Patents

Literature

2031 results about "Pull off test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The pull-off test, also called stud pull test in which an adhesive connection is made between a stud and the carrier (or object to be tested) by using a glue, possibly an epoxy or polyester resin, that is stronger than the bond that needs to be tested. The force required to pull the stud from the surface, together with the carrier, is measured. Simple mechanical hand-operated loading equipment has been developed for this purpose. When higher accuracy is required, tests can be performed with more advanced equipment called a bond tester. A bond tester provides more control and possibly automation. Applying the glue automatically and curing with UV light is the next step in automation. This methodology can also be used to measure direct tensile strength or/and the bond strength between two different layers.

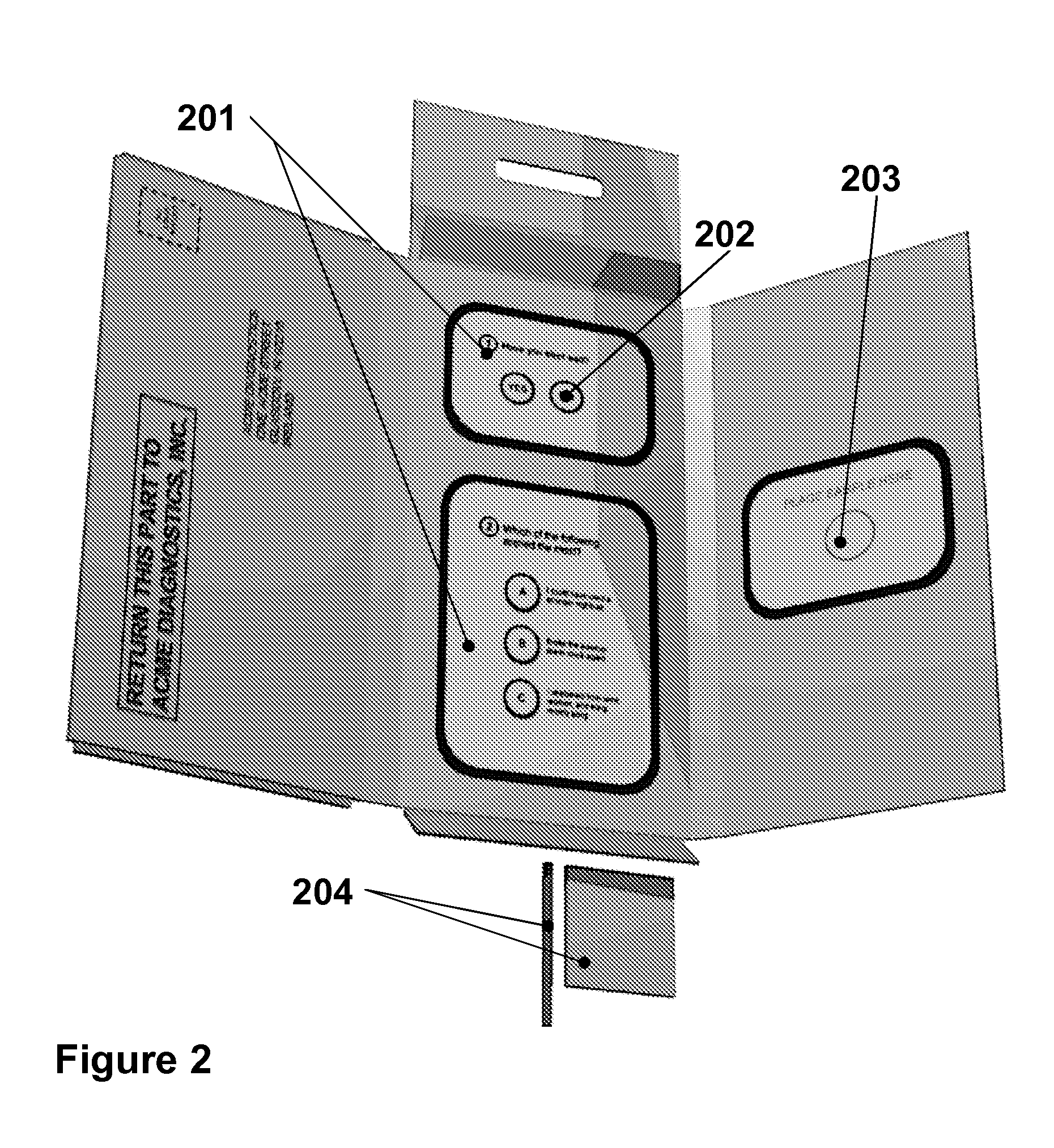

Single use, self-contained assay device for quantitative and qualitative measurements

InactiveUS20080053222A1ConfidenceReliable resultsFluid pressure measurementSpeed/acceleration/shock instrument detailsMeasurement deviceData acquisition

The invention comprises a single-use, self-contained measuring device, comprising a data entry- and sampling part including a sensor for measuring of physical or chemical property of a foreign substance and a data acquisition part including electronic processing- and storage means, where the parts are integral parts of a packaging, formed of a sheet-like, printable and foldable material, the packaging being designed to enclose and protect the parts contained therein. The packaging may also include various instruments needed to perform a test.

Owner:CYPAK +1

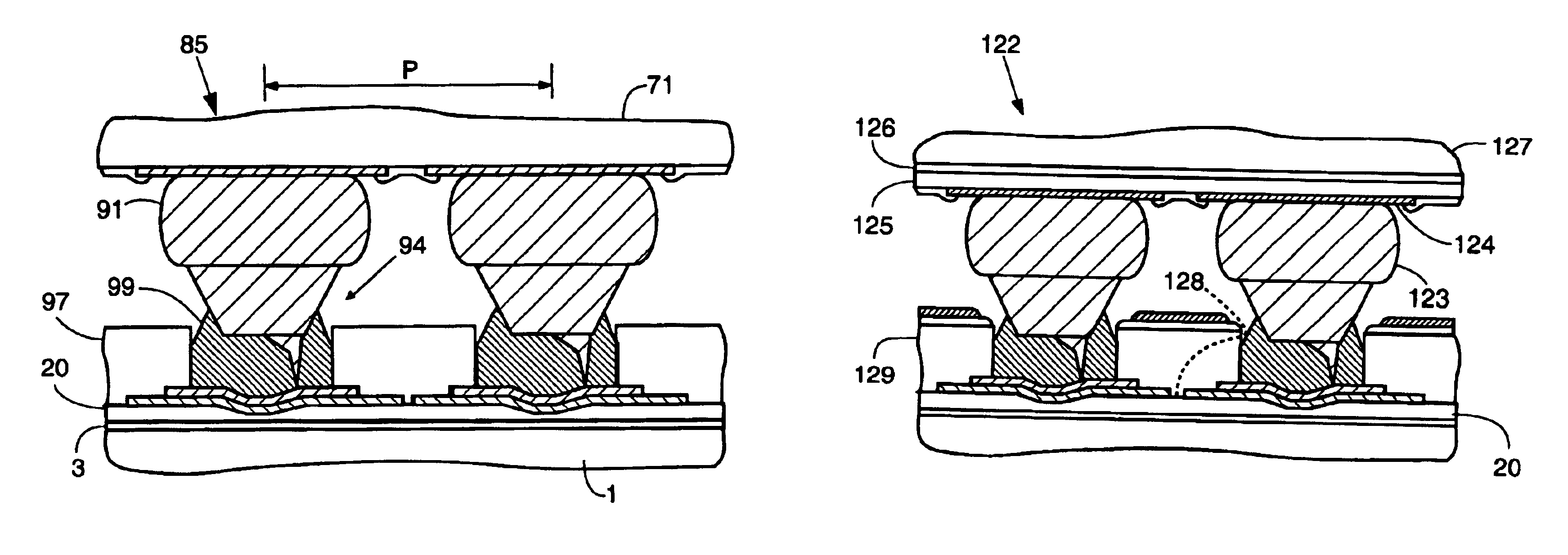

Electronic system modules and method of fabrication

InactiveUS6927471B2Good dimensional stabilityLow costPrinted circuit assemblingFinal product manufactureDielectricEngineering

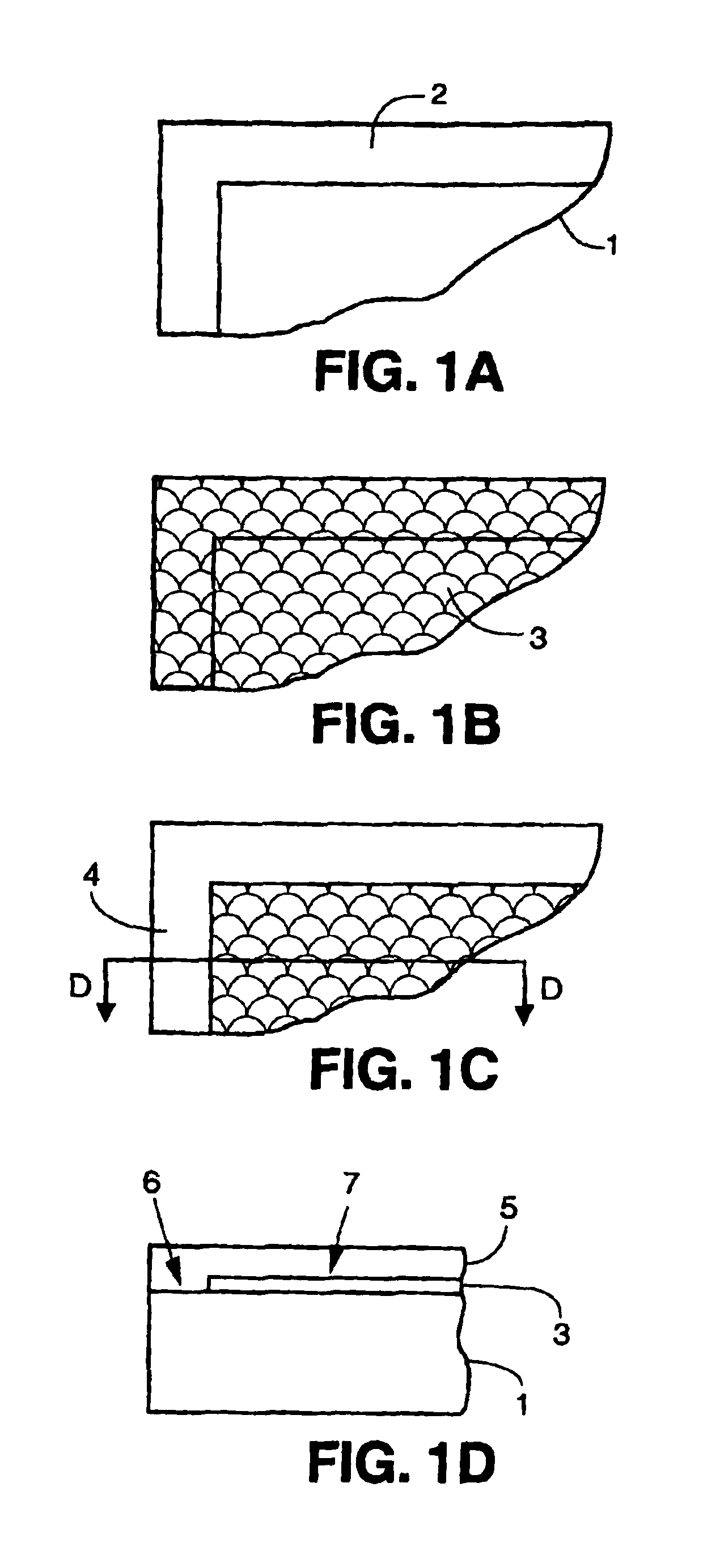

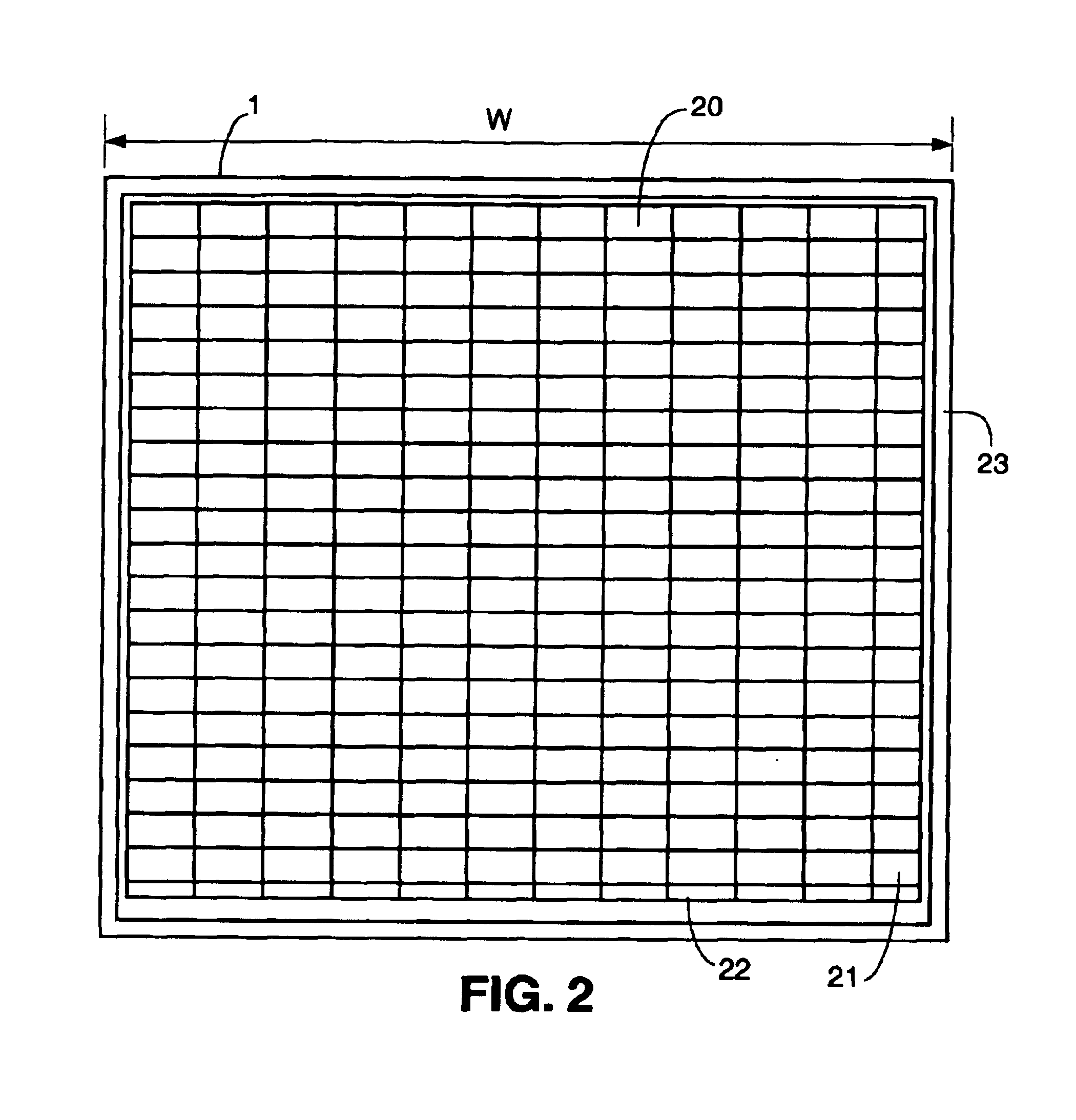

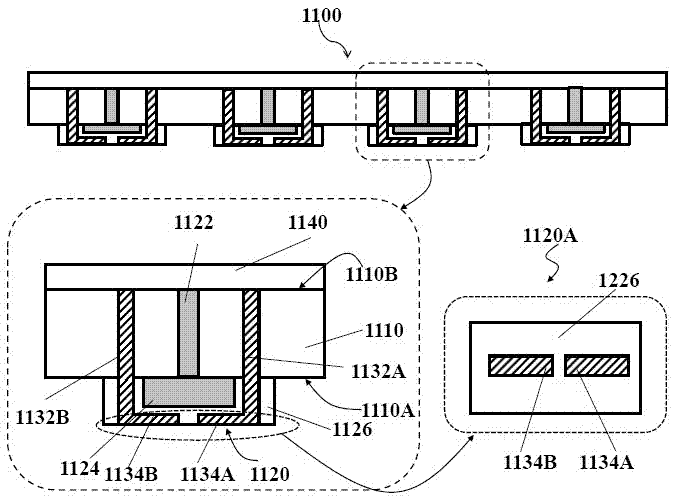

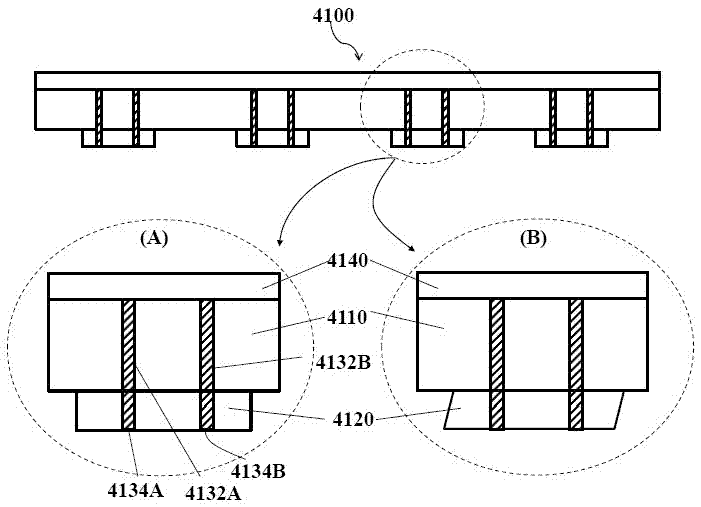

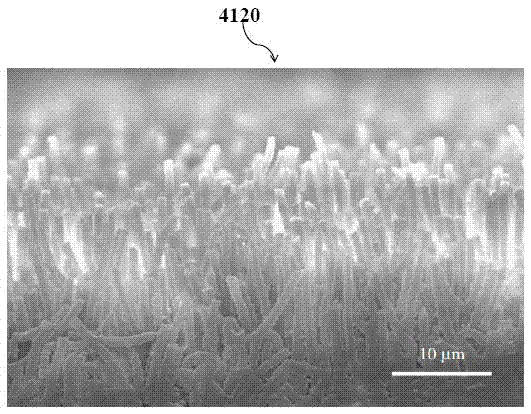

This specification describes techniques for manufacturing an electronic system module. The module includes flexible multi-layer interconnection circuits with trace widths of 5 microns or less. A glass panel manufacturing facility, similar to those employed for making liquid crystal display, LCD, panels is used to fabricate the interconnection circuits. A polymer base layer is formed on a glass carrier with an intermediate release layer. Alternate layers of metal and dielectric are formed on the base layer, and patterned to create an array of multi-layer interconnection circuits on the glass panel. A thick layer of polymer is deposited on the interconnection circuit, and openings formed at input / output (I / O) pad locations. Solder paste is deposited in the openings to form wells filled with solder. After dicing the glass carrier to form separated interconnection circuits, IC chips are stud bumped and assembled using flip chip bonding, wherein the stud bumps on the components are inserted into corresponding wells on the interconnection circuits. The IC chips are tested and reworked to form tested circuit assemblies. Methods for connecting to testers and to other modules and electronic systems are described. Module packaging layers are provided for hermetic sealing and for electromagnetic shielding. A blade server embodiment is also described.

Owner:SK HYNIX INC

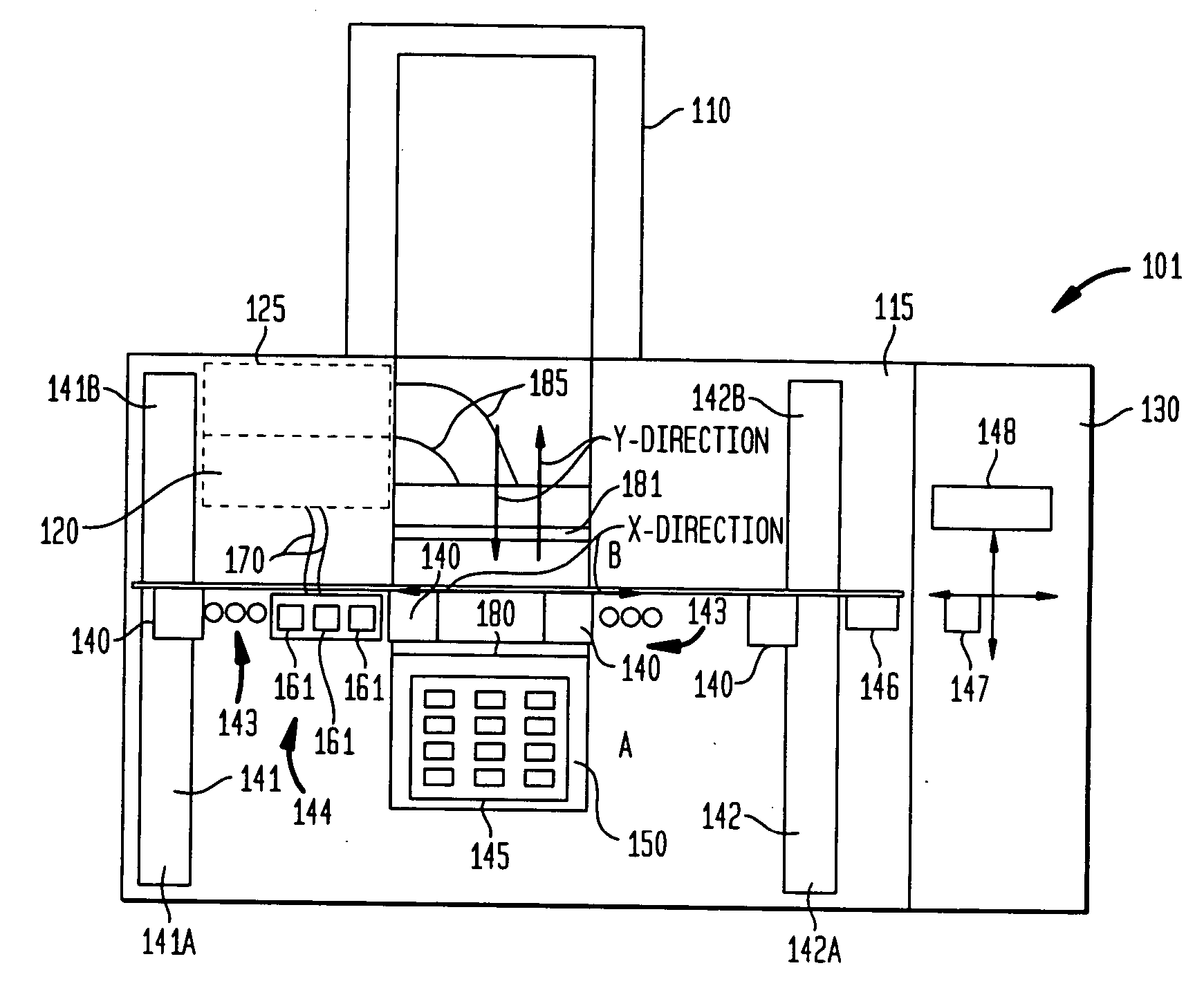

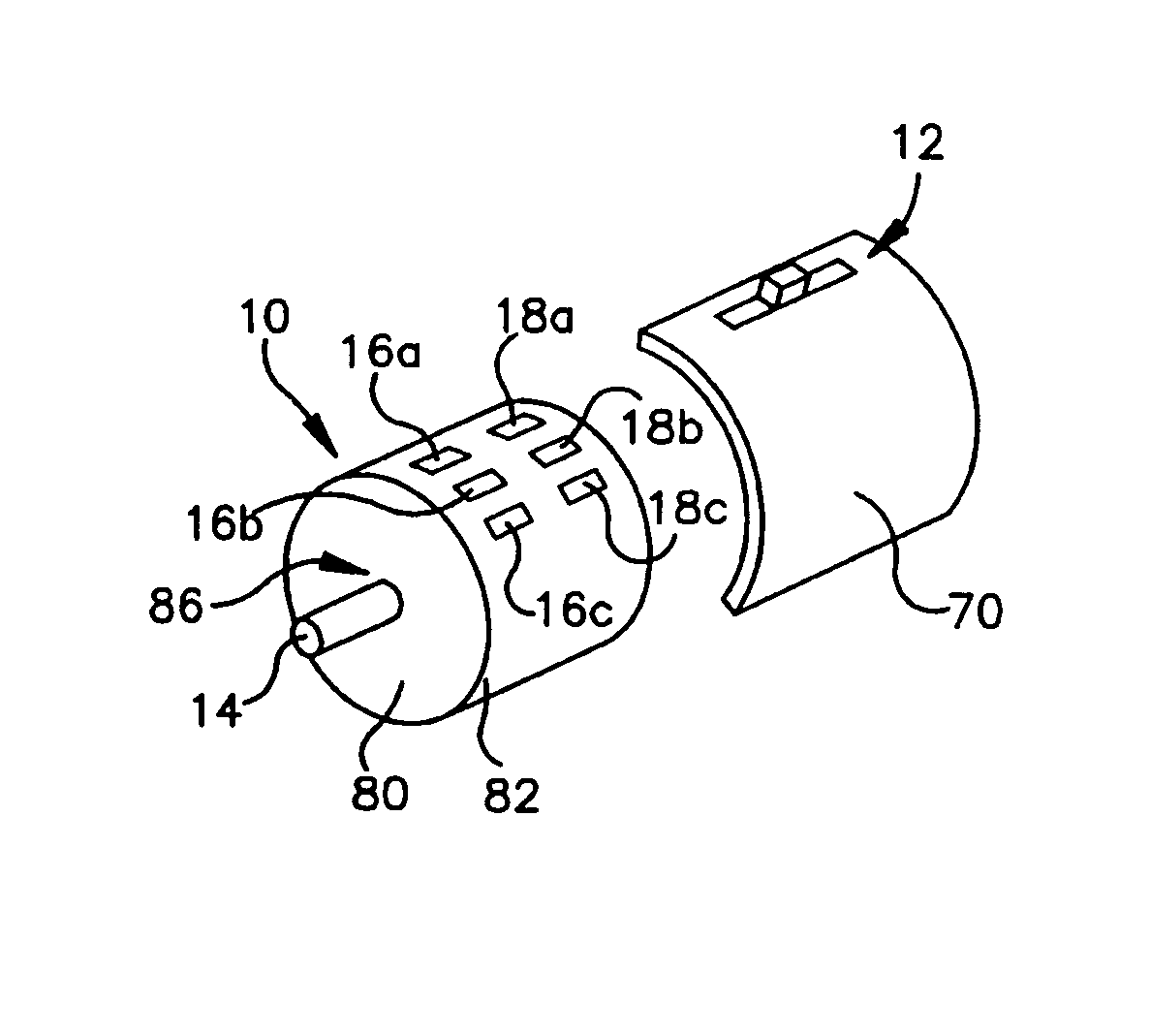

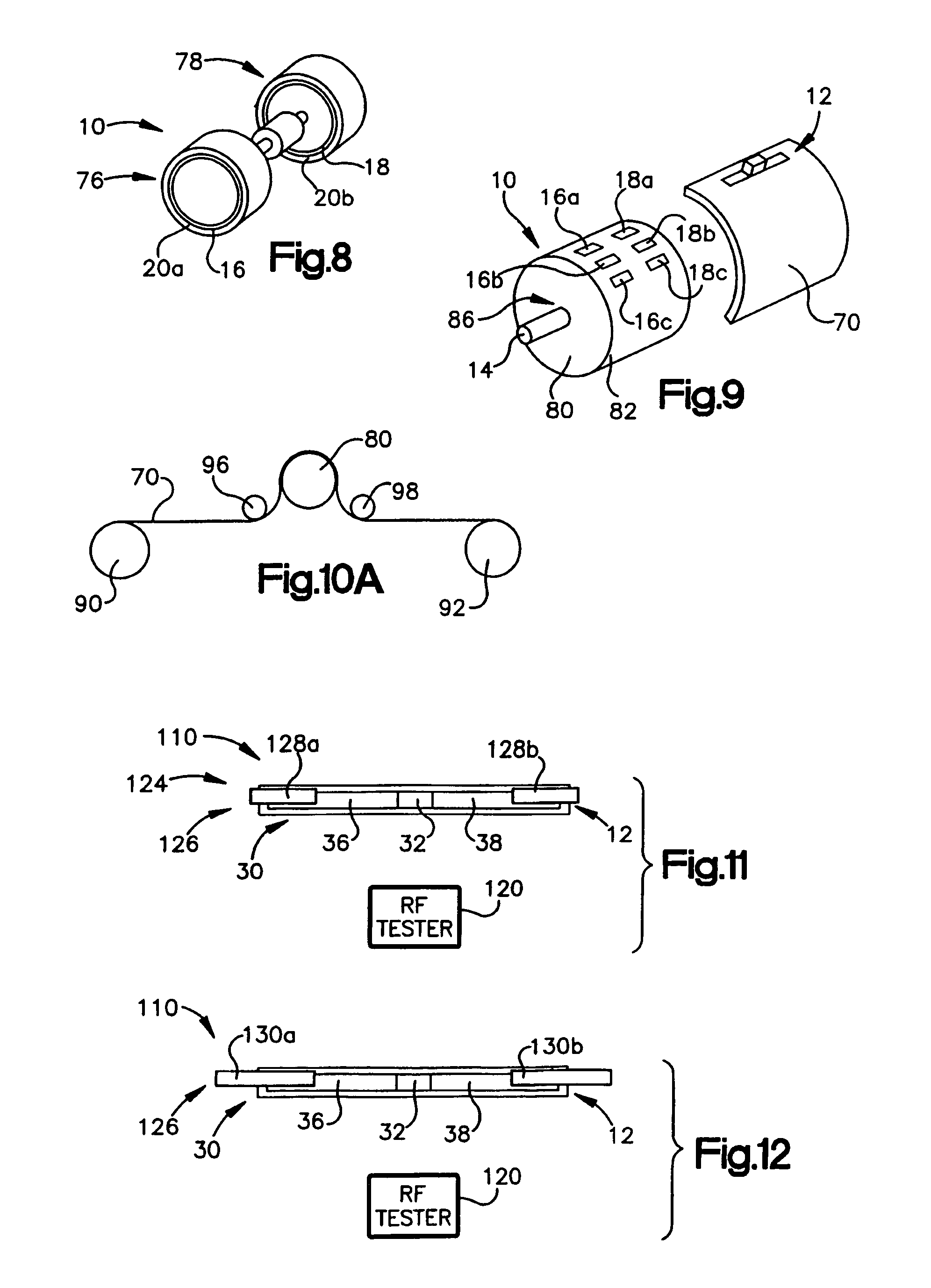

High-speed RFID circuit placement method and device

ActiveUS7623034B2Prevent bucklingPrinted circuit assemblingTesting sensing arrangementsInterposerEngineering

