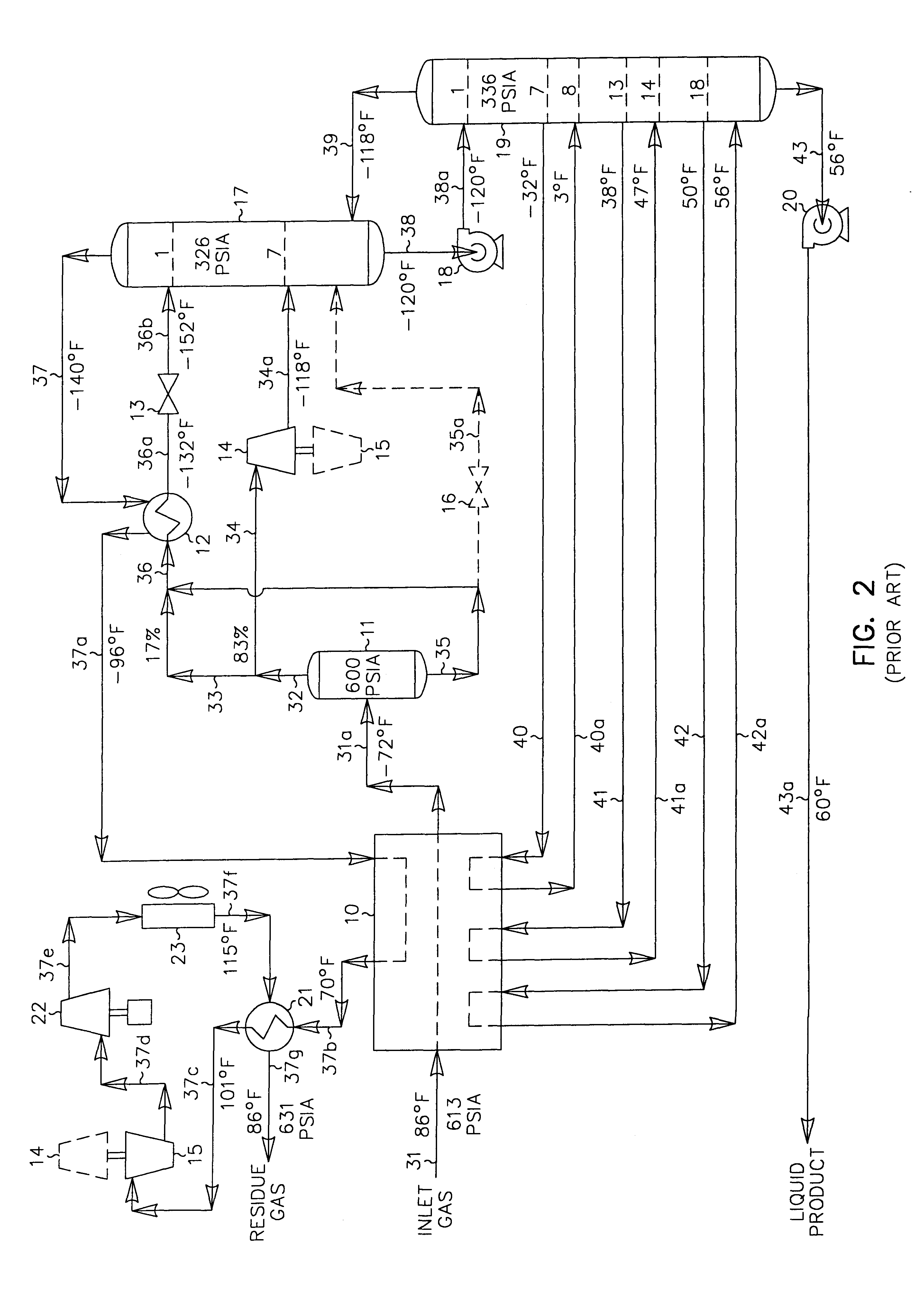

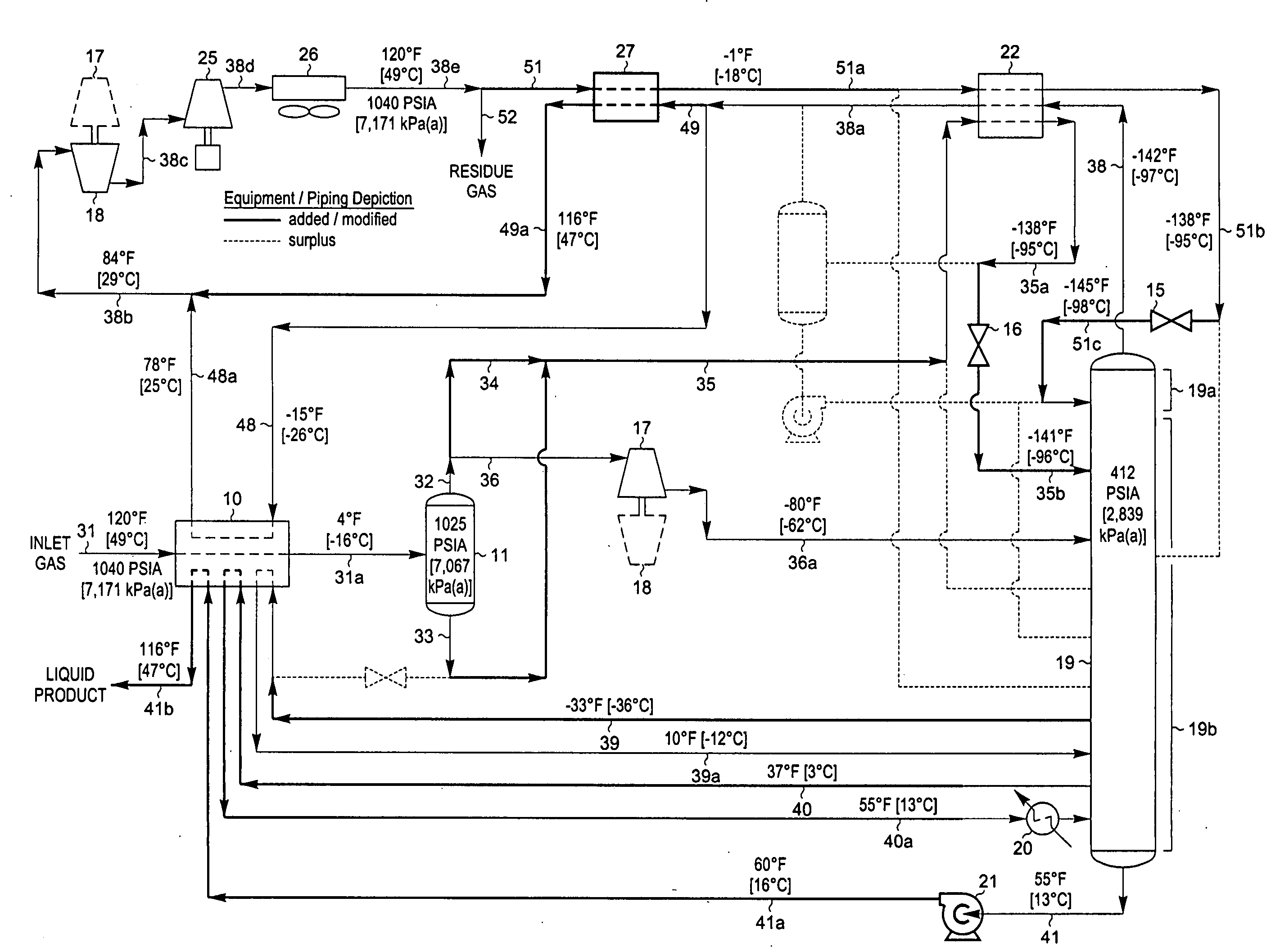

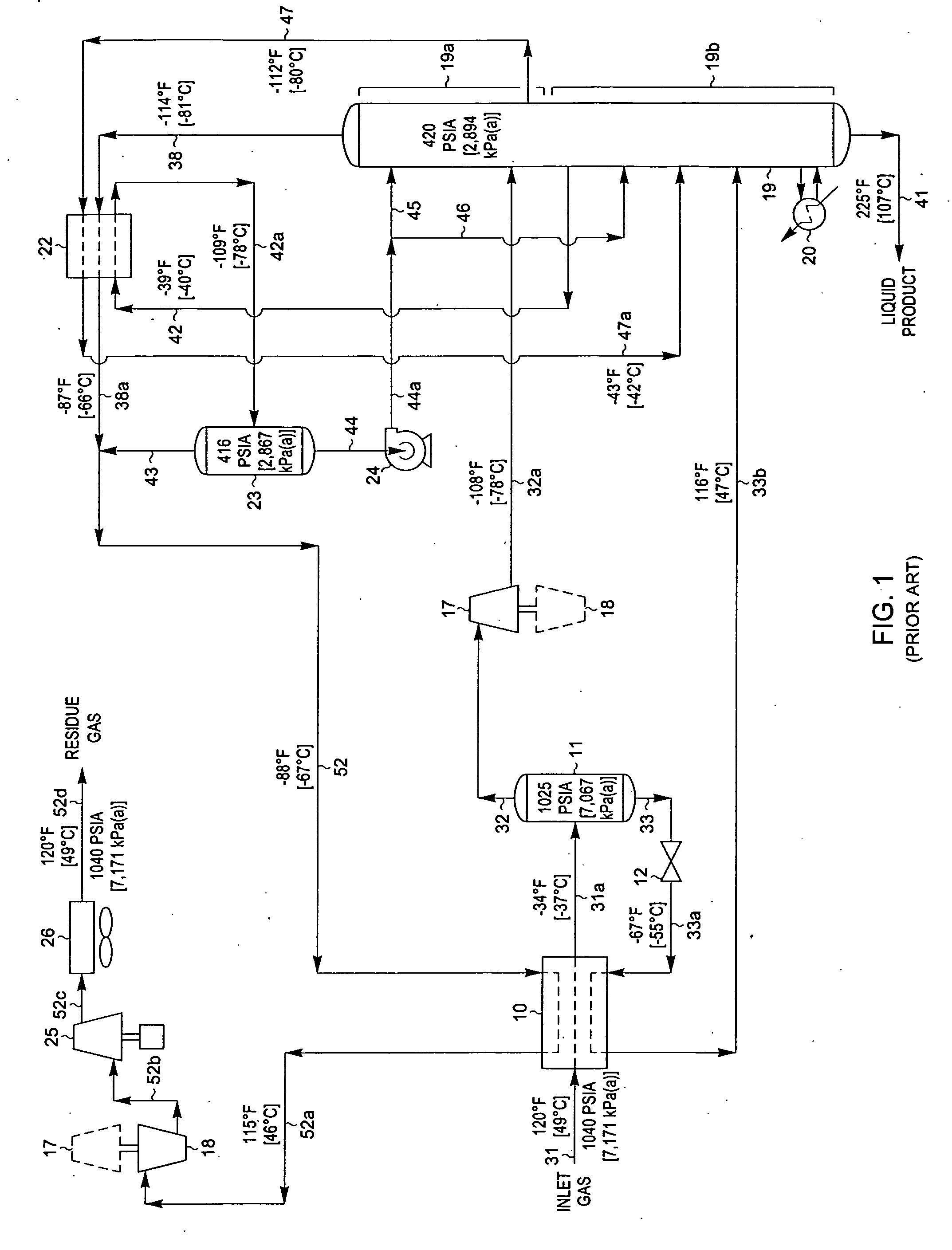

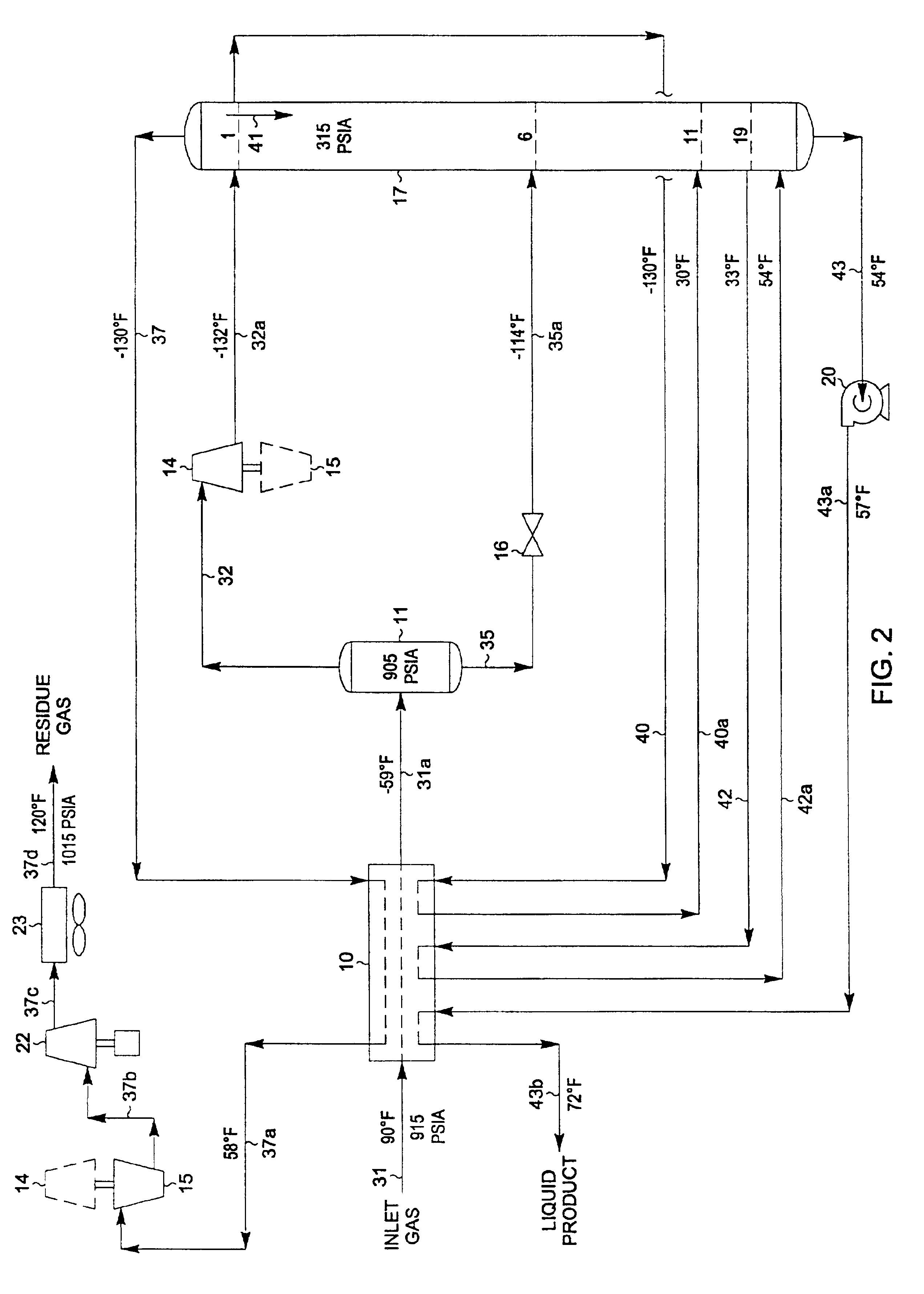

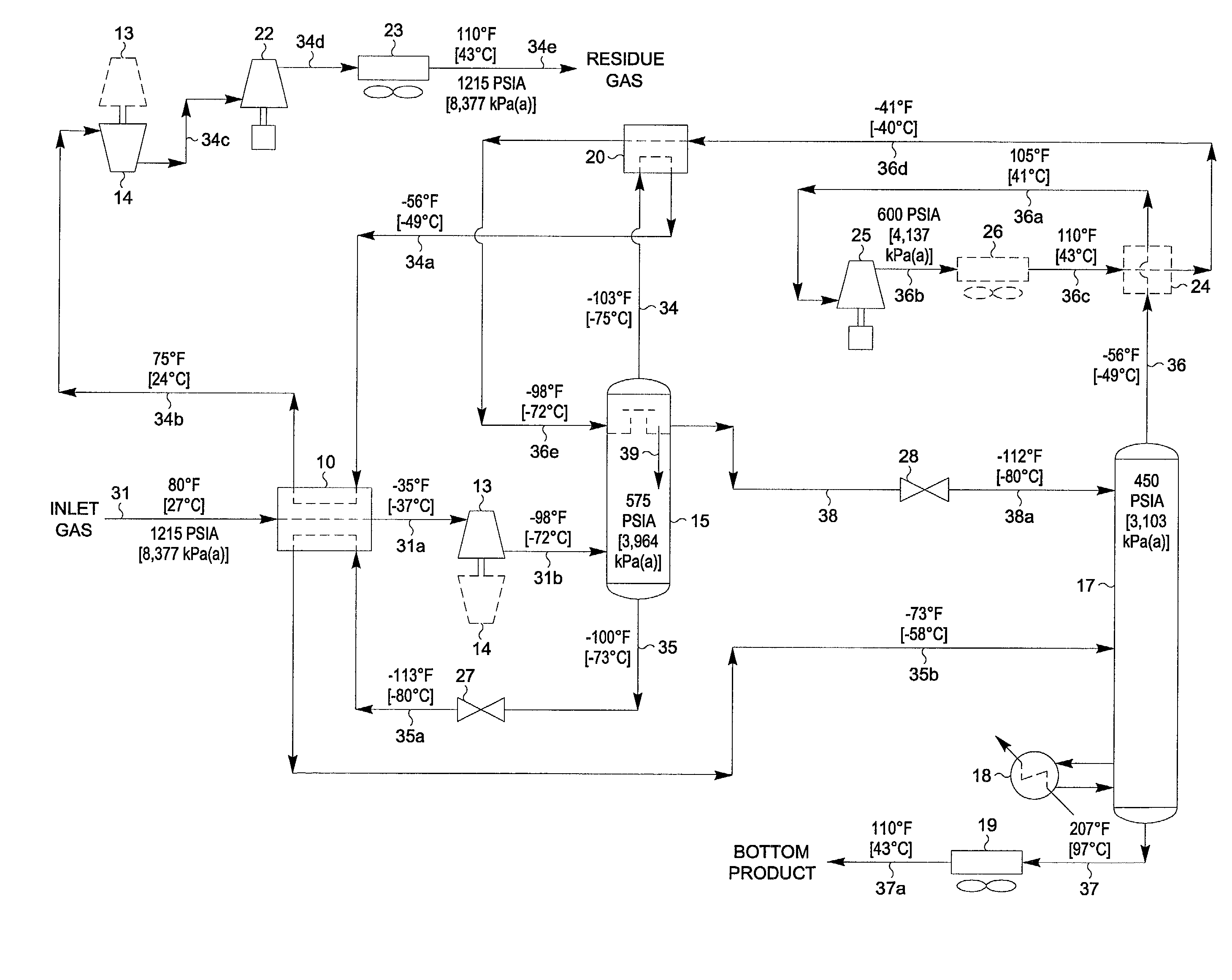

Hydrocarbon gas processing

A process for the recovery of ethane, ethylene, propane, propylene and heavier hydrocarbon components from a hydrocarbon gas stream is disclosed. In recent years, the preferred method of separating a hydrocarbon gas stream generally includes supplying at least portions of the gas stream to a fractionation tower having at least one reboiler, and often one or more side reboilers, to supply heat to the column by withdrawing and heating some of the tower liquids to produce stripping vapors that separate the more volatile components from the desired components. The reboiler and side reboilers (if any) are typically integrated into the feed stream cooling scheme to provide at least a portion of the refrigeration needed to condense the desired components for subsequent fractionation in the distillation column. In the process disclosed, the tower reboiling scheme is modified to use one or more tower liquid distillation streams from a point higher in the column than is used in the conventional reboiling scheme, providing colder stream(s) for the reboiler(s) that allow more effective cooling of the feed streams and thereby improve the efficiency with which the desired components are recovered. In addition, the tower liquid streams withdrawn from a higher point in the column contain larger quantities of the more volatile components, which when vaporized provide better stripping of undesirable components like carbon dioxide without reducing the recovery of the desired components. The heated distillation stream is returned to a lower point on the fractionation tower that is separated from the withdrawal point by at least one theoretical stage.

