Patents

Literature

1000 results about "Glow discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A glow discharge is a plasma formed by the passage of electric current through a gas. It is often created by applying a voltage between two electrodes in a glass tube containing a low-pressure gas. When the voltage exceeds a value called the striking voltage, the gas ionization becomes self-sustaining, and the tube glows with a colored light. The color depends on the gas used.

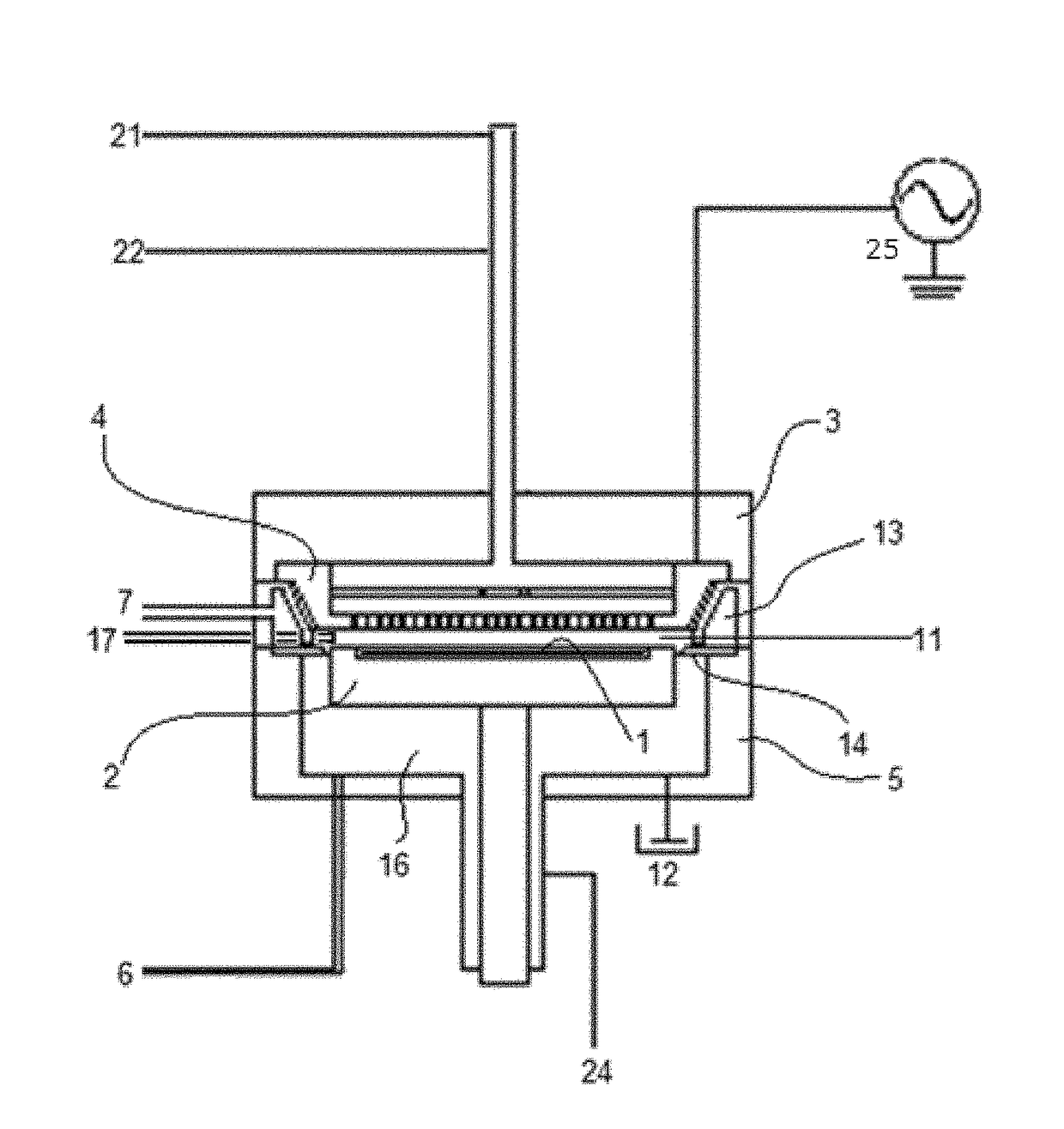

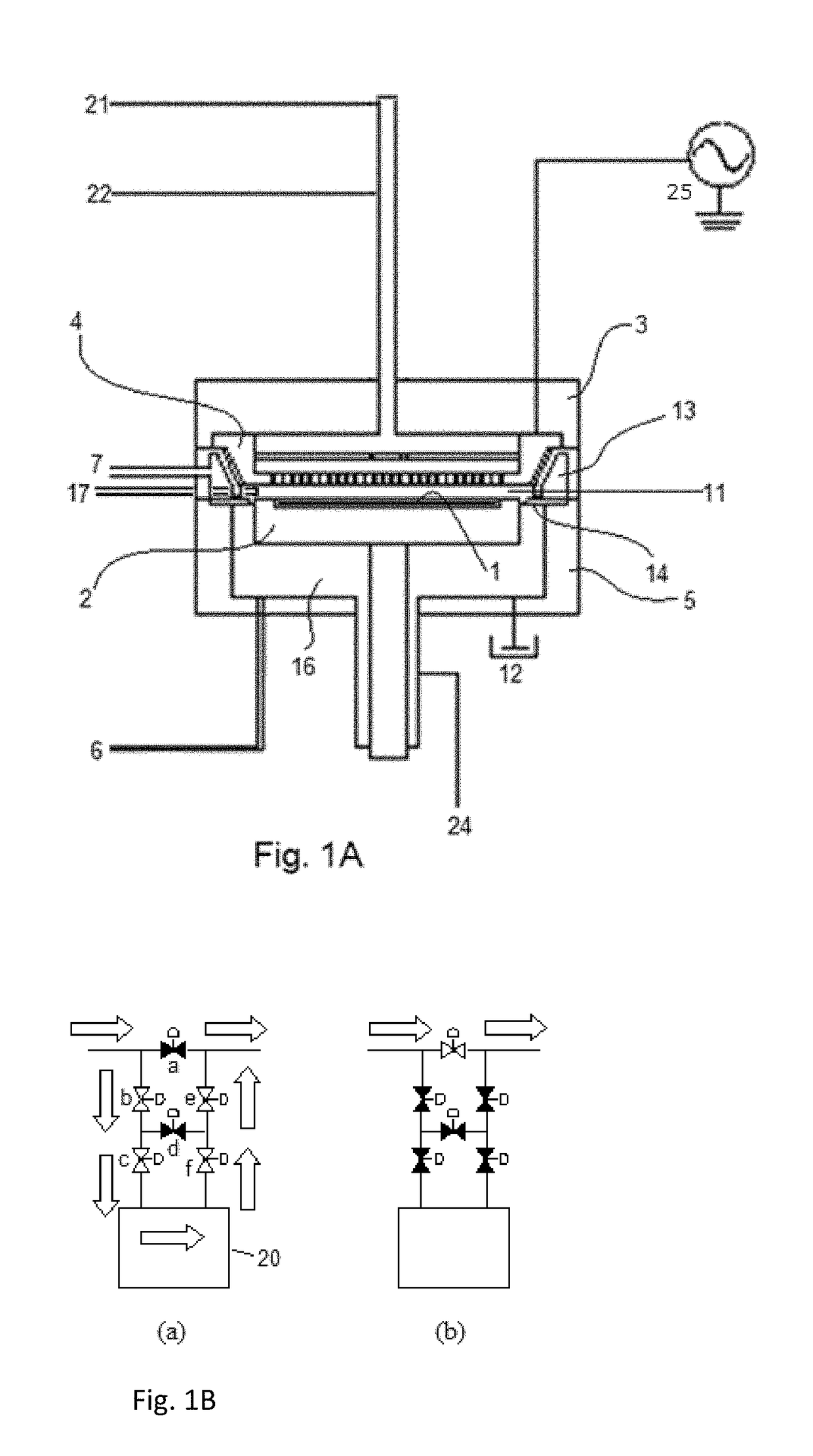

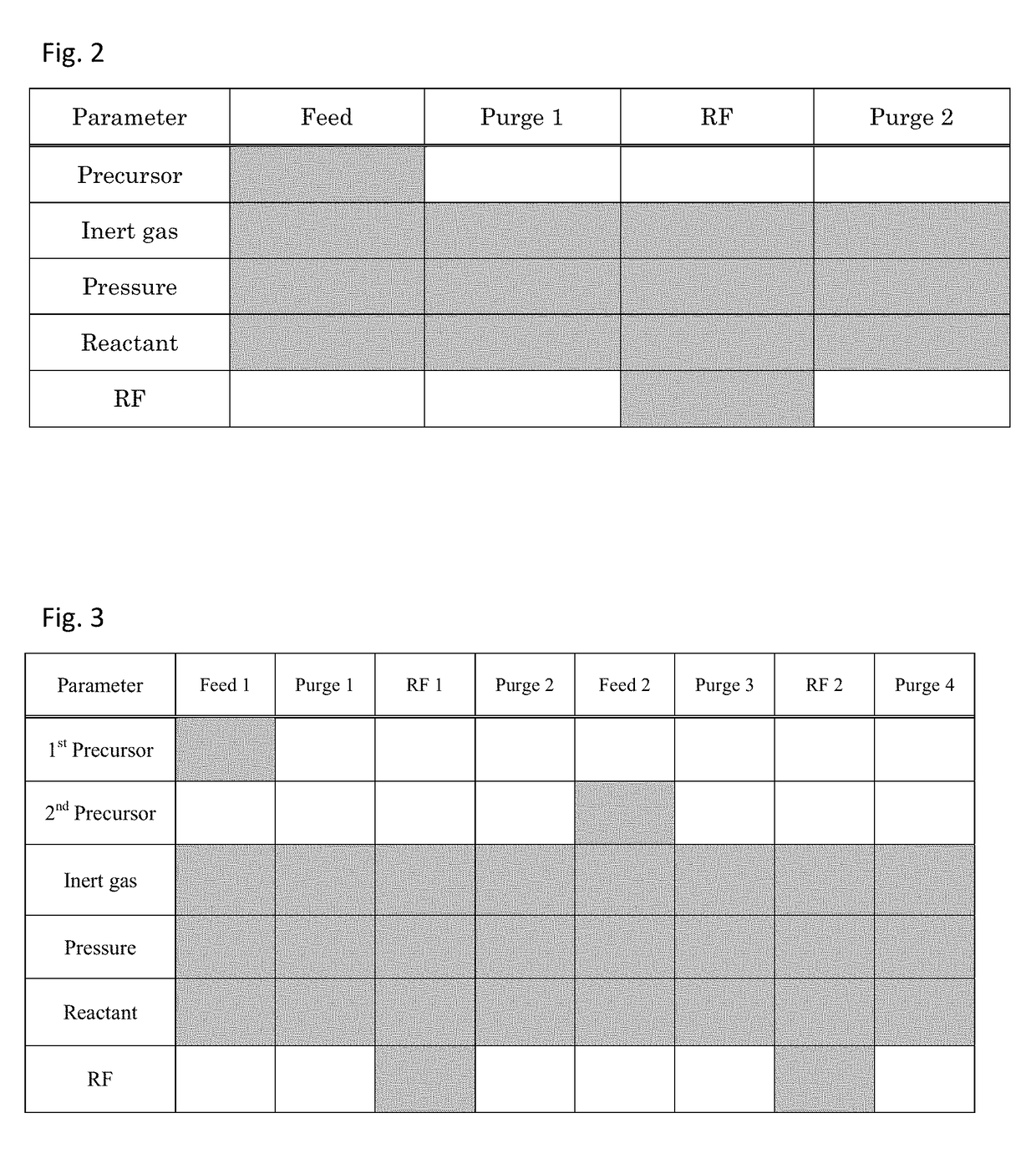

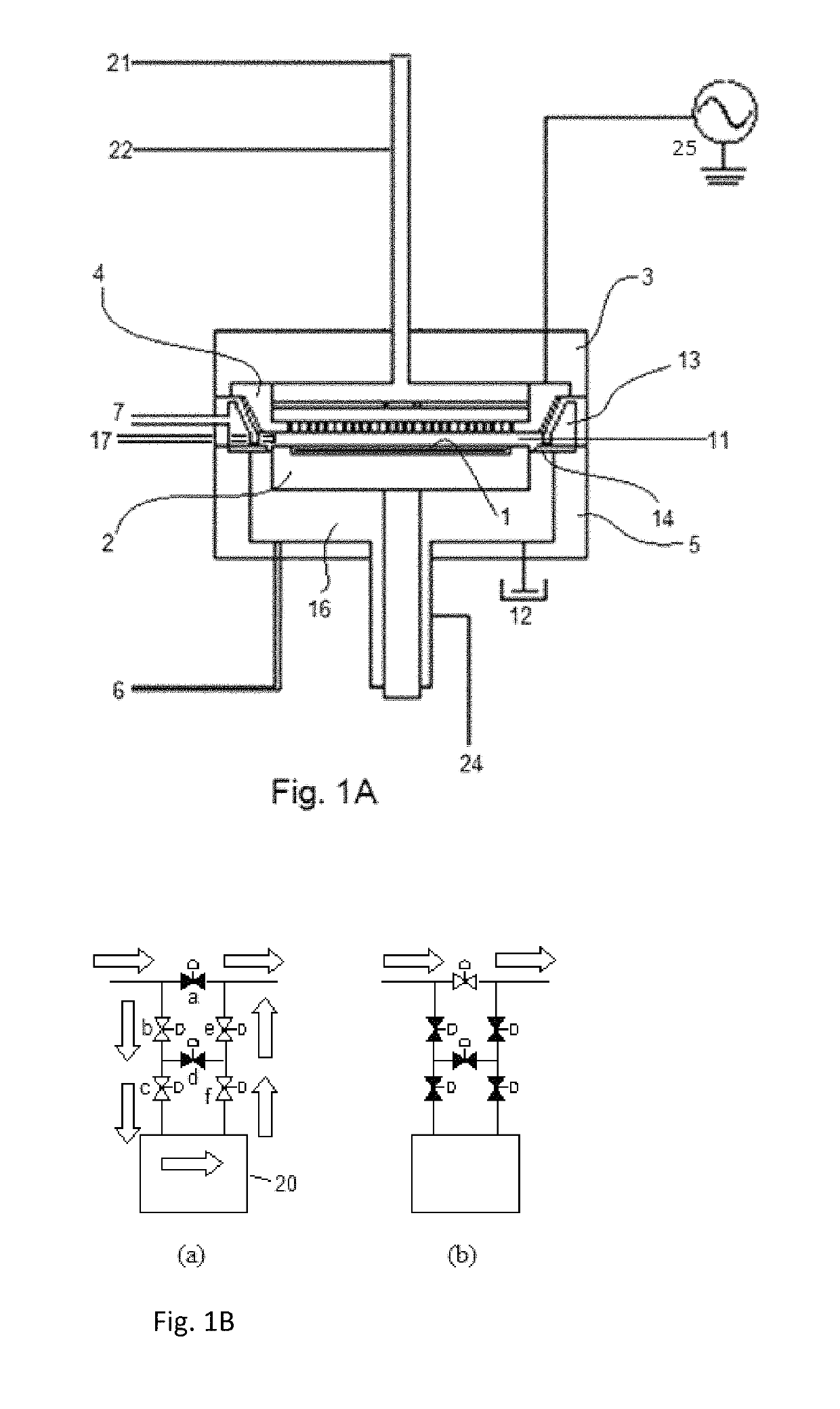

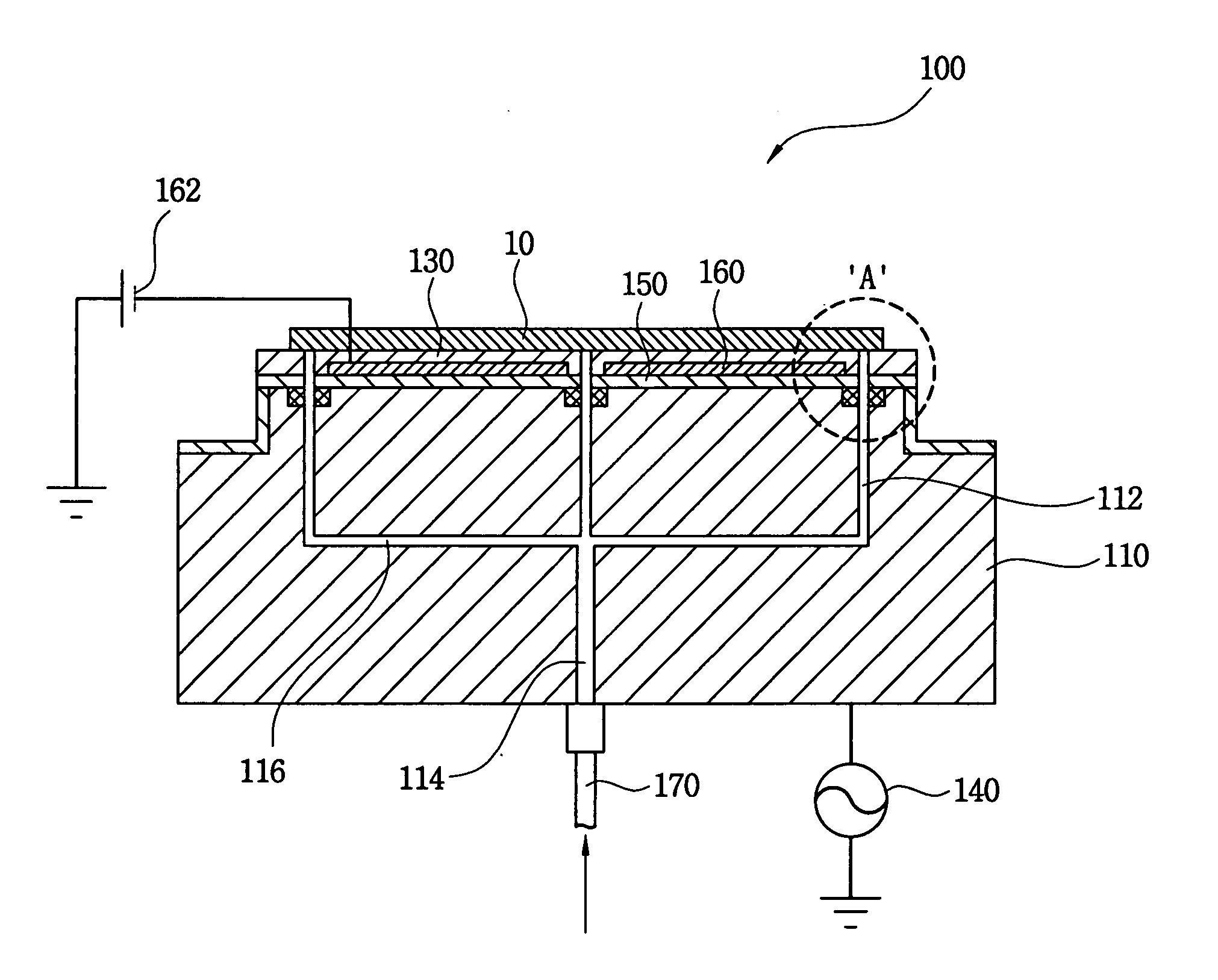

Method of subatmospheric plasma-enhanced ald using capacitively coupled electrodes with narrow gap

ActiveUS20180119283A1Poor conformalityGood shape retentionElectric discharge tubesChemical vapor deposition coatingCapacitanceParallel plate

