Patents

Literature

721 results about "Failure mechanism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of “failure mechanism”. “Failure mechanisms are the physical, chemical, thermodynamic or other processes that result in failure. Failure mechanisms are categorized as either over-stress or wear-out mechanisms.

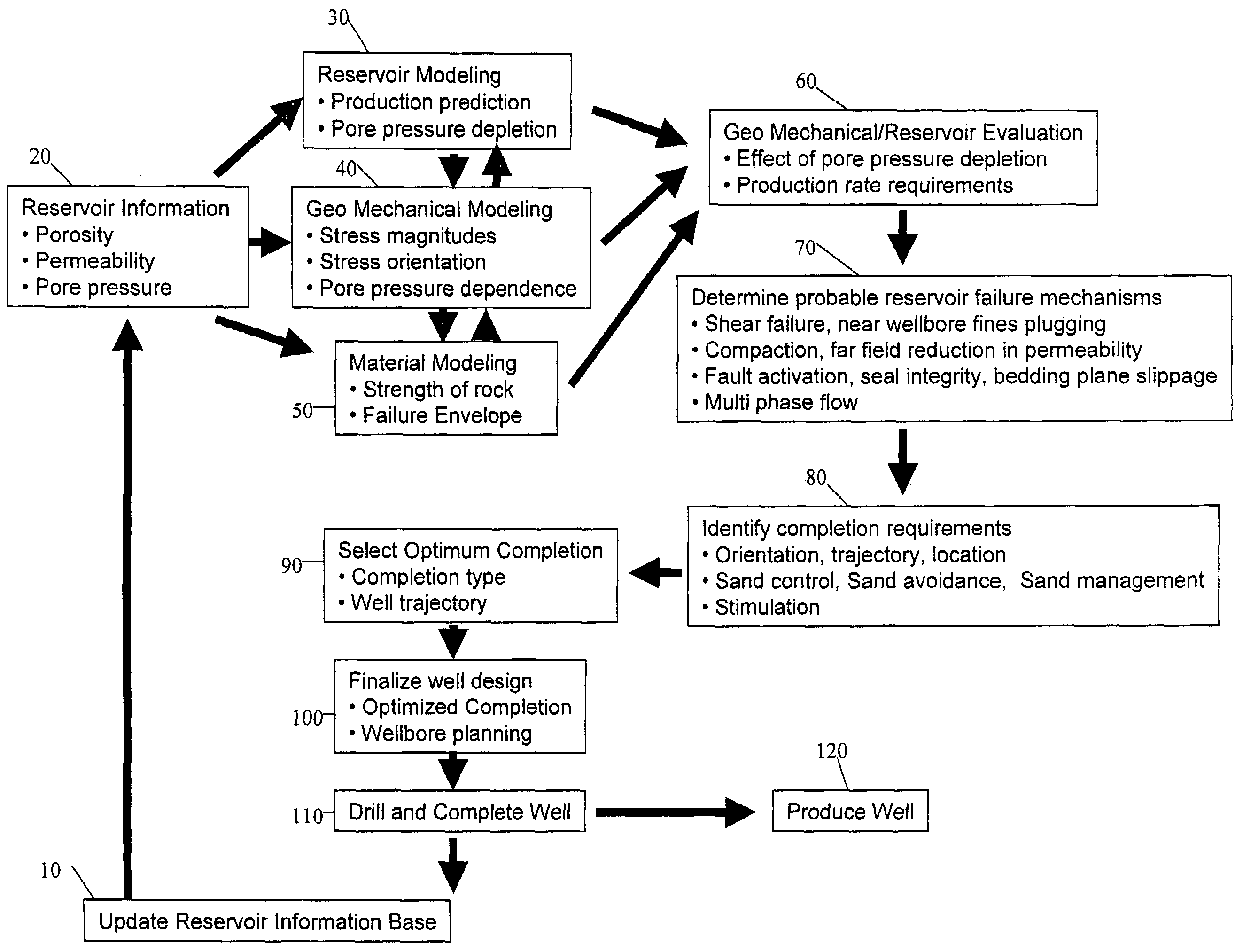

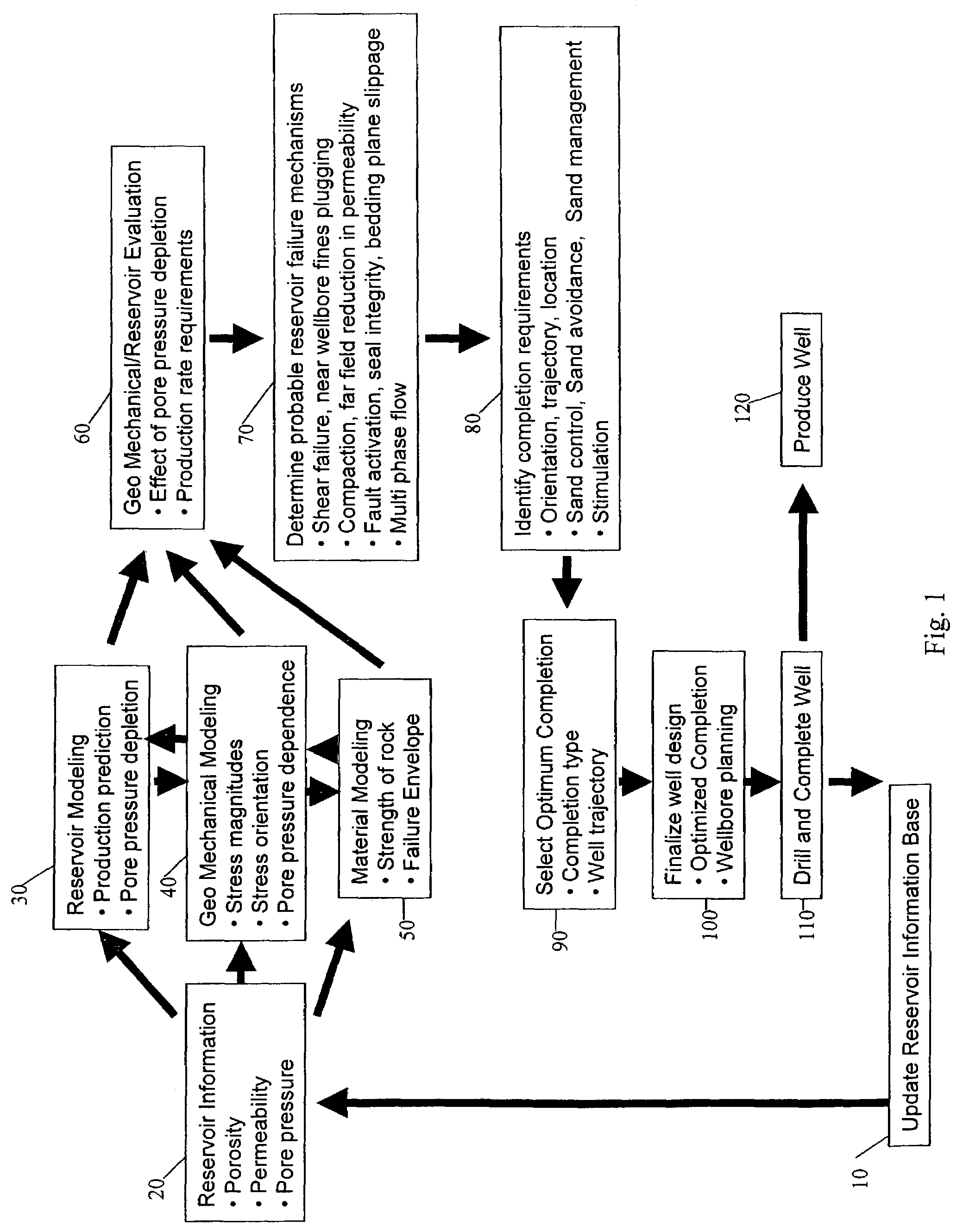

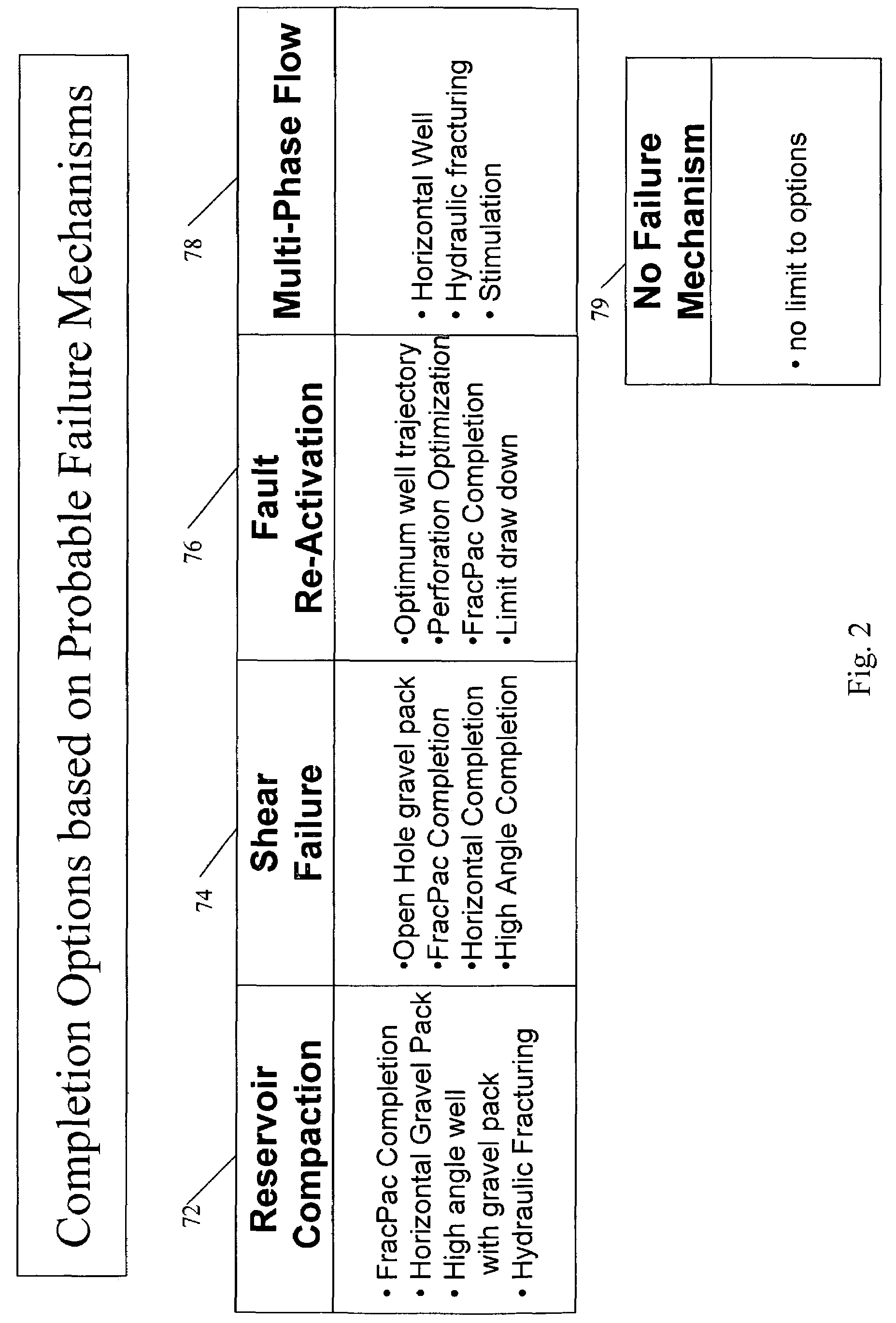

System and process for optimal selection of hydrocarbon well completion type and design

ActiveUS7181380B2Electric/magnetic detection for well-loggingSurveyUltimate tensile strengthFailure mechanism

A process to determine optimal completion type and design prior to drilling of a hydrocarbon producing well utilizing information from hydrocarbon recovery modeling such as reservoir, geo-mechanical, and material modeling over the production life of the well. An embodiment of the process includes obtaining information regarding pore pressure depletion, stress magnitudes and orientations, and strength of rock formation from hydrocarbon recovery modeling to determine optimum well completion design including the selection of a completion type, trajectory, and location. Additionally, the process may also consider probable failure mechanisms and identified completion requirements, and their corresponding effect on completion options.

Owner:GEOMECHANICS INT +1

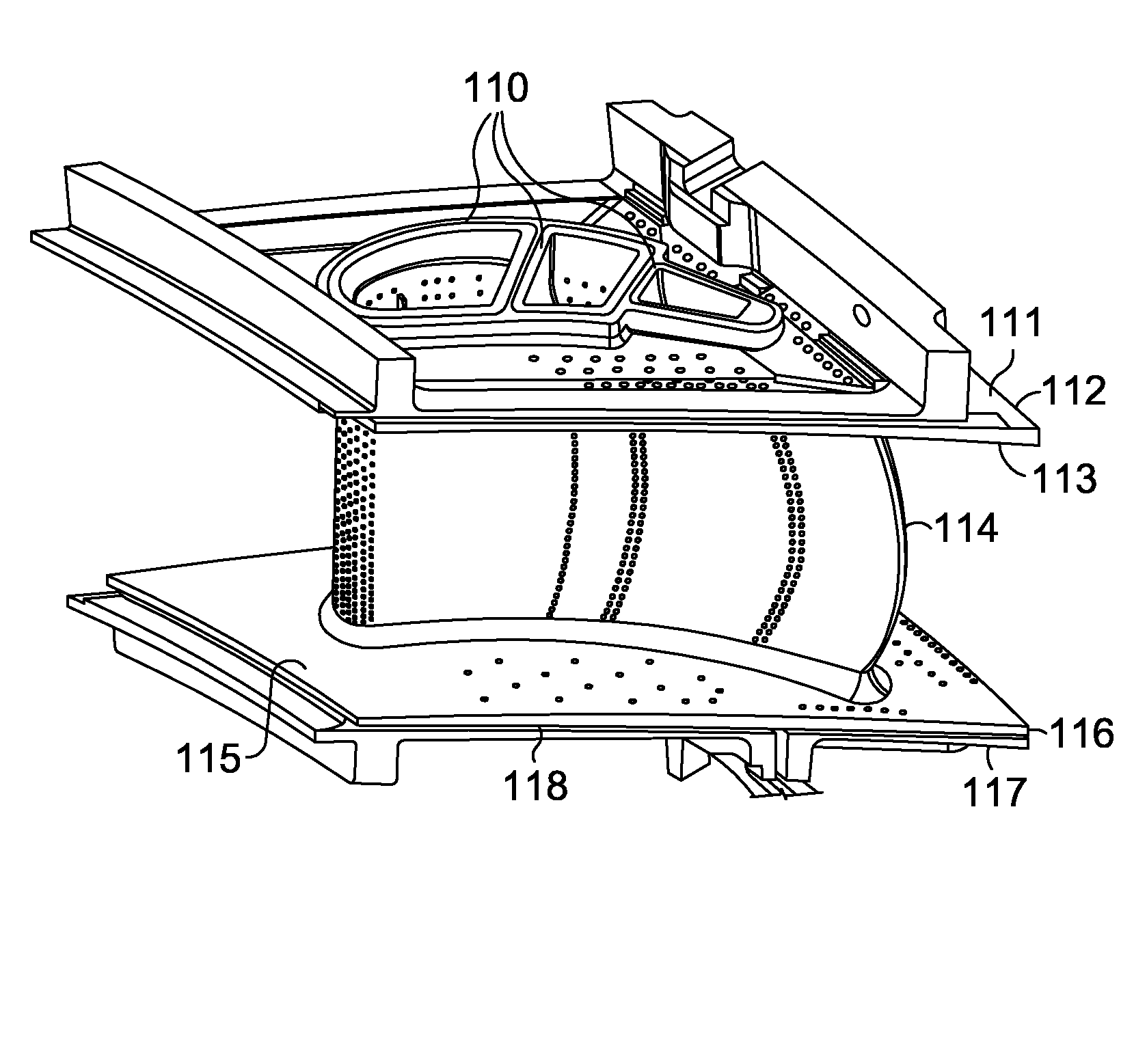

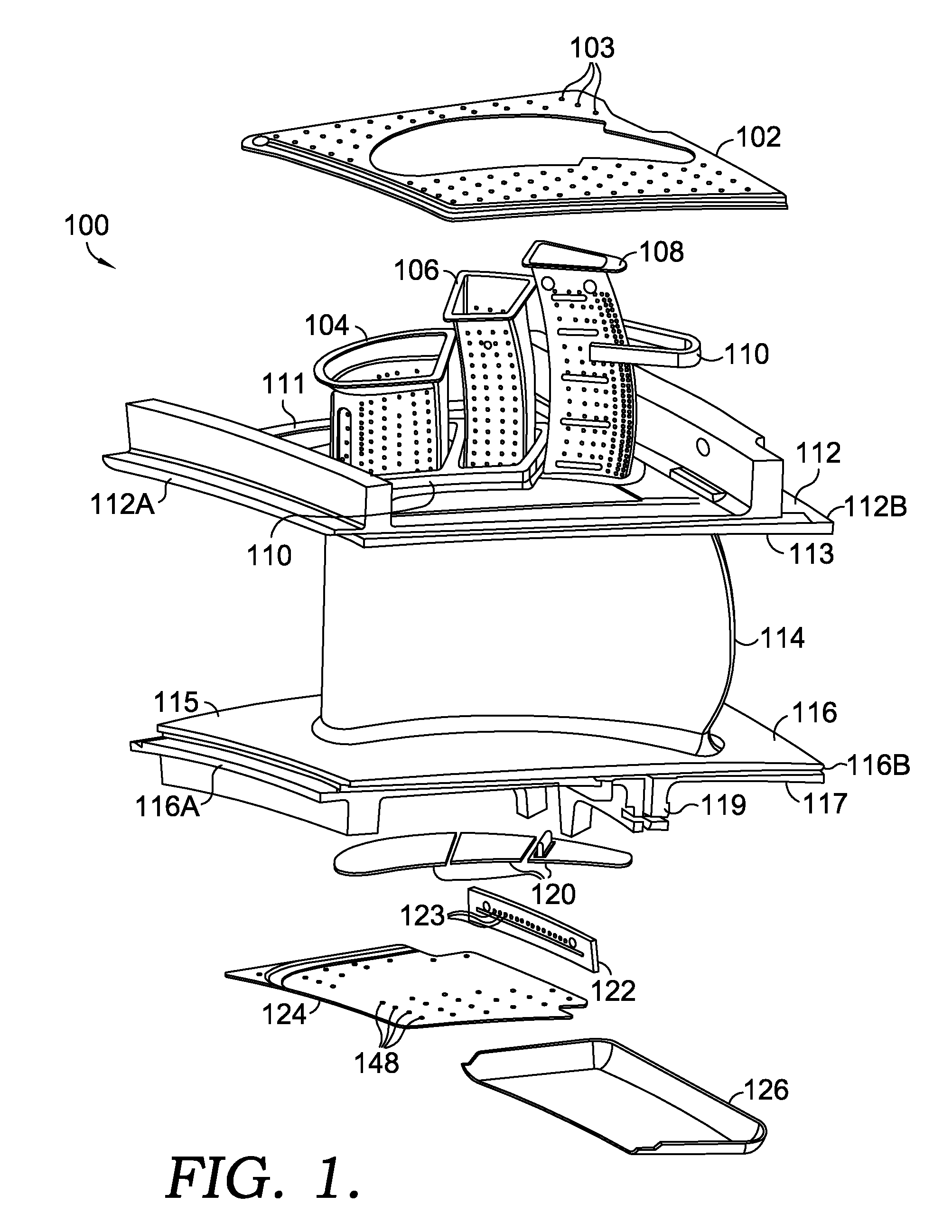

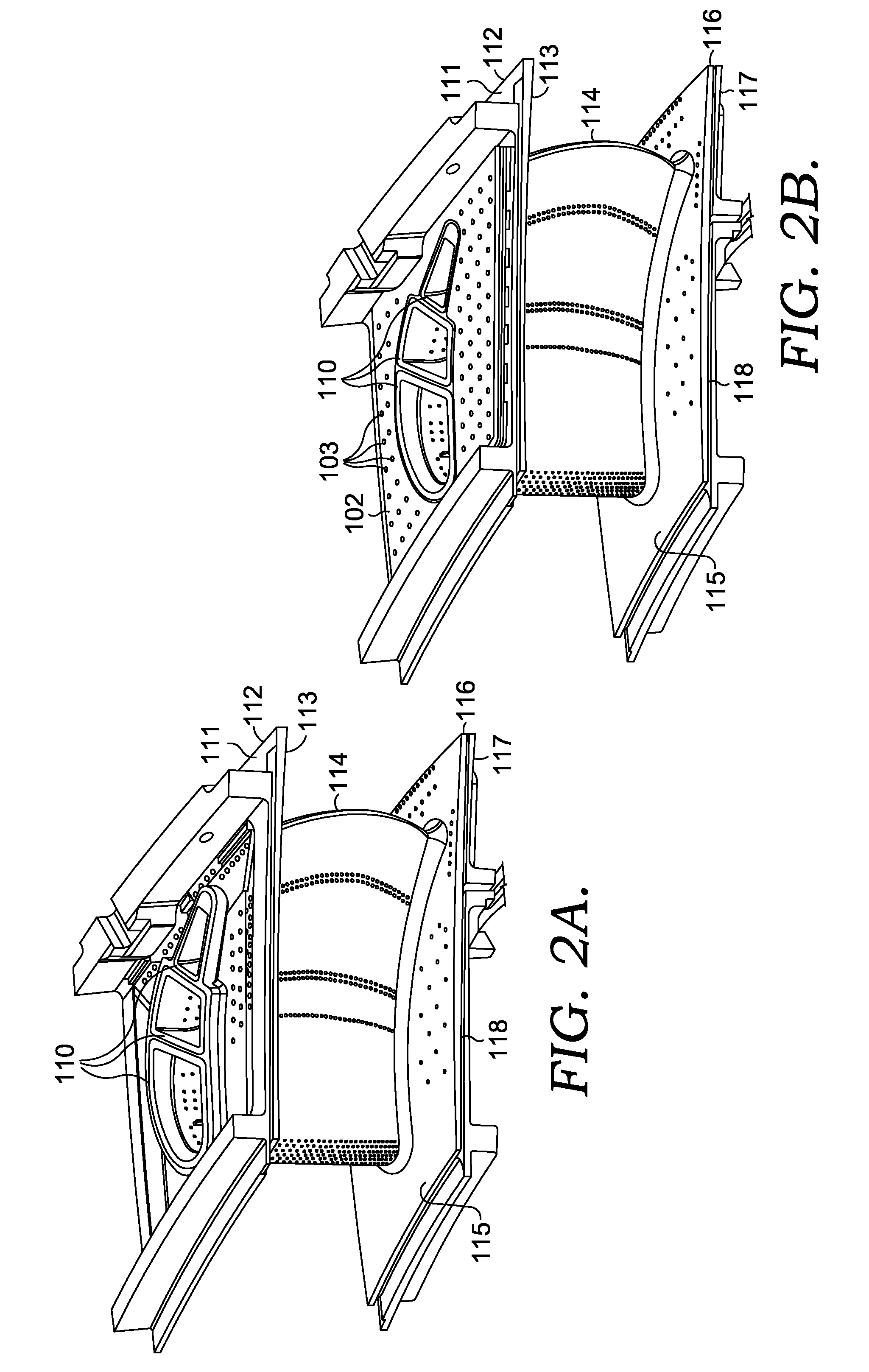

Cooled gas turbine vane assembly

ActiveUS20100129196A1Increased thermal deflectionReduce stiffnessPump componentsEngine fuctionsTrailing edgeGas turbines

A gas turbine vane to improve vane performance by addressing known failure mechanisms. A cooling circuit to the trailing edge of a vane airfoil is fed from the outer diameter platform, which prevents failure due to an oxidized and eroded airfoil trailing edge. The gas turbine includes an outer diameter platform, a hollow airfoil and an inner diameter platform with a plurality of cooling tubes extending radially through the airfoil. The cooling tubes are open at the outer diameter end and closed with covers at the inner diameter end. The inner diameter platform is also cooled and includes a meterplate for a portion of the cooling passageway and includes an undercut to improve thermal deflections of the inner diameter platform.

Owner:H2 IP UK LTD

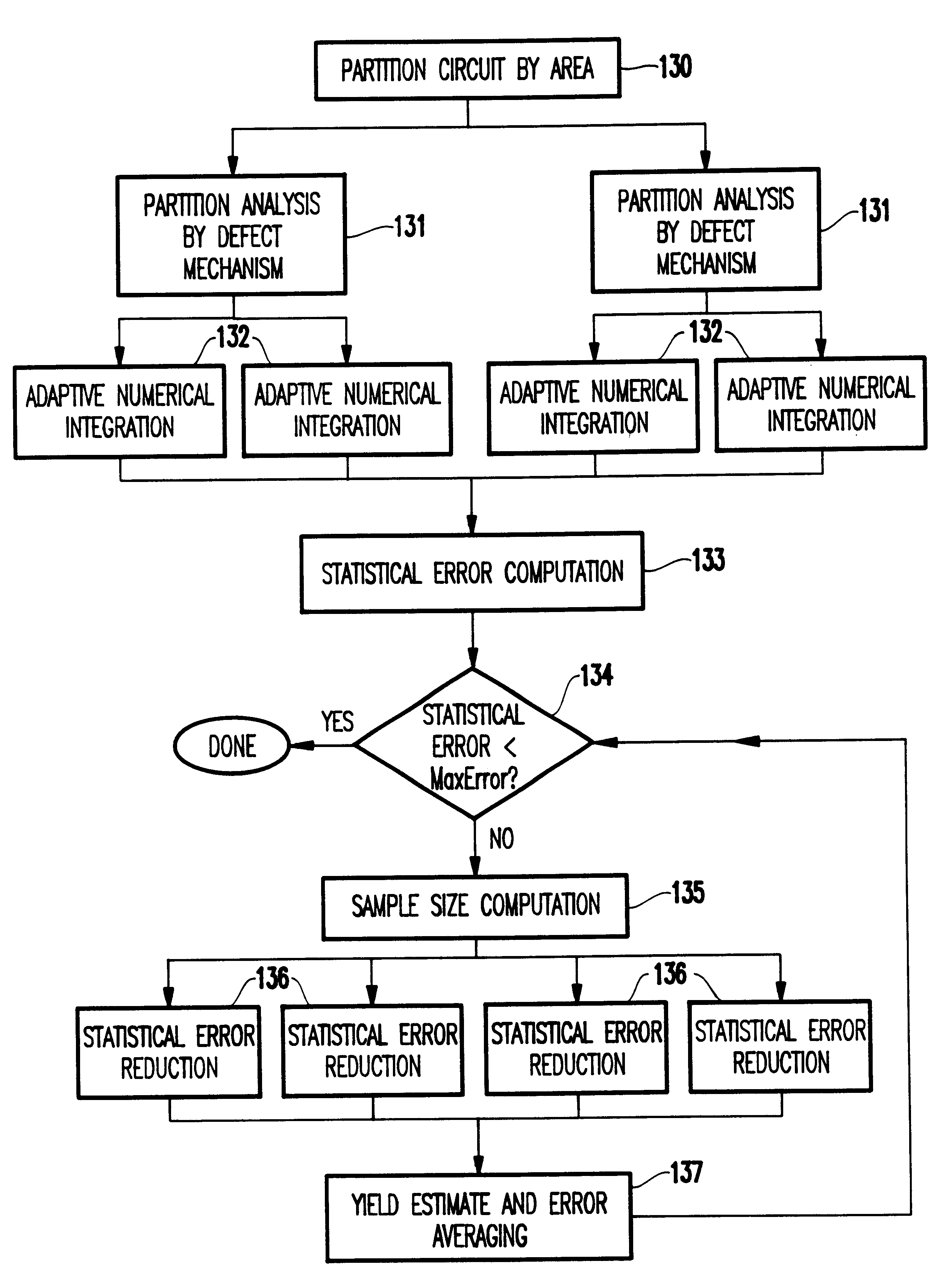

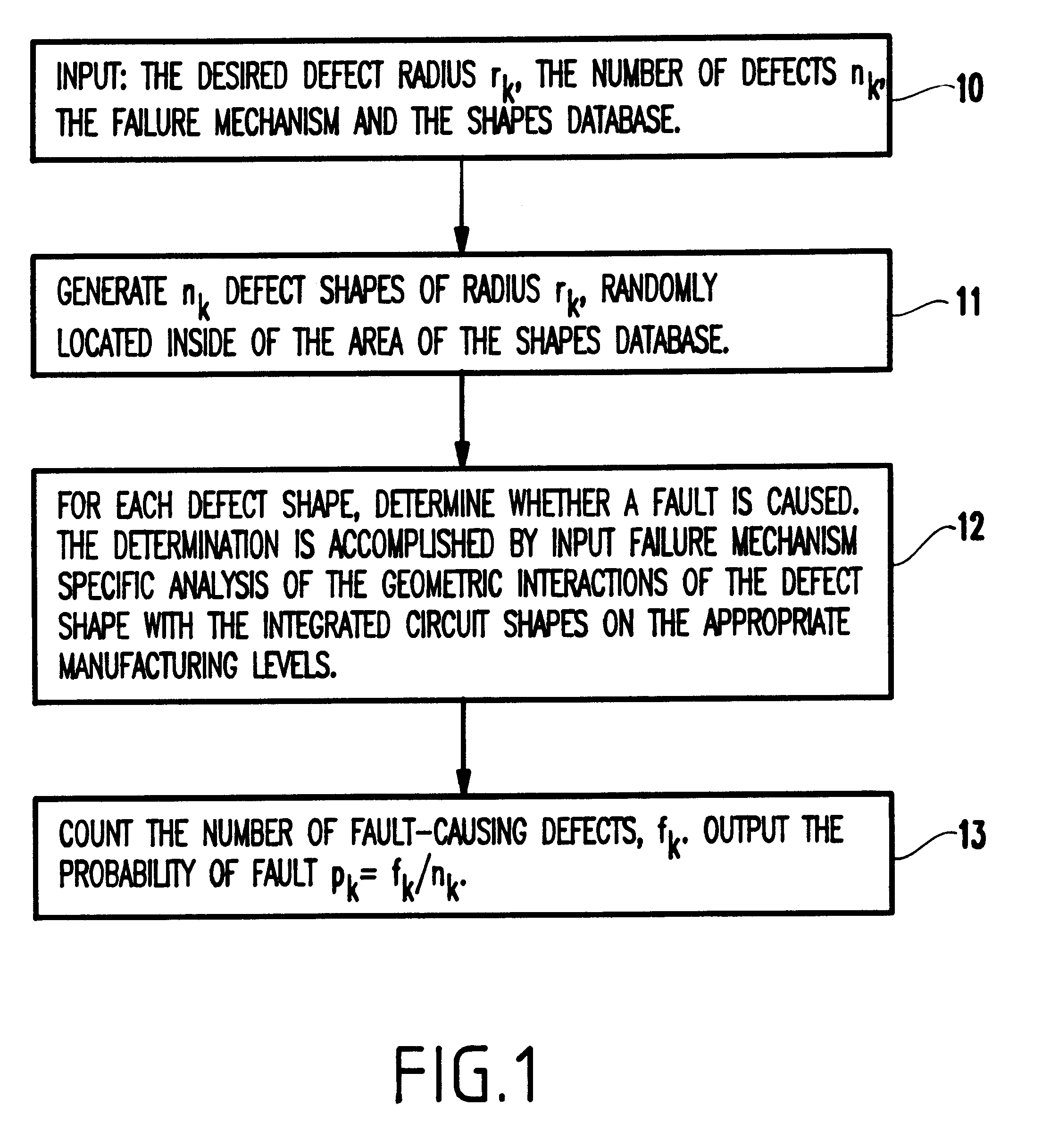

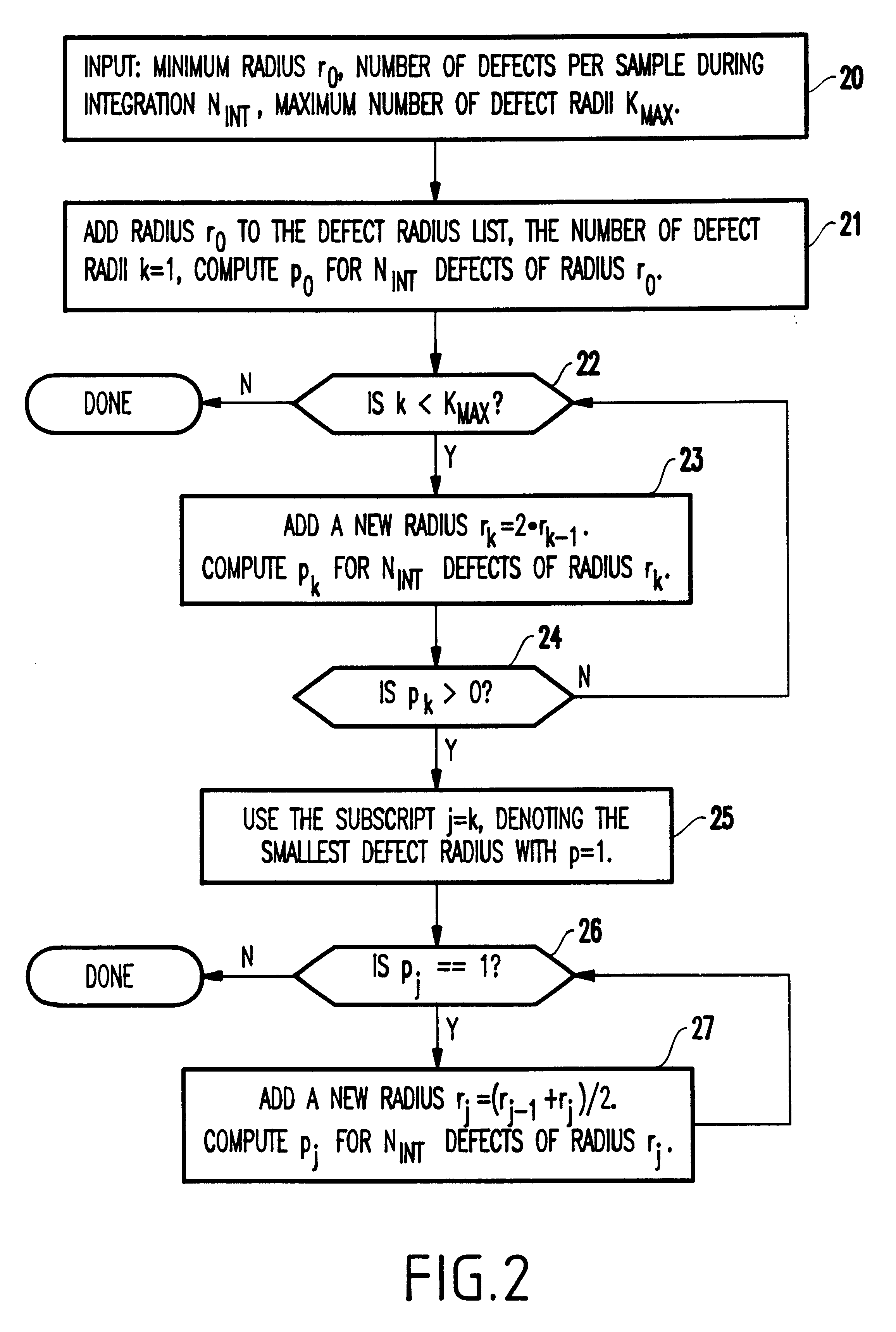

Method for prediction random defect yields of integrated circuits with accuracy and computation time controls

InactiveUS6738954B1Reduce the amount of calculationReduce errorsDigital circuit testingSemiconductor/solid-state device testing/measurementDefect sizeIntegrated circuit layout

A method of computing a manufacturing yield of an integrated circuit having device shapes includes sub-dividing the integrated circuit into failure mechanism subdivisions (each of the failure mechanism subdivisions includes one or more failure mechanism and each of the failure mechanisms includes one or more defect mechanisms), partitioning the failure mechanism subdivisions by area into partitions, pre-processing the device shapes in each partition, computing an initial average number of faults for each of the failure mechanisms and for each partition by numerical integration of an average probability of failure of each failure mechanism, (the numerical integration produces a list of defect sizes for each defect mechanism, and the computing of the initial average includes setting a maximum integration error limit, a maximum sample size for a population of each defect size, and a maximum number of allowable faults for each failure mechansim), and computing a final average number of faults for the integrated circuit by iterativelly reducing a statistical error of the initial average number of faults for each of the failure mechanisms until the statistical error is below an error limit.

