Patents

Literature

70results about How to "High damping value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

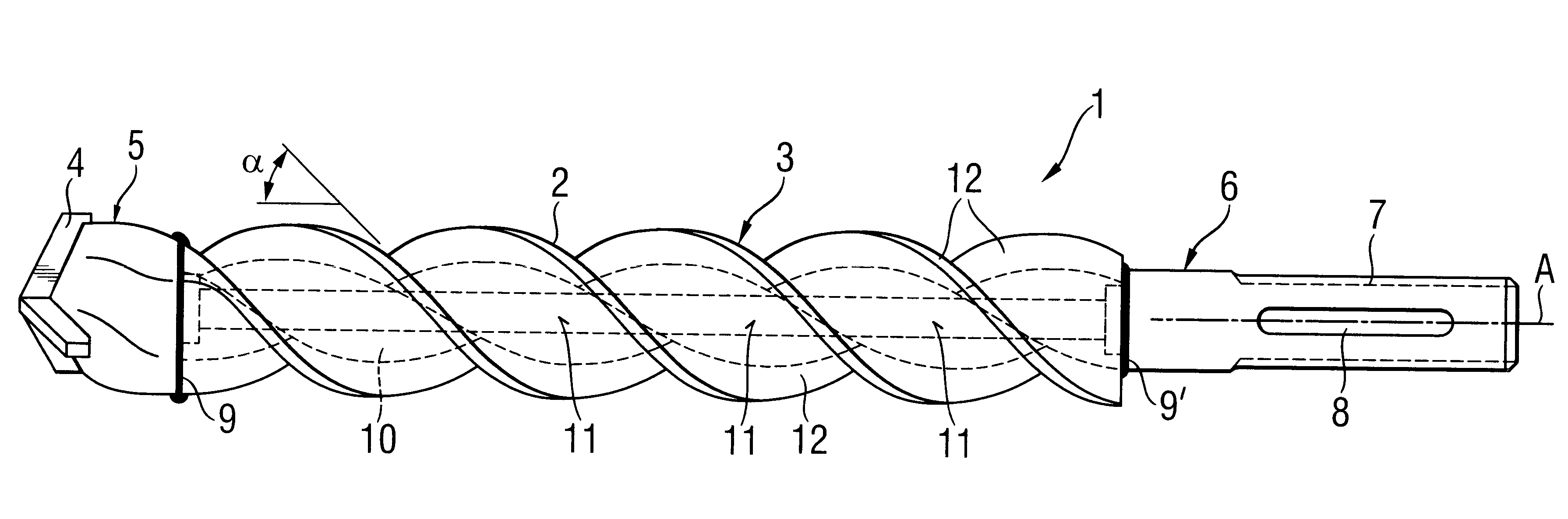

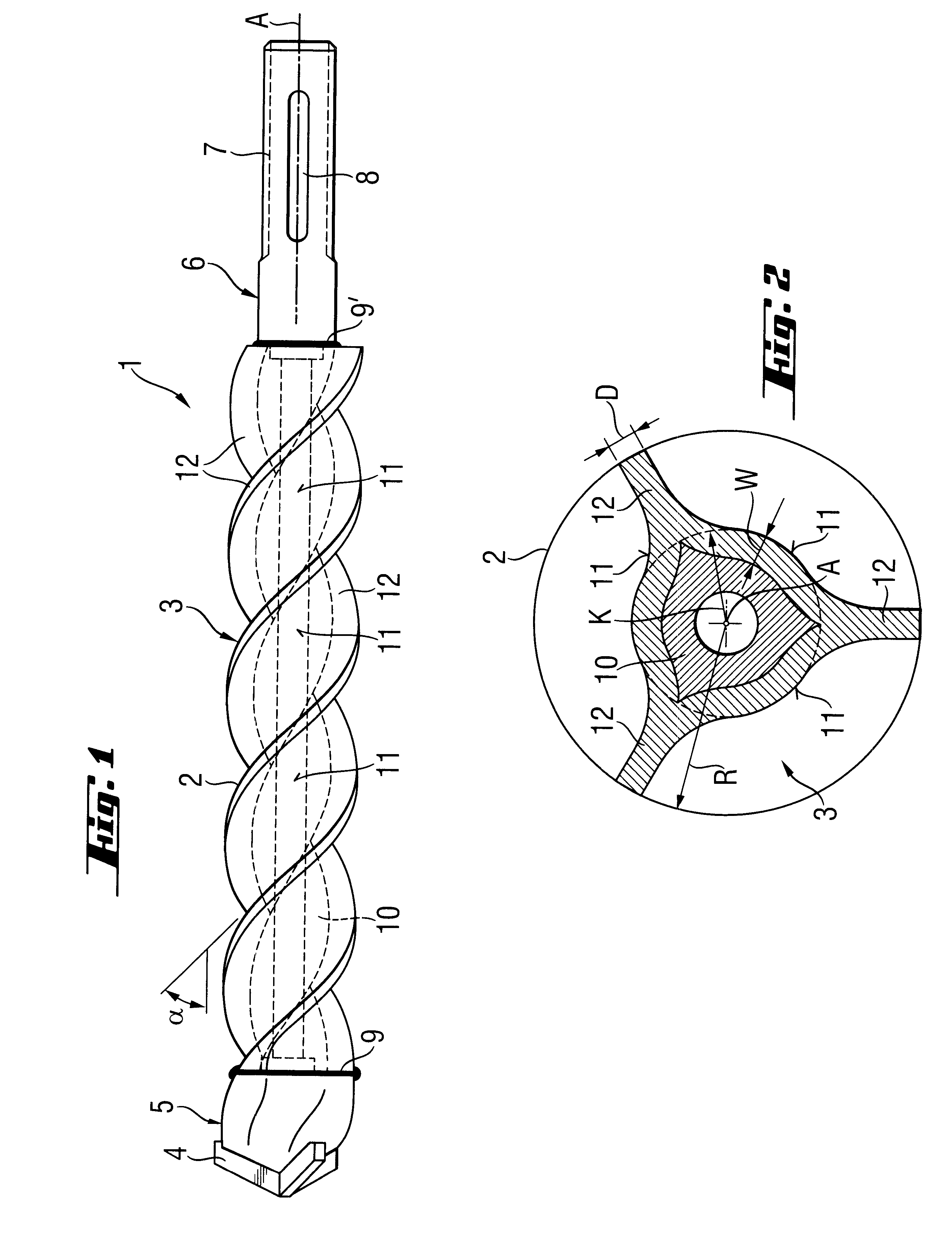

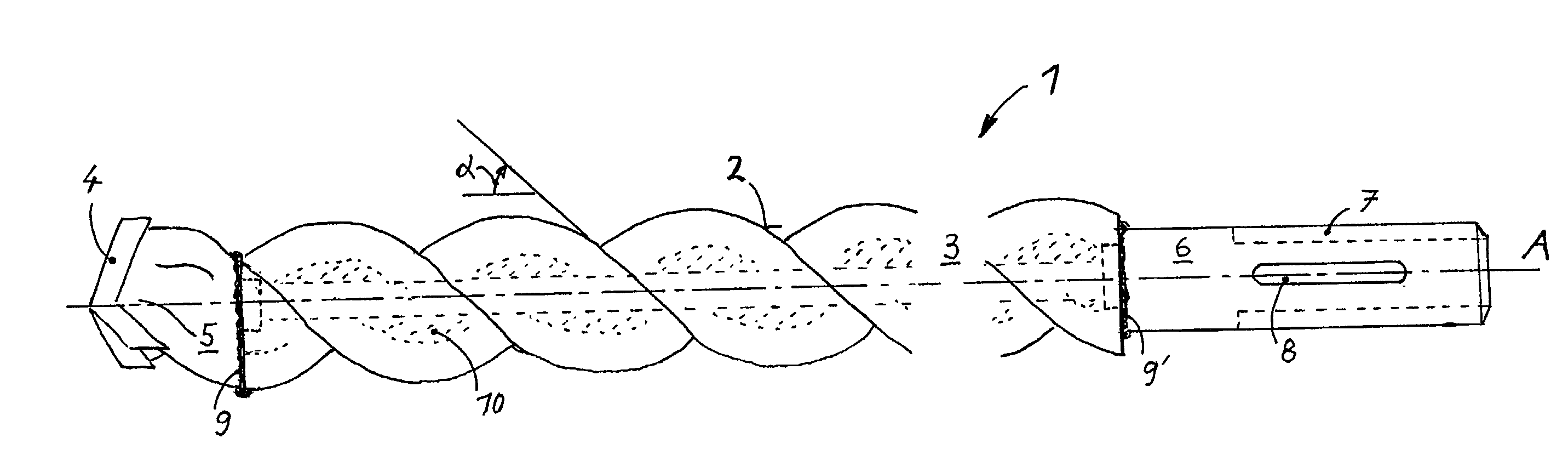

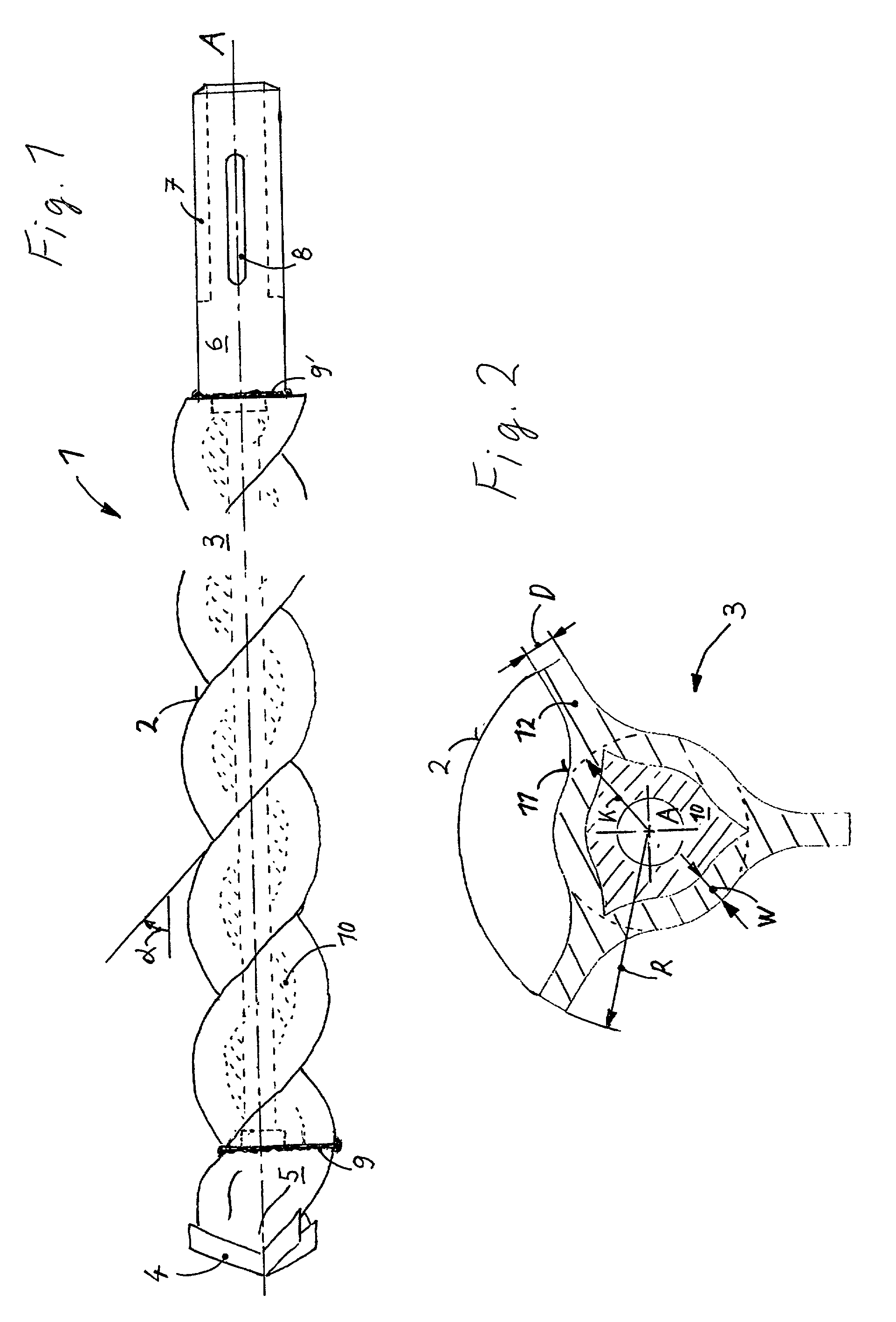

Twist drill

InactiveUS6601659B2Improve efficiencyImprove guidanceDrill bitsDrilling rodsEngineeringMechanical engineering

A twist drill including a spiral-forming hollow shaft (3) having a spiral-shaped inner surface, and drilling head(5) and shank (6) connected with the shaft (3) at its opposite ends, respectively; and a method for forming such a twist drill.

Owner:HILTI AG

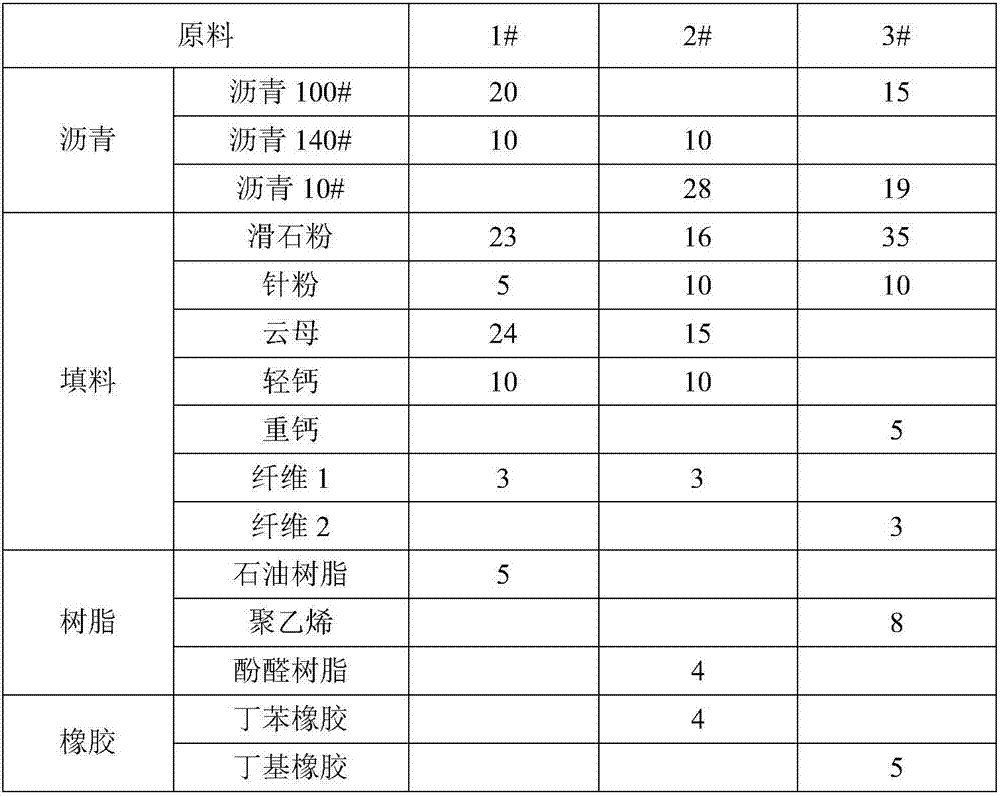

Aqueous damping coating having high acoustical insulation and low density and preparation method thereof

ActiveCN101041755AHigh damping valueWide damping temperature rangeUnspecified rubber coatingsPolyurea/polyurethane coatingsBenzeneWater based

The invention discloses a water-based damping material with high acoustical insulation and low density and preparing method, which comprises the following steps: (1) allocating one kind emulsion or multiple kinds of water-based propyl benzene emulsion, water-based polyurethane and various rubber latex with mass ratio; dissolving into water; setting the solid content at 20-60% in water solution; stirring; mixing; getting water-based emulsion mixture; (2) allocating powder form filler with mass ratio; adding into the allocating water-based emulsion; stirring with high speed; mixing; adding into disperser and deformer; adjusting consistency with thickener; getting the water-based damping paint.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

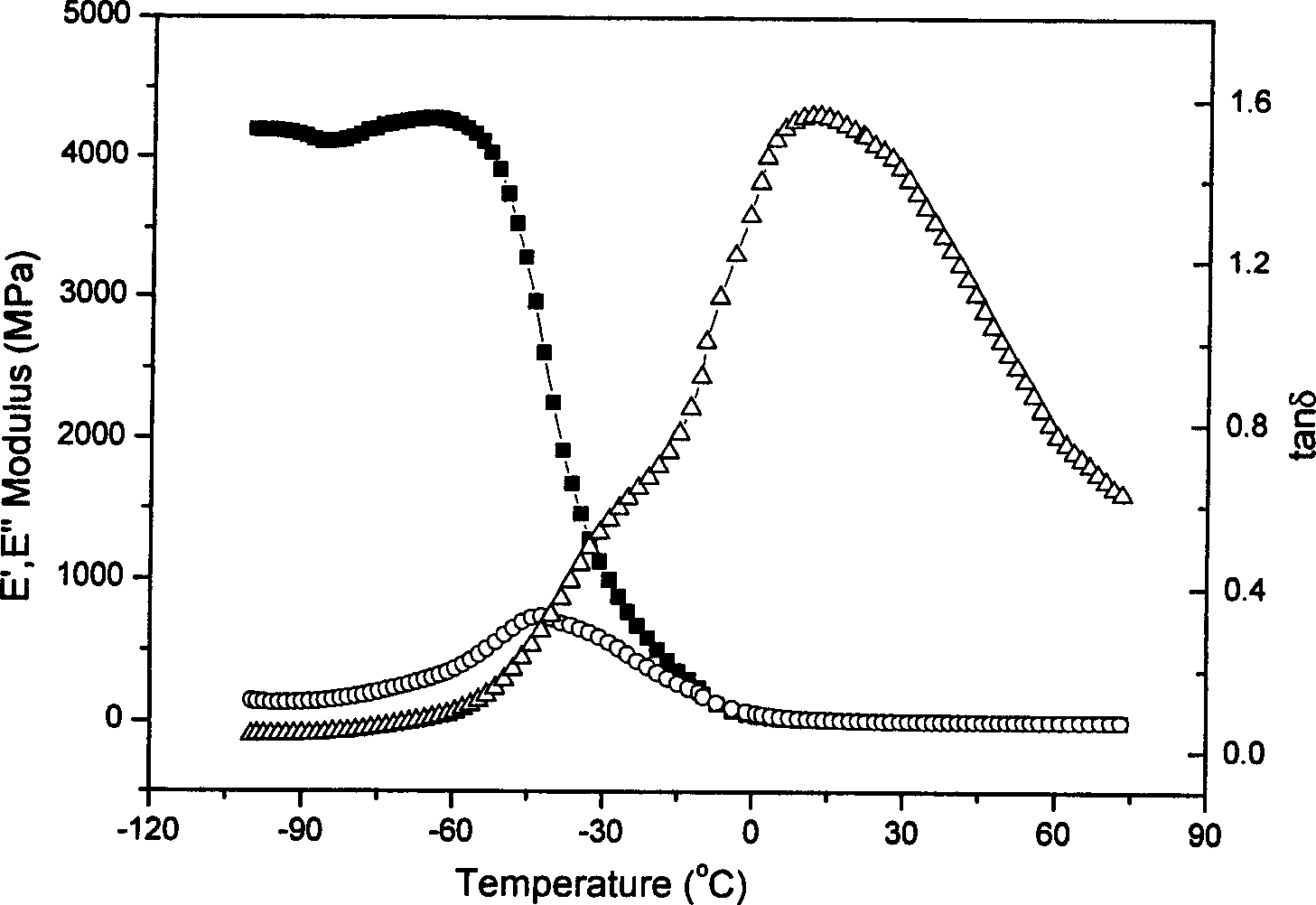

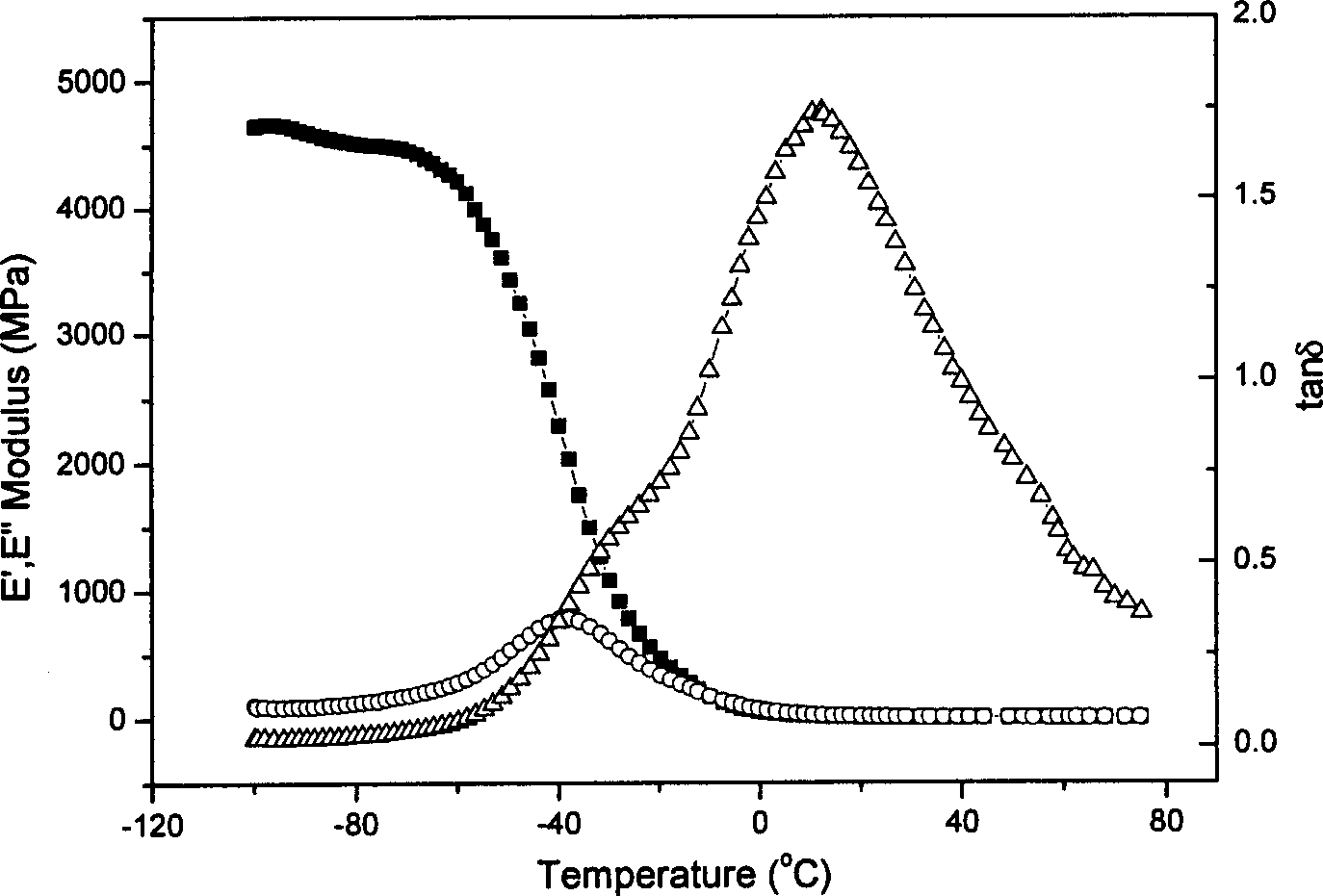

Blend sulfurized compound damping material of butyl rubber/chlorinated polyethylene olefin and prepn. process

This invention discloses a kind of butyl rubber / polyolefin chloride blend composite damping materials and its preparation method. It has the characteristics that 70 mass shares of butyl rubber and 30~100 mass shares of polyolefin chloride are blended in a double-roller glue cauldron or an extruder at a temperature of 100~160 deg. C for 5~20 minutes or directly in a double-roller glue cauldron at room temperature for 5~20 minutes. Then at a temperature of 30~60 deg. C, 9~30 mass shares of vulcanizing agent, 1.5~6.0 mass shares of auxiliary vulcanization agent and 5~15 mass shares of plasticizers are added and the homogeneous blend is compression molded in a hydraulic plate vulcanization machine at a temperature of 140~170 deg. C and a pressure of 5~10MPa for 10~30 minutes so as to produce butyl rubber / polyolefin chloride blend composite damping materials with extraordinary damping properties.

