Patents

Literature

495results about How to "No sticking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

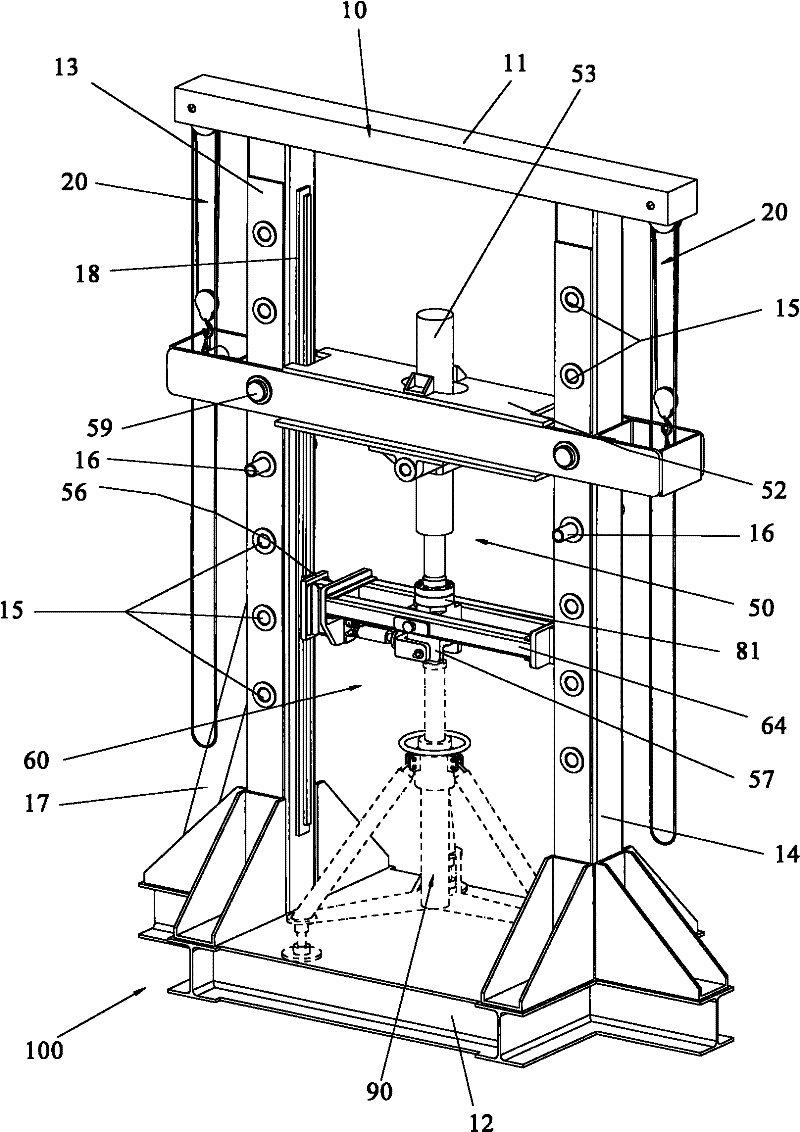

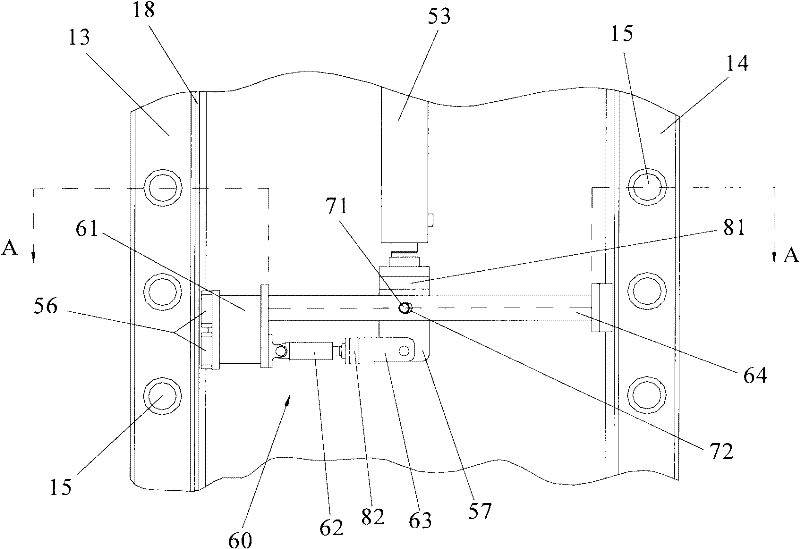

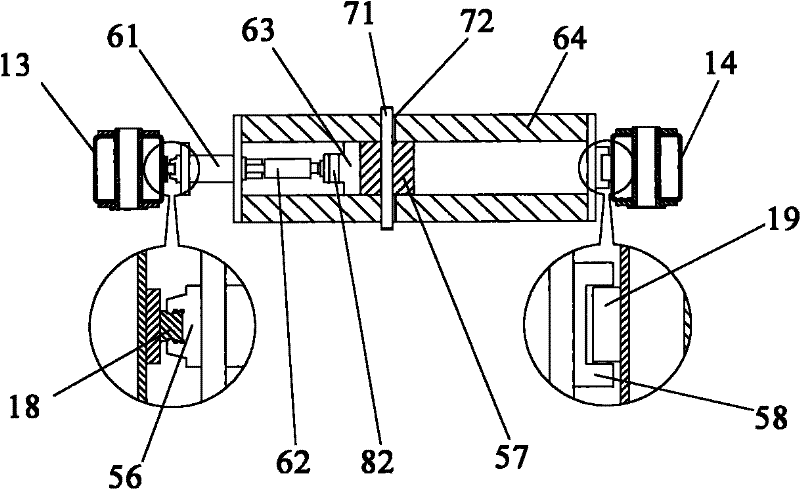

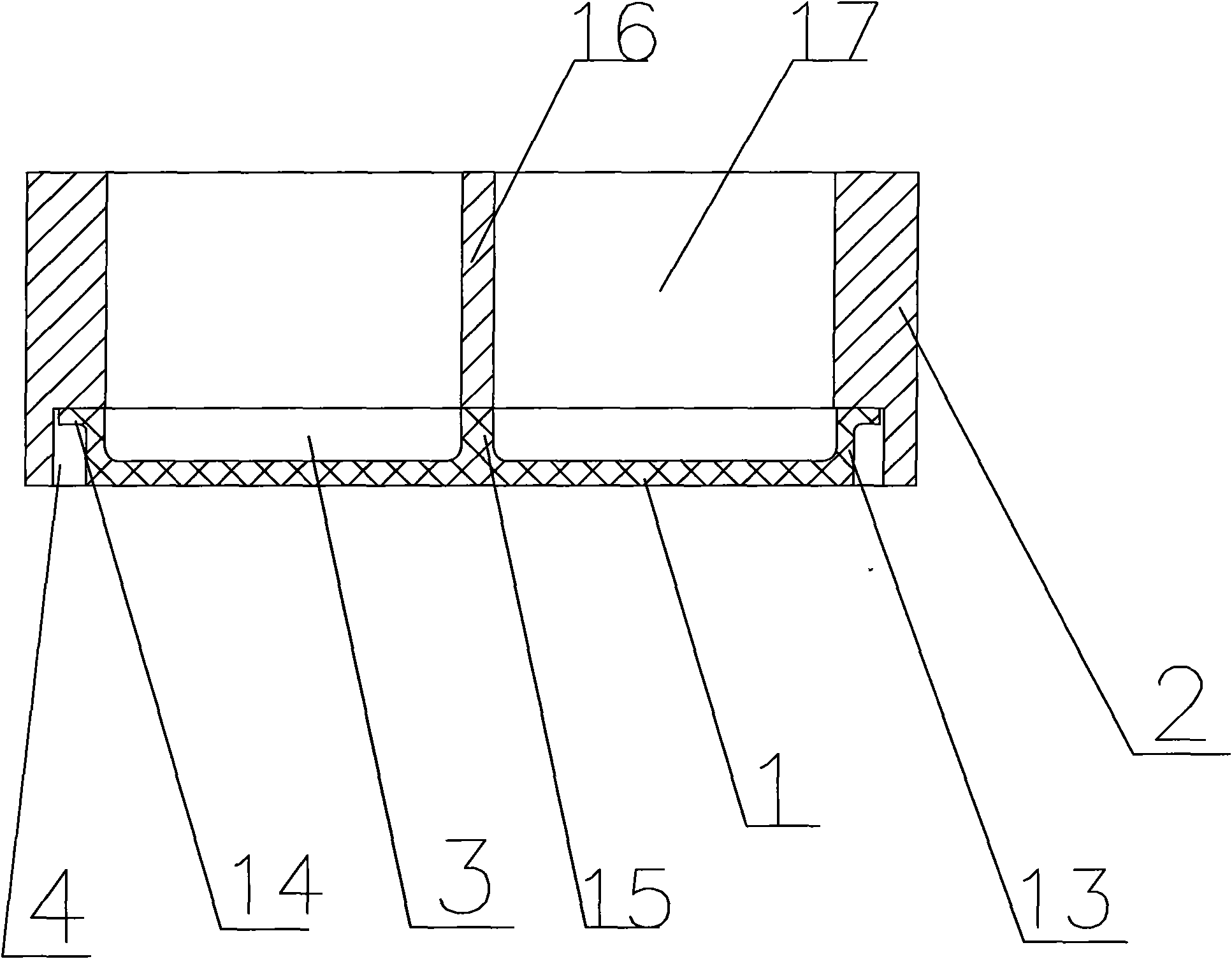

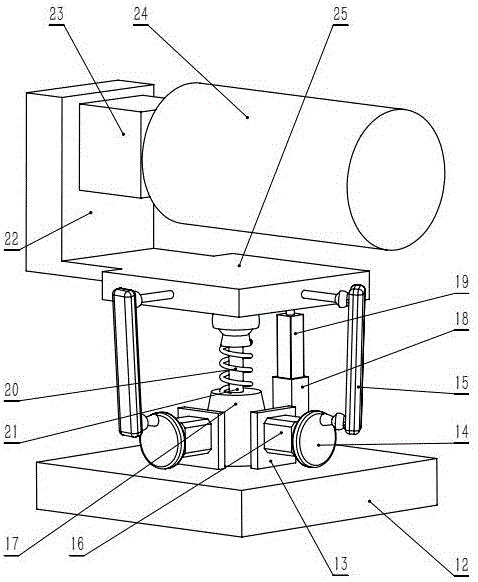

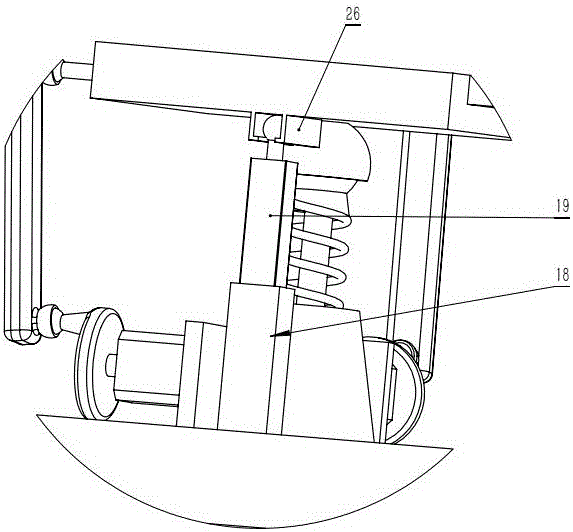

Loading test device

ActiveCN102235943ANo tiltNo stickingStructural/machines measurementEngineeringMechanical engineering

Owner:COMAC +1

Sample acquisition machine

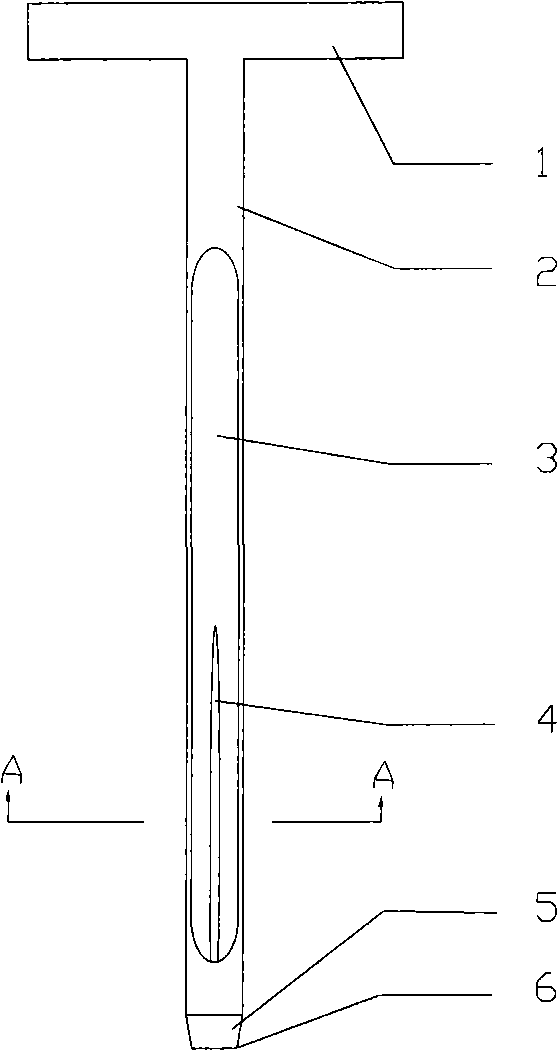

The invention discloses a soil sample collector comprising a handle, a drill rod and a drill bit. One end of the drill rod is connected with the handle and the other end thereof is connected with the drill bit; the drill rod and the drill bit is of a hollow structure; one side of the drill rod is provided with a sample outlet and the pipe wall of the other side of the drill rod is provided with a labor-saving groove; the upper end of the labor-saving groove is provided with a boosting pedal; and the drill bit is conical. The soil sample collector has the advantages and effects that the obtained soil column can separate from the inner wall of the drill rod naturally and is easy for transferring and bagging of soil samples; when the drill rod obtains the soil column, the soil column in the drill rod is easily poured out by only turning over a sample outlet downward; the handle, the drill rod and the boosting pedal are of a detachable-connected structure, thus being convenient to carry and store and having small occupied space; the boosting pedal can lead the hand and foot to apply force simultaneously; the soil sample collector is shorter in whole, smooth and portable, is easy to generate force, has small resistance, high working efficiency, simple technique, convenient material-obtaining and low cost and is convenient for promotion and application.

Owner:广东省农业科学院土壤肥料研究所

Feed raw material rich in energy and protein of omega-3 fatty acid and preparation method thereof

InactiveCN101473889AChange ingredientsChange natureAnimal feeding stuffAdditive ingredientAnti nutritional

The invention discloses a prescription for preparing an energy and protein feeding stuff raw material full of omega-3 fatty acid by using rubber seeds and a method thereof. The weight percentages of the omega-3 energy and protein feeding stuff raw materials are as follows: rubber seeds 20-80%, bean pulp, corn, rapeseed cake (pulp), cottonseed cake (pulp), rice bran and wheat bran or any combination thereof 20-80%. The preparation method is as follows: the exuviated and dried rubber seeds are mixed with various ingredients evenly and puffed, and then finished product is gained. By the invention, the nutrient components such as omega-3 fatty acid, energy and protein and the like contained in the rubber seeds can be used fully, meanwhile, anti-nutritional components such as hydrocyanic acid and the like contained in the rubber seeds are removed, the energy and protein raw materials full of omega-3 fatty acid widely accepted by the feeding stuff industry and applicable to various birds, livestock and fish feeding stuff are processed. The price of the energy and protein raw material is low.