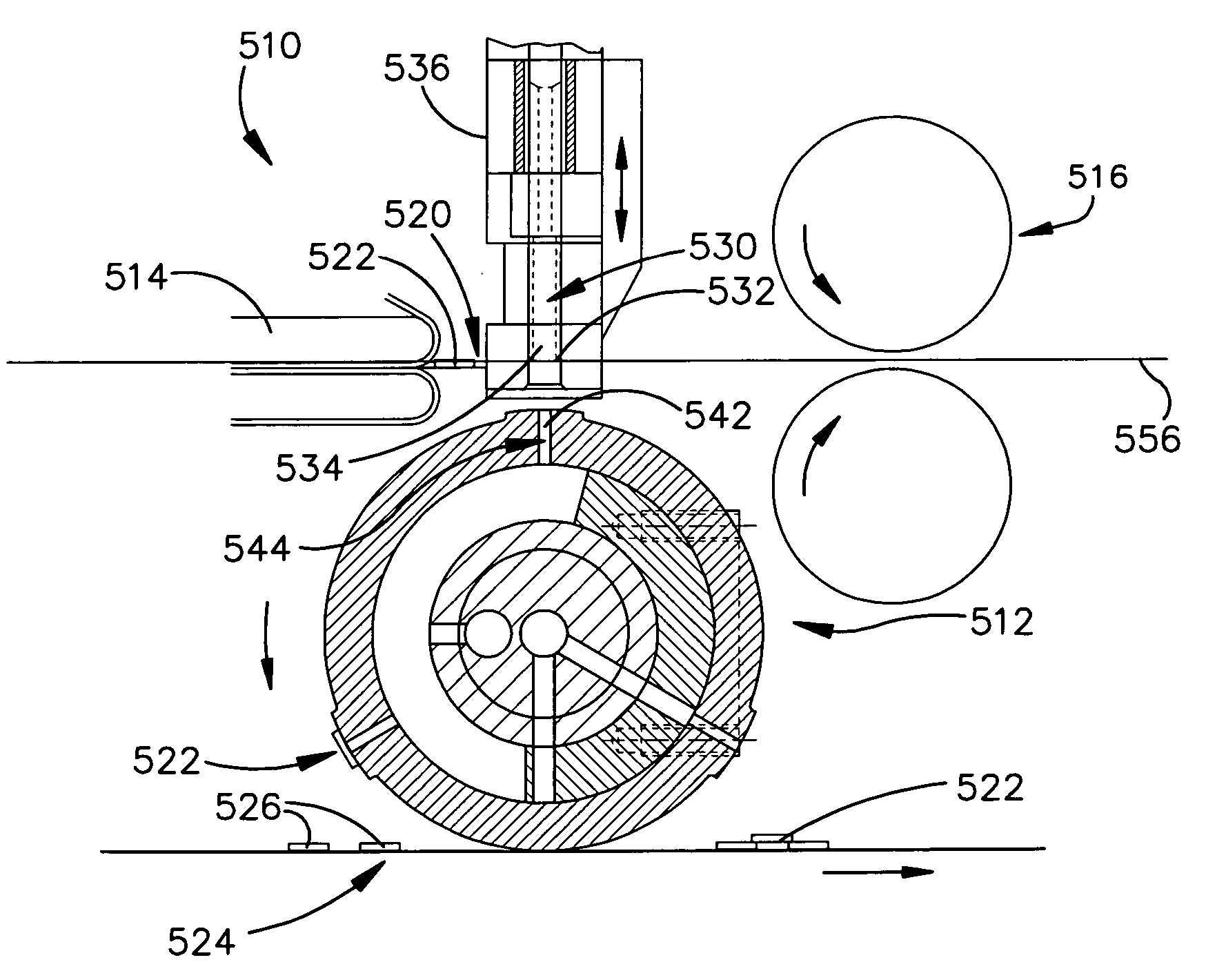

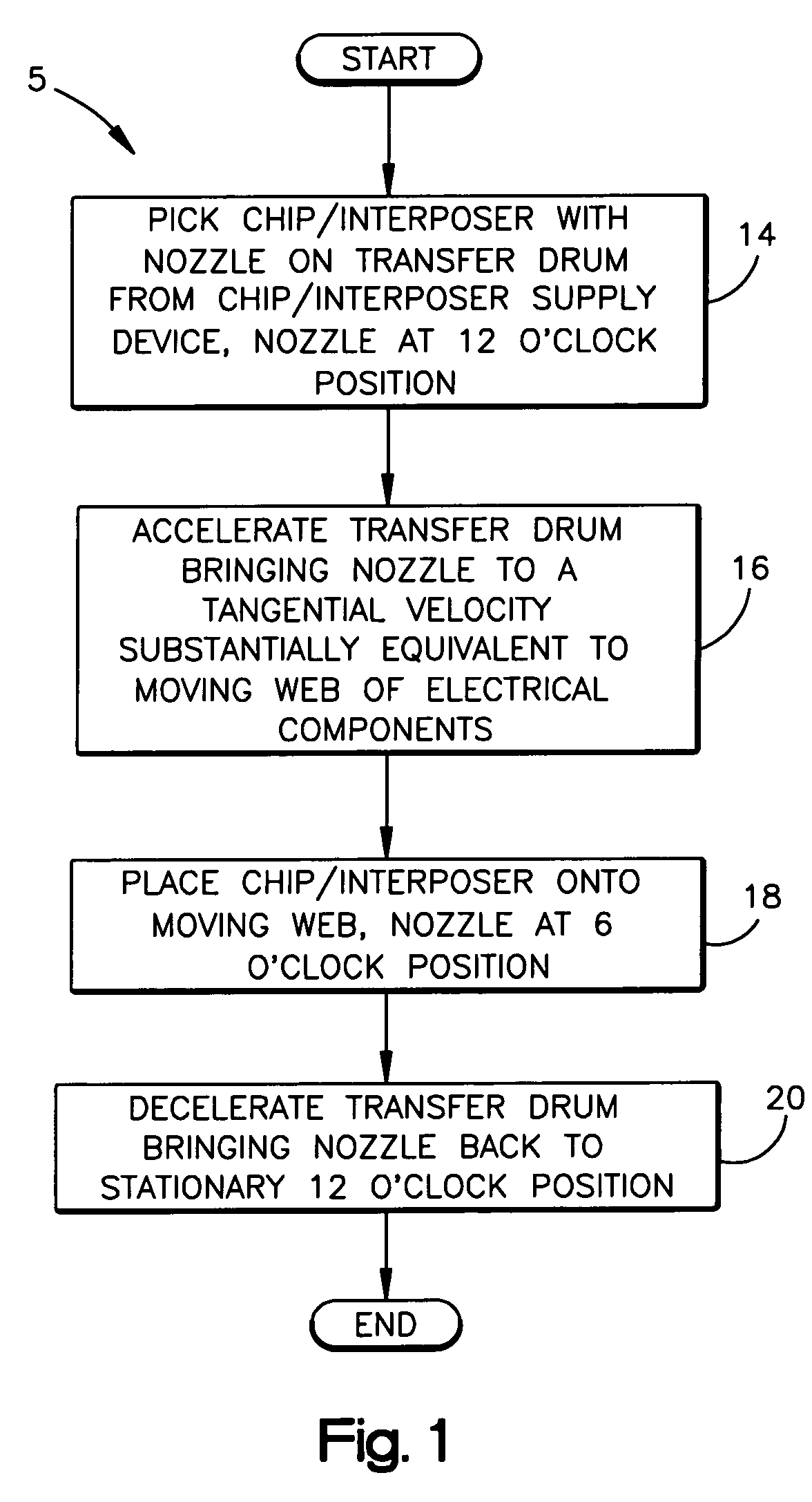

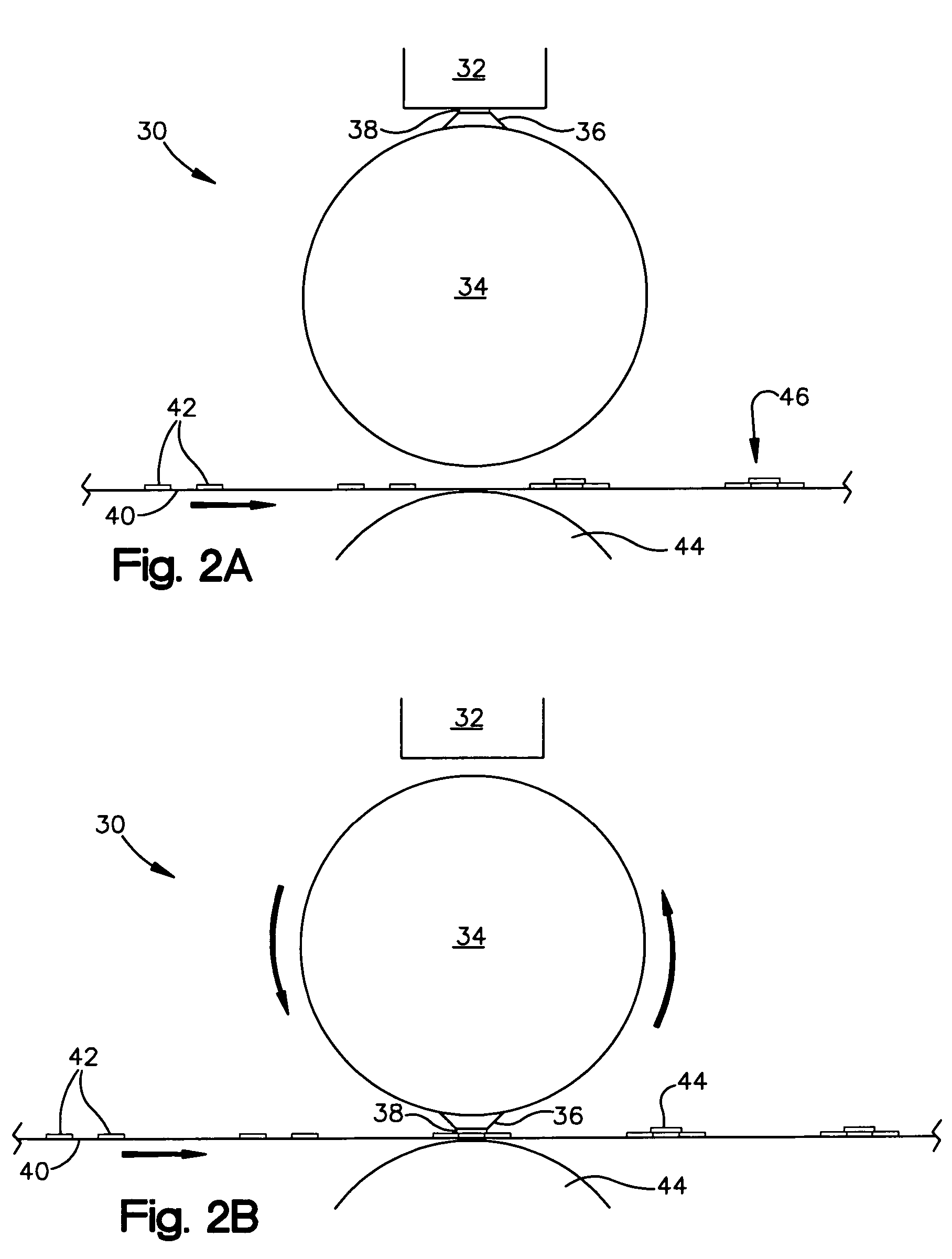

A high-speed machine and method for placing an RFID circuit onto an electrical component includes separating an RFID circuit from a web of RFID circuits, and placing the RFID circuit onto an electrical component with a placing device. The separating includes directing the RFID circuit onto a transfer drum of the placement device and separably coupling the RFID circuit to the transfer drum. According to one method, a separator device separates and directs chips or interposers onto a placement device. According to another method, chips or interposers are tested before being separated from a web, and if good, are separated from the web, directed onto a placement device, and placed on an electrical component. If defective, the chips or interposers are not directed onto a placement device and are removed by a scrap web removal device.

Owner:AVERY DENNISON CORP

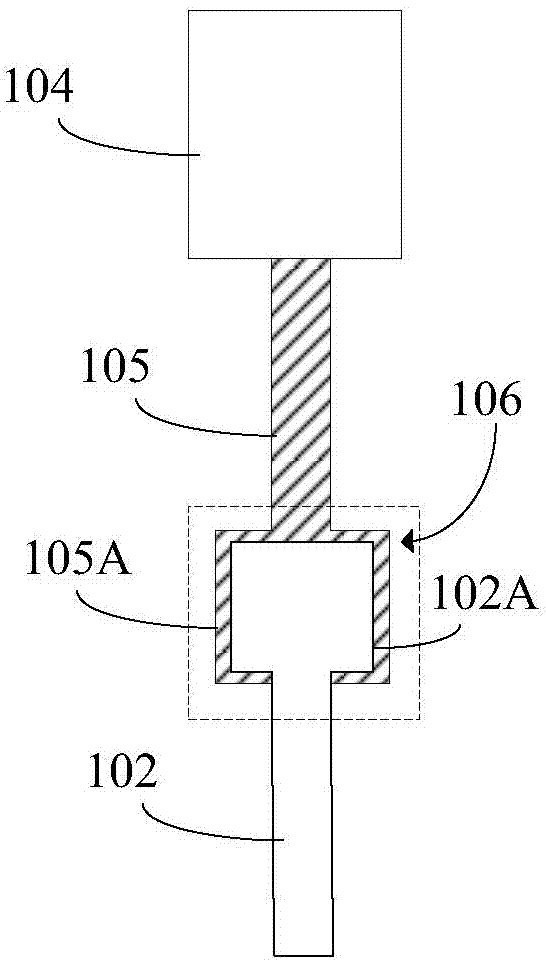

Micro-component transfer device, transfer method, manufacturing method, device, and electronic device

ActiveCN107039298ASemiconductor/solid-state device testing/measurementSolid-state devicesEngineeringElectron

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

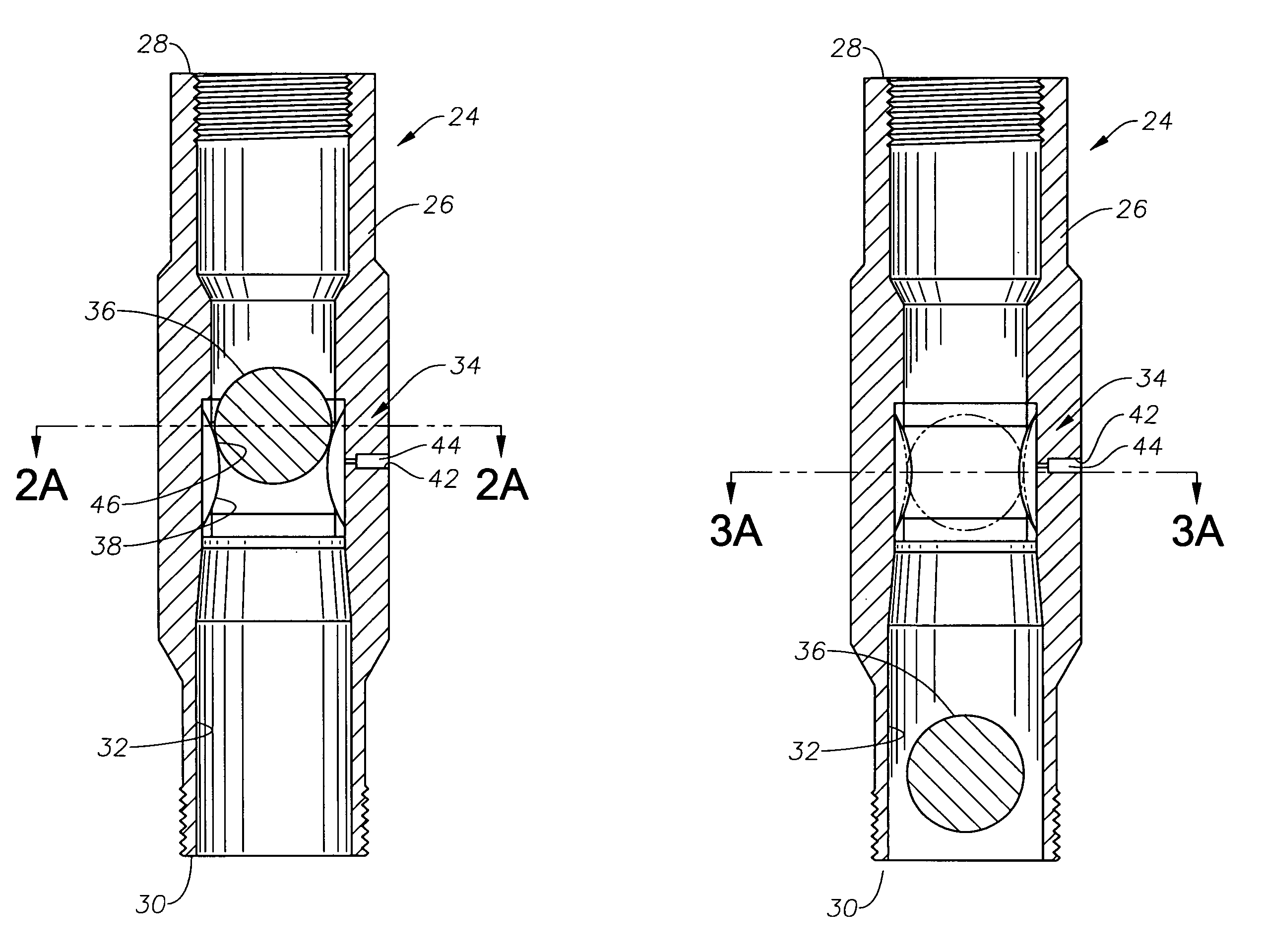

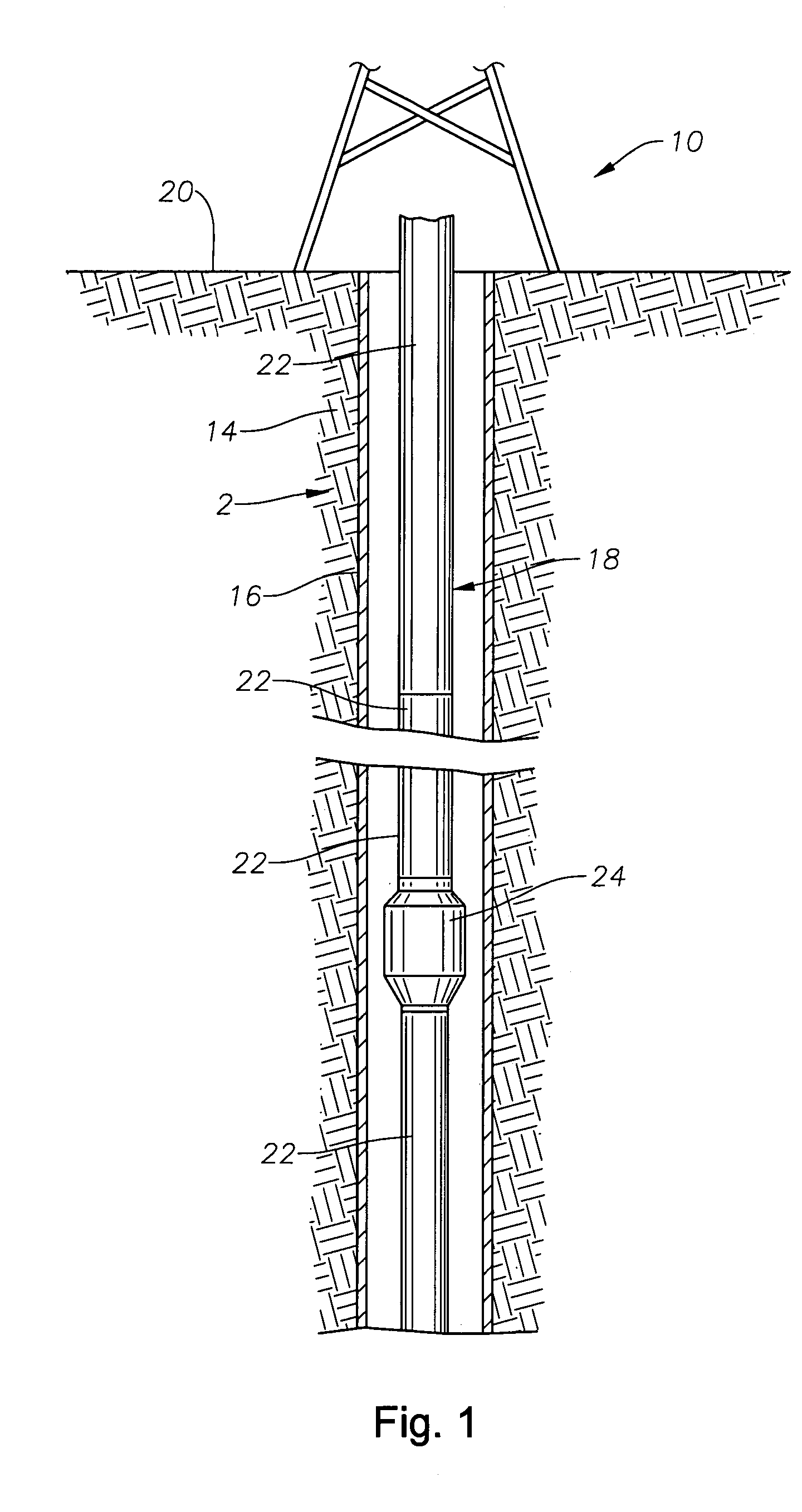

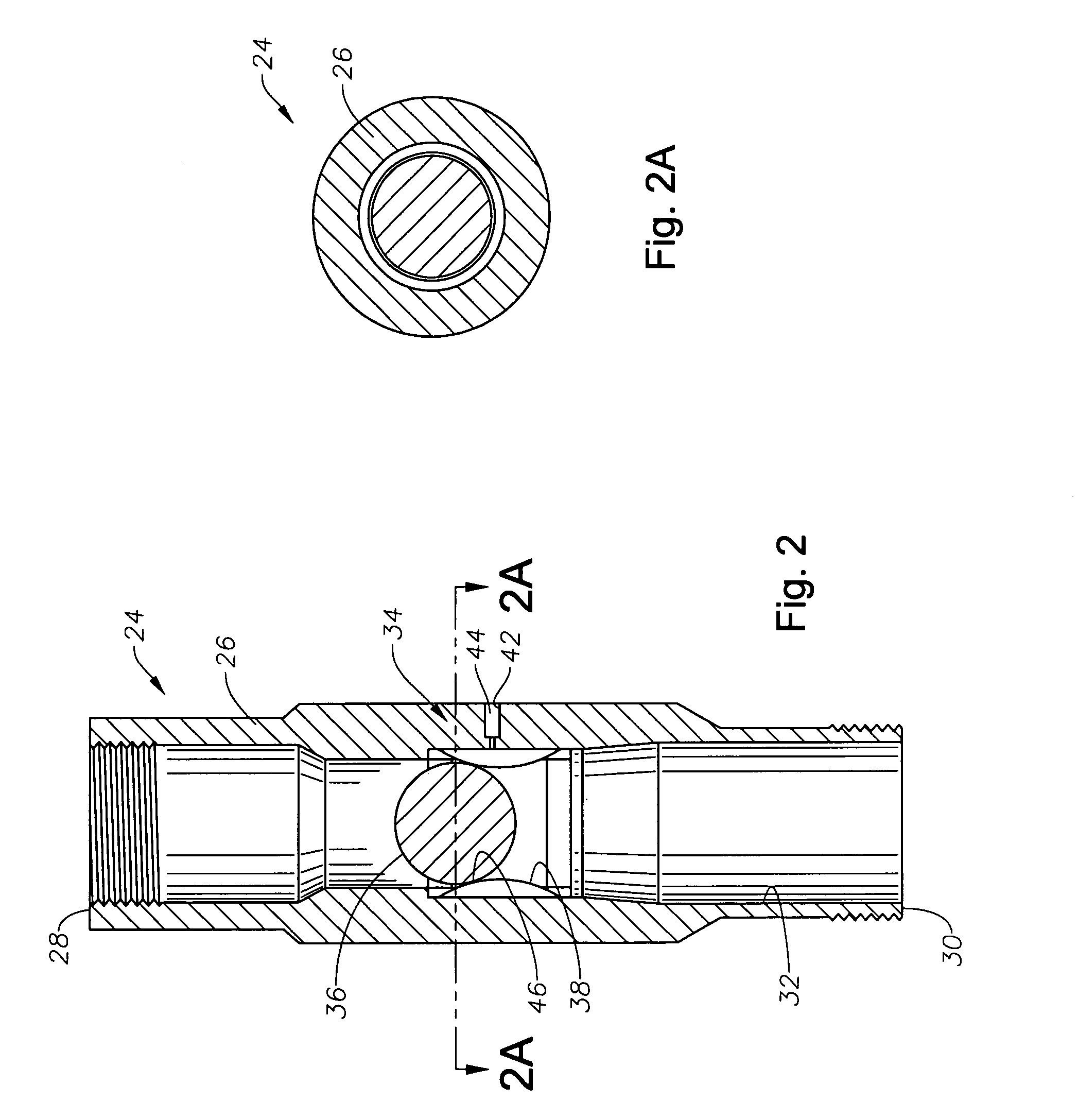

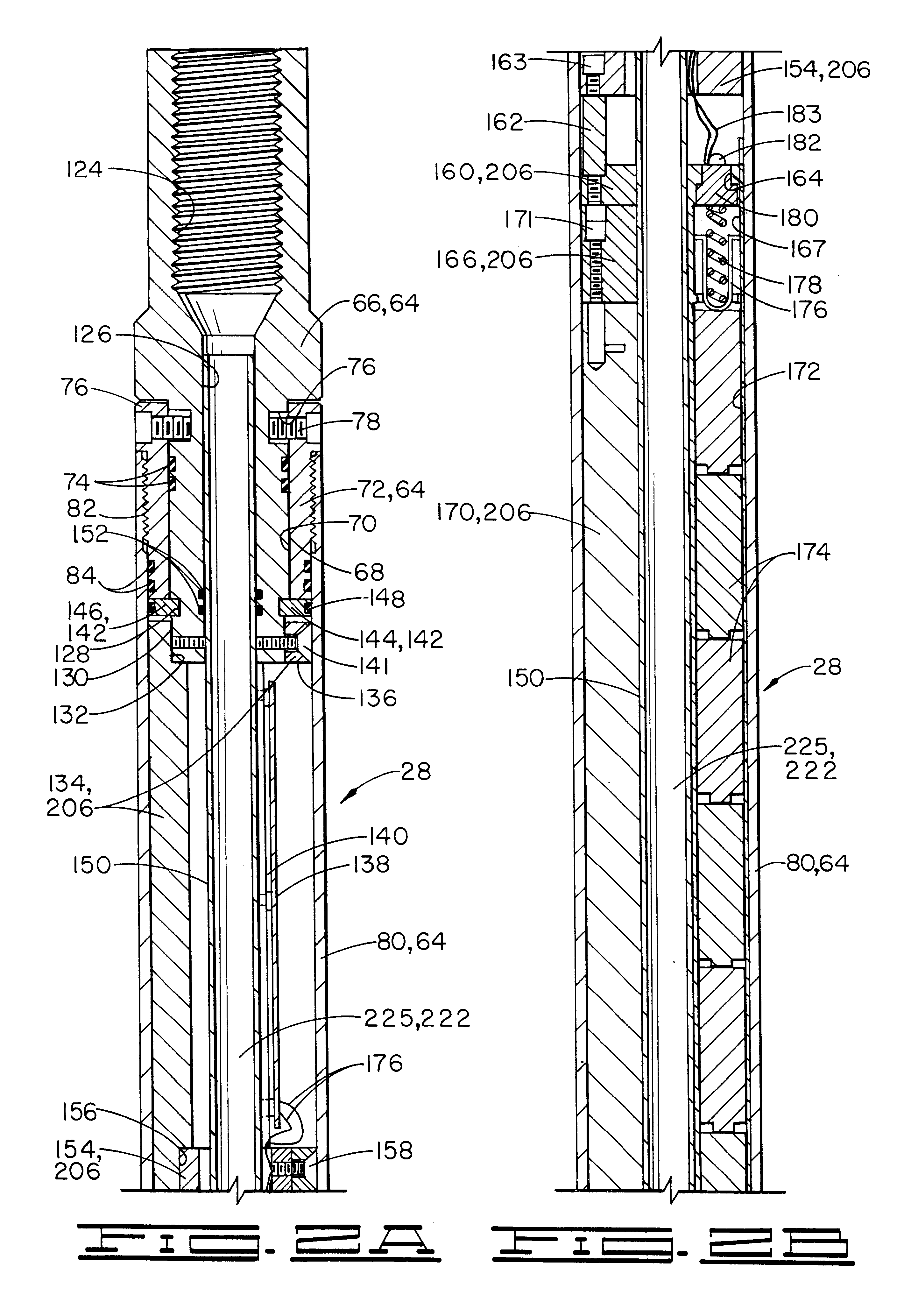

Plug and expel flow control device

Devices and methods for fluid flow control within a production tubing string wherein a temporary flow blockage is established and selectively removed from the tubing string so that pressure testing or operation of a hydraulic tool within the string may be performed. A flow control device includes a housing that defines a flowbore therethrough with a restricted diameter portion. The restricted diameter portion presents a seating surface for a plug member and is provided by an annular shell that is shaped to project convexly inwardly. The shell may be fashioned of metal, elastomer or another suitable material, and it is capable of yielding to permit passage of a plug member upon application of a suitably great amount of fluid pressure. In operation, a plugging member is dropped in to the tubing string from the surface of the well and seats upon the seating surface. The tubing string is then pressured up to a first fluid pressure level for testing, tool operation, or the like, and the pressuring up will urge the plugging member against the plug seat in order to effect a fluid seal. When it is desired to remove the plugging member from the tubing string, and reestablish fluid flow through the tubing string, fluid pressure above the plugging member is raised to a second, overpressure level. The plug is then urged through the restricted diameter portion and expelled from the device to the wellbore sump below.

Owner:BAKER HUGHES OILFIELD OPERATIONS LLC

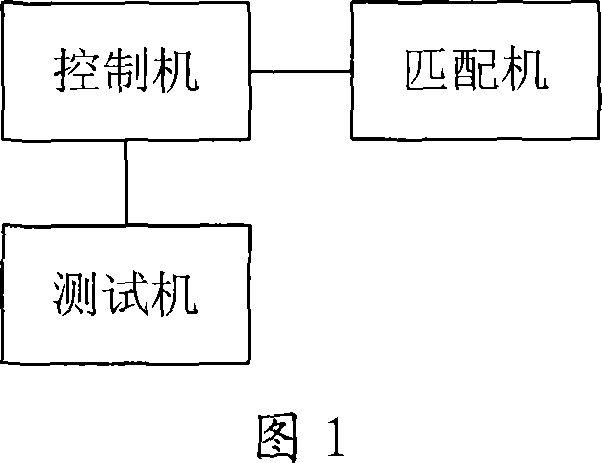

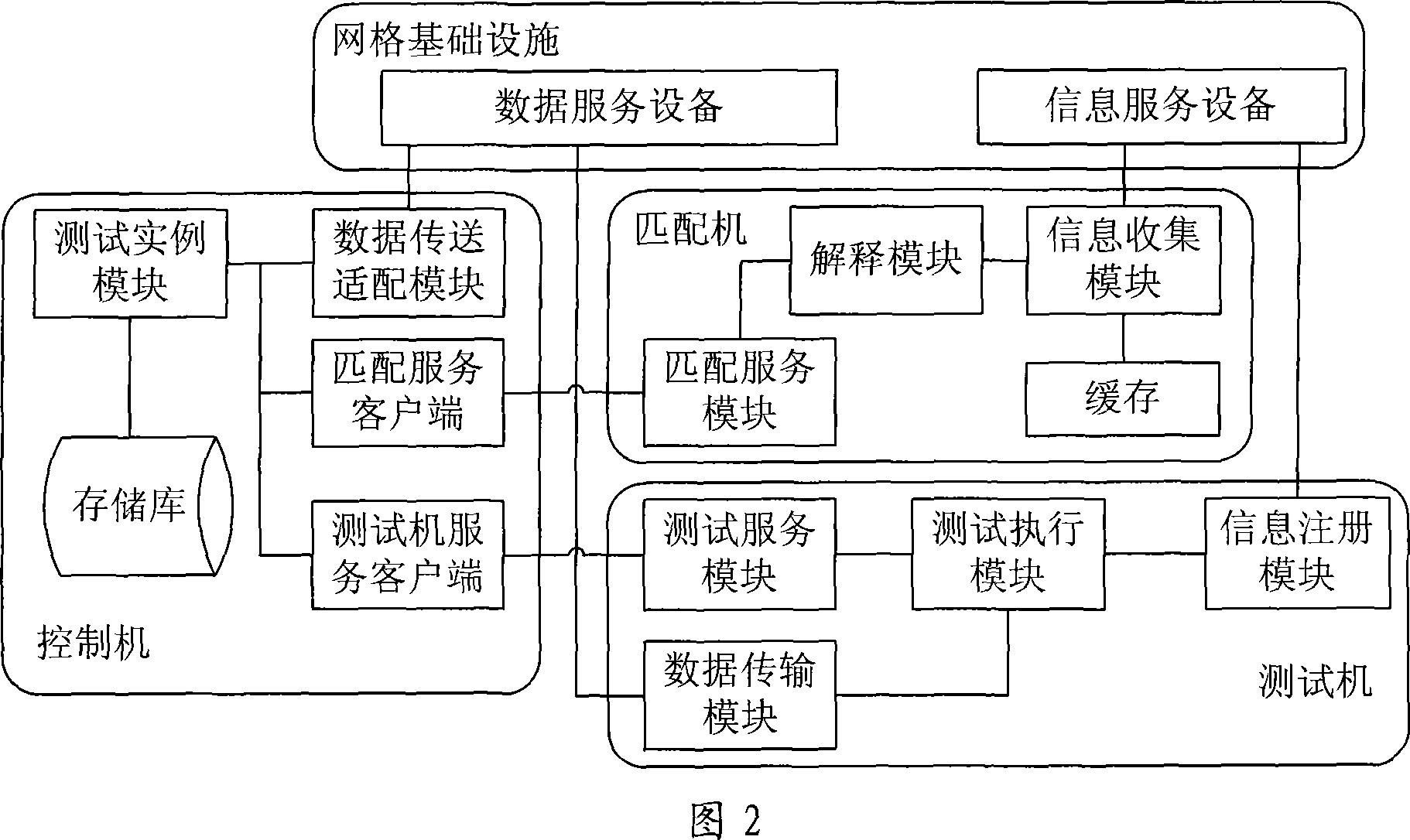

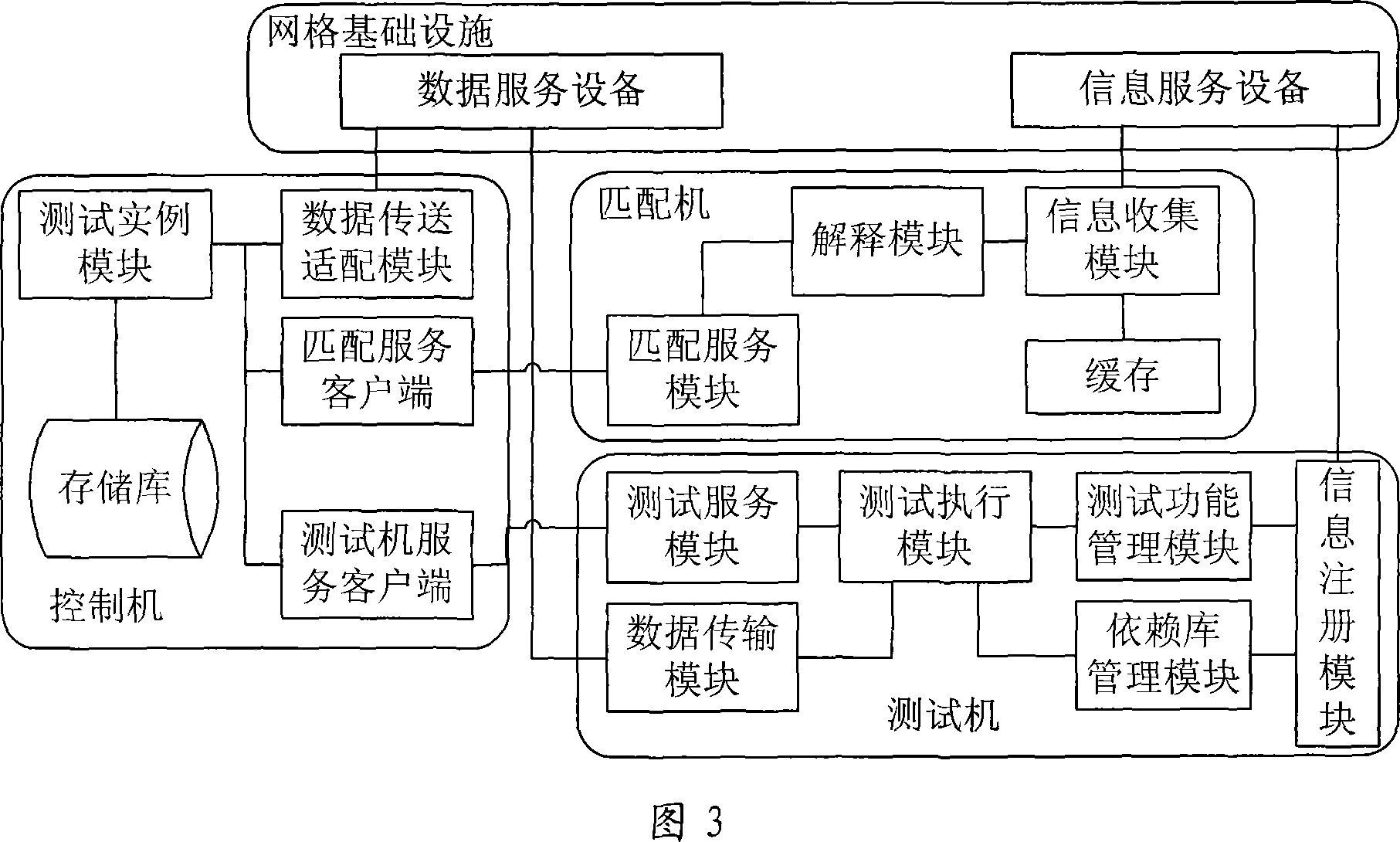

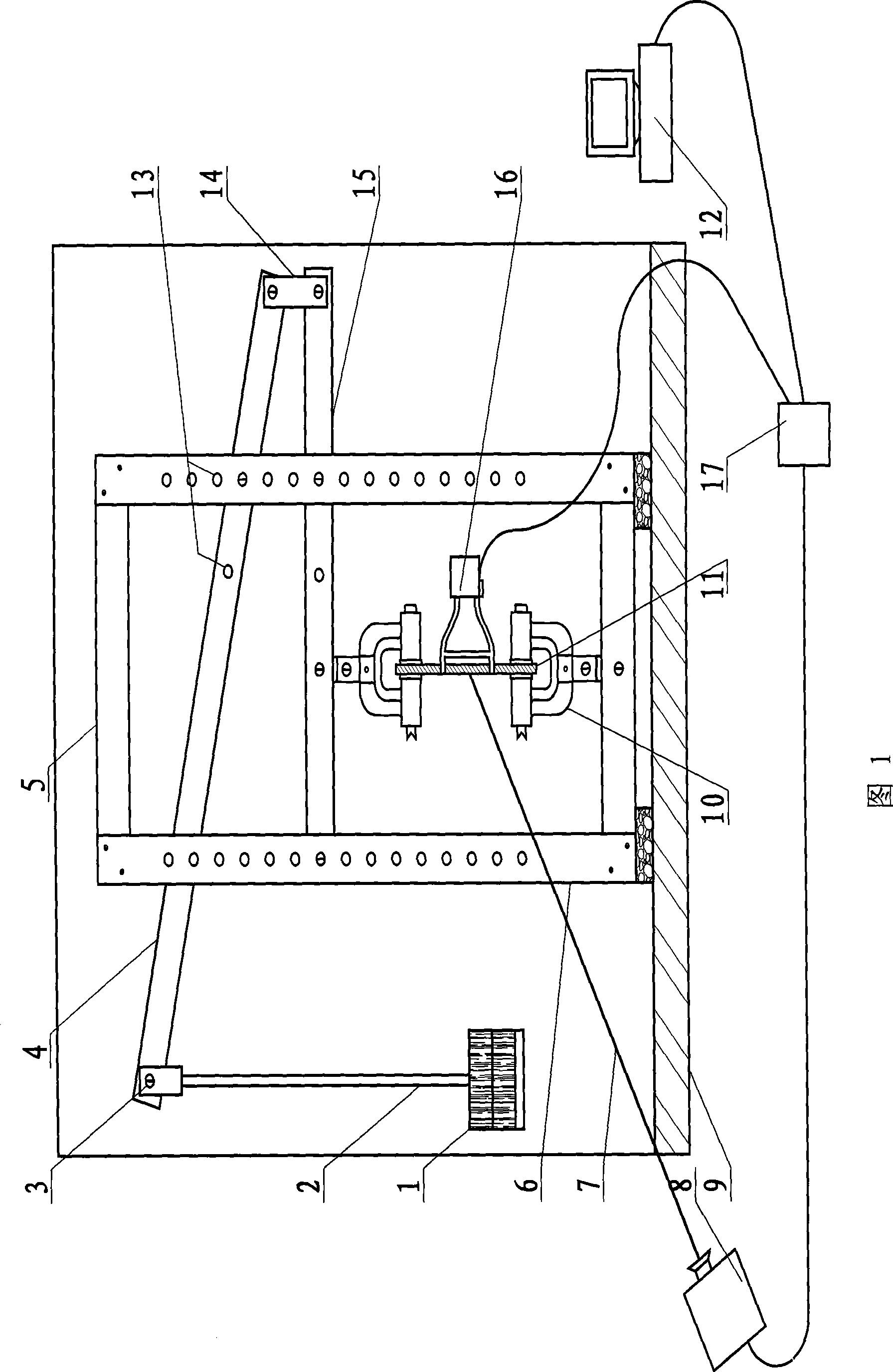

Software testing system and testing method

InactiveCN101042673ALower acquisition costsReduce maintenance costsSoftware testing/debuggingMatching testTest efficiency

This invention relates to one software test method, which comprises the following steps: analyzing test leg and establishing test sample; accordingly getting the test data; processing test machine according to the match; according to the match result fixing test environment; executing test spot and collecting test record and dismantling the test environment. This invention software test system comprises the following parts: control machine to analyze test leg and to establish test sample to adjust test machine and to send the data into the test machine fix environment and to record result and to collect test data according to the orders; match machine to match needed machines; test machine is to fix environment and to send order for relative aim.

