Patents

Literature

194 results about "Dlc coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

DLC (Diamond Like Carbon) Coating. DLC Coating or Diamond-Like Carbon Coating is a coating process in which an amorphous carbon material reflecting certain properties of Diamond is deposited on another material in order to increase the lifetime of the latter. DLC coating and Diamond like carbon coating is extensively used in several industries such...

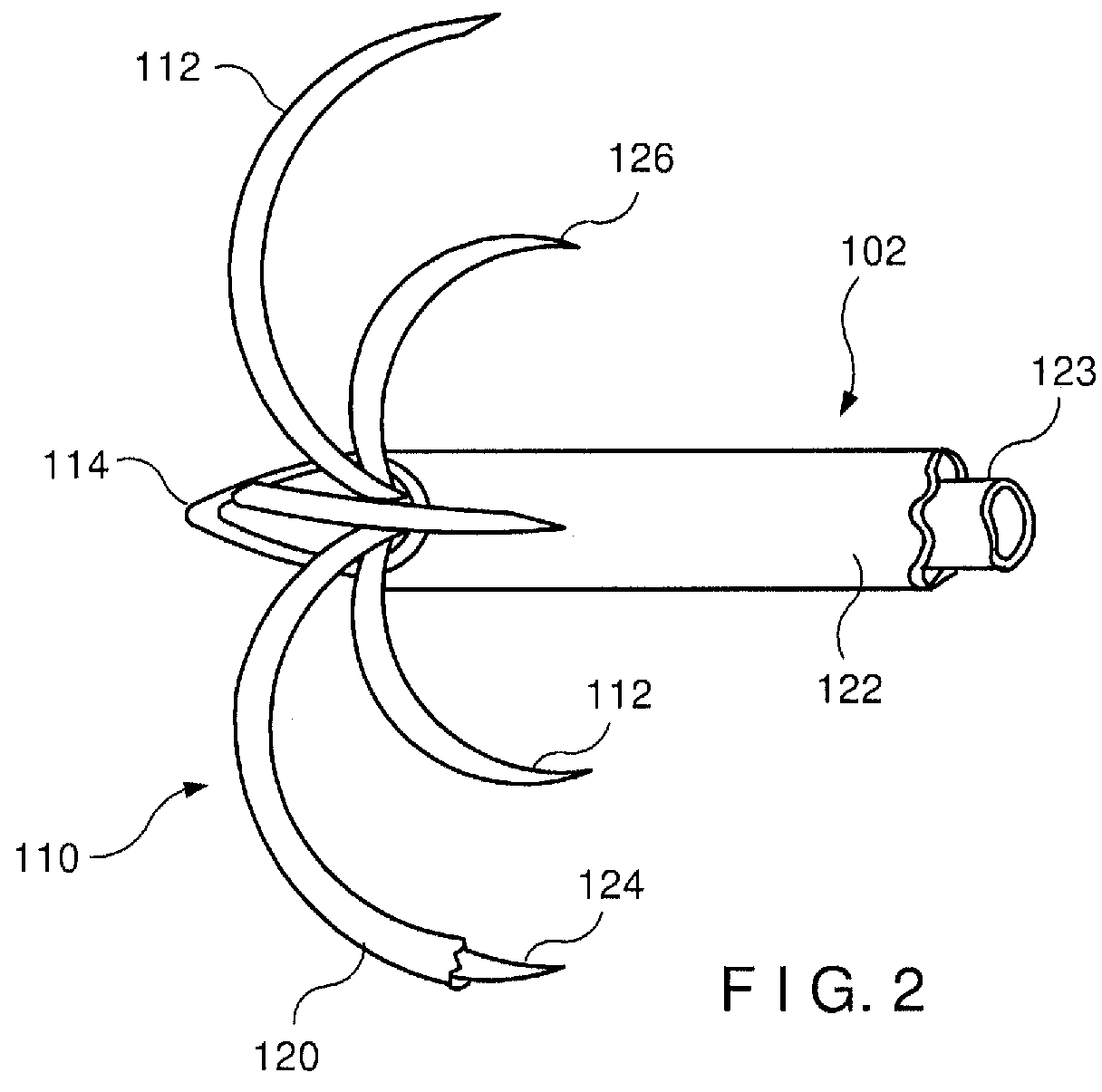

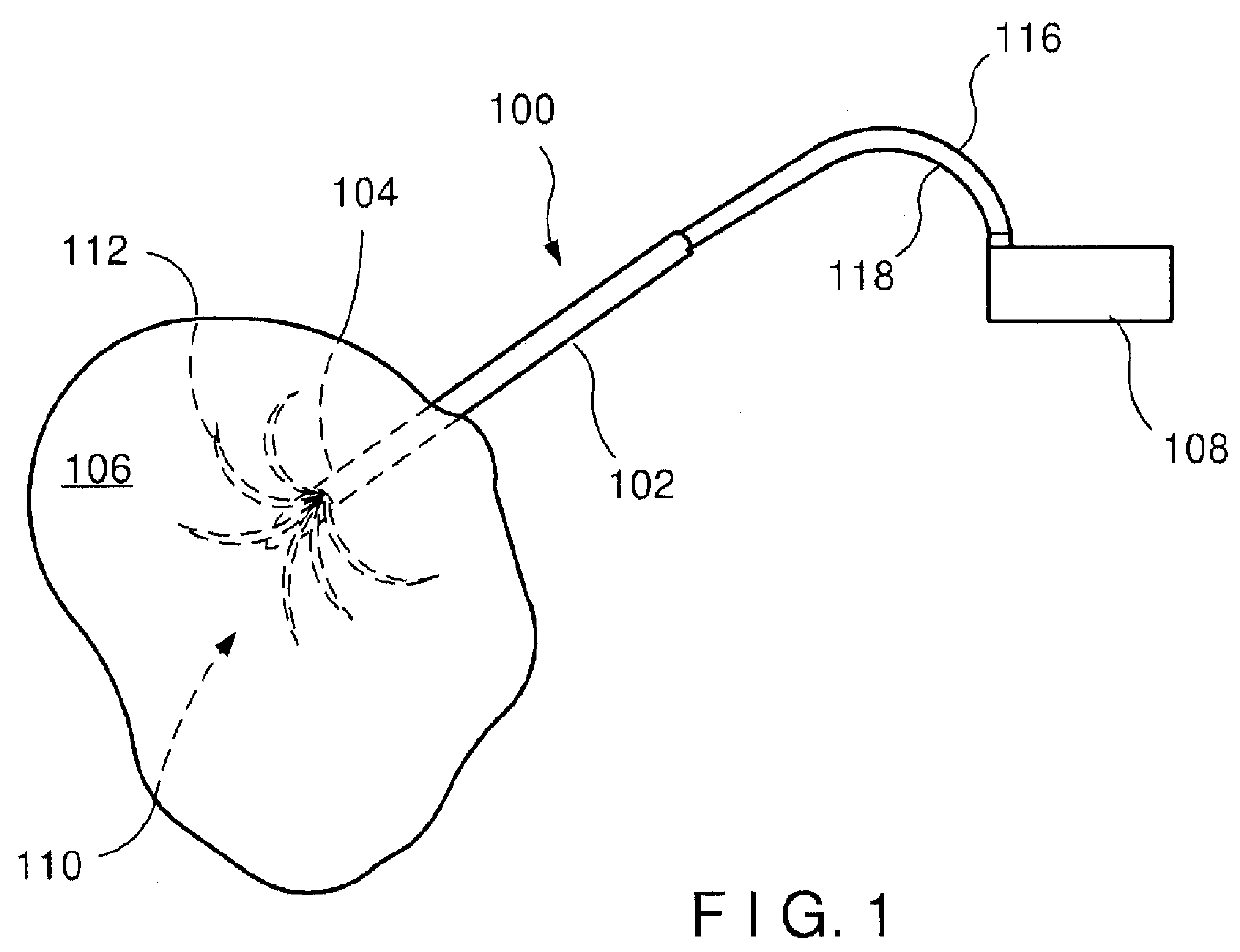

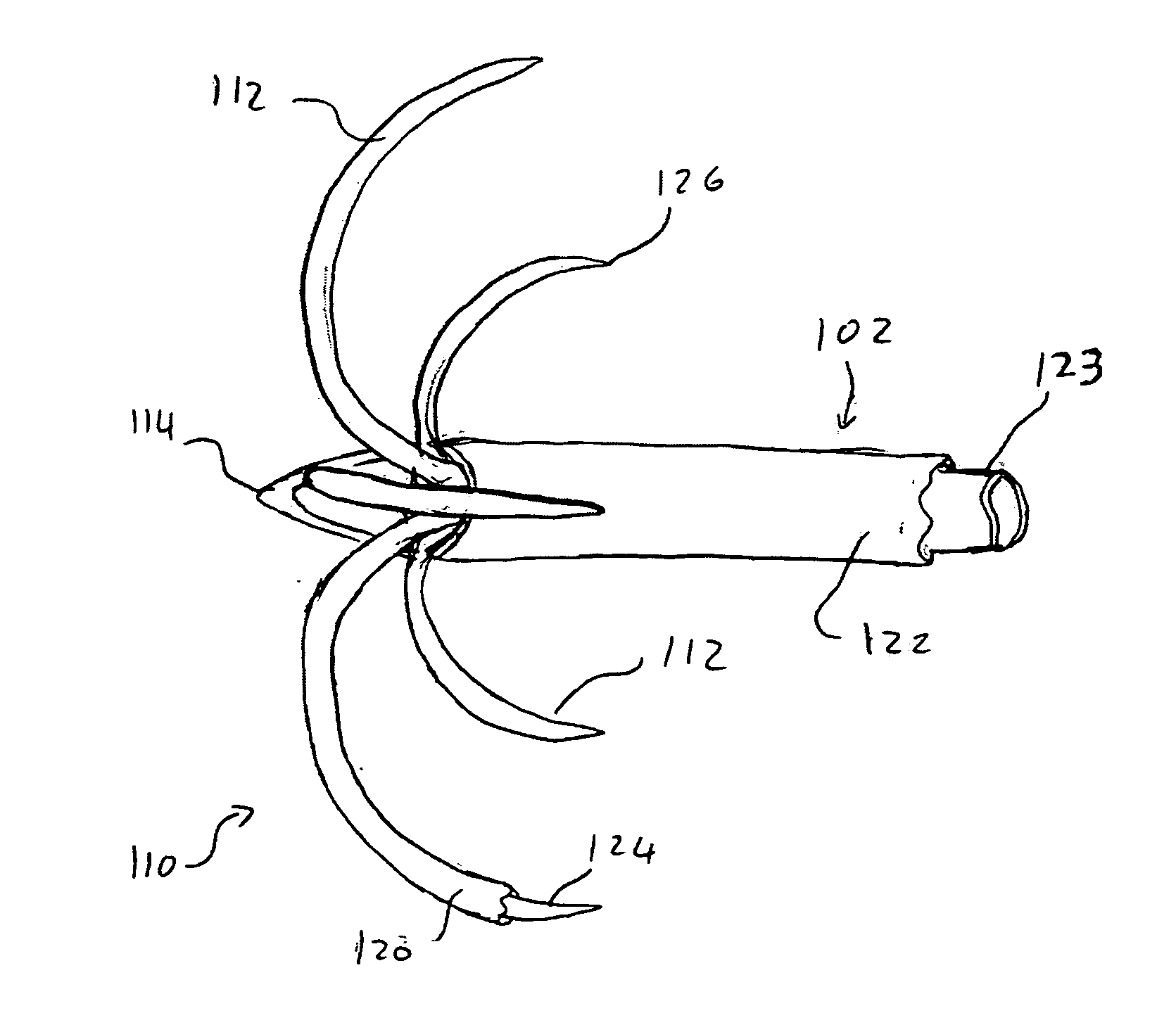

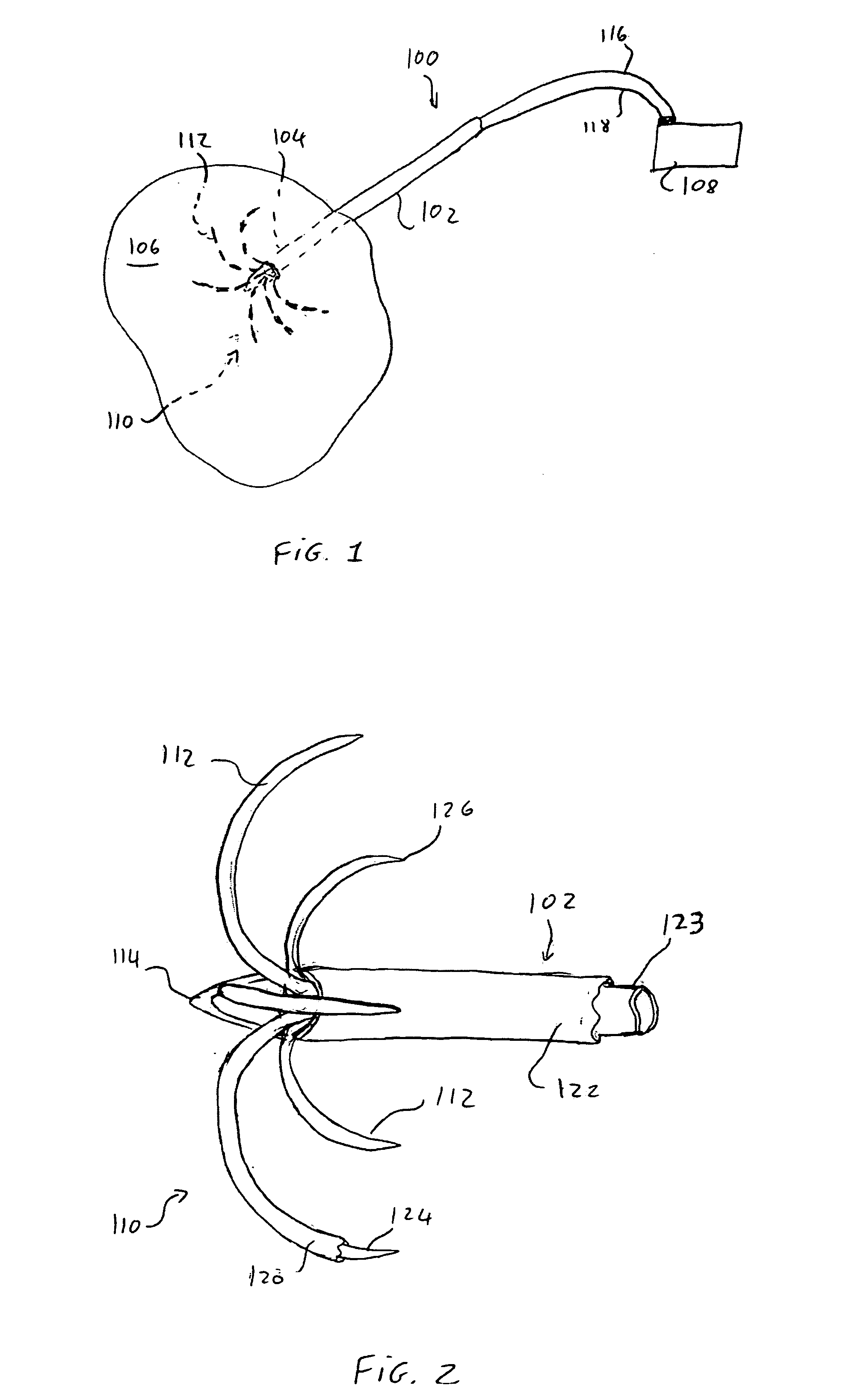

Diamond-like carbon electrode coating

An RF ablation device comprises an electrode including a DLC coating deposited on at least a portion thereof. A method of forming an RF ablation device, comprises forming a DLC coating on a portion of a metallic electrode.

