Patents

Literature

533 results about "Tonnage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tonnage is a measure of the cargo-carrying capacity of a ship. The term derives from the taxation paid on tuns or casks of wine. In modern maritime usage, "tonnage" specifically refers to a calculation of the volume or cargo volume of a ship. Tonnage should not be confused with displacement, which refers to the actual weight of the vessel. Tonnage is commonly used to assess fees on commercial shipping.

Intelligent molding environment and method of controlling applied clamp tonnage

InactiveUS20060082010A1Easy to operate and controlReduced component wearAuxillary shaping apparatusInjection pressureClosed loop

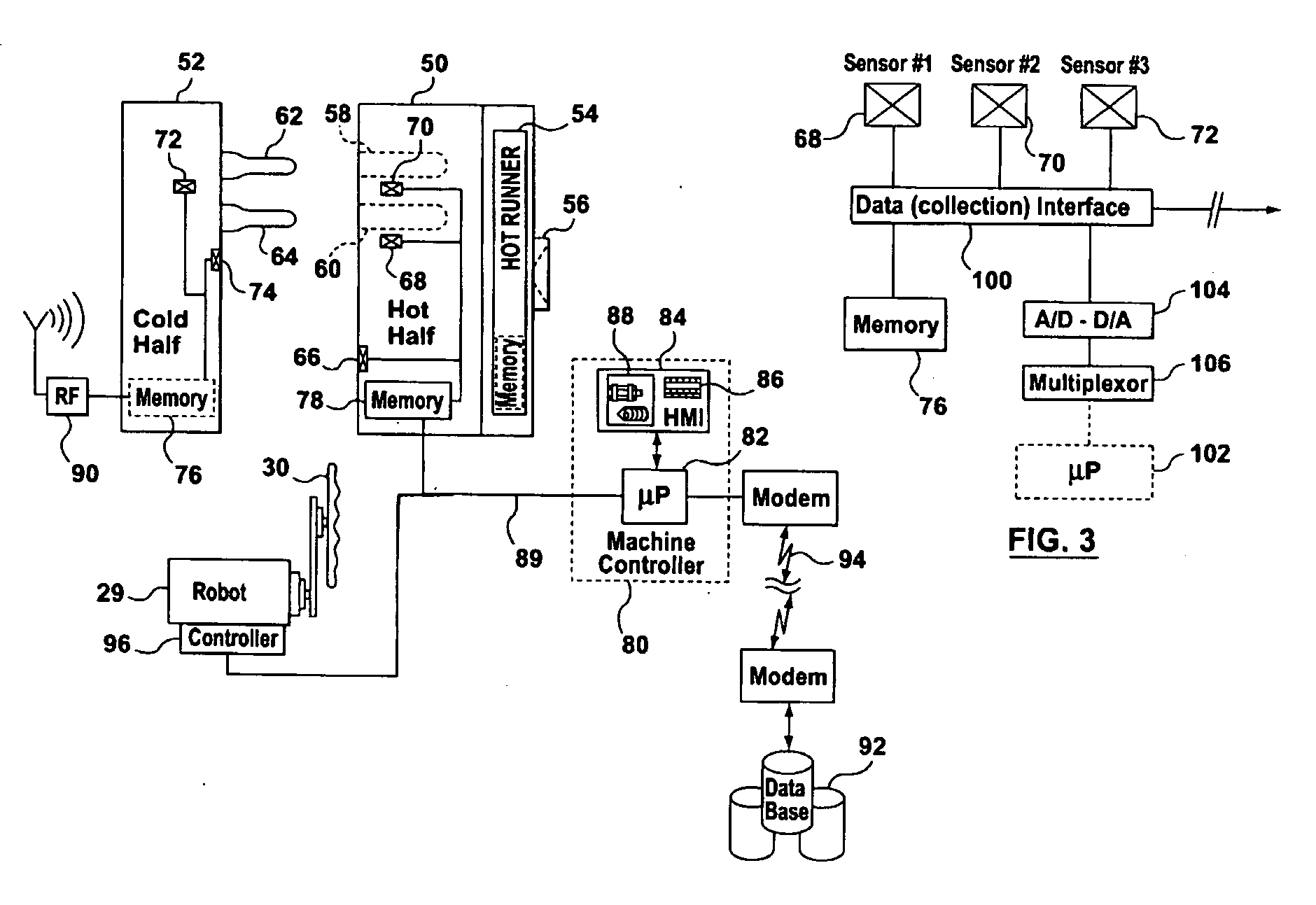

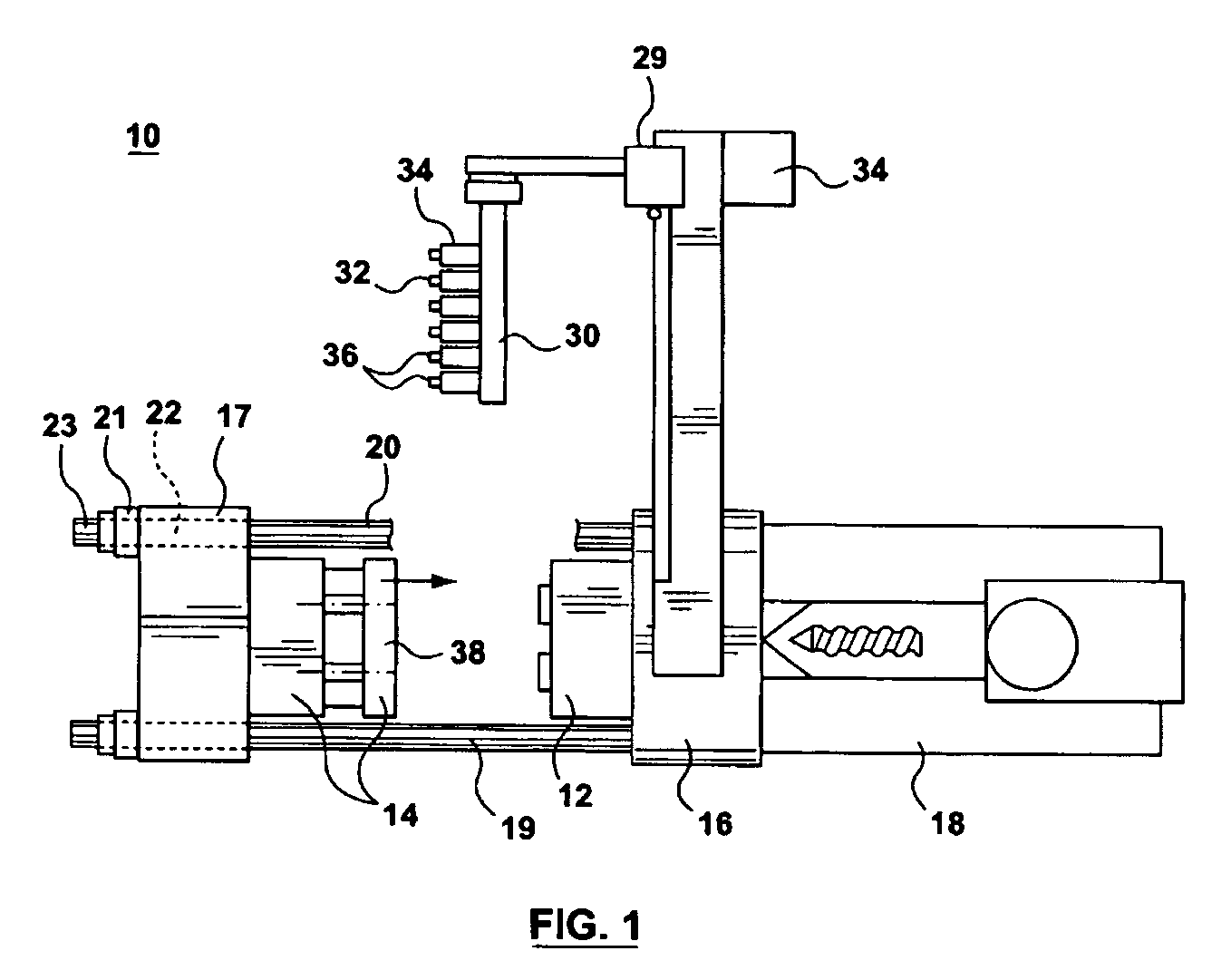

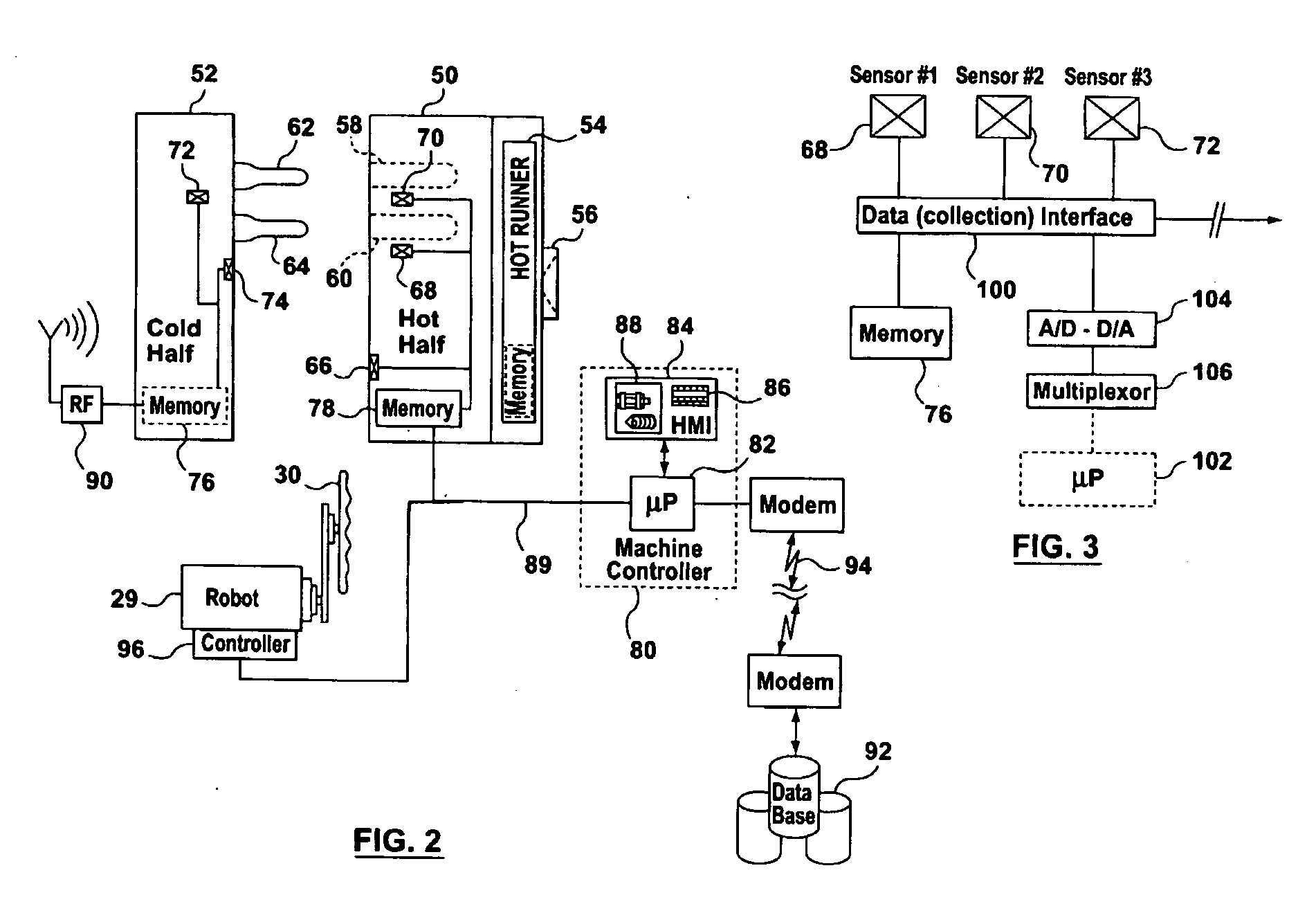

Rather than developing full closure tonnage for a substantial portion of the duration of an injection cycle, closed loop control of the clamp pressure (such as through control of hydraulic pistons) permits clamp pressure to balance exactly, but preferably slightly exceed, the instantaneous injection pressure. A first approach mimics the injection pressure profile with time, whereby applied tonnage is varied with time according to sensed pressure measurements. A second approach looks to pre-stored or historically accumulated injection pressure information and, instead of varying the tonnage, applies a constant tonnage reflecting the maximum recorded or most likely injection pressure to be experienced in the mold (as recorded stored in a look-up table associated with the particular mold configuration). A machine controller (80, 82) causes the application of applied tonnage through the platen (16, 17) and tie-bars (19, 20) of an injection molding machine (10). Pressure sensors (66-74) located either on a mold surface (50), relative to stack components (58-64) and / or relative to a force closure path of permit a microprocessor (82) to control applied clamp closure tonnage. In this way, the system consumes less power and component wear is reduced.

Owner:HUSKY INJECTION MOLDING SYST LTD

Ground source heat pump well field design and control strategy for large tonnage

InactiveUS7647773B1Optimal Control StrategyEasy to operateCollector components/accessoriesLighting and heating apparatusModularityGood practice

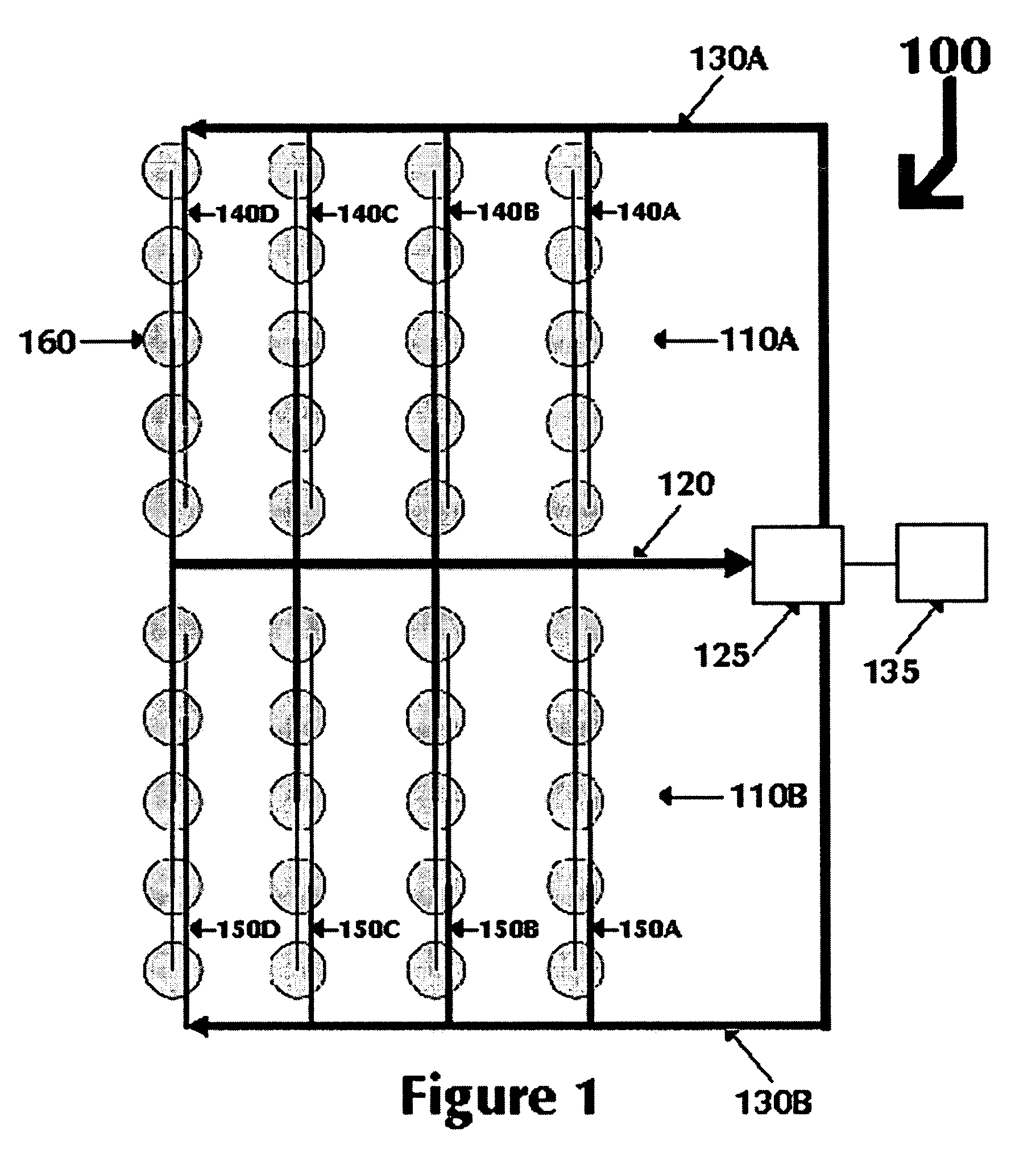

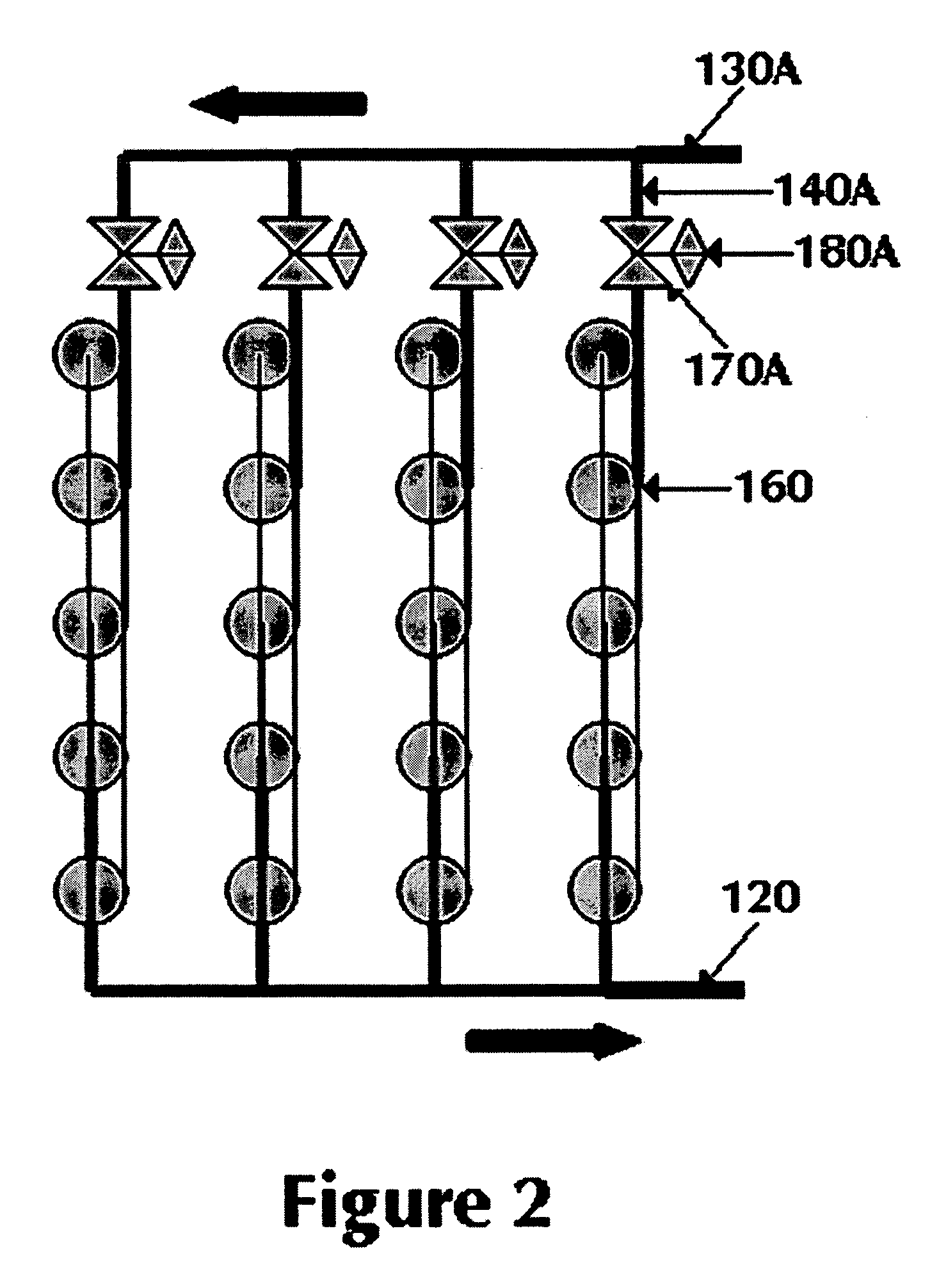

The present invention features geothermal systems that use of a well field open loop scheme by interconnecting the well field through a system of mains and controlled branches, the latter composed of multiple (2-5) wells. The proposed design lends itself to the use of modular well field kits that minimize installation cost, insures equal return water distribution to the active wells, creates standardization and insures best practices. The benefits of individual branch control include the ability to serve the building load in staged delivery, thereby minimizing well field parasitic load, and maximizing the time available for well field thermal relaxation and availability.