Owner:云南三环生物技术有限公司

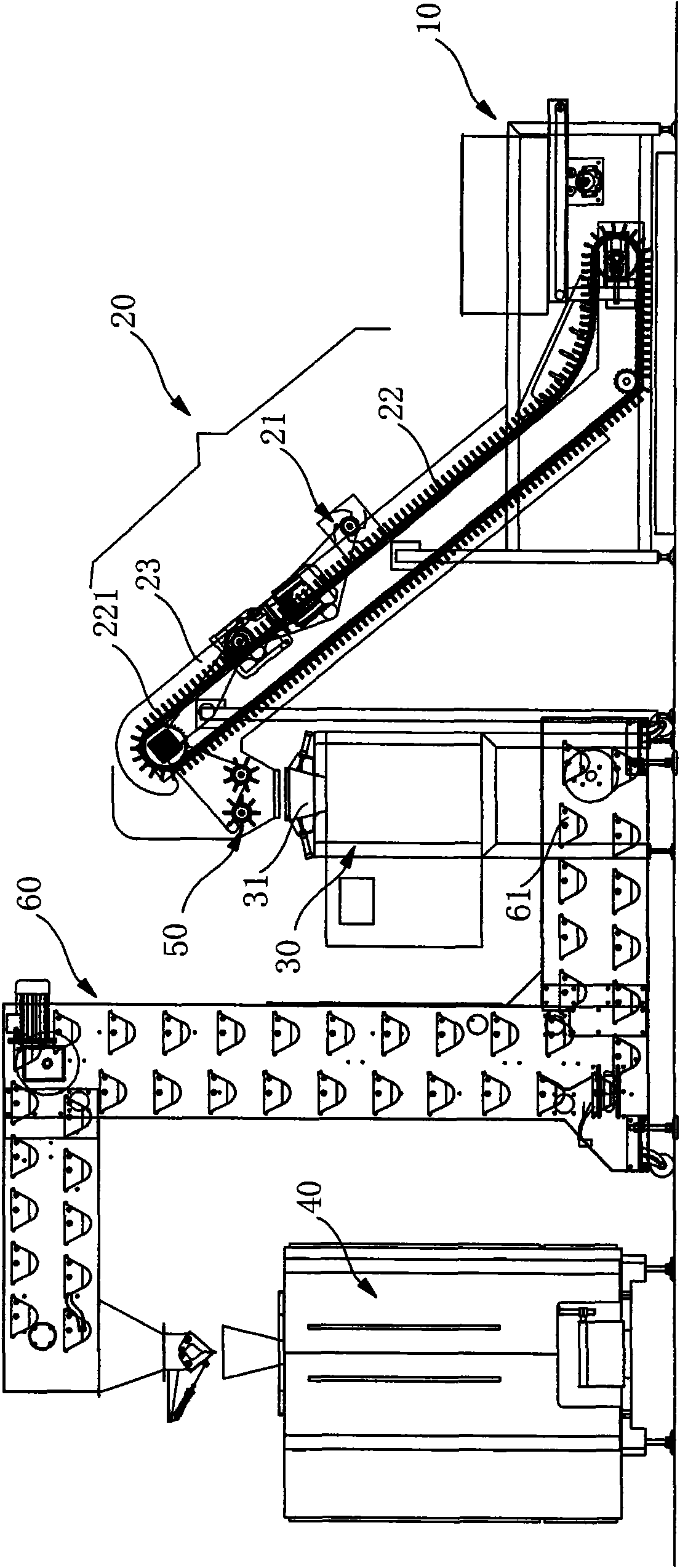

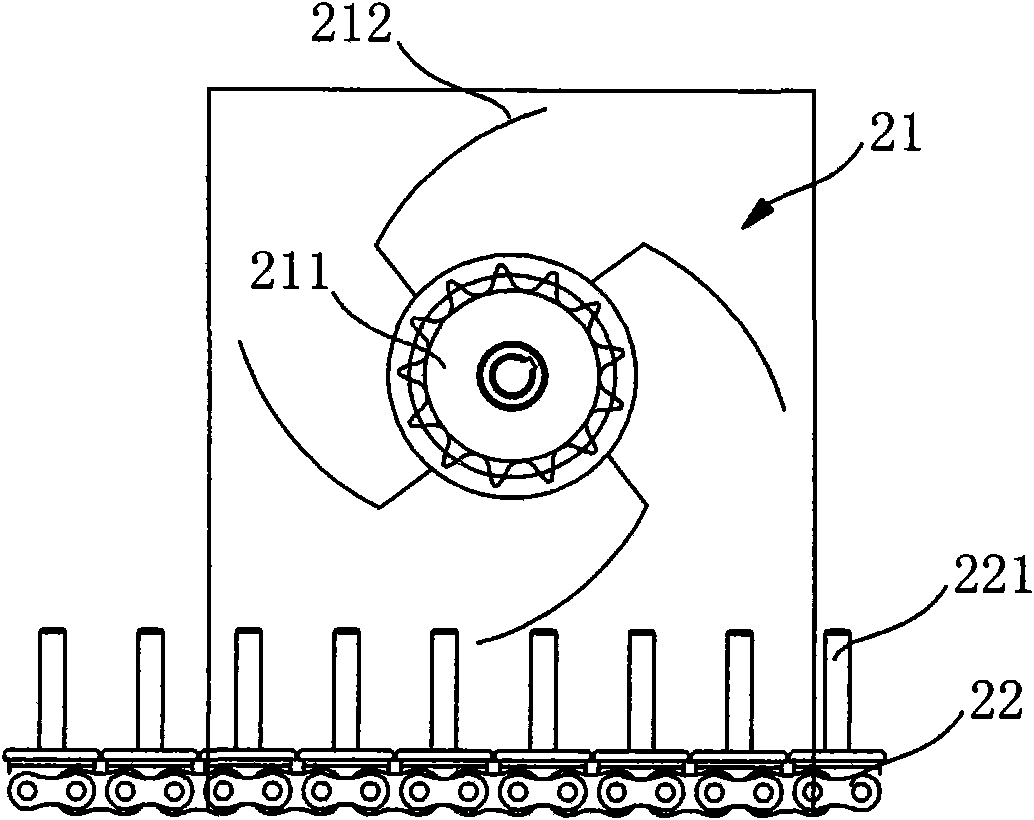

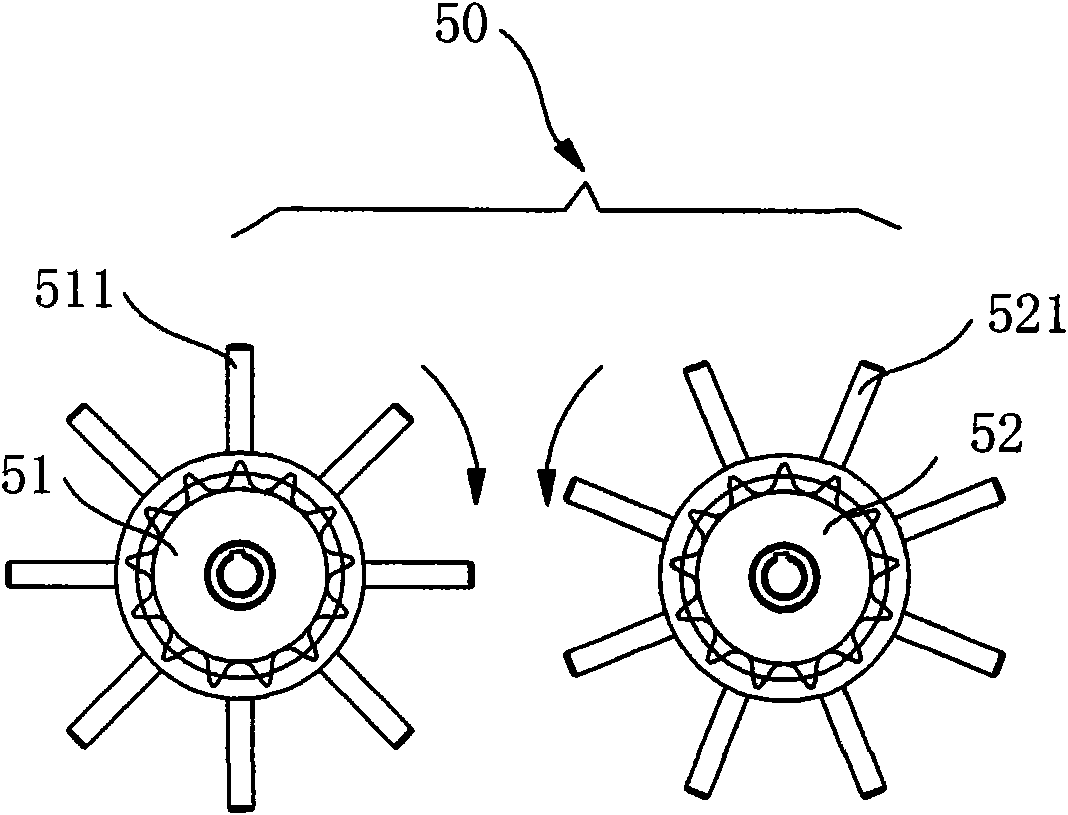

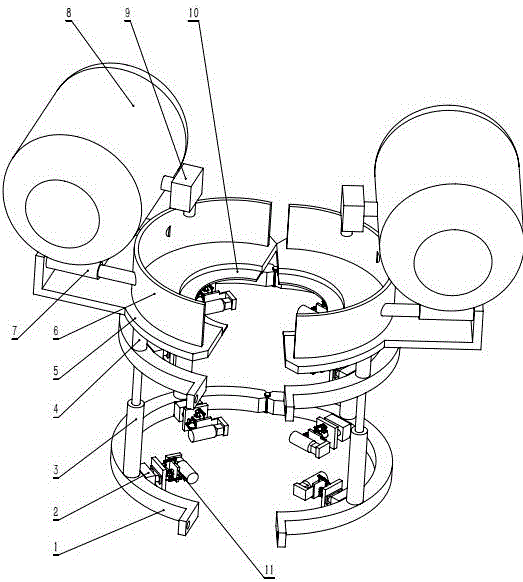

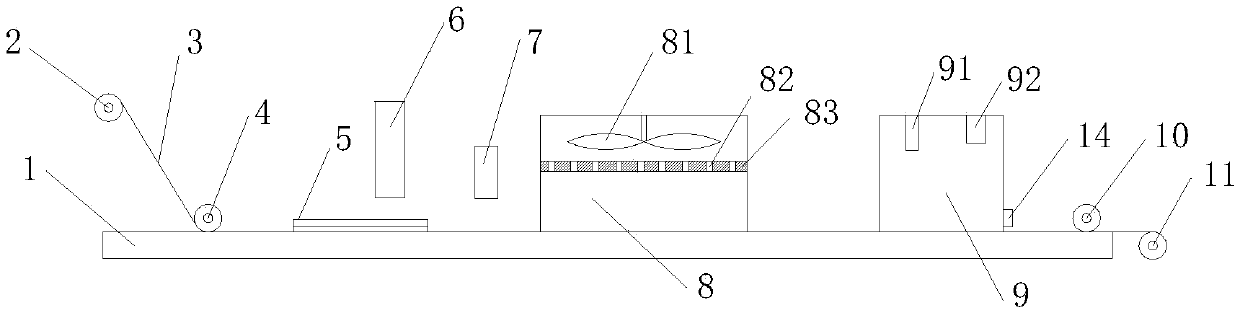

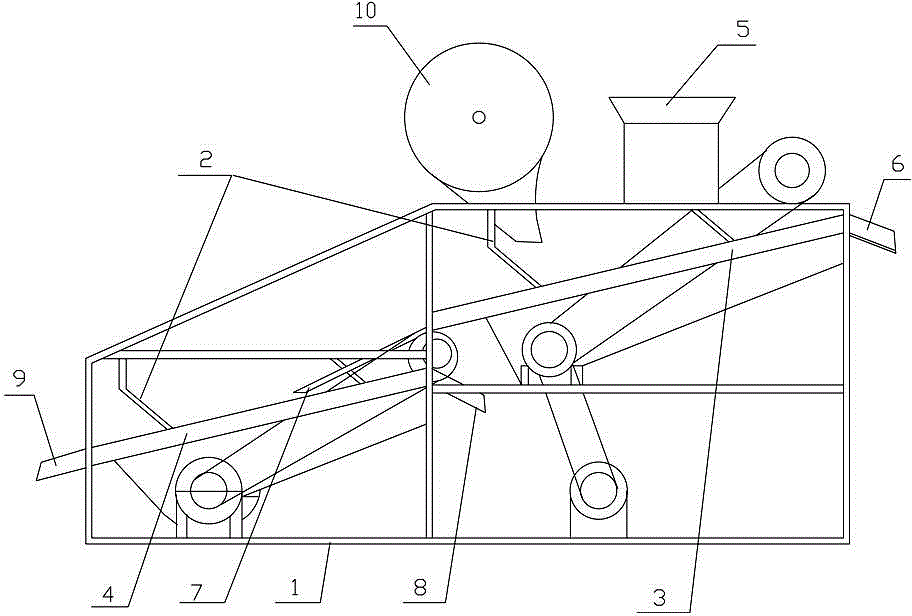

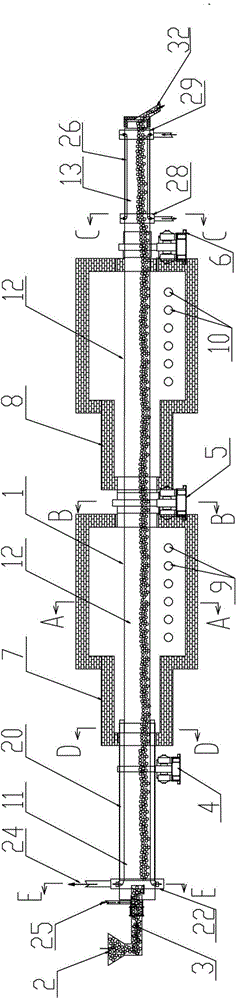

Automatic weighing and packaging system of strip-shaped materials

InactiveCN101654153AHigh precisionUniform thicknessPackaging automatic controlEngineeringMechanical engineering

The invention relates to an automatic weighing and packaging system of strip-shaped materials, in particular to a system for automatically feeding, weighing, bag-making, filling and packaging materials, mainly aiming at strip-shaped materials. The materials are conveyed into a lifting device by a feeding device, then weighed by a weighing device and quantitatively conveyed into a packaging deviceby a conveying device, and a carding mechanism is arranged on the lifting device. In the technical scheme, the carding mechanism is arranged on the lifting device, the materials are conveyed into thelifting device by the feeding device and then combed by the carding mechanism so that the materials are adjusted and combed into a straight state; the thickness of a material layer on the lifting device is also ensured to be even while the materials are combed into the straight state, and the adhesion phenomenon can not be generated, therefore, the weighing and metering accuracy of subsequent materials is improved.

Owner:ANHUI XINYUAN PACKING TECH

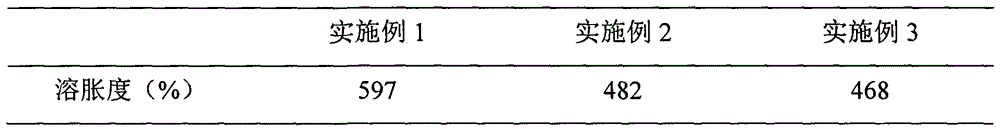

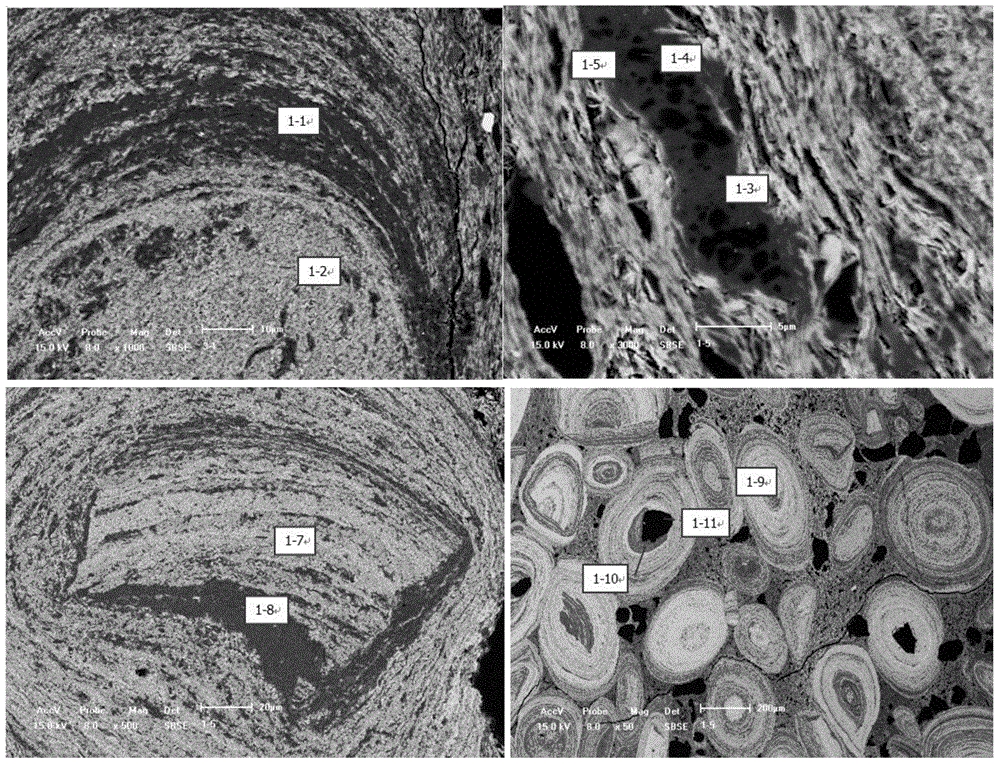

Superfine fiber polyurethane synthetic leather base fabric and preparation method thereof

ActiveCN101851865AEasy to processGood dimensional stability of the finished productMelt spinning methodsConjugated synthetic polymer artificial filamentsPolytetramethylene terephthalateMicrofiber

The invention discloses superfine fiber polyurethane synthetic leather base fabric and a preparation method thereof. The superfine fiber polyurethane synthetic leather base fabric comprises the following components based on weight percent: 15-58% of nylon6; 2-40% of polyester elastomer and 30-56% of polyurethane resin. The elastic polyester is selected from one or more from TPEE (Thermoplastic Polyester Elastomer) and polytrimethylene terephthalate; and the TPEE is a linear segmented copolymer with the hard segment of PBT (Polybutylene Terephthalate) and the soft segment of aliphatic polyester. In the invention, the synthetic leather base fabric has excellent elasticity and resilience and is easy to process, and the size stability of the finished product is good. The zonal elasticity of the finished product base fabric is further higher than the radial elasticity thereof, and the zonal resilience of the finished product base fabric is more remarkable than the radial resilience thereof, thereby the finished product base fabric can meet the requirements of clients on the unidirectional high resilience of the superfine fiber synthetic leather.

Owner:HUAFON MICROFIBER SHANGHAI

Polyester film with adhesion resisting function and preparation method of polyester film

ActiveCN102744945AGood thermal stabilityReduce environmental pollutionSynthetic resin layered productsChemistryPolyester

The invention discloses a polyester film with an adhesion resisting function. The polyester film is of a structure comprising a layer A, a layer B and a layer C, wherein the layer A and the layer C are surface layers; the layer B is a core layer; the layer A comprises the components of 65-80 percent of polyester slice for a general film and 20-30 percent of general adhesion resisting agent; the layer B comprises the components of 80-85 percent of master batch polyester slice for a functional film, 3-5 percent of general adhesion resisting master batch and 12-15 percent of high-performance adhesion resisting agent; and the layer C comprises the components of 50-65 percent of polyester slice for the general film and 35-50 percent of general adhesion resisting agent. The high heat resistance and excellent adhesion resistance are achieved by the steps of slicing, mixing, melting co-extrusion, longitudinal drawing, transverse drawing, drawing and trimming, coiling, splitting and forming a finished product. The products prepared by the preparation method disclosed by the invention is environment-friendly and can be directly recycled, so that the pollution to the environment is reduced; and the polyester film can be widely applied to packaging of cakes, seasonings, fast foods and candies and packaging of medical products.

Owner:JIANGSU SHUANGXING COLOR PLASTIC NEW MATERIALS

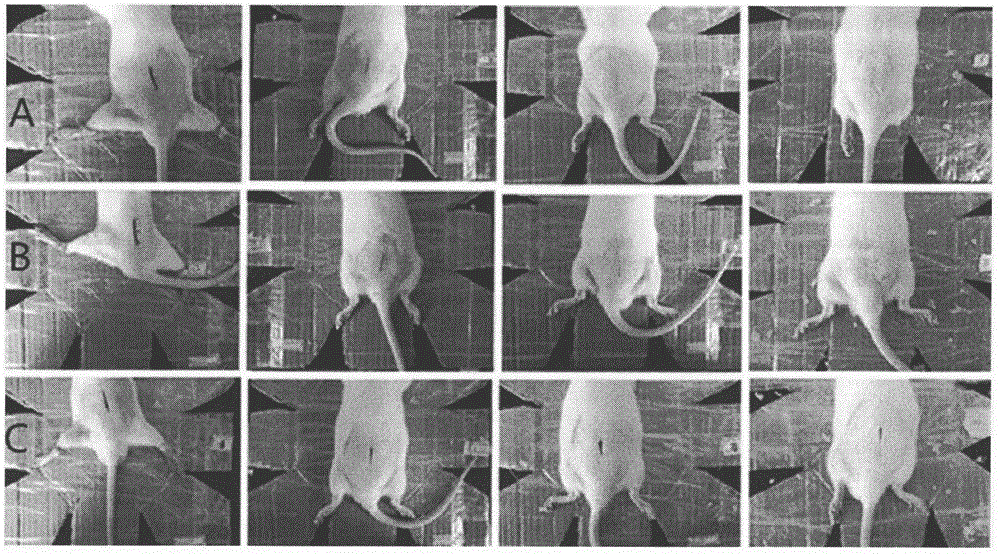

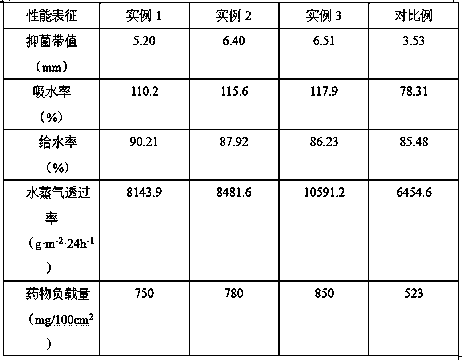

Hydrogel woundplast containing traditional Chinese medicine extracts and preparation method thereof

InactiveCN106310350AEasy to prepareGood biocompatibilityPharmaceutical delivery mechanismAbsorbent padsGlycerolPolyvinyl alcohol

The invention relates to a hydrogel woundplast containing traditional Chinese medicine extracts and a preparation method thereof. The hydrogel woundplast comprises a back lining layer, a medicated hydrogel layer and a stripping layer. The preparation method comprises the following steps: uniformly mixing the following components in percentage by weight: 0.5-4.0% of chitosan, 1.0-3.0% of polyvinyl alcohol, 0.2-1.0% of gelatin, 1.0-3.0% of glycerol, 0.5-2.5% of menthol, 0.2-1.0% of coptis extract, 1.0-2.5% of honeysuckle flower extract, 15-25% of anhydrous ethanol and 50-80% of distilled water; performing cyclic refrigerating-melting treatment to obtain the medicated hydrogel layer; bonding the back lining layer on one side of the hydrogel layer; and bonding the stripping layer on the other side of the hydrogel layer. The hydrogel woundplast containing traditional Chinese medicine extracts is simple in structure and convenient to use, and can absorb wound surface exudates and keep wound wetness; and meanwhile, the hydrogel woundplast has the effects of resisting bacteria, diminishing inflammation and stopping bleeding, and can effectively accelerate wound healing.

Owner:CHINA PHARM UNIV +1

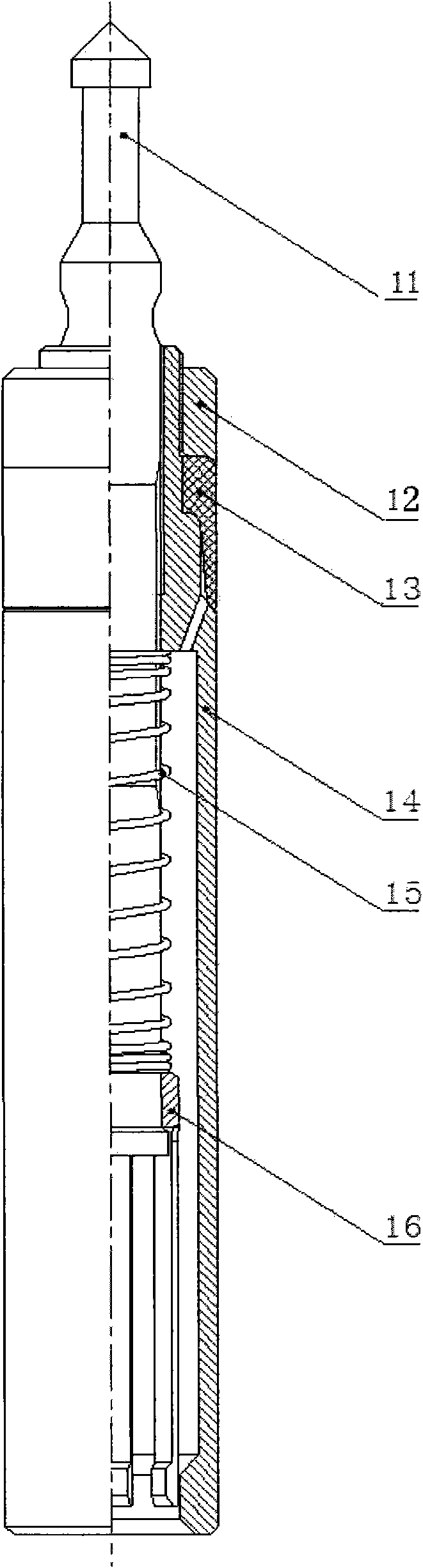

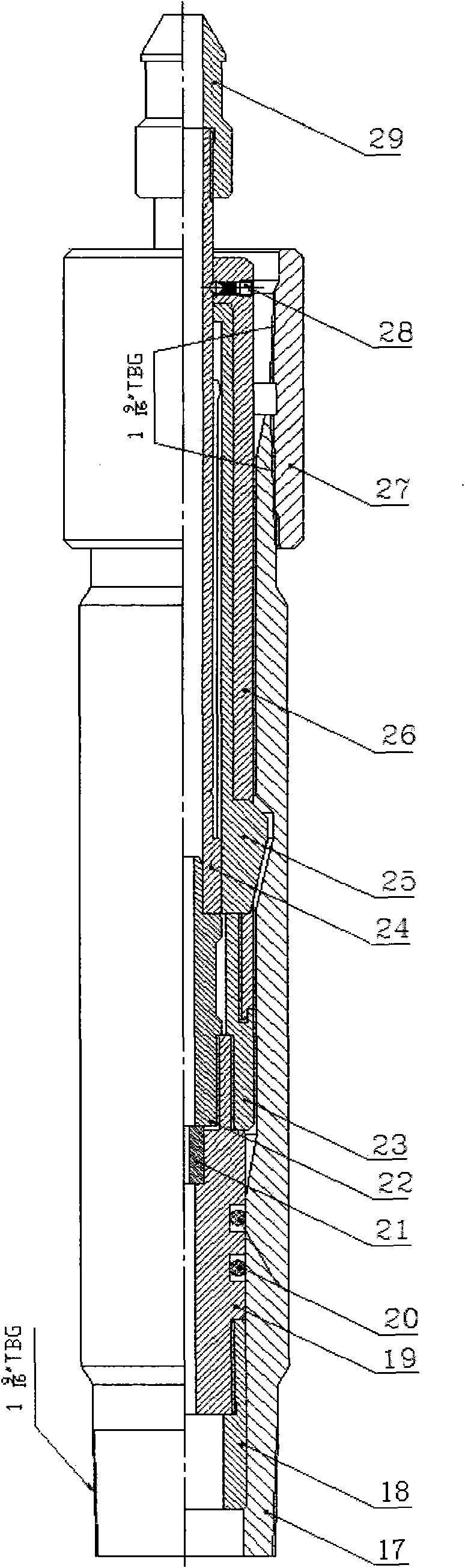

Method for throwing and fishing out underground restrictor from gas well without utilizing steel wires

The invention relates to a method for throwing and fishing out an underground restrictor from a gas well without utilizing steel wires, which is applied to gas production in the gas well. The method comprises the following steps: before throwing, placing an underground restrictor working barrel into a position of projected depth in the gas well; then installing a throwing and fishing catcher and an underground restrictor core, throwing the underground restrictor core, enabling the underground restrictor core to enter into the underground restrictor working barrel and be automatically locked and finishing throwing the underground restrictor core; and in the process of fishing, installing the throwing and fishing catcher and a fisher and fishing out the underground restrictor core. The lifting force of natural gas flow is utilized to lift the fisher and the underground restrictor core to the ground together. The invention has the effects that the on-site operation of the underground restrictor can be more convenient under the premise of not reducing the use effect of the underground restrictor; and compared with the process of throwing and fishing out the underground restrictor by utilizing a well testing truck, the method of the invention has the advantages of simple throwing and fishing process and simple and convenient on-site operation, not only can accurately and reliably throw the underground restrictor but also save throwing and fishing time and reduce throwing and fishing expenses.

