Patents

Literature

623 results about "Dry friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dry Friction. In general dry friction describes the reaction between two solid bodies in contact with each other when they are in motion (kinetic friction) and when they are not (static friction). Both static and kinetic friction are proportional to the normal force exerted between the two solid bodies.

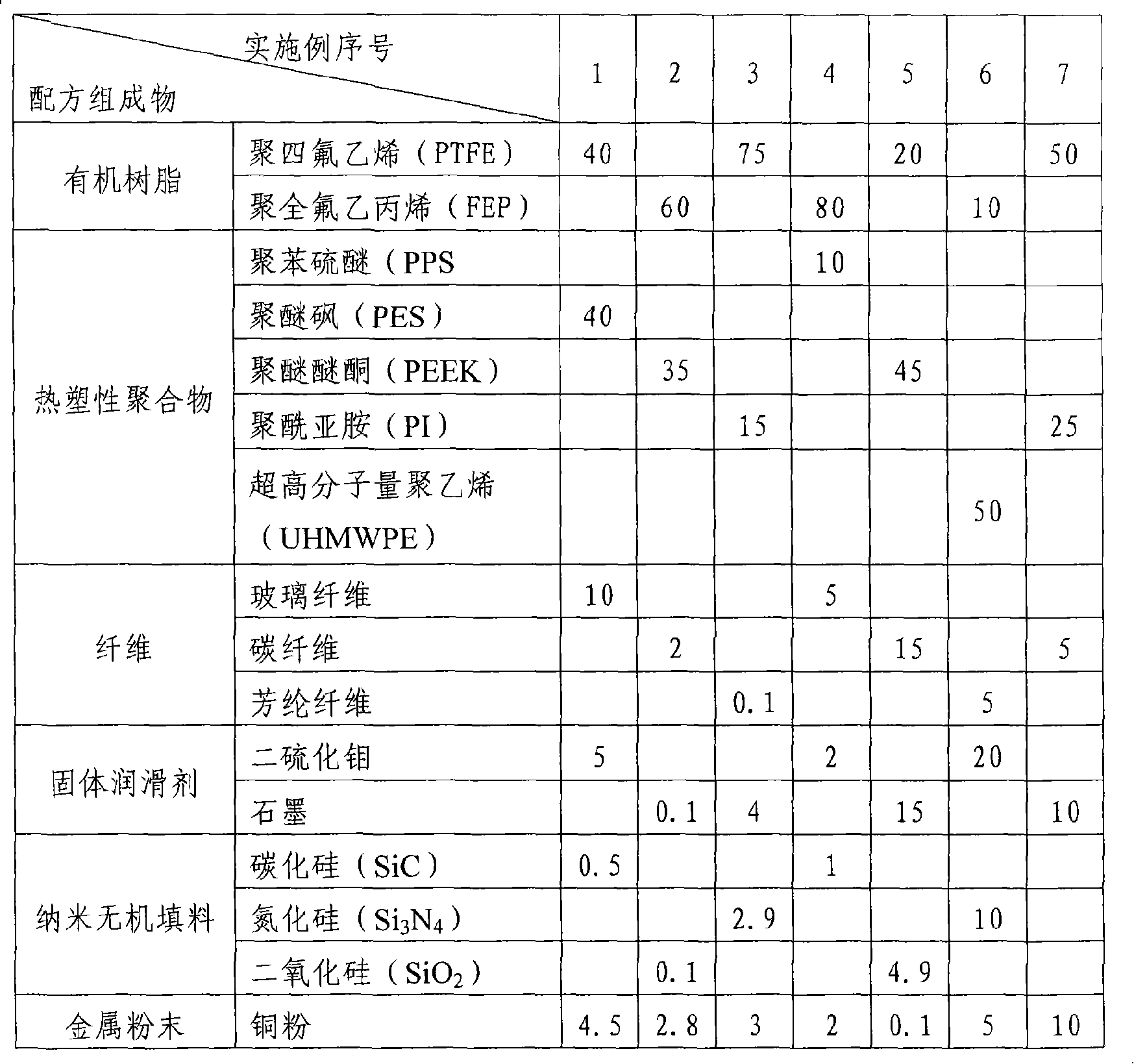

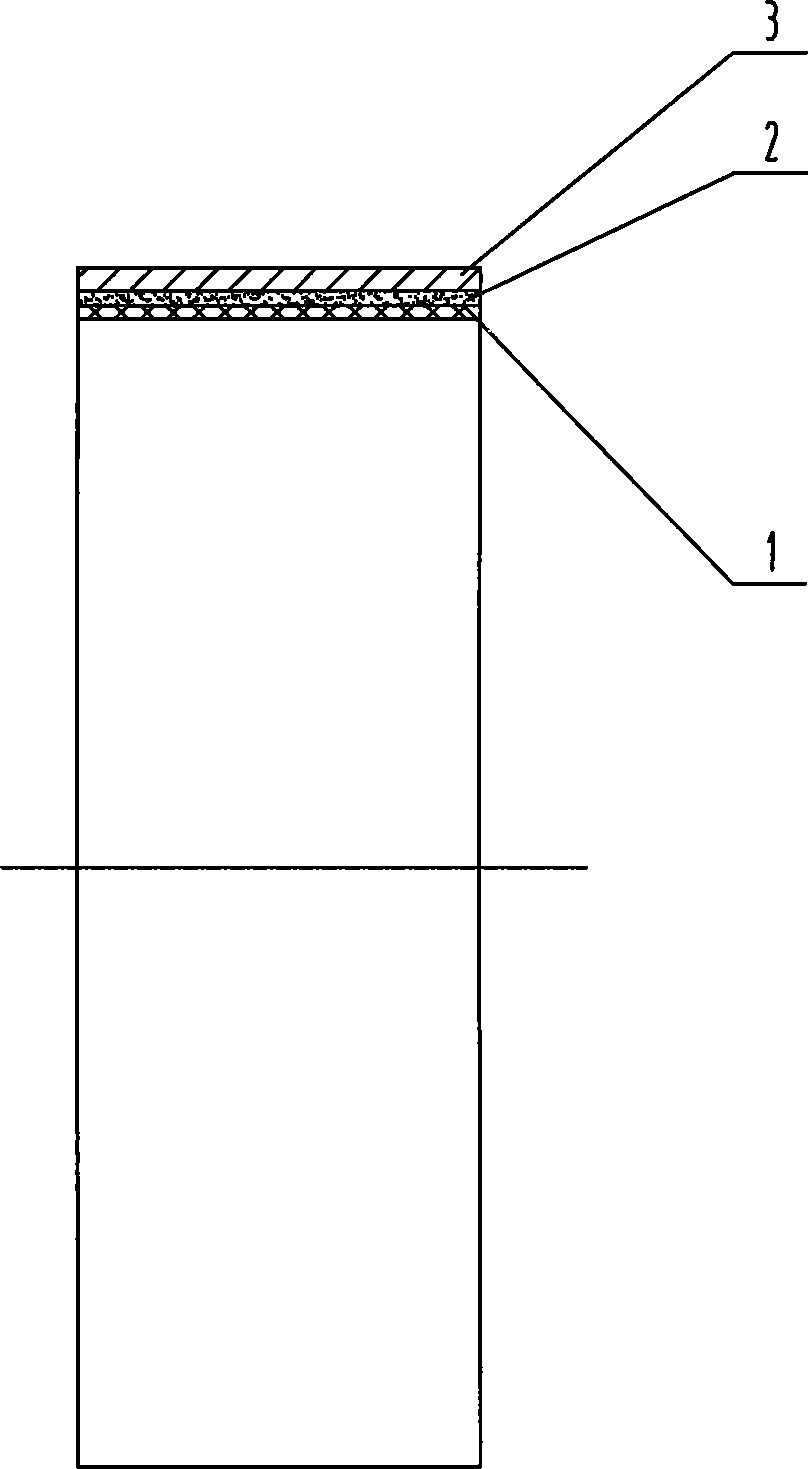

Self-lubricating sliding bearing material and its preparation method

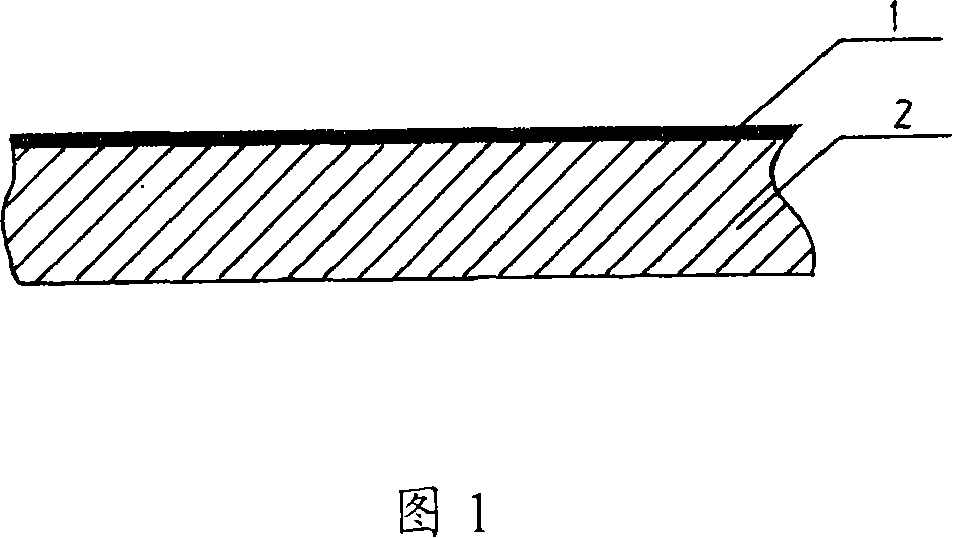

ActiveCN101126417AImprove carrying capacityReduce frictionBearing componentsCarrying capacityMetal sheet

The invention discloses a self-lubrication sliding bearing material and the preparation method, the self-lubrication sliding bearing material includes a self-lubrication sliding layer made of composite material which adopts the organic resin as the basis and a metal substrate, the sliding layer and the metal substrate are directly adhered together. During the preparation, the composite material for the self-lubrication sliding layer is blended proportionally and is laid on the metal sheet after being mixed mechanically, the surface of the metal sheet is treated, and then the metal sheet is sintered in a sintering furnace, then rolled immediately after the sintering process so that the surface coat is adhered on the metal substrate. The sliding bearing made of the material provided by the invention has the characteristics of higher carrying capacity and low friction and good wearing resistance, the metal substrate and the self-lubrication sliding layer can be stably adhered with each other, and is suitable for the dry friction and boundary or fluid friction conditions.

