Patents

Literature

1770 results about "Metallic electrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

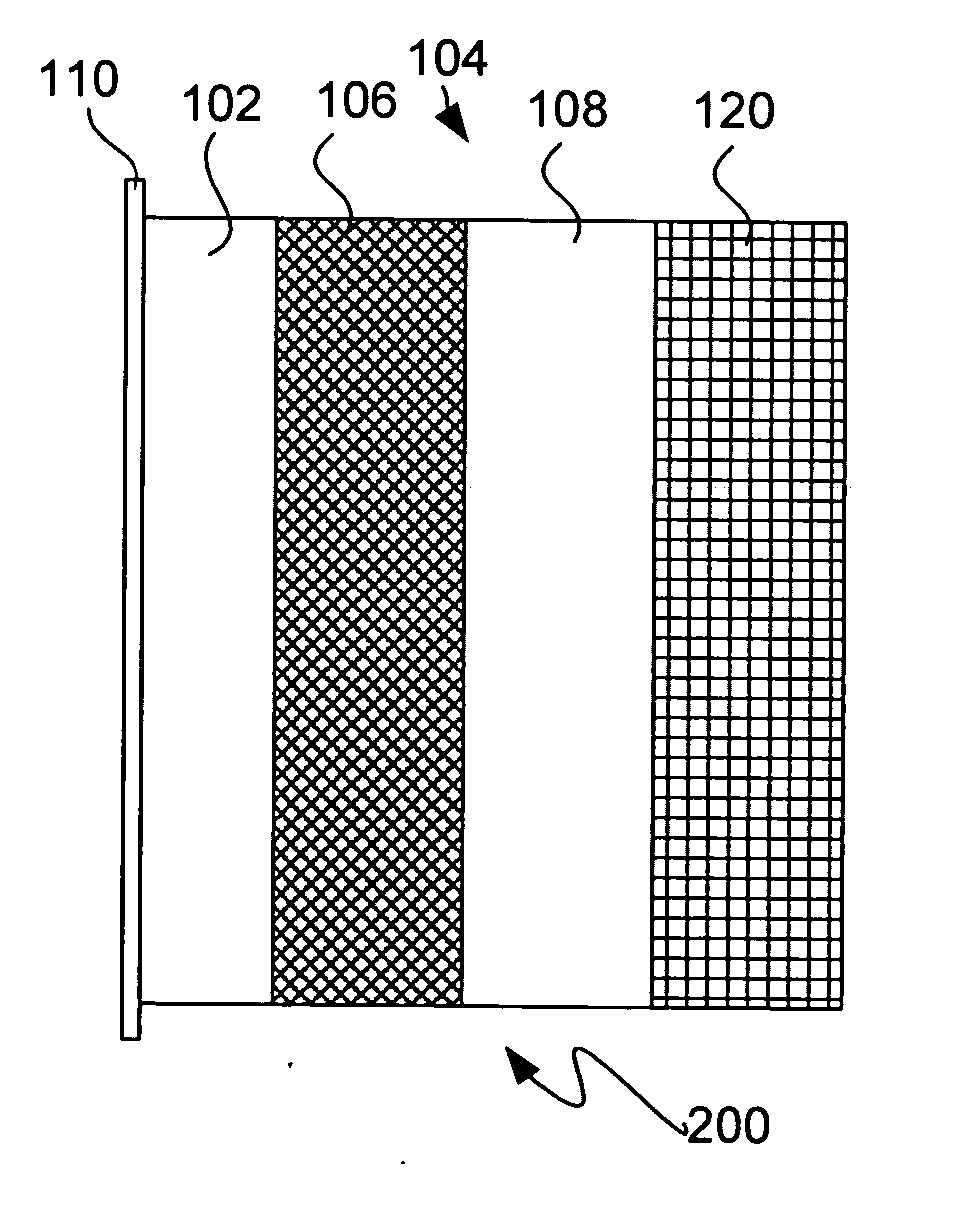

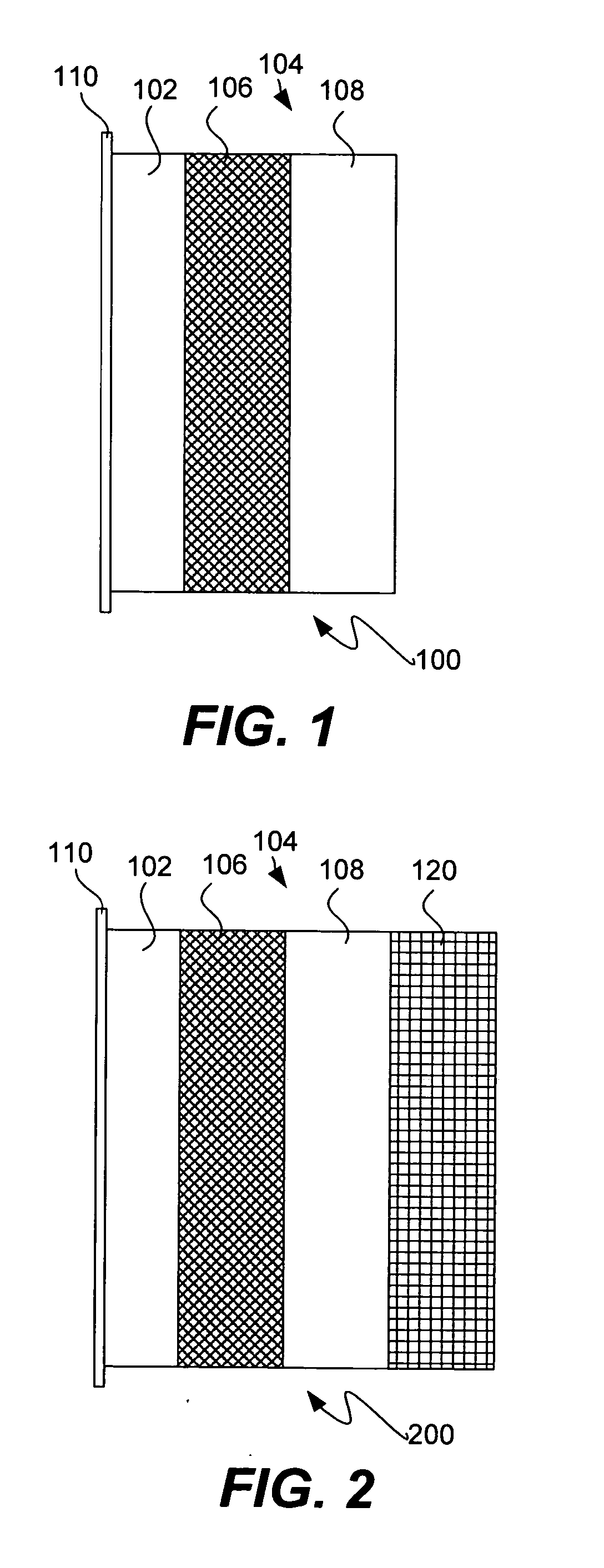

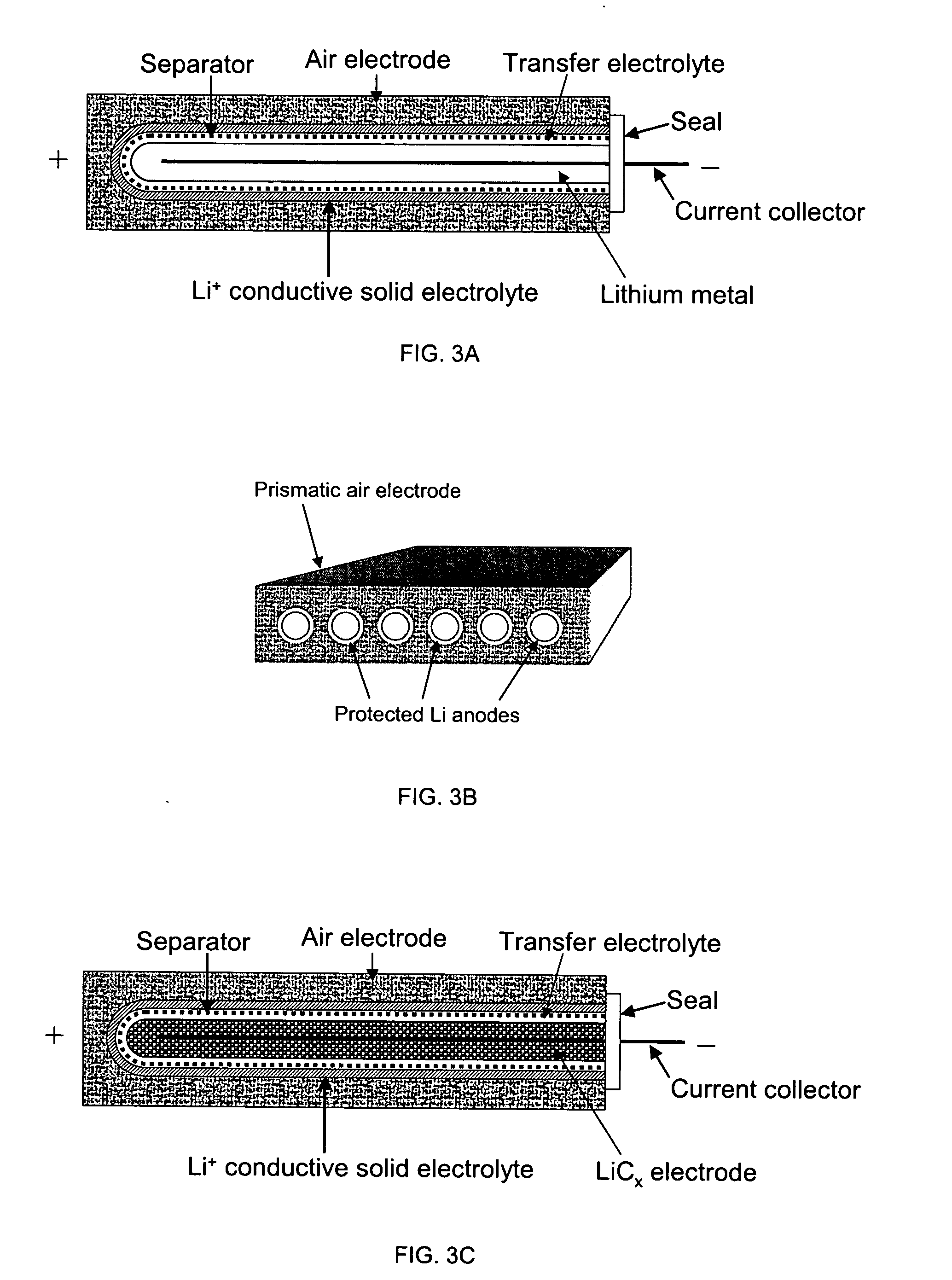

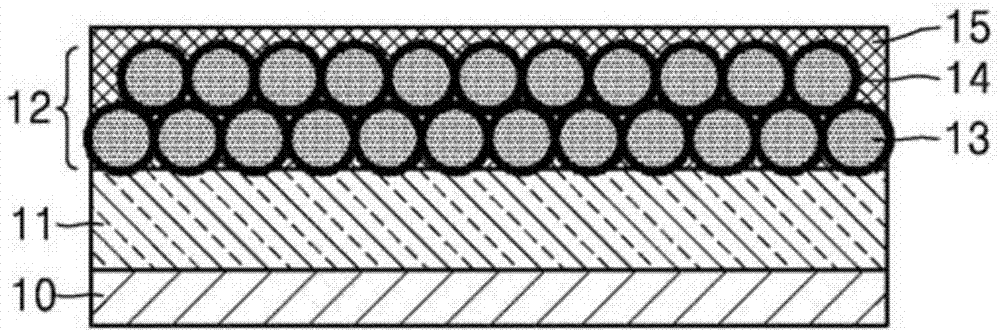

Protected active metal electrode and battery cell structures with non-aqueous interlayer architecture

ActiveUS20050175894A1Avoid harmful reactionsHybrid capacitor separatorsHybrid capacitor electrolytesMetal electrodesBattery cell

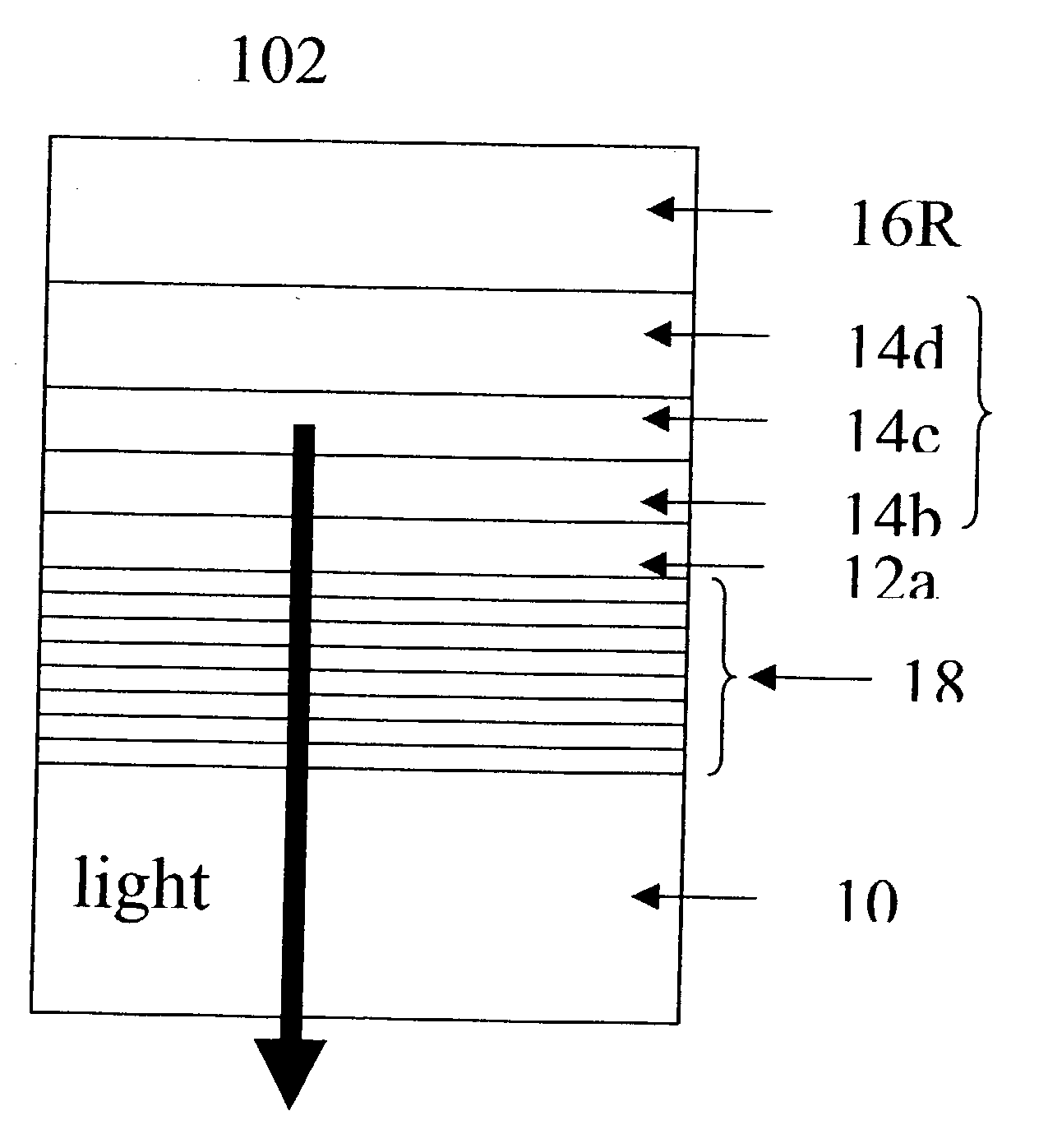

Active metal and active metal intercalation electrode structures and battery cells having ionically conductive protective architecture including an active metal (e.g., lithium) conductive impervious layer separated from the electrode (anode) by a porous separator impregnated with a non-aqueous electrolyte (anolyte). This protective architecture prevents the active metal from deleterious reaction with the environment on the other (cathode) side of the impervious layer, which may include aqueous or non-aqueous liquid electrolytes (catholytes) and / or a variety electrochemically active materials, including liquid, solid and gaseous oxidizers. Safety additives and designs that facilitate manufacture are also provided.

Owner:POLYPLUS BATTERY CO INC

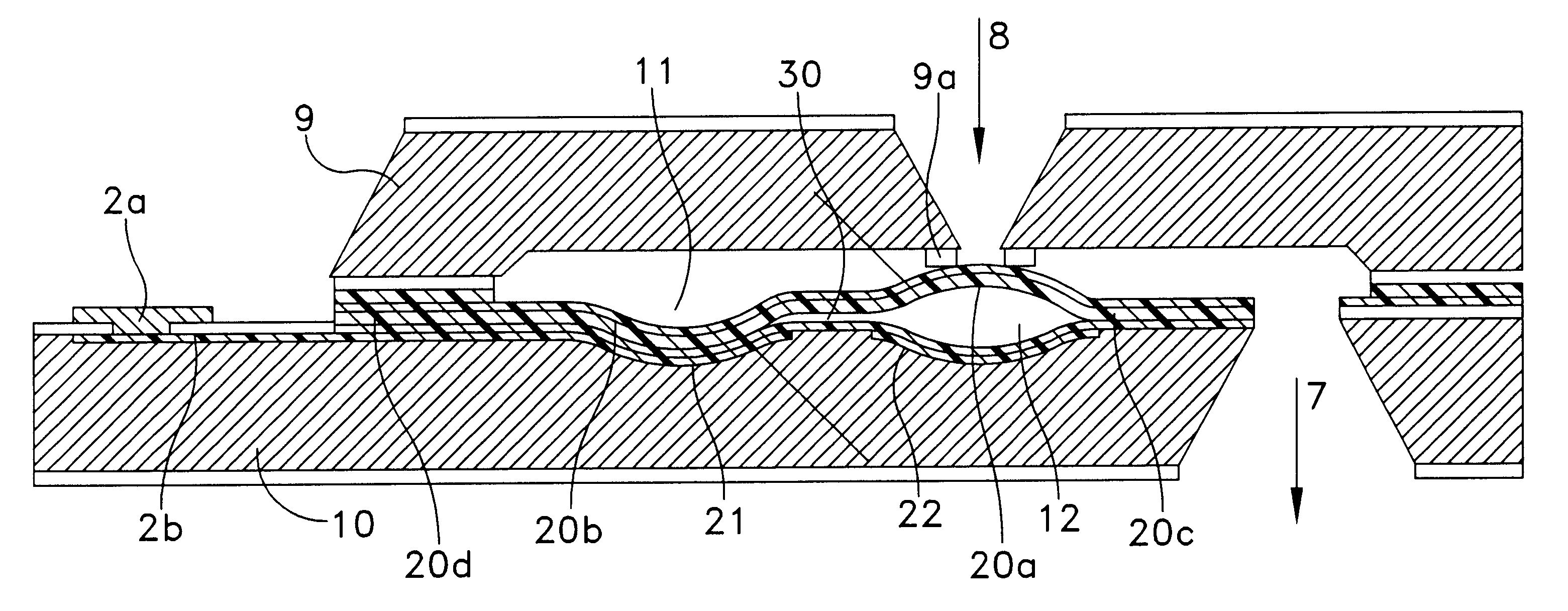

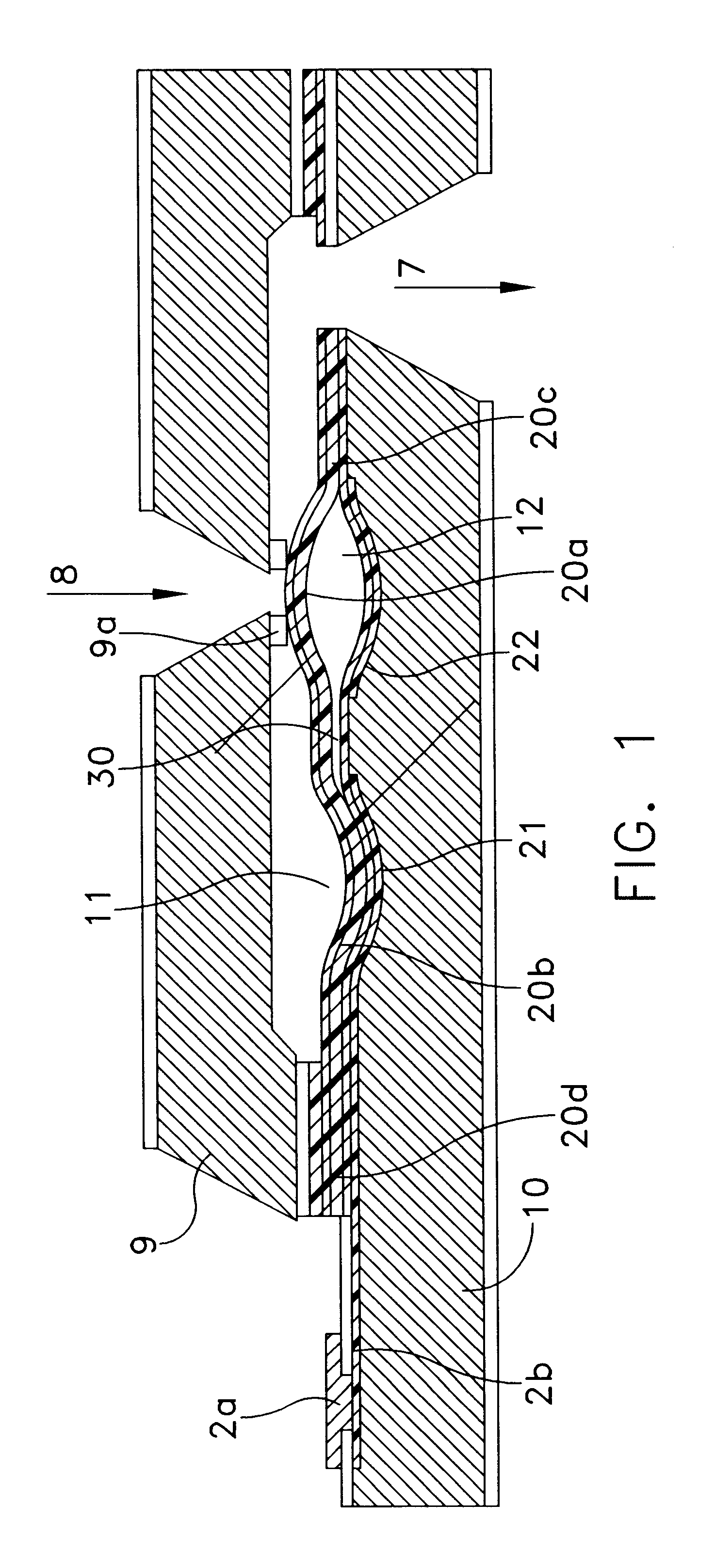

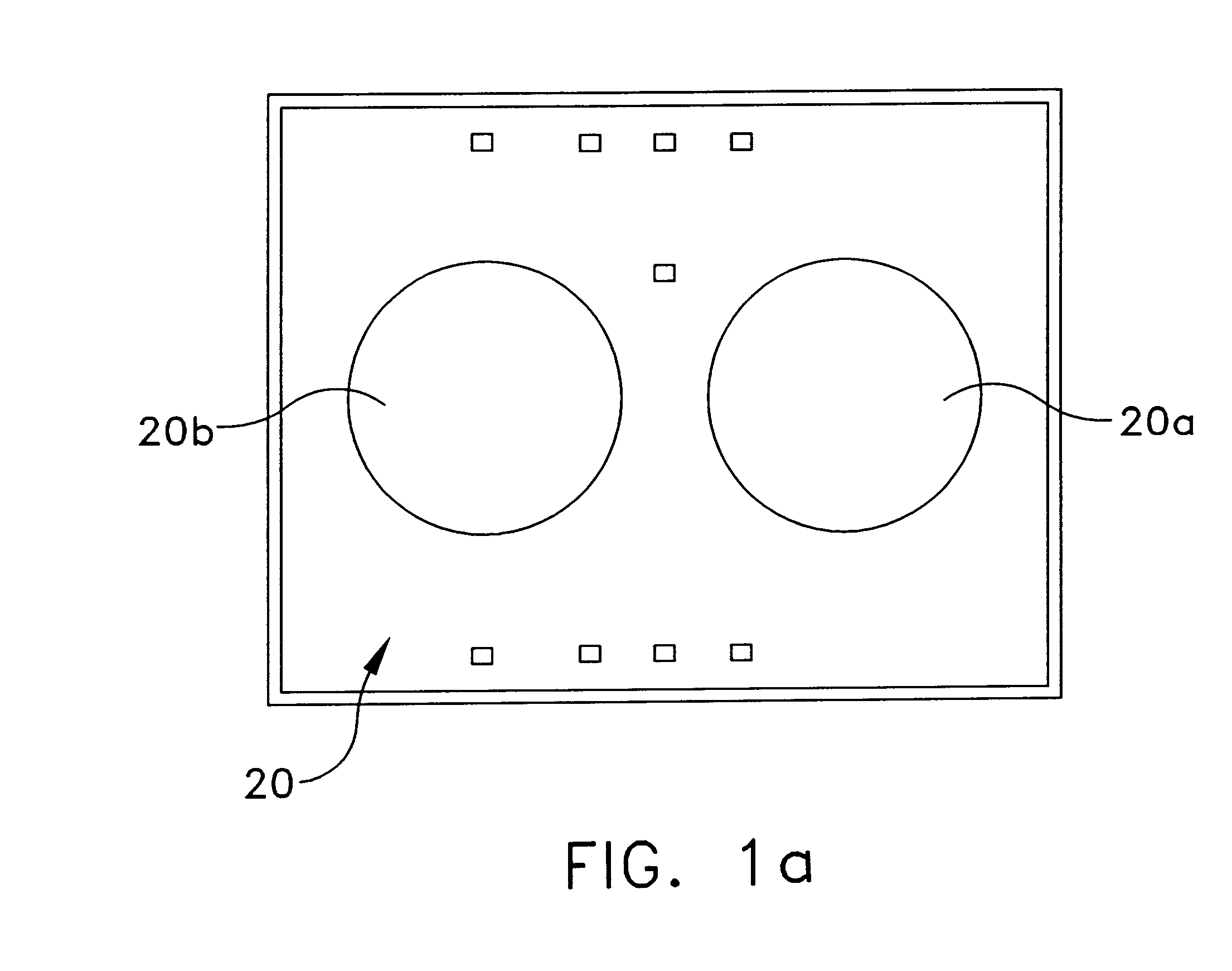

Bistable microactuator with coupled membranes

InactiveUS6168395B1Improves pneumaticImproves liquid couplingCircuit elementsDecorative surface effectsMetallic electrodeCoupling

A bistable electrostatic actuator with pneumatic or liquid coupling. The actuator has enclosed metallic electrodes. It can be used for a microvalve or micropump. The actuator has buckled membrane sections in pairs and curved substrate electrodes, locally associated with said membrane sections.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

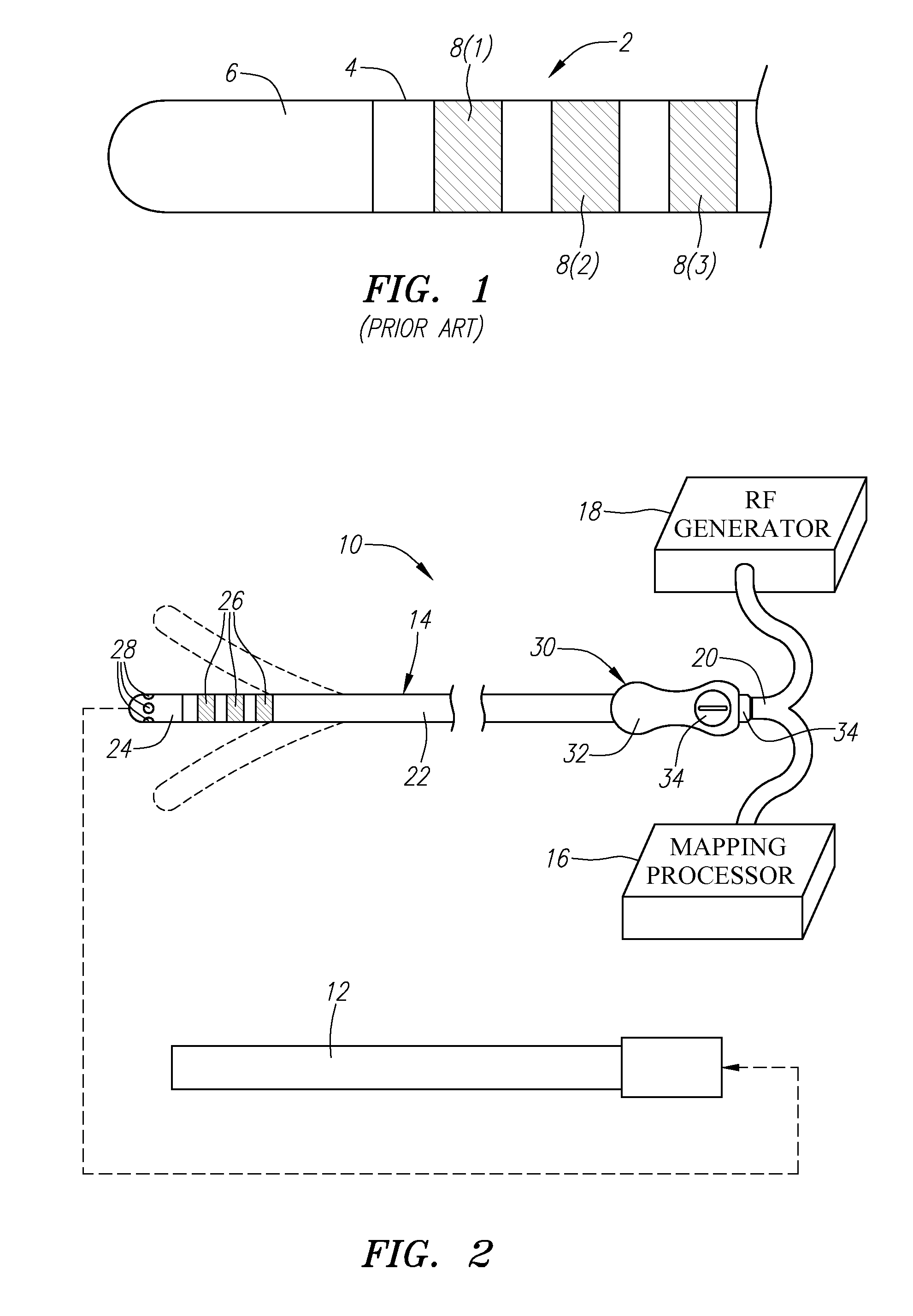

Diamond-like carbon electrode coating

An RF ablation device comprises an electrode including a DLC coating deposited on at least a portion thereof. A method of forming an RF ablation device, comprises forming a DLC coating on a portion of a metallic electrode.

Owner:BOSTON SCI SCIMED INC

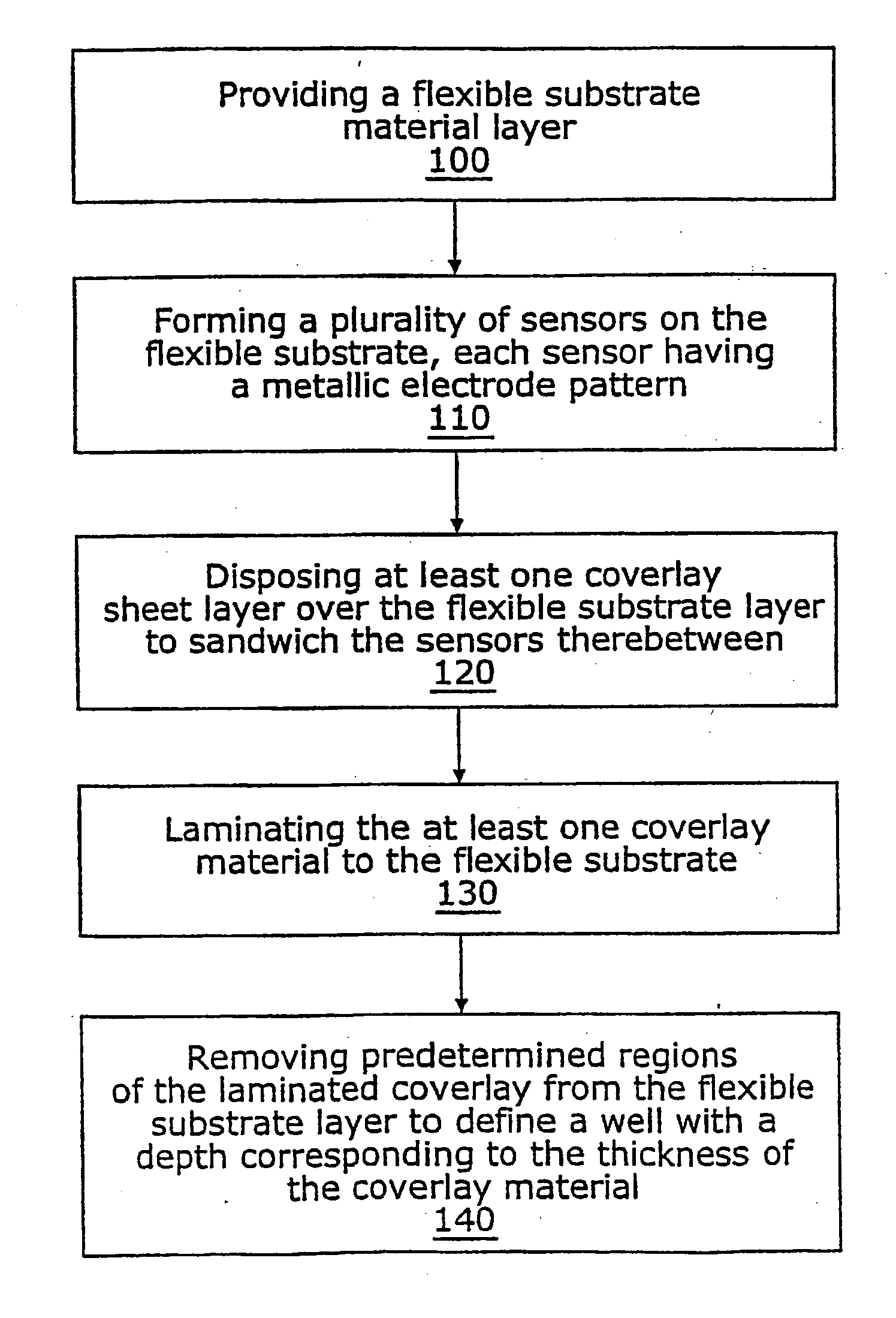

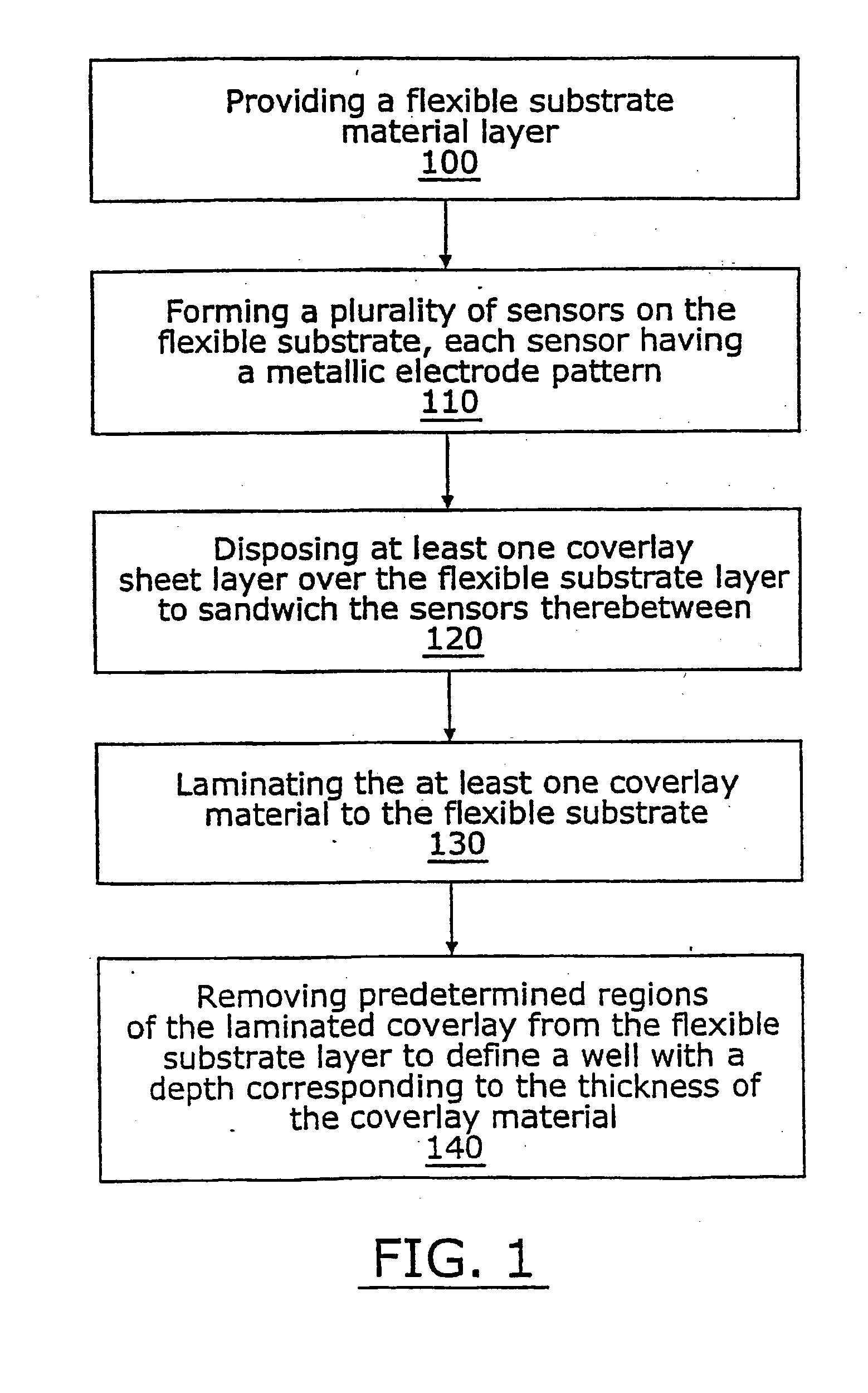

Biomedical electrochemical sensor array and method of fabrication

InactiveUS20050236361A1Decorative surface effectsSemiconductor/solid-state device manufacturingSensor arrayMetallic electrode

Methods for fabricating a plurality of sensors on a flexible substrate, with each sensor having associated electrodes and at least one well include (a) providing a flexible substrate material layer having a surface area defined by a length and width thereof; (b) forming a plurality of sensor elements onto the flexible substrate material layer, each sensor element comprising at least one metallic electrode; (c) disposing at least one coverlay sheet layer over the flexible substrate sandwiching the sensor elements therebetween; (d) laminating the at least one coverlay sheet layer having an associated thickness to the flexible substrate; and (e) removing predetermined regions of the laminated coverlay sheet layer from the flexible substrate layer to expose a portion of the underlying metallic pattern of each sensor element and to define a well with a depth corresponding to the thickness of the coverlay sheet layer. The disclosure also describes multi-layer laminated flexible sensors and arrays of sensors with wells having enhanced well capacity and / or depth.