Owner:PETROCHINA CO LTD

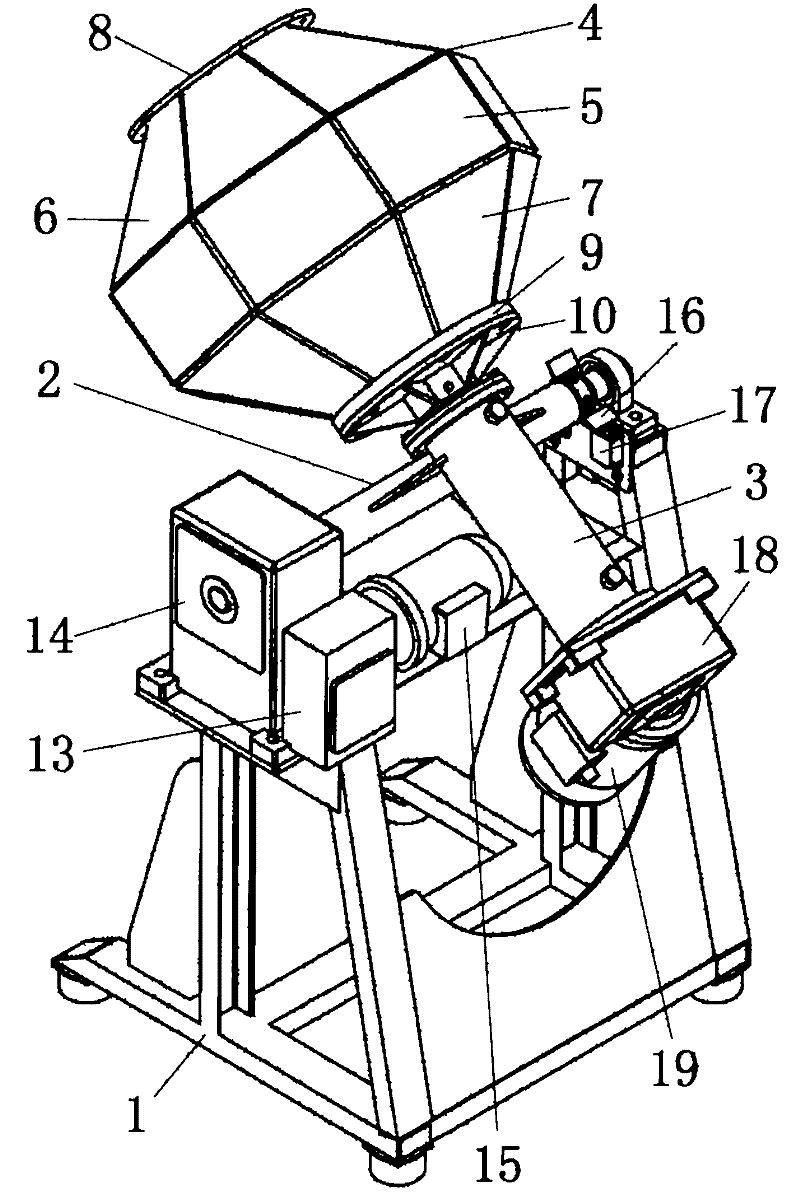

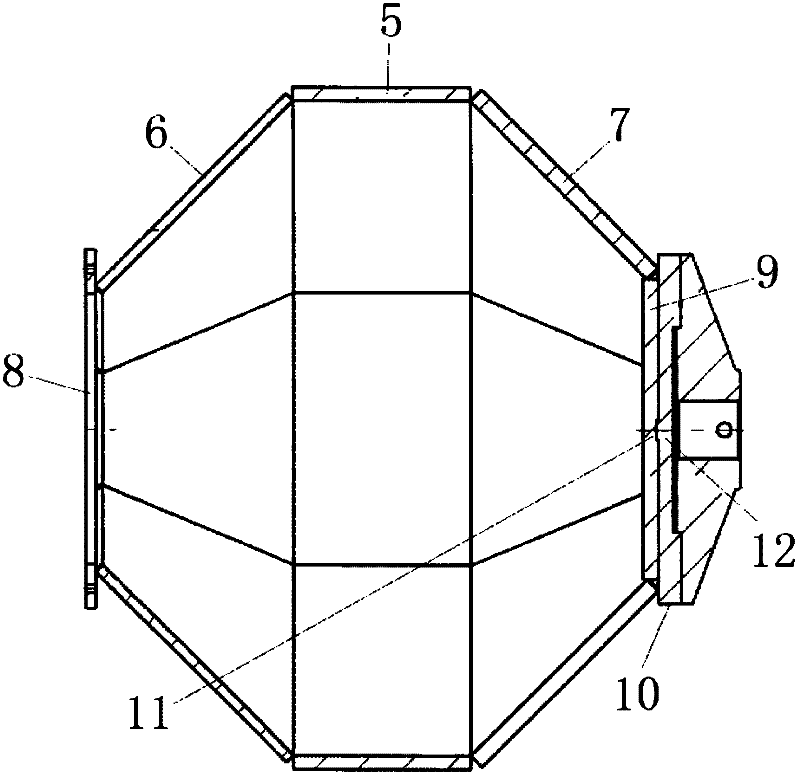

Tilting-type roller polisher machine

InactiveCN102398205ALow manufacturing and maintenance costsExtended service lifeEdge grinding machinesPolishing machinesSteel platesOpen structure

The invention discloses a tilting-type roller polisher machine. The roller (4) of the polisher machine is spliced by steel plates in different thicknesses. A feed port (8) is arranged at one end of the roller (4) while the other end opposite to the feed port (8) is driven by a rotary force to rotate automatically. The angles of depression and elevation of the roller (4) driven by a tilting force are adjusted. The roller provided by the invention is an open roller without a lining spliced by steel plates in different thicknesses so that the high temperature-resisting and wear-resisting properties of the roller are improved. As the roller provided by the invention is an open structure, the roller will not produce high pressure and high temperature steam during work so that the roller can be directly overturned to pour out the workpiece and grinding materials in the unloading process without problem of high pressure and high temperature steam jet produced to scald personnel or pollute the work site and ambient environment.

Owner:ZHEJIANG HUMO POLISHING GRINDER MFG

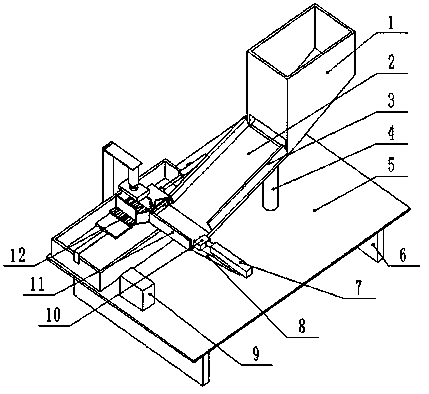

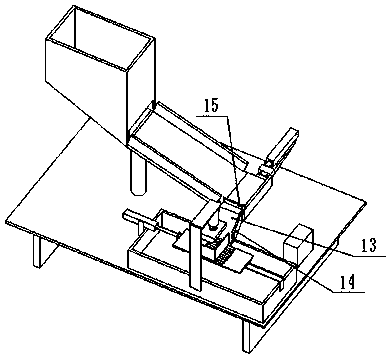

Automatic slicing device for fresh bamboo shoots

ActiveCN108262775AAvoid cloggingRealize fully automatic operationMetal working apparatusHydraulic cylinderSlide plate

The invention discloses an automatic slicing device for fresh bamboo shoots, and belongs to the field of food processing equipment. A storage box is fixed to the upper end of a second support, and a square hole is formed in the bottom end of a left-side baffle of the storage box; a slide plate is fixed between the storage box and a limit plate; a workbench is a rectangular iron plate; a first hydraulic cylinder is fixed to a first hydraulic cylinder base; a controller is fixed to the centre of the left side of the workbench; a push block is installed on the main shaft of the first hydraulic cylinder; the limit plate is installed between the slide plate and a charge port; a cutting device is fixed to the upper left corner of the workbench; the charge port is connected with the limit plate and the cutting device; and a one-way device is fixed to the limit plate. According to the automatic slicing device disclosed by the invention, a press block is driven to press the bamboo shoots through a third hydraulic cylinder, and a cutter is driven to act back and forth through a second hydraulic cylinder to cut the bamboo shoots into strips, so that manual labor is replaced, the slicing efficiency is increased, and the slicing quality is improved.

Owner:桃江县亿阳仑生态食品有限公司

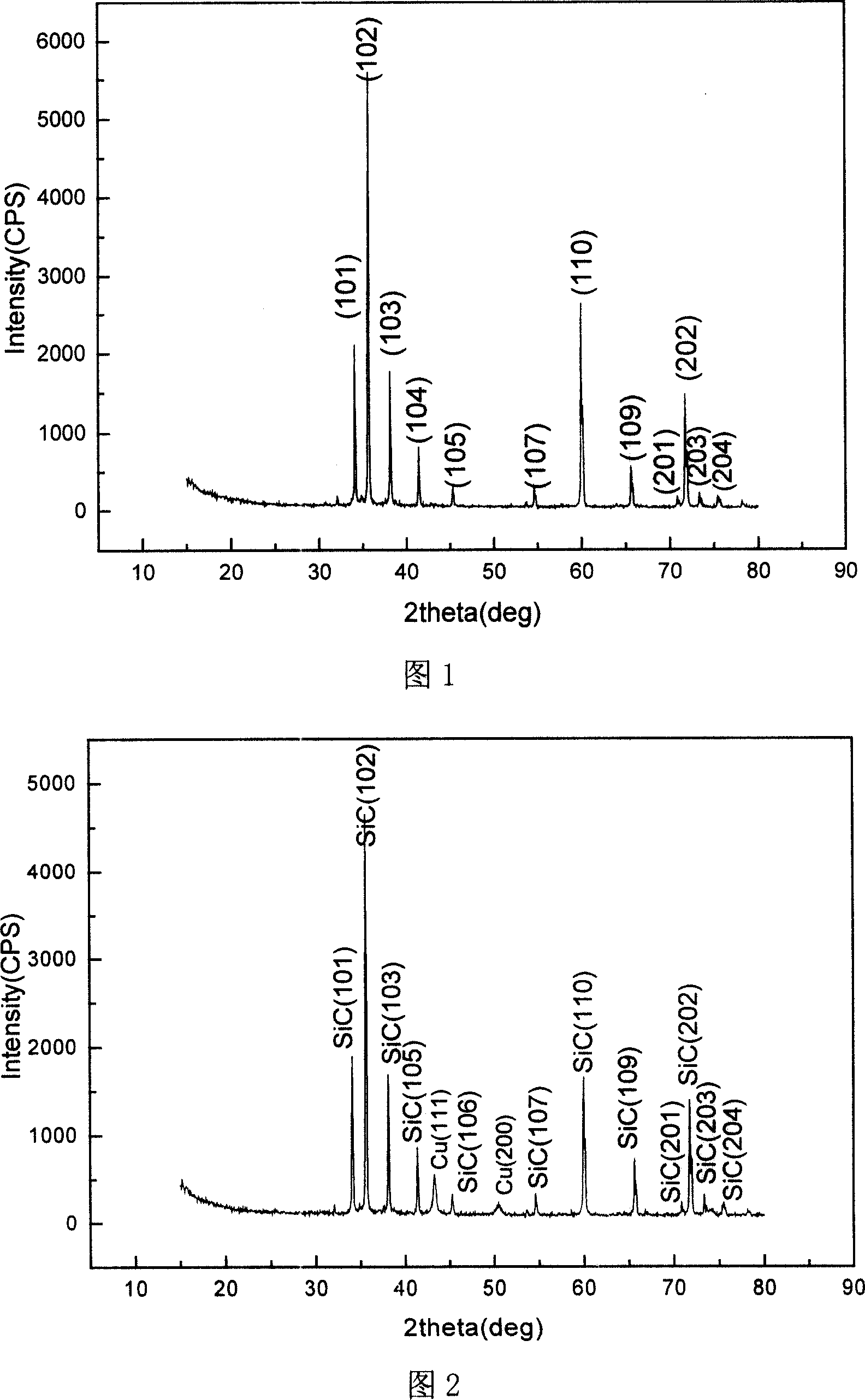

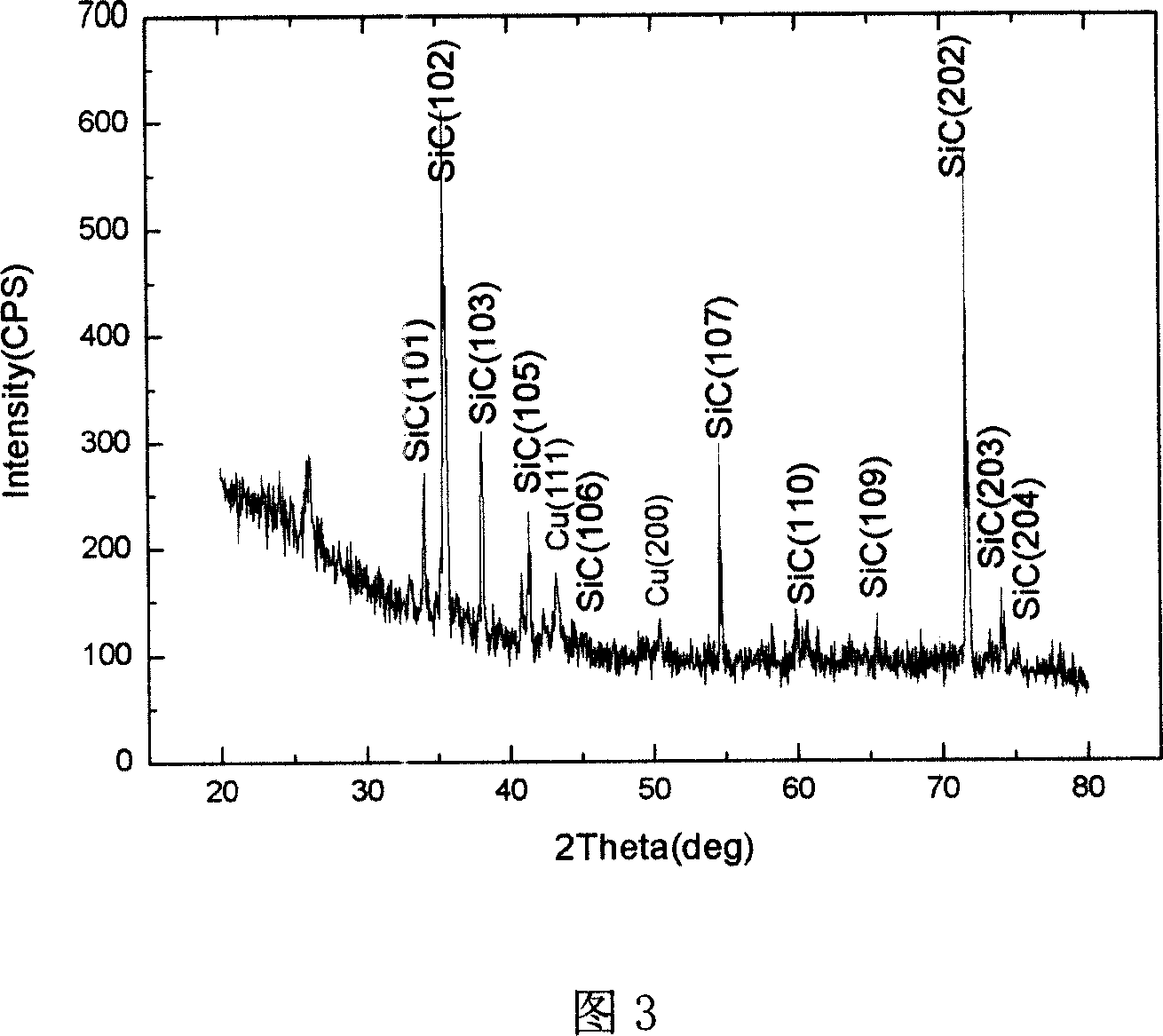

Method for magnetron sputtering coppering film on SiC micro-particle surface

InactiveCN101135045AUniform and continuous depositionImprove compactnessVacuum evaporation coatingSputtering coatingAtmospheric pressureCopper

The magnetically controlled sputtering process for coating copper film on the surface of SiC grain features that metal copper film is deposited on the surface of SiC grain in 0.1-500 micron size as the substrate inside magnetically controlled sputtering equipment with copper target of 99.999 % purity by means of regulating the vibrating power of ultrasonic wave and the oscillation frequency of sample holder to disperse SiC grains homogeneously and controlling the operation pressure inside the vacuum chamber, sputtering power, temperature, sputtering period and other technological conditions. The technological process is simple, low in cost and without waste pollution, and the prepared film is homogeneous and continuous.

Owner:CHINA NAT ACAD NANOTECH & ENG +2

Releasing agent for casting

InactiveCN105149498AEnhance self-support abilityNo pollutionFoundry mouldsFoundry coresSurface cleaningPolyvinyl alcohol

The invention belongs to the field of hub machining, and particularly discloses a releasing agent for casting. The releasing agent is composed, by mass percent, 8%-17% of sodium borate, 5%-7% of silicon dioxide, 20%-35% of ground glass, 7%-19% of a fluorinated surfactant, 1%-5% of polyvinyl alcohol, 7%-20% of sodium dodecyl benzene sulfonate and the balance silicon oil. The aim of the releasing agent is achieved better, the preparing technology is simple, the mold releasing effect is good, the concrete surface is clean, the cost is low, operation is convenient, the releasing agent is nonflammable and does not pollute the environment, the rustproof effect on an aluminum alloy template and a steel template can be further played, and the self-curing capacity of the concrete surface is improved.