Owner:COB PRECISION PARTS

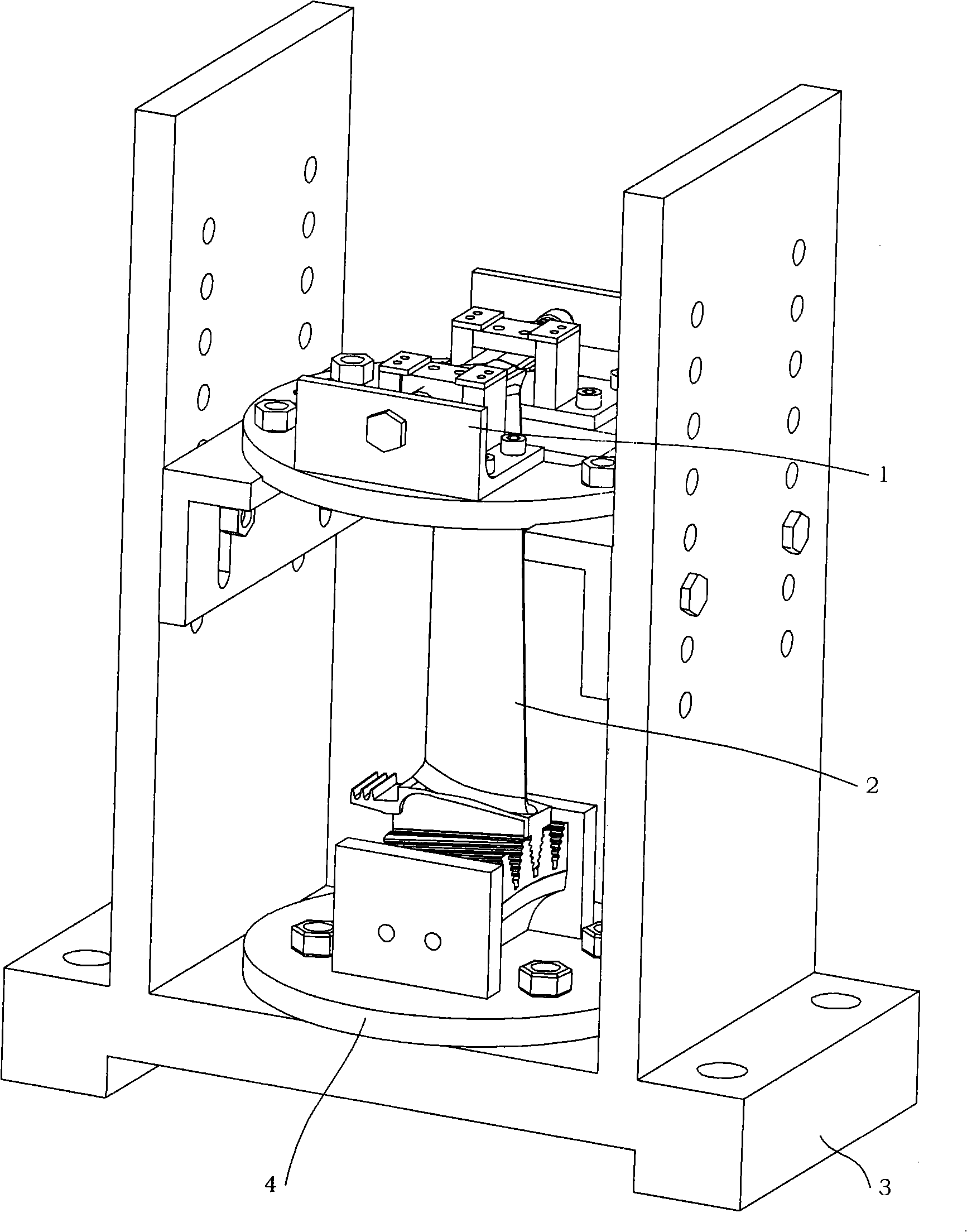

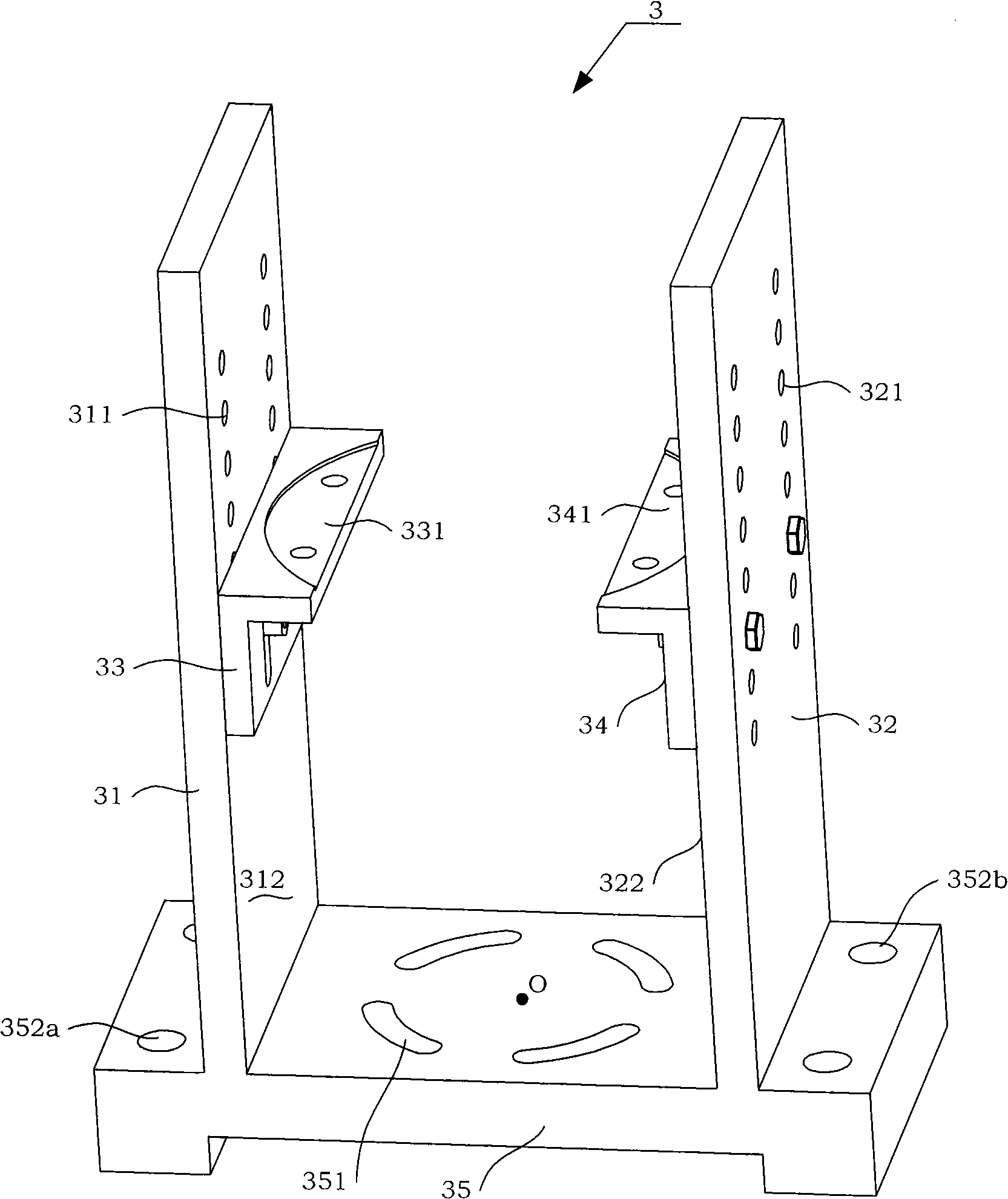

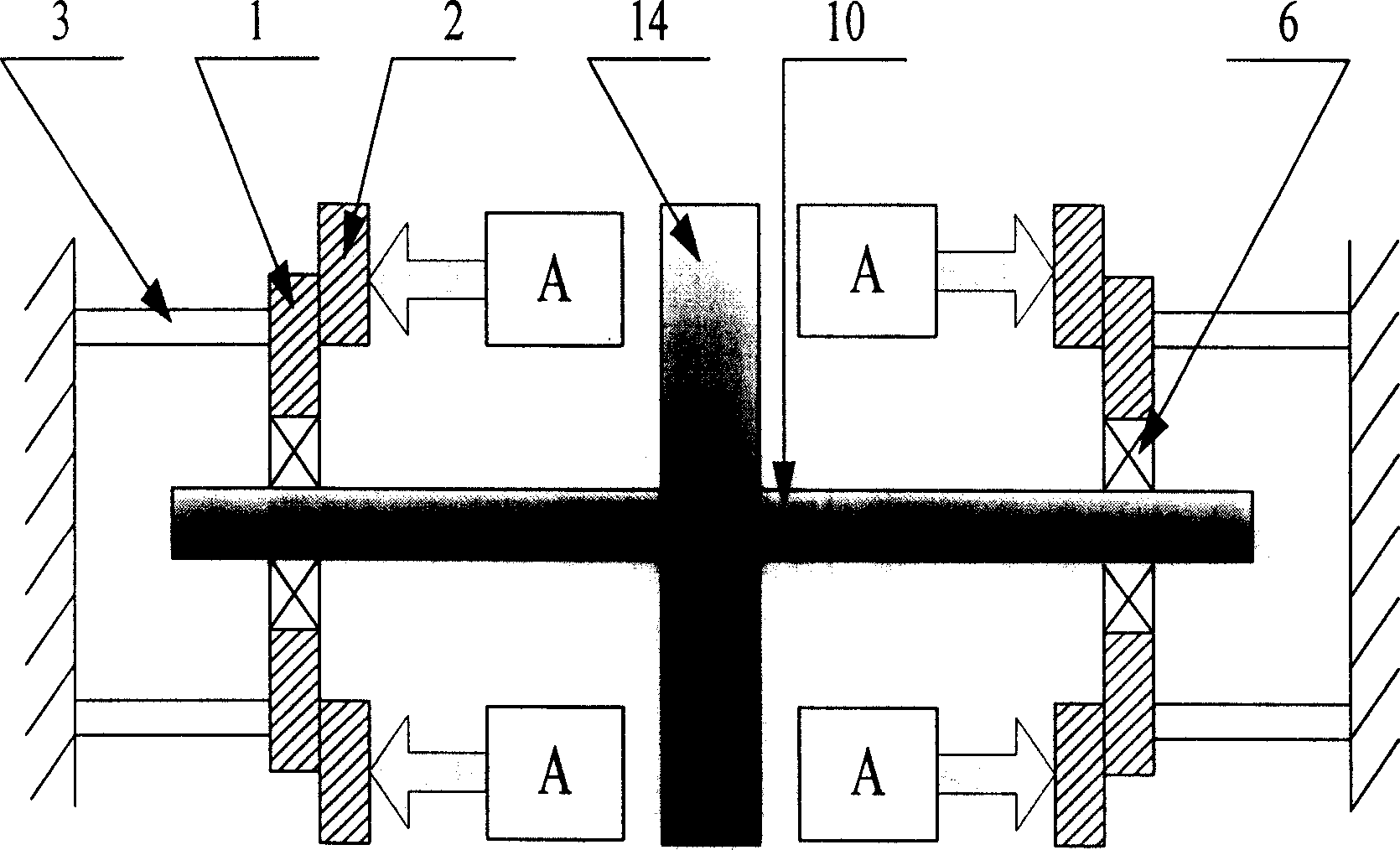

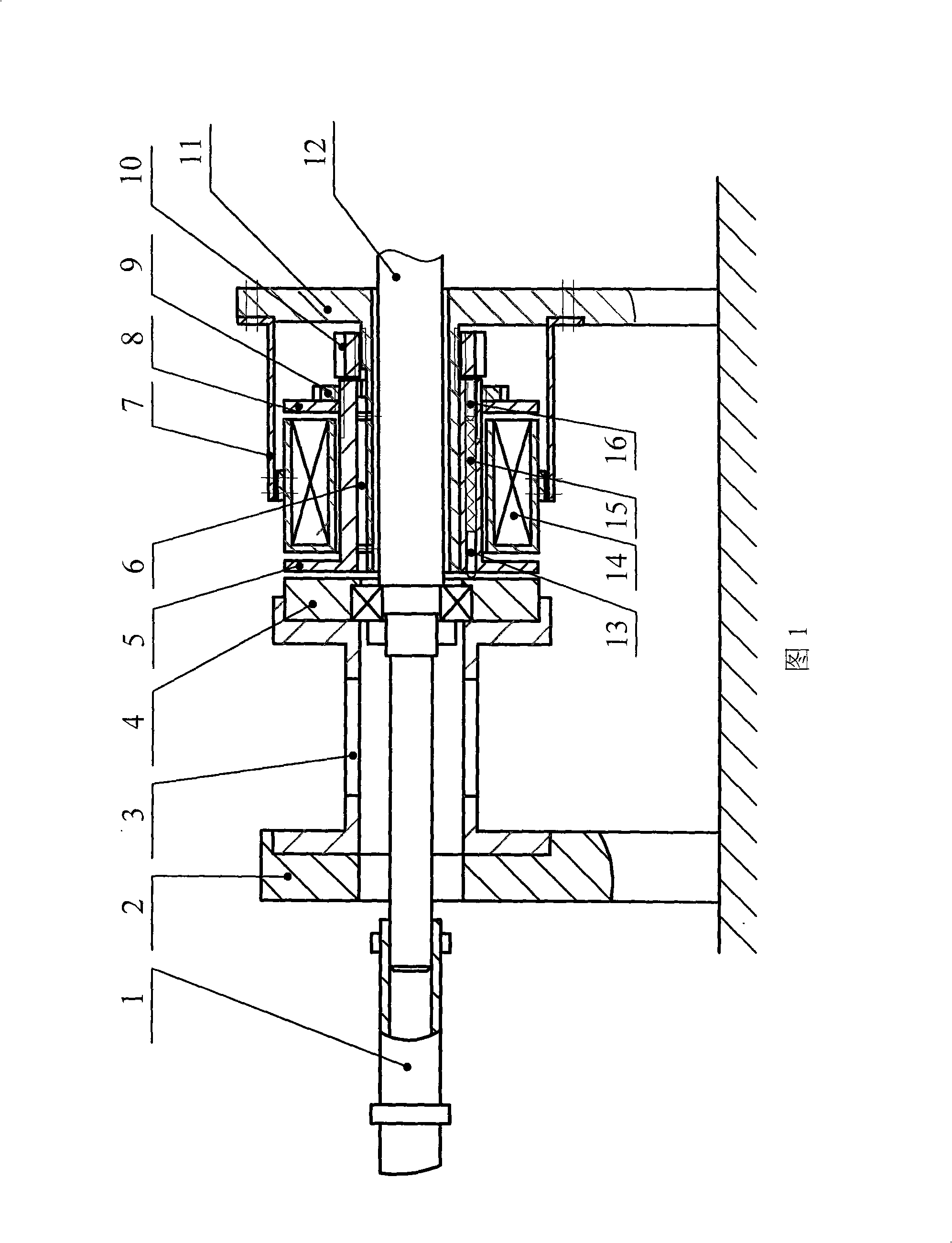

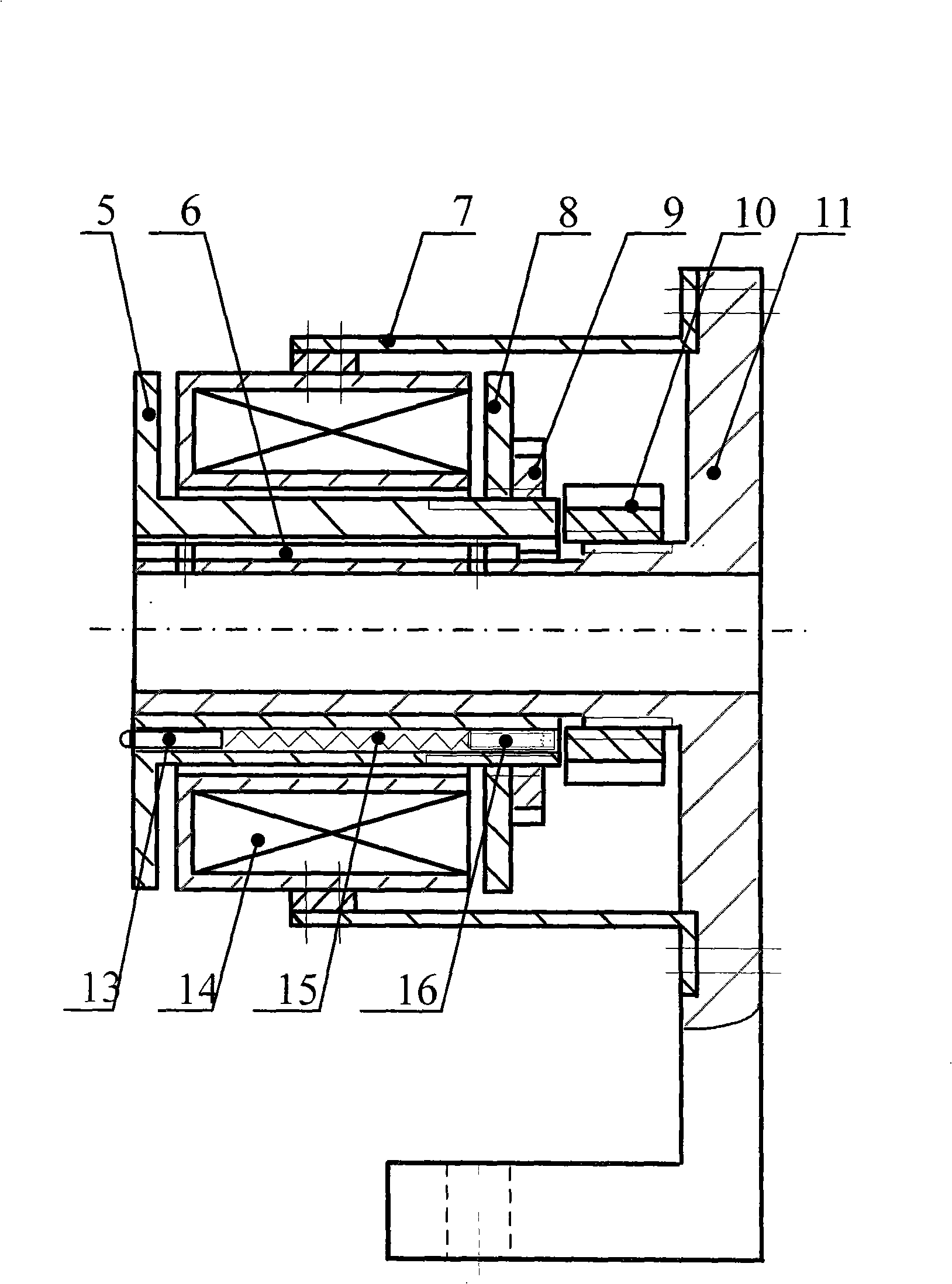

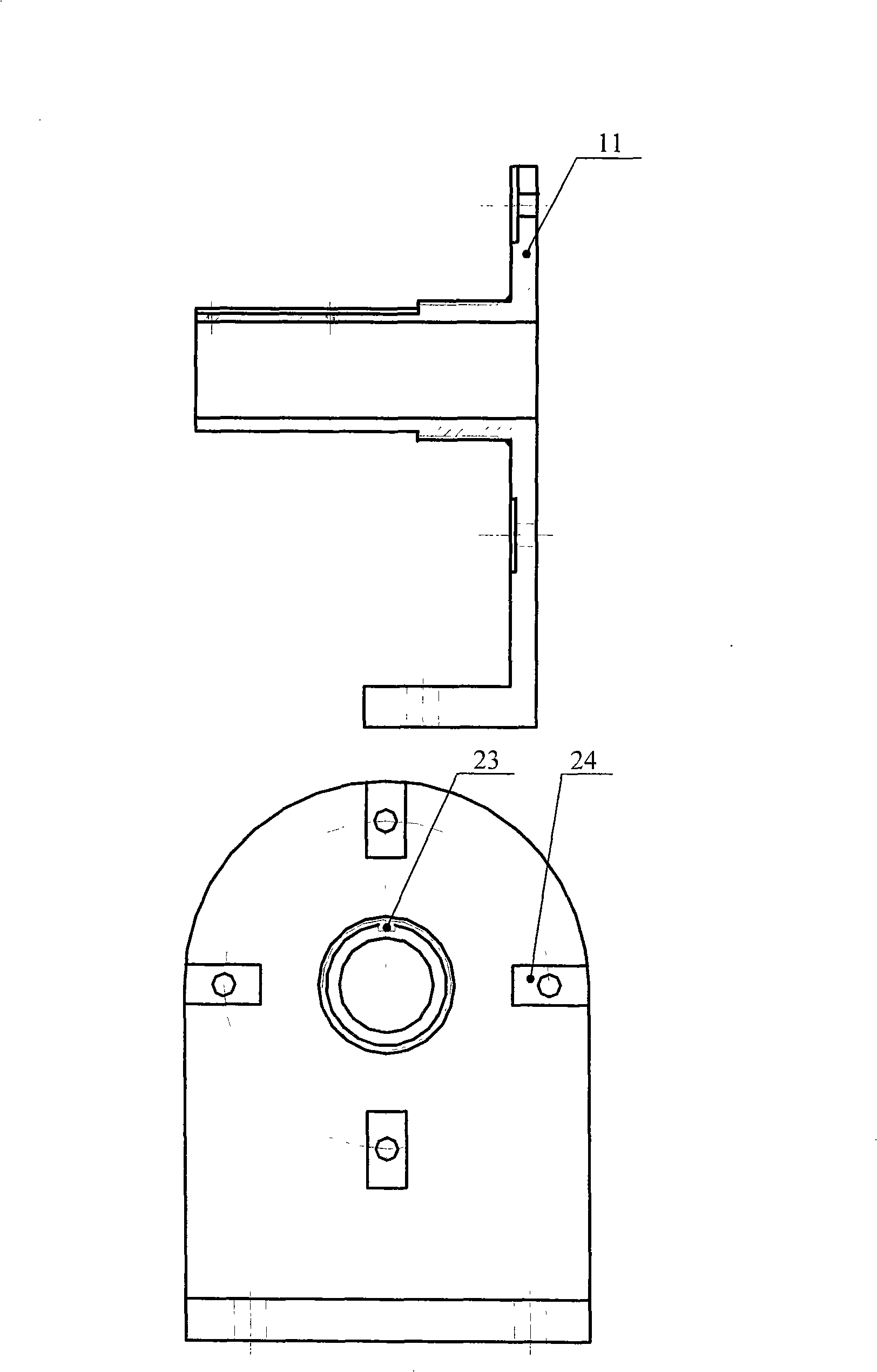

Vibration damping test device possessing dry damping structure vane

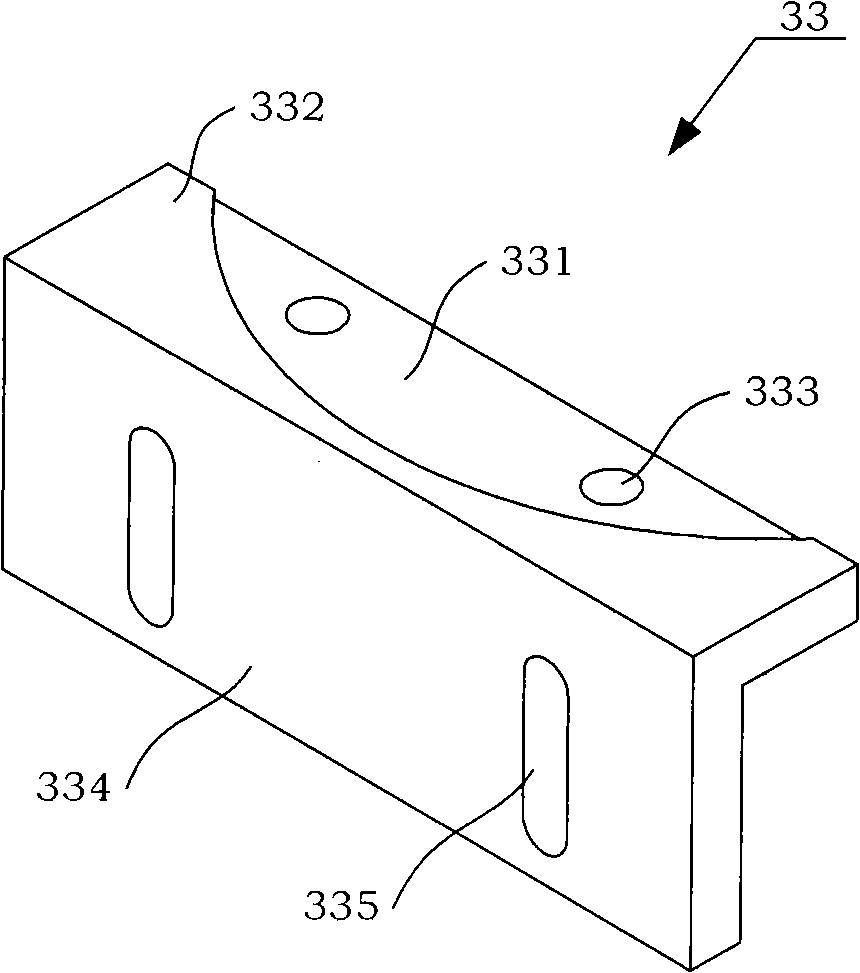

InactiveCN101308057ASolve the difficulty of accurately applying initial positive pressureVibration testingPositive pressureEngineering

The invention discloses a vibration reduction testing apparatus with a dry friction damping structure blade, the vibration reduction testing apparatus is composed of a positive pressure loading component, a fixture component and a base seat, the fixture component is mounted on a bottom plate of the base seat, the positive pressure loading component is arranged on a left supporting plate and a right supporting plate of the base seat, and a shroud of a blade with a dry friction damping structure is in contact with a friction block A and a friction block B on the positive pressure loading component. After loading the initial positive pressure and the exciting load, the vibration reduction testing apparatus of the invention can test vibration characteristics of different exciting forces, different initial positive pressures, different contact angles of a test piece (namely, the blade with the dry friction damping structure) and different installation positions of the test piece, and can utilize the test results to analyze the influence law of important parameters such as contact surface positive pressures of the test piece, contact angles of the test piece and installation positions of the test piece on the vibration reduction effect of the dry friction damping structure.

Owner:BEIHANG UNIV

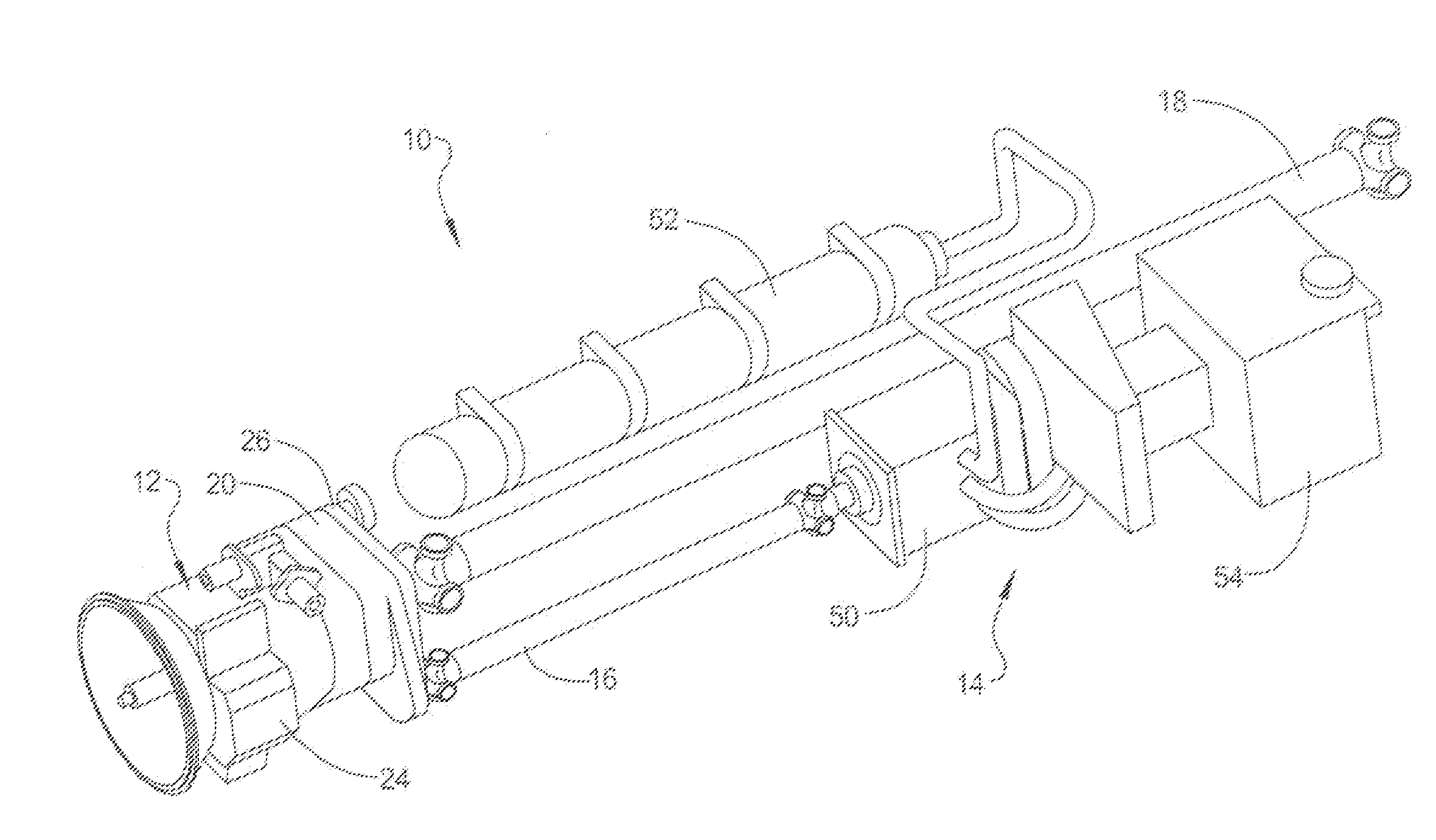

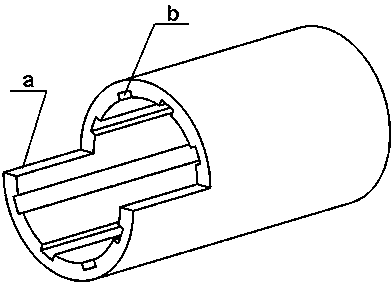

Elastic support dry-friction damper with intelligent structure

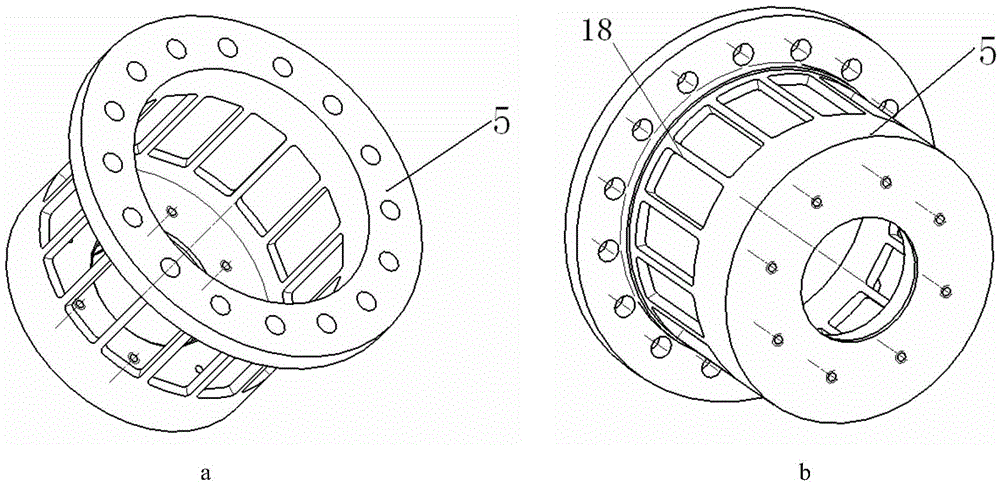

ActiveCN105526304AControl vibrationSuppression of destabilizing vibrationNon-rotating vibration suppressionAviationRolling-element bearing

The invention discloses an elastic support dry-friction damper with an intelligent structure. The elastic support dry-friction damper comprises a fold-back type elastic support, a supporting base, piezoelectric ceramic, a movable friction plate, a static friction plate, a plurality of strain gauges and three regulating bolts. The two ends of an inner mouse cage elastic support are respectively connected to the outer mouse cage elastic support and a rotary shaft. The end surface of one end, matched with a rolling bearing, of the inner mouse cage elastic support and the movable friction plate are connected through bolts. The end surface of one end, matched with the rolling bearing, of the inner mouse cage elastic support is connected to the movable friction plate. The static friction plate is arranged at one end of the rotary shaft in a sleeving mode. The movable friction plate is arranged on the rotary shaft in the sleeving mode. The outer mouse cage elastic support is arranged at the outer circumference of the inner mouse cage elastic support. After the elastic support dry-friction damper with the intelligent structure is introduced, a rotor is effectively controlled through vibration at a critical rotation speed, and unstable vibration of the rotor and sudden vibration increase caused by other unknown reasons further can be restrained, and therefore, the elastic support dry-friction damper has a wide application prospect in the fields of aviation and spaceflight.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

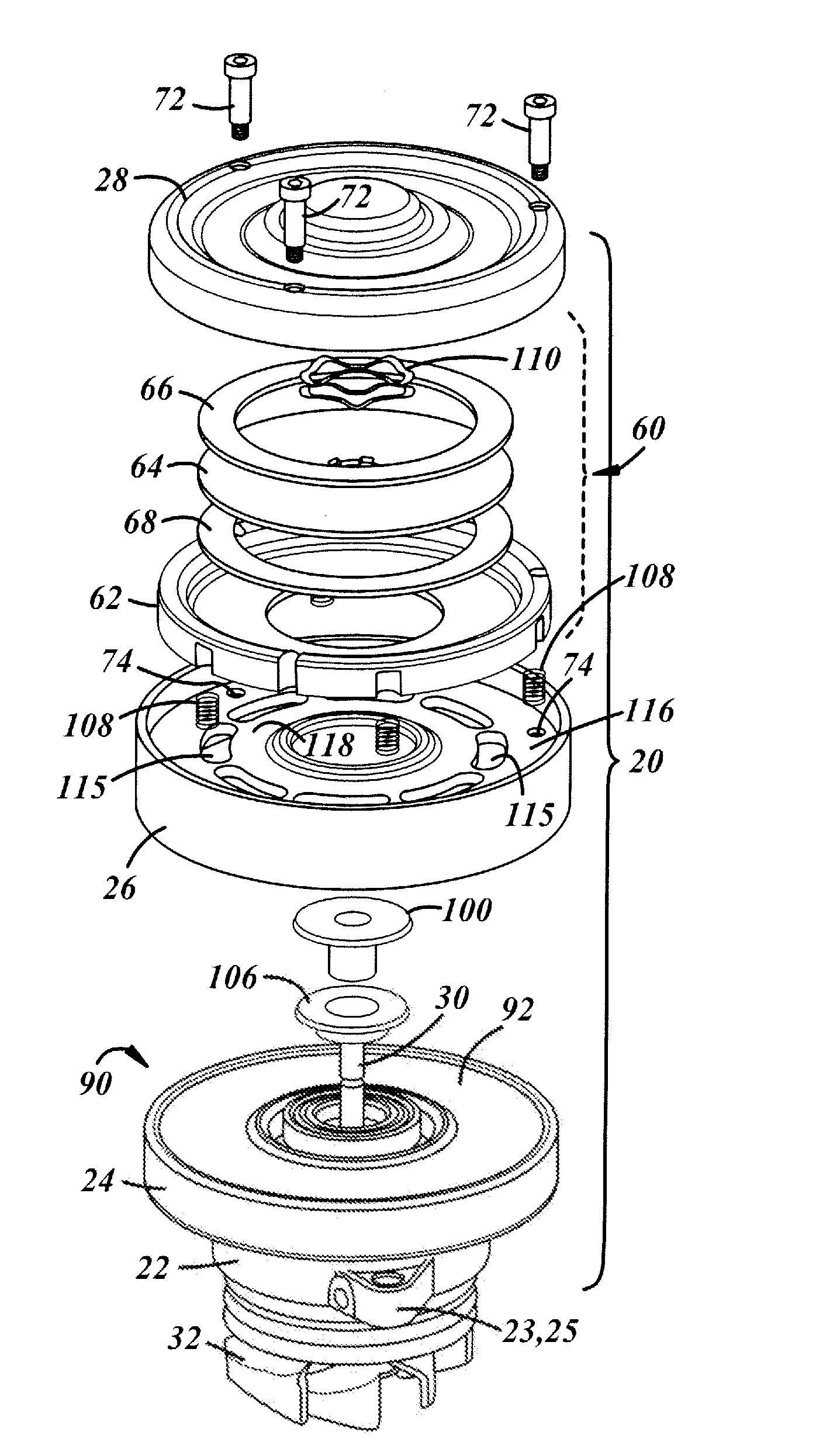

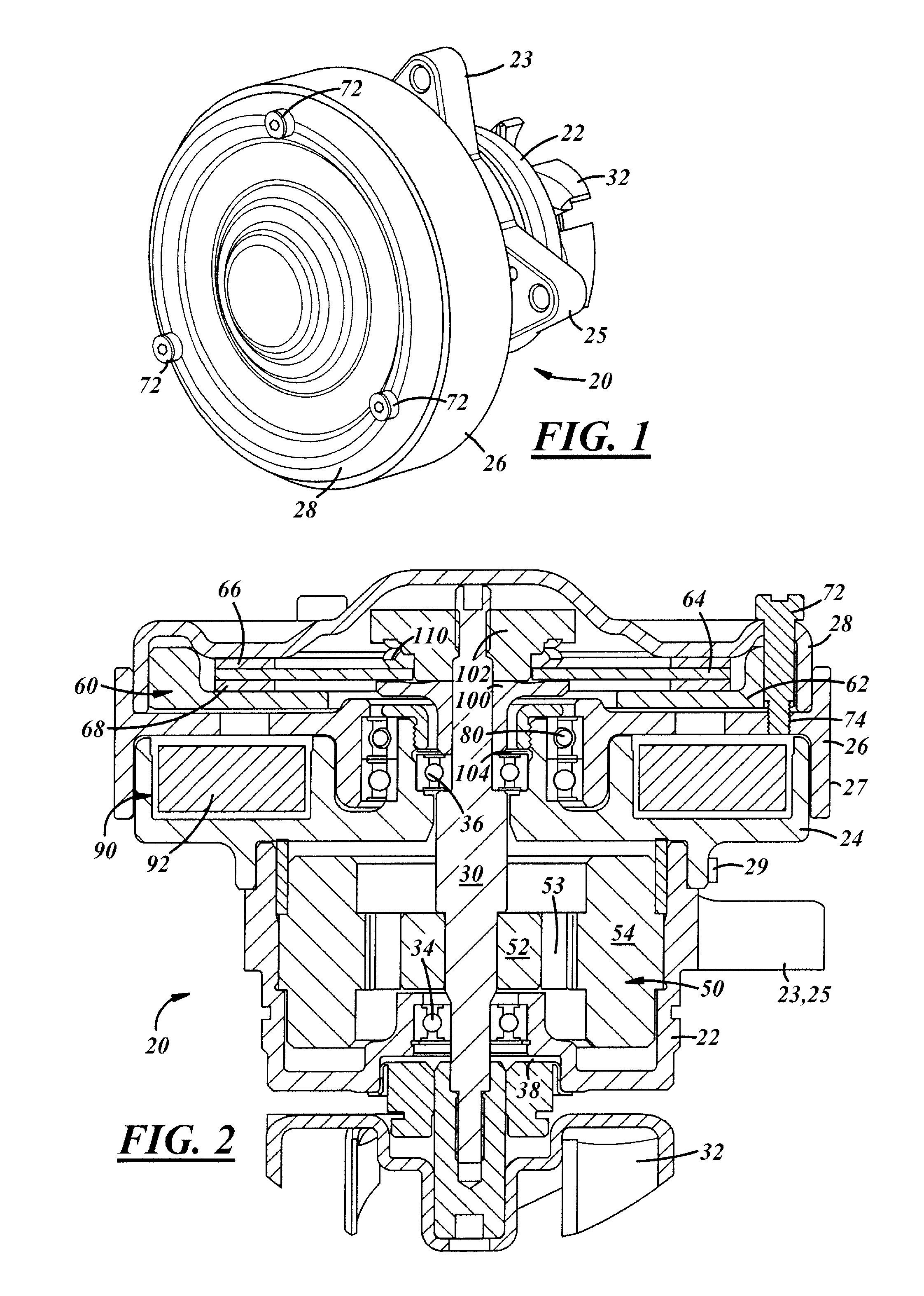

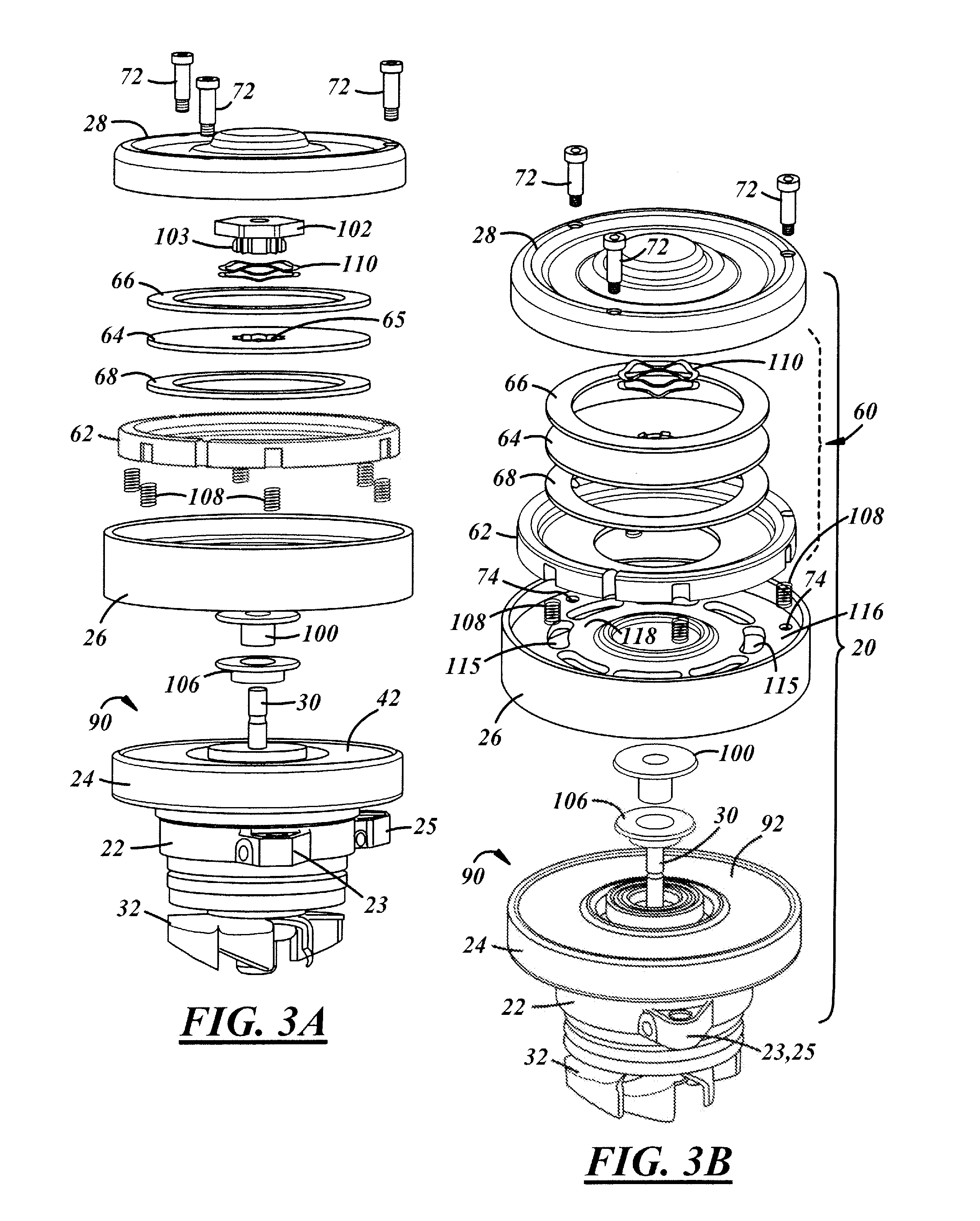

Fail-Safe Dry Friction Clutch For A Coolant Pump

InactiveUS20140174873A1Creating air gapEliminate interactionAuxillary drivesCoolant flow controlDual modeCoolant pump

Owner:BORGWARNER INC

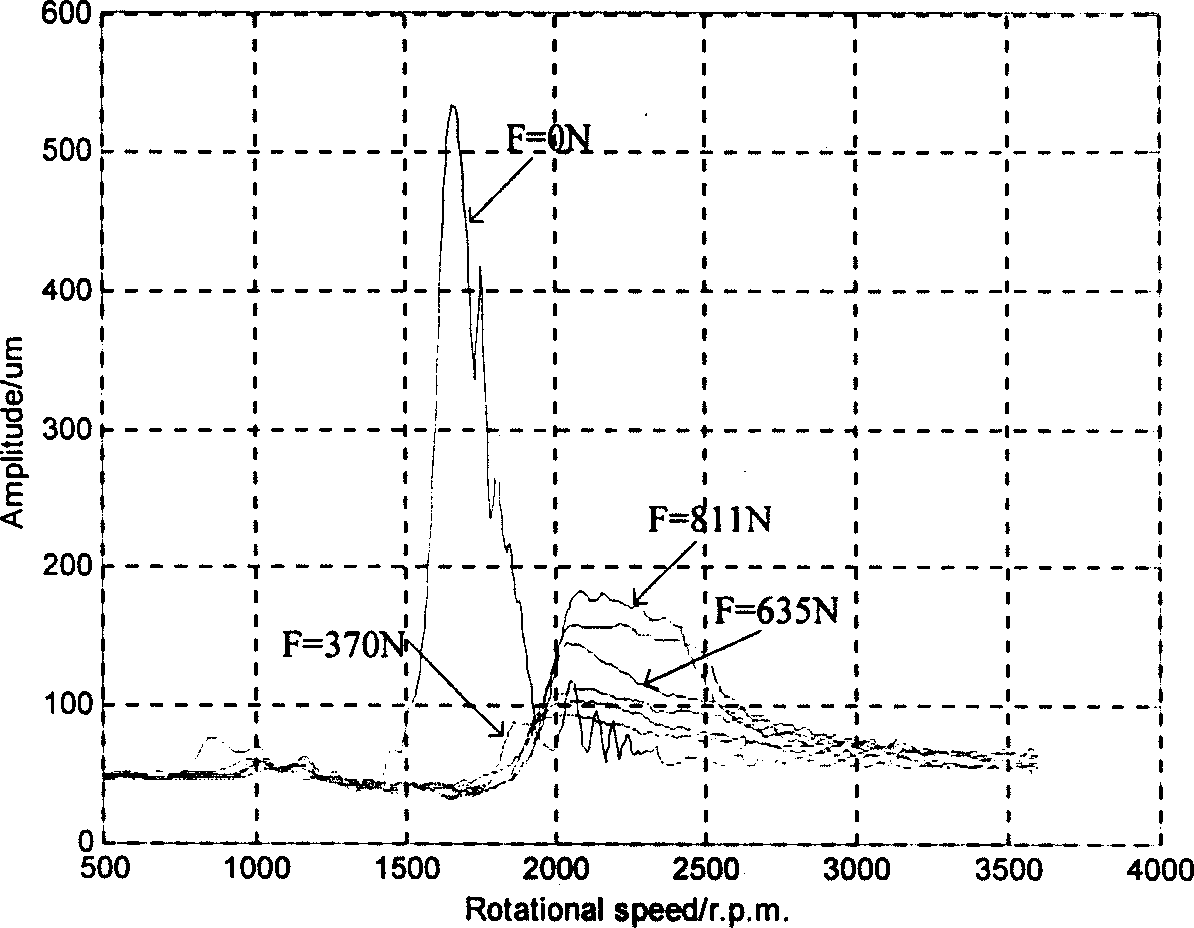

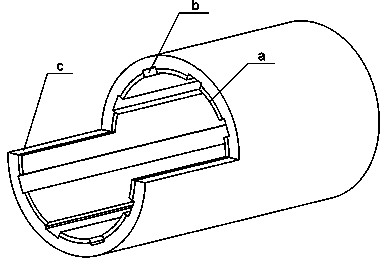

Method and device for suppression of vibration of rotor system with elastic support

InactiveCN1657800AReduce vibrationPrevent destabilizing vibrationNon-rotating vibration suppressionFriction dampersRelative motionFriction force

The invention is a method for preventing rotator system variation with flexible support and its device, aiming at solving the problems of high accuracy requirement and hard technique, by the relative movement of movable friction disc and still friction disc in dry friction damper to create frictional force, bring outer damping into the rotator system to decreased its variation in critical rotational speed, so that its stability is improved. The concrete method includes: mount movable friction disc and still friction disc onto axial, through pressure carried by force applicating and adjusting the pressure to change the damper value. After bringing into dry friction damper, the variation of rotator in critical rotational speed as well as its vibration can be prevented effectively; it has simple structure.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Self-lubricating slide bearing by oil lubrication or grease lubrication

InactiveCN101413544AImprove wear resistanceExcellent friction and wear resistanceBearing componentsVinyl etherFiber

The invention discloses a self-lubricating sliding bearing applicable to the working conditions of oil lubrication or grease lubrication. The sliding bearing is obtained by rolling three layers of composite materials which are respectively a metal substrate; a spherical porous copper powder layer which is sintered on one surface of the metal substrate; and an anti-friction wear resistant material layer that permeates and covers the copper powder layer, wherein, the copper powder layer consists of the following components by weight percentage: 8% of tin powder, 3% of zinc powder and copper powder; the anti-friction wear resistant material layer consists of the following components by weight percentage: 35-50% of polytetrafluoroethylene, 10-15% of polyether-ether-ketone, 10-15% of carbon fiber, 3-6% of molybdenum disulfide and tetrafluoroethylene-perfluoroalkoxy vinyl ether copolymer. The self-lubricating sliding bearing has good friction and wear resistant property under the conditions of the oil lubrication and the grease lubrication, and has excellent friction and wear resistant property especially under the alternative working conditions of the oil lubrication and the grease lubrication, the oil lubrication and dry friction or the grease lubrication and the dry friction.