Owner:BOSTON SCI SCIMED INC

Diamond-like carbon electrode coating

Owner:BOSTON SCI SCIMED INC

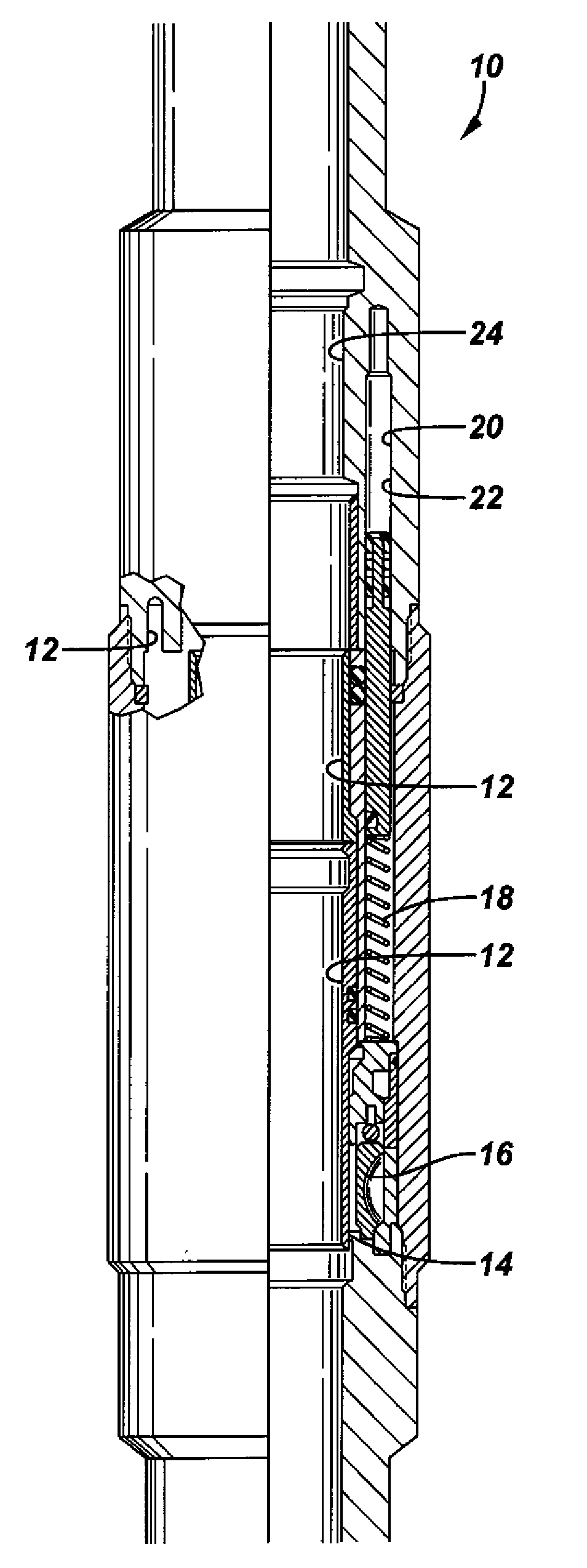

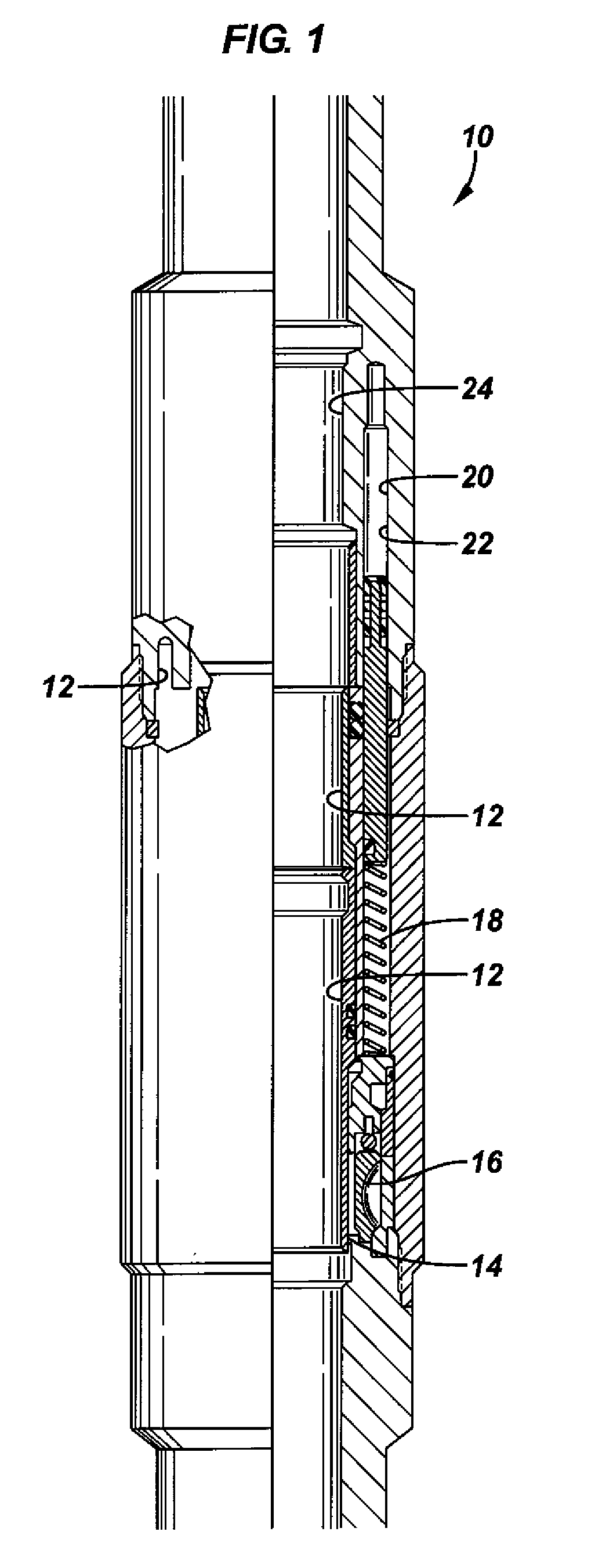

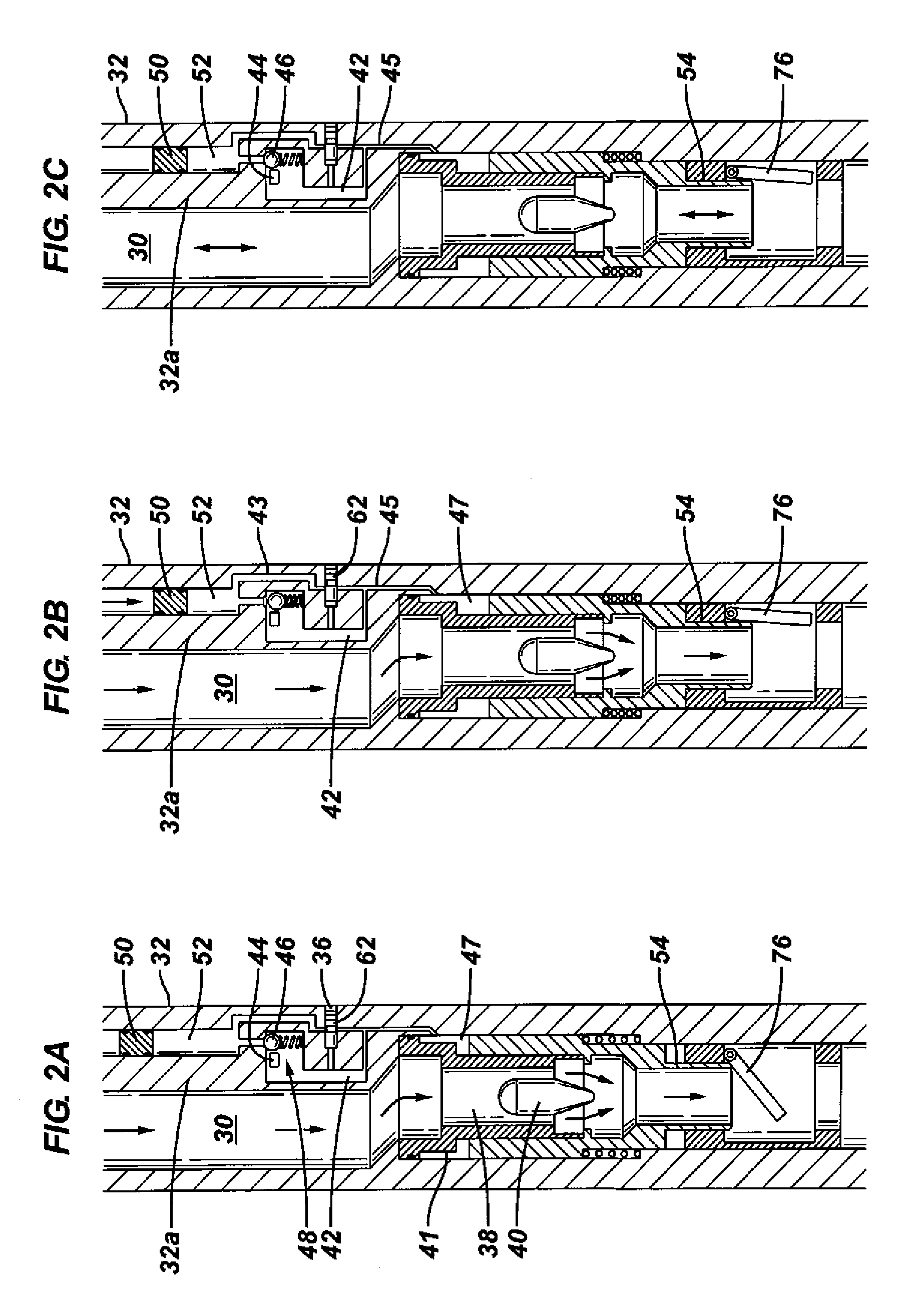

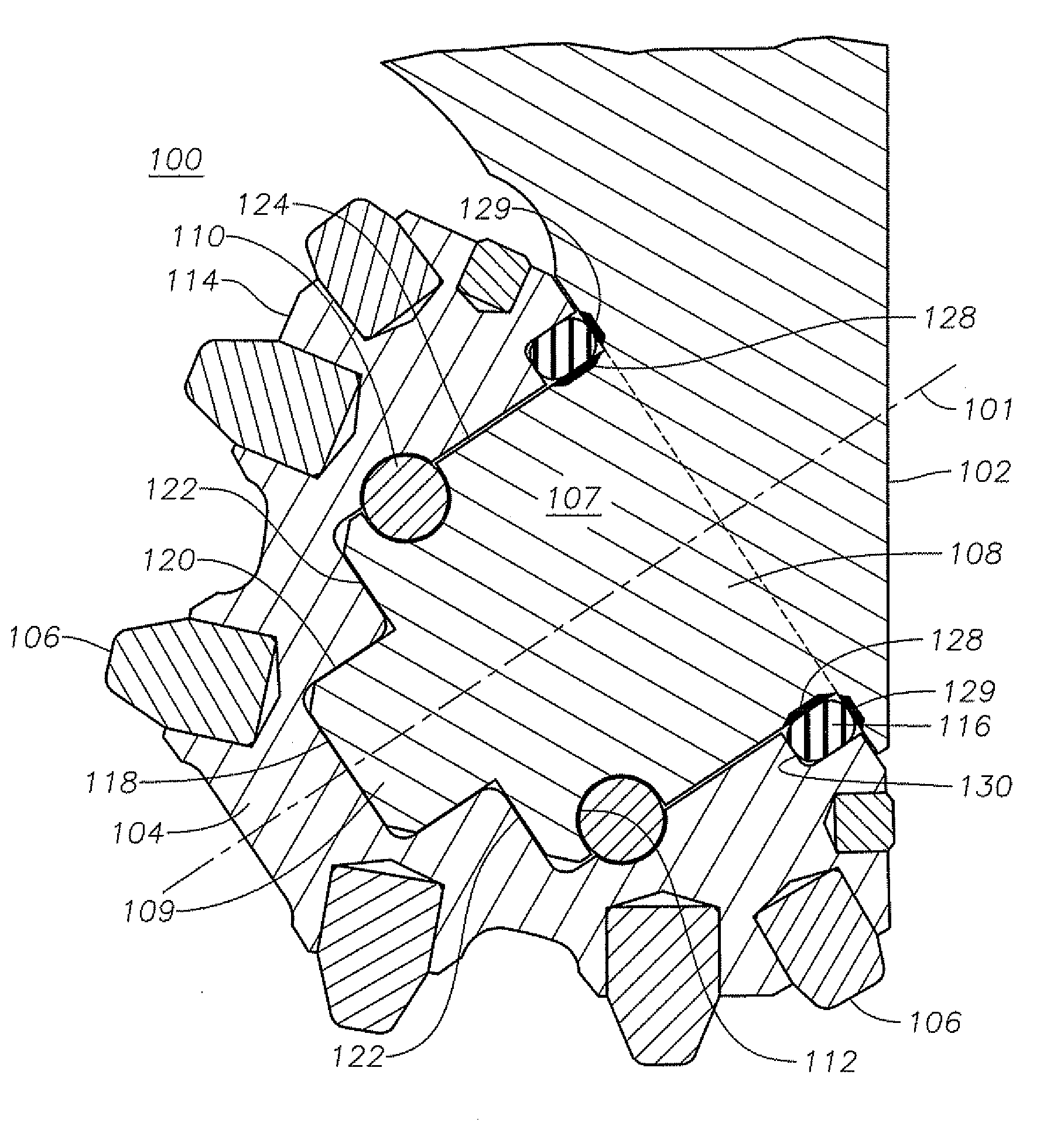

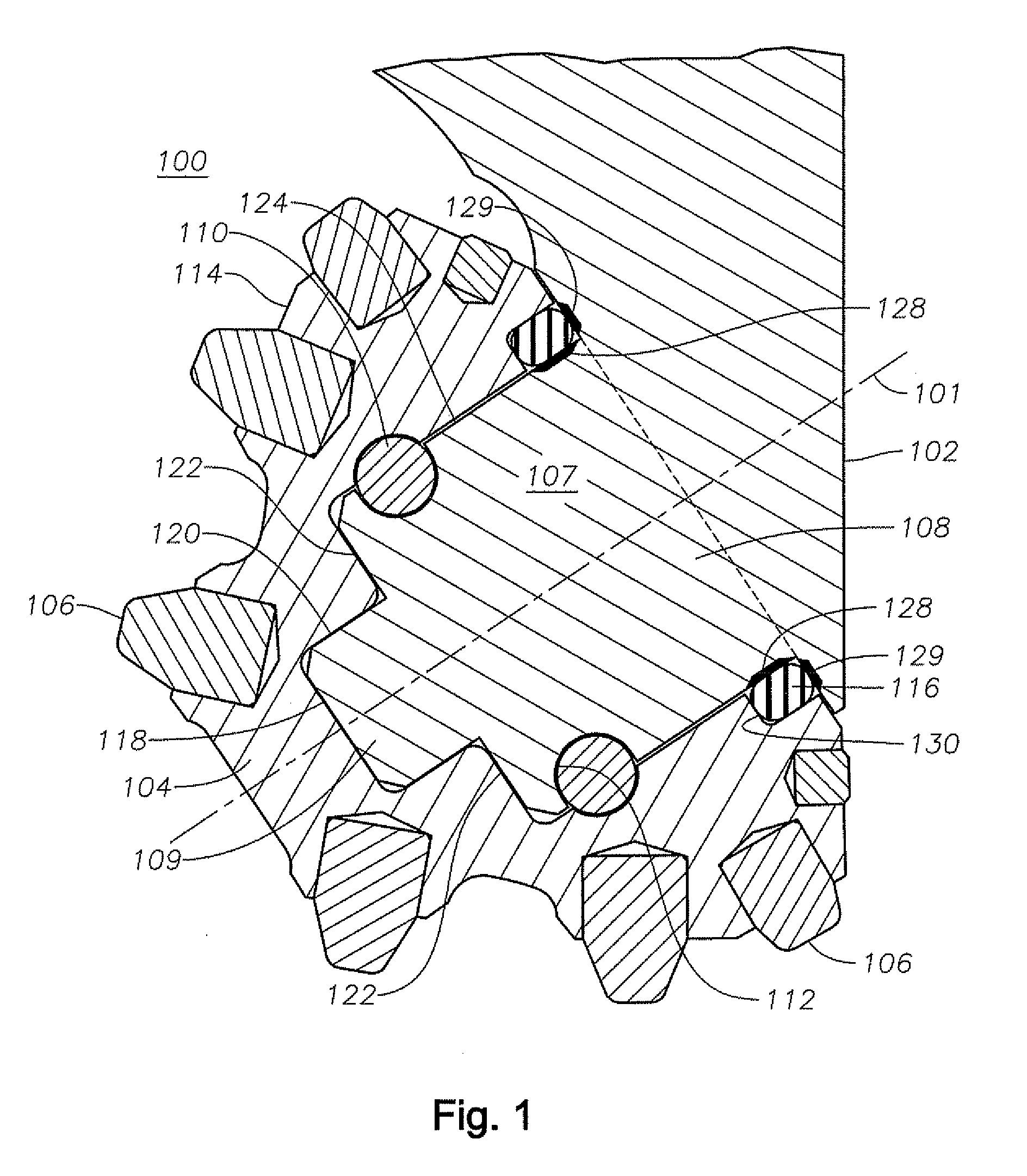

Downhole oilfield apparatus comprising a diamond-like carbon coating and methods of use

Downhole apparatus and methods of using the apparatus are described, the apparatus comprising at least one metallic component having a DLC coating thereon, the coating present at least on one or more internal passageways of the base metal or alloy to be exposed to downhole environments. Methods of using an apparatus in downhole oilfield operations are also described. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims.

Owner:SCHLUMBERGER TECH CORP

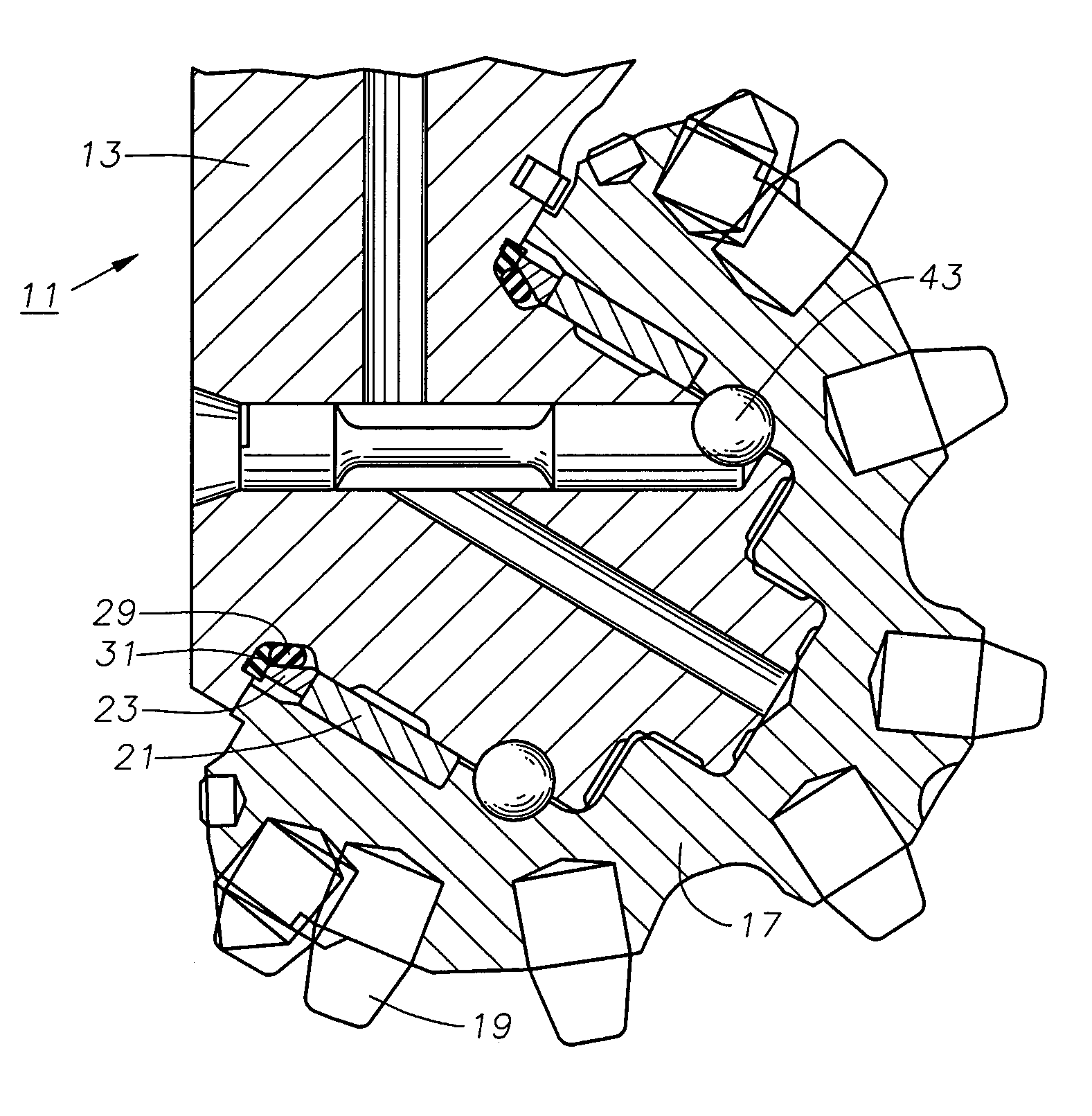

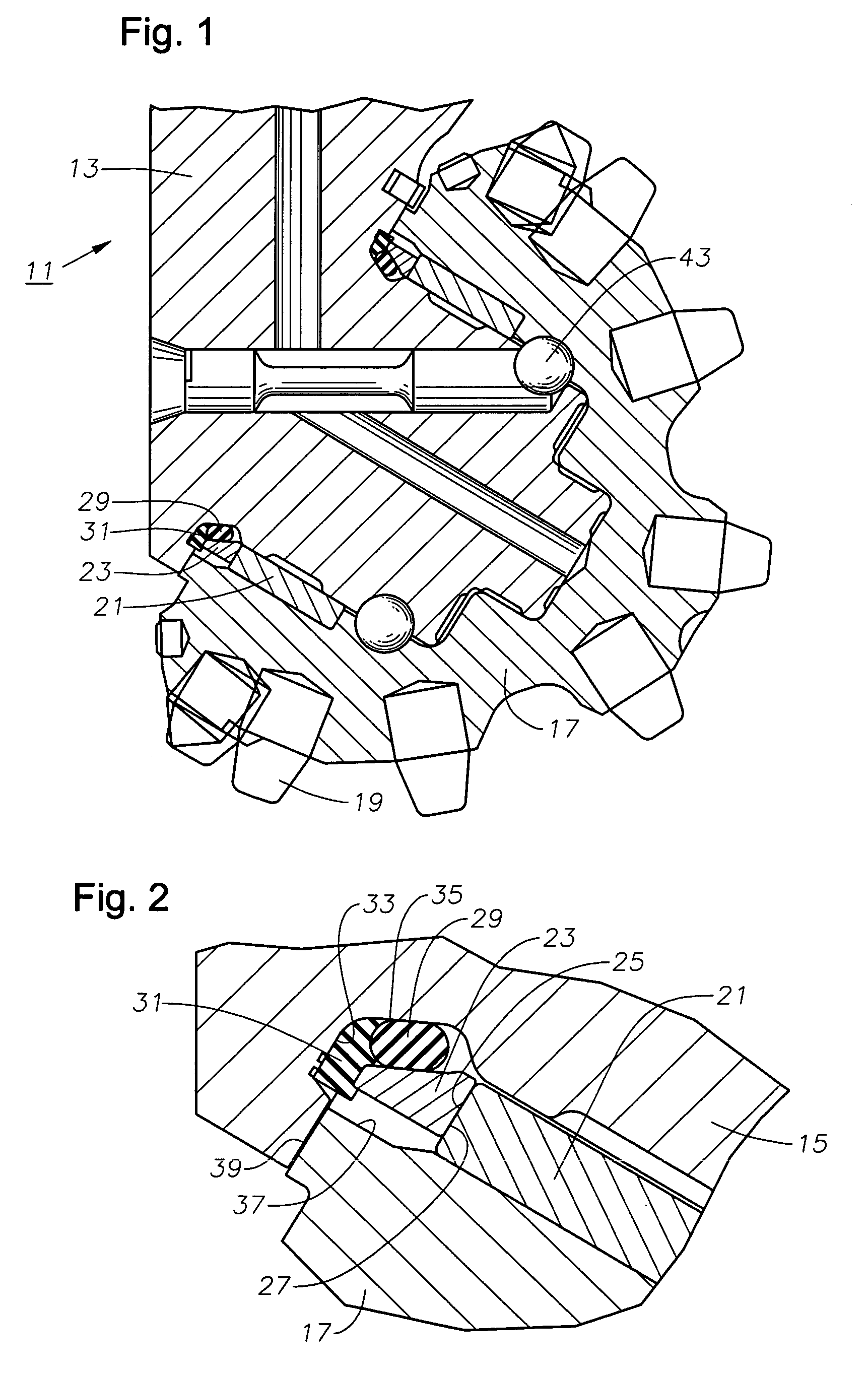

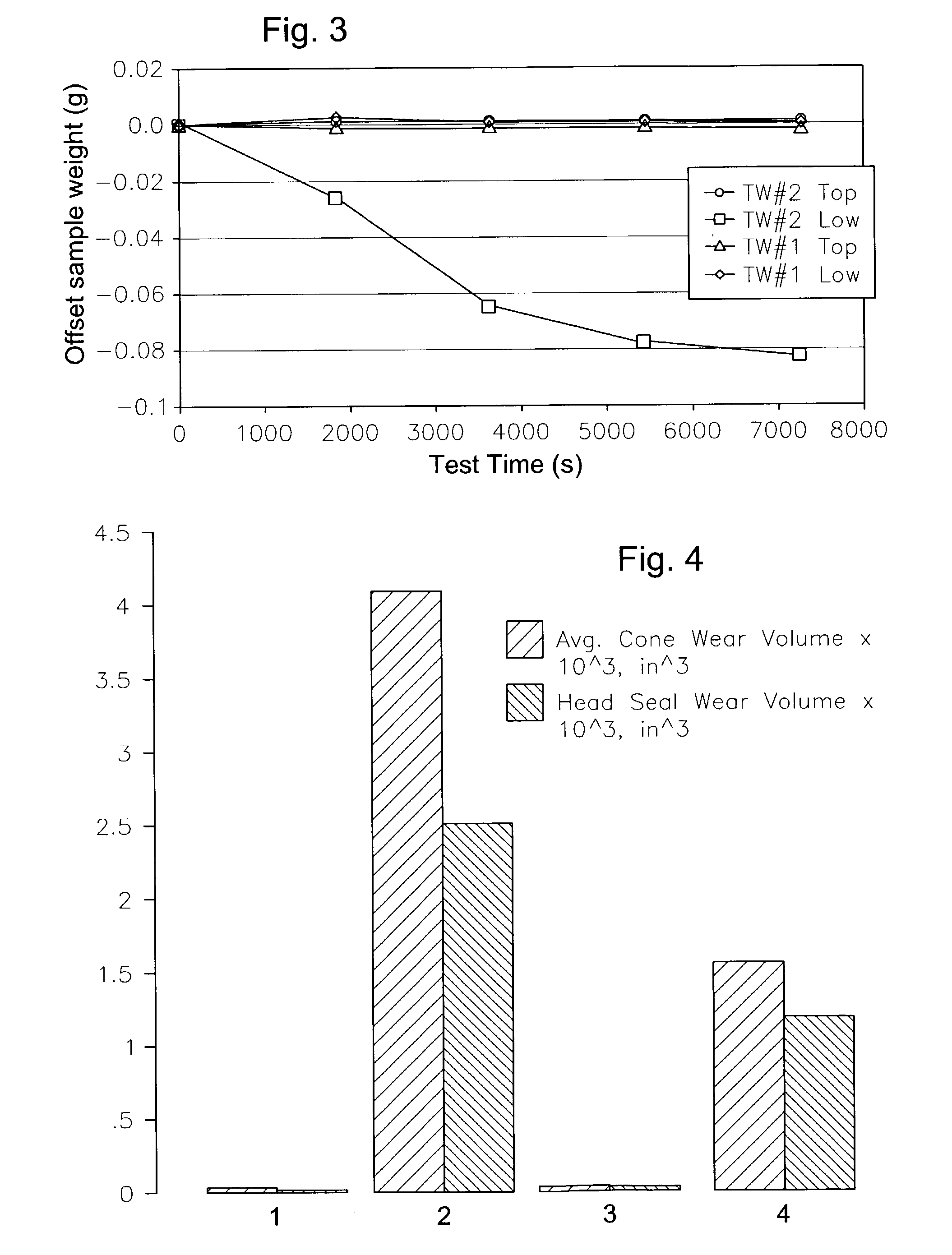

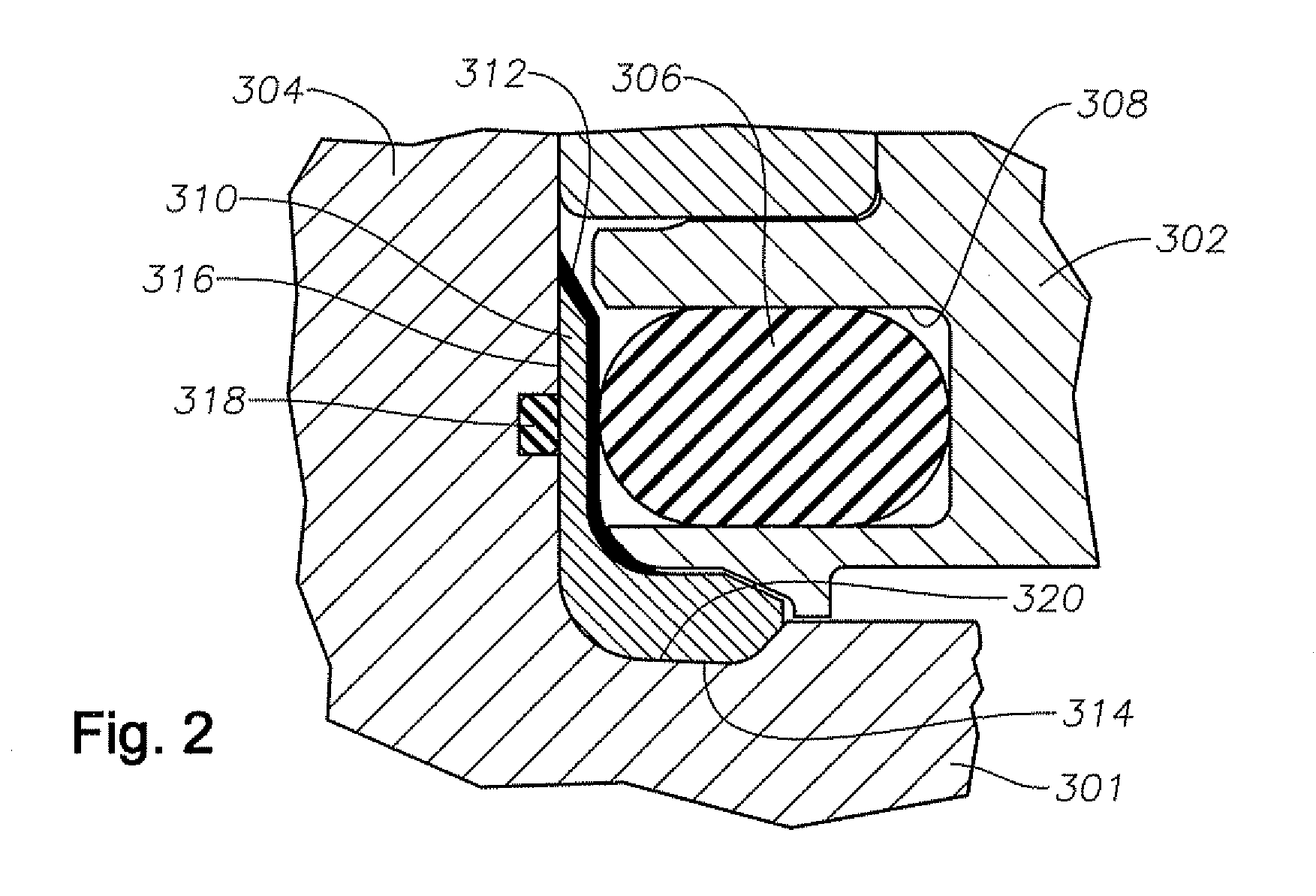

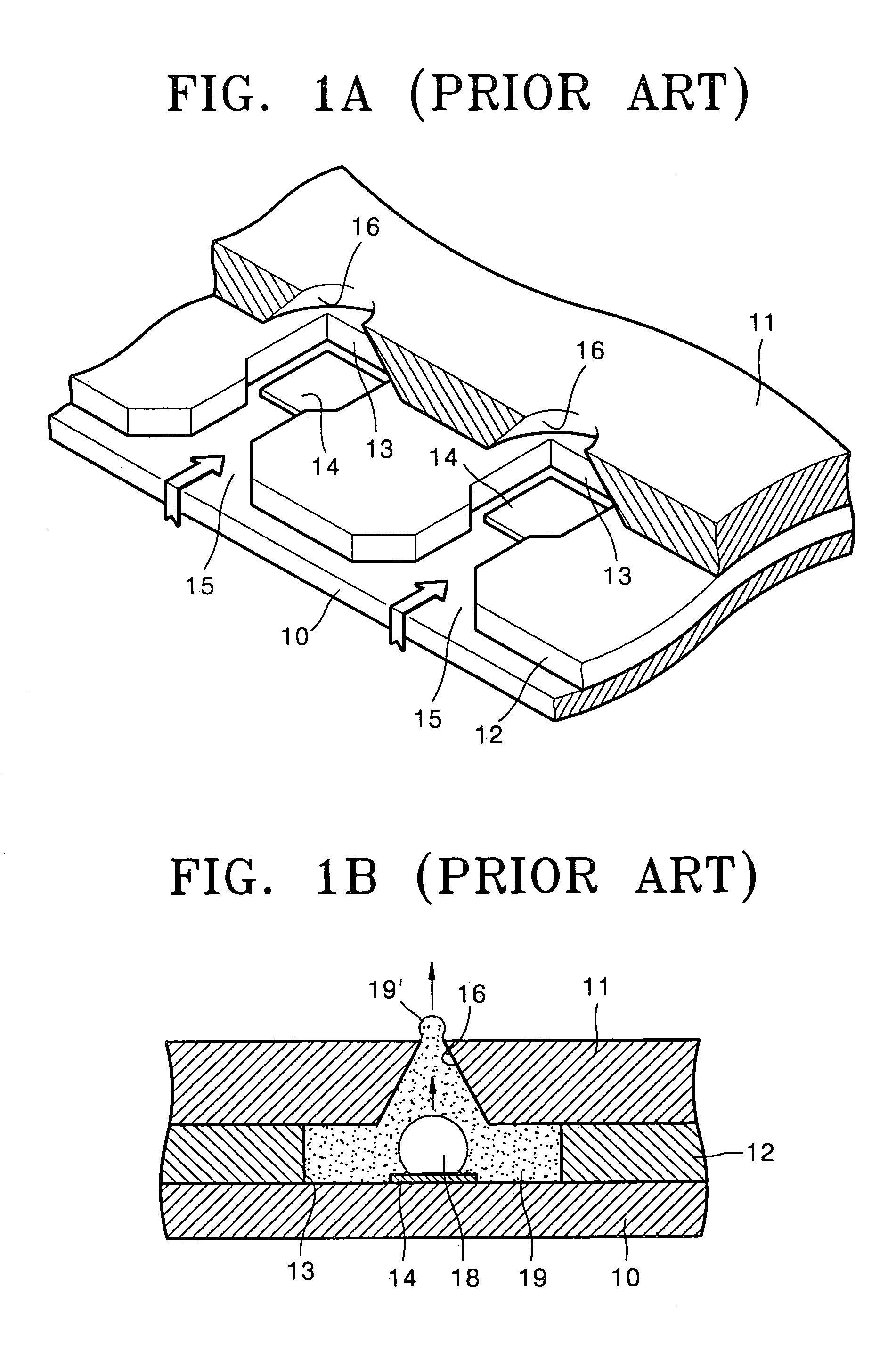

DLC coating for earth-boring bit seal ring

An earth-boring bit has a seal assembly with a seal face having a DLC coating. The seal assembly locates between a bearing pin and a cone of the bit. The seal assembly has at least one rigid ring that rotates against a mating surface. The DLC coating is diamond-like carbon that may be coated by different processes onto either the ring, the mating surface, or both.

Owner:BAKER HUGHES INC

Earth Boring Bit with DLC Coated Bearing and Seal

A roller cone bit is provided that includes a wear resistant diamond-like carbon coating applied to a bearing shaft, where it is in sliding contact with the bearing seal. The wear resistant diamond-like carbon coating reduces wear and corrosion of the head bearing shaft sealing surface and provides extended life to the bearing seal.

Owner:BAKER HUGHES INC

Method of making heat treatable coated article with carbon inclusive protective layer

InactiveUS20060166009A1Reducing and minimizing corrosionNot readily susceptible to fogging upFouling preventionVehicle cleaningDlc coatingHigh density

A soda inclusive glass substrate is coated with a highly tetrahedral amorphous carbon inclusive layer that is a form of diamond-like carbon (DLC). In certain embodiments, the amorphous carbon layer includes at least about 35% sp3 carbon-carbon bonds, more preferably at least about 70%, and most preferably at least about 80% of the sp3 carbon-carbon bonds. The high density (e.g. greater than or equal to about 2.4 gm / cm3) of the amorphous carbon layer prevents soda from exiting the glass and reacting with water at surface(s) of the glass, thereby minimizing visible stains (or corrosion) on the glass. The high density amorphous carbon layer also may repel water. In some embodiments, the highly tetrahedral amorphous carbon layer is part of a larger DLC coating, while in other embodiments the highly tetrahedral layer forms the entirety of a DLC coating on the substrate.