Owner:河北双球新材料科技有限公司

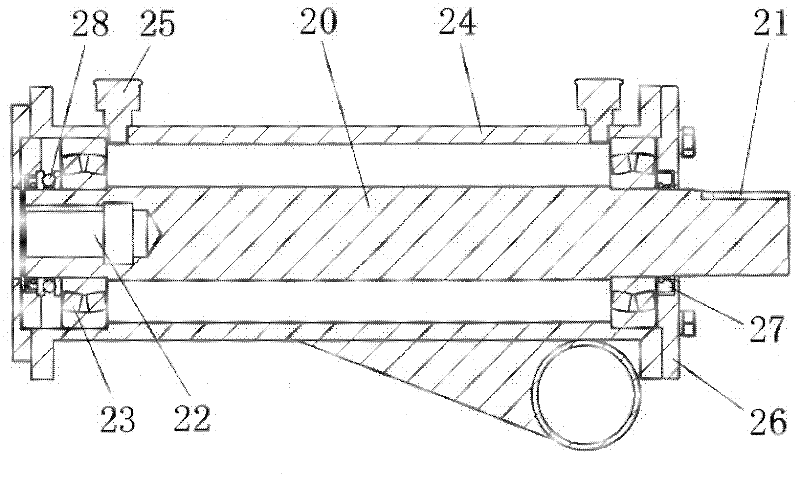

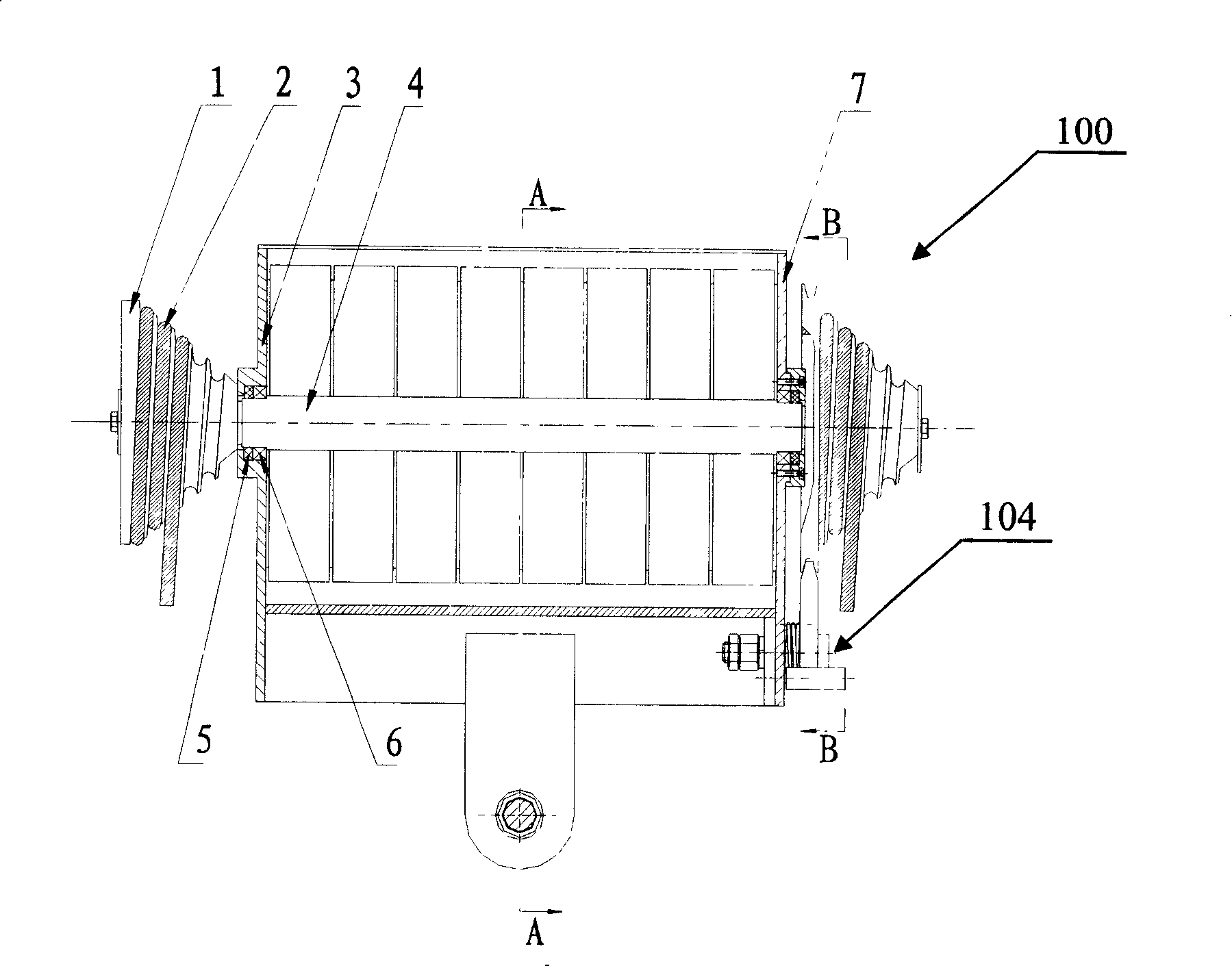

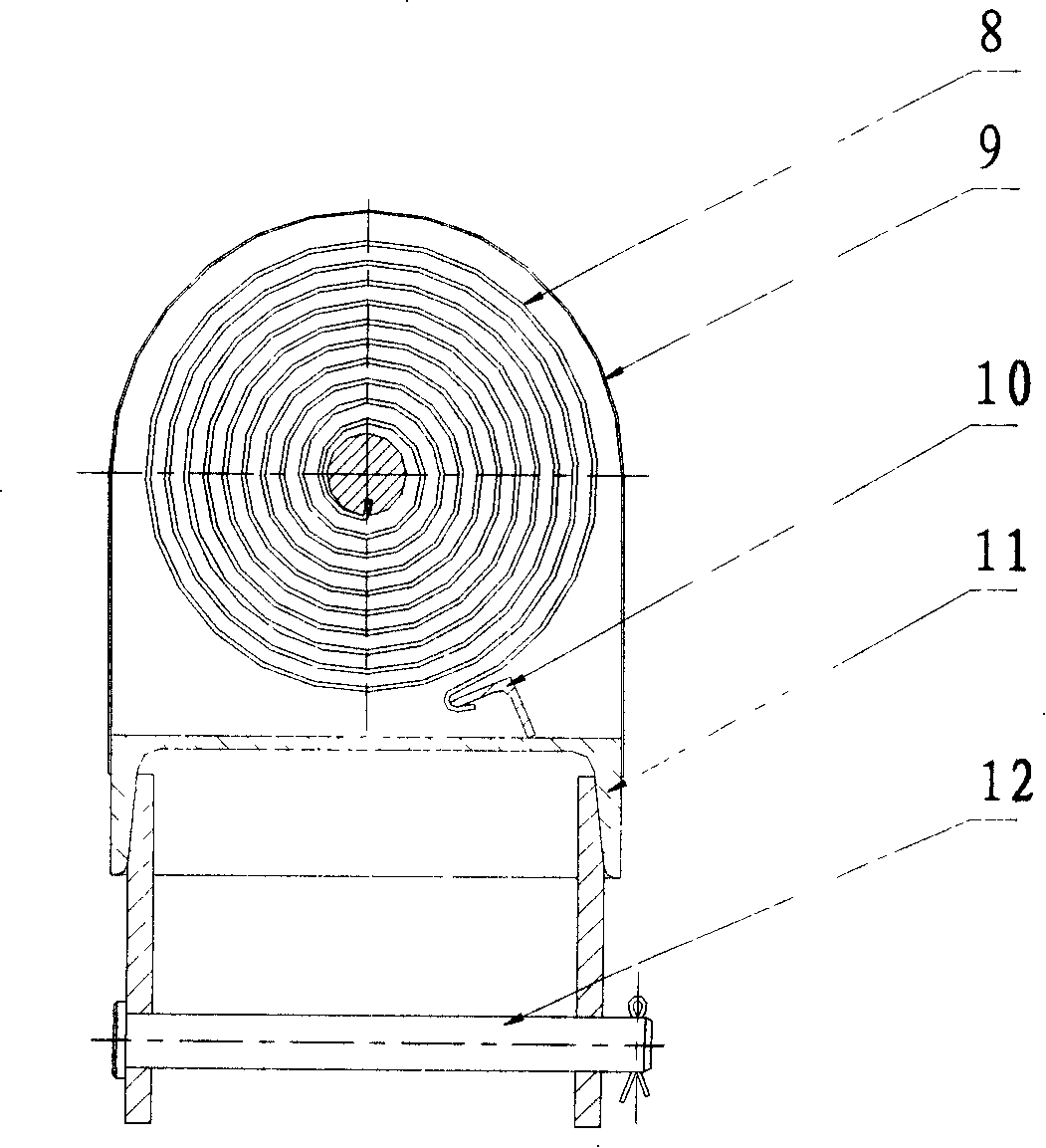

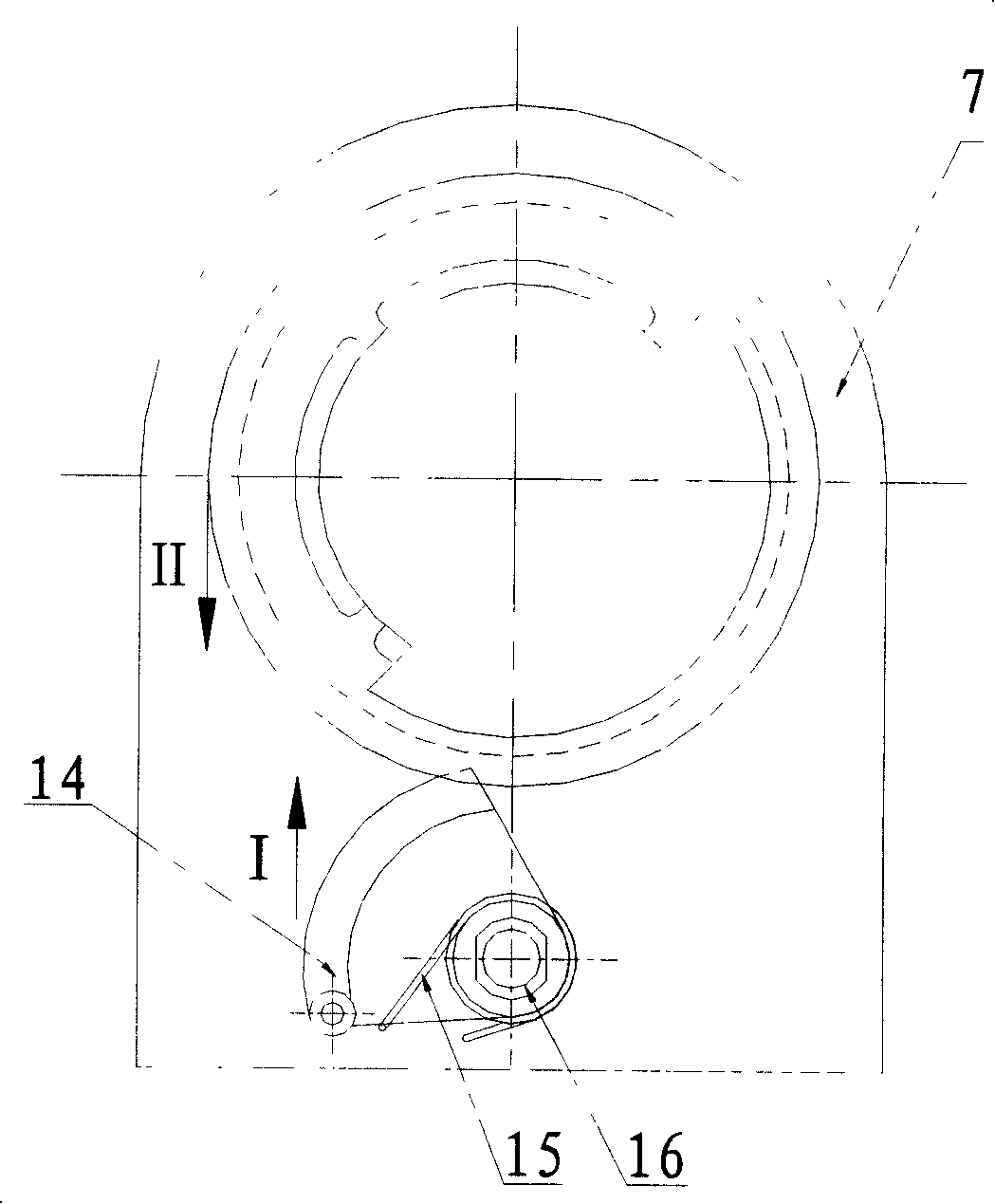

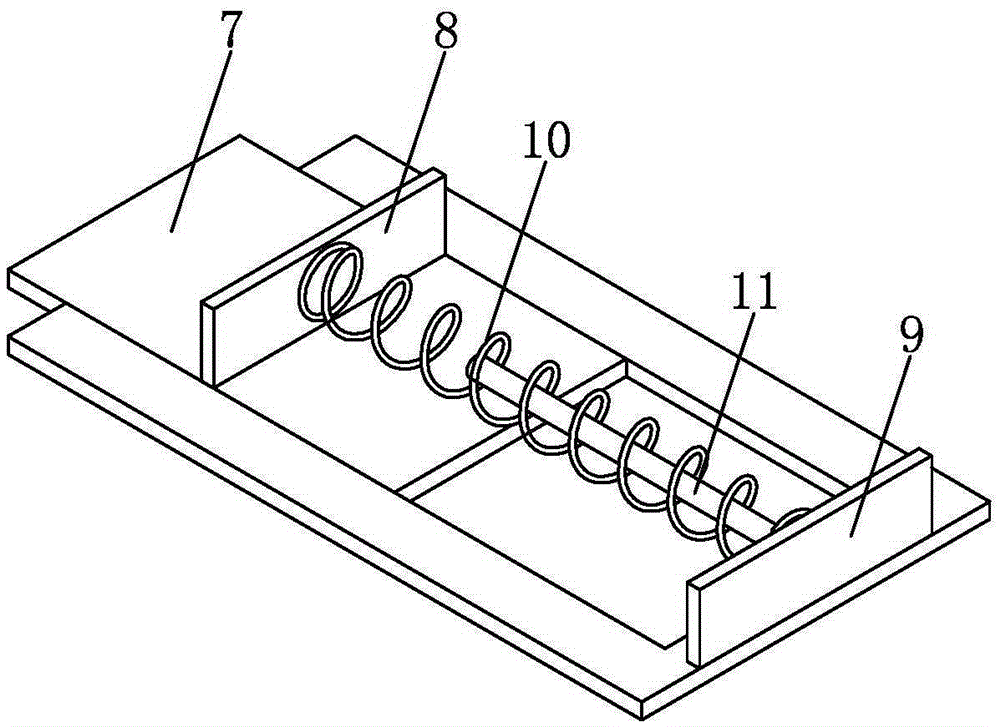

Constant tension spring compensating unit

The invention relates to a compensation device of a spring with constant tension, which essentially comprises a grooved pulley, a compensation rope, a left end plate, a main shaft, an oil seal, a bearing, a right end plate, a contact plane volute spring, an external cover, a fixed angle iron, an installation bottom plate, a hinge pin and a broken wire stopping device; wherein, the grooved pulley is fixed on the main shaft; the compensation rope is coiled and has an end fixed on the grooved pulley and the other end connected with an external contact net; the main shaft is supported on the left end plate and the right end plates by the oil seal and the bearing; the left end plate and the right end plate, the external cover, the fixed angle iron and the installation bottom plate form an enclosed box base; the hinge pin is connected to one side on the installation bottom plate far from the box base which is internally provided with the contact plane volute spring with an inner end bent hook connected with the main shaft and an outer end bent hook connected with the fixed angle iron on the box base. The compensation device of the spring with constant tension provided by the invention is compact in structure, small in size and light in weight. The invention can cause an electrified railway network to keep certain tension and reduce the loss catenary rate of the pantagraphs.

Owner:帖荣俊 +4

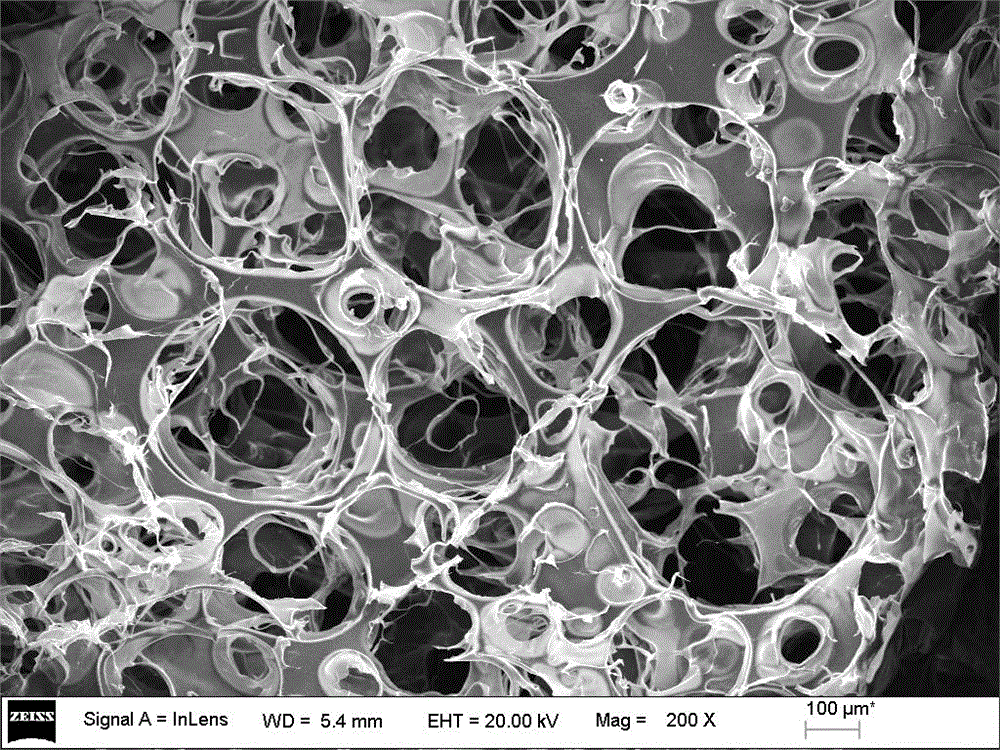

Compound dressing with high liquid absorption performance and preparation method of compound dressing

InactiveCN106344952AGood tissue compatibilityImprove the ability to absorb exudatePharmaceutical delivery mechanismAbsorbent padsFreeze-dryingMechanical property

The invention relates to compound dressing with high liquid absorption performance and a preparation method of the compound dressing. The compound dressing is prepared from chitosan serving as a raw material and consists of a supporting layer and a functional layer, wherein the supporting layer is functional nonwoven cloth; the functional layer is prepared by performing water dissolving, macromolecular crosslinking, foaming, freeze drying and the like on carboxymethyl chitosan. The compound dressing is high in mechanical property and pore-forming property; furthermore, by the compound design of a dual-layer structure, the liquid absorption performance is higher than that of common dressing, and the compound dressing is suitable for perpendicular absorption application. Chitosan is a natural macromolecular polymer and belongs to aminopolysaccharide, so that the dressing is high in mechanical property, high in seepage absorption, and also high in biological compatibility, degradability and nontoxicity, can induce tissue regeneration and remodeling, can effectively promote healing of a wound, and is a more ideal healing promotion material.

Owner:QINGDAO CHENLAND MARINE BIOTECH CO LTD

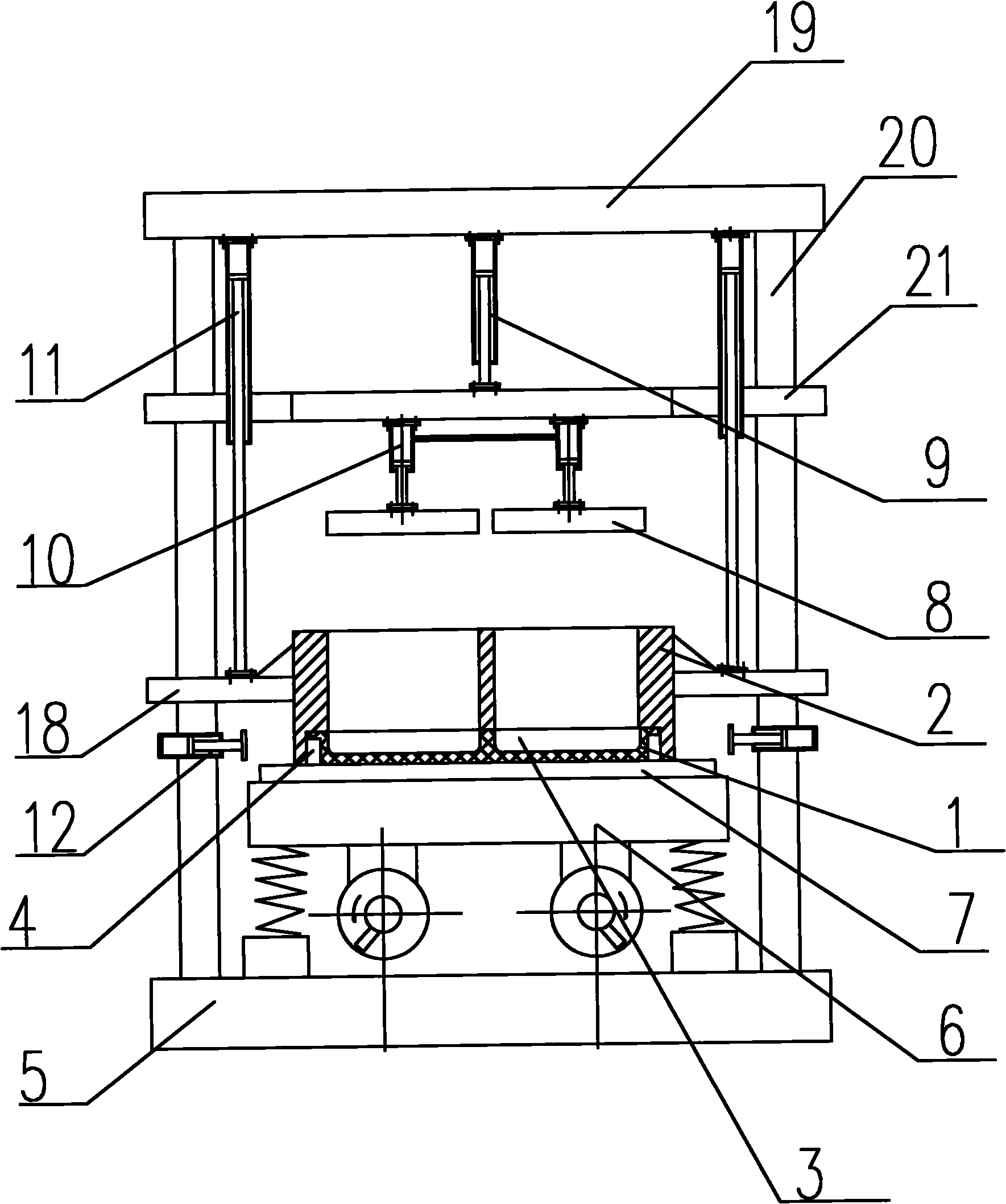

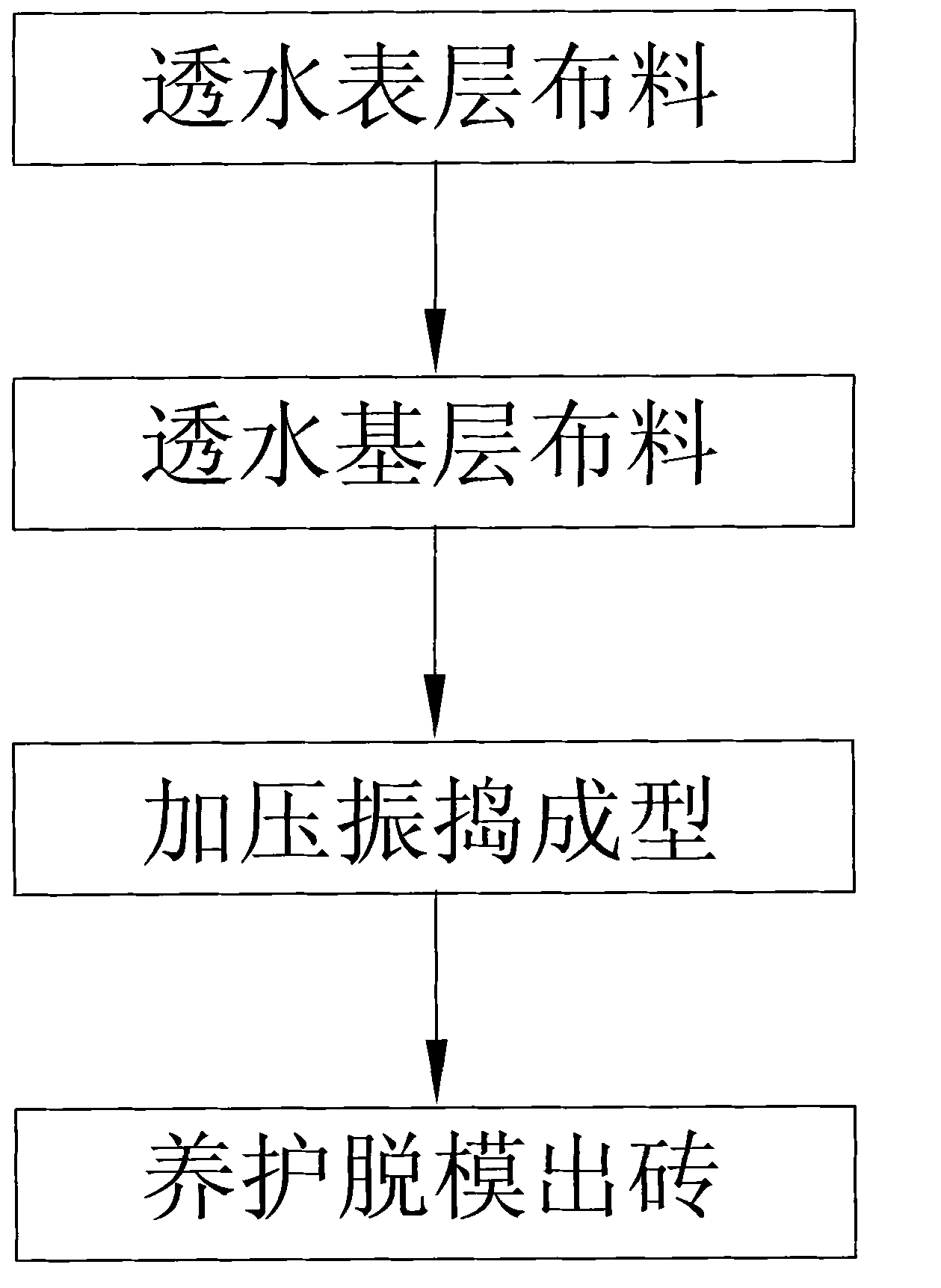

Production technology of composite water permeable brick

The invention relates to the field of composite type building materials, in particular to a production technology of a composite water permeable brick. The production technology of the composite water permeable brick comprises five steps of water permeable surface layer distribution, water permeable basement layer distribution, pressurization vibration forming, demoulding and maintenance brick delivery. In the pressurization vibration forming, pressure balanced devices which are respectively connected with each pressure head control the mould pressing pressures thereof, and the water permeable basement layer distribution also comprises a step of fixing a bottom die at the corresponding position of an upper die. The bottom die completes the water permeable basement layer distribution before being transferred to a compacting press, so the method of the invention prevents the pressure heads from being contacted with viscous materials; and meanwhile, a distribution treatment device smoothly clears up the materials of a water permeable surface layer, so the pollution and material bonding of the pressure heads are avoided, the surface quality and compactionness of the produced water permeable bricks are ensured to be uniform.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