Owner:BEIHANG UNIV

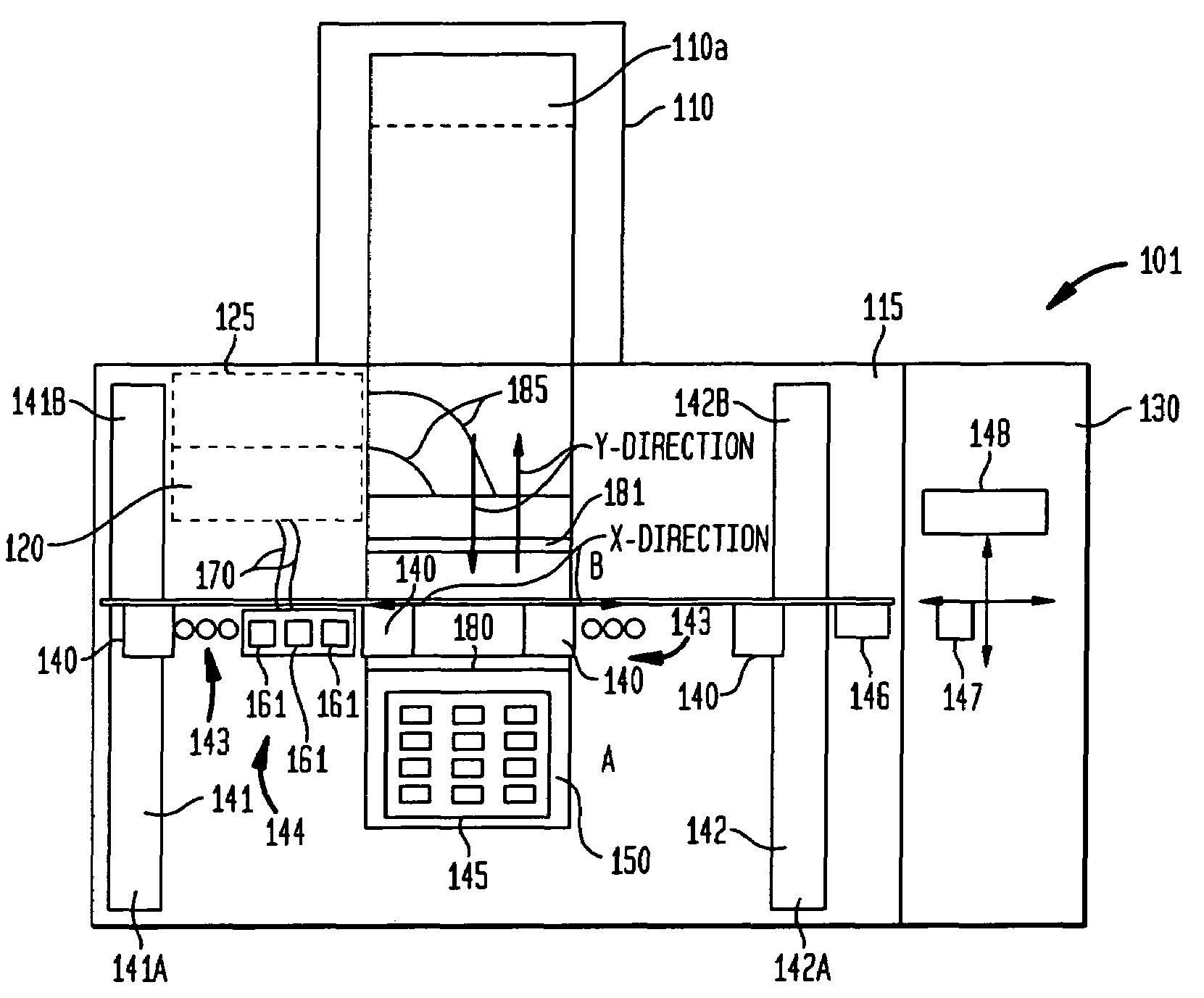

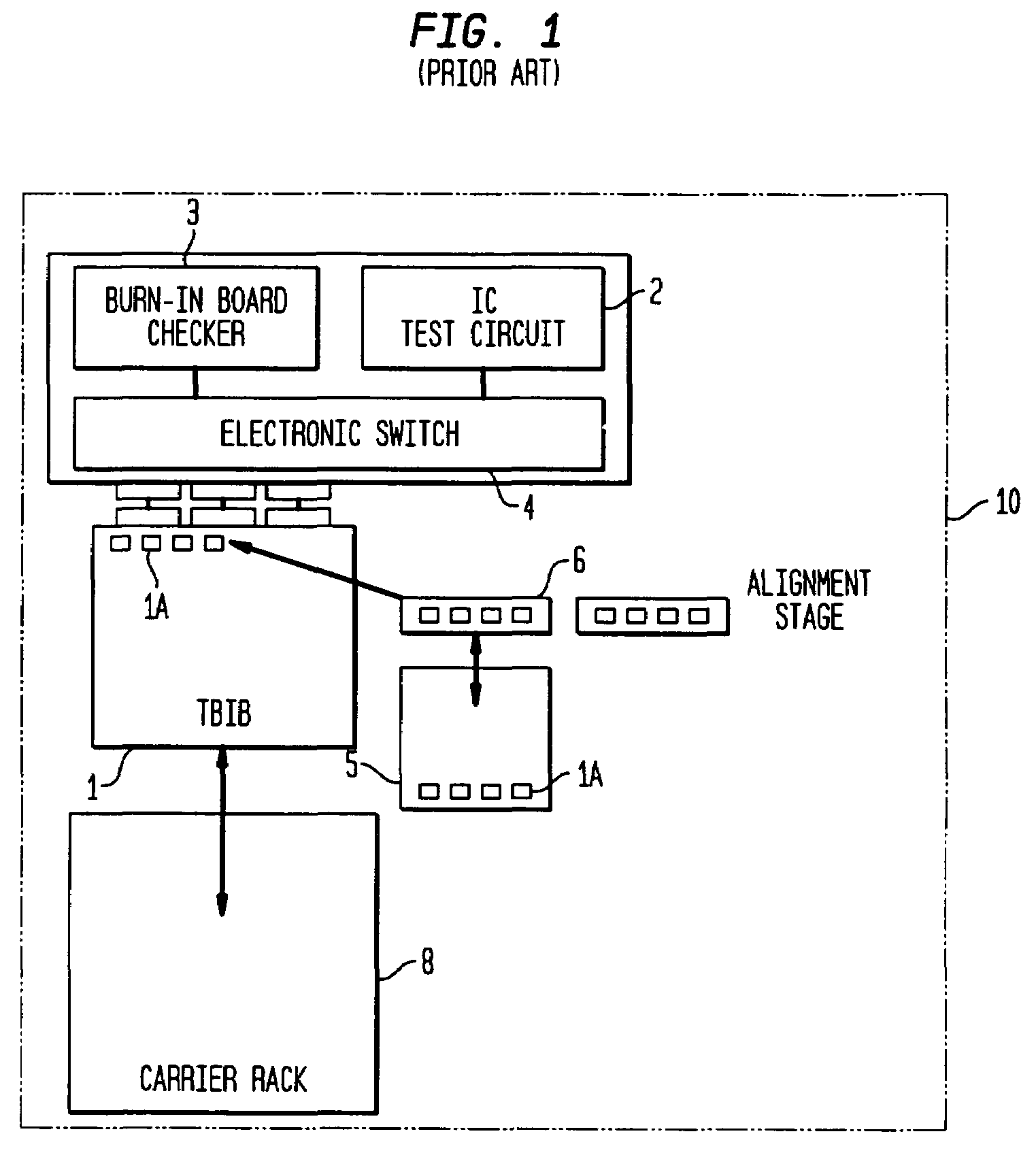

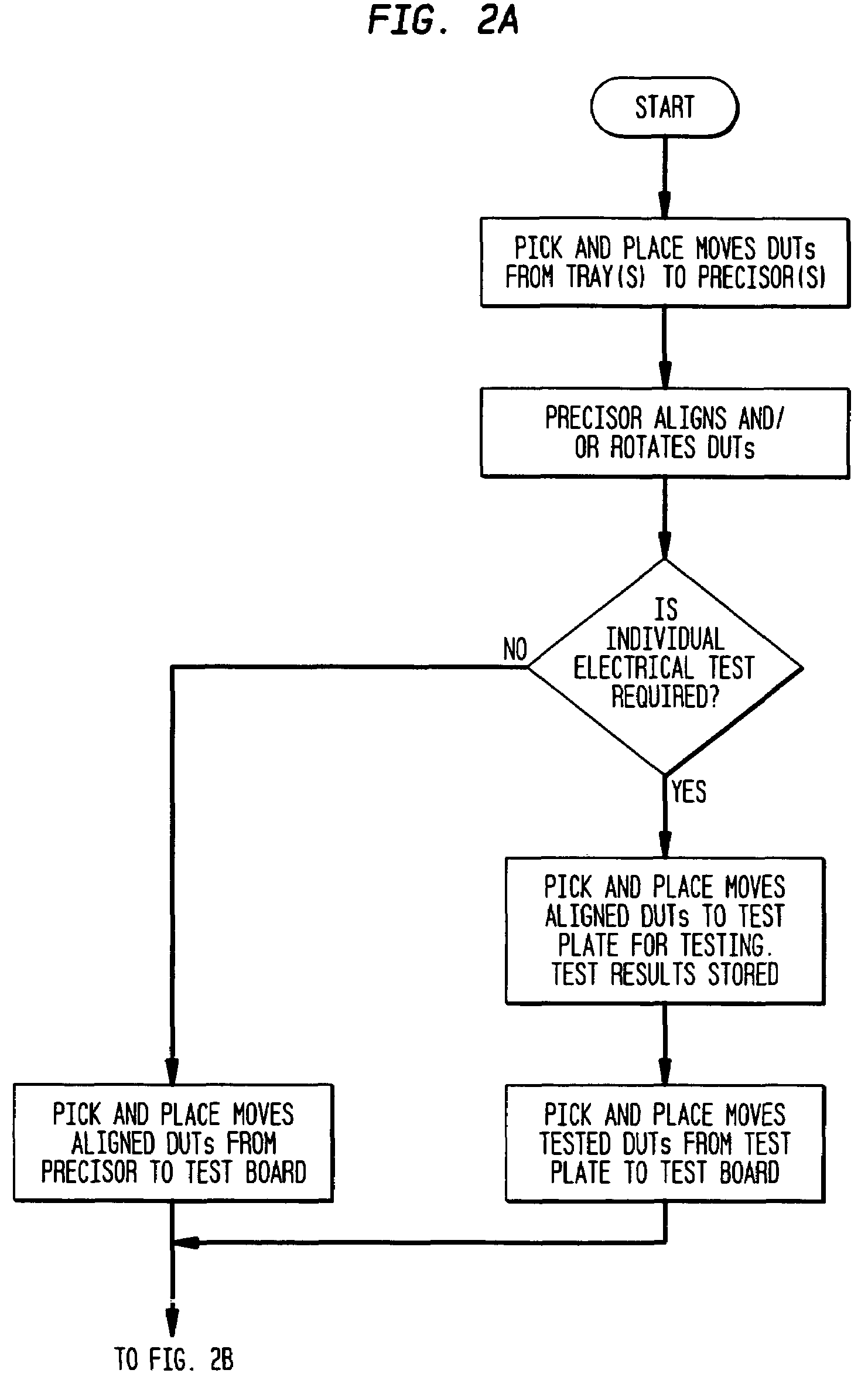

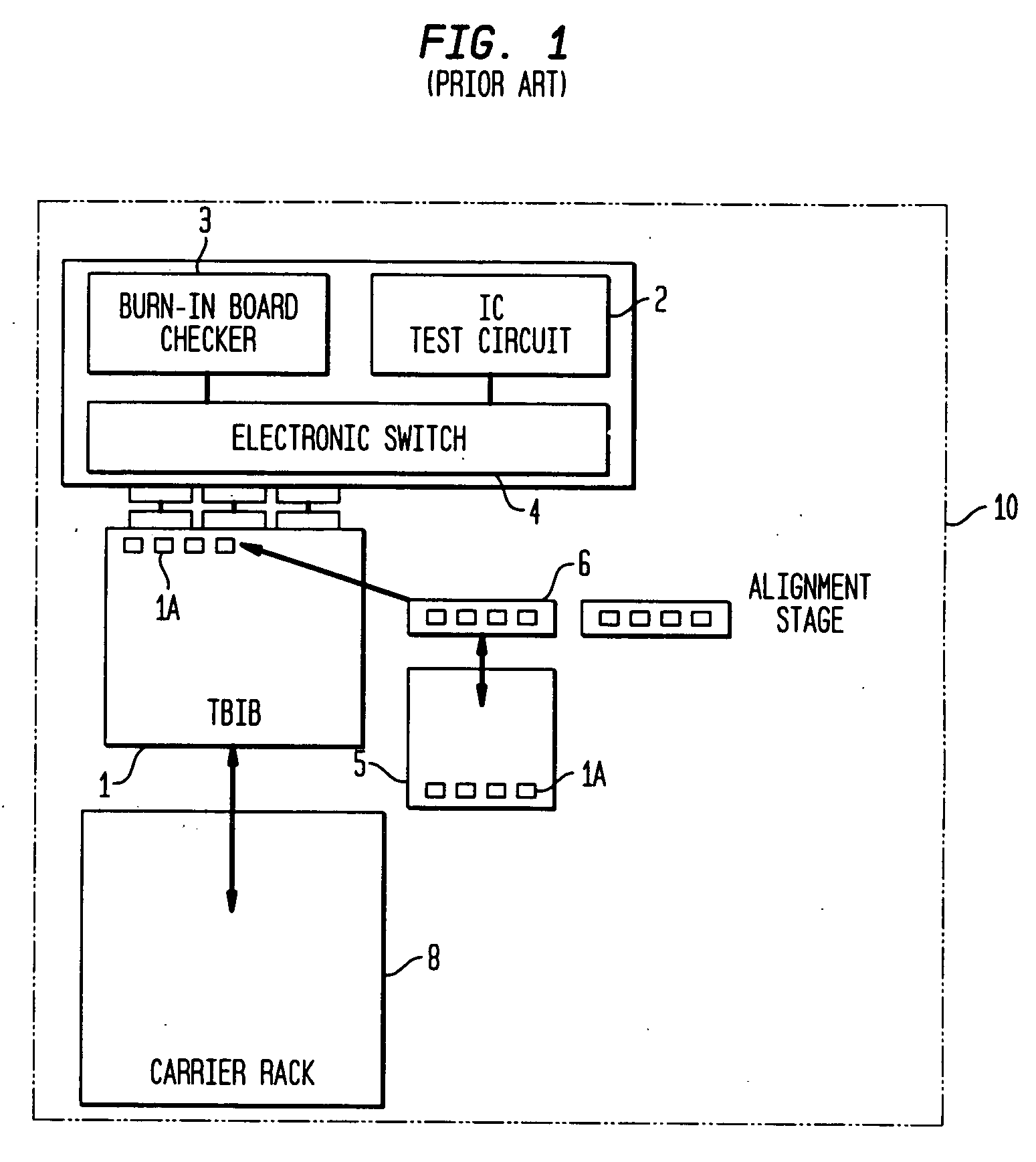

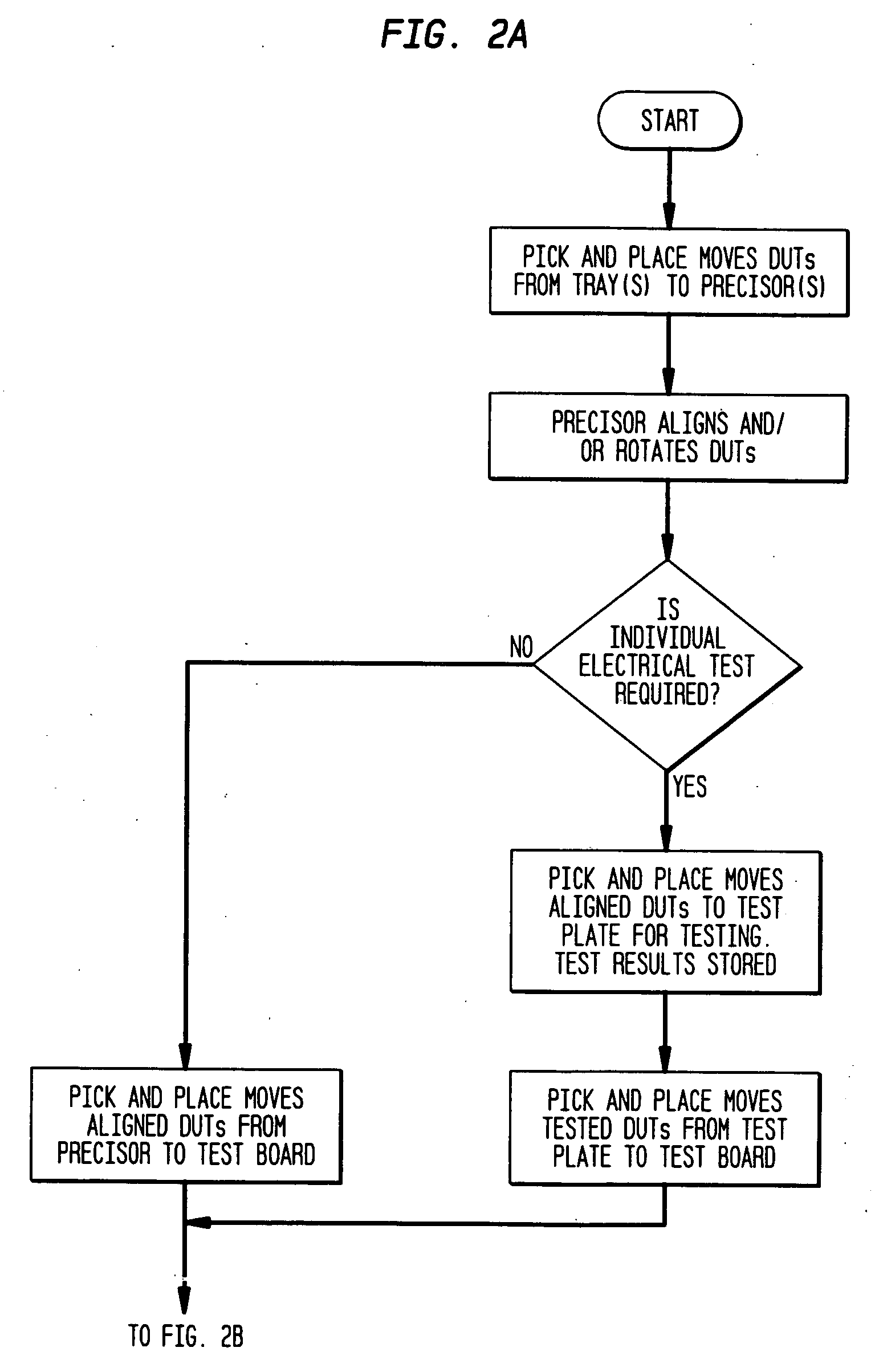

Method for testing semiconductor devices and an apparatus therefor

InactiveUS7151388B2Good flexibilityEfficient loadingSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsElectricityEngineering

A method for testing integrated circuit devices and loading such devices into a test board for further testing and an apparatus therefor is disclosed. The method allows for selection between two modes of operation. In a first mode, the integrated circuit devices are subjected to an electrical test before being placed into the test board for further testing. In a second mode, the integrated circuit devices are tested after being placed in the test board. The apparatus allows for the selection between the first mode and the second mode. In either mode, information about the tested devices and the sockets in the test board is used to load the test boards intelligently. Intelligent loading means that devices under test (DUTs) are not placed in bad sockets and devices that do test bad are removed from the test board, with an option of replacing the failed DUT with another DUT before subsequent environmental testing of the DUTs in the test board is carried out.

