Transmission and friction experiment table for multifunctional mechanical part

A technology of mechanical parts and test benches, which is applied in the testing of machine gears/transmission mechanisms and testing of wear resistance, etc. It can solve problems such as few detection parameters, narrow measurement range, and influence on transmission accuracy, and achieve highly unified boundary conditions and measurement The effect of large range and multiple detection parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

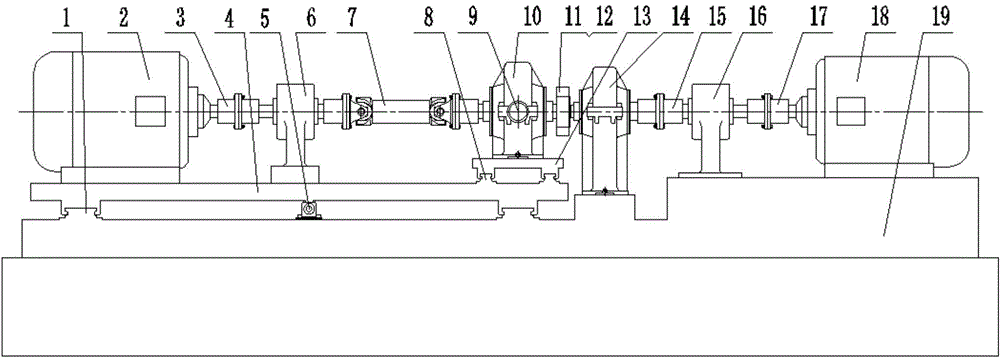

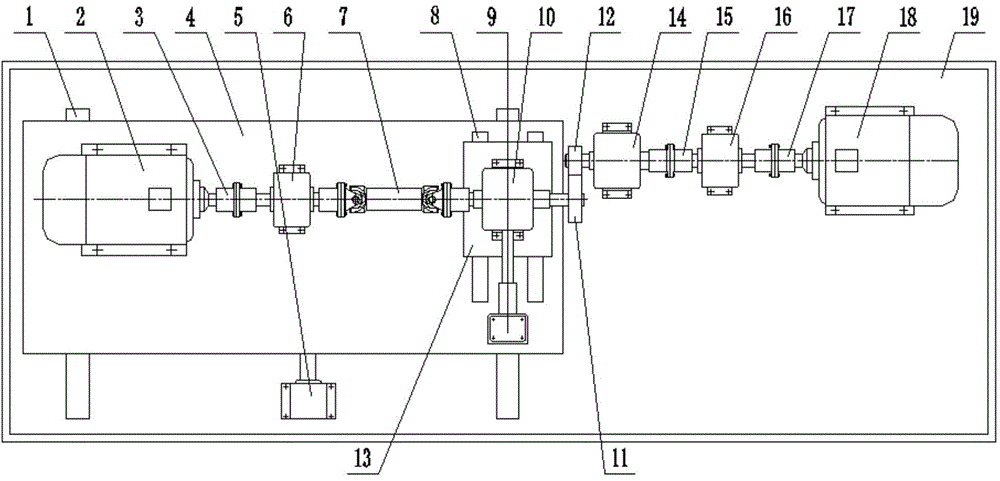

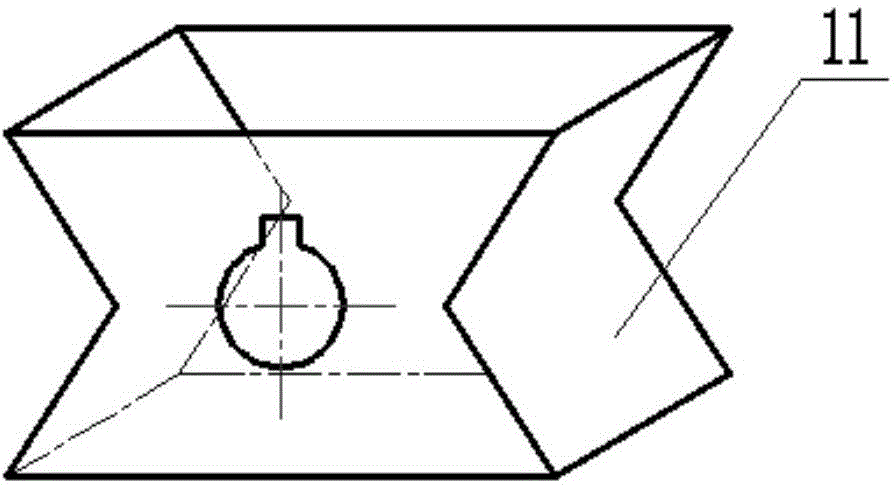

[0042] This embodiment is to adopt the experiment platform of the present invention to carry out multi-purpose clamping block and ring multi-line or single-line contact friction experiment, such as Figure 4 with Figure 5 . At this time, the multi-purpose clamping block is installed on the output end of the first headstock 10, and the ring is installed on the output end of the second headstock 14, and the first main shaft is rotated to Figure 4 The position shown is locked, adjust the center distance between the two test pieces to the contact state, start the main switch of the test bench, start the first drive motor 2 and the second drive motor 18, open the lubrication system and cooling system, and perform multi-purpose clamping block and Ring multi-line contact friction experiment; use the same multi-purpose clamping block, only need to rotate the first spindle 90° to Figure 5 The position shown is locked, and the center distance between the two test pieces is readjust...

Embodiment 2

[0044] The present embodiment is to adopt the experimental platform of the present invention to carry out the rolling bearing friction experiment, such as Image 6 . At this time, the multi-purpose clamping block is installed on the output end of the first headstock 10, the rolling bearing is installed on the output end of the second headstock 14, and the first main shaft is rotated to Image 6 The position shown is locked, and the rest of the operation process can refer to embodiment 1.

Embodiment 3

[0046] This embodiment is to use the experimental platform of the present invention to carry out the parallel axis gear meshing transmission experiment, such as Figure 7 with Figure 8 . Figure 7 For spur gear meshing transmission experiment, Figure 8 It is a helical gear mesh transmission experiment. At this time, two spur gears or helical gears are respectively installed on the output ends of the first headstock 10 and the second headstock 14 , and the rest of the operation process can refer to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com