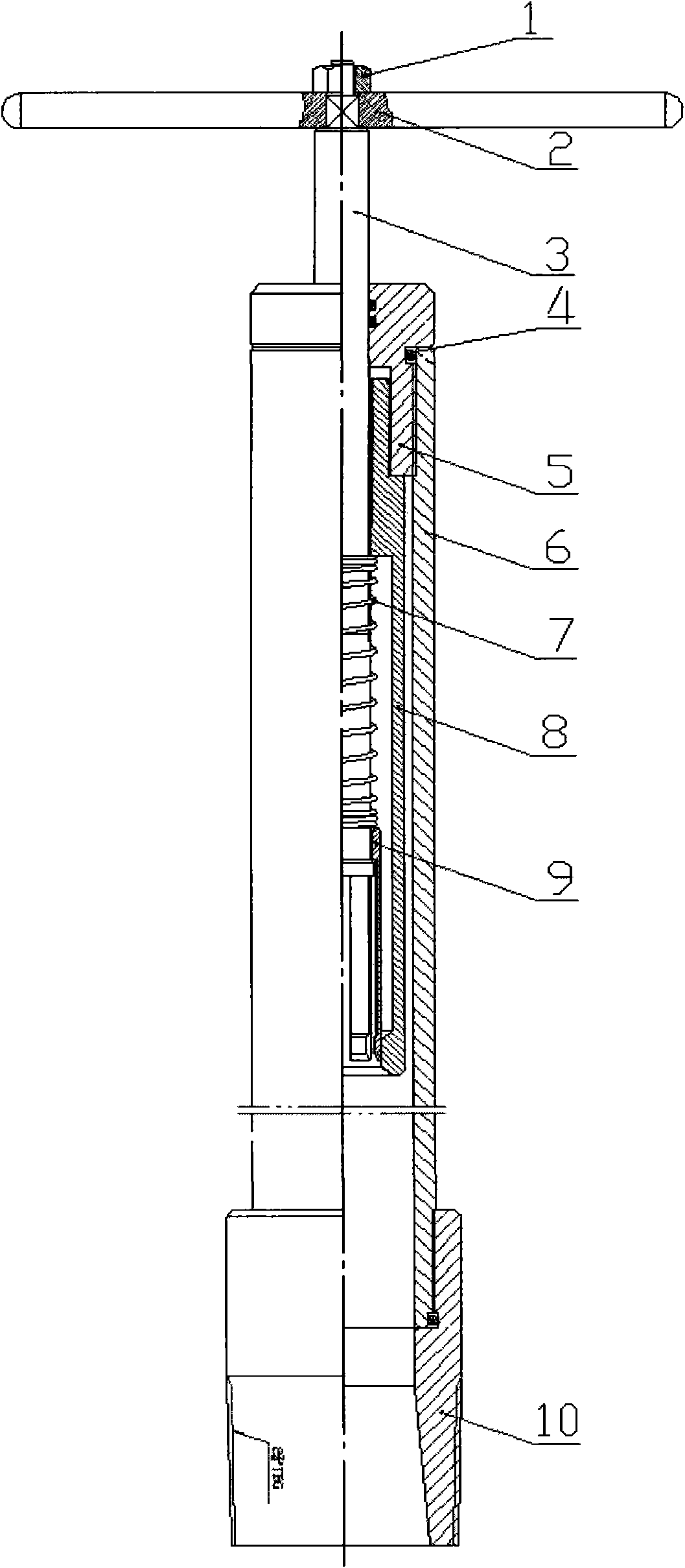

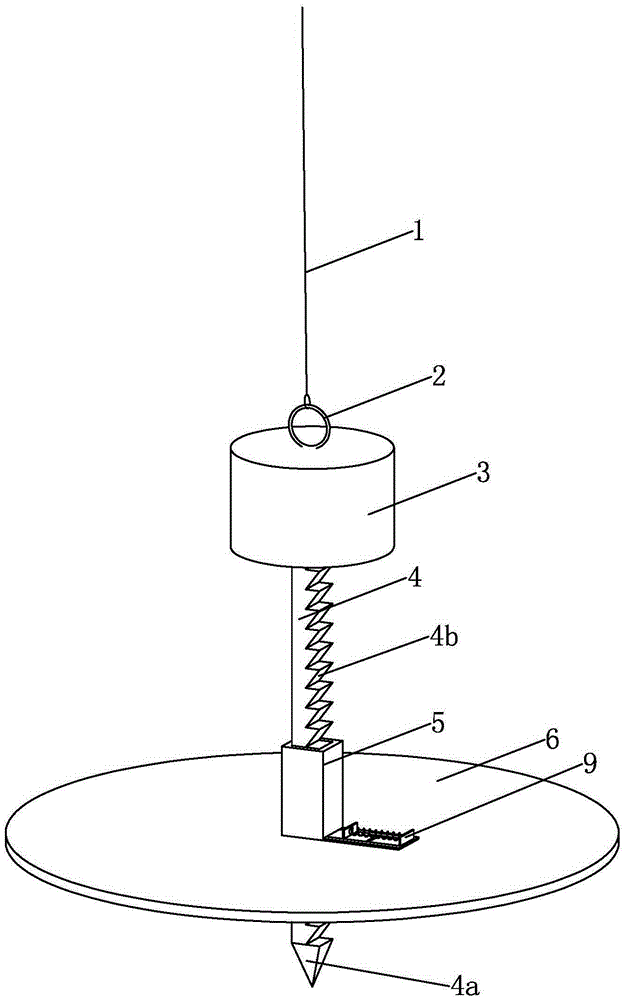

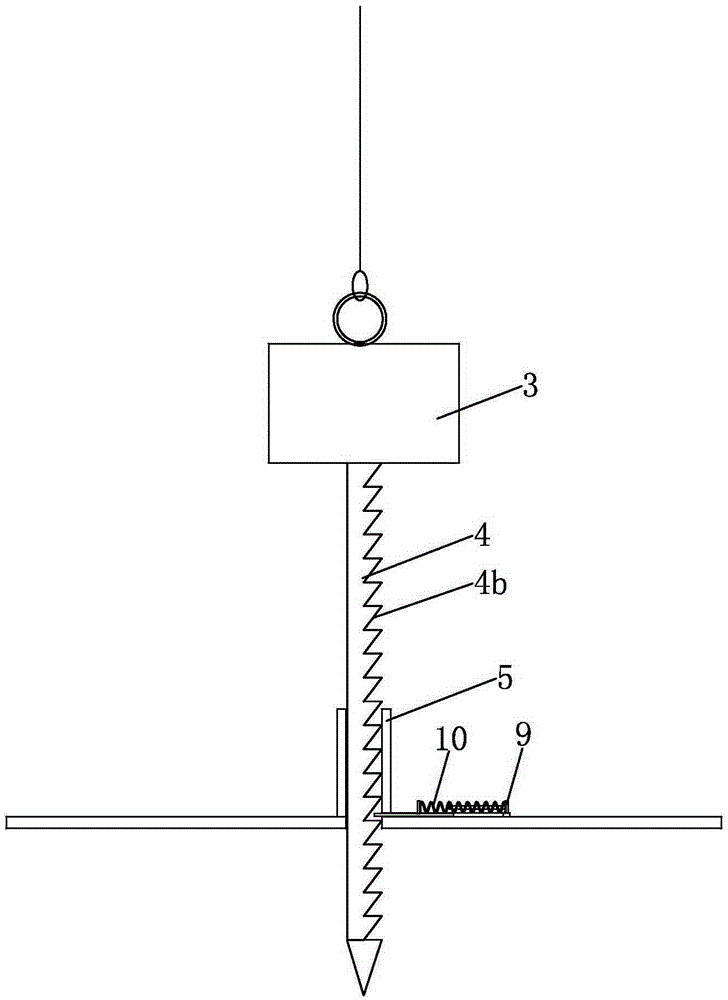

Rotary excavating pile sediment thickness measurer

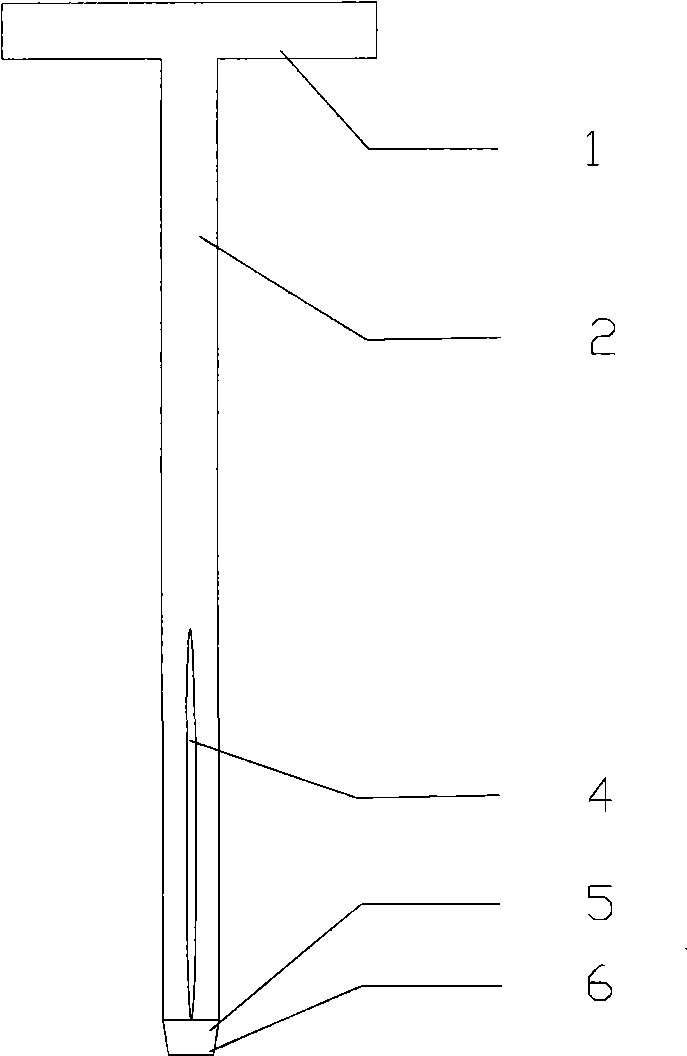

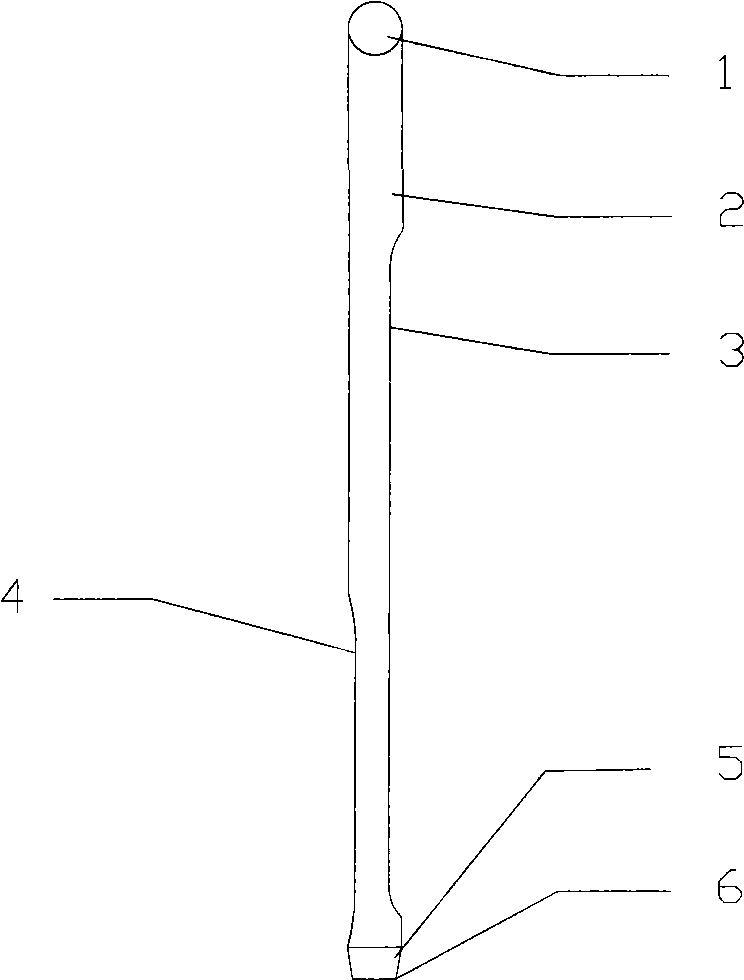

InactiveCN105352405AHigh measurement accuracyEasy to measureMechanical thickness measurementsMeasuring rulerEngineering

The invention discloses a rotary excavating pile sediment thickness measurer. The lower end of a lifting rope is fixed to a lifting lug; the upper end of a measuring ruler is fixed to the center of a bottom surface of a balancing weight, the lower end of the measuring ruler is a tip end, and a top surface of the tip end is a flat surface; a side face of the measuring ruler is provided with measuring scales along a length direction from the lower end to the upper end, each scale value of the measuring scales is 5mm, the bottom of the tip end corresponds to the ''zero'' point of the measuring scales, and the scale value of the upper end of the measuring scales is larger than 50cm; and one end face of the measuring ruler is provided with a set of sawteeth along the length direction which extend from the upper end of the tip end to the upper end of the measuring ruler. The rotary excavating pile sediment thickness measurer provided by the invention can measure the sediment thickness of each position, and can automatically measure a maximum sediment thickness, the measurement accuracy is high, measurement is simple, convenient and rapid, and the measurement efficiency is substantially improved.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

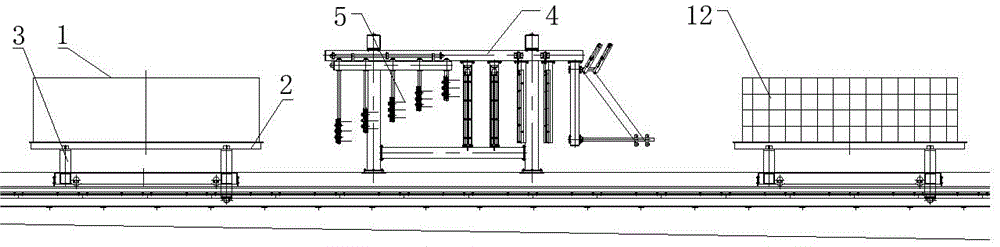

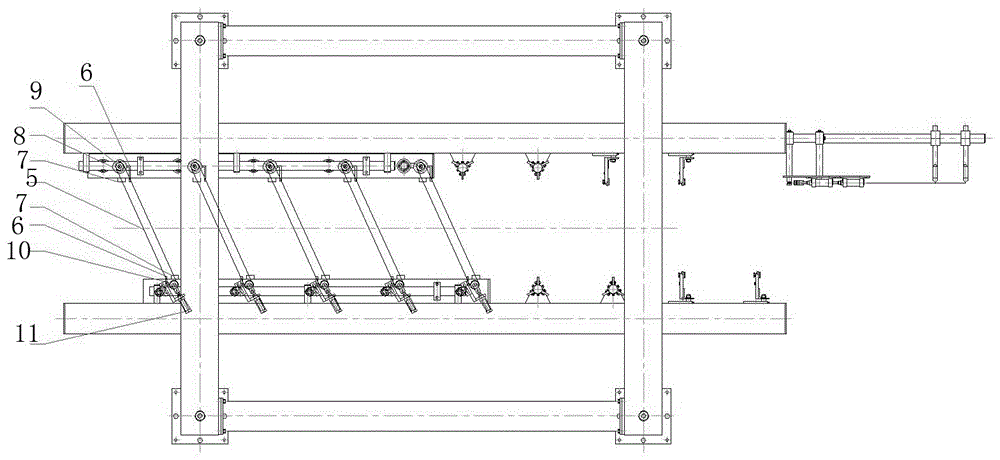

Horizontal cutting technology and cutting equipment for aerated concrete block

The invention discloses a horizontal cutting technology for an aerated concrete block. The horizontal cutting technology comprises the following steps: an aerated concrete block green body is provided, wherein the aerated concrete block green body is a green body prepared by the processes such as dosing, stirring, pouring and resting; the aerated concrete block green body and a side plate bearing the aerated concrete block green body in resting are arranged on a cutting trolley as a whole; the cutting trolley bears the aerated concrete block green body and moves towards a cutting device; when the cutting trolley bears the aerated concrete block green body and moves, a cutting steel wire cuts the aerated concrete block green body in the horizontal direction; and after the horizontal cutting, a layer of paraffin is formed on the cutting surface of the obtained aerated concrete block green body. The sticking of the cut aerated concrete block is avoided, and the yield of the aerated concrete block is increased.

Owner:SHANDONG GAOTANG TIANQI HYDRAULIC MACHINERY

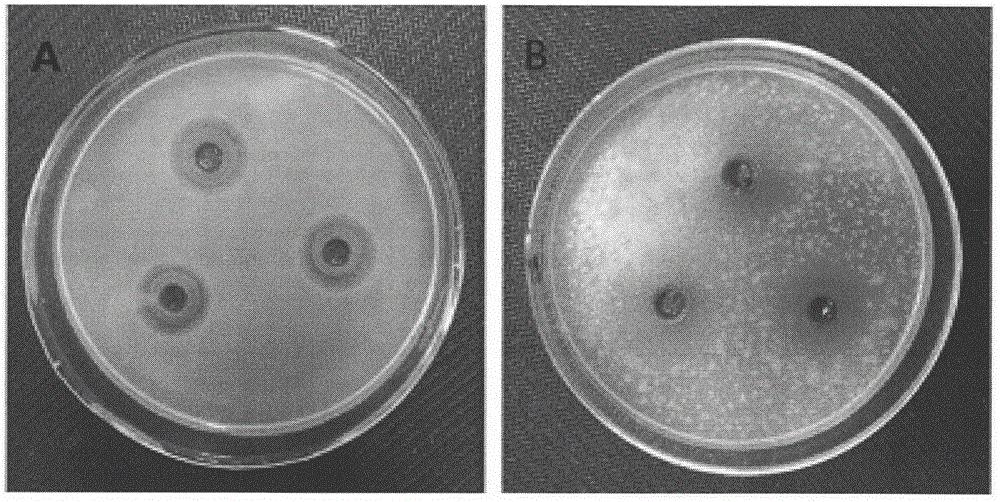

Preparation method of bacterial cellulose-based antibacterial dressing

InactiveCN108066814AImprove water absorptionGood biocompatibilityBandagesWound healingBiocompatibility Testing

The invention relates to a preparation method of a bacterial cellulose-based antibacterial dressing, and belongs to the technical field of medicinal materials. Silver nitrate, zinc nitrate, a trisodium citrate solution and the like are mixed into a silver and zinc antibacterial agent; then, the silver and zinc antibacterial agent is adhered to the surface of bacterial cellulose through a dopaminepolymerization reaction; through the silver and zinc ion reducing and chelating effects of the bacterial cellulose and polydopamine, spherical or subspheroidal nanosilver and nanozinc are produced byan in-situ silver and zinc ion reducing method; the nanosilver and the nanozinc are face-centered cubic crystal forms and are uniformly distributed in a three-dimensional network structure of the bacterial cellulose to prepare the bacterial cellulose-based antibacterial dressing which has good water absorbability and biocompatibility, can play roles in absorbing an exudate at a wound, keeping thewound moist, cleaning the wound and accelerating wound healing, can be closely adhered to the uneven wound without conglutination and is easy to replace.