Owner:AMERICAN REFINING GRP

Method for classifying vessels using features extracted from overhead imagery

ActiveUS8170272B1Character and pattern recognitionColor television detailsFeature extractionBlood vessel

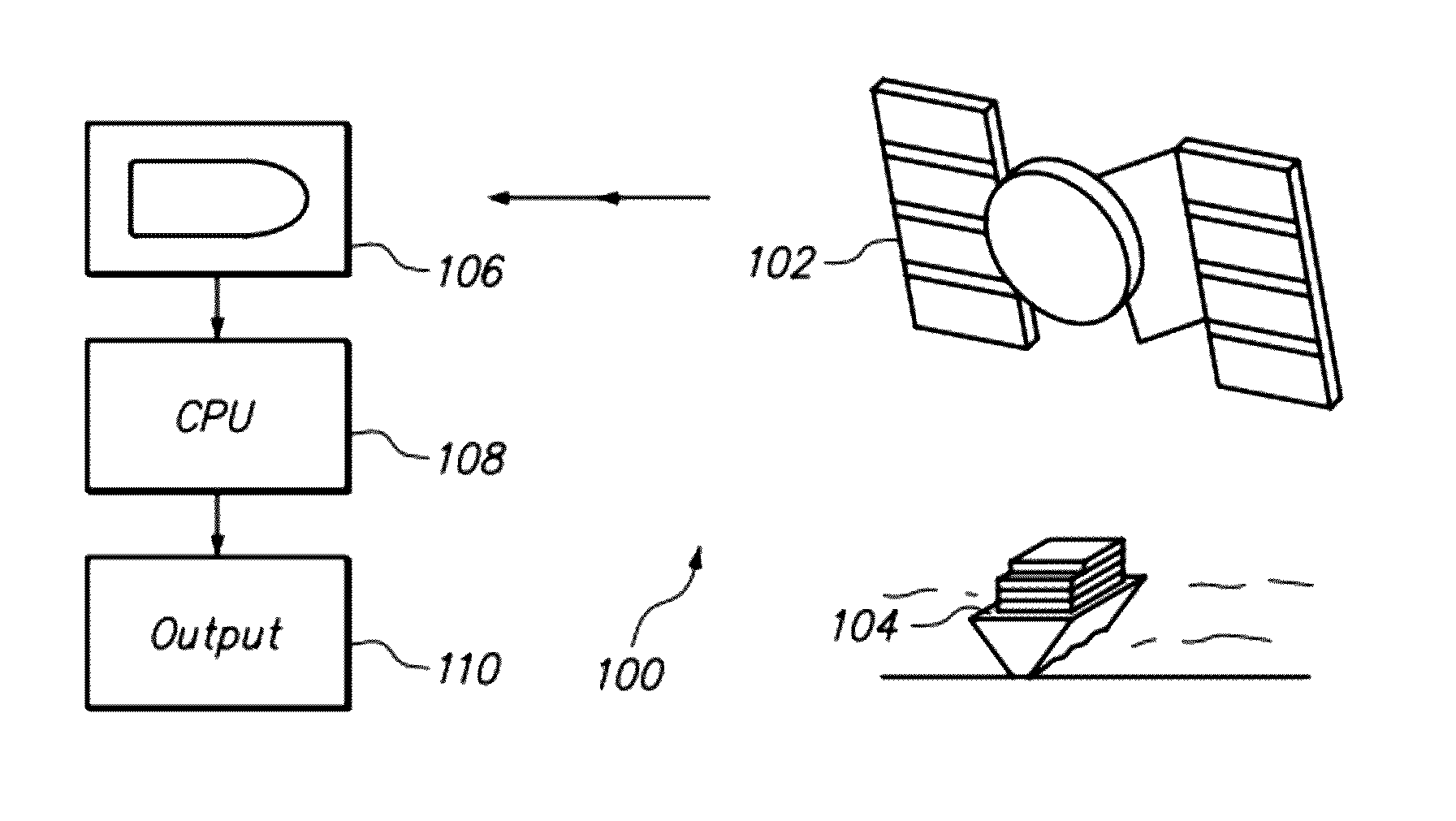

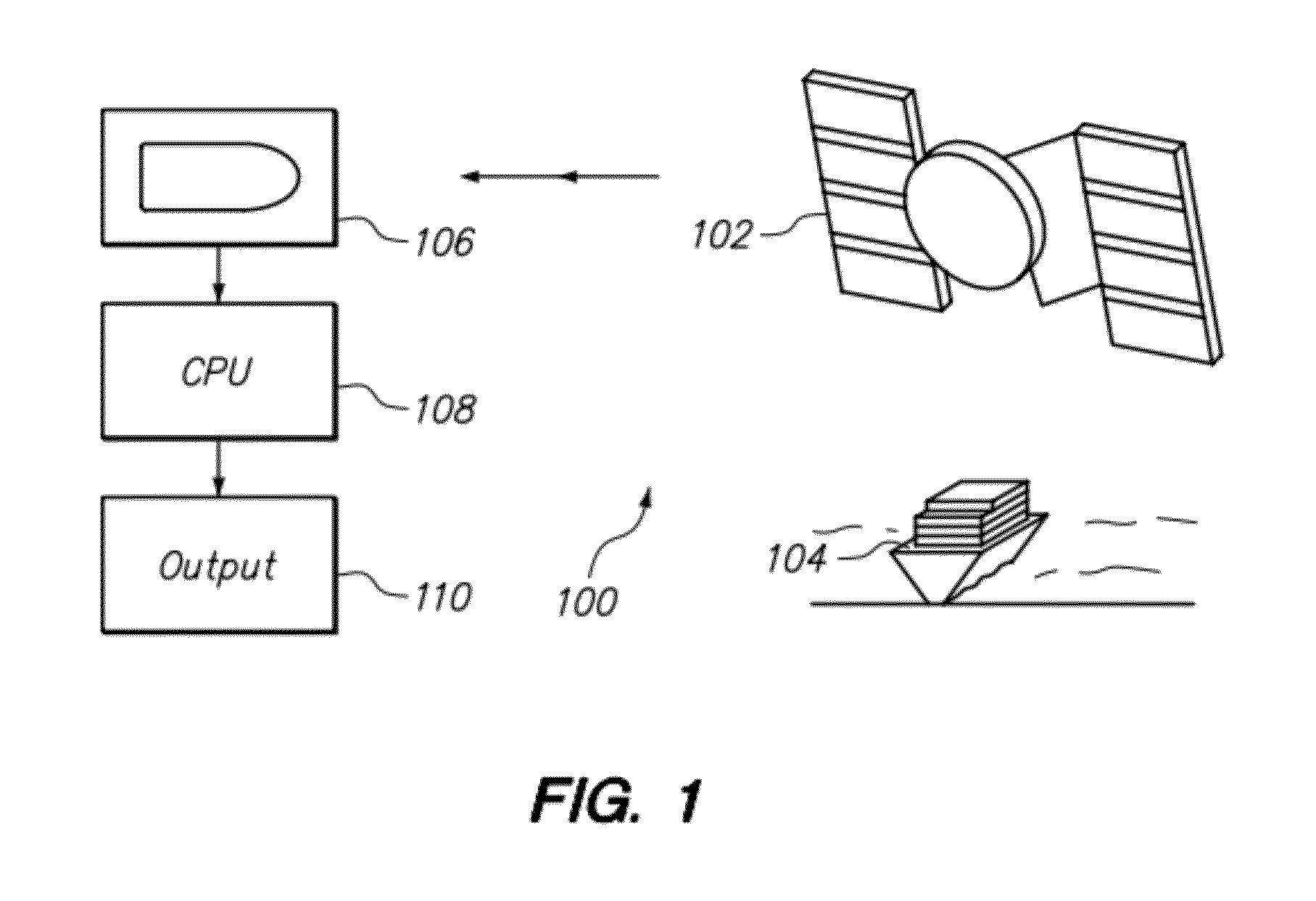

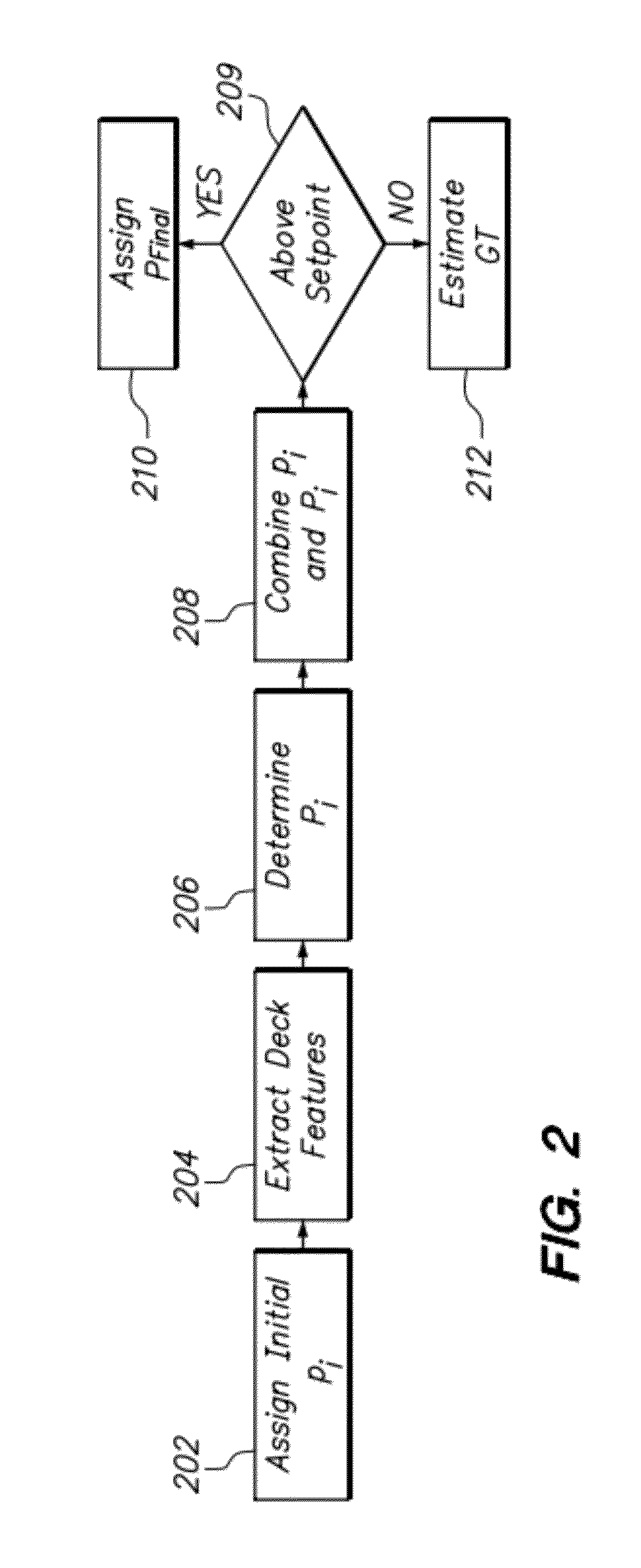

Methods for processing overhead imagery of a vessel include the step of determining an initial classification and classification probability based on the vessel length and length-to-width ratio. Next, mutually exclusive deck features can be extracted from the image. For several embodiments, the extracted deck features that can be spherical tanks, hatches and containers that are stored on deck. The initial classification probability is then weighted using the results of the deck feature extraction step to yield a posterior classification probability for the ship image. If the posterior classification probability is above a predetermined value, the image is assigned a posterior classification. If the posterior probability is below the predetermined value, the vessel image is classified as unknown, and the gross tonnage of the vessel is calculated using the length and width of the vessel.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

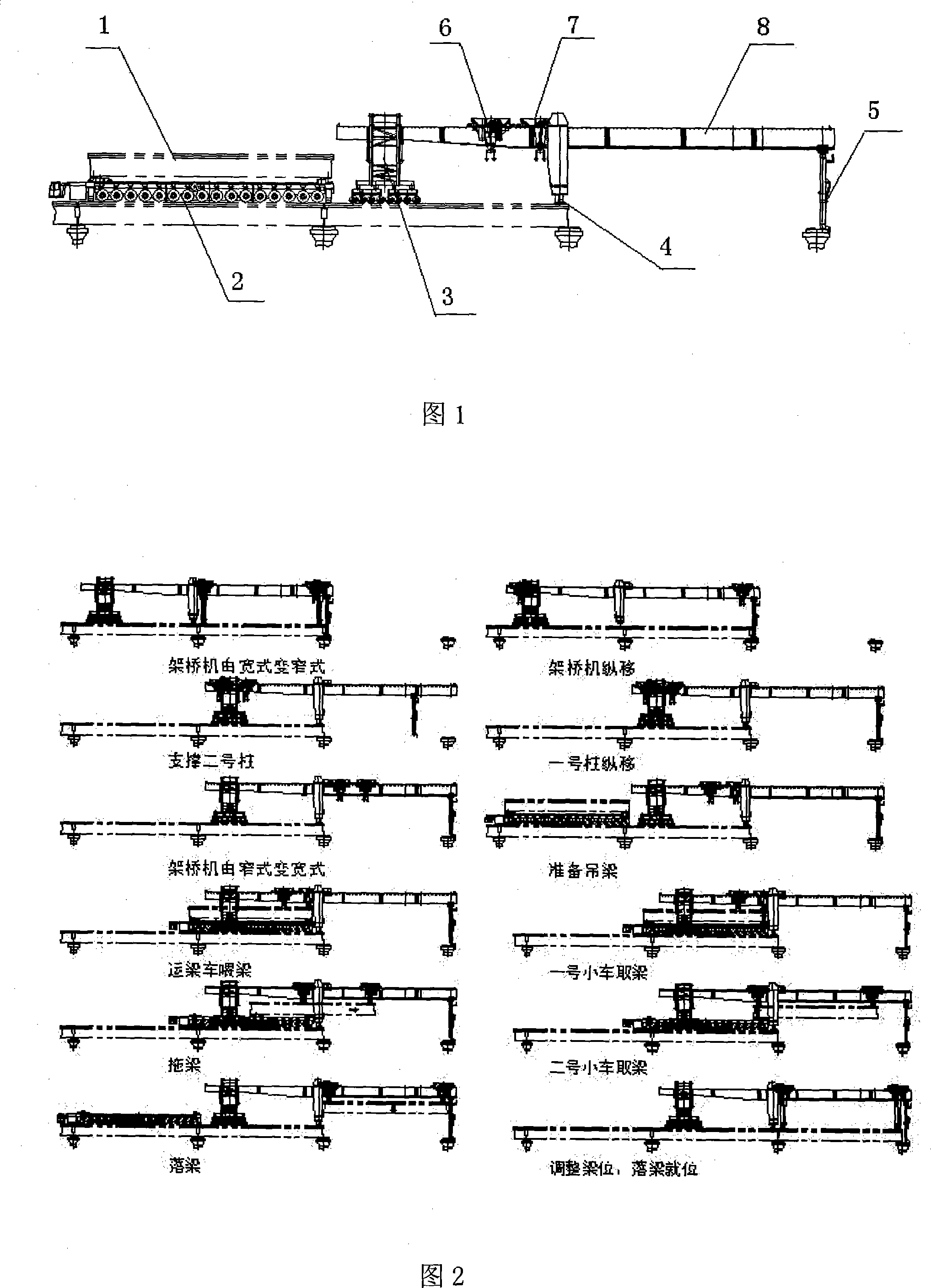

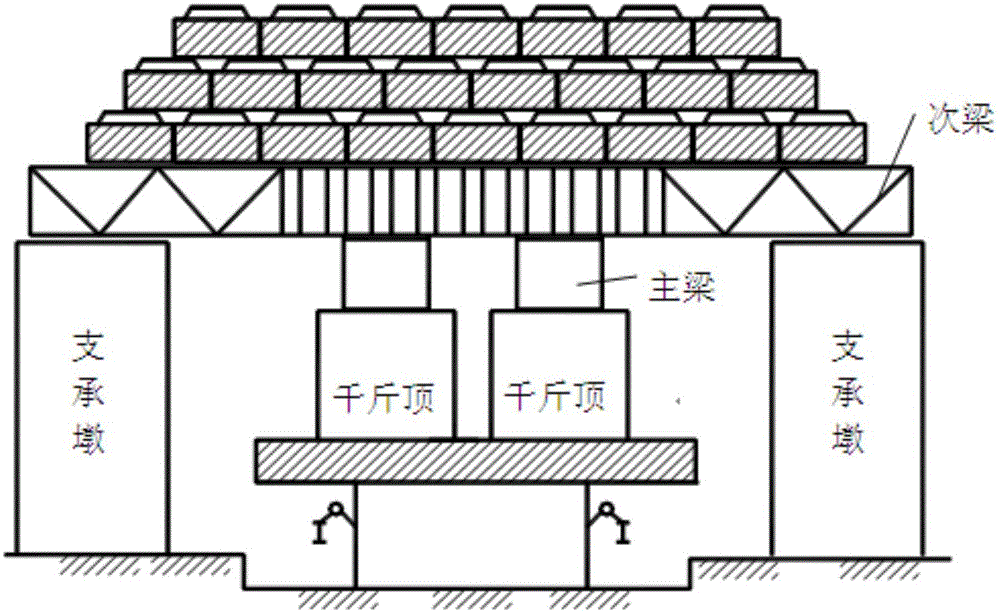

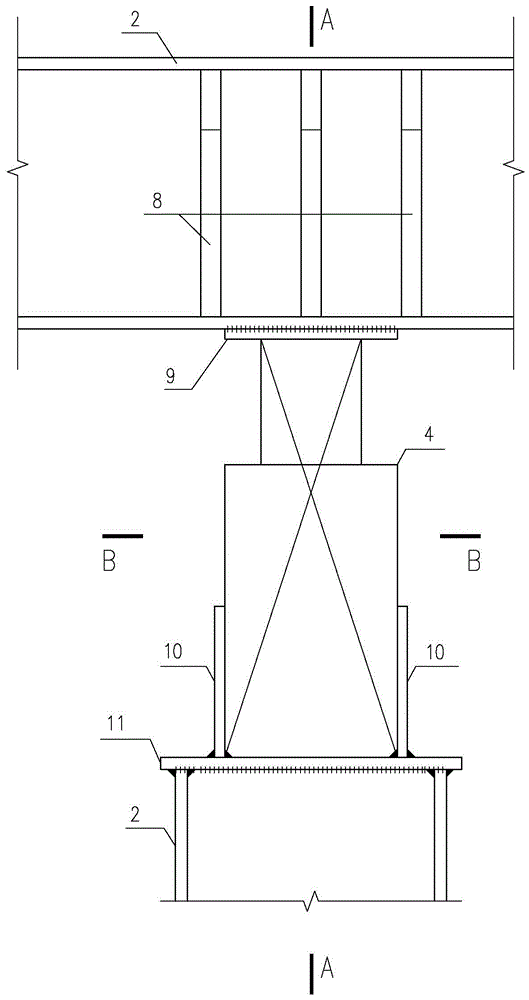

Large tonnage whole opening box girder transmitting and construction method

ActiveCN101144259AEasy transferShort time for auxiliary workBridge erection/assemblyEngineeringBox girder

The present invention discloses a large tonnage entire hole box beam for transporting and a method for construction, and comprises the transportation of the box beam and the erecting of the box beam. The transportation construction of the box beam mainly comprises the steps of beam transportation preparation, beam loading, beam transportation etc., and the erecting of the box beam comprises the erection of the bridge vertical over hole, beam feeding and beam hoisting for vertical shift. The method effectively solves a plurality of construction problems that the auxiliary operation time of the prior transportation construction and the prior erecting construction is long, the auxiliary equipment is more, the variable cross-beam erection and the parallel operation are not available, etc., and thus the present invention proposes a scientific construction method with short auxiliary operation time, less auxiliary equipment, and capability of parallel operation; meanwhile, the method can meet the variable cross-beam erection of a front hole beam and a tail hole beam. The method has high construction efficiency, convenient shift among the bridges and strong adaptability, and the present invention is not only suitable for the construction of the outsize bridge having a plurality of consecutive holes, but also can be well adapted to the bridge group construction with middle size and small size bridges dispersed in a bridge which only has a few box beams.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

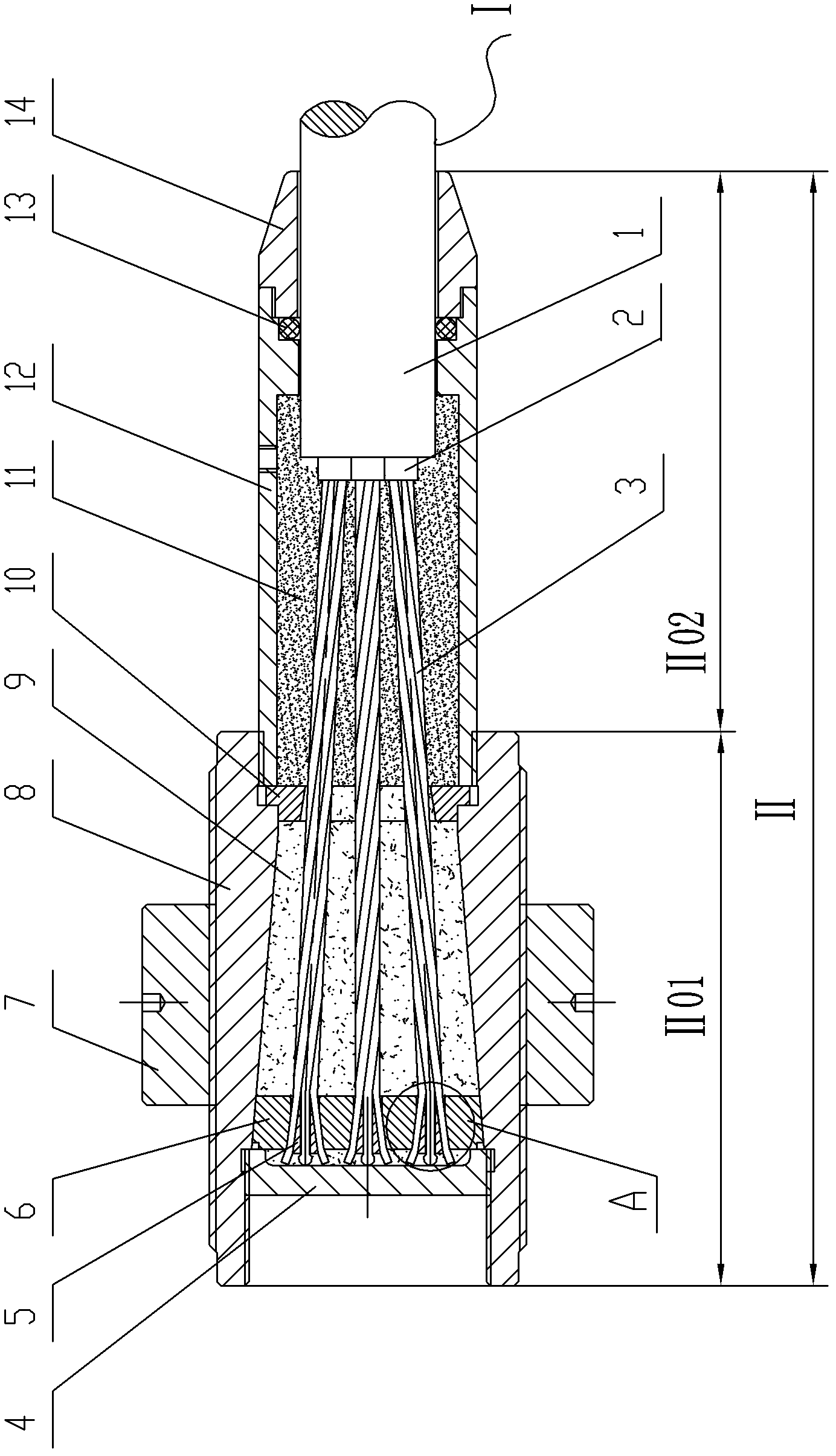

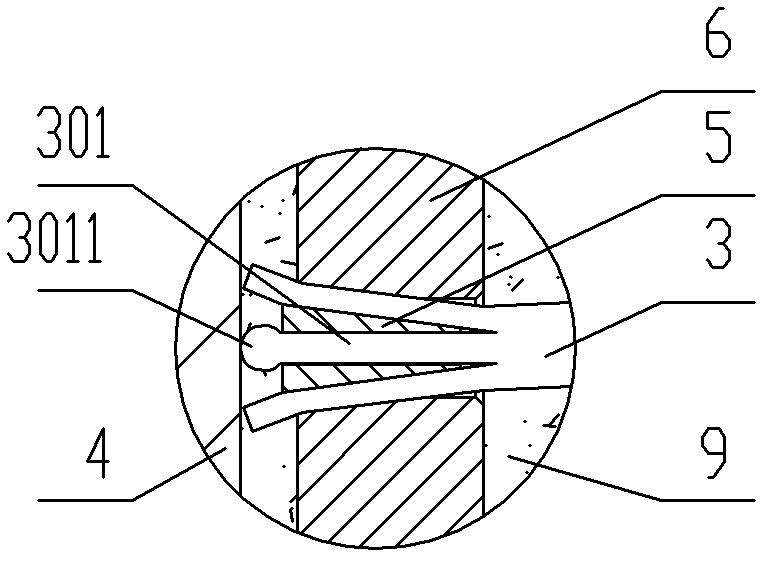

Steel strand finished stay cable and manufacturing method thereof

ActiveCN102587279ASimplify construction stepsShorten the construction periodBridge structural detailsBridge erection/assemblySingle strandCorrosion

A steel strand finished stay cable comprises a cable body and two anchoring parts, wherein the cable body consists of a plurality of single-stranded steel strands and an outer sheath, and the two anchoring parts are arranged at two ends of the cable body. Each anchoring part comprises an anchoring unit and a sealing unit, the anchoring unit comprises an end cap, a taper sleeve, an anchoring plate, an anchoring cup and a restraint ring, wherein the anchoring plate is provided with a conical anchor hole, and the structure of each single-stranded steel strand of the finished stay cable in the conical anchor hole includes: the taper sleeve is mounted on a central wire of one end of the single-stranded steel strand, the end of the central wire is headed, side wires are arranged outside the taper sleeve and dispersedly conically distributed and form a single-stranded steel strand anchoring unit with the conical anchoring hole of the anchoring plate, the end of the anchoring cup is capped with the end cap, epoxy packing is poured into the anchoring cup and anchoring of the multiple single-stranded steel strands can be completed after curing of the epoxy packing. The steel strand finished stay cable is fine in sealing and corrosion resistance and simple in construction, mounting and staying and is preformed in factories, and large-tonnage multi-stranded steel strand finished stay cables in various specifications can be manufactured according to needs, and are applicable to bridge construction and large-scale construction engineering.