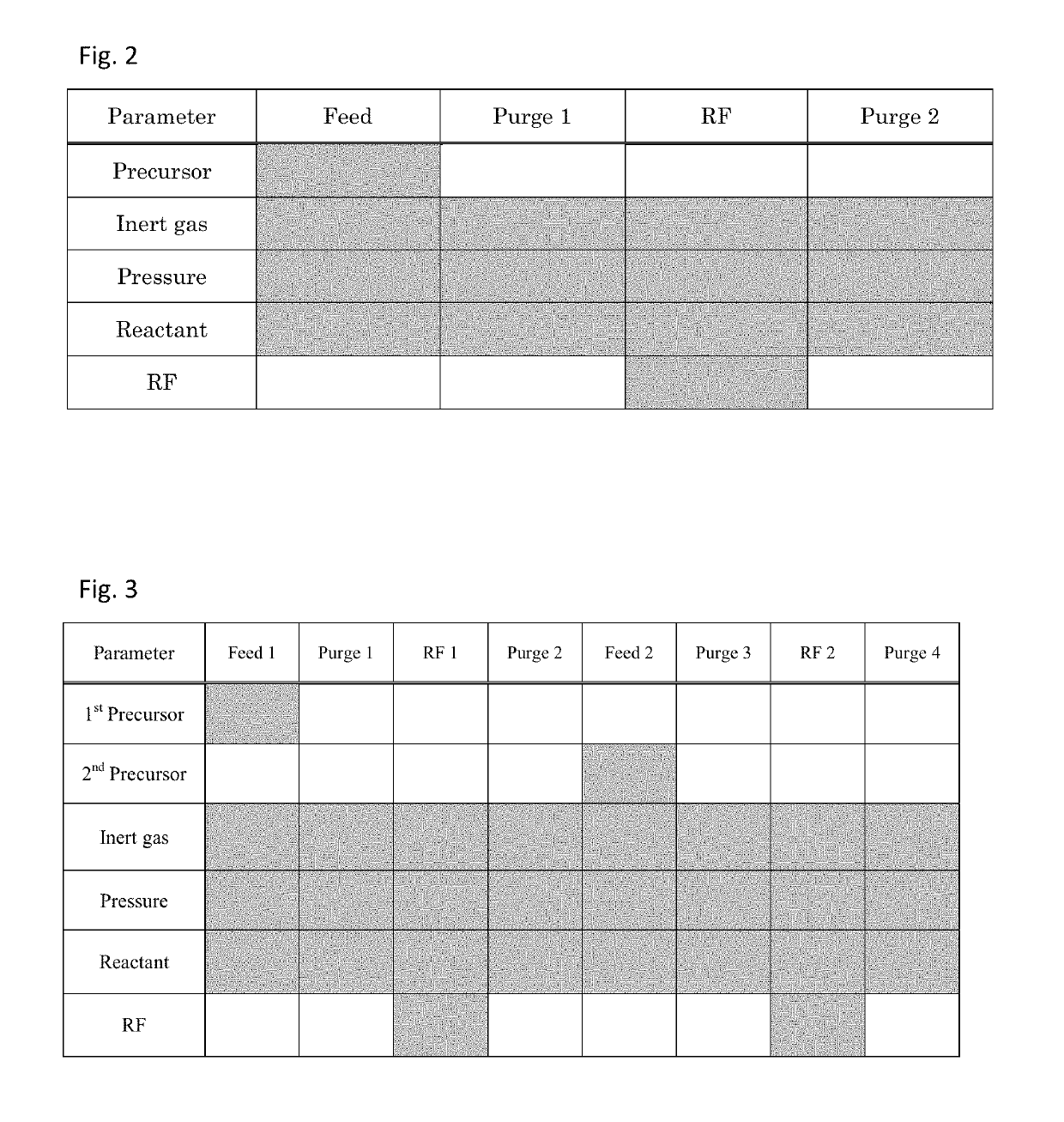

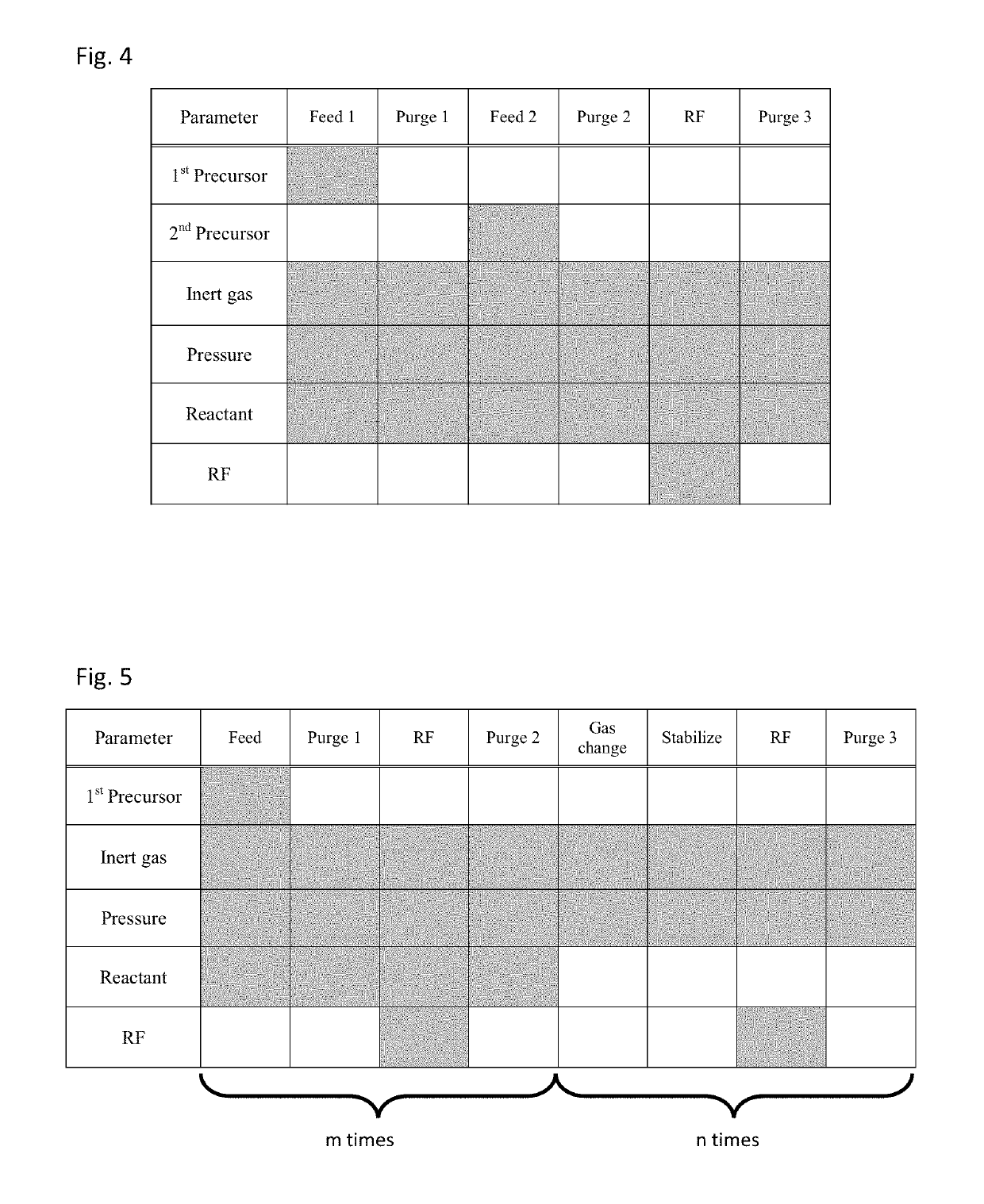

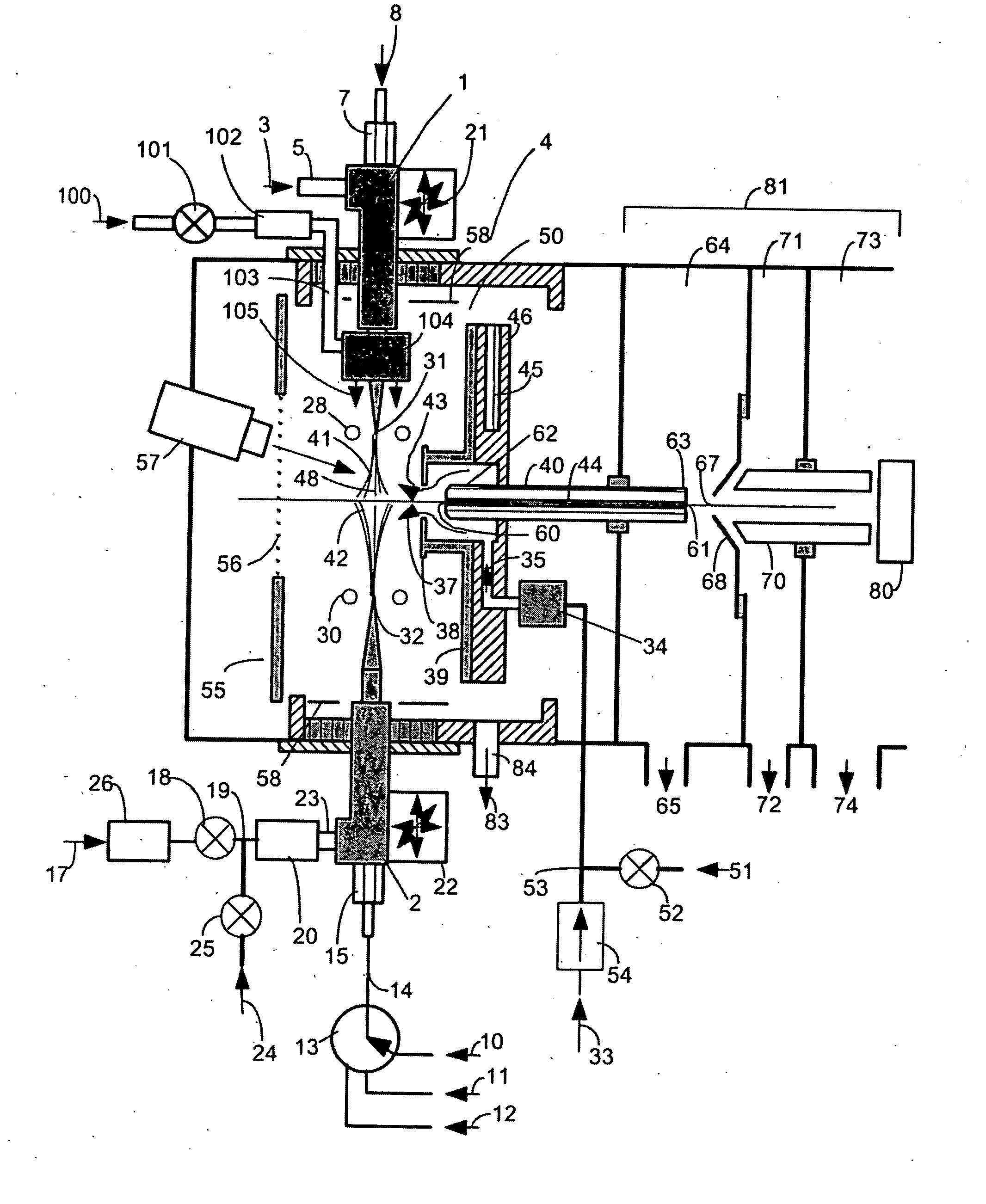

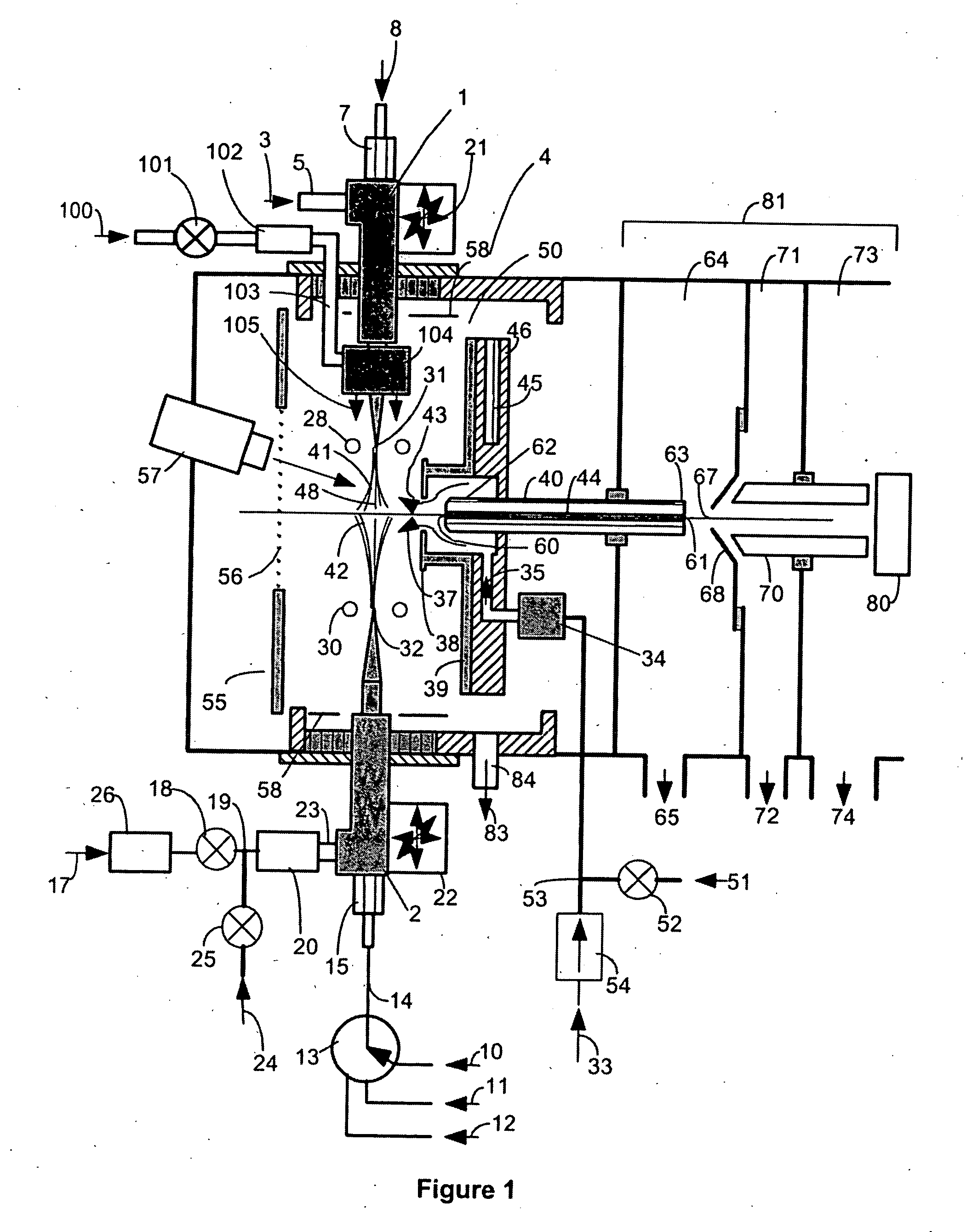

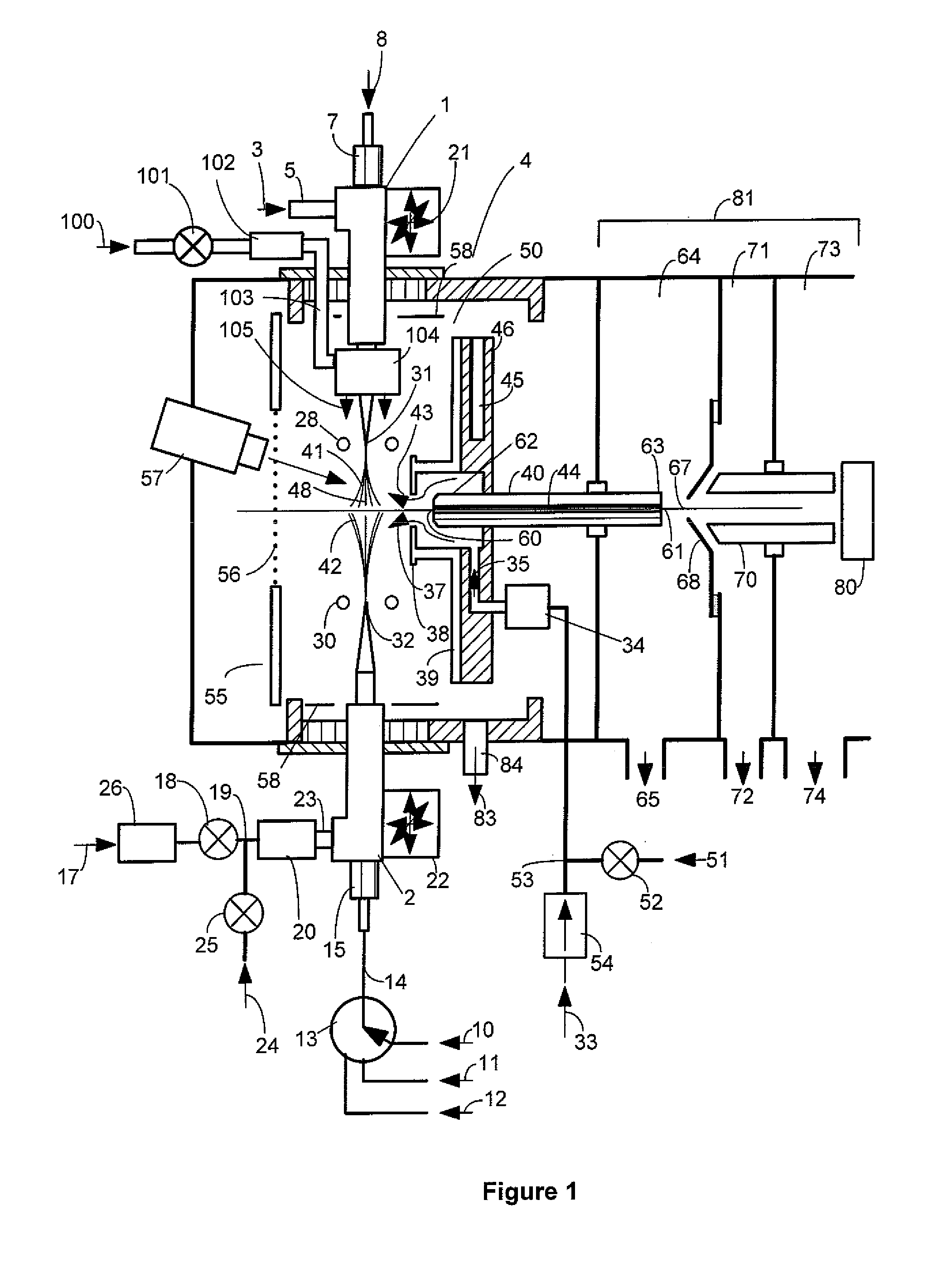

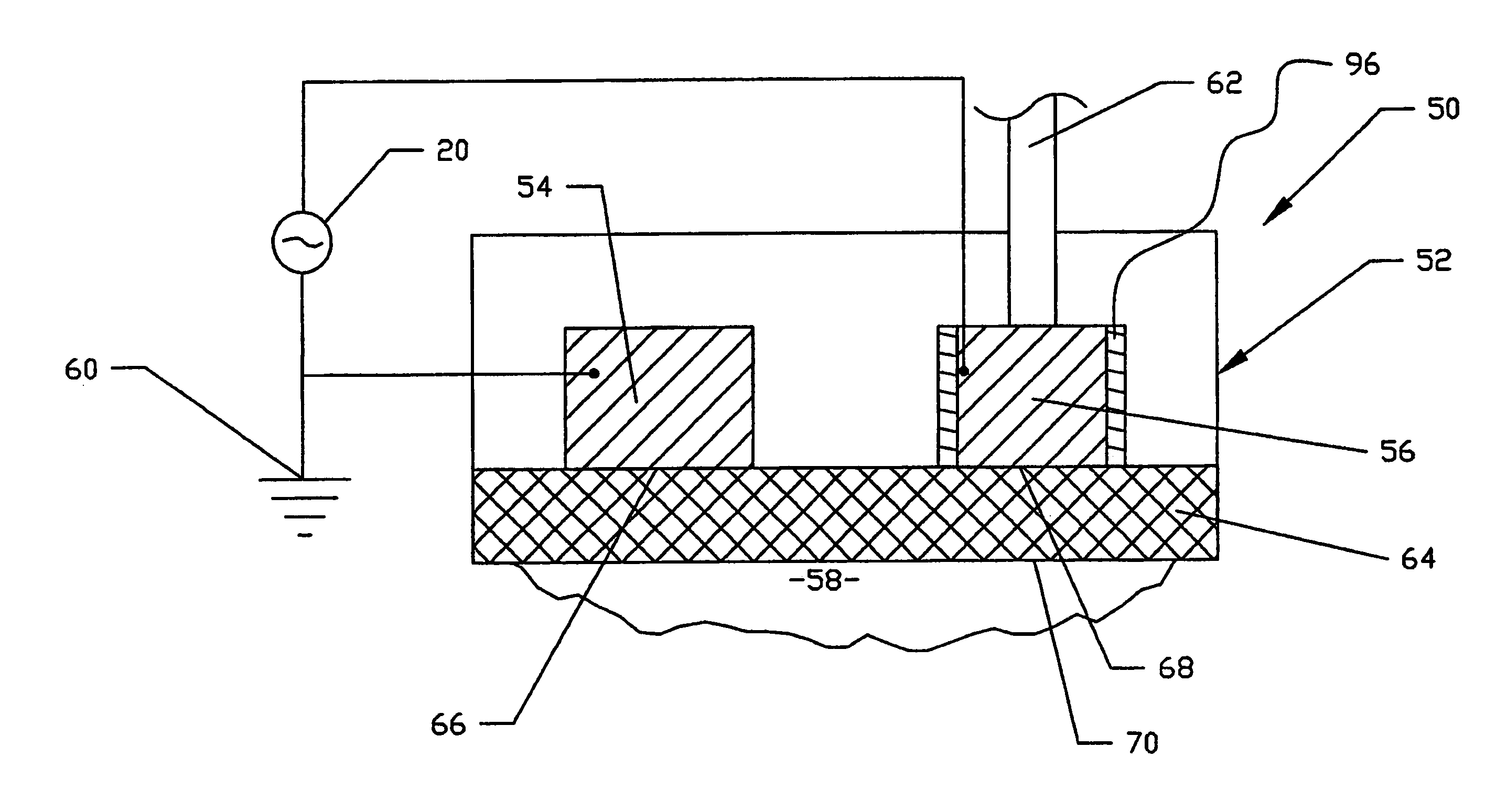

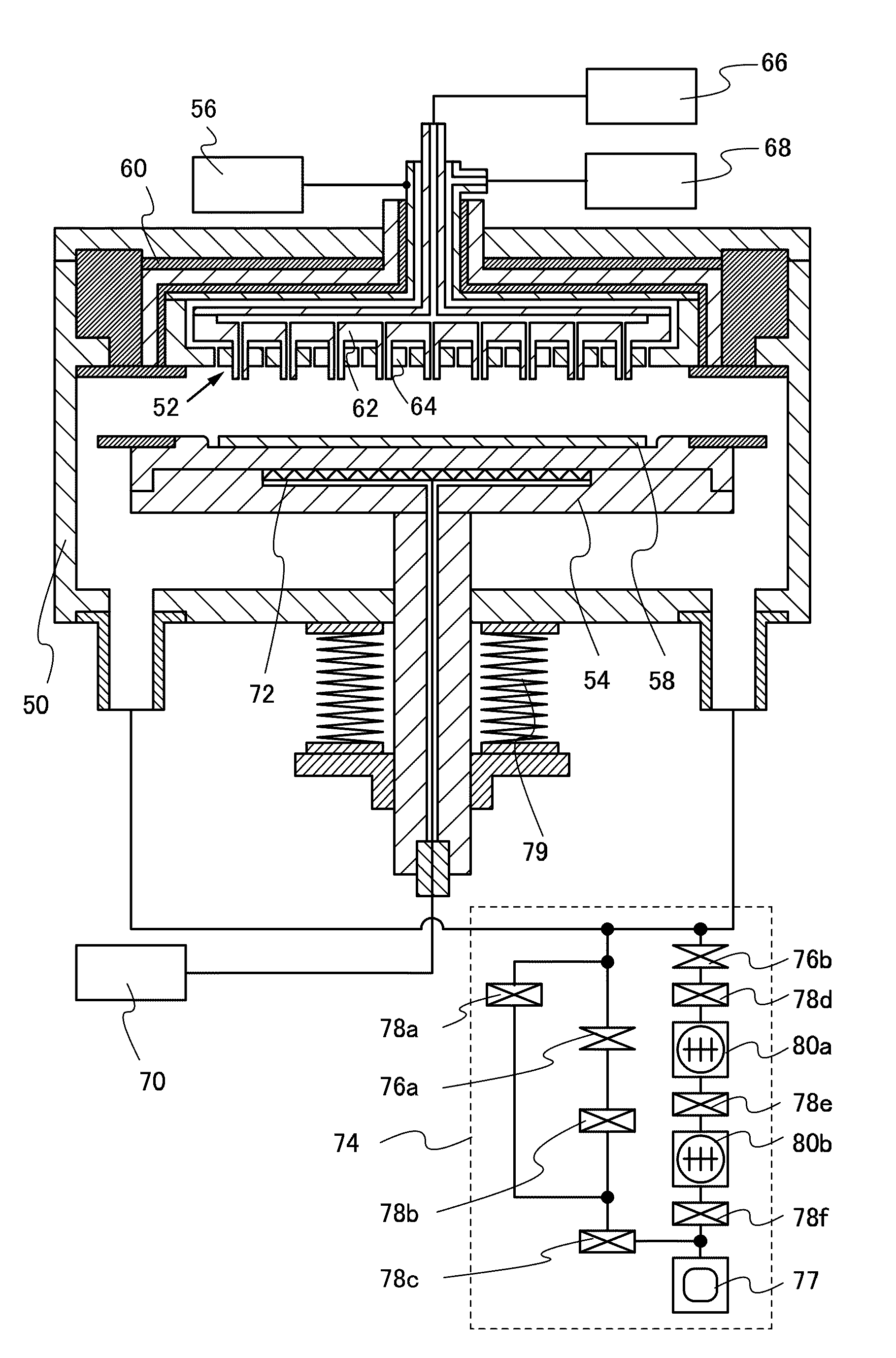

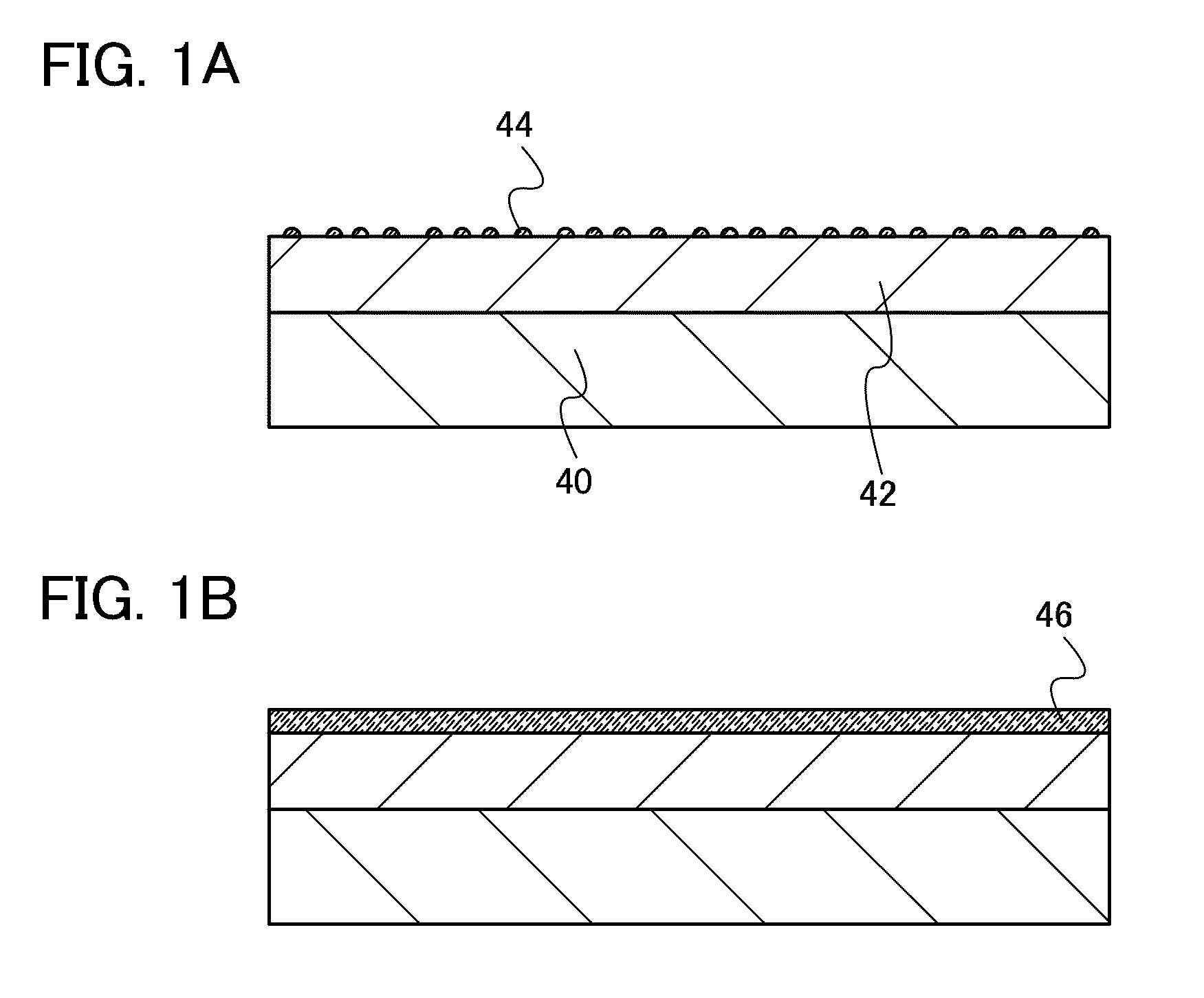

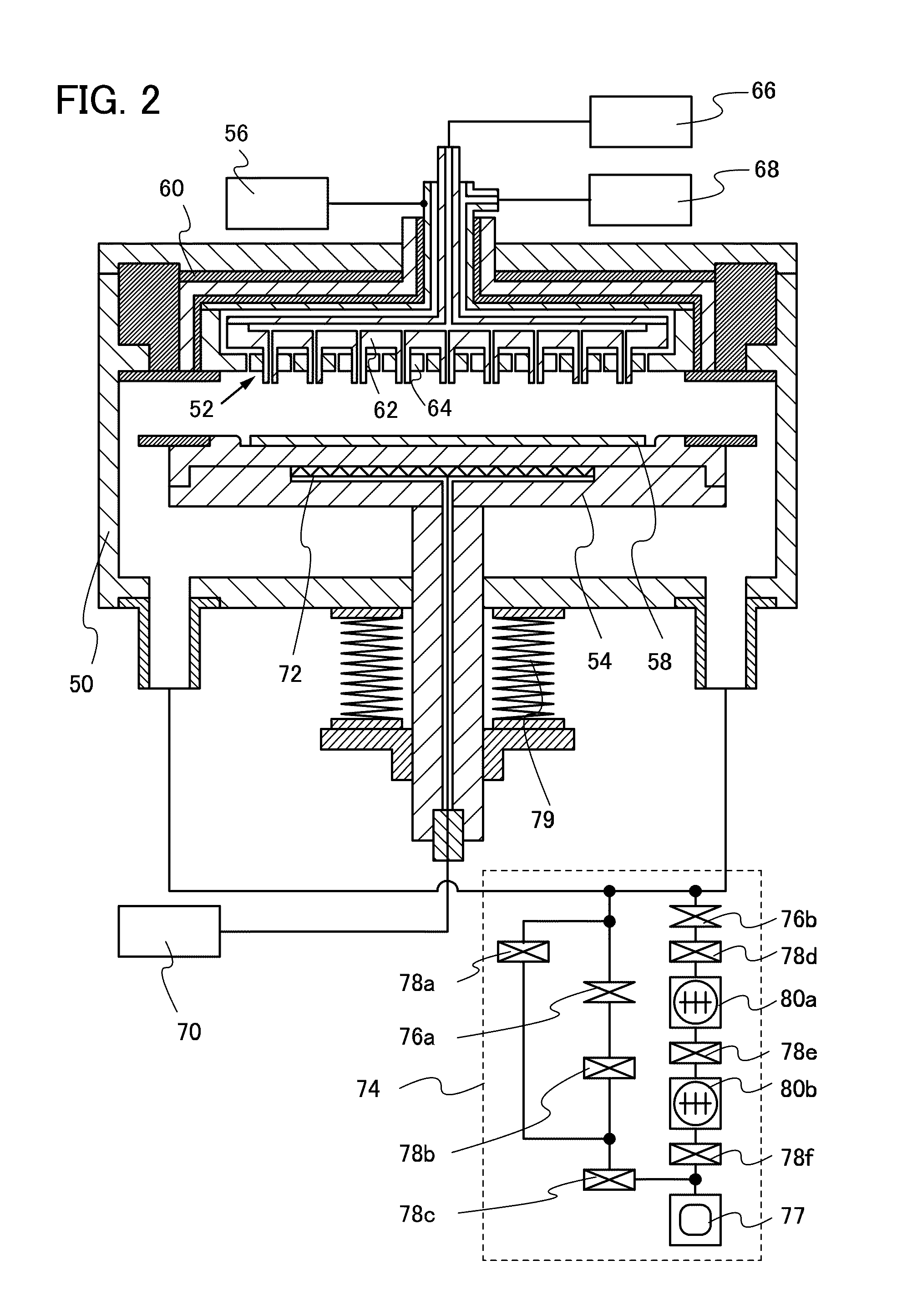

A method for depositing a film by plasma-enhanced subatmospheric-pressure atomic layer deposition (subatmospheric PEALD) is conducted using capacitively coupled parallel plate electrodes with a gap of 1 mm to 5 mm, wherein one cycle of subatmospheric PEALD includes: supplying a precursor in a pulse to the reaction chamber; continuously supplying a reactant to the reaction chamber; continuously supplying an inert gas to the reaction chamber; continuously controlling a pressure of the reaction chamber in a range of 15 kPa to 80 kPa; and applying RF power for glow discharge in a pulse to one of the parallel plate electrodes.

Owner:ASM IP HLDG BV

Method of subatmospheric plasma-enhanced ALD using capacitively coupled electrodes with narrow gap

ActiveUS10435790B2Poor conformalityGood shape retentionElectric discharge tubesChemical vapor deposition coatingCapacitanceParallel plate

A method for depositing a film by plasma-enhanced subatmospheric-pressure atomic layer deposition (subatmospheric PEALD) is conducted using capacitively coupled parallel plate electrodes with a gap of 1 mm to 5 mm, wherein one cycle of subatmospheric PEALD includes: supplying a precursor in a pulse to the reaction chamber; continuously supplying a reactant to the reaction chamber; continuously supplying an inert gas to the reaction chamber; continuously controlling a pressure of the reaction chamber in a range of 15 kPa to 80 kPa; and applying RF power for glow discharge in a pulse to one of the parallel plate electrodes.

Owner:ASM IP HLDG BV

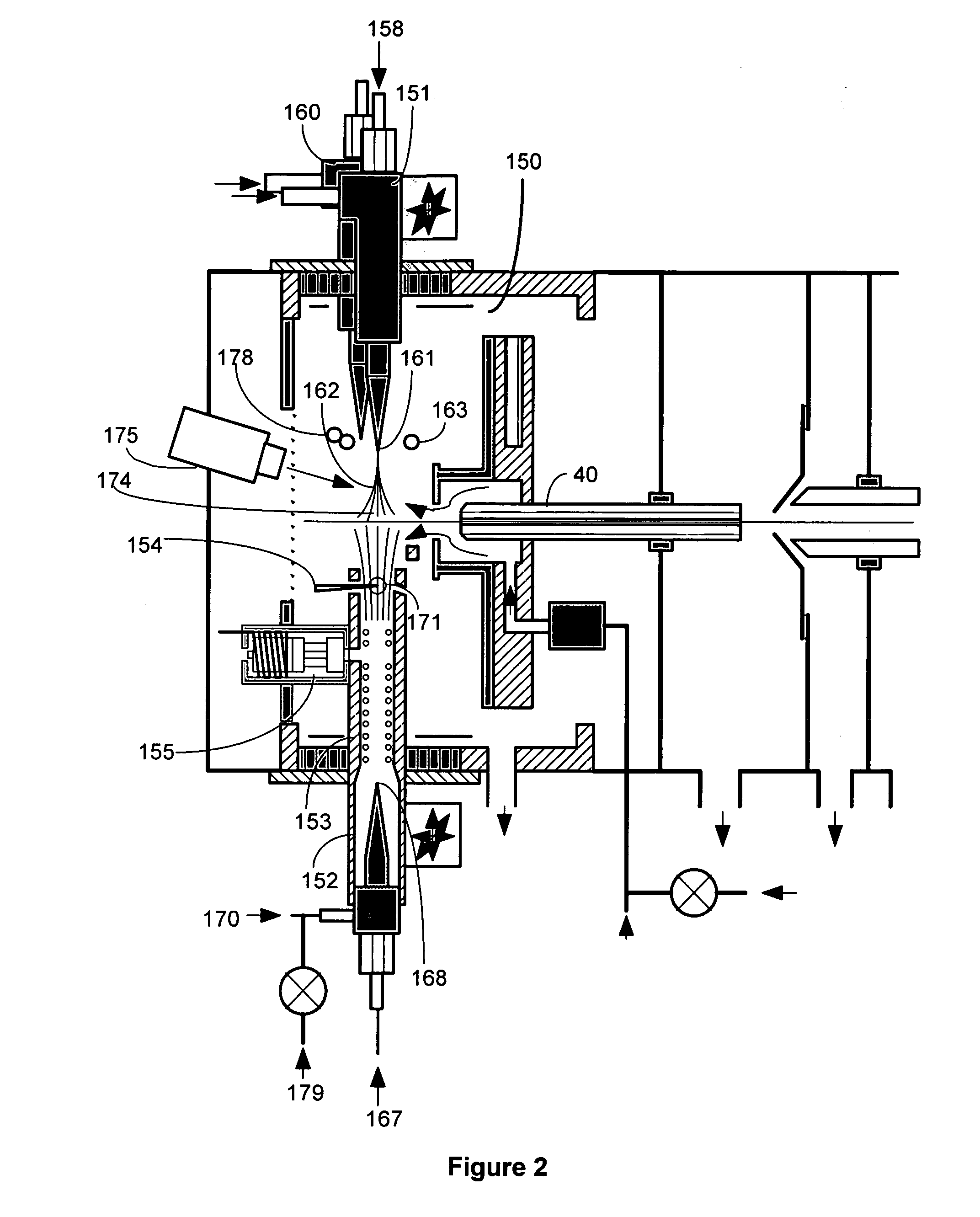

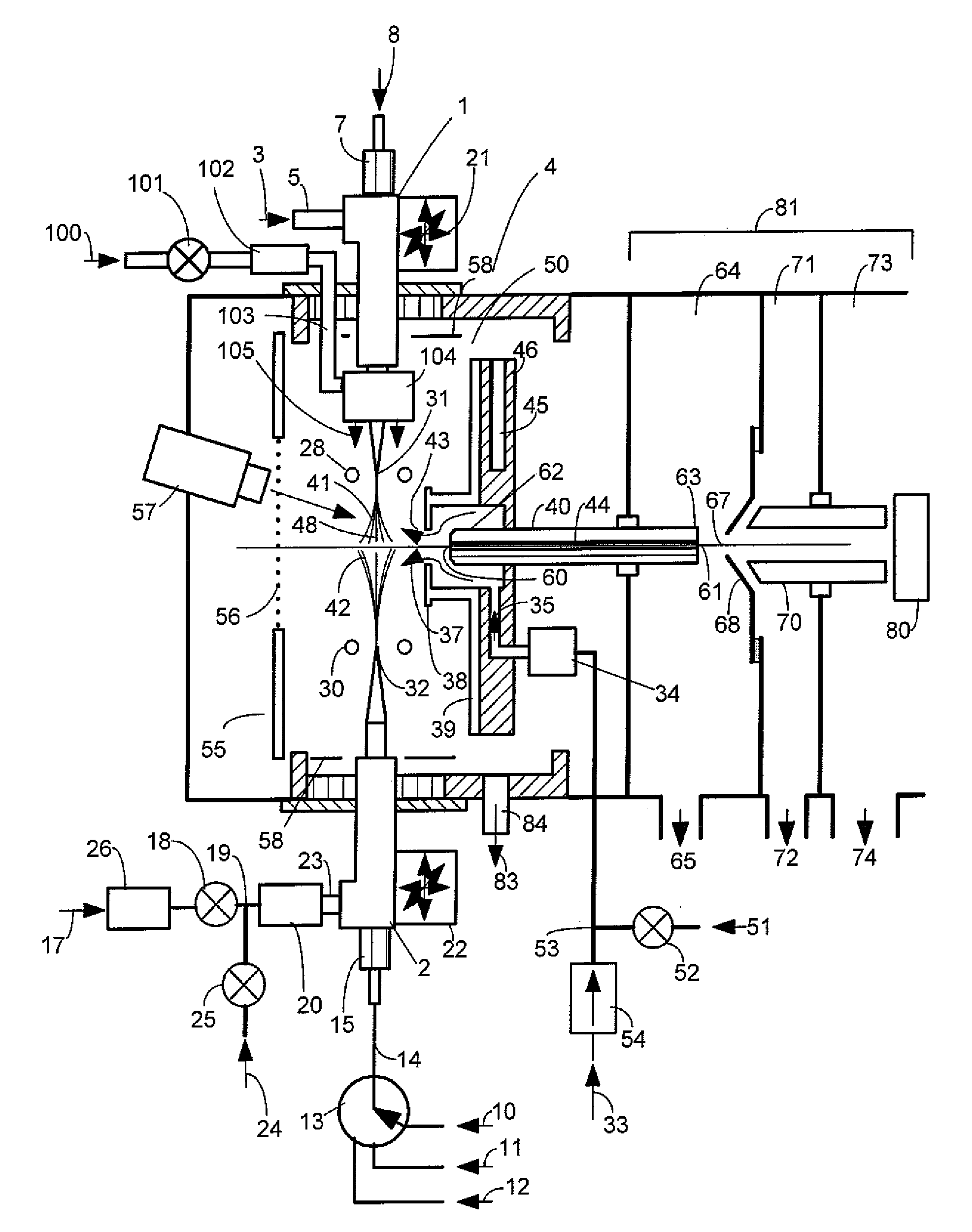

Atmospheric pressure ion source for mass spectrometry

InactiveUS20060255261A1Low costIncrease speedIsotope separationMass spectrometersGas phaseCorona discharge

A multiple function atmospheric pressure ion source interfaced to a mass spectrometer comprises multiple liquid inlet probes configured such that the sprays from two or more probes intersect in a mixing region. Gas phase sample ions or neutral species generated in the spray of one probe can react with reagent gas ions generated from one or more other probes by such ionization methods as Electrospray, photoionization, corona discharge and glow discharge ionization. Reagent ions may be optimally selected to promote such processes as Atmospheric Pressure Chemical Ionization of neutral sample molecules, or charge reduction or electron transfer dissociation of multiply charged sample ions. Selected neutral reagent species can also be introduced into the mixing region to promote charge reduction of multiply charged sample ions through ion-neutral reactions. Different operating modes can be performed alternately or simultaneously, and can be rapidly turned on and off under manual or software control.

Owner:WHITEHOUSE CRAIG +3

Method of coating an intravascular stent with an endothelial cell adhesive five amino acid peptide

InactiveUS6140127APromoting cell attachmentRestore patencyBiocidePeptide/protein ingredientsCell specificArginine

Endothelial cell attachment to an intravascular stent is promoted by coating the stent with an endothelial cell specific adhesion peptide. Coating is preferably carried out by activating the intravascular stent using plasma glow discharge, applying on the stent a layer or plurality of layers of a polymer such as poly(2-hydroxyethylmethacrylate), applying a tresylation solution containing pyridine and tresyl chloride, and applying a five amino acid peptide having the sequence glycine-arginine-glutamic acid-aspartic acid-valine.