Owner:KES SYST

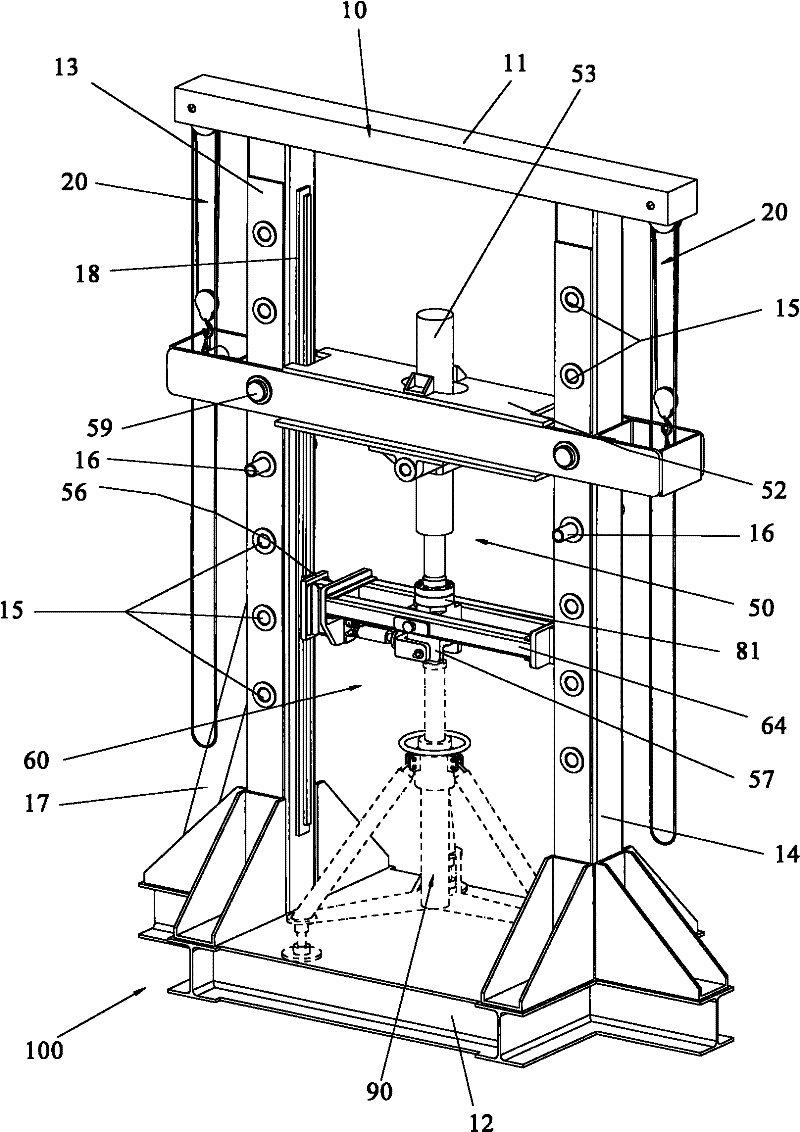

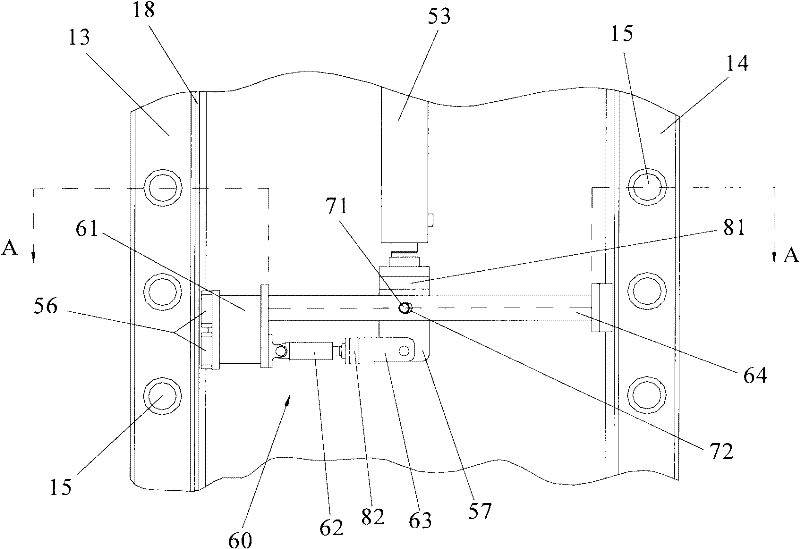

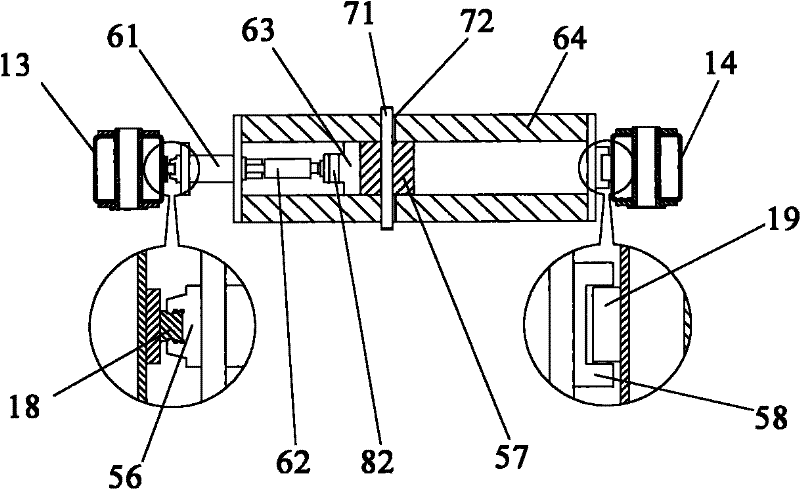

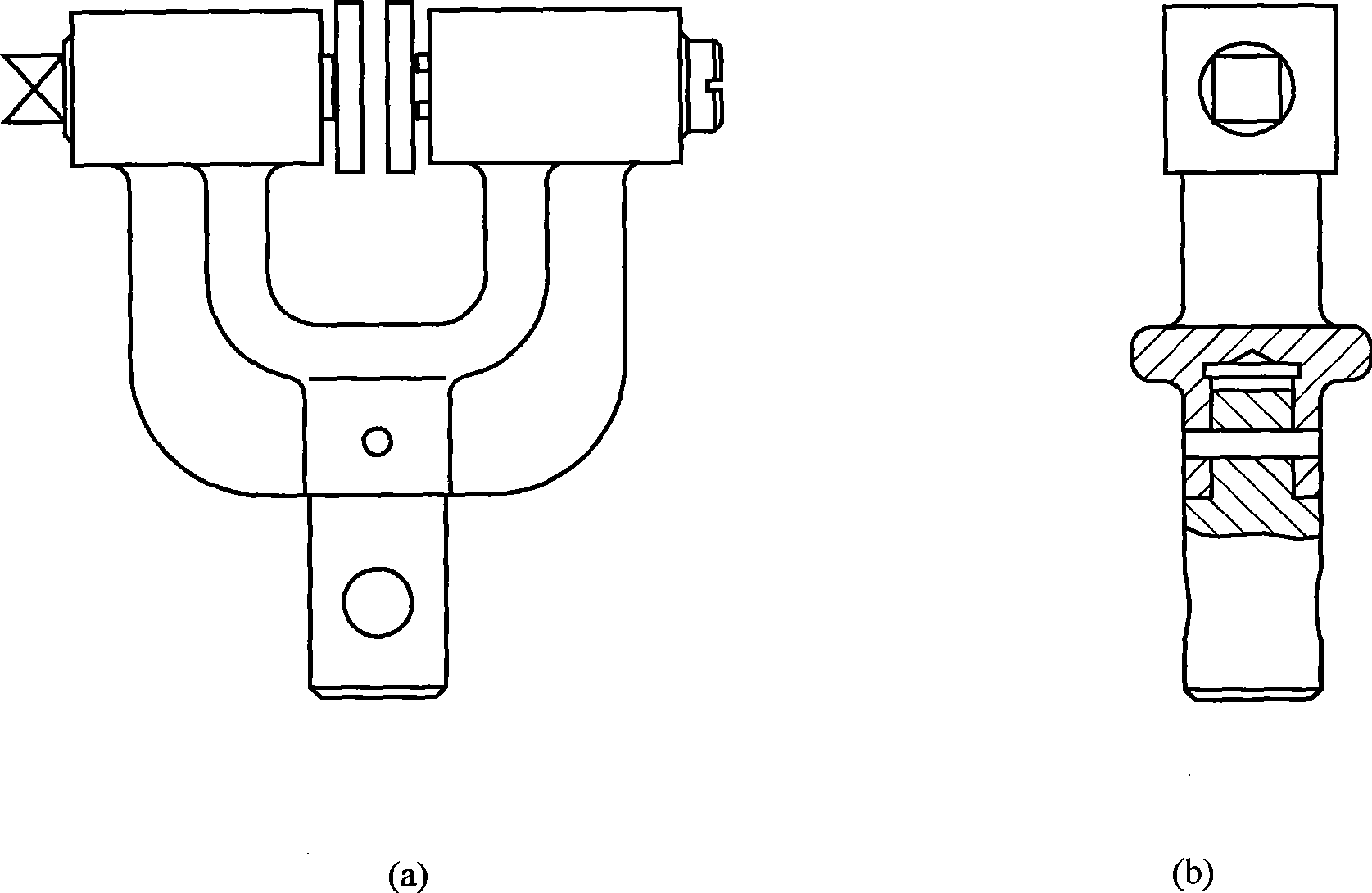

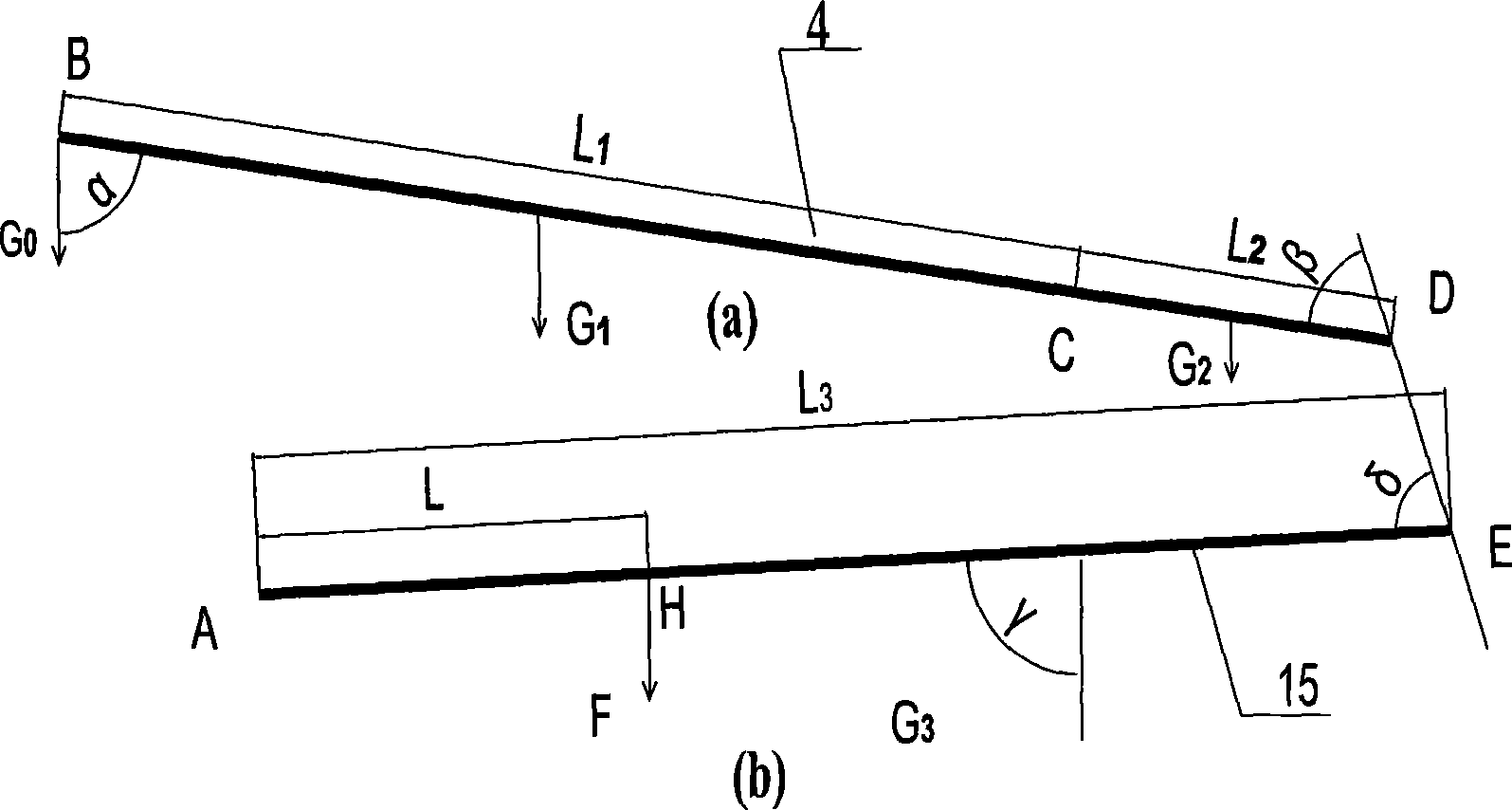

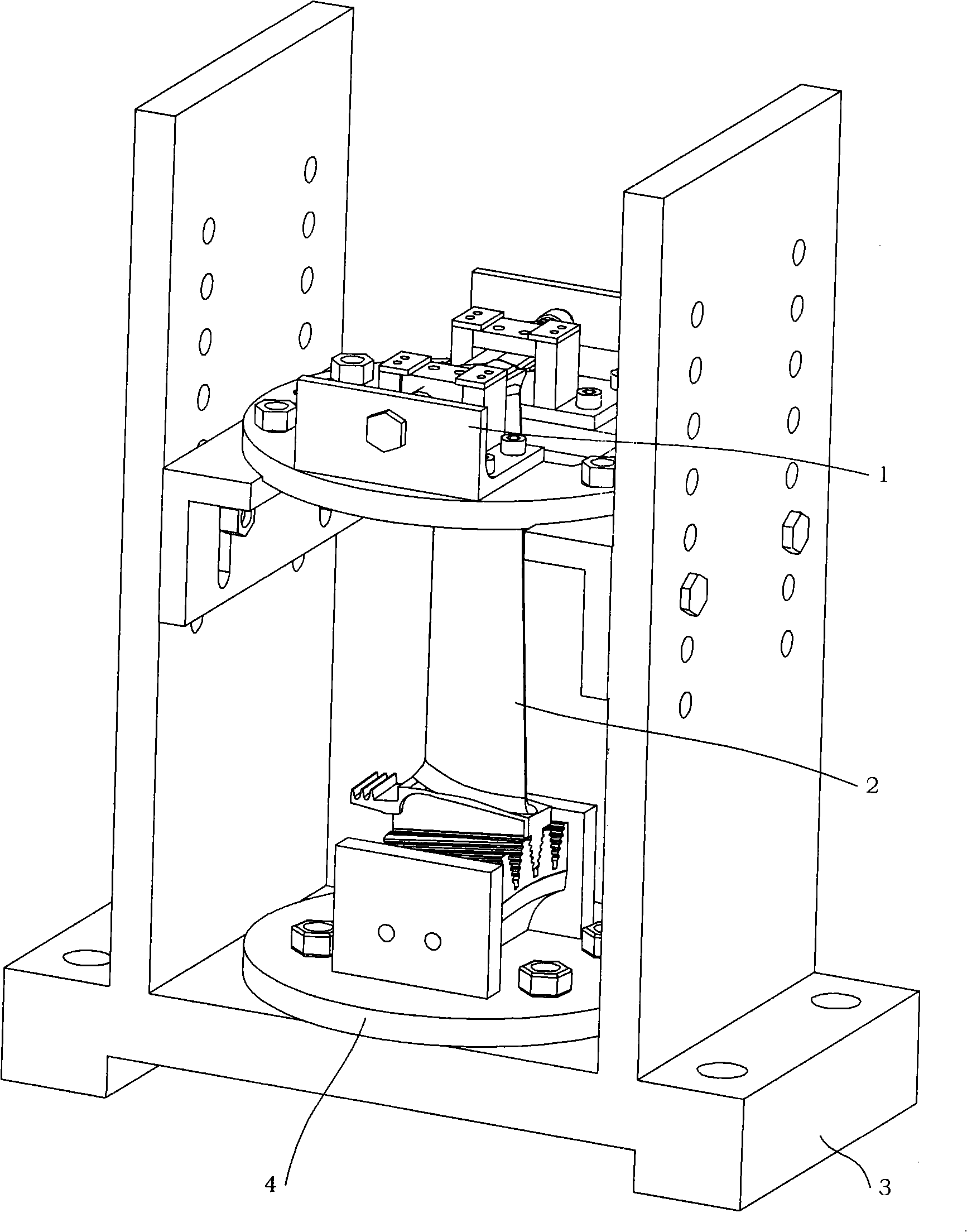

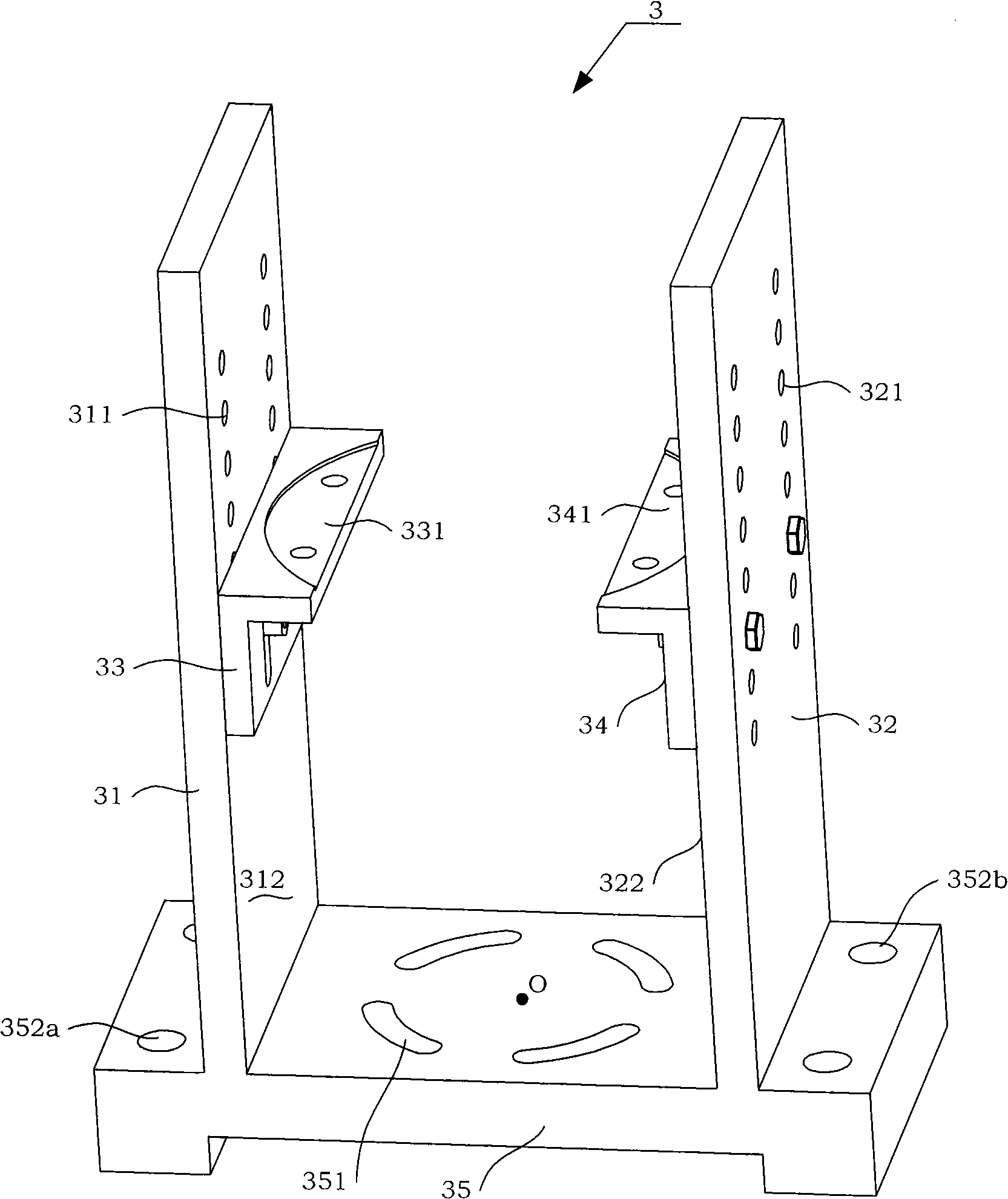

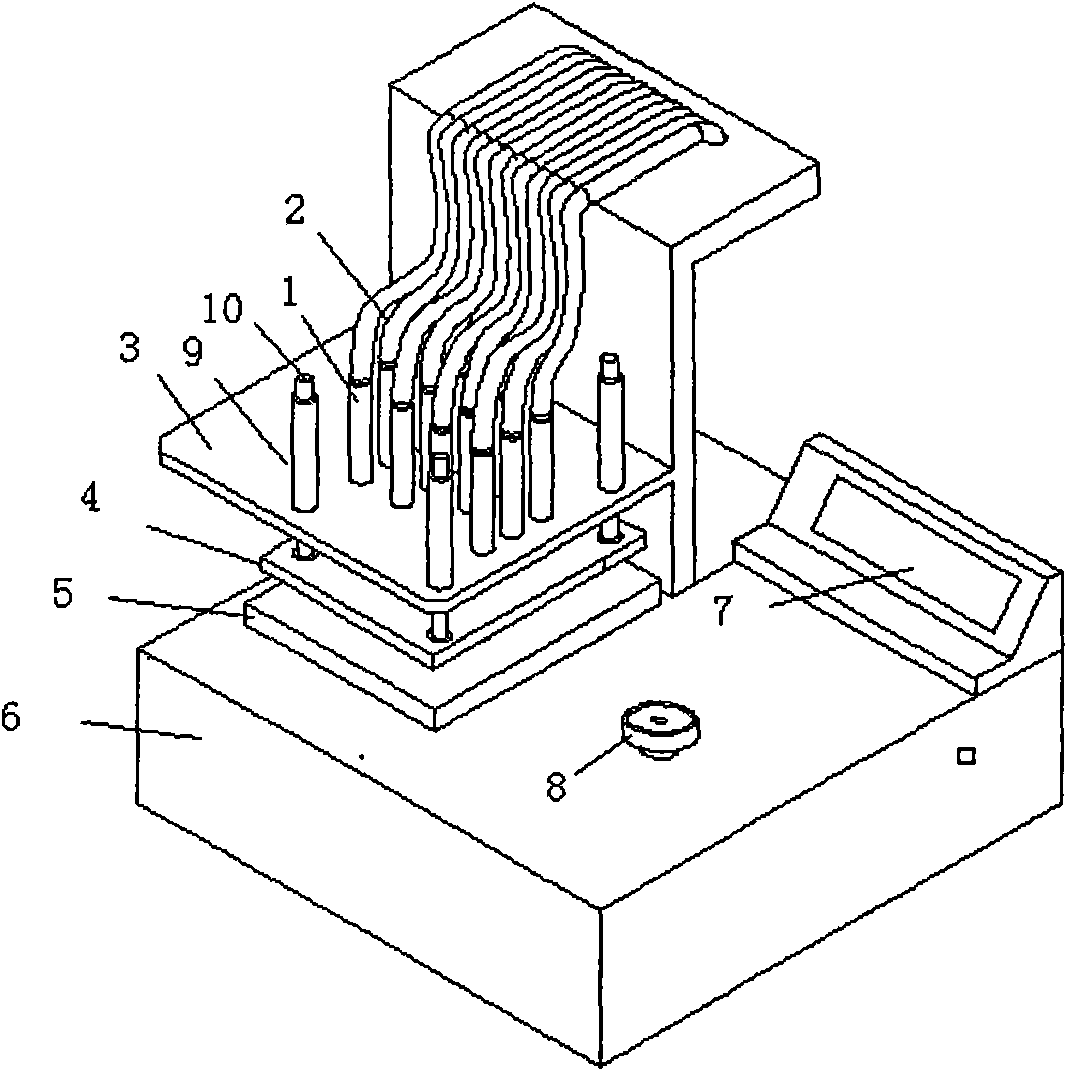

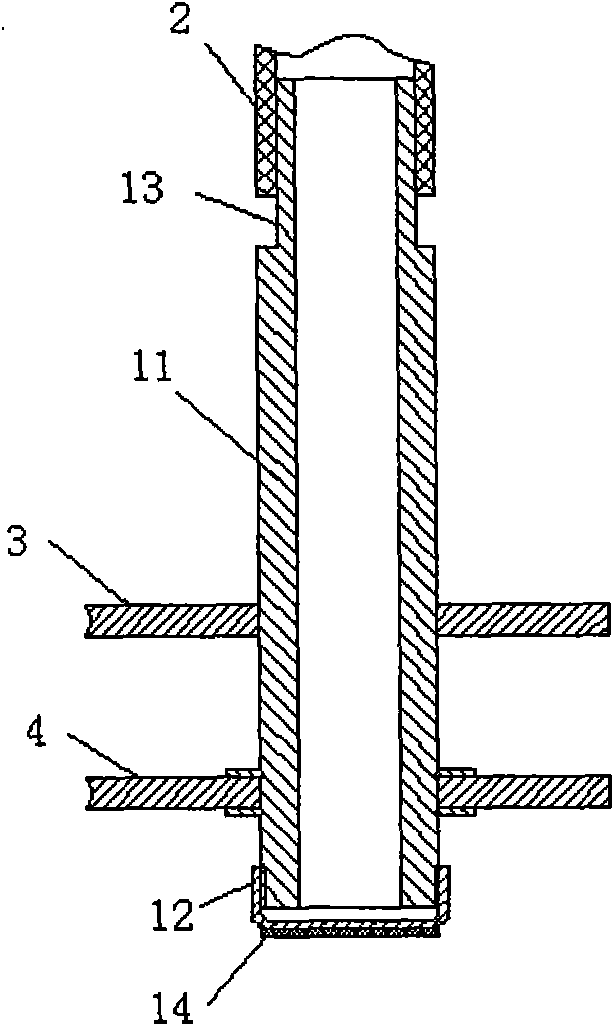

Loading test device

ActiveCN102235943ANo tiltNo stickingStructural/machines measurementEngineeringMechanical engineering

Owner:COMAC +1

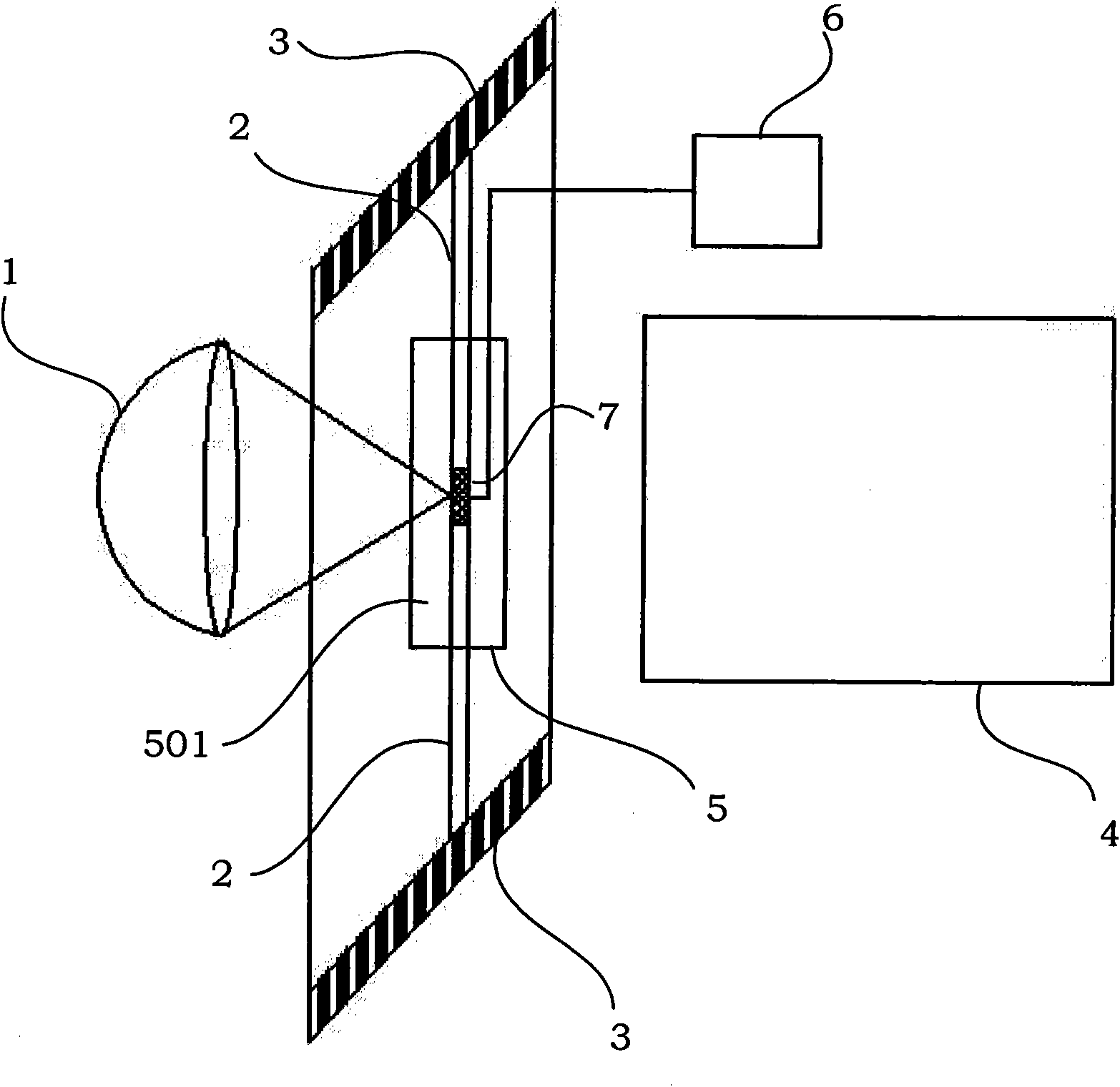

Test device for surface deformation and material and test method thereof

InactiveCN101672749AHeating up fastFast mechanical loadingMaterial strength using tensile/compressive forcesUsing optical meansOptical testStrength of materials

The invention discloses a test device for surface deformation of a material and a test method thereof, wherein the device comprises a material mechanical property test machine, an infrared fast heating device, a surface deformation optical test system, a temperature collecting device, a vacuum system and a clamp. The clamp fixes a sample in a vacuum chamber of the vacuum system and is connected with the material mechanical property test machine, the infrared fast heating device supplies thermal load for the sample, and the surface deformation optical test system measures the surface deformation of the sample. The device and the test method can simultaneously heat, apply stress and synchronously test deformation field in the surface. The coupling simulation of an aero-engine under service environment with high temperature and loading level, and the surface deformation condition of the structural material with high temperature under the environment are tested.

Owner:BEIHANG UNIV

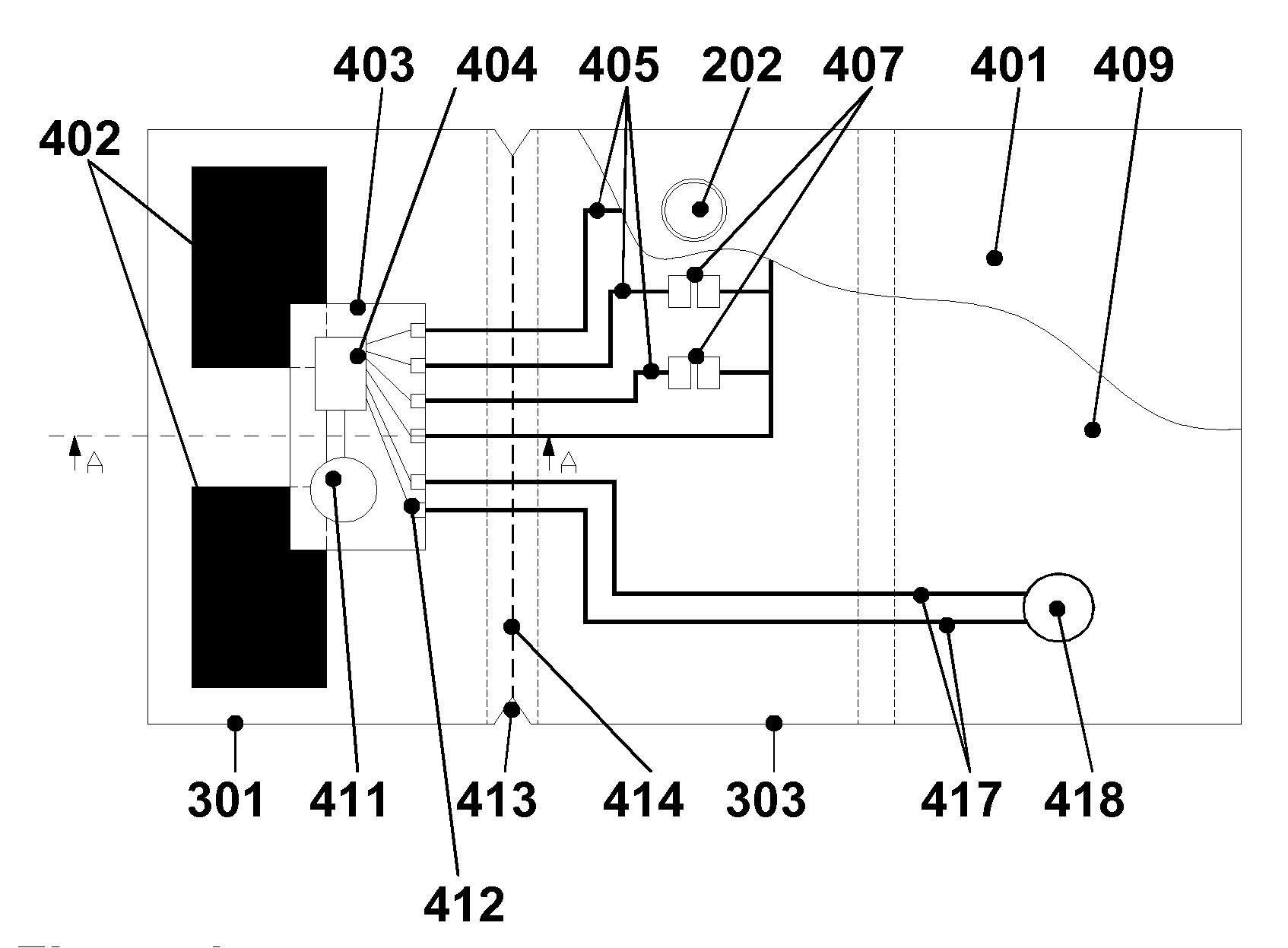

Method for testing semiconductor devices and an apparatus therefor

InactiveUS20060066293A1Good flexibilityEfficient loadingSemiconductor/solid-state device testing/measurementElectronic circuit testingElectricityEngineering

A method for testing integrated circuit devices and loading such devices into a test board for further testing and an apparatus therefor is disclosed. The method allows for selection between two modes of operation. In a first mode, the integrated circuit devices are subjected to an electrical test before being placed into the test board for further testing. In a second mode, the integrated circuit devices are tested after being placed in the test board. The apparatus allows for the selection between the first mode and the second mode. In either mode, information about the tested devices and the sockets in the test board is used to load the test boards intelligently. Intelligent loading means that devices under test (DUTs) are not placed in bad sockets and devices that do test bad are removed from the test board, with an option of replacing the failed DUT with another DUT before subsequent environmental testing of the DUTs in the test board is carried out.

Owner:KES SYST

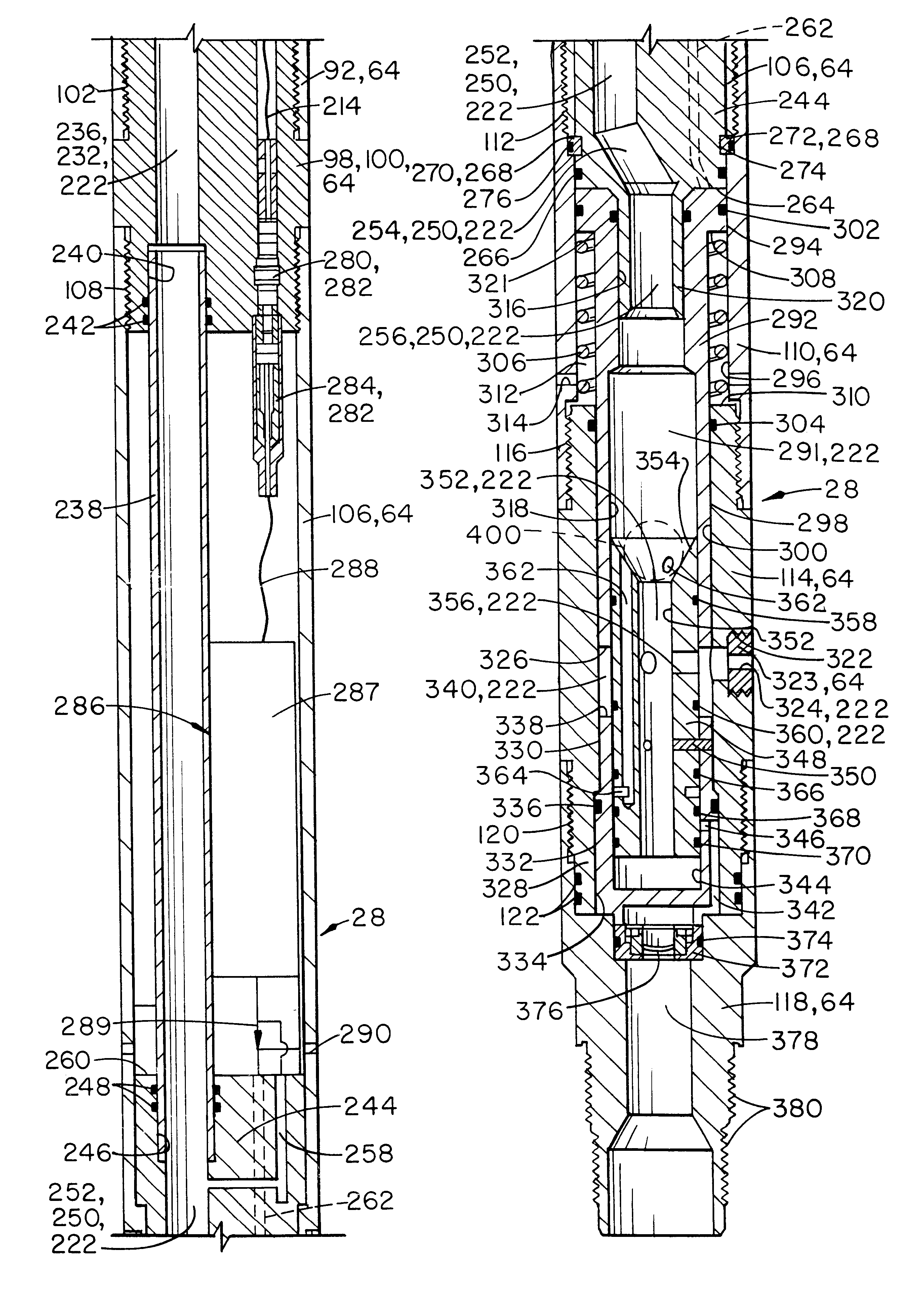

Wireless coiled tubing joint locator

A wireless coiled tubing joint locator for locating joints or collars in a production tubing string. An electromagnetic coil assembly or giant magnetoresistive digital field sensor senses the increased mass of a pipe joint, and provides a signal to an electric circuit which generates a signal received by a pilot solenoid valve. The solenoid valve momentarily opens a pilot passageway which activates a piston to close a circulation port in the joint locator, resulting in an increase in a surface pressure reading observable by the operator. In one embodiment, a rupture disk is provided so that pressure cannot be applied to any downhole tool below the joint locator prematurely. A seat sleeve prevents premature communication of fluid to the rupture disk but can be opened by dropping a ball into the joint locator. A second embodiment may be used for either logging or washing operations or both. The electronic circuit can provide a selected one of a plurality of time delays. A fixed test period in the circuit delays activation of the time delay so that the joint locator may be tested before it is run into the well. The electric circuit and power supply are provided in a removable case.

