Patents

Literature

4685results about How to "No deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method with functions of preheating and postheating for forming crack-free coating with high efficiency by three-light-beam laser-cladding technique

InactiveCN102383126ALow and adjustable dilution rateSmall heat affected zoneMetallic material coating processesLaser beam welding apparatusMelting tankHeat-affected zone

The invention discloses a method with functions of preheating and postheating for forming crack-free coating with high efficiency by a three-light-beam laser-cladding technique. The method comprises the following steps of: splitting a laser beam emitted by an Nd: YAG laser into two laser beams by using a laser beam splitter, namely a preheating laser beam for preheating the surface of a base material and a postheating laser beam for postheating the formed coating; then blowing alloy powder into a molten pool which is formed by focusing a laser beam emitted by a CO2 laser and acting the focused laser beam on the surface of the base material by using a powder nozzle, wherein after the CO2 laser beam moves away, a molten layer is cured and crystallized quickly to form the coating; and postheating the formed coating by adopting the postheating laser beam. The method has the advantages that: (1) the dilution rate of the coating is low and adjustable, and the coating is metallurgically combined with the base material, so the base material has a small thermal influence area and is deformation-free and crack-free; (2) residual inner stress in the coating can be eliminated effectively, a tissue can be improved, and the coating has high abrasion resistance, high corrosion resistance, high anti-cracking performance and high thermal shock resistance; and (3) relative to the processing efficiency in the conventional laser cladding technology, the processing efficiency in the method can be improved by 50 times to the maximum extent, so the processing cost is reduced greatly, and a large-scale industrialized application potential is realized.

Owner:NANCHANG HANGKONG UNIVERSITY

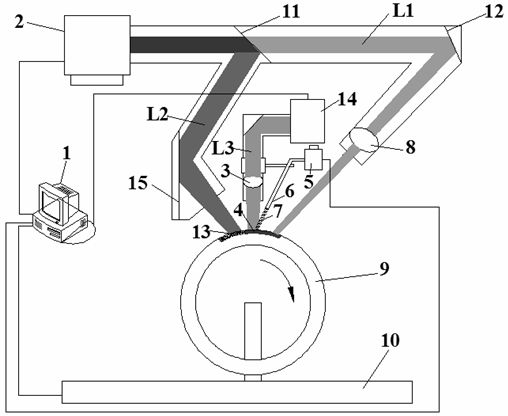

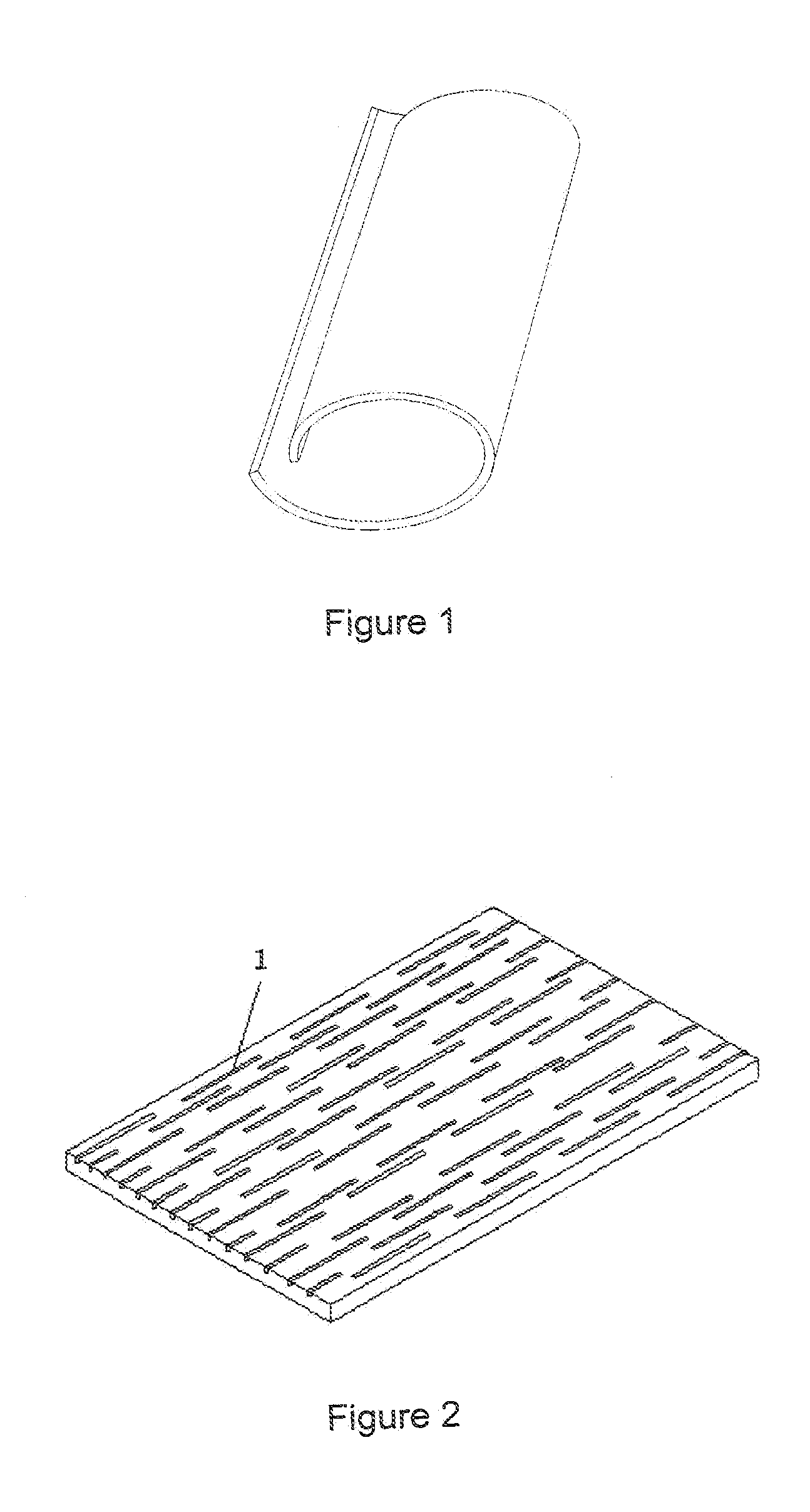

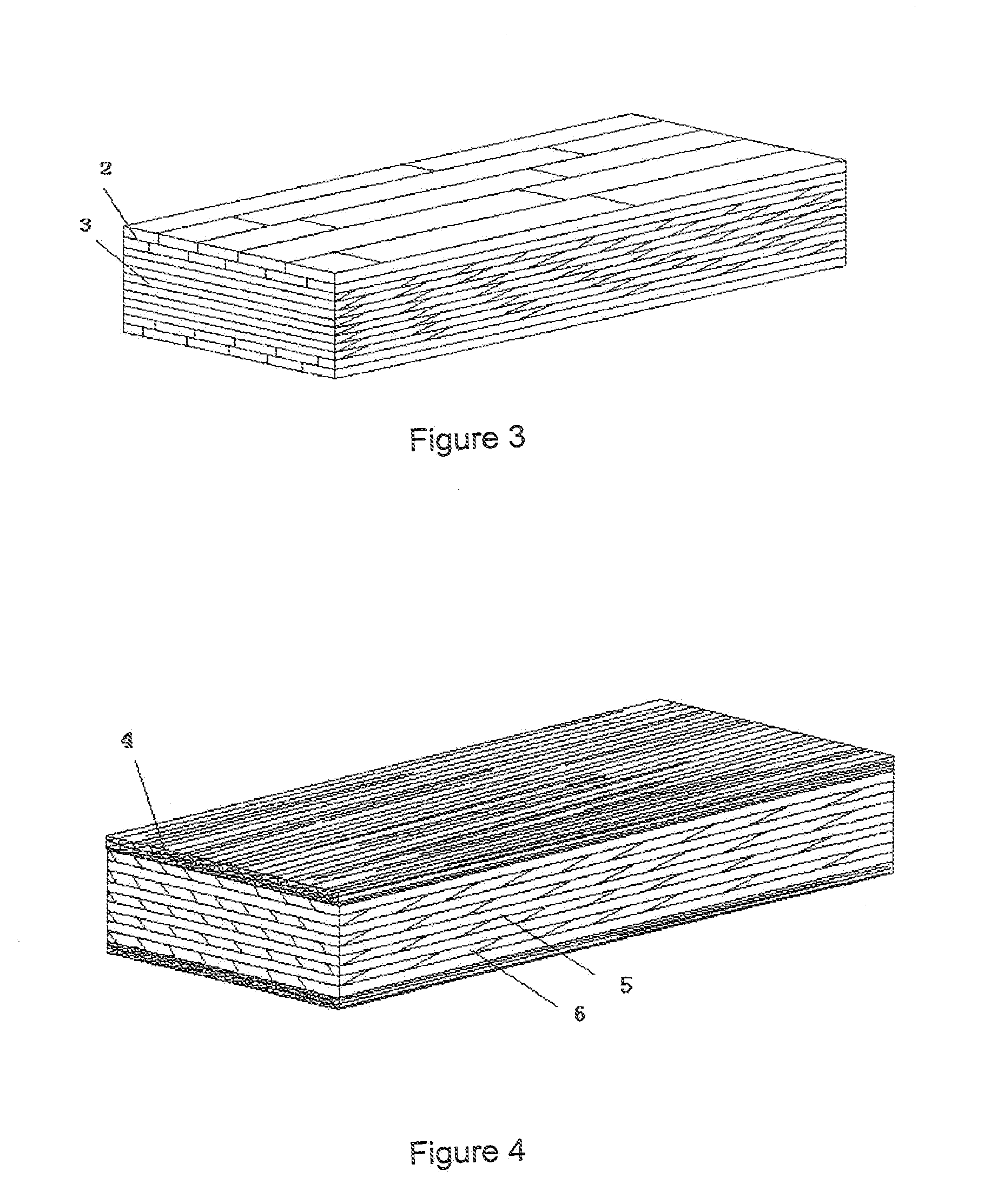

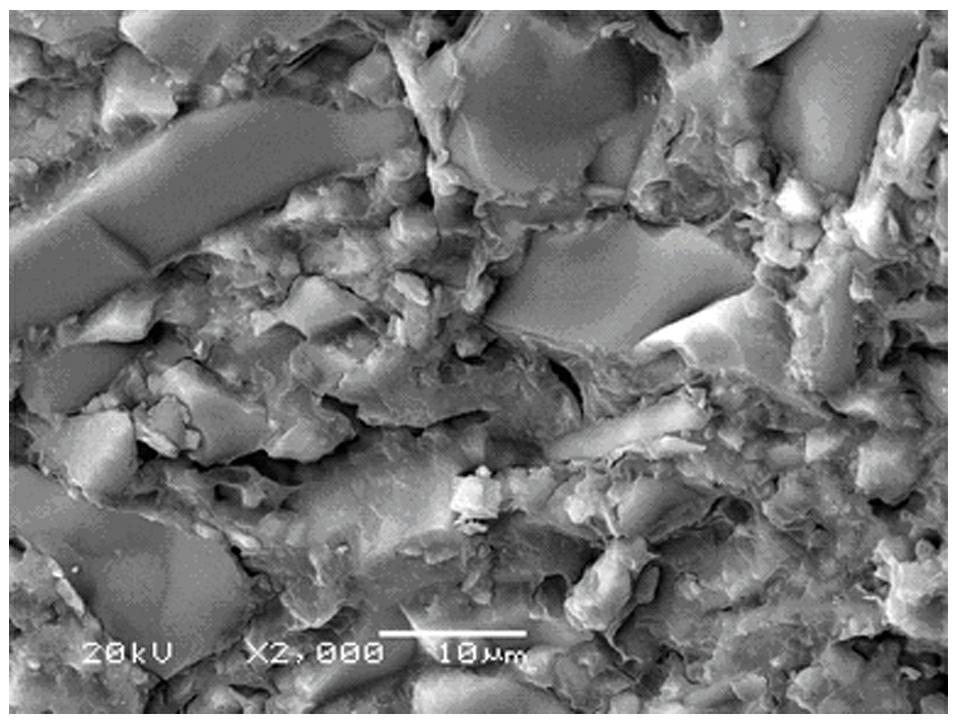

Ultra thick bamboo-wood composite panel, ultra thick solid wood composite panel and manufacturing methods thereof

InactiveUS20110274872A1Improve technologyLess amountWood veneer joiningPlant material mechanical workingLine segmentSolid wood

The present invention provides ultra-thick bamboo / wood and solid wood composite panels, comprising core board, surface board and back board; said core board is composed of ultra-thick peeling veneers with the thickness of 6 to 12 mm, both said surface board and back board are made of bamboo or wood; said core board comprises several layers of said ultra-thick veneers, and the veneers of contiguous layer are assembled with parallel structure; glue layer is arranged between contiguous said veneers, the adhesive in the glue layer is the aqueous macromolecule isocyanate adhesive; said ultra-thick veneers of the core layer are the veneers with stress degradation treatment, i.e., punctate or line segment cracks are formed along the grain of said veneer loose side in each layer. The glue spread amounts of said composite panels are obviously less than that of the existing composite panels with the same thickness, and the composite panels are without warping or deformation. The present invention also provides the manufacturing method of the above composite panels.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

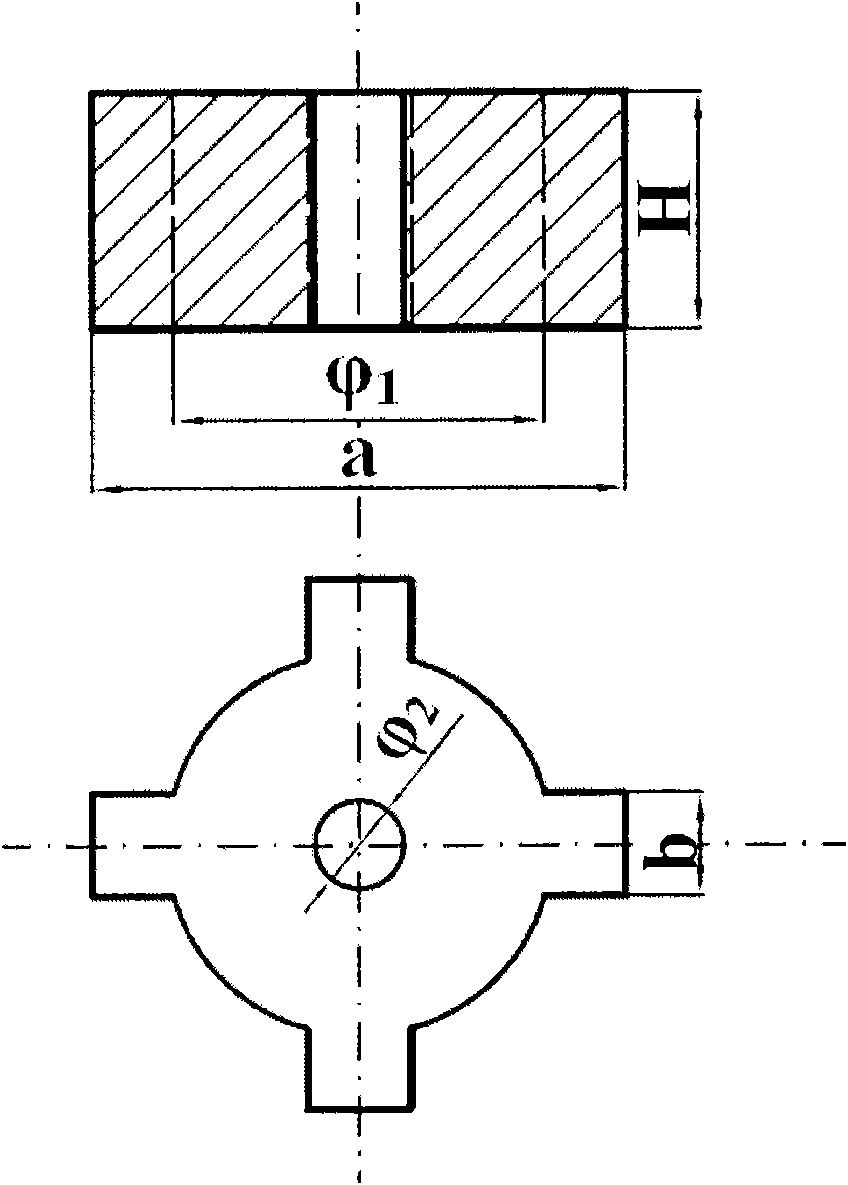

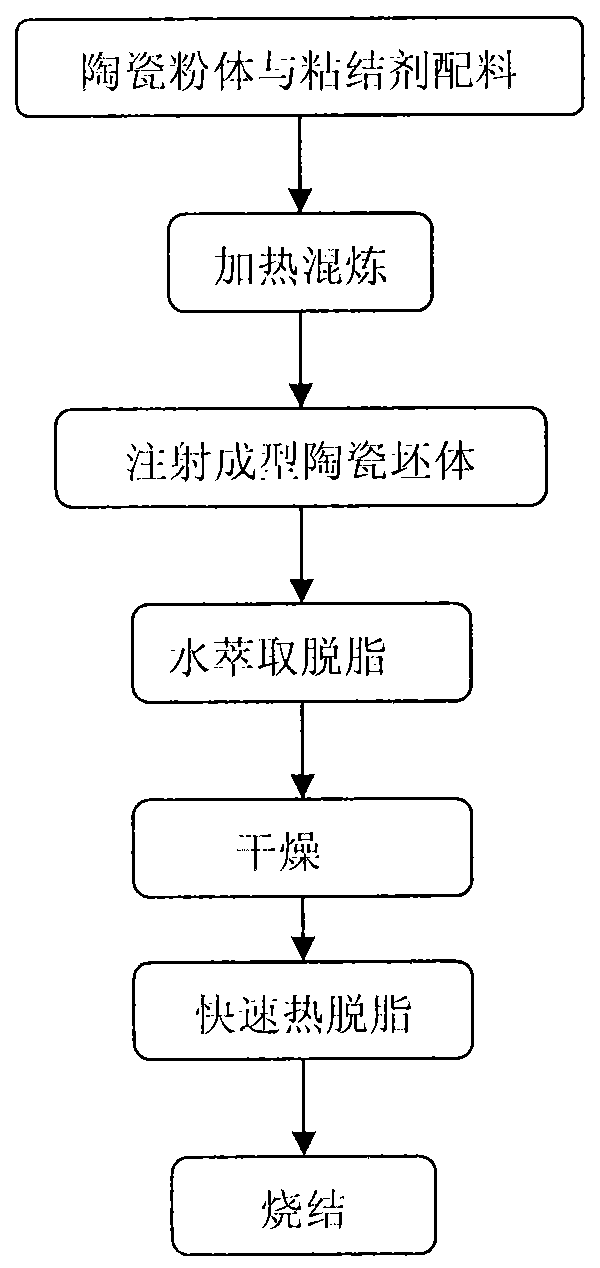

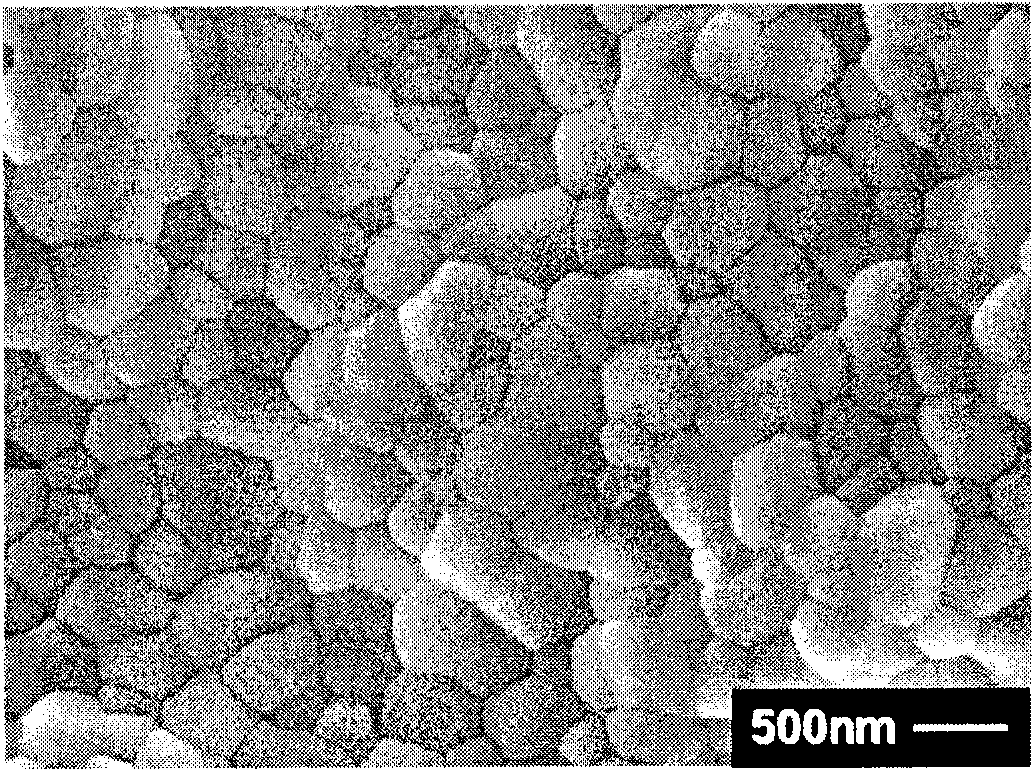

Method for manufacturing dentate special-shaped ceramic components by injection molding

InactiveCN101643360AEfficient preparationHigh precision manufacturingCeramic shaping apparatusSurface finishHigh dimensional

The invention discloses a method for manufacturing dentate special-shaped ceramic components by injection molding, belonging to the technical field of high-performance ceramic preparation. The methodcomprises the following steps: evenly mixing 81wt% to 90wt% of ceramic powder and 10wt% to 19wt% of organic binders by weight percentage to obtain an injection-molding mixture, injection-molding the injection-molding mixture on an injection-molding machine with the injection temperature being 175 to 195 DEG C, to obtain a green body, and de-molding within 2 minutes after the injection, so as to obtain a molded green body; and then, subjecting the molded green body to water-extraction degreasing and thermal degreasing, sintering the degreased green body at 1,350 to 1,550 DEG C, holding for 1 to4 hours and furnace-cooling to obtain the ceramic components. The invention has the advantages of high automation degree, high molding and degreasing efficiencies, even green body, high dimensional accuracy and surface smoothness of sintered products, and environment-friendly and energy-saving manufacture.