Owner:CORDIS CORP

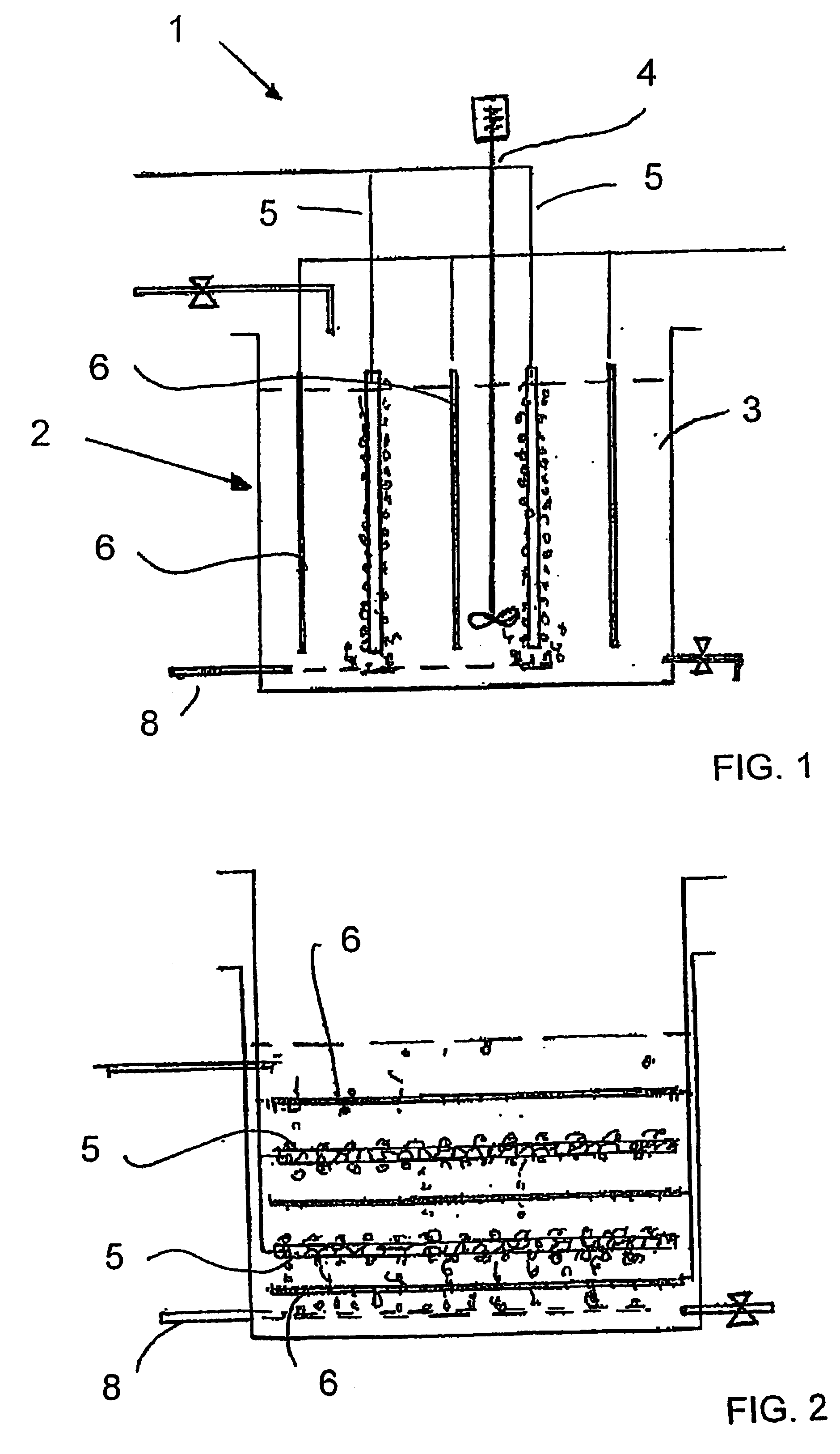

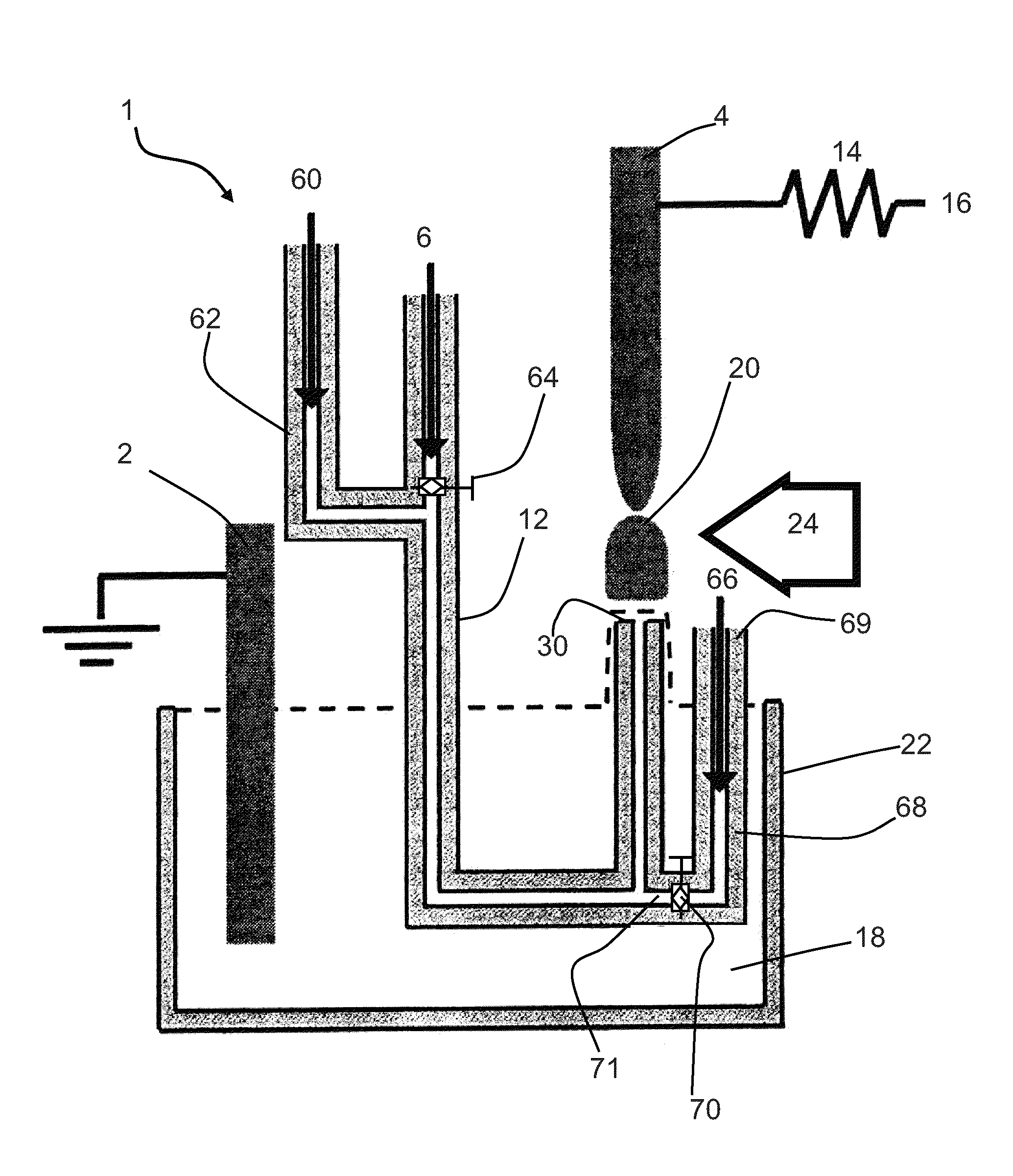

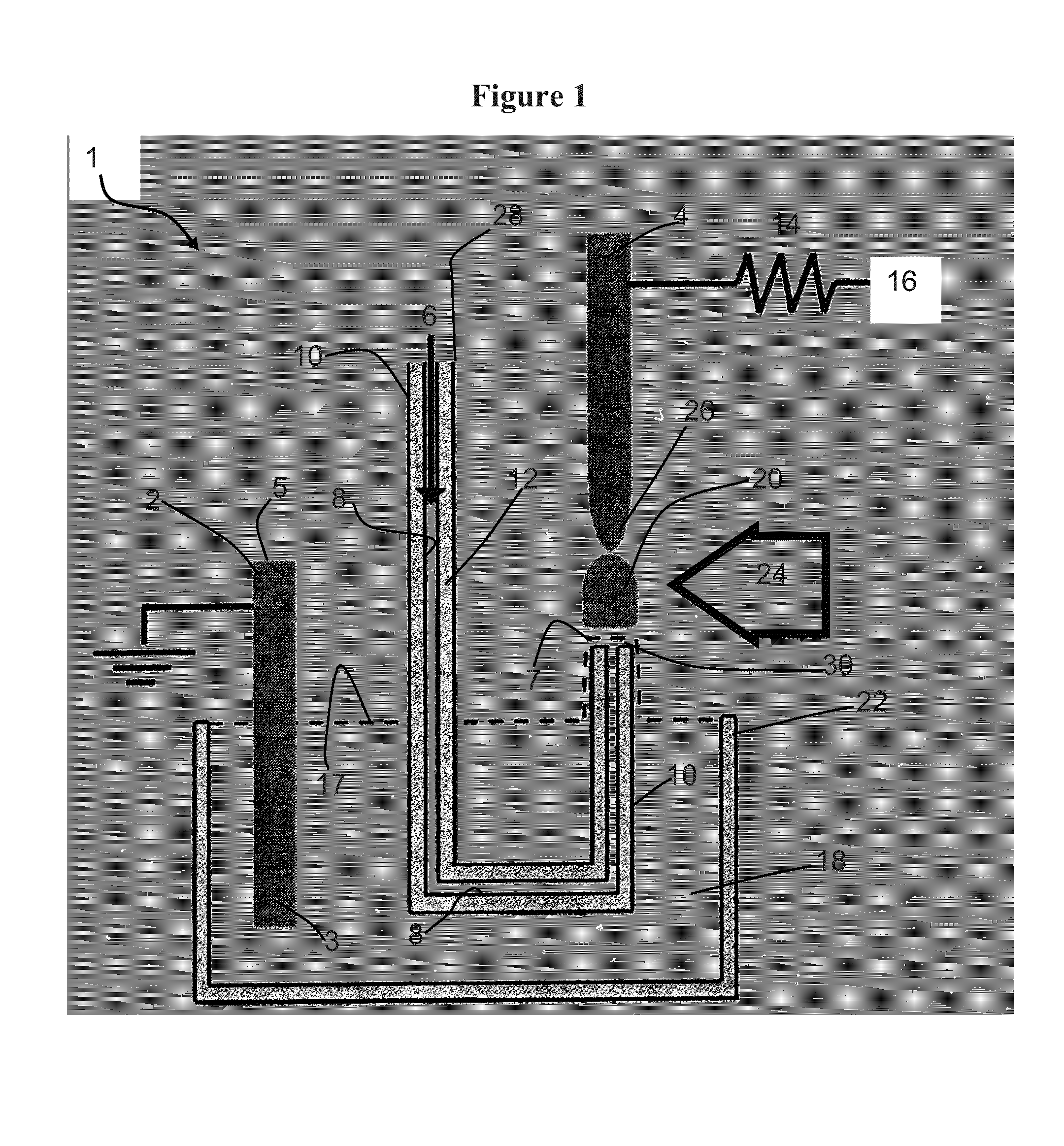

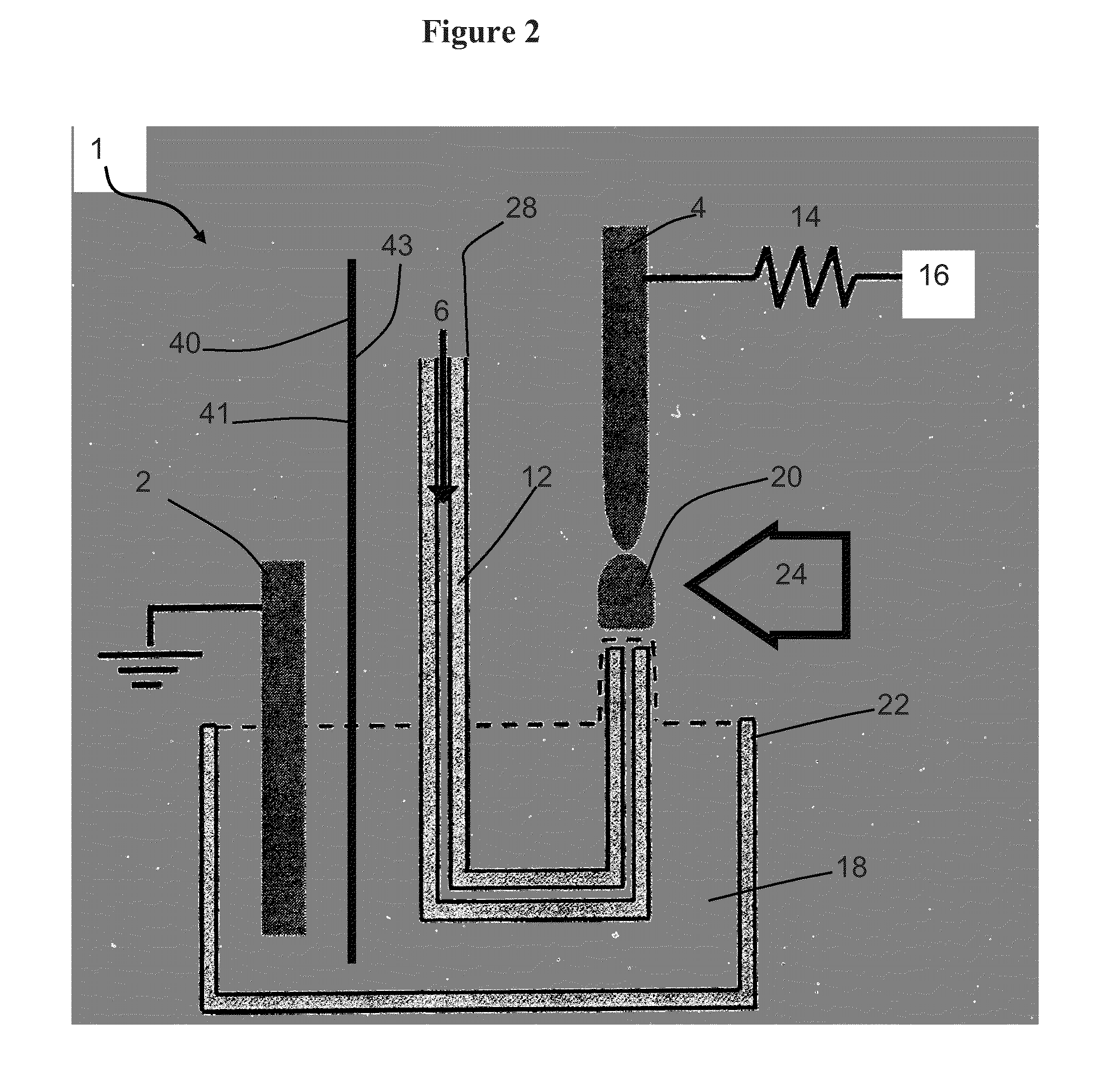

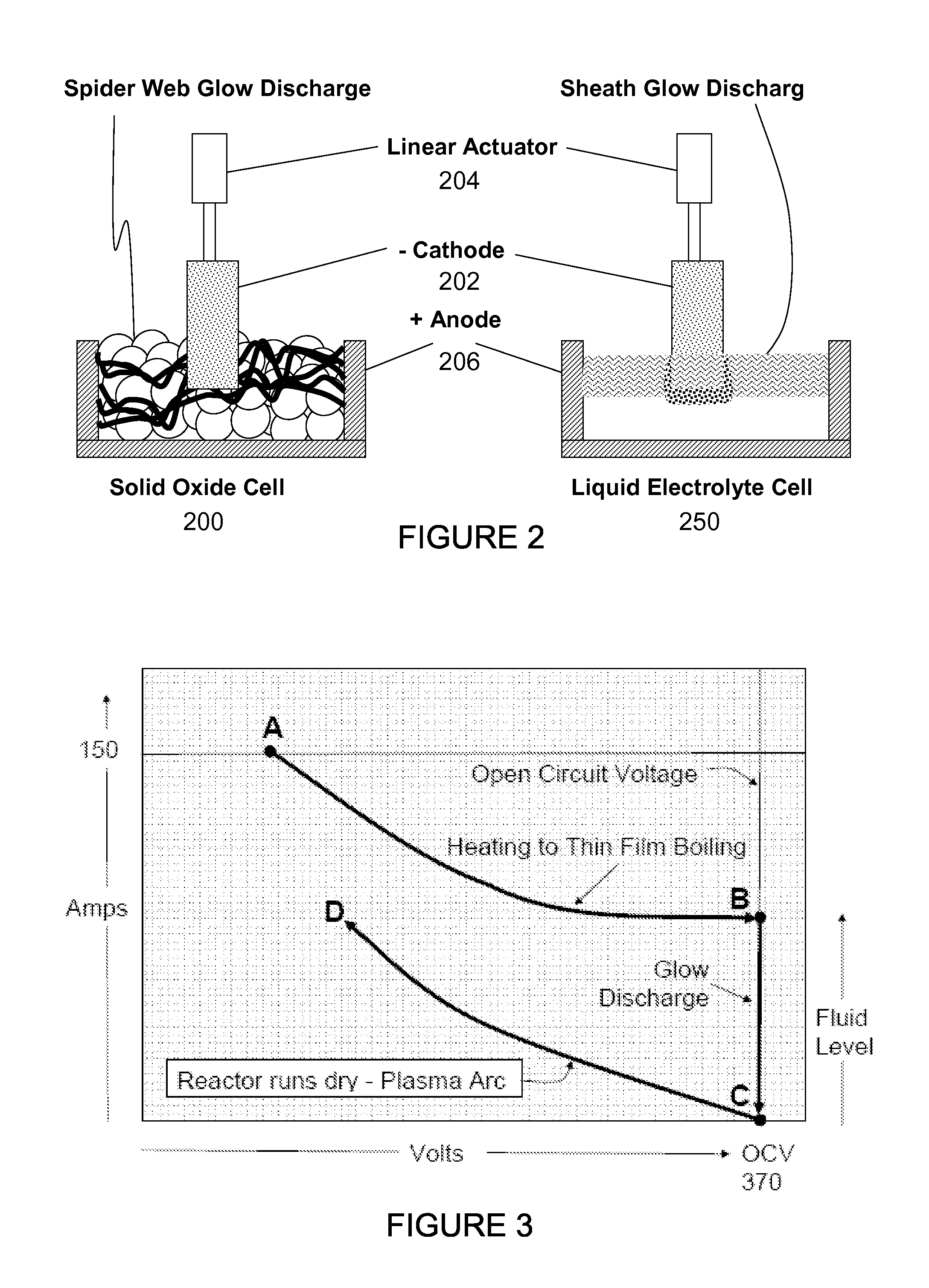

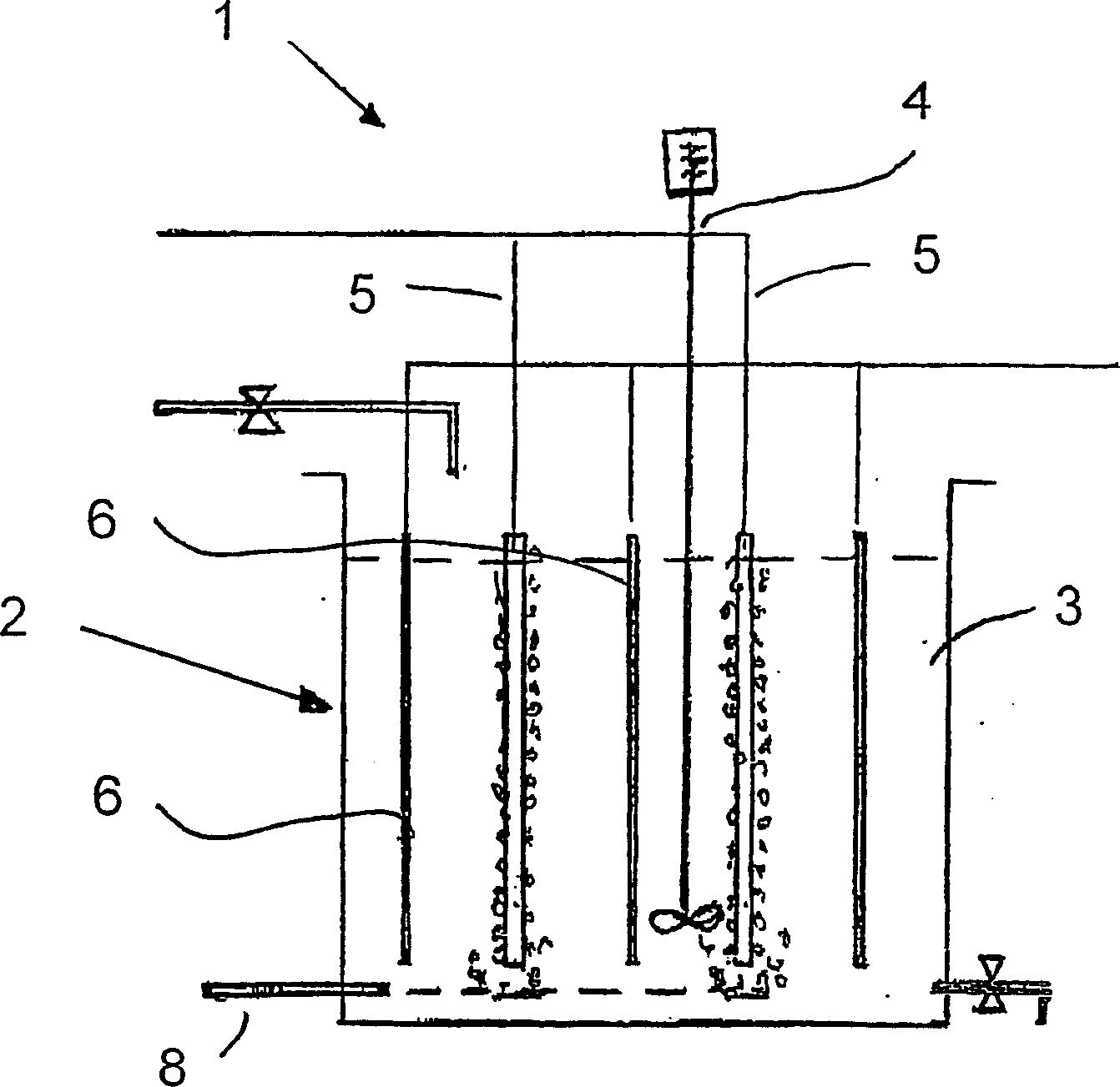

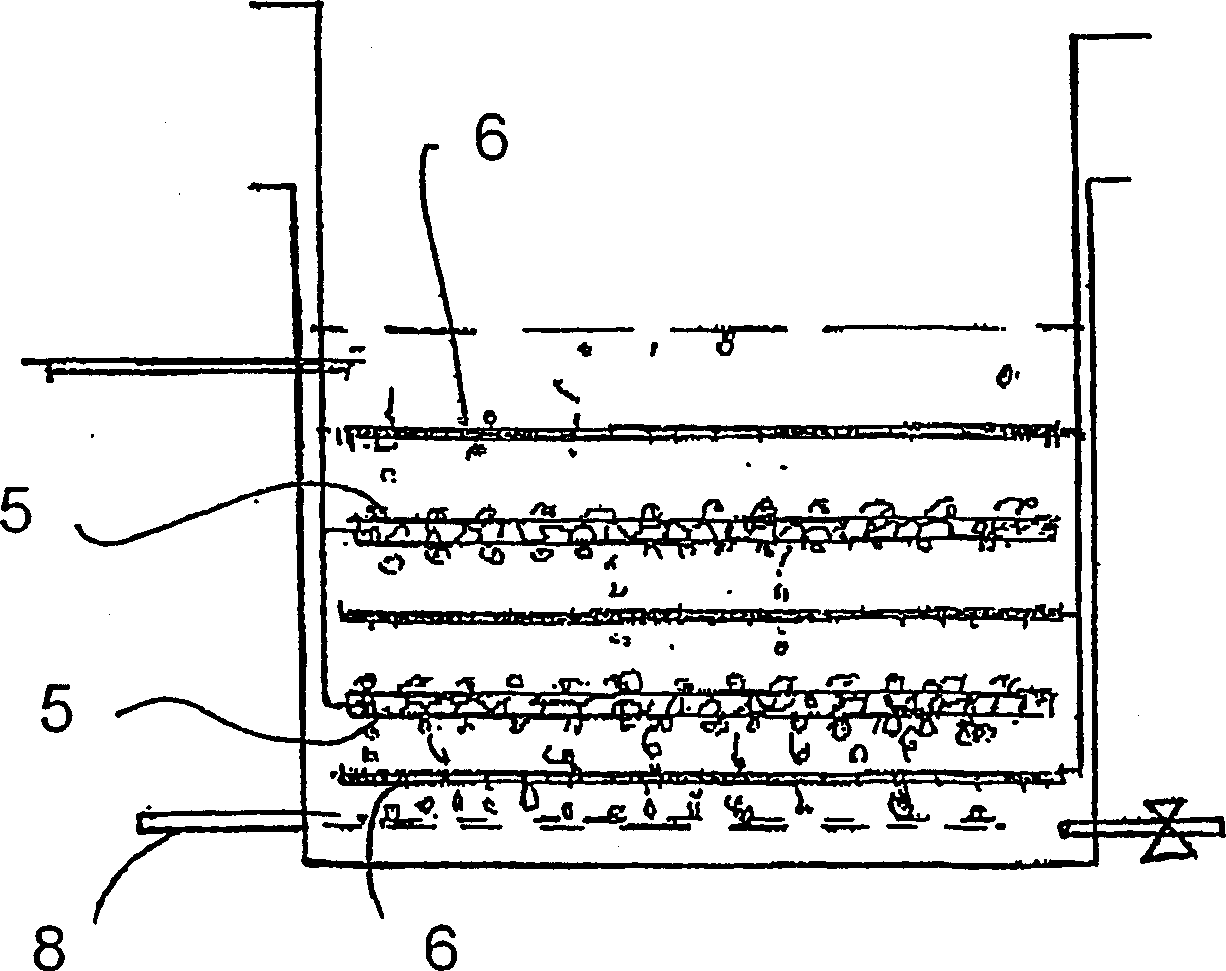

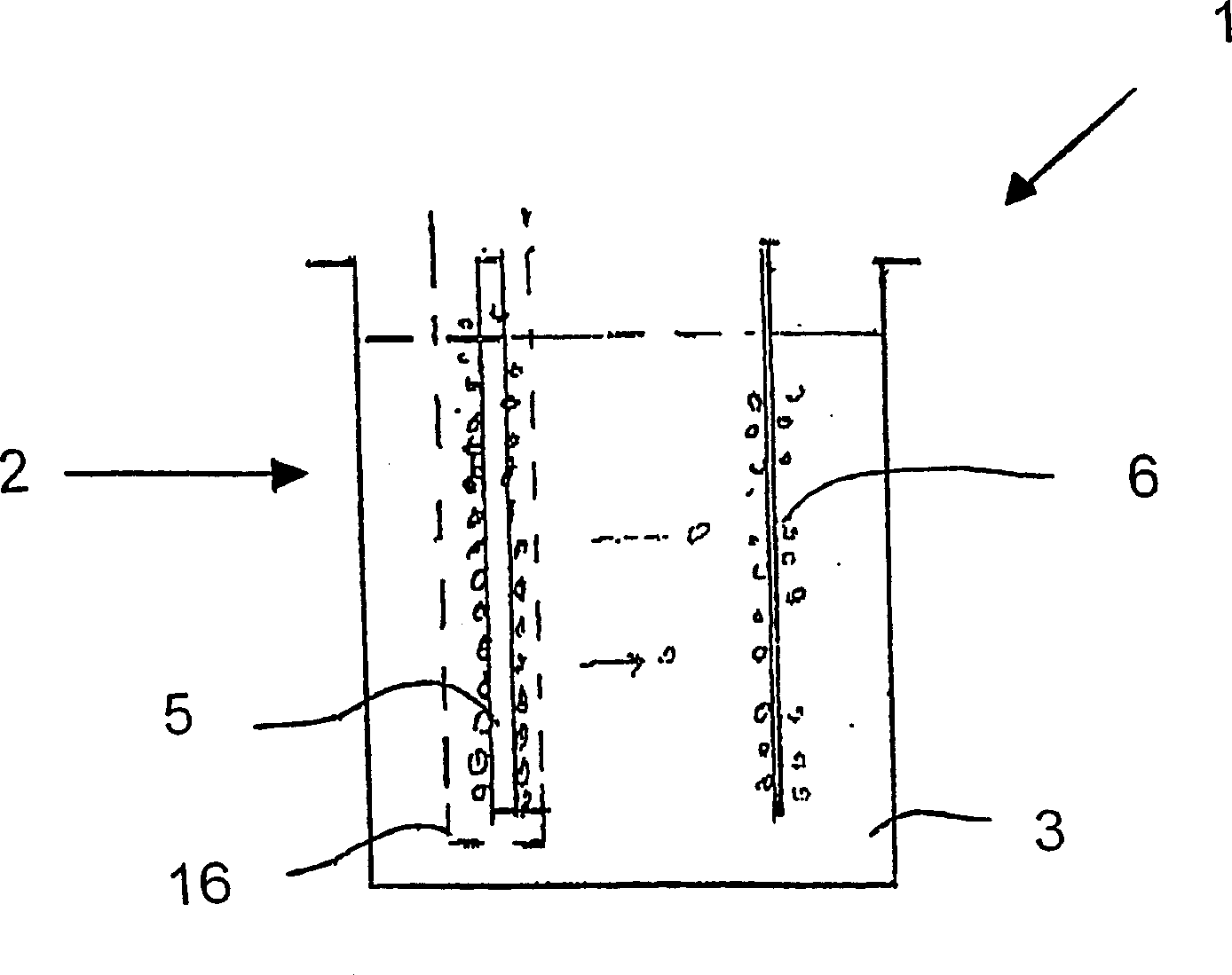

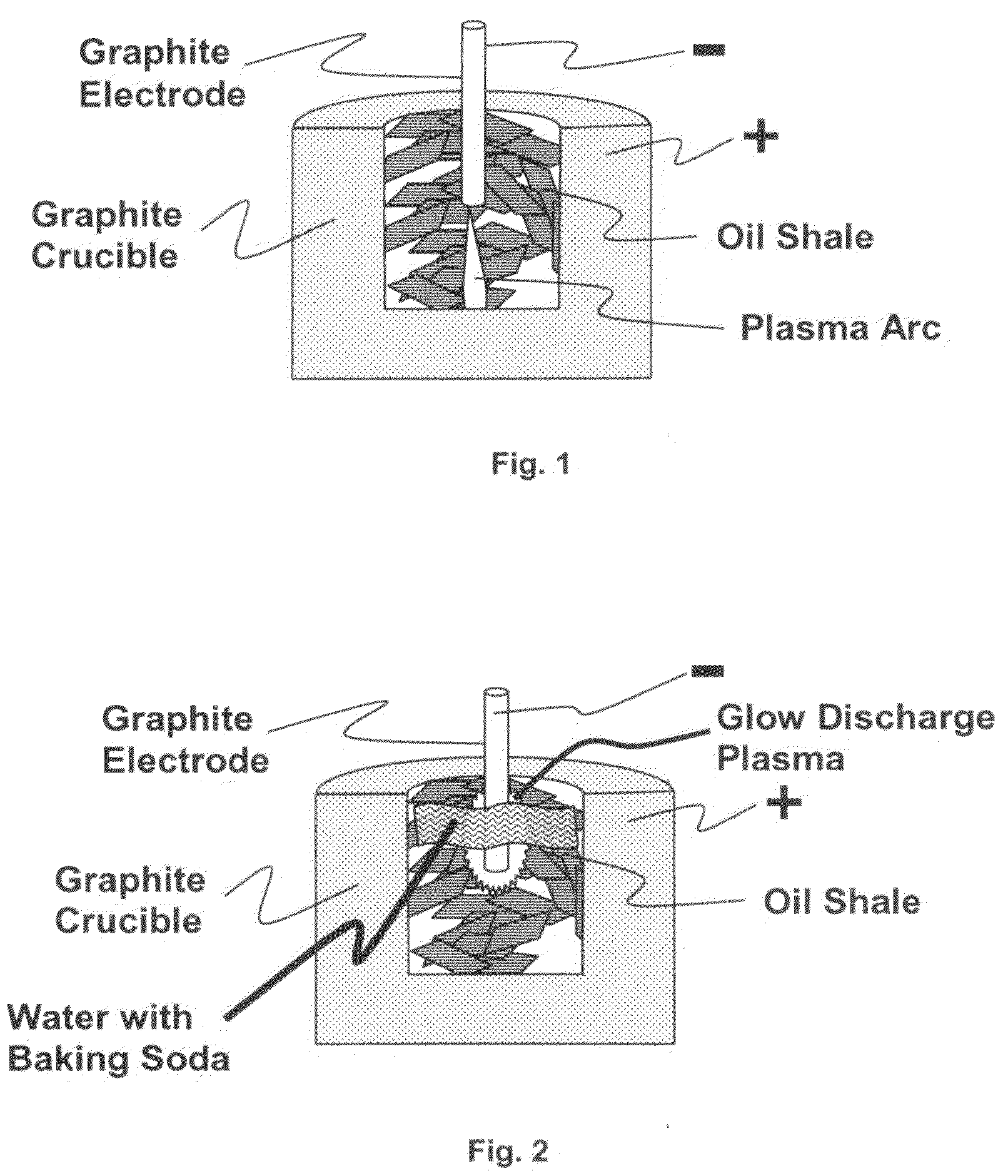

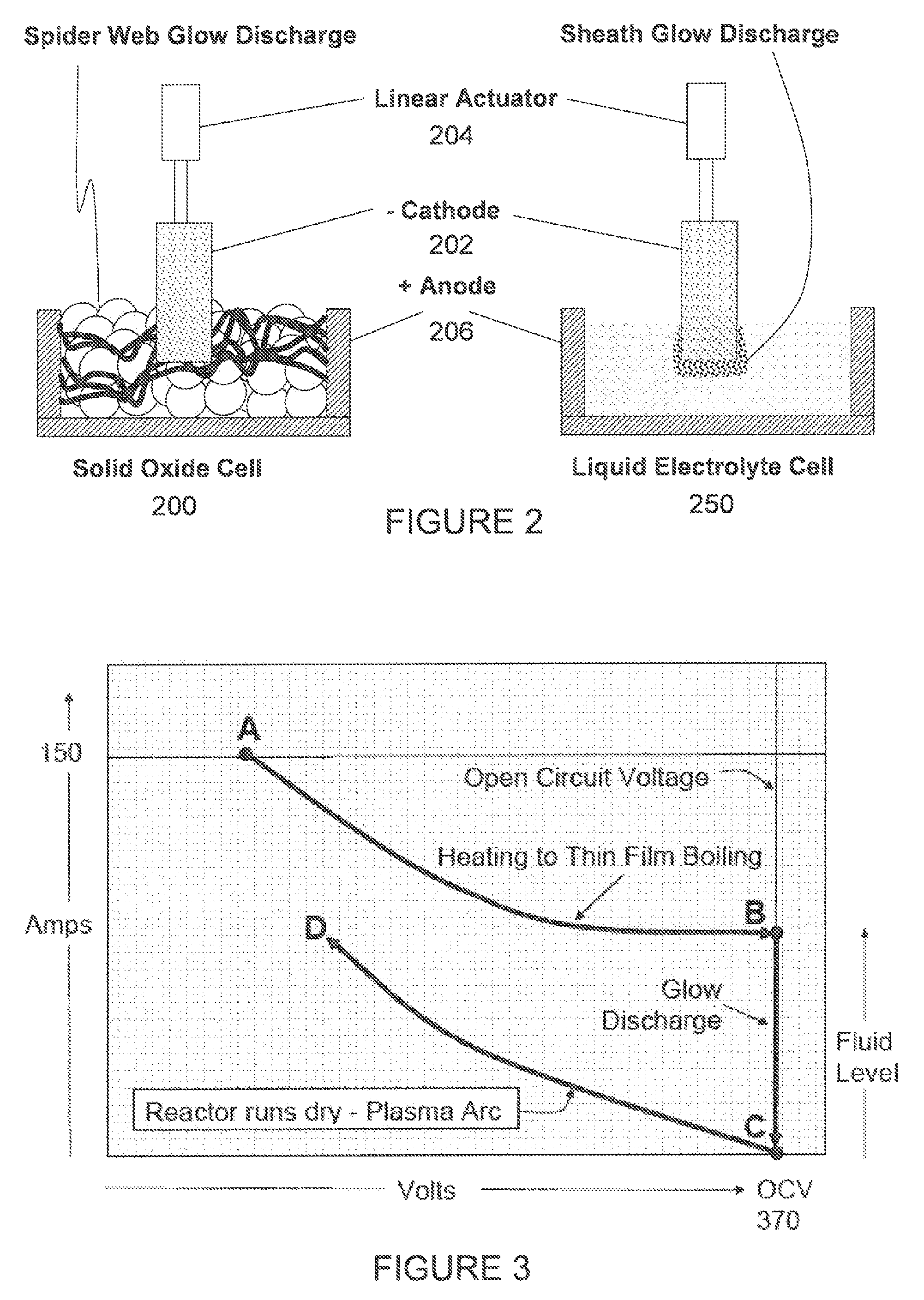

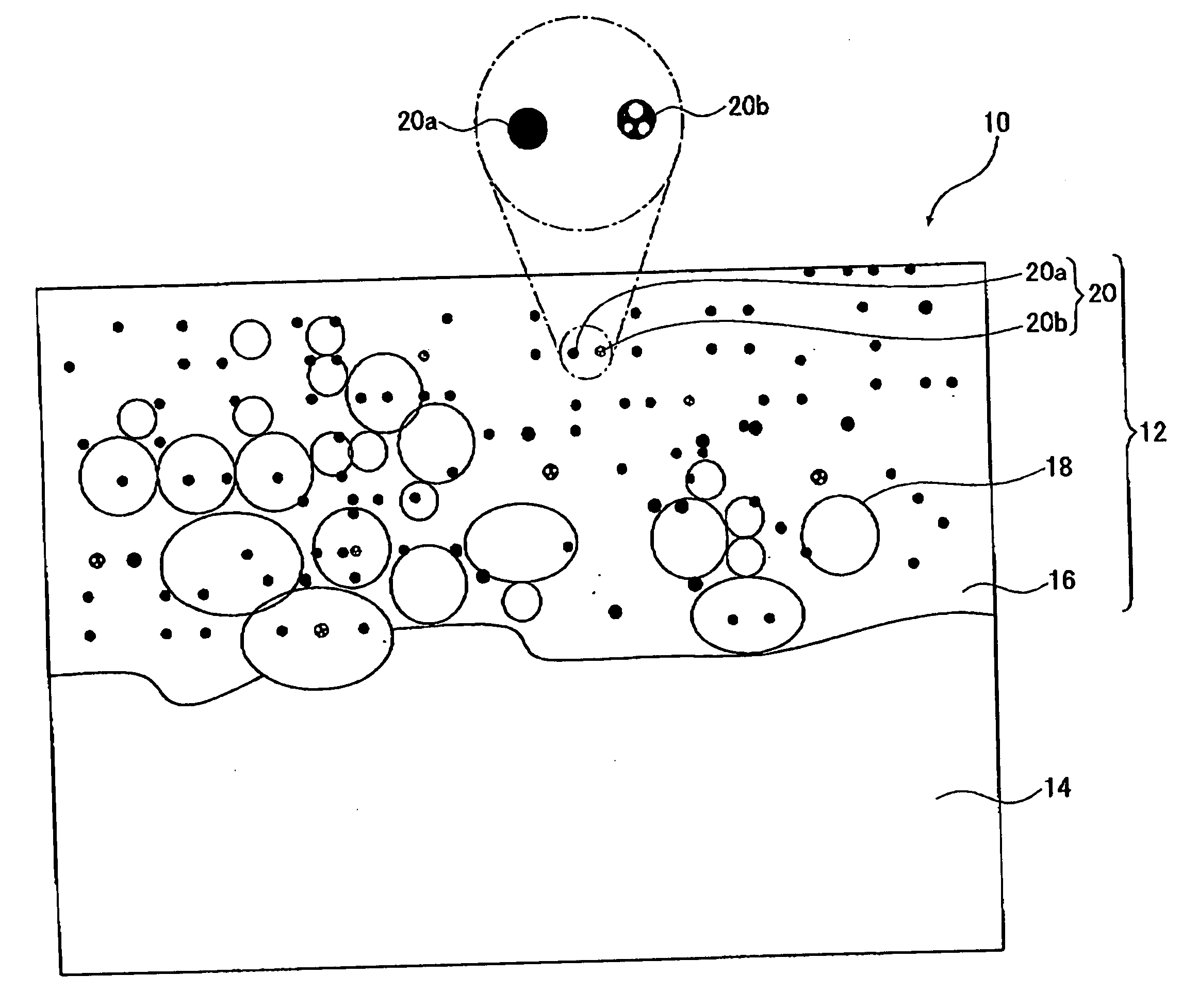

Plasma formed in a fluid

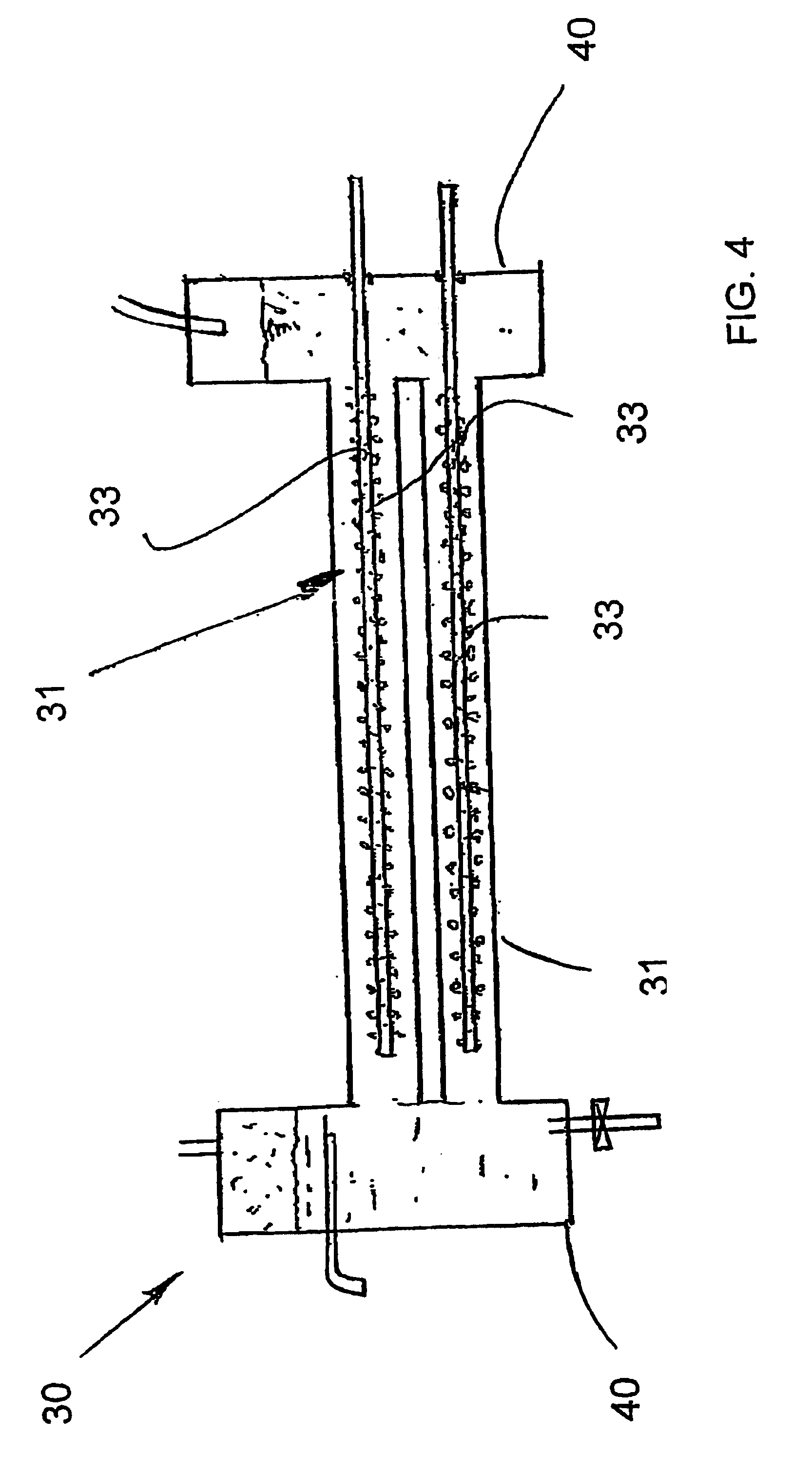

InactiveUS20060060464A1BuildEfficient electrolysisHydrogenWater/sewage treatment by irradiationElectrolysisPotential difference

A method and apparatus for generating plasma in a fluid. The fluid (3) is placed in a bath (2) having a pair of spaced electrodes (4, 6) forming a cathode and an anode. A stream of bubbles is introduced or generated within the fluid adjacent to the cathode. A potential difference is applied across the cathode and anode such that a glow discharge is formed in the bubble region and a plasma of ionized gas molecules is formed within the bubbles. The plasma may then be used in electrolysis, gas production, effluent treatment or sterilization, mineral extraction, production of nanoparticles or material enhancement. The method can be carried out at atmospheric pressure and room temperature. The electrodes may carry means to trap the bubbles in close proximity. Partitions may be present between the electrodes.