Owner:JIANGSU CCVI BEARING

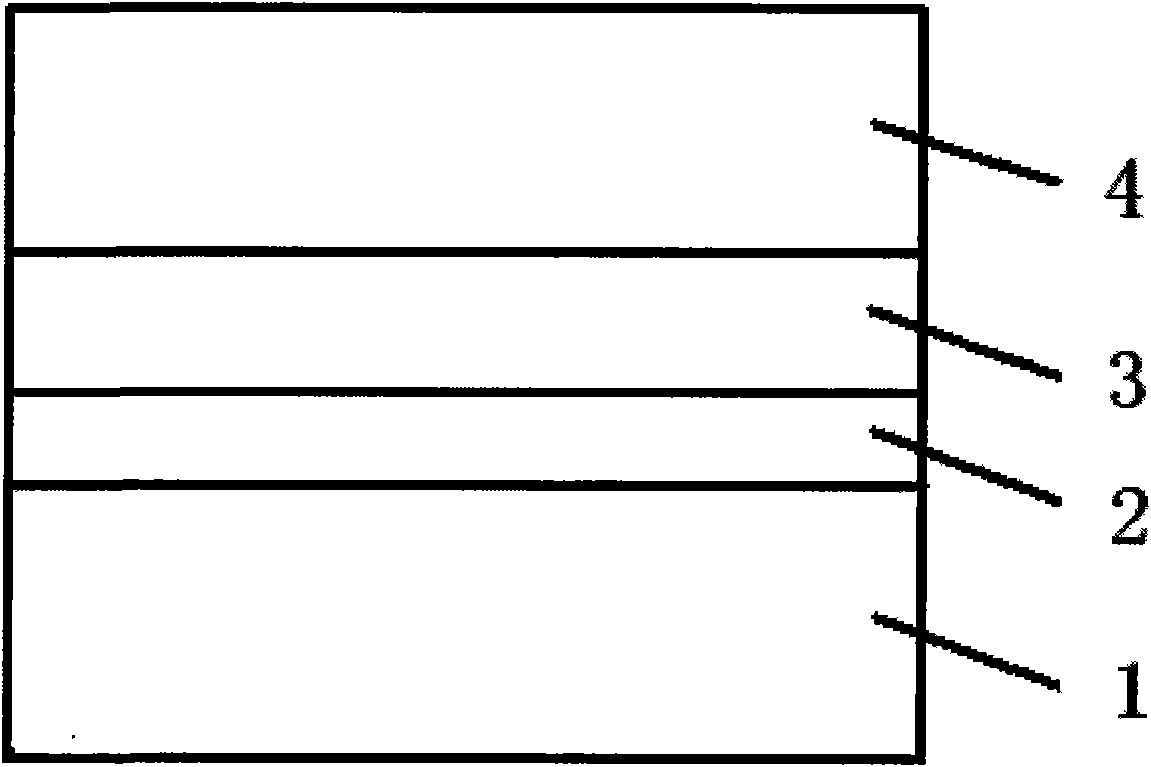

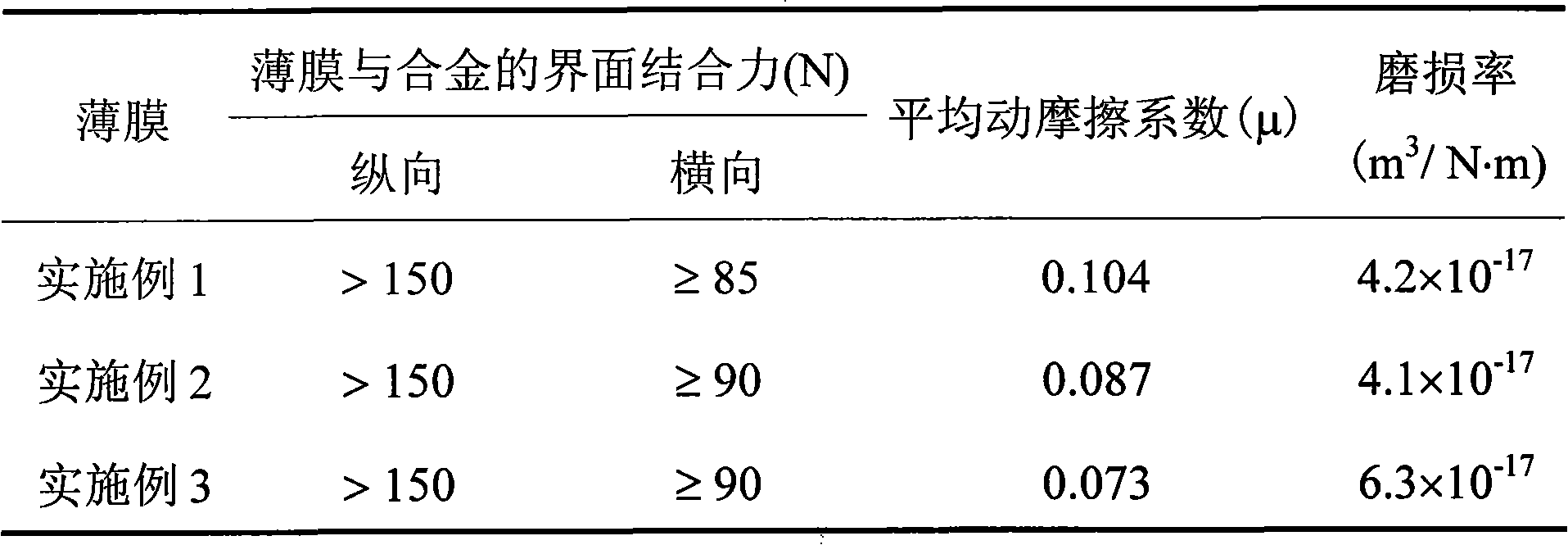

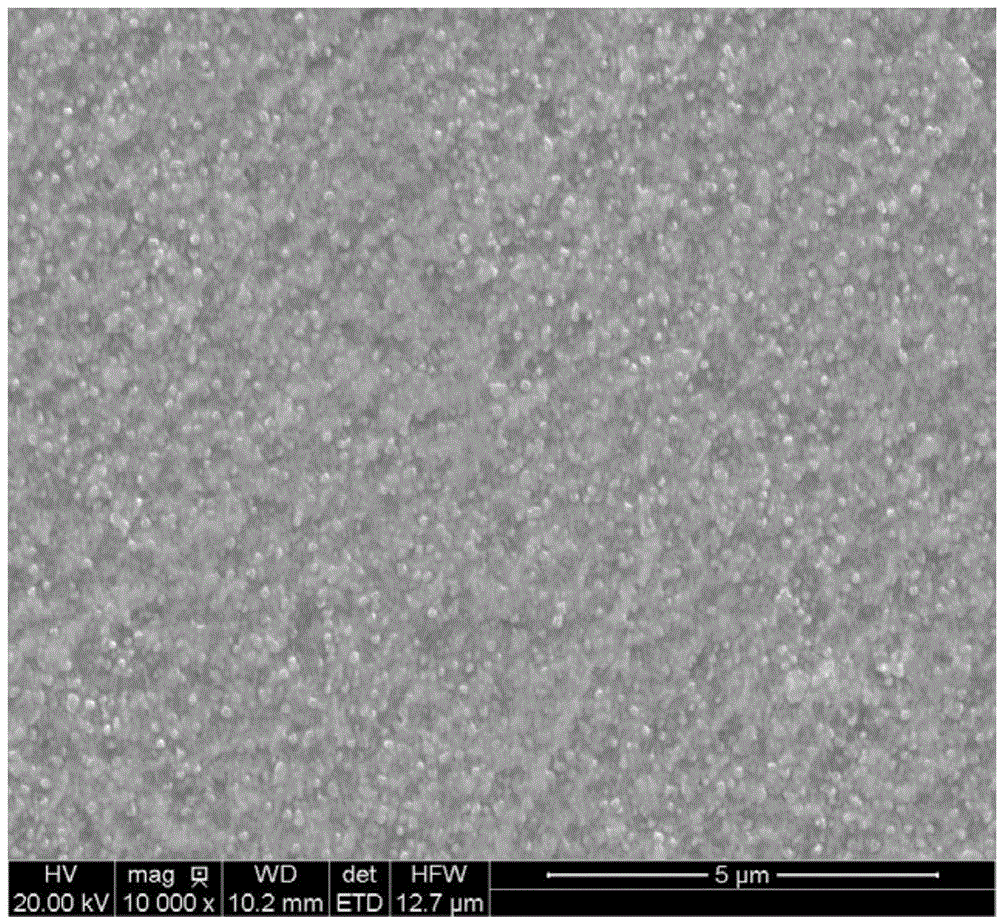

Ultra-hard carbon film and preparation method thereof

ActiveCN101554790AImprove bindingExtended service lifeVacuum evaporation coatingSputtering coatingCarbon filmHardness

The invention discloses an ultra-hard carbon film which is formed by a substrate, a pure Ti binding layer, a Ti plus C composite gradient transition layer and an amorphous pure carbon film layer mainly taking the sp structure, and prepared by adopting an unbalanced magnetron sputtering method. The binding force between the film and the substrate of the ultra-hard carbon film is significantly improved at the pure Ti binding layer and the Ti plus C composite gradient transition layer which are deposited on an alloy surface, the hardness of the amorphous pure carbon film layer mainly taking the sp structure can reach 41 to 53GPa, simultaneously, the carbon film contains lower internal stress, and the thickness of the ultra-hard carbon film is controllable. When dry friction experiment is implemented at atmospheric environment, the ultra-hard carbon film has extremely low friction coefficient and wear rate, presents excellent anti-frication and wear-resisting property, can be used for manufacturing protective films on the surface of spare parts of bearings and worm and gear and the like, and greatly prolongs the service life of the spare parts of machines.

Owner:ZHEJIANG UNIV

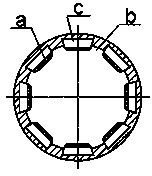

Electric control device of cartridge branch dry damping device

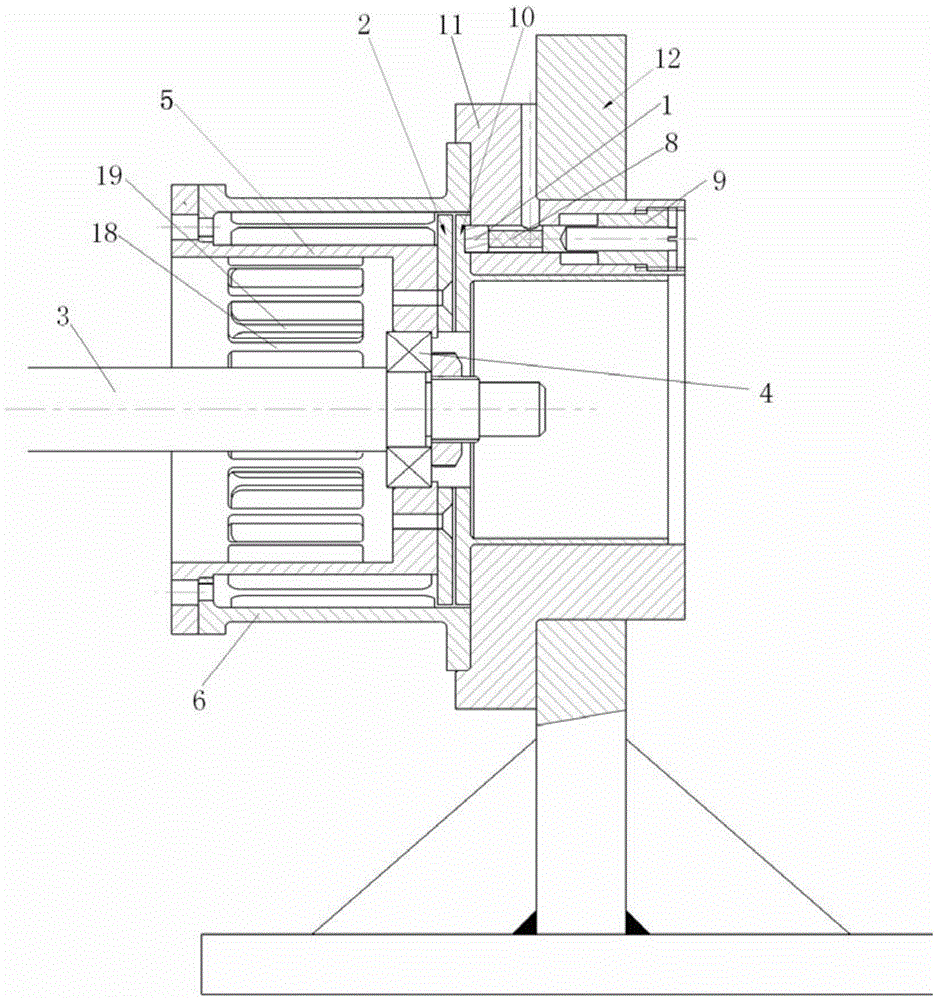

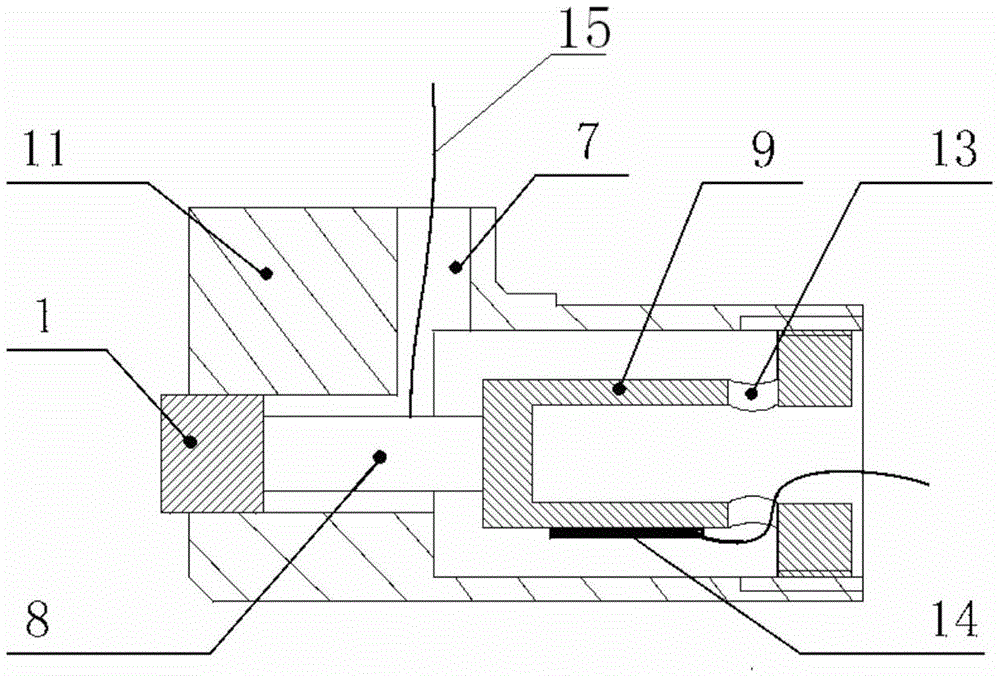

InactiveCN101275619ASolve contact problemsAdjust damping valueNon-rotating vibration suppressionMagnetic tension forceStatic friction

The invention relates to an shooting stem dry friction damper electric control device, including a static friction plate (5), a armature (8), a seat (11) and an electromagnet (14), wherein the seat is sleeved on the shaft, the static friction plate (5) is sleeved on the seat, the electromagnet is sleeved on the static friction plate. An electromagnet stand (7) is fixed on the seat (11), providing the resistance for the axial motion of the static friction plate (5) and the clamping force between a movable friction plate (4) and the static friction plate (5); the gap when the static friction plate (5) and the movable friction plate (4) are not working is adjusted through a locating nut (10). The invention solves the contact and the separating problems between the static friction plate (5) and the movable friction plate (4), also controls the force of friction between the static friction plate and the movable friction plate by electromagnetic force to adjust the outer damp added on the rotator.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

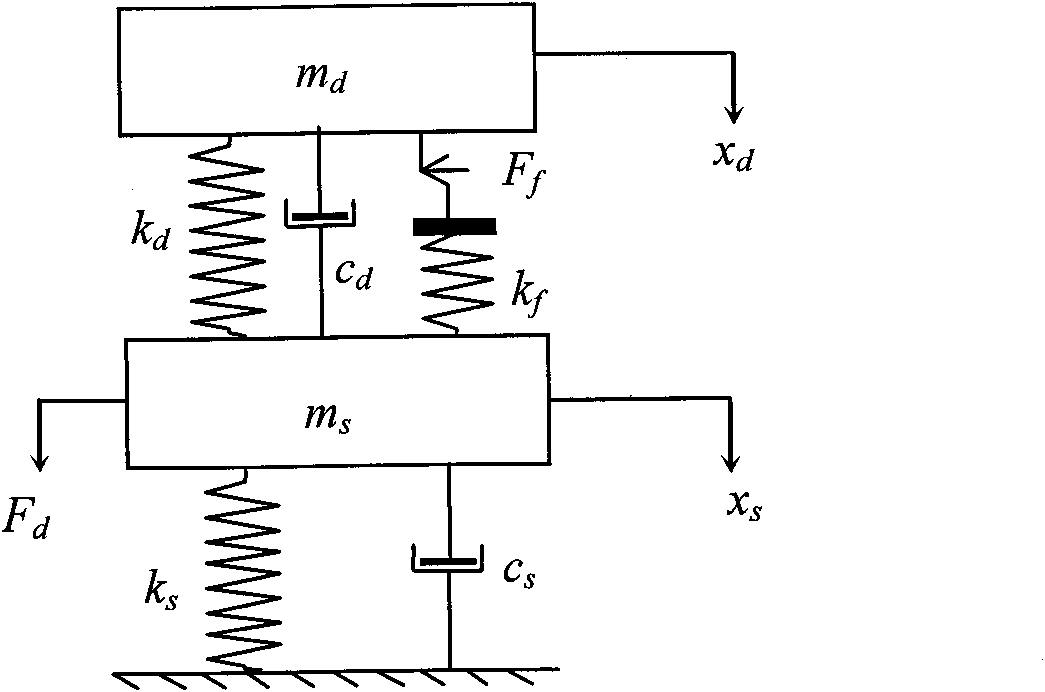

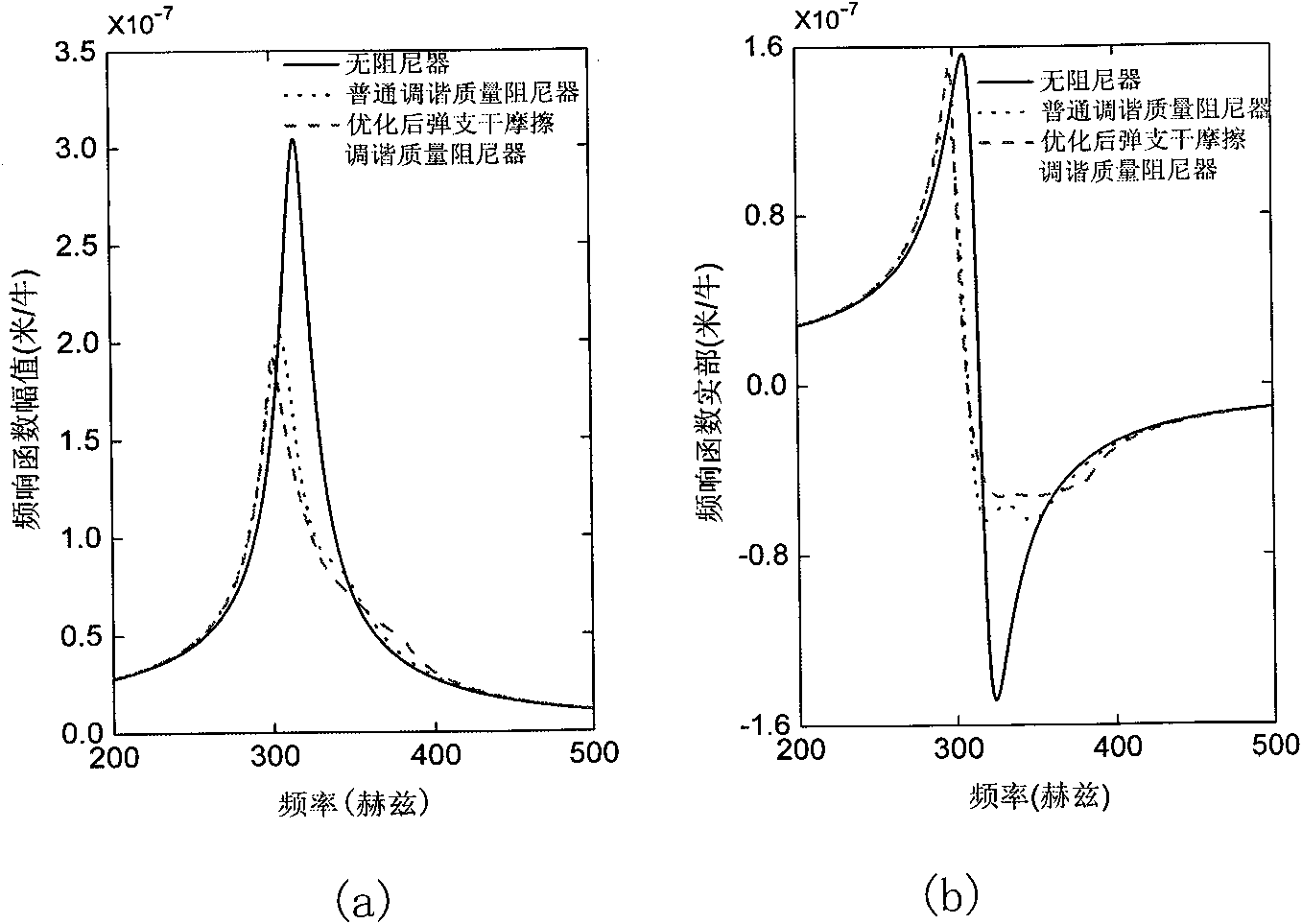

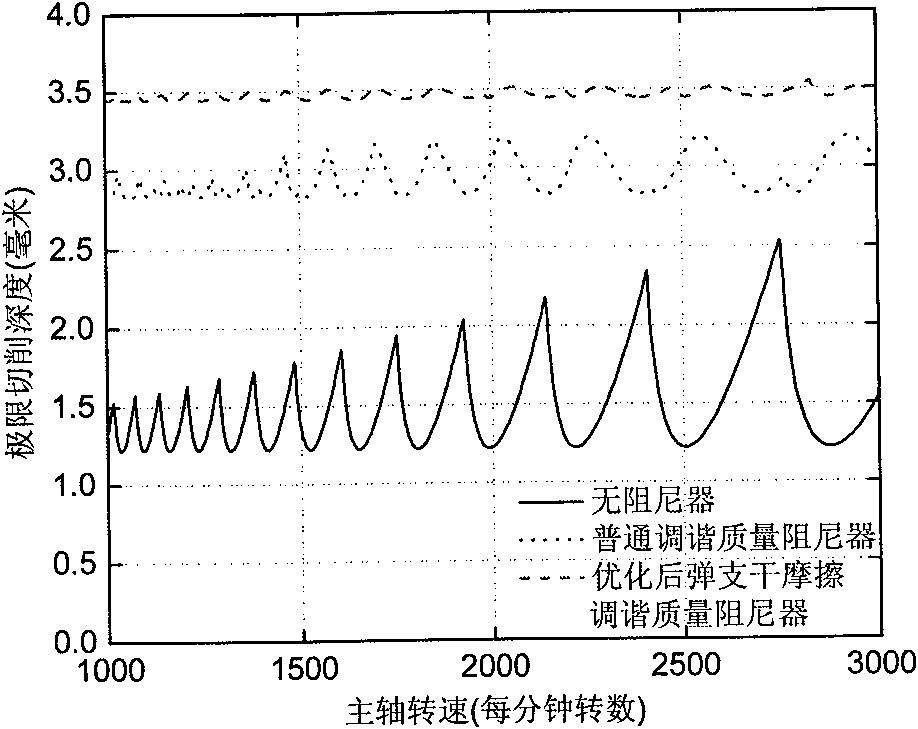

Optimization method of tuned mass damper of elastic support dry friction

InactiveCN101832359AImprove cutting stabilityNon-rotating vibration suppressionDamping factorModal testing

The invention relates to an optimal design method for a tuned mass damper of elastic support dry friction for controlling cutting vibration, relating to an optimization method of structural parameters for inhibiting a cutting vibration processing damper. The invention, aiming at an elastic support serial dry friction damper, provides the optimization method of structural parameters thereof, comprising the following steps of: firstly, acquiring the primary module state mass, the rigidity and the damping coefficient in a weak loop of a controlled cutting system through the module state testing technology; then establishing module dynamically for the cutting system additionally provided with the tuned mass damper of elastic support dry friction and acquiring the frequency responding function of the controlled cutting system through the numerical calculation method; and finally, carrying out the optimal design by adopting the numerical optimization method, and taking maximum negative real part of the frequency responding function of the controlled cutting system as the optimal object and fixed frequency, elastic support rigidity of the tuned mass damper of elastic support dry friction as the optimal parameters of the damper. The optimum design can exert two energy consumption abilities of friction damping and oscillator vibration at the same time to maximum extend so that the cutting stability is optimized.