Owner:TSINGHUA UNIV +1

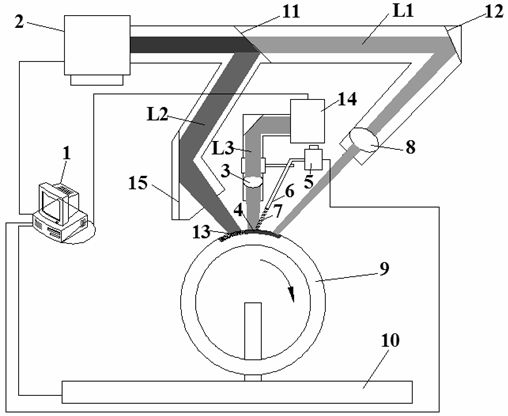

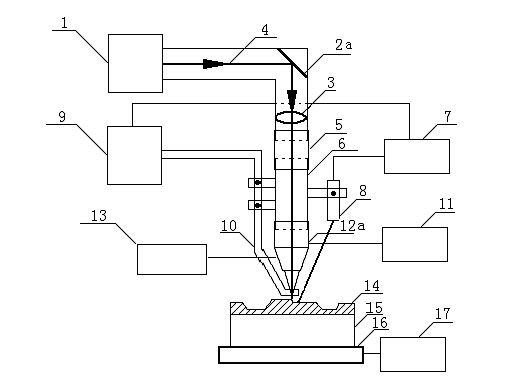

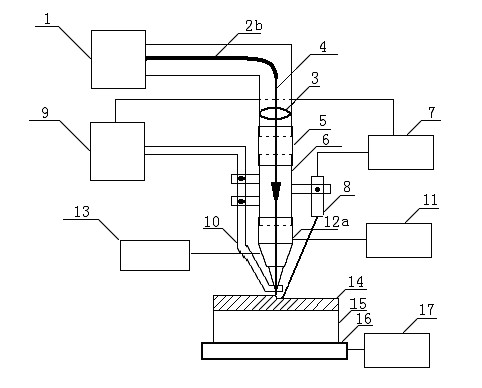

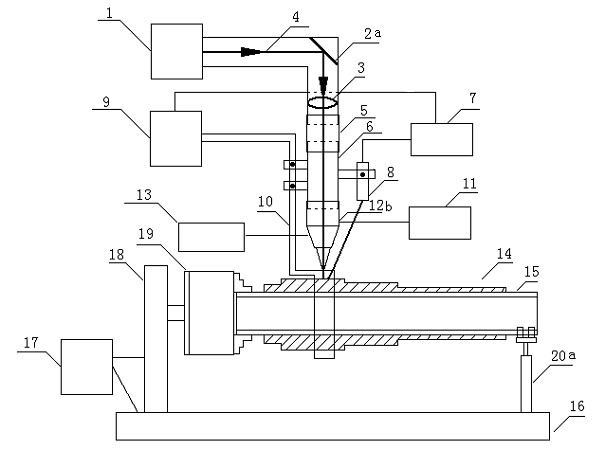

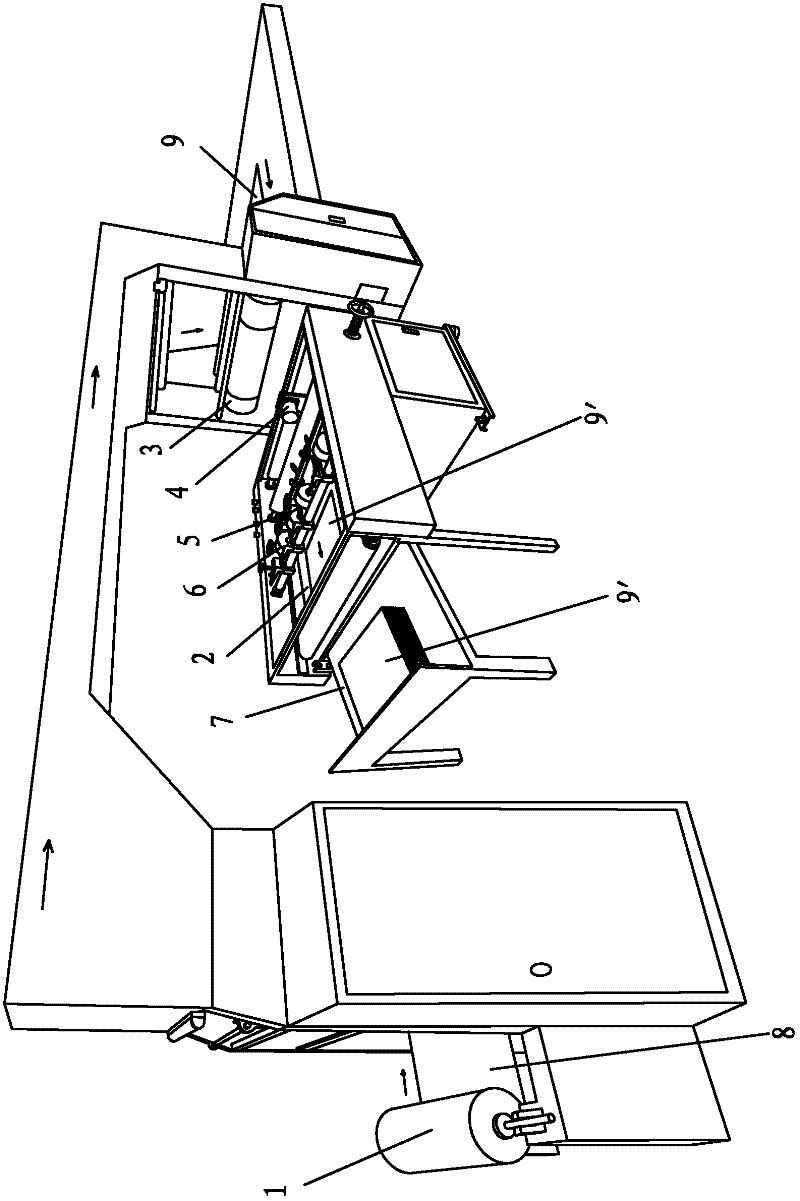

Laser-induction hybrid melting direct forming method and device

The invention discloses a laser-induction hybrid melting direct forming method and device. The laser-induction hybrid melting direct forming method comprises the following steps of: generating a three-dimensional model of a part through CAD (Computer-Aided Design) software, and then slicing the three-dimensional model and generating a G code to drive a numerical control system and a base body to move; and melting synchronously fed metal or metal / ceramic hybrid powder through a high-power laser beam and an induction heat source, and depositing the three-dimensional part in a designed shape layer by layer, wherein a temperature controller is used for monitoring and controlling the temperature of the base body in the processing process. The device for realizing the laser-induction hybrid melting direct forming method comprises a laser, a light path system, an induction heating and temperature control system, a powder feed system and the numerical control system. The device can be used for directly generating large and medium size three-dimensional parts on various metal base bodies, has the advantages of high processing efficiency, compact part structure, fine crystalline grain, excellent mechanical property, less residual stress without deformation or cracking phenomenon, high processing flexibility without tools and moulds, high material utilization ratio, cleanness without pollution and capability of designing the components of a metal-ceramic hybrid layer as required and even changing the components in a gradient manner.

Owner:HUAZHONG UNIV OF SCI & TECH

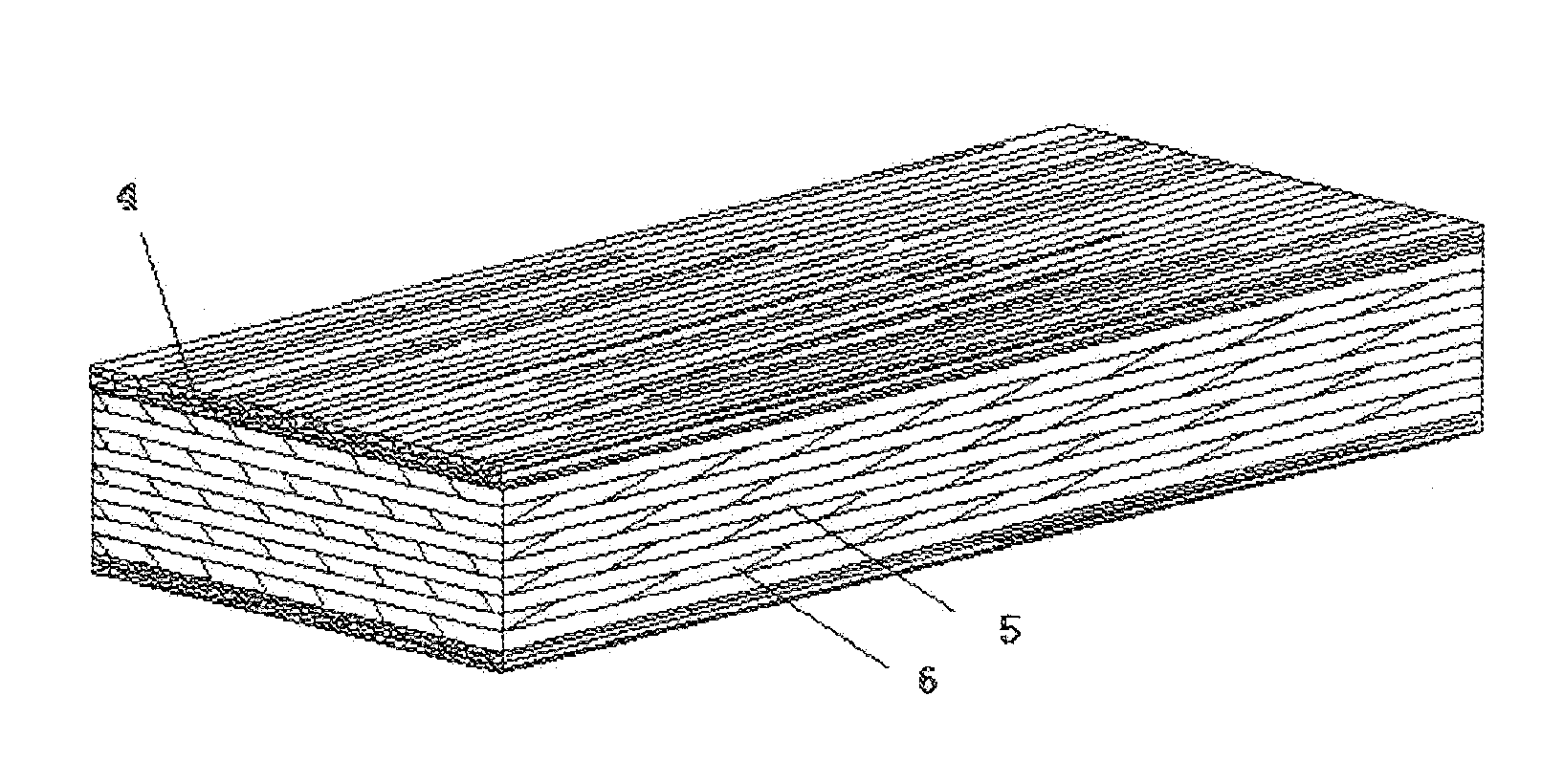

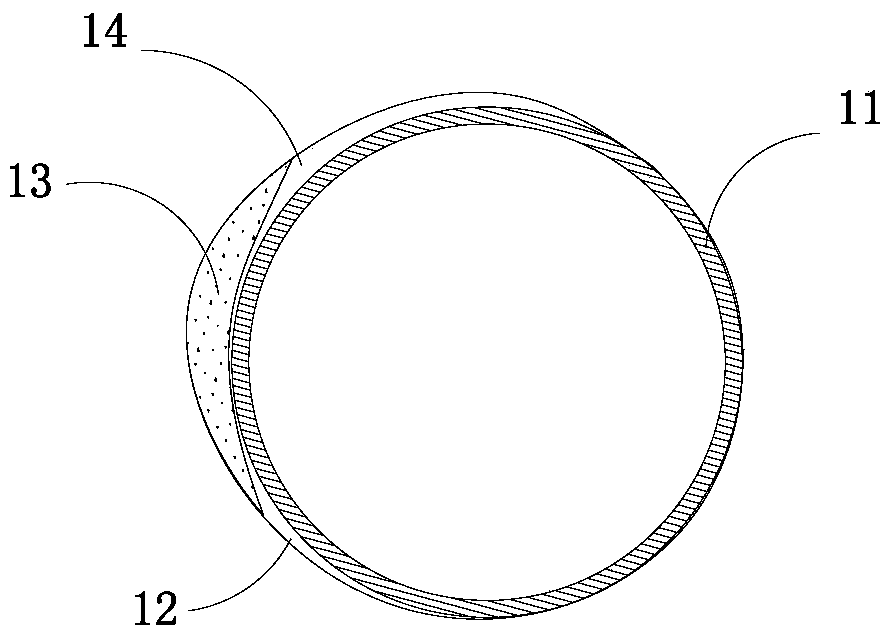

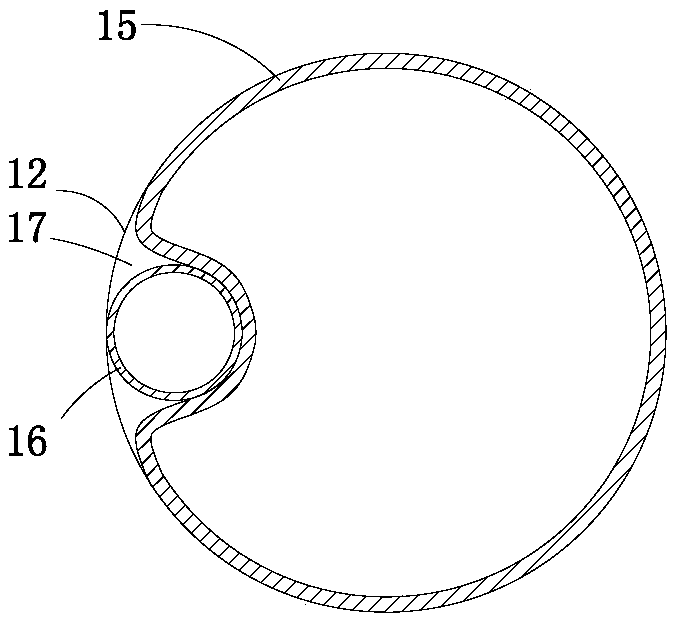

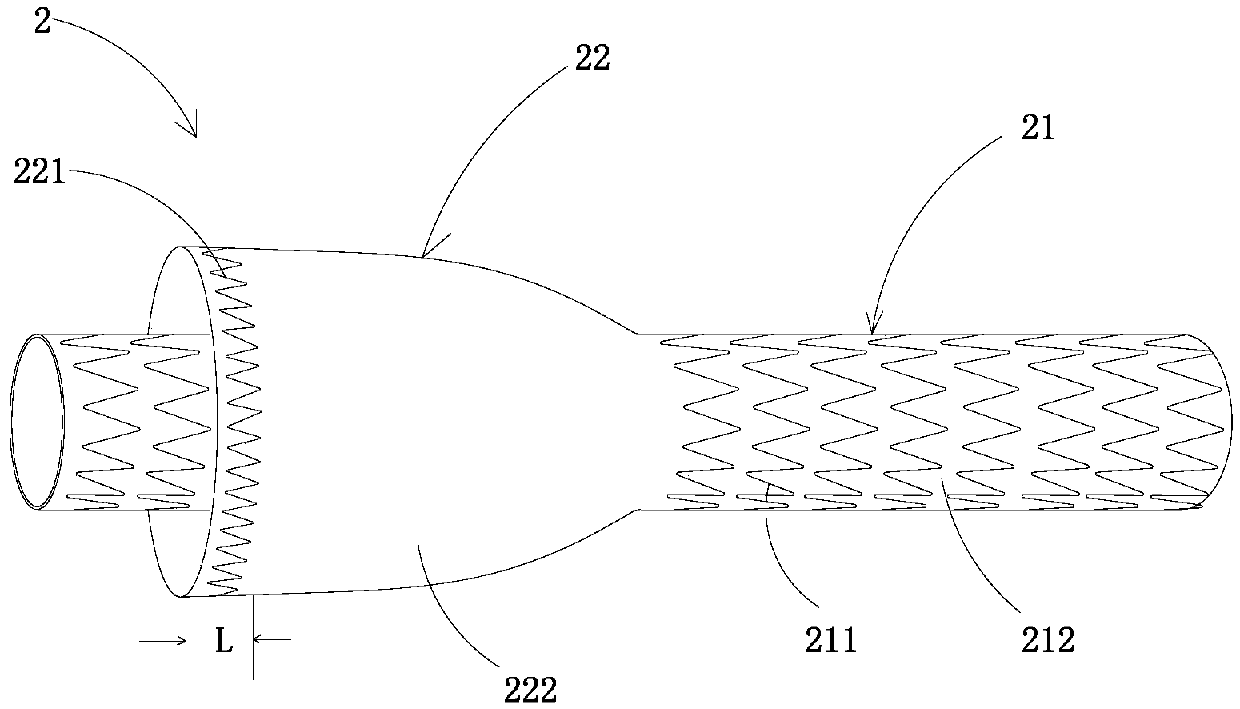

Pipe cavity bracket

The invention discloses a pipe cavity bracket. The pipe cavity bracket comprises a first pipe body and a second pipe body which sleeves the first pipe body, wherein at least one end of the second pipe body is in sealed connection with the outer surface of the first pipe body; in a radial supporting section of the pipe cavity bracket, the first pipe body comprises at least one first radial supporting structure which is arrayed along the peripheral direction of the first pipe body; the second pipe body comprises at least one second radial supporting structure which is arrayed along the peripheral direction of the second pipe body and a covering membrane covering the second radial supporting structure; a radial deformation capability of the second radial supporting structure is greater than that of the first radial supporting structure. After the pipe cavity bracket is planted, a semi-sealed gap can be formed between the first pipe body and the second pipe body or between the second pipe body and a pipe cavity wall; blood flowing into the gap can be used as a filling material to block an I type inner leakage channel, so that the blood is prevented from flowing into tumors or an interlayer. Under the impact of the blood, the first pipe body and the second pipe body both can keep a radial supporting shape and the end faces of near ends of the first pipe body and the second pipe body are not deformed, so that the blood flowing into the pipe cavity is prevented from being blocked.

Owner:LIFETECH SCIENTIFIC (SHENZHEN) CO LTD

Nutritional health bread rich in wheat bran dietary fiber and preparation method of nutritional health bread

The invention discloses a nutritional health bread rich in wheat bran dietary fiber and a preparation method of the nutritional health bread. The bread is light brown, full in appearance, smooth in surface and normal in size, and does not have cracks and is not deformed. The internal structure is uniformly spongy, fine, soft and flexible, and the bread has light fresh scent and sweet taste of wheat bran, does not have pungent smell, and is good in palatability. The bread has the advantages as follows: 1 the dietary fiber prepared from the raw material of wheat bran through compound enzymolysis is added into the bread, and the dietary fiber has the functions of moistening lung, moisturizing skin, preventing and resisting cancer, strengthening the spleen and harmonizing the stomach, blackening and strengthening hair and clearing intestines and stomach, so that the nutrition and functionality of the nutritional bread are improved; 2 the bran is soaked, washed and rinsed so as to remove protein, starch and phytic acid, so that the palatability of the bread is improved; 3 the water-soluble dietary fiber is added in raw materials of the bread, so that the rheological property and nutritional property of the bread are changed, and the nutrition arrangement of the bread is scientific and reasonable.