Owner:ROCHE DIABETES CARE INC

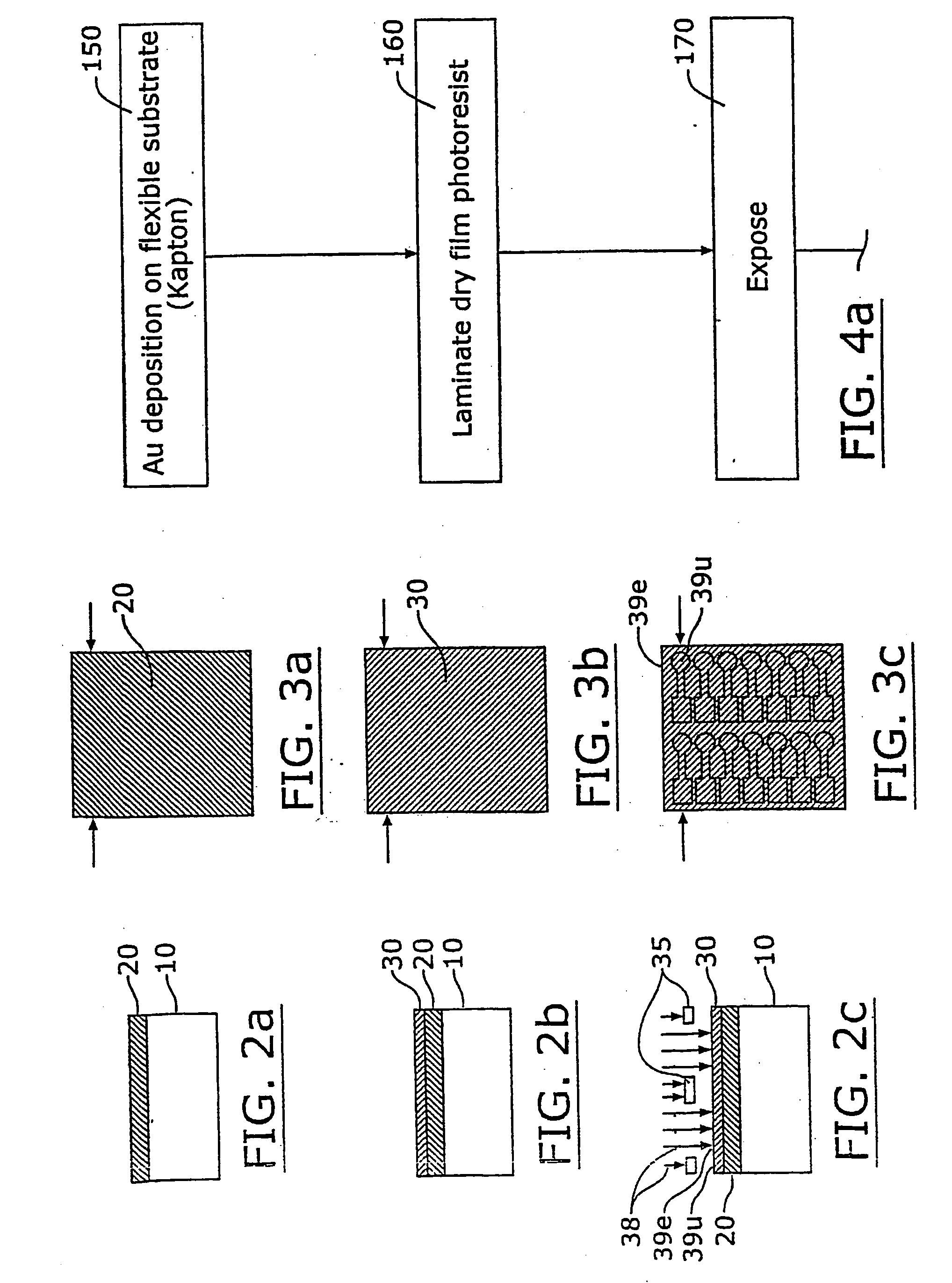

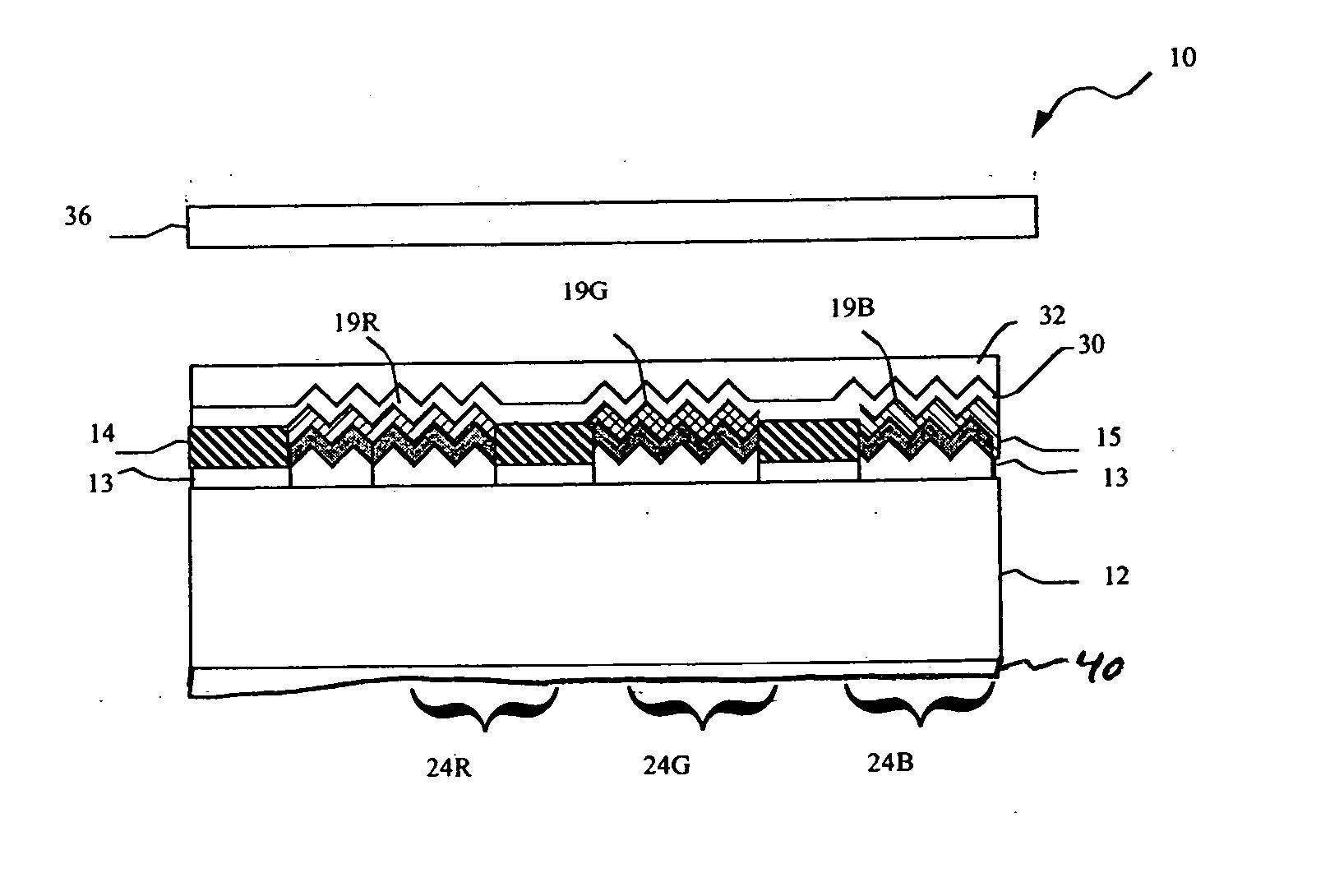

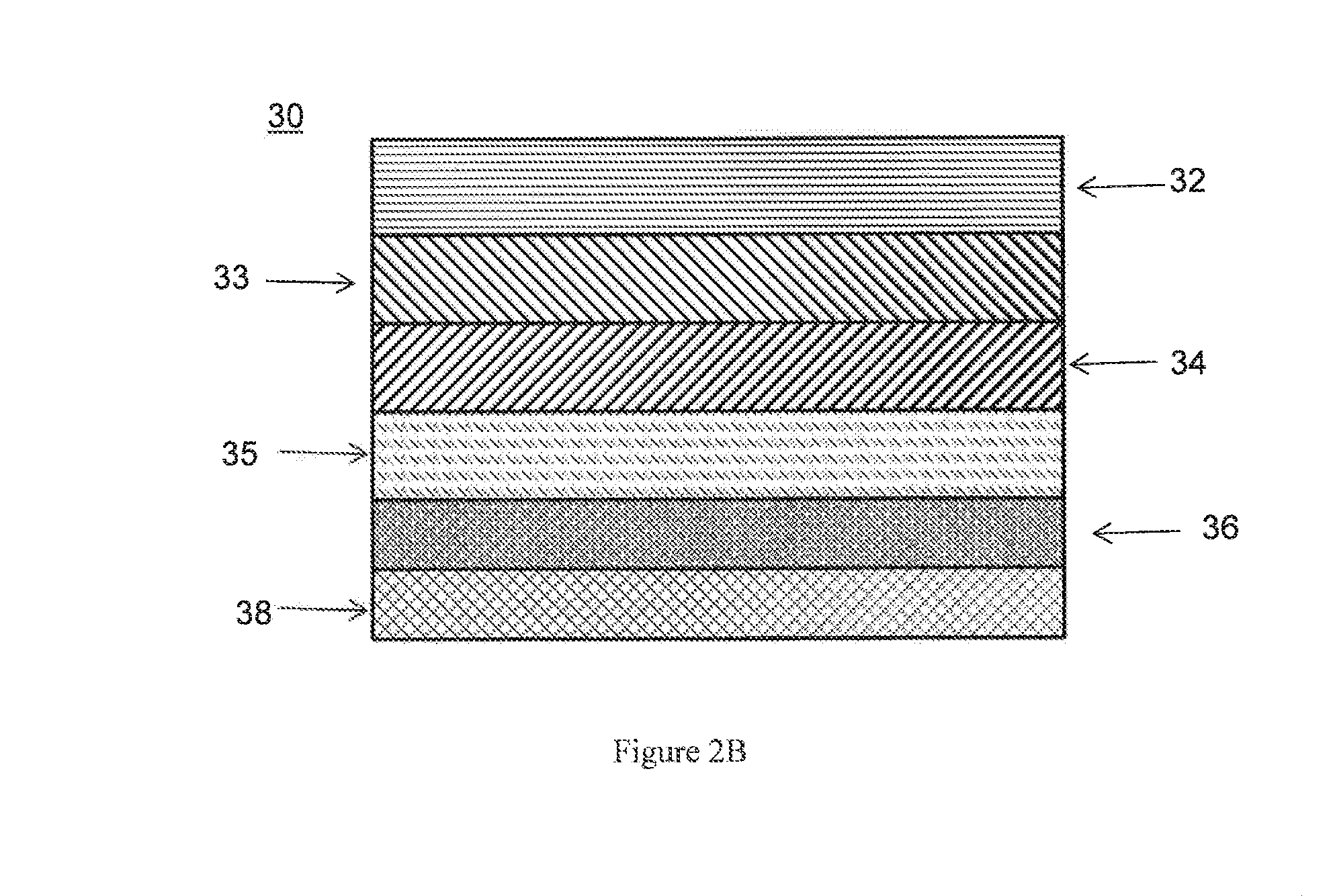

Tuned microcavity color OLED display

InactiveUS6861800B2Easy to makeImproved color quality and emission output efficiencyIncadescent screens/filtersDischarge tube luminescnet screensMetallic electrodeDisplay device

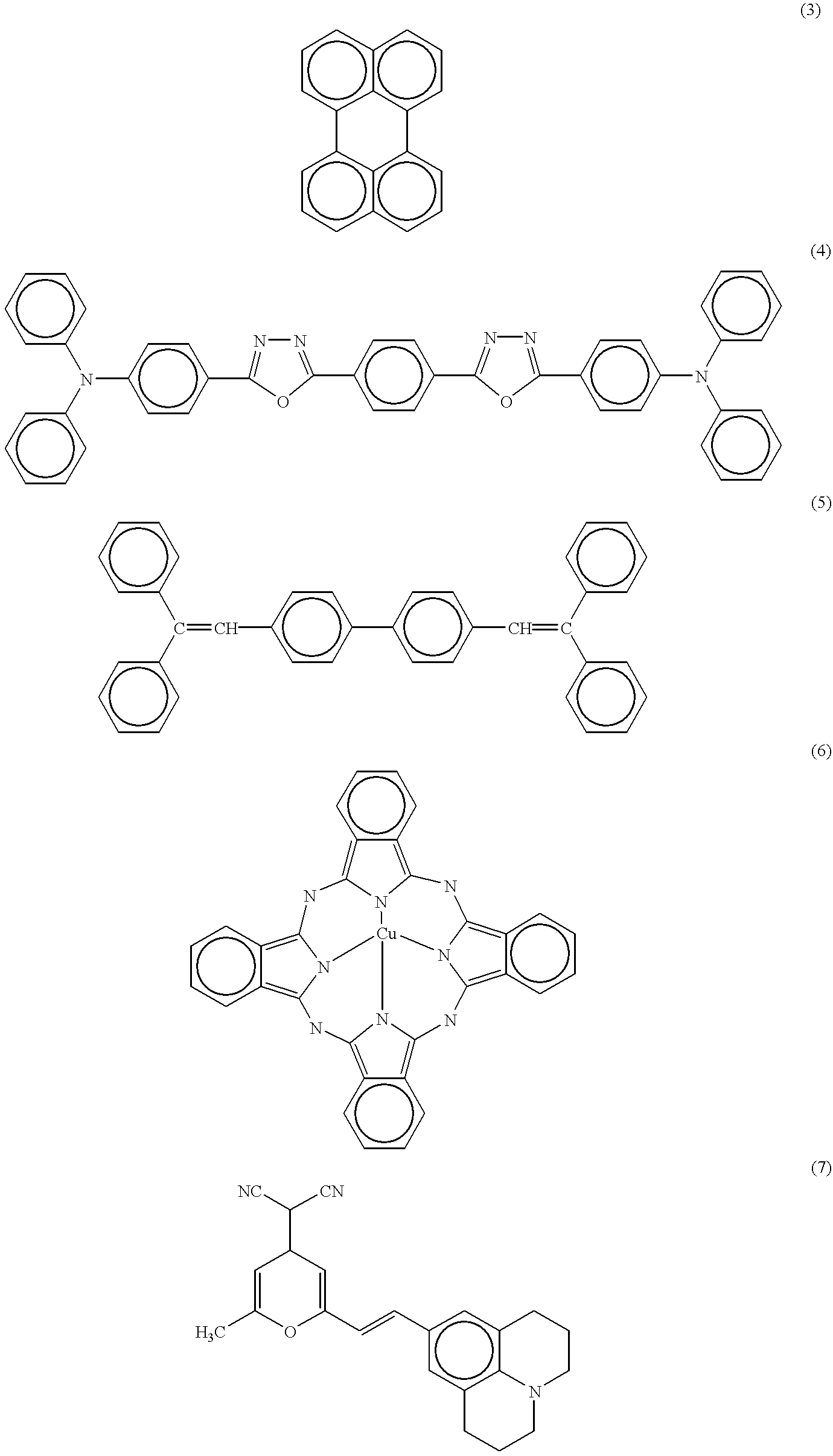

A color organic light-emitting display device having an array of pixels divided into at least two different color pixel sets each color pixel set emitting a different predetermined color light over a common substrate, wherein each pixel in the array includes a metallic bottom-electrode layer disposed over the substrate and a metallic electrode layer spaced from the metallic bottom-electrode layer; wherein the material for reflective metallic electrode layer includes Ag, Au, Al, or alloys thereof, the material for the semitransparent metallic electrode layer includes Ag, Au, or alloys thereof; and wherein the thickness of the semitransparent metallic electrode layer, the combined thickness of the organic layers and the transparent conductive phase-layer, and the placement of the light-emitting layer are selected so that each pixel in the display forms a tuned microcavity OLED device having an emission output efficiency above that of a comparable OLED device without the microcavity.

Owner:GLOBAL OLED TECH

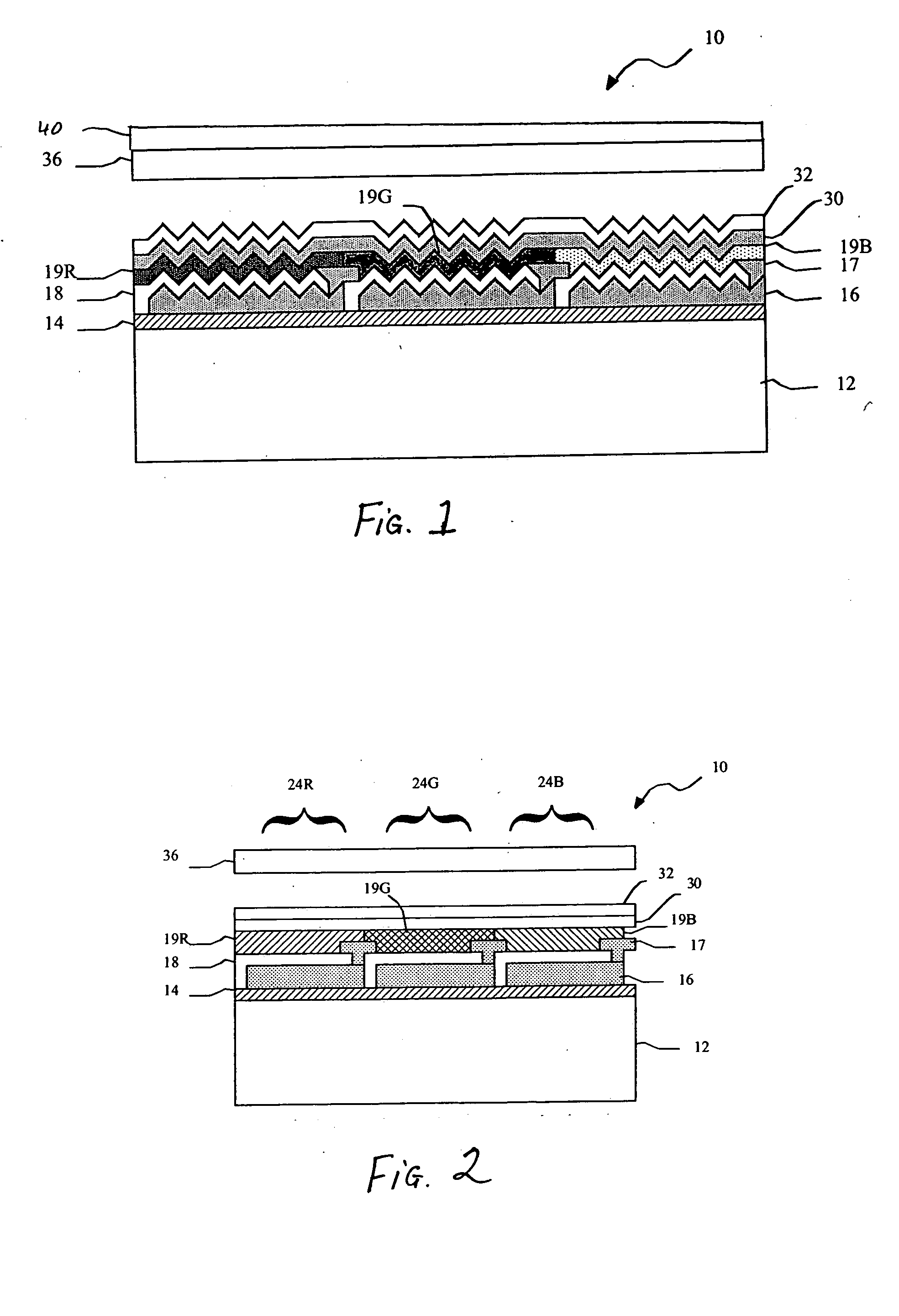

Microcavity OLED device

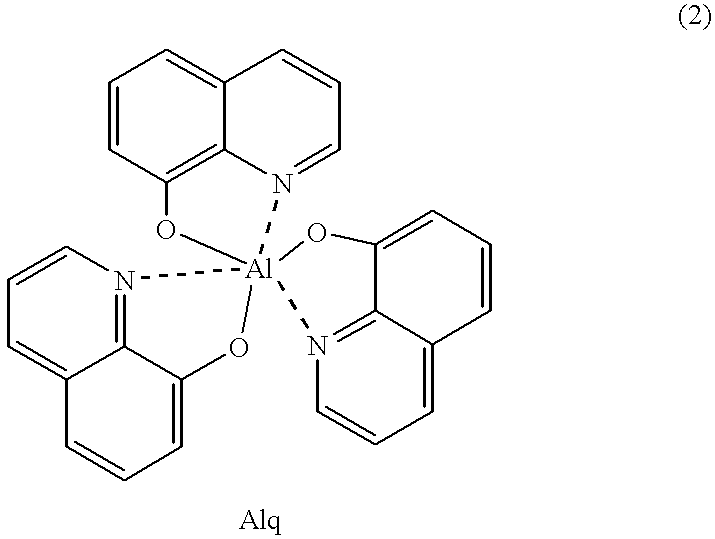

InactiveUS6917159B2Improve efficiencyQuality improvementDischarge tube luminescnet screensElectroluminescent light sourcesDopantMetallic electrode

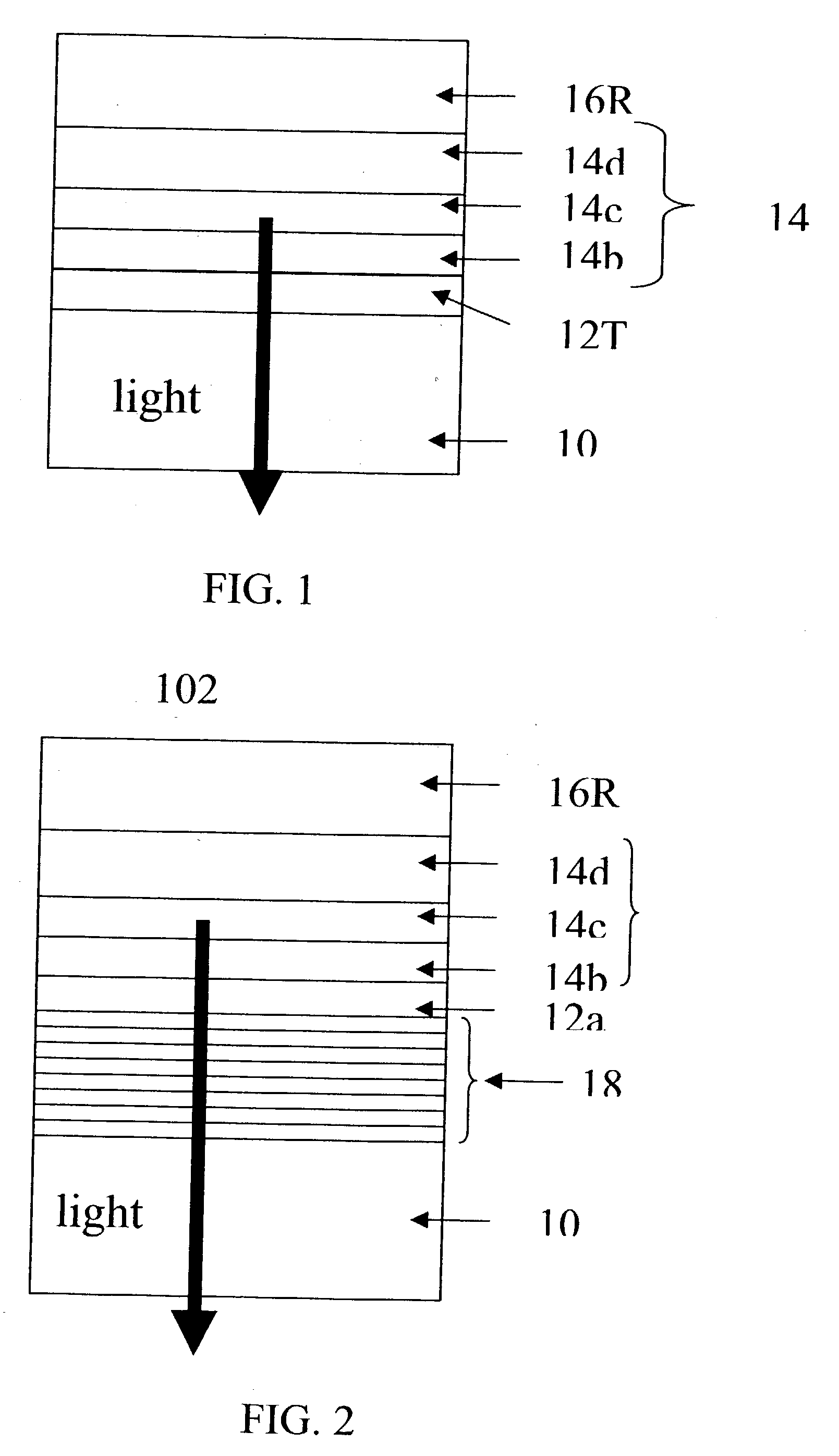

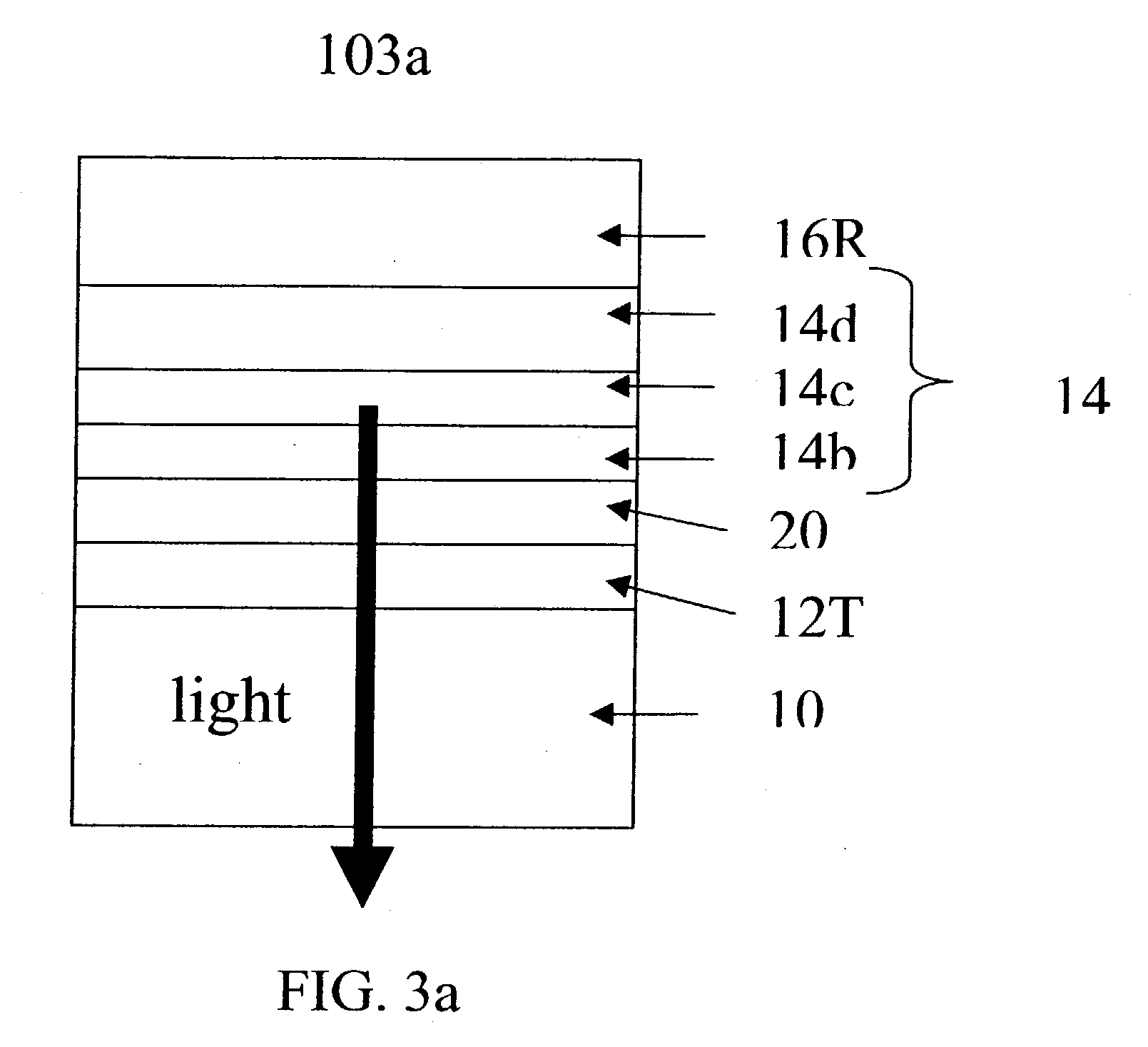

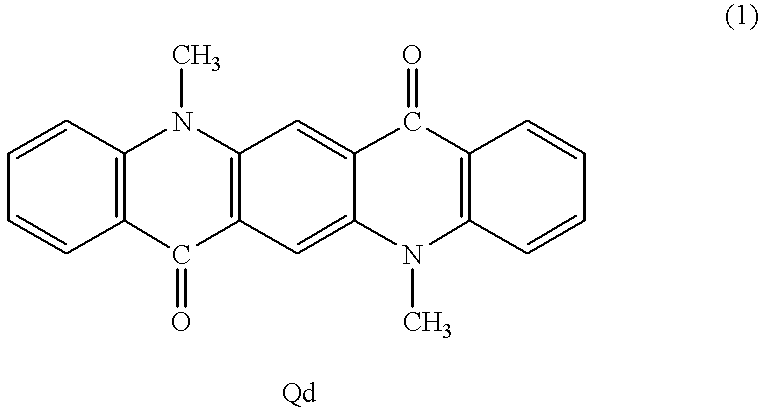

A microcavity OLED device including a substrate; a metallic bottom-electrode layer disposed over the substrate; a metallic top-electrode layer spaced from the metallic bottom-electrode layer; and an organic EL medium structure having a defined thickness, and including a light-emitting layer comprising a host material and at least one dopant disposed between the top-electrode layer and the bottom-electrode layer; wherein one of the metallic electrode layers is light transmissive and the other one is essentially opaque and reflective; wherein the material for reflective metallic electrode layer includes Ag, Au, Al, or alloys thereof, and the material for the light transmissive metallic electrode layer includes Ag, Au, or alloys thereof. The at least one dopant is selected to generate one of red, green, or blue light in the light-emitting layer. The defined thickness of the EL medium structure is selected so that the microcavity OLED device is tuned for emission of one of red, green, or blue light through the light transmissive electrode layer.

Owner:GLOBAL OLED TECH

Microcavity oled device

ActiveUS20050037232A1Improve luminous efficiencyImproved chromaticity of redIncadescent screens/filtersDischarge tube luminescnet screensDopantMetallic electrode

A microcavity OLED device including a substrate; a metallic bottom-electrode layer disposed over the substrate; a metallic top-electrode layer spaced from the metallic bottom-electrode layer; and an organic EL medium structure having a defined thickness, and including a light-emitting layer comprising a host material and at least one dopant disposed between the top-electrode layer and the bottom-electrode layer; wherein one of the metallic electrode layers is light transmissive and the other one is essentially opaque and reflective; wherein the material for reflective metallic electrode layer includes Ag, Au, Al, or alloys thereof, and the material for the light transmissive metallic electrode layer includes Ag, Au, or alloys thereof. The at least one dopant is selected to generate one of red, green, or blue light in the light-emitting layer. The defined thickness of the EL medium structure is selected so that the microcavity OLED device is tuned for emission of one of red, green, or blue light through the light transmissive electrode layer.

