Patents

Literature

313 results about "Viscoelastic damping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

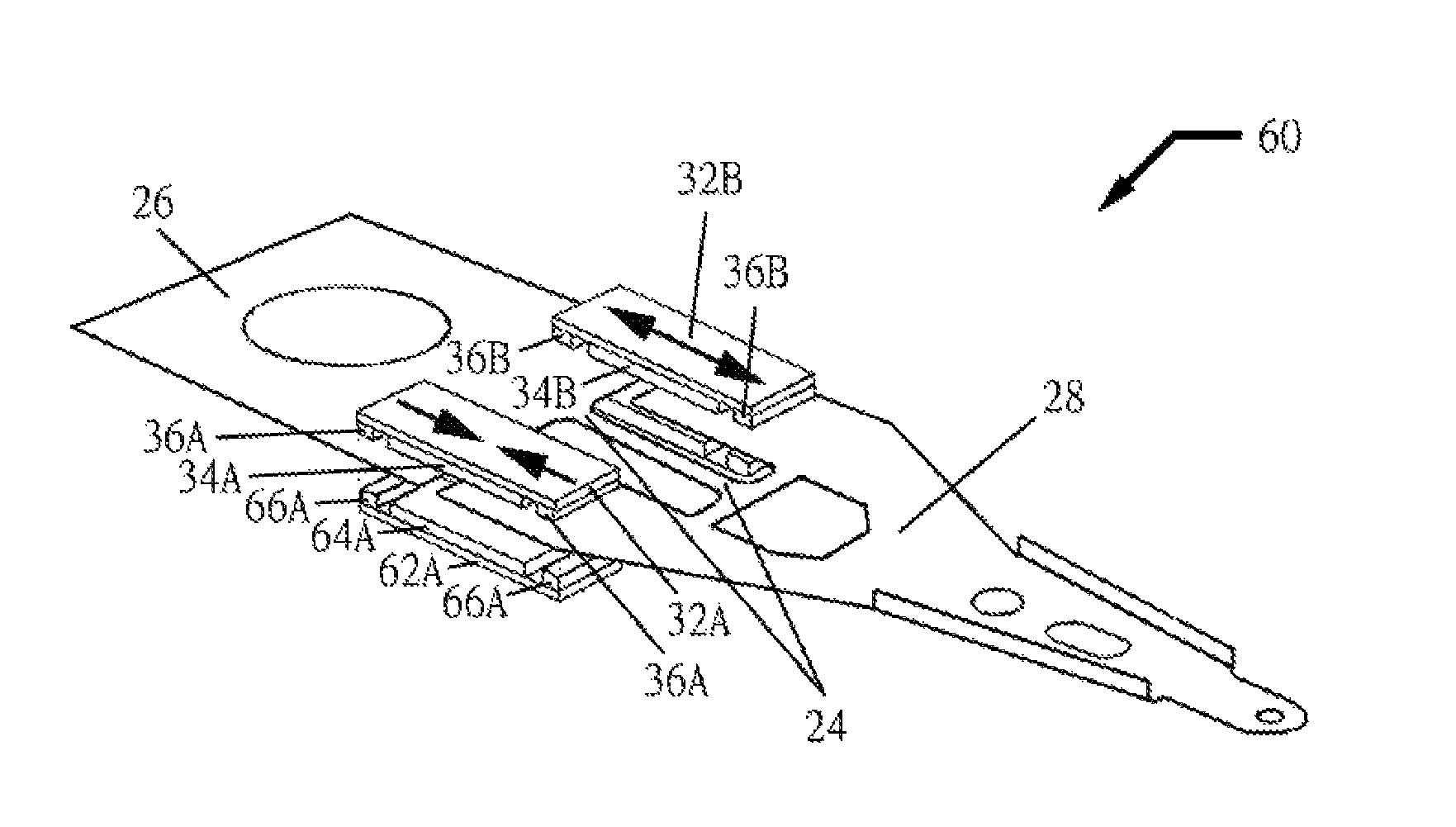

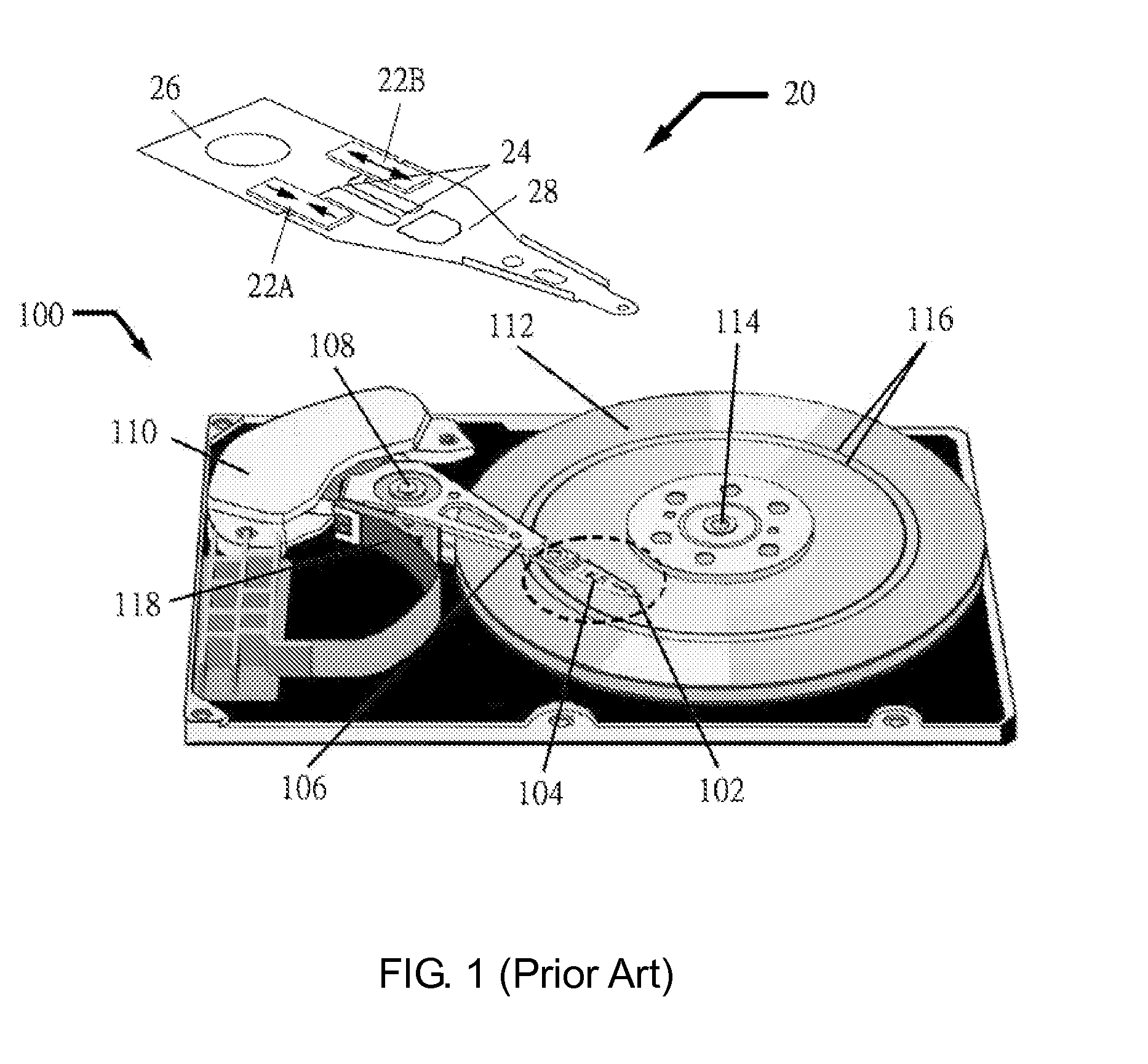

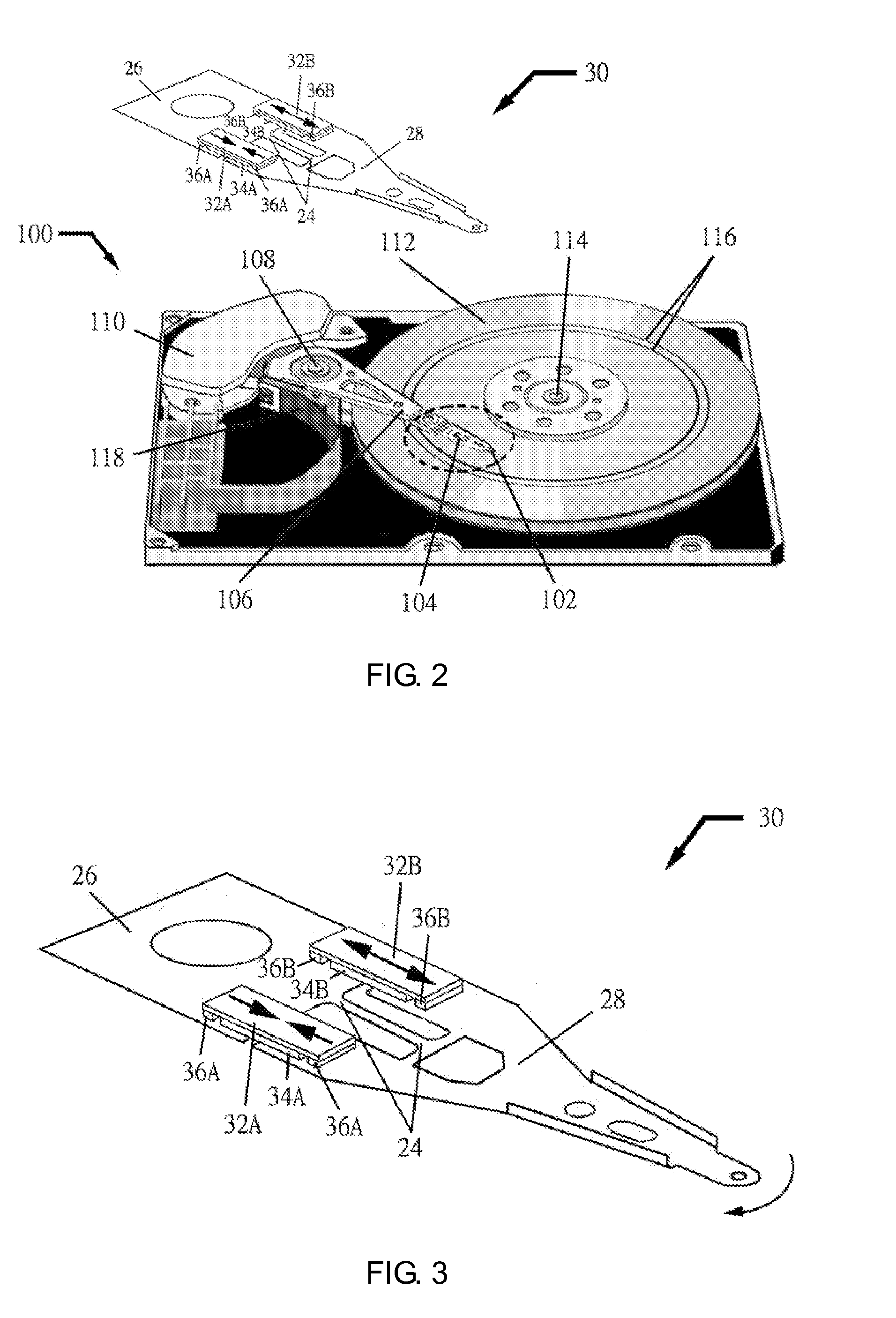

Piezoelectric actuated suspension with passive damping in hard disk drives

ActiveUS7983008B2Precise positioningSufficient shock resistanceArm with actuatorsRecord information storageViscoelastic dampingHard disc drive

A piezoelectric actuated suspension with passive damping is disclosed for precision positioning of hard disk drive while reducing undesired shock vibrations. Along the longitudinal axis of an etched suspension, two piezoelectric actuators dispose near the base plate to provide a push-pull motion. The actuators have two main portions. The first portion is piezoelectric elements to provide active positioning. The second portion is viscoelastic damping layers underneath the piezoelectric elements for passive damping. The complementary parts such as stiff edge elements and optional soft boundary covers are used to enhance the actuating abilities of the actuators and prevent any contaminants of the viscoelastic layers from going into the clean sealed chamber of the hard disk drive, respectively. The present invention further relates to a dual-stage servo system in a hard disk drive for fine positioning of the read / write head and better shock resistance via the piezoelectric actuated suspension with passive damping.