Owner:QINGDAO JIARUI BIOLOGICAL TECH

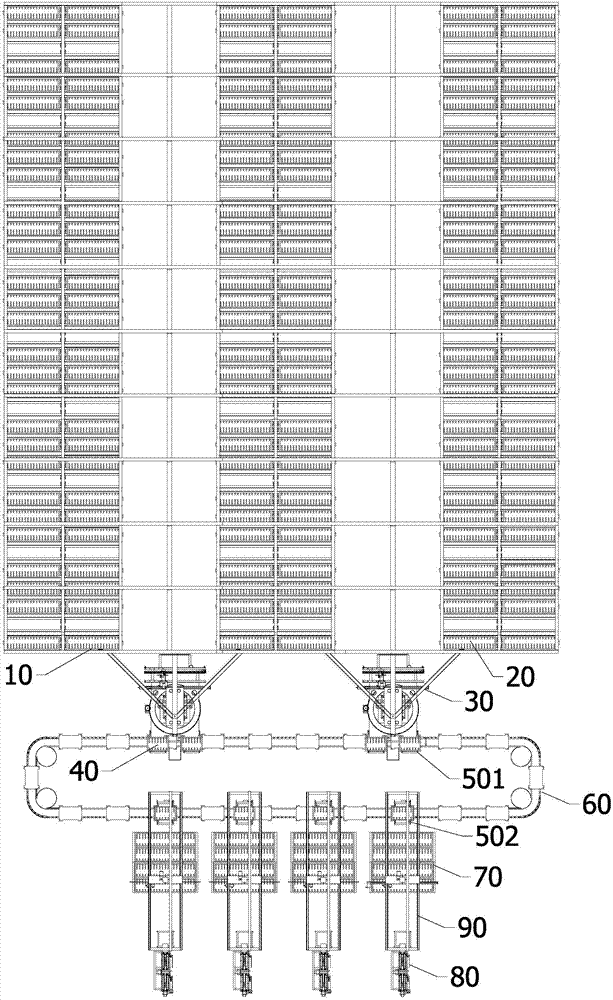

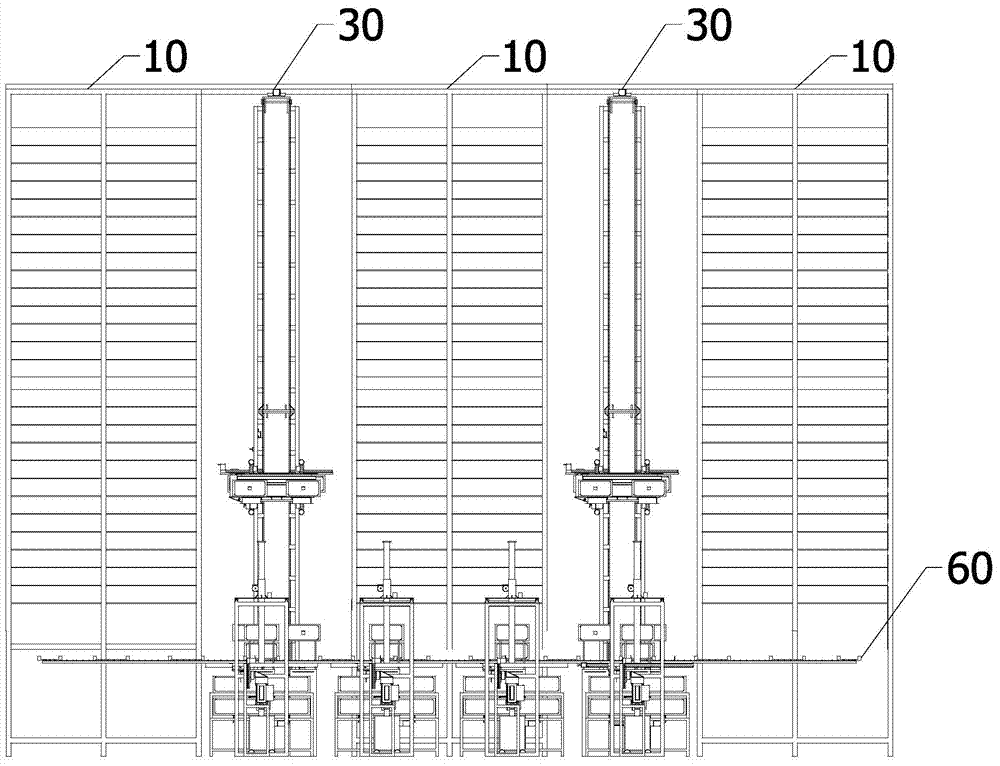

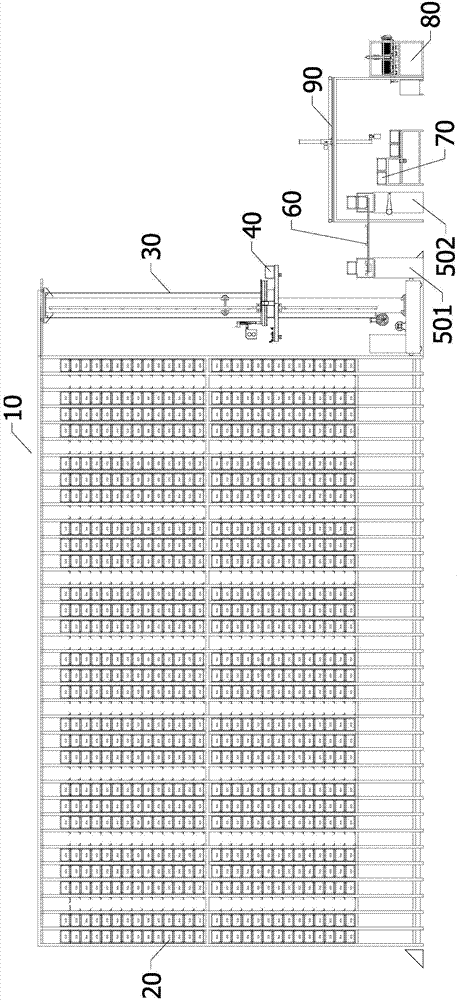

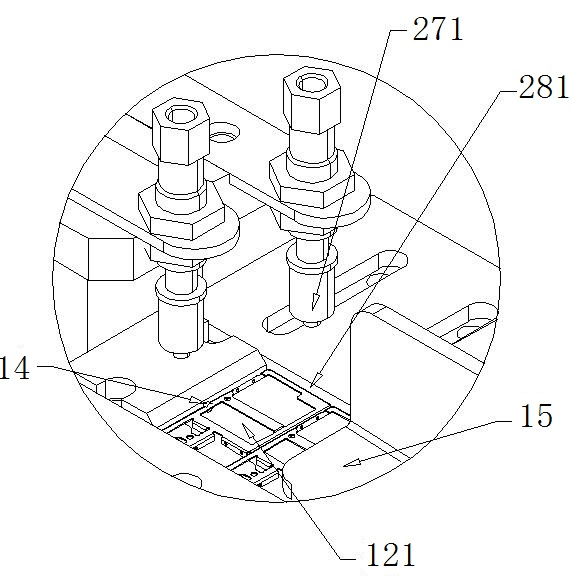

Automatic storing and extracting system capable of achieving high-density storage of articles

InactiveCN104495181AIncreasing the thicknessReduce in quantityStorage devicesAutomatic testingComputer science

The invention provides an automatic storing and extracting system capable of achieving high-density storage of articles. The automatic storing and extracting system comprises a frame, storing drawers, laneway trolleys, transport baskets, storing and extracting windows and transfer platforms. The frame is provided with a great number of drawer positions for holding the storing drawers, each laneway trolley is provided with an extracting device and transport basket positions, and the storing drawers are taken out of the frame or returned to the frame through the extracting devices. The transport baskets are movably arranged at the transport basket positions, a first clamping mechanism is arranged on each laneway trolley, and the first clamping mechanisms are used for completing exchange between the articles in the storing drawers on the extracting devices and the articles in the transport baskets at the transport basket positions. Each transfer platform is provided with a second clamping mechanism, and the second clamping mechanisms are used for completing article exchange between the transport baskets and the storing and extracting windows. Compared with the prior art, the automatic storing and extracting system has the advantages that the storage amount of the articles is increased, the laneway quantity is decreased, power mechanisms in the system are reduced, spatial span of middle transport mechanisms is decreased and system efficiency is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

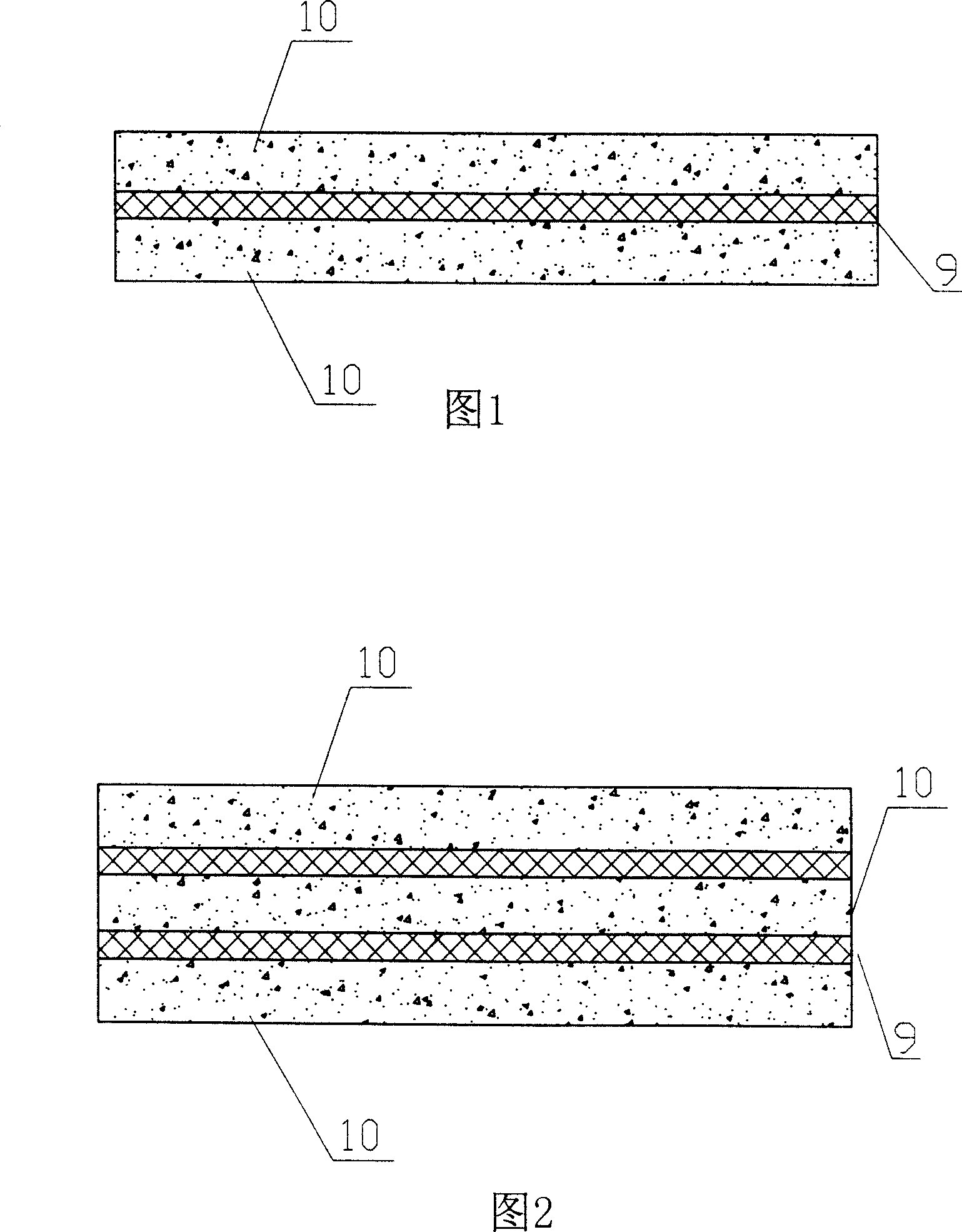

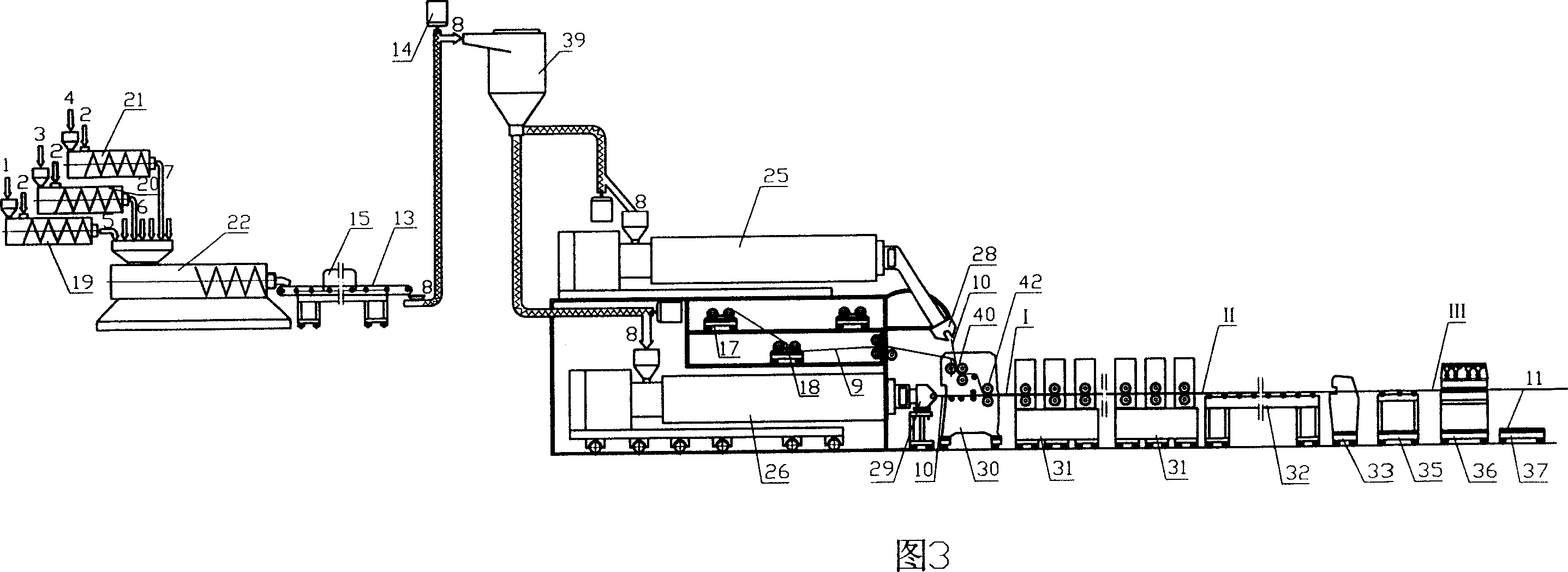

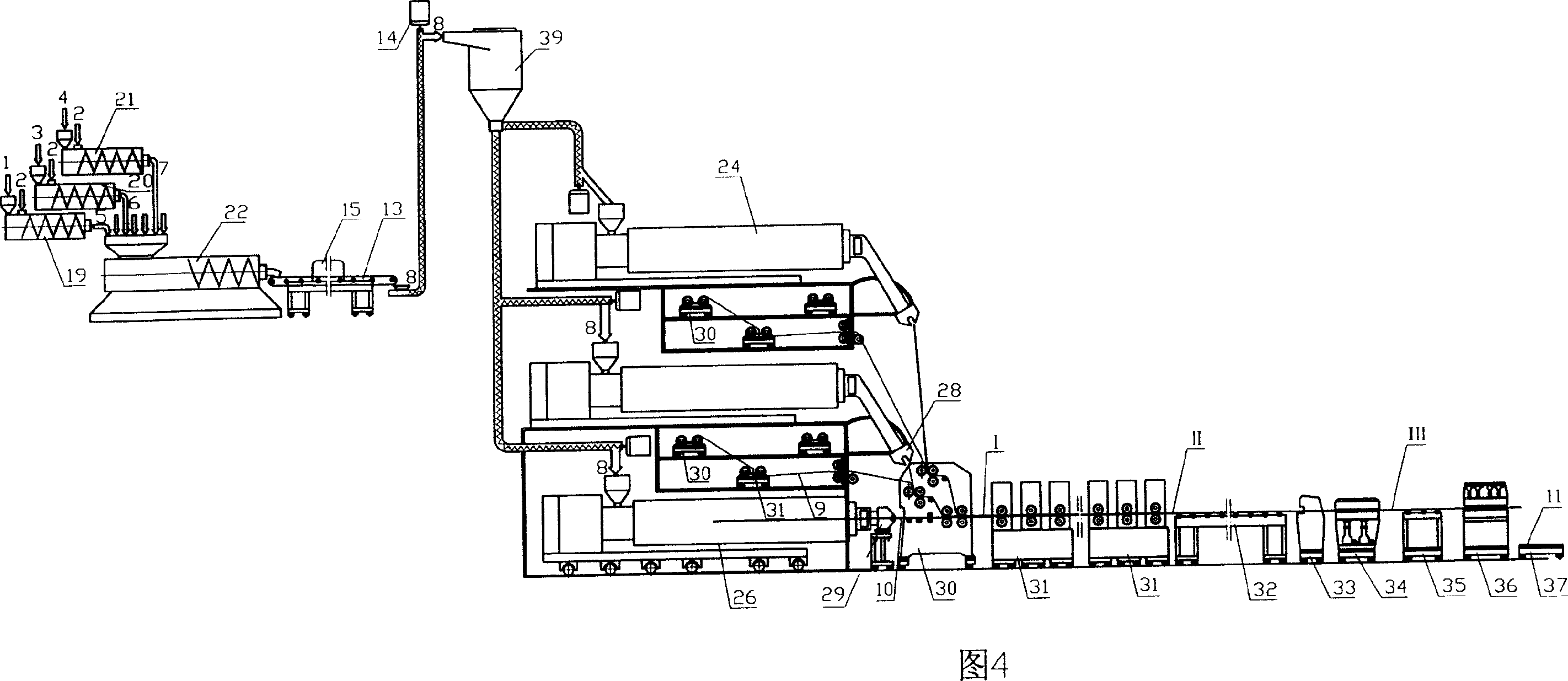

Wood-plastic formwork for construction engineering

InactiveCN1987018AExcellent mechanical propertiesFlat and smooth appearanceSolid waste managementLaminationFiberGlass fiber

A wood-plastics shuttering board for building engineering is composed of at least two basic wood-plastic ply layers made of the filler (vegetative fibers, glass fibers and plastics) and assistant (calcium carbonate, modifier, coupling agent and lubricant), and at least one lattice material layer between two basic wood-plastic ply layers and with two adhesive layers coated on its both surfaces. Its manufacture technology is also disclosed.