Owner:CHANG CHAK MAN THOMAS

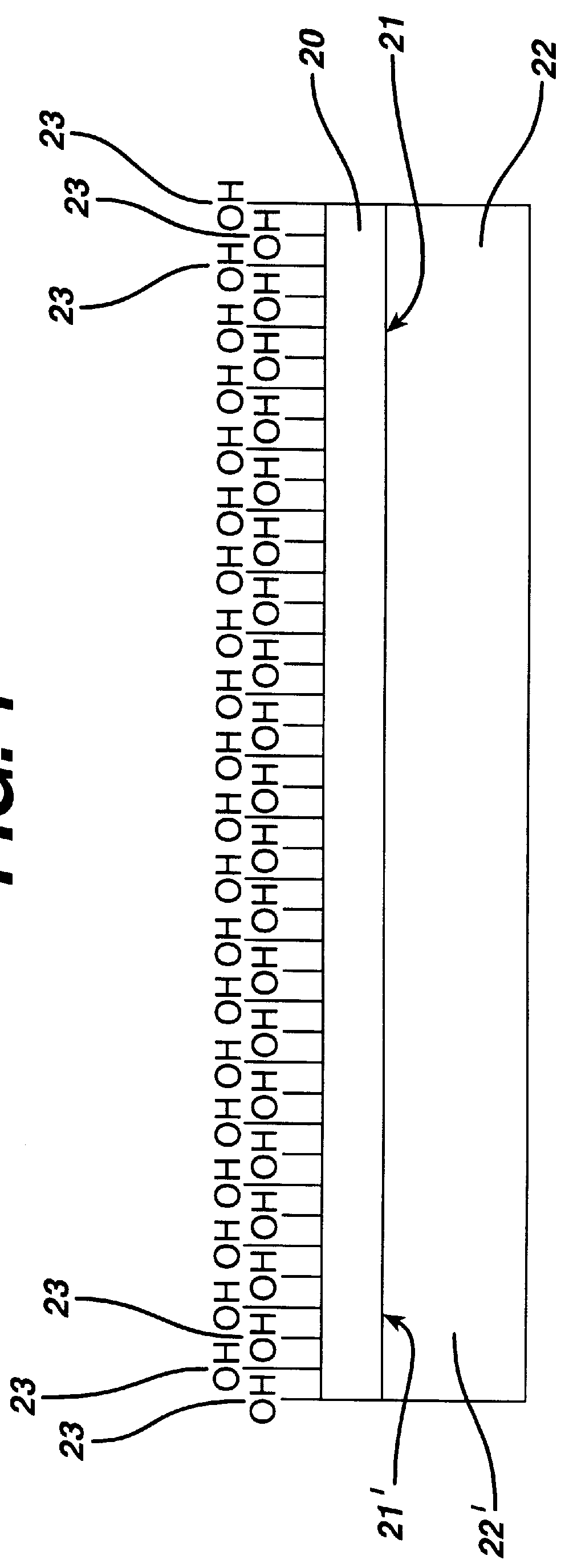

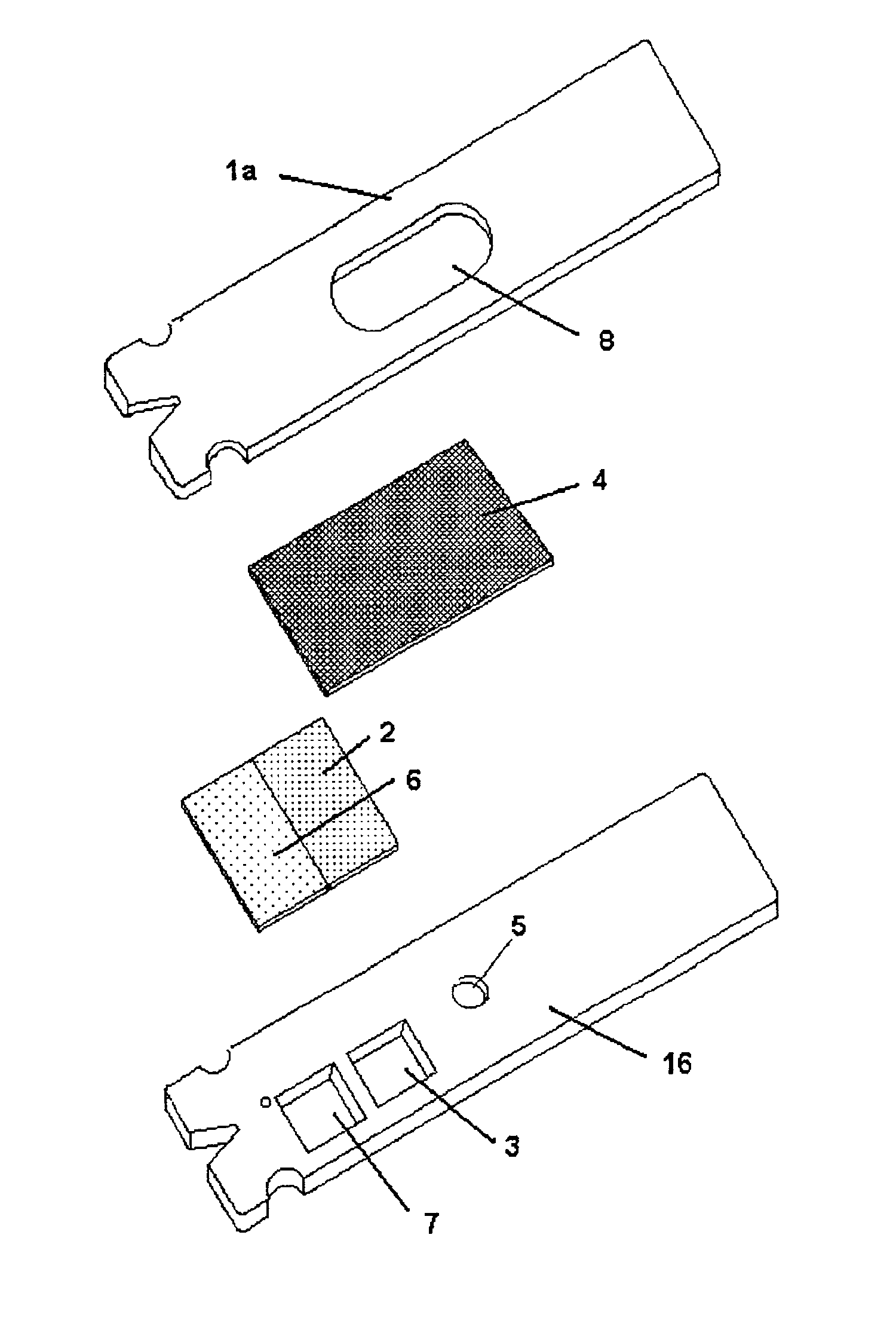

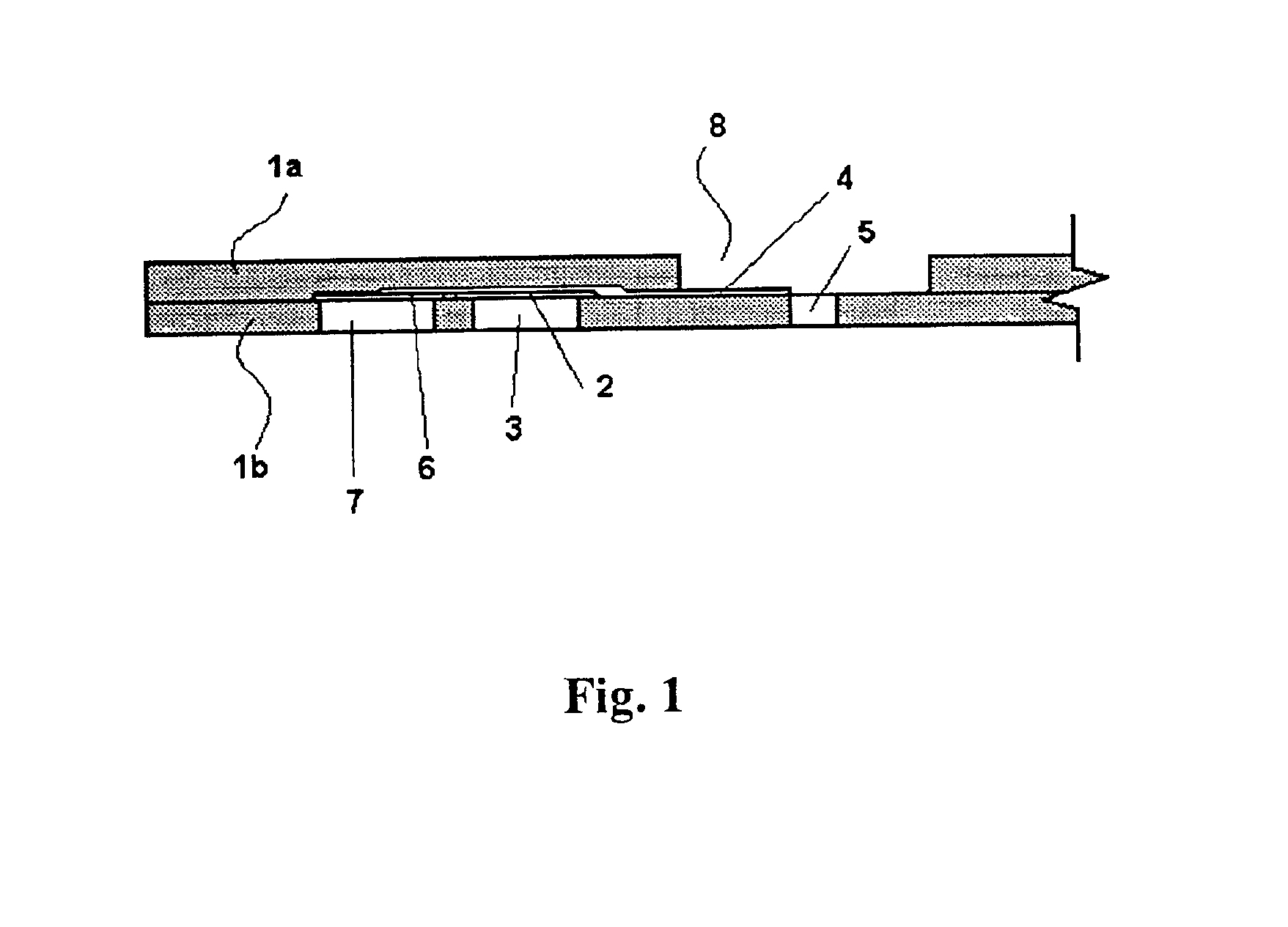

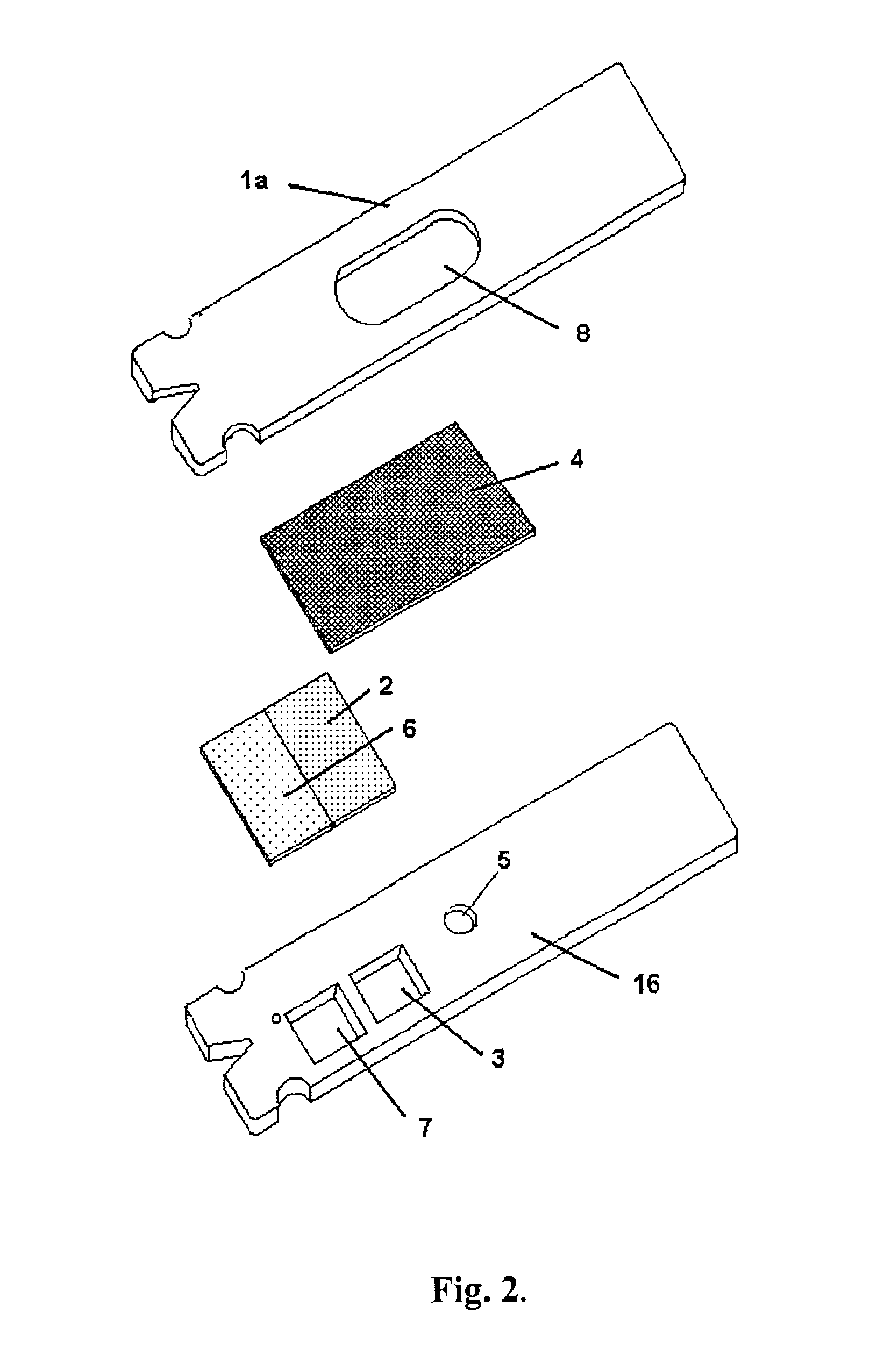

Surface-modified wick for diagnostic test strip

InactiveUS6967105B2Improve accuracyGood precisionAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorAlkaneBlood sugar

A wicking material is disclosed that exhibits a horizontal wicking velocity of at least about 1.0 millimeter per second when contacted with a physiological fluid such as blood, lymph or cellular interstitial fluid. This high wicking rate is achieved by means of treatment of a fibrous wicking material candidate with a low temperature gas plasma, particularly a glow discharge gas plasma formed in a gaseous blend made up predominantly of a mixture of oxygen with a saturated alkane chosen from the group consisting of methane, ethane and propane. Diagnostic test strips made with the surface-modified wicking material, and containing an immobilized reagent means for analysis of an analyte in a physiological fluid, show improved performance in terms of increased accuracy, finer precision of analyses, reduced time of analysis, a smaller fluid sample size requirement, and improved compliance with manufacturing standards resulting in lower manufacturing costs blood sugar determinations.

Owner:QUESTSTAR MEDICAL

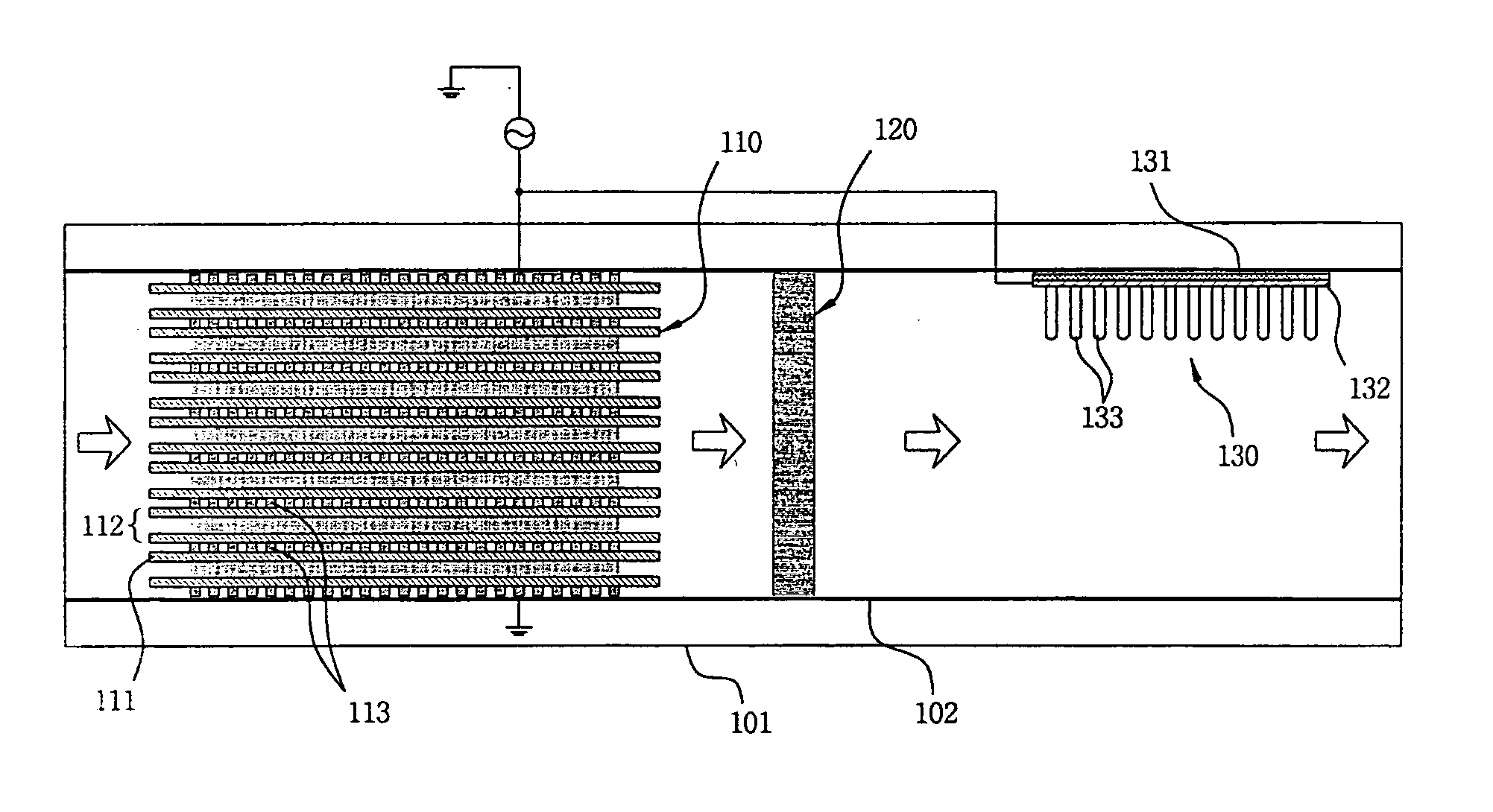

Hybrid-type air purifier for an automobile

InactiveUS20050142047A1Improve efficiencyImprove the bactericidal effectMaterial nanotechnologyMechanical apparatusHybrid typeAir purifiers

Air purifier systems particularly suitable for motor vehicles are provided that comprise an air flow passage; a glow discharging device; a photo-catalyst device; and a negative ion generator. Preferred air purifiers comprise a glow discharging device having mesh-structured electrodes which can purify air via dielectric barrier discharge, a photo-catalyst device that can further purify the air firstly purified by the glow discharging device, and a negative ion generator having nano tubes, which can treat the purified air with negative ions.

Owner:HYUNDAI MOTOR CO LTD +1

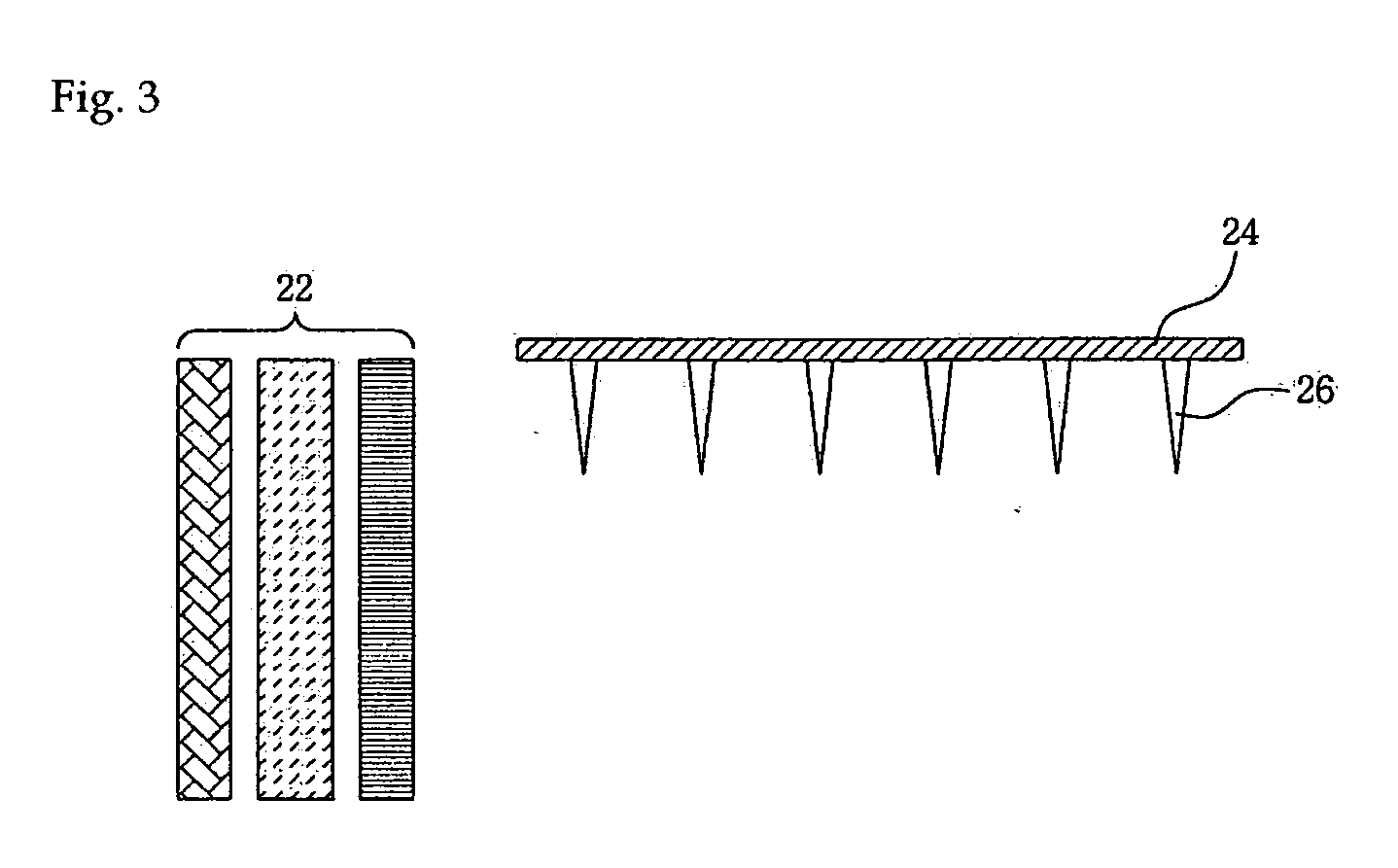

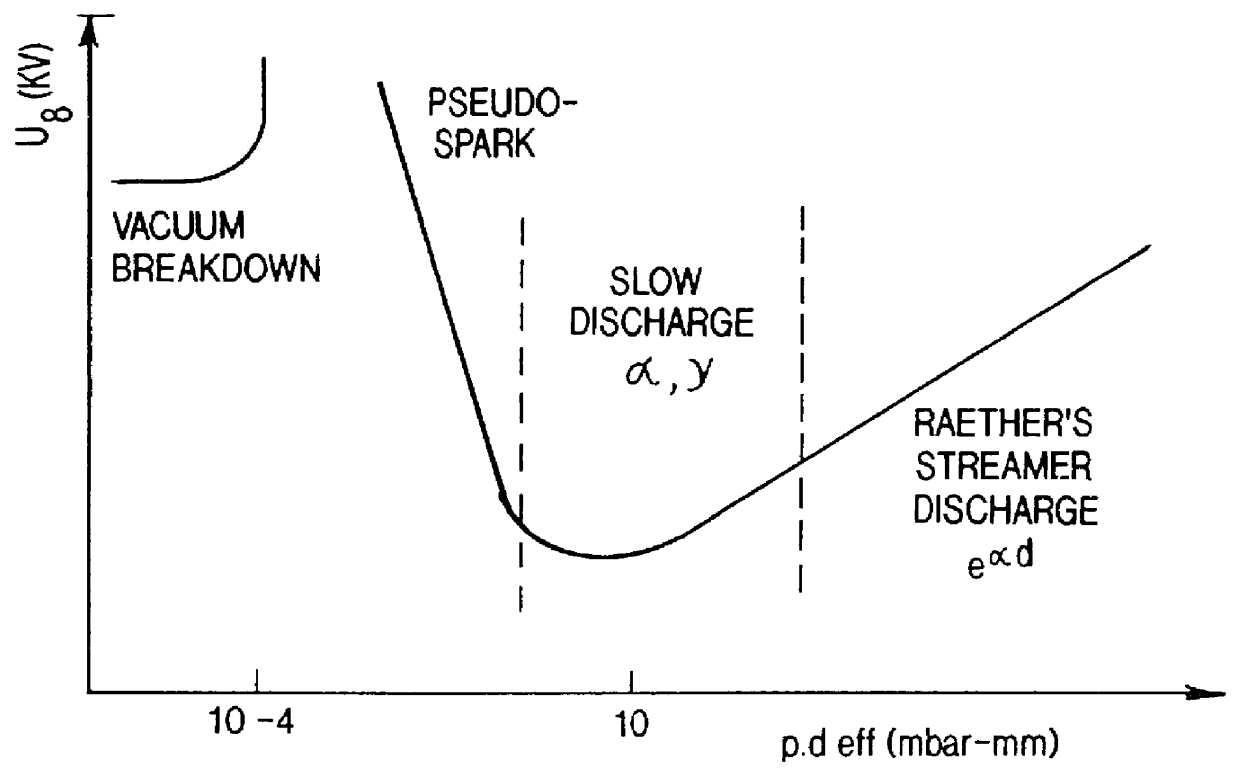

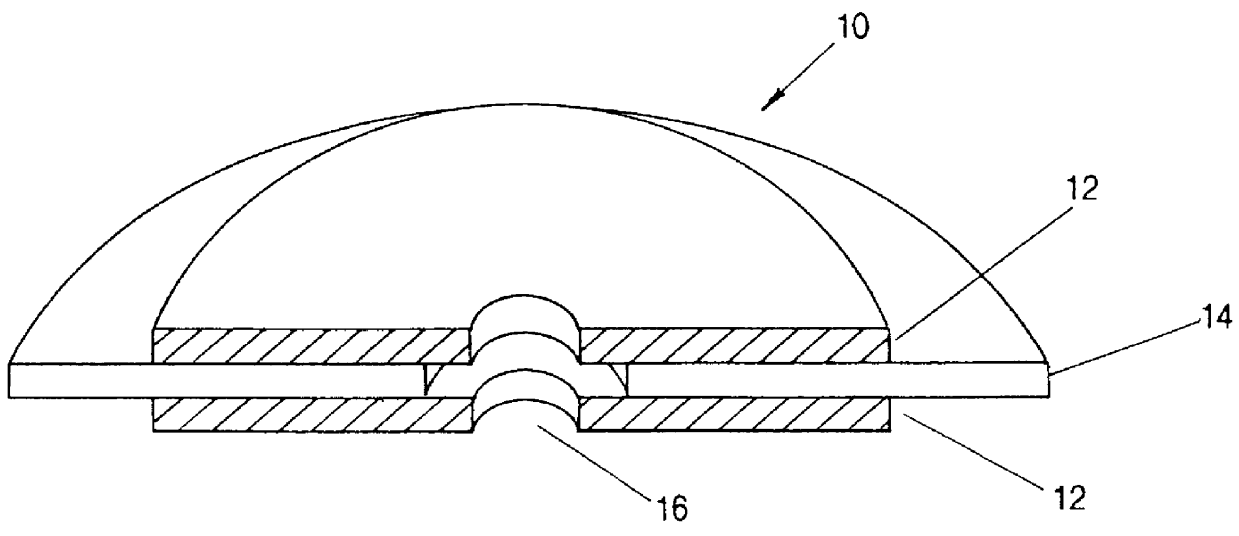

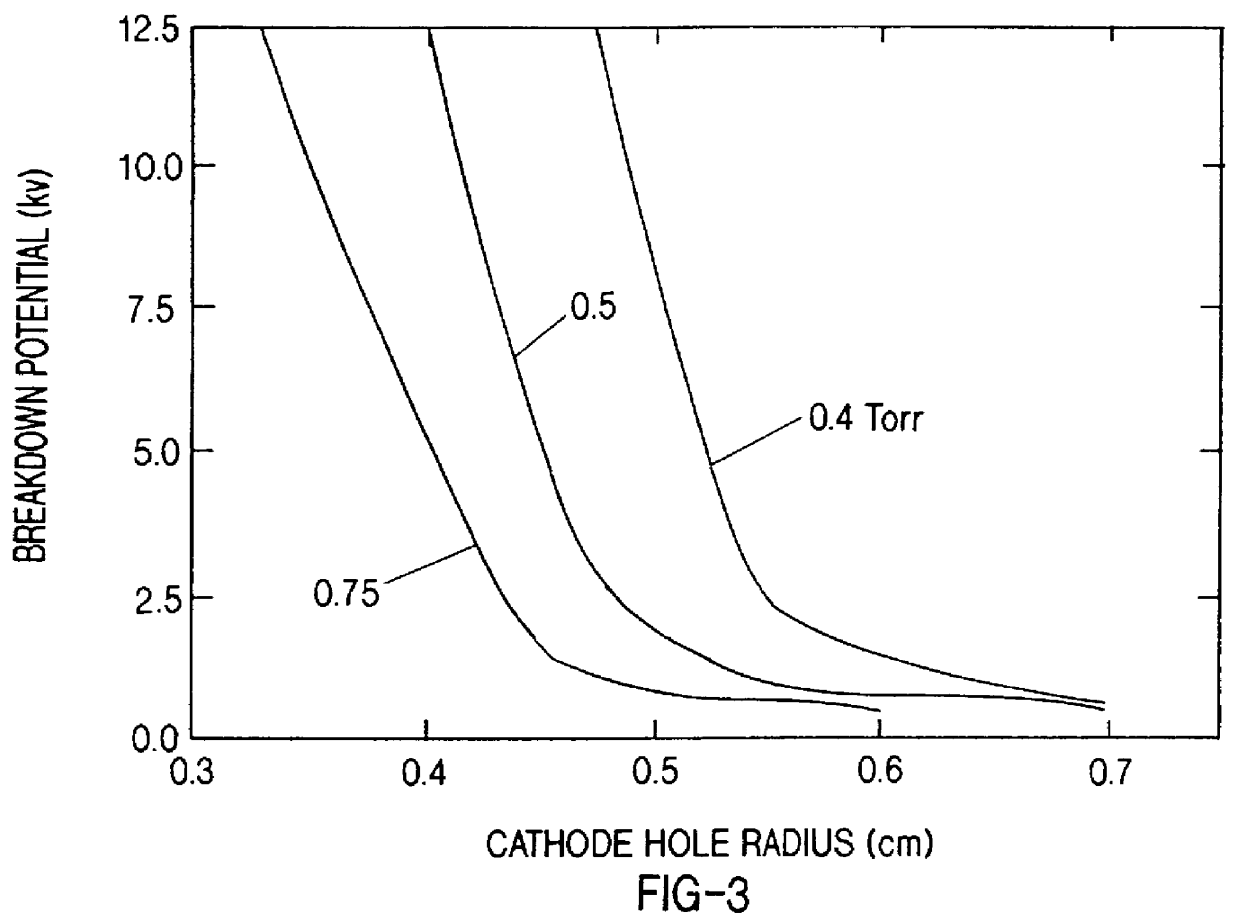

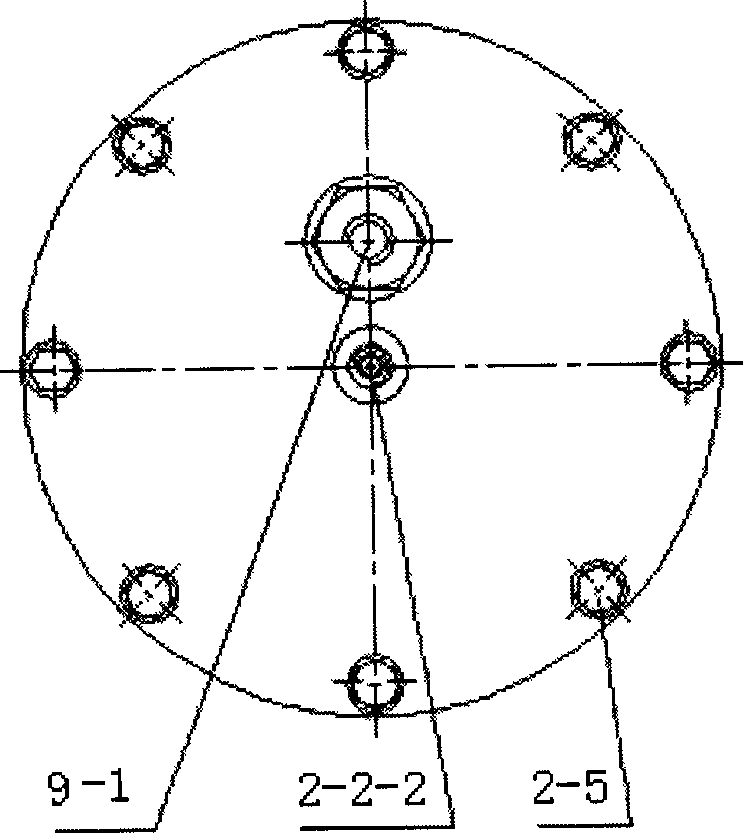

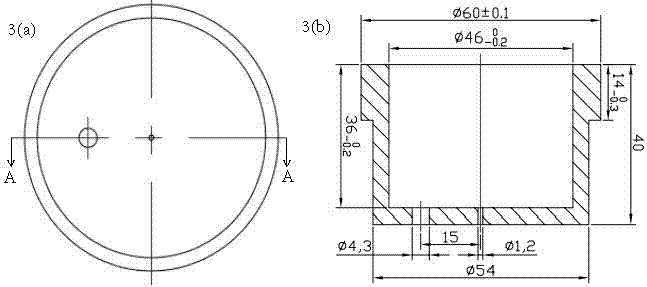

Linear aperture pseudospark switch

InactiveUS6104022AApply evenlyImprove current carrying capacityMaterial analysis by optical meansPhotoelectric discharge tubesPseudospark switchParticle collision

The present invention is of a glow discharge switch operating in the low pressure regime where gas breakdown is limited by the distance between electron-gas particle collisions (pseudospark discharge). The invention utilizes linear discharge apertures (length greater than width) in the electrodes. The linear apertures provide significantly higher current conduction without discharge constriction than conventional round-hole pseudospark switches. A radial version of the linear pseudospark switch also is disclosed that provides for self-canceling of the magnetic fields induced by the discharge, and thus prevents discharge constriction and provides for very high current conduction.

Owner:SDG LLC

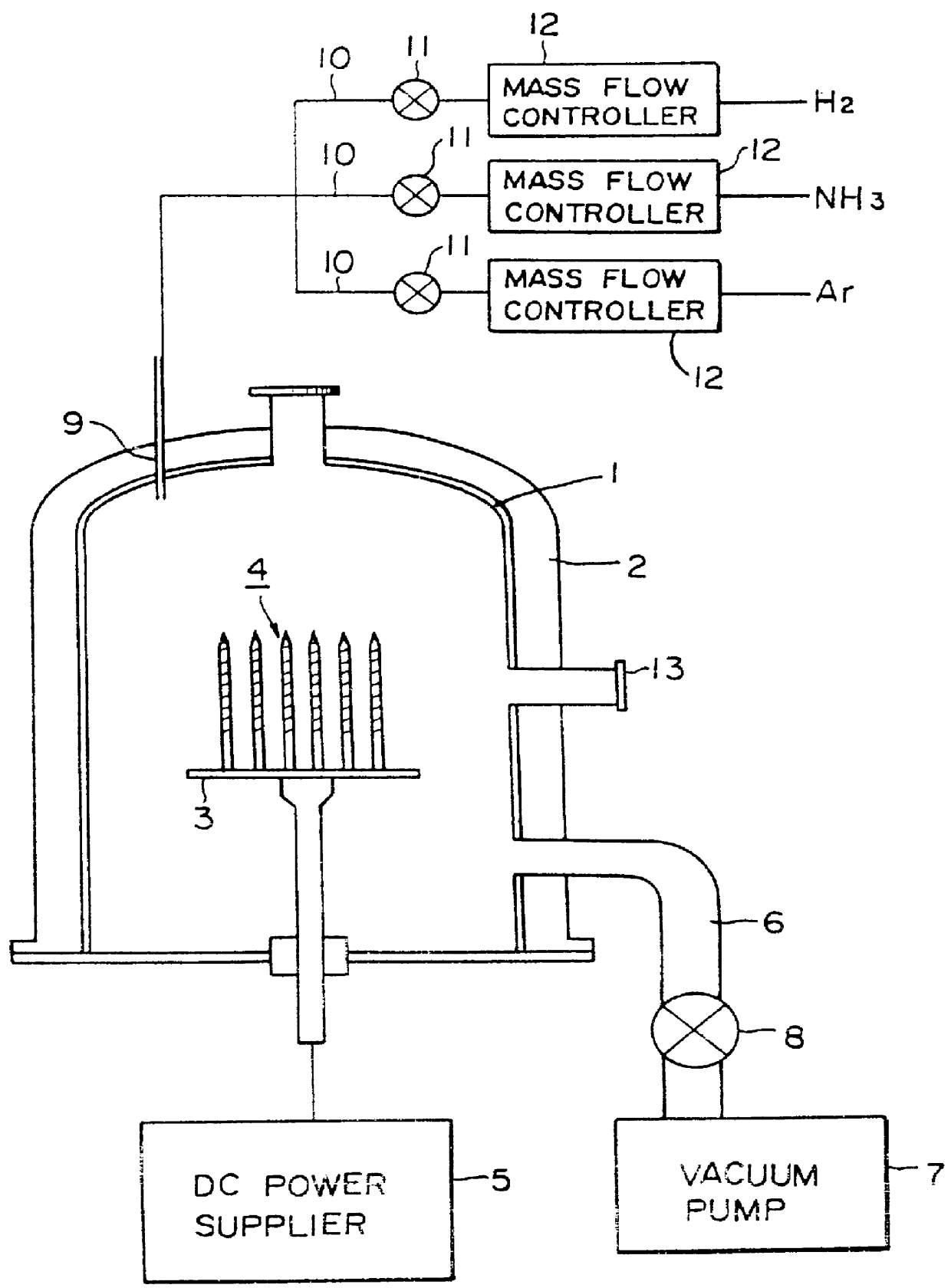

Duplex coated steel composite products and method of manufacturing them

InactiveUS6110571AEasy to useElevation is easyVacuum evaporation coatingSputtering coatingCarbidePlasma nitridation

Duplex coated steel composite products comprising a first layer of a nitrided layer formed by applying glow discharge at a current density from 0.001 to 2.0 mA / cm2 to the surface of metal parts by using gaseous ammonia and gaseous hydrogen while maintaining the temperature of the metal parts at 300 to 650 DEG C., thereby applying plasma nitriding and a second layer comprising a hard film comprising a nitride, carbide and / or carbonitride of one or more of elements selected from Ti, Zr, Hf, V, Nb, Ta and Cr coated on the first layer by the PVD method of a laminate film or a gradient laminate film of such hard film. The treated products are excellent in adhesion with the substrate and durability and have both oxidation resistance and wear resistance.

