Patents

Literature

4736results about "Machine bearings testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Force-sensing bearing

InactiveUS7316168B2Rolling contact bearingsMachine bearings testingElectrical conductorPulp and paper industry

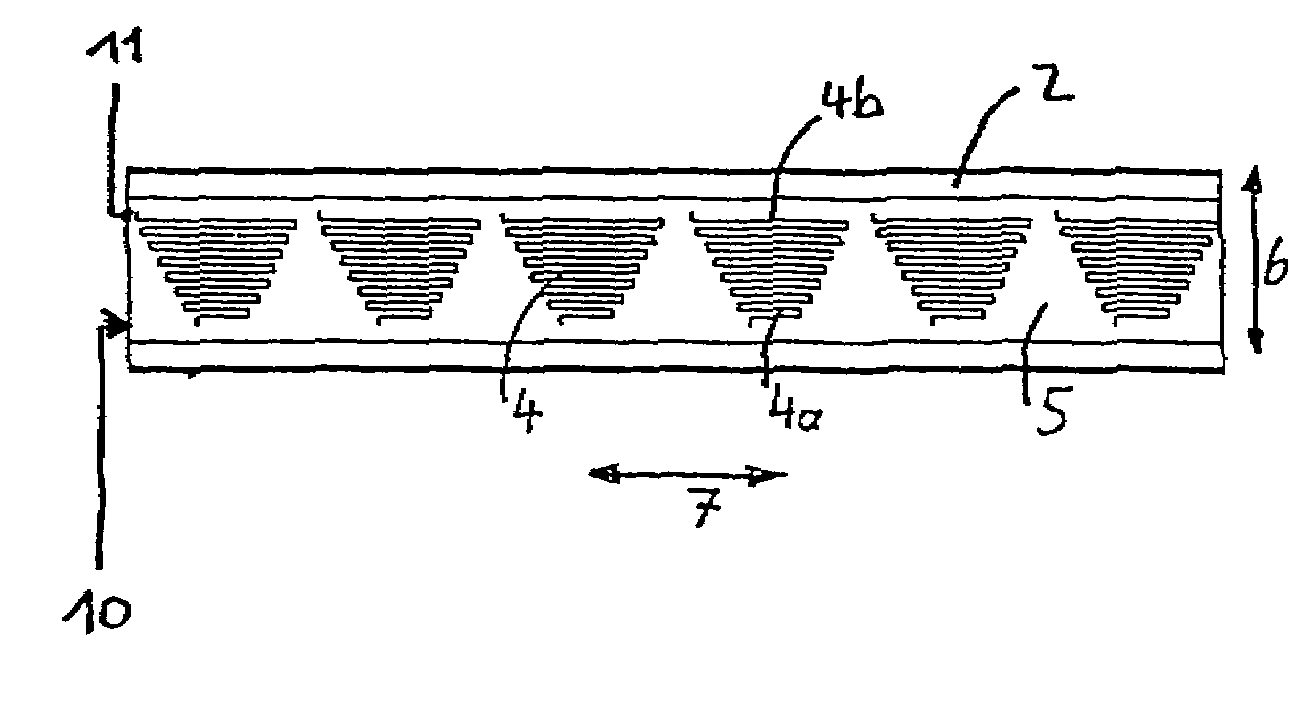

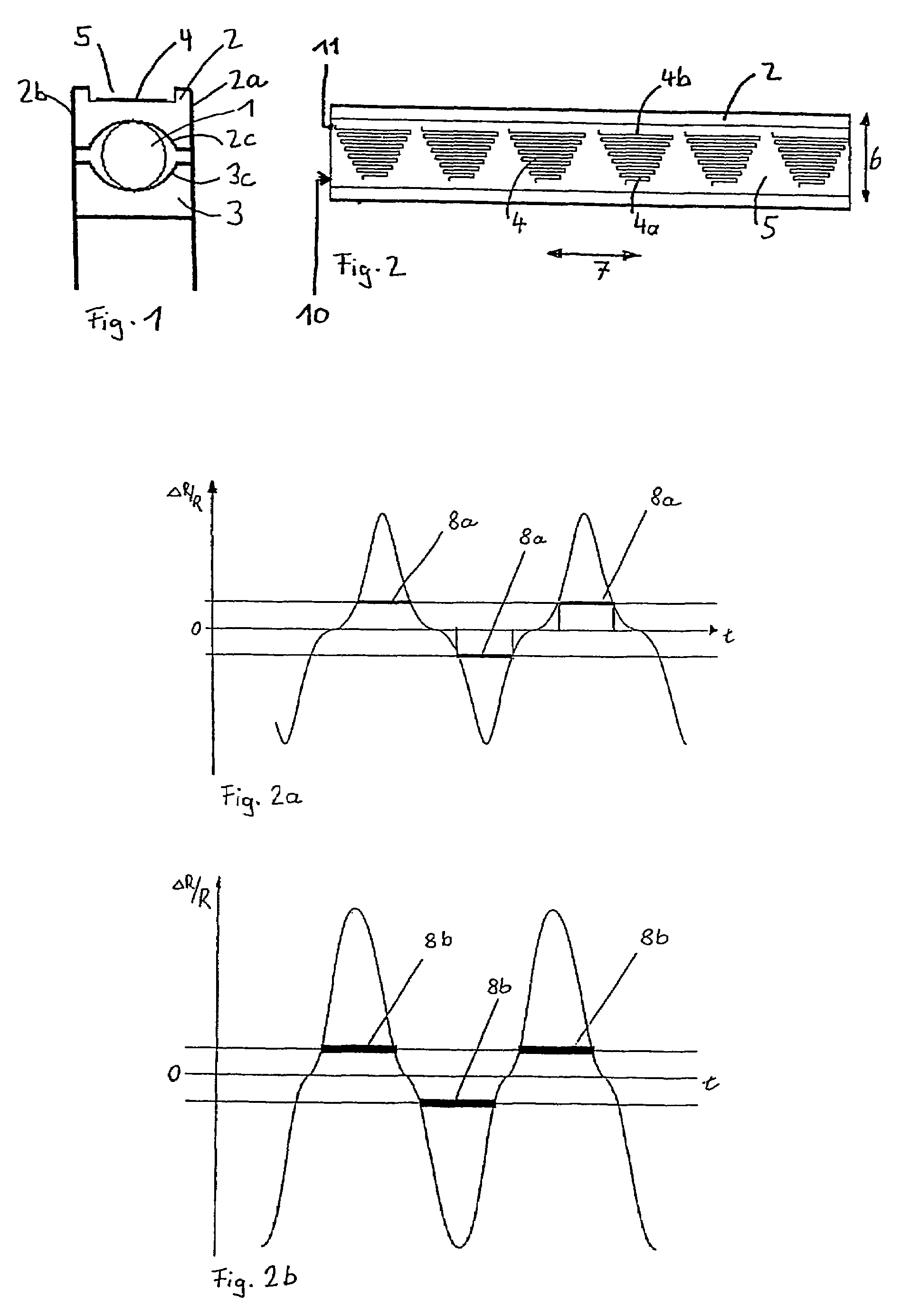

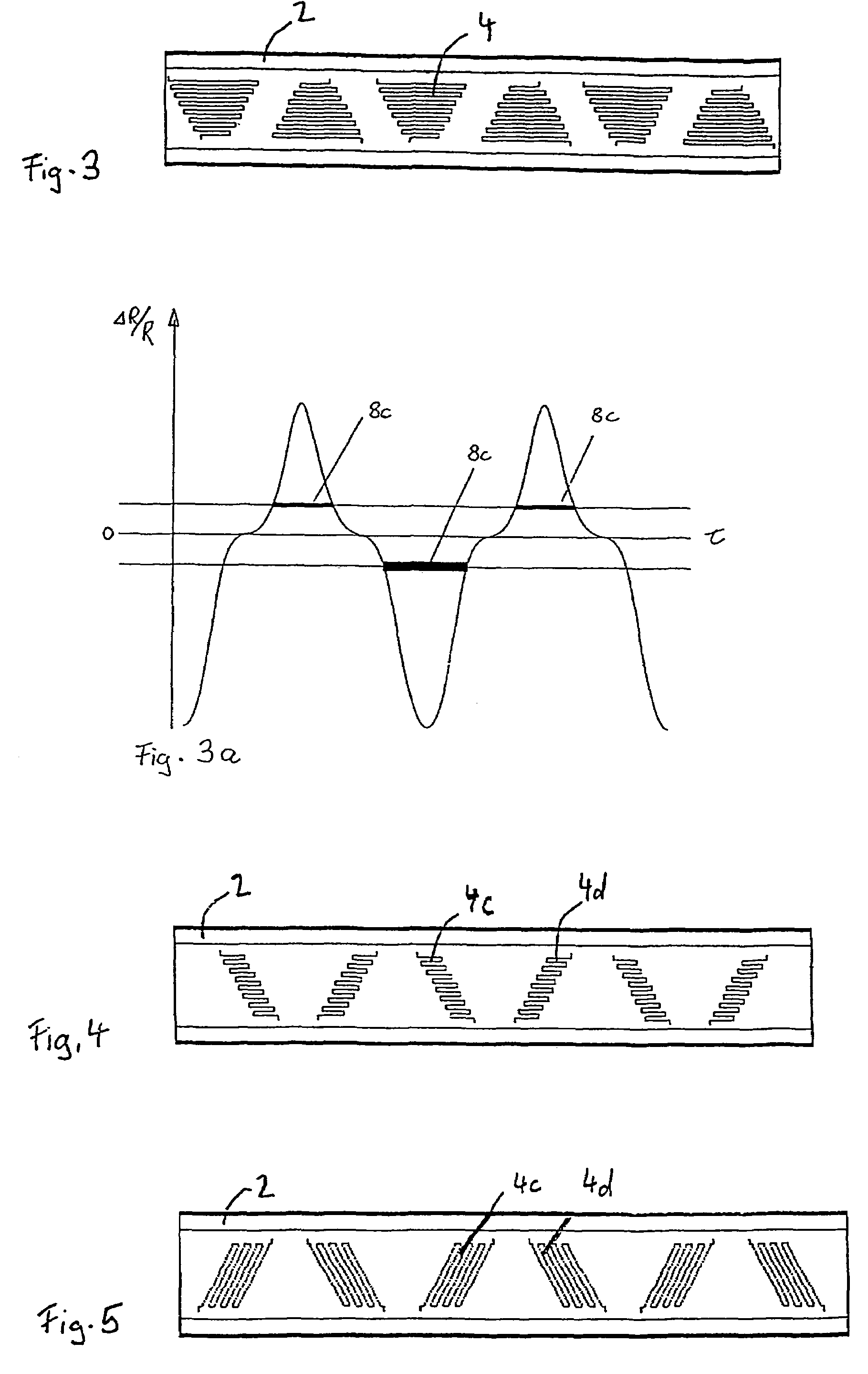

The invention relates to a roller bearing comprising curved running paths, in addition to roller bodies and strain gauge sensors which are arranged between said running paths, said sensors being located in a groove on the outer diameter of the outer ring and / or on the inner diameter of the inner ring. The length of two adjacent strip conductor sections of the strain gauge sensor varies in such a way as to measure the angular position of the roller bodies between the strip conductors.

Owner:INA SCHAEFFLER KG

Vibration measurement and analysis

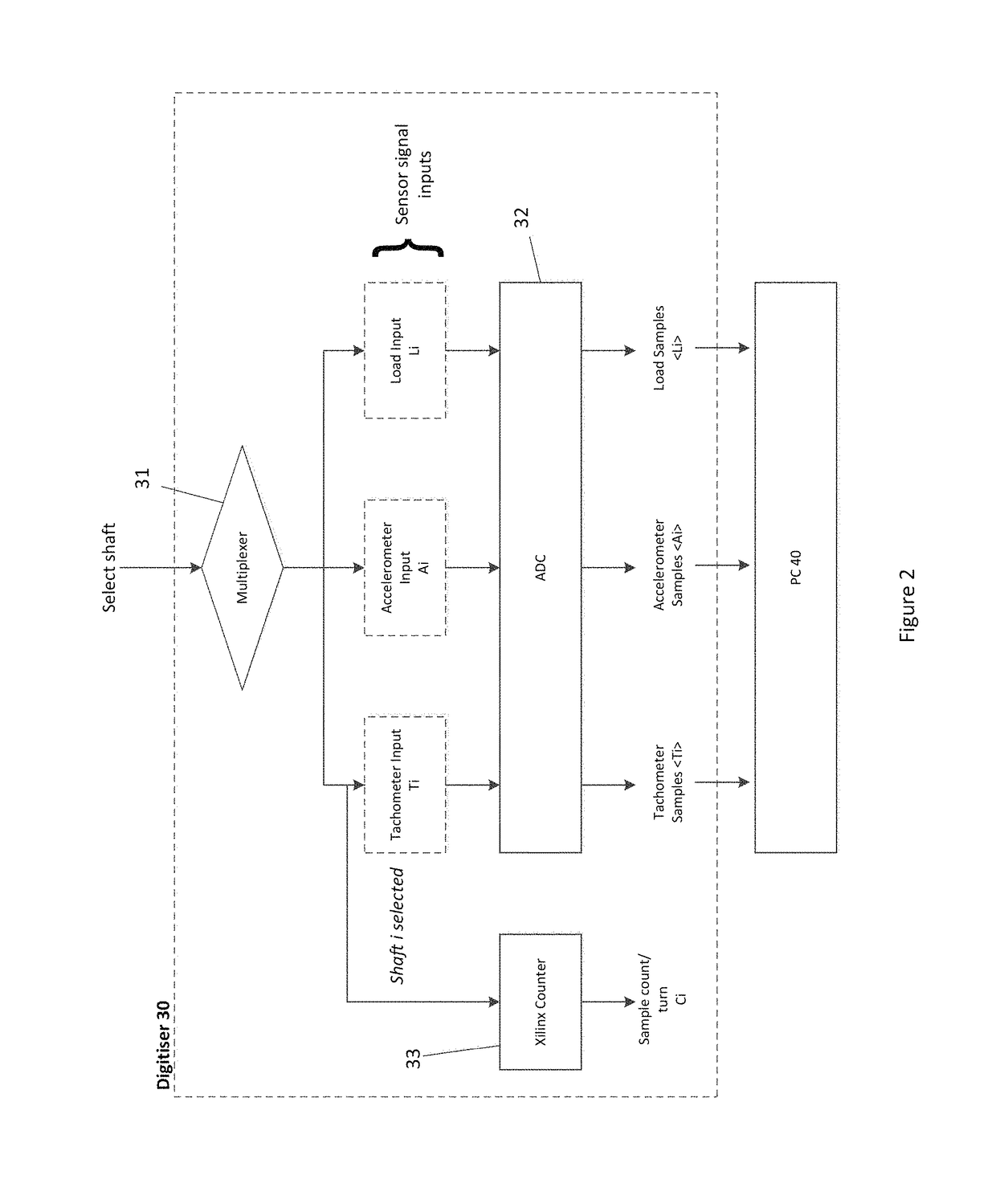

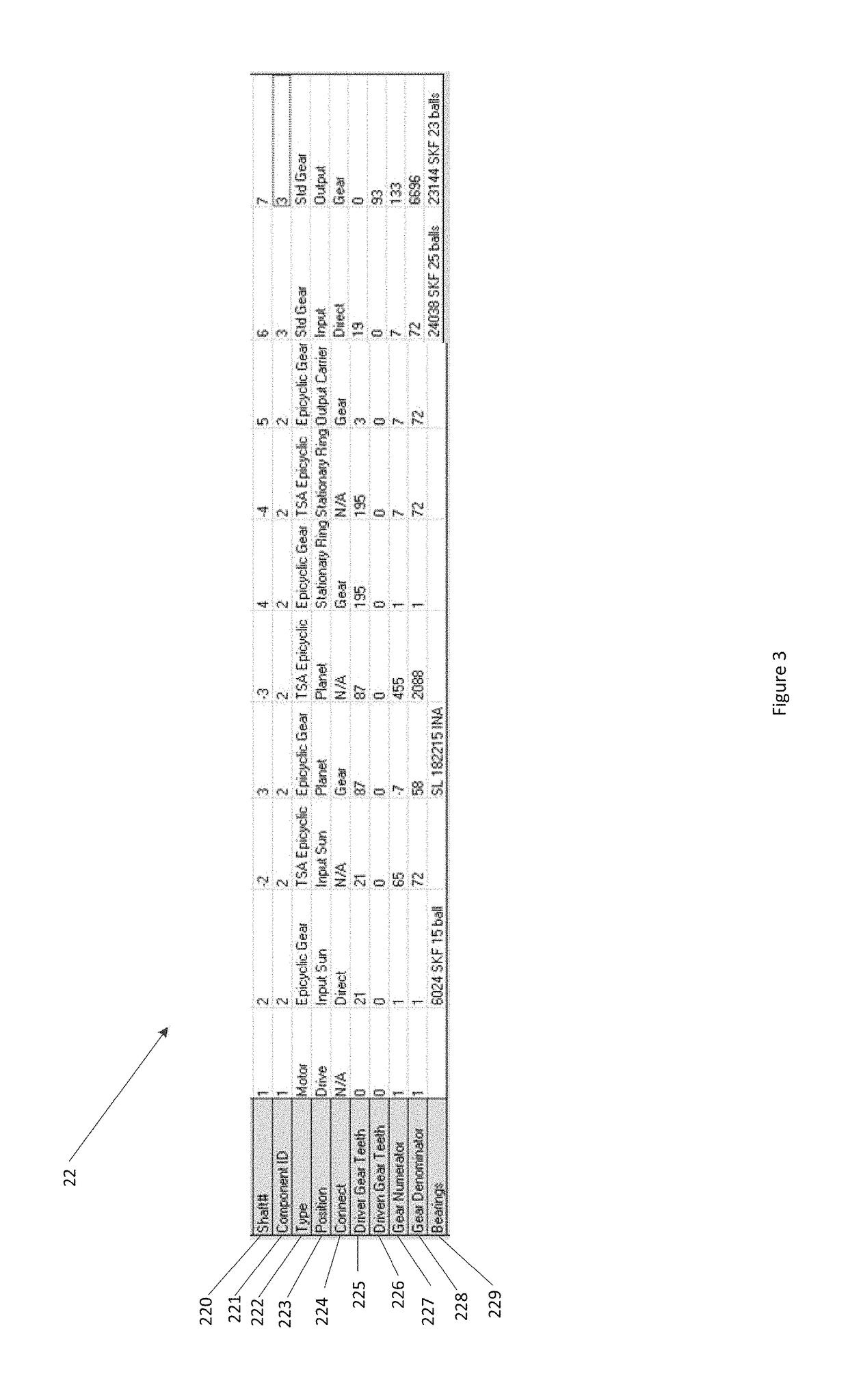

ActiveUS10168248B1Machine gearing/transmission testingMachine bearings testingVibration measurementEngineering

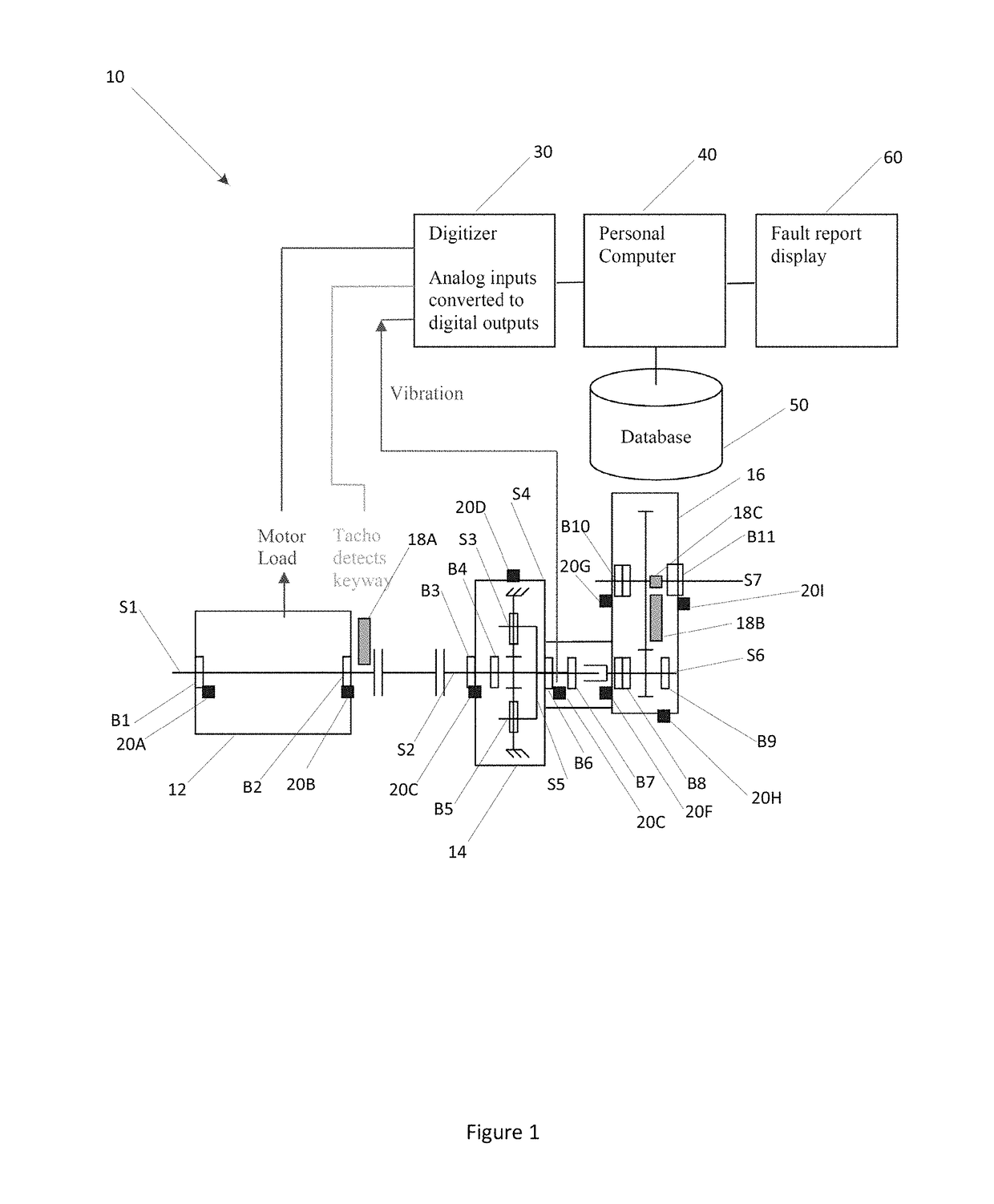

A method of measuring and analyzing vibrations of a mechanical system, e.g., for performing gear and bearing fault detection within a system having a reference shaft and a plurality of rotating components. The method may include the steps of tabulating gear ratios of the plurality of rotating components relative to the reference shaft in integer form, establishing a measurement specification and communicating the measurement specification to a digitizer, recording vibration data from the mechanical system during operation, and resampling the recorded vibration data using the tabulated gear ratios to obtain vibration data corresponding to the rotating components and a vibration signature for a component of interest at predetermined angular increments.

Owner:TENSOR SYST PTY LTD

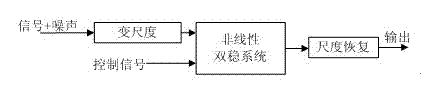

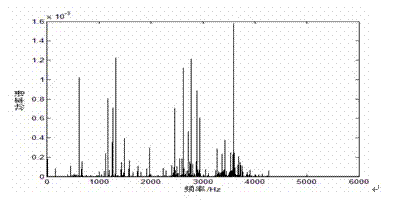

Bearing fault detection method based on manner of controlling stochastic resonance by external periodic signal

InactiveCN102226740AEnhanced spectral valueAccurate detectionMachine bearings testingControl signalEscape rate

The invention discloses a bearing fault detection method based on a manner of controlling stochastic resonance by an external periodic signal. According to the method provided in the invention, after a bearing fault signal is converted by a variable metric method, the converted signal is input in a bistable system; meanwhile, an external single frequency periodic signal is taken as a control signal to act directly on the system; contact barrier height of the bistable system and an escape rate of Kramers are changed by continuously adjusting an amplitude of the control signal. Therefore, stochastic resonance can be generated or increased artificially; a spectral value of an output power spectrum at the position of an input signal frequency can be effectively improved; and thus a characteristic signal of a bearing fault can be detected accurately at last. The detection method provided in the invention enables the effective control of the stochastic resonance to be realized, thereby providing a novel method for early detection of equipment faults.

Owner:CHINA JILIANG UNIV

Abnormality diagnosis system for machinery

ActiveCN1926413ALow costSave spaceSubsonic/sonic/ultrasonic wave measurementMachine bearings testingDifferential coefficientMoving average

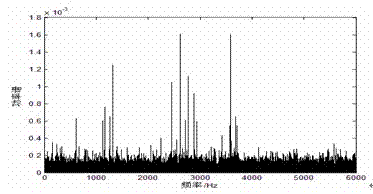

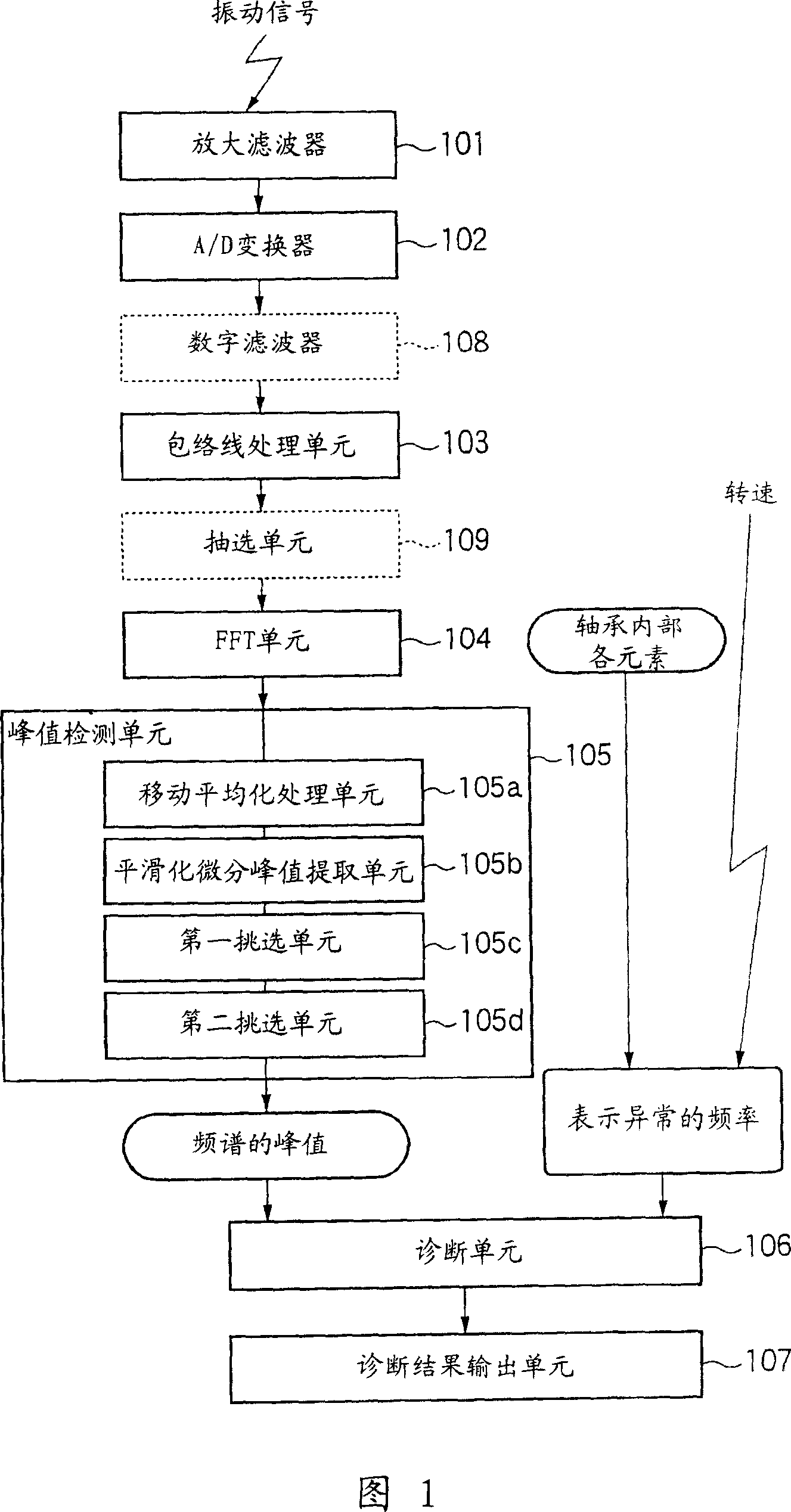

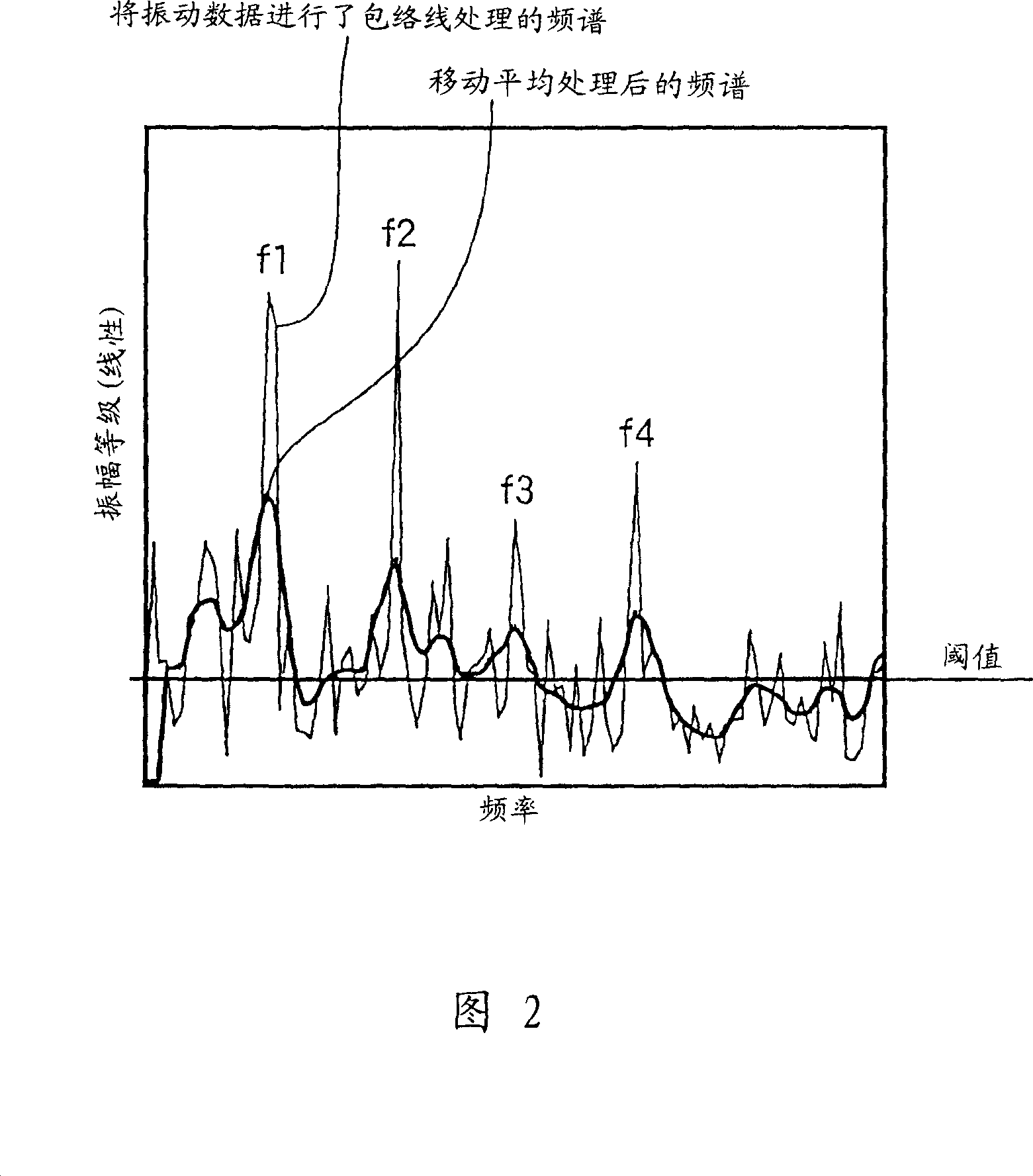

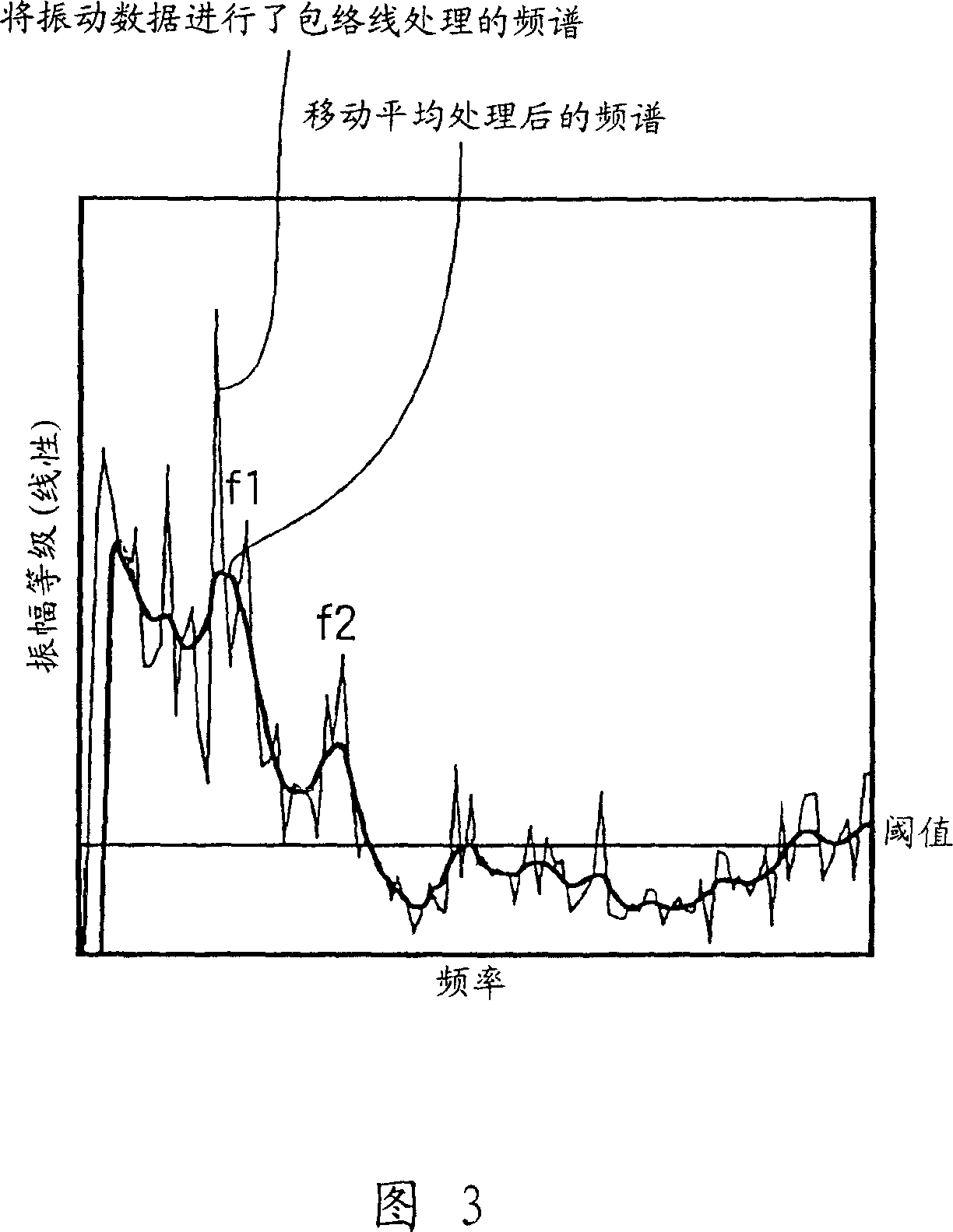

An abnormality diagnosis system for machinery comprises an envelope processing section (103) for determining the envelope of a detection signal, an FFT section (104) for converting the envelope into a frequency spectrum, a peak detecting unit (105) in which the frequency spectrum is smoothed by the moving average method, the resultant spectrum is subjected to a smoothed differentiation, frequency points at which the sign of differential coefficient changes from positive to negative are detected as peaks, peaks higher a predetermined threshold are extracted and sorted, and the higher ones are detected as peaks, and a diagnosis section (T) for performing abnormality diagnosis on the basis of the detected peaks.