Owner:徐肖虎

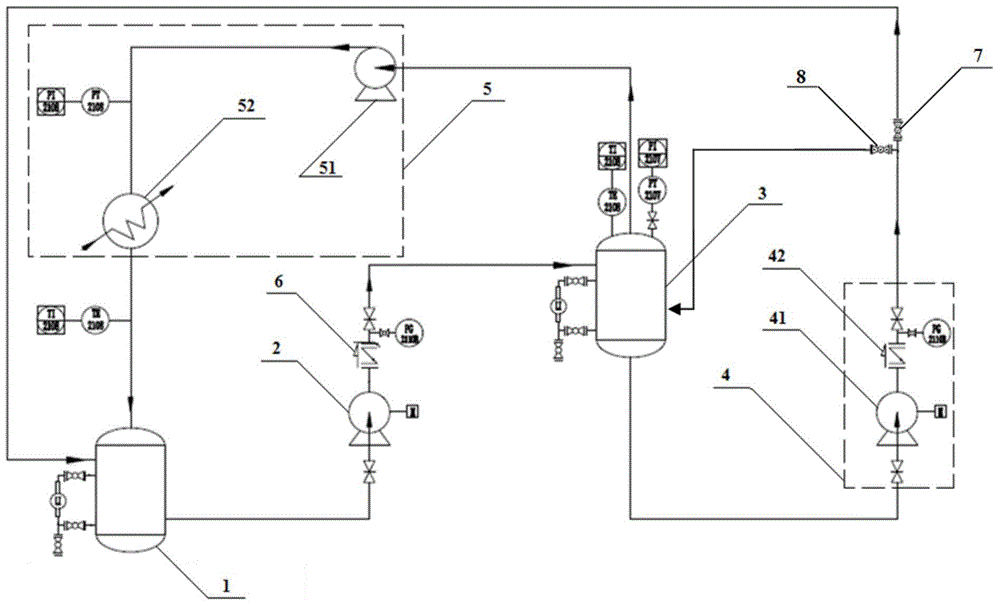

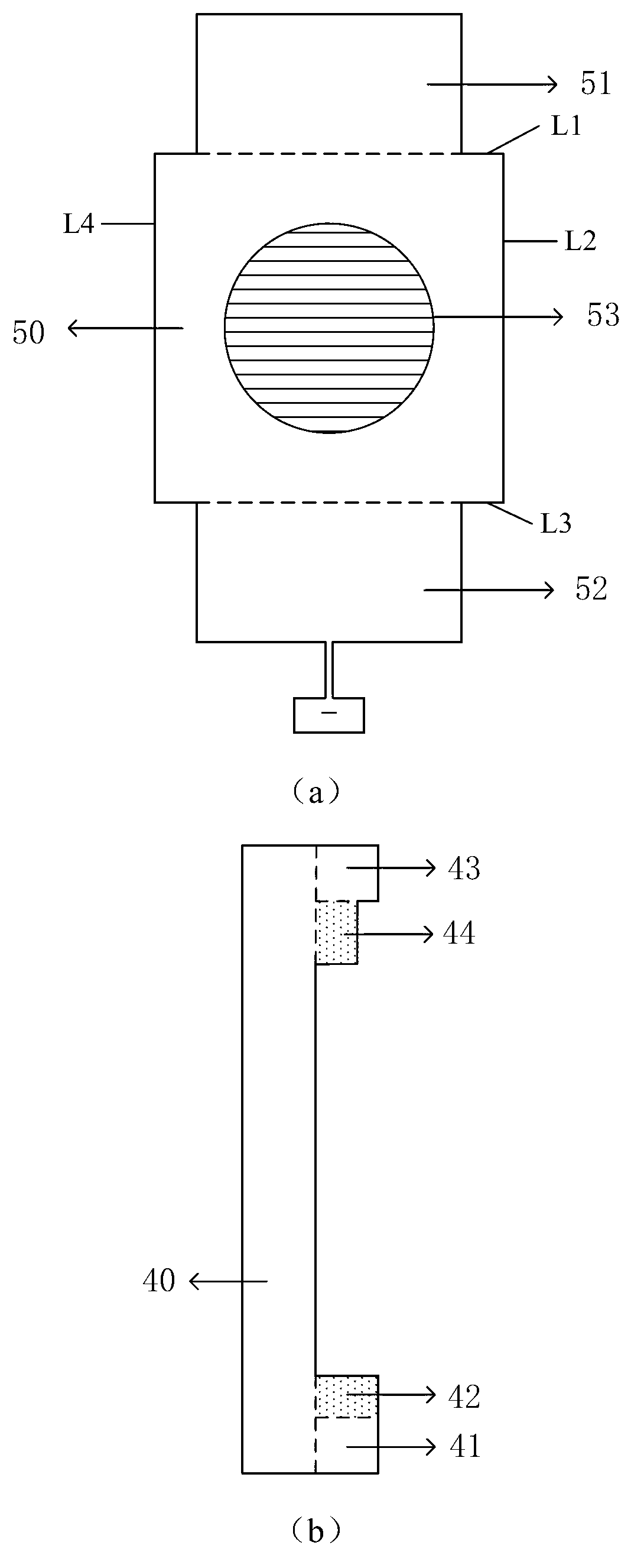

Paper deacidification agent, and paper deacidification system and method thereof

The invention belongs to the technical field of paper deacidification, and specifically relates to a paper deacidification agent, and a paper deacidification system and a paper deacidification method thereof. The paper deacidification agent comprises nanometer oxide particles, a silane coupling agent and n-perfluorooctane liquid, wherein the nanometer oxide particles are suspended in the n-perfluorooctane liquid after coated by the silane coupling agent, and the nanometer oxide particles can also be replaced by nanometer magnesium hydroxide particles. The paper deacidification system comprises a deacidification liquid storage tank, a centrifugation pump, a deacidification device and a circulation device which are in successive connection, wherein the outlet of the circulation device is respectively connected with the inlet of the deacidification liquid storage tank and the inlet of the deacidification device; a circulation loop is formed between the deacidification device and the circulation device; and the deacidification device is also connected with the deacidification liquid storage tank via a deacidification liquid recovery device. The paper deacidification method comprises the following steps: putting a literature into the deacidification device, then pumping the paper deacidification agent into the deacidification device, shaking the literature, subjecting deacidification liquid to circulation, pumping the deacidification liquid back, and carrying out condensation recovery. According to the invention, safety and effectiveness are obtained; and the paper deacidification agent has the advantages of easy recovery, good effects and low cost.

Owner:NAT LIBRARY OF CHINA

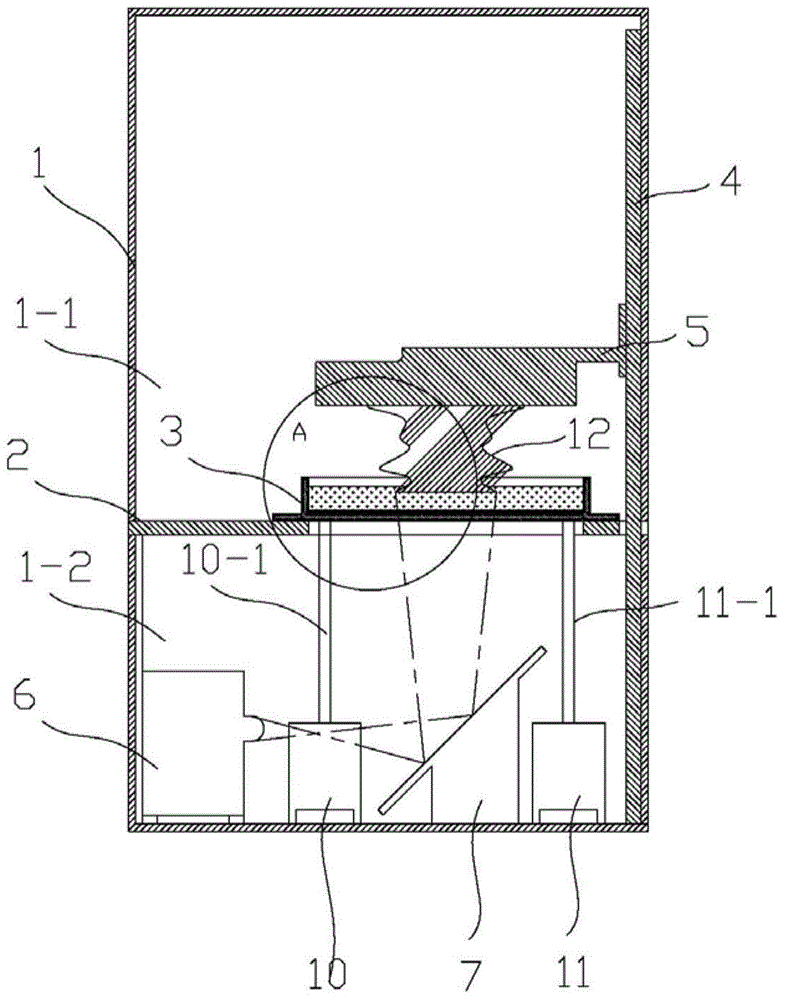

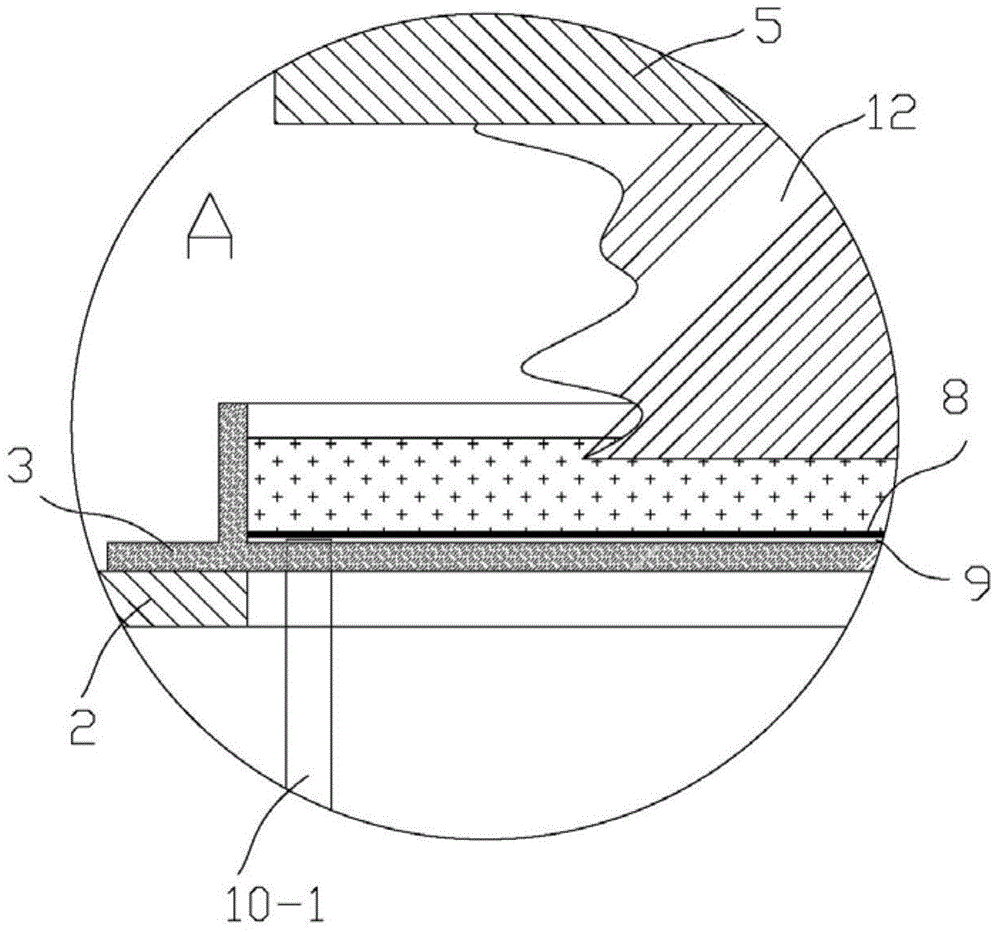

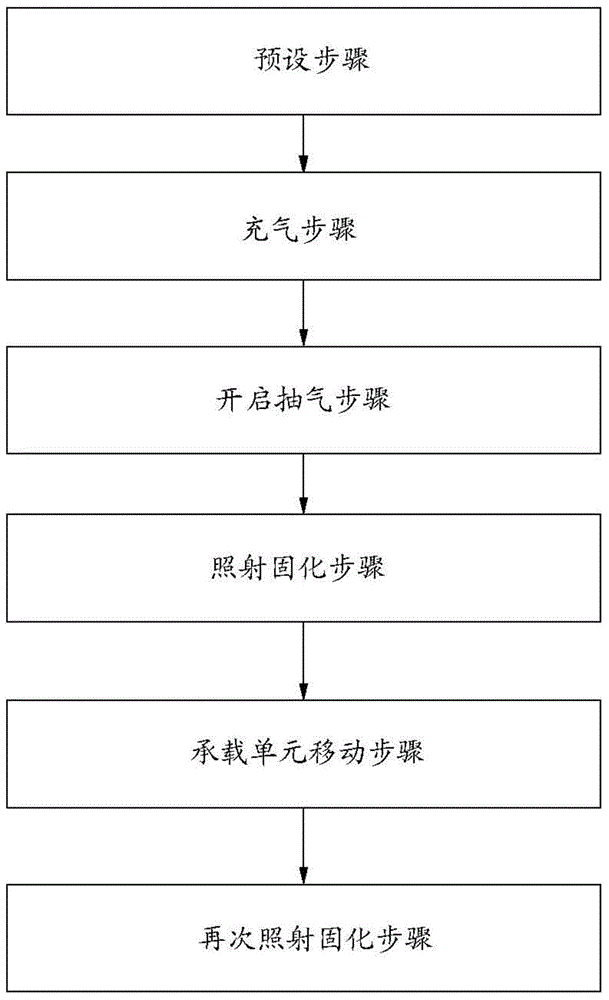

Photosensitive resin pool, photocuring 3D (three-dimensional) printer using photosensitive resin pool and printing method

ActiveCN104890245ASimple structureNot easy to stickAdditive manufacturing apparatusSemipermeable membraneOxygen

The invention provides a photosensitive resin pool. The photosensitive resin pool comprises a pool body, an oxygen molecule semipermeable membrane located above a bottom wall in the pool body as well as an air inlet and an air outlet, wherein the area of the oxygen molecule semipermeable membrane accords with that of the bottom wall of the pool body, and a cavity is formed between the oxygen molecule semipermeable membrane and the bottom wall of the pool body; the air inlet and the air outlet are formed in the side wall or the bottom wall of the pool body and communicated with the cavity. Besides, the invention further provides a 3D (three-dimensional) printer adopting the photosensitive resin pool and a printing method. The structures of the photosensitive resin pool and the 3D printer are simple, the printing quality is reliable, and the service life is longer. By means of the method, the starting time, the inflating volume and the air extracting volume of an inflation unit and an air extraction unit are correspondingly adjusted, the semipermeable membrane cannot swell while an oxygen molecule layer is formed on the upper surface of the semipermeable membrane, a print object cannot be easily bonded to the semipermeable membrane and is easy to separate, and the contact surface of the print object and the semipermeable membrane cannot be twisted or deformed.

Owner:广西玉林市由你造科技有限公司

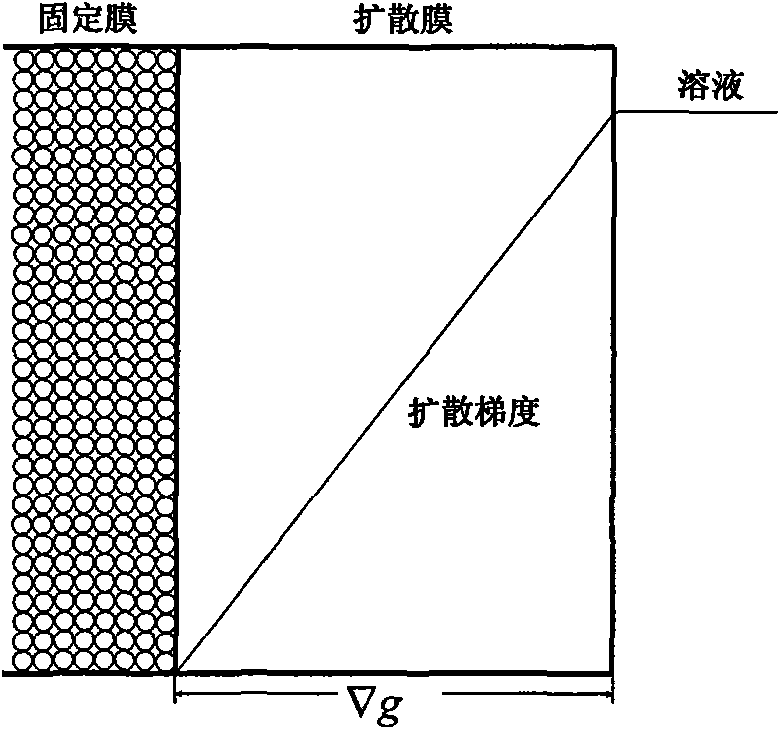

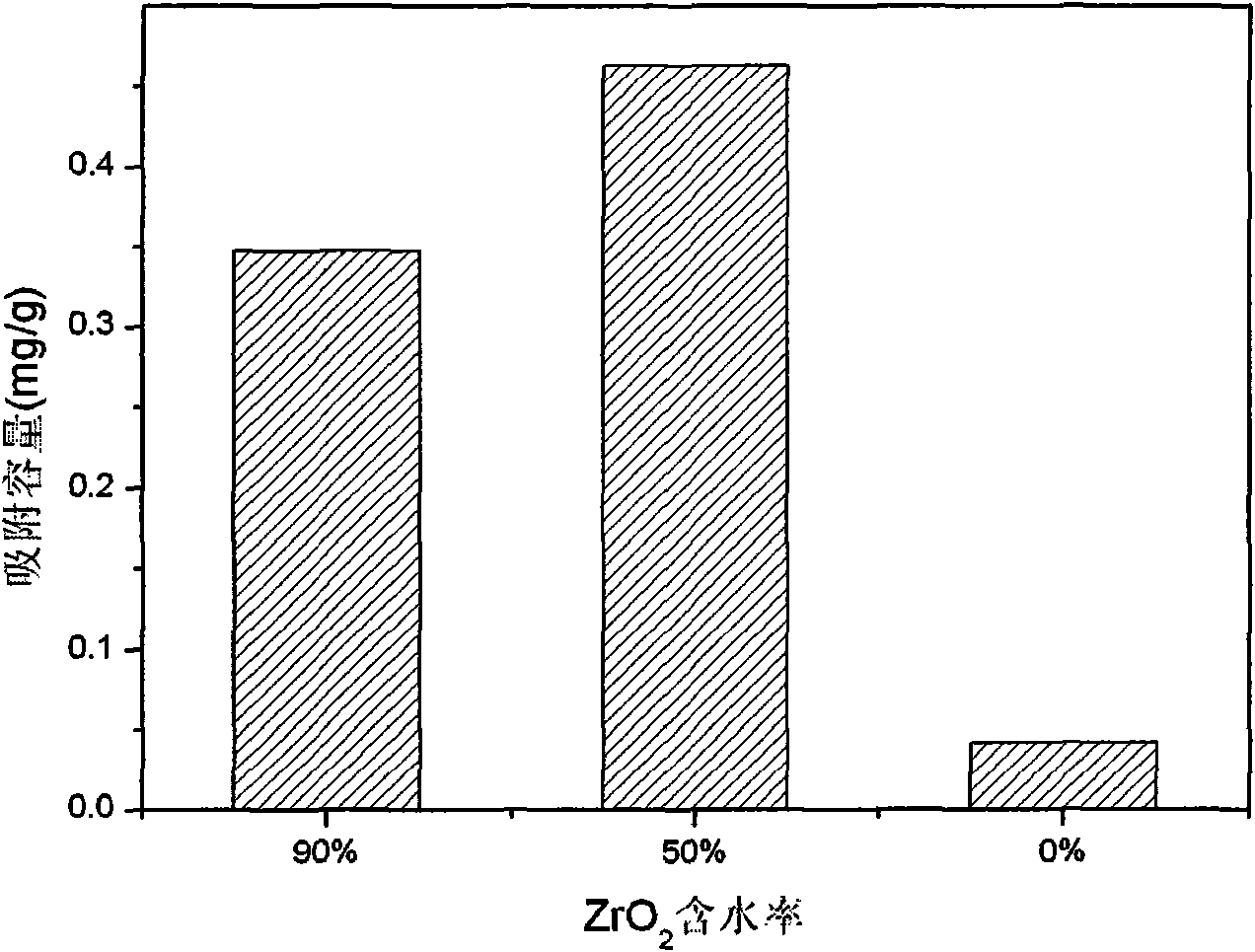

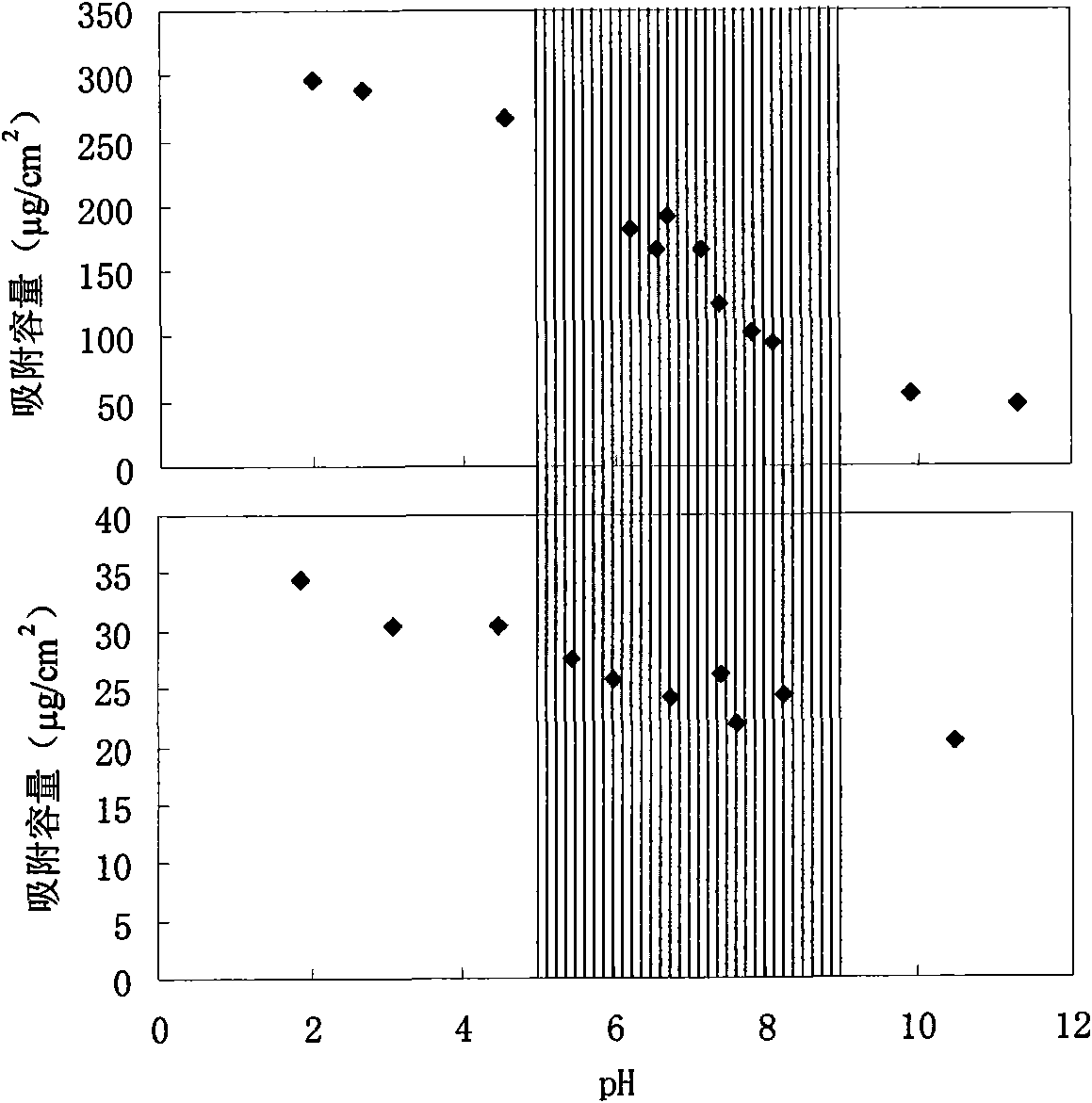

Phosphorus fixing film applied to diffusive gradients in thin-films measurement technology