Owner:THE CHINESE UNIVERSITY OF HONG KONG

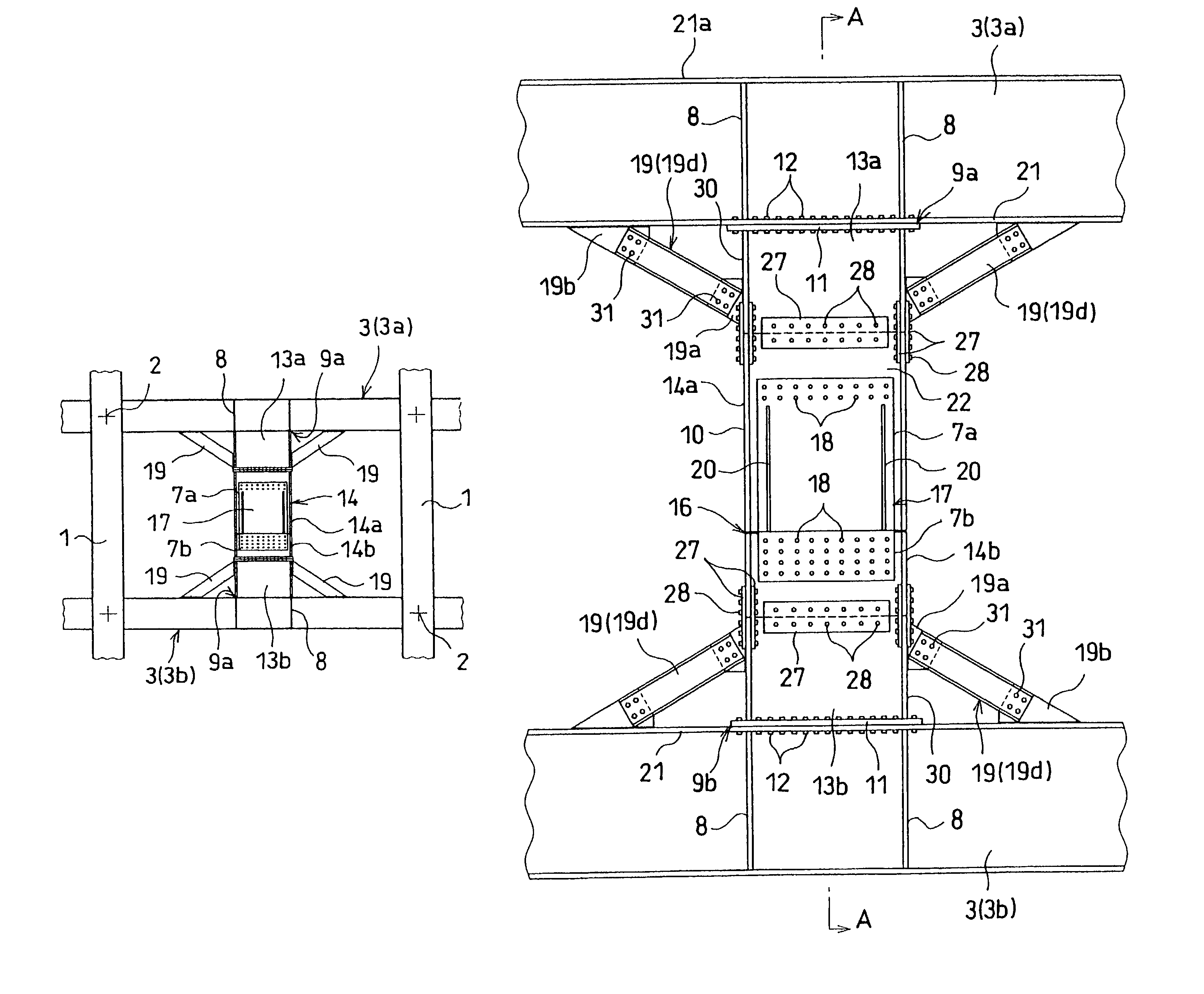

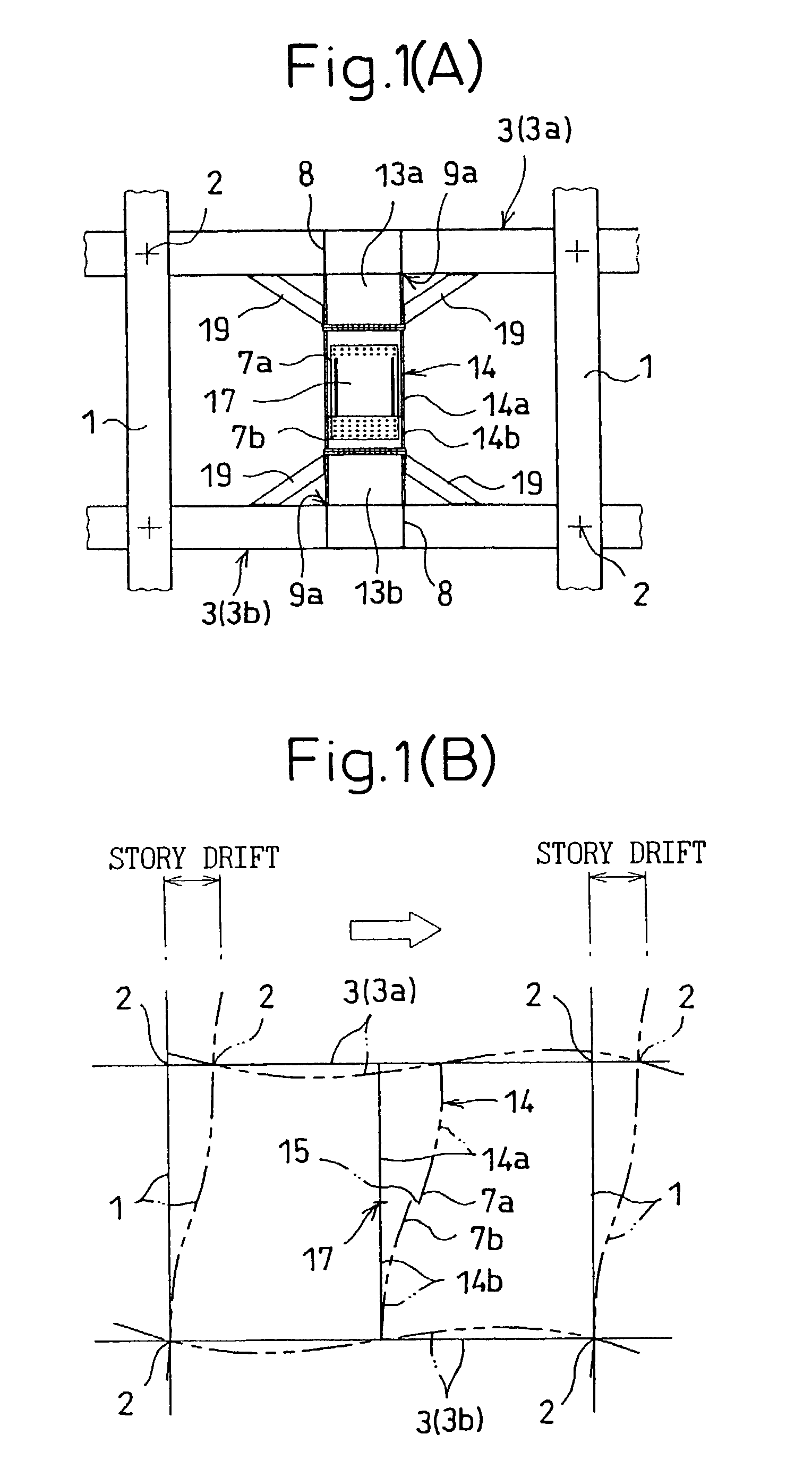

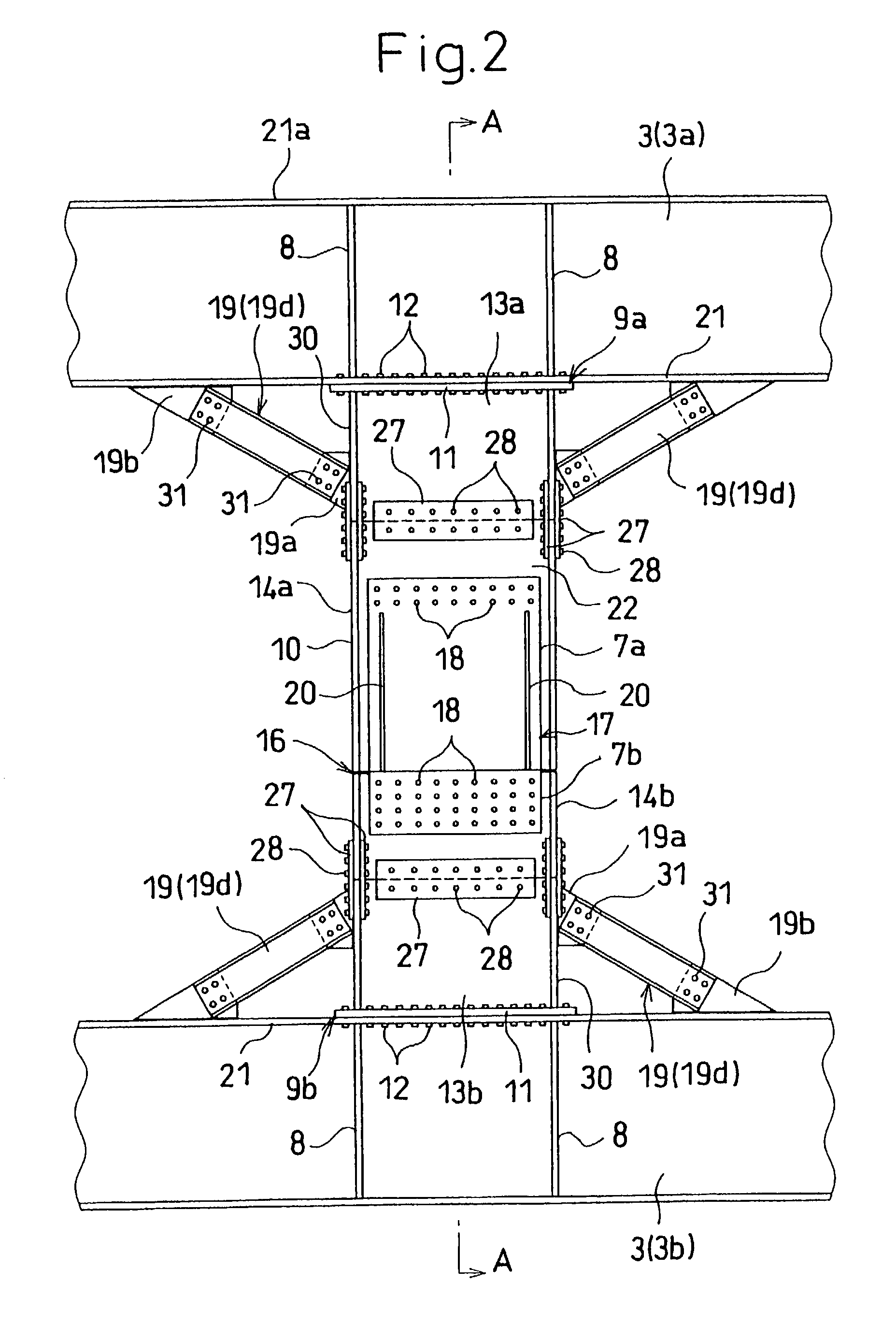

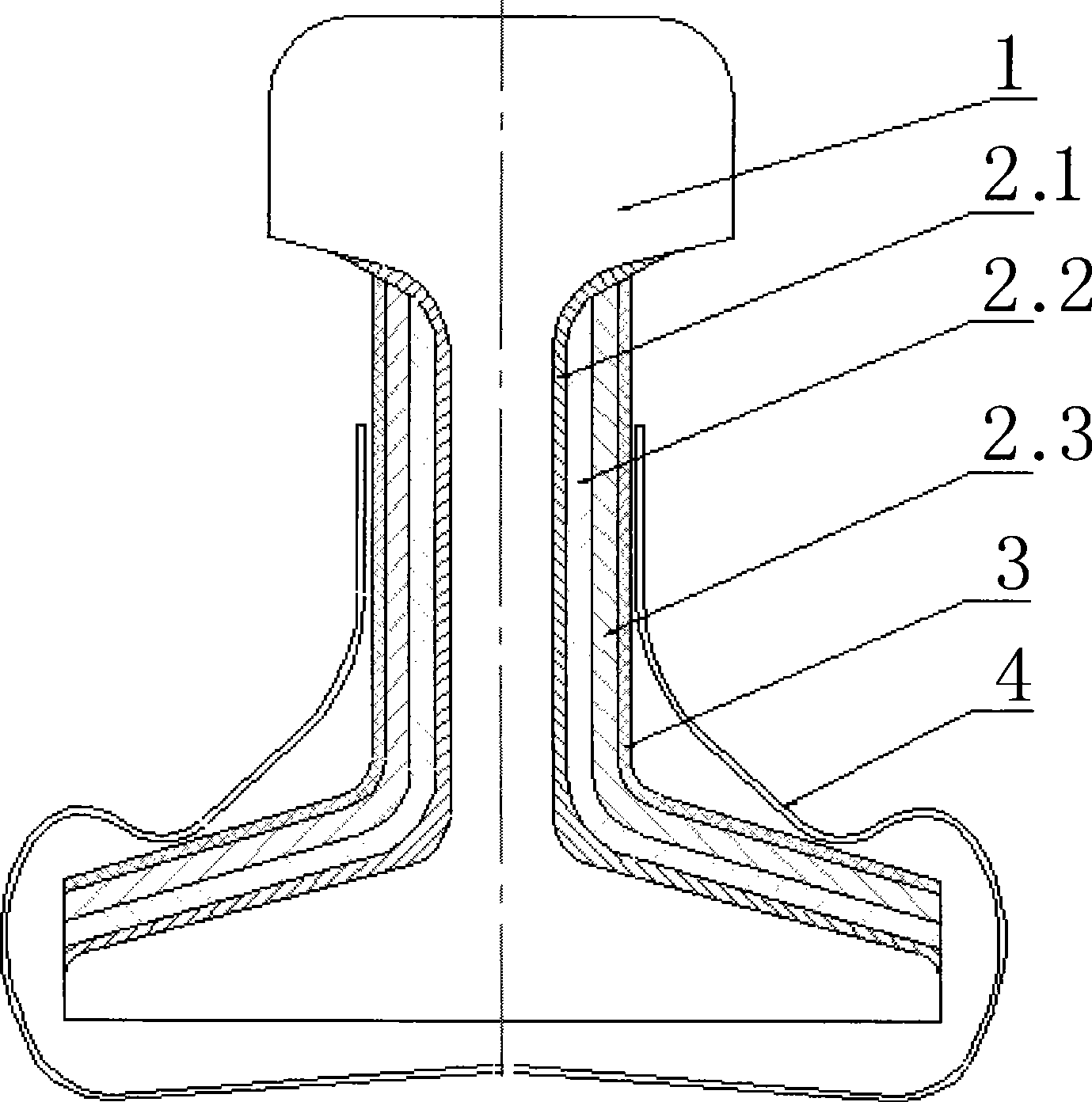

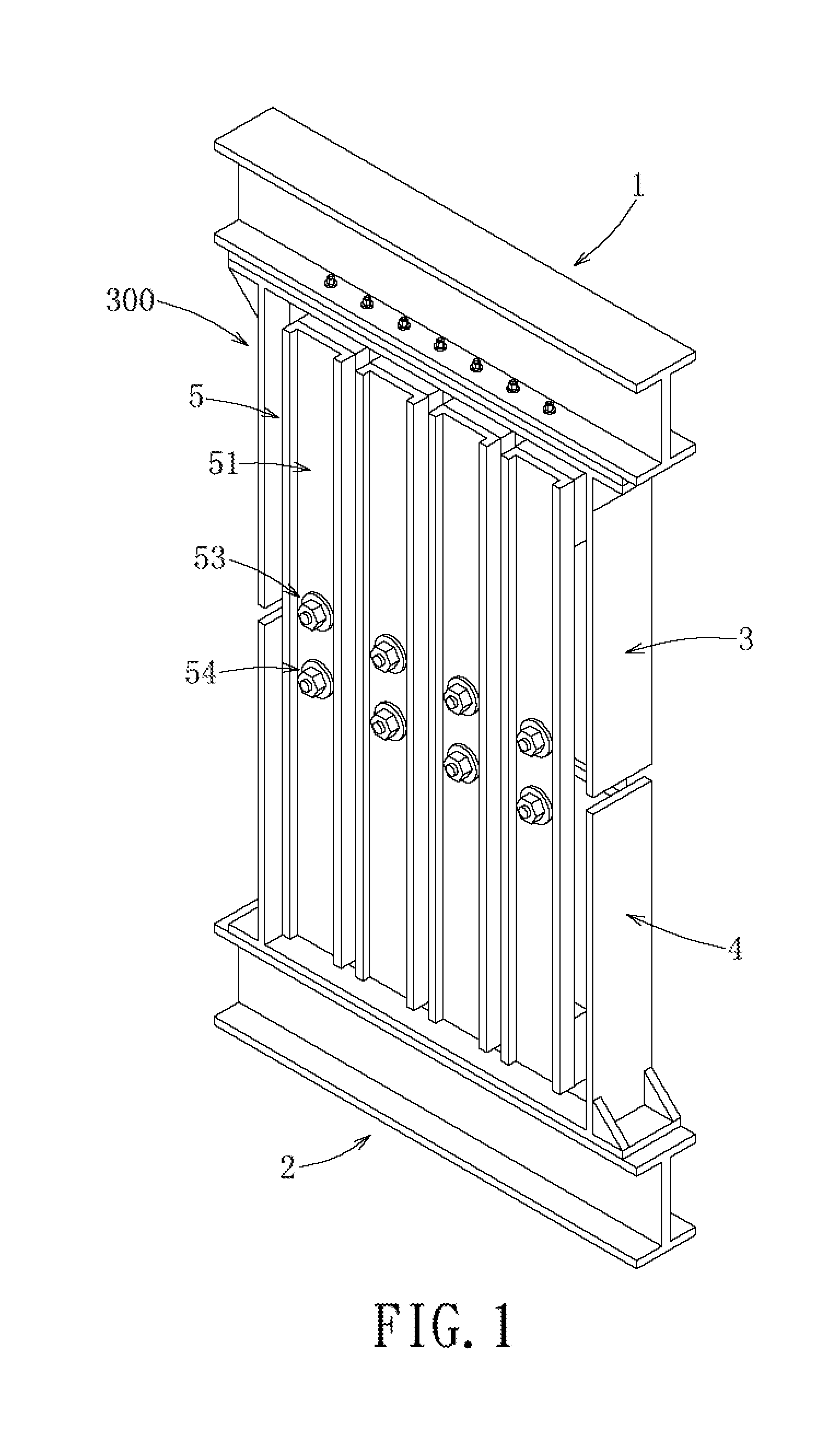

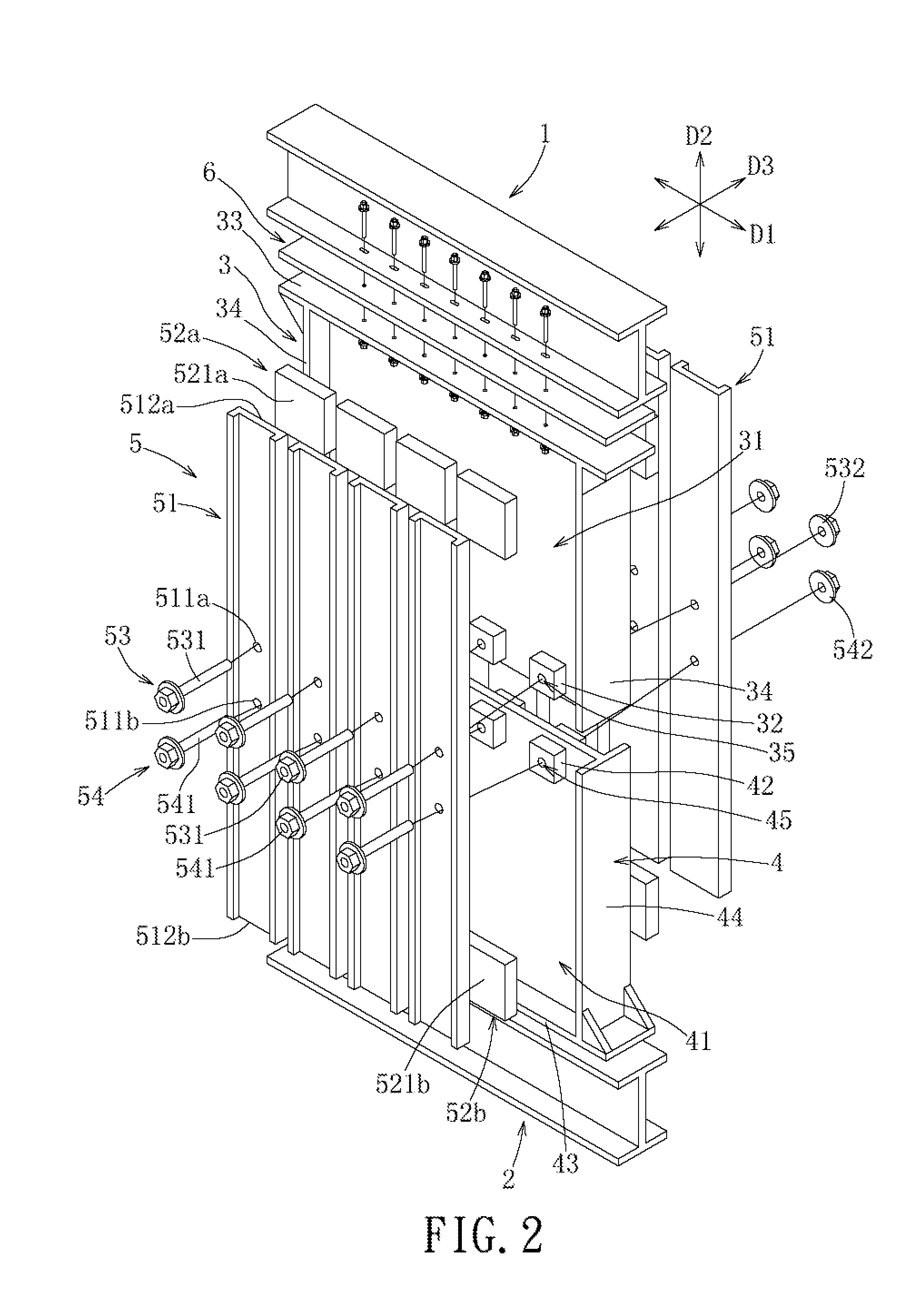

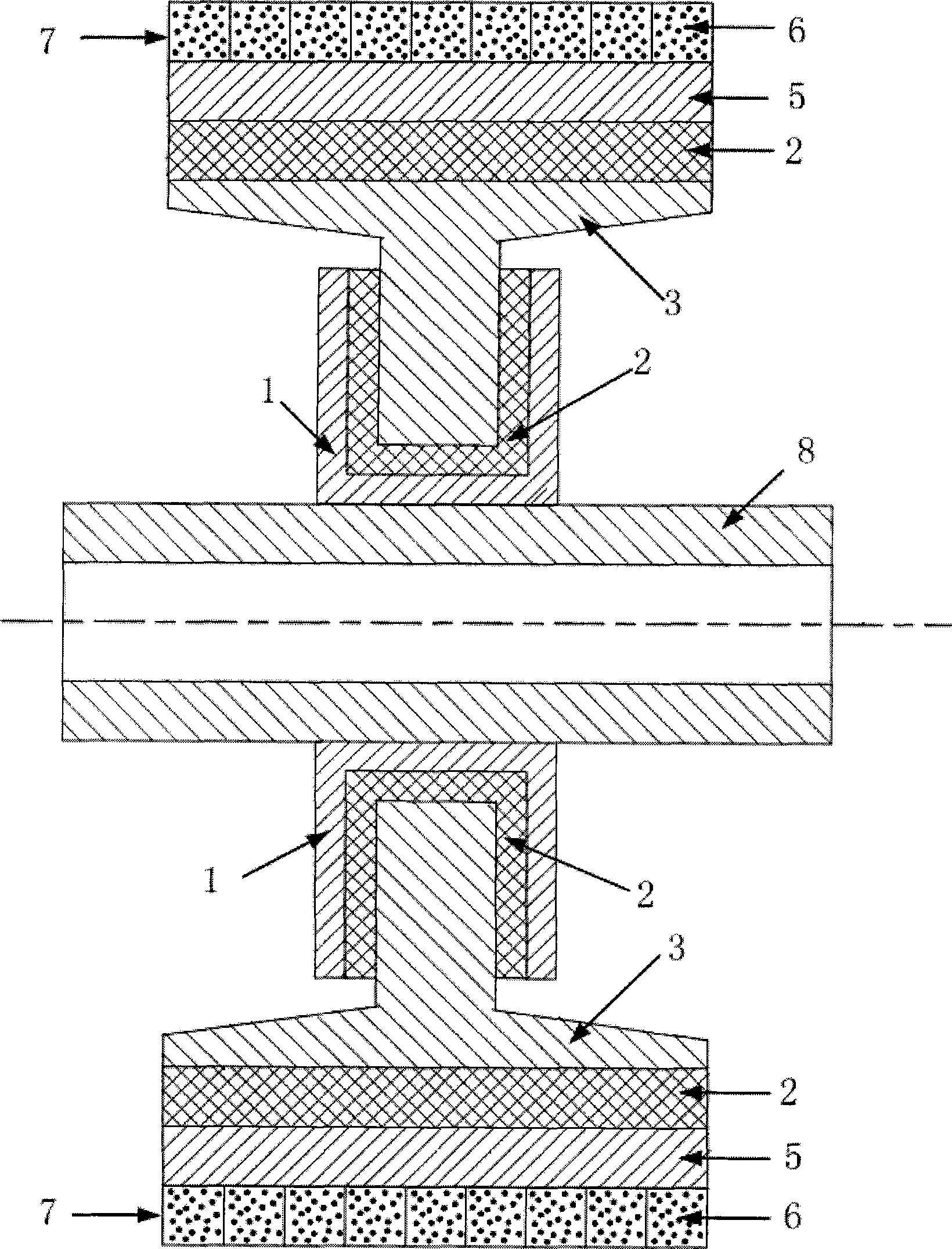

Damping intermediate pillar and damping structure using the same

InactiveUS7076926B2High strengthIncrease shear deformationNon-rotating vibration suppressionProtective buildings/sheltersHorizontal forceViscoelastic damping

A damping intermediate pillar, which can exhibit a sufficient resistance against the horizontal force of a strong earthquake by reinforcing the joins between the damping intermediate pillar and the upper and lower beams, is disclosed. A damping intermediate pillar 14, used for a building or a structure configured of pillars 1 and beams 3, is divided into upper and lower damping intermediate pillar portions 14a, 14b of H shape steel, and includes a plurality of inner steel plates 7b fixed on the damping intermediate pillar portion 14b and a plurality of outer steel plates 7a fixed on the other damping intermediate pillar portion 14a. The inner and outer steel plates are arranged alternately in a single or a plurality of layers, between which a viscoelastic member 15 is held to make up a viscoelastic damper 17. The coupling end surfaces of the intermediate pillar portions 14a, 14b directed vertically are fixed on the upper and lower floor beams 3a, 3b. Further, one or both sides of each of the damping intermediate pillar portions 14a, 14b (i.e. the coupling members 13a, 13b) and the upper and lower floor beams 3a, 3b are coupled to each other by knee braces 19.