Owner:GOOGLE LLC

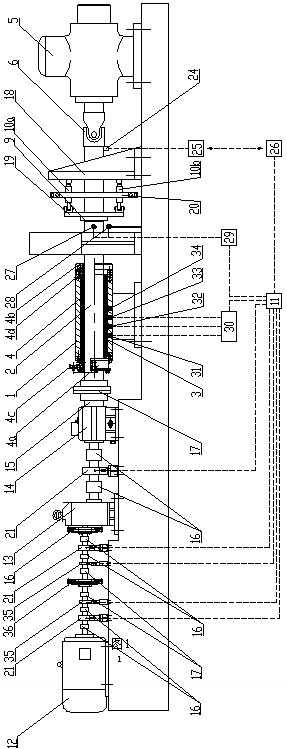

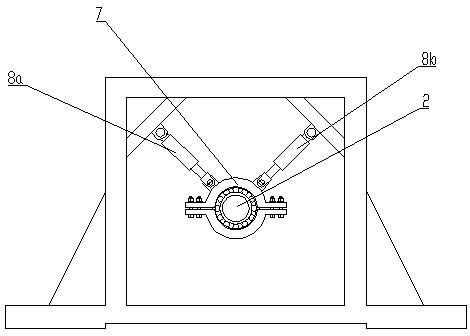

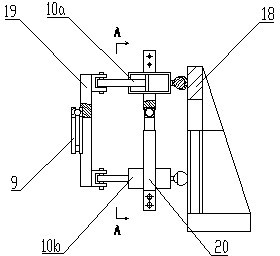

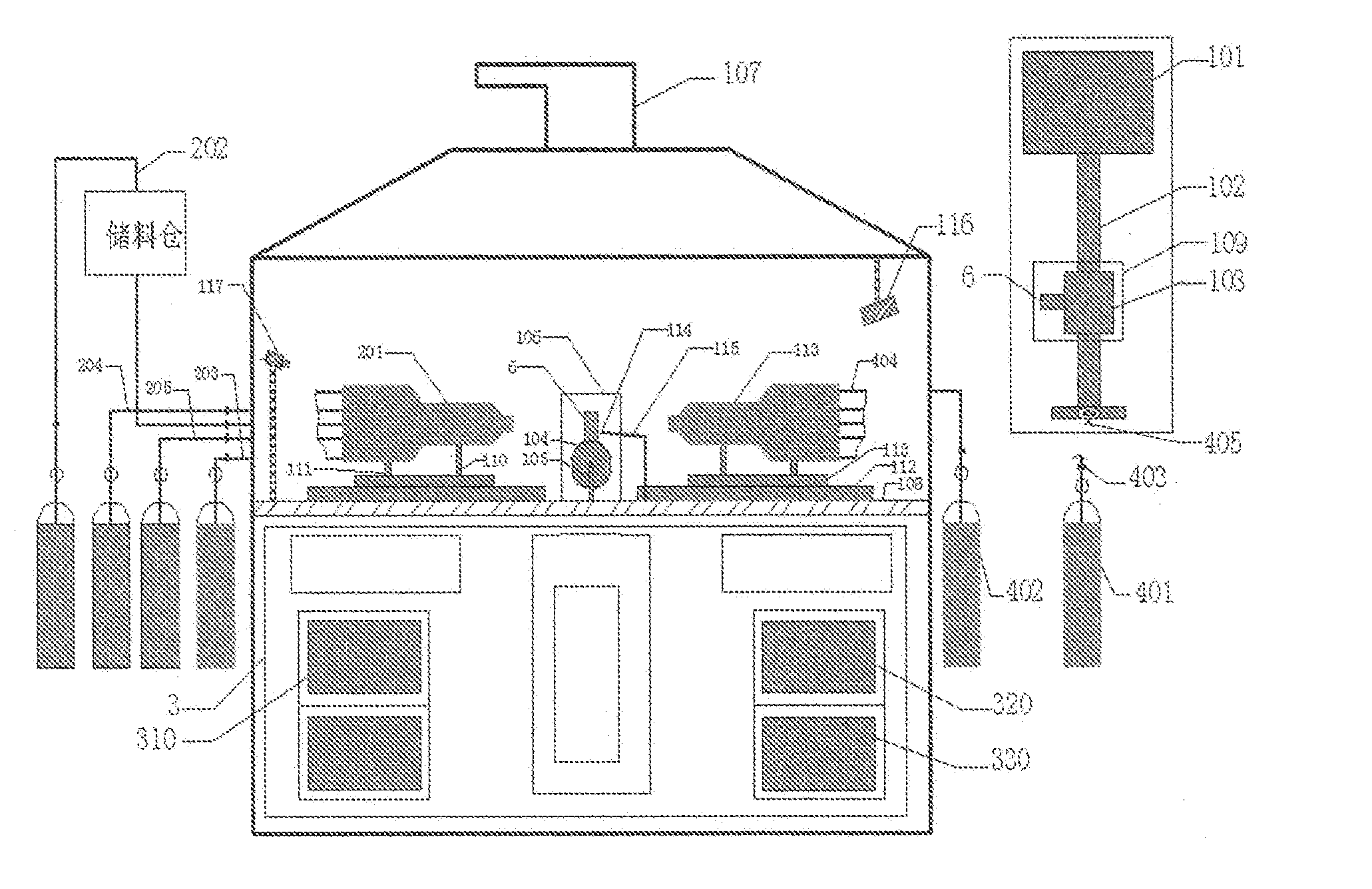

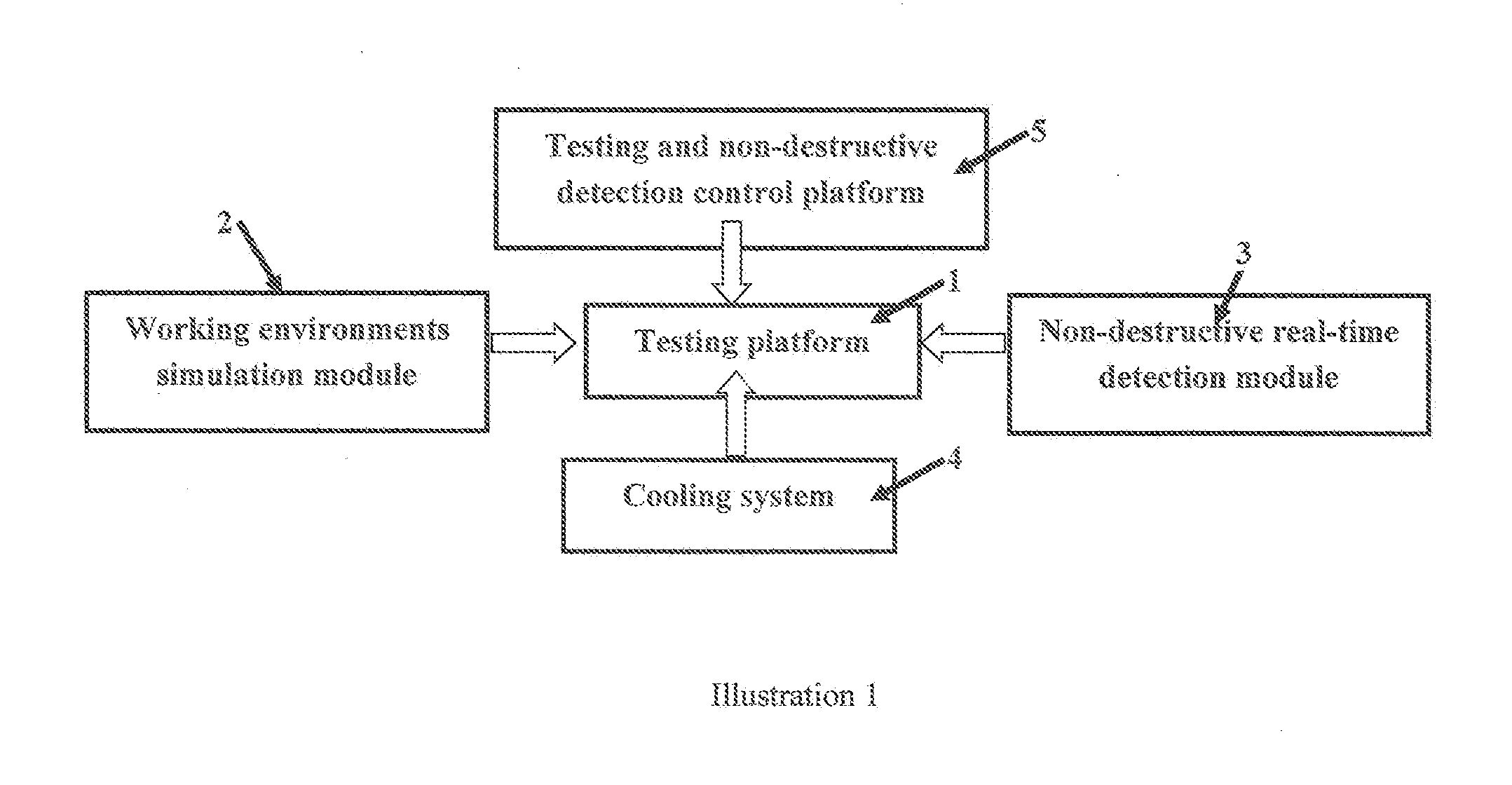

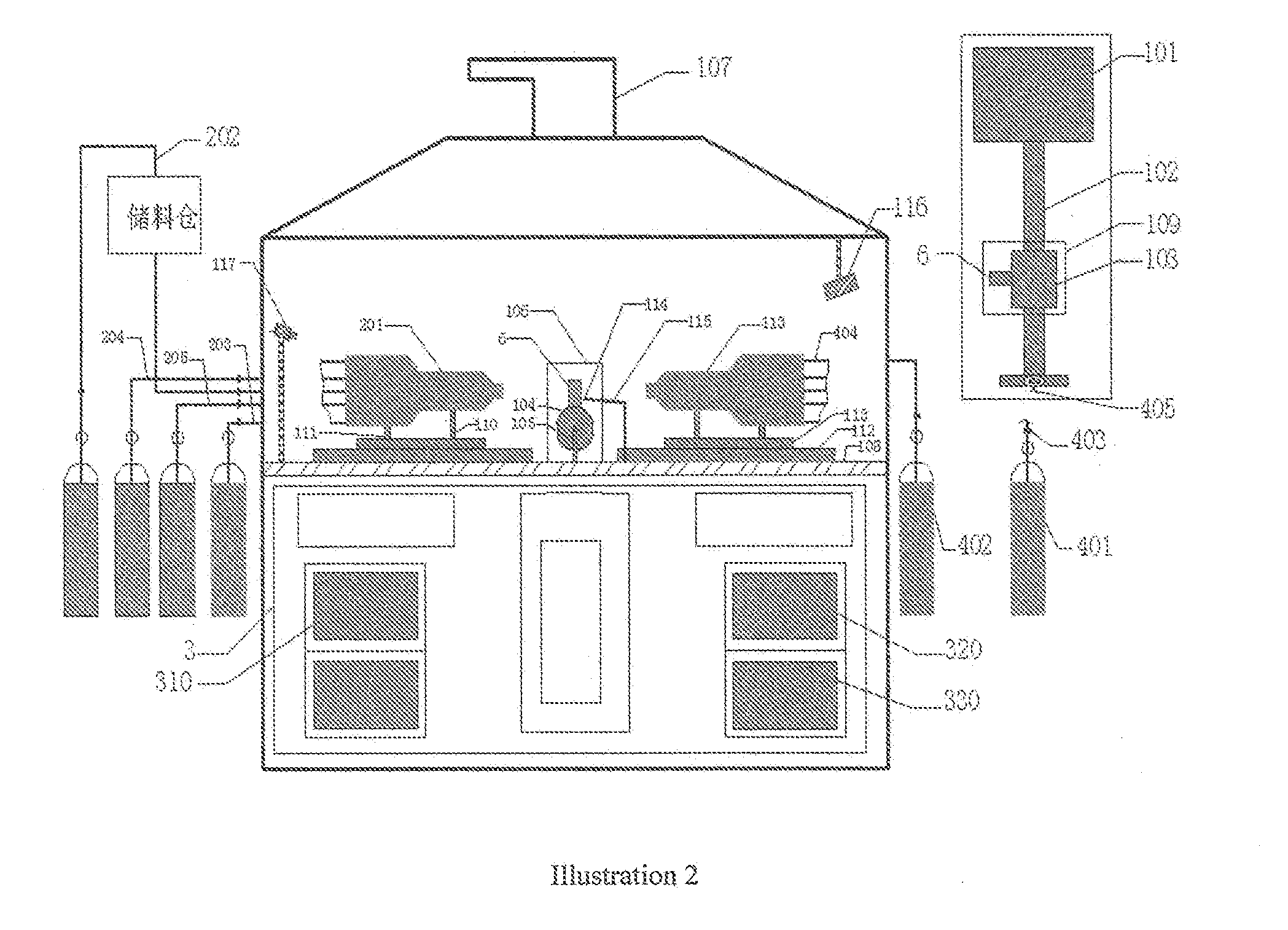

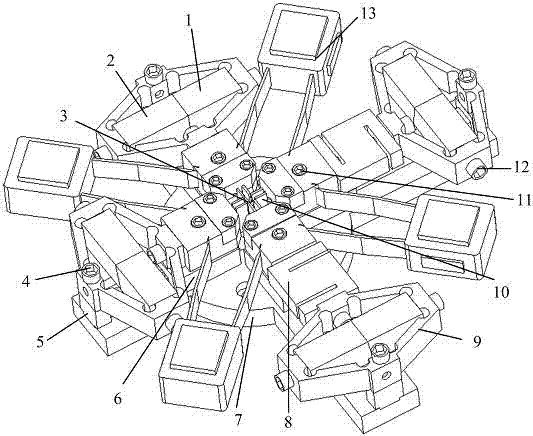

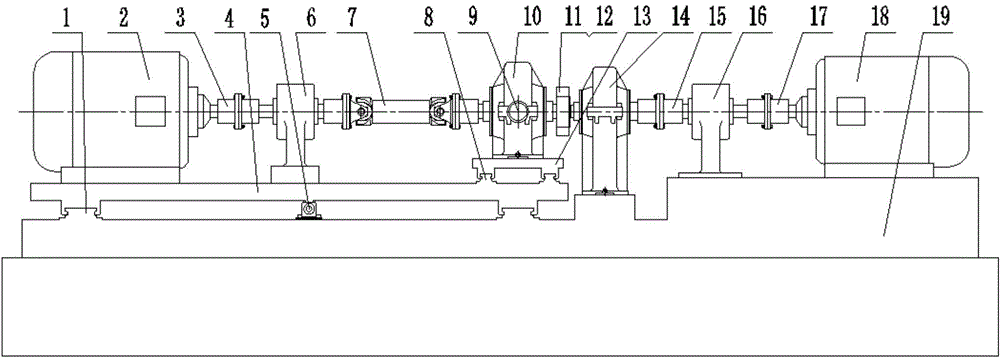

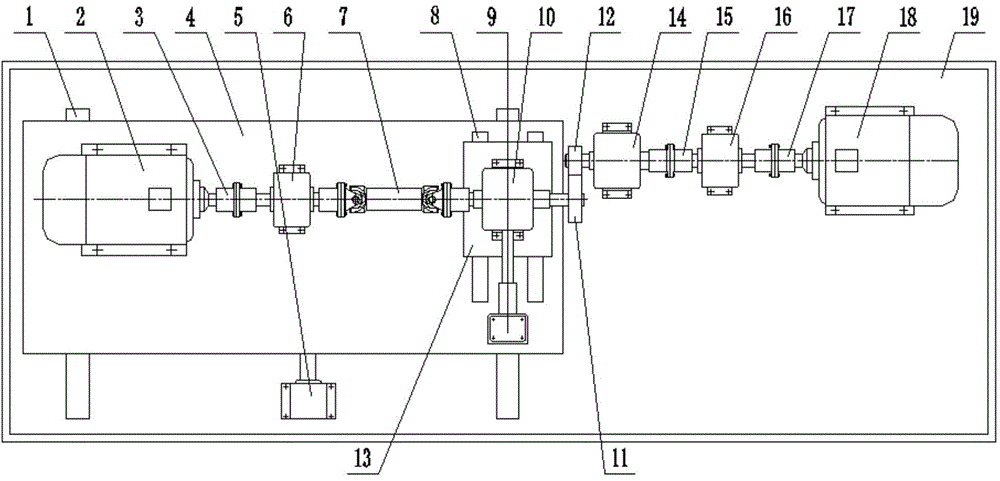

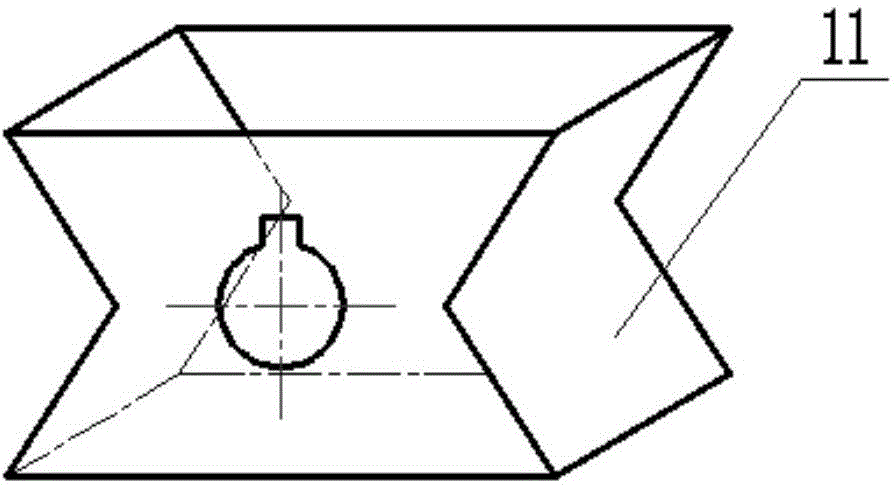

Comprehensive performance experiment platform for water-lubricated bearings and transmission systems

ActiveCN102269654AReal performance testPerformance testing is completeMachine gearing/transmission testingMachine bearings testingLow noiseDrive motor

The invention discloses a water lubricated bearing and transmission system comprehensive performance testing platform, which comprises a water lubricated bearing, a dynamic seal device, an elastic coupling, a gearbox, a water circulating system, a driving motor, an intermediate bearing, a bearing block, a loading and testing device and other parts. The loading device loads a test shaft in the circumferential direction, axial direction and radial direction so as to simulate complicated working conditions of the water lubricated bearing and the transmission system thereof; the testing system can detect various parameters of the water lubricated bearing, such as working speed, torque, temperature, frictional characteristics, water film pressure distribution, interface deformation distribution, shaft centerline orbit, noise and dynamic characteristics, and comprehensive performance of the dynamic seal, the elastic coupling and the transmission system on line; and the testing platform can be applied to research of scientific problems such as the loading bearing of a water lubricated friction pair, failure mechanism and evolution law, tribological performance and dynamic service behaviors, and provides a key scientific and technological basis for developing a pollution-free, low-noise, high-reliability, long-life, high-efficiency and energy-saving water lubricated bearing and a transmission system thereof.

Owner:CHONGQING UNIV

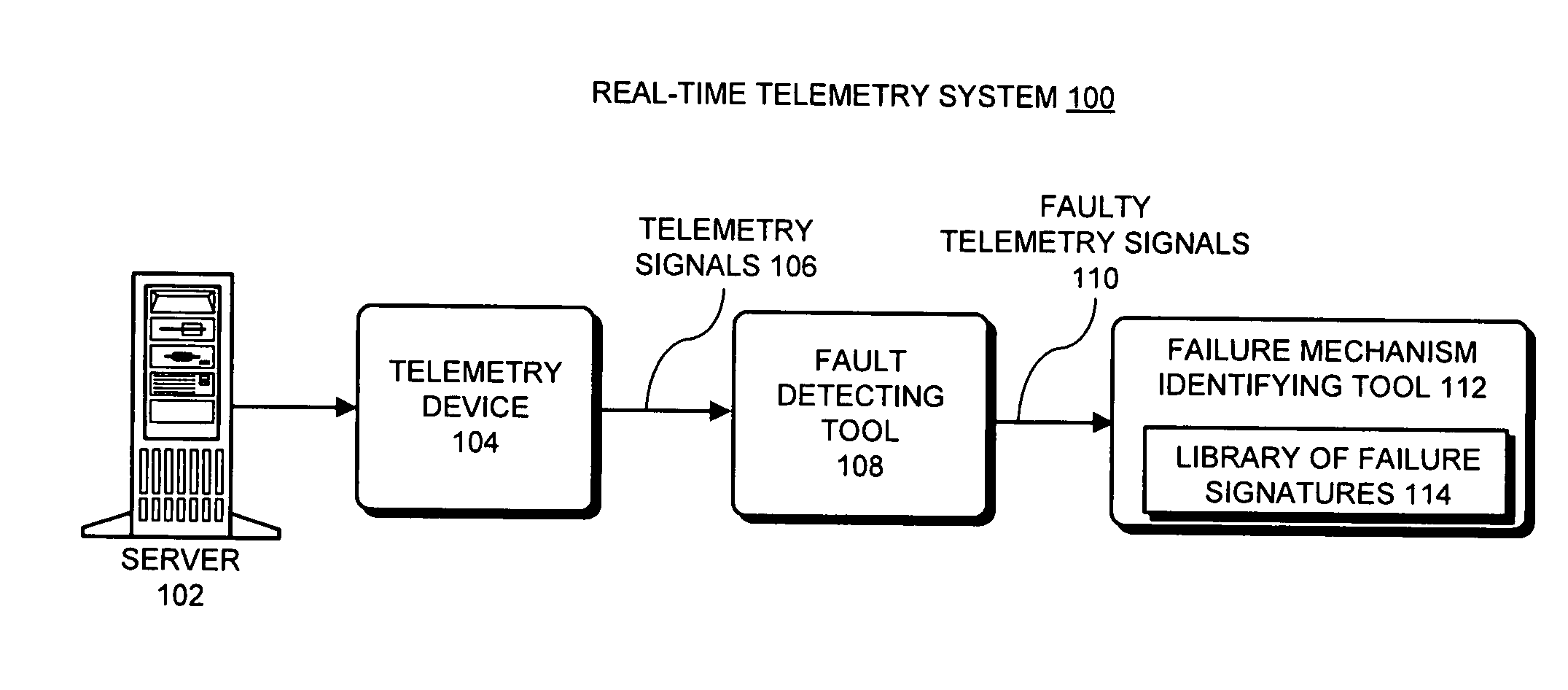

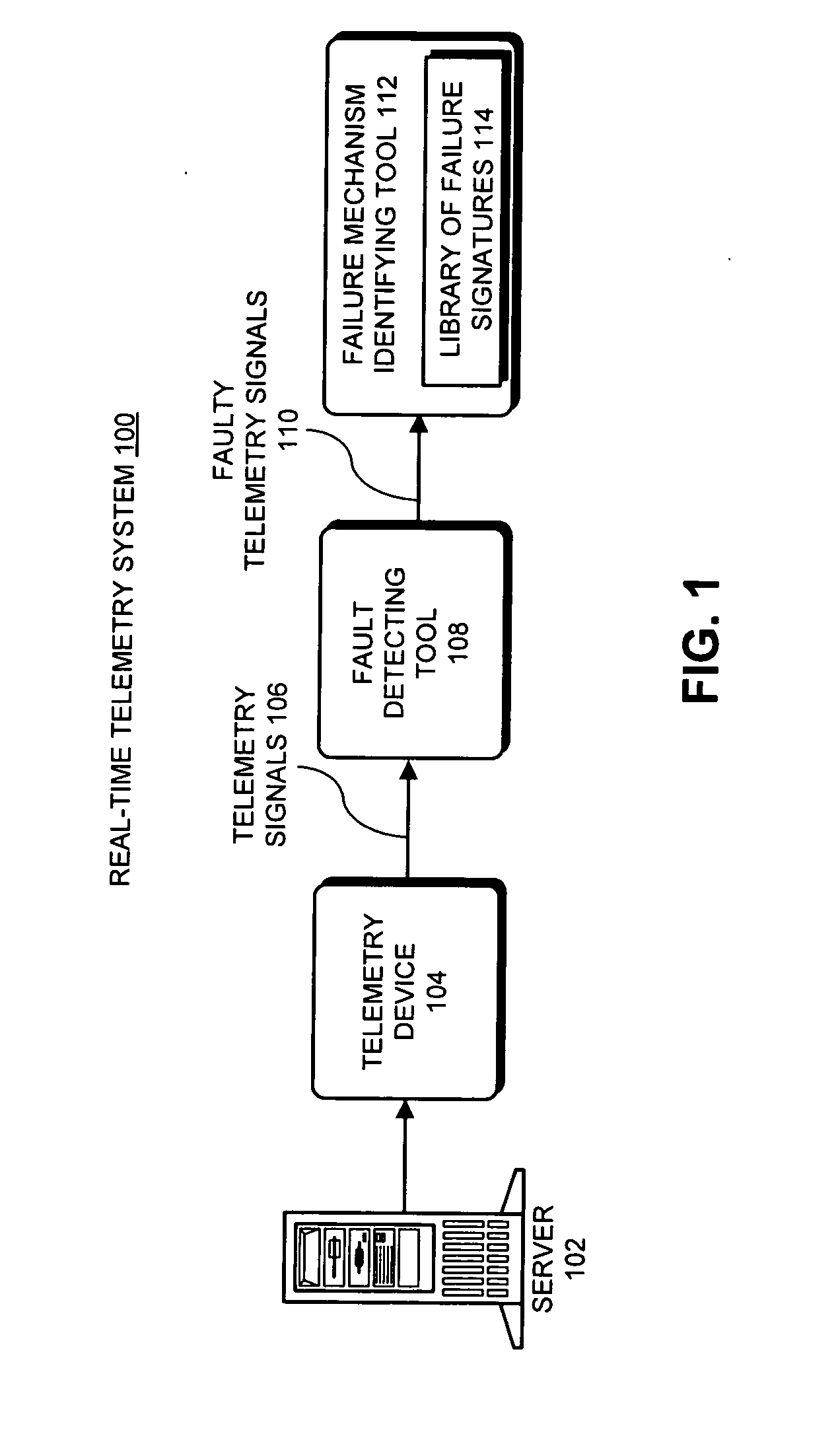

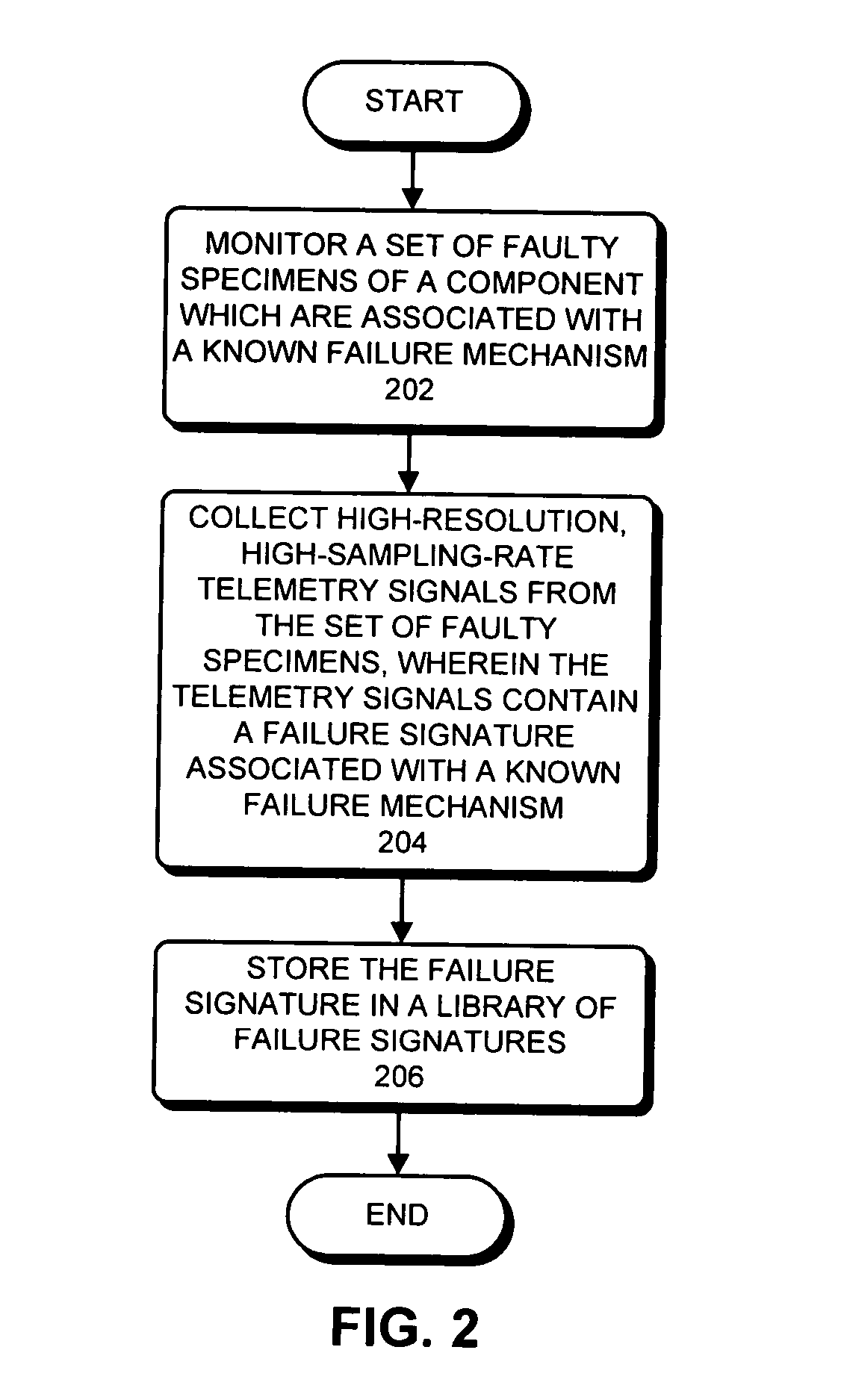

Method and apparatus for identifying a failure mechanism for a component in a computer system

ActiveUS20070294591A1Reduce resolutionNuclear monitoringDigital computer detailsPattern matchingFailure mechanism

One embodiment of the present invention provides a system that identifies a failure mechanism for a component. The system first constructs a library of failure signatures from a set of components, wherein each failure signature in the library characterizes a known failure mechanism associated with a component in the set of components. Next, the system receives a telemetry signal which is measured from a component under surveillance. The system then determines if there is an anomaly in the telemetry signal. If so, the system performs pattern-matching operations between the telemetry signal and failure signatures in the library. Next, if a match is found, the system identifies the failure mechanism for the component under surveillance based on the matching failure signature.

