Method for detecting shell drain voltage of working appliance (power) equipment and two-step anti-electric-shock scheme

A detection method and technology of leakage voltage, applied in the direction of measuring current/voltage, measuring electricity, measuring electrical variables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

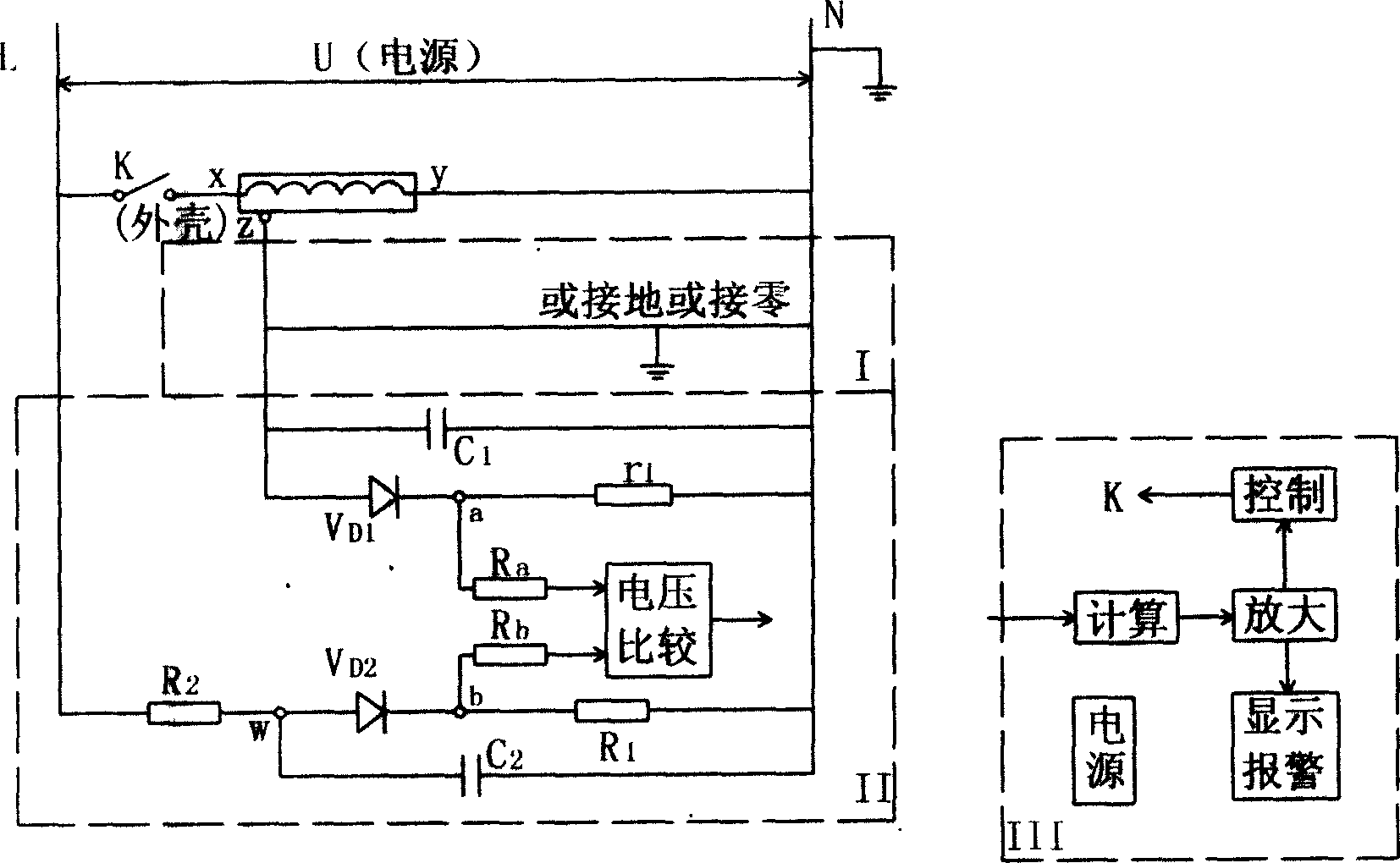

[0088] The method of detecting the leakage voltage of the shell of the operating equipment is applicable to the design of the leakage voltage detection instrument and the electric shock prevention instrument, see figure 1 The dotted line box II and the dotted line box III are analyzed below:

[0089] Includes circuit:

[0090] 1. Leakage voltage measurement circuit;

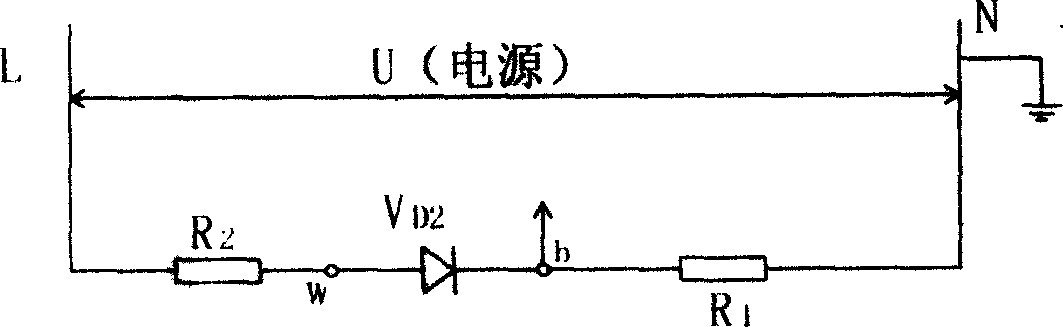

[0091] 2. Leakage voltage setting circuit;

[0092] 3. Voltage comparison circuit;

[0093] 4. Microcomputer monitoring circuit.

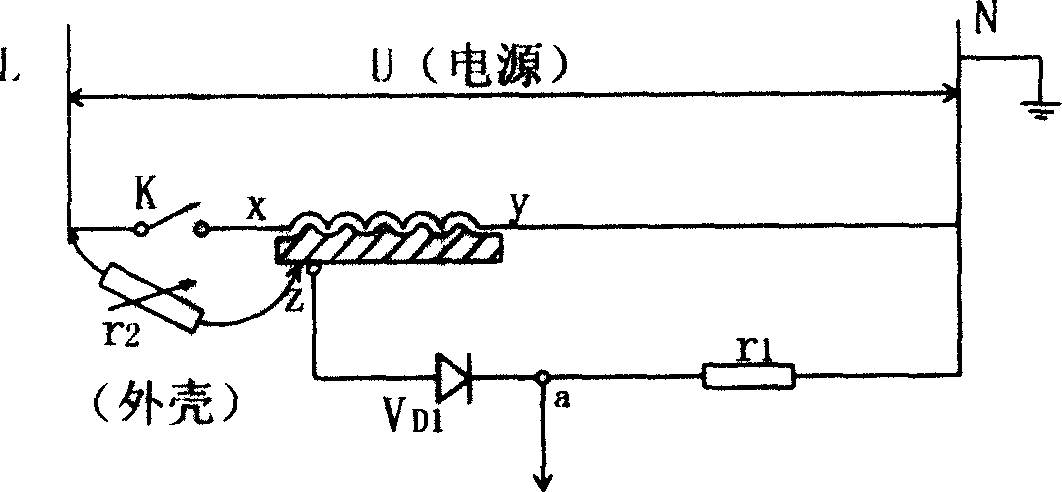

[0094] 1. The leakage voltage measurement circuit consists of end,

[0095] The order is from the power line L to the control switch K to the electrical winding xy through the insulation layer to the equipment shell z to the diode V D1 To take the measured electrical node a to the resistor r 1 To the ground neutral line N (PE); the other branch is routed from the equipment shell z to the filter capacitor C 1 To the ground neutral line N(PE).

[0096] The voltage of node a i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com