Owner:LIUZHOU OVM MASCH CO LTD +1

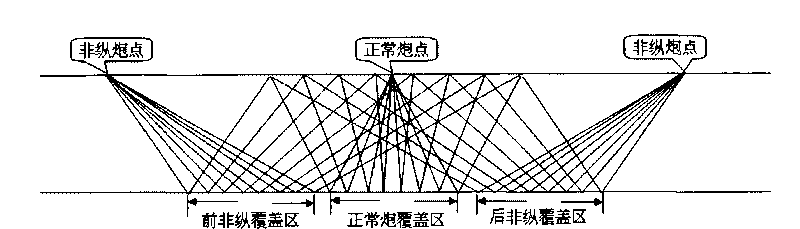

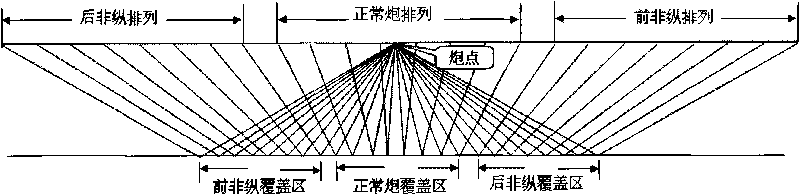

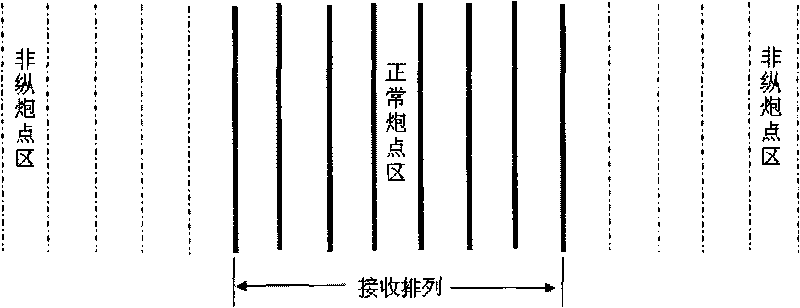

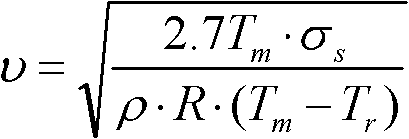

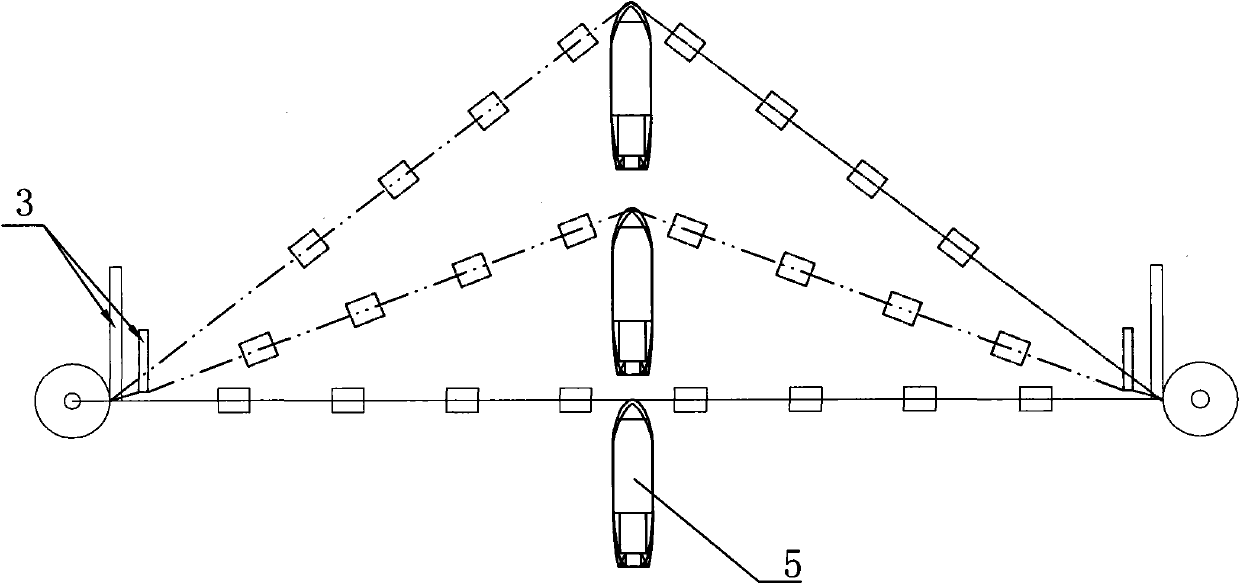

Bidirectional out-of-line rolling measuring seismic exploration and acquisition method

ActiveCN101710184AThe effect of the data is goodGuaranteed qualitySeismic energy generationSeismic signal receiversGeophoneSystems design

The invention provides a bidirectional out-of-line rolling measuring seismic exploration and acquisition method, which is applicable to the seismic exploration and acquisition in urban areas or hazards. The invention adopts light-tonnage controllable source and / or shothole source to stimulate earthquake waves and adopts an earthquake instrument of over 5000 paths and a moving-coil type geophone to receive earthquake signals. The method in the invention comprises the following steps: A. arranging construction point location; B. designing out-of-line observation system; C. implementing bidirectional out-of-line rolling observation; and D. implementing bidirectional out-of-line rolling measuring, and the key lies in accurately determining the position of the out-of-line shotpoint, and the out-of-line shotpoint and the normal shotpoint correspond to identical receiving arrangement. The invention has the effects of utilizing limited urban shothole shotpoint to repeat implementation, strengthening the stimulating energy of medium and deep layers, improving the signal to noise ratio of medium and deep layers in seismic exploration and acquisition, obviously improving energy in medium and deep layers in seismic exploration and acquisition data, obviously improving signal to noise ratio, and simultaneously ensuring construction time effectiveness and saving cost.

Owner:PETROCHINA CO LTD

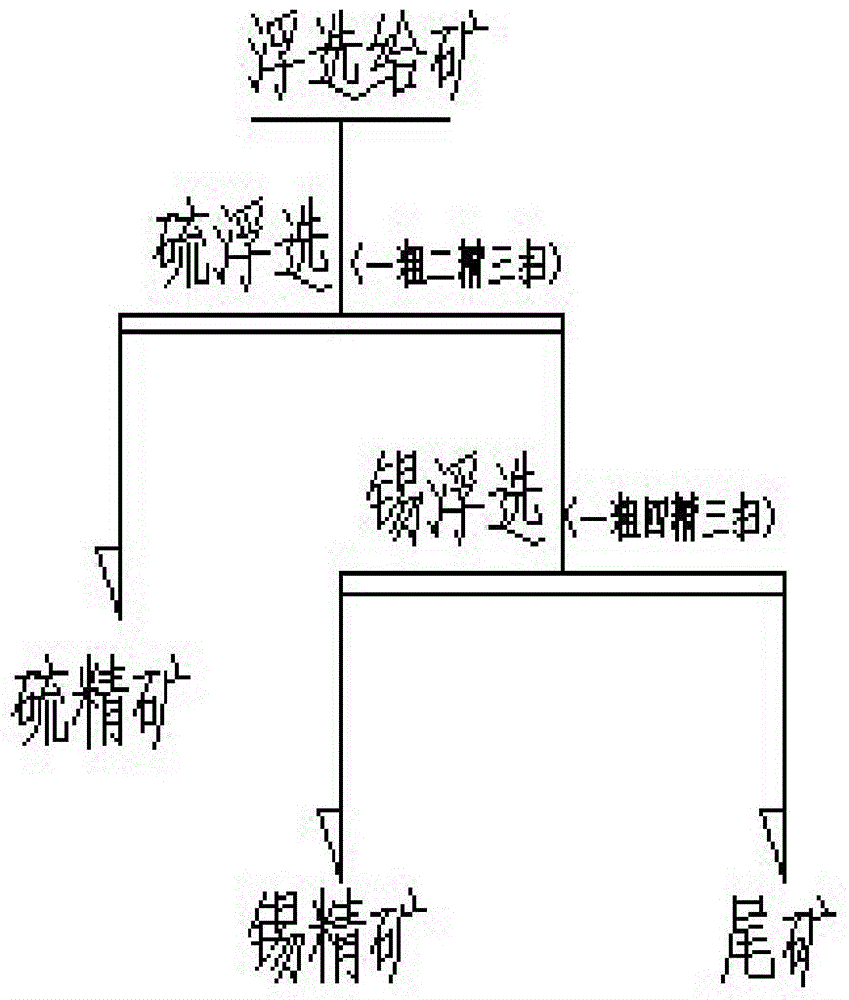

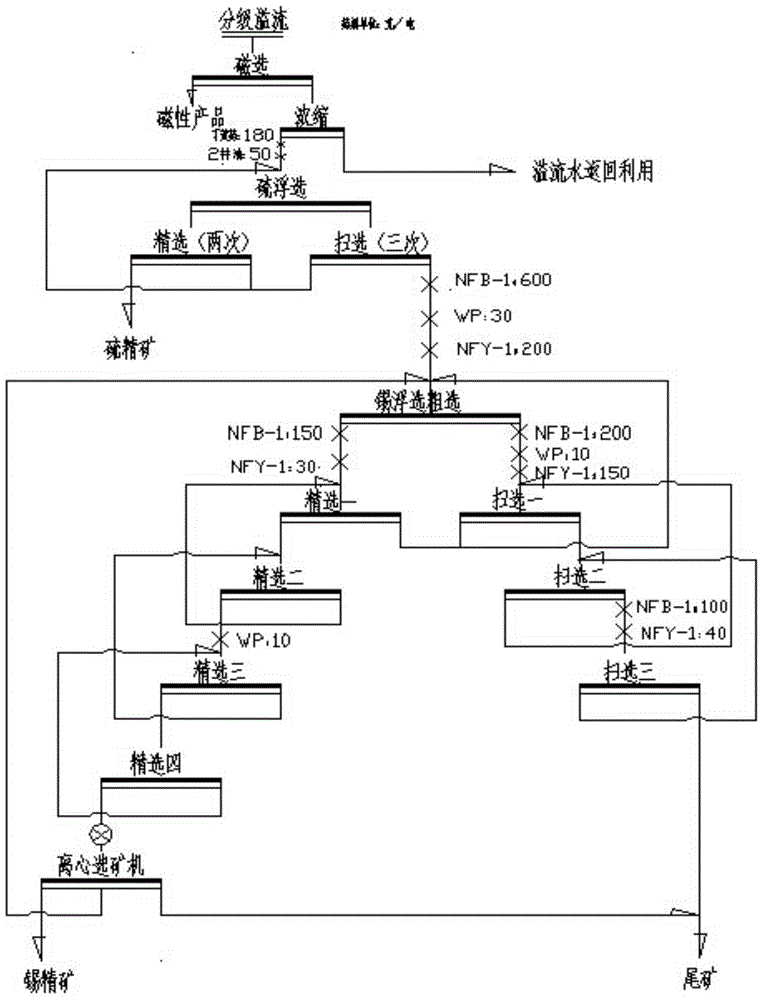

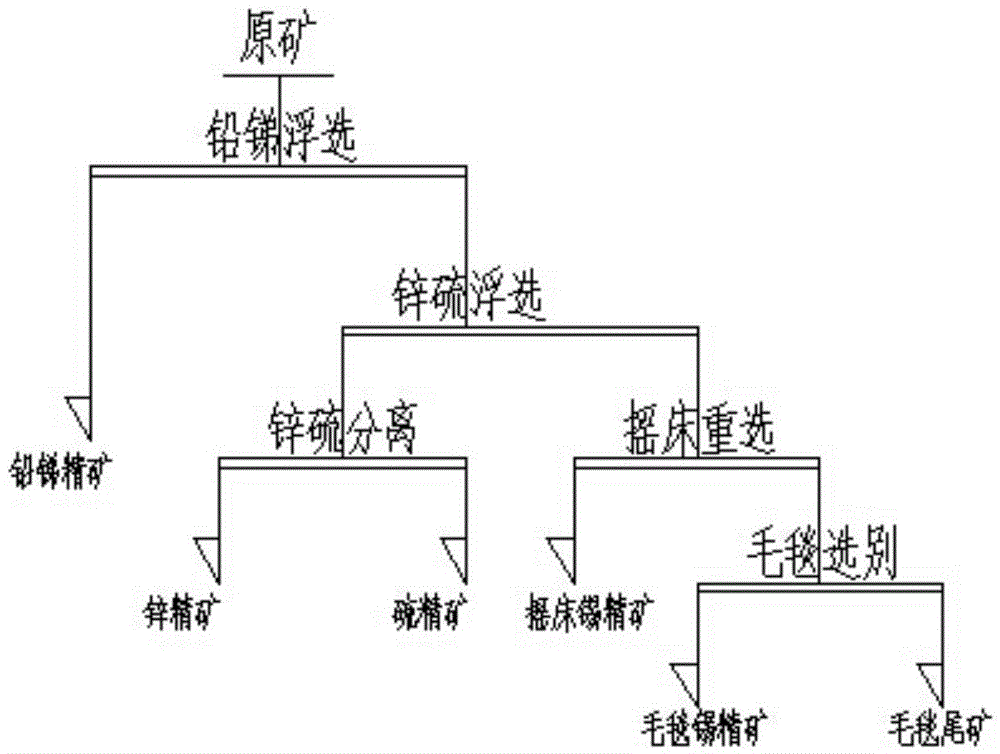

Cassiterite flotation agent composition

The invention provides cassiterite flotation agent composition. The cassiterite flotation agent composition comprises a collecting agent, a combined inhibitor and an optical auxiliary collecting agent, wherein the collecting agent comprises the following ingredients in percentage by weight: 30wt%-50wt% of styryl phosphoric acid, 20wt%-30wt% of aliphatic phosphoric acid (preferably selecting C6-C8 aliphatic series), 10wt%-20wt% of alkyl sulfonated succinic acid and 10wt%-20wt% of alkyl hydroximic acid. The cassiterite flotation agent composition provided by the invention is soluble under normal temperature, non-toxic and tasteless, good in dispersibility, efficient and environment-friendly and good in return water utilizability; mineral processing index of cassiterite flotation can be increased, the agent consumption can be reduced, the agent cost is reduced, and particularly for mineral processing on fine particle cassiterite, a unique effect is obtained; the loss of intermediate products during a tin rough concentrate recycling process is avoided; the industrial application processing capacity can be up to 50-60 tonnage / day, and more preferably, the industrial application processing capacity can be up to 80 tonnage / day; when the flotation ore feeding tin grade is 0.70%-0.80%, good technical indexes of 6%-10% of tin flotation concentrate grade and 60%-70% of operation recovery rate is obtained by agents; the dosage of the agents is greatly reduced.

Owner:临武县南方矿业有限责任公司

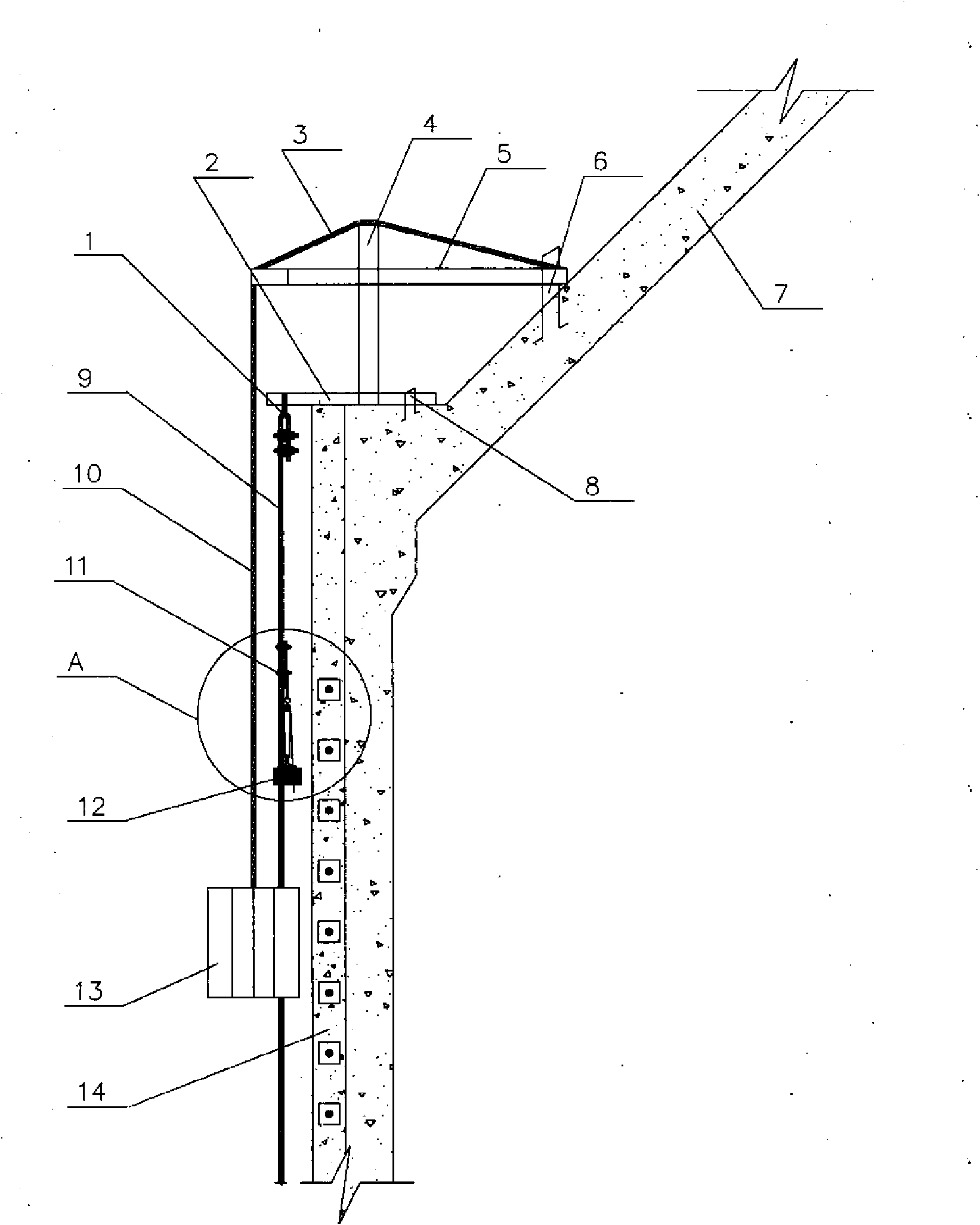

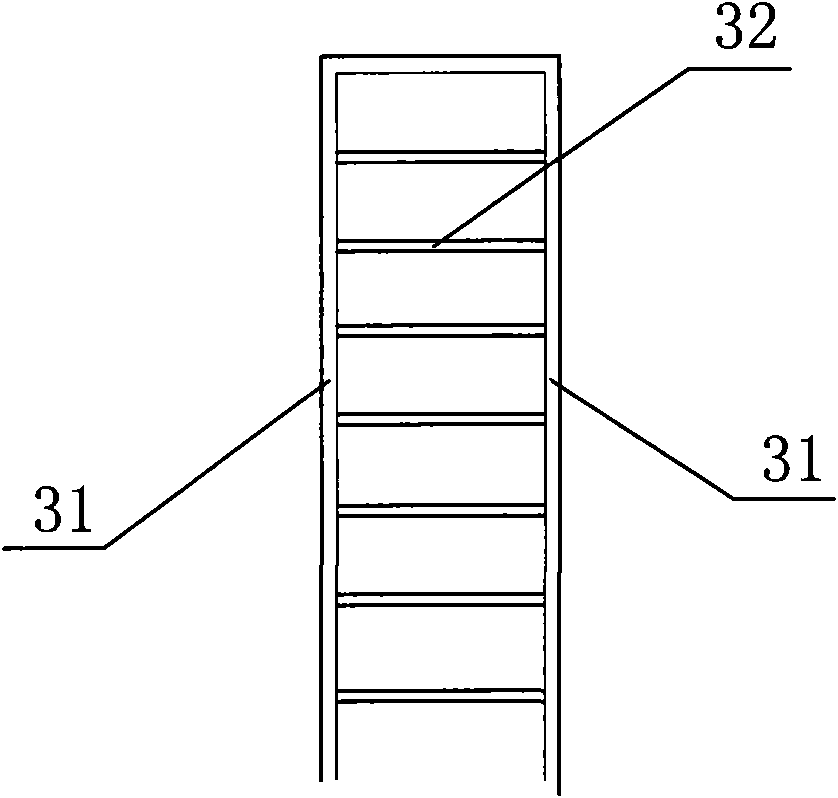

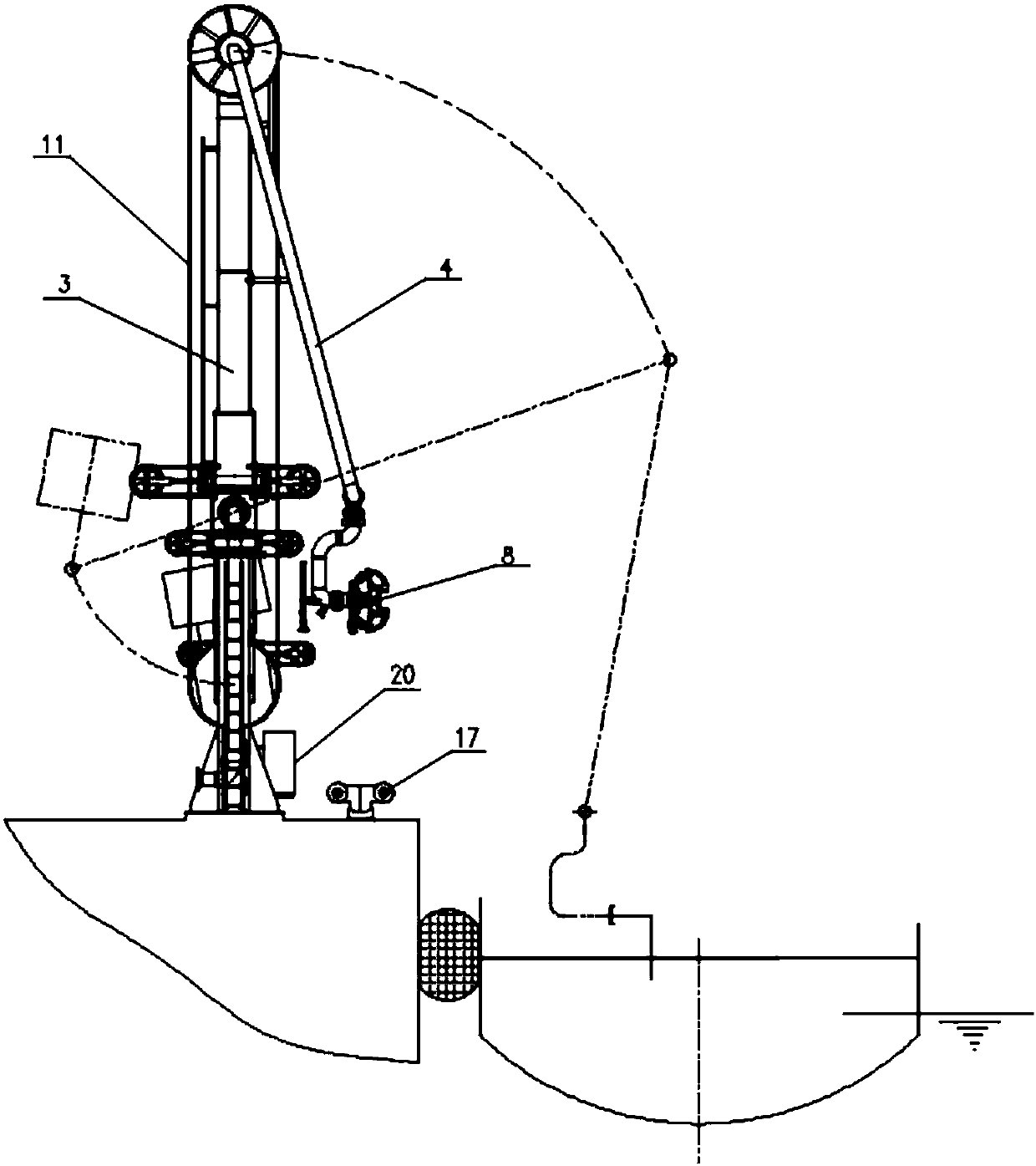

Large-tonnage jack tension construction technology for non-bonded prestressed silo

ActiveCN101597960AEven by forcePrevent rustBuilding material handlingBulk storage containerButtressNacelle

The invention discloses large-tonnage jack tension construction technology for a non-bonded prestressed silo. The invention aims to provide construction technology which uses a flat wrought iron anchor backing plate matched with an anchor device, takes a nacelle as an operation platform for tension construction, and uses a large-tonnage jack to perform cluster beam tension on prestressing tendons to improve construction quality, reduce construction cost and shorten construction period, wherein the anchor backing plate comprises a square wrought iron anchor backing plate body; and the square wrought iron anchor backing plate body is provided with an anchor eye and a mounting hole which correspond to the anchor device. A suspension mode of the nacelle is that a conical roof is provided with a nacelle suspension embedded part, which ensures that the conical roof of the silo becomes the balance weight of the nacelle; and a suspension mode of the jack is that the top of a buttress is provided with a jack hanger embedded part; the hanger embedded part is fixedly connected with a supporting beam; the outer end part of the supporting beam is welded with a lifting ring; one end of a steel wire rope is fixedly connected with the lifting ring; while the other end hangs down to the bottom of the silo; a connecting plate is connected with the steel wire rope; and the connecting plate is connected with a jack hanger.