Owner:UOP LLC

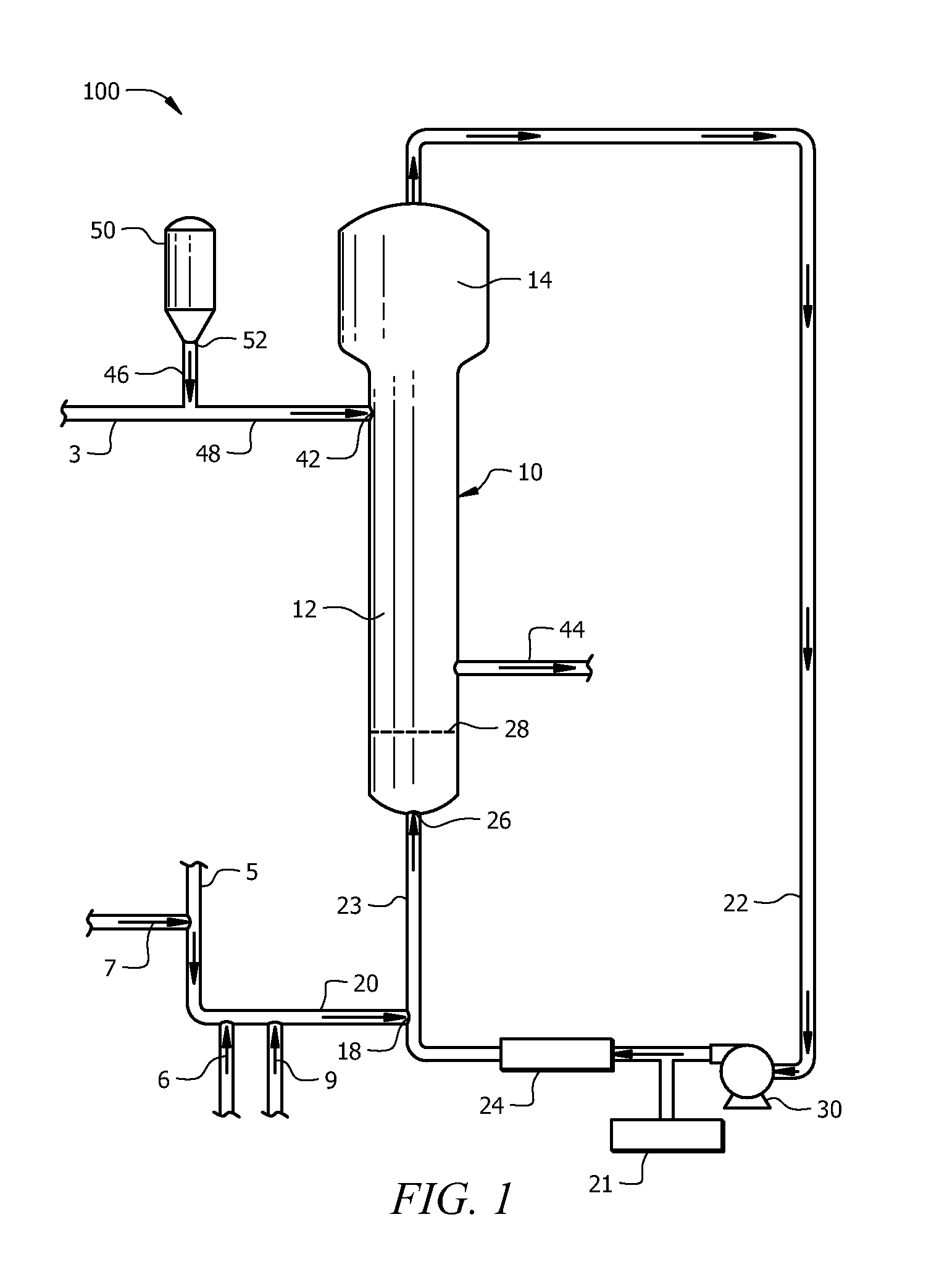

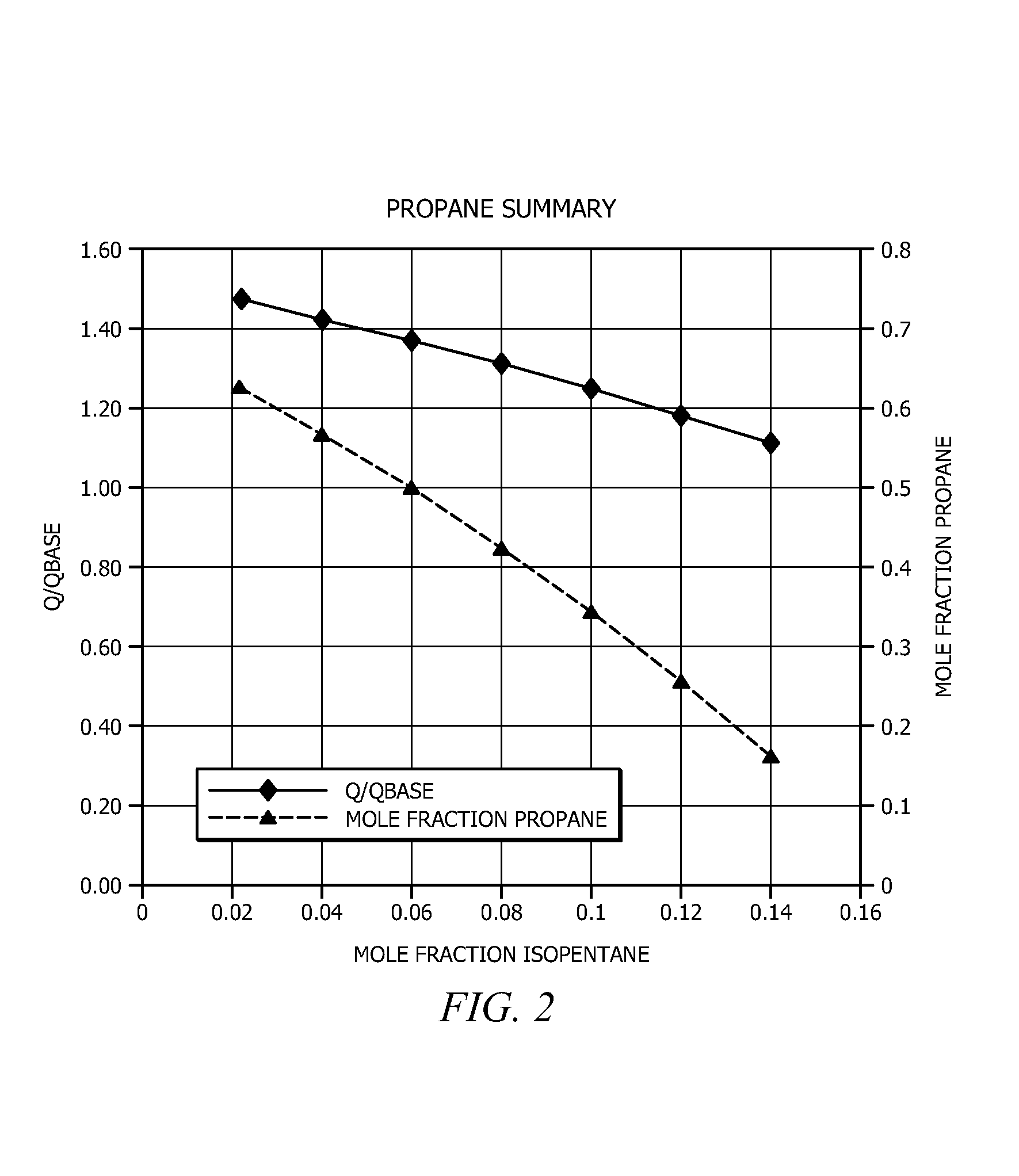

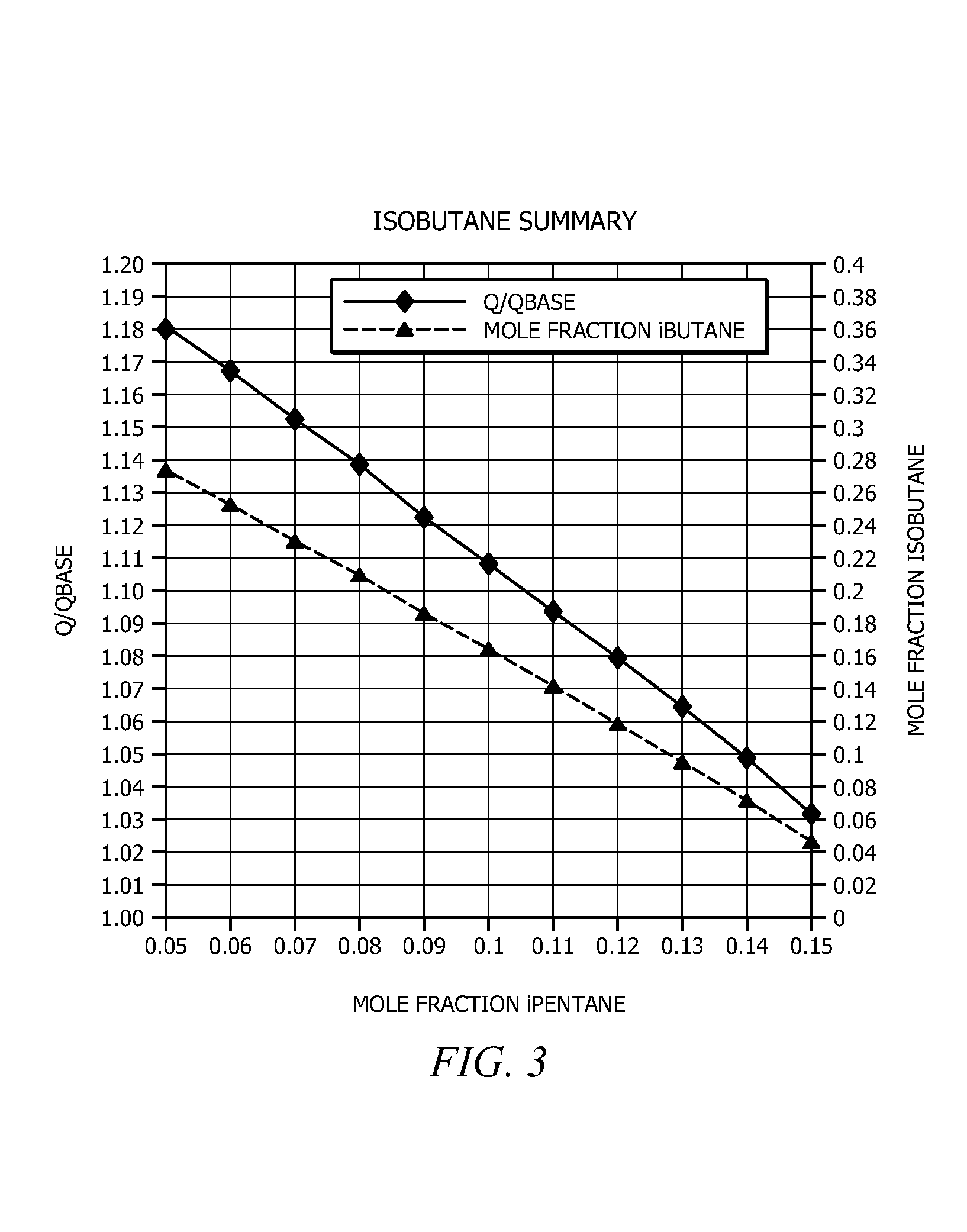

Method for operating a gas phase polymerization reactor

Disclosed herein is a method of operating a polymerization reactor for a polymerization reaction comprising modifying a recycle gas composition to increase the heat capacity of the recycle gas wherein the recycle gas composition is modified by reducing or eliminating the nitrogen concentration in the recycle gas. In an embodiment, the nitrogen concentration is reduced or eliminated by reducing or eliminating one or more nitrogen input sources to the polymerization reactor and replacing the nitrogen with an alternate inert fluid (a gas or liquid that is inert to the catalyst and reactants). The alternate inert fluid has a higher heat capacity and a higher molecular weight than nitrogen. In an embodiment, the nitrogen utilized to convey a catalyst into the polymerization reactor is replaced with an alternate inert fluid. In an embodiment, the alternate inert fluid is ethane, propane, isobutane, or combinations thereof.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

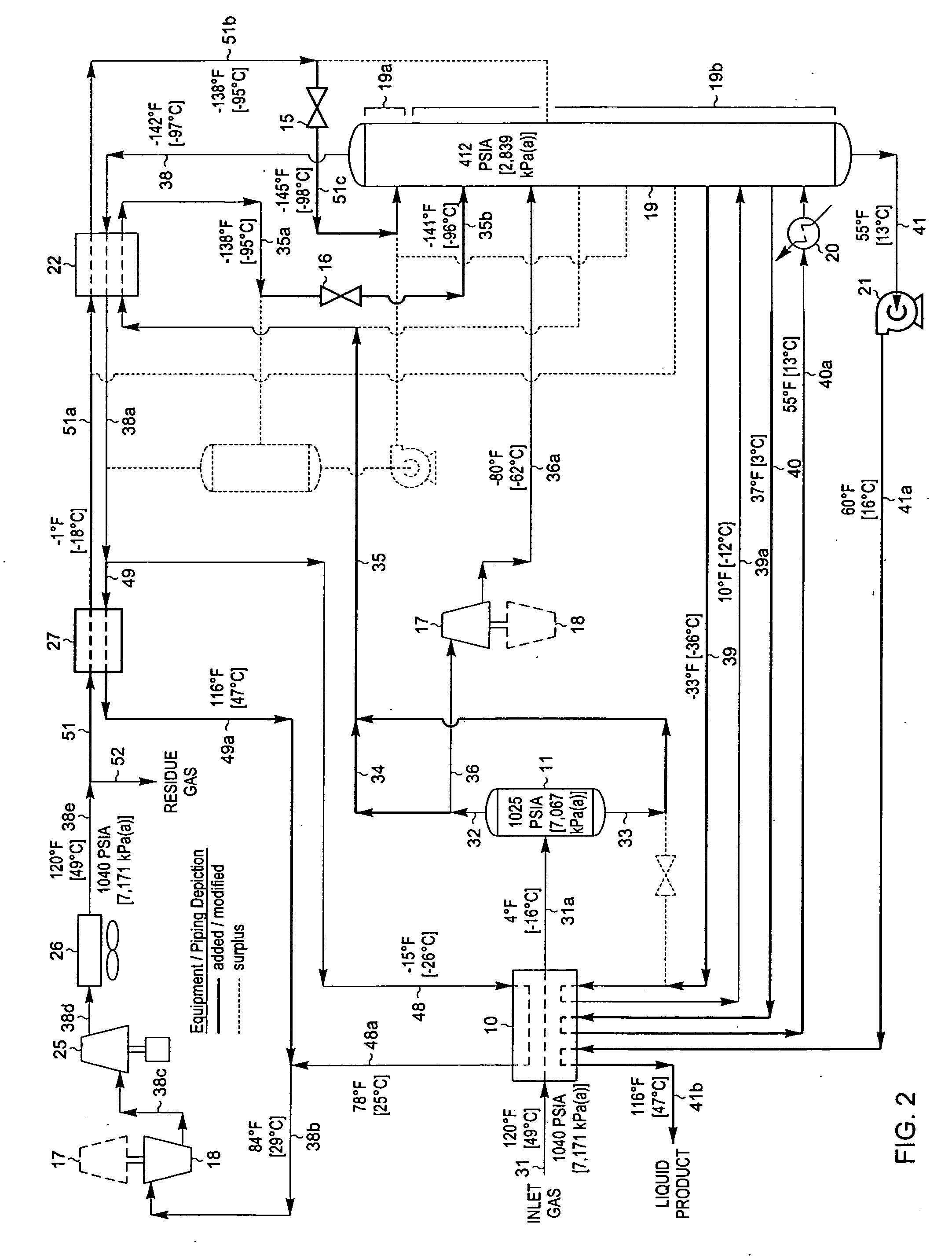

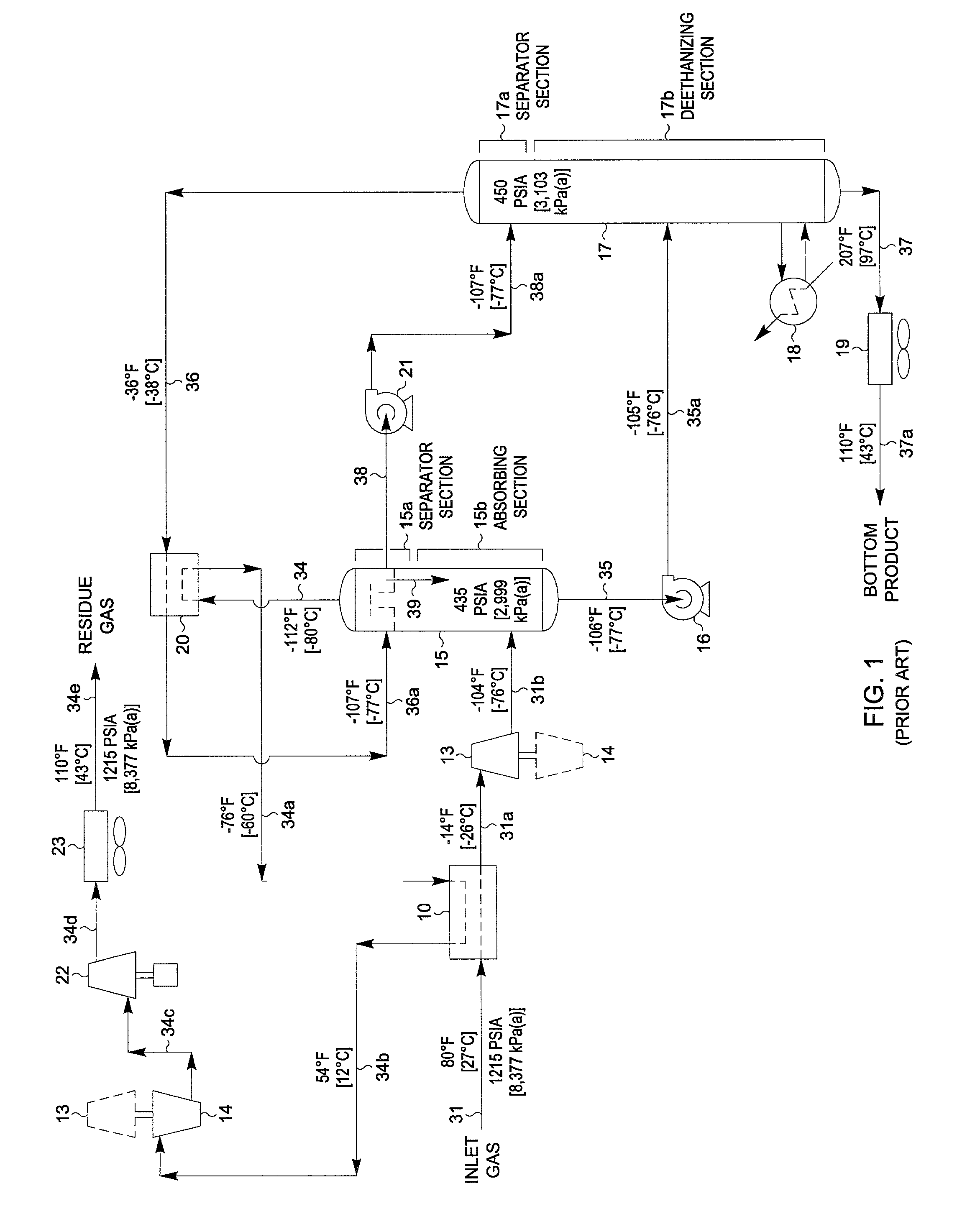

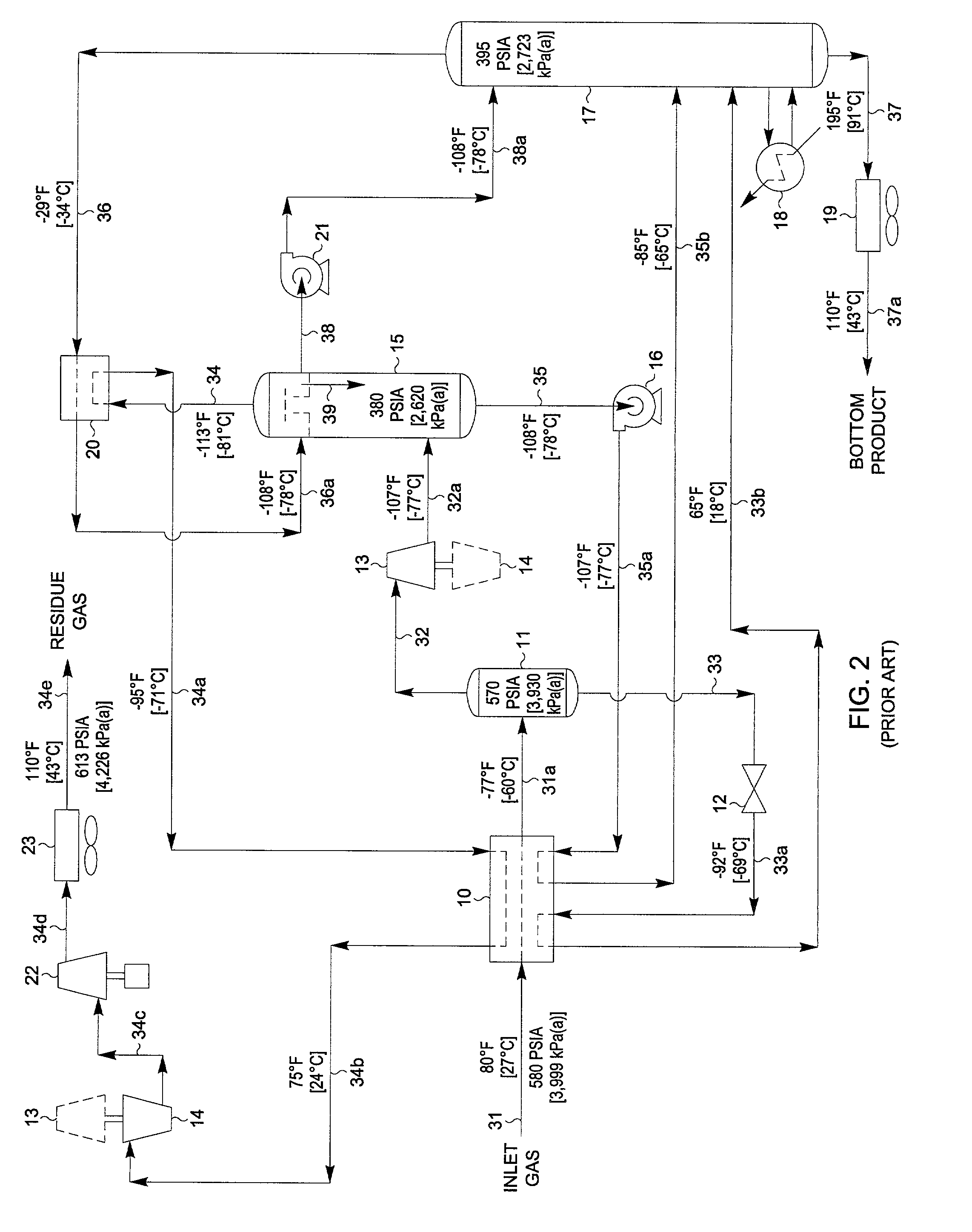

Hydrocarbon gas processing

ActiveUS20060283207A1Reduce the valueReduce investmentSolidificationLiquefactionFractionationFractionating column

A process for the recovery of ethane, ethylene, propane, propylene, and heavier hydrocarbon components from a hydrocarbon gas stream is disclosed. The stream is cooled and is thereafter expanded to the fractionation tower pressure and supplied to the fractionation tower at a lower mid-column feed position. A distillation stream is withdrawn from the column below the feed point of the stream and is then directed into heat exchange relation with the tower overhead vapor stream to cool the distillation stream and condense at least a part of it, forming a condensed stream. At least a portion of the condensed stream is directed to the fractionation tower at an upper mid-column feed position. A recycle stream is withdrawn from the tower overhead after it has been warmed and compressed. The compressed recycle stream is cooled sufficiently to substantially condense it, and is then expanded to the pressure of the fractionation tower and supplied to the tower at a top column feed position. The quantities and temperatures of the feeds to the fractionation tower are effective to maintain the overhead temperature of the fractionation tower at a temperature whereby the major portion of the desired components is recovered.

Owner:UOP LLC

Hydrocarbon gas processing

A process for the recovery of ethane, ethylene, propane, propylene and heavier hydrocarbon components from a hydrocarbon gas stream is disclosed. In recent years, the preferred method of separating a hydrocarbon gas stream generally includes supplying at least portions of the gas stream to a fractionation tower having at least one reboiler, and often one or more side reboilers, to supply heat to the column by withdrawing and heating some of the tower liquids to produce stripping vapors that separate the more volatile components from the desired components. The reboiler and side reboilers (if any) are typically integrated into the feed stream cooling scheme to provide at least a portion of the refrigeration needed to condense the desired components for subsequent fractionation in the distillation column. In the process disclosed, the tower reboiling scheme is modified to use one or more tower liquid distillation streams from a point higher in the column than is used in the conventional reboiling scheme, providing colder stream(s) for the reboiler(s) that allow more effective cooling of the feed streams and thereby improve the efficiency with which the desired components are recovered. In addition, the tower liquid streams withdrawn from a higher point in the column contain larger quantities of the more volatile components, which when vaporized provide better stripping of undesirable components like carbon dioxide without reducing the recovery of the desired components. The heated distillation stream is returned to a lower point on the fractionation tower that is separated from the withdrawal point by at least one theoretical stage.

Owner:UOP LLC

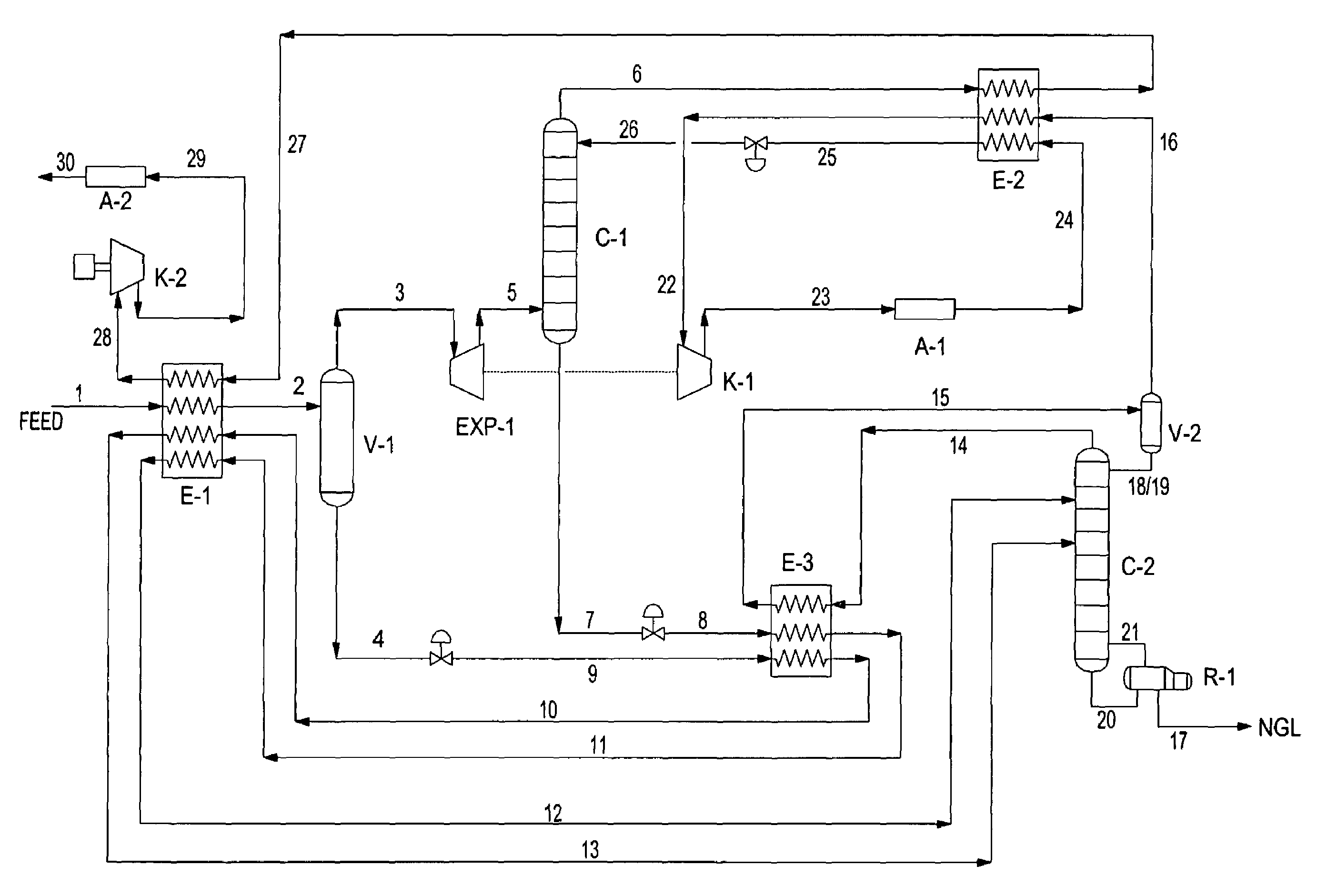

Ethane plus and HHH process for NGL recovery

InactiveUS7219513B1Good fractionation effectHeavy componentSolidificationLiquefactionFractionating columnPetrochemical

The present invention relates to methods for separating and recovering ethane, propane and heavier components from a feed gas, e.g. raw natural gas or a refinery or petroleum plant gas stream or a petrochemical plant gas stream. These methods employ a common new concept which is the use of the turbo-expander shaft compressor to generate the reflux requirement for the cryogenic absorber or distillation columns. The power of the turbo-expander which is absorbed by the shaft compressor is always high enough so that reflux generation by a specific gas compression through the expander shaft compressor and subsequent cooling, condensation and sub-cooling can always be easily maintained. The present invention allows for higher cryogenic absorber pressure and a lower demethanizer / de-ethanizer column pressure thus eliminating the common cryogenic pump at absorber bottom. The present invention ultimately results in a lower residue compression and utilities consumption. The present invention as such allows for a higher 99+% recovery of NGL from the feed gas stream.

Owner:MOSTAFA HUSSEIN MOHAMED ISMAIL

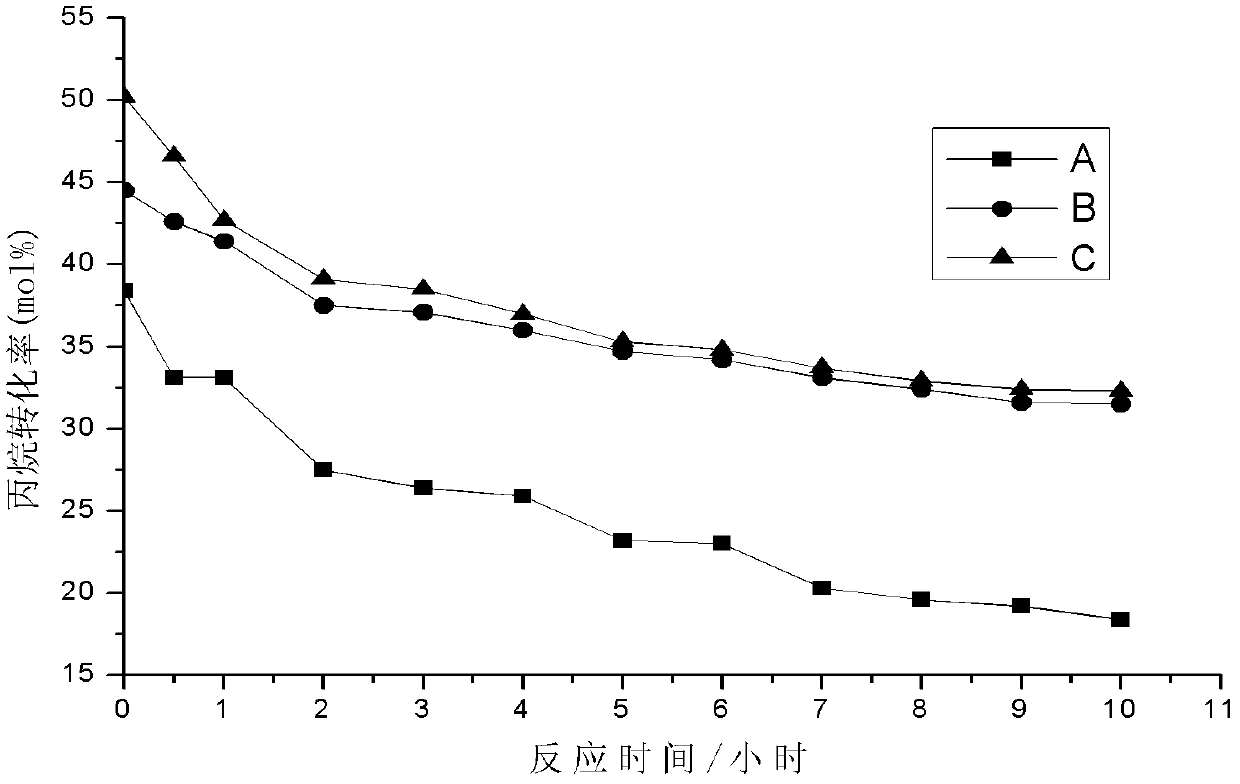

Catalyst for preparing propylene by propane dehydrogenation and its prepn.