Owner:GUARDIAN GLASS LLC

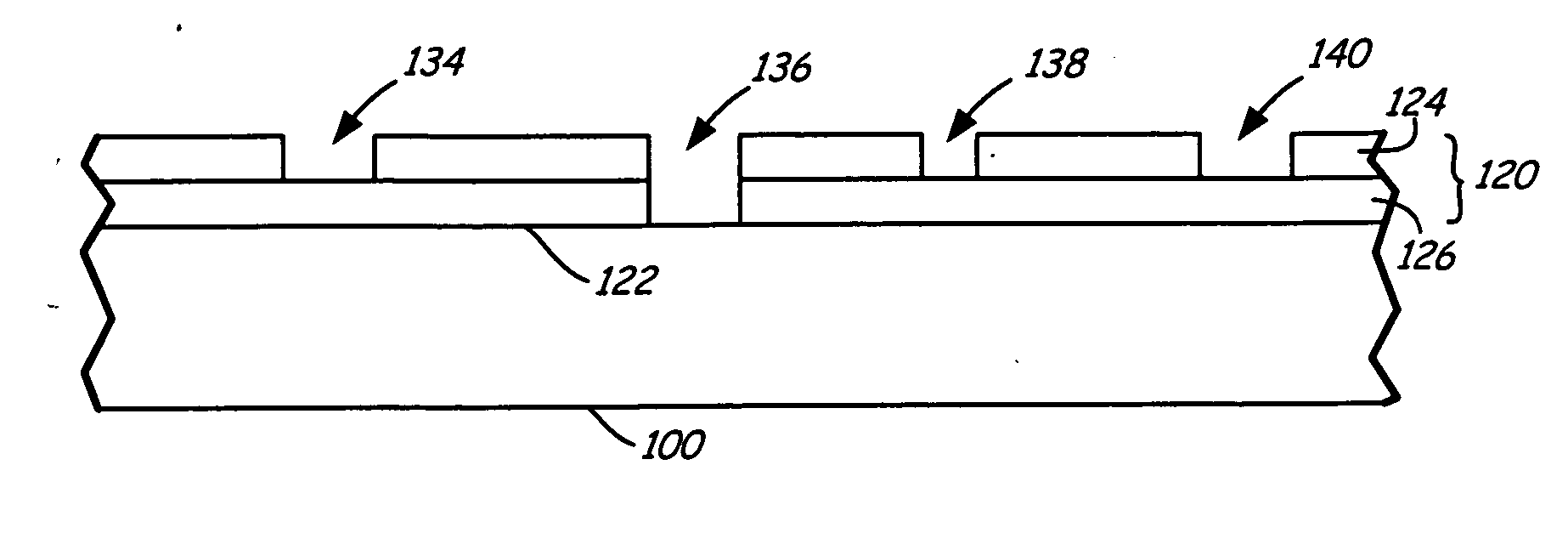

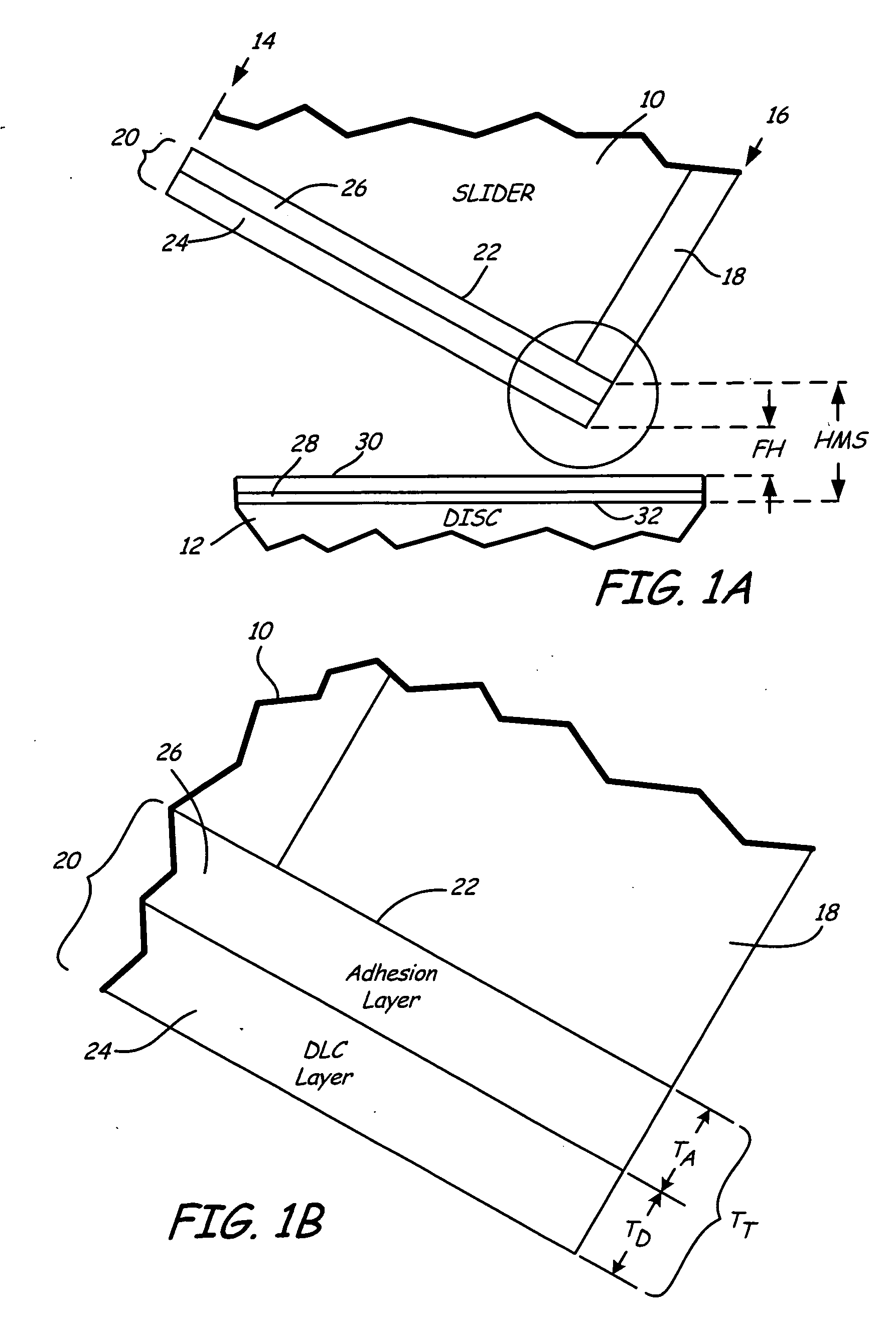

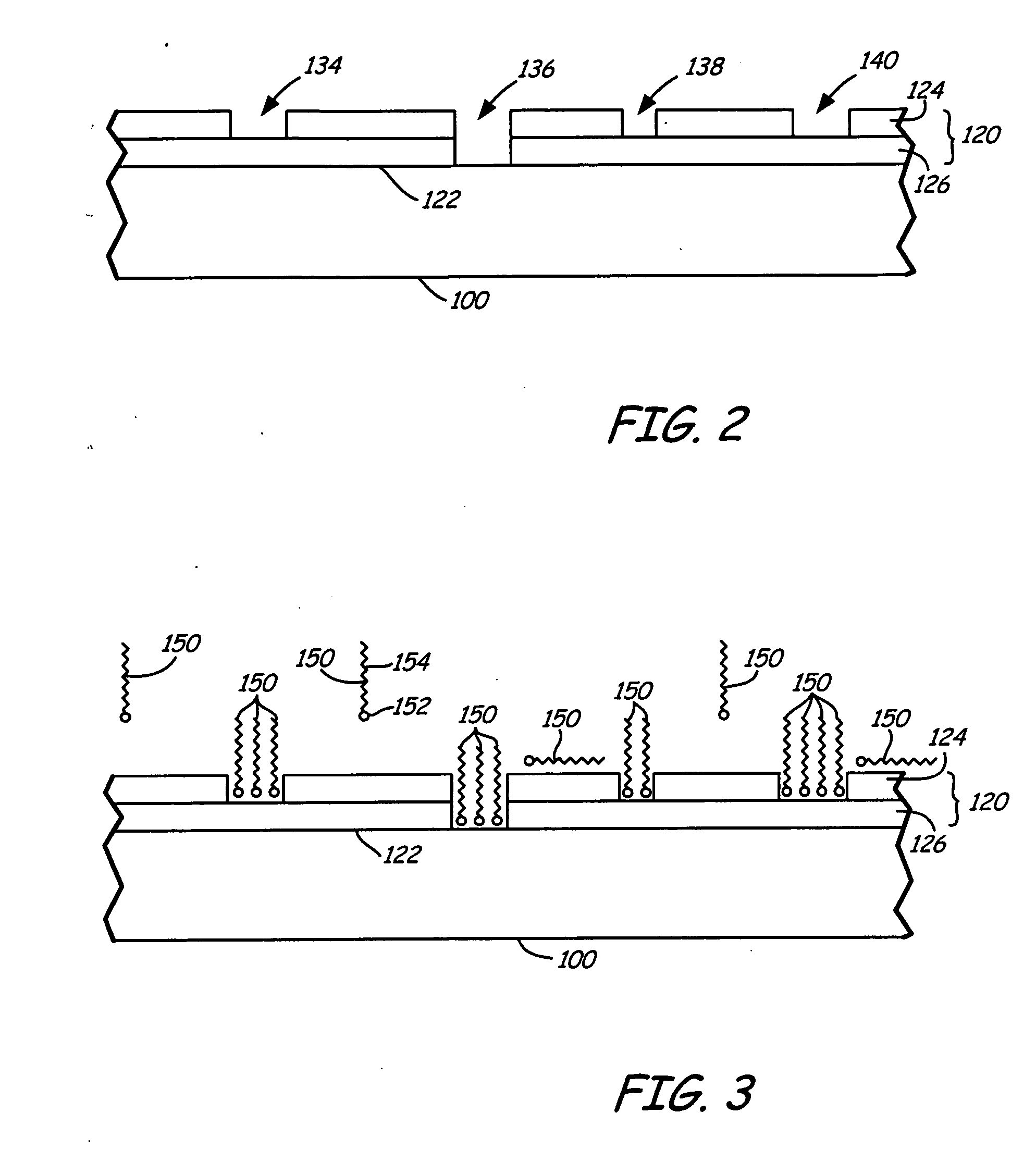

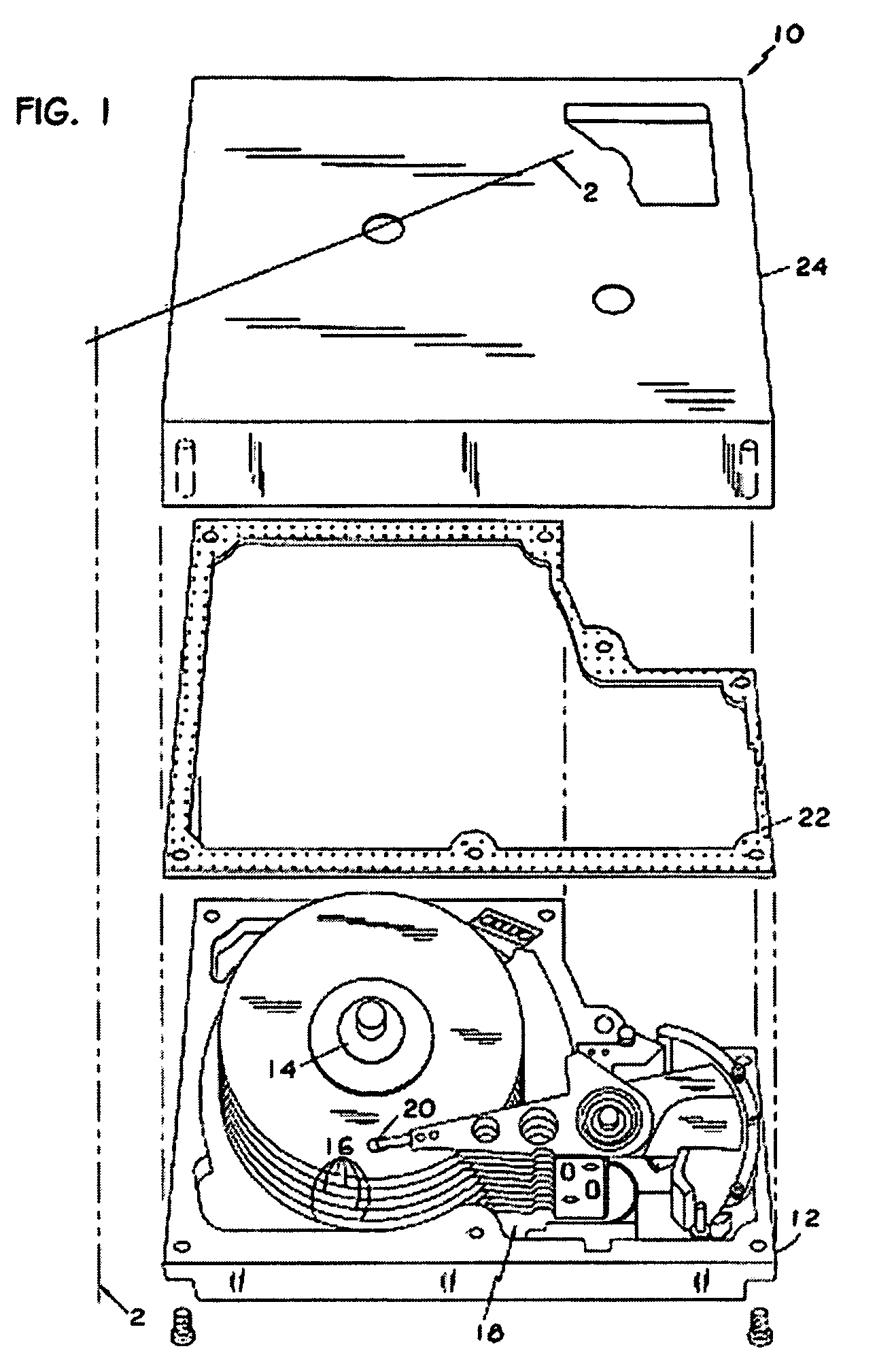

Self-assembled monolayer enhanced DLC coatings

InactiveUS20070042154A1Material nanotechnologyLiquid surface applicatorsDlc coatingSelf-assembled monolayer

A protective coating for a substrate includes a diamond-like carbon (DLC) layer overlying the substrate and having gaps where the substrate is not protected by the diamond-like carbon layer. The protective coating also includes a self-assembled monolayer formed in the gaps of the diamond-like carbon layer.

Owner:SEAGATE TECH LLC

Tungsten-titanium co-doped diamond coating material and preparation technique thereof

InactiveCN101787520AOvercoming the problem of increased coefficient of frictionSolve the brittleness problemVacuum evaporation coatingSputtering coatingDlc coatingGas phase

The invention discloses a tungsten-titanium co-doped diamond (DLC) coating material and a preparation technique thereof, which are characterized by: firstly, removing a pollution layer on the surface of a workpiece by ultrasonic cleaning, and performing argon-ion etching cleaning on the surface of the workpiece by glow discharge to obtain an atomic-scale clean surface; secondly, preparing a gradient transition layer by a reactive magnetron sputtering sedimentation method; and finally, preparing a preparing a DLC coating on the transition layer by magnetron sputtering and glow discharge plasma chemical vapor deposition method, wherein the synthesized DLC coating contains carbon element, tungsten element, titanium element and the like; the tungsten content is 2 to 5 percent; and the titanium content is 0.1 to 2.0 percent. The tungsten-titanium co-doped diamond (DLC) coating material is excellent in membrane / base binding force and low in friction coefficient and wear rate.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Multi-ion-beam sputter-deposition technology for doping with diamond-like carbon (DLC) coating

InactiveCN101787518AImprove performanceRealize complementary advantagesVacuum evaporation coatingSputtering coatingDlc coatingGrown film

The invention relates to a multi-ion-beam sputter-deposition technology for doping a diamond-like carbon (DLC) coating. The technology is characterized by comprising the following steps of: firstly, washing to removing a polluted layer on the surface of a workpiece by utilizing ultrasonic waves, and carrying out ion beam bombardment washing on the surface of the workpiece by utilizing an argon-ion beam generated by an ion source to obtain an atomic scale clean surface; then preparing a gradient transition layer by utilizing an auxiliary ion beam sputter-deposition method; and finally, synthesizing a multi-element doped DLC coating on the gradient transition layer by utilizing multi-ion-beam sputtering and low-energy ion beam auxiliary deposition. In the process of synthesizing the multi-element doped DLC coating by utilizing the multi-ion-beam sputtering and the low-energy ion beam auxiliary deposition, carbon particles and metallic particles which are generated by bombarding a graphite target and a metallic target are deposited by using a sputtering ion source, and gas ions generated by an auxiliary deposition ion source continuously bombard the surface of a grown film layer to regulate and control the microstructure of the film layer and realize multi-element doping.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

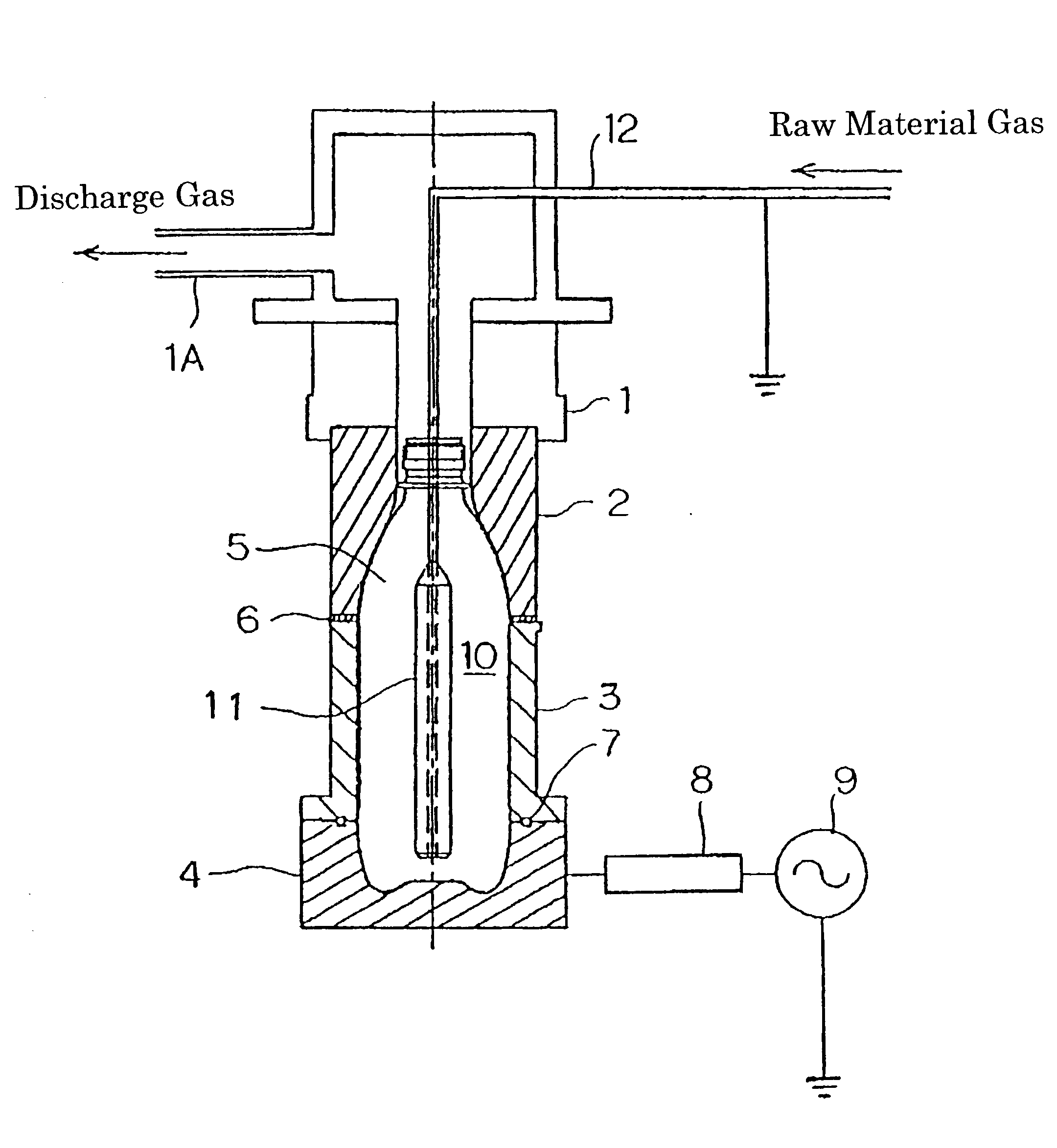

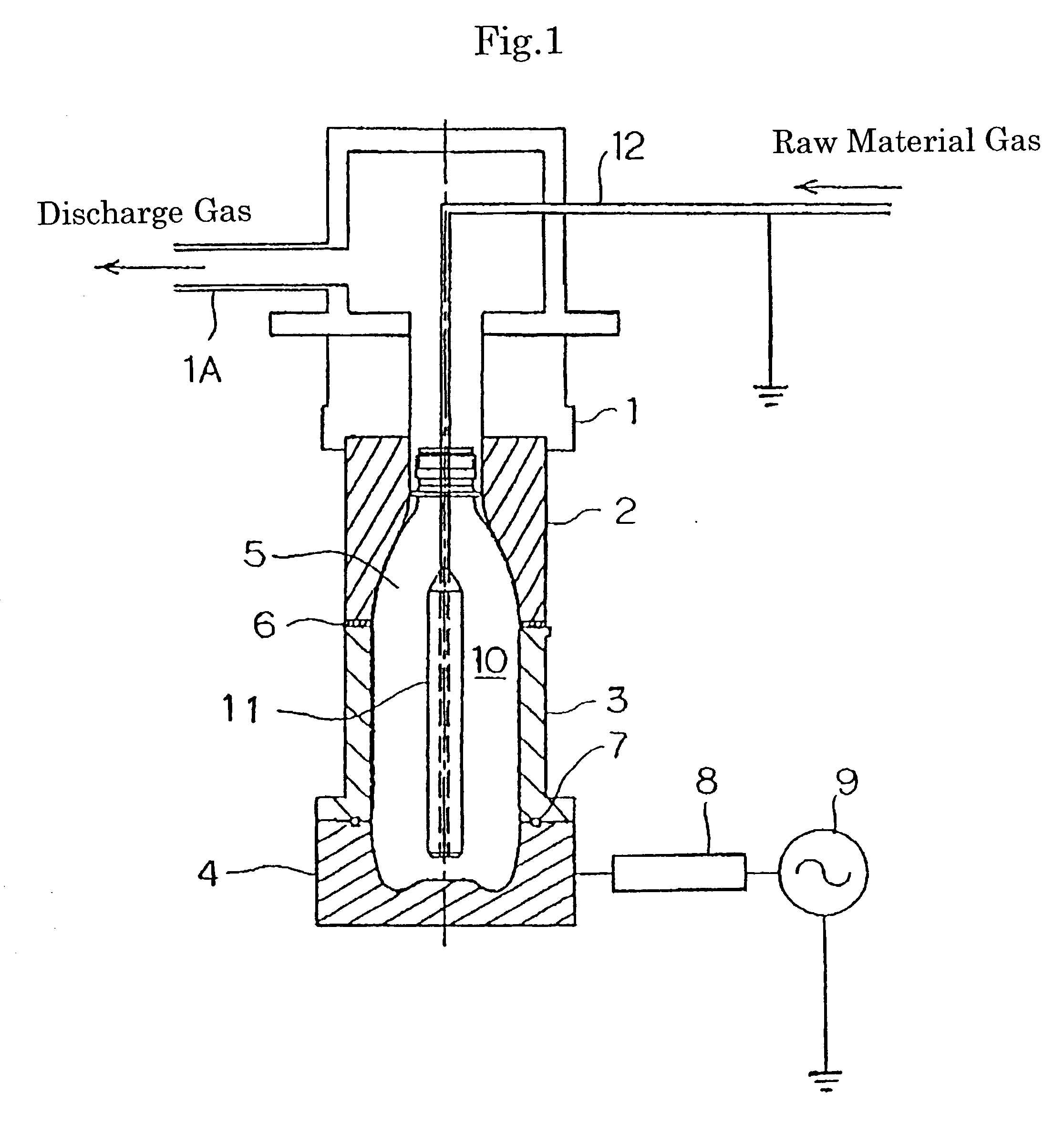

Pet container for foods and drinks containing recycled resin and having dlc coating film formed on surface thereof

InactiveUS20030087030A1Sufficient contaminant elution barrier propertySatisfactory fundamental container propertyBottlesPlastic recyclingDlc coatingIntrinsic viscosity

A PET container for foods and drinks having a DLC coating film formed on the inner surface thereof, characterized in that the PET container for foods and drinks is produced by the use of a molding material comprising a mixture of a recycled resin which is originated from a used PET container for foods and drinks and has not subjected to a treatment for adjusting its intrinsic viscosity with a fresh PET resin. The above PET container for foods and drinks can provide satisfactory barrier properties against a pollutant substance being present in a resin.