Owner:KAZUHIKO KASAI +1

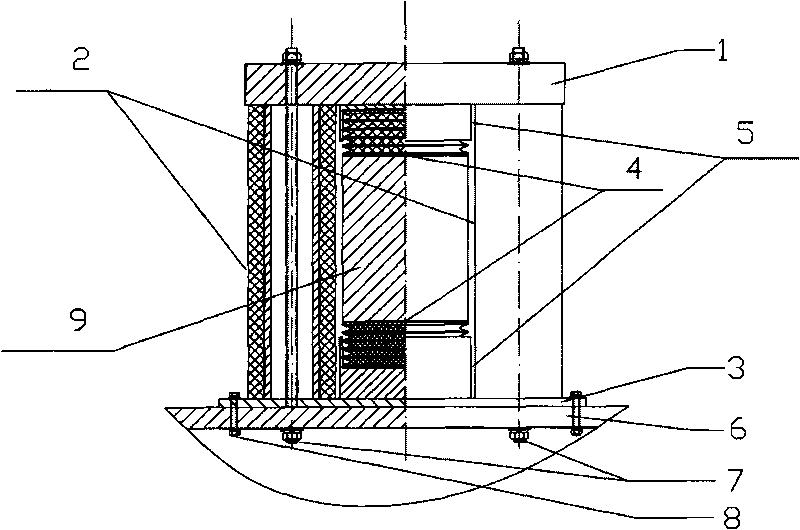

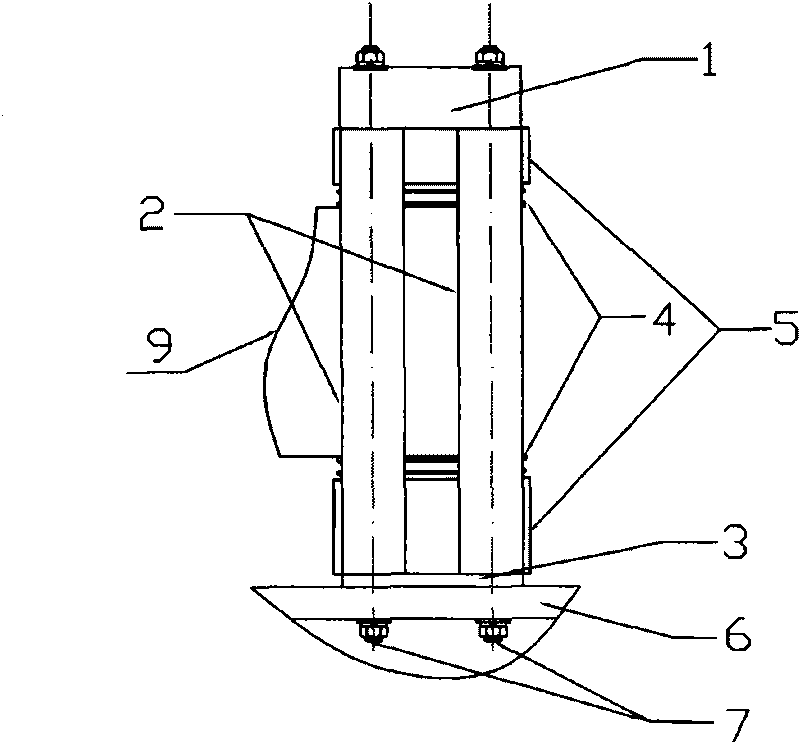

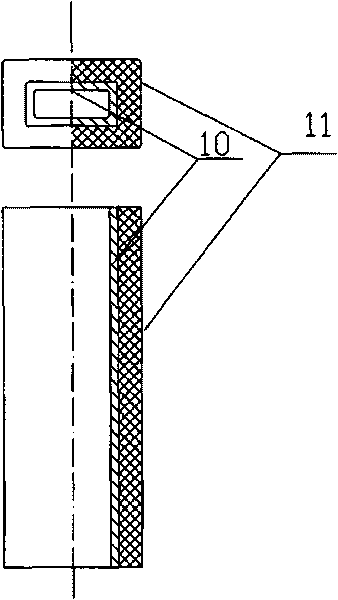

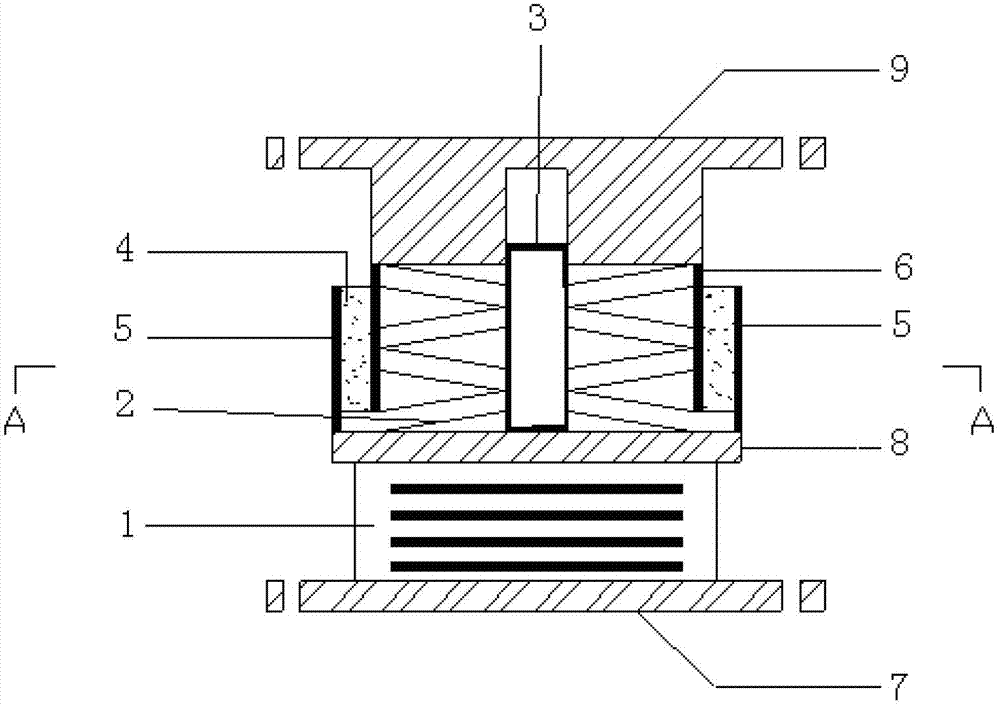

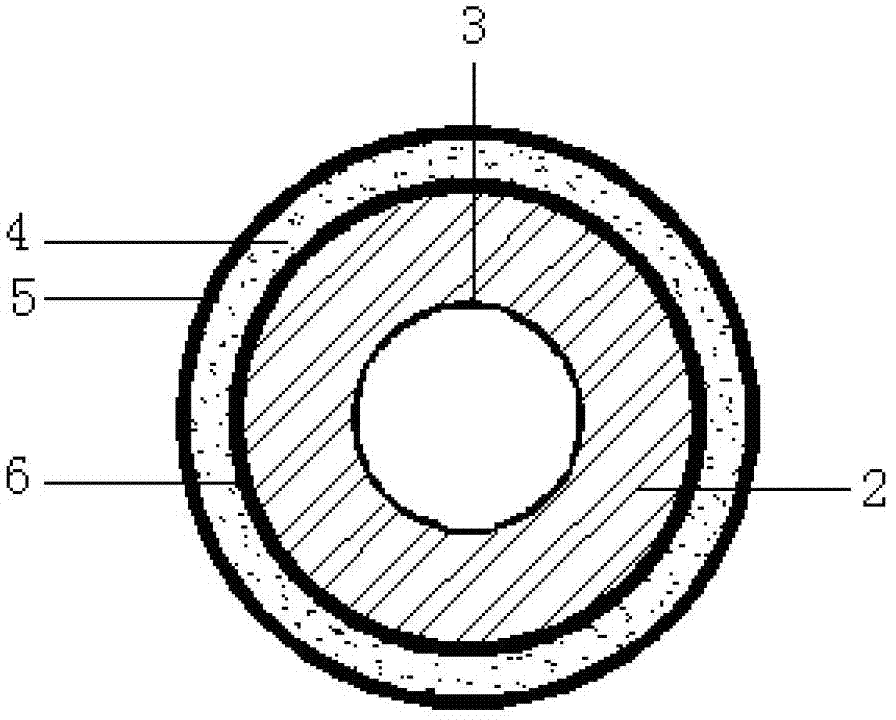

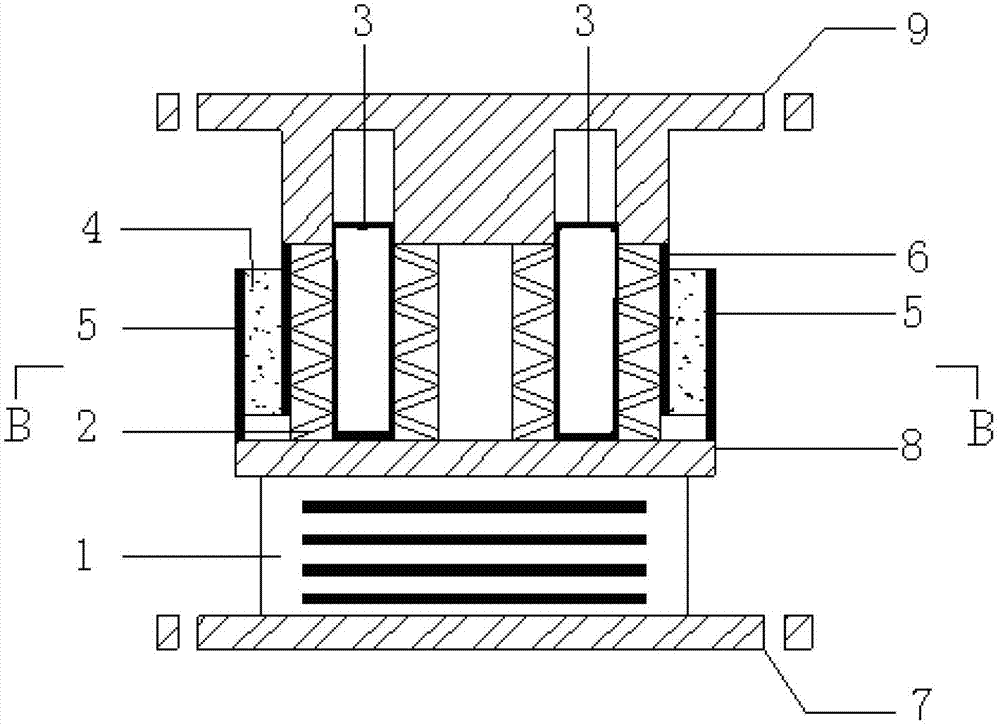

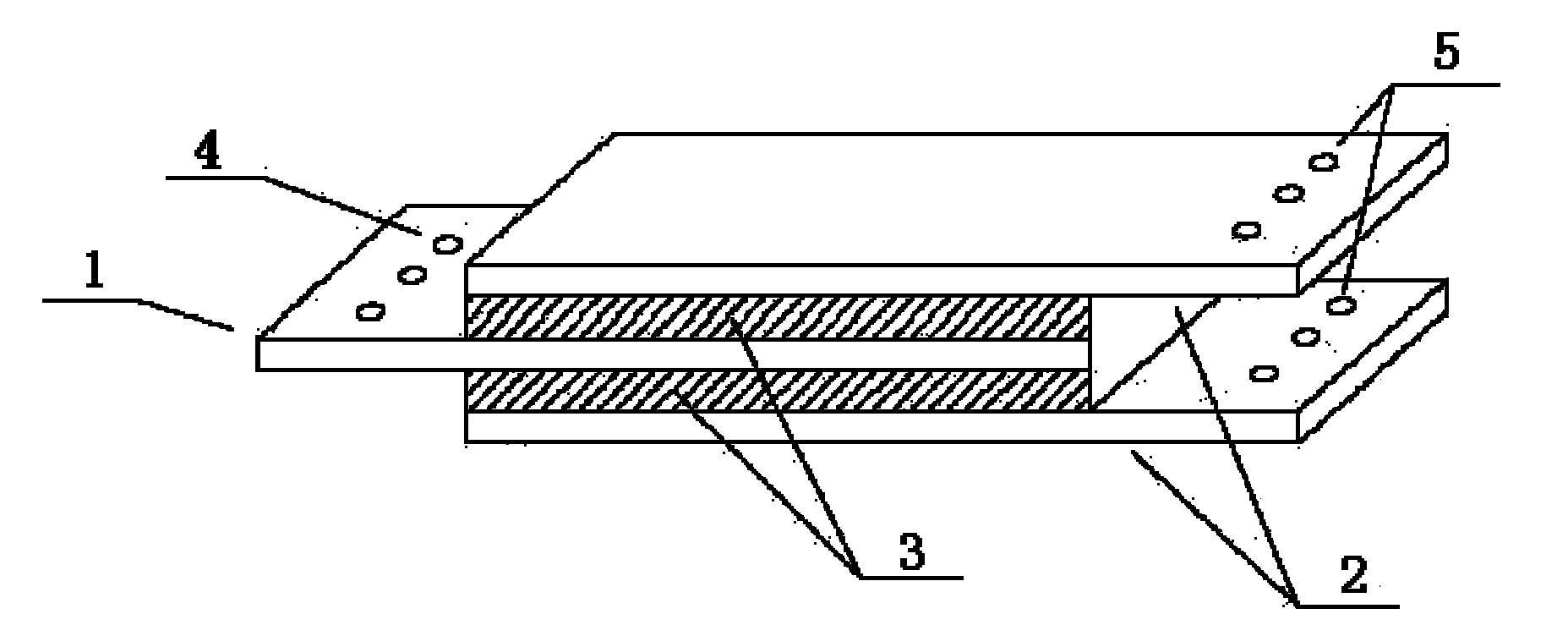

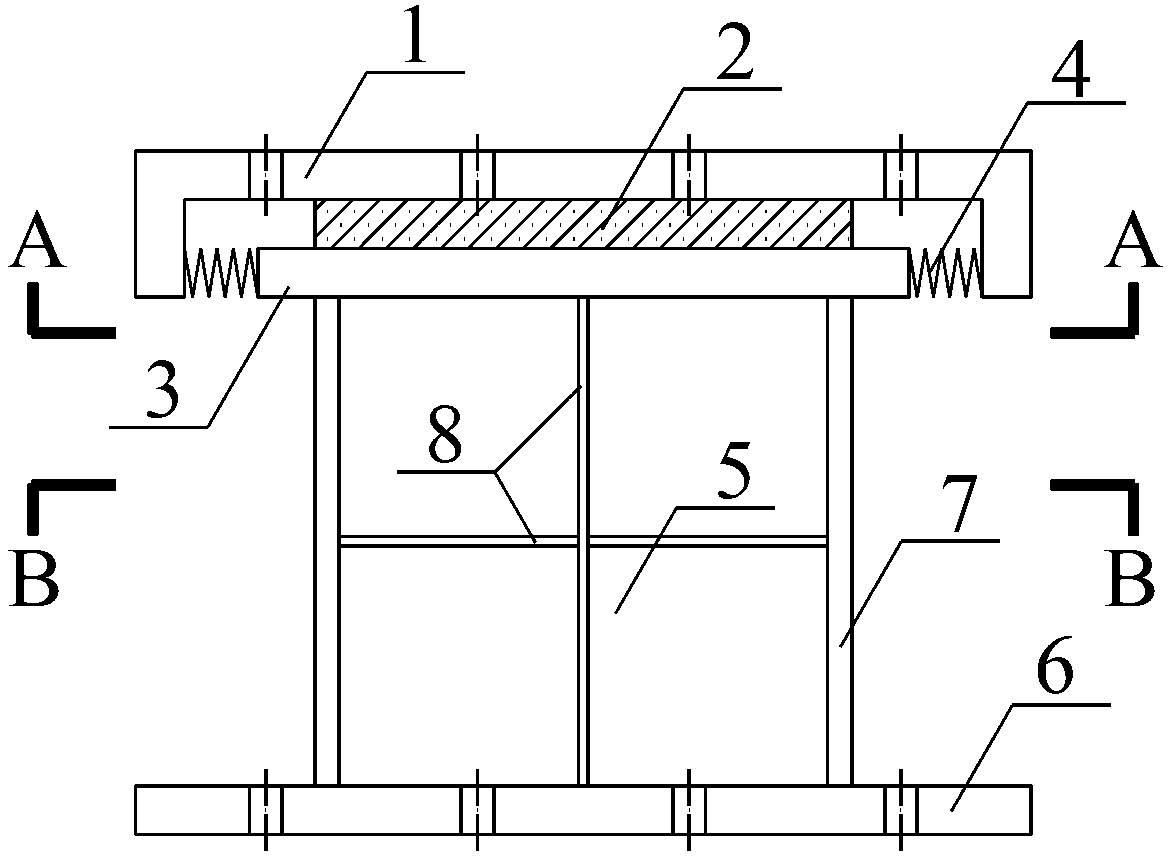

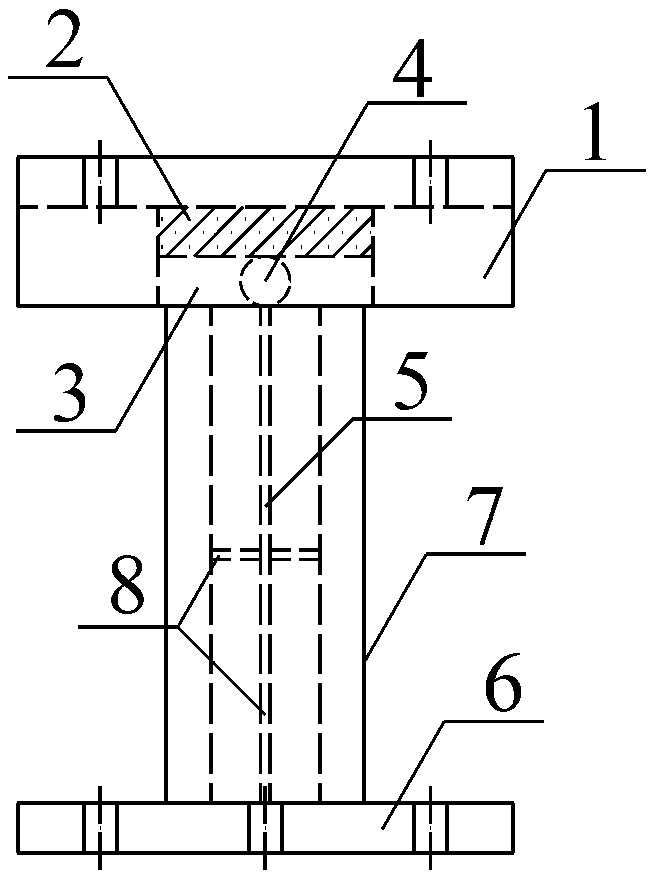

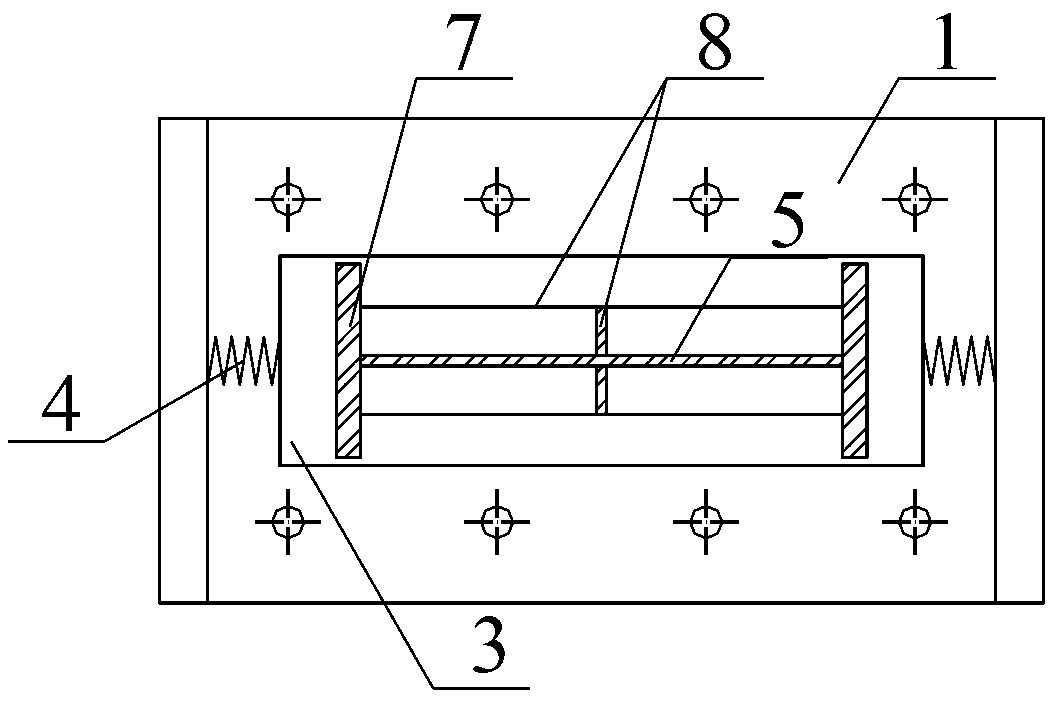

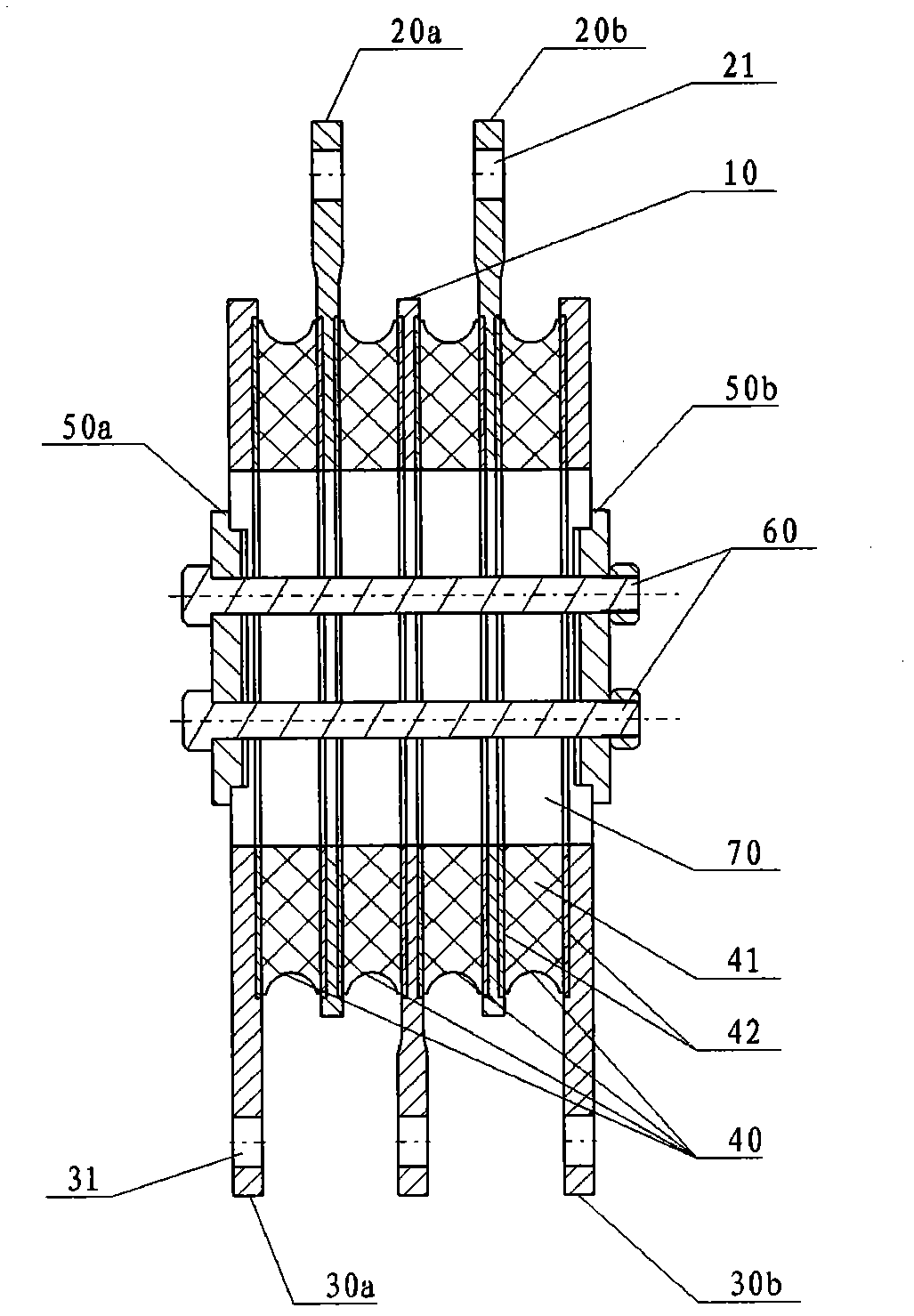

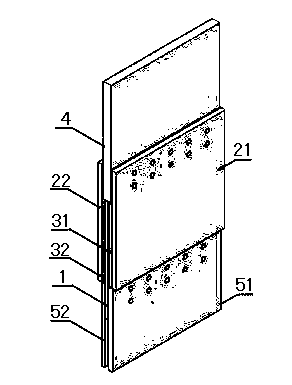

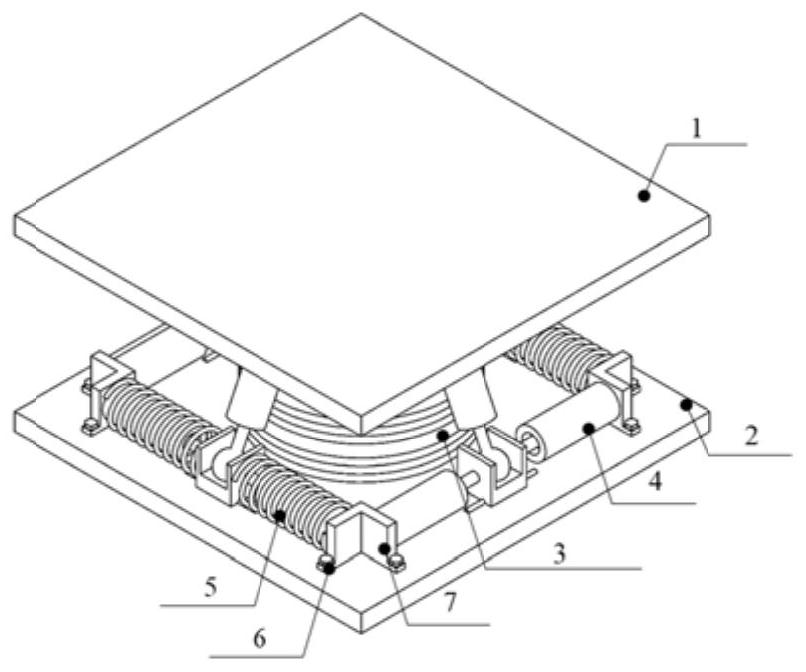

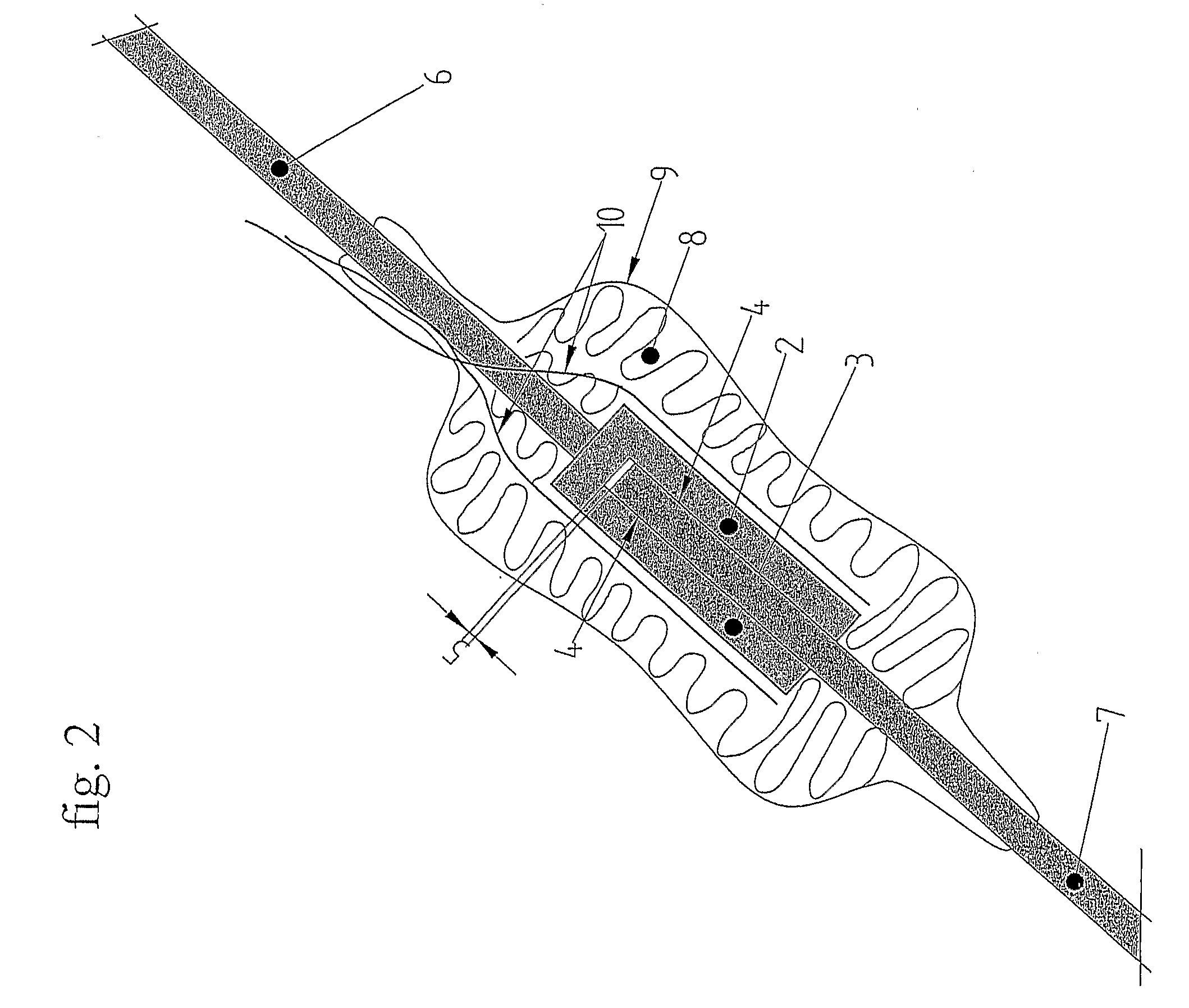

Damping composite type variable rigidity vibration attenuating support for gearbox of wind powered generator

InactiveCN101725482ALight weightLow costNon-rotating vibration suppressionMachines/enginesUltrasound attenuationElastomer

The invention belongs to the field of wind power generation, in particular to a damping composite type variable rigidity vibration attenuating support for a gearbox of a wind powered generator. The support mainly comprises an upper yoke (1), a lower yoke (3), four hollow vertical columns (2), an upper elastic body (4), a lower elastic body (4), an upper base (5) and a lower base (5), wherein the upper yoke (1), the lower yoke (3) and the four hollow vertical columns (2) form a combined type main frame of the vibration attenuating support; a viscoelastic damping vibration attenuating layer (11) is compounded on the main frame; after being respectively combined with the upper base (5) and the lower base (5), the upper elastic body (4) and the lower elastic body (4) are respectively fixed on the upper yoke (1) and the lower yoke (3); the vibration attenuating support is connected to the main machine frame (6), and a gearbox torque arm (9) is arranged between the upper elastic body and the lower elastic body. The invention has the characteristics of light dead weight and low cost, the rigidity of the vibration attenuating support can form a non-linear change along with the increase of loads, and the vibration attenuating support has damping attenuation capability and further reduces the transfer of the vibration and the noise of a system to a lower foundation.

Owner:洛阳双瑞橡塑科技有限公司

Composite three-dimensional shock isolation support of sandwich rubber-high damping disc spring

ActiveCN103195168ASimple structureReduce vibrationShock proofingViscoelastic dampingStructural engineering

The invention discloses a composite three-dimensional shock isolation support of a sandwich rubber-high damping disc spring. The composite three-dimensional shock isolation support of the sandwich rubber-high damping disc spring comprises a horizontal shock isolation support, a disc spring vertical shock isolator, a guide rod, a cylindrical viscoelastic damping layer, an external cylindrical vertical connection steel plate, an internal cylindrical vertical connection steel plate, a lower connecting plate, a middle connecting plate and an upper connecting plate. The composite three-dimensional shock isolation support of the sandwich rubber-high damping disc spring isolates horizontal earthquakes through the horizontal shock isolation support, improves certain damping, and reduces vibration of a structure under the effects of the horizontal earthquakes. The disc spring vertical shock isolator isolates vertical earthquakes, the cylindrical viscoelastic damping layer increases damping of the shock isolation support under the effects of the vertical earthquakes, vertical earthquake energy transmitted to the structure by the earthquakes is consumed, and swing of the structure under the effects of the vertical earthquakes is reduced.

Owner:SOUTHEAST UNIV

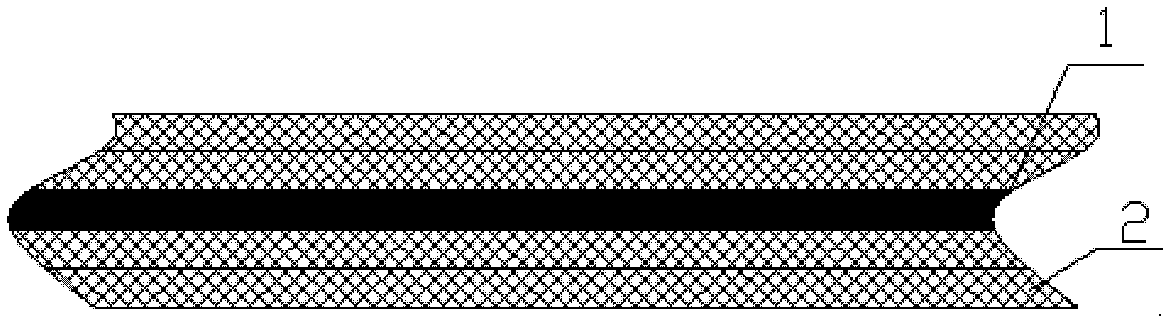

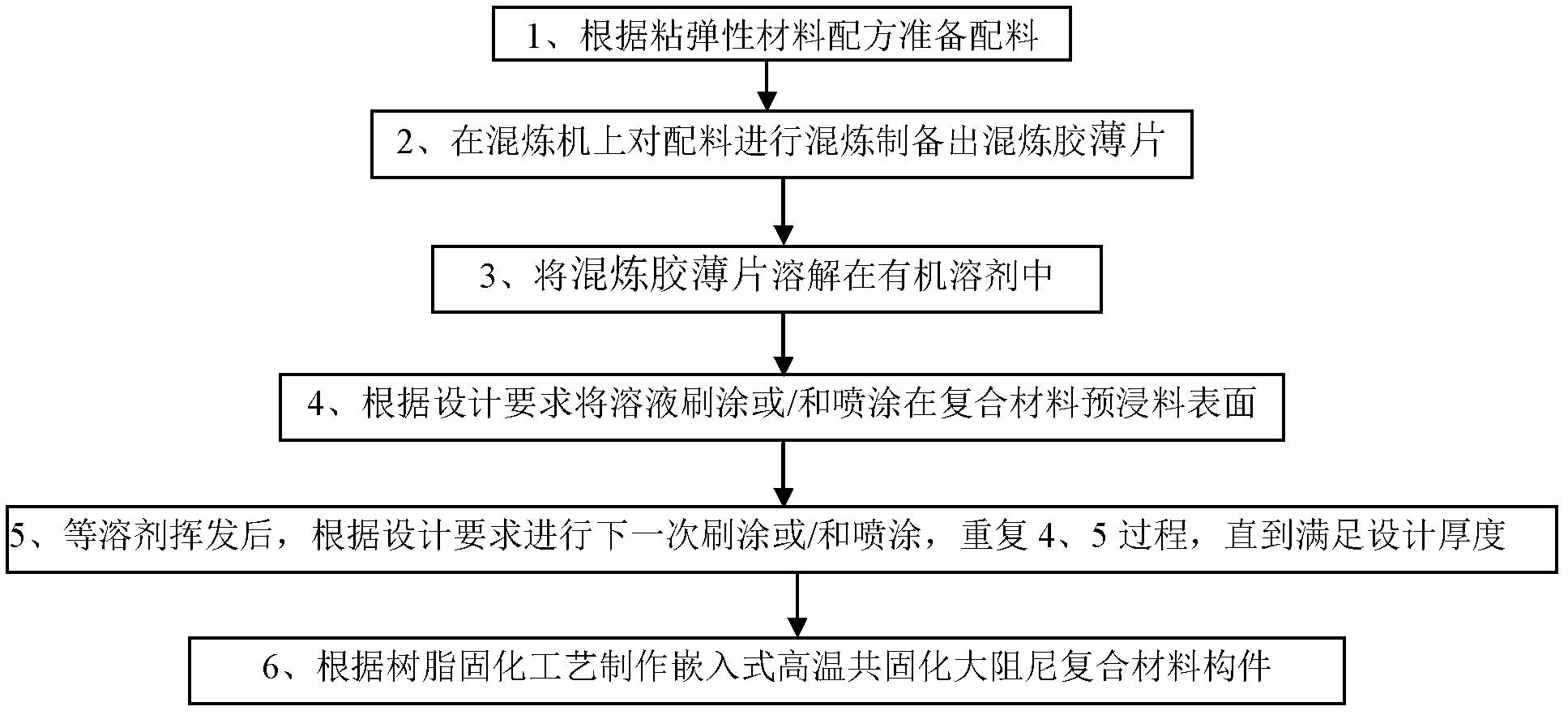

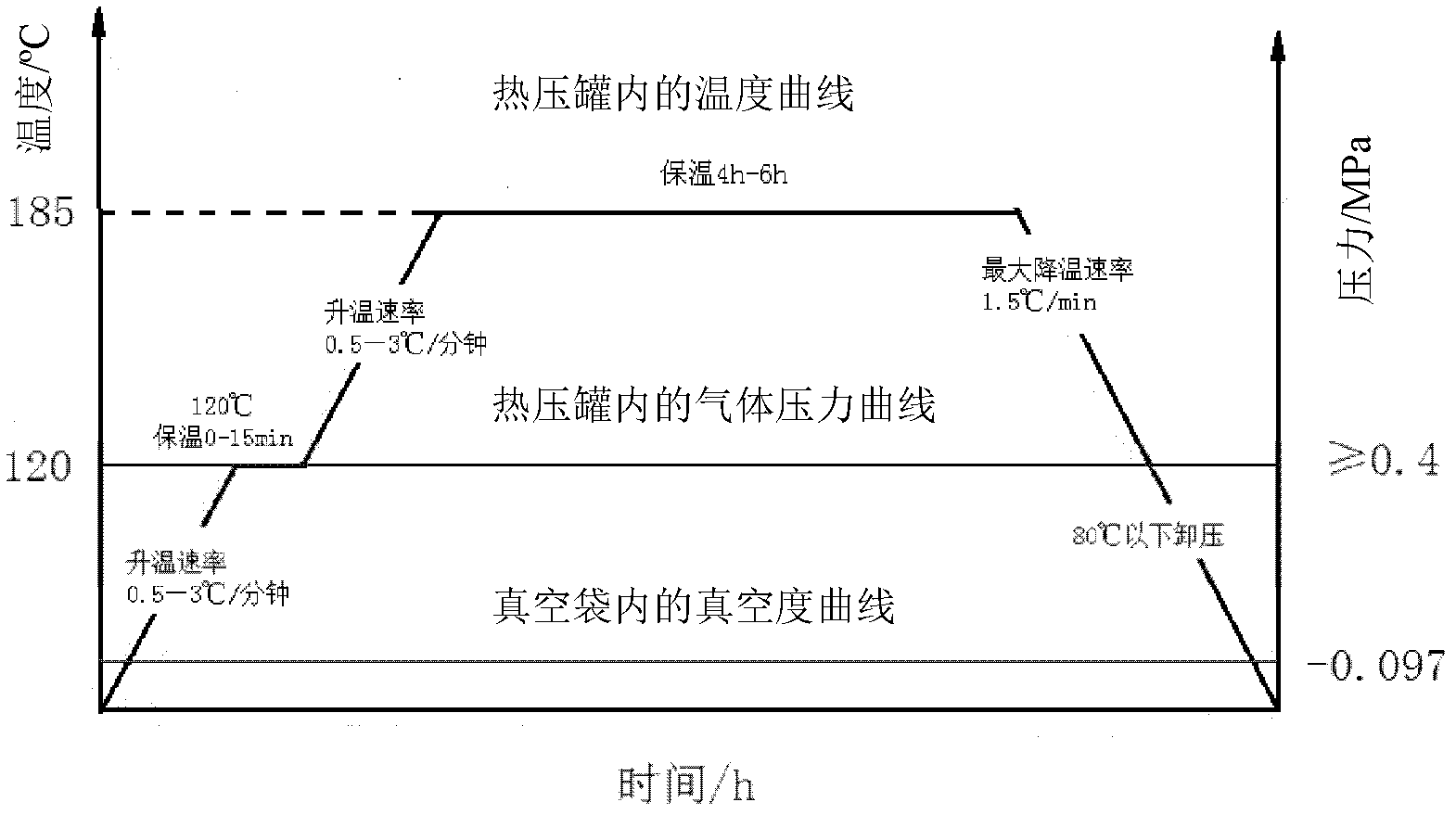

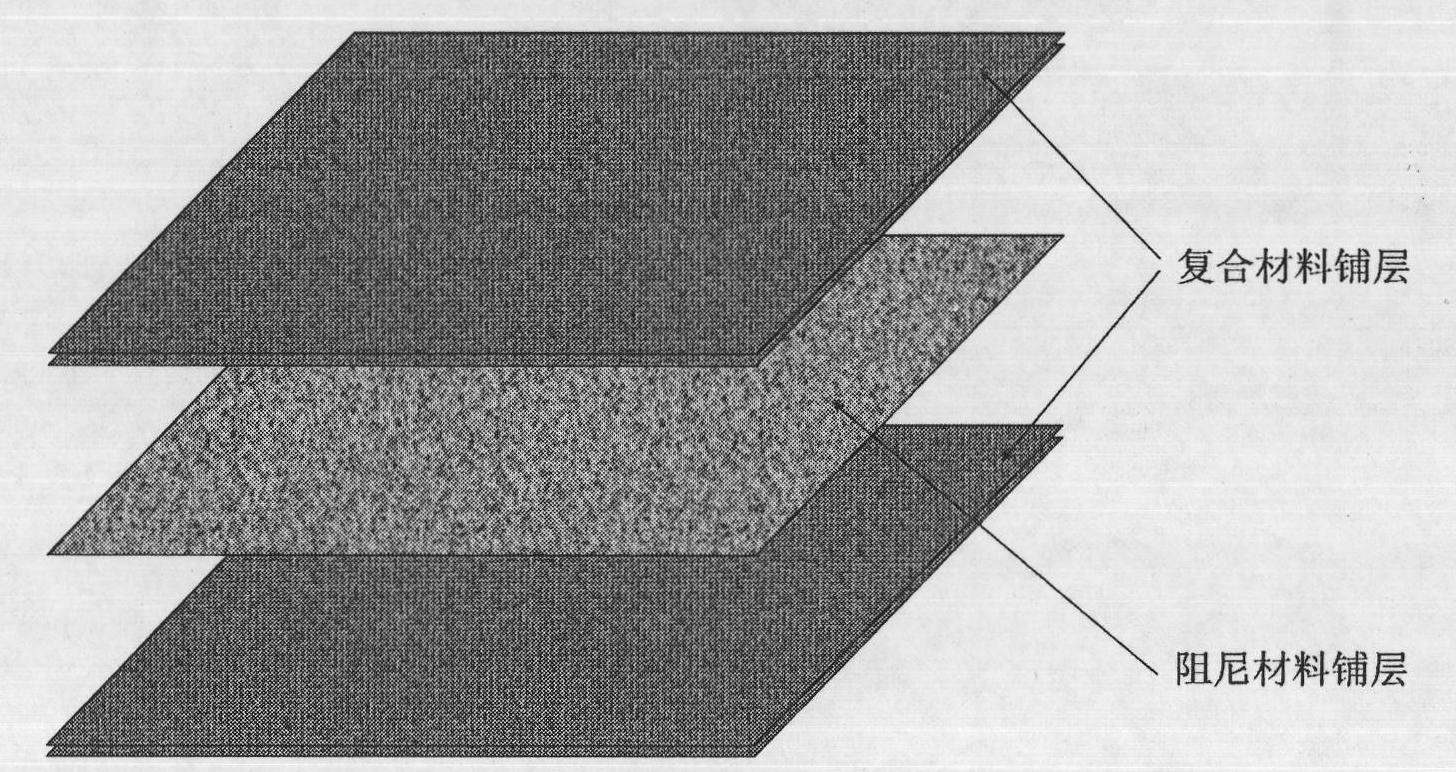

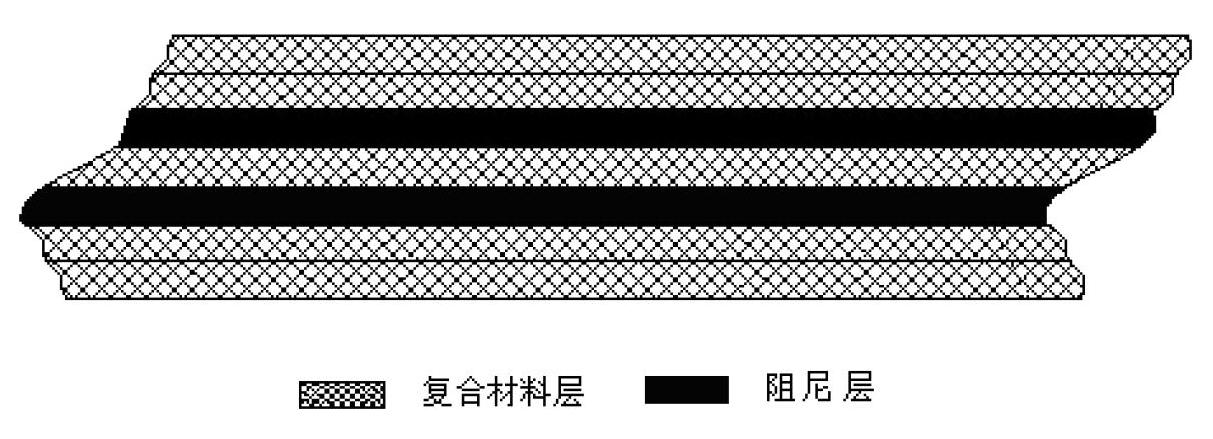

Embedded type high-temperature co-curing high-damping composite material and preparation process thereof

The invention discloses an embedded type high-temperature co-curing high-damping composite material. The embedded type high-temperature co-curing high-damping composite material comprises the following components in parts by weight: 92.5-93.5 parts of butyl rubber, 6.5-7.5 parts of chlorinated butyl rubber, 2.9-3.1 parts of chlorinated polyethylene, 3.9-4.1 parts of zinc oxide, 0.8-1 parts of stearic acid, 50-52 parts of carbon black and 5.9-6.1 parts of octyl phenolic resin. The invention also discloses a preparation method of the composite material. According to the method, the mixture of the butyl rubber and the chlorinated butyl rubber is taken as a main material, the mixture is dissolved in an organic solvent to be prepared into unvulcanized visco-elasticity damping material solution, the unvulcanized visco-elasticity damping material is brushed and coated on the prepreg surface of the composite material, by adopting a brush-coating method or / and spray-coating method, a damping layer is embedded in the structure of the composite material by being taken as a specific paving layer and then is processed into a damping-structure member of the embedded composite material by a co-curing process curve, and the damping-structure member of the embedded composite material has a wide application prospect in the high-tech fields such as high speed trains, aviation, aerospace and the like.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

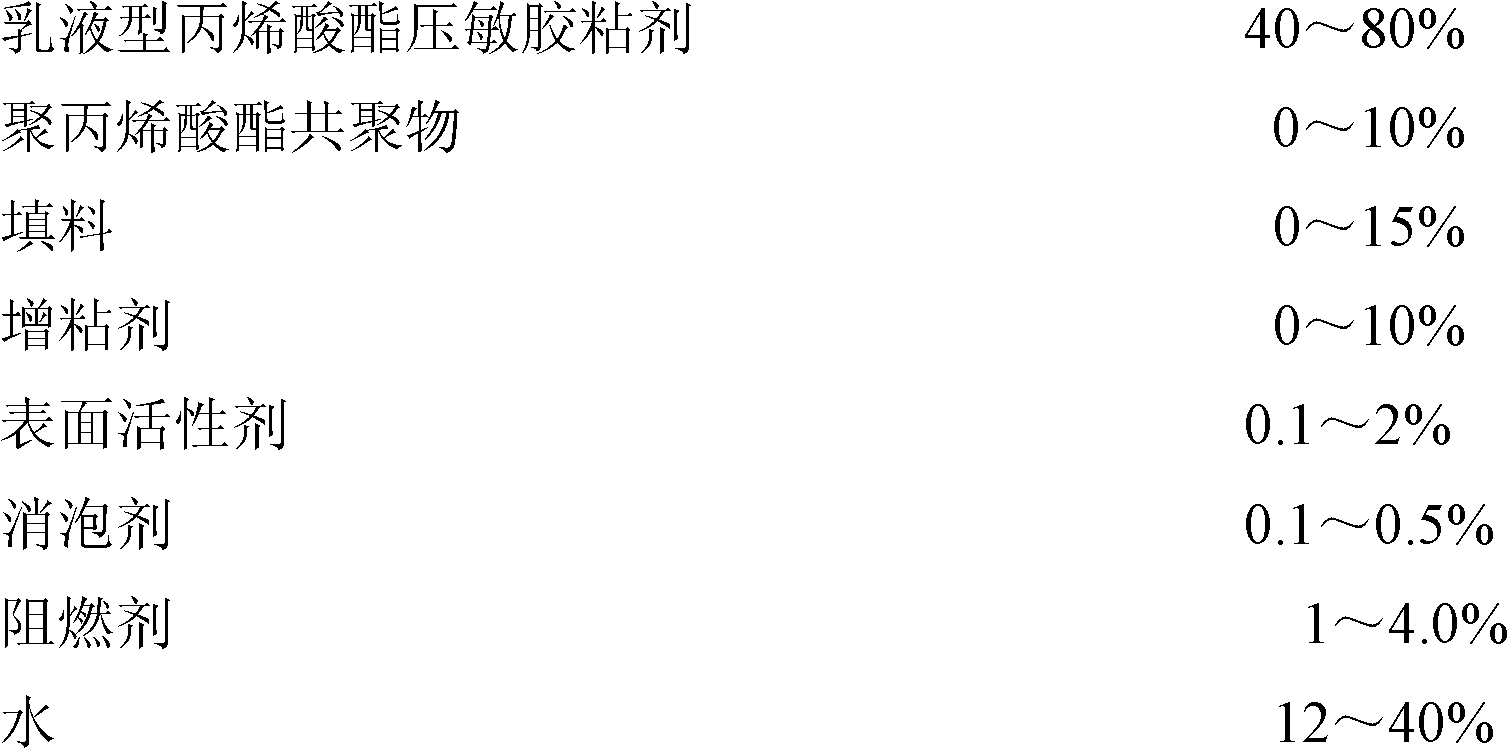

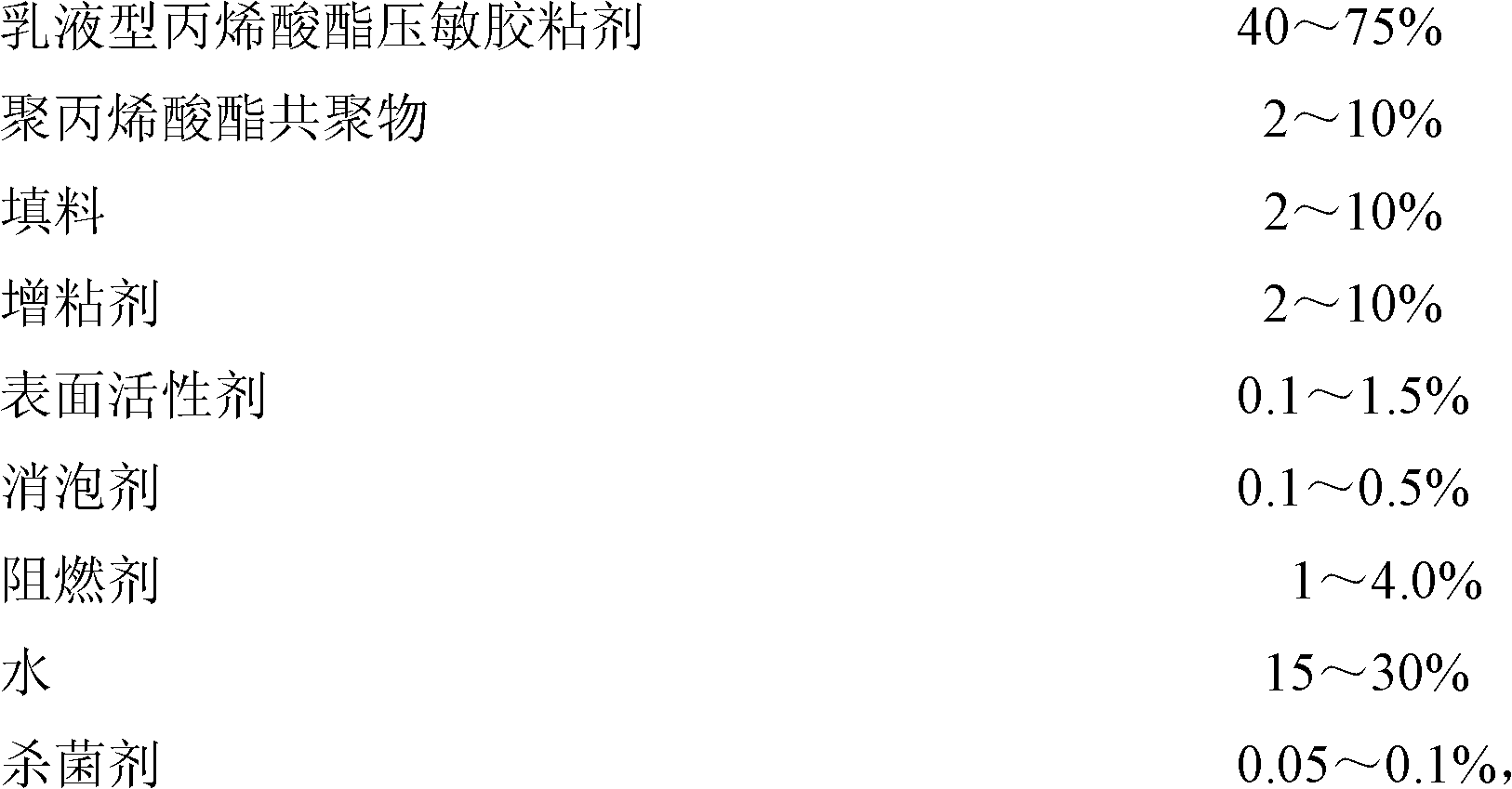

Water-based viscous-elastic damping sound-insulation adhesive

ActiveCN102492378AHigh damping valueWide temperature rangeNon-macromolecular adhesive additivesEster polymer adhesivesWater basedViscoelastic damping

The invention discloses a water-based viscous-elastic damping sound-insulation adhesive, comprising 40-80 wt% of emulsion aclylate pressure-sensitive adhesive, 0-10 wt% of polyacrylate copolymer, 0-15 wt% of filling material, 0-10 wt% of tackifier, 0.3-2 wt% of surfactant, 0.1-0.5 wt% of antifoaming agent, 1-4.0 wt% of fire retardant, 12-40 wt% of water, and 0.05-0.3 wt% of bactericide, wherein the summation of the weight percentages of all the ingredient is 100 wt%. The water-based viscous-elastic damping sound-insulation adhesive belongs to an environment-friendly type adhesive, has no toxicity and no harm, is friendly to human body and environment, has high damping value, wide temperature range, and strong caking property, can form a damping platform with a damping value of more than 0.9 and a temperature range of more than 100 DEG C, has a T-peel strength of larger than 31 N / cm, and has the dual effects of sound insulation and caking.