Owner:GLOBAL OLED TECH

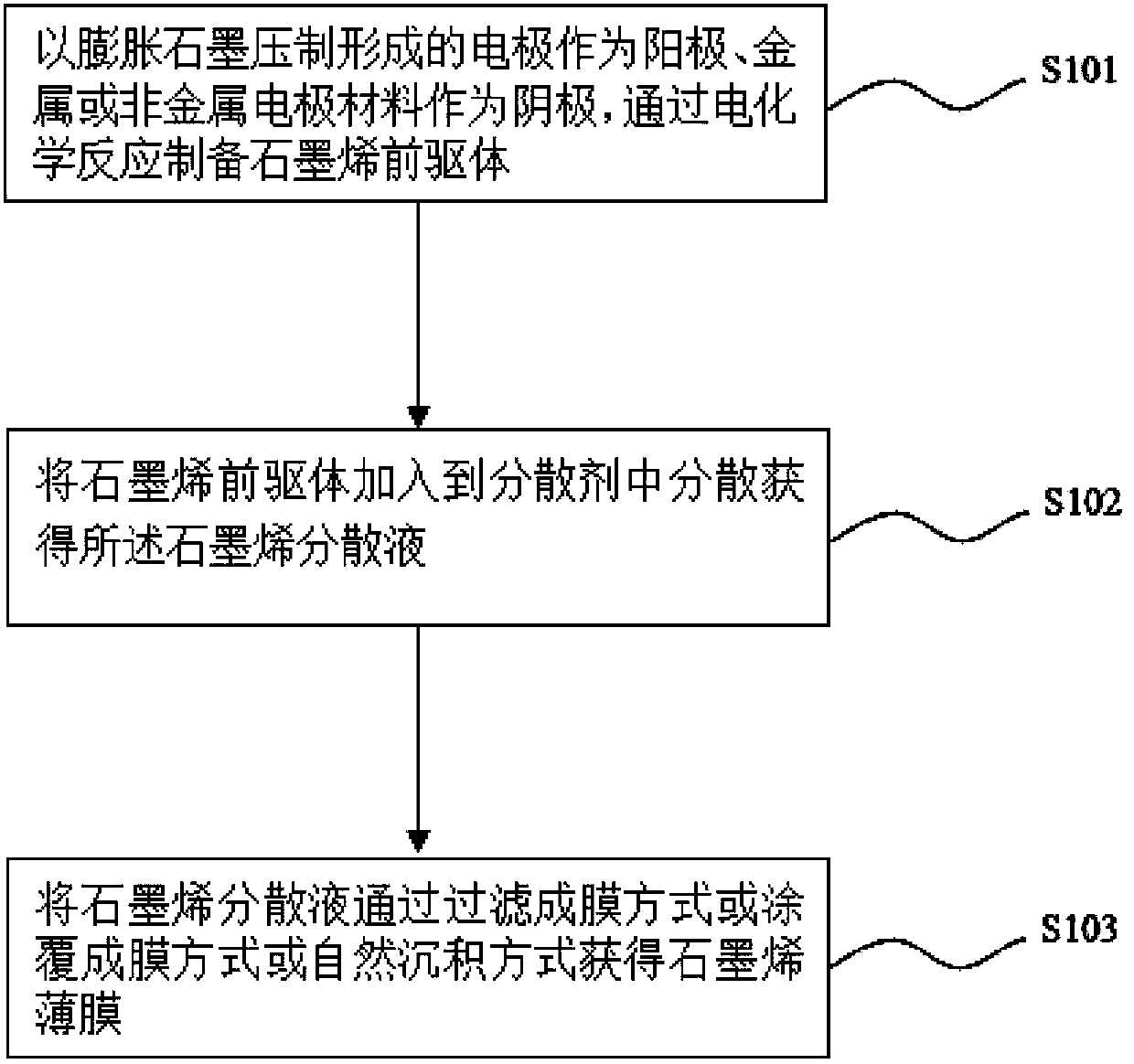

Preparation method of graphene dispersion liquid, and preparation method of graphene film

ActiveCN103466603AIncrease layer spacingIncrease concentrationMaterial nanotechnologyGrapheneElectrochemical responseMetallic electrode

The invention discloses a preparation method of a graphene dispersion liquid. The preparation method of the graphene dispersion liquid comprises the following steps: placing an expanded graphite compacted electrode and a metallic or non-metallic electrode material in an electrolyte solution as an anode and a cathode respectively, and applying a voltage of 1-20V and / or a current having a density of 1-200mA / cm<2> between the anode and the cathode for carrying out an electrochemical reaction for 1-120min; and washing an anode product obtained after the electrochemical reaction, adding to a dispersant, and carrying out ultrasonic or / and mechanical stirring dispersion to obtain the graphene dispersion liquid. The invention also discloses a preparation method of a graphene film. The graphene dispersion liquid forms the graphene film on a substrate in a filter film forming mode or a coating film forming mode or a natural deposition mode. The preparation methods have the advantages of simple process, easy operation, high controllability, low cost and mild reaction condition, and are suitable for the industrialized large-scale production.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

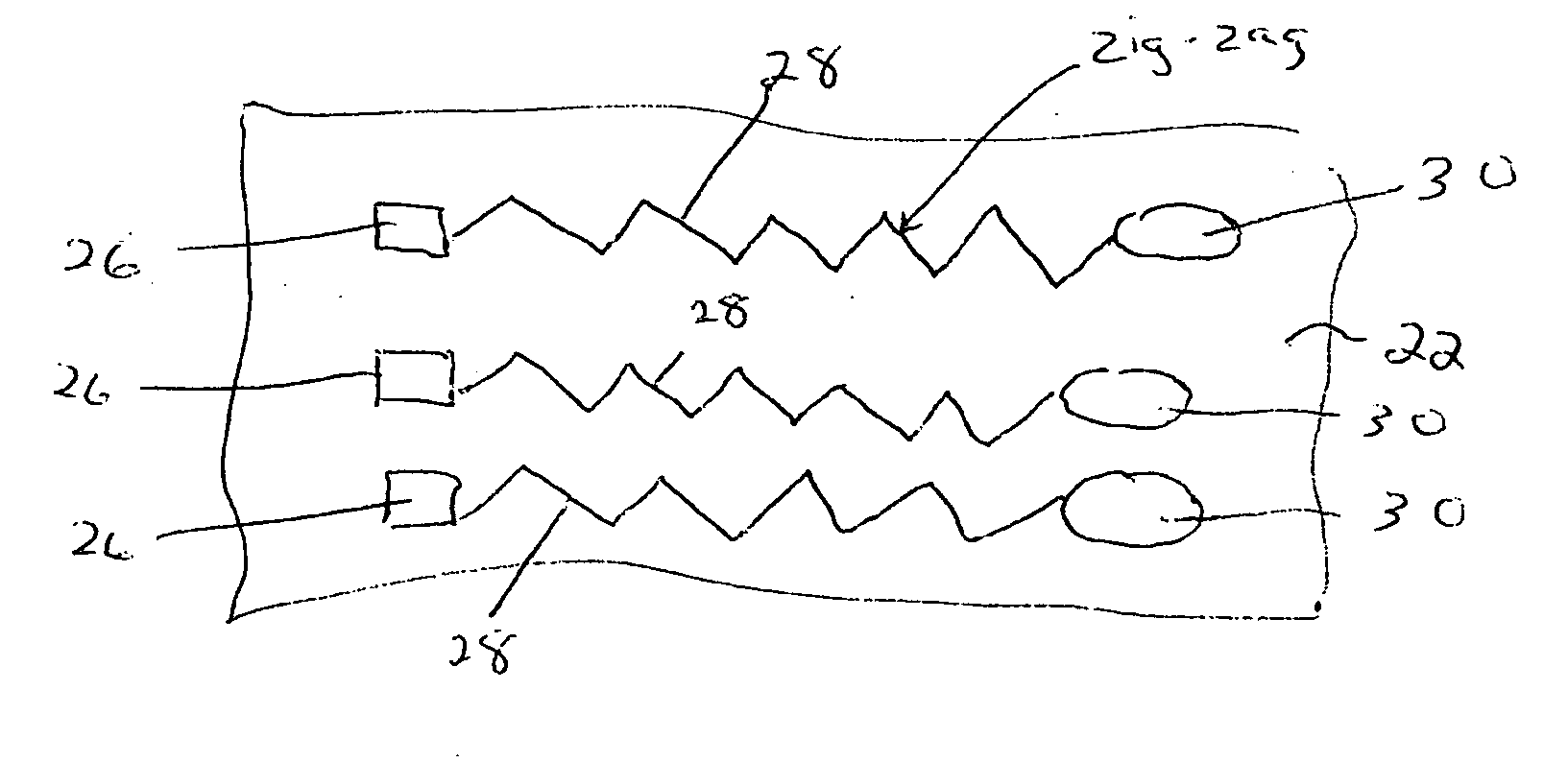

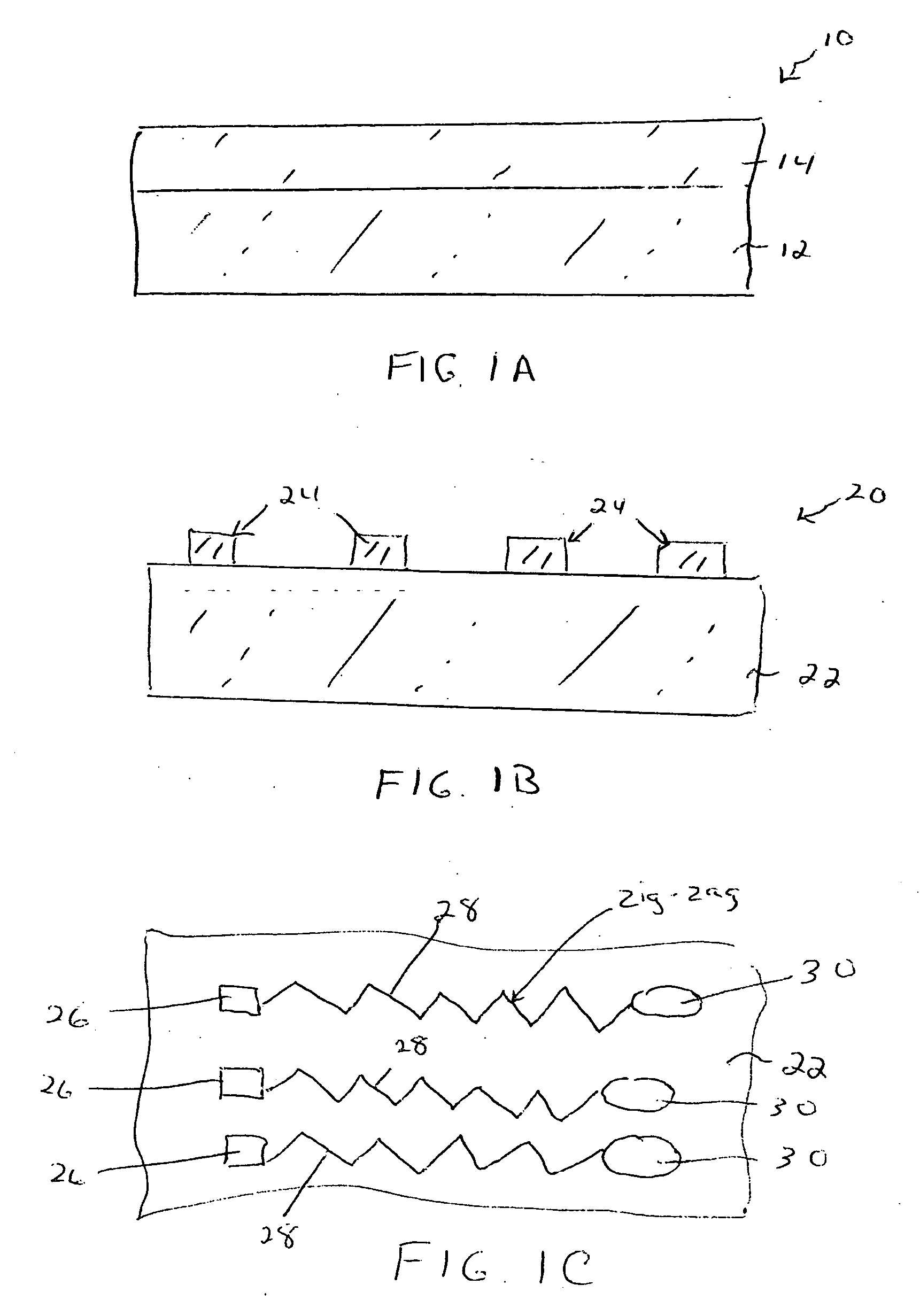

Method for producing flexible, stretchable, and implantable high-density microelectrode arrays

InactiveUS20070123963A1Increase the number ofSpinal electrodesHead electrodesMetallic electrodeContact pad

A high-density microelectrode array that is flexible and stretchable and can also be implanted within living tissue is provided. The microelectrode array includes at least first and second implantable and biocompatible polymeric layers in which a plurality of patterned conductive features, including metallic contact pads, metallic traces and metallic electrodes are sandwiched therebetween. Each metallic trace is located between a metallic contact pad and a metallic electrode and has substantially rounded corners and a zigzag pattern. The latter features are provided using stent technology. The present invention also provides a method of fabricating such a flexible, stretchable, and implantable microelectrode arrays which combined micromaching technology and stent technology as well as an implantable medical device that includes the inventive microelectrode array.

Owner:CORDIS CORP

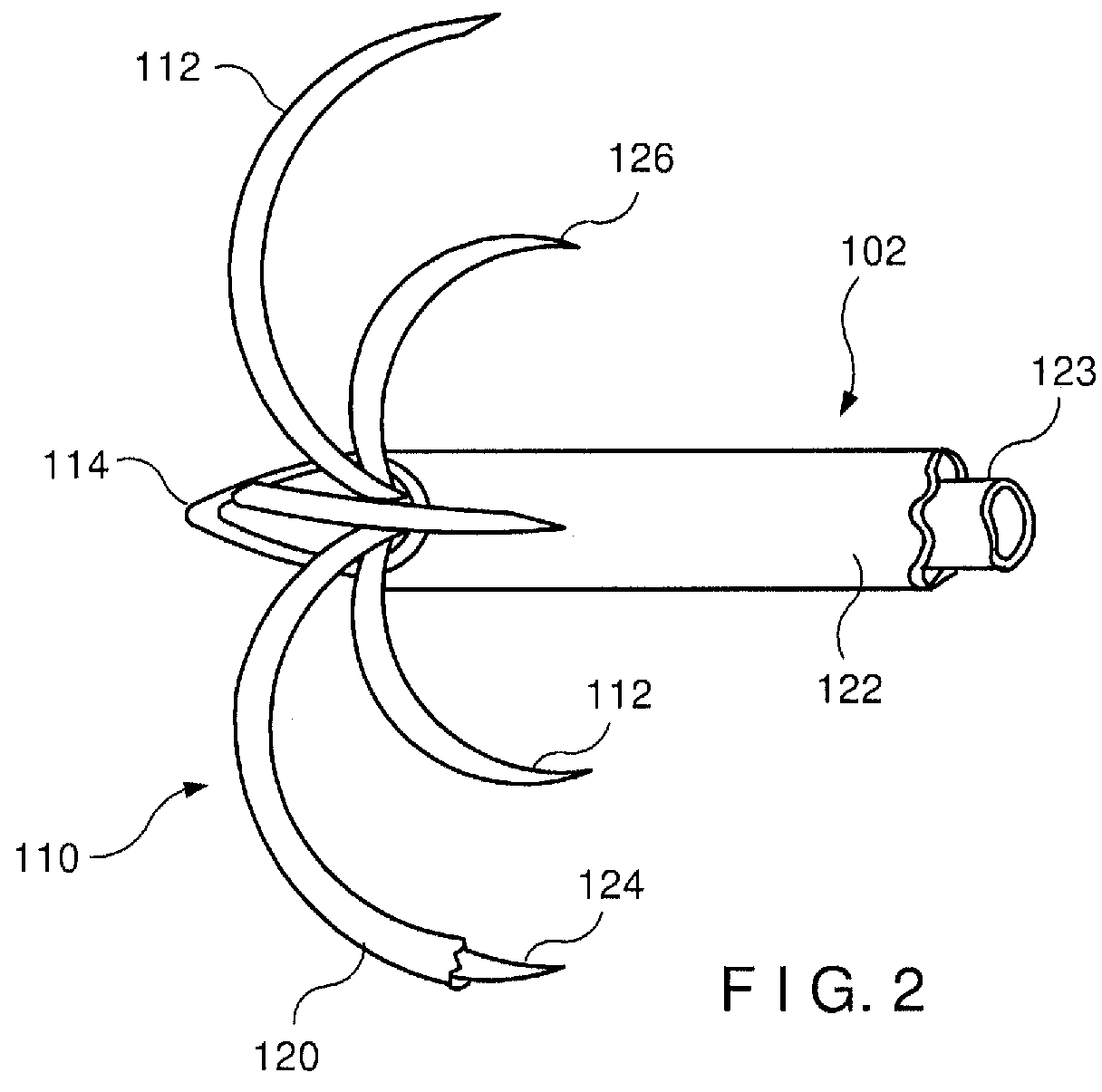

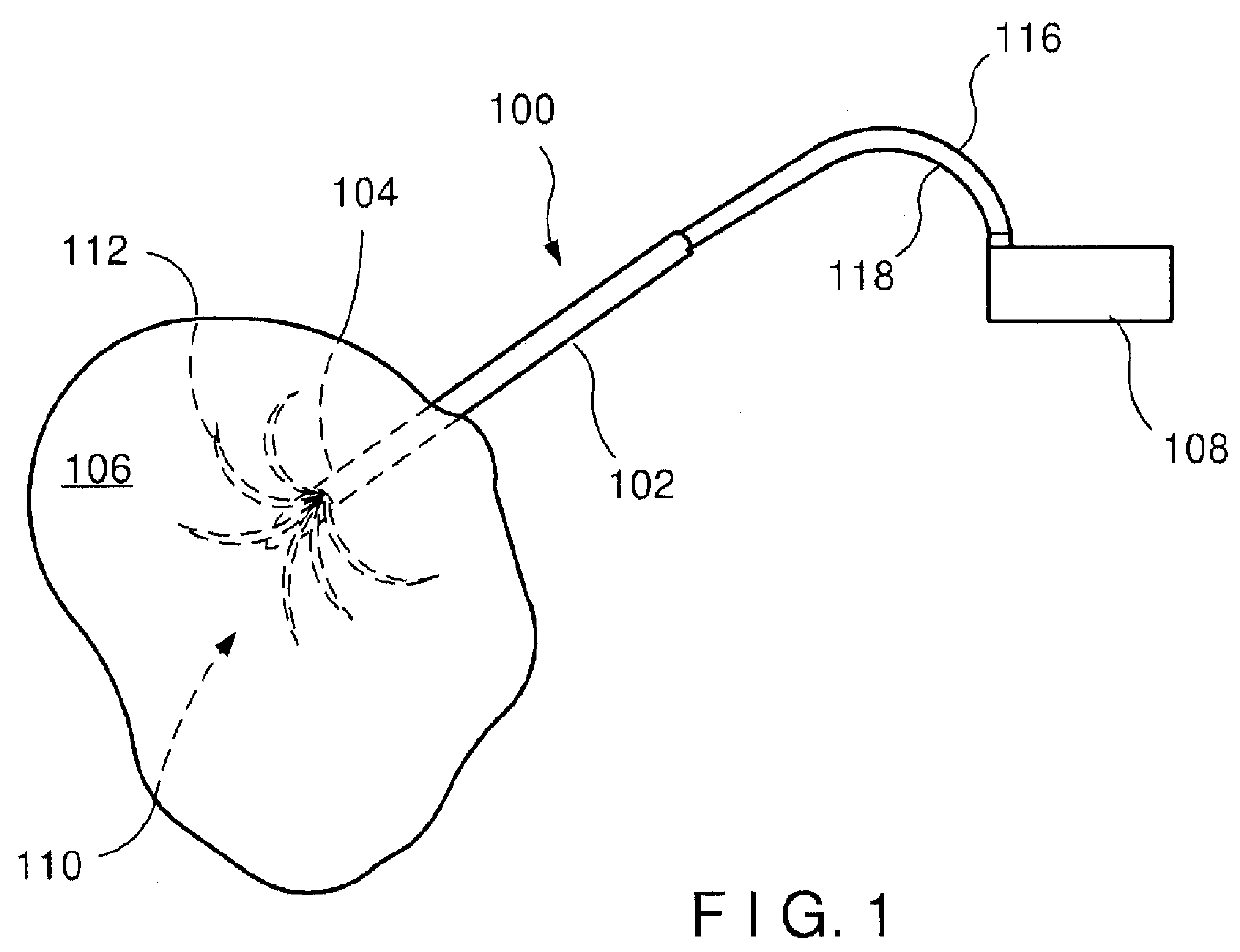

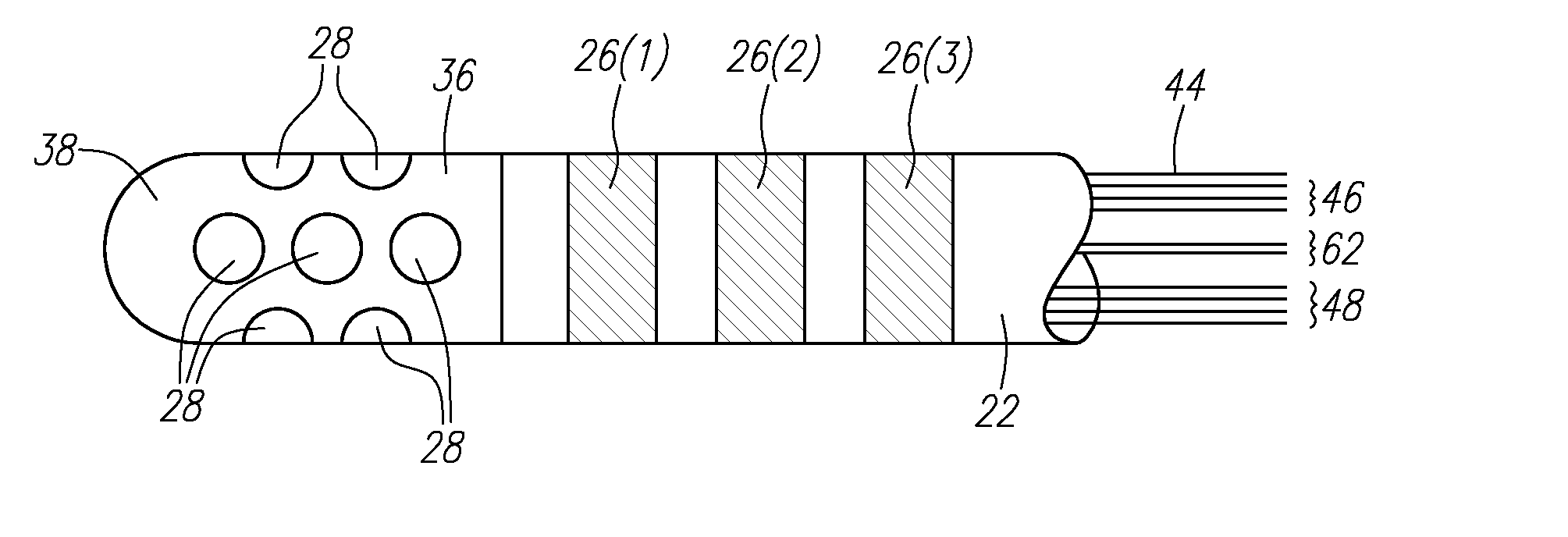

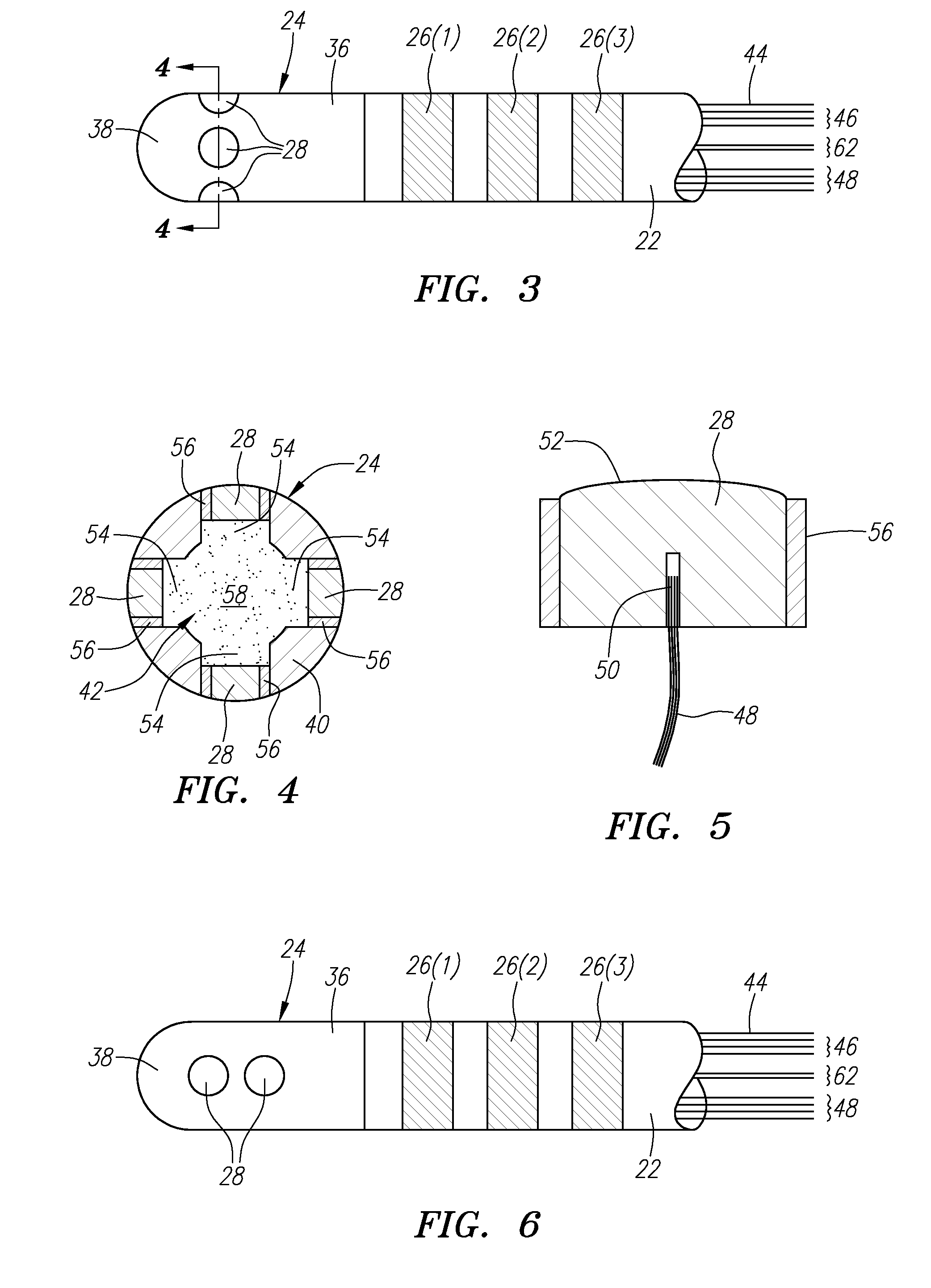

High resolution electrophysiology catheter

InactiveUS20150133914A1Improve fidelityImprove resolutionTransvascular endocardial electrodesCatheterMetallic electrodeMicroelectrode

An electrophysiology medical probes, which may be incorporated into a system and used to perform an electrophysiology procedure, is provided. The medical probe comprises an elongated member (e.g., a flexible elongated member), and a metallic electrode mounted to the distal end of the elongated member. In one embodiment, the metallic electrode is cylindrically shaped and comprises a rigid body. The medical probe further comprises a plurality of microelectrodes (e.g., at least four microelectrodes) embedded within, and electrically insulated from, the metallic electrode, and at least one wire connected to the metallic electrode and the microelectrodes.

Owner:BOSTON SCI SCIMED INC

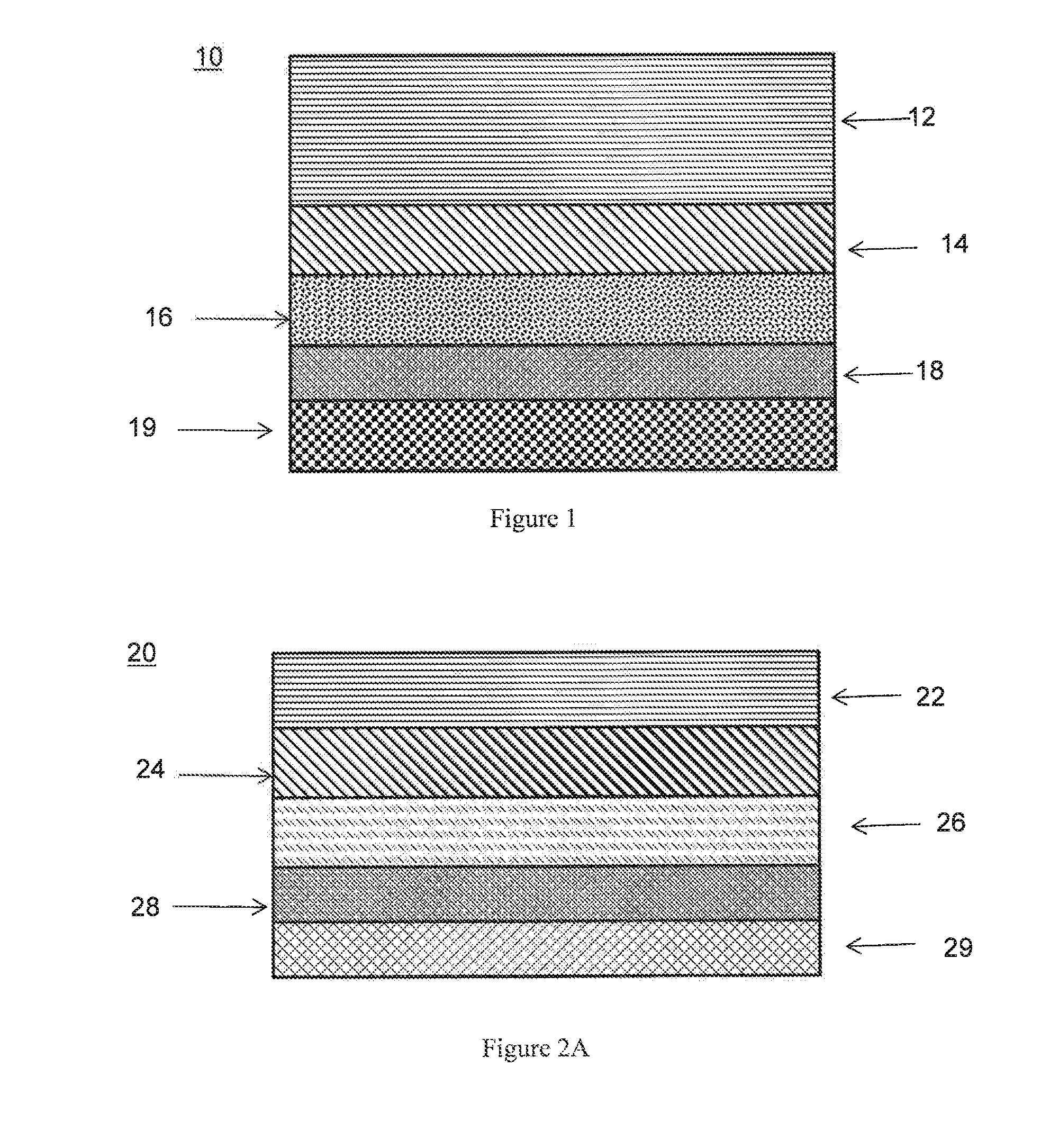

Microcavity OLED devices

InactiveUS20040140757A1Discharge tube luminescnet screensElectroluminescent light sourcesMetallic electrodeMaterials science

A microcavity OLED device including a substrate; a metallic bottom-electrode layer disposed over one surface of the substrate; an organic EL element disposed over the metallic bottom-electrode layer; and a metallic top-electrode layer disposed over the organic EL element, one of the metallic electrode layers is semitransparent and the other one is essentially opaque and reflective; and one of the metallic electrode layers is semitransparent and the other one is essentially opaque and reflective; and wherein the materials for the opaque and reflective metallic electrode layer are selected from Ag, Au, Al, or alloys thereof, the materials for the semitransparent metallic electrode layer are selected from Ag, Au, or alloys thereof, and the thickness of the semitransparent metallic electrode layer and the location of the light emitting layer are selected to enhance the emission output of the microcavity OLED device above that of a similar device without the microcavity.