Owner:SICHUAN UNIV

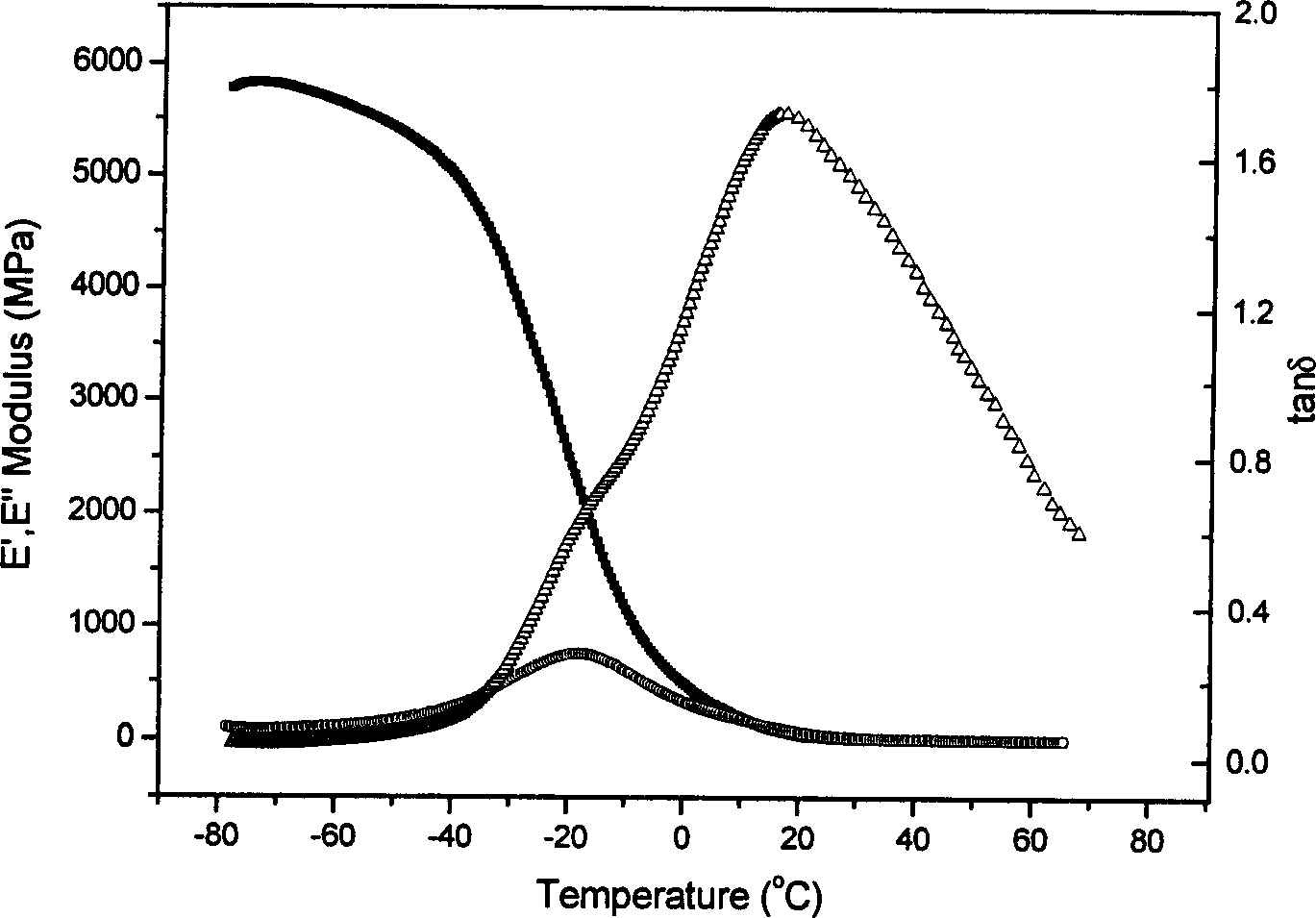

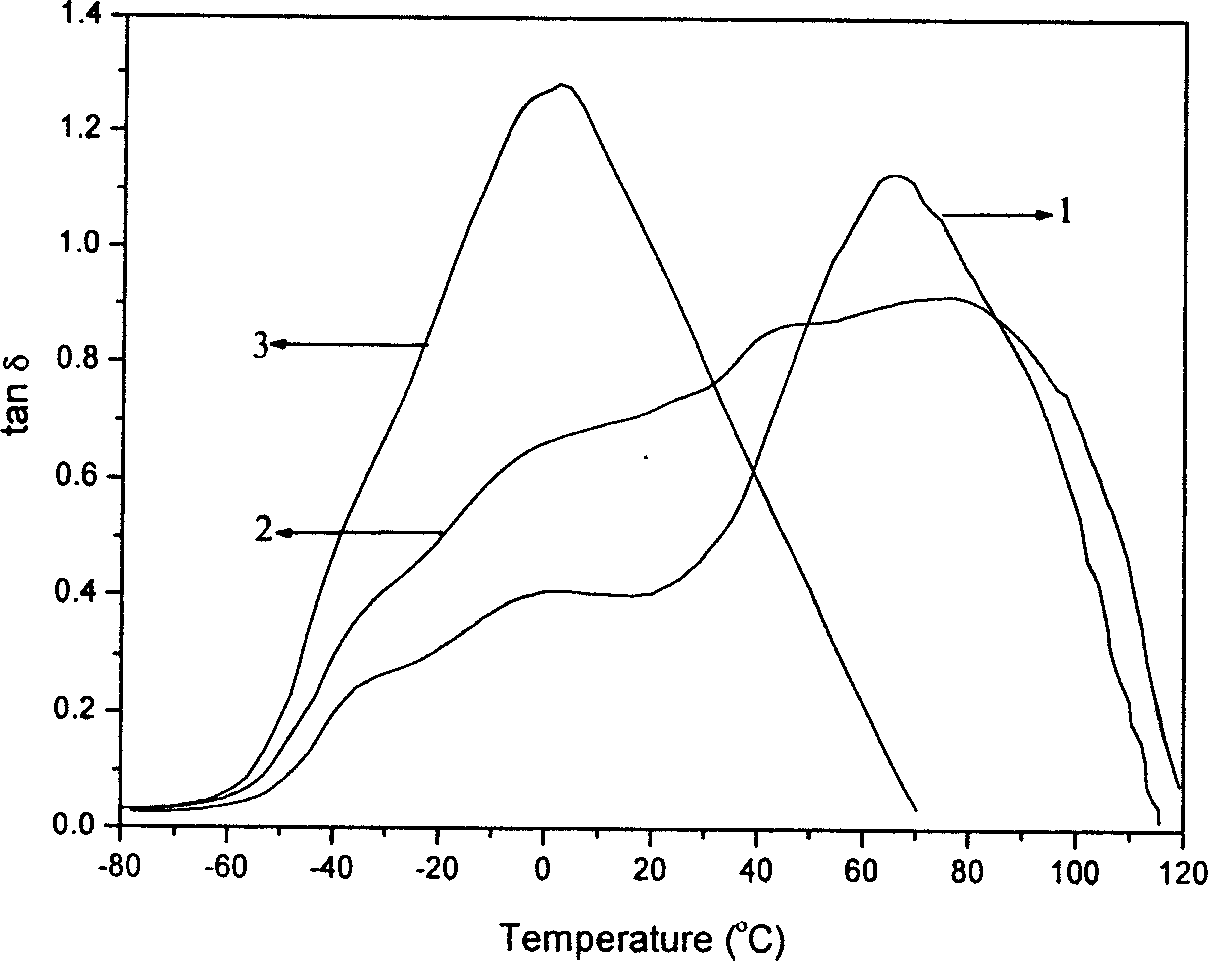

Butyl rubber/poly(meth)acrylate interpenetrating polymer networks damping material and process for preparing same

The interpenetrating butyl rubber / poly (methyl) acrylate polymer network damping material and its preparation process features that butyl rubber in 100 (in weight portions, the same below), sulfurizing agent 1-15, sulfurizing assistant 1.5-6.0 and stuffing 10-20 are first mixed homogeneously in a double-roller mixing machine, and pressed in a press at 140-170 deg.c and 5-10 MPa for 10-20 min to obtain the first sulfurized butyl rubber network; the sulfurized butyl rubber is then soaked in the mixture comprising acrylate or methacrylate monomer 100, crosslinking agent 1-10 and initiator 0.2-0.8 to reach a 30-40 % weight increase; and the above said mixture is finally in-situ reacted at 60-90 deg.c and 5-10 MPa and mold pressed for 4-8 hr to form the interpenetrating butyl rubber / poly (methyl) acrylate polymer network damping material with butyl rubber in 60-90 wt% and poly (methyl) acrylate polymer in 10-40 wt%.

Owner:SICHUAN UNIV

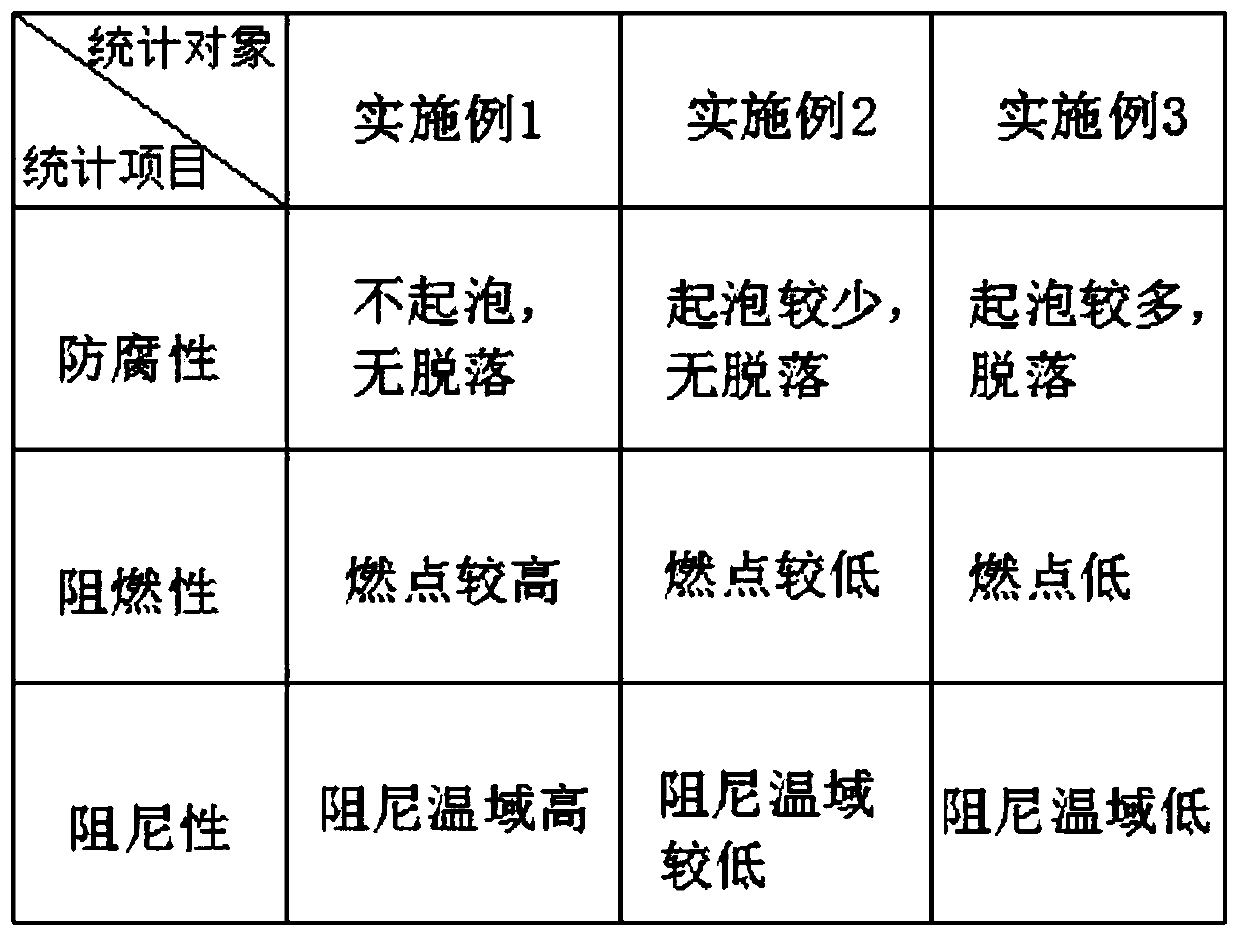

Environmental-friendly heat-isolating high-performance aqueous damping coating and preparation method thereof

The invention belongs to the technical field of coatings and discloses an environmental-friendly heat-isolating high-performance aqueous damping coating and a preparation method thereof. The coating is prepared from the following components in parts by weight: 30-45 parts of an aqueous emulsion, 5-20 parts of a damping pigment and filler, 10-20 parts of rigid polyurethane foam, 15-25 parts of inorganic filler, 5-10 parts of a flame retardant, 1-5 parts of an antifreezing agent, 0.5-1.0 part of a base material wetting agent, 1.0-5.0 parts of an aqueous wetting dispersing agent, 0.5-2.0 part of an aqueous defoamer, 0.5-3.0 parts of a coupling agent, 0.5-2.0 parts of a coalescing agent, 0.5-1.5 parts of a thickener and 5-10 parts of water. The aqueous emulsion is a self-crosslinked acrylate emulsion. The coating provided by the invention has the advantages of being high in damping value, wide in damping temperature domain, good in heat-isolating property and the like and is good in covering force to a base material and strong in decorativeness. The method provided by the invention is simple and easy to operate, and green and environmental-friendly.

