Touch sensor based on flexible pressure-sensitive conductive rubber

A tactile sensor and conductive rubber technology, applied in the field of sensing, can solve problems such as damage to electronic devices and their circuits, complex manufacturing processes, and influence on sensor reliability, and achieve a wide adjustment range, simplified manufacturing processes, and signal sampling circuit structure. Simplified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

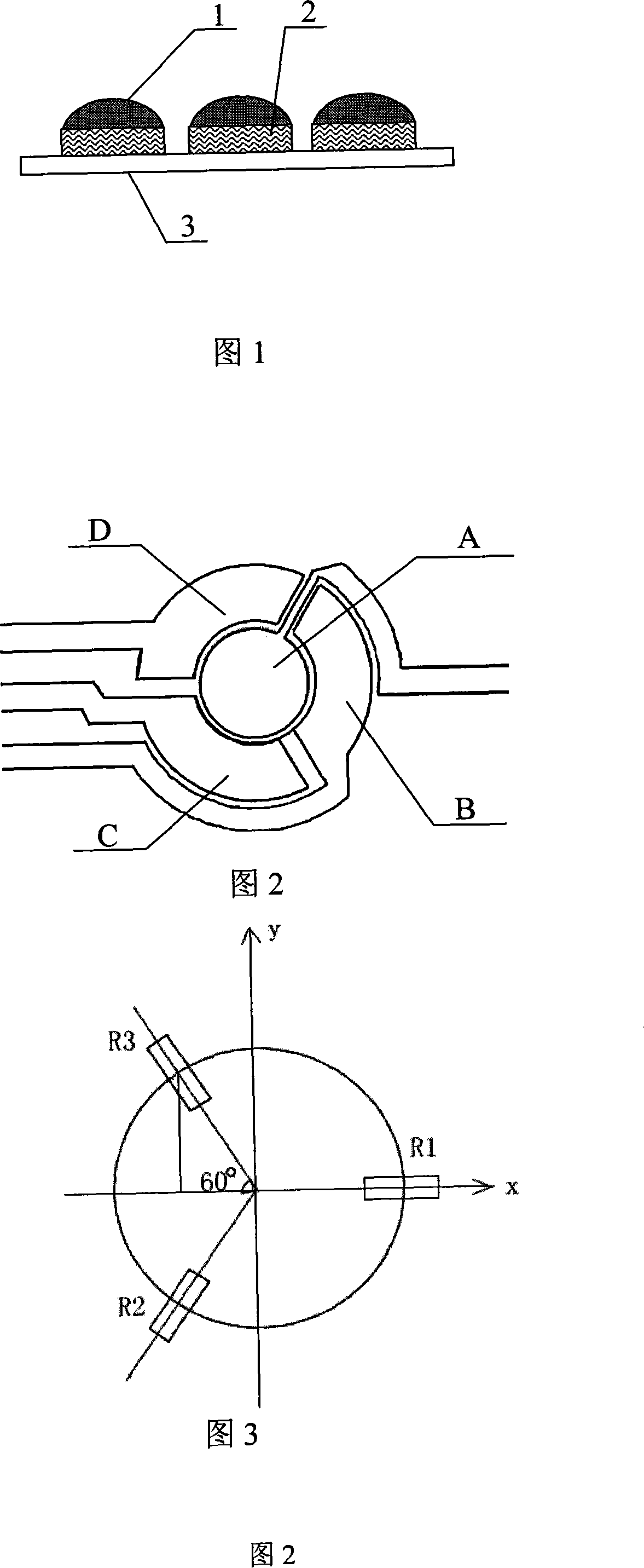

[0022] Referring to Fig. 1, the structural form of the sensing unit is as follows: the flexible circuit board 3 is used as the bottom plate, and the disc-shaped flexible pressure-sensitive conductive rubber 2 is placed on the flexible circuit board 3, and is electrically connected to the electrodes distributed on the flexible circuit board 3. connection, the top force-bearing surface of the flexible pressure-sensitive conductive rubber 2 is covered with the force-transmitting hemisphere 1;

[0023] Referring to Fig. 2, the flexible circuit board 3 has a four-electrode structure, wherein the common electrode A is a central circular electrode concentric with the disc-shaped flexible pressure-sensitive conductive rubber, and the signal electrode B, the signal electrode C and the signal electrode D are mutual electrodes. The fan-shaped electrodes are evenly distributed on the same circular surface around the central circular electrode at 120°.

[0024] As shown in Figure 3, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com