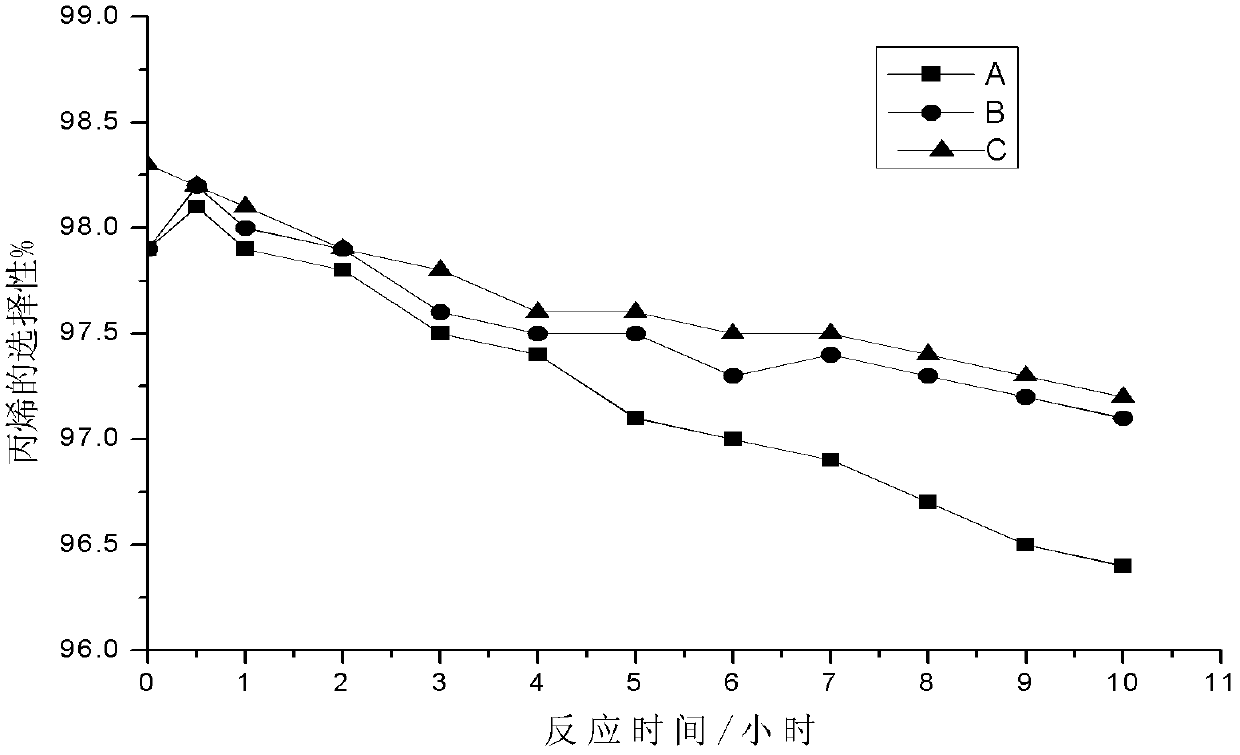

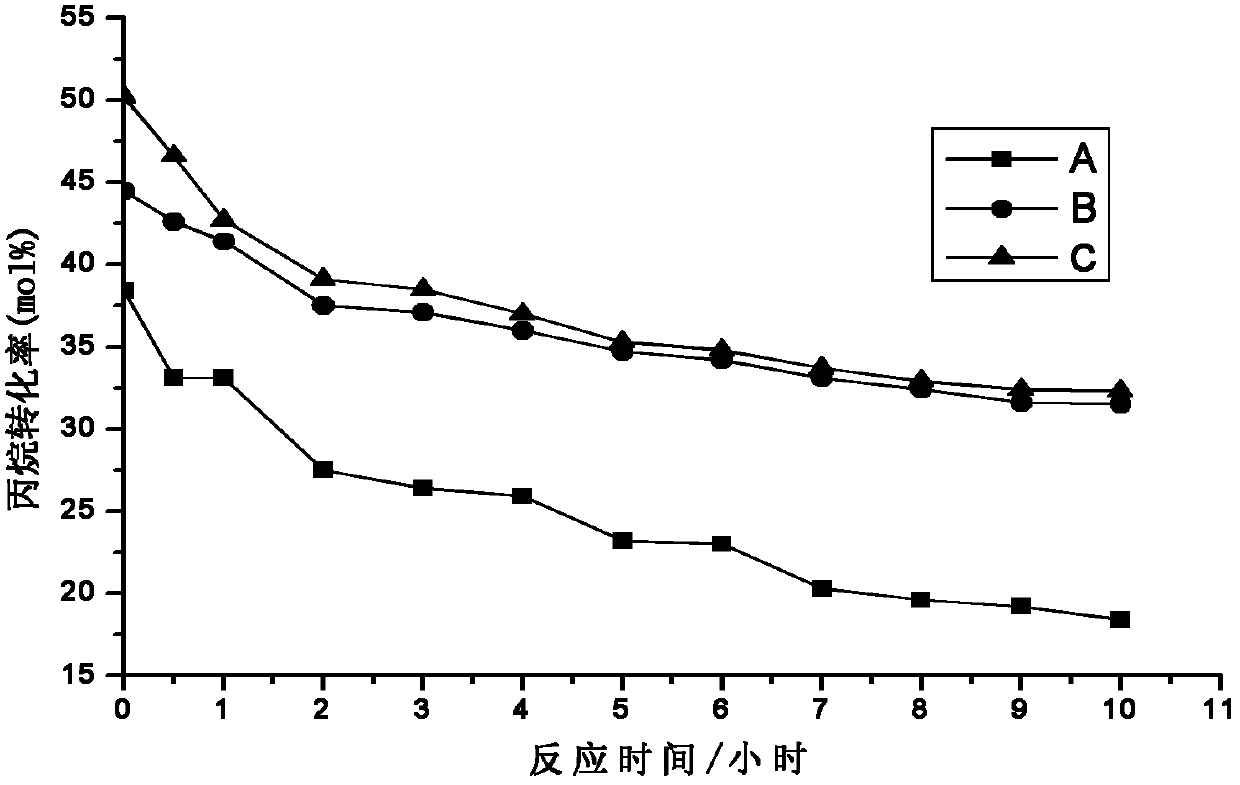

InactiveCN101015802AHigh selectivityImprove reaction stabilityCatalyst carriersHydrocarbonsAdhesiveDehydrogenation

The invention relates to a catalyst for dehydrogenating propane to prepare propone, which uses thermal-resistant oxide as carrier, uses palladium-group metal as main catalyst, uses IV A group metal and rare-earth metal as agents, uses halogen as modifier, and uses inorganic oxide with high temperature resistance as adhesive. The inventive catalyst under high temperature and low pressure has higher propane transfer rate, propone selectivity and reaction stability. And the preparation comprises that at 60-100Deg. C, immerging thermal-resistant oxide with rare-earth metal water solution for 2-10h, at 60-180Deg. C baking for 2-10h, at 400-600Deg. C baking for 3-10h, immerging said carrier and the water solution which contains palladium metal and IVA metal at 60-100Deg. C for 2-10h, and baking for 2-10h at 60-180Deg. C, adding adhesive, protruding agent and acid gel solvent, protruding and shaping, baking for 2-10h at 60-180Deg. C, activating for 3-10h at 400-600Deg. C, and reducing for 2-10h in hydrogen flow at 400-600Deg. C.

Owner:SOUTHEAST UNIV

Process for producing 1,1,1,3,3-pentafluoro-propane and/or 1-chloro-3,3,3-trifluoropropene

InactiveUS6403847B1Point becomes highManufactured continuously and efficientlyPreparation by dehalogenationPreparation by hydrogen halide split-offBoiling pointPropane

One or more materials selected from 1,1,1,3,3-pentachloropropane, 1,1,3,3-tetrachloropropene and 1,3,3,3-tetrachloropropene are used as the specific materials described above. Before submitting the materials and HF to a fluorination reaction, almost all water is removed from them.To continuously manufacture useful intended products efficiently as well as to prevent deactivation of the catalyst and the accumulation of organic substances with high boiling points when manufacturing said useful 1,1,1,3,3-pentafluoropropane and / or 1-chloro-3,3,3-trifluoropropene, by fluorinating the specific materials with HF in the presence of a catalyst.

Owner:DAIKIN IND LTD

Method for producing fluorinated organic compounds

ActiveUS8084653B2Preparation by hydrogen halide split-offPreparation by halogen replacementActivated carbonGas phase

Disclosed are processes for the production of fluorinated olefins, preferably adapted to commercialization of CF3CF═CH2 (1234yf). Three steps may be used in preferred embodiments in which a feedstock such as CCl2═CClCH2Cl (which may be purchased or synthesized from 1,2,3-trichloropropane) is fluorinated (preferably with HF in gas-phase in the presence of a catalyst) to synthesize a compound such as CF3CCl═CH2, preferably in a 80-96% selectivity. The CF3CCl═CH2 is preferably converted to CF3CFClCH3 (244-isomer) using a SbCl5 as the catalyst which is then transformed selectively to 1234yf, preferably in a gas-phase catalytic reaction using activated carbon as the catalyst. For the first step, a mixture of Cr2O3 and FeCl3 / C is preferably used as the catalyst to achieve high selectivity to CF3CCl═CH2 (96%). In the second step, SbCl5 / C is preferably used as the selective catalyst for transforming 1233xf to 244-isomer, CF3CFClCH3. The intermediates are preferably isolated and purified by distillation and used in the next step without further purification, preferably to a purity level of greater than about 95%.

Owner:HONEYWELL INT INC

Method for improving catalyst reacting activity in the propylene producing through propane dehydrogenation

InactiveCN101138734AHigh reactivityHigh mechanical strengthMolecular sieve catalystsHydrocarbonsRare earthDehydrogenation

A method to promote the activity of a catalyst for dehydrogenation of propane to propylene is as follows: (1) an inorganic oxide bonding agent, a promoter and an acid solvent are added into a heat-resistant oxide; then after the oxide bonding agent, the promoter, the acid solvent and the oxide are kneaded evenly, the oxide is molded by rolling or band-extruding; (2) the catalyst carrier prepared is dried for 2 to 10 hours under the temperature of 60 centigrade degrees, and calcined under the temperature of 400 to 800 degrees; (3) the calcined carrier is immersed in a rare earth metal water solution under the temperature of 60 to 100 centigrade degrees for 2 to 10 hours; (4) the catalyst carrier modified by the rare earth is immersed in a water solution comprising platinum metal elementsand the fourteenth metal elements under the temperature of 400 to 600 centigrade degrees for 2 to 10 hours, and then the carrier is filtered, washed with distilled water, dried under the temperature of 60 to 180 centigrade degrees for 2 to 10 hours, and calcined under the temperature of 400 to 600 centigrade degrees for 2 to 10 hours; (5) the catalyst prepared is activated in the air under the temperature of 400 to 600 centigrade degrees for 3 to 10 hours, and reduced in a hydrogen flow under the temperature of 400 to 600 centigrade degrees for 2 to 10 hours; the reduced catalyst is used for catalytic reaction for dehydrogenation of propane to propylene.

Owner:SOUTHEAST UNIV

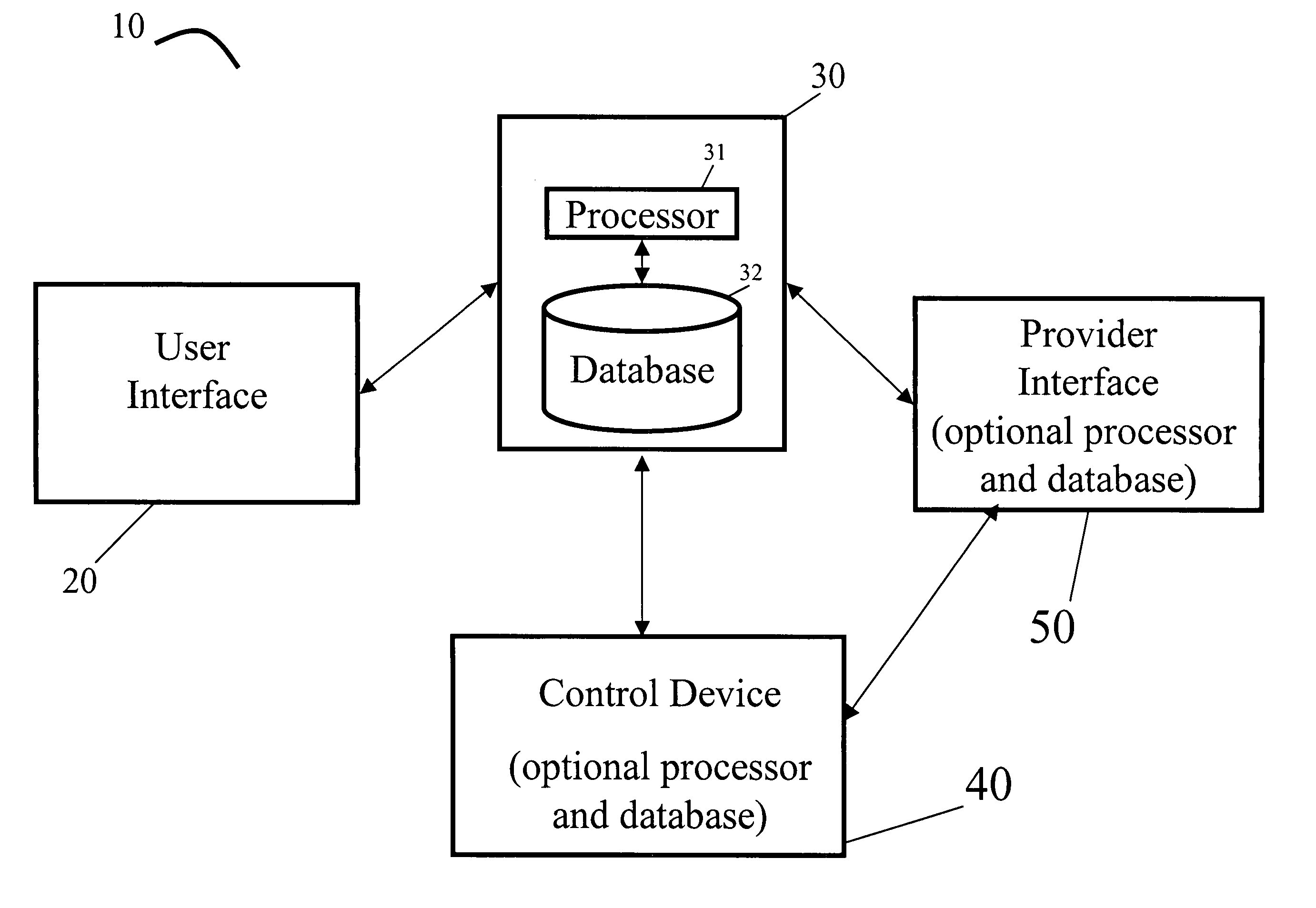

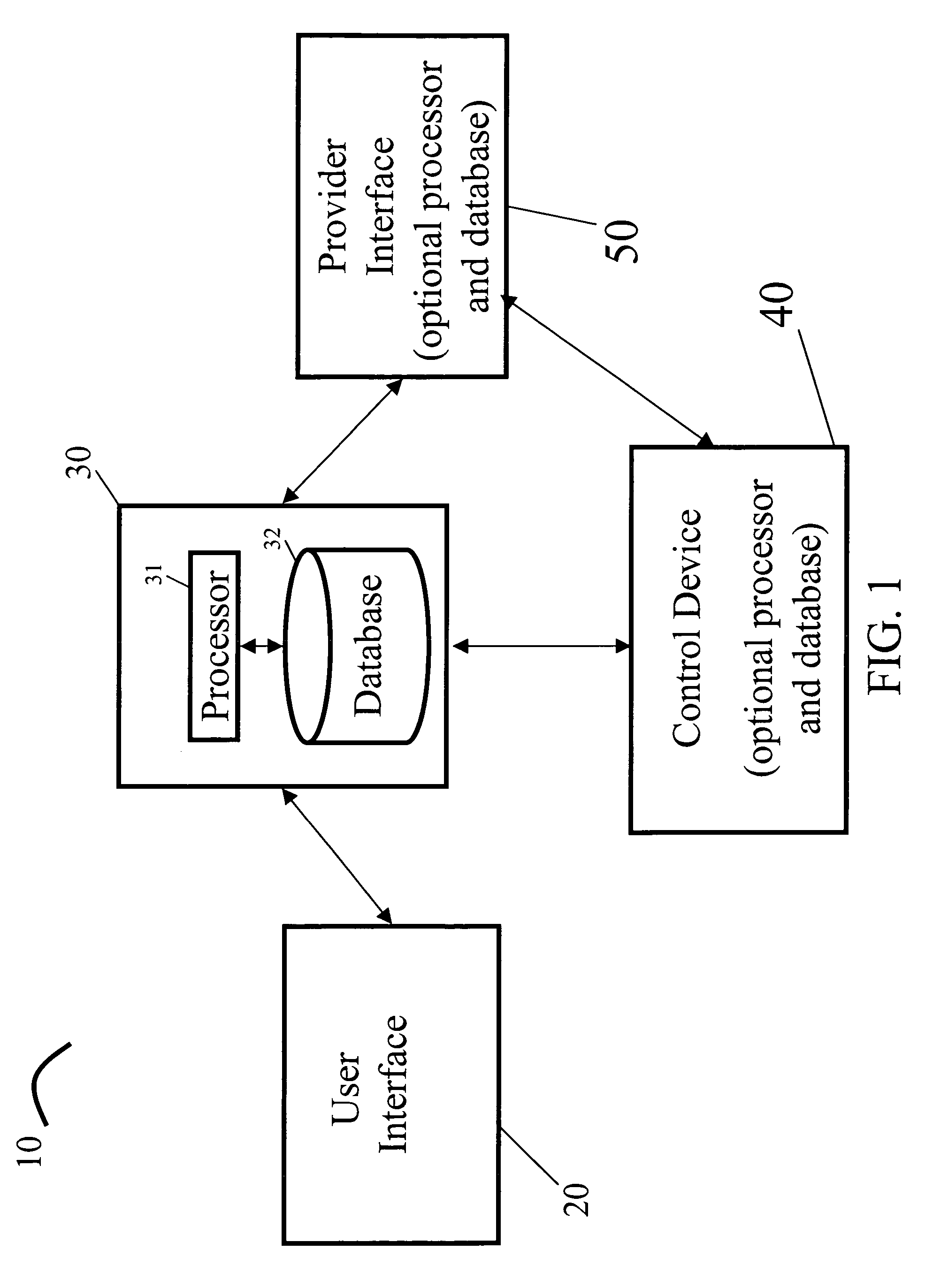

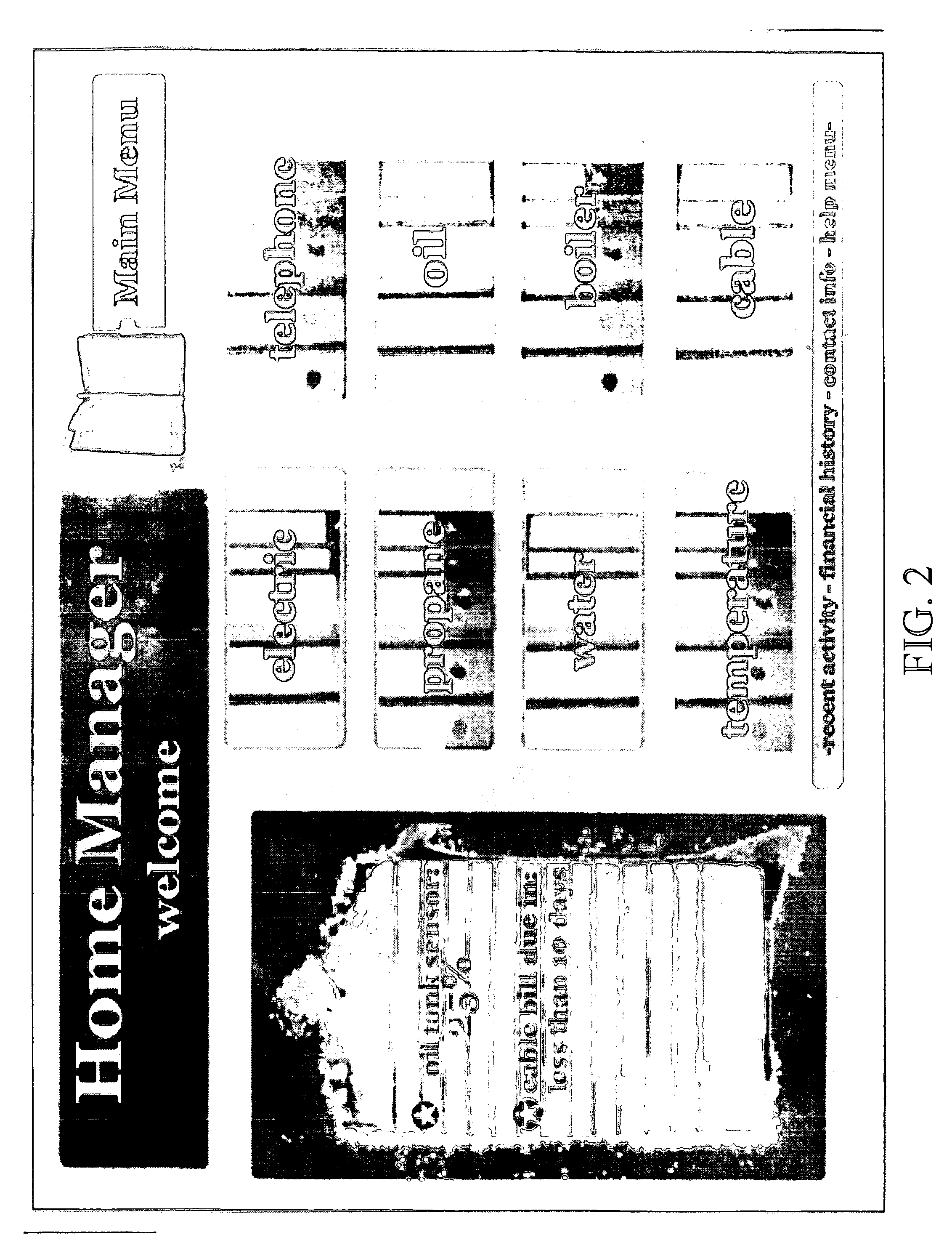

Systems and methods for managing buildings and finances

InactiveUS20070038563A1Avoid shortagePrevent credit card fraudFinancePayment architectureIntegrated softwareComputer science

In various embodiments, building management systems and methods are provided as a stand-alone, or network based system that utilizes integrated software that manages bills, consumables (e.g., oil, propane, water, electric, food, etc.), and appointments. In various embodiments, the building management system provides increased safety, security and convenience to a user.