Owner:常州市协旺纺织品有限公司

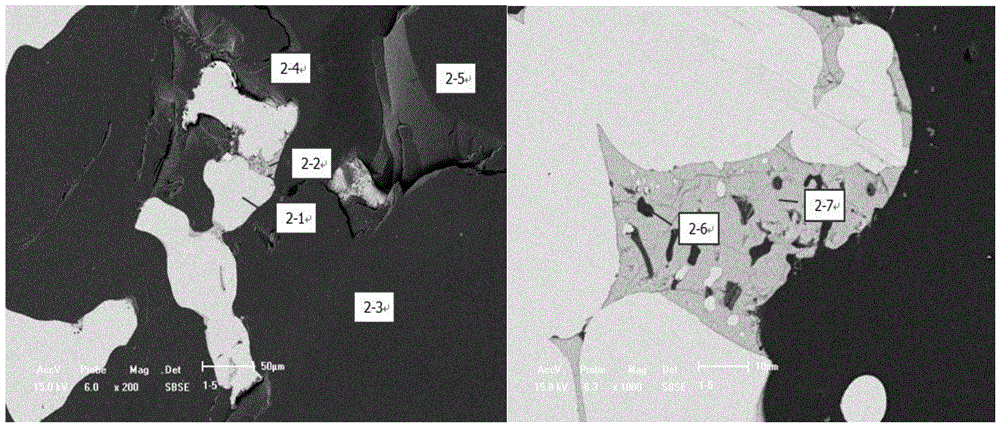

Preparation method of blast furnace sludge pre-reduced pellet

ActiveCN103451421AImproved metallurgical propertiesLow firing temperatureBlast furnace detailsSludgeDolomite

The invention provides a preparation method of a blast furnace sludge pre-reduced pellet. The blast furnace sludge pre-reduced pellet is prepared from the following raw materials in percentage by mass: 10-30% of blast furnace sludge, 3.5-10% of SiC powder, 60-85% of iron ore concentrate and 1.2-1.5% of bentonite. The preparation method comprises the following steps: uniformly mixing 20-30% of the total dosage of the bentonite with the blast furnace sludge and the SiC powder, respectively, and uniformly mixing the iron ore concentrate with 70-80% of the total dosage of the bentonite to prepare a mixture; in a pellet preparation process, firstly, preparing the mixture of the blast furnace sludge, the SiC powder and the bentonite to a pellet core; then, adding the mixture of the iron ore concentrate and the bentonite to continue the pellet preparation process; and wrapping a layer of dolomite accounting for 0.5-1.5% of the total mass of the raw materials on the formed pellet, and preparing the pre-reduced pellet according to a conventional production process. By adopting the preparation method provided by the invention, a large amount of blast furnace waste can be consumed, the roasting temperature of the pellet is reduced, the utilization proportion of non-magnetite concentrate is increased, and the finished product pellet is non-adhesive, good in metallurgical performance and beneficial to improving the blast furnace efficiency and reducing the coke ratio of a blast furnace.

Owner:ANGANG STEEL CO LTD

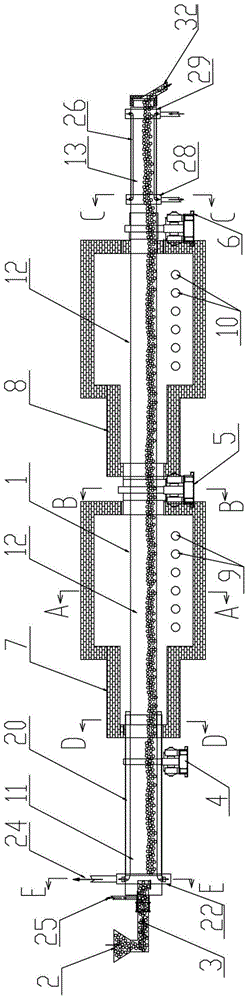

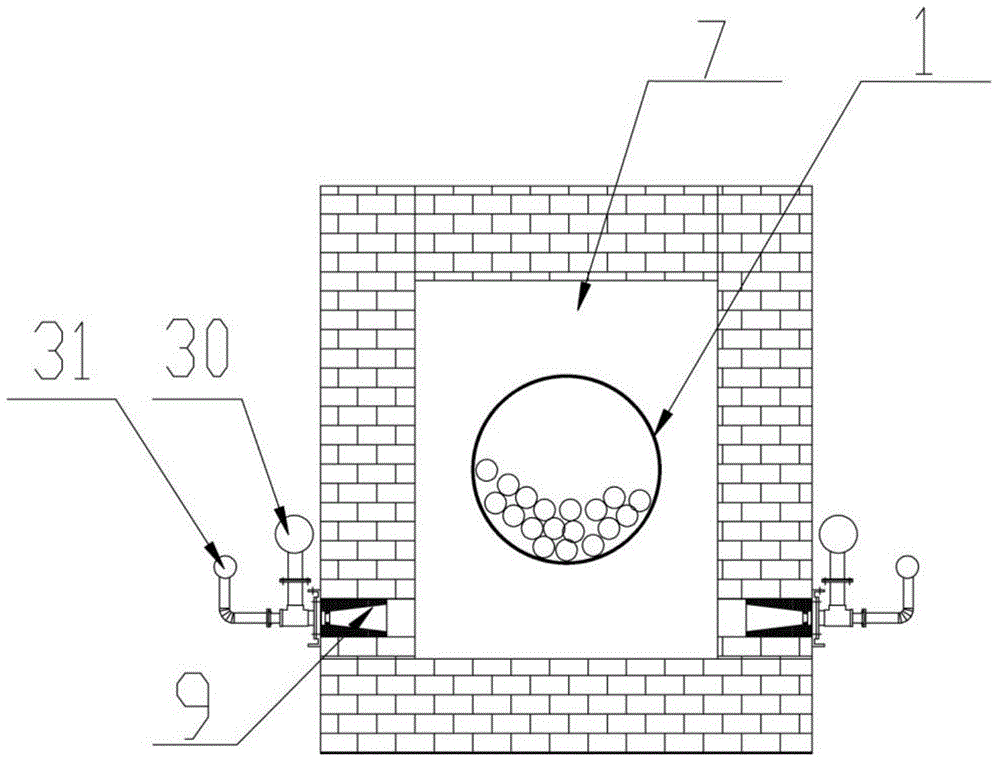

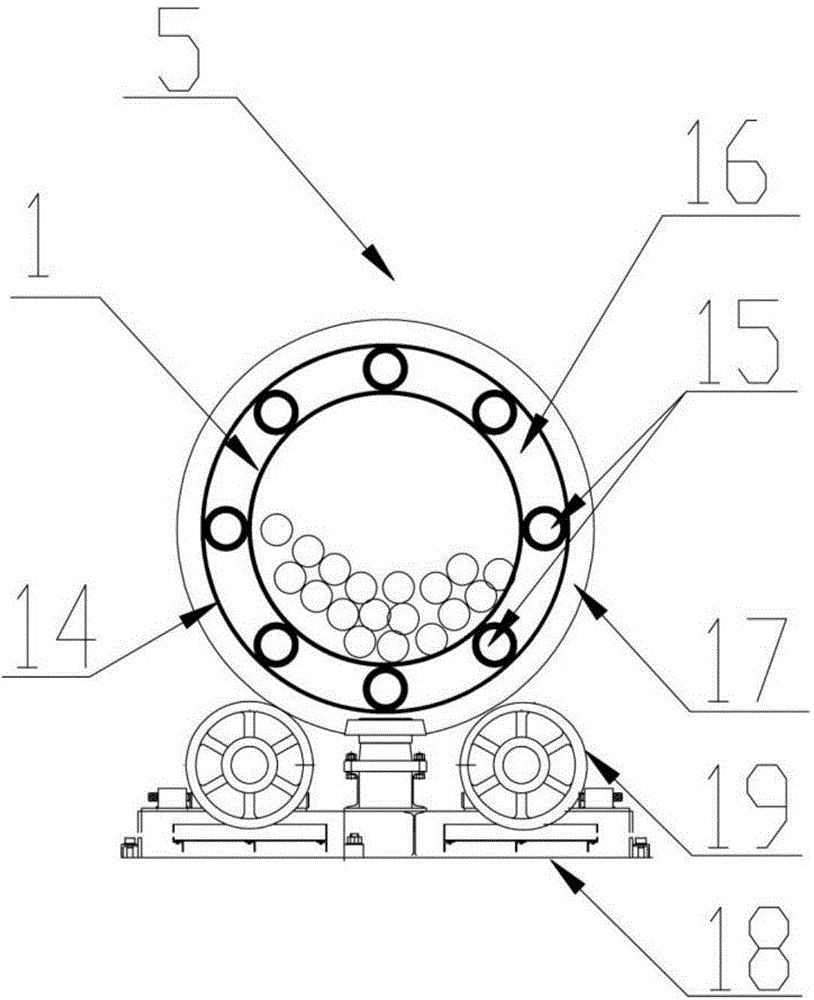

Whole-body type external-heating muffle type rotary kiln

InactiveCN104630407AContinuously stable temperatureReduced temperature required for reductionRotary drum furnacesRotary kilnLow graded

The invention belongs to the field of metallurgical equipment, and in particular relates to a whole-body type external-heating muffle type rotary kiln. A whole-body type continuous external heating muffle type coal-based rotary kiln device with a preheating section and a high-temperature section is adopted, the continuous stabilization of the temperature in a high-temperature area is realized, and a strict requirement on a reduction condition of reduced iron is met. By adopting a muffle-type heating mode, a reduction atmosphere in the rotary kiln is very full, the volatile gas is totally recycled, and the afterheat is fully utilized, so that the required reduction temperature of reduced materials can be greatly reduced, the reduction speed is greatly increased, the energy consumption is greatly reduced, and the carbon emission is reduced; by using non-caking coals with high granularity and high quality as reducing coals, the device is suitable for various iron raw materials with high grade, low grade and varieties, the reduction process is flexible, and the device has many advantages. According to a single production line of the device, the annual reduction treatment ore quantity can reach the maximum scale of 1,800,000-2,100,000 tons.

Owner:泉州寰锋冶金技术有限责任公司

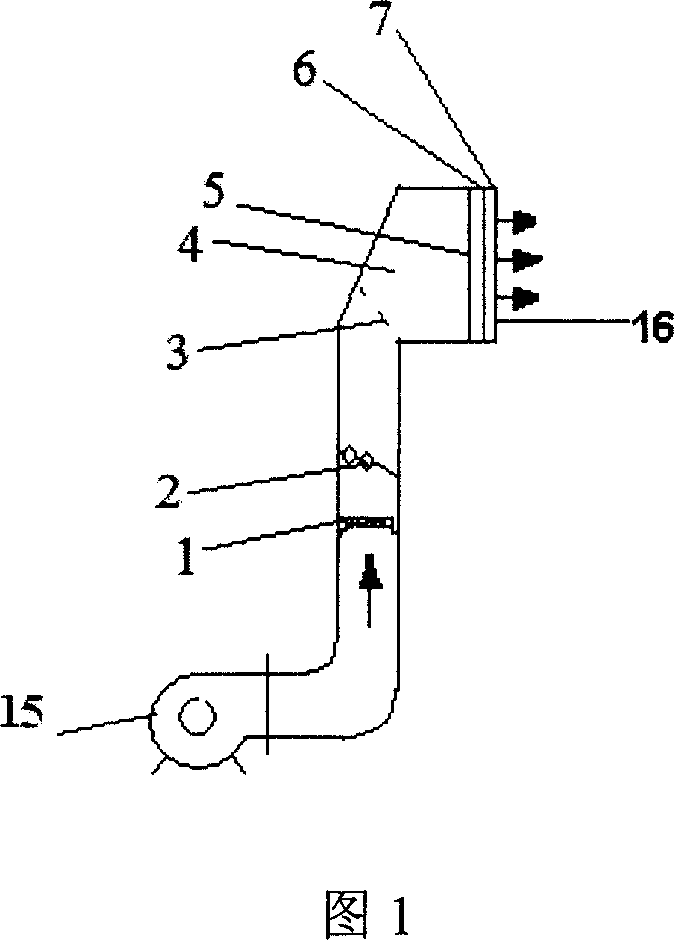

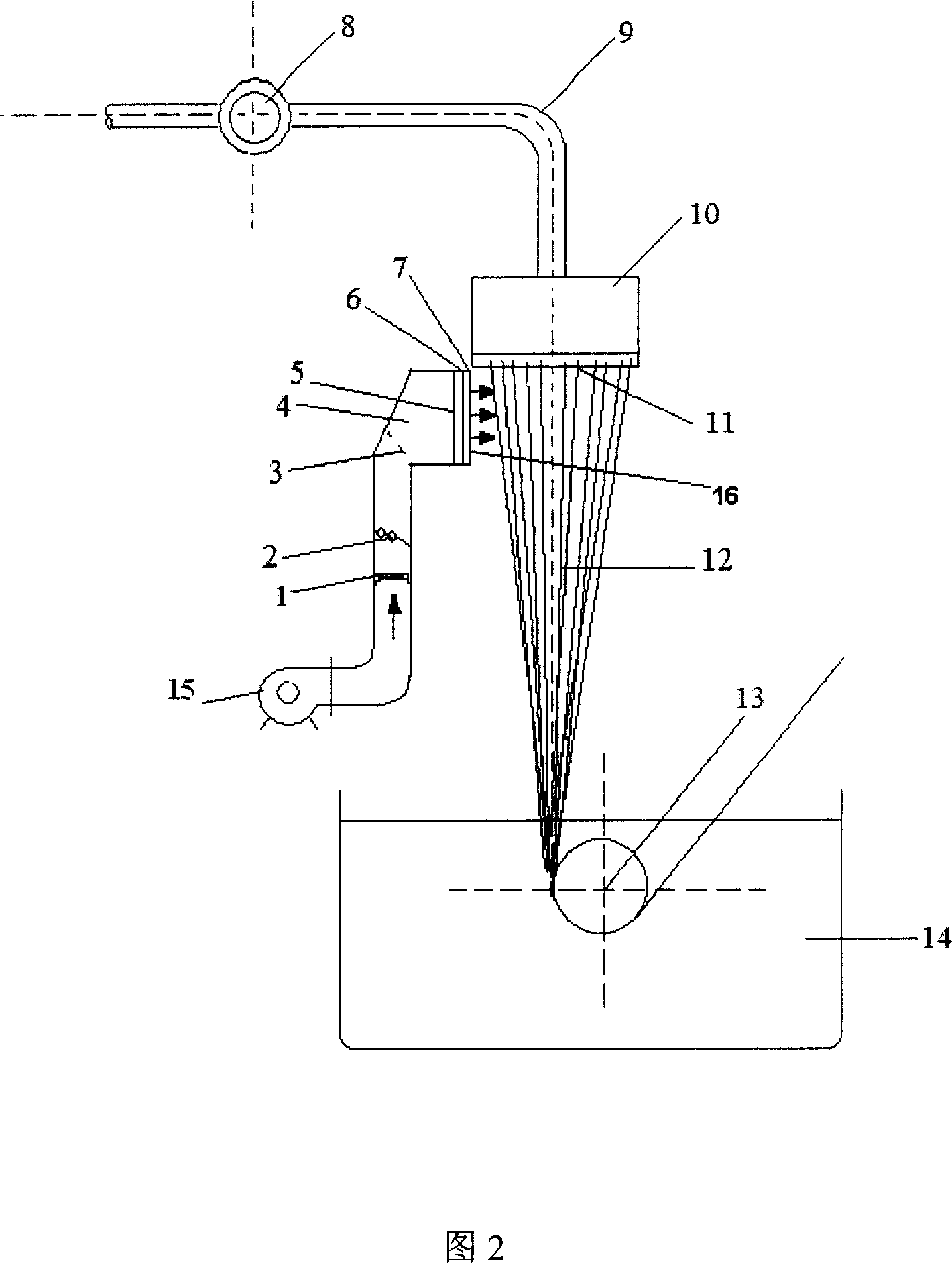

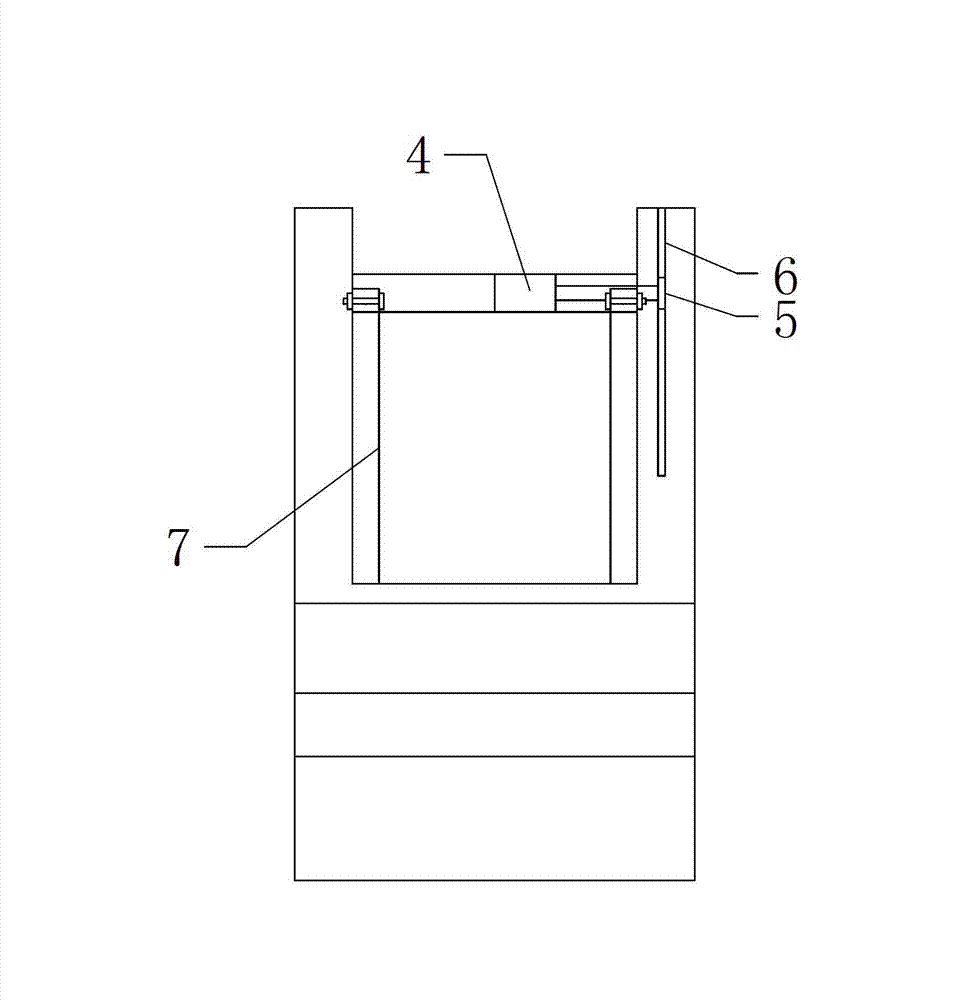

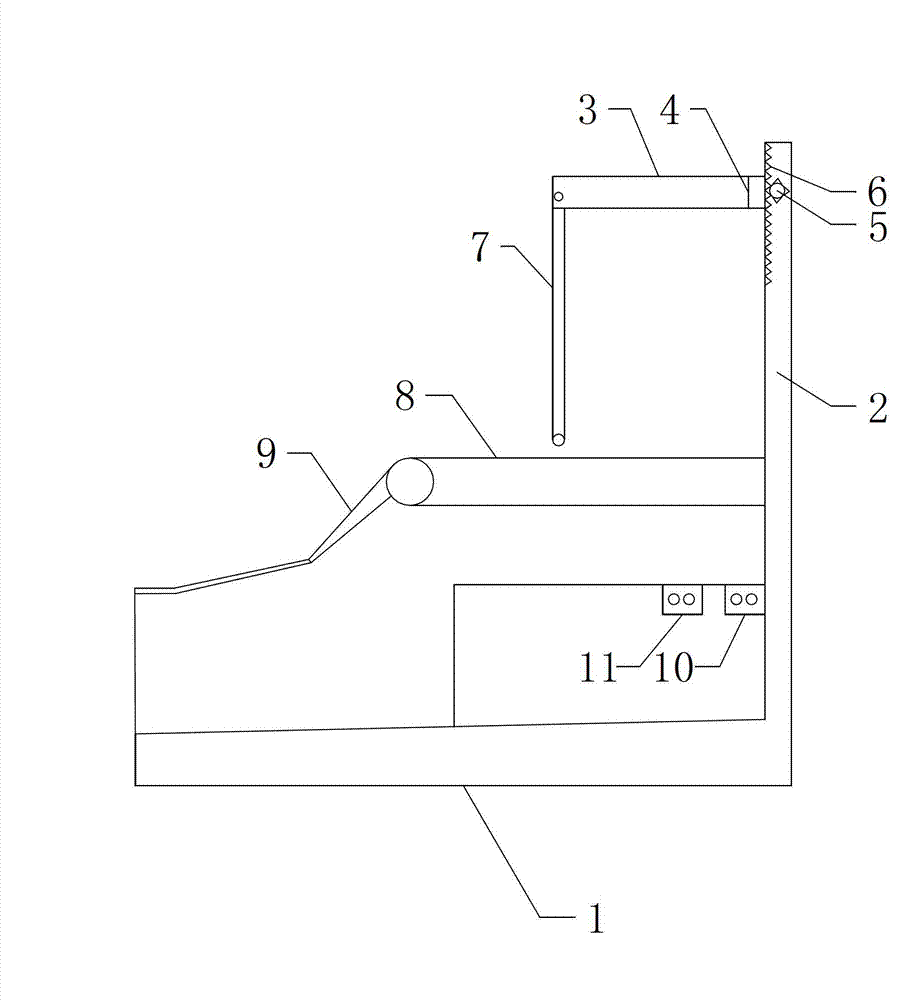

Cooling device and cooling method of solvent method cellulose fiber spinning

InactiveCN1924122ASimple structureImprove cooling effectArtificial filament physical treatmentCellulose fiberEngineering

This invention discloses one cooling device and method of solvent cellulose fiber spinning, which adopts side wind cooling device with speed as 2-12m / s and temperature as 10-35DEG C and relative temperature as 10%-80%. This invention device is of simple structure and easy control wind each parameter and good effect.