Owner:EASTMAN KODAK CO

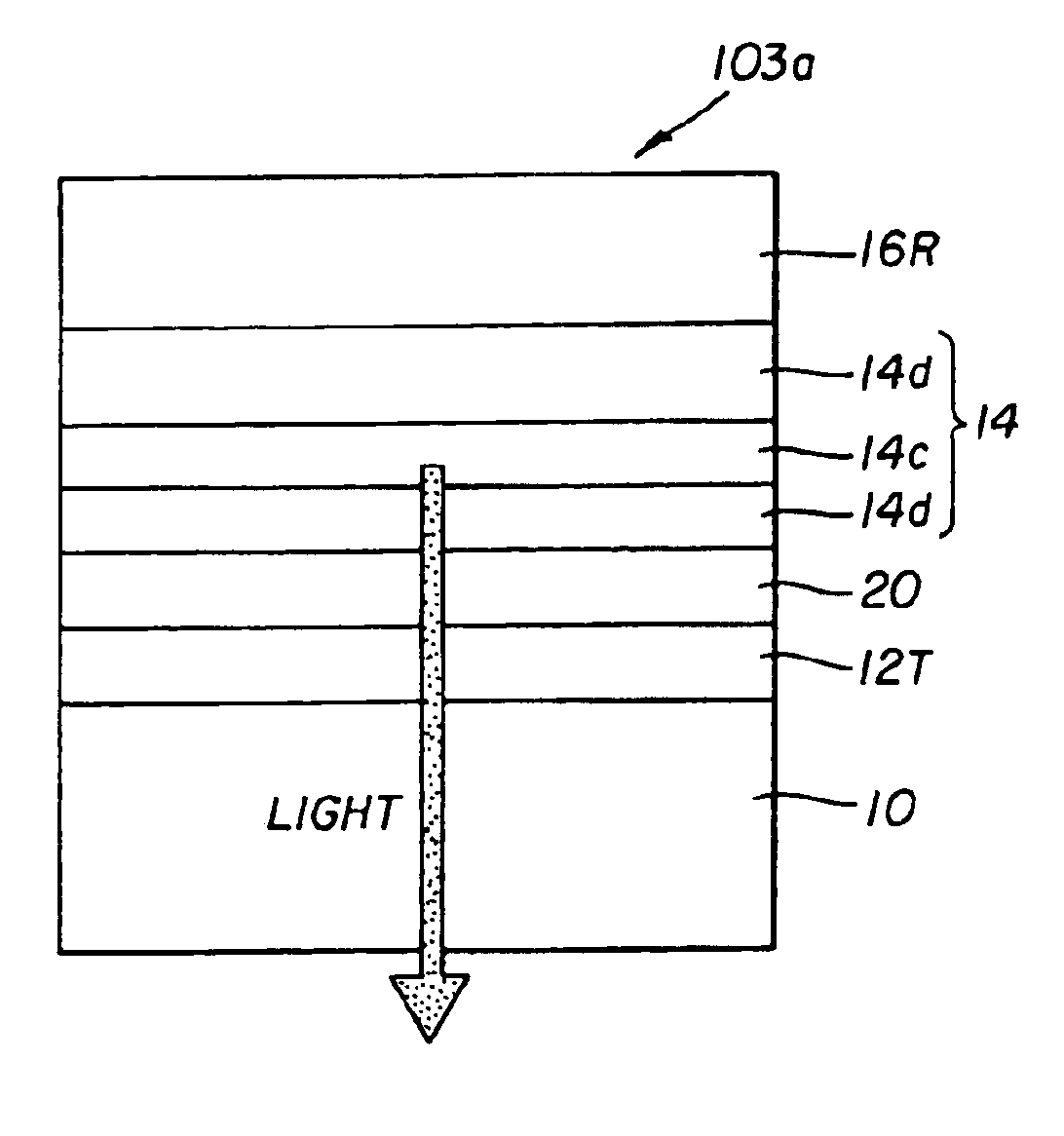

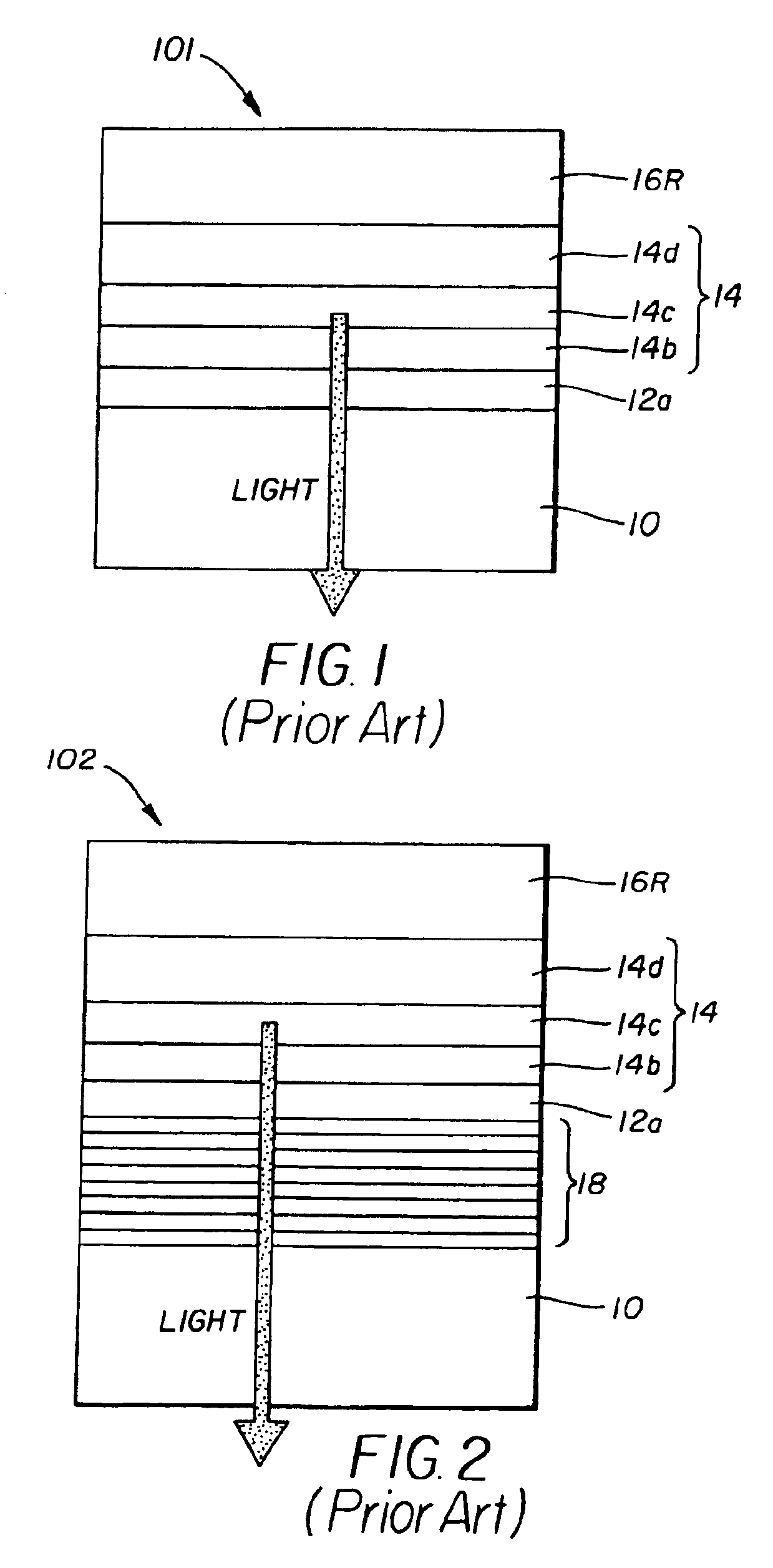

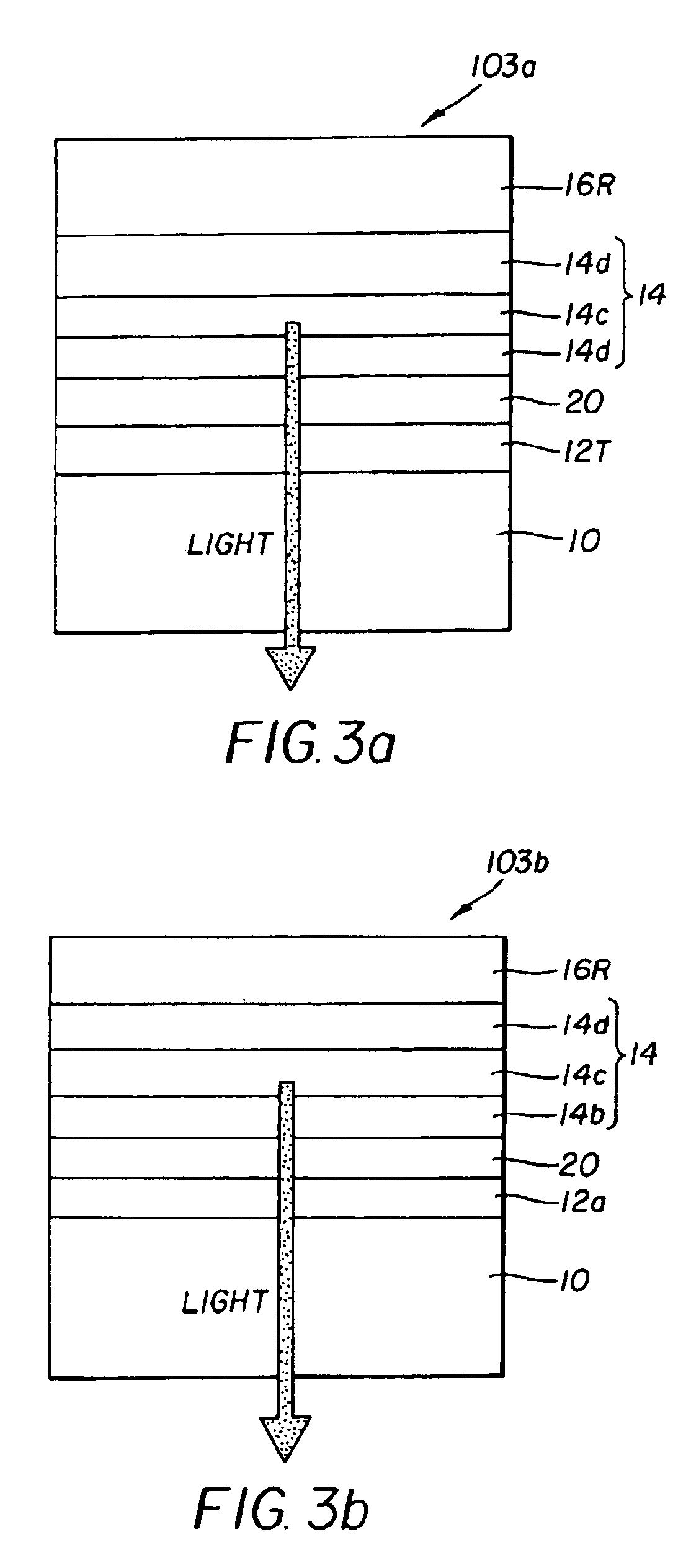

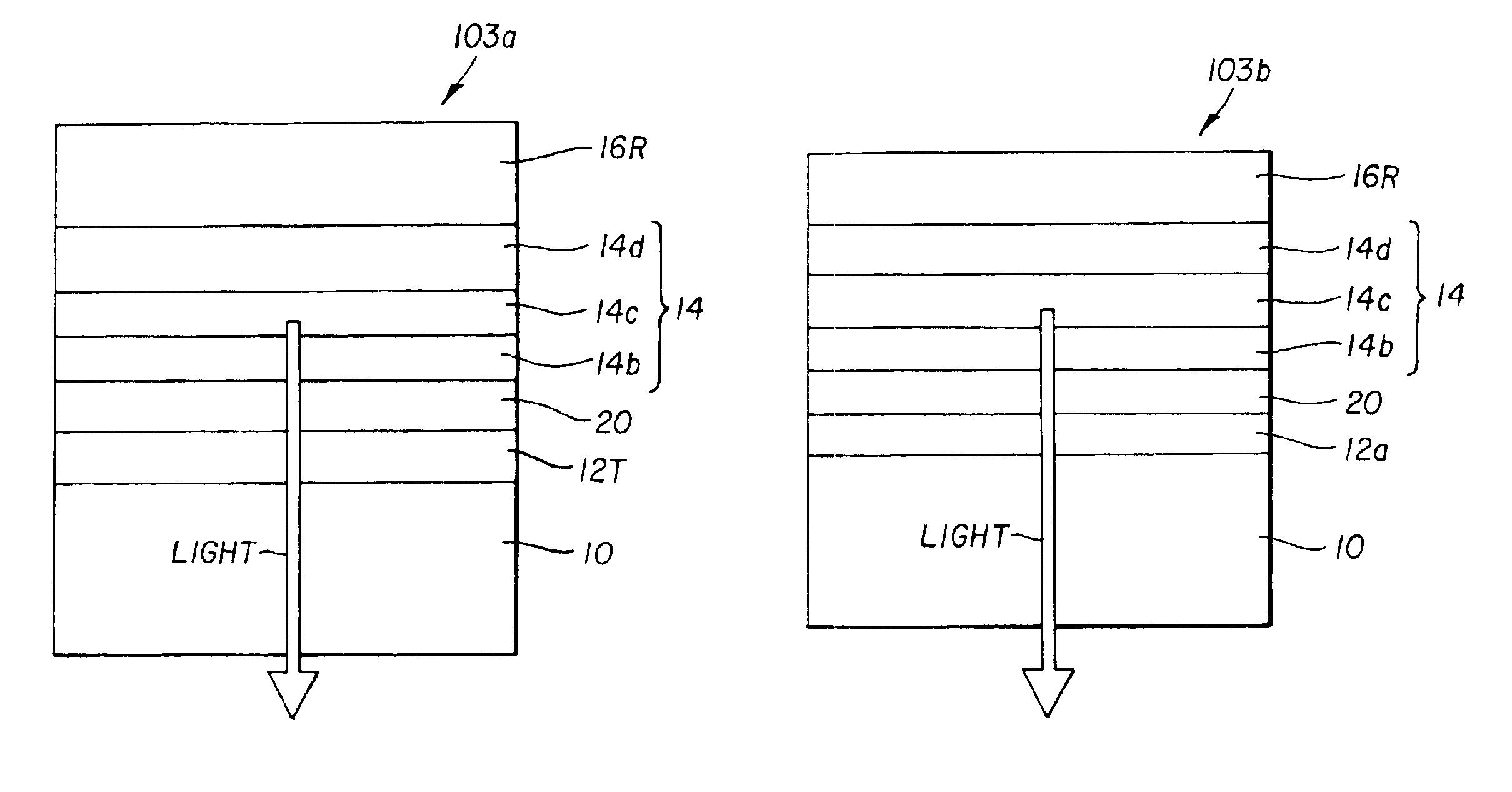

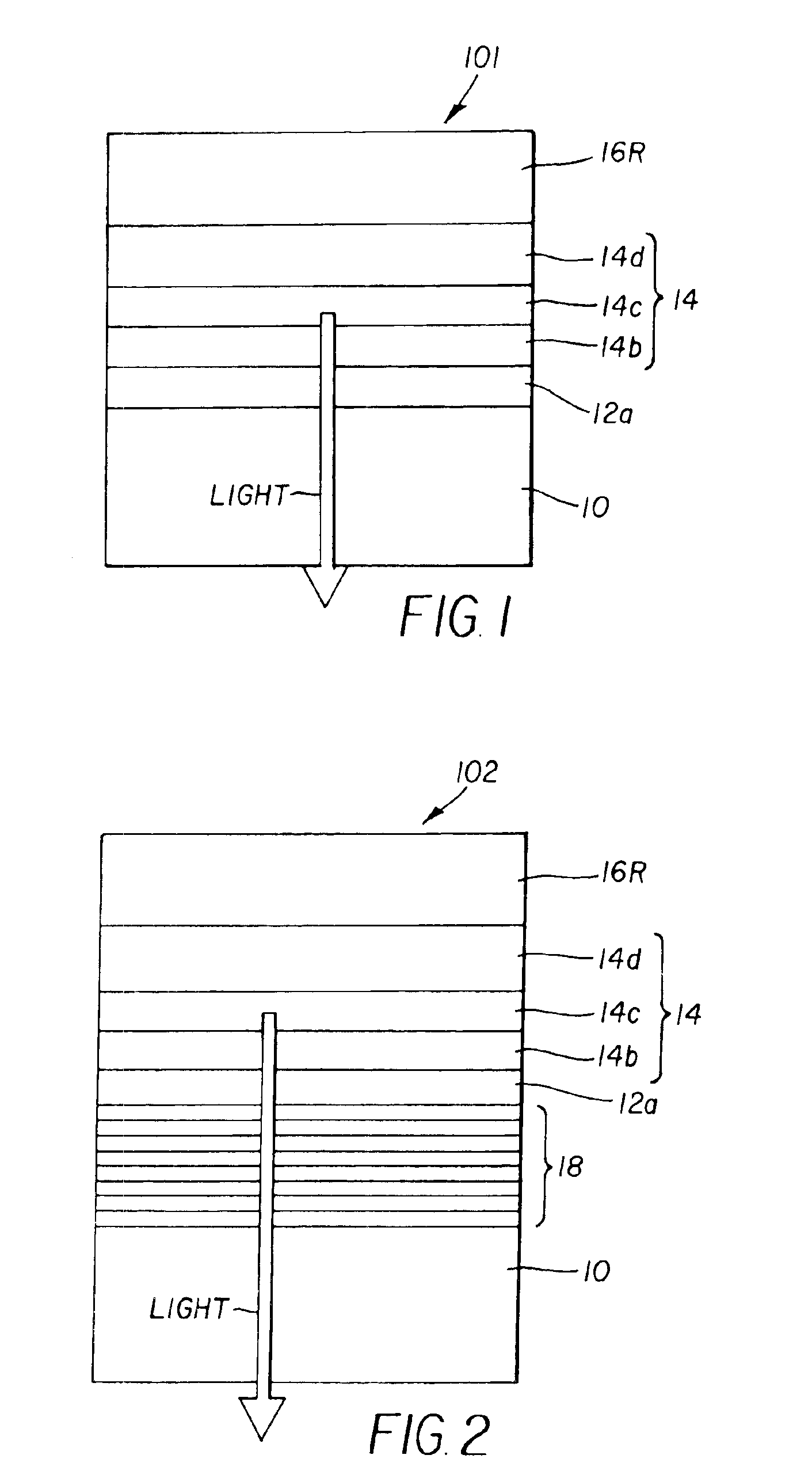

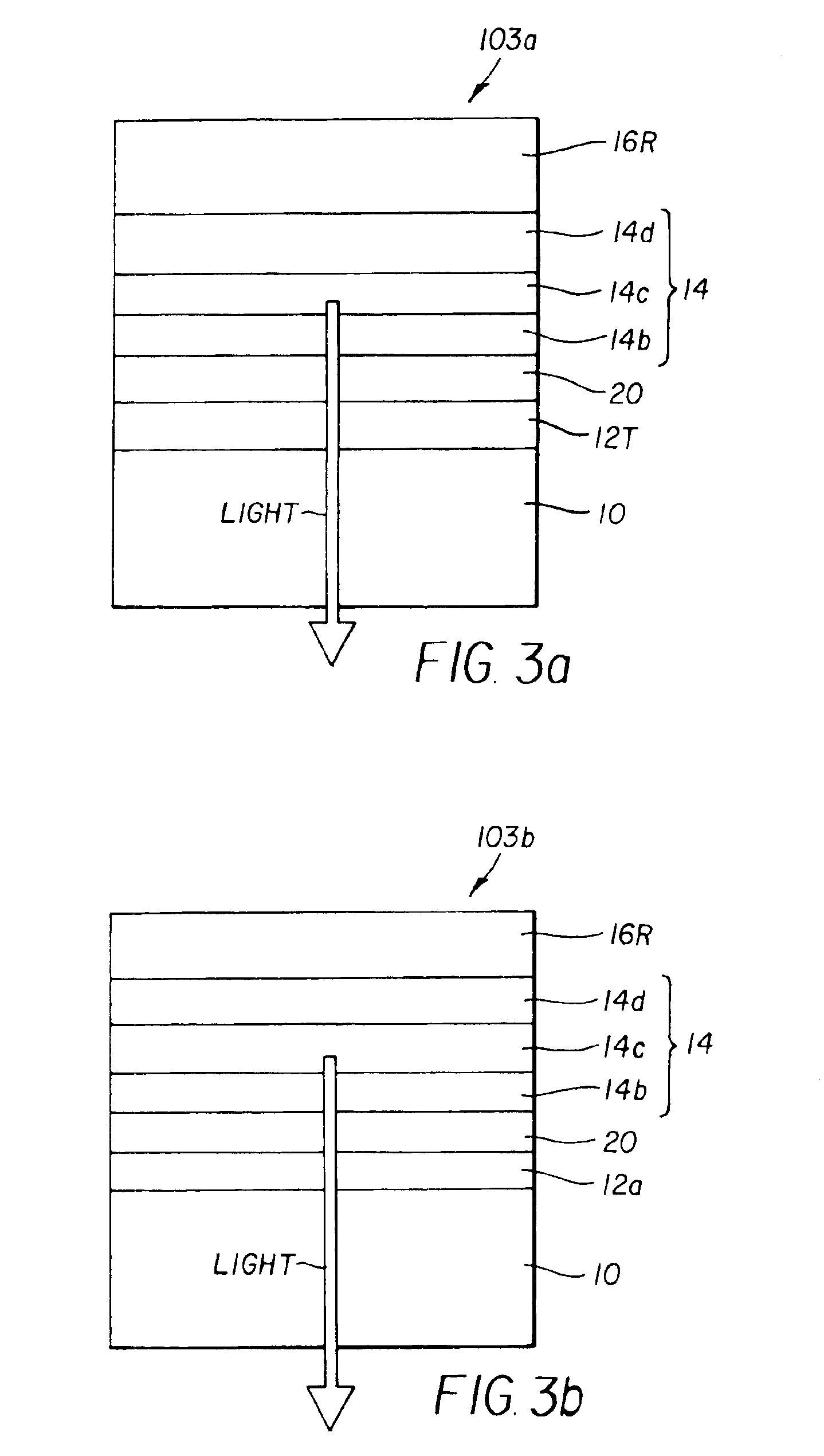

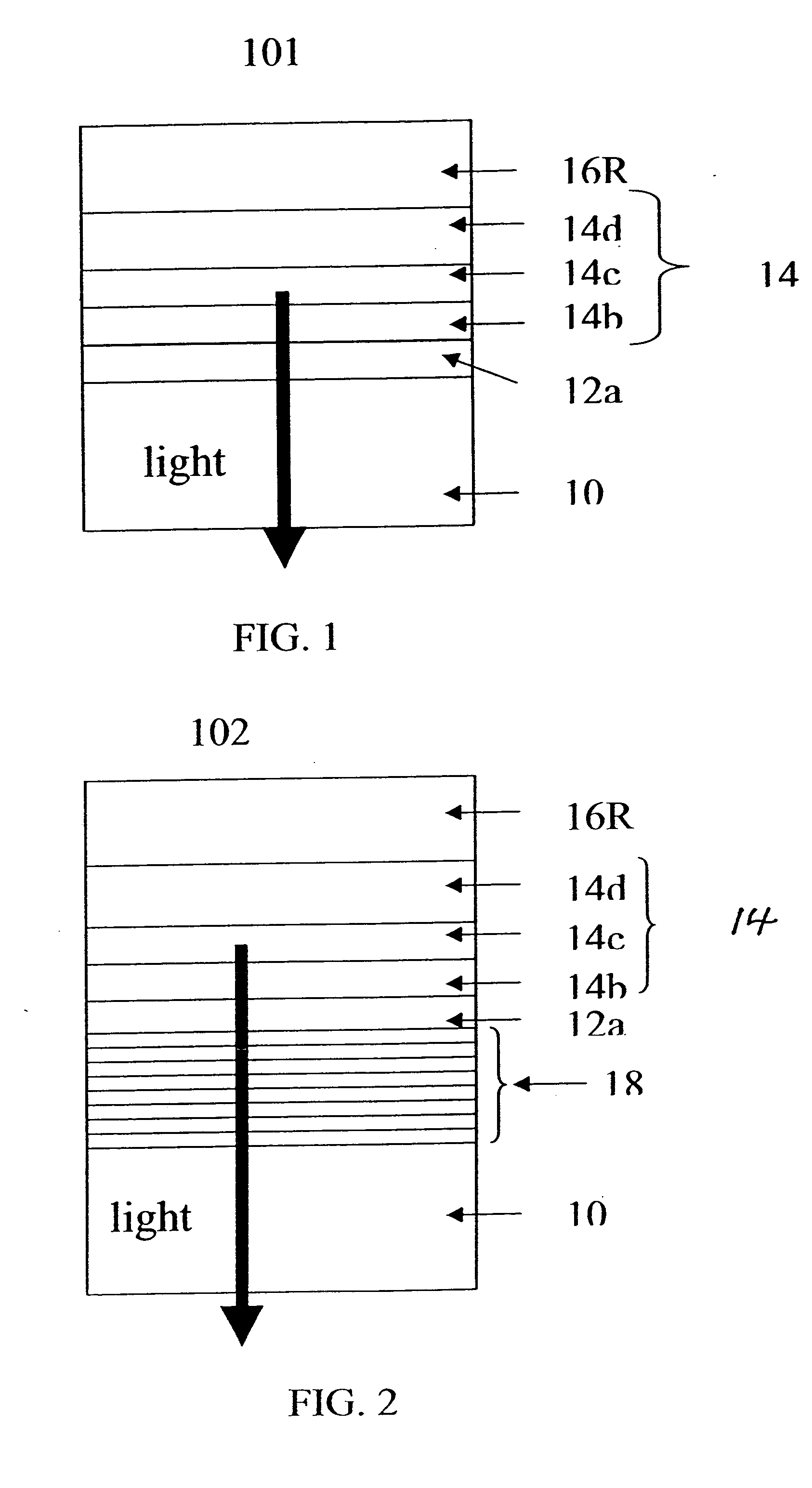

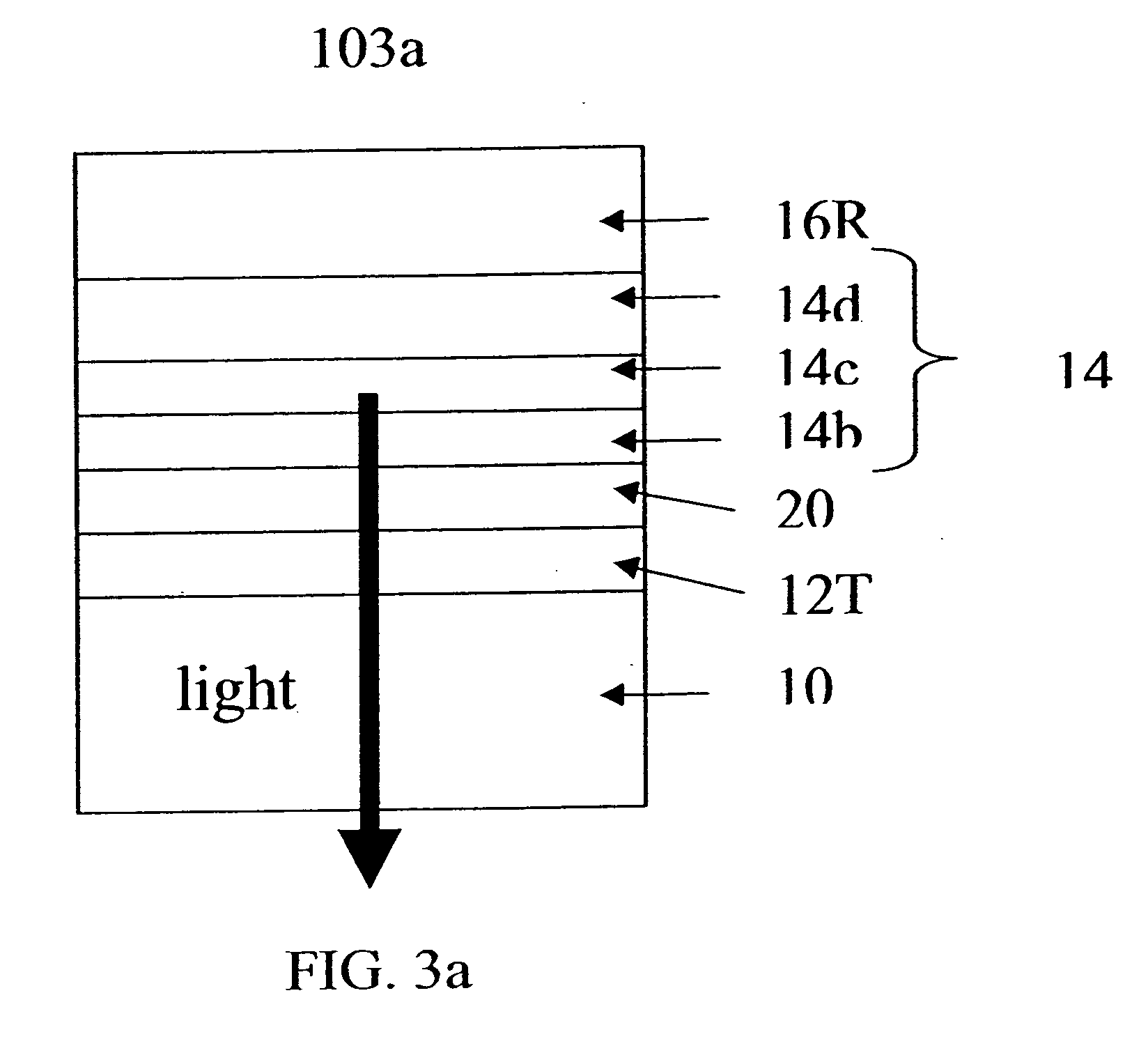

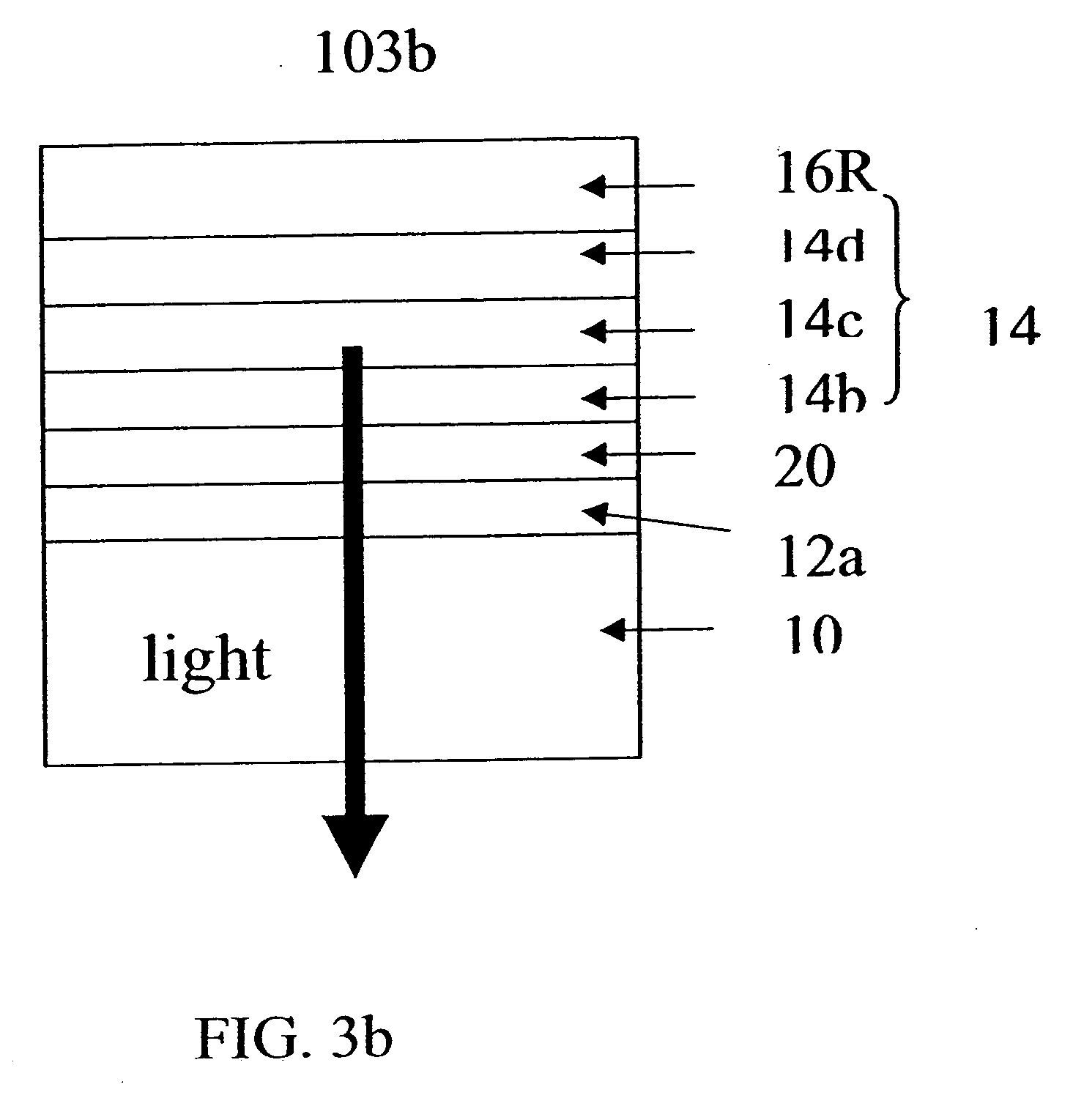

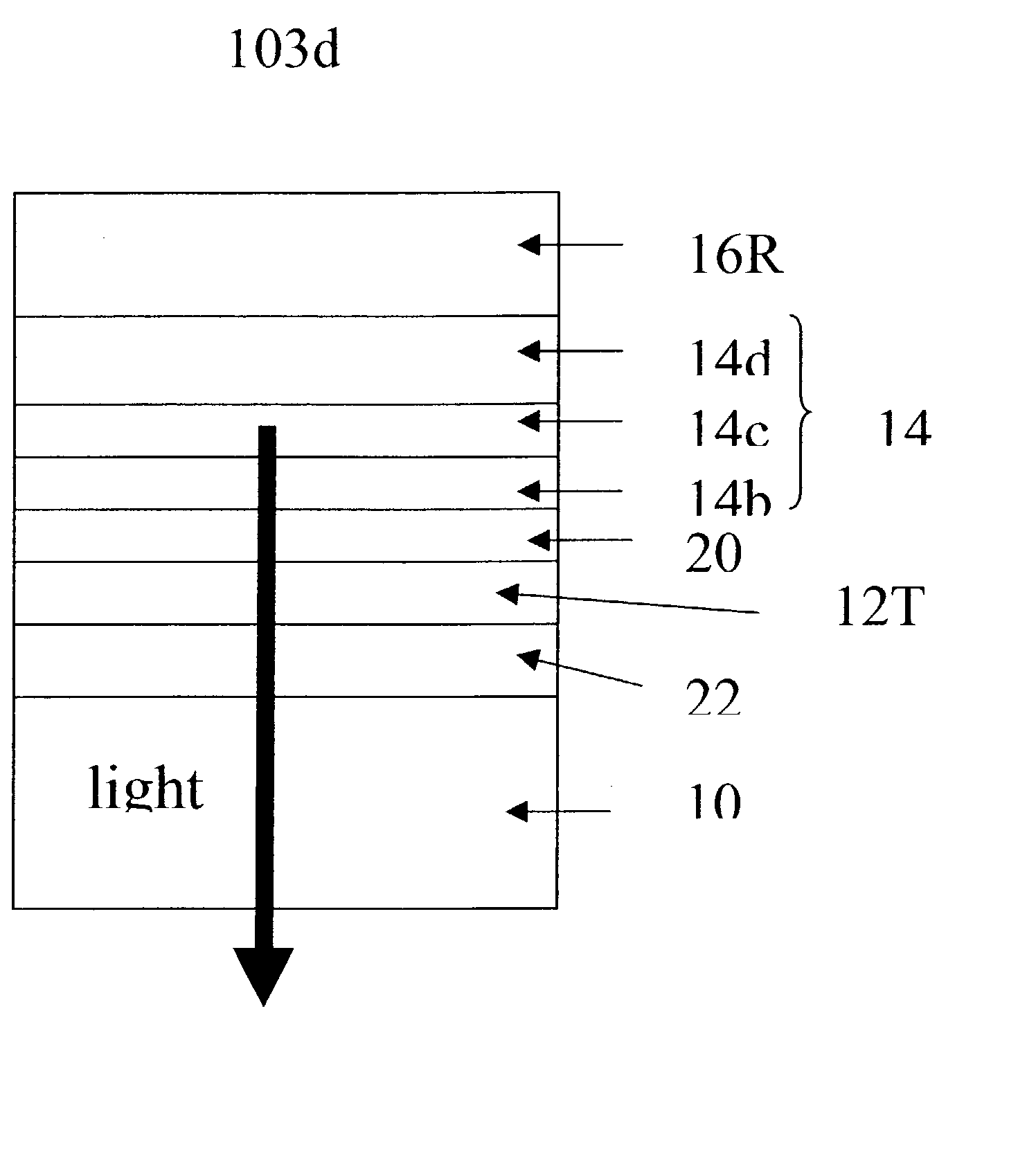

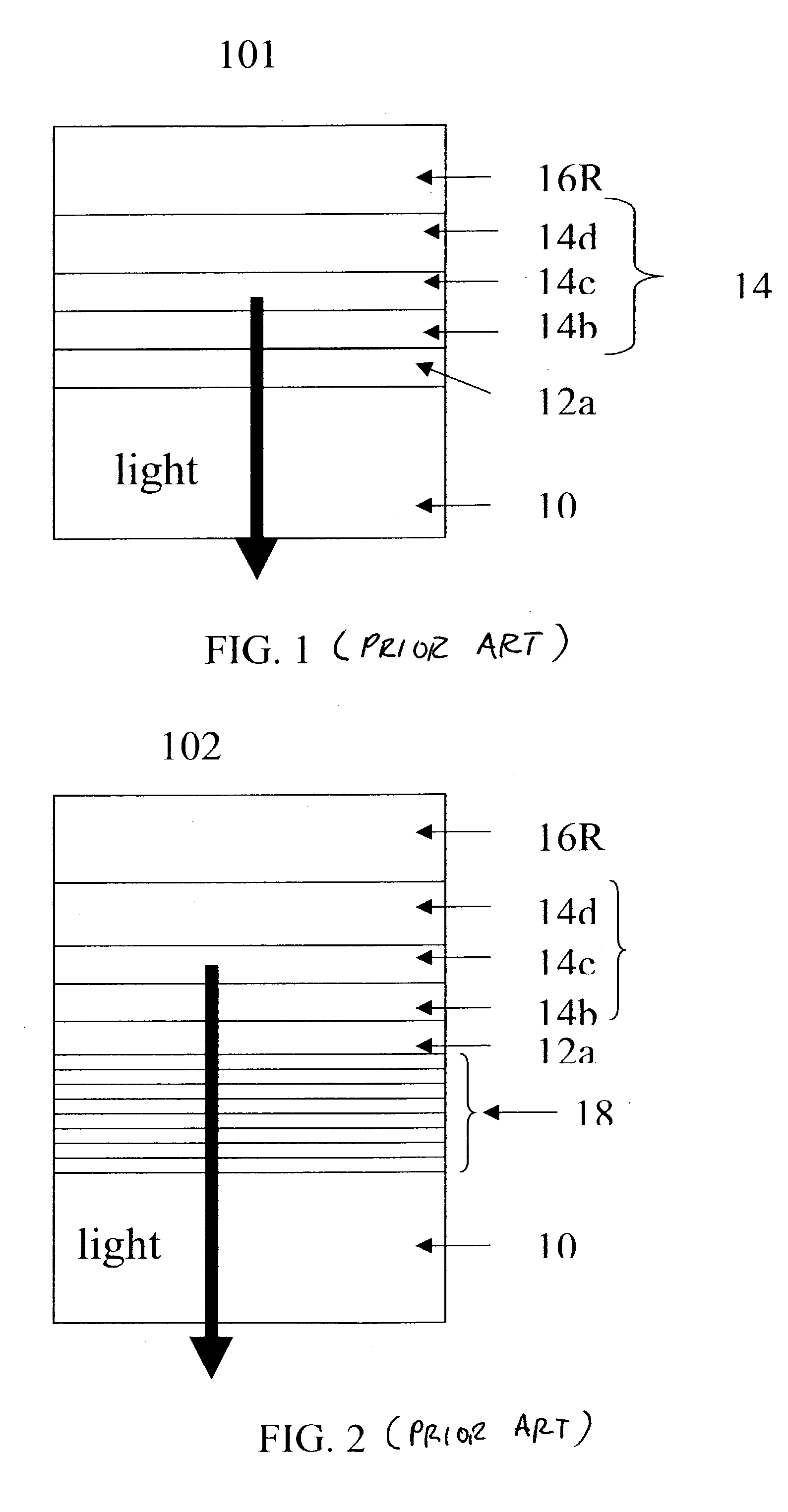

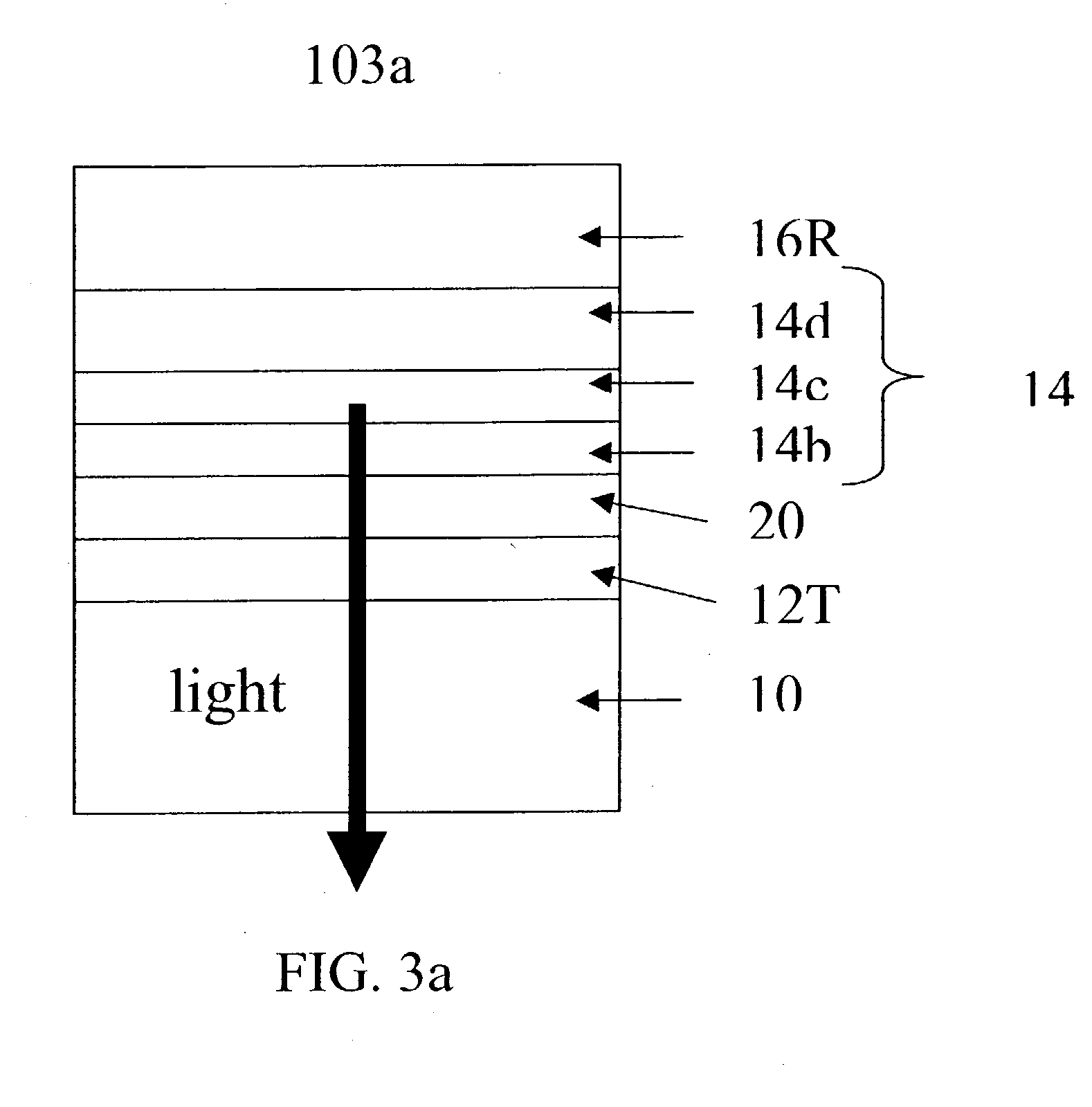

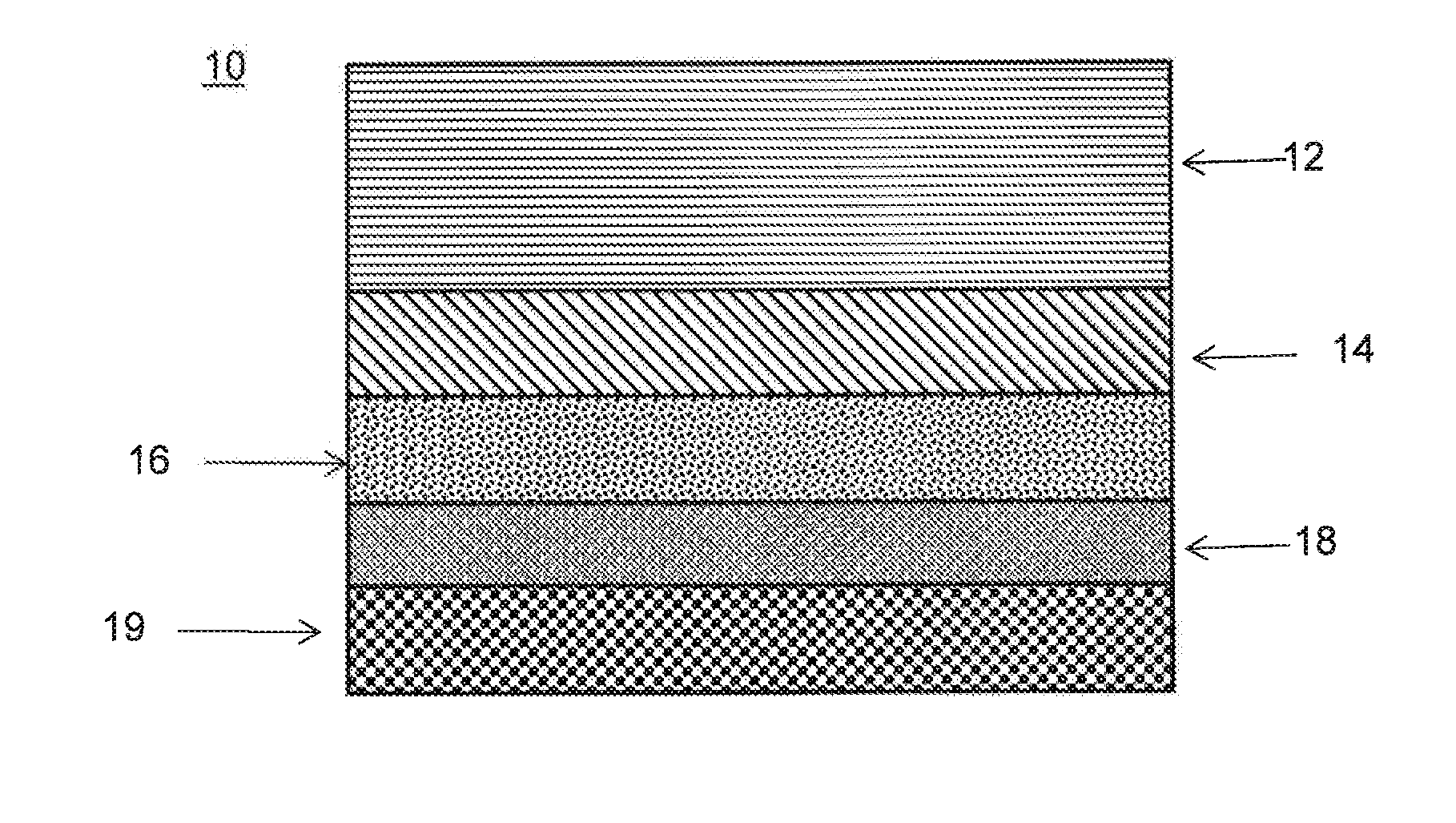

Optical resonator type organic electroluminescent element

InactiveUS6406801B1Characteristic can be preventedHigh currentDischarge tube luminescnet screensElectroluminescent light sourcesElectron holeMetallic electrode

An optical resonator type organic electroluminescent element has a multilayered film mirror 30, a transparent electrode 12, an electron hole transportation layer 14 and a luminescent layer 16 configuring an organic layer, and a metallic electrode mirror 20, formed on a glass substrate 10. The optical resonator type organic electroluminescent element amplifies a specific wavelength (especially, in a range of about 30 nm toward a shorter wavelength side from a luminescence peak wavelength of the organic layer) in luminescence light by a minute optical resonator, which comprises the multilayered film mirror 30 and the metallic electrode mirror 20. It is determined that the minute optical resonator has an optical length L which is twice as long as a resonance wavelength, the organic layer has a thickness of 100 nm or more, and the transparent electrode has a thickness of 50 nm or more or a thickness so to have a sheet resistance of 30 OMEGA / square or less. Thus, the transparent electrode can be prevented from generating heat even when a large current is caused to flow into it, and the element characteristics can be reliably prevented from being deteriorated. Moreover, the reliability of this element can be improved because the organic layer containing the luminescent layer has a sufficient thickness.