Owner:安徽贝卫新材料科技有限公司

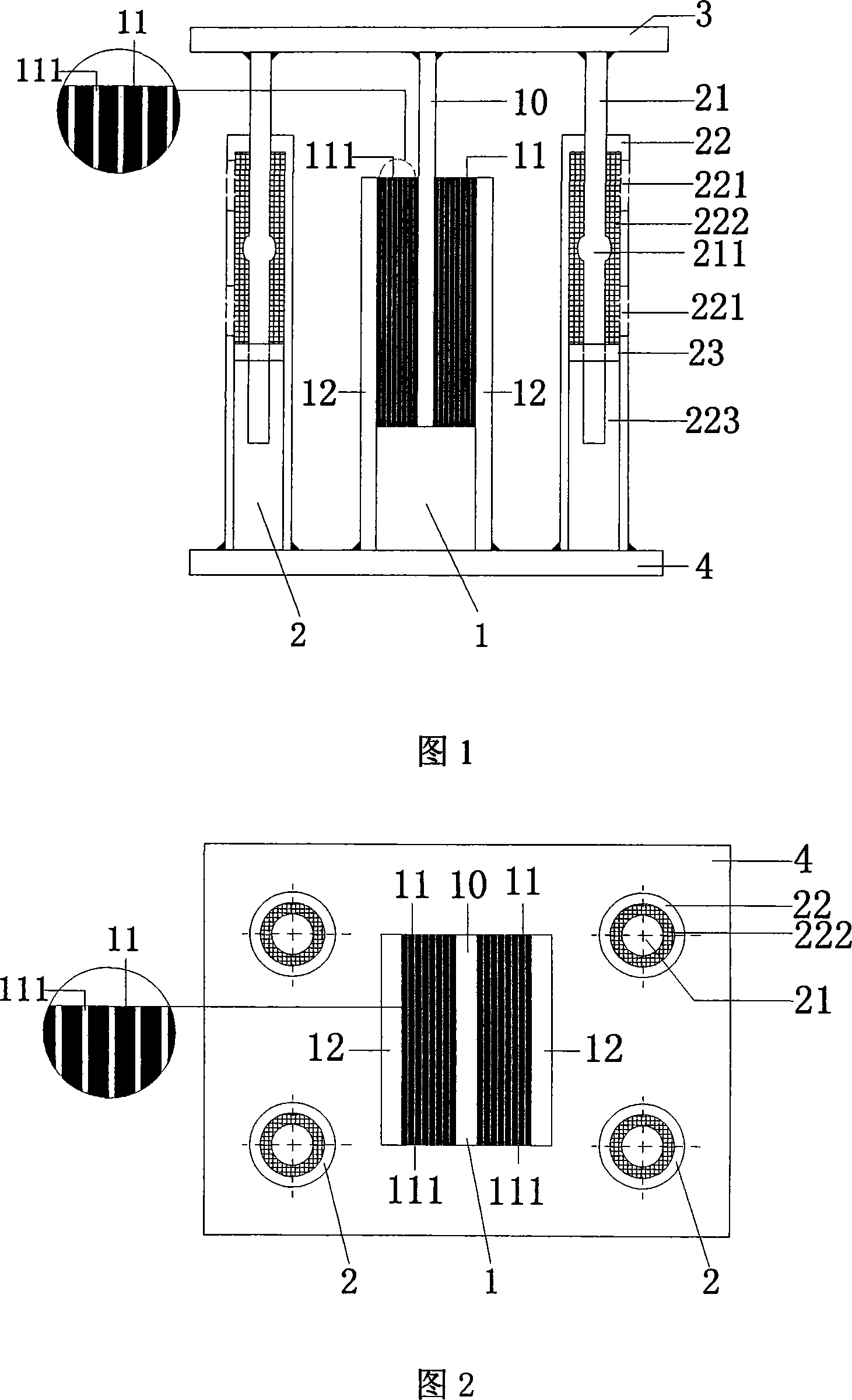

High-damping rubber fluid viscoelastic damper and manufacturing method thereof

ActiveCN102182256AReduce wind vibrationReduced responseBridge structural detailsBridge erection/assemblyHysteresisViscoelastic damping

The invention relates to the technical field of civil engineering, in particular to a damper and a manufacturing method thereof. A high-damping rubber fluid viscoelastic damper comprises a steel plate layer and a fluid viscoelastic material layer, wherein the steel plate layer comprises a middle steel plate and side steel plates arranged at two sides of the middle steel plate, the fluid viscoelastic material layer is arranged between the steel plate layer and the side steel plates, and the fluid viscoelastic material layer is the high-damping rubber fluid viscoelastic material layer made of high-damping rubber fluid viscoelastic material. Due to the adoption of the technical scheme, the invention has the following advantages: the vibration energy can be absorbed effectively by the deformation of the high-damping rubber fluid viscoelastic material, a hysteresis ring is full, and the fatigue resistance is good; and compared with the traditional fluid viscoelastic damper, the energy consumption property has stronger nonlinearity, and the energy consumption property is good under the condition of extremely small displacement and extremely low speed.

Owner:SHANGHAI EAGLE BRIDGE TECH

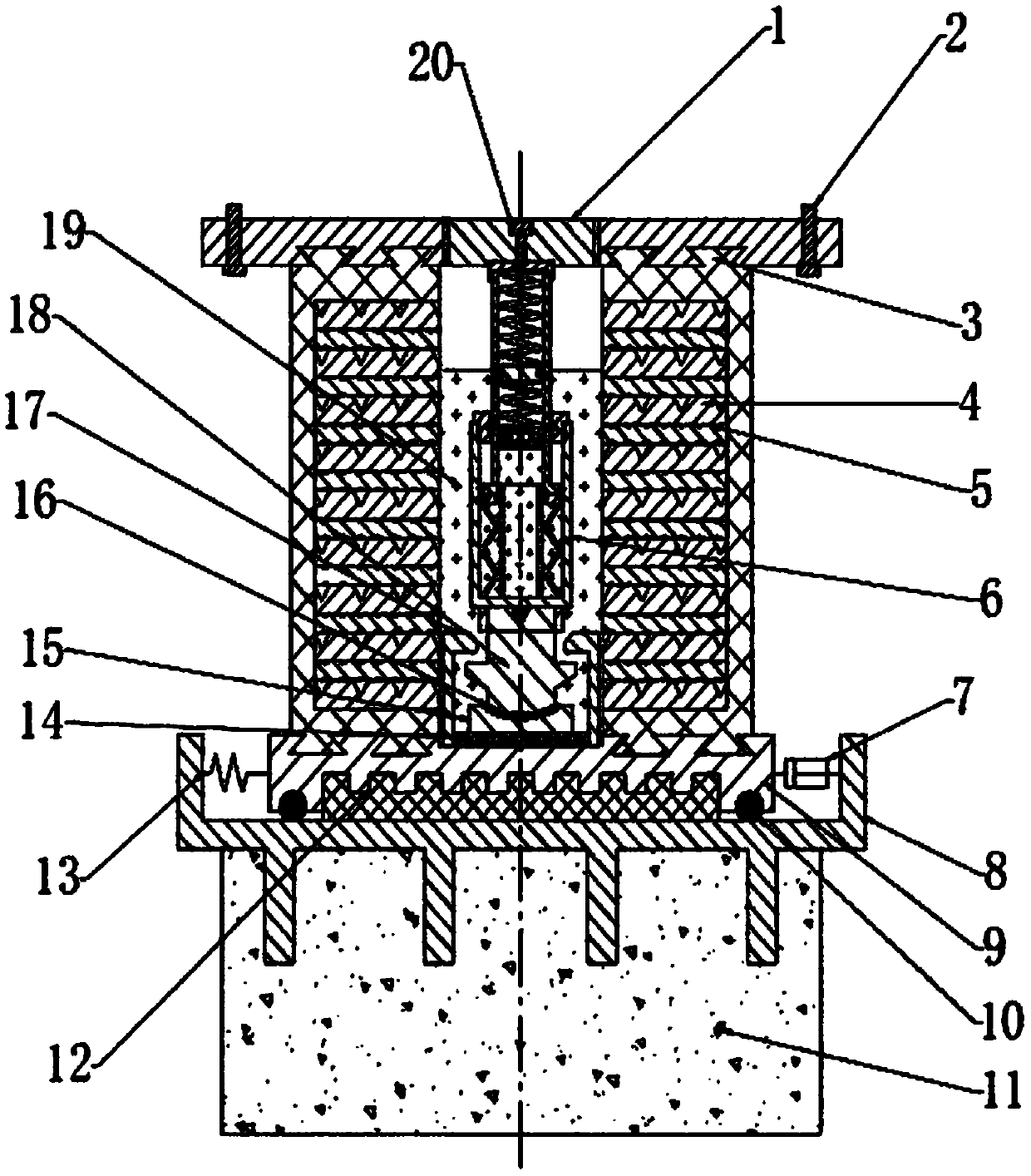

Building structure foundation module having three-dimensional shock isolation and vibration attenuation functions

ActiveCN109763581AReduce construction costsLow coefficient of sliding frictionClimate change adaptationProtective buildings/sheltersViscoelastic dampingVibration attenuation

The invention discloses a building structure foundation module having three-dimensional shock isolation and vibration attenuation functions. The building structure foundation module mainly comprises asteel structure small platform, a sliding support, a variable vertical stiffness combination laminated special rubber / steel plate support having a vertical self-regulating deformation capability, andviscoelastic damping energy absorption shock absorbers, wherein the centers of the viscoelastic damping energy absorption shock absorbers are connected in parallel; the sliding support uses an oily self-lubricating liquid phase-solid phase material, the coefficient of sliding friction is relatively low, the horizontal seismic component is effectively stopped from transferring to an upper structure, the shock absorber and a liquid / solid special rubber support having a damping characteristic are connected together in parallel and have a vibration attenuation effect, so that the effects of three-dimensional shock isolation, vibration attenuation and protection are achieved. The technical scheme has more sensitive and efficient actions on the earthquake.

Owner:李鑫

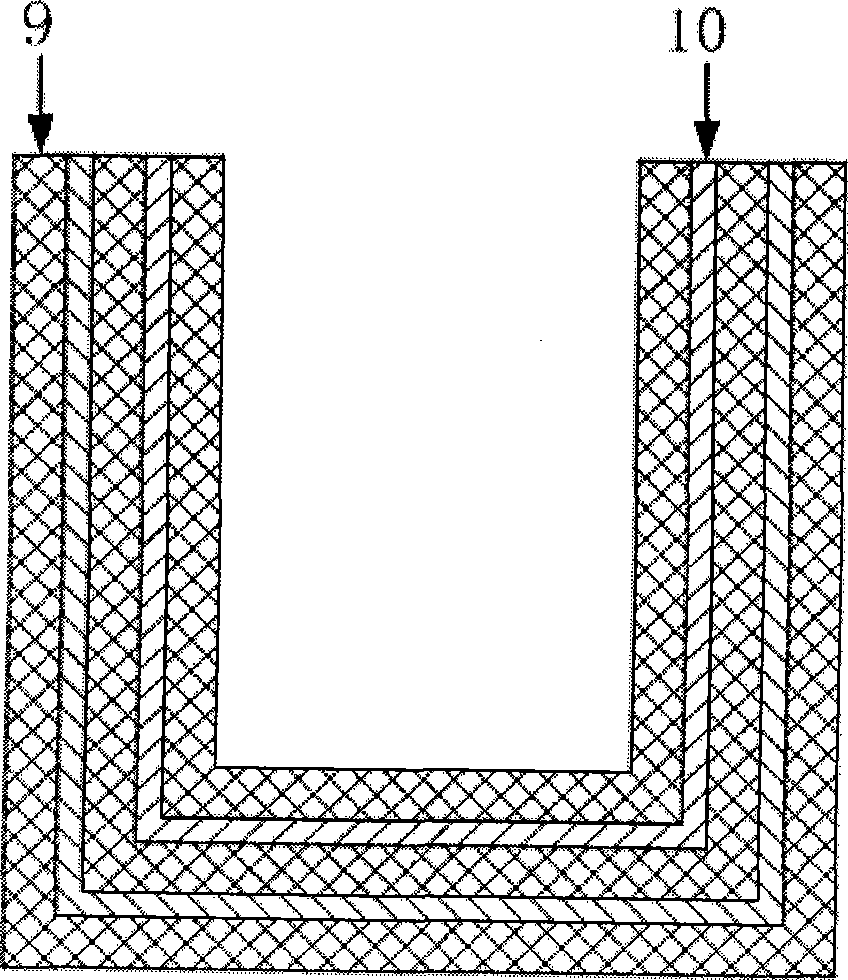

Viscoelastic-mild steel shear-type combined energy consumer

ActiveCN103216022AAvoid damageSimultaneously control wind vibrationShock proofingHysteresisViscoelastic damping

The invention discloses a viscoelastic-mild steel shear-type combined energy consumer which comprises a viscoelastic damper and a shear energy-consuming combined panel; the shear energy-consuming combined panel comprises a horizontal division board, an energy-consuming web and a connecting end plate; the horizontal division board and the connecting end plate are respectively arranged on the upper end and the lower end of the energy-consuming web fixedly; and the viscoelastic damper is arranged on the horizontal division board, and comprises a U-shaped cover plate and a viscoelastic damping interlayer which is arranged between the U-shaped cover plate and the horizontal division board. The viscoelastic damper and the hear energy-consuming combined panel work collaboratively, the damage to a main structure is reduced by shearing the vibration energy in a hysteresis deformation dissipation input structure, so that the purposes of controlling wind vibration and absorbing shock are achieved simultaneously.

Owner:TONGJI UNIV

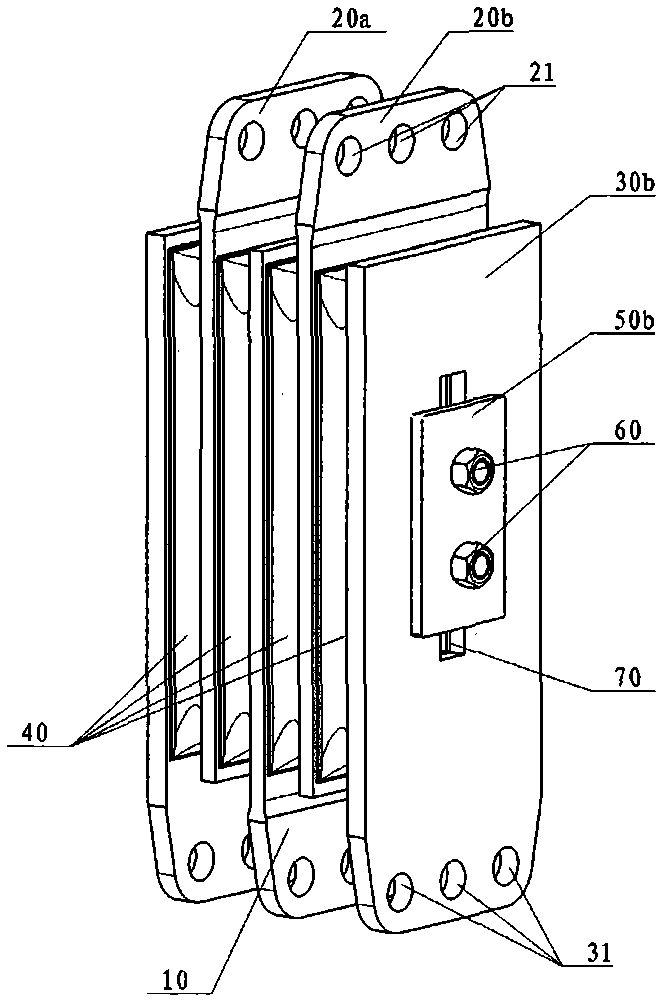

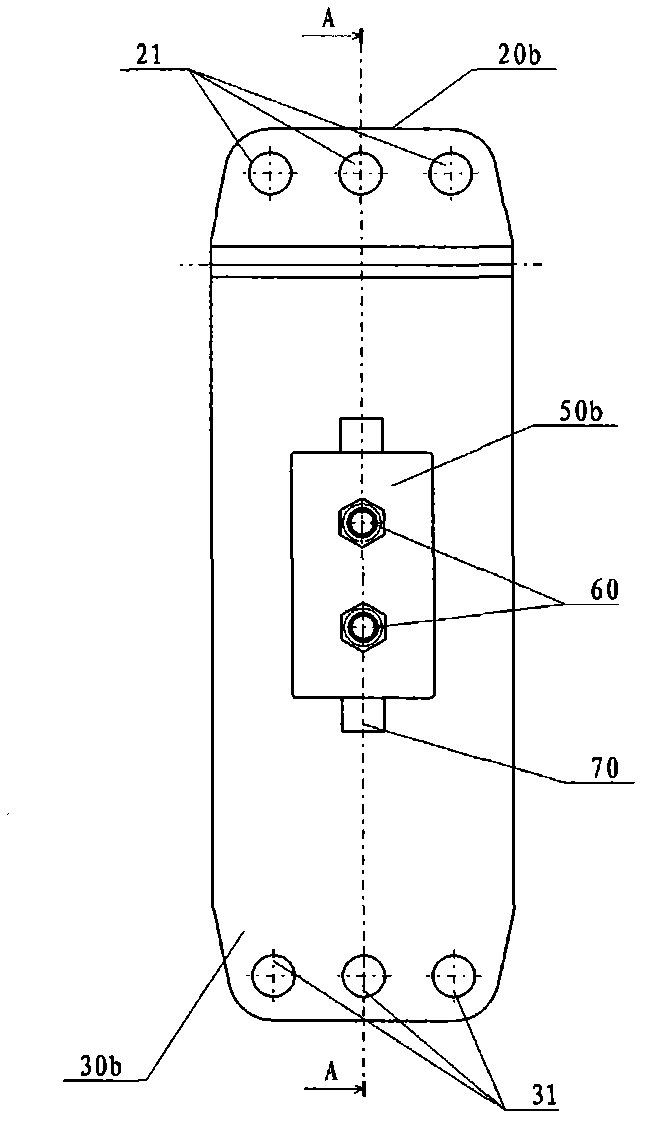

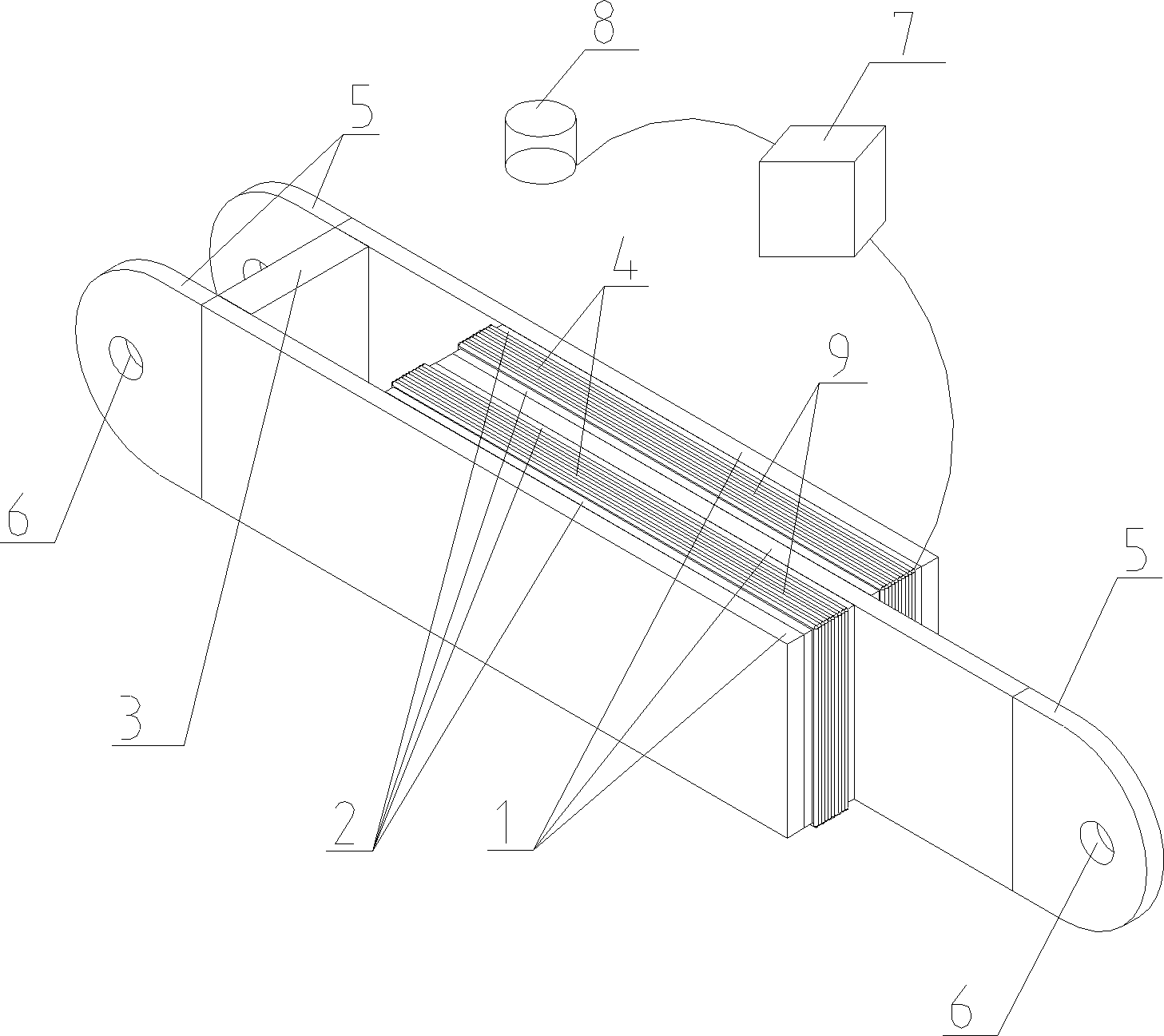

Band type damper and preparation method thereof

The invention belongs to the technical field of multilayer shearing viscoelastic dampers, and relates to an improvement on a band type damper of a helicopter rotor wing. The band type damper comprises five rigid slabs and four sandwich plates, wherein, the four sandwich plates are positioned between the five rigid slabs. A preparation method of the band type damper comprises the steps as follows: the sandwich plates of the band type damper are prepared firstly, and then the five rigid slabs and the four sandwich plates are assembled so as to form the band type damper. The band type damper can be used for adjusting the thickness of rubber plates of the sandwich plates or the number of the sandwich plates so as to satisfy the rigidity and damping requirements of different helicopter rotor wing systems; the band type damper is easy to form, convenient to process and easy to assemble, and has the advantages of low cost, small installation space and overload limiting capability; the band type damper is convenient to maintain, the sandwich plates can be checked visually, the sandwich plates out of operation are convenient to replace, the rigid slabs can be used for a long time without replacement, and maintenance cost is saved; and the band type damper is easy to dissipate heat, and prolongs the service life.

Owner:BAIMTEC MATERIAL CO LTD

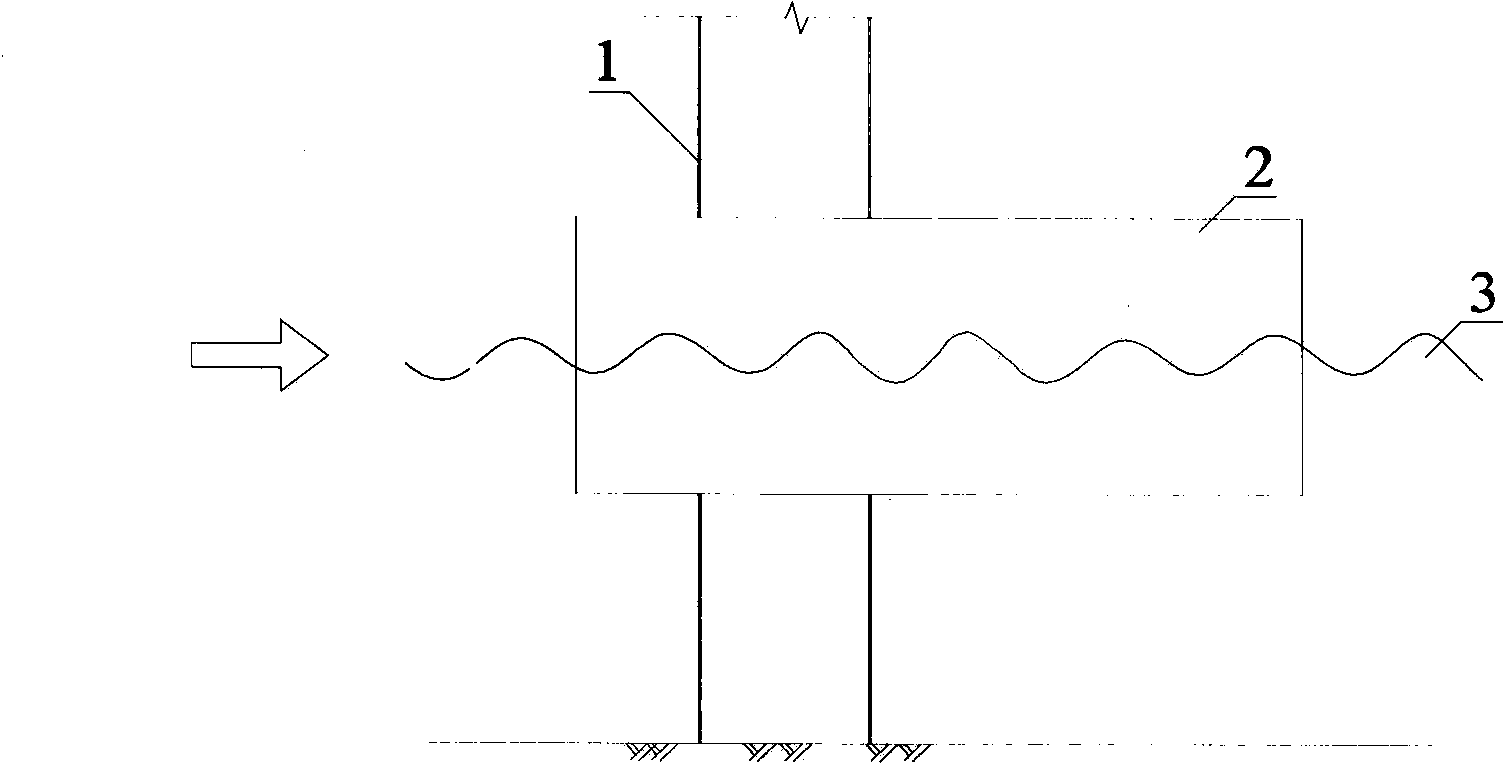

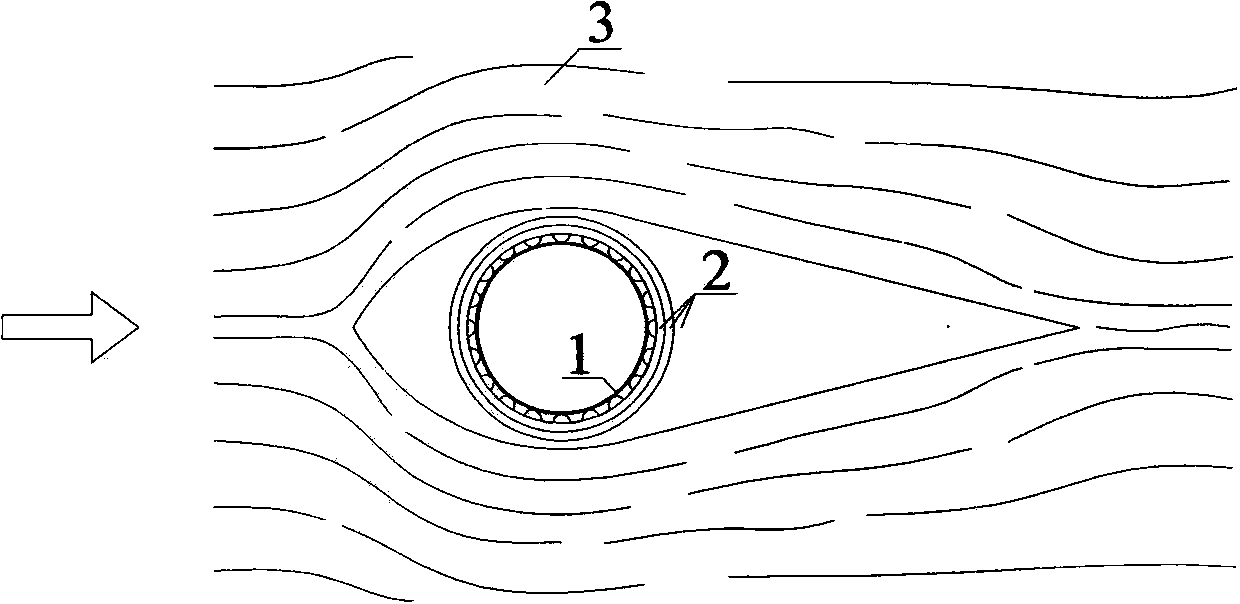

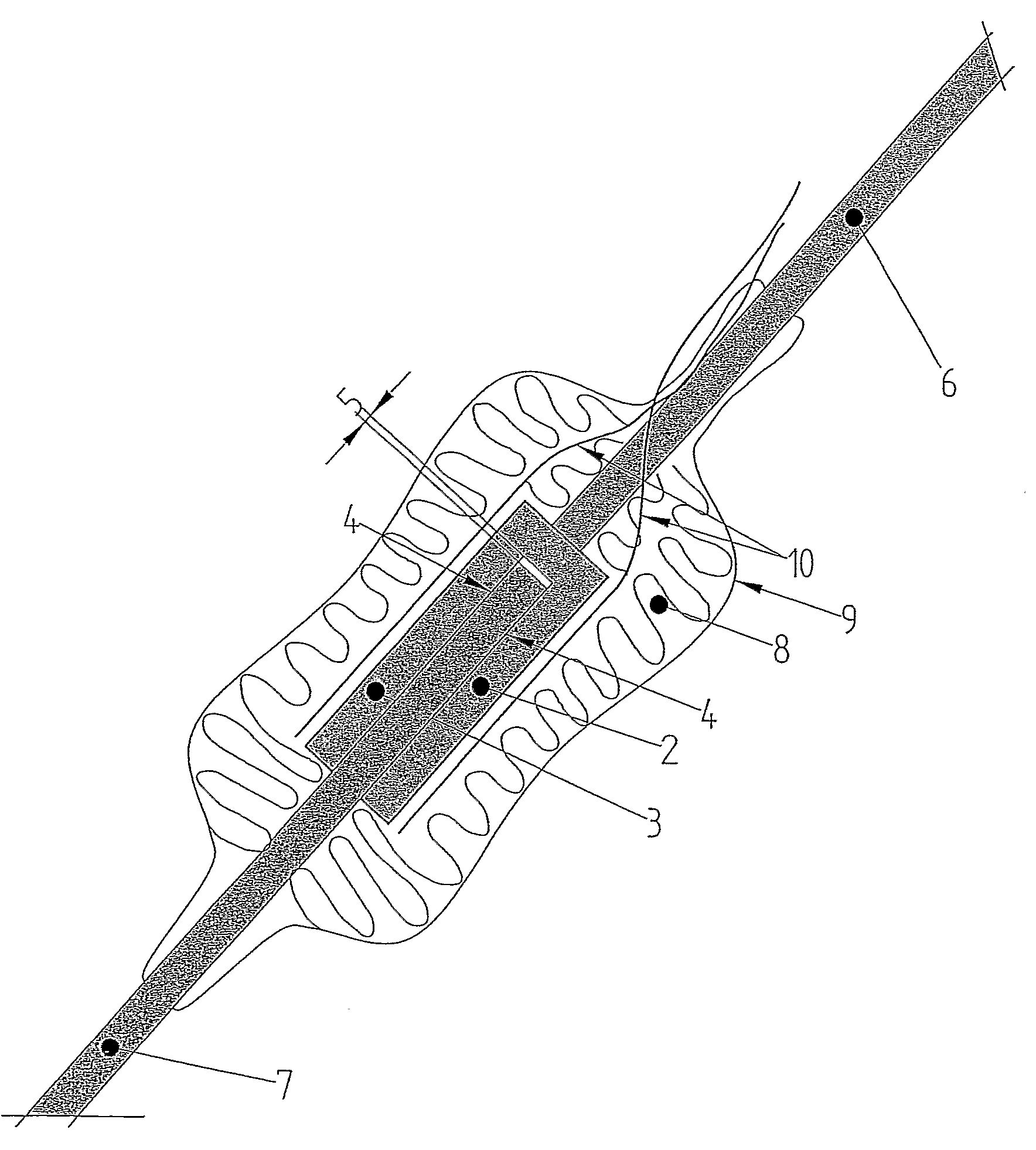

Reduction method for basic wave current vibration of offshore wind power single pile

ActiveCN103469830AReduce vibration responseAvoid fatigue damageProtective foundationViscoelastic dampingSuction force

The invention relates to a reduction method for basic wave current vibration of an offshore wind power single pile. A flexible damping device is arranged outside the basic wall surface of the single pile, wave currents are smoothed and flowing states are improved by utilizing a wing-shaped wall surface with a short head and a long tail, various water power stimulations are reduced from vibration sources, and passed loads are separated and absorbed through viscoelastic damping materials, so that the purpose of reducing pile foundation vibration is achieved. According to the reduction method for the basic wave current vibration of the offshore wind power single pile, the damping device which automatically moves up and down along water level change is always in a main stimulation area of the wave currents by changing water body weights inside a balancing water tank and adjusting relative position of a device and the water surface and under combined actions of the gravity and buoyancy force, the damping device enables the head and tail to be maintained consistent with wave current directions and plays role in damping flexibly along with change of wave current directions under combined actions of head pressure and tail suction of the wing-shaped overflowing wall surface. The reduction method for the basic wave current vibration of the offshore wind power single pile has the advantages of enabling the pile foundation vibration to be reduced by more than 70 % and being simple in structure and convenient to achieve.