Owner:ORACLE INT CORP

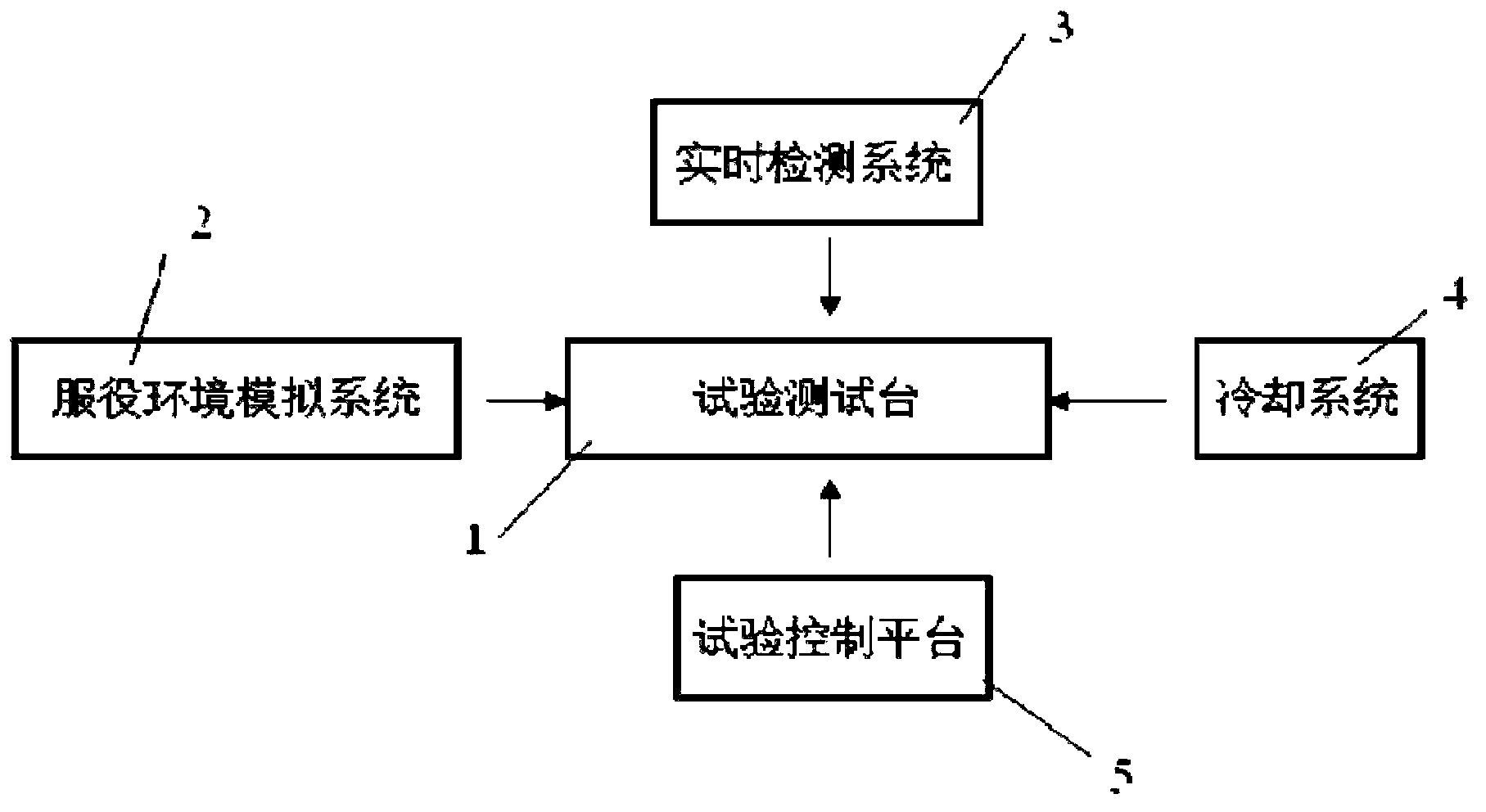

Type of testing equipment for detecting the failure process of thermal barrier coating in a simulted working environment

ActiveUS20150355074A1Better understandingReliable assessmentWeather/light/corrosion resistanceEngine testingSurface oxidationTurbine blade

A type of testing equipment for detecting the failure process of thermal barrier coating in a simulated working environment; it belongs to the field of simulated special working environment equipment. Testing equipment includes testing platform equipped with static or dynamic specimen holding apparatus, simulated module of working environment, real-time detection module, control panel. This invention is capable of simulating a high temperature, erosive, corrosive working environment for thermal barrier coated turbine blade of aero-engines; simulate high speed spinning working environment for thermal coated blade, simulate static working environment for guiding blade; perform real-time testing of temperature field, 3-D displacement field, crack initiation and expansion, surface oxidation, etc. This invention has achieved complete integration of high temperature, erosive, corrosive working environment for thermal barrier coating and complete integration static or dynamic working environment, complete integration of simulated working environment and real-time testing, thus providing a crucial testing platform and reference data to properly understand the failure mechanism of thermal barrier coated blade and to improve relevant designs; strong applicability.

Owner:XIANGTAN UNIV

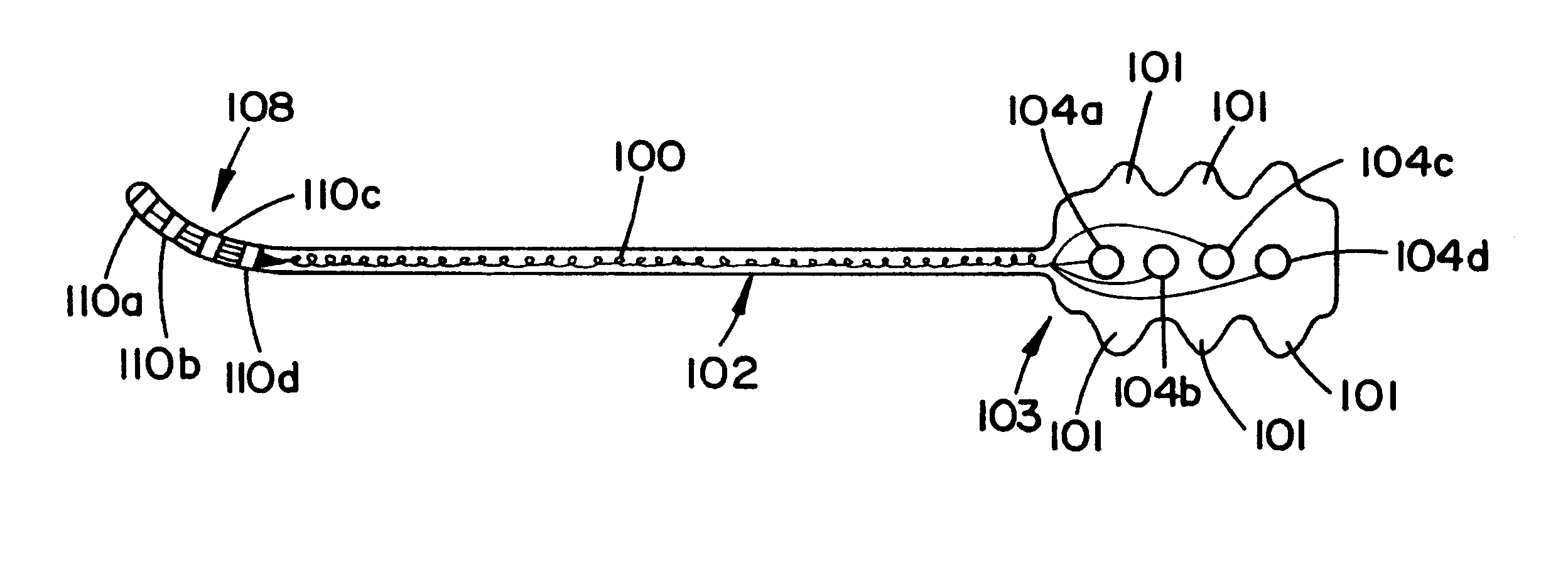

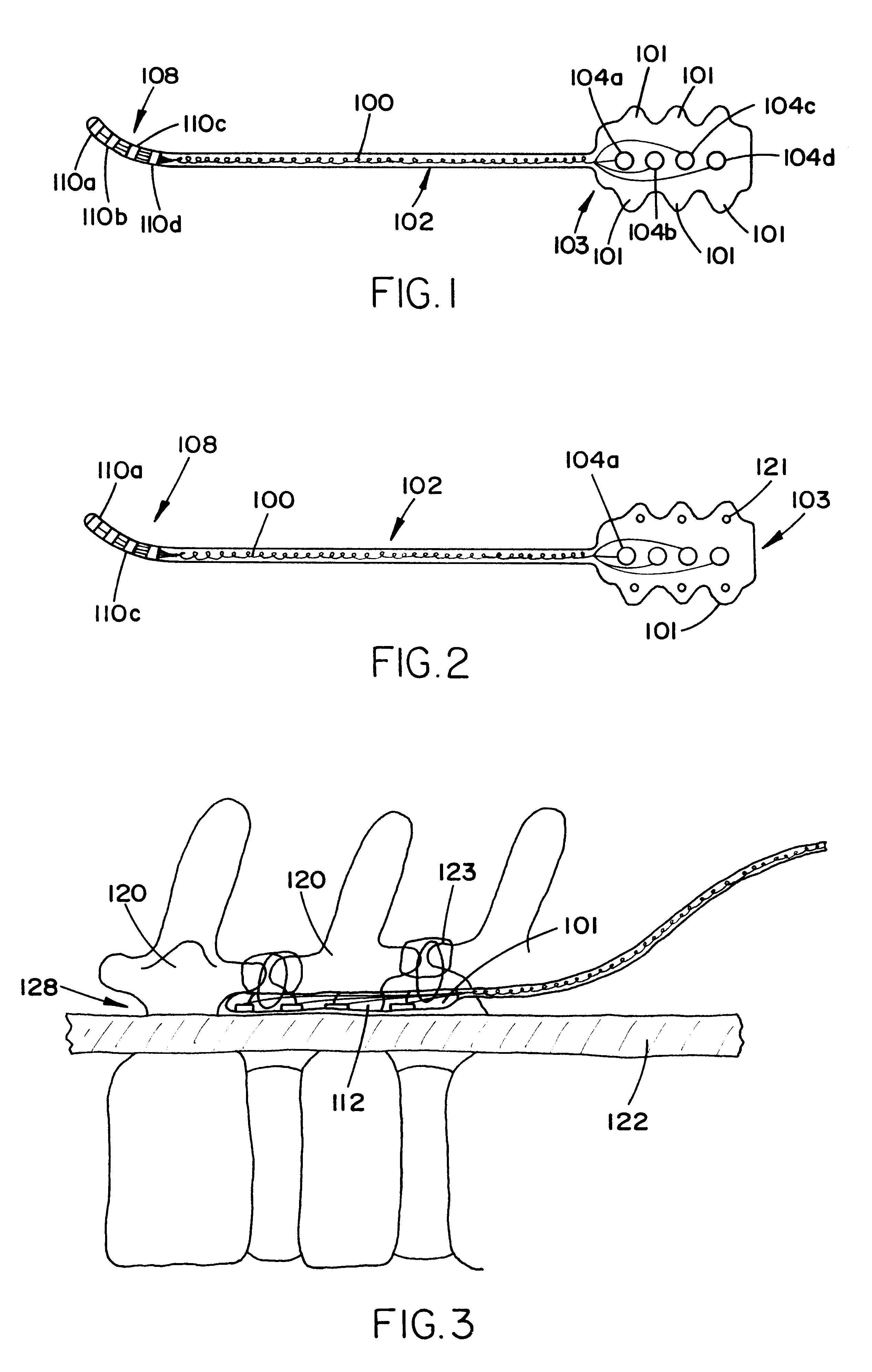

Spinal cord electrode assembly having laterally extending portions

InactiveUS6175769B1Risk minimizationEasy to identifySpinal electrodesExternal electrodesFailure mechanismSpinous process

A spinal electrode for use in spinal cord stimulation having portions which are specifically provided for coupling the electrode to the adjacent spinal tissue so that displacement of the electrode cannot easily occur by normal bodily motion as is a failure mechanism of prior electrode designs. The distal end of the electrode which includes the electrical contacts also includes at least one laterally extending non-electrical portion. The extending portions are provided for receiving a suture or wire therethrough. The laterally extending portions may include a readily identifiable distinguishing feature, such as a color dye or a textural difference, so that it can be readily seen as a safe region through which a suture may be passed. Alternatively (or in addition), the laterally extending portions may include a through hole so that the tip of the electrode may be tied to the spinous process (or other spinal bone) by a wire.

Owner:ELECTRO CORE TECH

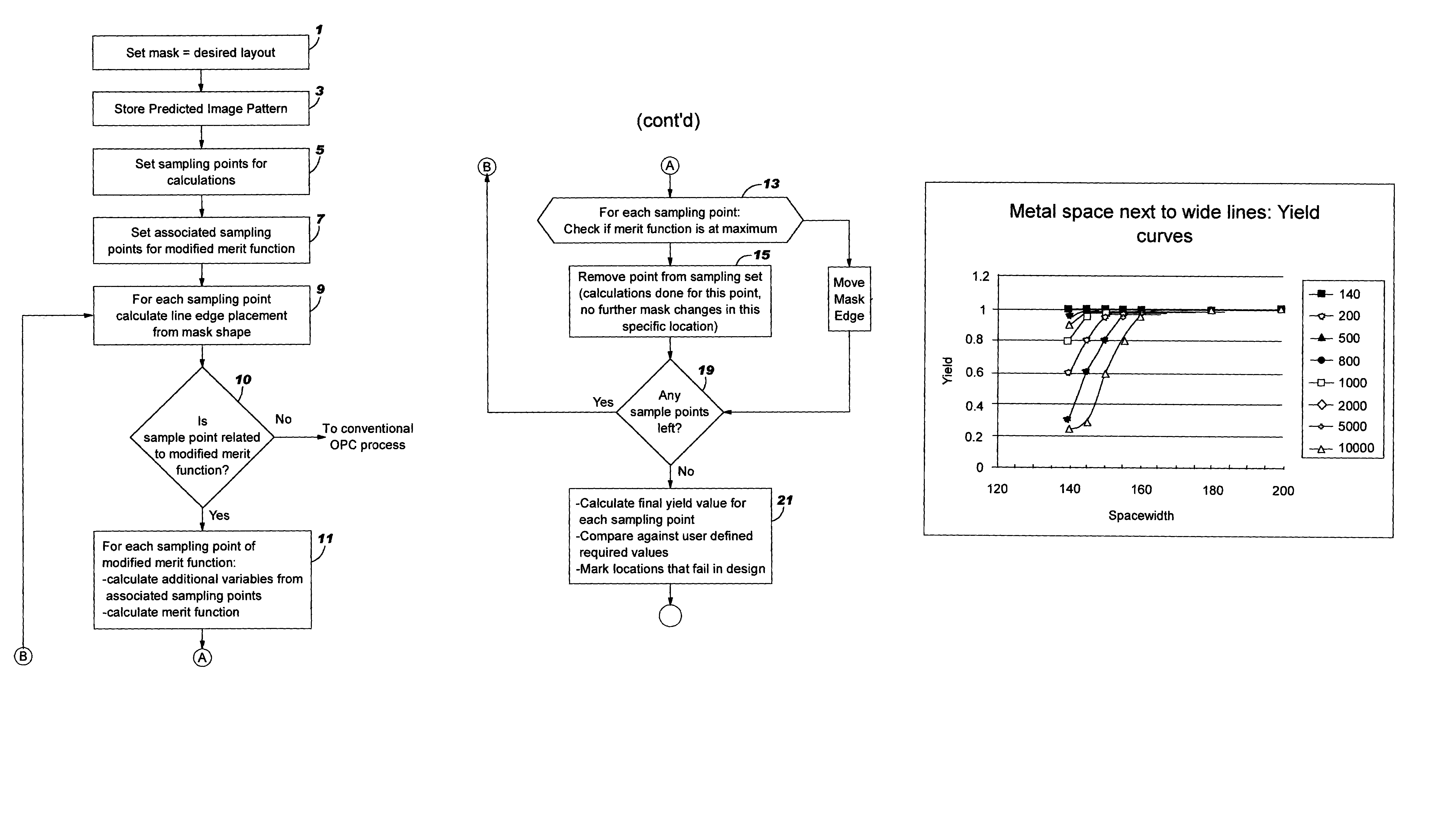

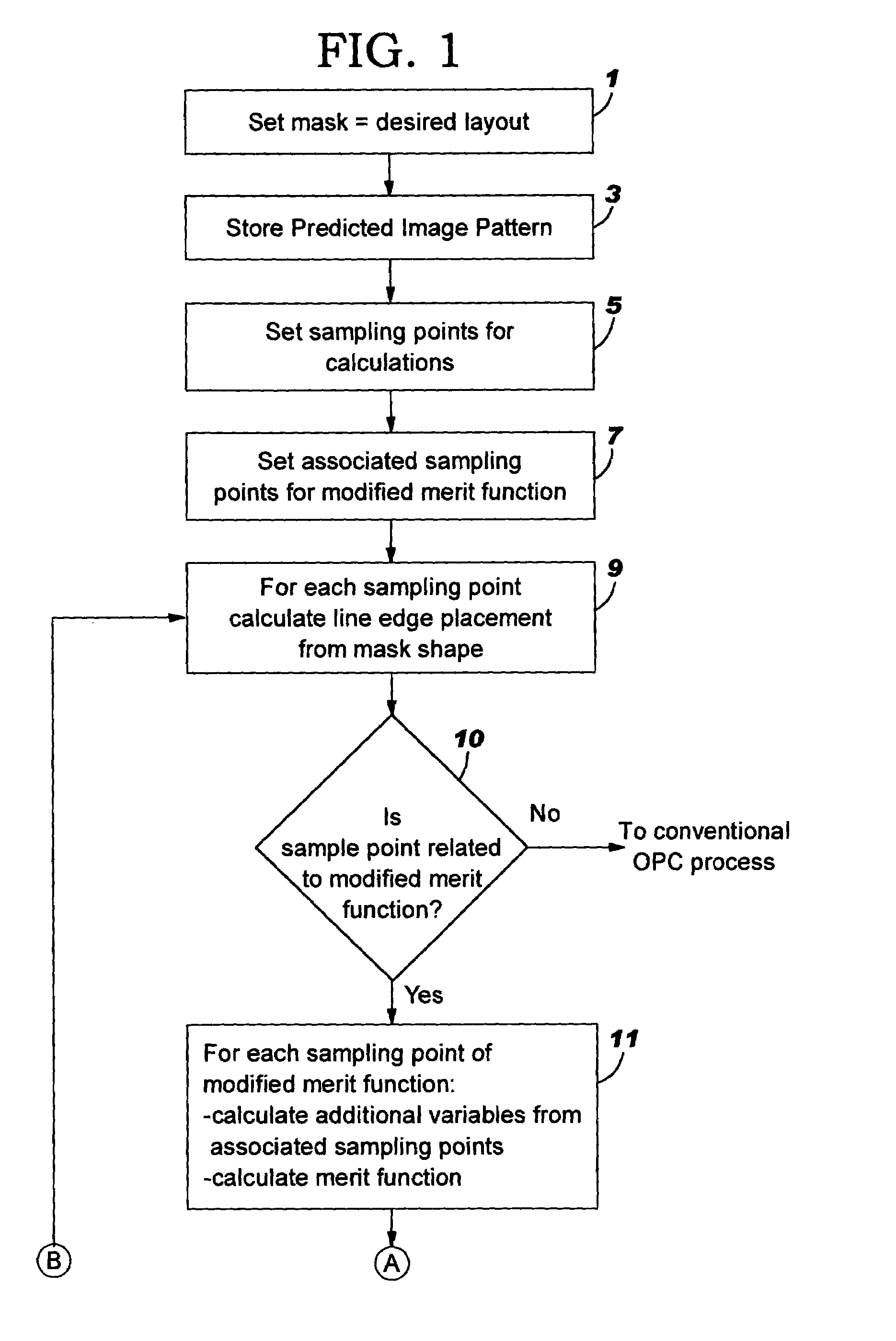

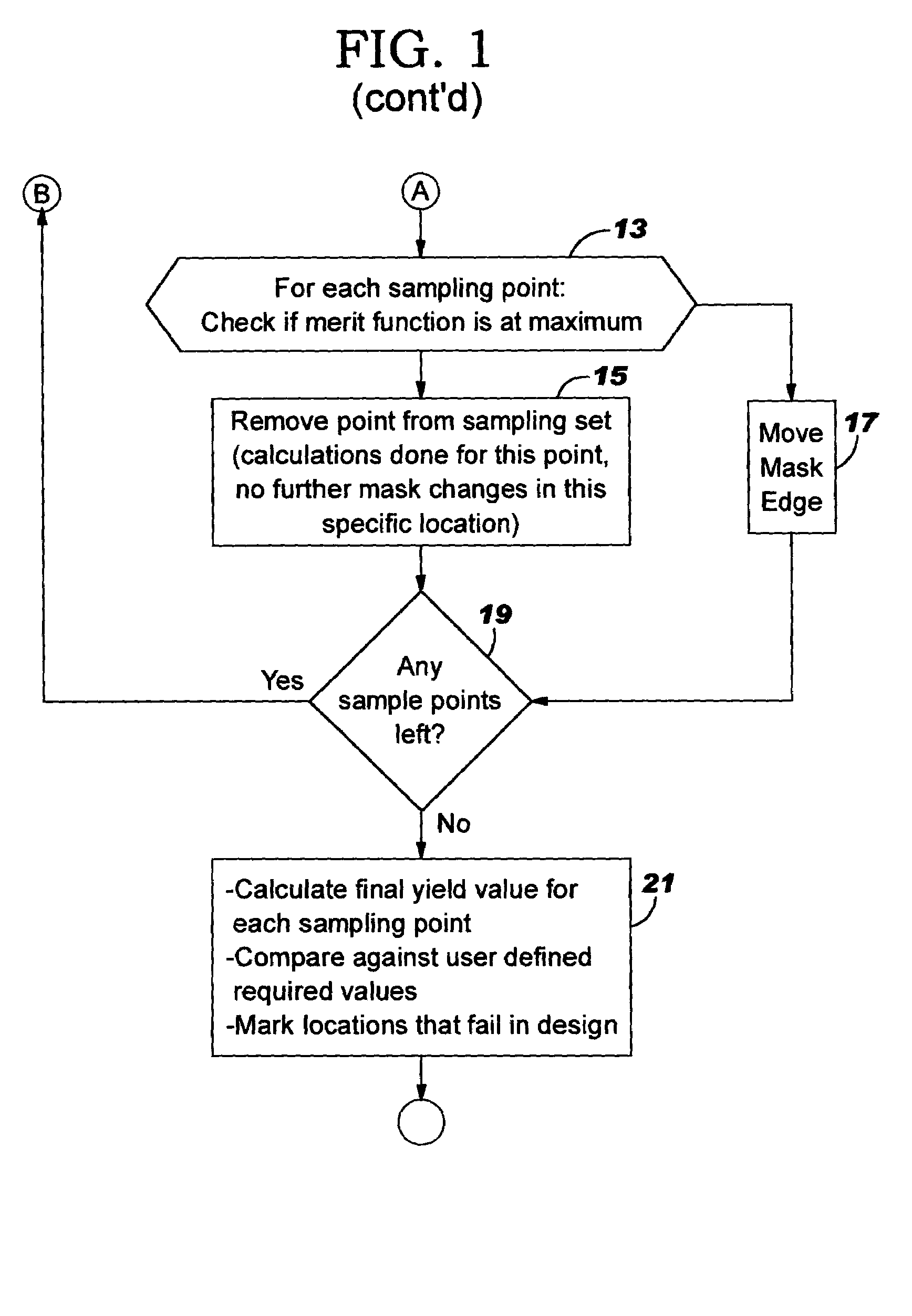

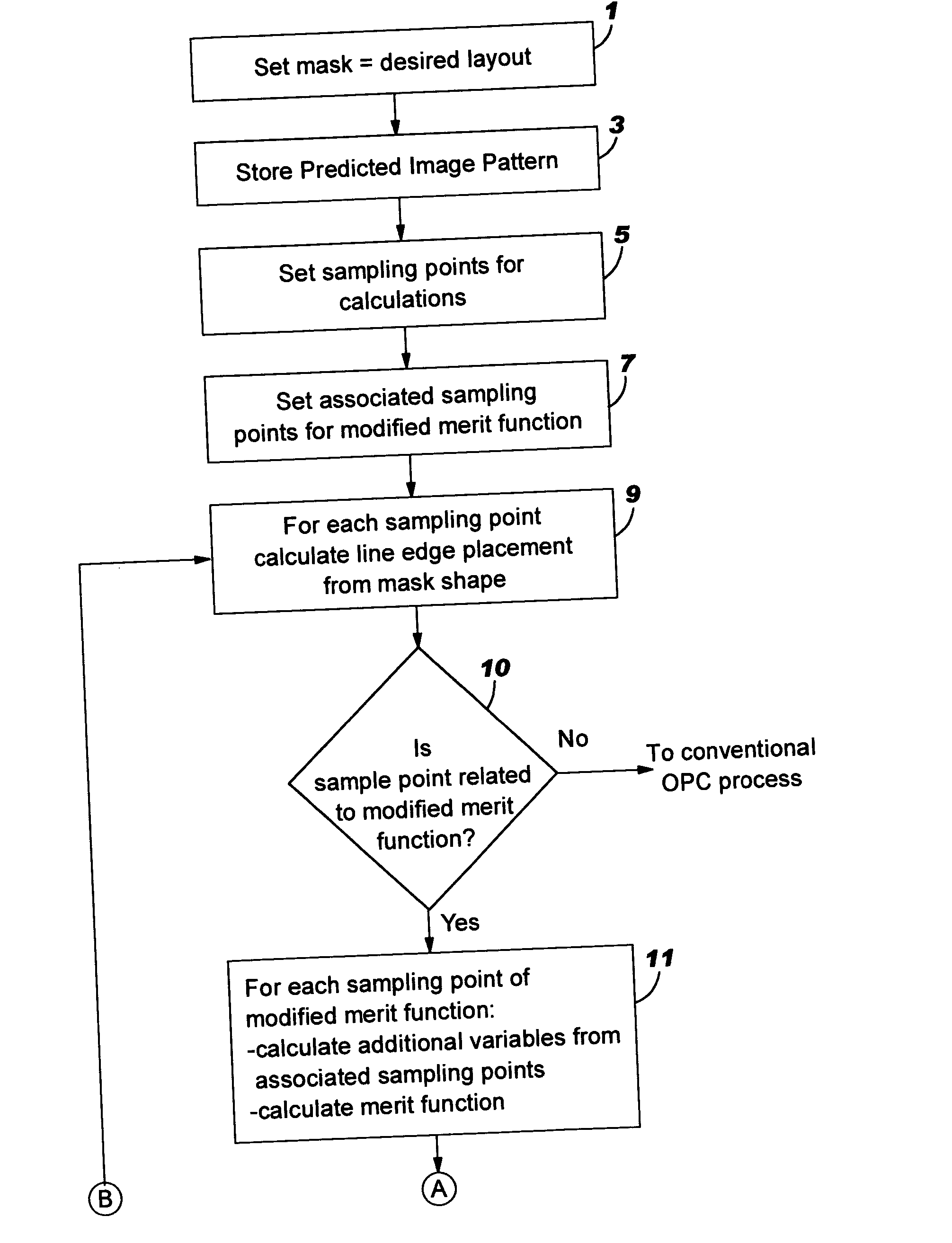

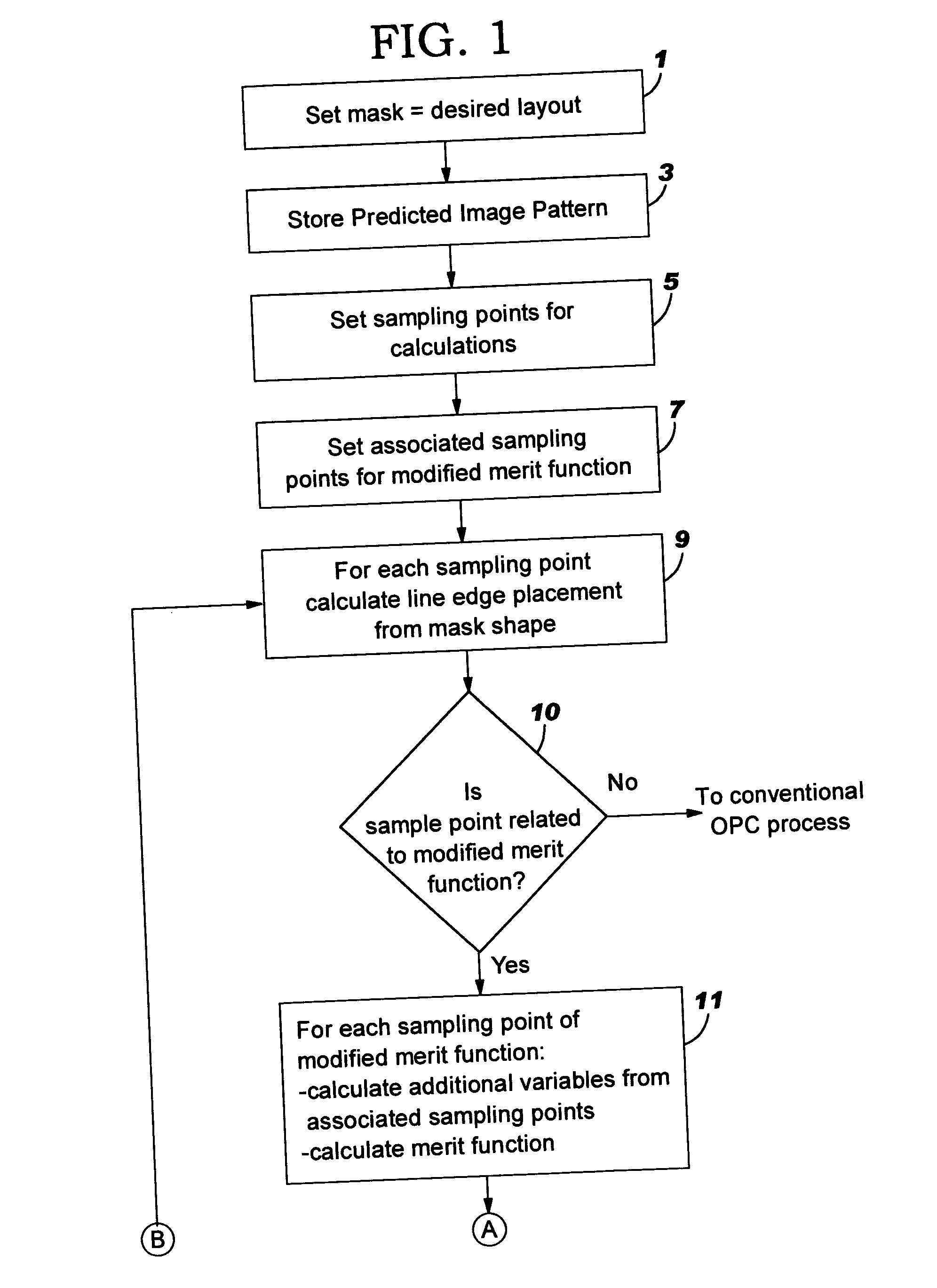

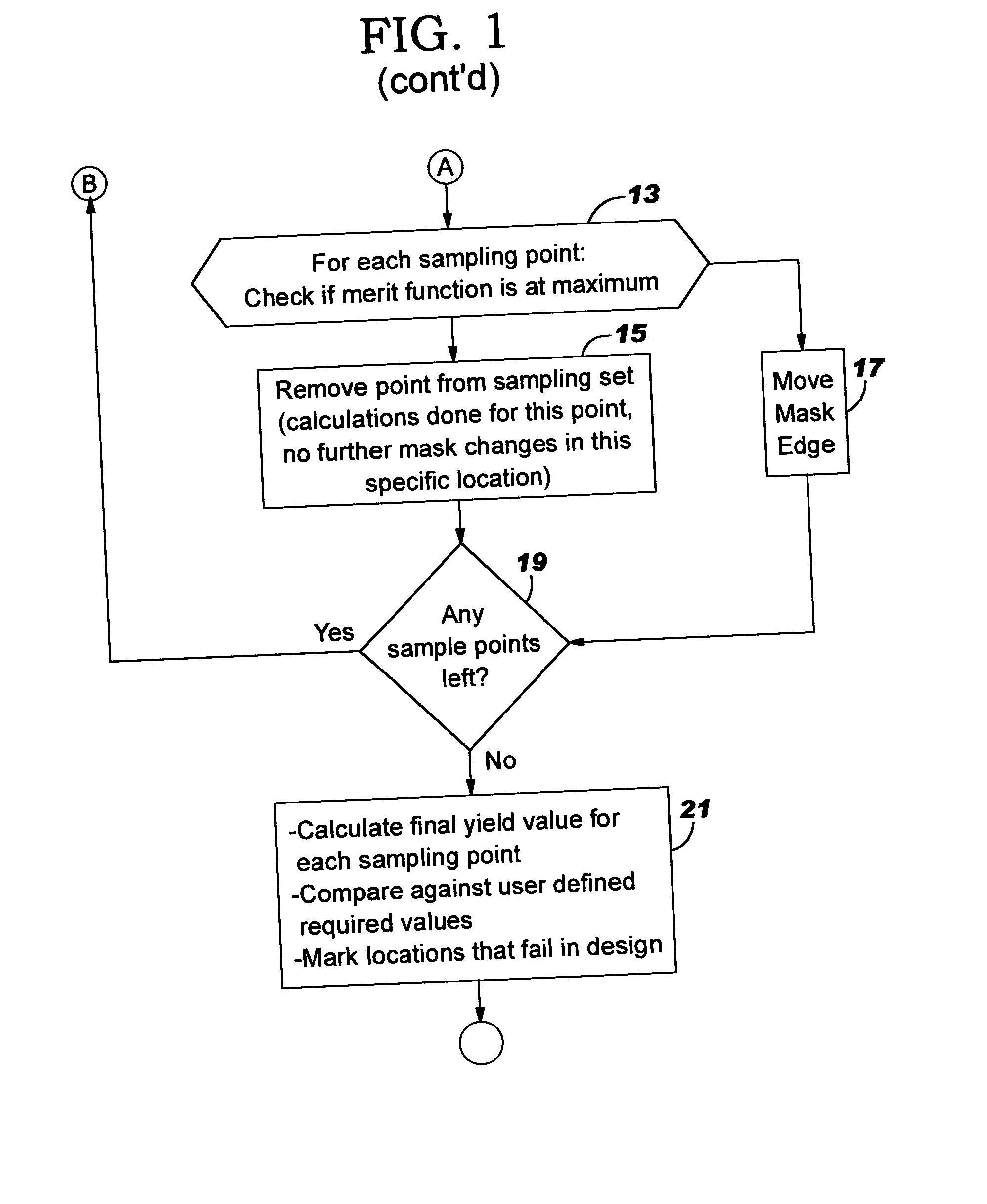

Method for interlayer and yield based optical proximity correction

InactiveUS6961920B2Improve lithographic processIncrease proximityPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringMerit function

An optical proximity correction method is provided using a modified merit function based upon yield. Known failure mechanisms related to layout geometries are used to derive yield functions based upon distance values between layout features, such as, edge features. In comparing the edge points on the predicted layout pattern with the corresponding point on the design layout pattern, a yield test is first undertaken before movement of the points on the predicted layout pattern to a position of higher yield. Where yield is acceptable, no further movement is made. Where incremental movement of points results in coming within acceptable proximity before acceptable yield is reached, the point is flagged for further consideration.