Owner:SUMITOMO METAL MINING CO LTD

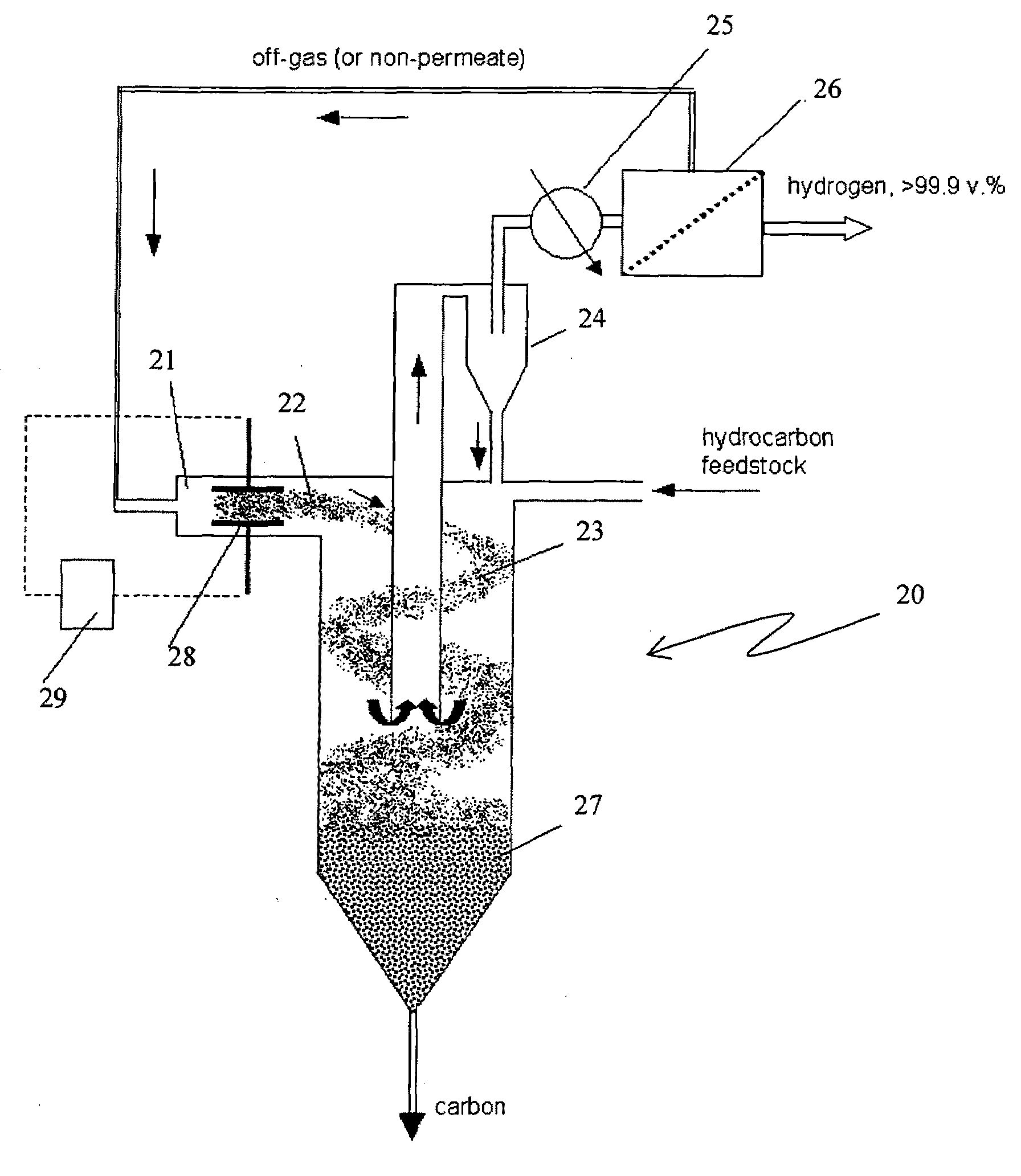

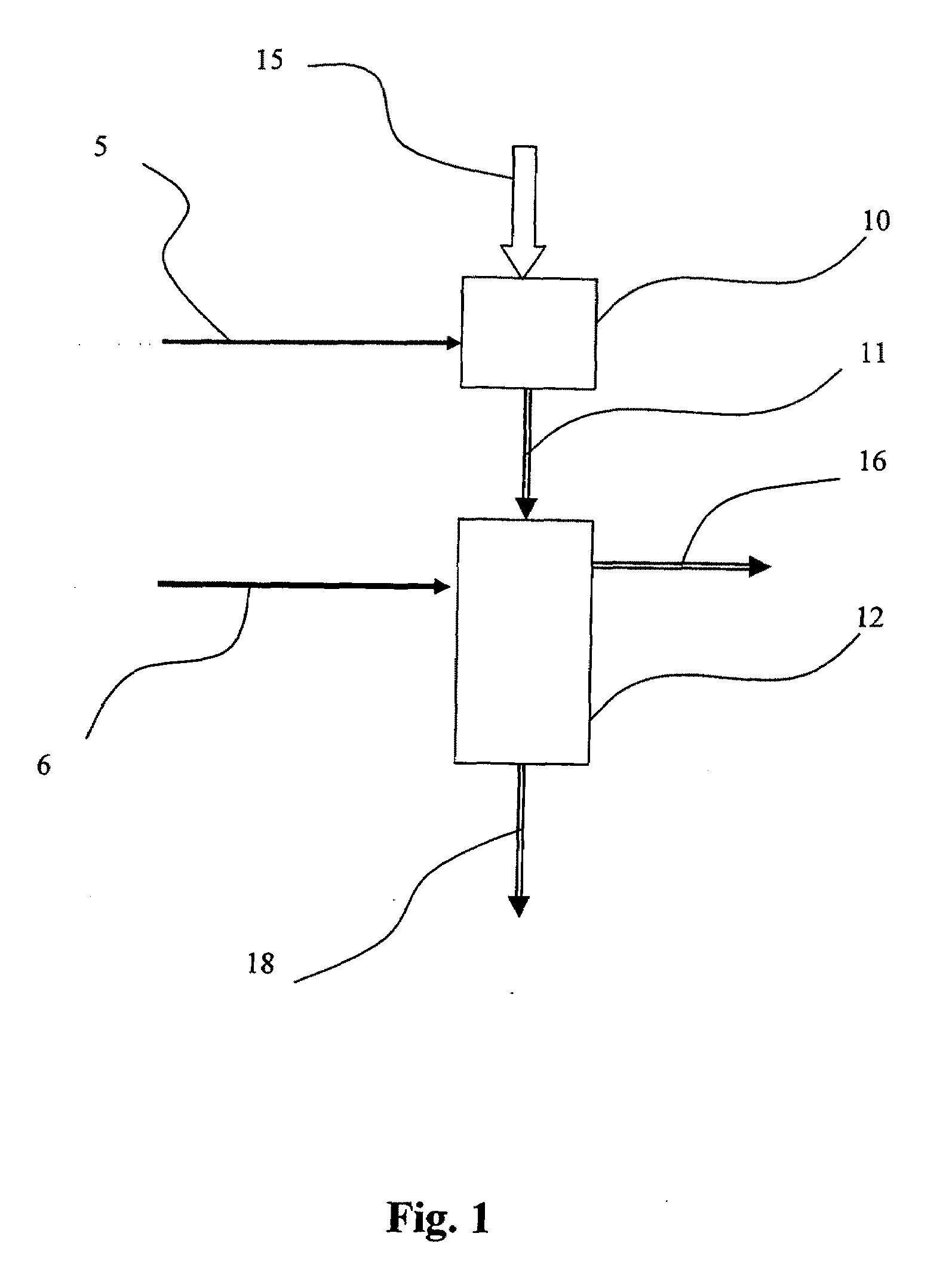

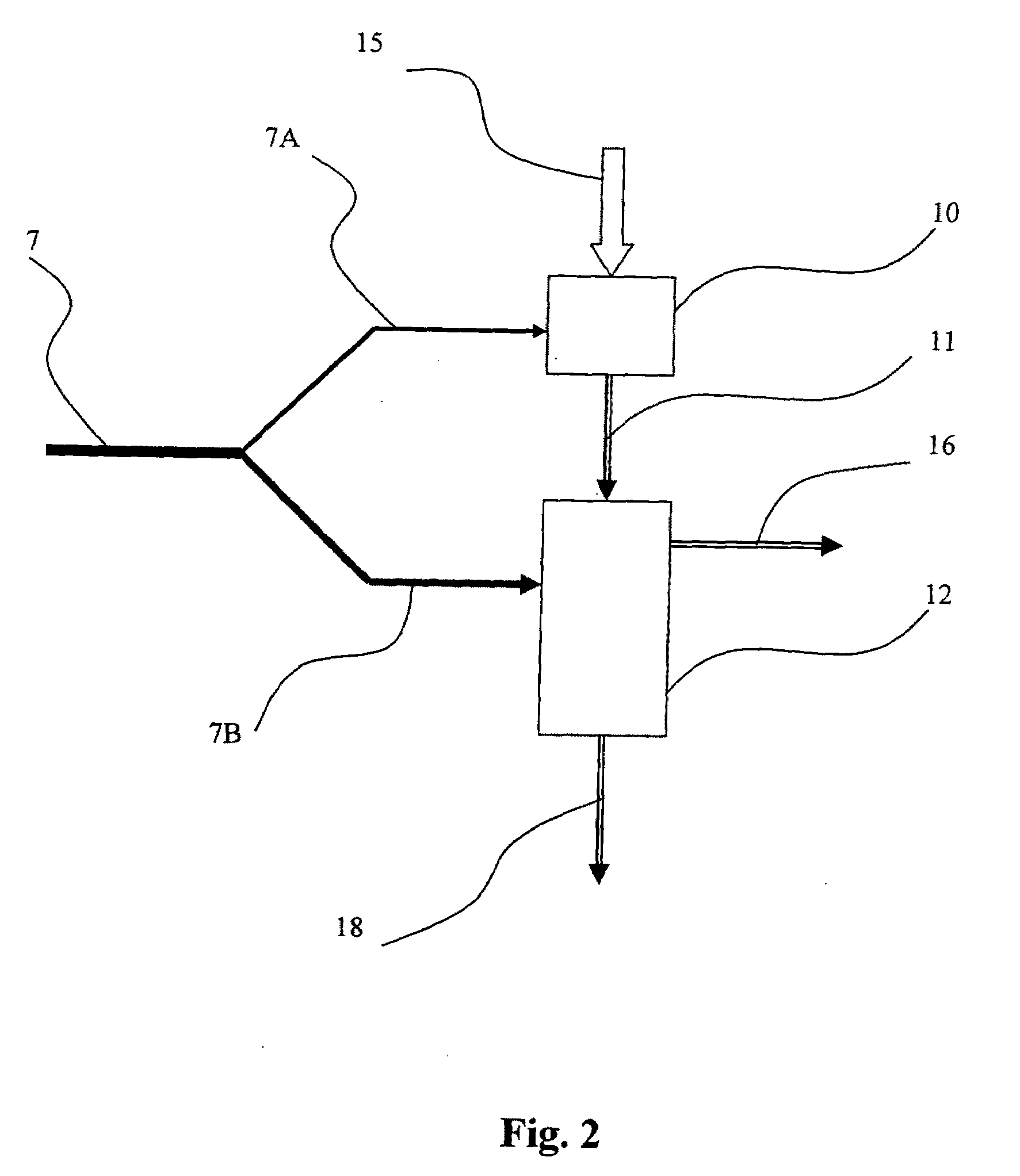

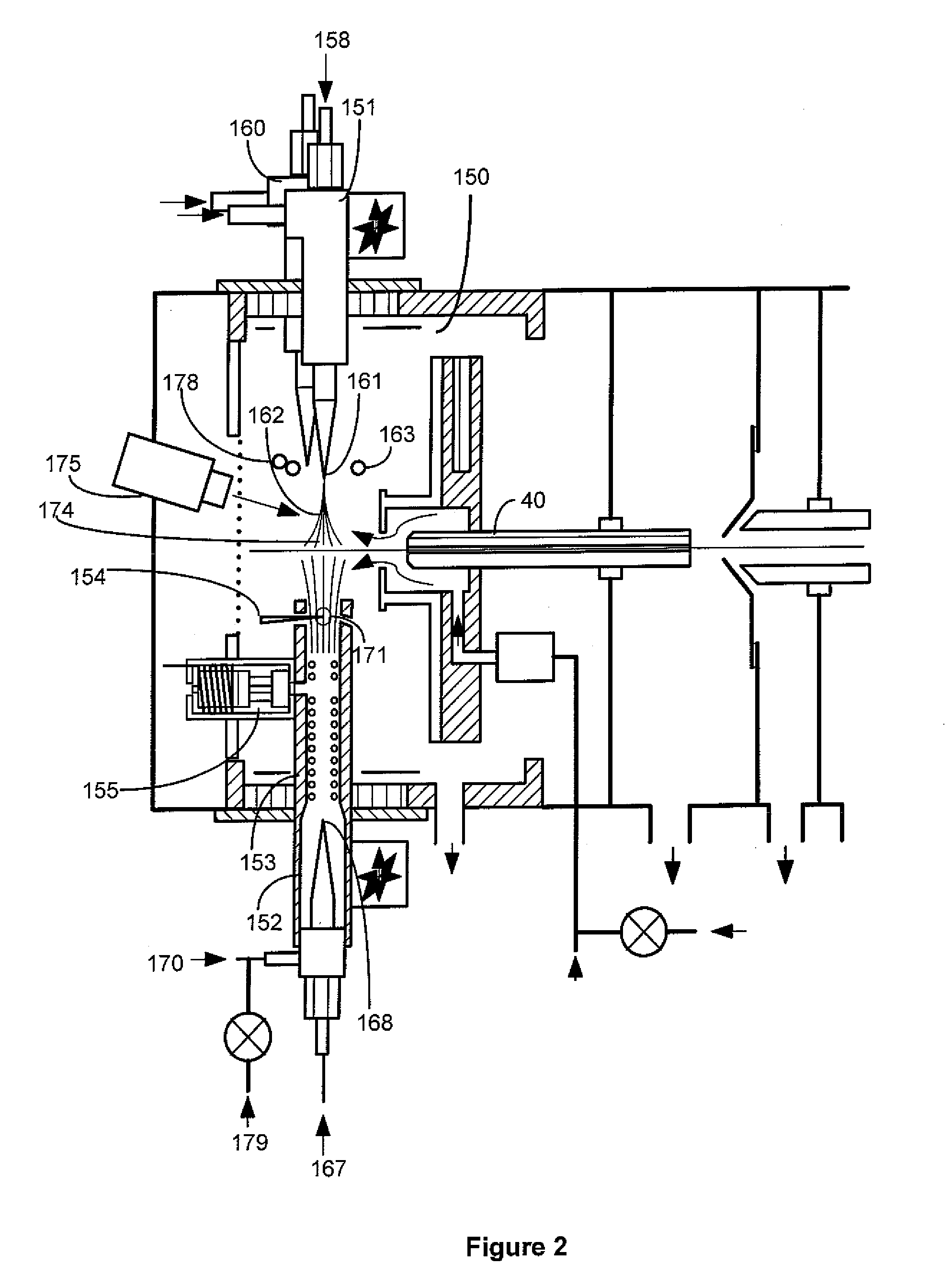

Process and apparatus for hydrogen and carbon production via carbon aerosol-catalyzed dissociation of hydrocarbons

The present invention relates to a novel process for sustainable, continuous production of hydrogen and carbon by catalytic dissociation or decomposition of hydrocarbons at elevated temperatures using in-situ generated carbon particles. Carbon particles are produced by decomposition of carbonaceous materials in response to an energy input. The energy input can be provided by at least one of a non-oxidative and oxidative means. The non-oxidative means of the energy input includes a high temperature source, or different types of plasma, such as, thermal, non-thermal, microwave, corona discharge, glow discharge, dielectric barrier discharge, or radiation sources, such as, electron beam, gamma, ultraviolet (UV). The oxidative means of the energy input includes oxygen, air, ozone, nitrous oxide (NO2) and other oxidizing agents. The method, apparatus and process of the present invention is applicable to any gaseous or liquid hydrocarbon fuel and it produces no or significantly less CO2 emissions compared to conventional processes.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

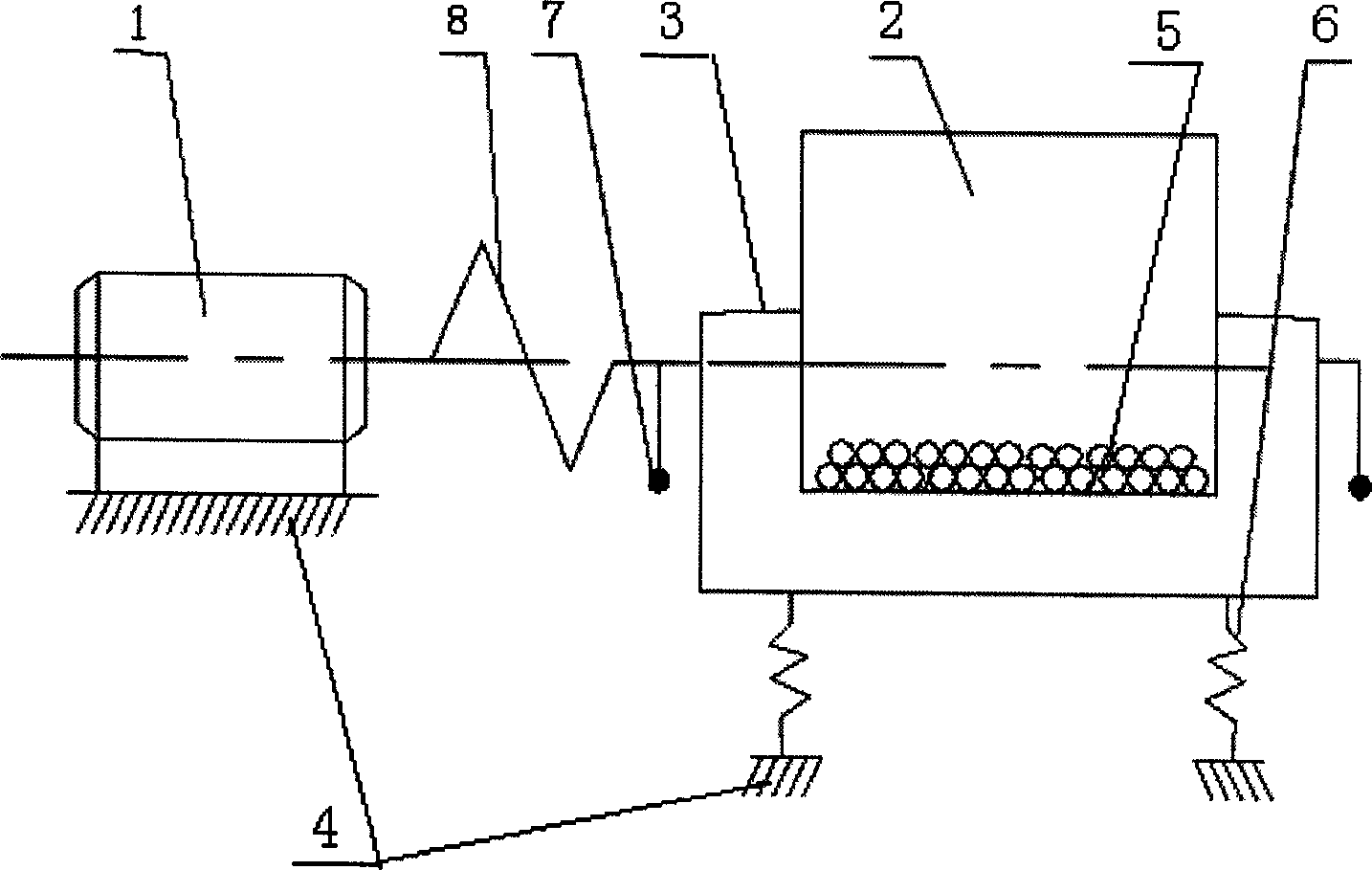

High energy ball mill method with plasma aid

A plasma aided high-energy ball grinding method includes such steps as installing the front cover plate and rod electrode of ball grinder, respectively connecting the ball grinder and rod electrode to the poles of plasma power supply, loading the powder to be ground in the ball grinder, pumping negative pressure, filling discharging gas medium, turning on the plasma power supply, regulating discharge parameters for corona discharge or glow discharge, and turning on the motor to drive the vibration exciting block for ball grinding.

Owner:SOUTH CHINA UNIV OF TECH

Ambient-atmosphere glow discharge for determination of elemental concentration in solutions in a high-throughput or transient fashion

InactiveUS7929138B1Easy to analyzeLow internalRadiation pyrometrySpectrum investigationSpectrometerAtmosphere

An ambient atmosphere glow discharge spectrometer is disclosed having a capillary, two electrodes and a means for recording the atomic emissions.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

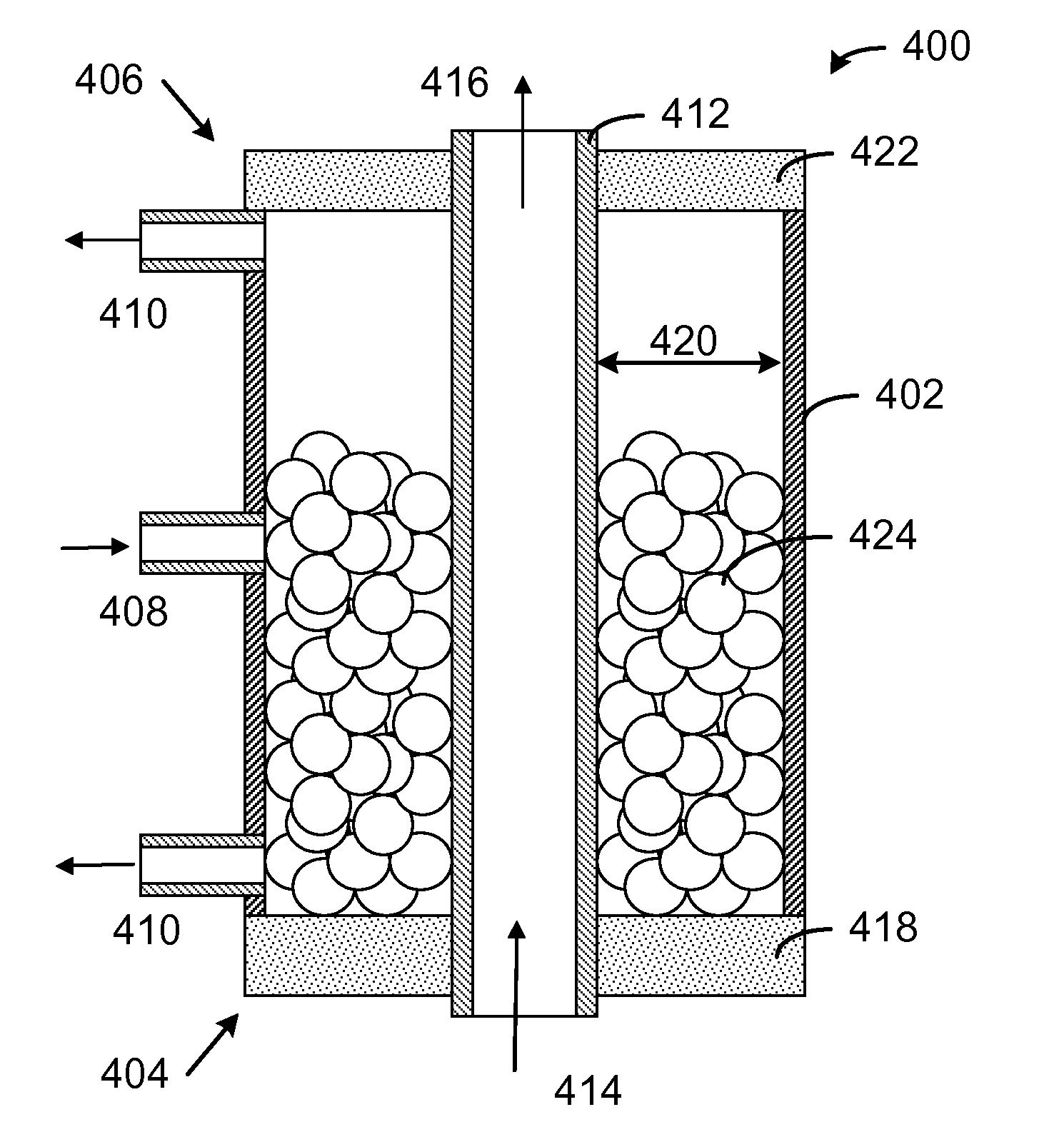

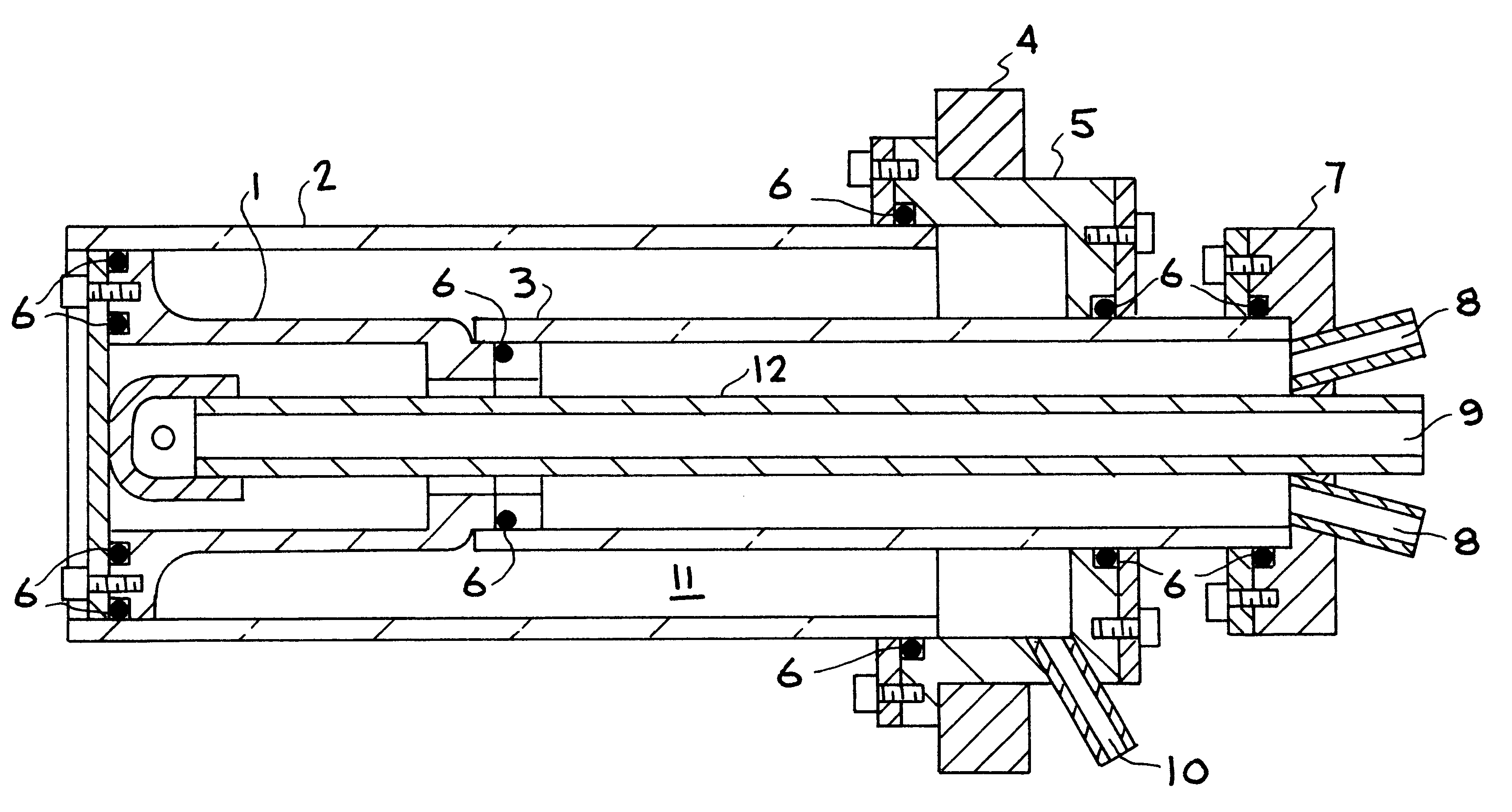

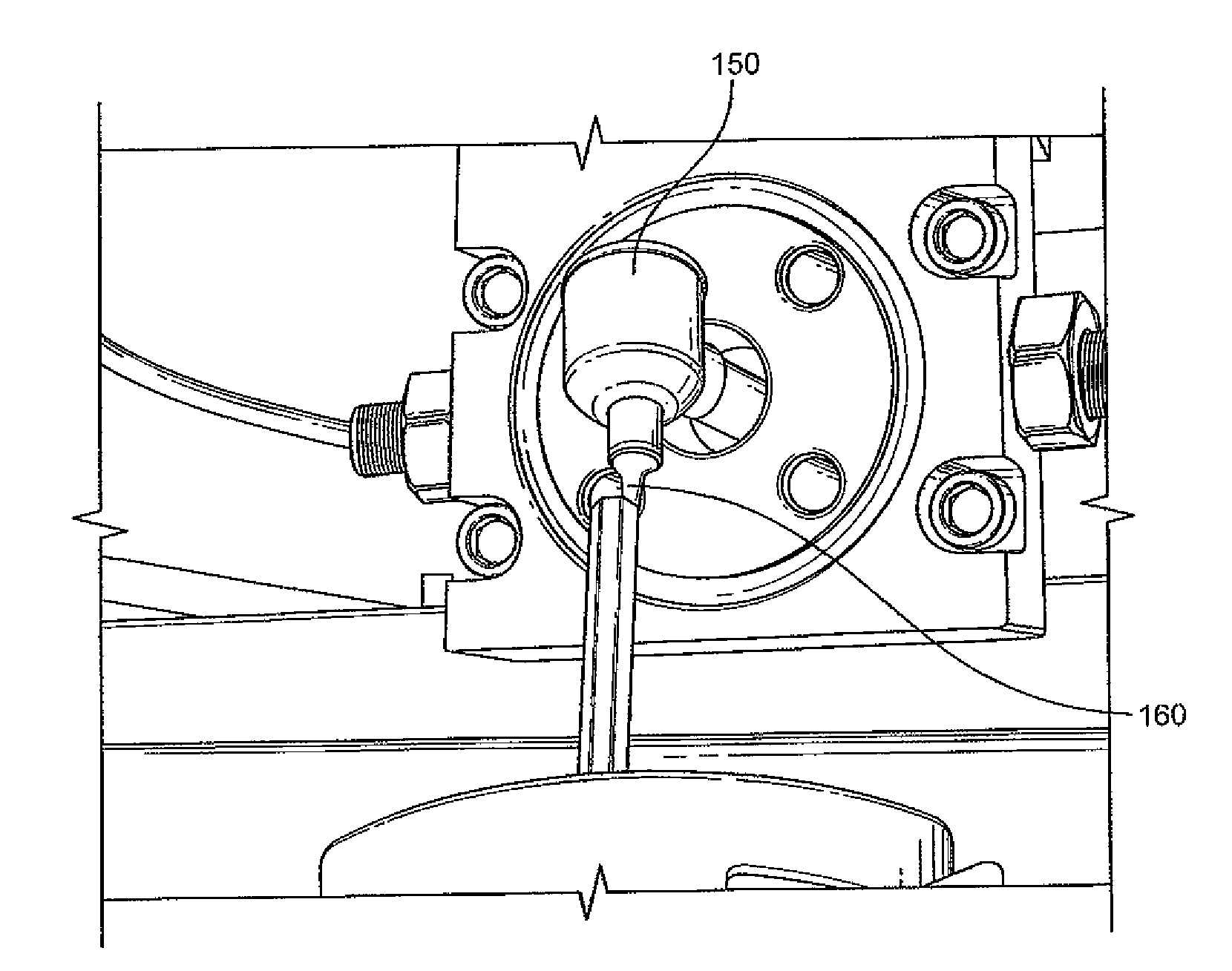

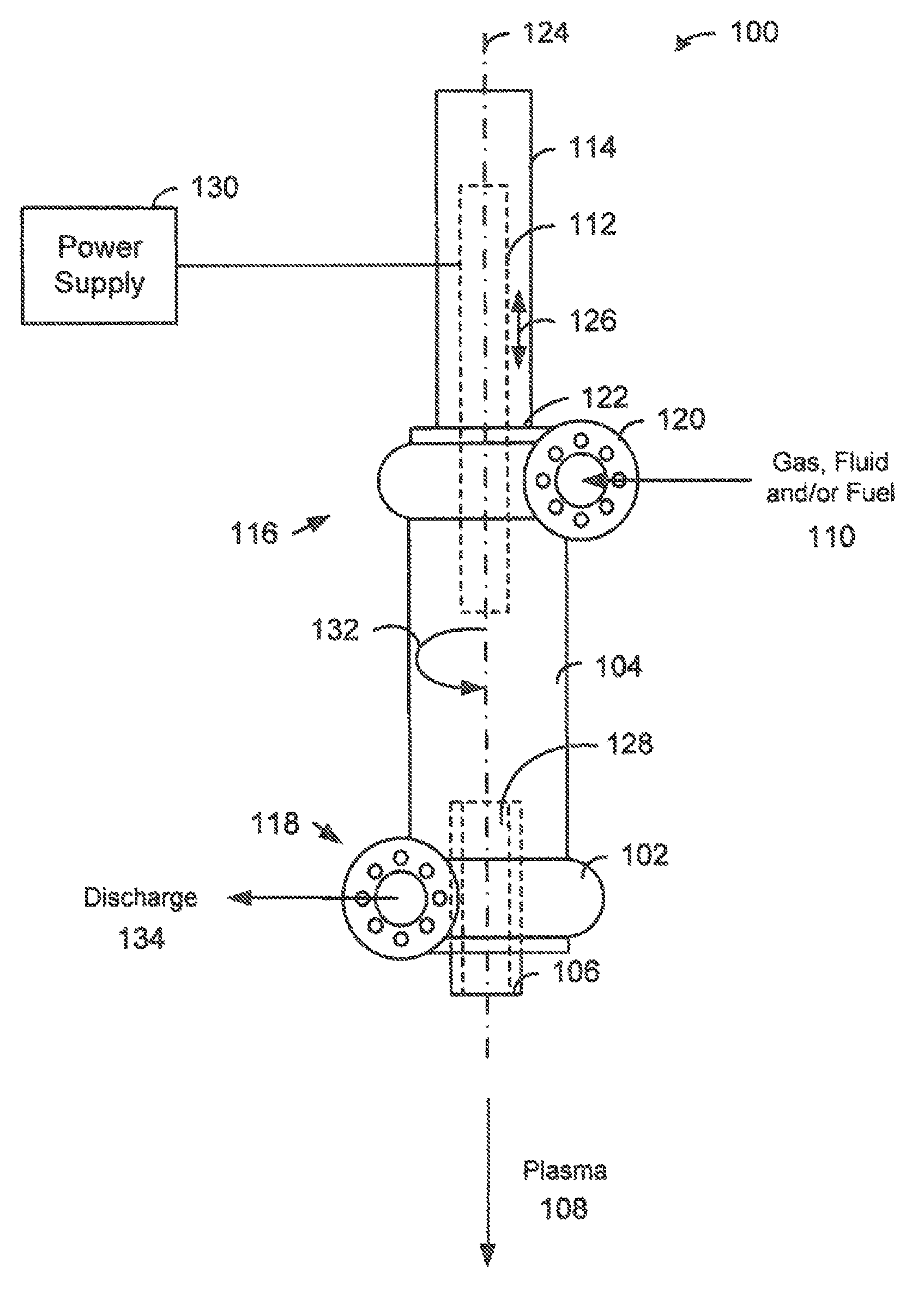

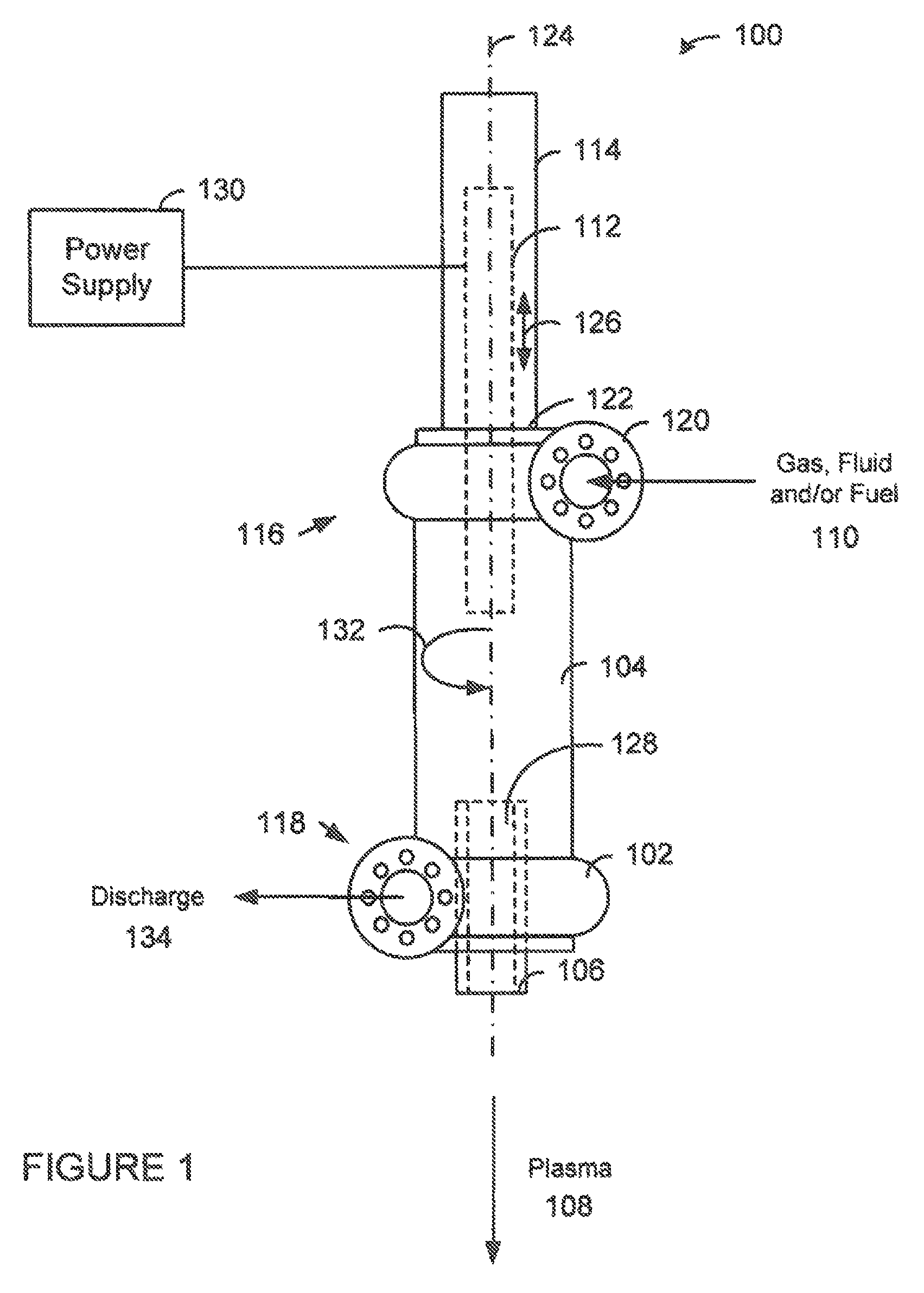

Solid oxide high temperature electrolysis glow discharge cell

The present invention provides a glow discharge cell comprising an electrically conductive cylindrical vessel having a first end and a second end, and at least one inlet and one outlet; a hollow electrode aligned with a longitudinal axis of the cylindrical vessel and extending at least from the first end to the second end of the cylindrical vessel, wherein the hollow electrode has an inlet and an outlet; a first insulator that seals the first end of the cylindrical vessel around the hollow electrode and maintains a substantially equidistant gap between the cylindrical vessel and the hollow electrode; a second insulator that seals the second end of the cylindrical vessel around the hollow electrode and maintains the substantially equidistant gap between the cylindrical vessel and the hollow electrode; a non-conductive granular material disposed within the gap, wherein the non-conductive granular material (a) allows an electrically conductive fluid to flow between the cylindrical vessel and the hollow electrode, and (b) prevents electrical arcing between the cylindrical vessel and the hollow electrode during a electric glow discharge; and wherein the electric glow discharge is created whenever: (a) the glow discharge cell is connected to an electrical power source such that the cylindrical vessel is an anode and the hollow electrode is a cathode, and (b) the electrically conductive fluid is introduced into the gap.