Owner:TOYOTA CENT RES & DEV LAB INC

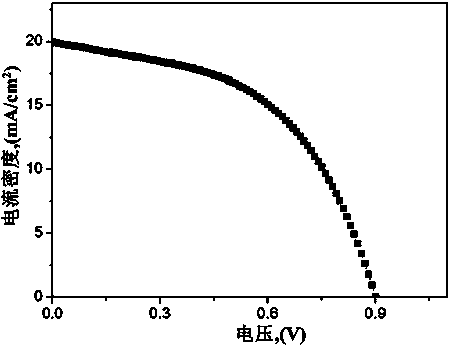

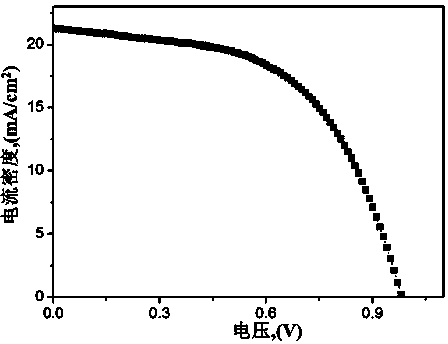

Perovskite solar battery and preparing method thereof

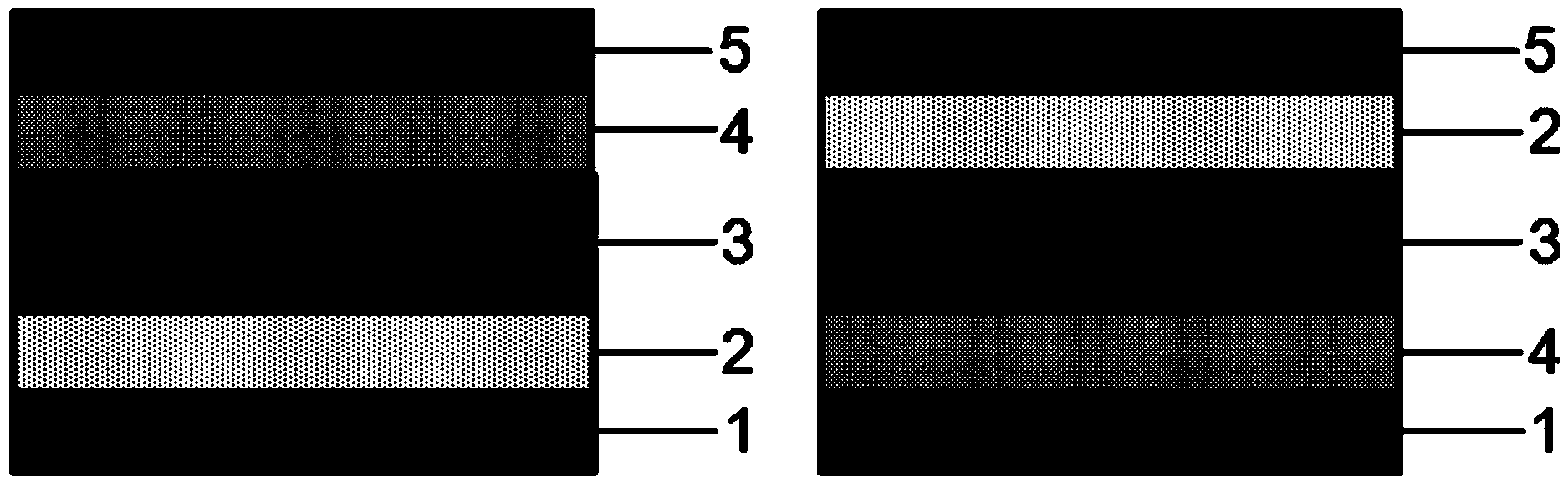

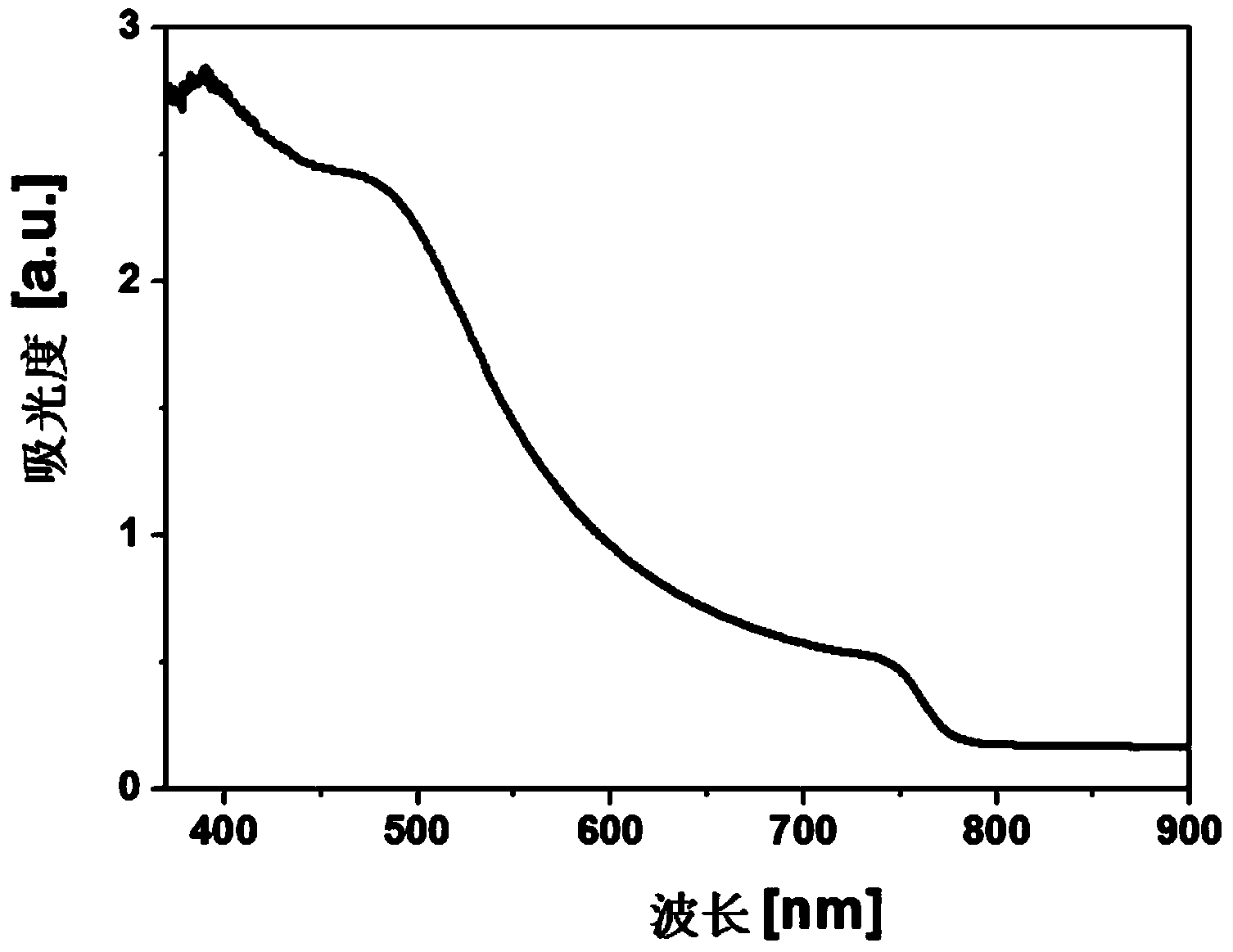

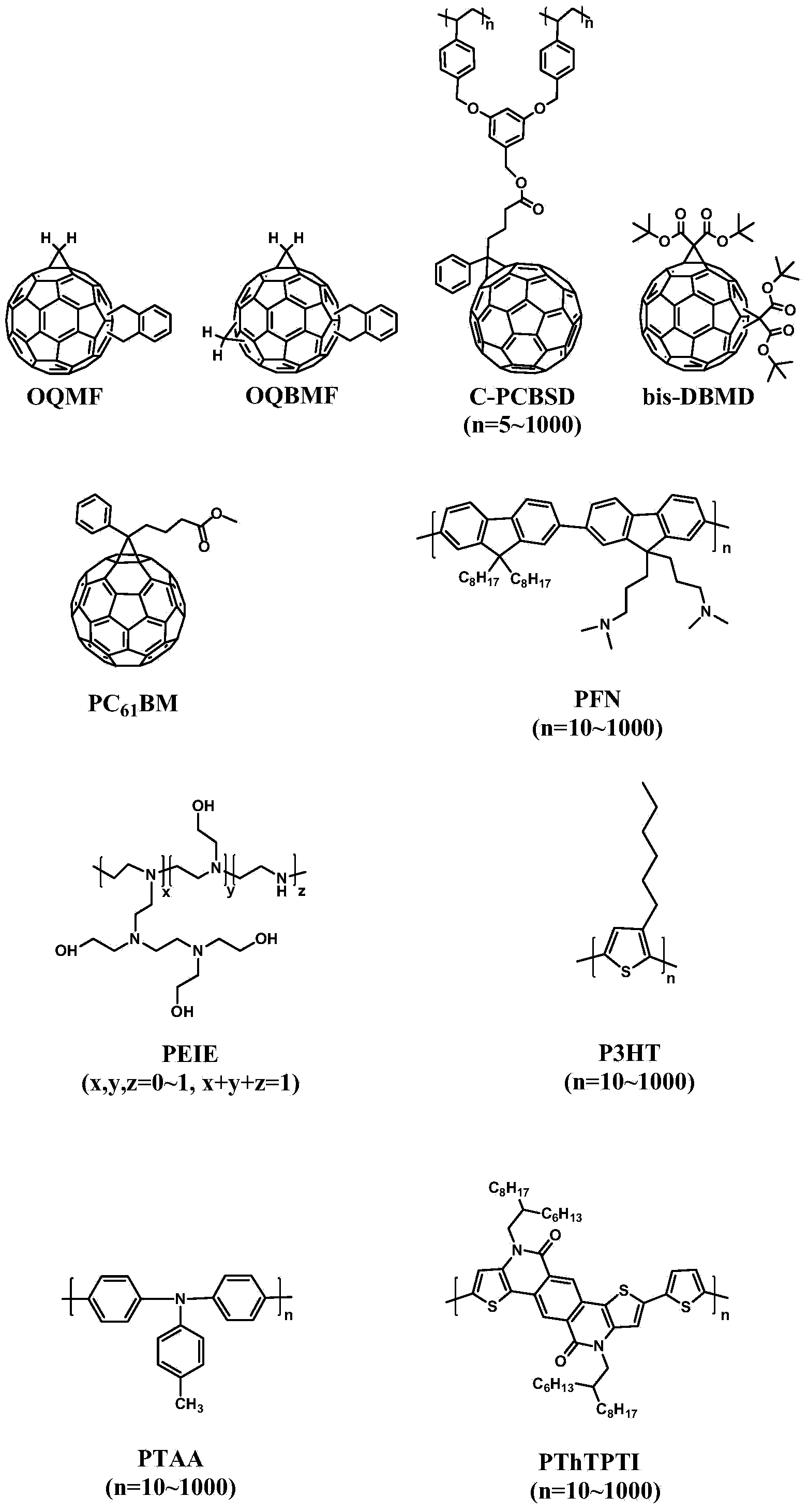

InactiveCN103855307ASimple processHigh industrial application valueFinal product manufactureSolid-state devicesElectronic transmissionHole transport layer

The invention relates to a perovskite solar battery and a preparing method thereof. The perovskite solar battery comprises a transparent electrode, a hole transmission layer, a perovskite light absorption layer, an electronic transmission layer and a metal electrode. The hole transmission layer comprises at least one of PEDOT: PSS, P3HT, PTAA, PThTPTI, metallic oxide and graphene oxide. The electronic transmission layer comprises at least one of 58 pi-electronic fullerene PCBM, 56 pi-electronic fullerene OQMF, 54 pi-electronic fullerene OQBMF, PFN, PEIE, ZnO, TiO2, doped or modified ZnO or TiO2. The perovskite solar battery is high in energy exchange efficiency and low in cost and can be produced on a large scale, and the preparing method is simple in technology.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Organic polarized light emitting diode display with polarizer

InactiveUS20050088084A1Discharge tube luminescnet screensElectroluminescent light sourcesMetallic electrodeLED display

An organic light emitting diode display includes a substrate; a plurality of OLEDs formed on the substrate, the OLEDs emitting polarized light wherein the OLEDs comprise a layer defining a periodic grating structure; a first electrode layer conforming to the grating structure; an OLED material layer formed over the first electrode layer and conforming to the grating structure; and a second electrode layer formed over the OLED material layer and conforming to the grating structure, wherein the first and / or second electrode layers are metallic layers, whereby the periodic grating structure induces surface plasmon cross coupling in the metallic electrode layer(s) to emit polarized light; and a polarizer located over the substrate through which the polarized light is emitted.

Owner:EASTMAN KODAK CO

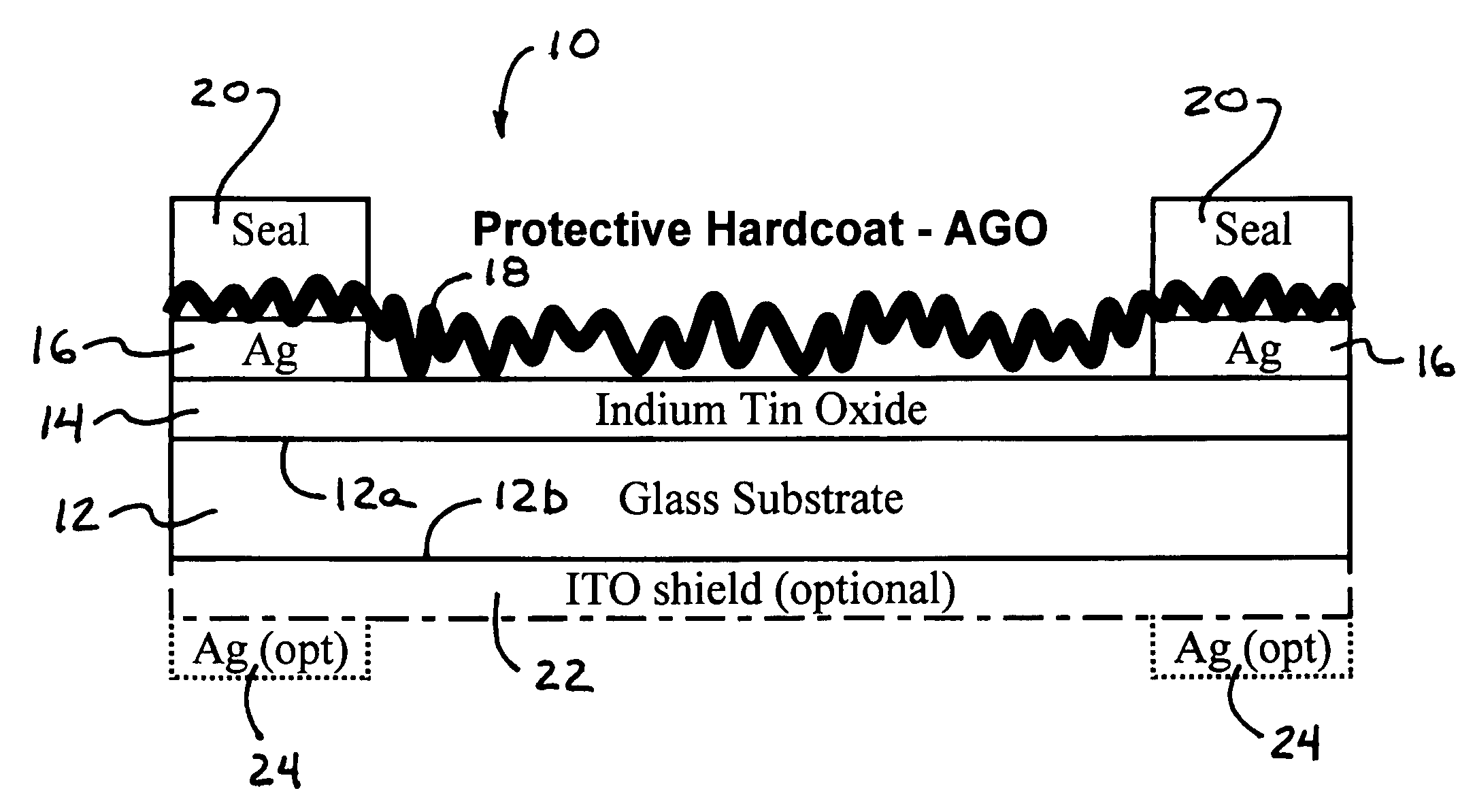

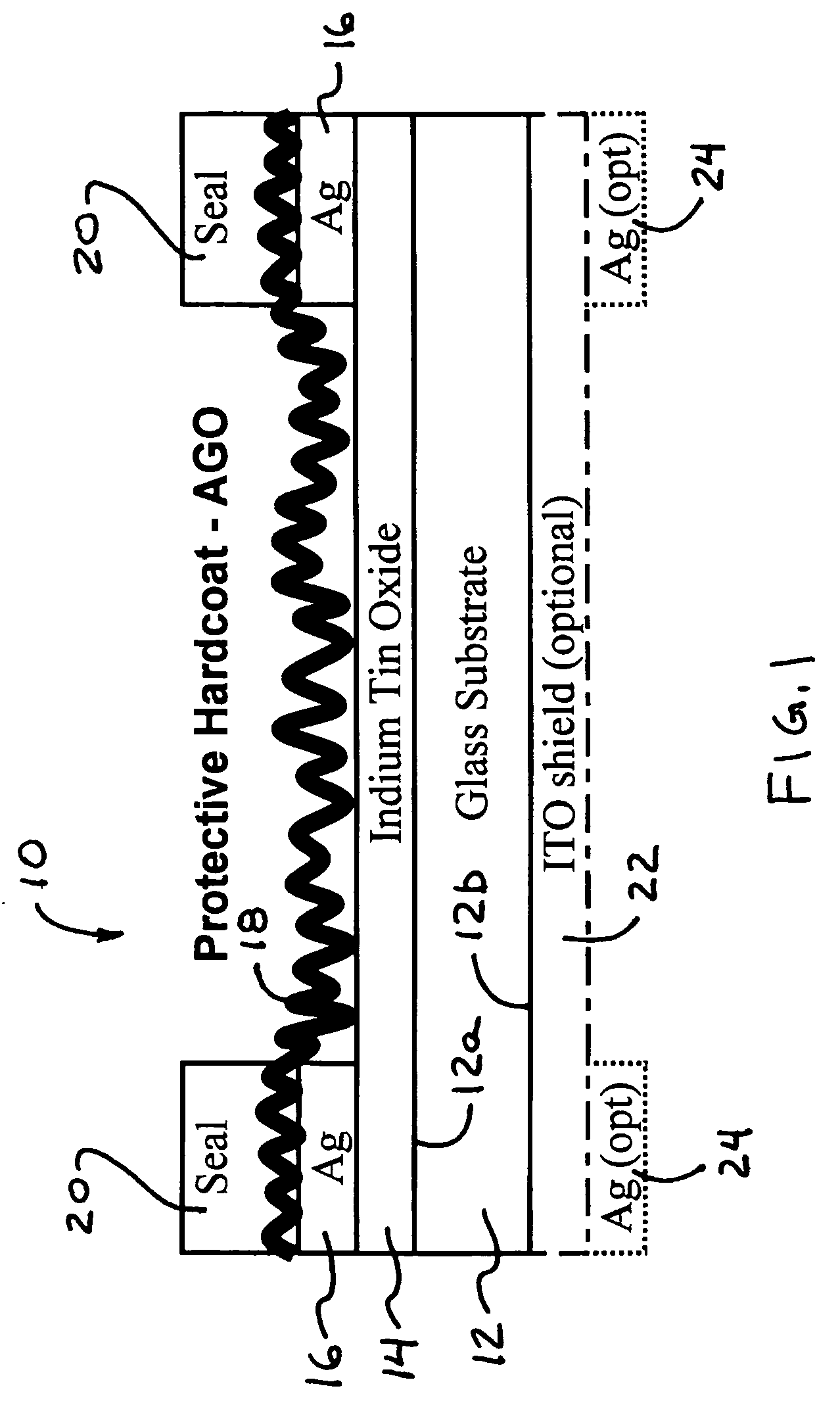

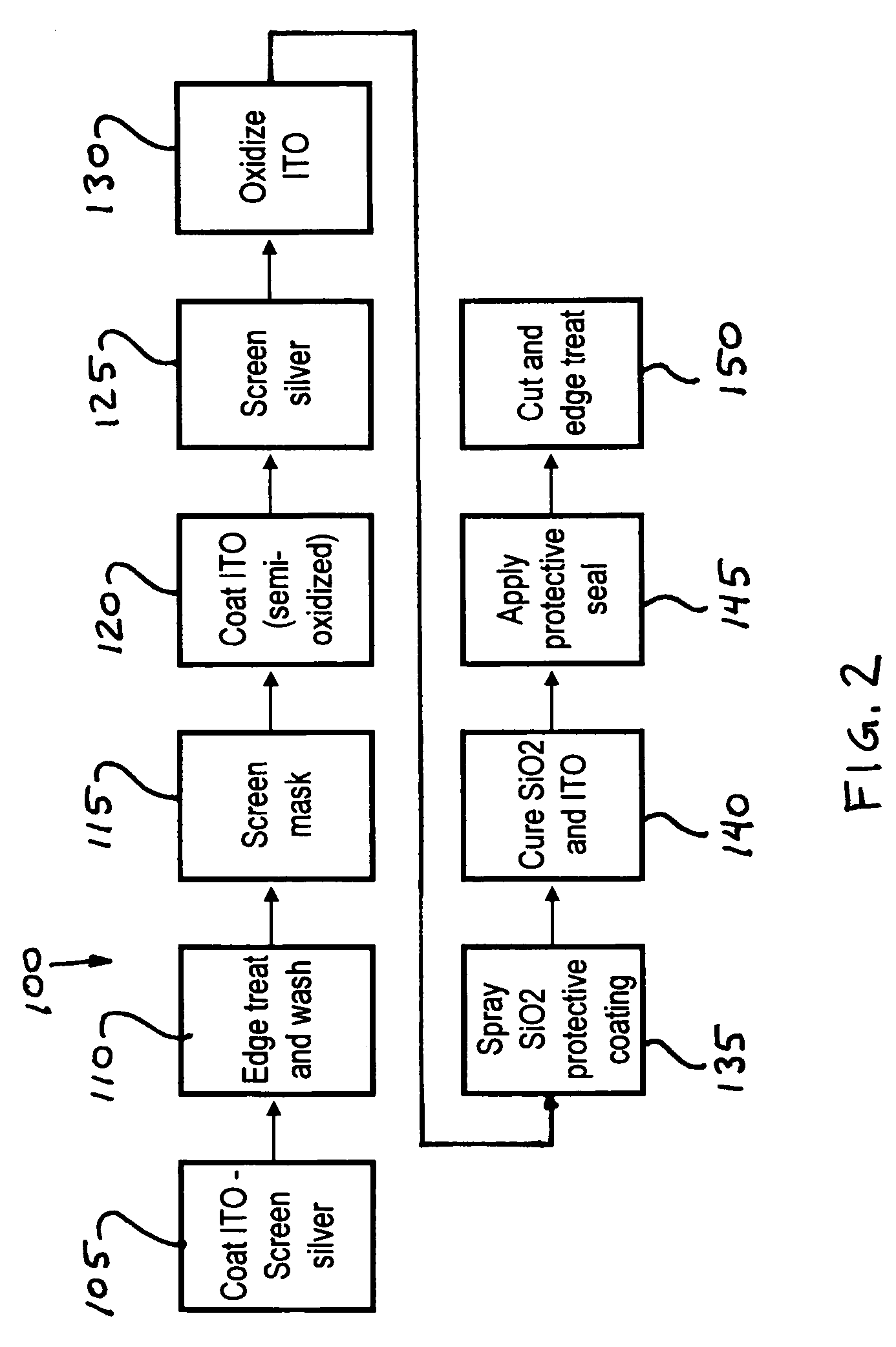

Capacitive touch screen and method of making same

ActiveUS20060266640A1Enhanced and substantially uniform conductivityImprove conductivityVacuum evaporation coatingPretreated surfacesEpoxyMetallic electrode

A capacitive touch screen and method of manufacturing such a touch screen includes providing a substrate and coating a surface of the substrate with a transparent conductive coating. An uncured conductive electrode material, such as an uncured silver epoxy material or an uncured silver or equivalent conducting metallic paste material, is disposed at least over a portion of the transparent conductive coating to establish a precursor of at least one metallic electrode at the substrate surface. A precursor of a protective hardcoat is established at least over the transparent conductive coating and / or the metallic electrode. Such precursor / undercured / uncured layers are then cured via a single common curing / firing process, which may heat the substrate and coatings to an elevated temperature, such as at about 500 degrees Celsius or above.