Owner:MITSUBISHI SHOJI PLASTICS

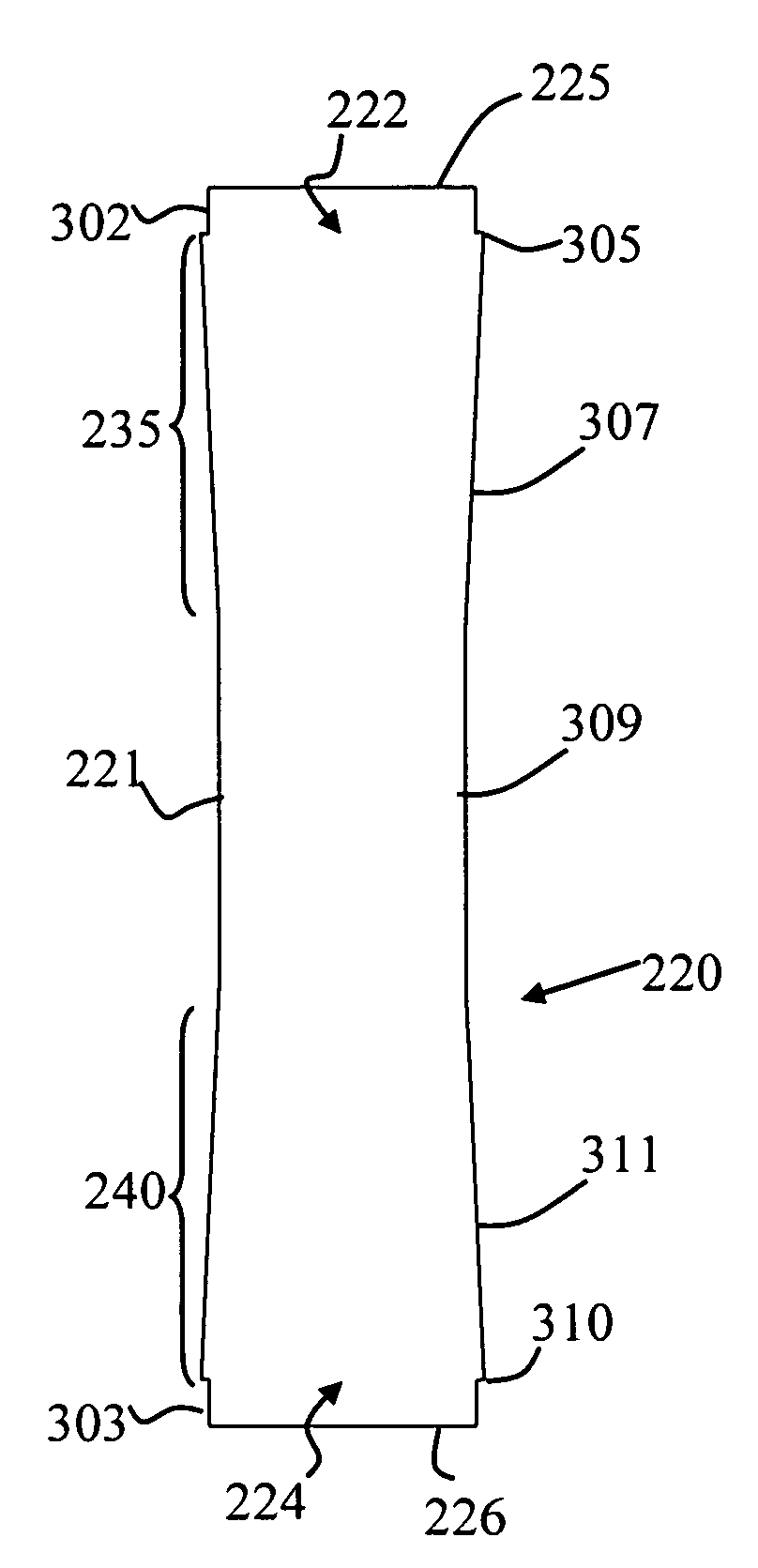

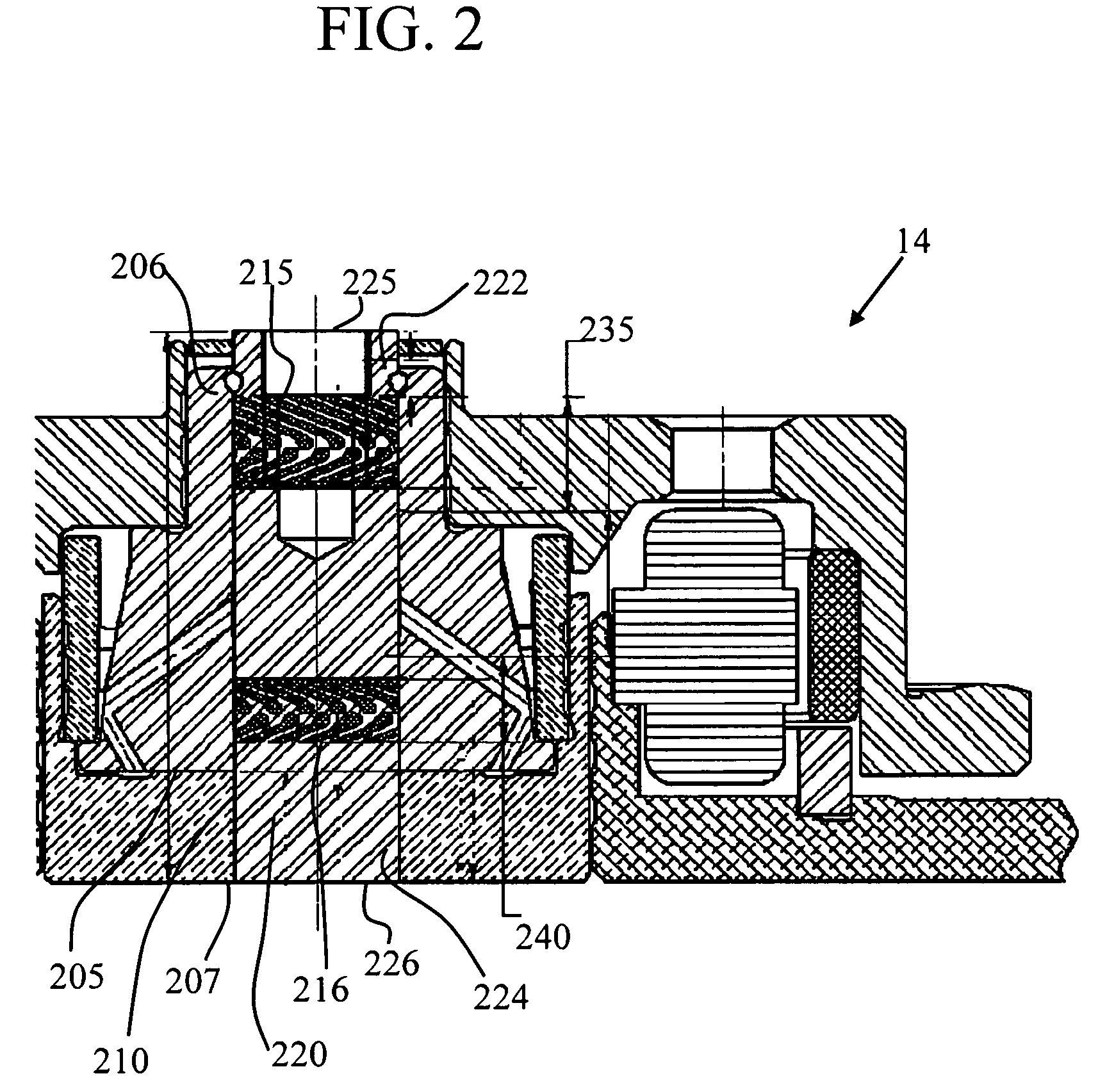

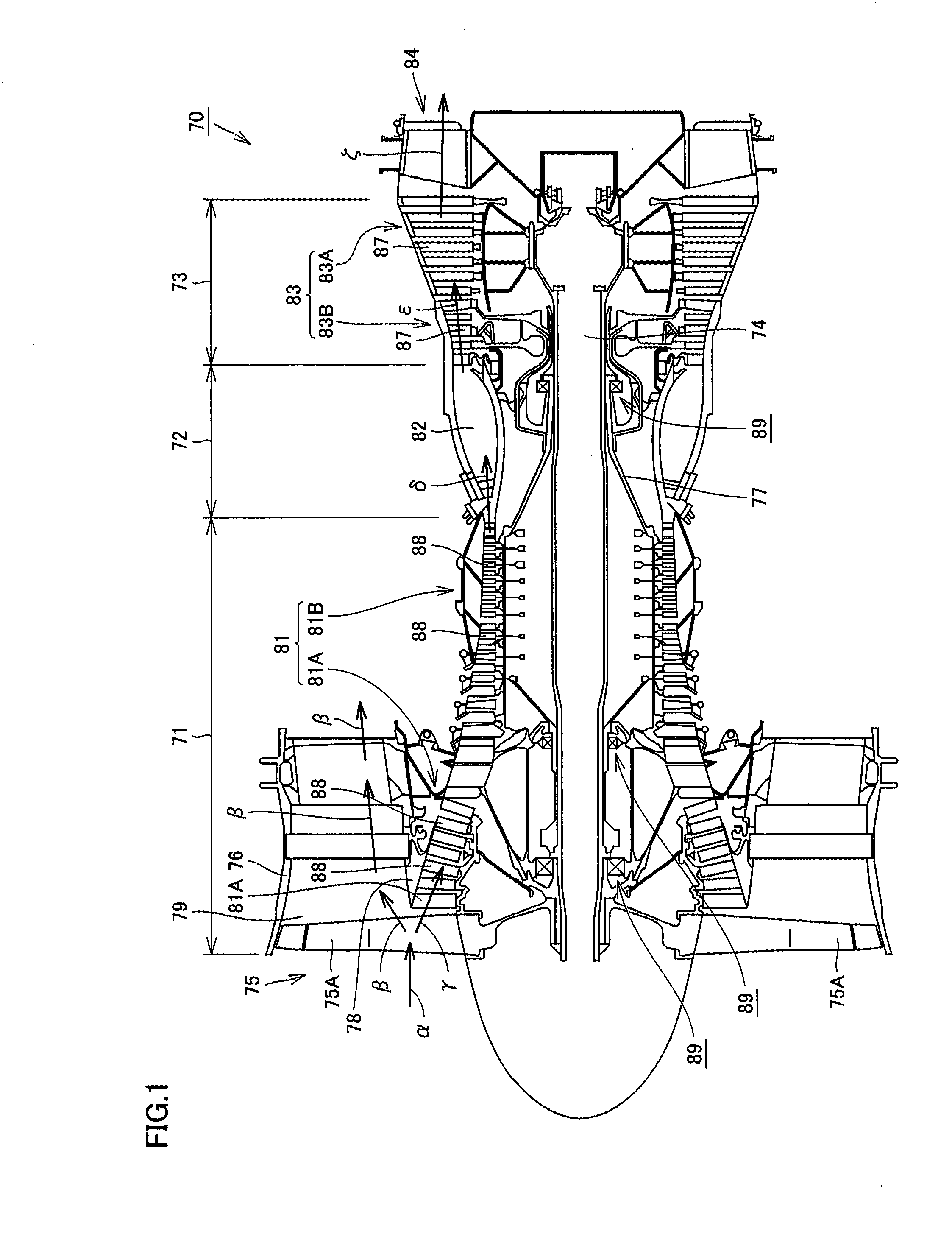

FDB motor with tapered shaft for improved pumping efficiency

For motors having a journal with one or more groove regions and a shaft for relative rotation in the journal, aspects include providing a dual tapered shaft. The shaft may be tapered by the application of a wear resistant coating at least opposite the groove regions. The coating introduces a shaft taper from near a top end and from near a bottom end towards the shaft middle. The shaft taper may provide for improved pumping efficiency. The coating may be applied in various processes such as chemical vapor deposition or physical vapor deposition to establish a thickness gradient of coating material from near the top end and near the bottom end towards the shaft middle. In one example, the coating includes a DLC coating. Additionally, shaft portions may be shielded to prevent coatings thereon.

Owner:SEAGATE TECH LLC

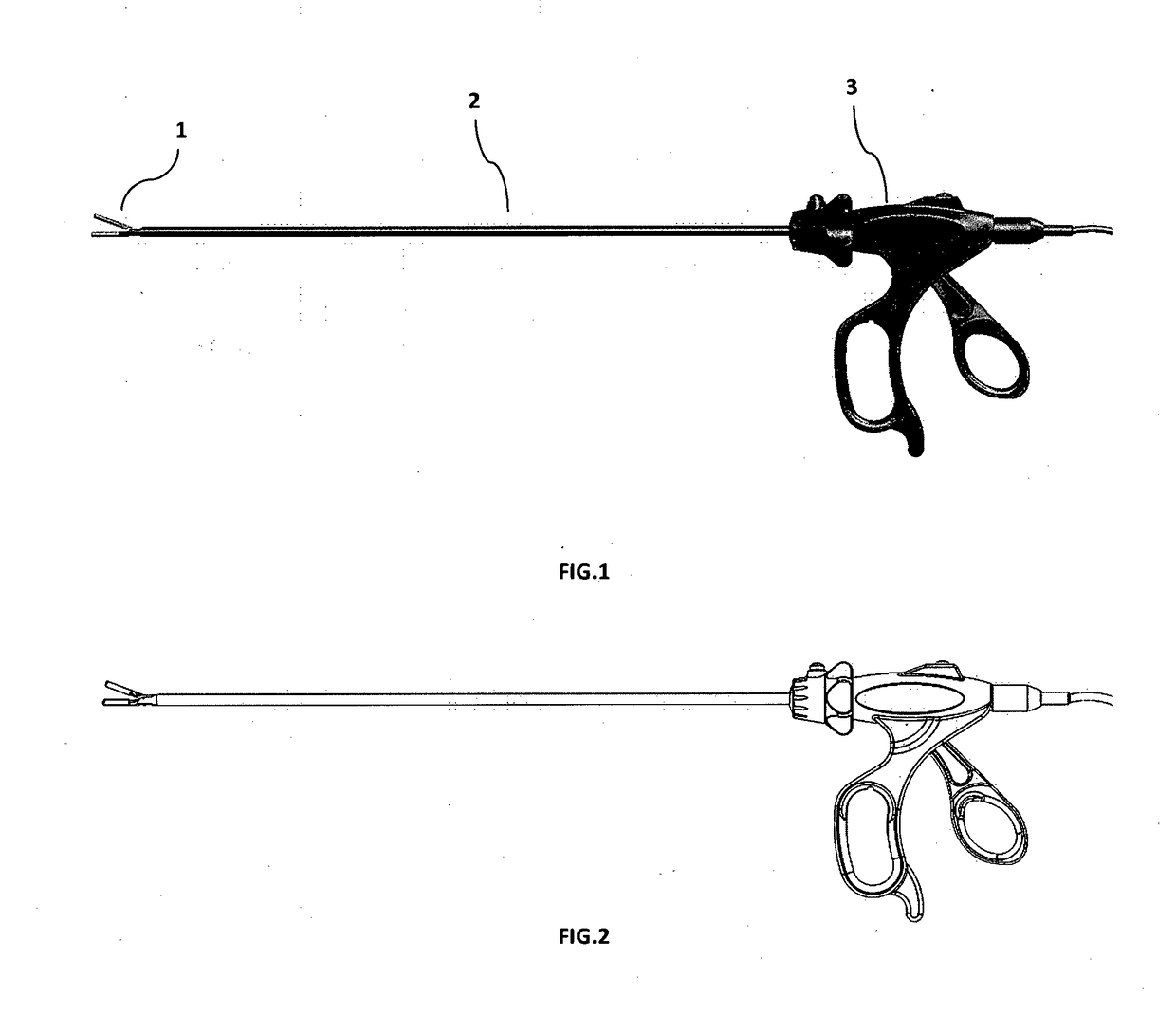

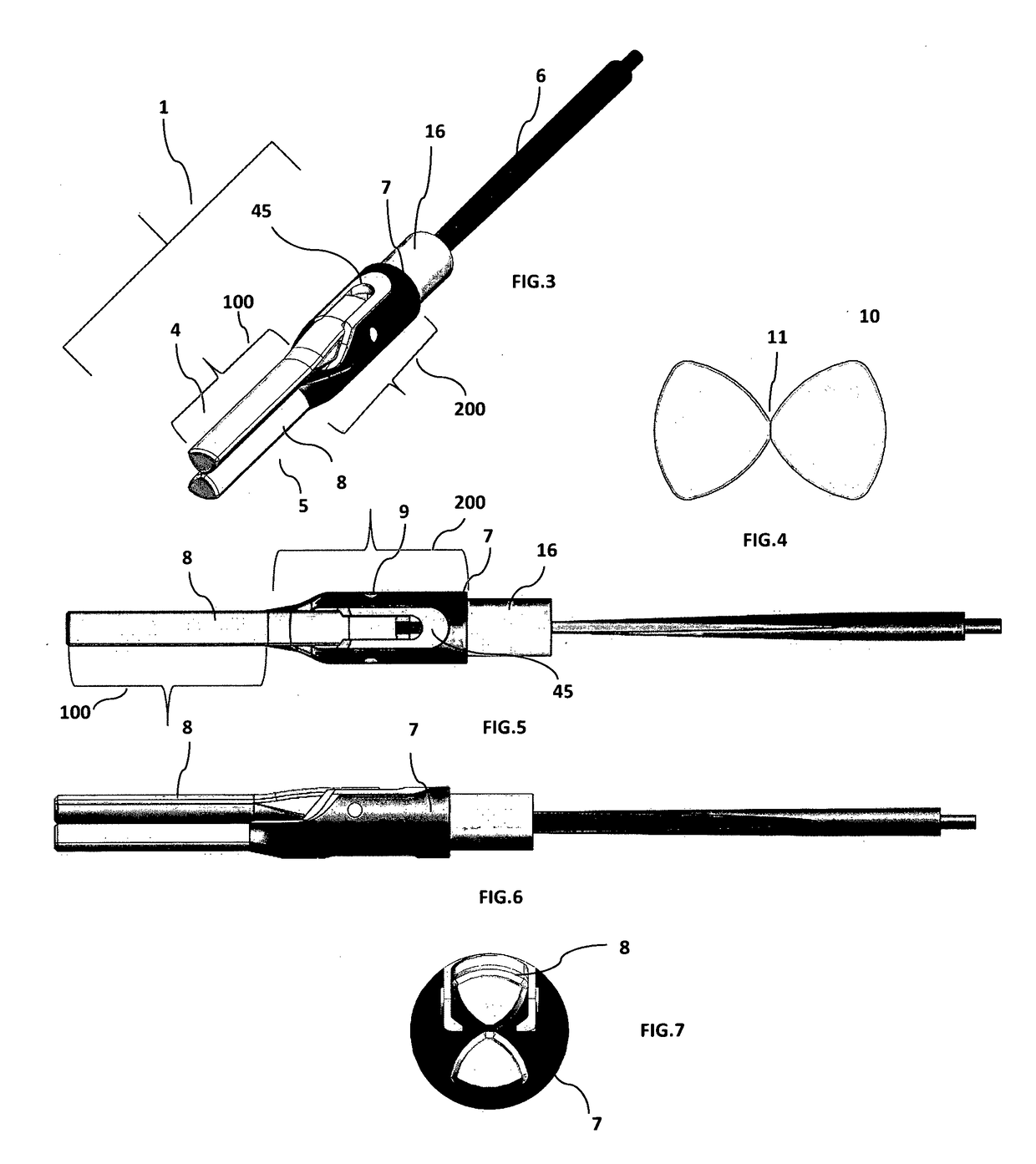

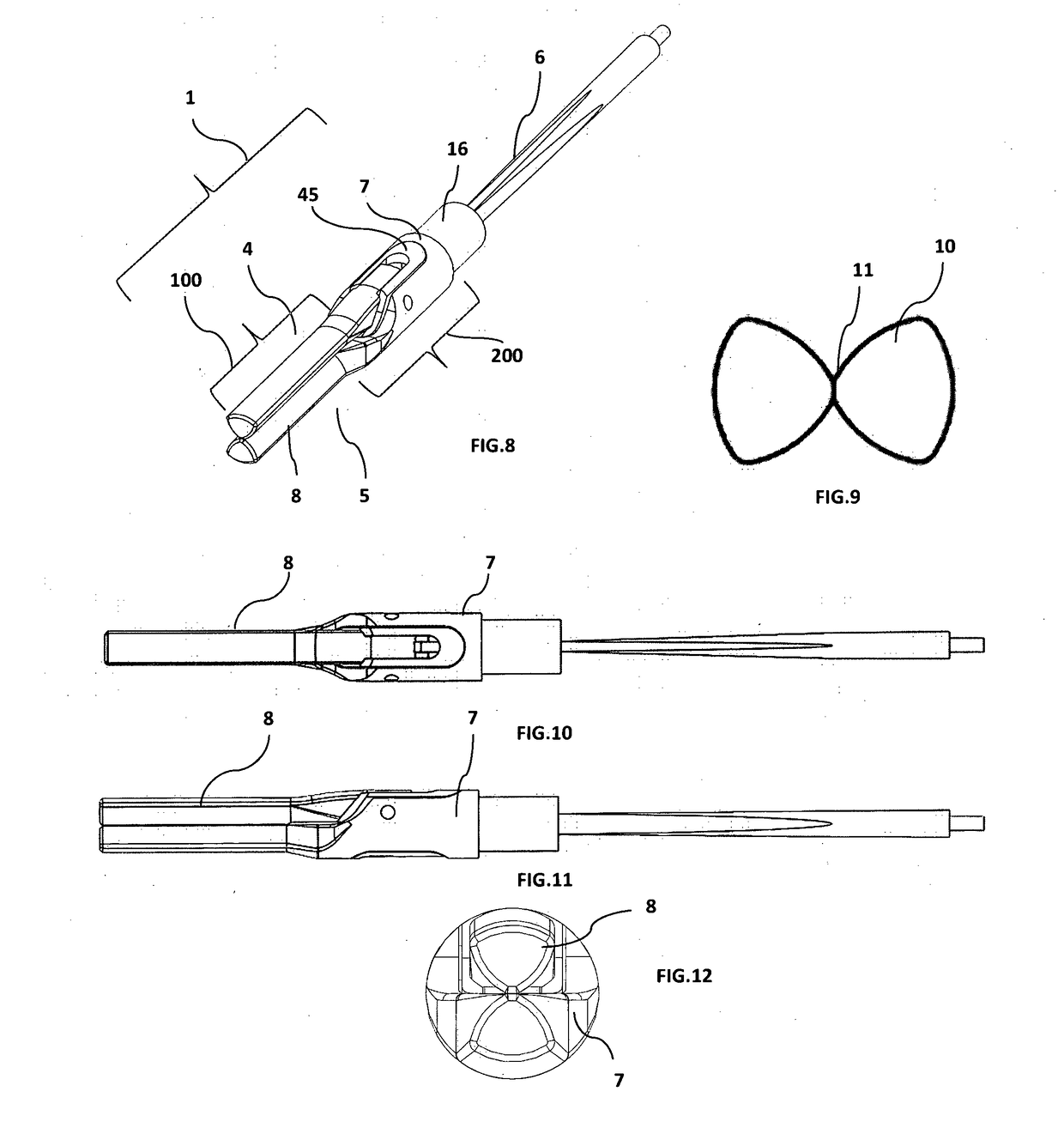

Tissue/vessel sealer and/or cutter with variable shapes of jaw assembly with partial

PendingUS20190029746A1Much burning of vessel/tissueEnergy requiredSurgical instruments for heatingSurgical manipulatorsDlc coatingReusability

A surgical instrument having vessel / tissue sealer and / or cutter jaws are described designed with variety of shapes and more safer jaws. Optional ceramic insert, partial DLC coating on the substantially back portion and TiN coating is a combination in the jaw assembly which increases its safety, performance and reusability compared to other existing jaws.