Owner:FORET PLASMA LABS

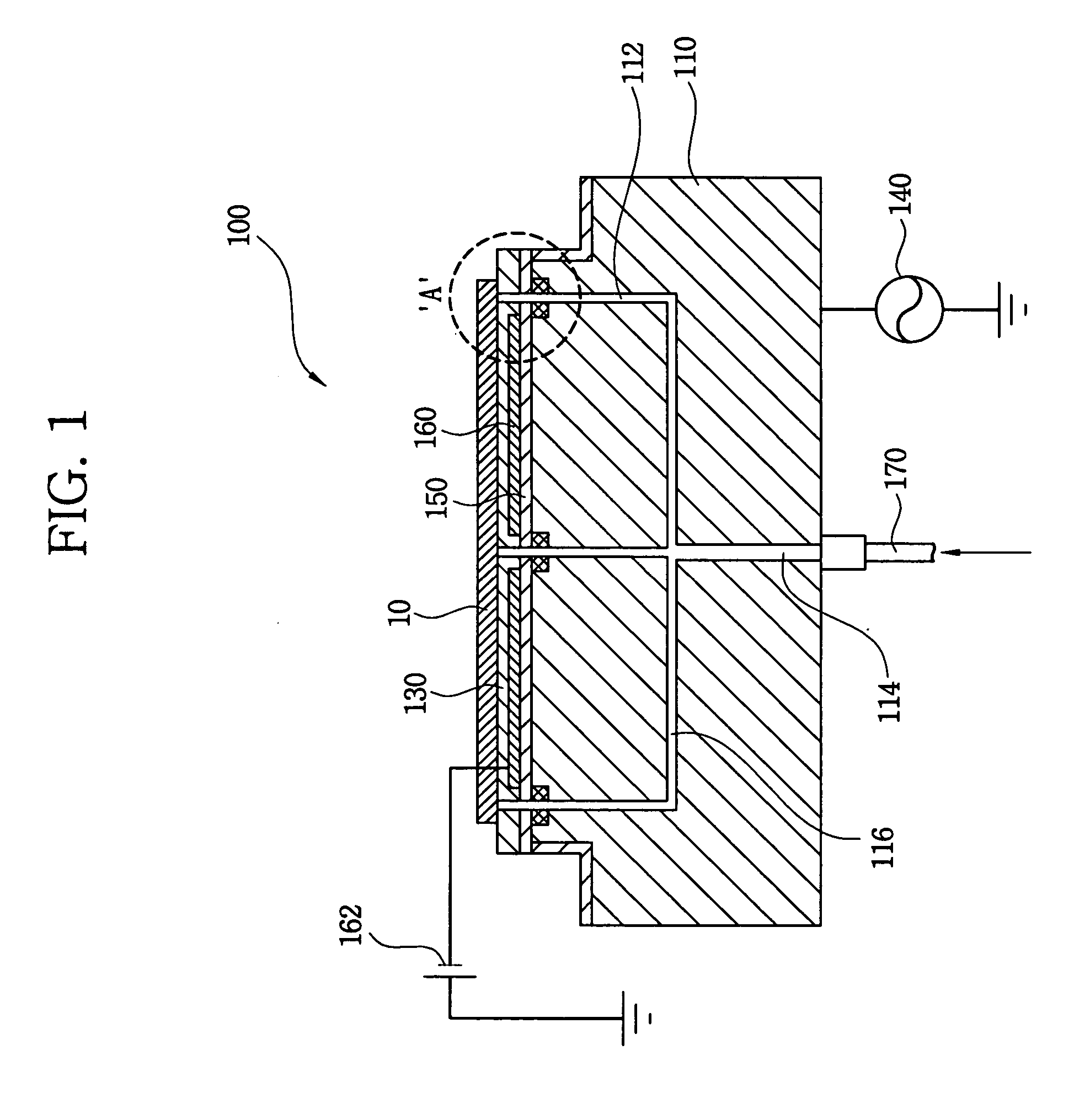

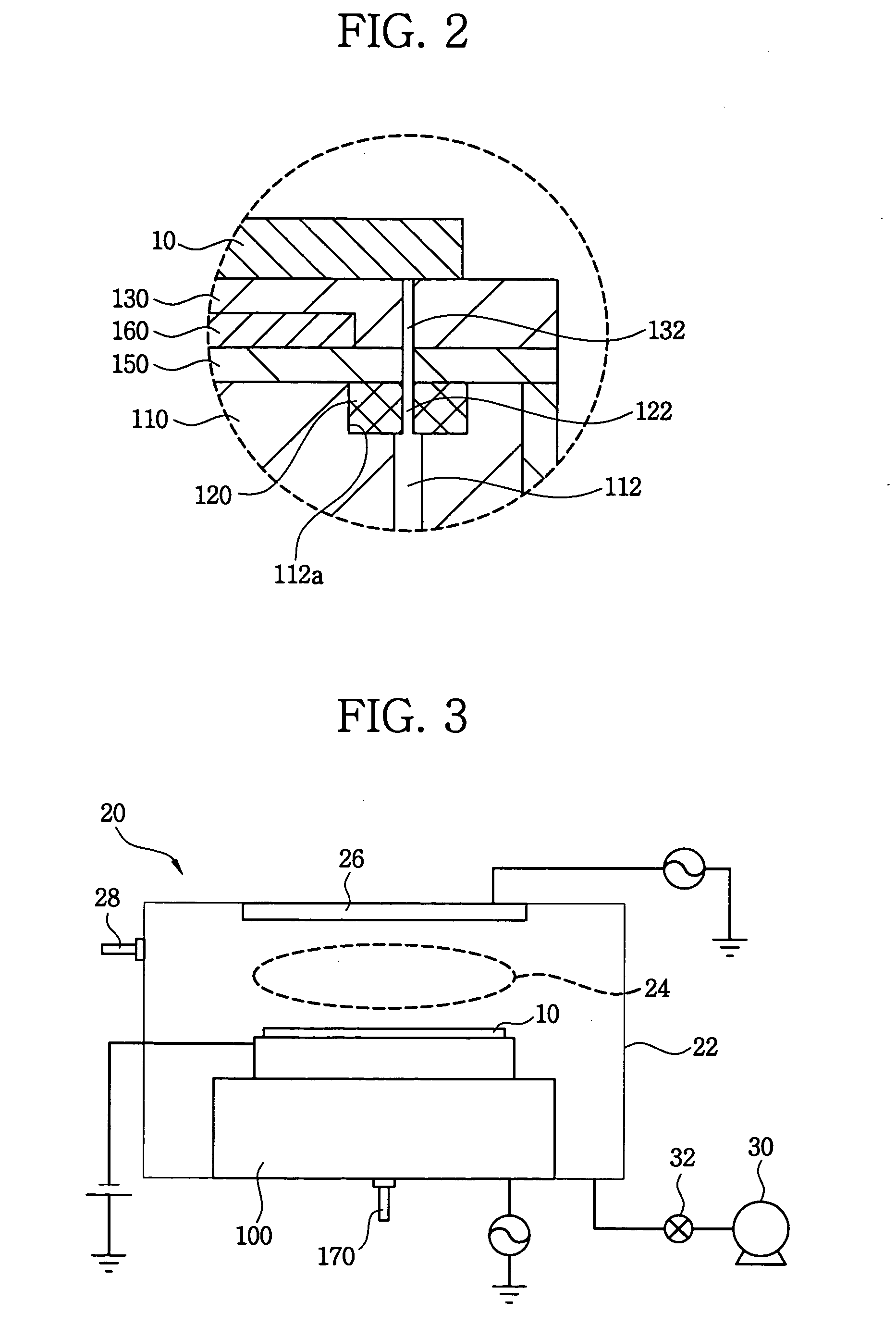

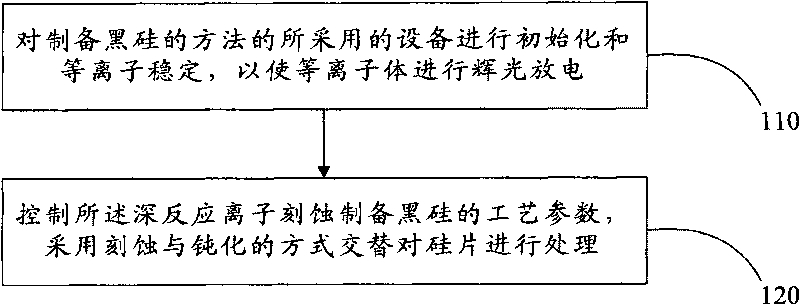

Electrostatic chuck for supporting a substrate

InactiveUS20050105243A1Avoid damageMinimizationEmergency protective arrangement detailsSemiconductor/solid-state device manufacturingEngineeringDielectric layer

An electrostatic chuck to minimize an arc and a glow discharge during processing of a semiconductor substrate is provided, In one aspect, an electrostatic chuckin a processing chamber includes a body having a first hole for providing a cooling gas to a backside of a substrate to control a temperature of the substrate, an inner electrode for generating an electrostatic force and a dielectric layer. A ceramic block is tightly inserted into a first hole and has a second hole connected to the first hole. A third hole formed through the dielectric layer is connected to the first hole and the second hole. The cooling gas is provided to the backside of the substrate through the first hole or the second hole. Since the first hole is covered with the ceramic block, the generation of an arc or a glow discharge inside the first hole may be minimized, thereby preventing damage to the electrostatic chuck and improving production yields.

Owner:SAMSUNG ELECTRONICS CO LTD

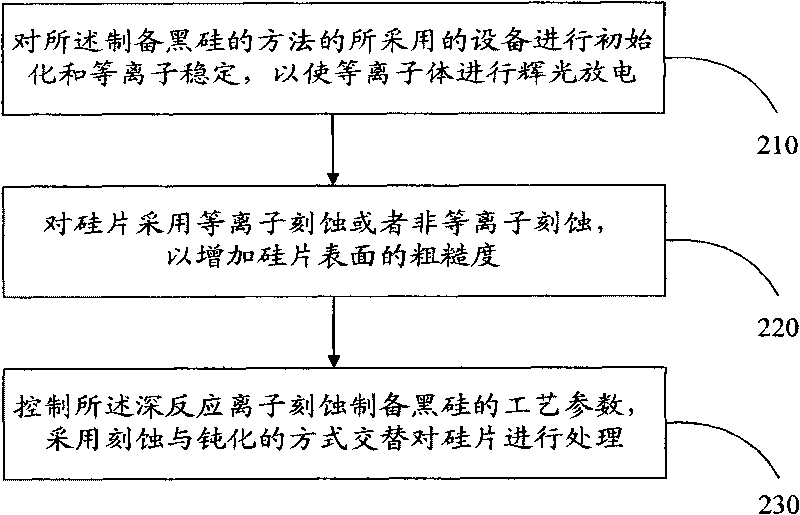

Maskless method for preparing black silicon by deep reactive ion etching

ActiveCN101734611AImprove efficiencyWon't breakNanostructure manufactureDecorative surface effectsNanostructureLarge range

The invention discloses a maskless method for preparing black silicon by deep reactive ion etching, which comprises the following steps: performing initialization and plasma stability on equipment adopted by the method for preparing the black silicon so as to make plasma perform glow discharge; and controlling technological parameters for preparing the black silicon by deep reactive ion etching, and adopting etching and passivating modes to alternately process a silicon chip, wherein the parameters comprise plasma gas flow, panel etching power, panel passivating power, coil power, and etching and passivating cycle and temperature. The maskless method directly performs plasma processing on the surface of the silicon chip, and can generate large-range high-intensity nanostructures on the surface of the silicon chip in case of no nano mask by adjusting and selecting proper etching technological parameters. Meanwhile, the method for preparing the black silicon has high efficiency and low cost, and can be integrated with other micro-fabrication technology.

Owner:PEKING UNIV

A plasma formed in a fluid

InactiveCN1653865AReduce corrosionCompensation for lossHydrogenWater/sewage treatment by irradiationChemical physicsElectrolysis

A method and apparatus for generating plasma in a fluid. The fluid (3) is placed in a bath (2) having a pair of spaced electrodes (4, 6) forming a cathode and an anode. A stream of bubbles is introduced or generated within the fluid adjacent to the cathode. A potential difference is applied across the cathode and anode such that a glow discharge is formed in the bubble region and a plasma of ionised gas molecules is formed within the bubbles. The plasma may then be used in electrolysis, gas production, effluent treatment or sterilisation, mineral extraction, production of nanoparticles or material enhancement. The method can be carried out at atmospheric pressure and room temperature. The electrodes may carry means to trap the bubbles in close proximity. Partitions may be present between the electrodes.

Owner:译民·托马斯·张

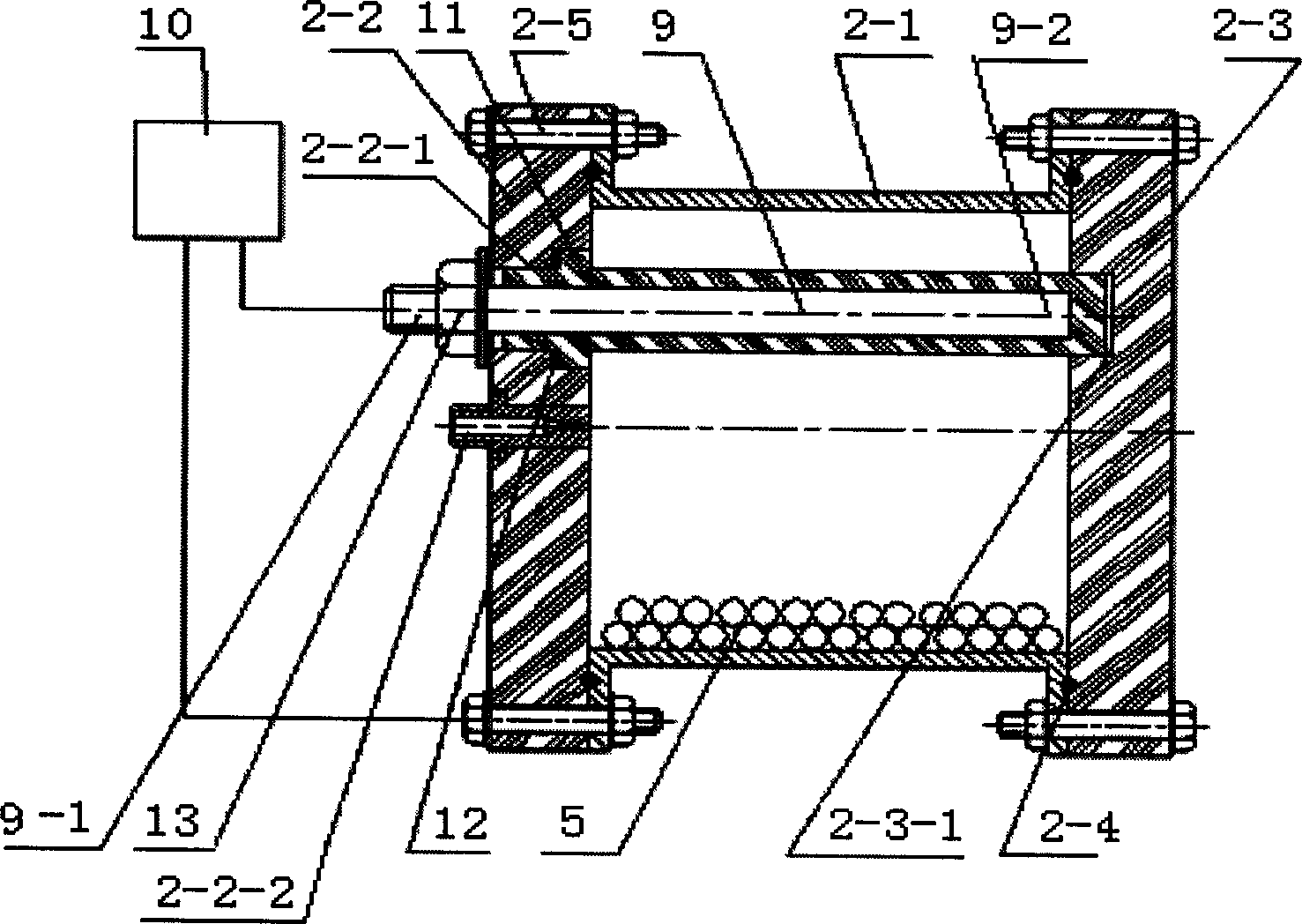

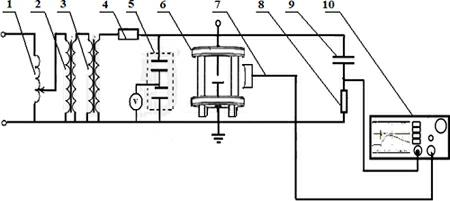

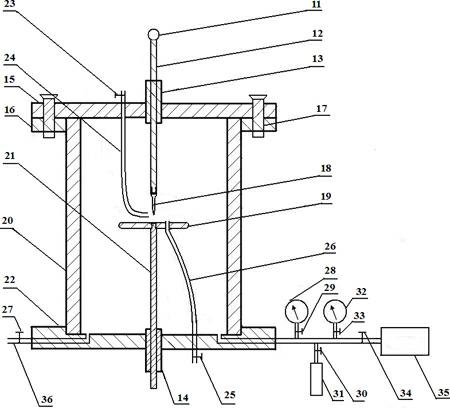

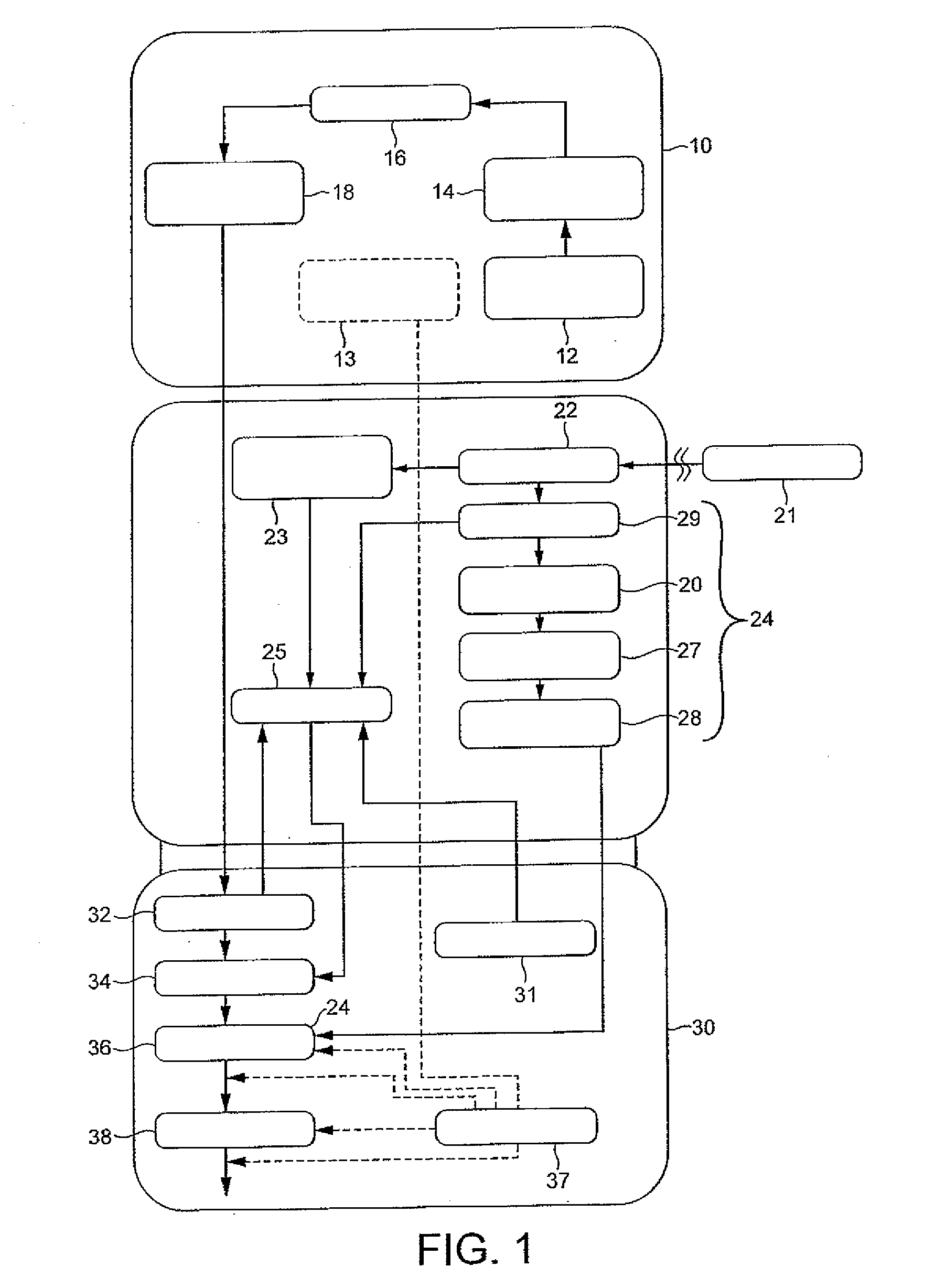

Multi-region detection system for partial discharge decomposition components of insulating gas and method thereof

ActiveCN102608505AImprove sealingImprove applicabilityTesting dielectric strengthElectrical measurement instrument detailsCapacitanceGas cylinder

The invention relates to a multi-region detection system for the partial discharge decomposition components of insulating gas and a method thereof, which belong to the technical field of on-line gas-insulated equipment insulation monitoring. The system comprises a voltage regulator, an isolation transformer, a corona-free test transformer, a partial discharge-free protective resistor, a capacitive divider, an insulating gas discharge decomposition device, an ultrahigh-frequency antenna, an oscillograph, a gas chromatograph-mass spectrometer and the like, and the insulating gas discharge decomposition device comprises a housing, insulating sleeves, connecting rods, electrodes, valves, a vacuum meter, a gas pressure meter, a vacuum pump, an SF6 gas bottle, a pure compressed air bottle and the like. The method utilizes the system to respectively detect the discharge decomposition components of multiple regions in the insulating gas discharge decomposition device. The invention can accurately detect the components and component contents of the decomposed gas of a main gas chamber, a glow discharge region and an electron drift region and provide a standard. The invention can be widely applied to the on-line monitoring of gas-insulated equipment insulation, in particular to the on-line monitoring of GIS (gas-insulated switchgear) insulation.

Owner:CHONGQING UNIV +2

Atmospheric pressure ion source for mass spectrometry

ActiveUS20100096542A1Increase speedIncrease rangeSamples introduction/extractionMaterial analysis by optical meansGas phaseCorona discharge

A multiple function atmospheric pressure ion source interfaced to a mass spectrometer comprises multiple liquid inlet probes configured such that the sprays from two or more probes intersect in a mixing region. Gas phase sample ions or neutral species generated in the spray of one probe can react with reagent gas ions generated from one or more other probes by such ionization methods as Electrospray, photoionization, corona discharge and glow discharge ionization. Reagent ions may be optimally selected to promote such processes as Atmospheric Pressure Chemical Ionization of neutral sample molecules, or charge reduction or electron transfer dissociation of multiply charged sample ions. Selected neutral reagent species can also be introduced into the mixing region to promote charge reduction of multiply charged sample ions through ion-neutral reactions. Different operating modes can be performed alternately or simultaneously, and can be rapidly turned on and off under manual or software control.

Owner:PERKINELMER U S LLC +1

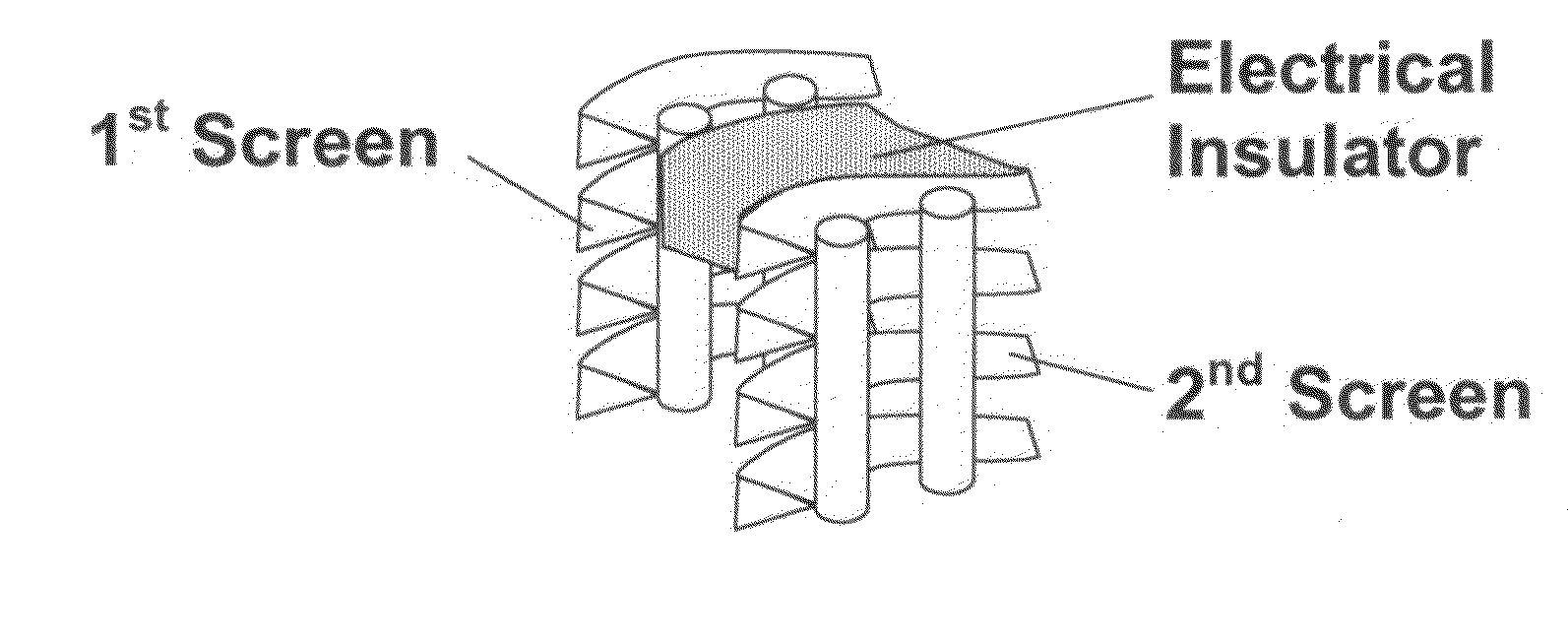

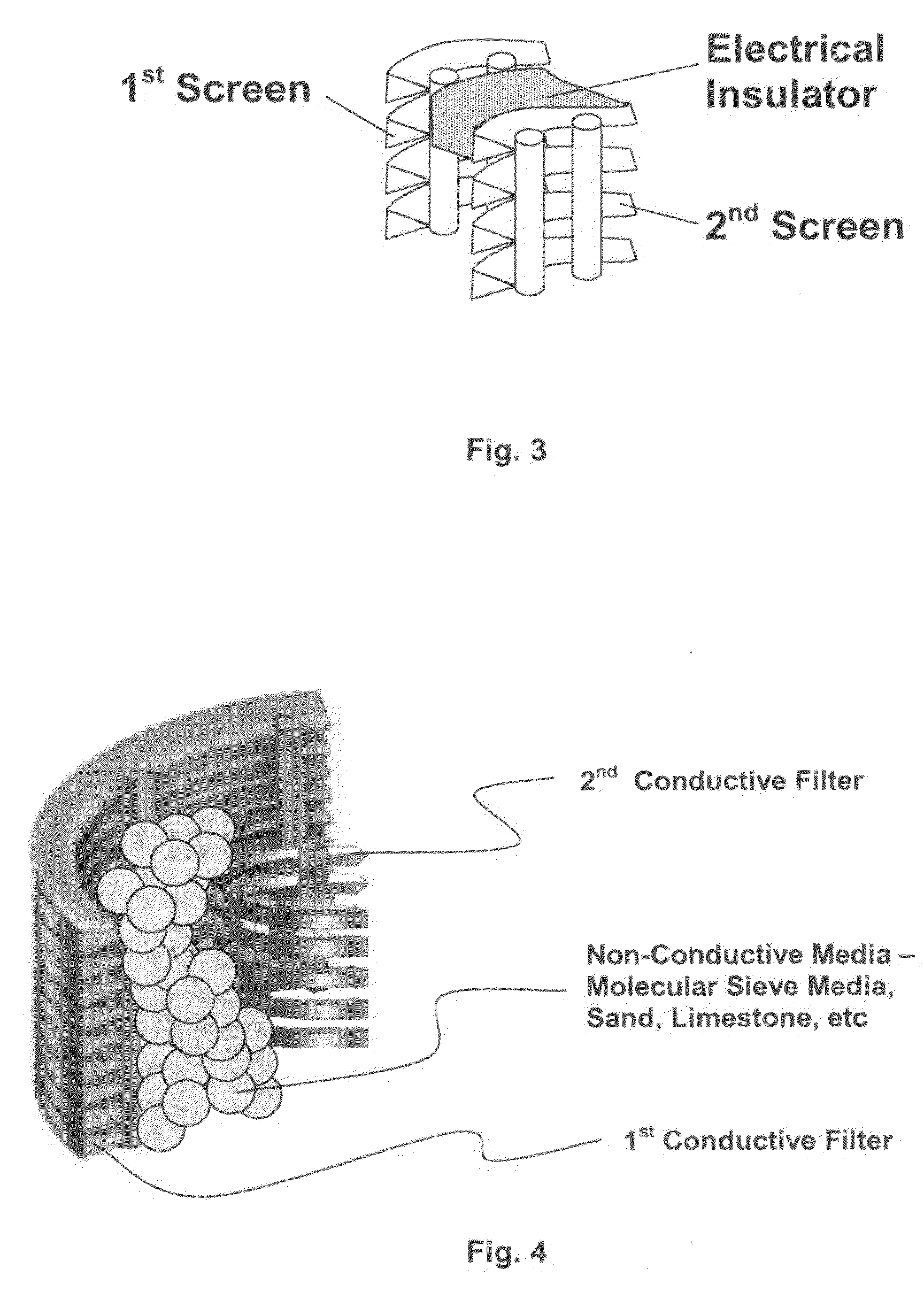

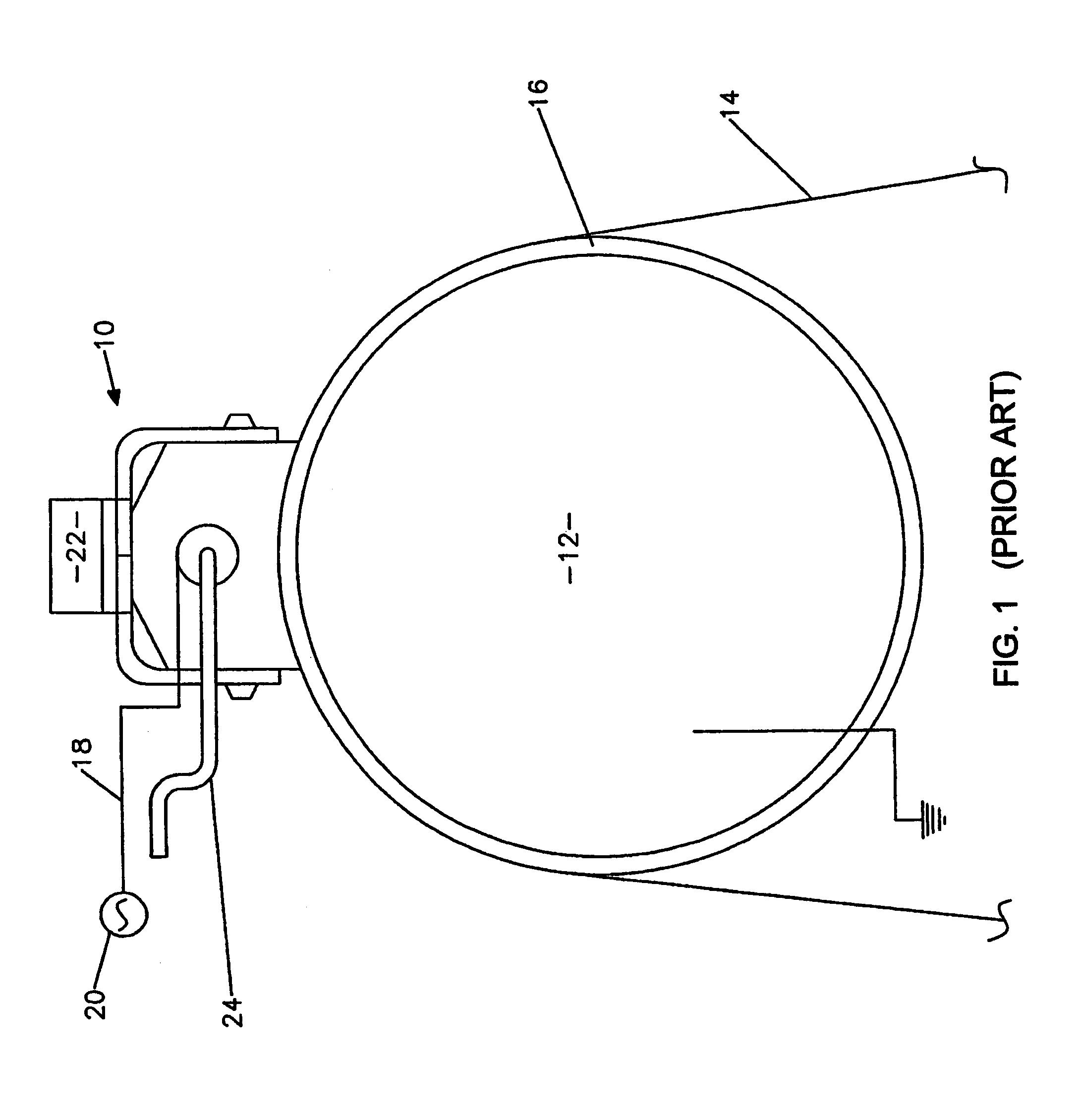

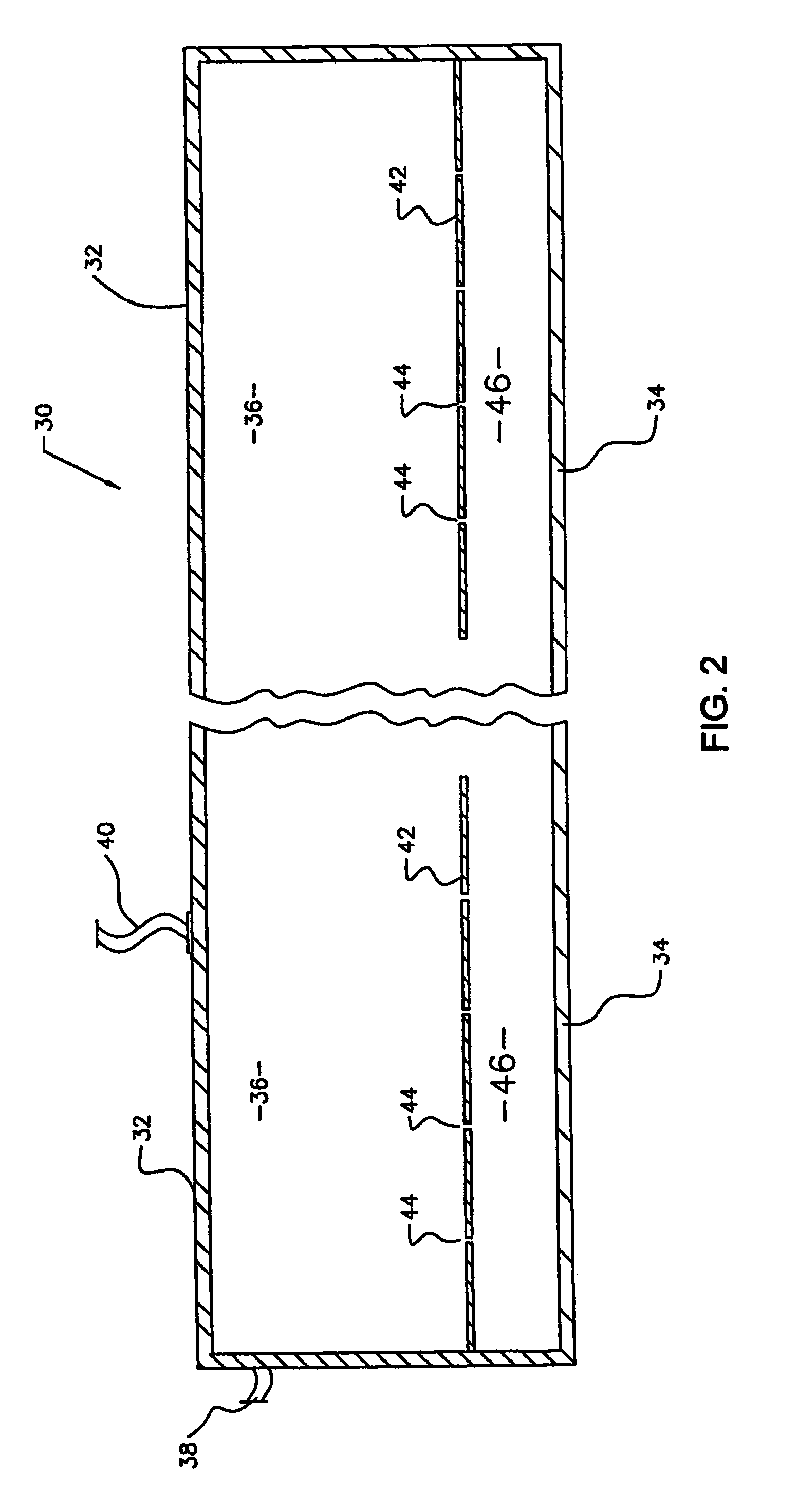

System, method and apparatus for creating an electrical glow discharge

The present invention provides system, method and apparatus for creating an electric glow discharge that includes a first and second electrically conductive screens having substantially equidistant a gap between them, one or more insulators attached to the electrically conductive screens, and a non-conductive granular material disposed within the gap. The electric glow discharge is created whenever: (a) the first electrically conductive screen is connected to an electrical power source such that it is a cathode, the second electrically conductive screen is connected to the electrical power supply such that it is an anode, and the electrically conductive fluid is introduced into the gap, or (b) both electrically conductive screens are connected to the electrical power supply such they are the cathode, and the electrically conductive fluid is introduced between both electrically conductive screens and an external anode connected to the electrical power supply.