Owner:RYZERSKI ERIC

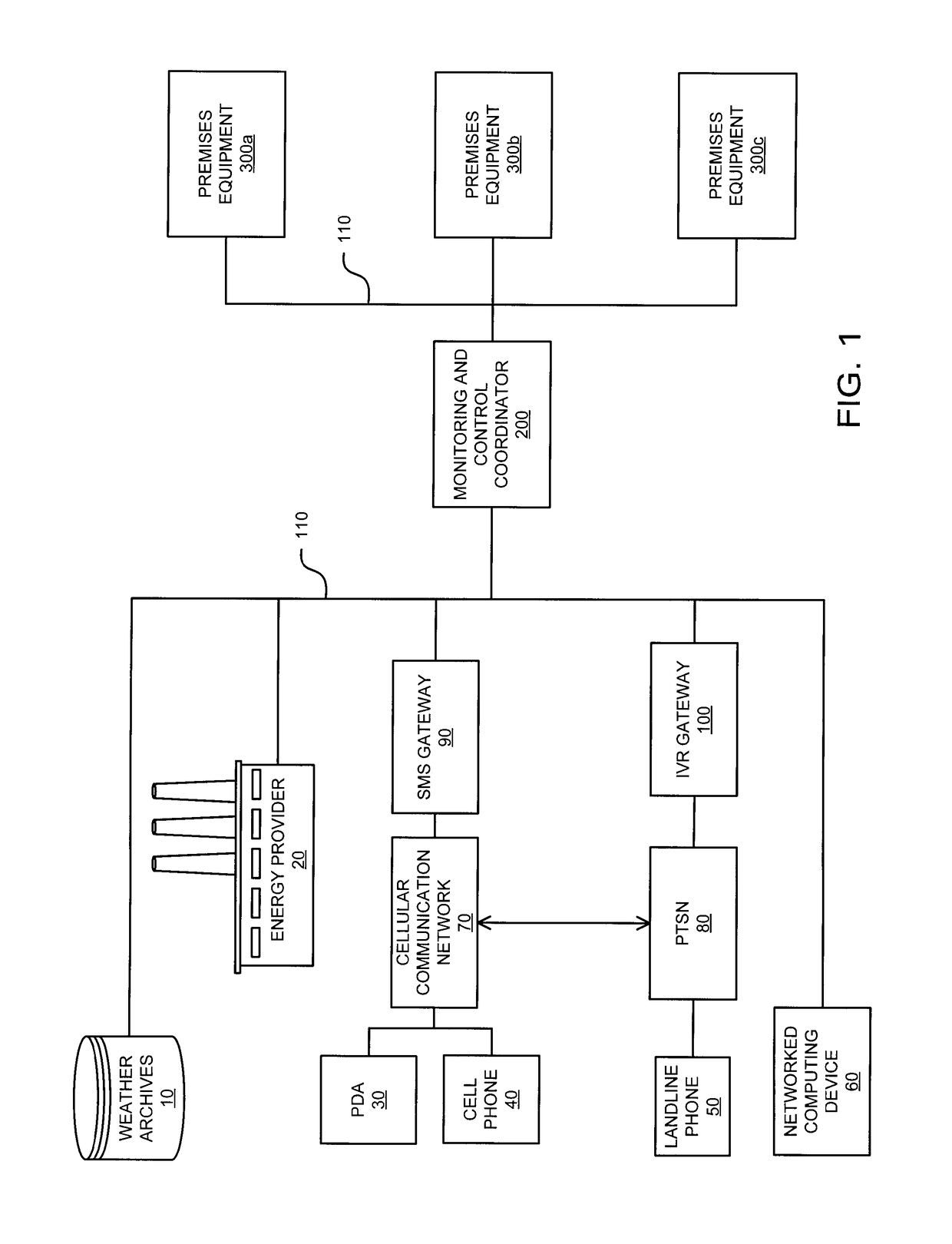

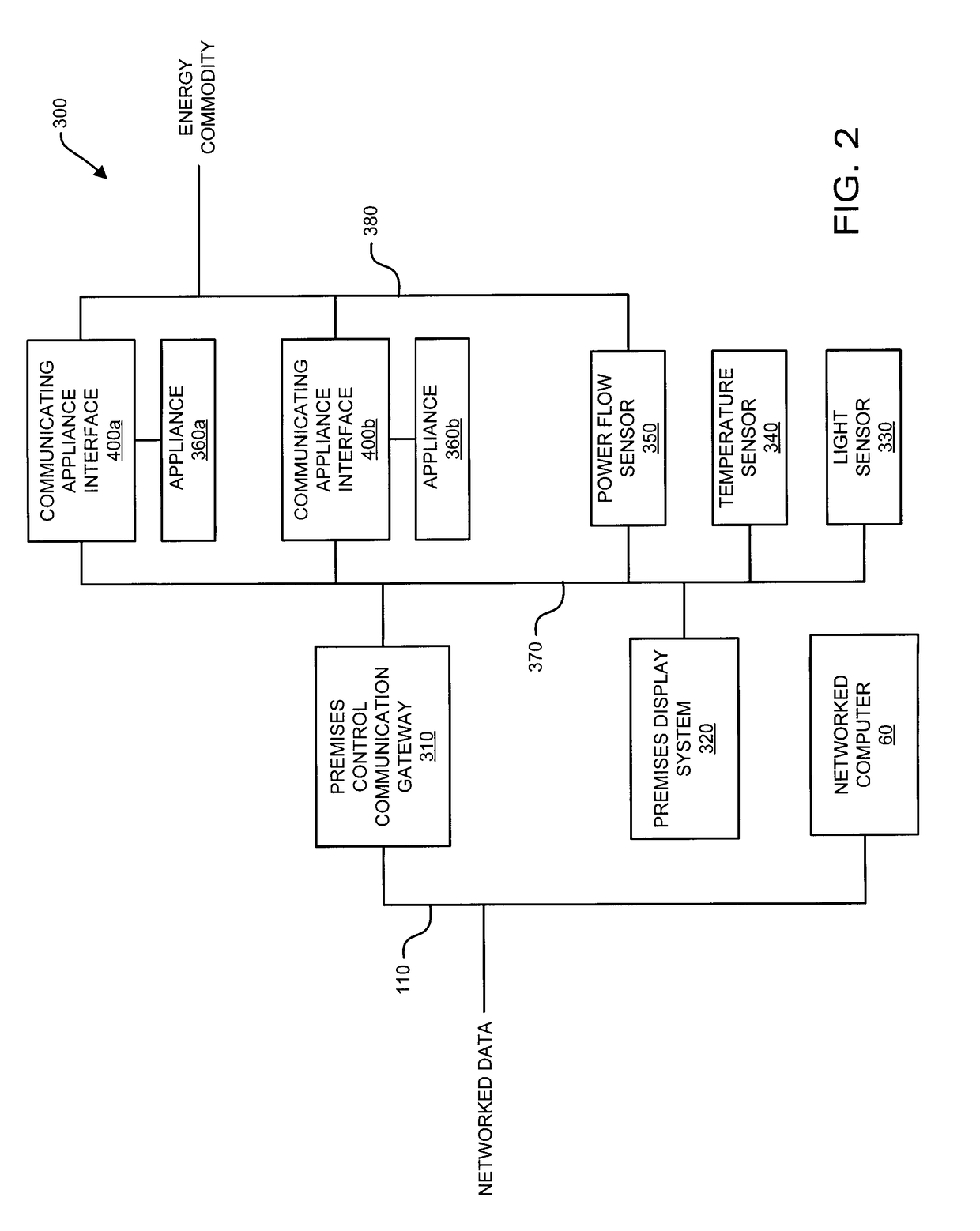

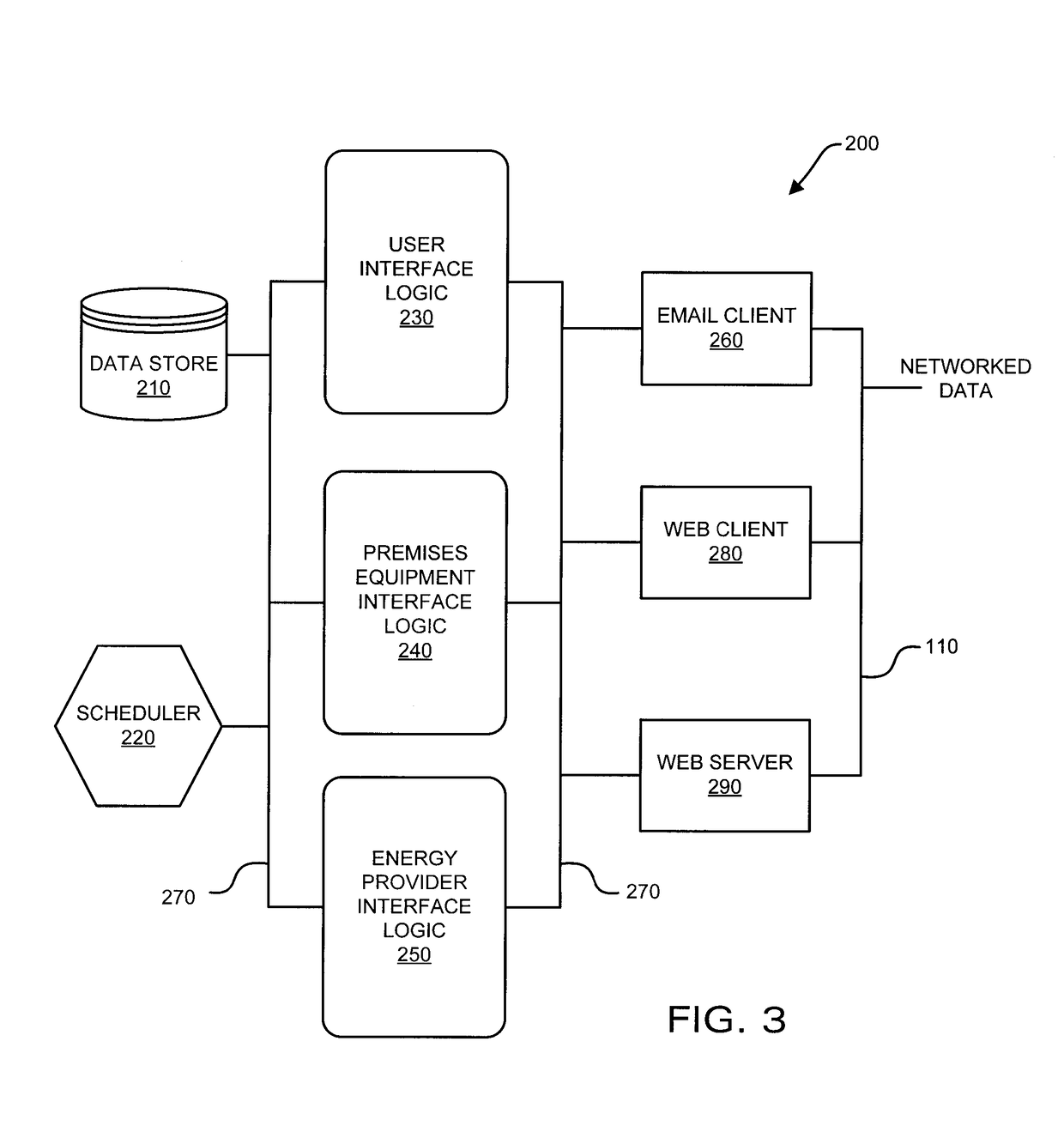

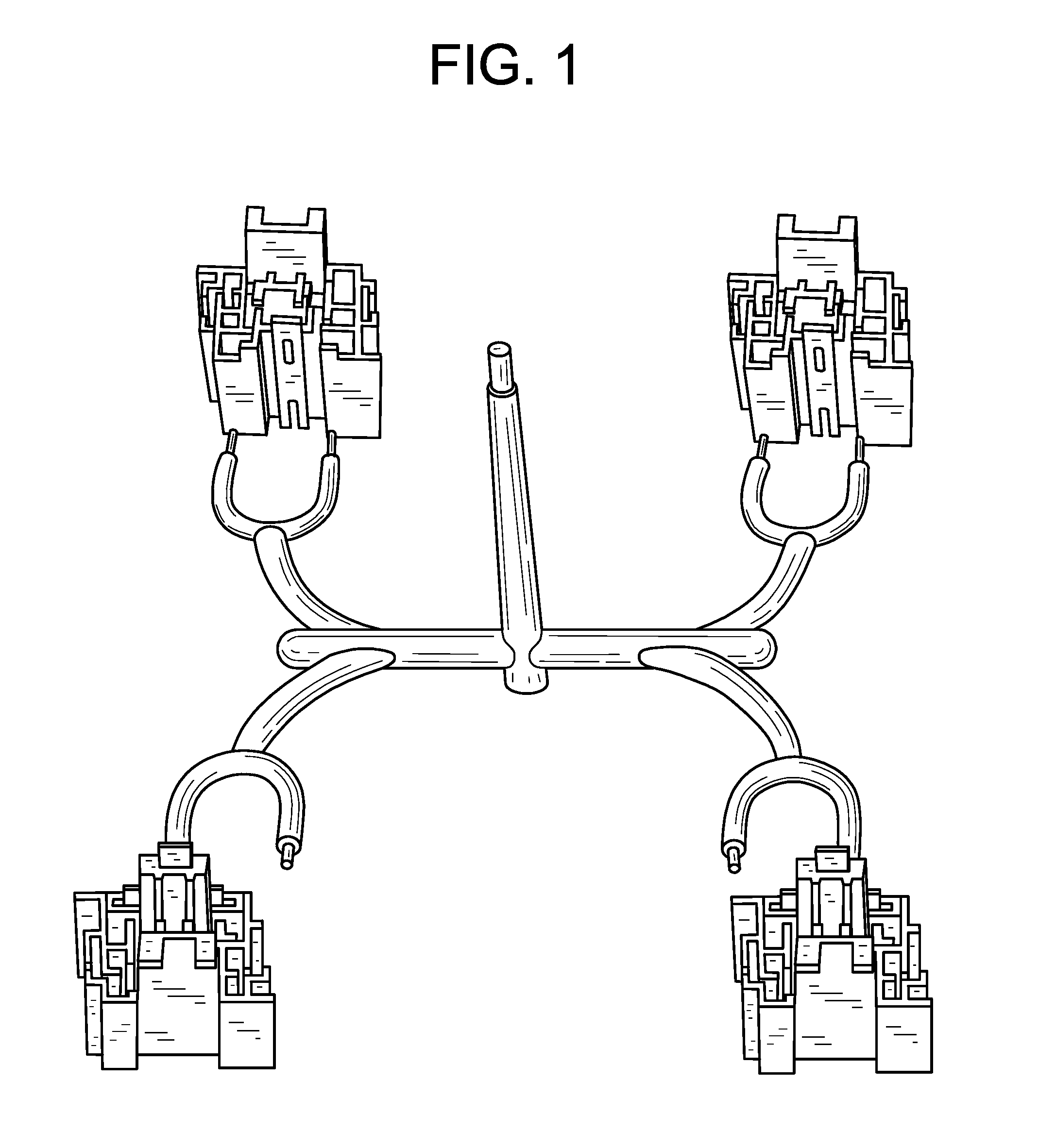

Interconnected premises equipment for energy management

Energy commodities in the form of electricity and combustible fuel (e.g. natural gas, propane) are used by appliances in a fashion which is monitored and controlled through a Premises Energy Management System (PEMS). The system facilitates direct monitoring and control of energy-consuming appliances, in real time, utilizing automated programmatic control and a plurality of human interfaces including local display and control, email, web browser, text messaging, and integrated voice response (IVR). A Monitoring and Control Coordinator (MCC) provides centralized coordination of functions and one or more Communicating Appliance Interfaces (CAI) interacting with energy consuming appliances are interconnected via wired and wireless communication networks and protocols. The system may retrieve information from third parties, such as weather services, for optimizing energy usage. An interface may be provided to the energy provider / purveyor to enhance the provision of energy by providing additional real-time services such as demand management and service outage management.

Owner:PATTON ELECTRONICS

Method for preparing high-quality ethylene raw material with petroleum naphtha hydrogenation

ActiveCN101343557AImprove qualityIncrease productionOrganic chemistryBulk chemical productionVegetable oilPetroleum naphtha

The invention relates to a method for generating the high quality ethylene raw material through naphtha hydrogenation. The method takes naphtha fraction and animal and vegetable oil as the raw material oil, under the condition of hydrofining, the raw material oil and hydrogen are mixed and passed through a hydrofining reaction area, the hydrogen-rich gas recycling utilization can be acquired through separating the hydrofining generated oil, and low Sulfur, low hydrogen and low aromatic naphtha can be acquired through removing hydrogen sulfide of the separated liquid with an air stripping tower. Compared with the prior art, the method has the advantages that the oil is mixed in the naphtha hydrogenation raw material, the quality of the product as the ethylene cracking raw material, in particular to aromatic long chain hydrocarbon nC16 to 18 and propane acquired through the animal and vegetable oil hydrogenation, can be remarkably improved, the cracking furnace ethylene output can be increased and the cracking furnace life can be prolonged through adding the aromatic long chain hydrocarbon nC16 to 18 and propane in the ethylene cracking raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

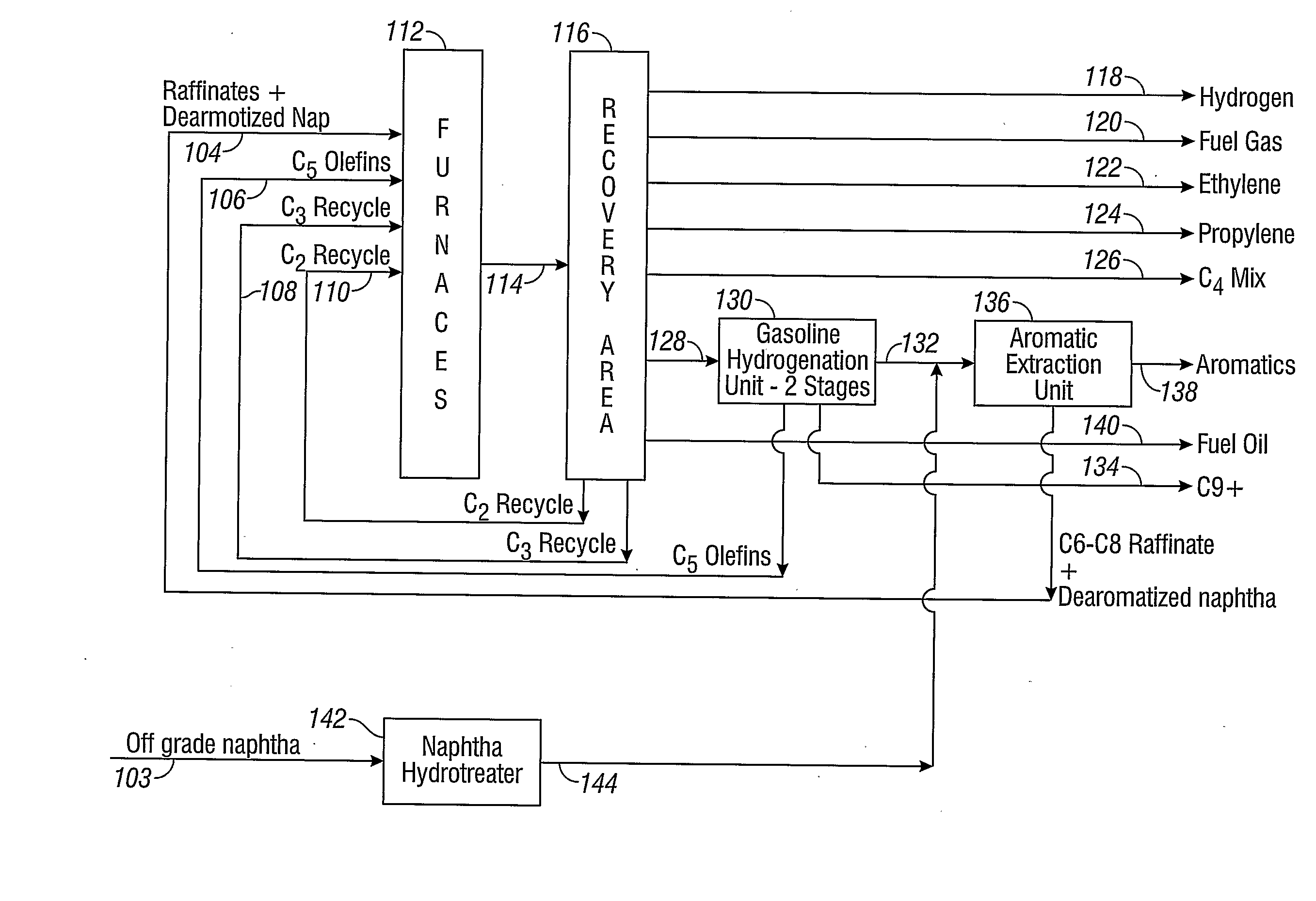

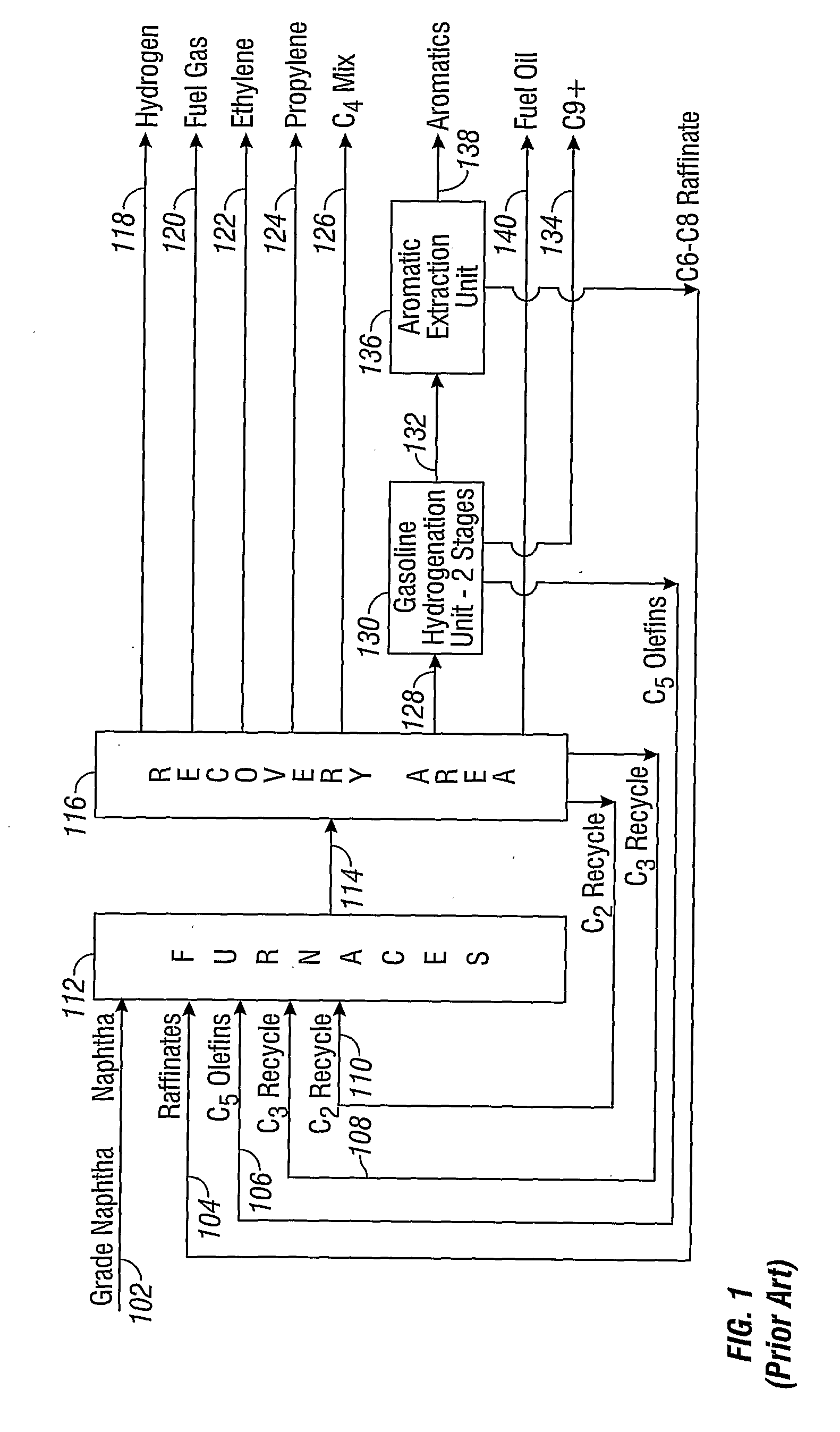

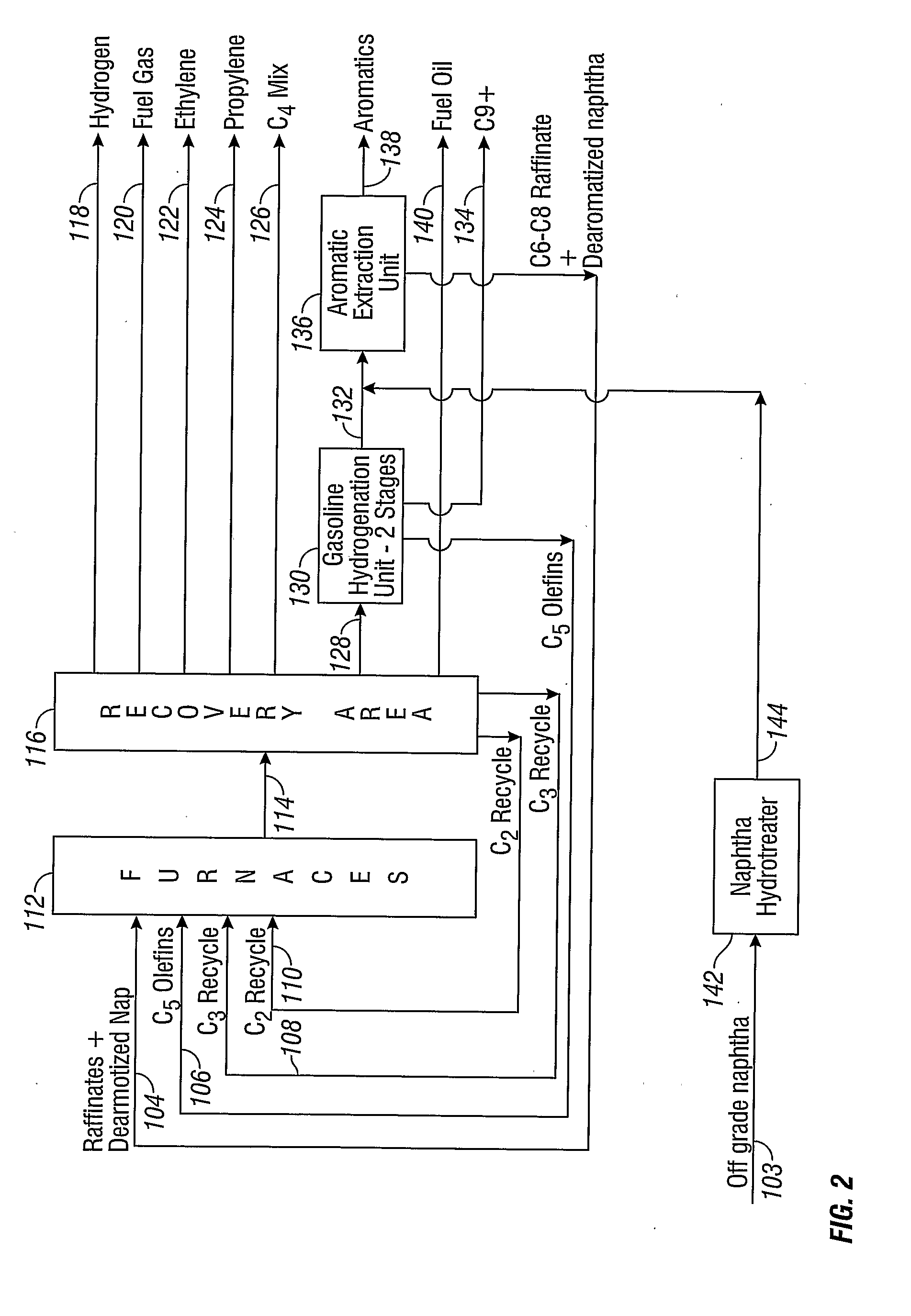

Steam Cracking with Naphtha Dearomatization

Disclosed is a process for upgrading a naphtha feed stream comprising light naphtha, heavy naphtha, or a combination thereof, for supplying to a cracking process. A naphtha feed stream can be supplied to a hydrotreater 142 to remove impurities, followed by dearomatization in an aromatics extraction unit 136. A dearomatized naphtha stream 104 can be supplied to a cracking process 112 and a recovery process 116 to produce various streams including ethylene 122 and propylene 124 for collection, ethane 110 and propane 108 for recycle to the cracking process 112, and a pyrolysis gas stream 128 which can be further treated to produce a C5 olefins stream 106, a C6-C8 stream 104, a C9+ stream 134, and a fuel oil stream 140.