InactiveCN101629881AHeat resistantChemically stablePreparing sample for investigationColor/spectral properties measurementsHigh absorptionAbsorption capacity

The invention relates to a phosphorus fixing film applied to diffusive gradients in thin-films measurement technology. A fixing film and dispersion film superposed structure is arranged in the diffusive gradients in thin-films measurement technology, ions pass through a dispersion film in a dispersion way and is captured by a fixing film immediately to form the linear gradient distribution on the dispersion film. The phosphorus fixing film capturing phosphorus ions is characterized by using zirconium dioxide powder and acrylamide as raw materials, the raw materials are uniformly mixed to form mixed solution according to the weight volume ratio of 1:1.5-1:4, the mixed solution is slowly infused into a clearance of two glass plates clamping a u-shaped plastic sheet, the glass plates are placed for 2-4h horizontally at lower temperature of 10-15 DEG C after bubbles are removed, the temperature is risen to 30-35 DEG C after the zirconium dioxide powder is freely settled so as to enable the mixed solution to be gelated to form a film, the film has higher absorption capacity ratio to phosphate radicals than the prior iron film material by at least 4 times under the condition that the pH value is 5-9, so the analysis requirement of the DGT technology to phosphorus in different environment media is completely met.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

A kind of foam concrete and preparation method thereof

The invention relates to a foamed concrete and a preparation method thereof. The foamed concrete adopts a chemical foaming method, and a foam stabilizer, an early strength agent, and a water reducer are respectively added to ordinary Portland cement slurry and stirred evenly, and then chemical foaming agent is added. The foaming agent is fully stirred evenly, then injection molded, cured at room temperature, and hardened. The dry apparent density range of the foamed concrete prepared by this method is 150-300kg / m3, the corresponding compressive strength is 0.10-0.50MPa, and the thermal conductivity is lower than 0.10W / mK. It can be used as roof insulation project, floor heating project, light Cushion material, especially suitable for external wall insulation system, energy-saving composite panels, etc. used in building energy-saving projects.

Owner:NANJING UNIV OF TECH

Sugar-free bread and method for producing the same

The invention relates to a sugar-free bread, characterized by comprising the materials with the following components: high-gluten flour 150-900 parts, low-gluten flour 200-800 200-800 parts, water-free ghee 50-200 parts, sugar-free modifier 50-200 parts, sugar-free milk 10-150 parts, egg 50-10 parts, bread modifier 1-20 parts, yeast 10-20 parts, ghee 200-800 parts. The inventive technology avoids coldness or heat in fed materials contacted with yeast, causing the yeast to exert optimal fermentation ability. The prepared sugar-free nutritious bread is deeply favored by wide consumers.

Owner:天津金世制药有限公司

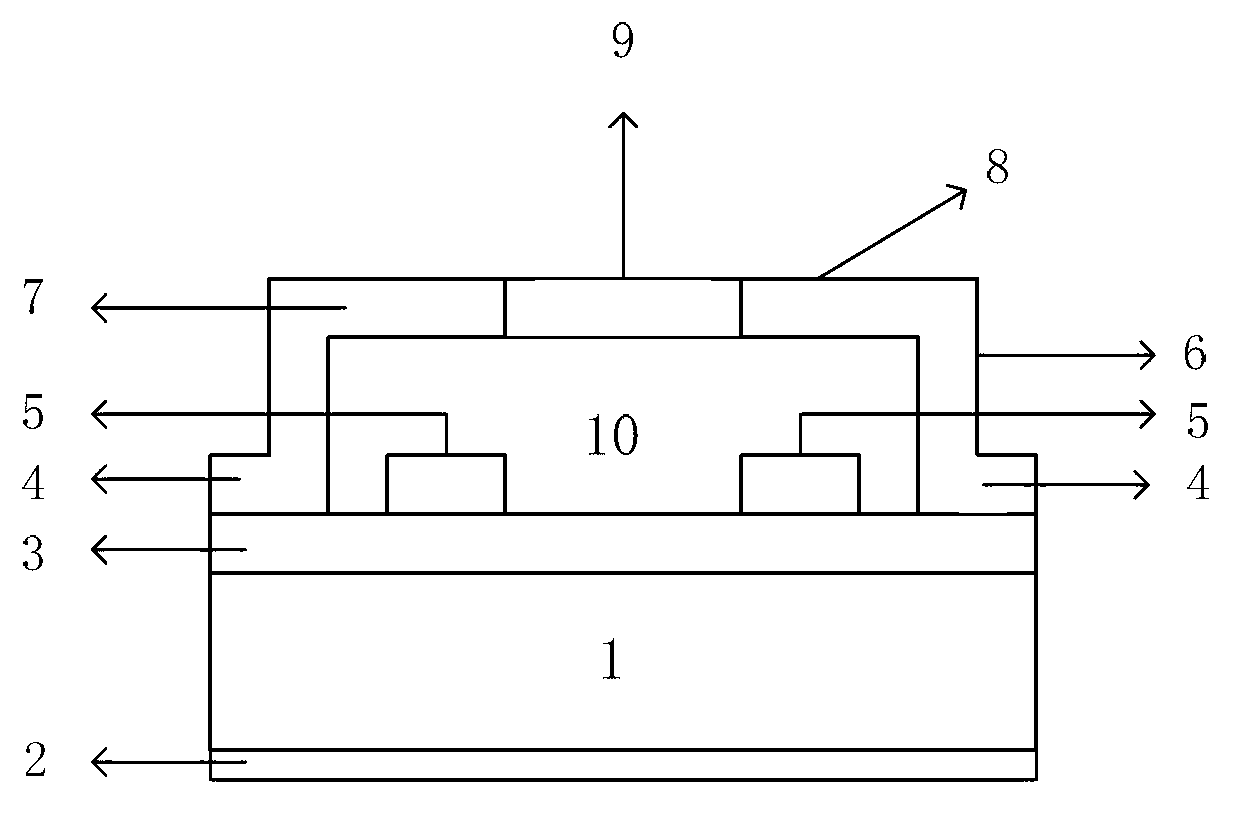

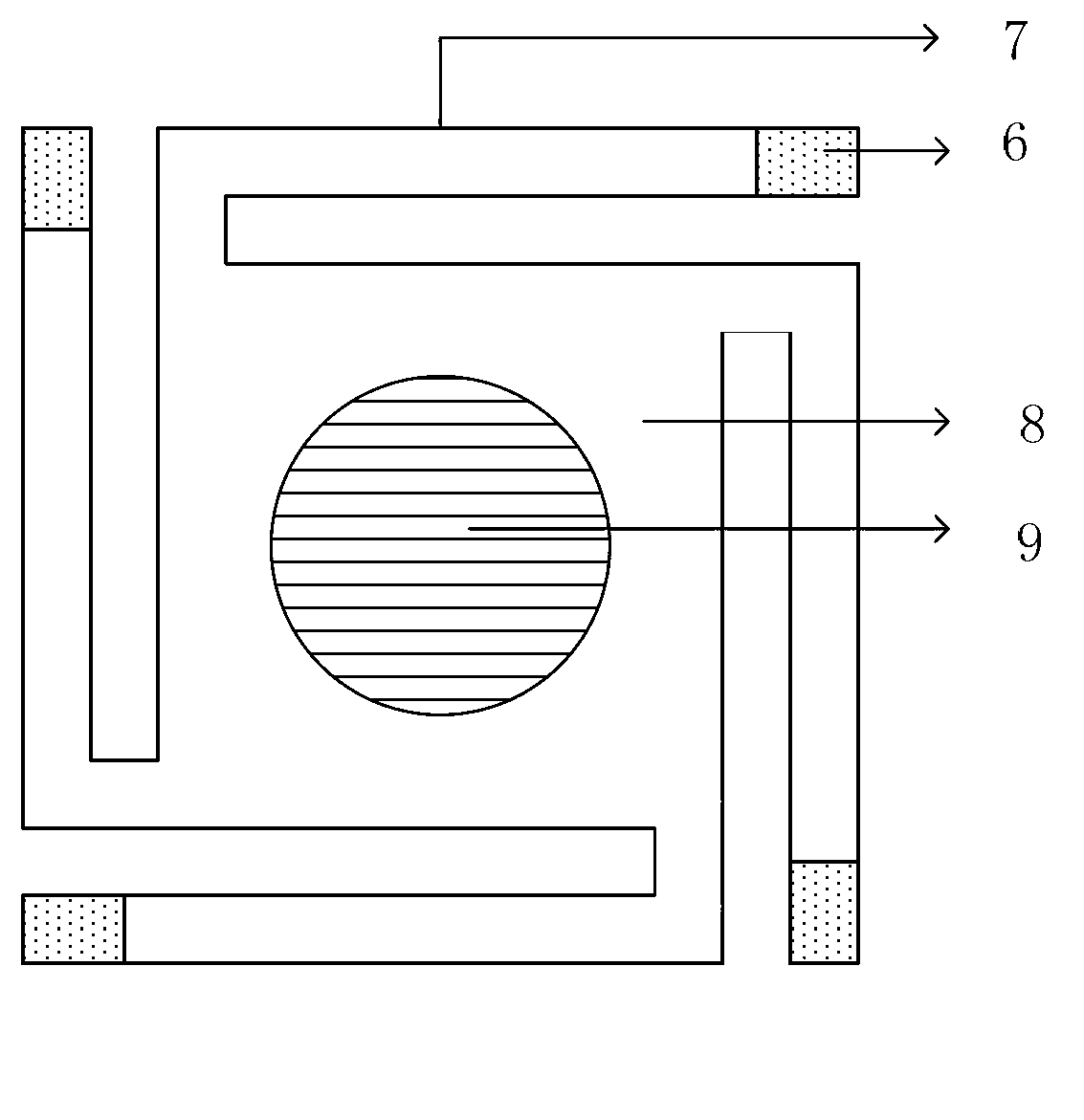

Miniature F-P (Fabry-Perot) cavity tunable filter and method for manufacturing same

InactiveCN103293660ALarge deformationLarge tuning rangeDecorative surface effectsChemical vapor deposition coatingPhysicsResonant cavity

The invention discloses a miniature F-P (Fabry-Perot) cavity tunable filter and a method for manufacturing the same. The miniature F-P cavity tunable filter comprises a substrate. An antireflection film is attached to one surface of the substrate, a first bragg reflector is attached to the other surface of the substrate, and a first electrode and a second electrode are attached onto the first bragg reflector; four metal piers are attached onto the first electrode, and a bridge surface is attached onto the four metal piers; the bridge surface comprises four cantilever beams and a movable diaphragm, each cantilever beam is L-shaped, one end of each cantilever beam is perpendicularly fixedly connected with the corresponding metal pier, and the other end of each cantilever beam is connected with the movable diaphragm; the movable diaphragm is square, and a second bragg reflector is inlaid in the center of the movable diaphragm; the first bragg reflector and the second bragg reflector form a resonant cavity of an F-P cavity; after the miniature F-P cavity tunable filter is powered on, the four cantilever beams elastically deform and can drive the movable diaphragm and the second bragg reflector to move in the direction perpendicular to the first bragg reflector, so that the length of the resonant cavity is changed, and a tunable function of the filter is realized. The miniature F-P cavity tunable filter and the method have the advantage that the filter is wide in tunable range and high in response speed.

Owner:HUAZHONG UNIV OF SCI & TECH +2

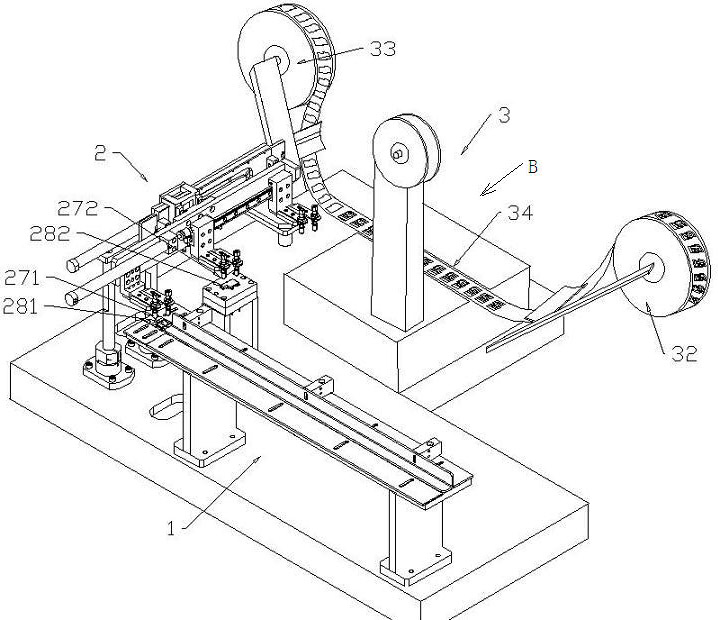

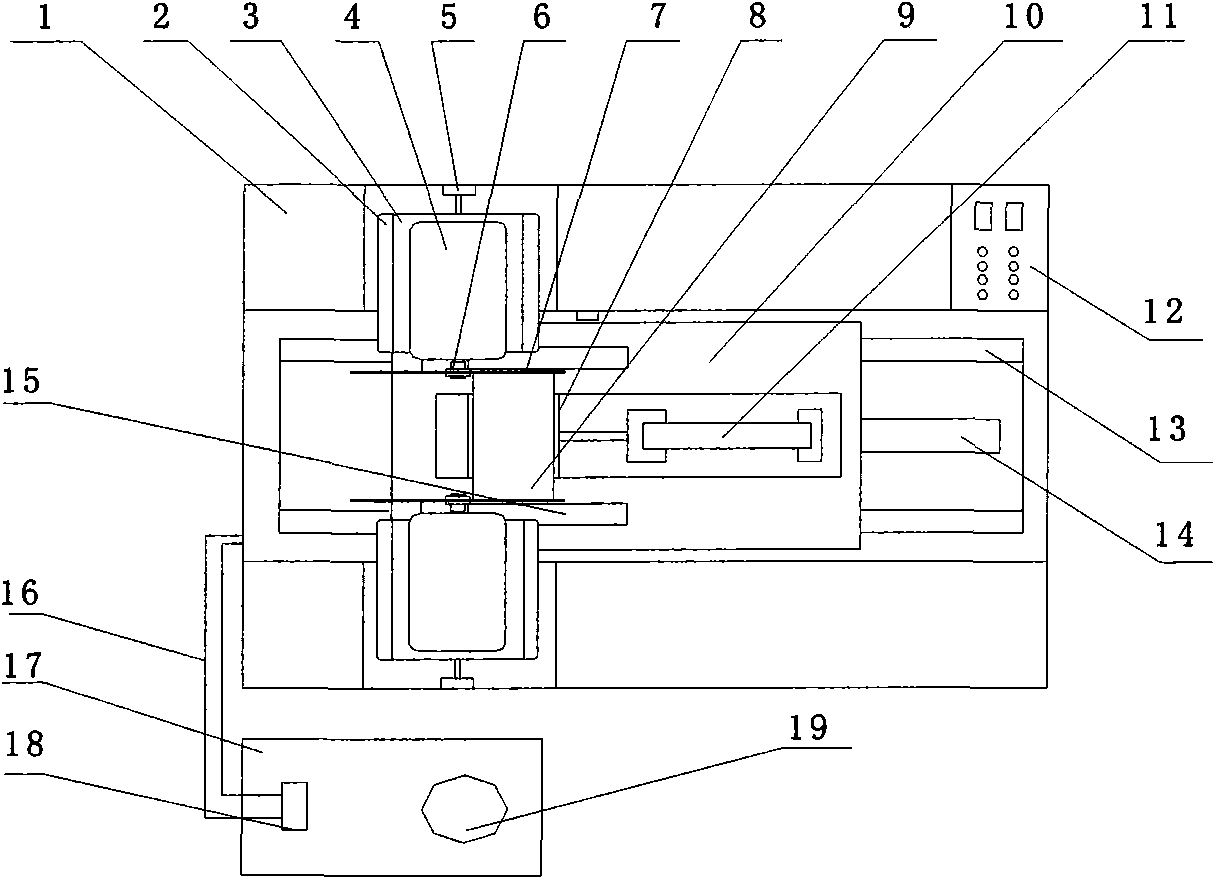

Integrated machine for automatically detecting flatness and packaging carrier belt for shielding case

ActiveCN102673822AFully automatedReduce quality impactPackaging automatic controlEngineeringAutomation

The invention discloses an integrated machine for automatically detecting flatness and packaging a carrier belt for a shielding case. The integrated machine comprises a blowing and feeding mechanism, a double stroke transmission mechanism, an automatic packaging mechanism and a controlling device. Shielding cases to be detected enter into a first work station in the blowing and feeding mechanism orderly, the controlling device controls the double stroke transmission mechanism to execute a first stroke, a first nozzle sucks the shielding cases at the first work station and conveys the shielding cases to a second work station for flatness detection, a second nozzle sucks the qualified shielding cases detected at the second work station and conveys the shielding cases to a third work station to be arranged on the carrier belt, and the carrier belt where the shielding cases are arranged is automatically packaged by an adhesive tape and coiled automatically by a receiving disc. The integrated machine provided by the invention detects and conveys the shielding cases automatically, sorts qualified and unqualified products and arranges the qualified products on the carrier belt automatically. The carrier belt is automatically packaged by the adhesive tape and operators do not contact with the detection and packaging process of the shielding cases, thereby realizing automation of the packaging process of the shielding cases.

Owner:南通诚业德精密组件有限公司

Novel environment-friendly polyvinyl chloride cable material

The invention provides a novel environment-friendly polyvinyl chloride cable material. The material consists of polyvinyl chloride WS-1300, plasticizer UN399, stabilizer CZ-756E (105), epoxidized soybean oil, bisphenol A antioxygen, antimonous oxide (SB203), polyethylene (PE), activated light calcium carbonate and carbon black. The chemical substance content of the material is reduced by improving the formula of the cable material, so that the product has the advantages of effectively solving the problem of toxic gases releasing in polyvinyl chloride material heating and plastifying process, reducing the harm to the human bodies in the production process, resisting the temperature of between 40 and 105 DEG C, along with cleanness and environmental protection, light specific gravity, high plasticization degree, no deformation, fracture or aging, superior product performance, and wider application range and field.