Owner:NSK LTD

Method and device for monitoring status of mechanical equipment and abnormality diagnosing device

An abnormality-diagnosing device is used to diagnose if a bearing device used on the axle of a railway vehicle is normal. The abnormality-diagnosing device comprises a detection processing part, an operation processing part, a result output part and a control processing part, wherein, the detection processing part outputs the signal generated by the bearing device, which is regarded as an electric signal, the operation processing part conducts an abnormality diagnosis on the bearing device according to the output of the detection processing part, the result output part outputs the judgement result of the operation processing part, and according to the judgement result, the control processing part returns a control signal to the control system of the railway vehicle.

Owner:NSK LTD

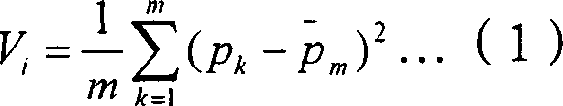

Rolling bearing fault diagnosis method based on variation mode decomposition and permutation entropy

InactiveCN105758644AImplement fault diagnosisImprove recognition accuracyMachine bearings testingCharacter and pattern recognitionSupport vector machineDecomposition

The invention relates to a rolling bearing fault diagnosis method based on variation mode decomposition and permutation entropy. Vibration signals are decomposed with a variation mode decomposition method, so that reactive components and mode aliasing are effectively reduced, all the mode components include characteristic information of different time scales of original signals, and effective multi-scale components are provided for subsequent signal characteristic extraction. With the combination of the features that permutation entropy is simple in calculation, high in noise resisting ability and the like, bearing fault characteristics of all the mode components are extracted from multi-scale angles. Compared with single permutation entropy analysis of rolling bearing vibration, the characteristic information of the signals can be more comprehensively represented through the permutation entropy characteristic extracting method based on multiple scales, the recognition accuracy of a support vector machine is improved, and fault diagnosis of rolling bearings is better achieved.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Fault detection in rotor driven equipment using rotational invariant transform of sub-sampled 3-axis vibrational data

InactiveUS20160245686A1Vibration measurement in solidsMachine bearings testingAnalysis dataData profiling

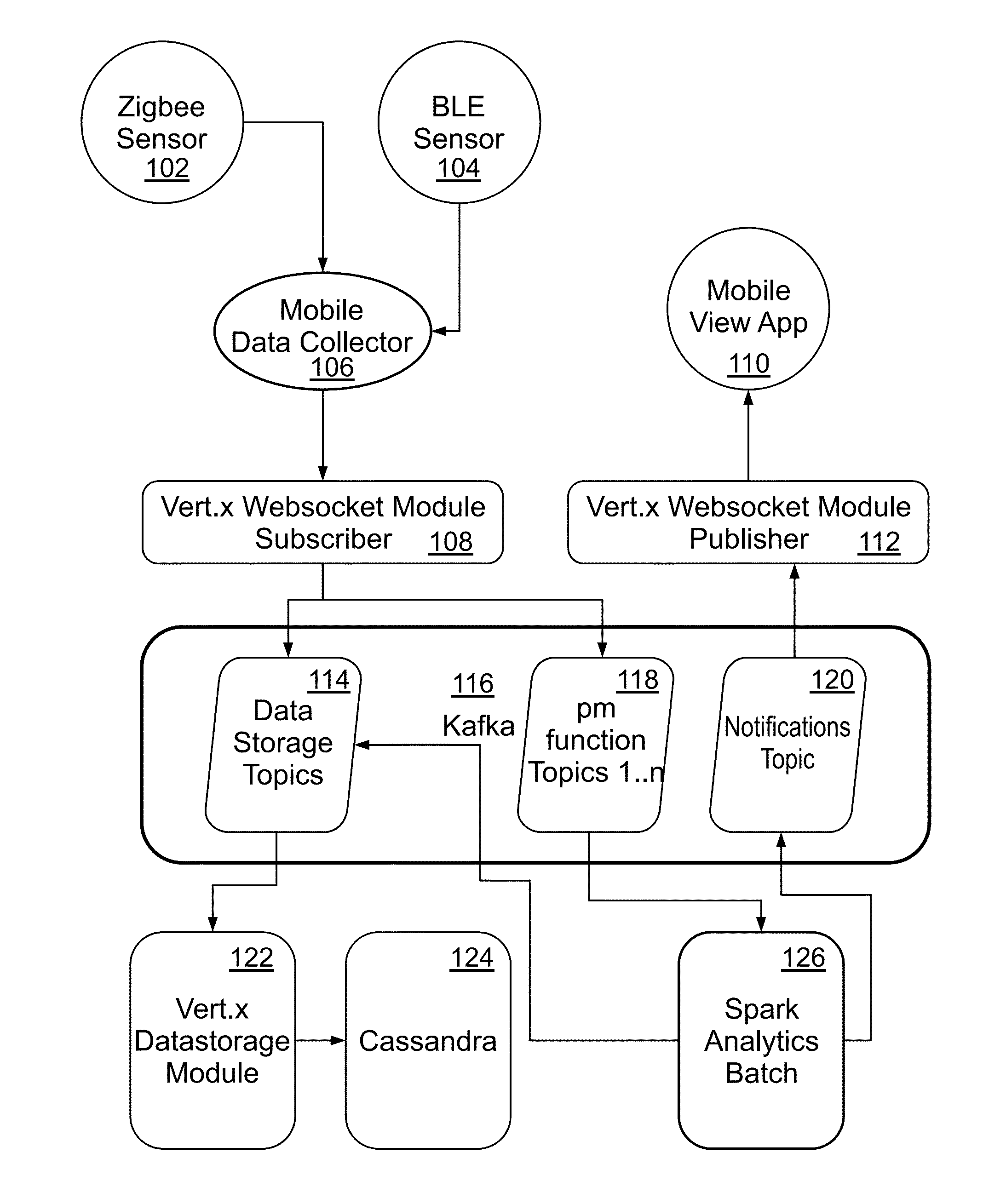

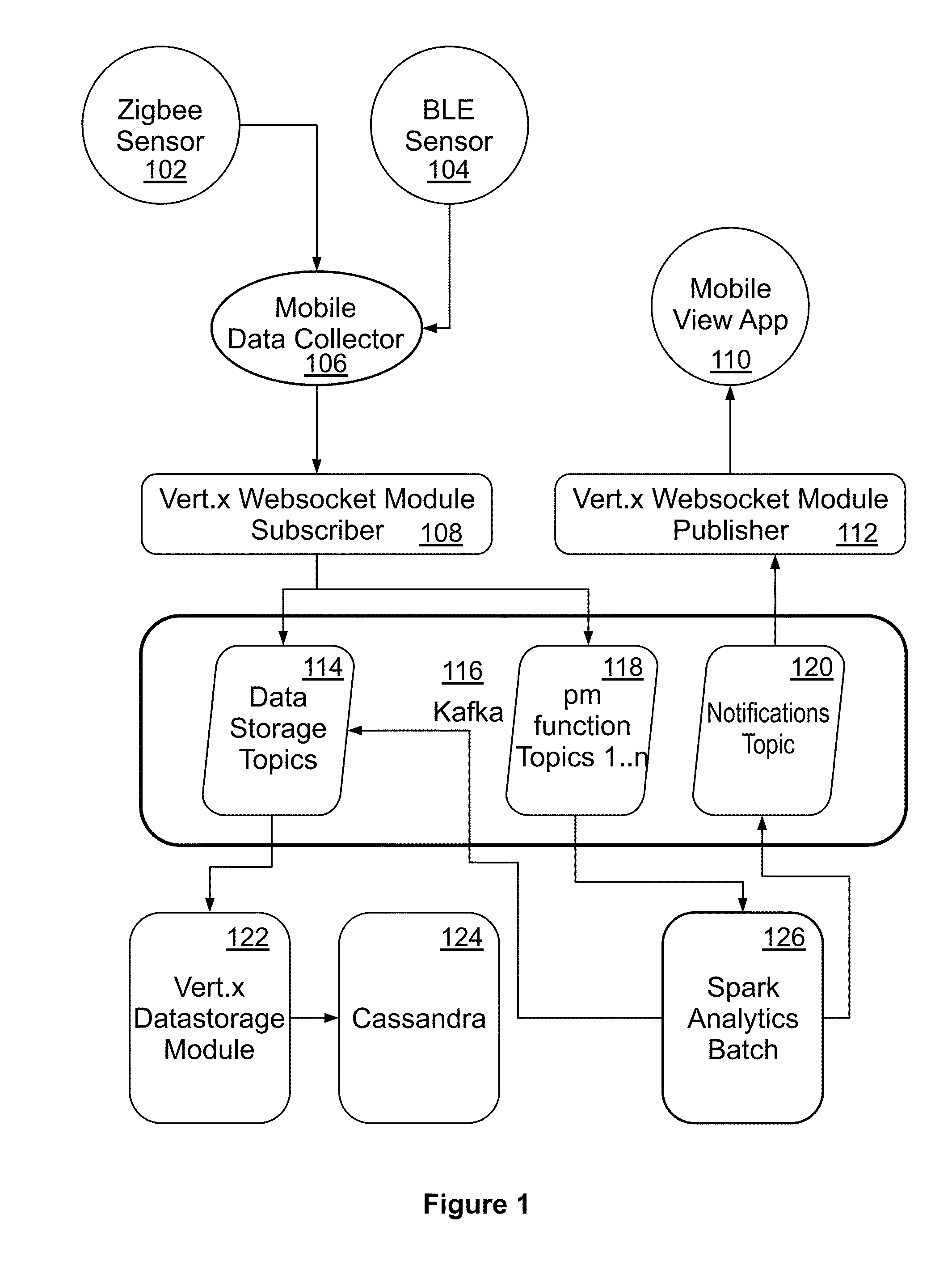

A method and system of detecting faults in rotor driven equipment includes generating data from one or more vibration sensors communicatively coupled to the rotor driven equipment. The data from the one or more machine wearable sensors is collected onto a mobile data collector. The data is sampled at random to estimate a maximum value. Further, a sampling error may be controlled under a predefined value. The data may be analyzed through a combination of Cartesian to Spherical transformation, statistics of the entity extraction (such as variance of azimuthal angle), big data analytics engine and a machine learning engine. A fault is displayed on a user interface associated with the rotor driven equipment.

Owner:MACHINESENSE LLC

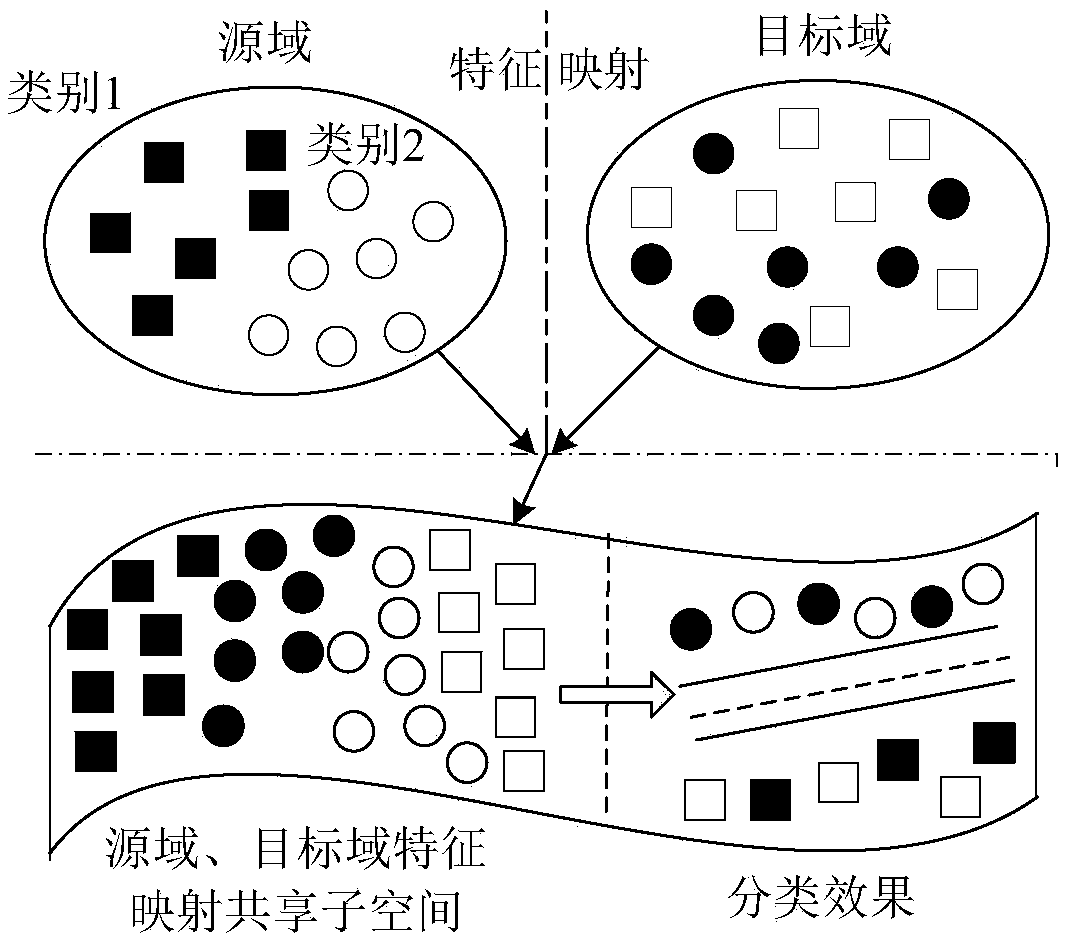

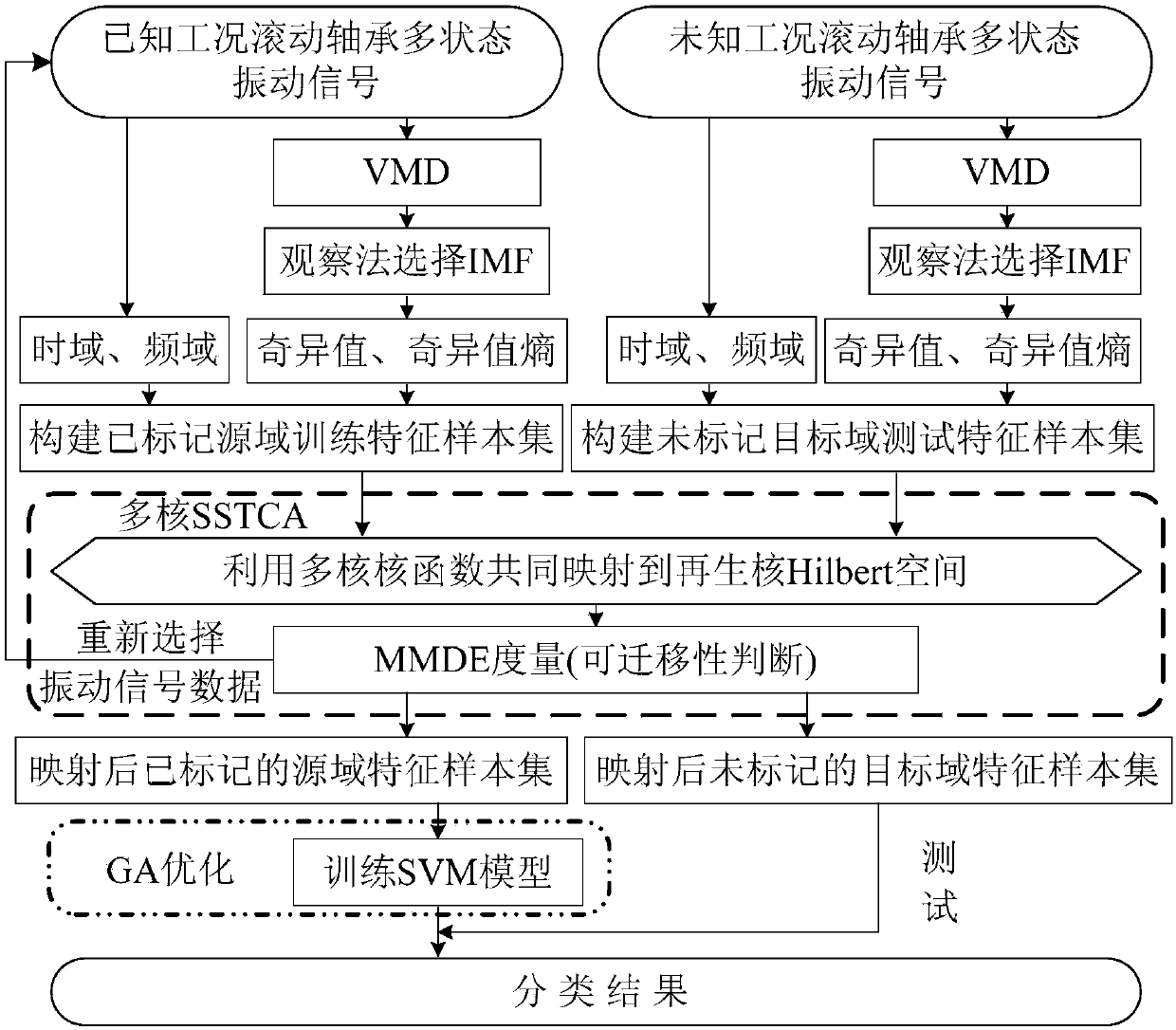

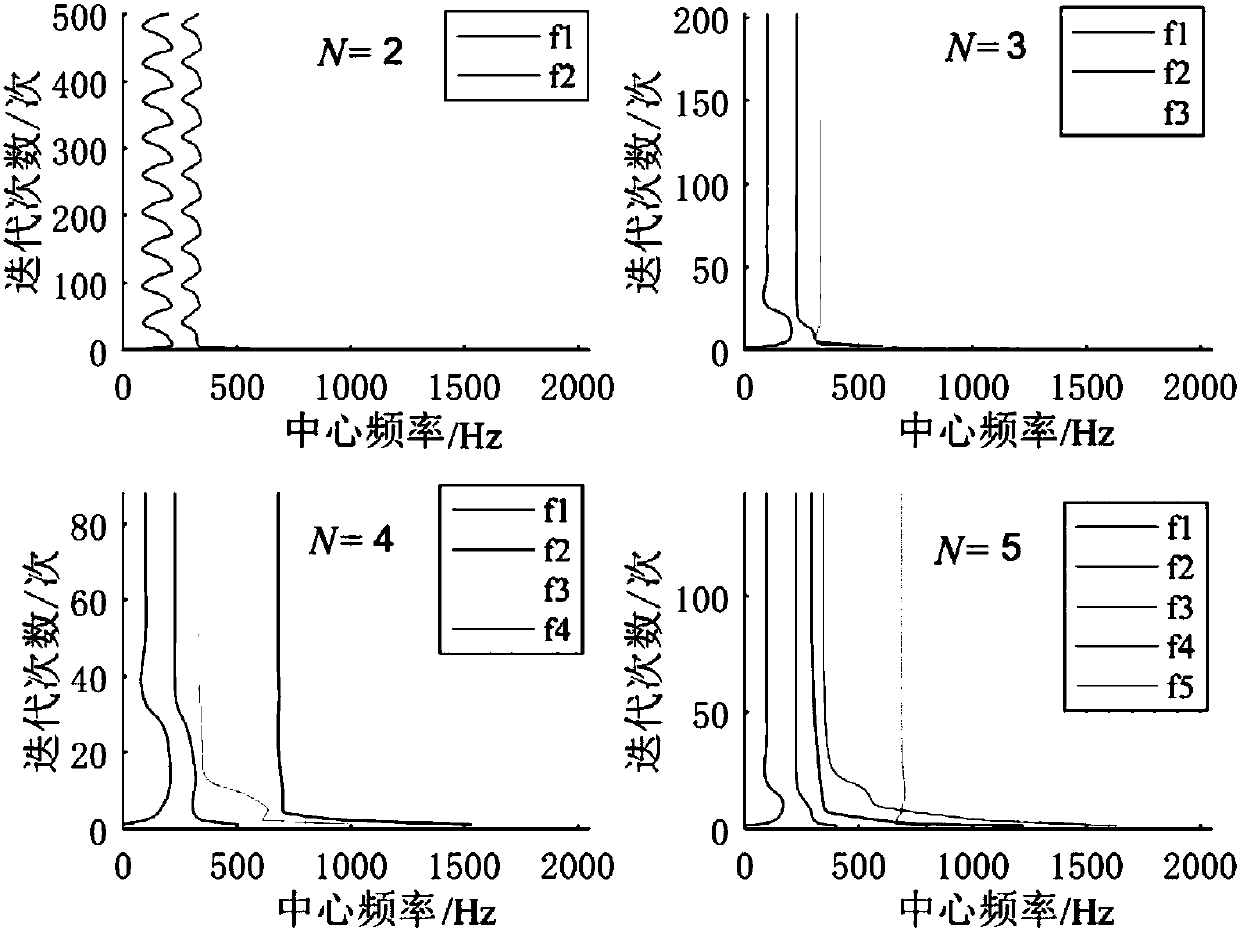

Rolling bearing fault diagnosis method in various working conditions based on feature transfer learning

ActiveCN108414226ABest mapped kernel matrixImprove accuracyMachine bearings testingSingular value decompositionDecomposition

The present invention provides a rolling bearing fault diagnosis method in various working conditions based on feature transfer learning, and relates to the field of fault diagnosis. The objective ofthe invention is to solve the problem that a rolling bearing, especially to various working conditions, is low in accuracy of diagnosis. The method comprise the steps of: employing a VMD (VariationalMode Decomposition) to perform decomposition of vibration signals of a rolling bearing in each state to obtain a series of intrinsic mode functions, performing singular value decomposition of a matrixformed by the intrinsic mode functions to solve a singular value or a singular value entropy, combining time domain features and frequency domain features of the vibration signals to construct a multi-feature set; introducing a semisupervised transfer component analysis method to perform multinuclear construction of a kernel function thereof, sample features of different working conditions are commonly mapped to a shared reproducing kernel Hilbert space so as to improve the data intra-class compactness and the inter-class differentiation; and employing the maximum mean discrepancy embedding to select more efficient data as a source domain, inputting source domain feature samples into a SVM (Support Vector Machine) for training, and testing target domain feature samples after mapping. Therolling bearing fault diagnosis method in various working conditions has higher accuracy in the rolling bearing multi-state classification in various working conditions.

Owner:HARBIN UNIV OF SCI & TECH

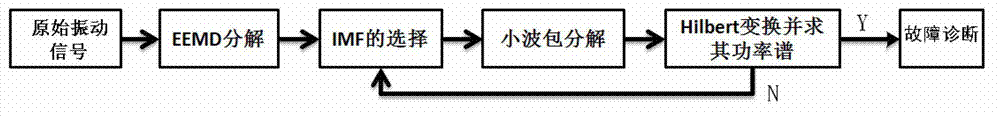

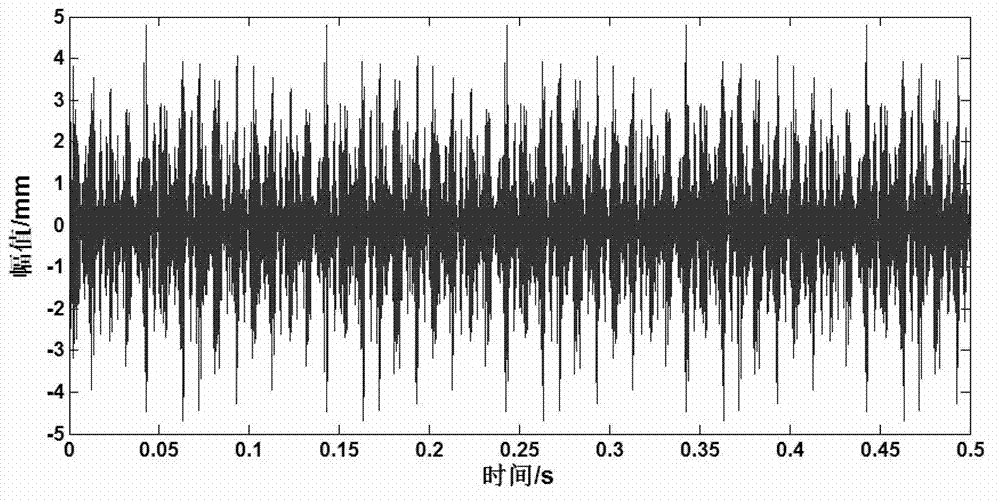

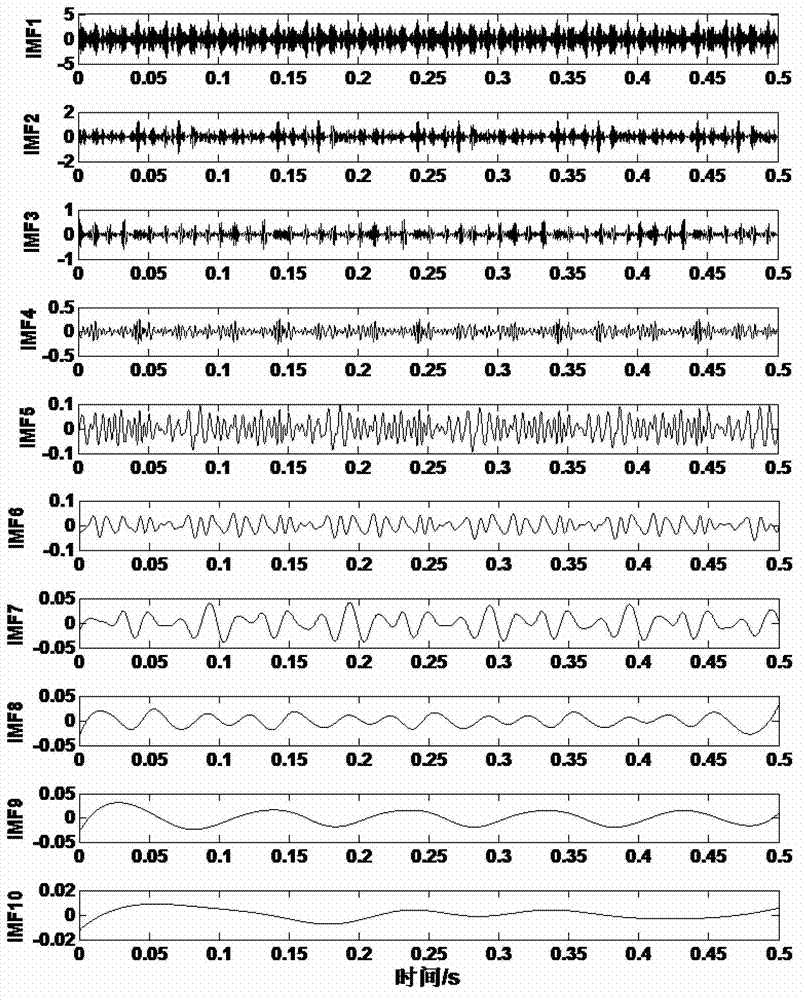

Extraction method for early failure sensitive characteristics based on ensemble empirical mode decomposition (EEMD) and wavelet packet transform

InactiveCN103091096AGuaranteed Adaptive Accurate PartitioningAdaptive Precise Partition PreciseMachine gearing/transmission testingMachine bearings testingNODALDecomposition

The invention relates to an extraction method for early failure sensitive characteristics based on ensemble empirical mode decomposition (EEMD) and wavelet packet transform. The extraction method for the early failure sensitive characteristics based on the EEMD and the wavelet packet transform includes the following steps: (1), collected original vibration signals of mechanical and electrical equipment are decomposed according to the EEMD, white noise is added, and intrinsic mode function (IMF) components are obtained through decomposition; (2), the sensitive IMF components closely related to failure are chosen, and other irrelative IMF components are ignored; (3), the sensitive IMF components chosen through step (2) are decomposed in an orthogonal wavelet packet mode, and a wavelet coefficient of each node is obtained; and (4), envelopes are extracted from the obtained wavelet packet coefficients by adoption of the Hilbert transform and the Fourier transform, power spectrums are calculated, the power spectrum corresponding to each wavelet packet coefficient is obtained and serves as the early failure sensitive characteristic , and the sensitive characteristics are automatically obtained. Self-adapting signals can be decomposed, the sensitive characteristics can be convenient to obtain automatically, diagnosis precision and speed are improved, and a mechanical and electrical system can be diagnosed quickly, accurately and stably. The extraction method for the early failure sensitive characteristics based on the EEMD and the wavelet packet transform can be applied to the field of mechanical and electrical equipment failure diagnosis.