Owner:BHIRUD VASANT L

Portable hydrogen generator-fuel cell apparatus

InactiveUS6653005B1Increase specific energy and overall energy efficiencyHydrogenFuel cell auxillariesKeroseneImpurity

A compact hydrogen generator is coupled to or integrated with a fuel cell for portable power applications. Hydrogen is produced via thermocatalytic decomposition (cracking, pyrolysis) of hydrocarbon fuels in oxidant-free environment. The apparatus can utilize a variety of hydrocarbon fuels, including natural gas, propane, gasoline, kerosene, diesel fuel, crude oil (including sulfurous fuels). The hydrogen-rich gas produced is free of carbon oxides or other reactive impurities, so it could be directly fed to any type of a fuel cell. The catalysts for hydrogen production in the apparatus are carbon-based or metal-based materials and doped, if necessary, with a sulfur-capturing agent. Additionally disclosed are two novel processes for the production of two types of carbon filaments, and a novel filamentous carbon product. The hydrogen generator can be conveniently integrated with high temperature fuel cells to produce an efficient and self-contained source of electrical power.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

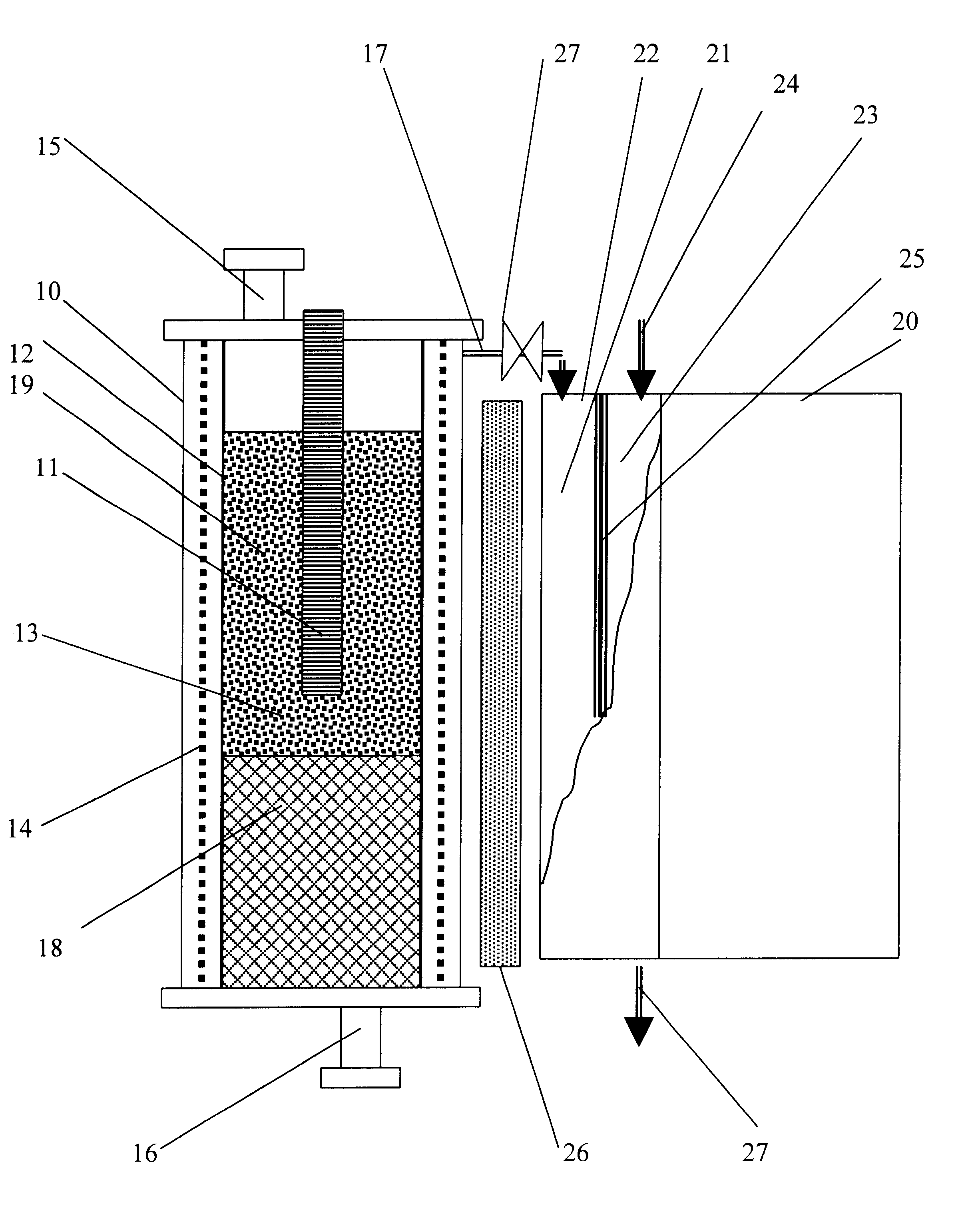

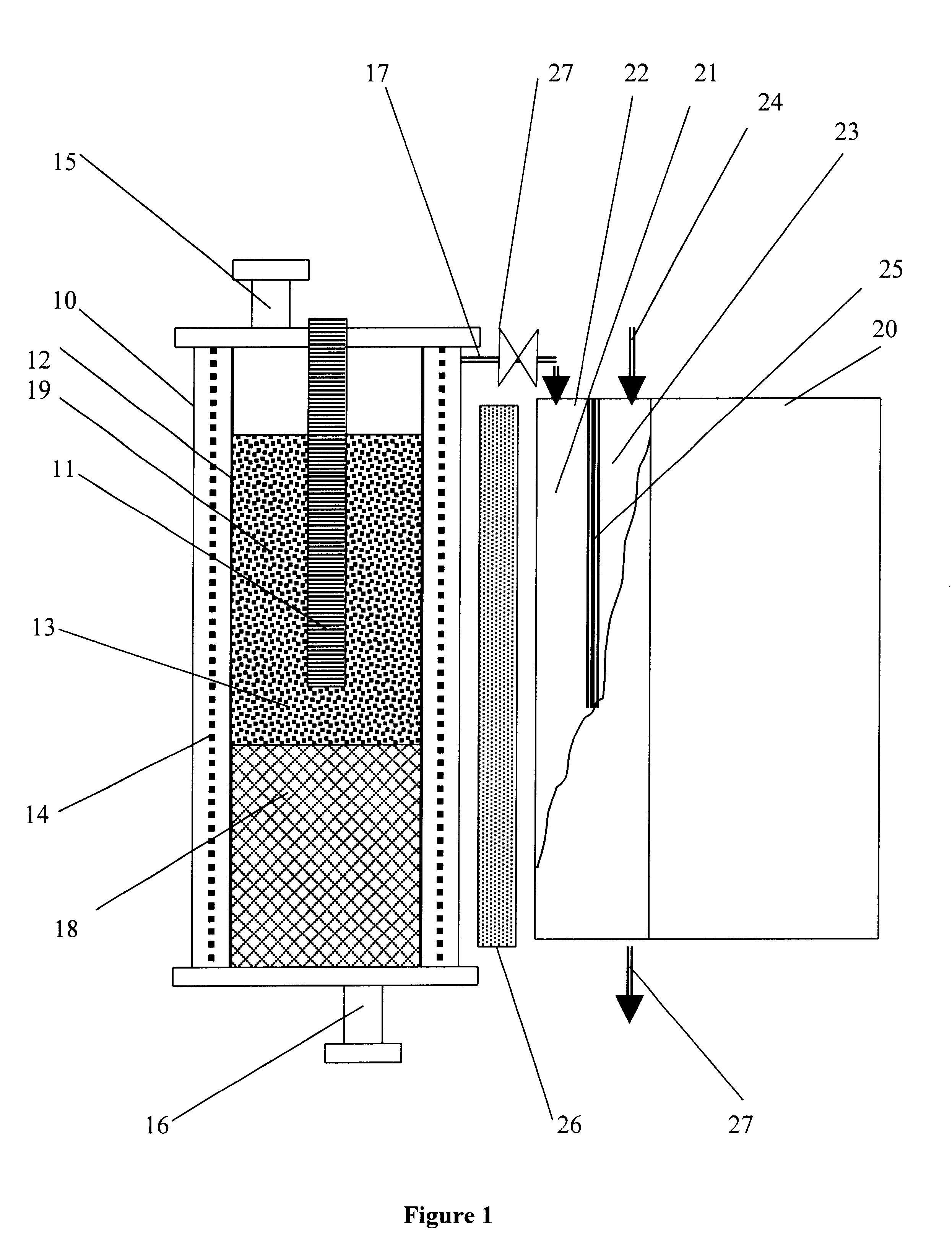

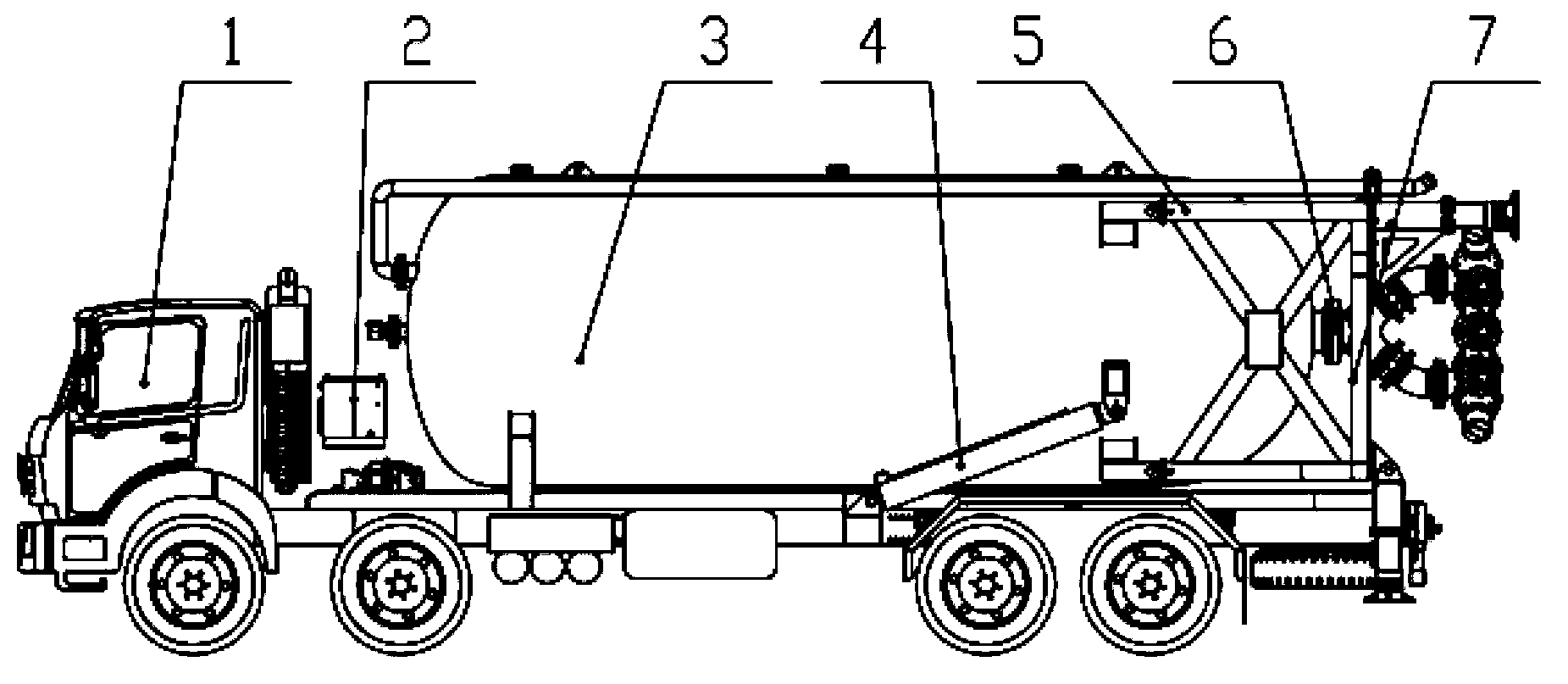

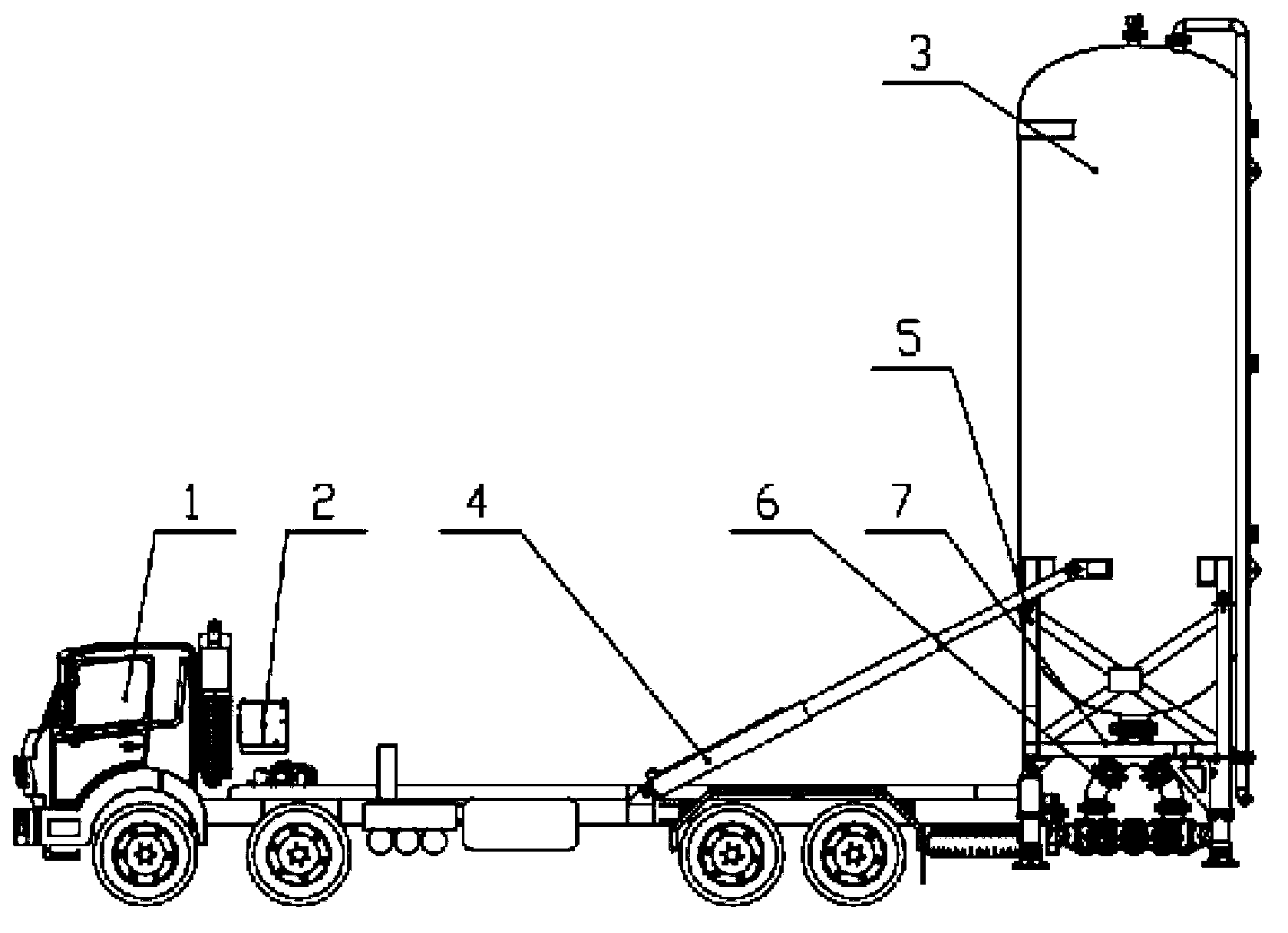

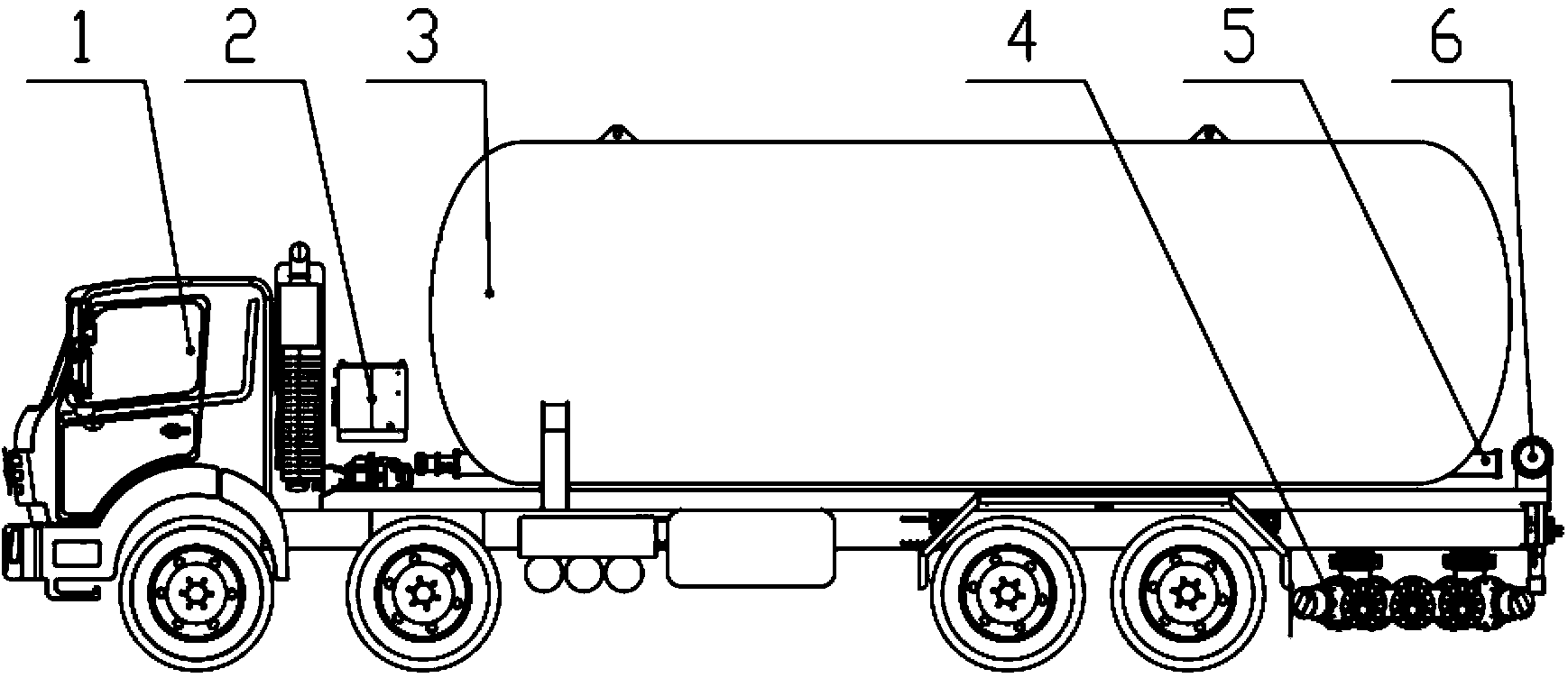

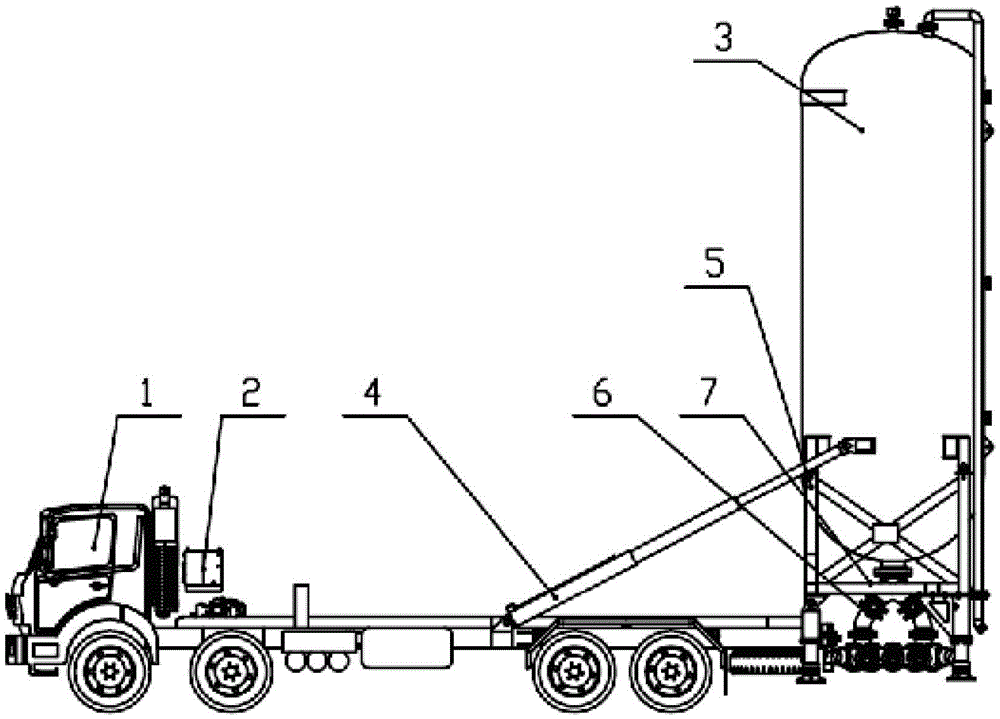

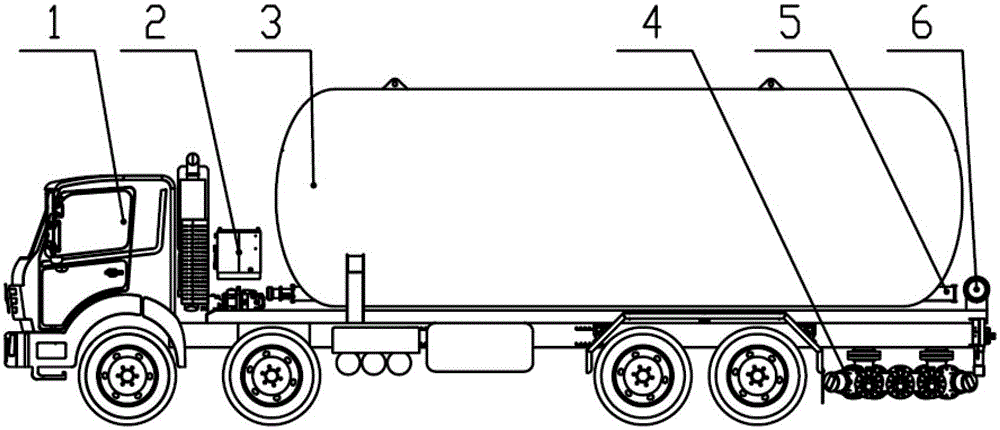

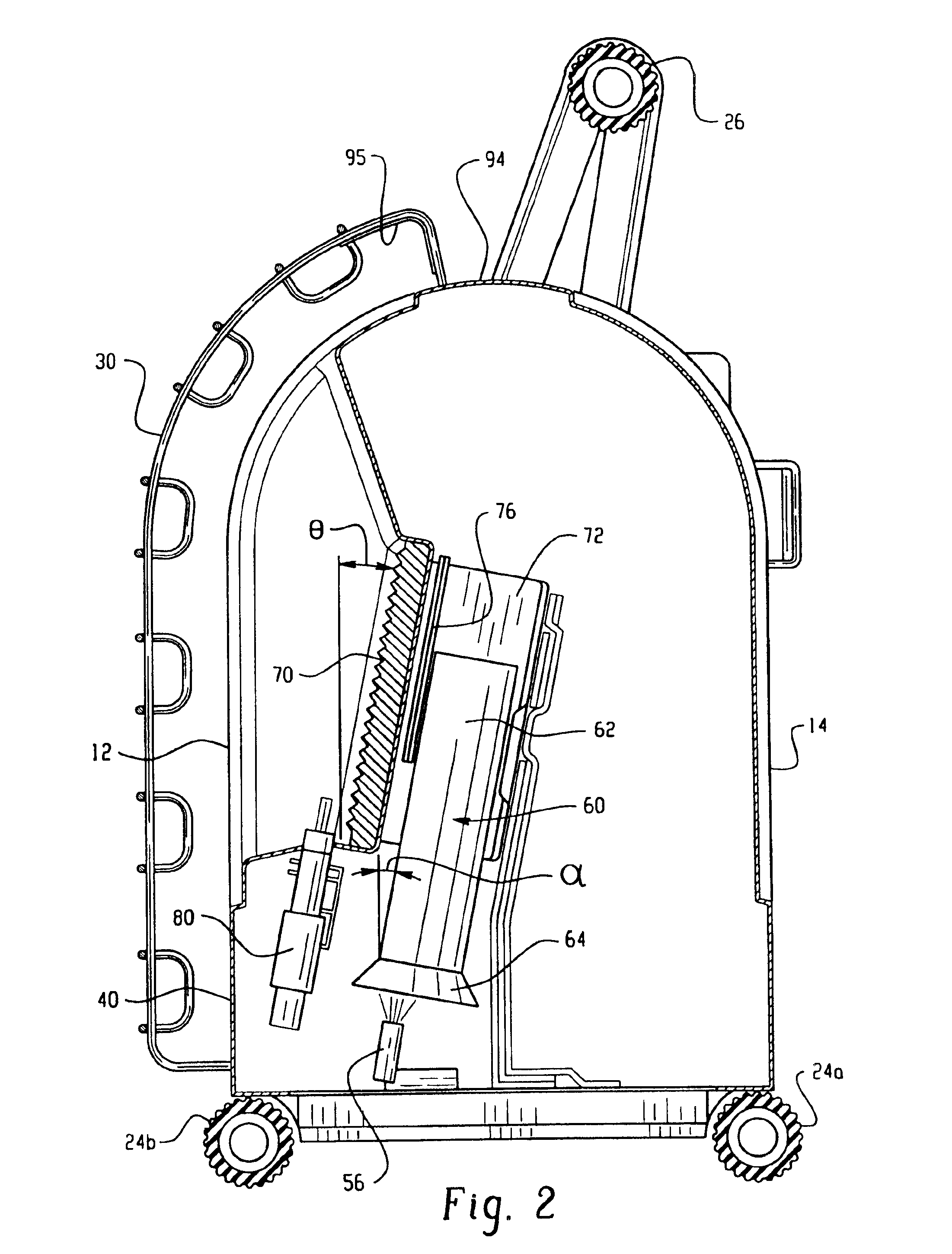

Fracturing sand mixing device

The invention provides a fracturing sand mixing device used for mixing fracturing fluid. The fracturing sand mixing device comprises a solid-liquid mixing device, and the solid-liquid mixing device is a pressure container. The solid-liquid mixing device comprises a solid lead-in port capable of leading in solid particles of the fracturing fluid, a base fluid lead-in port for leading in base fluid of the fracturing fluid, a mixing inner cavity for accommodating the solid particles and the base fluid and a solid-liquid lead-out port for leading out the fracturing fluid formed by mixing. Substances such as carbon dioxide or petroleum gas which are in a gas state under normal temperature can be kept in a liquid state by high pressure through the fracturing sand mixing device and are mixed with the solid particles to form the fracturing fluid, and the goal of preparing the fracturing fluid with liquid carbon dioxide or liquefied petroleum gas (propane) serving as the base fluid is achieved.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