Owner:SOUTH CHINA UNIV OF TECH

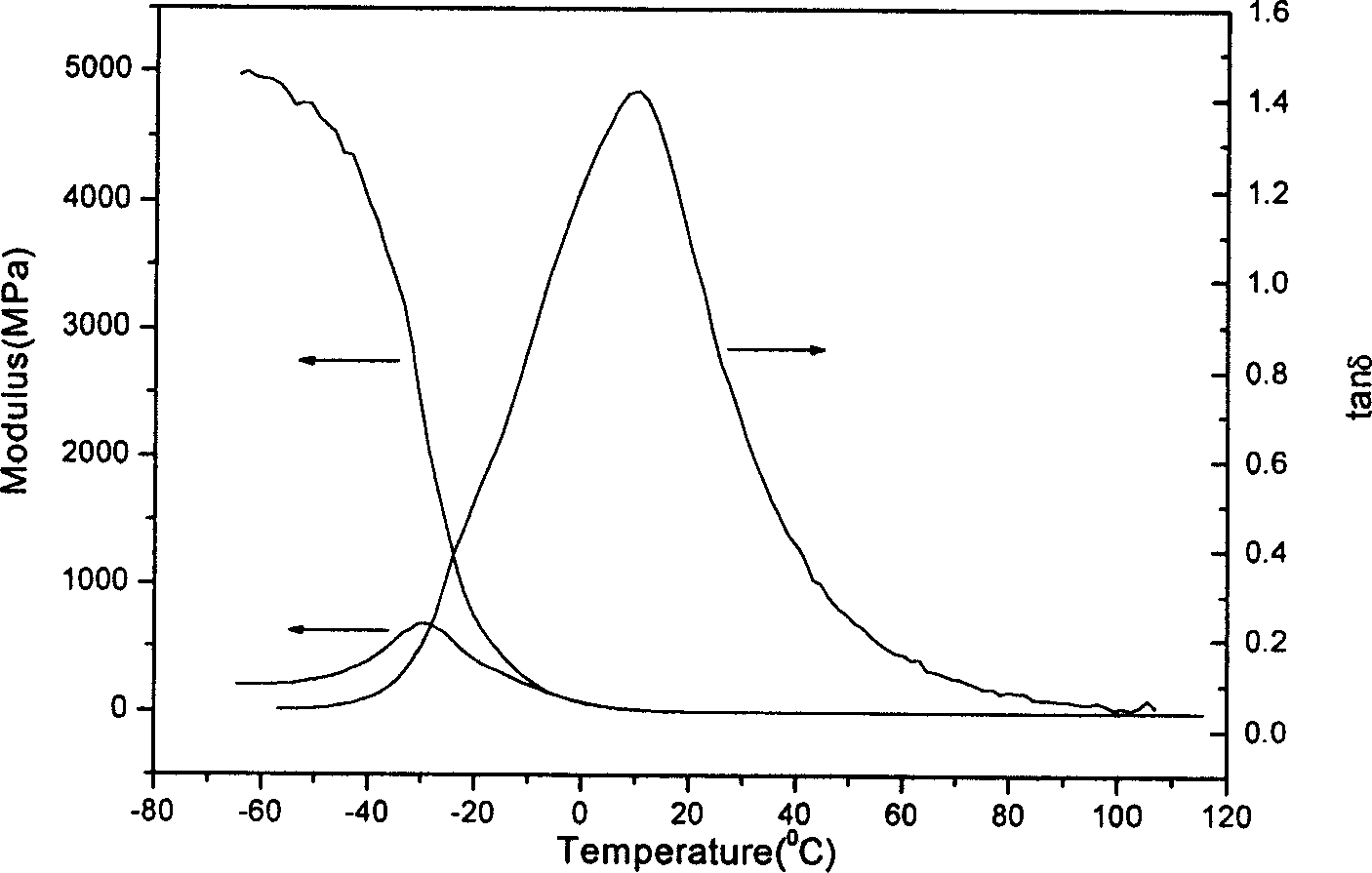

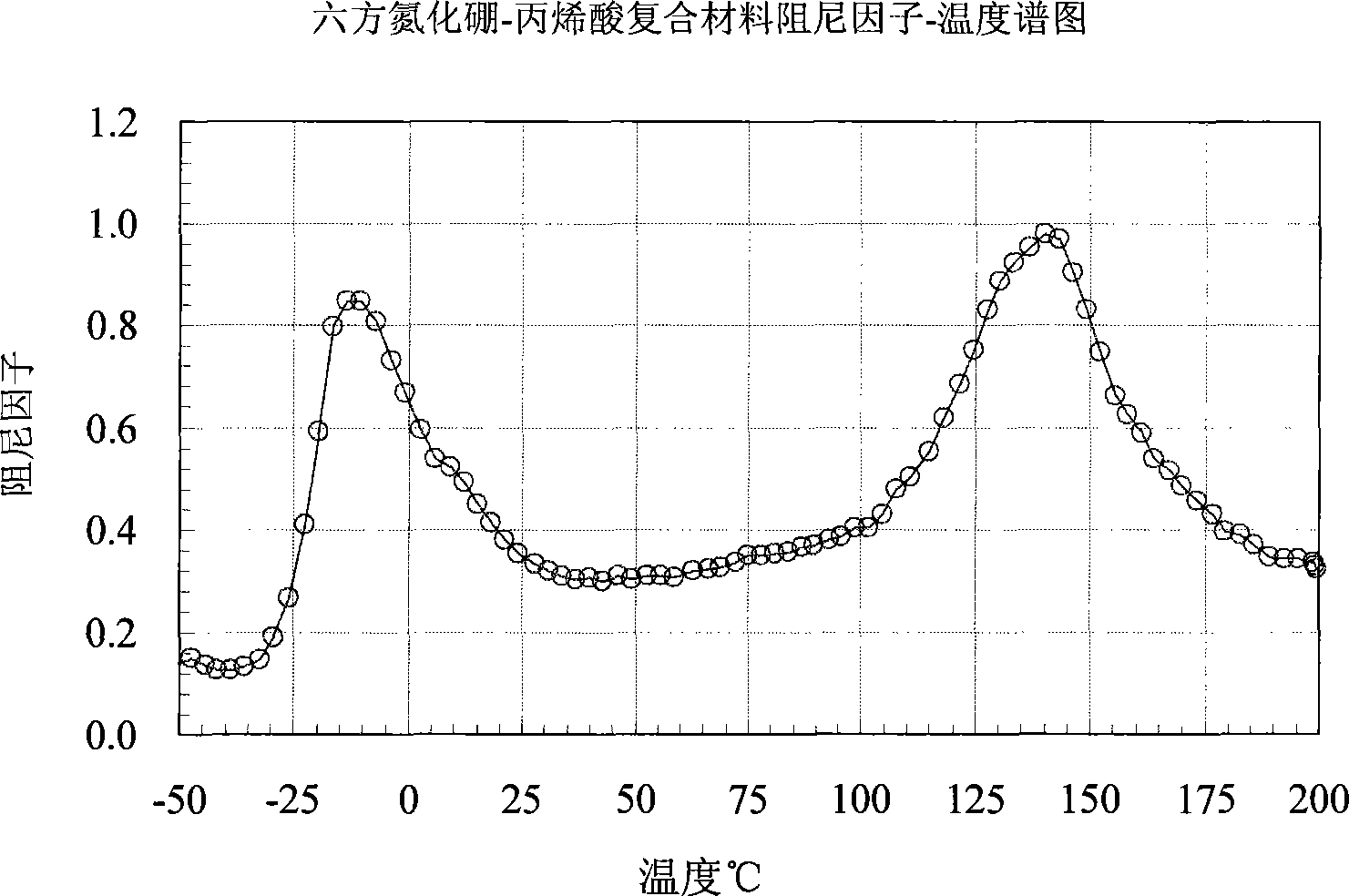

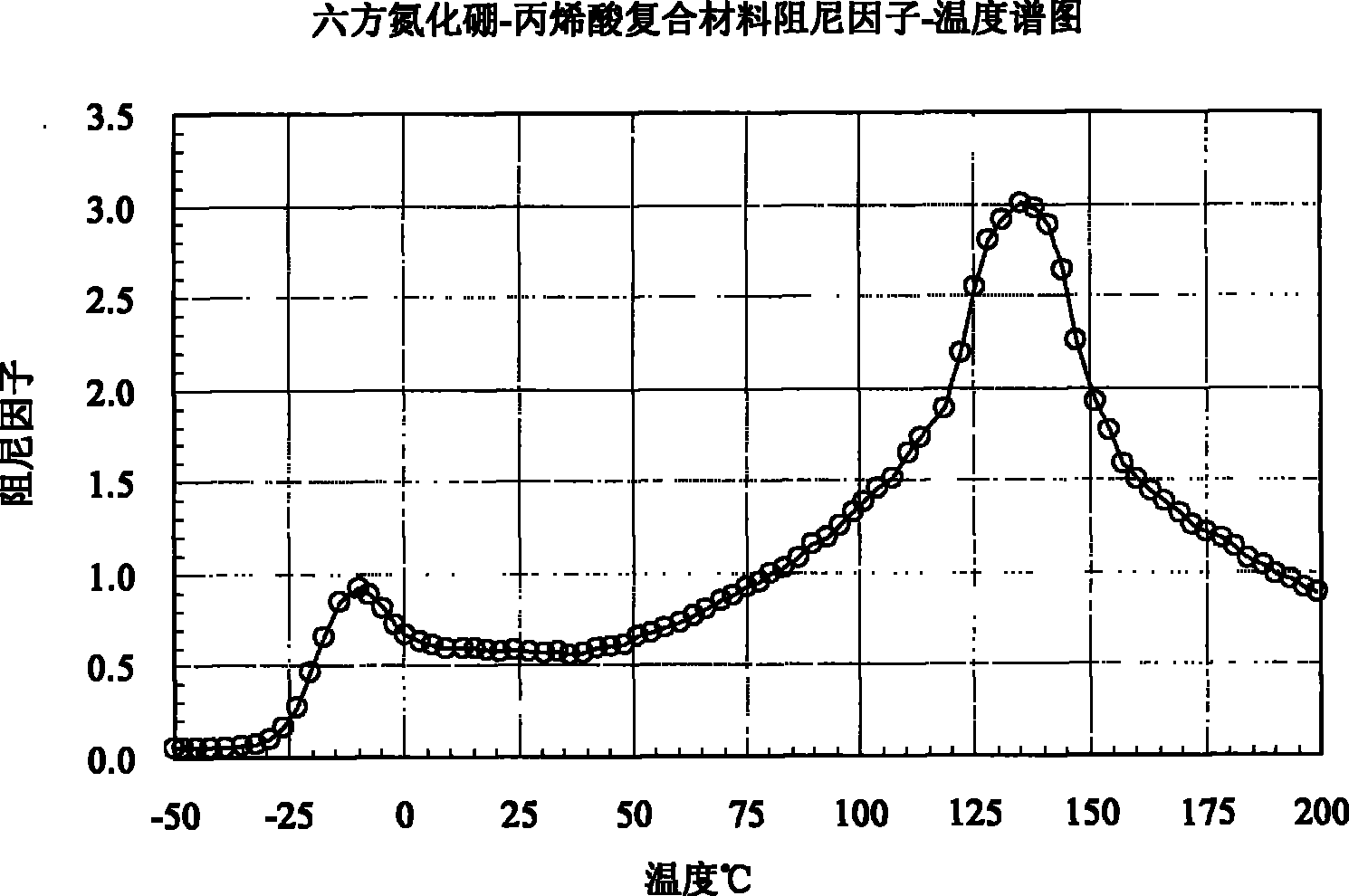

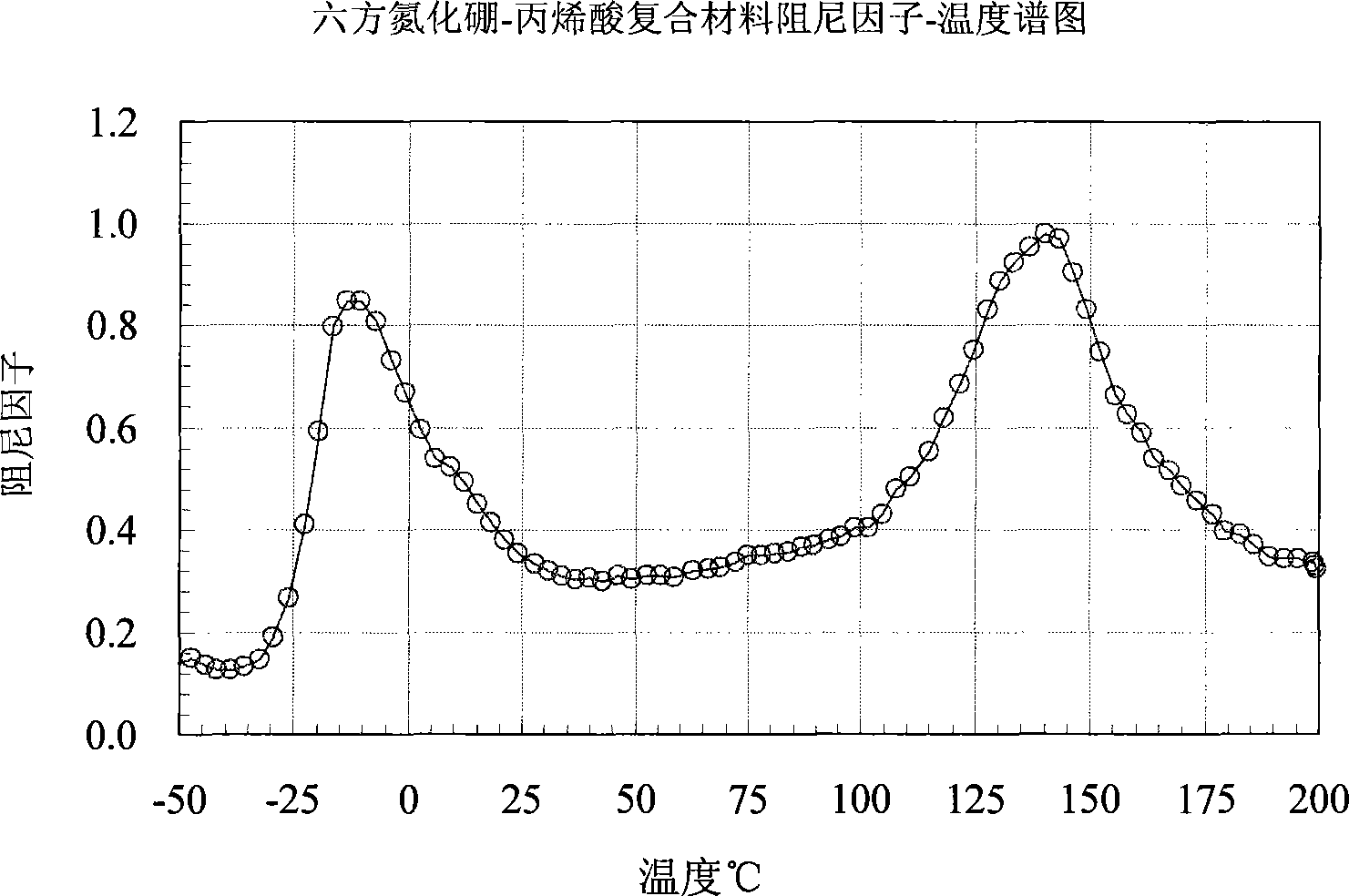

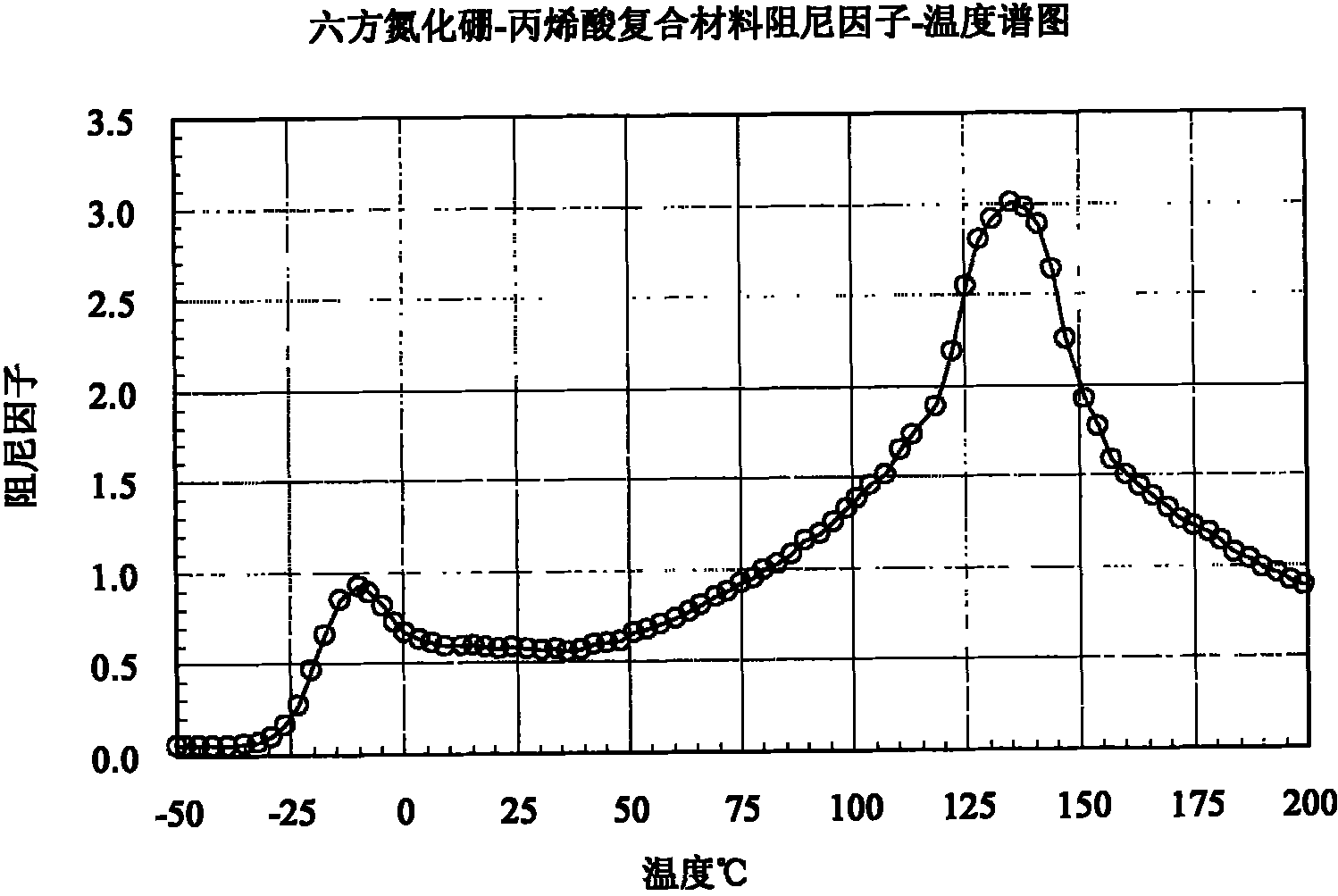

Method for preparing wide temperature range high damping acrylic emulsion material

InactiveCN101250246AThe synthesis process is simpleDoes not affect the preparation methodDamping factorSynthesis methods

The invention relates to a preparation method of acrylic emulsion function material which is composited from inorganic and organic, with wide temperature range and high damping property, belonging to the technical field of organic polymer material. The invention is characterized in that the invention uses acrylate as polymerization monomer, uses organic silicon as organic composite material, and uses nanometer boron nitride and mica as inorganic composite materials, without changing the synthesis of emulsion to prepare a serial of polymer material whose damping temperature is higher than 135DEG C and damping factor is higher than 0.30, wherein the damping factor of the best material is higher than 0.5 when in the damping temperature higher than 135DEG C. The polymerization method is characterized in that the invention can prepare interpenetrating network polymer damping material in short reaction via simple synthesis method.

Owner:UNIV OF SCI & TECH BEIJING

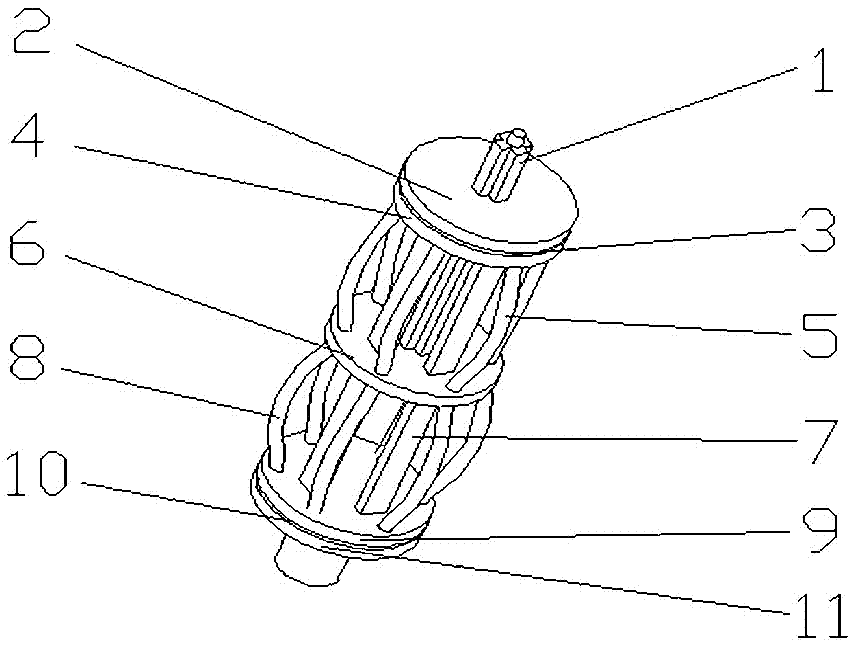

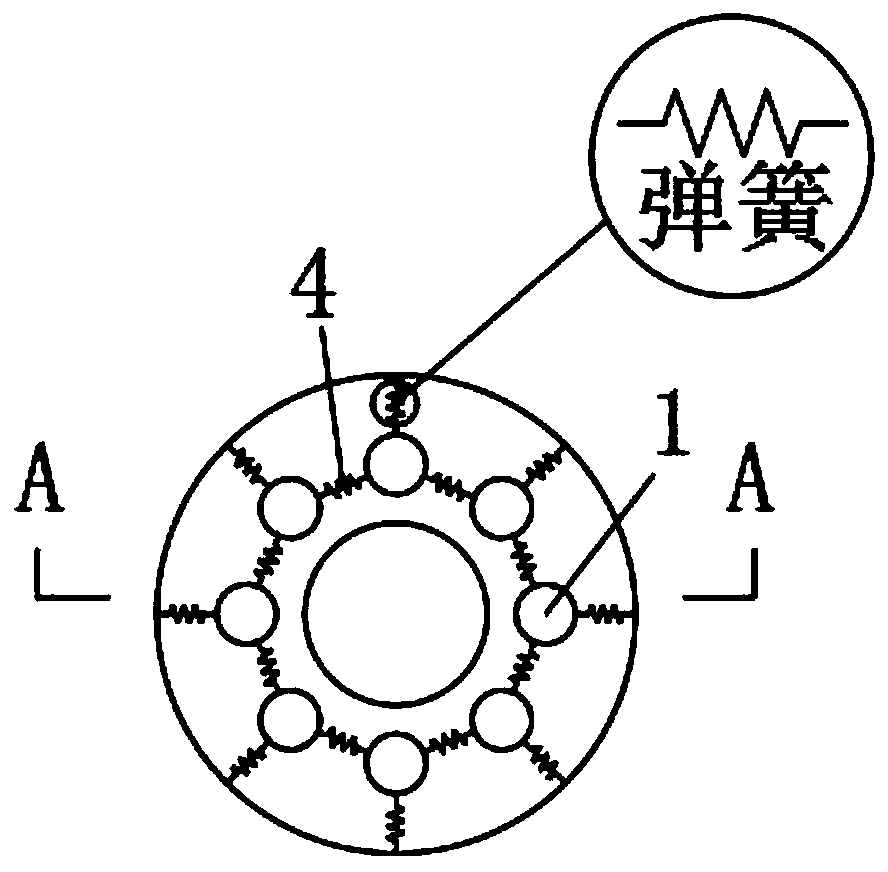

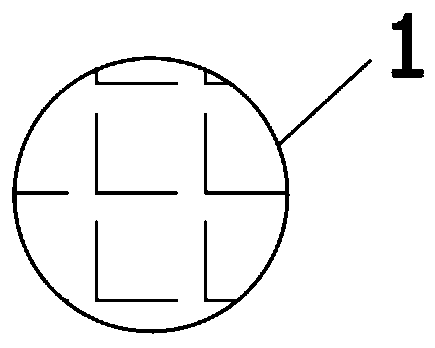

Wide-frequency high-damping vibration isolator

ActiveCN109812530AGood vibration isolationStable mechanical propertiesShock absorbersNoise controlVibration control

The invention provides a wide-frequency high-damping vibration isolator, and belongs to the technical field of vibration noise control. The vibration isolator comprises supporting combined beams, connecting bosses, an upper equilateral triangle connecting plate and a lower equilateral triangle connecting plate, wherein the supporting combined beams are formed by bonding metal gaskets, flexible material gaskets and metal thin-wall beams through bonding agents. The three supporting combined beams are symmetrically arranged on the outer sides of the upper equilateral triangle connecting plate andlower equilateral triangle connecting plate through the connecting bosses in parallel. The connecting bosses are fixedly connected with the equilateral triangle connecting plates by screws. The movement direction of the upper equilateral triangle connecting plate is consistent with the length direction of the supporting combined beams and is perpendicular to the bending direction of the supporting combined beams. Force is transmitted to the upper equilateral triangle connecting plate after a vibration control object moves. Wide-frequency high-damping dynamic vibration reduction can be realized by the bending energy consumption of the supporting combined beams. The wide-frequency high-damping vibration isolator is large in bearing force, high in damping, capable of isolating vibration andeffectively reducing the amplitude, stable in vibration isolation, high in reliability, simple in structure and convenient to install and does not need extra energy.

Owner:北京朝暾科技发展有限公司

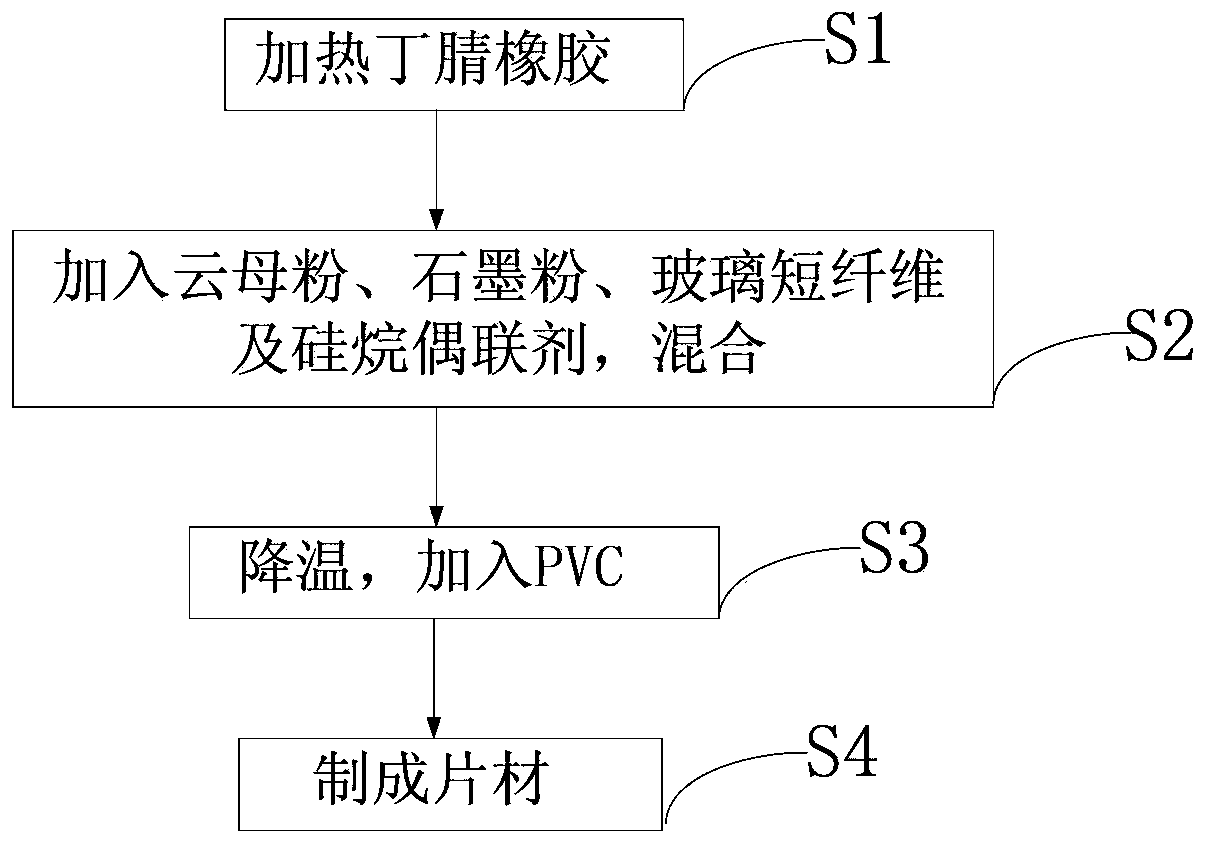

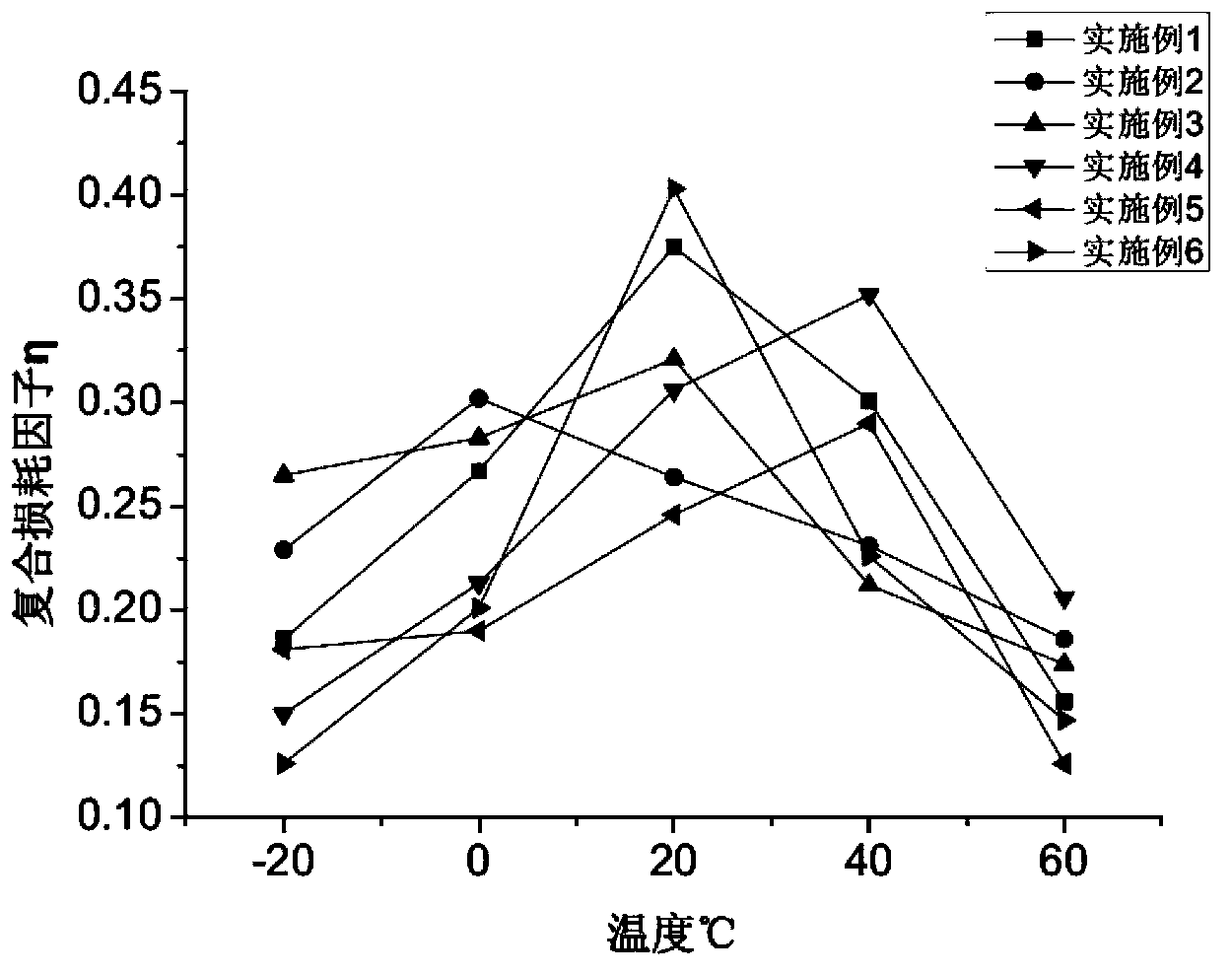

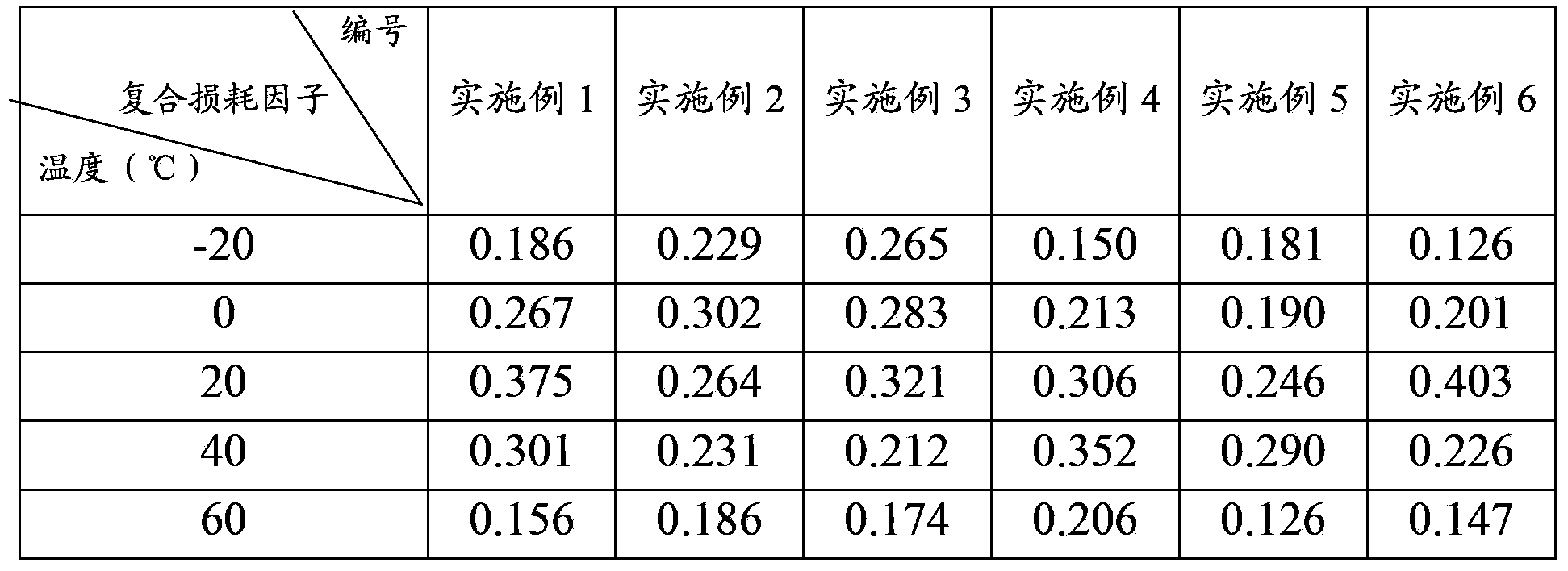

Damping rubber plate and preparation method thereof

The invention discloses a damping rubber plate which comprises the following main components in parts by weight: 15-40 parts of nitrile-butadiene rubber, 10-30 parts of PVC Polyvinyl Chloride), 15-45 parts of mica powder, 5-25 parts of graphite powder, 5-10 parts of glass fiber, and 1-5 parts of silane coupling agent. The invention further discloses a preparation method of the damping rubber plate. The damping rubber plate with a high damping value within different temperature region ranges can be obtained by adjusting the use amount of the components, and the damping rubber plate is free of an organic solvent, is safe and environment-friendly, and has no pollution to an environment.