Owner:GLOBALFOUNDRIES INC

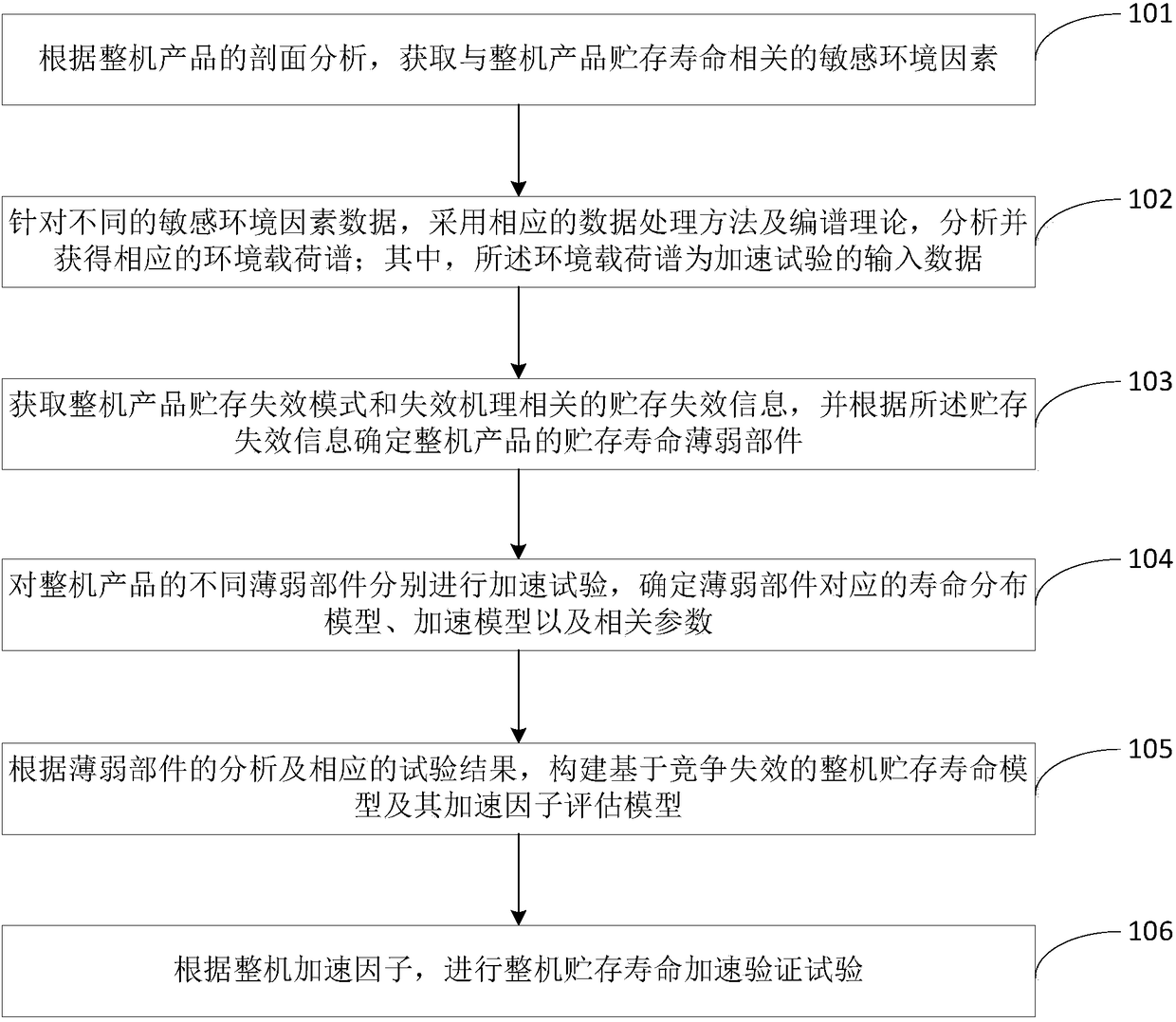

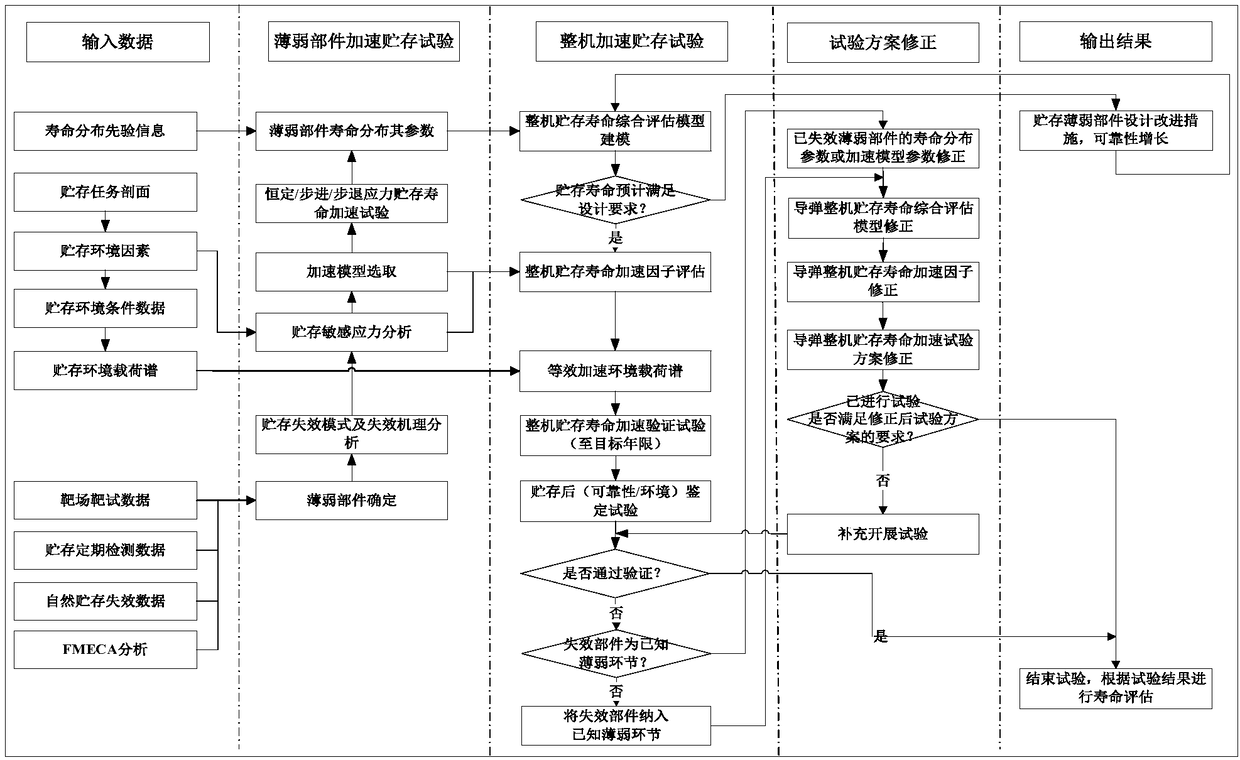

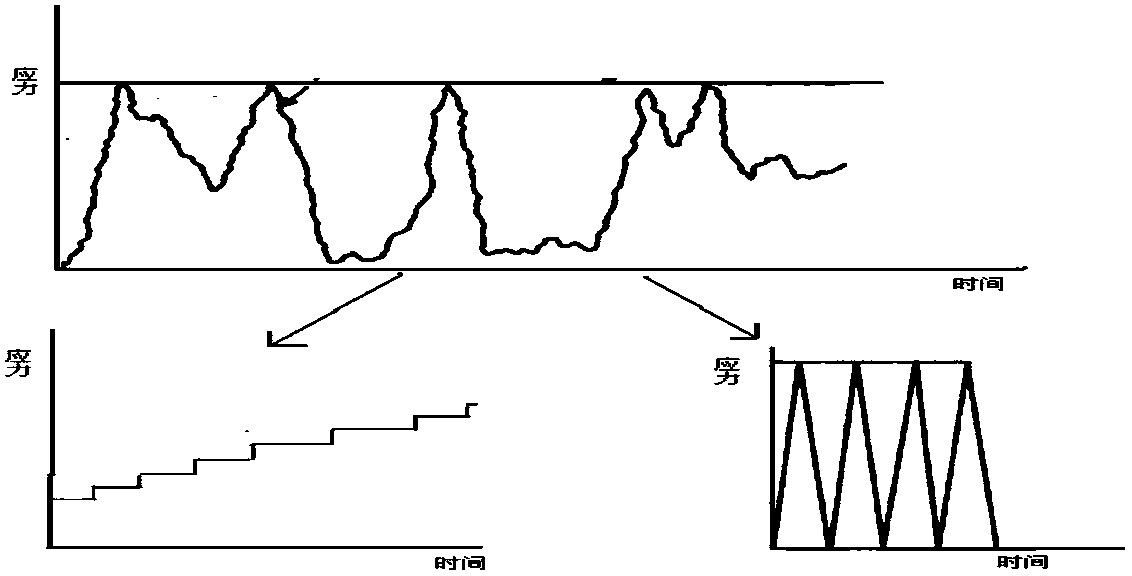

Complete machine level product storage life acceleration test method

ActiveCN108333208AAccelerated storage life test is effectiveAccelerated test is validMaterial thermal analysisAcceleration factorSection analysis

The invention discloses a complete machine level product storage life acceleration test method. The method comprises steps as follows: sensitive environment factors related to the storage life are acquired according to cross-section analysis; the environment loading spectrum is analyzed and acquired with a corresponding data processing method and spectrum compiling theories; storage failure information related to a complete machine product storage failure mode and a failure mechanism is acquired, and storage life weak components of a complete machine product are determined according to the storage failure information; acceleration tests are performed on different weak parts, corresponding life distribution models, acceleration models and related parameters of the weak components are determined; a complete machine storage life model based on competing failure and an acceleration factor evaluation model of the complete machine storage life model are constructed according to analysis andcorresponding test results of the weak components; complete machine storage life acceleration verification tests are performed according to acceleration factors. By means of the complete machine levelproduct storage life acceleration test method, effective acceleration storage tests can be performed on the complete machine product, and the accurate life analysis result of the complete machine product is obtained.

Owner:CASIC DEFENSE TECH RES & TEST CENT

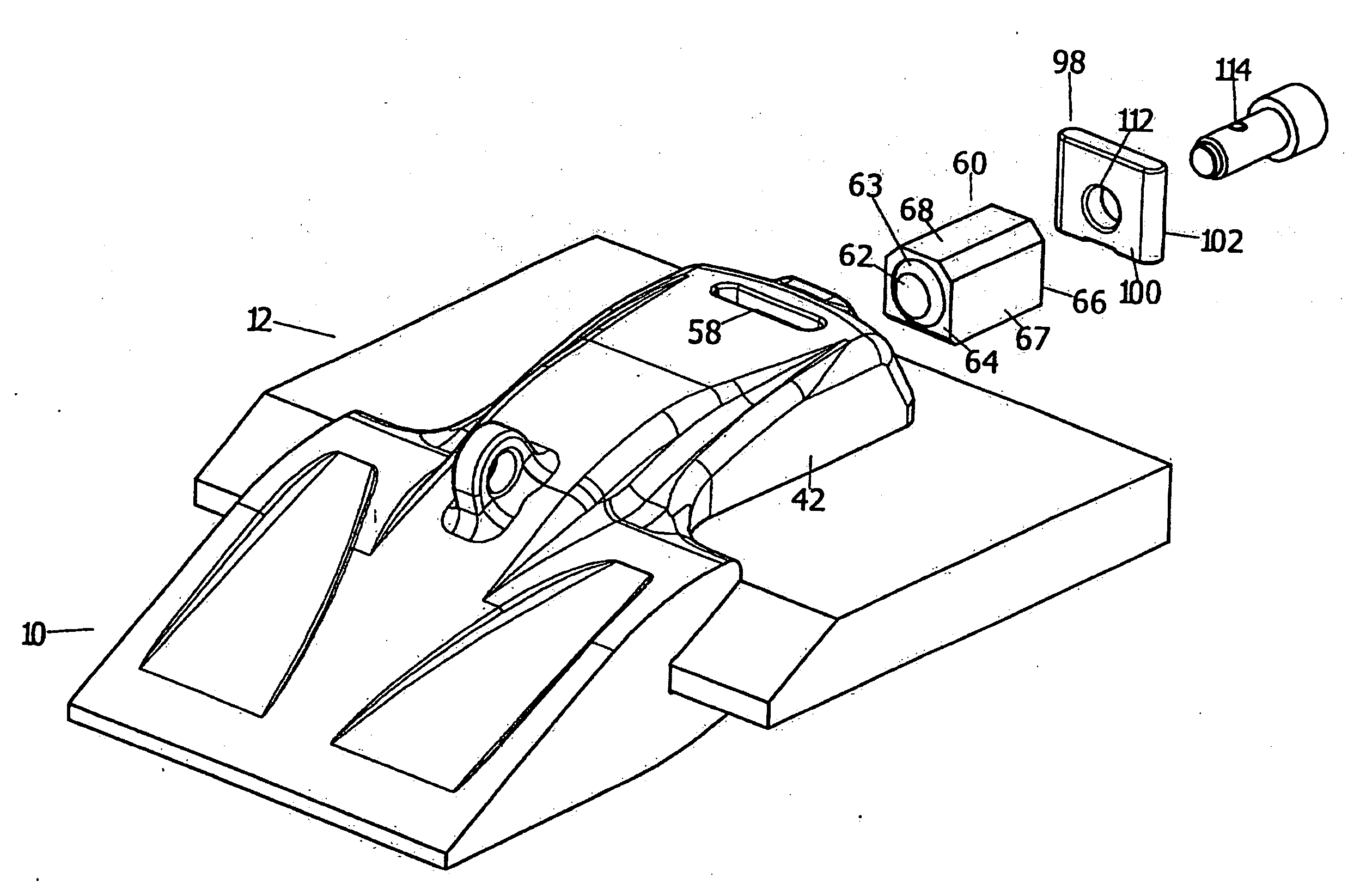

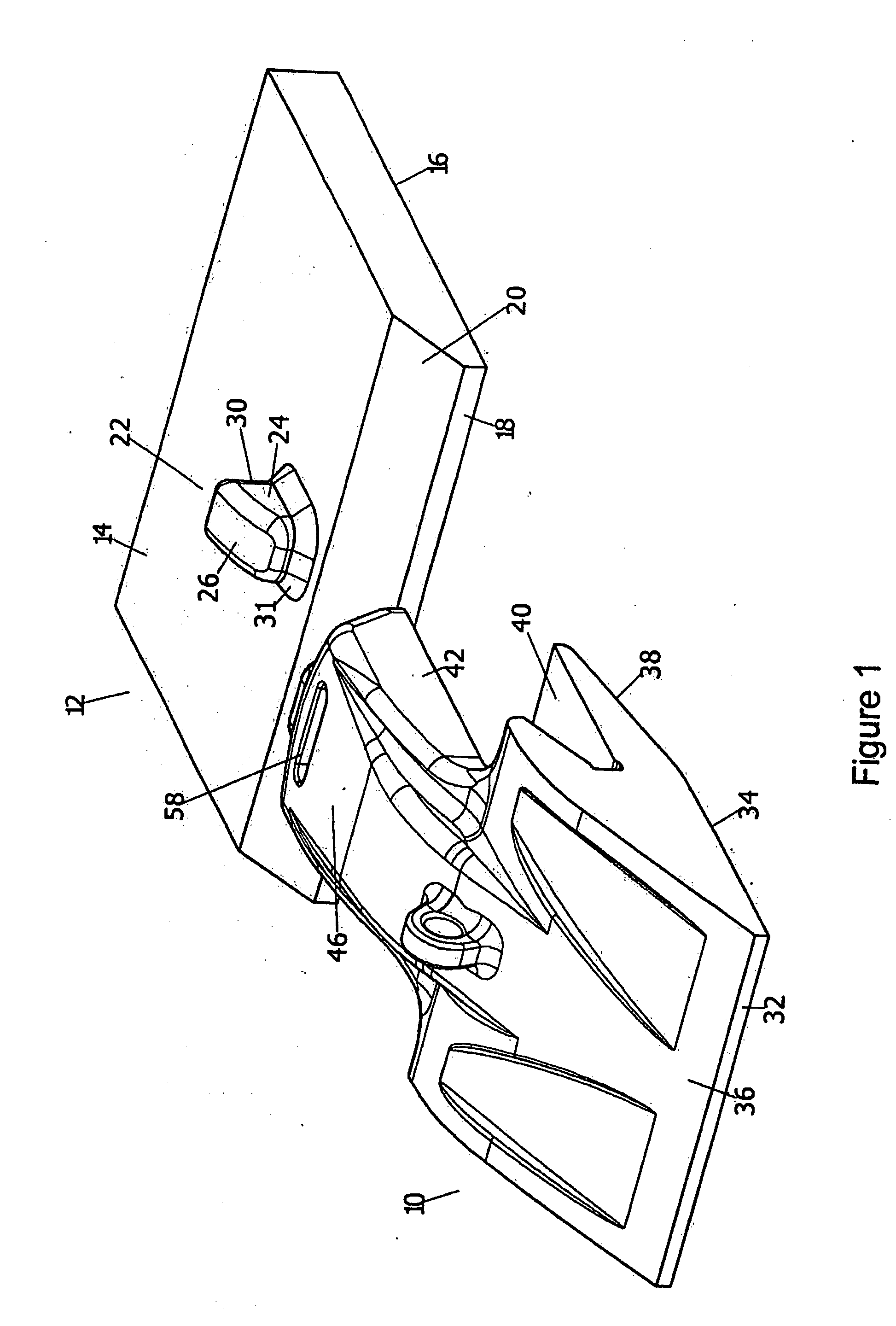

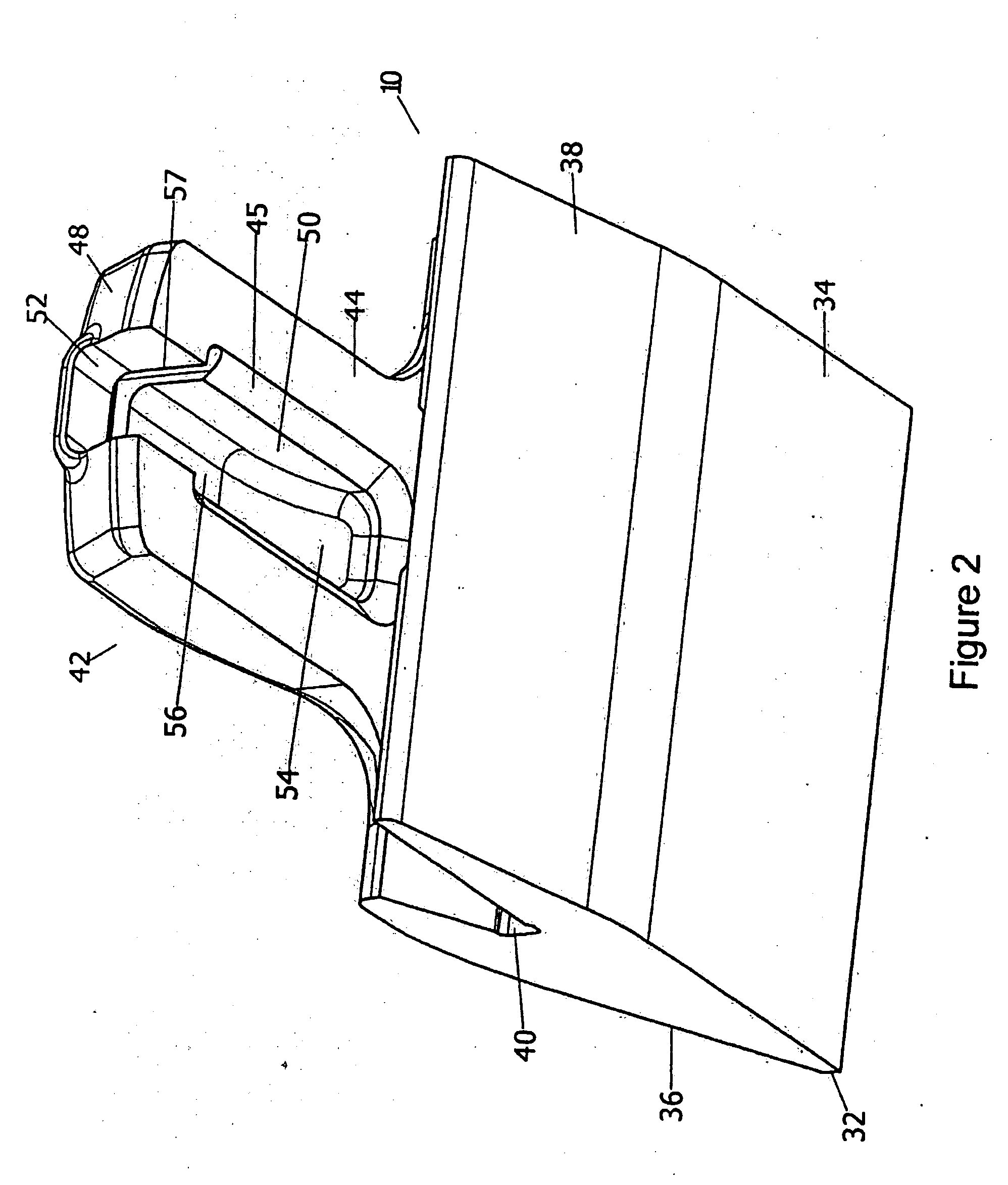

Mechanical attachment system and associated failure mechanism

InactiveUS20090282711A1Rod connectionsSoil-shifting machines/dredgersEngineeringMechanical engineering

Owner:SANDVIK SHARK

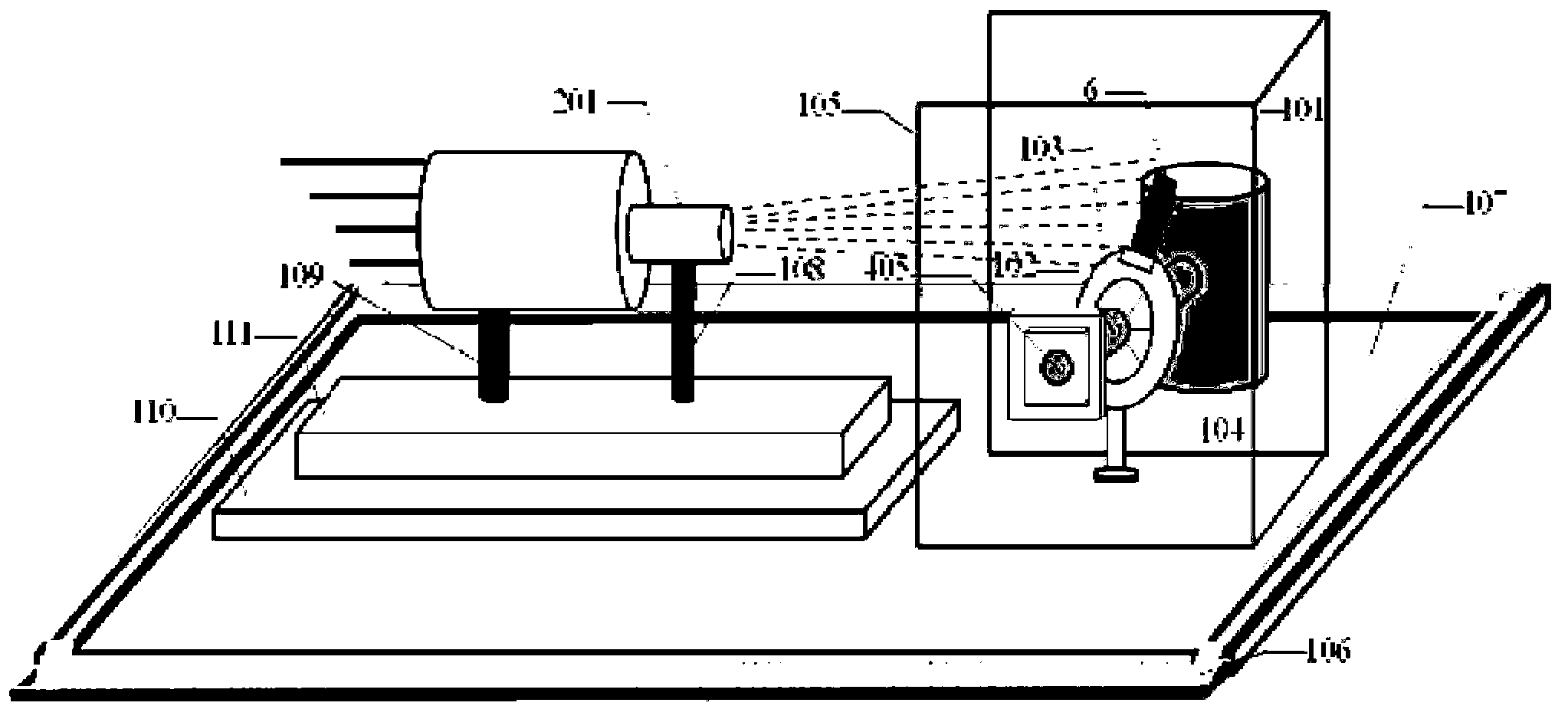

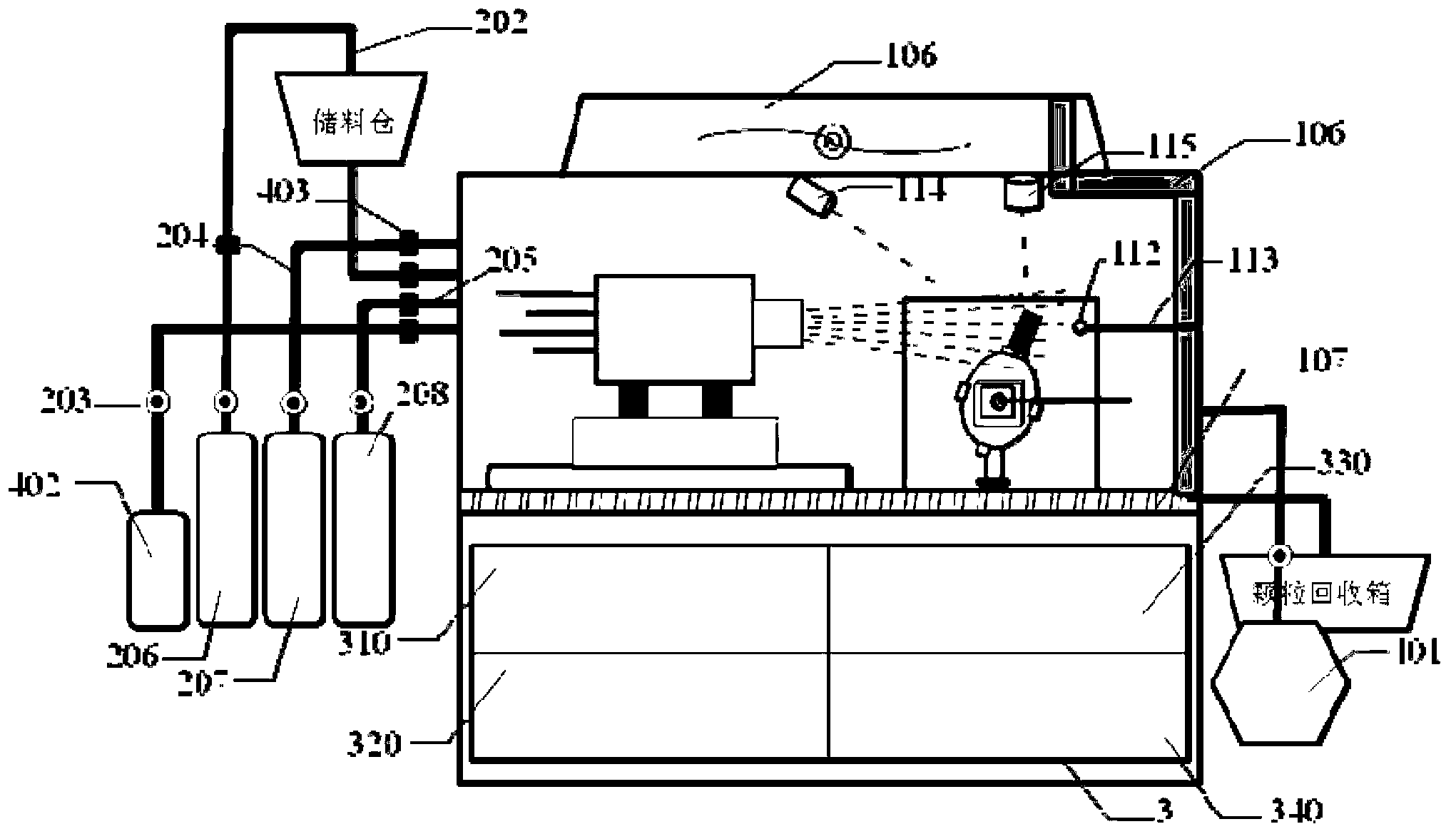

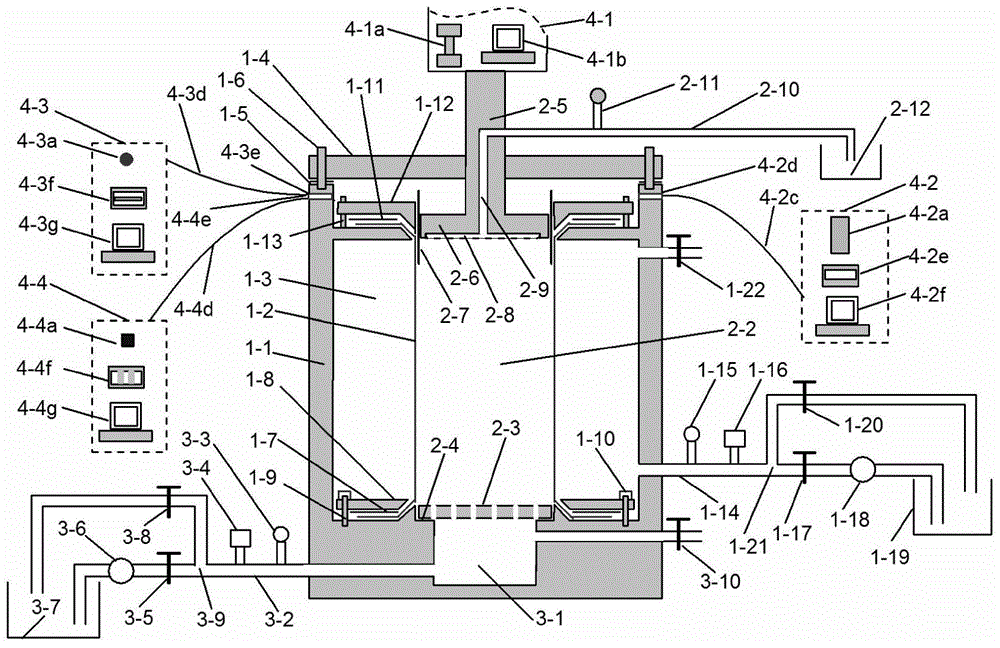

Testing device for simulation and real-time detection of erosion of thermal barrier coatings of turbine blades

ActiveCN103063534AEasy to realize included angleFast heating rateInvestigating abrasion/wear resistanceTest platformTopography

The invention discloses a testing device for simulation and real-time detection of erosion of thermal barrier coatings of turbine blades, belonging to the field of simulation devices in a special service environment. The testing device comprises an erosion particle feeding system, a test testing platform (1), a temperature test system, an acoustic emission nondestructive testing system, a control platform and the like. An erect fixed shaft (101) is arranged on the test testing platform (1) and is connected with a horizontal supporting shaft. The testing device can be used for simulating the erosion service environment in which hard particles in a high-performance aero-engine repeatedly impact thermal barrier coatings of turbine blades due to the driving of airflow. By controlling the parameters such as erosion speed, angle, size and the like of erosion particles, the process that the coatings are eroded by different hard particles in the service process is realized and the real-time test and analysis of data, such as the temperature, the surface topography evolution, the interfacial oxidation of a sample and the like can be synchronously realized. The device can provide an important test platform for effectively assessing the erosion failure process and the failure mechanism of coatings of turbine blades in the special service environment.