Owner:K NINE WRITING SYST PVT LTD +1

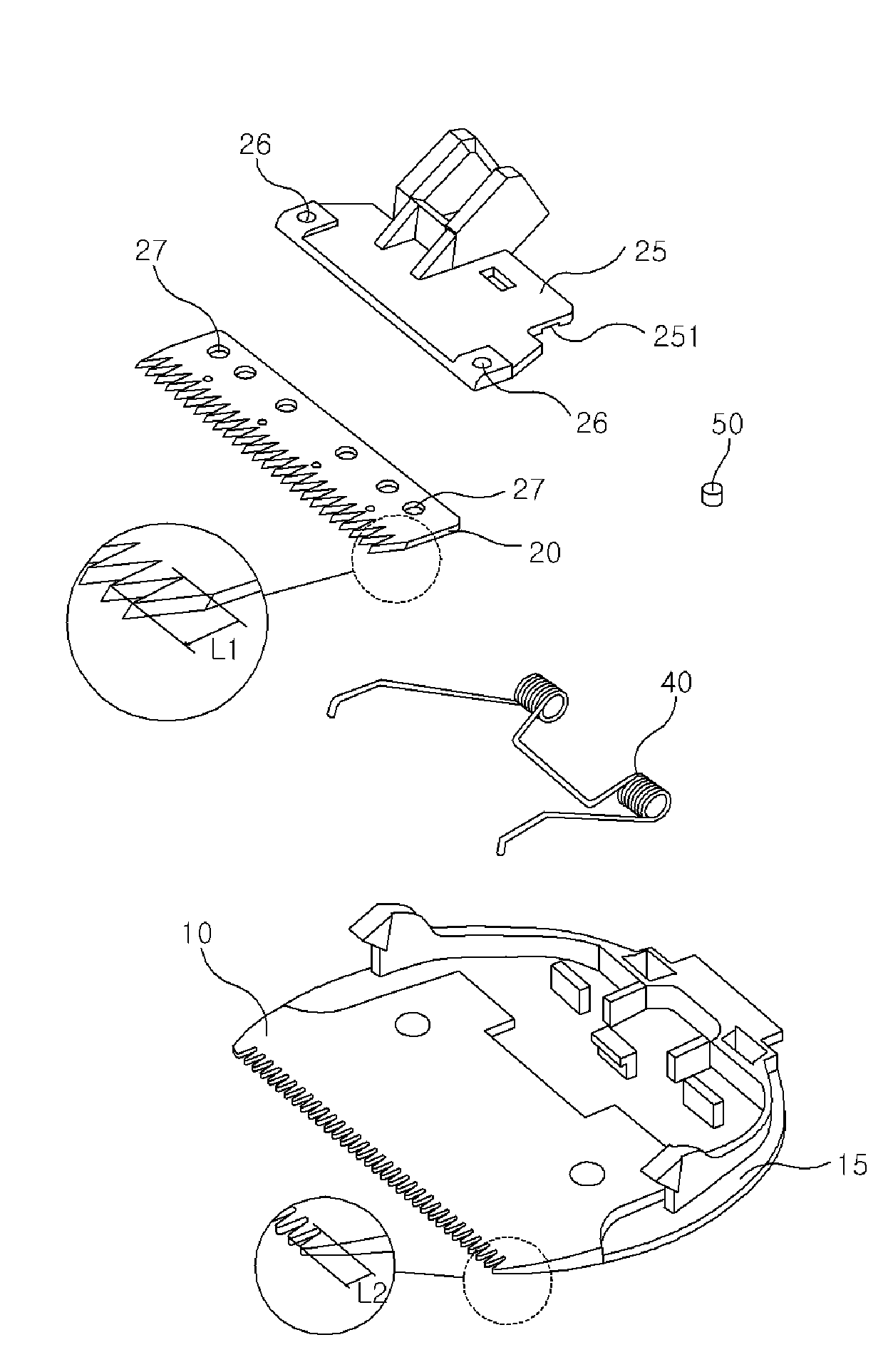

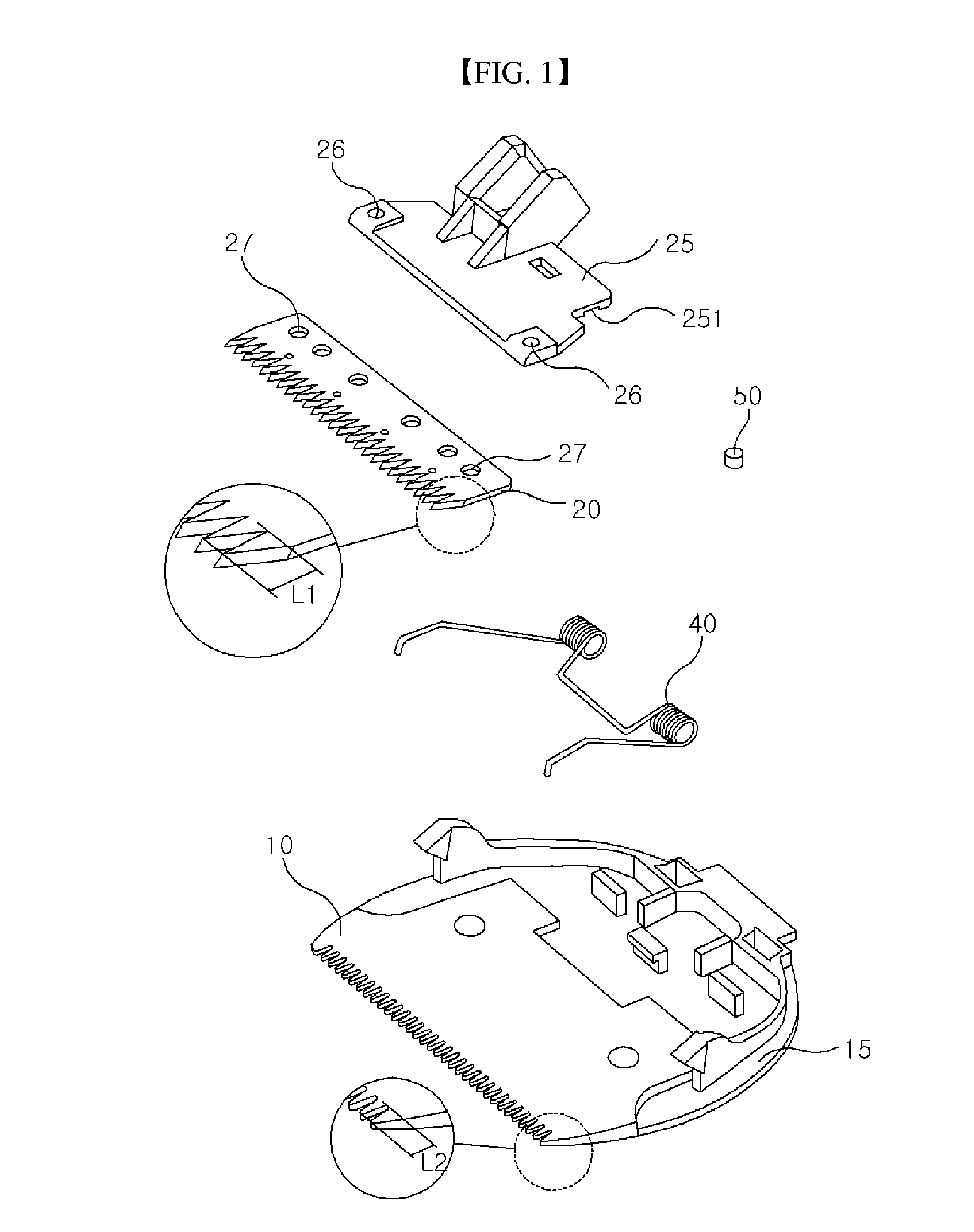

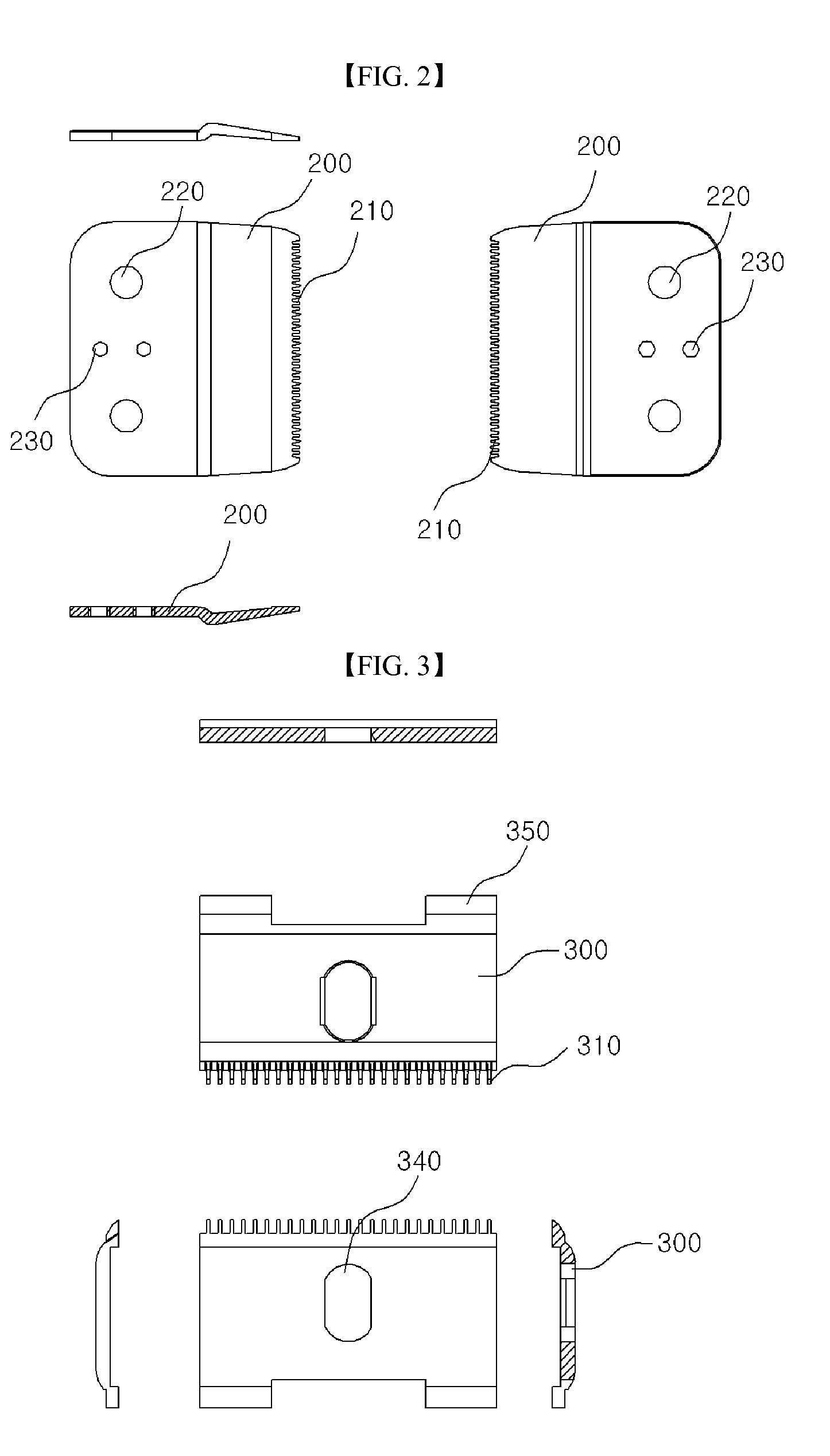

Hair clipper blade assembly

The present invention relates to an electric hair clipper blade assembly having a guide plate connected with a fixed blade and a movable blade that moves in a left and right direction or horizontal direction and a connection / fixed member. In particular, the present invention relates to an electric hair clipper blade assembly having fixed and movable blades with depths deeper than those of conventional fixed and movable blades and a blade body DLC-coated, on which a portion of the guide plate, the fixed blade, and the movable blade are formed, to maintain fairly good cutting power in cutting short hair or curly hair.

Owner:KINGDOM INT

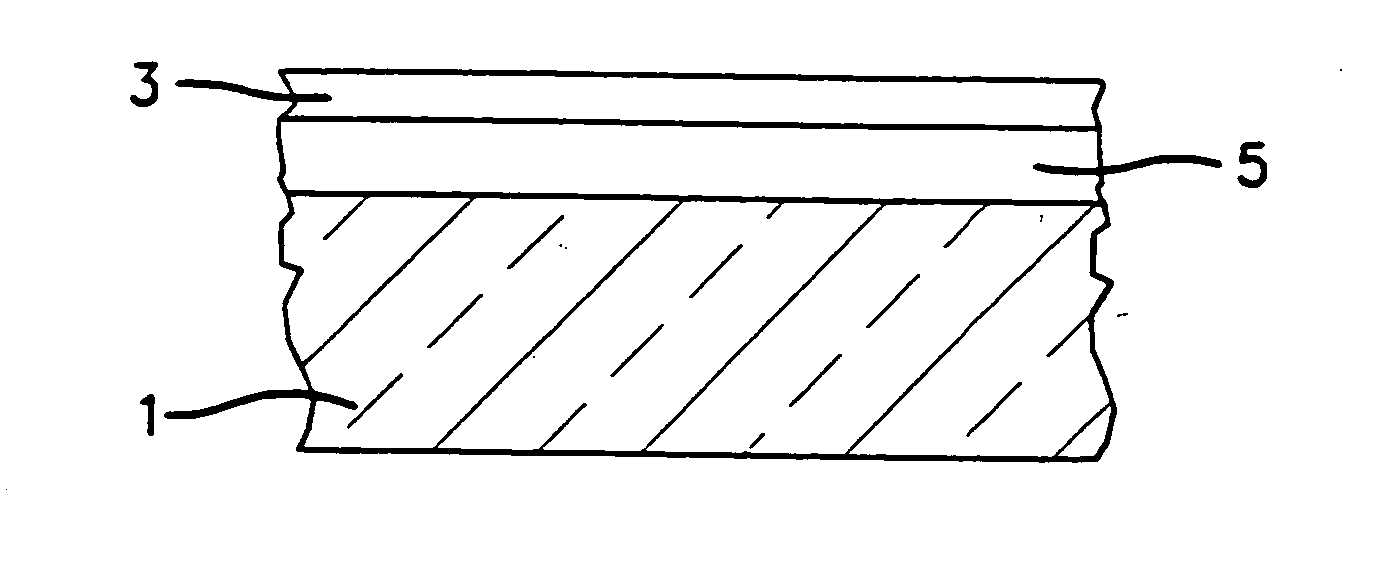

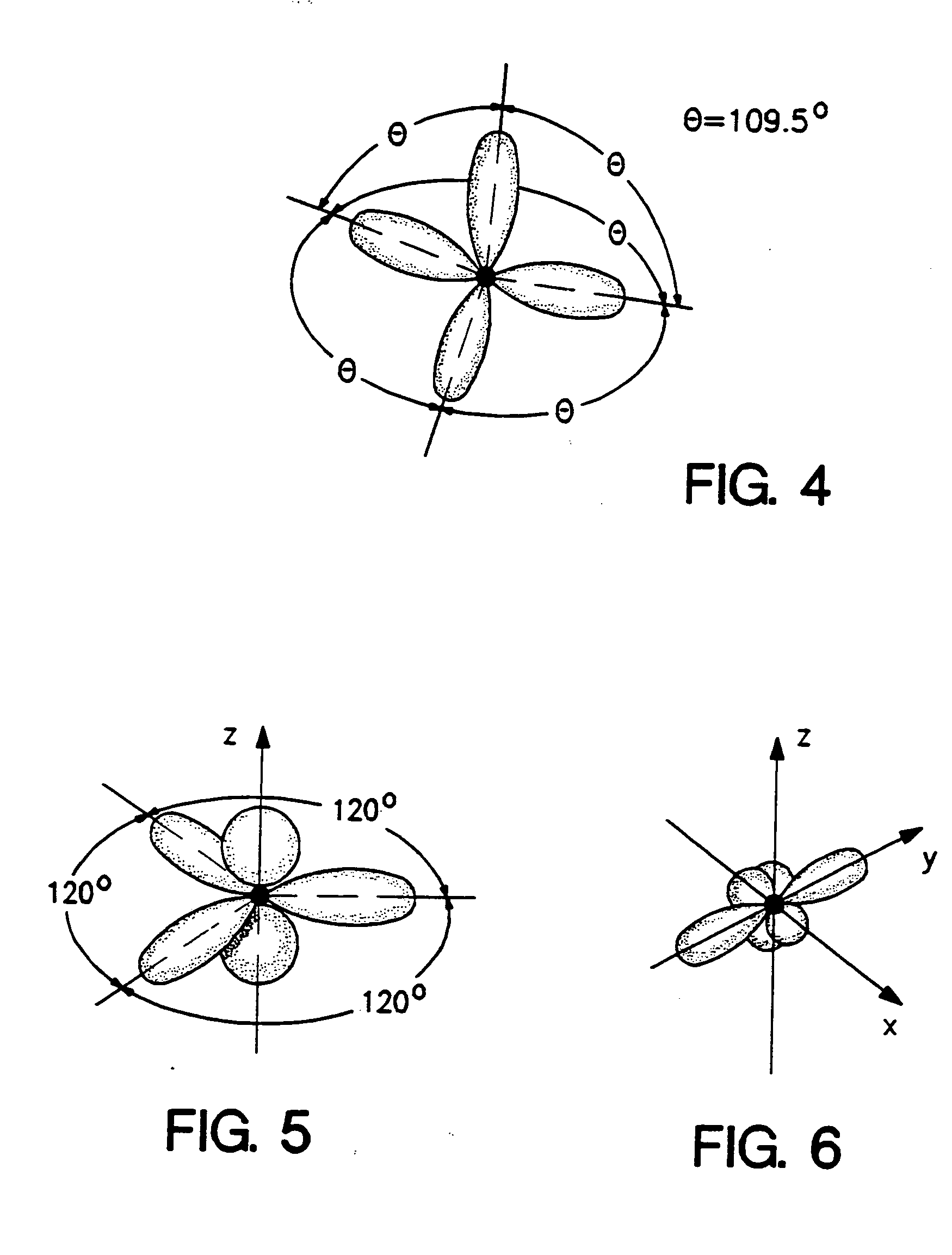

Piston ring

ActiveUS20110101620A1Less effortImprove adhesionPiston ringsBraking action transmissionDlc coatingPiston ring

A piston ring with a DLC coating comprises an adhesive layer on a base material from inside to outside, an amorphous metallic hydrocarbon layer and an amorphous non-metallic hydrocarbon layer, wherein primarily sp2 bonds predominate in the metallic hydrocarbon layer and the non-metallic hydrocarbon layer comprises sp2and sp3 bonds, the sp3 bond fraction being higher than in the metallic hydrocarbon layer so that an electrical resistance of the DLC coating arises, said resistance being in the range greater than 5000 ohms, in particular greater than 5000 kohms.

Owner:FEDERAL MOGUL BURSCHEID

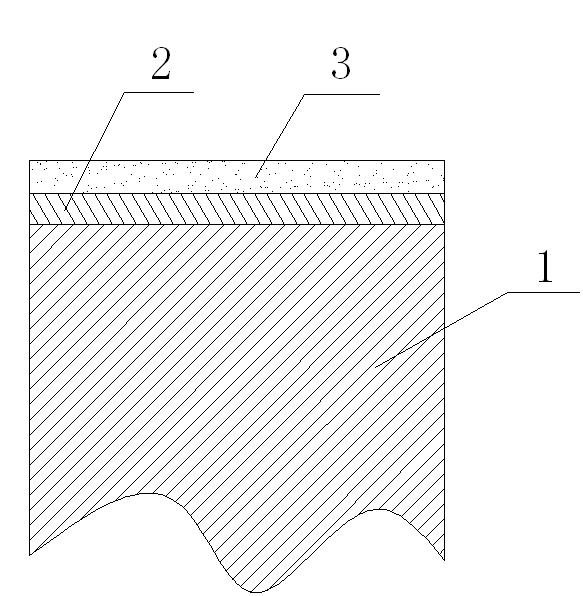

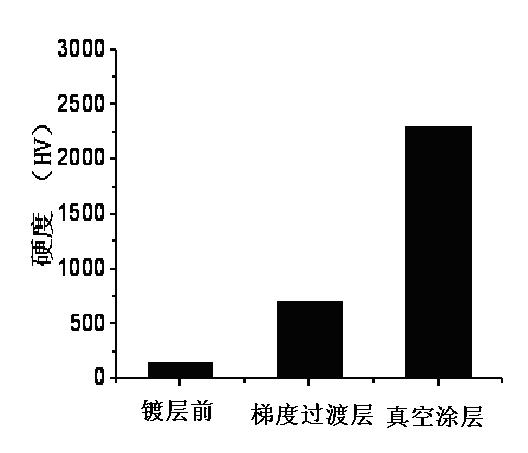

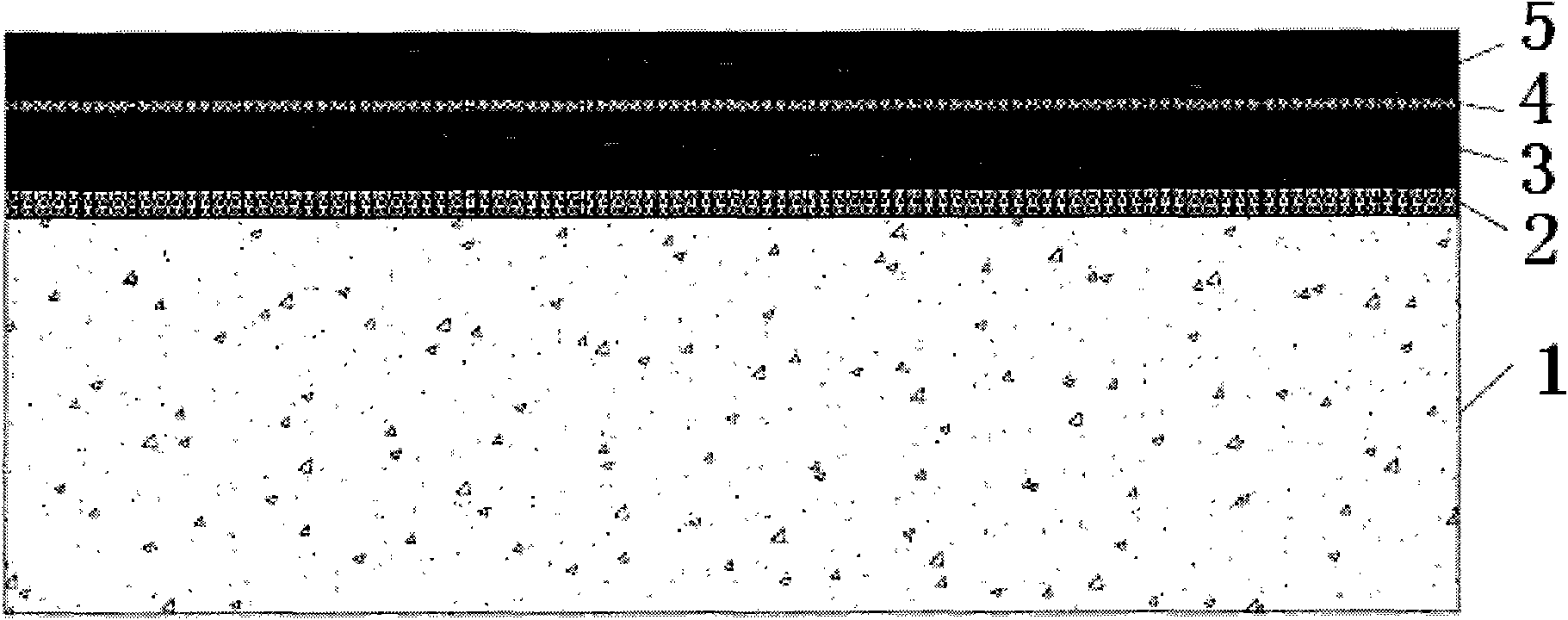

Surface compound strengthening process for aluminum alloy material

ActiveCN102115883AHigh bonding strengthHigh hardnessSuperimposed coating processDlc coatingChemical plating

The invention discloses a surface compound strengthening process for an aluminum alloy material, aiming to solve the problems that chemical plating of Ni, Ni-P and Ni-W-P or electroplating of Ni and Cr for aluminum and aluminum alloy has good bonding strength but low rigidity and poorer wear resistance, and vacuum coatings of CrN, TiN, TiAlN, TiCN or DLC for an aluminum alloy material have high rigidity and good wear resistance but poorer bonding strength with a substrate. The surface compound strengthening process disclosed by the invention comprises the following steps: firstly, plating a 2-10mu m thick gradient transition layer on the surface of an aluminum alloy substrate, then baking for 1-2 hours at constant temperature of 75-85 DEG C in a dry environment, and finally depositing oneor multiple coatings of CrN, TiN, TiAlN, TiCN or DLC on the aluminum alloy substrate by a vacuum coating technology. The surface compound strengthening process can improve the bonding strength between the vacuum coating and the aluminum alloy substrate, and simultaneously the surface of the aluminum alloy substrate has higher rigidity and wear resistance.