Owner:NANJING HYDRAULIC RES INST

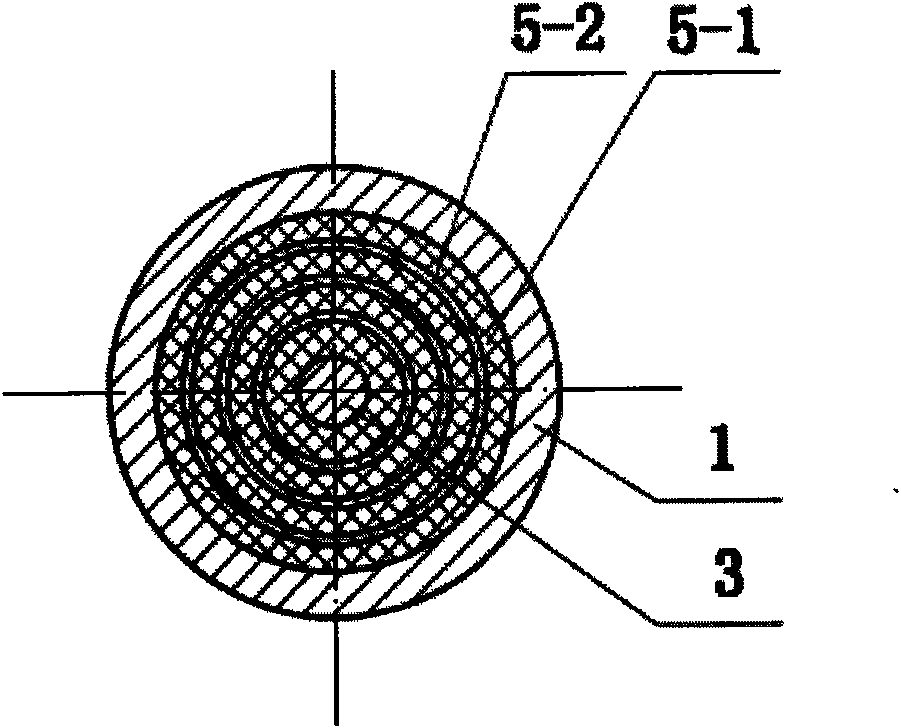

Viscous damper

InactiveCN101956780AHigh initial stiffnessReduce surface roughness requirementsSolid based dampersViscoelastic dampingElastomer

The invention relates to a vibration damper, in particular to a viscous damper taking a viscous substance as a vibration damping medium. End covers at the two ends of a cylinder (1) of the damper are elastic bodies (5); the two elastic bodies (5), the cylinder (1) and a piston rod (3) are vulcanized into a whole at high temperature; the elastic body (5) consists of an annular viscoelastic material layer (5-1) and an annular sheet steel layer (5-2) which are alternately laminated and vulcanized at high temperature; and the ratio of the diameter to width of the elastic body (5) is 2 to 4. In the damper of the invention, the elastic bodies (5) at the two ends of the cylinder (1), the cylinder (1) and the piston rod (3) are vulcanized into a whole to form a viscoelastic damper, so that the initial rigidity of the whole damper is remarkably improved.

Owner:GUANGZHOU UNIVERSITY

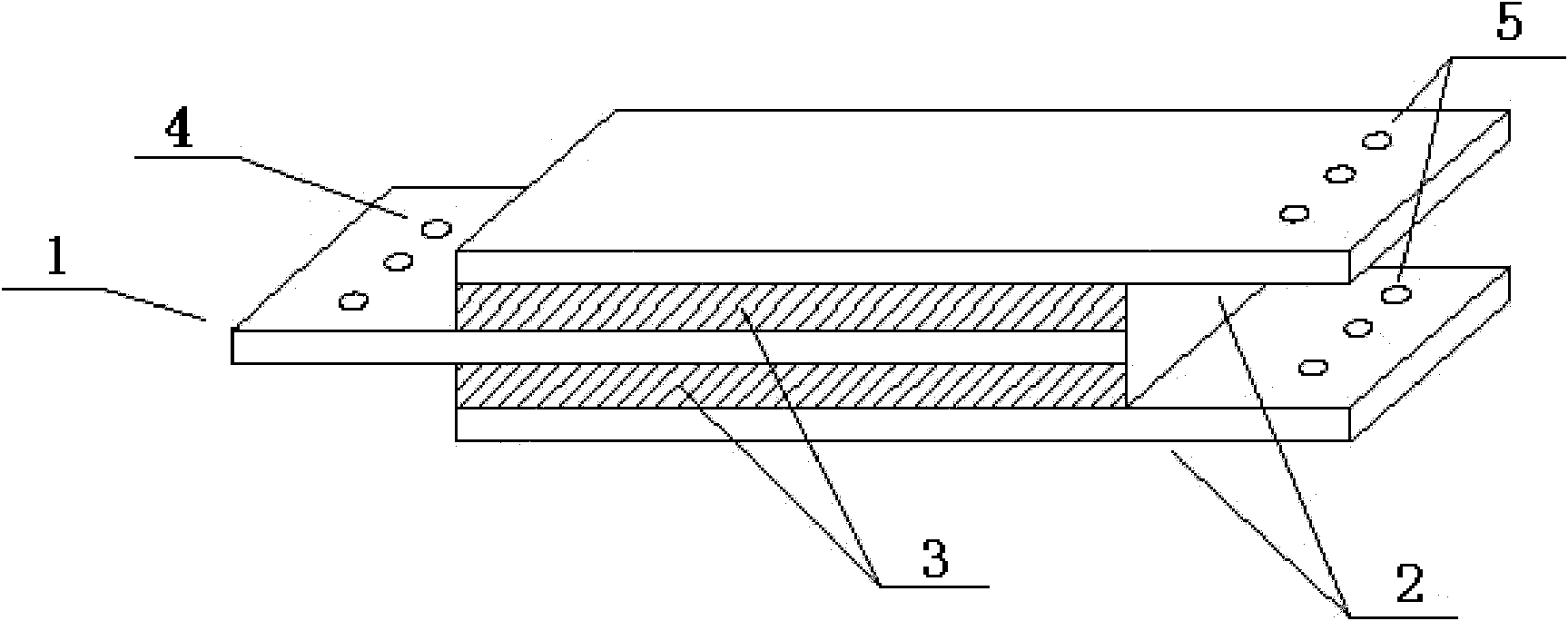

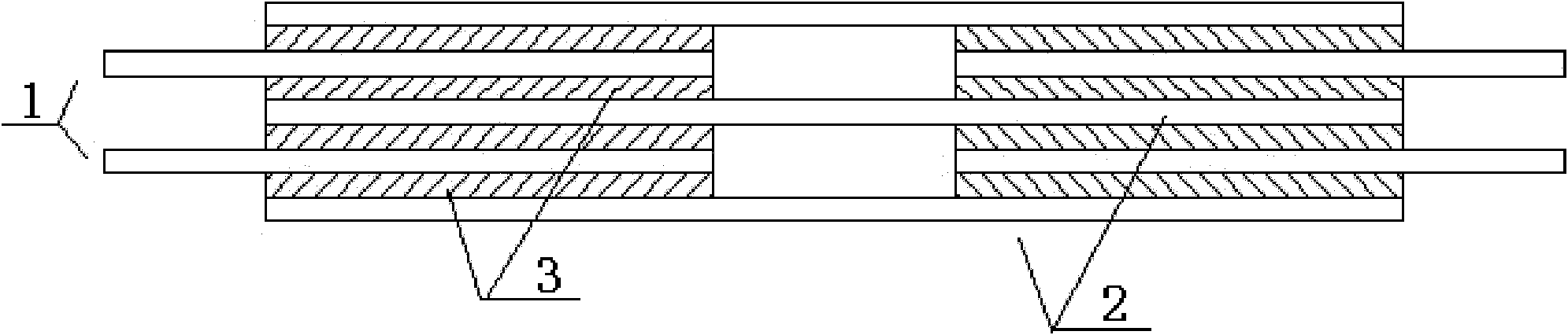

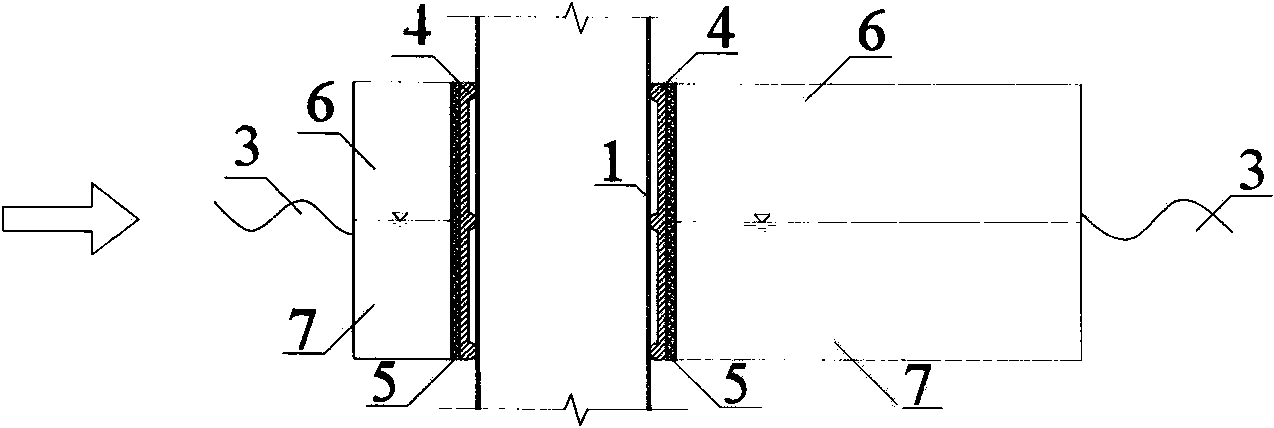

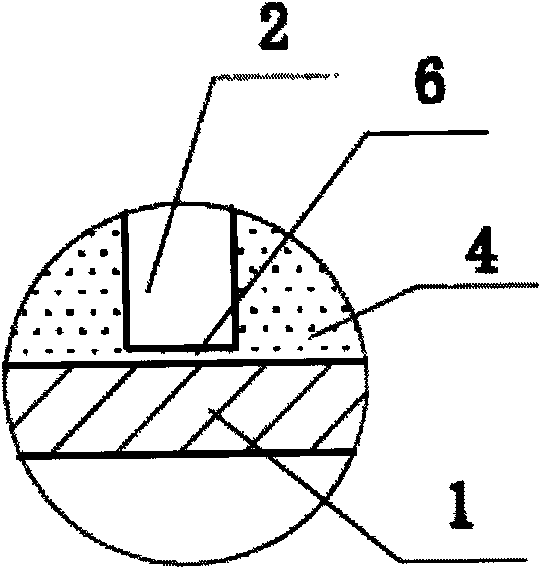

Steel rail vibration damping noise reduction method for self-absorption composite magnetic damping plate

The invention discloses a method for vibration absorption and noise reduction of steel rails by self-attraction type combined magnetic damping sheets, which comprises the following steps: a rail web and a rail foot of a steel rail (1) are symmetrically provided with the combined magnetic damping sheets (2); the outer layers of the combined magnetic damping sheets are symmetrically provided with constraint metal plates (3) which are fixed at both sides of the steel rail by a U-shaped magazine clip (4); the combined magnetic damping sheets have the magnetism and are attracted on the side surfaces of the steel rail; related interfaces inside the combined magnetic damping sheets and between the combined magnetic damping sheets and the steel rail as well as between the combined magnetic damping sheets and the constraint metal plates can cause vibration friction and slide relatively during the vibration of the steel rail; the mechanical energy of the vibration is converted into thermal energy to be dissipated to eliminate the vibration energy or the vibration amplitude of the steel rail; and the combined magnetic damping sheets and the steel rail are not adhered, so the viscoelastic damping mechanism is lost, which ensures that the range of the vibration frequency is wider, the temperature change has smaller influence, and good vibration absorption and noise reduction effects exist in a wider range of frequency domain and temperature domain. The method has convenient installation and replacement, and obvious vibration absorption and noise reduction effects, and can be widely used for vibration absorption and noise reduction engineering of track traffic.

Owner:洛阳双瑞橡塑科技有限公司

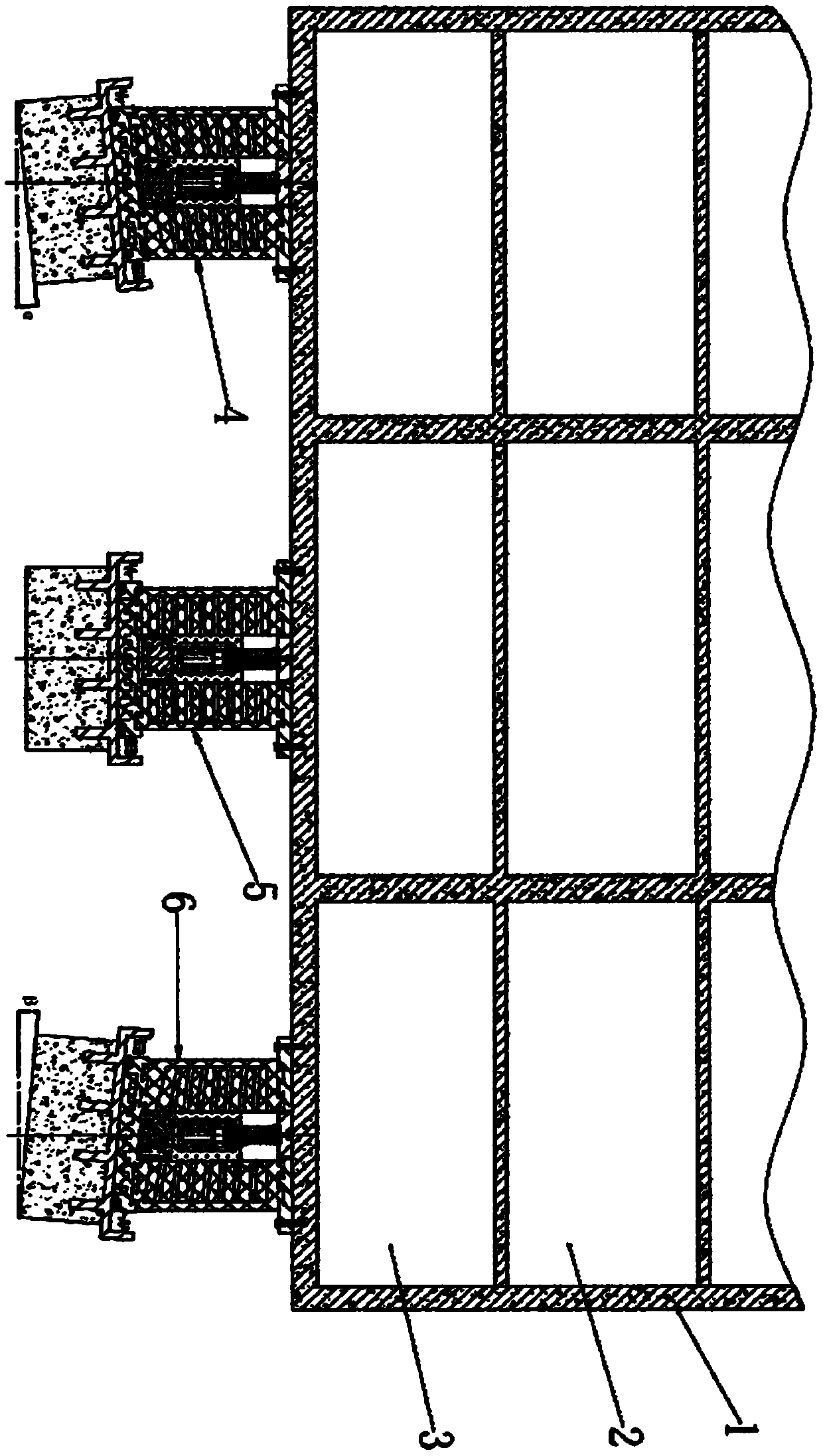

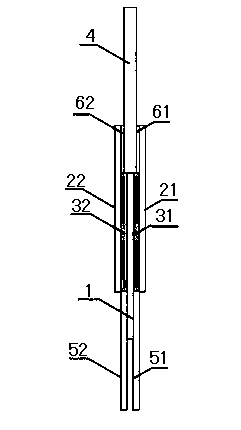

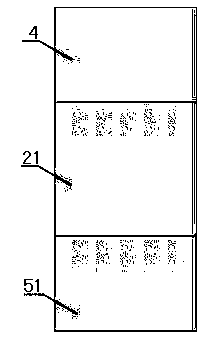

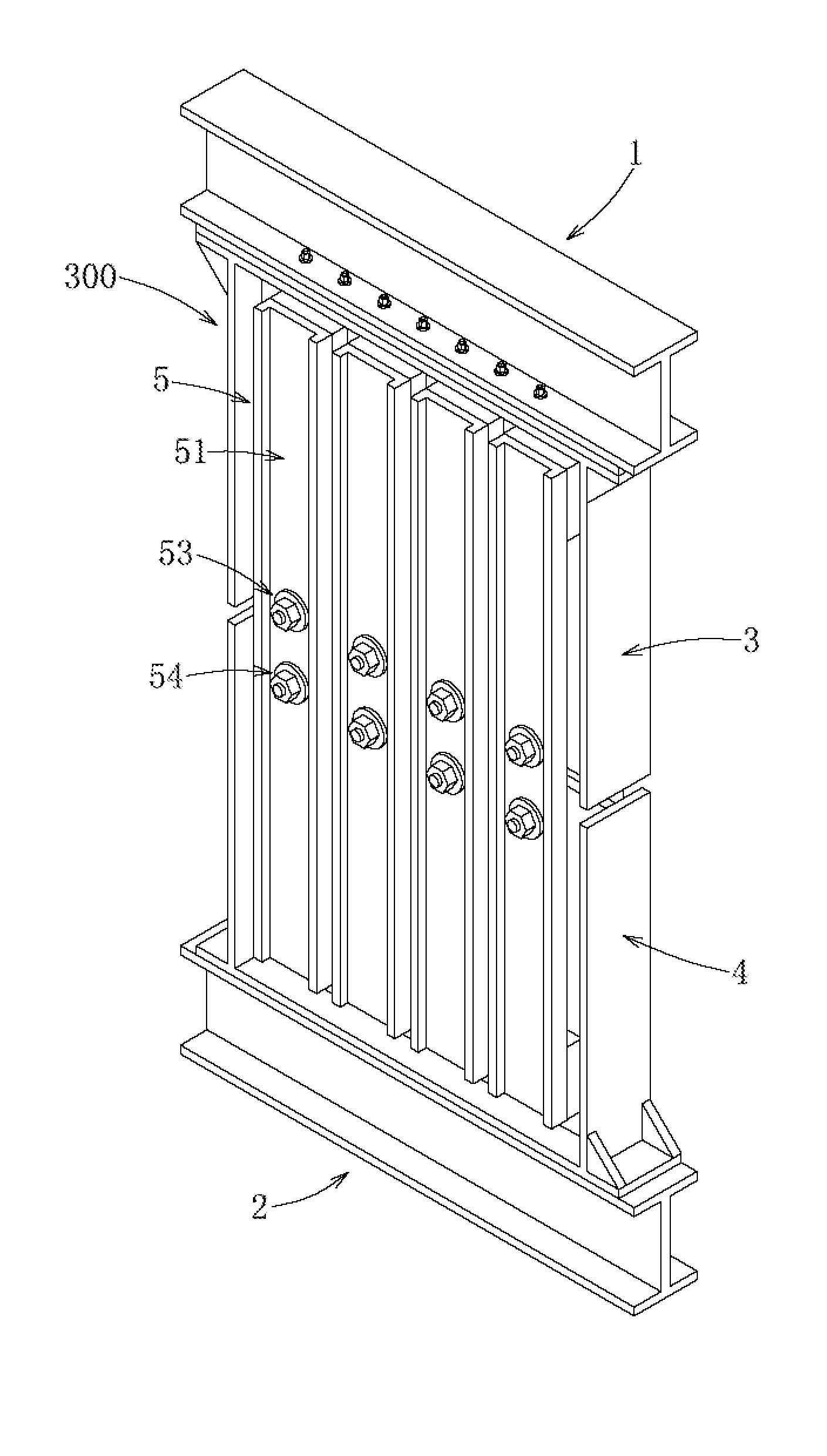

Assembly-type viscoelastic damping wall

InactiveCN103233531AThe mechanical model is simpleDynamic stabilityWallsShock proofingViscoelastic dampingBonding process

The invention relates to the field of energy dissipation and vibration damping control of architecture structures, particularly to an assembly-type viscoelastic damping wall. The damping wall includes a middle steel plate, viscous-elastic material layers, two outside steel plates, an upper portion wall connecting steel plate, backing boards and two lower portion wall connecting steel plates, wherein the middle steel plate, the viscous-elastic material layers and the two outside steel plates are bonded together, the viscous-elastic material layers are respectively arranged between the middle steel plate and the two outside steel plates, the viscous-elastic materials are high attenuation rubber series viscous-elastic materials, and the viscous-elastic material layers are respectively firmly and reliably bonded with the middle steel plate and the two outside steel plates by utilizing a rubber and steel plate bonding process. The two outside steel plates, the upper portion wall connecting steel plate and the backing boards are firmly connected together through high-strength bolts, and the middle steel plate and the two lower portion wall connecting steel plates are firmly connected together through high-strength bolts. The assembly-type viscoelastic damping wall is high in energy-dissipating capacity, can provide relatively more use space for the architecture structures, facilitates installation and maintenance and meets the requirements of the design and functionality of the architecture structures.

Owner:欧进萍

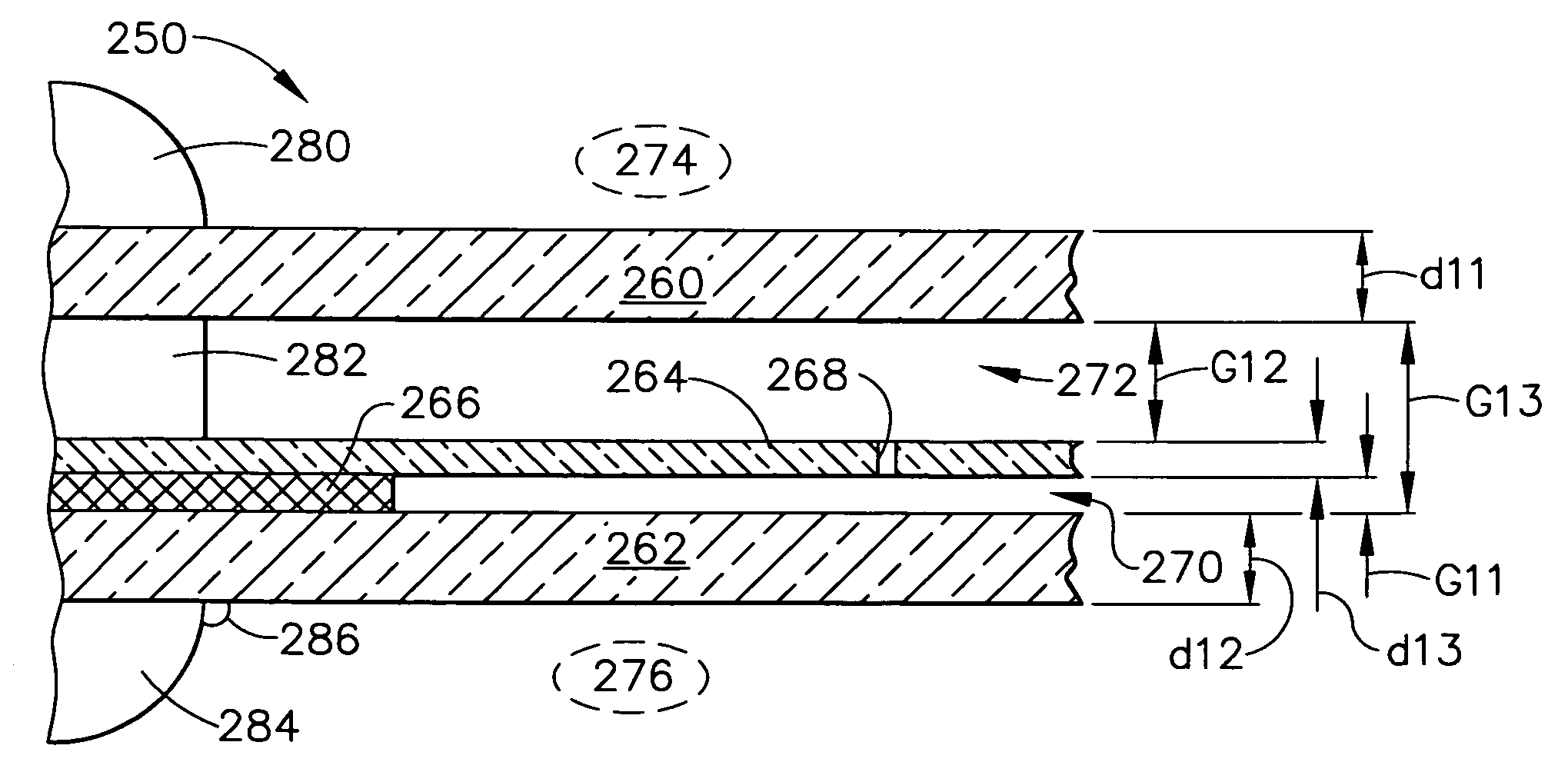

Vibration damping apparatus for windows using viscoelastic damping materials

ActiveUS7721844B1Reduce acoustic energy energyReduce vibrational energyVehicle seatsSpringsViscoelastic dampingEngineering

An improved vibration damping system is provided for use with window structures. The window damping system employs both air-film damping technology and viscoelastic damping materials to increase mechanical and / or acoustic vibration damping in window structures.

Owner:DAMPING TECH

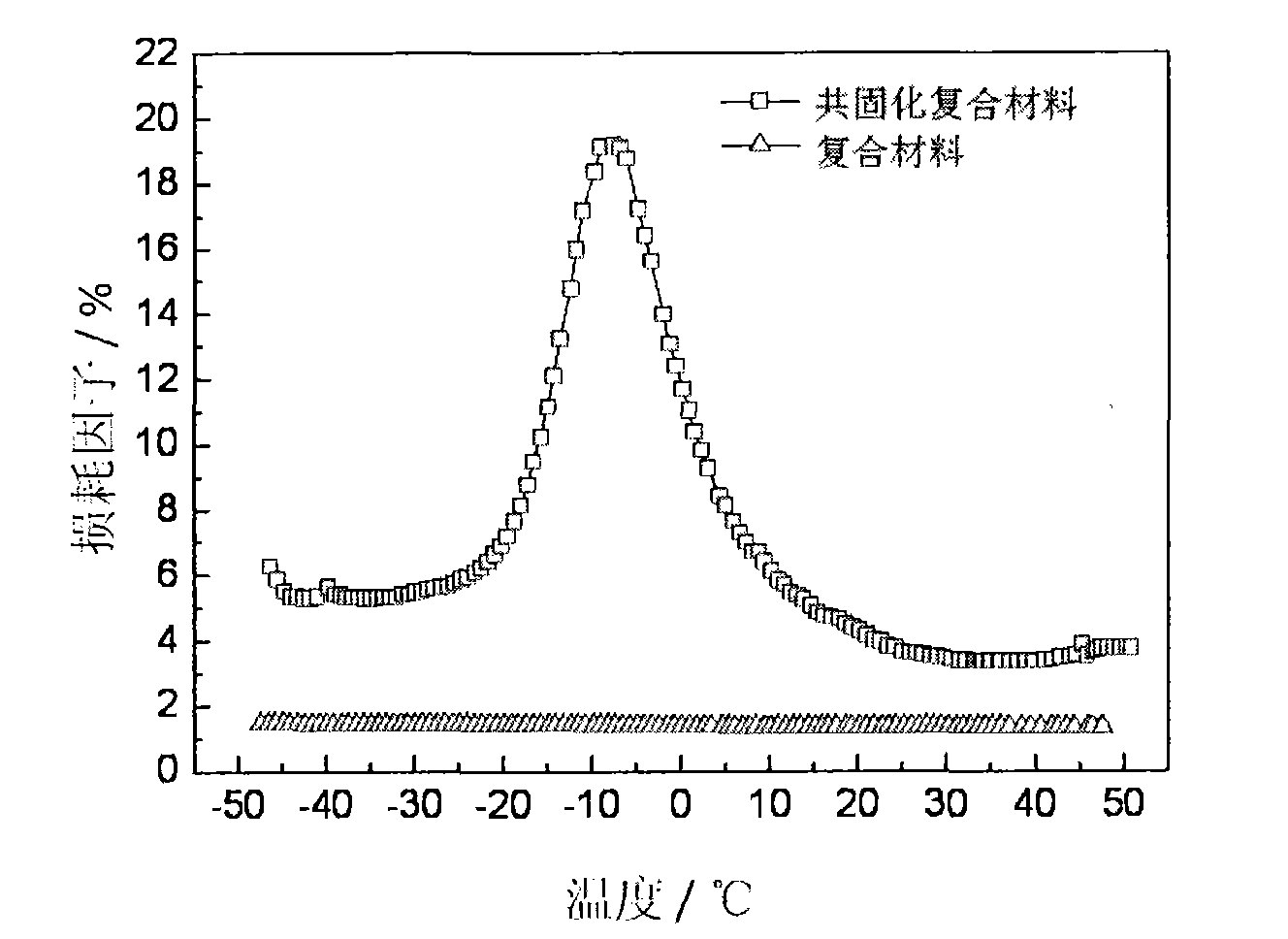

Preparation method of a co-cured high damping composite material

InactiveCN101786356AGuaranteed StrengthGuaranteed stiffnessLaminationLamination apparatusEpoxyViscoelastic damping

The invention provides a preparation method of a co-cured high damping composite material, which greatly improves the damping performance of a resin base composite materials under the condition that the strength and the rigidity are ensured. The method comprises the following steps: taking nitrile-butadiene rubber with the thickness of 0.3mm as a viscoelastic damping material, and T700 carbon fiber / 16 layers of epoxy resin as the prepreg of the composite material; laying the nitrile-butadiene rubber layer between the eighth layer and the ninth layer of the prepreg of the composite material; carrying out autoclave process on the nitrile-butadiene rubber layer and the prepreg of the composite material; setting the temperature and pressure according the curing condition of the epoxy resin; and co-curing to obtain the high damping composite material. The invention has the beneficial effects that the damping performance of the composite material is effectively improved under the condition that the strength and the rigidity of the composite material are ensured; the damping material is not easy to peel in the process of use; and the mechanical properties and the forming process of the resin base composite materials are not influenced.