Owner:BEIJING UNIV OF TECH

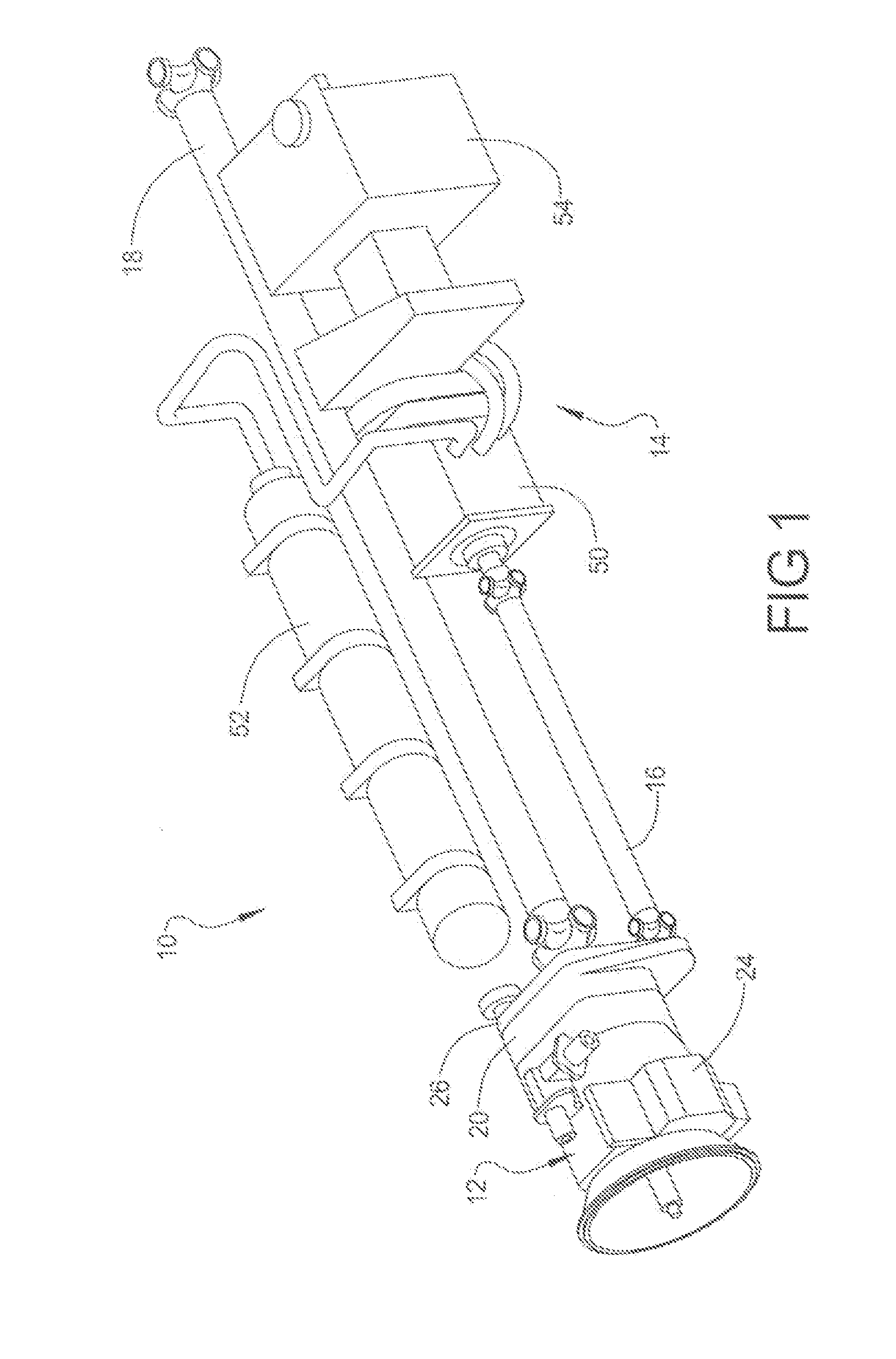

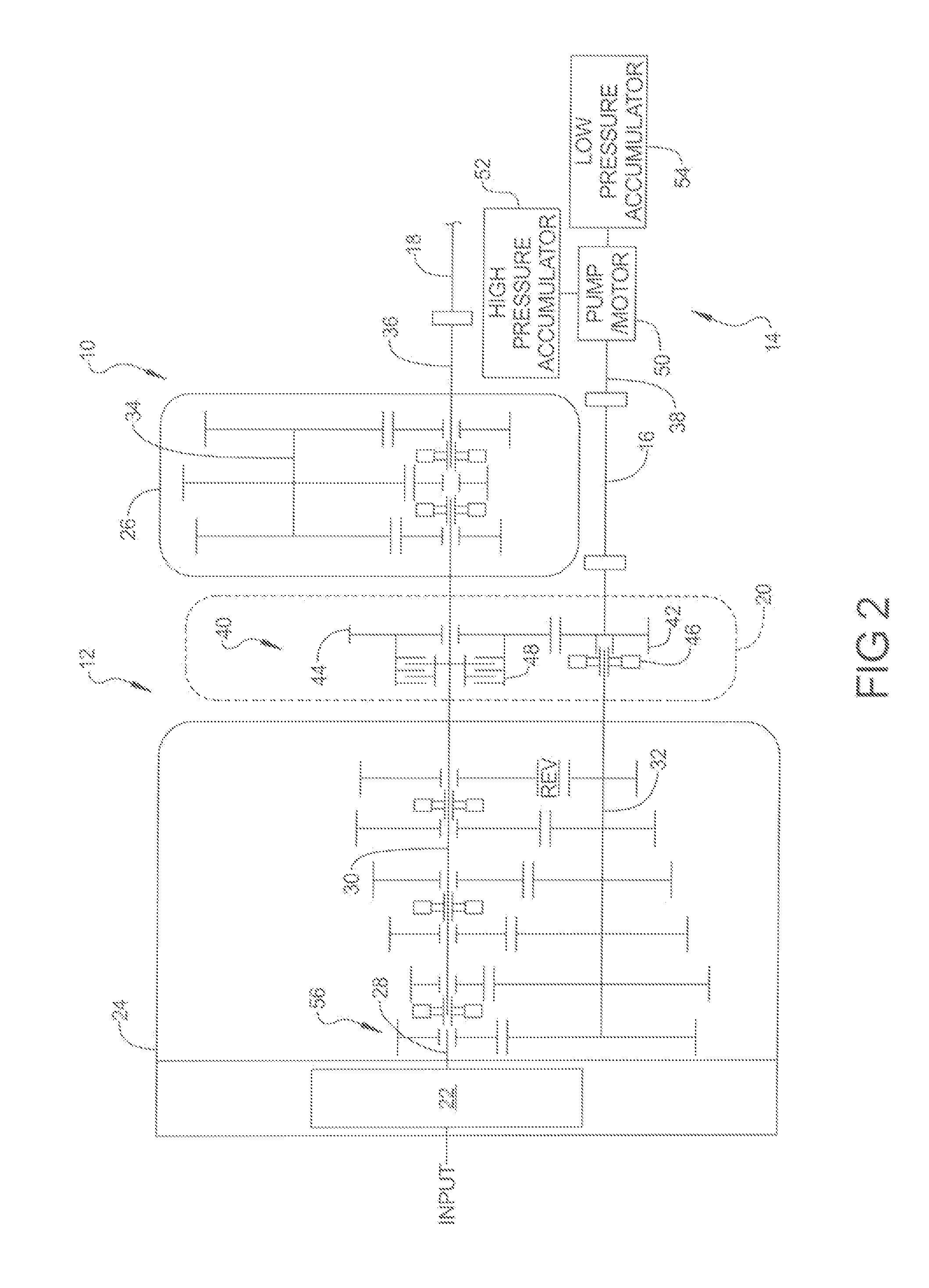

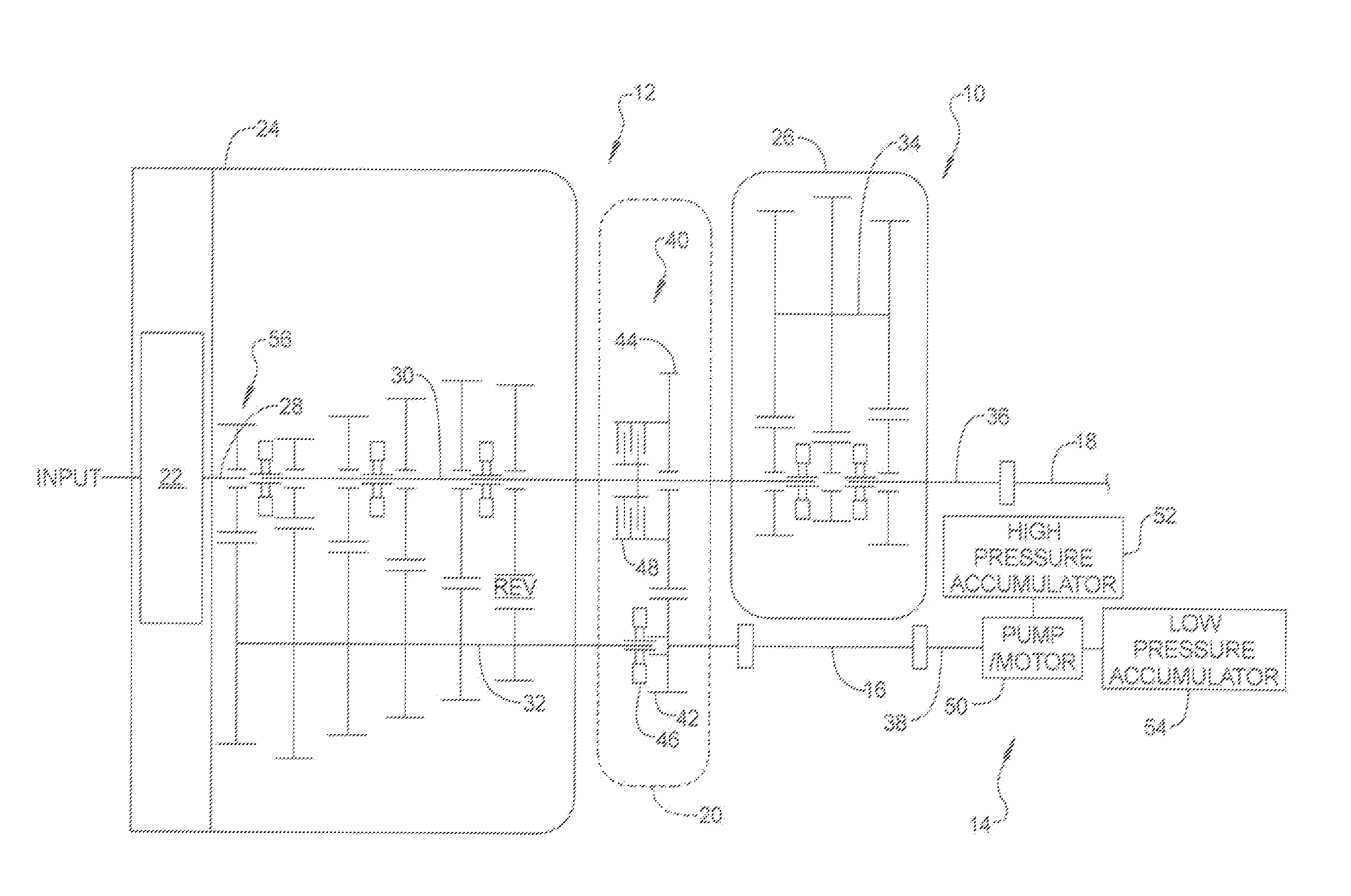

Adapter for Connecting a Countershaft Transmission with an Electric Hybrid System

InactiveUS20110303048A1Increase heightOvercomes clutch wear concernGas pressure propulsion mountingToothed gearingsHybrid systemDrive wheel

This invention provides a common means of coupling an alternative power source to a vehicle's drive wheels which is particularly well suited for use with a countershaft-type transmission. This invention also addresses clutch wear by eliminating the need to engage the frictional clutch to launch the vehicle. This invention also improves the acceleration of the vehicle compared to a typical dry friction clutch launch by relying on a supplemental motor and associated control system to transfer more power to the drive wheels more quickly than would be transferred by a typical launch engagement of a dry friction clutch in a commercial vehicle.

Owner:EATON CORP

Nickel-aluminum bronze alloy and preparation method thereof

The invention discloses a nickel-aluminum bronze alloy. The nickel-aluminum bronze alloy comprises the following chemical elements in percentage by mass: 9.5-11.5% of Al, 3.0-4.5% of Fe, 3.5-4.5% of Ni, 3-4% of Mn and the balance of Cu. The invention further provides a preparation process of the nickel-aluminum bronze alloy. The preparation process comprises the following steps: according to the mass percent of all chemical elements and by taking burning loss quantity into consideration, preparing raw materials; putting the raw materials into a furnace for melting and cooling molten raw materials into an ingot; heating the ingot to 950-980 DEG C from room temperature at the speed of 8-10 DEG C / min; keeping heat for 2 h above; taking out a sample and putting the sample into water for quenching; heating to 300-450 DEG C at the speed of 8-10 DEG C / min; keeping heat for 1-3 h; and putting the sample in air for cooling, so as to obtain the nickel-aluminum bronze alloy. The nickel-aluminum bronze alloy provided by the invention is high in hardness and wear resistance, the dry friction coefficient of the nickel-aluminum bronze alloy is about 0.25, microhardness can reach 460 HV and the nickel-aluminum bronze alloy has a wide application prospect in the fields of marine propellers, large-sized pump blades, fasteners, seawater pipe fittings, welding, explosion-proof equipment and sea water desalination.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

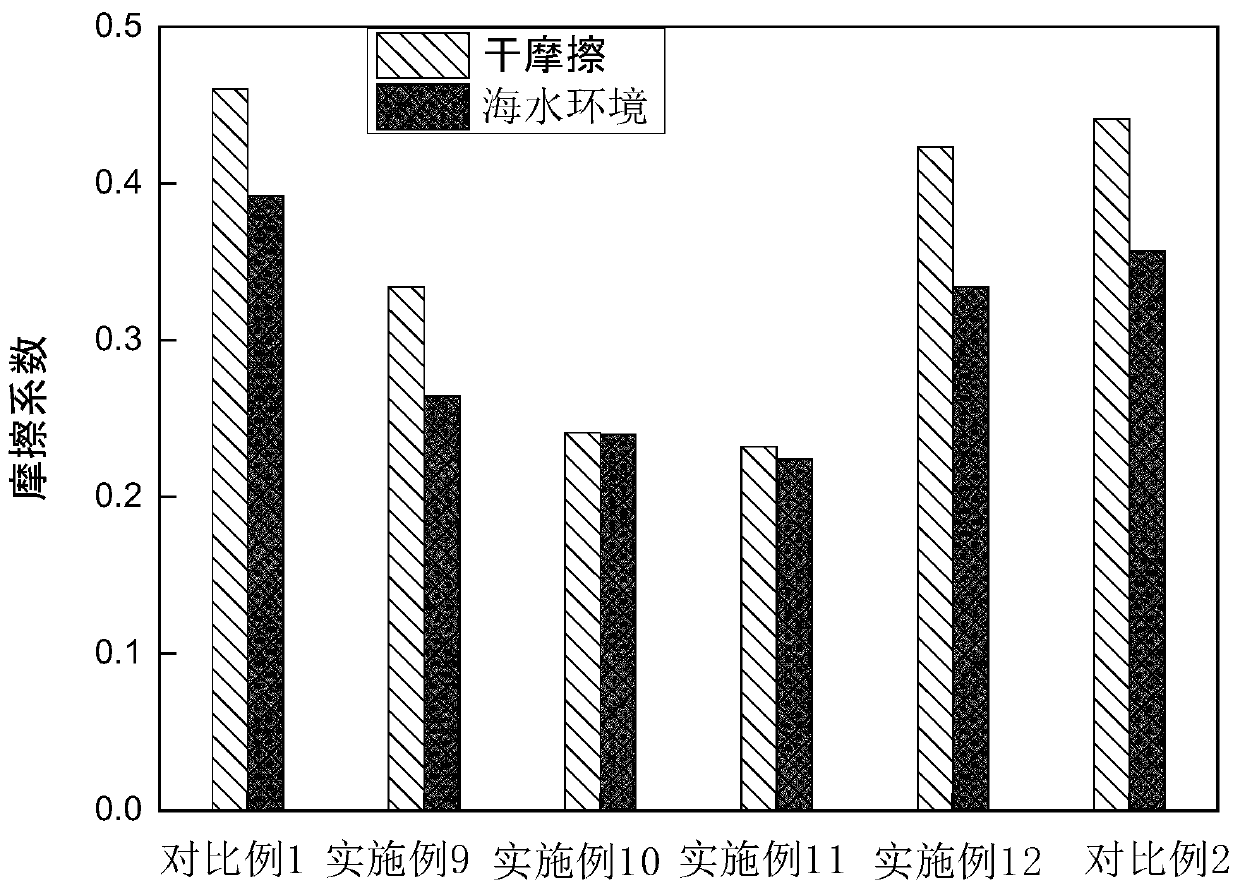

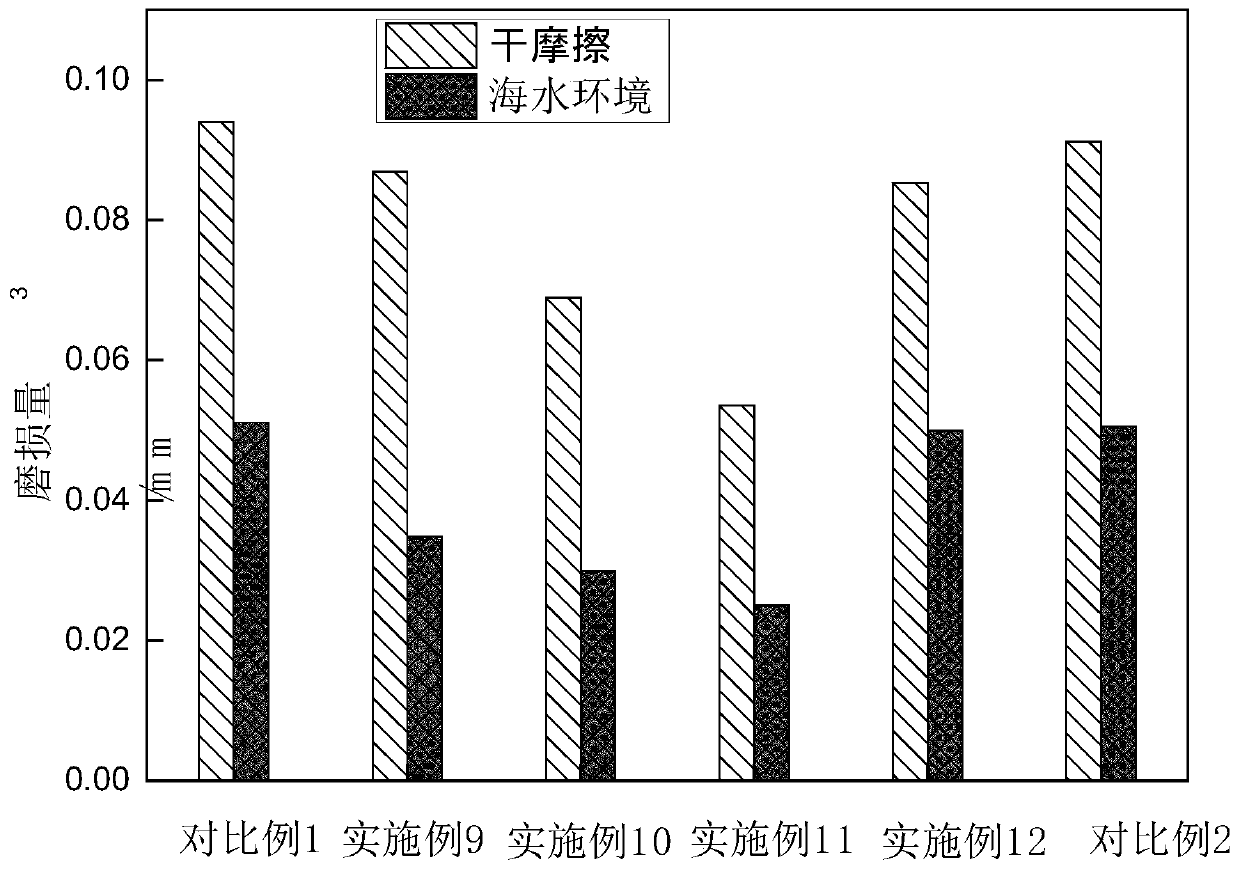

Composition for preparing self-lubricating wear-resistant material, self-lubricating wear-resistant paint, self-lubricating wear-resistant coating, and self-lubricating wear-resistant material

InactiveCN110016277AImprove wear resistanceStable and excellent lubricating propertiesEpoxy resin coatingsWear resistantWear resistance

The invention relates to a composition for preparing a self-lubricating wear-resistant material, a self-lubricating wear-resistant paint, a self-lubricating wear-resistant coating, and a self-lubricating wear-resistant material, and belongs to the technical field of self-lubricating materials. The composition for preparing the self-lubricating wear-resistant material is mainly composed of a resinand the following components in parts by weight: 11-12 parts of molybdenum disulfide, and 0.088-0.3 part of graphene. The composition uses molybdenum disulfide as a lubricant and graphene as a lubricating additive, the similarity of the two-dimensional layered structure of molybdenum disulfide and graphene is utilized, molybdenum disulfide and graphene are compounded according to a specific ratioto prepare the wear-resistant material, the synergistic lubricating effects of molybdenum disulfide and grapheme can be exerted, and thus the wear resistance and self-lubricating property of the wear-resistant material are significantly improved. Particularly the self-lubricating anti-friction wear-resistant coating prepared by using the composition has good lubrication and anti-friction property,wear resistance and environmental adaptability under dry friction and seawater conditions.