Owner:HALLIBURTON ENERGY SERVICES INC

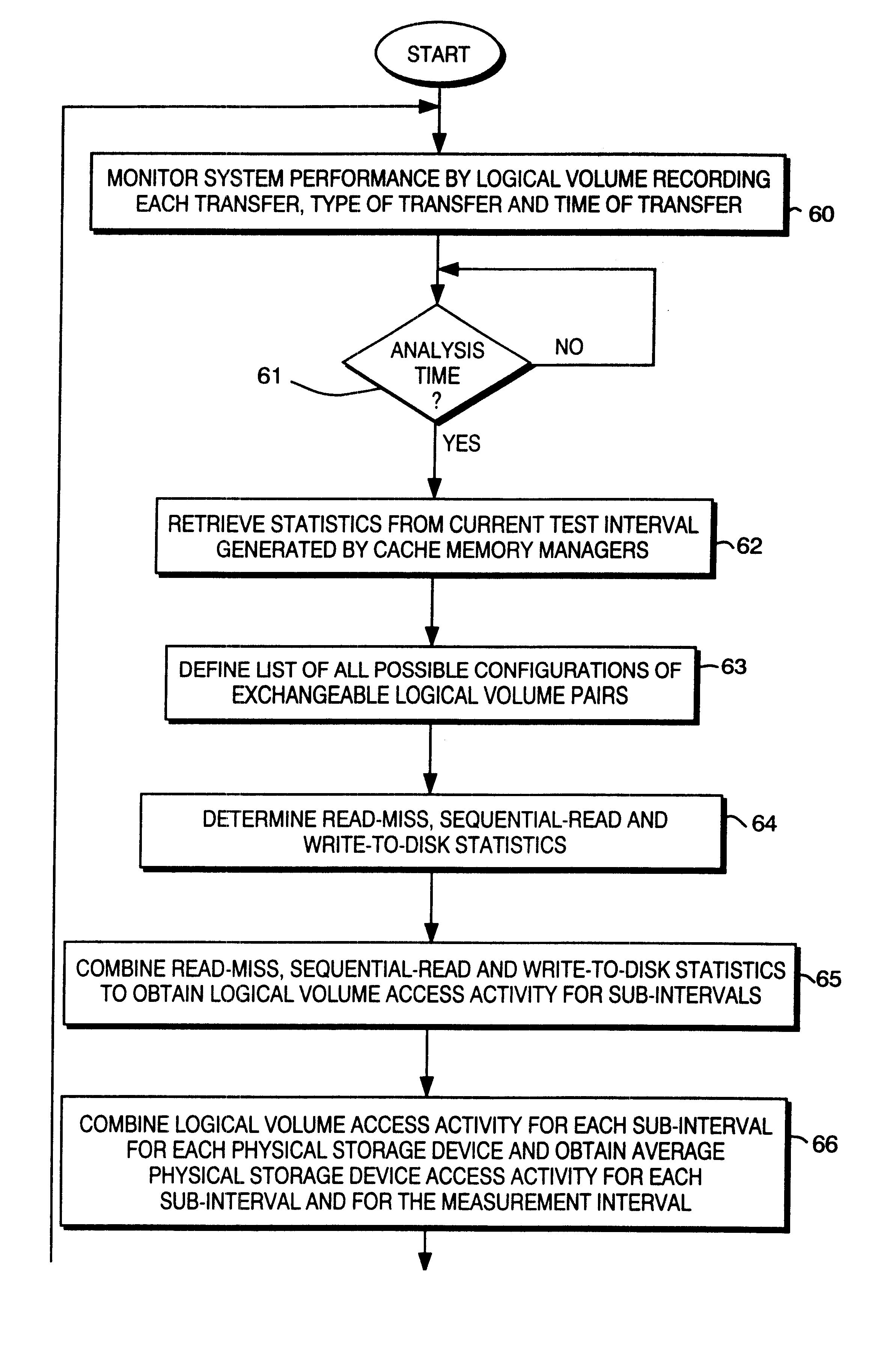

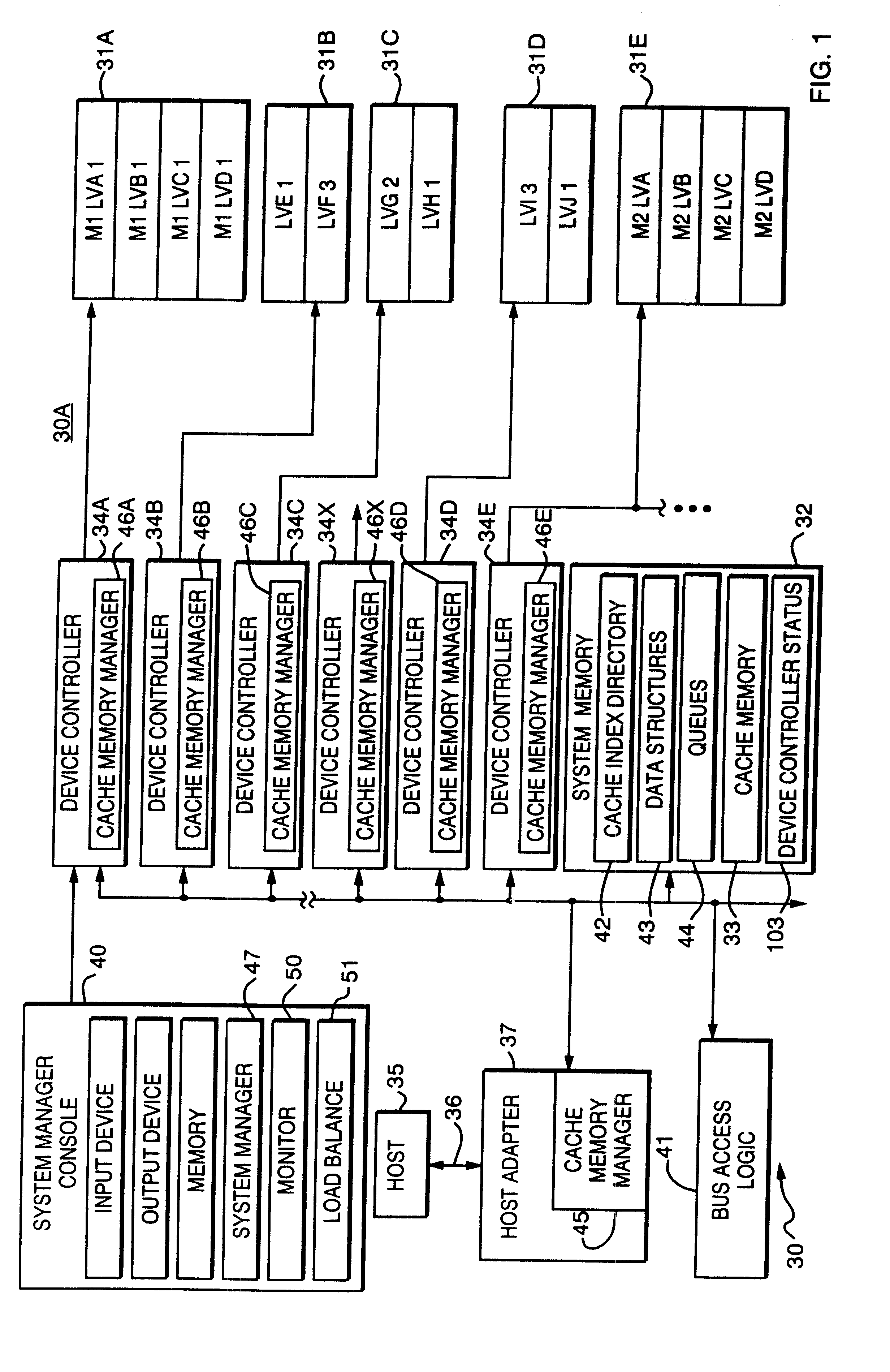

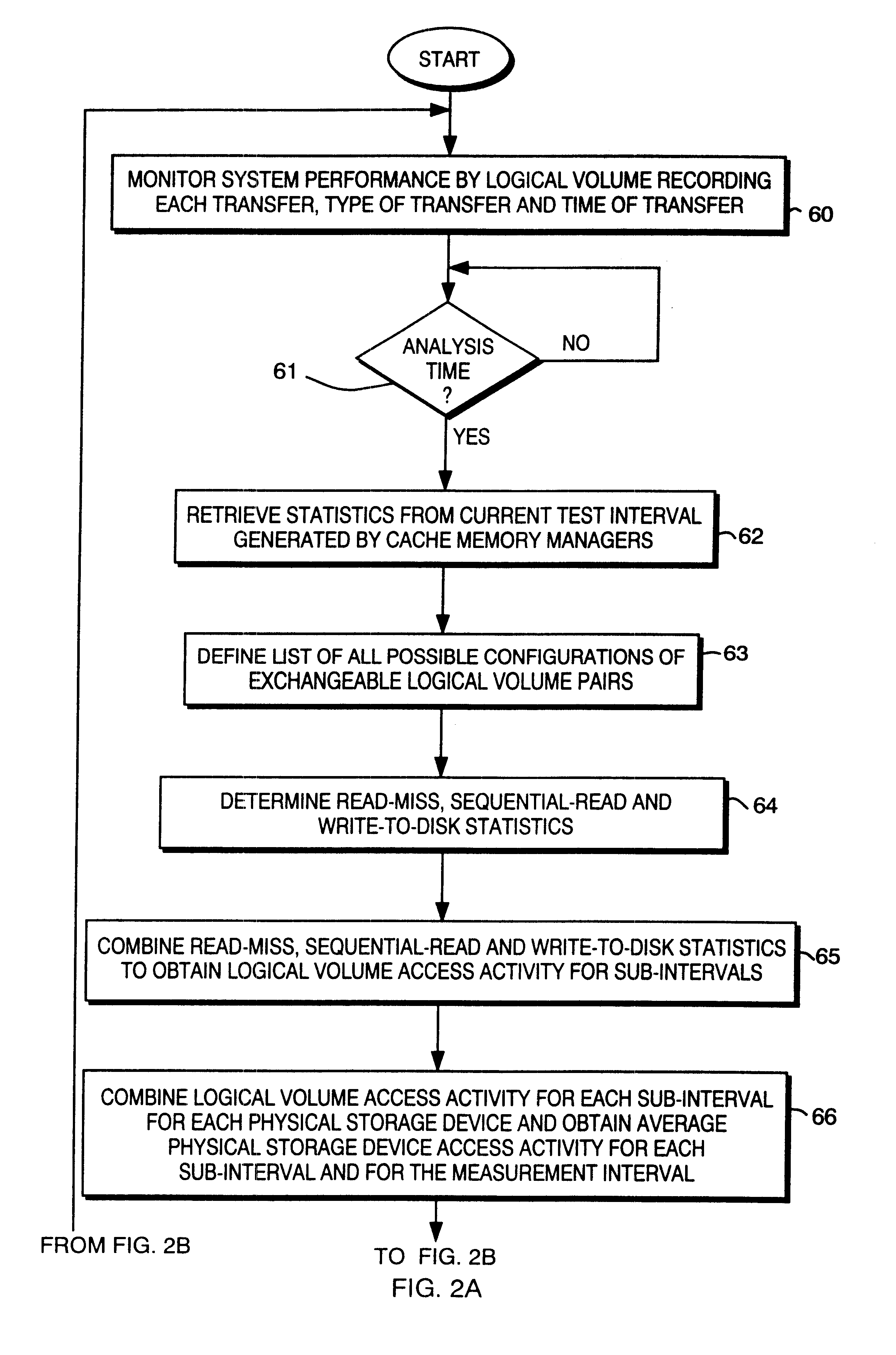

Maximizing sequential output in a disk array storage device

InactiveUS6442650B1Reduce imbalanceLoad balancingInput/output to record carriersMemory adressing/allocation/relocationData transmission timeDisk array

Load balancing of activities on physical disk storage devices is accomplished by monitoring reading and writing operations to blocks of contiguous storage locations on the physical disk storage devices. A list of exchangeable pairs of blocks is developed based on size and function. Statistics accumulated over an interval are then used to obtain access activity values for each block and each physical disk drive. These activities are represented as disk seek, latency and data transfer times. A statistical analysis leads to a selection of one block pair. After testing to determine any adverse effect of making that change, the exchange is made to more evenly distribute the loading on individual physical disk storage devices.

Owner:EMC IP HLDG CO LLC

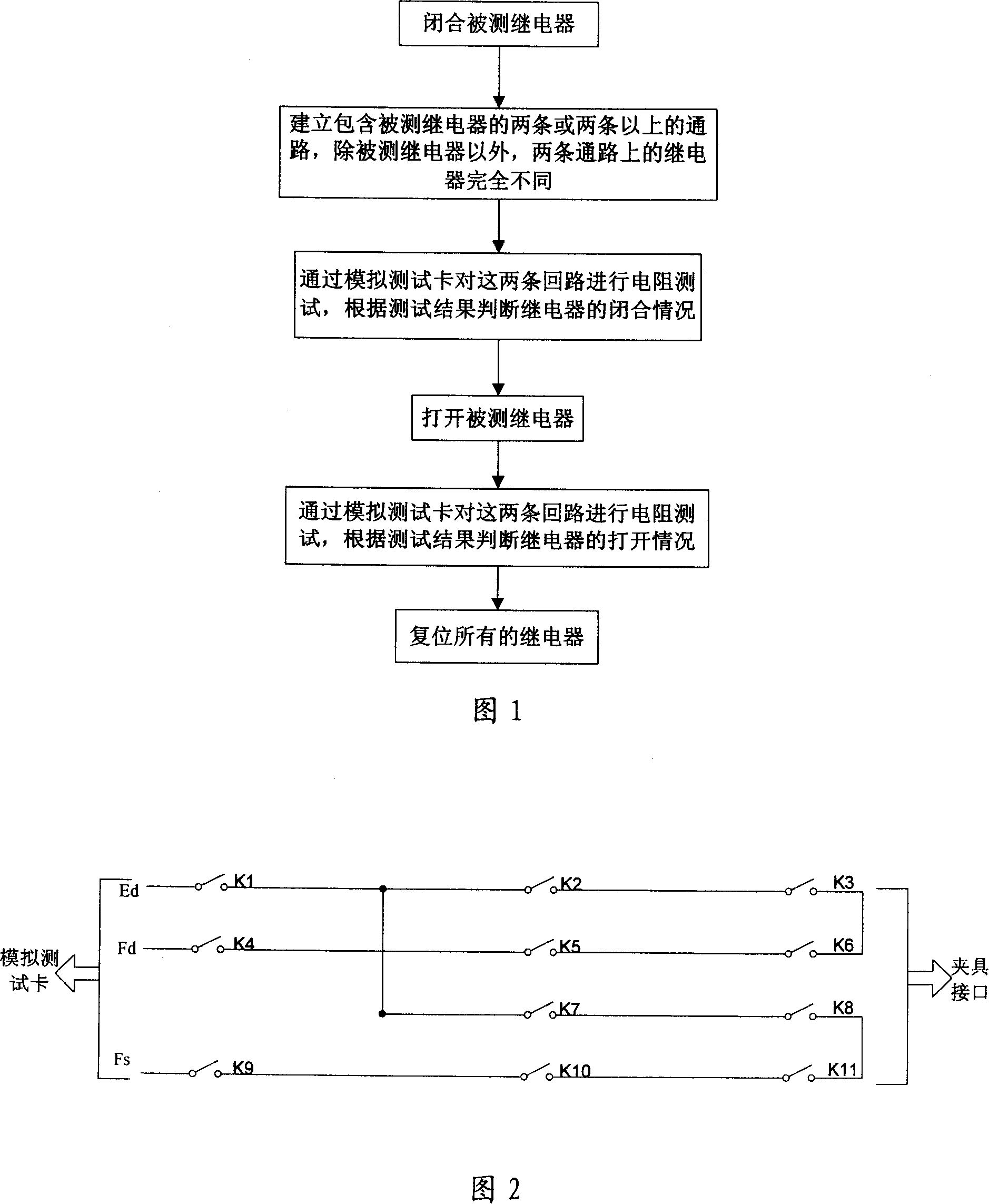

Relay test method for on-line testing instrument

ActiveCN101071158ADoes not affect judgmentReduce misjudgmentCircuit interrupters testingClosed loopTester device

This invention discloses an online Meter Relay testing method, including the following steps: the establishment of the redundancy tested Relay access, namely the establishment of a number of pathways, in addition to the measured relay, the relay through each pathway are totally different. Under the circumstances the relay damaged in one pathway, another pathway formed closed-loop, continue to test. The invention method used at least two relays because of a closed-loop access, to test. Iif the two access roads are in good condition and do not affect the judgment of the measured relay, even though one access road has problems, another pathway can still guarantee test loop . Compared with the existing technology, the invention has been greatly reduced wrong judgment because of the other relay pathway damage, can rapidly and accurately positioning of Relay, and reduce the time to maintain DRC card relay.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

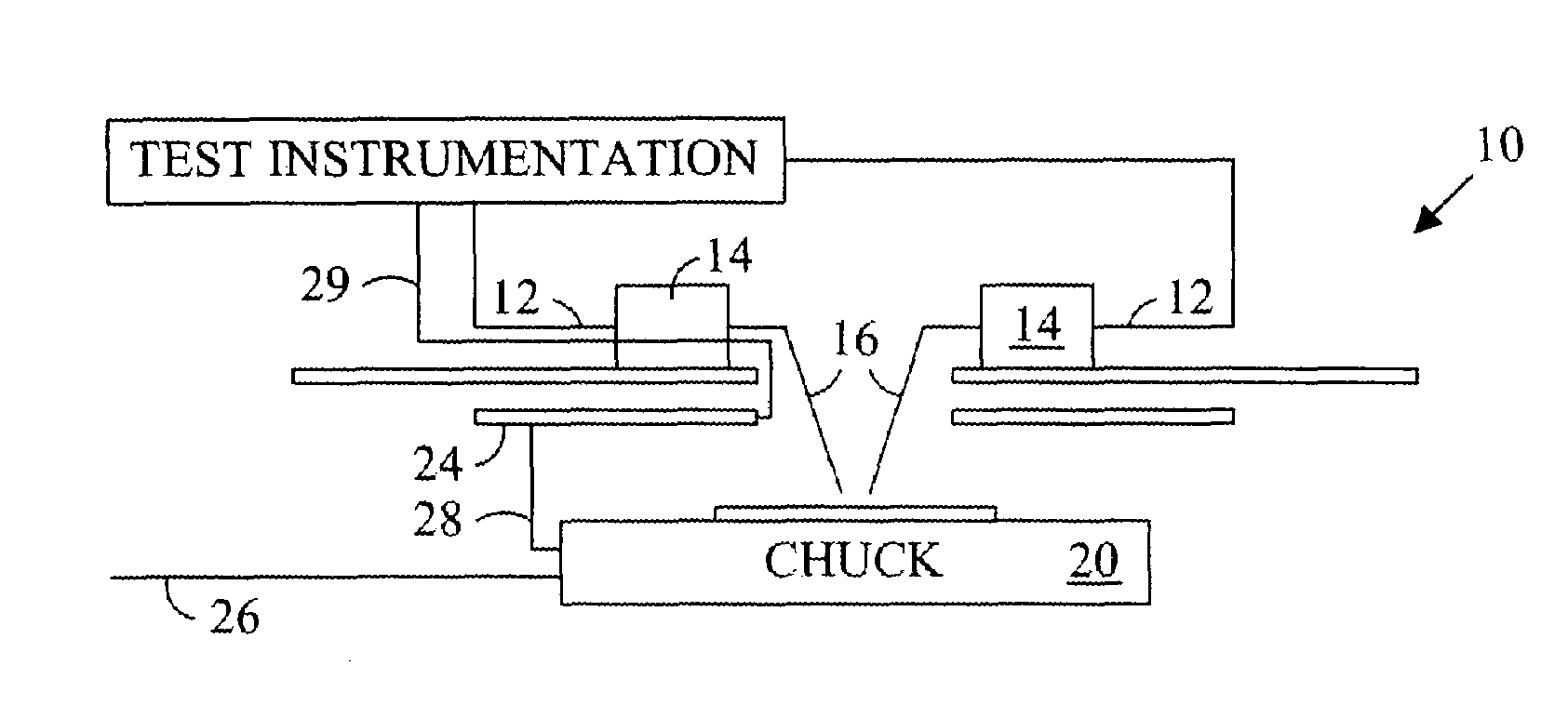

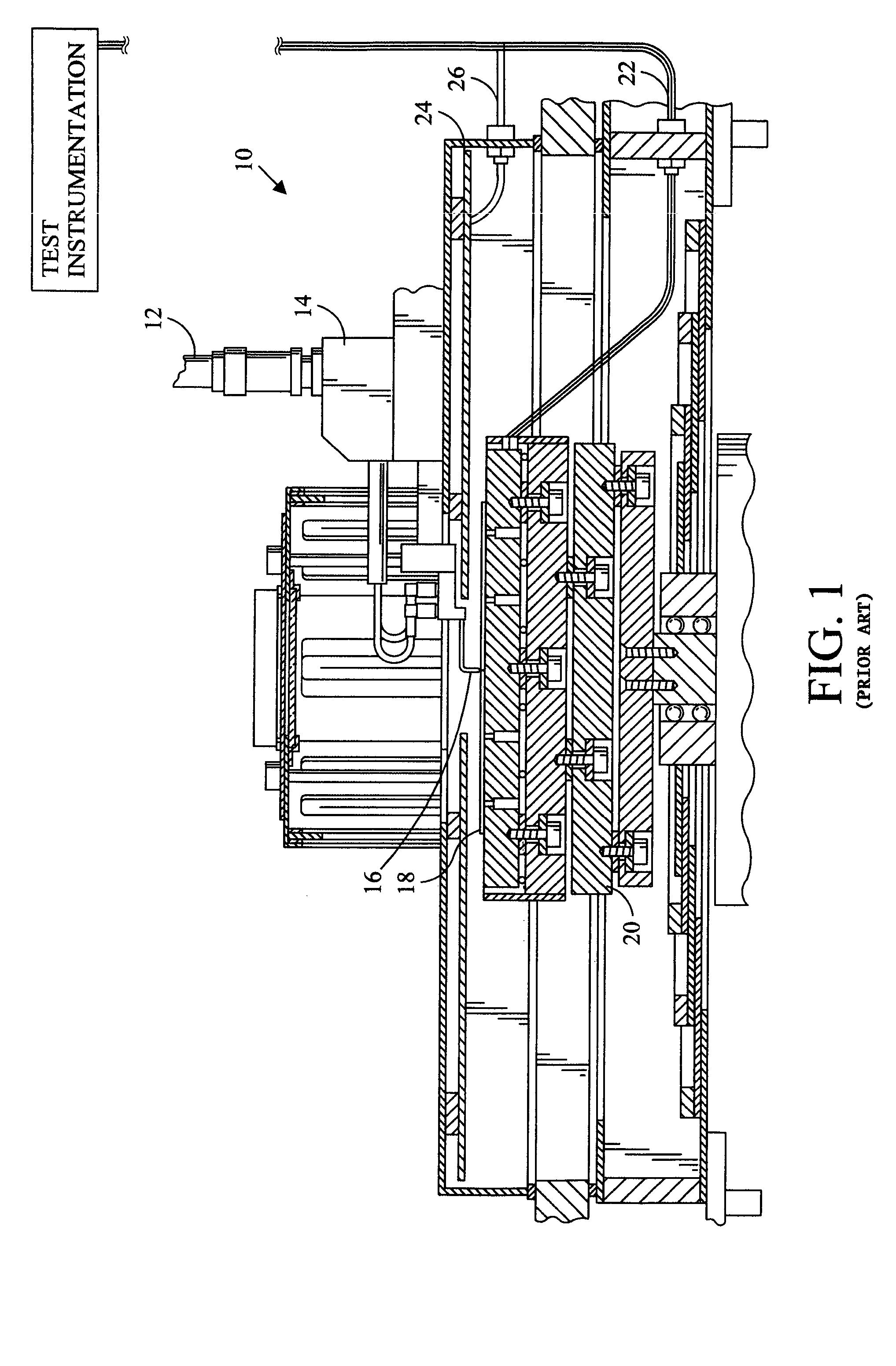

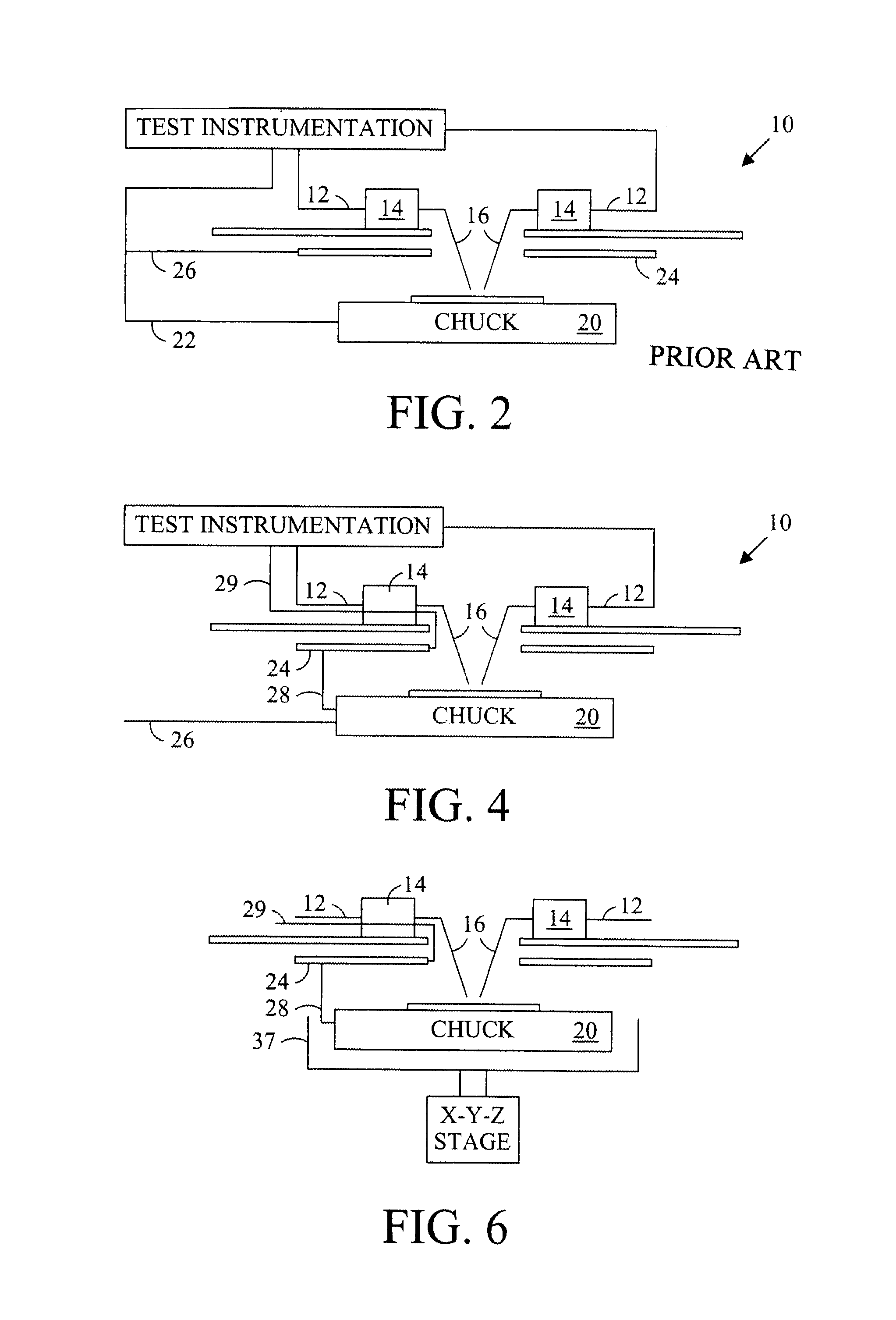

Probe station with low inductance path

InactiveUS7250779B2Electrical measurement instrument detailsContactless circuit testingTest measurementElectrical devices

A probe assembly suitable for making test measurements using test signals having high currents. The disclosed probe assembly provides for a test signal exhibiting relatively low inductance when compared to existing probe assemblies by preferably reducing the electrical path distance between the test instrumentation and the electrical device being tested.

Owner:FORMFACTOR INC

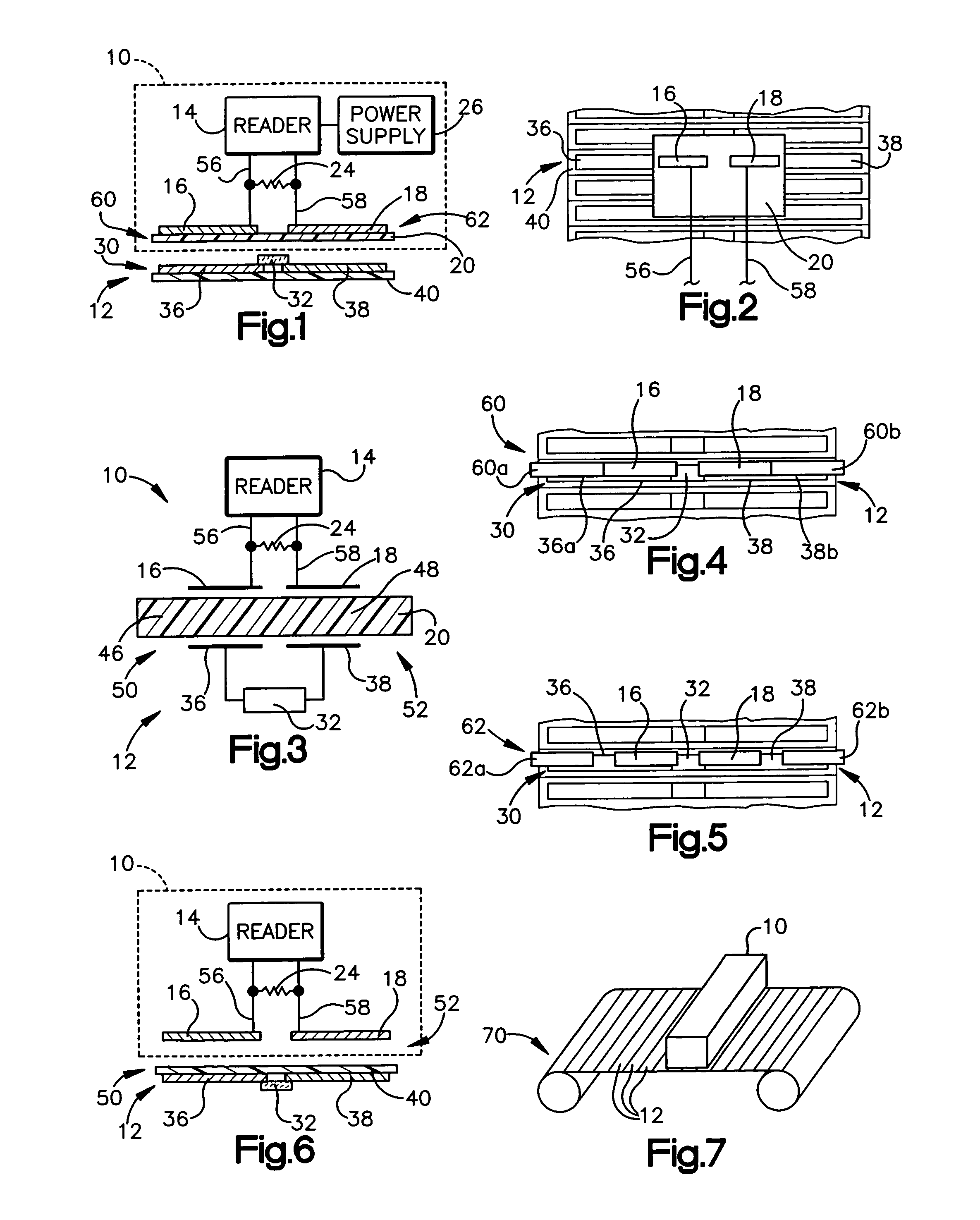

RFID device tester and method

InactiveUS7306162B2Ticket-issuing apparatusTesting sensing arrangementsCapacitanceCapacitive coupling

Owner:AVERY DENNISON CORP

Aging test method and apparatus under wet, heat and power multiple-field coupling

InactiveCN101435811AImplement burn-in testingTest accurateWeather/light/corrosion resistanceMulti fieldData acquisition

The invention relates to an aging test method and an aging test device under the multi-field coupling of humidity, heat and force. The method is used for testing polymer materials and test specimens produced by composite materials of the polymer materials, and the test is based on the dynamic monitoring to the tensile creep compliance of the materials under the multi-field coupling of the humidity, the heat and the force. The device is based on a standard humid and hot environmental box controlled by a microcomputer, a test specimen clamping and loading mechanism is arranged in a box of the device, and an electronic extensometer and a laser extensometer are arranged to form a double displacement sensor and are connected to the microcomputer through an acquisition device after the data acquisition. The method and the device have the advantages of accurate and convenient test and low cost, and are suitable for the research of viscous-elastic mechanical properties and aging performances under the operation of polymers and composite materials of the polymers.

Owner:SHANGHAI UNIV

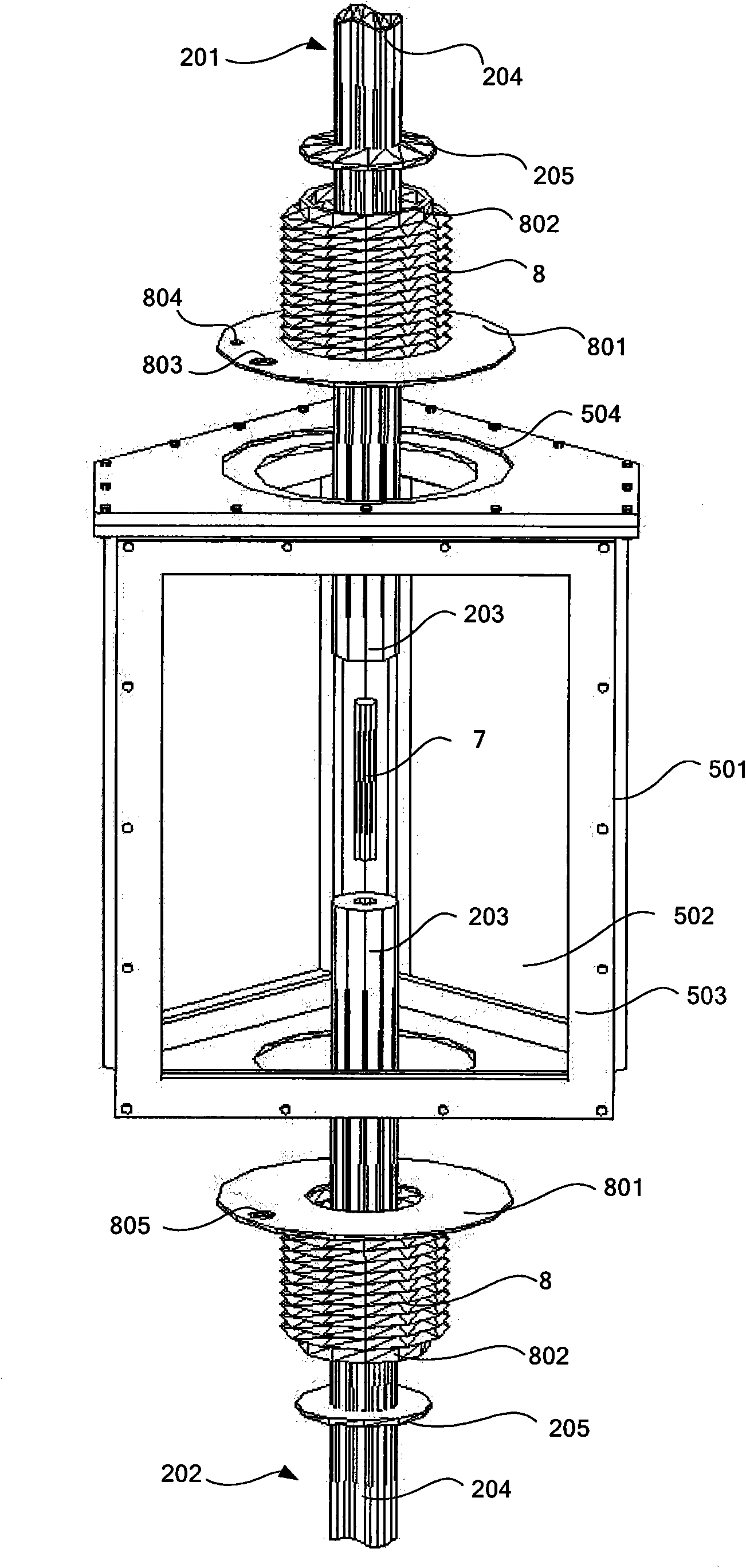

Vibration damping test device possessing dry damping structure vane

InactiveCN101308057ASolve the difficulty of accurately applying initial positive pressureVibration testingPositive pressureEngineering

The invention discloses a vibration reduction testing apparatus with a dry friction damping structure blade, the vibration reduction testing apparatus is composed of a positive pressure loading component, a fixture component and a base seat, the fixture component is mounted on a bottom plate of the base seat, the positive pressure loading component is arranged on a left supporting plate and a right supporting plate of the base seat, and a shroud of a blade with a dry friction damping structure is in contact with a friction block A and a friction block B on the positive pressure loading component. After loading the initial positive pressure and the exciting load, the vibration reduction testing apparatus of the invention can test vibration characteristics of different exciting forces, different initial positive pressures, different contact angles of a test piece (namely, the blade with the dry friction damping structure) and different installation positions of the test piece, and can utilize the test results to analyze the influence law of important parameters such as contact surface positive pressures of the test piece, contact angles of the test piece and installation positions of the test piece on the vibration reduction effect of the dry friction damping structure.