Owner:BEIJING INFORMATION SCI & TECH UNIV

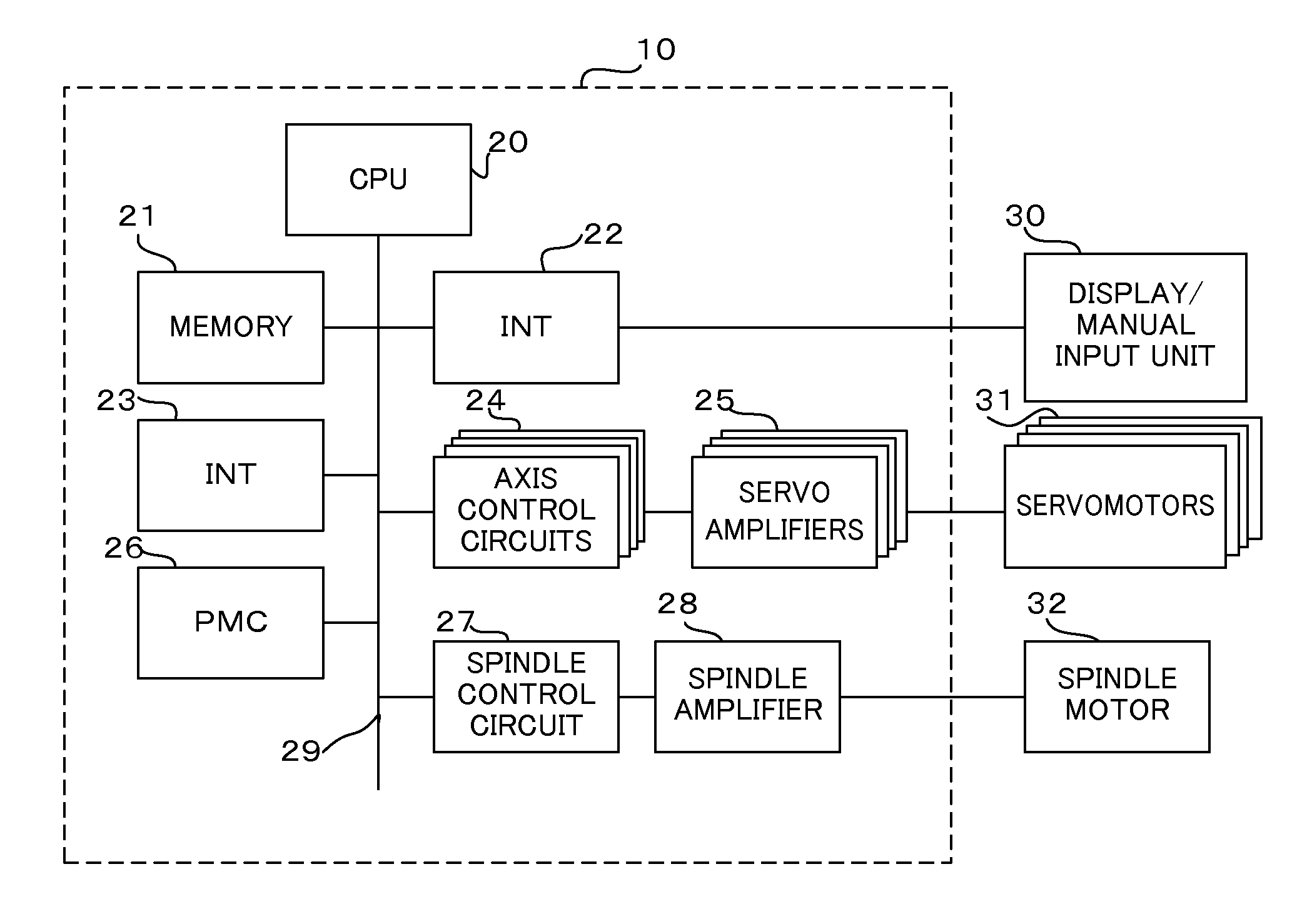

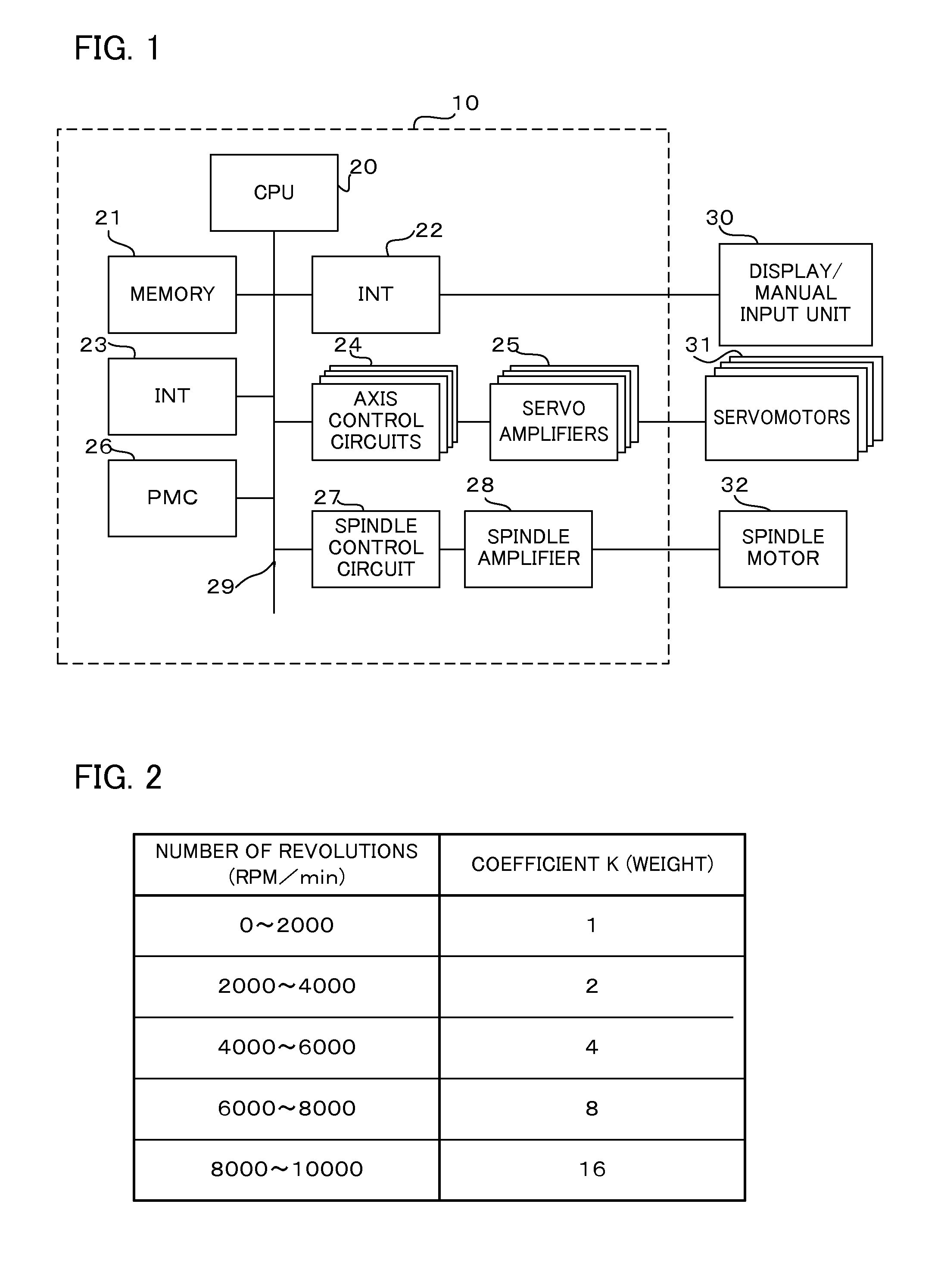

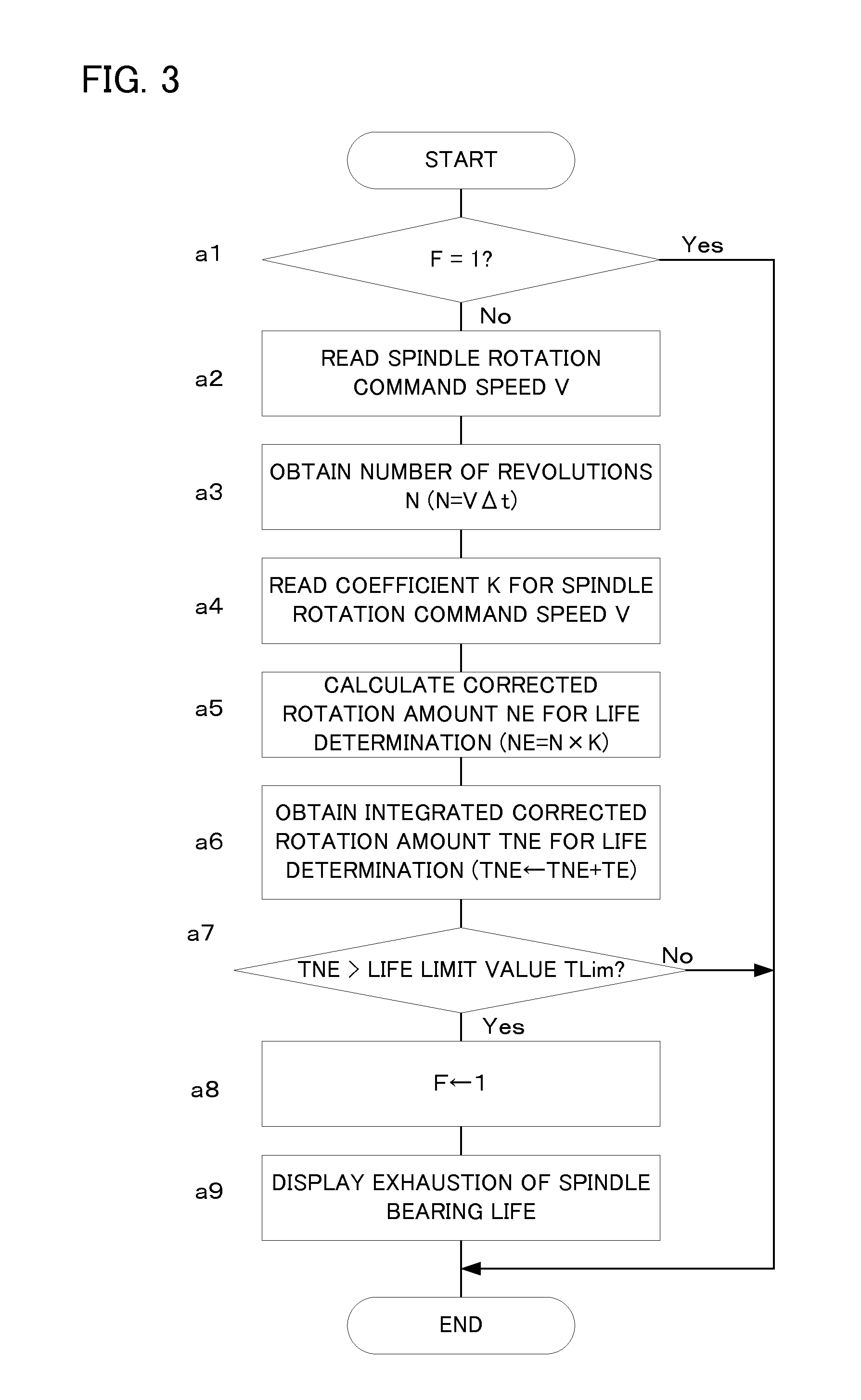

Bearing life determination device

A corrected rotation amount, based on conversion to a rotation amount at a reference rotational speed, is obtained by multiplying a command speed read in each period by a period time and a coefficient value corresponding to the rotational speed. An integrated corrected rotation amount is obtained by integrating the corrected rotation amount. If this integrated corrected rotation amount exceeds a life limit value, the life of a bearing is determined to be exhausted.

Owner:FANUC CORP

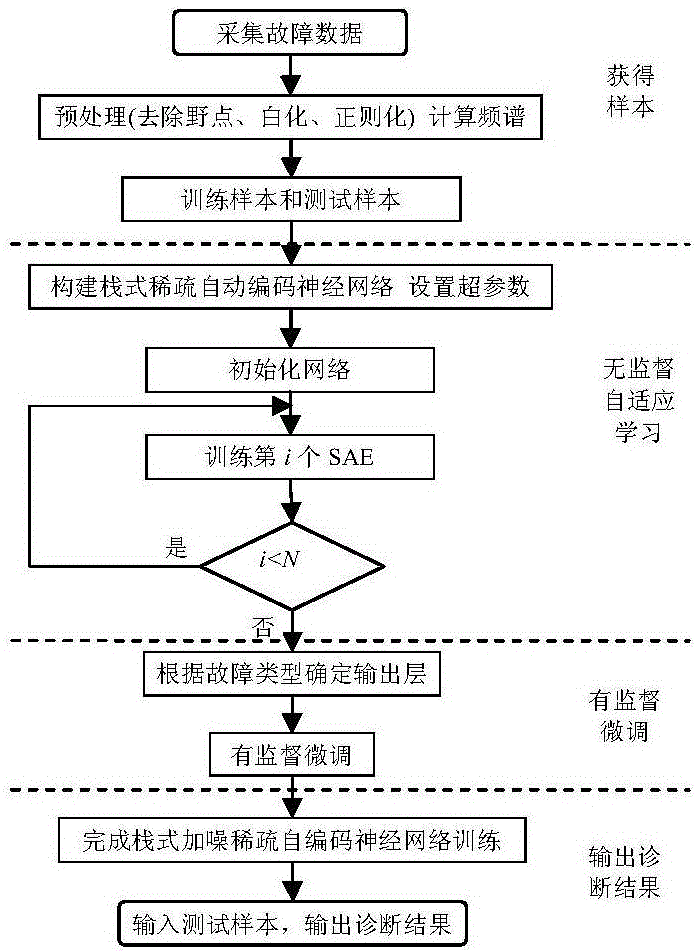

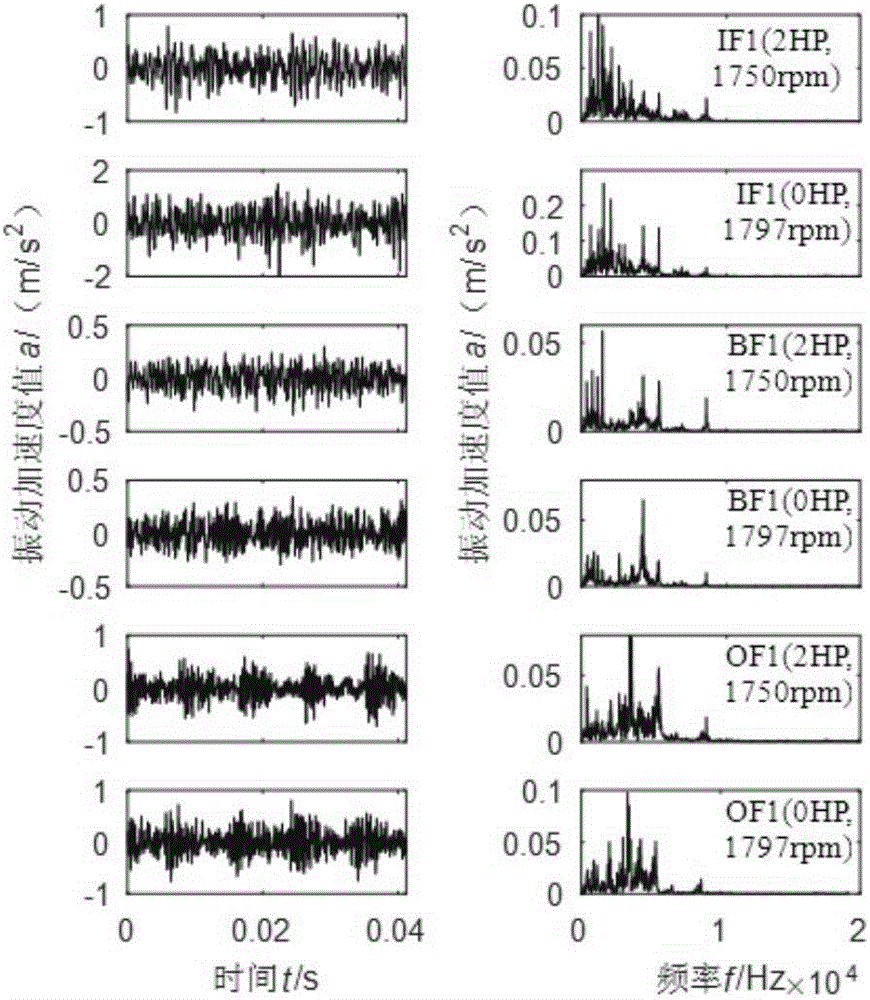

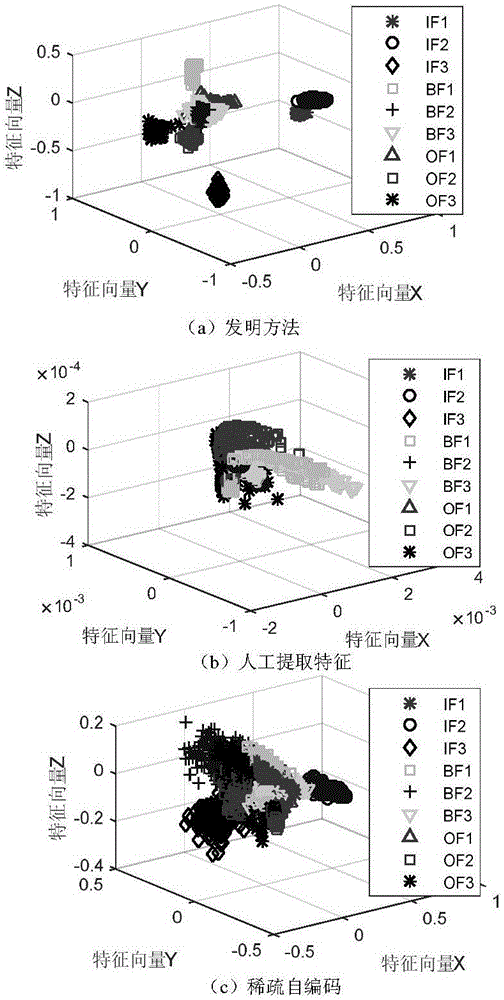

Adaptive extraction and diagnosis method for degree features of mechanical fault through stack-type sparse automatic coding depth neural network

InactiveCN106323636AImprove robustnessRealize intelligent diagnosis of fault levelMachine bearings testingNeural learning methodsAdaptive learningFeature extraction

The invention relates to an adaptive extraction and diagnosis method for degree features of a mechanical fault through a stack-type sparse automatic coding depth neural network, and belongs to the technical field of mechanical equipment state monitoring and reliability evaluation. The method aims at a problem of intelligent diagnosis of the degree of the mechanical fault, and comprises the steps: carrying out the stacking of sparse automatic coding, adding a classification layer, and constructing the stack-type sparse automatic coding depth neural network which integrates the adaptive learning and extraction of the degree features of the fault and fault recognition; employing the advantage that the sparse automatic coding can automatically learn the internal features of data, and adding noise coding to be integrated in the sparse automatic coding for improving the robustness of feature learning; carrying out the layer-by-layer no-supervision adaptive learning and supervision fine tuning of the original input complex data through multilayer sparse automatic coding, completing the automatic extraction and expression of the degree features of the mechanical fault and achieving the intelligent diagnosis of the degree of the fault. The method is used for the diagnosis of the degree of faults of rolling bearings under different work conditions, and obtains a good effect of feature extraction and diagnosis.

Owner:CHONGQING JIAOTONG UNIVERSITY

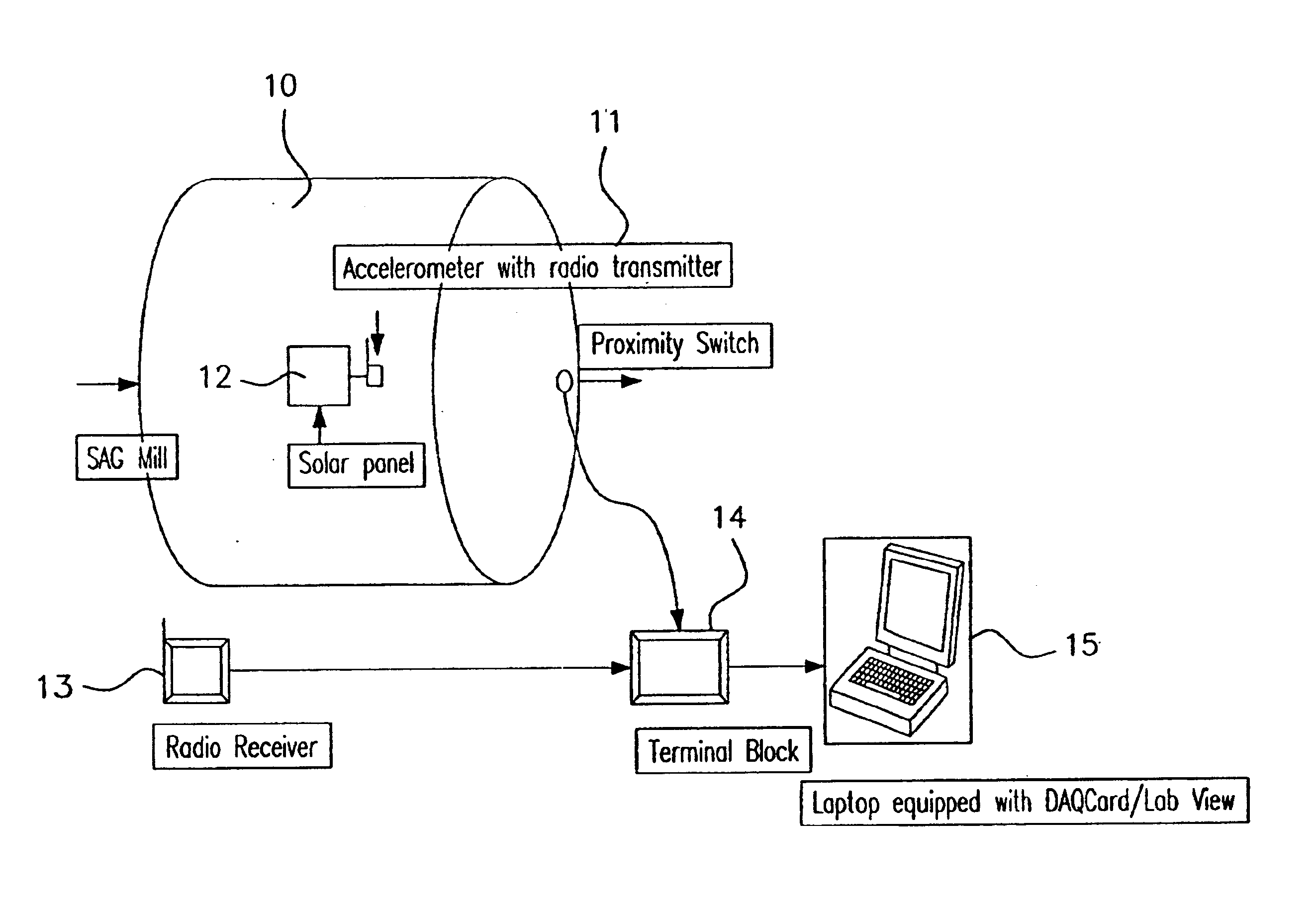

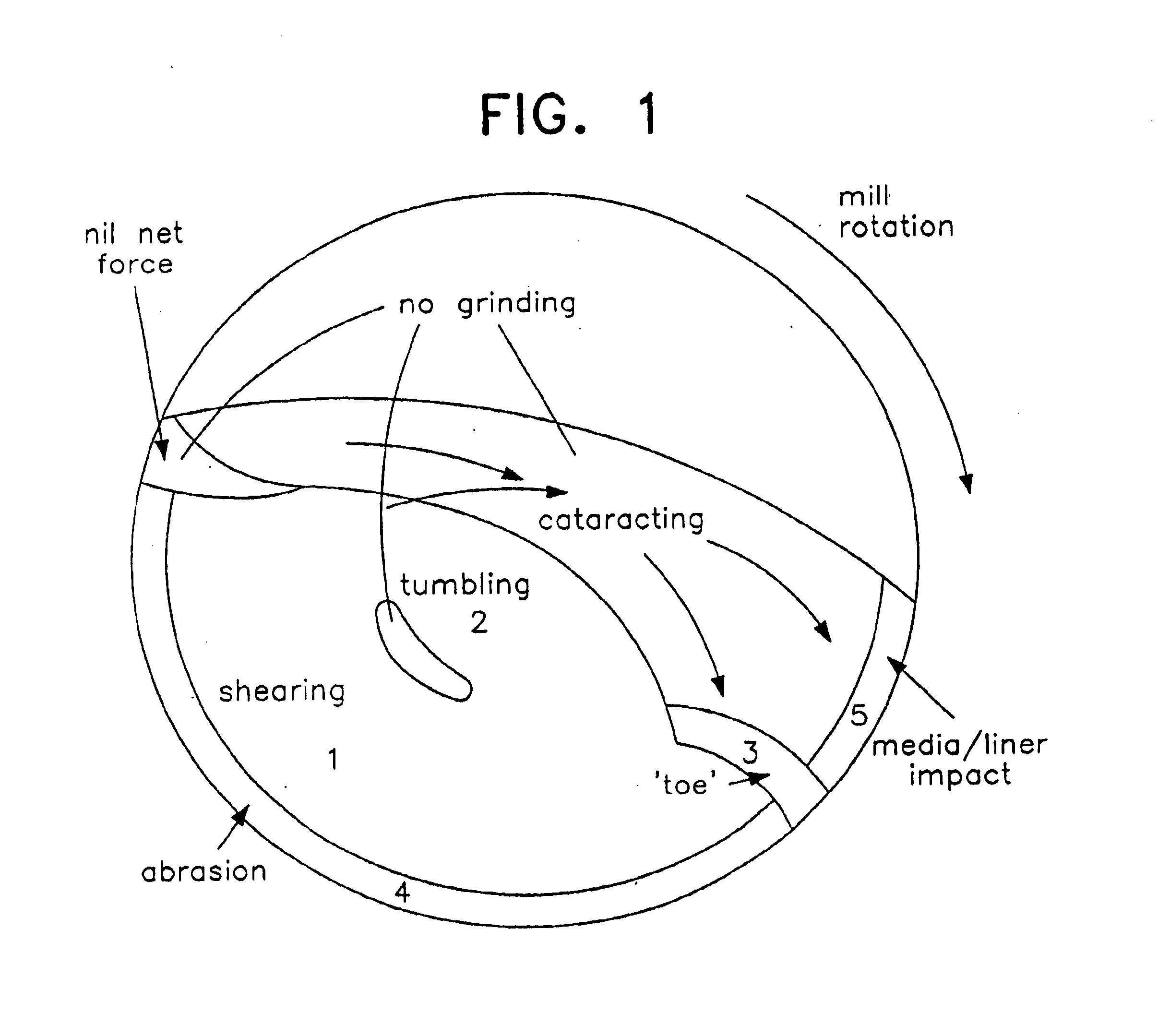

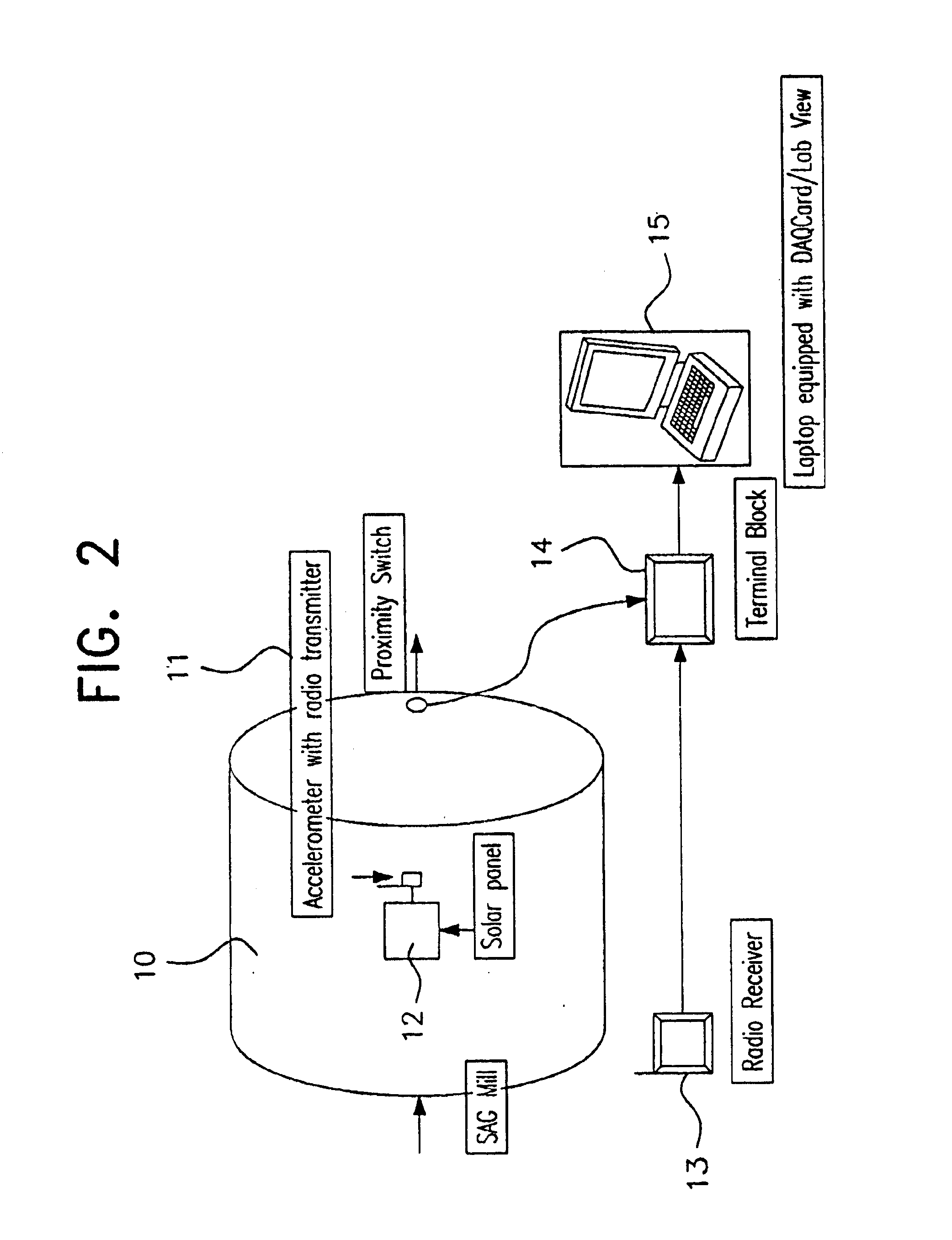

System for monitoring mechanical waves from a moving machine

InactiveUS6874364B1Minimise number/amplitude/frequencyMinimizes valueVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesParticulatesEngineering

A system for monitoring mechanical waves from a machine which in operation has moving particulate matter therein, the system including at least one sensor located on the machine at a location away from the central axis of the machine, the sensors being for sensing acoustic waves and including a transmitter for transmitting signals representing the sensed mechanical waves to a receiver at a location remote from the sensor(s), a data processor connected to the receiver for receiving signals from the receiver which signals represent the mechanical waves and processing the signals to produce output signals for display on a display means, wherein the output signals for display represent one or more parameters indicative of mechanical waves emitted from the machine over a predetermined period of time.