Owner:TRENDON TOUCH TECHNOLOGY CORPORATION

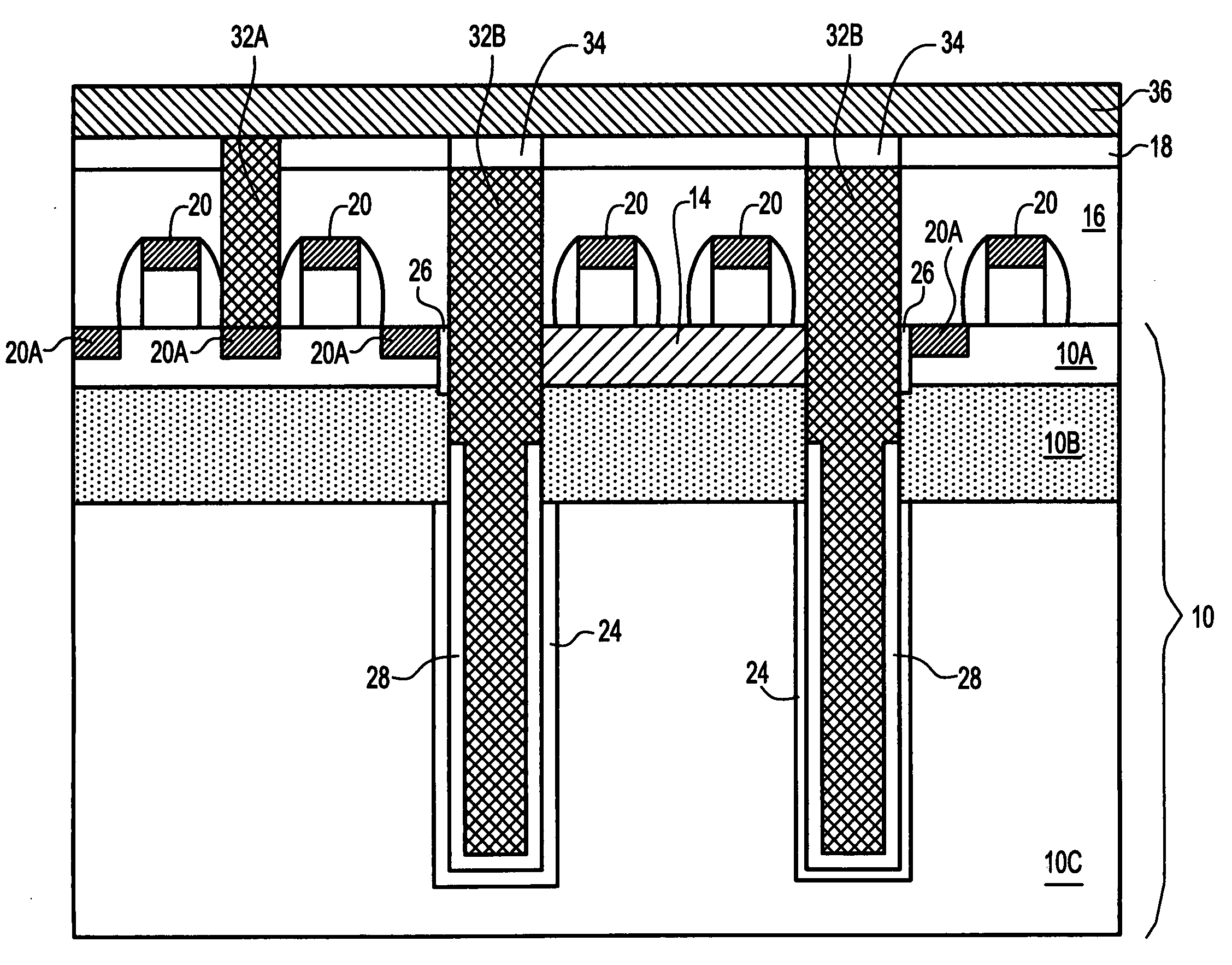

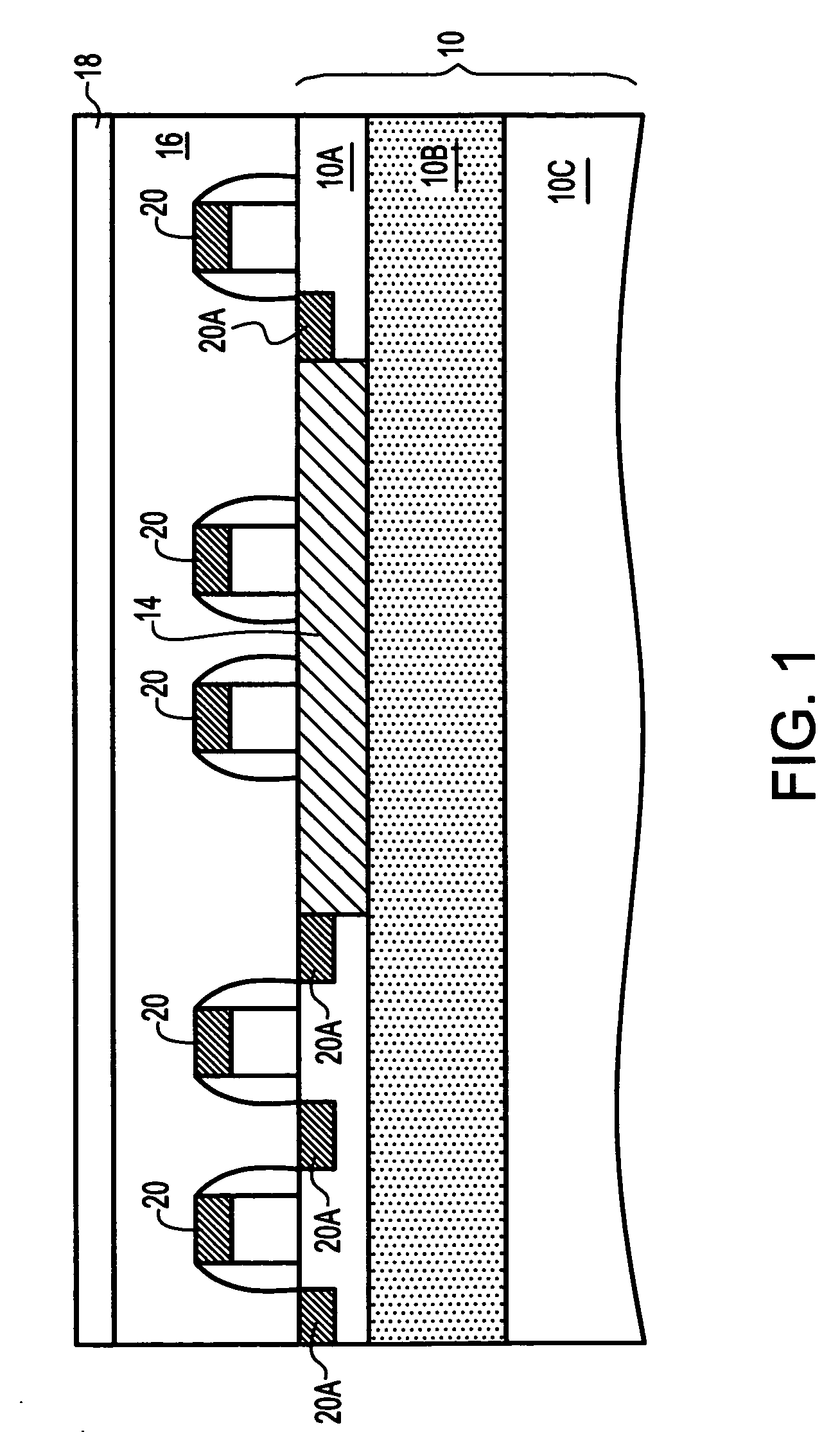

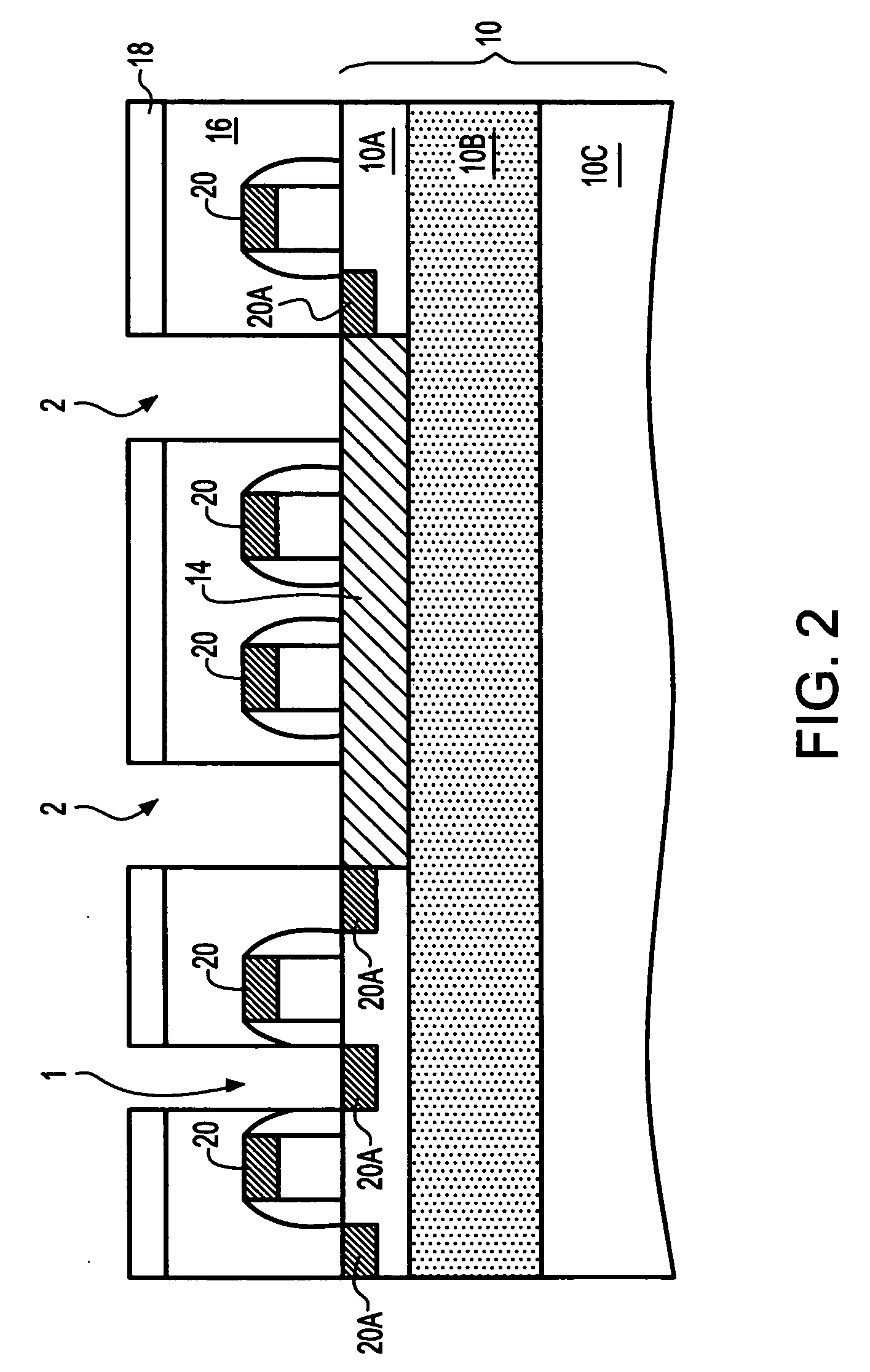

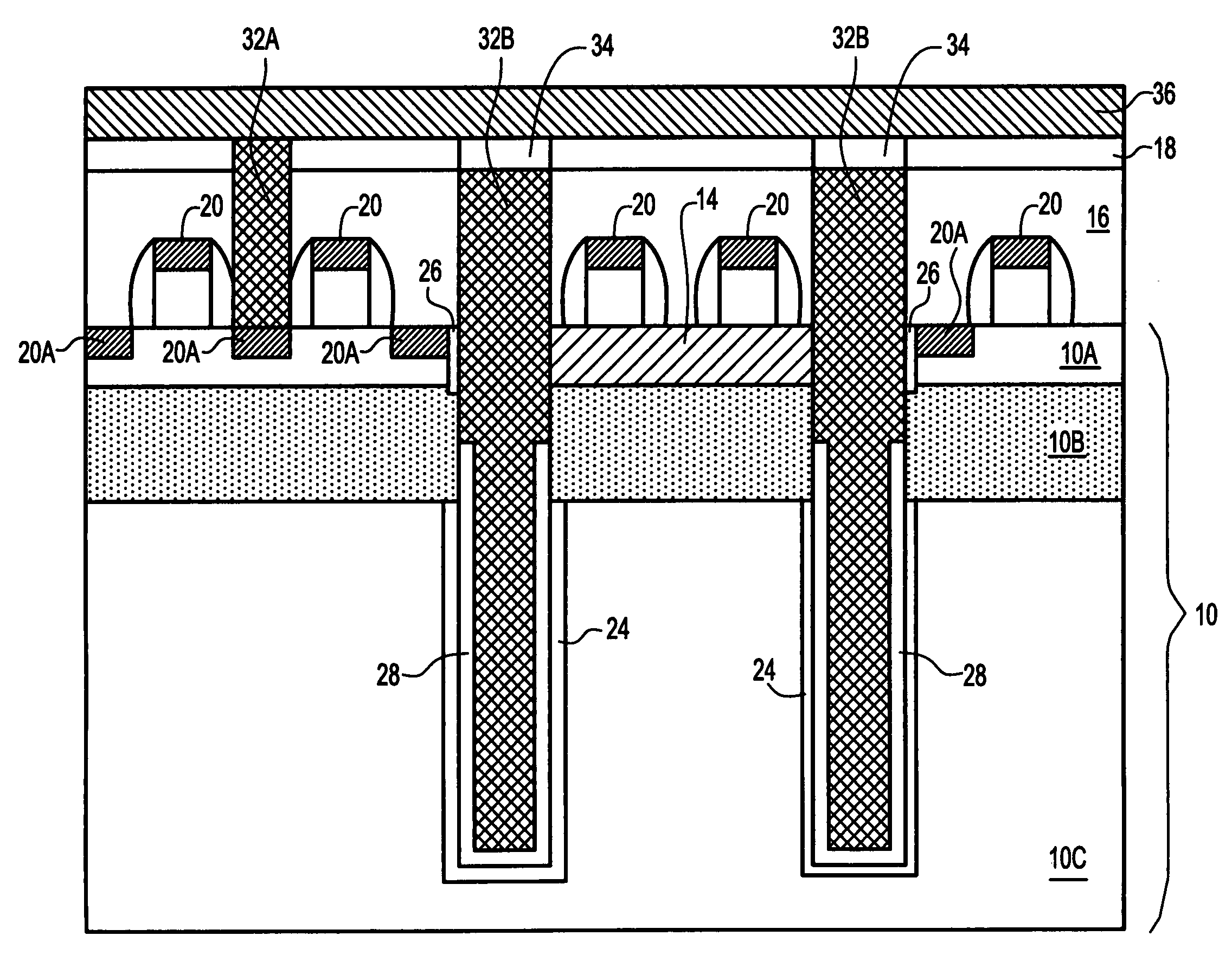

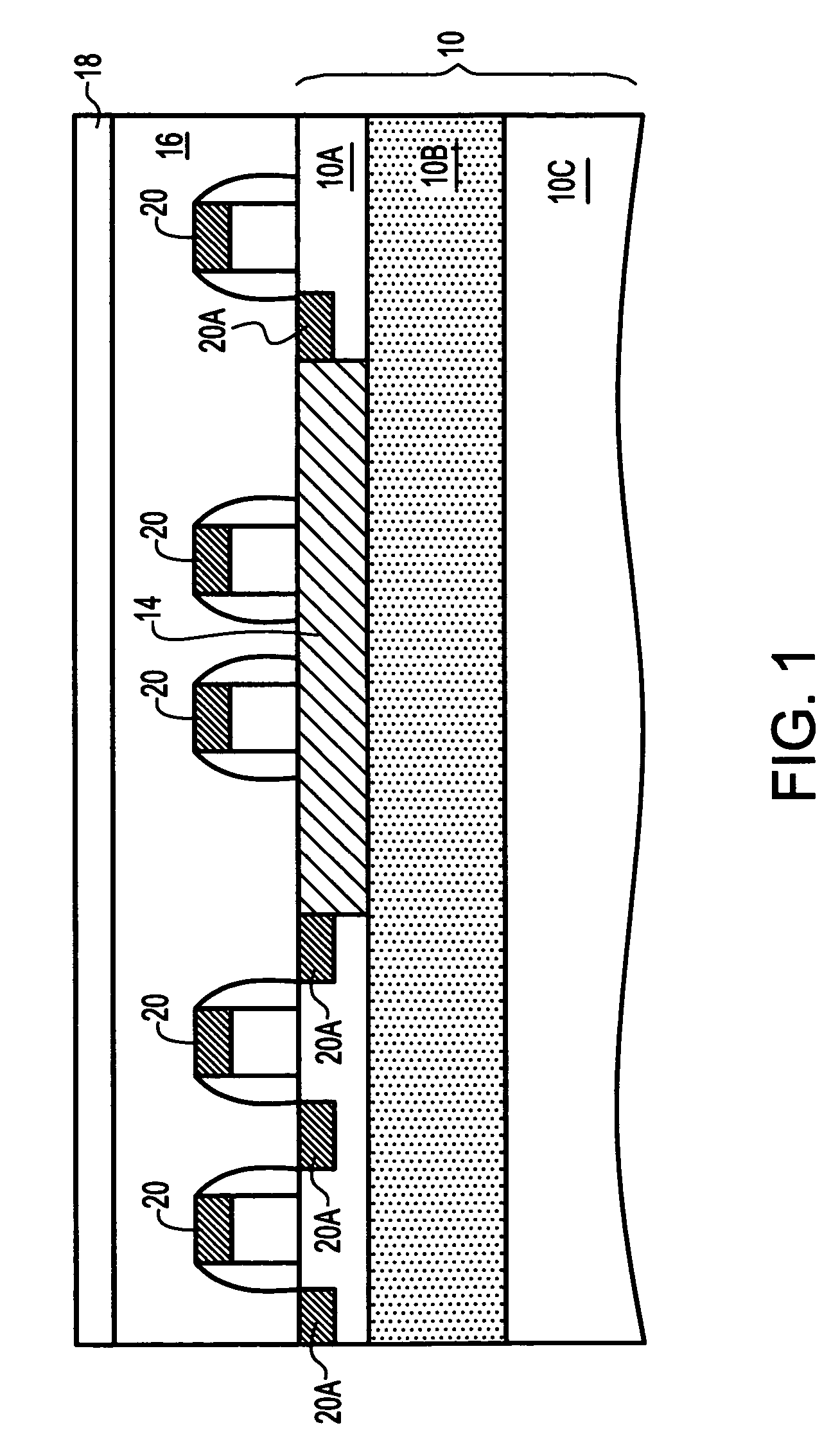

Trench metal-insulator-metal (MIM) capacitors integrated with middle-of-line metal contacts, and method of fabricating same

The present invention relates to a semiconductor device that contains at least one trench metal-oxide-metal (MIM) capacitor and at least one other logic circuitry component, preferably at least one field effect transistor (FET). The trench MIM capacitor is located in a trench in a substrate and comprises inner and outer metallic electrode layers with a dielectric layer therebetween. The FET comprises a source region, a drain region, a channel region, and at least one metal contact connected with the source or drain region. The present invention also relates to a fabrication process, which integrates the processing steps for fabricating the trench MIM capacitor with the conventional middle-of-line processing steps for fabricating metal contacts, so that the inner metallic electrode layer of the trench MIM capacitor and the metal contact of the FET or other logic circuitry components are formed by a single middle-of-line processing step and comprise essentially the same metallic material.

Owner:GLOBALFOUNDRIES INC

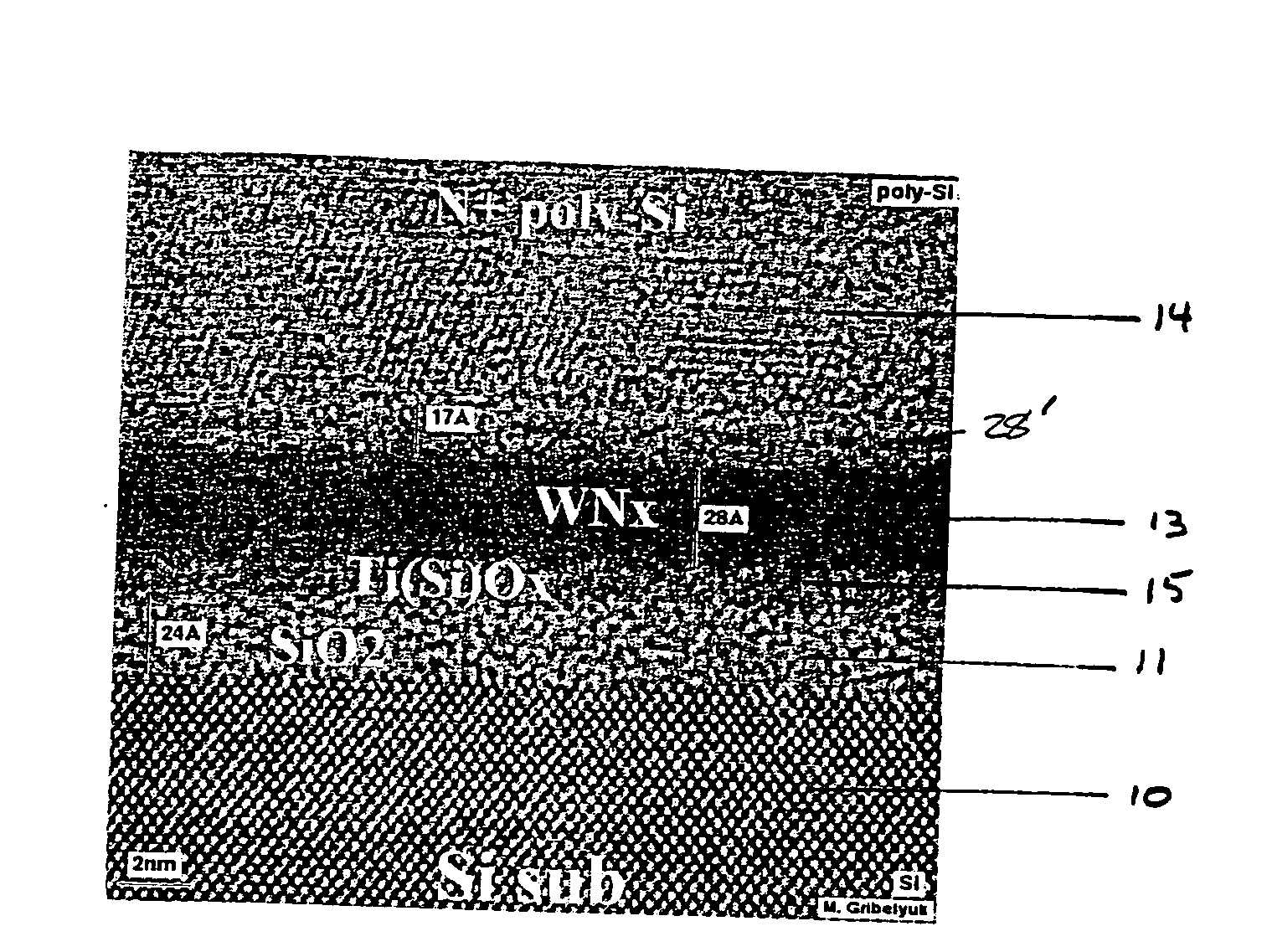

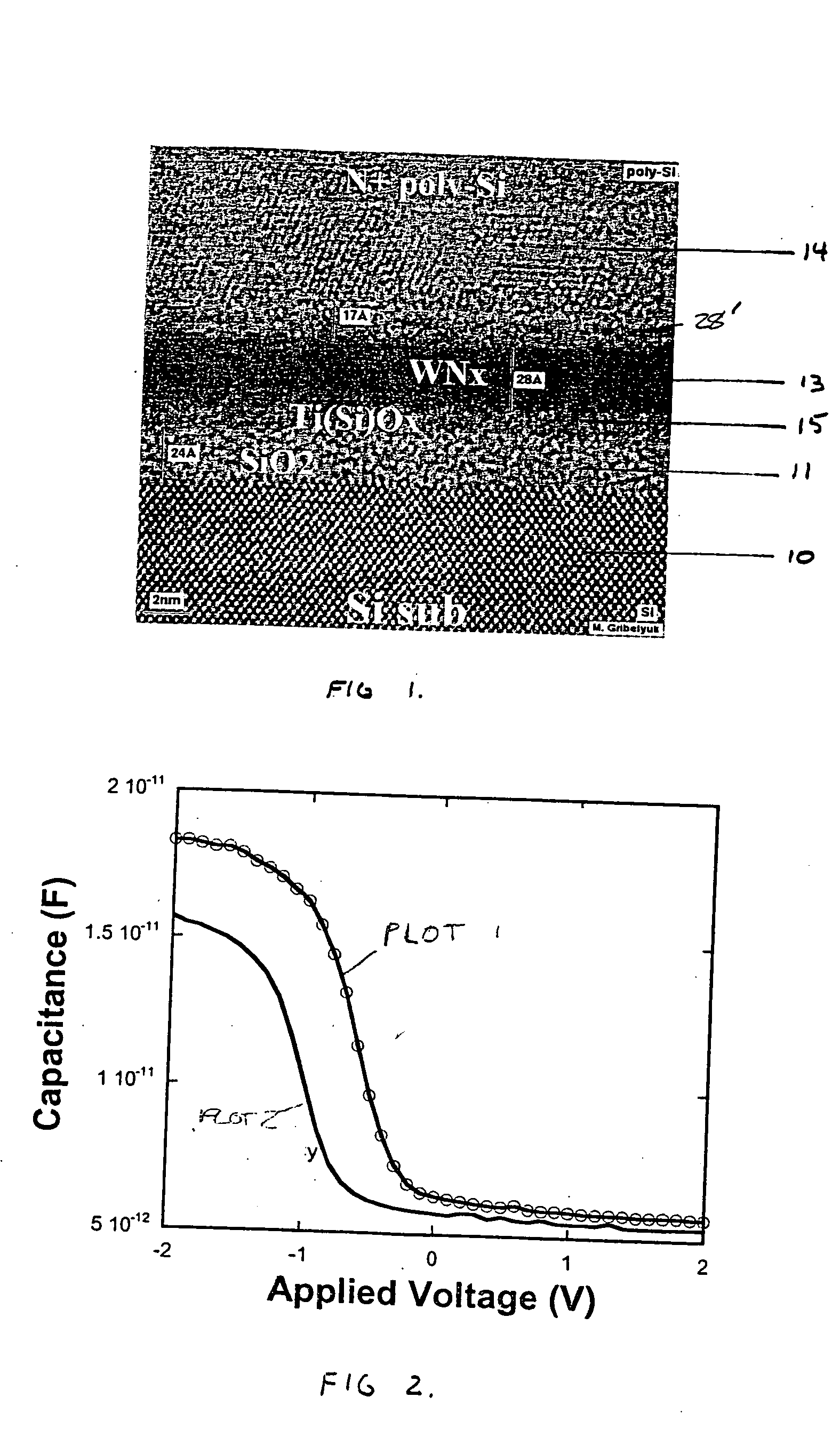

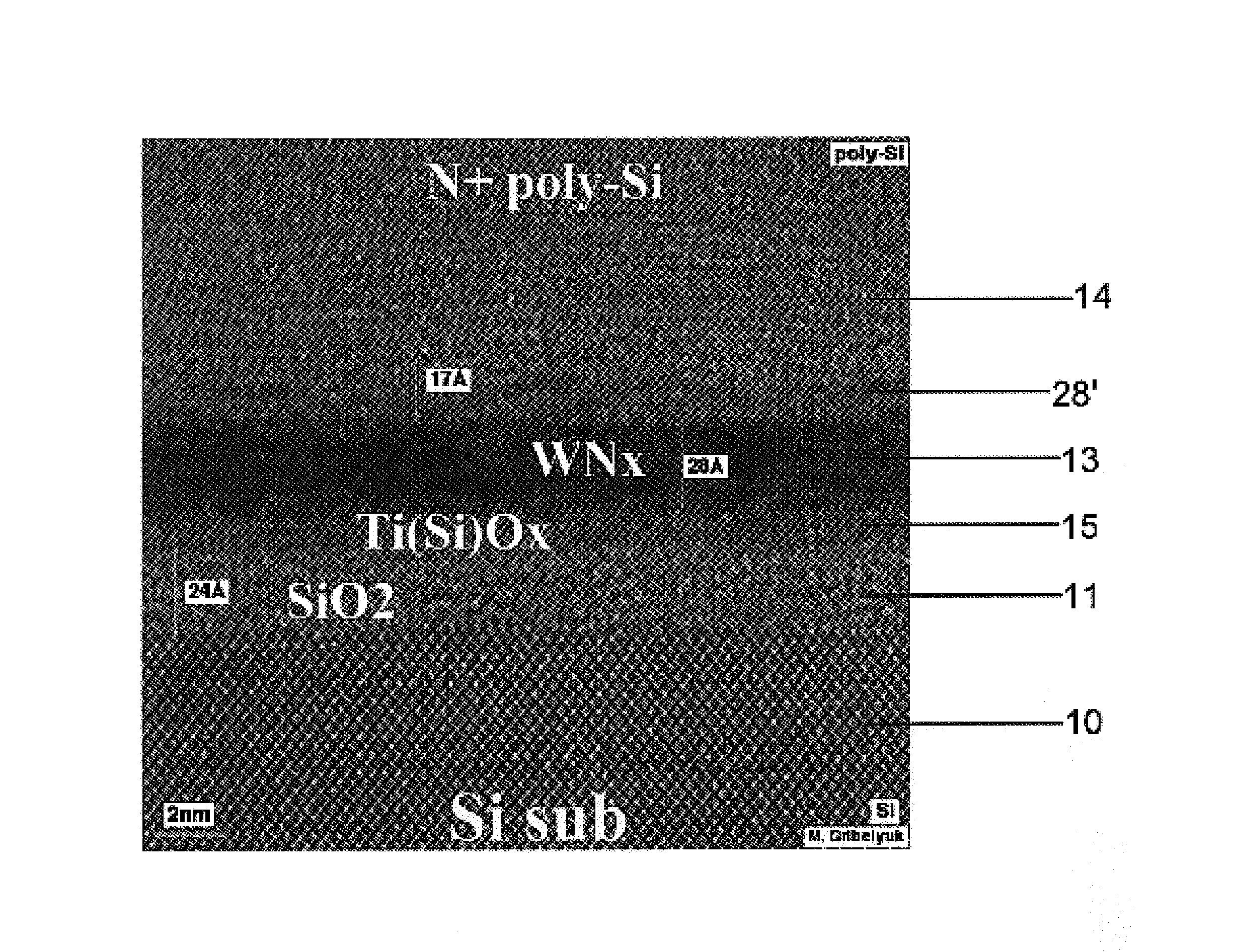

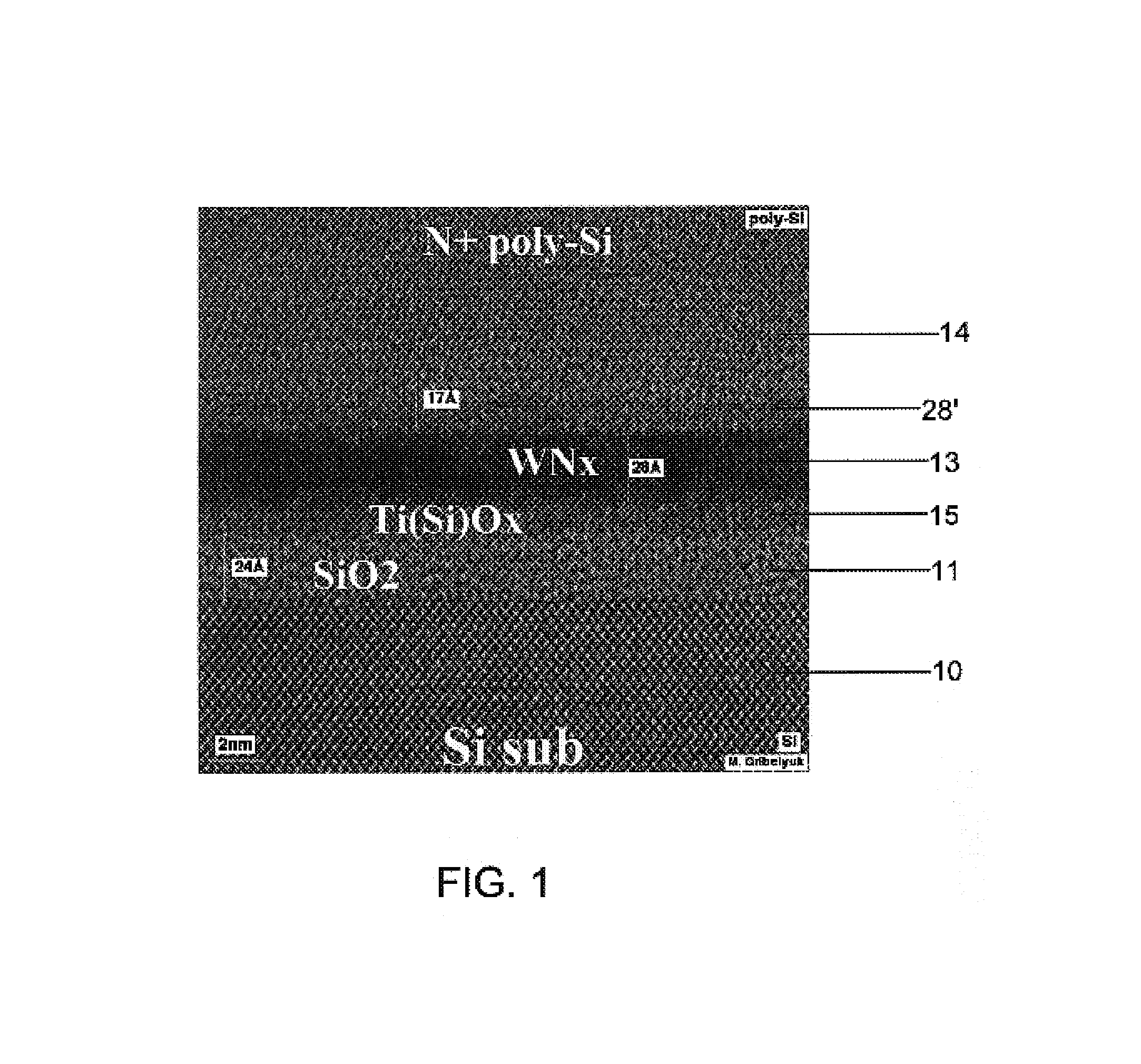

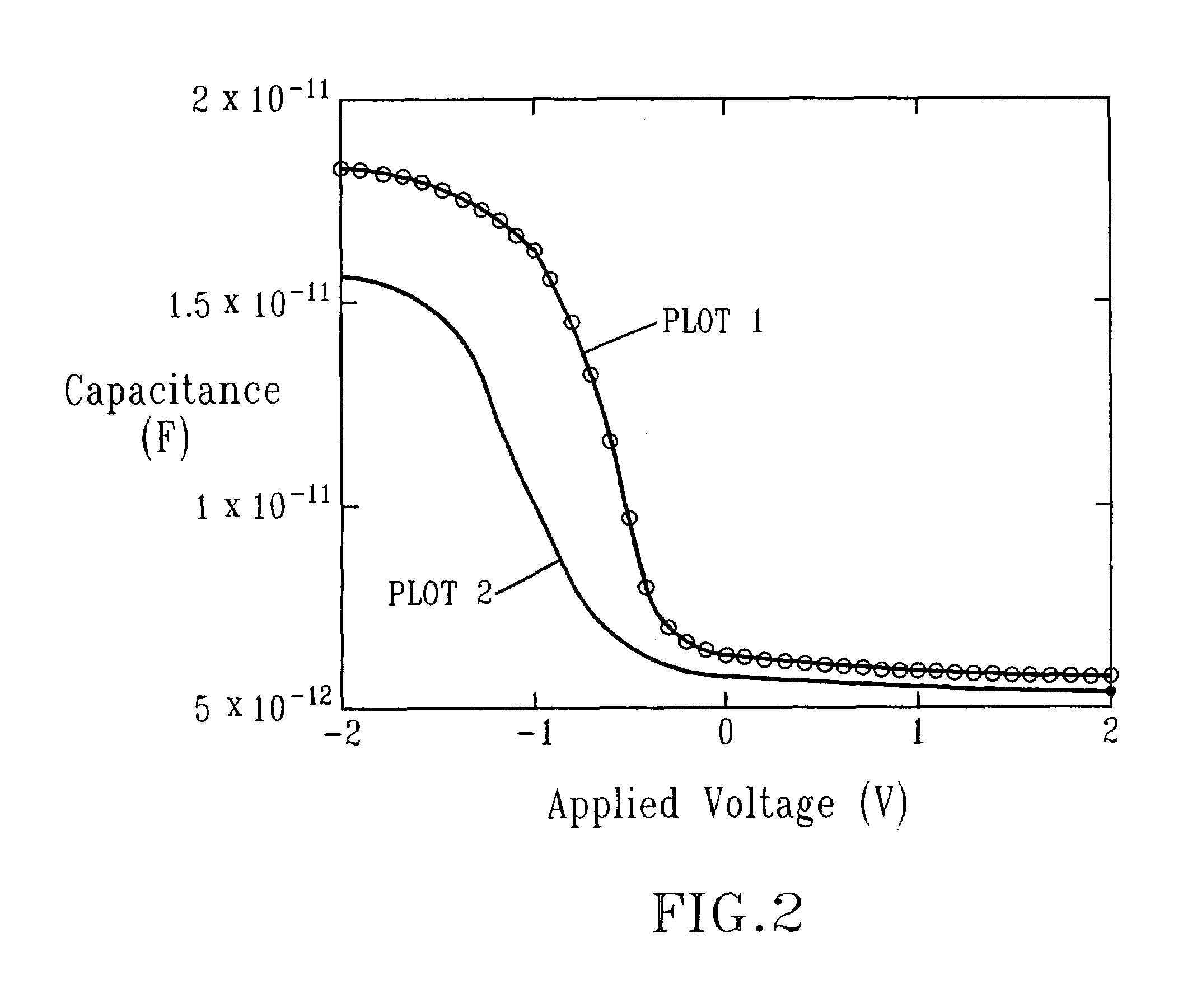

High-temperature stable gate structure with metallic electrode

InactiveUS20050282341A1Semiconductor/solid-state device manufacturingSemiconductor devicesMetallic electrodeElectrical conductor

The present invention provides a method for depositing a dielectric stack comprising forming a dielectric layer atop a substrate, the dielectric layer comprising at least oxygen and silicon atoms; forming a layer of metal atoms atop the dielectric layer within a non-oxidizing atmosphere, wherein the layer of metal atoms has a thickness of less than about 15 Å; forming an oxygen diffusion barrier atop the layer of metal atoms, wherein the non-oxidizing atmosphere is maintained; forming a gate conductor atop the oxygen diffusion barrier; and annealing the layer of metal atoms and the dielectric layer, wherein the layer of metal atoms reacts with the dielectric layer to provide a continuous metal oxide layer having a dielectric constant ranging from about 25 to about 30 and a thickness less than about 15 Å.

Owner:GLOBALFOUNDRIES INC

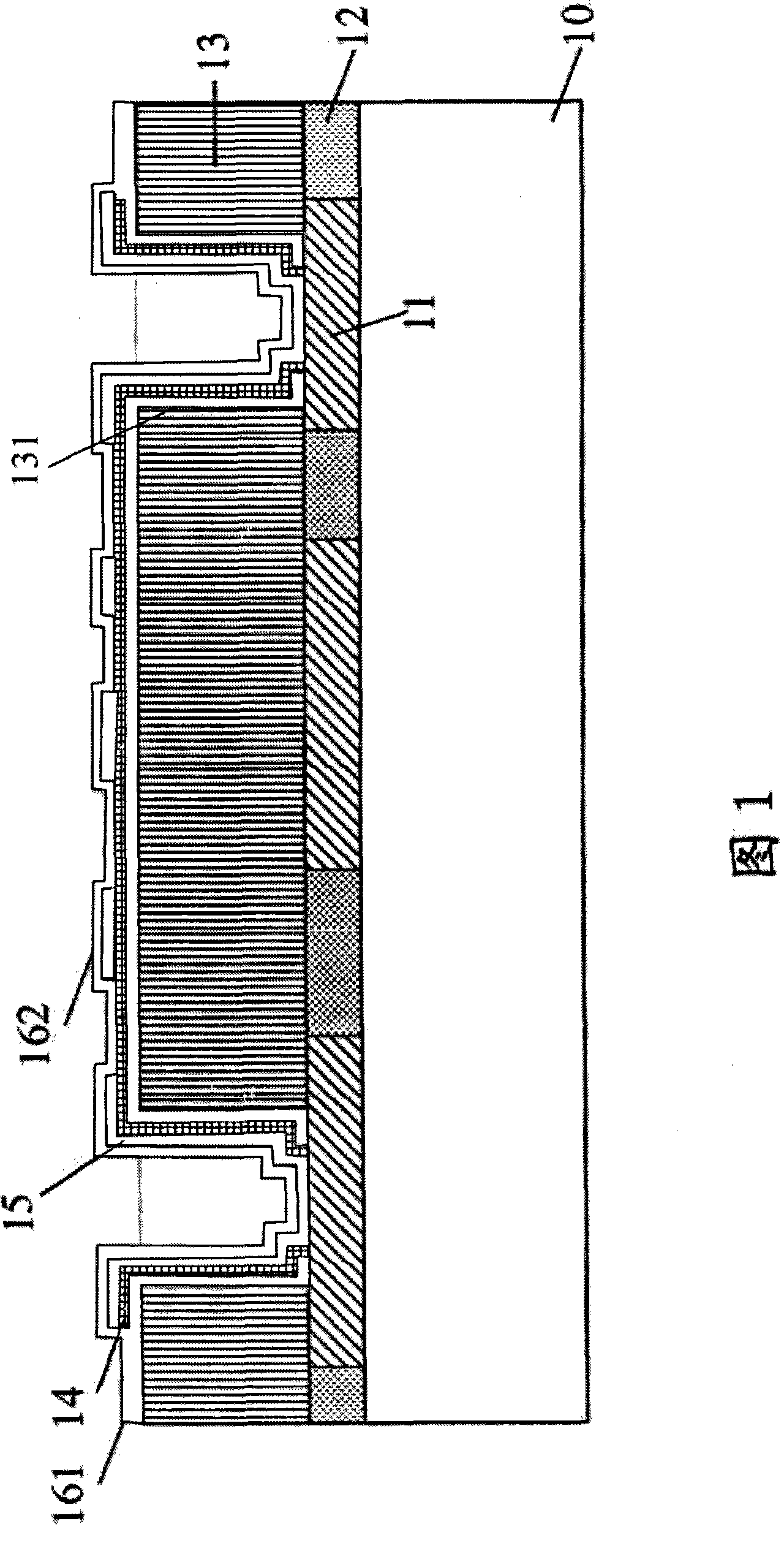

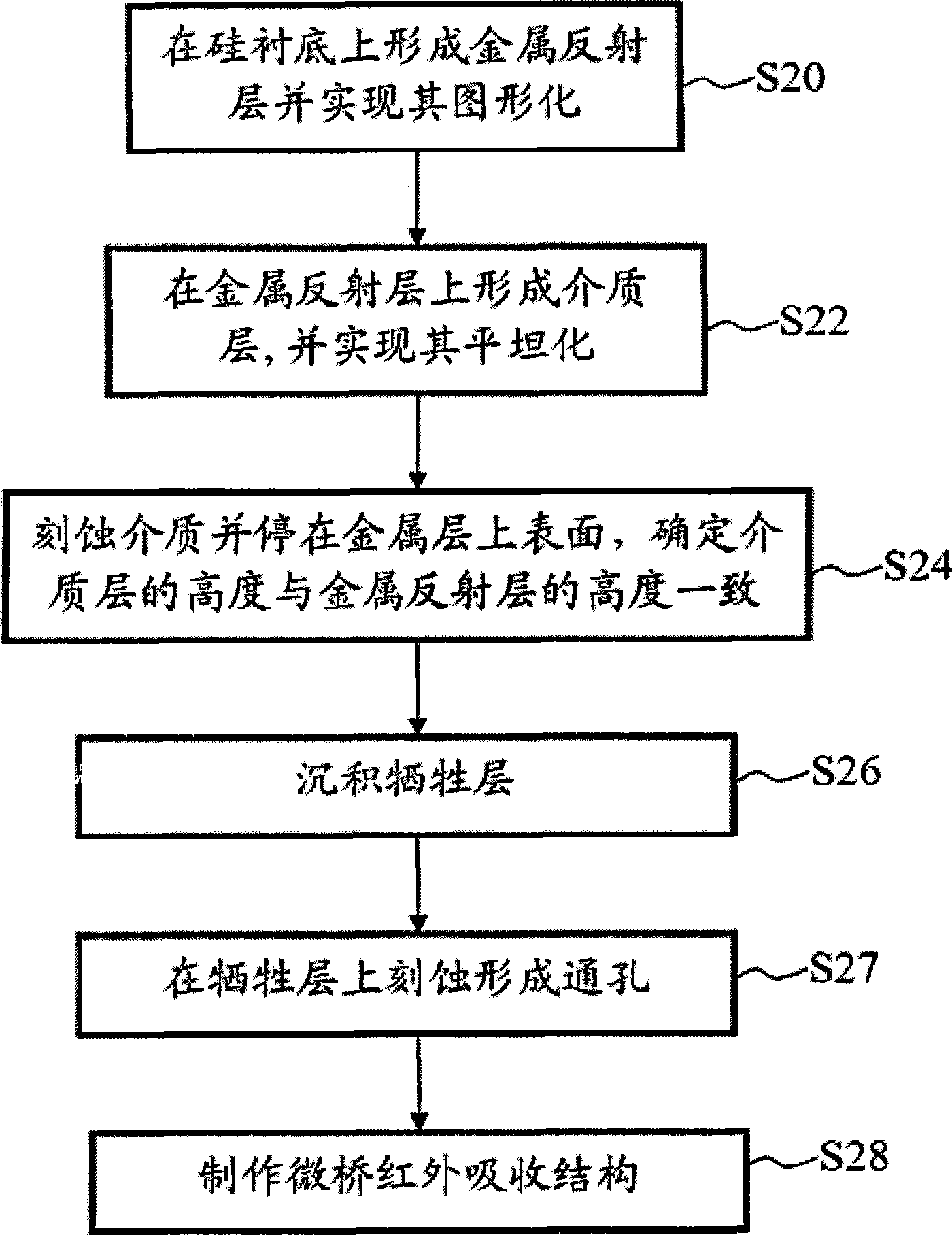

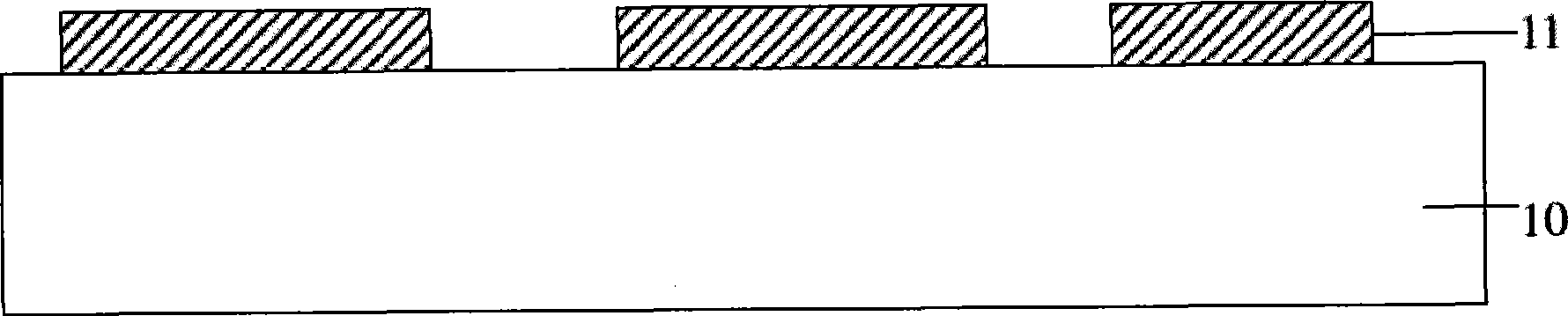

Infrared receiver and manufacturing method thereof

ActiveCN101445215AAvoid short circuitSolve the process surface planarization problemTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesMetallic electrodeInfrared detector

The invention provides an infrared receiver and a manufacturing method thereof. A metallic reflecting layer, a dielectric layer, a sacrifice layer, a sensitive material detecting layer and a metallic electrode are precipitated on a silicon bulk of the infrared receiver in sequence. The metallic reflecting layer is provided with a metallic reflection pattern. The height of the dielectric layer and the height of the metallic reflecting layer are the same. The invention also provides the manufacturing method of the infrared receiver, comprising the following steps: the metallic reflecting layer is formed on the silicon bulk and patterning is carried out on the metallic reflecting layer; the dielectric layer is formed on the metallic reflecting layer and planarization is carried out on the dielectric layer; medium is etched and reserved on the surface of a metallic layer, and the height of the dielectric layer and the height of the metallic reflecting layer are confirmed to be the same; the sacrifice layer is precipitated; and a microbridge infrared absorption structure is fabricated.