Owner:XIANGTAN UNIV

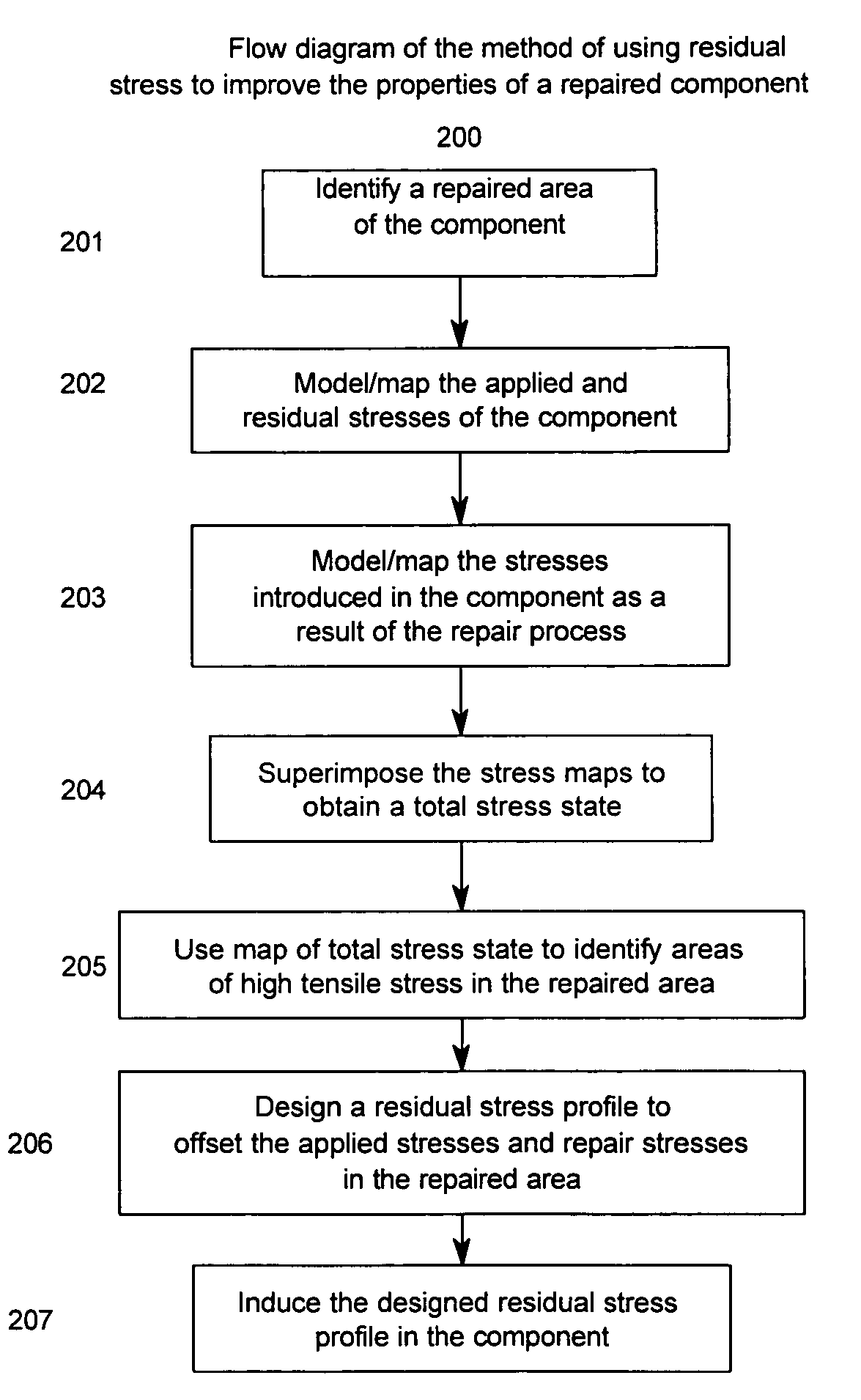

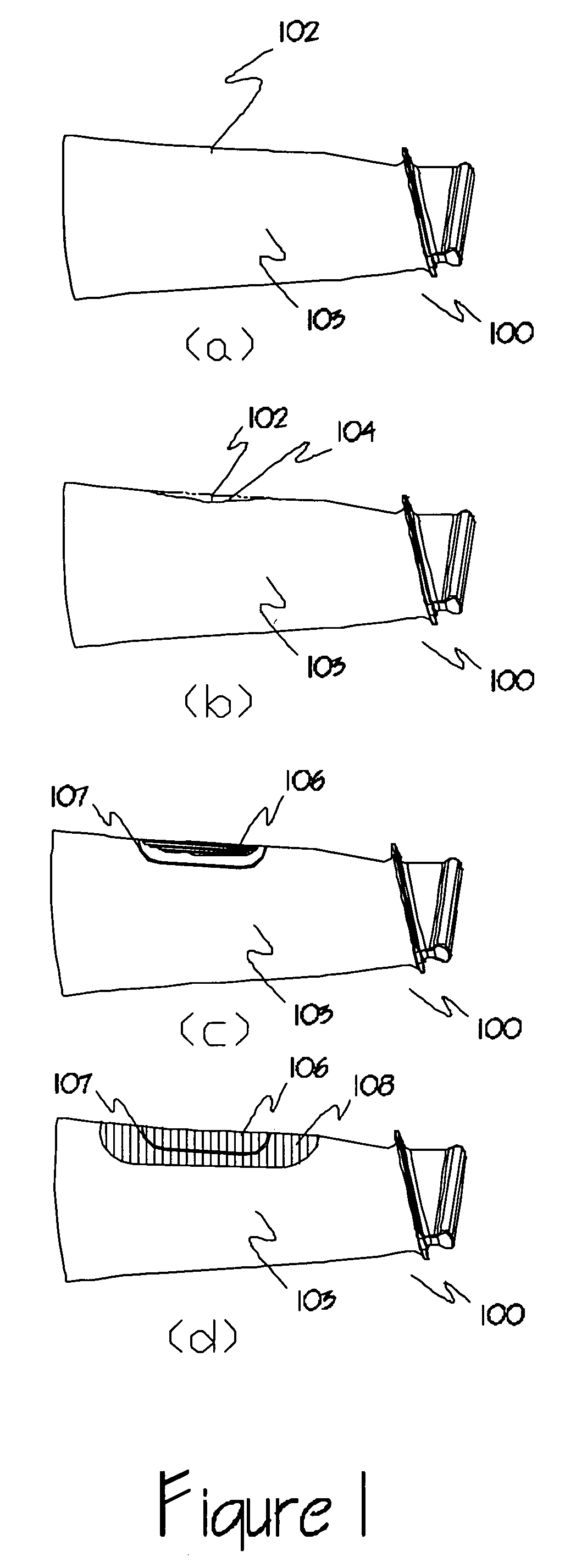

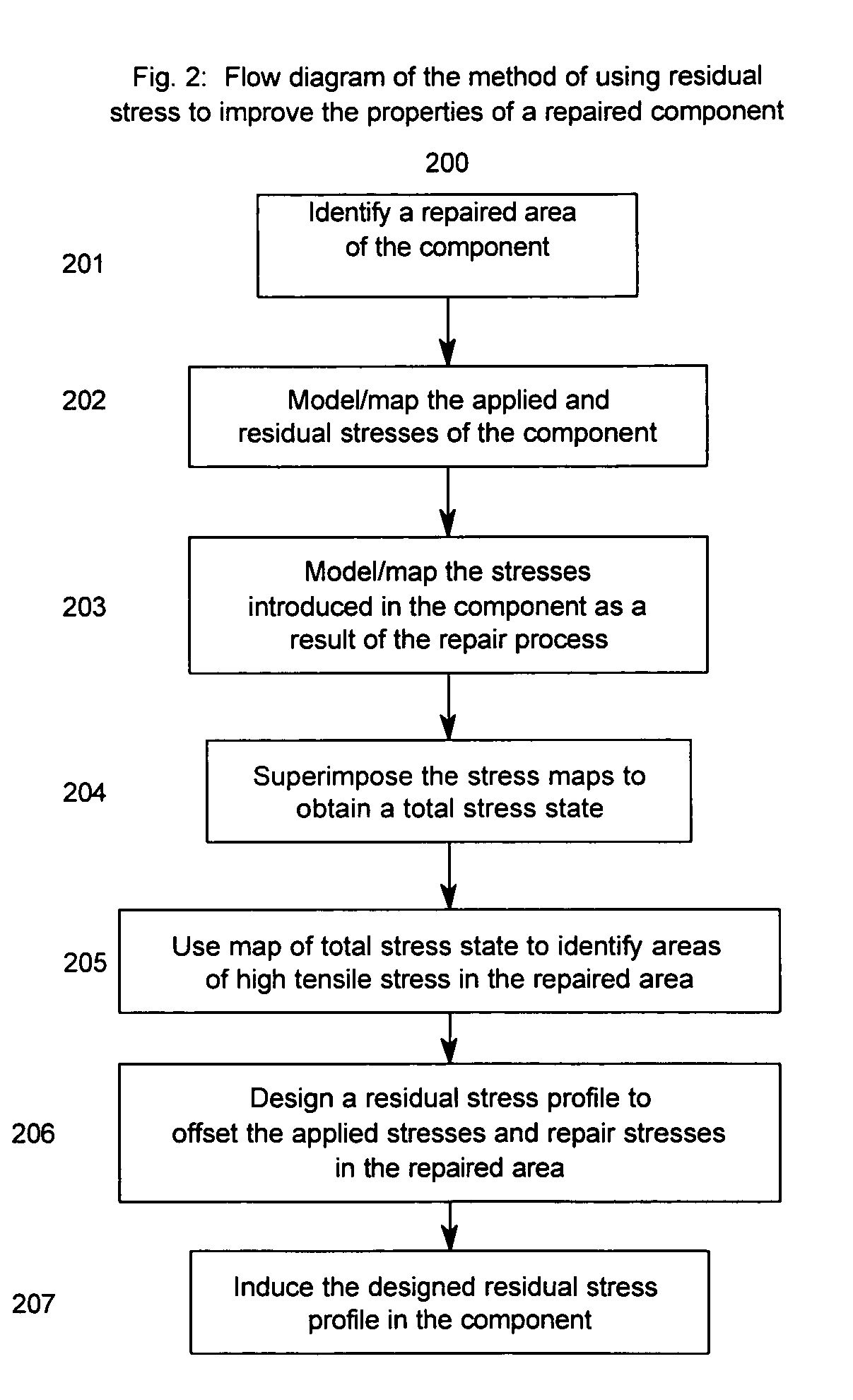

Method of improving the properties of a repaired component and a component improved thereby

InactiveUS20070157447A1Improved material and mechanical propertySimple materialBlade accessoriesEfficient propulsion technologiesForeign matterForeign object damage

A repaired component with improved material and mechanical properties and a method of improving the properties of a repaired component are provided. The repaired component comprises a body, a repaired area integral with the body, and an area of compressive residual stress wherein the area of compressive residual stress comprises at least a portion of the repaired area. One method for improving the fatigue performance, foreign object damage tolerance, and resistance to stress related failure mechanisms of a repaired component includes inducing a designed residual compressive stress distribution with a controlled amount of cold work in the repaired area to offset high-applied tensile stresses and stresses introduced as a result of the repair procedure as well as to improve the properties of the material added to the component during the repair.

Owner:PREVEY PAUL S

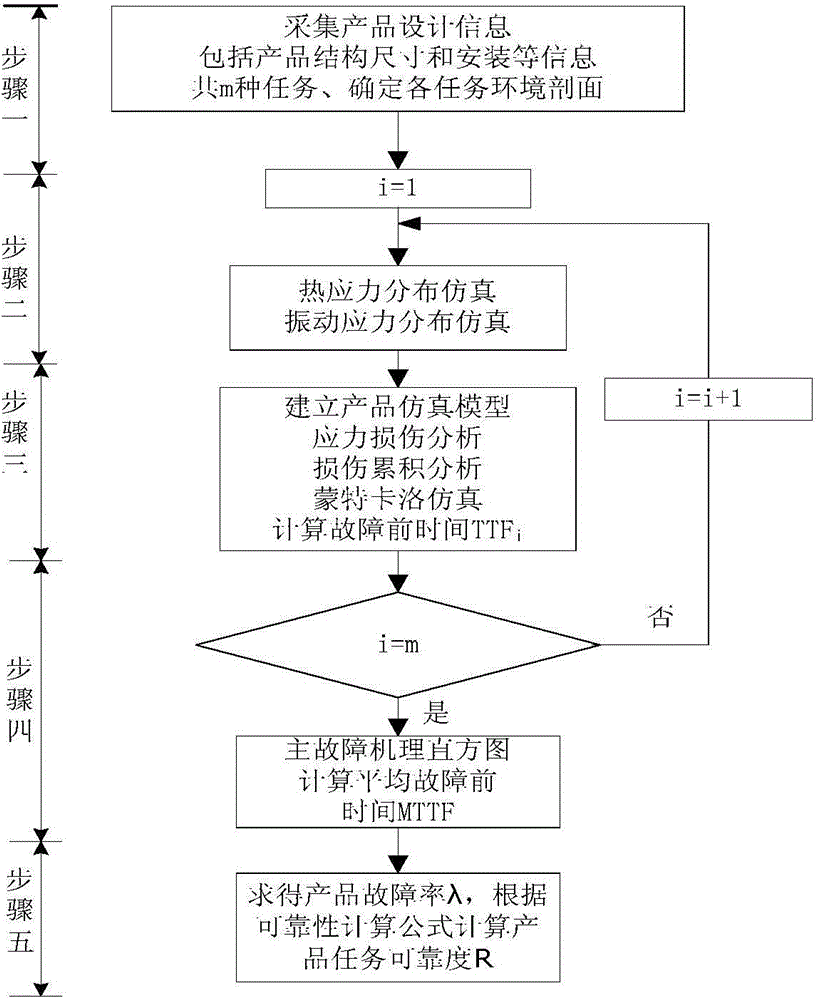

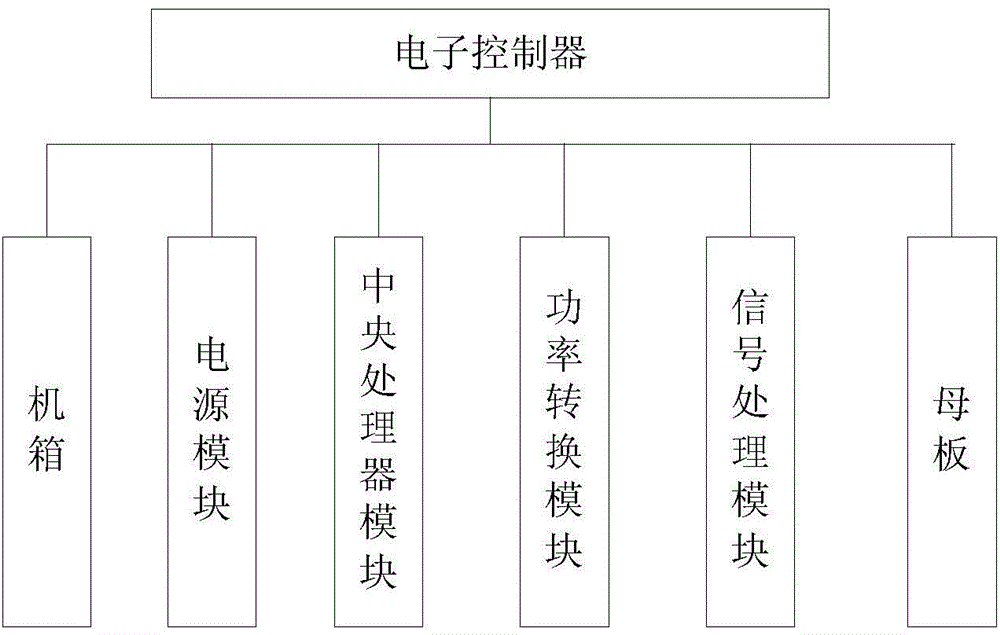

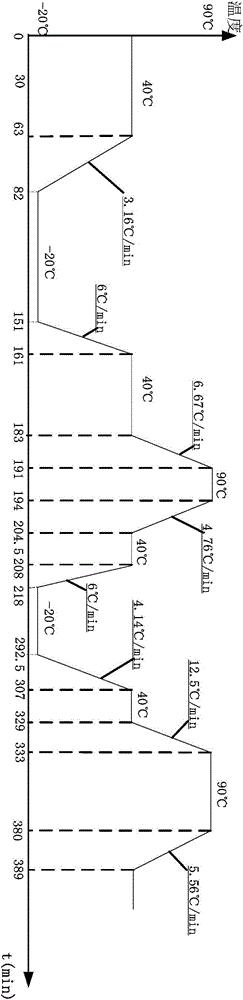

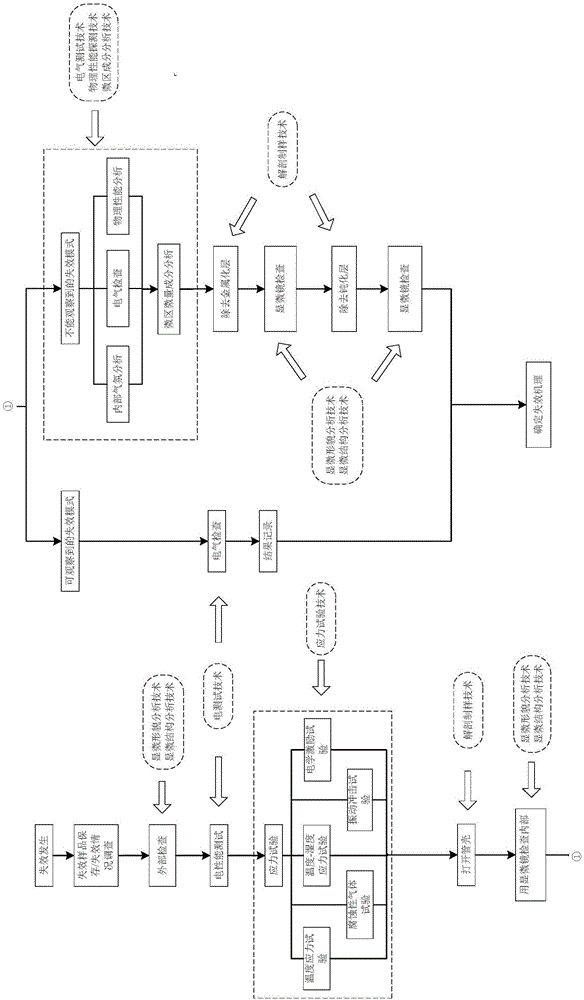

PoF (physics of failure) based method for calculating mission reliability of electronic product

ActiveCN103559418AIn line with the real situationReflect the stress situationSustainable transportationSoftware simulation/interpretation/emulationComputing MethodologiesDesign improvement

A PoF based method for calculating mission reliability of an electronic product comprises steps as follows: step one, information of all mission profiles of the product is collected, and an environment profile of each mission is determined; step two, thermal simulation and vibration simulation of environmental stress of each mission are performed, and a local response of the product to an environmental load is obtained; step three, a product simulation model is established; step four, simulation calculation of the product in all the mission profiles is completed, and the mean time to failure and a main failure mechanism of the product are obtained; and step five, the mission reliability of the product is calculated according to the mean time to failure. According to the PoF based method for calculating the mission reliability of the electronic product, all missions of the product during lifetime use are considered, the environmental stress of each mission is simulated, and the mean time to failure and the mission reliability of the product are comprehensively calculated. By means of a PoF model, the direction relation between parameters of a product material, structure, process and the like and the reliability can be obtained, and a design improvement direction is clearly and directly provided for the product.

Owner:BEIHANG UNIV

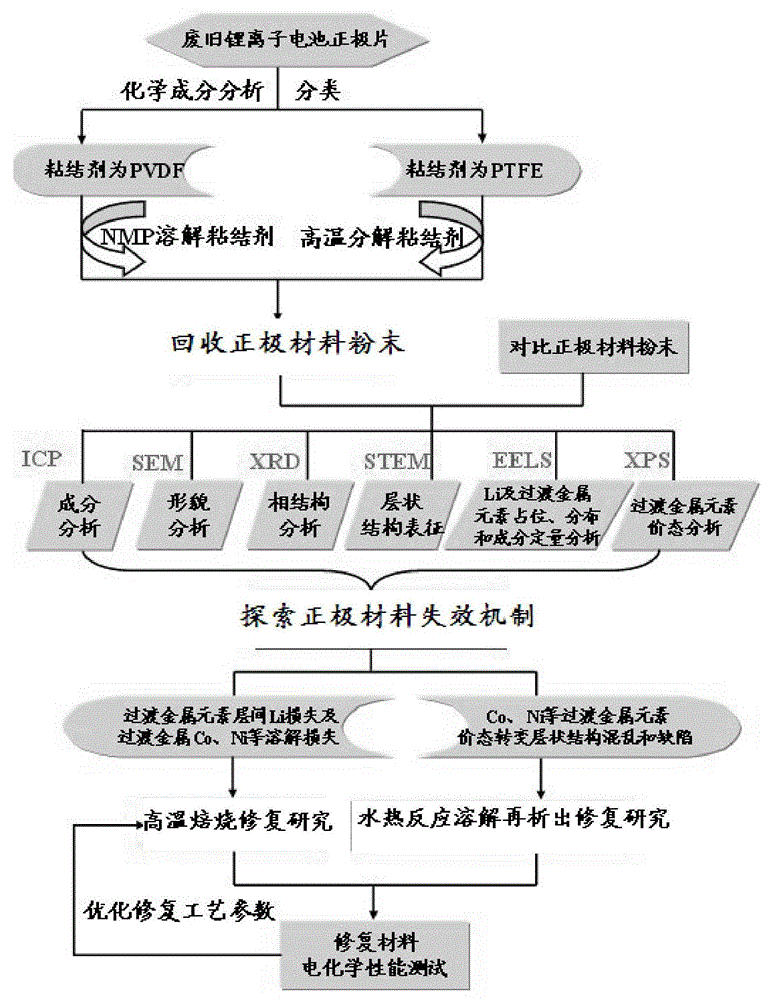

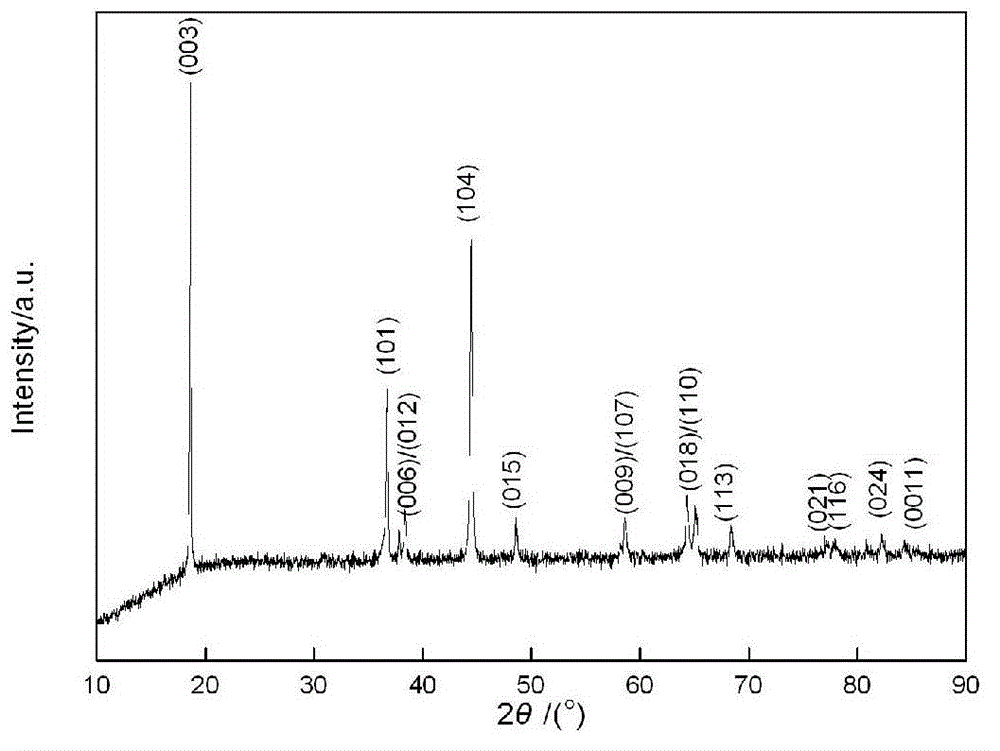

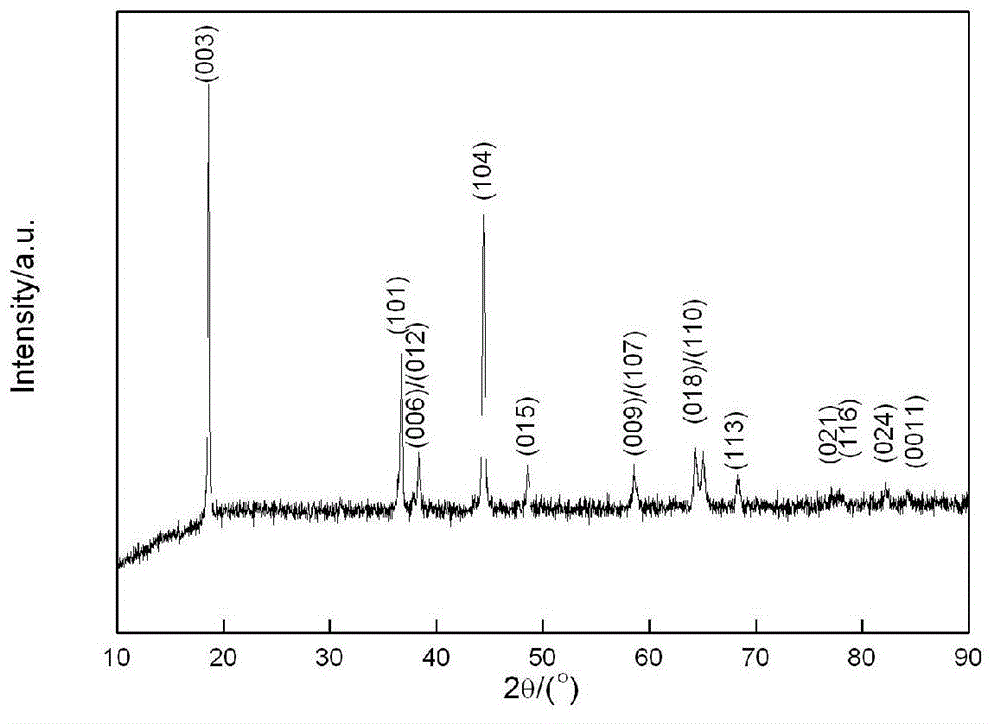

Method for direct recovery and restoration of lithium ion battery positive electrode material

ActiveCN103915661AAvoid leachingPrevent extractionWaste accumulators reclaimingProcess efficiency improvementLiquid wasteCharge discharge

The invention discloses a method for direct recovery and restoration of a lithium ion battery positive electrode material, and belongs to the field of resource recycling. According to the method, waste positive electrode pieces of lithium cobaltate or lithium nickel manganese cobalt multi-element layered oxide or a positive electrode piece leftover material and defective products are used as a positive electrode material; the materials are classified according to the type of binder by component analysis, the binder is directly damaged, cleaning and separation of the positive electrode material and a current collector are realized; by use of a heavy liquid separation principle, the positive electrode and a conductive agent are separated; the positive electrode failure mechanism is studied by use of SEM (scanning electron microscope), XRD (X-ray diffraction), STEM (scanning transmission electron microscope), XPS (X-ray photoelectron spectroscopy) and other analysis means; chemical components of the positive electrode material with the layered structure not damaged can be repaired by high temperature roasting, the layered structure of the positive electrode material with disordered and defective crystal lattice can be repaired by dissolving with a hydrothermal reaction and then precipitation, and the positive electrode material with good charge discharge performances can be again obtained. The method avoids the dissolving leaching process, reduces waste liquid generation, and simplifies the technological process.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

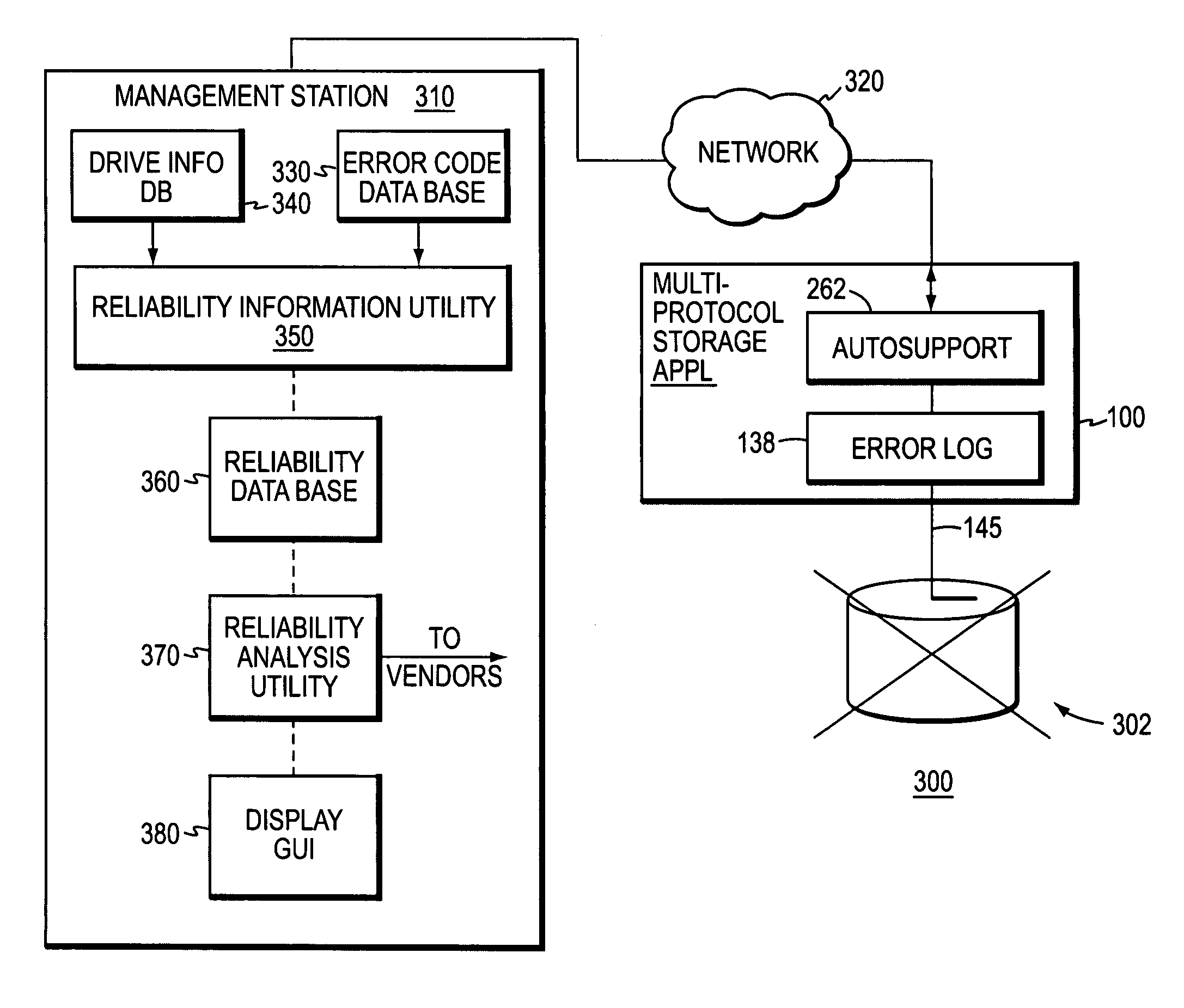

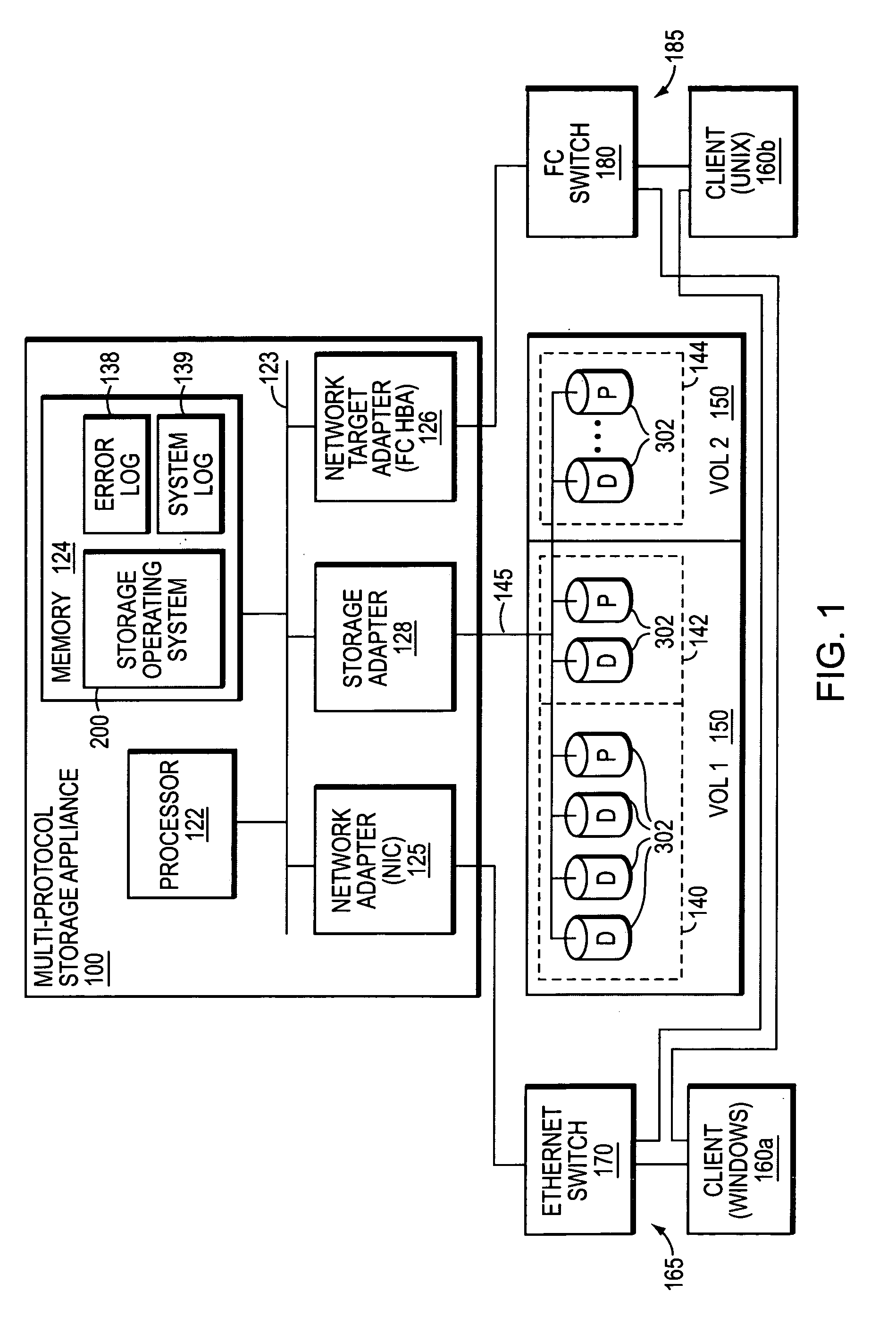

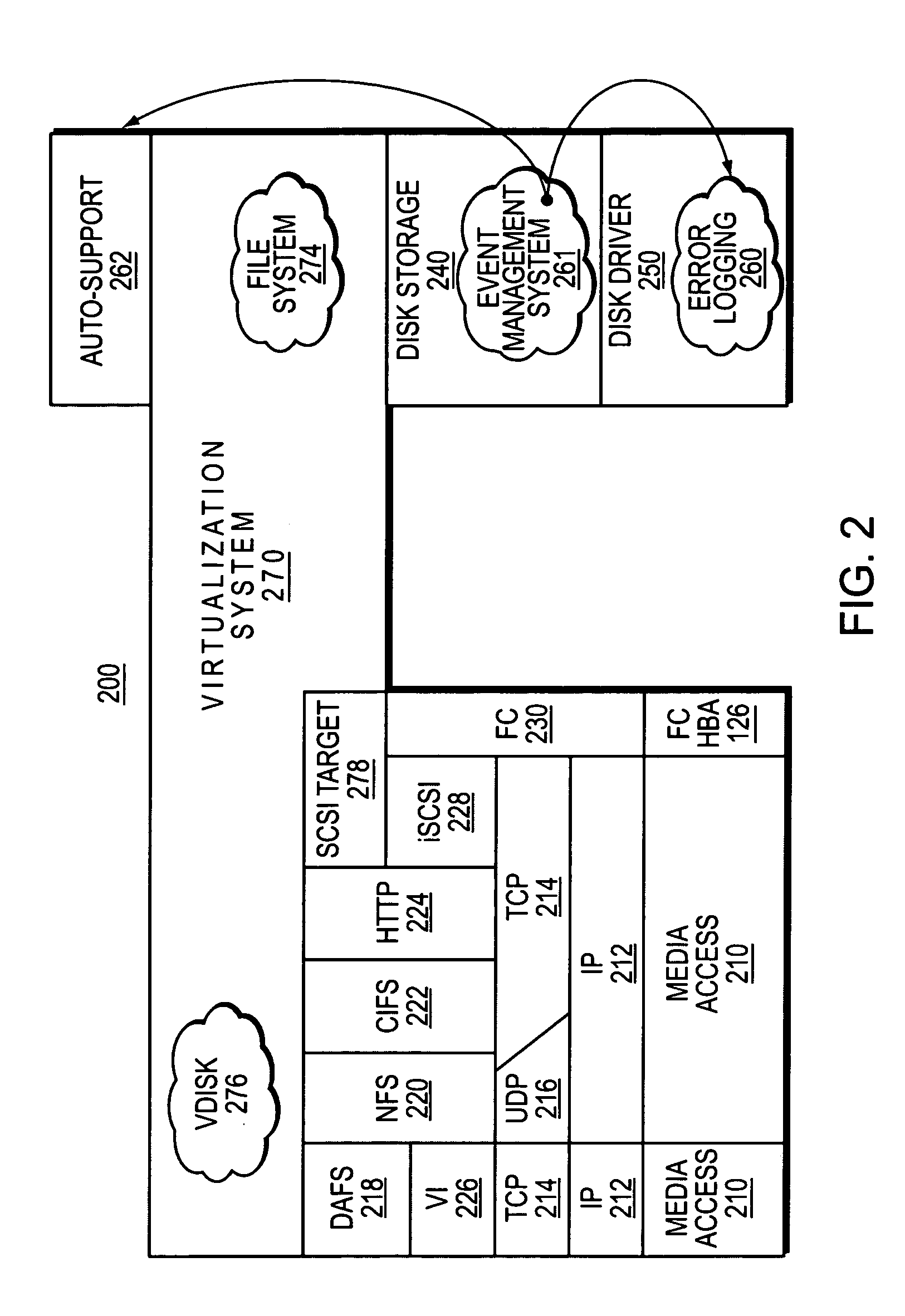

Method and system for reliability analysis of disk drive failures

ActiveUS7136768B1Improve disk drive reliabilityImprove driving reliabilityVehicle testingAerodynamic testingFault indicatorCode conversion

A method and system for performing reliability analysis of disk drive failure mechanisms is provided. The information for performing the analysis is obtained in accordance with the invention from a database generated from identification information stored about individual drives, and drive families, that are deployed in the field. An error database stores error codes that are issued by a disk drive upon a particular event. These error codes are reported to a storage system administrator and recorded in the error database. The disk drive information and the error codes are mapped, and error codes are translated into failure mechanisms for a particular drive family. An analysis is performed whereby a hazard rate plot is provided for either all failure indicators or selected failure indicators or subpopulations for a particular drive family over a given time.