Owner:ZHENJIANG HUAYIN INSTR & ELECTRICAL EQUIP

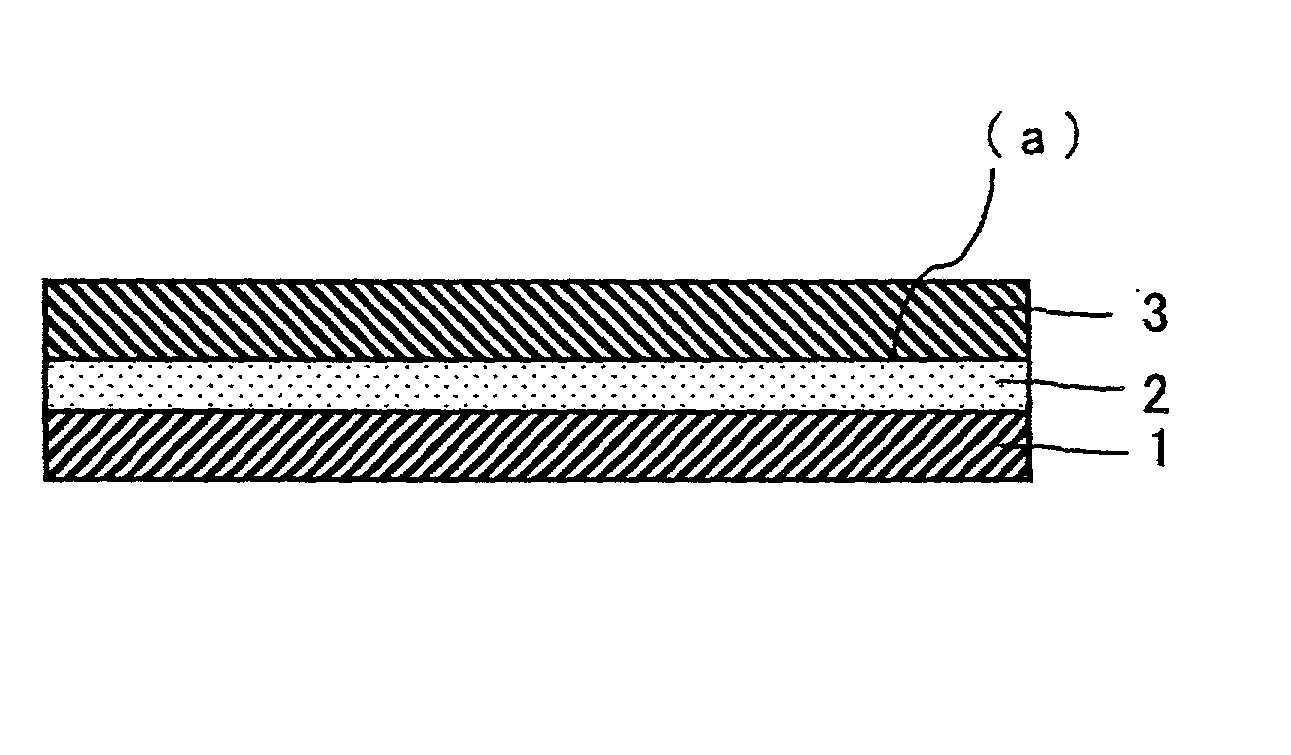

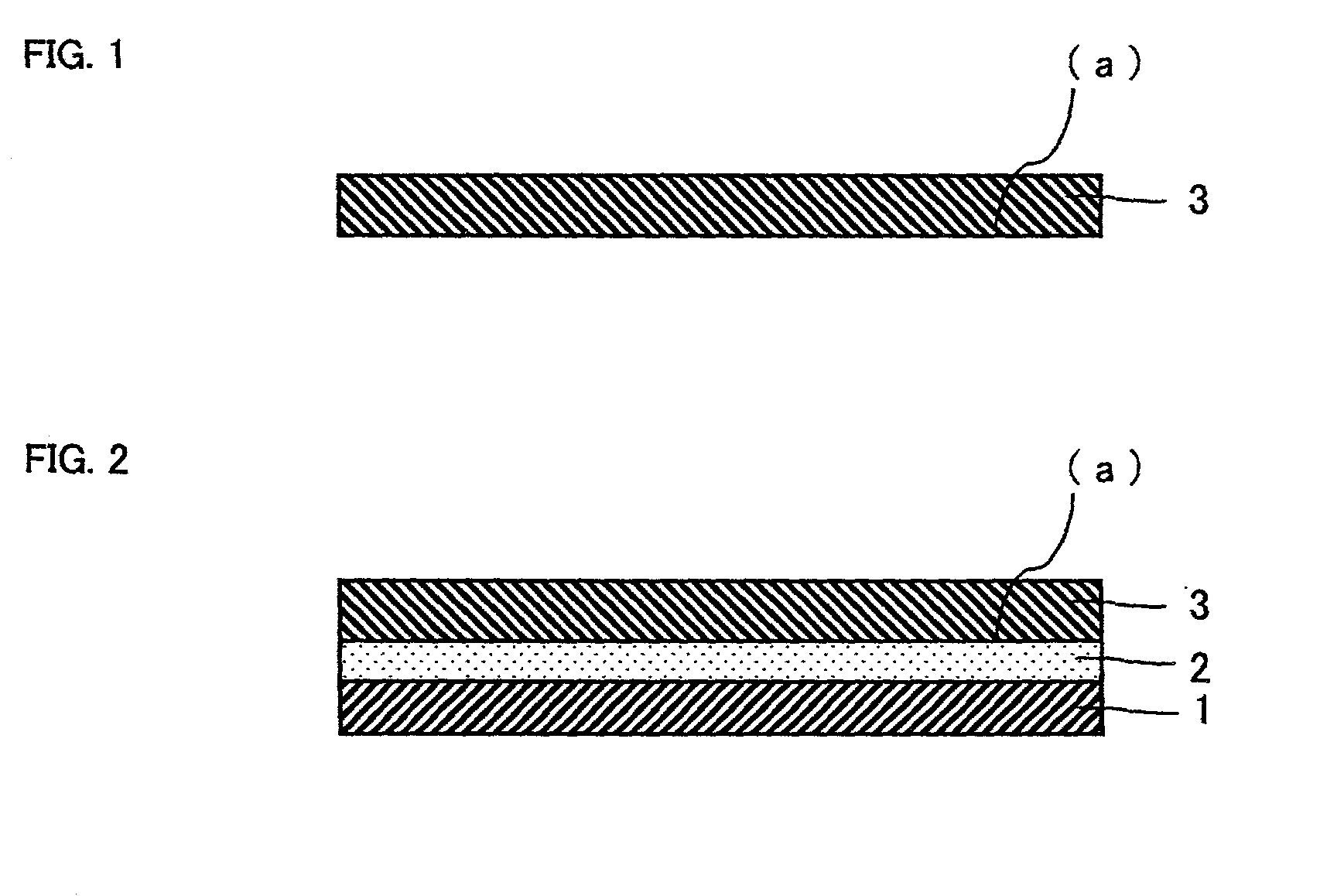

Transparent protective film for polarizing plate, process for producing the same, polarizing plate, and optical film and liquid crystal display using polarizing plate

InactiveUS20020186461A1Facilitate adhesion surfaceNo deformationPolarising elementsNon-linear opticsTectorial membraneLiquid-crystal display

A transparent protective film for polarizing plate being provided via an adhesive layer on at least one surface of a polarizer, wherein a ratio of constituent elements (oxygen ratio / carbon ratio) on the polarizer-adhering surface of the transparent protective film for polarizing plate, which is determined by X-ray photoelectron spectrometry, is larger than 0.75 has facilitate adhesion surface and no deformation without problems attributable to saponification.

Owner:NITTO DENKO CORP

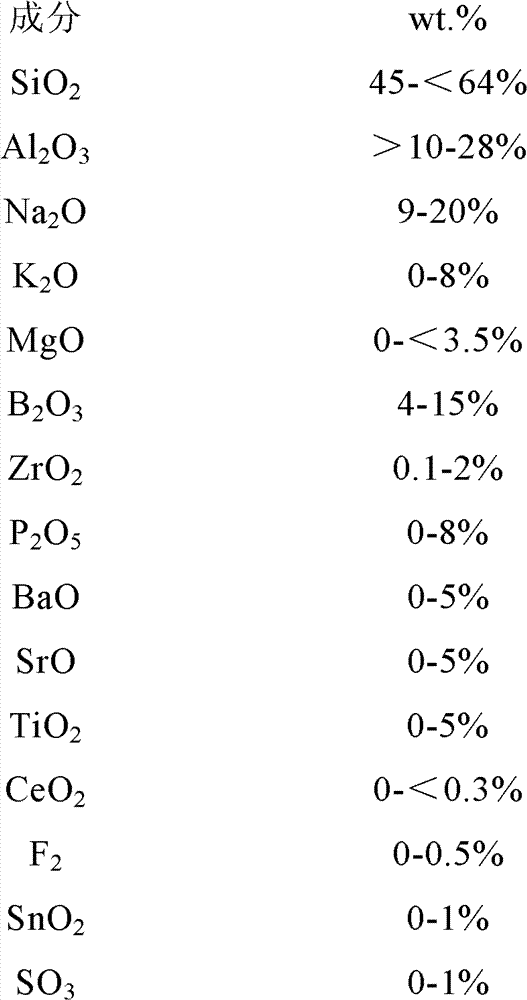

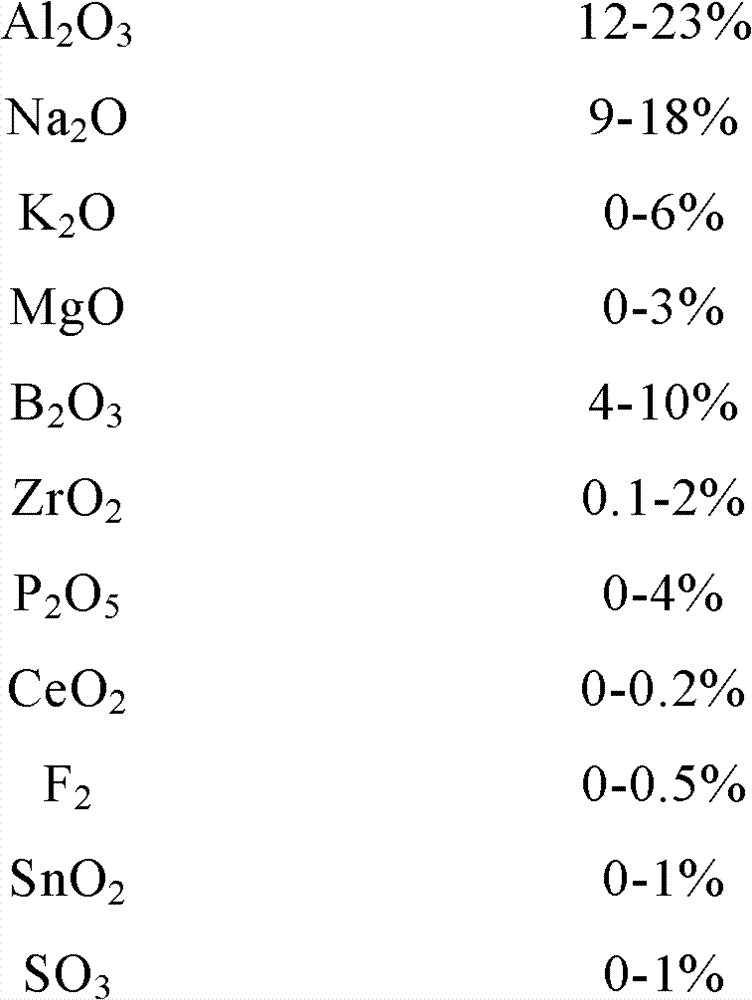

Deformation-resistant high-yield-point and light zirconium boron-alumina silicate glass

ActiveCN103359934ALow densityHigh elastic modulusGlass forming apparatusSurface stressSilicate glass

The invention relates to deformation-resistant high-yield-point and light zirconium boron-alumina silicate glass and particularly relates to alumina silicate glass containing ZrO2 and B2O3. The glass has the characteristics that the elasticity modulus E is more than or equal to 60 GPa and less than or equal to 78 GPa after the glass is chemically tempered; the yield point At is more than or equal to 620 DEG C and less than or equal to 850 DEG C; the coefficient of thermal expansion (CET) is more than or equal to 7.5*10<-6> / K and less than or equal to 9.8*10<-6> / K; the density is less than or equal to 2.5 g / cm<3>; the surface pressure stress is at least 700 MPa; and the thickness of a surface stress layer is at least 25 microns. The glass has deformation resistance, is high in yield point and is light in weight.

Owner:SCHOTT GLASS TECH (SUZHOU) CO LTD

Preparation method for polyimide with cross-linked structure and application of polyimide nanofiber membrane in lithium battery diaphragm

InactiveCN103474600ASolve the lack of mechanical propertiesReduce thicknessMaterial nanotechnologySecondary cellsPolymer sciencePolyolefin

The invention provides a preparation method for a polyimide nanofiber membrane with a cross-linked structure and application of the polyimide nanofiber membrane in a lithium battery diaphragm, belonging to the field of high polymer materials. The preparation method comprises the following steps: subjecting a polyamide acid solution to electrostatic spinning to prepare a polyamide acid nanofiber membrane; etching the polyamide acid nanofiber membrane in an aqueous ammonia solution with a pH value of 8 to 10 for 60 s to form the cross-linked structure; and carrying out washing, drying and imidization at a temperature of 300 DEG C so as to prepare the polyimide nanofiber membrane. The lithium ion battery diaphragm provided by the invention has high mechanical properties, heat stability, high porosity and excellent electrochemical performance. The battery diaphragm has the cross-linked structure and high mechanical properties, thereby overcoming the problems of low strength and an over-open pore structure of a nonwoven polyimide nanofiber membrane. Meanwhile, the diaphragm has porosity of about 80% and can resist a high temperature of 300 DEG C without any deformation, thereby overcoming the disadvantages of low porosity and poor temperature resistance of a polyolefin microporous diaphragm. In particular, the diaphragm provided in the invention has specific capacity substantially better than that of the traditional polyolefin microporous diaphragm under the conditions of high-rate rapid charging and discharging.