Owner:NAXAU NEW MATERIALS CORP

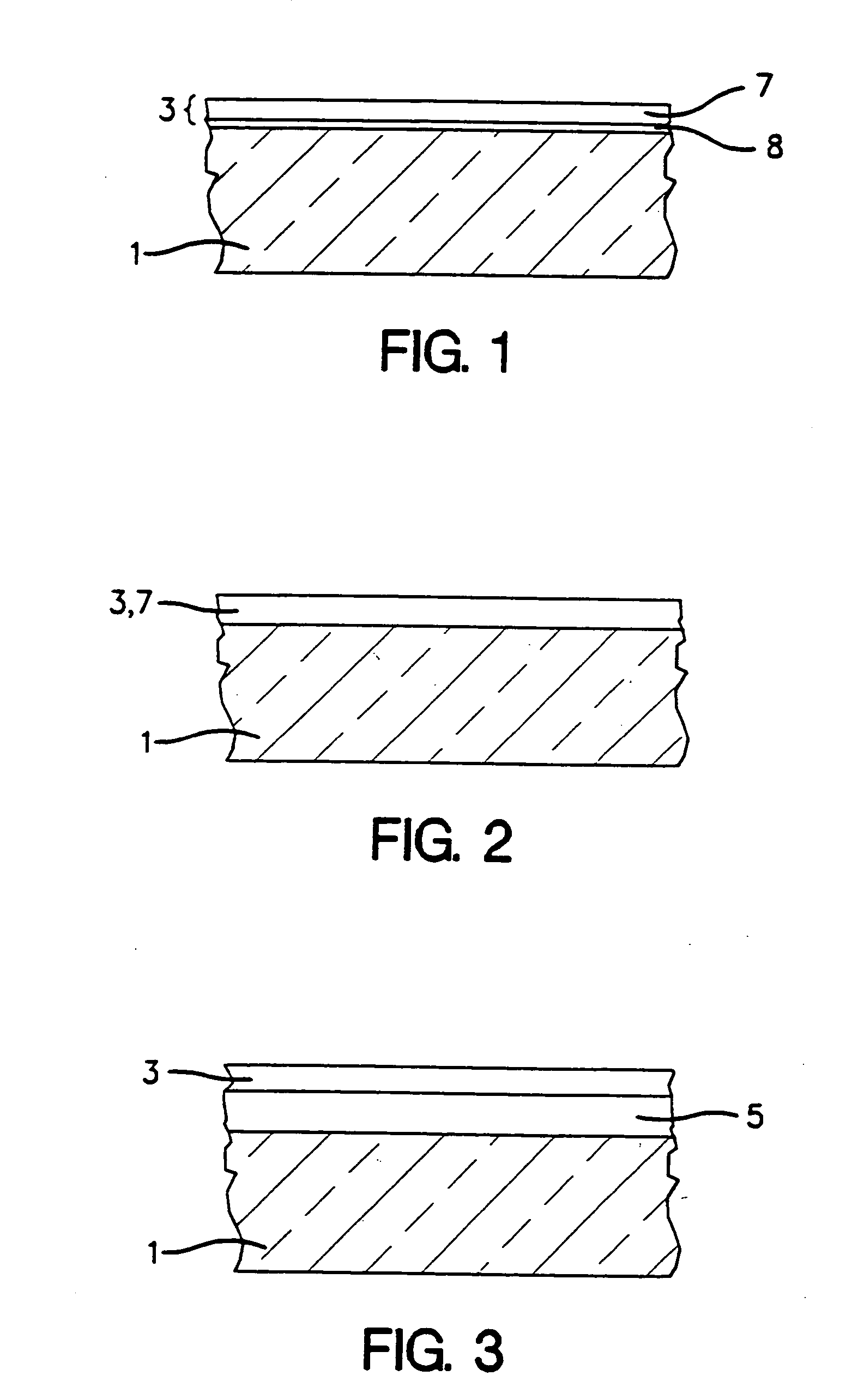

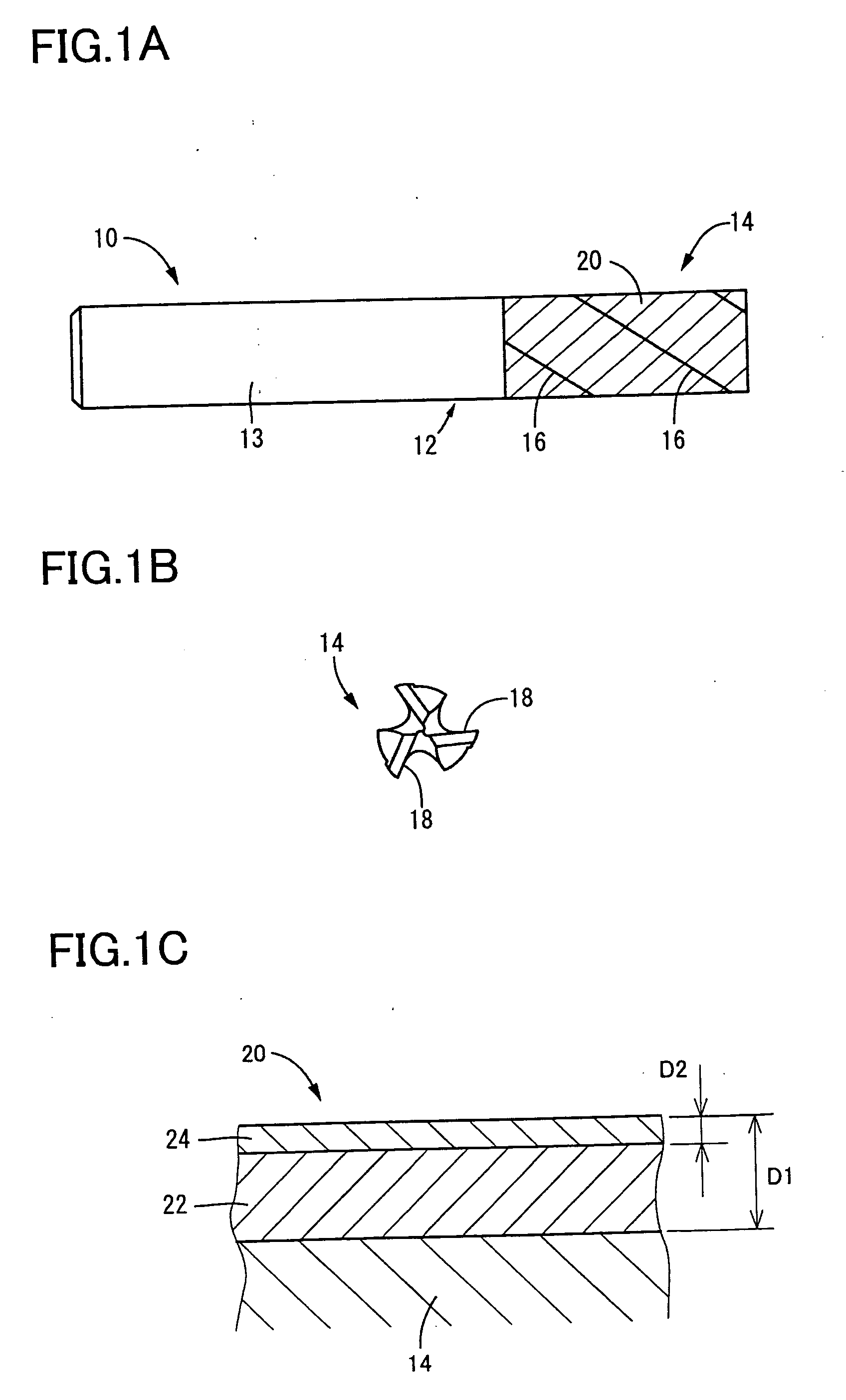

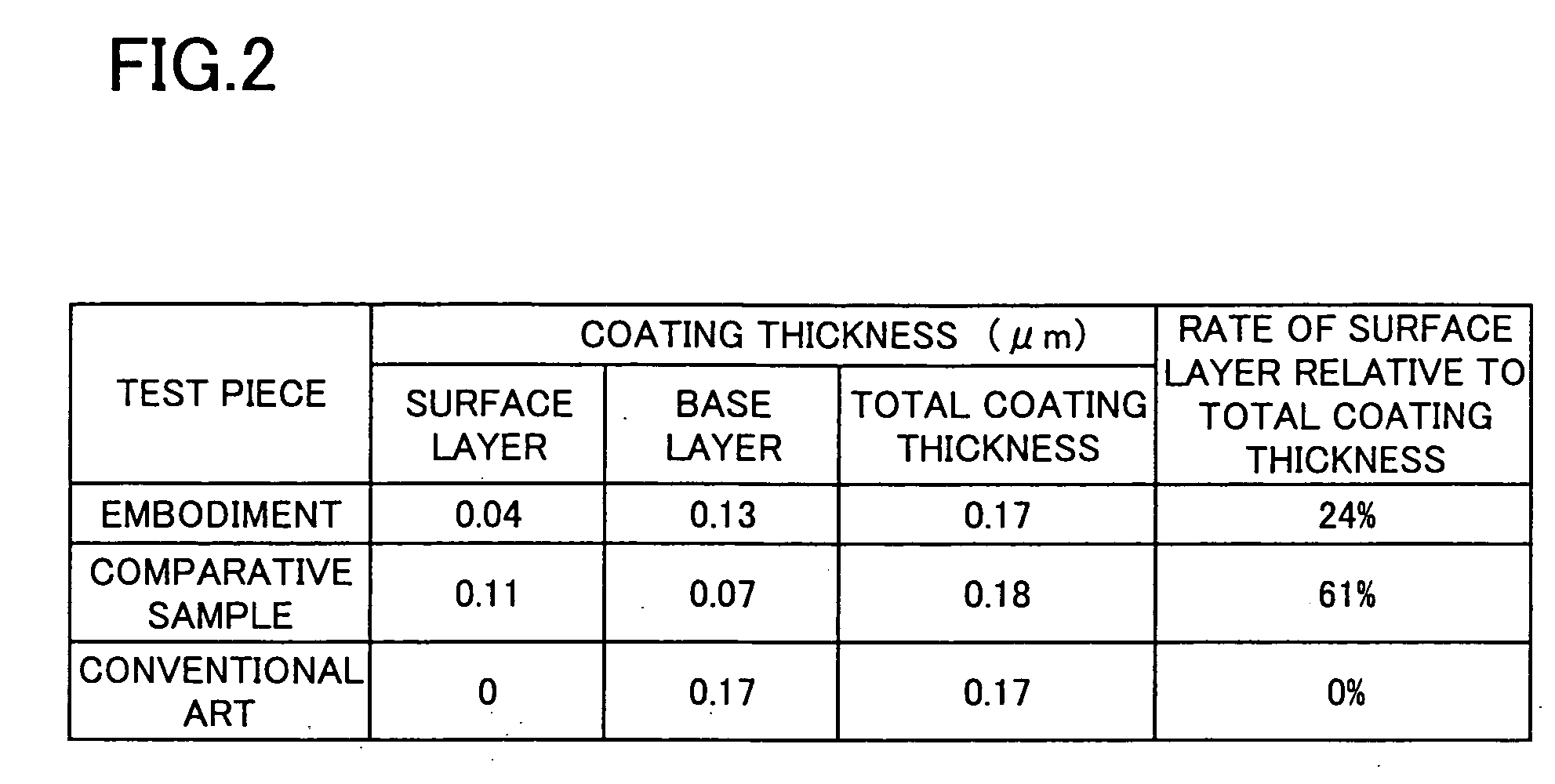

DLC coating, and DLC coating coated tool

InactiveUS20070104953A1Satisfactory lifetimeAvoid excessive hardnessLayered productsMilling cuttersDlc coatingHydrogen

A DLC coating (20) coating a surface of a predetermined member (12) comprises a base layer (22) not containing hydrogen substantially, and a hydrogen containing layer (24) containing hydrogen ranging from 2 atom % to 20 atom %. The base layer (22) and the hydrogen containing layer (24) disposed thereon constitute a two-layer structure.

Owner:OSG

Preparation method of Ti-doped diamond-like carbon (DLC) coating

InactiveCN102925862AImprove bindingImprove toughnessVacuum evaporation coatingSputtering coatingDlc coatingHardness

The invention discloses a method for preparing a Ti-doped diamond-like carbon (DLC) coating, which comprises steps as follows: a pretreated matrix is put on a turner post of electric arc-magnetron sputtering composite coating equipment; by using a column arc Ti target as a Ti source and three pairs of planar C targets as C sources, the column arc Ti target and planar C targets are uniformly distributed on the inner wall of the furnace body, and high-purity Ar is used as a main ionization gas to ensure the effective glow discharge process; and high-purity N2 used as a reactant gas is ionized and combined with elements Ti and C so as to deposit and form the Ti-doped DLC coating on the matrix surface. The prepared Ti-doped DLC coating appears black, and has a smooth and compact surface; the coating hardness is 28GPa, the film-base binding force is up to 60N, and the coating thickness is 2.5 mu m; and when the friction pair is Al2O3 balls, the dry friction coefficient of the coating is 0.2. Thus, the Ti-doped DLC coating has favorable wear resistance and anti-friction property.

Owner:XIAN HAOYUAN COATING TECH

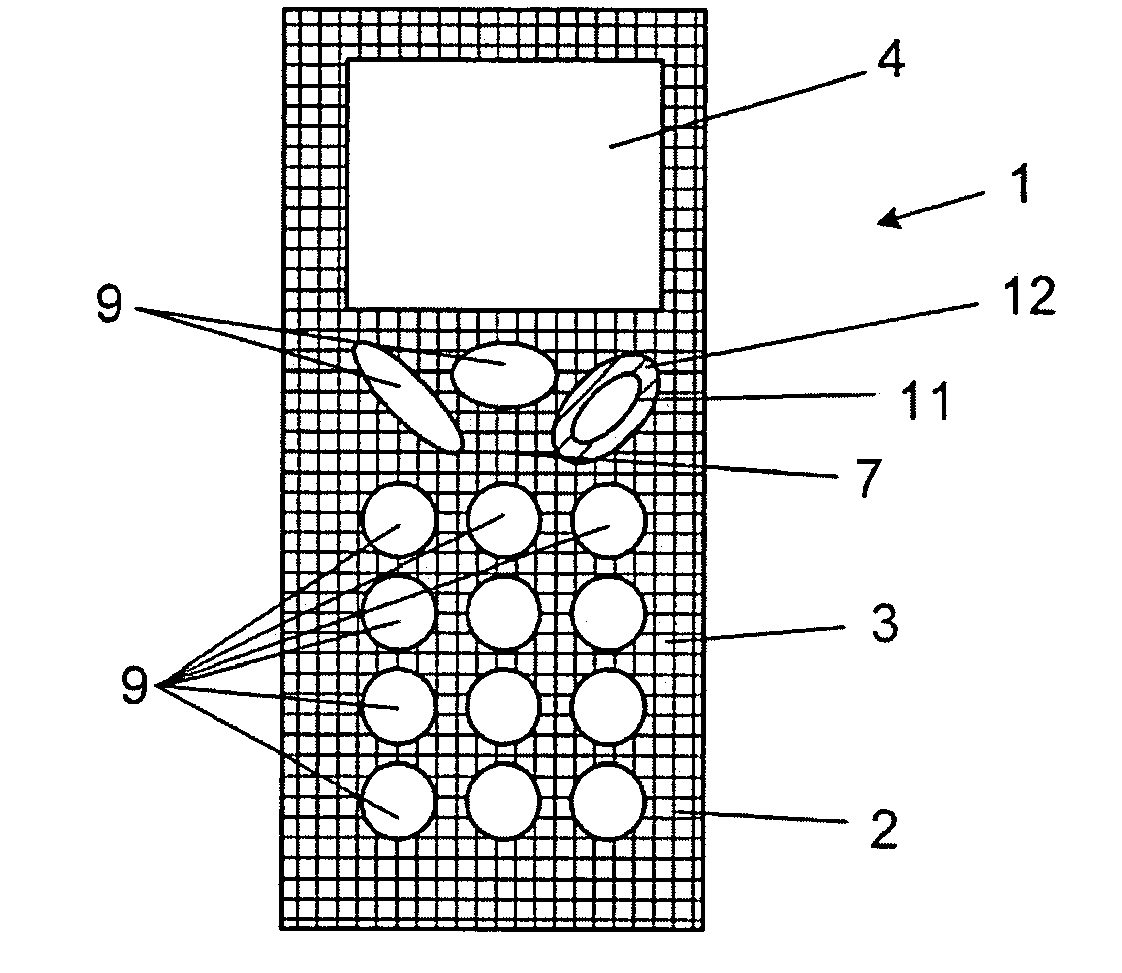

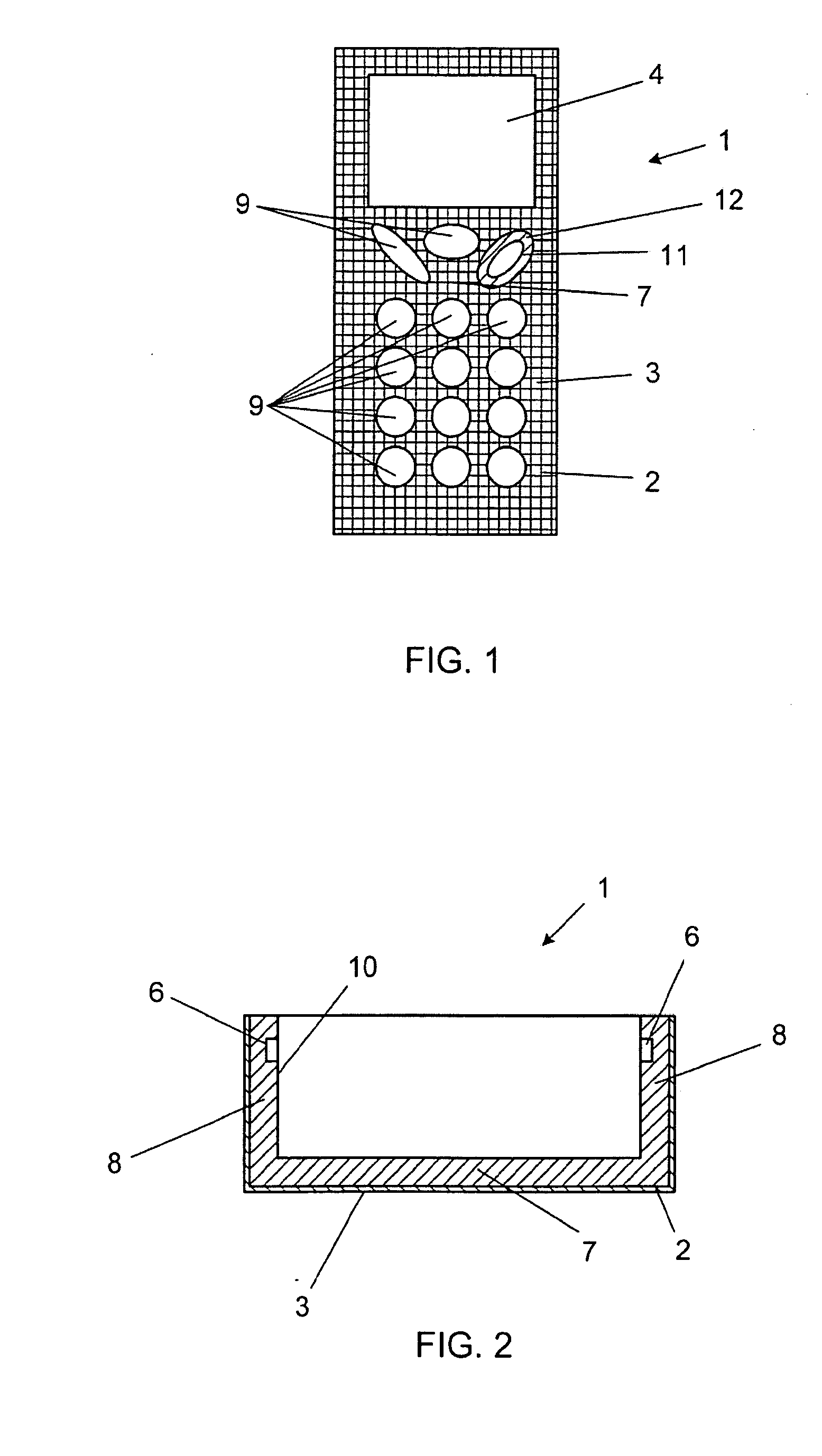

Cover, mobile communications apparatus and method for producing a coated cover

InactiveUS20060240260A1Special visual functionSimply and inexpensively achievedLayered productsVacuum evaporation coatingDlc coatingAmorphous diamond

The invention relates to a cover, a mobile communications apparatus and a method for producing a coated cover for an electronic apparatus. According to the invention at least a part of the cover is coated with a DLC-coating, also called an amorphous diamond coating.

Owner:SPYDER NAVIGATIONS L L C

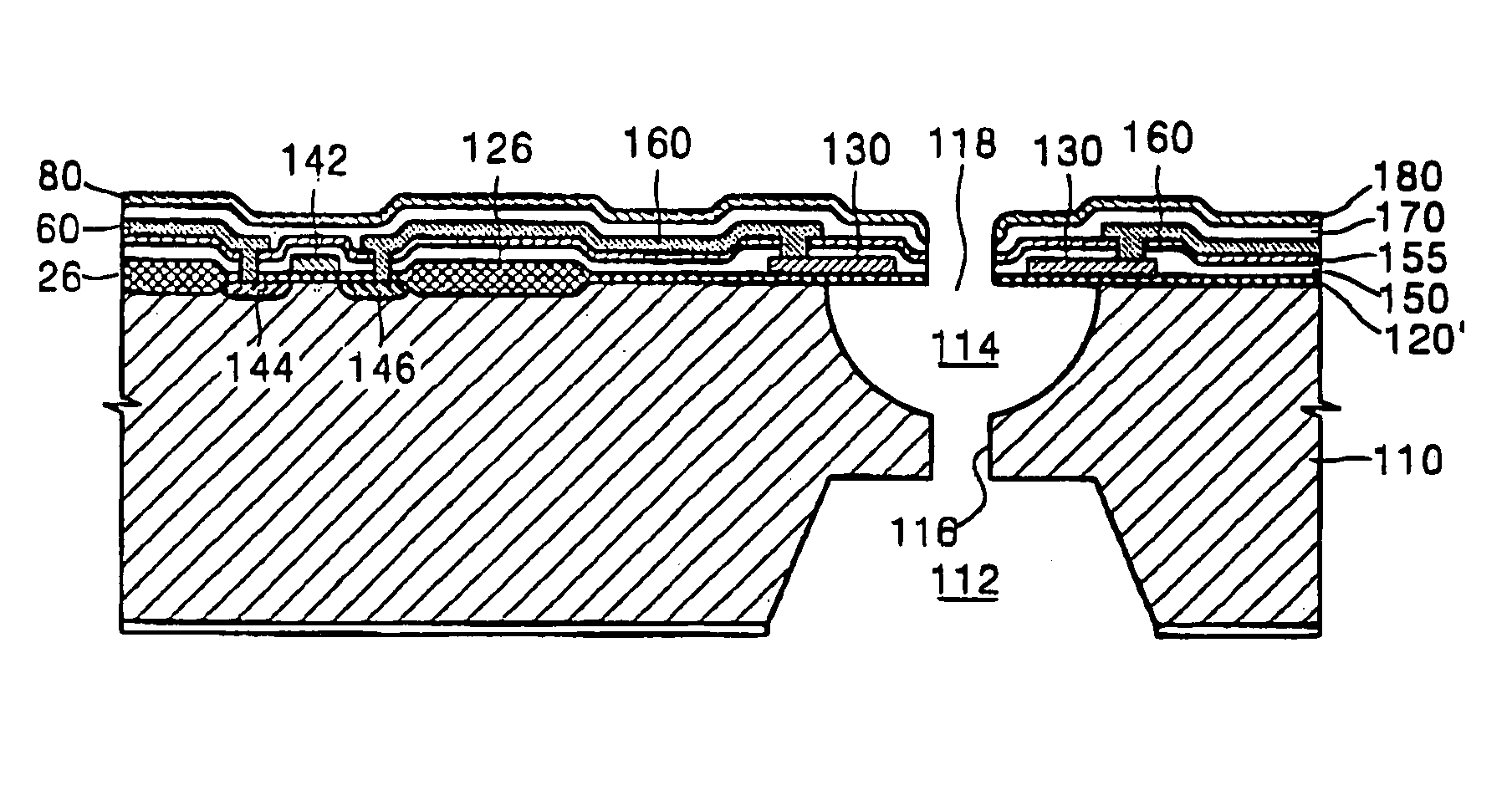

Method for manufacturing a monolithic ink-jet printhead

ActiveUS7275308B2Increased durabilityHigh propertyInking apparatusWriting implementsDlc coatingMOSFET

A method for manufacturing the same, wherein the monolithic ink-jet printhead includes a manifold for supplying ink, an ink chamber having a hemispheric shape, and an ink channel formed monolithically on a substrate; a silicon oxide layer, in which a nozzle for ejecting ink is centrally formed in the ink chamber, is deposited on the substrate; a heater having a ring shape is formed on the silicon oxide layer to surround the nozzle; a MOS integrated circuit is mounted on the substrate to drive the heater and includes a MOSFET and electrodes connected to the heater. The silicon oxide layer, the heater, and the MOS integrated circuit are formed monolithically on the substrate. Additionally, a DLC coating layer having a high hydrophobic property and high durability is formed on an external surface of the printhead.

Owner:HEWLETT PACKARD DEV CO LP

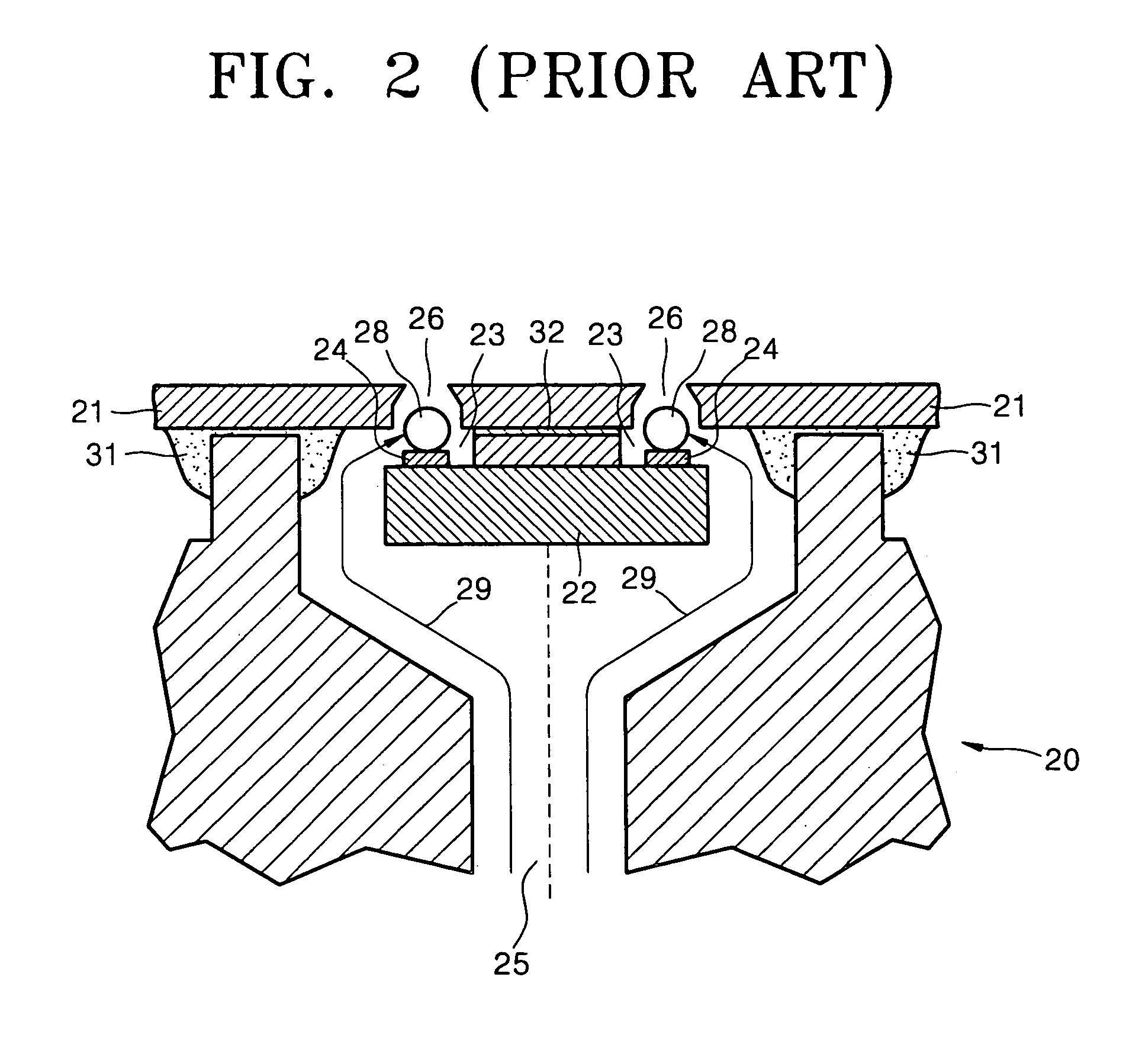

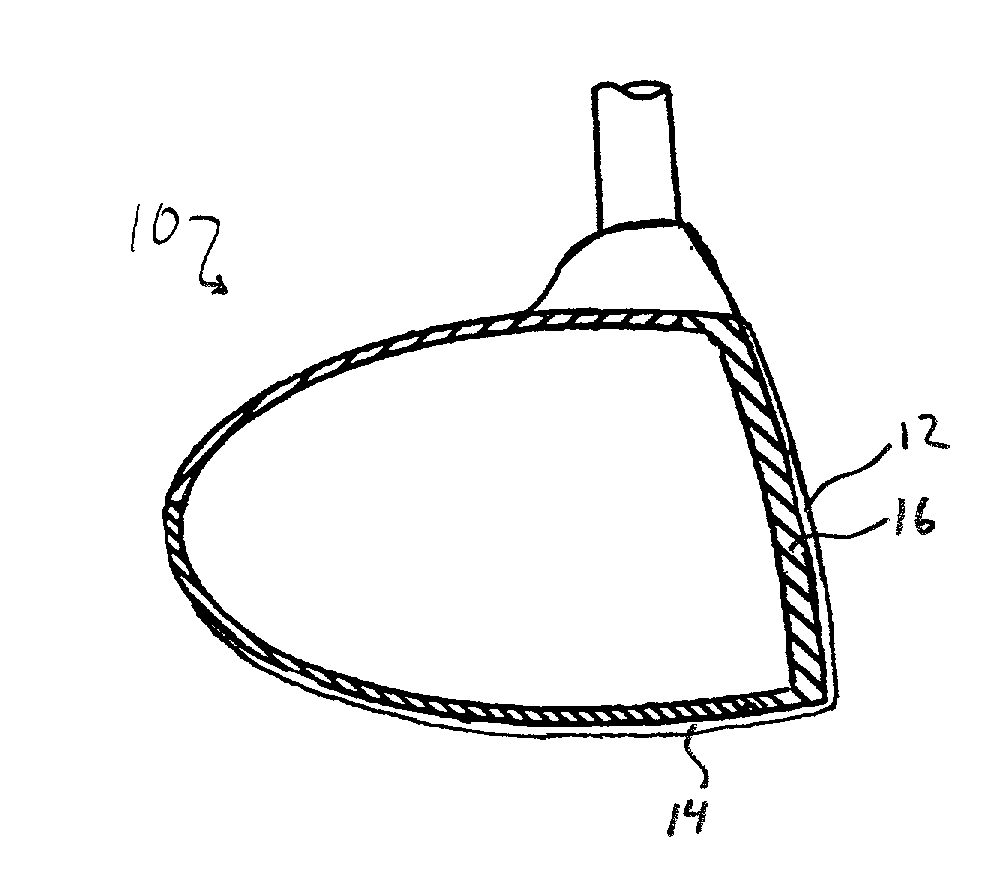

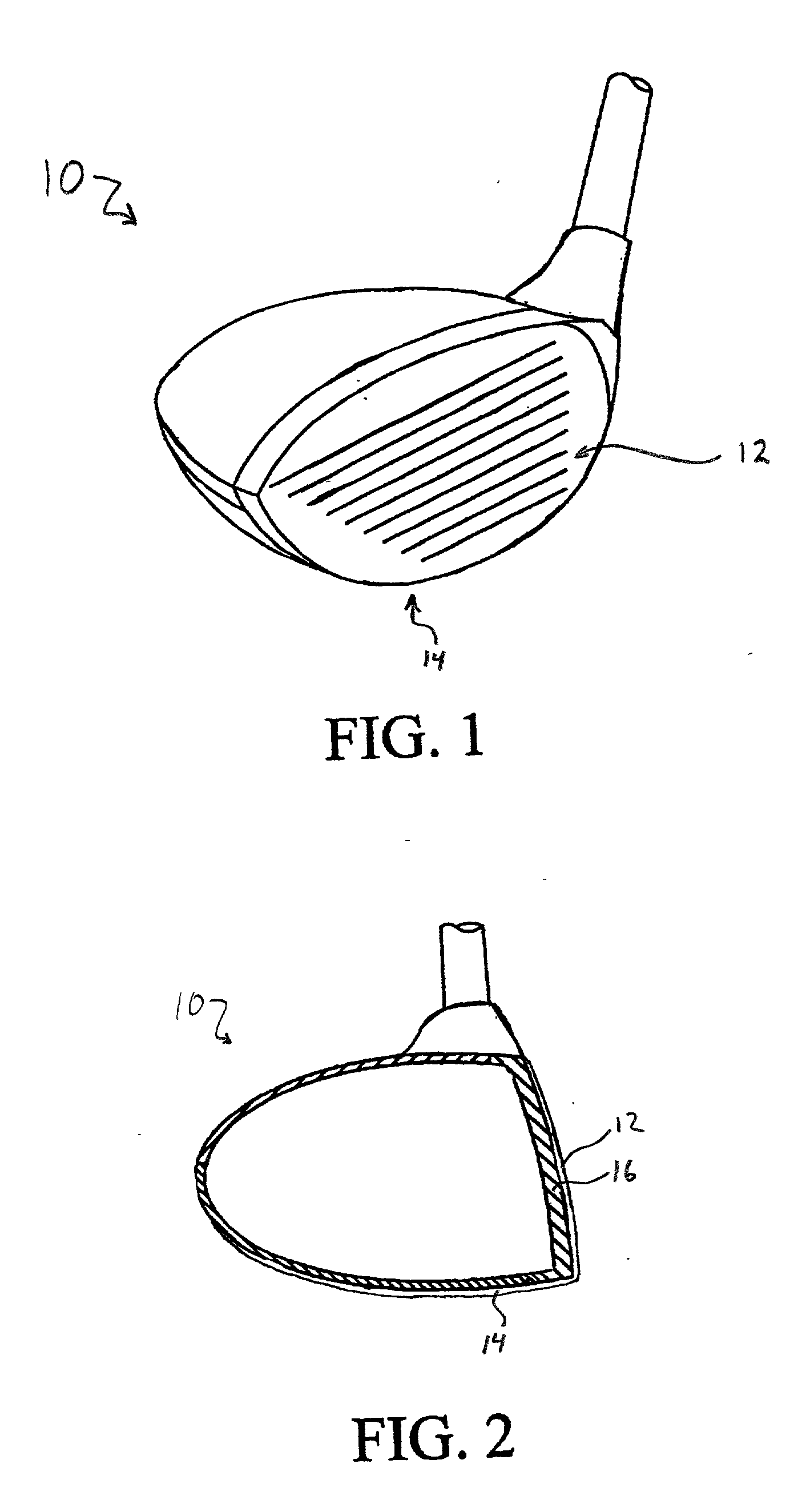

Diamond-like carbon coated golf club head

InactiveUS20020004426A1Increase frictionLess desirable levelGolf clubsRacket sportsDlc coatingAdamite