Owner:李延春 +2

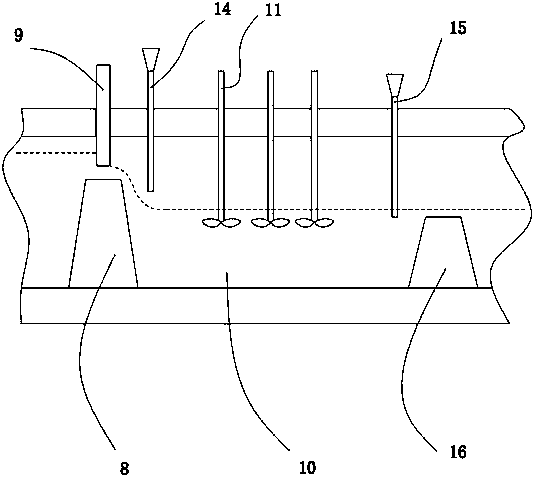

Translation locating device and method for annular block of hull

The invention provides a translation locating device and method for an annular block of a hull, belongs to the field of hull sectional assembly, and is designed for solving the problems that an existing device and method are low in translation locating efficiency, and the like. The translation locating device for the annular block of the hull comprises a power module vehicle, a locating device and a control device. The power module vehicle is used for translating the annular block; the locating device is a tracking type total station and used for capturing the location of the annular block transported by the power module vehicle in real time; the control device is used for receiving the location information of the annular block and controlling the power module vehicle to transport the annular block to the given target location. The translation locating method for the annular block of the hull is designed on the basis of the device. According to the invention, the module vehicle is taken as the translation device, a plurality of the module vehicles can be combined according to the tonnage of the annular block, the application range is wide, accurate locating is achieved while the locating device and the control device realize the translation, safety is guaranteed, and the efficiency is high.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

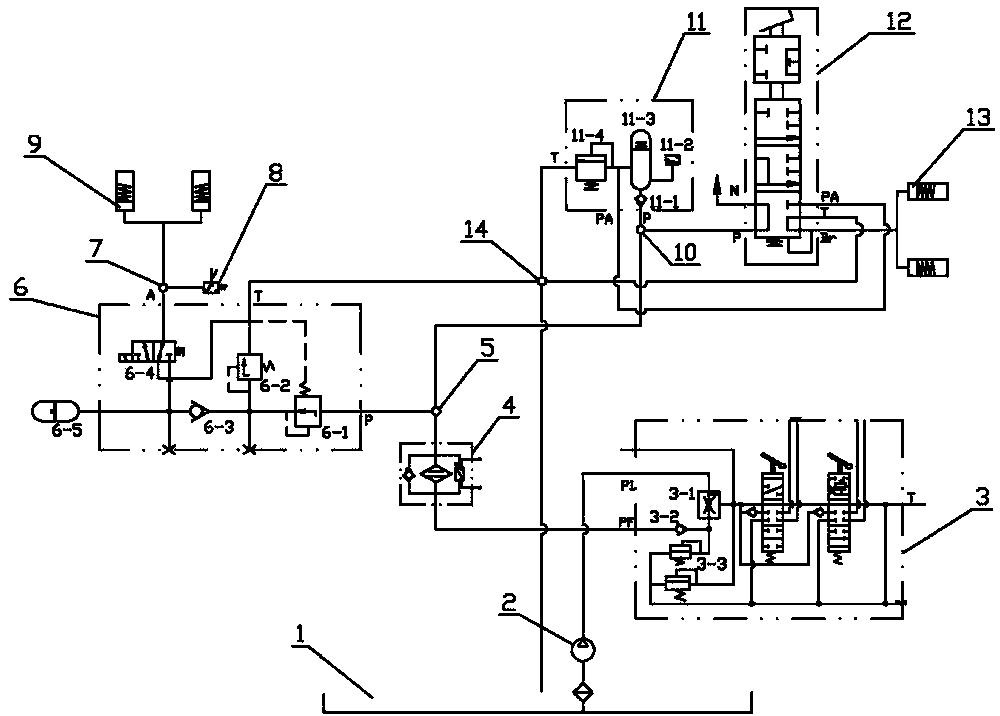

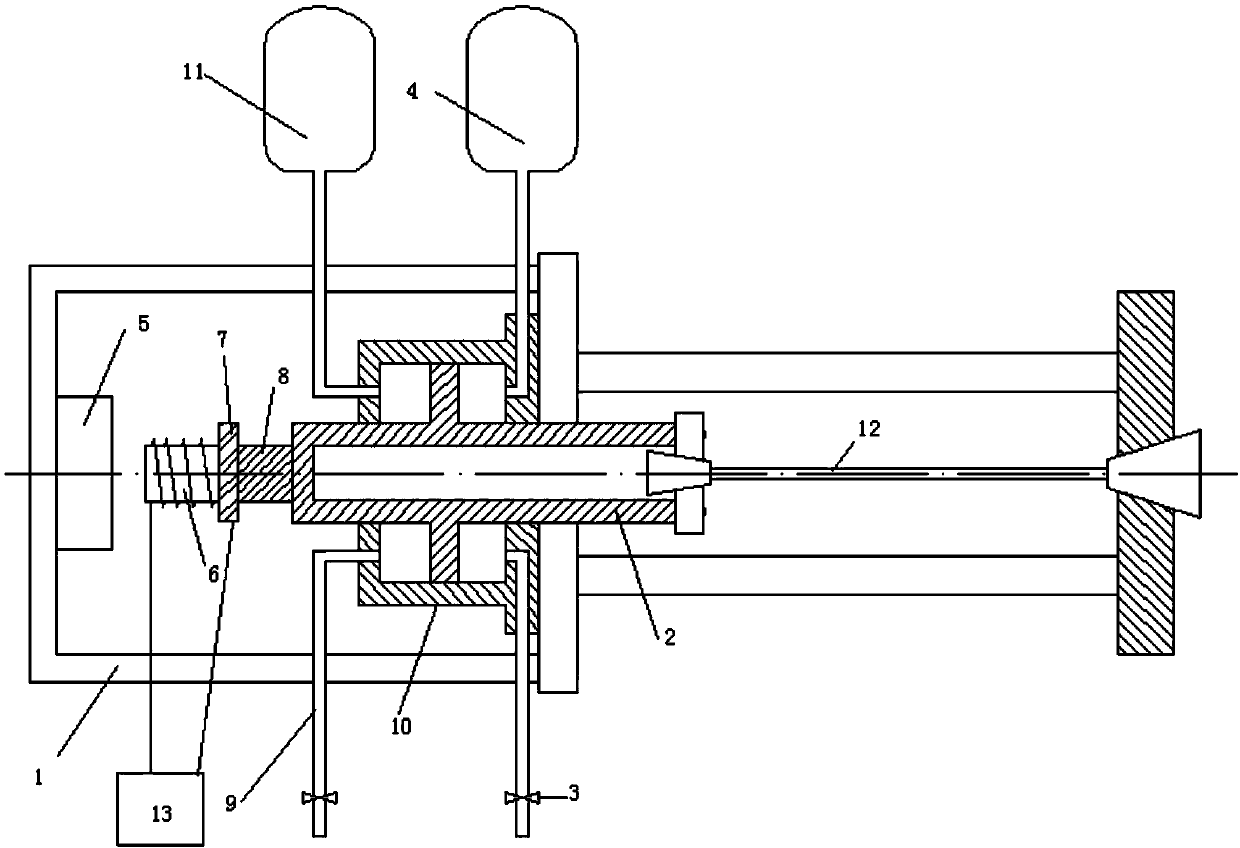

Hydraulic braking system of large-tonnage electric fork-lift truck

The invention relates to a hydraulic braking system of a large-tonnage electric fork-lift truck. The invention aims to provide a hydraulic braking system of a large-tonnage electric fork-lift truck, which is simple in structure, safe and reliable. According to the technical scheme of the invention, the hydraulic braking system comprises a parking brake, a power brake valve and a service brake; an oil source is provided for the system by a hydraulic work system; the hydraulic work system comprises an oil tank, an oil pump and a multi-way reversing valve; the hydraulic braking system is characterized by further comprising a parking integrated valve and an energy accumulator; the PF port of the multi-way reversing valve is connected with a pipeline filter; the oil outlet of the pipeline filter is connected with a front tee joint; after flow is divided by the front tee joint, one path is communicated with the P port of the parking integrated valve, and the other path is respectively connected with the P port of the power brake valve and the P port of the energy accumulator; the PA port of the energy accumulator is connected with the PA port of the energy accumulator; the N port of the power brake valve is connected with a steering system; the Br port of the power brake valve is communicated with an oil port of the service brake.

Owner:HANGCHA GRP

Manufacturing method of ultra-fine grain high-temperature alloy plate blanks

ActiveCN103008659AExcellent high temperature strengthExcellent fatigue resistanceUltra fineSuperalloy

The invention discloses a manufacturing method of ultra-fine grain high-temperature alloy plate blanks. The manufacturing method comprises the following steps of 1, preparation of high-temperature alloy powder; 2, heat treatment of the high-temperature alloy powder; 3, selection of a high-temperature alloy core tube; 4, high-temperature spray deposition and composite recrystallization of plate blanks; and 5, heat treatment of the plate blanks, and finally forming the high-temperature alloy plate blanks in ultra-fine microstructures. According to the manufacturing method disclosed by the invention, the high-temperature alloy powder is prepared by adopting a gas atomization technology, and the obtaining of an oxygen-free and segregation-free well-closed formation is controlled through a heat treatment system; the element composition is controlled by selecting the high-temperature alloy core tube, and the real-time control for the temperature during a forming process is controlled; and the forming of high-temperature alloy is carried out on the outer surface of the high-temperature alloy core tube by adopting the high-temperature spray deposition technology, the composite recrystallization is synchronously carried out, the growth of grains in the microstructure is controlled as a large temperature gradient is simultaneously formed, and the high-temperature alloy plate blanks in the ultra-fine microstructures are finally formed through the heat treatment. According to the manufacturing method disclosed by the invention, the microstructure of the plate blanks is compact, the size is large, and most of all, a forging machine or an extrusion device in large tonnage is not needed.

Owner:BAOSHAN IRON & STEEL CO LTD

Process for manufacturing ship hatch cover of ten-thousand-tonnage container ship

ActiveCN102756790AIncrease productivityReduce energy consumptionWatercraft hull designVessel hatches/hatchwaysFillet weldIndustrial engineering

A process for manufacturing a ship hatch cover of a ten-thousand-tonnage container ship belongs to the shipbuilding field and comprises the following steps of: manufacturing an assembly jig; calibrating the levelness of the assembly jig before building and dividing the assembly jig rationally according to the product; lofting and blanking, detailing shrinkage allowance to each part of the hatch cover, and elaborately setting the shrinkage allowance; fabricating parts: dividing the hatch cover into three major assembly areas, requiring that all structures of the part areas are connected through flat fillet weld or butt weld; assembling the structure of the hatch cover, and then checking and meeting various accuracy requirements; mounting a container foot; performing tracking, supervision and measurement by using QC from container seat marking, before welding of the container seats and after welding of the container seats, repairing the unaccepted container seat immediately, and finally performing a container hoisting test to perfectly guarantee the accuracy of the container foot. With the abovementioned process research and improvement, the production efficiency can be improved to a large extent; and compared with the traditional building way, about 8% of energy can be saved for each set and the building period can be shorted by about three weeks.

Owner:浙江扬帆通用机械制造有限公司

A driver-less goods transport system and transport method

ActiveCN105235714AReduce investmentEliminate cost increasesRailway traffic control systemsRoute devices for controlling vehiclesTransport systemGps positioning system

The invention provides a driver-less goods transport system and transport method. The transport system comprises a main line driver-less transport system, a loading and unloading site goods automatic loading and unloading system and a maintenance shop wireless remote control system. The main line driver-less transport system comprises a control center, a track circuit or a GPS and whole-journey ultra-narrow rails or narrow rails and has whole-journey wireless 4G double network coverage; each train comprises a plurality of train units; each train unit is equipped with a set of signal system vehicle-mounted equipment. The maintenance shop wireless remote control system comprises an emitter, a receiver and a vehicle-mounted antenna. Computer-controlled train tracking is adopted, and the tracking time and the spacing distance between trains are reduced and the transport density is increased; train sets run without drivers for the whole journey; the marshalling is characterized by power distribution, so that the longitudinal impact on trains is reduced and the traction tonnage of a single train is increased; multi-unit traction is employed for trains, so that the accelerating performance is better and the transport efficiency is higher.

Owner:CRRC ZIYANG CO LTD

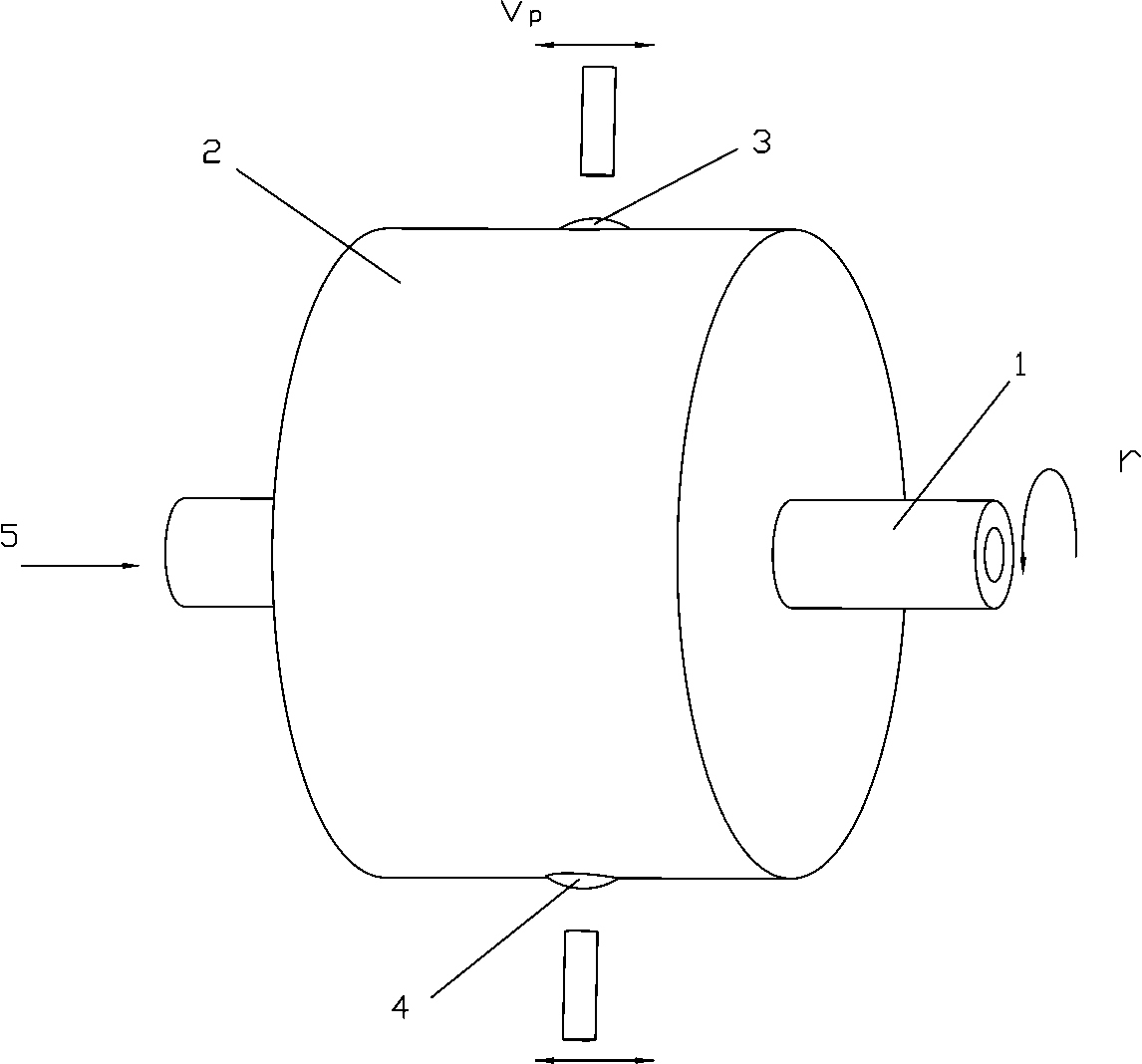

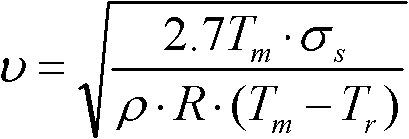

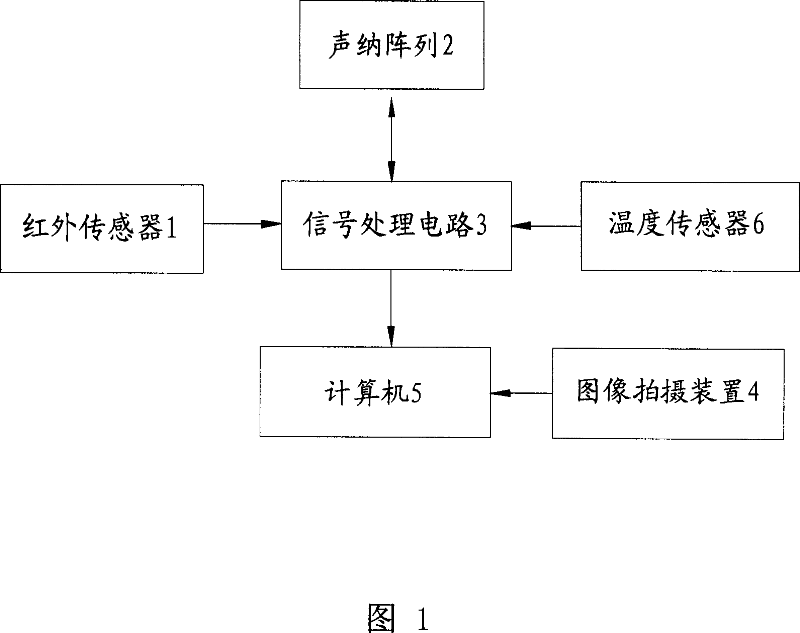

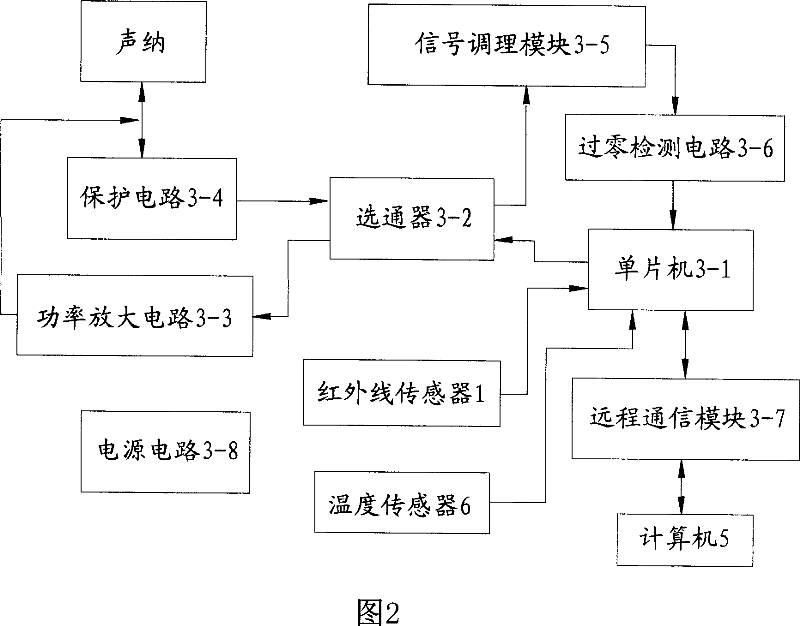

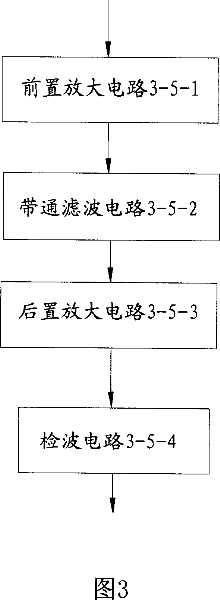

Intelligent measuring system and measuring method of tonnage of ship

InactiveCN101038204AAccurate measurementAutomate operationsPhotogrammetry/videogrammetrySpecial purpose weighing apparatusLine sensorSonar

The present invention relates to an intelligent measuring system of ship for tonnage a measuring method. The measuring system includes: at least two infrared sensors positioned on the two sides of quaywall of the channel section to be measured; a sonar array provided on the two sides of riverbed wall of the channel section to be measured; two image shooting devices positioned on the upper side and the lateral side of the channel section to be measured; a signal processing circuit for controlling the sonar scanning and for transmitting the signals output by the infrared sensor and the sonar signals to the computer; the image information collected by the image shooting devices is transmitted to the computer directly. The whole tonnage, the net tonnage and real loading tonnage of the ship can be measured accurately in time. The method in the present invention has the characteristics of high degree of automation, accurate measuring and high efficiency etc. comparing the method of person observing and coarse estimate. Thus, the automation operation in the ship department can be realized and the accuracy of the statistic data, the efficiency and the intelligent level of the shipping trade are all improved.