Owner:NETWORK APPLIANCE INC

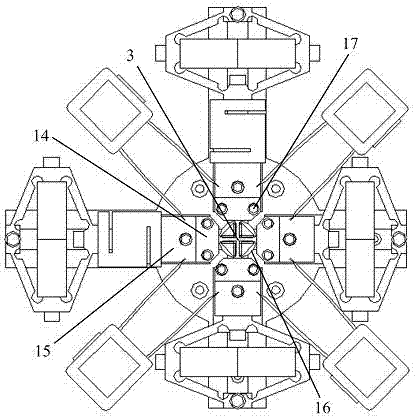

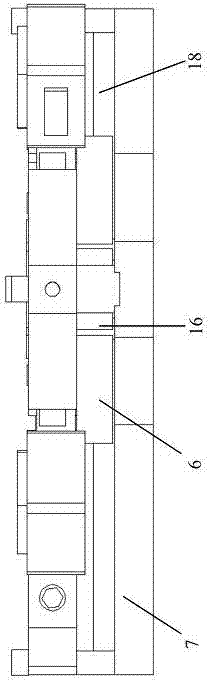

Online material biaxial static-dynamic performance test platform under service temperature

ActiveCN104502202AImprove reliabilityImprove stabilityMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesAlloyEngineering

The invention relates to an online material biaxial static-dynamic performance test platform under service temperature, belonging to the field of precision drive. The large-stroke biaxial synchronous identical-speed or synchronous different-speed displacement output is realized by virtue of four groups of piezoelectric actuators which are orthogonally distributed, and the biaxial static tensile test or dynamic fatigue test for a block-shaped material or a film material with a characteristic size being in a millimeter scale can be carried out under a high / low temperature service condition by combining with an embedded high temperature electrothermal alloy sheet / parr patch. The online material biaxial static-dynamic performance test platform is likely to use in conjunction with a scanning electron microscope with a relatively-large vacuum cavity or other microimaging device with an open-type carrier space, such as an optical microscope, an atomic power microscope and a high speed camera, so that the multimode biaxial static tensile test or the large-frequency-range biaxial dynamic fatigue test can be carried out, and the research for the microstructure evolution behavior and fatigue failure mechanism of various structural materials or functional materials under a complicated service condition such as a high / low temperature condition and a static-dynamic plane stress condition can be facilitated.

Owner:JILIN UNIV

Pressure rock failure and instability process and dynamic permeability test apparatus and method thereof

ActiveCN104977234AEasy to replaceUniform confining pressureAnalysing solids using sonic/ultrasonic/infrasonic wavesPermeability/surface area analysisCouplingInstability

The invention relates to a pressure rock failure and instability process and dynamic permeability test apparatus and a method thereof. A stress strain signal, a sound emission signal and an apparent resistivity signal in the pressure rock failure and instability process are acquired and processed by using a large pressure rock permeability test device to obtain the stress strain relationship, the quantity and positions of sound emission events and the rock apparent resistivity change rule induced by pressure water permeability increase in large pressure rock failure and instability process in order to obtain the dynamic evolution role of crack expansion, perforation and instability in the rock failure process under hydraulic-mechanical coupling action and the corresponding dynamic permeability. The hydraulic-mechanical coupling failure mechanism and the pressure permeability of rocks, and the deformation and strength characteristics, the crack expansion, perforation and failure characteristics and the permeability evolution rule of pressure water in the crack expansion-perforation-failure process of the rocks under the hydraulic-mechanical coupling action are researched in the invention. The apparatus and the method have important engineering values in realization of safe mining under water pressure on pressure water.

Owner:ANHUI UNIV OF SCI & TECH

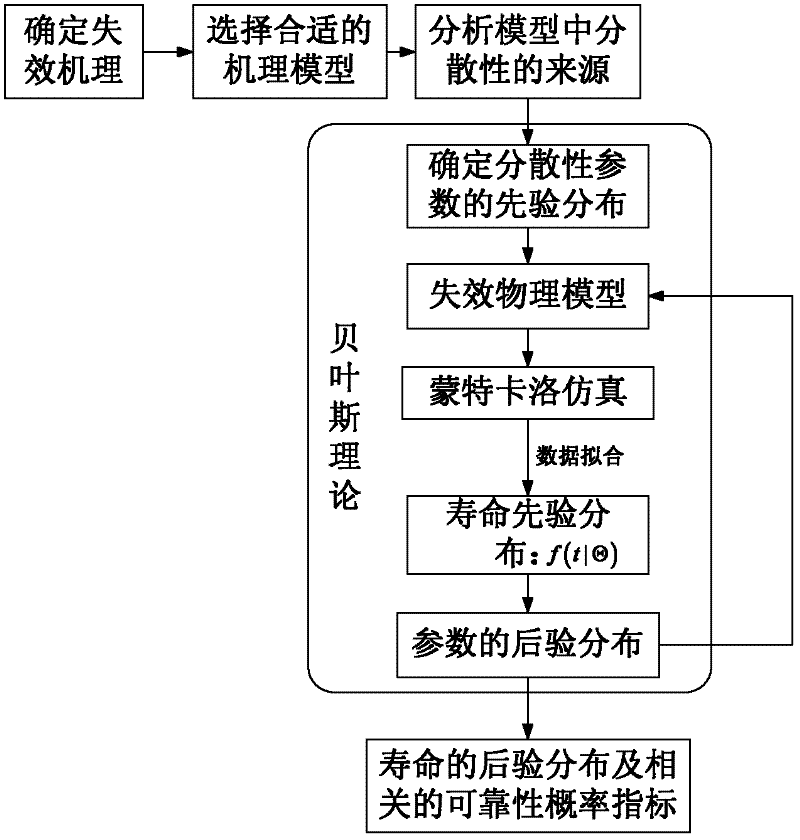

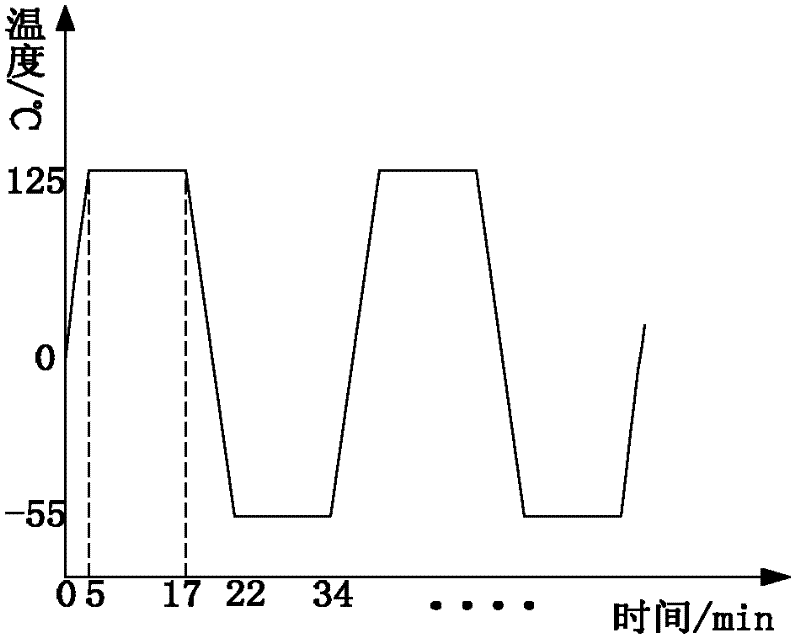

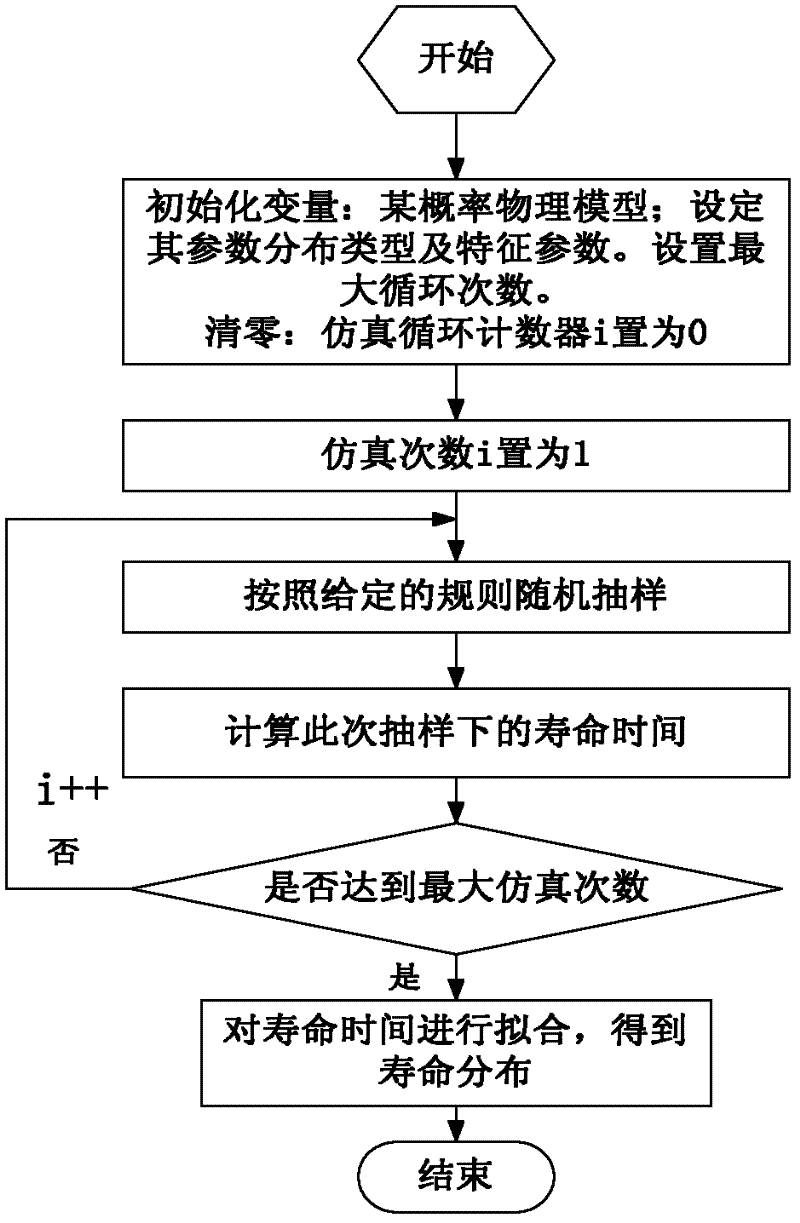

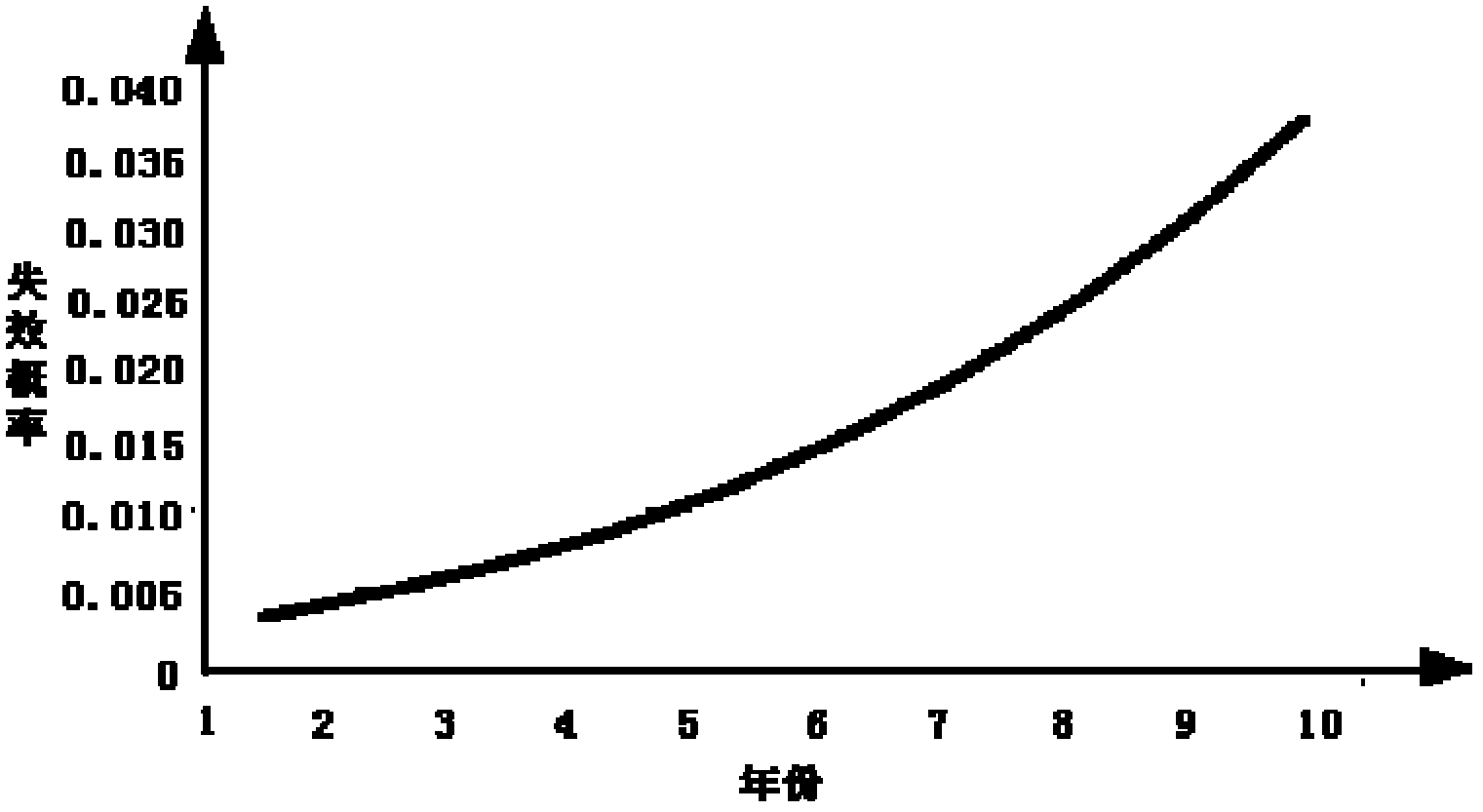

Probability method of electronic product service life model based on Bayesian theory

ActiveCN102651054AShorten the timeSave costsSpecial data processing applicationsPhysical modelParameter distribution

The invention discloses a probability method of an electronic product service life model based on a Bayesian theory. The probability method comprises four steps of: step 1, determining a main failure mechanism and a physical model; step 2, determining the source and a characterization method of each dispersibility in the main failure mechanism; step 3, determining the service life distribution obeyed by the main failure mechanism; and step 4, updating the parameter distribution according to the Bayesian theory, and obtaining the numerical solution of a probability service life model by combining a failure physical model and utilizing a Monte Carlo sampling method. The method disclosed by the invention is used for calculating the failure probability of a highly-reliable and long-service-life electronic product based on a stress damage model; and by analyzing diepersibility and a description method of factors such as the attribute, the size and the stress of each material causing the electronic product failure and considering the dispersibility factors on the basis of the traditional failure physical model, the probability of the failure physical model is realized, and a new approach is provided for describing the failure more accurately and forecasting the product storage life.

Owner:BEIJING LANWEI TECH CO LTD

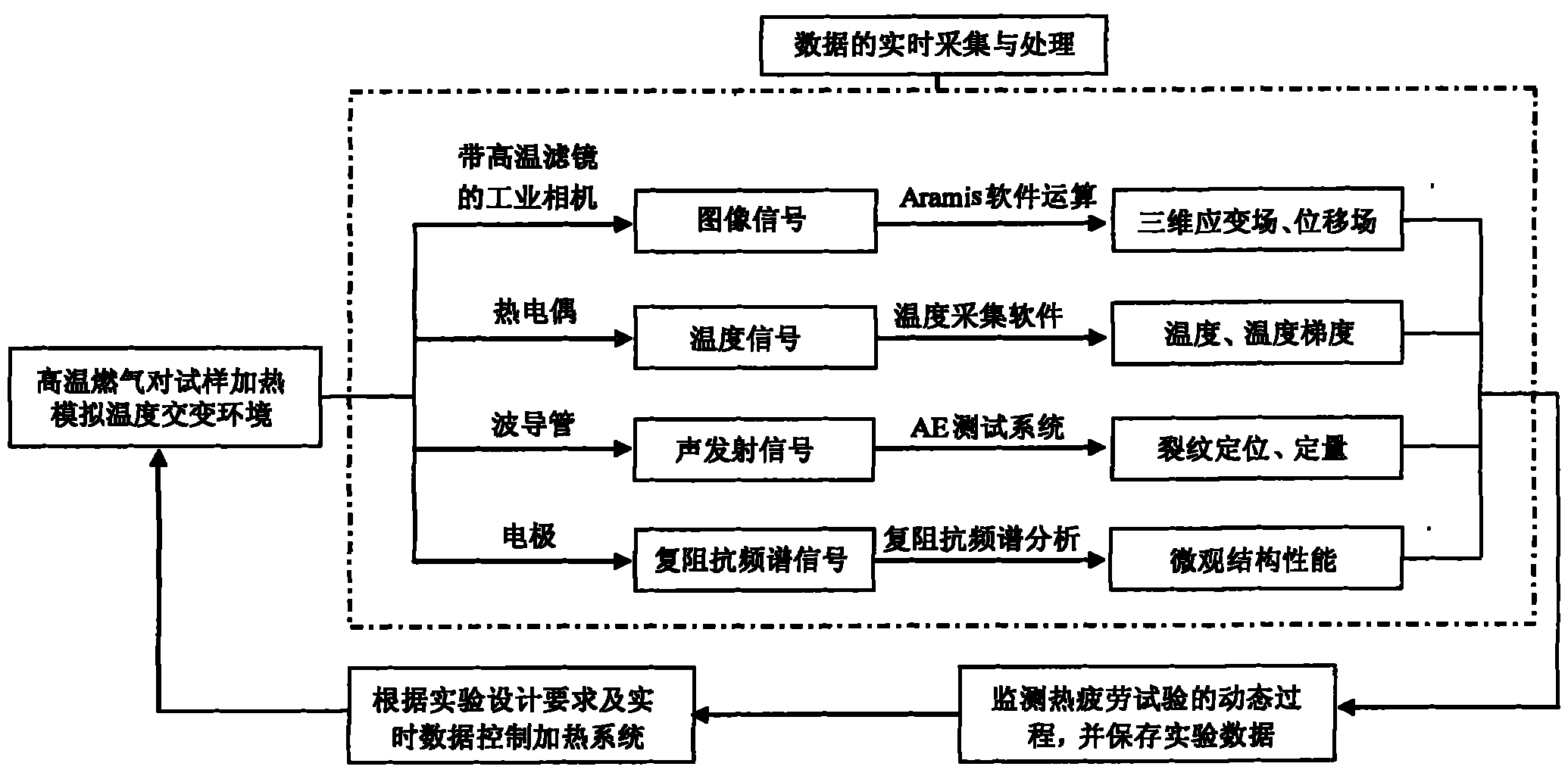

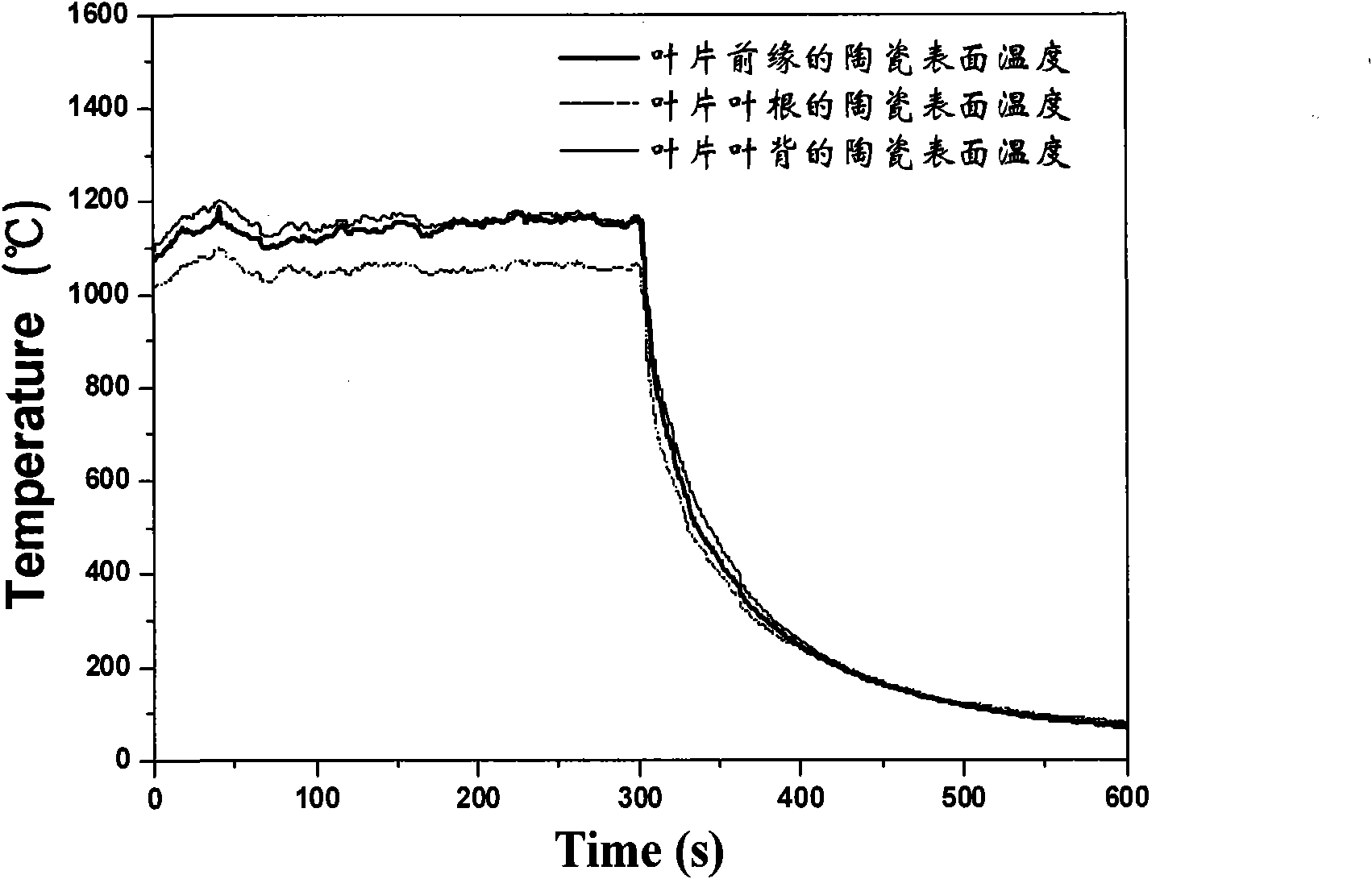

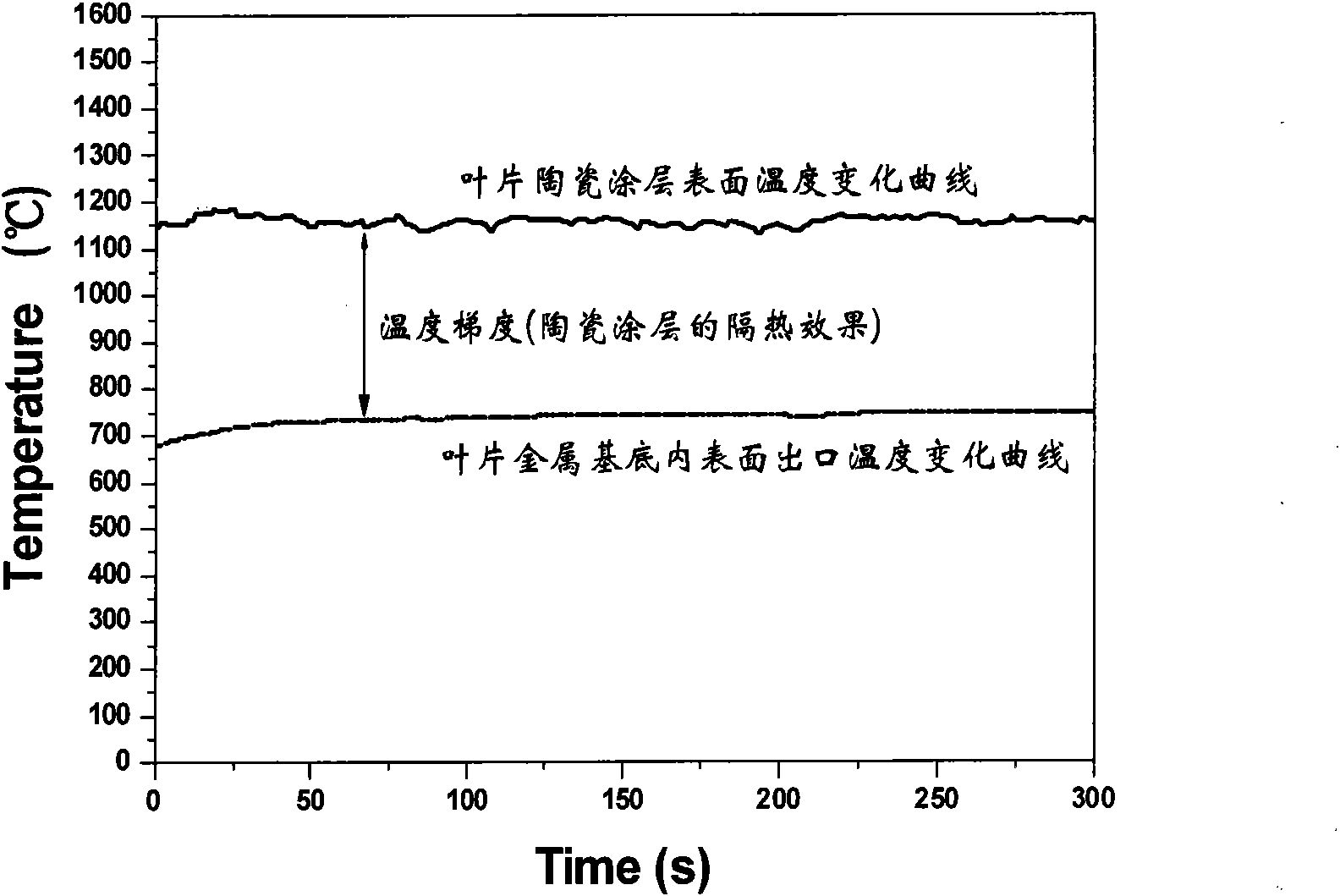

Simulation test method of thermal fatigue failure of blade with thermal barrier coating

ActiveCN101776645AMonitor temperature in real timeReal-time monitoring of temperature gradientsMaterial analysis using acoustic emission techniquesThermometers using electric/magnetic elementsAviationCeramic coating

The invention belongs to the technical field of turbine blade performance detection in the aviation industry, in particular to a simulation test method of thermal fatigue failure of a blade with thermal barrier coating. The method can simulate the thermal fatigue work environment of temperature alternating circulation of various blades in an aircraft engine with high performance, and simultaneously tests and analyzes data, such as temperature, temperature gradient, surface topography image evolution, three dimensional deformation field, three dimensional displacement field, interface oxidation layer and thickening rule thereof, thermal fatigue flaw initiation and expansion, cooling airflow and the like of a blade sample with a thermal barrier coating, thus realizing real-time monitoring of three dimensional thermal strain and stress of the blade in the process of thermal fatigue experiments, and providing an important means for predicting thermal fatigue damaging position and invalidation time of the blade. The experimental data obtained by the method can provide important experiment basis for effectively evaluating the failure mechanism of the aircraft engine blade in the environment of high-temperature gas and predicting ceramic coating dropping position, dropping time and service life.