A diamond-like carbon (DLC) coated golf club head primarily for reduction of friction between the hitting surface and the golf ball at impact. The DLC coating comes in two varieties including dehydrogenated DLC or hydrogenated DLC and is thinly applied between about 0.1 and 10 mum. The diamond particle size of individual diamond-like carbon molecules or crystals can be less than 0.1 mum, and preferably less than 1 nanometer. The DLC coating may be bonded to the golf club head or hitting surface using cathodic arc method or other applicable methods at temperatures of less than 200° C.

Owner:KINIK CORP +1

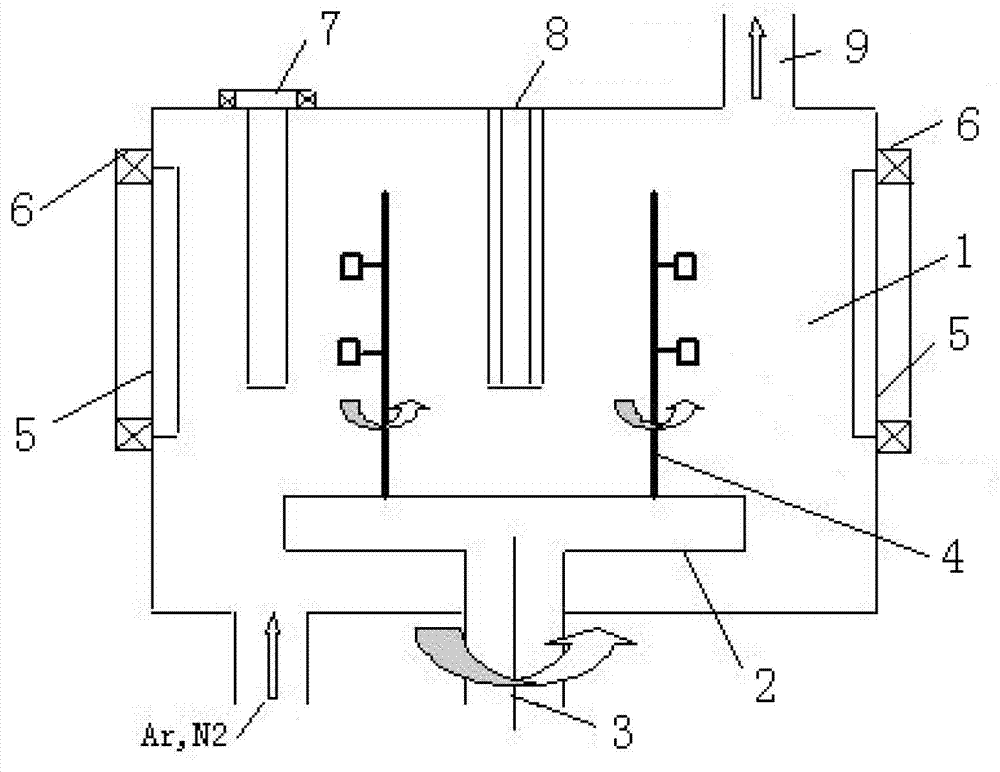

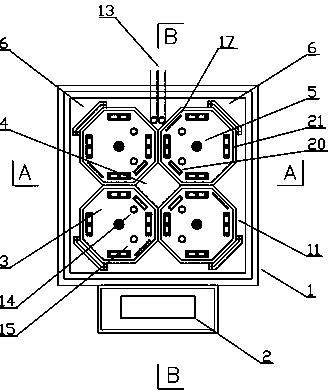

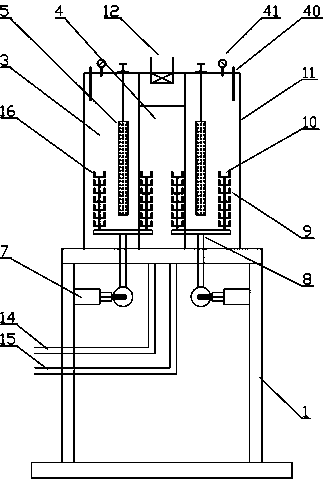

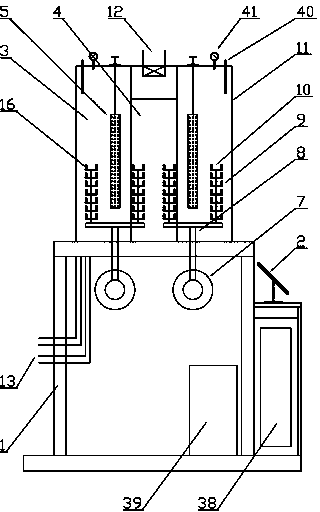

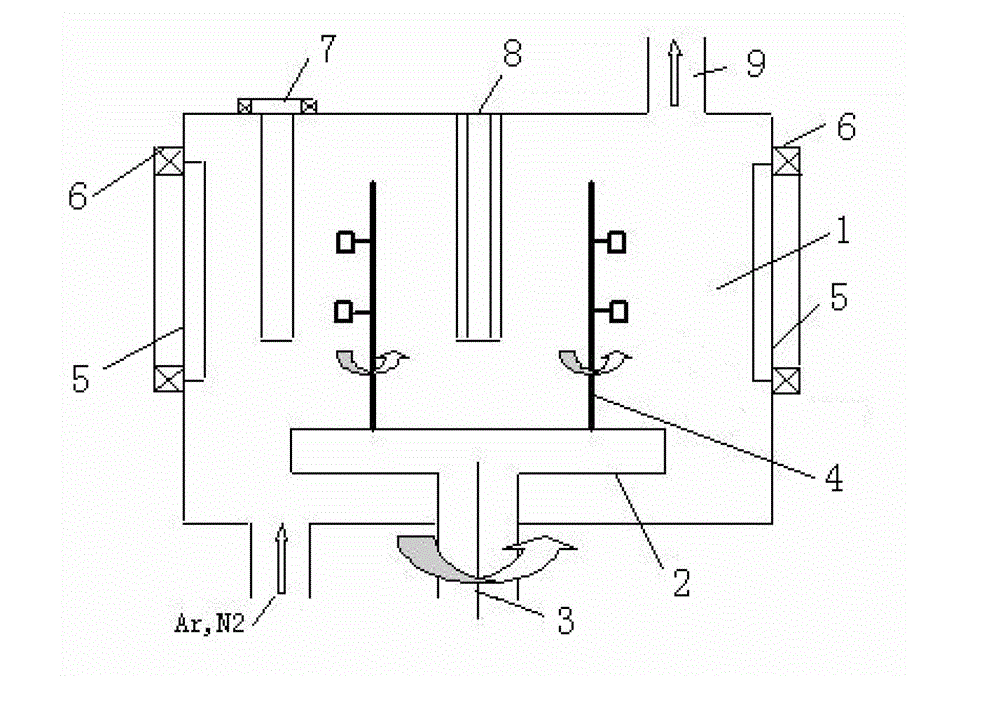

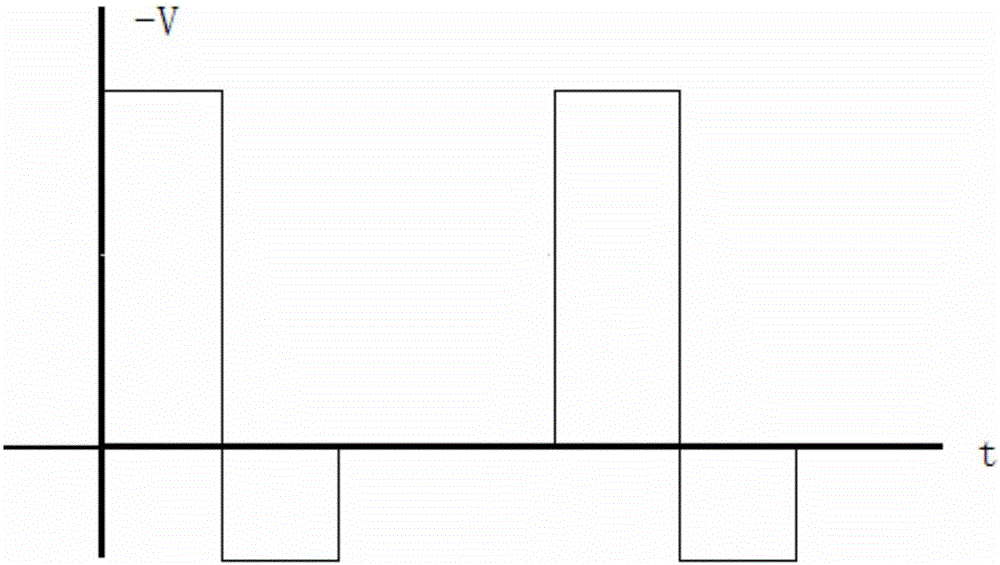

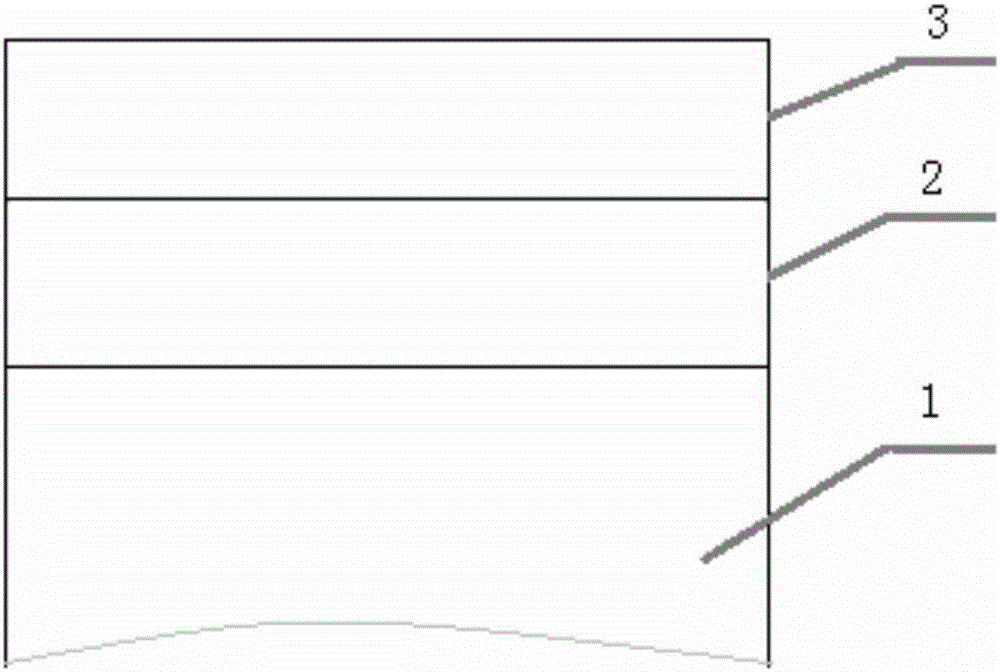

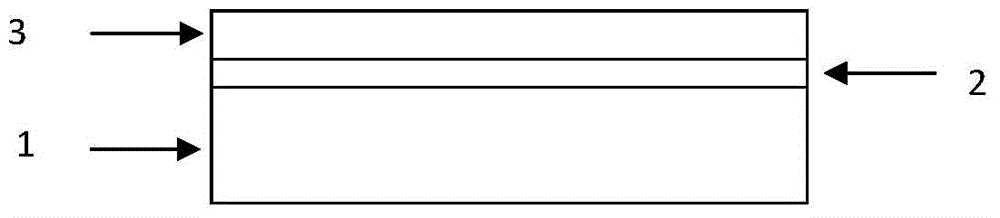

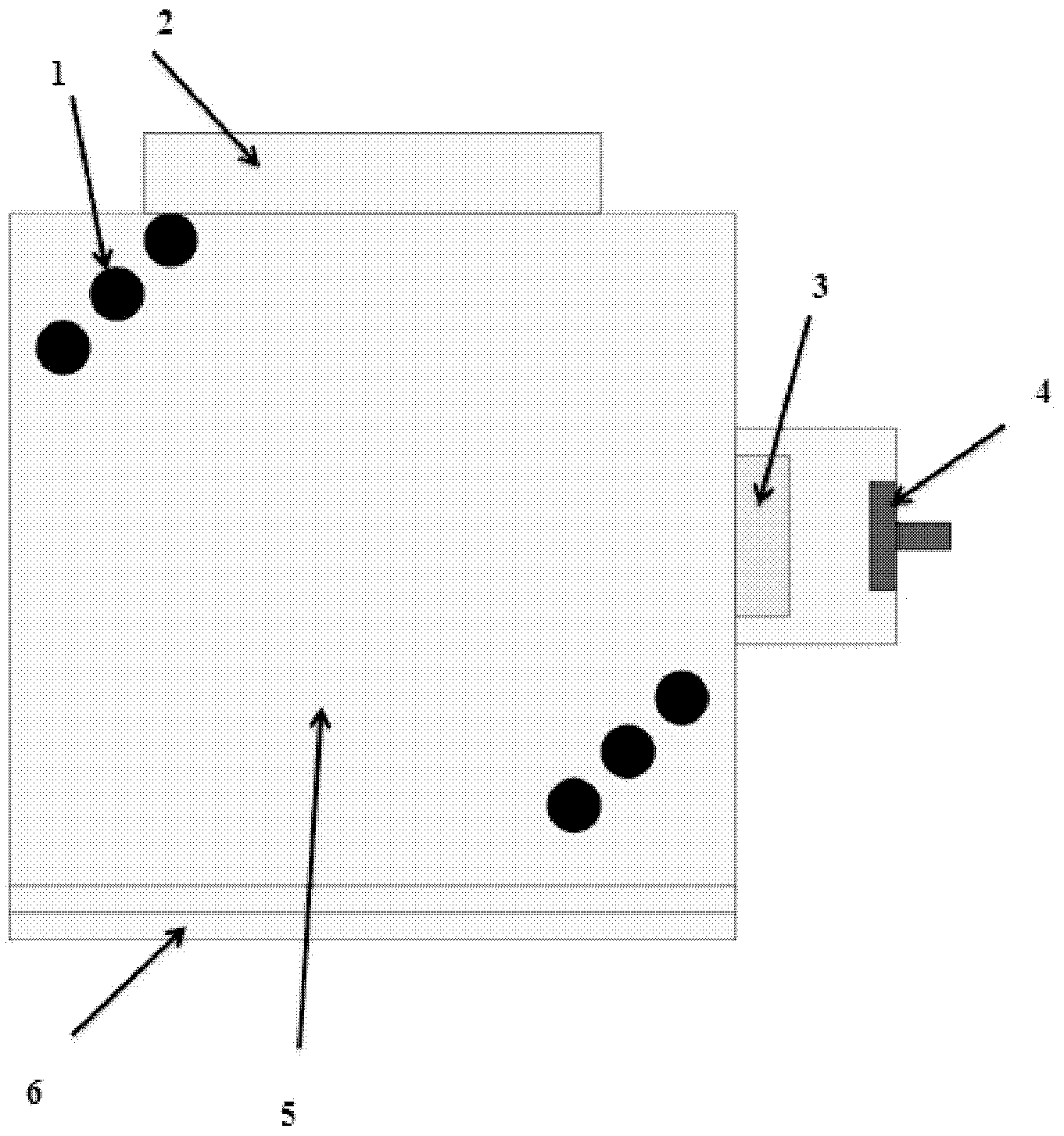

Method and equipment for preparing ultra-hard DLC coatings through PVD and HIPIMS

InactiveCN104213076AHigh hardnessImprove friction resistanceVacuum evaporation coatingSputtering coatingDlc coatingHigh volume manufacturing

The invention discloses a method and equipment for preparing ultra-hard DLC (Diamond-like Carbon) coatings through PVD (Physical Vapor Deposition) and HIPIMS (High Power Impulse Magnetron Sputtering). By adopting a multilayer film compositing technology and using a PVD process and an HIPIMS method, and through cathode and anode bias adjustment and acetylene gas flow control, and the design of the equipment for preparing the DLC coatings in an industrialized manner, that the ultra-hard DLC coatings are prepared by the equipment on surfaces of workpieces is achieved, and the coatings are ultra-high in hardness, high in friction resistance, high in wear resistance and high in self-lubricating performance. According to the method and equipment, provided by the invention, the coating process is simple; conditions for compositing the coatings are accurate and controllable; the film formation quality is high; the performance is stable; the product yield is high; and the cost is low. The coatings are ultra-hard and excellent in self-lubricating performance and the wear resistance. The equipment for the coatings is provided with four sets of large-scale coating units, is stable and reliable in production quality, can be applied to mass production, is convenient for lowering the manufacturing cost and achieves industrialization.

Owner:慕恩慈沃迪

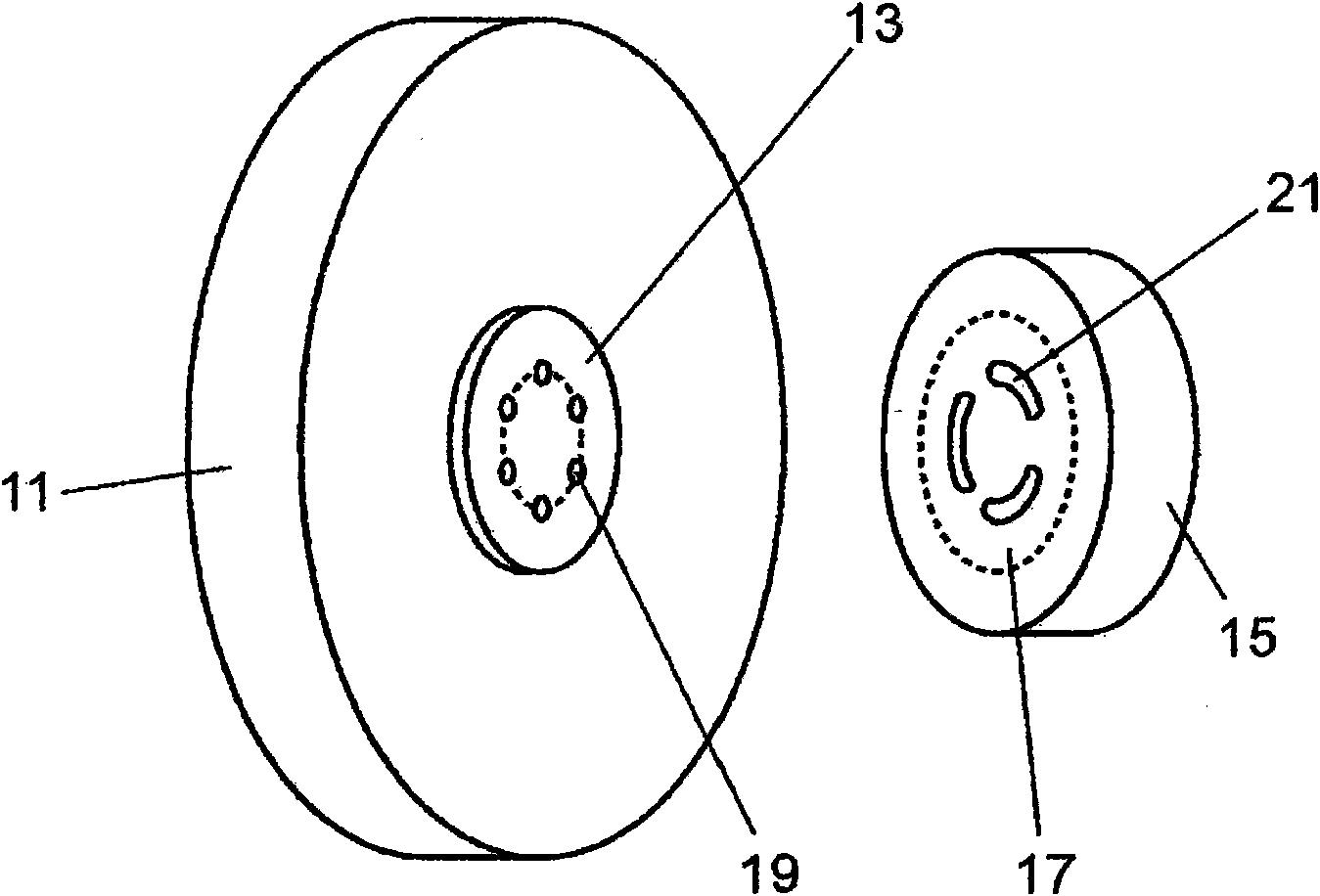

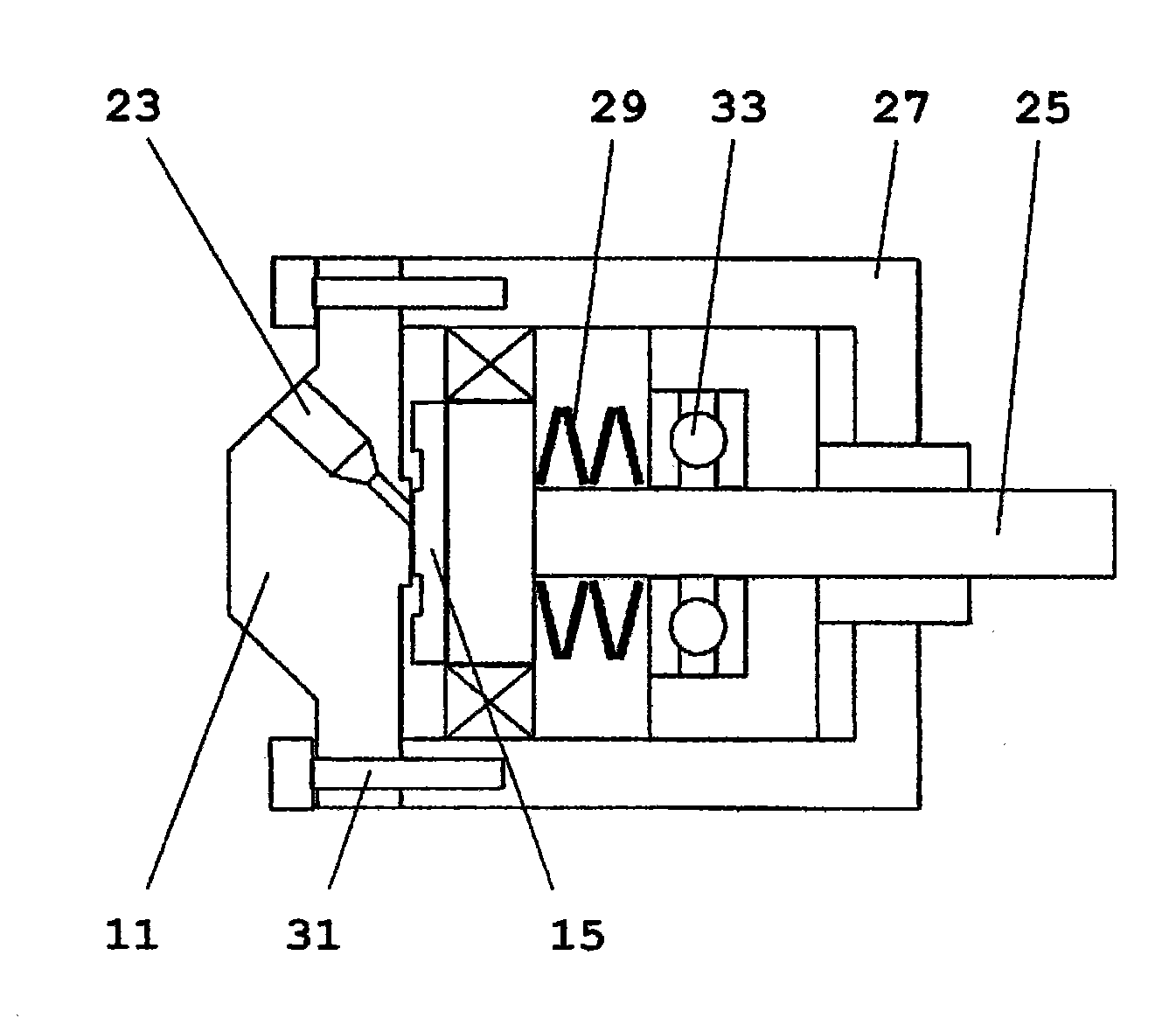

Flow channel switching valve

InactiveCN101896750AHigh torqueInhibit deteriorationComponent separationMultiple way valvesDlc coatingEngineering

In order to enhance the durability of a rotor, provided is a flow channel switching valve which has a stator (11) with contact face (13) and a rotor (15) with contact face (17). The stator (11) on the contact face (13) has throughflow holes (19) to be connected to multiple flow channels, respectively. The rotor (15) has at least one groove (21) for communication between two of the throughflow holes (19) of the stator (11). The rotor is urged against the contact face (13) of the stator (11) and makes rotational slide so as to attain switching of the throughflow holes (19) of the stator (11) to be brought into communication. The contact face (13) of the stator (11) results from application of DLC coating and subsequent polishing processing. On the other hand, the contact face (17) of the rotor (15) consists of a resin.