Owner:HOHAI UNIV CHANGZHOU

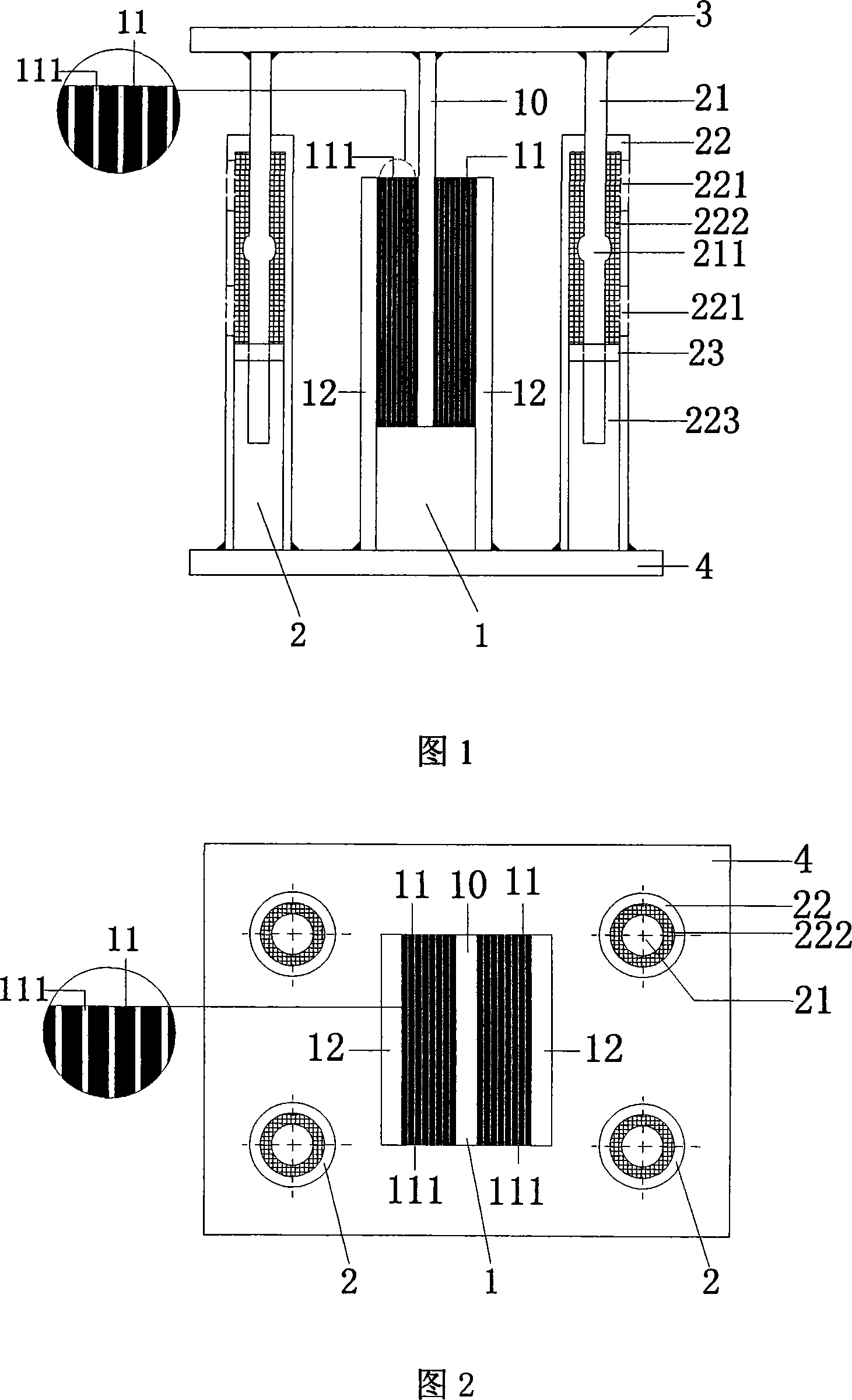

Large-deformation large-tonnage composite viscoelasticity damper

InactiveCN101100879AImproved performance characteristicsGood damping propertiesBridge structural detailsShock proofingViscoelastic dampingSnubber

An anti-knock device of large distortion and heavy load visco-elasticity damper is composed by a large distortion visco-elasticity damper and lead compacting damper. The large distortion visco-elasticity damper is put in the middle and surrounded by several lead compacting dampers with the top and bottom linked to the armor plate to from an integrated damper.