Owner:FORET PLASMA LABS

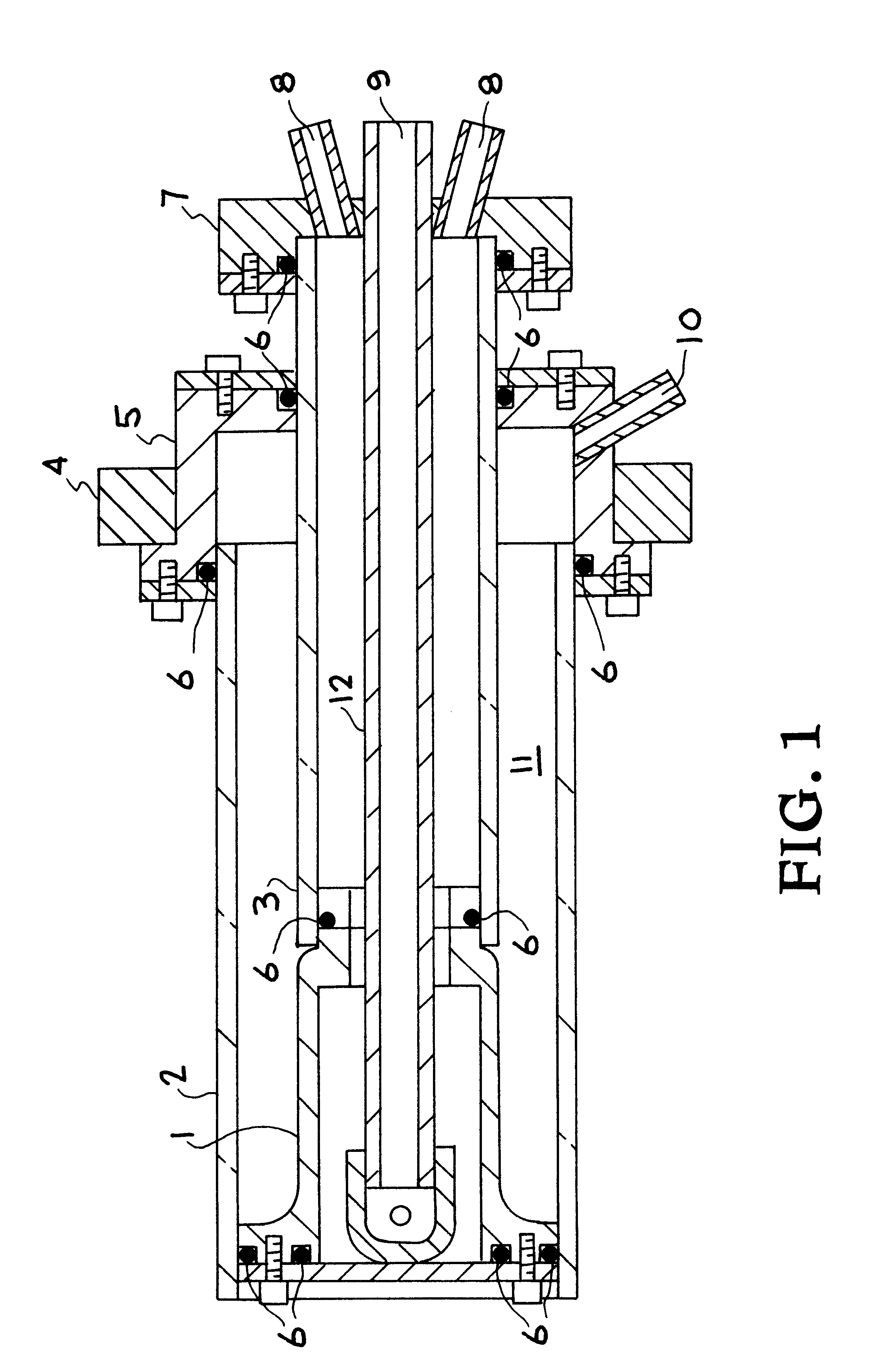

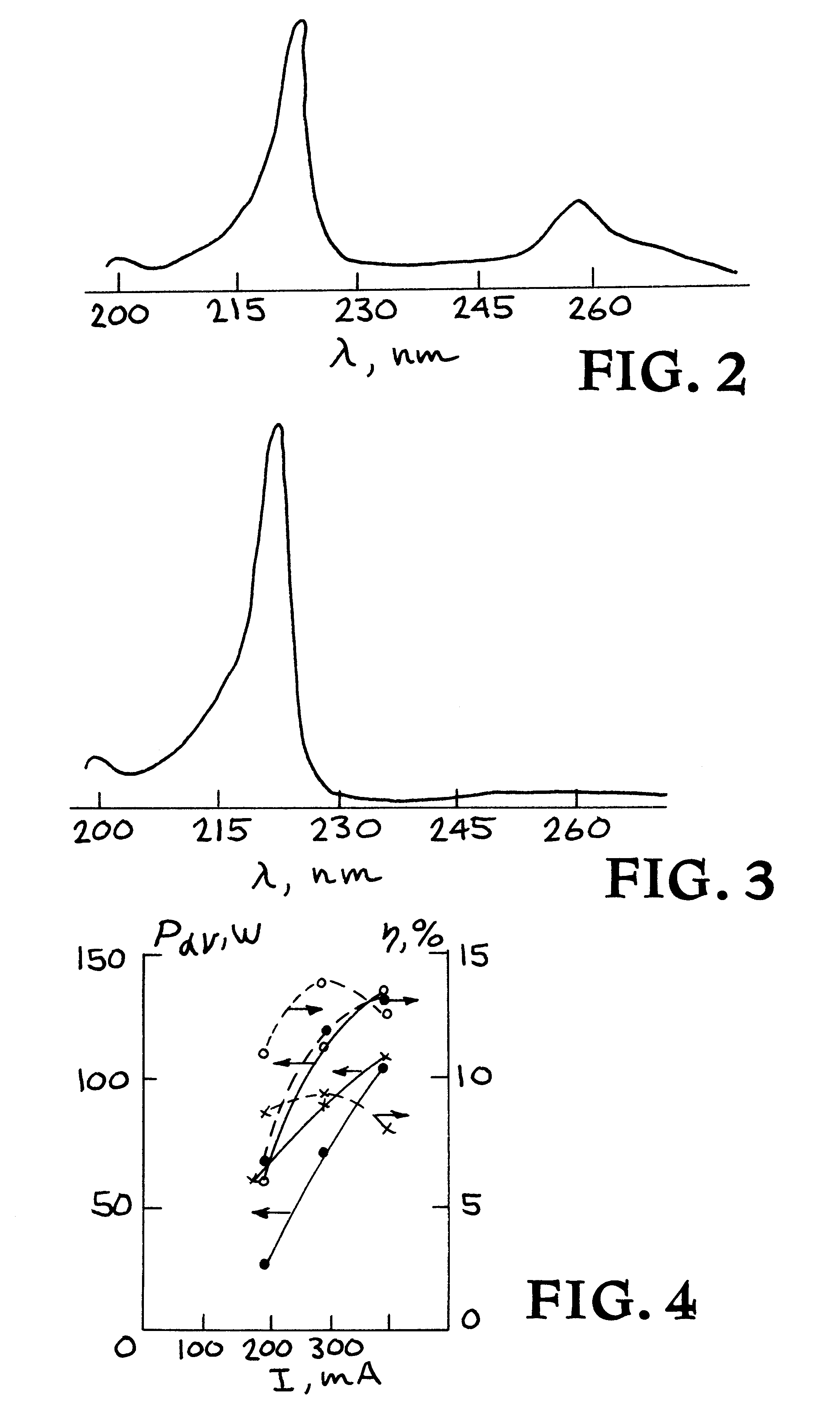

Powerful glow discharge excilamp

A powerful glow discharge lamp comprising two coaxial tubes, the outer tube being optically transparent, with a cathode and anode placed at opposite ends of the tubes, the space between the tubes being filled with working gas. The electrodes are made as cylindrical tumblers placed in line to one other in such a way that one end of the cathode is inserted into the inner tube, one end of the anode coaxially covers the end of the outer tube, the inner tube penetrating and extending through the anode. The increased electrodes' surface area increases glow discharge electron current and, correspondingly, average radiation power of discharge plasma. The inner tube contains at least one cooling liquid tube placed along the axis of the inner tube along the entire lamp length to provide cathode cooling. The anode has a circumferential heat extracting radiator which removes heat from the anode. The invention is related to lighting engineering and can be applied for realization of photostimulated processes under the action of powerful radiation in required spectral range.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Active gases and treatment methods

InactiveUS20120064016A1Optimise populationNegative side effectCosmetic preparationsBiocideKryptonNoble gas

A method of making an active gas by generating a glow discharge, non-thermal plasma, in a gas mixture of a carrier gas and a more readily ionisable gas. The gas mixture is exposed to water vapour at or downstream from the generator to form the active gas. The gas mixture includes helium as the carrier gas and up to 40% by volume of at least one noble gas such as argon, krypton, or xenon as the more readily ionisable gas. The gas mixture is ejected at a temperature between 5° C. to 42° C. The active gas may be used for oral treatment such as cosmetic whitening of teeth, medical or non-clinical cleaning of teeth or for cleaning laundry or dishwashing items.

Owner:LINDE AG

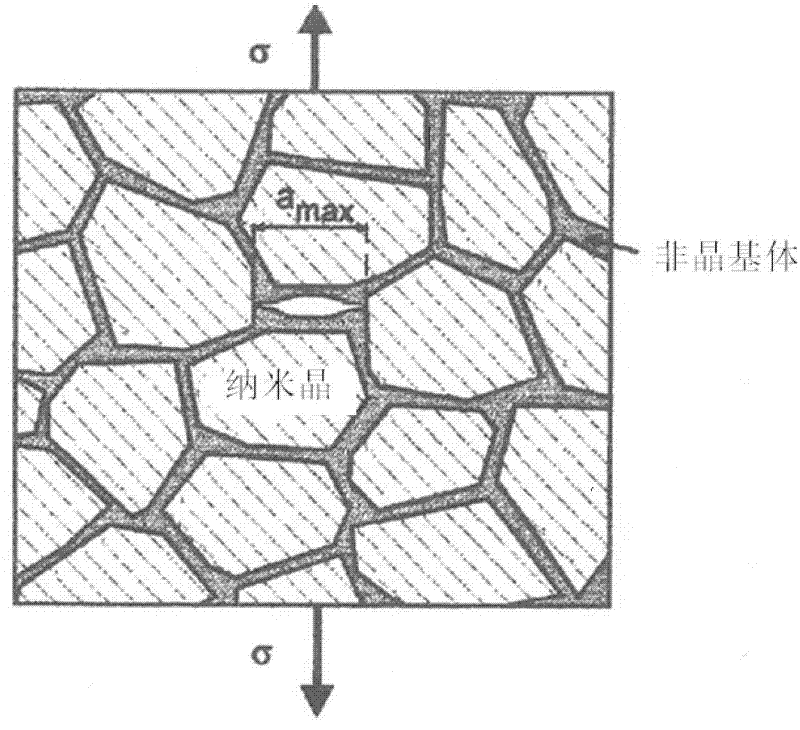

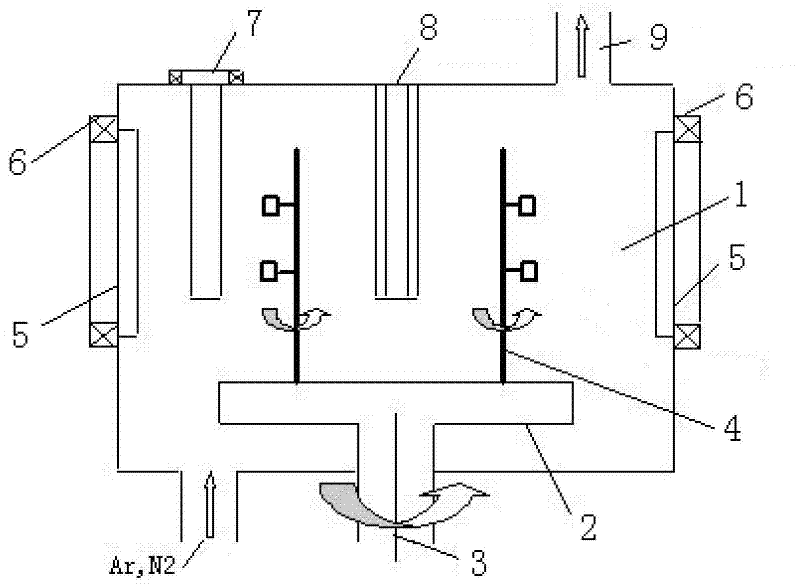

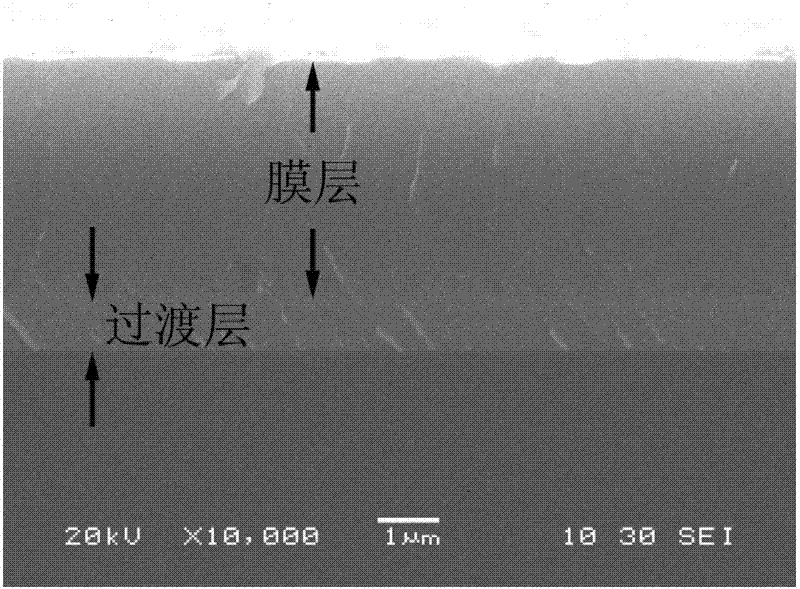

Preparation method of abrasion-resistant and oxidation-resisting TiAlSiN nanometer composite superhard coating

InactiveCN102653855AImprove antioxidant capacityVacuum evaporation coatingSputtering coatingSputteringPower flow

The invention discloses a preparation method of an abrasion-resistant and oxidation-resisting nanometer composite TiAlSiN superhard coating. The preparation method is characterized in that a basal body is pretreated and placed in electrical arc and magnetron sputtering composite deposition equipment, a pillar arc Ti target is used as a Ti source, and the power supply current of the pillar arc controls the sputtering rate of the pillar arc Ti target; a flat surface Si target and a flat surface Al target are used as sources of corresponding elements, the flat surface Si target and the flat surface Al target are placed on the inner wall of a furnace body in an opposite manner, and the sputtering rates of the targets are controlled by adjusting the power of a medium-frequency pulse power supply; high-purity Ar is adopted as a main ionization gas, and an effective glow discharge process is guaranteed; and high-purity N2 is adopted as a reacting gas, is ionized and combined with the Ti, Si and Al elements so as to deposit on the surface of the basal body to form a TiAlSiN coating. The thickness of the prepared TiAlSiN coating is 3.5 micrometers, and the microhardness of the coating is 40 GPa; and the friction factor is 0.7, the antioxidation temperature of the TiAlSiN coating achieves 1000 DEG C, and the TiAlSiN coating has good antioxidation property and abrasion-resistant property.

Owner:马胜利

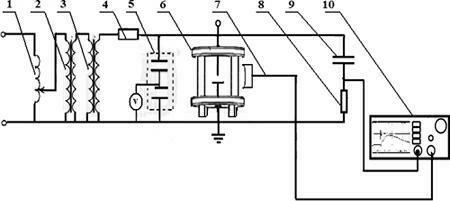

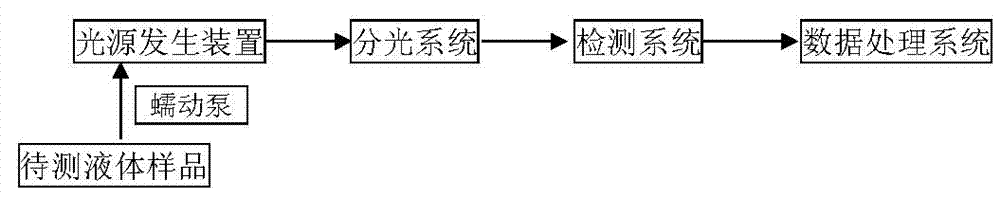

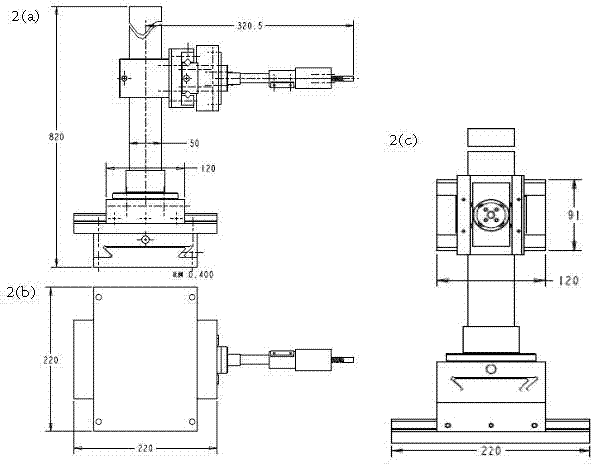

Liquid cathode glow discharge emission spectrum detection metal ion apparatus

InactiveCN103163116ASimple structureReduce volumeAnalysis by electrical excitationProcess systemsHigh pressure

The invention relates to a liquid cathode glow discharge emission spectrum detection metal ion apparatus, which comprises a light source generation part used for generating glow discharge, a splitting system used for performing light splitting treatment on glow discharge emission spectrum generated by the light source generation part, a detection apparatus used for detecting the emission spectrum after light splitting treatment, and a data process system used for analyzing and processing the signals of the detection apparatus; wherein, the light source generation part comprises a metal anode connected to the anode of high voltage supply, a liquid pool filled with an electrolyte connected to the cathode of the high voltage supply; and a sample introduction unit, which comprises a sample introduction pipe which is vertically passed through the liquid pool, and the top of the sample introduction pipe is positioned below the metal anode; the sample introduction unit enables a solution to be measured to escape from the top of the sample introduction pipe, thereby the solution to be measured overflowed from the top of the sample introduction pipe and the metal anode form a glow discharge area.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

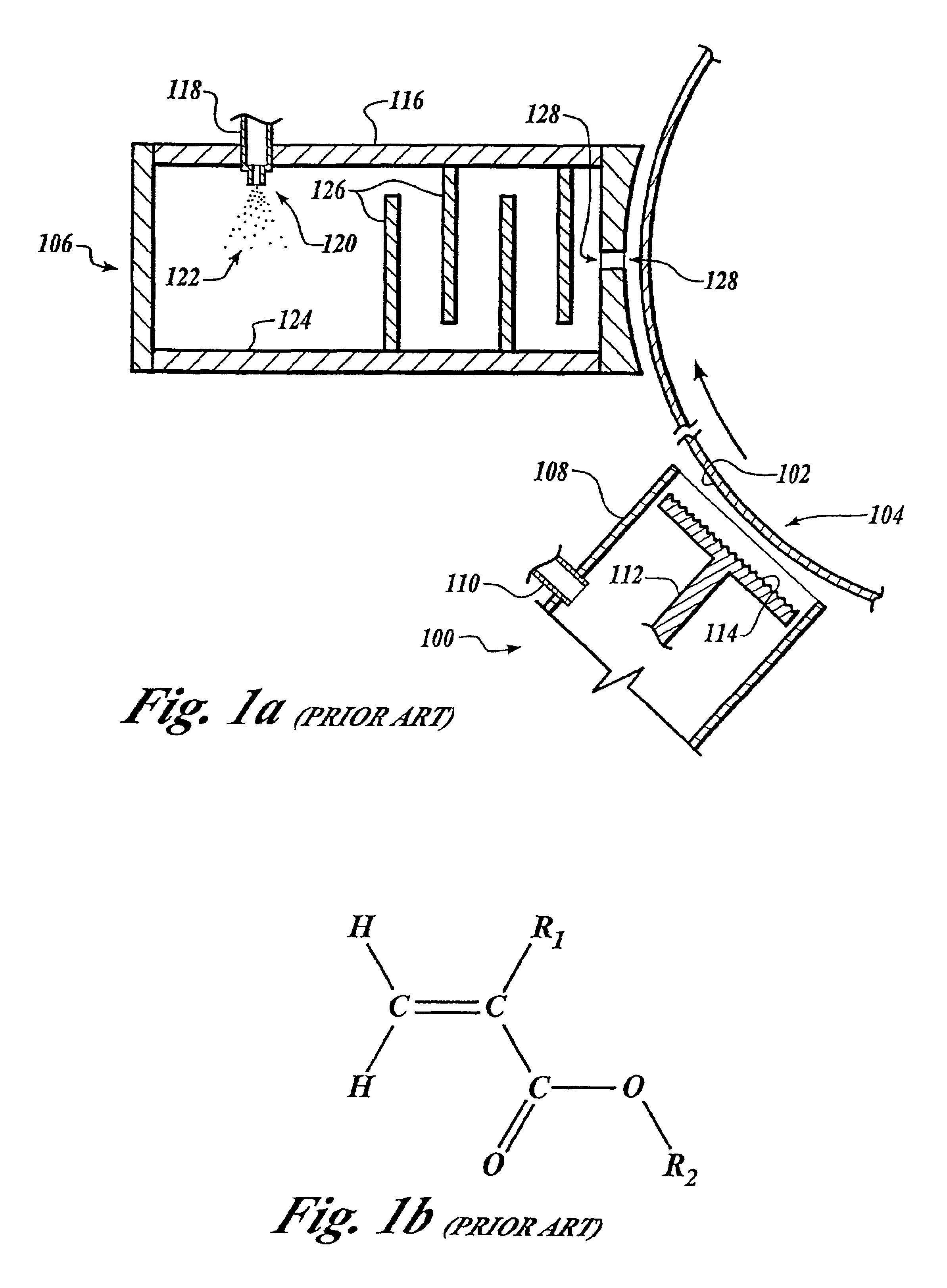

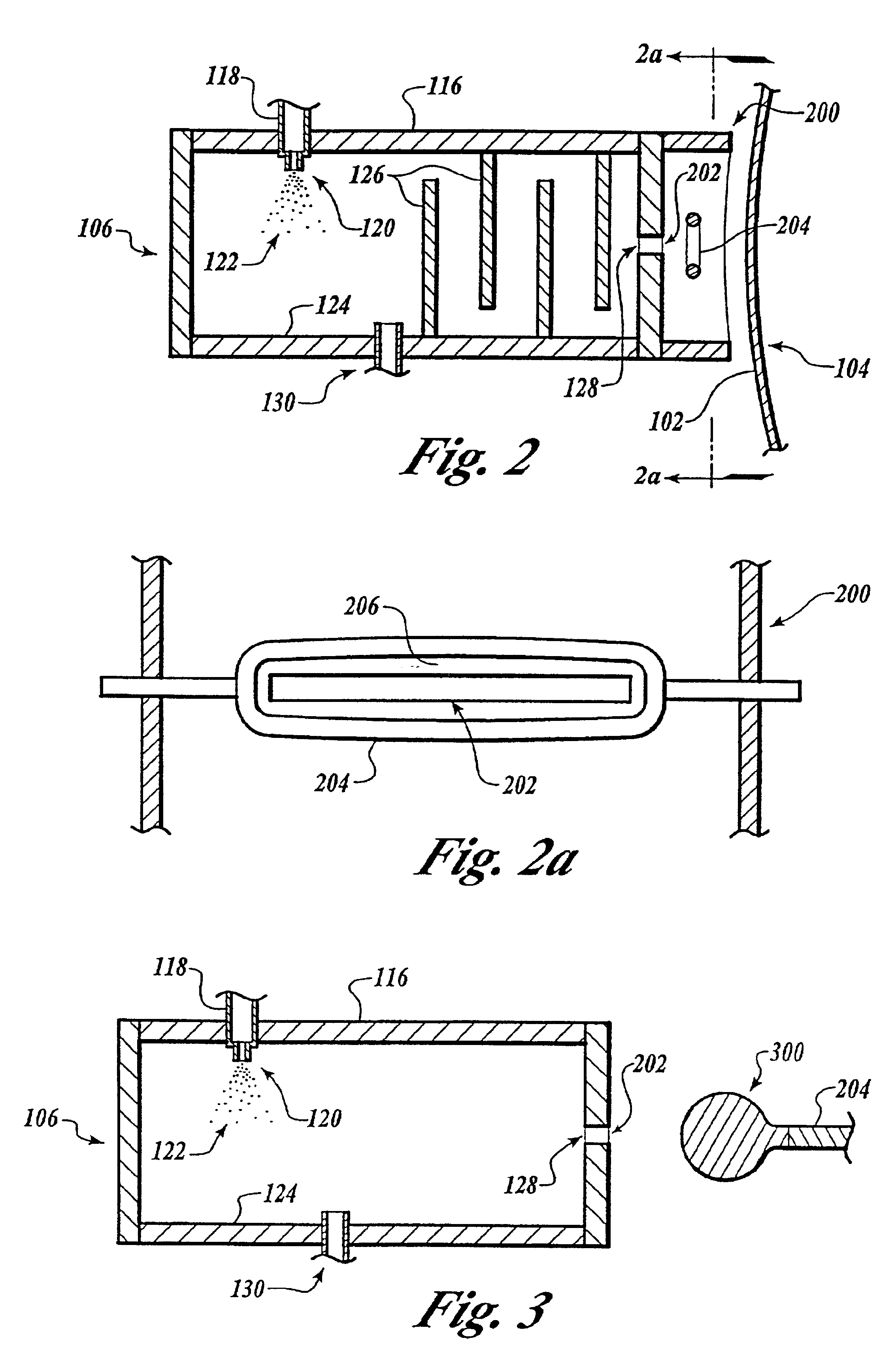

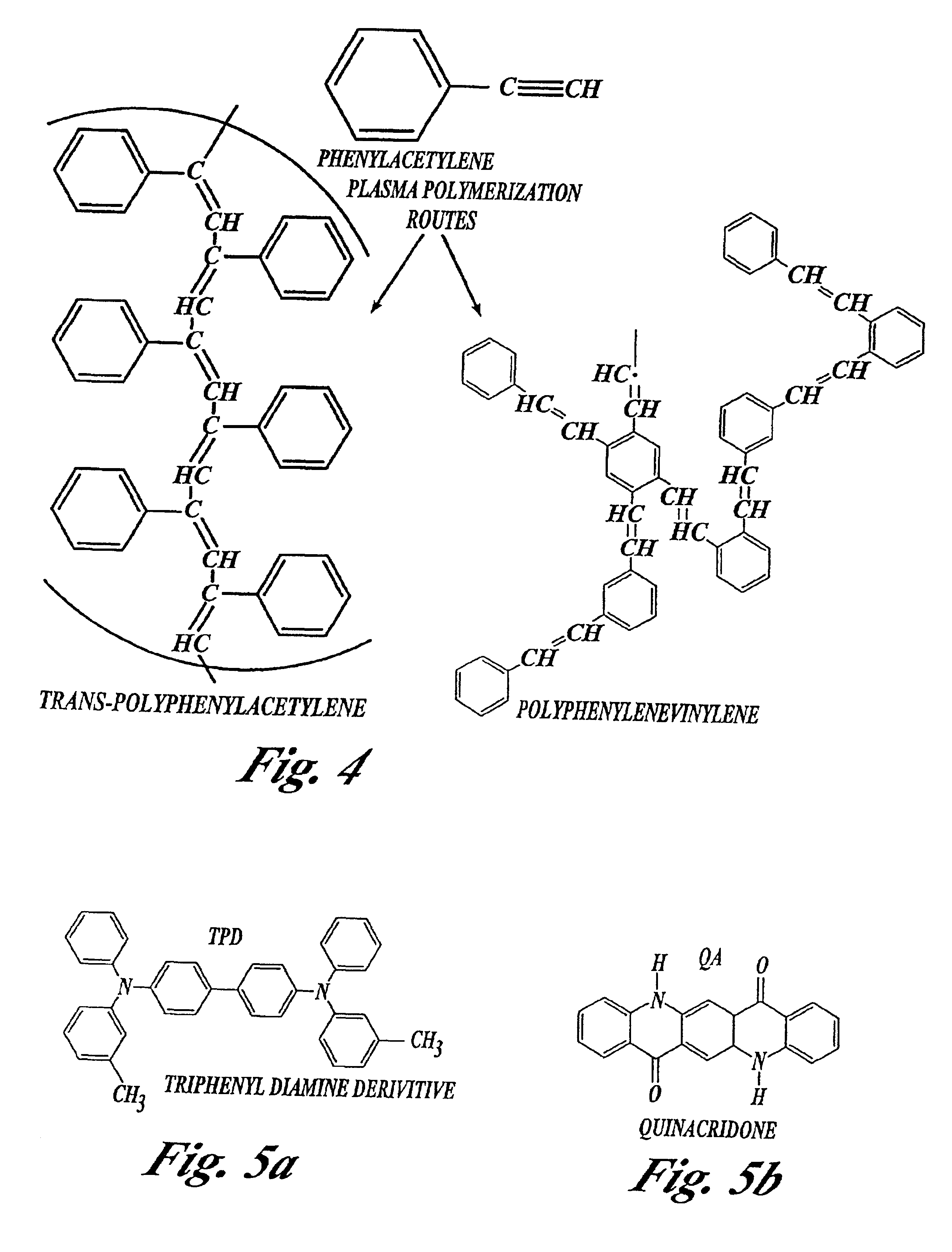

Plasma enhanced chemical deposition for high and/or low index of refraction polymers

InactiveUS6858259B2Enhanced vapor depositionPermit usePretreated surfacesChemical vapor deposition coatingCross-linkPolymer science

A method for making a polymer layer with a selected index of refraction. The method includes flash evaporating a polymer precursor material capable of cross linking into a polymer with the selected index of refraction, forming an evaporate, passing the evaporate to a glow discharge electrode creating a glow discharge polymer precursor plasma from the evaporate, and cryocondensing the glow discharge polymer precursor plasma on a substrate as a condensate and crosslinking the condensate thereon, the crosslinking resulting from radicals created in the glow discharge polymer precursor plasma, forming a polymer having the selected index of refraction.

Owner:SAMSUNG DISPLAY CO LTD

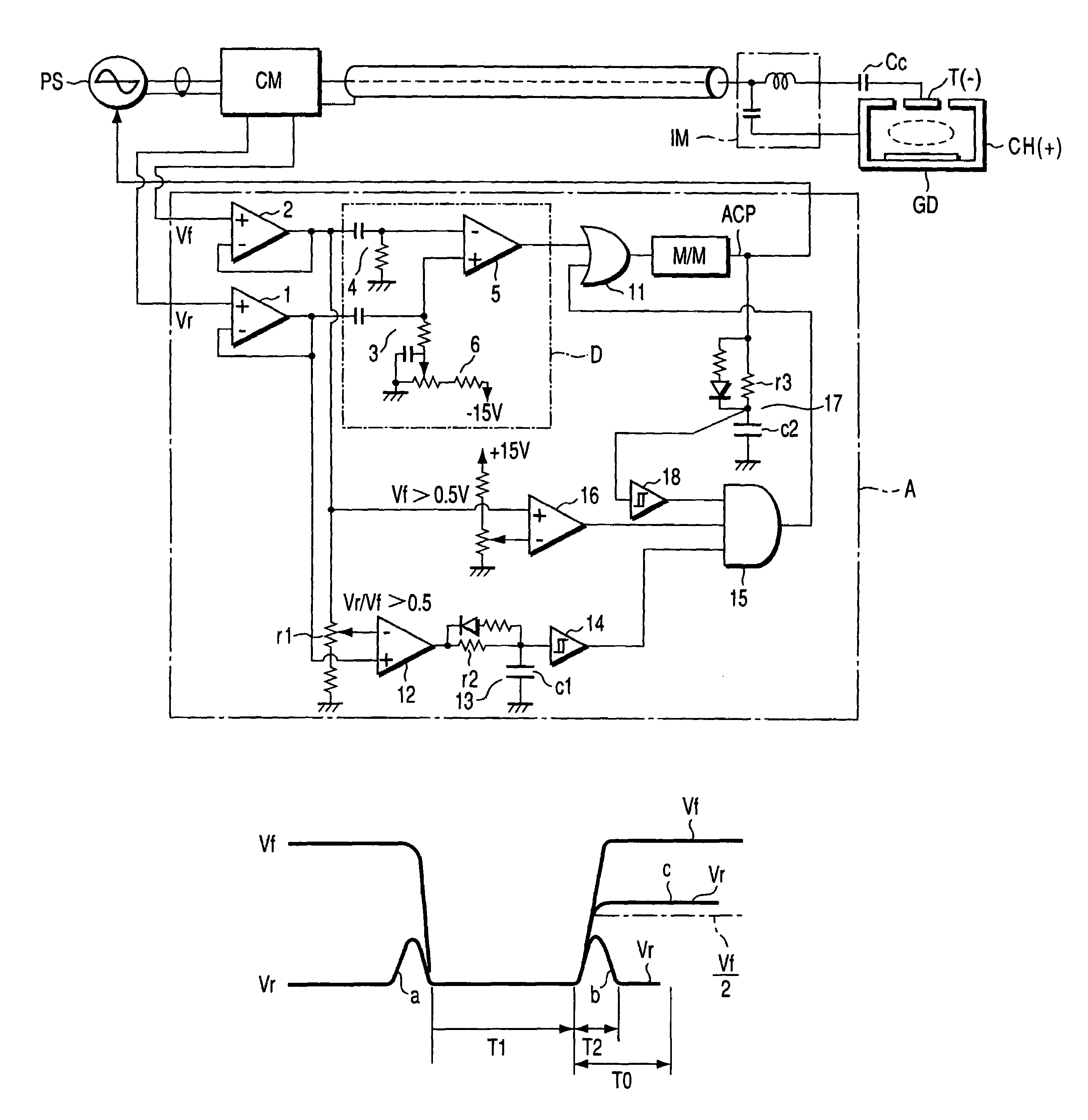

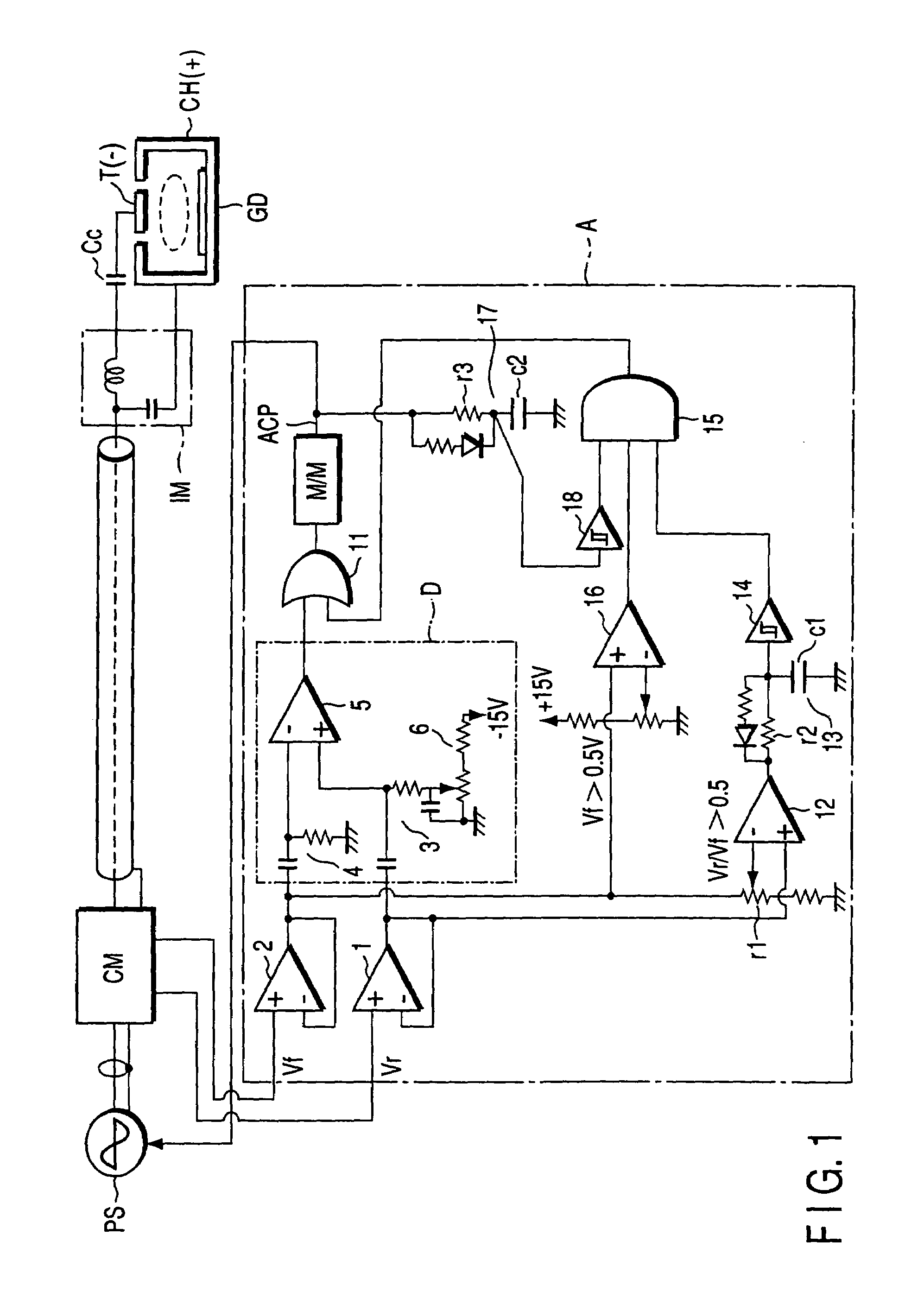

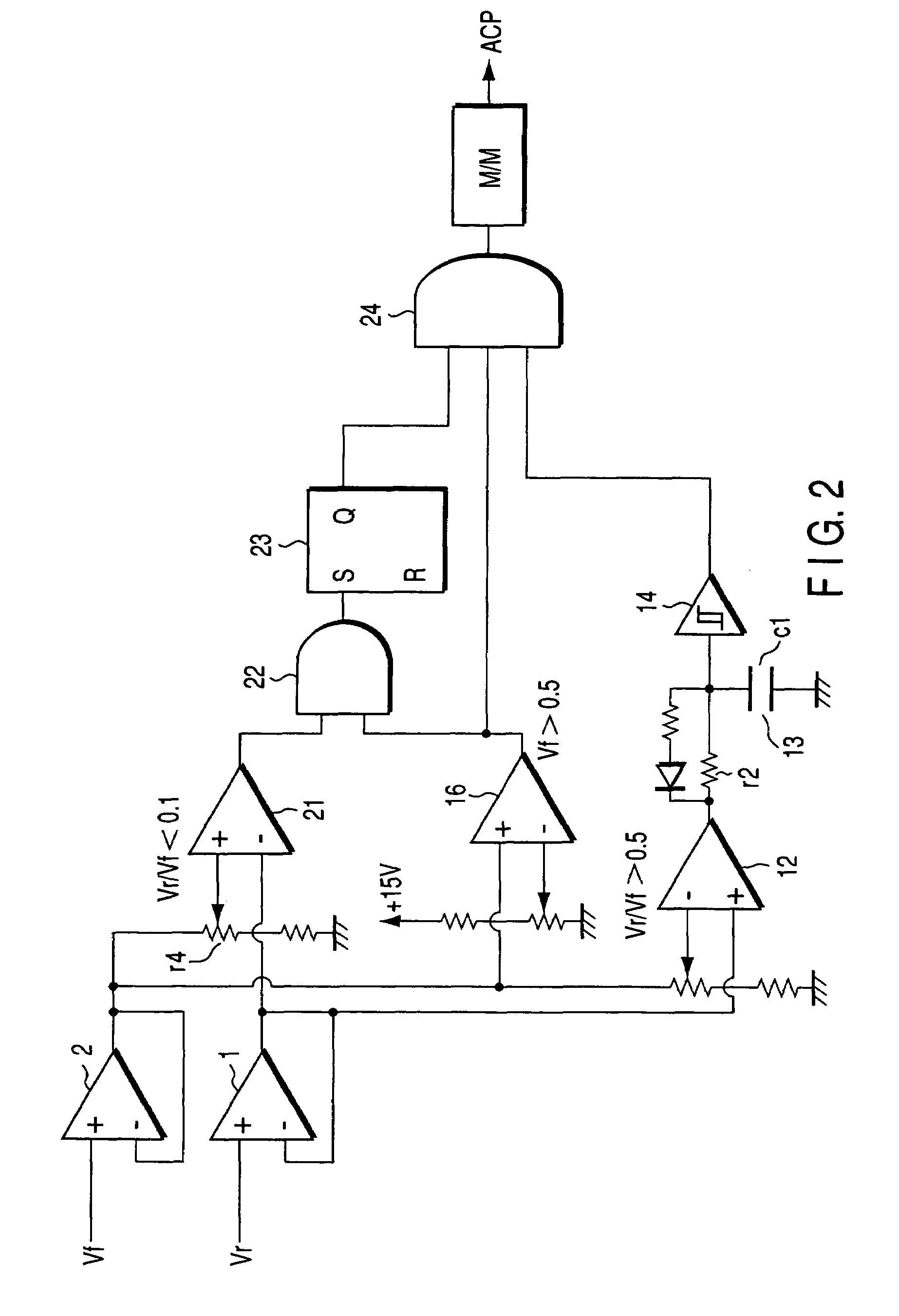

Method of detecting an arc in a glow-discharge device and apparatus for controlling a high-frequency arc discharge

In a method of detecting arc discharge in a glow-discharge apparatus GD that has a high-frequency power source PS, a cutting pulse is output for time T1 to the high-frequency power source PS to stop a supply of power to the glow-discharge apparatus GD, when dVr / dt−dVf / dt increases over a first level, where Vf and Vr are a traveling-wave voltage and a reflected-wave voltage applied to the glow-discharge apparatus GD, respectively. Arc discharge is determined to have developed in the glow-discharge apparatus, when Vr / Vf increases to a second level or a higher level within a preset time To after the supply of power to the glow-discharge apparatus is stopped.