Owner:BEIHANG UNIV

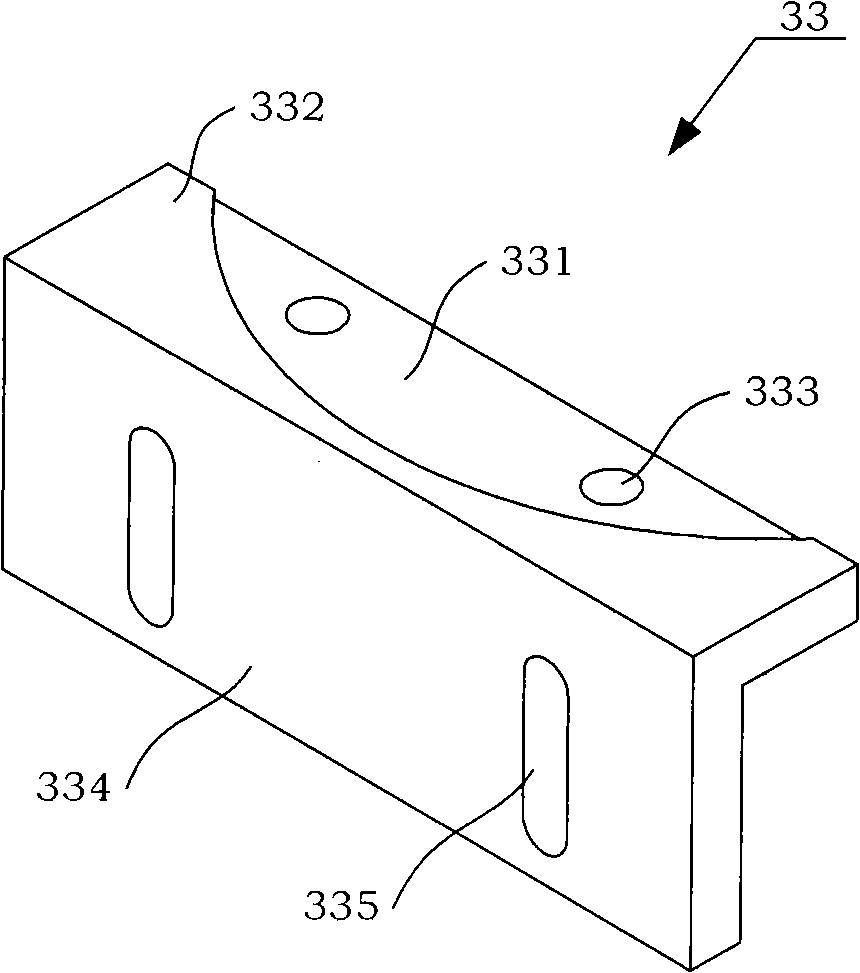

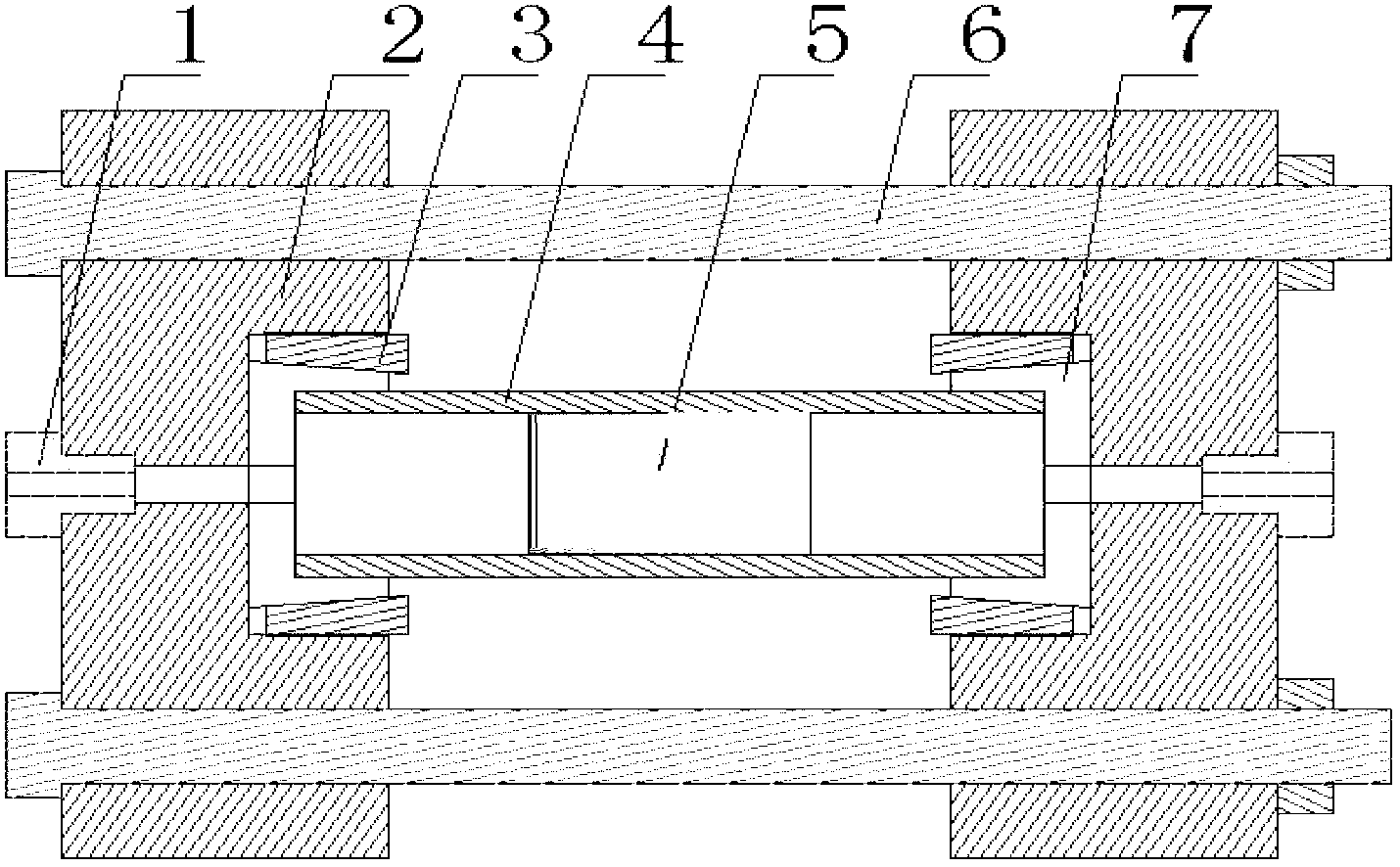

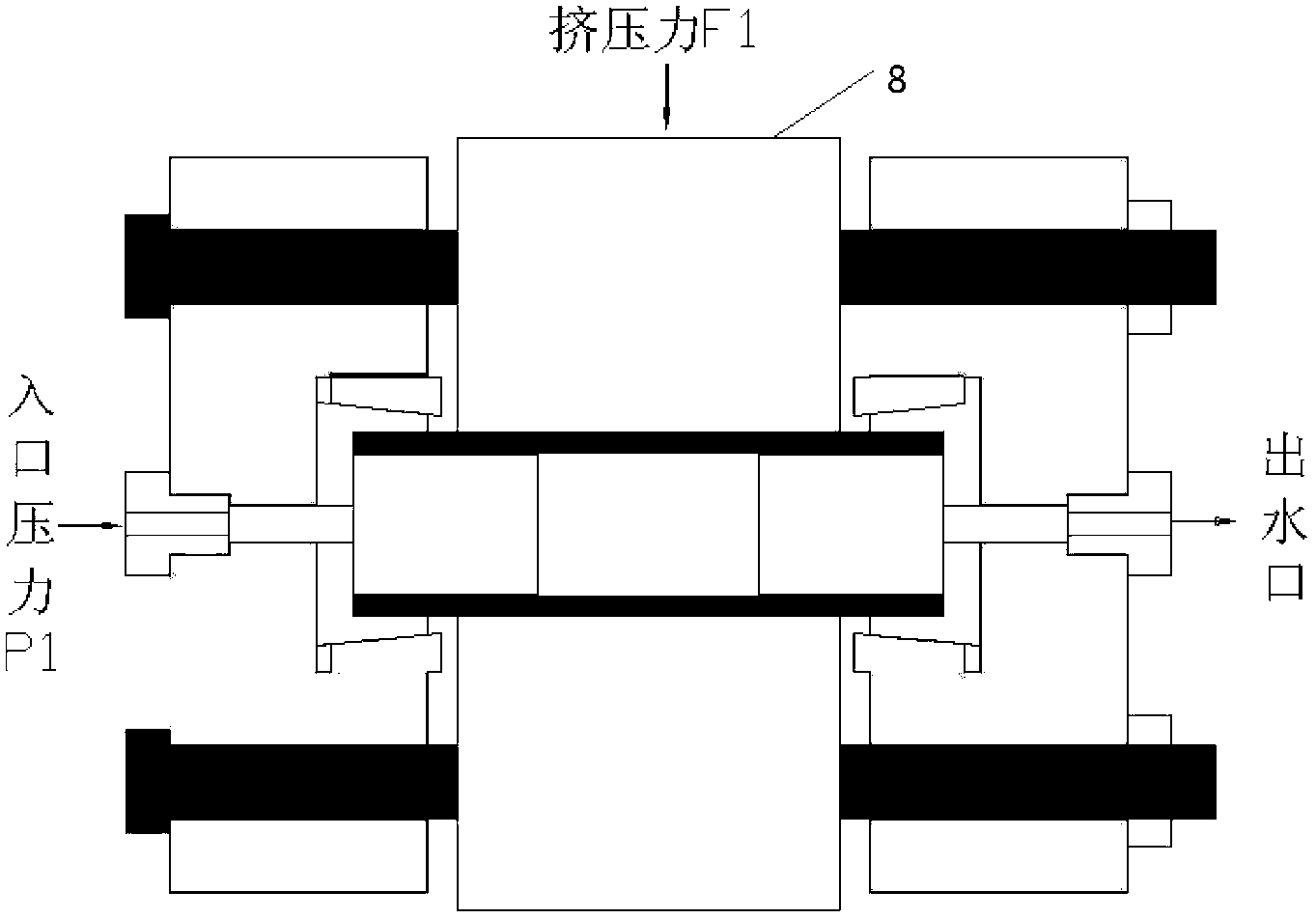

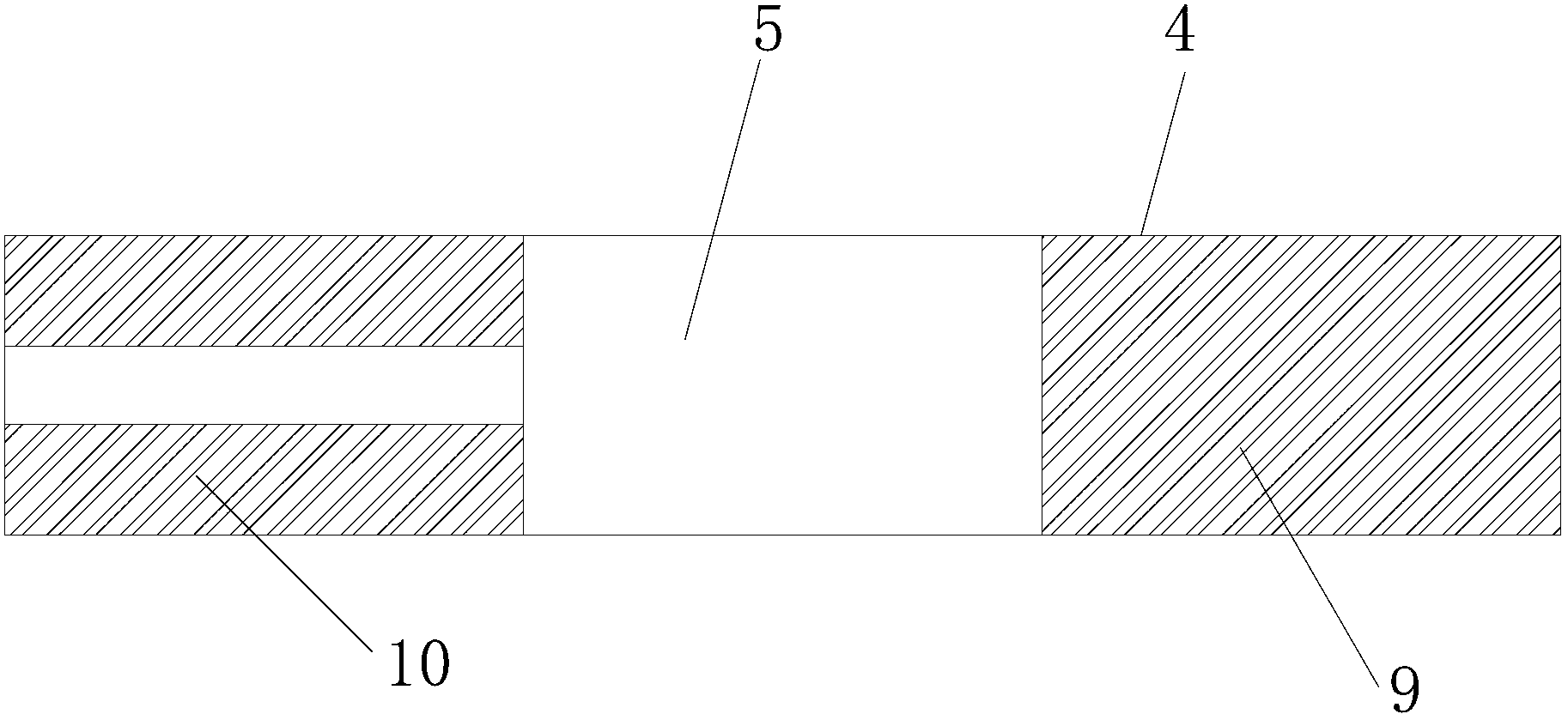

Well cementation cement sheath integrity simulation and evaluation tester

A well cementation cement sheath integrity simulation and evaluation tester includes pressing joints, wherein the pressing joints are arranged on compress packings; screwing compression rings are connected with compress discs through screw threads, and fix trapezoid rubber seal rings onto the compress discs and a steel tube; the steel tube containing a well cementation cement solidified body test sample is clamped tightly by screw rod and screw nut connecting assemblies and connected with the screw rod and screw nut connecting assemblies into a whole; pressing blocks and a mechanical pressure device are connected together to exert mechanical extrusion force to simulate the process that underground pressure variation causes damage and micro cracks to an oil well cement sheath; the pressing joints and a fluid pressing device are connected, so as to exert fluid pressure, simulate fluid pressure of the formation fluid on the well cementation cement sheath, and test and evaluate anti-channeling strength of the well cementation cement sheath; cured samples are placed in the well cementation cement sheath mechanical property simulation tester for test and analysis; and the tester can detect variation situations of the anti-channeling strength of the well cementation cement sheath under different conditions, so that impacting ductility and packing reliability of the well cementation cement sheath can be evaluated accurately.

Owner:XI'AN PETROLEUM UNIVERSITY

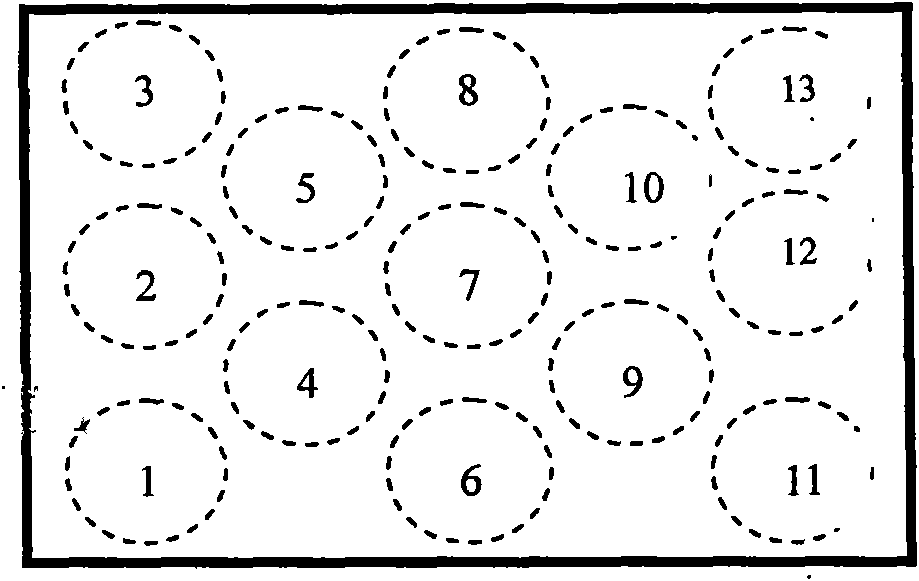

Process for testing capacitance type touch screen

InactiveCN101982783AImprove test efficiencySuitable for mass productionElectrical testingInput/output processes for data processingCapacitanceMultiple point

The invention relates a capacitance type touch screen testing process by simulating a human hand to touch a touch screen of a mobile phone by multiple points. The process adopts the method of simulating the human hand to touch the touch screen of the mobile phone by multiple points, and multipoint simulated human hand touch action is completed by a special touch screen tester, so that points to be tested cover the effective range of the whole screen. Before testing, a thin metal plate cap of a pneumatic touch head is in a non-stressed state, the thin metal plate cap maintains a normal-state shape, at the moment, the pneumatic touch head and a detected point of the touch screen are in clearance contact; when testing, an air pipe is connected with an air source, under the action of air pressure, the thin metal plate cap is elastically deformed to protrude downwards, the conductive rubber on the surface of the thin metal plate cap simulates fingers of the human hand to press the detected point of the touch screen; when the air source is cut by the air pipe, the thin metal plate cap is recovered to the normal-state shape; and a test chip circuit is connected with a capacitor of the detected point of the touch screen, and a singlechip determines the touch position by measuring capacitor changes and acquires capacitor changing information.

Owner:TIANJIN ZHONGHUAN HI TECH

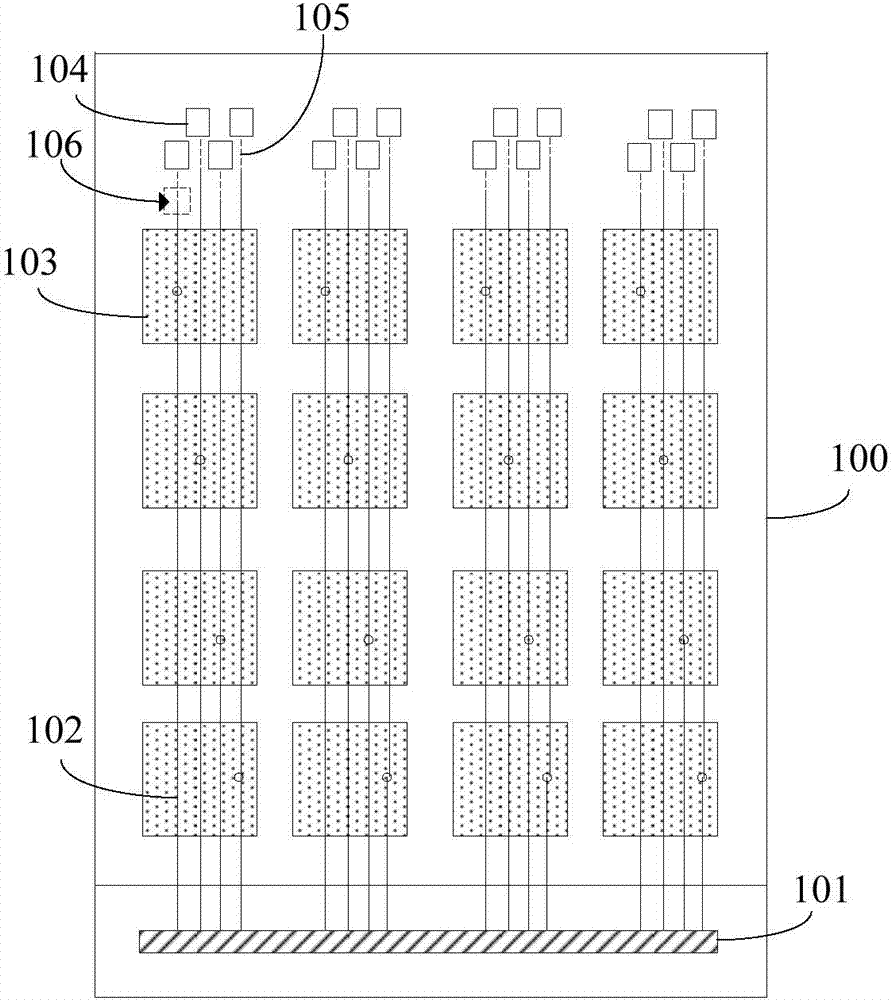

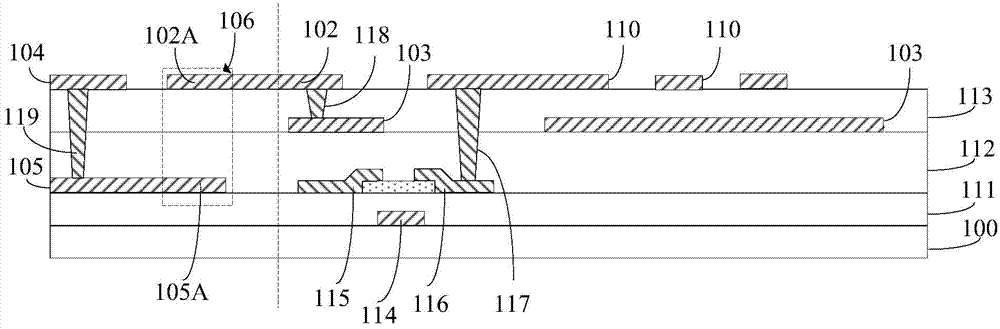

Array substrate and touch-control display device and testing method thereof

ActiveCN104777637AEasy accessImprove accuracyStatic indicating devicesNon-linear opticsElectrode potentialElectricity

The invention provides an array substrate and a touch-control display device and a testing method thereof. The array substrate comprises a substrate base, a common electrode structure and an electric conduction testing structure, wherein the common electrode structure and the electric conduction testing structure are arranged on the same side of the substrate base, and the common electrode structure and the electric conduction testing structure are mutually insulated; the projection shadows of the common electrode structure and the electric conduction testing structure in the direction perpendicular to the substrate base have an overlapped area, and the overlapped area can be subjected to laser scorification to enable the electric conduction testing structure to be electrically connected with the common electrode structure. When the electric potential of a common electrode is needed to be tested, the laser scorification can be conducted on the overlapped area, the electric conduction testing structure is electrically connected with the common electrode structure, a probe is stabbed into the electric conduction testing structure, and therefore the difficulty of common electrode potential testing is lowered, in addition, the probe is not prone to making contact with other components around the common electrode structure, and the accuracy of the testing results is improved.

Owner:SHANGHAI AVIC OPTOELECTRONICS +1

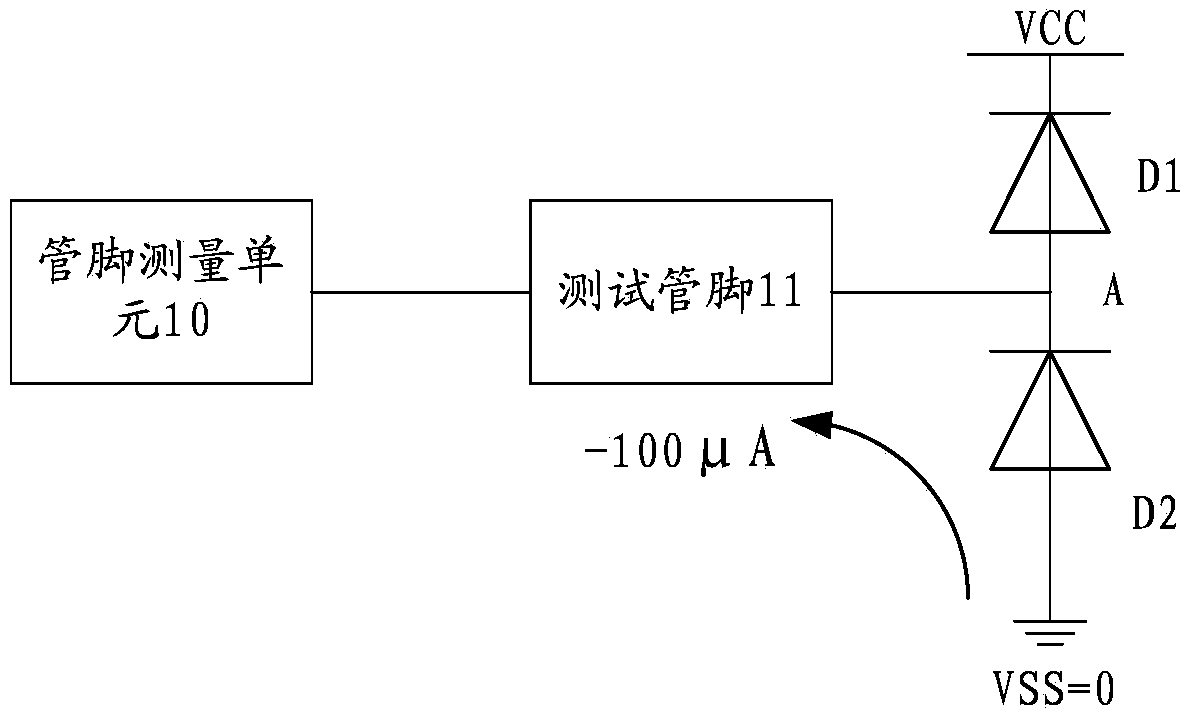

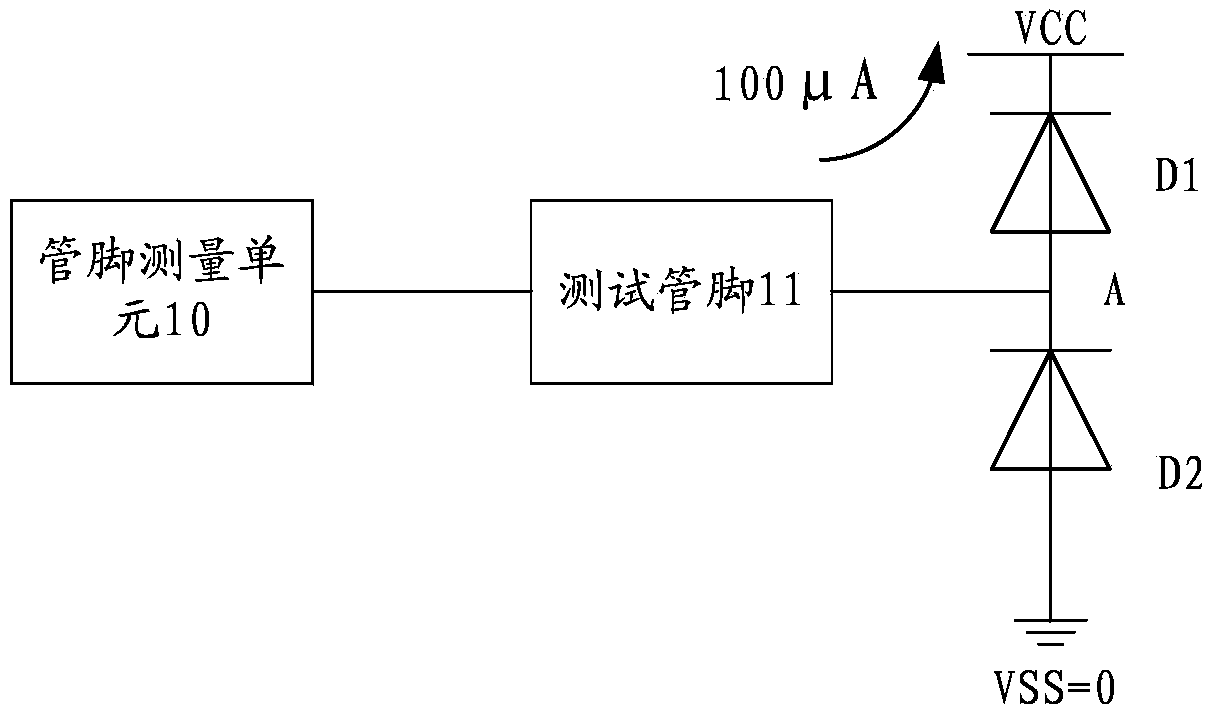

Open circuit short circuit test device and test method of chip base pin

ActiveCN103698654AReduce in quantityReduce testing costsElectrical testingShort-circuit testControl signal

The invention provides an open circuit short circuit test device and an open circuit short circuit test method of a chip base pin. The test device comprises at least one test board card, wherein a main control chip group and a base pin measuring unit array are arranged on each test board card, the base pin measuring unit array receives control signals output by the main control chip group and comprises a plurality of base pin measuring units, a channel switching switch array is also arranged on the test board card, the channel switching switch array comprises a plurality of channel switching switch units, a channel interface is also formed in the test board card, the channel interface comprises a plurality of test passages, each channel switching switch unit can be used for switching more than two test passages for testing, and the test passages of one base pin measuring unit are switched by each channel switching switch unit. The test method belongs to a method for testing the base pin of a chip by adopting the method. The device and the method provided by the invention have the advantages that the base pin of the chip can be fast tested, in addition, the size of the test device is small, and the test cost is low.

Owner:ALLWINNER TECH CO LTD

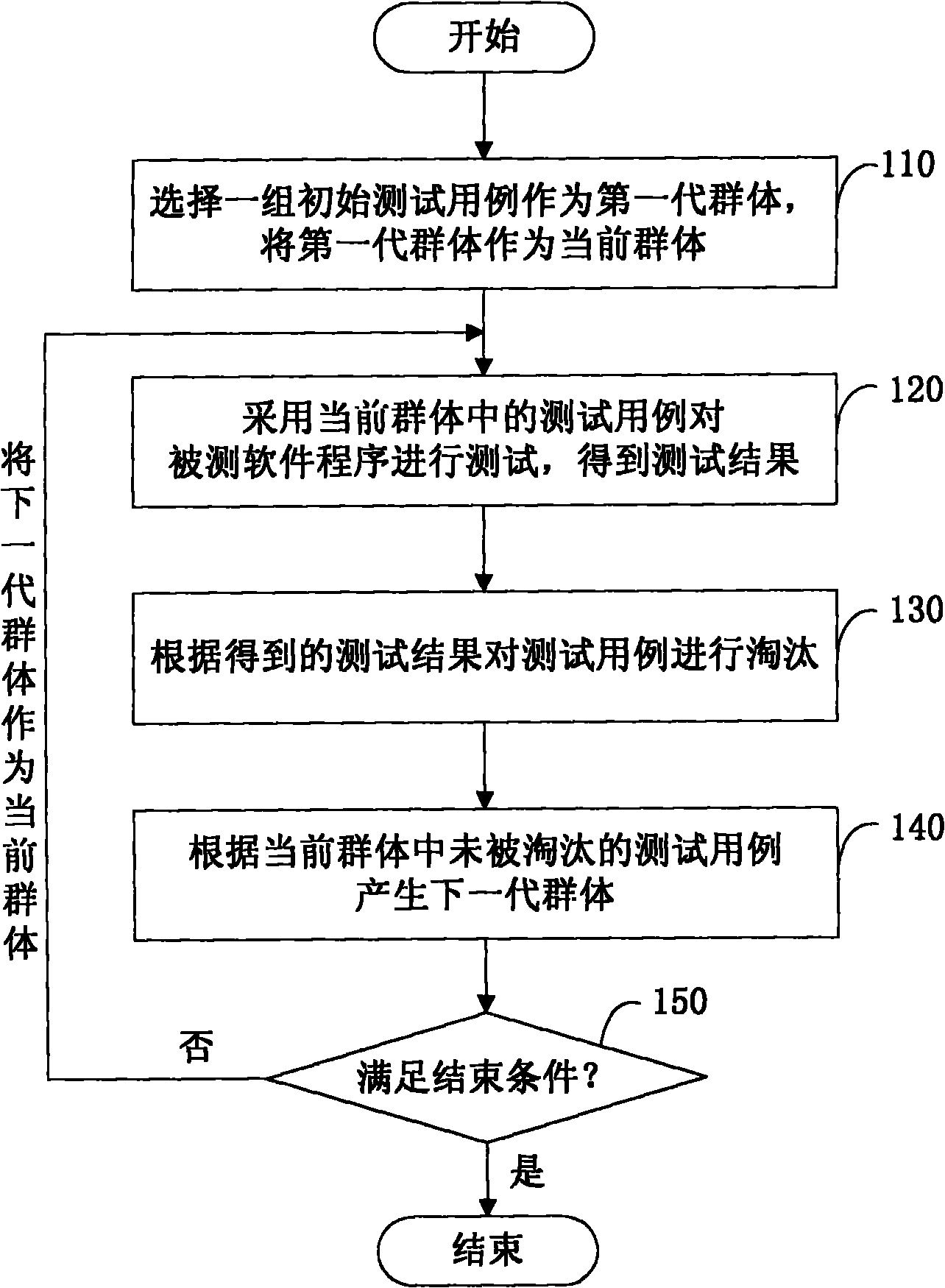

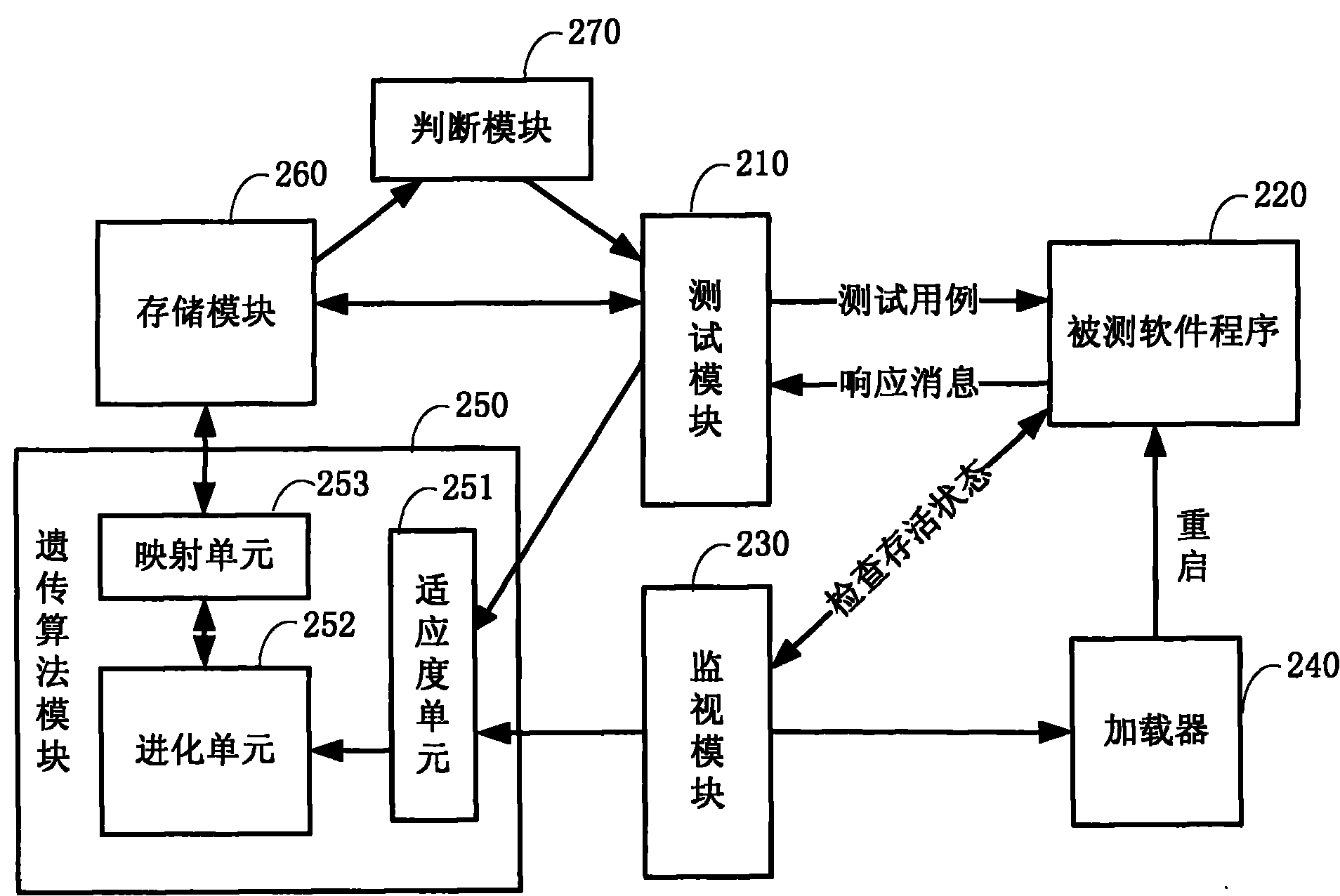

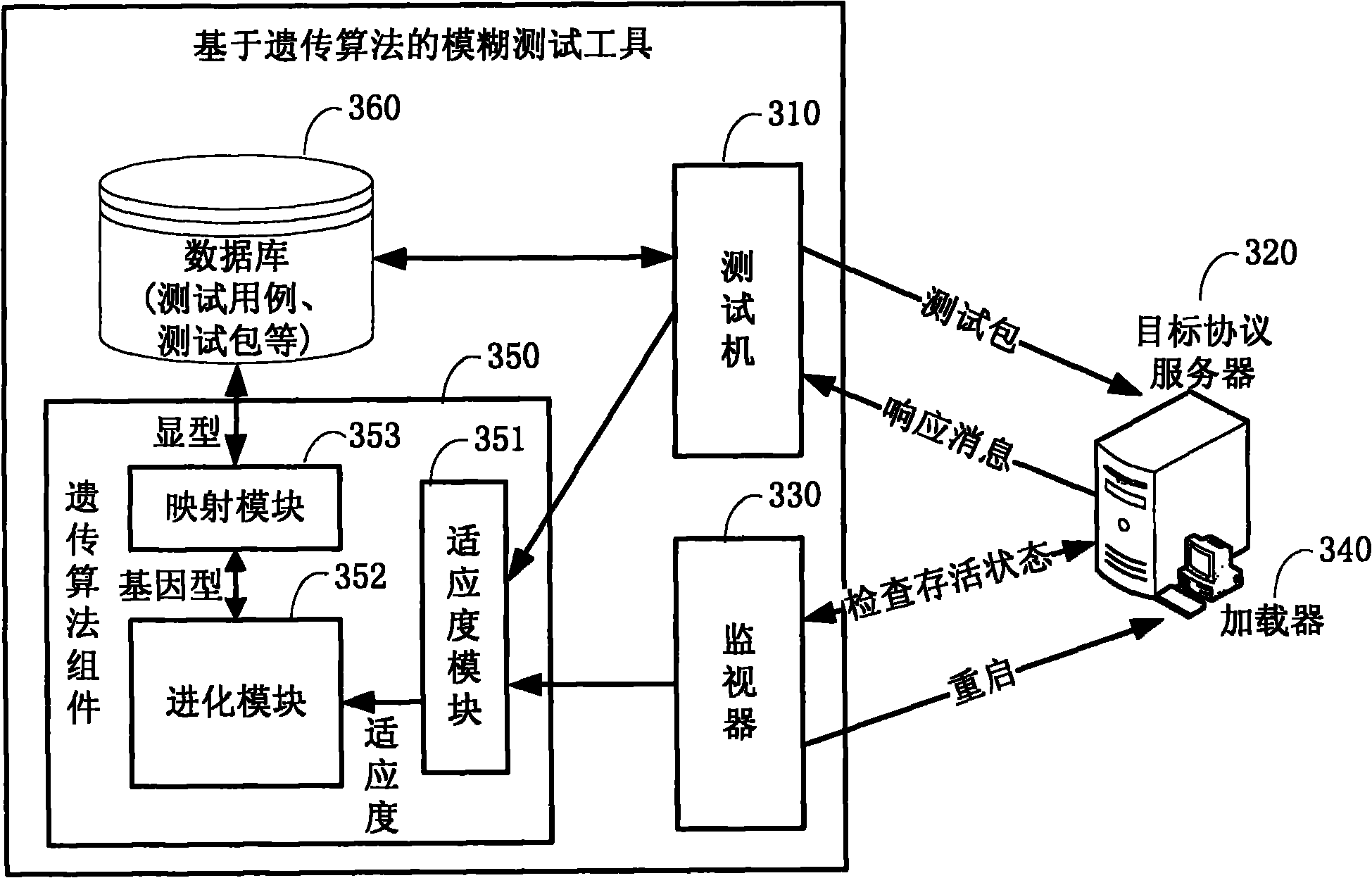

Method and system for fuzz testing

ActiveCN101859274AFind security flawsSecurity Defect ExclusionSoftware testing/debuggingFirst generationTest case

The invention discloses a method for fuzz testing, which comprises the following steps that: first, selecting a group of initial test cases as a first-generation group, and the first-generation group serves as a current group; then adopting the test cases in the current group to test a tested software program, eliminate the test cases according to the obtained test results, and generate a next-generation group according to the test cases which are not eliminated in the current group; at this time, if the end conditions are satisfied, ending the test; and if the end conditions are not satisfied, the obtained next-generation group serves as the current group to continue the test in a circulating way until the end conditions are satisfied. The invention also discloses a system for fuzz testing. The invention can improve the security of the tested software program.