Owner:COMMONWEALTH SCI & IND RES ORG

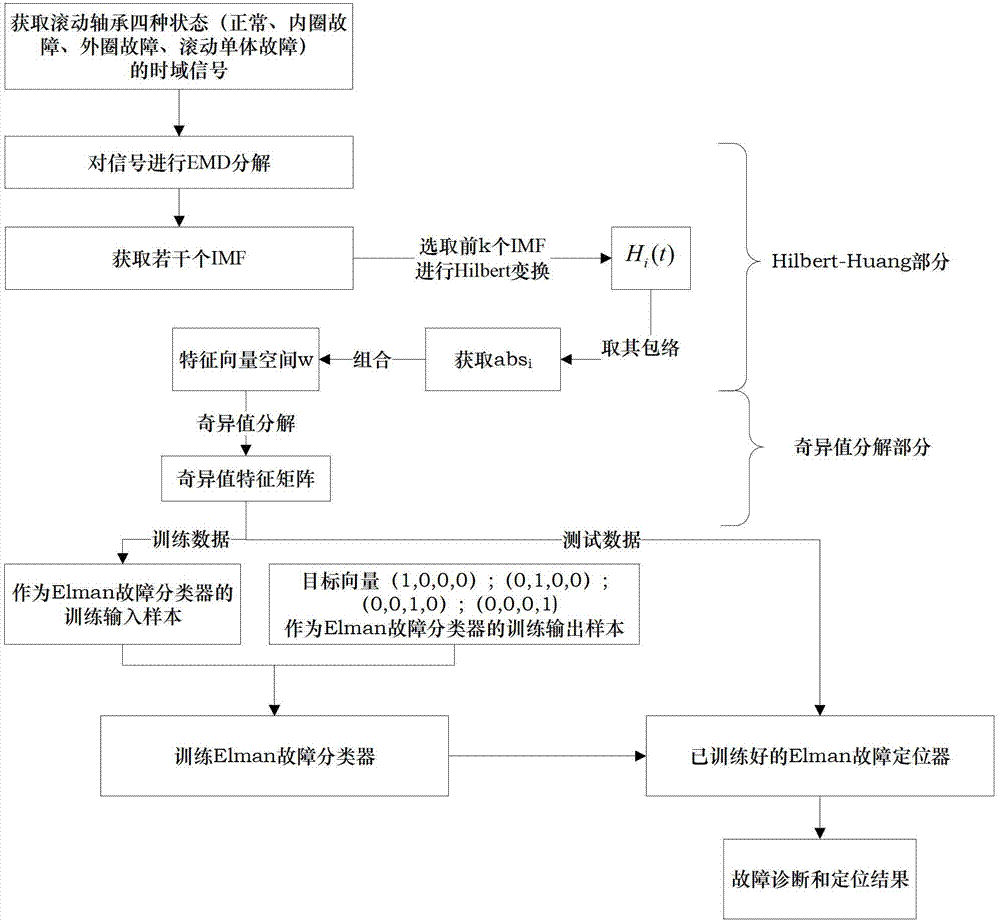

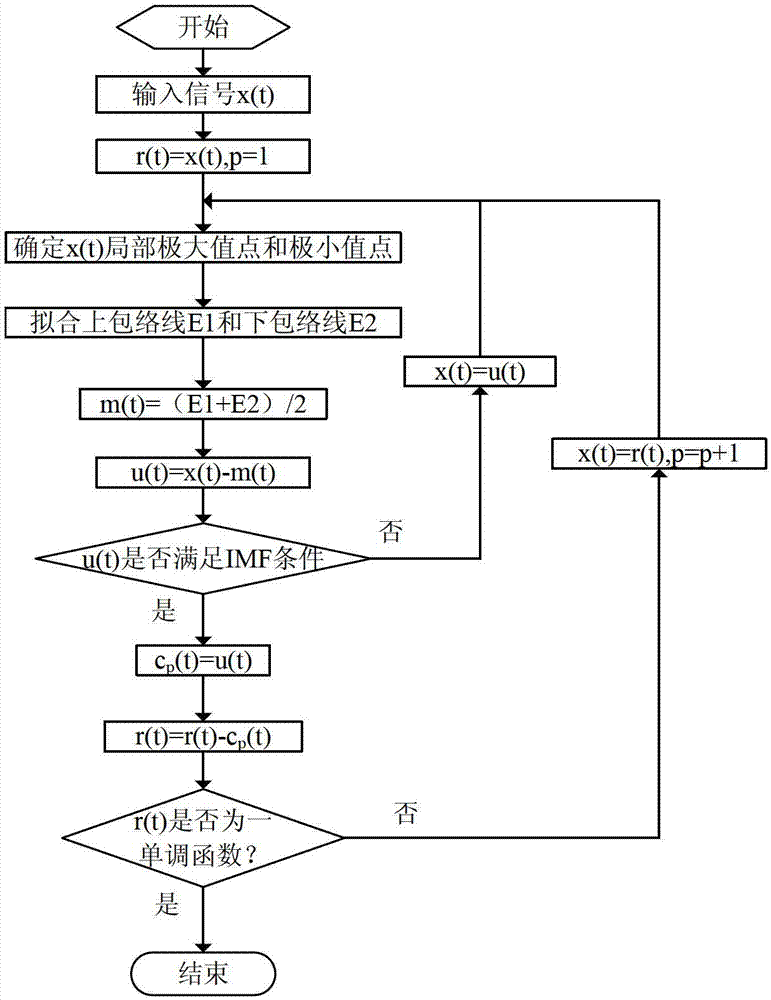

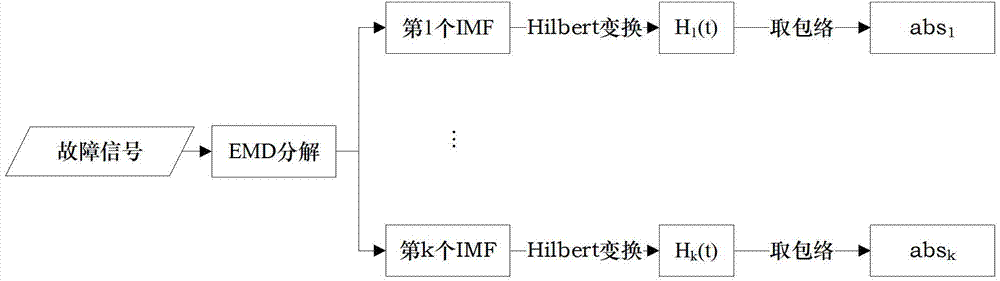

Fault diagnosis method of rolling bearing under variable working conditions

InactiveCN103048137AAccurate analysisPlay the role of demodulationMachine bearings testingFeature vectorDecomposition

The invention relates to a fault diagnosis method of a rolling bearing under variable working conditions. The method comprises the steps of: extracting a characteristic vector of a signal by means of Hilbert-Huang conversion, carrying out EMD (Empirical Mode Decomposition) to a signal to obtain a plurality of IMFs (Intrinsic Mode Function), and selecting useful IMFs to carry out Hilbert conversion respectively to obtain analytic signals Hi(t) and taking envelopes respectively to form a characteristic vector w; then, carrying out singular value decomposition for w by a singular value decomposition method, and using a singular value matrix as the final fault characteristic vector; using the singular value matrixes in four modes of the rolling bearing as input and four matrixes corresponding to the four modes as output to train an Elman neural network. When the rolling bearing fails, whether the rolling bearing is faulted or not can be judged and direction of faults can be accurately positioned through analysis and judgment of a signal at t moment by the trained Elman neural network. According to the invention, classification of fault modes of the rolling bearing under variable working conditions can be effectively finished, and higher precision is maintained.

Owner:BEIHANG UNIV

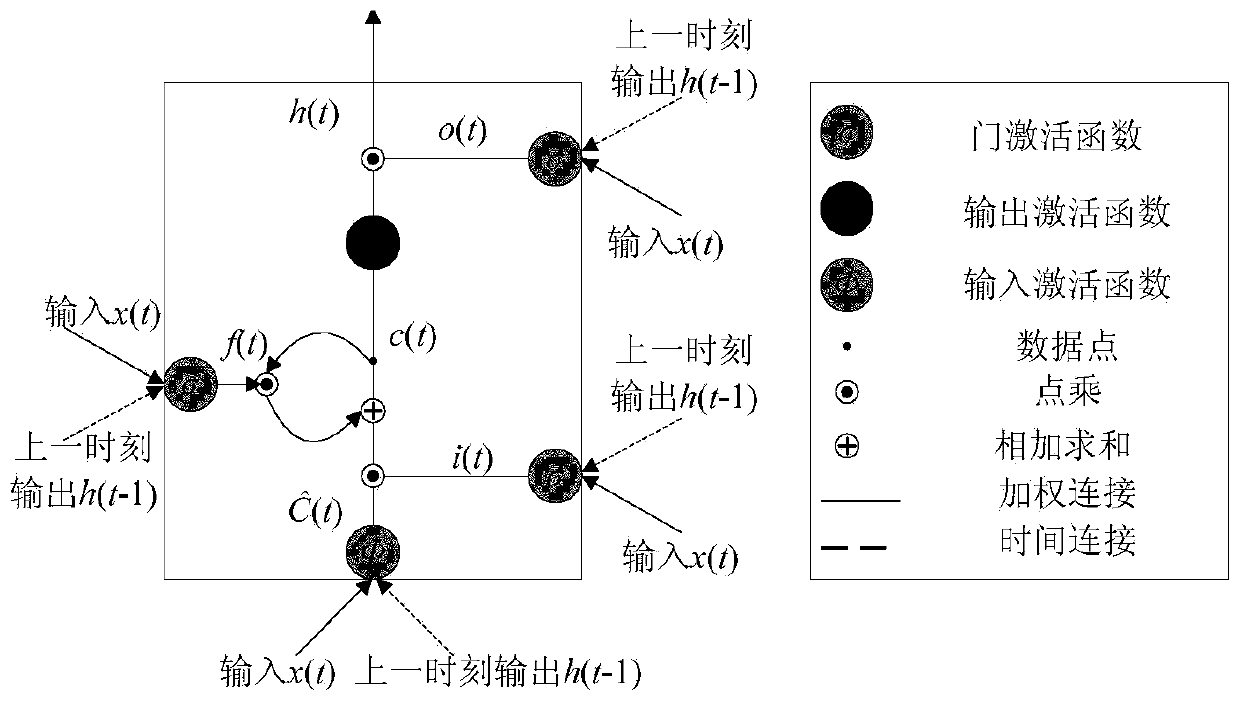

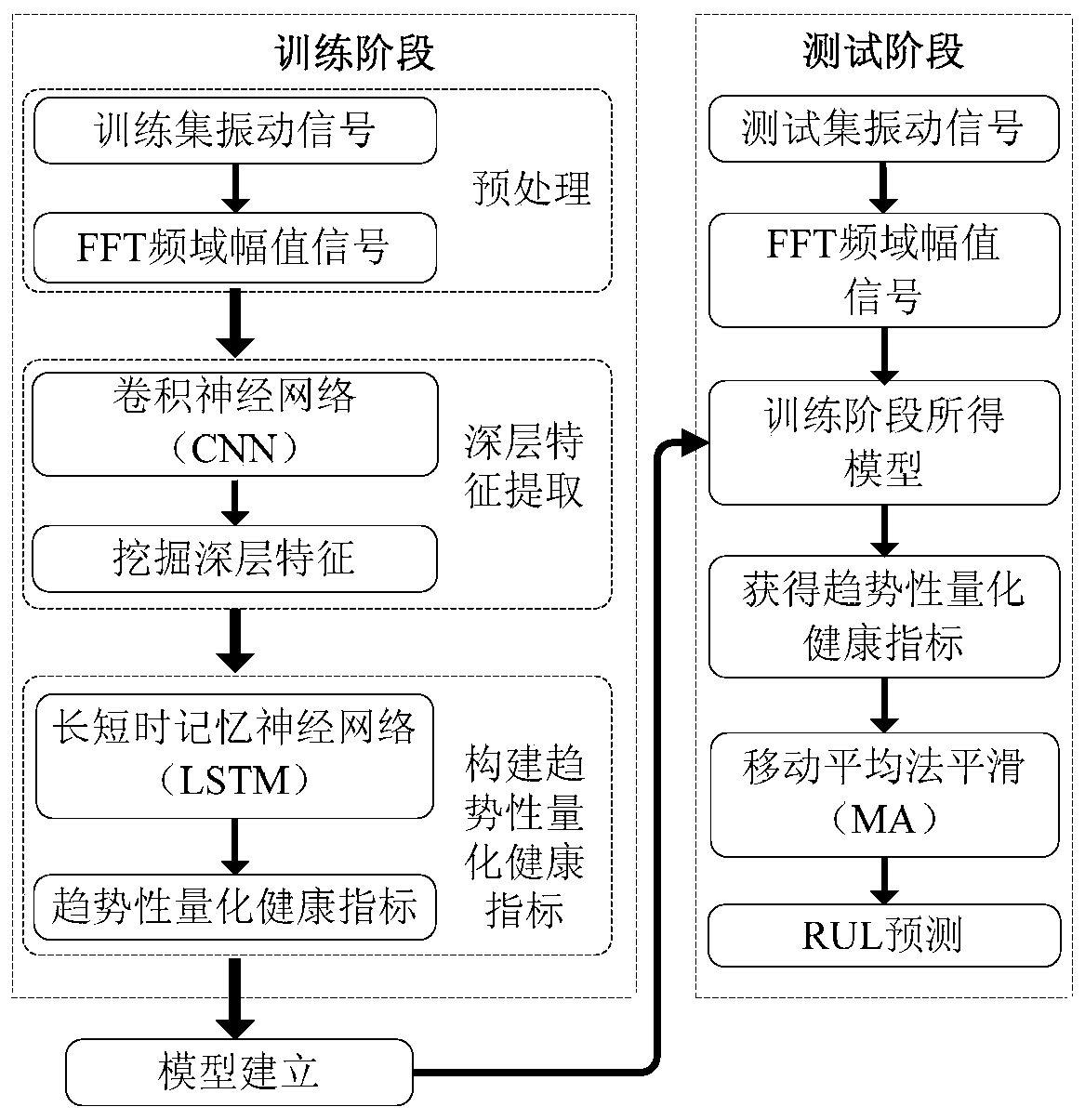

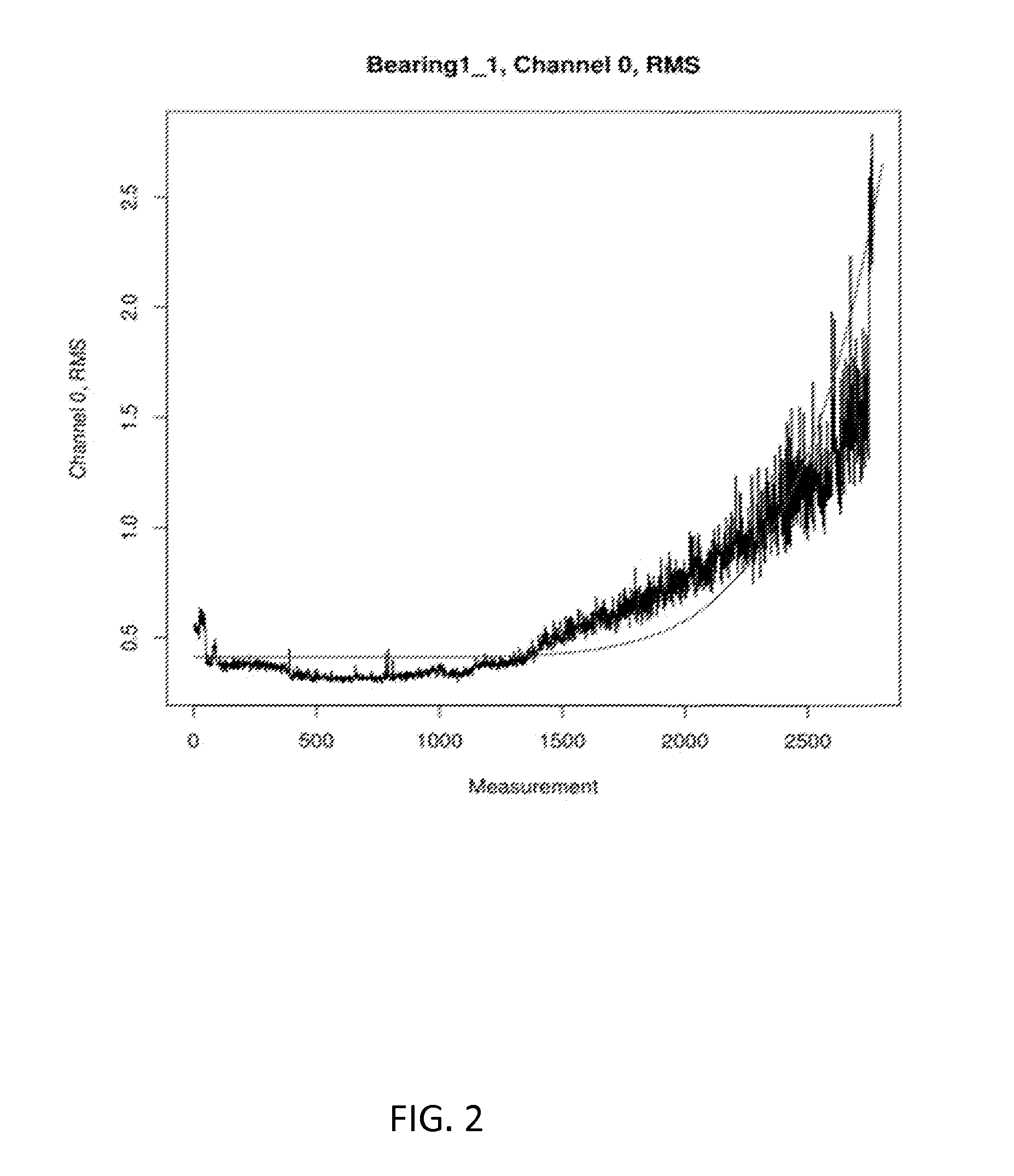

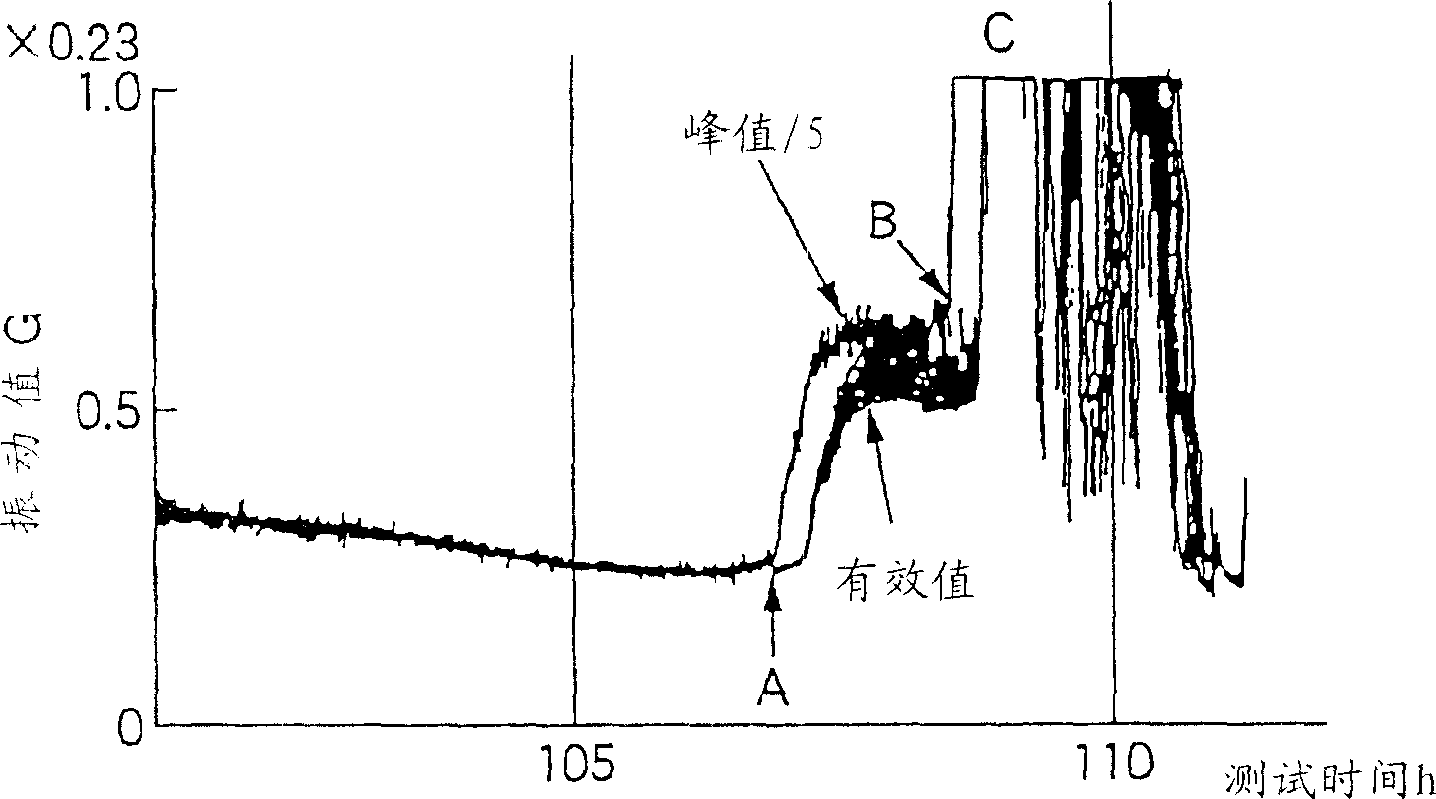

A CNN and LSTM-based rolling bearing residual service life prediction method

ActiveCN109726524AGood monotonic trendImprove approachMachine bearings testingCharacter and pattern recognitionMoving averageFast Fourier transform

The invention discloses a CNN and LSTM-based rolling bearing residual service life prediction method, and relates to the field of rolling bearing life prediction. The method aims to solve the problemthat residual service life (RUL) prediction of a rolling bearing is difficult in two modes of performance degradation gradual change faults and sudden faults. The method comprises the following stepsof: firstly, carrying out FFT (Fast Fourier Transform) on an original vibration signal of the rolling bearing, then carrying out normalization processing on a frequency domain amplitude signal obtained by preprocessing, and taking the frequency domain amplitude signal as the input of a CNN (Convolutional Neural Network); The CNN is used for automatically extracting data local abstract informationto mine deep features, and the problem that a traditional feature extraction method depends too much on expert experience is avoided. the deep features are input into an LSTM network, a trend quantitative health index is constructed, and a failure threshold value is determined at the same time; And finally, smoothing processing is carried out by using a moving average method, eliminating local oscillation, and a future failure moment is predicted by using polynomial curve fitting to realize rolling bearing RUL prediction. And the prediction result can be well close to the real life value.

Owner:HARBIN UNIV OF SCI & TECH

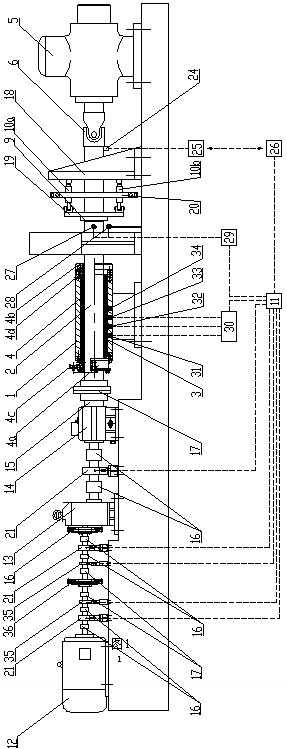

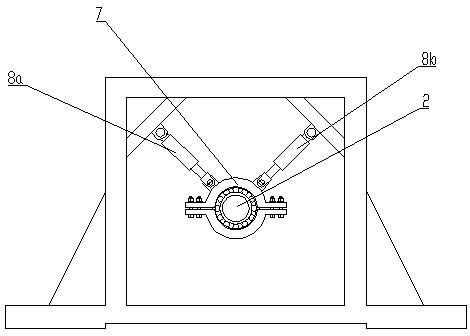

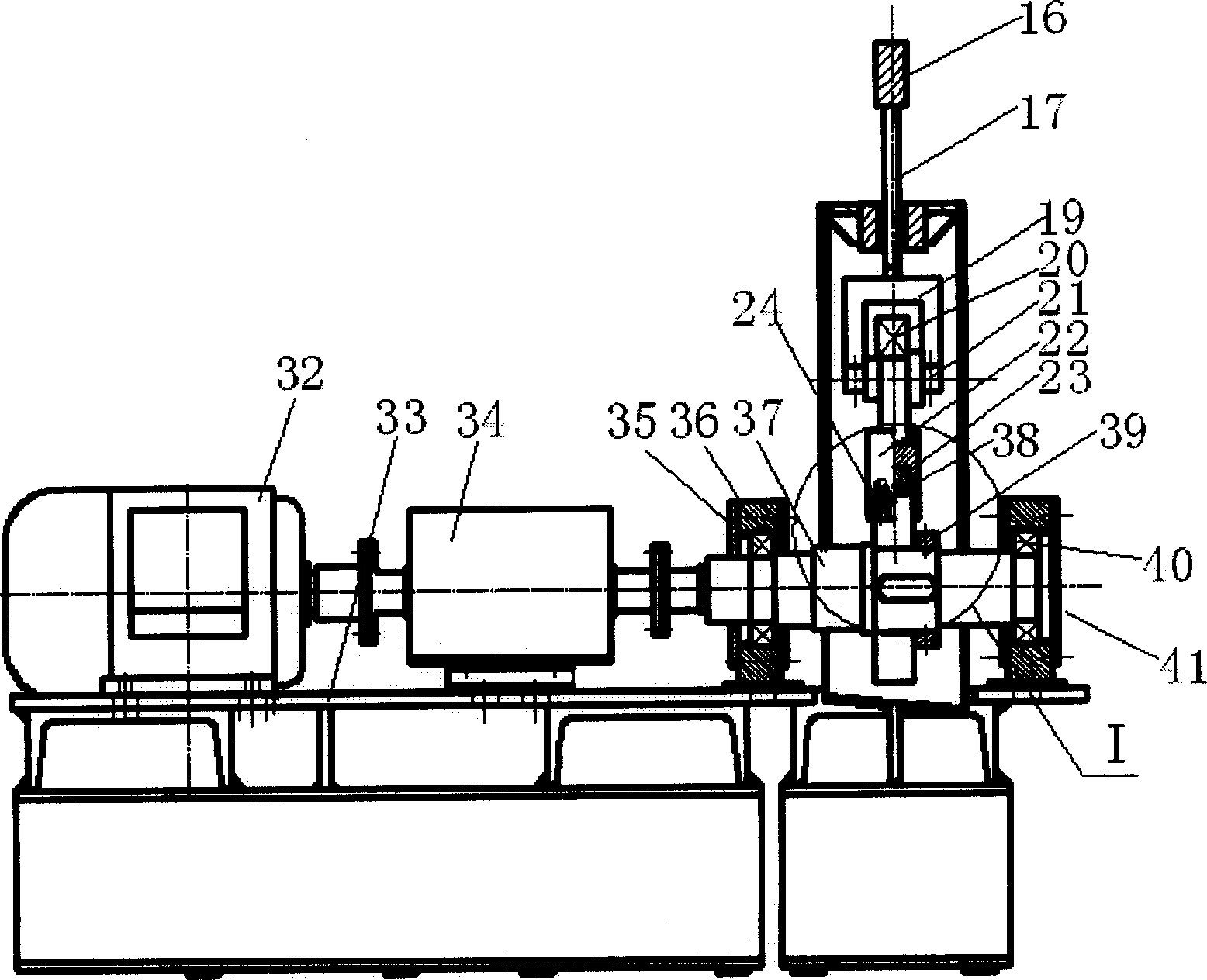

Comprehensive performance experiment platform for water-lubricated bearings and transmission systems

ActiveCN102269654AReal performance testPerformance testing is completeMachine gearing/transmission testingMachine bearings testingLow noiseDrive motor

The invention discloses a water lubricated bearing and transmission system comprehensive performance testing platform, which comprises a water lubricated bearing, a dynamic seal device, an elastic coupling, a gearbox, a water circulating system, a driving motor, an intermediate bearing, a bearing block, a loading and testing device and other parts. The loading device loads a test shaft in the circumferential direction, axial direction and radial direction so as to simulate complicated working conditions of the water lubricated bearing and the transmission system thereof; the testing system can detect various parameters of the water lubricated bearing, such as working speed, torque, temperature, frictional characteristics, water film pressure distribution, interface deformation distribution, shaft centerline orbit, noise and dynamic characteristics, and comprehensive performance of the dynamic seal, the elastic coupling and the transmission system on line; and the testing platform can be applied to research of scientific problems such as the loading bearing of a water lubricated friction pair, failure mechanism and evolution law, tribological performance and dynamic service behaviors, and provides a key scientific and technological basis for developing a pollution-free, low-noise, high-reliability, long-life, high-efficiency and energy-saving water lubricated bearing and a transmission system thereof.