Owner:张博明 +1

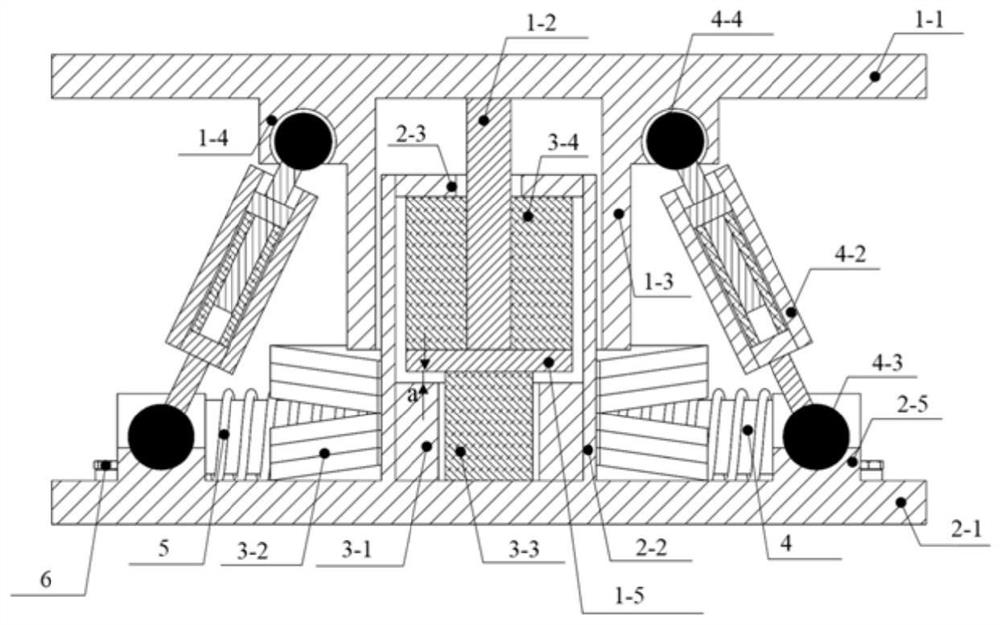

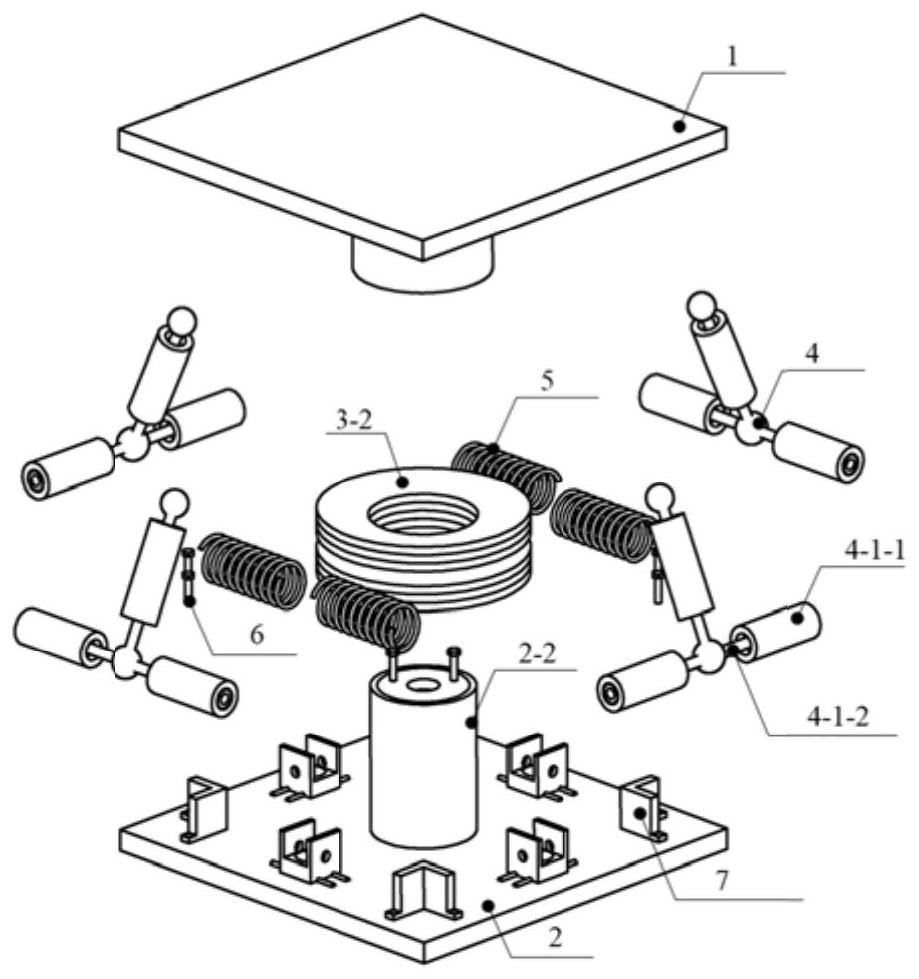

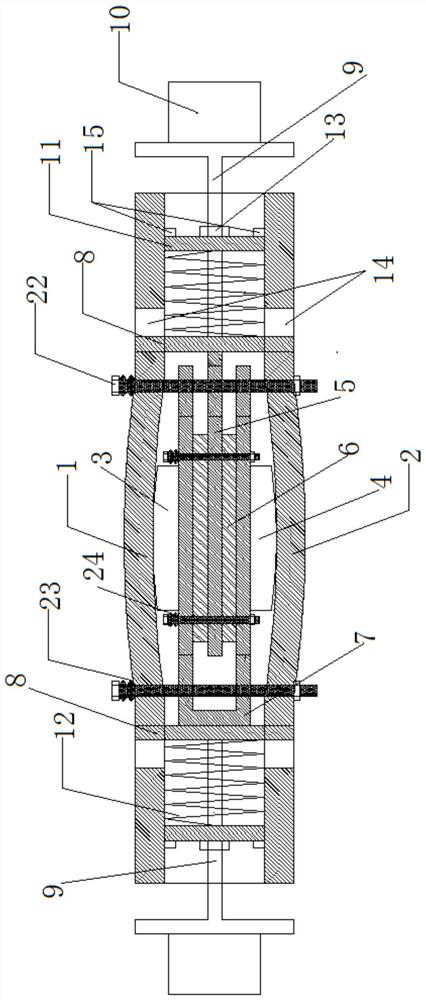

Infrastructure large-load multidirectional vibration isolation and reduction device and disaster prevention method thereof

ActiveCN112161018AOvercome the disadvantages of poor vibration damping performanceImprove work performanceNon-rotating vibration suppressionViscoelastic dampingVertical vibration

The invention relates to an infrastructure large-load multidirectional vibration isolation and reduction device and a disaster prevention method thereof. The device comprises an upper end cover, a base, a vertical vibration reduction part, horizontal vibration reduction parts and the like. Under the action of a vertical load, a pressing cylinder of the upper end cover of the device extrudes a belleville spring of the vertical vibration reduction part, a pressing shaft extrudes energy dissipation and vibration reduction blocks of the vertical vibration reduction part, and the belleville springand the energy dissipation and vibration reduction blocks isolate and consume vibration in the vertical direction together. The base is provided with a limiting table to ensure that the vertical displacement of a main structure is within an allowable range. Under the action of horizontal earthquakes, viscoelastic damping materials of the horizontal vibration reduction parts plays a role in energydissipation and damping through compressive deformation. Under the action of torsion or eccentricity, oblique force transmission units ensure that the device does not roll over or overturn through thespatial arrangement of the oblique force transmission units. The device has the advantages of being large in bearing capacity, high in damping and capable of achieving multi-direction vibration isolation and reduction, and good energy dissipation capacity is provided for the device through the use of the energy dissipation vibration reduction blocks.

Owner:SOUTHEAST UNIV

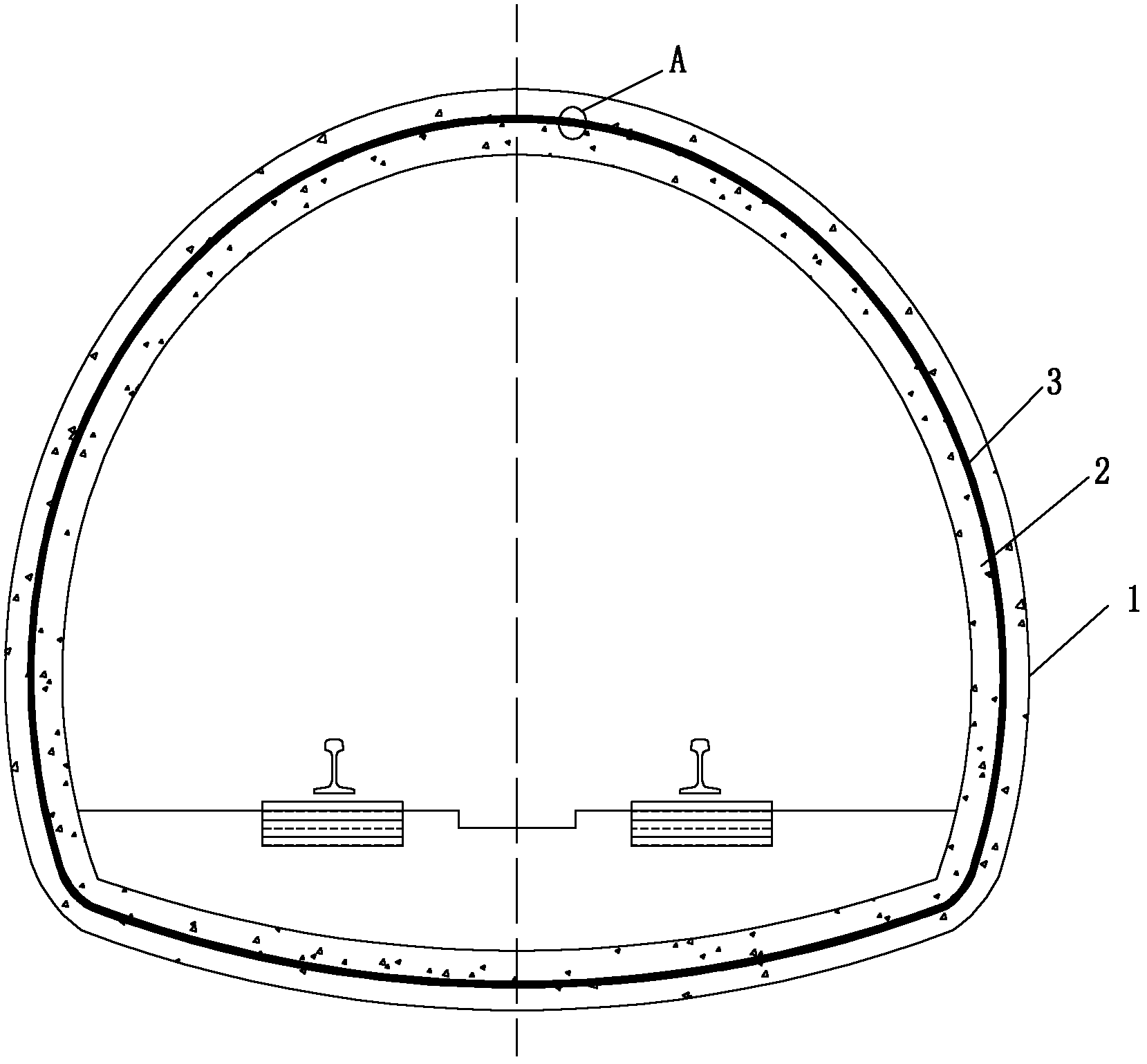

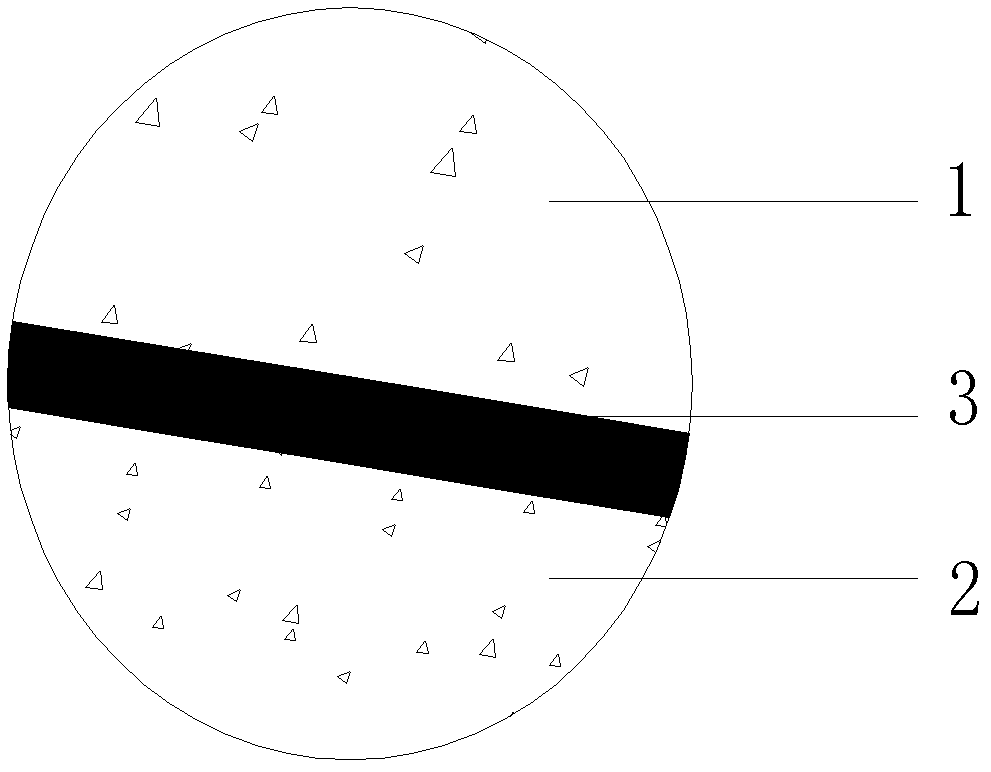

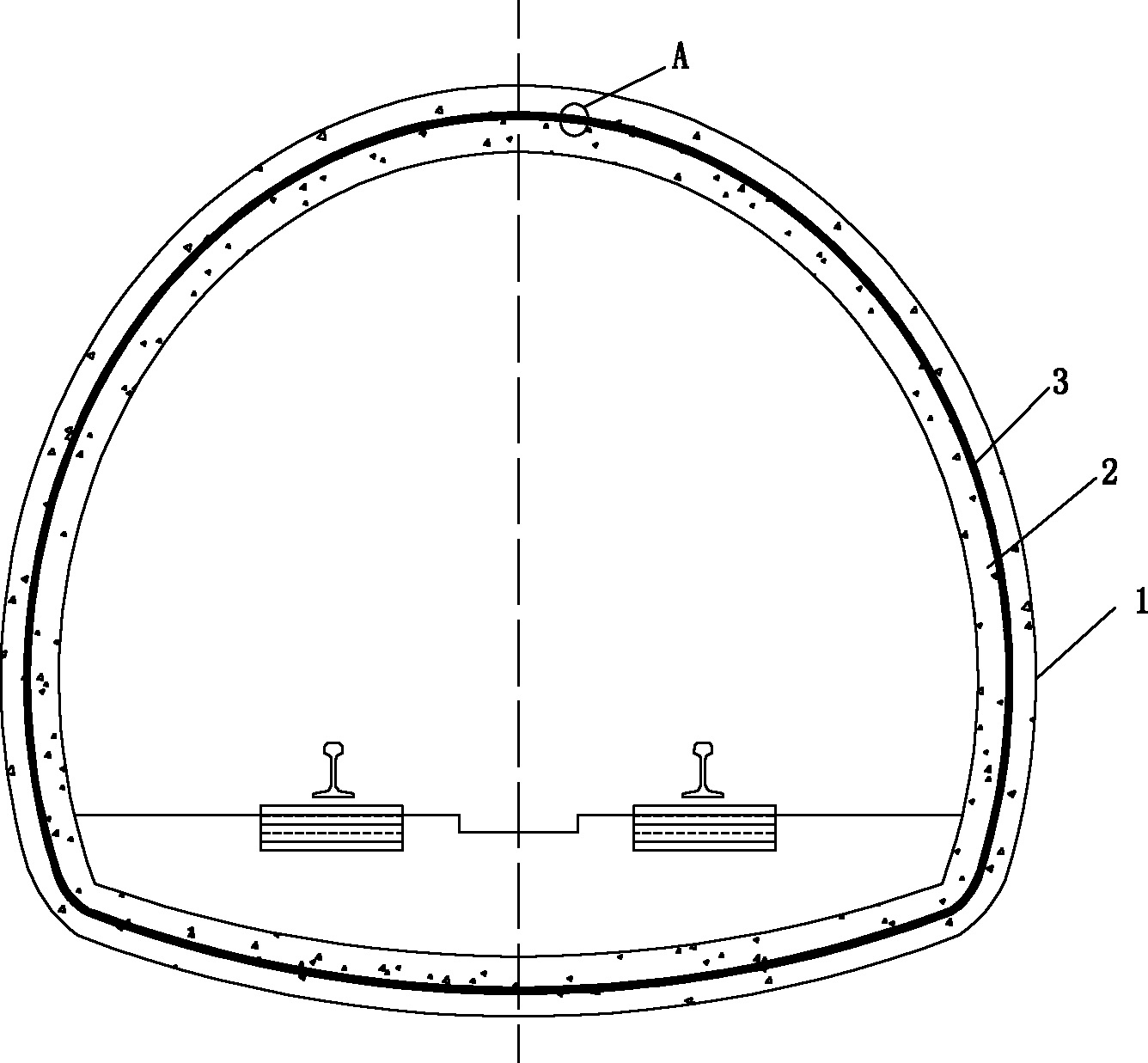

Vibration damping protection tunnel with constrained damping structure and construction method of tunnel

InactiveCN102678135AQuick and effective absorptionReduce adverse effectsUnderground chambersTunnel liningViscoelastic dampingRailway tunnel

The invention relates to an underground railway tunnel structure and specifically relates to a vibration damping and noise reduction protection tunnel spraying a damping constrained structure and a construction method thereof.. The vibration damping protection tunnel with the constrained damping structure, disclosed by the invention, comprises a tunnel preliminary supporting concrete layer, wherein a viscoelastic damping layer is laid on the tunnel preliminary supporting concrete layer, and a secondary lining concrete layer is arranged on the surface of the viscoelastic damping layer. In the vibration damping protection tunnel disclosed by the invention, the vibration damping and protection structure integrates multiple functions and takes damping, vibration damping and noise reduction functions as main functions; and simultaneously, a waterproof function, an anti-corrosion function, an insulation function and other functions are further provided, waterproofness and leakage problems of the tunnel are solved, the durability of a whole underground structure is improved, stray current in a subway is isolated and the safety of traffic and staff can be ensured.

Owner:青岛市地下铁道公司 +1

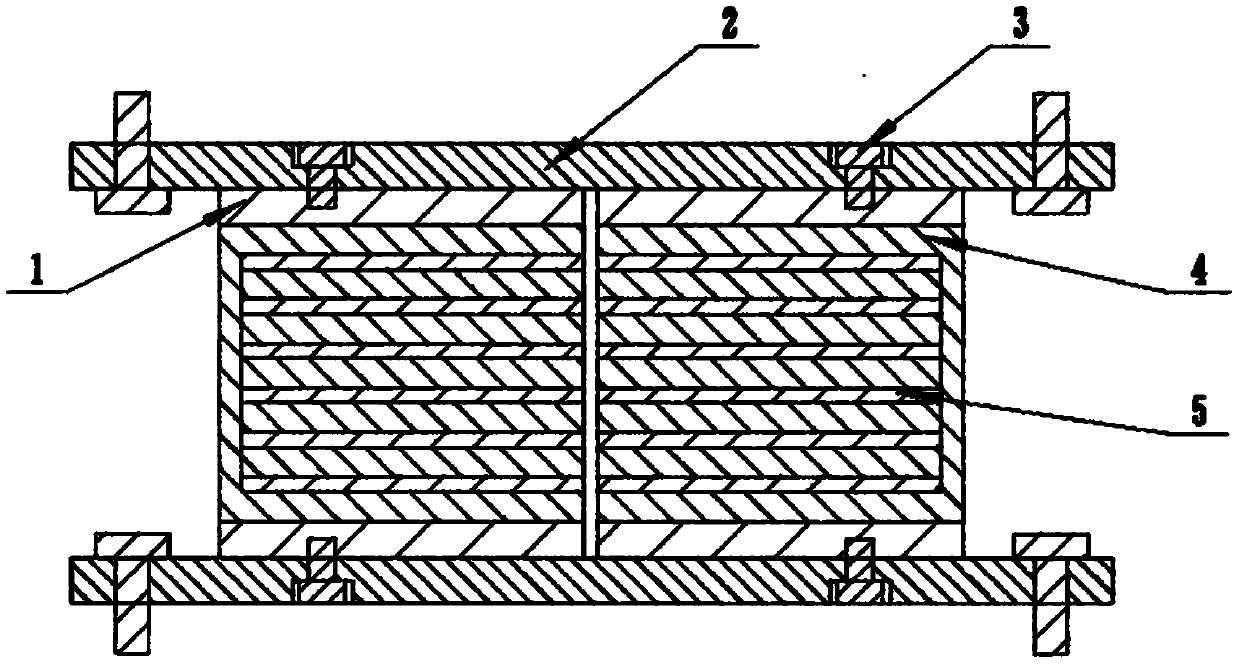

Large-deformation large-tonnage composite viscoelasticity damper

InactiveCN101100879AImproved performance characteristicsGood damping propertiesBridge structural detailsShock proofingViscoelastic dampingSnubber

An anti-knock device of large distortion and heavy load visco-elasticity damper is composed by a large distortion visco-elasticity damper and lead compacting damper. The large distortion visco-elasticity damper is put in the middle and surrounded by several lead compacting dampers with the top and bottom linked to the armor plate to from an integrated damper.

Owner:SOUTHEAST UNIV

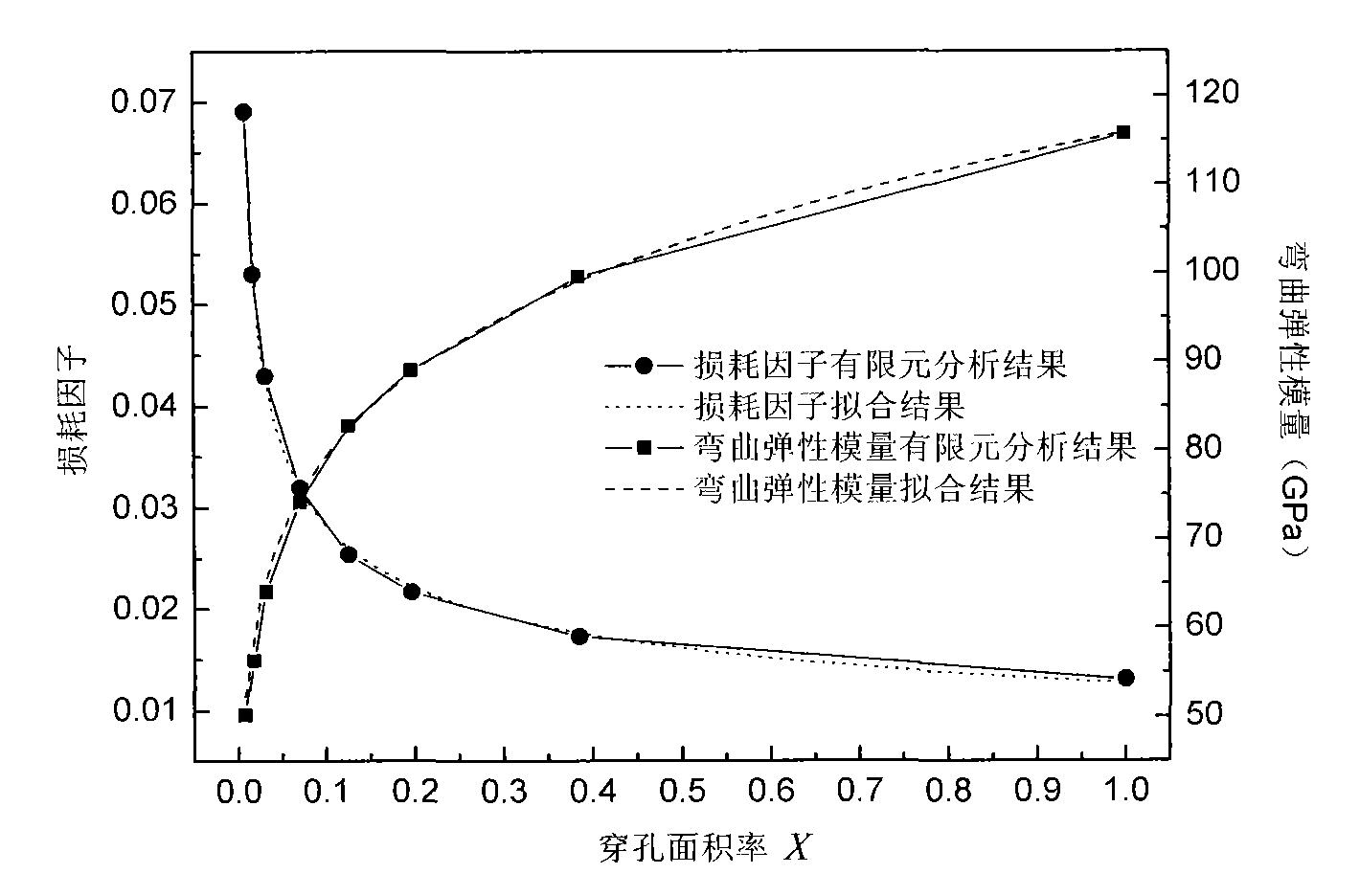

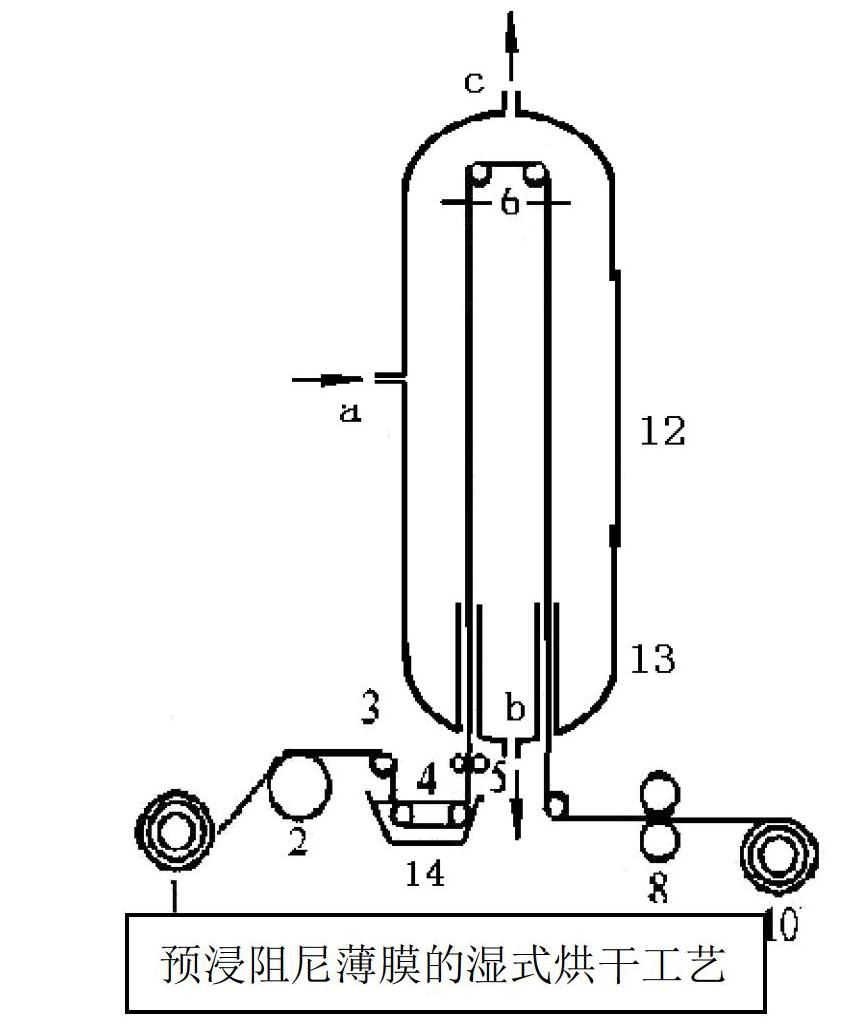

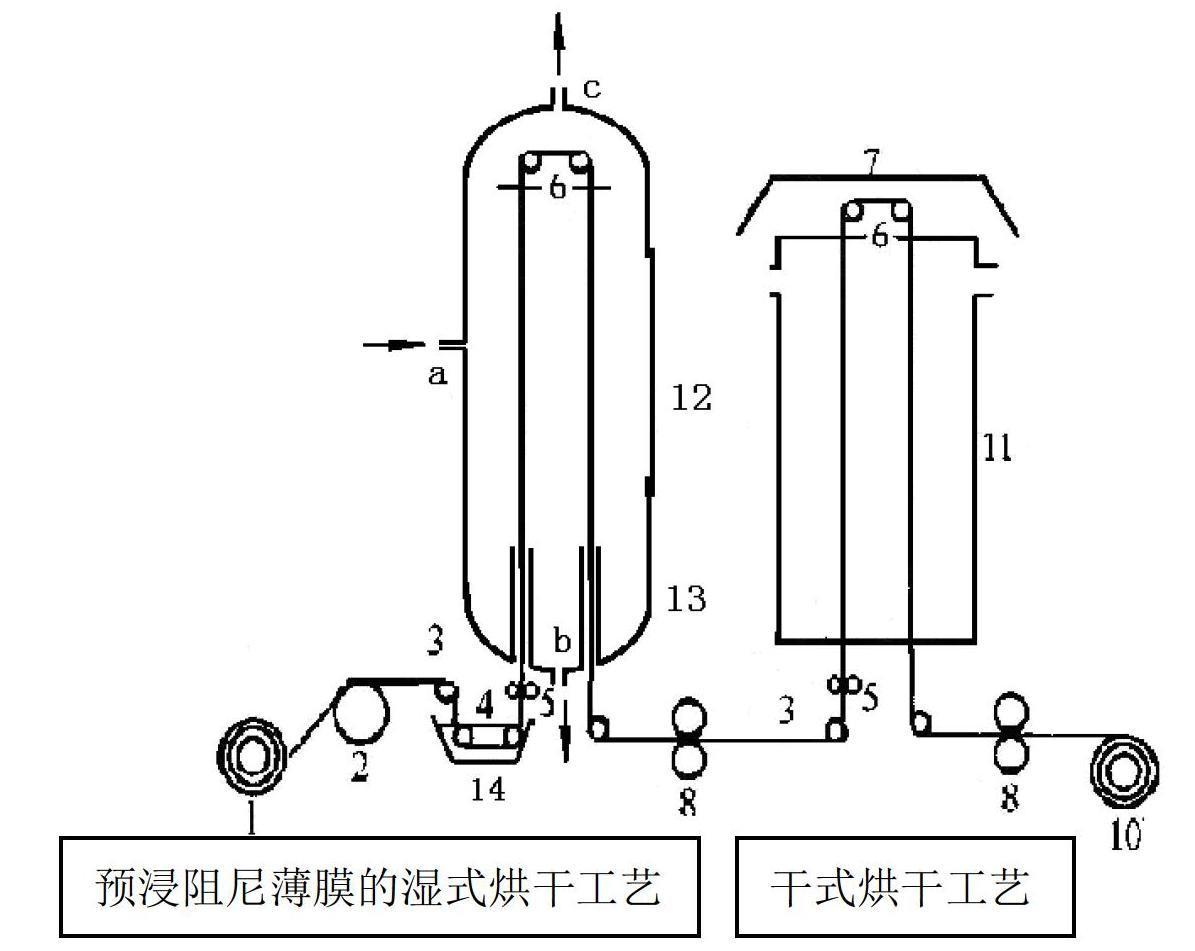

Manufacturing process of composite material laying tape of embedded co-curing continuous presoaking damping film

The invention discloses a manufacturing process of a composite material laying tape of an embedded co-curing continuous presoaking damping film. The manufacturing process comprises the following steps: 1) preparing raw materials; 2) preparing gross rubber; 3) preparing viscoelastic damping material solution; 4) conducting presoaking process of at least once for a presoaking material of a composite material by utilizing a viscoelastic damping material prepared in the step 3) to produce the presoaking material of the composite material with a damping film; meanwhile, utilizing a wet-type drying process or a process combining wet-type drying with dry-type drying for change No.120 gasoline into gaseous gasoline, cooling the mixture of the gaseous gasoline and steam through a heat exchanger, and then sending the cooled oil-water mixture into an oil-water separator to separate and recycle the No.120 gasoline; and 5) embedding the presoaking material of the composite material with the damping film manufactured in the step 4) into a composite material structure as a specific laying layer, placing the mixture into a vacuum bag of a hot pressing tank together, and highly vacuumizing so as to complete the preparation of an embedded co-curing composite material damping structure workpiece by using a co-curing process.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Lever viscoelastic damping wall assembly

A lever viscoelastic damping wall assembly includes a first wall, a second wall and a viscoelastic damper. The first and second walls are connected respectively to a first structural member and a second structural member. The viscoelastic damper includes a swing rod connected pivotally to the first and second walls, a first viscoelastic unit connected between the first wall and an end portion of the swing rod, and a second viscoelastic unit connected between the second wall and an opposite end portion of the swing rod. The swing rod is driven to pivot relative to the first and second walls, and to thereby generate shear deformations of the first and second viscoelastic units to damp a relative movement between the first and second structural members.