Owner:QINGDAO AIR NEW MATERIALS

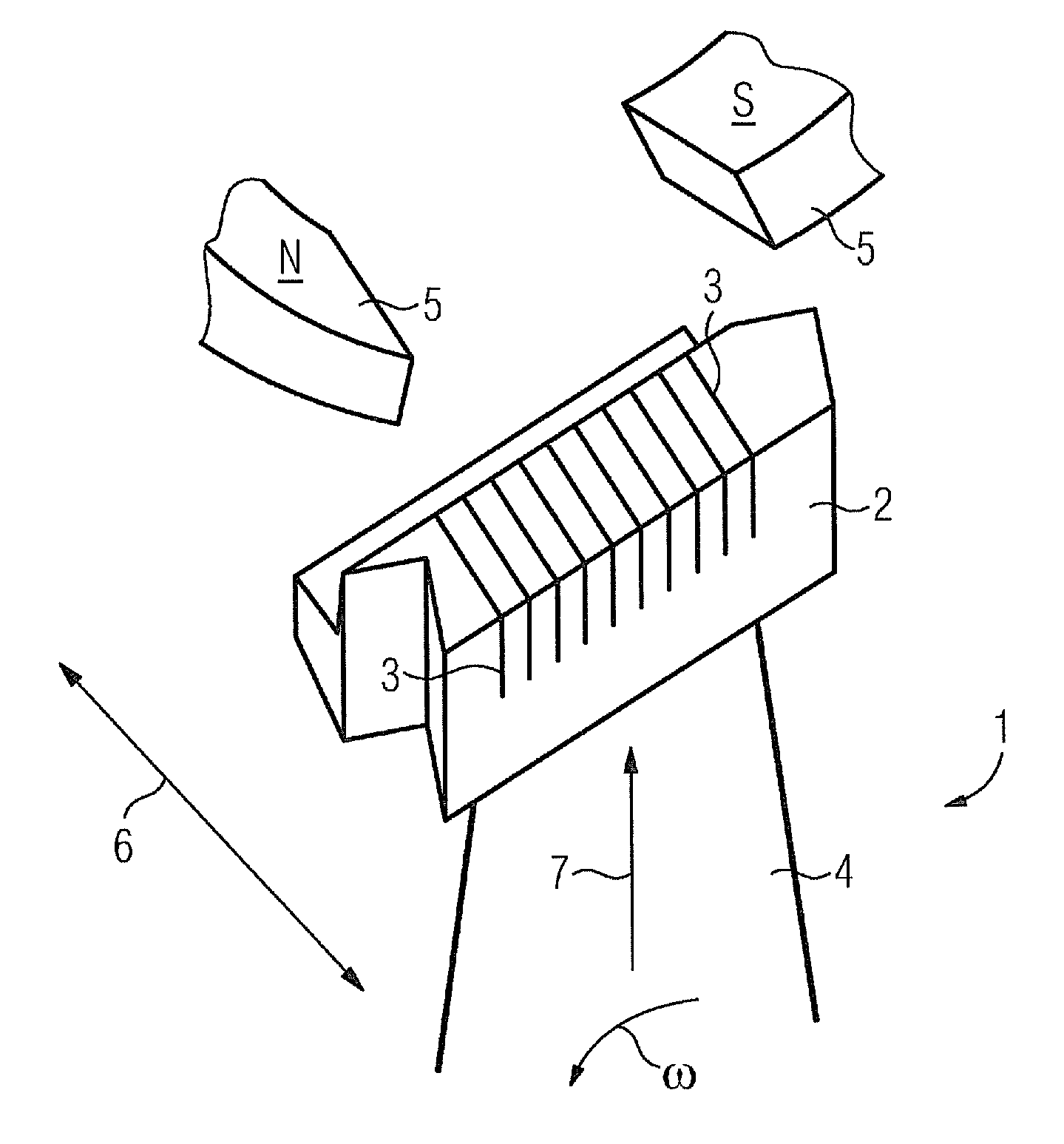

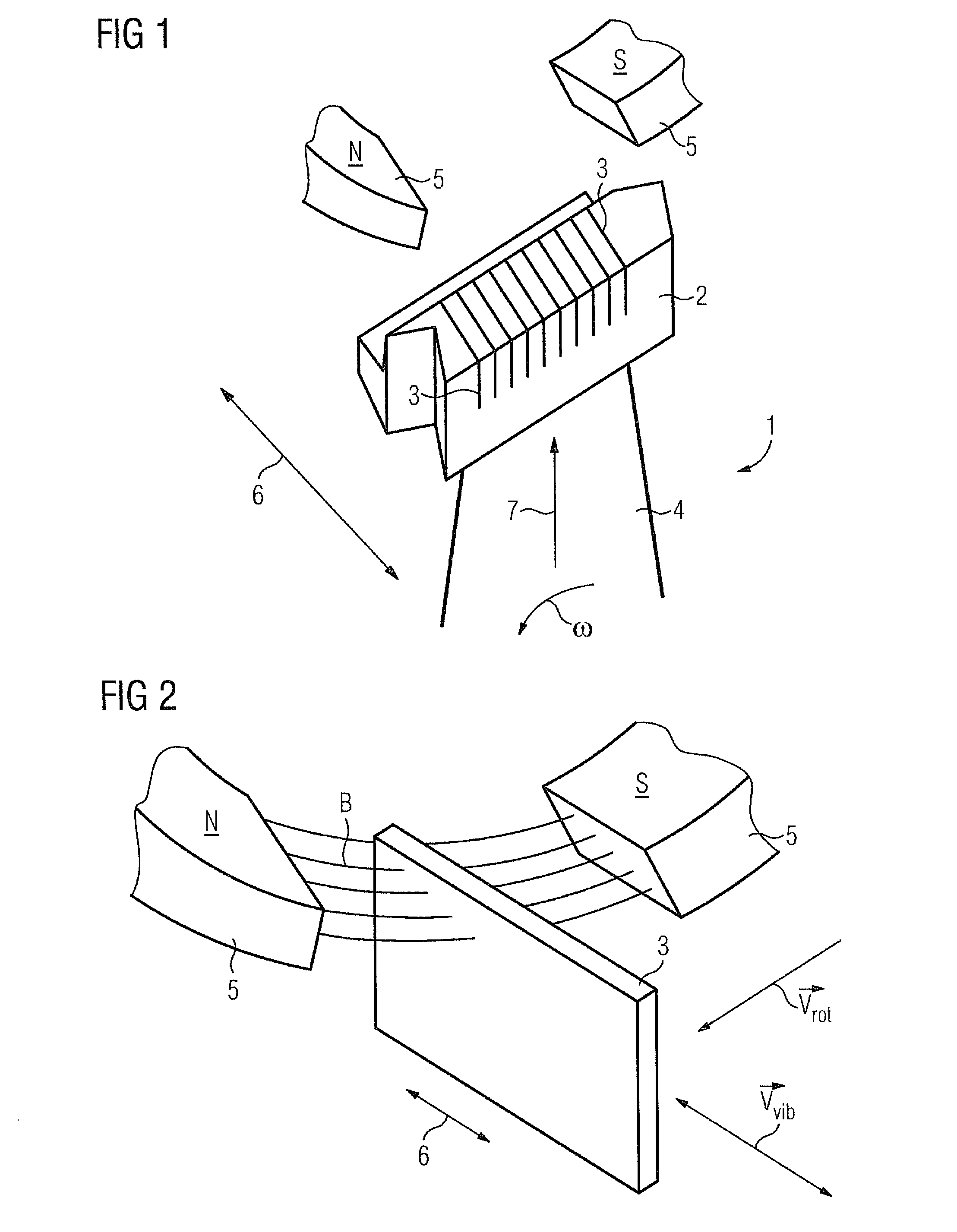

Magnetic device for damping blade vibrations in turbomachines

An arrangement for damping blade vibrations in a turbomachine is provided. The blade vibrations are due to an arrangement made of magnets and multiple induction plates and the undesired vibrations of the blade are damped by creating turbulent flows, wherein the induction plates are directed parallel to the rotation axis, and the magnetic field caused by the magnets is formed homogenously in the circumferential direction.

Owner:SIEMENS AG

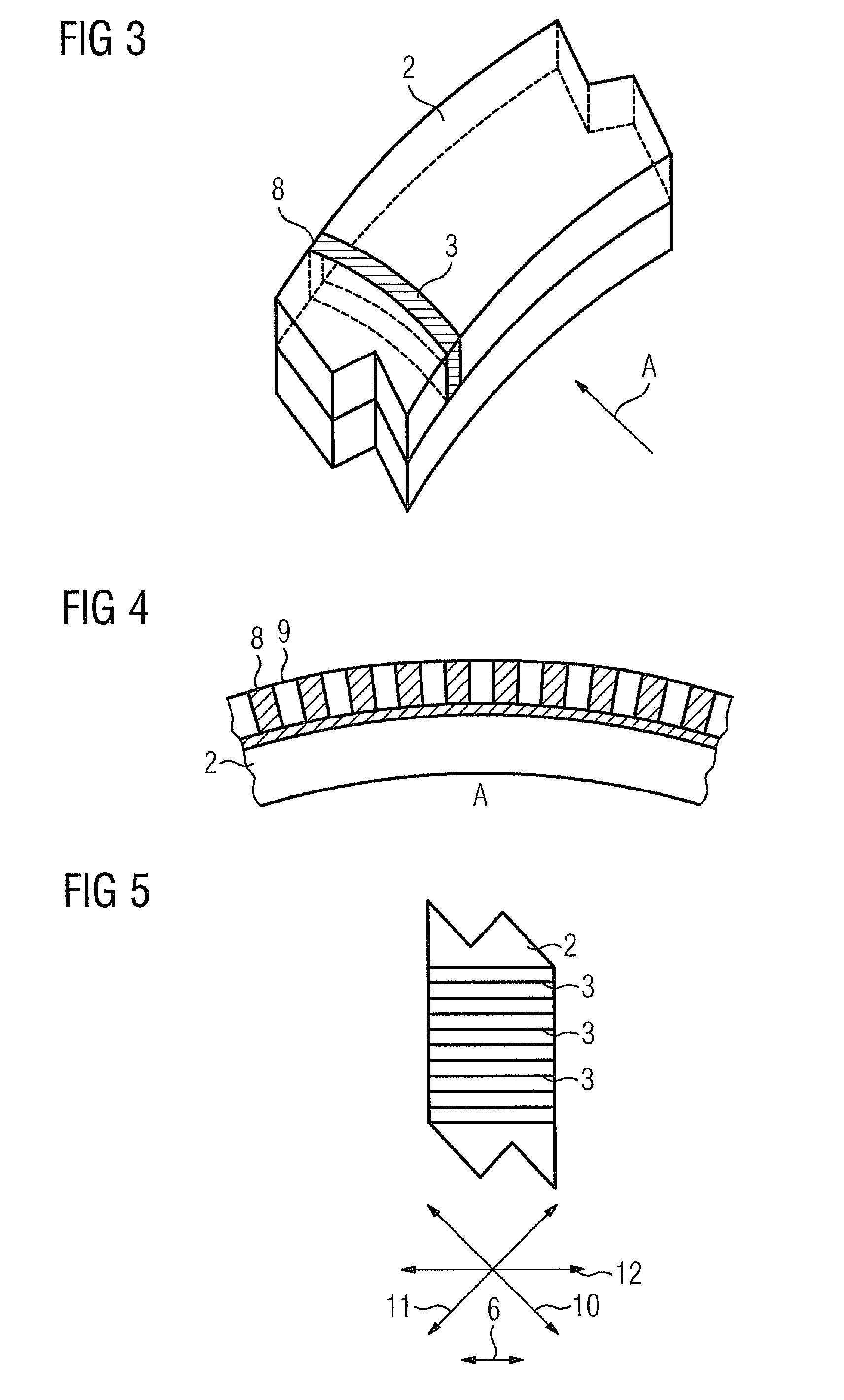

Efficient driven vibration insulation and reduction platform imitating physiological structure of head of woodpecker

ActiveCN103486194AOvercoming structural complexityOvercome the disadvantages of energy consumptionNon-rotating vibration suppressionVariable stiffnessInsulation layer

The invention discloses an efficient driven vibration insulation and reduction platform imitating the physiological structure of the head of a woodpecker. The efficient driven vibration insulation and reduction platform comprises a driven vibration-reduction assembly, a variable-stiffness various-damping air spring assembly, a combination bearing platform and an outer frame, the driven vibration-reduction assembly comprises a hard rubber pad and a cutting type viscoelastic damper, the variable-stiffness various-damping air spring assembly comprises two or more than two double-air-chamber air springs which are symmetrically distributed along a machine base, the combination bearing platform comprises a top board, a bottom board and side boards, wherein the top board, the bottom board and the side boards are made of steel boards, insulation layers are arranged among the top board, the bottom board and the side boards, and the outer frame is symmetrically arranged on two sides of the machine base. The efficient driven vibration insulation and reduction platform imitating the physiological structure of the head of the woodpecker has no acting part and is low in energy consumption. Compared with a vibration-reduction platform under driving control, the efficient driven vibration insulation and reduction platform can greatly lower manufacturing cost and operation cost, save energy, and be economical and practical.

Owner:SHANDONG UNIV

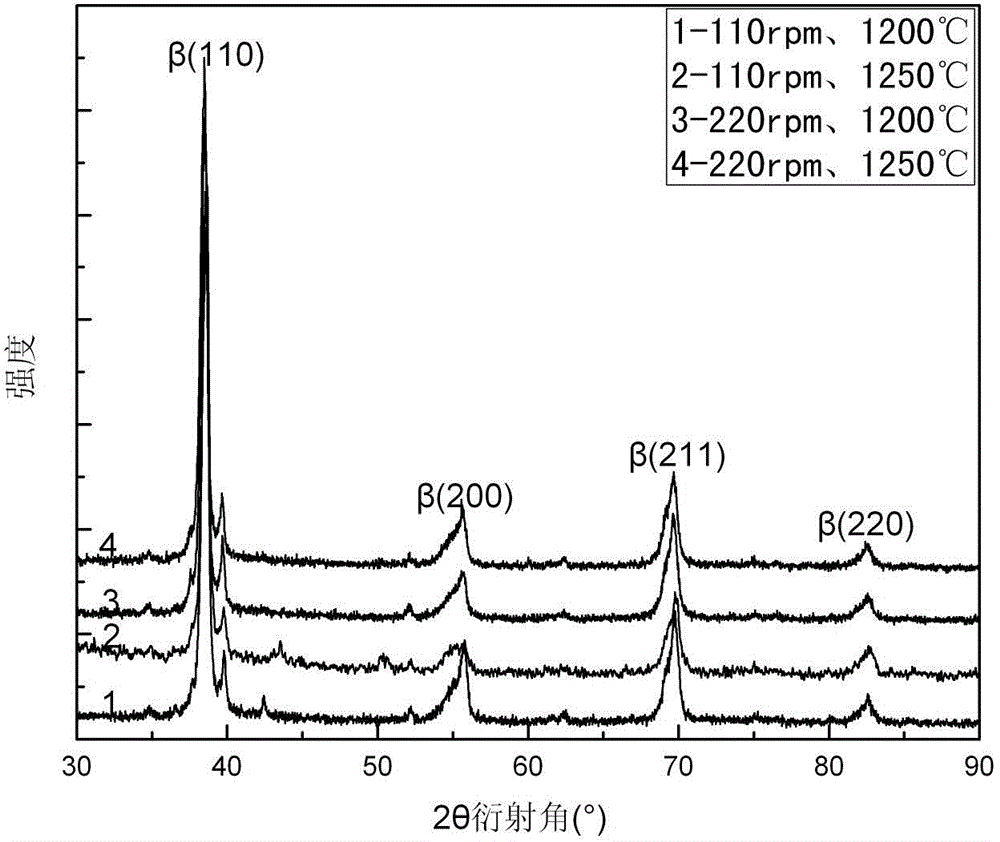

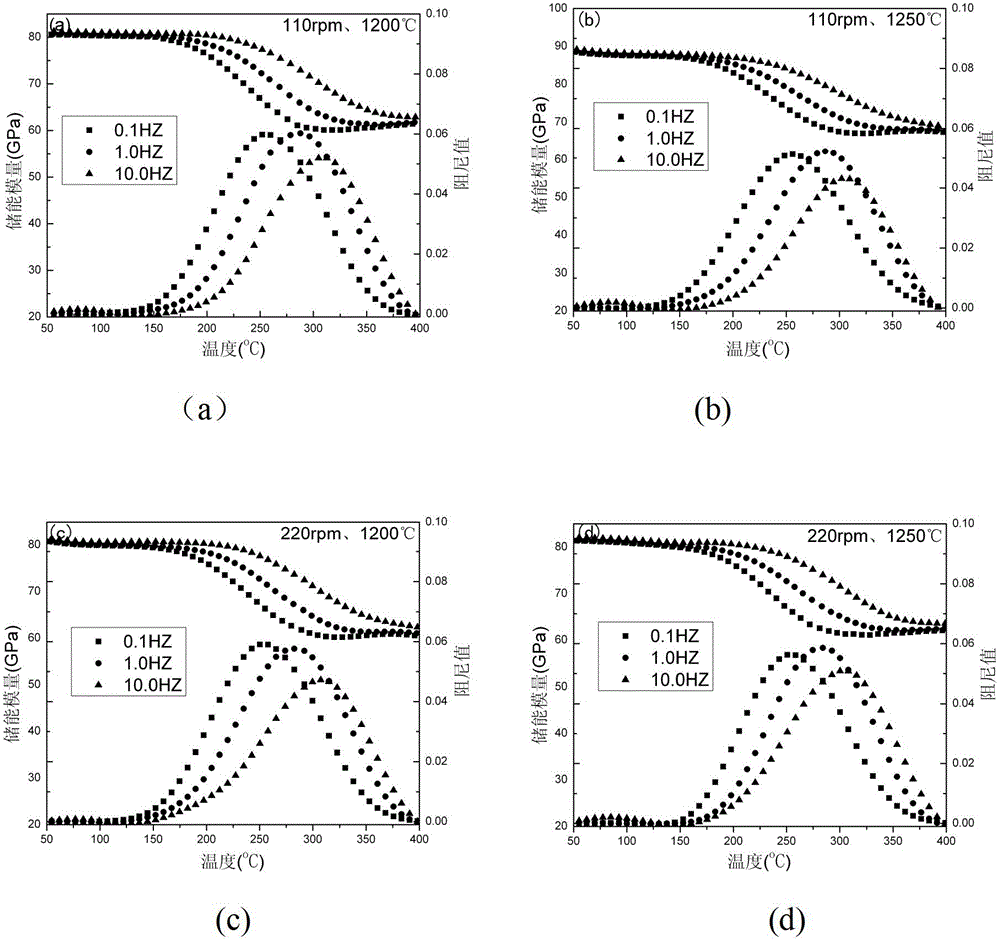

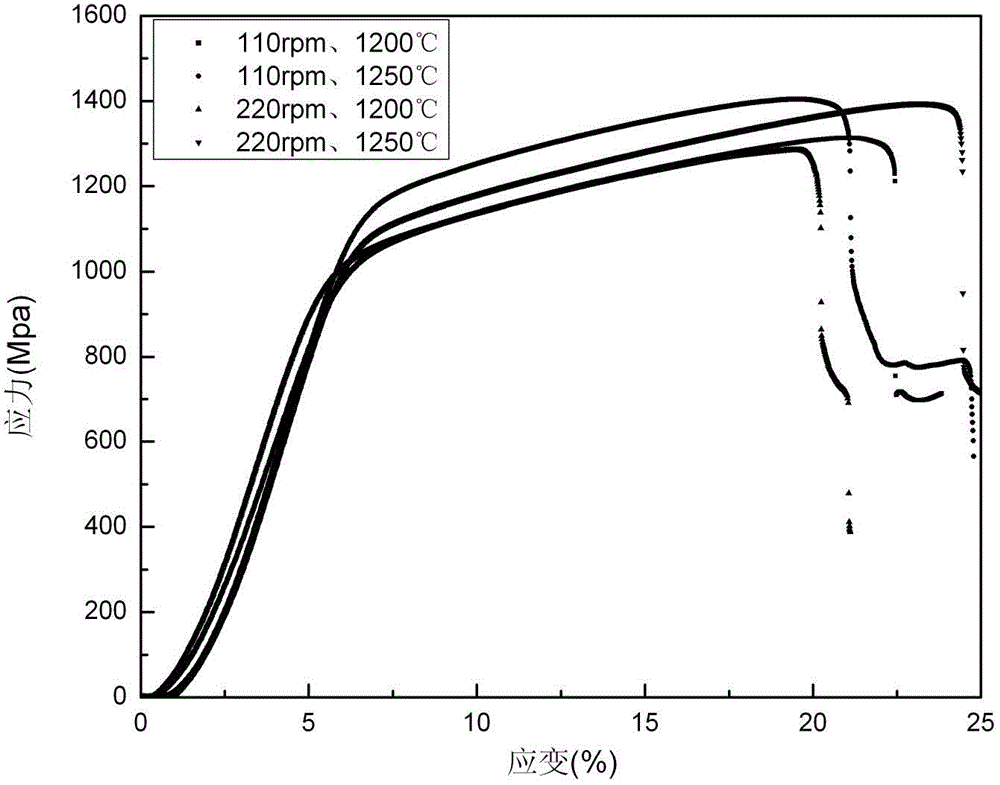

Ti-Nb-O high damping titanium alloy and powder metallurgy preparation method thereof

The invention discloses a Ti-Nb-O high damping titanium alloy and a powder metallurgy preparation method of the Ti-Nb-O high damping titanium alloy. The alloy comprises the following elements in percentage by atoms: 25 percent of Nb, 1.5 percent of O and the balance of Ti. The alloy is a metastable beta type high damping titanium alloy and is prepared by adopting the powder metallurgy method; and the high damping titanium alloy with excellent damping performance and mechanical property is obtained by adopting a ball milling, cold pressing and sintering method and regulating a powder metallurgy technology. The high damping titanium alloy can be used at the temperature between 200 and 350 DEG C, has the advantages of high damping value, high mechanical property and the like, and can be developed and used in a method for preparing high damping materials.

Owner:TIANJIN UNIV

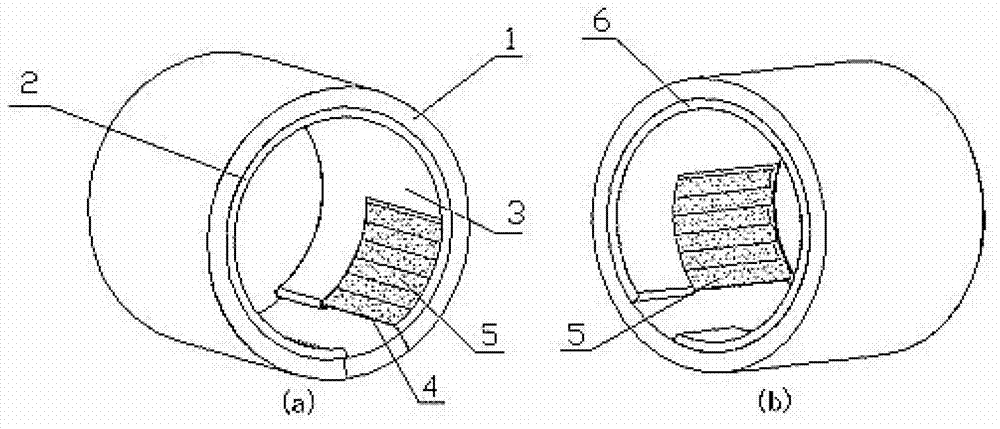

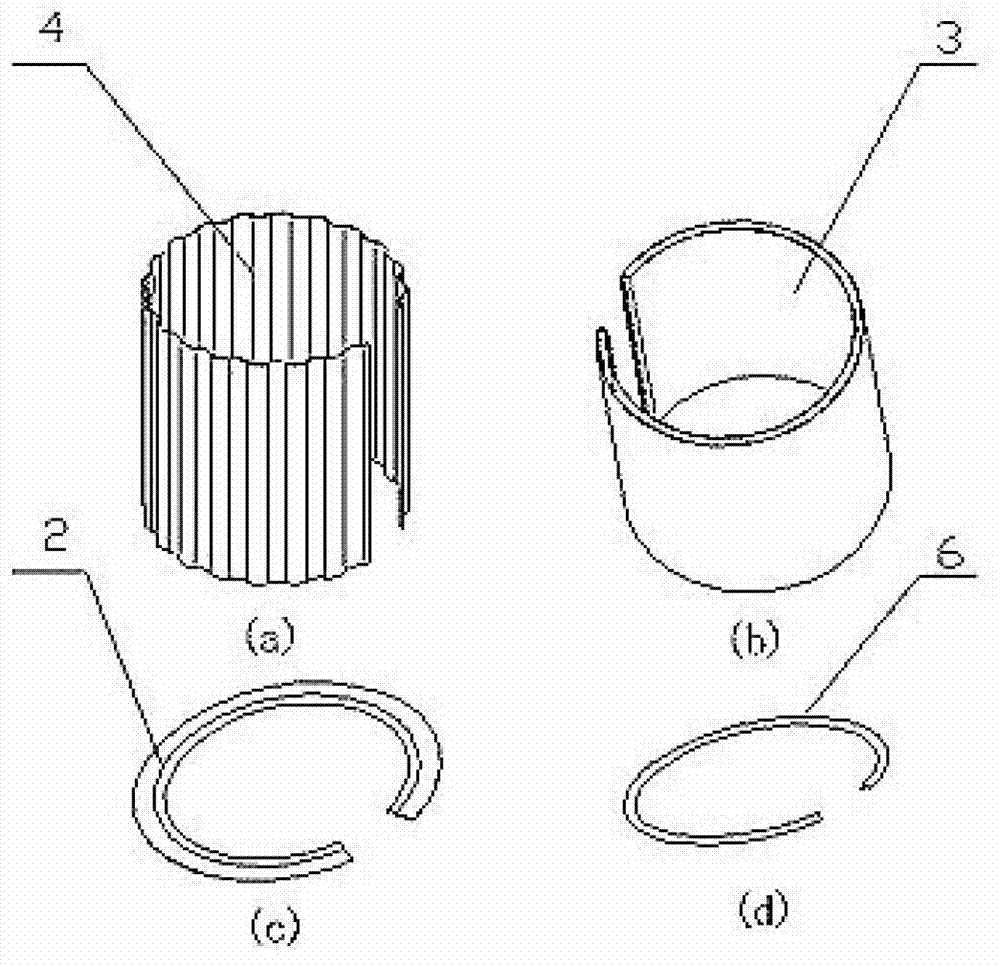

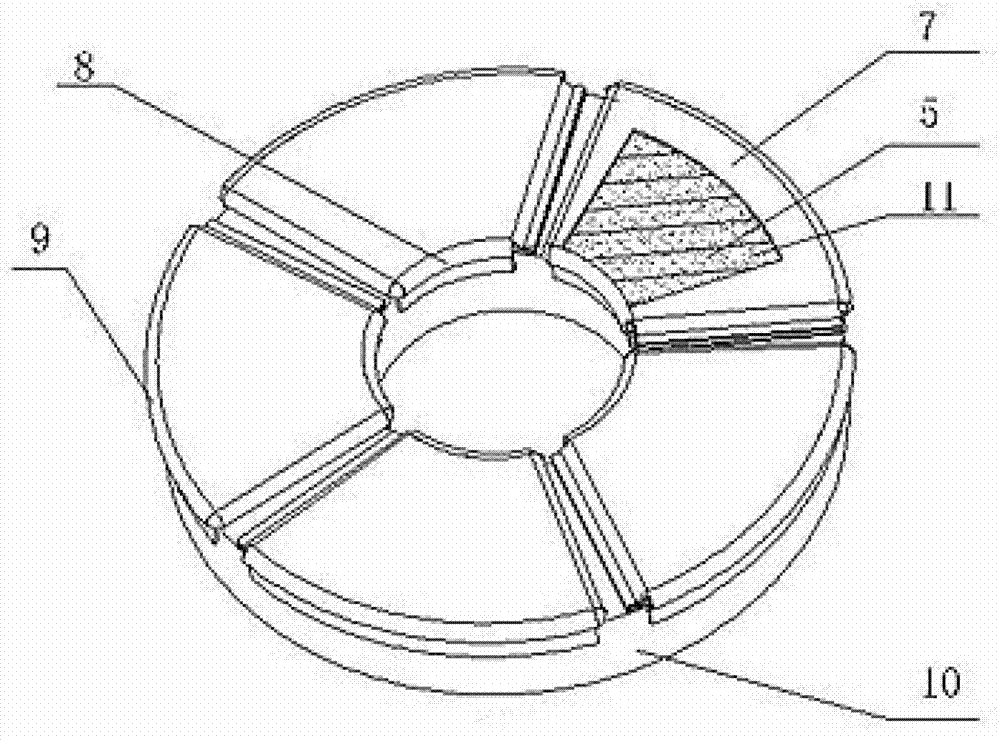

High damping foil dynamic pressure gas bearing filled with metal particles

ActiveCN102954102AHigh damping valueIncrease stiffnessSliding contact bearingsTemperature resistanceInstability

The present invention relates to a high damping foil dynamic pressure gas bearing filled with high temperature resistance metal particles, wherein a base structure comprises sleeve foil and an elastic foil bearing substrate. The gas bearing is characterized in that high temperature resistance metal particles are filled into a position between foils or a gap of the foil and are sealed, the metal particles produce friction during bearing working, and energy of vibration impact is absorbed so as to increase bearing damping. Compared with the existing foil gas bearing structure, the gas bearing of the present invention has the following characteristics that: the gap inside the foil is completely utilized, filling of the metal particles into the gap is adopted to improve bearing damping so as to solve the problem of easy instability of the gas bearing during high-speed operation to a certain degree and improve reliability of the gas bearing.