Owner:SIEMENS CHINA

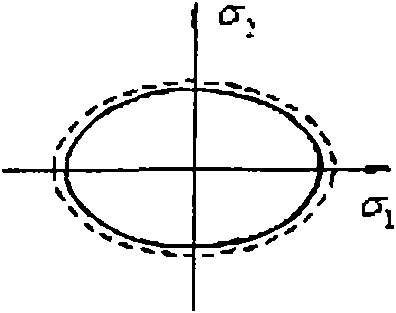

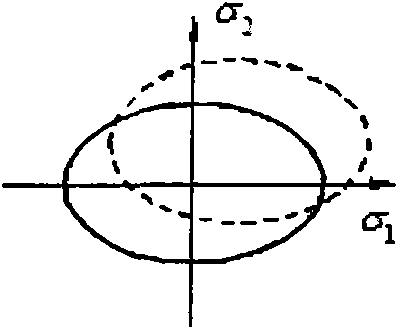

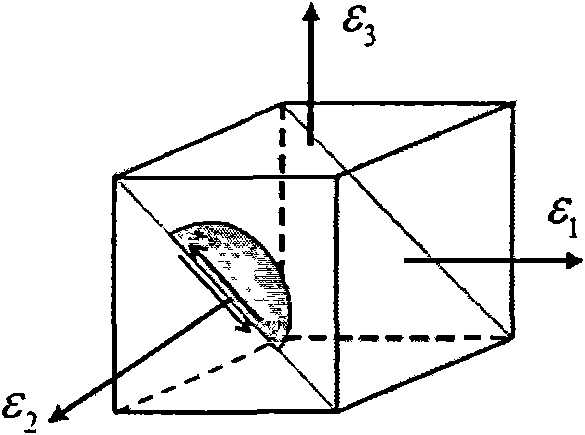

Method for predicting multiaxial fatigue of automobile rear suspension

InactiveCN101592552AImprove calculation accuracyVehicle testingMachine part testingGround contactElement analysis

The invention discloses a method for predicting multiaxial fatigue of an automobile rear suspension, which comprises the following steps: performing rear suspension elastic plasticity finite element analysis based on a uniaxial cyclic stress-strain relationship, performing biaxiality analysis on the rear suspension, determining a rear suspension bearing multiaxial nonproportional load condition and possible crack propagation form thereof, and selecting a Bannantine model and a Wang-Brown model based on a critical plane method to test the multiaxial fatigue life of the rear suspension. The method has the advantages of avoiding the problem that an actual load condition of the automobile rear suspension cannot be truly considered in the conventional uniaxial fatigue life test, considering nonlinear factors of a rear suspension structure, rubber connecting elements and wheel tyres, contacting condition of the tyres and the ground and the like, and improving calculation accuracy.

Owner:TONGJI UNIV

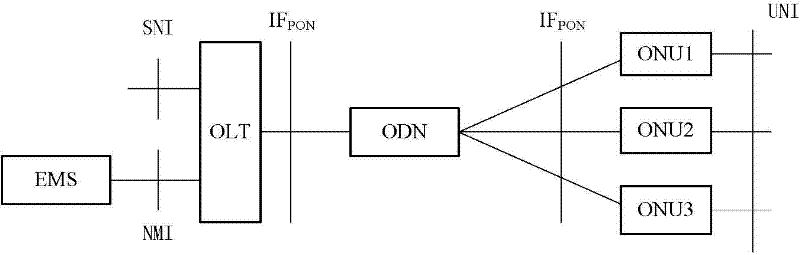

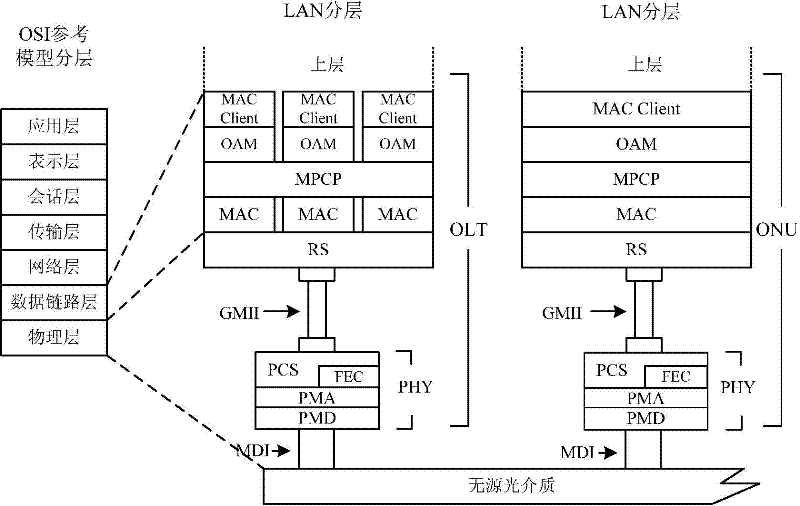

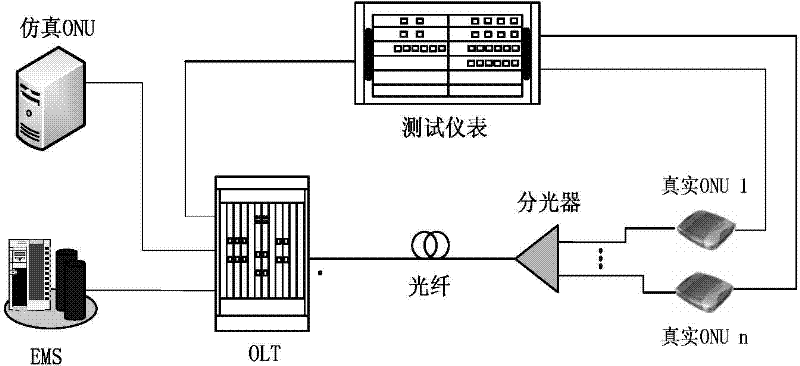

System and method for carrying out EPON (Ethemet-based passive optical network) performance test based on emulational ONU (optical network unit)

ActiveCN102571198ASimplify the test networkReduce complexityElectromagnetic transmissionOptical network unitEmbedded system

The invention discloses a system and a method for carrying out an EPON (Ethemet-based passive optical network) performance test based on an emulational ONU (optical network unit). The system comprises an Ethemet management system (EMS), an optical line terminal (OLT), an optical splitter, a plurality of real ONUs, a test instrument and an emulational ONU, wherein the OLT is connected with the EMS by adopting an internally-built or externally-built interface, and the OLT is sequentially connected with the optical splitter, the plurality of real ONUs and the test instrument end to end so as to form a ring-shaped test network. The method comprises the following steps: carrying out initialization on the system for carrying out the EPON performance test based on the emulational ONU; carrying out an emulation test by applying the system; and carrying out analysis on test results so as to obtain a test result. In case of carrying out the test on an EPON system by adopting the system and the method disclosed by the invention, the test complexity can be greatly reduced, and the test cycle can be reduced.

Owner:FENGHUO COMM SCI & TECH CO LTD

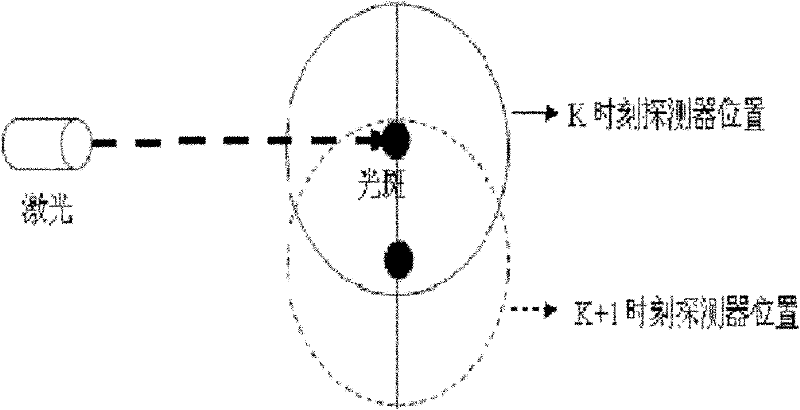

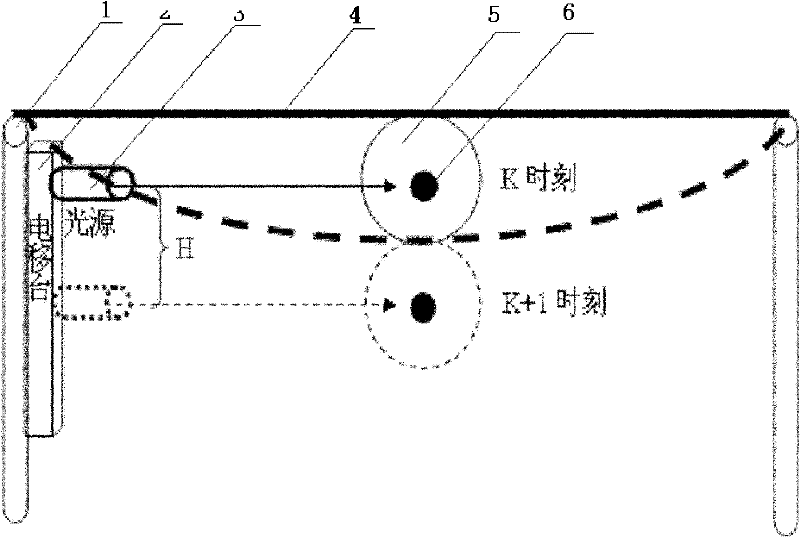

Method for testing deflection/longitudinal displacement change of bridge based on four-quadrant position detector

InactiveCN102564323AHigh precisionReal-time monitoring of security statusUsing optical meansFour quadrantsLight spot

The invention discloses a method for testing a deflection / longitudinal displacement change of a bridge based on a four-quadrant position detector. The method is characterized by comprising the following steps: firstly, the four-quadrant position detector is installed in the centre of the bridge or other points to be tested at the bottom of a bridge deck; a laser source is installed on a pier and / or a certain point below the bridge deck through an electric displacement table; then, testing is carried out by matching the four-quadrant detector with the laser source, so that the light spot of laser is over against the centre of the detector; when the deflection of the bridge deck changes, the four-quadrant detector longitudinally moves together with the point to be tested; the light spot position, formed on the four-quadrant detector, of the laser moves oppositely relative to the detector; and different position coordinates of the light spot on the detector before and after the deflection of the bridge changes and light spot position variable quantity on the four-quadrant detector, namely deflection position variable quantity of the point to be tested on the bridge deck can be calculated. The method disclosed by the invention has the advantages of simple structure, good controllability and high precision and is capable of realizing real-time online test of the deflection / longitudinal displacement of the bridge.

Owner:DALIAN MARITIME UNIVERSITY

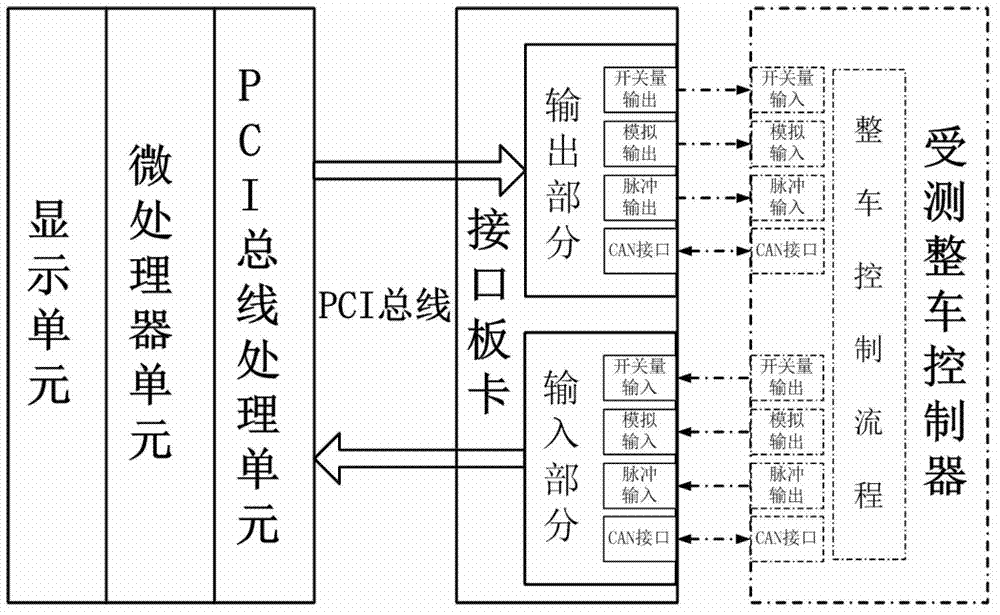

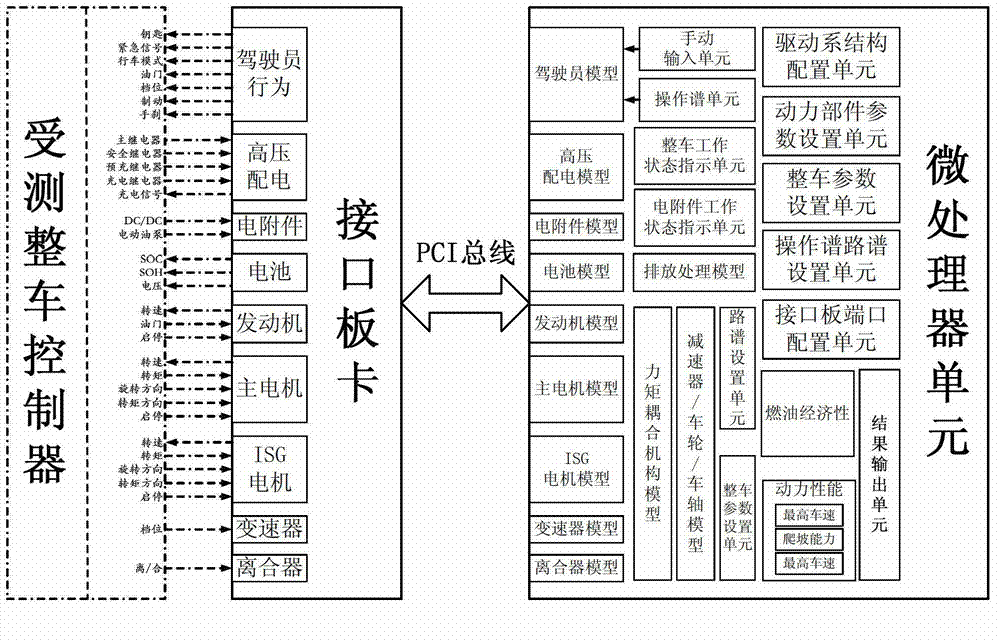

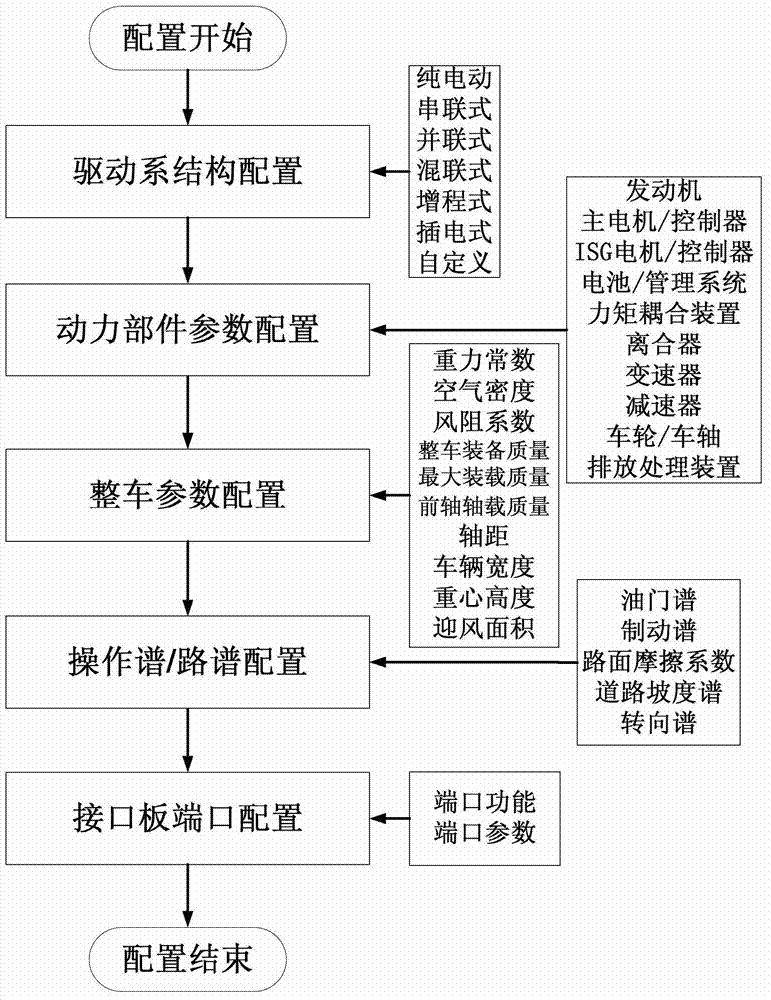

Device and method of simulation and testing of finished car controller of hybrid power car

ActiveCN103197667AImprove stabilityImprove reliabilityElectric testing/monitoringPci interfaceTest fixture

The invention discloses a device and a method of simulation and testing of a finished car controller of a hybrid power car. Due to the fact that a PCI interface and a micro processor are used for communication, the device of simulation and testing of the finished car controller of the hybrid power car has the advantages of being good in reliability, high in transmission rate of data, and good in extendibility. Due to the fact that a mathematical model of a power unit is used for simulating a working state of an actual power unit, cost of a system is greatly reduced. The device of simulation and testing of the finished car controller of the hybrid power car comprises a micro processor unit, a PCI bus processing unit, a display unit and an interface board card. The display unit and the PCI bus processing unit are respectively connected with the micro processor unit. The interface board card is connected with the PCI bus processing unit through a PCI bus. The interface board card is connected with the finished car controller to be detected. Therefore, configuration can be conveniently carried out on the structure of a finished car, relevant power unit parameters, an operation spectrum / a road spectrum, and port attributes of an interface board, and the system is good in generality. When the device and the method of simulation and testing of the finished car controller of the hybrid power car are used for testing a hybrid power finished car controller, a test period is shortened, test cost is reduced, and test results are good in stability and high in accuracy.

Owner:HUNAN UNIV

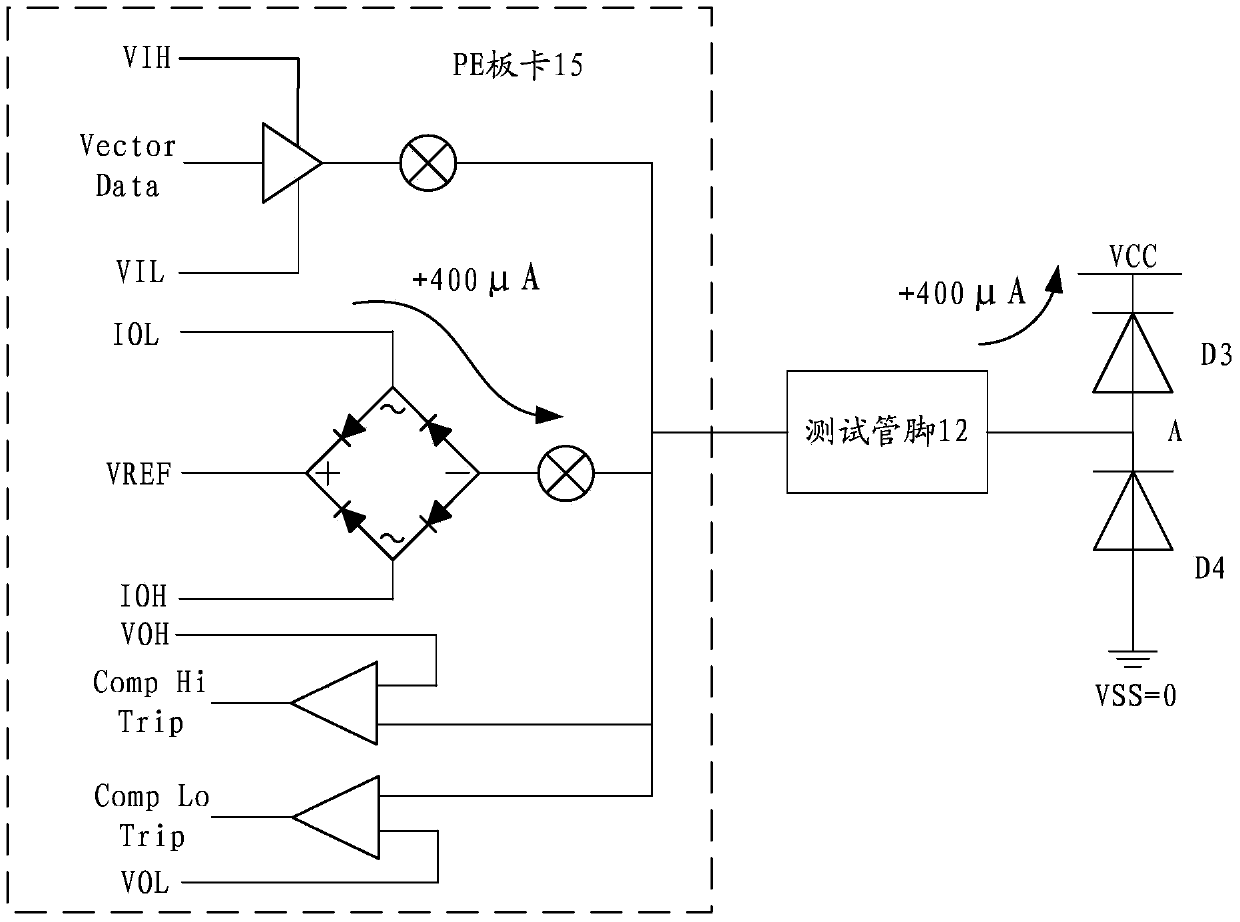

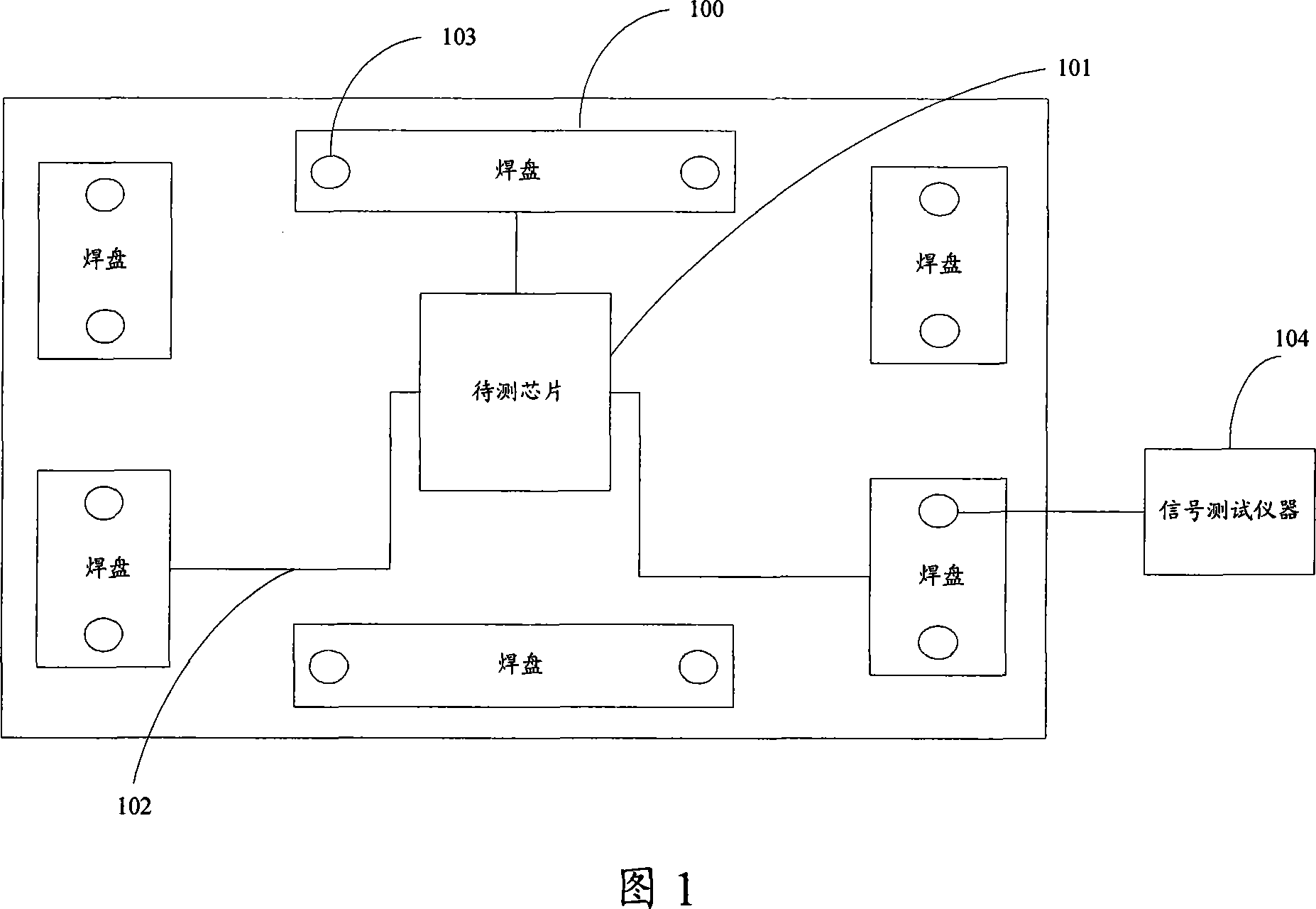

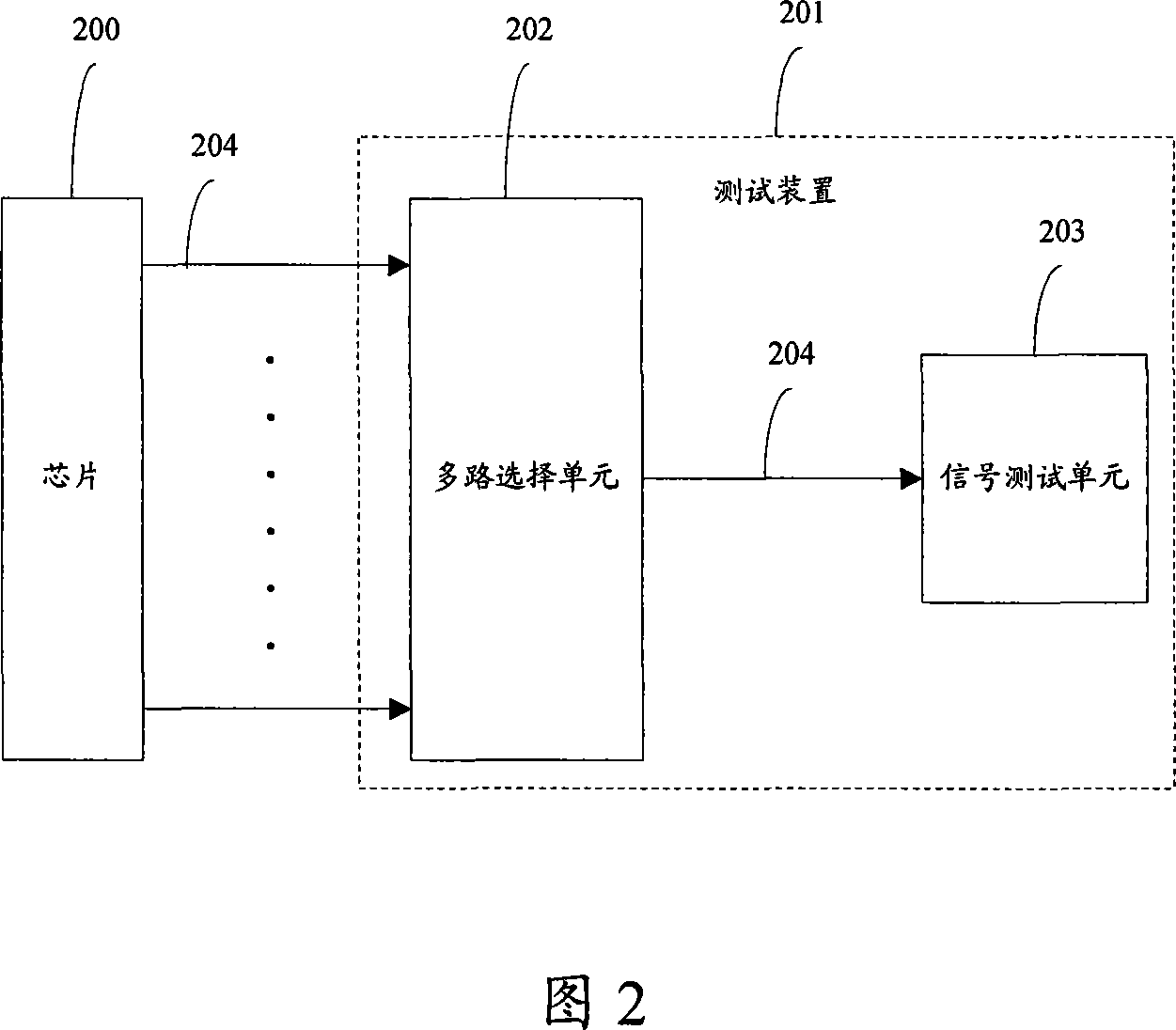

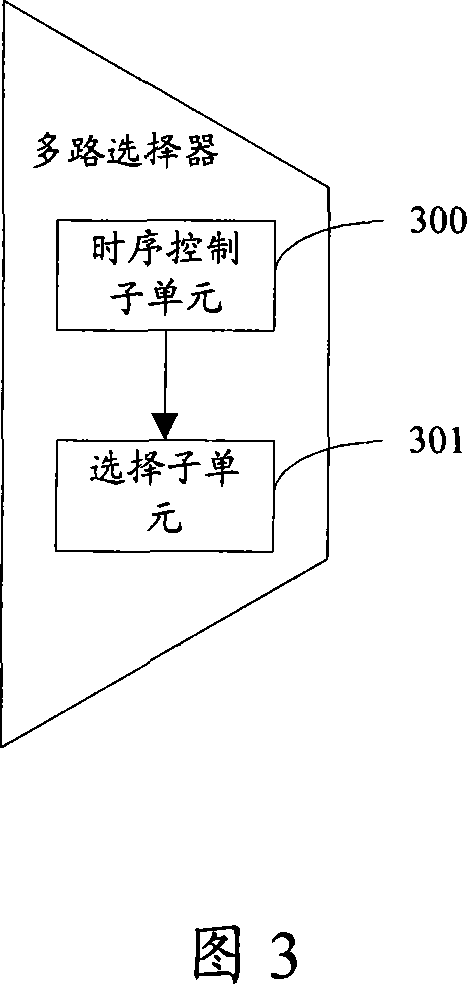

Method and arrangement for implementing chip test

InactiveCN101063700AImprove efficiencySimplify complexityElectronic circuit testingMeasurement instrument housingComputer scienceTest employment

This invention discloses one chip test method and its device, which comprises the following steps: receiving chip to be tested leg signal; selecting different leg signal from the leg signals in different time; testing the leg signal for selected one. This invention discloses one chip test device, which adopts the method to improve work efficiency and to simplify the work complexity.