Owner:CHONGQING UNIV

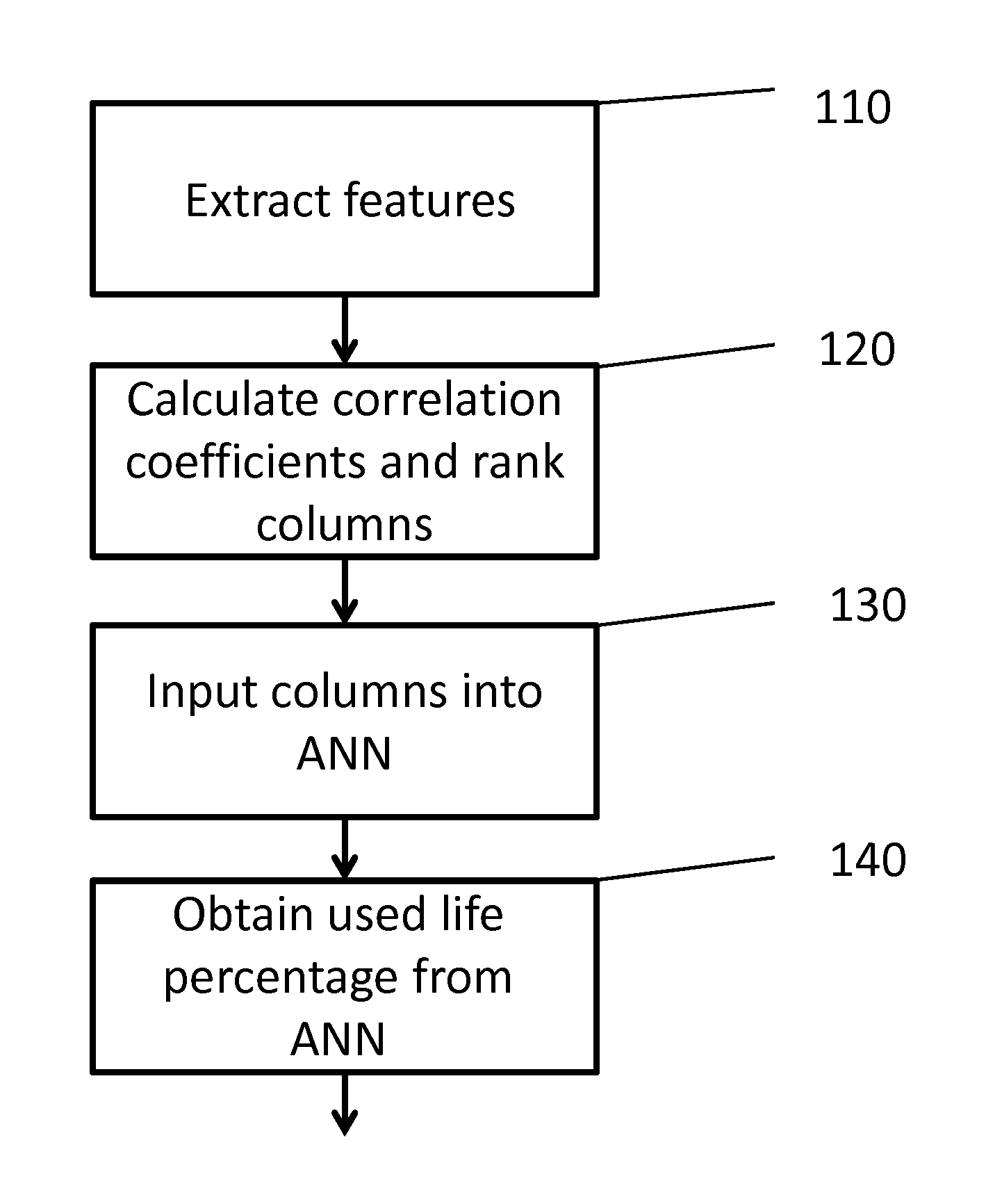

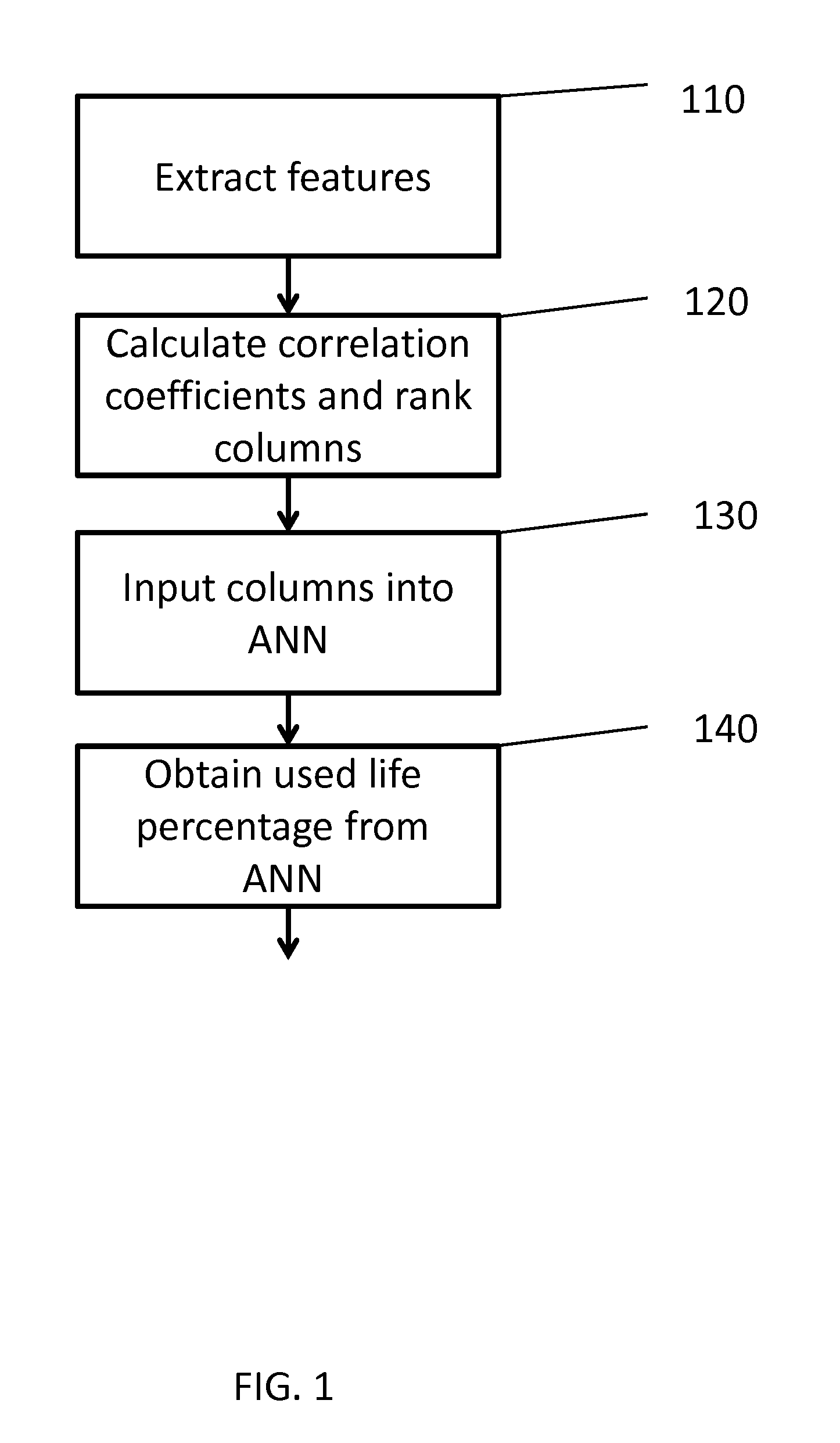

System and Method for Calculating Remaining Useful Time of Objects

ActiveUS20150262060A1Machine bearings testingDigital computer detailsMechanical componentsCondition monitoring

An aspect of the present invention is to provide a system and method for predicting the remaining useful time of mechanical components such as bearings. Another aspect of the present invention is to provide a system and method for predicting the remaining useful time of bearings based on available condition monitoring data. Another aspect of the present invention is to provide a system and method for automatically deciding which columns of input information are the most significant for predicting the remaining useful life of bearings. Another aspect of the present invention is to provide a system and method for performing an analysis of both test bearings and training bearings and determining which training bearings are most similar to a given test bearing. Another aspect of the present invention is to provide a system and method for training an artificial neural network.

Owner:SPARKCOGNITION INC

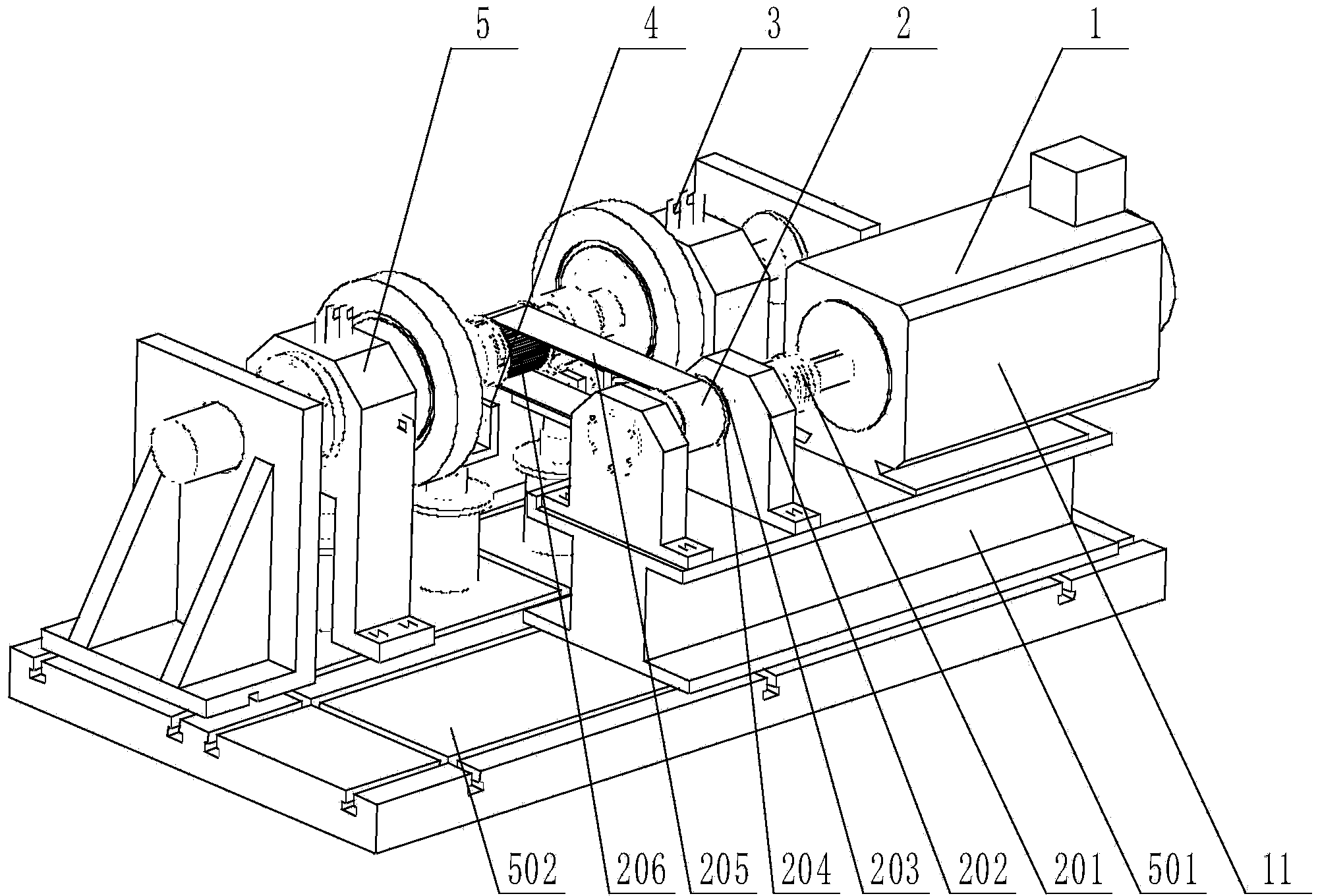

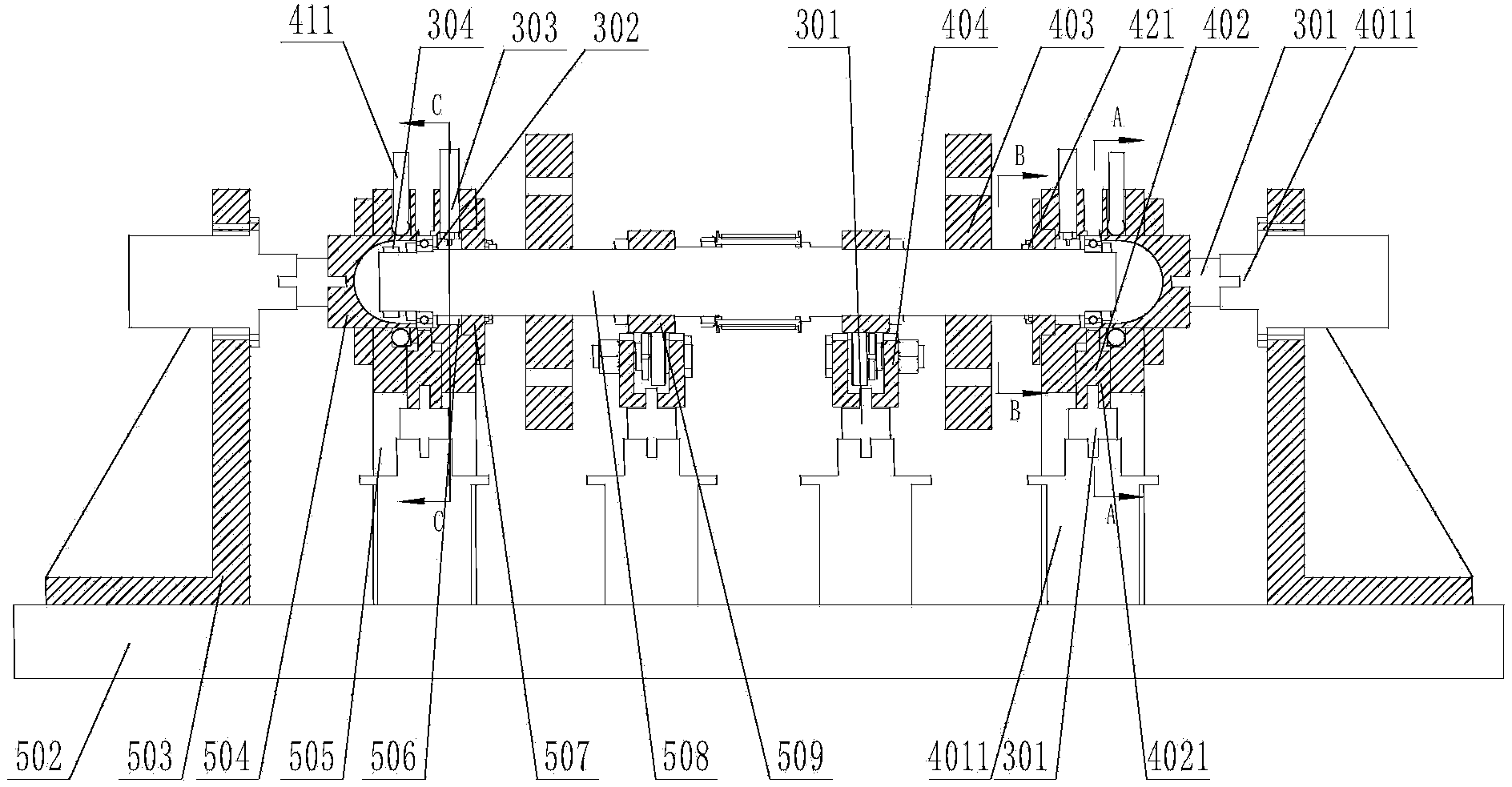

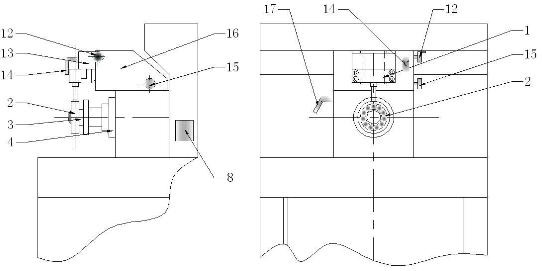

Bearing integrated dynamic performance test device and method

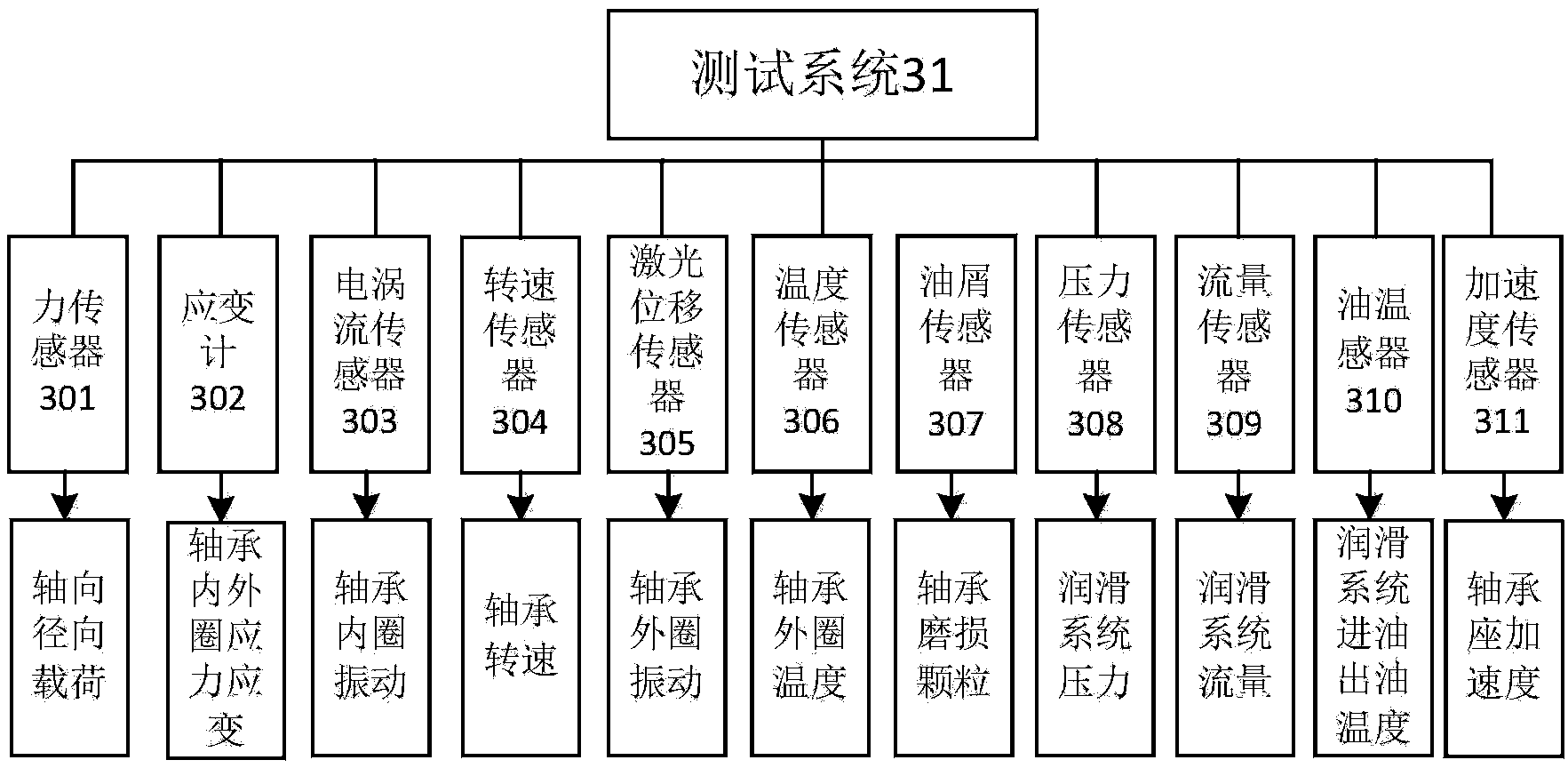

The invention relates to the technical field of bearing testing, in particular to a bearing integrated dynamic performance test device and method. The bearing integrated dynamic performance test device comprises a drive system, a transmission system, a measurement and control system, an environmental simulation system and a mechanical body structure. A motor is adopted by the drive system for driving. The measurement and control system controls the rotation speed of the motor. The transmission system is in a belt transmission mode or a coupler transmission mode. The measurement and control system is provided with a force sensor, a strainmeter, an eddy current transducer, a rotation speed sensor, a laser displacement sensor, a temperature sensor, a magnetic oil residue sensor, a pressure sensor, a flow sensor, an oil temperature sensor, an acceleration sensor and other related sensors used for bearing testing. The control system is driven in a servo mode, and is composed of a frequency converter, a hydraulic solenoid valve, a heating controller, a flow control device and a pressure control device. The environmental simulation system is adopted for simulating a real bearing testing working condition, and the performance and service life testing of the real bearing testing working condition is achieved.

Owner:DALIAN UNIV OF TECH

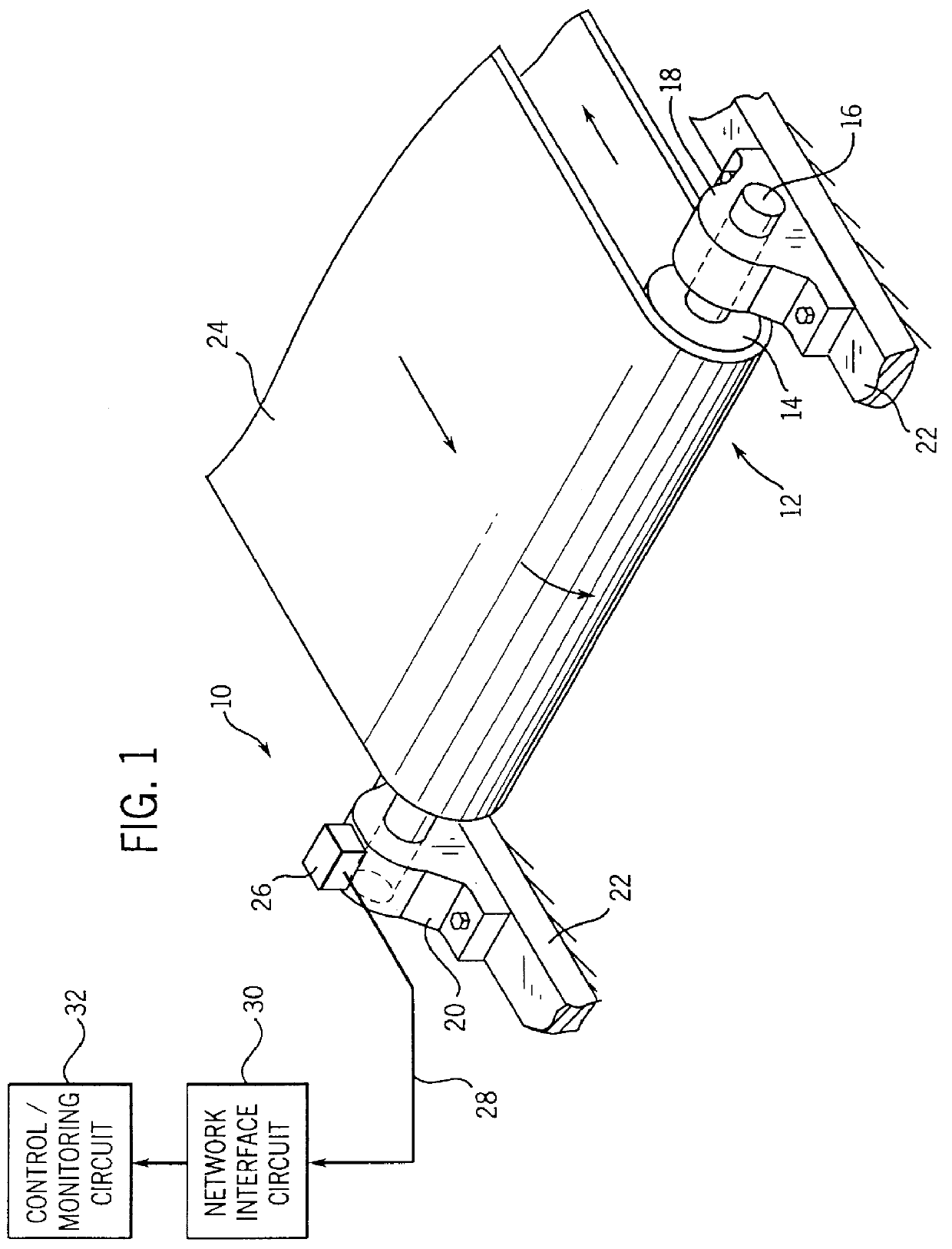

Method and apparatus for identifying defects in a rotating machine system

InactiveUS6116089AVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesAccelerometerEngineering

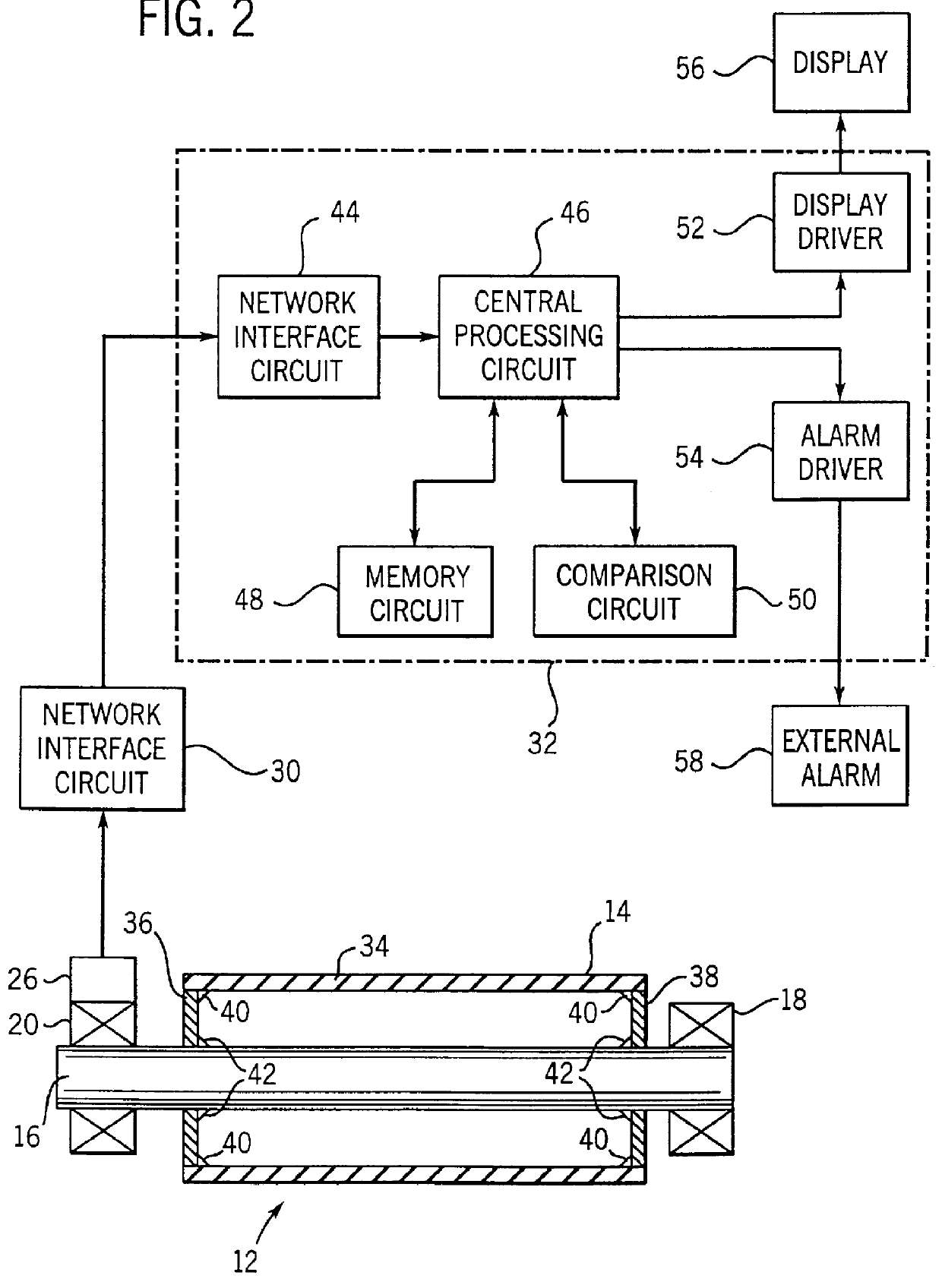

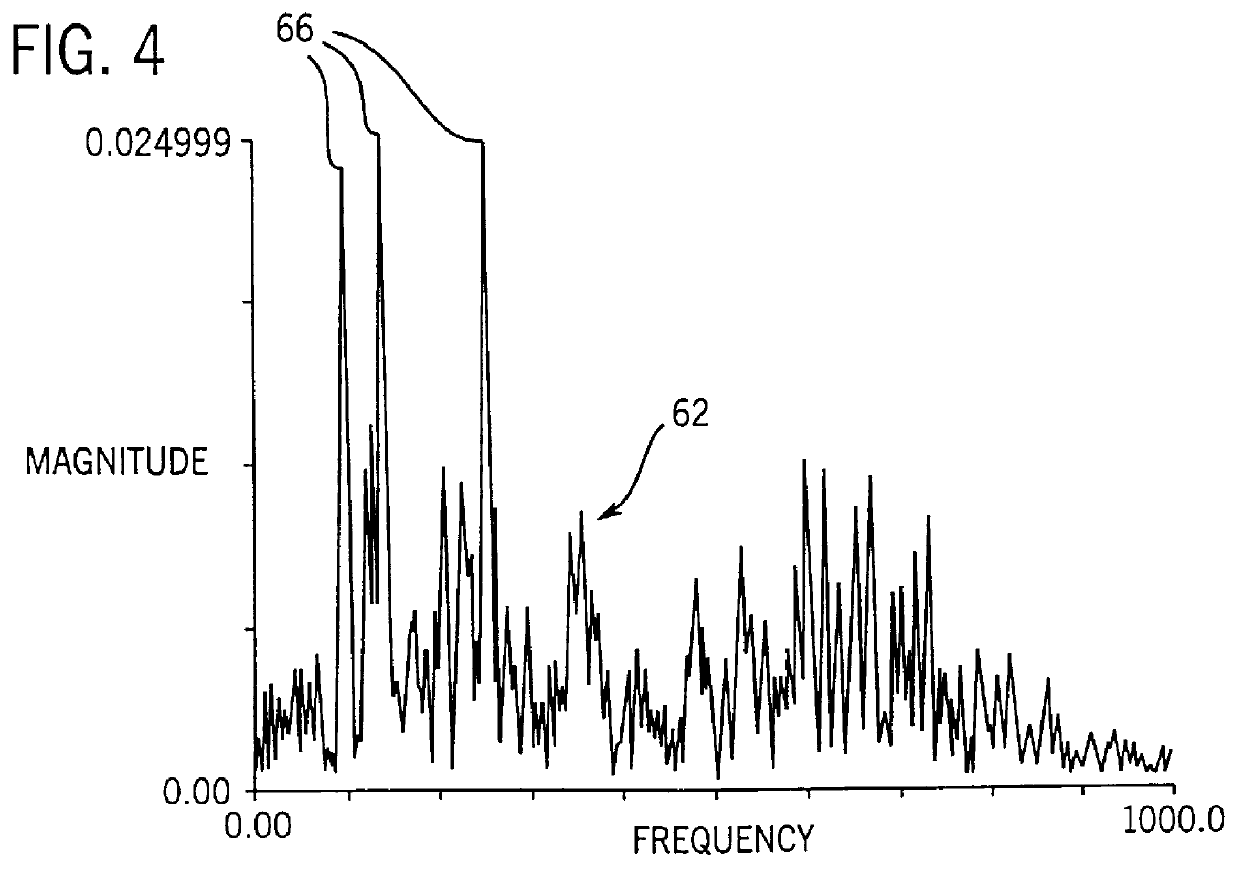

A system for detecting defects in a rotating machine system includes a sensor such as an accelerometer coupled to the machine system for detecting vibrations of a rotating element. Output of the accelerometer is transmitted, preferably via a network data link to a monitoring / control circuit. The monitoring / control circuit analyzes the vibration data to develop a normal vibration profile for the machine system during a normal operating phase. The normal vibration profile is stored in a memory circuit for later reference. During subsequent operation of the machine system, the monitoring / control circuit cyclically analyzes vibration data to develop actual vibration profiles. The actual vibration profiles are compared to the normal vibration profile and, where variations between the profiles exceed preset tolerances, the circuit provides an indication of a malfunction or defect in the machine system. The technique is particularly well suited to conveyor systems such as drum pulleys and the like in which cracks, breaks and other defects can result in unexpected failure and maintenance.