Owner:XIANGTAN UNIV

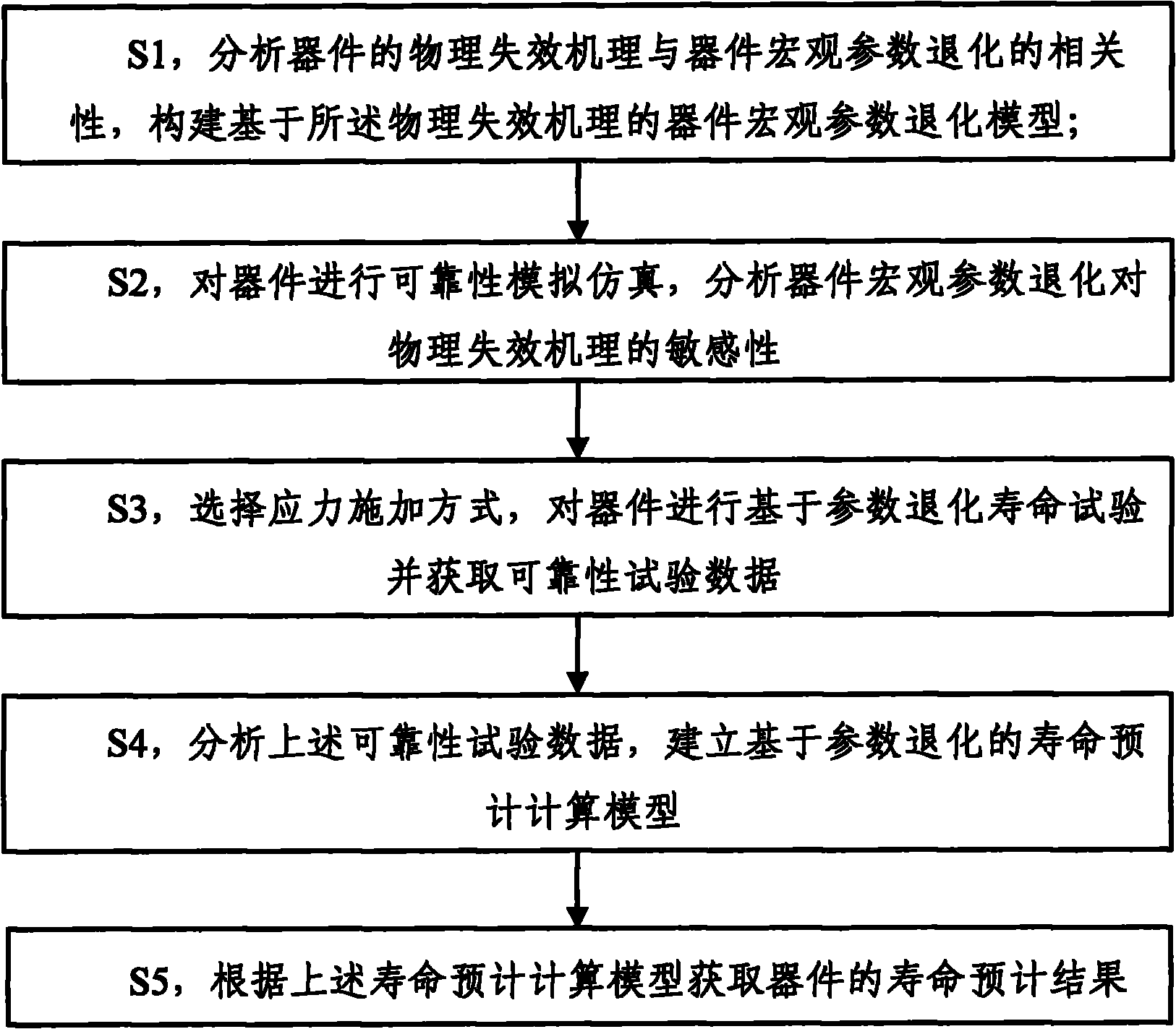

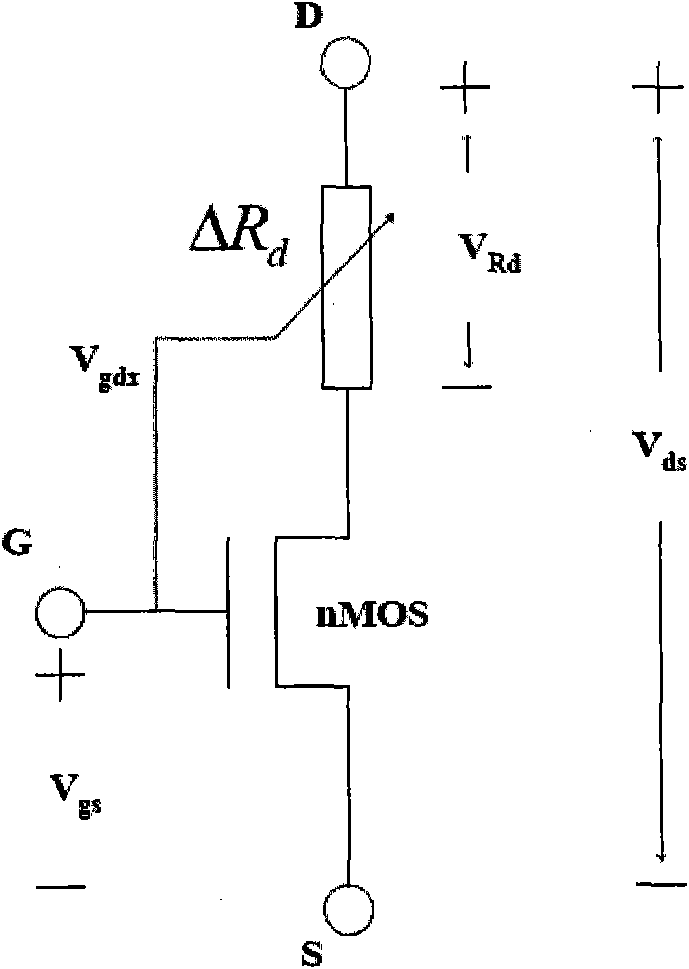

Method and system for estimating service life of MOS (Metal Oxide Semiconductor) device

InactiveCN102567560AExtend your lifeResolve accuracySpecial data processing applicationsTest sampleComputational model

The invention discloses a method for estimating service life of an MOS (Metal Oxide Semiconductor) device. The method comprises the steps of: analyzing the relevance of a physical failure mechanism and a device macroparameter degradation, constructing a device macroparameter degradation model based on the physical failure mechanism; carrying out reliability analog simulation on a device, analyzing the sensitivity of the device macroparameter degradation to the physical failure mechanism; selecting a stress applying mode, carrying out a parameter degradation service life-based test on the device and obtaining reliability test data; analyzing the reliability test data, establishing a parameter degradation-based service life estimating computing model; and obtaining a service life estimating result of the device according to the service life estimating computing model. By using the method, the problems of accuracy and maneuverability of the traditional device service life predicting method under the novel technical conditions are solved, the quantity of test samples is reduced, the testing cost is lowered, and the accuracy of predicting the testing result is improved.

Owner:BEIJING SHENGTAOPING TEST ENG TECH RES INST

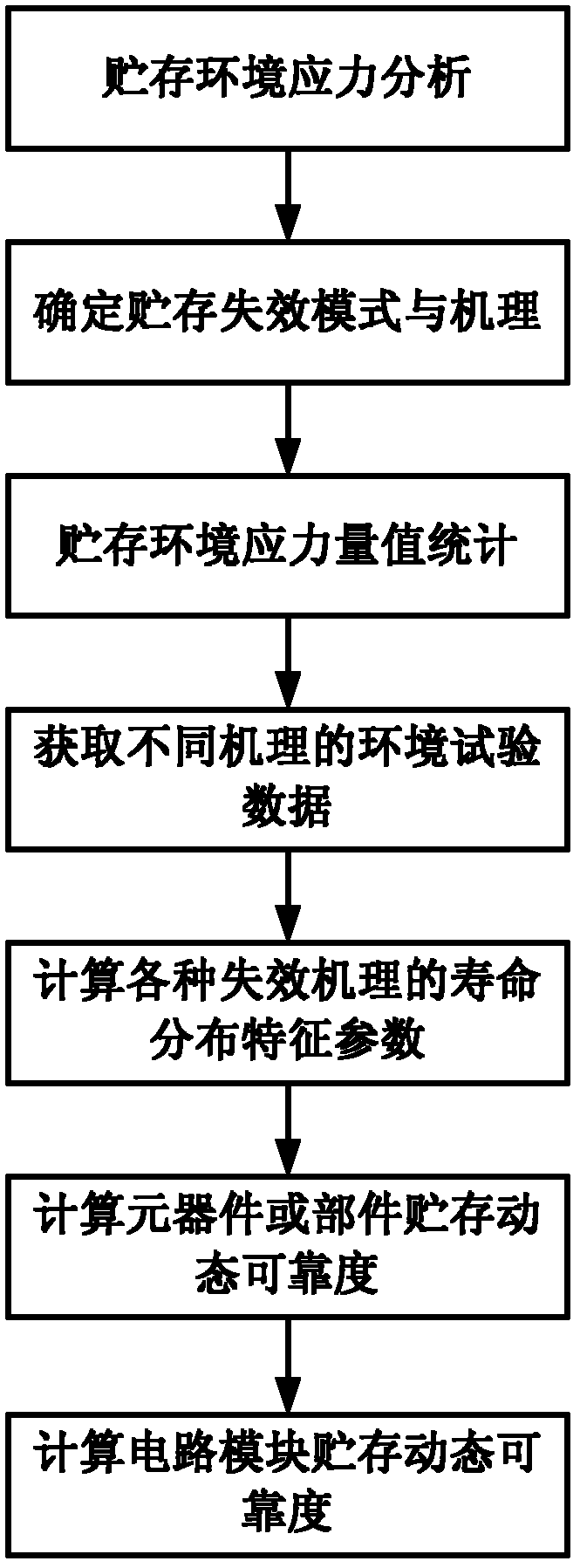

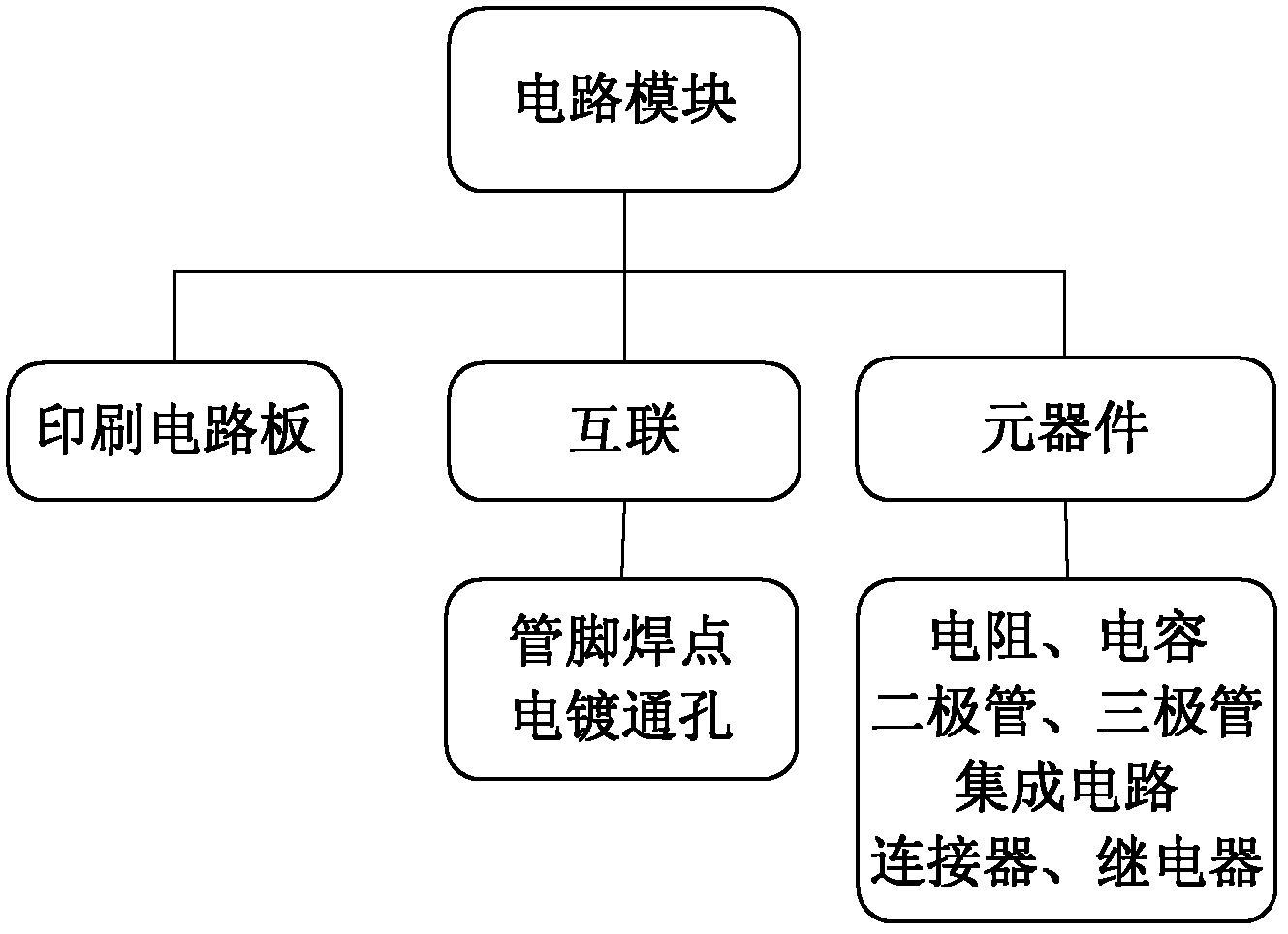

Computing method of storage dynamic reliability for aviation drive circuit module

ActiveCN102592052AIn line with engineering practiceAvoid Storage TestsSpecial data processing applicationsAviationStatistical analysis

Disclosed is a computing method of storage dynamic reliability for an aviation drive circuit module. The computing method includes steps of selecting, classifying and statistically analyzing main storage environmental stress; determining storage failure modes and failure mechanisms of the aviation drive circuit module; statistically analyzing storage environmental stress magnitudes; obtaining environmental test data of a component or a part on the premise that the failure mechanisms remain unchanged while the test environmental stress changes; computing life distribution characteristic parameters of various failure mechanisms in the module storage process; computing the life distributions of various failure mechanisms in the whole storage period; and obtaining an expression of the life distributions due to the life distribution characteristic parameters are known, integrating life distribution functions of various failure mechanisms in the storage period to obtain a failure probability F p (t) and a R p(t) reliability of various failure mechanisms at various times. According to the computing method of the storage dynamic reliability for the aviation drive circuit module, a more precise assessment result can be obtained on the premise of saving of test costs, and evidence can be provided for the reliability design of the aviation drive circuit module.

Owner:厦门蓝威可靠性系统工程研究院有限公司

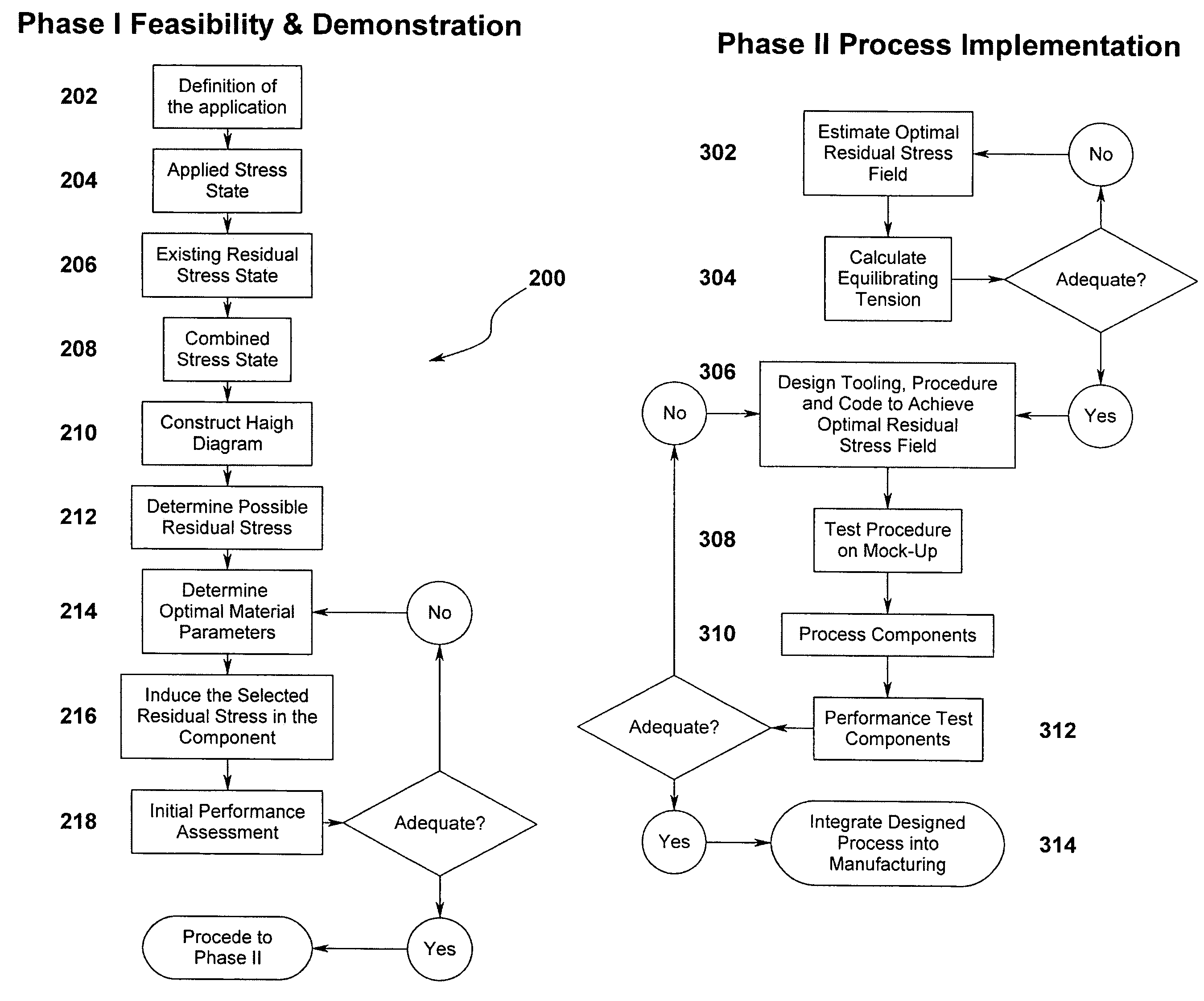

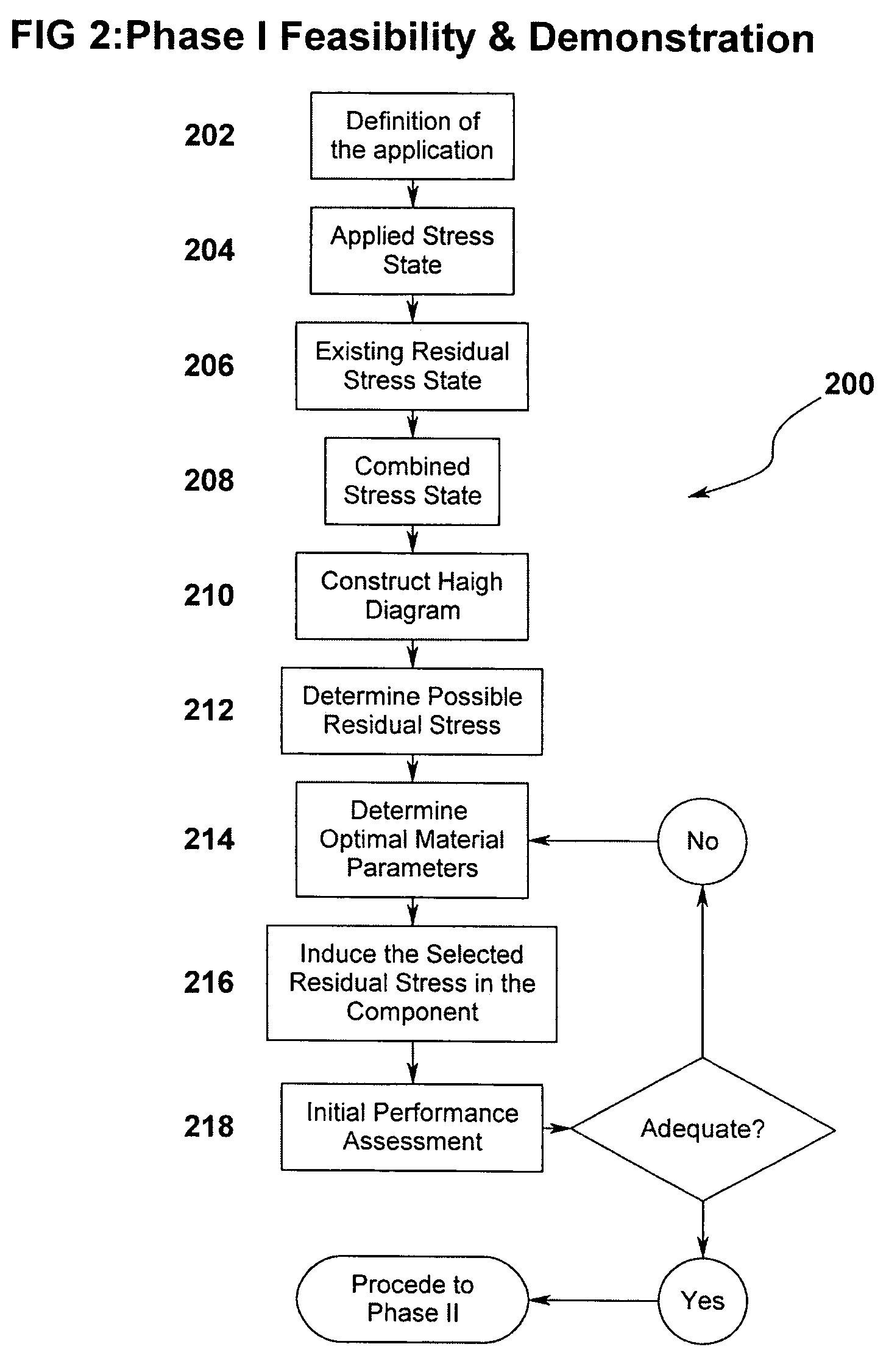

Method and system for improving a part's resistance to stress induced failure

ActiveUS7219044B1Offsetting effectUsing mechanical meansComputer aided designStress inducedStressed state

A method and system for designing a part with improved fatigue life and resistance to stress corrosion cracking in which residual stresses existing in the part are accounted for. The performance criteria and operating conditions of the part are assessed and a total stress state is determined from the sum of the residual stresses and applied stresses acting on the part. Unified Fatigue Performance Model or Smith-Topper-Neuber parameters are used to determine fatigue life functions which, in turn, are used in conjunction with a fatigue design diagram to determine the appropriate residual stress to introduce in order to optimize the part's resistance to stress induced failure mechanisms. A residual stress distribution is then designed to avoid distortion of the part while still imparting the beneficial effects of compressive residual stress.

Owner:SURFACE TECH HLDG

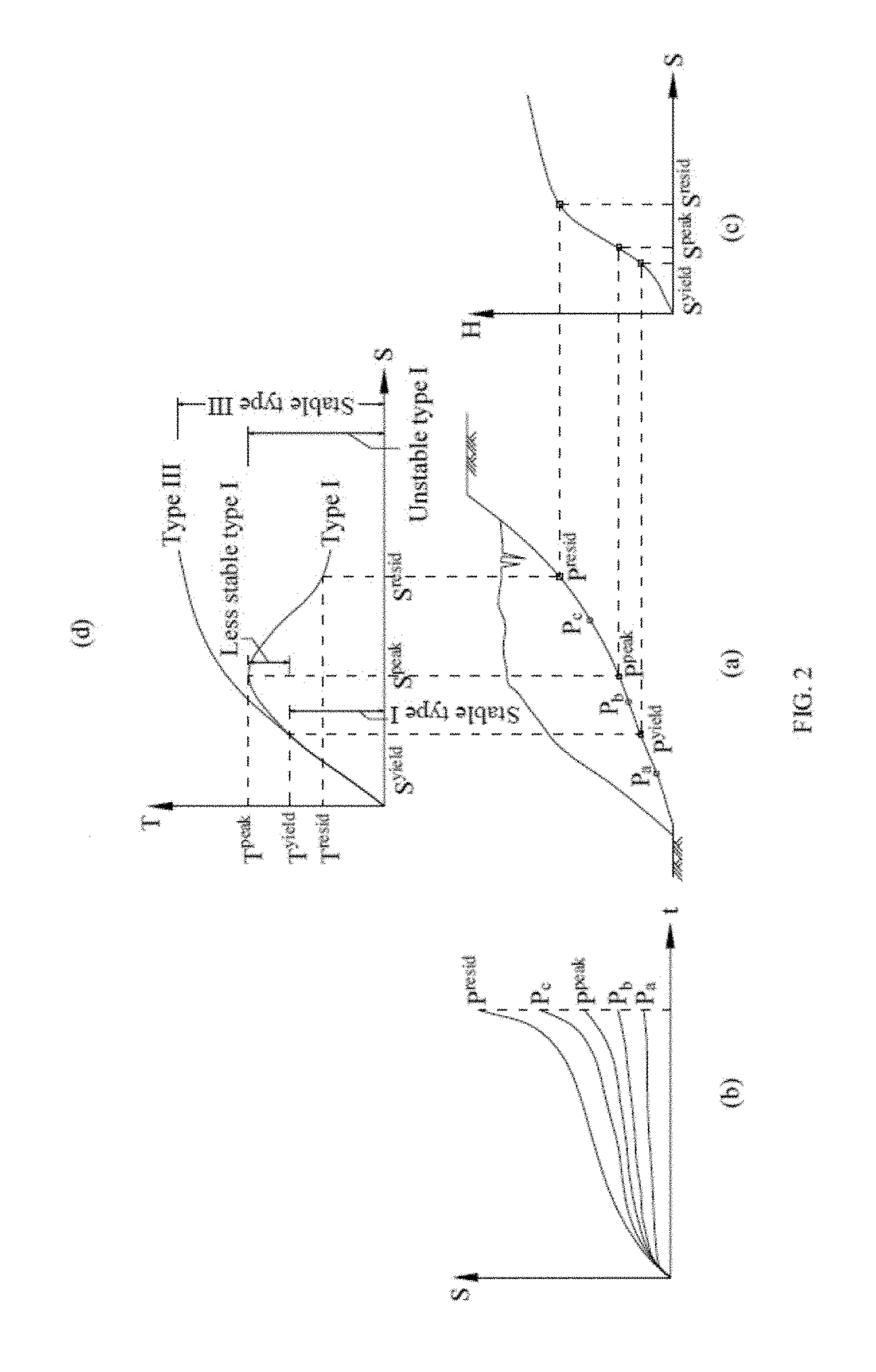

Method of critical displacement forecast based on the deformation failure mechanism of slope

InactiveUS20180292299A1Increased durabilityEarthquake measurementDesign optimisation/simulationSlope monitoringPredictive methods

In a method of critical displacement forecast based on the deformation failure mechanism of slope, a sliding surface displacement, a calculation based on status stability factors and a slope surface displacement are determined, and applied for forecast based on a thrust-type slope deformation mechanism, a key compartment division, a relation between stress and strain mechanics properties of sliding surface of geo-material, and an analysis of evolution characteristics at different points of the sliding surface. The method provides advantages of determining deformation values at different points of a sliding surface, a slope body and a slope surface during slope failures; describing the process of a progressive failure, deformations and force changes of a slope; combining slope monitoring values to perform the stability analysis and the calculation of the magnitude of the stability factors in different deformation statuses of the slope; and assessing the durability of protective measures to the slope.

Owner:HUBEI UNIV OF TECH

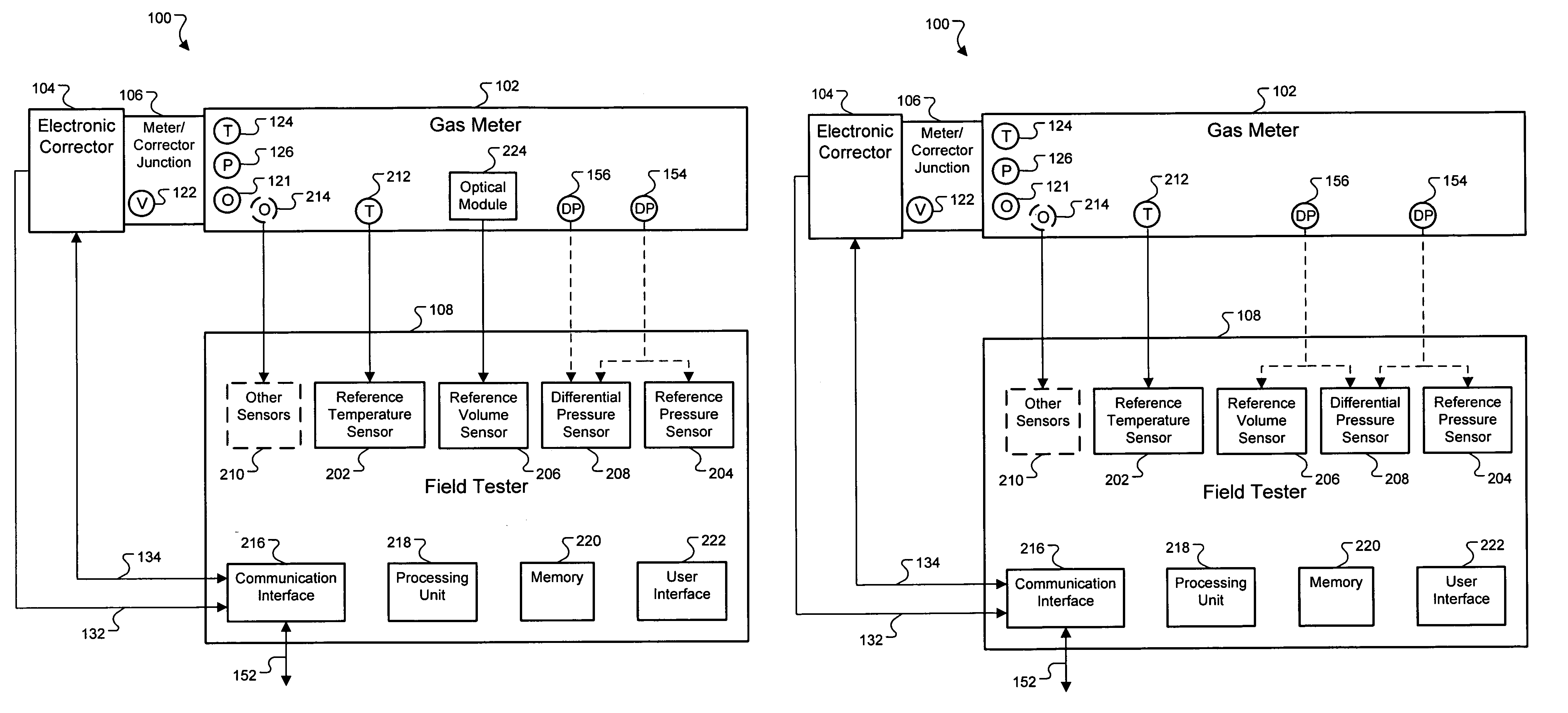

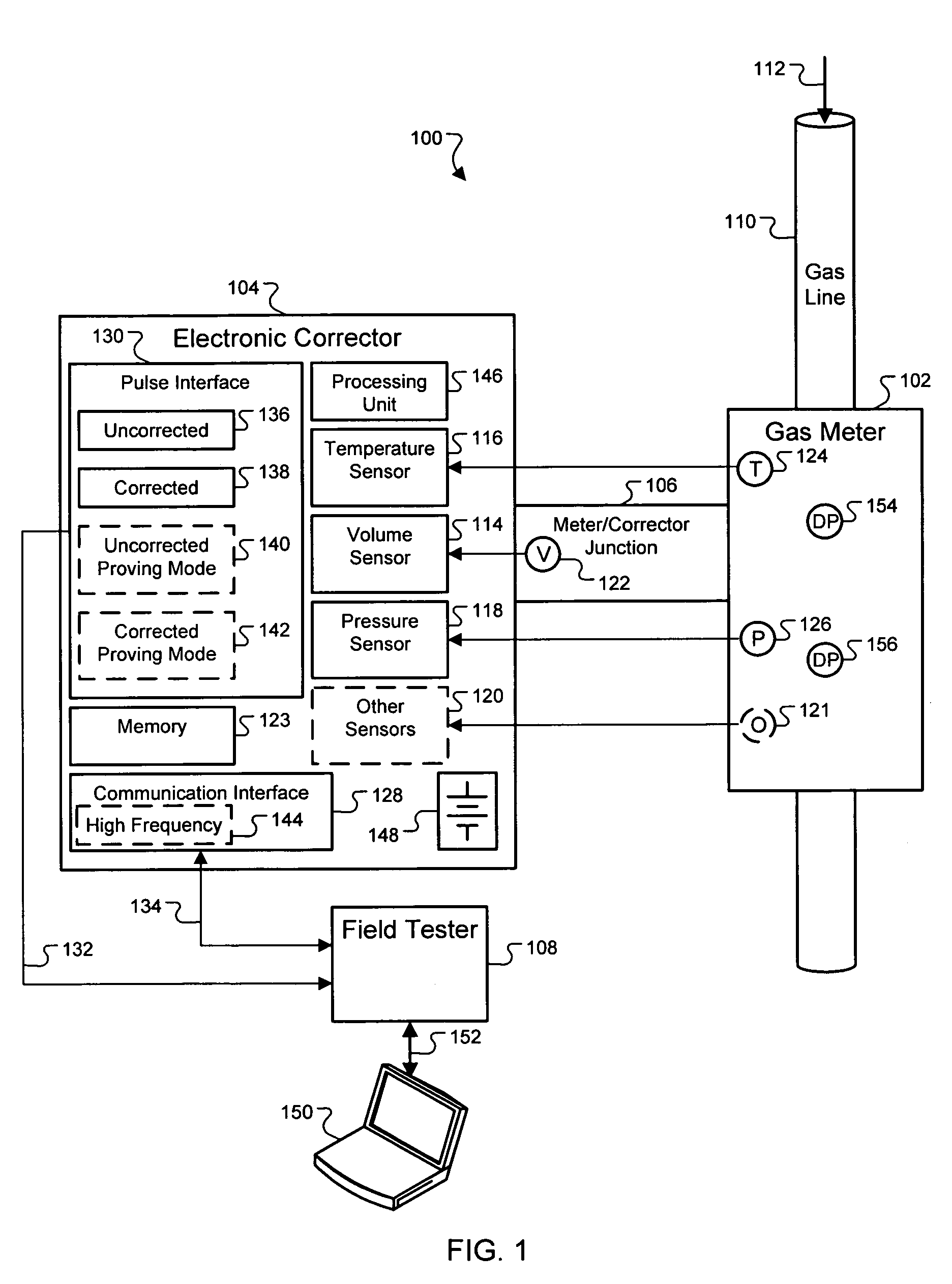

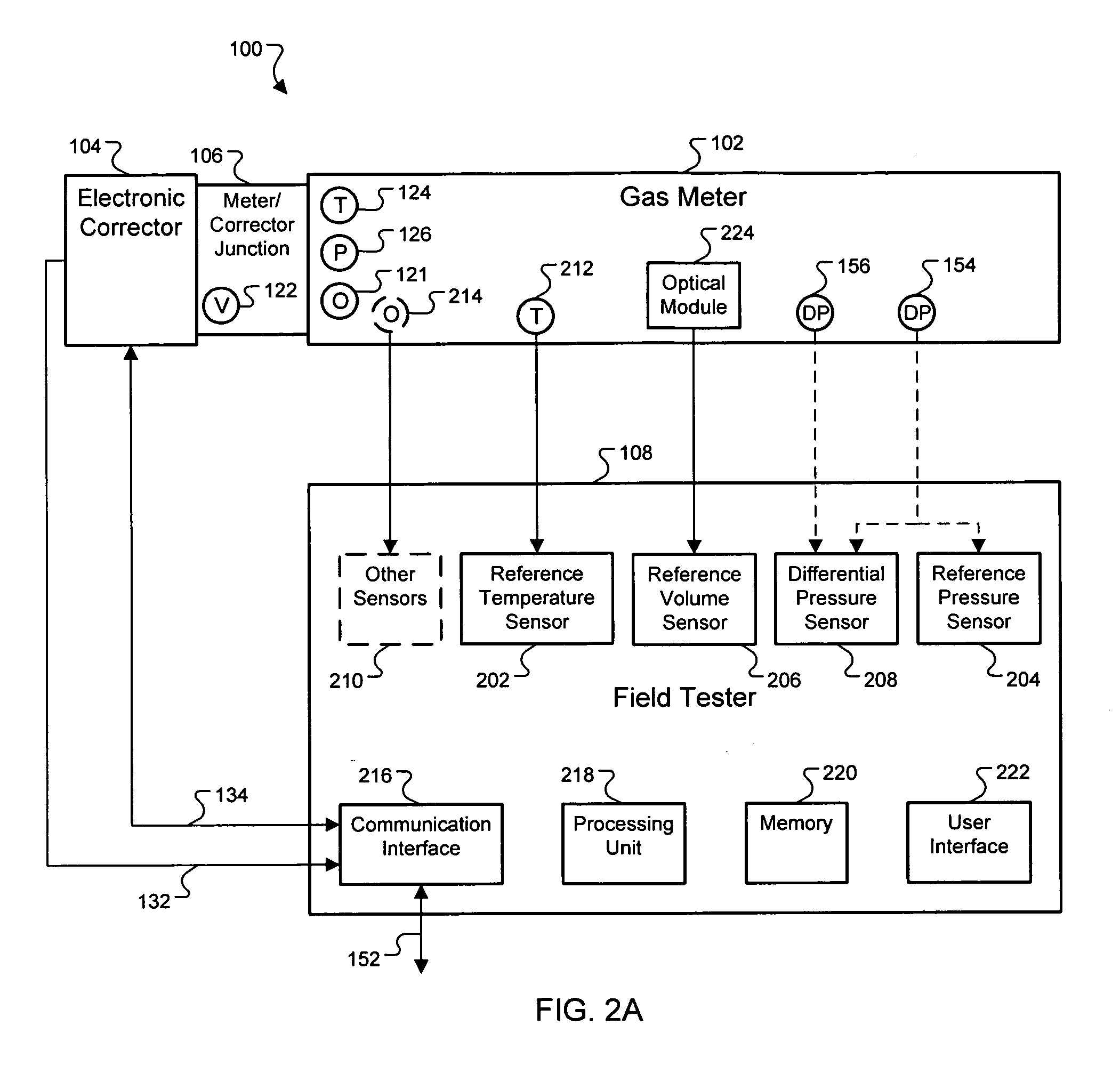

Portable diagnostic analysis of gas meter and electronic corrector

Systems and associated apparatus, methods, and computer program products, relate to a small, portable diagnostic instrument for checking the correct operation of a gas metering system that include a gas meter, an electronic corrector, and a junction there between. Some embodiments may use calibrated sensors to check the operation of a rotary or other positive displacement type gas meter or turbine meter. For example, reference sensors may be temporarily applied to monitor gas temperature and pressure, as well as the motion of a flow-responsive element (e.g., impellers, turbine, or diaphragm) in the gas meter. Measured volume signals from the gas meter system may be compared to reference volume signals determined from the reference sensors to check operation of the junction, and / or the electronic corrector. Some embodiments may detect other failure mechanisms, such as bearing-related problems in the gas meter, for example.