Owner:HUNAN UNIV

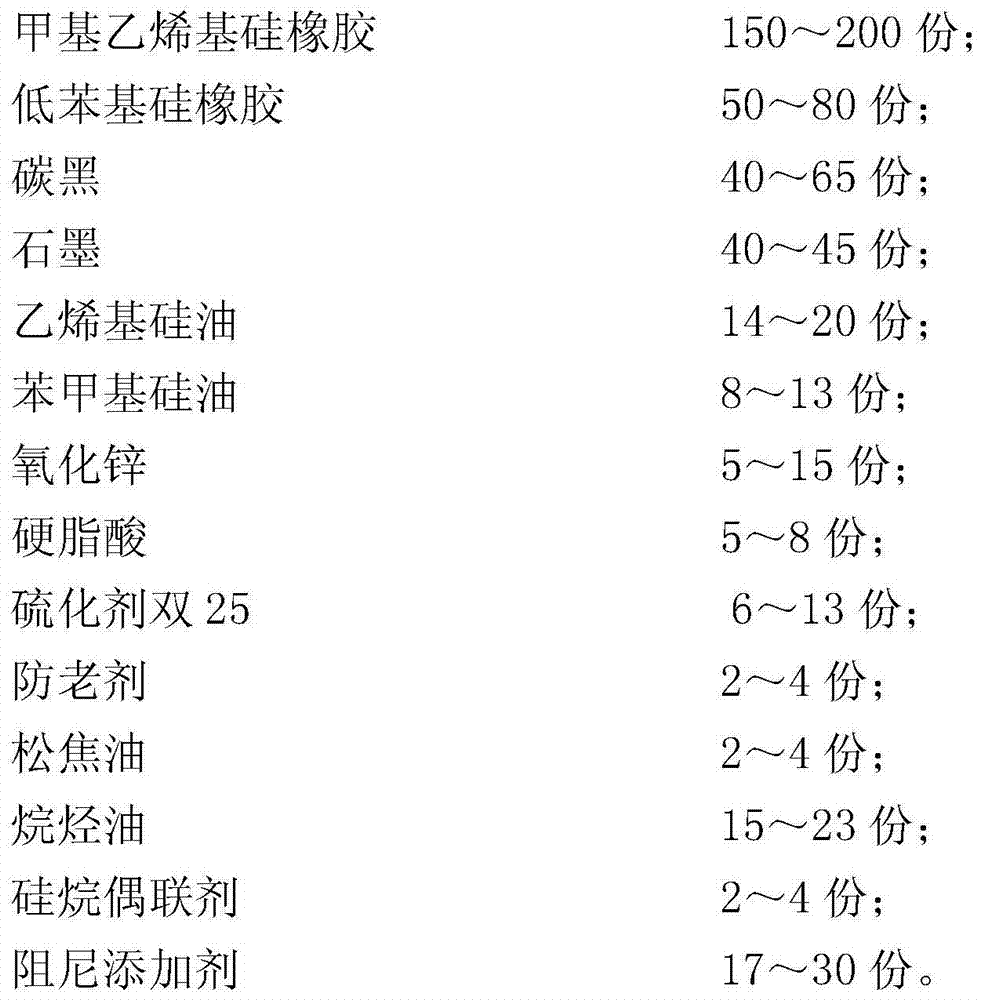

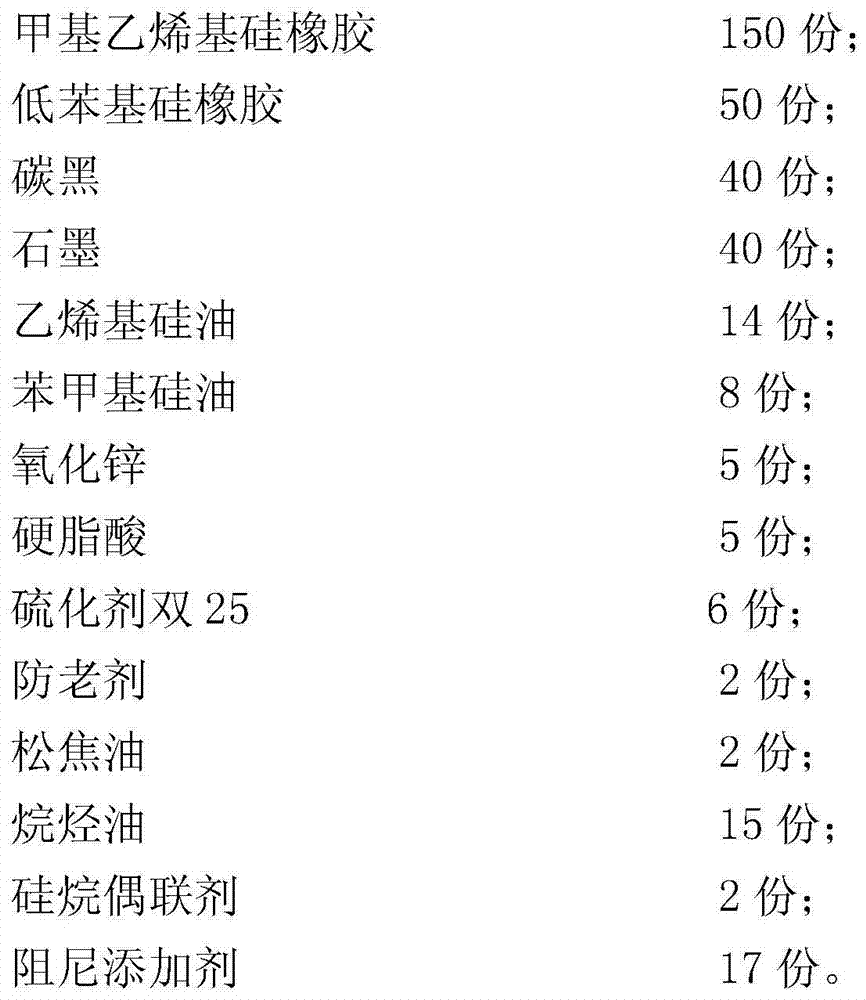

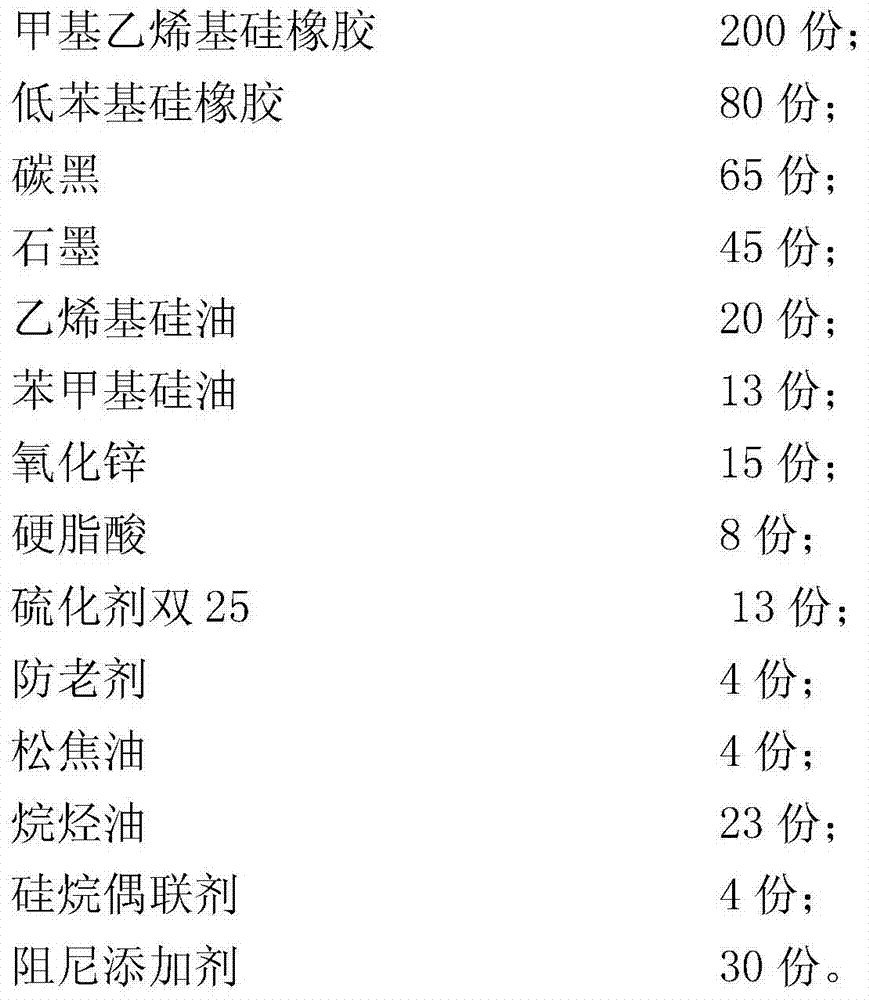

High-damping silicon rubber

The invention discloses high-damping silicon rubber comprising the following components in parts by weight: 150-200 parts of methyl vinyl silicone rubber, 50-80 parts of low-phenyl silicon rubber, 40-65 parts of carbon black, 40-45 parts of graphite, 14-20 parts of vinyl silicone oil, 8-13 parts of phenyl methyl silicone oil, 5-15 parts of zinc oxide, 5-8 parts of stearic acid, 6-13 parts of 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, 2-4 parts of an anti-aging agent, 2-4 parts of pine tar, 5-23 parts of alkane oil, 2-4 parts of a silane coupling agent and 17-30 parts of a damping additive. The high-damping silicon rubber disclosed by the invention has the advantages of low cost, high damping value, good shock absorption effect and the like.

Owner:SUZHOU JIN TENG ELECTRONICS TECH

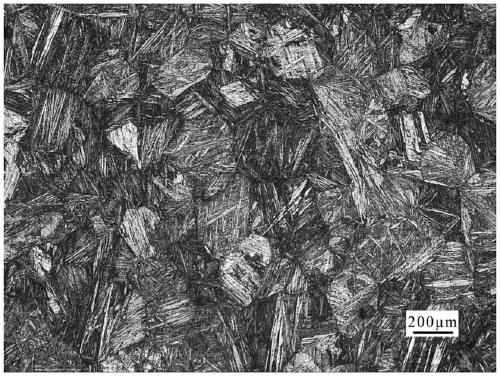

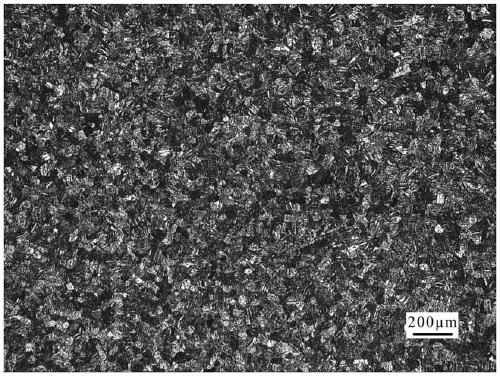

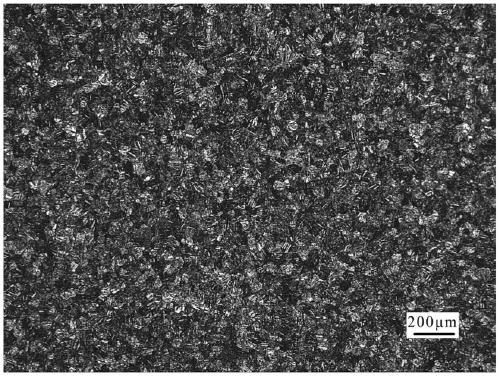

Preparation method of fine-grain cualmn shape memory alloy

The invention discloses a preparing method for a fine grain CuAlMn shape memory alloy and relates to a physical structure changing a copper-base alloy. The preparing method comprises the steps: preparing an Al-based LaScB nucleating agent thin strip; and preparing the fine grain CuAlMn shape memory alloy. By designing the new Al-based LaScB nucleating agent and using its nucleating and refining actions, the fine grain CuAlMn shape memory alloy of which the mechanical property is obviously improved while the high damping characteristic is kept is prepared, and the defects that the grain refining effect of the copper-base shape memory alloy in the prior art is insufficient, and the development trend of the current mechanical equipment to the requirements of high speed, efficiency, intelligentization and automation cannot be met are overcome.

Owner:HEBEI UNIV OF TECH

Twist drill

InactiveUS20020170752A1Improve efficiencyImprove guidanceDrill bitsDrilling rodsEngineeringMechanical engineering

A twist drill including a spiral-forming hollow shaft (3) having a spiral-shaped inner surface, and drilling head(5) and shank (6) connected with the shaft (3) at its opposite ends, respectively; and a method for forming such a twist drill.

Owner:HILTI AG

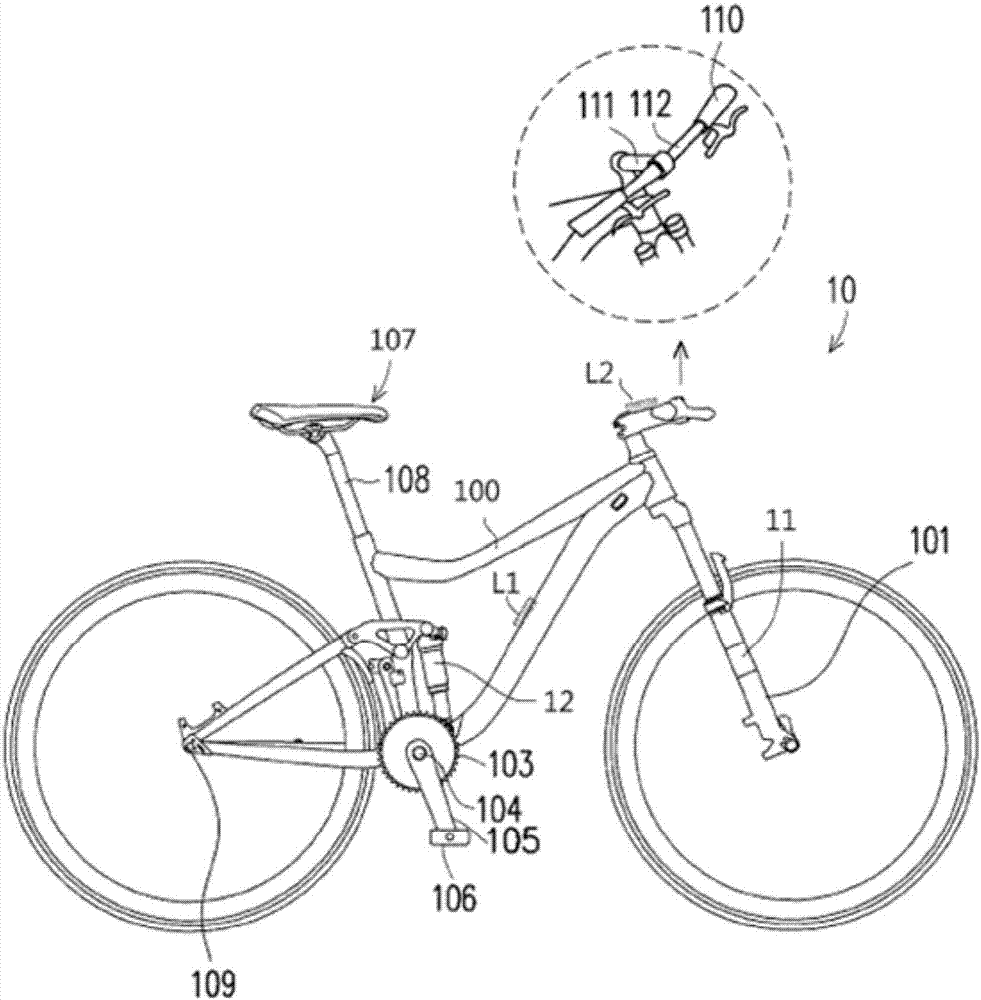

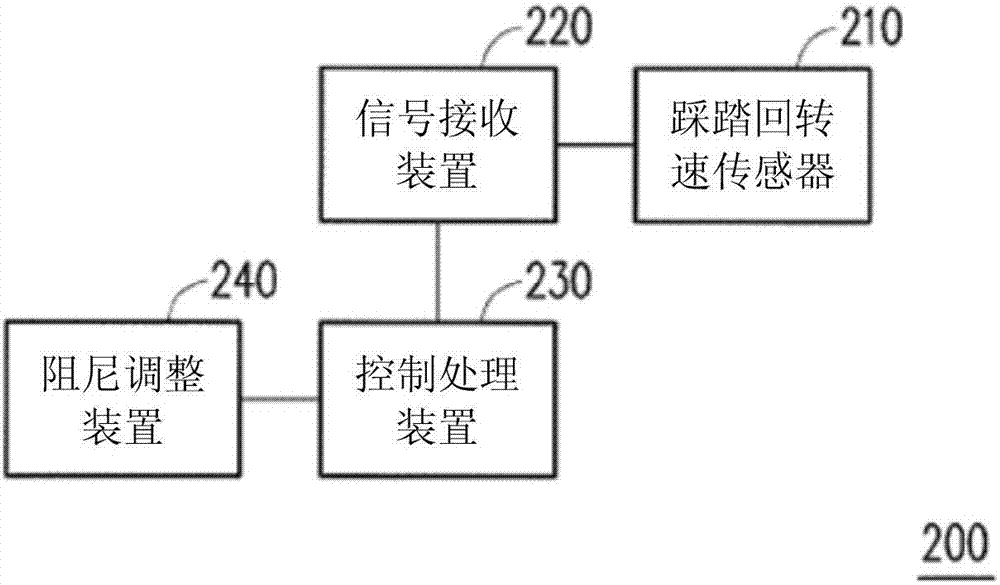

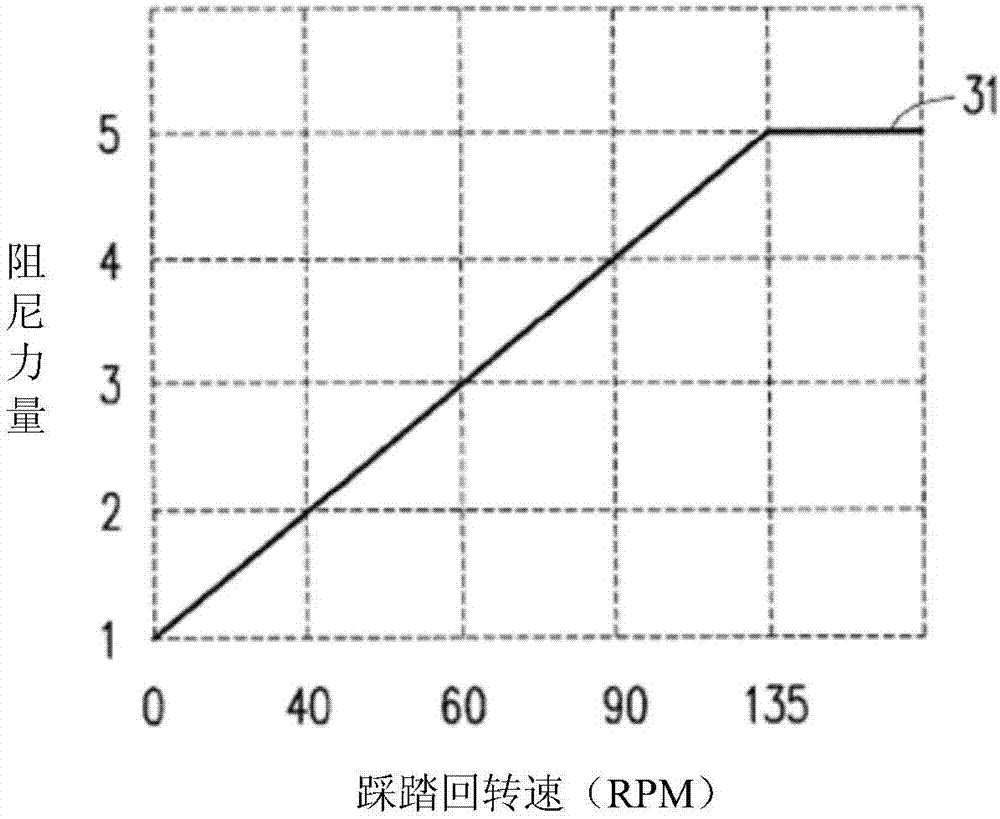

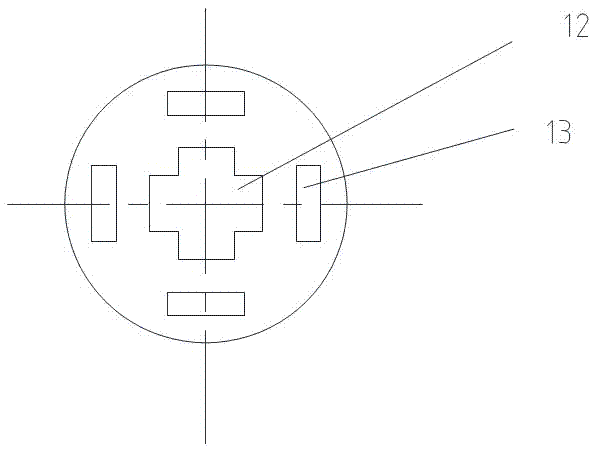

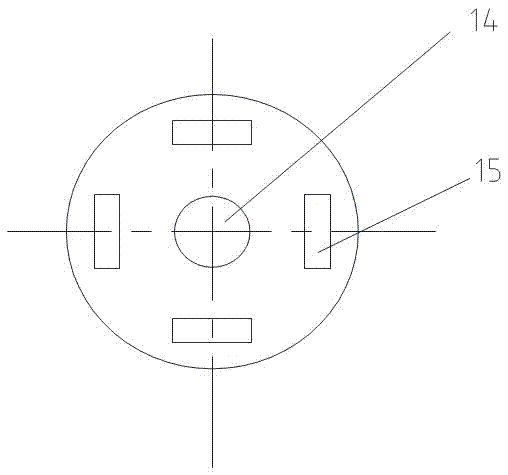

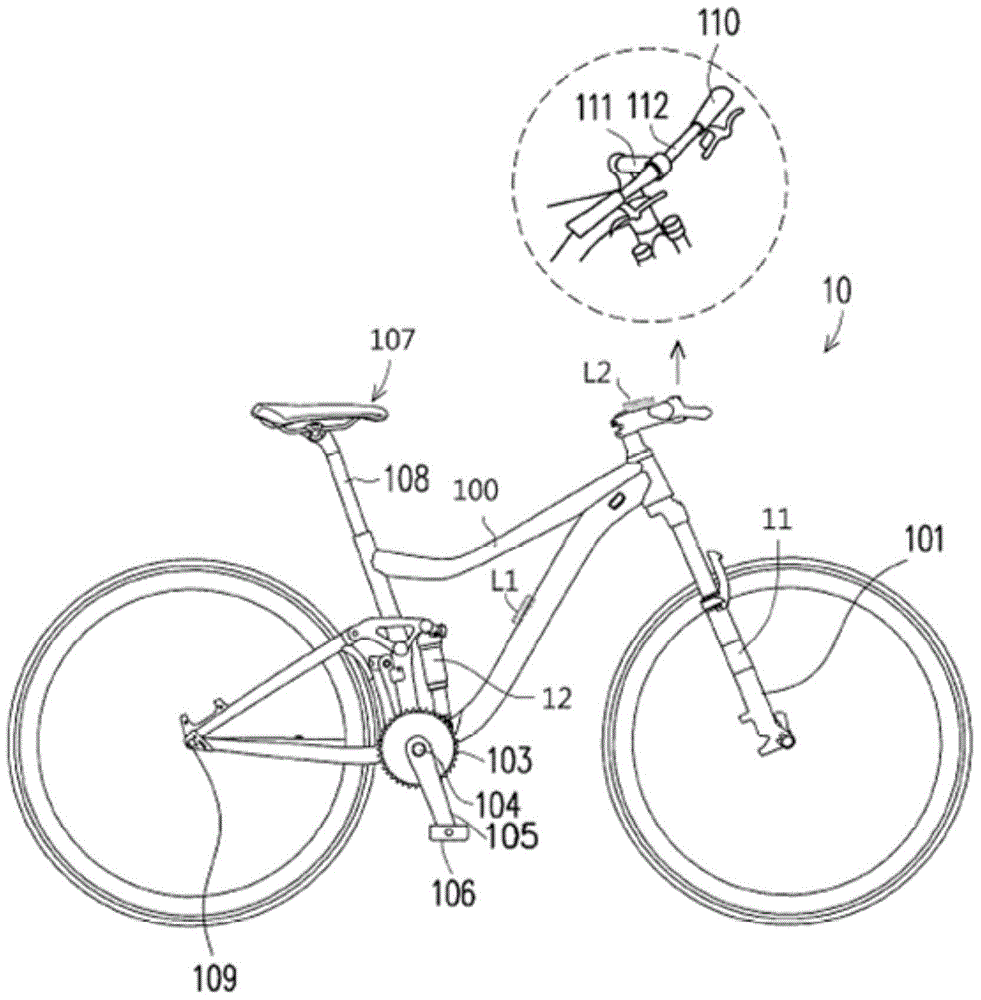

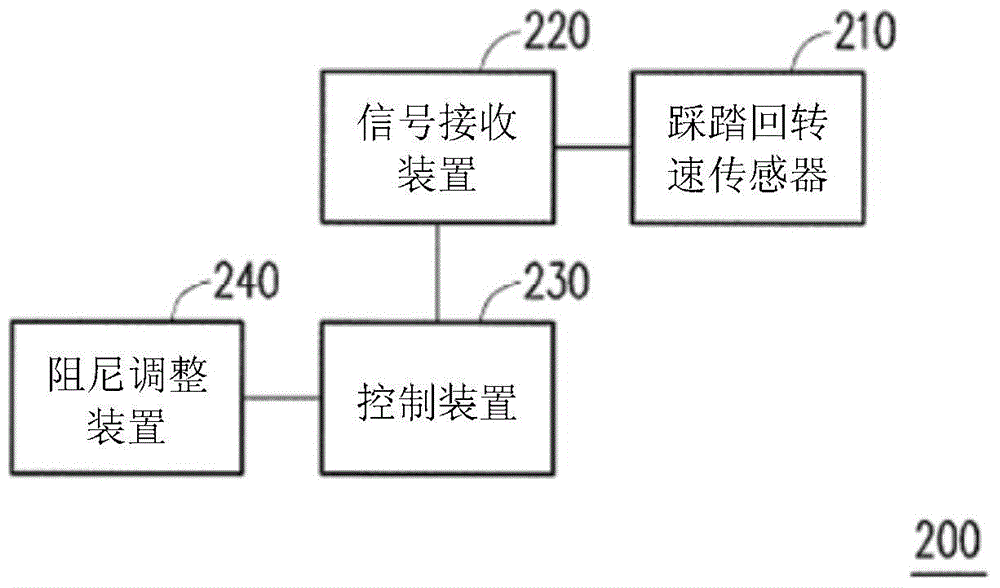

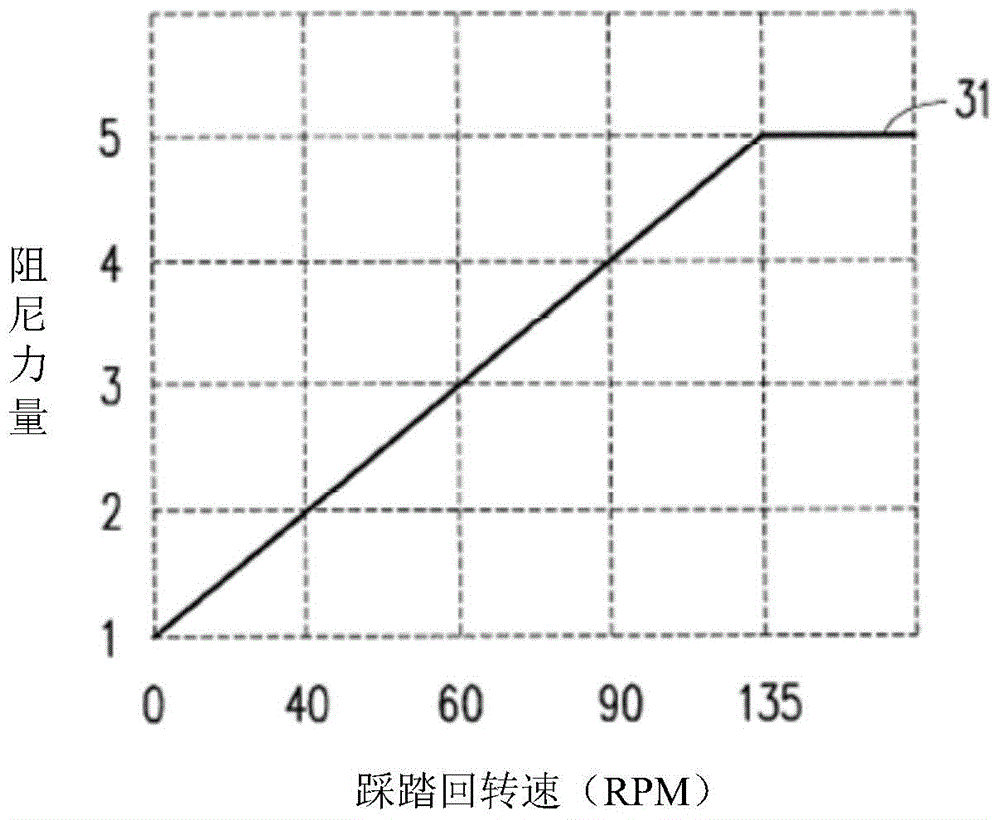

Automatic shock absorber system for bicycle

ActiveCN107097892AHigh damping valueSuppress energy lossSpringsAxle suspensionsAutomatic controlControl signal