Owner:NAT APPLIED RES LAB

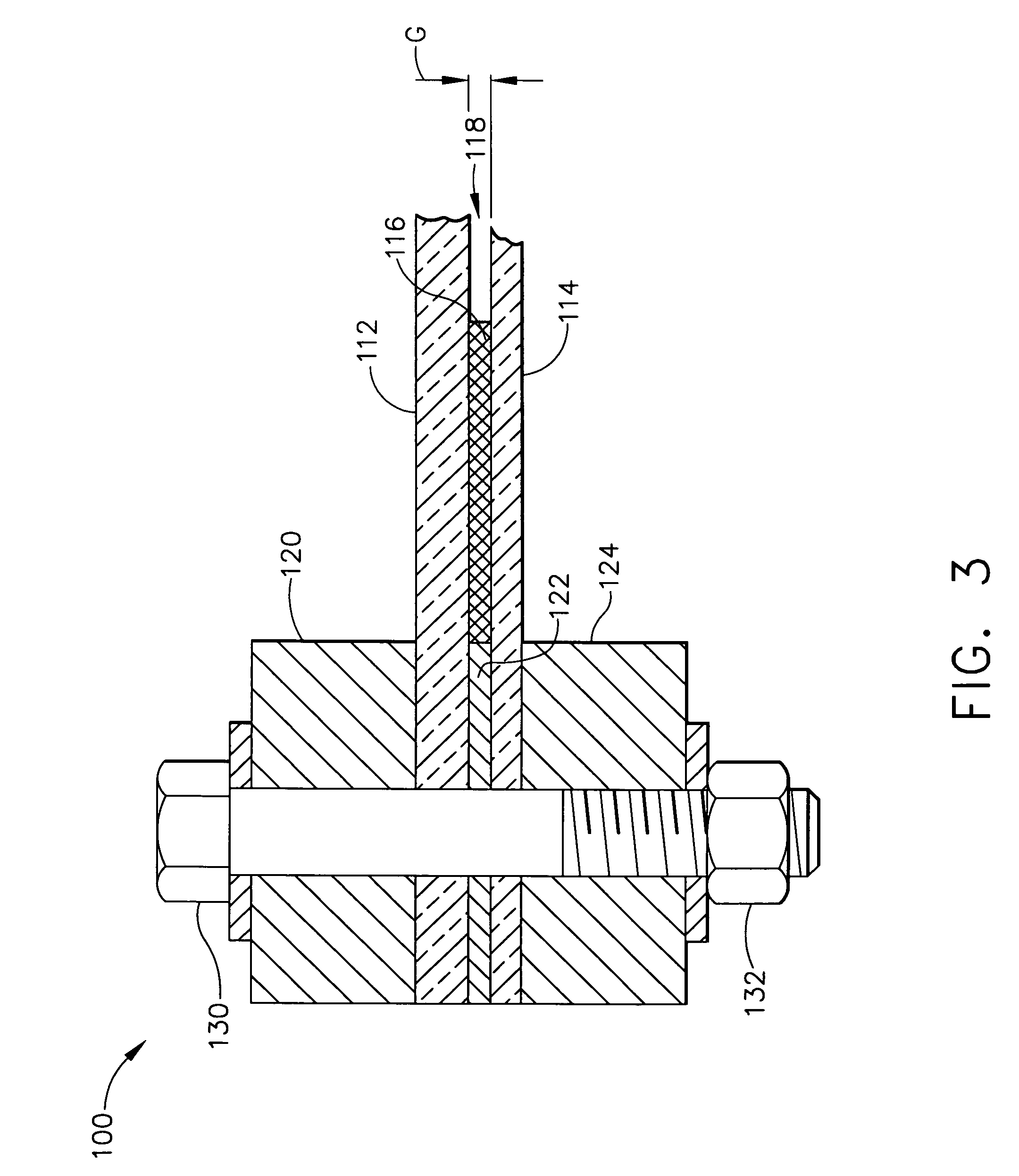

Visco Elastic Damping In A Piping System

InactiveUS20080036200A1Reduce vibrationSimple structurePipe supportsSpringsViscoelastic dampingTemperature control

A piping system for visco elastic damping, which system oscillates with high frequency, small amplitude oscillations. The system includes one or more autonomous visco elastic dampers that includes one or more layers of visco elastic damping material fixedly bonded between stiff members. The visco elastic dampers may be provided with a temperature controlling element.

Owner:INGEMANSSON TECH +1

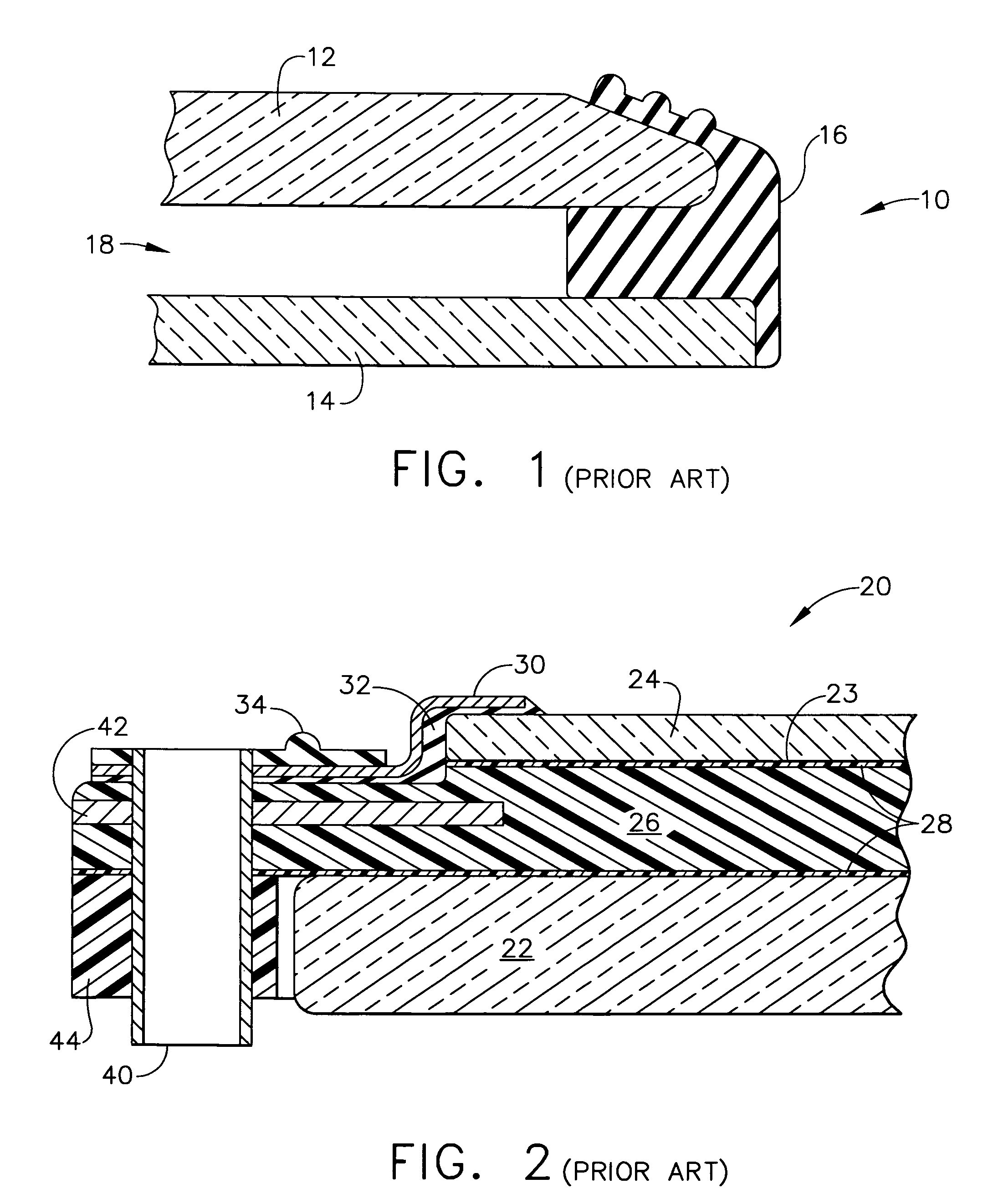

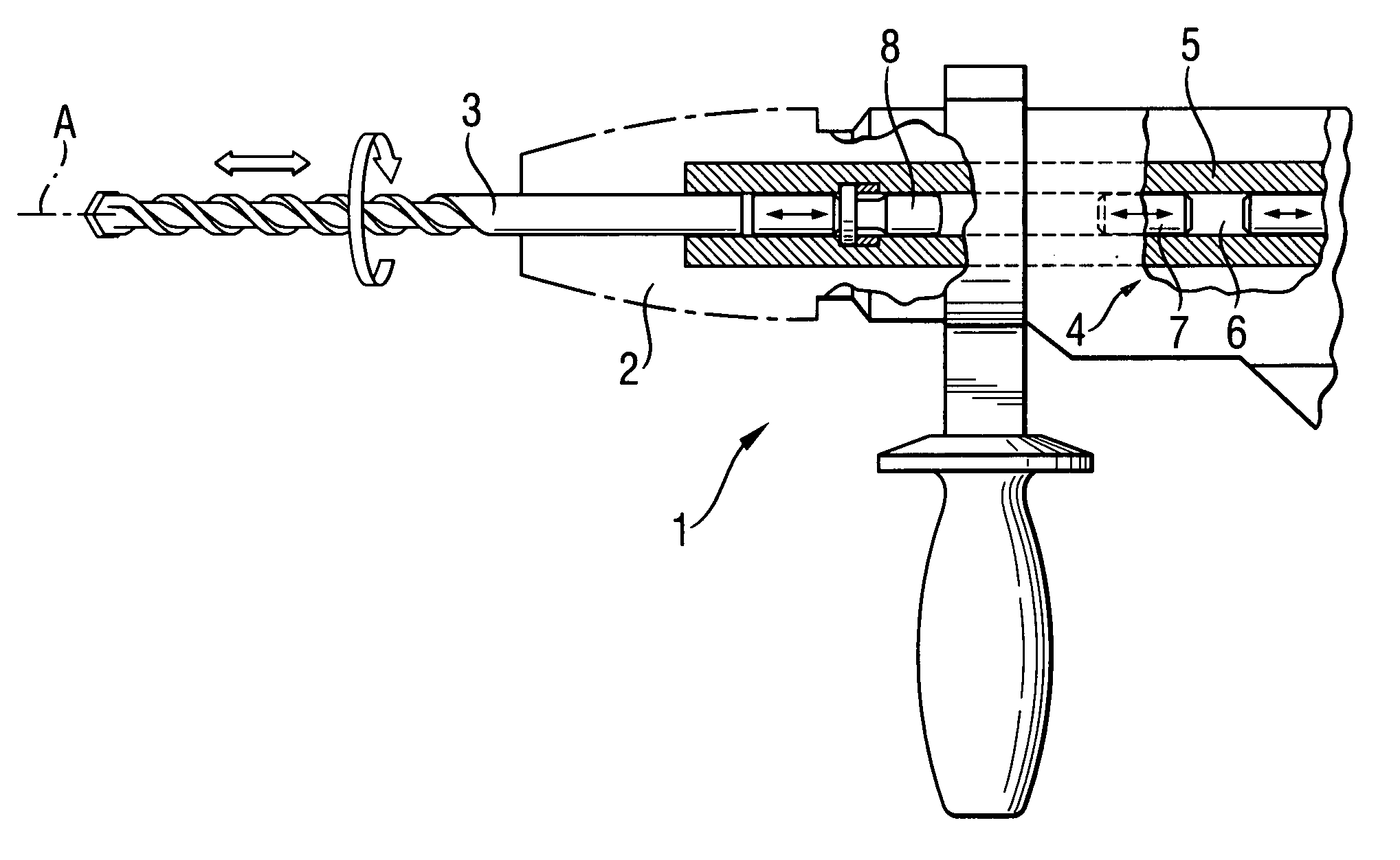

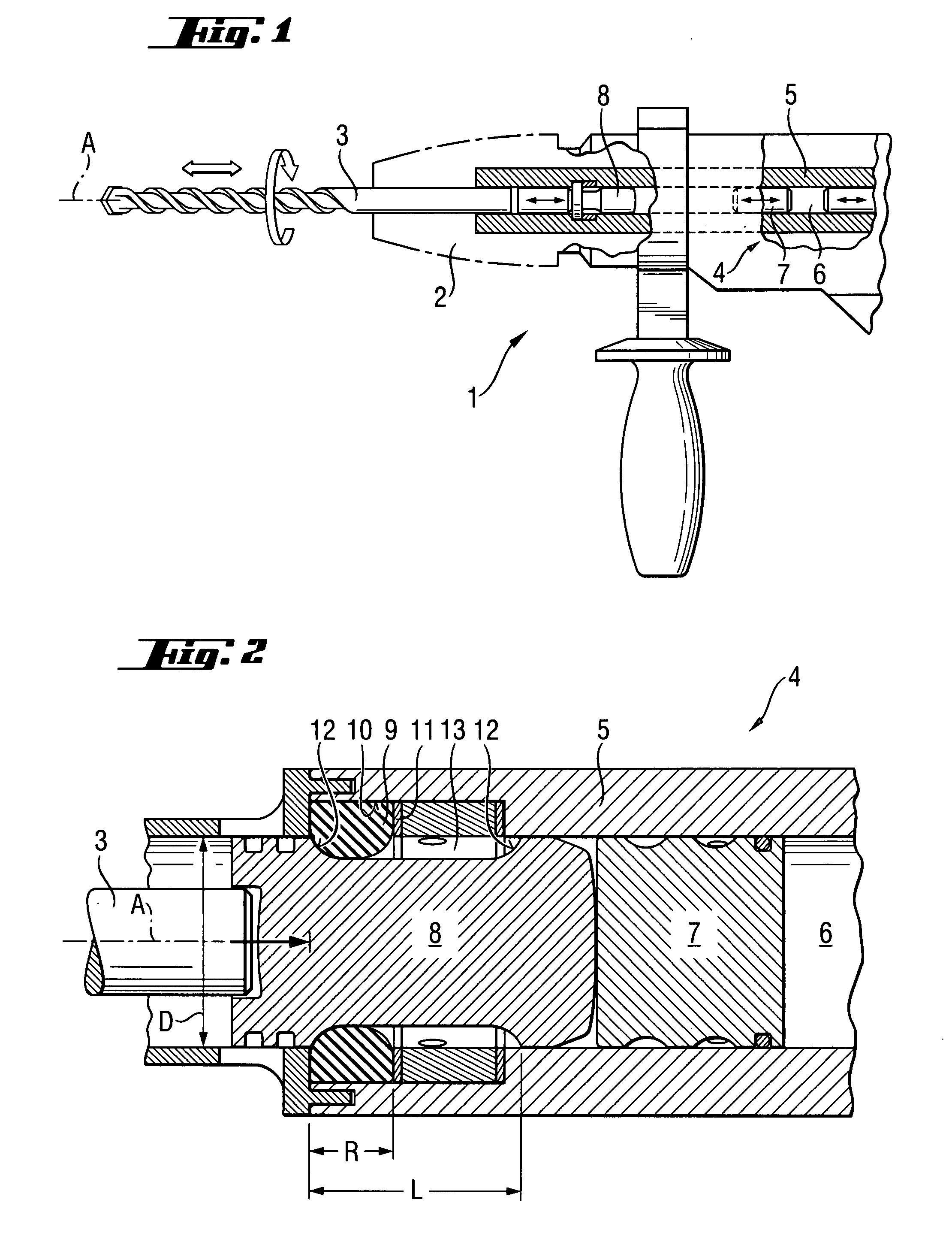

Hand-held power tool with pneumatic percussion mechanism

InactiveUS20080029283A1Dissipating its motion energyAdequate dampingReciprocating drilling machinesConstructionsViscoelastic dampingAir spring

A hand-held power tool for percussively driving a working tool (3) includes a percussion mechanism (4) having a guide tube (5), in which a percussion piston (7) which is driven by an air spring (6), is axially displaceable for applying axial impacts to an anvil (8) that applies axial blows to the working tool (3), and a viscoelastic damping member (9) arranged in the guide tube (5) and engaging in a circumferential radial groove (13) of the anvil (8) and which is axially limited at opposite sides thereof.

Owner:HILTI AG

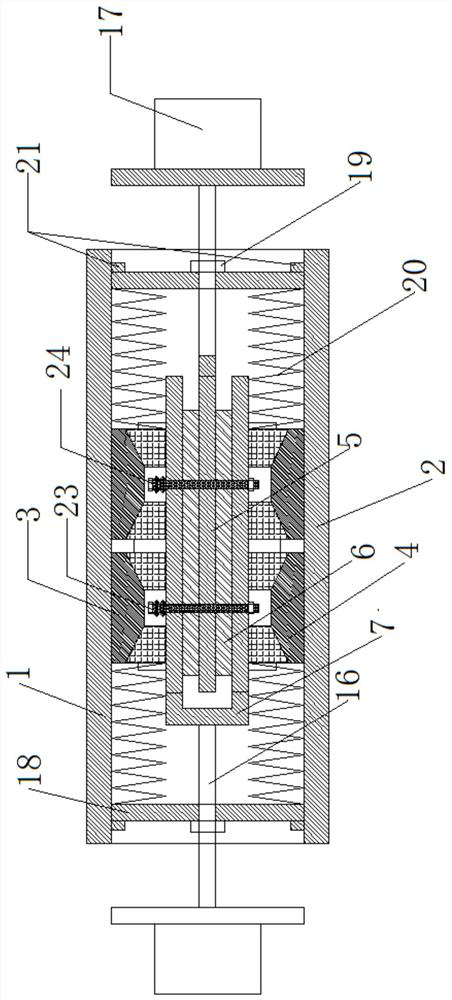

Self-resetting variable-damping variable-rigidity viscoelasticity and friction composite damper

ActiveCN112922182AImprove energy consumptionRealize the function of energy dissipation and shock absorption protectionProtective buildings/sheltersShock proofingViscoelastic dampingEarthquake resistance

The invention belongs to the field of earthquake resistance and shock absorption of buildings, particularly relates to a self-resetting variable-damping variable-rigidity viscoelasticity and friction composite damper, and is suitable for the field of building new construction, reinforcement and repair. The damper comprises a first friction base plate and a second friction base plate which are oppositely and fixedly arranged and a viscoelastic damper arranged between the first friction base plate and the second friction base plate in the length direction; a first friction plate and a second friction plate are arranged on the two corresponding sides of the fixed end of the viscoelastic damper respectively; and the first friction plate and the second friction plate are correspondingly connected with the first friction base plate and the second friction base plate in a pressed mode. According to the self-resetting variable-damping variable-rigidity viscoelasticity and friction composite damper, an internal viscoelastic damper unit can perform energy dissipation and shock absorption on high-frequency-band and small-displacement seismic oscillation, and an external self-resetting variable-friction damper unit can perform energy dissipation and shock absorption on low-frequency-band and large-displacement seismic oscillation, so that the energy dissipation and shock absorption capacity of a single damper is improved, and the performance defect of a single energy dissipation mode can be overcome.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

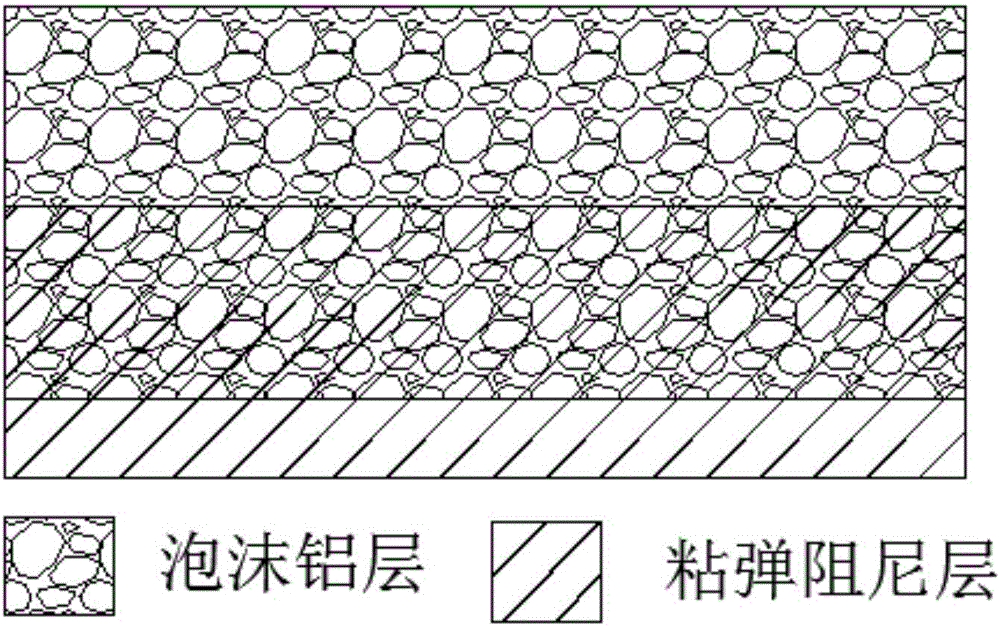

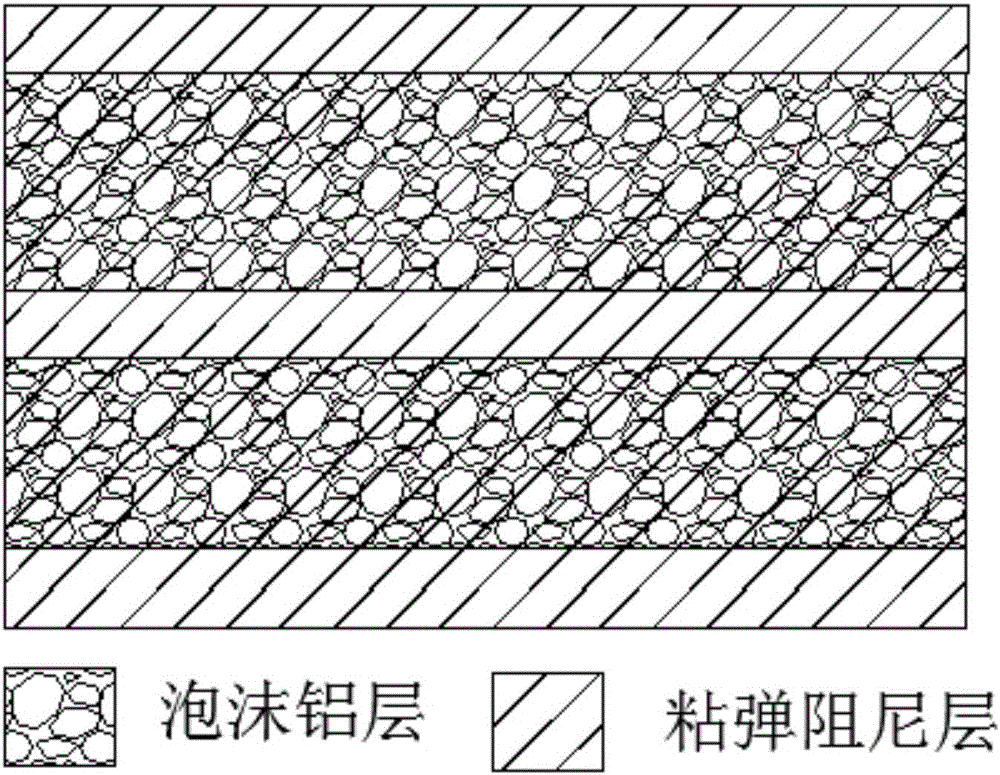

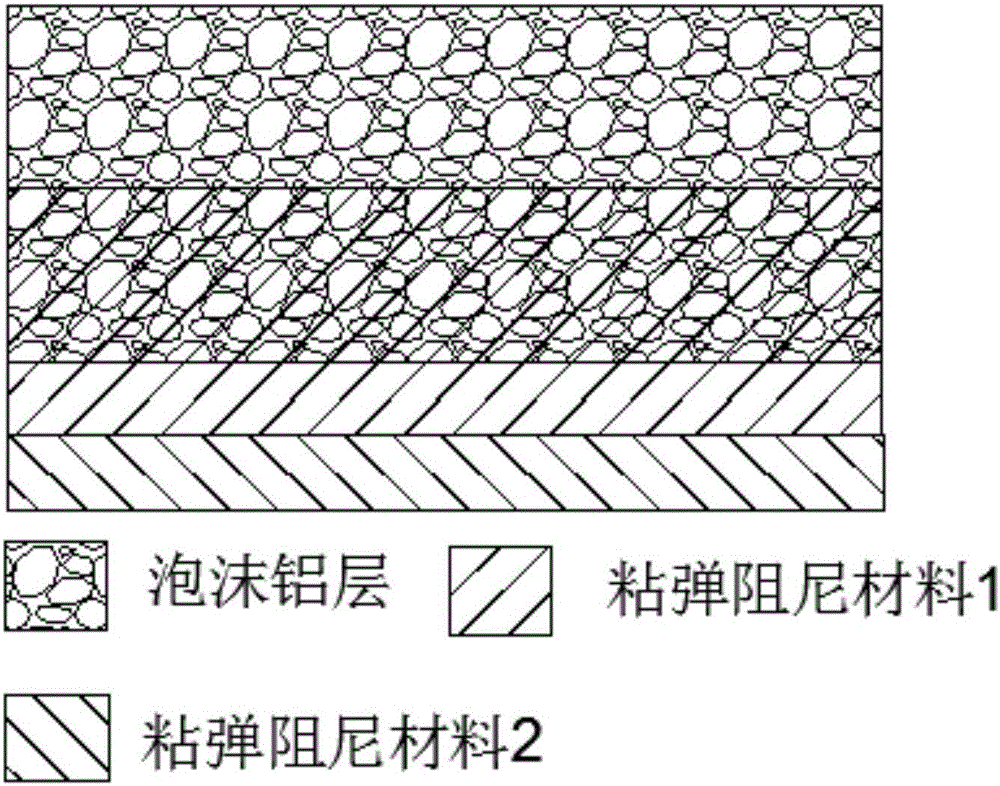

Foamed aluminum and viscoelastic damping composite material and preparation method

