Heat treatment method of FeGa-based high damping alloy

A technology of high damping alloy and heat treatment method, which is applied in the field of heat treatment of FeGa-based high-damping alloy, can solve the problems of inability to improve the damping performance of FeGa-based alloy, and achieve the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

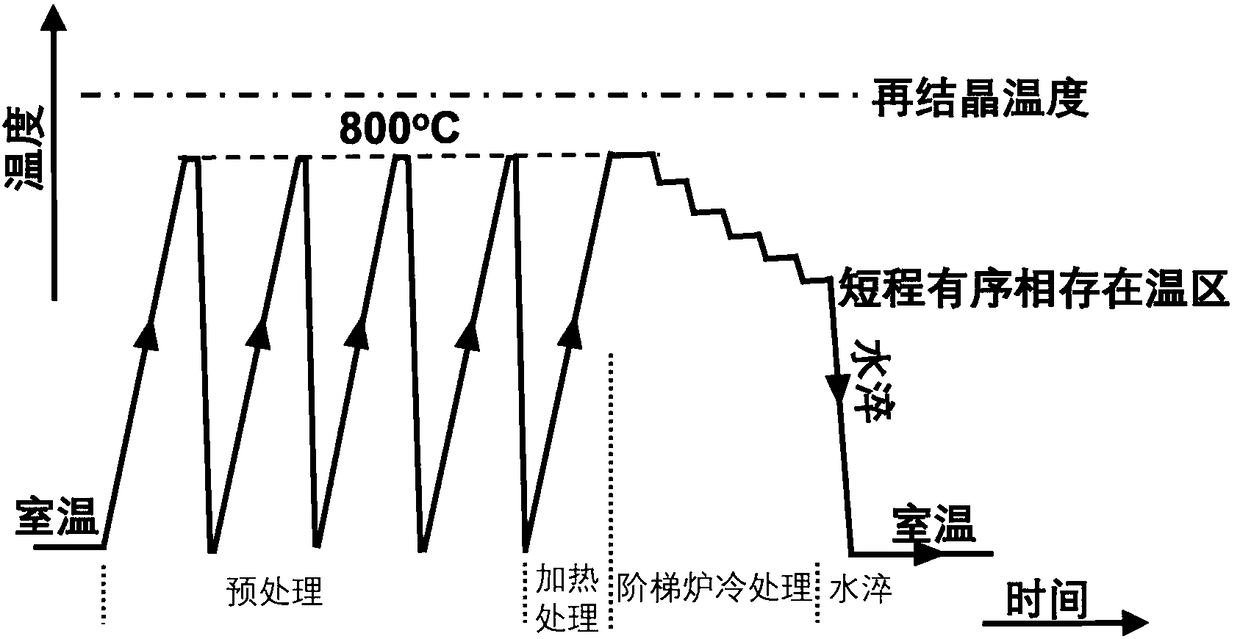

[0029] This embodiment provides a heat treatment method for a wide temperature range high damping FeGa-based alloy, such as figure 1 shown, including the following steps:

[0030] (1) Pretreatment: Place the alloy sample in a tubular heat treatment furnace, heat it up to 800°C at a heating rate of 120°C / h under a protective atmosphere of argon, hold it for 1 hour, and then cool it at a rate of 120°C / h Cool to room temperature with the furnace, a total of 4 cycles;

[0031] (2) Heat treatment: In a tubular heat treatment furnace, under a protective atmosphere of Ar gas, heat to 800°C at a heating rate of 120°C / h, and hold for 1h;

[0032] (3) Furnace cooling treatment: cooling treatment is carried out by heating the alloy sample, the cooling rate is 90°C / h, and the temperature is kept at 750°C, 700°C, 680°C, 660°C, and 640°C for 0.5h during the cooling process;

[0033] (4) Quenching treatment: Rapidly perform water quenching treatment on the sample kept at 640° C. for 0.5 h,...