Owner:SHIMADZU SEISAKUSHO CO LTD

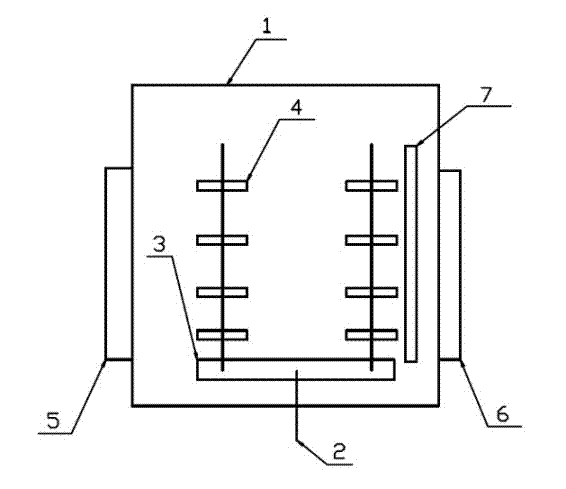

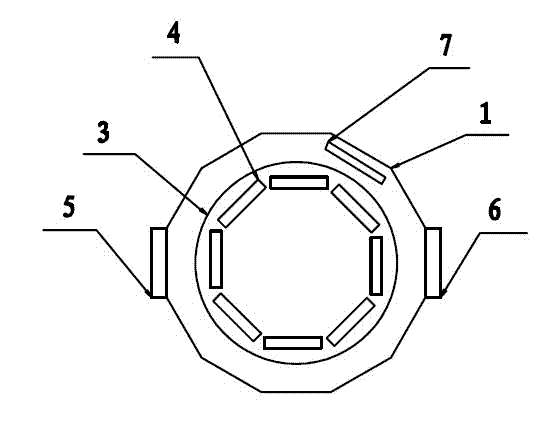

Coating method for DLC (diamond-like carbon) coating on spinning reed and equipment

InactiveCN102534614AImprove performanceExtended service lifeVacuum evaporation coatingSputtering coatingDlc coatingSpinning

The invention discloses a coating method for a DLC (diamond-like carbon) coating on a spinning reed. The coating method comprises the steps of preparing a metal depletion layer through a vacuum sputter coating or multi-arc ion beam technology and preparing the DLC coating through a vacuum ion coating technology. The invention further discloses equipment capable of applying the coating method. The invention has the outstanding effects as follows: the DLC coating is successfully applied to the spinning reed, so as to solve the problem on surface abrasion resistance of the reed and improve the film rigidity of the reed to HV0.025 2500 to 3500; and the DLC coating has the properties of abrasion resistance, corrosion resistance, high binding force and low friction coefficient, thereby effectively improving the property of the reed, prolonging the service life of the reed, improving the spinning efficiency, saving the spinning cost and ensuring the quality of textile products.

Owner:STARARC COATING TECH SUZHOU

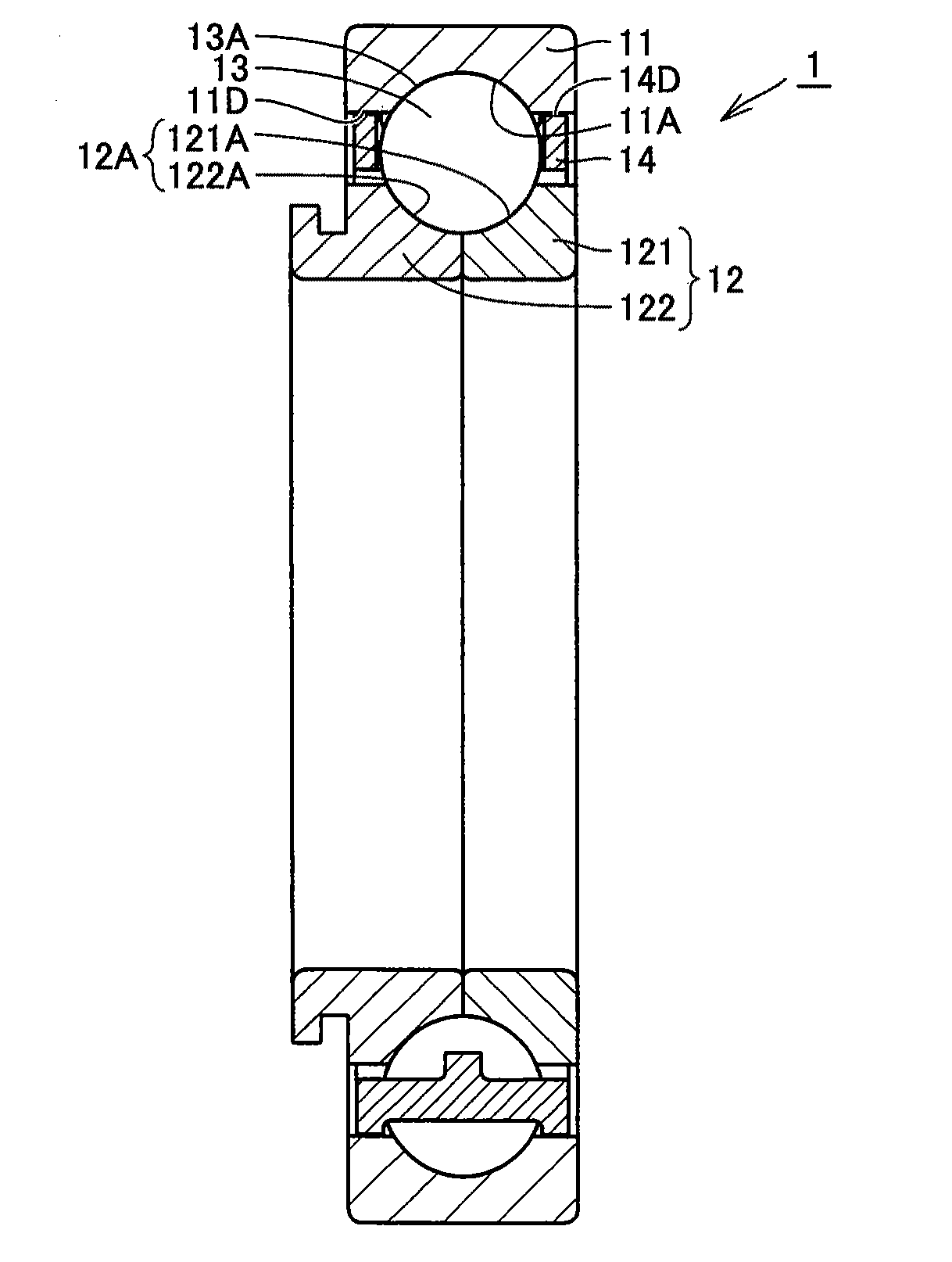

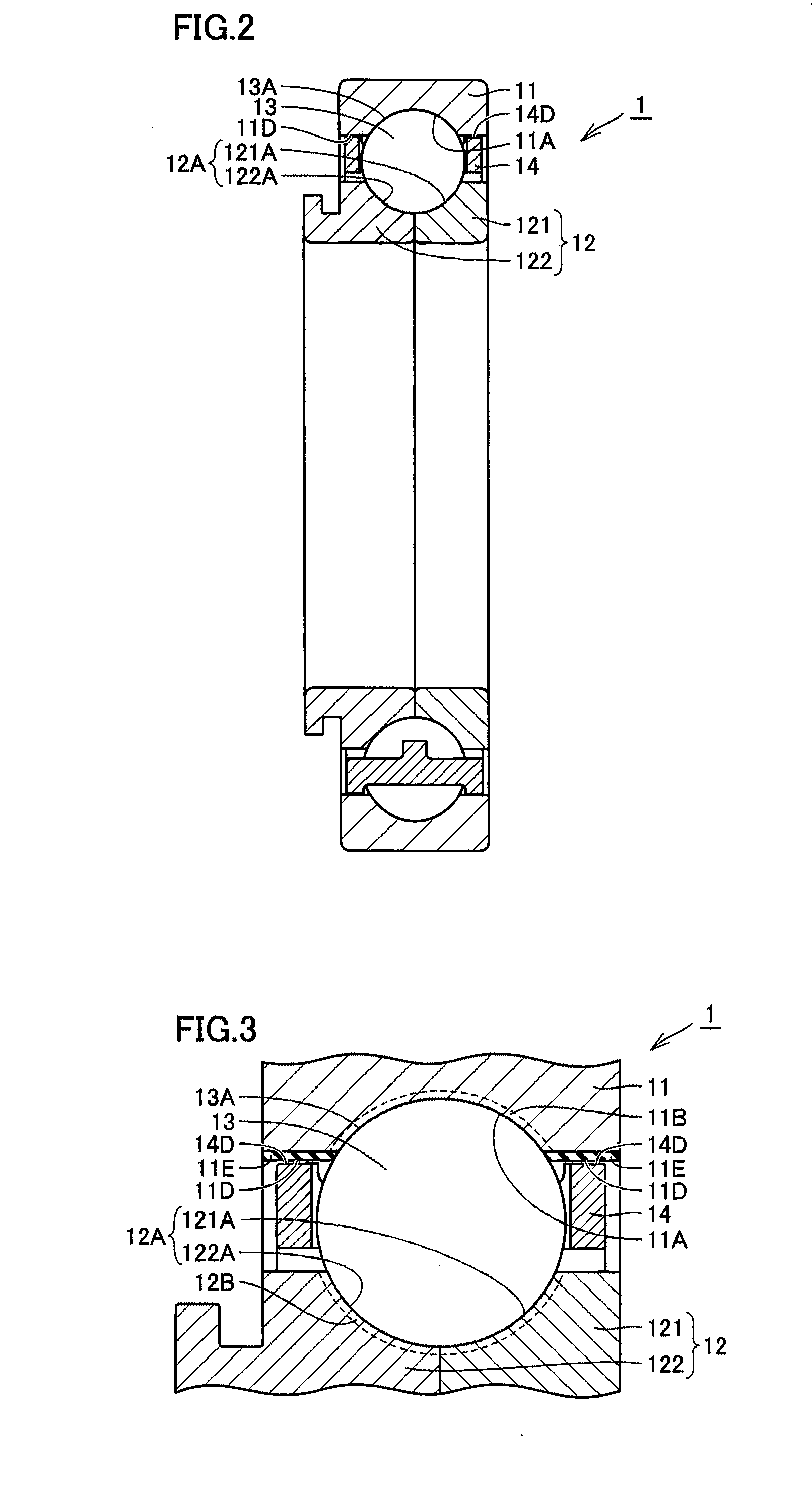

Rolling bearing

InactiveUS20090245706A1Reduce hardnessIncreased durabilityRoller bearingsShaftsDlc coatingRolling-element bearing

An outer ring and an inner ring of a rolling bearing are constituted of steel containing 0.77 to 0.85% of carbon, 0.01 to 0.25% of silicon, 0.01 to 0.35% of manganese, 0.01 to 0.15% of nickel, 3.75 to 4.25% of chromium, 4 to 4.5% of molybdenum and 0.9 to 1.1% of vanadium with the rest consisting of iron and impurities, a nitrogen-enriched layer having a nitrogen concentration of at least 0.05 mass % is formed on a region including a rolling surface, and the total of a carbon concentration and the nitrogen concentration in the nitrogen-enriched layer is at least 0.82 mass % and not more than 1.9 mass %. A DLC coating layer is arranged on a region including an outer ring contact surface.

Owner:NTN CORP

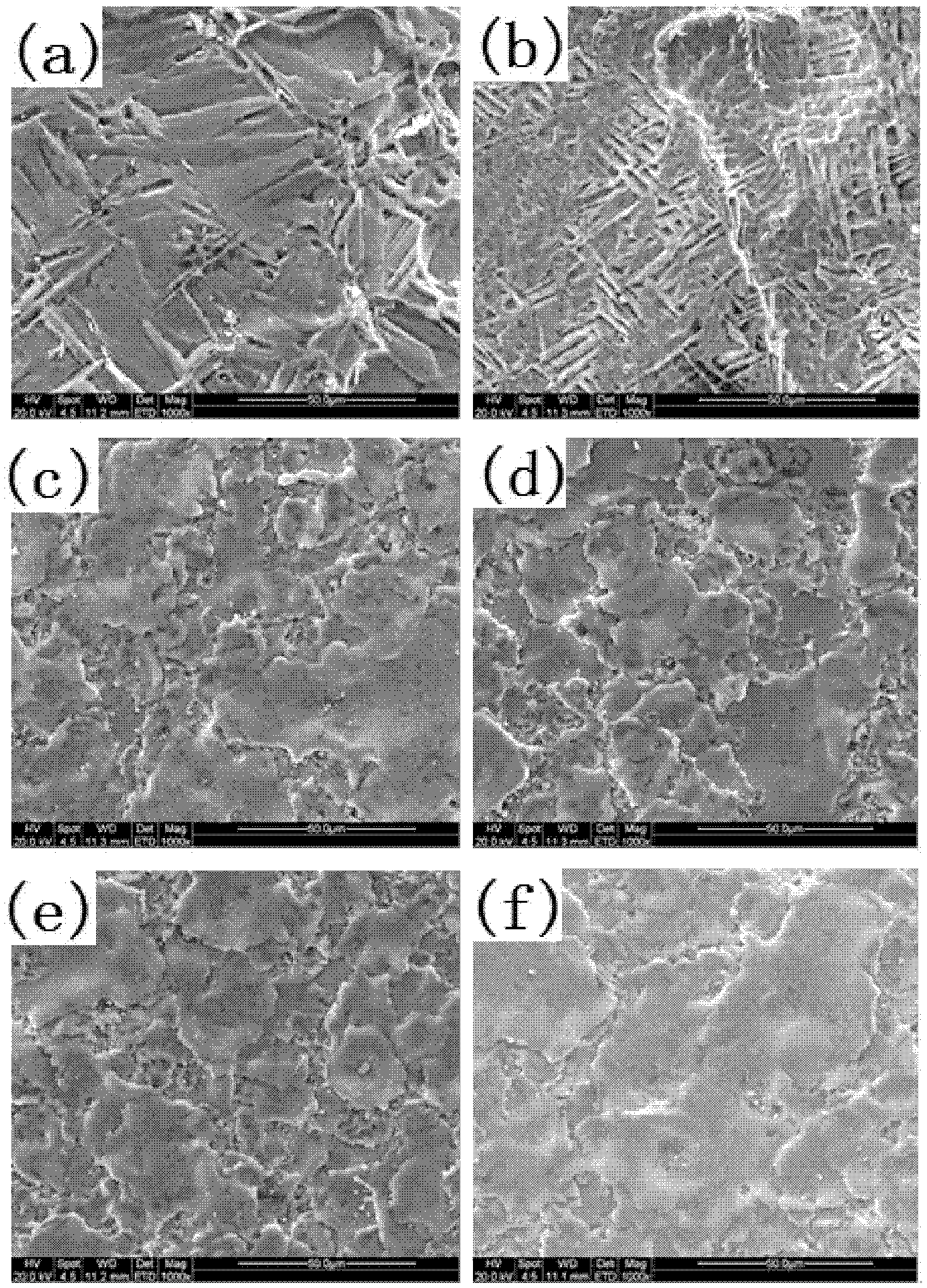

Cr-doped DLC (diamond-like carbon) coating with anticorrosion and antifriction properties and preparation method

InactiveCN102912298AImprove bindingSmooth and dense surfaceVacuum evaporation coatingSputtering coatingDlc coatingSputtering

The invention discloses a method for preparing a corrosion-resistant antifriction Cr-doped DLC (diamond-like carbon) coating. The method comprises the steps of placing a pretreated substrate on a rotating stand rod of arc and magnetron sputtering composite deposition equipment, taking a post arc Cr target as a Cr source and three pairs of flat targets C targets as C sources, and installing the three pairs of flat targets C on the inner wall of a furnace body in an opposite manner; adopting high-purity Ar as a main ionization gas to guarantee an effective glow discharge process; and adopting high-purity N2 as a reacting gas, ionizing the reacting gas and combining the reacting gas with Cr and C elements to deposit on the surface of the substrate so as to form the Cr-doped DLC coating. The prepared Cr-doped DLC coating has a smooth and compact surface, hardness of 20 GPa, binding force with the substrate of 80N, coating thickness of 2.0 micrometers, and excellent corrosion resistance and antifriction performance.

Owner:XIAN HAOYUAN COATING TECH

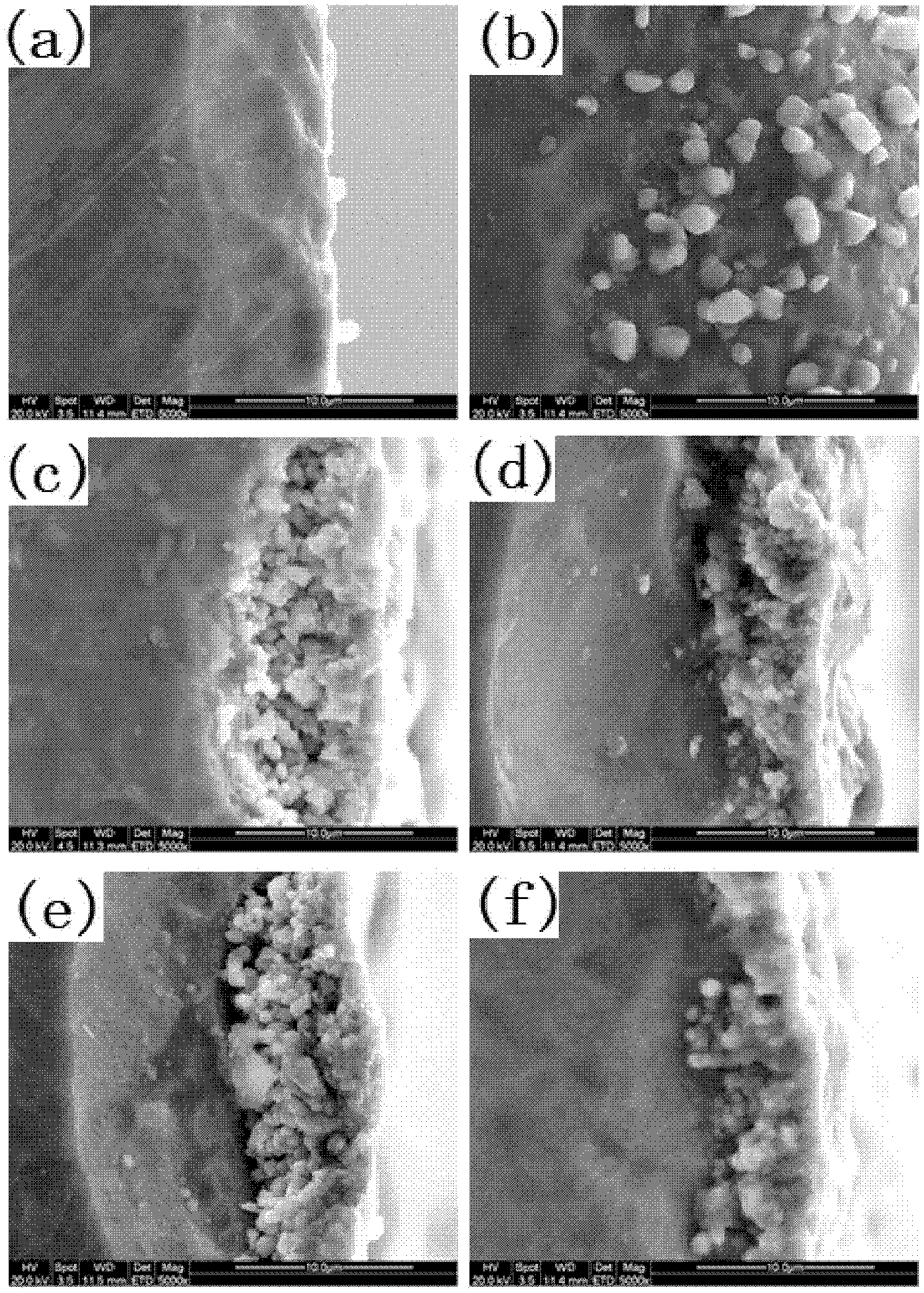

Diamond-like carbon film on surface of easy-to-rust metal piece and preparation method of diamond-like carbon film

ActiveCN105908143AUniform thicknessHigh densityVacuum evaporation coatingSputtering coatingDlc coatingCarbon ion

The invention discloses a diamond-like carbon film on the surface of an easy-to-rust metal piece and a preparation method of the diamond-like carbon film. The preparation method comprises the following steps: performing pretreatment on the surface of the metal piece at first, thereby removing pollutants on the surface of the metal piece; then, fixing the pretreated metal piece on a workpiece frame, and bombarding the surface of a to-be-cleaned sample with an iron source; preparing a transition layer of 0.1-0.5 micrometer; and preparing an a-C:HDLC layer of 1-3 micrometers. The preparation method provided by the invention is different from a conventional DLC coating preparation method, and has the advantages that the ionization rate of a hydrocarbon is improved, the substrate temperature is reasonably improved, and the diffusivity and mobility of adsorbing particles on the surface of the metal piece are improved, so that carbon ions can move towards grooves or pits and the dense film can be generated even if the surface of the metal piece is a brushed / sand-blasted non-smooth surface. The diamond-like carbon film, namely the coating obtained according to the preparation method, is still excellent in corrosion resistance and film substrate adhesion.

Owner:广州今泰科技股份有限公司 +1

Corrosion and abrasion resistant Cr-DLC coating for aluminum alloy surface and preparation methods of Cr-DLC coating

InactiveCN105525258AHigh bonding strengthHigh hardnessVacuum evaporation coatingSputtering coatingDlc coatingCoated surface

The invention discloses a corrosion and abrasion resistant Cr-DLC coating for an aluminum alloy surface and preparation methods of the Cr-DLC coating. The Cr-DLC coating comprises a Cr primer and a DLC coating, wherein the Cr primer is directly formed on the surface of an aluminum alloy substrate; and the DLC coating is directly formed on the Cr primer and doped with Cr. Among the preparation methods, one typical preparation method comprises the following steps that graphite and chromium are taken as cathode target materials, and the Cr-DLC coating is prepared on the aluminum alloy surface by use of a magnetron sputtering technology. The Cr-DLC coating has the advantages that the DLC coating doped with Cr is smooth in surface, compact in structure, high in rigidity, small in coefficient of friction, and resistant to both abrasion and corrosion; and meanwhile, the preparation process is simple, the repeatability and the reliability are high, and the cost is low.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for coating at least the inner face of a piston ring and piston ring

ActiveCN103620085AEffective wear protectionReduce coefficient of frictionPiston ringsElectric discharge tubesDlc coatingPiston ring

In a method for coating at least part of the inner face of a piston ring, said ring preferably consisting of cast iron or steel, a PVD and / or DLC coating is applied by means of at least one of the following methods: PA-CVD, glow discharge and / or HIPIMS. A piston ring has a coating that is formed at least on part of the inner face of said ring, said coating being a PVD and / or DLC coating that preferably has been applied by means of PA-CVD, glow discharge and / or HIPIMS.

Owner:FEDERAL MOGUL BURSCHEID

Novel heat sink and production method thereof

InactiveCN101853822AImprove thermal conductivityImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesDlc coatingSputtering

The invention provides a novel heat sink prepared with high thermal-conductivity DLC coating. By means of magnetron sputtering and ion beam techniques, a plurality of layers of DLC coating containing chromium are deposited on a metal base material, and thereby the high thermal conductivity is realized. The heat sink comprises a heat-conducting part and fins, wherein the heat-conducting part abuts against a heat source, the fins are connected with the heat-conducting part, and the heat-conducting part consists of the metal base material and the high thermal-conductivity coating deposited on the metal base material. The invention has the following main advantages that: the diamond-like coating (DLC) has high thermal conductivity, the novel heat sink prepared with the DLC coating has excellent heat conductivity and heat dispersion, and the heat-conducting direction is not limited.

Owner:苏州热驰光电科技有限公司

Method for in-situ synthesis of composite TiC-DLC coating on surface of titanium

InactiveCN104141109AImprove bindingImprove uniformityVacuum evaporation coatingSputtering coatingDlc coatingChemical reaction

The invention discloses a method for in-situ synthesis of a composite TiC-DLC coating on the surface of titanium. The method comprises the following steps of placing a Ti target in a coating chamber and introducing a hydrocarbon gas, vacuumizing the film plating chamber and maintaining the temperature of the coating chamber, evaporating Ti ions out from the Ti target by virtue of arc ion plating, and ionizing the hydrocarbon gas by virtue of arc discharge to form the composite TiC-doped DLC coating on the Ti target. According to the method, by adopting the in-situ synthesis technology, the composite coating is formed by direction chemical reaction on the surface of the Ti target material, the uniformity of the composition of the composite coating and the binding force of the coating can be significantly improved and the method has the advantages of simple preparation process, low cost and high efficiency and has good application prospects in the preparation of the DLC coating.

Owner:WUHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com