Owner:BALDOR ELECTRIC COMPANY

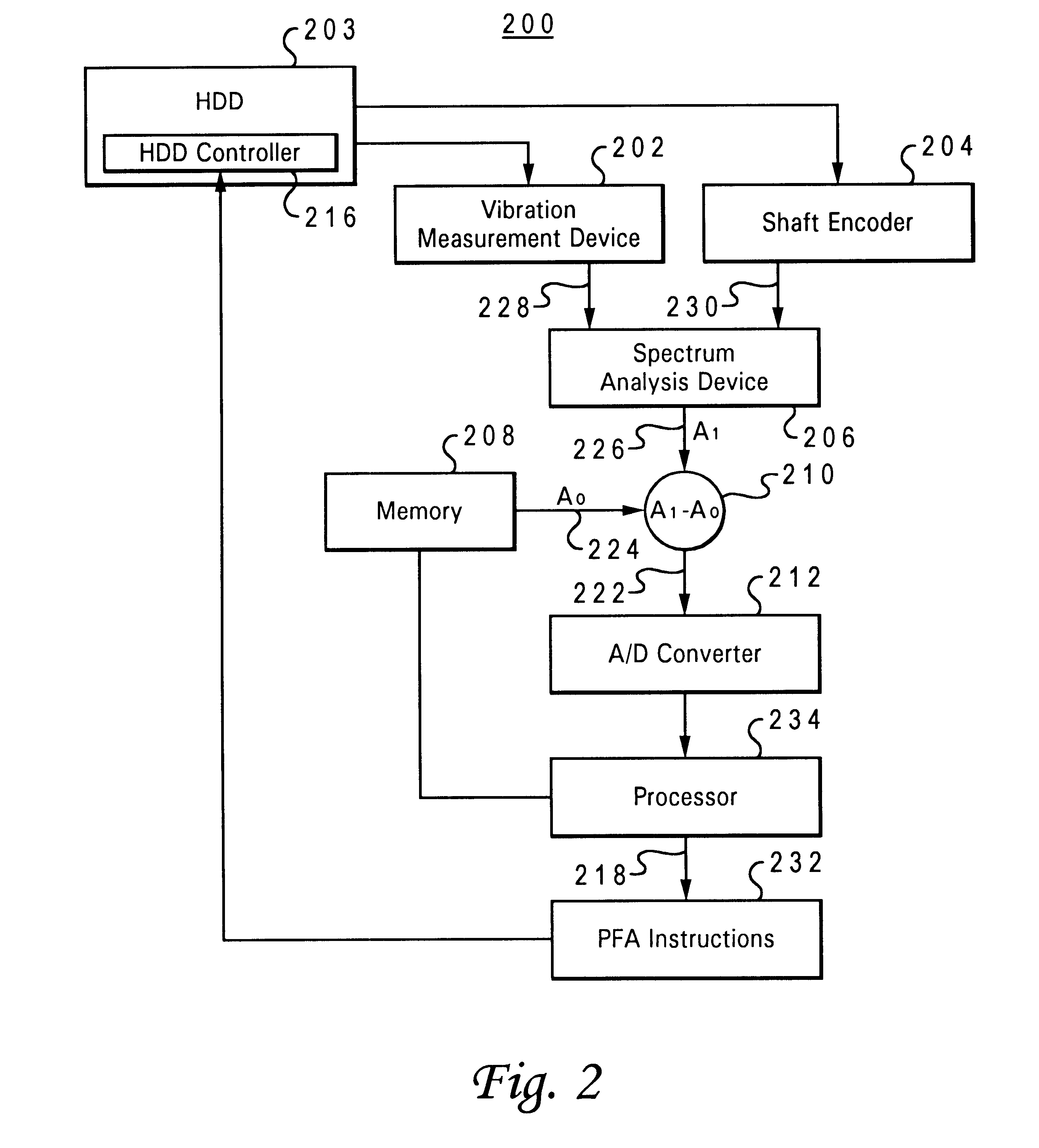

Method and system for predicting disk drive failures

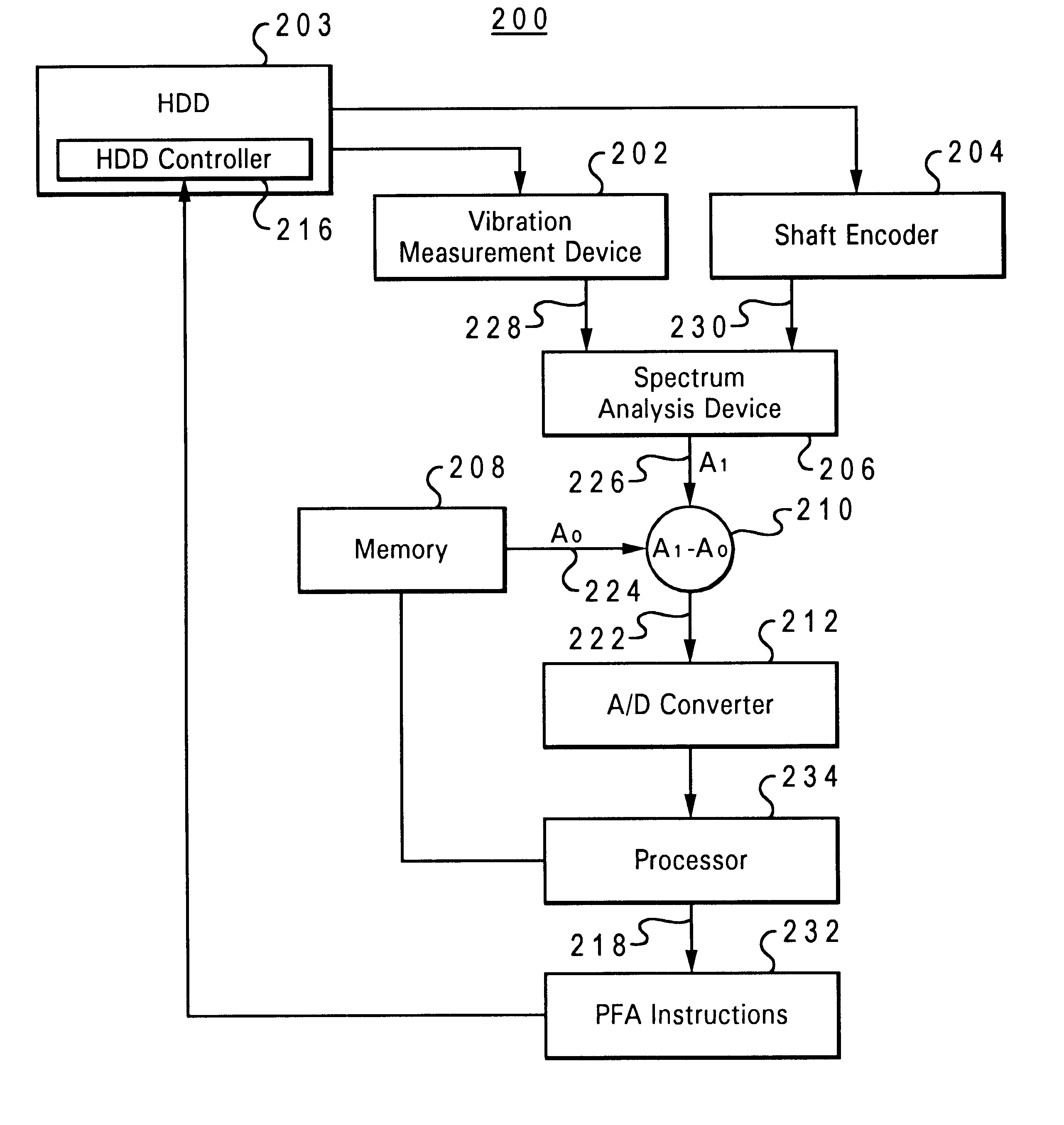

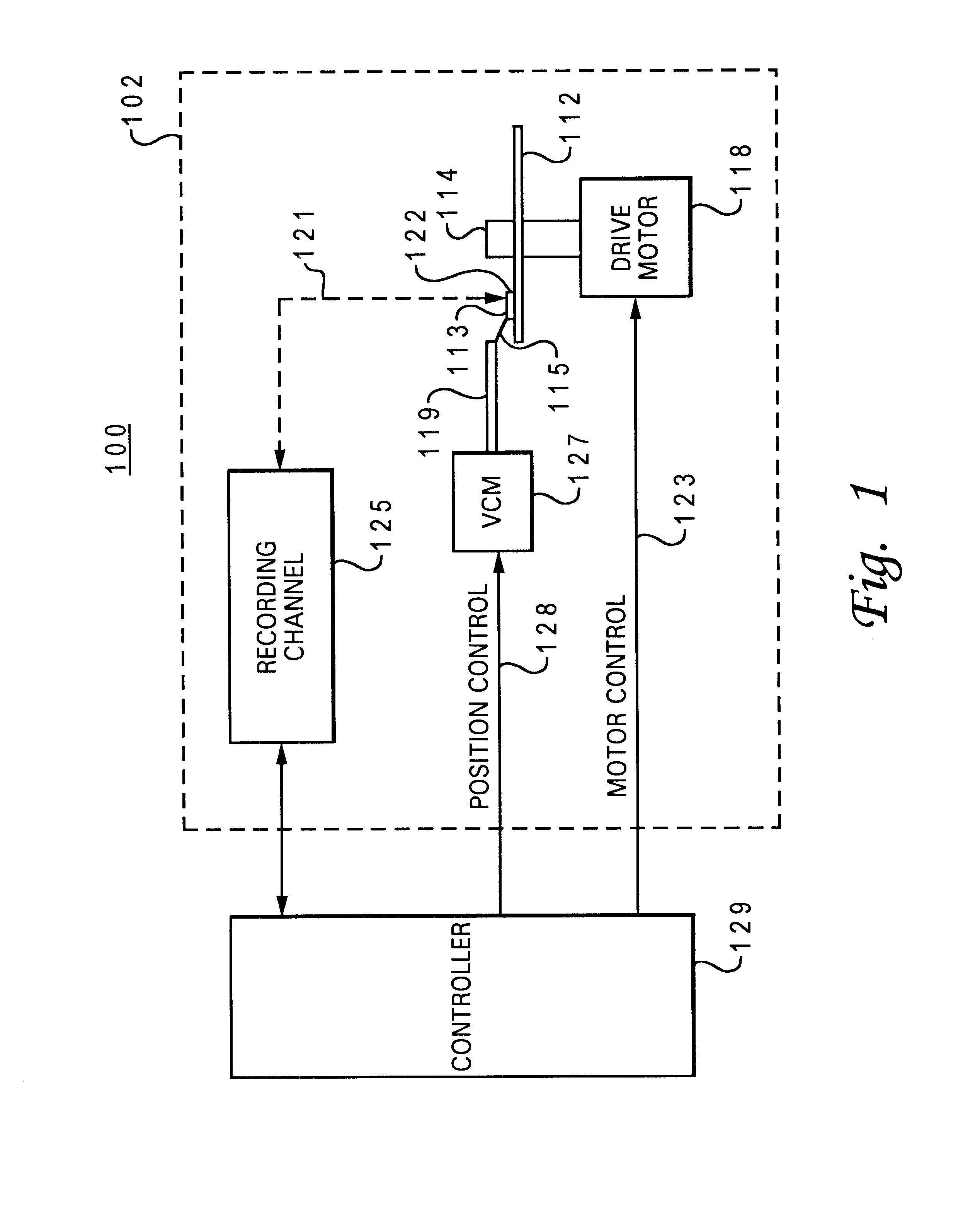

InactiveUS6415189B1Not easy to failAvoid data lossVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesData processing systemHard disc drive

A method and system within a data processing system for predicting failure of a hard disk drive having a fluid bearing during runtime operation of said hard disk drive, wherein said fluid bearing has an established signature dynamic fluid response. First, a runtime vibration level of the fluid bearing is measured. This runtime vibration level is then translated into a runtime dynamic fluid response which provides an indication of the operating condition of the fluid bearing. The runtime dynamic fluid response is compared with the baseline dynamic fluid response in real-time during operation of the hard disk drive. Finally, in response to a predetermined departure of the runtime dynamic fluid response from the baseline dynamic fluid response, a protective response is initiated, such that data loss within the data storage system due to fluid bearing failure is prevented.

Owner:WESTERN DIGITAL TECH INC

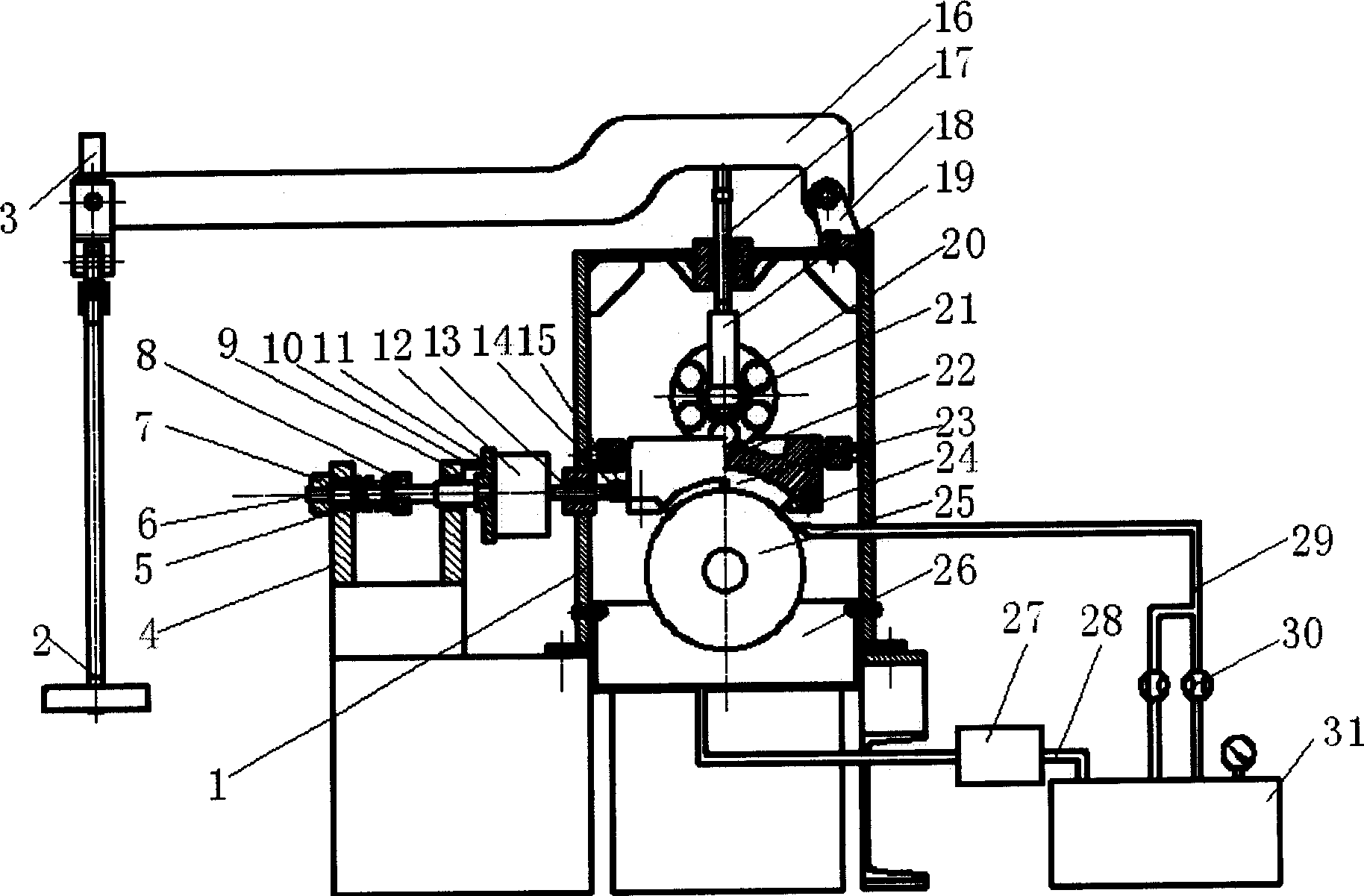

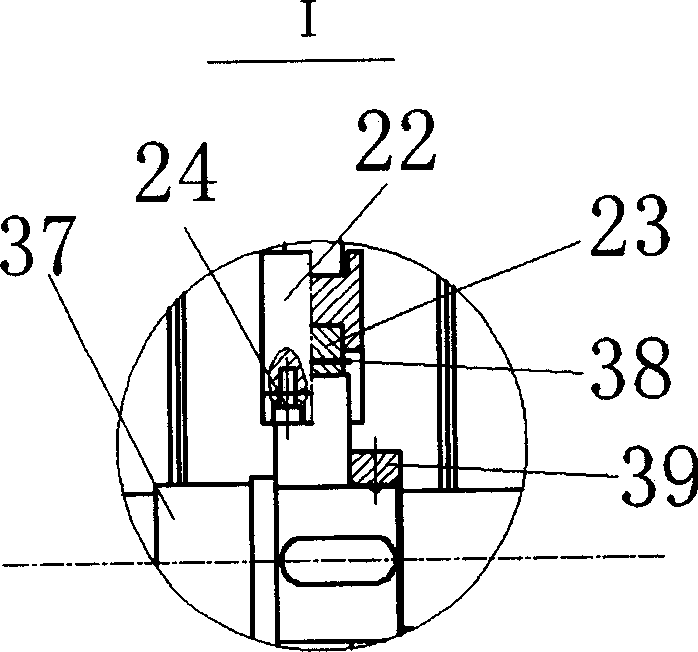

On-line measuring and testing machine for radial sliding bearing friction and wearing

InactiveCN1828264AProtection of transient contact surface statesMachine bearings testingUsing mechanical meansTested timeEngineering

The tester comprises: a clamp (22) to fix the upper sample (23) on its arc groove above the lower sample (25) connected to the middle of supporting shaft (37) by a flat key, a oil bath (26) to accommodate part (25), and a pressure bearing (20) with outside circle contacted to the upper arc surface of (22). This invention can protect the failure condition, and cuts wear test time.

Owner:YANSHAN UNIV

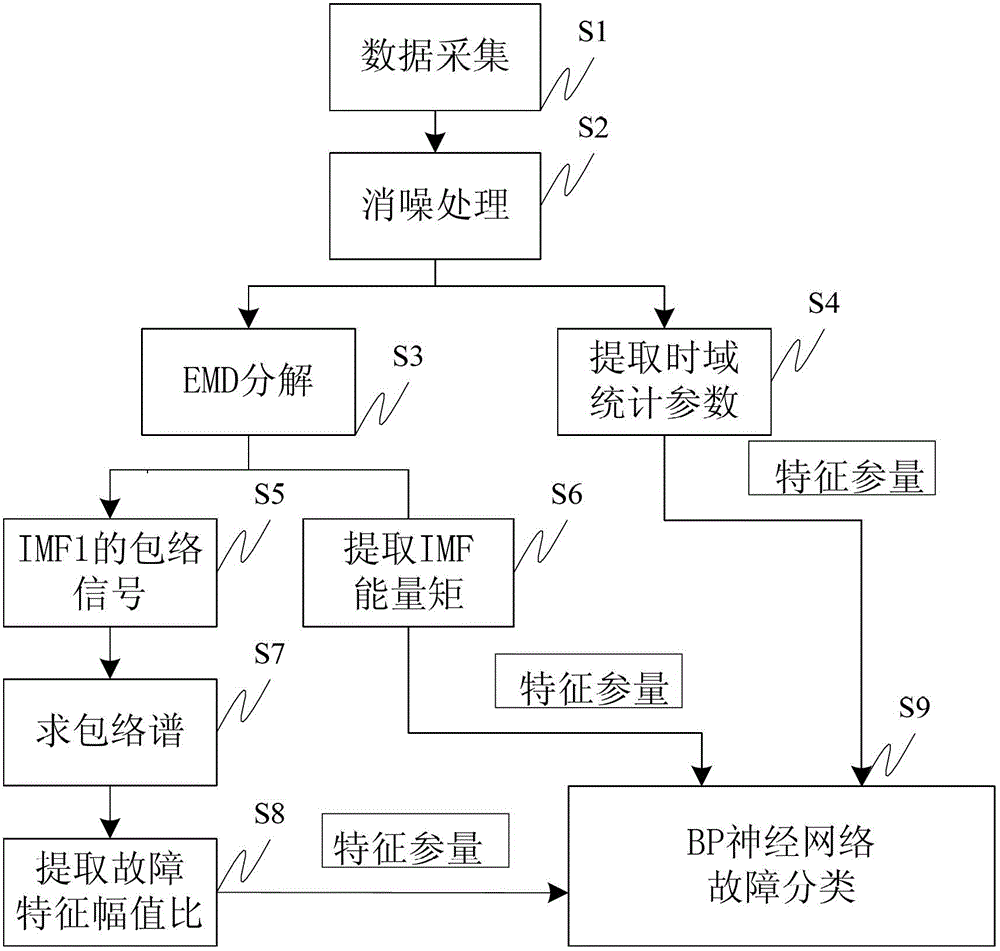

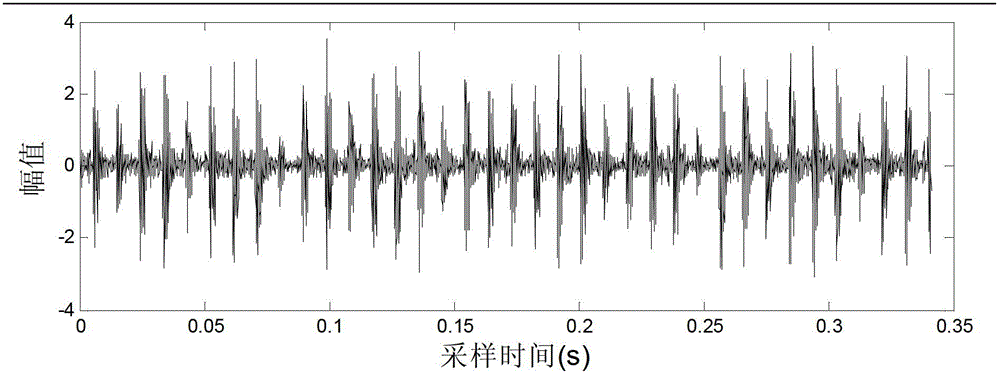

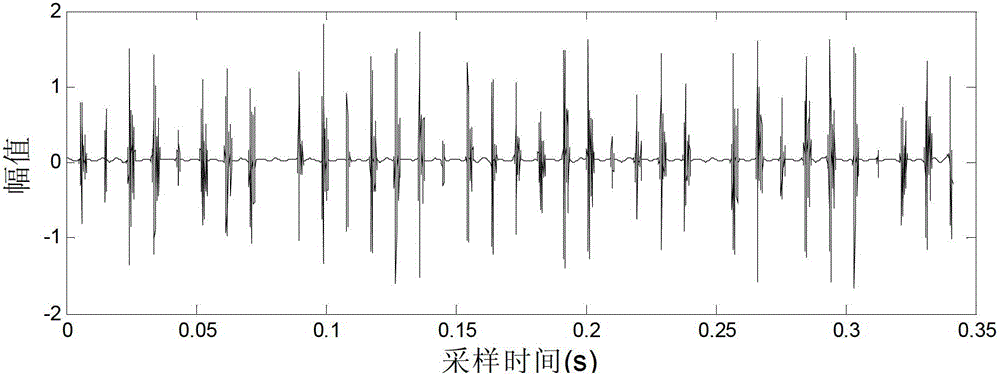

Rolling bearing failure diagnostic method based on multi-characteristic parameter

ActiveCN102721545AReflect work statusImprove diagnostic accuracyMachine bearings testingBiological neural network modelsTime domainVibration source

The invention discloses a rolling bearing failure diagnostic method based on a multi-characteristic parameter, which comprises the following steps of: (1) pre-processing the collected vibrating signals, and removing the interference of the noise and other vibrating sources; (2) extracting a time domain statistical parameter capable of reflecting different working conditions of the rolling bearing from the vibrating signals; (3) figuring out the envelope signal of the pre-processed vibrating signals, decomposing the envelope signal through an improved empirical mode decomposition method to obtain a series of intrinsic mode functions; (4) selecting multiple intrinsic mode functions concentrating most part of energy, and calculating an energy torque; (5) performing envelope spectrum analysis on the first decomposed intrinsic mode function, and calculating the failure characteristic amplitude ratio; and (6) serving a plurality of characteristic parameters extracted in the step as input vector of a BP neural network, and outputting the diagnosis result through the network. The rolling bearing failure diagnostic method disclosed by the invention can fully reflect the operation condition of the rolling bearing, improve the diagnosis accuracy and facilitate realization of the online monitoring of the rolling bearing.

Owner:BEIJING JIAOTONG UNIV

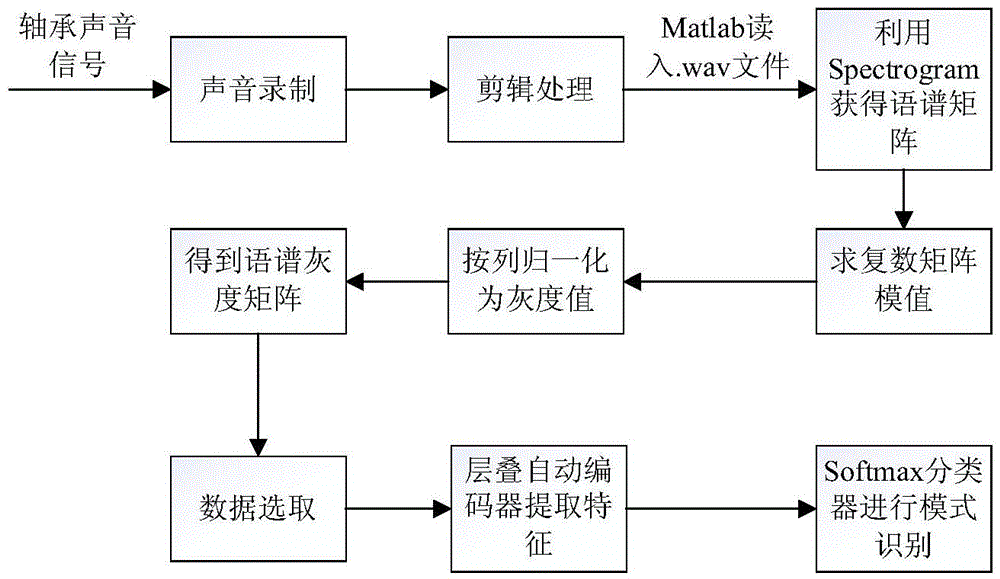

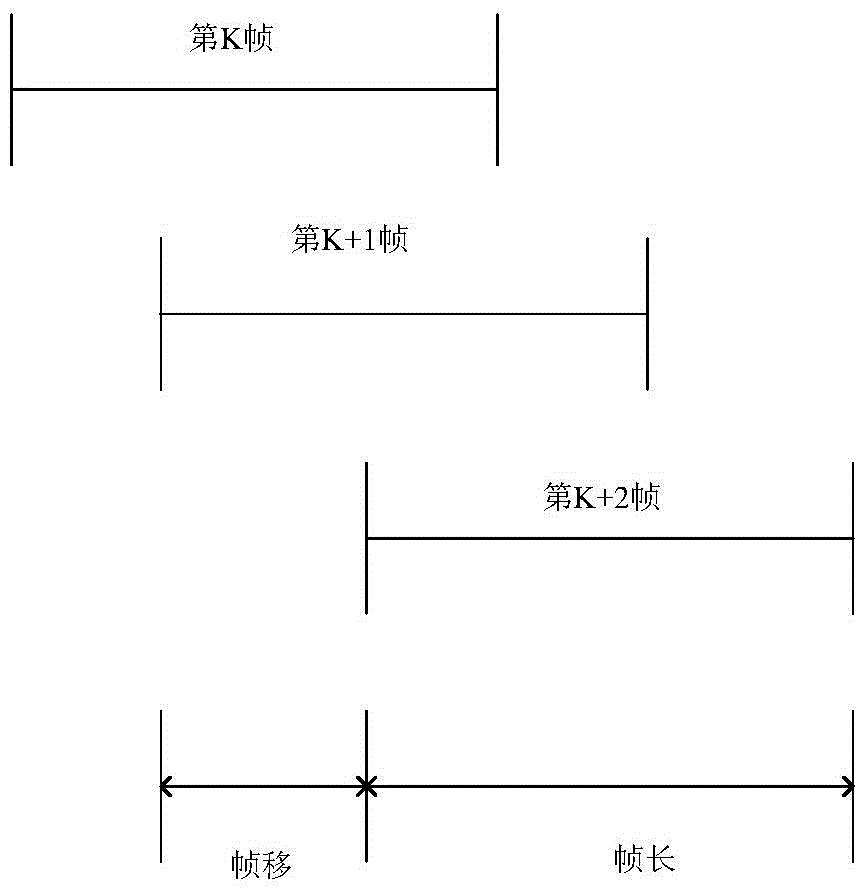

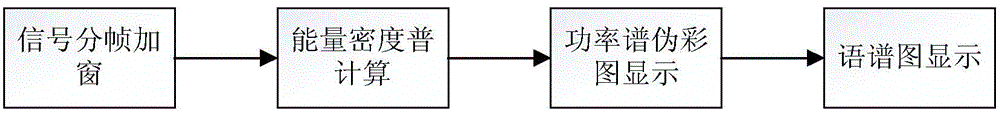

Rolling bearing sound signal fault diagnosis method based on short-time Fourier transform and sparse laminated automatic encoder

InactiveCN104819846AEasy to digFeature Effectively ImplementedMachine bearings testingFast Fourier transformFourier analysis

The invention discloses a rolling bearing sound signal fault diagnosis method based on short-time Fourier transform and a sparse laminated automatic encoder. According to the method of the invention, firstly a smart mobile phone is used for acquiring a sound signal of the rolling bearing fault; then short-time Fourier analysis is performed on the sound signal for obtaining a spectrogram matrix; then the modulus value of the matrix is acquired and gray scale normalization processing is performed; then the normalized data are selected and input into a deep studying network for automatically extracting characteristics; and finally the characteristic which is extracted by a neural net is input into a Softmax classifier for identifying the fault mode. The invention provides the rolling bearing sound signal fault diagnosis method based on smart mobile phone sound signal short-time Fourier transform (STFT) and the sparse laminated automatic encoder (SAE). Through testing result analysis, the rolling bearing sound signal fault diagnosis method can accurately determine the fault mode of the rolling bearing.

