Hoist and steering control system and method of nine-shaft automobile chassis

An automotive chassis and steering control technology, applied in the field of automotive control systems, can solve the problems of complex steering control system design, limited chassis space structure, poor cornering ability and poor maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

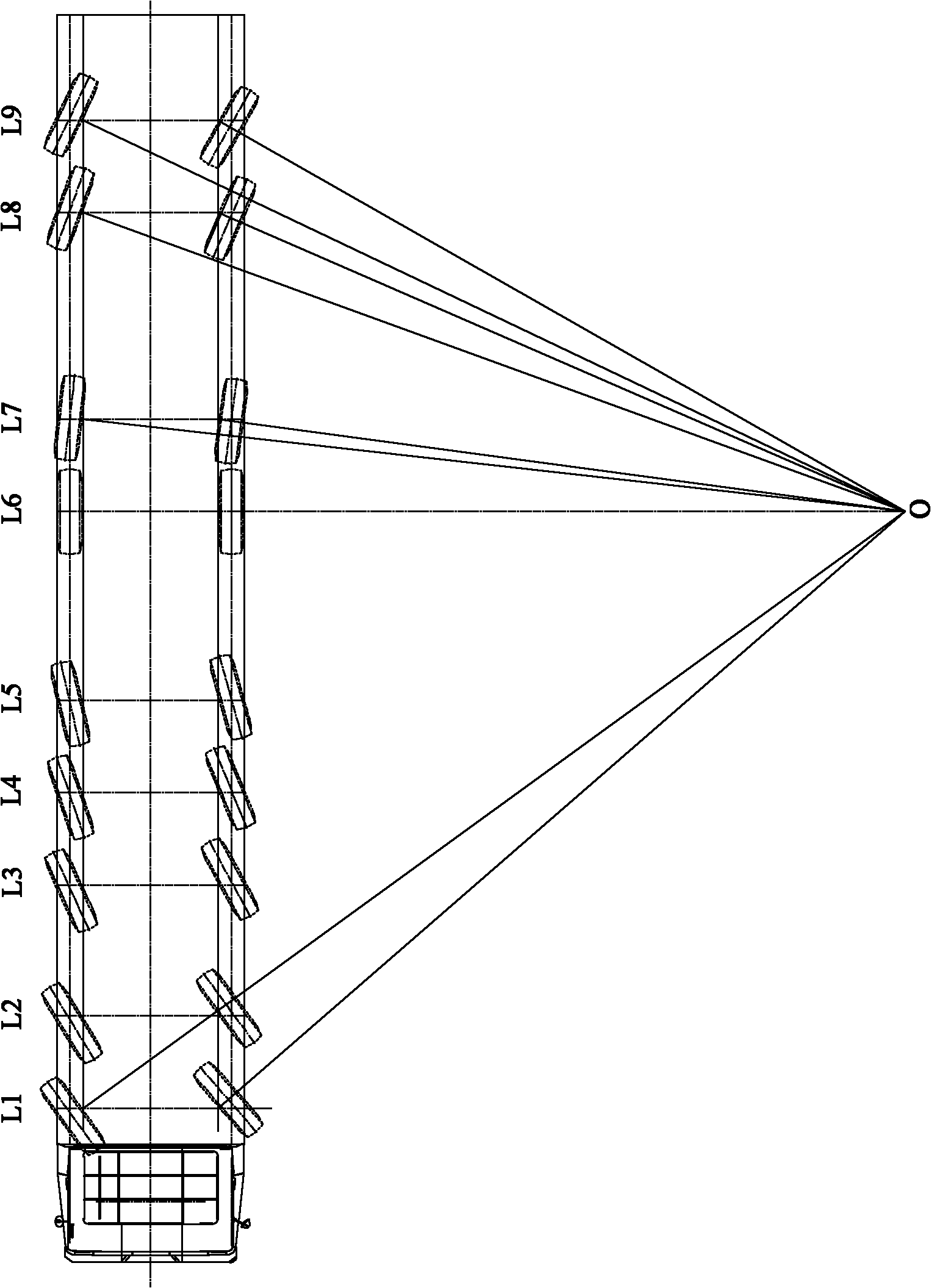

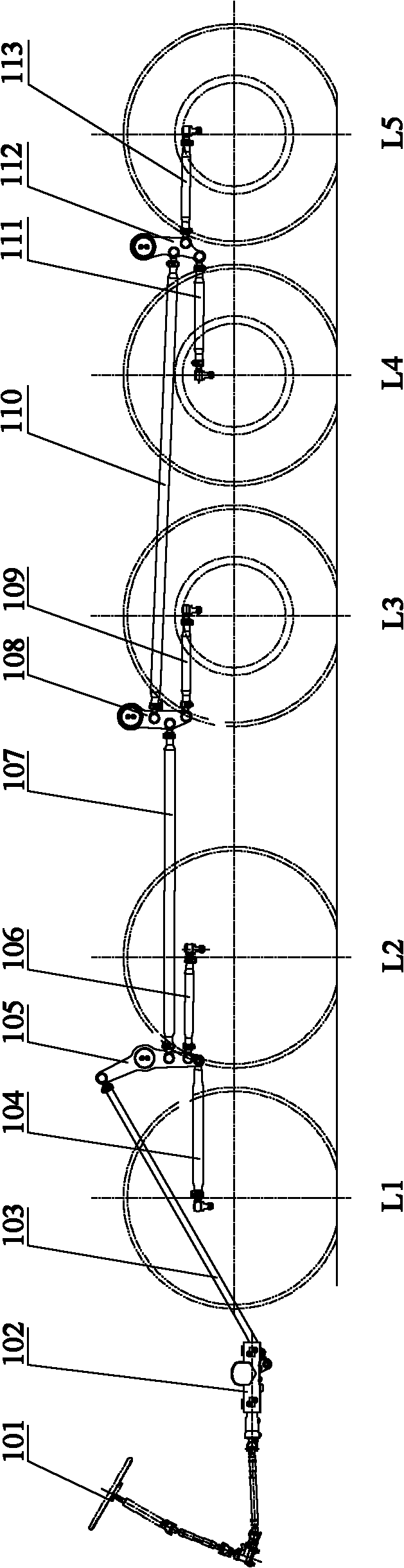

[0066] The core of the present invention is to provide a steering control system and method for a nine-axle automobile chassis, so that construction machinery such as all-terrain cranes using the automobile chassis have multiple turning diameters, improve their ability to pass