Embodiment 2

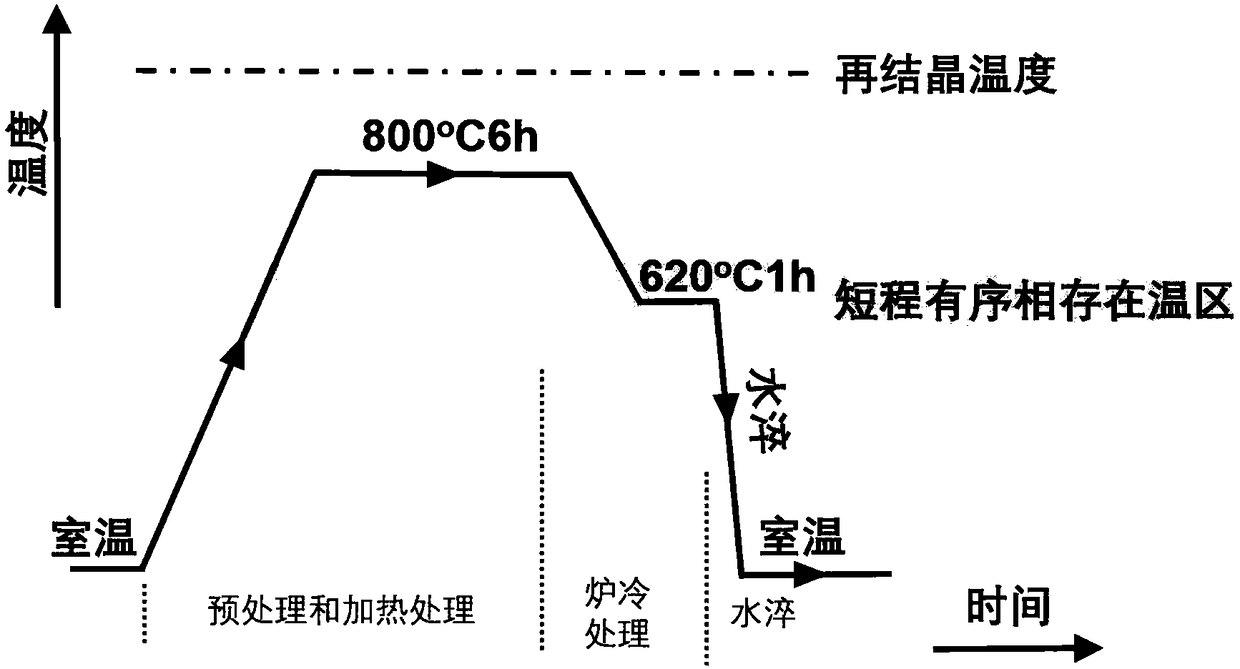

[0035] This embodiment provides a heat treatment method for a wide temperature range high damping FeGa-based alloy, such as figure 2 shown, including the following steps:

[0036] (1) Pretreatment and heat treatment: place the alloy sample in a tubular heat treatment furnace, and heat it to 800°C at a heating rate of 120°C / h under the protective atmosphere of argon, and keep it for 6h;

[0037] (2) Furnace cooling treatment: conduct cooling treatment on the alloy sample through heating treatment, the cooling rate is 90°C / h, when the temperature drops to 620°C, keep it for 1h;

[0038] (3) Quenching treatment: the sample kept at 620° C. for 1 hour was quickly subjected to water quenching treatment, and cooled to room temperature.

Embodiment 3

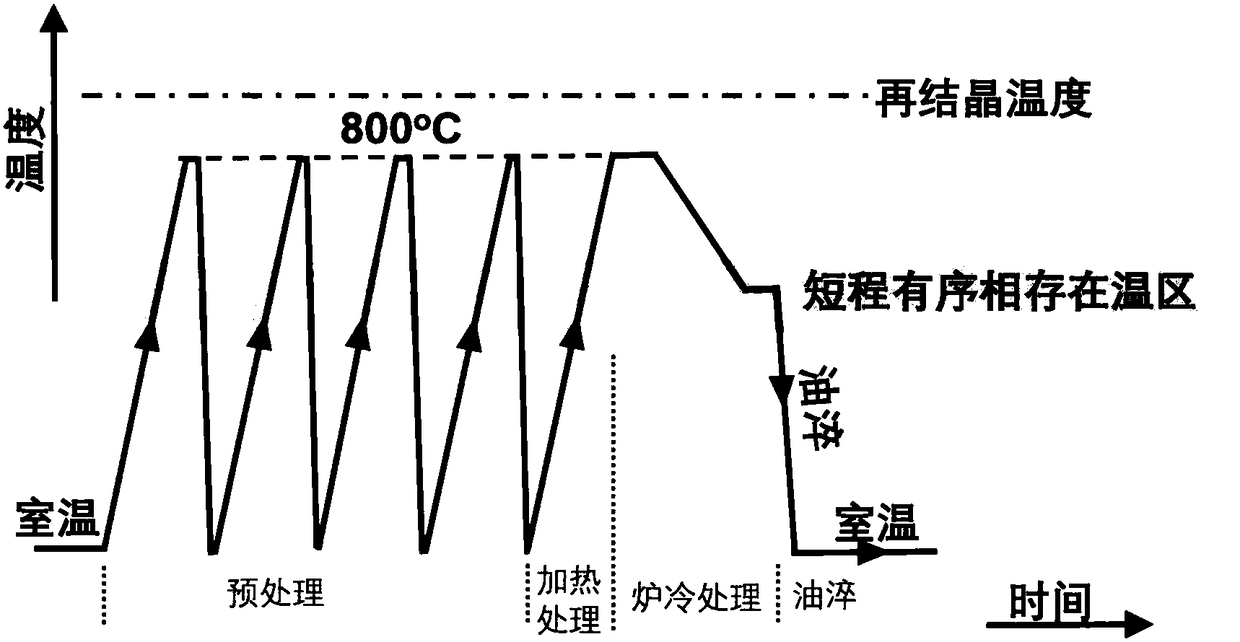

[0040] This embodiment provides a heat treatment method for FeGa-based high damping alloys, such as image 3 shown, including the following steps:

[0041] (1) Pretreatment The temperature of the FeGa-based alloy material is first raised to 800°C at a rate of 120°C / h by means of alternating cold and heat cycles, and after holding for 1 hour, it is then lowered to room temperature with the furnace at a rate of 120°C / h. cycle, a total of 4 cycles to reduce the internal stress of the material;

[0042] (2) Heat treatment: In a tubular heat treatment furnace, under a protective atmosphere of Ar gas, heat to 800°C at a heating rate of 120°C / h, and hold for 1h;

[0043] (3) Furnace cooling treatment: the heat-treated alloy sample is cooled to a certain temperature of 450-750°C at a rate of 90°C / h, and kept for 0.5h.

[0044] (4) Quenching treatment: quickly oil quench the sample kept for 0.5h, and cool it to room temperature.

[0045] The damping performance of the material proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com