Owner:HENAN UNIV OF SCI & TECH

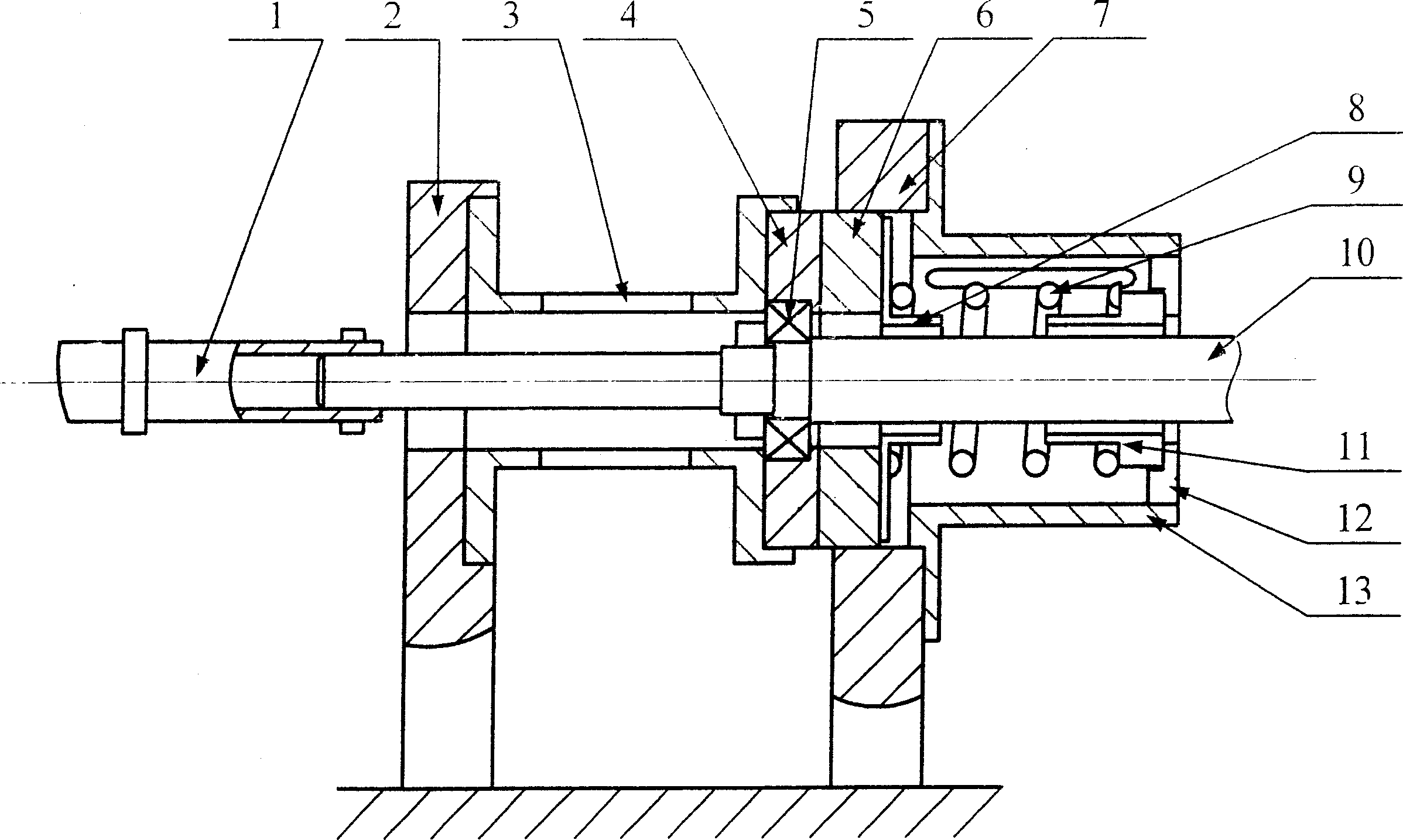

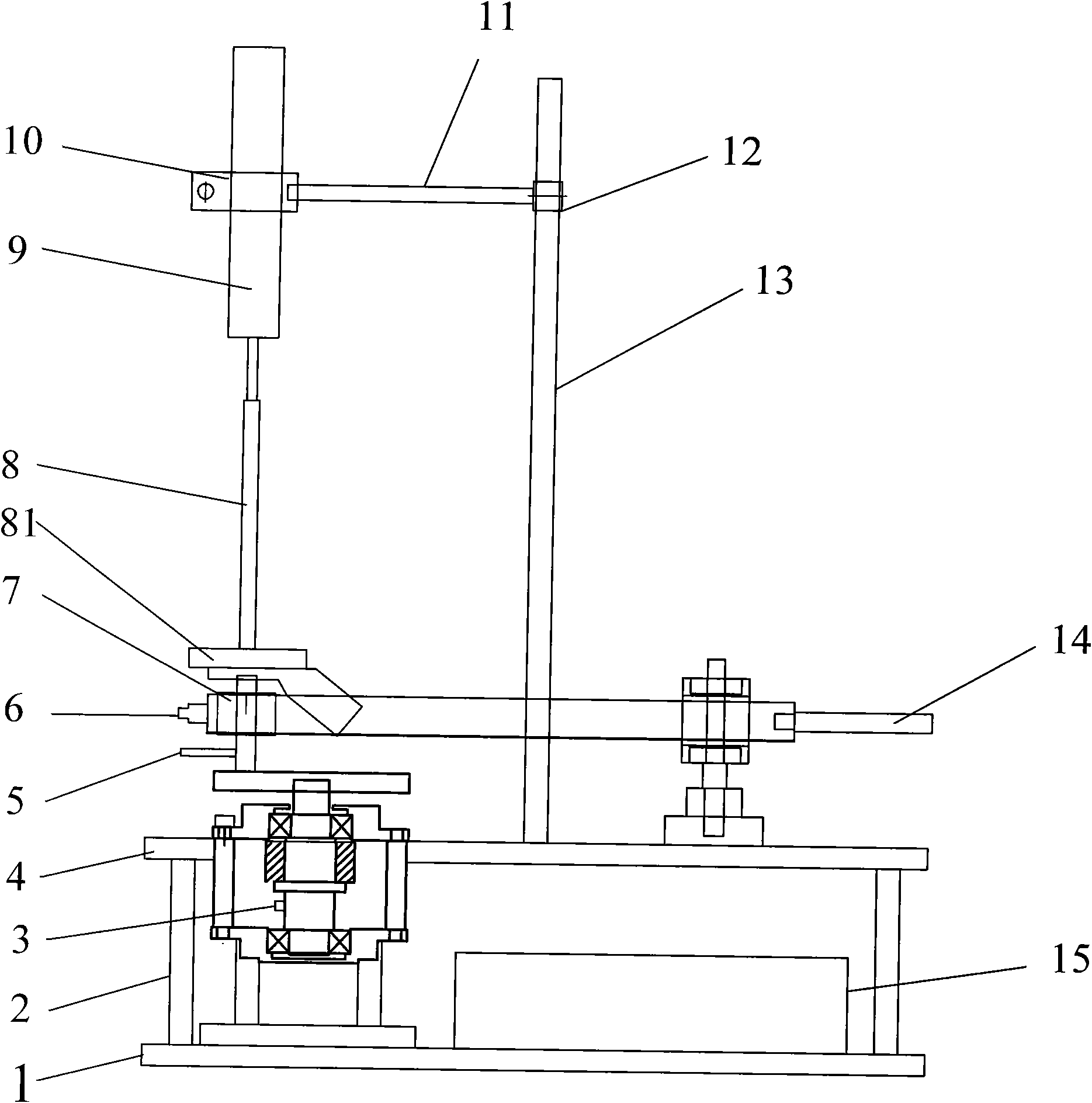

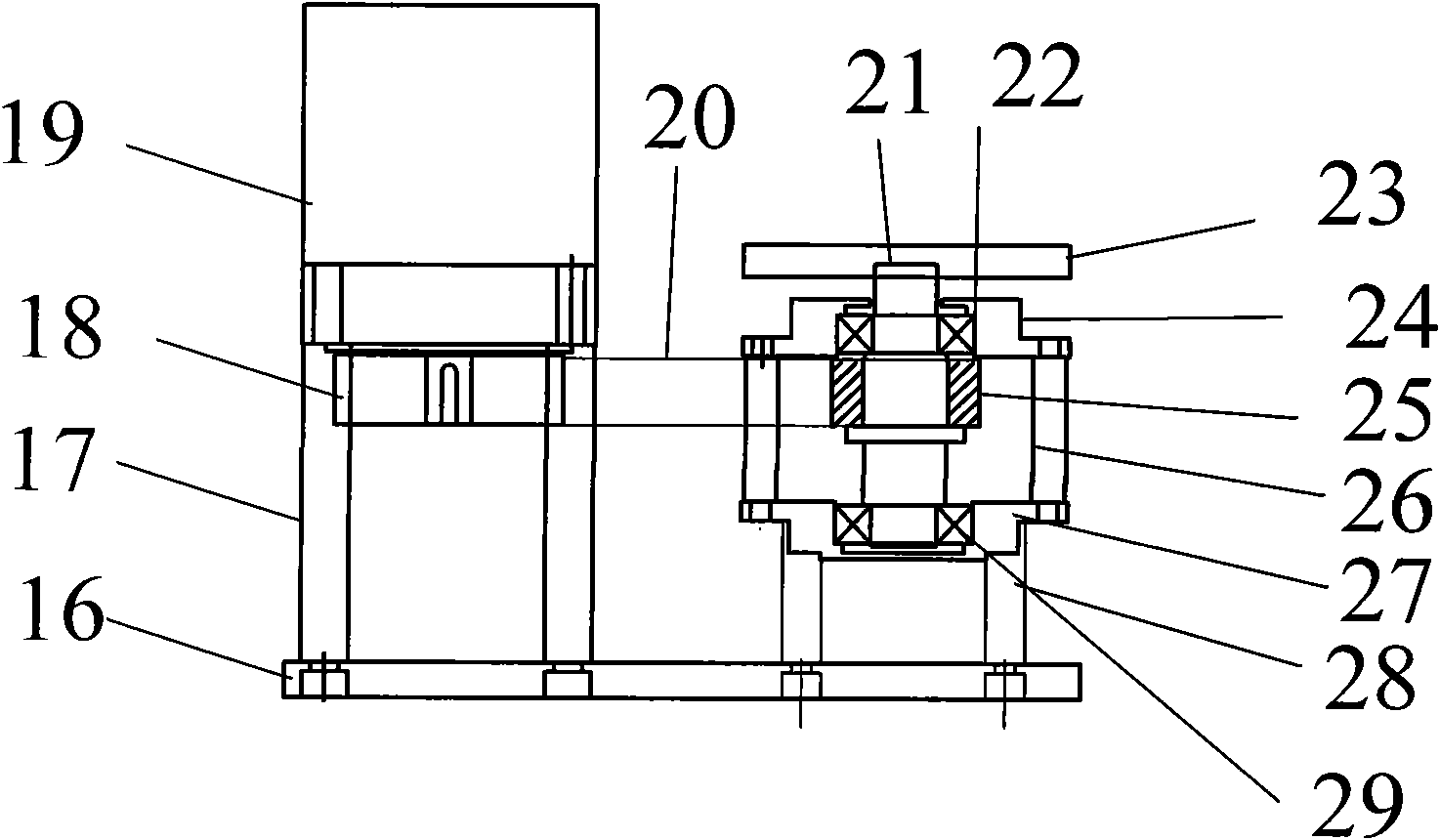

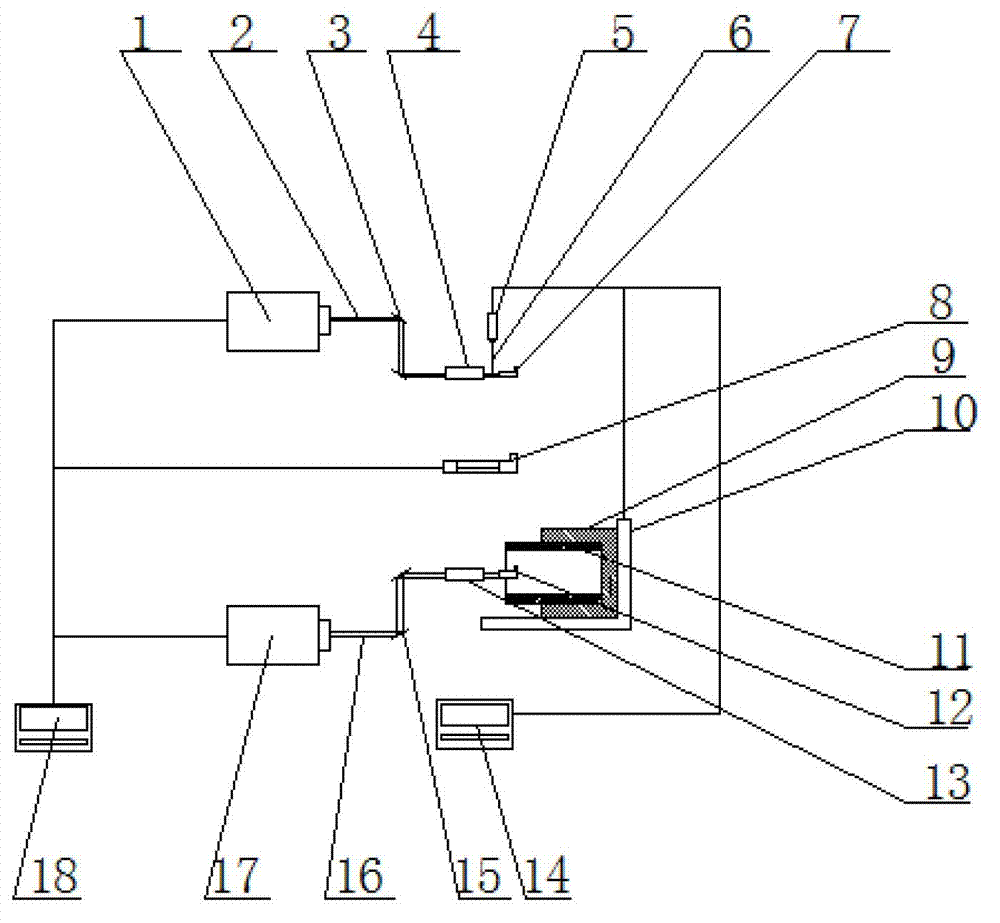

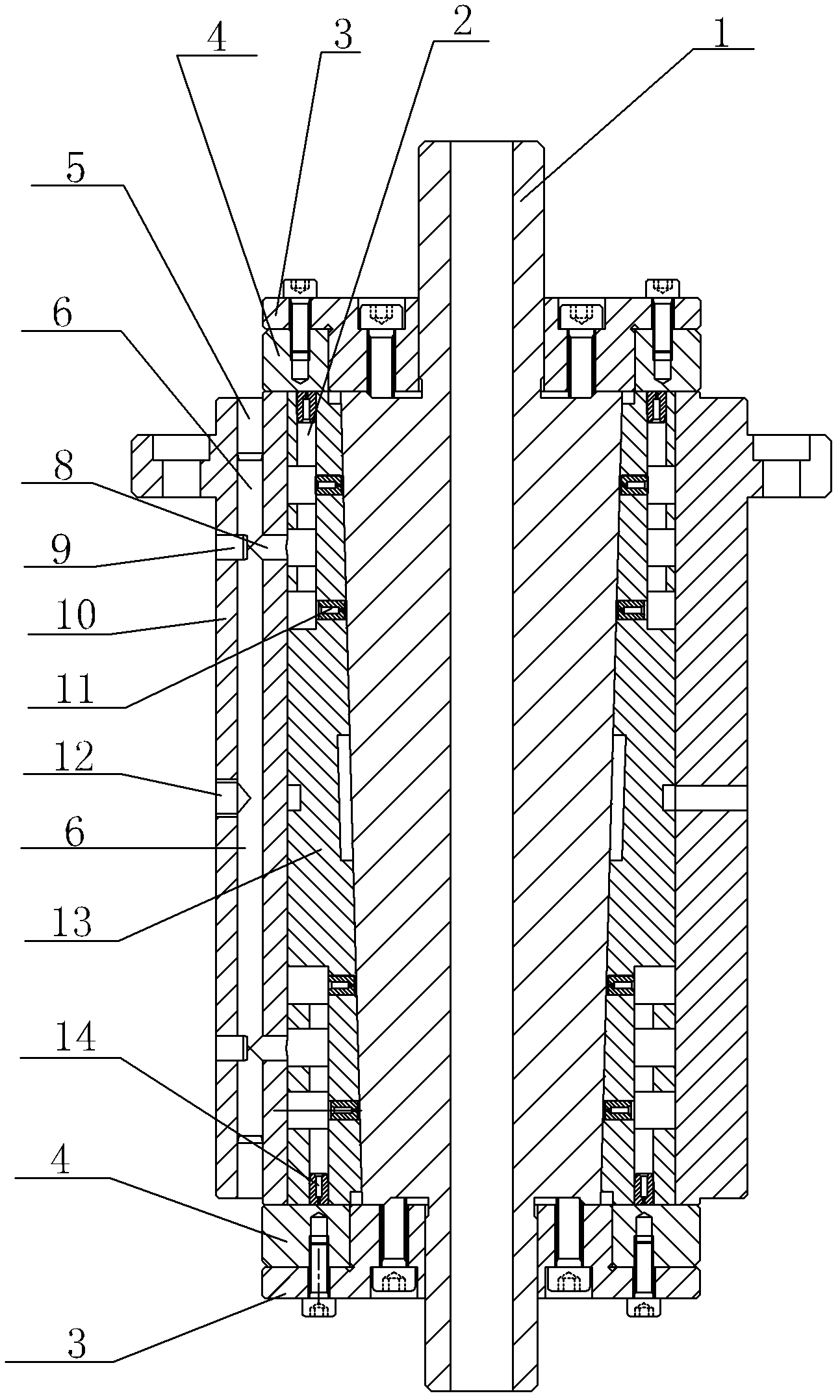

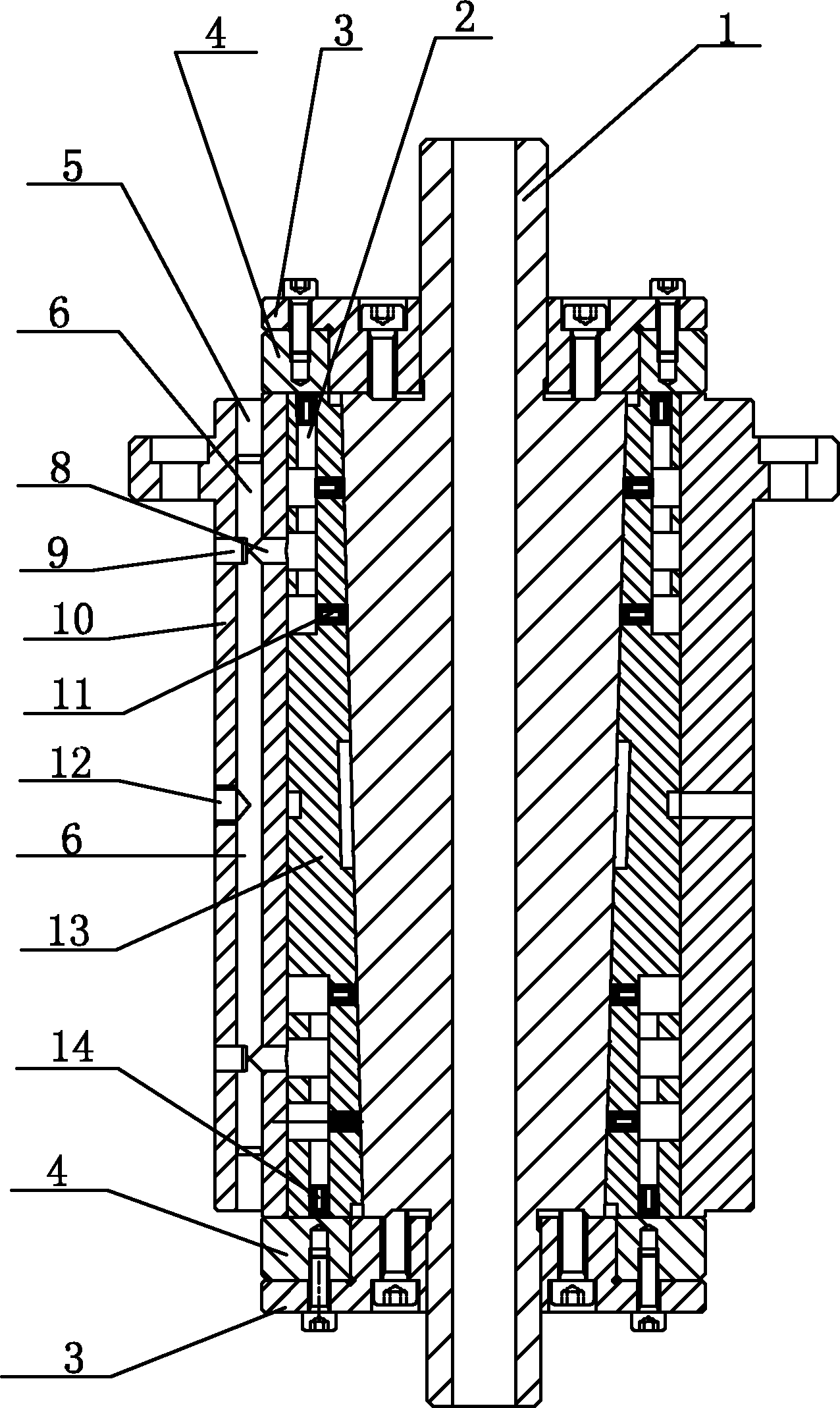

Remanufactured part surface coating accelerated wear life testing machine and detection method thereof

ActiveCN101957296AAccurate acquisition of wear lifeEasy extractionInvestigating abrasion/wear resistanceMicro nanoOriginal data

The invention discloses a remanufactured part surface coating accelerated wear life testing machine. The testing machine comprises a friction driving component, a freedom degree loading component and a signal test acquisition component. The invention introduces a displacement sensor and an acceleration sensor, increases characteristic parameters currently mainly including friction coefficient and wear quantity for judging the coating wear invalidation and enriches the means of accurately acquiring the wear life of spray coating. A test life data alarm value is set in advance; and when the alarm value is reached, data acquisition is automatically ended and a test report is generated so as to facilitate extraction of the wear life and provide original data for subsequent test research. The testing machine has compact structure and high stability and can implement long-time conventional wear life tests as well as accelerated wear tests under four acceleration conditions of heavy load, addition of micro-nano abrasive grains into lubricating oil, dry friction and high rotation speed by adjusting friction pair setting. The invention has good application prospect.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

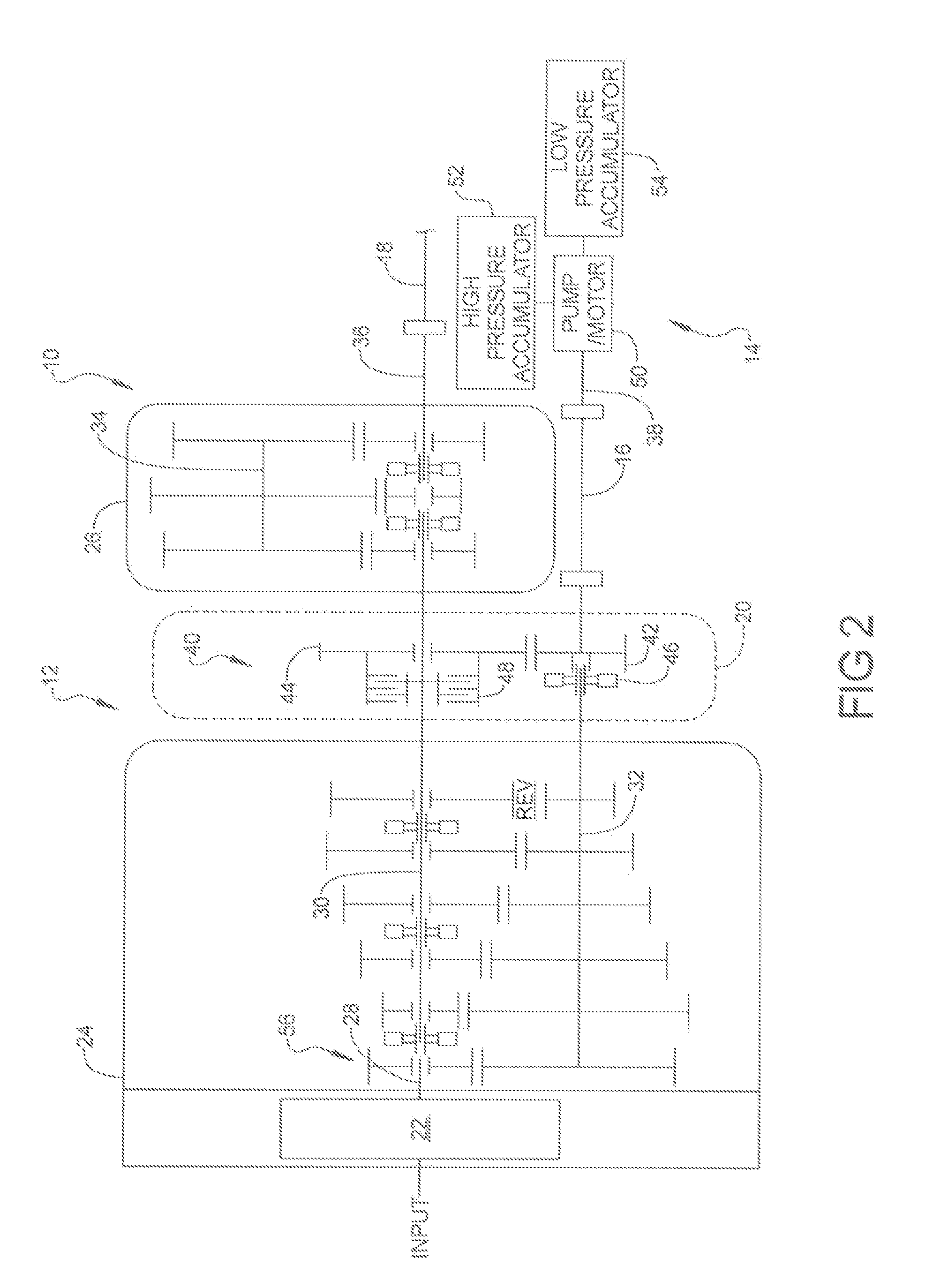

Adapter for Connecting a Countershaft Transmission with a Hydraulic Launch Assist System

InactiveUS20110126652A1Overcomes clutch wear concernIncrease heightToothed gearingsPlural diverse prime-mover propulsion mountingDrive wheelEngineering

This invention provides a common means of coupling an alternative power source to a vehicle's drive wheels which is particularly well suited for use with a countershaft-type transmission. This invention also addresses clutch wear by eliminating the need to engage the frictional clutch to launch the vehicle. This invention also improves the acceleration of the vehicle compared to a typical dry friction clutch launch by relying on the HLA system to transfer more power to the drive wheels more quickly than would be transferred by a typical launch engagement of a dry friction clutch in a commercial vehicle.

Owner:EATON INTELLIGENT POWER LIMITED

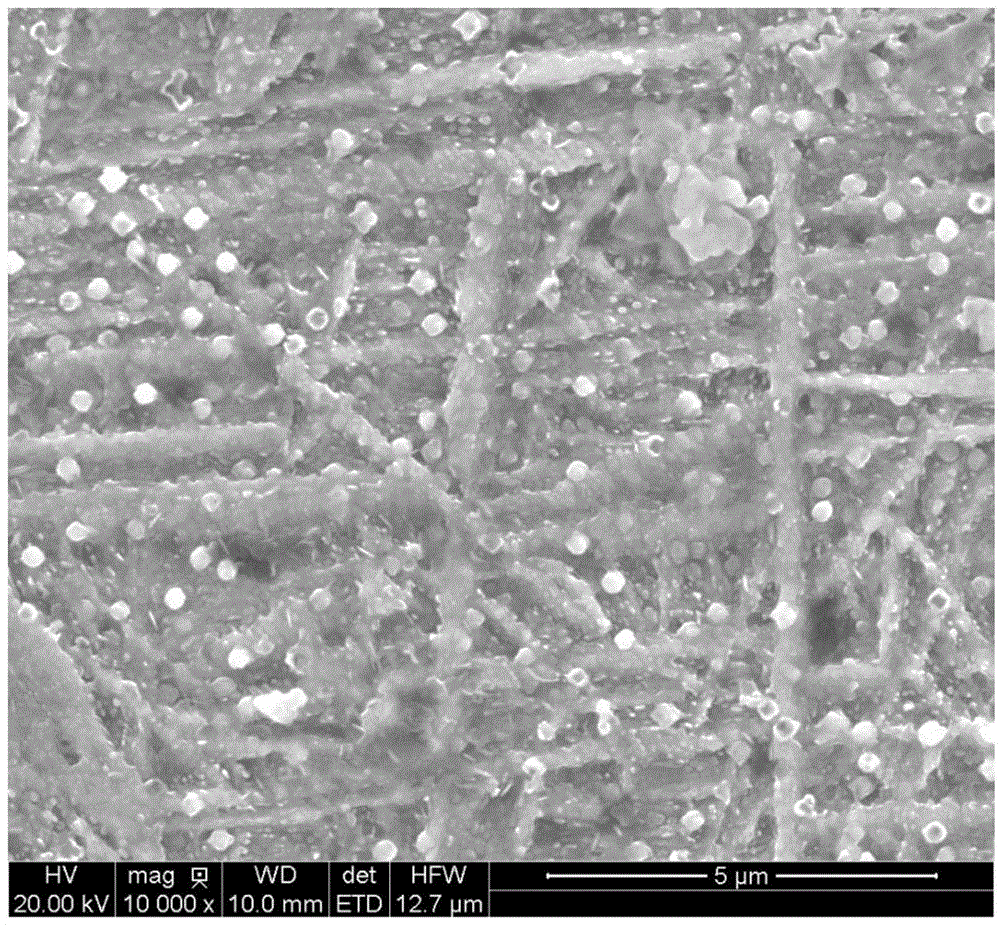

Method and device for forming micro-texture in composite mode on inner surface of cylinder sleeve through laser

InactiveCN103111752AImprove mechanical propertiesImprove friction performanceLaser beam welding apparatusFriction reductionShock wave

The invention provides a method for forming micro-texture in a composite mode on the inner surface of a cylinder sleeve through laser. The method comprises the following steps: step (1), a femtosecond laser device is used for processing a needed microcosmic shape on the inner surface of the cylinder sleeve; and step (2), a nanosecond laser device is used for strengthening the area of the microcosmic shape processed in the step (1) through laser shock waves. Under the condition of dry friction, micro-concave surface texture can be used as a storage device for storing wear particles to reduce abrasive wear and furrows on the friction surface, and therefore the wear rate is lowered. The laser shock waves can eliminate residual tension after the micro-texture is formed on the inner surface of the cylinder sleeve, and therefore deep residual compressive stress is formed, grain refinement is enabled to be more uniform, the hardness, the abrasive resistance and the anti-fatigue performance of the cylinder sleeve are improved, and the service life of the cylinder sleeve is prolonged. The invention further provides a device for forming the micro-texture in the composite mode on the inner surface of the cylinder sleeve through the laser at the same time.

Owner:WENZHOU UNIVERSITY +1

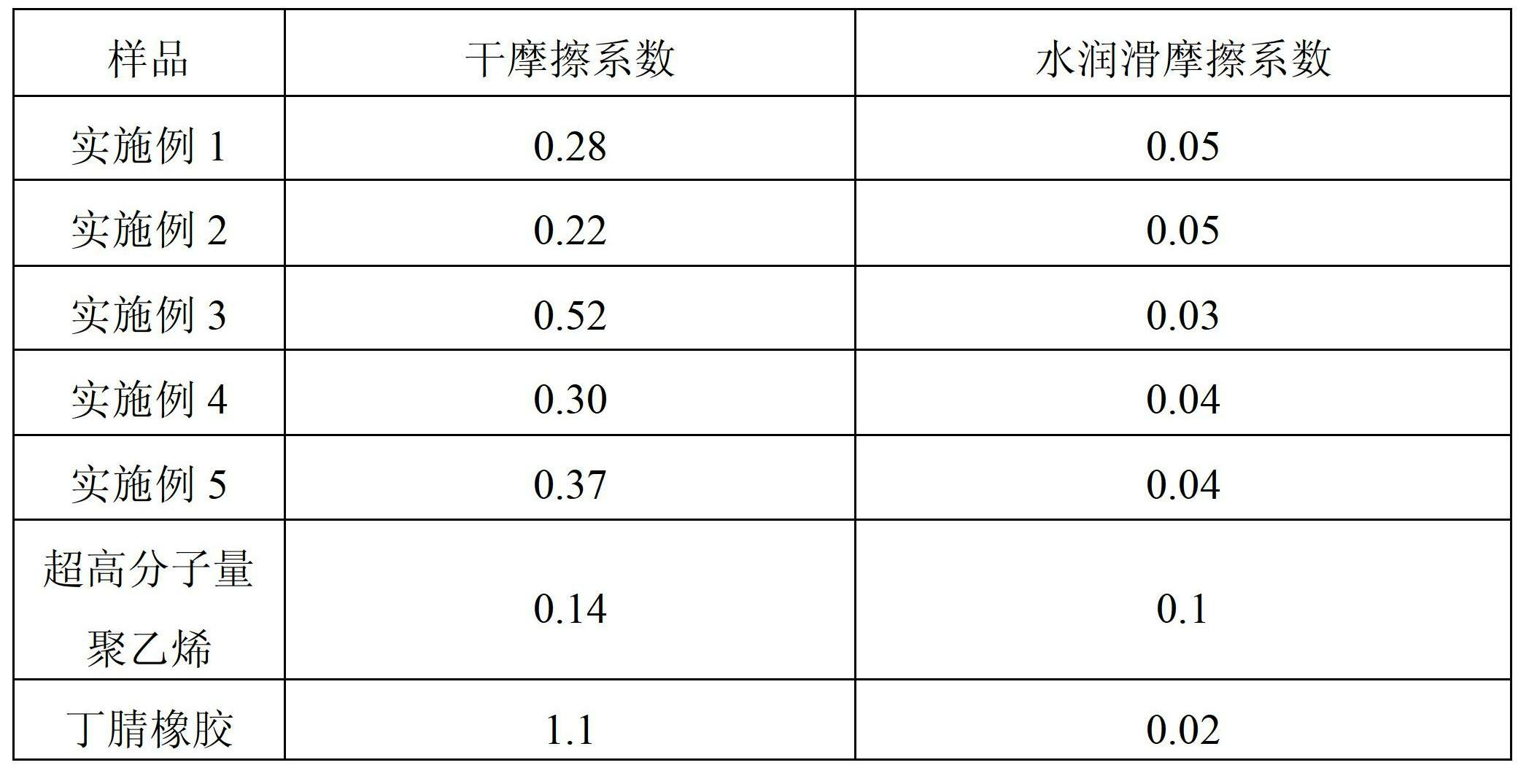

Ultra-high molecular weight polyethylene composite material for water lubricated bearing

InactiveCN102660066AImprove wear resistanceImprove water lubrication friction performanceBearing componentsCross-linkAntioxidant

The invention provides an ultra-high molecular weight polyethylene composite material for a water lubricated bearing, belonging to the field of high molecular composite materials. The invention solves the problem that the ultra-high molecular weight polyethylene as a bearing material can not easily form complete water lubrication and has a high water lubrication friction factor under water lubrication conditions in the prior art. The composite material is prepared by blending and cross-linking the following components in parts by weight: 100 parts of ultra-high molecular weight polyethylene, 10-50 parts of nitrile-butadiene rubber, 10-40 parts of self-lubricating agent, 0.5-5 parts of zinc oxide, 0.1-1 part of stearic acid, 0.1-3 parts of crosslinking agent and 0.2-3 parts of antioxidant. The composite material has favorable dry friction and water lubrication properties, and is suitable to be used as a water lubricated bearing material for ships.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

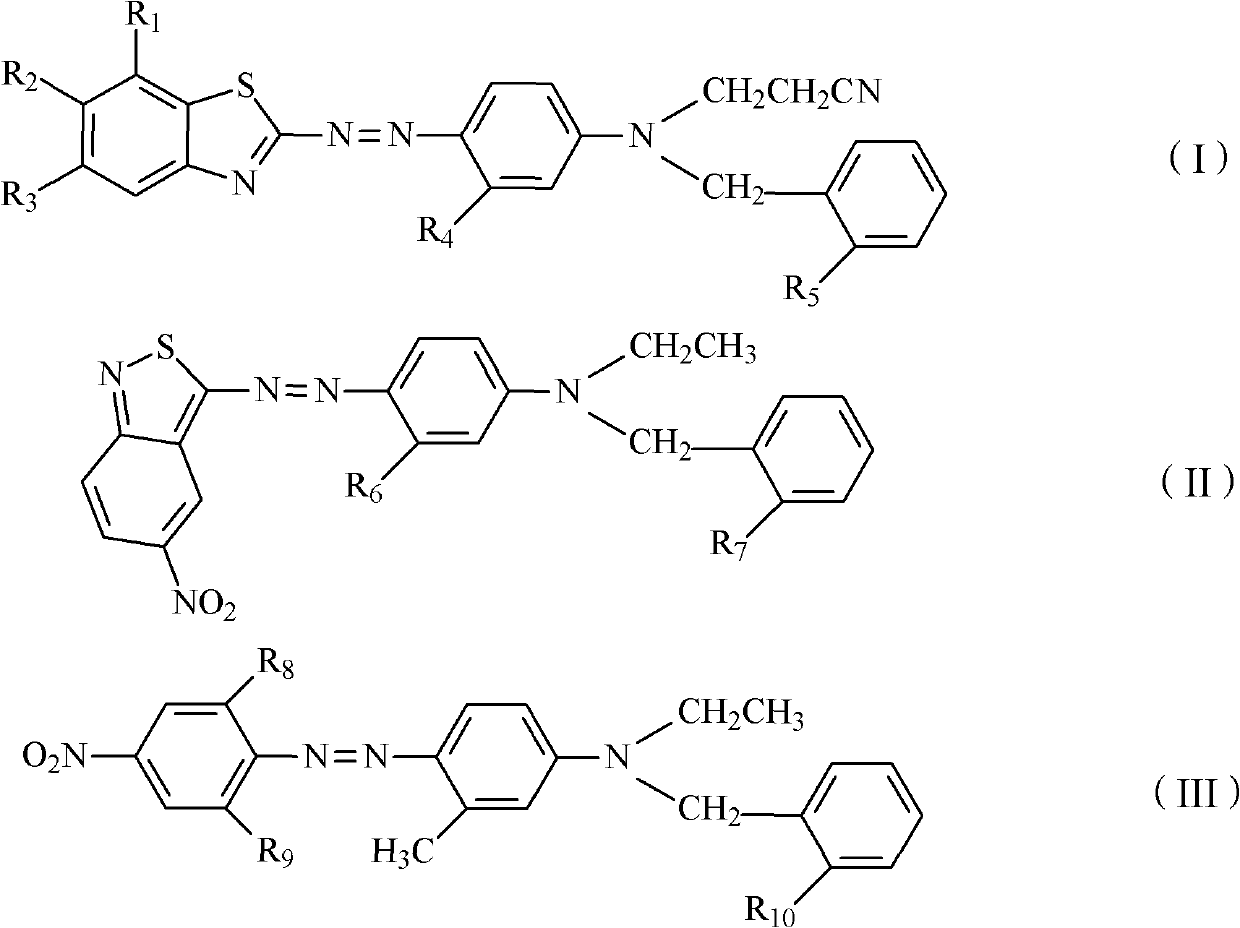

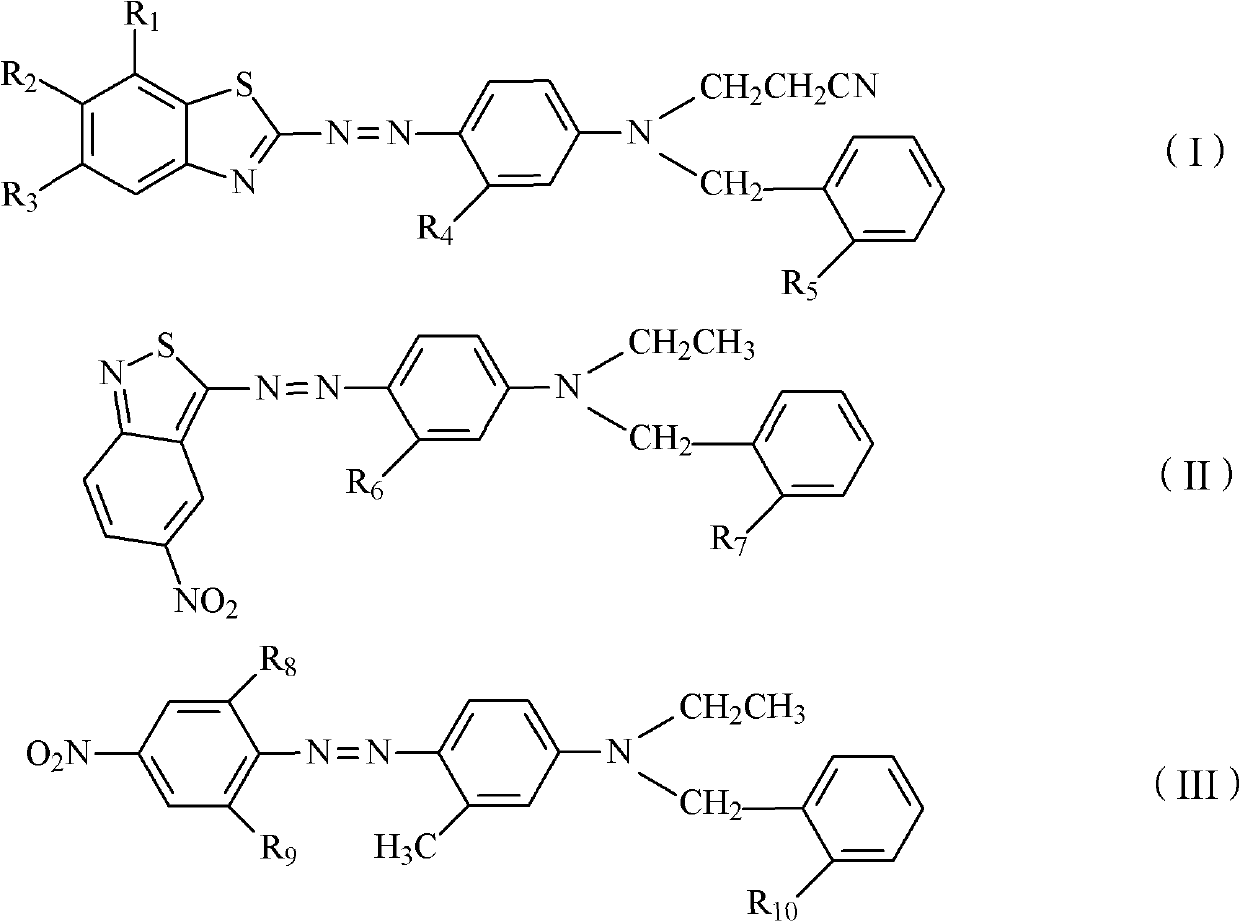

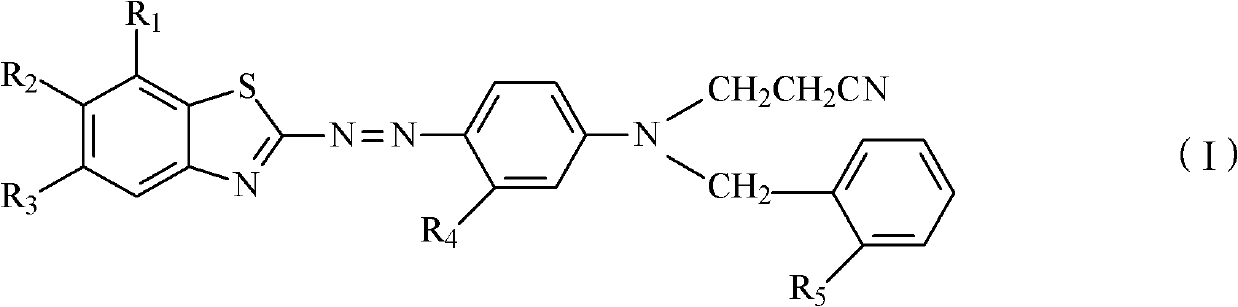

Disperse dye composite, dyeing method and preparation method for disperse dye composite