Owner:BEIJING UNIV OF CHEM TECH

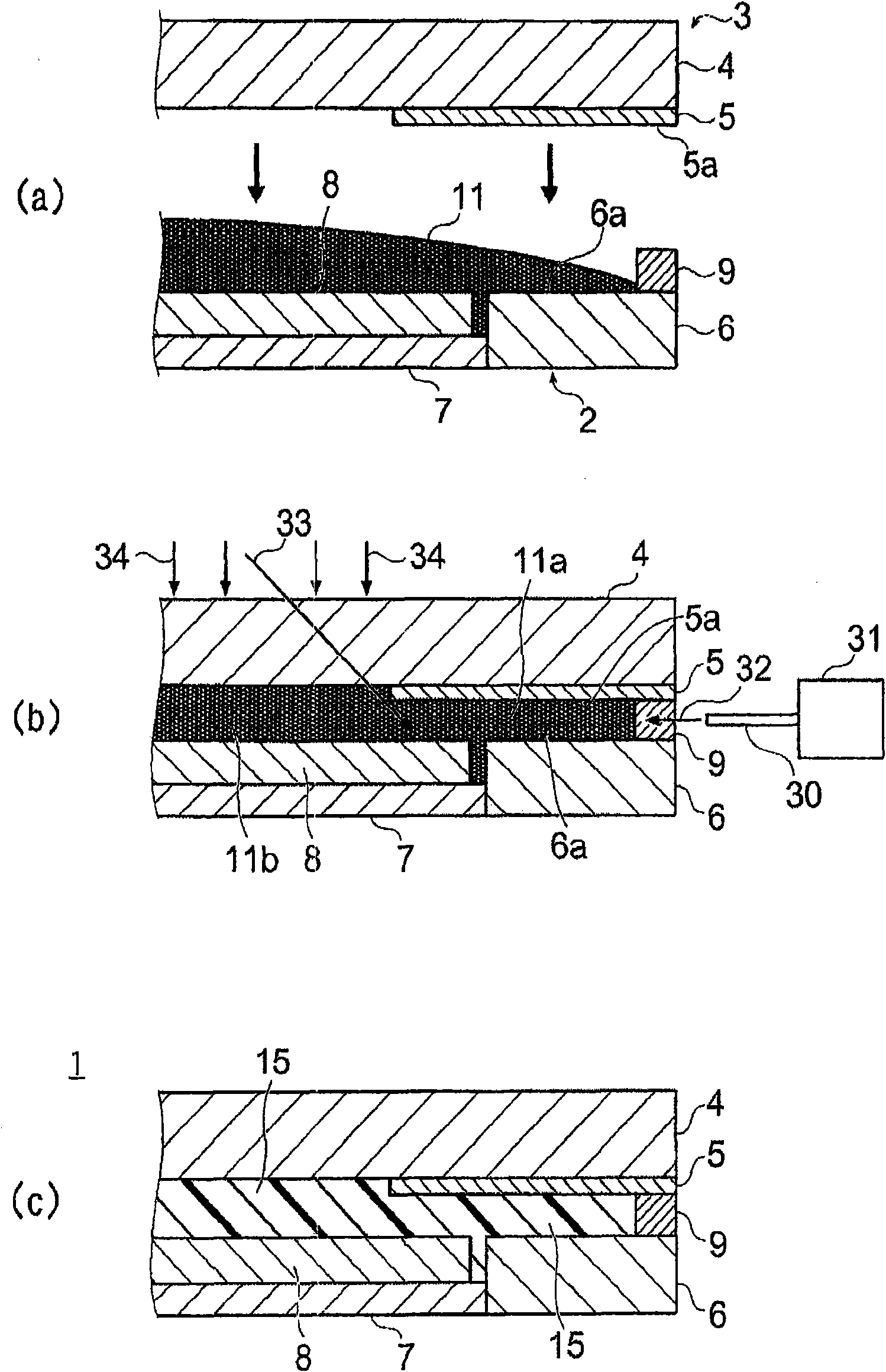

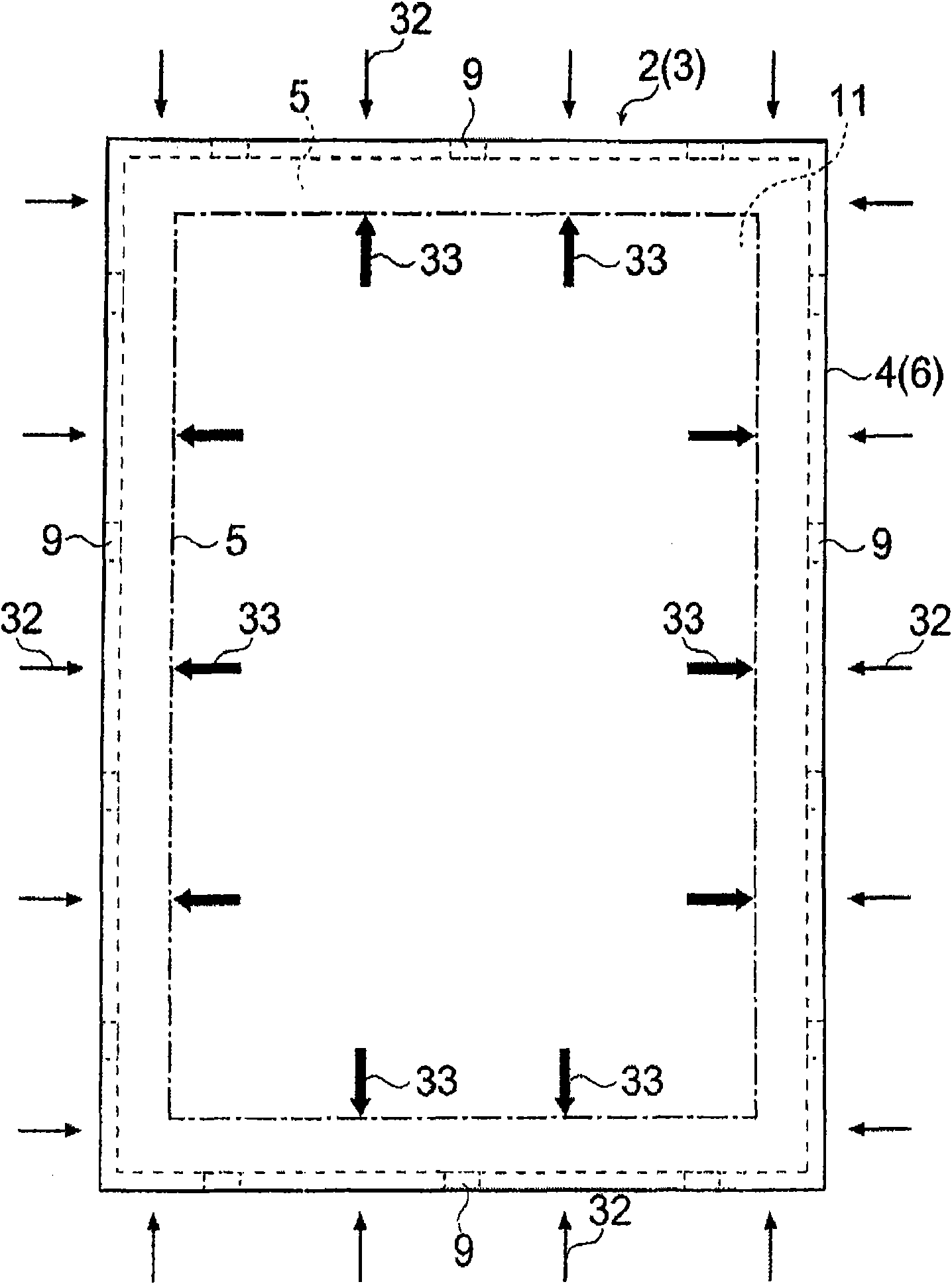

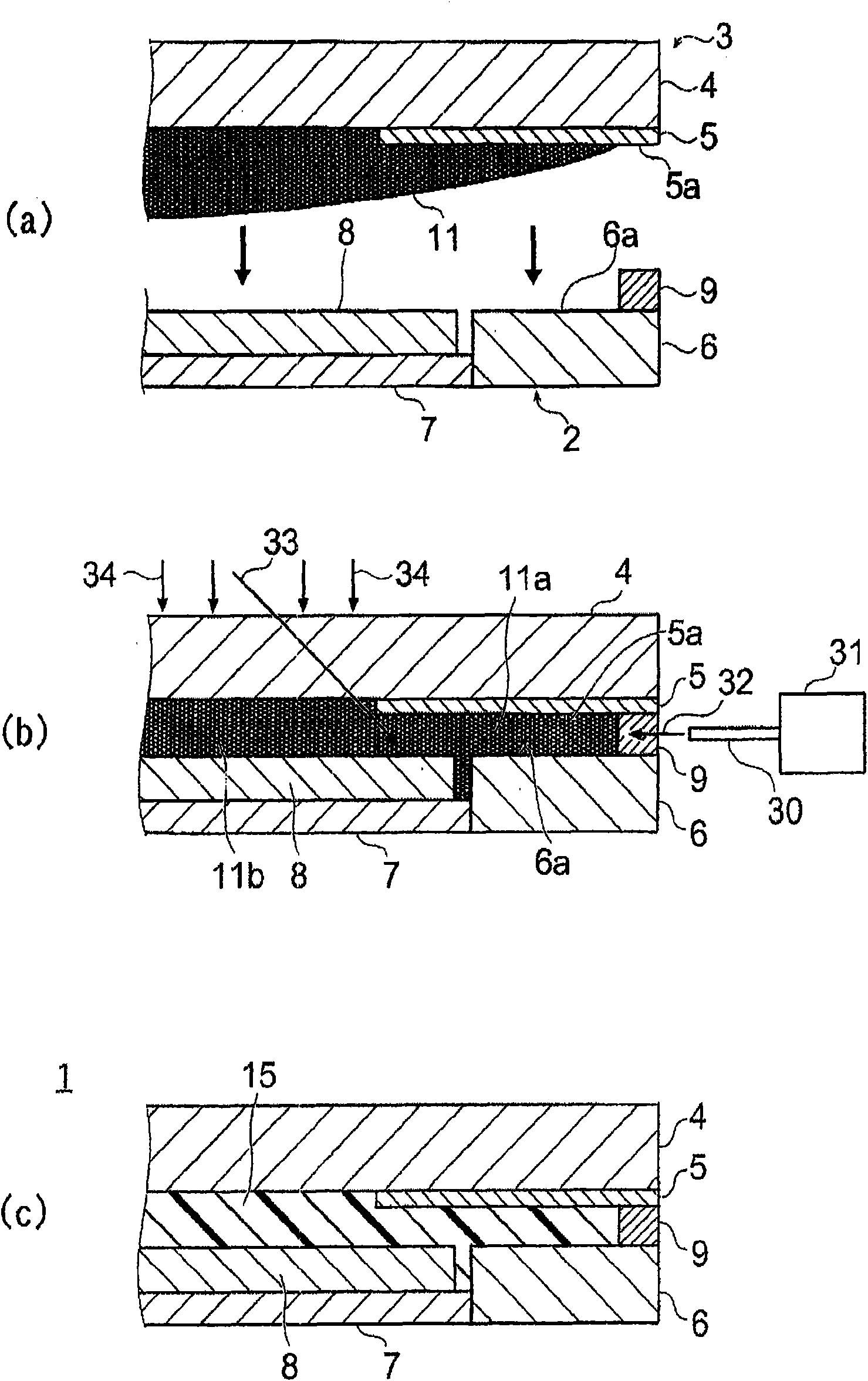

Method for manufacturing image display

ActiveCN101652803APrevent orientation confusionFully curedNon-linear opticsIdentification meansHigh contrastTransmittance

Disclosed is a method for manufacturing an image display (1), which comprises a step wherein a photocurable resin composition (11) is interposed between a base unit (2) having an image display unit such as a liquid crystal display panel (8) and a light-transmitting protective unit (3) having a light-shielding portion (5), and a cured resin layer (15) is formed by photocuring the resin composition(11). In this method, a resin composition having a curing shrinkage rate of not more than 5% and a storage modulus of the cured product at 25 DEG C of not more than 1.0 OE10<7> Pa, which enables to obtain a cured resin layer (15) having a visible light transmittance of not less than 90% is used as the photocurable resin composition (11). The method further comprises a step wherein a curable resincomposition (11a) containing a thermal polymerization initiator is interposed at least between the light-shielding portion (5) and the base unit (2) and then the curable resin composition (11a) is heated. Consequently, the resin in a forming-region of the light-shielding portion (5) is sufficiently cured, while attaining a high-luminance, high-contrast display without having display defects due todeformation of the image display unit (8), during manufacture of the thin image display (1) wherein the resin is interposed between the protective unit (3) having the light-shielding portion (5) andthe image display unit (8).

Owner:DEXERIALS CORP

High-strength aluminum alloy slab and manufacturing method thereof

The invention relates to a high-strength aluminum alloy slab and a manufacturing method thereof. The alloy mainly comprises the following components: less than 0.35% of Si, less than 0.45% of Fe, 1.25-1.95% of Cu, less than 0.30% of Mn, 2.25-2.85% of Mg, 0.19-0.27% of Cr, 5.2-6.0% of Zn, less than 0.2% of Ti, less than 0.04% of Zr and the balance of Al and unavoidable elements. The manufacturing method of the high-strength aluminum alloy slab is free of a rolling process and comprises the following flows: proportioning raw materials, smelting, casting a flat ingot, carrying out two-stage soaking, sawing the head and bottom of the flat ingot, carrying out fixed-length sawing and width-fixed sawing, sawing upper and lower surfaces of the flat ingot, sawing the flat ingot into the aluminum plate according to requirements, carrying out solid solution quenching, stretching and flattening and carrying out aging treatment. By the manufacturing method, the production process flows can be shortened, such problems of the slab manufactured by a hot rolling method as uneven microstructure and performance, poor flatness and uneven thickness are solved, the yield is increased, the cost of the product is decreased and the economic benefits are increased.

Owner:广西南南铝加工有限公司

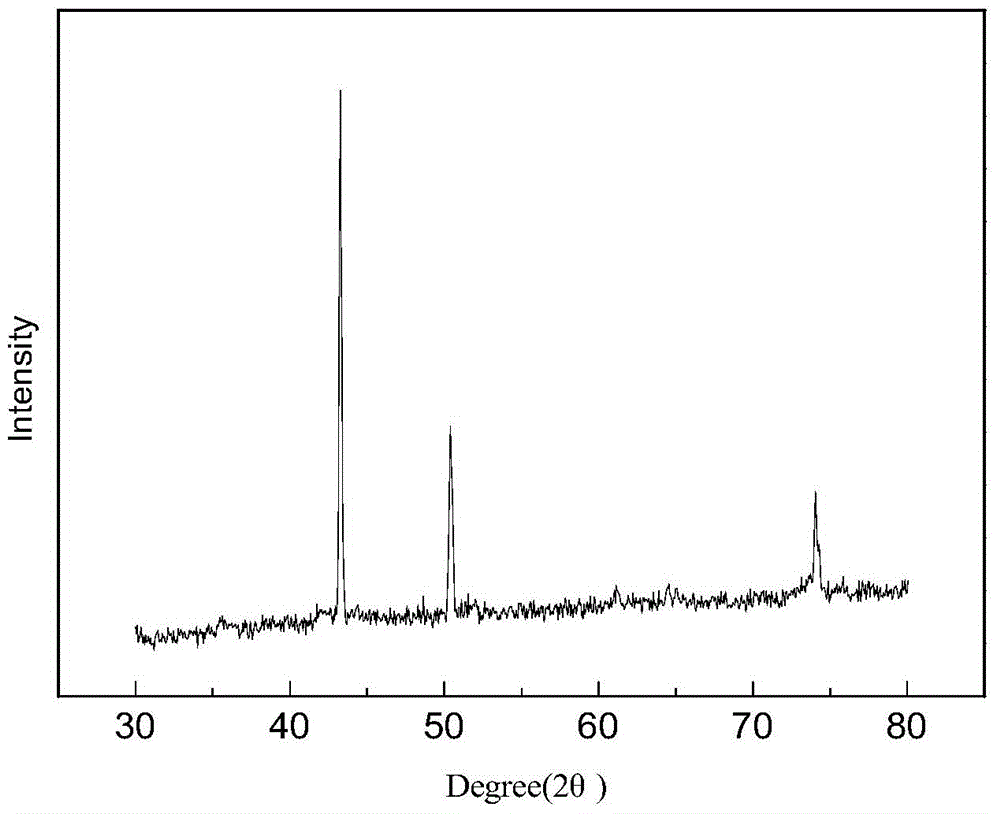

Method for preparing high-entropy alloy coating

InactiveCN103556146AHigh hardnessImprove wear resistanceArc welding apparatusMetallic material coating processesHigh entropy alloysGas tungsten arc welding

The invention relates to the field of multi-principal element high-entropy alloy materials and in particular relates to a method for preparing a high-entropy alloy coating, belonging to the field of coating preparation. The method for preparing the high-entropy alloy coating comprises the following steps: pretreating a substrate, so that the surface of the substrate is clean and flat; preparing high-entropy alloy powder, uniformly mixing, and adding 3-6wt% of organic solution in the alloy powder; uniformly mixing the organic solution and the high-entropy alloy powder, and preparing into paste; uniformly coating the pasty alloy powder on the treated substrate, wherein the thickness of the coating layer is 0.3-6mm; baking the treated coating layer and substrate in an oven at the temperature of 55-80 DEG C for 20-30 hours; cladding the coating layer on the surface of the substrate through gas tungsten arc welding. According to the method for preparing the high-entropy alloy coating, the high-entropy alloy coating with the thickness of 0.3-6mm can be prepared, a heat affected zone to the substrate in the preparation process is small, and the coating is uniform in distribution and firmly bound to the base material.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

Treatment method of black hard microarc oxidation ceramic membrane on surface of magnesium alloy

InactiveCN102021631AUniform colorImproved color stabilityAnodisationElectrolysisPlasma electrolytic oxidation

The invention belongs to the treatment technology of a black hard ceramic membrane on the surface of magnesium alloy, in particular relating to a treatment method of a black hard microarc oxidation ceramic membrane on the surface of magnesium alloy. The invention mainly solves the technical problems that the colour of a ceramic membrane treated by magnesium alloy microarc oxidation is white or grey white mostly and the deep colour and even black ceramic membranes can not be obtained in the prior art. The method provided by the invention comprises the steps that sodium phosphate, sodium fluoride, sodium hydroxide, sodium molybdate, potassium carbonate, sodium tungstate, copper sulphate and potassium dichromate are added into water and prepared into an alkaline electrolytic solution, and the solution is stirred for later use; and then magnesium alloy and a stainless steel plate are immersed into the alkaline electrolytic solution, the magnesium alloy is taken as an anode, the stainless steel plate is taken as a cathode, and microarc oxidation treatment is carried out until a compact black hard ceramic membrane grows in situ on the surface of the magnesium alloy.

Owner:杭州意来客电器设备有限公司

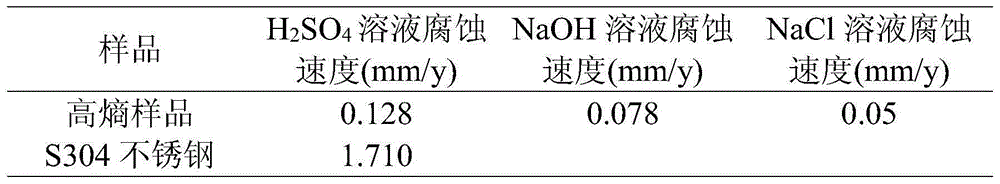

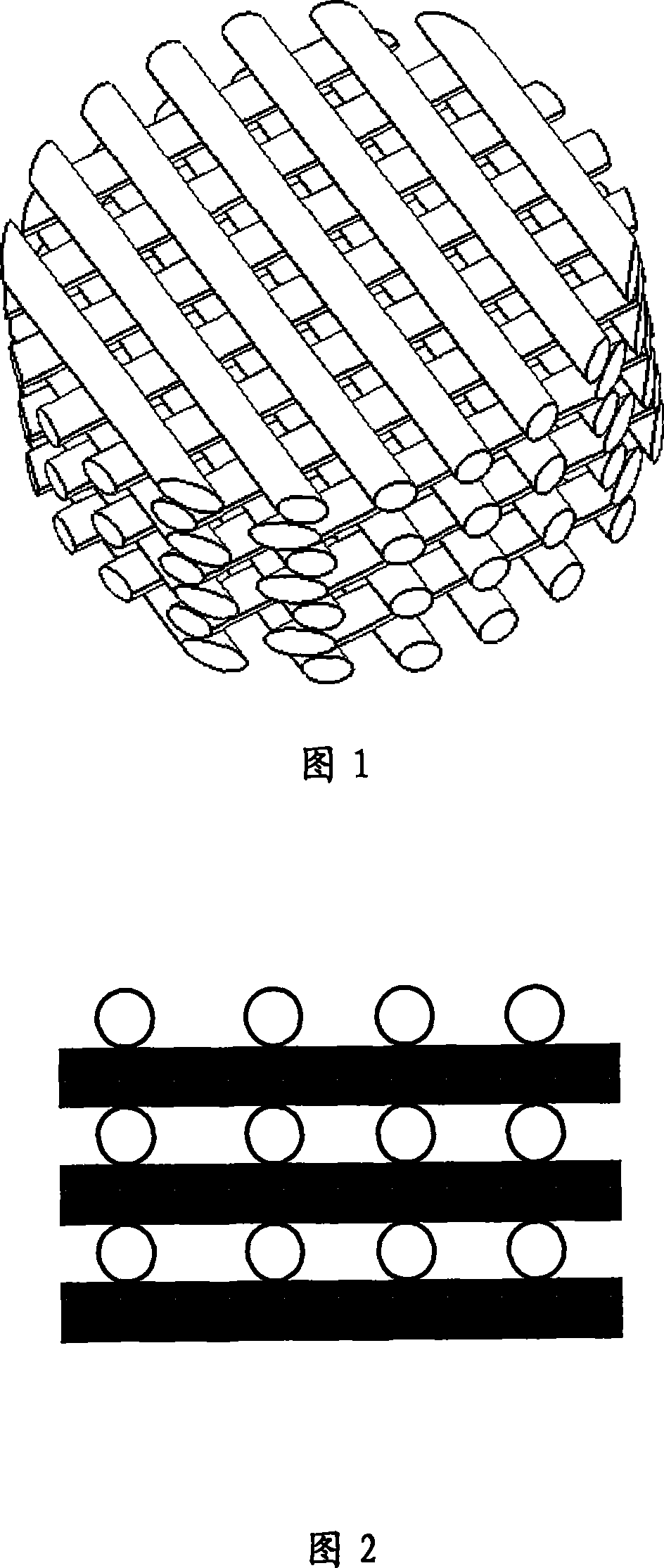

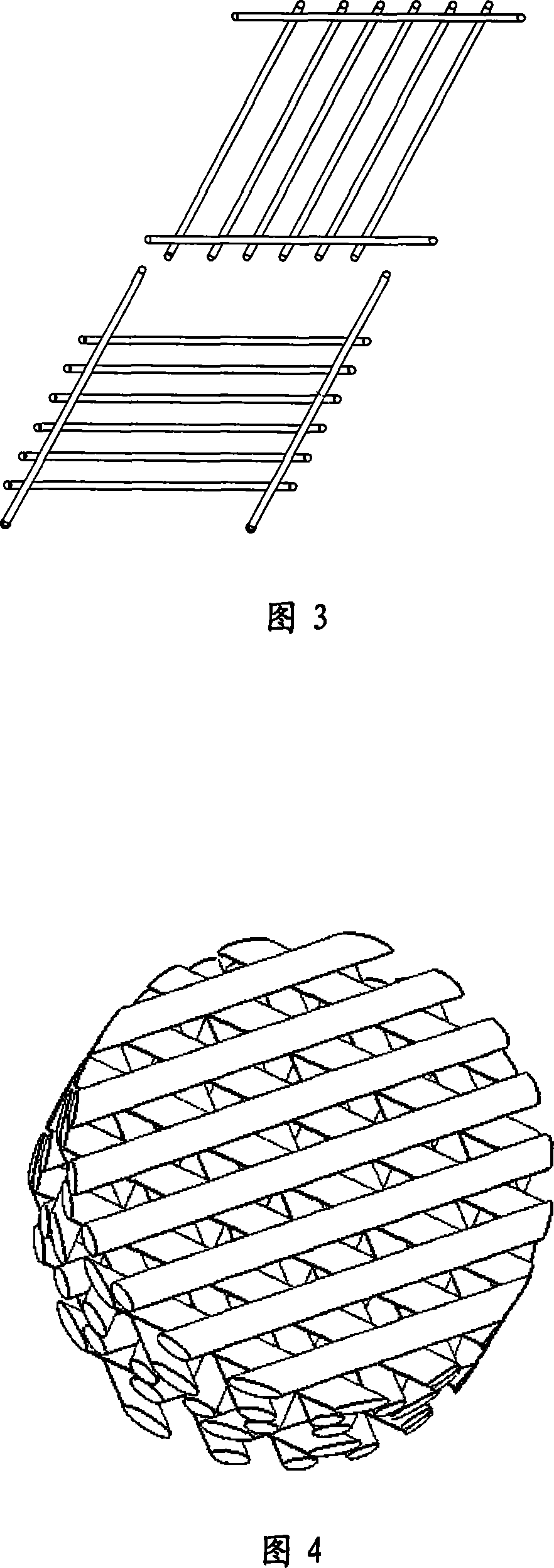

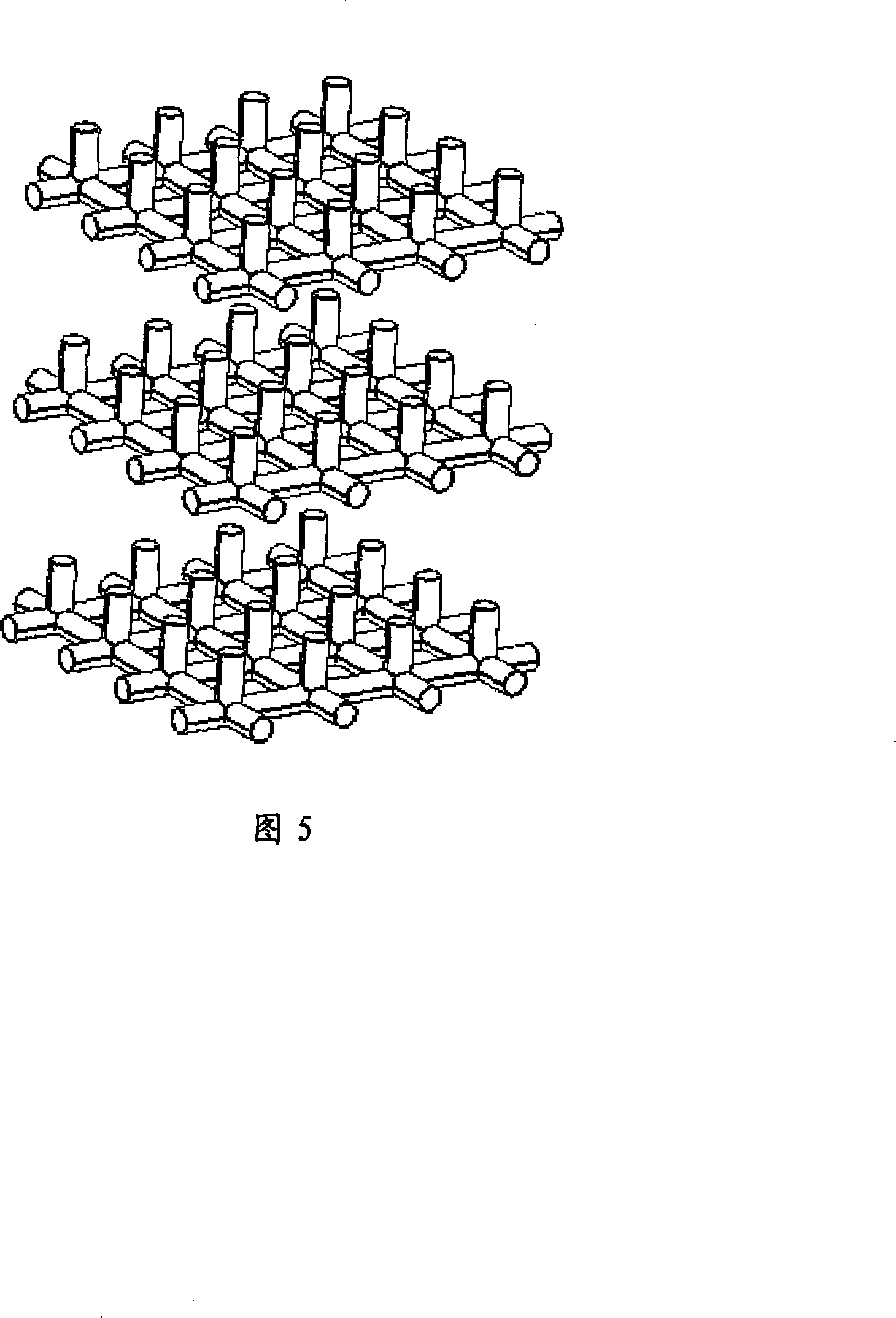

Three dimensional cell culture construct and apparatus for its making

InactiveCN101245313AWell-defined structureEasy to useTissue/virus culture apparatusBiological material testing proceduresFiberNormal cell

The present invention relates to a three dimensional construct formed from non-biodegradable and non-cytotoxic polymers that provide an internal and external space for living cells to attach, proliferate and differentiate. The construct is composed of polymer struts and / or fibers which are joined together in a designed 3 dimensional pattern. The 3 dimensional cell culture construct (cell culture insert) is intended to be used together with cell / tissue culture plate, tissue culture flask, bioreactor and the like under normal cell culture conditions. The invention further provides methods of making the 3 dimensional cell culture construct. Finally, the invention provides kits comprising one or more 3 dimensional porous cell culture construct in a package together with other cell culture supplies, such as tissue culture plate and flasks.