Owner:SOUTHEAST UNIV

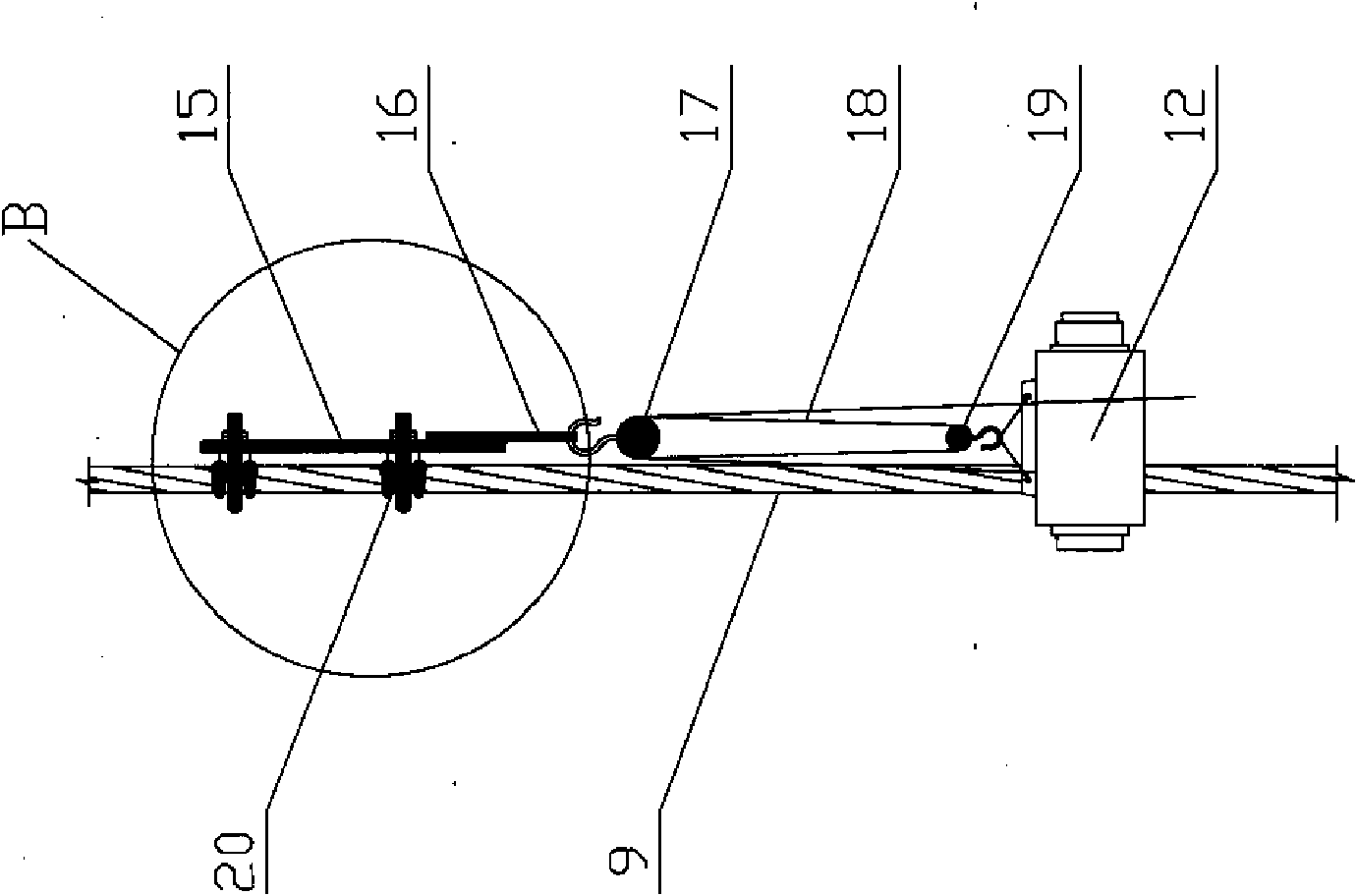

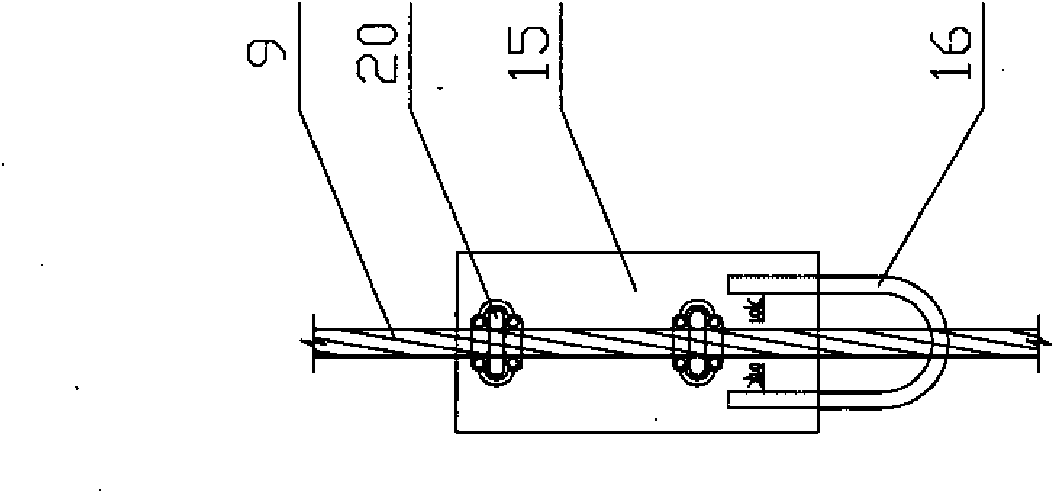

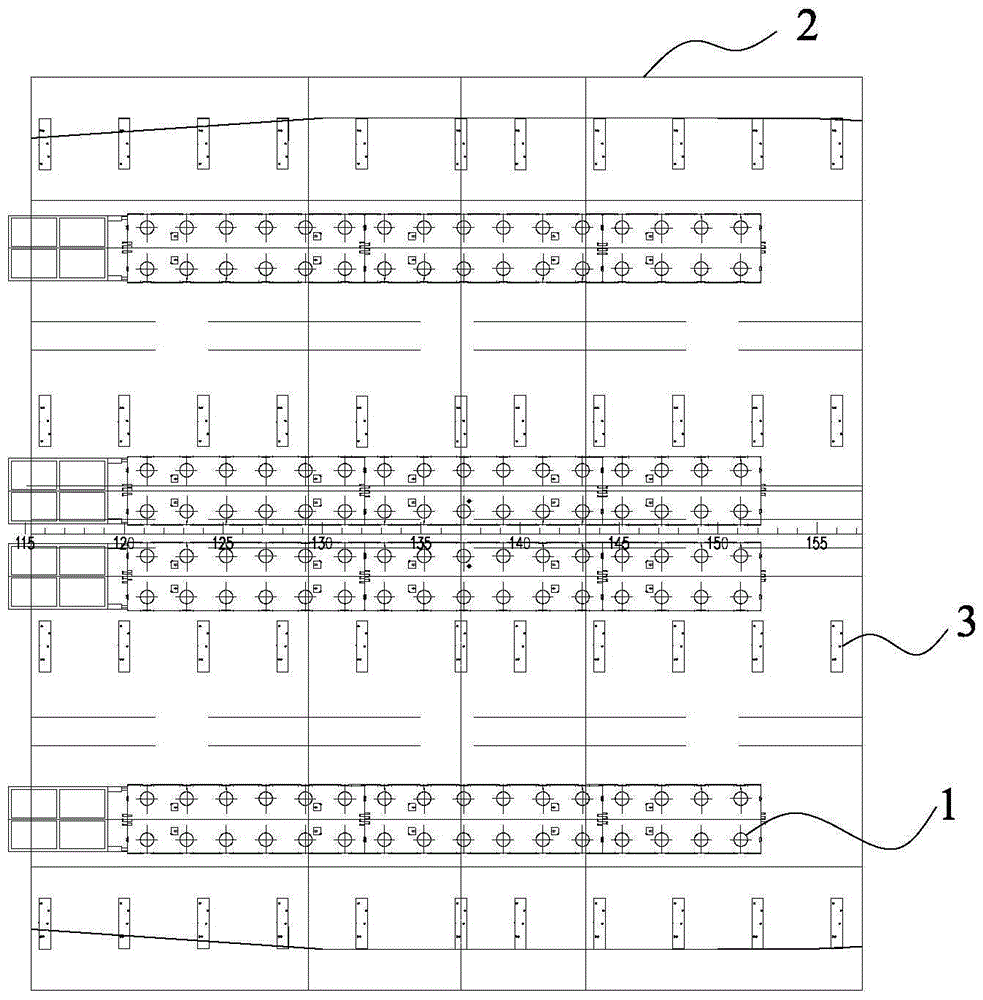

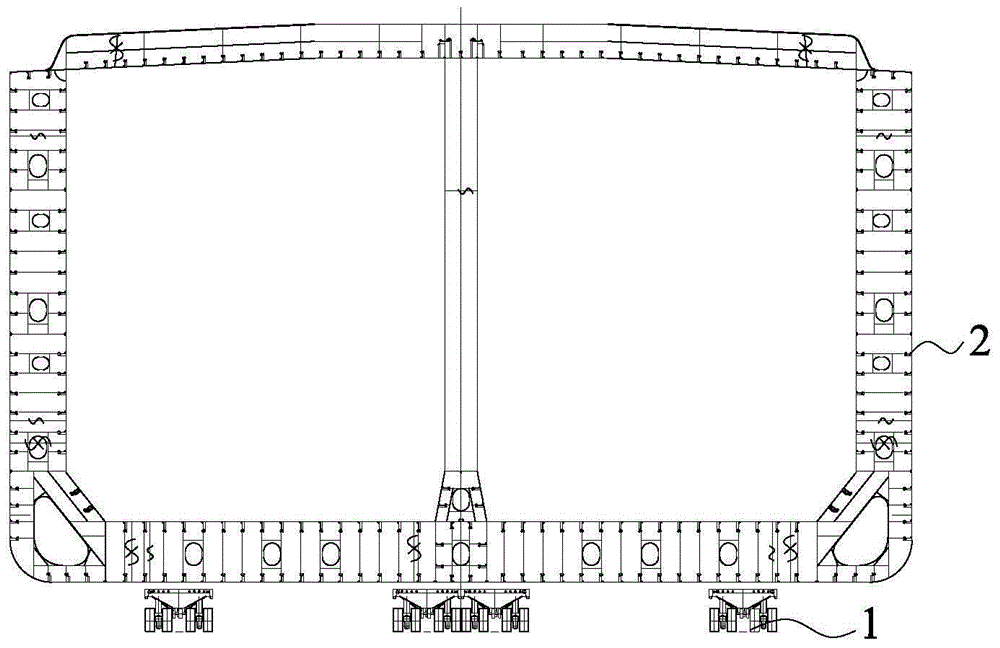

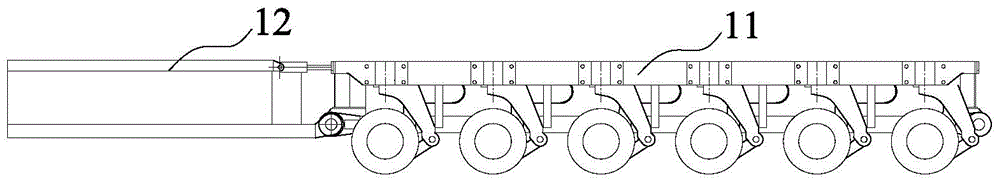

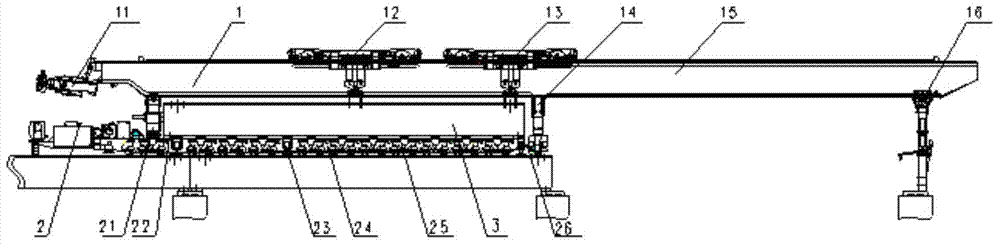

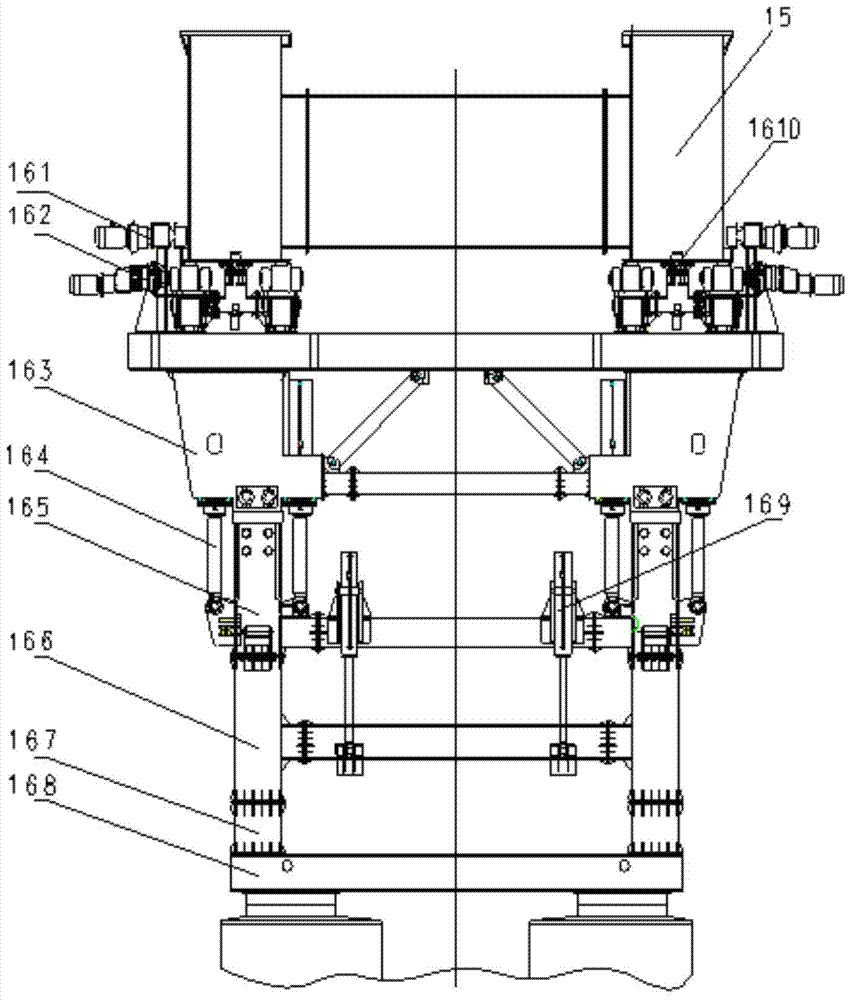

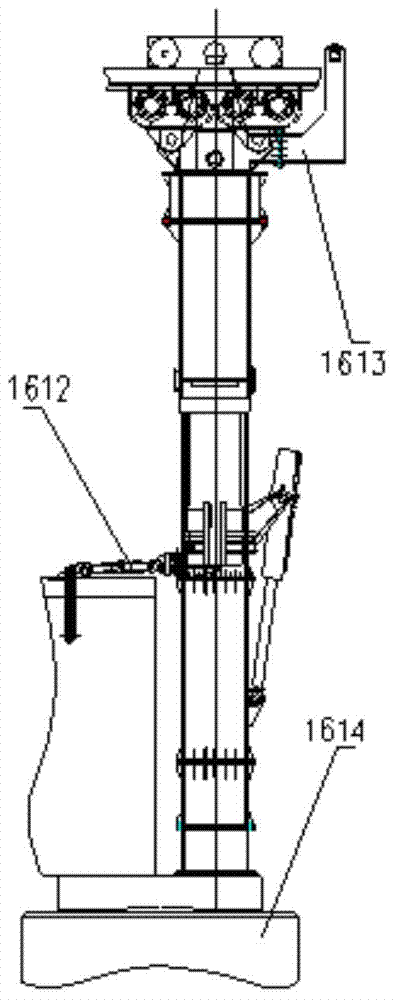

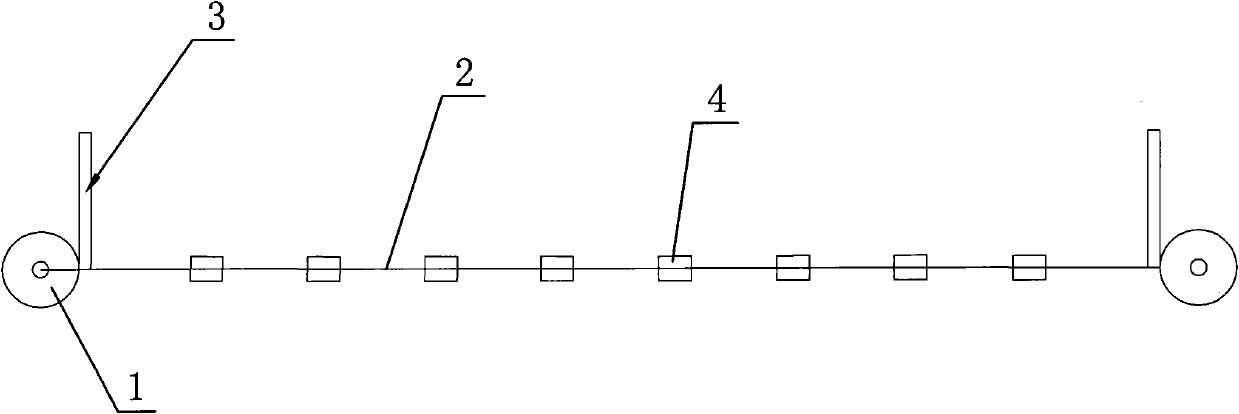

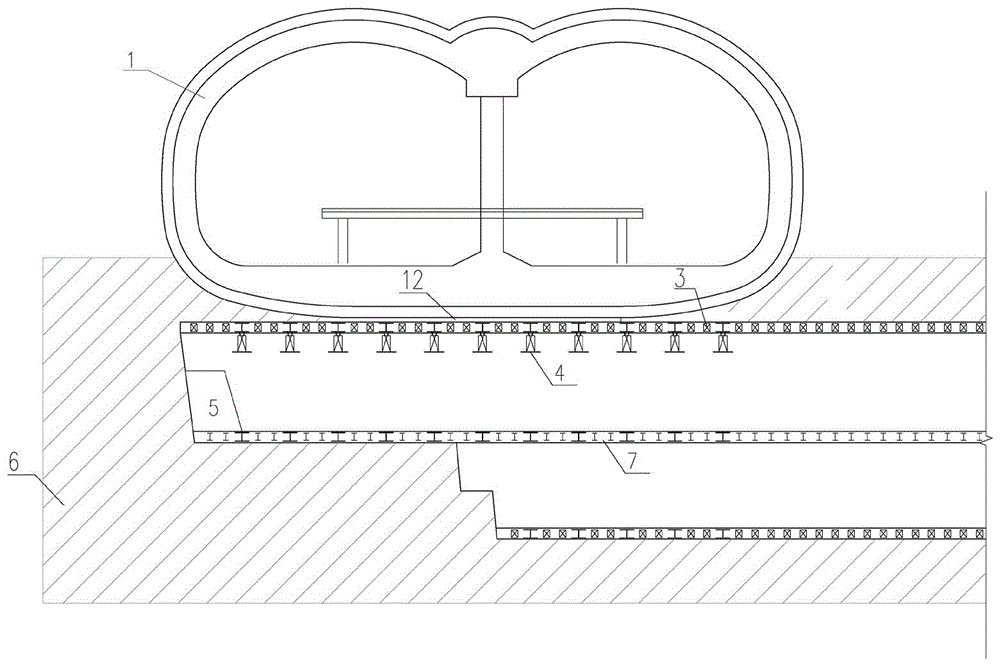

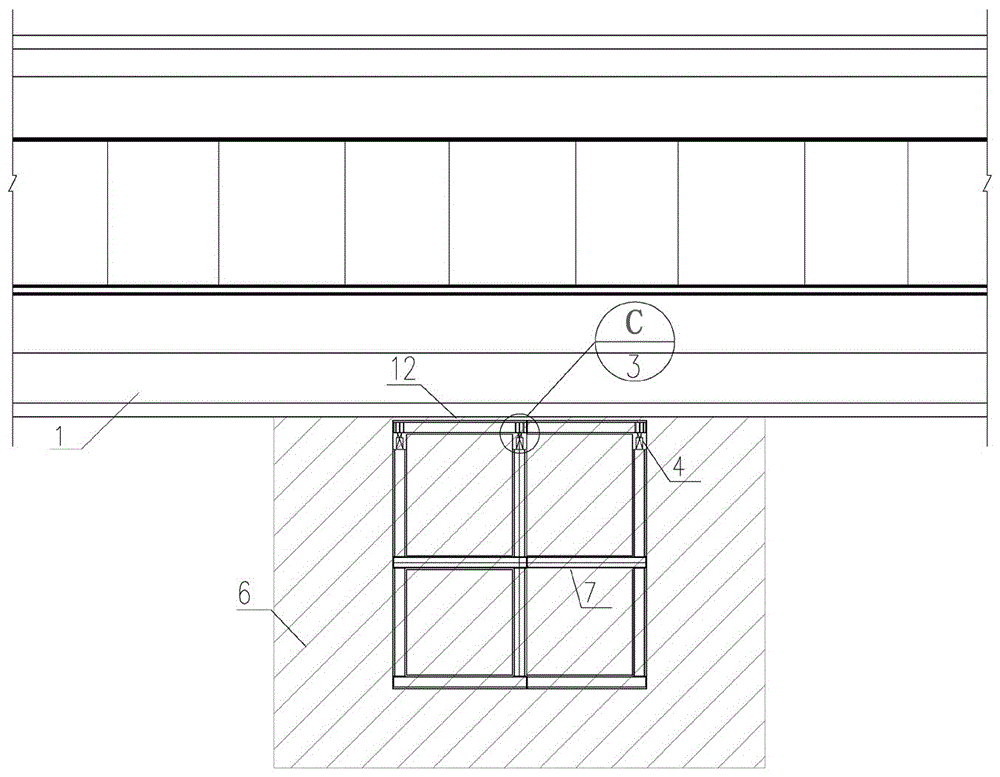

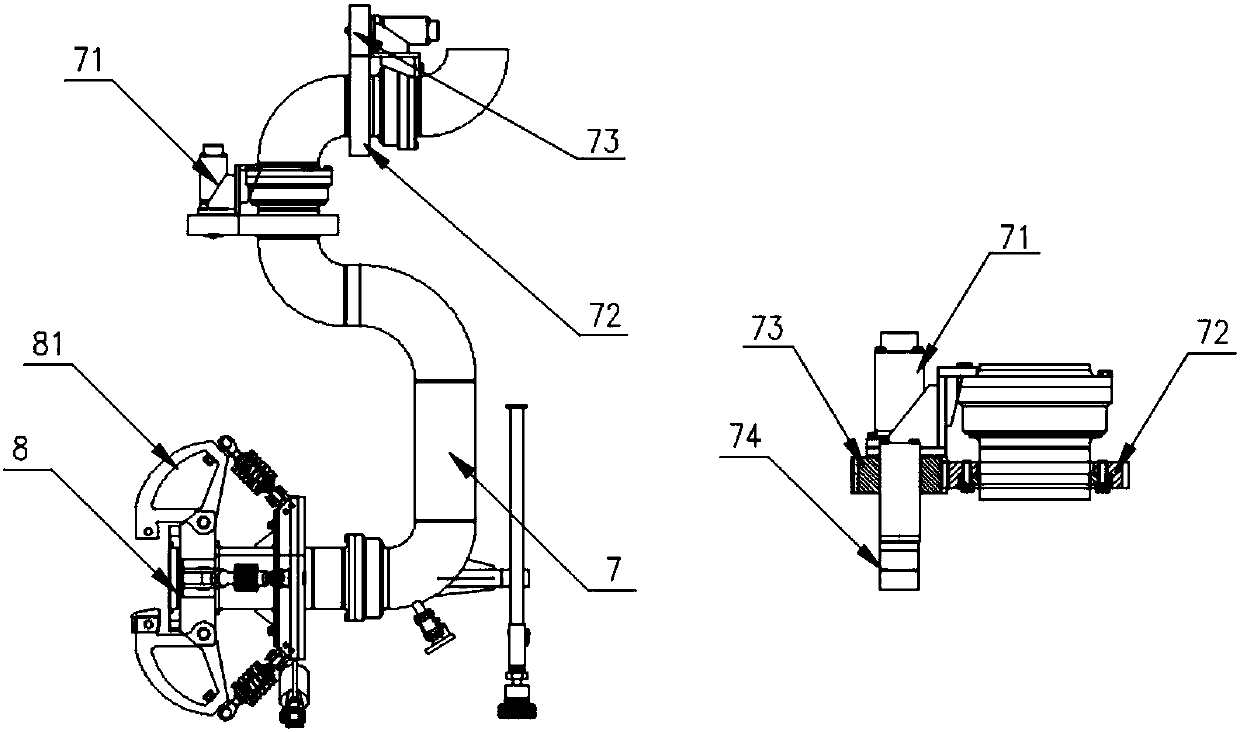

Large-tonnage beam erection and transportation system in tunnel and beam erection span change procedure thereof

ActiveCN104762885ALow costSimplify the beam erection processBridge erection/assemblyRoller chainBack support

The invention discloses a large-tonnage beam erection and transportation system in a tunnel and a beam erection span change procedure thereof, is used for transporting and erecting large prefabricated box beams in high-speed railway and passenger railway lines, and in particular, is suitable for transporting and erecting the box beams in the tunnel. A bridge erection machine comprises main beams, wherein back support legs are arranged at the bottoms of the back ends of the main beams; a downwards recessed front lifting trolley and a back lifting trolley are driven through driving devices by fixed roller chains, are rolled to walk by sliding devices, and are stridden over double main beams; extensible middle support legs are arranged at the bottoms of the middles of the main beams; front support legs capable of moving and extending are arranged at the bottoms of the front ends of the main beams; a beam transporting vehicle comprises a vehicle body; and extension legs, a movable beam support trolley, at least two sets of oil cylinder support legs in the beam support place, multiple wheel sets and front anchor pull rods mounted at the front ends are arranged above the tail end of the vehicle body. The system can satisfy the erection of multiple specifications of passenger railway lines, satisfies the beam erection conditions in tunnel entrances and exits and in the tunnel, simplifies the beam erection procedures, improves the equipment stability, is high in construction efficiency and reasonable and innovative in structural design, and improves the construction efficiency.

Owner:CHINA RAILWAY ENG MASCH RES & DESIGN INST CO LTD

Method for arresting large-tonnage ships

ActiveCN101793016ALong life spanEasy to replaceClimate change adaptationMarine craft traffic controlEngineeringBuoy

The invention discloses a method for arresting large-tonnage ships, which is characterized in that at least two fixed piers are arranged above water, at least a constant resistance device is arranged between the two adjacent fixed piers, then an arresting gear with ultimate tension less than or equal to the horizontal strike resistant force of the fixed piers is taken, one end of the constant resistance device is connected with the arresting gear and the other end thereof is connected with the fixed piers, finally a plurality of spaced buoys are arranged between the two adjacent fixed piers and the arresting gear is fixedly connected with the upper parts of the buoys. The method has the following advantages: the large-tonnage ships at higher speed can be effectively arrested, the fixed piers and the arresting gear can be prevented from damage or breakage due to excessive stress, the method ensures the effectiveness of arresting and is suitable for extensively protecting the large-tonnage ships with immense kinetic energy from striking the bridges; in addition, the arresting system used in the method has long life cycle, is convenient to replace and maintain and has relatively low cost, thus being suitable for engineering.

Owner:NINGBO UNIV

Double-faced flat-bulging process of pure aluminum panel

The invention relates to a double-faced flat-bulging process of a pure aluminum panel. The double-faced flat-bulging process comprises the following steps of a. roughening and blowing down the surfaces of three shearing-formed aluminum panels with different thicknesses; b. forming different graphite lines on two roughened surfaces of a thinner aluminum panel by using a graphite printing method; c. jointing two surfaces of the thinner aluminum panel with roughened surfaces of two thicker aluminum panels, aligning three sides, riveting along the edges; d. heating the aluminum panels in a continuous heating furnace to a certain temperature and maintaining for a certain time, carrying out hot rolling to form a composite aluminum panel after taking out; e. softening and annealing the composite aluminum panel, cooling, then drilling a process hole in a position of the aluminum panel graphite line to a graphite layer, and prying an opening in an air inlet pipe; and f. placing the composite aluminum panel on a large-tonnage oil press bulged template, aligning the process hole to an air inlet, jointing an upper template on the upper surfaces of the aluminum panels, filling high-pressure fluid in a pipeline until the pipeline expands to form a composite aluminum panel with two smooth surfaces and a groove channel formed in the interlayer in the middle. A composite aluminum panel pipeline bulged by using the process is high in jointing strength, and is capable of bearing high pressure without deforming.

Owner:ZHEJIANG JIAXI TECH CO LTD

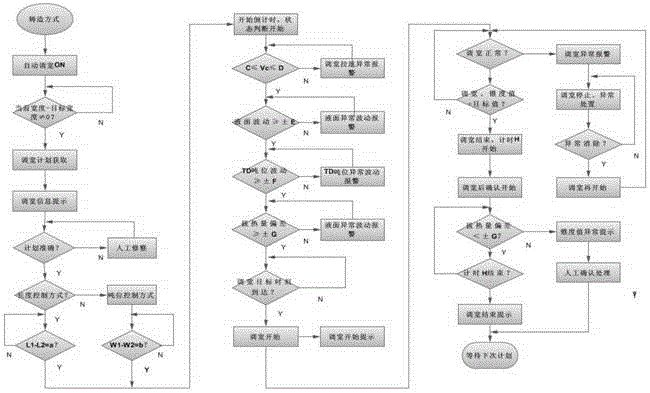

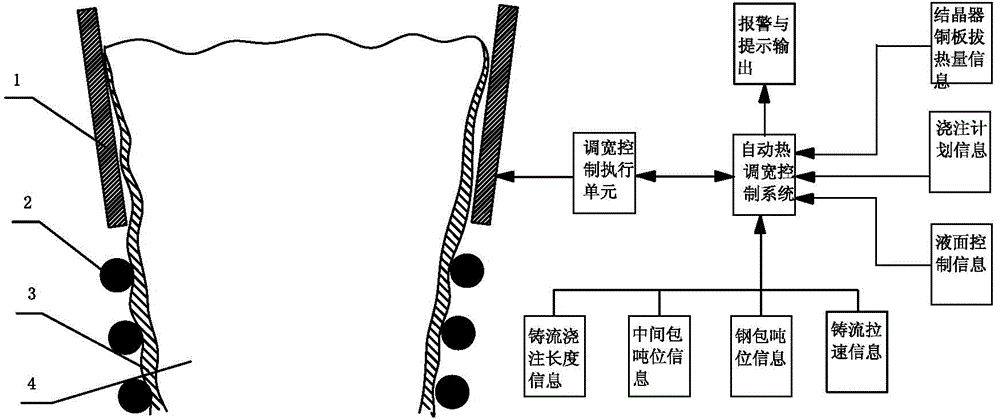

Automatic on-line width adjustment control system for continuous casting and process control method

The invention discloses an automatic on-line width adjustment control system for continuous casting and a process control method and belongs to the field of continuous casting machines and process control. According to the automatic on-line width adjustment control system for continuous casting and the process control method, on the basis of an existing basic automated information computer and a width adjustment control execution unit, a crystallizer hot width adjustment control system is additionally arranged; and in the pouring process, the control system automatically acquires casting flow pouring plan information, current pouring length information, current casting flow liquid surface control information, current casting flow pulling rate information, ladle tonnage information, tundish tonnage information and casting flow crystallizer copper plate pulling heat information from the basic automated information computer and a production management computer, reading, judging and controlling execution of related information are carried out according to the rule set by the system, and related information and an alarm are output in the execution process to remind an operator. By the adoption of the automatic on-line width adjustment control system for continuous casting and the process control method, the continuous casting automatic hot width adjusting function can be achieved, on-site unmanned operation is achieved, operation is simplified, meanwhile the safety of the hot width adjustment work of a casting machine can be guaranteed, and quality control and production anomaly accidents are prevented.

Owner:BAOSHAN IRON & STEEL CO LTD

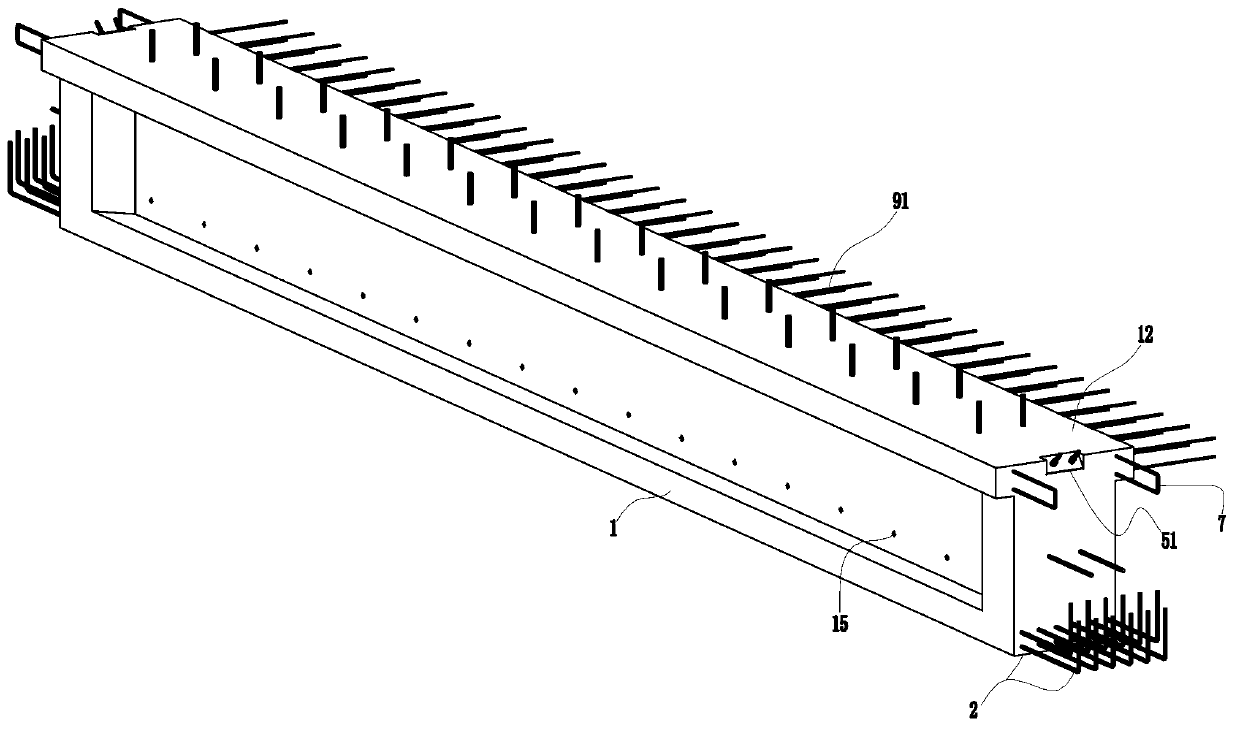

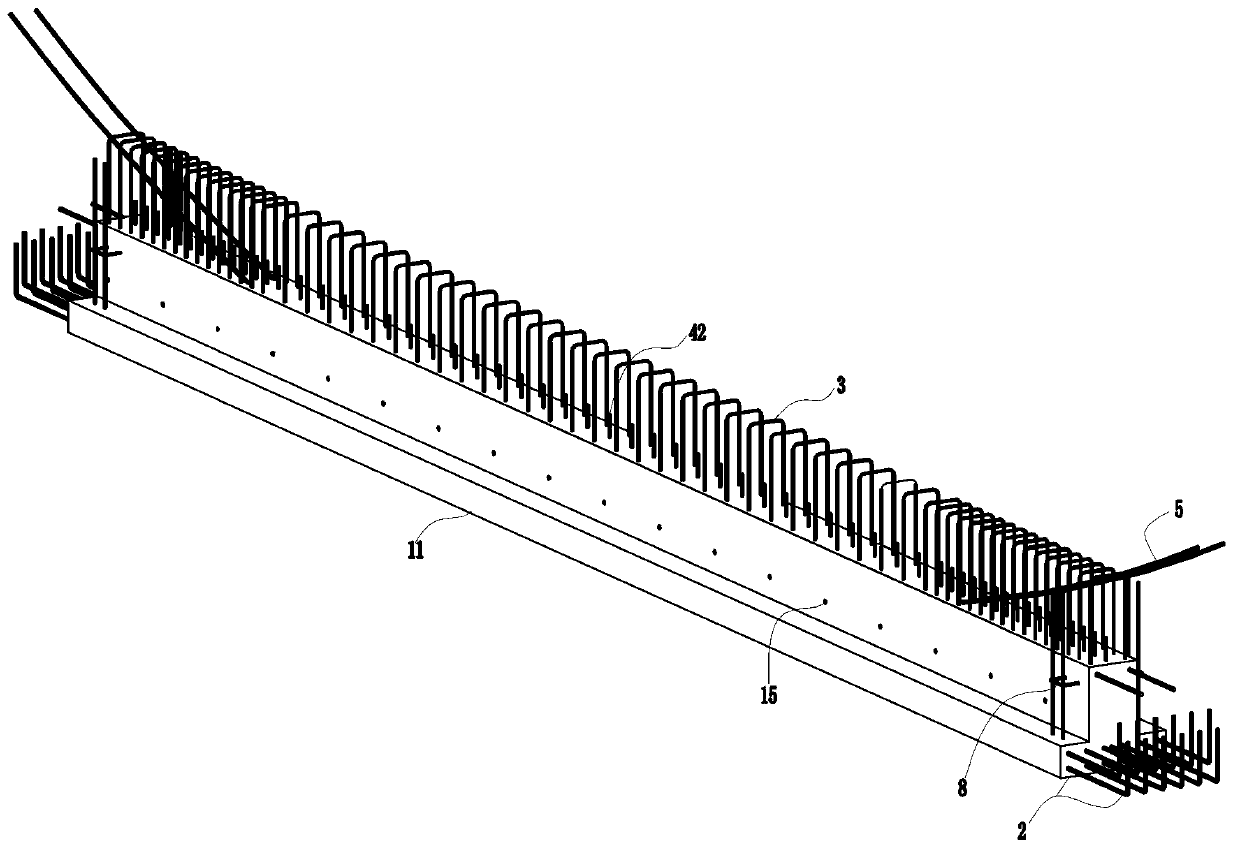

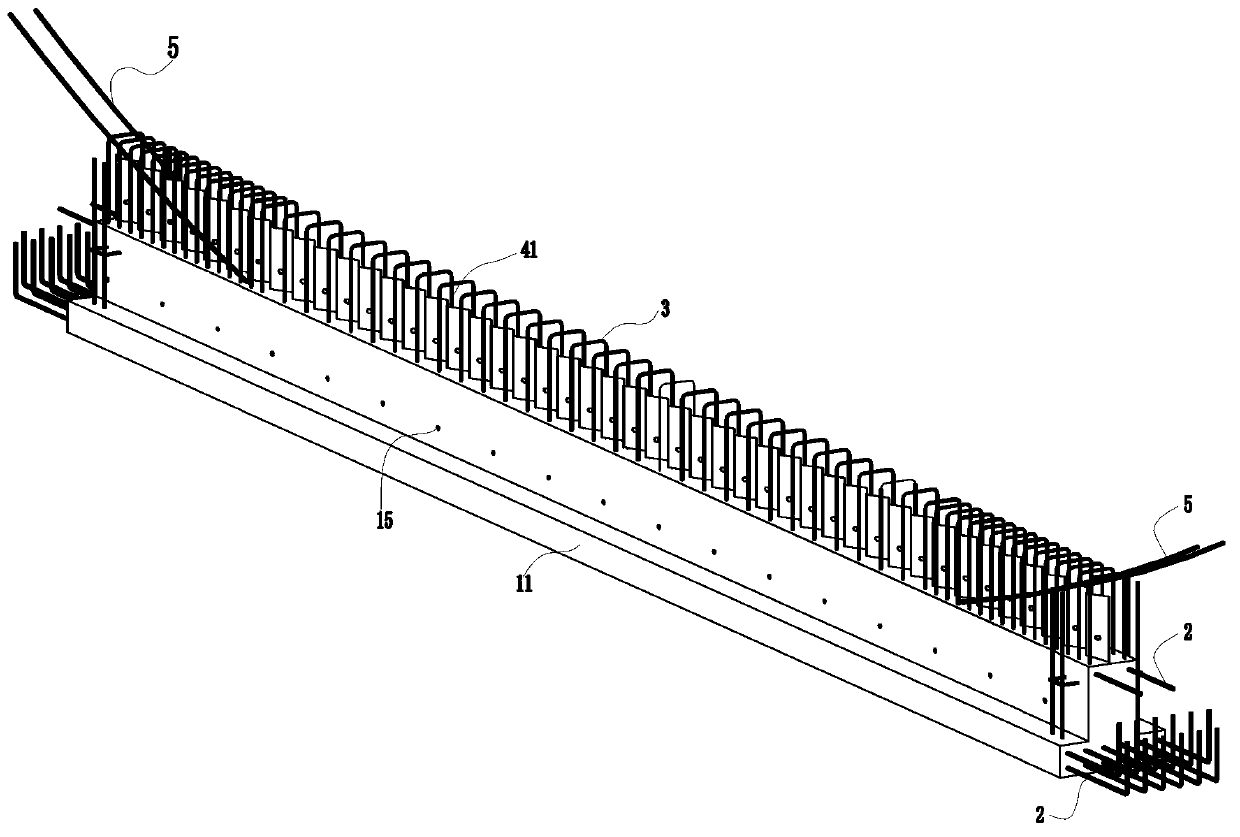

Large-tonnage prestressed superposed crane beam and construction method

ActiveCN102852276ALow bending stiffnessSolve the problem of anti-cracking of oblique sectionGirdersJoistsPre stressInverted t

The invention discloses a large-tonnage prestressed superposed crane beam, which comprises an inverted T-shaped precast beam part and a T-shaped cast-in concrete part, wherein the two parts are combined to form an I-shaped crane beam; and the large-tonnage prestressed superposed crane beam is characterized in that the inverted T-shaped precast beam part comprises a web plate, wherein the web plate and the bottom flange are uniform sections along the longitudinal direction; a pre-tensioning method prestressed steel strand is longitudinally buried in the beam body; a stirrup is buried in the web plate of the beam body; the stirrup is exposed out of the upper surface of the web plate for a certain length and is buried in the cast-in concrete part; a shear-resistant piece is connected to the joint surface of a precast part and the cast-in-situ part. The inverted T-shaped uniform-section prestressed precast part is manufactured by a long line method in a factory, the die is a standard universal template, the template is low in distribution expense and convenient to manufacture, and because a bottom die is not required on the cast-in-situ part on a construction site, the die is particularly convenient to erect.