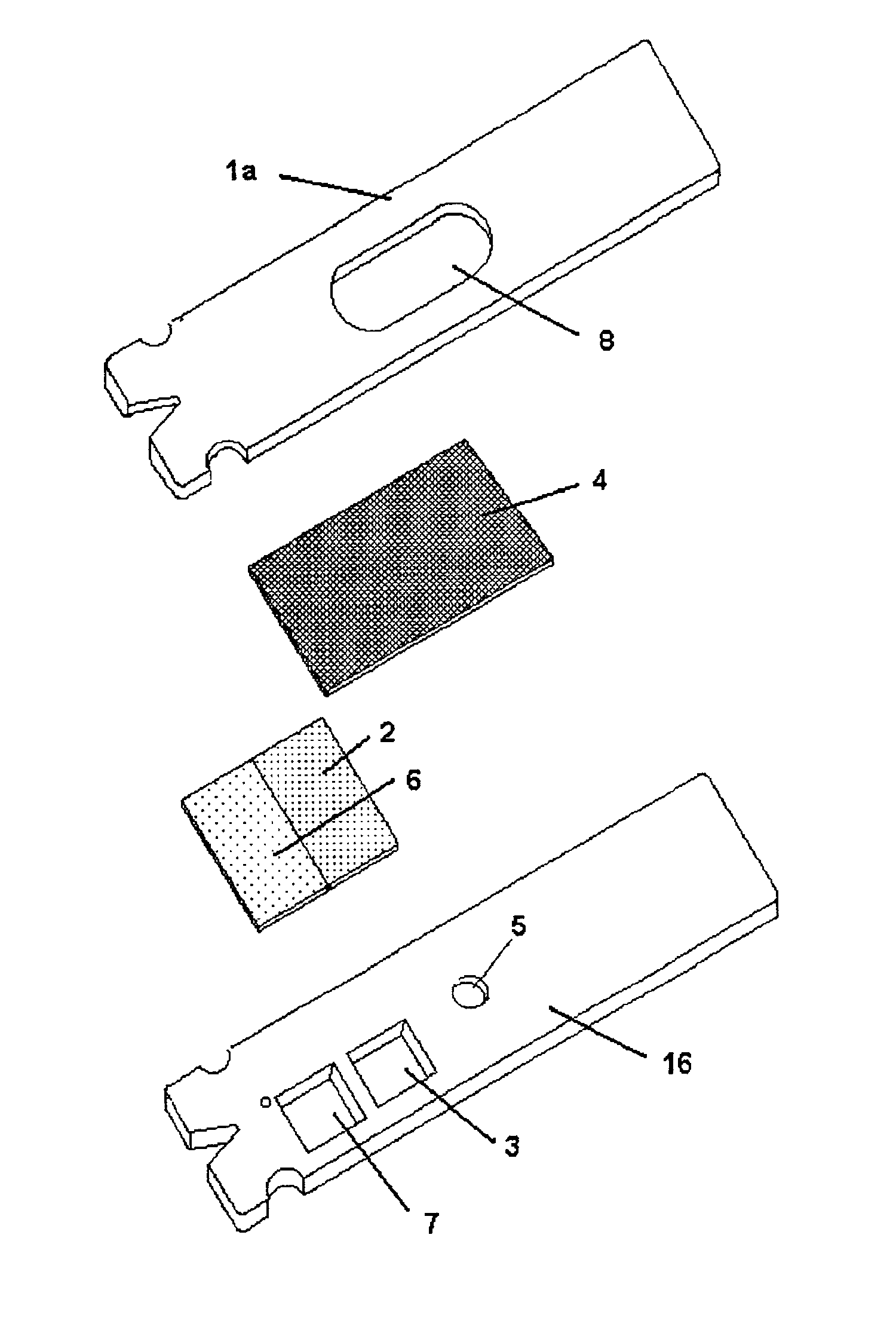

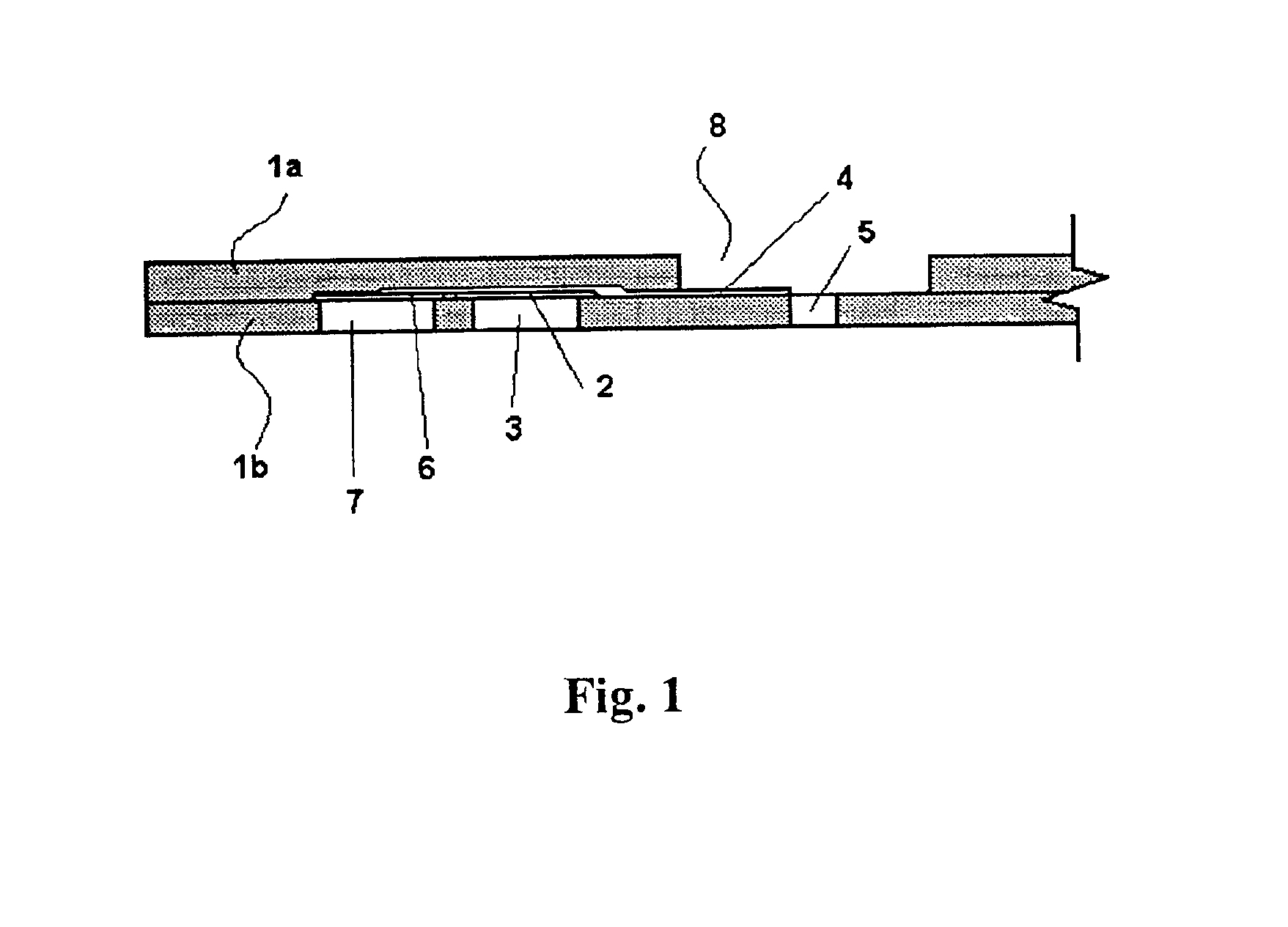

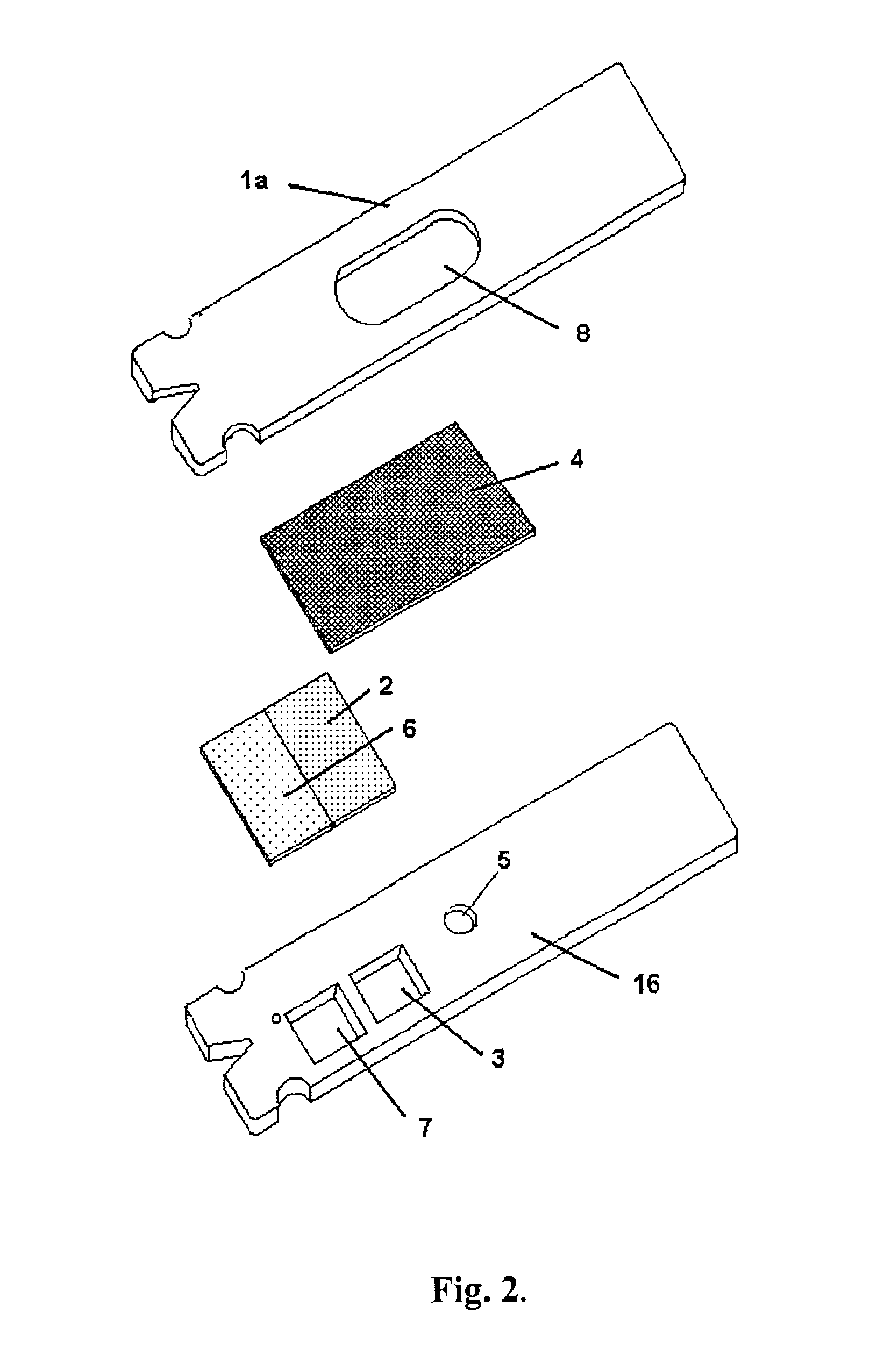

Surface-modified wick for diagnostic test strip

InactiveUS6967105B2Improve accuracyGood precisionAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorAlkaneBlood sugar

A wicking material is disclosed that exhibits a horizontal wicking velocity of at least about 1.0 millimeter per second when contacted with a physiological fluid such as blood, lymph or cellular interstitial fluid. This high wicking rate is achieved by means of treatment of a fibrous wicking material candidate with a low temperature gas plasma, particularly a glow discharge gas plasma formed in a gaseous blend made up predominantly of a mixture of oxygen with a saturated alkane chosen from the group consisting of methane, ethane and propane. Diagnostic test strips made with the surface-modified wicking material, and containing an immobilized reagent means for analysis of an analyte in a physiological fluid, show improved performance in terms of increased accuracy, finer precision of analyses, reduced time of analysis, a smaller fluid sample size requirement, and improved compliance with manufacturing standards resulting in lower manufacturing costs blood sugar determinations.

Owner:QUESTSTAR MEDICAL

Catalyst propane using aluminium oxide modified mesonore molecular sieve as carrier for dehydrogenation producing propylene

InactiveCN101125298AHigh propane conversionGood dehydrogenation stabilityMolecular sieve catalystsHydrocarbonsMolecular sievePlatinum

The invention relates to a catalyst to make the propene by dehydrogenation propane which takes the modifying alumina medium molecular sieve as the carrier. The catalyst takes the modifying medium molecular sieve by the Al2O3 as the carrier; the platinum and tin double metal catalyst has an alumina weight proportion of 5.0 to 30.0 percent. The active component of the catalyst is the platinum; the weight proportion of the platinum is 0.4 percent; and the weight proportion of the accessory ingredient Sn is 0.1 to 2.0 percent.