Owner:哈尔滨工程大学船舶装备科技有限公司 +1

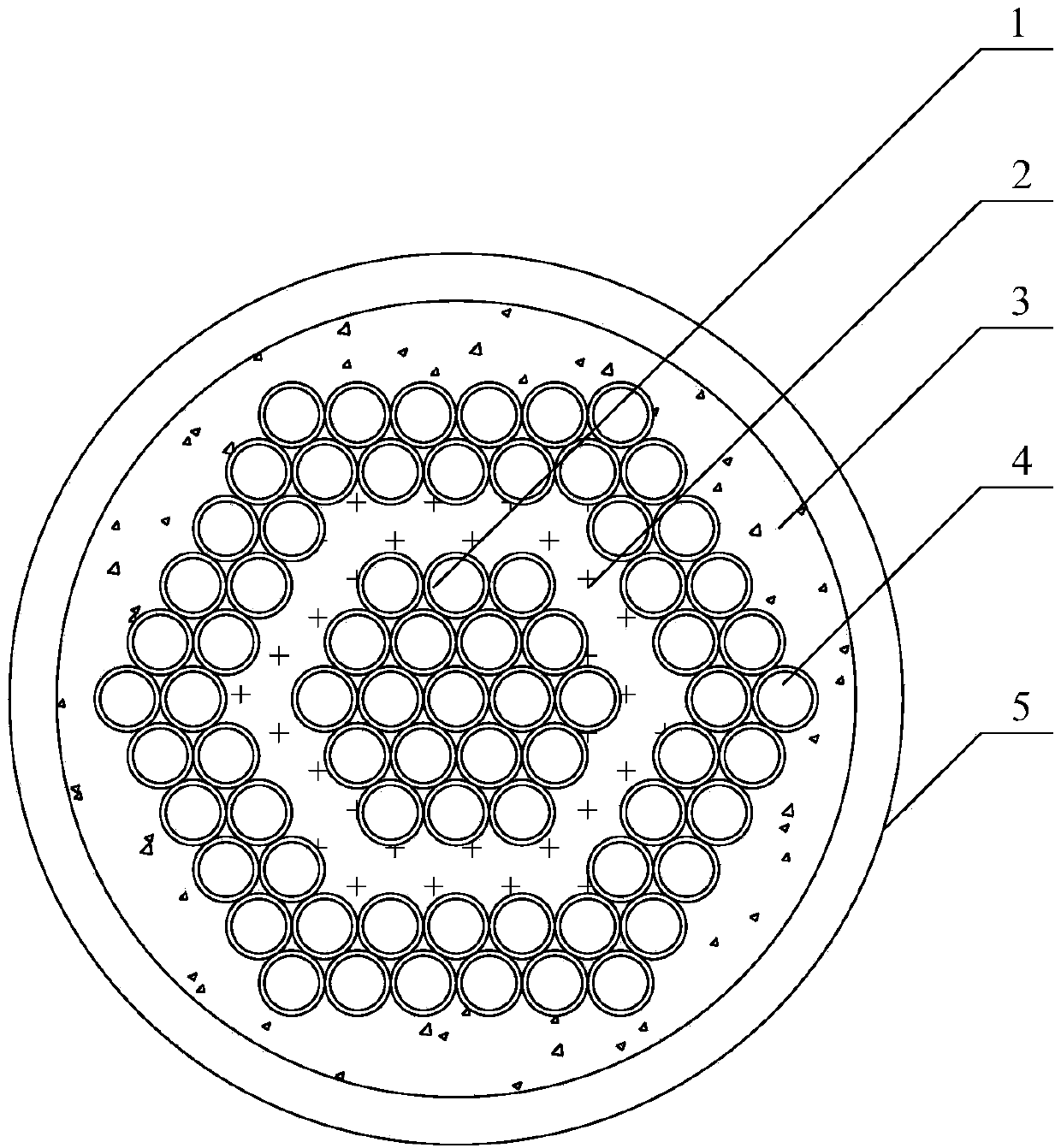

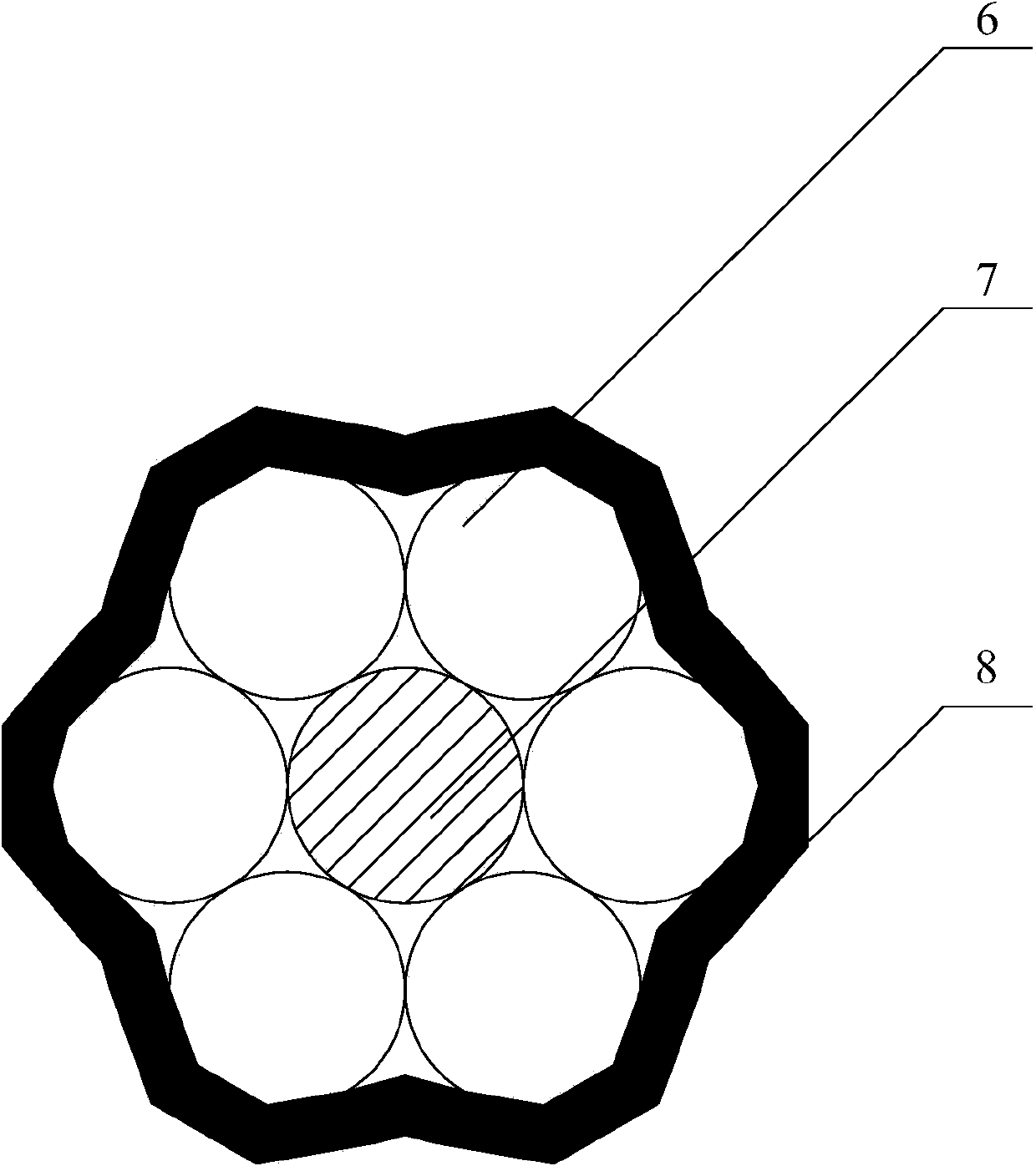

High-damping composite stay cable based on carbon fibers and steel strands

ActiveCN104213507ARaise the log reduction rateAccelerate the attenuation of vibrationCable-stayed bridgeBridge structural detailsFiberVibration attenuation

The invention discloses a high-damping composite stay cable based on carbon fibers and steel strands, and relates to the field of stay cables. The high-damping combined stay cable comprises a core layer, 2-4 composite layers and 1-2 layers of sheaths which are arranged in sequence from inside to outside, wherein a sticky elastic damping material is filled between the core layer and each composite layer; the core layer consists of a plurality of high-intensity steel strands which are tightly arrayed; the composite layers consist of a plurality of composite fibers which are tightly arrayed; the adjacent composite layers are tightly attached; the composite fibers are prepared from a high-intensity steel wire and six carbon fibers; the six carbon fibers wrap the periphery of the high-intensity steel wire and are twisted to form a whole. Vibration attenuation of the stay cable can be accelerated, and the wind-resistant stability of an ultralong stay cable is effectively improved; the weight of the stay cable is reduced, and the transverse shear strength of the stay cable is guaranteed; furthermore, single-cable transportation and cable hanging can be realized, and the ultralong stay cable construction difficulty is reduced.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

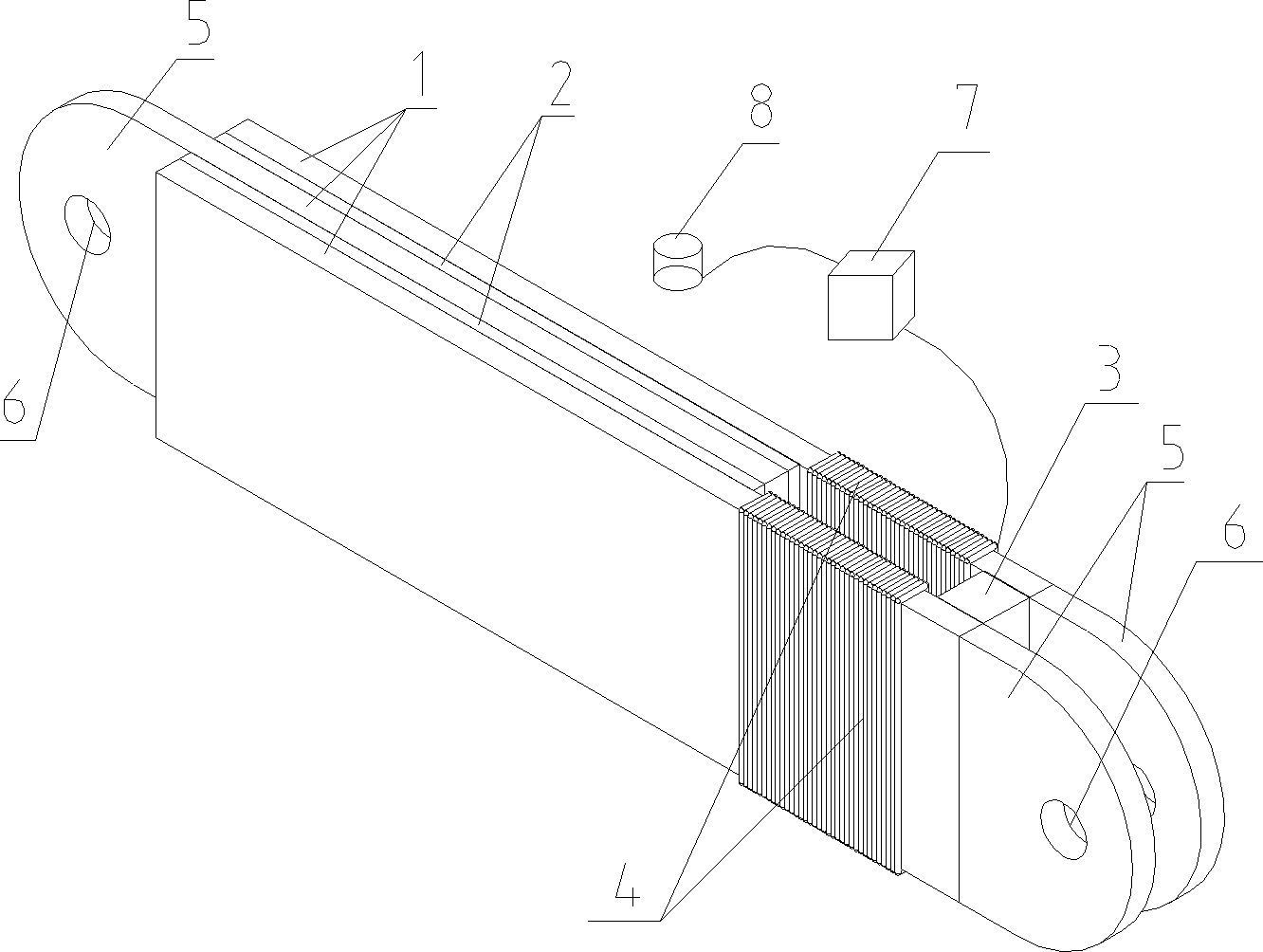

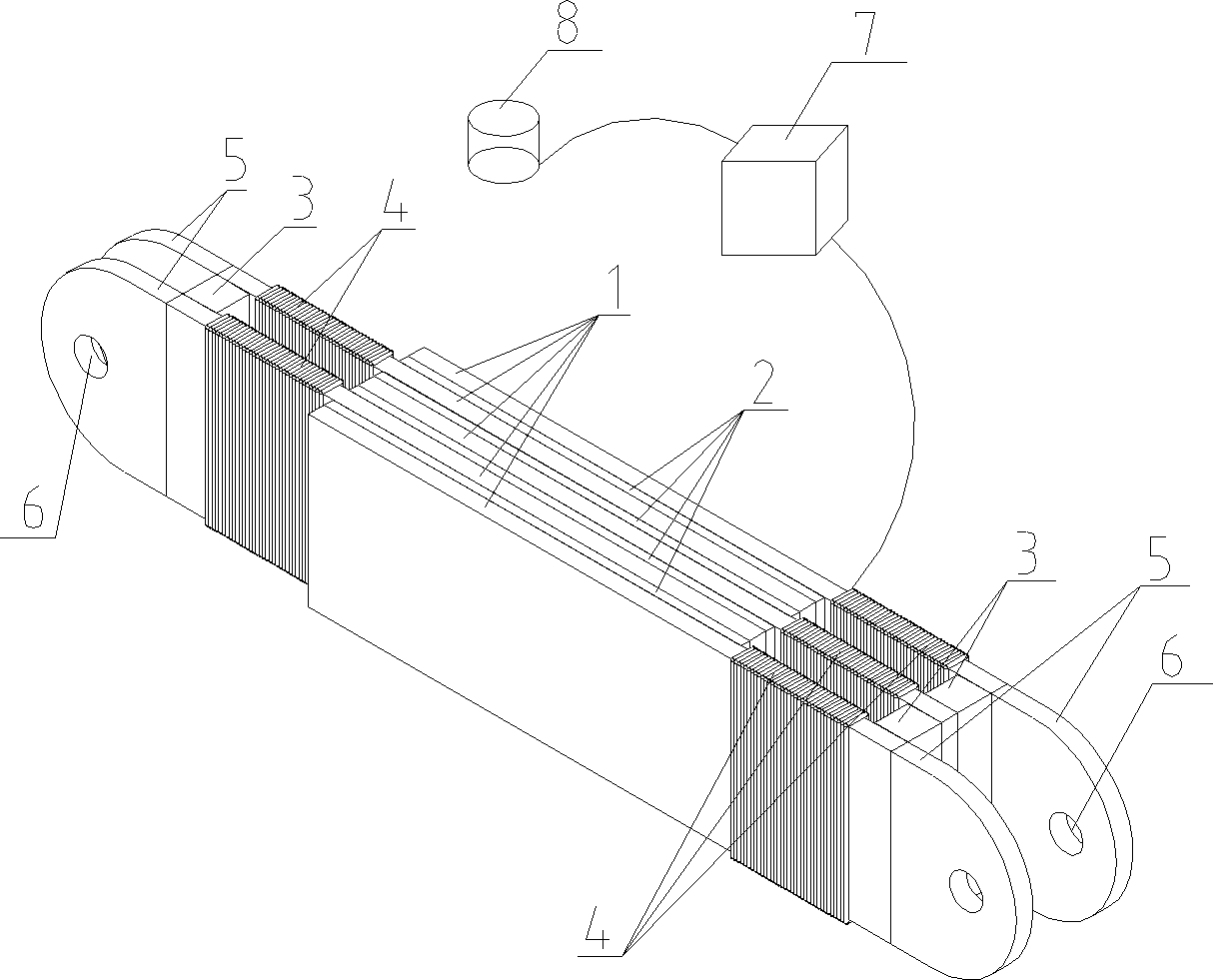

Viscoelastic damper with intelligent controllable damping force

ActiveCN102287475AChange the size of the damping forceChange storage modulusNon-rotating vibration suppressionVolumetric Mass DensityConductor Coil

The invention relates to a viscoelastic damper capable of intelligently controlling damping force and discloses a viscoelastic damper capable of adaptively adjusting shearing rigidity and damping. The damper mainly comprises a magnetic component, a controller (7) and a sensor (8), wherein the magnetic component forms a complete closed magnetic circuit, provides magnetic energy input through a coil and changes magnetic flux density in the magnetic circuit by changing current in the coil; and the controller (7) is connected with the sensor (8) and a coil winding (4) of the magnetic component through a data line respectively. A temperature softening effect of the common viscoelastic material is made up by utilizing a rheological effect of a magnetized damping layer, so that reduced energy storage modulus of the viscoelastic material due to temperature rise can be compensated by adding an external magnetic field; and compared with the traditional viscoelastic damper, the damper can intelligently control the damping force according to the need and has a good control effect.

Owner:涂建维

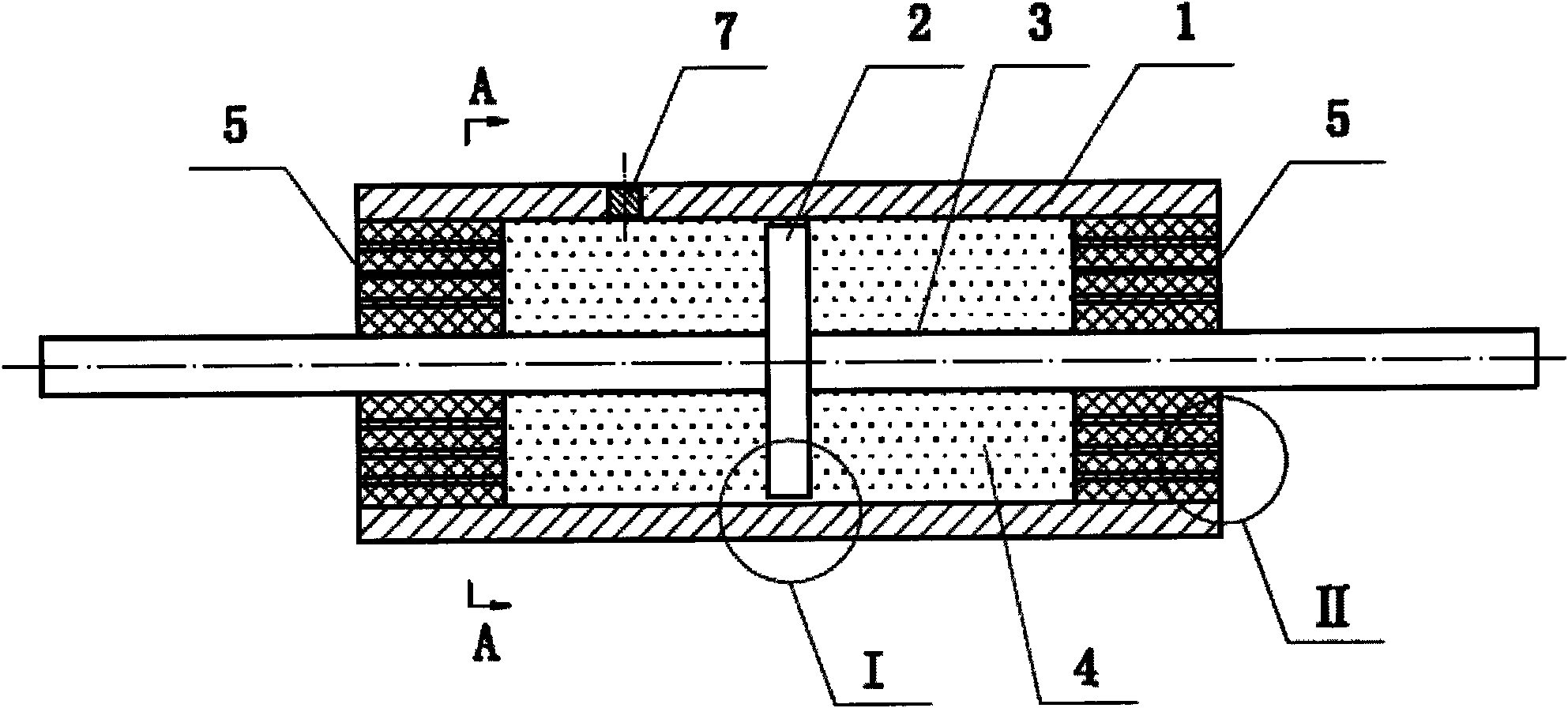

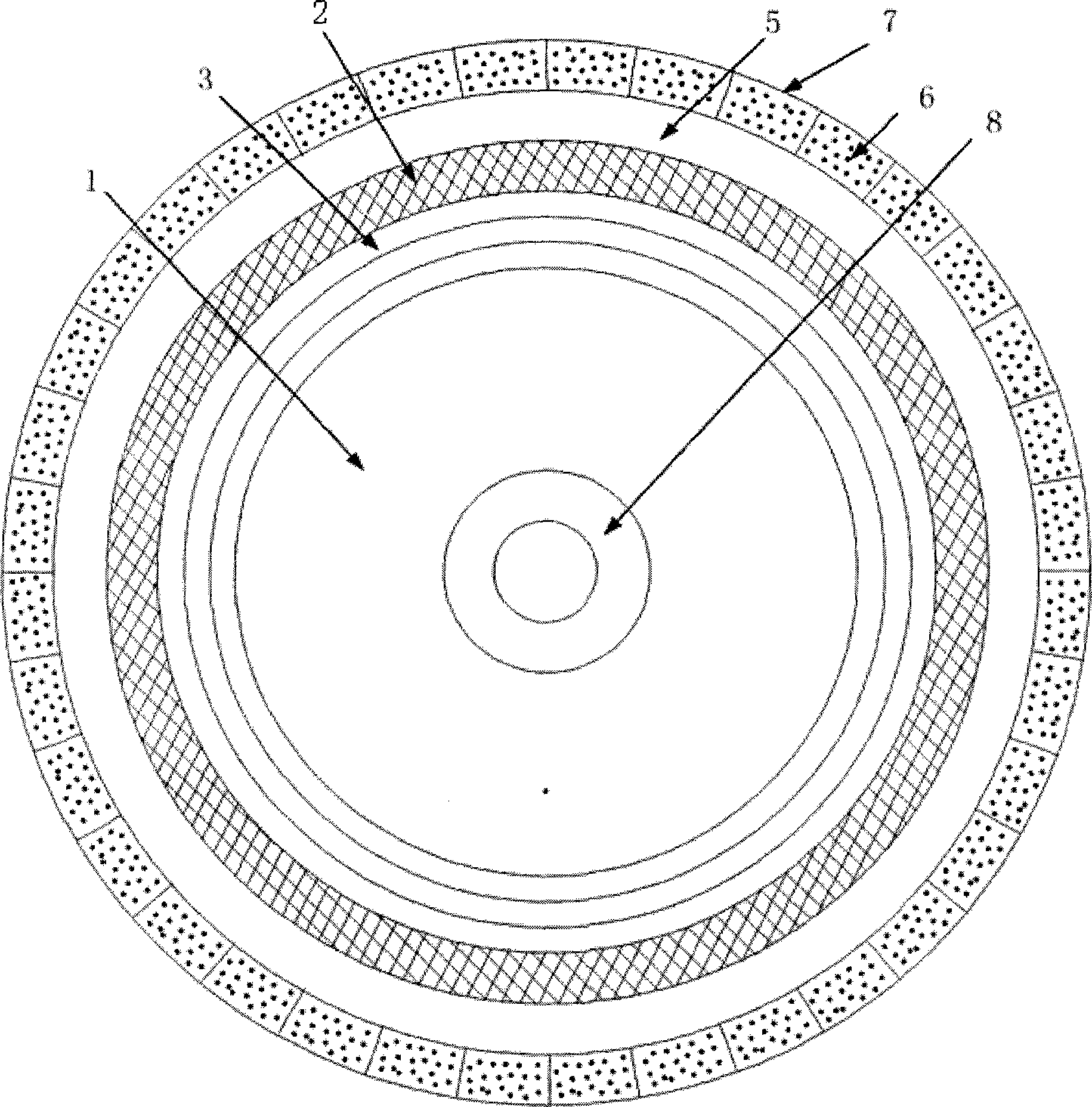

Fly wheel type composite damper for transmission shafting

InactiveCN101363500AImprove vibration damping effectLow costRotating vibration suppressionViscoelastic dampingVibration control

The invention relates to a transmission shafting flywheel-type composite damper, in particular to a shafting vibration control damper. The invention is characterized in that: the shafting vibration control damper comprises a restriction flange (1) which is arranged on a shaft and further includes a hub (2); the restriction flange is sheathed on the shaft, the hub is mounted in a groove of the restriction flange by an inner ring thereof, the inner ring of the hub and the inner side wall of the groove of the restriction flange are provided with a viscoelastic damping layer, an outer ring of the hub is connected with an inner ring of a flywheel (5) by another viscoelastic damping layer, an outer ring of the flywheel is further provided with a damping layer (7) which is internally filled with damping particles (6) and is of honeycomb structure. The shafting vibration control damper can control torsional vibration, longitudinal vibration and transverse vibration of the shafting at the same time and can effectively save cost and space.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Viscoelastic damping magnetorheological elastomer material

The invention discloses a viscoelastic damping magnetorheological elastomer material, which is characterized by being prepared by blending 100 parts of rubber substrate, 365 to 569 parts of magnetic particles, 0 to 110 parts of reinforcing system, 12 to 15 parts of vulcanizing system, 2 to 6 parts of anti-aging system, an operating assistant and a processing assistant. The viscoelastic damping magnetorheological elastomer material of the invention has high frequency shift property and energy consumption property in a service environment with the magnetic field intensity of 0 to 1,000mT, frequency of 0.1 to 50Hz and temperature of 20 DEG C below zero and 50 DEG C. And when a loss factor is between 0.5 and 0.9, the viscoelastic damping magnetorheological elastomer material can be used for making various intelligent shock isolating and absorbing devices.

Owner:SOUTHEAST UNIV

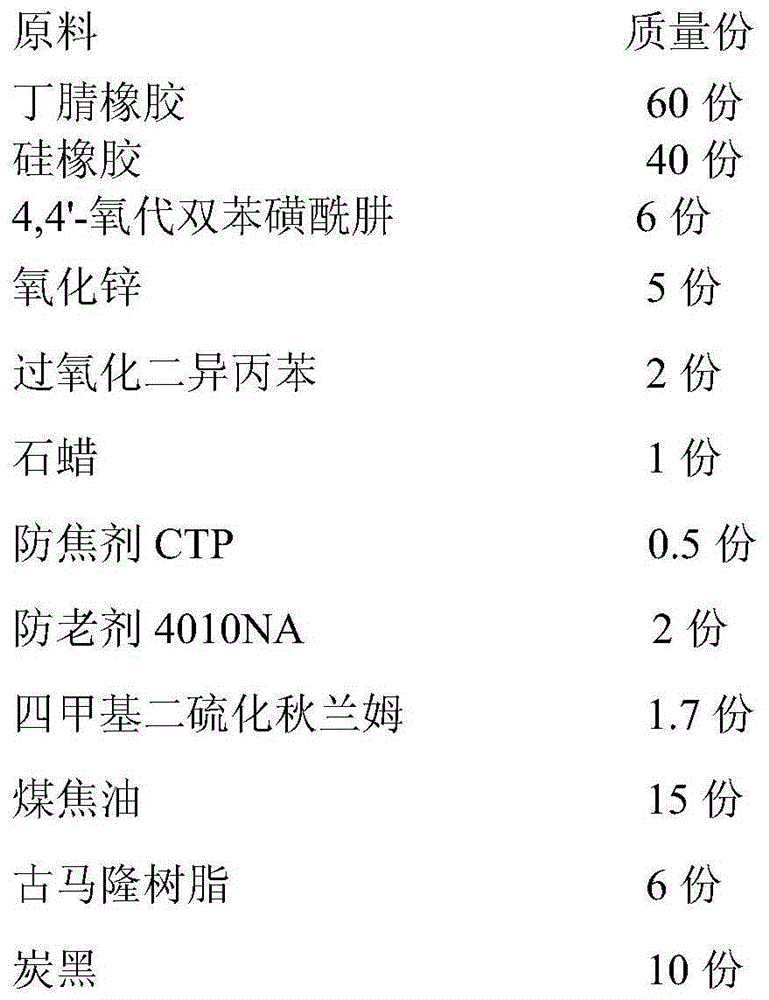

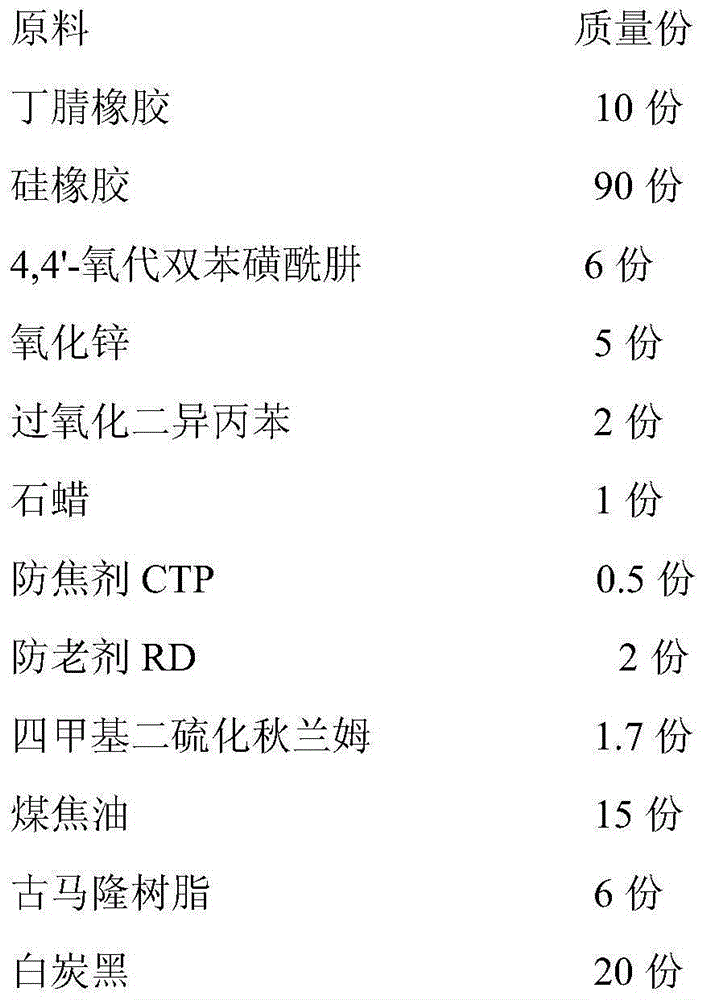

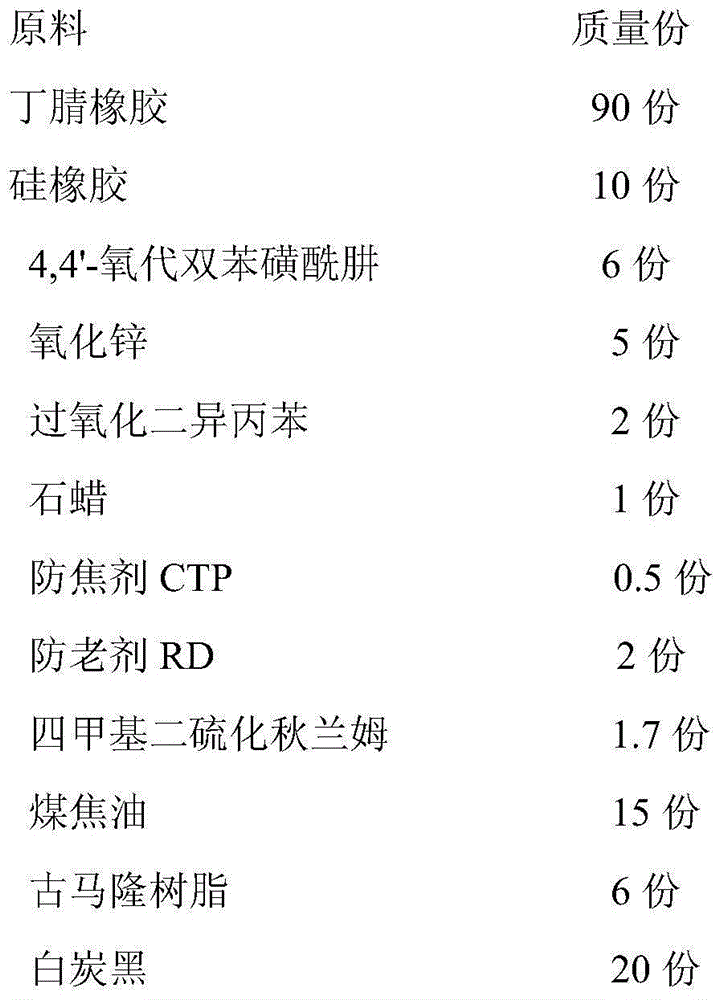

Compound damping foam rubber material and preparation method thereof

ActiveCN106543500AImprove sound absorption performanceOptimizing the Ratio of Raw RubberRubber materialSound energy

The invention provides a compound damping foam rubber material. The material is prepared from rubber, reinforcing filling and addition agents, wherein the addition agents comprise a vulcanizing agent, a dispersant, an anti-scorching agent, an anti-ageing agent, an accelerant, a secondary accelerant and a softening agent; the rubber is selected from at least two of silicone rubber, nitrile butadiene rubber, butadiene rubber, isoprene rubber and ethylene propylene rubber; and the addition agents also comprise a foaming agent. The compound damping foam rubber material provided by the invention has the advantages of light weight, cost reduction, good transformer oil resisting performance, good electric insulating performance and the like; a pore structure generated by foaming and the rubber material have a viscoelastic damping synergistic effect to enhance sound energy dissipation and improve noise-reduction performance of the compound damping foam rubber material; and the compound damping foam rubber material can be used as a sound-absorption and noise-reduction material to be applied to vibration absorption and noise reduction of a transformer body, and has remarkable economic and social benefits.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com