Owner:DONGHUA UNIV

Electric heating wire cutting knife for paraffin wax

InactiveCN102962867AImprove buffering effectNo stickingMetal working apparatusParaffin waxGear wheel

The invention discloses an electric heating wire cutting knife for paraffin wax. The electric heating wire cutting knife comprises a fixing frame, a sliding channel, a cutting arm and a conveying belt, wherein the sliding channel is fixed on the upper end surface of the fixing frame; the sliding channel with inner teeth is formed in the inner wall of the sliding channel; a cutting motor is arranged at the rear end of the cutting arm, and a gear matched with the inner teeth of the sliding channel is arranged at the output end of the cutting motor, namely the cutting arm is in limited connection with the sliding channel in the vertical direction in such a way that the gear at the output shaft end of the cutting motor is engaged with the inner teeth of the sliding channel; a second cutting arm is fixed at the front end of the cutting arm; an electric heating wire is arranged at the bottom end of the second cutting arm; and the conveying belt is positioned at the lower end of the second cutting arm. According to the electric heating wire cutting knife adopting the technical scheme, the paraffin wax to be cut is conveyed to the lower end of the second cutting arm through the conveying belt, the cutting motor is started through a cutting control switch (the electric heating wire is heated at the same time), the cutting motor rotates, the cutting arm is promoted to move up and down with the rotation direction of the cutting motor in such a way that the gear is engaged with the inner teeth of the sliding channel, and the cutting arm is pressed down, so that the paraffin wax is cut by the electric heating wire.

Owner:DALIAN LONSIN NEW MATERIALS

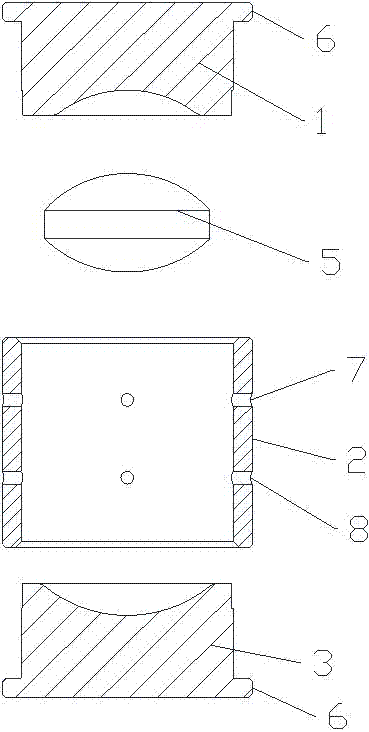

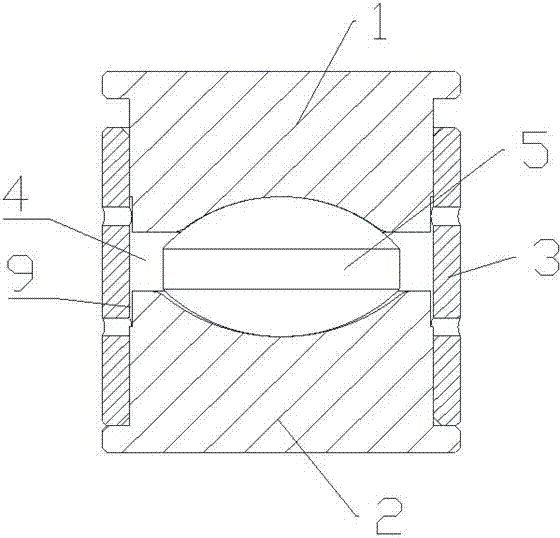

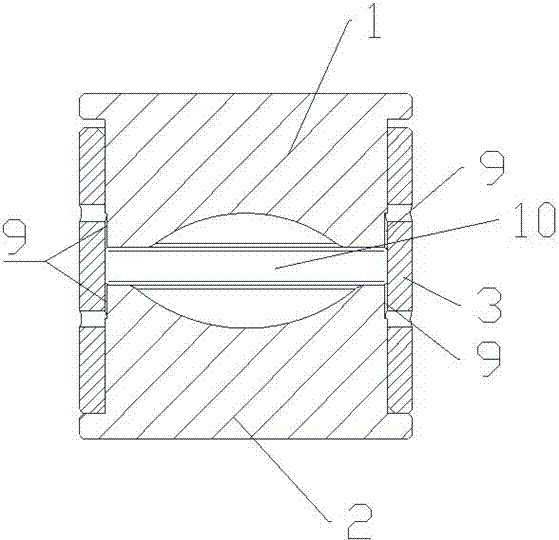

Preparation method of large-diameter aspheric lens

ActiveCN107298524AReduce structural differencesSmooth dischargeGlass pressing apparatusVacuum pumpingNitrate

The invention discloses a preparation method of a large-diameter aspheric lens. The preparation method comprises the following steps: (1) making a die kernel and a glass nitrate material; (2) putting the glass nitrate material in the die kernel; (3) putting the die kernel on a die pressing station; (4) vacuum-pumping the station; (5) injecting nitrogen gas into the station; (6) increasing the temperature; (7) enabling the temperature to be uniform; (8) molding by die pressing; (9) annealing; (10) reducing the temperature; (11) discharging the nitrogen gas; (12) taking out the die kernel; (13) taking out a product. The preparation method disclosed by the invention has the benefits that the adjustment of an internal structure of the lens is finished through the relatively-slow temperature reducing process, so that a structural difference among all parts of glass is reduced; the residual stress inside the lens is released, so that an aspheric outline of a molding body is fixed on the status quo of the completed die-pressing stage; the residual stress inside the lens is reduced to a reasonable range so as to prevent the molded lens from cracking due to non-uniform temperature distribution in the subsequent quenching procedure.

Owner:深圳市天阳谷科技发展有限公司

Intelligent power line pole repairing robot

The invention provides an intelligent power line pole repairing robot. The intelligent power line pole repairing robot comprises four semicircular ring fixing frames, eight double-rod air cylinders and the like, and is characterized in that two of the four semicircular ring fixing frames form one group and the two groups of semicircular ring fixing frames are arranged on upper and lower layers; the two groups of semicircular ring fixing frames of the upper and lower layers are connected together by adopting four first electric cylinders; rear end parts of the two semicircular ring fixing frames in each group are hinged together; mounting holes for mounting bolts are formed in the front end parts of the semicircular ring fixing frames; the two semicircular ring fixing frames on the same side of the upper and lower layers are connected by adopting two first electric cylinders; and a damaged part of a power line pole is repaired by adopting a method for pouring cement from the outer part, so that the service life of the power line pole is prolonged.

Owner:广州启赋知识产权有限公司哈尔滨分公司

Method for gluing two seams of spatial reflector

InactiveCN104749741AGuaranteed coaxialityImprove uniformityMountingsStress distributionLayer thickness

The invention provides a method for gluing two seams of a spatial reflector, relates to the technical field of spatial optical remote sensing, and aims at solving the problems of small positioning precision, non-uniform glue layer thickness, reduction of surface figure accuracy of the spatial reflector caused by residual stress after solidifying of a glue layer, and unstable stress distribution in the existing method of gluing the spatial reflector and an embedded part through three jackscrew. The method is that glue coats the lower side of the inner hole wall of the spatial reflector; the upper side of the inner hole wall of the spatial reflector is in match with a large seam of a double-seam adhering tool; meanwhile, the glue coats the outer wall of the embedded part; the inner wall of the embedded part is in match with a small seam of the double-seam adhering tool to finish the adhering of the spatial reflector and the embedded part; the large seam and the small seam of the double-seam adhering tool are processed based on the same reference, so that the coaxiality of the two seams can be ensured, and the uniformity of the glue layer thickness can be greatly improved; the glue layer is uniform in thickness; the residual stress is small after the solidifying of the glue layer; therefore, the surface figure accuracy of the spatial reflector can be fully ensured. The method is simple and reliable to operate.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