An automatic control shock absorber system for a bicycle is provided. A pedaling cadence sensor is configured to detect a pedaling cadence of the bicycle. A control processing device outputs a level control signal to a damping adjustment device according to a pedaling signal such that the damping adjustment device adjusts a level of a damping force according to the level control signal.

Owner:GIANT MFG

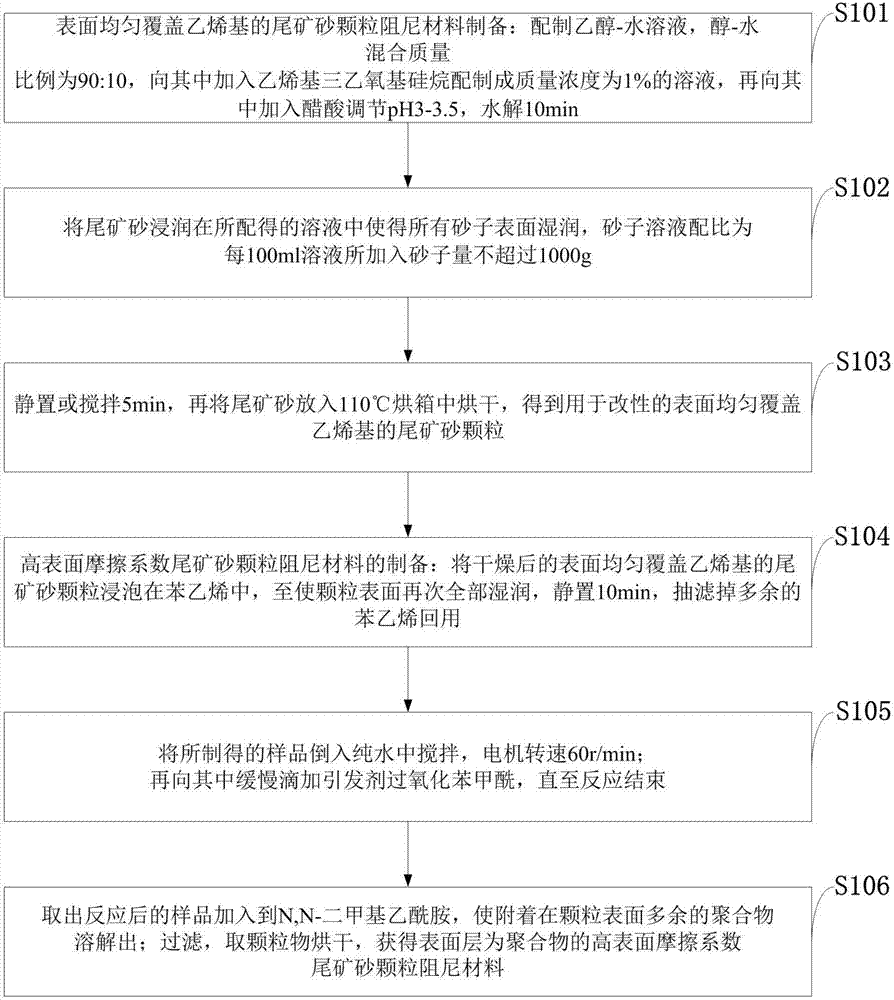

Preparation method of surface friction coefficient and viscosity modified iron mine tailing damping material

The invention belongs to the technical field of preparation of damping materials, and discloses a preparation method of a surface friction coefficient and viscosity modified iron mine tailing damping material. The method comprises the following steps: carrying out stepped modification by using vinyltriethoxysilane and styrene; uniformly covering the surface of mine tailing with a layer of vinyl groups by using the vinyltriethoxysilane as a preliminary modifier of the surface of the mine tailing, and controlling the content of the vinyltriethoxysilane to be 1% of the mass of an ethanol and mixed water solution comprising ethanol and a water solution according to a mass ratio of 90:10; and initiating polymerization with potassium persulfate by using the styrene as a secondary modifier to produce mine tailing with the surface being uniformly covered with a layer of polymer in order to regulate the damping performance of particles from the surface friction coefficient and the surface structure. The method changes the component structure of the surface of the mine tailing, increases the surface friction coefficient, changes the viscosity, and makes the damping value of the modified damping material 10% higher than that of common granular damping materials.

Owner:NANCHANG HANGKONG UNIVERSITY

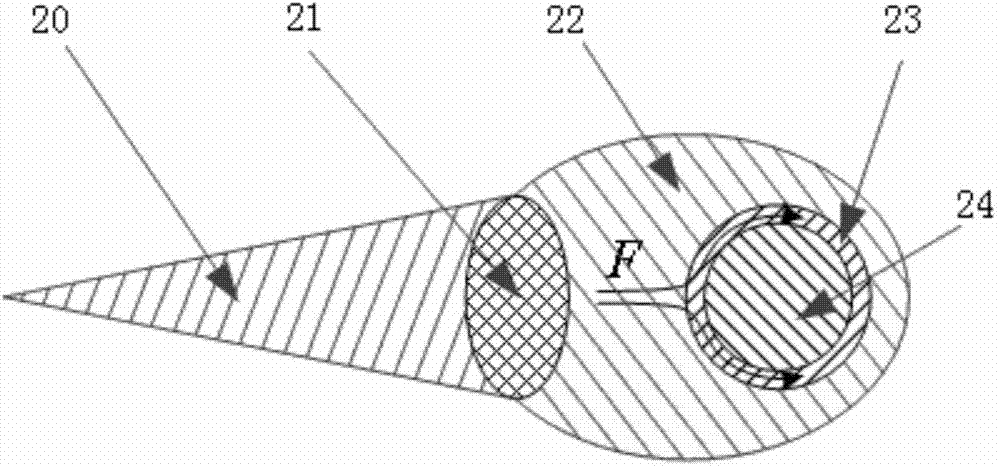

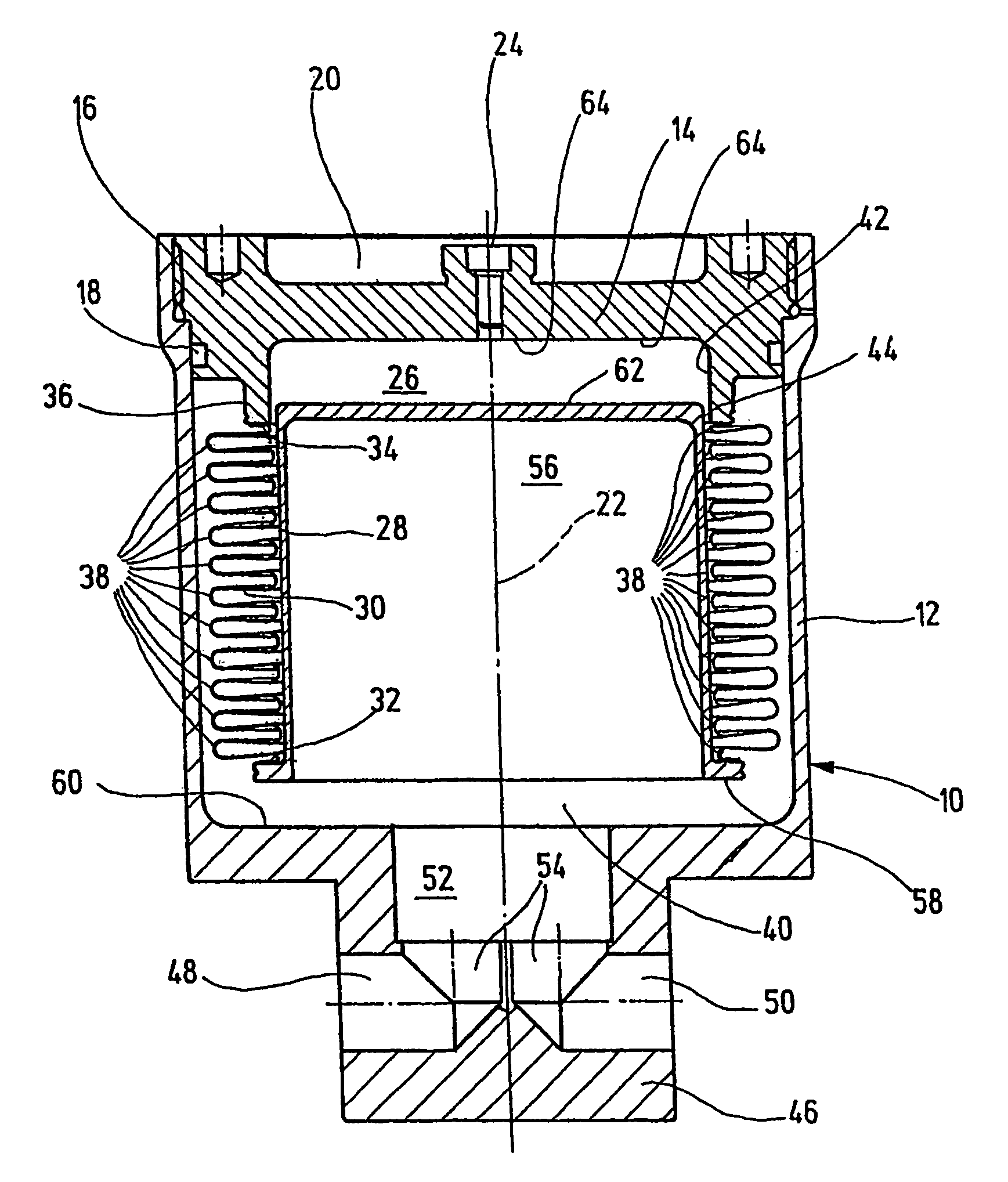

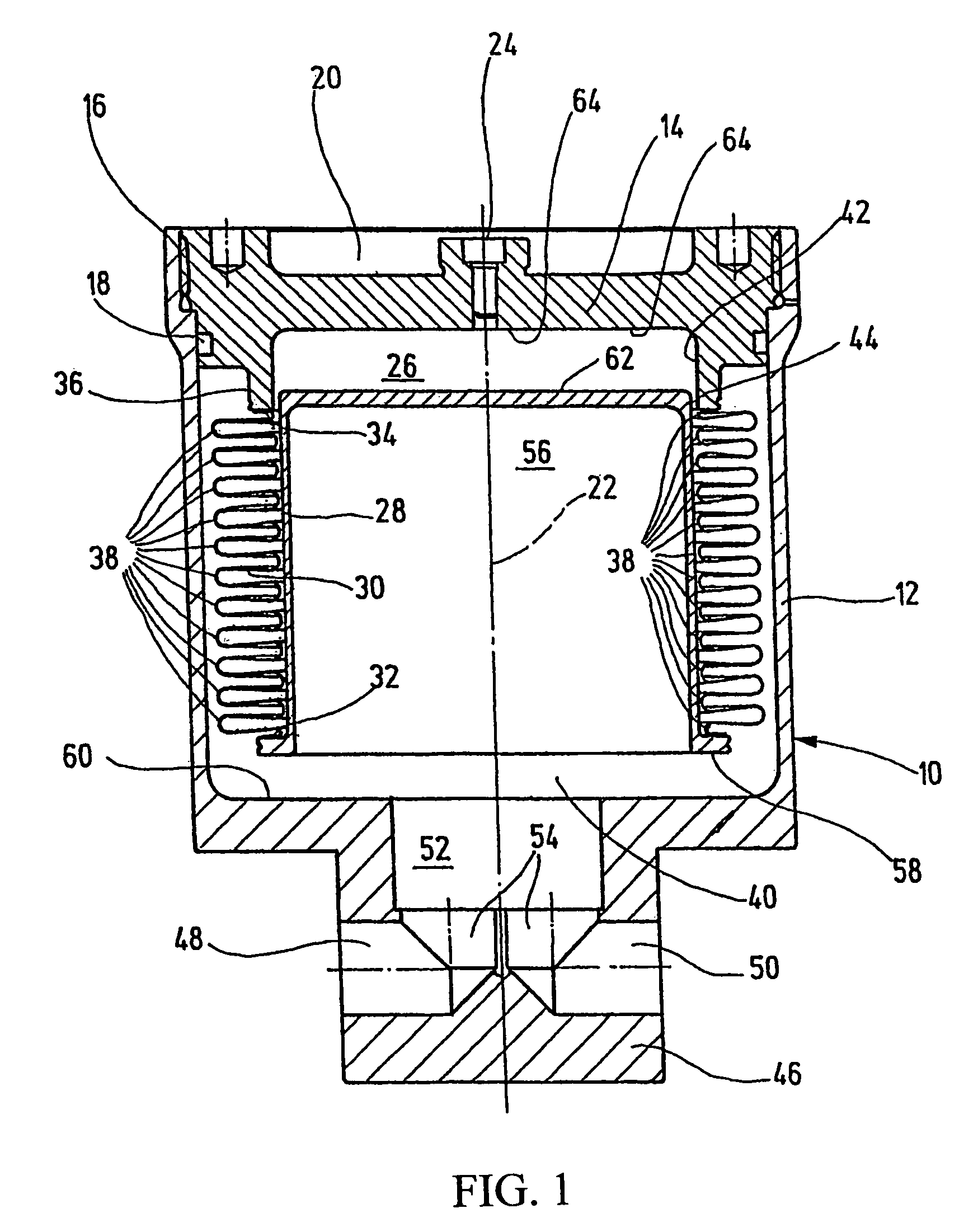

Pressure accumulator, especially pulsation damper

ActiveUS7857006B2Substantial measureGuaranteed uptimeAccumulator installationsPipe elementsEngineeringGas chamber

A pressure accumulator, especially a pulsation damper, includes an accumulator housing (10) and a piston element (28) disposed in it. A bellows-type separative element (30) is supported on the piston part (28) with its one end (32) and with its other end (34) on the accumulator housing (10). The separative element (30) separates two working chambers (26, 40) within the accumulator housing (10) from each other, especially a gas chamber (26) from a fluid chamber (40), in a fluid-tight, especially gas-tight manner. To one working chamber (26), in addition to a defined volumetric proportion of a working gas, is filled with a fluid. In this manner, the working gas allows for a compression to a certain degree and for a dampening and smoothening of the pulsations of the fluid medium migrating to and occurring on the fluid side of the accumulator.

Owner:HYDAC TECH GMBH

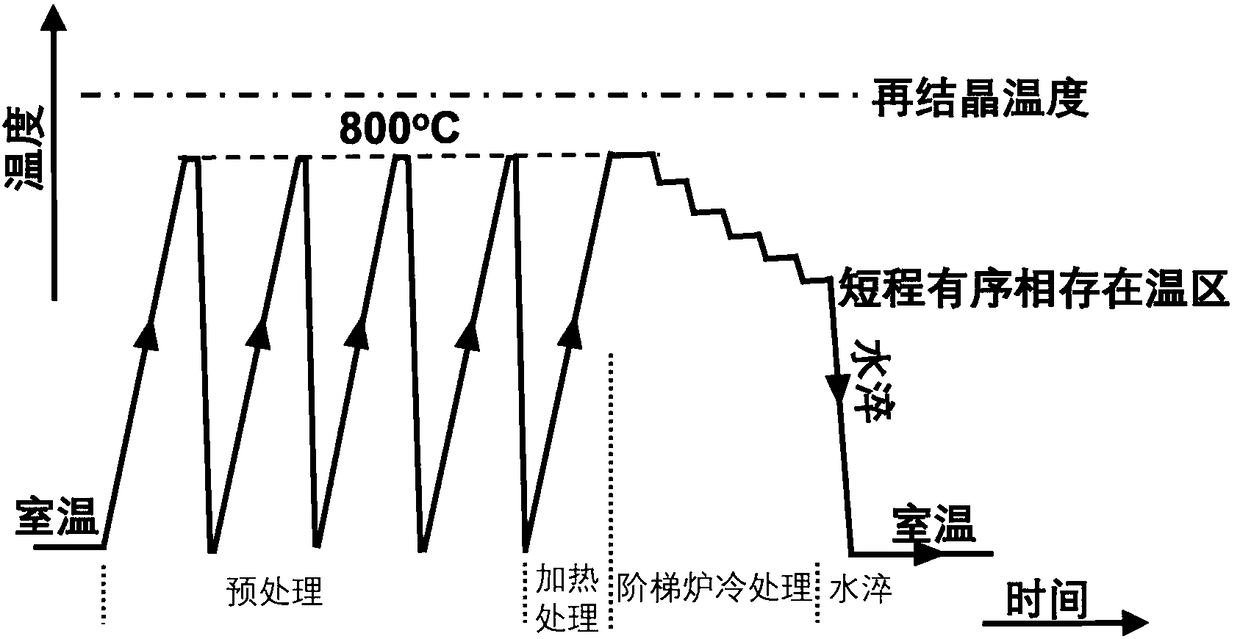

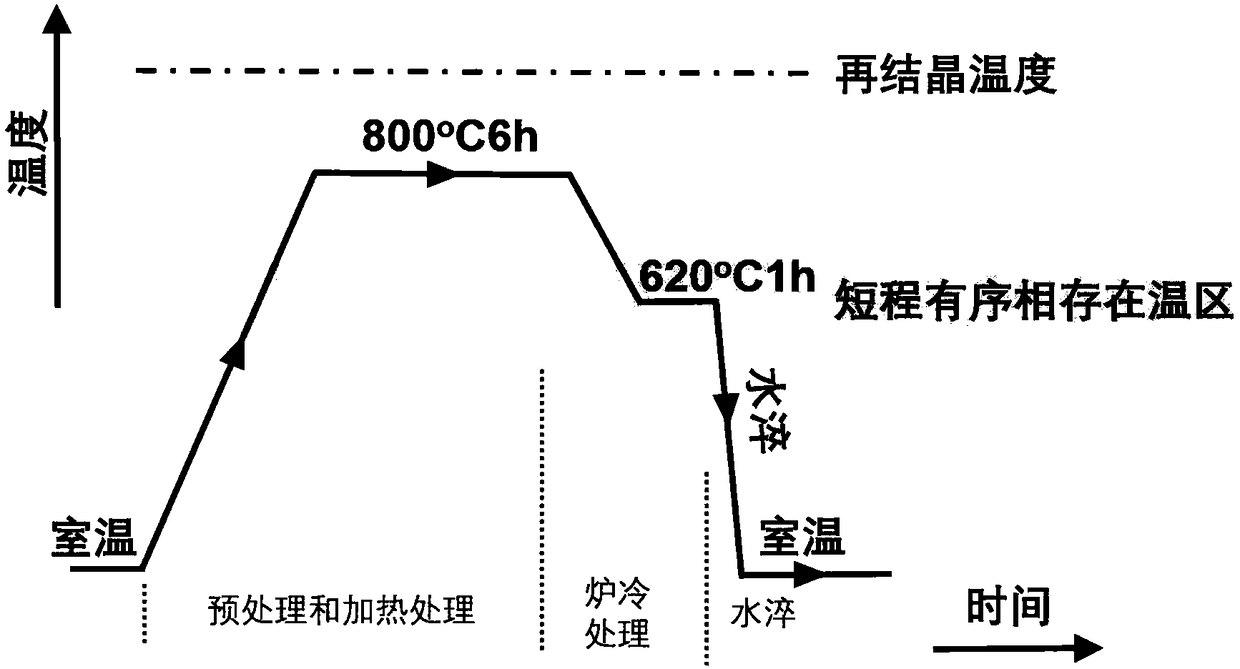

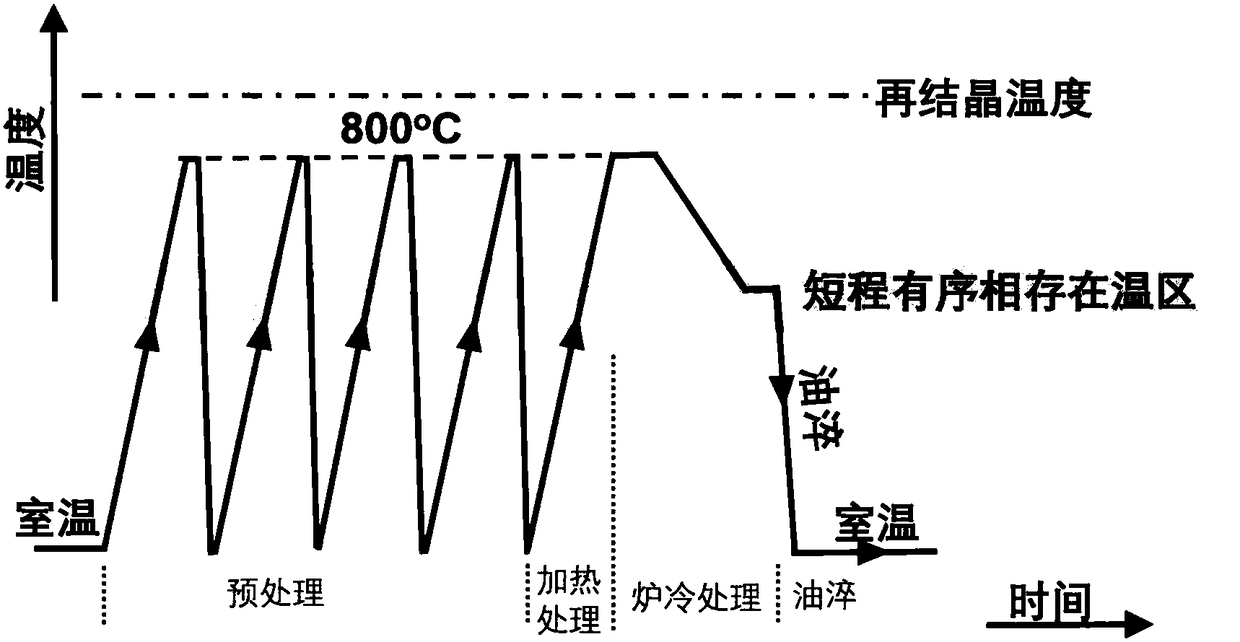

Heat treatment method of FeGa-based high damping alloy

The invention discloses a heat treatment method of FeGa-based high damping alloy. The method comprises the steps: eliminating the inner defects of a material by pretreatment, then heating to 800 DEG Cat the heating rate of 120 DEG C / h and remaining for 1h, furnace-cooling to 580-660 DEG C at the rate of 120 DEG C / h and remaining for 0.5h, and thus enabling the inner temperature of the material tobe uniform; and fully conducting order-disorder transition and phase transition, and finally conducting quenching treatment. Compared with the current heat treatment process, the method can greatly improve the intrinsic damping performance of the material at low amplitude (at least 120*10-6), the damping value is increased for 1.5-3 times compared with an original sample, and the damping value isincreased for 2-3.5 times compared with the traditional heat-treated Fe-based high damping material. Meanwhile, the method has the advantages that the whole heat treatment process is conducted belowrecrystallization temperature, the damping performance of the material is greatly improved, and the mechanical properties of the material is almost not damaged.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