InactiveCN102618079AImprove oxidation resistanceGood alkali resistanceFibre treatmentOrganic dyesDisperse dyeDispersity

The invention discloses a disperse dye composite, which consists of the original dye and an aid, wherein the original dye consists of 2 to 4 kinds selected from 0 to 2 kinds of dyes shown as a general formula (I), 0 to 2 kinds of dyes shown as a general formula (II) and 0 to 2 kinds of dyes shown as a general formula (III), wherein in the general formula (I), R1 and R3 is hydrogen or chlorine independently, R2 is chlorine or nitryl, R4 is hydrogen, methyl, ethyl or methoxyl, and R5 is hydrogen, nitryl or methyl; in the general formula (II), R6 is methyl, ethyl or methoxyl, and R7 is hydrogen, nitryl or methyl; and in the general formula (III), R8 is chlorine or nitryl, R9 is hydrogen or chlorine, and R10 is hydrogen, nitryl or methyl. The disperse dye composite has the advantages of high dispersity and oxidative resistance, and is suitable for processing technologies of pretreatment and one-bath dyeing of polyester fabrics in the presence of an oxidant; and the polyester fabrics dyed by the disperse dye composite are gorgeous in color and high in soaping fastness, dry friction fastness and wet friction fastness.

Owner:ZHEJIANG WANFENG CHEM

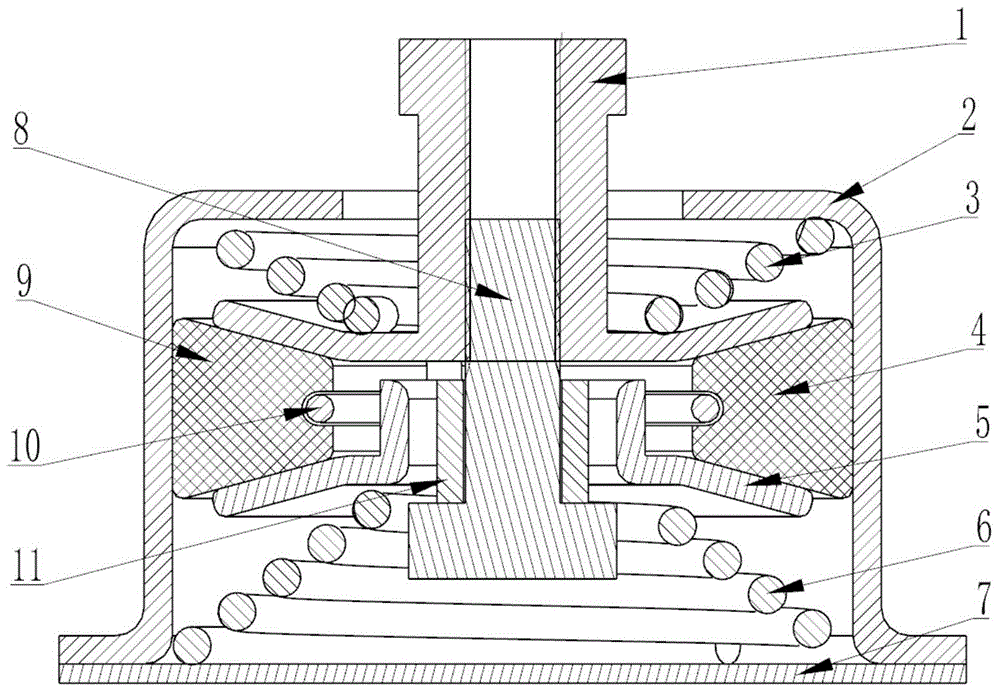

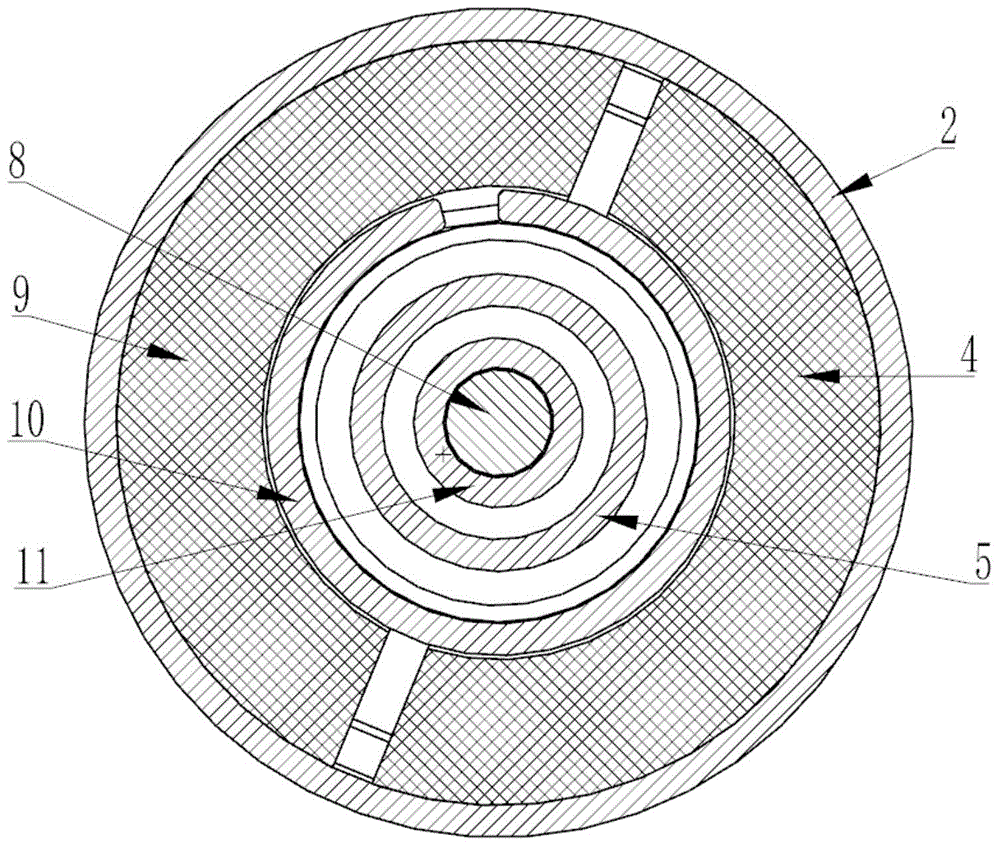

High-effect dry friction damping spring vibration isolator

ActiveCN104930100ACompact structureHeavy loadShock absorbersFriction dampersReciprocating motionMechanical energy

The invention discloses a high-effect dry friction damping spring vibration isolator and aims at providing a friction damping vibration isolator which is compact in structure, large in friction damp, high in load and good in environmental adaptation. According to the technical scheme, in a vibration environment, left friction pieces and right friction pieces of a disc-pressing upper cone spring (3) and a disc-pressing lower cone spring (6) perform reciprocating motion to axially extrude a right friction ring piece (4) and a left friction ring piece (9) on two sides, the left friction ring piece, the right friction ring piece, an upper guide umbrella disc (1) and a lower guide umbrella disc (5) are driven to perform constant friction motion on the inner wall of a housing (2), vibration mechanical energy is converted into heat energy so as to achieve vibration energy consumption and reduction. The high-effect dry friction damping spring vibration isolator utilizes low frequency of a conical spring and a damping characteristic of a symmetric semi-ring damping pad, can effectively inhibit spring fluctuation during high-frequency impact, also has composite multiple vibration isolation effect and has large damp under the low-frequency condition compared with a traditional rubber vibration isolator.

Owner:10TH RES INST OF CETC

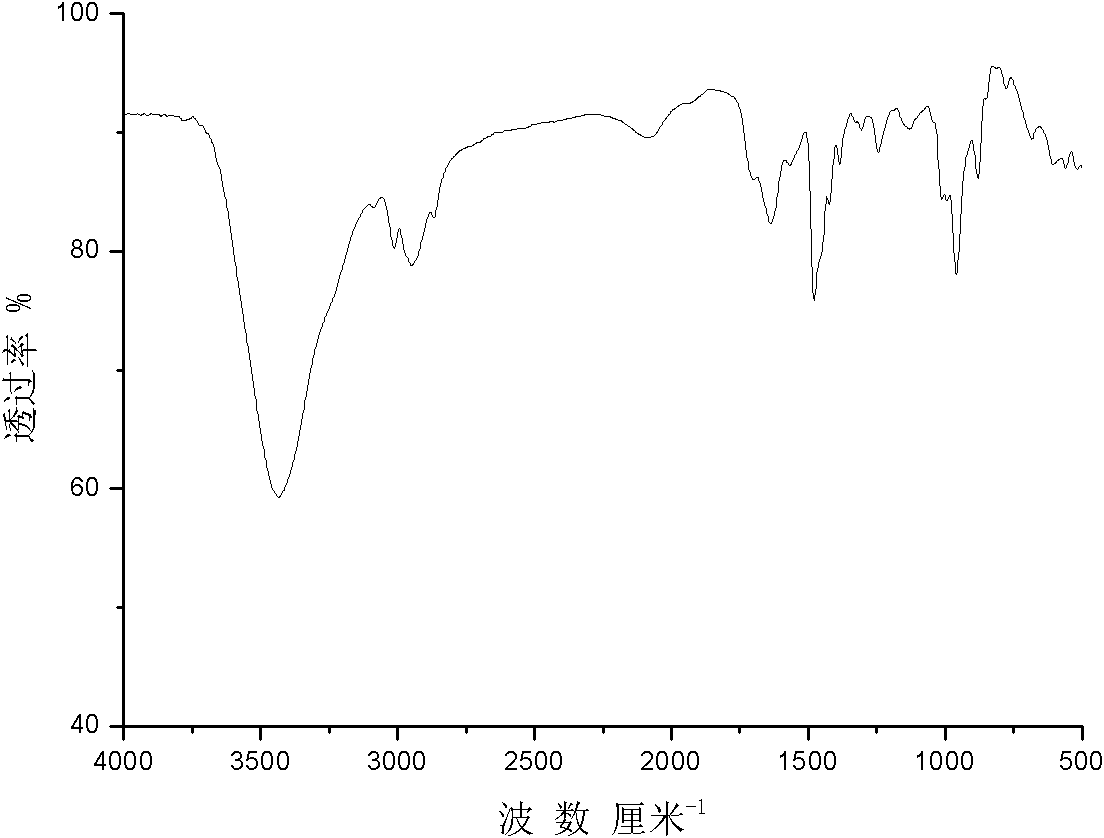

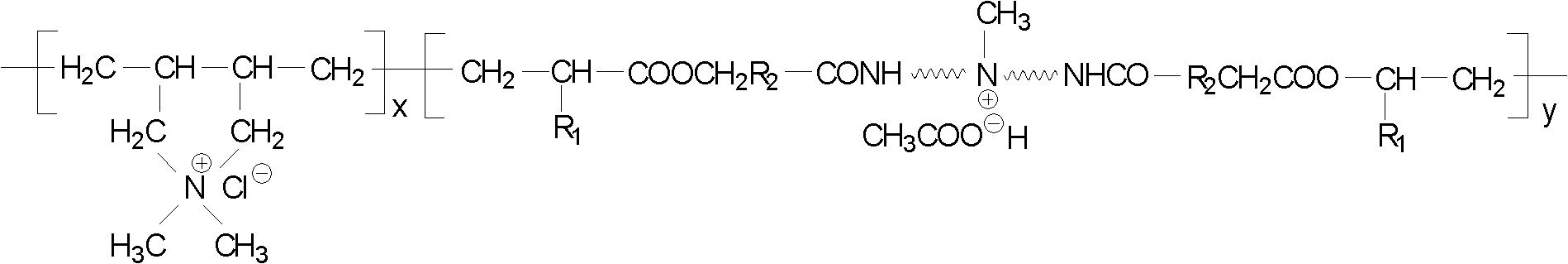

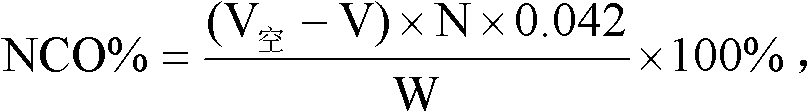

Method for preparing cationic poly(urethane-dimethyldiallylammonium chloride) color fixing agent

The invention discloses a method for preparing a cationic poly(urethane-dimethyldiallylammonium chloride) color fixing agent, which comprises: synthesizing vinyl terminated cationic polyurethane prepolymer by using isocyanate, polyol, N-methyldiethanolamine and acrylate functional monomers as polymerization monomers; hydrating and dispersing the vinyl terminated cationic polyurethane prepolymer, and performing reversed emulsion polymerization of the vinyl terminated cationic polyurethane prepolymer and dimethyl diallyl ammonium chloride in a water soluble initiator to obtain the formaldehyde-free poly(urethane-dimethyldiallylammonium chloride) color fixing agent. The cationic poly(urethane-dimethyldiallylammonium chloride) color fixing agent contains no formaldehyde, retains the property of a polyurethane material, realizes the organic combination of the high performance of the two kinds of resins due to the high positive charge density of a poly(dimethyl diallyl ammonium chloride) chain segment and can effectively improve the color fastness of the dyed fabrics. When the color fixing agent is used, the color fastness of the fabrics dyed with direct dye and active dye is as follows: the dry friction fastness is grade 5, the wet friction fastness is grade 3 to 4, and the brushing fastness is 4 to 5.

Owner:ANHUI UNIVERSITY

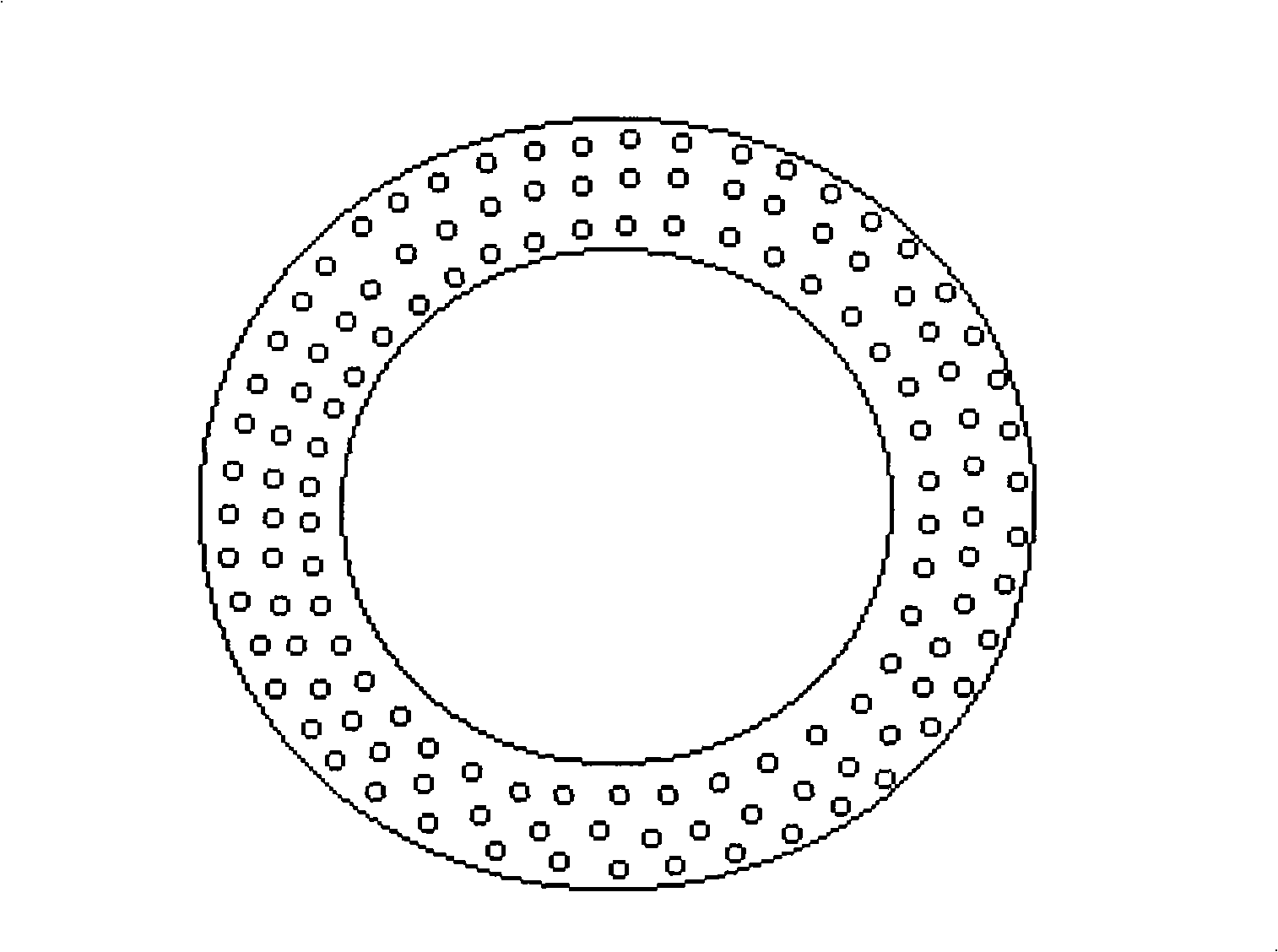

Water lubricated bearing with high bearing capacity and self lubricity

The invention discloses a water lubricated bearing with high bearing capacity and self lubricity. The water lubricated bearing is composed of synthetic polyurethane, a solid lubricant and a fiber reinforcing agent. The bearing has a microstructure being a homogeneous structure, has a hardness of ShoreD55-65, a compression modulus of elasticity of above 600MPa and a dry friction coefficient of 0.20 or less, and has a friction coefficient (water) of 0.25 or less in water environment when the linear velocity is 0.05m / s; and when the linear velocity is greater than 0.5m / s, the friction coefficient (water) is not greater than 0.03, so a use requirement of the radial load of 5-70MPa can be satisfied. When the bearing is in water shortage environment, the bearing has excellent self lubrication and wear resistance performances, can prevent noises and bearing occlusion, and can be widely applied to rotating, swinging or sliding positions of underwater propeller motor drivers, propeller stern bearings, rudder bearings and water pumps.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

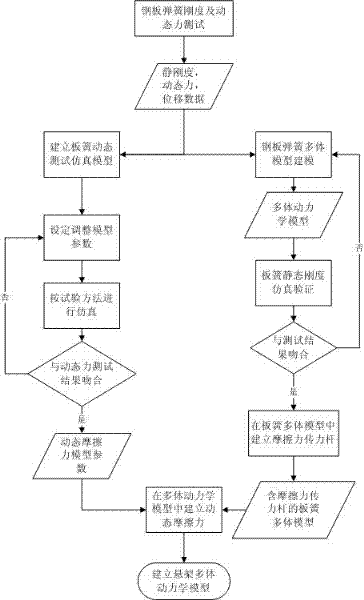

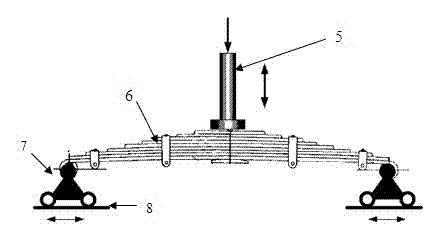

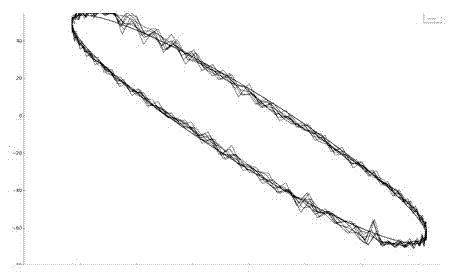

Construction method of car steel plate spring multi-body model

ActiveCN102609578AAccurately reflect dynamic force characteristicsAccurate Ride SimulationSpecial data processing applicationsDynamic stiffnessStructural engineering

The invention discloses a construction method of a car steel plate spring multi-body model. The construction method comprises the following steps: firstly, testing static stiffness and dynamic force of a steel plate spring; secondly, establishing a dynamic friction model; thirdly, establishing the steel plate spring multi-body model in a multi-body dynamics program; fourthly, adding a dynamic dry friction model to the steel plate spring multi-body model; and fifthly, establishing a suspension system model for simulating a suspension and an entire car. In the construction method, dry friction among steel plate spring reeds is uniformly processed as characteristics of plate spring assembly, and assembly dry friction is described by the dynamic friction model, therefore, dynamic force characteristics of the car steep plate spring can be accurately reflected to reflect the dynamic stiffness formed by the friction, and ride comfort simulation is more accurate.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

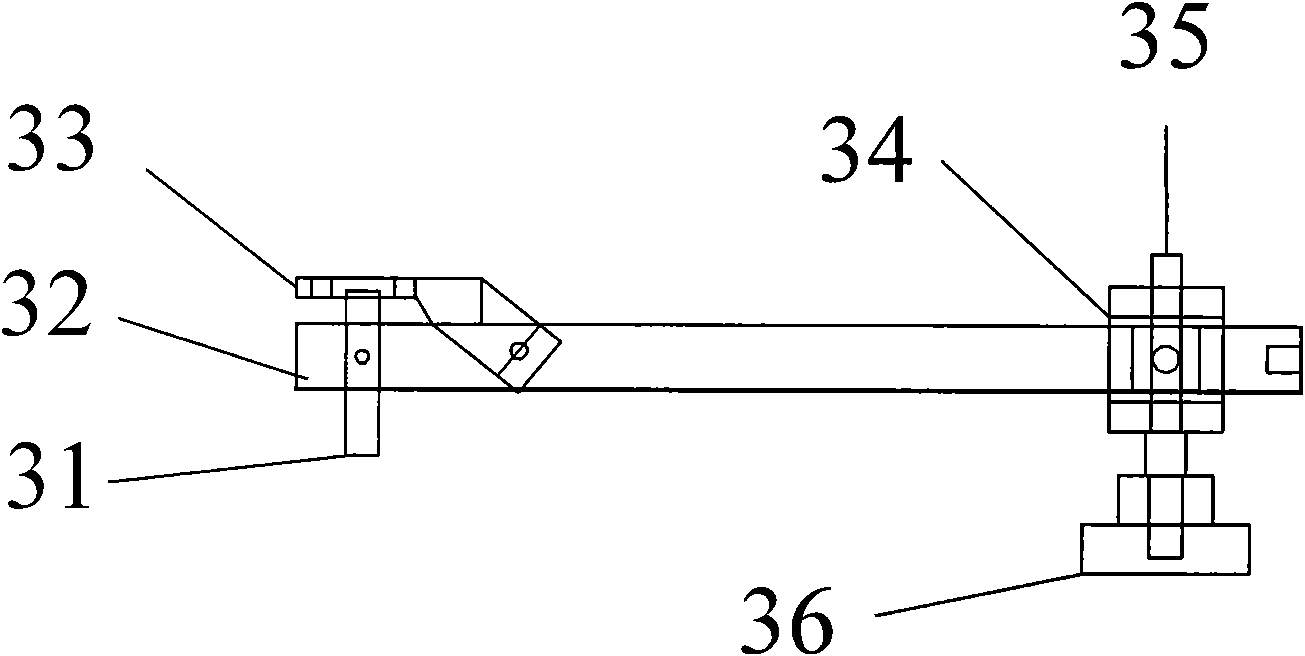

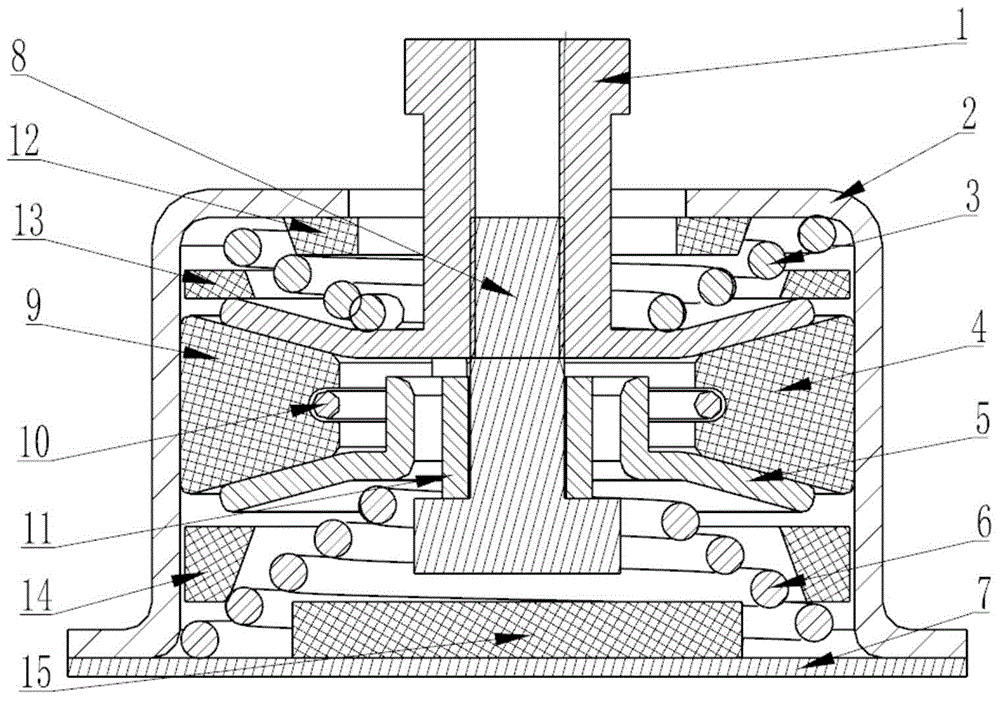

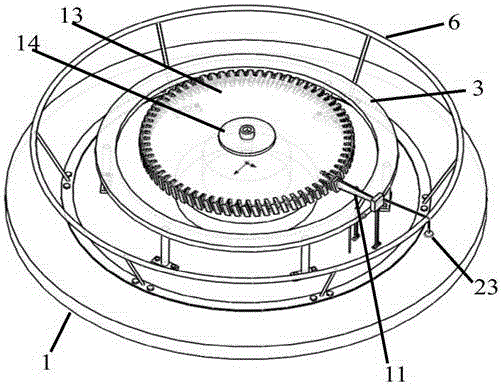

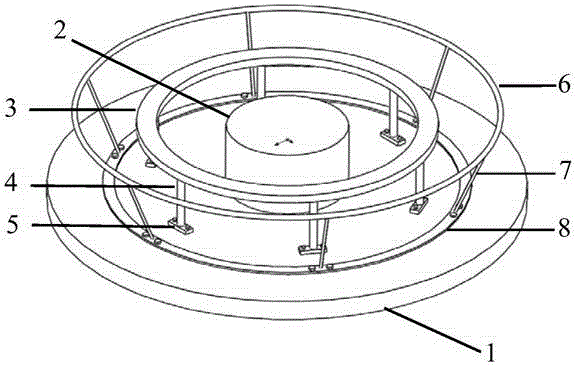

Vibration testing device of damping mistuning blade-turbine disk with damping block structure

ActiveCN105928676ASolve the problem that the rotation state is inconvenient to measureSolve the problem of inconvenient measurementMachine part testingVibration testingBlock structureFailure analysis

The invention discloses a vibration testing device of a damping mistuning blade-turbine disk with a damping block structure. A turbine disk fixing device is fixed at the center of the bottom plate of a base frame; the pre-tightening force of a blade root fixing device can be increased by adjusting a nut, so that the blade root fixing device can be fixed between the edge of a turbine disk and the root of a blade; one end of a centrifugal force loading device is connected onto a damping block of a vane shroud ring, and the other end of the centrifugal force loading device winds around a slide rod and is vertically arranged; the centrifugal force loading device is used for controlling and making the centrifugal force of the blade damping block mistuned; an excitation generating device is fixed on an excitation plate of the base frame; and a measuring device is installed inside and outside the excitation plate and is fixed on the bottom plate of the base frame through bolts. The vibration testing device can be used for measuring the vibration feature of the damping mistuning blade-turbine disk system with the nonlinear dry friction damping block structure under an actual operating condition and can provide a reference basis for the design and failure analysis of the blade-turbine disks of high-performance engines, gas turbines and turbines.