Owner:NANJING UNIV

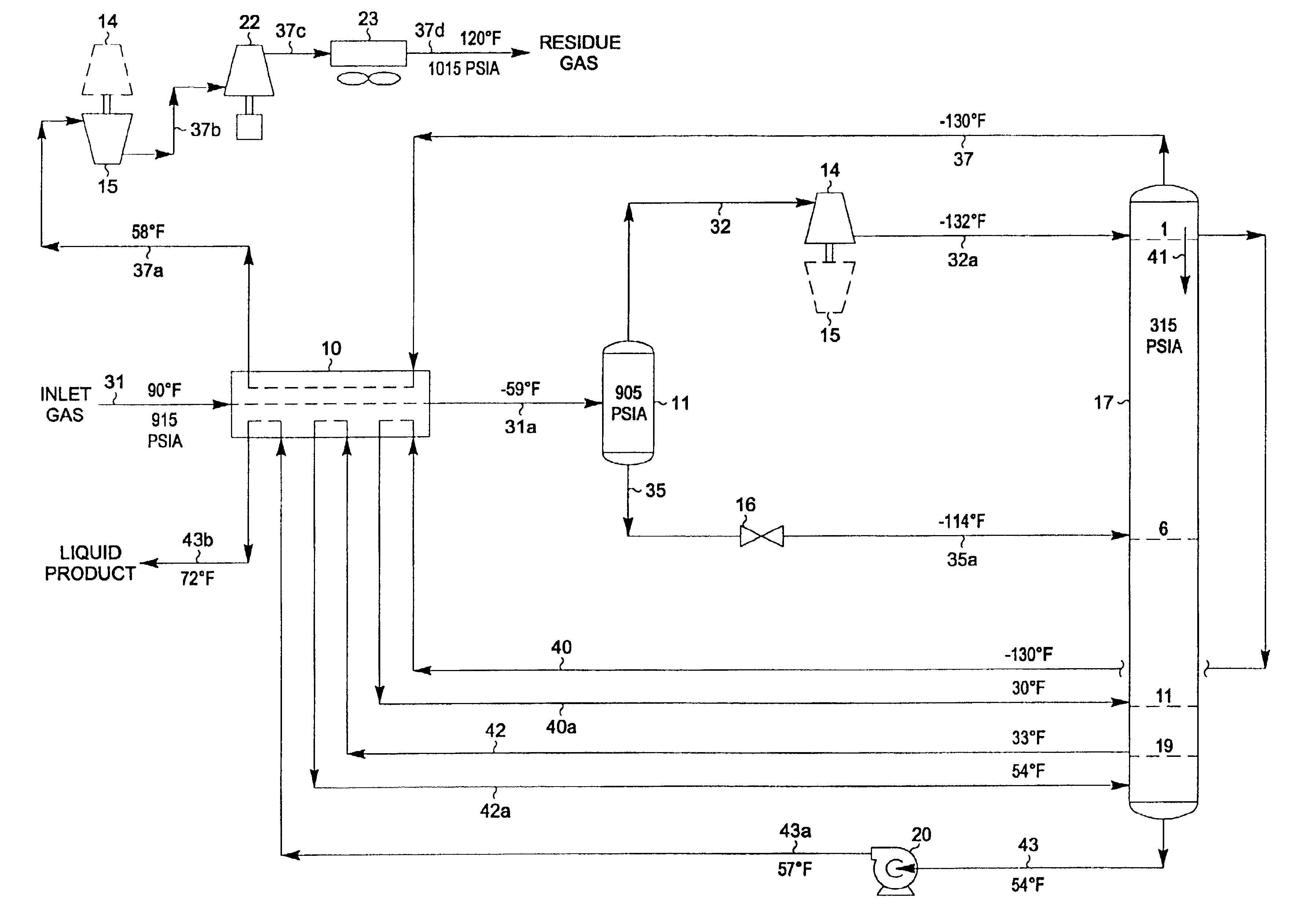

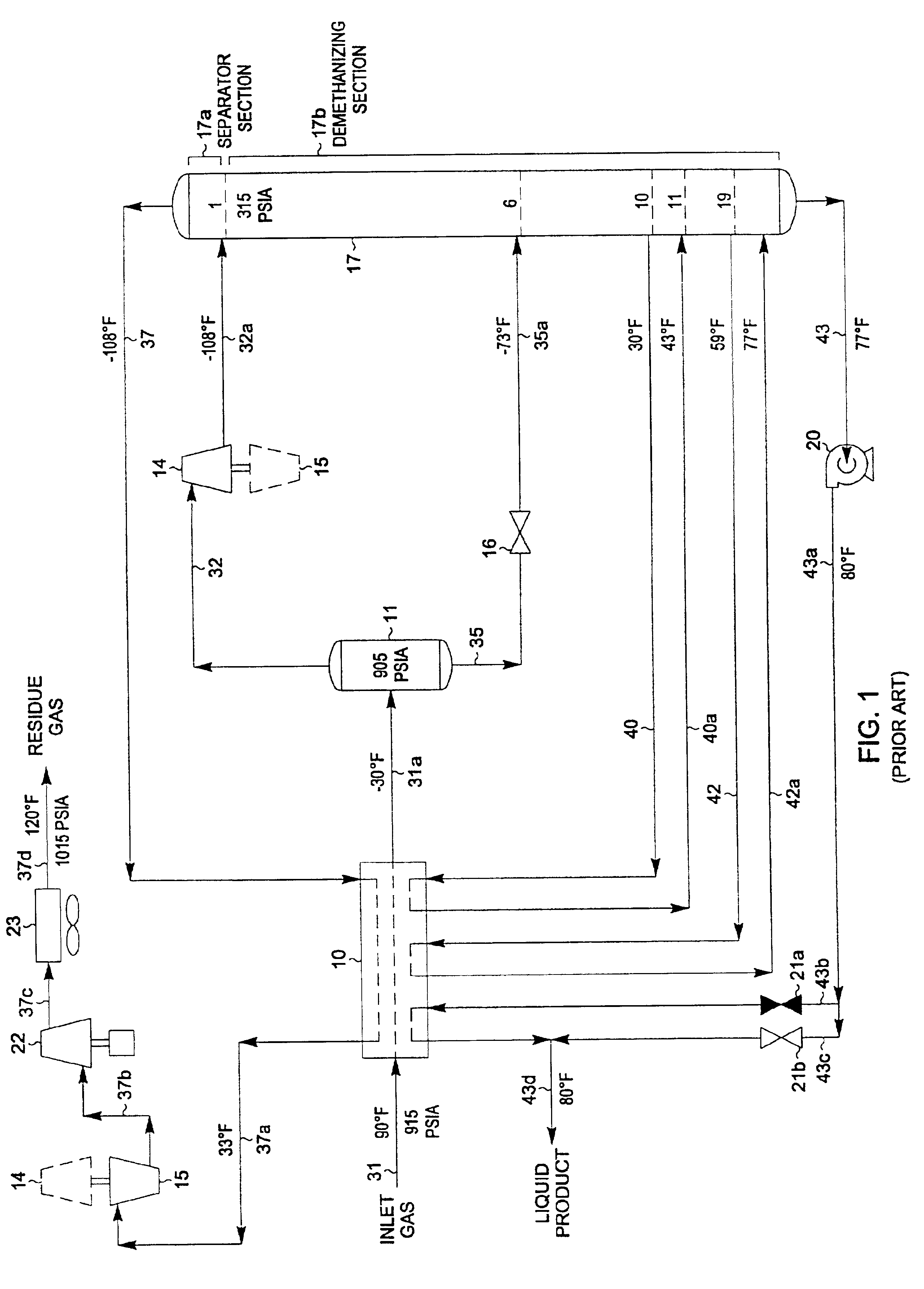

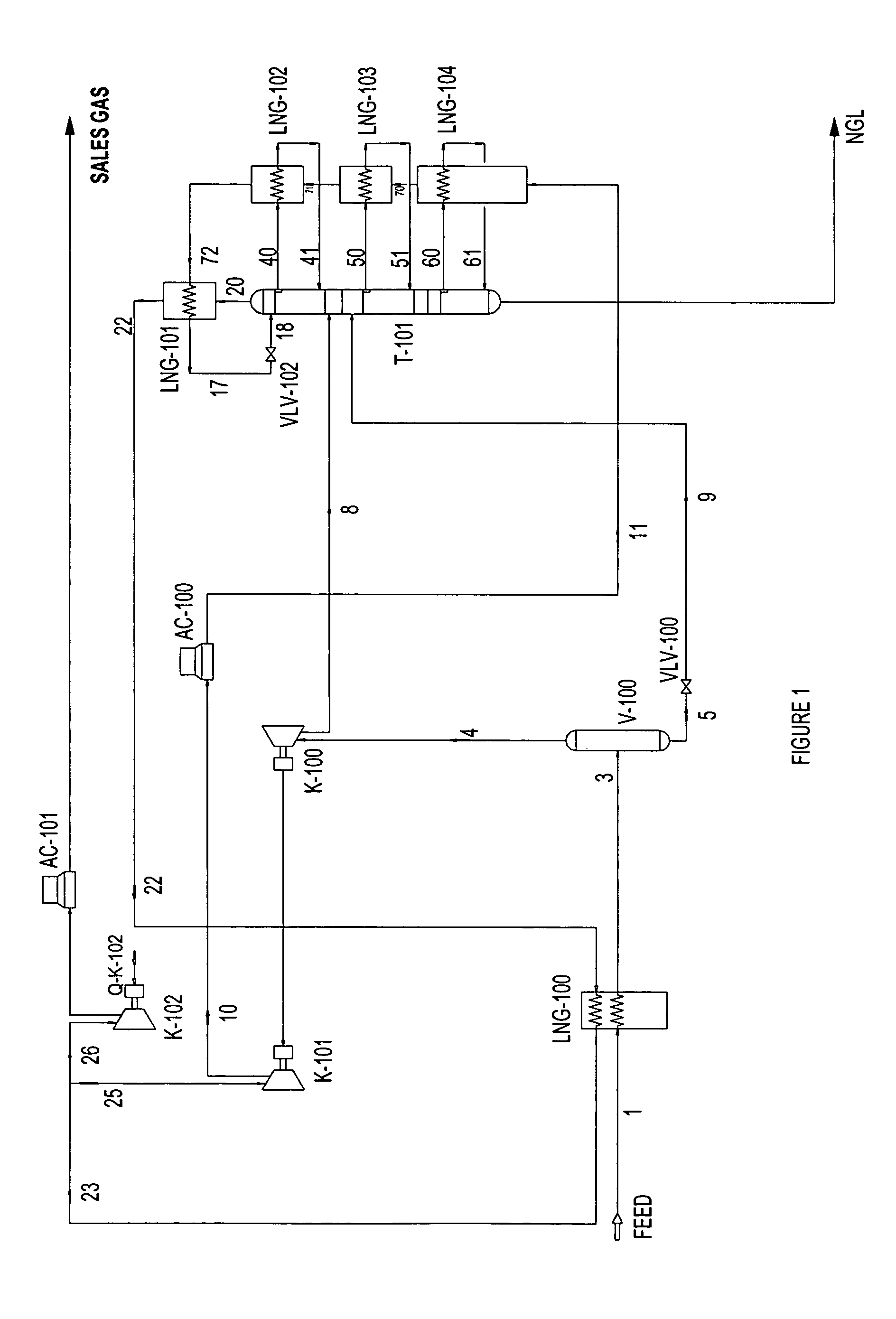

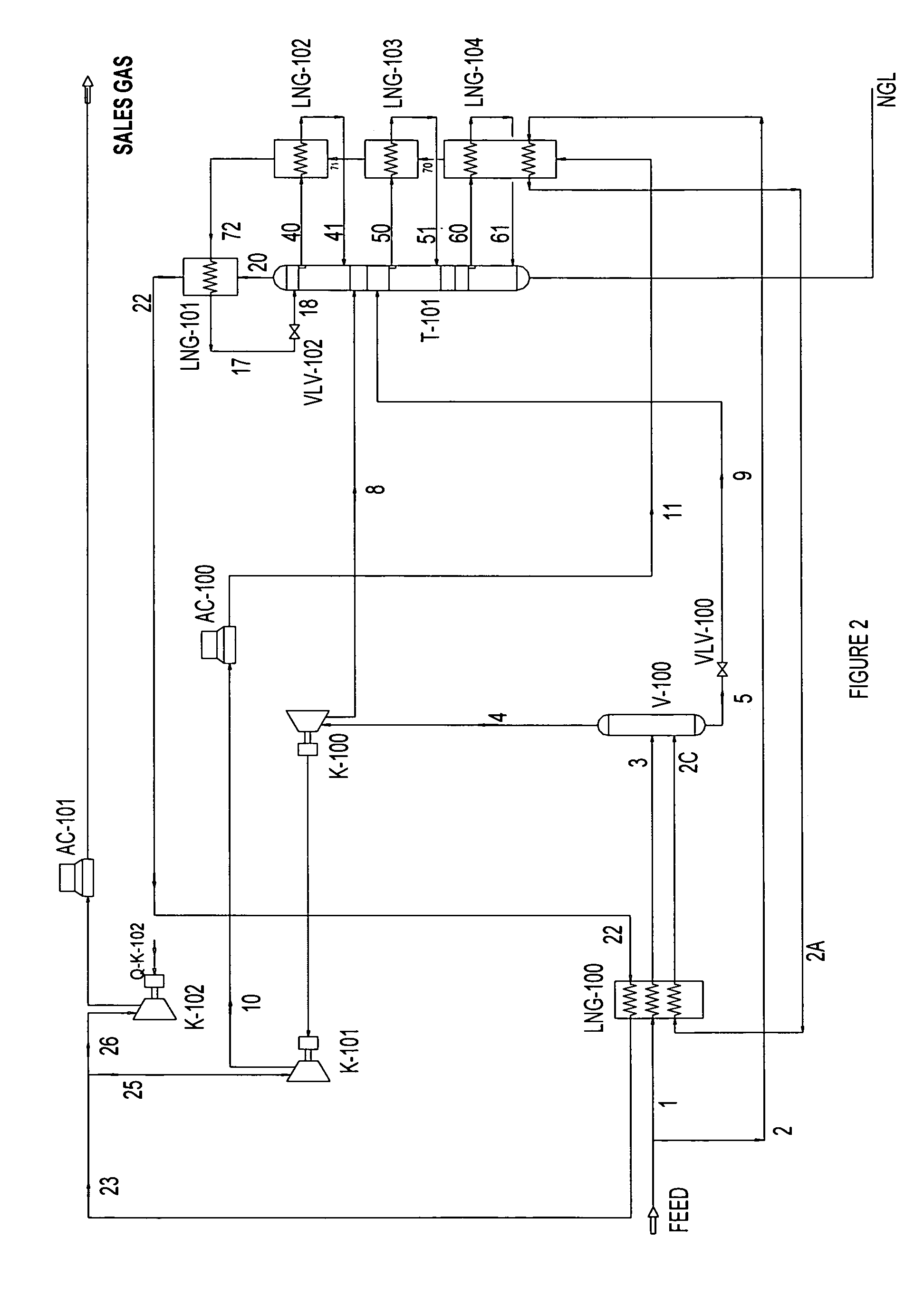

Hydrocarbon gas processing

A process for the recovery of propane, propylene and heavier hydrocarbon components from a hydrocarbon gas stream is disclosed. The stream is cooled and / or expanded to partially condense it, then separated to provide a first vapor stream. The first vapor stream is directed into a contacting device whereby vapors and liquids are formed. The liquids are directed to a distillation column operating at lower pressure wherein a second vapor stream is separated to recover a product containing the major portion of the C3 components and heavier hydrocarbon components. The second vapor stream is directed into heat exchange relation with the vapors to cool the second vapor stream and condense at least a part of it, forming a condensed stream. At least a portion of the condensed stream is directed to the contacting device to intimately contact the first vapor stream; the remaining portion (if any) of the condensed stream can be supplied to the distillation column as its top feed. The quantities and temperatures of the feeds to the contacting device and the distillation column are effective to maintain the overhead temperatures of the contacting device and the distillation column at temperatures whereby the major portion of the desired components is recovered.

Owner:ELCOR CORP

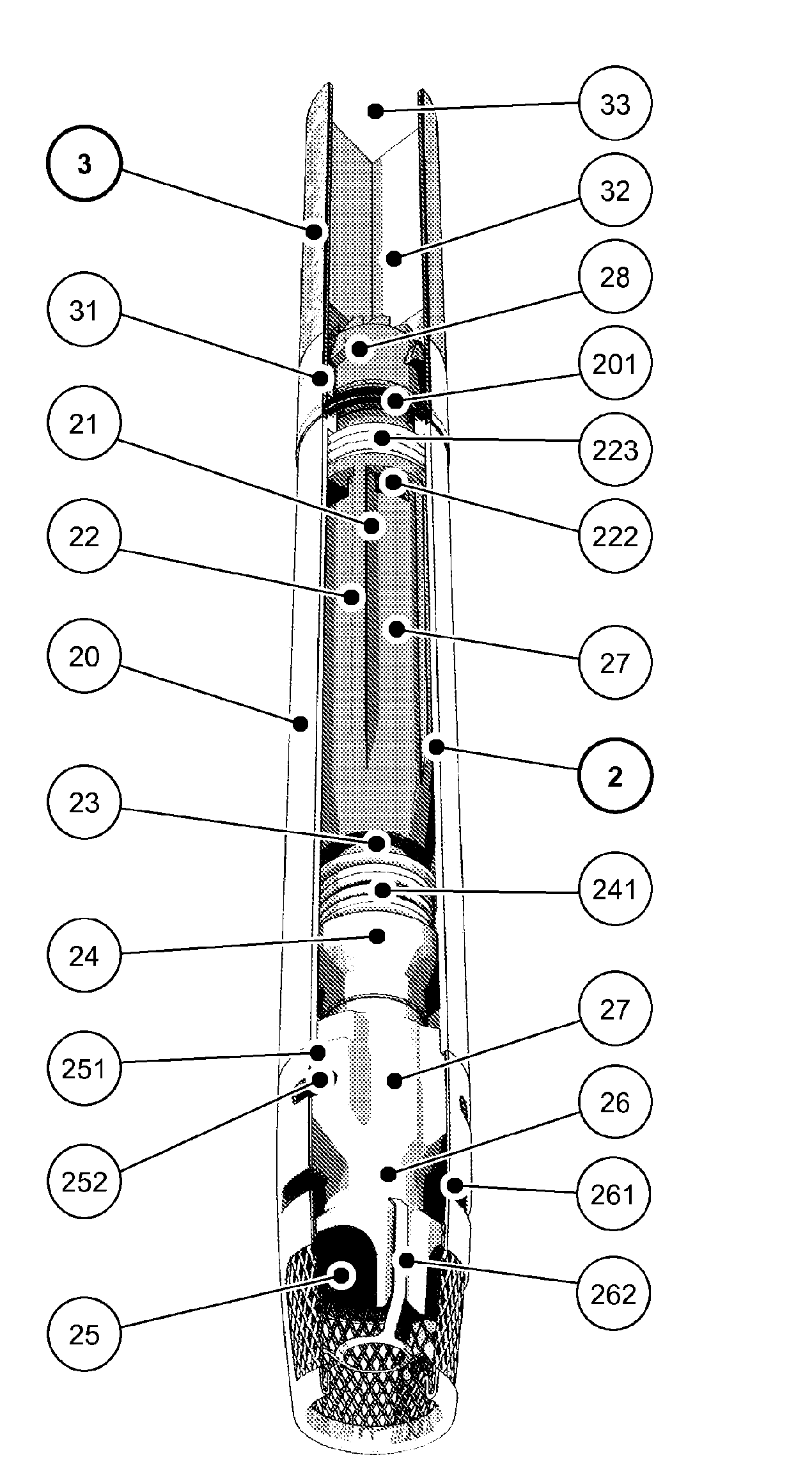

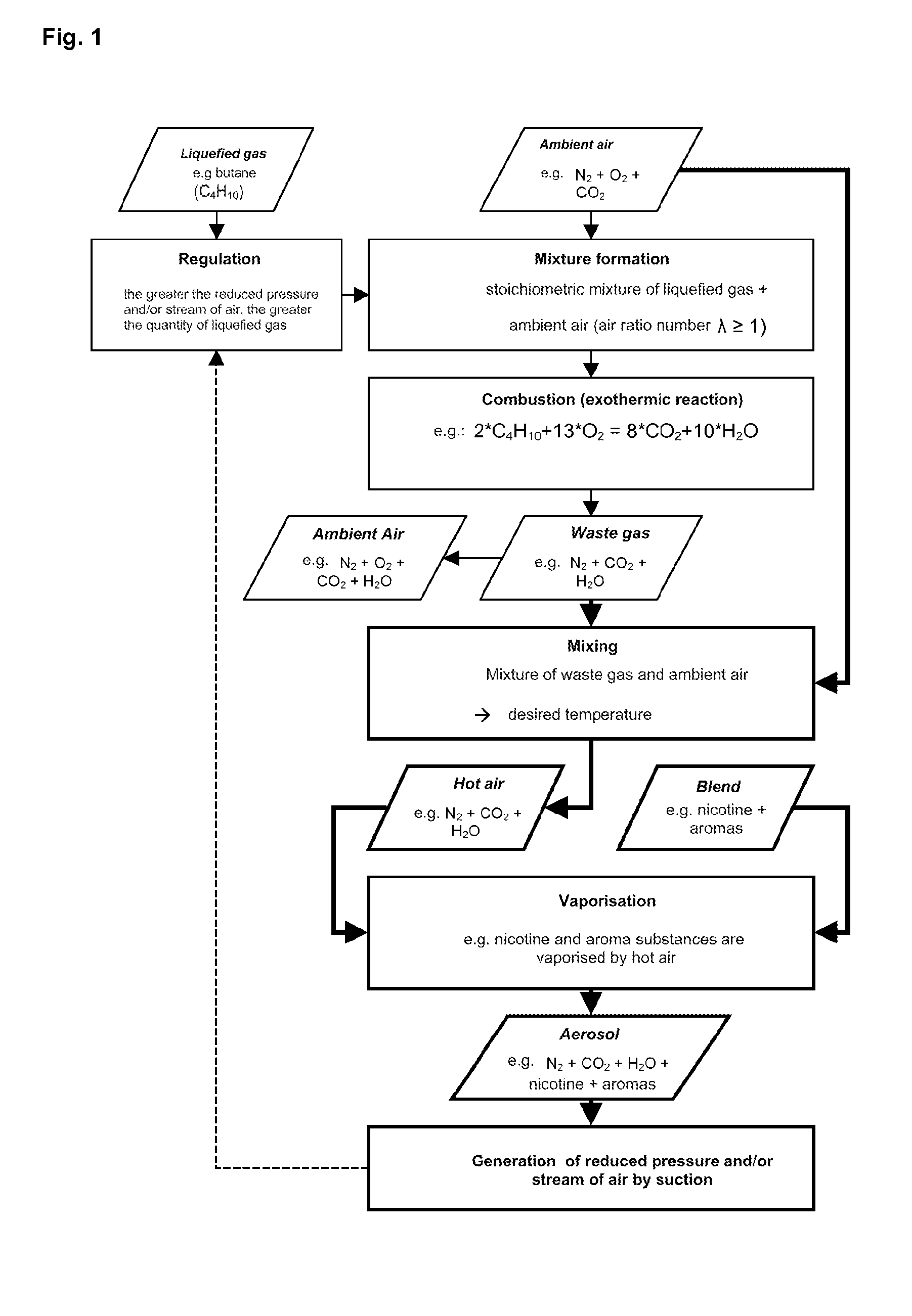

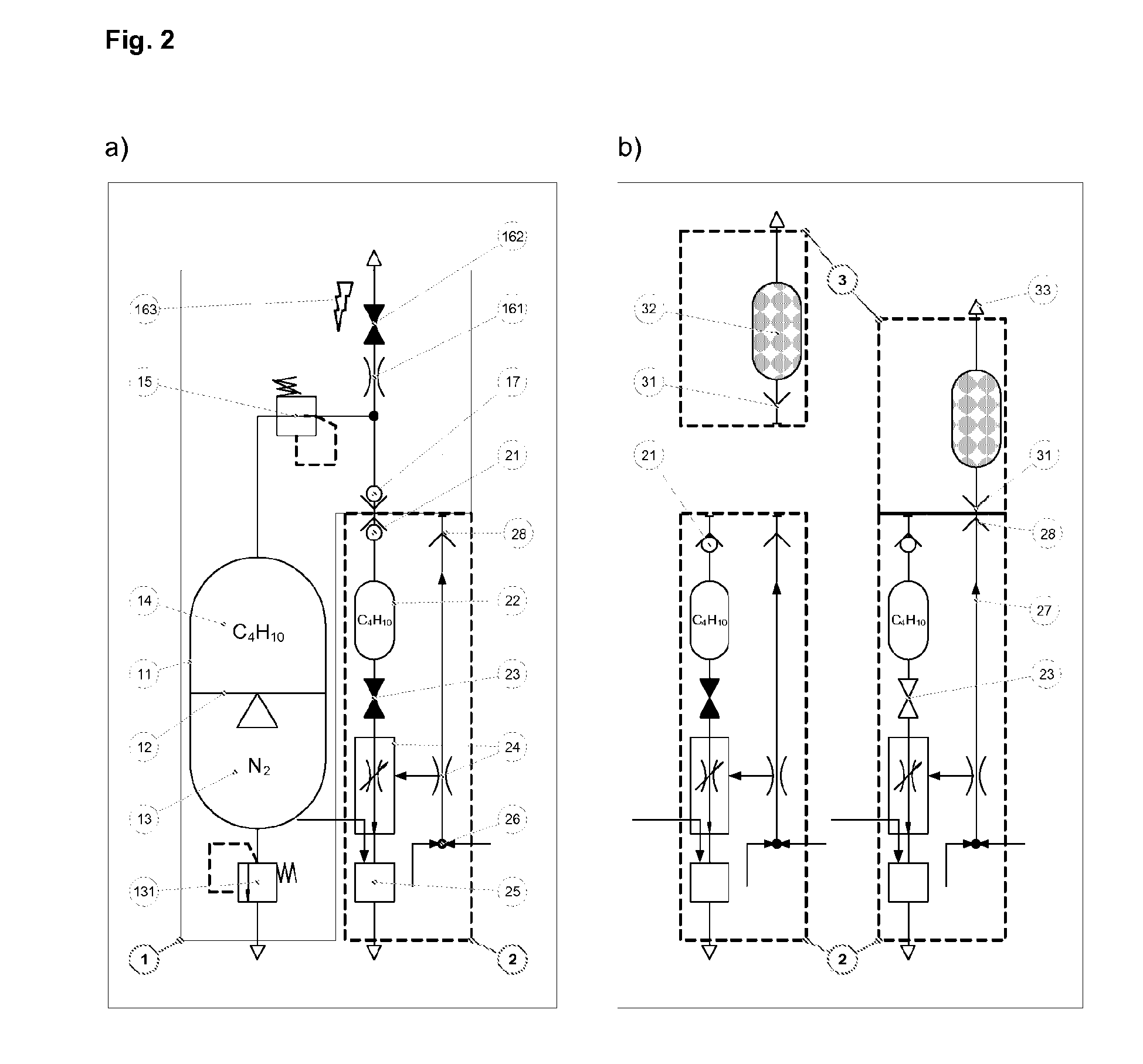

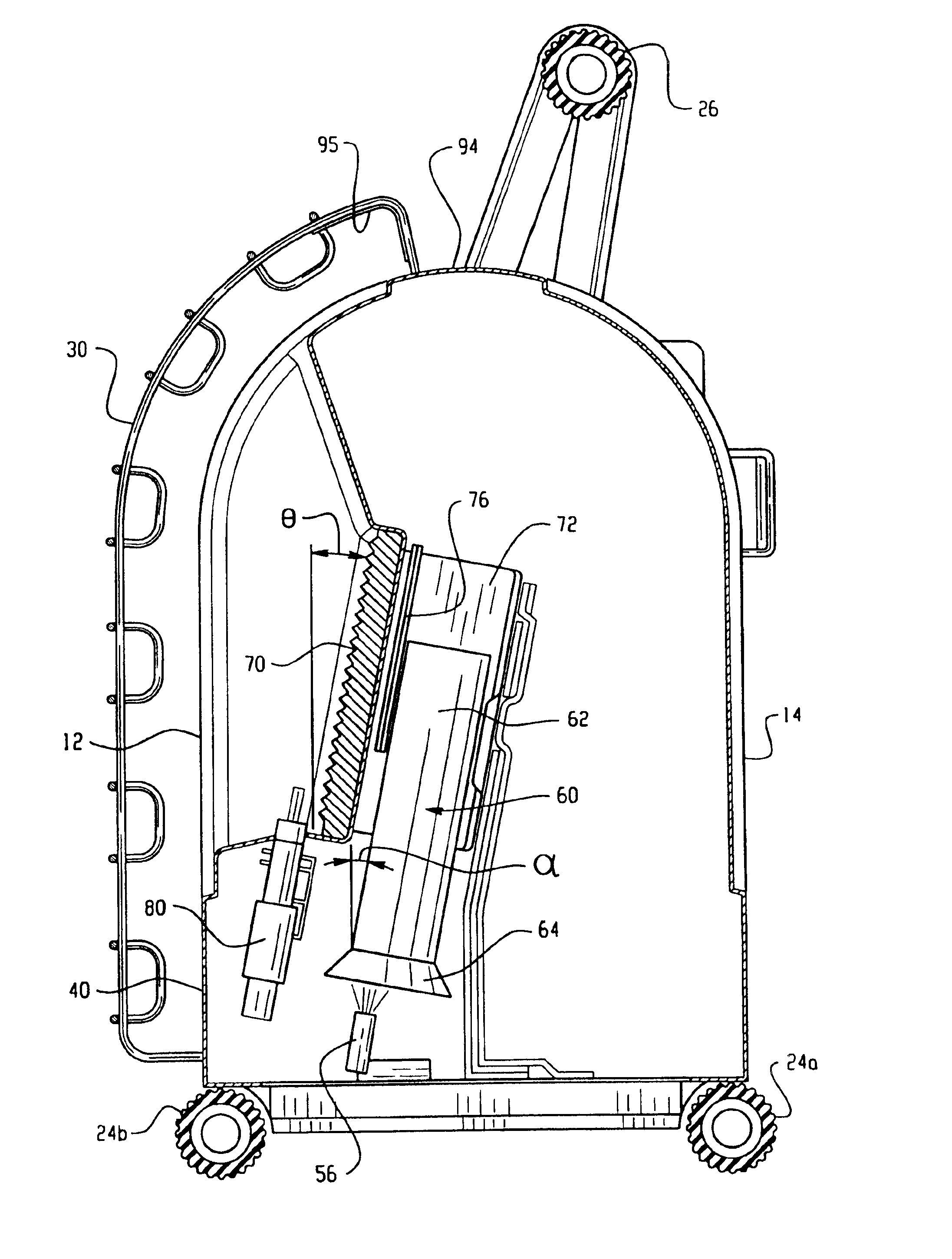

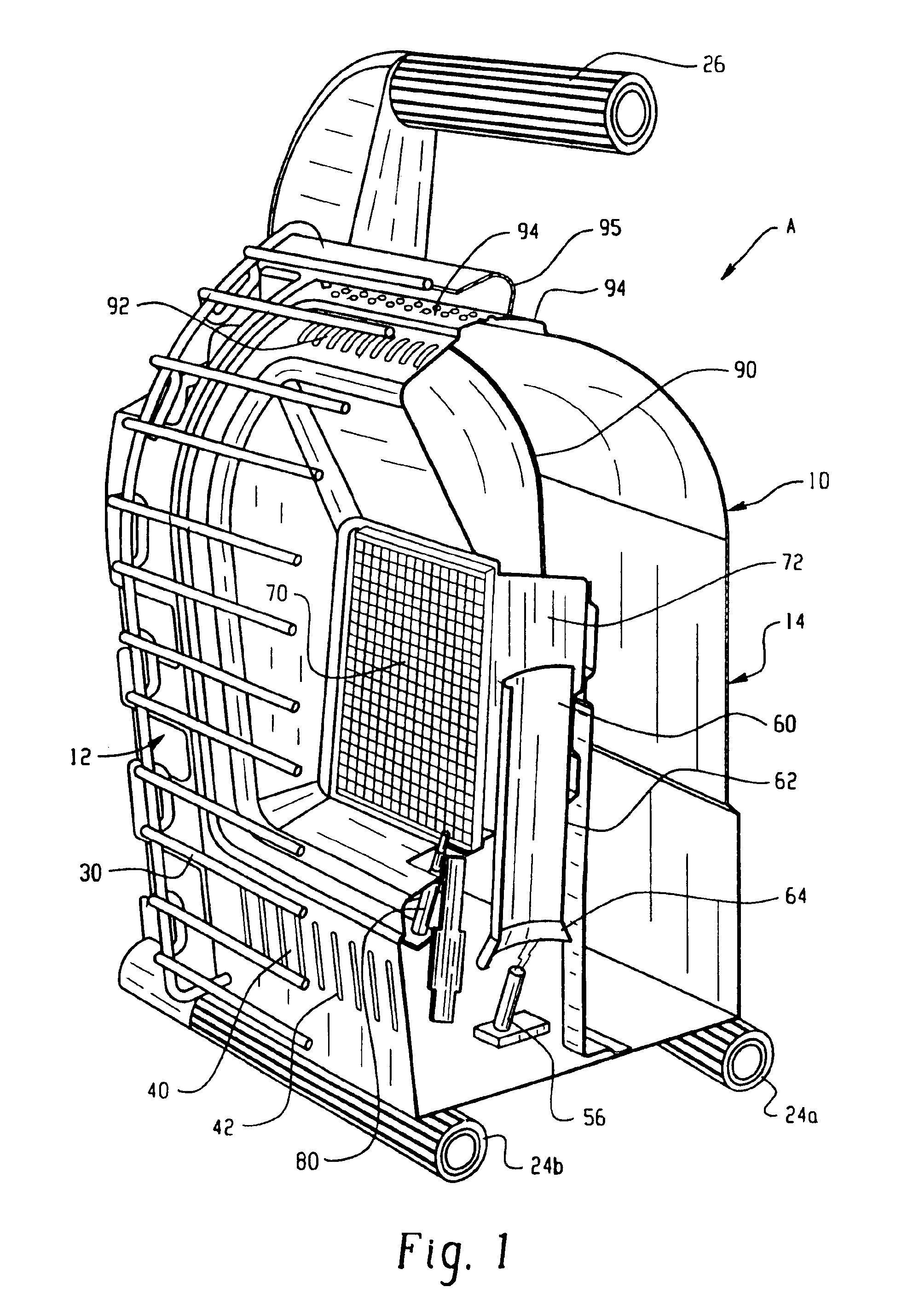

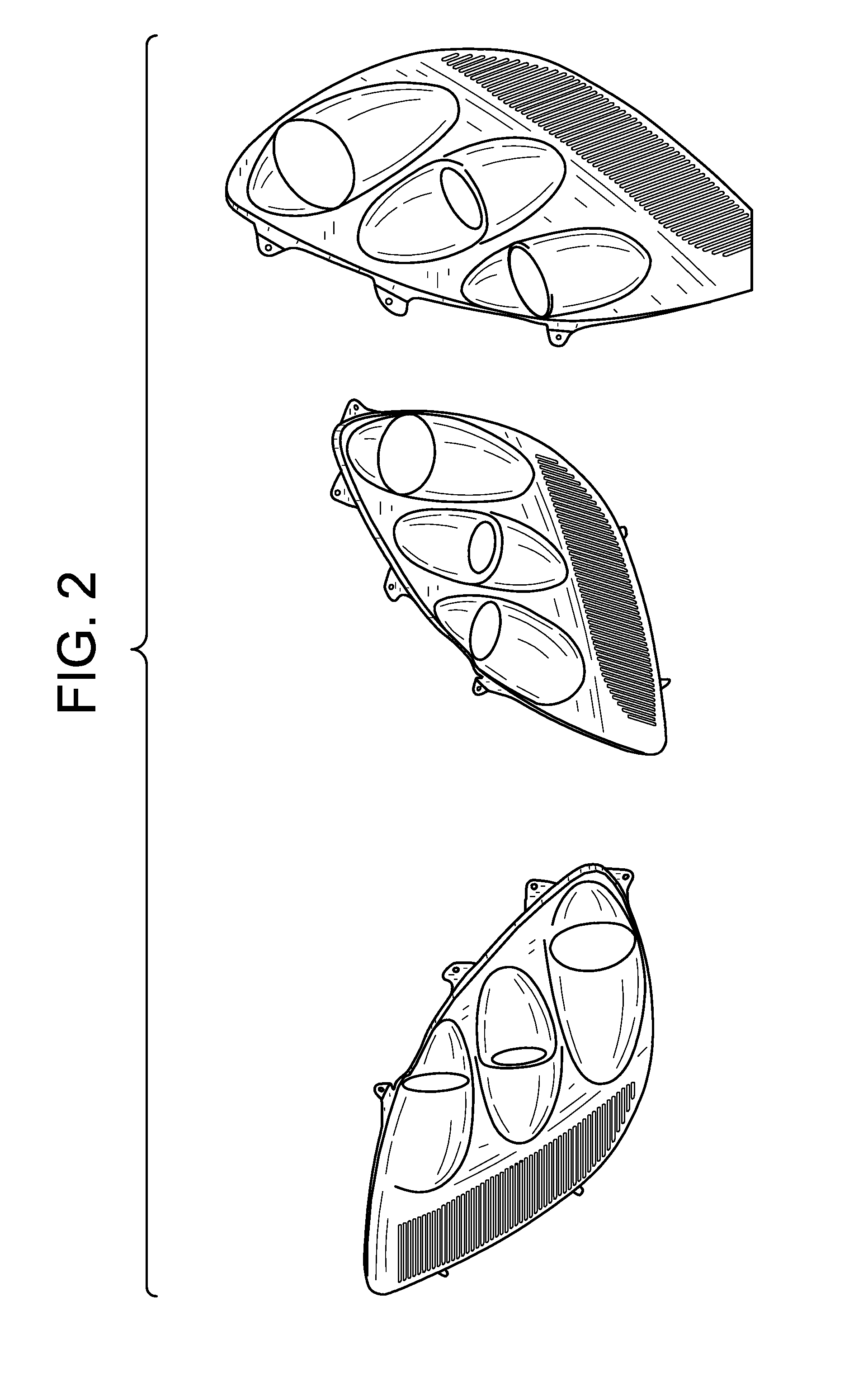

Smoke-free substitute cigarette product

ActiveUS20100126505A1Straightforwardly be carriedReduce weightTobacco treatmentTobacco devicesFlammable gasCigarillo

A method for volatilising active and / or aroma substances for the purpose of releasing an inhalable aerosol, wherein combustion gases of a flammable gas, which is preferably combusted with an excess of air, are passed partially or entirely, optionally mixed with ambient air, through an active and / or aroma substance depot and wherein a desired temperature is selectable by the proportion of combustion gases and optionally by the mixing ratio of said combustion gases with ambient air and the device implementing the method in the shape and dimensions of a cigarette or cigar for releasing an inhalable aerosol, comprising a mouthpiece (3) containing an active and / or aroma substance depot (32), a heating member (2) with a housing sleeve with one or more air inlets and one or more hot air outlets at the mouthpiece end, a filling valve (21) for filling a gas tank (22) with a flammable gas, preferably propane or butane gas, a regulating valve (24) for the controlled release of the gas from the gas tank (22) to a burner (25) and a mass transfer exchanger (26) for heating the air by the hot combustion gases produced by means of the burner (24), wherein the mouthpiece (3) is detachably connected to the heating member (2) and control of the regulating valve (24) is effected by means of the reduced pressure and / or stream of air generated by a user's suction on the mouthpiece (3). Fuelling station for such a device.