Owner:ZHEJIANG DALI TECH +1

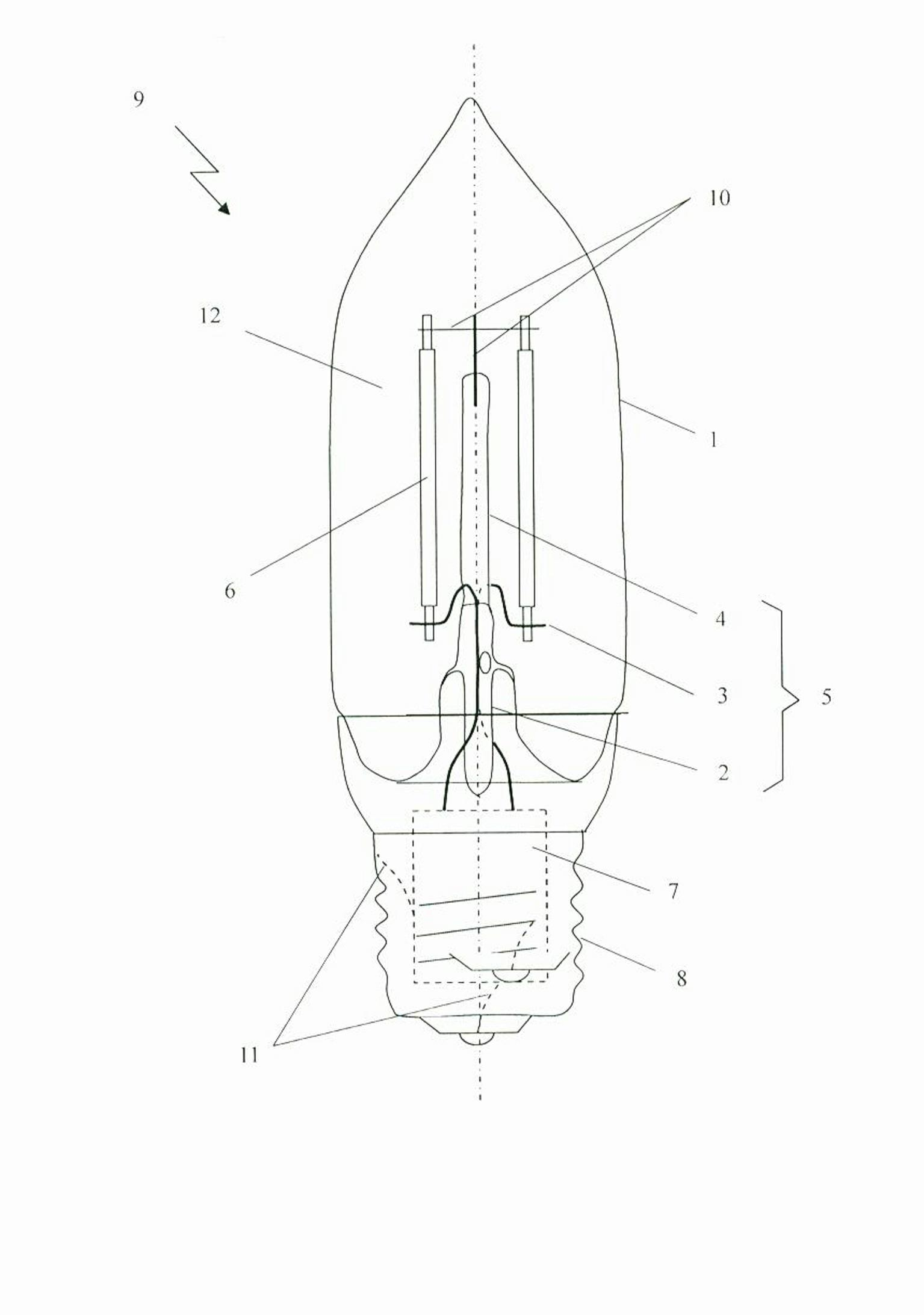

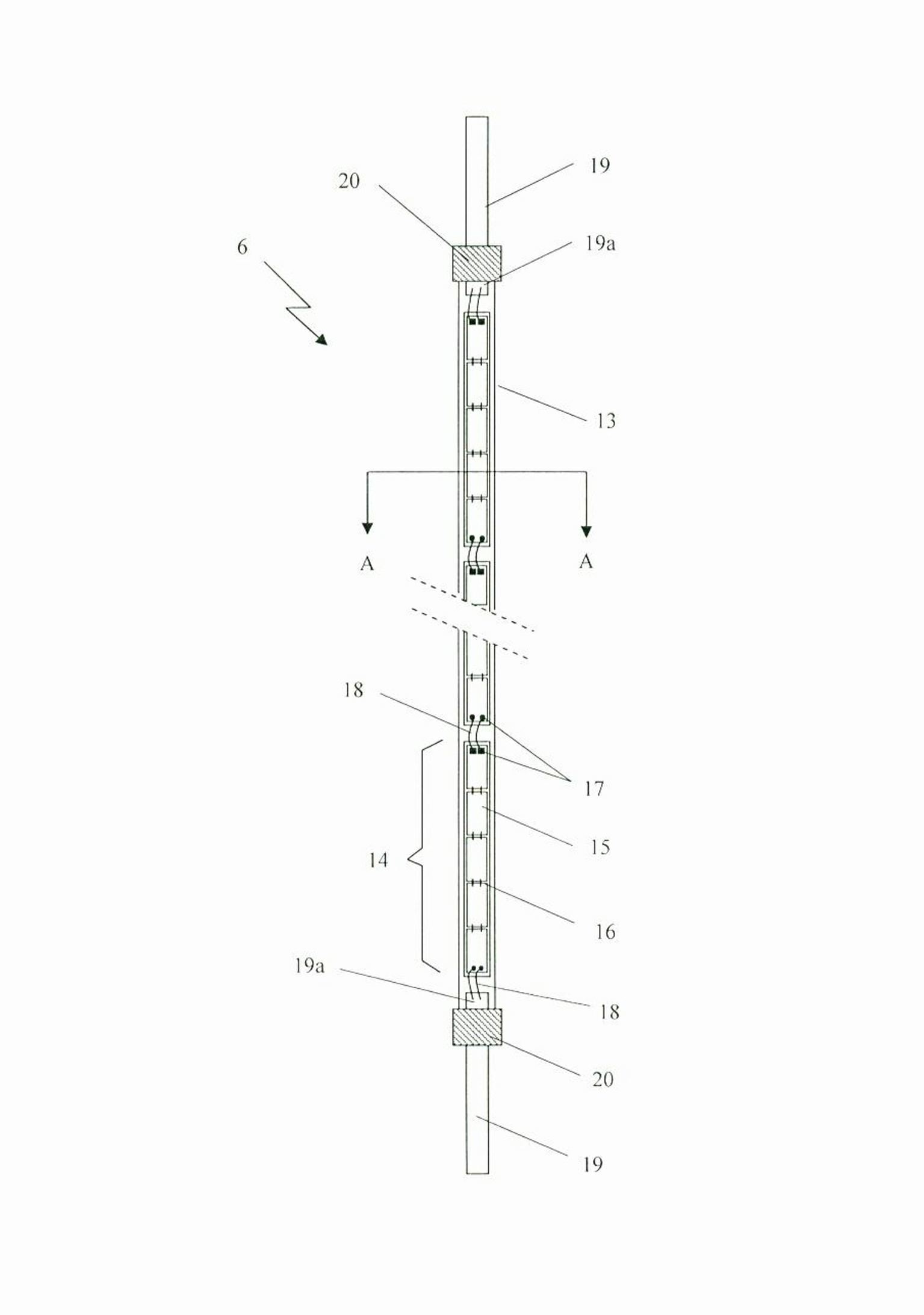

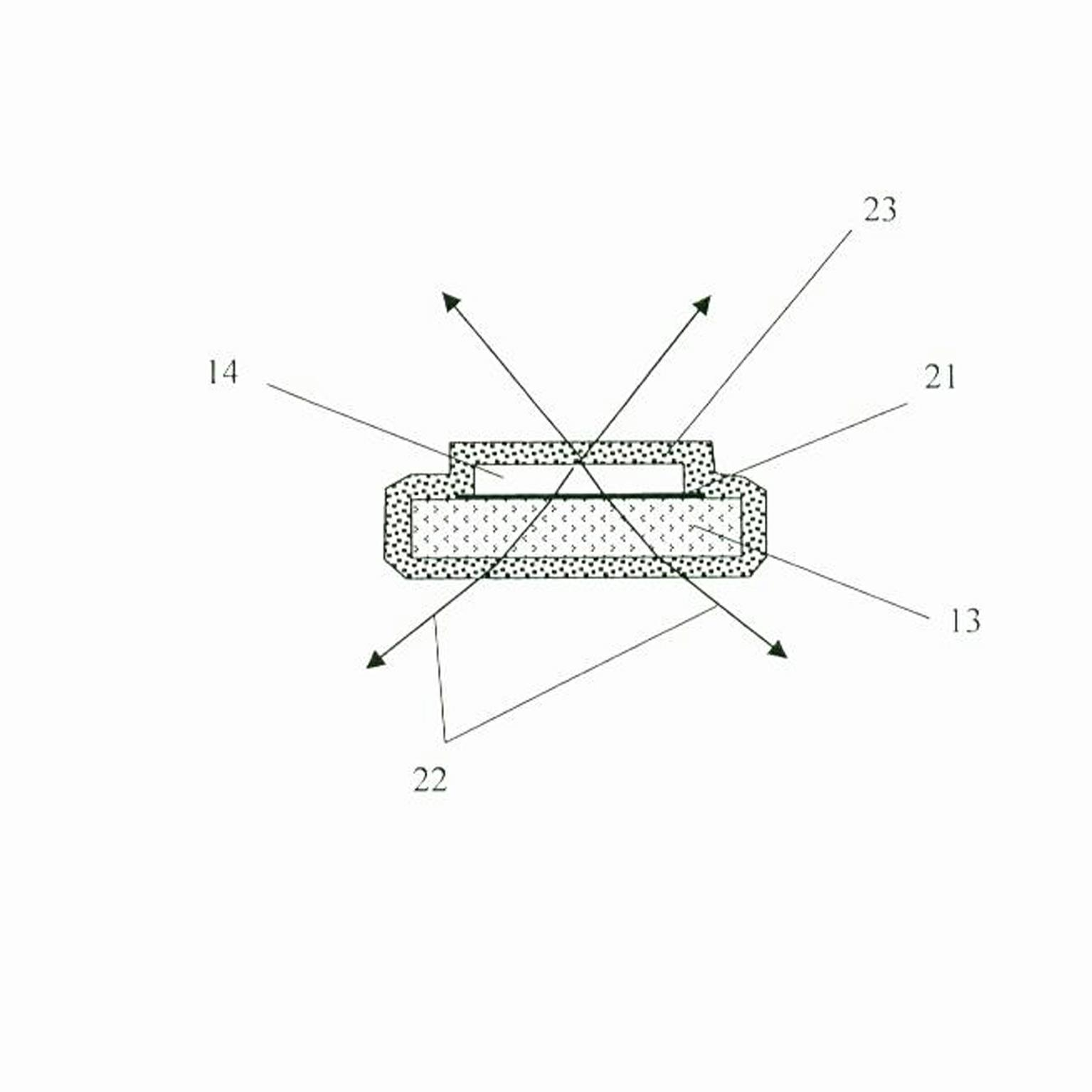

P-N junction 4pi light emitting high-voltage light emitting diode (LED) and LED lamp bulb

ActiveCN102109115AImprove reliabilityLess welding linesPoint-like light sourceElectric circuit arrangementsMetallic electrodeEngineering

The invention discloses a P-N junction 4pi light emitting high-voltage light emitting diode (LED) and an LED lamp bulb. The high-voltage LED comprises a transparent substrate, wherein the two ends of the transparent substrate are provided with electrical lead-out wires; the transparent substrate is provided with at least one string of high-voltage LED chips; each high-voltage LED chip comprises at least two LED P-N junctions which are connected with each other in series; at least one electrical connecting line is arranged between every two P-N junctions; and the two ends of each high-voltage LED chip are provided with at least one metal electrode for welding a bonding wire respectively. The LED lamp bulb comprises a light transmitting bulb shell, a core column, at least one high-voltage LED, a driver and an electrical connector, wherein the core column is provided with an exhaust pipe, an electrical lead-out wire and a bracket; the high-voltage LED consists of the high-voltage LED chips and is fixed on the core column, and the electrodes of the high-voltage LED are connected with the driver and the electrical connector which can be connected with an external power source through electrode lead-out wires of the core column; and the core column and the light transmitting bulb shell are sealed under vacuum to form a sealed cavity which is filled with high-heat-conductivity low-viscosity gas. The invention has the characteristics of high overall lamp efficiency, high reliability, low cost, long life and the like.

Owner:ZHEJIANG LEDISON OPTOELECTRONICS

High-temperature stable gate structure with metallic electrode

InactiveUS7279413B2Semiconductor/solid-state device manufacturingSemiconductor devicesMetallic electrodeElectrical conductor

The present invention provides a method for depositing a dielectric stack comprising forming a dielectric layer atop a substrate, the dielectric layer comprising at least oxygen and silicon atoms; forming a layer of metal atoms atop the dielectric layer within a non-oxidizing atmosphere, wherein the layer of metal atoms has a thickness of less than about 15 Å; forming an oxygen diffusion barrier atop the layer of metal atoms, wherein the non-oxidizing atmosphere is maintained; forming a gate conductor atop the oxygen diffusion barrier; and annealing the layer of metal atoms and the dielectric layer, wherein the layer of metal atoms reacts with the dielectric layer to provide a continuous metal oxide layer having a dielectric constant ranging from about 25 to about 30 and a thickness less than about 15 Å.

Owner:GLOBALFOUNDRIES INC

Trench metal-insulator-metal (MIM) capacitors integrated with middle-of-line metal contacts, and method of fabricating same

The present invention relates to a semiconductor device that contains at least one trench metal-oxide-metal (MIM) capacitor and at least one other logic circuitry component, preferably at least one field effect transistor (FET). The trench MIM capacitor is located in a trench in a substrate and comprises inner and outer metallic electrode layers with a dielectric layer therebetween. The FET comprises a source region, a drain region, a channel region, and at least one metal contact connected with the source or drain region. The present invention also relates to a fabrication process, which integrates the processing steps for fabricating the trench MIM capacitor with the conventional middle-of-line processing steps for fabricating metal contacts, so that the inner metallic electrode layer of the trench MIM capacitor and the metal contact of the FET or other logic circuitry components are formed by a single middle-of-line processing step and comprise essentially the same metallic material.

Owner:GLOBALFOUNDRIES INC

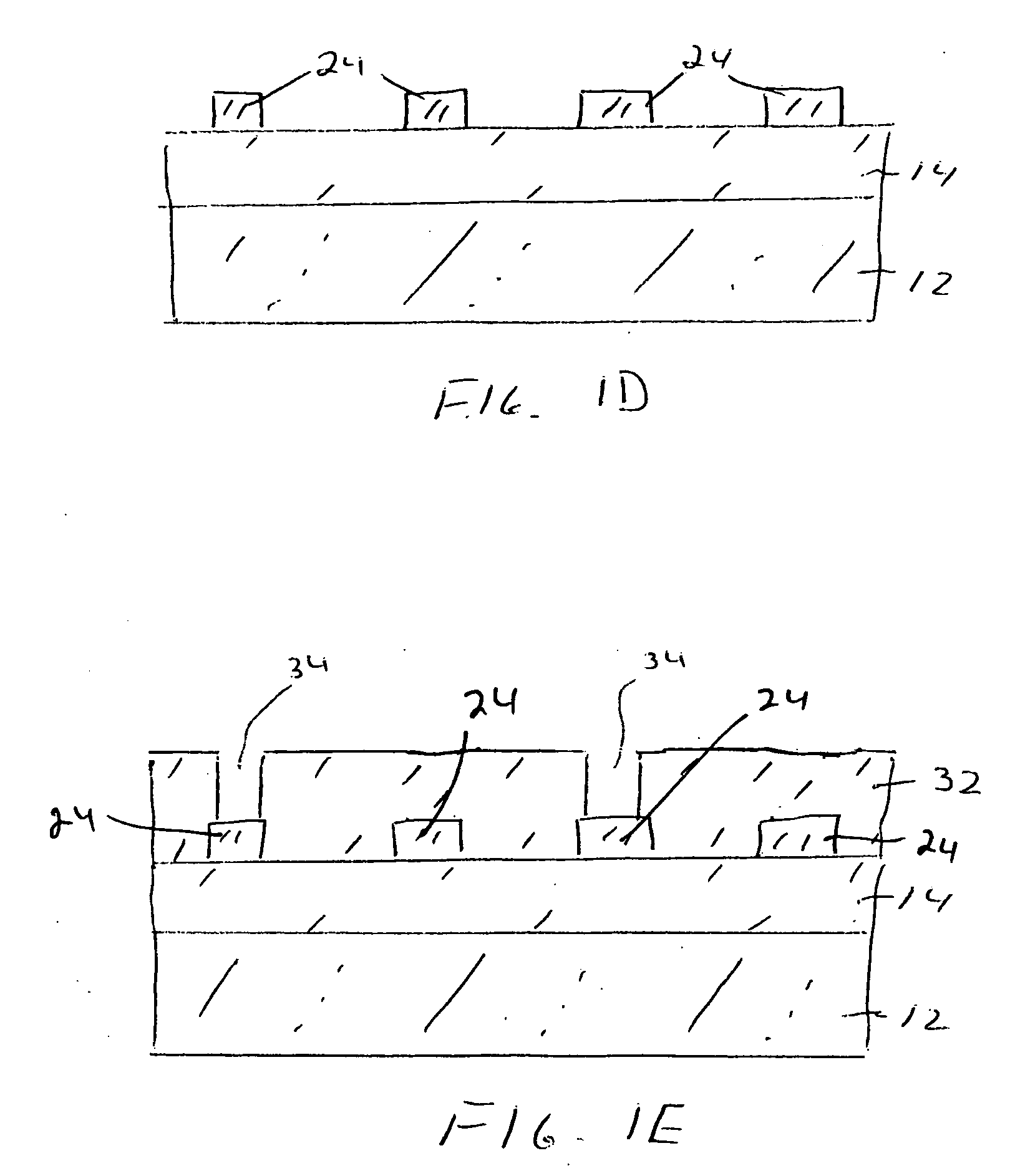

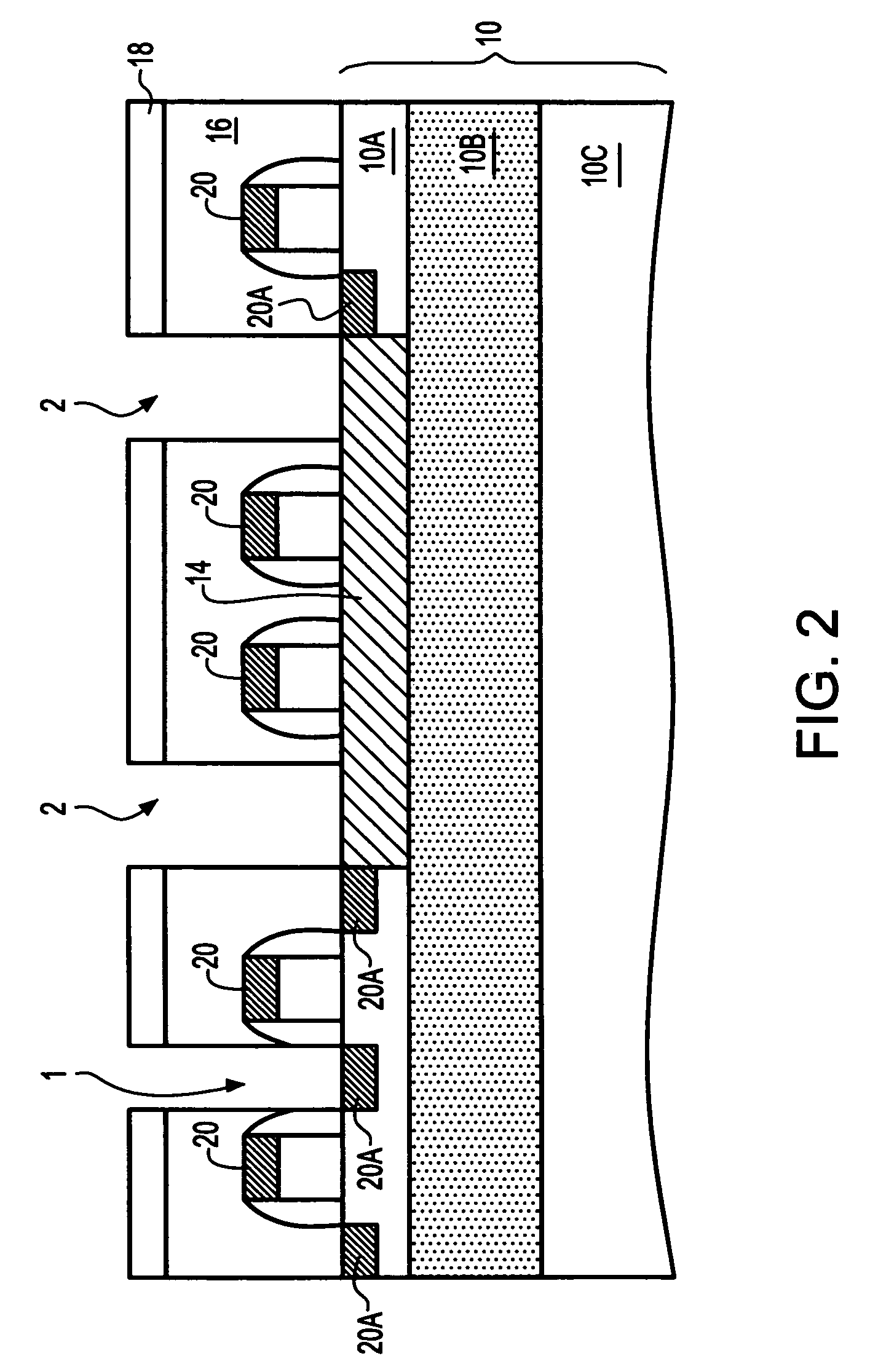

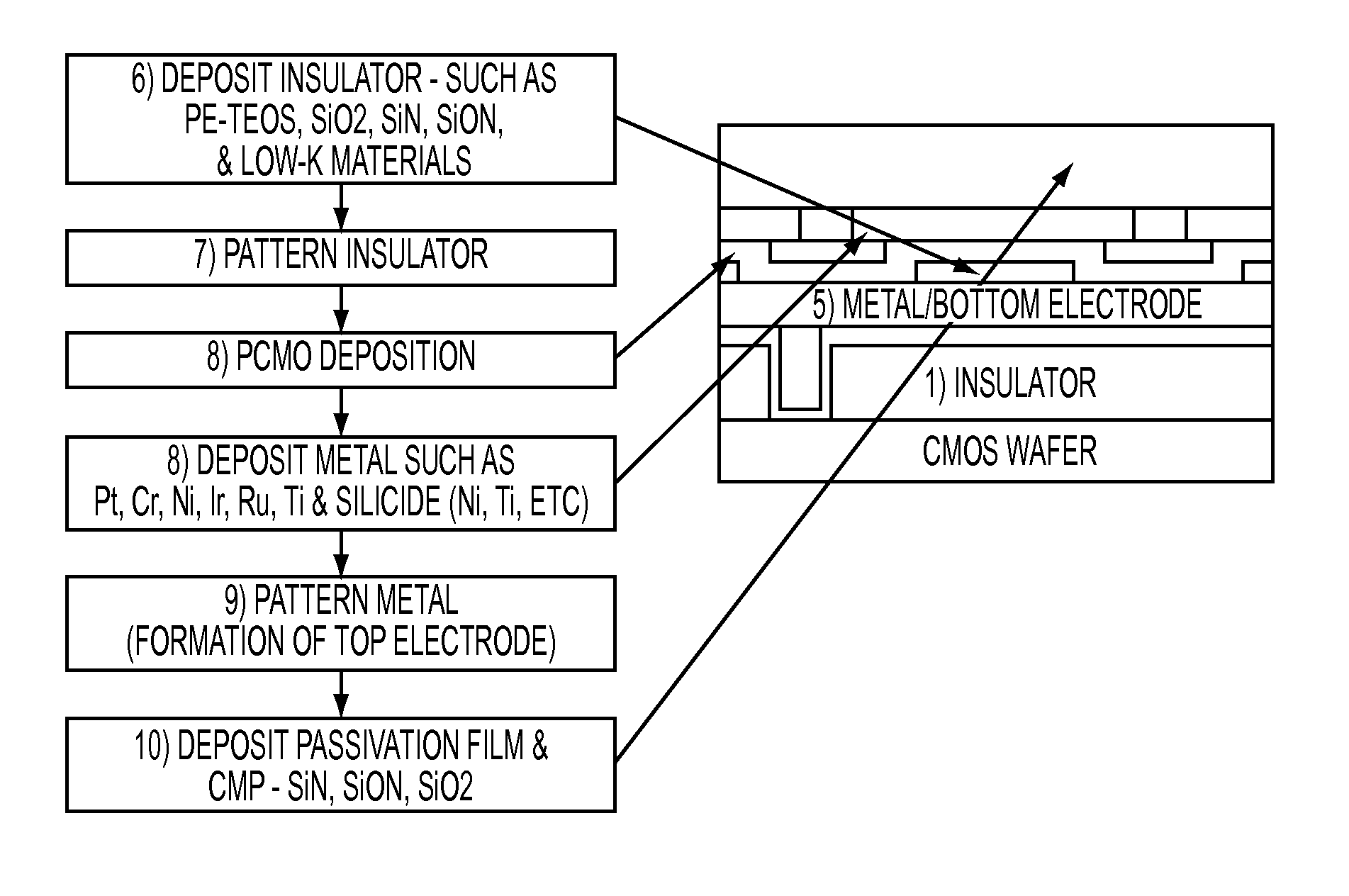

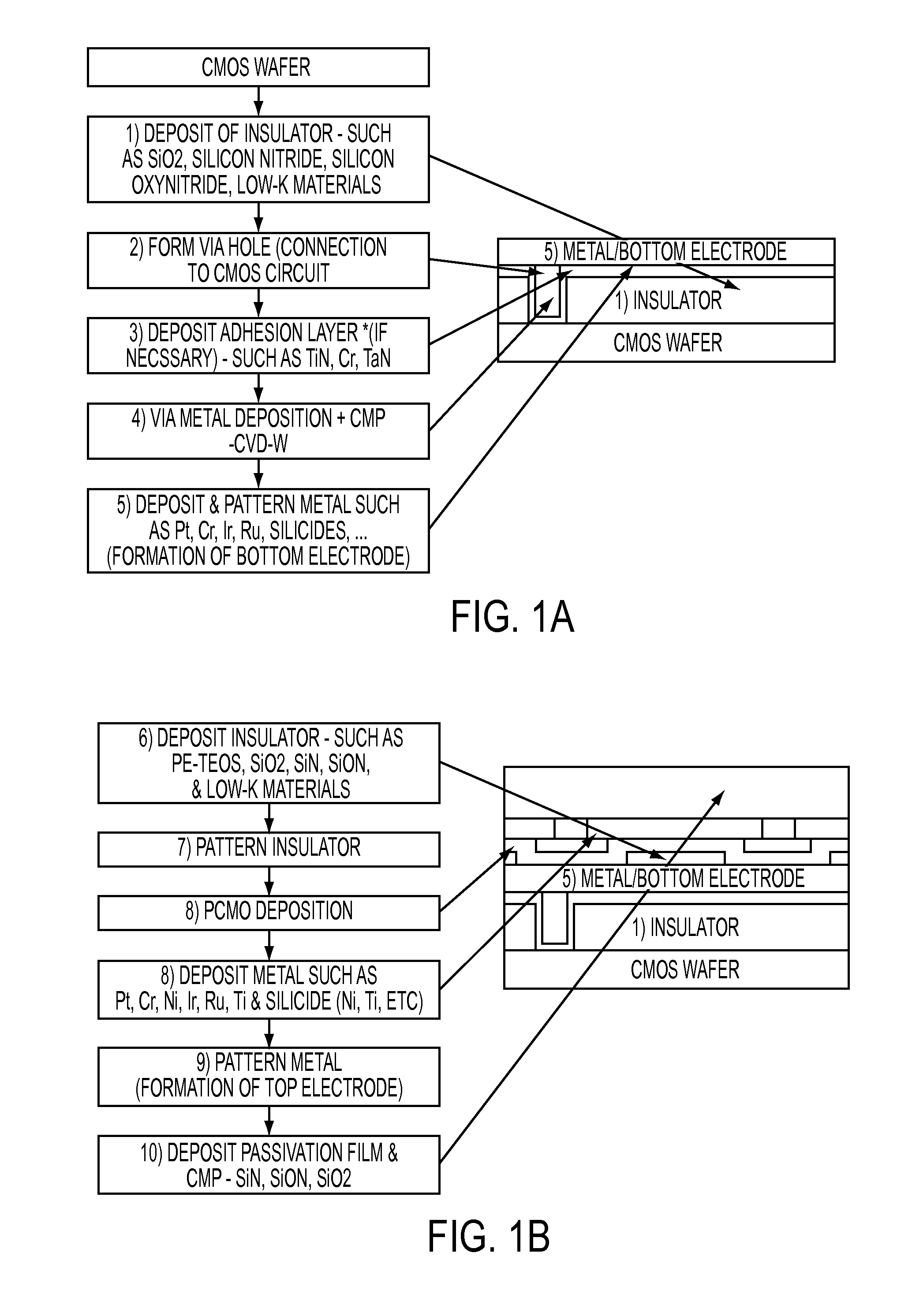

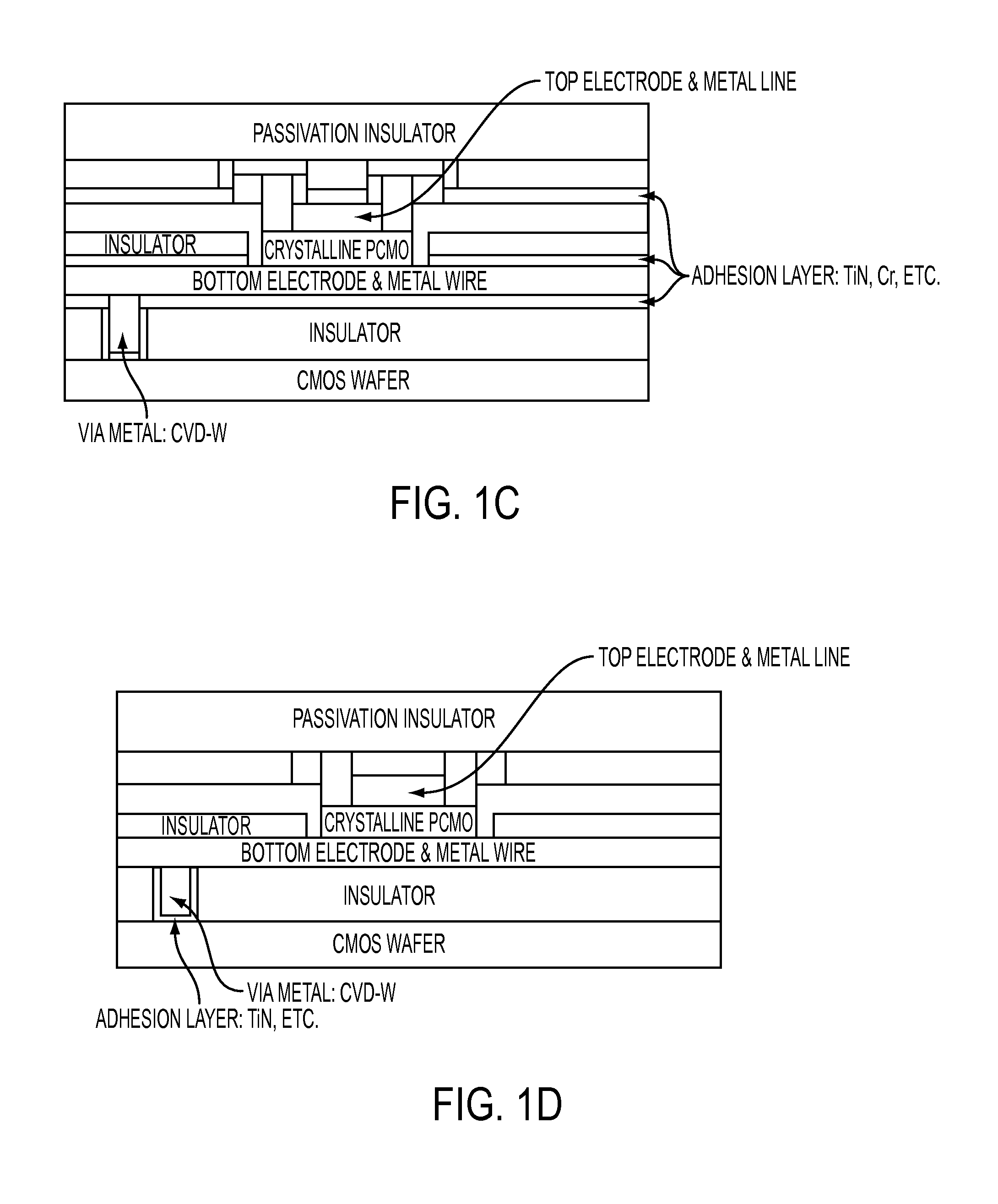

Systems and methods for fabricating self-aligned memory cell

ActiveUS20120122290A1High densityLow costSolid-state devicesSemiconductor/solid-state device manufacturingMetallic electrodeMemory cell

Systems and methods are disclosed to form a resistive random access memory (RRAM) by forming a first metal electrode layer; depositing an insulator above the metal electrode layer and etching the insulator to expose one or more metal portions; depositing a Pr1-XCaXMnO3 (PCMO) layer above the insulator and the metal portions, wherein X is between approximately 0.3 and approximately 0.5, to form one or more self-aligned RRAM cells above the first metal electrode; and depositing a second metal electrode layer above the PCMO layer.