Owner:SHIBAURA MECHATRONICS CORP

Atmospheric glow discharge with concurrent coating deposition

InactiveUS7067405B2Improve adhesionImprove curingElectric discharge tubesSemiconductor/solid-state device manufacturingMetallic electrodeGas phase

A plasma is produced in a treatment space by diffusing a plasma gas at atmospheric pressure and subjecting it to an electric field created by two metallic electrodes separated by a dielectric material, a precursor material is mixed with the plasma, and a substrate film or web is coated by vapor deposition of the vaporized substance at atmospheric pressure in the plasma field. The deposited precursor is cured by electron-beam, infrared-light, visible-light, or ultraviolet-light radiation, as most appropriate for the particular material being-deposited. Plasma pre-treatment and post-treatment steps are used to enhance the properties of the resulting coated products. Similar results are obtained by atomizing and spraying the liquid precursor in the plasma field.

Owner:SIGMA LAB OF ARIZONA

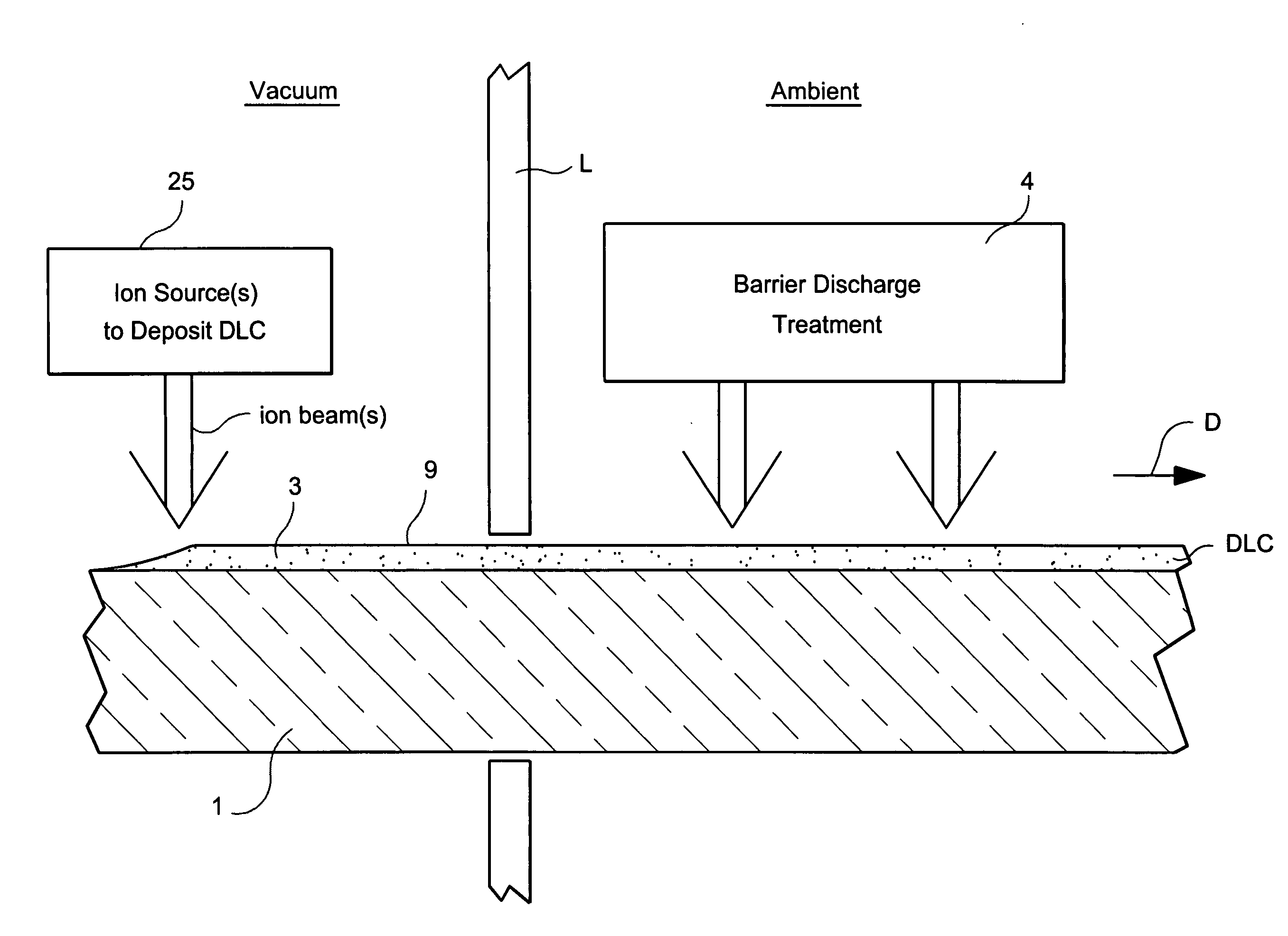

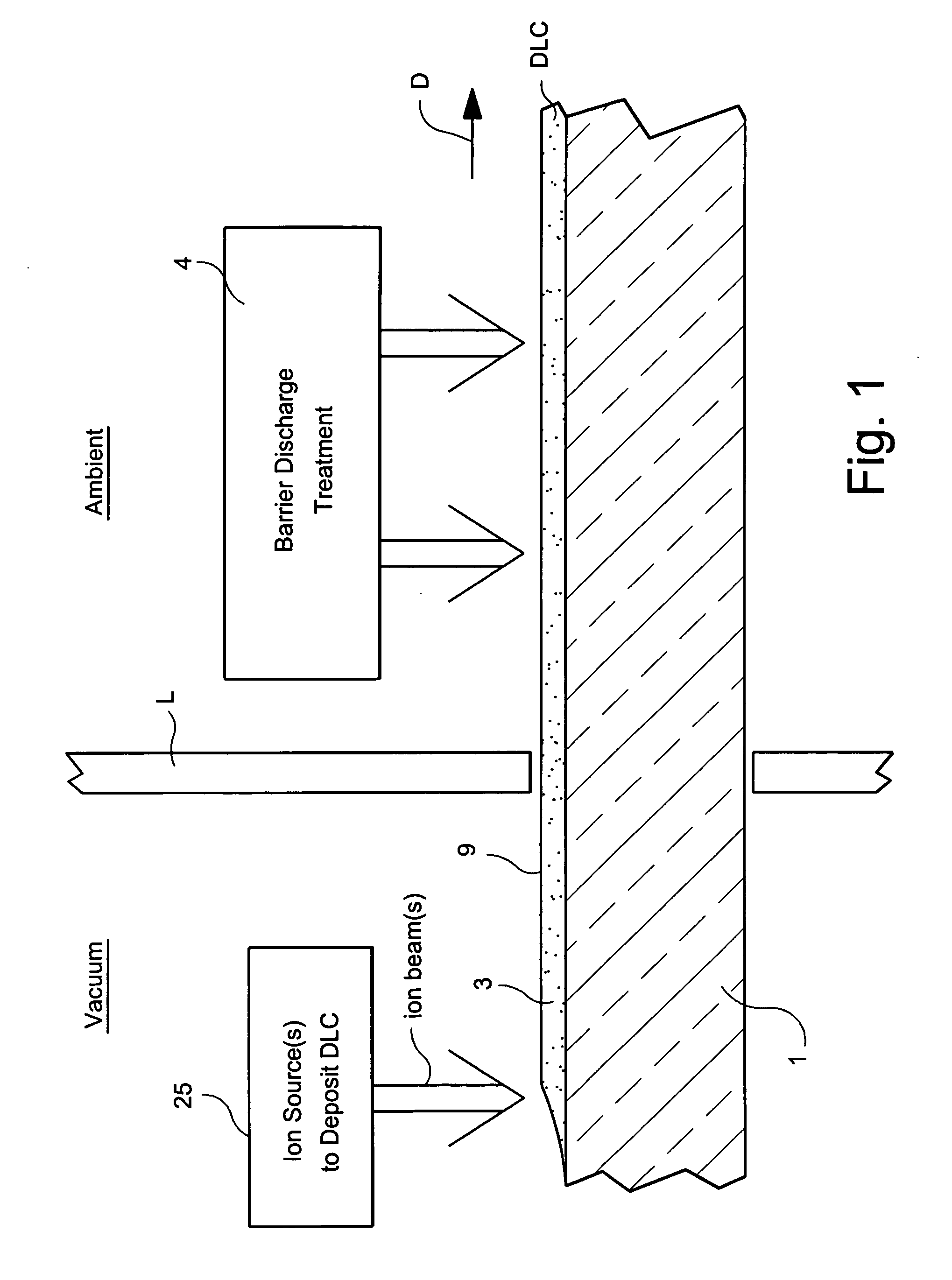

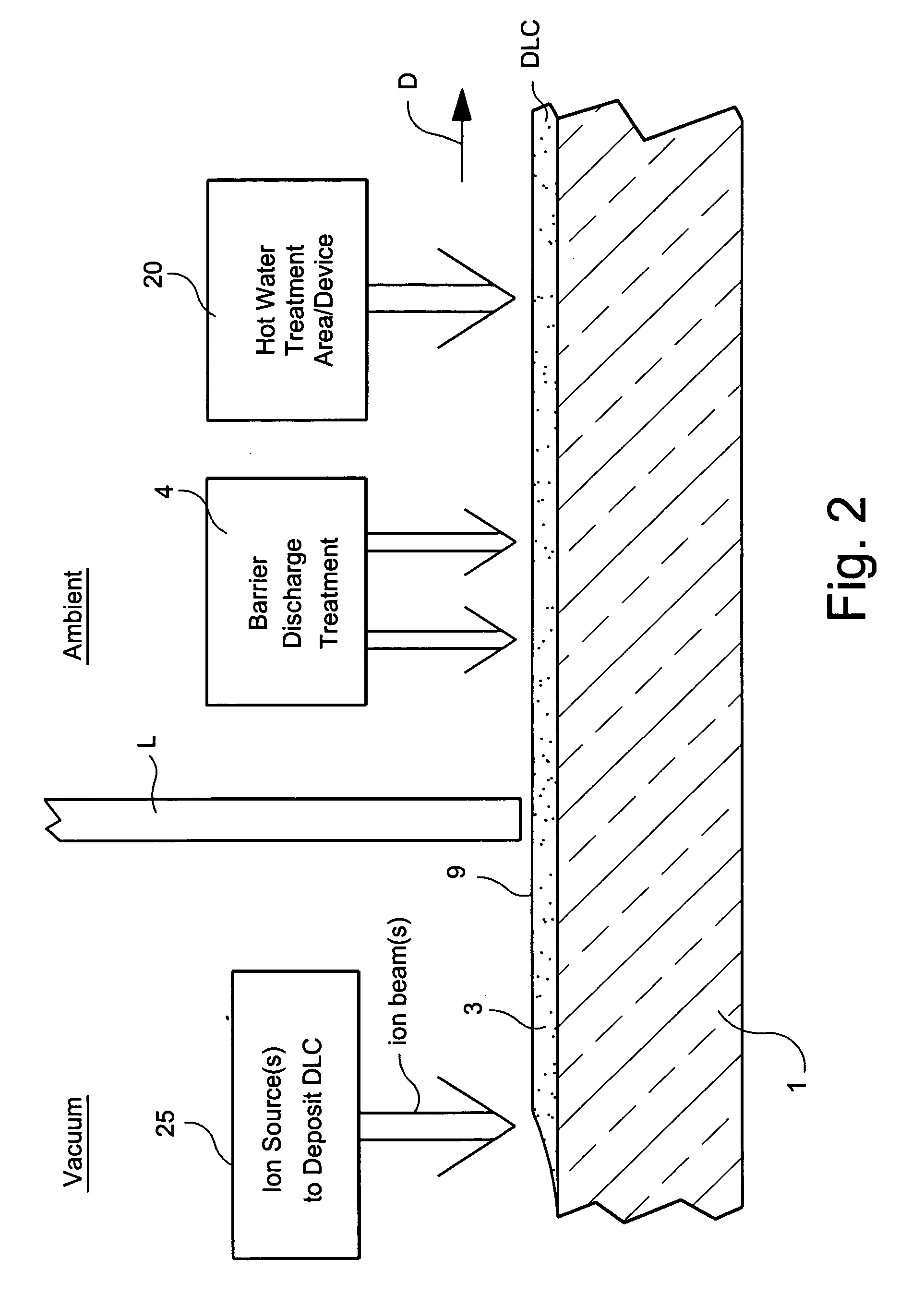

Hydrophilic DLC on substrate with barrier discharge pyrolysis treatment

InactiveUS20060246218A1Short timeLower contact anglePretreated surfacesChemical vapor deposition coatingDiamond-like carbonOxygen

A substrate is coated with a layer(s) or coating(s) that includes, for example, amorphous carbon in a form of diamond-like carbon (DLC). The DLC is then subjected to barrier discharge treatment (or some other type of plasma treatment) in order to cause the contact angle θ thereof to decrease. In certain example embodiments, an atmospheric plasma is used in the barrier discharge treatment, and the glow discharge produces oxygen radicals which impinge on the DLC and cause the contact angle to decrease.

Owner:GUARDIAN GLASS LLC

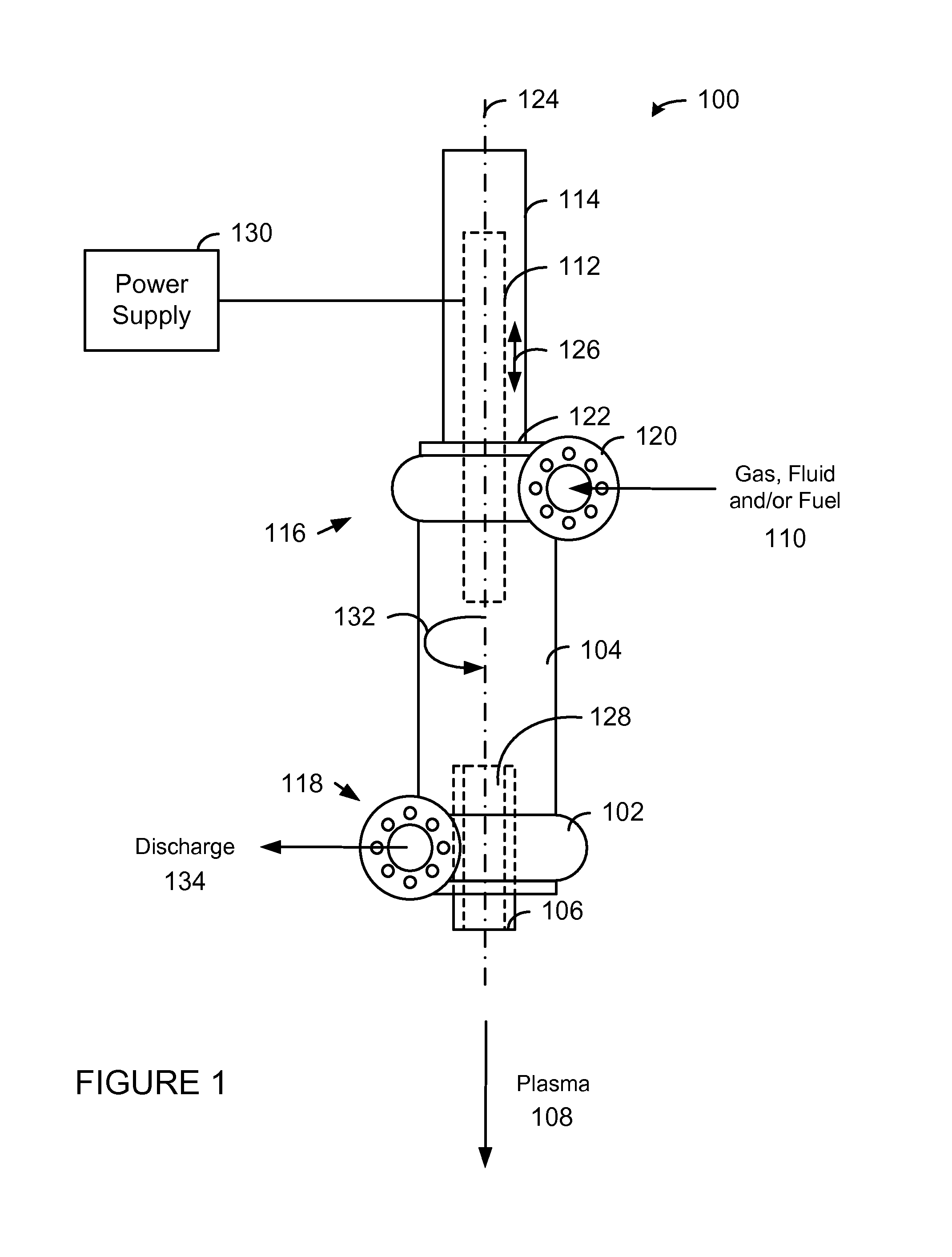

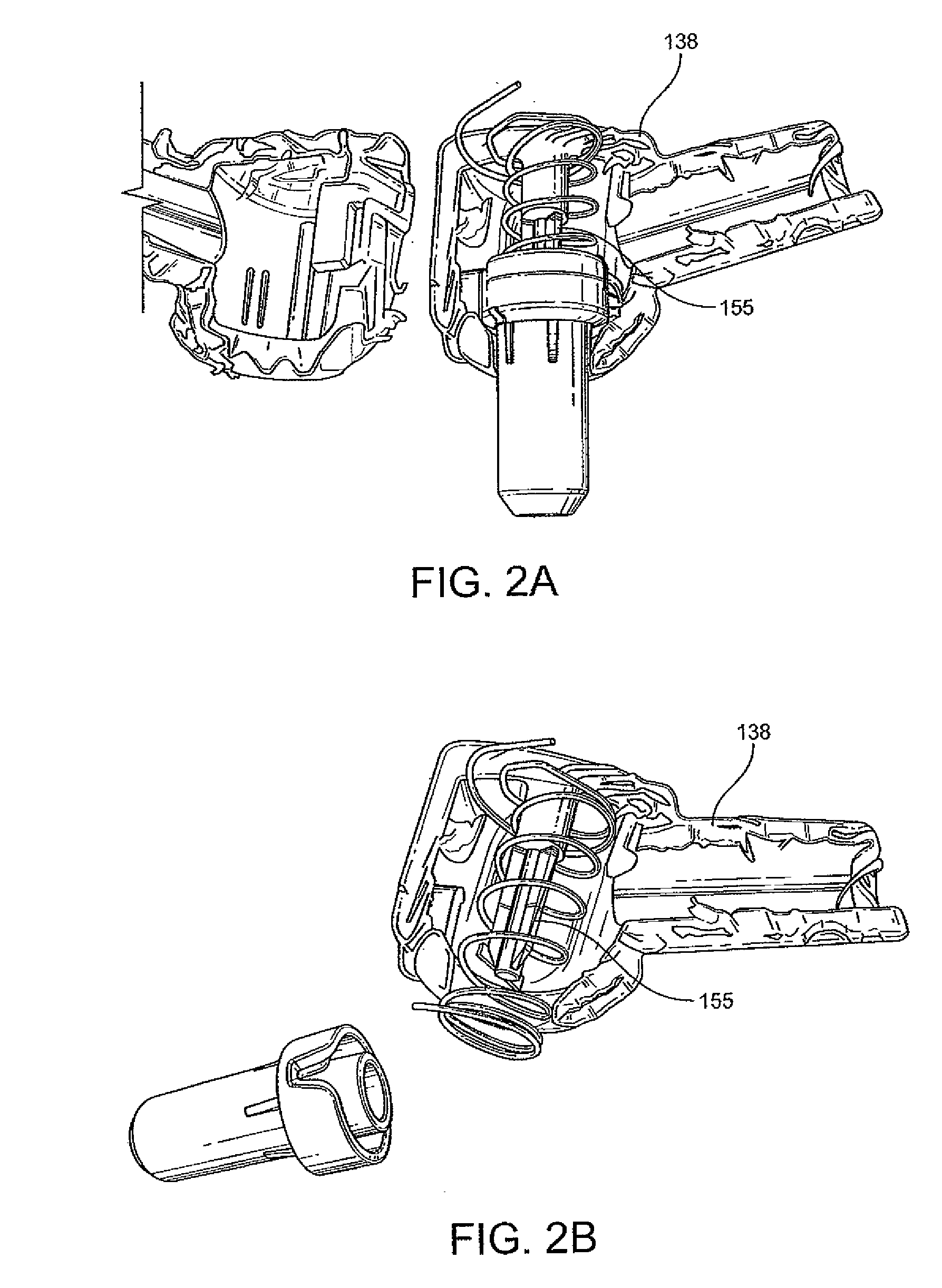

Plasma arc torch having multiple operating modes

Owner:FORET PLASMA LABS

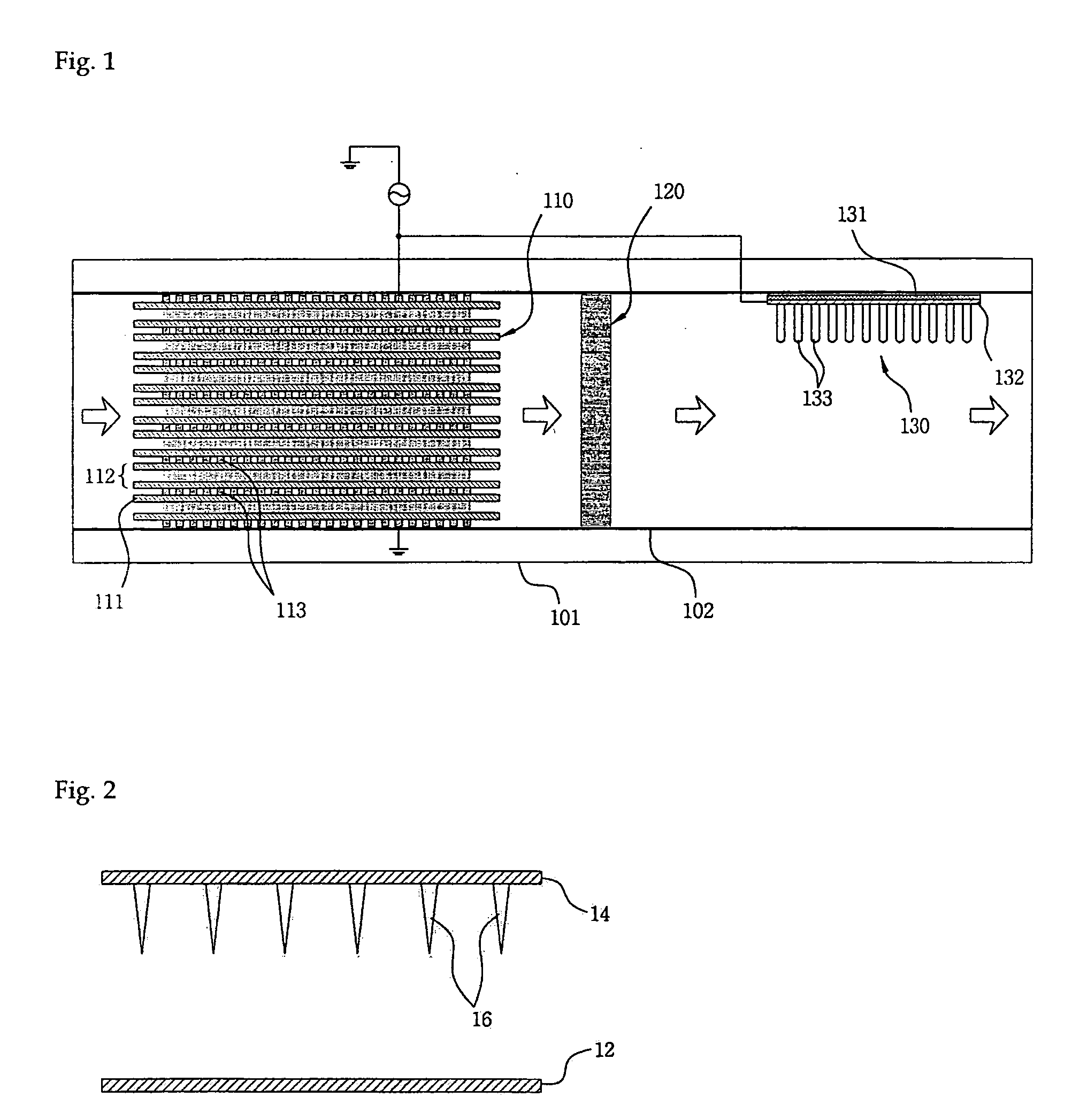

Method for manufacturing microcrystalline semiconductor film and thin film transistor

InactiveUS20110039402A1High crystallinitySmall off-currentElectric discharge tubesSemiconductor/solid-state device manufacturingProduction rateHigh frequency power

A microcrystalline semiconductor film with high crystallinity is manufactured. In addition, a thin film transistor with excellent electric characteristics and high reliability, and a display device including the thin film transistor are manufactured with high productivity. A deposition gas containing silicon or germanium is introduced from an electrode including a plurality of projecting portions provided in a treatment chamber of a plasma CVD apparatus, glow discharge is caused by supplying high-frequency power, and thereby crystal particles are formed over a substrate, and a microcrystalline semiconductor film is formed over the crystal particles by a plasma CVD method.

Owner:SEMICON ENERGY LAB CO LTD

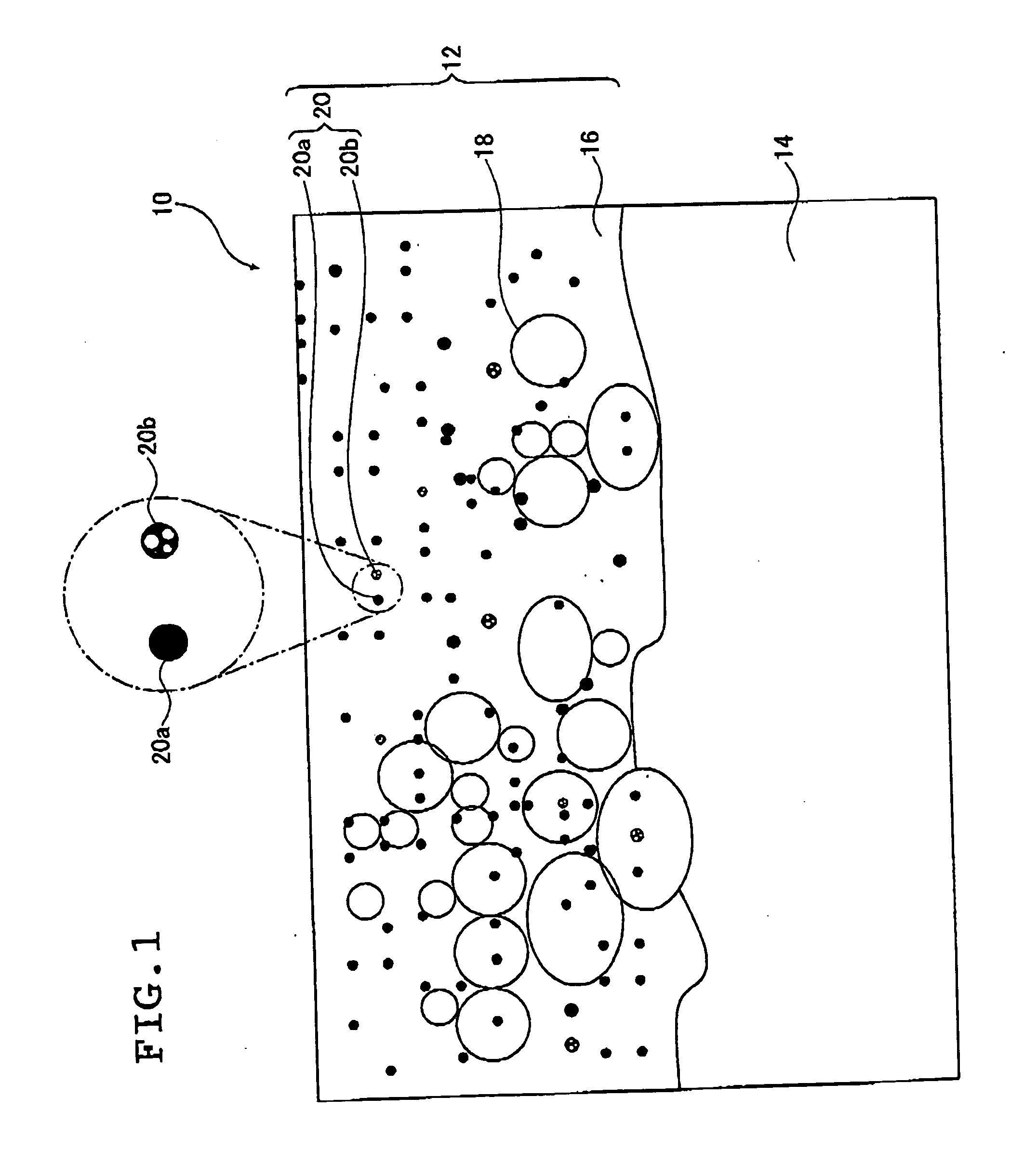

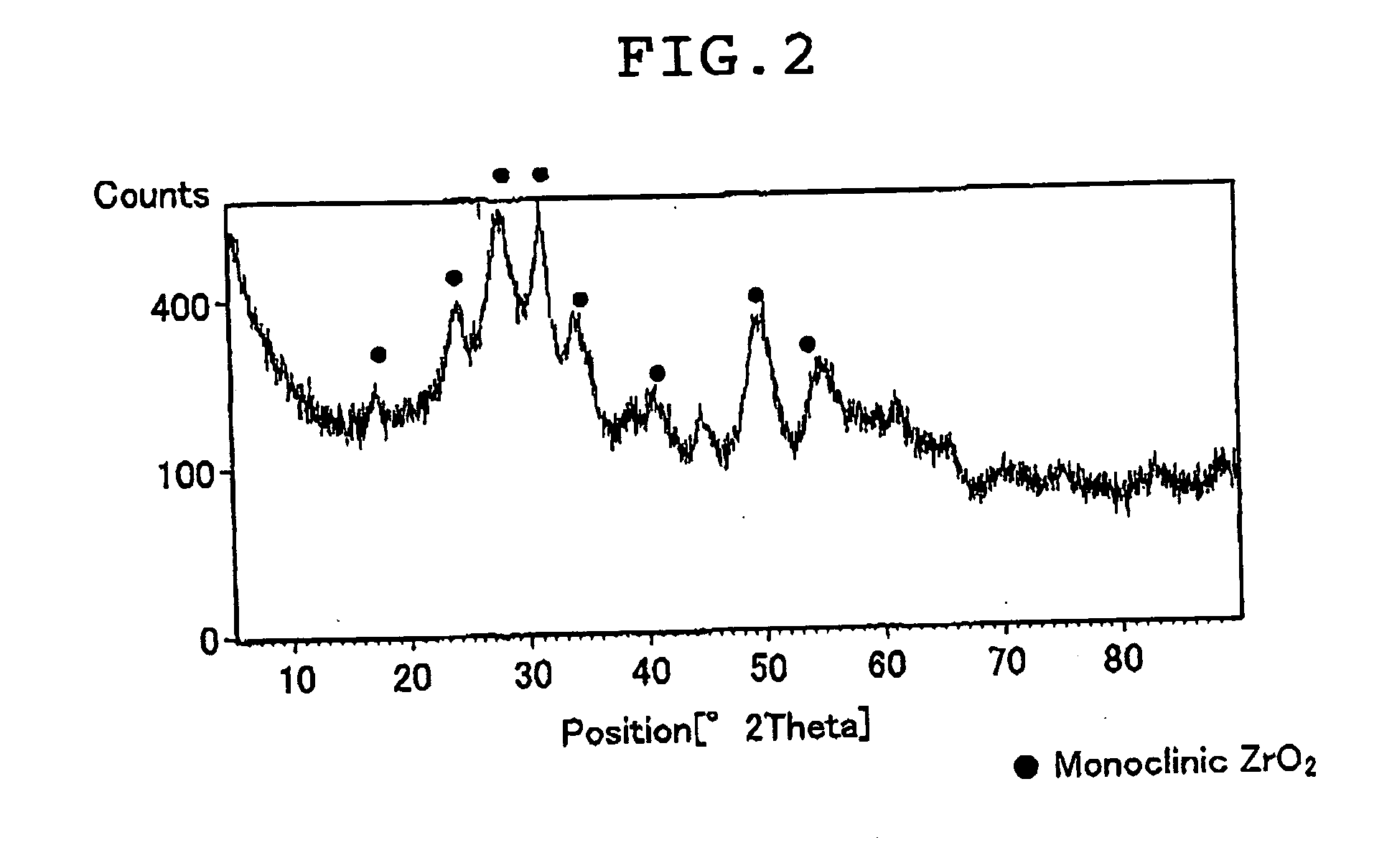

Method for coating a metal with a ceramic coating, electrolyte used therefor, ceramic coating, and metal material

InactiveUS20100025253A1Excellent abrasion resistanceReduce attackAnodisationElectrolytic inorganic material coatingElectrolysisCeramic coating

This invention provides a method for coating a ceramic film on a metal, which can form dense films on various bases of metals such as magnesium alloys. The formed ceramic film has excellent abrasion resistance, causes no significant attack against a counter material, and has excellent corrosion resistance. The method comprises electrolyzing a metallic base in an electrolysis solution using the metallic base as a working electrode while causing glow discharge and / or arc discharge on the surface of the metallic base to form a ceramic film on the surface of the metallic base. The electrolysis solution contains zirconium oxide particles having an average diameter of not more than 1 μm, satisfies the following formulae (1) to (3): 0.05 g / L≦X≦500 g / L (1), 0 g / L≦Y≦500 g / L (2), and 0≦Y / X≦10 (3); and has a pH value of not less than pH 7.0. In the formulae (1) to (3), X represents the content of zirconium oxide particles in the electrolysis solution; and Y represents the content of a compound of at least one element selected from the group consisting of Mg and the like, other than zirconium oxide.

Owner:NIHON PARKERIZING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com