Owner:BEIHANG UNIV

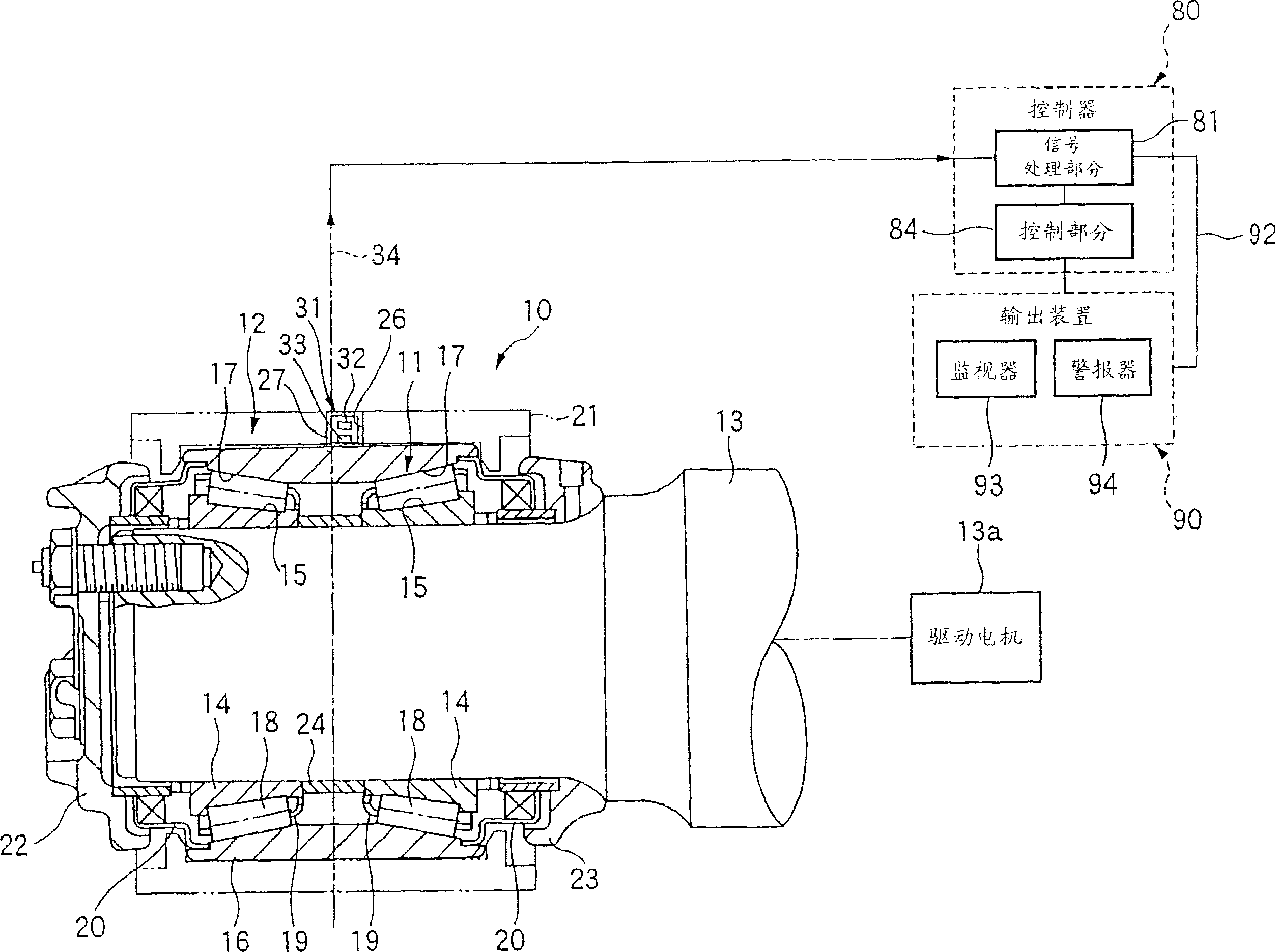

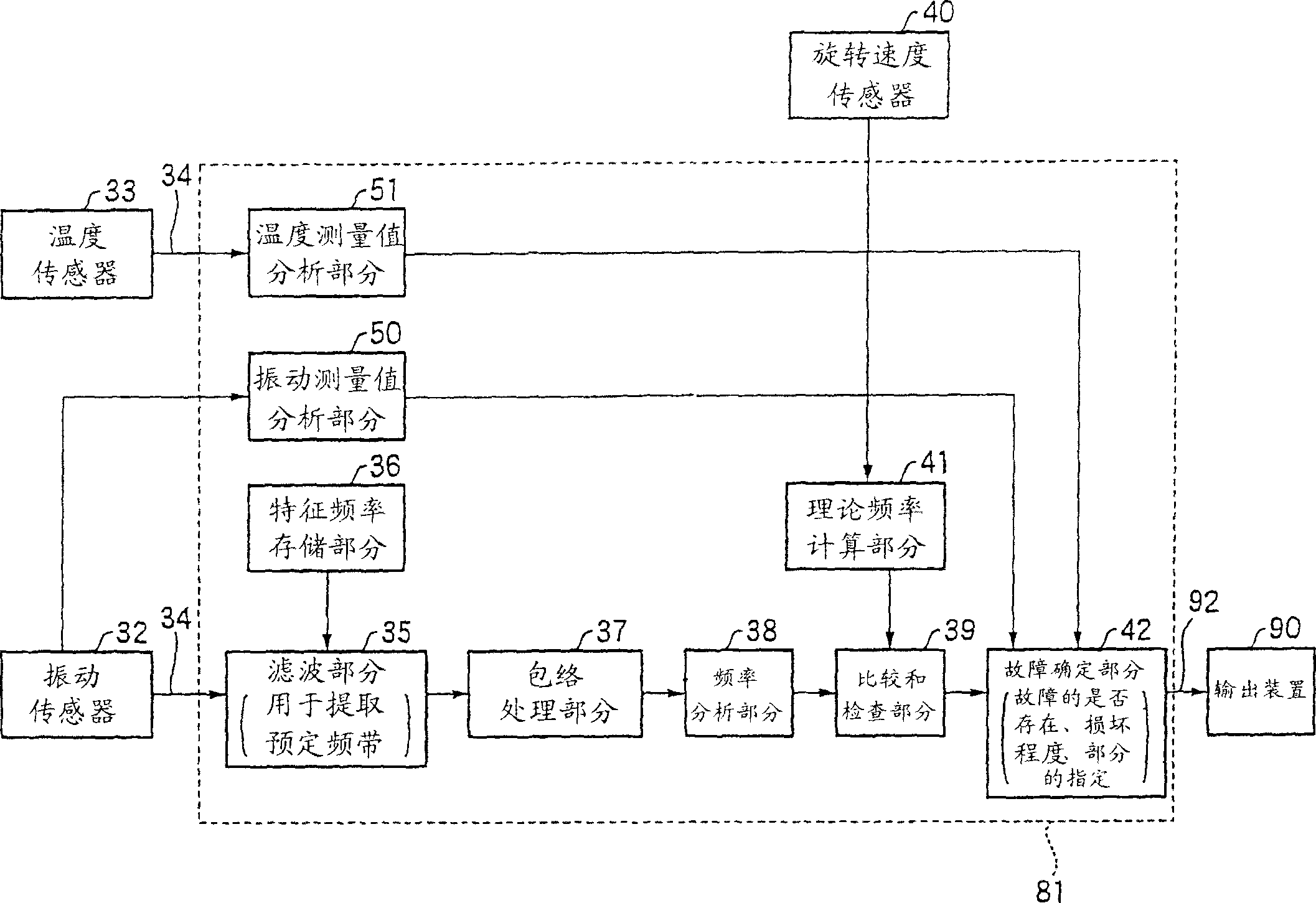

Abnormality diagnosis device and abnormality diagnosis method

InactiveCN1906473AImprove reliabilityEffective maintenanceRolling contact bearingsSubsonic/sonic/ultrasonic wave measurementDiagnosis methodsBiomedical engineering

An abnormality diagnosis device used for a machine apparatus having a part rotating and sliding relative to a stationary member is provided with a detection section (31) and a signal processing section (81). The detection section (31) is fixed to the part rotating or sliding or to the stationary member and has a vibration sensor (32) and a temperature sensor (33). The signal processing section (81) determines the condition of the part based on a signal detected and outputted by the detection section (31). The signal processing section (81) determines whether there is an abnormality in the part, or whether there is an abnormality in the part and the degree of damage of the part.

Owner:NSK LTD

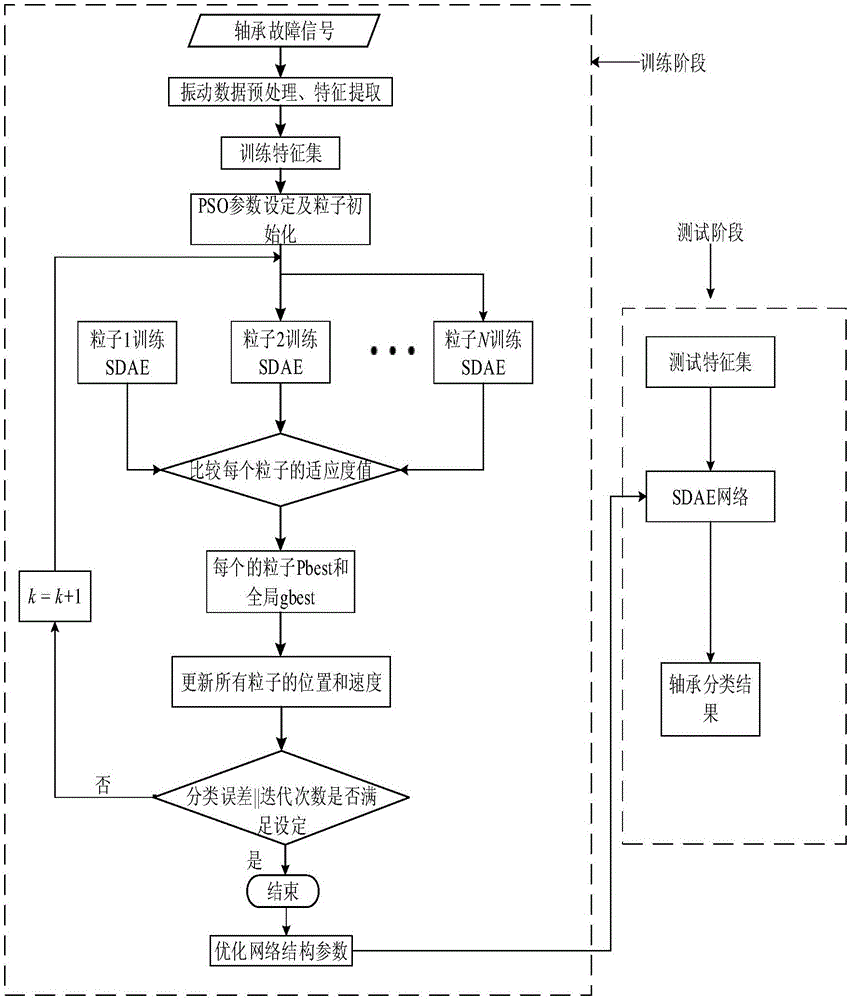

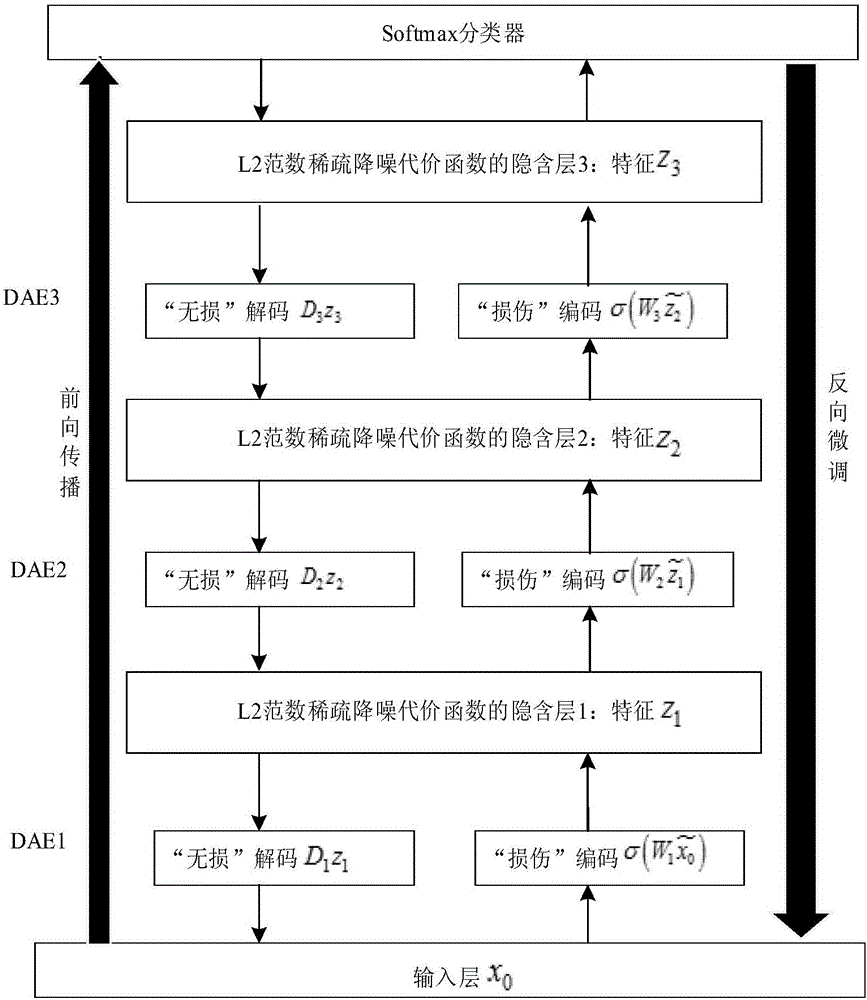

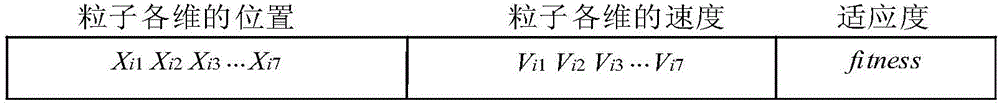

Pile-up noise reduction own coding network bearing fault diagnosis method based on particle swarm optimization

ActiveCN106682688ARobustGood feature learning abilityMachine bearings testingCharacter and pattern recognitionHidden layerDiagnosis methods

The invention discloses a pile-up noise reduction own coding network bearing fault diagnosis method based on particle swarm optimization. The bearing fault diagnosis method provides an improved pile-up noise reduction own coding network SADE bearing fault diagnosis method, SDAE network hyper-parameters, such as cyber hidden layer nodes, sparse parameters, input data random zero setting ratio, are selected adaptively by particle swarm optimization PSO, a SADE network structure is determined, top character representation of malfunction inputting a soft-max classifier is obtained and a classification of defects is discerned. The bearing fault diagnosis method has better feature in learning capacity and more robustness than feature of learning of ordinary sparse own coding device, and builds a SDAE diagnostic model having multi-hidden layer by optimizing the hyper-parameters of noise reduction own coding network deepness network structure with the particle swarm optimization, accuracy of the classification of defects is improved at last.

Owner:SOUTH CHINA UNIV OF TECH

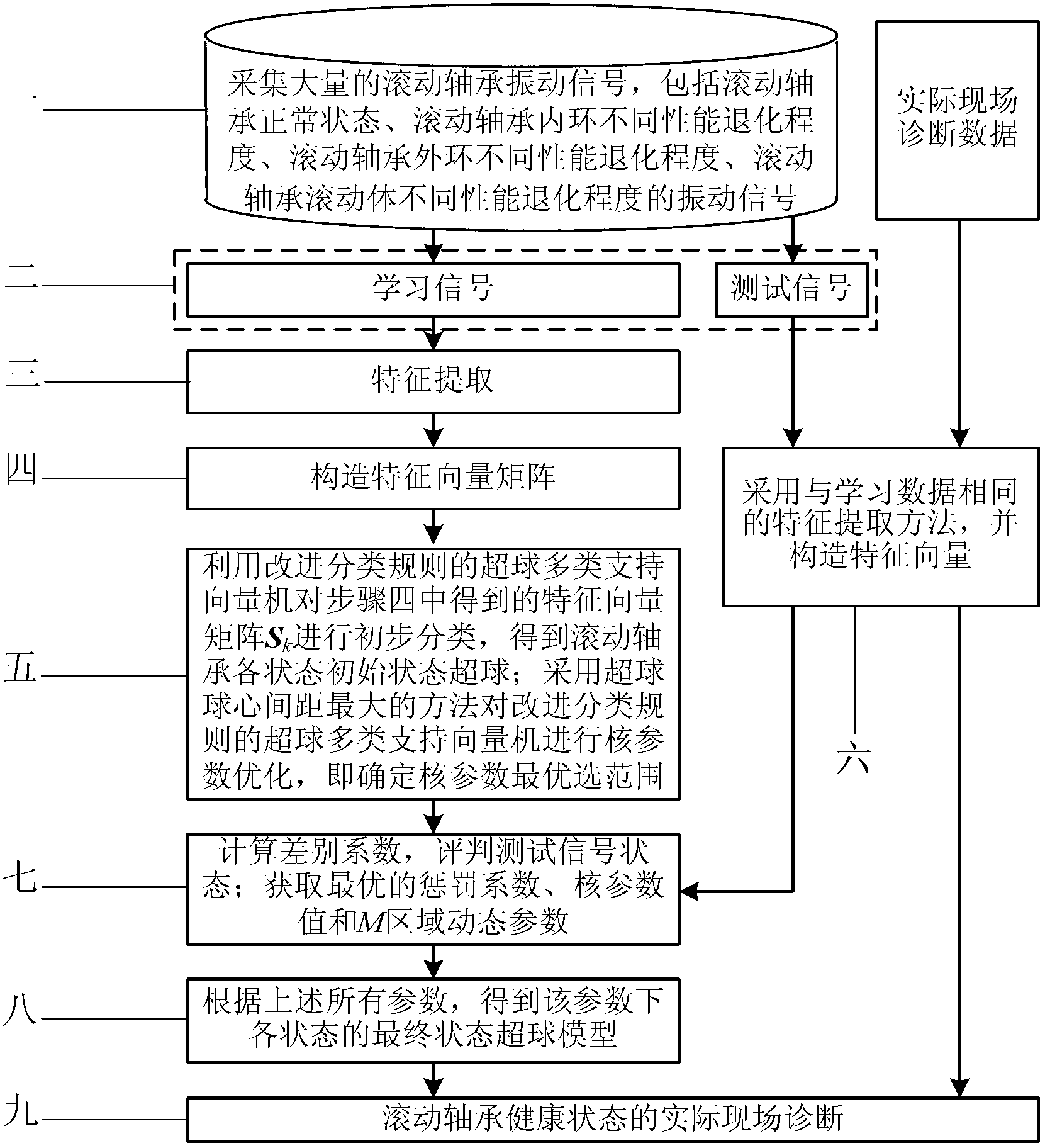

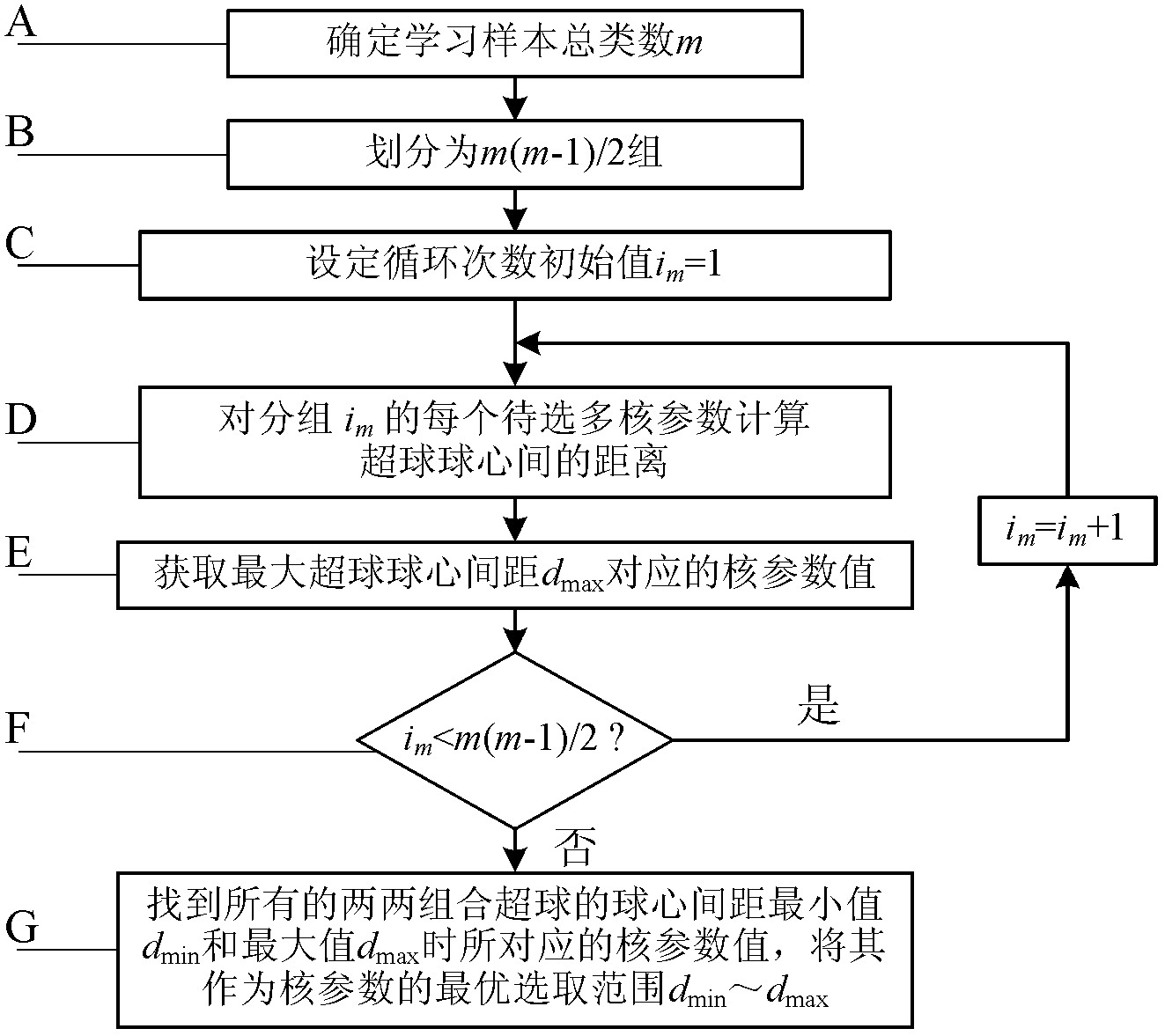

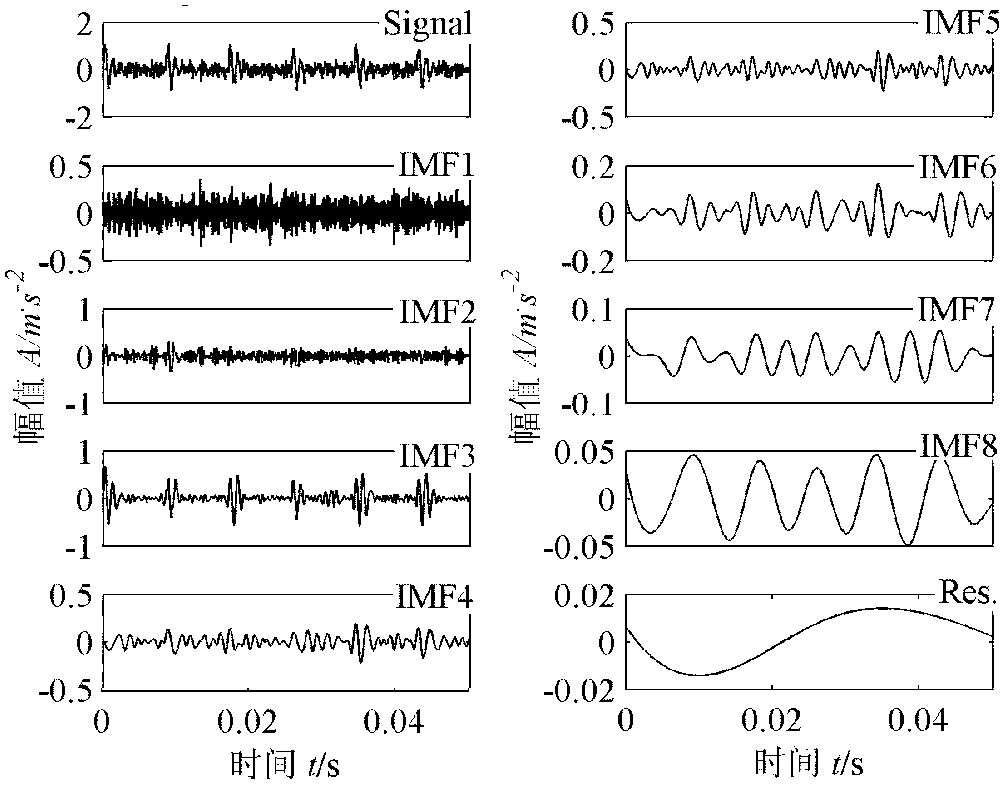

Diagnosis method for fault position and performance degradation degree of rolling bearing

InactiveCN102854015AOptimization determination methodReduce consumptionMachine bearings testingSingular value decompositionSupport vector machine

The invention discloses a diagnosis method for the fault position and the performance degradation degree of a rolling bearing, belonging to the technical field of fault diagnosis for bearings, and solving the problems of low accuracy of diagnosis for fault position and performance degradation degree, and high time consumption of training existing in an intelligent diagnosis method for a rolling bearing in the prior art. A white noise criterion is added in the disclosed integrated empirical mode decomposition method, so that artificial determination for decomposition parameters can be avoided, and the decomposition efficiency can be increased; and via the disclosed nuclear parameter optimization method based on a hypersphere centre distance, the small and effective search region of nuclear parameters in a multi-classification condition can be determined, so that training time is reduced, and the final state hypersphere model of a classifier is given. The intelligent diagnosis method based on parameter-optimized integrated empirical mode decomposition and singular value decomposition, and combined with a nuclear parameter-optimized hypersphere multi-class support vector machine based on the hypersphere centre distance is higher in identification rate compared with the existing diagnosis method. The diagnosis method disclosed by the invention is mainly applied to intelligent diagnosis on the fault position and the performance degradation degree of the rolling bearing.

Owner:HARBIN UNIV OF SCI & TECH

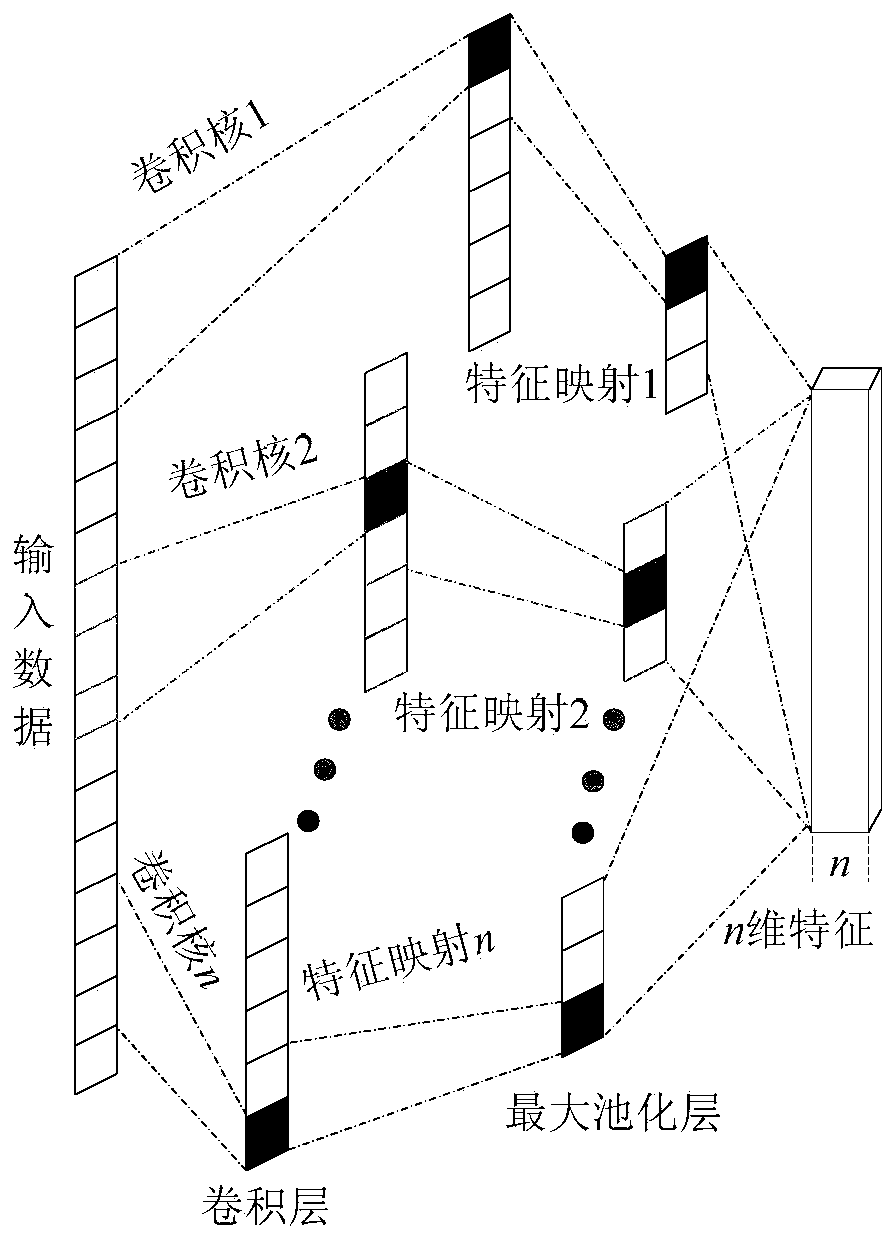

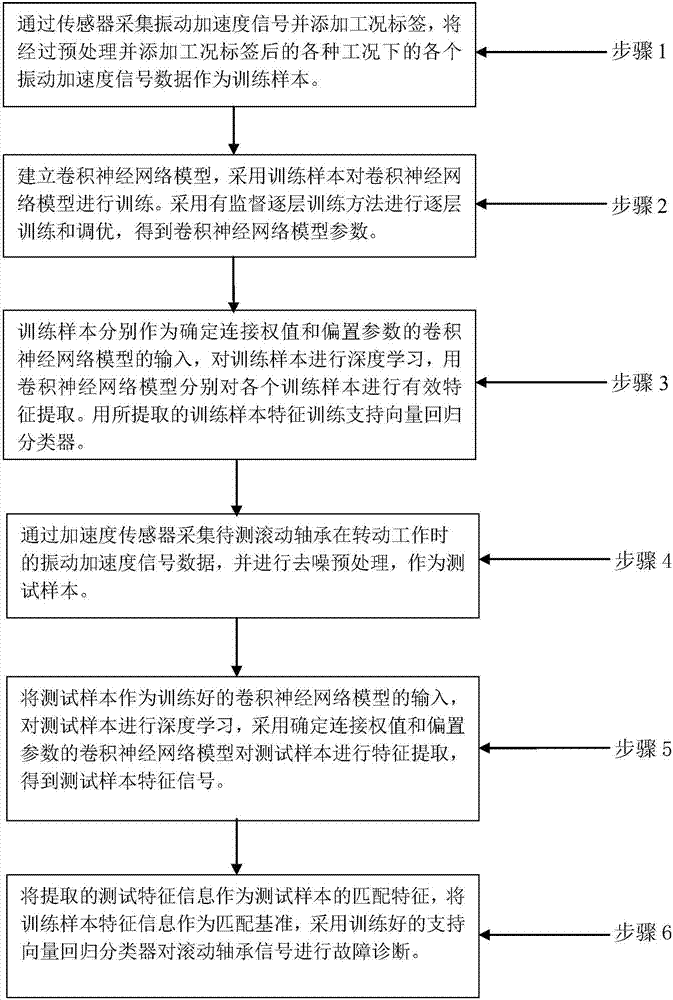

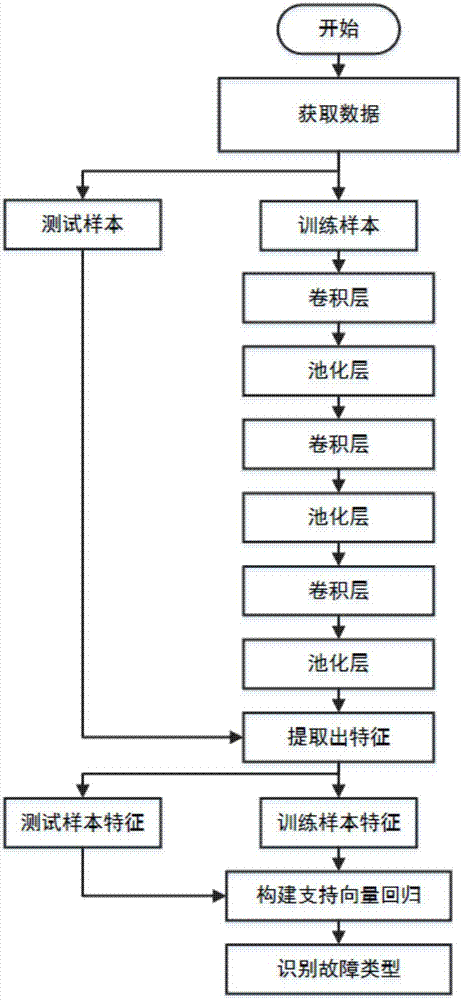

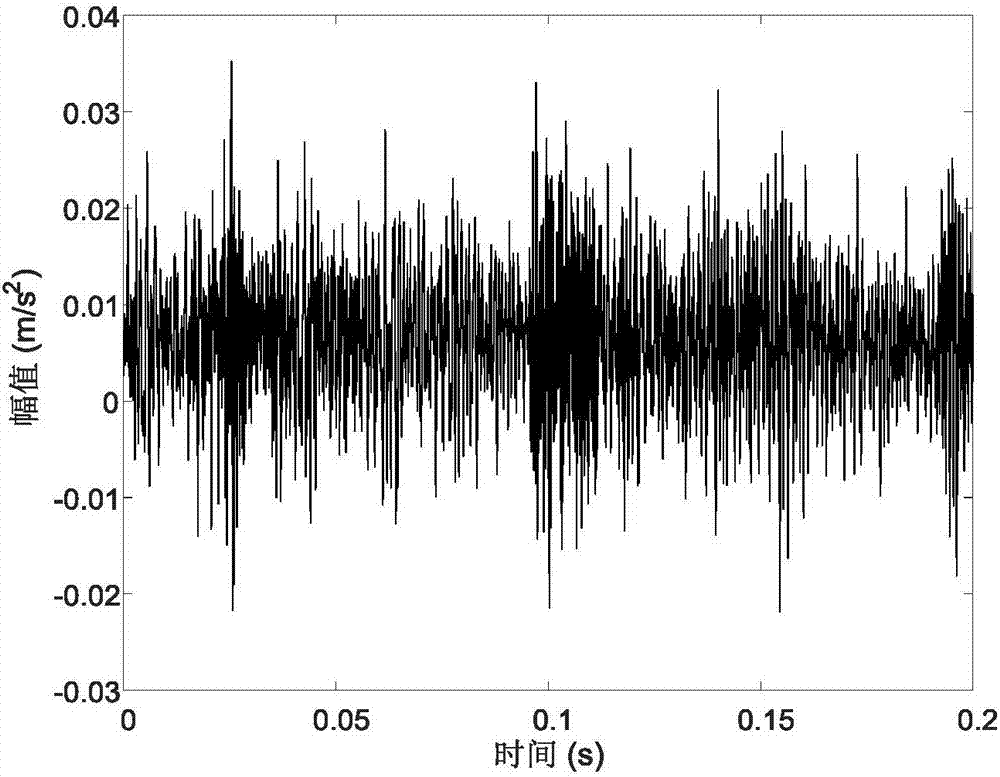

Rolling bearing fault diagnosis method

InactiveCN106874957AGet rid of dependenceSave labor timeMachine bearings testingCharacter and pattern recognitionAviationChemical industry

The invention relates to a rolling bearing fault diagnosis method. The method uses a learning algorithm of a CNN (Convolutional Neural Network) theory to complete a feature extraction task needed by fault diagnosis, and does not rely one manual selection, intrinsic features of input data are extracted automatically from simple to complex and from low-level to high-level, and abundant information hidden in known data can be dug out automatically; and a support vector regression method is used to identity a test sample in a classifying manner, support vector regression with a high generalization capability can be used to identity an unknown new sample in higher precision, and the disadvantage that a default classifier of deep learning tends to be low in the generalization capability can be overcome when support vector regression serves as a classifier to identify samples in the classified manner. The rolling bearing fault diagnosis accuracy and validity can be improved, a new effective approach is provided for solving problems in rolling bearing fault diagnosis, and the method of the invention can be widely applied to fault analysis of complex mechanical systems in the fields of chemical industry, metallurgy, electric power, aviation and the like.