Owner:NATURAL GAS SOLUTIONS NORTH AMERICA LLC

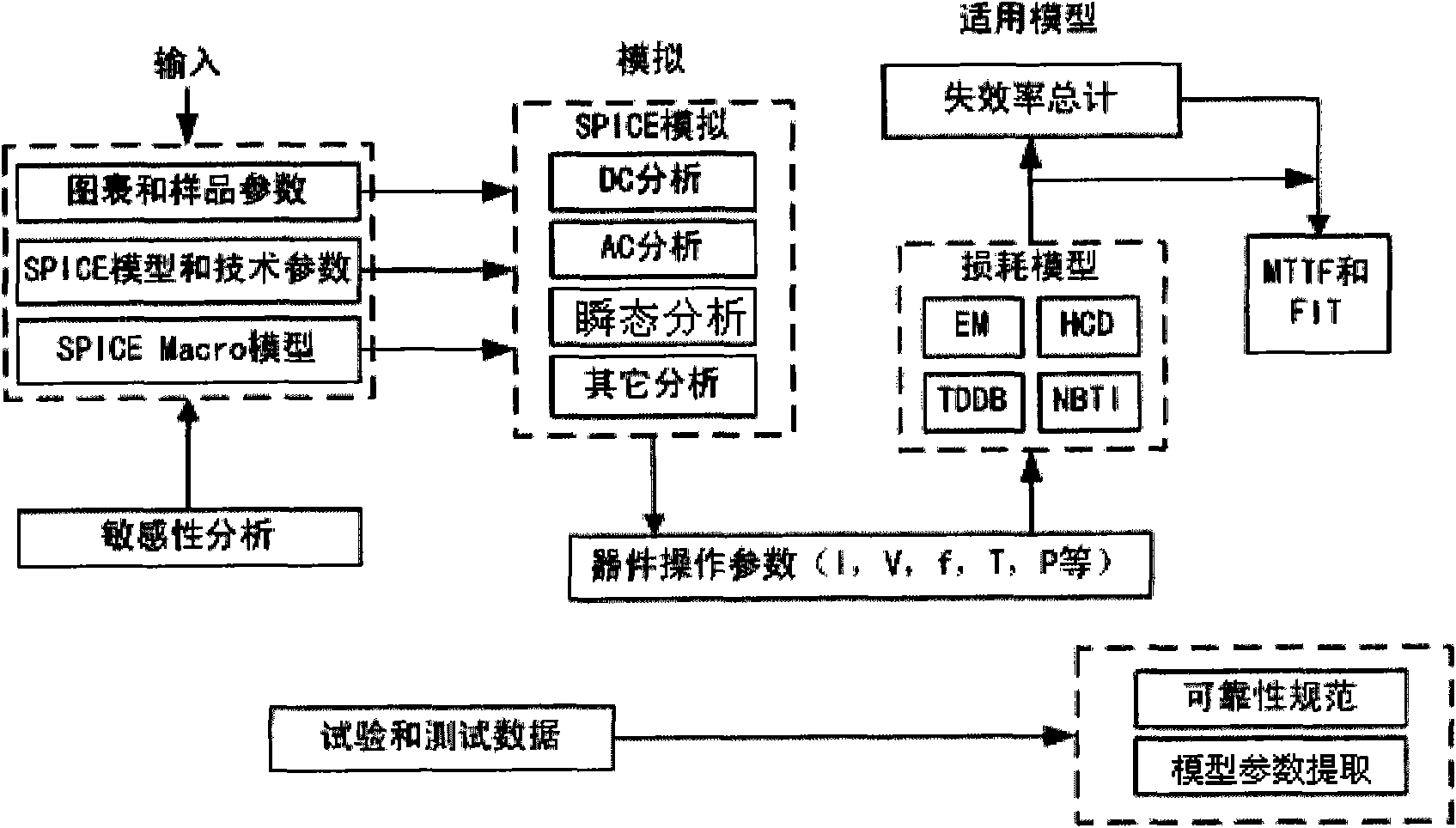

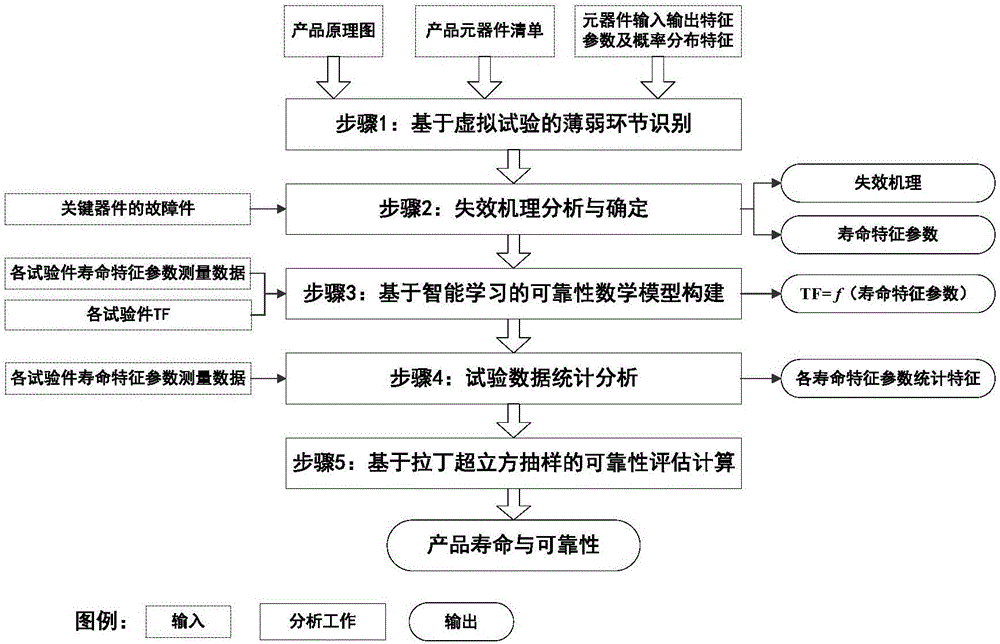

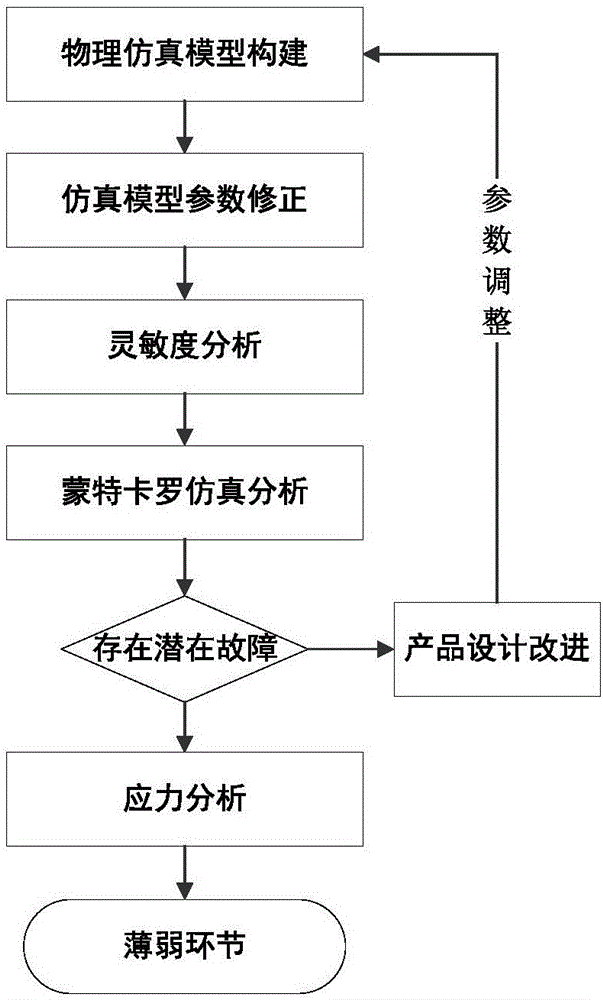

Evaluation method of reliability of aerospace electronic product

InactiveCN106529090ATight performanceBoost Design ImprovementsProbabilistic CADSpecial data processing applicationsDependabilityReliability model

The invention discloses an evaluation method of reliability of an aerospace electronic product based on a failure mechanism. On the basis that an analysis method with a combination of physical simulation and a test is adopted, a physical simulation model of the electronic product is constructed, the means such as sensitivity analysis, Monte Carlo analysis, and stress analysis are adopted, and product key elements are identified and in combination with actual working conditions of the elements, a failure mechanism analysis is conducted. Currently, the failure mechanism analysis aiming at the elements is a means used for analyzing a failure reason after a failure occurs during the test or in the using process of the electronic product, thus pertinent improvement is conducted on the product, the service life of the product is prolonged, and the reliability of the product is improved; the failure mechanism analysis aims at finding key characteristic parameters which affect the service life and the reliability of weak elements as an independent variable of the reliability model.

Owner:CHINA AEROSPACE STANDARDIZATION INST

Method for interlayer and yield based optical proximity correction

InactiveUS20050066300A1Improve lithographic processEasy to optimizePhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringMerit function

An optical proximity correction method is provided using a modified merit function based upon yield. Known failure mechanisms related to layout geometries are used to derive yield functions based upon distance values between layout features, such as, edge features. In comparing the edge points on the predicted layout pattern with the corresponding point on the design layout pattern, a yield test is first undertaken before movement of the points on the predicted layout pattern to a position of higher yield. Where yield is acceptable, no further movement is made. Where incremental movement of points results in coming within acceptable proximity before acceptable yield is reached, the point is flagged for further consideration.

Owner:GLOBALFOUNDRIES INC

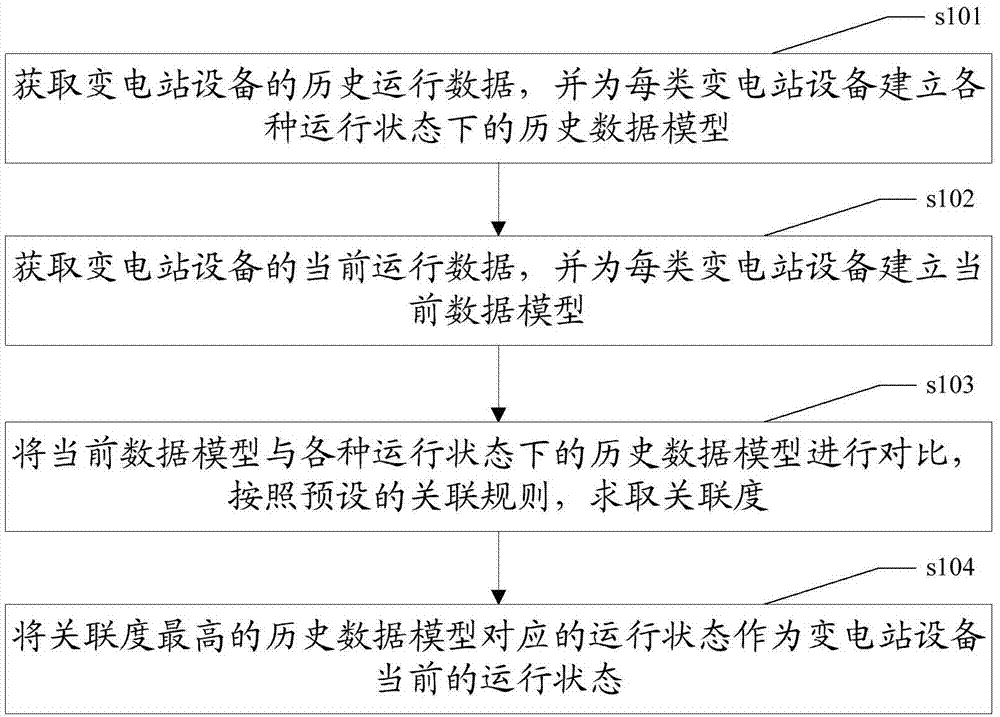

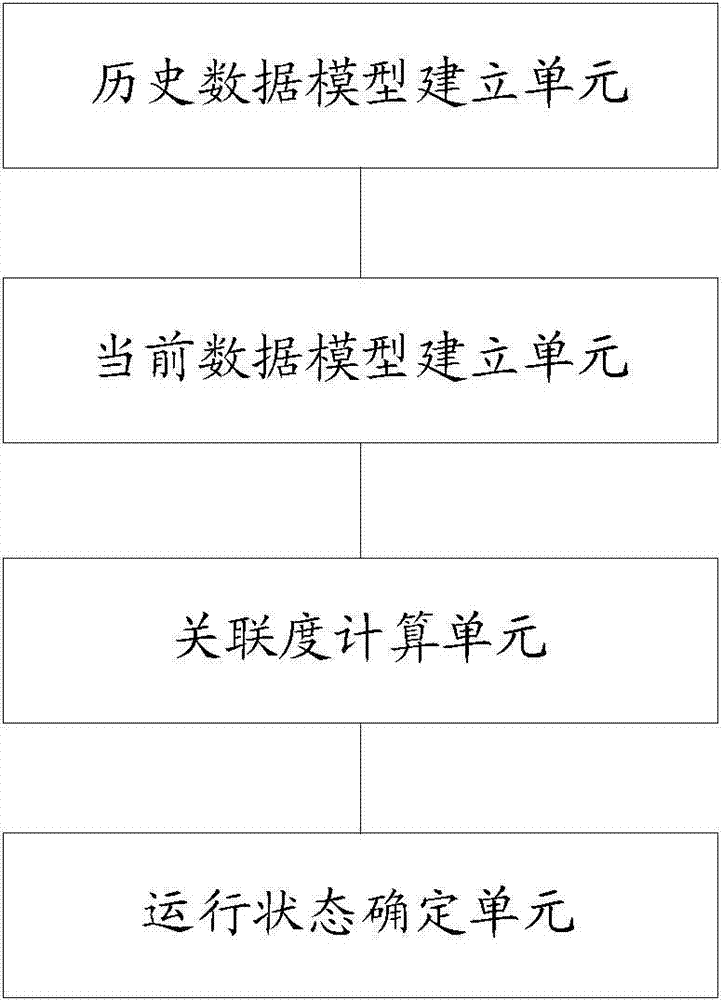

Method and system for detecting operating states of substation equipment

The invention discloses a method and system for detecting operating states of substation equipment. Different from a diagnostic method purely based on a failure mechanism, the method is characterized in that real-time historical data of the substation equipment are utilized; historical data models under the various operating states are set as reference; compared with models set according to current state data, the historical data models can obtain the relevancy degree representing the level of similarity; the current corresponding operating state of the substation equipment is judged according to the relevancy degree. Thus, once the level of similarity of the current state data of the equipment and the historical failure state data exceeds a threshold value, an early warning message can be sent out, and accordingly early signs of potential faults of the substation equipment are early warned, and relevancy of fault types is analyzed.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

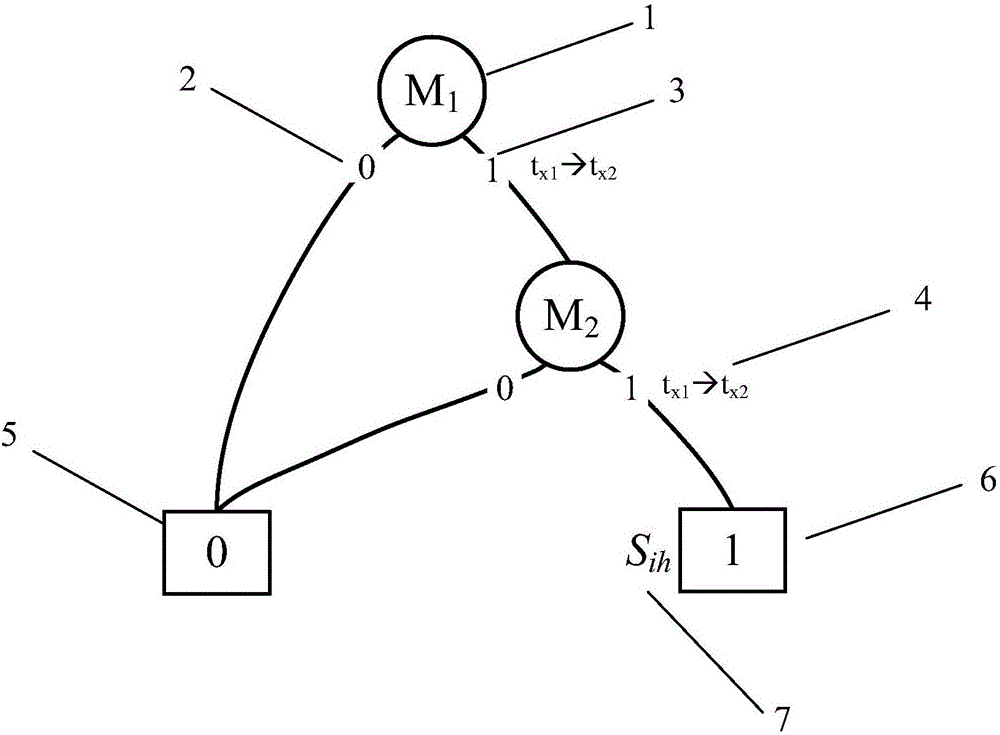

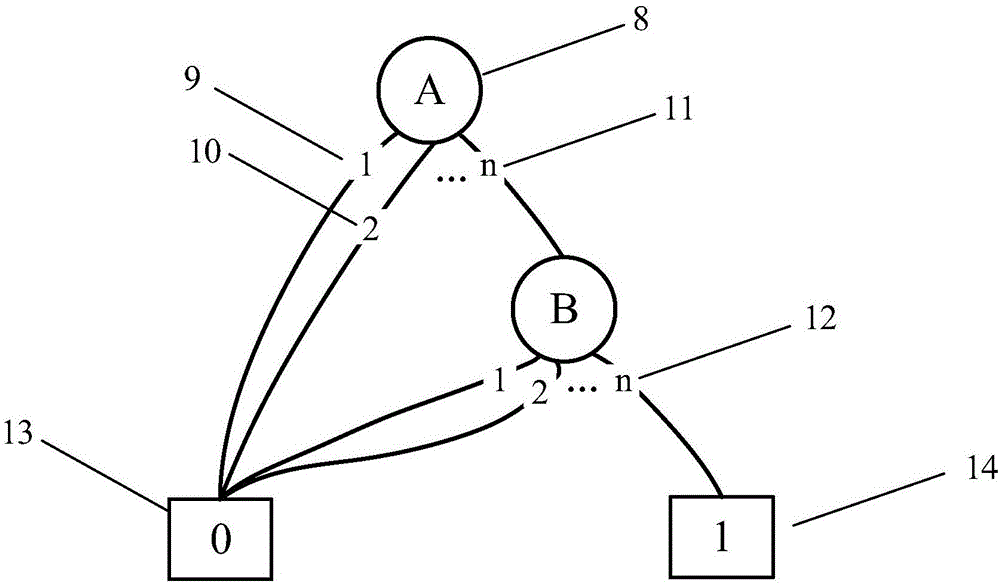

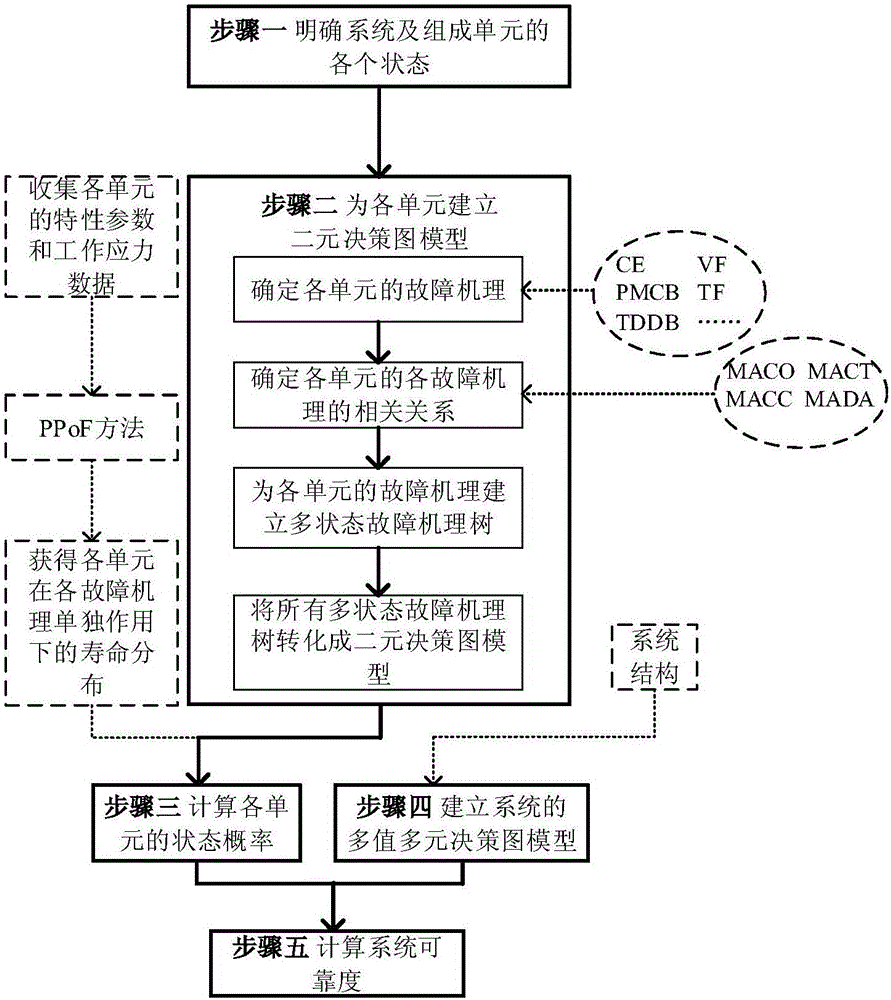

Reliability modeling method for related multi-mode system based on failure mechanism

ActiveCN106503368AExpress multi-state featuresSolve the problem of calculating the state probability of multi-state componentsDesign optimisation/simulationSpecial data processing applicationsDecision graphBinary decision diagram

The invention provides a reliability modeling method for a related multi-mode system based on a failure mechanism. The method comprises the following steps: analyzing system components and confirming and limiting various states of the system and the components; respectively confirming the failure mechanism of each component and the related relation of each failure mechanism under the working environments of the limited states and the function conditions, and establishing a binary decision graph model related to the failure mechanism for each component; calculating the state probability of each component according to the binary decision graph model established in the step (2) under the condition of the service life distribution of each known component under the independent effect of each failure mechanism and establishing a multi-mode multi-value decision graph model based on each component for the system according to the logic relation of each component in the system; substituting the state probability of each component acquired in the step (3) into the logic expressed by the multi-mode multi-value decision graph model established in the step (4) and calculating the state probability of the whole system and the system reliability.

Owner:BEIHANG UNIV

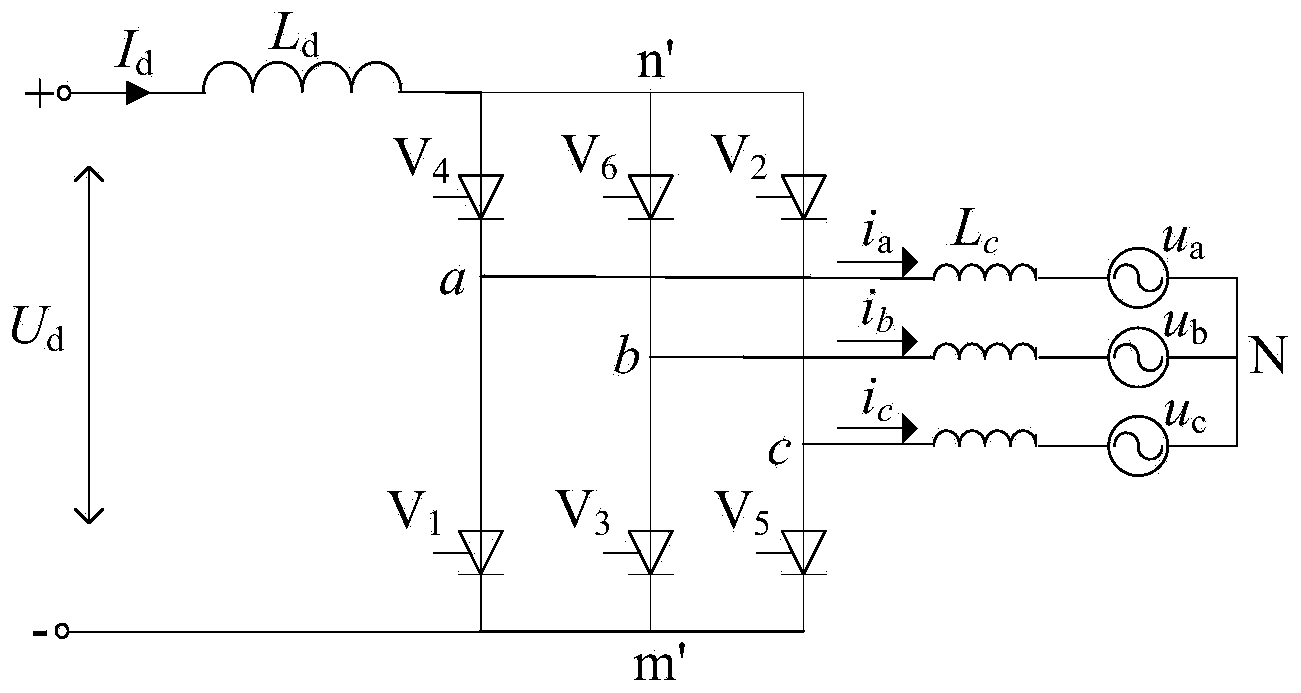

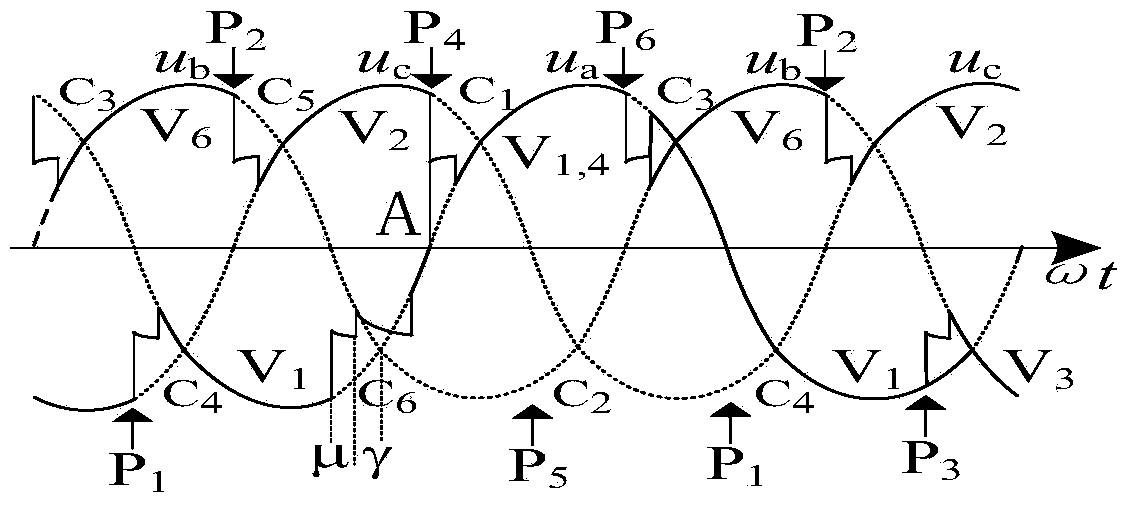

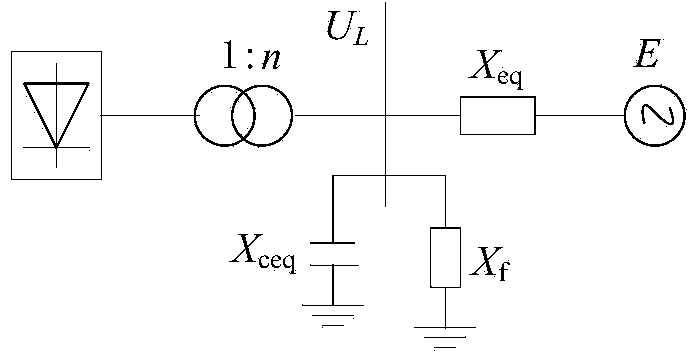

HVDC commutation failure fault diagnosis method based on valve voltages or valve currents

The invention discloses an HVDC commutation failure fault diagnosis method based on valve voltages or valve currents. The method comprises the following steps that a commutation failure mechanism and commutation failure influence factors are analyzed; commutation failure process analysis is carried out, and a commutation failure criterion is determined; an HVDC model contravariant side equivalent circuit is built, and a commutation failure critical inductance value is determined; whether the diagnosis result is accurate or not is verified through simulation. According to the fast commutation failure diagnosis method based on the converter valve voltages or the valve currents, the theoretical analysis and stimulation result proves the accuracy and effectiveness of the method, no blind diagnosis area exists, and the method is simple in theory and easy to implement, and has certain project application value.

Owner:STATE GRID CORP OF CHINA +1

Transmission and friction experiment table for multifunctional mechanical part

InactiveCN104155102ARealize online detectionWide range of test objectsMachine gearing/transmission testingInvestigating abrasion/wear resistanceResearch ObjectVibration acceleration

The invention relates to a transmission and friction experiment table for a multifunctional mechanical part. The transmission and friction experiment table comprises a first guiding rail, a second guiding rail, a first driving motor, a second driving motor, a first supporting plate, a second supporting plate, a first main shaft box, a second main shaft box, a first test-piece, a second test-piece,a first torque sensor, a second torque sensor, a first rigid coupler, a second rigid coupler, a third rigid coupler, a first supporting plate sliding driving motor, an universal coupler, a loading electric cylinder, a bedplate, an acceleration vibration sensor, a temperature sensor, a displacement sensor, a pressure sensor, a lubricating system, a cooling system and a general controlling computer. According to the invention, various low and high friction pairs in a contact zone can be tested online for frictional wear, energy consumption, vibration and material behaviors under the different loads, rotating speeds and lubrication conditions, and transmission parts and systems can be conducted with friction and transmission process experiments; when testing data is gathered, parts and systems to be tested can be analyzed for the following situations such as frictional wear, power consumption, stress and the service behaviors of transmission pairs, so that the behavior features, variation rules and failure mechanisms of research objects in the operating process can be obtained.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com