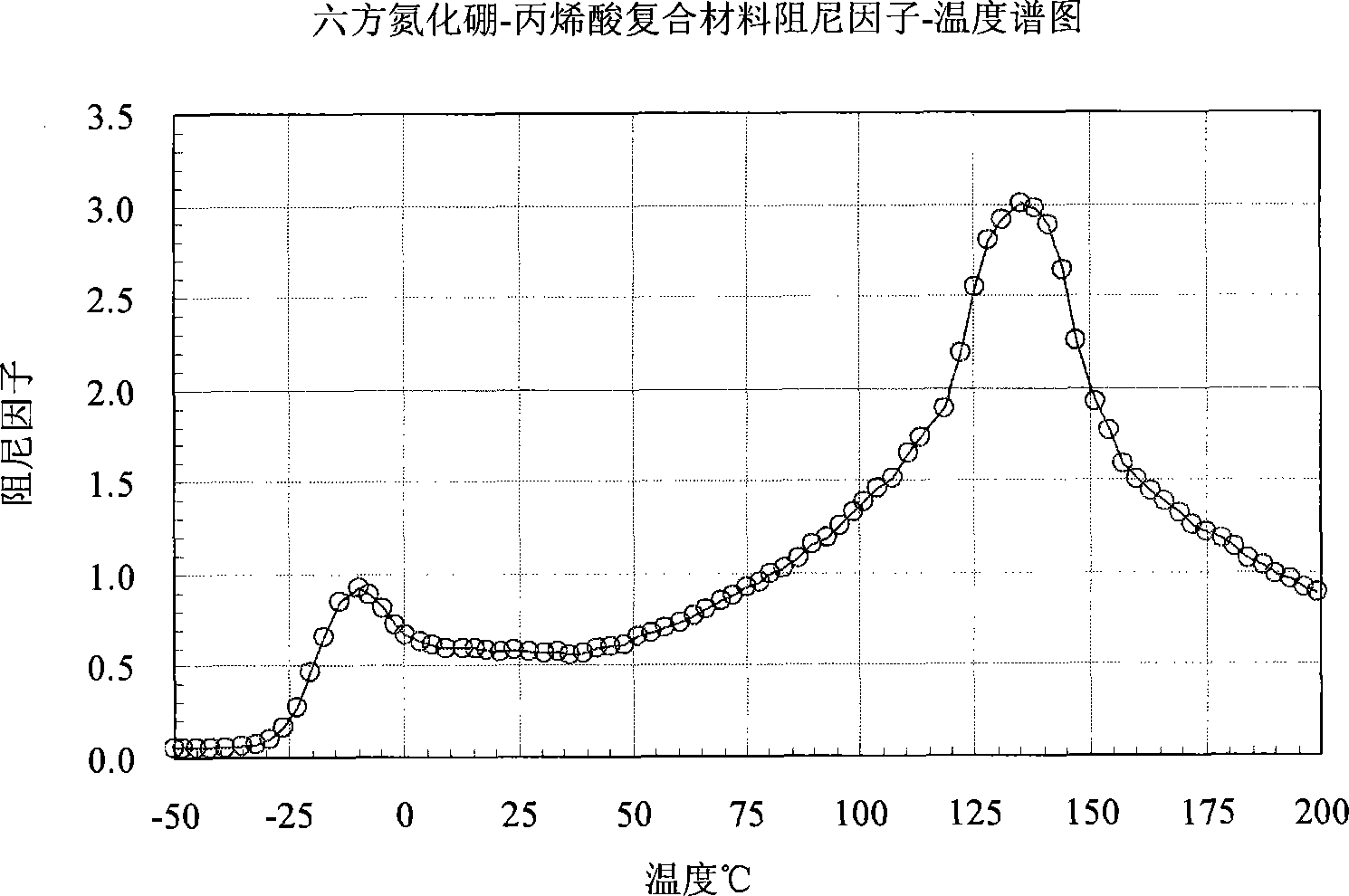

Method for preparing wide temperature range high damping acrylic emulsion material

InactiveCN101250246BThe synthesis process is simpleDoes not affect the preparation methodDamping factorEmulsion

The invention relates to a preparation method of acrylic emulsion function material which is composited from inorganic and organic, with wide temperature range and high damping property, belonging to the technical field of organic polymer material. The invention is characterized in that the invention uses acrylate as polymerization monomer, uses organic silicon as organic composite material, and uses nanometer boron nitride and mica as inorganic composite materials, without changing the synthesis of emulsion to prepare a serial of polymer material whose damping temperature is higher than 135DEG C and damping factor is higher than 0.30, wherein the damping factor of the best material is higher than 0.5 when in the damping temperature higher than 135DEG C. The polymerization method is characterized in that the invention can prepare interpenetrating network polymer damping material in short reaction via simple synthesis method.

Owner:UNIV OF SCI & TECH BEIJING

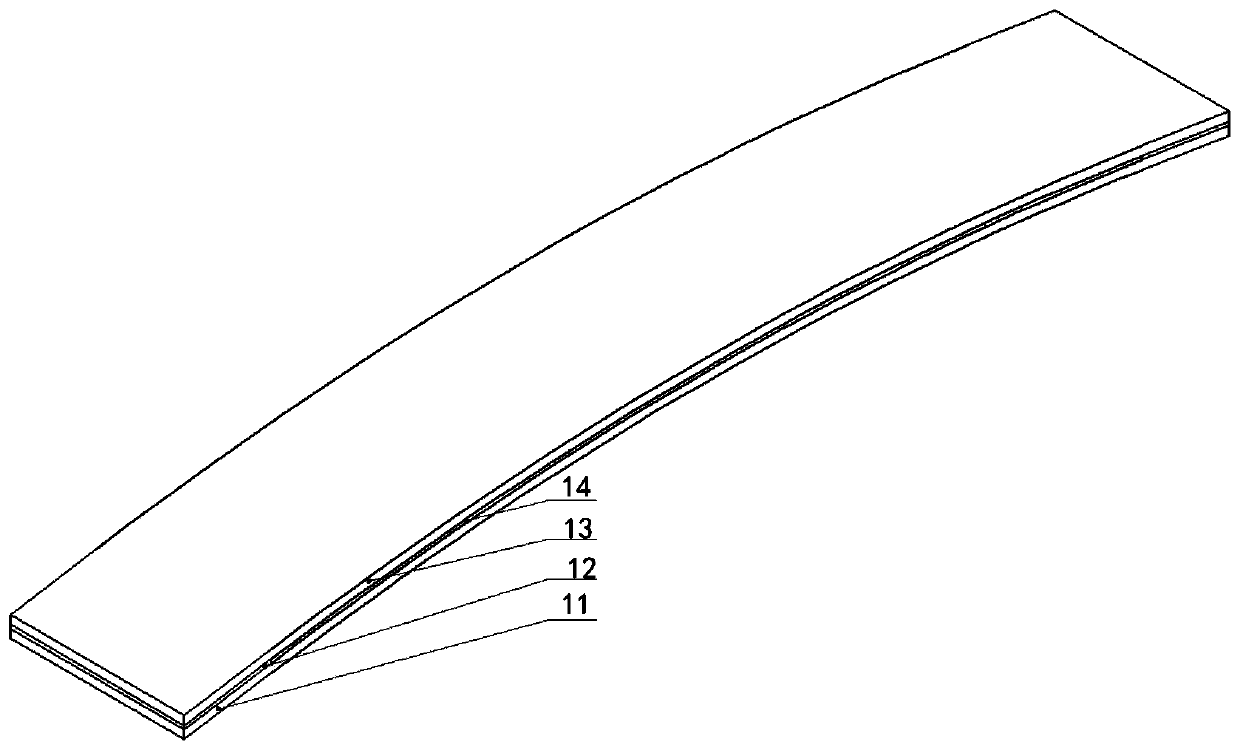

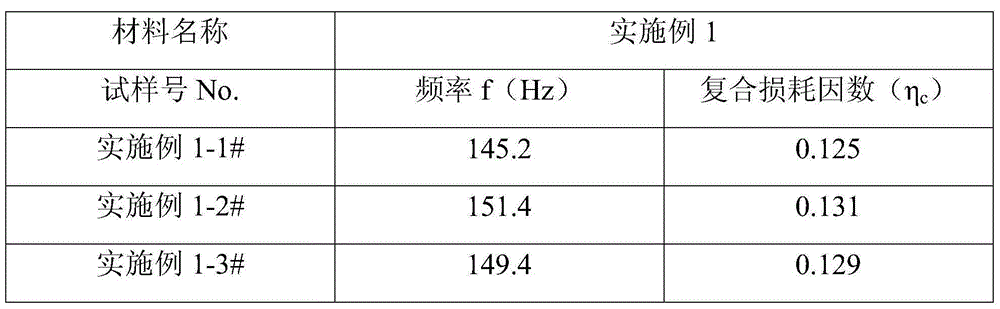

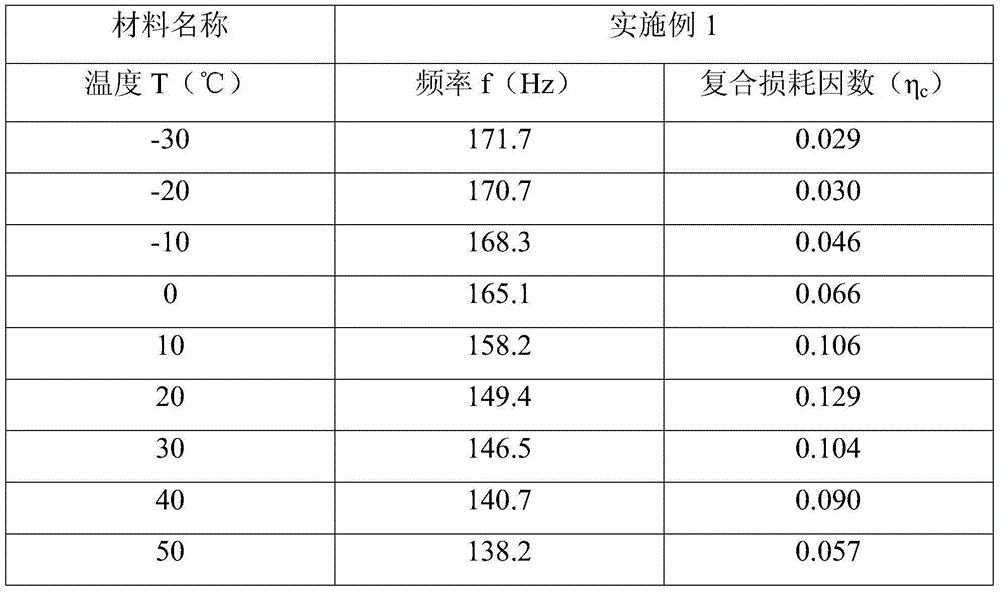

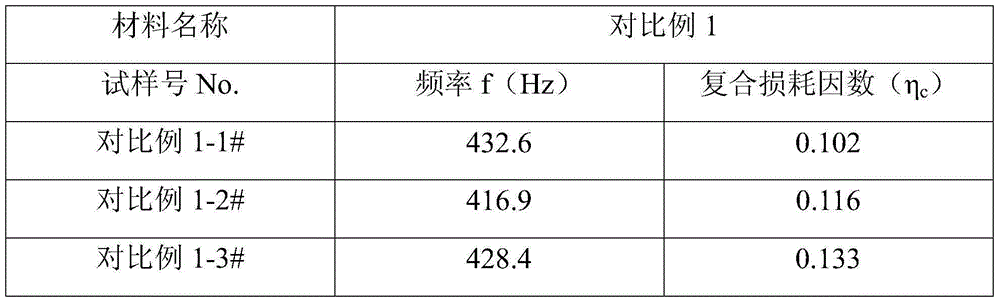

Environment-friendly thermoplastic composite damping rubber plate for vehicle and preparation method of environment-friendly thermoplastic composite damping rubber plate

InactiveCN107353656AHigh damping valueImprove thermal stabilitySynthetic resin layered productsLaminationEnvironmental resistanceMaterials preparation

The invention provides an environment-friendly thermoplastic composite damping rubber plate for a vehicle and a preparation method of the environment-friendly thermoplastic composite damping rubber plate and belongs to the technical field of material preparation. The environment-friendly thermoplastic composite damping rubber plate for the vehicle is formed by a damping layer, a viscoelastic layer and a bound layer by sequential compositing. For the preparation process, a damping layer plate and a bound layer plate are prepared firstly, and then the damping layer plate and the bound layer plate are composited with a hot melt adhesive. The prepared composite damping rubber plate has the advantages of high damping value, good heat stability, good environment friendliness, high material use ratio and the like, and the damping value in the range from subzero 20 DEG C to 50 DEG C can reach 0.06-0.15.

Owner:JILIN UNIV

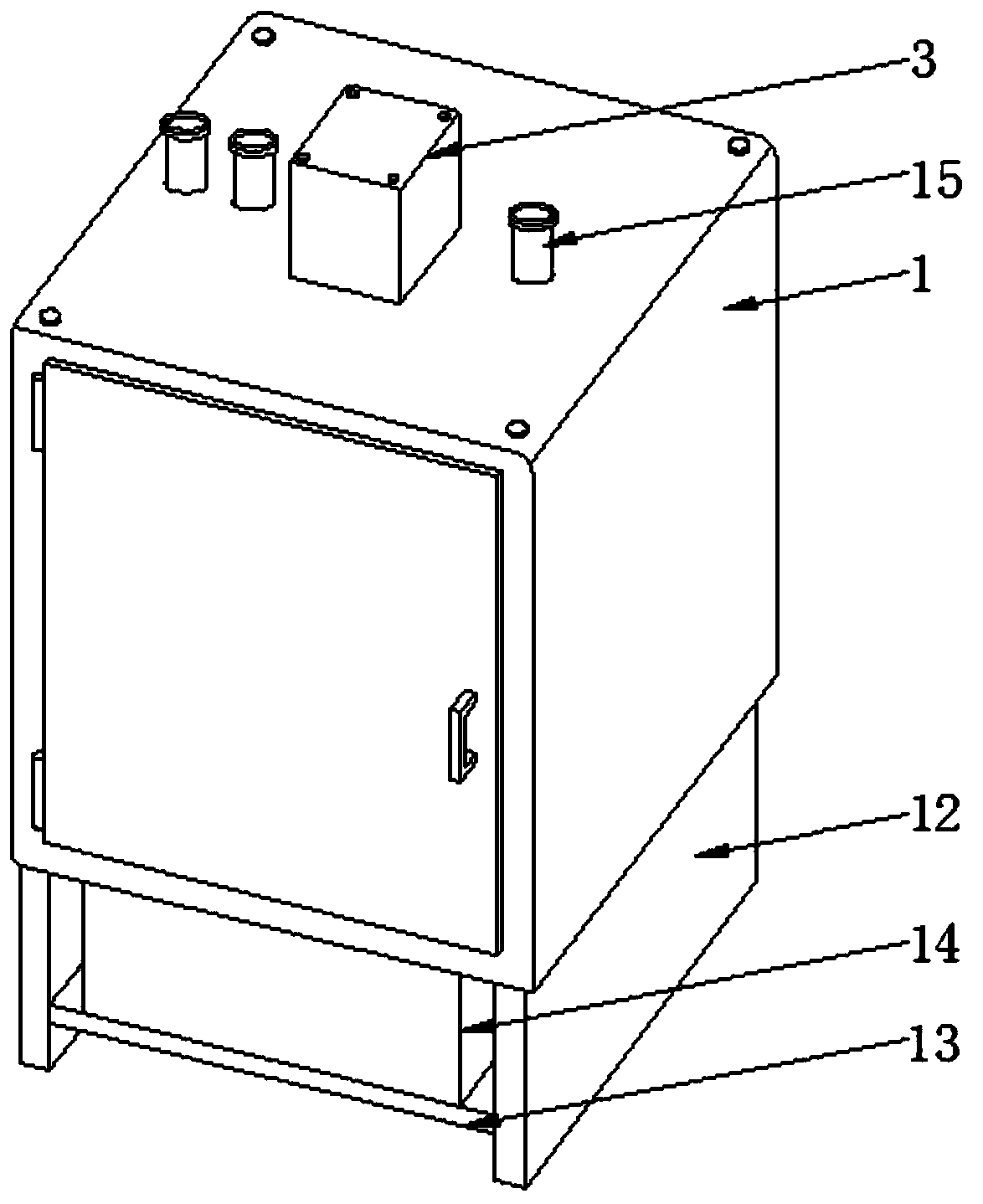

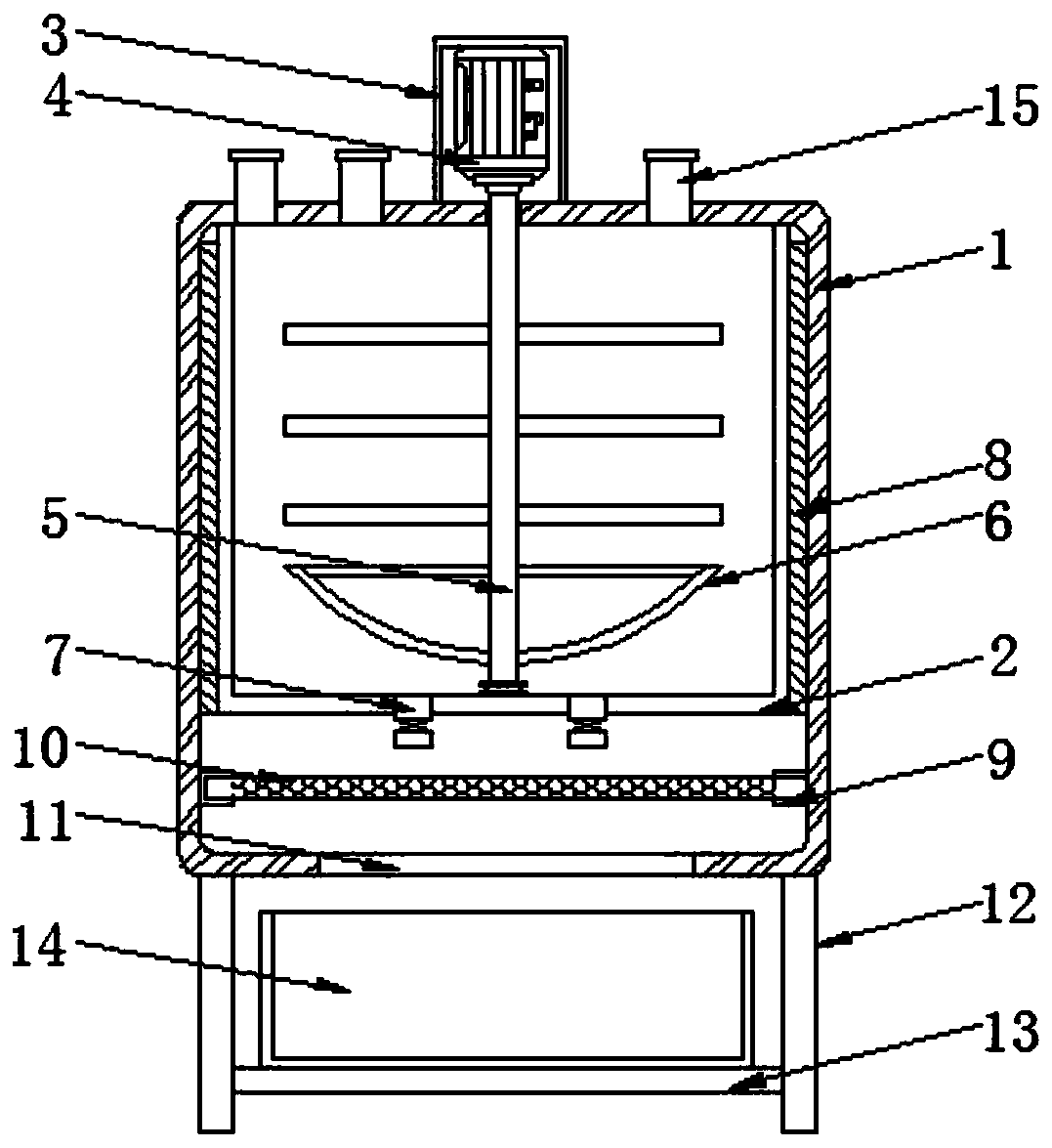

Aqueous anticorrosive damping coating material for automobile chassis, preparation method and equipment thereof

InactiveCN110951338ALess vulnerableExtended service lifeFireproof paintsRotary stirring mixersFiberEmulsion

The invention discloses an aqueous anticorrosive damping coating material for an automobile chassis, a preparation method and equipment thereof, wherein the coating material is prepared from the following components in parts by weight: 55-75 parts of an aqueous polymer elastic resin emulsion, 30-40 parts of a damping pigment filler, 20-40 parts of aluminum fiber, 10-20 parts of a preservative, 8-16 parts of a flame retardant, 6-10 parts of a film forming aid, 20-30 parts of deionized water, 1-3 parts of a thickening agent, 0.7-0.9 part of a defoaming agent, 2-4 parts of a compatilizer and 0.6-0.8 part of a coupling agent. The invention relates to the technical field of aqueous damping coating materials. According to the invention, by improving the matching of the components, the preparation method and the equipment of the material, the problems of low comprehensive performance, complex preparation process, many devices and high comprehensive manufacturing cost of the material are solved, the comprehensive performance of the material is improved, the preparation process is simplified, the number of the equipment is reduced, and all steps can be completed in one equipment so as to reduce the comprehensive manufacturing cost.

Owner:清远明宇材料科技有限公司

Stretching and compressing both-way steel wire rope vibration isolator

ActiveCN105443633AConstrained degrees of freedomNo bendingShock absorbersClassical mechanicsVibration isolation

The invention provides a stretching and compressing both-way steel wire rope vibration isolator to overcome the defects of an existing vibration isolator. The stretching and compressing both-way steel wire rope vibration isolator comprises a cross guide rod, an upper outer side limiting block, an upper inner side limiting block, upper vibration isolation steel wire ropes, a sliding block, plate-shaped connecting pieces, lower vibration isolation steel wire ropes, a lower inner side limiting block and a lower outer side limiting block. The stretching and compressing both-way steel wire rope vibration isolator has the technical beneficial effects that the freedom degree of axial rotation of the vibration isolator is completely restrained, meanwhile, it is guaranteed that the vibration isolator cannot be bent, and the performance of the vibration isolator is guaranteed.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST +1

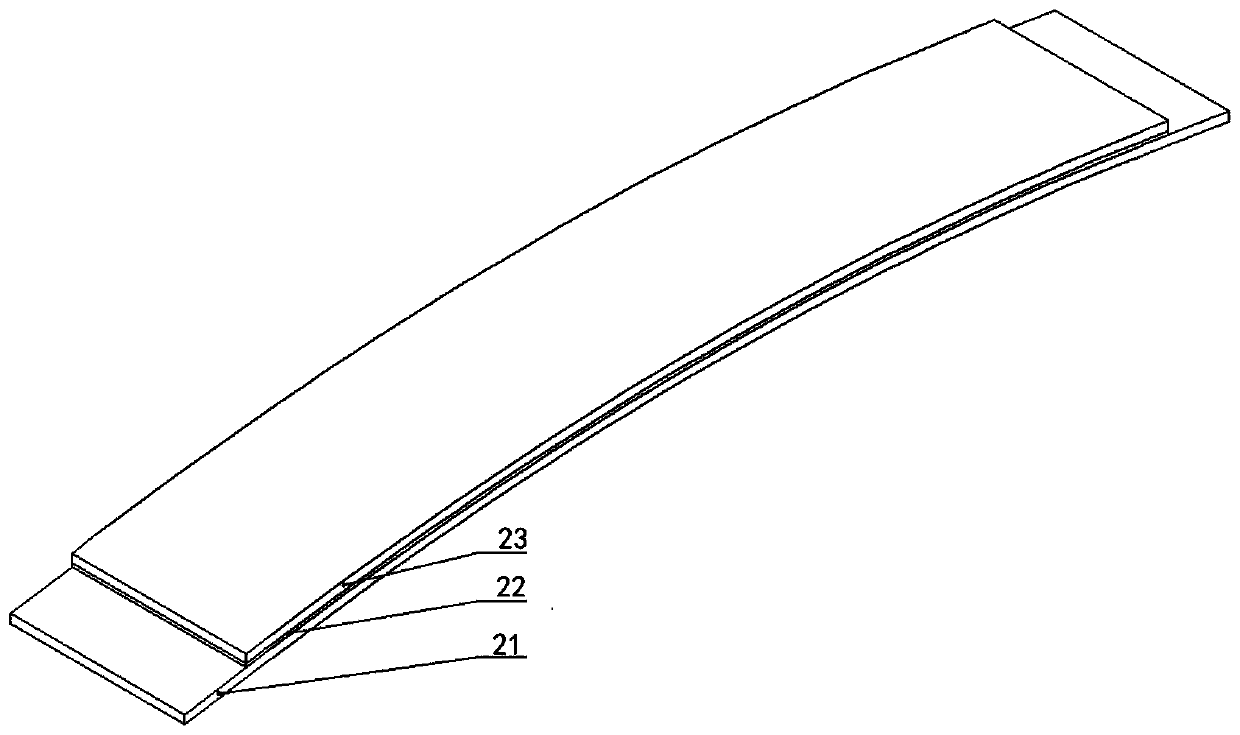

Environment-friendly composite damping board for vibration and noise reduction and preparation method

ActiveCN111114039AEnhancement effect is goodImprove acceleration performanceMetal layered productsEpoxyGlass fiber

The invention discloses an environment-friendly composite damping board for vibration and noise reduction and a preparation method. The environment-friendly composite damping board comprises a dampinglayer, a restraint layer and a bonding layer; the damping layer and the restraint layer are compounded through the bonding layer; and the damping layer is prepared from the following components in parts by weight: 100 parts of rubber, 5-15 parts of carbon black, 5-15 parts of reinforced fibers, 10-15 parts of a plasticizer, 25-45 parts of a damping agent, 200-500 parts of a flame retardant and 30-50 parts of tackifying resin, wherein the reinforced fibers comprise aramid staple fibers subjected to surface preprocessing and long glass fibers subjected to surface preprocessing, and the surfacepreprocessing is carried out through dipping processing of a phosphoric acid solution and an epoxy resin solution in sequence. The damping board material is environmentally friendly, free of peculiarsmell, good in flame retardant property and low in smoke density and smoke toxicity during combustion; the damping board has high shearing strength, is firmly adhered to a base material and is not easy to fall off; the damping value is high, the damping temperature range is wide, and the vibration and noise reduction effect is excellent.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Bicycle automatic shock absorber system for

InactiveCN104627307AImprove pedaling efficiencyTo achieve the effect of safe ridingSpringsAxle suspensionsControl signalControl theory

The invention provides a bicycle automatic shock absorber system. A treading rotating speed of the bicycle can be detected by a treading rotating speed sensor. A control processing device can be used to output level control signals to a damping adjusting device according to the treading signals, and the damping adjusting device can be used to adjust the level of the damping force according to the level control signals.