Owner:SUZHOU UNIV

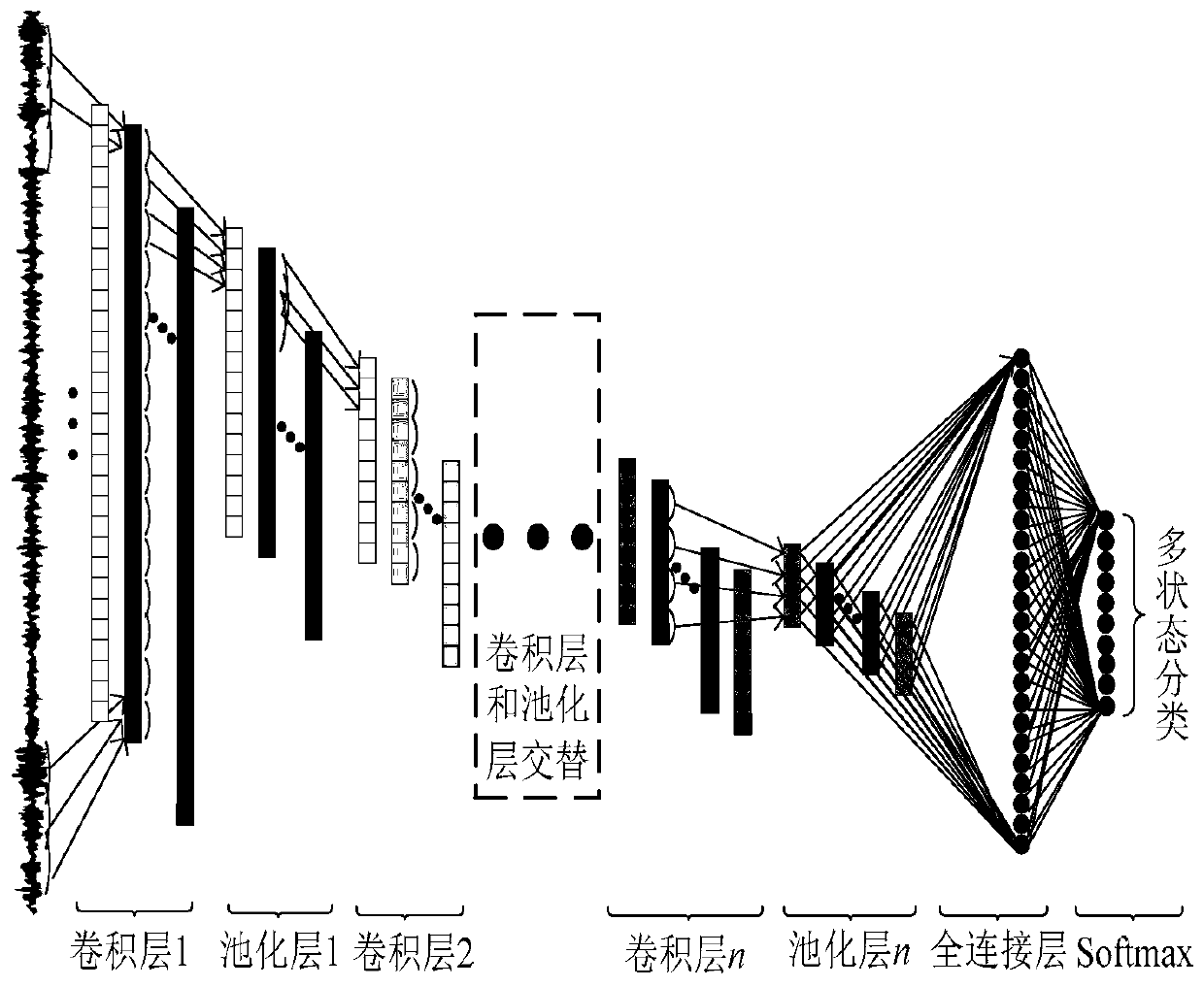

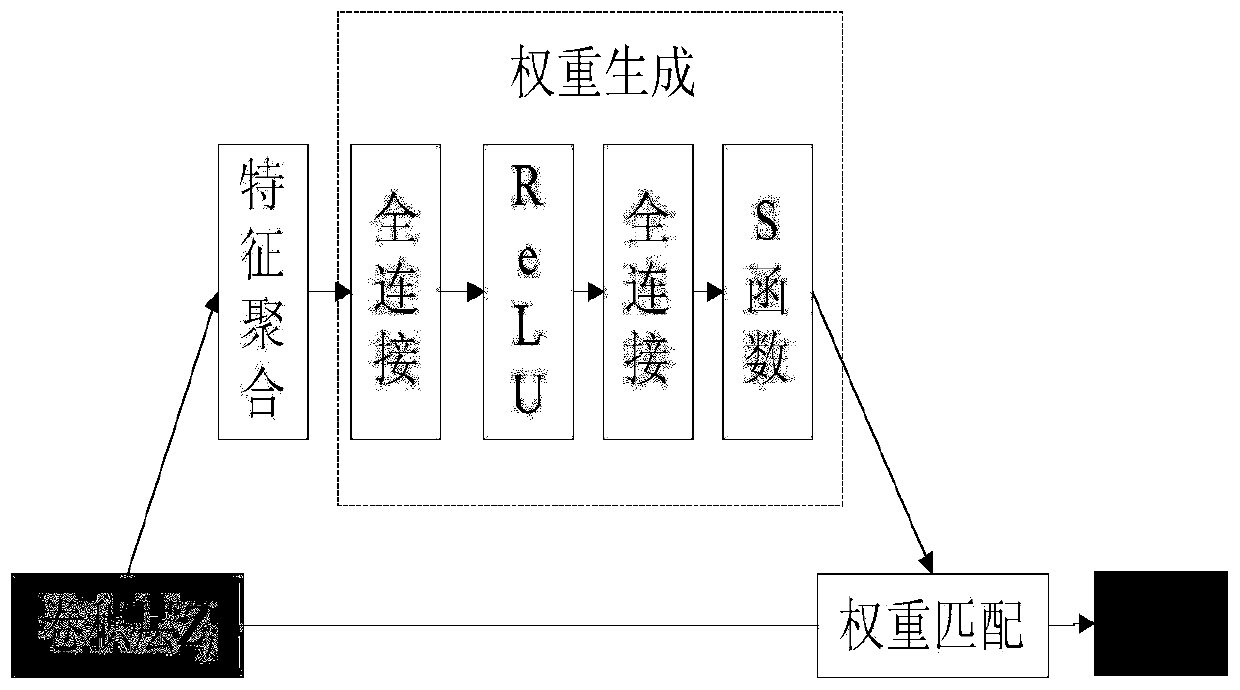

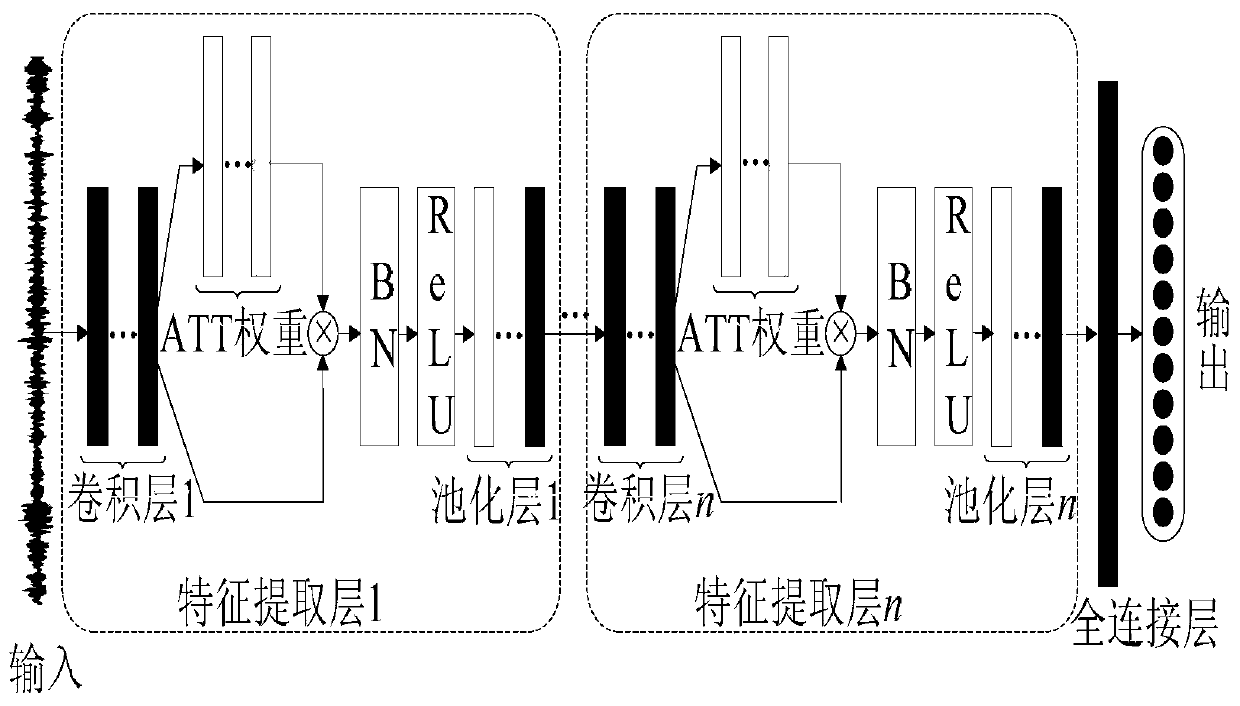

A rolling bearing fault identification method under variable working conditions based on ATT-CNN

ActiveCN109902399ASolve the fault identification problemIncreased sensitivityMachine bearings testingNeural architecturesAlgorithmBearing vibration

The invention discloses a rolling bearing fault identification method under variable working conditions based on ATT-CNN, and relates to a rolling bearing fault identification technology. The problemthat the generalization ability of an existing rolling bearing fault recognition method under variable working conditions is limited to a certain extent for a complex classification problem is solved.The method comprises the following steps: firstly, mapping vibration data to a nonlinear space domain through a convolutional neural network (CNN), and adaptively extracting rolling bearing fault characteristics under variable working conditions by utilizing the characteristic that the CNN has invariance on micro displacement, scaling and other distortion forms of an input signal; Secondly, an attention mechanism (ATT) thought is put forward to be fused into a CNN structure, and the sensitivity of bearing vibration characteristics under variable working conditions is further improved; And meanwhile, more abundant and diverse training samples are obtained through a data enhancement method, so that the network can be learned more fully, and the robustness is improved. The proposed fault diagnosis model based on the attention mechanism CNN (ATT-CNN) can realize multi-state recognition and classification of the rolling bearing under variable working conditions, and compared with other methods, higher accuracy can be obtained.

Owner:HARBIN UNIV OF SCI & TECH

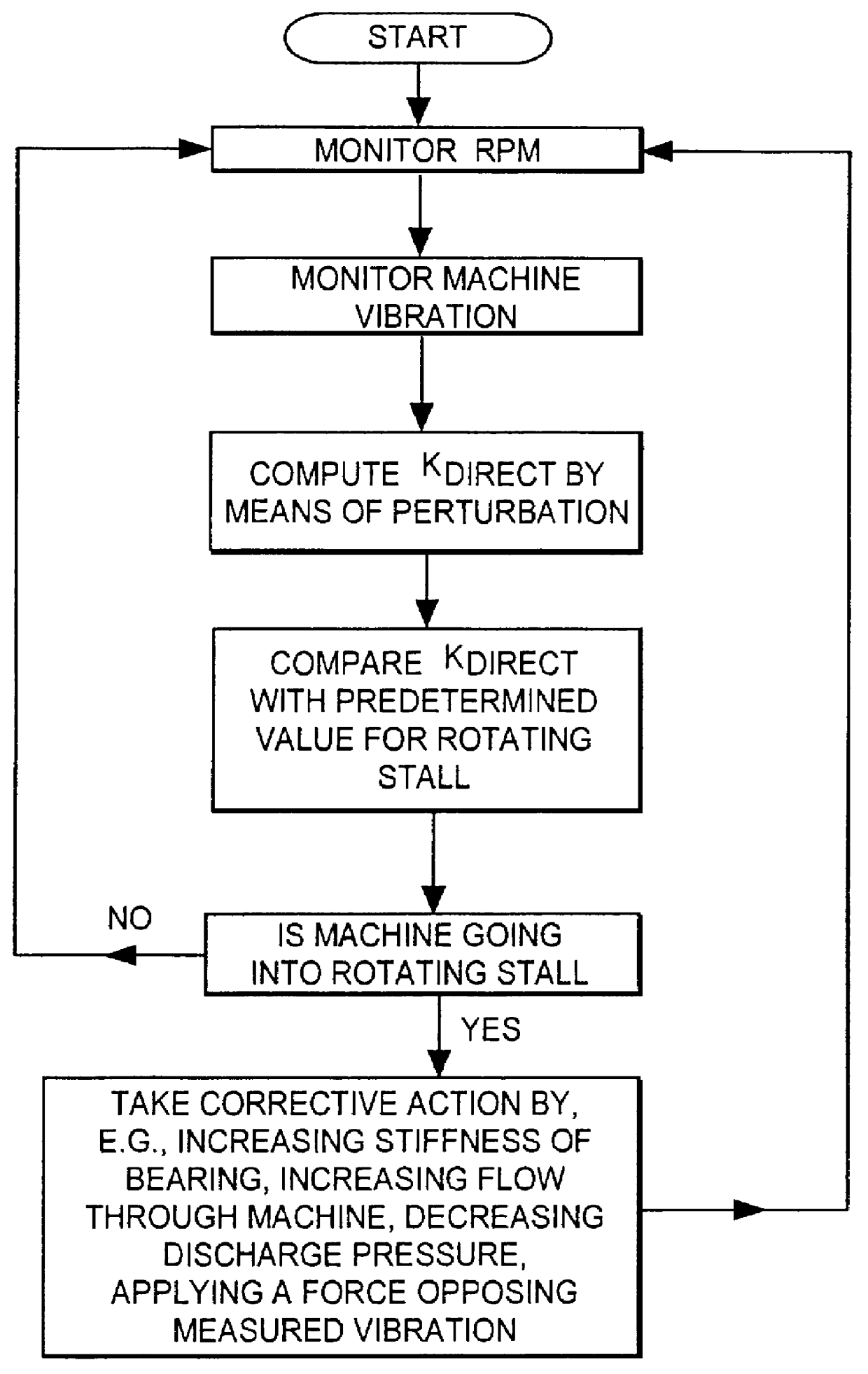

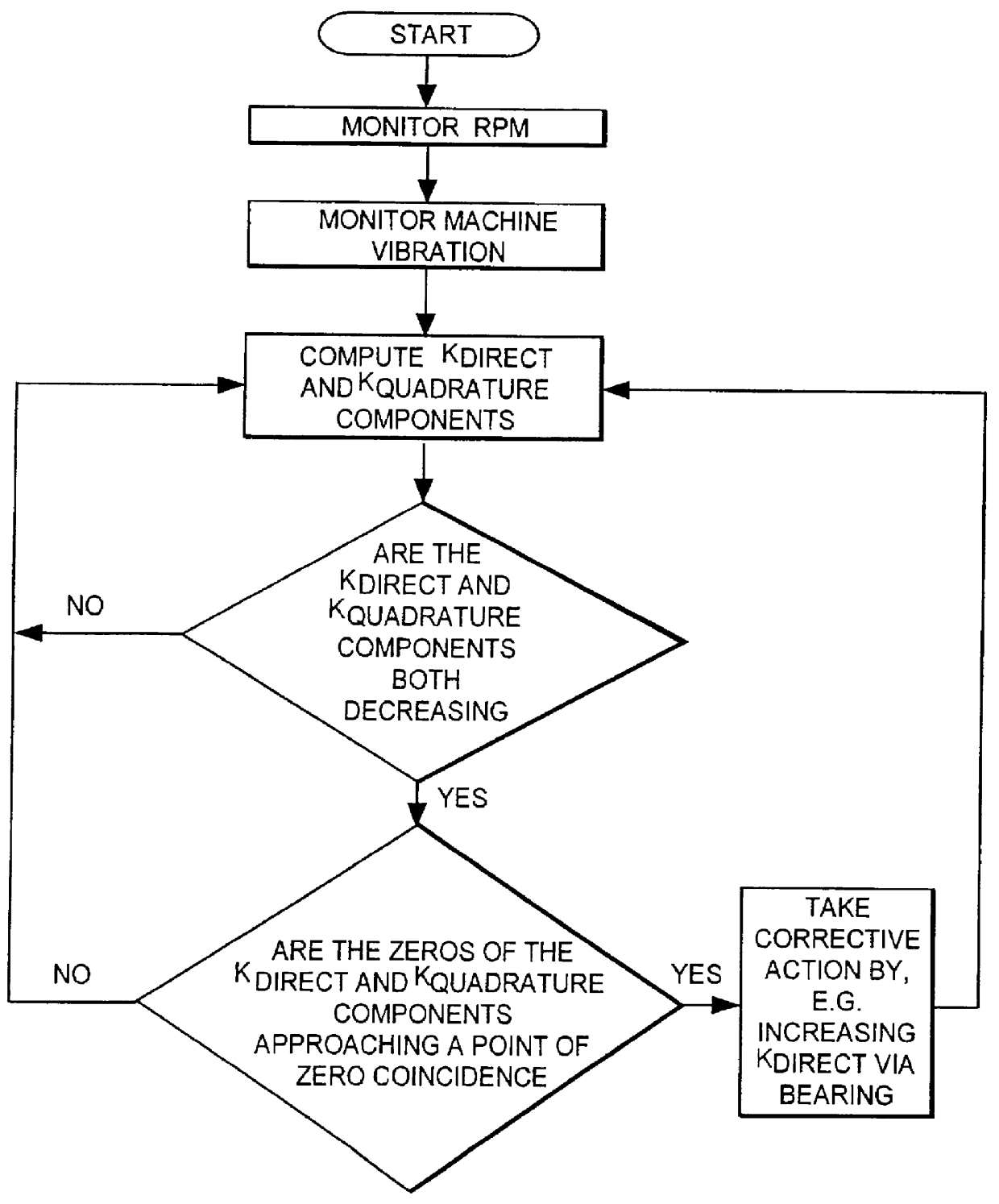

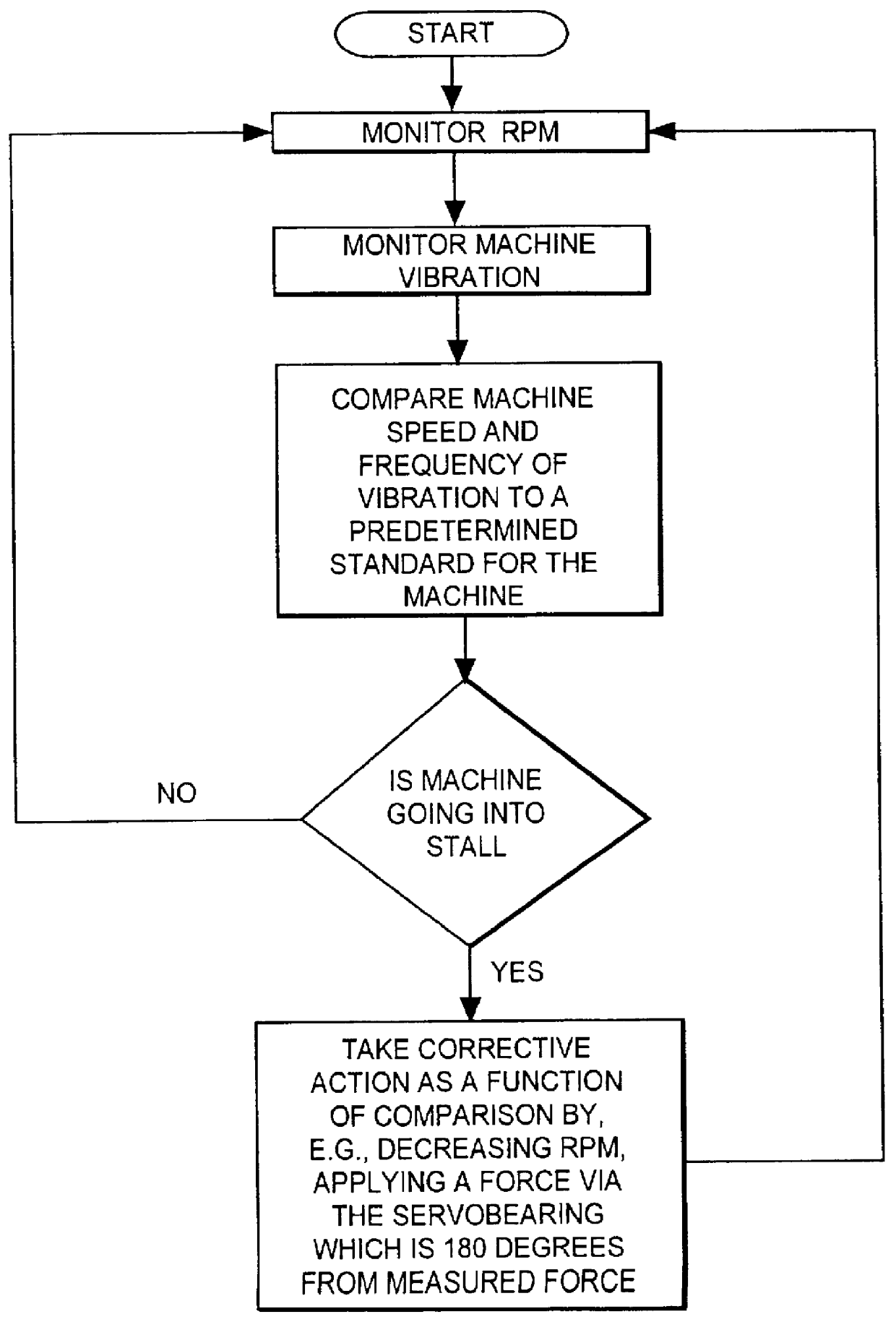

Method and apparatus for diagnosing and controlling rotating stall and surge in rotating machinery

InactiveUS6092029AProtection from damageMachine bearings testingFlow propertiesDynamic stiffnessPrecession

A method and apparatus is provided for diagnosing and correcting rotating stall and surge in rotating machines by monitoring dynamic shaft precession and comparing this precession with a standard and altering the precession as the machine approaches a destabilizing condition when indicated by the comparison step. Axial vibration monitoring means is also provided for monitoring and comparing a dynamic axial vibration of the machine with a standard and altering the axial vibration as the machine approaches a destabilizing condition. Furthermore, the instant invention measures the complex dynamic stiffness of the machine and computes the direct dynamic stiffness and the quadrature dynamic stiffness for use as a destabilizing warning device by monitoring for a drop in direct dynamic stiffness and / or a coincidence of zero crossing of both the direct dynamic stiffness and the quadrature dynamic stiffness components. One embodiment for altering the rotating stall and / or surge is by a controlled active servobearing.

Owner:BENTLY NEVADA CORP

Bearing fault diagnosis method based on fuzzy support vector machine

InactiveCN104502103AMachine bearings testingSpecial data processing applicationsFrequency spectrumClassification methods

The invention discloses a bearing fault diagnosis method based on a fuzzy support vector machine. Three faults, namely an inner ring single-point fault, an outer ring single-point fault and a ball single-point fault, are taken for example, and fault feature extraction, including demodulation on a time domain feature parameter and a vibration signal by Hilber transformation, is carried out by combining normal operation of a bearing; a demodulated signal is subjected to spectral analysis so as to find a frequency domain fault feature frequency. These feature parameters form a training sample and a test sample; a fuzzy membership degree is added into the training sample by a fuzzy C means clustering algorithm, and the fault judgment is carried out by a support vector machine multi-classification method. A fault diagnosis example analysis part displays the bearing fault diagnosis correctness of a constructed FSVM (fuzzy support vector machine) model, so that high classification performance and high noise resistance are achieved, and a theoretical method is provided in order to avoid accidents, economical loss and the like which are caused by the bearing fault; the bearing fault diagnosis method has important reference value.

Owner:BEIJING UNIV OF TECH

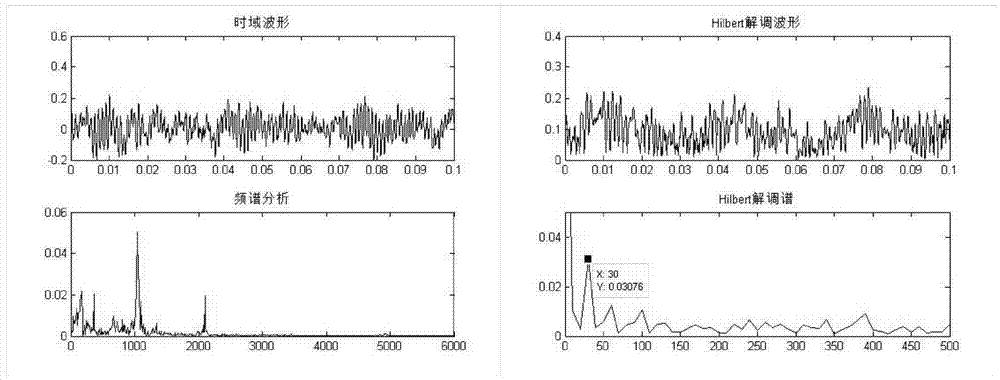

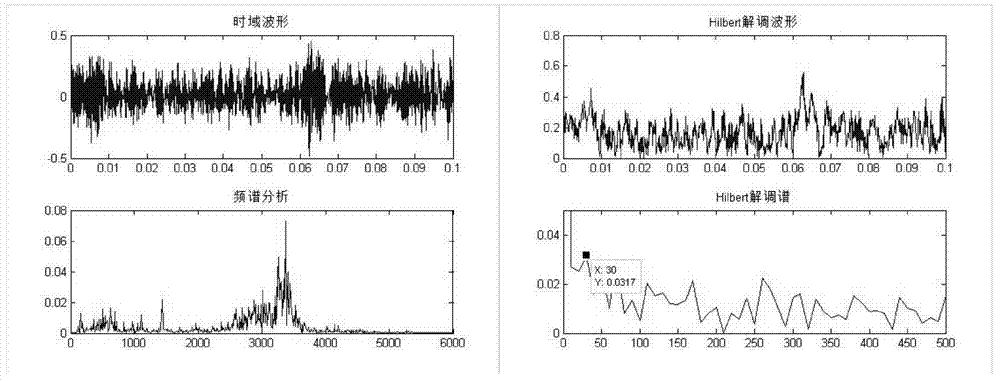

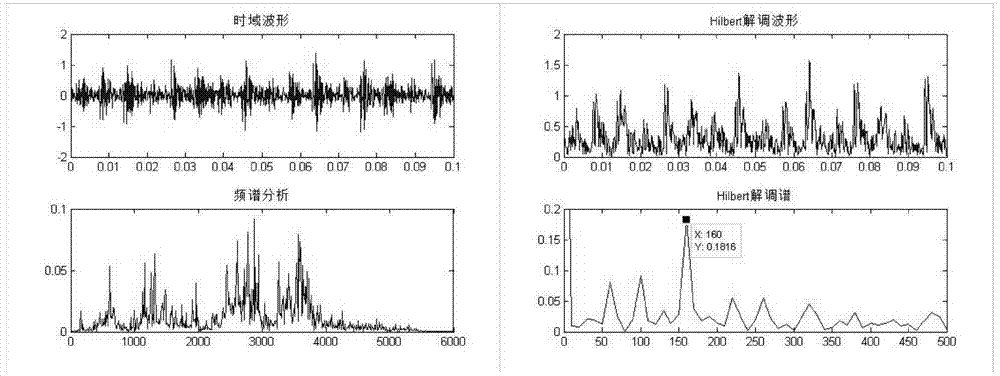

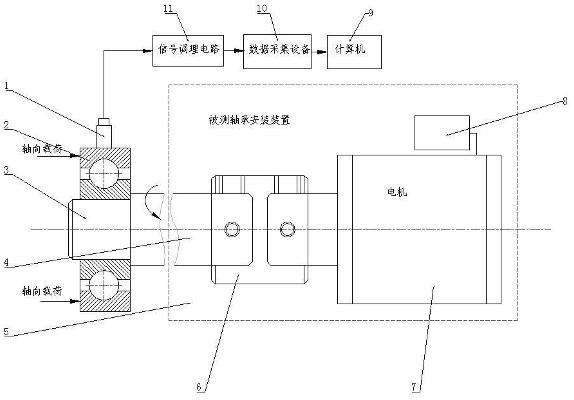

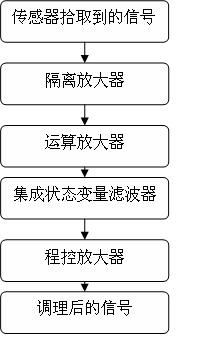

Device and method for vibration measurement and failure analysis of rolling bearing

InactiveCN102183366AAccurate measurementImprove anti-interference abilityVibration measurement in solidsMachine bearings testingVibration measurementSignal conditioning circuits

The invention relates to a device and method for vibration measurement and failure analysis of a rolling bearing. The device comprises a detected bearing mounting device, a speed sensor, a signal conditioning circuit, a data collection device and a computer, wherein a detected bearing is mounted on a mandrel of the detected bearing mounting device; a vibration rod of the speed sensor is arranged on a middle plane of an outer cylindrical surface of an outer ring of the detected bearing with prescribed pressure, the measurement direction is along the radial direction of the bearing and vertical to the axis of the bearing, and the signal conditioning circuit and the data collection device are connected to the computer; the speed sensor measures radial vibration speed signals of the outer ring of the bearing, the picked bearing radial vibration speed signals are converted into corresponding electric signals which are processed by the signal conditioning circuit and then transferred to the data collection device which carries out A / D conversion of the conditioned signals to convert the conditioned signals into digital signals capable of being processed by the computer, and finally the computer carries out analysis and processing of the digital signal. The device and the method are applicable to production test and user acceptance of finished bearings by laboratories and bearing manufacture factories.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com