Owner:XI AN JIAOTONG UNIV

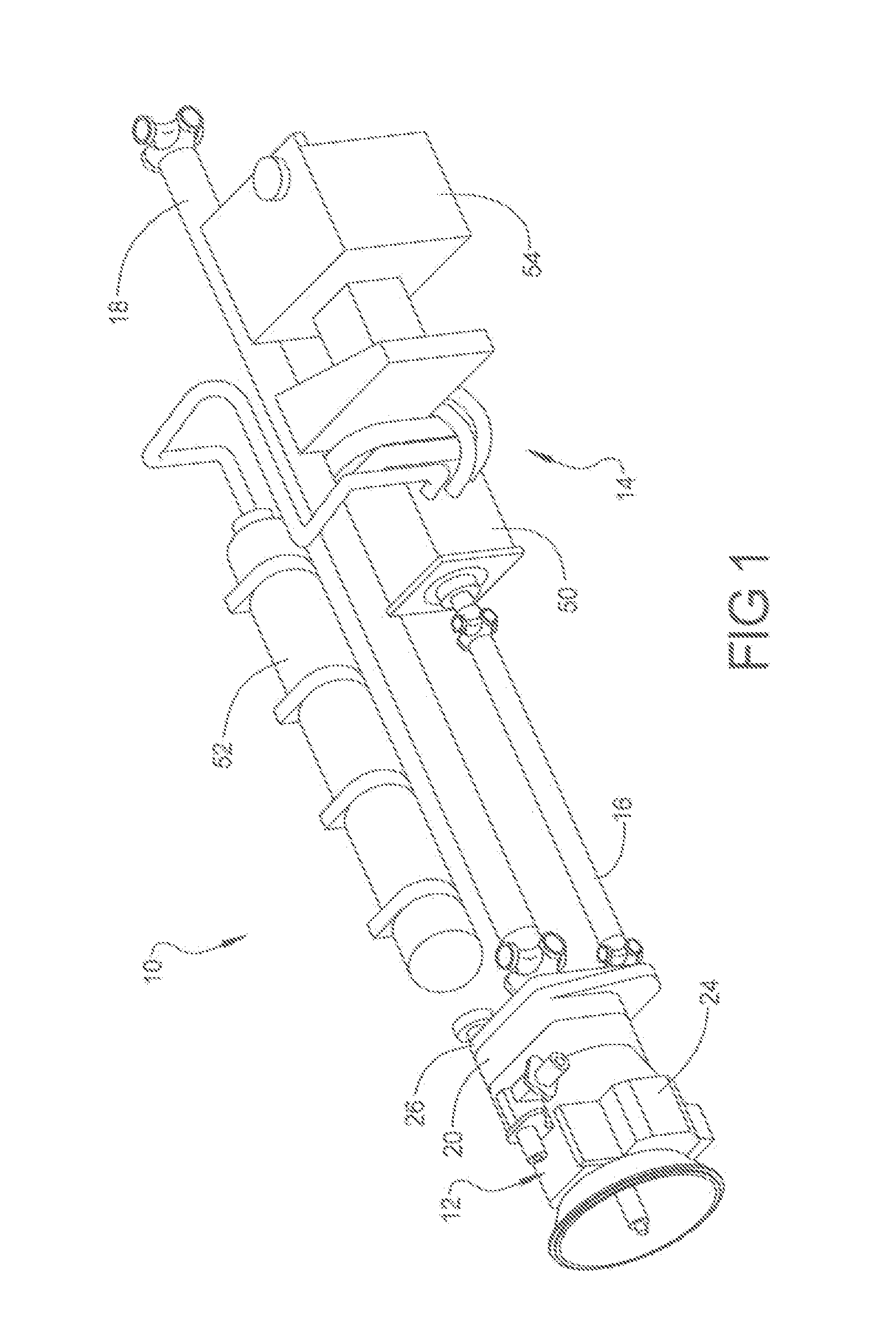

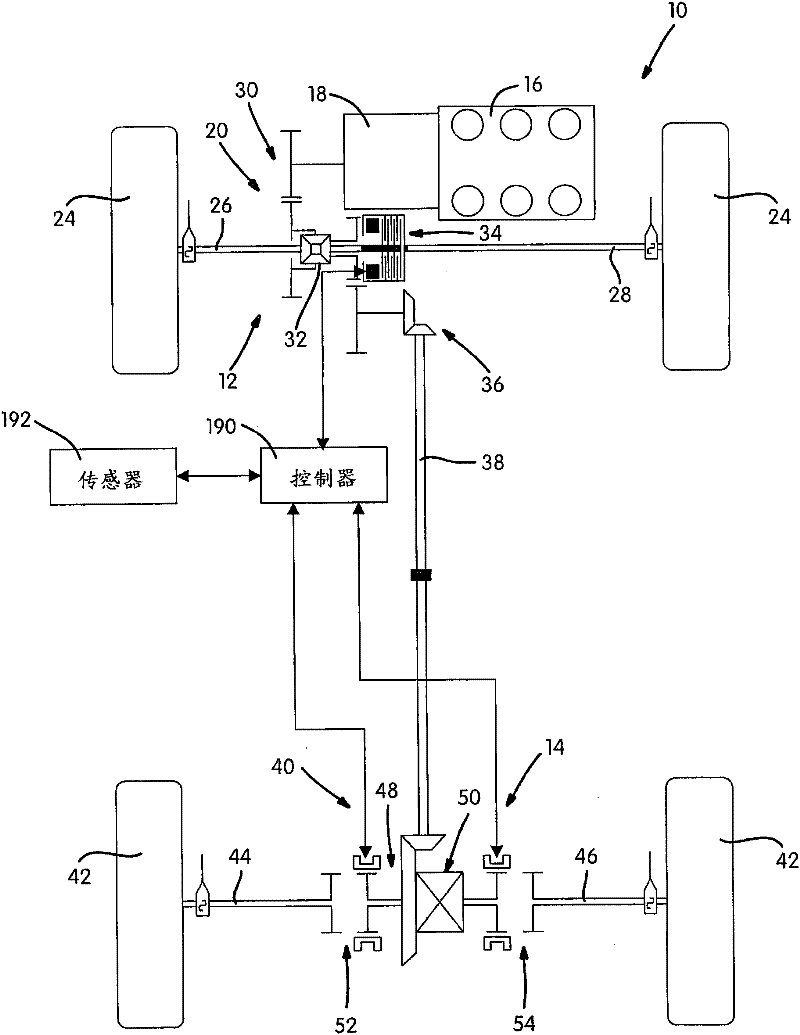

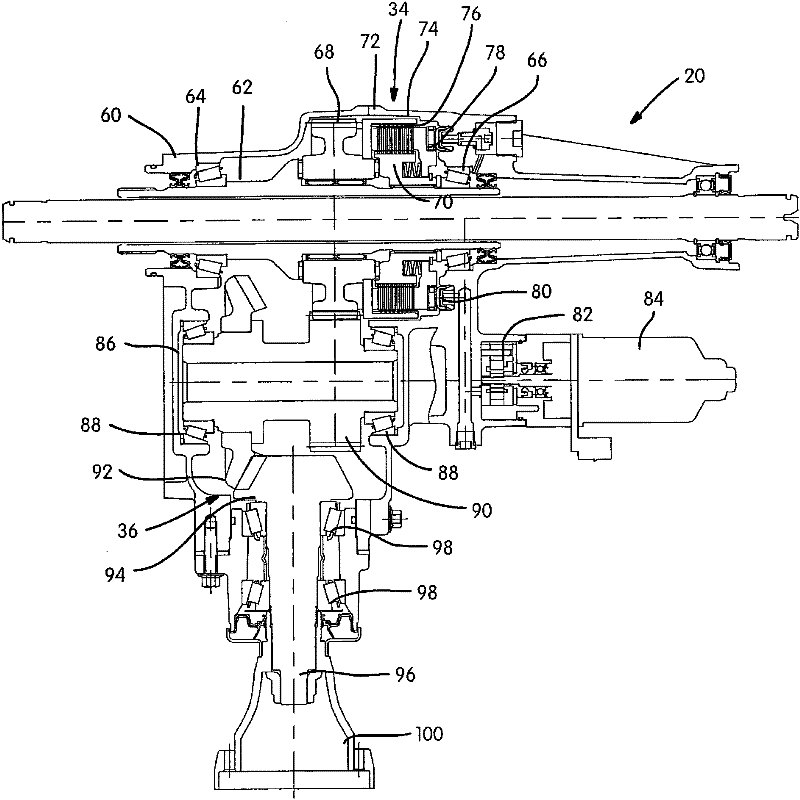

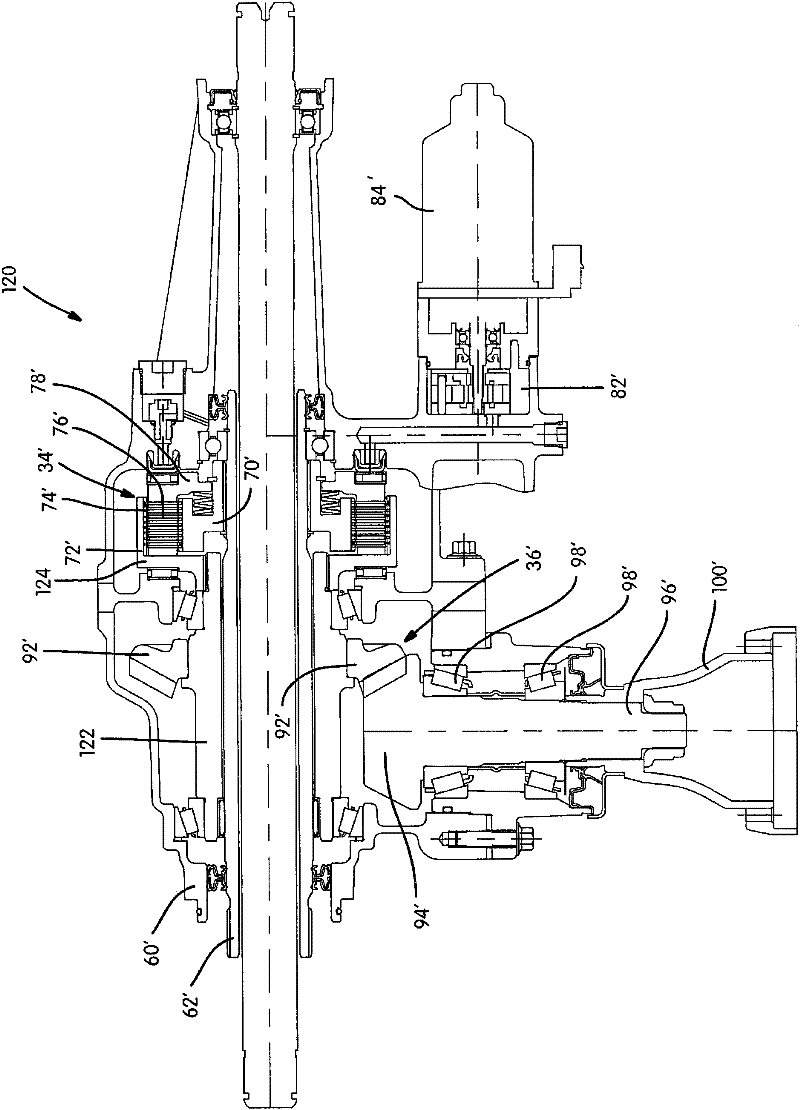

All-wheel drive with active dry disconnect system

ActiveCN102341261AImprove applicabilityGearboxesInternal combustion piston enginesTorque transmissionControl theory

A vehicle drive train for transferring torque to first and second sets of wheels includes a first driveline adapted to transfer torque to the first set of wheels and a first power disconnection device. A second driveline is adapted to transfer torque to the second set of wheels and includes a second power disconnection device. A hypoid gearset is positioned within one of the first driveline and the second driveline in a power path between the first and second power disconnection devices. The hypoid gearset is selectively disconnected from being driven by the first driveline and the second driveline when the first and second power disconnection devices are operated in a disconnected, non-torque transferring, mode. At least one of the first and second power disconnection devices includes an active dry friction clutch.

Owner:MAGNA POWERTRAIN USA

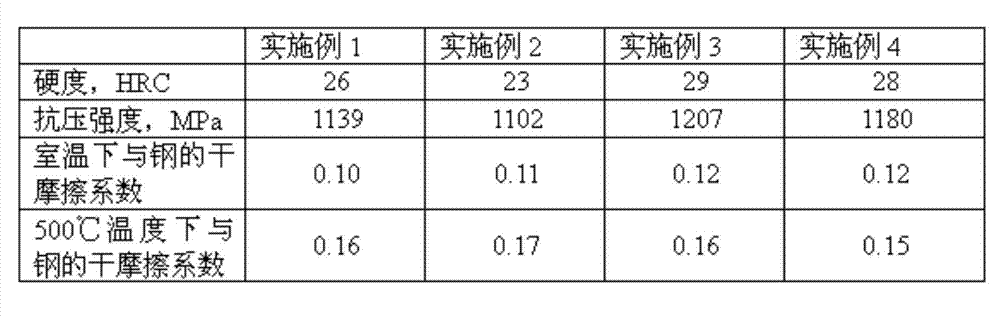

Heatproof anti-wear self-lubrication material and preparation method thereof

The invention relates to a heatproof anti-wear self-lubrication material and a preparation method thereof, and belongs to the technical field of powder metallurgy solid self-lubrication materials. The self-lubrication material comprises, by mass, 10-20% of copper-clad iron composite metal powder, 10-20% of nickel-coated graphite composite powder, 3-10% of nickel-coated molybdenum disulfide composite powder, 1-3% of metal molybdenum powder and the balance dispersion strengthening metal iron powder containing 1% of Al2O3. The raw materials are uniformly mixed after proportioned and then filled in a grinding tool to be subjected to spark plasma sintering to obtain the material. The method has the advantages that physical and mechanical properties of the prepared solid self-lubrication material are reflected in that hardness is greater than or equal to HRC20, compressive strength is 1100-1200MPa, and dry friction coefficient with steel is 0.1-0.2 at the room temperature and 0.15-0.22 at the temperature of 500 DEG C.

Owner:CHINA IRON & STEEL RES INST GRP +1

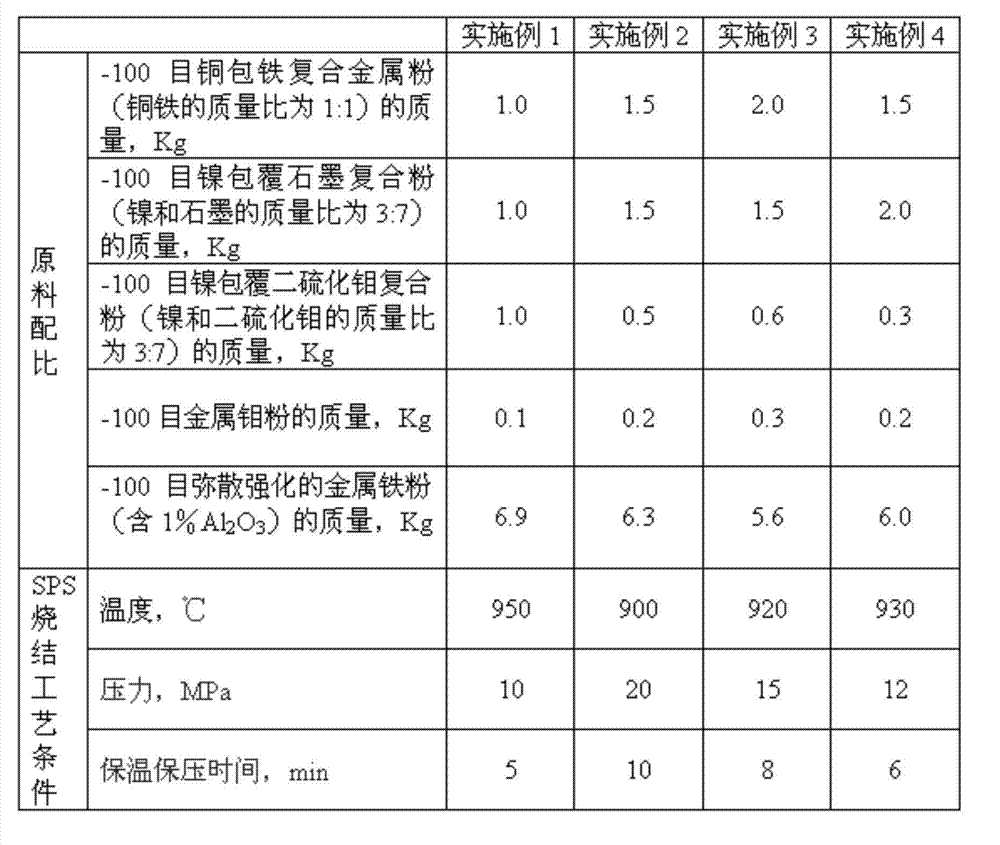

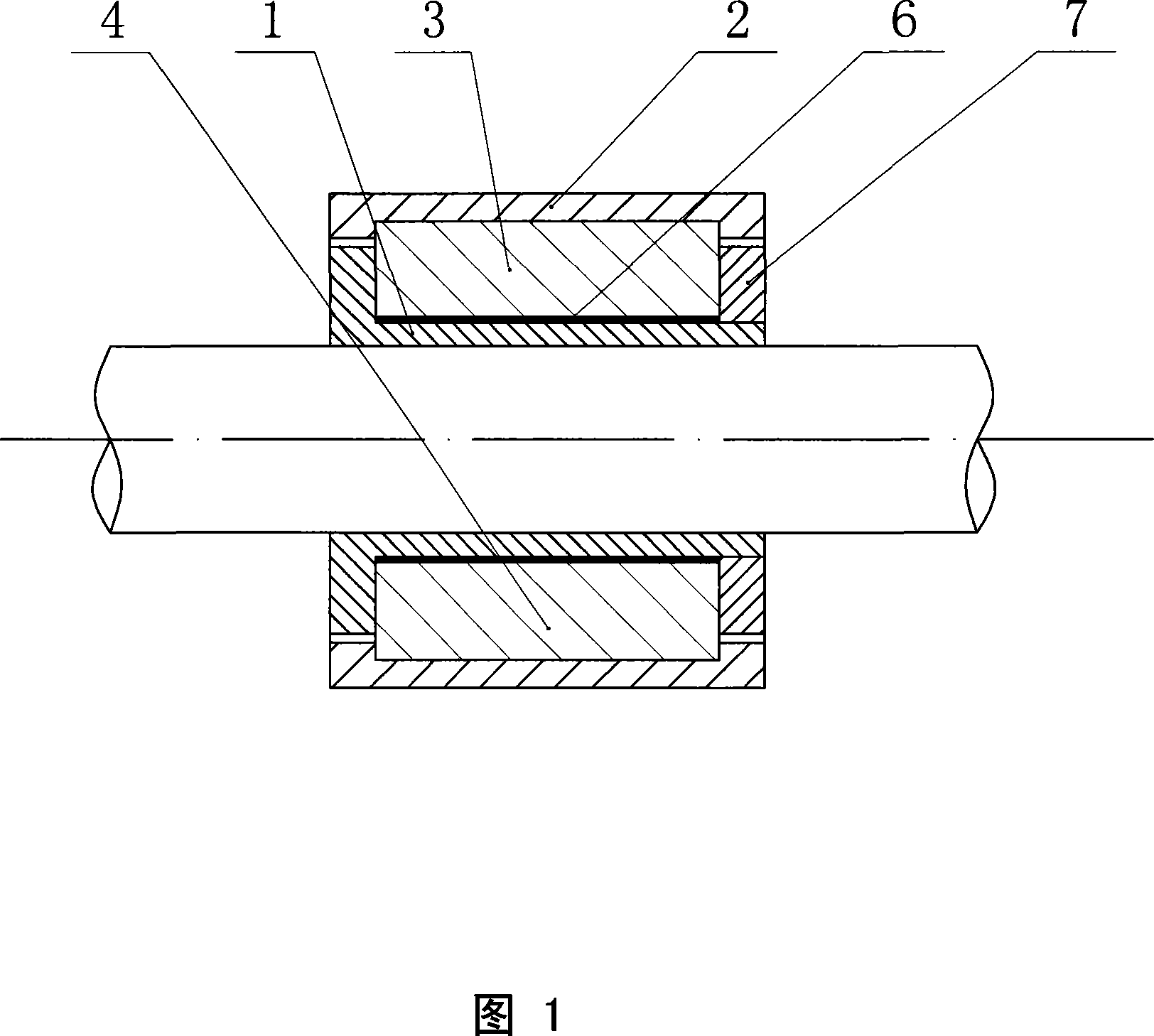

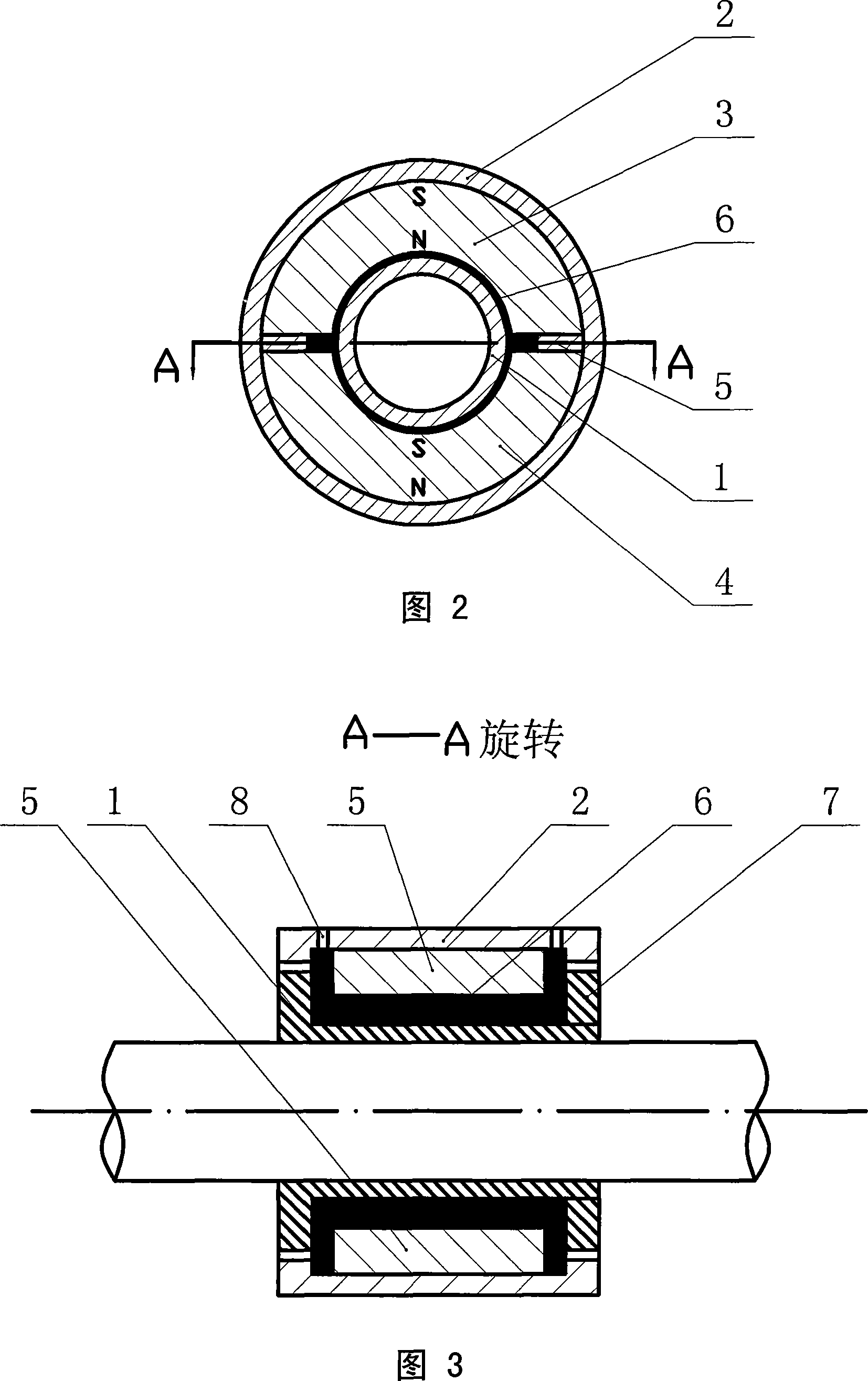

Hydromagnetic bearing

The magnetic fluid bearing comprises a bearing internal sleeve with shoulder on one end, a bearing external sleeve, a permanent magnet, magnetic fluid and an internal sleeve fixing ring. The permanent magnet is in hooped-column shape and is formed by two half hooped-column shape permanent magnets which are opposite each other and with contrary magnetic pole and separated by a separation piece. The bearing external sleeve is fixedly mounted on the ex-circle of the hooped-column shape permanent magnet, and the bearing internal sleeve is fixedly mounted on the inner circle of the permanent magnet by the internal sleeve fixing ring. Between the permanent magnet and the bearing internal sleeve there is provided with clearance in which the said magnetic fluid is provided. Advantages: good lubrication effect, strong sealing performance, no dry friction and impaction in rotation, stable operation and very low sound, suitable especially to high rotation speed and environment with dust.