through curves, and have sensitive steering Response, stronger handling stability and steering control precision, while reducing abnormal tire wear and ensuring driving safety. The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

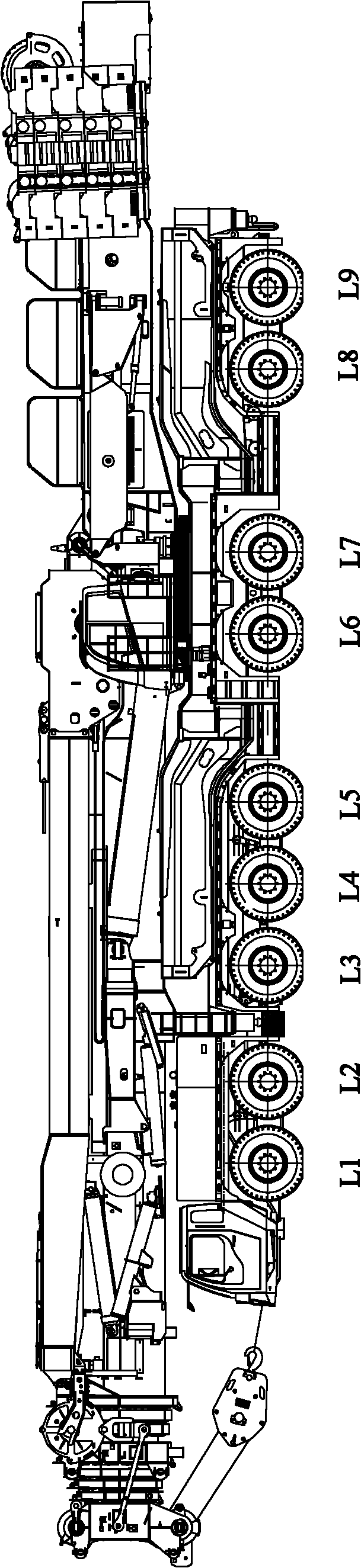

[0067] Without loss of generality, this article takes the nine-axle all-terrain crane as an example for detailed description, please refer to figure 1 , which shows a schematic diagram of the overall structure of the crane. It should be noted that the technical solutions provided by the present invention are not limited to application on nine-axle all-terrain cranes, and are applicable to other con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com