Owner:刘青

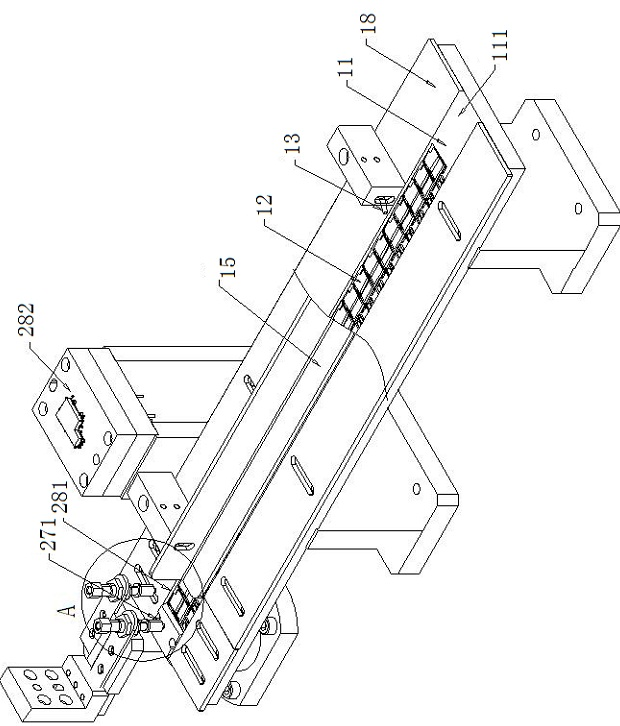

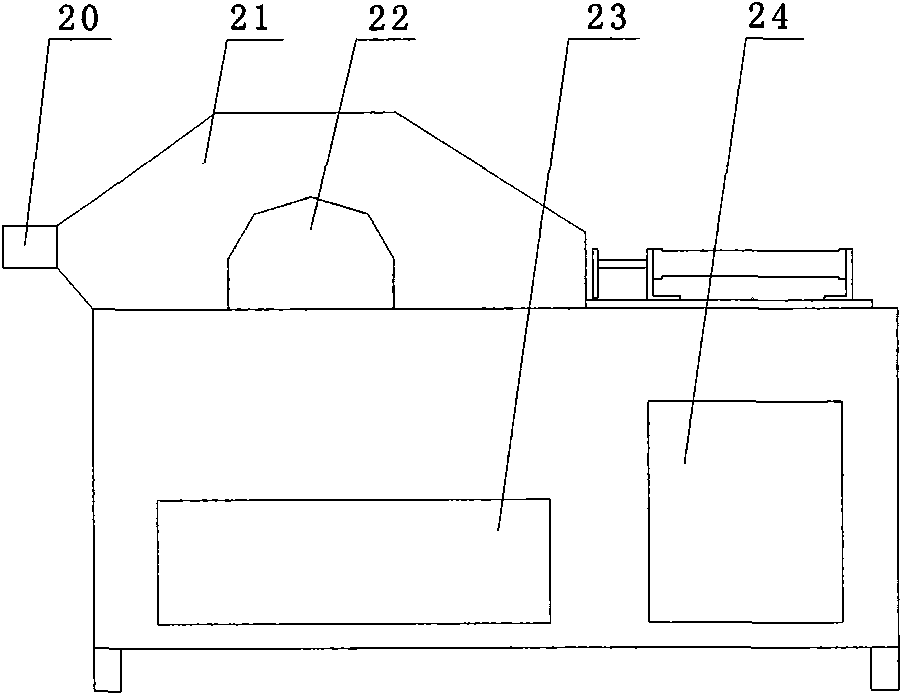

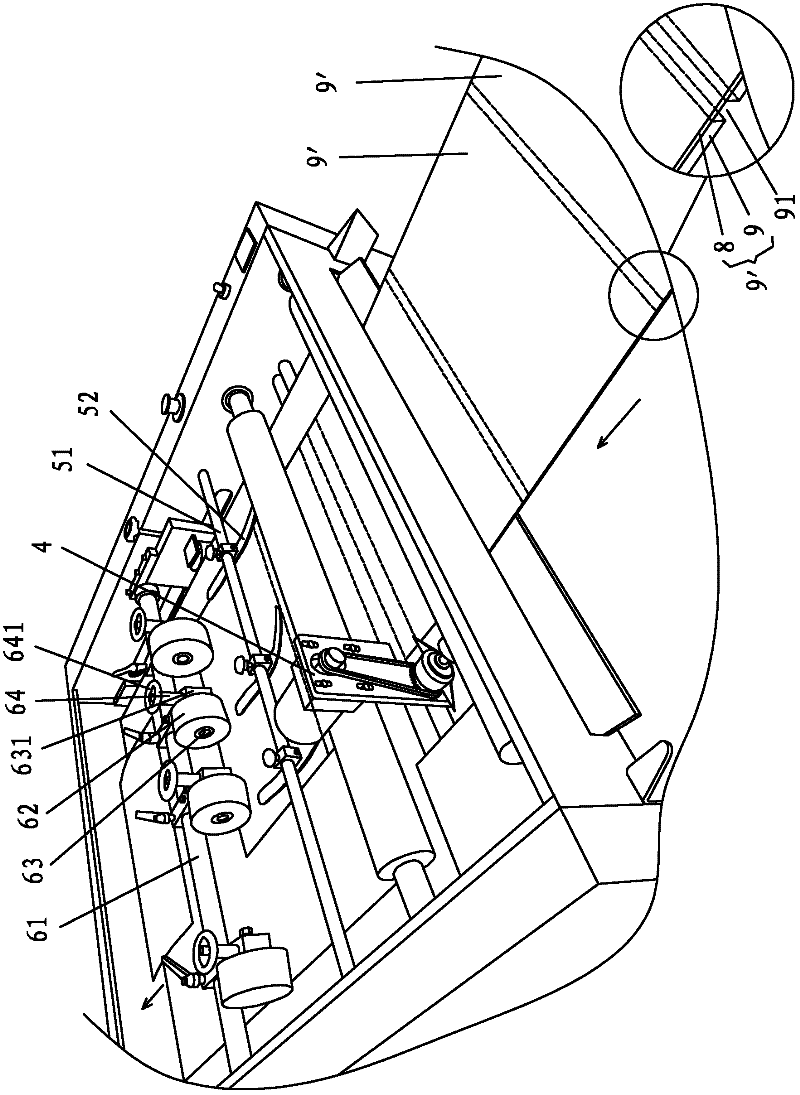

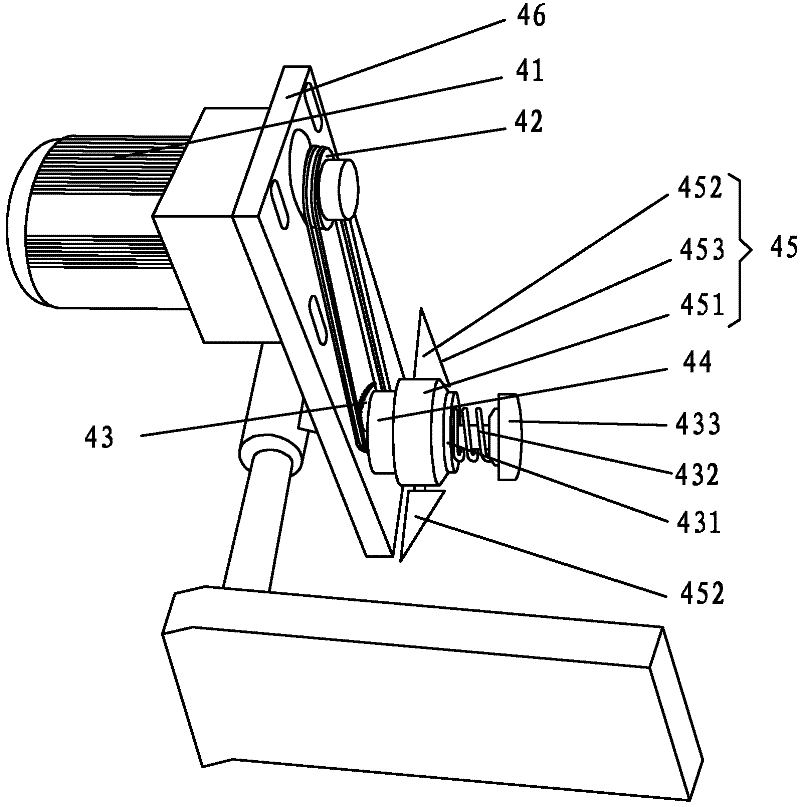

Honeycomb ceramic dry green body dual-blade cutting machine

InactiveCN101579887ANo deformationNo damageCeramic shaping apparatusWorking accessoriesControl systemElectric machinery

The invention relates to a honeycomb ceramic dry green body dual-blade cutting machine, which consists of a cutting device, a linear working table, a hydraulic system, a dust collector and a control system, wherein the cutting device adopts a dual-blade structure, and two parallel round diamond blades are connected with a main shaft driven by one or two motors respectively; and the linear working table conveys a green body to the cutting device and consists of a green body clamping device and a green body conveying device provided with a travel switch for controlling motion. The green body clamping device consists of a cylinder, a green body clamp and a green body liner plate and is used for clamping and cutting a dry green body, and the clamping degree of the green body is controlled by adjusting the pressure of compressed air with a pressure adjusting valve so that a finished product after cutting is not deformed and damaged; and the green body conveying device drives the working table to perform linear feeding motion under the control of the hydraulic system and the travel switch.

Owner:JIANGSU GAOCHUN CERAMICS +1

Automatic laminating machine and cutting device thereof

ActiveCN102501562ASave manual cuttingAvoid deformationLamination ancillary operationsLaminationAutomationHot press

The invention discloses a cutting device of an automatic laminating machine, which comprises a cutting tool and a fixing frame. The cutting tool can be installed on the fixing frame in a rotating mode, and the cutting tool is provided with a tip portion provided with a blade. The invention further discloses the automatic laminating machine, which comprises a film conveying device, a conveying belt, a hot pressing device, the cutting device, a pressing device and a material collecting platform. A feeding port of the conveying belt is arranged at the position of a thin film roll outlet of the film conveying device, and a discharging port of the conveying belt sequentially penetrates through the hot pressing device, the cutting device and the pressing device to be arranged at the position of the material collecting platform. The cutting device of the automatic laminating machine can cut a small opening on a thin film arranged between film-coated plates connected together. The automatic laminating machine can automatically cut a long belt of the film coated plate into single sheets of film coated plates so as to save labor cost, automation degree is high, and the cutting edge of each film coated plate is tidy without deformation, thereby improving the finished product ratio.

Owner:SHISHI XINGGANG PLASTIC PACKAGING

High-strength diamond saw blade

The present invention is a high-strength diamond saw blade, which includes a substrate and a diamond cutter head. The substrate of the diamond saw blade includes the following components by weight: 28-37 parts of copper powder, 0-5 parts of aluminum powder, and 2-6 parts of tin powder , 2-4 parts of zinc powder, 5-8 parts of rare earth, 15-18 parts of titanium powder, 11-15 parts of nickel powder, 8-12 parts of cobalt powder, 1-3 parts of manganese powder, 0-1 part of phosphorus powder, silicon 1-3 parts of vanadium powder, 0.2-0.9 parts of vanadium powder, 2-5 parts of silver powder, 2-6 parts of molybdenum powder, 0.1-2 parts of tungsten powder, 0.5-3 parts of chromium powder, and the rest are iron and unavoidable impurities; diamond The cutter head of the saw blade includes the following components by weight: copper powder 35‑40 parts, tin powder 8‑11 parts, zinc powder 1‑2 parts, titanium powder 6‑10 parts, diamond 13‑18 parts, iron powder 9‑ 14 parts, nickel powder 1-5 parts, rare earth 1-4 parts, tungsten powder 1-3 parts. The invention can effectively improve the cutting performance of the diamond saw blade, and has high strength, high wear resistance, firmness and durability, great pressure resistance and low cost.

Owner:JIANGSU SUPER PEAK TOOLS CO LTD

Method for preparing ceramic material by process steps of powder green body dipping and precursor cracking

The invention provides a method for preparing a ceramic material by process steps of powder green body dipping and precursor cracking. The method comprises the following steps: (1) preparing ceramic powder into a required green body by using a conventional method; (2) drying the green body for 1-30 hours at the drying temperature of 80-150 DEG C to obtain a porous green body; (3) dipping the porous green body into a liquid ceramic precursor for 1 hour or more in vacuum or at a certain pressure; (4) placing the porous green body with the ceramic precursor in an airtight high-pressure kettle, introducing inert gas, raising the temperature to 60-300 DEG C at the pressure of 0.1-30 MPa, and then performing heat insulation for 10-55 hours so that the precursors in the holes of the powder green body are crosslinked and cured; and (5) placing the green body with the cured ceramic precursor in a high temperature furnace, protecting with nitrogen, heating to 1200-1400 DEG C, and then performing heat insulation for 50-70 minutes, so that the cured precursor is cracked and converted into ceramic. The method has the advantages of high production efficiency, high yield and low production cost, and can be used for preparing various ceramic materials such as silicon carbide, silicon nitride, silicon oxide, boron nitride, boron carbide, alumina, aluminium nitride, zirconia and the like.

Owner:NAT UNIV OF DEFENSE TECH

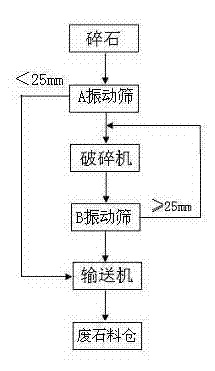

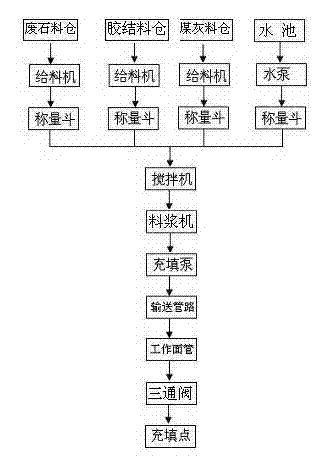

Filling method and system of coal mine goaf

ActiveCN102865101AImprove protectionAvoid missingMaterial fill-upMining engineeringPulverized fuel ash

The invention relates to a filling method and system of coal mine goaf. The filling system comprises a filling bin, a feeder, a weighing hopper, a stirrer, a slurry machine, a filling pump, a delivering pipeline, a working face pipe and a tee pipe, wherein the filling bin is respectively connected with the inlet of the stirrer through the feeder and the weighing hopper; and the outlet of the stirrer is connected to a filling point through the slurry machine, the filling pump, the delivering pipeline and a tee valve. The filling method comprises the steps that barren rocks with granularity of less than 25mm, a cementing agent, pulverized fuel ash and water are delivered to the weighing hopper through the feeder for weighing; the barren rocks, the cementing agent and the pulverized fuel ash are mixed in a mass ratio of 1:(0.22-0.80):(0.35-0.57), and are added with water to produce slurry in a mass concentration of between 70 and 83 percent through the stirrer; and the slurry is delivered to the filling point for filling through the slurry machine, the filling pump, the delivering pipeline, the working face pipe and the tee valve. According to the filling method and system, the sources of filling materials can be enlarged, the filling substance strength and durability can be increased, the filling material can be delivered to the filling point and uniformly filled by delivering and filling in a slurry state, and the filling effect can be improved.

Owner:河北充填采矿技术有限公司

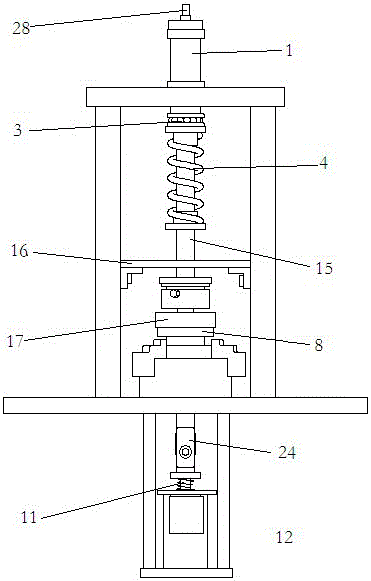

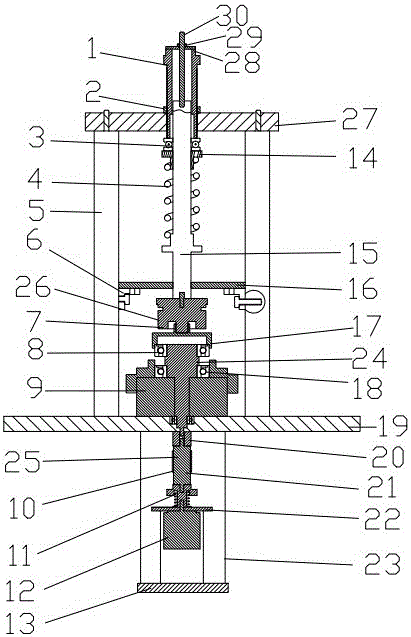

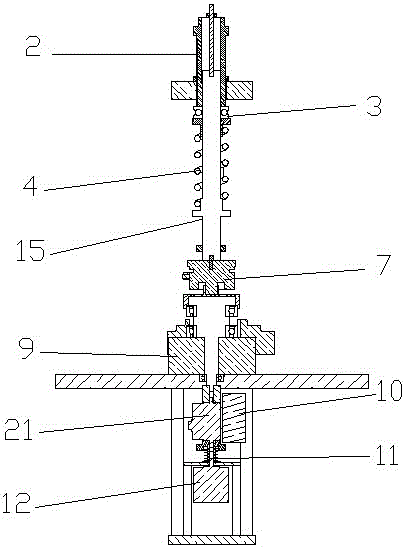

Bearing rotation torque test device

Provided is a bearing rotation torque test device. The center shaft of an axial loading member is connected with a thrust bearing and a spring spacer. A micro-load rod matches a pressure sensor connected with an axial loading sleeve. A measuring member is formed through clearance fit between the inner holes of two identical upper and lower detection bearings and a test shaft. The lower end of the test shaft is connected with an elastic coupler. The outer diameter of the upper detection bearing matches the axial loading sleeve mounted on the pressure sensor, and the outer diameter of the lower detection bearing matches a three-claw chuck mounted on a test bench. The shaft of a stepper motor is additionally equipped with a torque overload device, so damage to a torque sensor by detection overload is avoided. The thrust bearing, the spring spacer and the elastic coupler are provided with an aligning function, so the concentricity of the device is guaranteed. After loading, the three-claw chuck is released. The bearings are undirected, and are completely unaffected by tilting load and other pressures. The test values are more accurate. The trouble of detection tool replacement for test of bearings of different specifications is reduced. The problem that inaccurate values, poor repeatability and poor practicability are caused by loading deformation of the detection bearings is solved completely.

Owner:CIXING GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com