Owner:PHILIP MORRIS PROD SA

Catalyst for preparing propylene through propane catalytic dehydrogenation and preparation method thereof

InactiveCN102389831ALarge specific surface areaHigh catalytic activityMolecular sieve catalystsHydrocarbonsDehydrogenationEconomic benefits

The invention relates to a catalyst for preparing propylene through propane catalytic dehydrogenation, which is a load type platinum-based catalyst and is characterized in that home-made mesoporous molecular sieves MCM-41 are used as carriers, metal Pt is used as an active ingredient, and metals Sn, Sn-Ce or Sn-Ce-Ca are used as auxiliary agents. In a preparation method, an isovolumetric continuous immersion method is adopted for preparation. The catalyst and the preparation method have the advantages that the isovolumetric continuous immersion method is adopted for preparing multi-component catalysts, wherein the content of any one component is easy to control, the prepared catalyst has higher specific surface area (700 to 900m<2> / g) and has high catalytic activity, the propane conversion rate is high, the propylene selectivity is good, the one-path stability is good, in addition, the service life is longer, the preparation method of the catalyst carriers is simple and feasible, the economic benefit is obvious, and good industrial development and application prospects are realized.

Owner:NANKAI UNIV

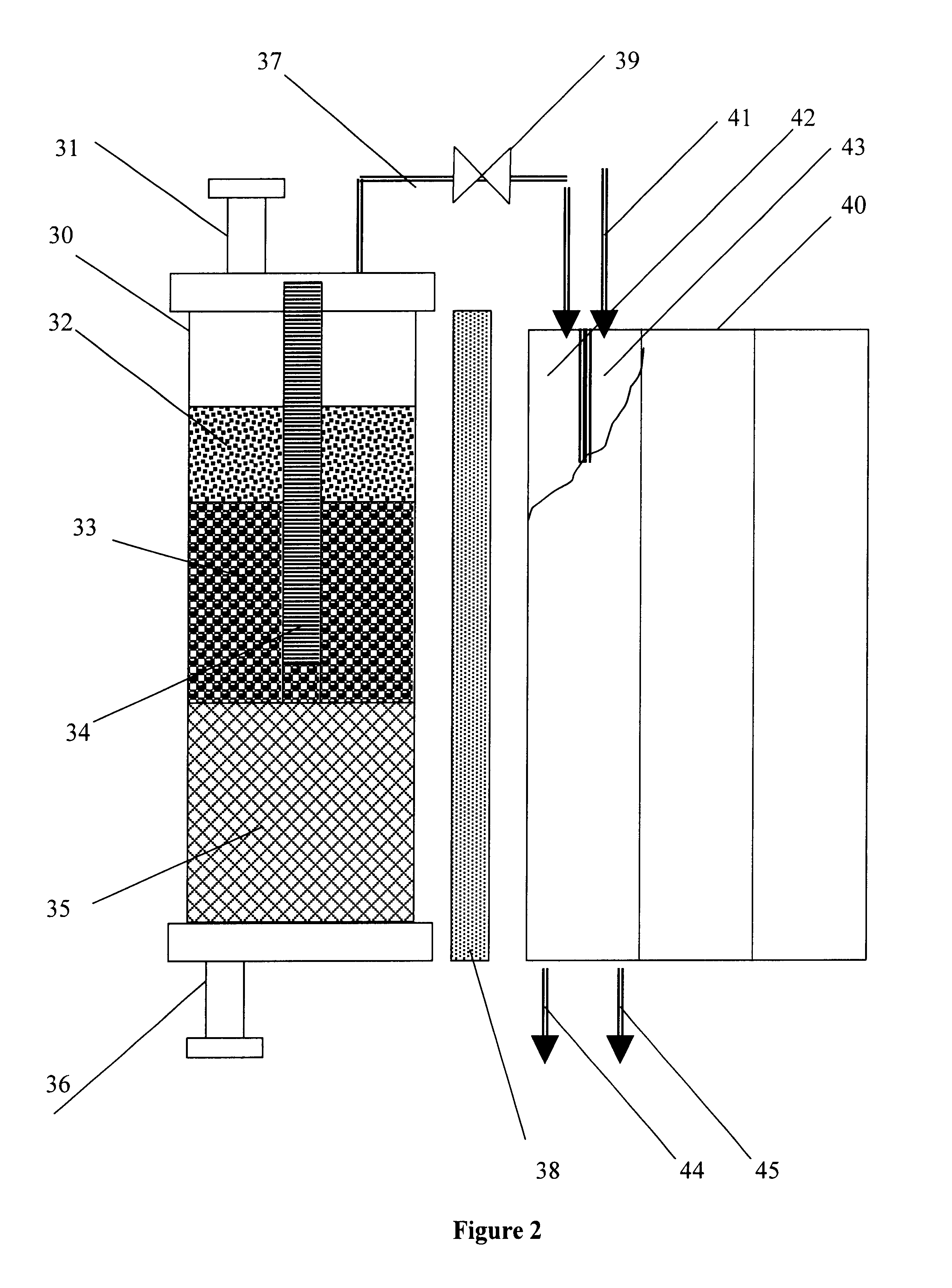

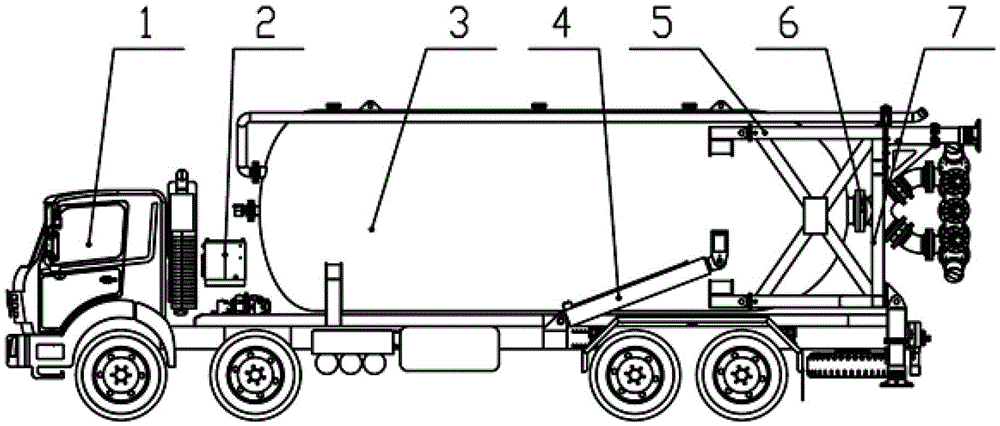

Fracturing sand mixing device

The invention provides a fracturing sand mixing device used for mixing fracturing fluid. The fracturing sand mixing device comprises a solid conveying device and a solid-liquid mixing device communicated with the solid conveying device, wherein the solid-liquid mixing device is a pressure container. The solid-liquid mixing device comprises a solid lead-in port capable of leading in solid particles of the fracturing fluid output by the solid conveying device, a base fluid lead-in port for leading in base fluid of the fracturing fluid, a mixing inner cavity for accommodating the solid particles and the base fluid and a solid-liquid lead-out port for leading out the fracturing fluid formed by mixing. Substances such as carbon dioxide or petroleum gas which are in a gas state under normal temperature can be kept in a liquid state by high pressure through the fracturing sand mixing device and are mixed with the solid particles to form the fracturing fluid, and the goal of preparing the fracturing fluid with liquid carbon dioxide or liquefied petroleum gas (propane) serving as the base fluid is achieved.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

A fracturing sand mixing device

The invention provides a fracturing sand mixing device used for mixing fracturing fluid. The fracturing sand mixing device comprises a solid-liquid mixing device, and the solid-liquid mixing device is a pressure container. The solid-liquid mixing device comprises a solid lead-in port capable of leading in solid particles of the fracturing fluid, a base fluid lead-in port for leading in base fluid of the fracturing fluid, a mixing inner cavity for accommodating the solid particles and the base fluid and a solid-liquid lead-out port for leading out the fracturing fluid formed by mixing. Substances such as carbon dioxide or petroleum gas which are in a gas state under normal temperature can be kept in a liquid state by high pressure through the fracturing sand mixing device and are mixed with the solid particles to form the fracturing fluid, and the goal of preparing the fracturing fluid with liquid carbon dioxide or liquefied petroleum gas (propane) serving as the base fluid is achieved.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

A fracturing sand mixing device

The invention provides a fracturing sand mixing device used for mixing fracturing fluid. The fracturing sand mixing device comprises a solid conveying device and a solid-liquid mixing device communicated with the solid conveying device, wherein the solid-liquid mixing device is a pressure container. The solid-liquid mixing device comprises a solid lead-in port capable of leading in solid particles of the fracturing fluid output by the solid conveying device, a base fluid lead-in port for leading in base fluid of the fracturing fluid, a mixing inner cavity for accommodating the solid particles and the base fluid and a solid-liquid lead-out port for leading out the fracturing fluid formed by mixing. Substances such as carbon dioxide or petroleum gas which are in a gas state under normal temperature can be kept in a liquid state by high pressure through the fracturing sand mixing device and are mixed with the solid particles to form the fracturing fluid, and the goal of preparing the fracturing fluid with liquid carbon dioxide or liquefied petroleum gas (propane) serving as the base fluid is achieved.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

Gas fired portable unvented infrared heater

InactiveUS6884065B2Reduce the temperatureIncrease air velocityMechanical apparatusDomestic stoves or rangesFresh airEngineering

A portable heater adapted for use in a recreational enclosure or temporary work enclosure includes a housing having an air inlet on the lower front face. A gas supply is partially enclosed by the housing which provides propane to the mouth of a burner venturi located within the housing. Air is drawn through the air inlet and also enters the mouth of the burner venturi. The air and gas are mixed thoroughly as they travel upwardly through the burner venturi. A chimney effect increases fresh air flow velocity into the burner venturi and allows the heater to operate at a reduced fuel gas pressure. Upon exiting the burner venturi, the air / gas mixture is to a plenum and radiant surface where combustion takes place. Any conventional means may be provided to ignite the air / gas mixture in order to cause combustion. The combustion products deflect off a deflector, which is cooled on a rear face by air flow through the housing, which decreases the temperature of the combustion products before exiting an outlet. An oxygen depletion system (ODS) shuts off the portable heater when oxygen levels begin to drop and consequently carbon monoxide levels begin to rise.

Owner:ENERCO GROUP

Articles derived from compositions containing modified polybutylene terephthalate (PBT) random copolymers derived from polyethylene terephthalate (PET)

ActiveUS20070275242A1Useful performance propertyPlastic recyclingSpecial tyresPolytetramethylene terephthalatePolyethylene terephthalate glycol

Compositions of matter including articles derived from (a) from 5 to 99.99 wt % of a modified polybutylene terephthalate random copolymer that (1) is derived from polyethylene terephthalate and (2) contains a at least one residue derived from polyethylene terephthalate selected from the group consisting of antimony, germanium, diethylene glycol groups, isophthalic acid groups, cis isomer of cyclohexane dimethanol, trans isomer of cyclohexane dimethanol, sodium benzoate, alkali salts, napthalane dicarboxylic acids, 1,3-propane diols, cobalt, cobalt-containing compounds, and combinations thereof, and (b) from 0.01 to 95 wt. % of a member selected from the group consisting of (1) fillers, (2) a carboxy reactive component, (3) polyethyelene terephthalate, (4) a component including a polycarbonate and an impact modifier. The articles may be derived from various conversion processes, e.g., injection molding processes, extrusion processes, thermoforming processes, melt-blown process.

Owner:SHPP GLOBAL TECH BV

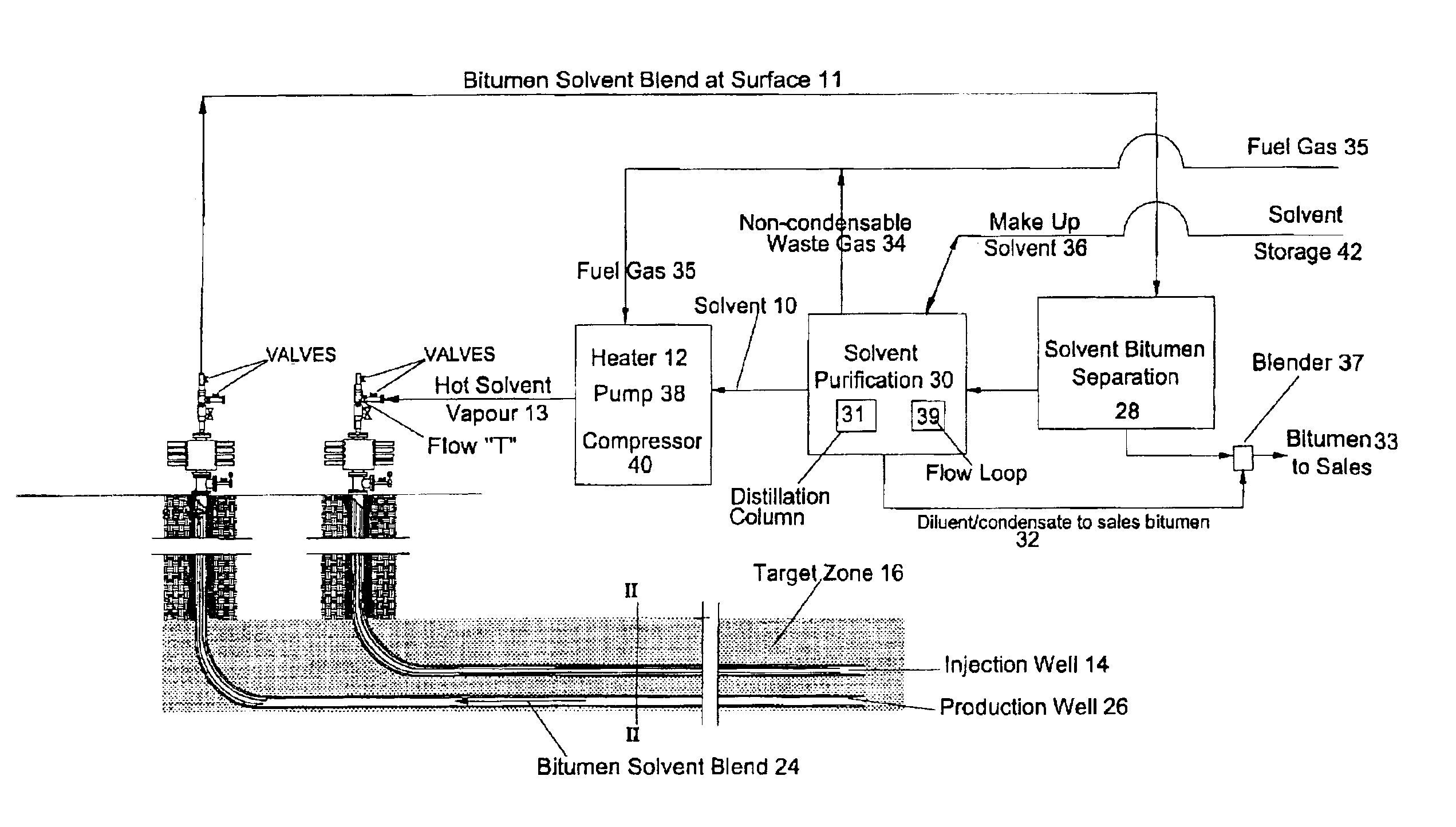

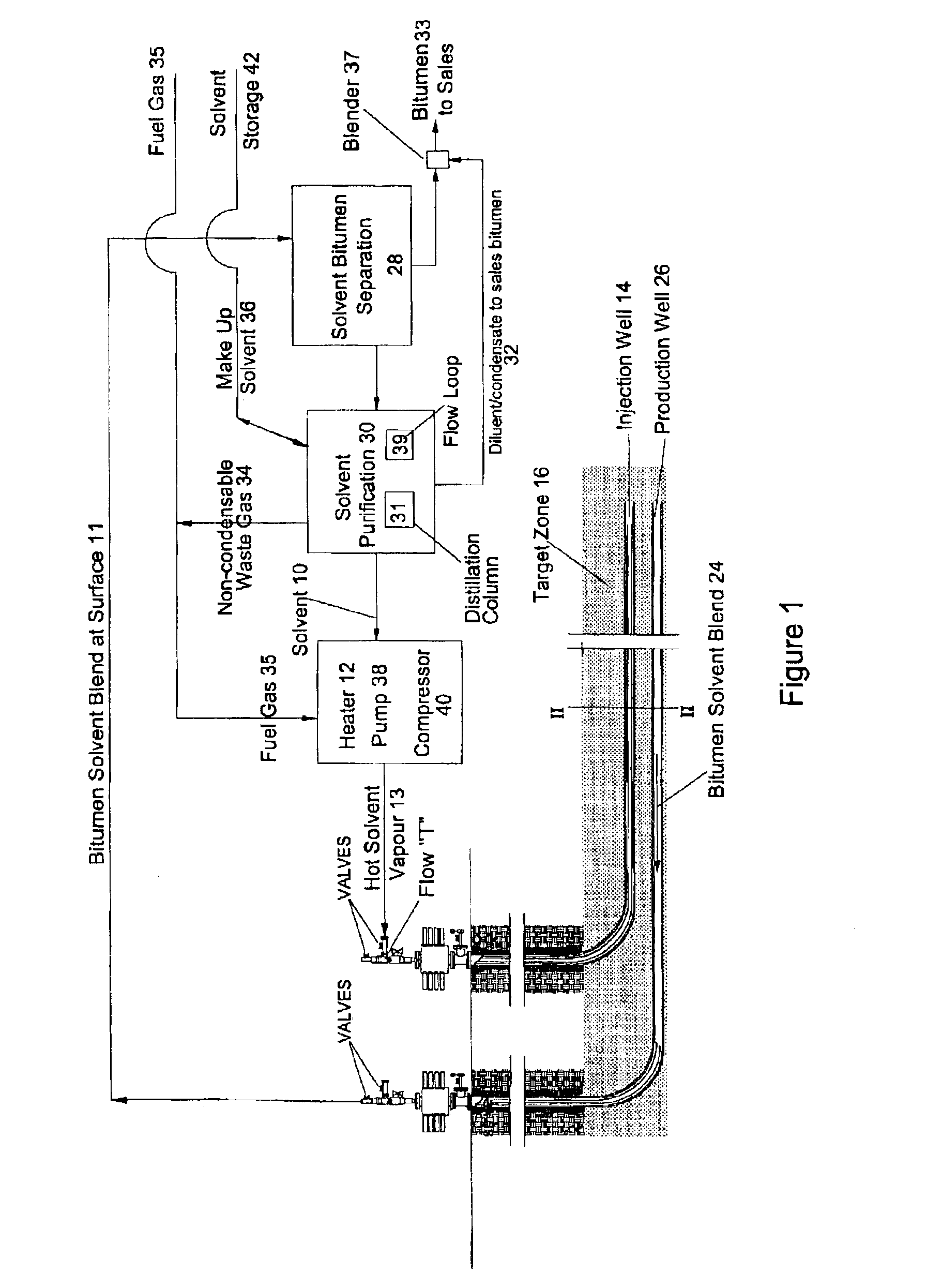

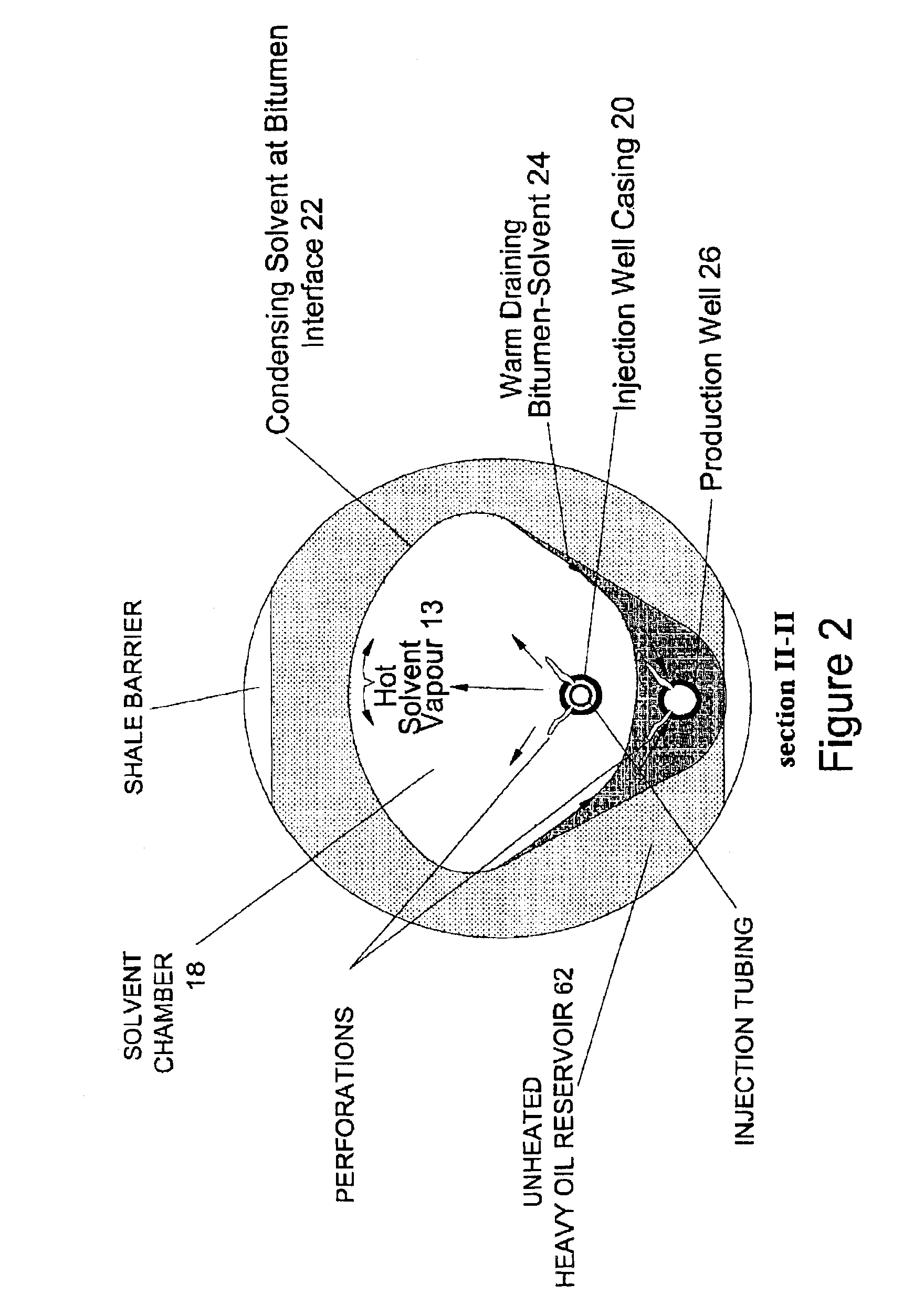

Method and apparatus for stimulating heavy oil production

InactiveUS6883607B2Reduce the total massReduce transferInsulationFluid removalFuel oilOil production

A process for the recovery of hydrocarbons from a hydrocarbon bearing formation having an extraction chamber where the extraction chamber has an extraction surface. The process has the steps of heating a solvent, such as propane, and then placing the solvent into the extraction chamber at a temperature and a pressure sufficient for the solvent to be in a vapor state in the chamber and to condense on the extraction surface. The next step is to produce a liquid blend of solvent and heavy oil and then to separate the solvent from said heavy oil. Then the solvent is purified, before being re-injected into the formation again. The purification step removes less condensable fractions from the solvent to ensure a purity that is high enough to support continued heat transfer at extraction conditions. The pressure and temperature are set to levels to cause less condensable fractions to drain away with the liquid bitumen and solvent blend that is produced, thus mitigating heat transfer poisoning.

Owner:HATCH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com