Owner:VIMICRO CORP

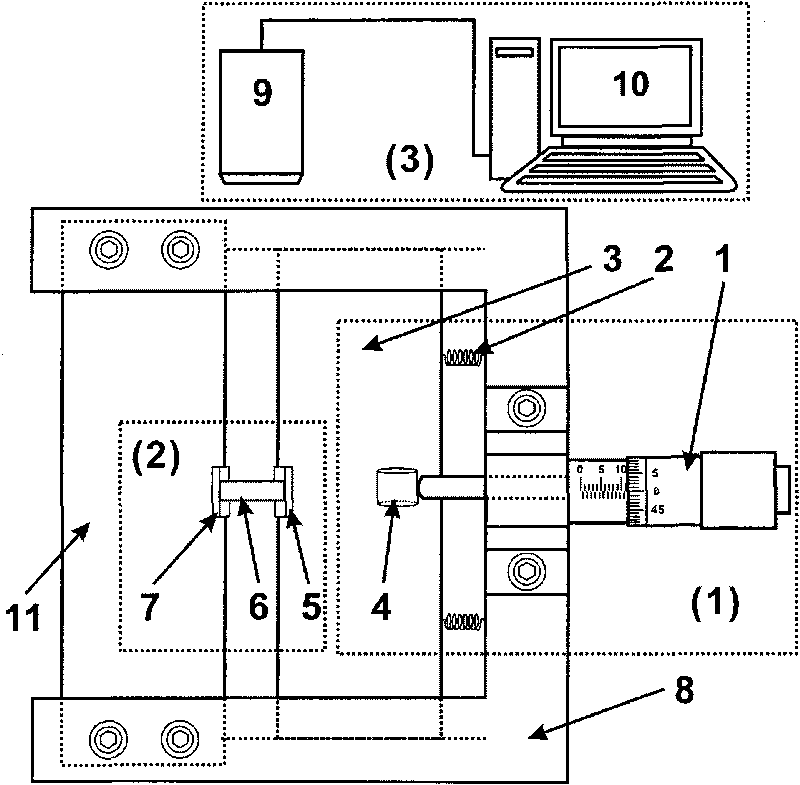

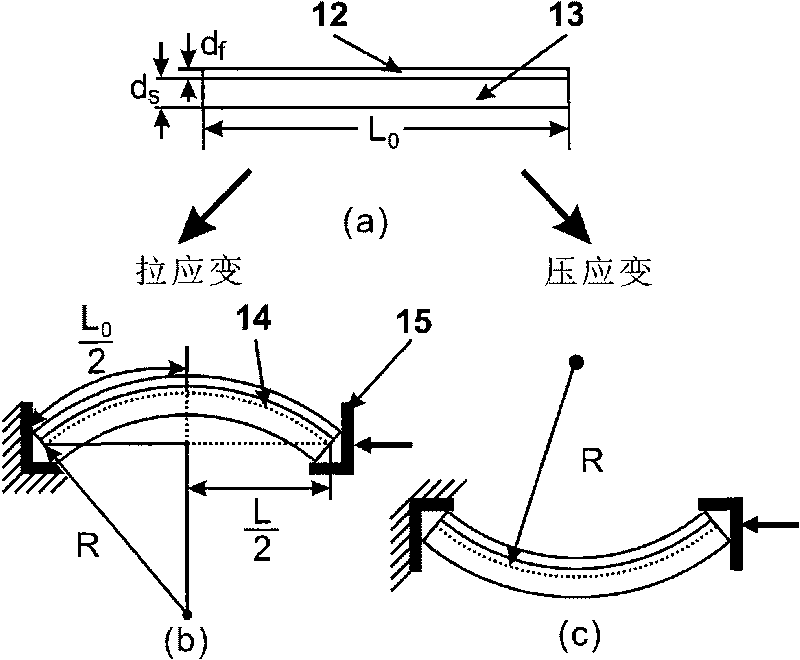

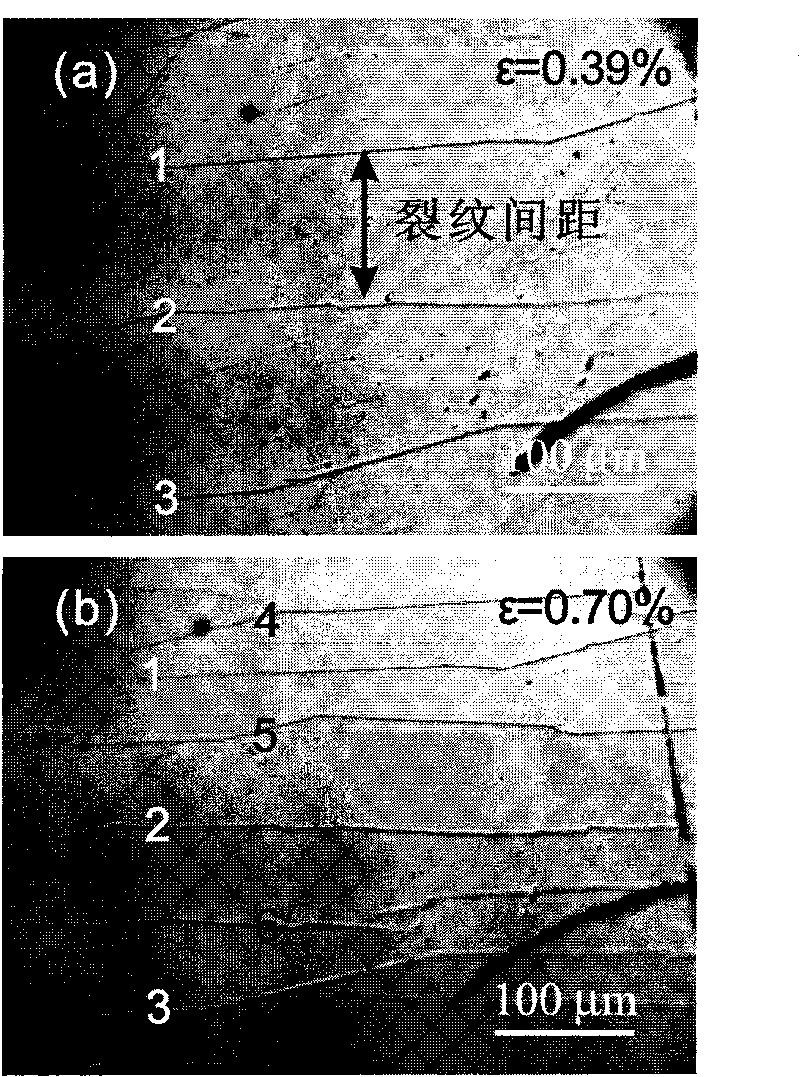

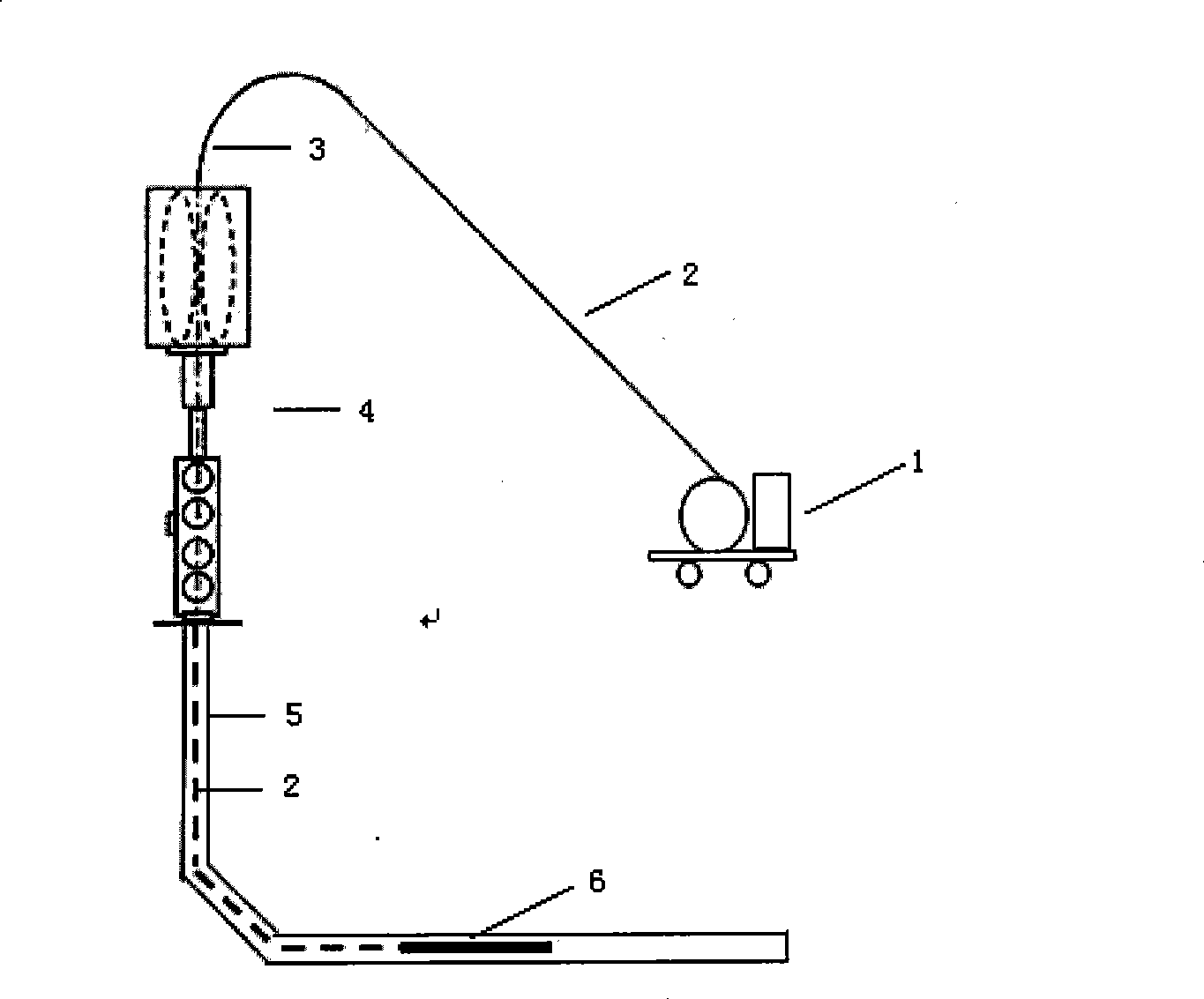

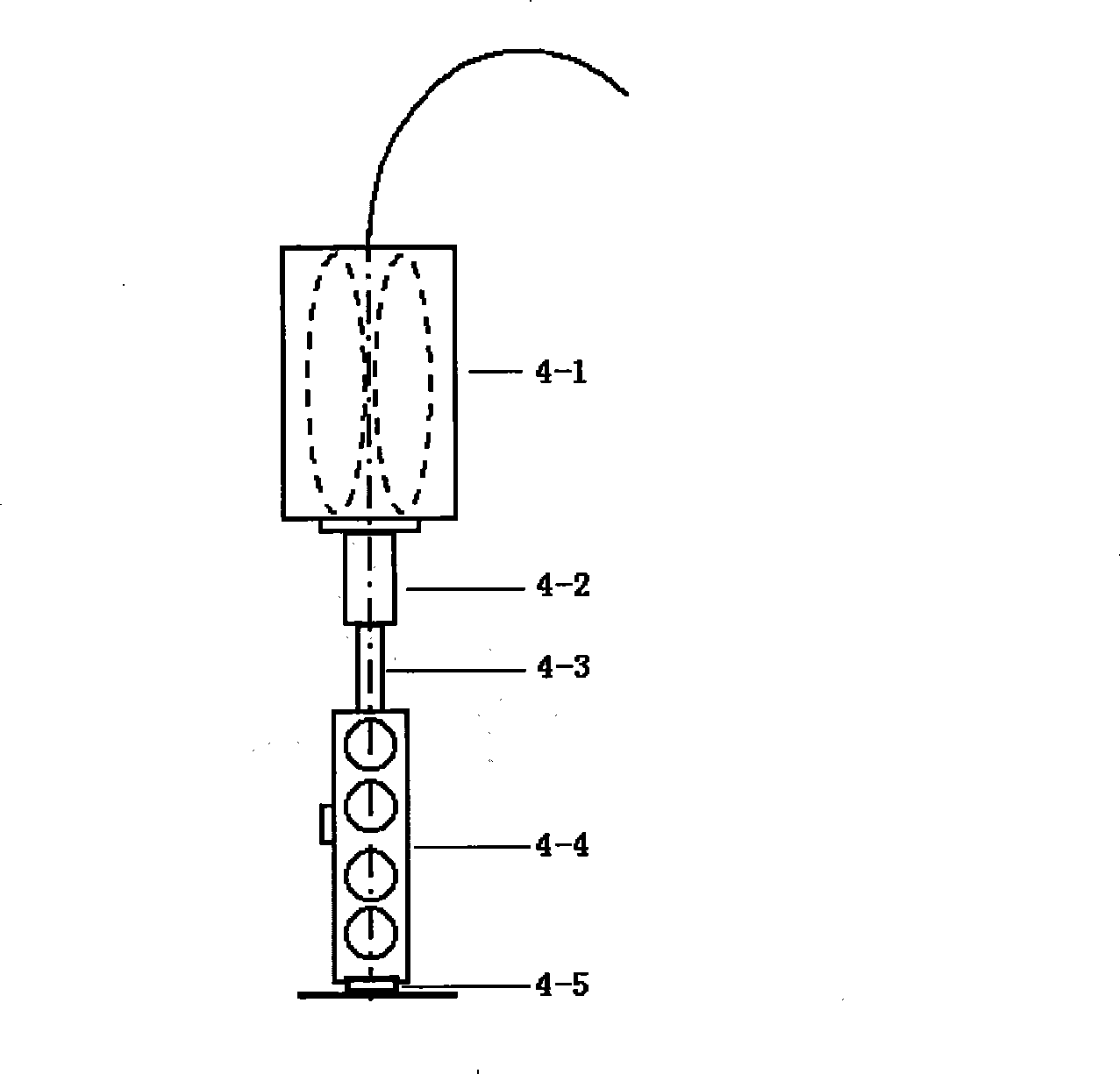

In situ evaluation system and method of reliability of thin-film materials on flexible electronic substrate

InactiveCN101726442AGet rid of the disadvantages of inaccurate resistance value measurementImprove test accuracyMaterial strength using steady bending forcesMicroscopic observationMechanical reliability

The invention relates to establishment for a test device and a test method for the bending fracture performance of thin-film materials, in particular to an in situ evaluation system and a method of the mechanical reliability of a layer or a plurality of layers of thin-film materials with the micron to nanometer thickness on a flexible electronic substrate. The system comprises a high-precision micrometer caliper, a balance spring, a translational slide block, a freely supported beam fixed end, a freely supported beam movable end, and the like, wherein a composite beam comprising the micrometer caliper and a flexible substrate exerts precise and controllable step displacement to implement freely supported beam bending experiments; real-time exerted strain corresponding to a freely supported beam span is computed according to parameters and geometrical relationship of the freely supported beam span, sample sizes, and the like; and the bending fracture performance and critical cracking strain of the kind of thin film are tested and evaluated by combining in situ microscopic observation and subsequent scanning electron microscope characterization. The invention does not need to consider the electroconductibility of the thin-film materials, and is still adaptable for non-conductive thin-film materials. The experiment operation is simple and fast, in situ real-time positioning observation and analysis can be carried out on samples.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

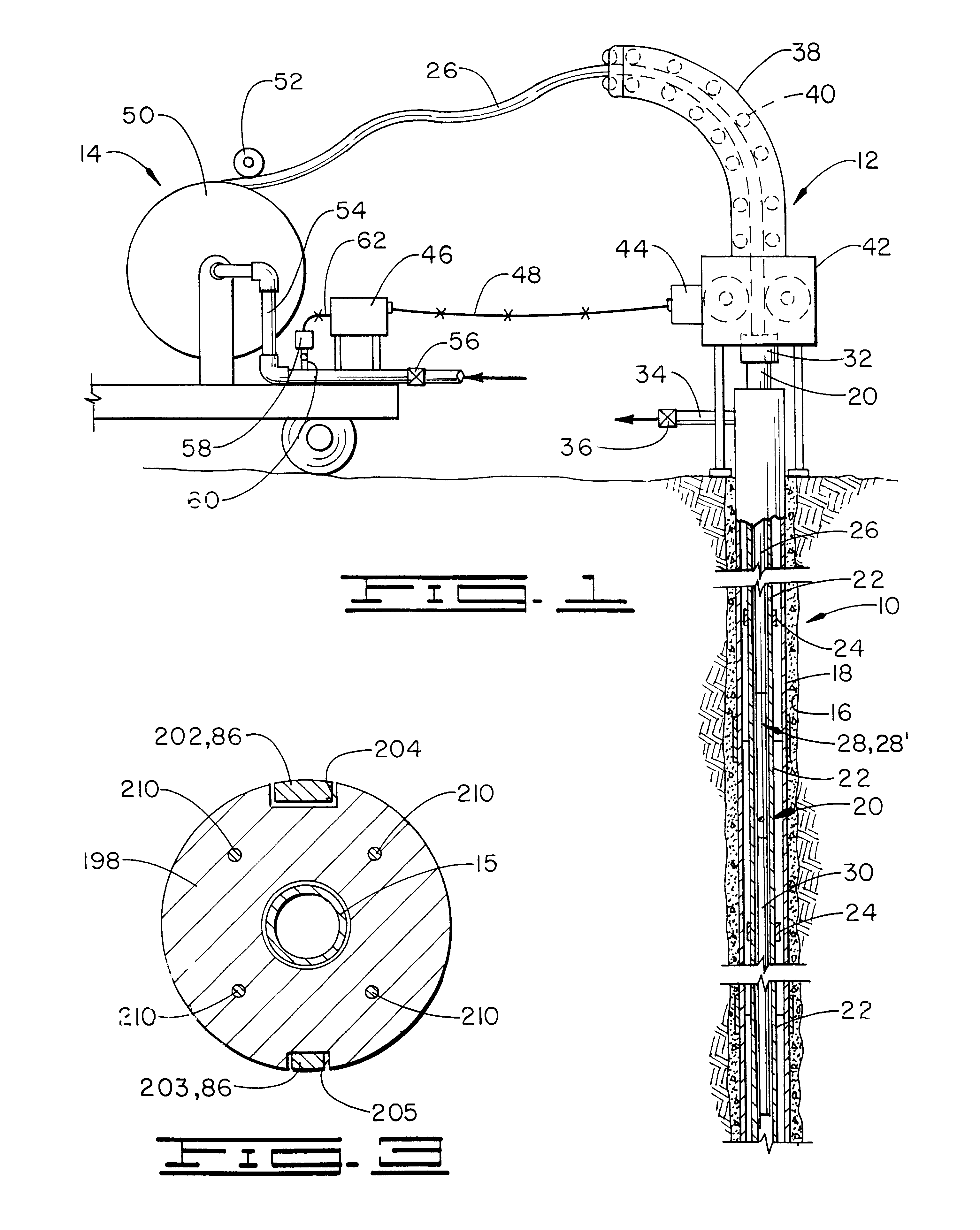

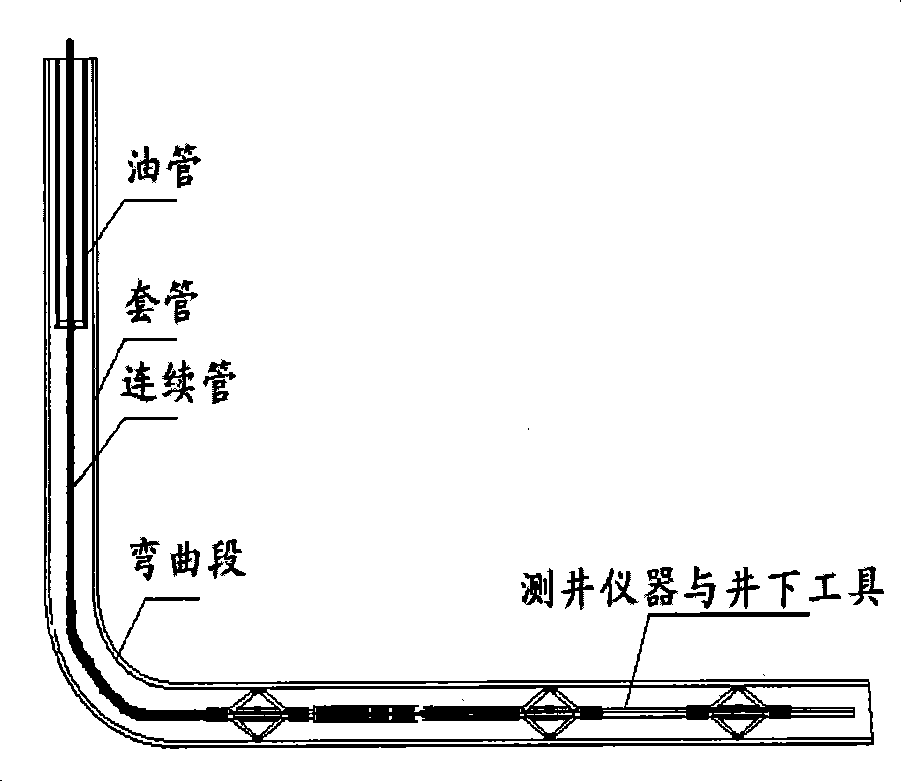

Continuous tube horizontal borehole process and device

The invention relates to a horizontal well logging technology with a continuous tube and a device thereof. The technology uses a high-strength and high-tenacity continuous tube as tools to convey down-hole logging instruments so as to ensure that the down-hole instruments perform tests under various horizontal wells. The adopted device comprises a continuous tubing unit, the continuous tube, a wellhead device, connecting joints between the continuous tubes and the down-hole instruments, down-hole logging instruments and tools for the horizontal wellbore, a ground numerical control logging system, a depth system of the continuous tube and a signal transmission system of the continuous tube. The invention can ensure the down-hole instruments to perform tests under various horizontal holes by using the continuous tube as the conveyance tool of the down-hole instruments; the technology uses few application equipment and has the advantages of good maneuverability, convenient operation and high construction efficiency thanks to the application of continuous tubing unit and other special devices.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

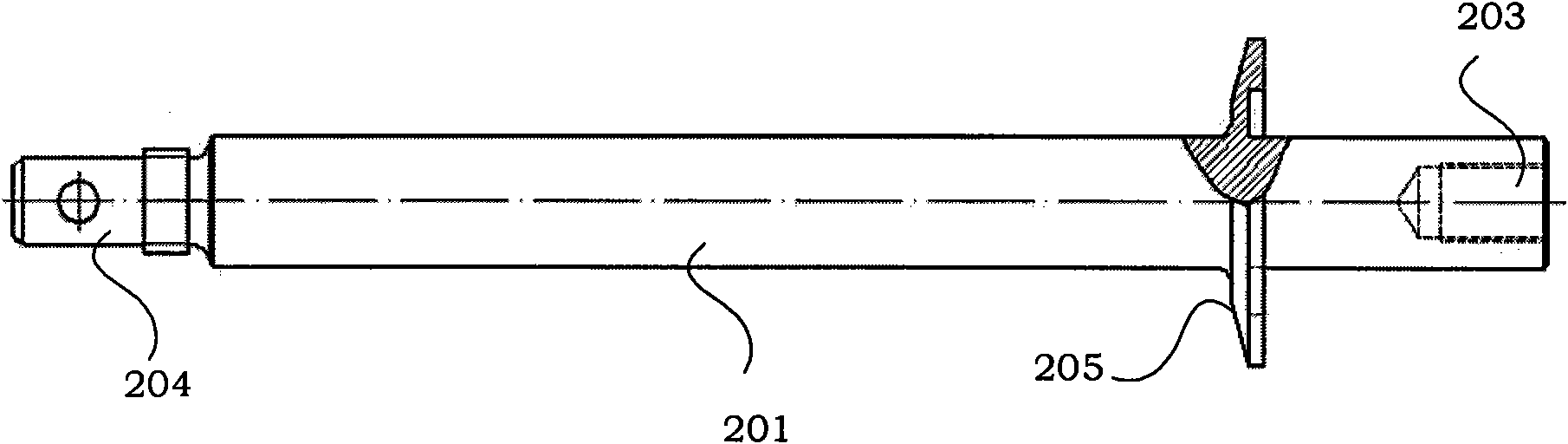

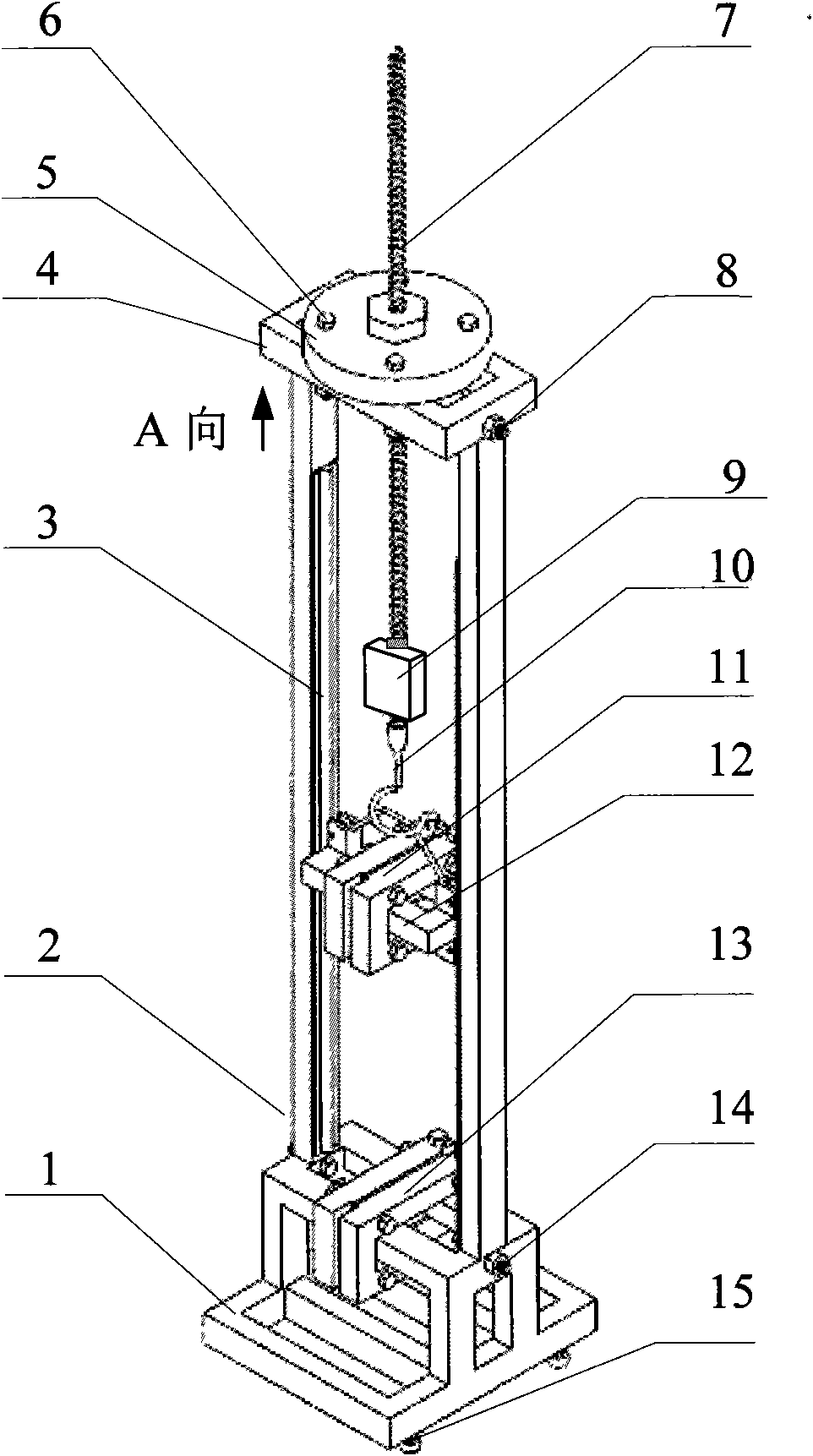

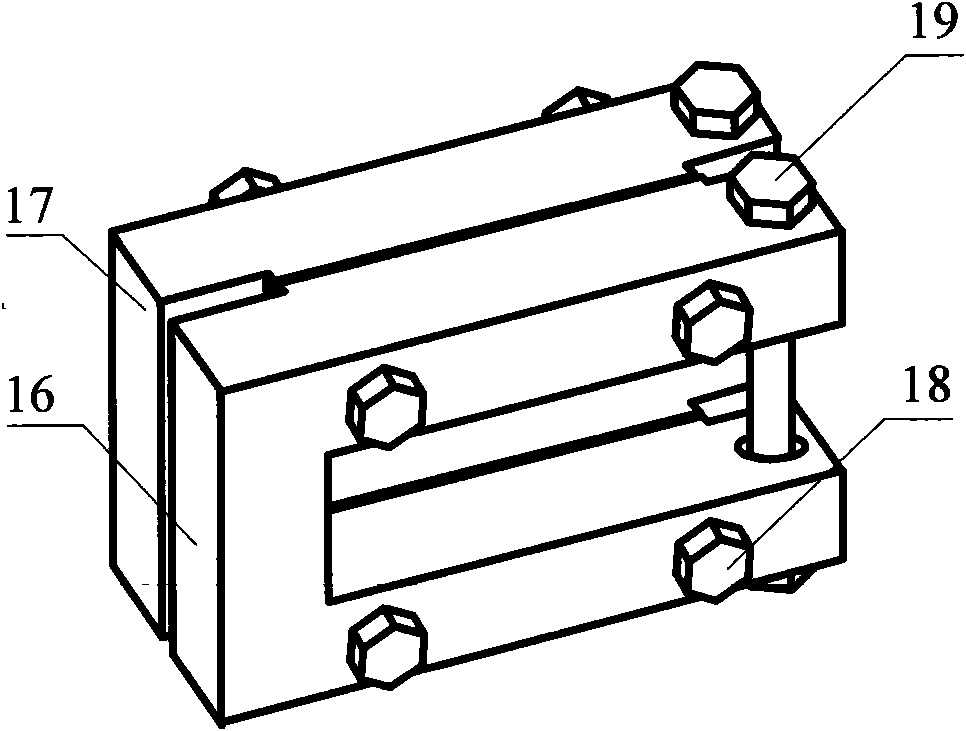

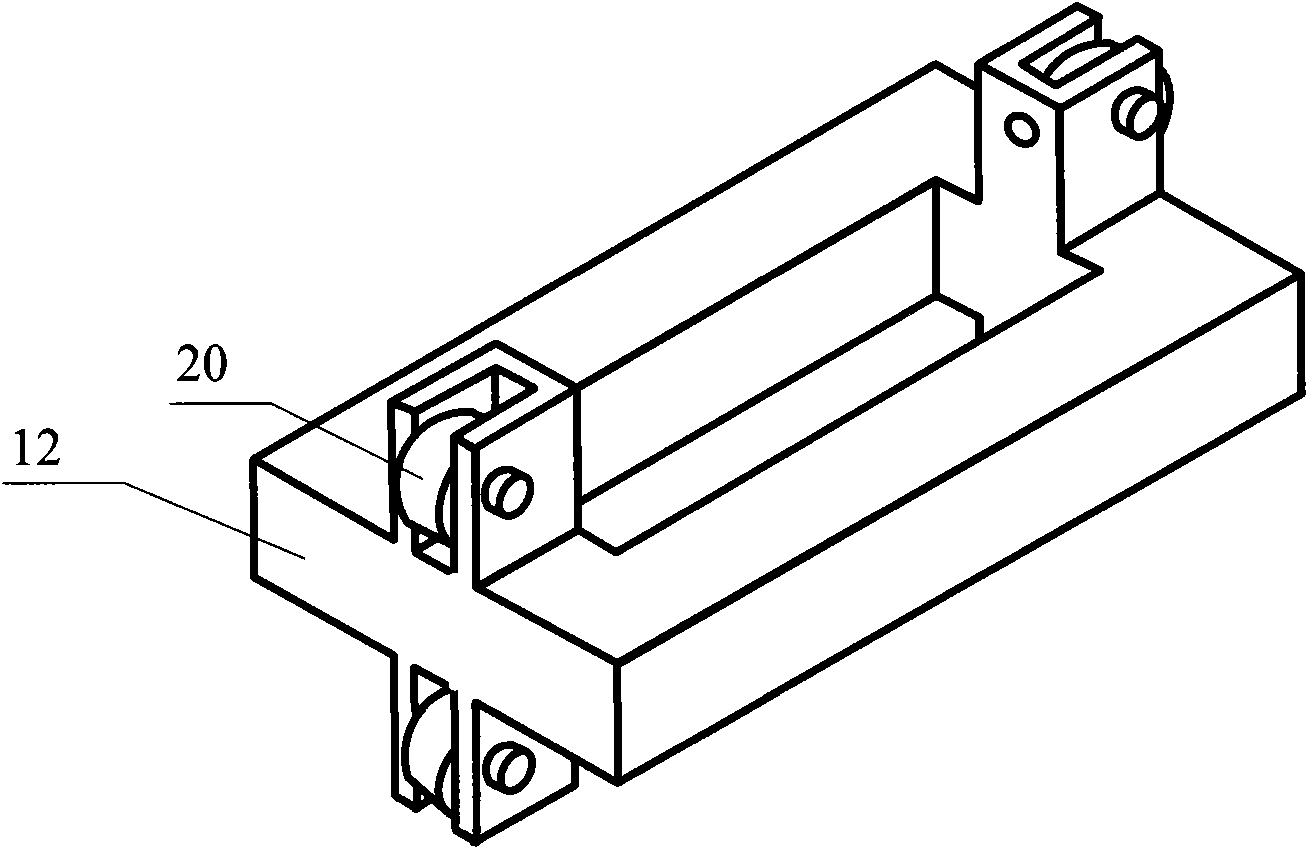

Field portable experiment system for tensile mechanical property of plant root system

InactiveCN101603899AGuaranteed tensile strengthImprove reliabilityMaterial strength using tensile/compressive forcesUsing optical meansPlant rootsPull force

The invention relates to a field portable experiment system for tensile mechanical property of a plant root system, which consists of a machine, a testing system, a notebook computer and a test recording software, wherein the machine comprises a fixing stand, a vertical guiding traction mechanism and a root system clamping system; the testing system comprises a left infrared distance measuring sensor, a right infrared distance measuring sensor, a tensile sensor, a tensile transducer, a data acquisition card and a sensor power module; the plant root system can be clamped by an upper clamping mechanism and a lower clamping mechanism of the root system clamping mechanism; when the upper clamping mechanism is lifted, the tensile force and deformation born by the root system is measured out by the testing system and transmitted to the portable notebook computer; a signal is analyzed through the test recording software; and the record is stored. The parts of the machine of the system can be detached into various parts or single piece, are convenient to carry, reduce spatial dimension, can be conveniently transported to a field needing to test the tensile mechanical property of the root system and test the tensile strength, deformation, strain and tensile elasticity modulus of the plant root system.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com