Owner:杨众 +1

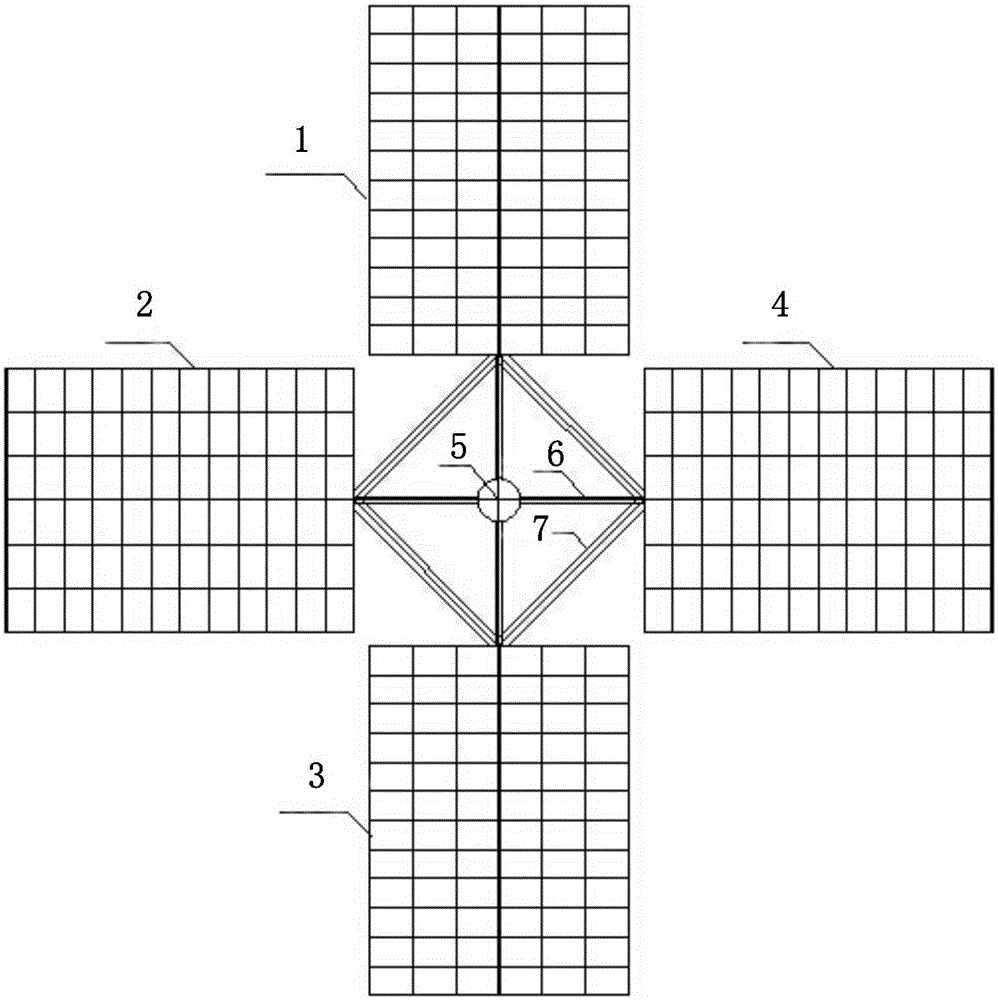

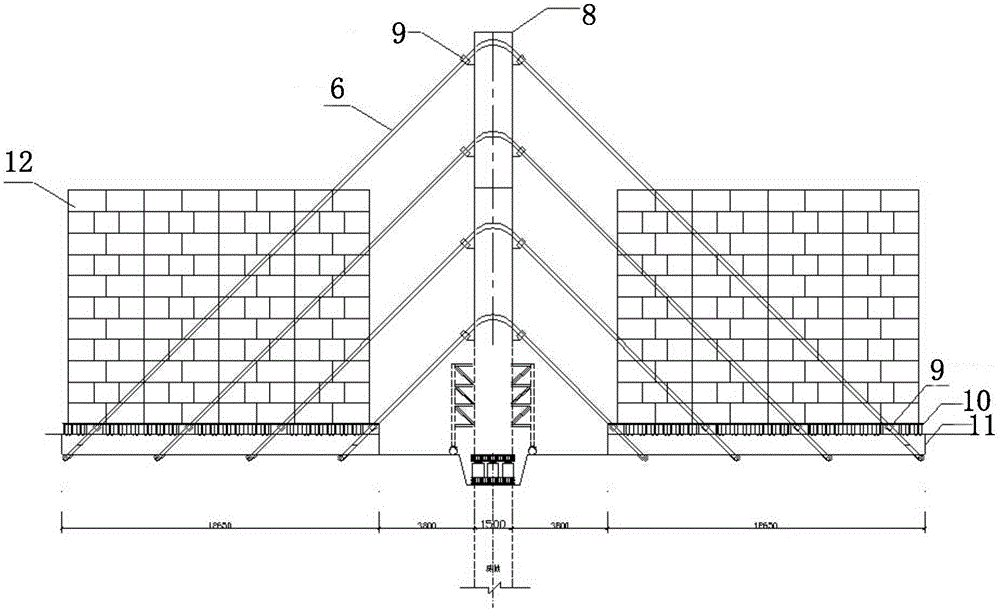

Counter-force device for super tonnage blasting platform

The invention relates to a counter-force device for a super tonnage blasting platform. The counter-force device comprises a sub-stack blasting platform which is of a cross shape, wherein an intersection of the cross is coincided with the central point of a main tower; the beam ends of main beams of the sub-stack blasting platform are respectively supported by two ends of non-slip cross arms, two ends of stay cables are sequentially and respectively connected with the sub-stack blasting platform and the main tower by virtue of quick connectors, and a plurality of balancing weights are respectively and uniformly arranged on the sub-stack blasting platform. The counter-force device has the beneficial effects that the tonnage can be increased by virtue of each sub-stack, and the expansibility of the tonnage is high; requirements on bearing capacity of foundation soil are low; the platform is high in stability and security; the balancing weights are convenient to mount, each sub-stack can be independently mounted, and a working plane has multiple points, so that the mounting progress is facilitated; the working environment is safe, and detectors do not need to work in a bottom passage of the platform, so that the security of the working environment for personnel is greatly improved; the unit-tonnage construction cost of the platform is low, and each component of the platform is small in size and low in weight, so that the lifting and the transportation are facilitated, the utilization rate of the load weight is high, and the transportation and lifting costs of buttresses can be saved.

Owner:林春伟

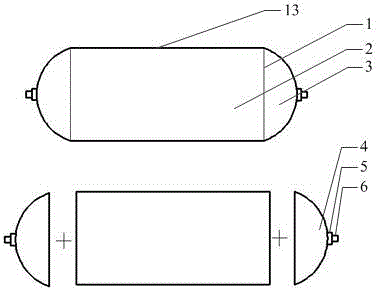

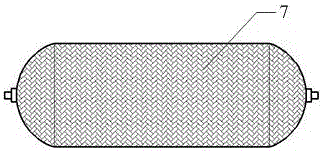

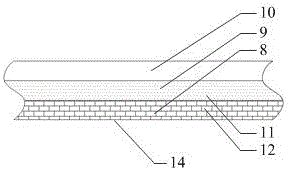

Ship launching fiber-reinforced rubber air bag and molding technique thereof

The invention belongs to the field of ship launching and discloses a ship launching fiber-reinforced rubber air bag and a molding technique thereof. The ship launching fiber-reinforced rubber air bag is characterized in that bag heads at the two ends of a core mold are of an isostress structure, and a rubber air bag body is provided with a rubber layer, a fiber-reinforced layer and a protection layer. The molding technique includes the steps that firstly, a rubber band is wound around the core mold to cover the surface of the core mold, so that the rubber layer is formed; dry fiber yarns cover the surface of the rubber layer through a specific geodesic line winding technology, so that the fiber-reinforced layer is formed; then the surface of the fiber-reinforced layer is wound with multiple layers of rubber bands, so that the protection layer is formed; and finally the rubber air bag obtained through winding is subjected to sulfuration and demolding. By means of the technique, automatic machining of one machine can be achieved, the machining environment is optimal, the labor intensity is low, and the production efficiency is high. The ship launching fiber-reinforced rubber air bag is good in flexibility, low in mass, low in cost, long in service life, stable in reinforced structure, capable of being recycled, and capable of bearing high-tonnage ship launching.

Owner:HARBIN UNIV OF SCI & TECH

Supporting structure for zero distance underneath pass of existing station of rectangular tunnel section and construction method

InactiveCN106050245AControl deformationGuaranteed operational safetyUnderground chambersTunnel liningSupporting systemSynchronous control

The invention relates to a supporting structure for zero distance underneath pass of an existing station of a rectangular tunnel section and a construction method. Settlement deformation of underneath pass of the existing station of a newly-built line is large. Before a tunnel is dug, deep hole grouting reinforcing bodies are constructed on the tunnel face of the tunnel, the method of ring-excavation with the core soil reserved is adopted to symmetrically dig upper guide holes and lower guide holes on the inner side and the outer side of a left line and a right line, a preliminary support is constructed in time, jacks are longitudinally arranged below the existing station, and a side wall vertical profile steel frame is erected. Through the synergistic effect of the steel frame + H steel + the hydraulic jacks + reinforcing rob plates +grouting materials and the like, a hydraulic synchronous control jack-up technique is adopted in combination with other auxiliary measures, the multiple large-tonnage jacks which are mounted on a newly-built preliminary supporting structure in advance form group jacking and supporting to provide reaction force compensation for an existing subway structure, a rigid and adjustable joint supporting system is formed, an upper existing station structure is supported, and the purpose of effectively controlling deformation of the existing station structure is achieved.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

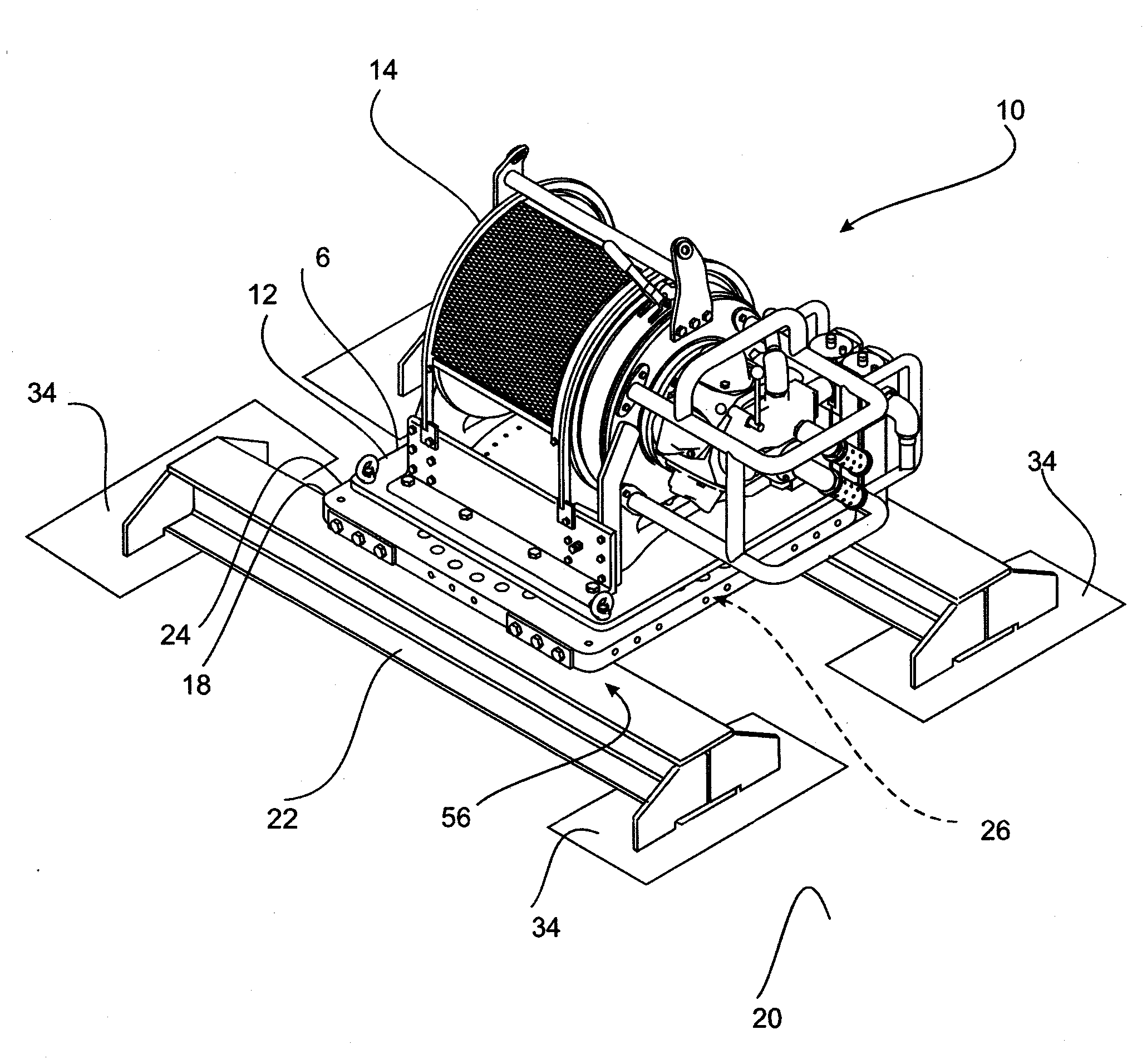

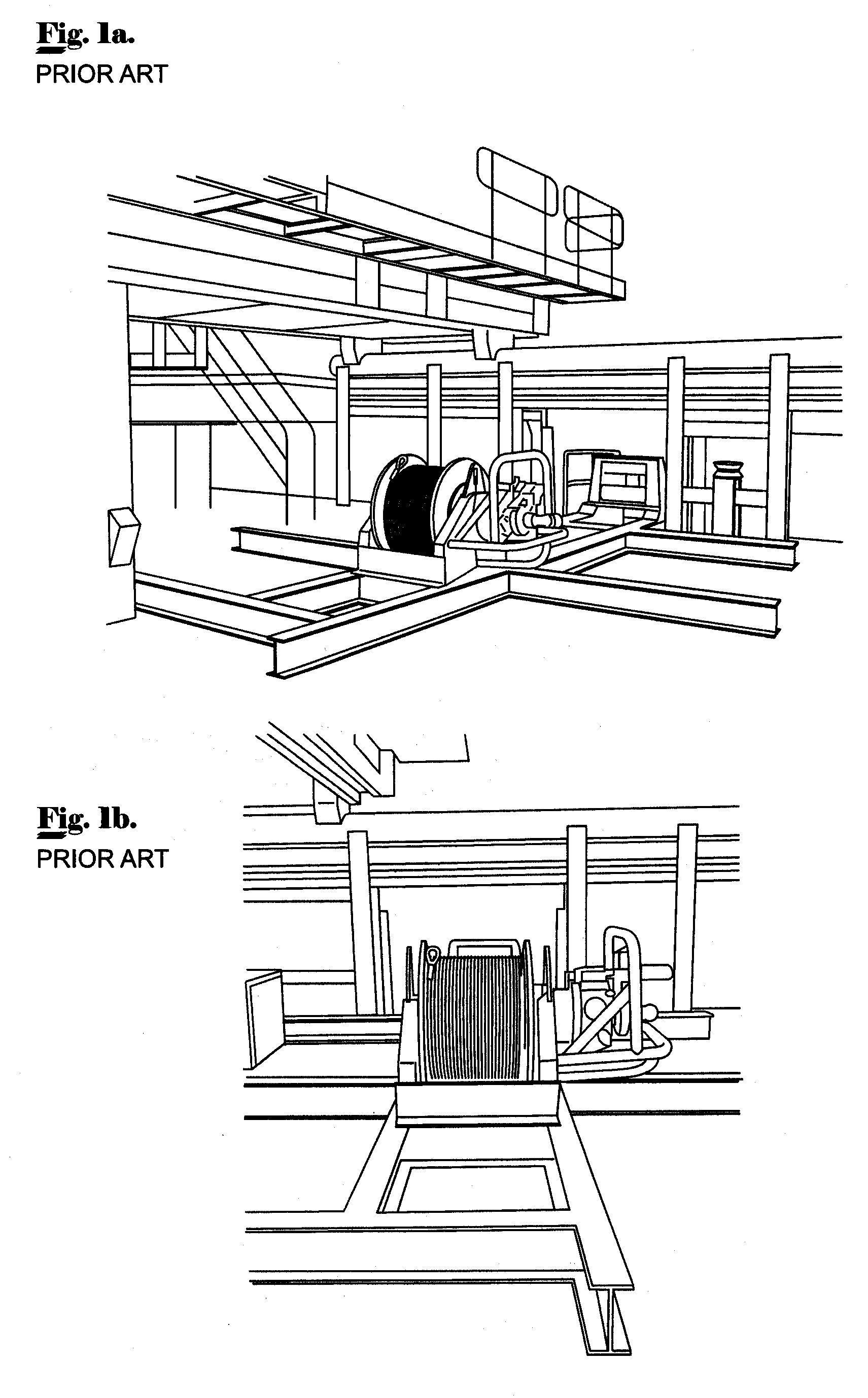

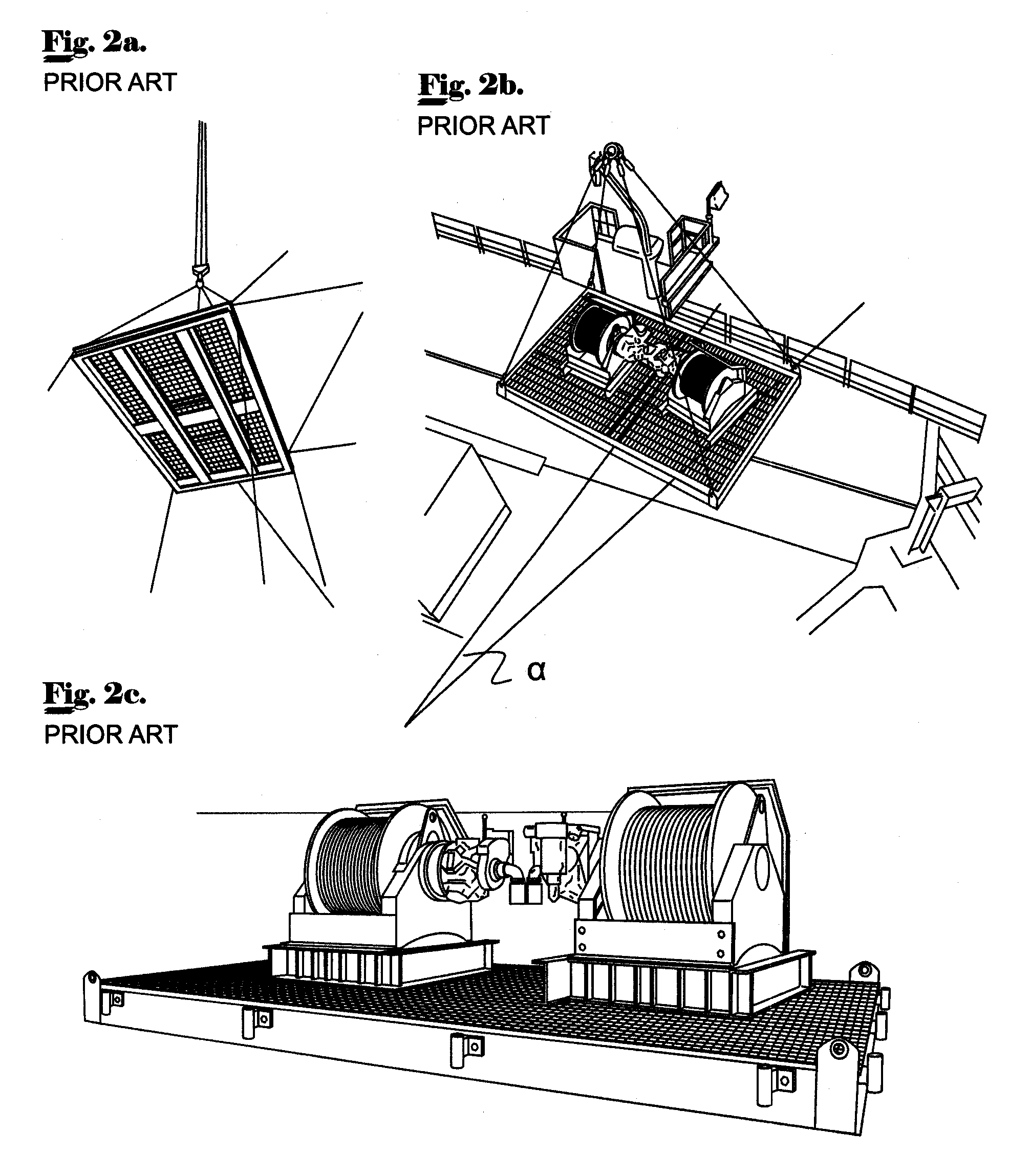

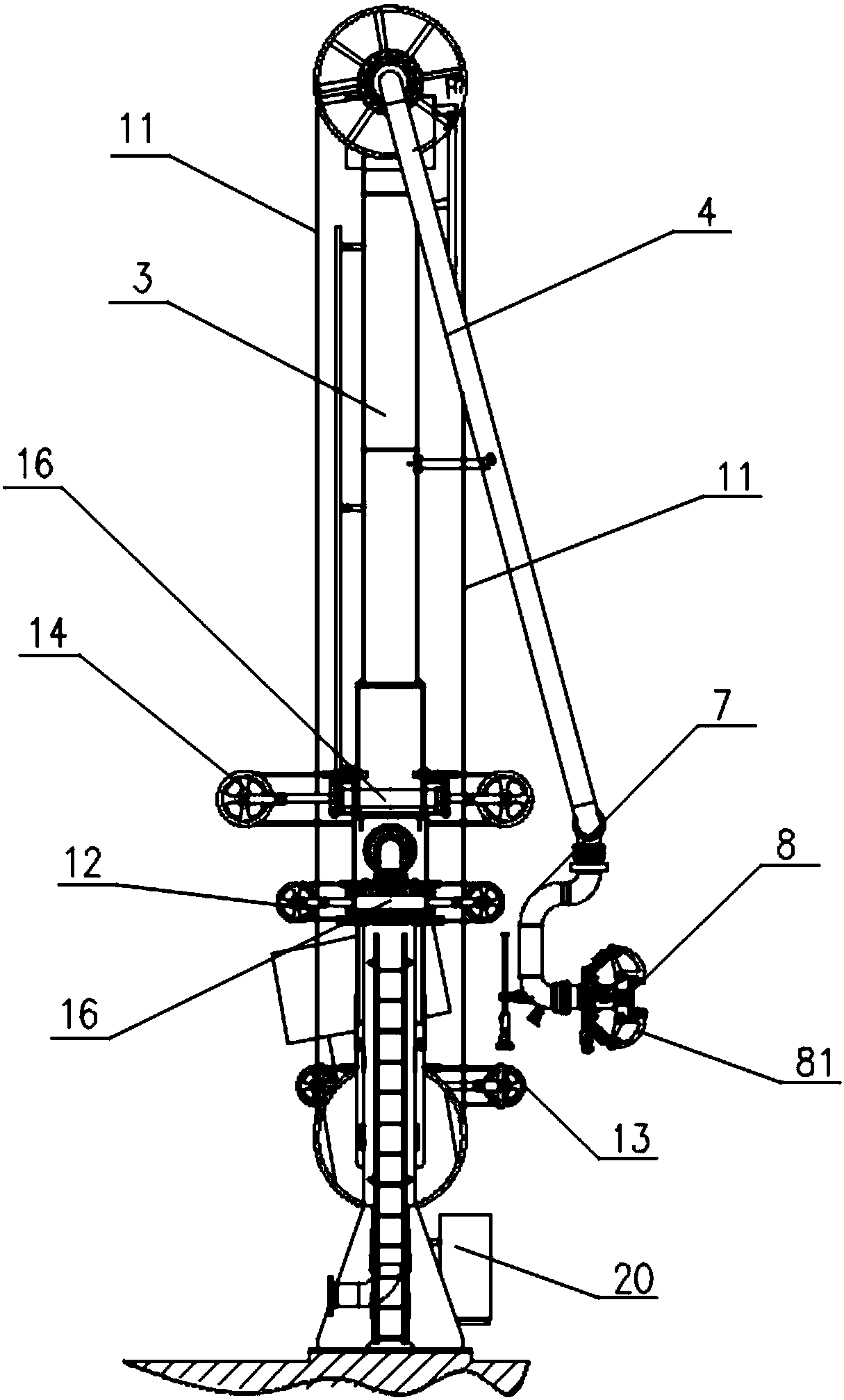

High Tonnage Winch Systems and Methods

InactiveUS20110291061A1Easy to installIncrease loadWinding mechanismsMetal working apparatusWinchOffshore construction

In one preferred form of the present invention, shown in FIG. 1, there is provided a high tonnage winch system (10) for use in offshore construction, transport and docking operations. The winch system (10) includes a winch (14) and a first arrangement (12) supporting the winch (14). A second arrangement (18) is provided for being mounted to a foundation structure in the form of a deck (20). The first arrangement (12) advantageously comprises a first low profile arrangement (16). The second arrangement (18) advantageously comprises a second low profile arrangement (24). The winch system (10) advantageously includes a low profile roller element bearing (26) connecting the first and second arrangements (12), (18) and allowing rotation of the winch (14) about the second arrangement (12), when the winch (14) is connected to the first arrangement (12) and the second arrangement (18) is mounted to the deck (20). The second arrangement is mounted to the deck (20) using high tonnage winch grillage (22).