Owner:伍劲刚 +1

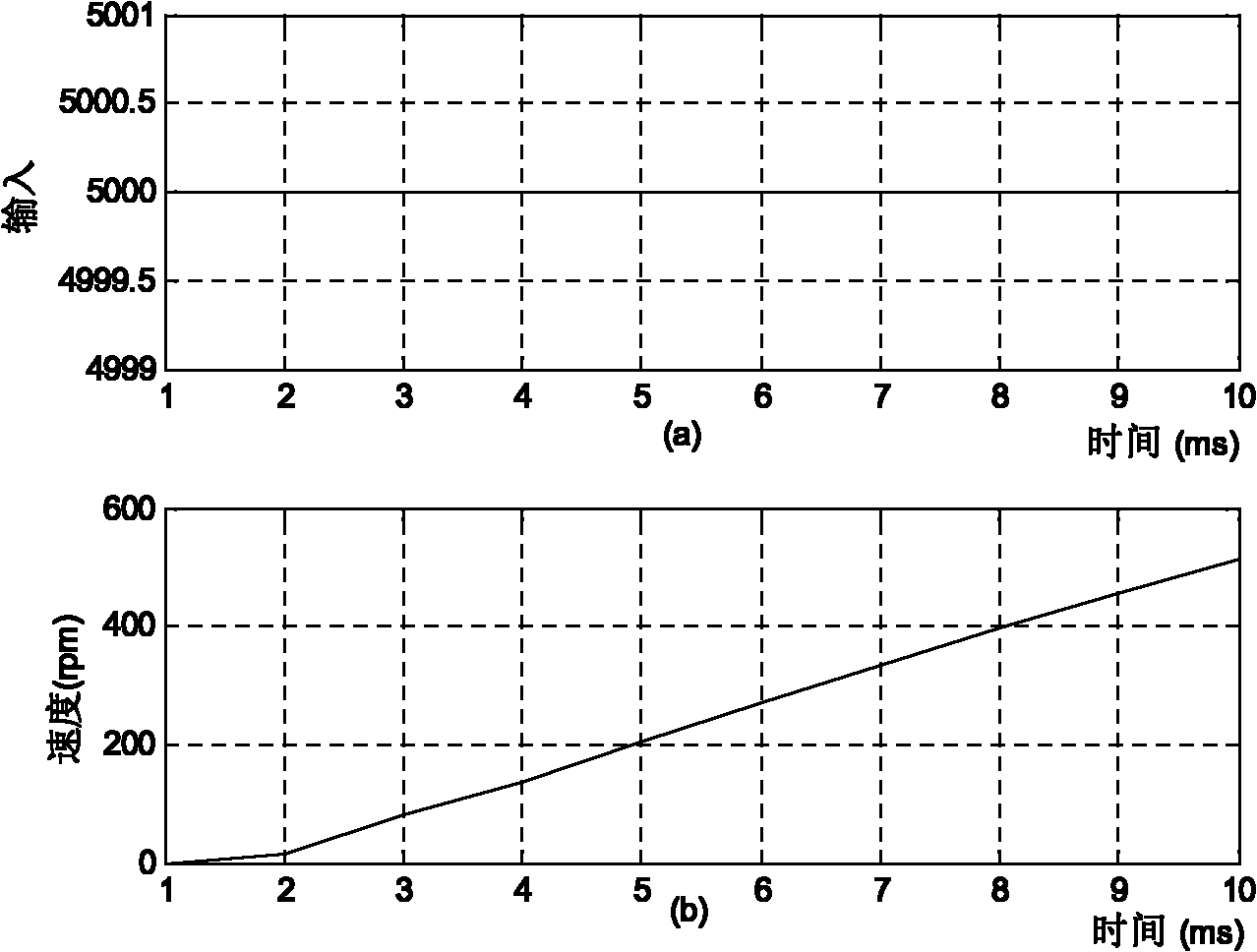

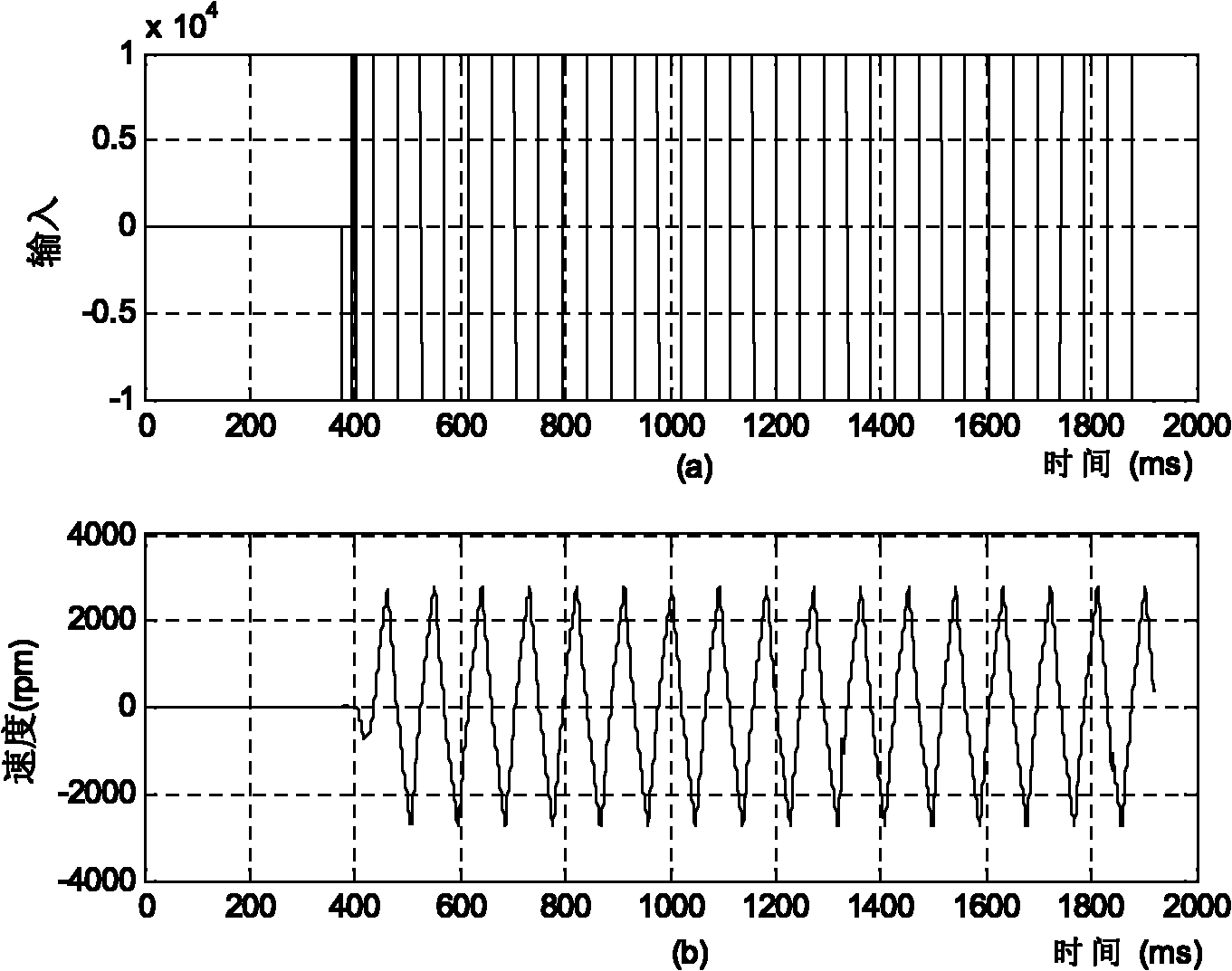

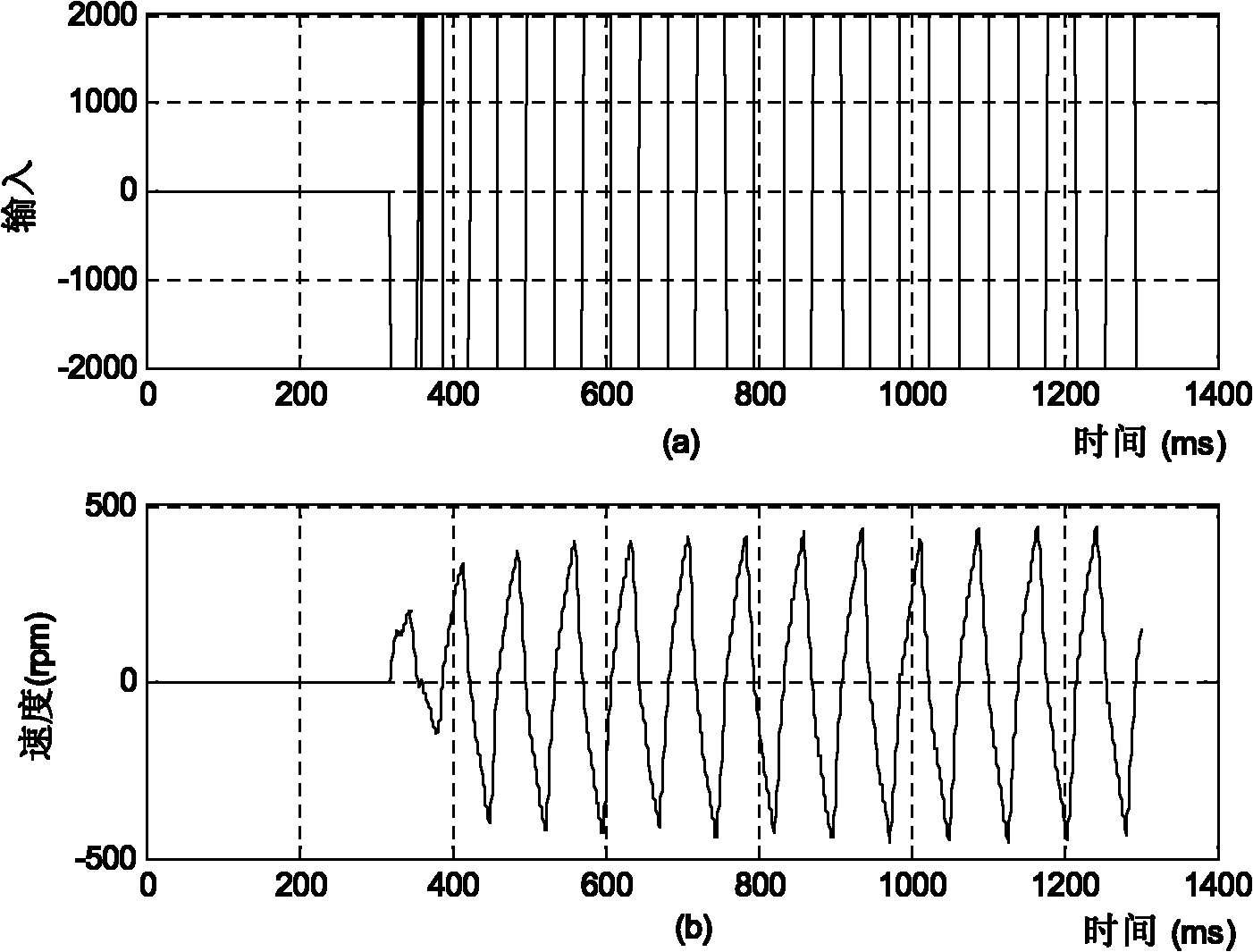

Servo system control method based on relay feedback

ActiveCN101807878AHigh control precisionCompensation for dry frictionElectric motor controlLower limitTime delays

The invention relates to a servo system control method based on relay feedback, belonging to the technical field of motion control. The method comprises the following steps of: controlling a servo system for the first time by using a relay with an initial amplitude value to acquire a rotation rate after initial motion time; acquiring a relay amplitude value corresponding to the upper limit and the lower limit of the rotation rate according to the motion information of the first time, and respectively carrying out motion control on the servo system for the second time and the third time under the amplitude value through the relay in a time delay mode to acquire a stable response amplitude and a stable response cycle; identifying system model parameters and a dry friction magnitude according to the motion information of the second time and the third time; and carrying out optimization of control parameters and feedforward compensation of dry friction based on the identified parameters. The method of the invention can be used for quickly optimizing controller parameters and realizing effective compensation of friction, thereby improving the control accuracy of the servo system.

Owner:SHANGHAI JIAO TONG UNIV

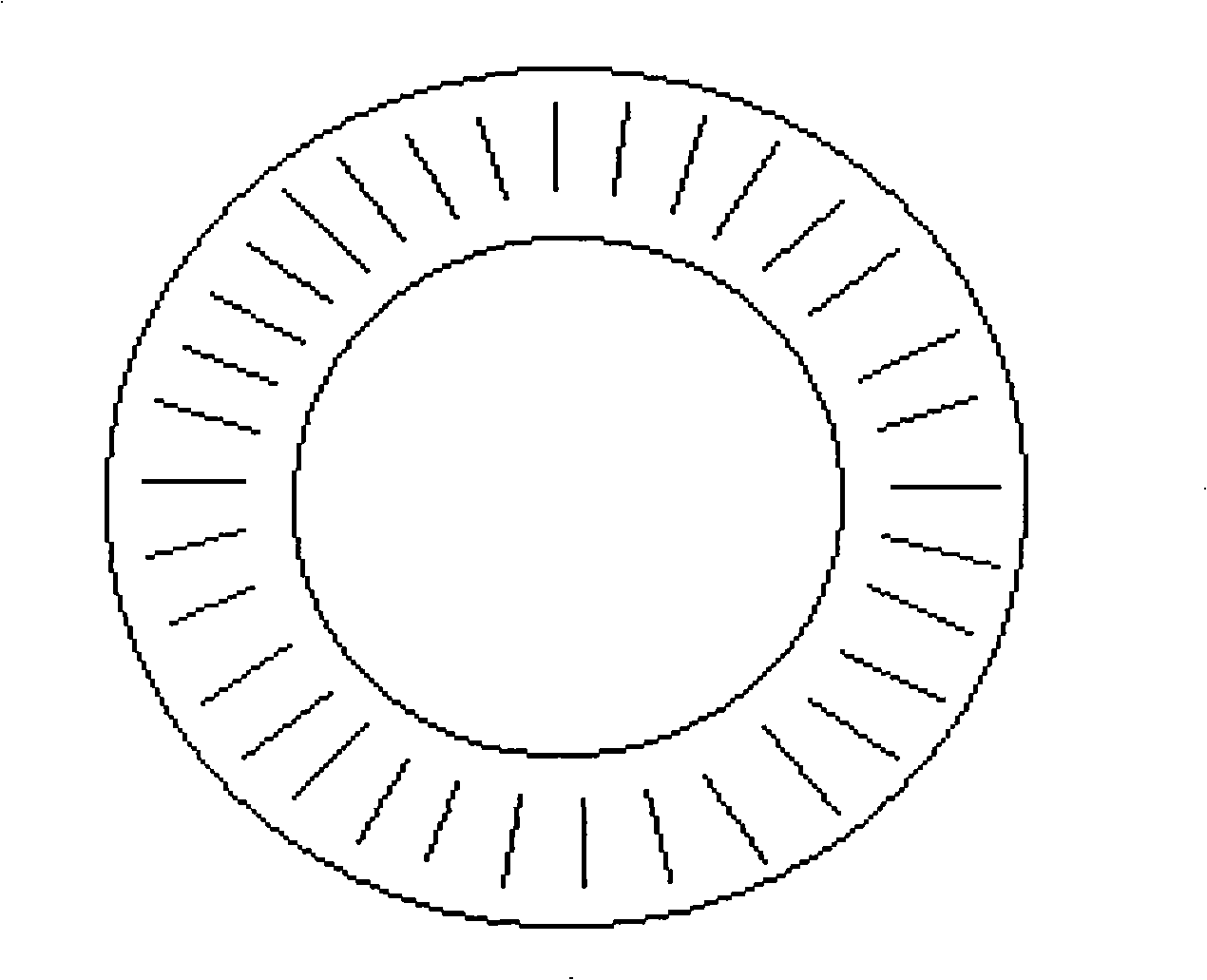

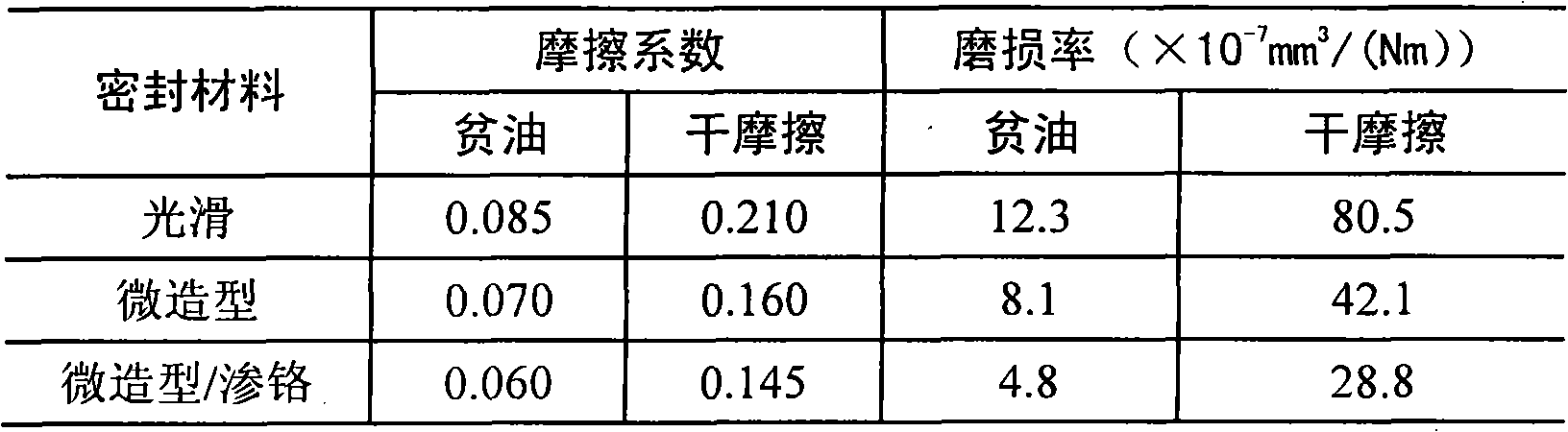

Composite modification sealing friction pair of laser texturing and alloyage and processing method thereof

InactiveCN101526136AReduce coefficient of frictionReduce wear rateEngine sealsSolid state diffusion coatingMaterials scienceLaser

The invention discloses a composite modification sealing friction pair of laser texturing and alloyage and a processing method thereof. The surface of the material alloyage comprises texturing. The surface of the material alloyage of the friction pair is the surface of plasma chromium impregnation or molybdenum impregnation. The texturing on the surface of the friction pair materials is a miniature hole or a groove. The processing method based on the sealing friction pair comprises the following steps: first, a sealing sample is polished and treated and cleaned by ultra audible sound; then, the surface of the polished sealing sample is sculptured with texturing by a pulse laser; and finally, after being sculptured with the texturing, the sample carries out plasma chromium impregnation or molybdenum impregnation treatment. The sealing friction pair reduces the friction coefficient of a sealing friction pair by using laser texturing and improves the surface friction resistance performance by using the surface alloyage. The composite modification of the laser surface texturing and the surface alloyage improves the frictional wear performance of the sealing friction pair in the states of lean oil and dry friction. The processing method of the sealing friction pair is simple and easy to carry out and convenient to implement.

Owner:NANJING UNIV OF SCI & TECH

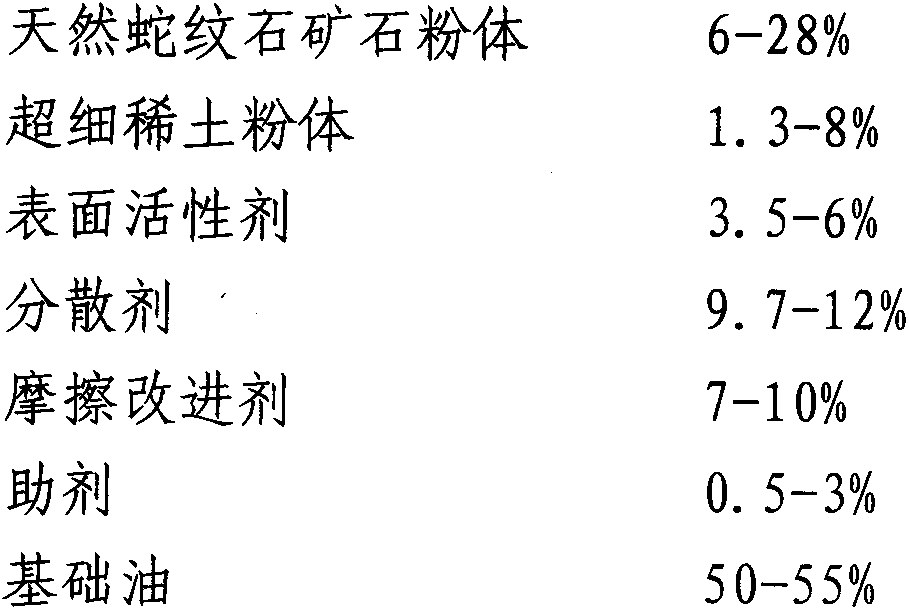

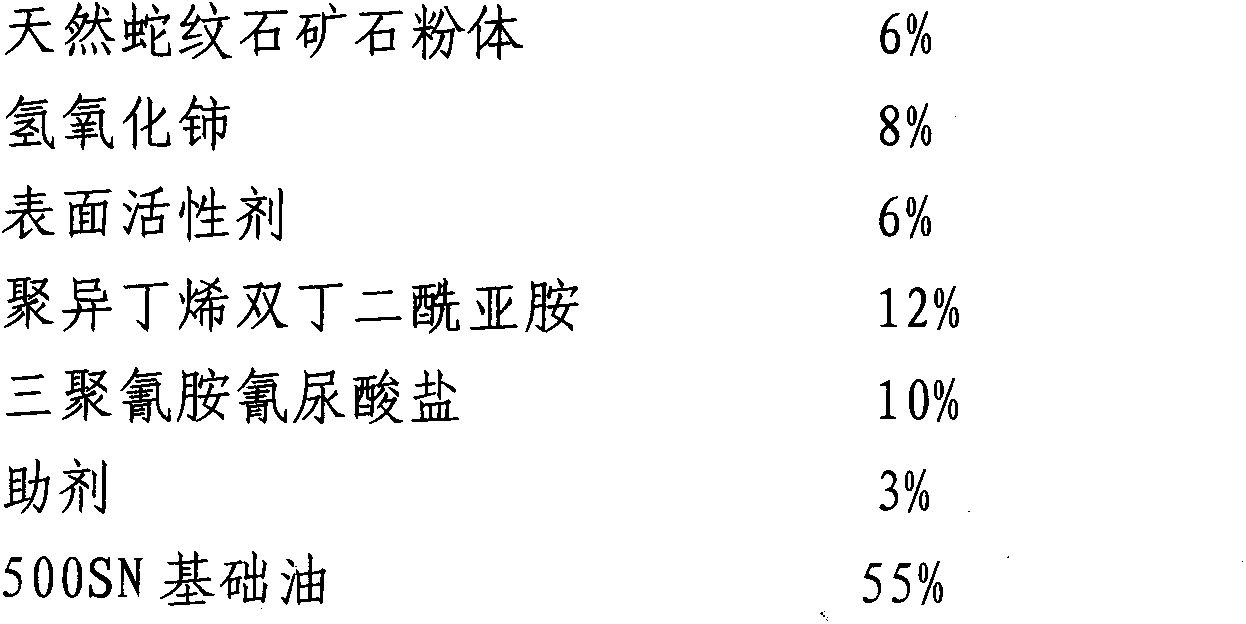

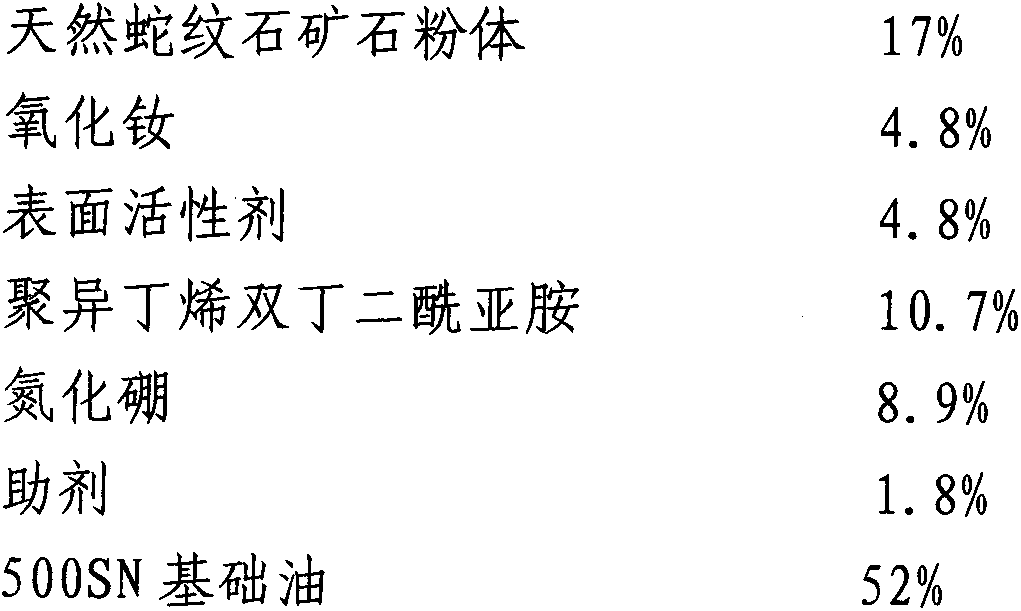

Lubricating oil additive containing ultrafine rare-earth powder

InactiveCN103642569AAvoid direct contactReduce harmful ingredientsLubricant compositionPhosphateOil additive

The invention relates to a lubricating oil additive containing ultrafine rare-earth powder. The additive consists of the following components in percentage by mass: natural serpentine mineral powder, ultrafine rare-earth powder, surfactant, a dispersing agent, a friction modifier, an auxiliary and base oil, wherein the ultrafine rare-earth powder is one of cerium hydroxide, neodymium oxide and cerium fluoride; the surfactant is borate, span-60 or oleic acid; the dispersing agent is either polyisobutene dibutyl succinimide or high molecular weight polyisobutene dibutyl succinimide; the friction modifier is one of melamine cyanurate, boron nitride and calciuym nitride; the auxiliary comprises 72% of dialkyl disulfo oxygen molybdenum phosphate sulfide, 18% of polymethyl tetradecyl acrylate and 10% of a vinyl-propylene copolymer; and the base oil is 500SN base oil. The additive has obvious corrosion resistance; and after an engine is treated technically by using the self-repairing additive, the dry friction coefficient of the machine is reduced from original 0.05 to be less than 0.005 and therefore the surface abrasion is reduced.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE +2

Conical air floating shaft system

The invention relates to a conical air floating shaft system, which comprises an air floating main shaft, an air floating inner shaft sleeve, an air floating outer shaft sleeve, and positioning plates, wherein the air floating inner shaft sleeve is arranged on the outer side of the air floating main shaft, and is matched with the air floating main shaft, the air floating outer shaft sleeve is arranged on the outer side of the air floating inner shaft sleeve, and is matched with the air floating inner shaft sleeve, and the positioning plates are arranged on both ends of the air floating main shaft. The positioning plates are fixedly connected with the air floating main shaft. Both ends of the air floating outer shaft sleeve are provided with an anti-thrust plate. The anti-thrust plate is fixedly connected with the positioning plate. In the prior art, the positioning accuracy of the existing air floating shaft system is not high, and the dry friction is easily generated. With the present invention, the technical problems in the prior art are solved, and the conical air floating shaft system is provided, wherein the conical air floating shaft system integrates the advantages of the air floating main shaft, the air floating main shaft is matched with the air floating shaft sleeves so as to effectively improve the stiffness of the shaft system, the conical surface match is adopted so as to provide high centering accuracy, and it can be ensured that the air floating shaft system of the present invention has high accuracy when the off-axis end surface is high.

Owner:西安威而信精密仪器有限公司

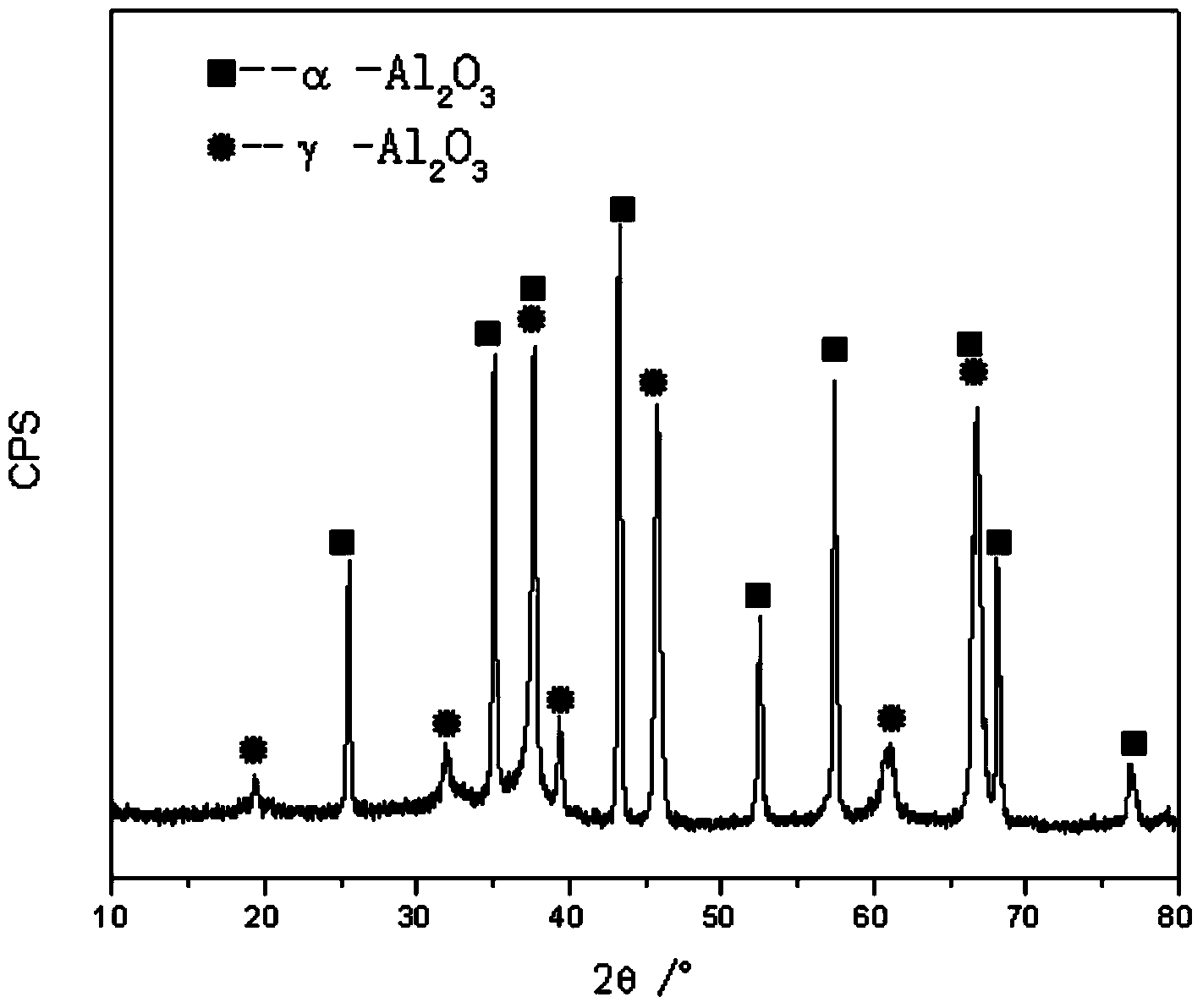

Two-step micro-arc oxidation method for producing super wear-resistant coating on surface of aluminium alloy

ActiveCN103820832ASmooth film formationFast film formationSurface reaction electrolytic coatingAluminateHigh concentration

The invention relates to the field of electrochemistry, and discloses a two-step micro-arc oxidation method for producing a super wear-resistant coating on the surface of an aluminium alloy. The method uses the aluminium alloy as a base body and uses the low-concentration and high-concentration aluminate solutions as mediums, and an aluminium oxide layer with a compact single layer structure is quickly formed through the two-step micro-arc oxidation, wherein the content of a corundum (alpha-Al2O3) component is more than 40%. A film with the thickness of about 40 to 50 micrometers can be formed only needing 8 to 10 min of the micro-arc oxidation. The film has excellent wear resistance, for the film with the thickness of about 40 to 50 micrometers, under the ball-block type dry friction condition, the wear of the film is just slight when being subjected to friction with load of 80 N for 30 min (the depth of the wearing scratch is 12 micrometers), and for the silicate micro-arc oxidation film taken as comparison, under the condition with the load of 80 N, the film can be worn after 5 min of friction, and the depth of the friction scratch reaches 109 micrometers.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com