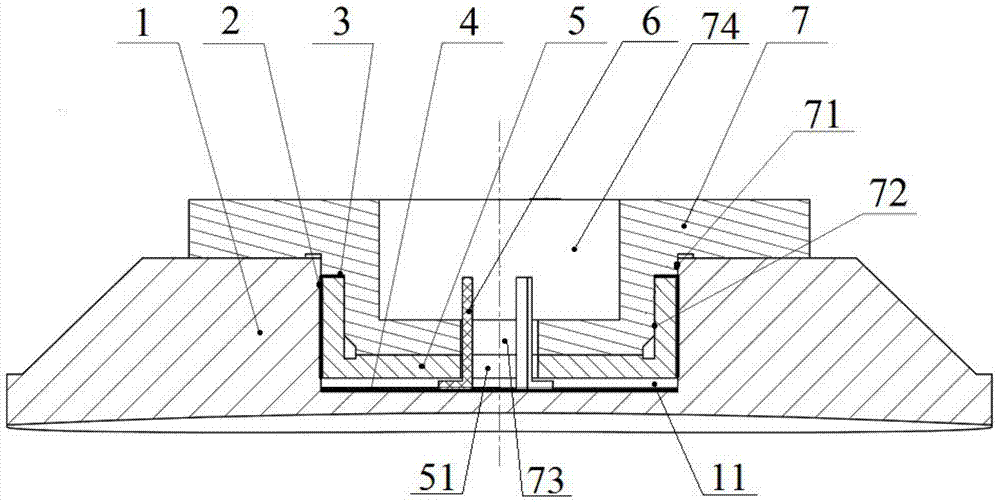

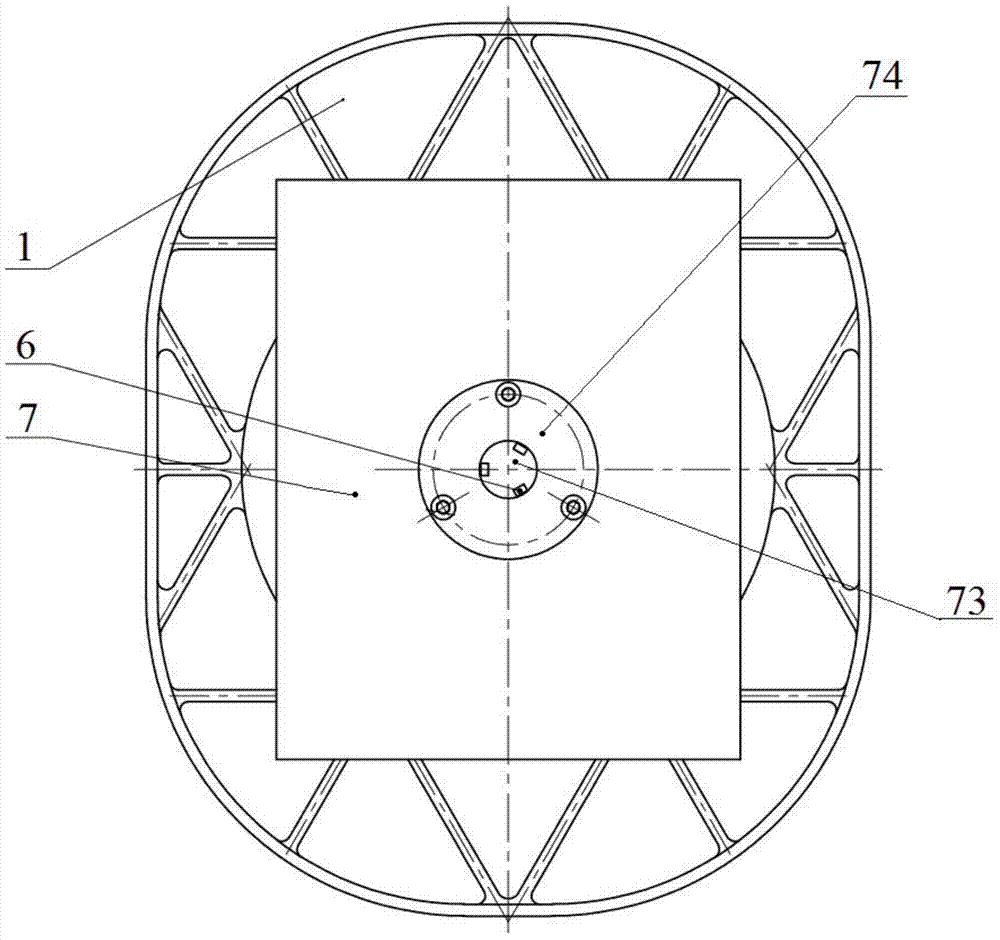

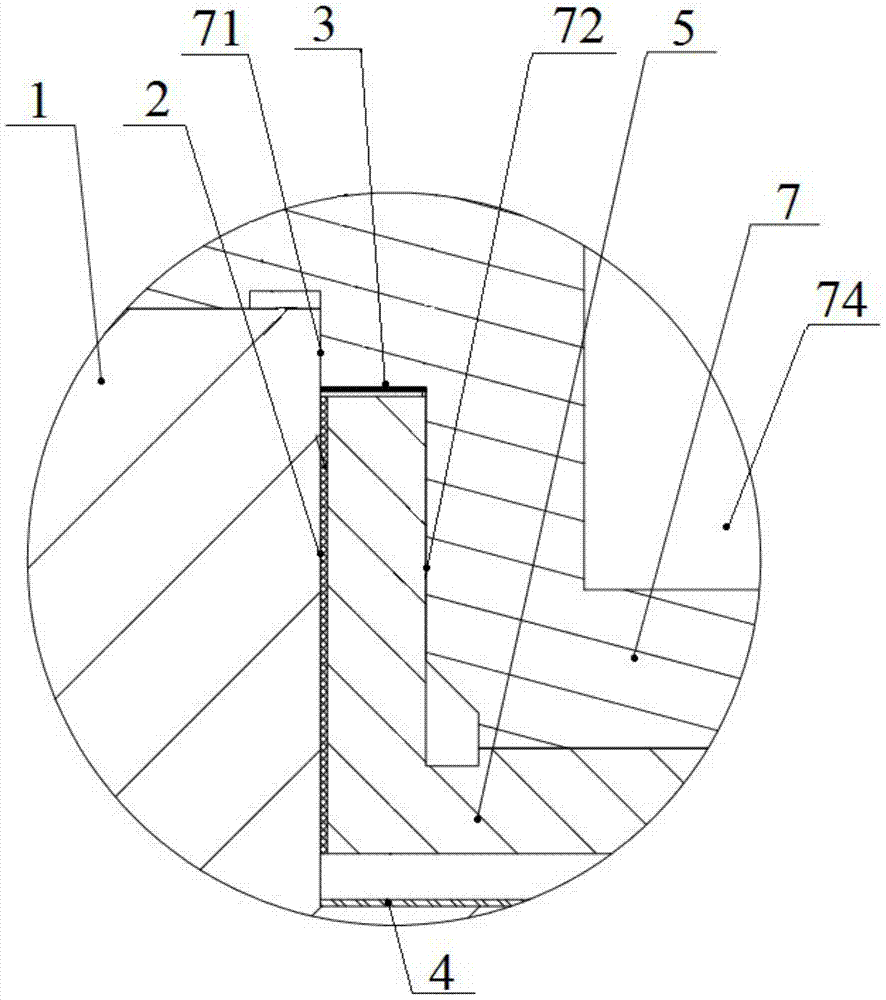

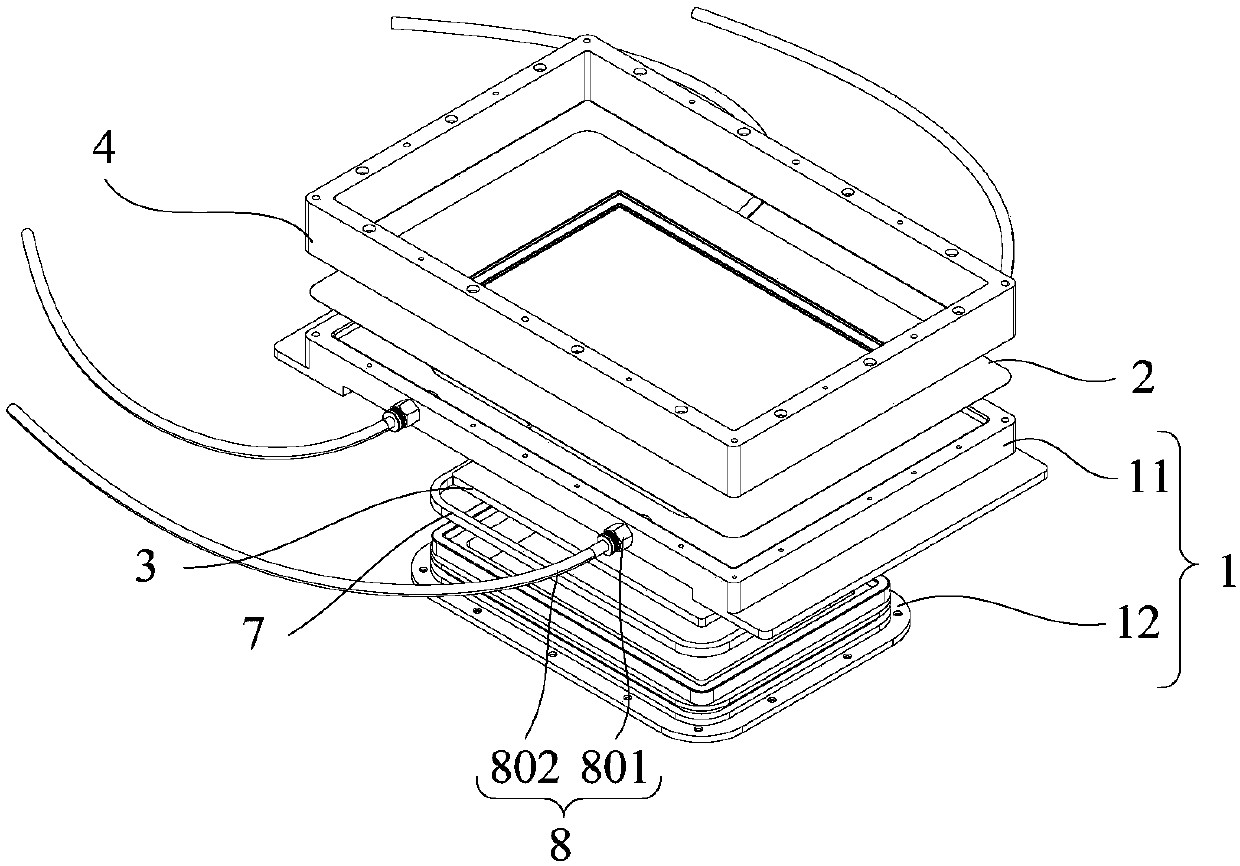

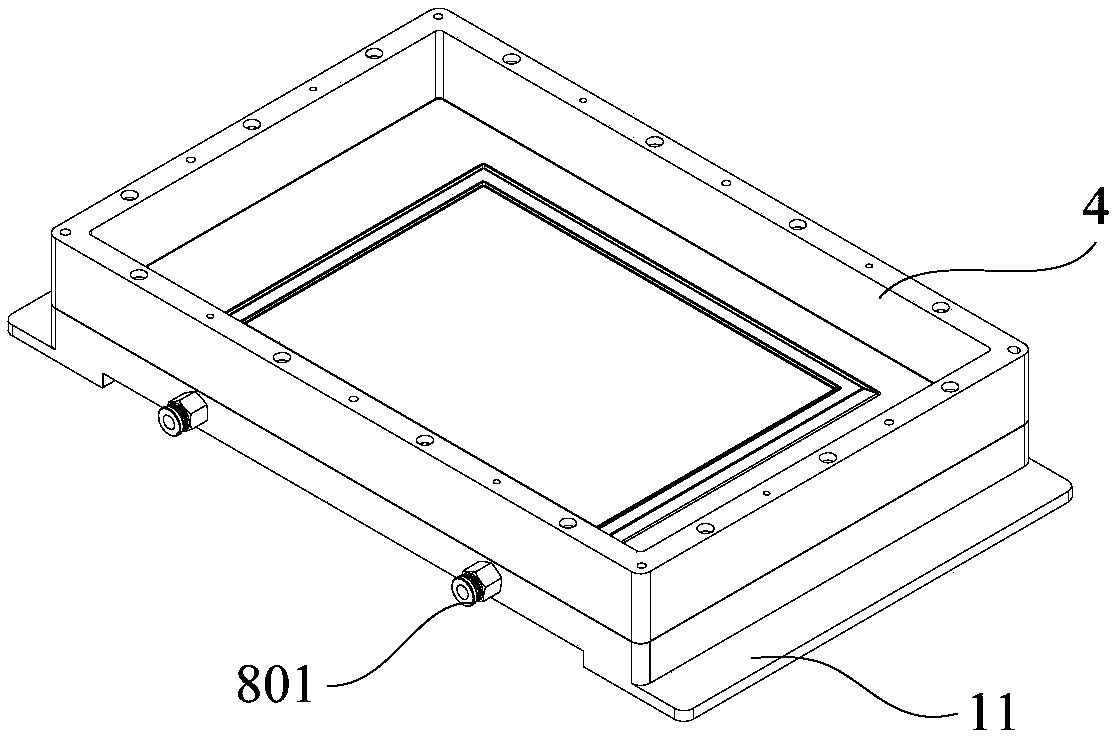

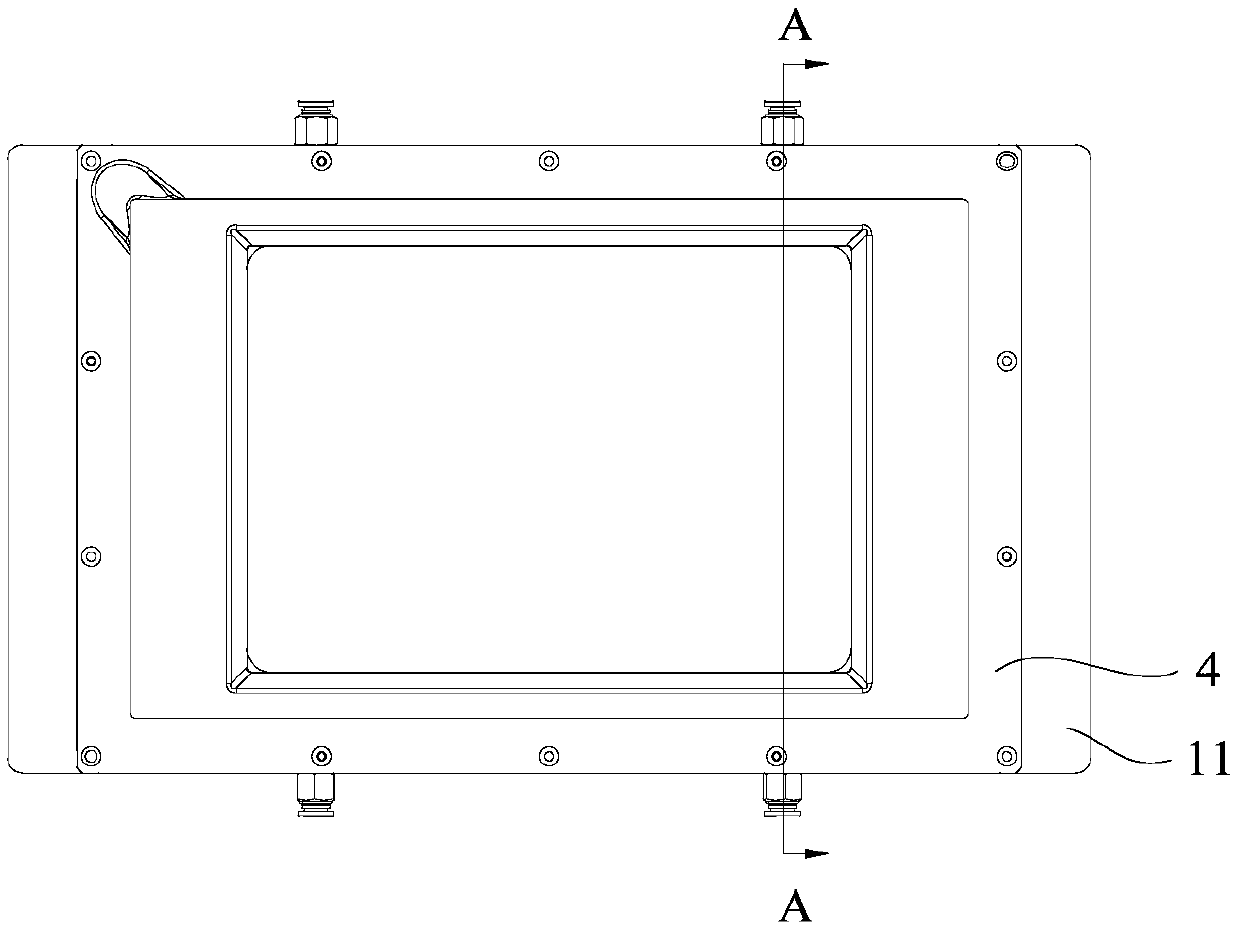

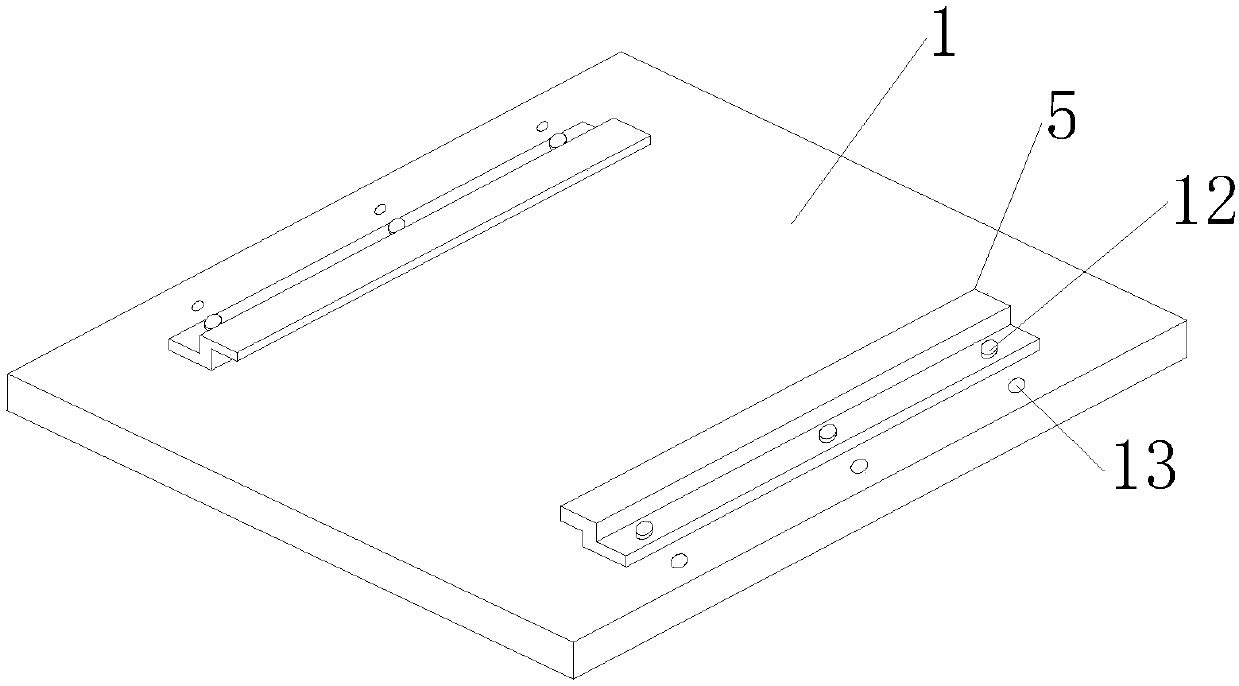

3D printing charging tray and exposure stripping technology of 3D printing charging tray

PendingCN109664507ASimple structureEasy to replaceManufacturing enclosures3D object support structuresPositive pressureEngineering

The invention relates to the technical field of 3D printing, in particular to a 3D printing charging tray and an exposure stripping technology of the 3D printing charging tray. The 3D printing charging tray comprises a base, a releasing film, light-transmitting glass and a clamping plate. The base is provided with a first groove and a second groove, the first groove and the second groove penetratethrough the top end face of the base, the light-transmitting glass is arranged in the first groove, the upper surface of the light-transmitting glass is higher than the bottom wall face of the secondgroove, the release film is arranged on the top end face of the base and is pressed between the base and the clamping plate, a first cavity is defined by the release film, the inner wall of the firstgroove and the light-transmitting glass, a second cavity is defined by the release film and the inner wall of the second groove, and the two cavities communicate. During exposure, the cavities are pumped to from negative pressure, the release film can be tightly attached to the glass, bubbles do not exist between the release film and the glass, tensioning of the release film is achieved, the printing precision is improved, when the release film is released, air is inflated to the cavities, the cavities form positive pressure, the release film and the light-transmitting glass are stripped, andthe aim is easily achieved.

Owner:GUANGZHOU HEIGE ZHIZAO INFORMATION TECH CO LTD

Anti-counterfeit printing device and method

InactiveCN107554060AImprove accuracyImprove printing qualityPattern printingInksAgricultural engineeringPrinting press

The invention discloses an anti-counterfeiting printing device, comprising a printing table, a paper feed roller is connected to the entrance of the printing table, a first pressure roller is arranged at the entrance of the printing table, and a positioning block is arranged on the right side of the first pressure roller , the positioning block is provided with screws, the printing table is provided with screw holes corresponding to the screws, a printing machine is provided above the positioning block, a photoelectric sensor is provided on the right side of the positioning block, and the photoelectric sensor There is a drying chamber on the right side of the drying chamber, a fan is provided on the top of the drying chamber, a partition is provided at the lower end of the fan, a through hole is provided on the partition, and a proofreading room is provided on the right side of the drying chamber. , the interior of the pair of chambers is provided with an ultraviolet lamp and a high-speed camera, the right side of the proofreading room is provided with a punching device, the right side of the punching device is provided with a second pressure roller, and the exit of the printing table is connected with a roll roll. The invention can improve the printing efficiency of bills, and conveniently remove problematic bills.

Owner:合肥汇融文印有限责任公司

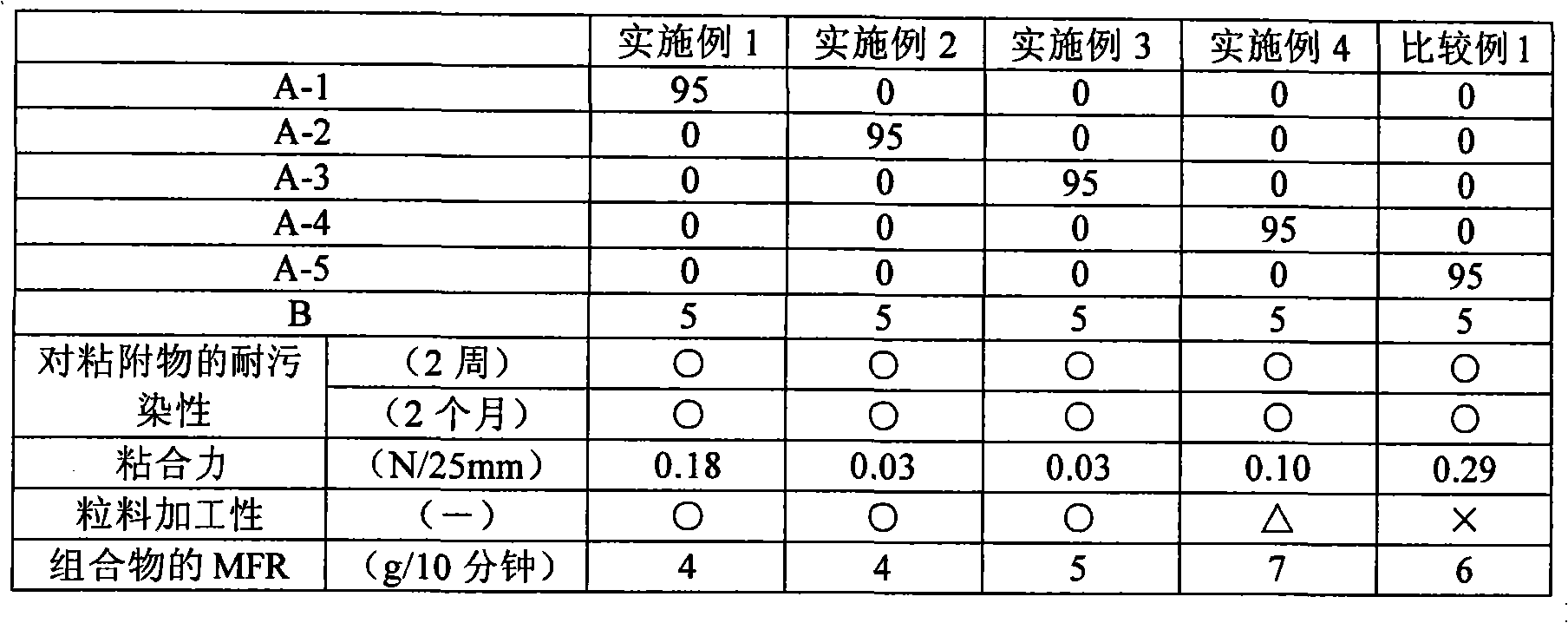

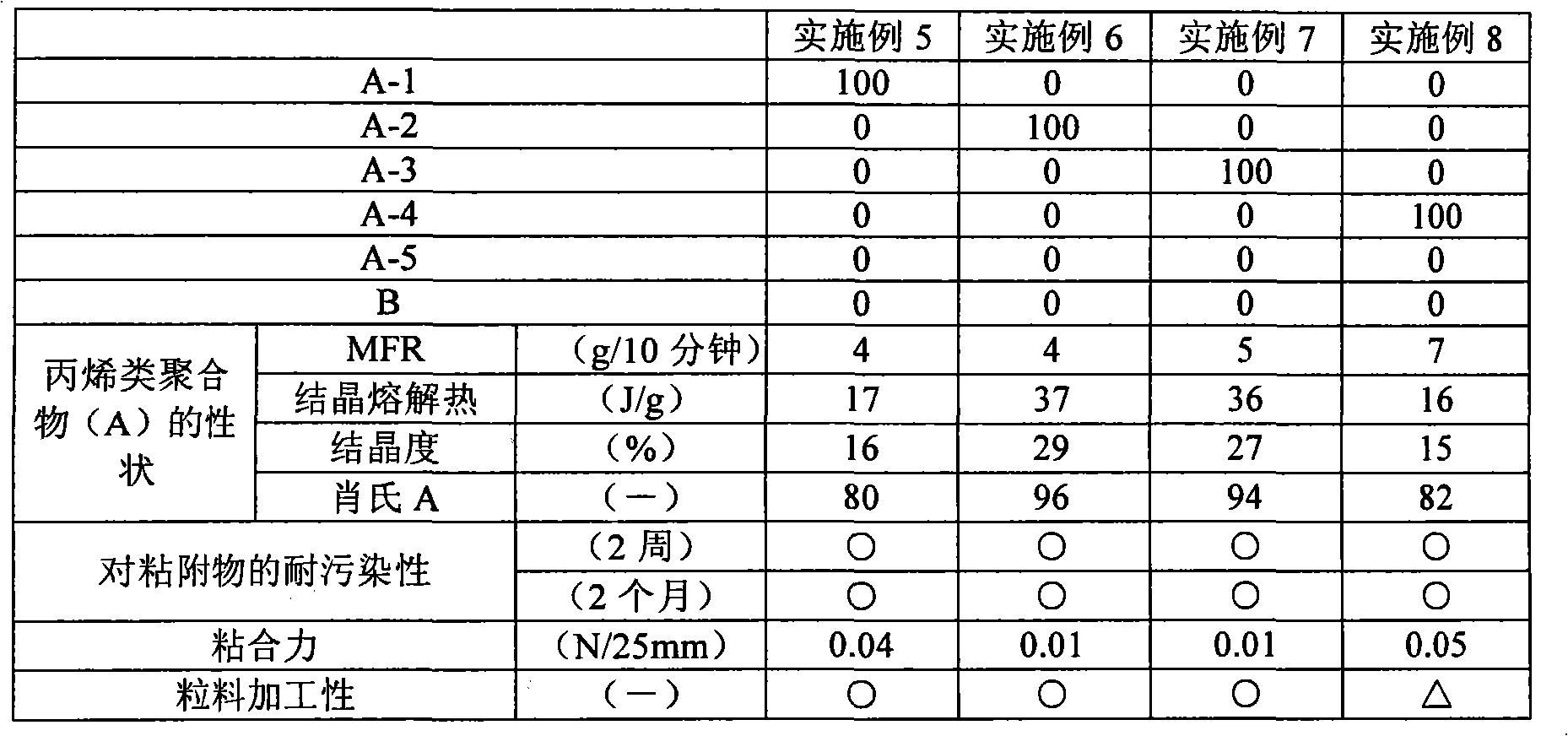

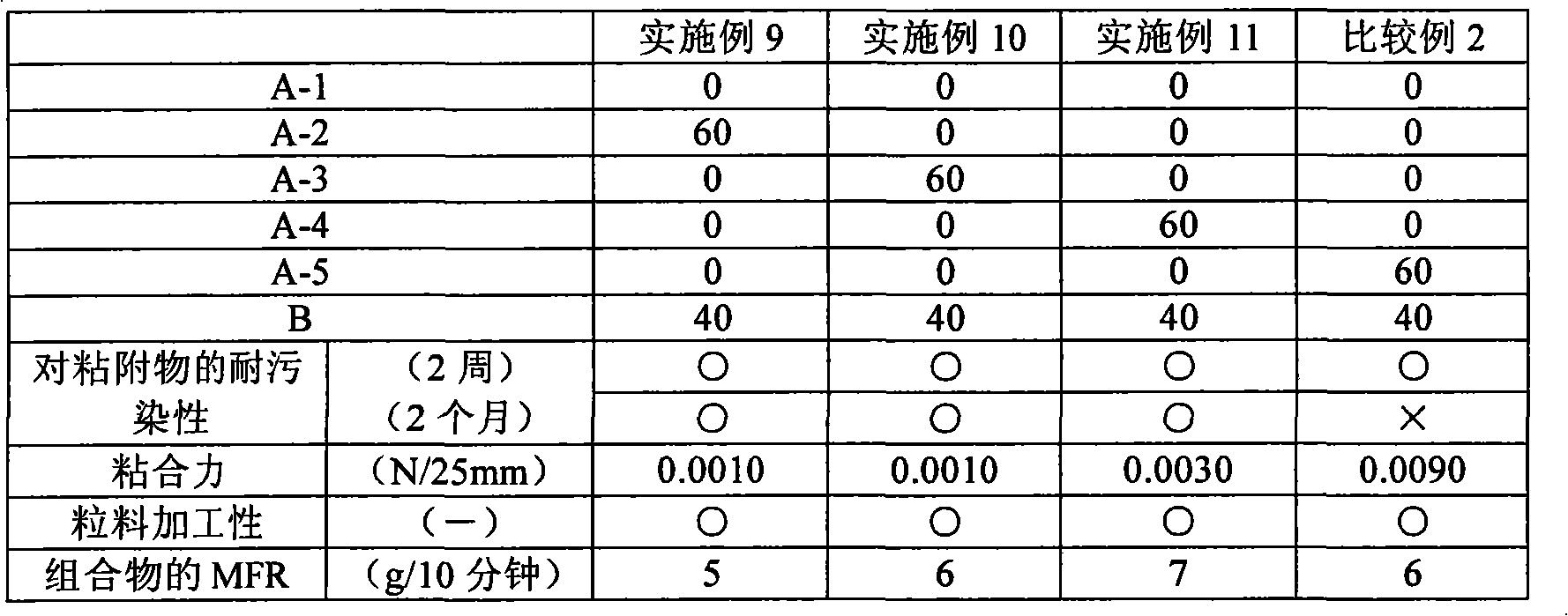

Propylene polymer, propylene polymer composition, pellet, and adhesive agent

Owner:MITSUI CHEM INC

Hulling separation method for rapeseeds and special separation device

InactiveCN103555414AImprove separation efficiencyNo stickingSievingScreeningVegetationMetal impurities

The invention discloses a hulling separation method for rapeseeds. The hulling separation method comprises the following steps of cleaning rapeseed raw materials to remove sand and vegetation impurities to enable the impurity content to be less than or equal to 2 percent; then performing drying at the drying temperature of 160 DEG C, wherein the water content of the dried rapeseeds is 5-8 percent; cooling the rapeseeds to normal temperature, performing magnetic separation to remove metal impurities, conveying the rapeseeds into a rapeseed huller for shearing, grinding and extruding to obtain hull and kernel mixtures, and then conveying the mixtures into a separation sieve in a special separation device, wherein under the joint action of a vibration sieve and a fan, the upper layer of hulls with small density are removed through the fan, and the lower layer of seeds with large density are discharged through a front port of the special separation device and are collected. The hulling separation method has the advantages that the hulling rate is high, the primary hulling separation rate can be up to 98 percent, and the hulling effect is good; the proportion of naturally split half kernels to integrated kernels is up to about 75 percent; the powder rate is lower than 3 percent; the kernel and hull separation efficiency is high; the phenomenon that the kernels and the hulls are adhered is avoided.

Owner:HENAN YIFENG EDIBLE OILS +1

Combined method for extracting iron and dephosphorizing by reducing, smelting and dressing low-grade high-phosphorus hard-dressing iron (manganese) ore

The invention belongs to the technical field of metallurgy and in particular relates to a combined method for extracting iron and dephosphorizing by reducing, smelting and dressing low-grade high-phosphorus hard-dressing iron (manganese) ore. Raw ore is firstly subjected to fine grinding, dressing, iron extracting and dephosphorizing to obtain relatively low-phosphorous rich ore powder, then separation of iron from slag and reduction are carried out on the low-phosphorous rich ore powder, and after reduced metallized pellets are cooled, fine grinding and wet magnetic separation are carried out, so that metal iron powder / manganese-containing metal iron powder with TFe content more than or equal to 90%, etaFe content more than or equal to 92% and P content less than or equal to 0.07% is obtained. The combined method for extracting iron and dephosphorizing by reducing, smelting and dressing the low-grade high-phosphorus hard-dressing iron (manganese) ore has the advantages that low reduction temperature and short reduction time are controlled, increase of P content in the final product is avoided as high temperature above 1250 DEG C and long reaction time are adopted in the traditional method and P element and Fe in phosphorite react to generate phosphide, especially stable Fe3P; and if the raw ore is ferrous manganese ore, a manganese-rich powder byproduct with Mn content more than or equal to 45% can be obtained, additional value of the product is high, and energy conservation, environmental protection and low carbon content are realized.

Owner:泉州寰锋冶金技术有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com