Owner:GREENMONSTER OFFSHORE

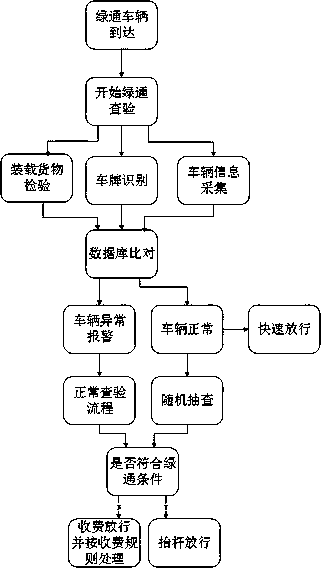

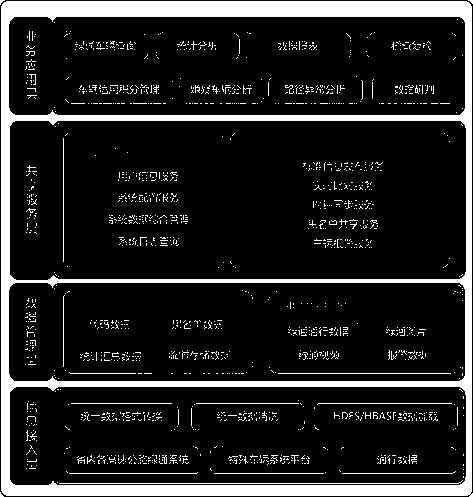

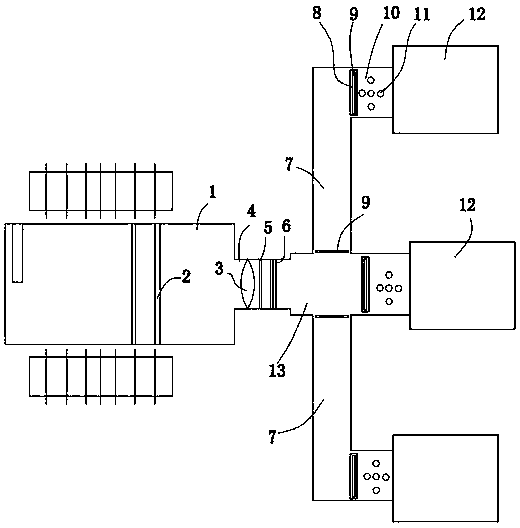

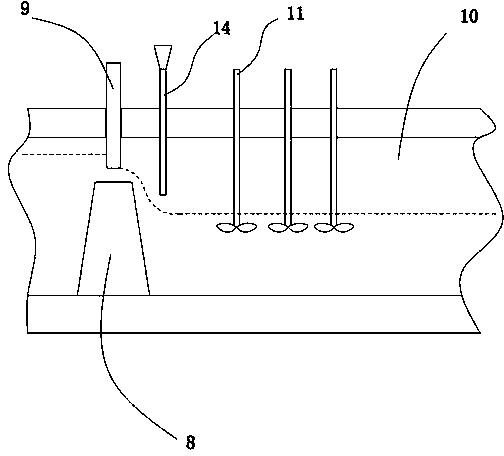

Green channel vehicle checking method based on big data analysis, research and judgement

InactiveCN110415369ATransparent structureEasy to developData processing applicationsTicket-issuing apparatusTraffic capacityToll road

The invention relates to a green channel vehicle checking method based on big data analysis, research and judgement. The method comprises the steps that green channel checking data is combined with charged vehicle passage data to form a green channel information big data database, on the basis, starting from the license plate number, tonnage, money amount, entrance-exit stations, vehicle types, cargo types and other attributes, analysis, research and judgement are conducted, data support is provided for green channel vehicle checking, green channel checking of the front end is guided in transition from manual judgement and experience judgement to data judgement, and accordingly the checking efficiency is improved; green channel vehicles are subjected to compiled analysis, the statistics workload is reduced, the efficiency of checking the green channel vehicles is improved, the inspection and rechecking difficulty is lowered, the effectiveness of cracking down the green channel vehicleswhich do not accord with the standard is high, analyzed, researched and judged cargo, vehicle, section and space-time distribution provides powerful decision support and guidance for the toll road management department and the transportation department, and the speed of checking the green channel vehicles and the traffic capacity of toll stations are improved.

Owner:SHIJIAZHUANG HANBANG TECH +1

Single-furnace multicolor float glass production line

The invention relates to a single-furnace multicolor float glass production line. The shortcomings of difficulty in color changing of a melting furnace, long coloring period and high raw material waste rate and glass scrap rate, which are caused by the coloring of conventional colored glass at the position of the melting furnace, are overcome. The production line comprises a large-tonnage melting furnace and a primary constricted neck, wherein a flow division device is connected behind the primary constricted neck, and is provided with a plurality of flow passages for dividing molten glass discharged from the primary constricted neck; a secondary constricted neck, a cooling part, a float glass production tin bath and a subsequent device are sequentially connected to each flow passage; a return liquid baffle plate is arranged at an inlet of the secondary constricted neck of each flow passage; a coloring device is arranged behind each return liquid baffle plate. According to the production line, the coloring devices are arranged at the inlets of the secondary constricted necks, and a formula for producing colored glass by virtue of a small-tonnage melting furnace can be utilized, so that the burden of a raw material processing procedure is reduced; coloring materials in each flow passage can be different, so that the aim of simultaneously producing different colored glass by one large-tonnage melting furnace is fulfilled.

Owner:长兴旗滨玻璃有限公司

Horizontal high-tonnage energy-saving fatigue experiment device

InactiveCN103994936ASave energyMaterial strength using repeated/pulsating forcesSoft magnetMetallic materials

The invention discloses a horizontal high-tonnage energy-saving fatigue experiment device which is applied to the field of mechanical design and metal material performance testing. The horizontal high-tonnage energy-saving fatigue experiment device comprises a shell, an actuating cylinder, an actuating cylinder piston rod, actuating cylinder oil inlet and outlet pipelines, hydraulic servo flow valves, a first energy accumulating device, a second energy accumulating device and an electromagnetic loading device, wherein the electromagnetic loading device comprises a soft magnet, an electric magnet, a load sensor, an electromagnetic loading actuating rod and an electromagnetic controller. According to the technical scheme, the electromagnetic loading device is combined with a conventional dual-output-rod high-tonnage fatigue testing machine, and thus the horizontal high-tonnage energy-saving fatigue experiment device is technically an innovation. In addition, after an average load required by a test is loaded on the high-tonnage actuating cylinder, the high-tonnage actuating cylinder is closed, the electromagnetic loading device is started, and electric energy is converted into magnetic energy which is then converted into kinetic energy by the electromagnetic loading device; compared with a mode of continuously using a large high-tonnage fatigue testing machine, the mode with the device has the advantage that energy sources can be saved by above 70 percent.

Owner:UNIV OF SCI & TECH BEIJING

Automatic butt-joint method and device suitable for wharf oil conveying pipe loading and unloading arm and ship flange

PendingCN107790987APrecise dockingAvoid pollutionImage enhancementImage analysisButt jointControl system

The invention discloses an automatic butt-joint method and device suitable for a wharf oil conveying pipe loading and unloading arm and a ship flange. The method is characterized in that a positioningdevice is utilized and comprises a laser positioning device and a vision positioning device, primary positioning and precise positioning are conducted on the oil conveying pipe loading and unloadingarm and a ship target flange, a drive control system is used for controlling a horizontal drive device, an outer arm drive device and an inner arm drive device which are arranged on the oil conveyingpipe loading and unloading arm, and the drive arm moves till a hydraulic drive rapid connector and the ship target flange are in accurate butt joint. A set of CCD cameras are arranged in the vision positioning device to monitor the position of an oil conveying port in real time, a processing module in the vision positioning device outputs coordinate signals to the drive control system, accordingly, the hydraulic drive rapid connector of the oil conveying pipe arm and the target flange are driven to be in accurate butt joint, and the butt joint precision is improved; and it is guaranteed that oil liquid cannot leak, the problem of environment pollution is solved, the requirement for large-tonnage wharf work is met, and economic benefits are greatly increased.

Owner:连云港远洋流体装卸设备有限公司 +1

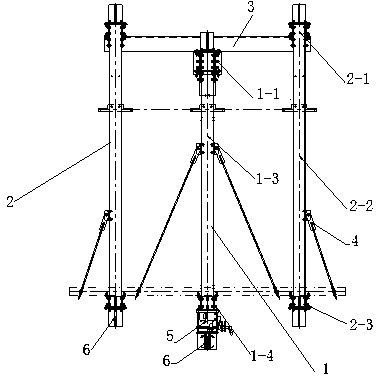

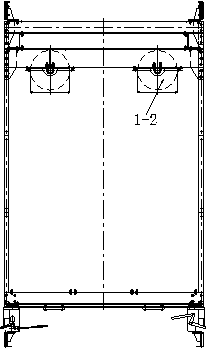

Freight lift car frame device

InactiveCN103072879ASafe and reliable supportImprove stabilityBuilding liftsEngineeringStructural framework

The invention relates to a freight lift car frame device which is used for large-tonnage lift loading. The freight lift car frame device comprises a main lift car frame (1), secondary lift frames (2), transverse beam channel steel (3) and pull bar screw rod assemblies (4), wherein the main lift car frame (1) comprises a main upper beam assembly (1-1), a car top wheel assembly (1-2), a main vertical beam assembly (1-3) and a main lower beam assembly (1-4); each secondary lift frame (2) comprises a secondary upper beam assembly (2-1), a secondary vertical beam assembly (2-2) and a secondary lower beam assembly (2-3); assemblies forming the main lift car frame (1) and the secondary lift frames (2) form an integral structural framework through bolts; the transverse beam channel steel (3) penetrates through the main lift car frame (1) and the secondary lift frames (2); and the pull bar screw rod assemblies (4) are arranged at the two sides of the main lift car (1) and those of the secondary lift frames (2). The device disclosed by the invention is mainly divided into one main car frame and two secondary car frames; and the total weight of a lift car are shared to three car frames so as to reduce bad influences caused by partial offset load on a guide rail, guide shoes and the like. Each one of the main car frame and the secondary car frames is formed by the related upper beam assembly, the related vertical beam assembly, the related lower beam assembly and the like, and the main car frame and the secondary car frames are strengthened and fastened by the transverse beam channel steel; and vertical beams of all the car frames are connected with a lift car supporting frame through the pull bar screw rod assemblies so that the structure of a lift is more stable. The freight lift car frame device is simple and reliable in structure and can be applicable to large-tonnage freight lifts.

Owner:CANNY ELEVATOR

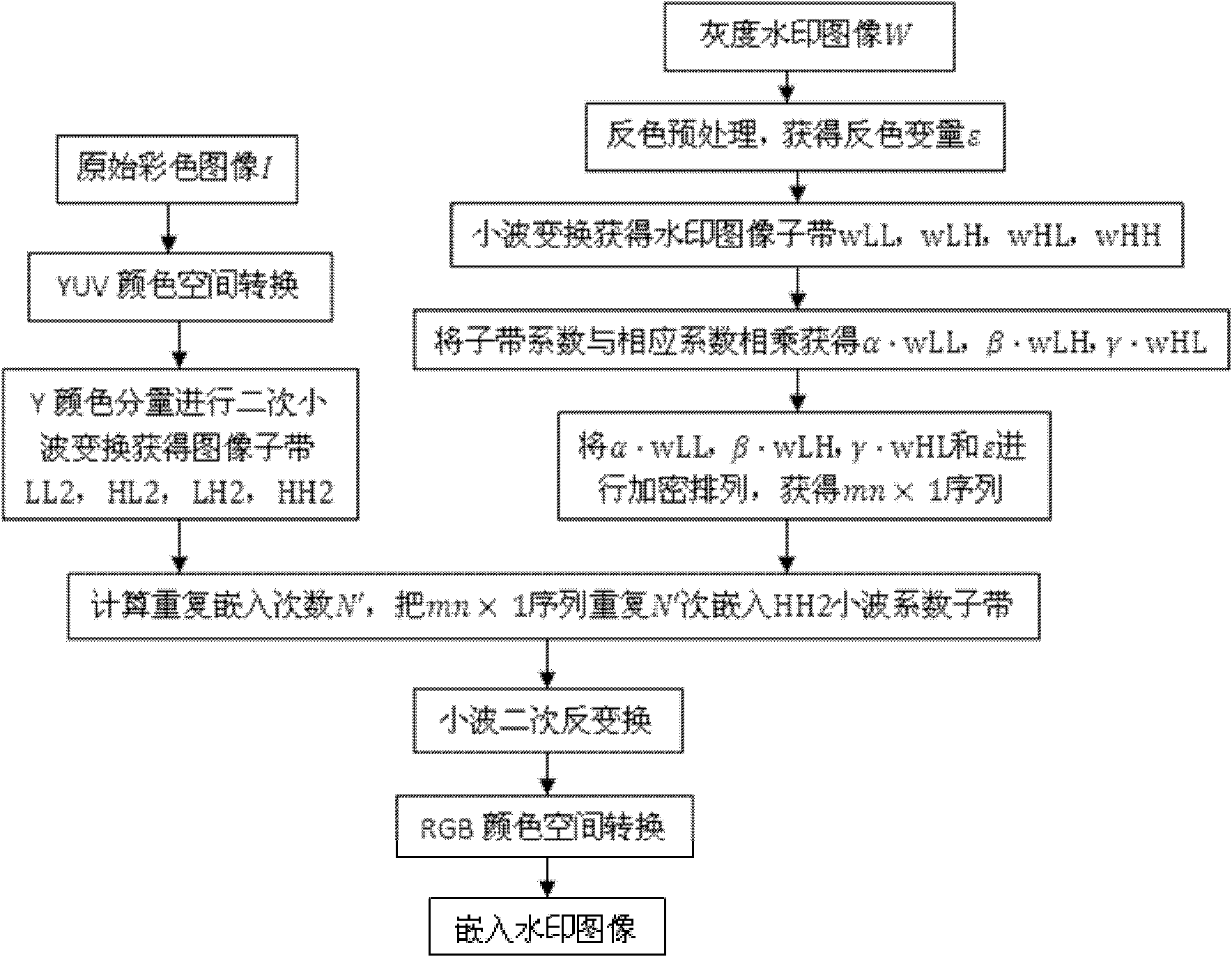

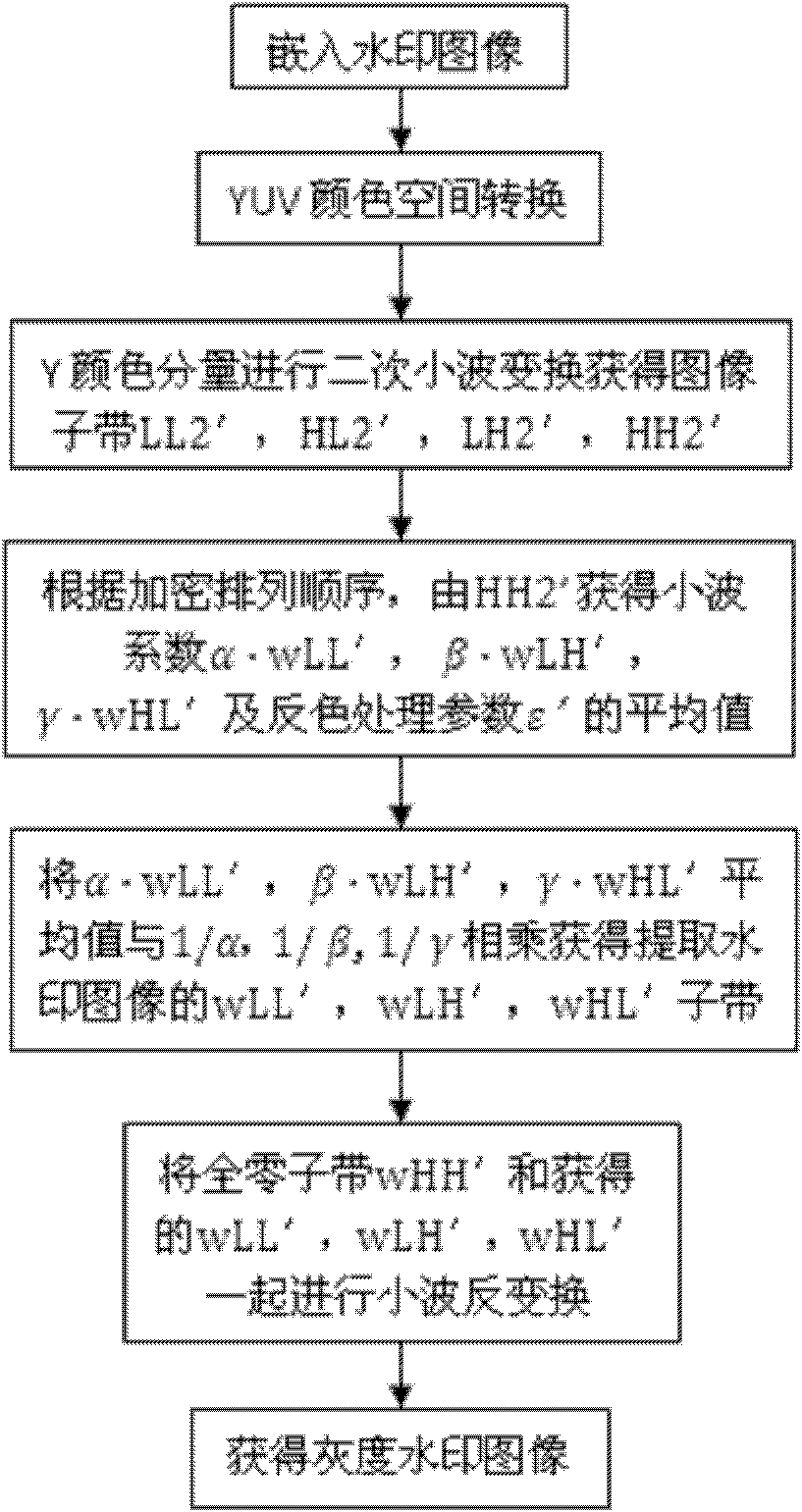

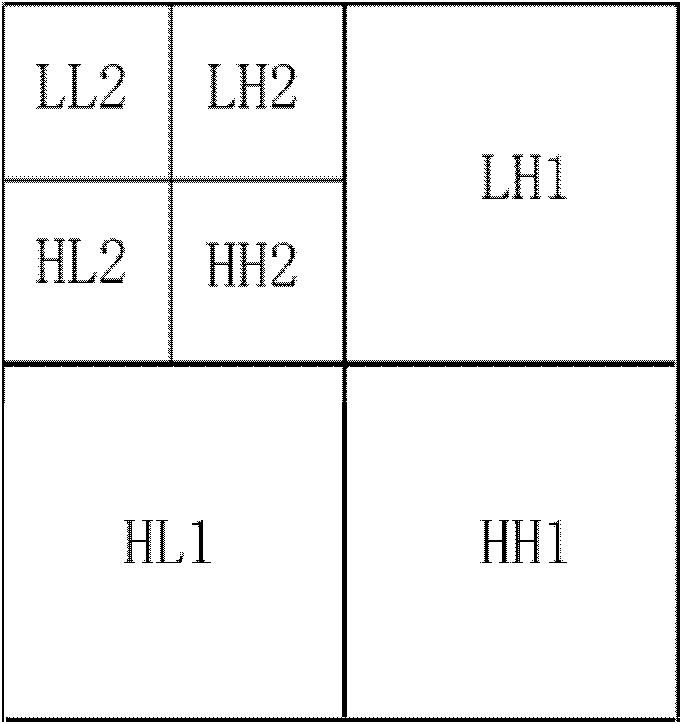

Deadweight tonnage (DWT) domain-based digital watermark method and system

ActiveCN102496135AGuaranteed concealmentEnsure safetyImage data processing detailsWatermark methodJPEG

The invention discloses a deadweight tonnage (DWT) domain-based digital watermark method. A watermark embedding process comprises the following steps that: inverse pretreatment of a gray-scale watermark image; luminance-bandwidth-chrominance (YUV) color space conversion of an original colorful image; wavelet secondary transformation of weight Y; wavelet transformation of gray-scale watermark image; difference value storage of watermark image wavelet coefficient; encryption arrangement of watermark image wavelet coefficient; insertion of watermark image wavelet coefficient and inverse coefficient; and wavelet inverse transformation of inserted watermark image; and the watermark extraction process comprises the following steps that: YUV color space conversion of the inserted watermark image; wavelet secondary transformation of weight Y of the inserted watermark image; wavelet coefficient restoration of the gray-scale watermark image according to the encryption arrangement of the gray-scale watermark image; all-zero compensation of a gray-scale watermark image wavelet coefficient diagonal band; and wavelet coefficient inverse transformation of the gray-scale watermark image. Due to the adoption of the method and the system, the invisibility of a watermark can be guaranteed, and good robustness on the attacks such as compression, noise plus and filtering of a joint photographic experts group (JPEG) can be realized.

Owner:ENJOYOR COMPANY LIMITED +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com