Owner:GIANT MFG

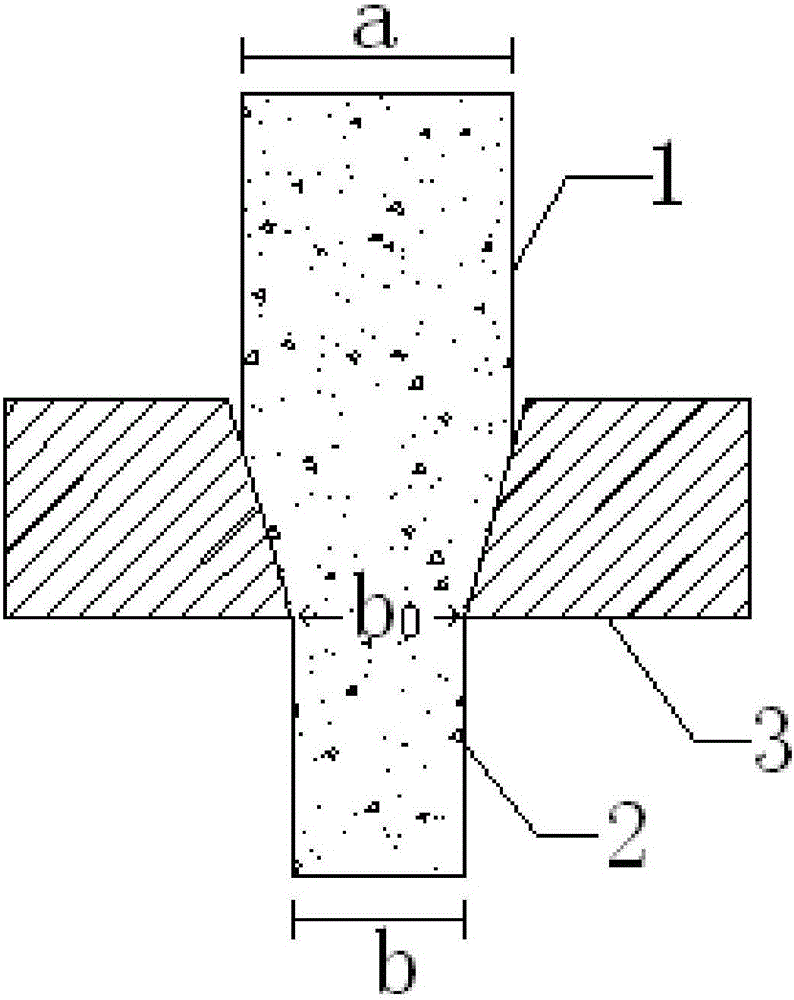

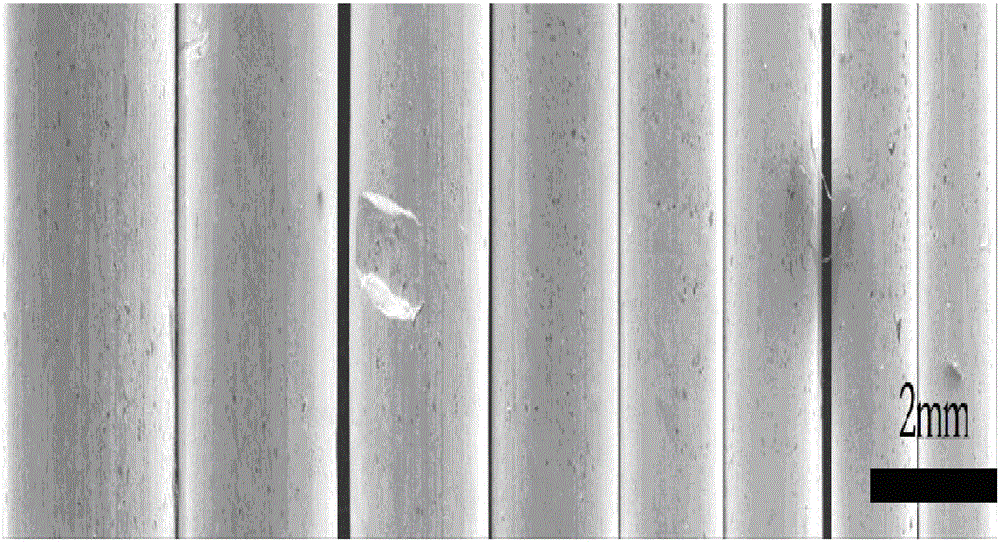

Method for manufacturing CuZnAl or CuZn alloy continuous fiber through cold drawing

The invention discloses a method for manufacturing CuZnAl or CuZn alloy continuous fiber through cold drawing and relates to a manufacturing method for alloy fiber. The method aims at solving the problems that a CuZnAl or CuZn alloy is low in yield strength, and the difficulty for manufacturing small fiber of the CuZnAl or CuZn alloy is high. The method includes the steps that firstly, an original cast ingot is manufactured; secondly, the original cast ingot is subjected to hot extrusion to form a bar; thirdly, the bar is corroded; fourthly, cold drawing is conducted; fifthly, the alloy fiber with the target diameter are manufactured; and sixthly, the alloy fiber is annealed after cold drawing. By means of the method, the problem that the CuZnAl or CuZn alloy continuous fiber is low in yield strength under the room temperature condition, and consequently, shape memory, superelasticity and the damping characteristic are affected are solved; in addition, a cold drawing method is utilized for enabling the thick bar to be subjected to cold drawing to become the CuZnAl or CuZn alloy continuous fiber with the diameter being dozens of microns to hundreds of micrometers, and the problem that the difficulty of manufacturing the CuZnAl or CuZn alloy continuous fiber even in diameter and small in fiber is high is solved; and the method is suitable for manufacturing the CuZnAl or CuZn alloy continuous fiber.

Owner:HARBIN INST OF TECH

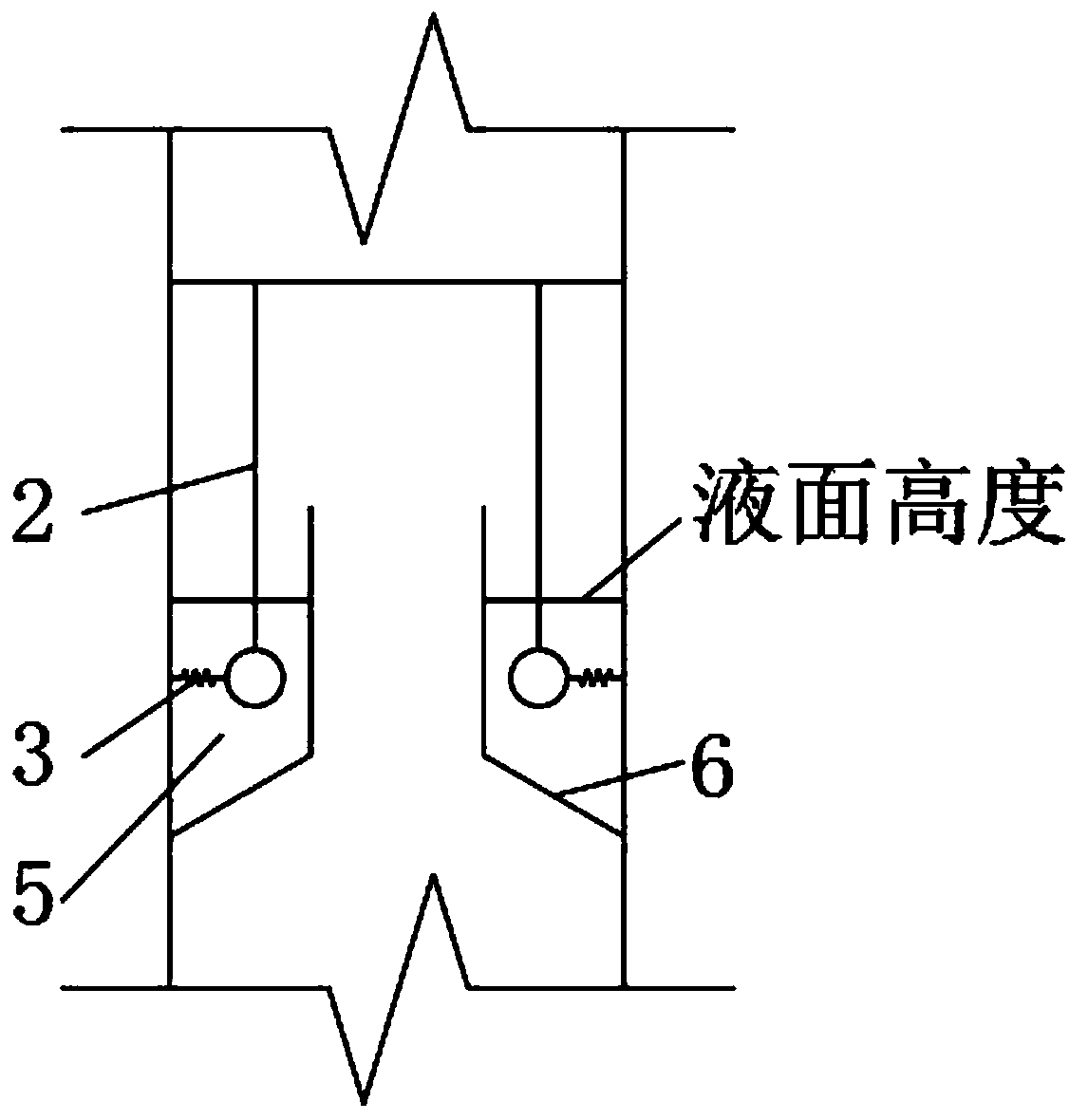

TLMD vibration isolation system

ActiveCN110500375AImprove vibration damping abilityReduce vibrationSpringsShock absorbersBroadbandEngineering

The invention discloses a TLMD vibration isolation system. The system comprises a TLD and multiple TMDs, and each TMD comprises a mass block, a first spring, a second spring, a third spring and liquid; the TLD also comprises liquid and a liquid storage box, and operation steps comprise that before parameters of all parts of the TMDs are selected, the main frequency and external excitation frequency spectrum characteristics of a needed vibration isolation structure are measured, through the vibration isolation need, the modal mass ratio of the TMD and a main structure is determined, and the selection range is 1 to 5%; according to the vibration isolation frequency range determined in S1 and the corresponding mass value, the TMD swing rod length and the spring rigidity are designed, and theTMDs are symmetrically arranged relative to a main structure. The vibration frequency of the mass blocks of the multiple TMDs is adjusted according to the outer motivation, the broadband vibration isolation is achieved, TLD liquid serves as TMD damping liquid, meanwhile, the TLD liquid can vibrate, and through shaking and collision with the wall of the liquid storage box, vibration isolation is achieved.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

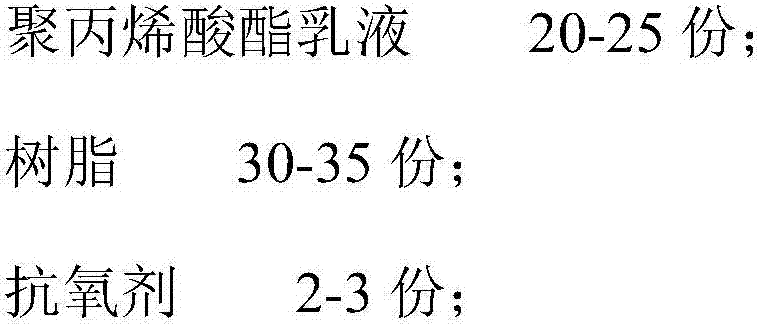

Multi-efficient high-molecular damping material

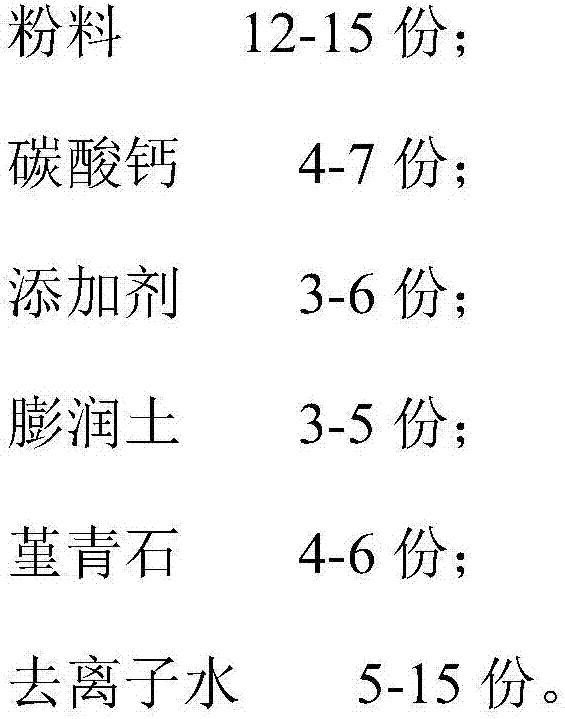

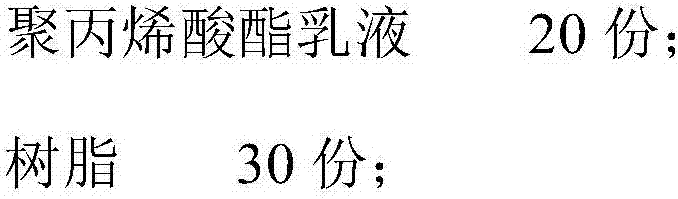

The invention discloses a multi-efficient high-molecular damping material. The multi-efficient high-molecular damping material is prepared from, by weight, 20-25 parts of polyacrylate emulsion, 30-35 parts of resin, 2-3 parts of antioxidant, 12-15 parts of powder, 4-7 parts of calcium carbonate, 3-6 parts of additive, 3-5 parts of bentonite, 4-6 parts of cordierite, and 5-15 parts of de-ionized water. The multi-efficient high-molecular damping material has the beneficial effects of being safe and toxic-free and good in environmental protection effect for applying bentonite and powder; meanwhile, the damping material prepared by scientifically matching with other raw materials is good in binding performance, not easy to deform after coating and drying, big in damping value, high in reliability, high in performance cost during the using process, and can meet the demand of building industry.

Owner:JIANGSU DAOQ NEW MATERIAL TECH CO LTD

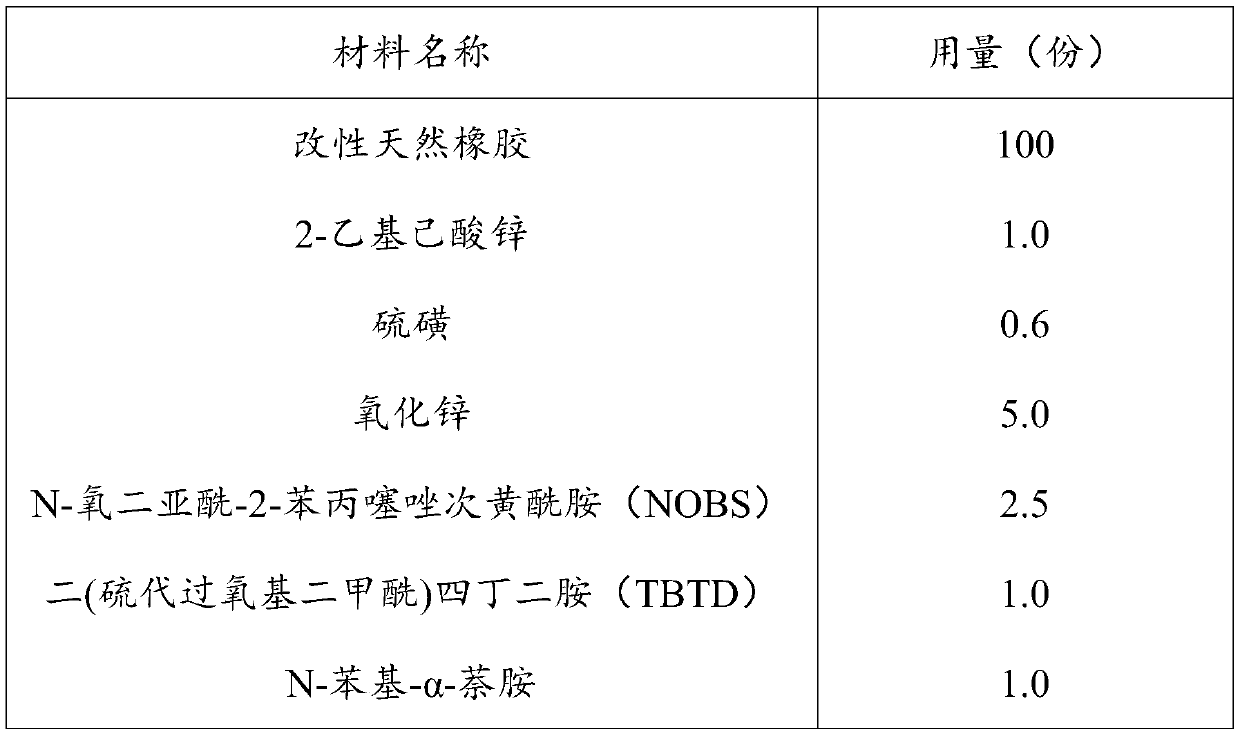

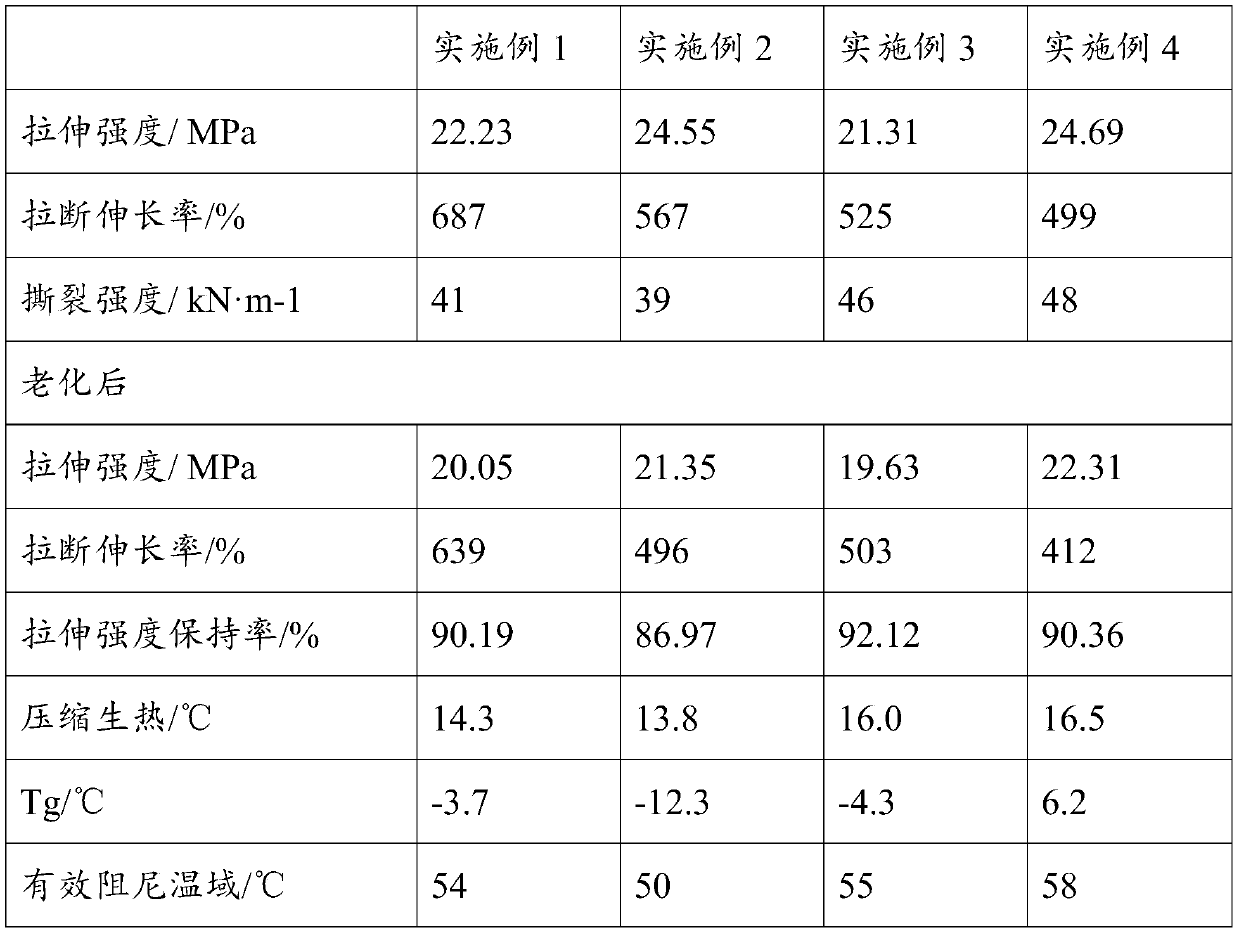

High-performance rubber damping material and preparation method thereof

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

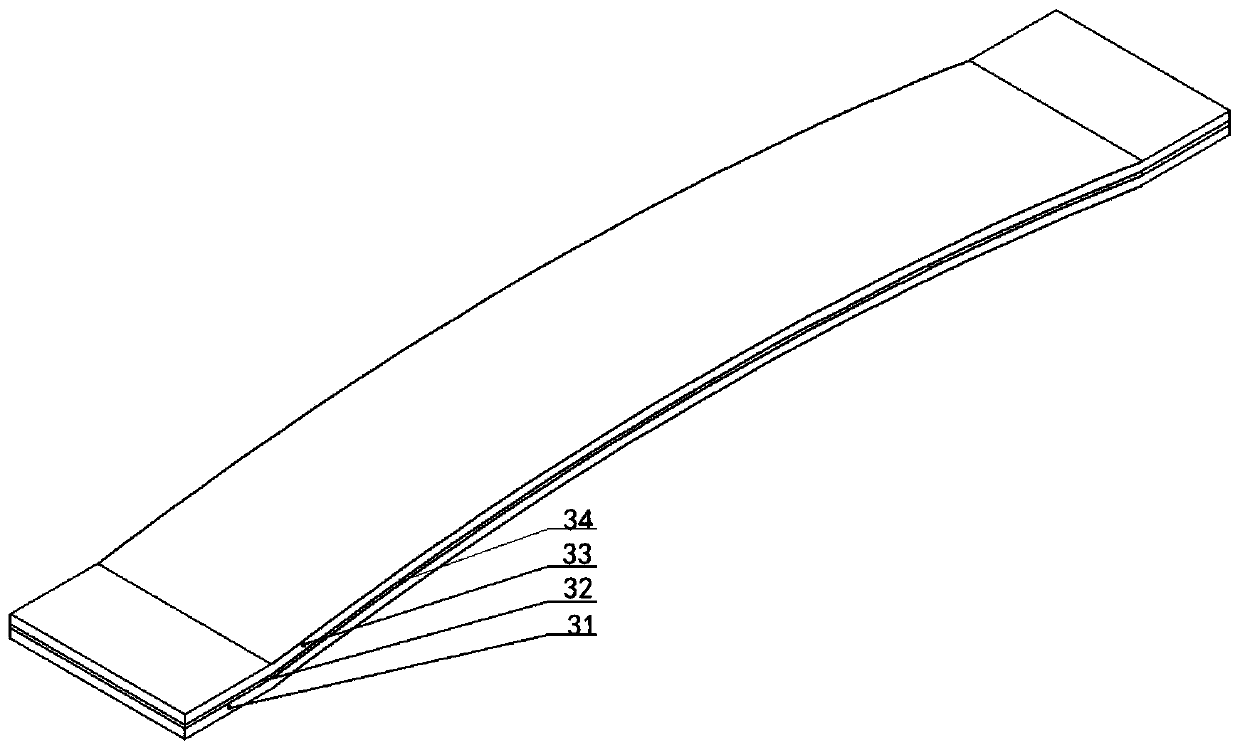

Self-adhesive and environment-friendly damping rubber plate and preparation method therefor

ActiveCN105131850AHigh damping valueAvoid deformationNon-macromolecular adhesive additivesFilm/foil adhesivesEngineeringFire retardant

The present invention provides a self-adhesive and environment-friendly damping rubber plate. The self-adhesive and environment-friendly damping rubber plate comprises a metal plate, reinforcing ribs, release paper and damping rubber, wherein the damping rubber comprises the following raw materials in parts by weight: 15-70 parts of modified rubber, 1-5 parts of pigments, 10-30 parts of a flame-retardant agent and 15-45 parts of a damping filler. The present invention provides a preparation method of the self-adhesive and environment-friendly damping rubber plate at the same time. The method comprises the steps of: adding raw materials, preparing the damping rubber, coating the damping rubber, adding the reinforcing ribs, pressing upwards and downwards, and paving a layer of release paper. The self-adhesive and environment-friendly damping rubber plate has the beneficial effects the self-adhesive and environment-friendly damping rubber plate has a high damping value in different temperature ranges, is of an enhanced structure, and is environment-friendly, free of pollution to the environment and good in flame-retardant property.

Owner:QINGDAO AIR NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com