Owner:4D S

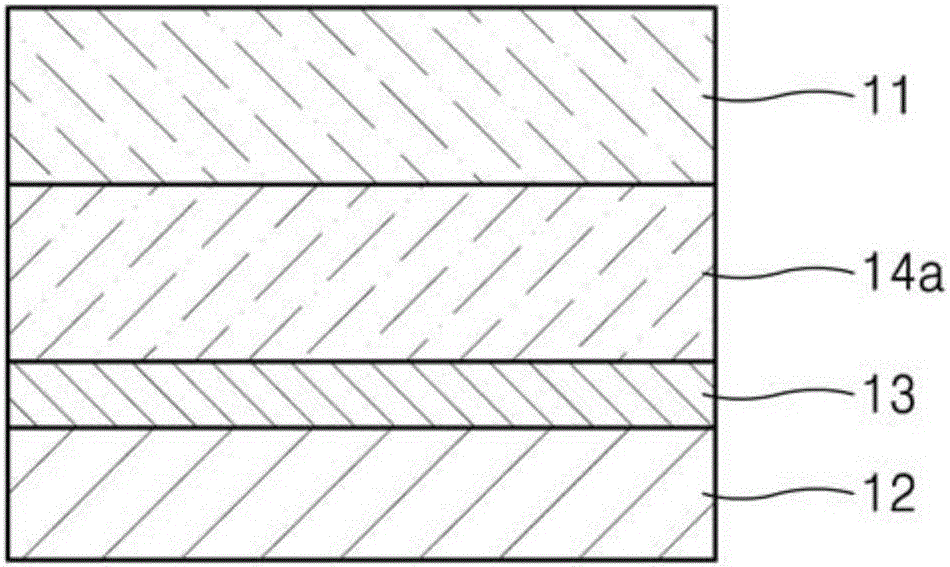

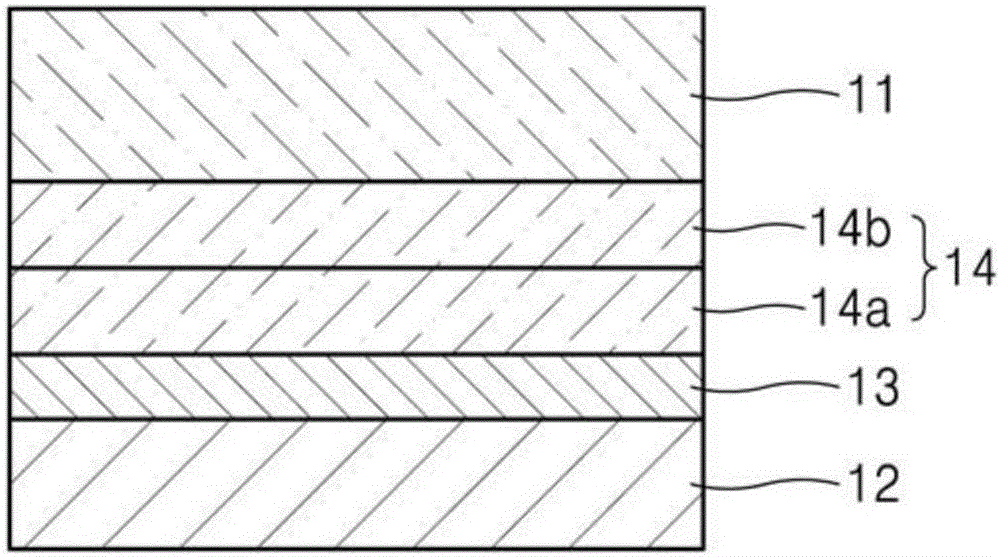

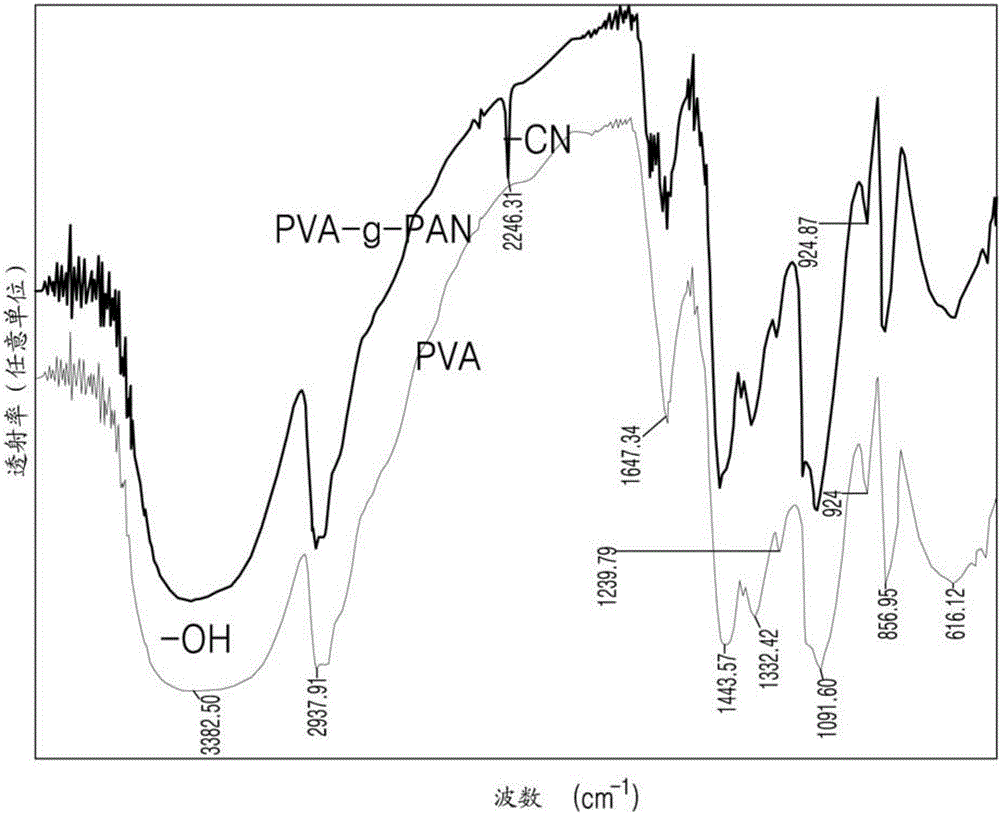

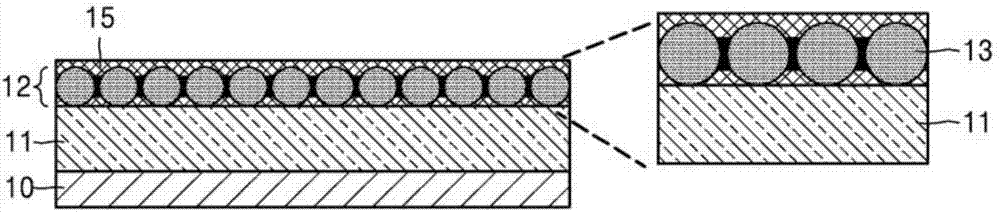

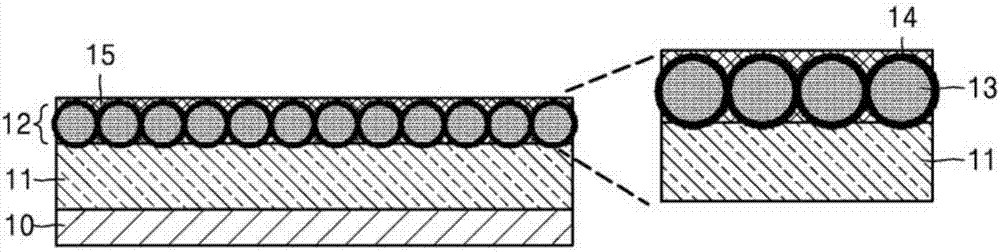

Negative electrode for lithium metal battery and lithium metal battery including the same

ActiveCN106299244AImprove adhesionKeep depositingElectrode thermal treatmentFinal product manufactureMetallic electrodePolyvinyl alcohol

A negative electrode for a lithium metal battery, the negative electrode including: a lithium metal electrode; and a protection film disposed on at least a portion of the lithium metal electrode, wherein the protection film includes at least one first polymer selected from a polyvinyl alcohol graft copolymer, a crosslinked copolymer formed from the polyvinyl alcohol graft copolymer, a polyvinyl alcohol crosslinked copolymer, and a blend thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

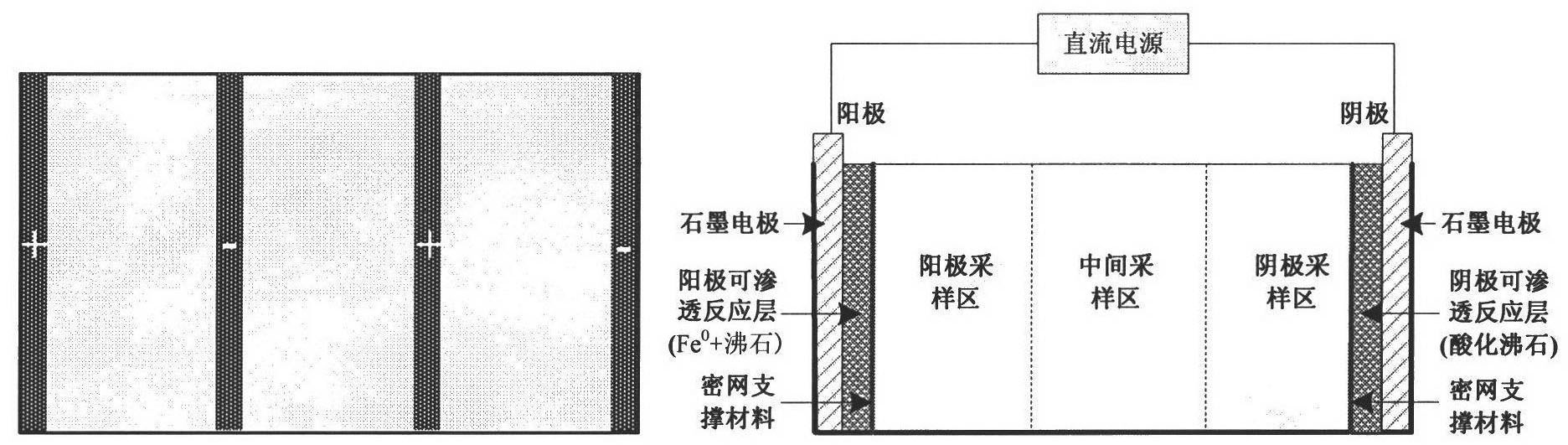

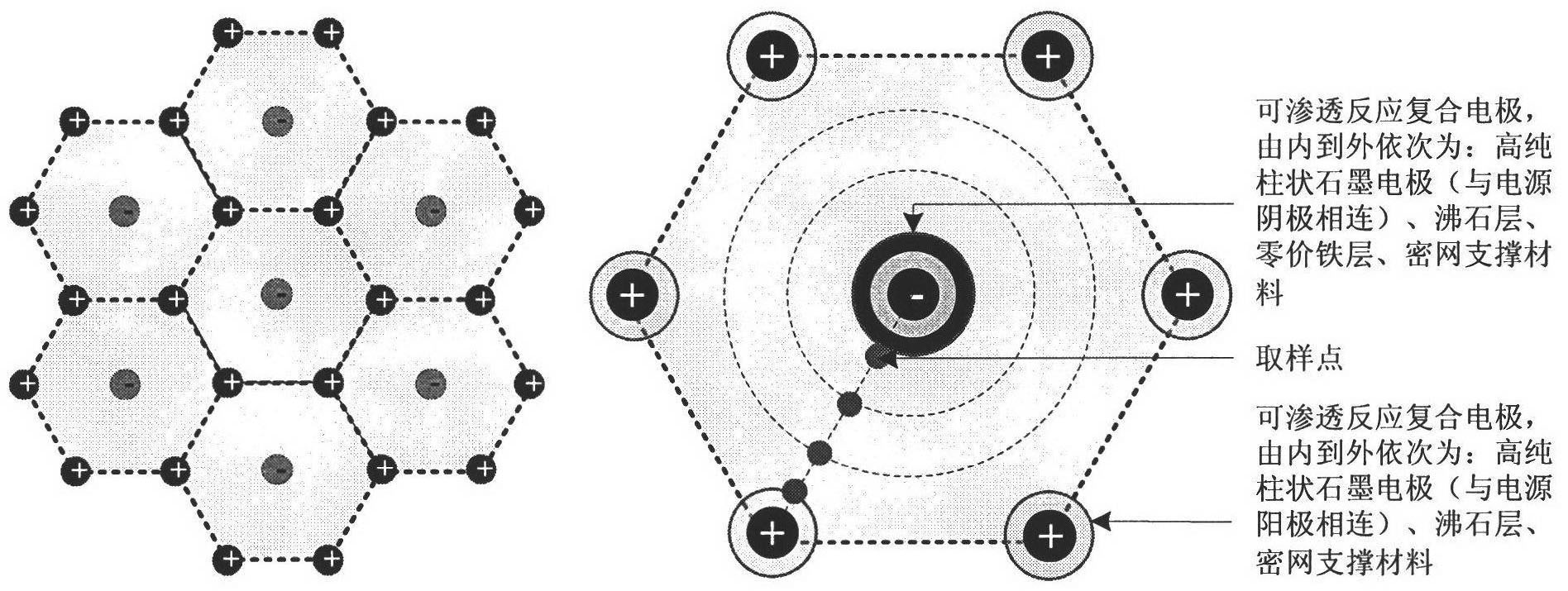

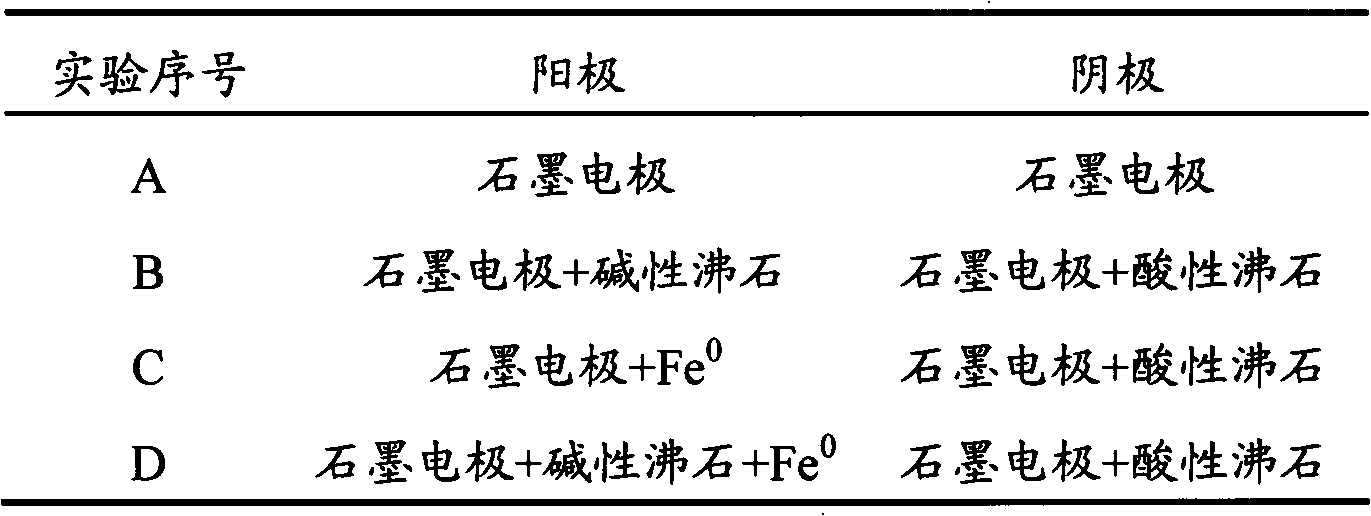

Electrokinetic remediation method of heavy metal polluted soil by composite electrodes

ActiveCN102441564AEffective pH controlWeaken the big changeContaminated soil reclamationGraphite electrodeElectrokinetic remediation

The invention relates to composite electrodes and an electrokinetic remediation method of heavy metal polluted soil by using the composite electrodes. According to the electrodes, an active material layer is adhered to the surface of graphite electrodes or metal electrodes of an anode and a cathode so as to form integrated composite electrodes with permeable reactive performance. By the permeablereactive layer, on one hand, H<+> and OH<-> generated from the electrode reaction can be neutralized and adsorbed, the pH value of the soil can be effectively controlled, and the heavy metal can be prevented from being prematurely deposited in the soil. On the other hand, migrated heavy metal pollutants can be captured, and in situ removal of the heavy metal pollutants in the soil can be realizedby removing the composite electrodes.

Owner:上海环境保护有限公司

Negative electrode for lithium metal battery and lithium metal battery comprising the same

A negative electrode for a lithium metal battery, the negative electrode including: a lithium metal electrode comprising lithium metal or a lithium metal alloy; and a protective layer on at least a portion of the lithium metal electrode, wherein the protective layer has a Young's modulus of about 106 Pascals or greater, wherein the protective layer includes at least one first particle, wherein the first particle includes an organic particle, an inorganic particle, an organic-inorganic particle, or a combination thereof, and wherein the first particle has a particle size of greater than 1 micrometer to about 100 micrometers, and a crosslinked material comprising a polymerizable oligomer, which is disposed between first particles of the at least one first particle.

Owner:SAMSUNG ELECTRONICS CO LTD +1

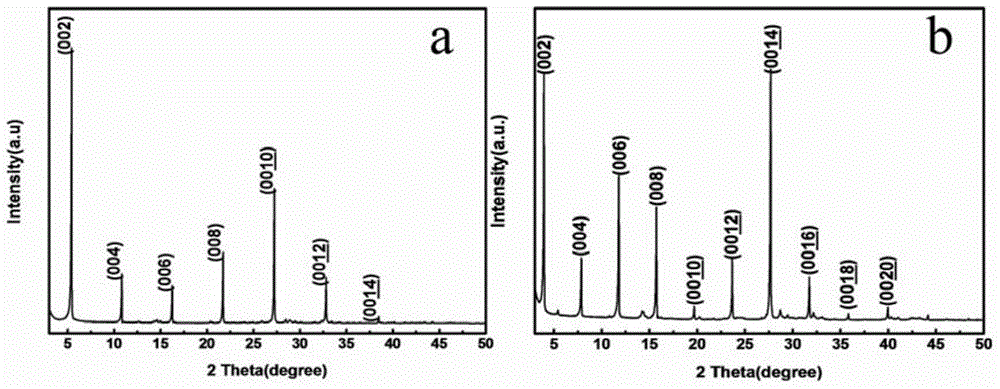

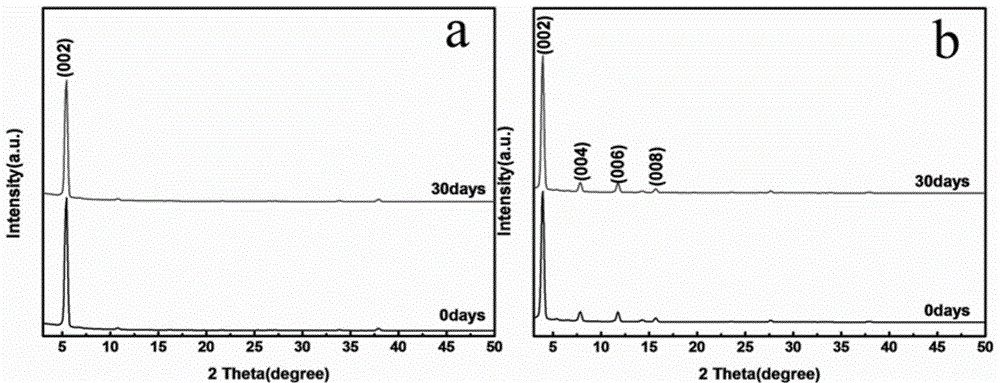

Perovskite solar cell and method for manufacturing same

InactiveCN104795501ASimple and fast operationLow costFinal product manufactureSolid-state devicesHole transport layerMetal electrodes

The invention relates to a perovskite solar cell and a method for manufacturing the same. The perovskite solar cell comprises an FTO (fluorine-doped tin oxide) transparent conducting glass substrate, an electron transport layer, a light absorption layer, a hole transport layer and a metal electrode. The light absorption layer is made of (C<6>H<5>CH<2>CH<2>NH<3>)<2>(CH<3>NH<3>)<n-1>Pb<n>I<3*n+1> (the n is equal to 1 or 2) materials which are of two-dimensional layered structures. The perovskite solar cell and the method have the advantages that the layered perovskite light absorption layer is manufactured by the aid of a spin coating process, the method is simple and is excellent in film-forming property, the materials of the light absorption layer can be changed along with the layer number n, gaps of the materials can be adjusted, and the materials are excellent in chemical stability and still can keep the excellent layered structures without chemical decomposition after being exposed at high air humidity (50-80%) for 30 days, solar cell prototype devices with excellent and stable performance can be obtained, and the perovskite solar cell and the method are favorable for promoting perovskite solar cell commercialization progress.

Owner:WUHAN UNIV OF TECH

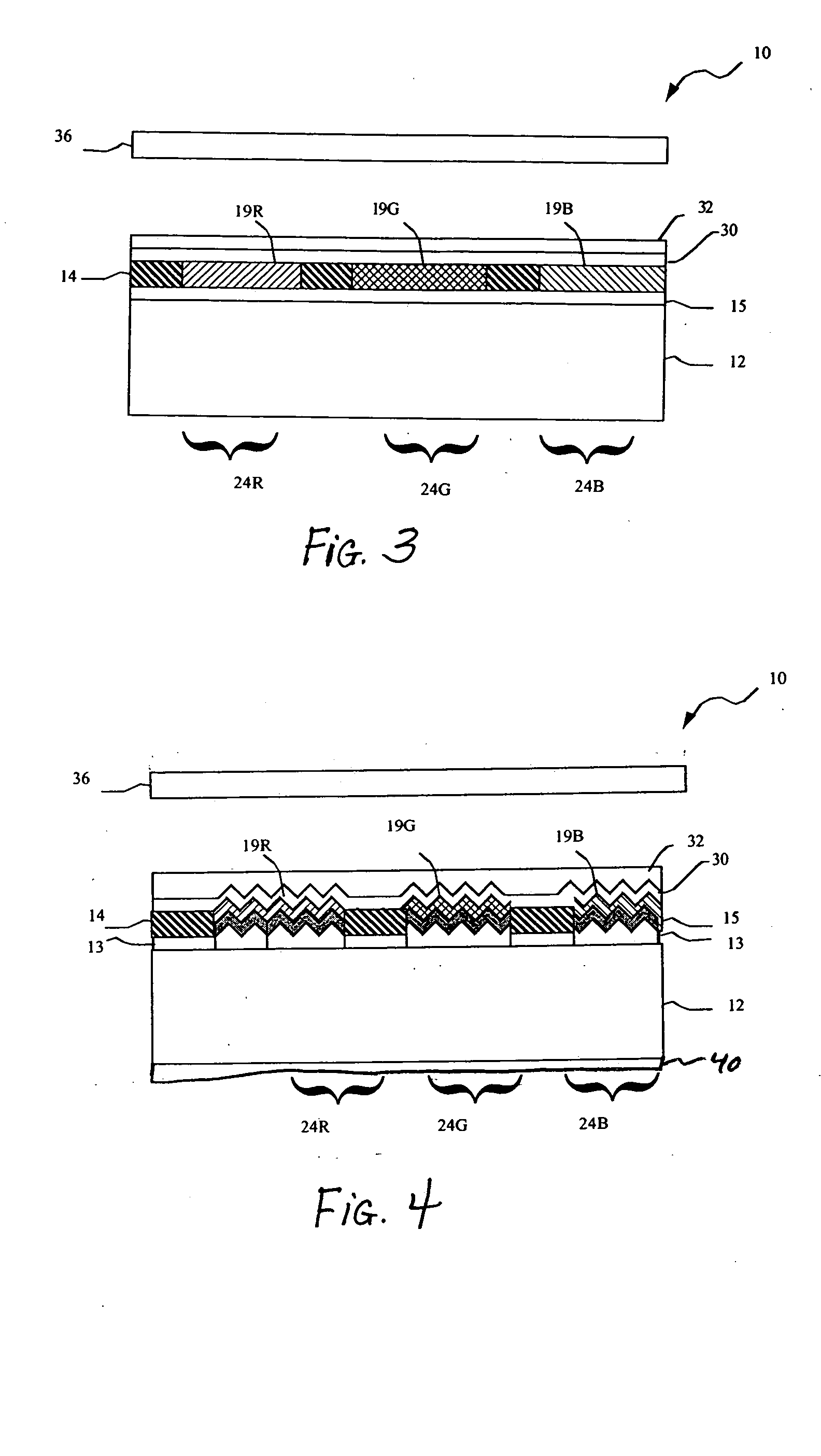

Color OLED display with improved emission

InactiveUS20040149984A1Electroluminescent light sourcesSolid-state devicesMetallic electrodeOptoelectronics

A color organic light-emitting display having an array of pixels divided into at least two different color pixel sets each color pixel set emitting a different predetermined color, wherein each pixel in the array includes a metallic bottom-electrode layer; an organic EL element including a light-emitting layer for emitting the predetermined color light and a metallic top-electrode layer over the organic EL element, spaced from the metallic bottom-electrode layer by a distance selected to improve the emission light output efficiency; and wherein one of the metallic electrode layers is semitransparent and the other one is essentially opaque and reflective; wherein the material for the semitransparent metallic electrode and the reflective electrode includes specific materials; and the thickness of the semitransparent metallic electrode layer and the position of the light-emitting layer between the electrodes are selected to enhance emission light output efficiency.

Owner:EASTMAN KODAK CO

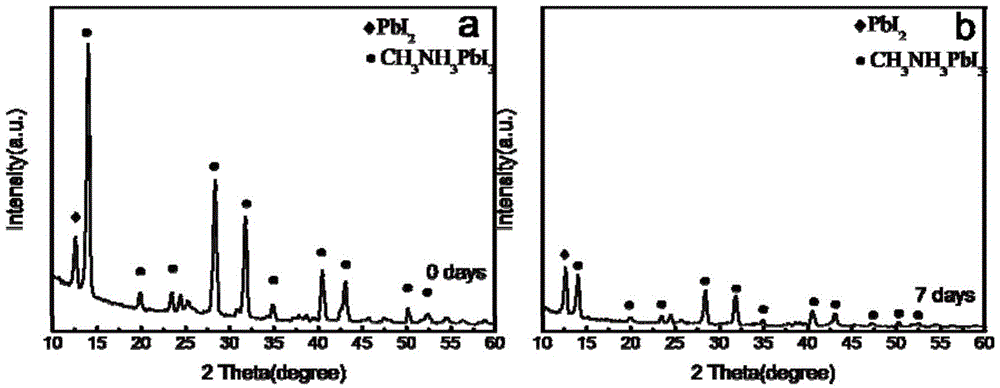

Perovskite thin-film photovoltaic cell and manufacturing method thereof

ActiveCN103872248ASimple structureReduce manufacturing costFinal product manufactureSolid-state devicesMetallic electrodeManufacturing technology

The invention relates to a perovskite thin-film photovoltaic cell and a manufacturing method of the perovskite thin-film photovoltaic cell. The perovskite thin-film photovoltaic cell is composed of a conducting transparent substrate, a perovskite light-absorbing layer, a hole transfer layer and a metal electrode. The perovskite thin-film photovoltaic cell has the advantages that the structure is quite simple, a traditional electron transfer layer which needs high-temperature sintering is omitted due to the fact that a perovskite material serves as the light-absorbing layer and achieves the electron transfer function, and a porous layer is not needed either; the perovskite material is high in light-absorbing performance, the whole cell is manufactured at a low temperature, the complicated processes such as high-temperature sintering are not needed, and therefore the manufacturing cost of the cell is effectively reduced; the great promotion function is achieved on the flexibility of the cell and the large-sized reel-to-reel printing manufacturing of the cell; the whole manufacturing technology of the cell is simple, the popularization of the technology is facilitated, high photoelectric converting efficiency (approximate to 14 percent) and good device stability are obtained particularly, and therefore the industrial application prospect is achieved.

Owner:WUHAN UNIV

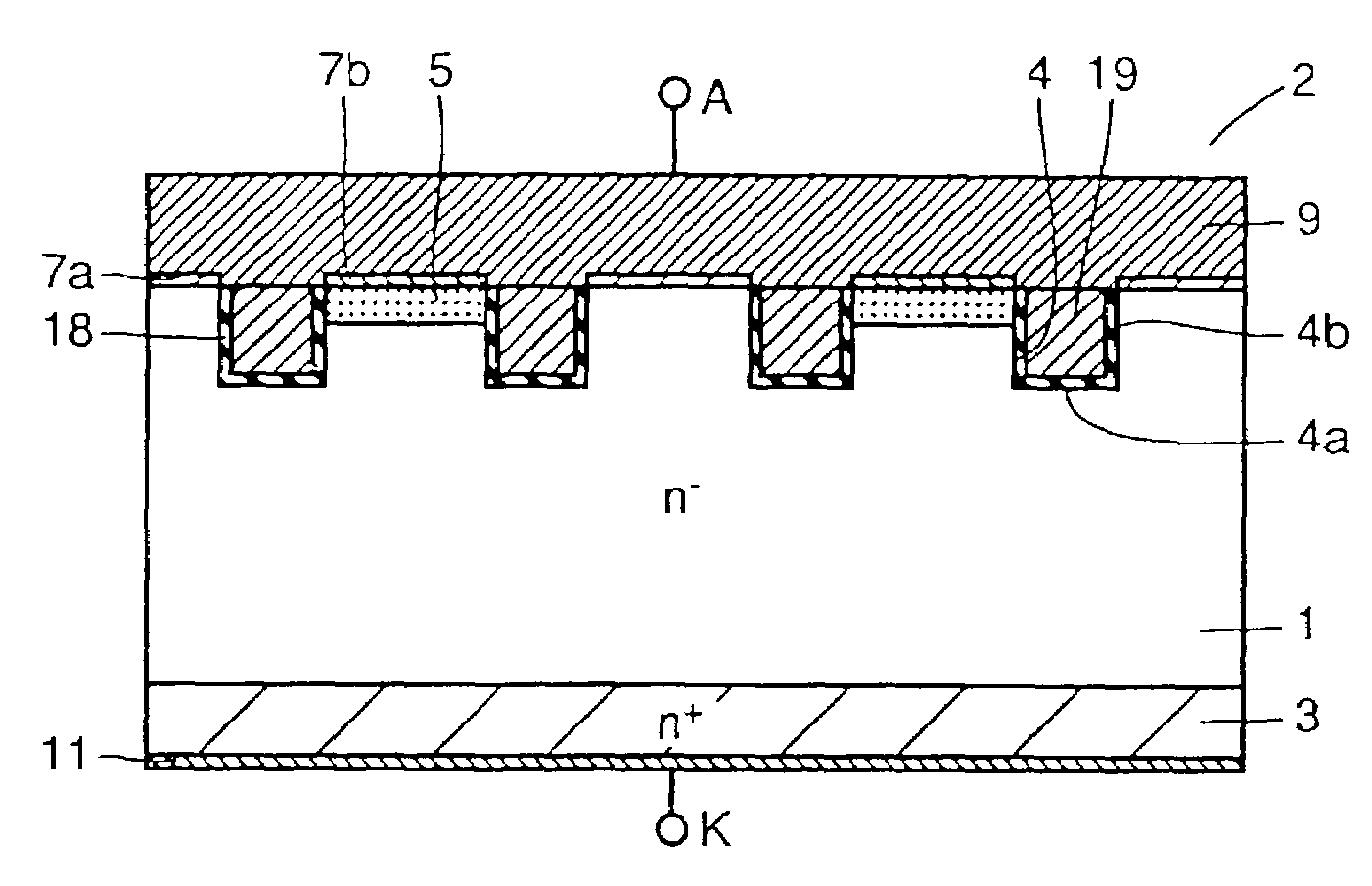

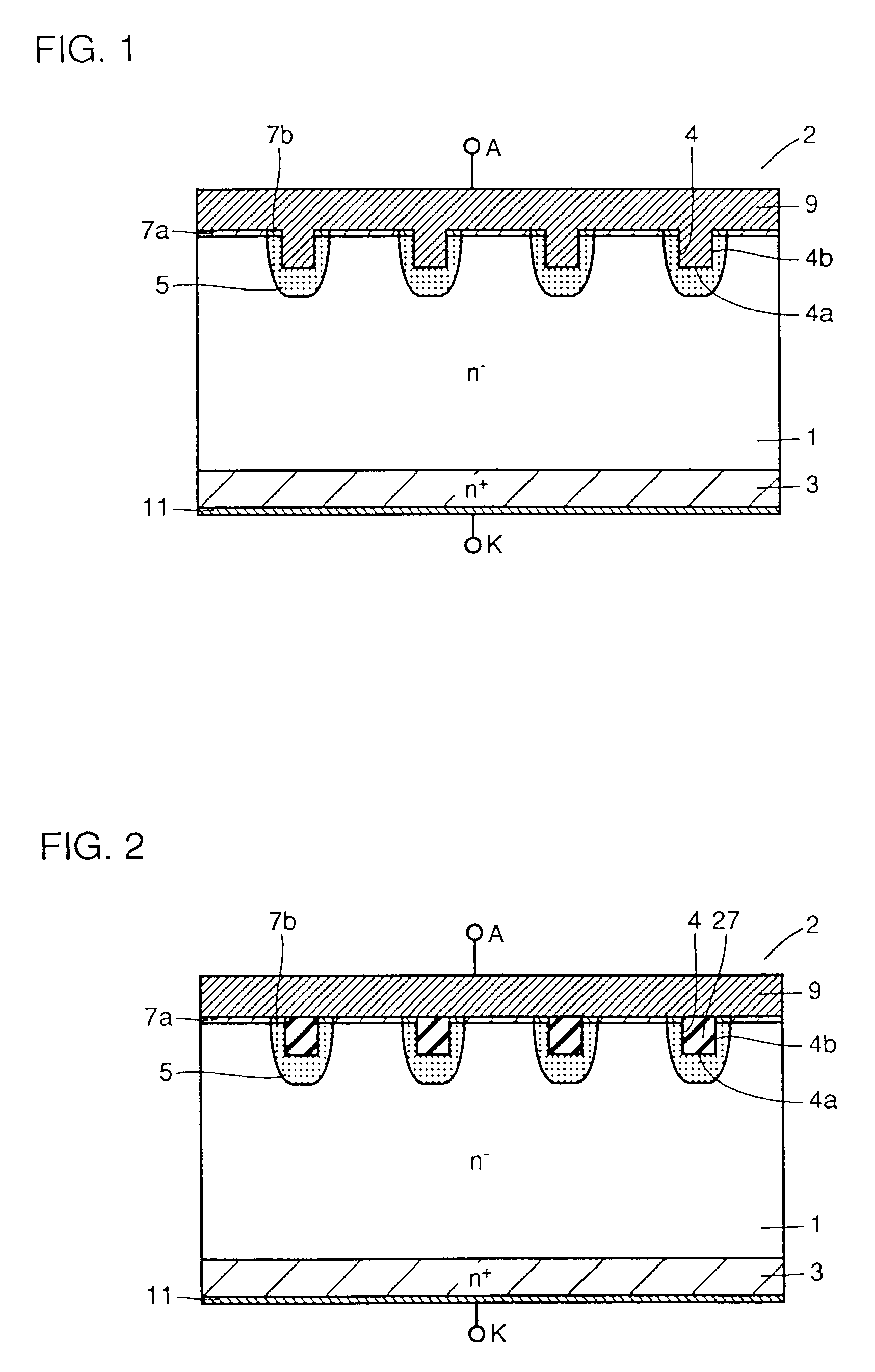

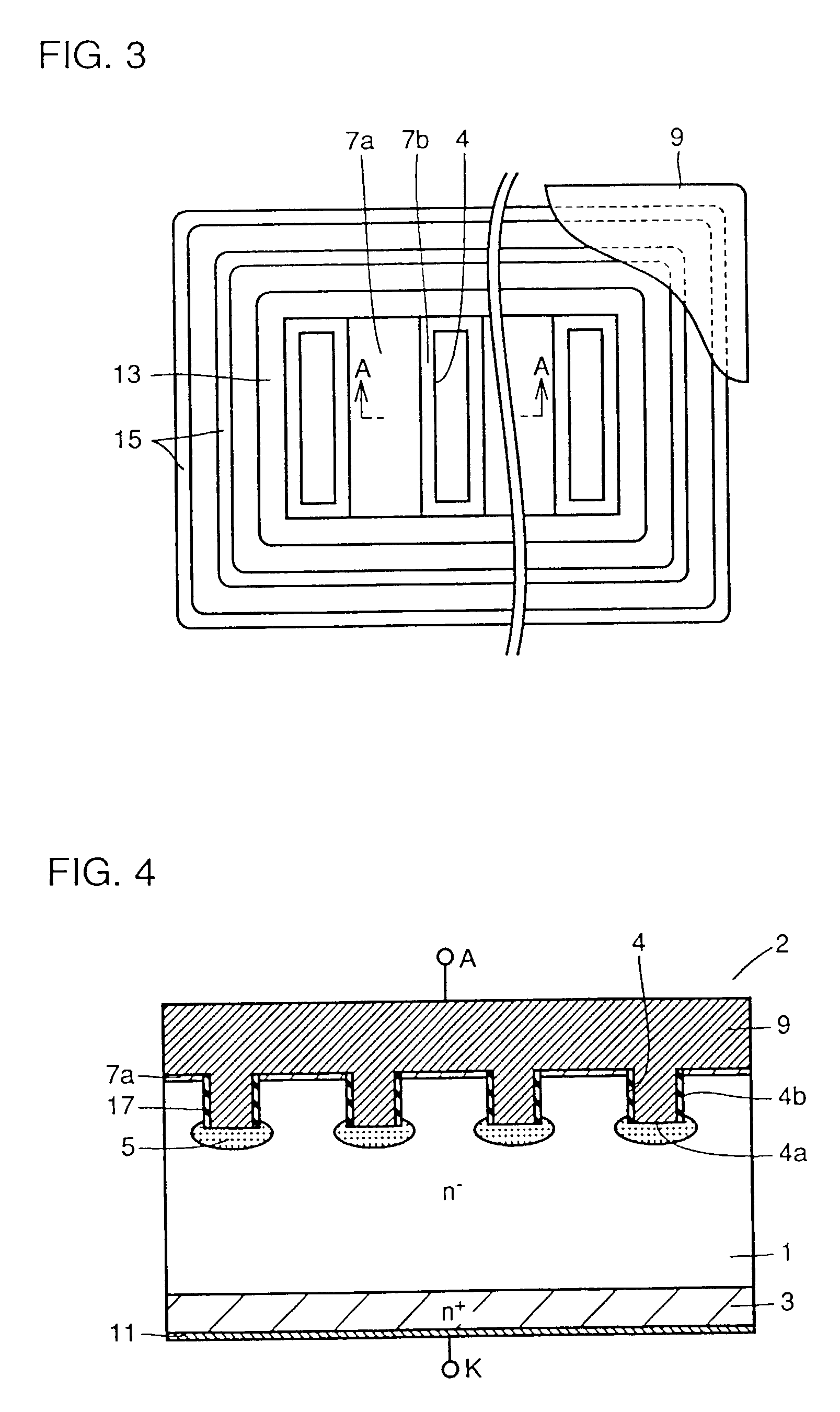

Semiconductor device and method of manufacturing thereof

InactiveUS6979874B2Reduce the amount requiredImprove pressure resistanceTransistorSemiconductor/solid-state device manufacturingMetallic electrodeReverse recovery

A plurality of p anode regions are formed at one surface of an n− substrate. A trench is formed in each p anode region. An ohmic junction region is formed between an anode metallic electrode and the p anode region. The p anode region has a minimum impurity concentration at a portion near the ohmic junction region which enables ohmic contact. A cathode metallic electrode is formed at the other surface of the n− substrate with an n+ cathode region interposed. Accordingly, a semiconductor device which has an improved withstand voltage and in which the reverse recovery current is reduced can be obtained.

Owner:MITSUBISHI ELECTRIC CORP

Method of metallizing dielectric film

InactiveUS20150231802A1Layered product treatmentPiezoelectric/electrostriction/magnetostriction machinesDielectricPolymer science

The present invention provides a method of producing a metallized polymer-electrode composite comprising transferring a conductive metal foil from a metal transfer film to a surface of a polymer film The inventive method may be used to produce a polymer film with optionally textured, conductive metal electrodes on one or both sides. The method of Hie invention may find utility in producing electroactive polymer transducers and other thin film devices requiring flexibility or stretchability such as thin film batteries, sensors, speakers, reflective plastic displays, solar cells, and supercapacitors.

Owner:PARKER HANNIFIN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com