Preparation method of Ti-doped diamond-like carbon (DLC) coating

A coating and bottom layer technology, which is applied in the field of preparation of diamond-like coatings (hereinafter referred to as DLC coatings), can solve the problems that cannot be completely eliminated, poor surface roughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present embodiment provides a method for preparing a Ti-doped DLC coating. It should be noted that the method for preparing a Ti-doped DLC coating of the present invention can be carried out on any material selected for cutting tools, molds and mechanical wear-resistant parts. , not limited to this example.

[0022] The concrete preparation process of this embodiment is:

[0023] (1) A high-speed steel (W18Cr4V) substrate with a hardness of HRC=60 after quenching at 1170°C and tempering at 550°C was used as the sample. After surface degreasing and polishing, it was immersed in acetone for ultrasonic cleaning and alcohol dehydration.

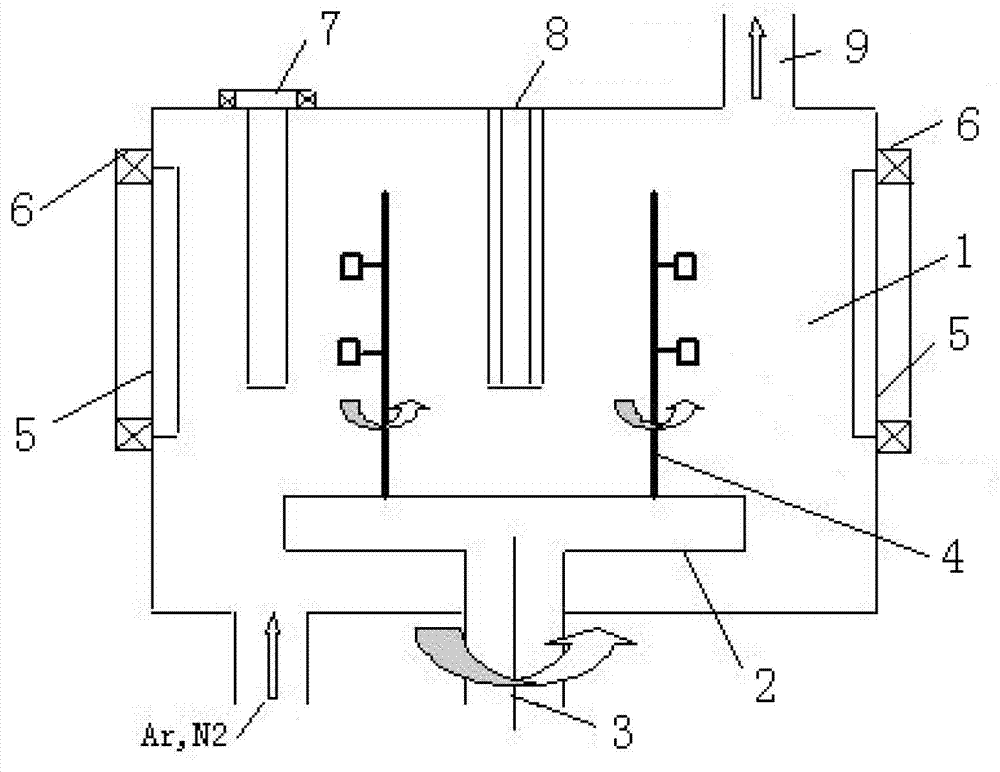

[0024] (2) Put the pretreated sample into the arc and magnetron sputtering composite coating equipment. like figure 1 As shown, the arc and magnetron sputtering composite coating equipment at least includes a vacuum chamber 1, a turret 2, a bias voltage 3, a turret rod 4, a plane C target 5, a permanent magnet 6, a column arc Ti targ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com